Patents

Literature

977results about "Milling tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

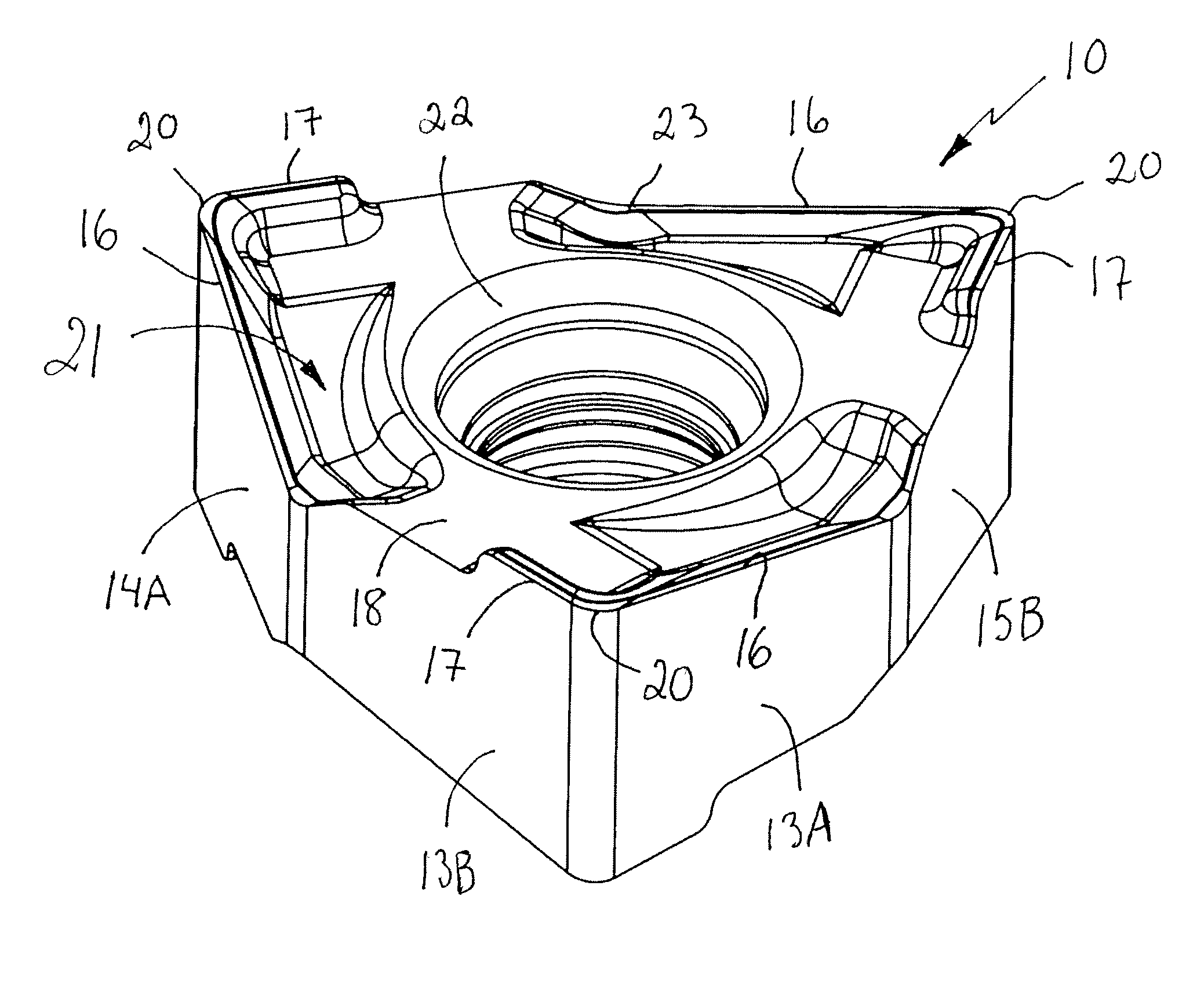

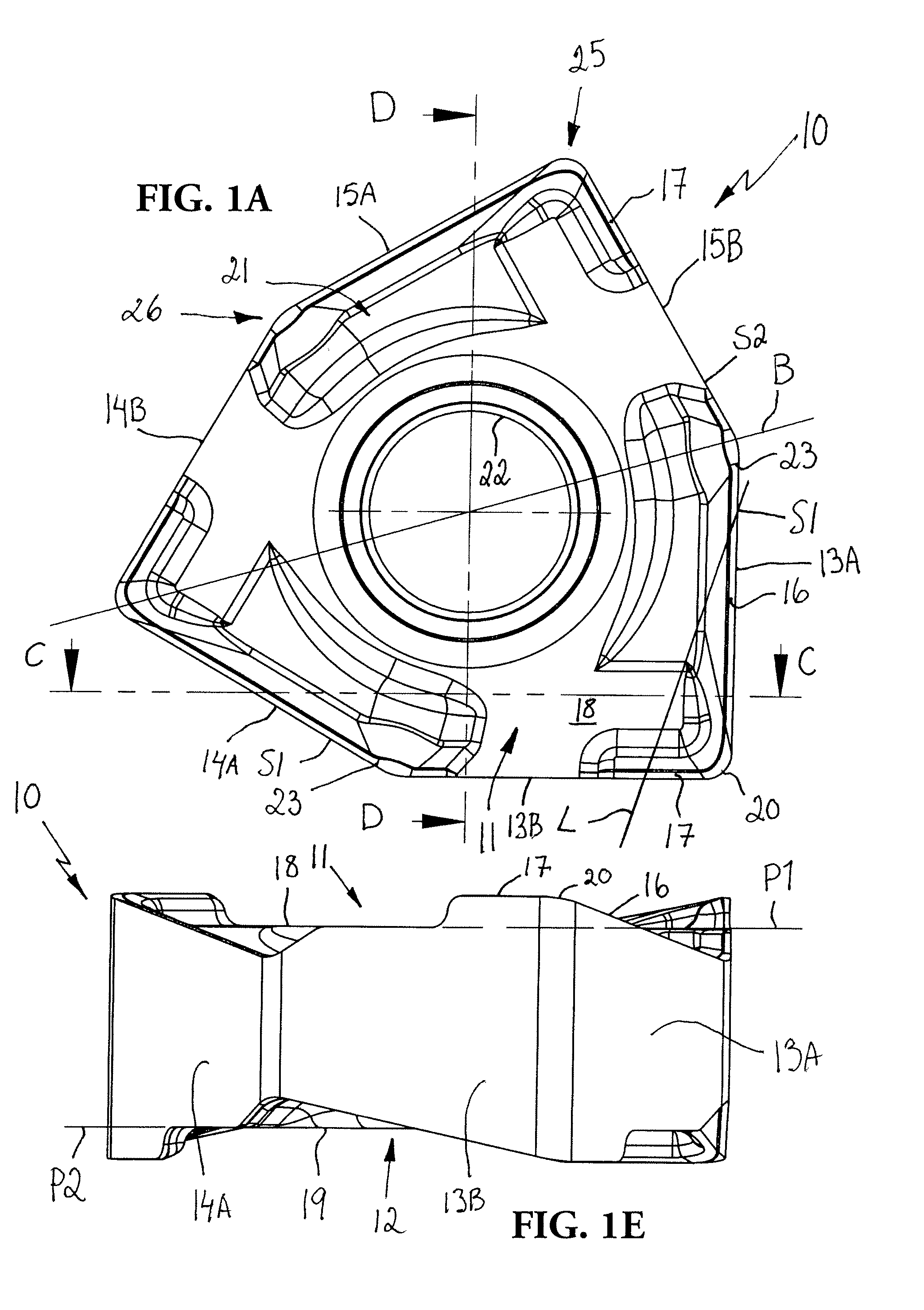

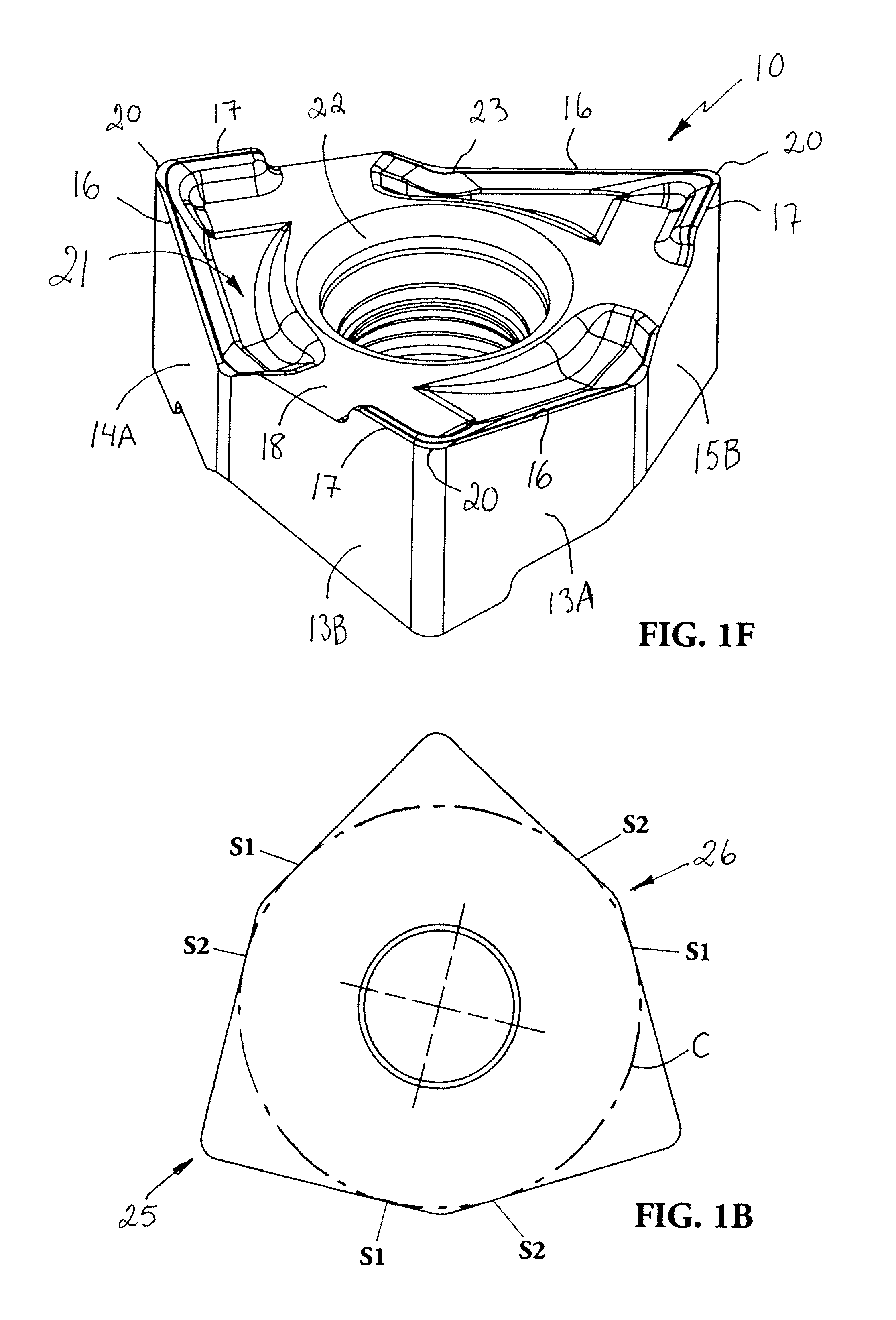

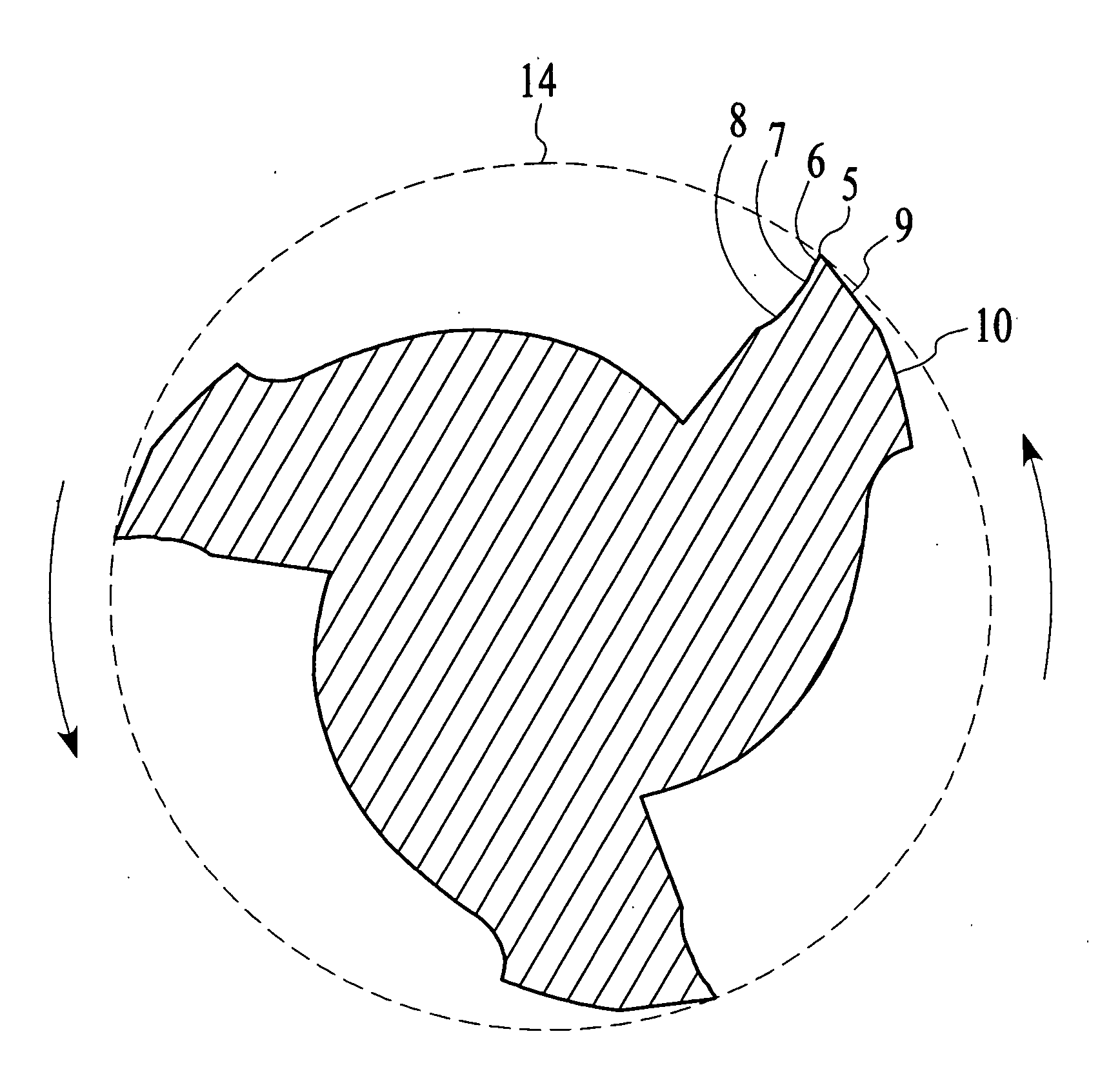

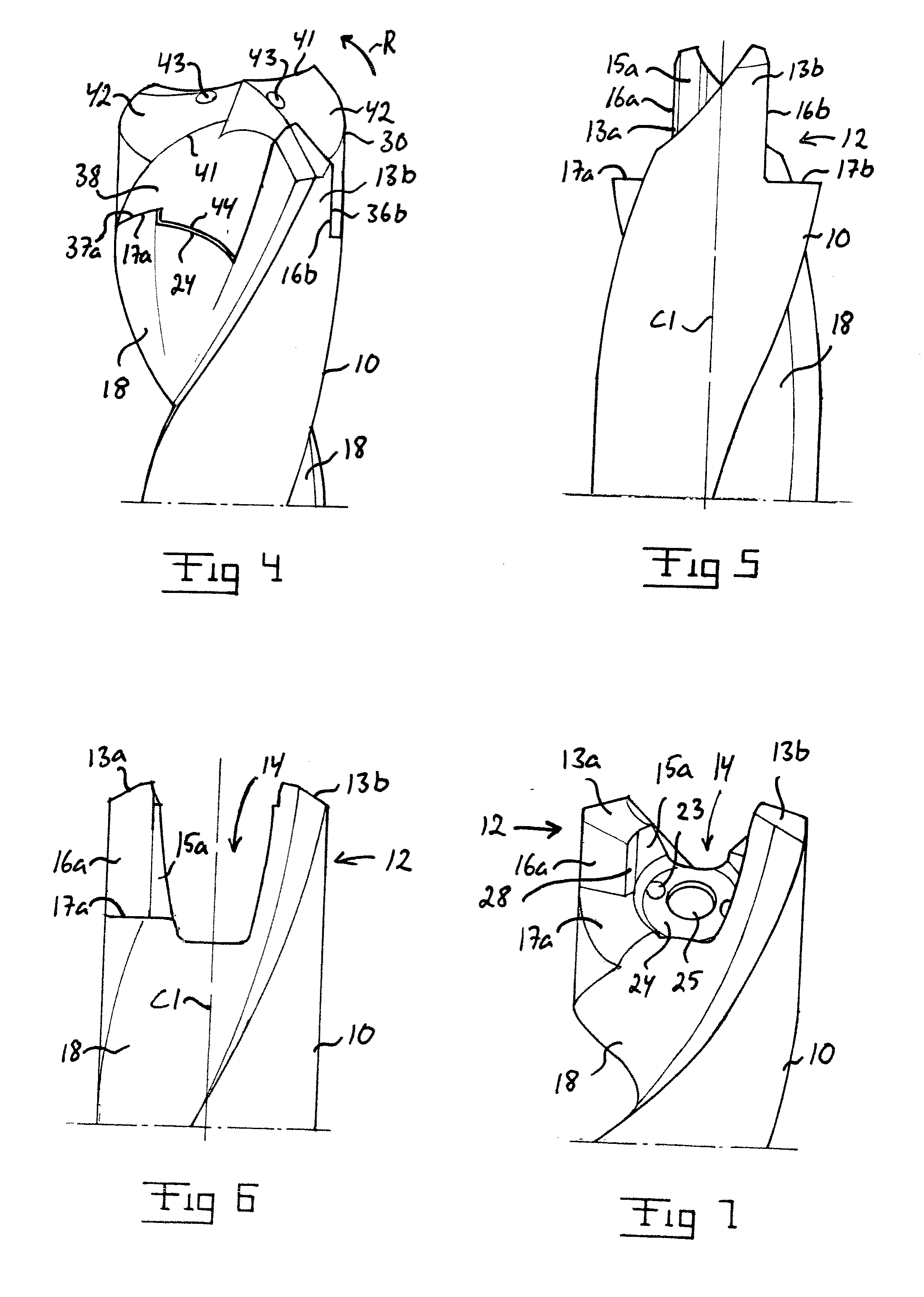

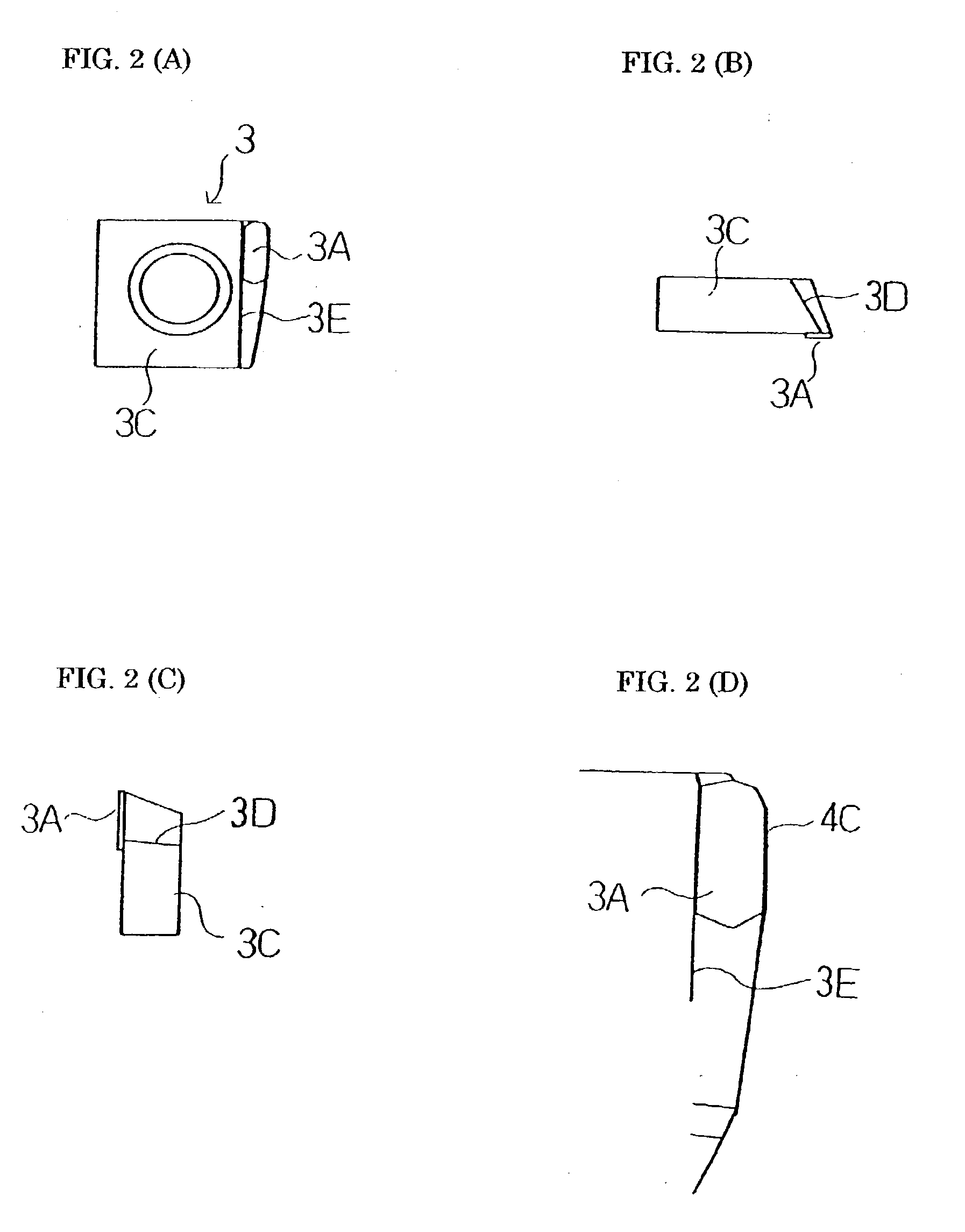

Milling insert and a milling tool

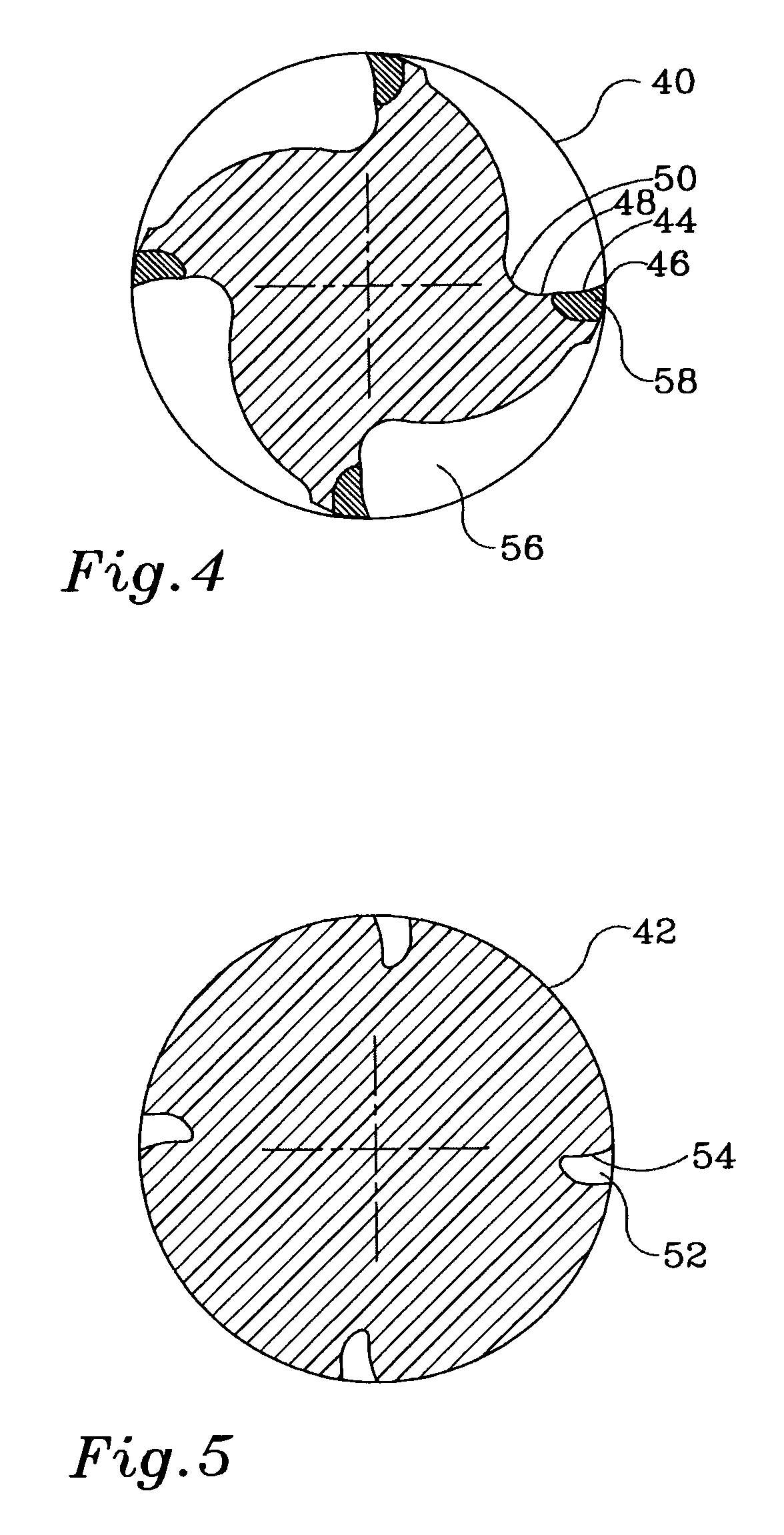

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

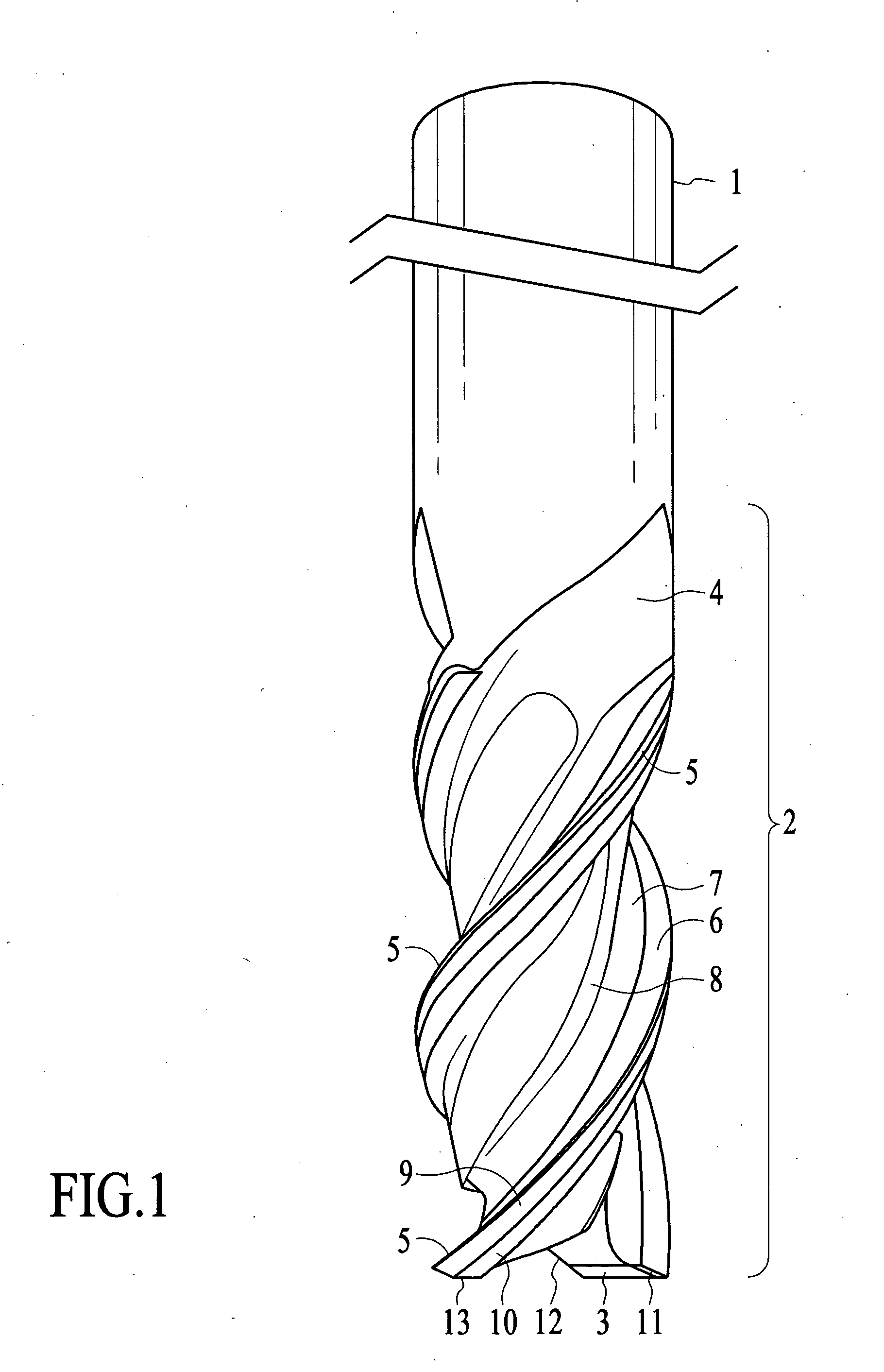

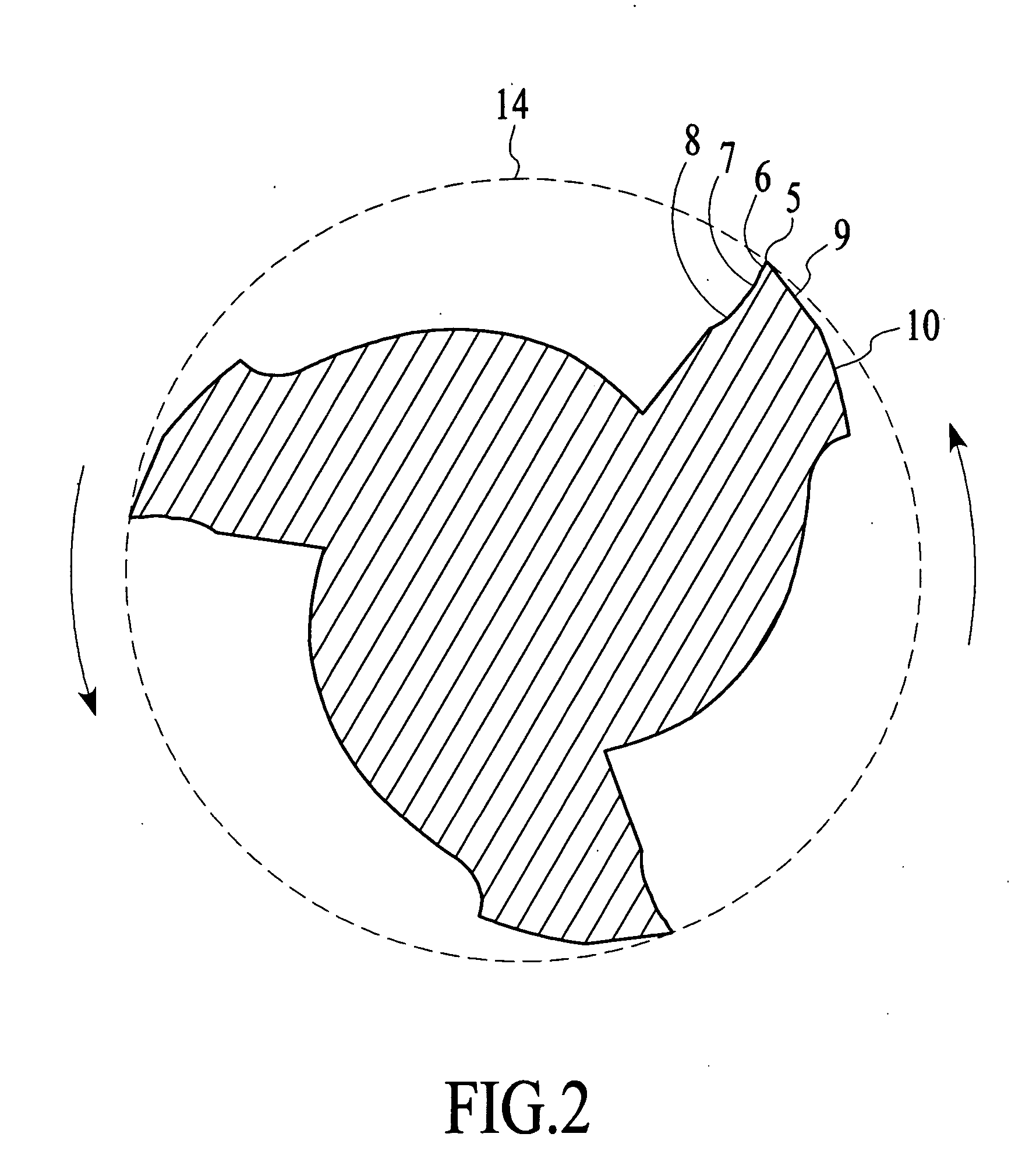

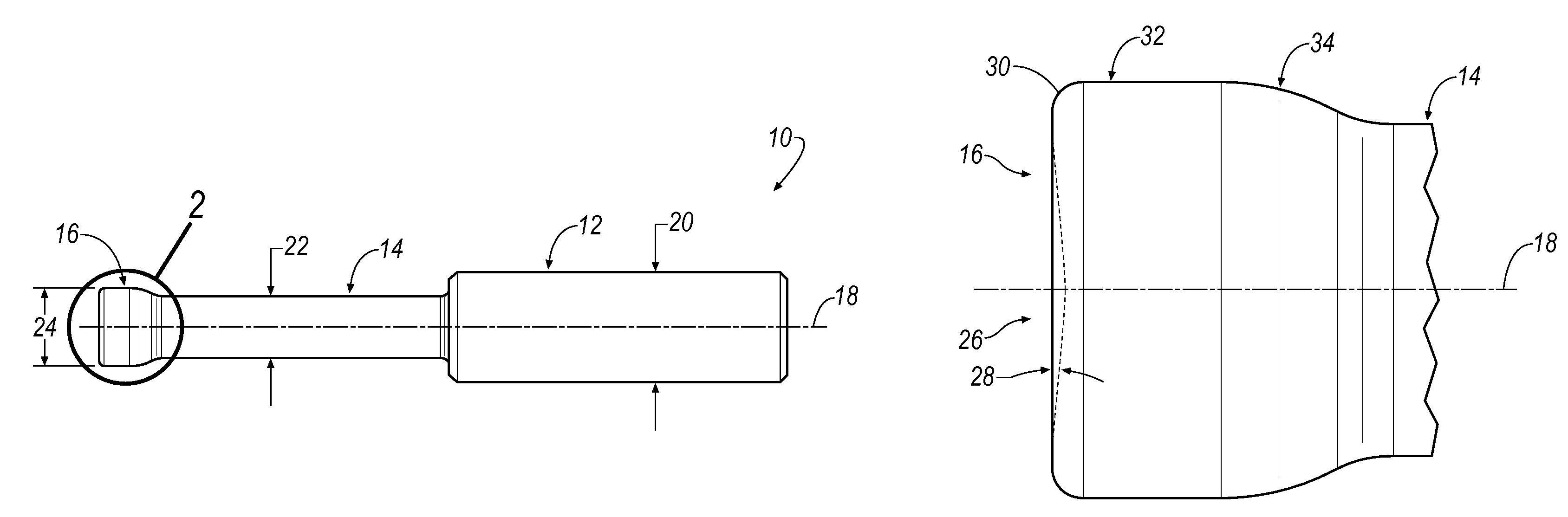

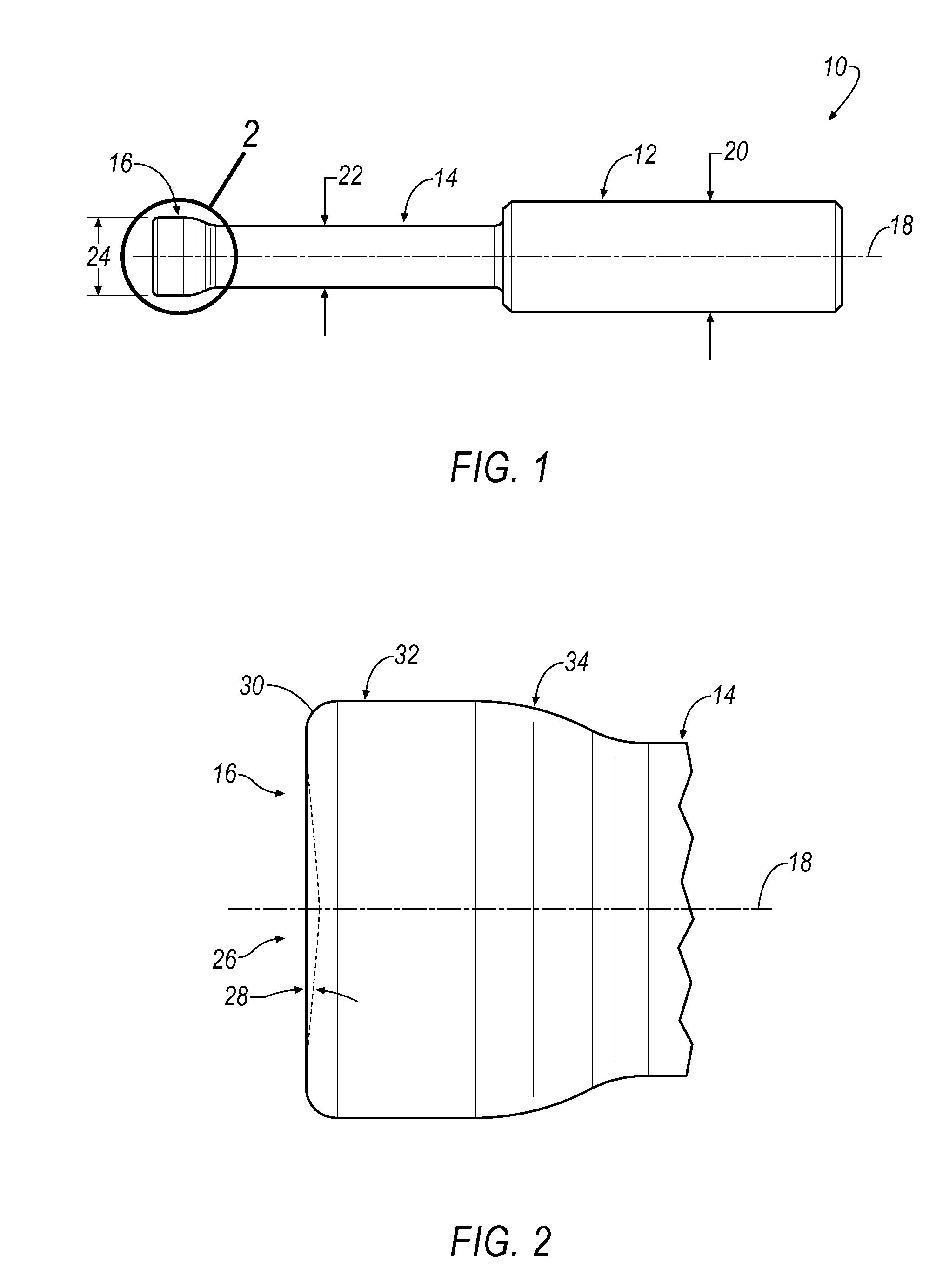

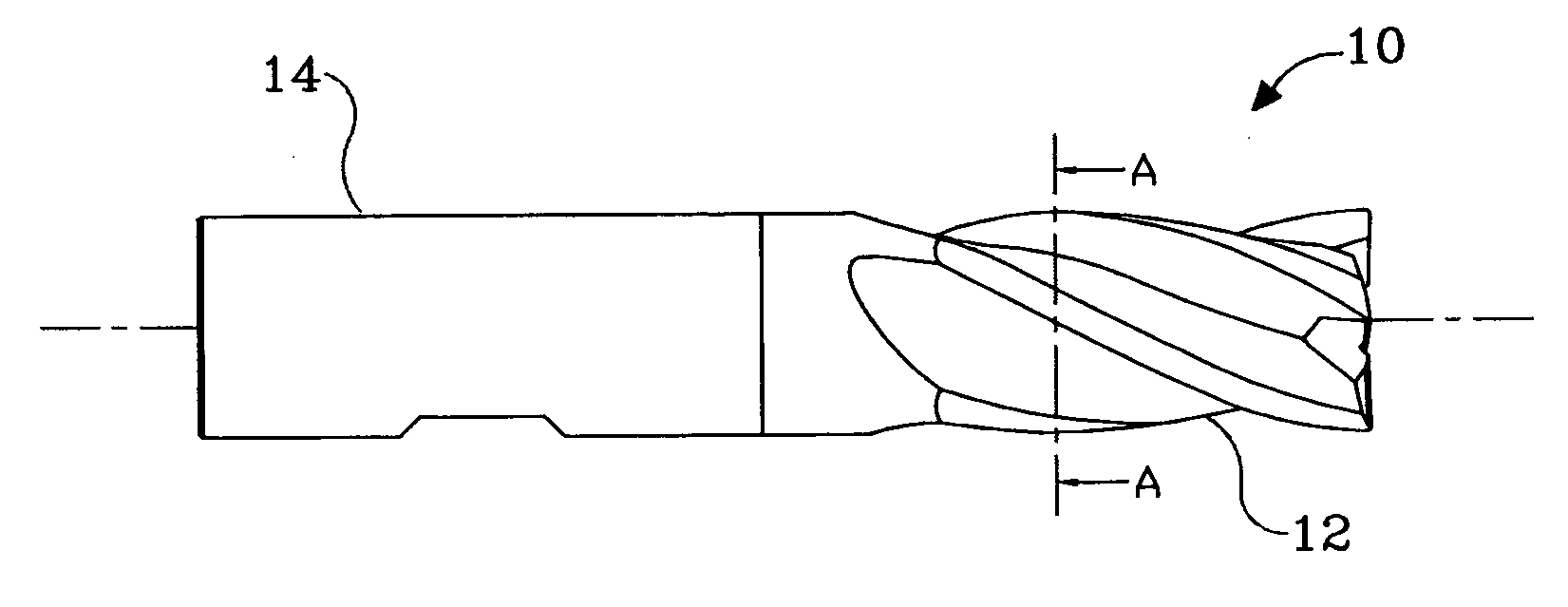

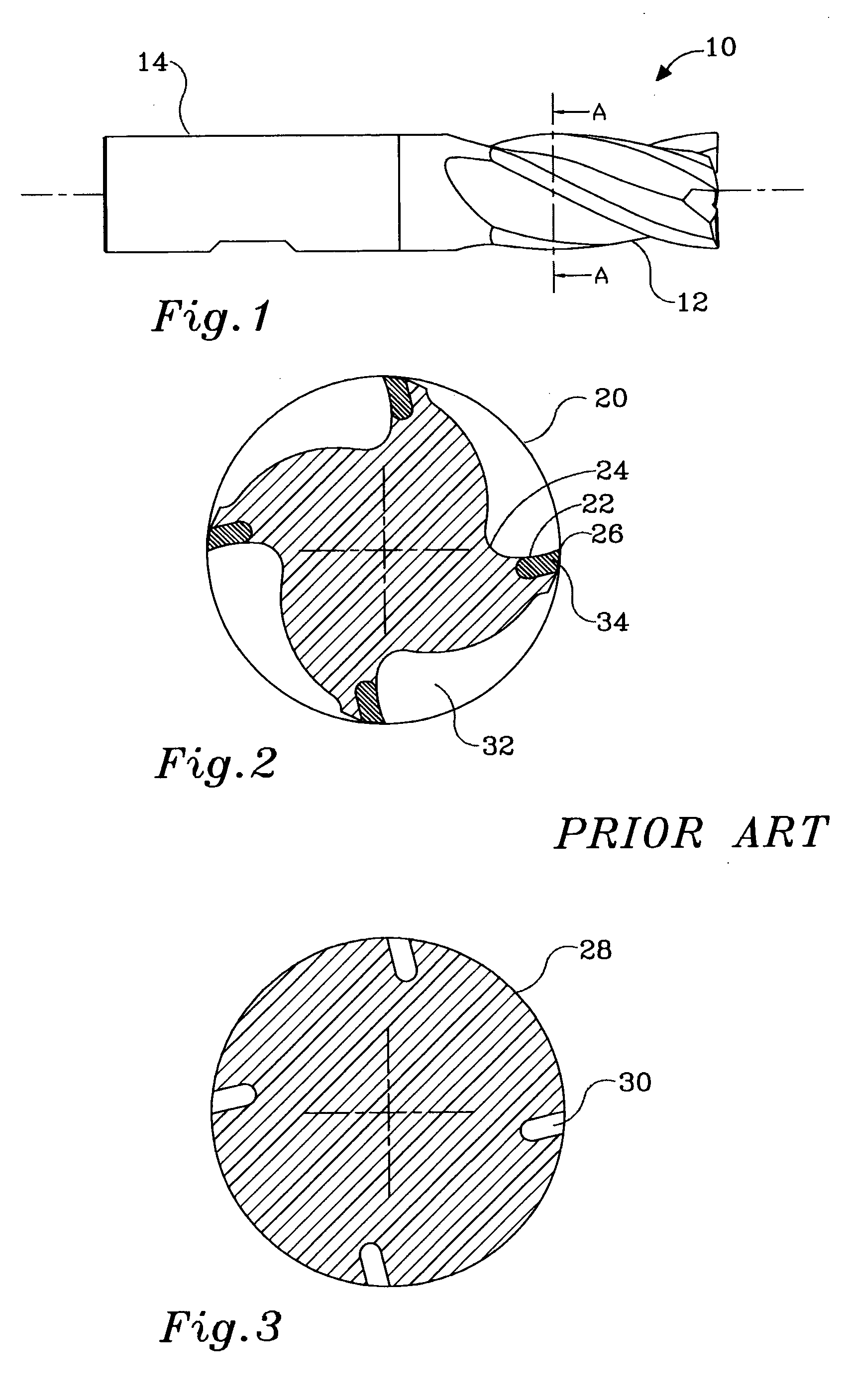

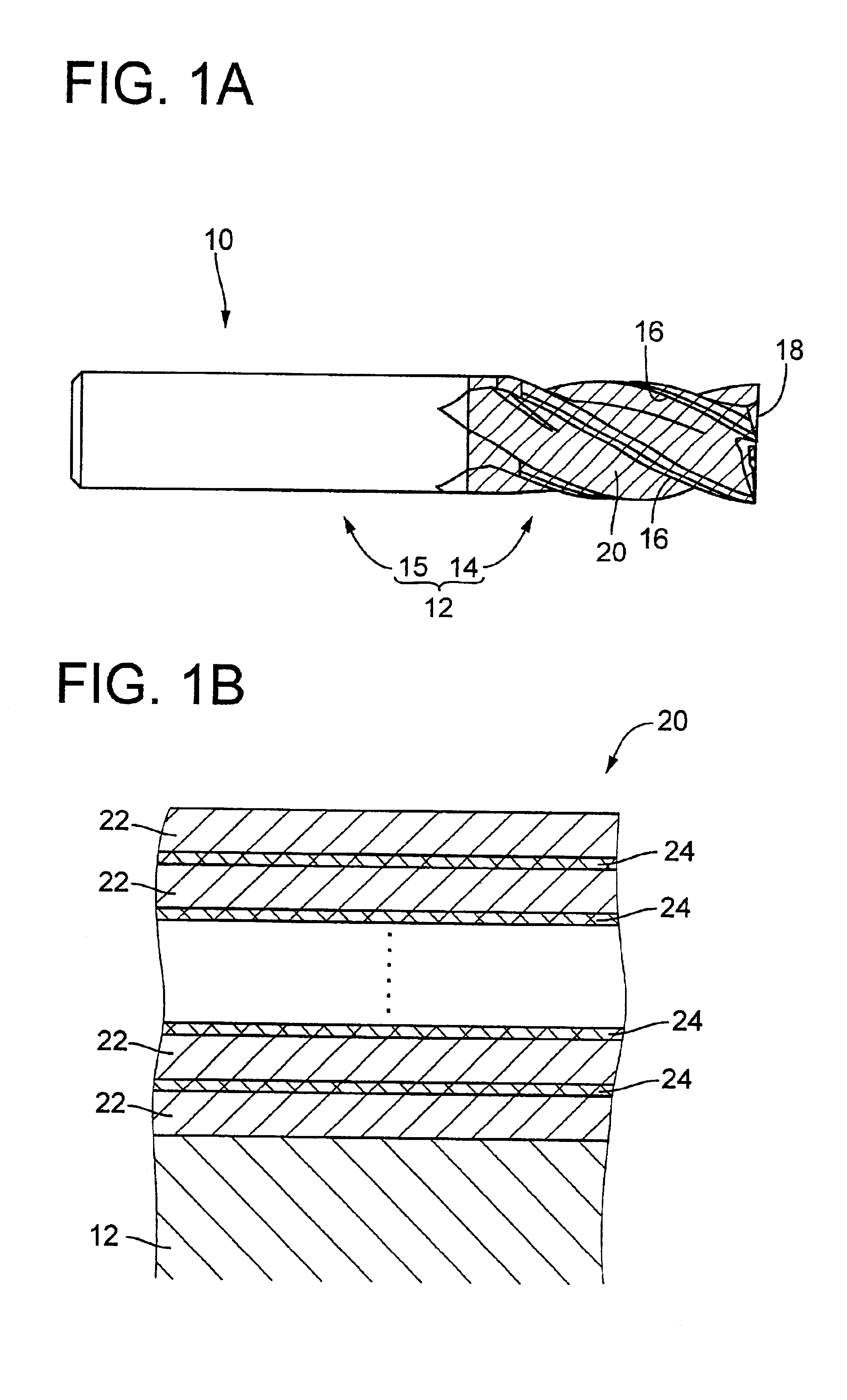

End mill

InactiveUS20060067797A1Aggressive and deep cutLess forceMilling cuttersWorkpiecesUltra fineEngineering

An end mill with a peripheral margin which increases in width from the terminal end of the tool to the shank portion of the tool. The end mill also has a tooth face made up of three tooth-face walls The depth of the tool face gradually decreases from the terminal end to the shank portion of the tool. The end mill also has an end cutting face which includes a flat, narrow land at the outmost region of the end cutting end. The end mill has chip breakers with rounded peripheral corners. The end mill can be made up of ultra-fine micro grain tungsten carbide with a cobalt content which varies throughout the length of the tool.

