Patents

Literature

375 results about "Titanium carbonitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

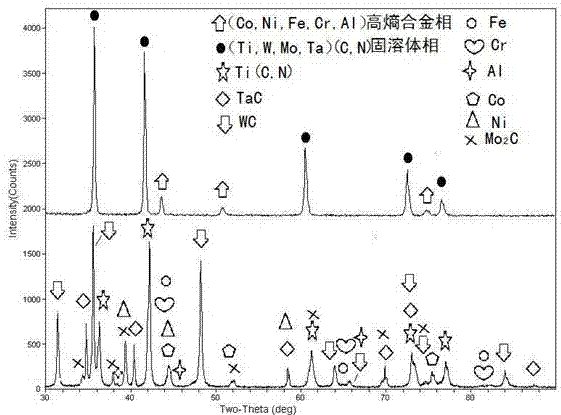

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

Ceramic cladding powder and preparation method thereof

InactiveCN101423398AThere will be no phenomenon of grain aggregation and growthEvenly distributedCeramic coatingTitanium nitride

The invention relates to ceramic coating powder the ceramic phase of which is coated by a metallic phase cobalt or / and a metallic phase nickel. The metallic phase cobalt and the metallic phase nickel are obtained by means of a liquid phase reduction method; and the ceramic phase is at least one of titanium carbonitride, titanium carbide, titanium nitride, tungsten carbide, silicon carbide, niobium carbide, tantalum carbide, aluminum oxide, zirconium oxide, magnesium oxide, boron nitride and silicon nitride. A method for preparing the ceramic coating powder is the liquid phase reduction method to carry out a reduction reaction between cobalt or / and nickel ions in a plating solution to generate the metallic phase cobalt or / and nickel which is deposited on the surface of a ceramic core to form the ceramic coating powder; and the process steps are as follows: (1) pre-treatment of the ceramic powder; (2) preparation of the plating solution; (3) liquid-phase reduction reaction; and (4) plating post treatment.

Owner:SICHUAN UNIV

Method for preparing metallic titanium

The invention provides a method for preparing metallic titanium. The method comprises the following steps of: in the process of melting titanium slag by using titanium concentrate, directly adding excessive carbon-containing reducing agents to obtain titanium carbide or introducing nitrogen while directly adding the excessive carbon-containing reducing agents to prepare titanium nitride or titanium carbonitride in the melting process of the titanium slag; electrolyzing molten salts containing low-valence chloride of titanium to obtain metallic titanium powder by taking the prepared titanium carbide, the titanium nitride or the titanium carbonitride as a soluble anode and a metal material as a cathode; in addition, further electrolyzing and refining products obtained in the later period of the electrolysis to obtain high-purity titanium. The method has the advantages of simple process, low raw material cost, low energy consumption, small investment in permanent assets and the like. In addition, the prepared metallic titanium has high purity and ferrotitanium can be prepared by further electrolyzing residual anode titanium powder remained by the anode.

Owner:PANZHIHUA IRON AND STEEL +2

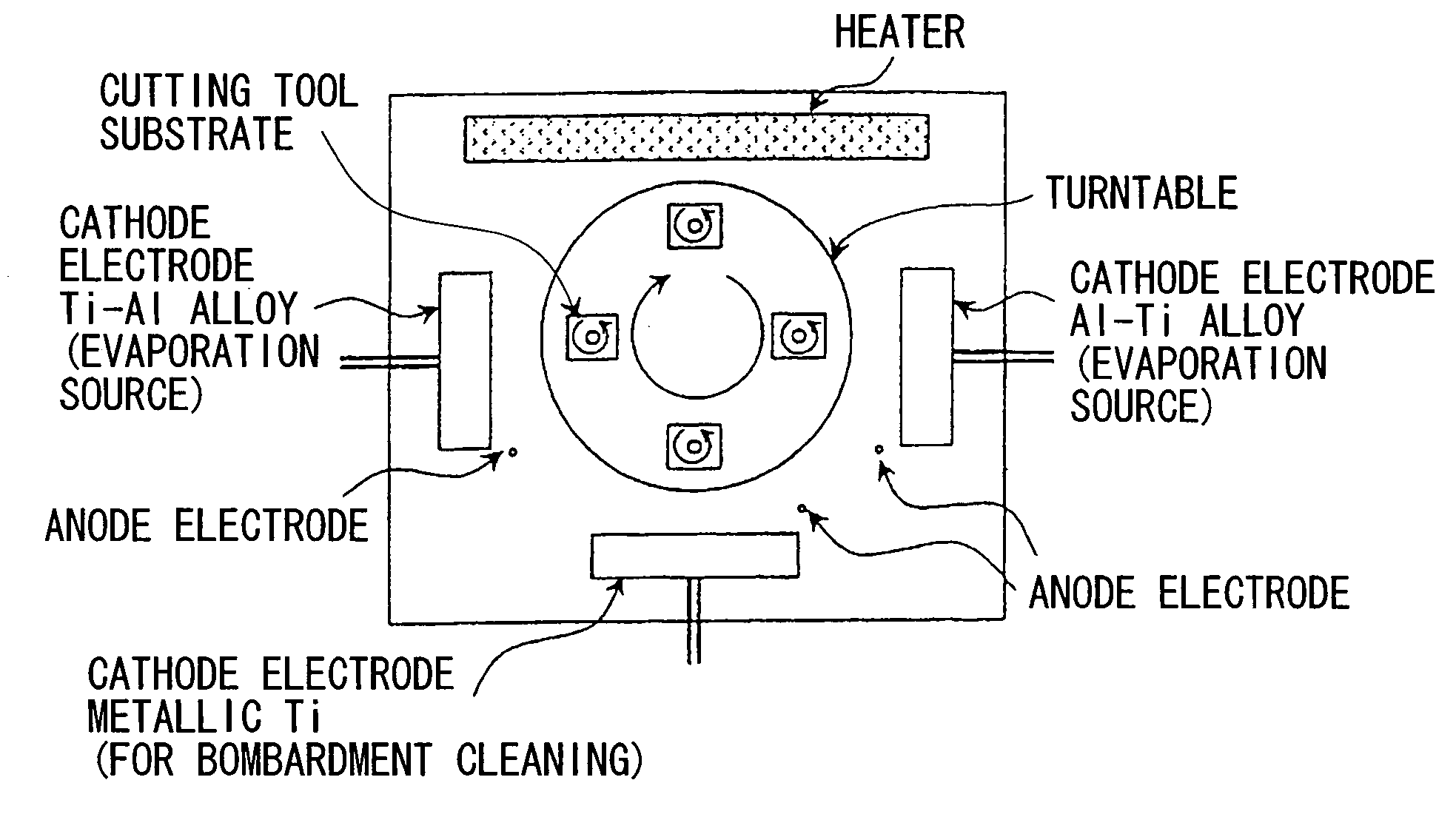

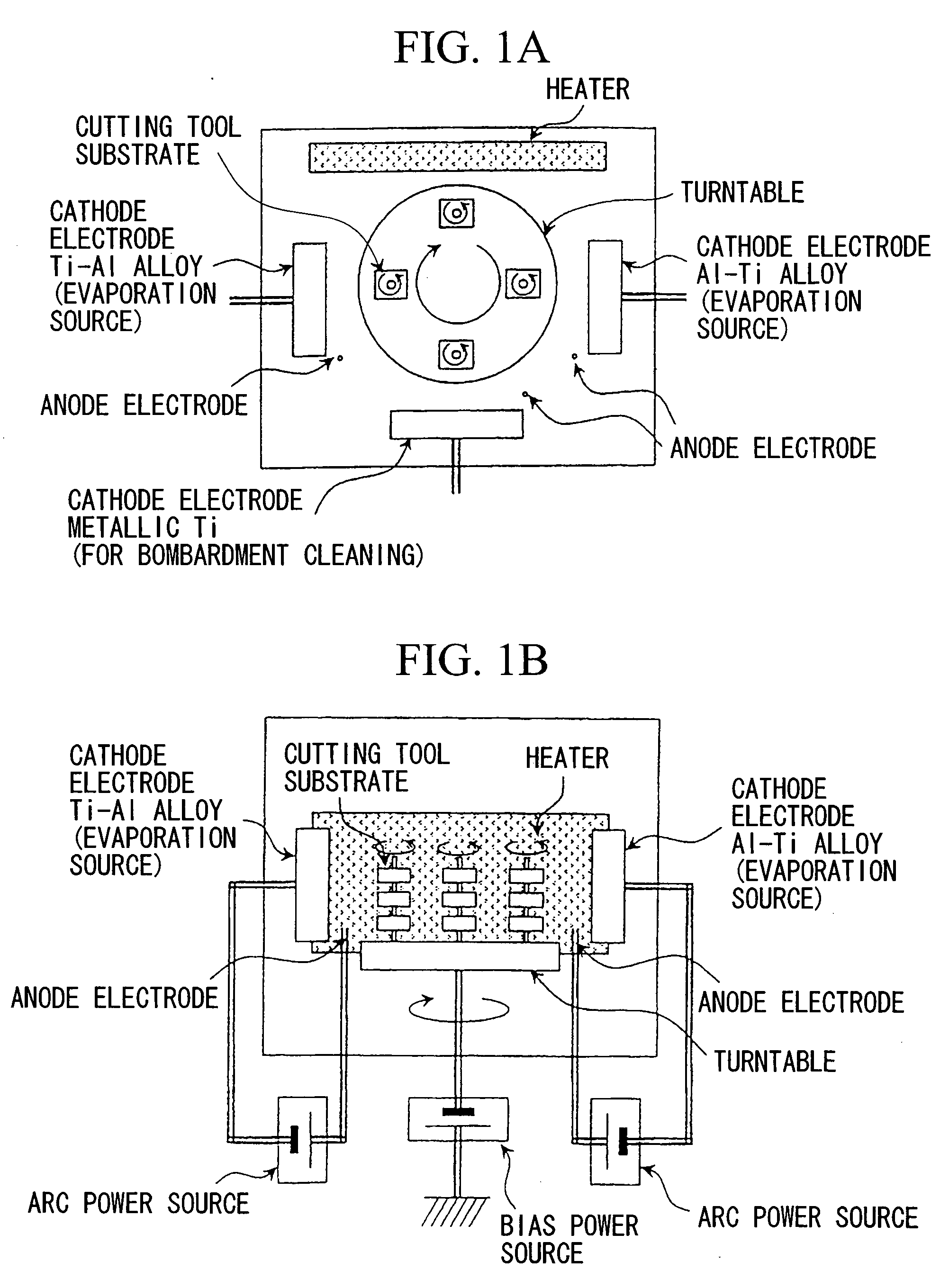

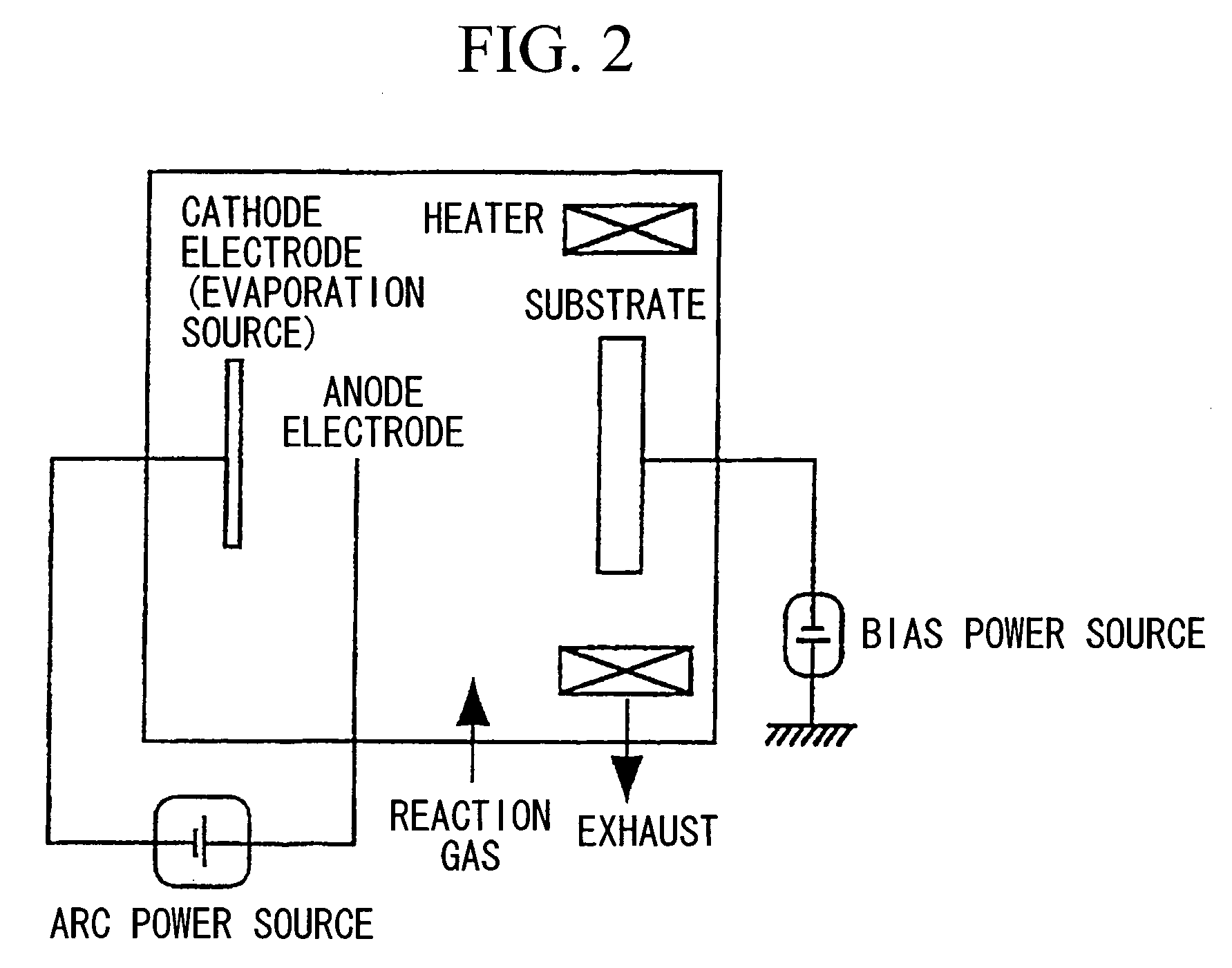

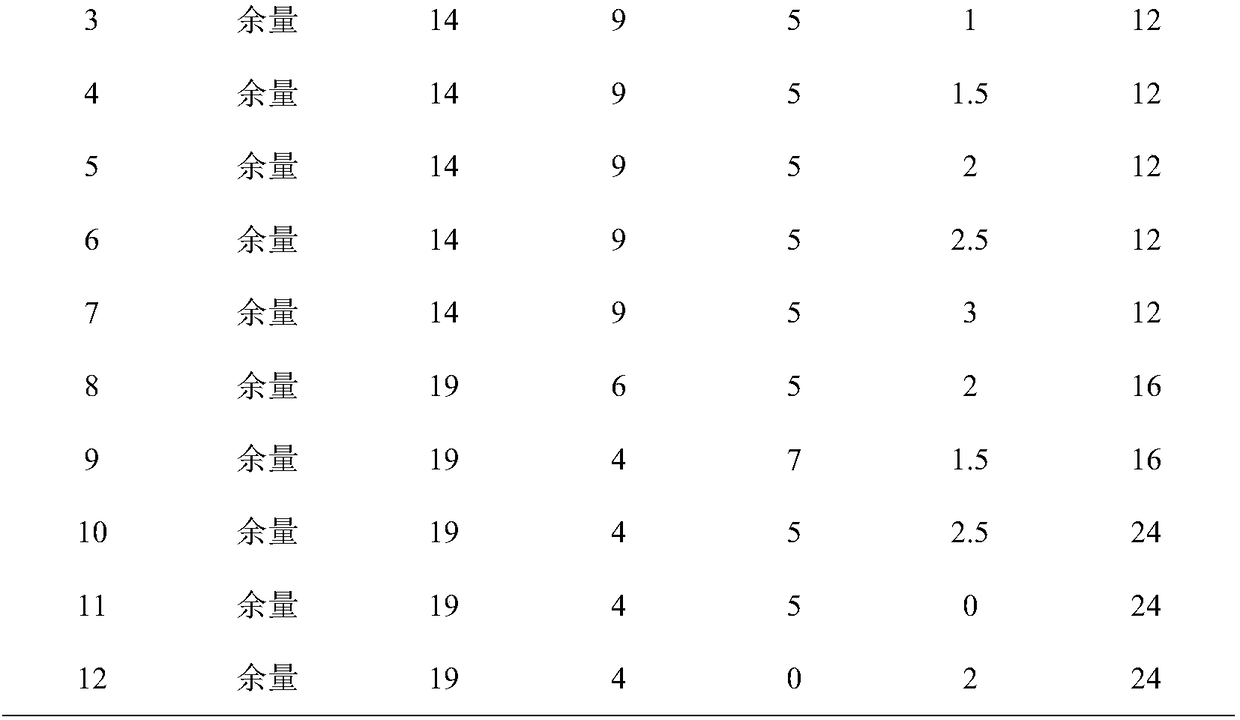

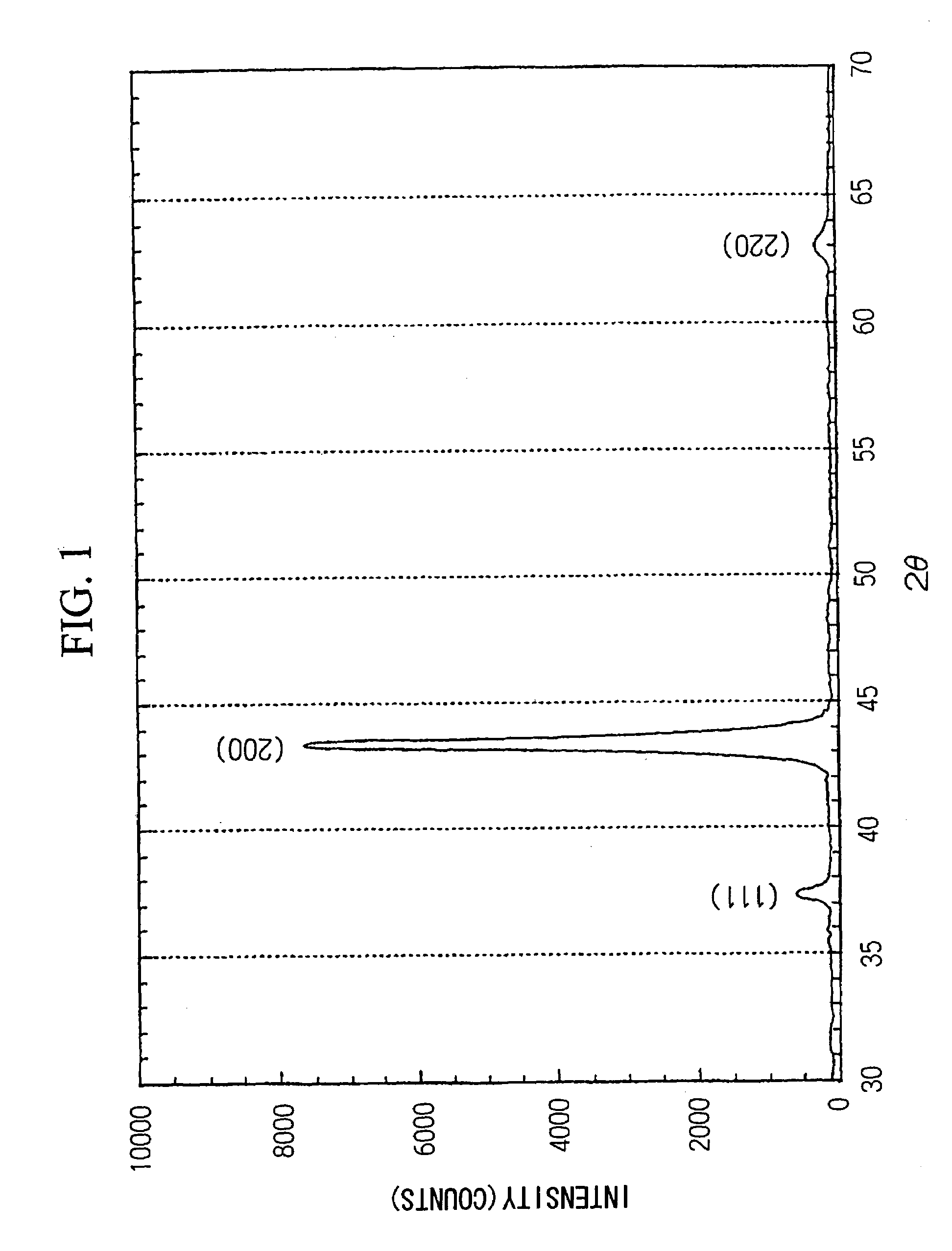

Surface-coated cutting tool member having hard coating layer exhibiting superior wear resistance during high speed cutting operation and method for forming hard coating layer on surface of cutting tool

