Ti(C,N) base metal ceramic and preparation method thereof

A base metal and ceramic technology, applied in the composition design, preparation process and application field of Ti-based cermet, can solve the problems of high price of TaC raw materials, increase product cost, tool failure, etc., to save manufacturing cost, long tool life, The effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

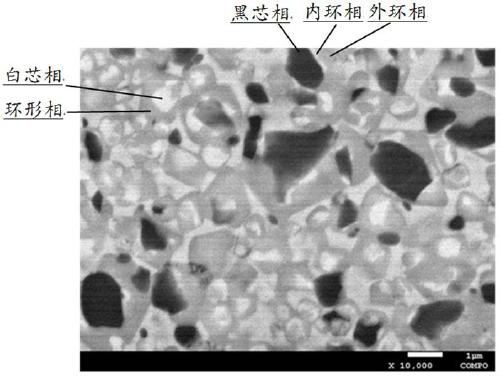

Image

Examples

Embodiment 1

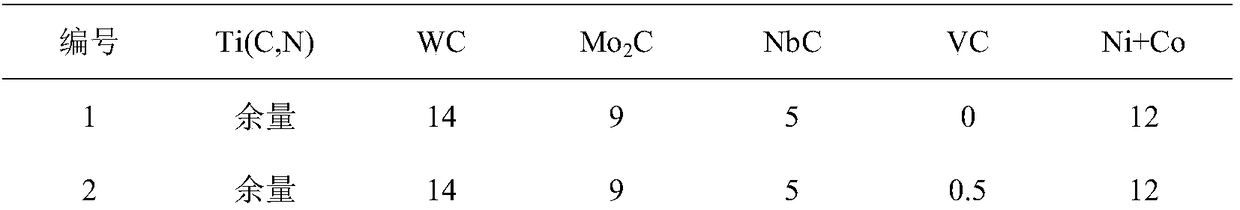

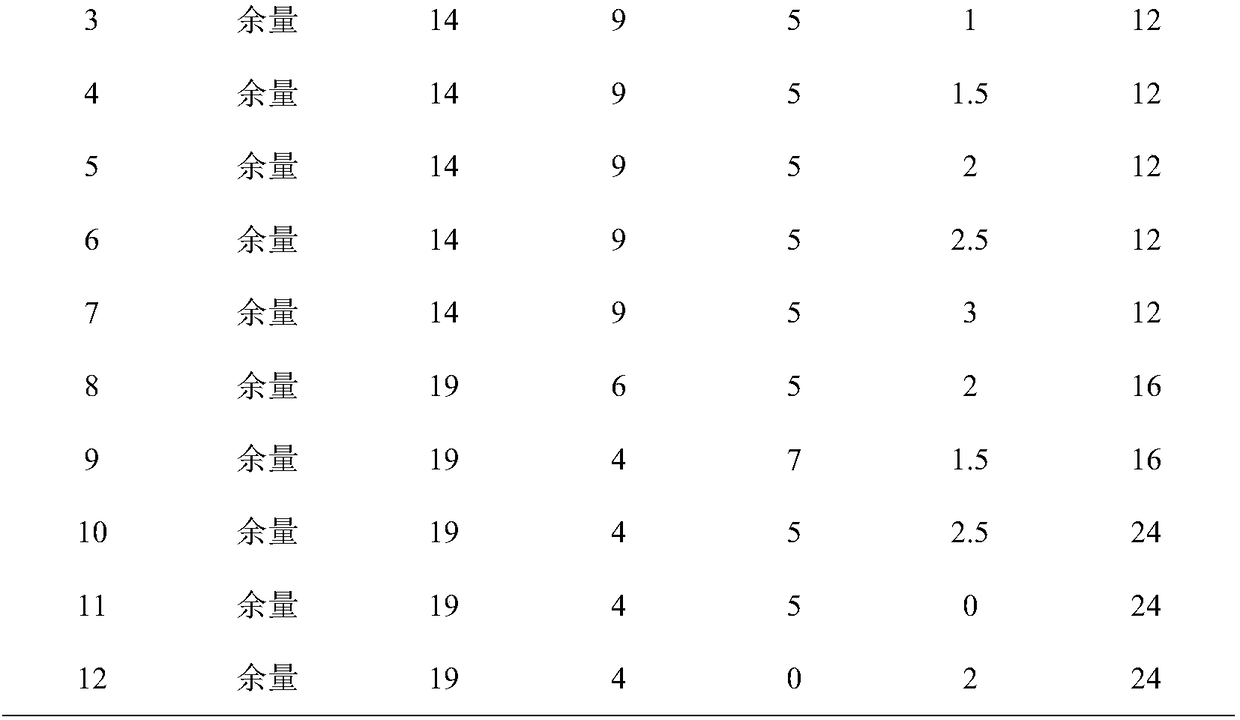

[0021] Ti(C,N)-based cermets were prepared from commercially available powders. Ti(C 0.5 ,N 0.5 ) powder Fisher particle size 1.5μm, WC powder Fisher particle size 1.0μm, Mo 2 The Fischer particle size of C powder is 1.85 μm, that of NbC powder is 2.0 μm, that of VC powder is 2.0 μm, that of Co powder is 1.5 μm, and that of Ni powder is 1.5 μm.

[0022]The raw material powders were weighed according to the composition ratio in Table 1 to prepare Ti(C,N)-based cermets with different compositions. Mixing is carried out on a planetary ball mill, using absolute ethanol as the dispersion medium, hard alloy balls with a diameter of Φ8-Φ10 as the ball milling medium, and adding 4wt.% PEG of the total amount of the mixed powder as the dispersant and forming agent. The rotational speed of the planetary ball mill is 250r / min, and the mixing ball milling time is 48h. The slurry was dried in a vacuum oven at 80°C. The samples were bidirectionally pressed with a pressing force of 100 ...

Embodiment 2

[0032] The cermets with No. 1, 5, 10, and 12 components in Table 1 were selected for indentation-quenching test to evaluate the thermal shock resistance. The indentation-quenching method is an effective method developed in recent years to evaluate the thermal shock resistance of brittle materials. The specific implementation steps are as follows: load a 20Kg or 30Kg load on a Vickers hardness tester with a cross-section polished sample, so that microcracks (prefabricated cracks) are generated at the tip of the diamond-shaped indentation. Then, under the protection of Ar, the sample was heated to 300 °C in a tube furnace muffle furnace until the temperature was uniform, and then quickly quenched into 25 °C water. Under the action of thermal stress, the prefabricated crack expands partially or completely. The relative heat resistance of Ti(C,N)-based cermets can be qualitatively evaluated by comparing the non-diffusion of pre-cracks, the ratio of steady-state growth and unstabl...

Embodiment 3

[0037] Select Ti(C,N)-based cermets with No. 4 and No. 9 components in Table 1 to make cutting tools, cermets with No. 4 components to make turning tools, and cermets with No. 9 components to make milling cutters.

[0038] The specific implementation steps for preparing Ti(C,N)-based cermet cutters are as follows: Weigh the raw material powder according to the composition ratio of No. 4 and No. 9 in Table 1, and mix the materials on a drum mixer. The alloy ball is a ball milling medium, and 2wt.% PEG of the total amount of the mixed powder is added as a dispersant. After the slurry is spray-dried and prepared, the No. 4 and No. 9 component mixed powders are respectively molded into indexable insert CNNG120408 and CCMT060204 compacts. The sintering is carried out in a degreasing-sintering integrated furnace, the sintering temperature is 1470-1520°C, the sintering time is 1h, and the vacuum degree is maintained in the range of 1-10Pa. After the sintered body is ground, it is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com