Owner:CALAMIA GUY ALLEN

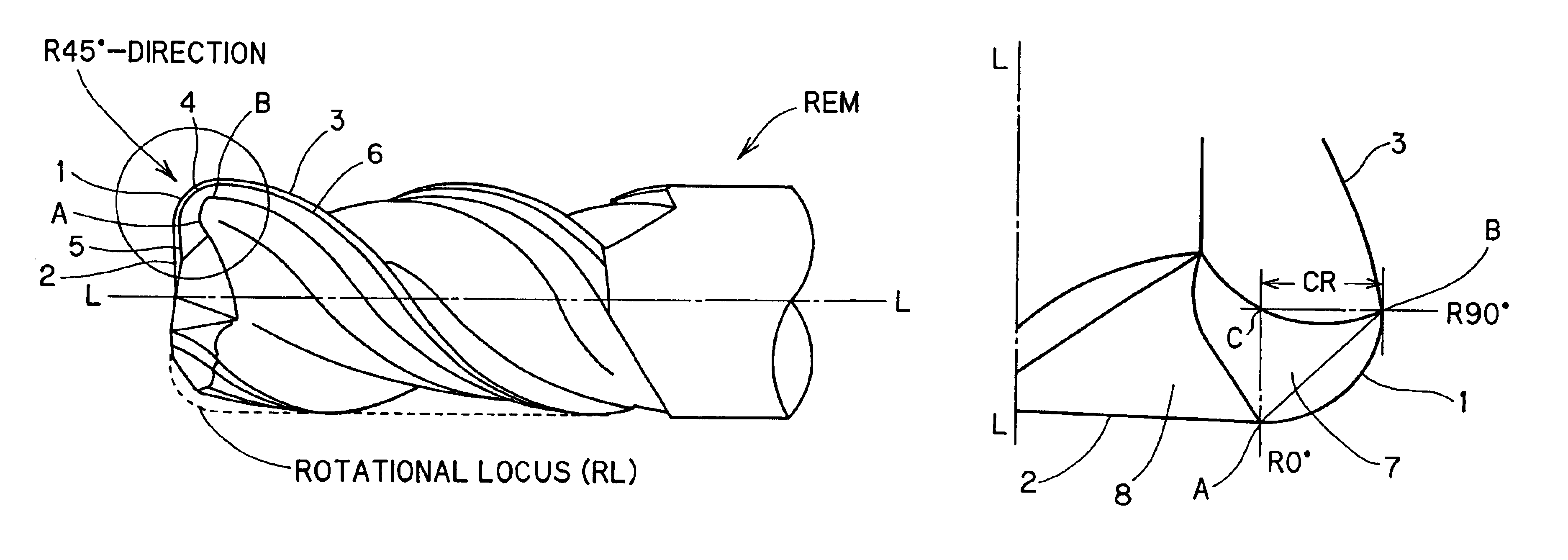

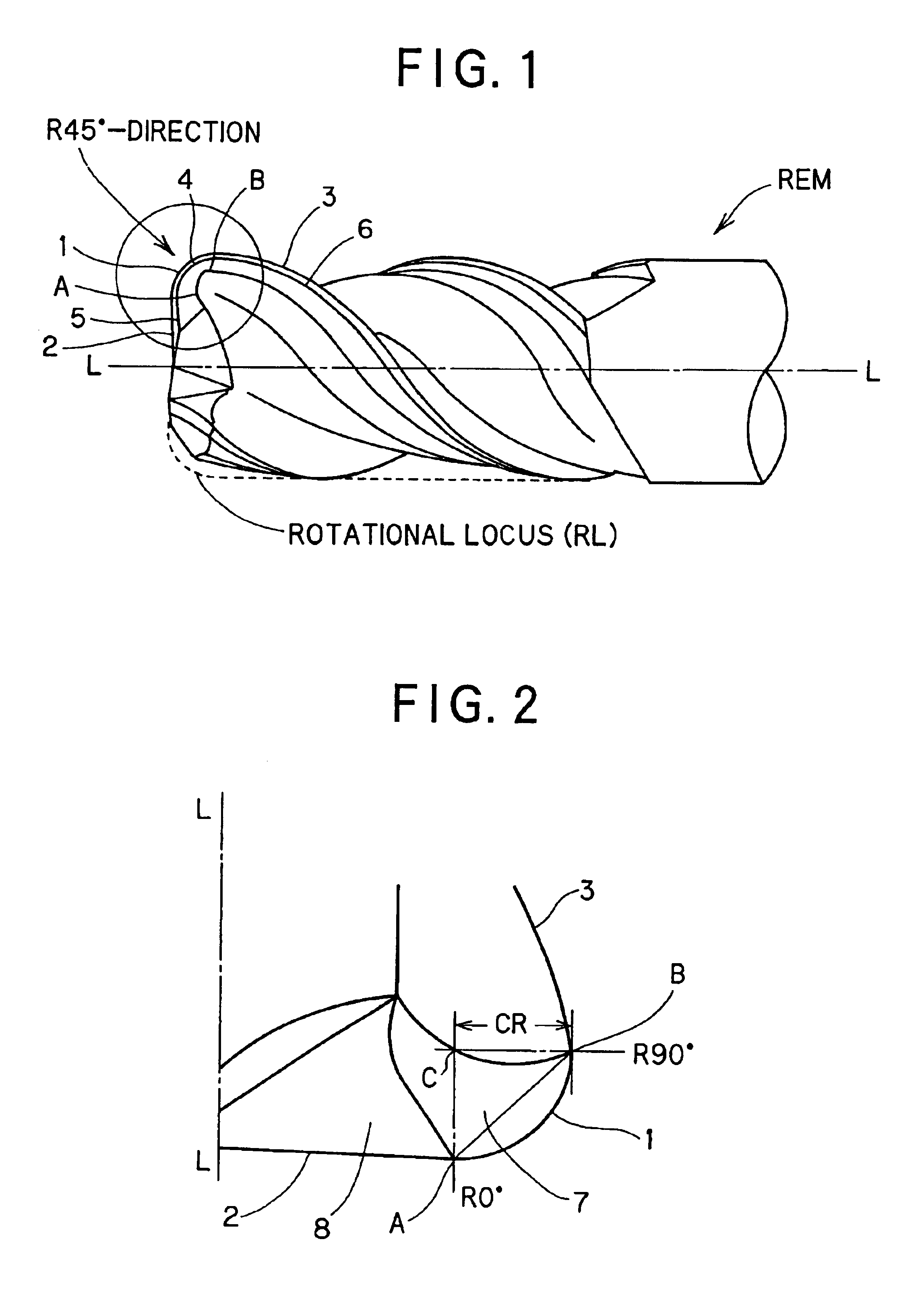

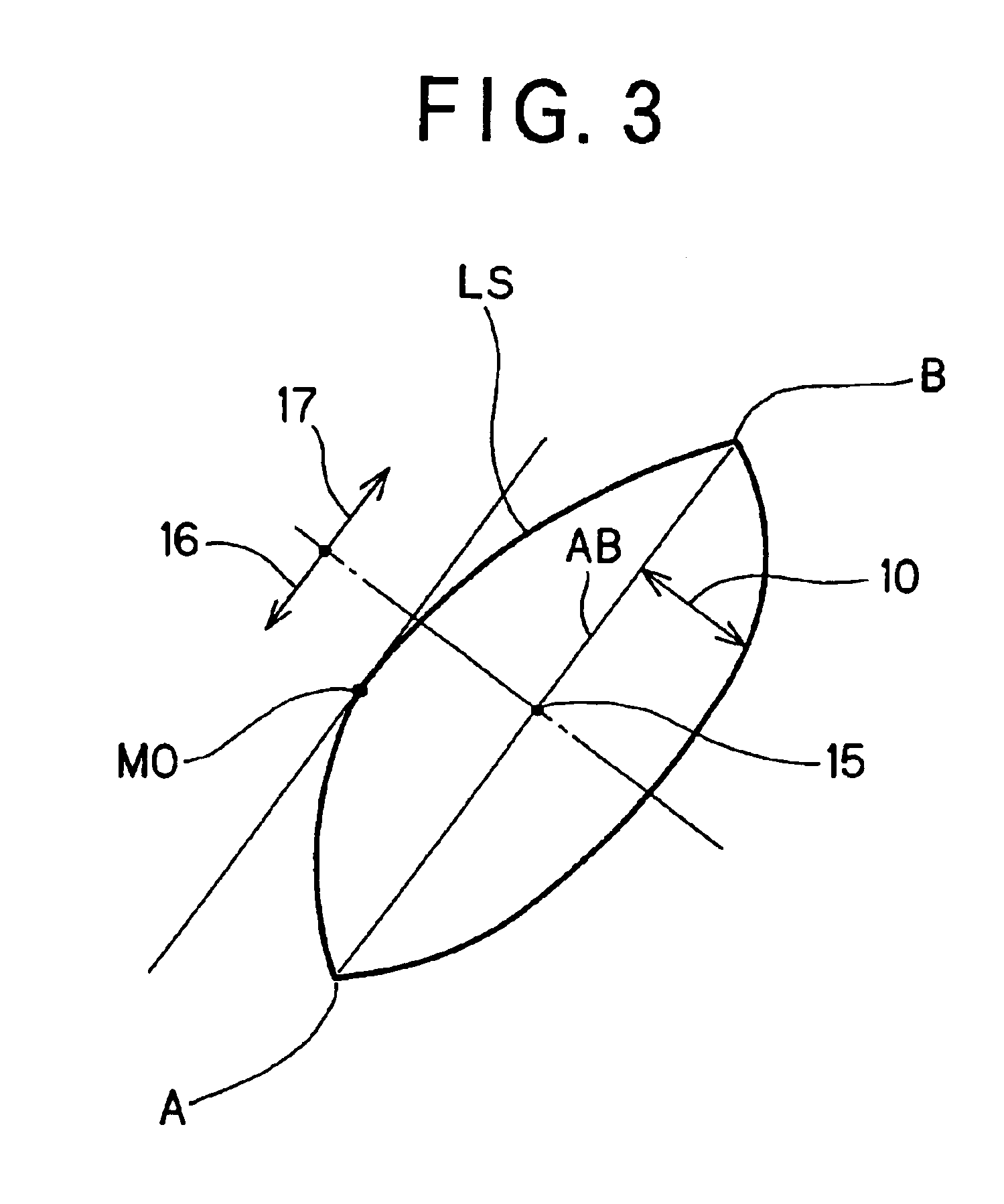

Radius end mill having radius edge enhanced in resistance to chipping and fracture

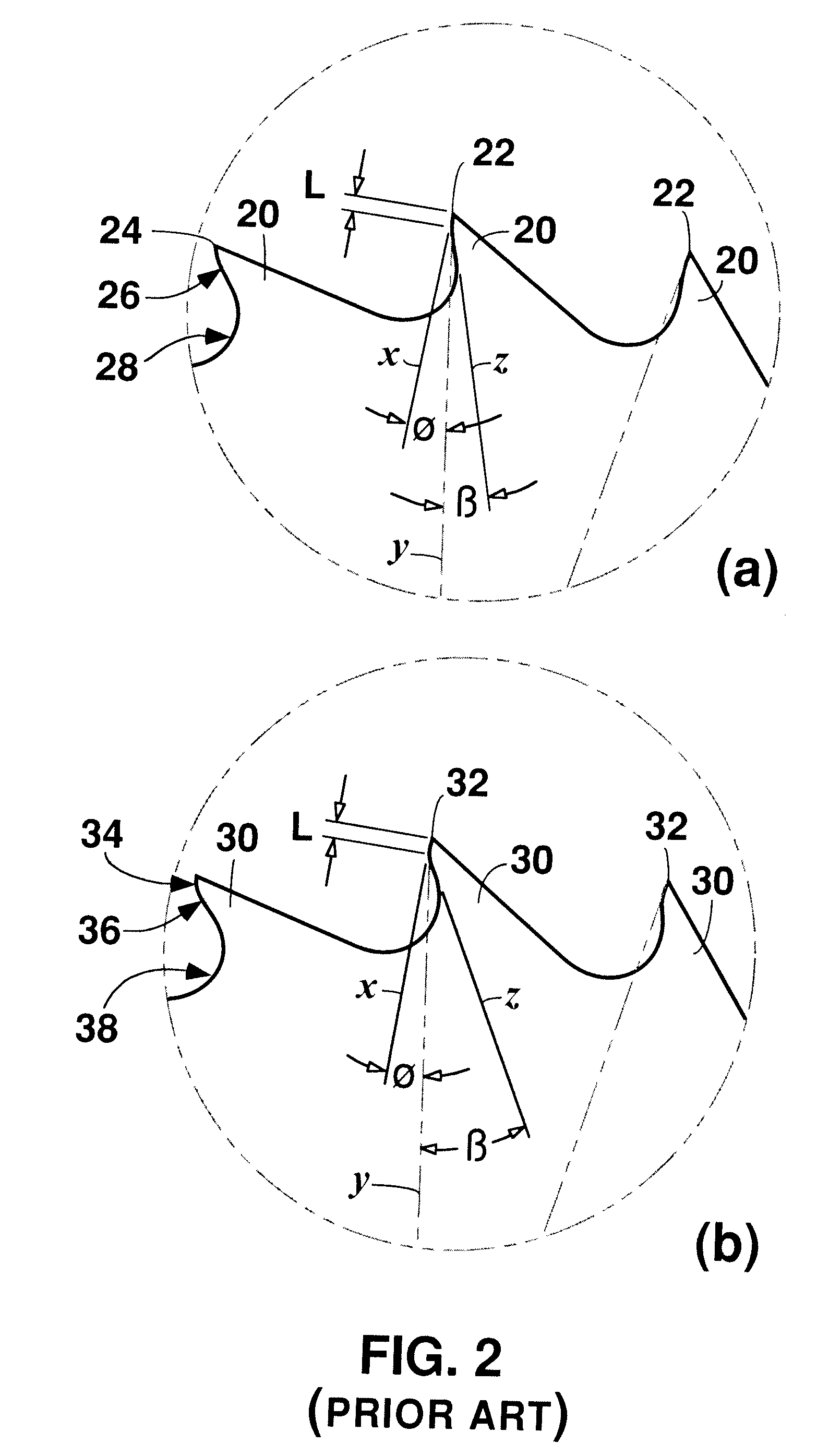

InactiveUS6846135B2Suppress chipping and fractureHigh-feed cuttingMilling cuttersWorkpiecesEngineeringCurve line

In a radius end mill having a bottom edge formed on the end face thereof, a radius edge designed in a substantially quarter arc shape and formed at a corner portion thereof, and an outer peripheral edge formed spirally on the side surface thereof, the bottom edge and the radius edge being continuously connected to each other at a connecting point A while the radius edge is continuously connected to each other at a connecting point B, when a view taken along a plane that passes through the connecting points A and B and crosses a rake face of the radius edge is represented by an R cross-sectional view, the rake face of the radius edge is designed to have a convex curved line extending from the connecting point A to the connecting point B in the R cross-sectional view.