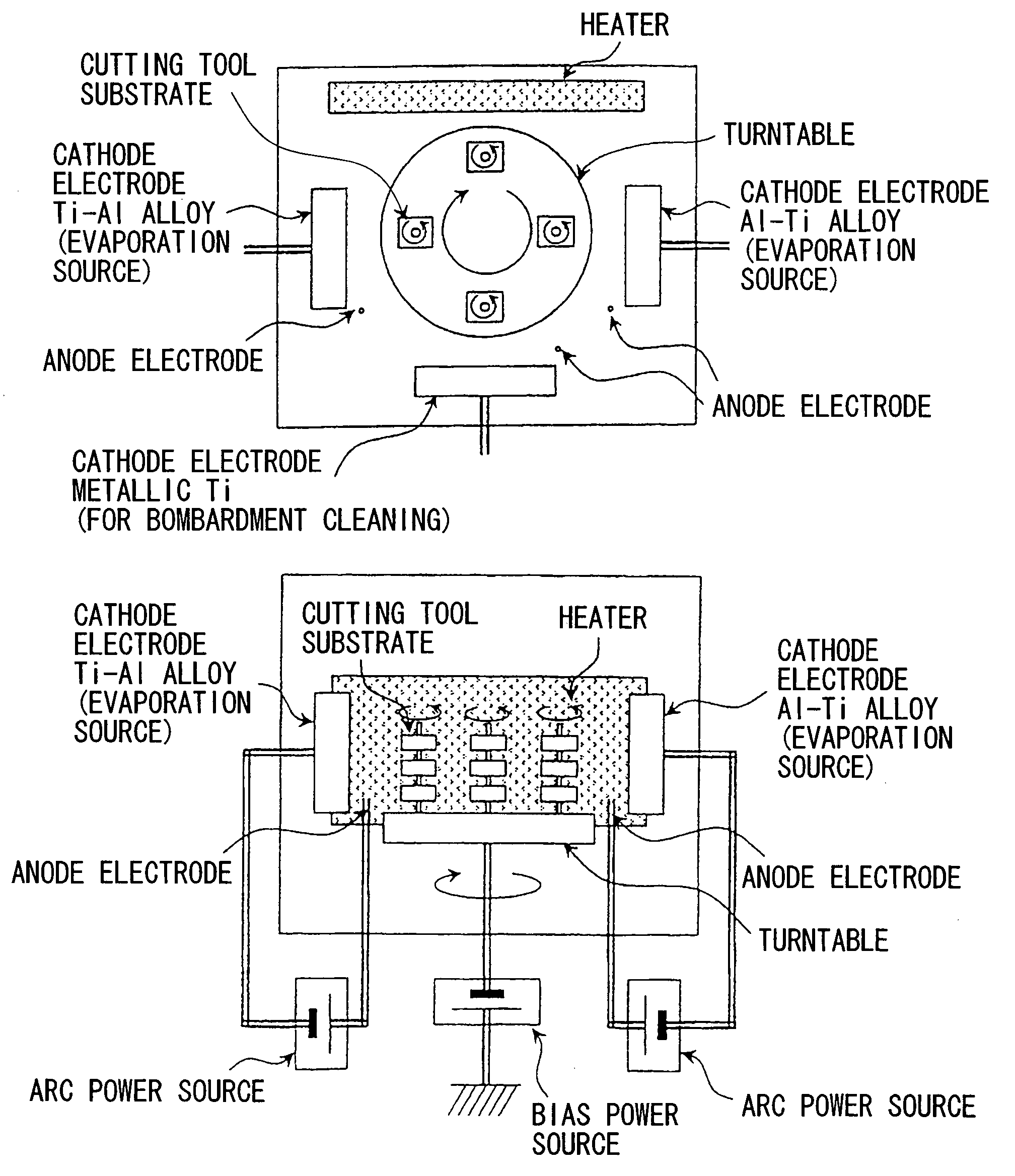

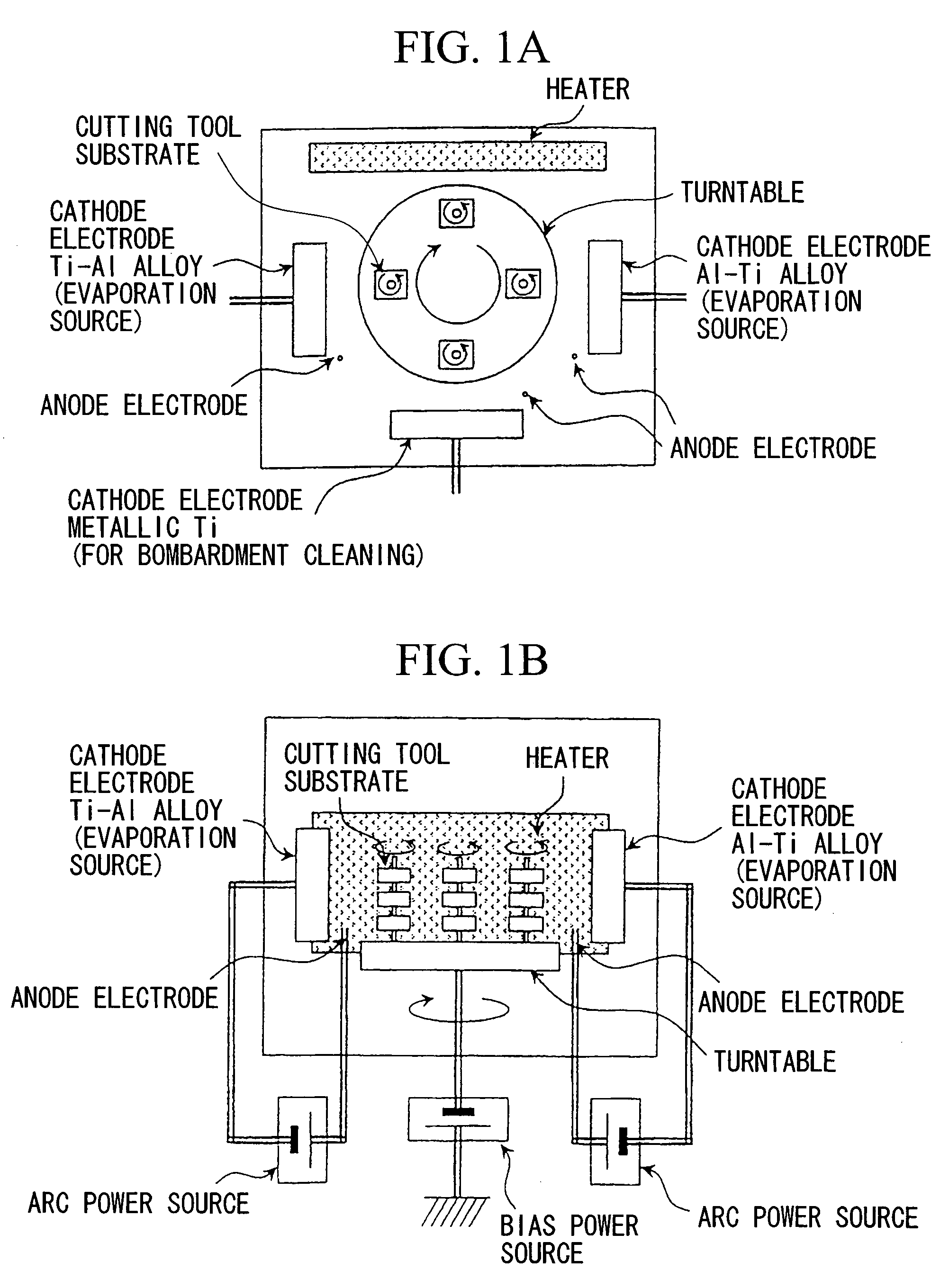

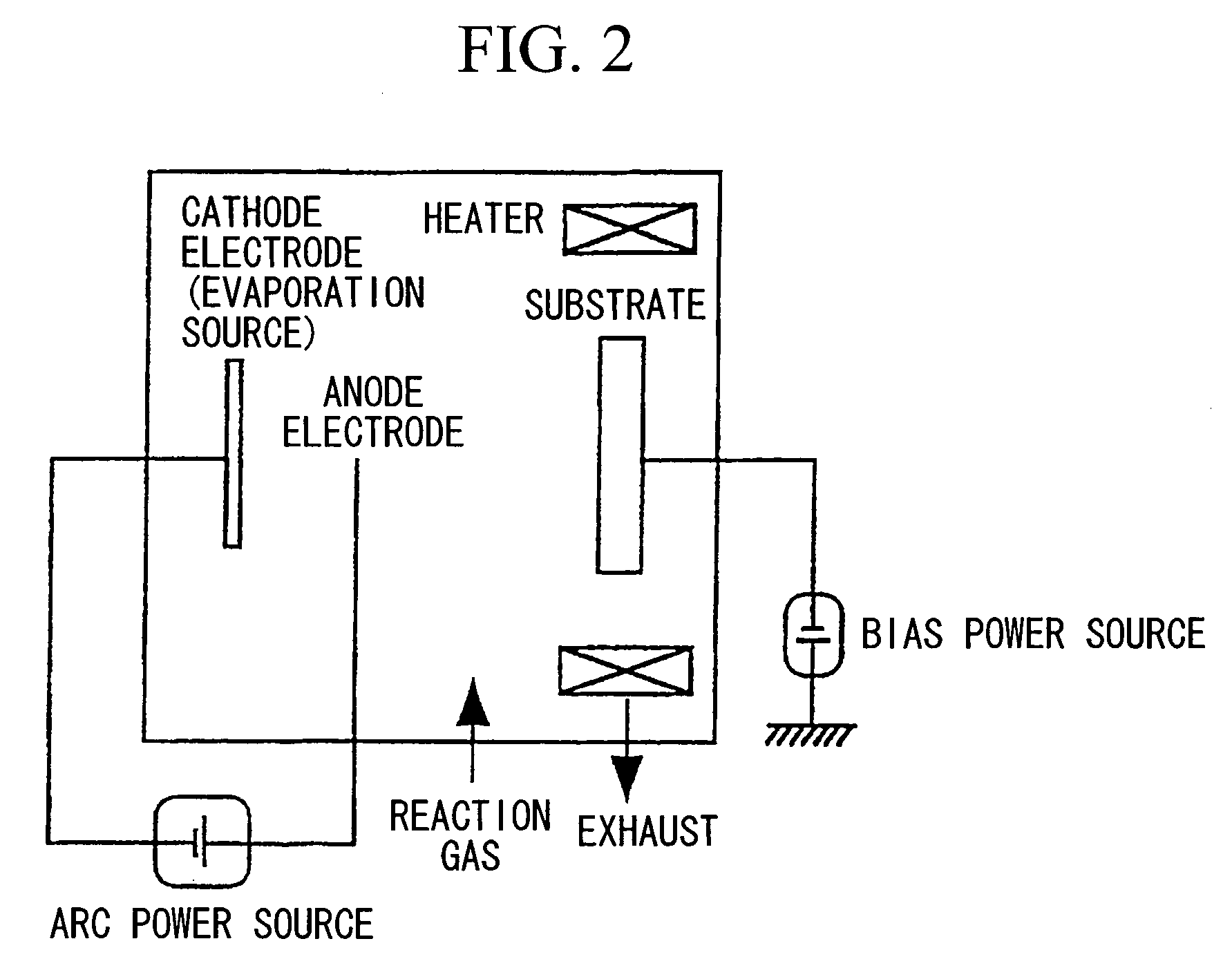

A surface-coated cutting tool member includes a tungsten carbide based cemented carbide substrate, a titanium carbonitride based cermet substrate, or a cubic boron nitride based sintered substrate; and a hard coating layer of a nitride compound containing aluminum and titanium, formed on a surface of the substrate using a physical vapor deposition method in an overall average thickness of 1 to 15 μm. The hard coating layer has a component concentration profile in which maximum aluminum containing points and minimum aluminum containing points appear alternatingly and repeatedly at a distance from 0.01 to 0.1 μm in a direction of thickness of the hard coating layer. The amount of contained aluminum (or titanium) is changed from the maximum aluminum containing points to the minimum aluminum containing points. The maximum aluminum containing points satisfy a formula: (AlXTi1−X)N, wherein X is between 0.70 to 0.95. The minimum aluminum containing points satisfy a formula: (AlYTi1−Y)N, wherein Y is between 0.40 to 0.65.