Owner:HITACHI TOOL ENG LTD

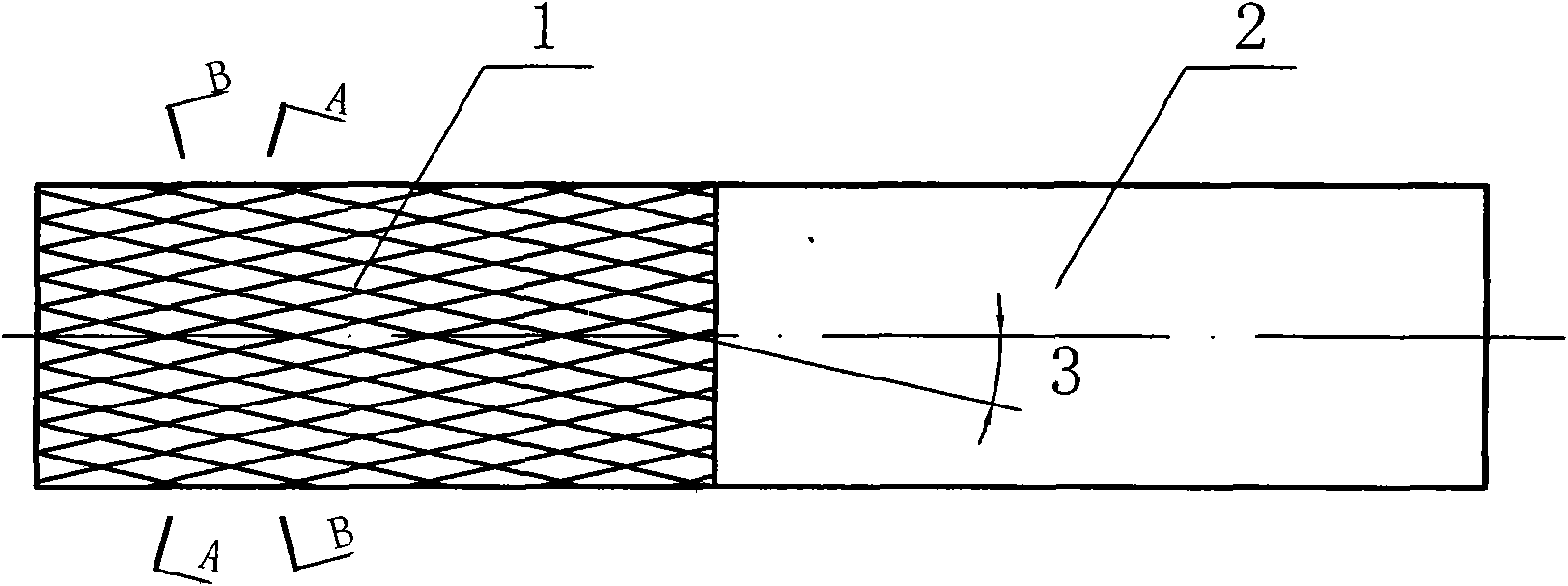

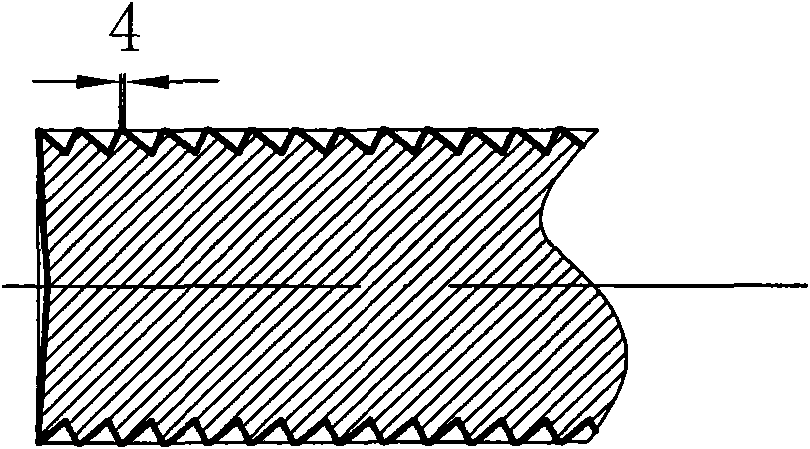

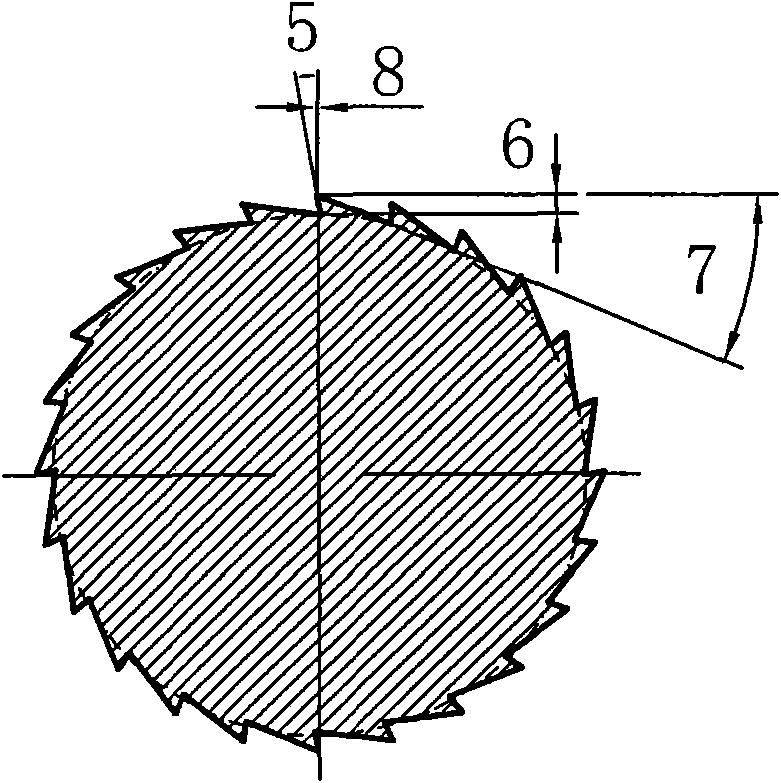

Integral carbide goldfish scale milling cutter

InactiveCN101623778AExtended service lifeImprove processing efficiencyMilling cuttersWorkpiecesGlass fiberFiber

The invention discloses an integral carbide goldfish scale milling cutter used for milling and processing composite materials such as carbon fiber, glass fiber and the like. The milling cutter of the invention comprises a milling cutter blade and a milling handle, wherein the cutting blade on the milling cutter blade is a cutting unit formed by left and right-handed rotation symmetrical staggered spiral grooves, and the number of the left spiral groove is two more than that of the right spiral groove; the length of the cutting blade of each cutting unit is 0.05-0.1mm, and the width of the rear cutter surface of the cutting blade along the cylinder surface is 0-0.01mm; the anterior angle of the cutting blade is 10-15 degrees, the front cutter surface is a straight line on a normal plane; the relief angle of the cutting blade is 20-25 degrees; the depth of the spiral cutter groove is 7-8% of the diameter of the cutter. The invention has the advantages that the cutting blade of the integral carbide goldfish scale milling cutter is composed of a plurality of cutting units and is sharp, which greatly lowers cutting resistance and realizes high speed cutting so as to obtain the effect of using milling for replacing abrading, so that the processing efficiency and the surface quality of the composite materials can be improved, and the service life of the milling cutter can be prolonged.