Owner:MITSUBISHI MATERIALS CORP

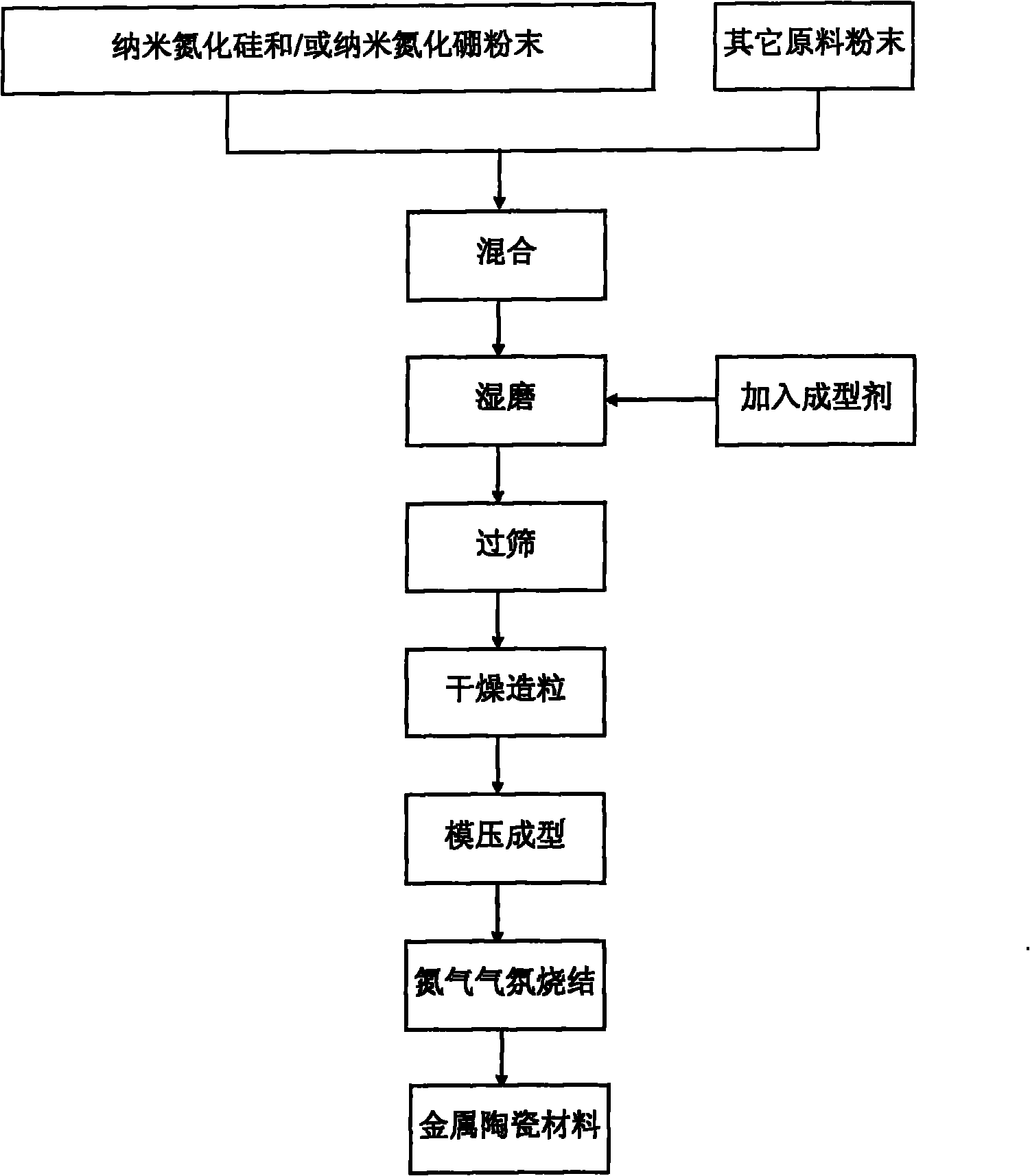

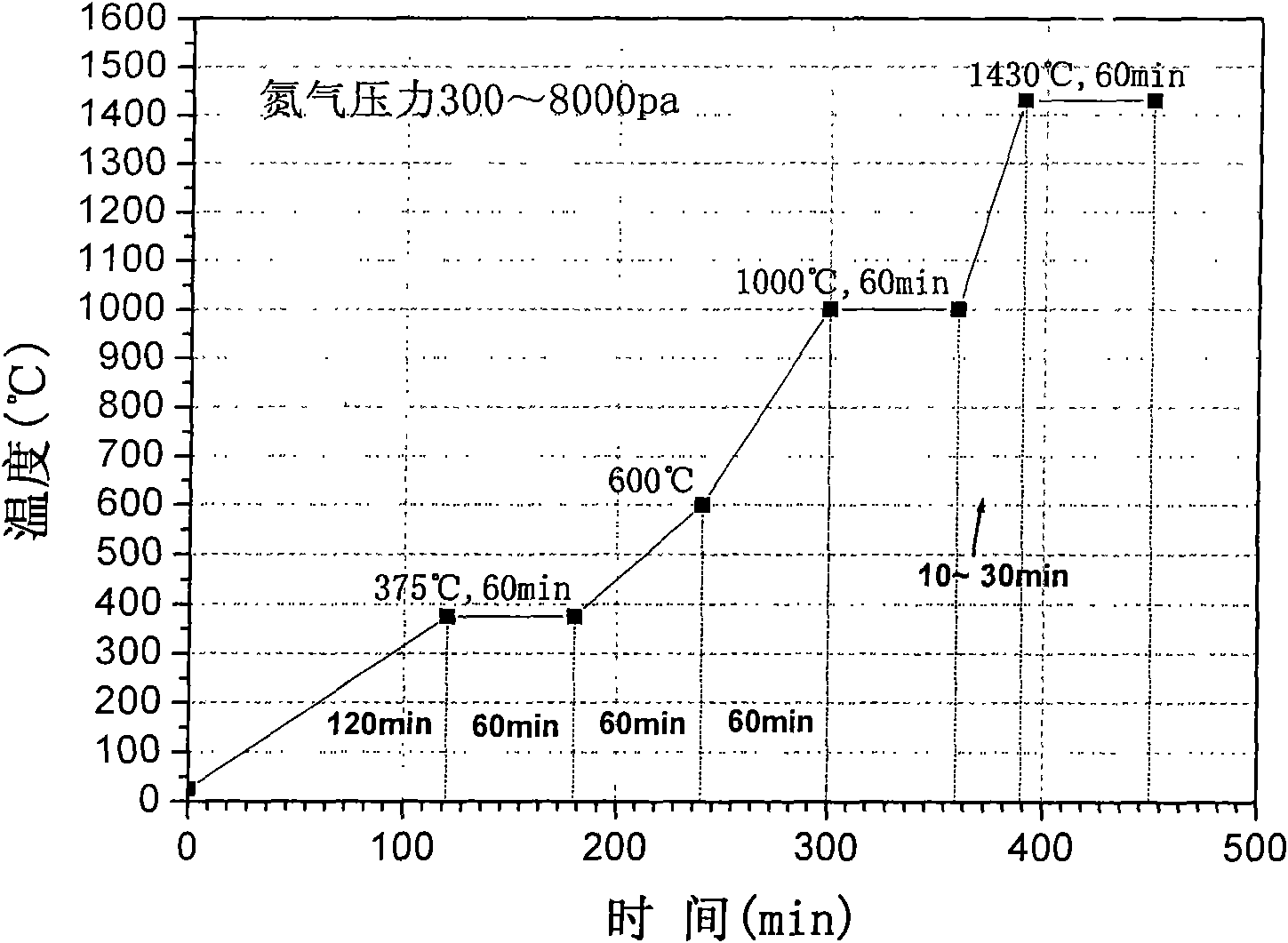

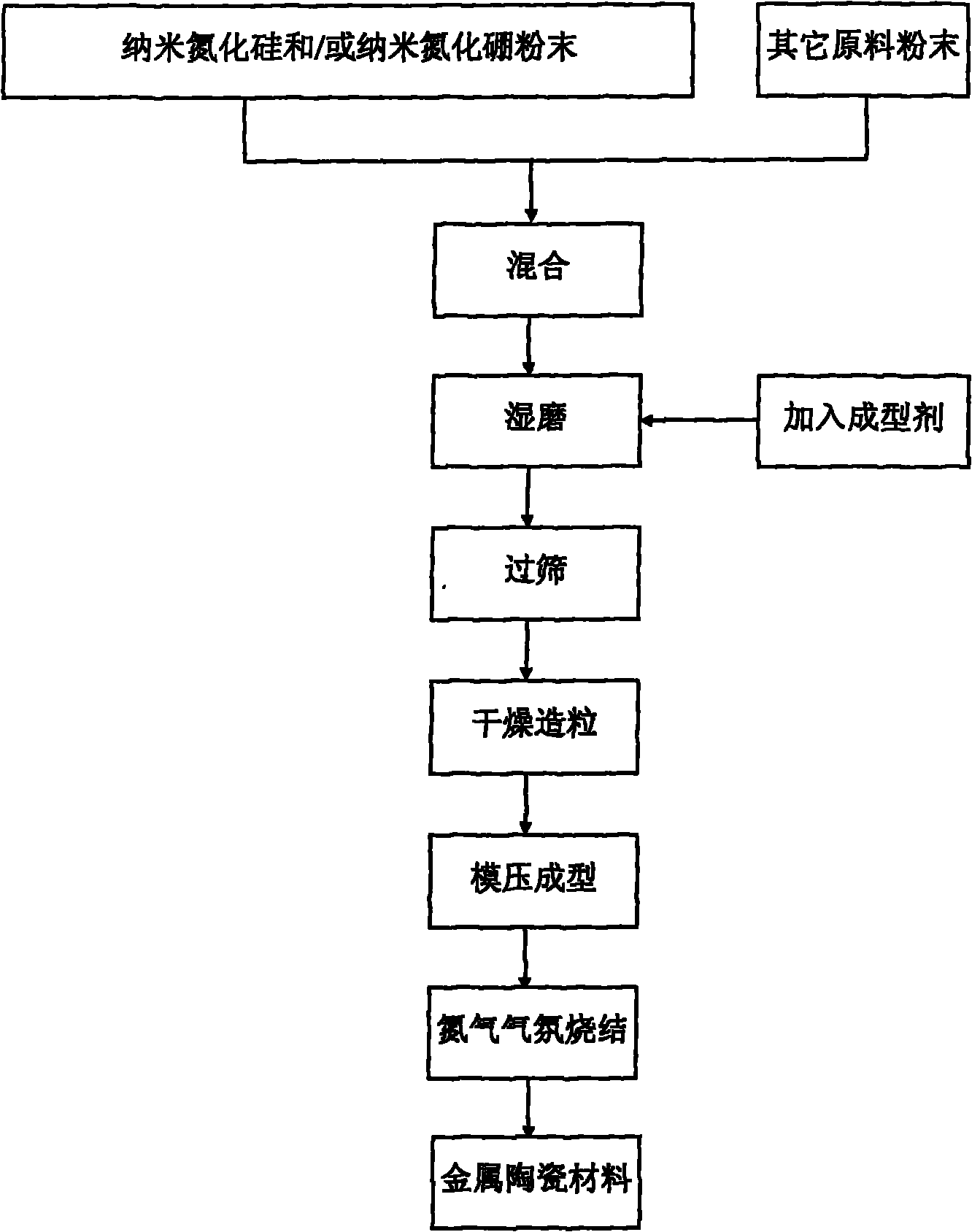

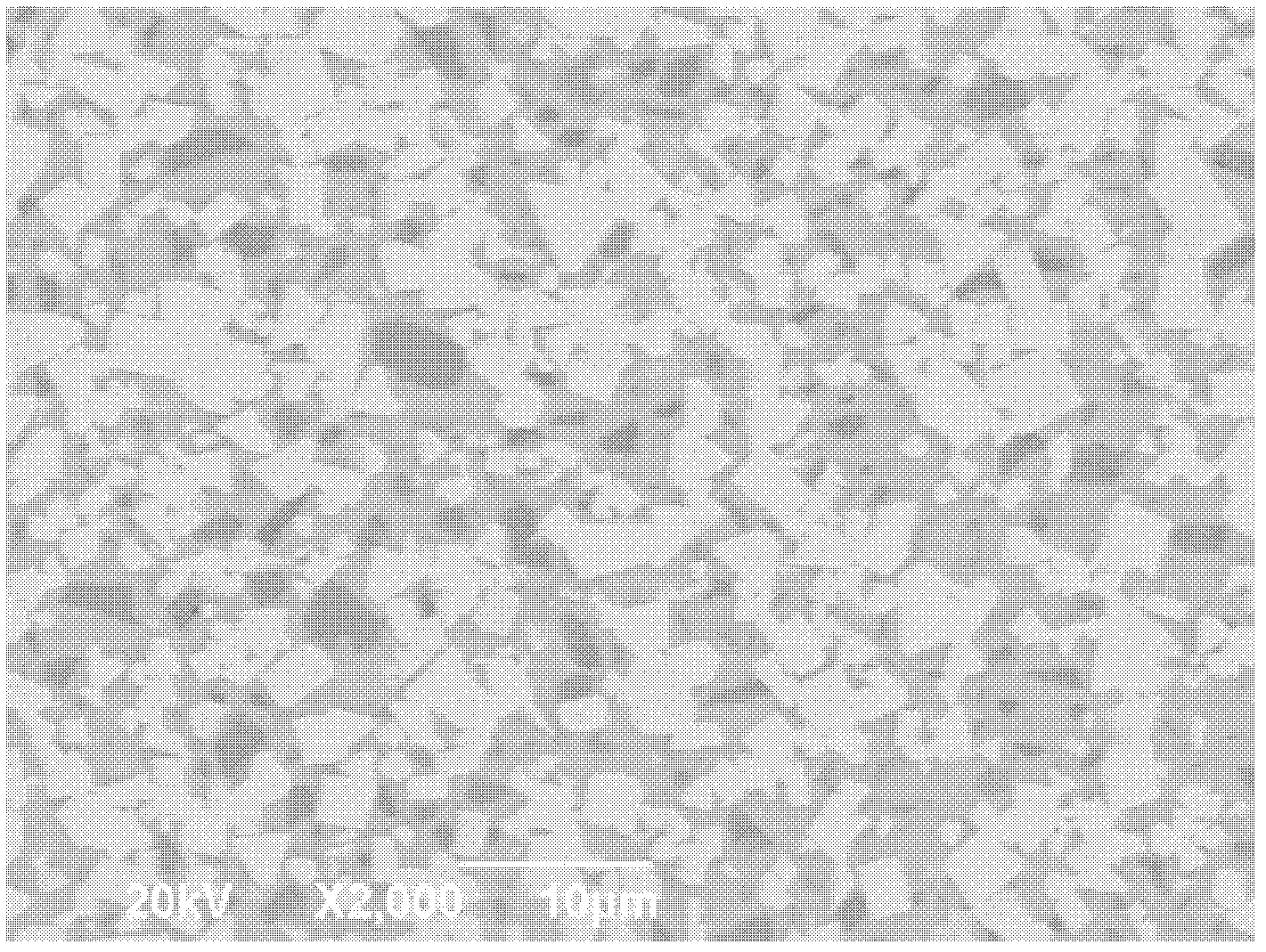

Nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet

The invention discloses a nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet. A reinforced phase is added into a base material having a main phase of titanium carbonitride Ti(C, N) and a binder phase of nickel and cobalt metals, is at least one of nano silicon nitride and nano boron nitride, and is 0.5 to 2.5 volume percent of the base material. The preparation method comprises the following process flows: preparing raw material powder containing the nano silicon nitride and / or nano boron nitride; mixing; adding a forming agent; performing wet grinding; sieving; drying and granulating; performing compression molding; sintering in nitrogen; and obtaining the cermet. The cermet has the advantages of high hardness, high strength and high toughness, and can be widely applied to middle and low carbon steel and low alloy steel high-speed cutting tool materials; and the preparation process is easy to control and is suitable for large-scale industrial production.

Owner:XIAMEN UNIV OF TECH

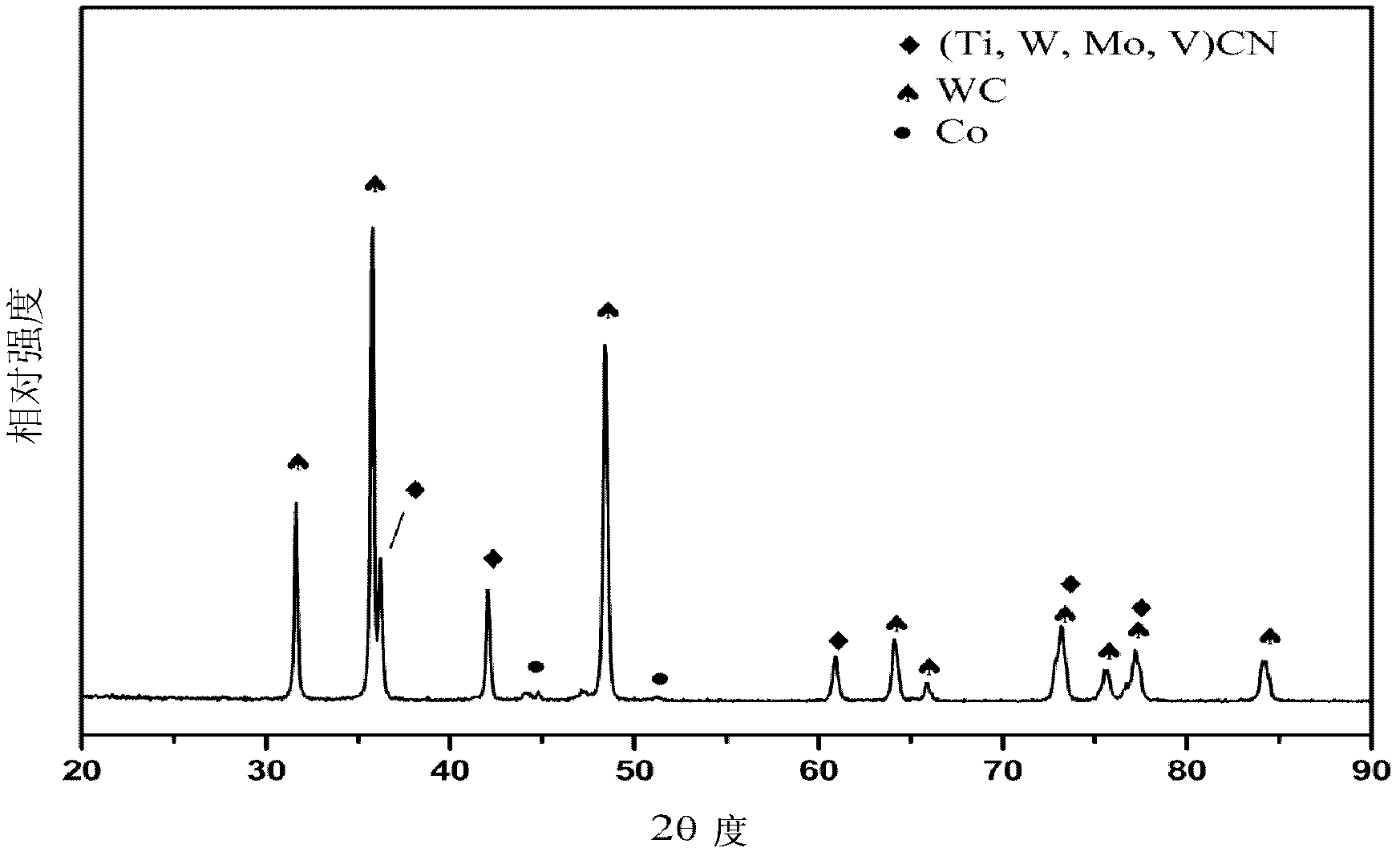

Nitrogen-containing hard alloy based on multi-element composite titanium carbonitride solid solution and preparation method for nitrogen-containing hard alloy

The invention discloses a nitrogen-containing hard alloy based on a multi-element composite titanium carbonitride solid solution. A hard phase of the alloy is WC and a solid solution (Ti, M) (Cx, N1-x); a binding phase is Co and / or Ni; the hard phase and the binding phase are uniformly distributed in the hard alloy; raw materials of the hard alloy are Co and / or Ni powder, WC powder and solid solution (Ti, M) (Cx, N1-x) powder, and the nitrogen element in the hard alloy is introduced through the solid solution (Ti, M) (Cx, N1-x) powder; and in the solid solution (Ti, M) (Cx, N1-x), x is more than 0 and less than 1, and a component M is at least two of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanides. A preparation method for the hard alloy comprises the following steps of: (1) mixing the raw materials and granulating; (2) molding; and (3) sintering under low pressure.

Owner:SICHUAN UNIV

Surface-coated cutting tool member having coating layer exhibiting superior wear resistance during high speed cutting operation and method for forming hard coating layer on surface of cutting tool

InactiveUS20050129986A1Pigmenting treatmentOther chemical processesTitanium carbonitrideBoron nitride

A surface-coated cutting tool member includes a tungsten carbide based cemented carbide substrate, a titanium carbonitride based cermet substrate, or a cubic boron nitride based sintered substrate; and a hard coating layer of a nitride compound containing aluminum and titanium, formed on a surface of the substrate using a physical vapor deposition method in an overall average thickness of 1 to 15 μm. The hard coating layer has a component concentration profile in which maximum aluminum containing points and minimum aluminum containing points appear alternatingly and repeatedly at a distance from 0.01 to 0.1 μm in a direction of thickness of the hard coating layer. The amount of contained aluminum (or titanium) is changed from the maximum aluminum containing points to the minimum aluminum containing points. The maximum aluminum containing points satisfy a formula: (AlXTi1-X)N, wherein X is between 0.70 to 0.95. The minimum aluminum containing points satisfy a formula: (AlYTi1-Y)N, wherein Y is between 0.40 to 0.65.

Owner:MITSUBISHI MATERIALS CORP

Enhanced metal ceramic abrasion-resistant composite material and preparation method thereof

The invention discloses an enhanced metal ceramic abrasion-resistant composite material and a preparation method thereof. The composite material is composed of, by mass, 25-35 parts of nano molybdenum carbide, 15-25 parts of nano ceramic powder, 10-15 parts of glass fiber, 5-10 parts of cobalt, 10-15 parts of chrome, 10-15 parts of titanium carbonitride, 1-3 parts of zirconium oxide, 3-5 parts of silicon oxide, 8-10 parts of cerium oxide, 1-3 parts of aluminium oxide, 5-10 parts of niobium carbide, 5-15 parts of silicon carbide, 1-3 parts of vanadium carbide, 4-9 parts of copper, 1-5 parts of titanium powder, 1-5 parts of coupling agents, 1-3 parts of antistatic agents and 1-3 parts of curing agents. The preparation method of the enhanced metal ceramic abrasion-resistant composite material just comprises mixing, drying, sintering and cooling. The metal ceramic composite material has good properties that the bending resistant strength is up to 2500 MPa and the Rockwell hardness is up to 93; in addition, the metal ceramic composite material also has good properties of abrasion resistance and high temperature resistance; the preparation method is simple and feasible and suitable for application and popularization on a large scale.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Titanium carbonitride base metal ceramic machinery sealing material and preparation method thereof

InactiveCN101265543AImprove mechanical propertiesTaking into account high temperature resistanceTitanium carbonitrideHardness

The invention relates to an engineering material, particularly to a titanium carbonitride-base metal ceramic material for sealing pumps, valves and other machines. The titanium carbonitride-base metal ceramic material is prepared from Ti (C, N) powder, which has wide sources and low cost, as basic material, and binder, inhibitor and other additives as adjuvant materials. The preparation method comprises the steps of completely mixing the raw materials in ethanol or acetone solvent, drying, pressure moulding, placing the obtained blank into a reaction furnace, performing liquid sintering under vacuum or gaseous protection condition, and optimizing to obtain dense material with high hardness, and high bending strength and fracture toughness property. The inventive material has the advantages of resistance against high temperature, corrosion and abrasion, and low cost; and can be used for sealing pumps, valves and other machines. The preparation method has the advantages of simple process and applicability to industrial production; and has wide market application prospect.