Owner:SHENYANG AIRCRAFT CORP

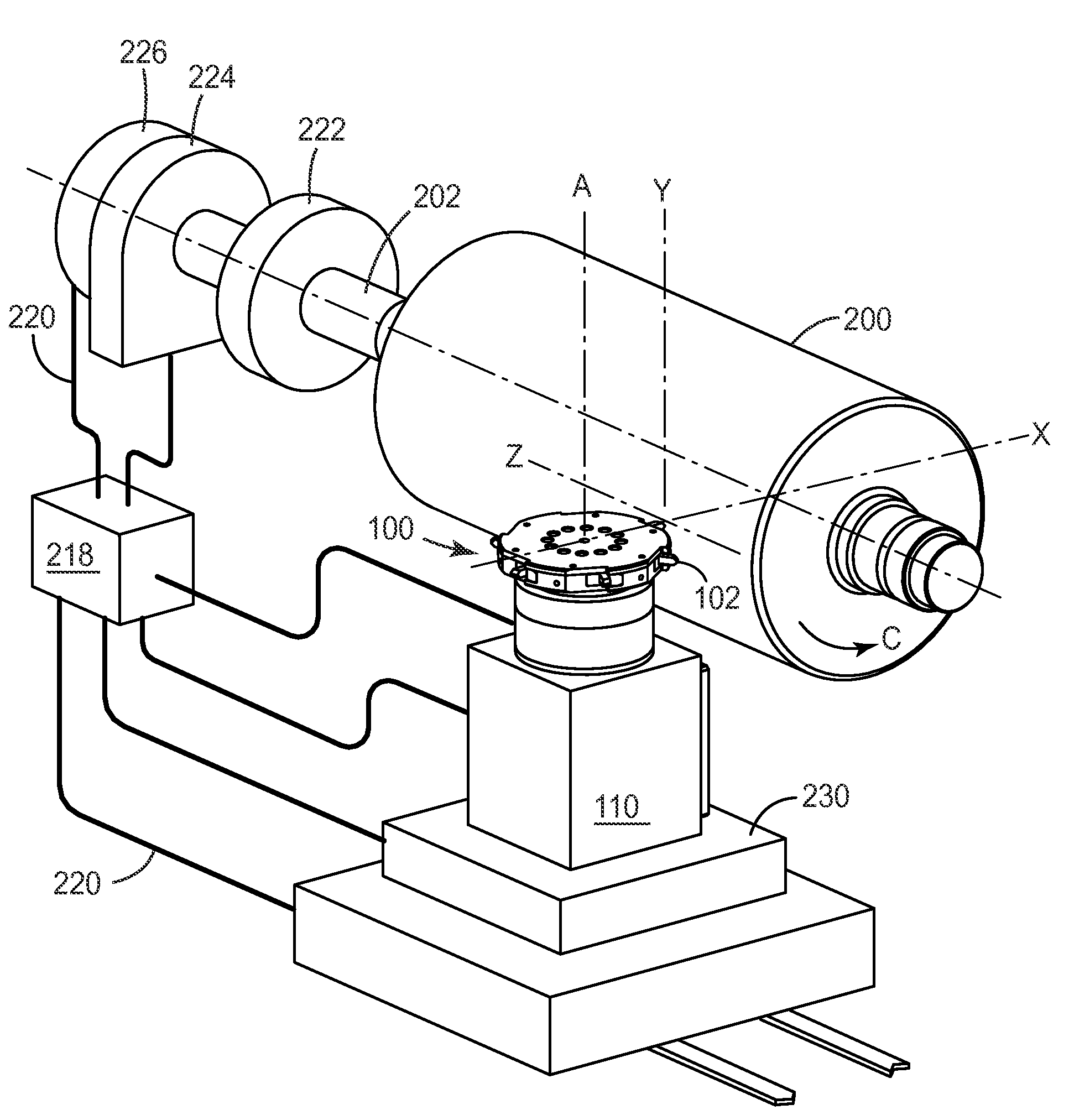

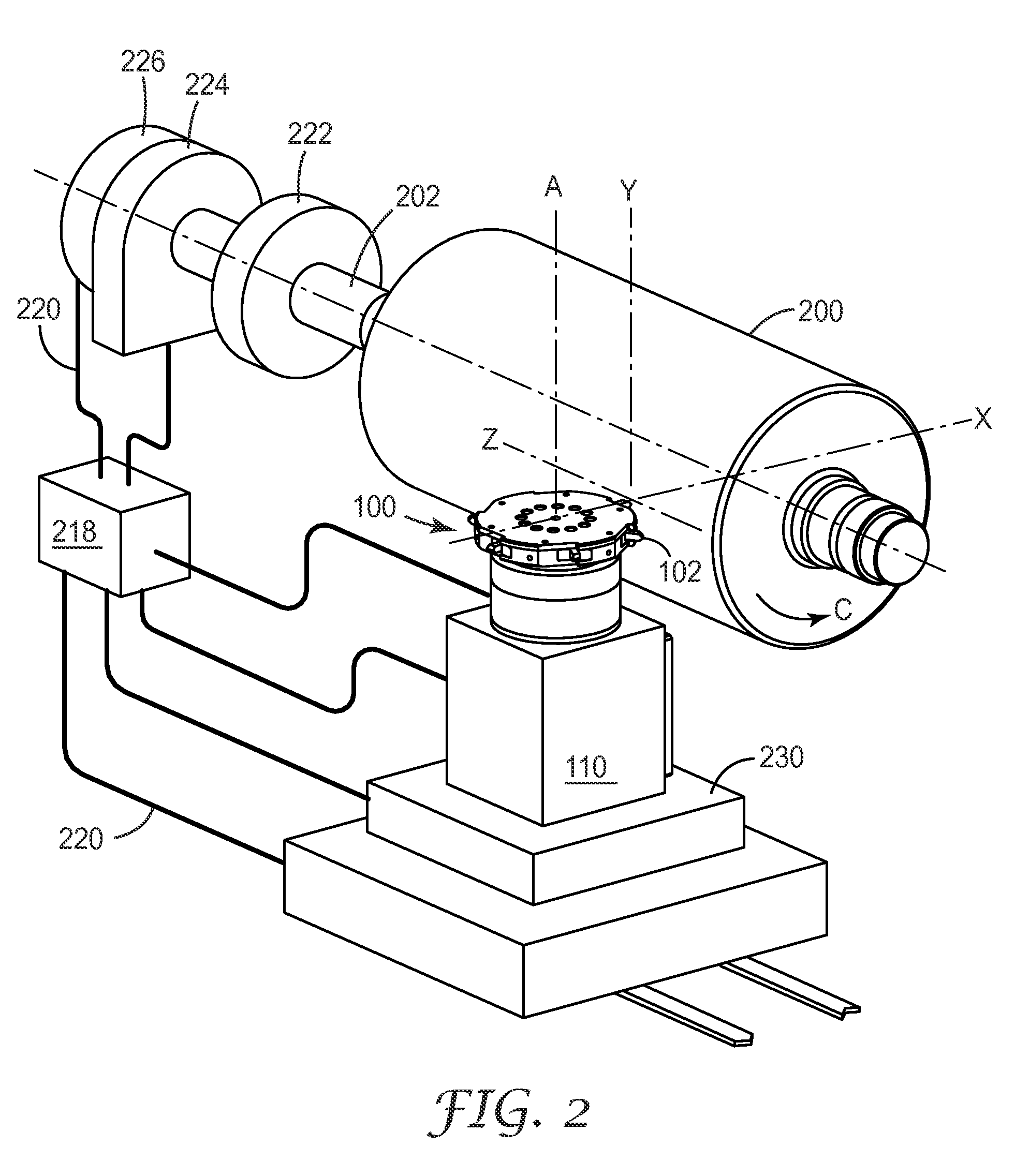

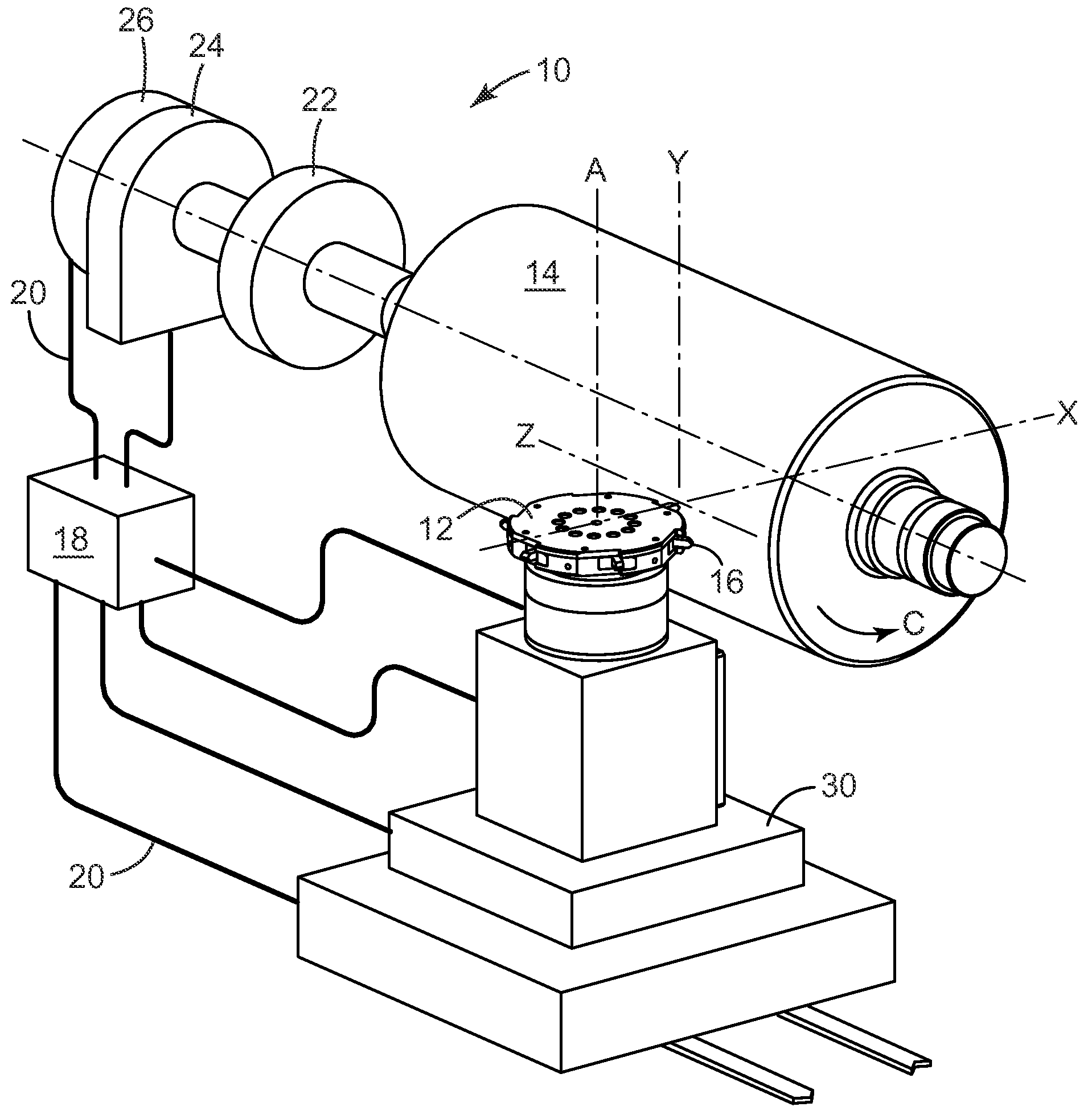

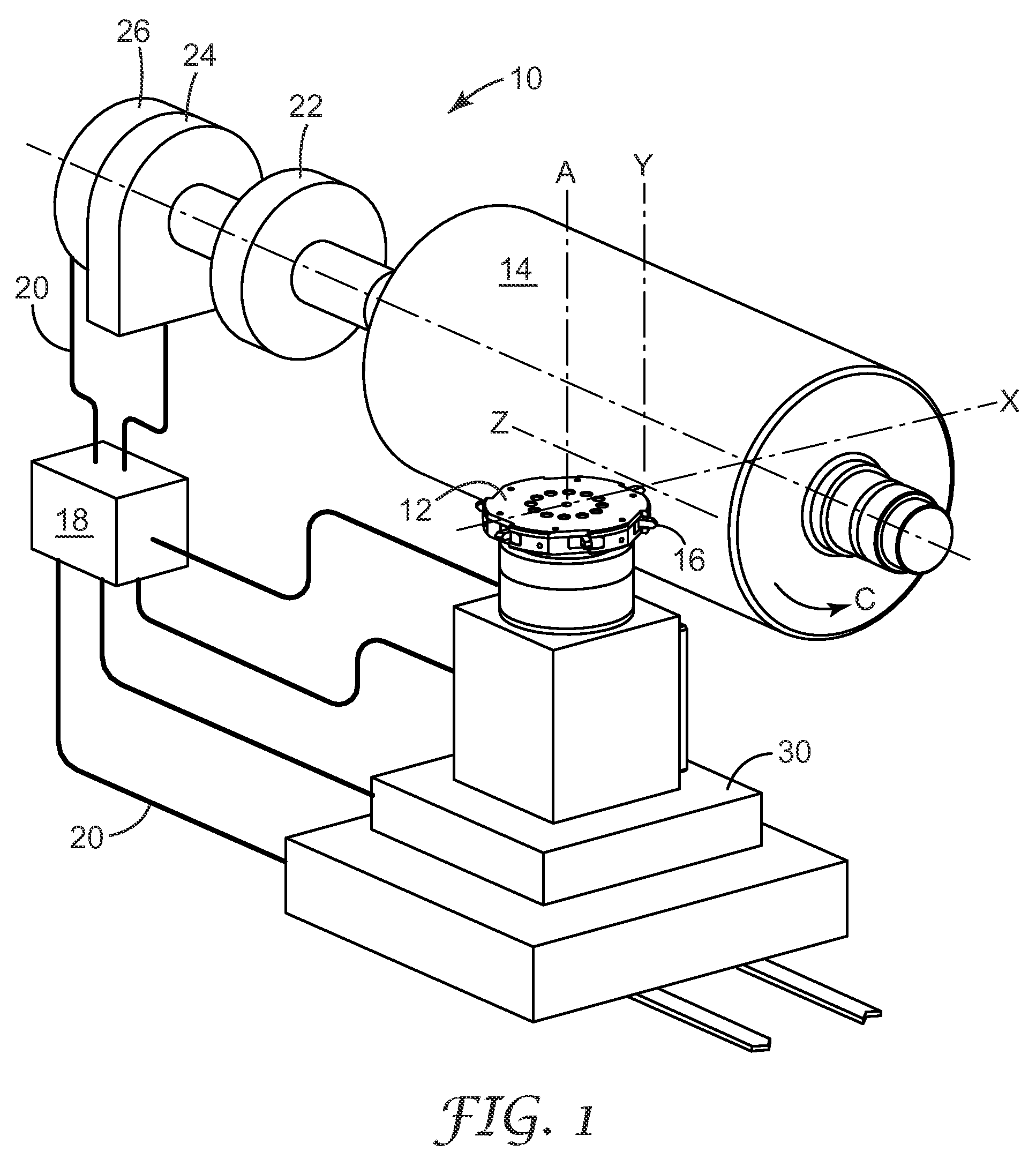

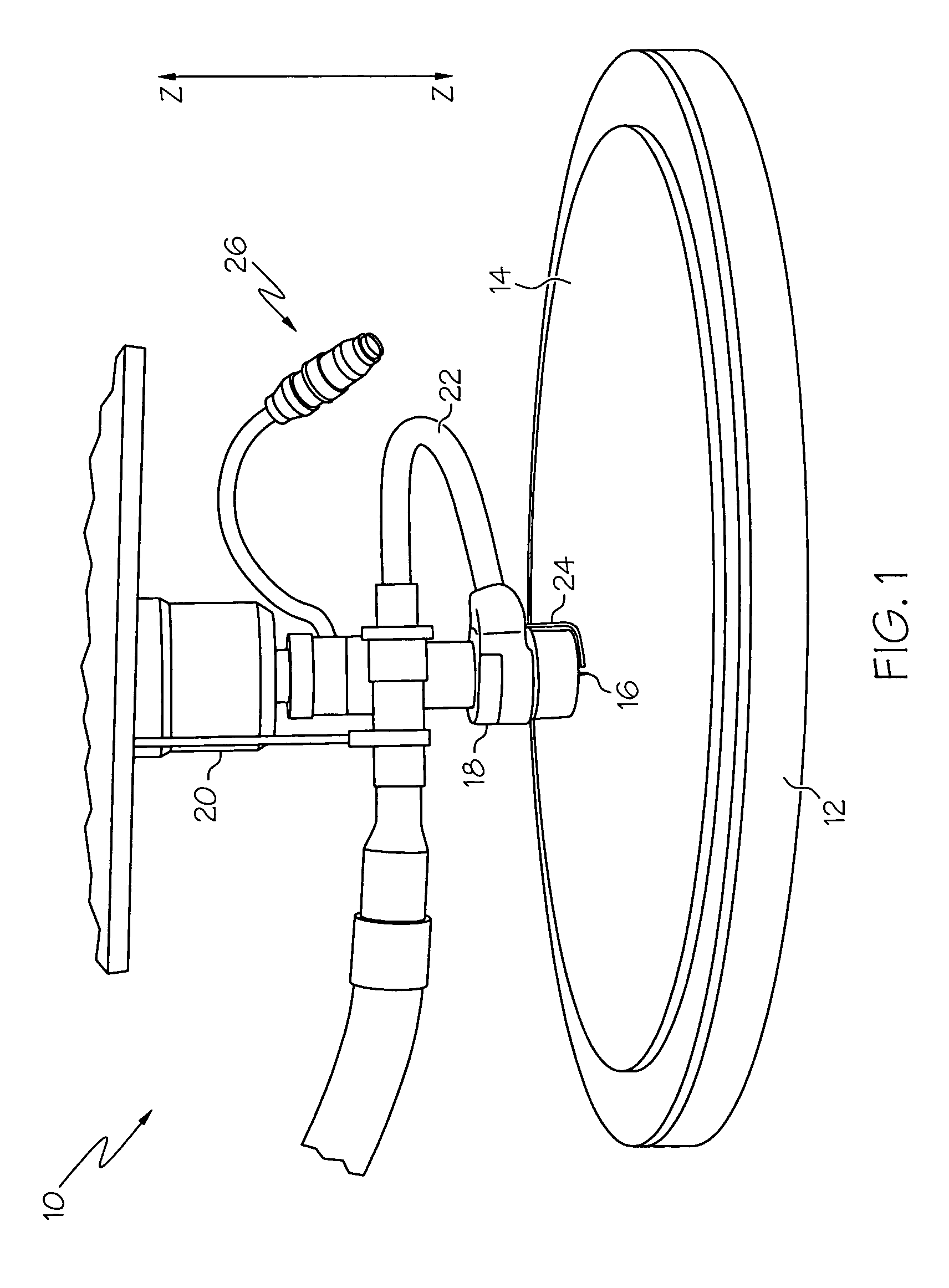

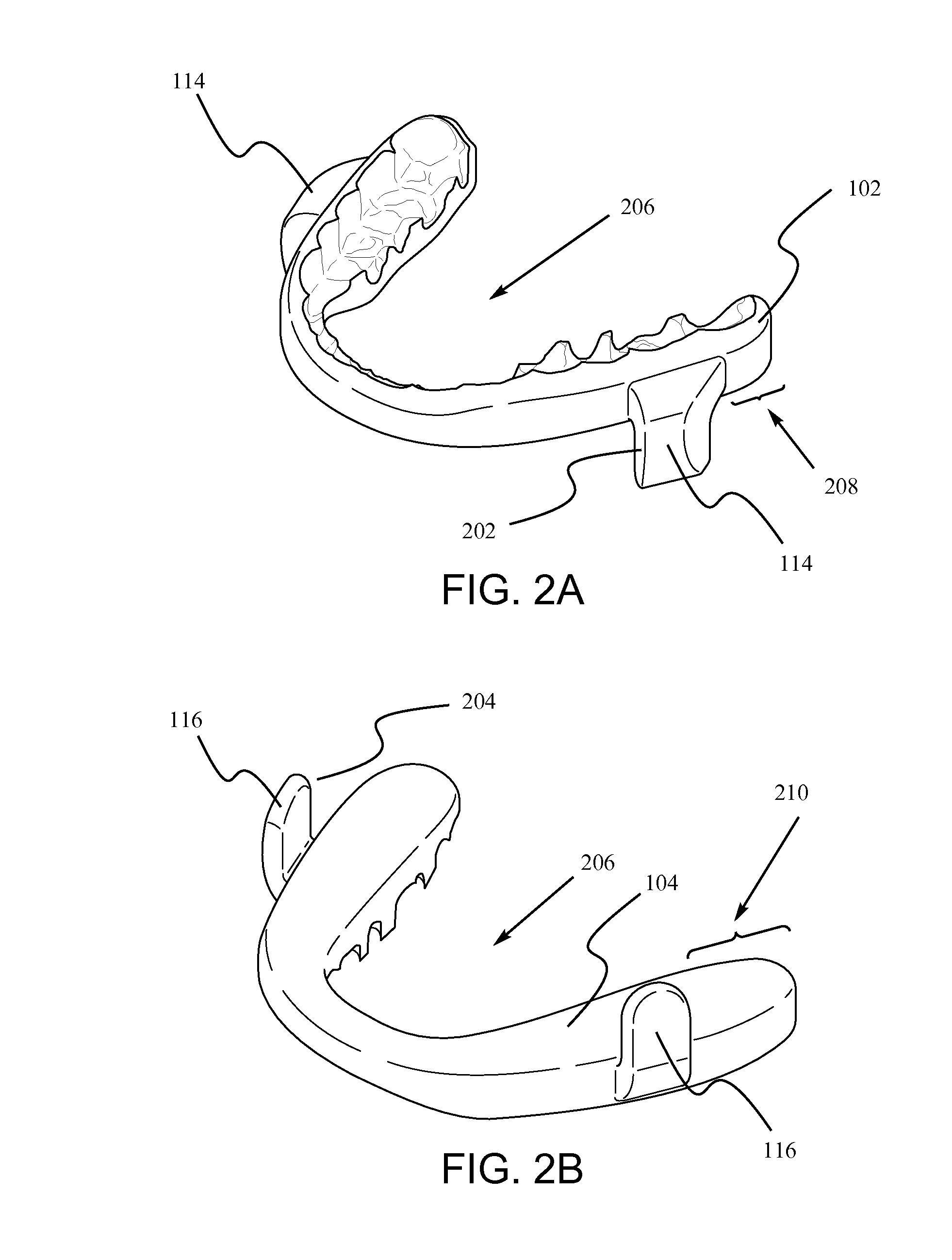

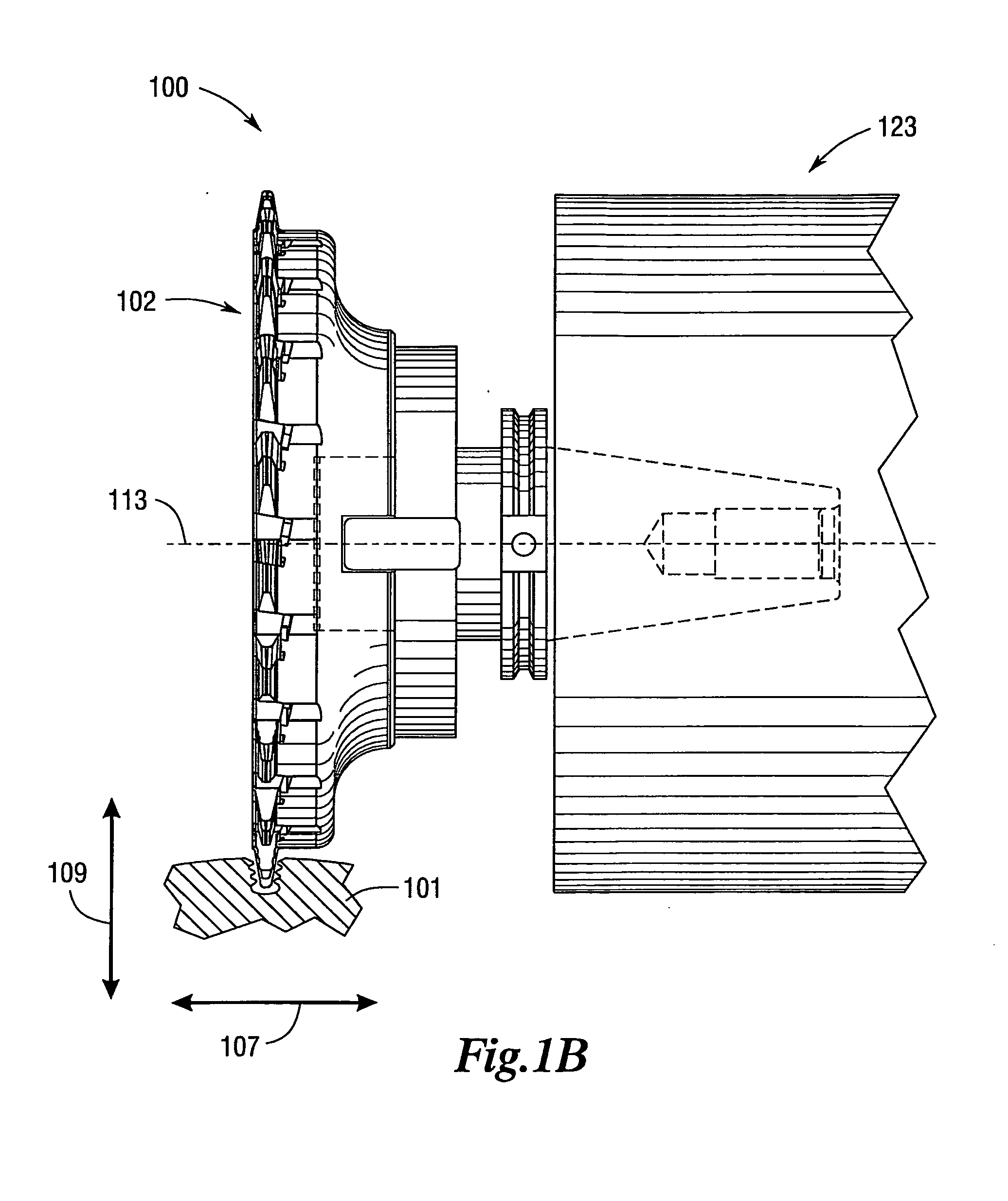

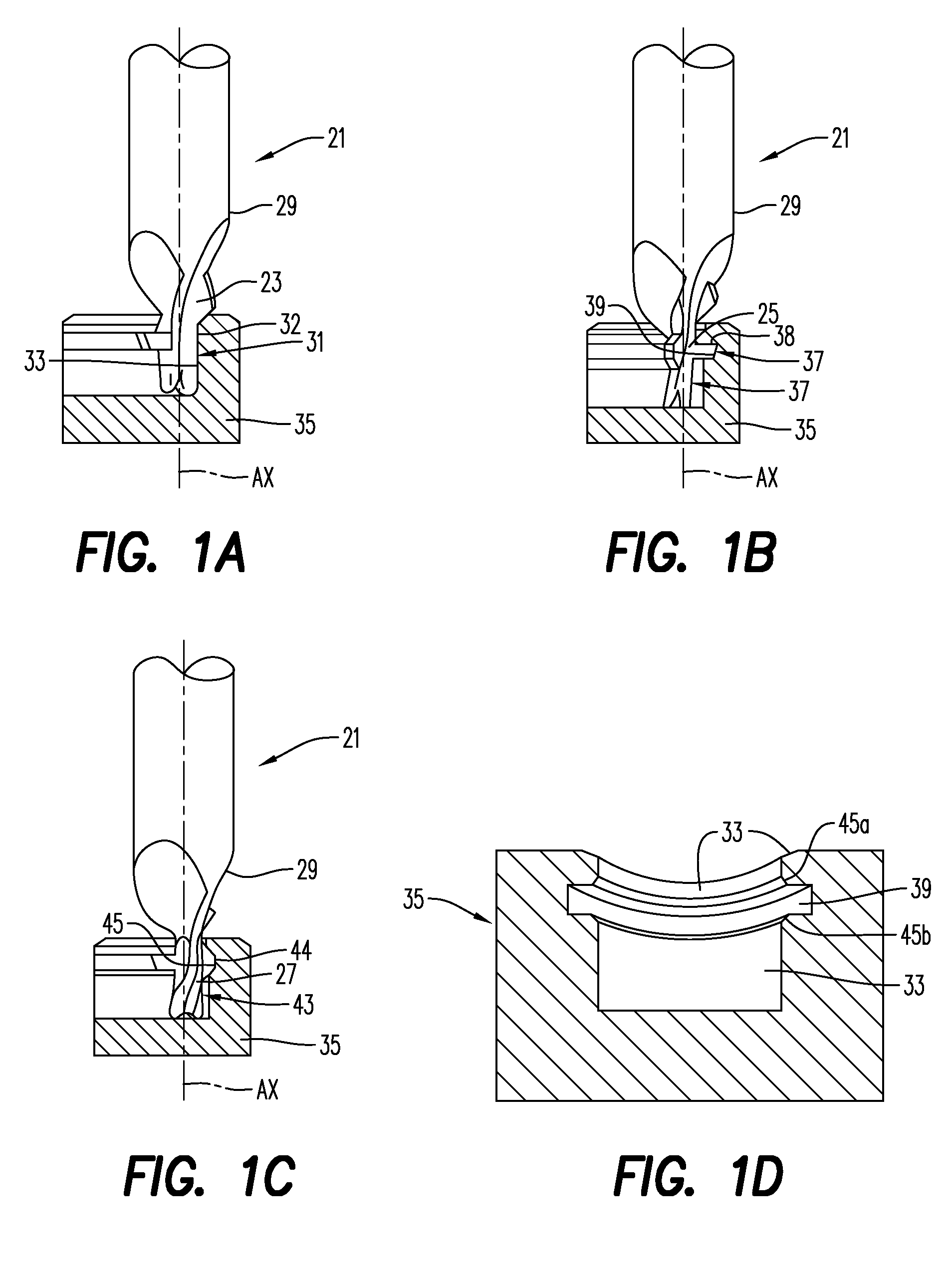

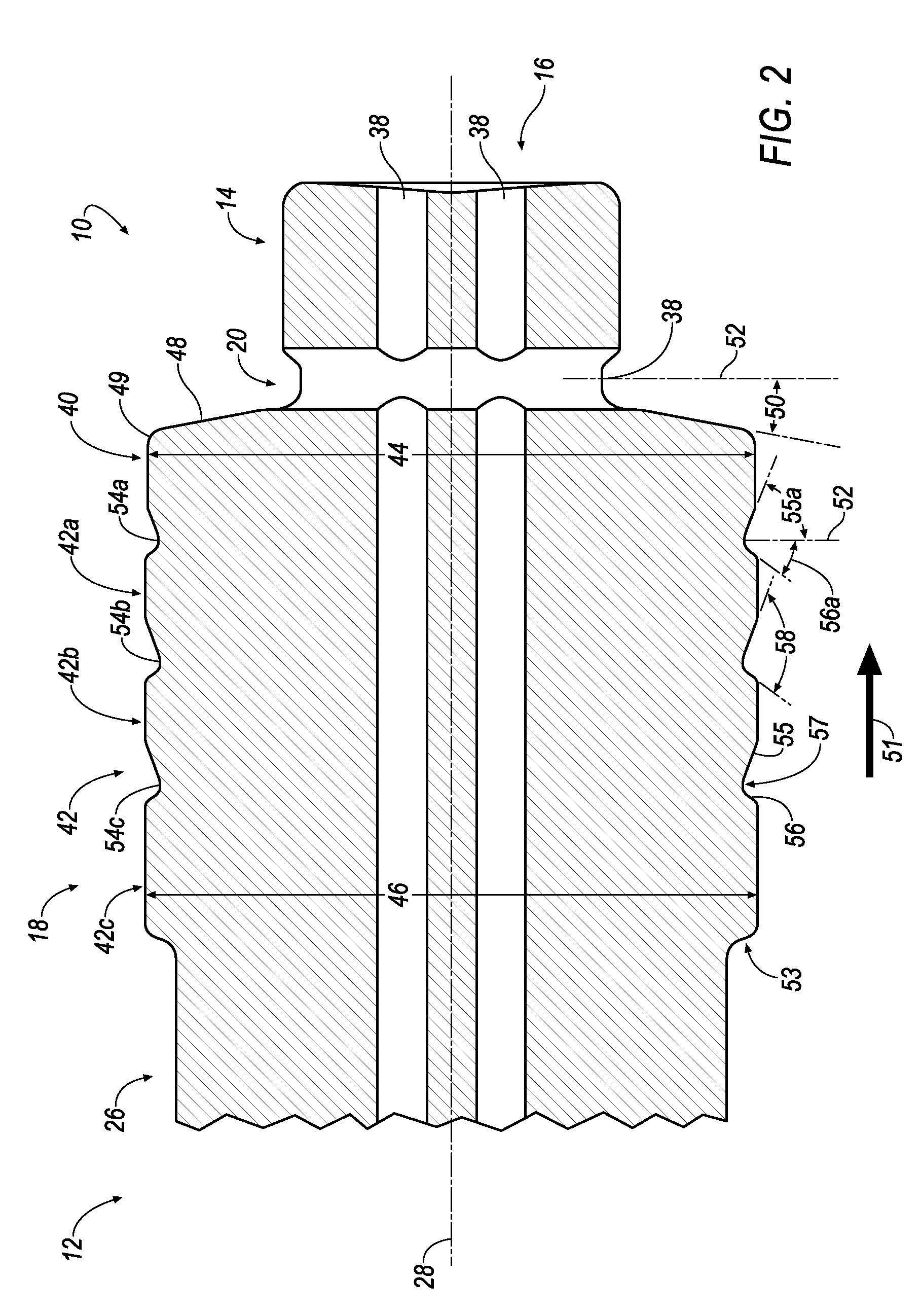

Fly-cutting system and method, and related tooling and articles

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

Rotary Burr Comprising Cemented Carbide

InactiveUS20090136308A1Improve cutting performanceImprove wear resistanceWood turning toolsTransportation and packagingFluteEngineering

A rotary burr comprising cemented carbide for removing material from a workpiece includes a shank and a working portion and a shank. A surface of the working portion includes a plurality of right-handed helically oriented flutes that define a plurality of cutting teeth on the working portion. Each of the plurality of cutting teeth defined by the right-handed flutes includes a front face, a back face, a tip, and a positive front face angle, and lacks a radial land adjacent the tooth tip and at the periphery of the working portion.

Owner:ATA TOOLS

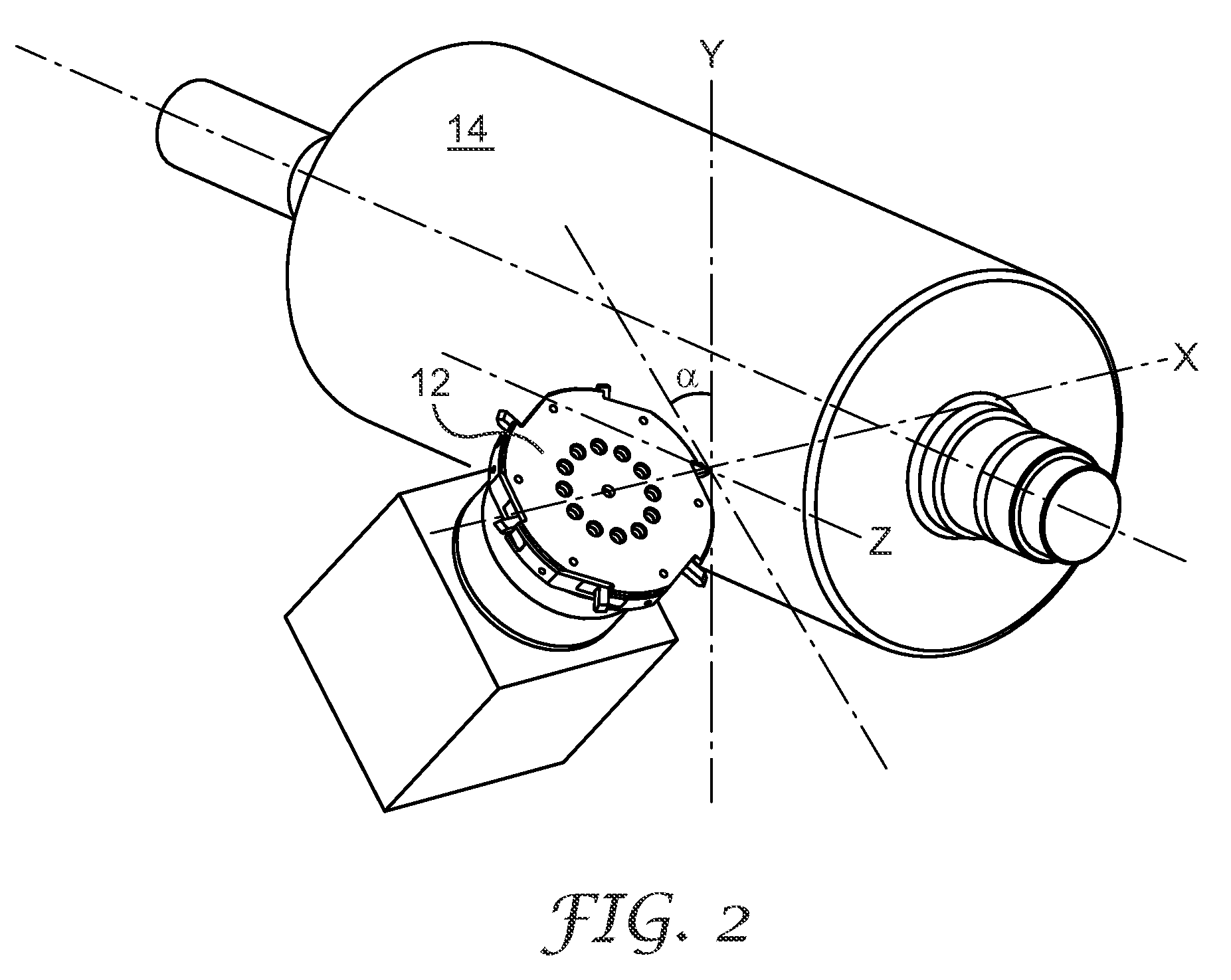

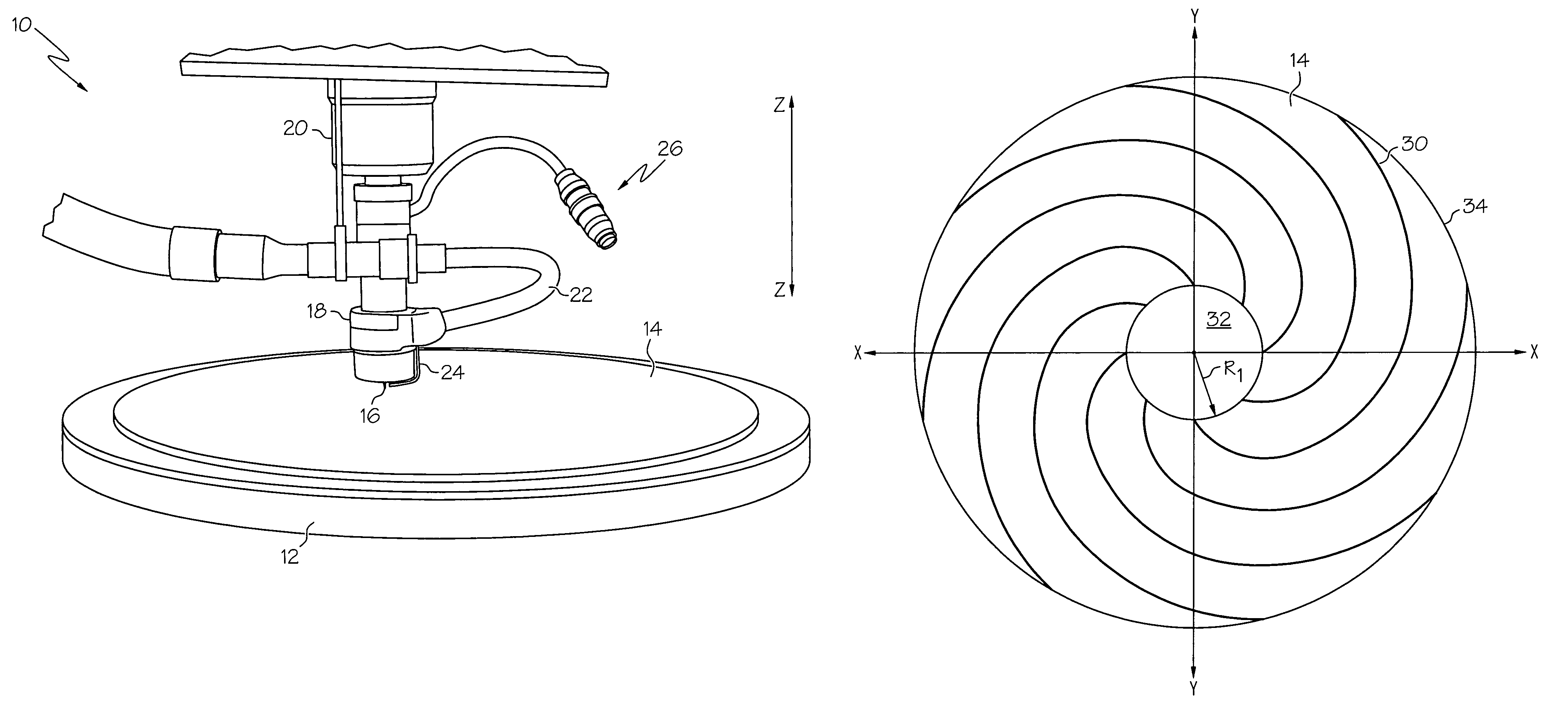

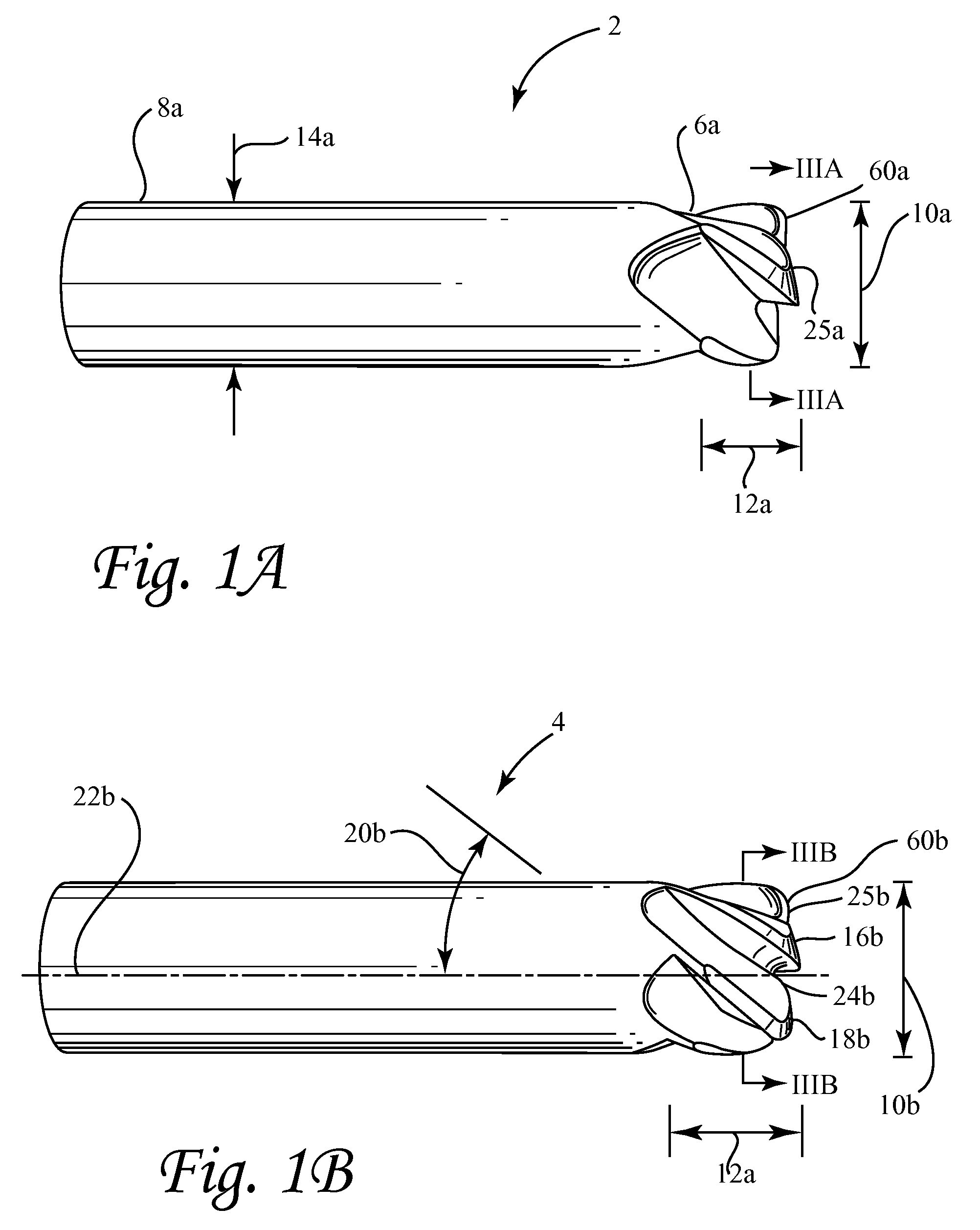

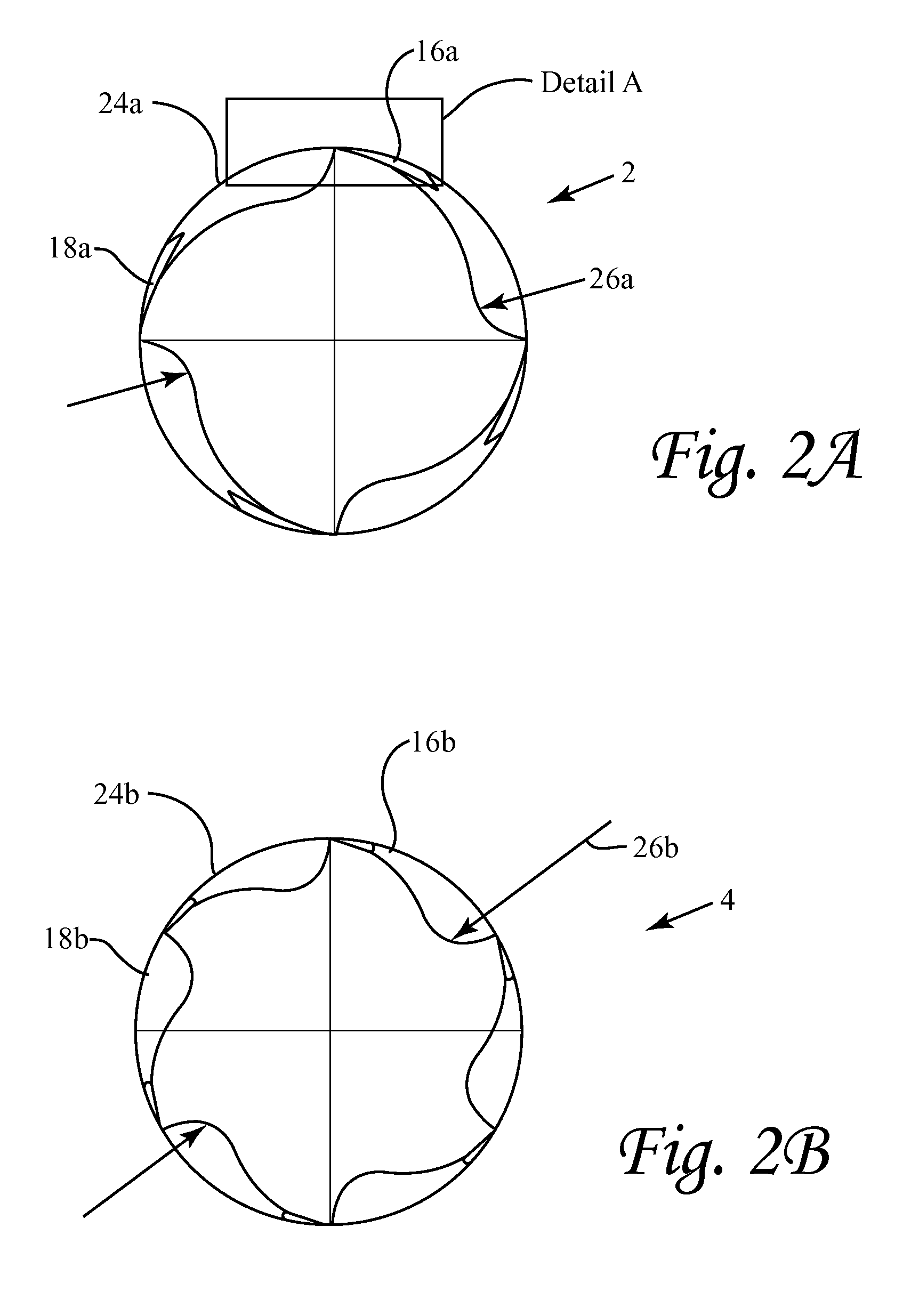

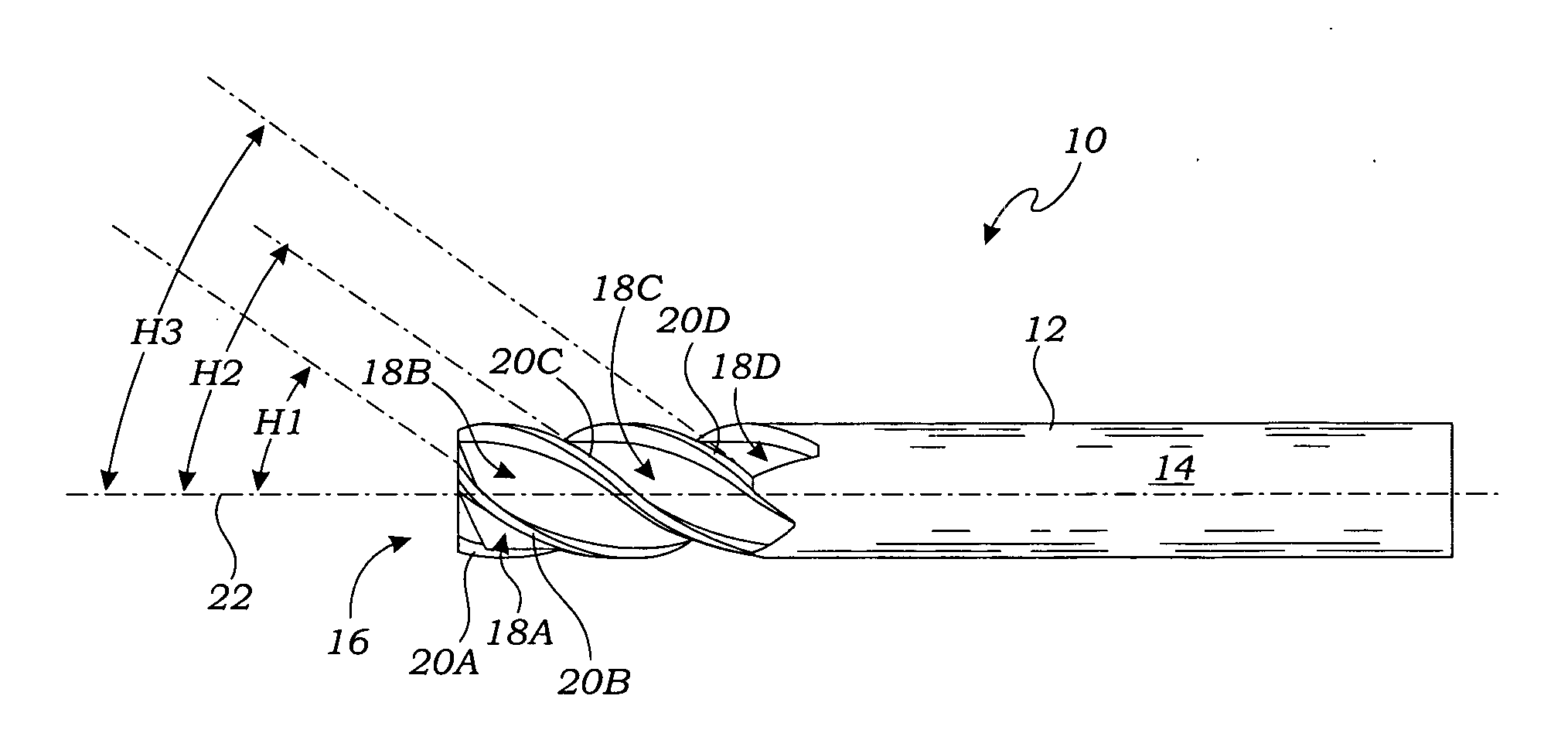

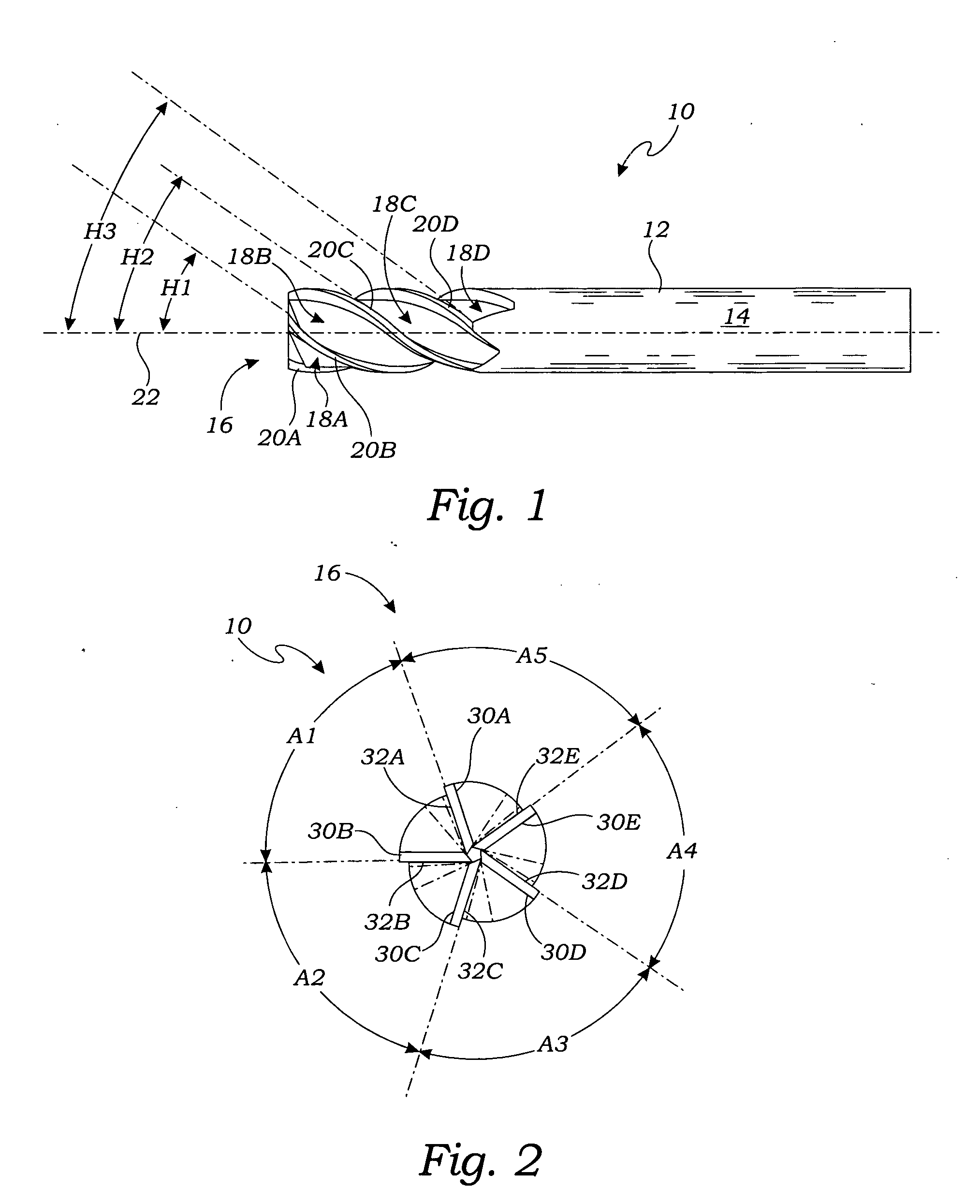

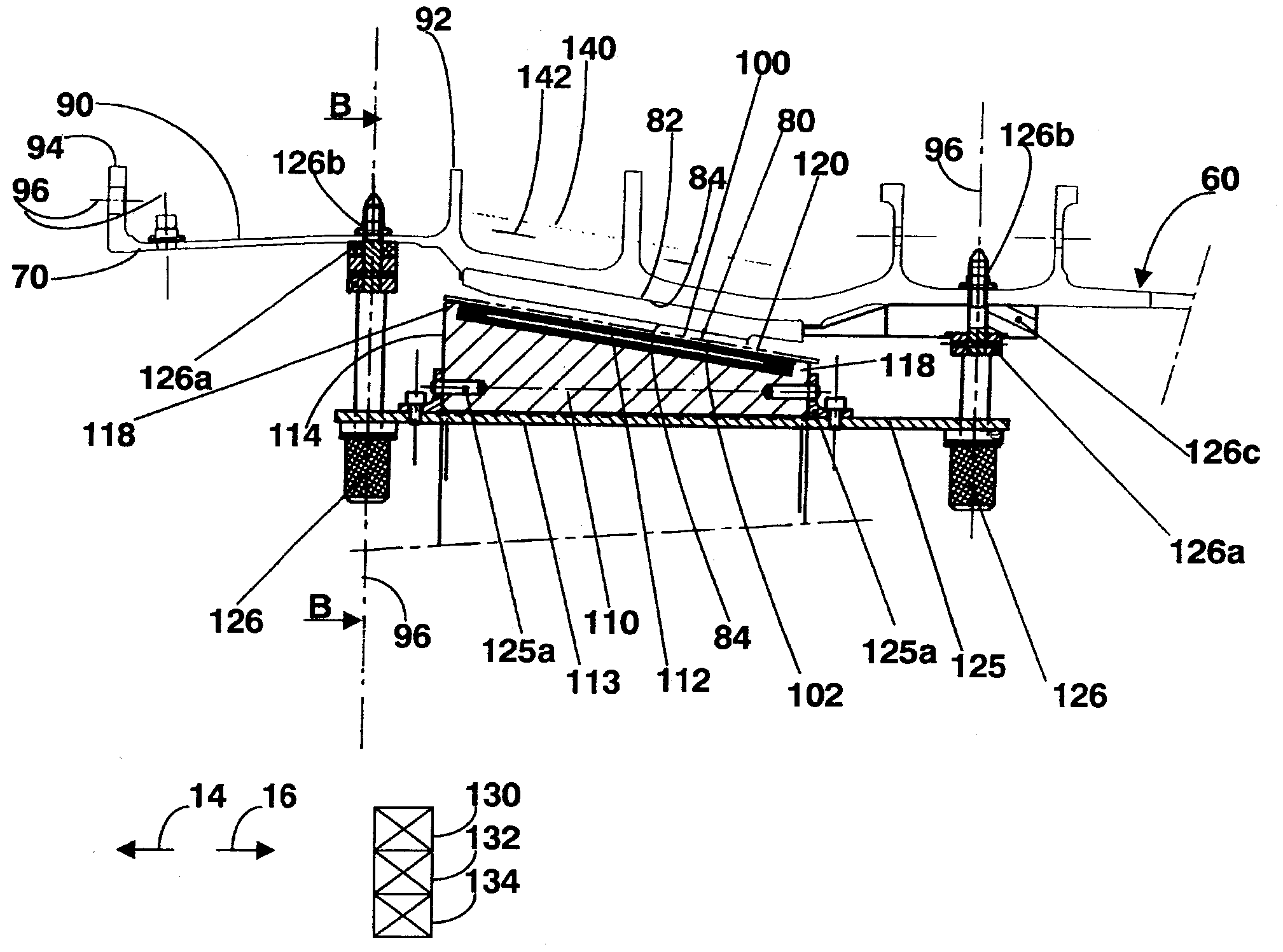

Fly-cutting head, system and method, and tooling and sheeting produced therewith

A fly-cutting system is disclosed, and in particular one that comprises a dynamically-controllable actuator for controlling the position, orientation, or both position and orientation of a cutting element carried by a fly-cutting head. In certain embodiments, the actuator can adjust the position or orientation of a cutting element, or both, hundreds or thousands of times per second, enabling precise control over the shape of features formed by the cutting element in a surface of a workpiece.

Owner:3M INNOVATIVE PROPERTIES CO

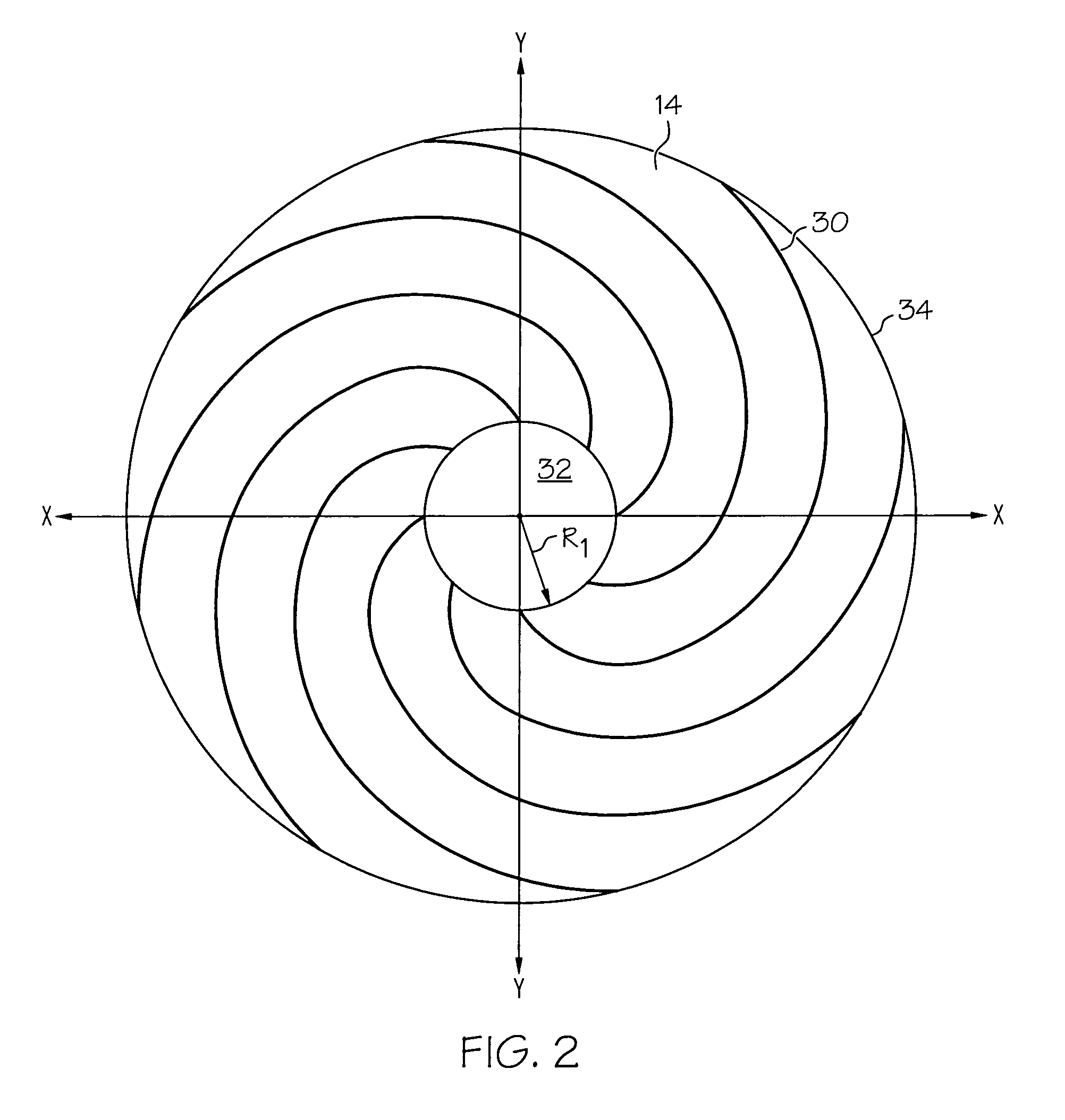

Curved grooving of polishing pads

ActiveUS7234224B1Improve productivityEfficiently formedMilling cuttersAbrasion apparatusHigh rateEngineering

A method is provided for forming grooves in a polishing pad useful for planarizing a substrate in a chemical mechanical planarization process. The method maintains average velocity as a function of bit diameter to enable groove formation using a rotating bit, whereby grooves can be formed at a higher rate while maintaining high groove quality and low defectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

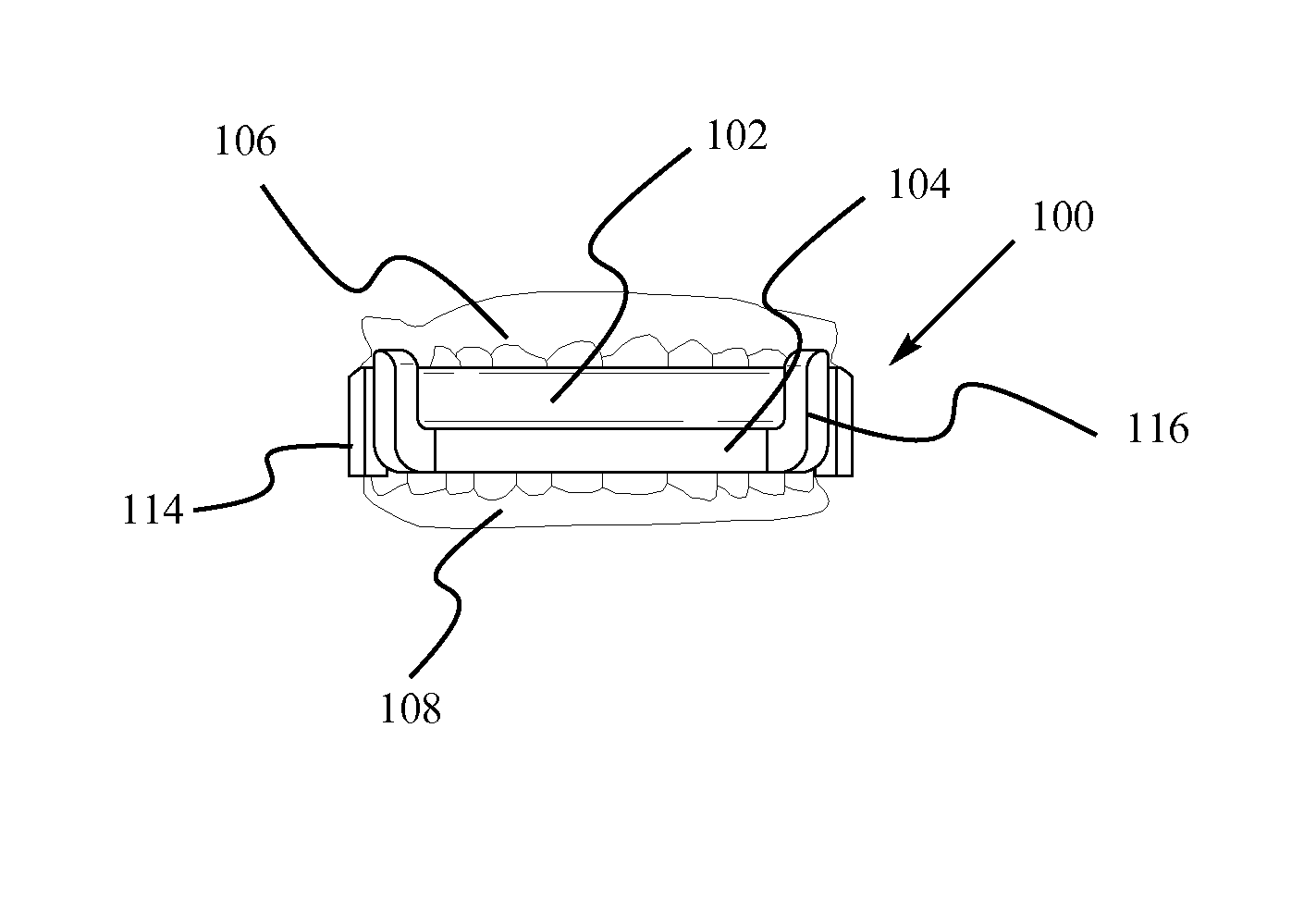

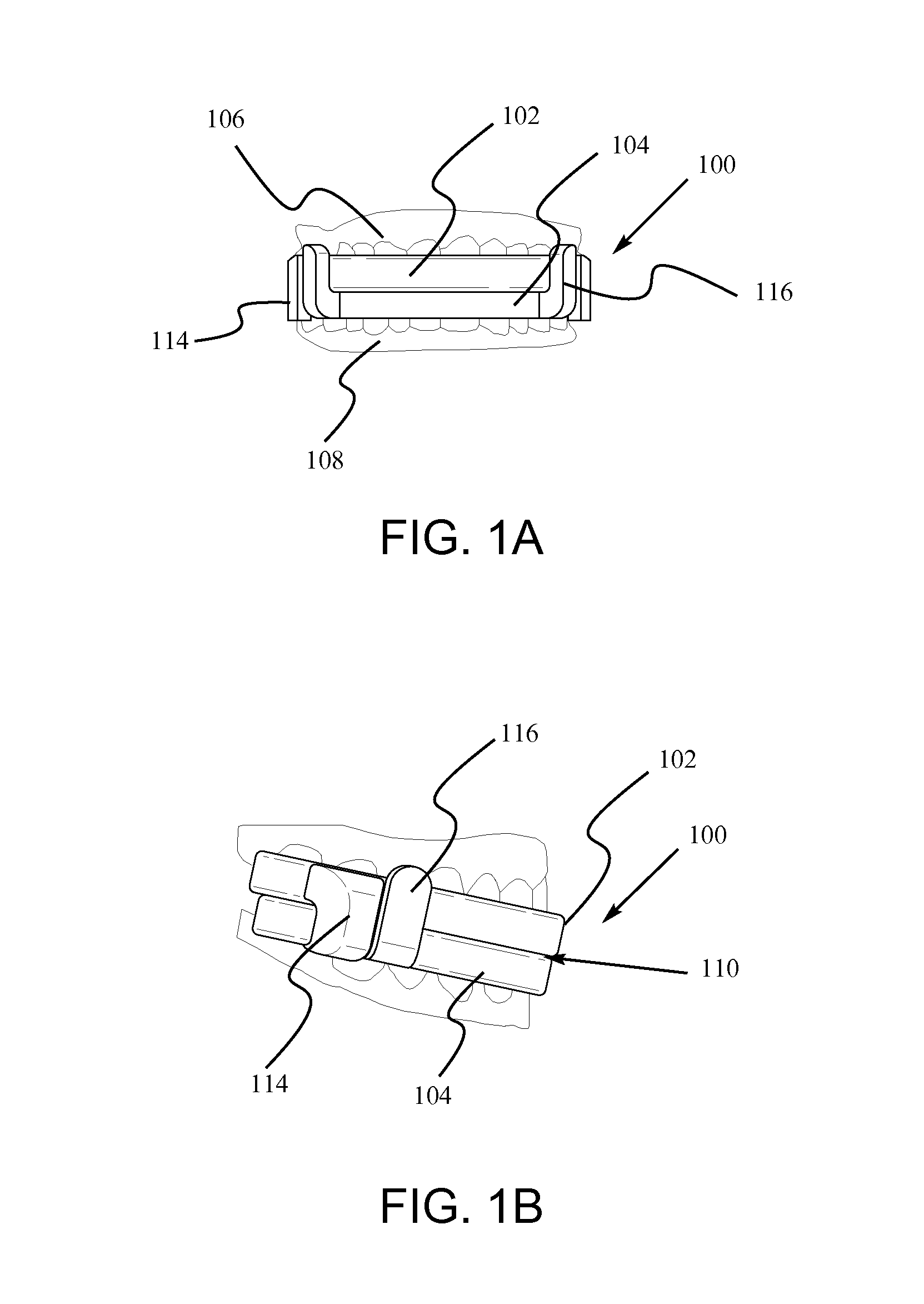

Mandibular advancement device

ActiveUS20160184129A1Reducing partial constriction of airwayOthrodonticsSnoring preventionDentitionConstriction

Disclosed herein are mandibular advancement devices comprising an upper splint and a lower splint, where the upper splint comprises one or more upper fins, where each upper fin is located at a distance UD from back of the upper splint; the lower splints comprise one or more lower fins, where each lower fin is located at a distance LD from back of the lower splint; where the position of the upper and lower fins is unchangeable. Also disclosed are methods of reducing partial constriction of airway during sleep for a patient, the method comprising identifying a patient in need thereof; and administering to the patient the disclosed mandibular advancement device. Also disclosed are methods of manufacturing a mandibular advancement device, the method comprising obtaining measurements from a patient's dentition; digitally designing a mandibular advancement device; and milling the mandibular advancement device.

Owner:PROSOMNUS SLEEP TECH INC

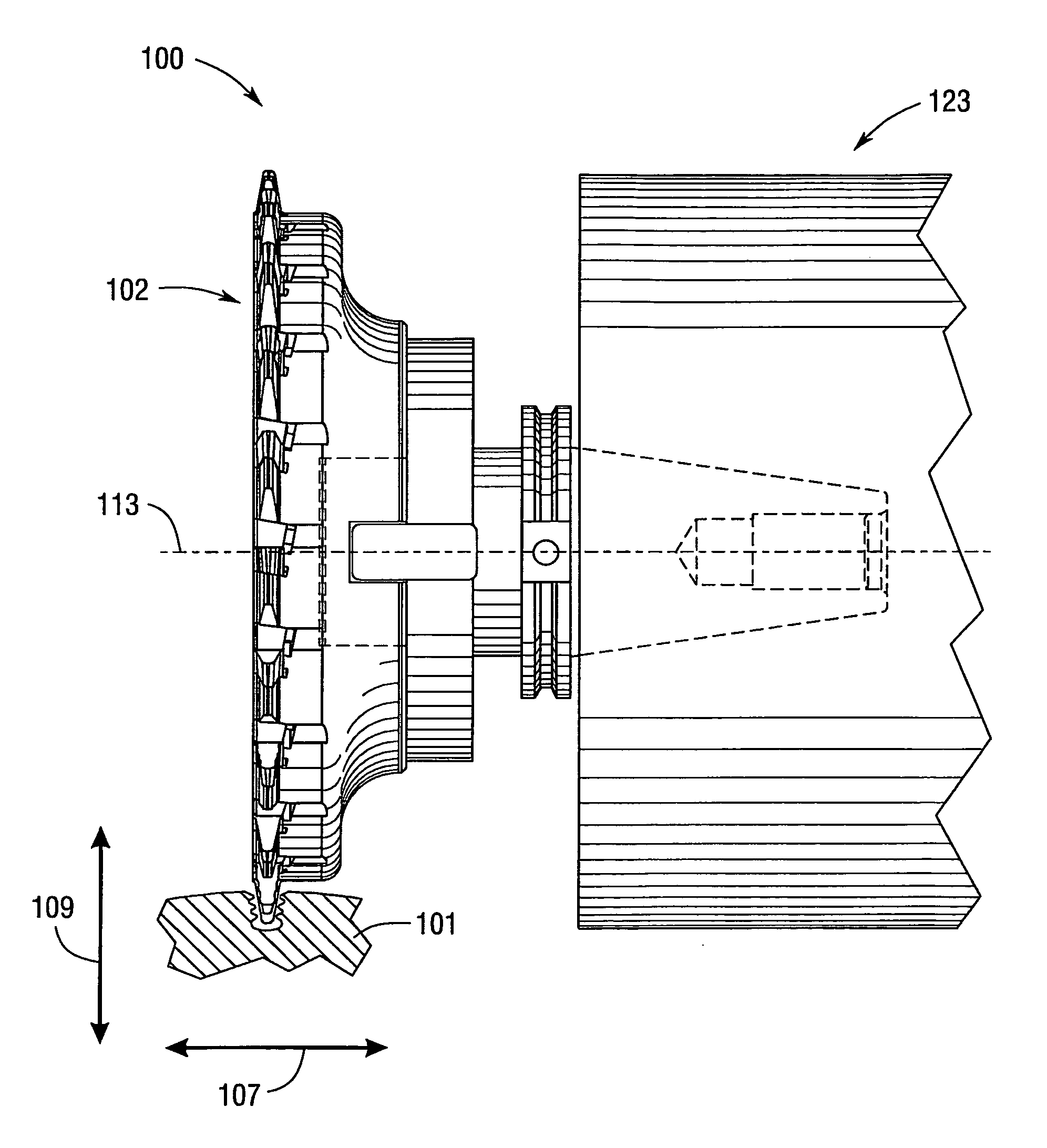

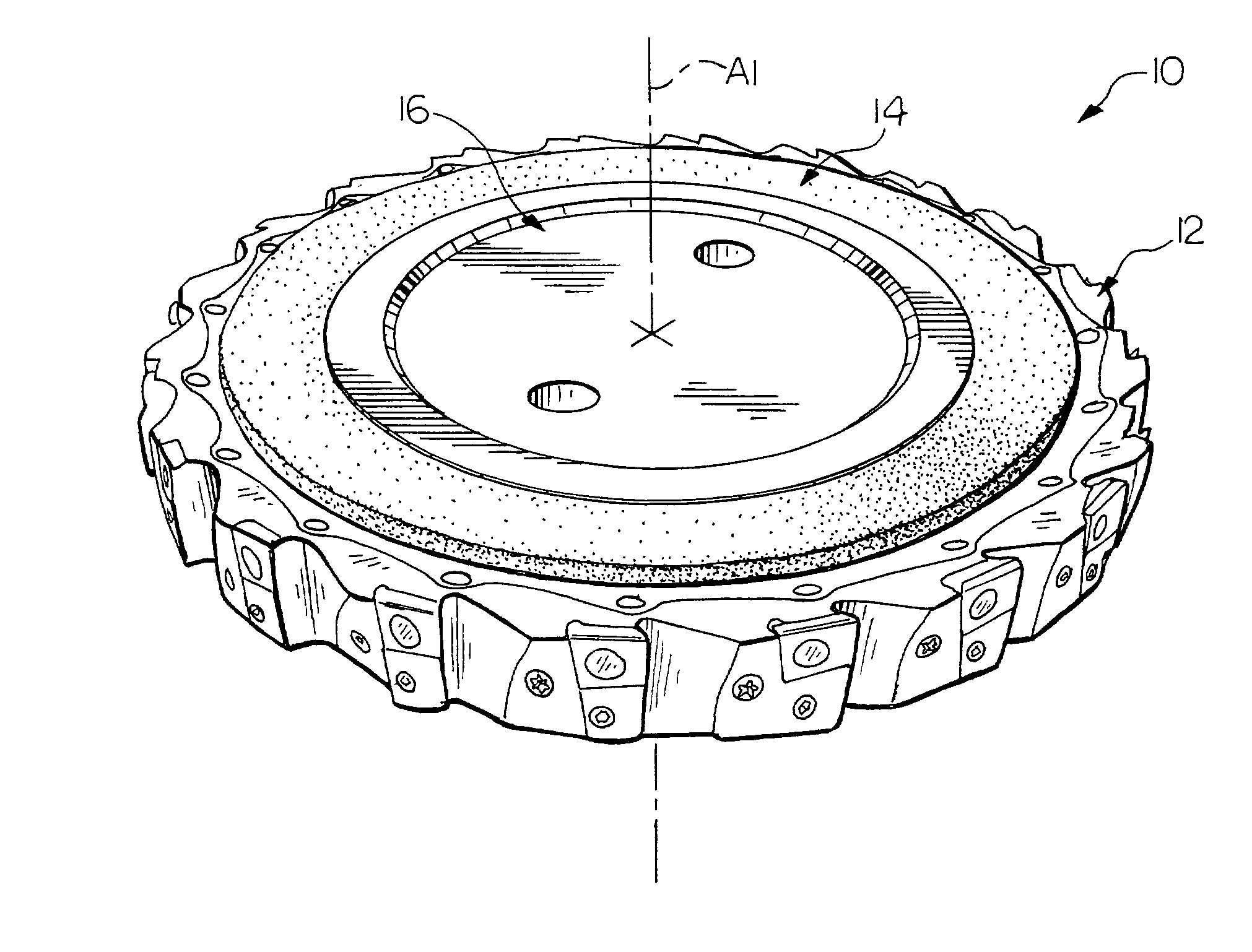

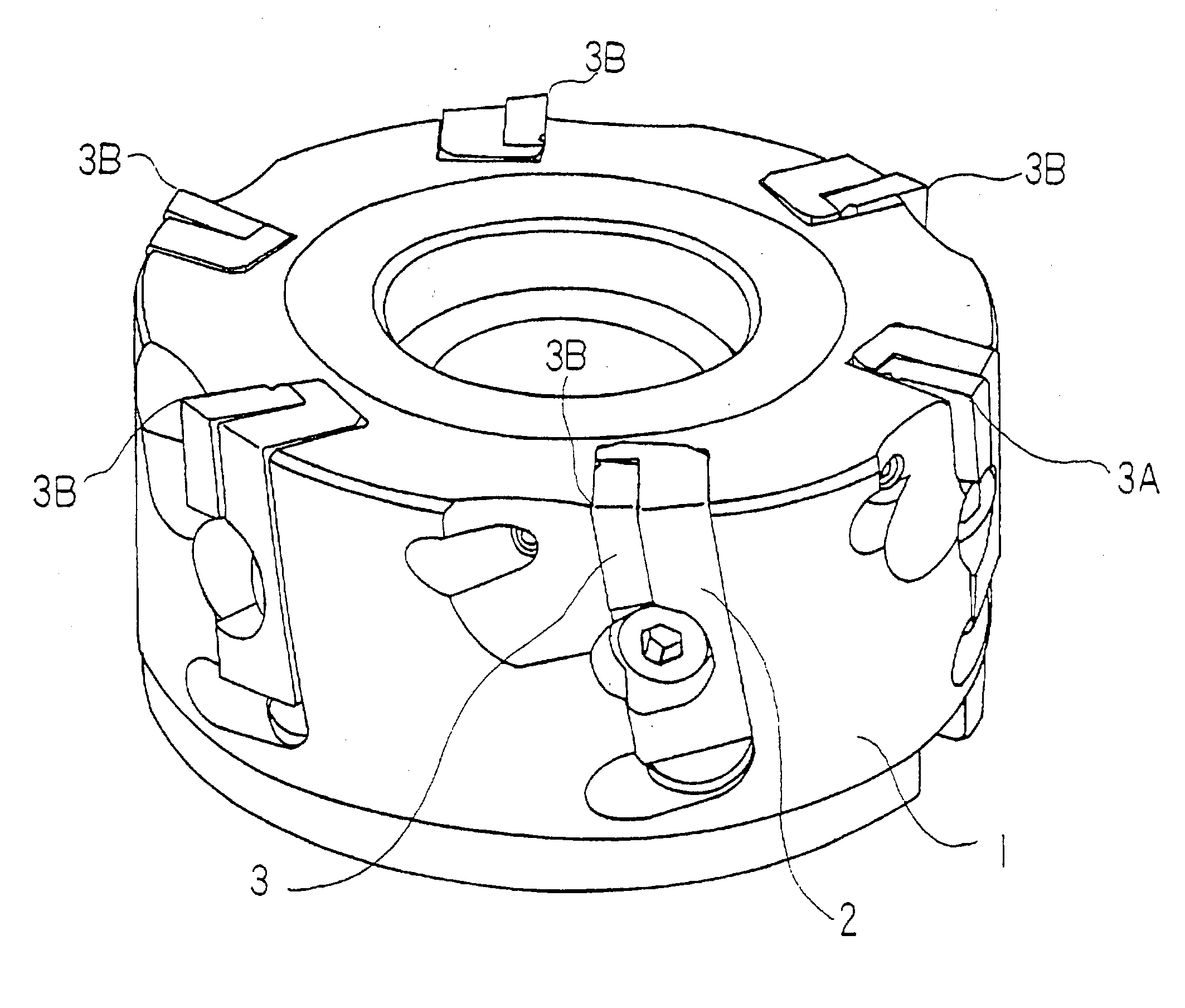

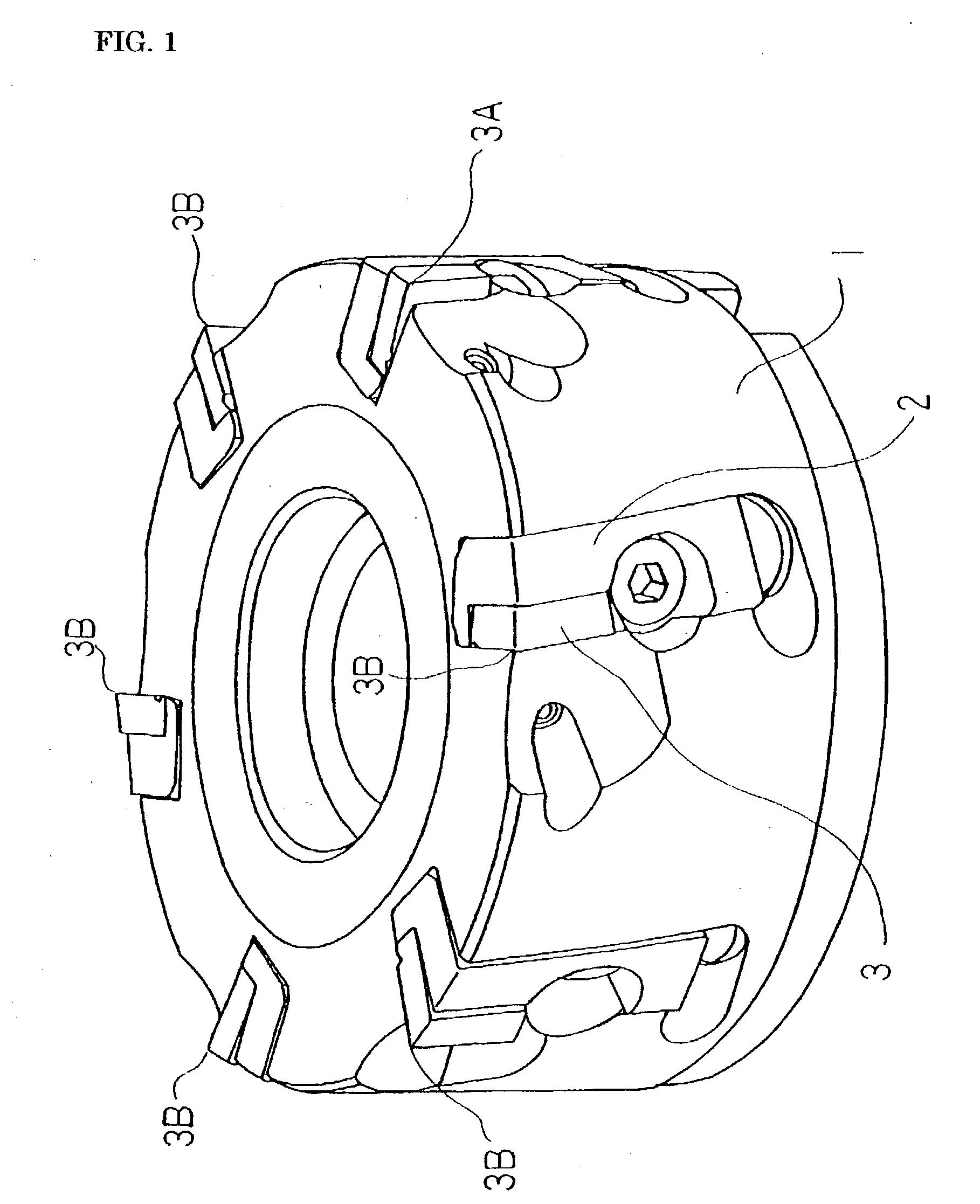

Slotting cutter and inserts for same

The present invention is directed to an insert, a slotting cutter assembly and a method for machining a plurality of slots in a metallic alloy part. The insert may comprise a cutting edge, at least one primary radius, at least two secondary radii and a clearance angle. The cutting edge may form a narrow outer end at a tip of the insert and a larger width region at a distance inward from the narrow outer end. The clearance angle may extend rearward from the cutting edge. The slotting cutter assembly may comprise a plurality of inserts and a cutter body. The cutter body may comprise a plurality of retaining slots and a plurality of support portions. The retaining slot may be configured to receive the insert. The support portion may provide support for the insert.