Owner:SICHUAN UNIV

Surface-coated cermet cutting tool with a hard coating layer exhibiting excellent chipping resistance

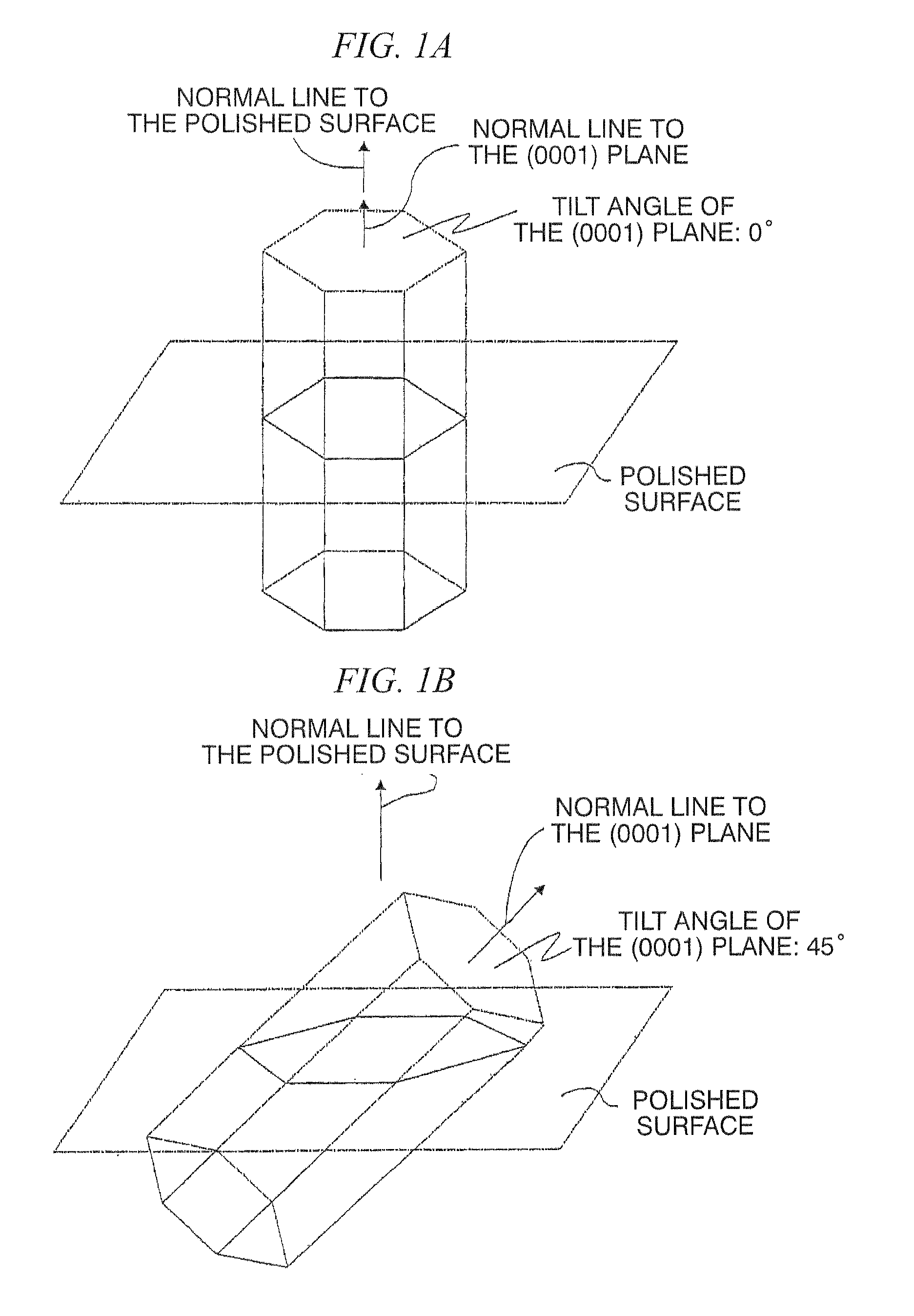

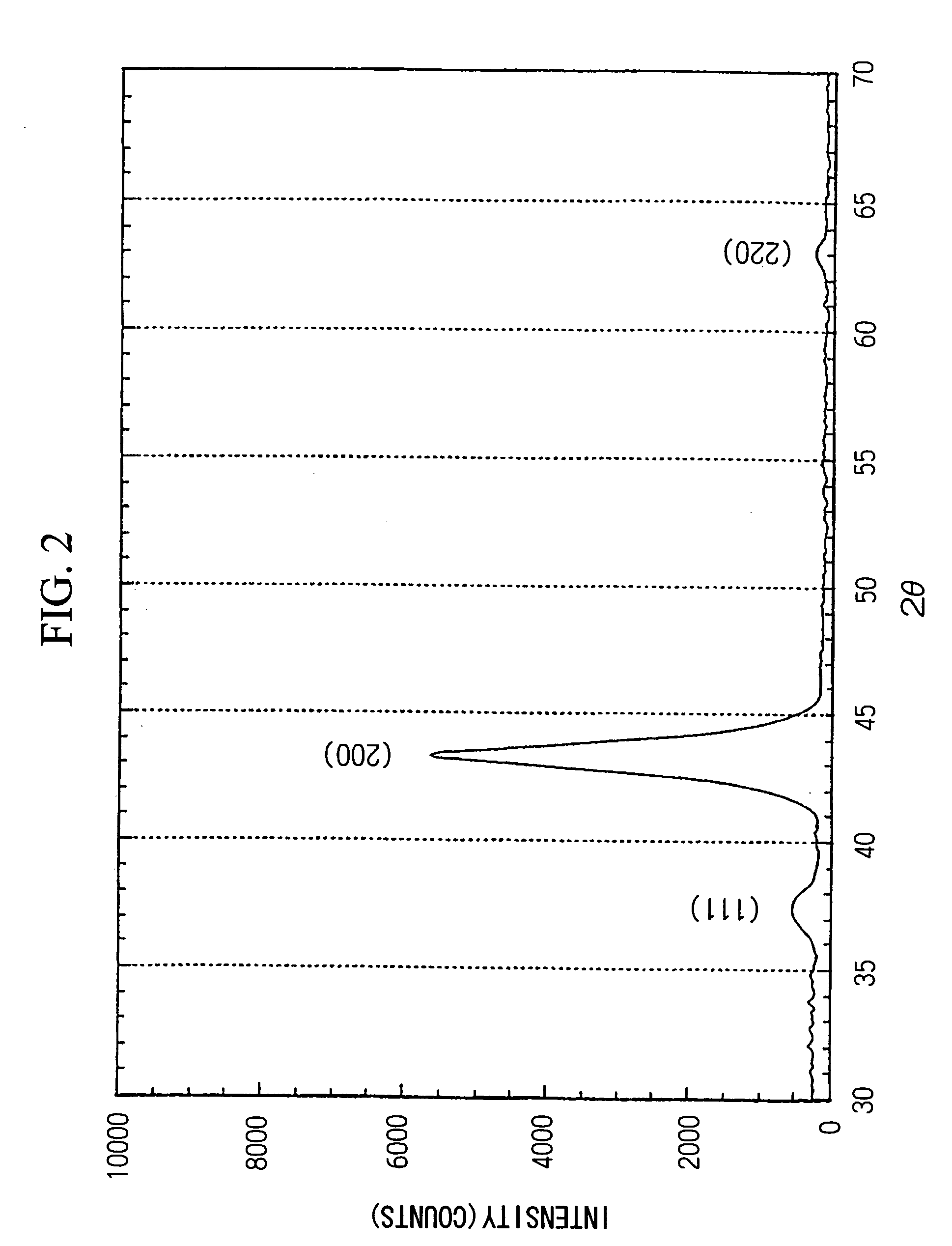

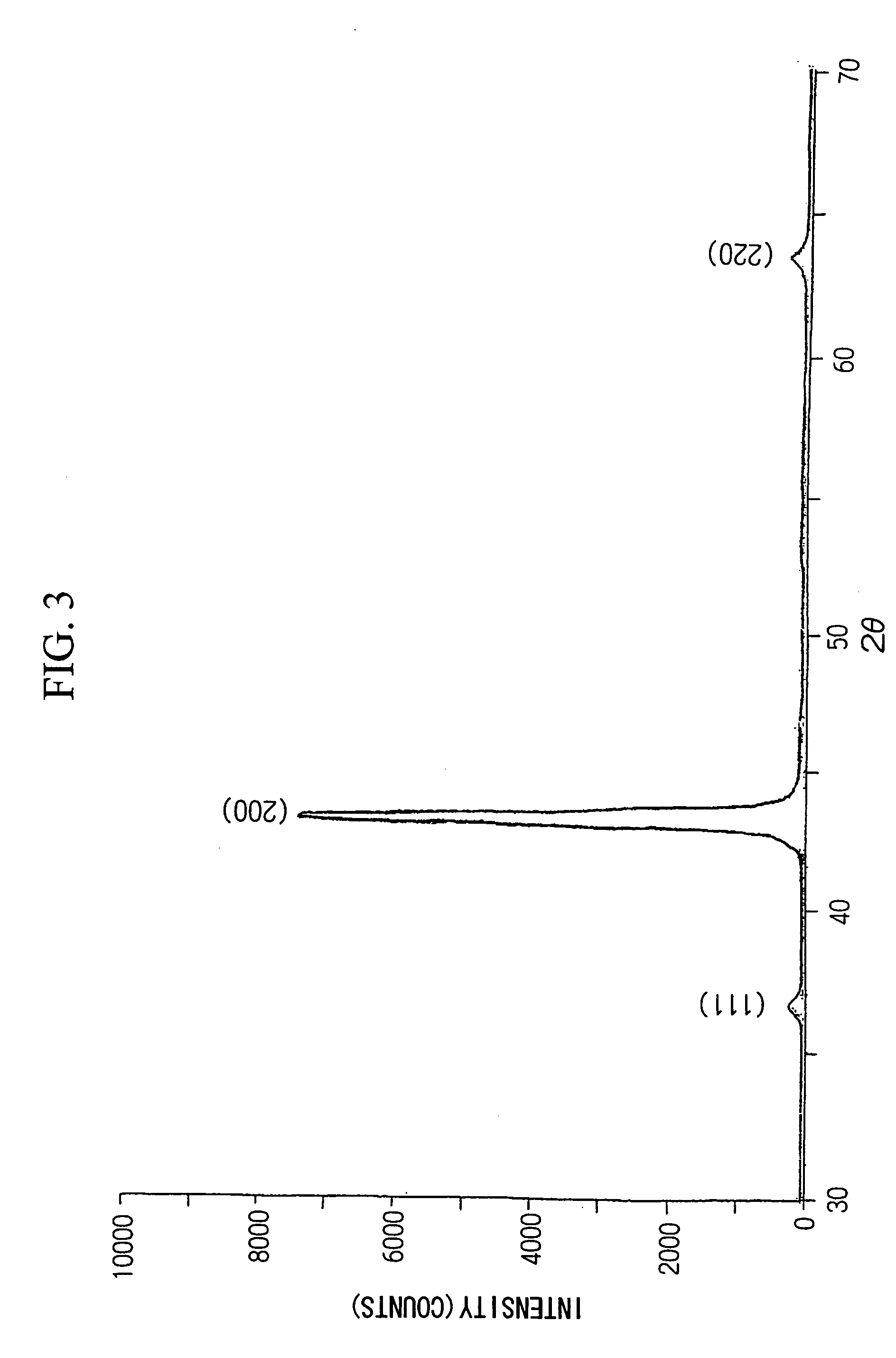

ActiveUS7276301B2Improve chip resistancePigmenting treatmentOther chemical processesCrystal structureTitanium nitride

A surface-coated cermet cutting tool with a hard-coating layer having excellent chipping resistance. The hard coating layer is formed on a surface of a tool substrate that constitutes the surface-coated cermet cutting tool. The hard coating layer includes(a) as the lower layer, a titanium compound layer having at least one or two of a titanium carbide layer, a titanium nitride layer, a titanium carbonitride layer, a titanium carboxide layer and a titanium oxycarbonitride layer, and (b) as the upper layer, a heat-transformed α-type Al—Zr oxide layer formed by carrying out a heat-transforming treatment in a state that a titanium oxide layer satisfying the composition formula: TiOY, ¥ The heat-transformed α-type Al—Zr oxide layer is chemically deposited on a surface of an Al—Zr oxide layer having a κ-type or θ-type crystal structure and satisfying the composition formula: (Al1−XZrX)2O3 to transform the crystal structure of the Al—Zr oxide layer having the κ-type or θ-type crystal structure into an α-type crystal structure.

Owner:MITSUBISHI MATERIALS CORP

Titanium carbide nitride slide board fire resistant material and preparation method thereof

The invention discloses a titanium carbonitride sliding fireproof material and making method, which comprises the following parts: 65-80wt% corundum, 1-20wt% one or more component of zirconium dioxide or zirconium corundum or zirconium mullite, 1-10wt% alumina micro-powder, 0. 2-5wt% titanium oxide powder, 0-5wt% boron carbide powder, 0-5wt% carborundum powder, 0. 5-5wt% aluminium powder, 0. 5-5wt% silicon powder, 1-5wt% graphite and 2-6wt% organic connecting agent, wherein the materials are blended to smelt and mould, which are sintered under 1300-1600 deg. c. The invention saves manufacturing cost, which improves high-temperature strength and abrasion resistant.

Owner:WUHAN UNIV OF SCI & TECH

Nano WC-Co composite powder modified Ti(CN) based metal ceramic and preparation thereof

The invention discloses a nanometer WC-Co composite powder modified Ti(CN) based cermet and the preparing method thereof. Titanium carbonitride is used as the main parent metal, metal cobalt and / or nickel are / is used as the binder of raw material powder, carbide and tantalum-niobium sosoloid are used as the additive. The cermet is characterized in: the cermet is added with 6.0% to 27% by weight of raw material power nanometer WC-Co composite powder; the cermet is prepared with the raw material powder by ball grinding crushing, dispersing the nanometer WC-Co composite powder, uniformly mixing, press forming, vacuum or pressure sintering, etc. Compared with traditional cermet, since the cementing phase and the crystal boundary are strengthened, the nanometer WC-Co composite powder modified Ti(CN) based cermet has better wearing resistance, higher strength, fracture toughness and red hardness, thus a tool bit manufactured with the cermet has superior cutting property.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Boron-containing titanium carbide nitride based metal ceramic cutter material and preparation technique thereof

ActiveCN101255512AHigh thermal conductivityImprove high temperature strengthSingle substanceBoron carbide

The invention discloses a boracic titanium carbonitride based cermet tool bit material and the preparing method thereof. The tool bit material is based on carbonitride as the parent metal, characterized in the tool bit is composed of 0.005% to 0.25% by mass of boron, 6% to 11% by mass of C, 2% to 7% by mass of N, 35% to 70% by mass of Ti, 5% to 20% by mass of W, 0 to 12% by mass of Mo, 0 to 9% by mass of Ta, 1% to 7% by mass of Nb and 6% to 25% by mass of Co and Ni, wherein boron is prepared by adding one or more selected from single substance boron, titanium diboride, molybdenum boride, boron carbide and boric oxide which are in raw material power form. The tool bit material is prepared mainly by mixing the raw material, ball-milling dispersing, press forming, pre-sintering and high-temperature sintering, its high-temperature hardness, high-temperature strength, red hardness and inoxidability are obviously improved, the cutting speed is greatly increased, and the service life is notably entended.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Cermet insert and cutting tool

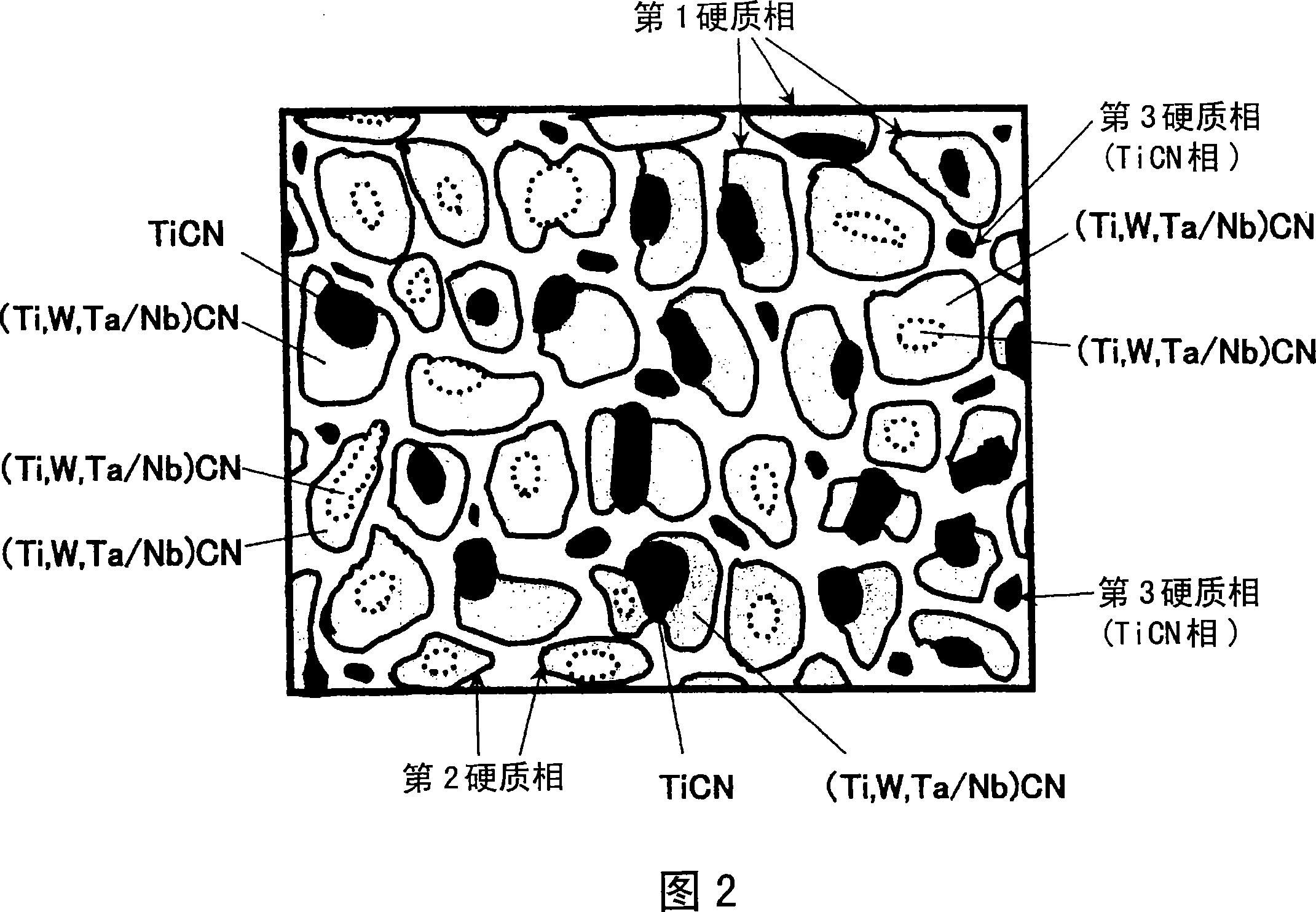

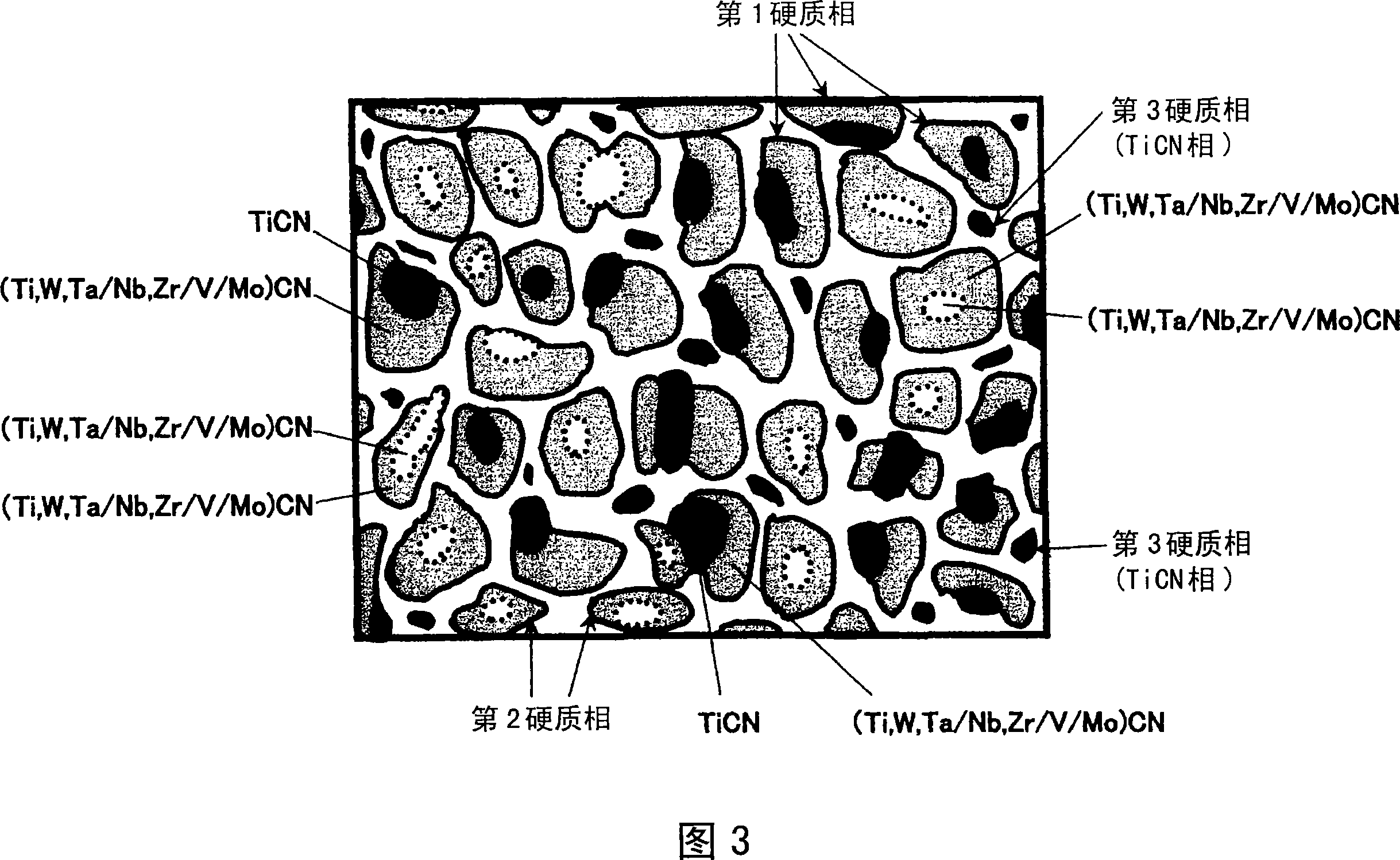

InactiveCN101189090AExcellent abrasion resistanceImprove wear resistanceTurning toolsCarbideTitanium carbonitride

One mode of the blade made of titanium carbonitride-based cermet is that it has a structure composed of 75-90 area % of hard phase and the balance is a binding phase. The hard phase has: the core is made of titanium carbonitride Phase composition, the peripheral part is composed of a first hard phase with a core structure composed of Ta and / or Nb, Ti, and W complex carbonitride (hereinafter expressed as (Ti, W, Ta / Nb)CN) phase; Both the core and the peripheral part are the second hard phase with a core structure composed of (Ti, W, Ta / Nb) CN phase; the third hard phase with a single-phase structure composed of TiCN phase, and the binding phase has: Co: 18-33%; Ni: 20-35%; Ta and / or Nb, and Ti, the total amount: 5% or less; W: 40-60%. Another form of the titanium carbonitride-based cermet blade is the sum of the value of Ti converted into carbonitride, the value of Ta and / or Nb converted into carbide, and the value of W converted into carbide It is 70-95% by mass, the value of W converted into carbide is 20-35% by mass, Co and Ni are 5-30% by mass, and have a structure composed of hard phase and binder phase. The hard phase has (Ti , W, Ta / Nb) CN, the binding phase is mainly composed of Co and / or Ni, and W, and 40-65% by mass of W is contained in the hard phase. This cutting tool has a holder and the cermet blade fixed by the holder.

Owner:MITSUBISHI MATERIALS CORP +1

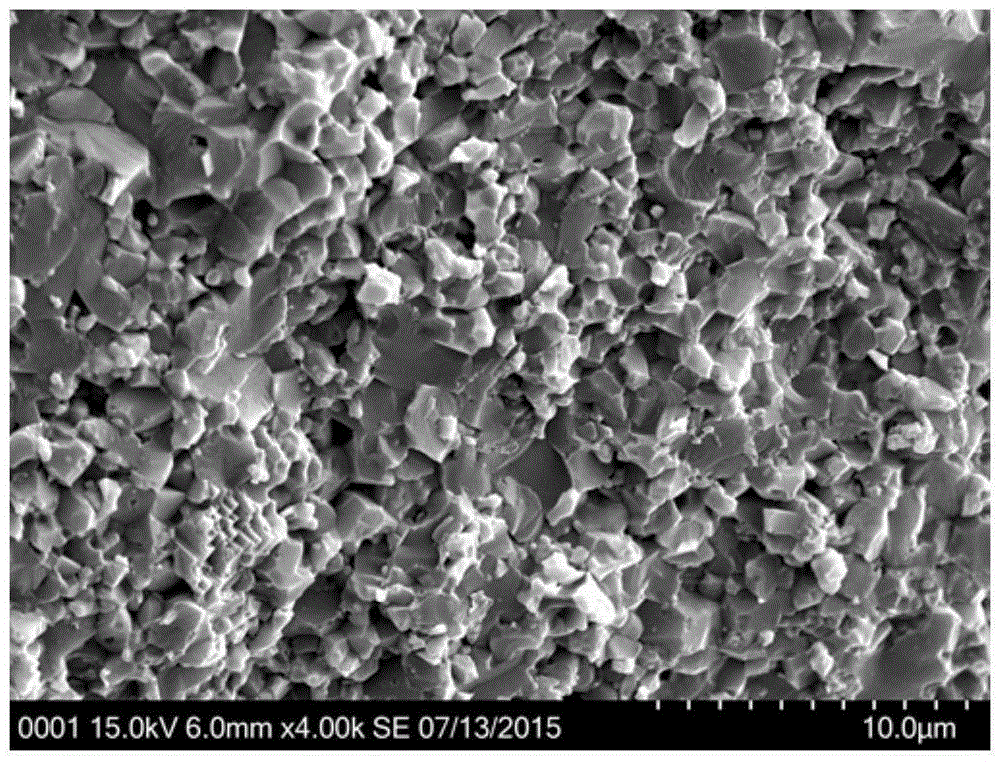

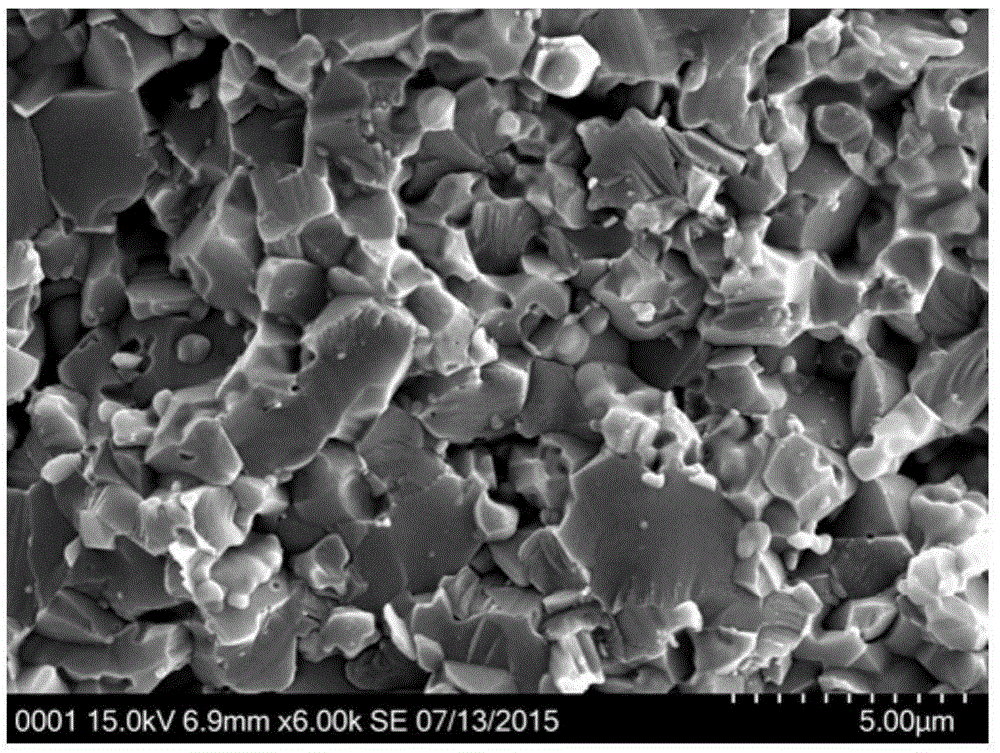

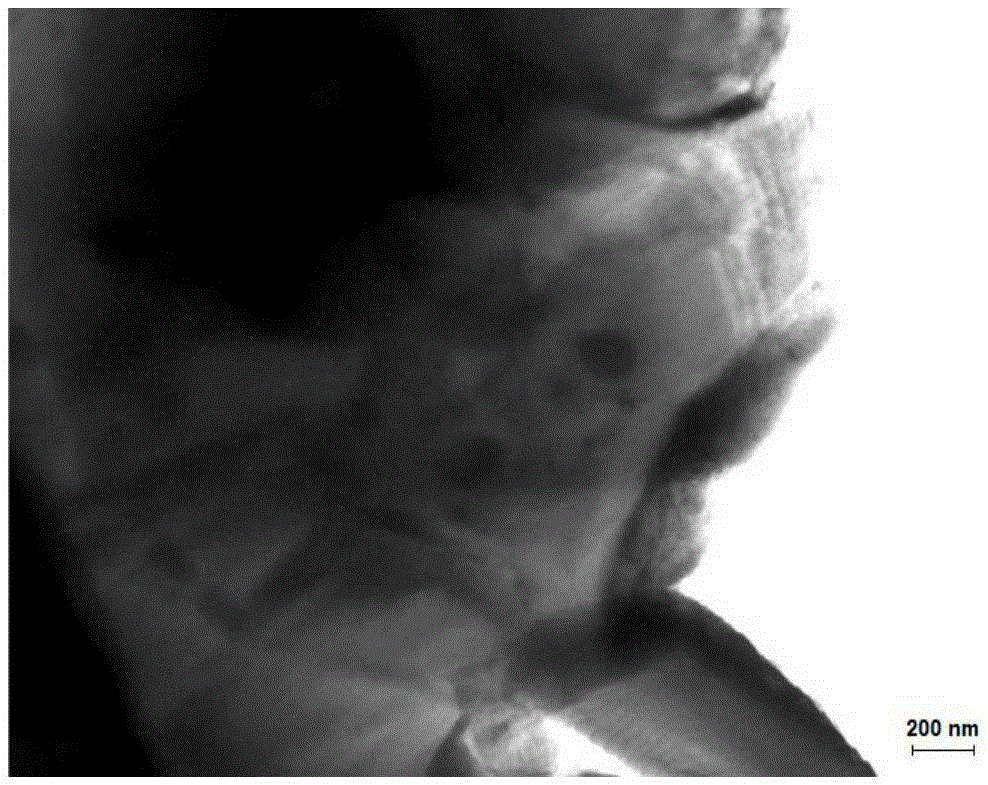

Method for preparing superfine titanium carbonitride

The invention belongs to the field of metal ceramic material preparation, and provides a method for preparing superfine titanium carbonitride. The method comprises the following steps of: firstly, ball-milling and mixing nano TiO2 with an organic carbon source, and preparing into a piece material in a cold pressing mode; feeding the piece material into a vacuum sensing furnace, vacuumizing till the pressure inside the furnace is less than or equal to 50Pa, increasing the temperature to 300-800 DEG C and preserving the temperature for 0.5-2h; subsequently increasing the temperature to be 1000-1900 DEG C and preserving the temperature for 0.5-2h, wherein vacuumizing is constantly performed in the temperature preservation process; stopping vacuumizing after the temperature preservation is accomplished, introducing nitrogen so as to make the pressure in the furnace be of 1.1-1.2 atmosphere pressures; preserving the temperature for 1-4h to sufficiently nitridize the raw material; and subsequently decreasing the temperature, taking out the piece material, crushing, ball-milling and grading so as to obtain the superfine titanium carbonitride of which the Fisher particle size is less than 1mm. A TiCN powder material prepared by using the method is high in purity, few in impurities, small in particle size, uniform in particle size distribution and spherical in morphology, and can be used as a raw material of a cutting tool, a metal ceramic, a spraying material and the like.