Owner:GREENLEAF TECH CORP

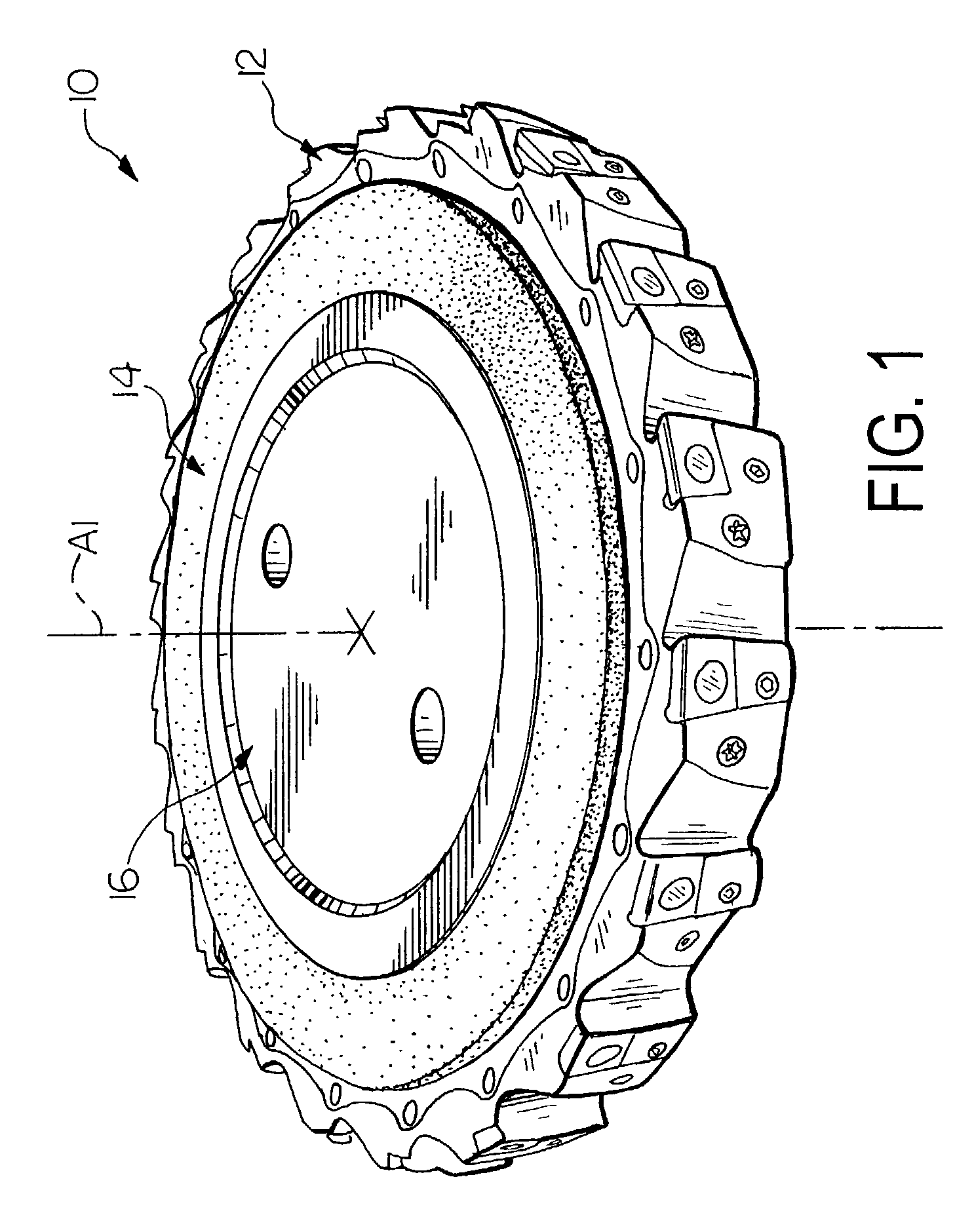

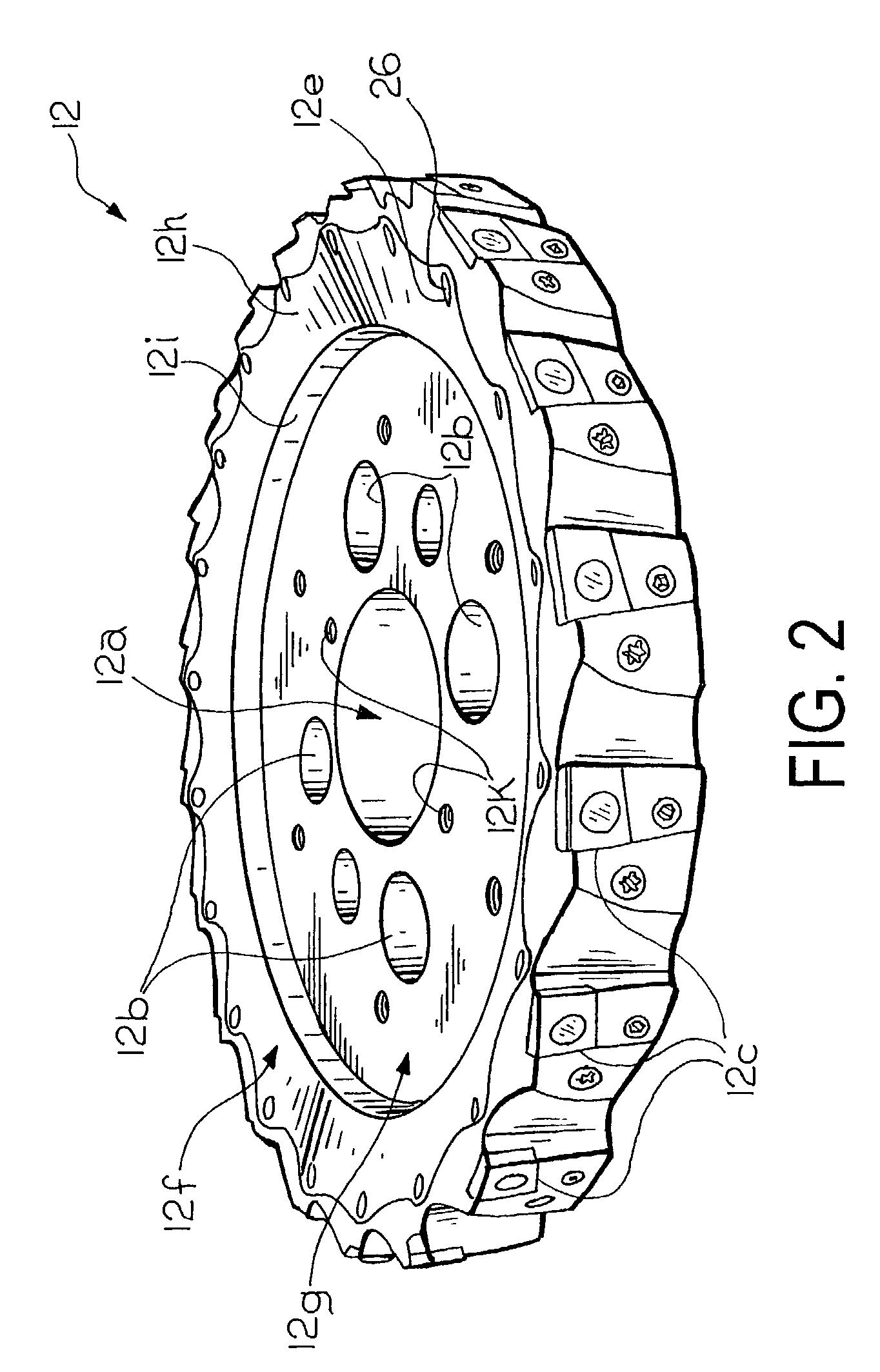

Cutting tool for rough and finish milling

A milling cutter comprises a cutter body having two concentric annular rings. An outer ring is provided for rough milling and includes a plurality of cutting inserts equally spaced about the periphery of a cutter body. An inner finish ring comprises a ring member having a coating of abrasive material. As a result, a workpiece can be milled by a single milling cutter with the rough cutting inserts and then the abrasive material.

Owner:KENNAMETAL INC

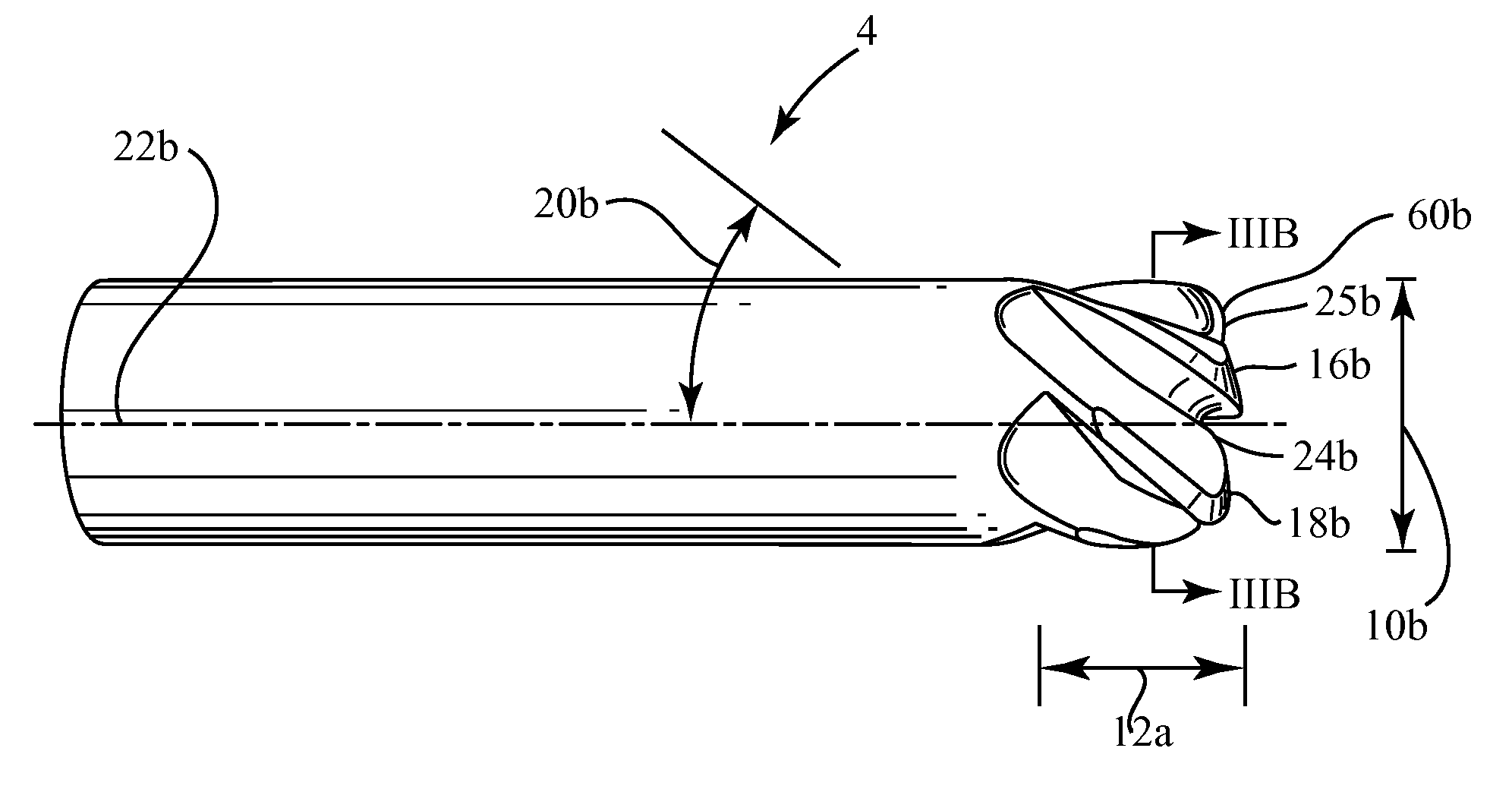

End mill for orbital drilling of fiber reinforced plastic materials

A center or non-center cutting end mill for orbital drilling of fiber reinforced plastic (FRP) materials includes a shank, a neck, a cutting head and two or more flutes. The end mill has a tool geometry with the following features: a dish angle between about 2 degrees to about 6 degrees; a helix angle between about 5 degrees to about 18 degrees; an end teeth radial rake angle between about 0 degrees and about 15 degrees; a peripheral teeth radial rake angle between about 8 degrees and about 16 degrees; a gashing axial rake angle between about 3 degrees to about 10 degrees; and a primary clearance angle between about 10 degrees to about 18 degrees. The end mill is made from a tungsten carbide substrate with cemented cobalt in a range between about 3 to 10 wt. % and a diamond coating having a thickness in a range between about 8 to 20 μm.

Owner:KENNAMETAL INC

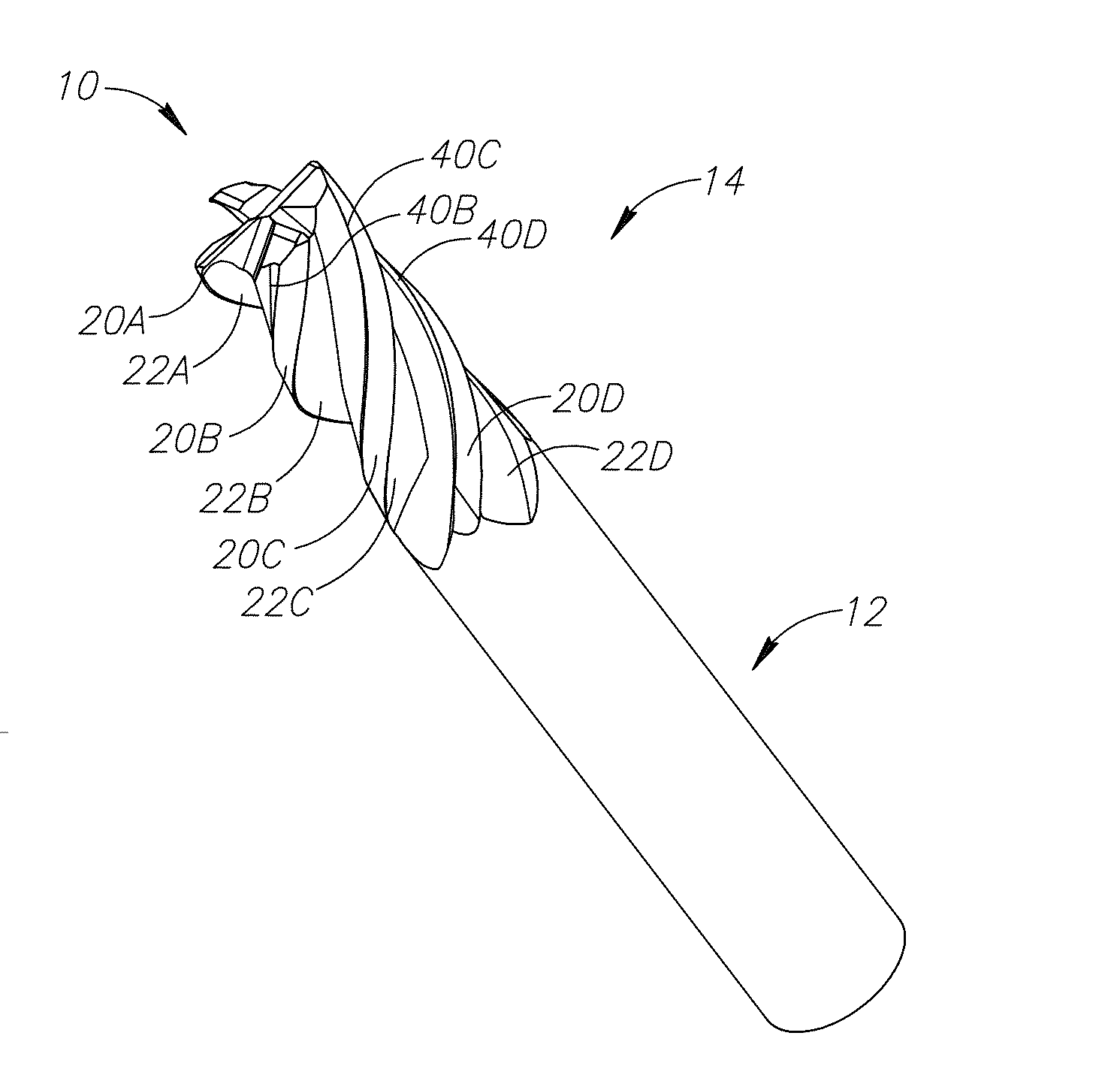

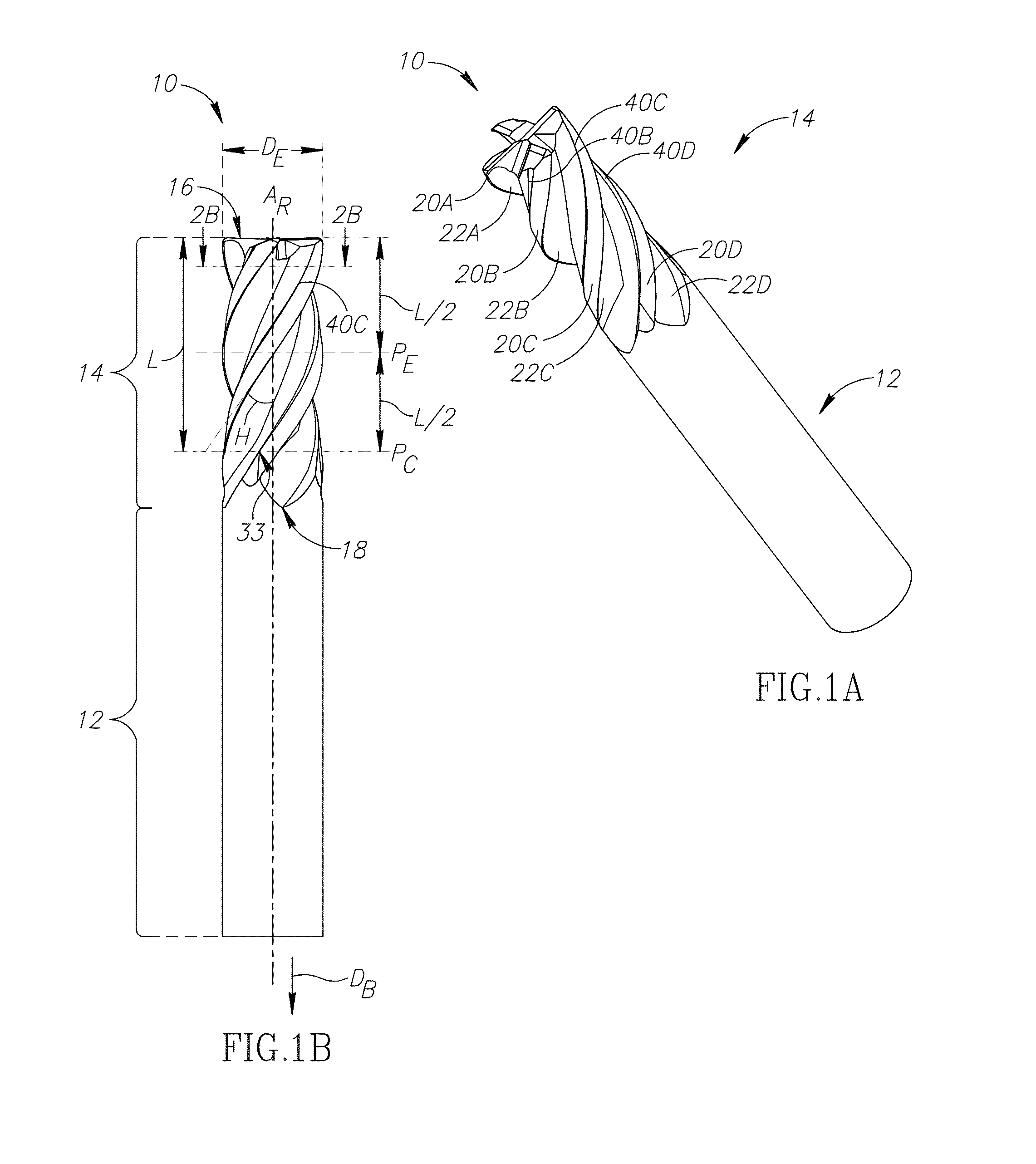

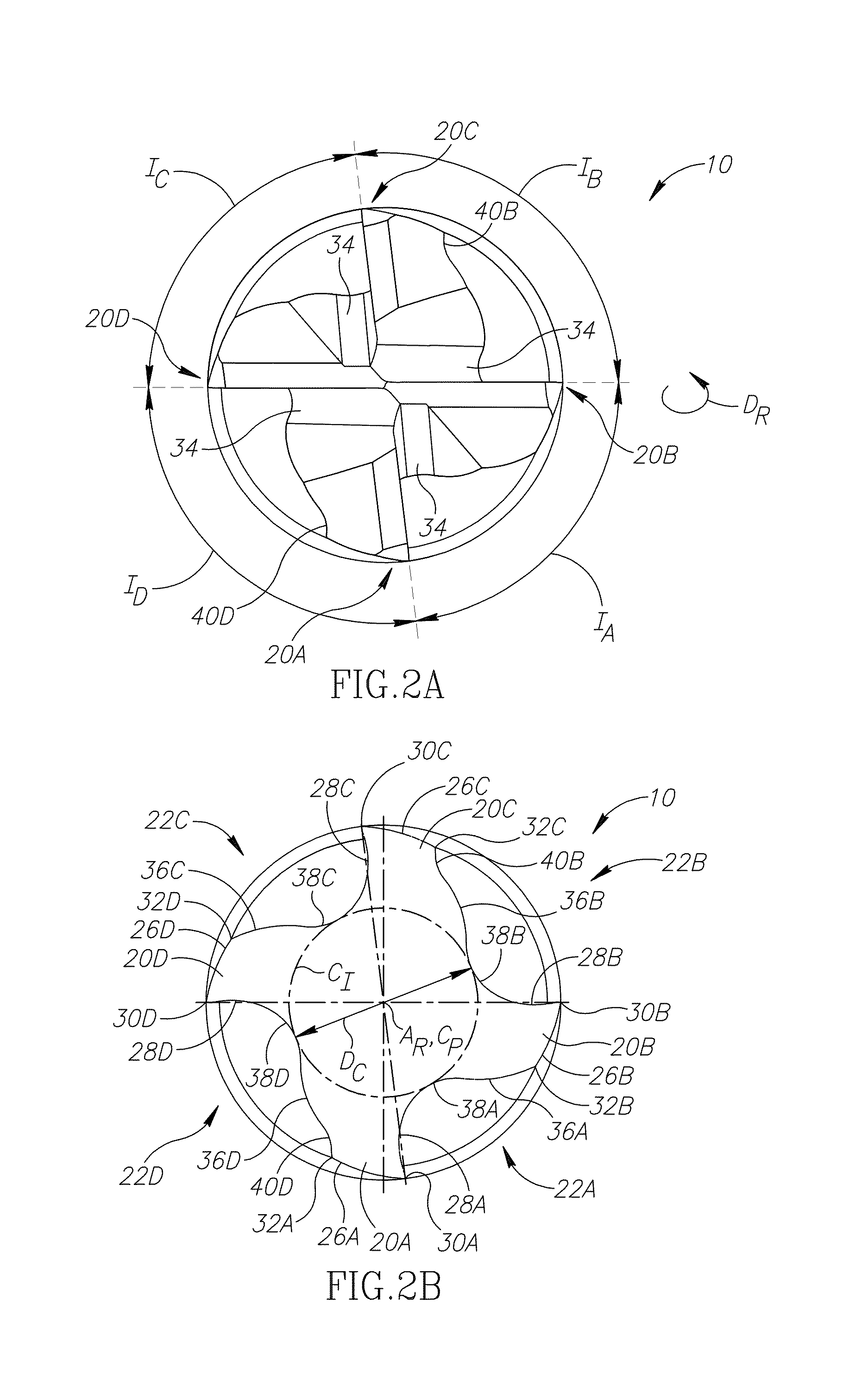

Cutting tool with multiple flutes defining different profiles, and method

ActiveUS7862263B2Minimize thermal expansionHigh strengthMilling cuttersWorkpiecesLeading edgeMechanical engineering

A cutting tool having multiple cutting edges includes a tool body having a longitudinal axis, a first cutting edge including a first leading edge that defines a first profile when rotated about the longitudinal axis, and a second cutting edge including a second leading edge that defines a second profile when rotated about the longitudinal axis, the first and second profiles being different from each other and being adapted to cut a workpiece in succession. A method is also disclosed.

Owner:SECO TOOLS AB

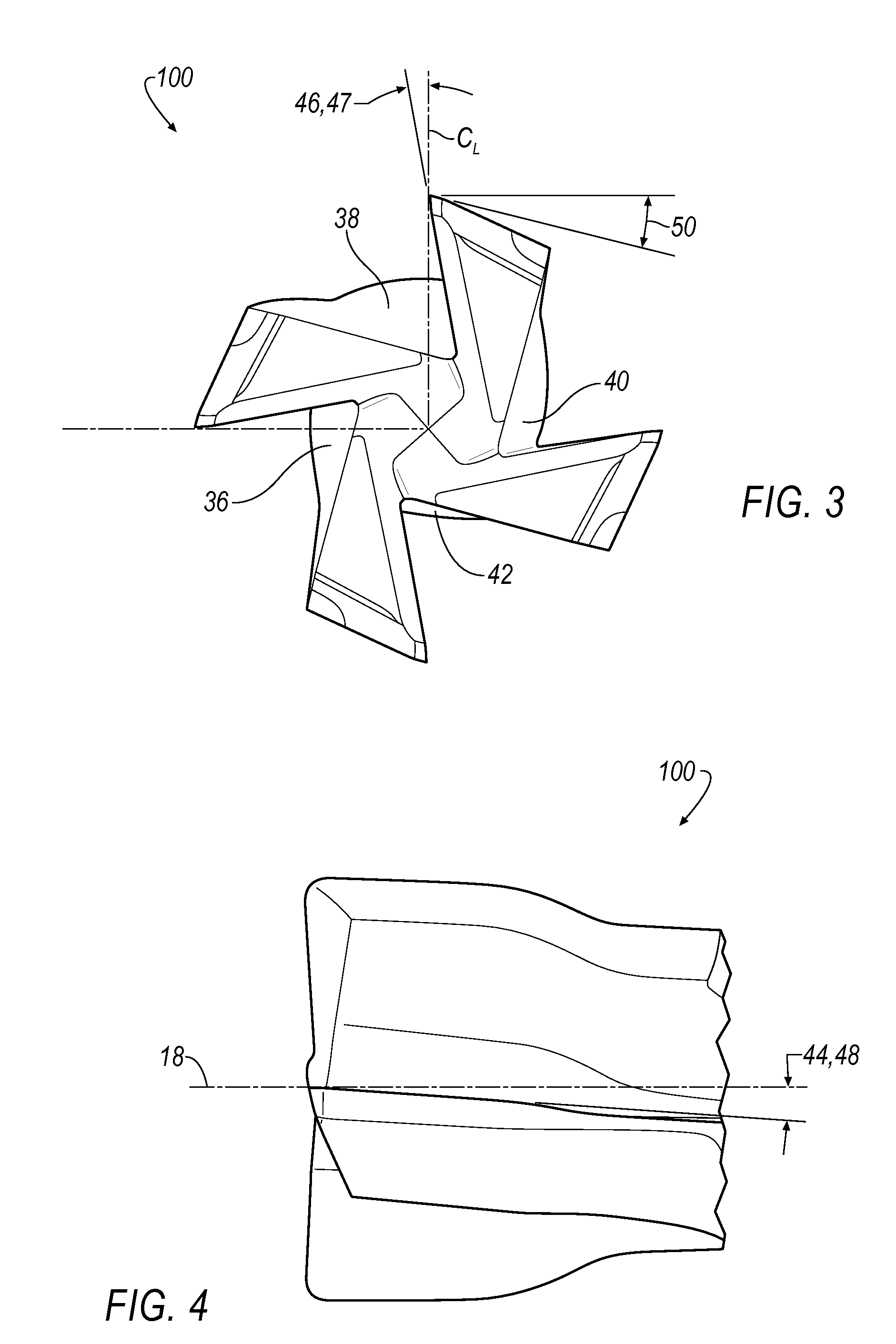

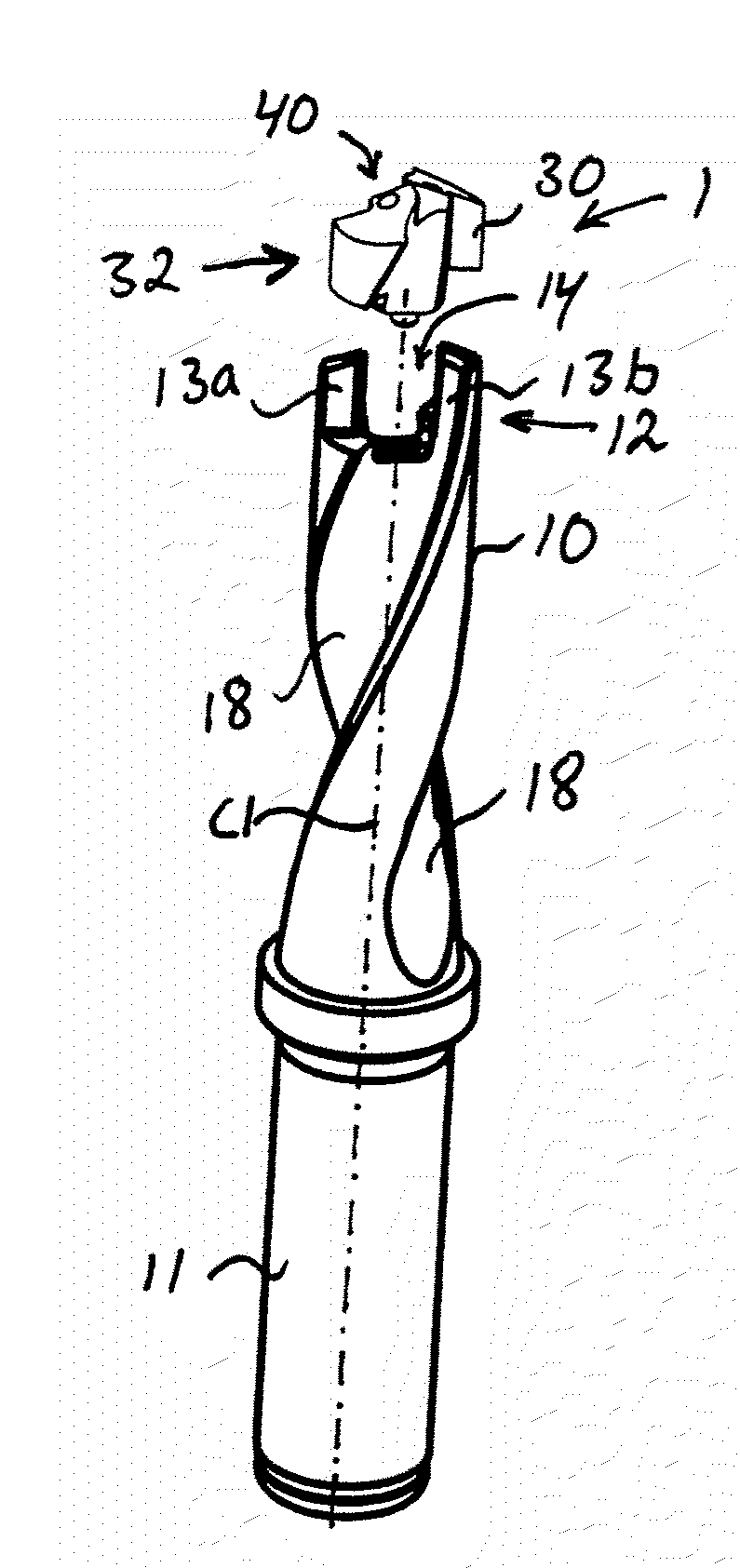

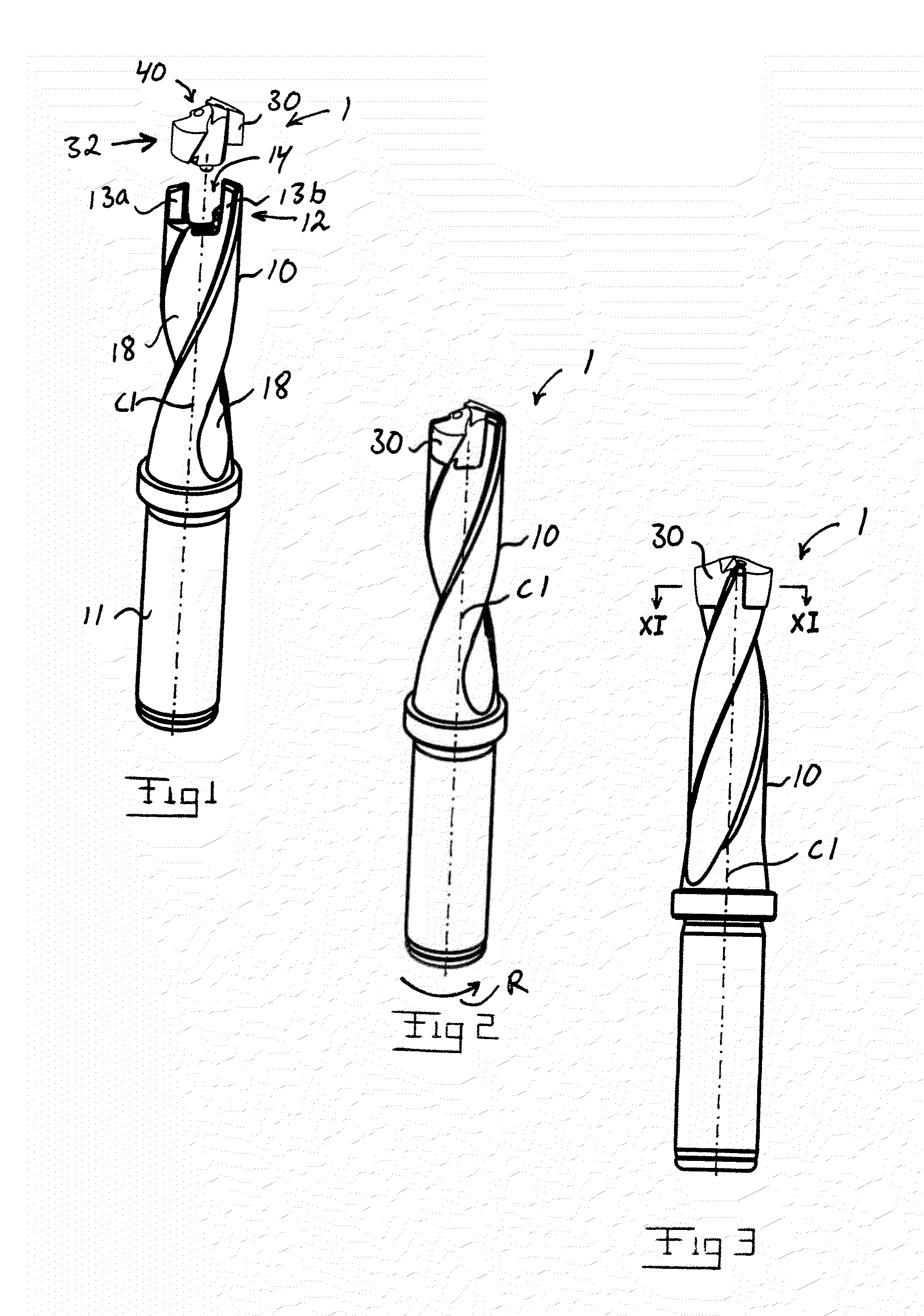

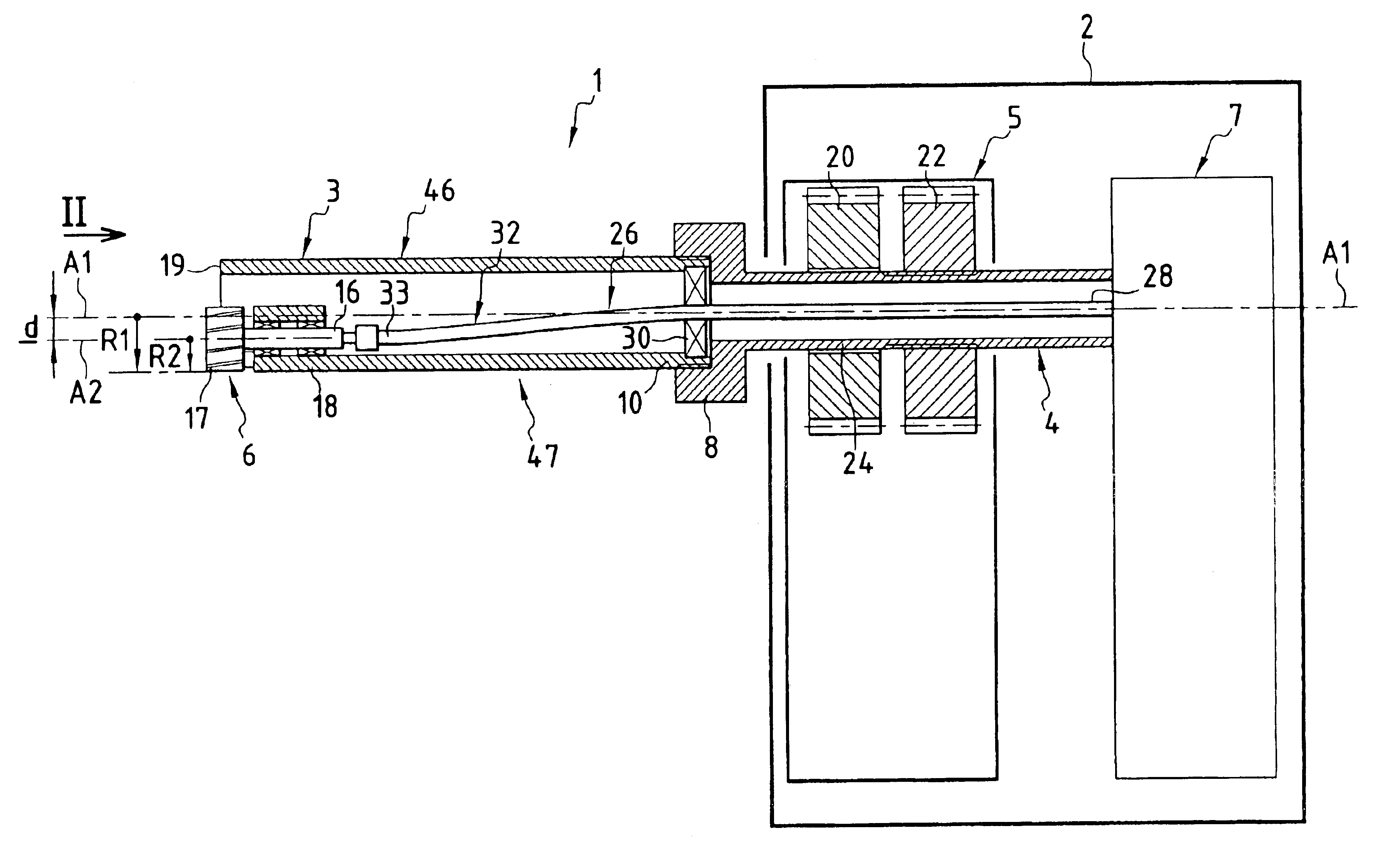

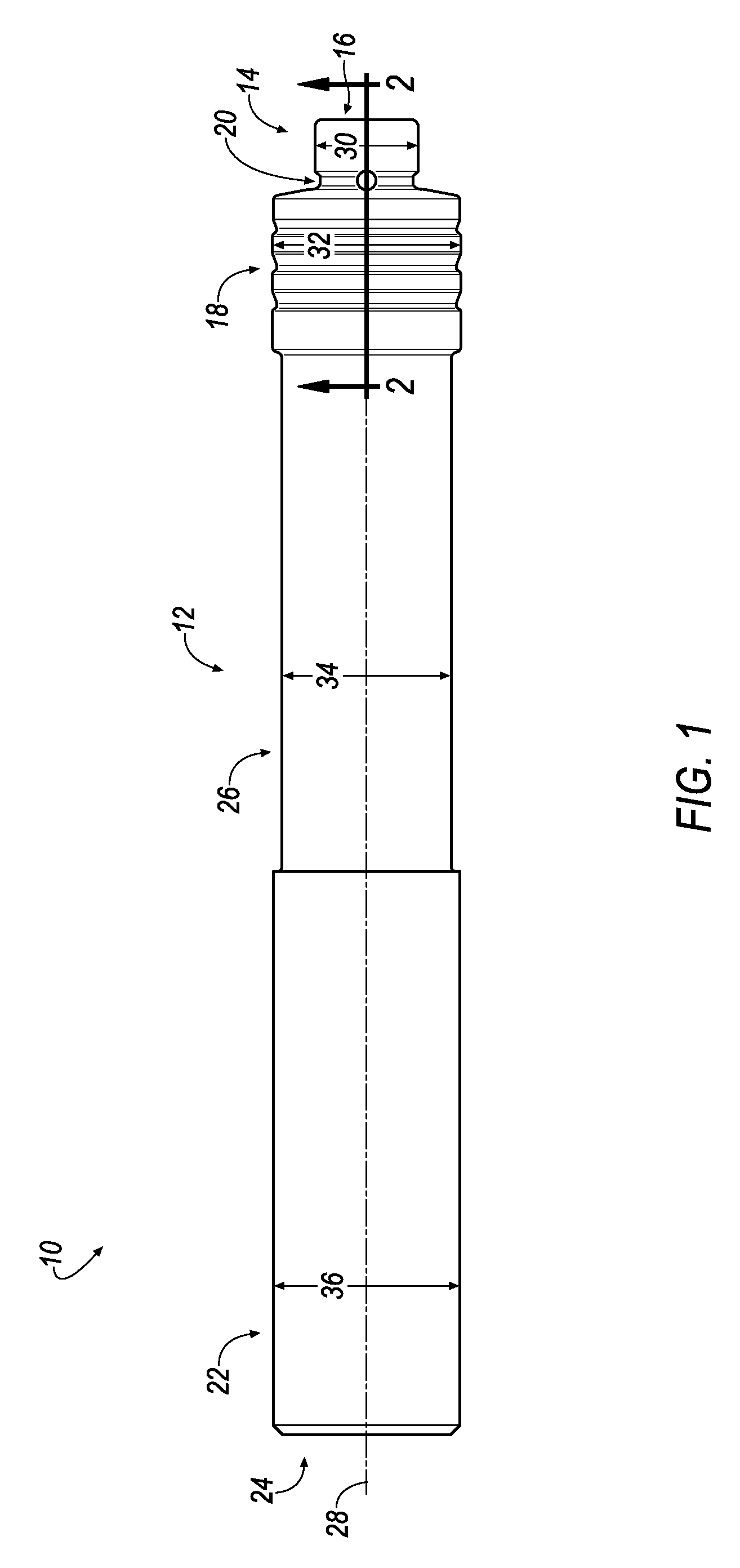

Tool, tool body and cutting head

ActiveUS20100021253A1High standardComplicate to achieveThread cutting toolsTool workpiece connectionCouplingMachining

A tool for rotary cutting machining includes a tool body and a replaceable cutting head detachably attachable to the tool body. The cutting head has a coupling portion which is receivable in a space between two axially projecting coupling legs of the tool body. Cylindrical internal gripping surfaces are arranged in said space and designed for engagement with corresponding cylindrical external gripping surfaces of the cutting head. The gripping surfaces of the cutting head and the gripping surfaces of the tool body are dimensioned so as to prevent, by engagement with each other, the cutting head from being displaced in axial direction away from the tool body when the cutting head is attached to the tool body. A tool body and a cutting head included in such a tool are also disclosed.

Owner:SECO TOOLS AB

End Mill Having A Symmetric Index Angle Arrangement For Machining Titanium

An end mill for machining titanium includes a cutting portion having blunt cutting edges alternated with flutes. Each flute includes, in order from the cutting edge, a rake surface, a concavely shaped bending portion, a convexly shaped ejecting portion and a tooth relief edge. The convexly shaped ejecting portion has an ejection height E, which is measurable between an apex of the ejecting portion to an imaginary straight line extending from a nadir of the adjacent bending portion of the flute to the adjacent tooth relief edge. In a plane perpendicular to a rotation axis of the end mill, the ejection height E and a cutting portion diameter DE, fulfill the condition 0.010DE<E<0.031DE.

Owner:ISCAR LTD

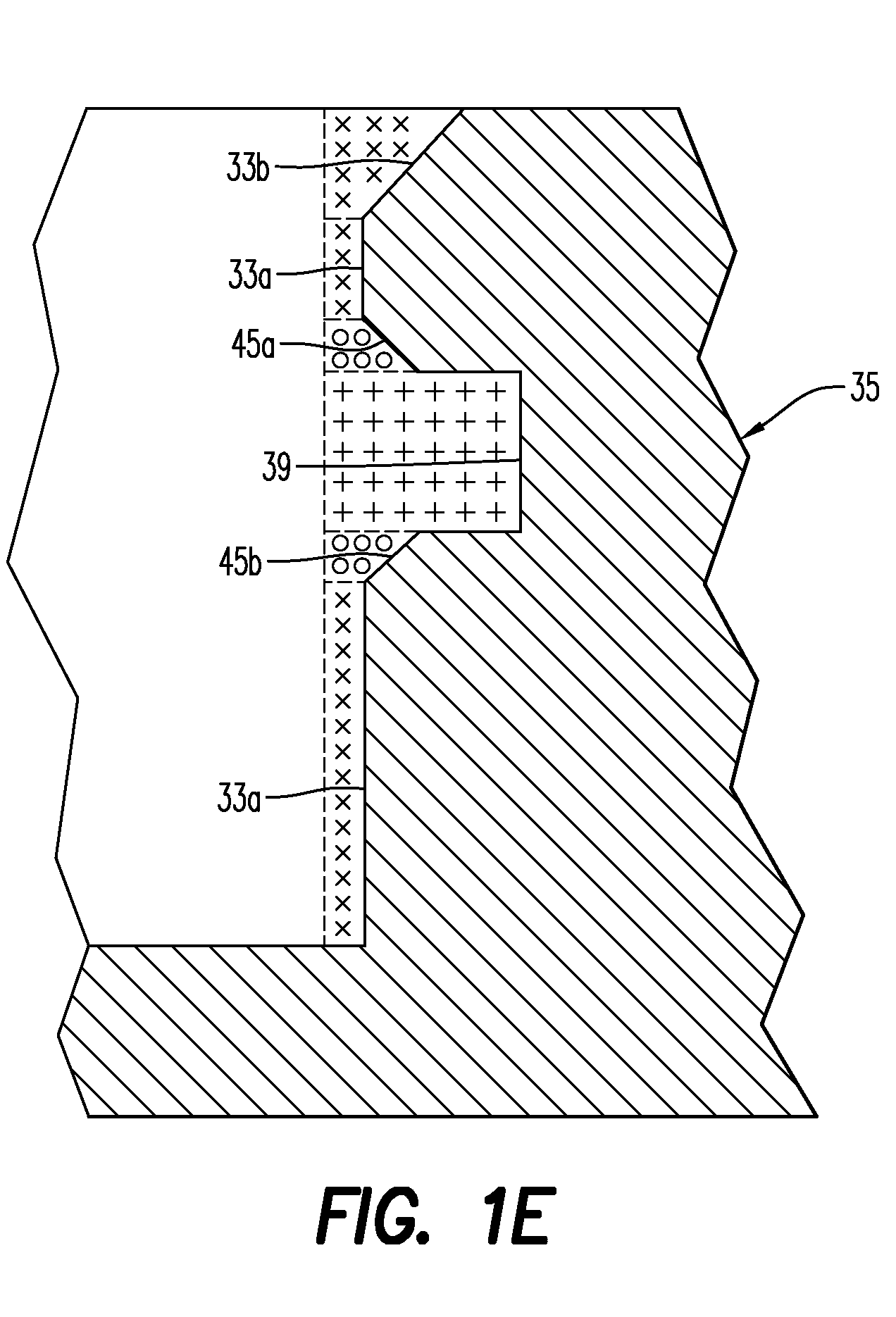

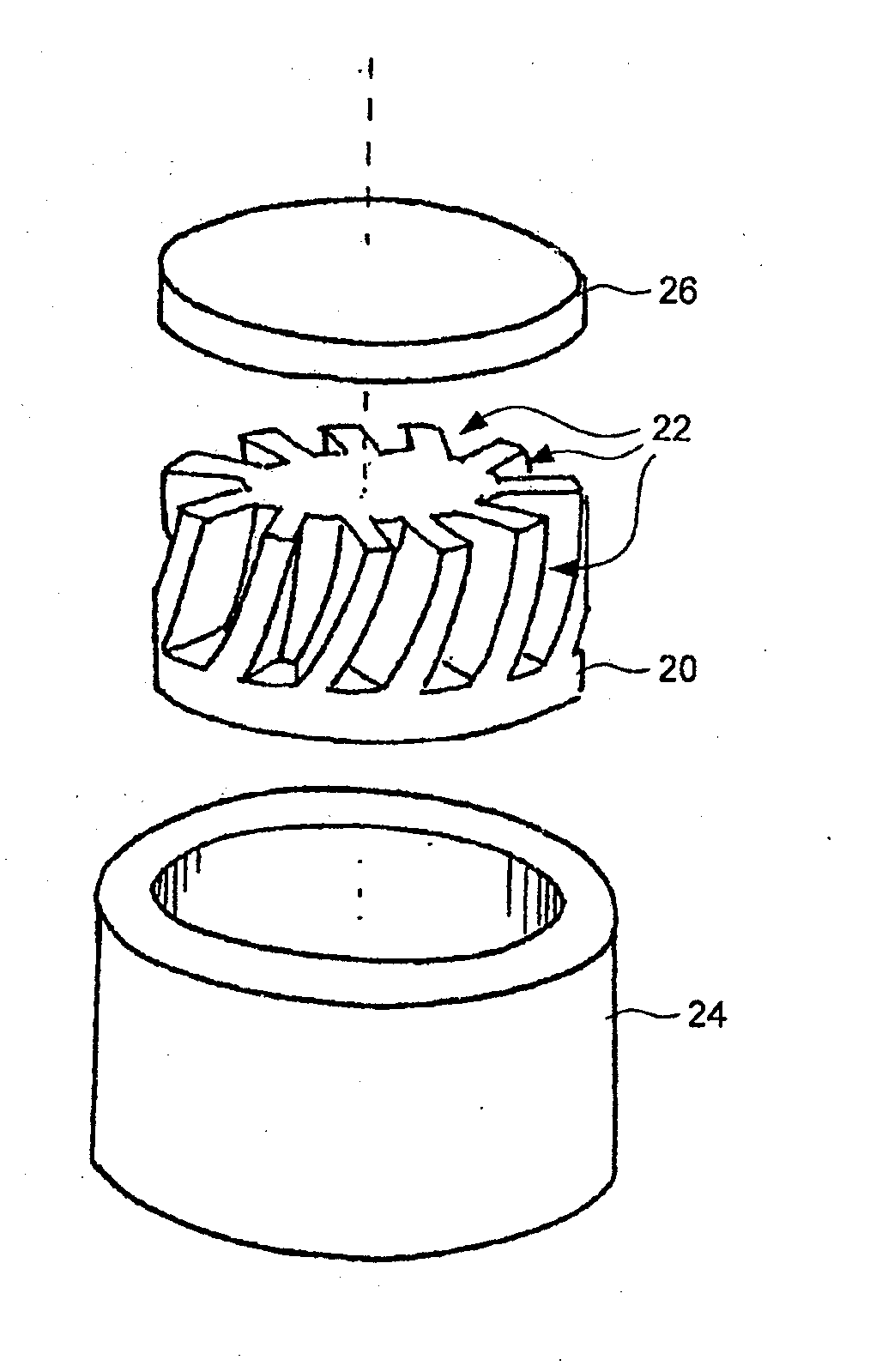

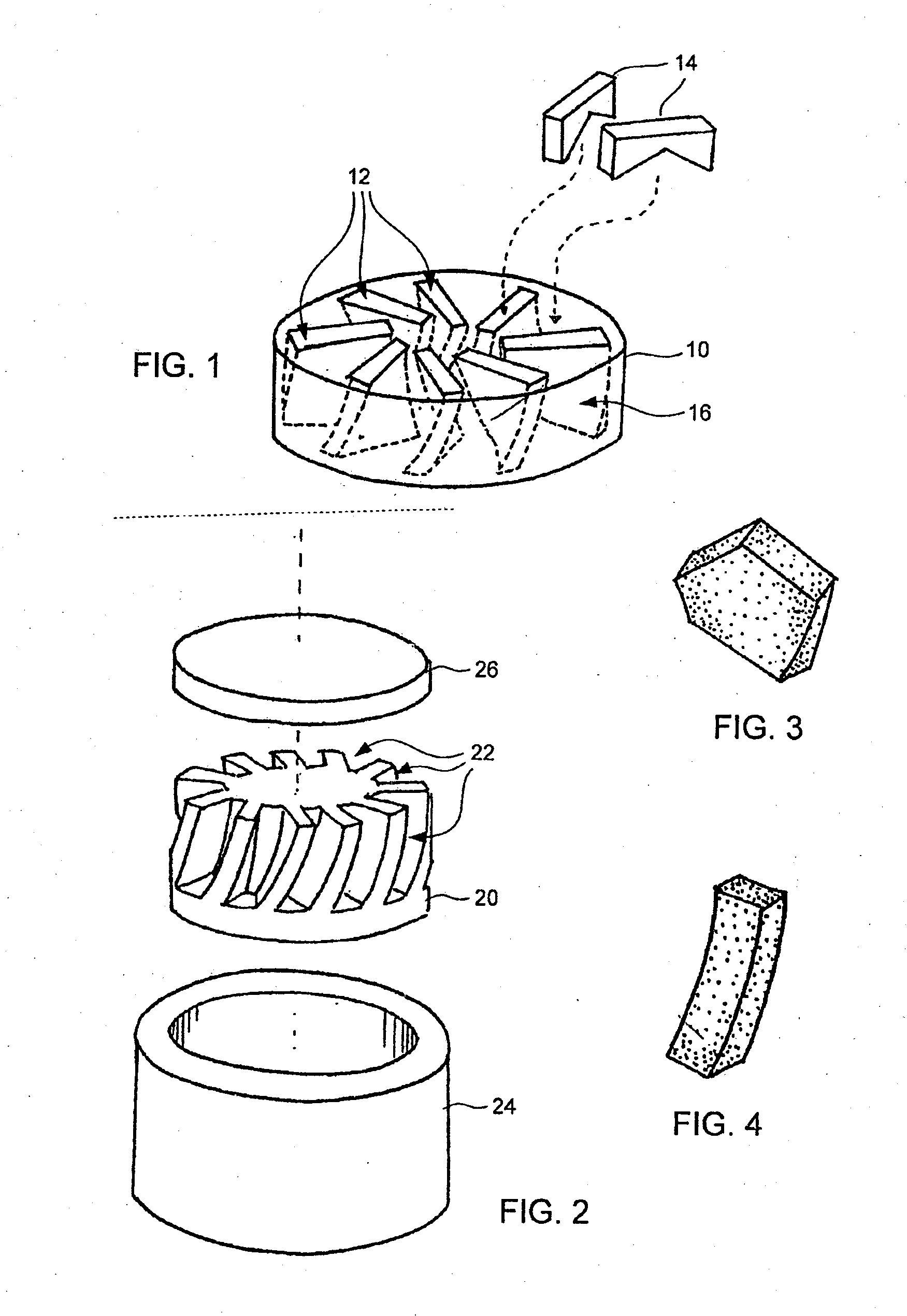

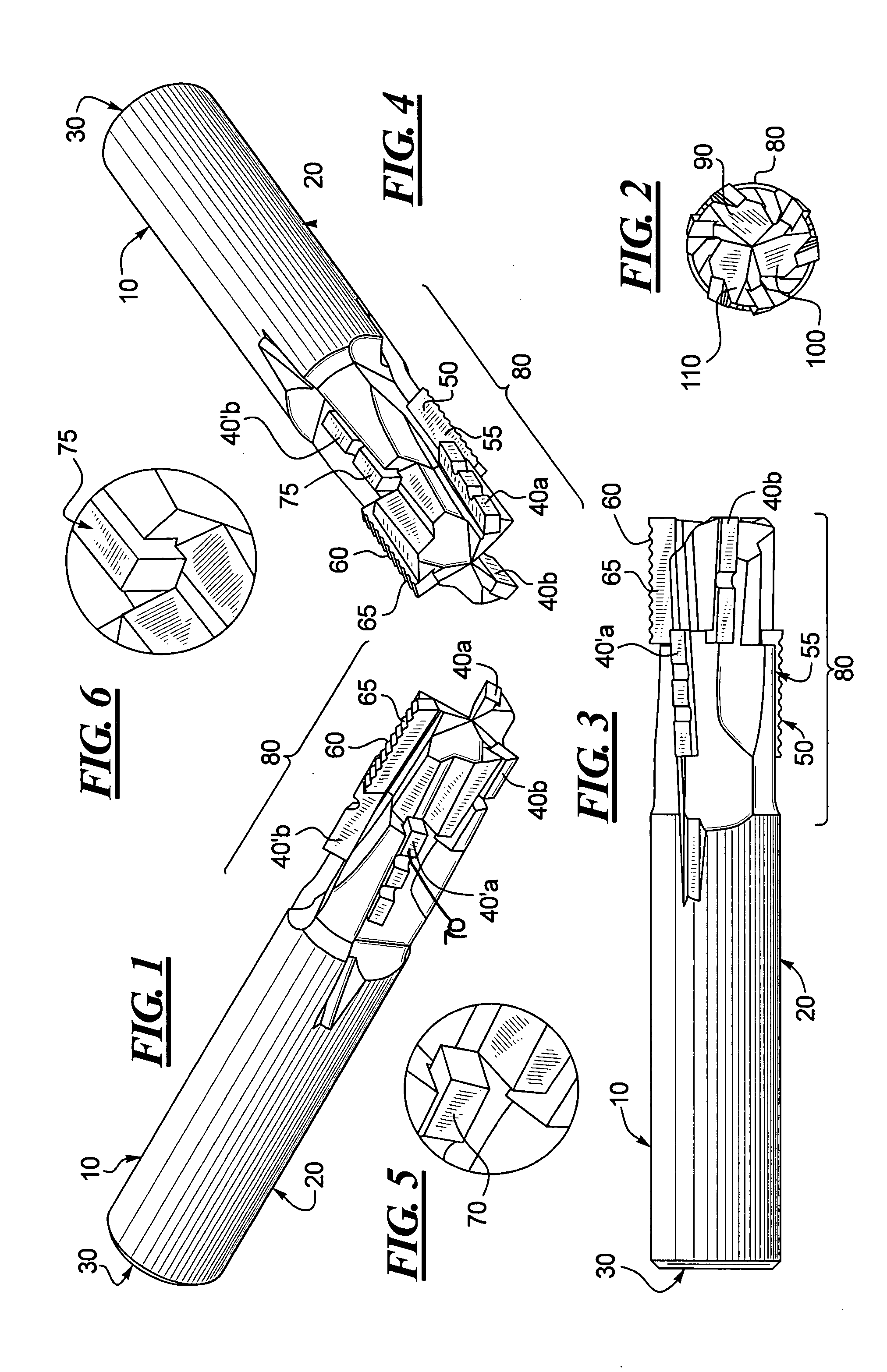

Contoured pcd and pcbn segments for cutting tools containing such segments

Contoured helical solid polycrystalline PCD and PCBN superabrasive segments are provided for attachment to cutting tool substrates such as twist drill tips, reamers, burrs and endmills. Segments are provided in near to net shape for attachment to a tool substrate thereby requiring reduced finishing steps and providing increased tailorability of grade and quality of final polycrystalline segments. Cutting tools comprising cutting tool substrates having attached thereto a contoured helical solid polycrystalline PCD and PCBN superabrasive segments are also disclosed.

Owner:CHO H SAM +4

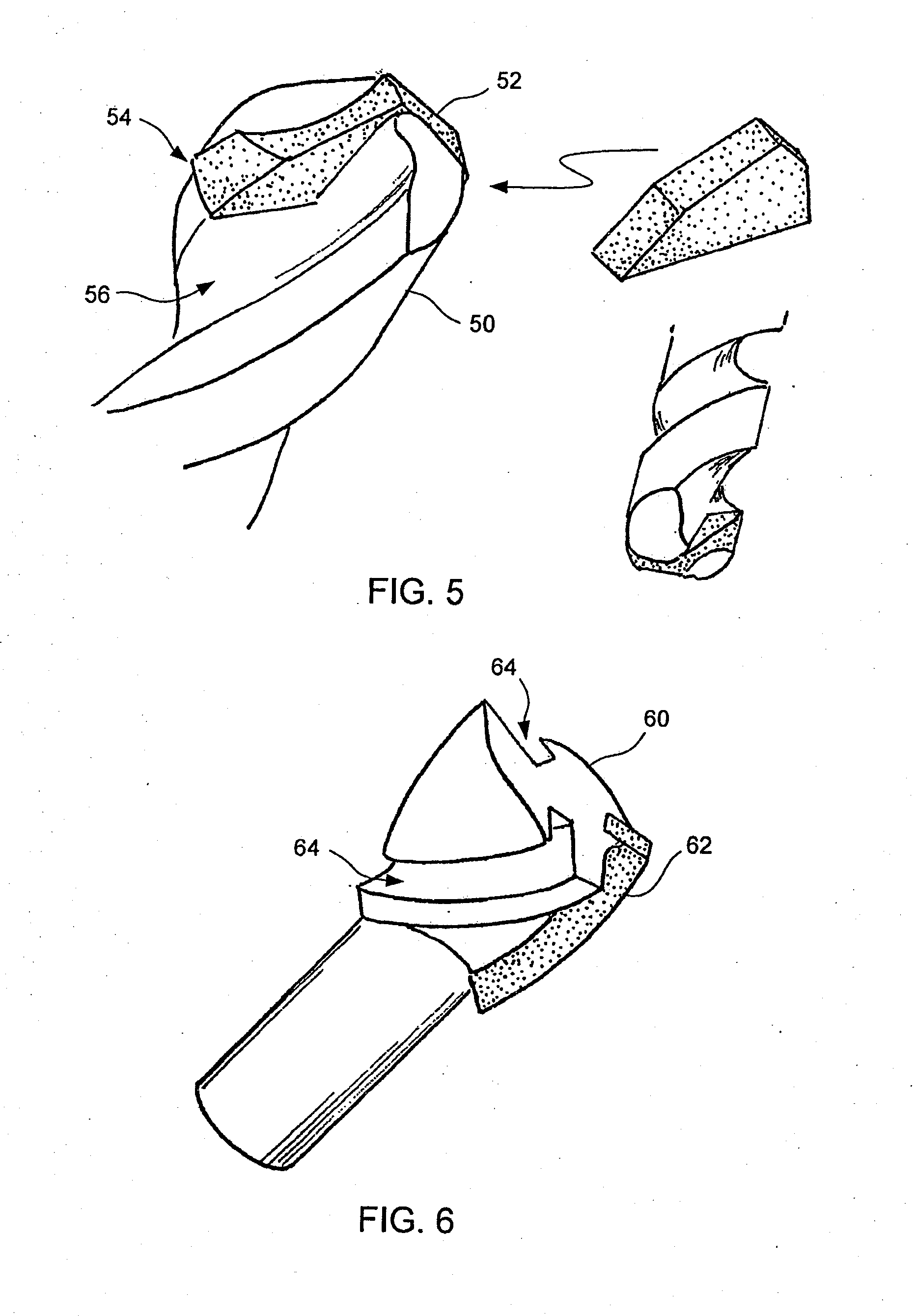

Polycrystalline diamond tool for cutting

A tool has a shaft and a tip on the shaft. The tip supports rougher and chipbreaker finisher wings which, for example, may be polycrystalline diamond wings. Also, the rougher and chipbreaker finisher wings may be arranged, for example, to provide either upshear or downshear forces. As another example, both upshear and downshear rougher and chipbreaker finisher wings may be arranged to produce corresponding upshear and downshear forces.