Owner:长沙伟徽高科技新材料有限公司

Cutting tool

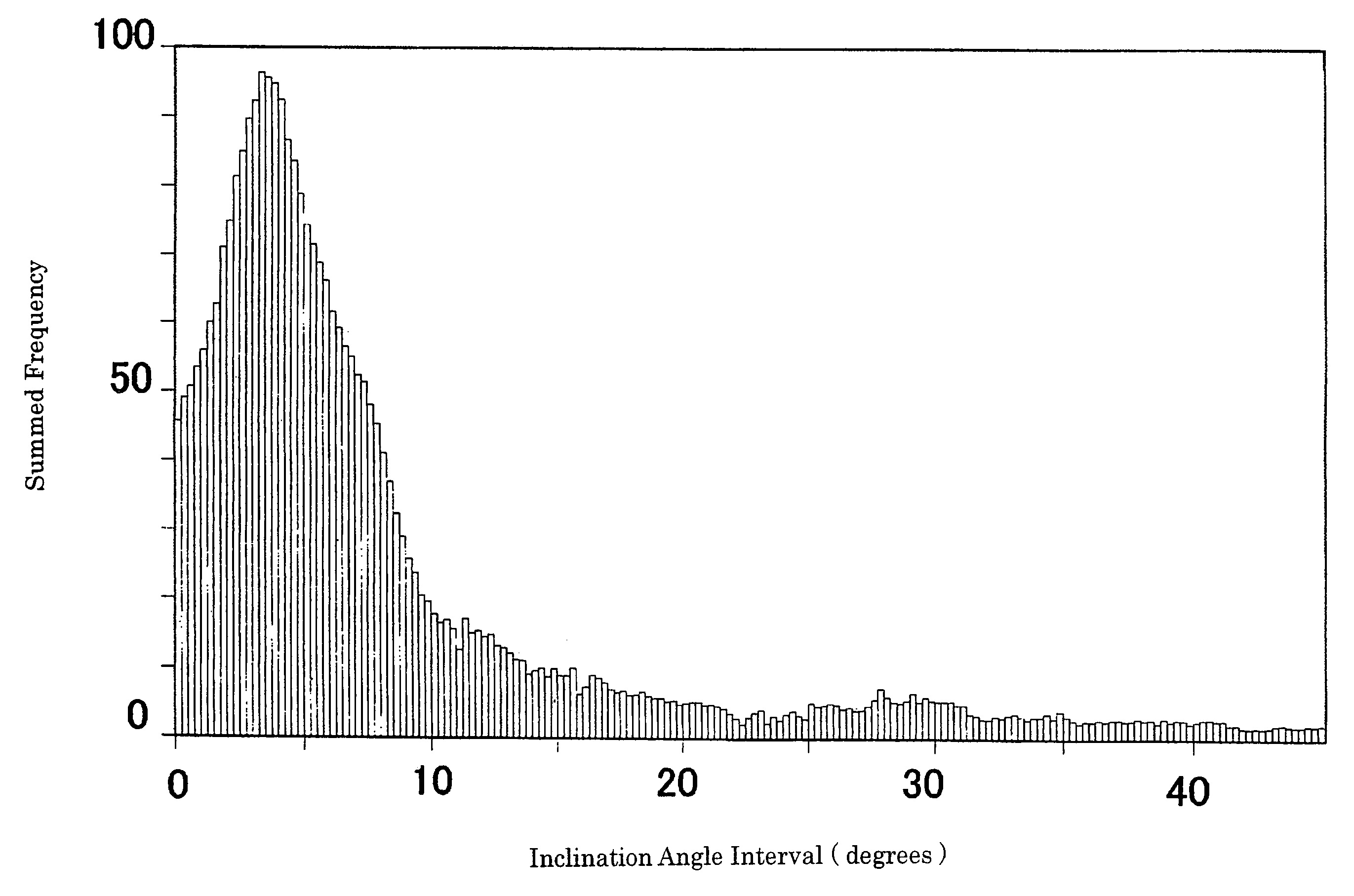

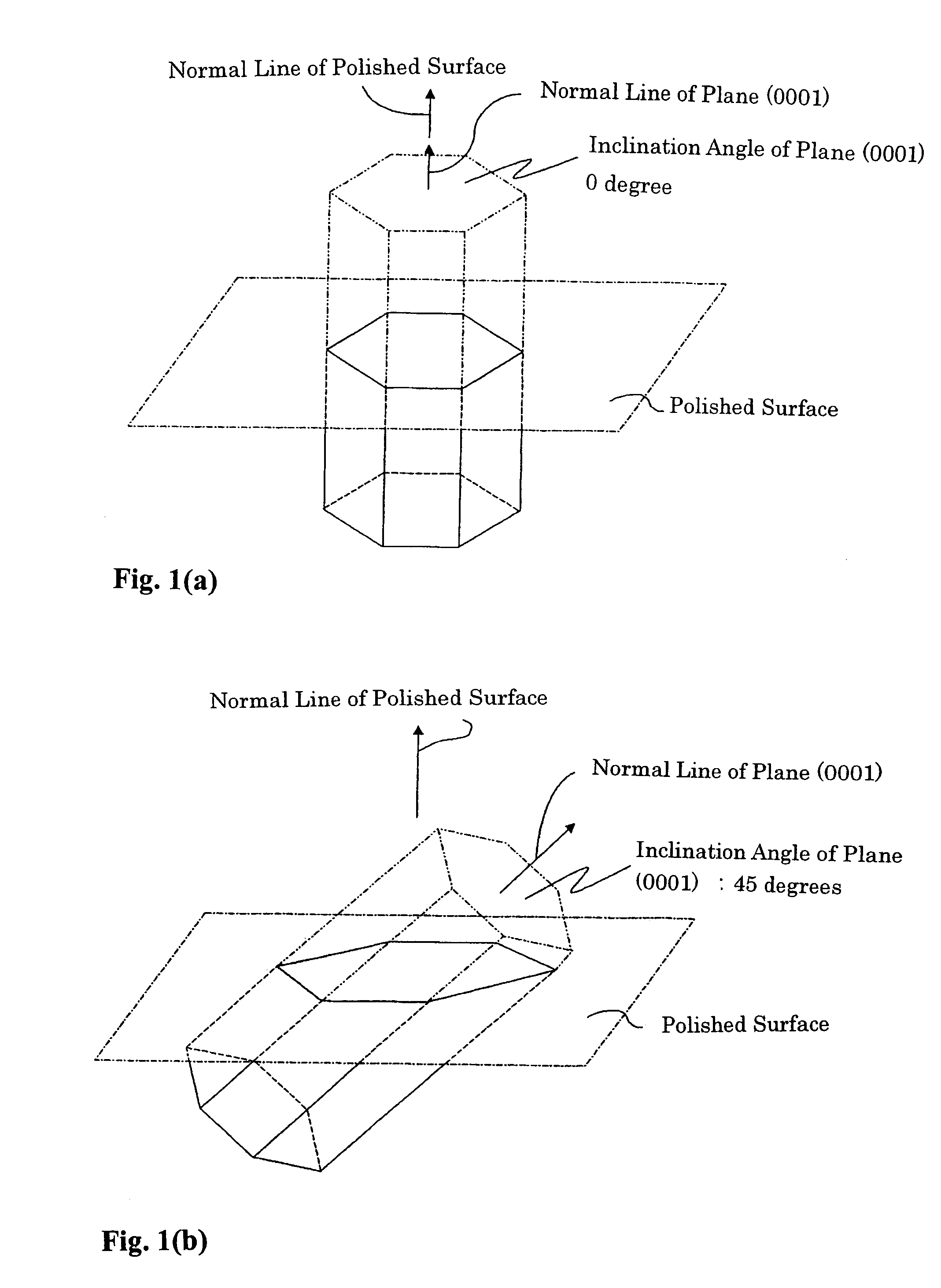

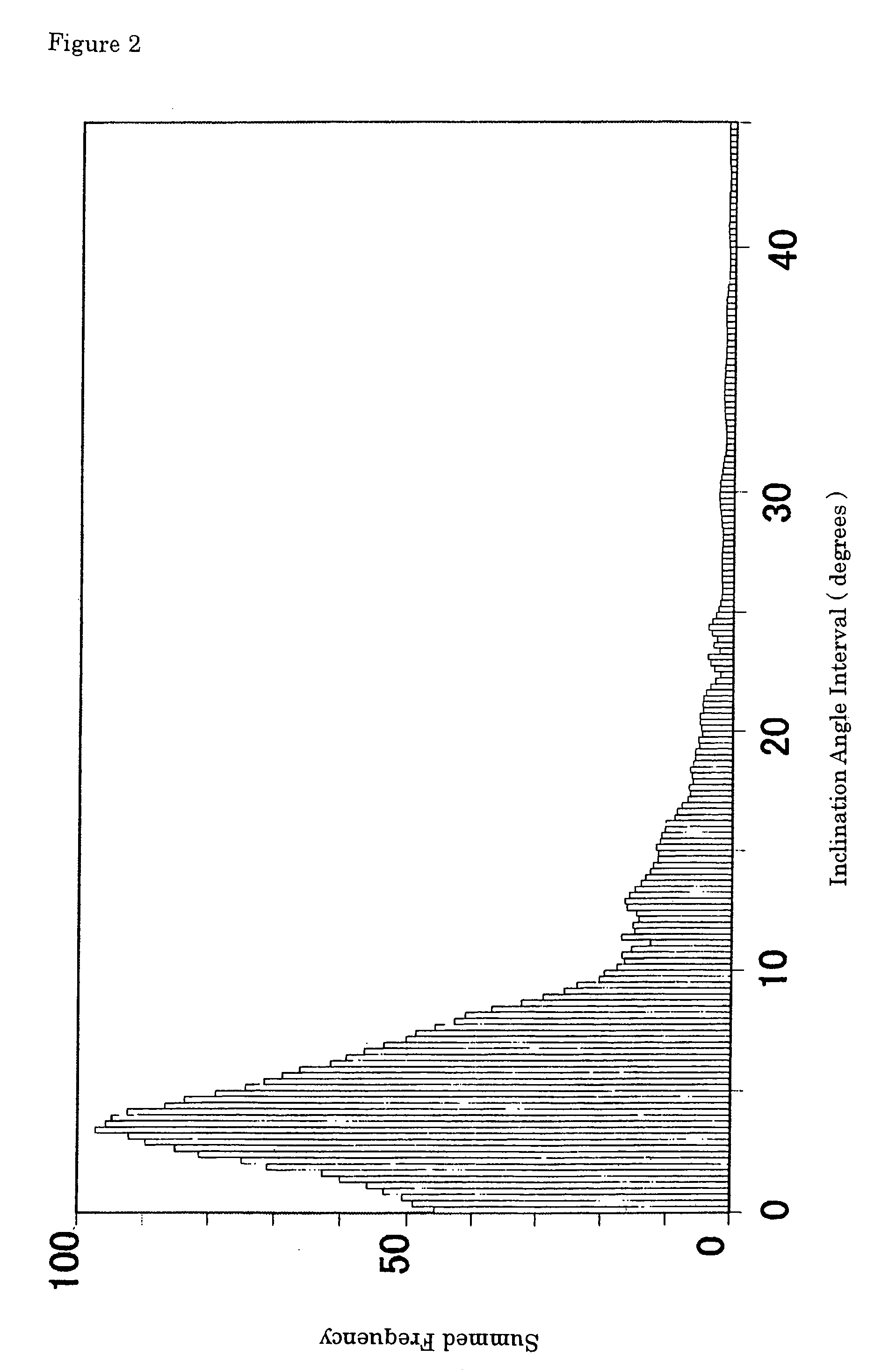

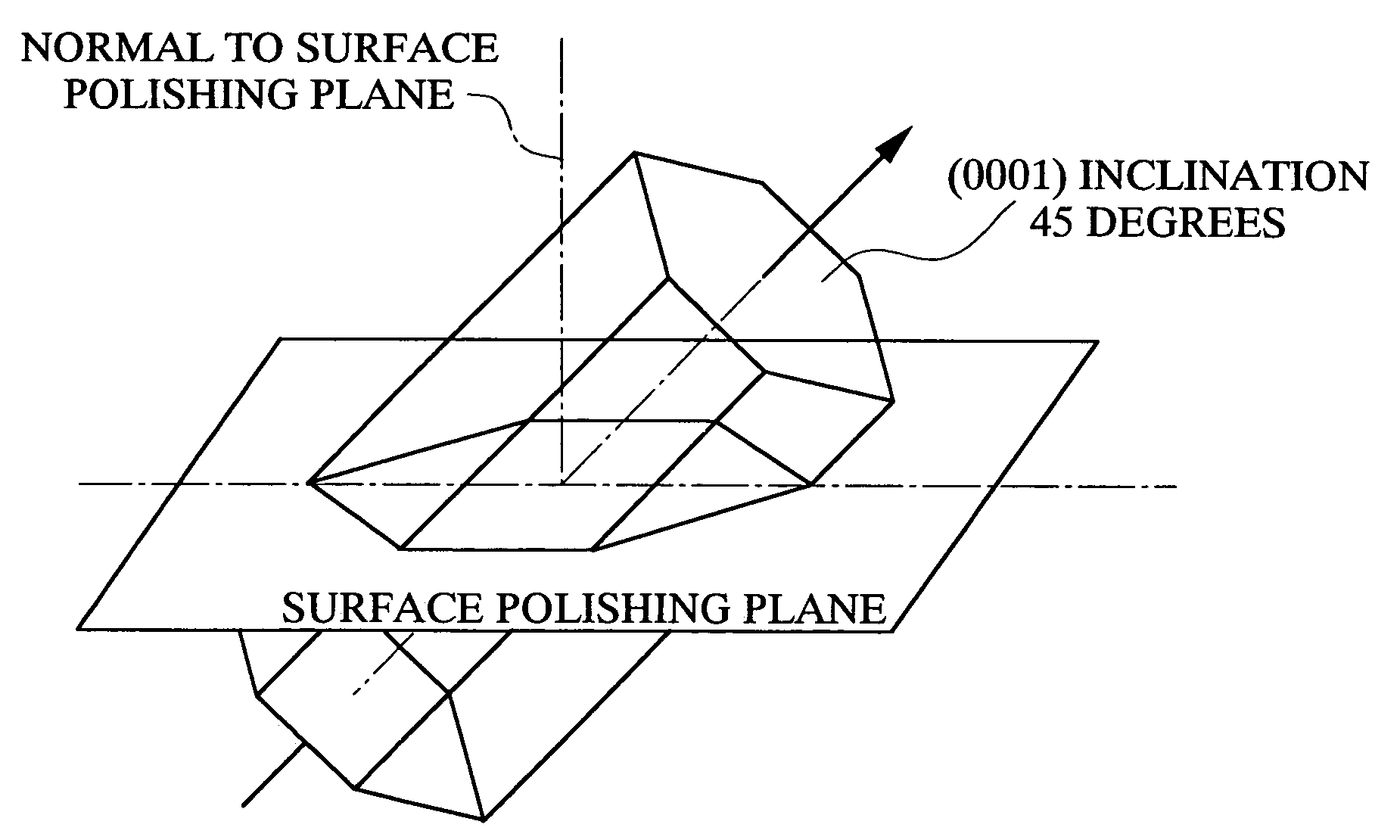

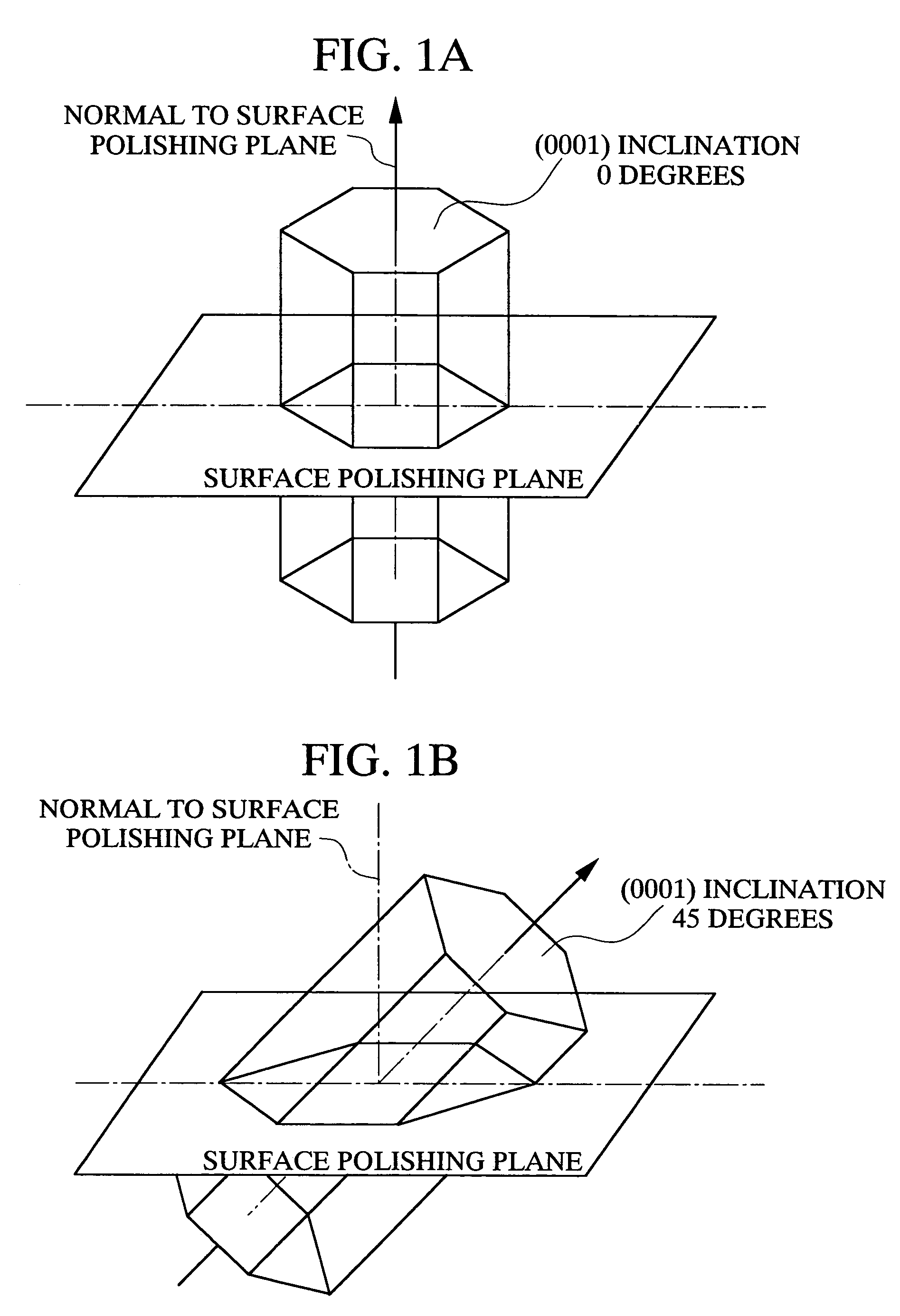

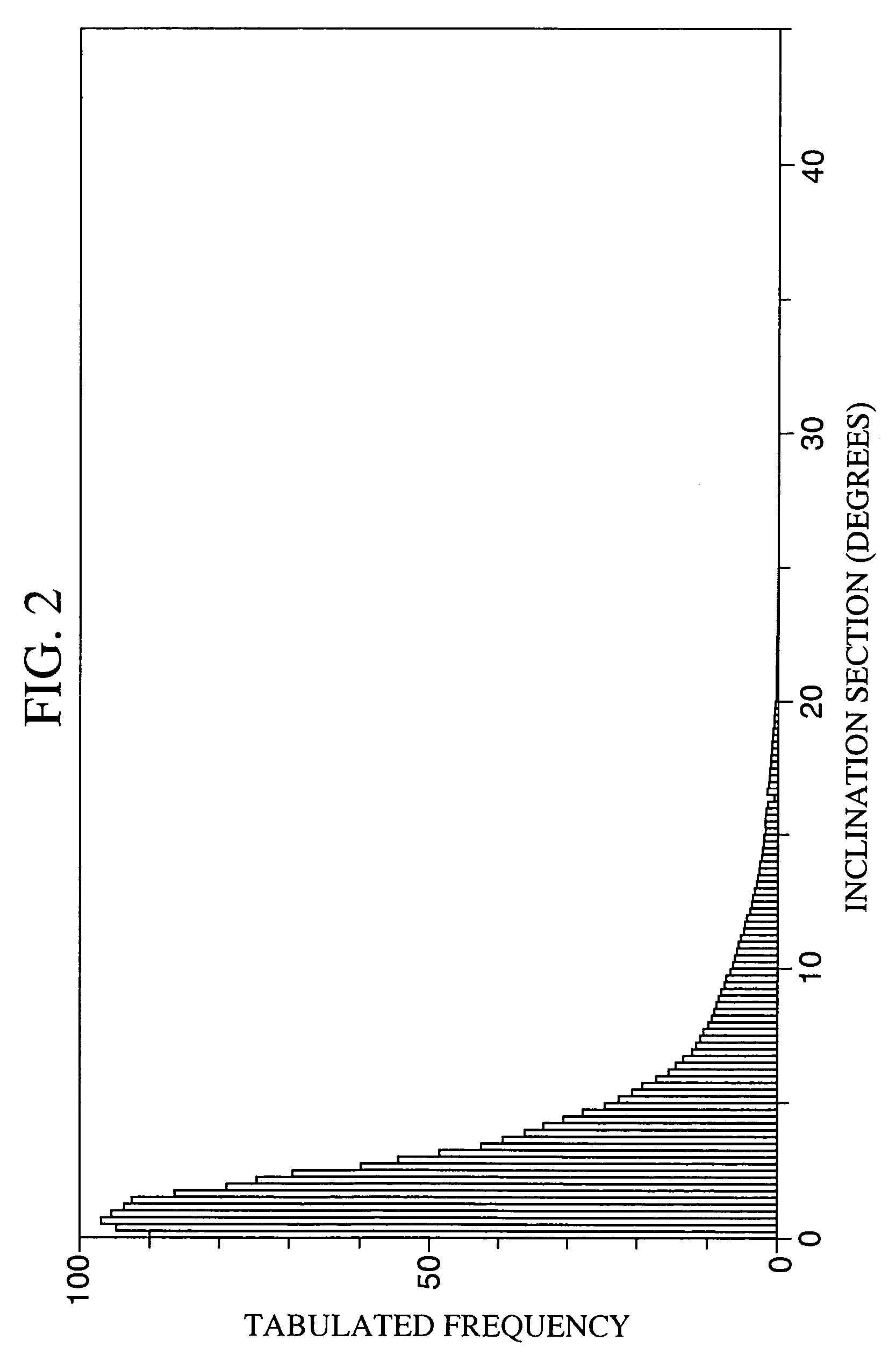

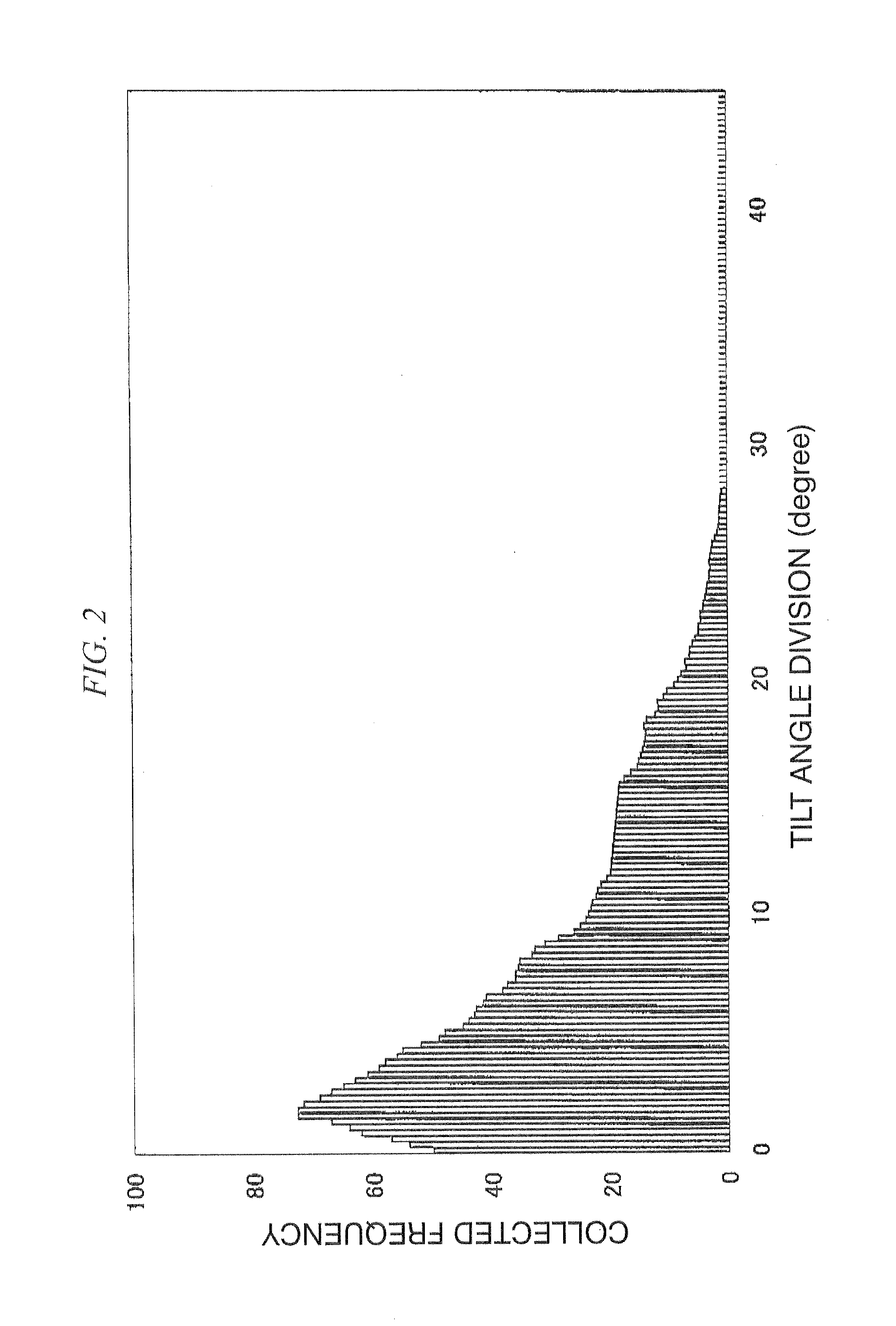

ActiveUS7201956B2Improve chip resistanceImprove cutting performancePigmenting treatmentMilling cuttersCrystal structureTitanium carbonitride

The present invention provides a cutting tool in which the hard coating layer demonstrates superior chipping resistance. The cutting tool has a tool base composed with tungsten carbide-based cemented carbide or titanium carbonitride-based Cermet, and a hard coating layer provided on the surface thereof; wherein the hard coating layer includes: (a) a Ti compound and / or Zr compound layer, which is a lower layer, comprising one or more layers of a TiC layer, TiN layer, TiCN layer, TiCO layer, TiCNO layer, ZrC layer, ZrN layer, ZrCN layer, ZrCO layer, ZrCNO layer and (b) an aluminum oxide layer having an α crystal structure which is an upper layer, including the highest peak in the inclination section within a range of 0–10.

Owner:MITSUBISHI MATERIALS CORP

Ti(C,N) base metal ceramic and preparation method thereof

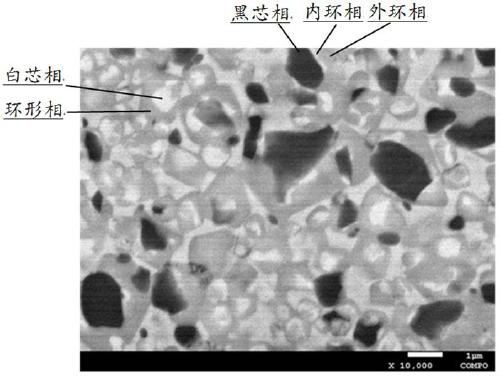

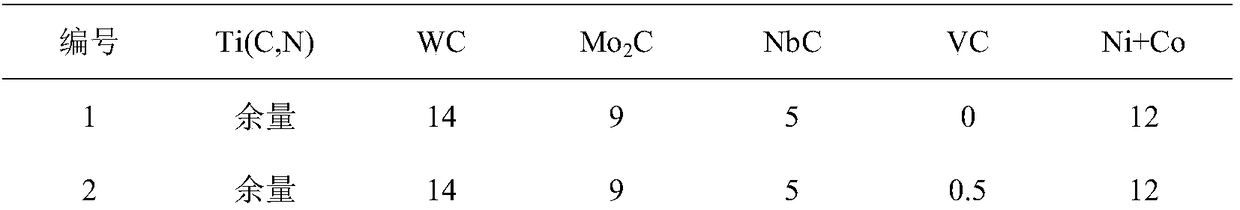

ActiveCN108950342AAdjust machinabilityMachinability satisfactionMilling cuttersWorkpiecesTitanium carbonitrideMolybdenum carbide

The invention discloses Ti(C,N) base metal ceramic and a preparation method thereof. Raw materials of the metal ceramic comprise titanium carbonitride Ti(0.5 of C and 0.5 of N), tungsten carbide WC, molybdenum carbide / molybdenum Mo2C / Mo, niobium carbide NbC, vanadium carbide VC, cobalt Co and nickel Ni powder, wherein the content of NbC ranges from 3 wt% to 15 wt%, the VC content is 0.3-3%, and the VC content changes along with the content of NbC. Hard phases formed by the materials are of two core-ring structures, one structure is a ring-shaped phase structure containing typical black core phases and inner ring phases, or outer ring phases and black core phases, and the other structure is a ring-shaped phase structure containing white core phases. The total credit of the black core phasesin the ring-shaped phase structure containing the black core phases and the inner ring phases, or the outer ring phases and the black core phases is 10-20%, the total credit of the inner ring phasesis 0.5-2%, and the total credit of the white core phases in the ring-shaped structure containing the white core phases is 5-10%. Chemical components of some or all white core phases are different fromthose of the inner ring phases, and the content of the Nb element in some or all white core phases is 30-40 wt% higher than the content of the Nb element in the inner ring phases. The Ti(C,N) base metal ceramic has thermal shock resistant performance and cutting performance.

Owner:CHINA THREE GORGES UNIV

Surface-coated cutting tool

ActiveUS20120003452A1Improve high temperature strengthImprove surface propertiesLayered productsTurning toolsTitanium nitrideTitanium carbonitride

A surface-coated cutting tool includes a tool substrate made of tungsten carbide-based cemented carbide or titanium carbonitride-based cermet; and a hard coating layer formed by vapor-depositing in order, a lower layer (a), an intermediate layer (b), and an upper layer (c) on the tool substrate. The lower layer (a) is a Ti layer composed of one or more of a titanium carbide layer, a titanium nitride layer, a titanium carbonitride layer, a titanium carboxide layer, and a titanium oxycarbonitride layer, and having a thickness of 3 to 20 μm. The intermediate layer (b) is an aluminum oxide layer having a thickness of 1 to 5 μm, and having an α-type crystal structure in a chemically vapor-deposited state. The upper layer (c) is an aluminum oxide layer having a thickness of 2 to 15 μm, and containing one or more elements of Ti, Y, Zr, Cr, and B.

Owner:MITSUBISHI MATERIALS CORP

Method for preparing reaction nitrogen arc surfacing titanium carbonitride reinforced titanium based complex coating

InactiveCN101590558AImprove production efficiencyEasy to prepareArc welding apparatusWelding/cutting media/materialsTitanium nitrideTitanium carbonitride

The invention provides a method for preparing a reaction nitrogen arc surfacing titanium carbonitride reinforced titanium based complex coating. The method comprises the following steps: adopting the prior direct current tungsten nitrogen arc welding equipment; taking tungsten electrode as cathode and substrate of titanium and titanium alloy as anode; using nitrogen arc surfacing under the protection of nitrogen gas; and performing the reaction on the surfaces of the substrates of titanium and titanium alloy to synthesize the titanium carbonitride reinforced titanium based complex coating. The titanium carbonitride reinforced titanium based complex coating prepared by the method has the advantages of large thickness, metallurgical bonding with the substrates, high bonding strength, high hardness of the coating, and good wear resistance.

Owner:HEBEI AGRICULTURAL UNIV.

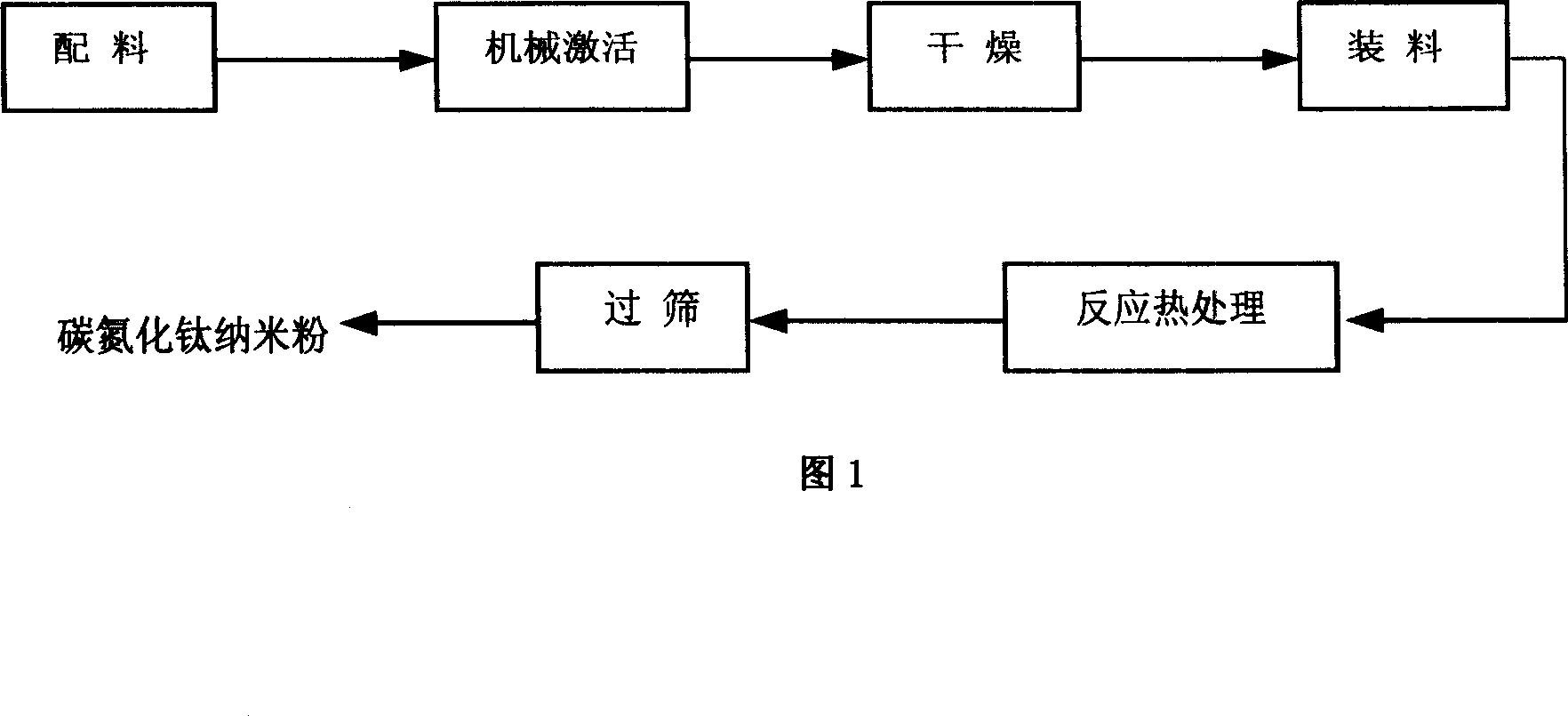

Mechanical activation-reaction heat treating preparation process of nanometer titanium carbonitride

InactiveCN1974403AGood dispersionThe temperature of the carbothermal nitriding reaction is loweredNitrogen compoundsTitanium compoundsGranularityTechnological factor

The mechanical activation-reaction heat treatment process of preparing nanometer titanium carbonitride powder with nanometer titania and nanometer carbon powder as material includes the technological steps of: compounding, mechanical activating, (drying,) loading, reaction heat treatment, and sieving. The process is simple, low in cost and easy in industrial scale production. By means of controlling C / Ti ratio, mechanical ball milling activation time, reaction heat treatment temperature and time, nitrogen pressure and other technological factors, nanometer titanium carbonitride powder in different carbon contents ay be synthesized. The prepared nanometer titanium carbonitride powder is spherical, and has high dispersivity, average granularity below 100 nm and purity over 99 %.

Owner:SICHUAN UNIV

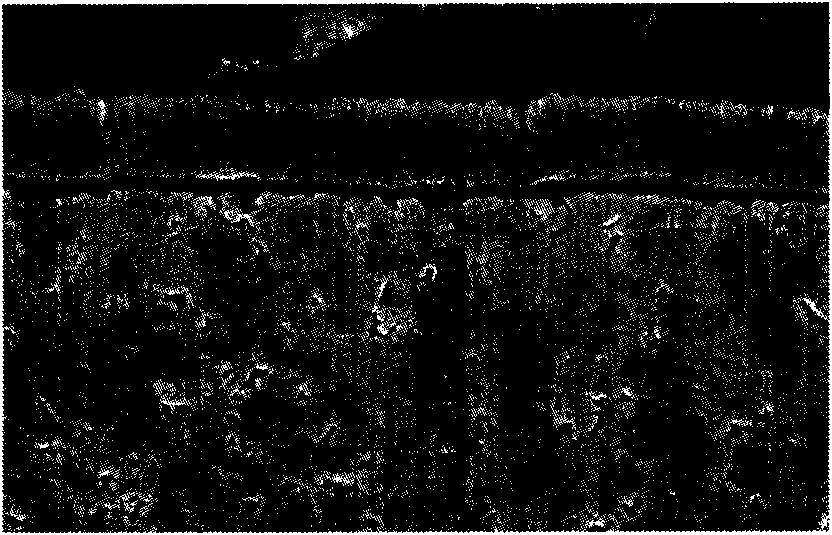

Etching agent for titanium carbonitride coating on surface of hard alloy cutter and method for using same

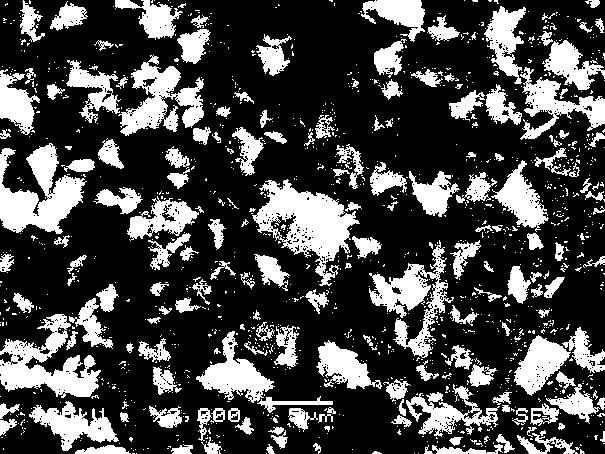

InactiveCN101603894ADistinguish grain boundariesMaterial analysis using wave/particle radiationPreparing sample for investigationHydrofluoric acidStructure analysis

The invention provides an etching agent for a titanium carbonitride coating on the surface of a hard alloy cutter and a method for using the same, and relates to a cutter coating etching agent, in particular to an etching agent formula for analyzing the microstructure of a MT-CVD titanium carbonitride coating on the surface of the hard alloy cutter and a method for using the same. The invention provides the etching agent for the titanium carbonitride coating on the surface of a hard alloy cutter, which can effectively show the microstructure of the MT-CVD titanium carbonitride coating on the surface of the hard alloy cutter, and a method using the same. The etching agent comprises the following components in portion by weight: 30 to 40 portions of nitric acid, 10 portions of hydrofluoric acid and 10 portions of water. The using method comprises the following steps of: sample preparation, namely hot-pressing, inserting, grinding and polishing; and etching operation, namely before etching, washing the sample, drying the sample, putting the sample in the etching agent for etching, taking the sample out, washing the sample, putting the sample in absolute ethyl alcohol for ultrasonic washing, drying the sample, storing the sample in a dryer and then observing the sample by a scanning electron microscope.

Owner:XIAMEN UNIV

Cutting tip of metal ceramic based on titanium carbonitride toughened by crystal whisker, and preparation method

This invention relates to a method for preparing SiC whiskers toughened Ti(CN)-based metal ceramic tool blade. The tool blade is composed of Ti (CN) as the major phase, SiC whiskers as the toughening agent, and metal binding phase and carbide hard phase as the additives. The method comprises: mixing the above components, molding, and sintering in vacuum to obtain a high compactness. Compared with traditional TN metal ceramic tool blade, the SiC whiskers toughened Ti(CN)-based metal ceramic tool blade has such advantages as high strength, high toughness, high wear resistance, high heat resistance, and high cuttability, and can be used for high speed milling, finish turning or semi-finish turning of carbon steel, stainless steel, hardened steel, wear-resistant cast iron and high-strength steel.

Owner:SECTION OF SCI & TECH DEV

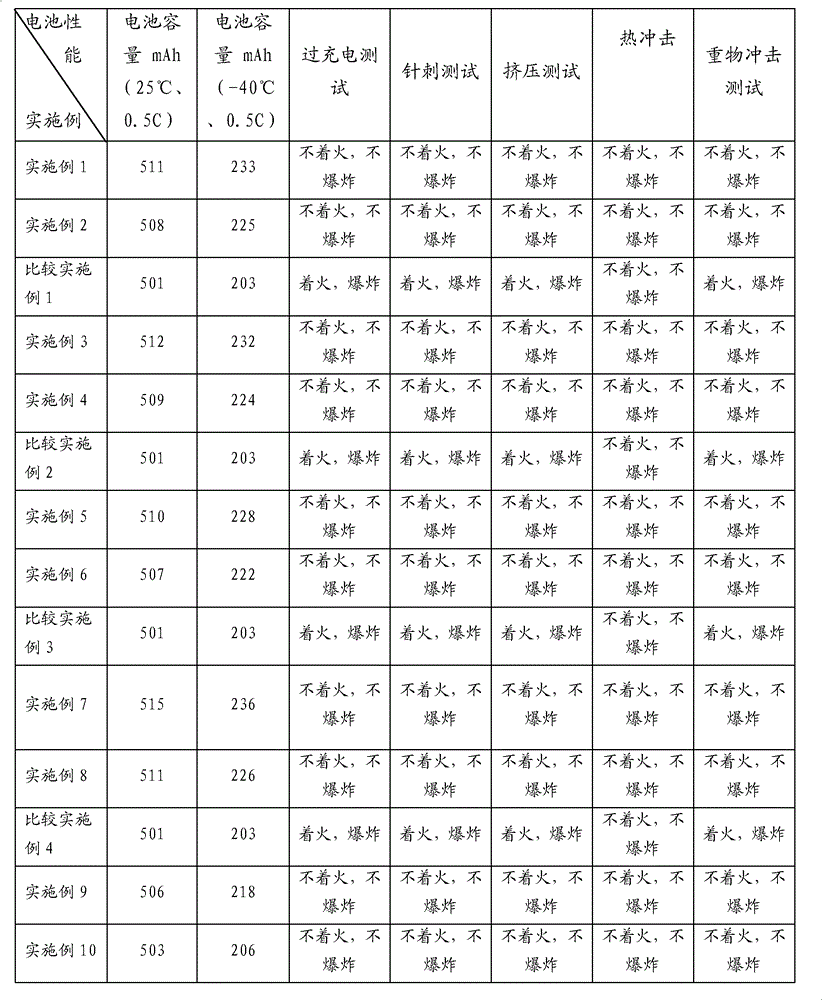

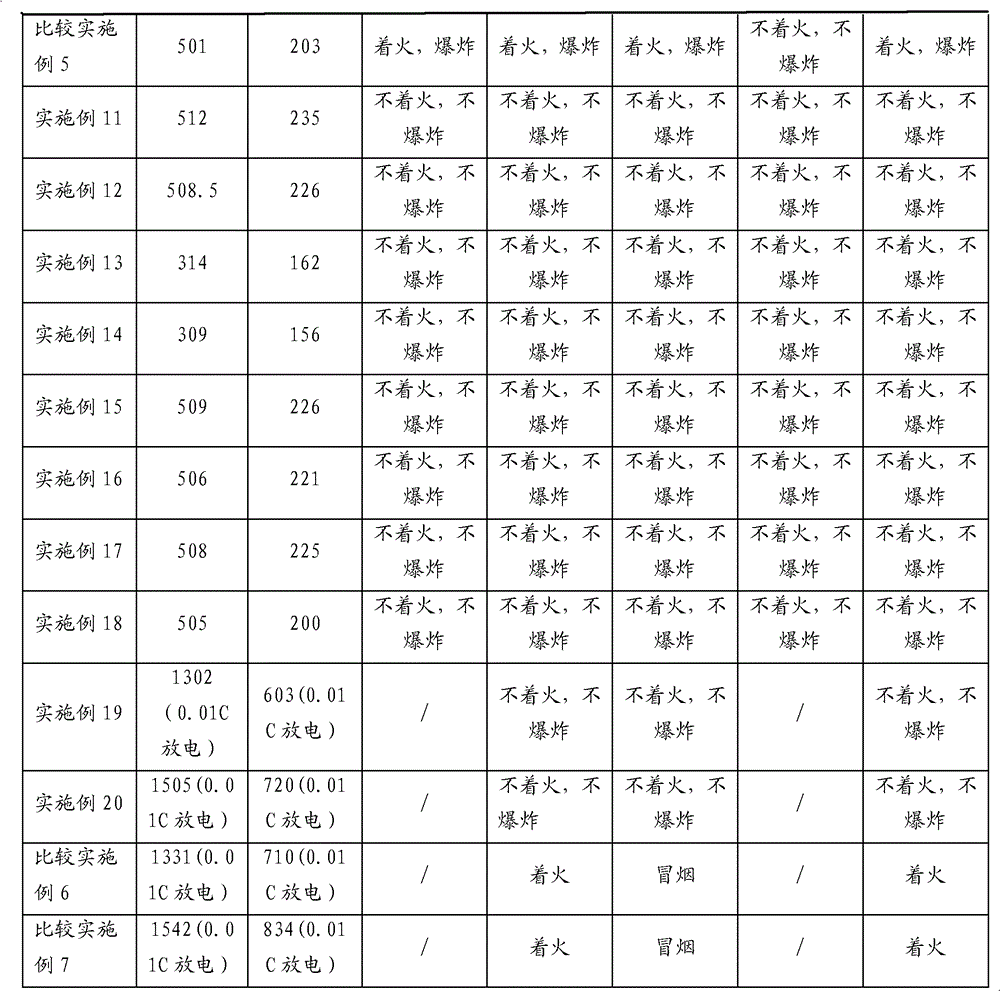

High capacity lithium ion battery containing metal conductive substances

ActiveCN102751530AImprove corrosion resistanceImprove antioxidant capacityCell electrodesSecondary cellsTitanium nitrideUranium carbide

The present invention discloses a high capacity lithium ion battery containing metal conductive substances. The battery comprises a positive electrode sheet, a negative electrode sheet, separation membranes, an electrolyte, a binder and a sealing material. A conductive substance of the positive electrode sheet comprises a metal carbide, a metal boride or a metal nitride. A conductive substance of the negative electrode sheet comprises a metal carbide, a metal boride or a metal nitride. The metal carbide is titanium carbonitride, tungsten carbide or titanium carbide, vanadium carbide, tantalum carbide, or a co-melting body of tungsten carbide and titanium carbide. The metal boride is a molybdenum boride, tungsten boride or vanadium boride. The metal nitride is titanium nitride, tungsten nitride or tantalum nitride. The conductive material of the positive electrode sheet further can contain powder metal, and the conductive material of the negative electrode sheet further can contain powdered metal, wherein the powdered metal is nickel powder, copper powder or chromium powder.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

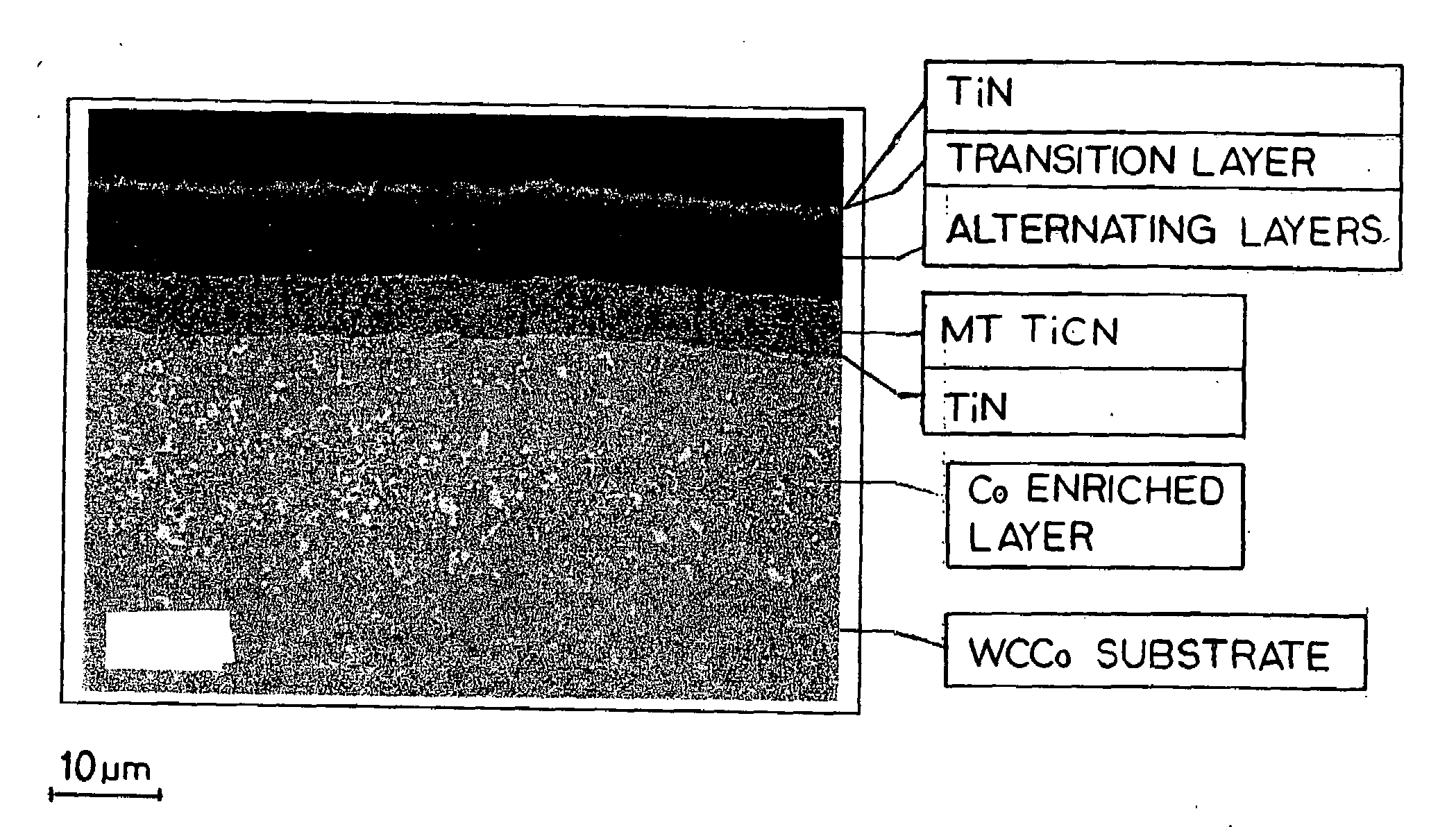

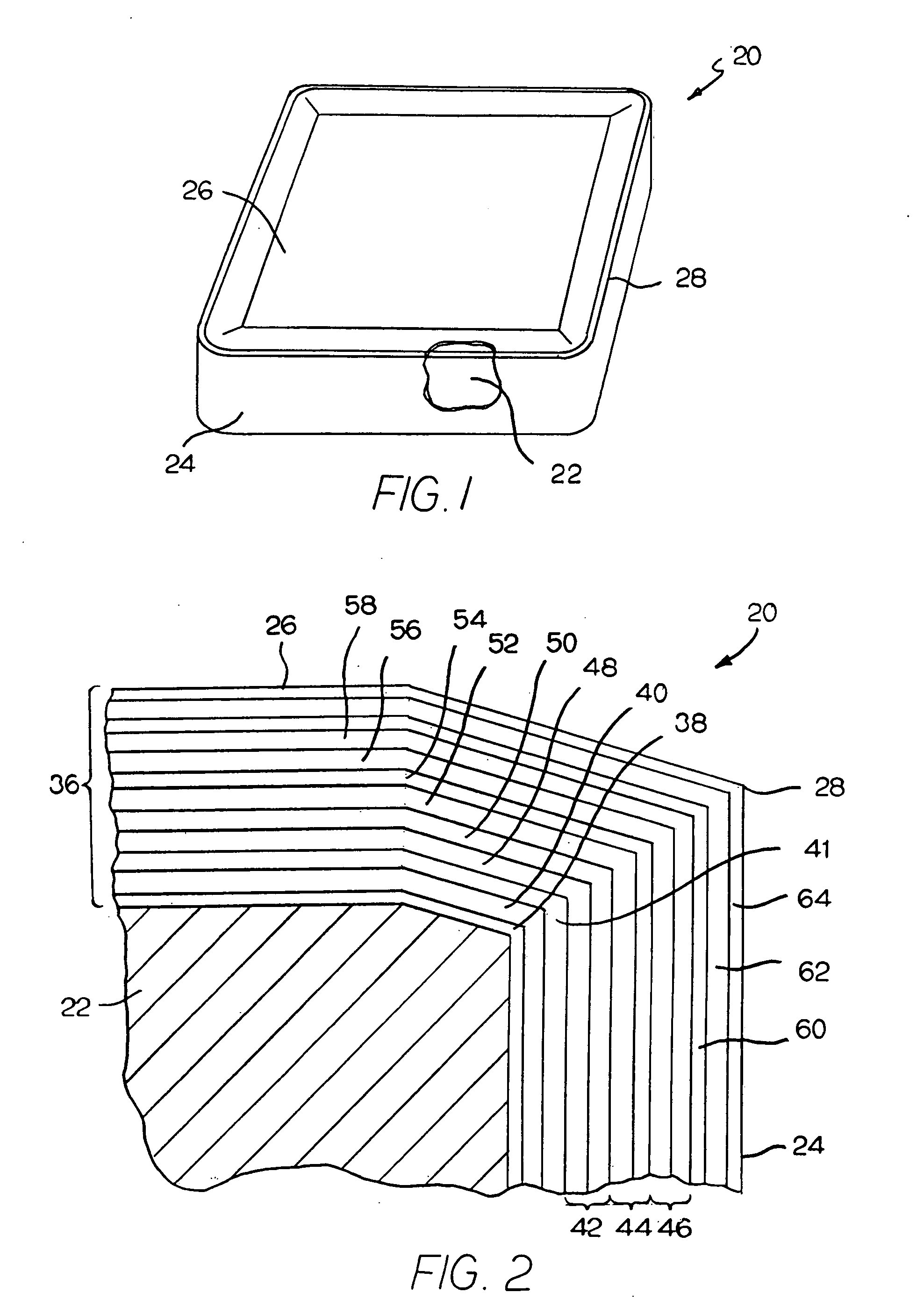

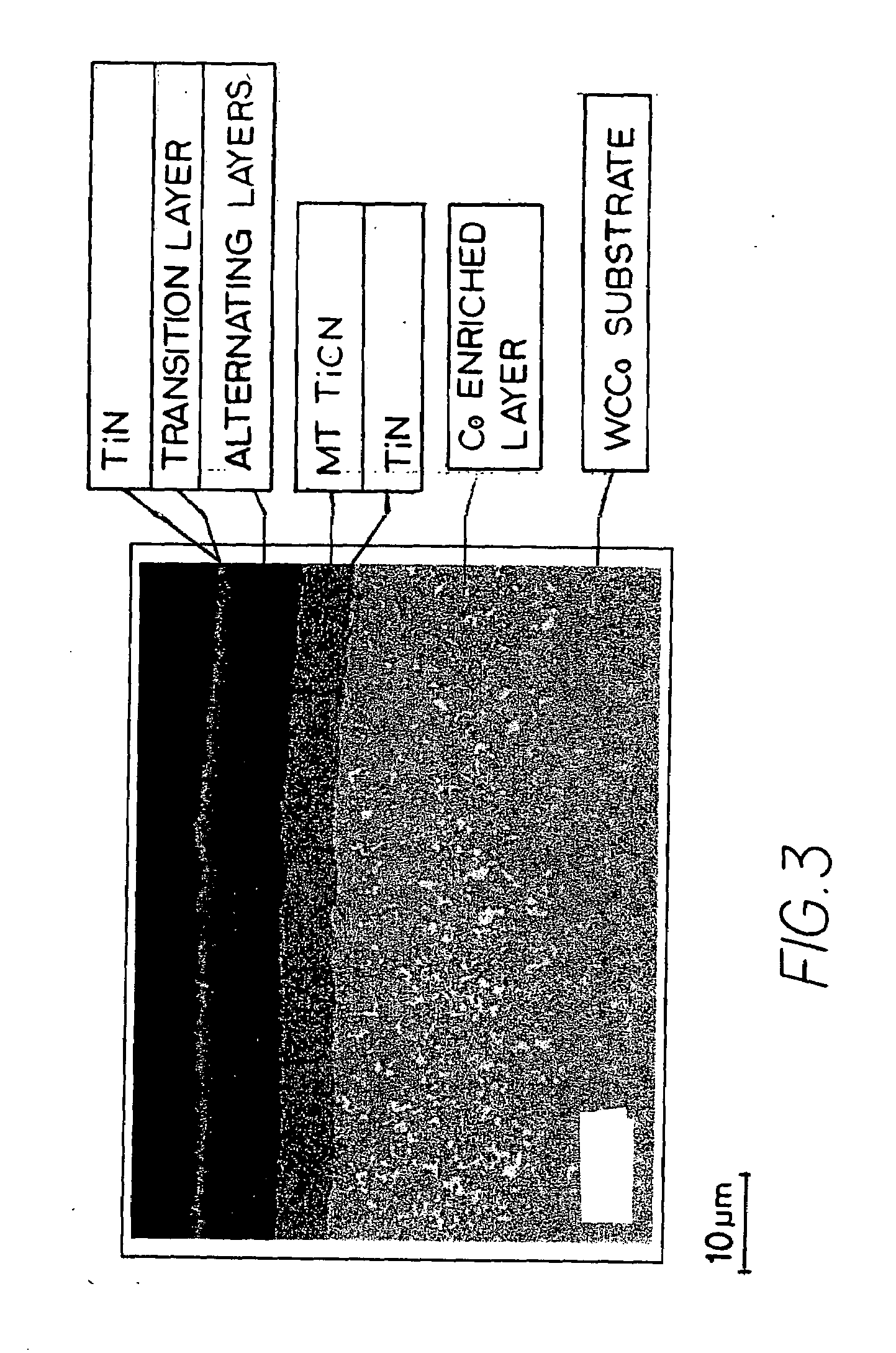

CVD coating scheme including alumina and/or titanium-containing materials and method of making the same

ActiveUS20070298232A1Vacuum evaporation coatingSputtering coatingTitanium carbonitrideMaterials science

A coated body that includes a substrate and a coating scheme on the substrate. The coating scheme includes a CVD titanium carbonitride coating layer containing titanium carbonitride grains that are of a pre-selected grain size. The coating scheme further includes a first titanium / aluminum-containing coating layer containing first titanium / aluminum-containing grains applied so as to be farther away from the substrate than the titanium carbonitride coating layer. The first titanium / aluminum-containing grains are of a pre-selected grain size. The coating scheme also includes a CVD alumina coating layer containing alumina grains applied so as to be farther away from the substrate than the first titanium / aluminum-containing coating layer. The alumina grains are of a pre-selected grain size.

Owner:KENNAMETAL INC

Surface coated cemented carbide cutting tool having hard coating layer exhibiting excellent wear resistance in high speed machining

InactiveUS7150925B2Improve adhesionHigh hardnessPigmenting treatmentVacuum evaporation coatingHysteresisGas phase

Owner:MITSUBISHI MATERIALS CORP

Non-stick paint and preparation method thereof

The invention relates to the field of chemical engineering high molecular materials and provides non-stick paint and a preparation method thereof in order to solve the problems of poor abrasive resistance, rigidity and the like of the existing polytetrafluoroethylene non-stick paint. The non-stick paint comprises the following ingredients by weight percentage: 20-65% of blended modified emulsion, 5-35% of pigment, 10-38% of filling, 0.15-25% of thickening agent, 2-28% of amorphous silica, 1.2-16% of surfactant (II), 10-55% of solvent, 0.5-25% of titanium carbonitride, 0.3-13% of defoaming agent, 0.6-12% of pH (potential of hydrogen) regulator and 0.3-25% of film former, wherein the sum of the weight percentages of the ingredients is 100%. The non-stick paint has the characteristics of lower surface energy, better abrasive resistance and high rigidity.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Briquette for iron-smelting blast furnace lining and its preparation method

The invention relates to a briquet fireproof material for brasque of blast furnace and the method for preparation. The adopted technique scheme is as following: mixing uniformly electrical calcining anthracite, man-made graphite, metal silicon, carbonized silica fume and titanium dioxide, then adding resin, stirring, forming, drying and burning in an inter carbon ambience. The weight percent of components is: electrical calcining anthracite 50-80%, man-made graphite 10-20%, metal silicon 3-15%, carbonized silica fume 2-8%, titanium dioxide 1-10%, added resin 5-15%. The cost of titanium dioxide used in this invention is relatively cheap, thus the production cost reduces effectively. Titanium carbon nitrogen possesses high melting point, high hardness, perfect chemical stability and excellent resistance to hot metal and loss performance, so resistance to hot metal and loss performance of briquet for brasque of blast furnace is enhanced greatly. The prepared briquet is characterized in that the cost is low, the resistance to hot metal and loss performance is excellent and the thermal conductivity factor is high.

Owner:WUHAN UNIV OF SCI & TECH

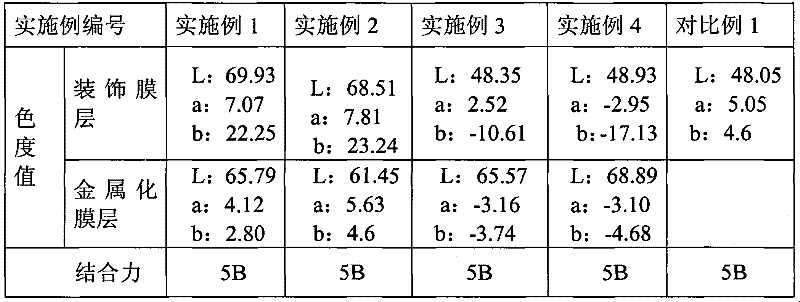

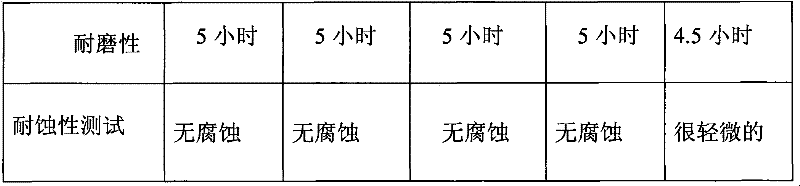

A kind of decorative material and preparation method thereof

InactiveCN102294856ARich in colorUniform colorVacuum evaporation coatingSputtering coatingTungsten nitrideChromium

Provided are a composite structure and a method of preparing the same. The composite structure may comprise: a substrate; a decoration coating formed on the substrate which is made from the material selected from the group consisting of titanium carbonitride, titanium aluminum nitride, and tungsten nitride; and a metallization coating formed on the decoration coating, which is made from the material selected from the group consisting of tungsten, aluminum, titanium, chromium, and stainless steel. Also provided is an electronic device with at least a part thereof being made of the composite structure.

Owner:BYD CO LTD

Al2O3/Ti(C,N) composite ceramic tool material and microwave sintering process thereof

The invention discloses an Al2O3 / Ti(C,N) composite ceramic tool material and a microwave sintering process thereof. The Al2O3 / Ti(C,N) composite ceramic tool material is prepared from, by mass, 61%-70% of alumina (Al2O3), 25%-35% of titanium carbonitride (Ti(C,N)), 2%-6% of nickel (Ni) and 1%-3% of molybdenum (Mo). Ceramic tool materials are sintered in a microwave sintering furnace with nitrogen as protection atmosphere through the characteristics that whole microwaves can conduct non-gradient heating, material compactness is promoted and environment friendliness is achieved, wherein the frequency of the microwave sintering furnace is 2.45 GHz. The prepared tool material is uniform in microstructure and small in crystalline grain, has high density, high fracture toughness and high harness, and the performance of the prepared tool material meets the use requirement of tools; meanwhile, the sintering process is advanced, the production efficiency is high, cost is low, large-scale production can be easily conducted, and popularization value is achieved.

Owner:NANJING UNIV OF SCI & TECH

Cubic Boron Nitride Compact

InactiveUS20080302023A1Poor EDM-cuttabilityImprove conductivityPigmenting treatmentOther chemical processesBorideAluminium carbide

A polycrystalline cubic boron nitride compact which comprises greater than 75 volume % and not greater than 90 volume % cubic boron nitride particles, the cubic boron nitride particles comprising particles of at least two average particle sizes, and a binder phase constituting the balance of the compact and comprising at least one titanium compound selected from titanium boride, titanium nitride, titanium carbide and titanium carbonitride and at least one aluminium compound selected from aluminium oxide, aluminium boride, aluminium nitride, aluminium carbide and aluminium carbonitride.

Owner:GOUDEMOND IAIN PATRICK +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com