Owner:ONSRUD CUTTER LP

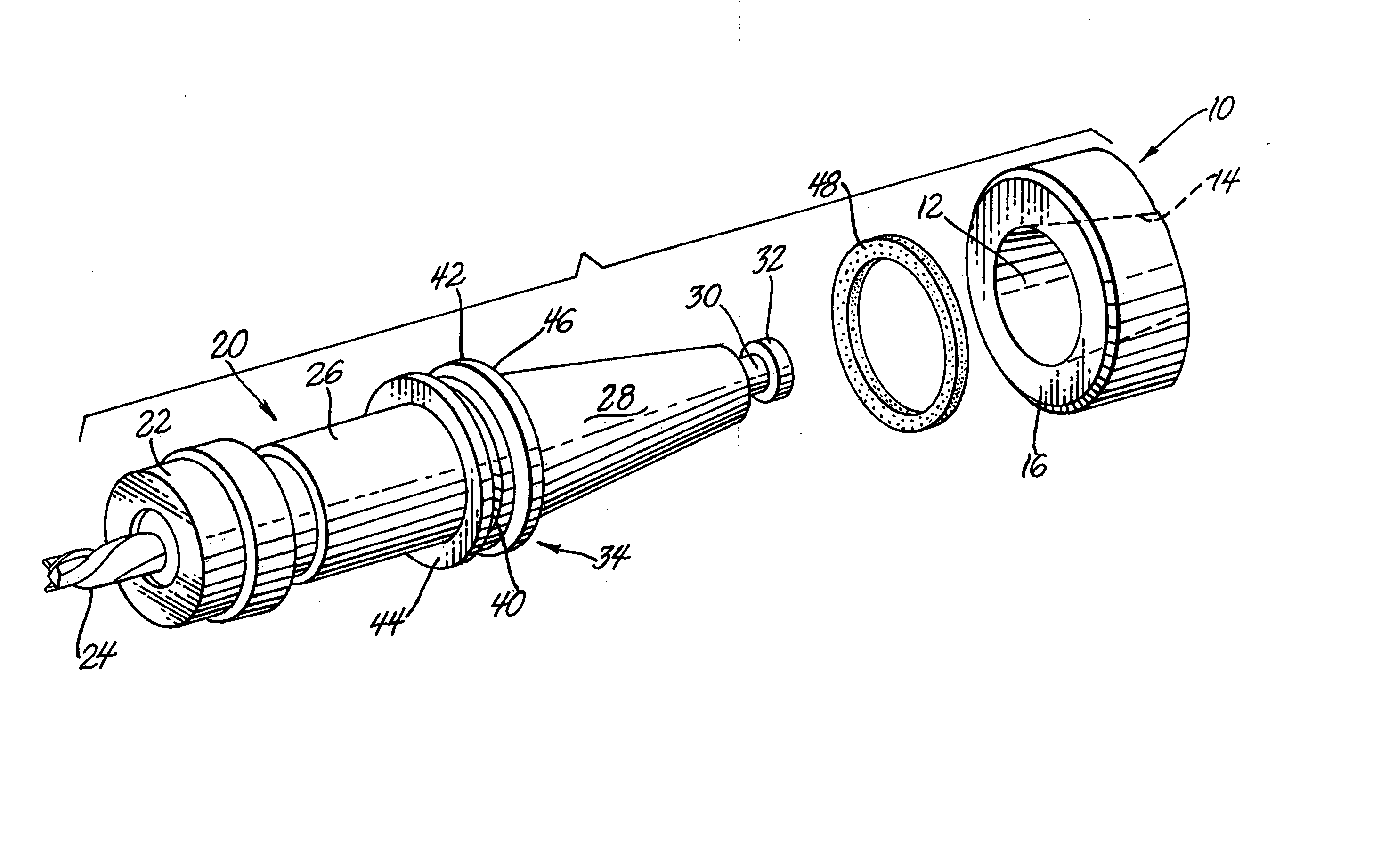

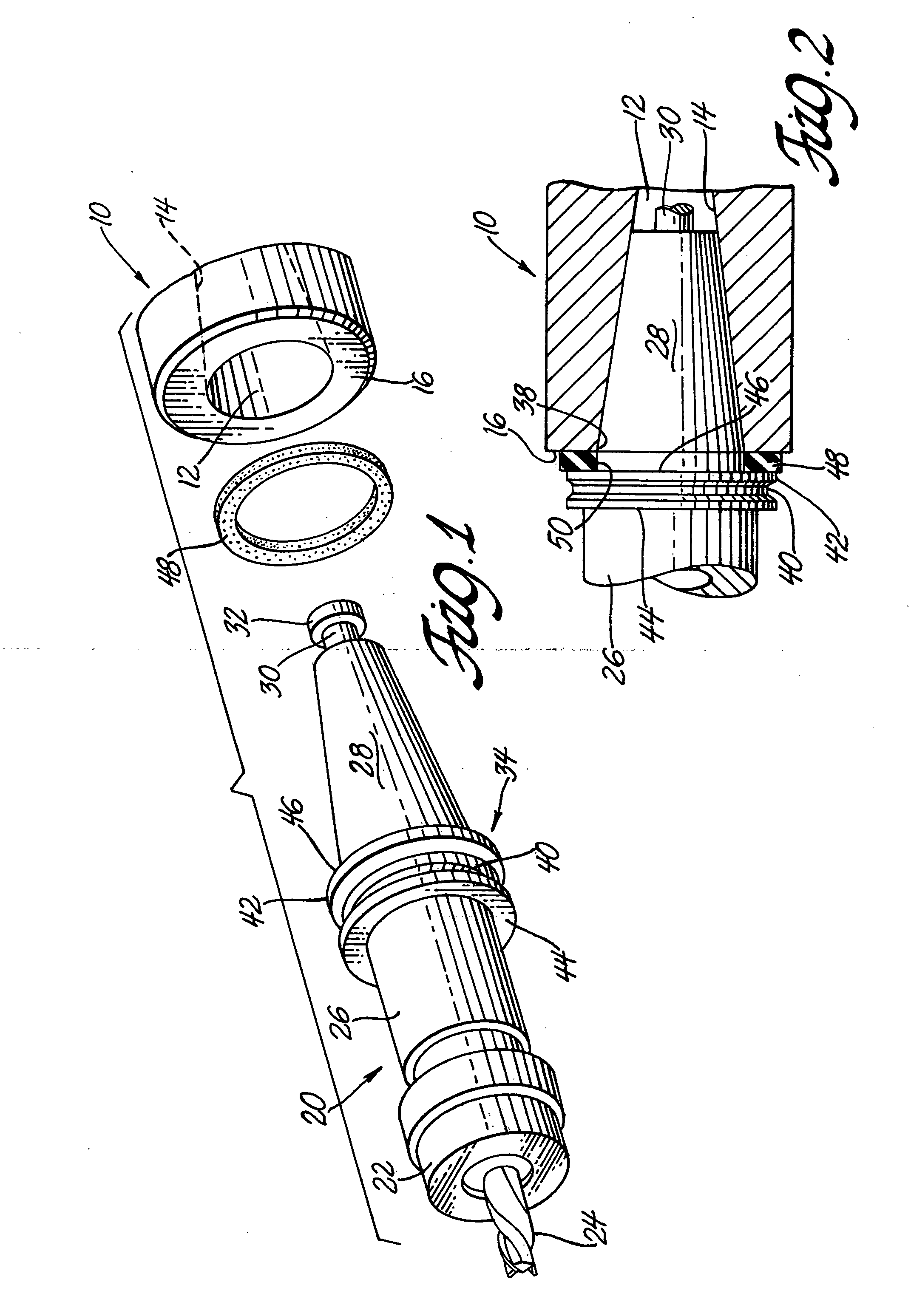

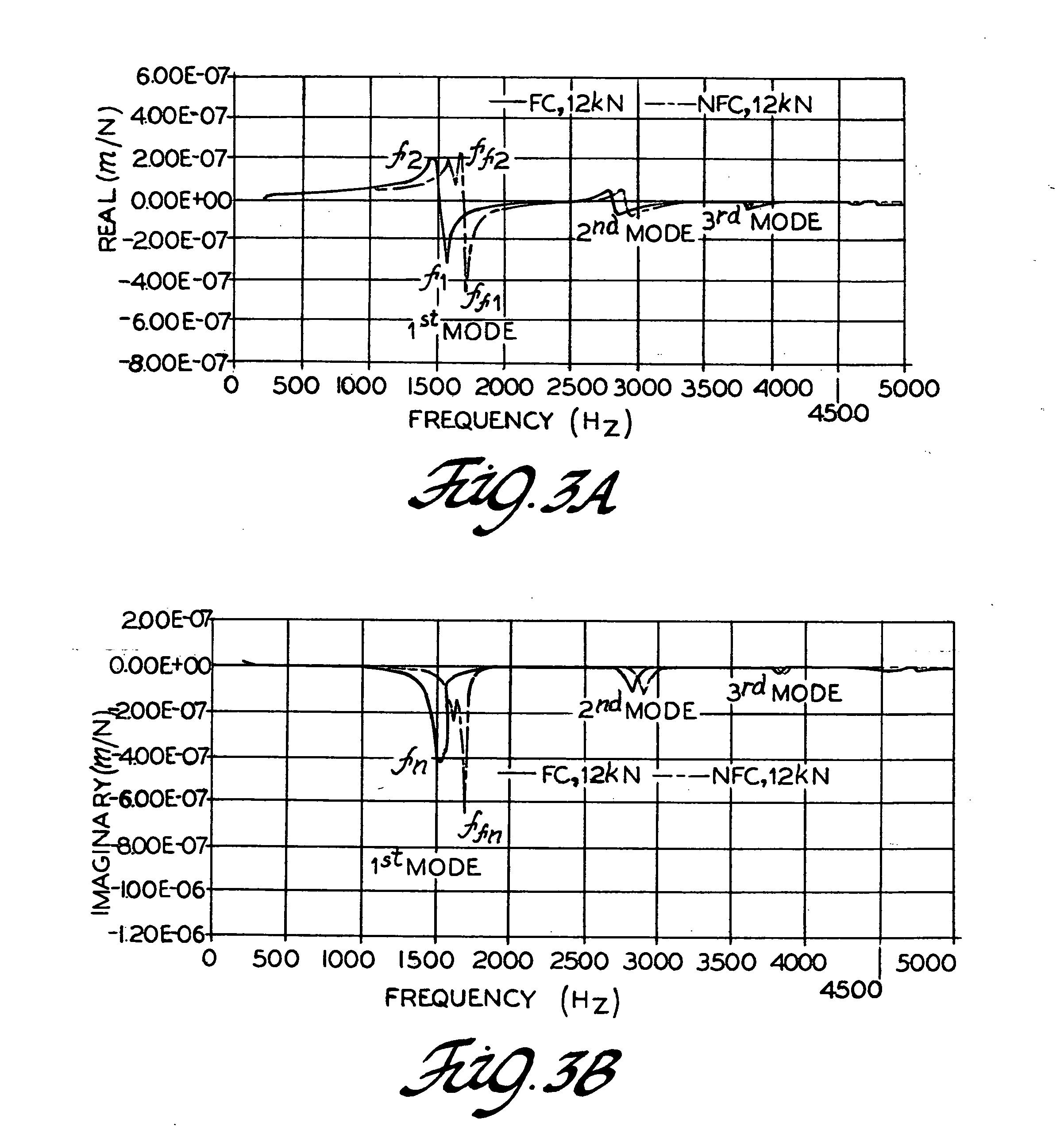

Spacer adapter for toolholders

InactiveUS20050214087A1Reduce vibrationSuitable flexibilityWorkpiecesMilling machinesEngineeringShaft collar

A toolholder for a cutting tool is disclosed for use with a machine tool having a main shaft or spindle with a flared or tapered end socket. The toolholder has a tool-holding end for a cutting tool and a tapered shank end for placement in the tapered socket of the machine tool spindle. The toolholder also has an annular flange near its tapered shank, the flange or collar generally being used for location and gripping by a tool exchange mechanism. An elastic spacer ring is used and compressed between said flange and the face of said machine tool shaft in machining operations for dampening vibrations and flexing of the toolholder and cutting tool.

Owner:GENERAL MOTORS COMPANY

Compression cutting tool

InactiveUS20130294852A1Trend downOrganic active ingredientsMilling cuttersMechanical engineeringEngineering

A rotating tool includes a tool body including a first end and a second end. A plurality of first helical flutes extend from the first end of the tool body, each first helical flute of the plurality of helical flutes defining a respective first cutting edge. A plurality of second helical flutes intersect with the first helical flutes at non-zero distances from the first and the second ends of the tool body, each second helical flute of the plurality of second helical flutes defining a respective second cutting edge. The first helical flutes and the second helical flutes are of opposite hands. The first helical flutes have a first pitch and the second helical flutes have a second pitch. A plurality of chip divider recesses are formed along each first cutting edge.

Owner:SECO TOOLS AB

Monolithic ceramic end mill

End mills are disclosed which may be made monolithically of ceramic or other materials. The cutting portions of the end mills have lengths of cut that are no more than twice their cutting diameters and cores which are at least 0.7 times their cutting diameters. Their axial blades have cutting edges with negative radial rake and are separated by helical flutes. Their cutting ends have negative axial rake and are gashed ahead of center and have radial cutting edges with negative rake. Such end mills also have radiused corners and gashes transitioning from radial to axial at a flute. Methods of milling materials using such ceramic end mills are also disclosed.

Owner:KENNAMETAL INC

Cutting tip for rotating cutting tool and rotating cutting tool using the tip, and method of machining using the tool

InactiveUS20030133763A1Improve bottom surface roughnessUneven finished surfaceMilling cuttersWorkpiecesSingle crystalKnife blades

Owner:SUMITOMO ELECTRIC IND LTD

Rotary cutting tool having multiple helical cutting edges with differing helix angles

A rotary cutting tool is disclosed including a substantially cylindrical main body having a shank portion at one end and a point at an opposite end. Five flutes are formed in an outer surface of the main body. Each of the flutes extends continuously from the point to the shank portion, and defines a helical cutting edge having a helix angle between about 32 degrees and approximately 34 degrees with respect to an axis of the main body. At least 2 of the flutes define helical cutting edges having different helix angles.

Owner:CARBIDE GRINDING CO INC +1

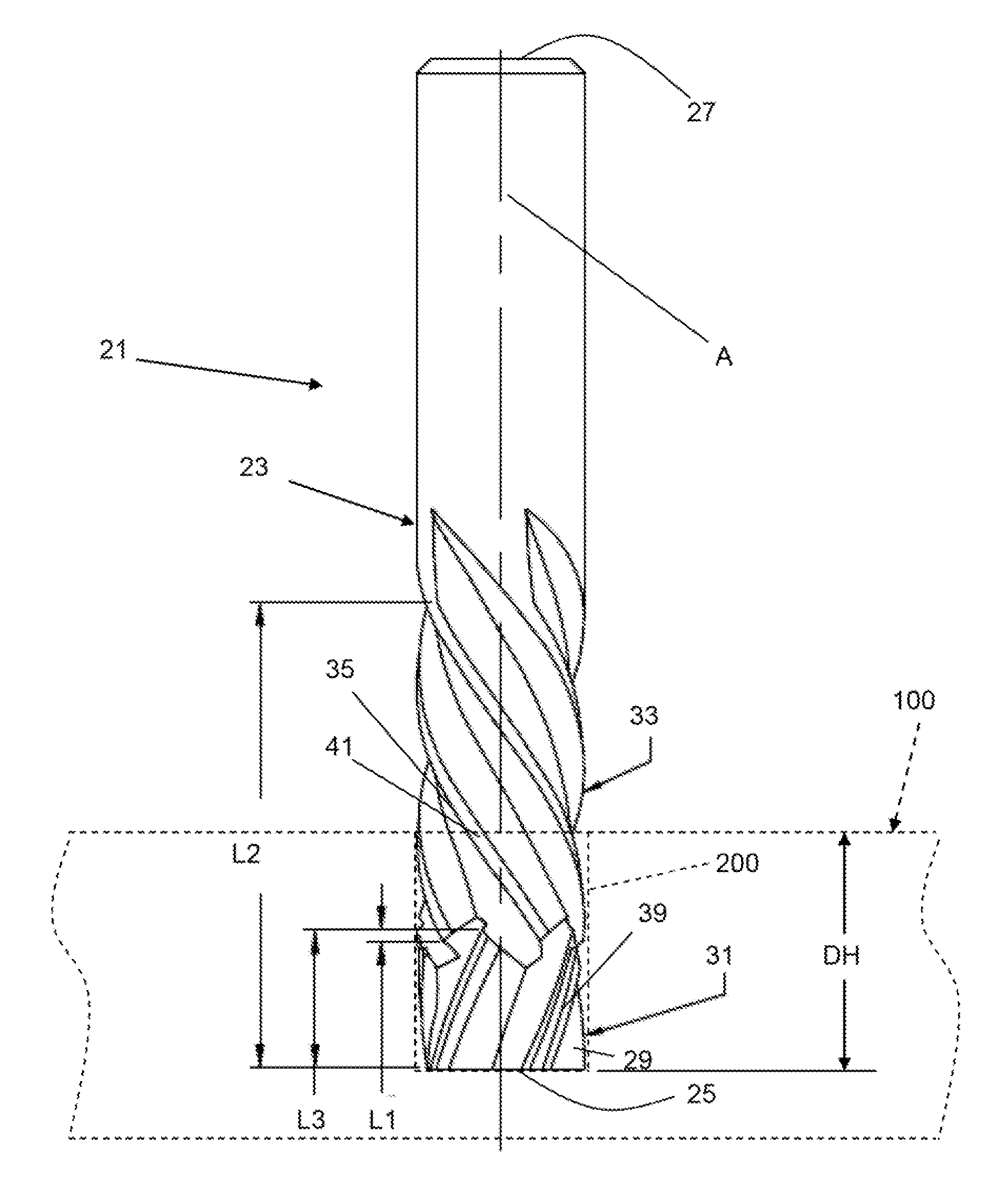

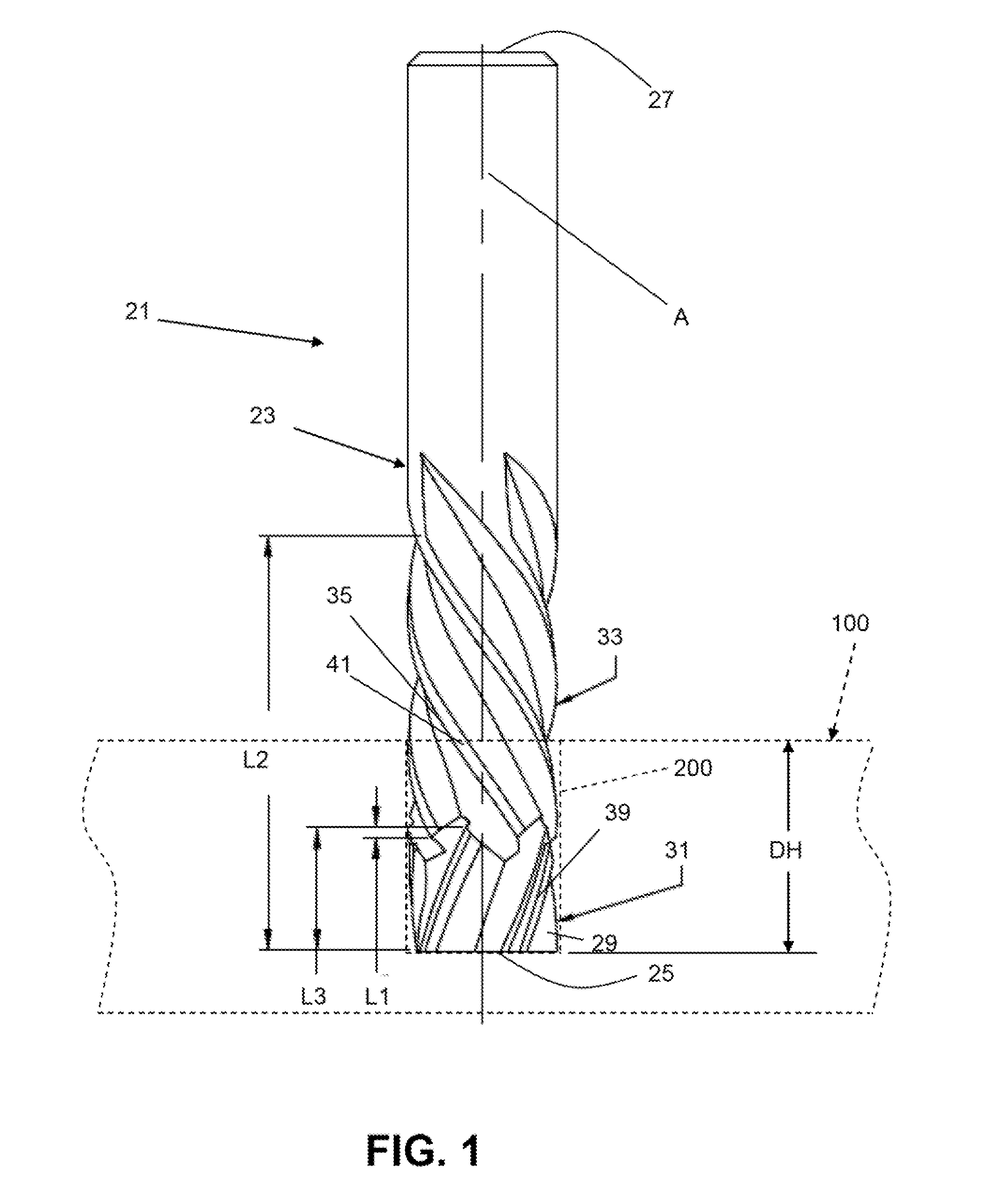

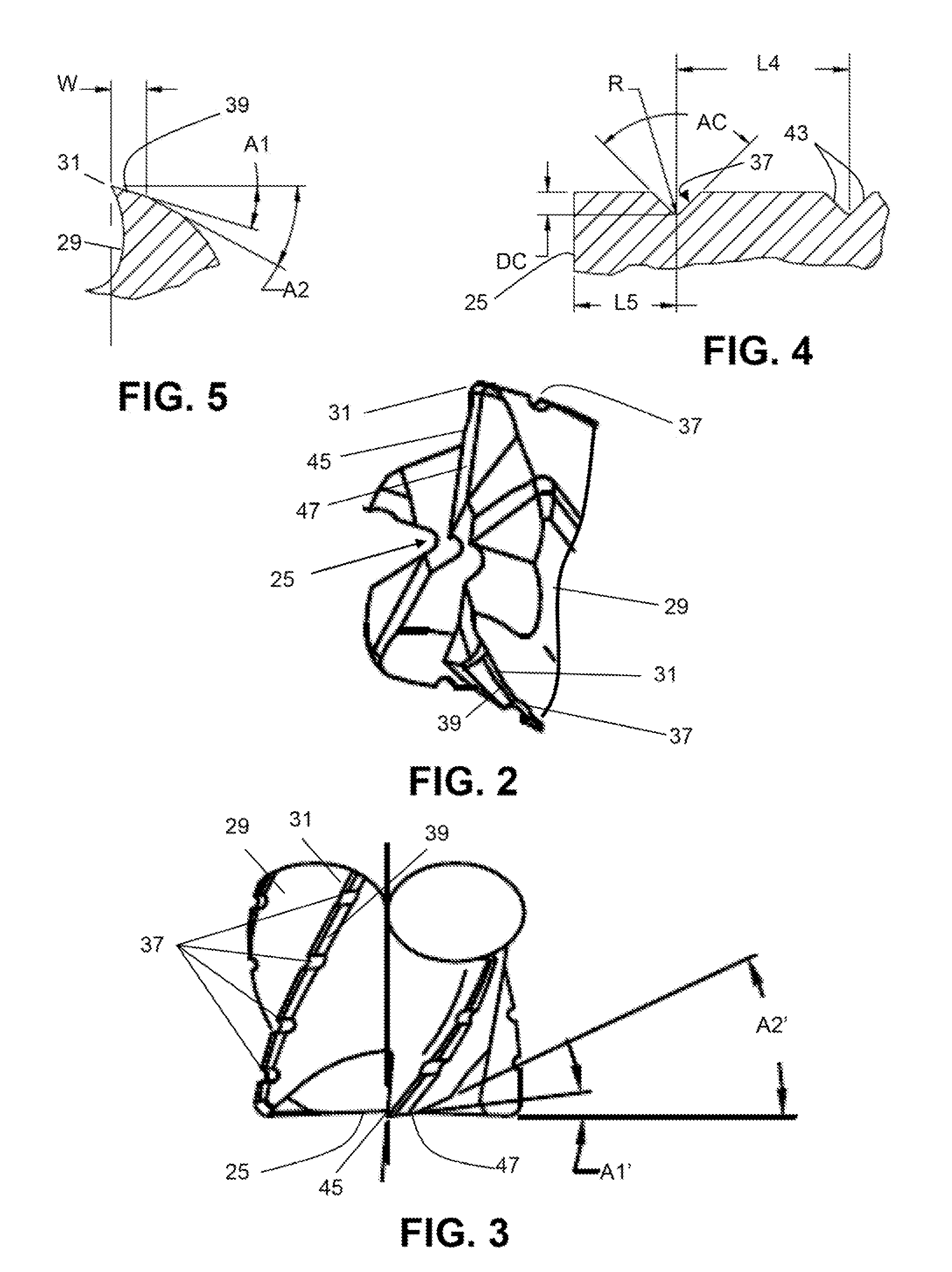

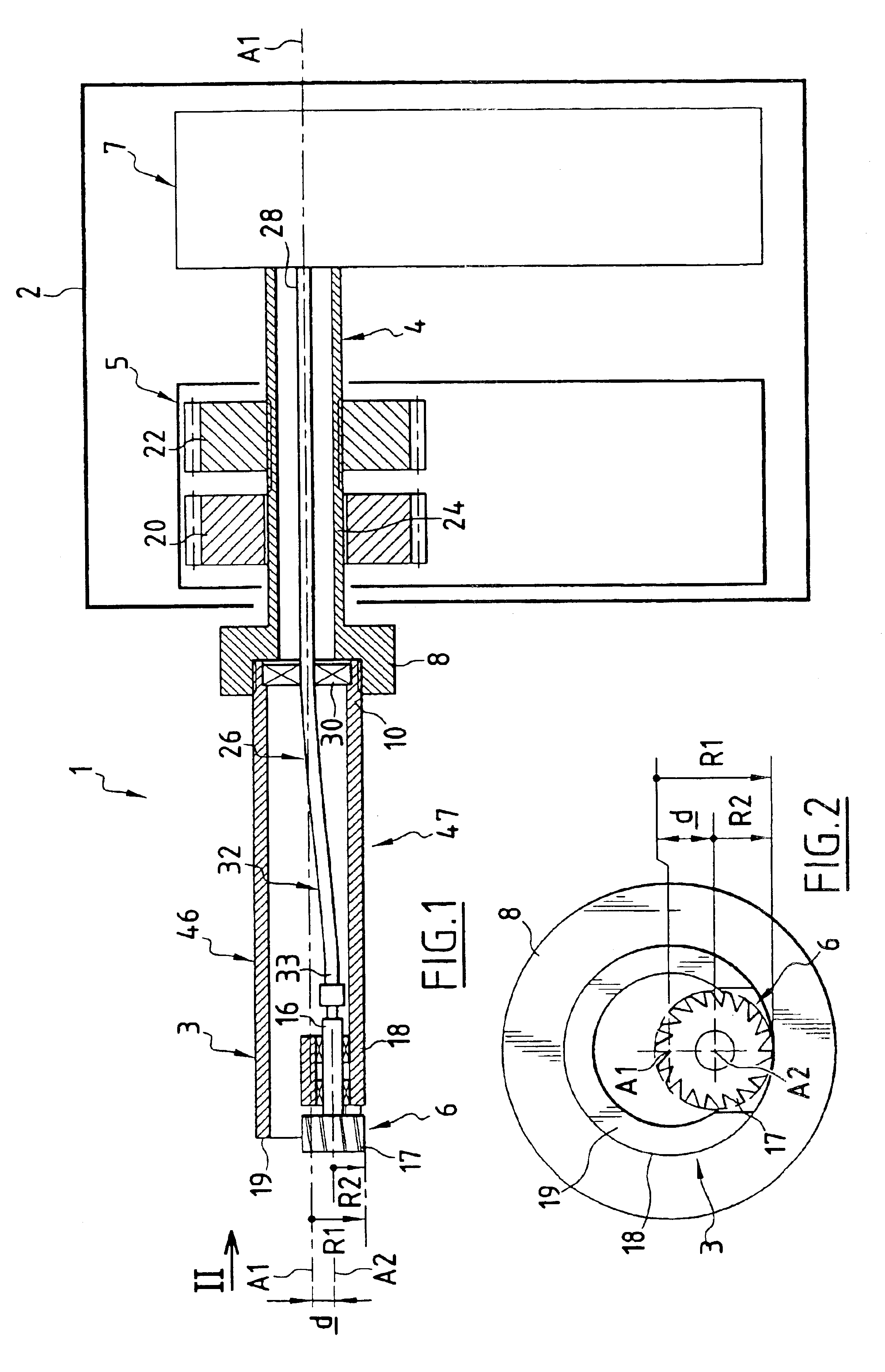

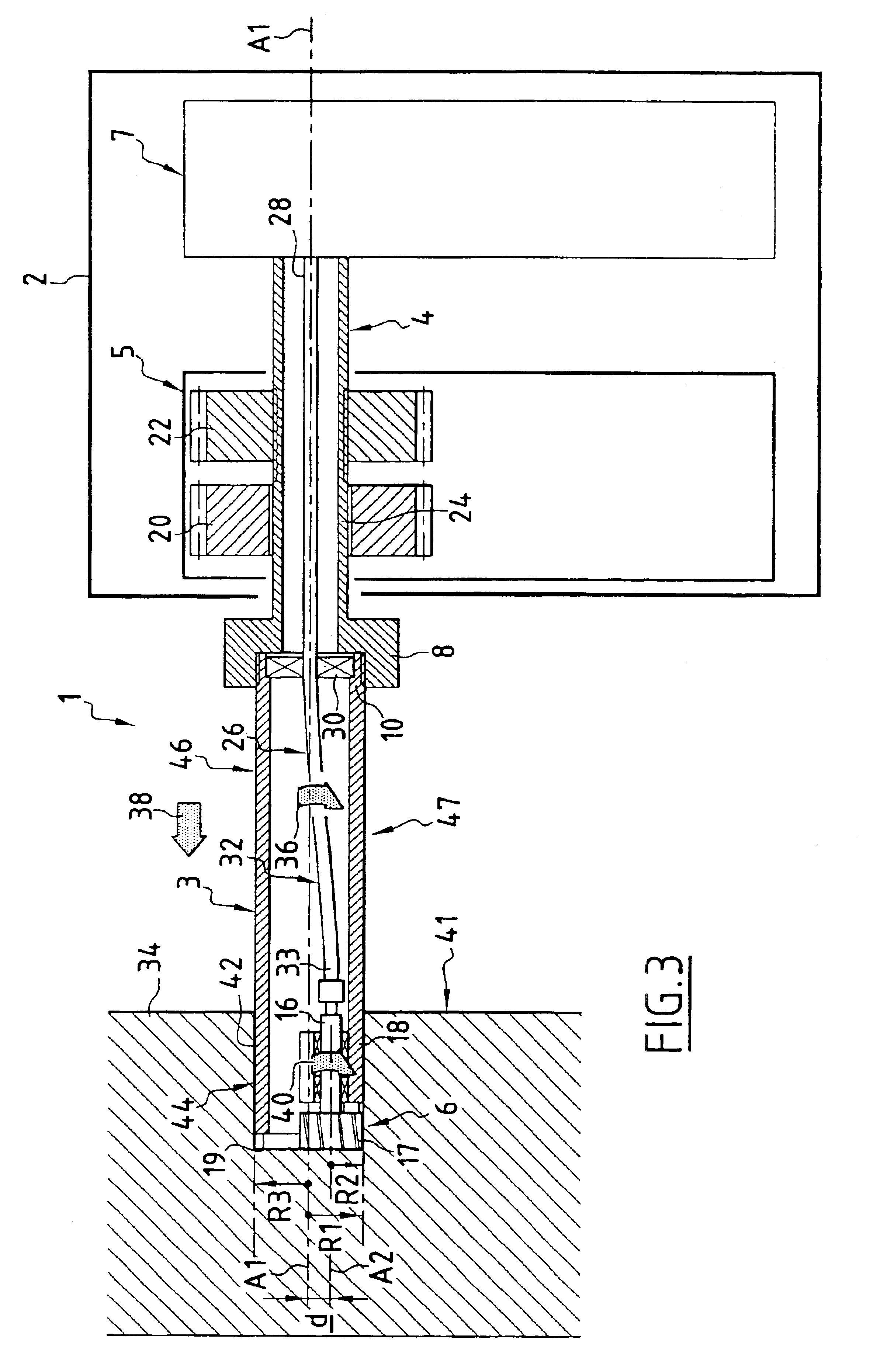

Tool, a machine, and a method for orbitally drilling an orifice

The tool comprises firstly a cutter support for being driven in rotation about a first axis of rotation that is to coincide with the axis of the orifice, and a cutter rotatably mounted on the cutter support to rotate about a second axis of rotation parallel to the first axis of rotation and spaced apart therefrom by a non-zero offset distance. A front segment of the cutter support has maximum radial extent relative to the first axis of rotation that is less than or equal to the radius of the orifice to enable the front segment to penetrate into the orifice during drilling. The tool is particularly applicable to drilling machines used in the aviation industry.

Owner:APEX BRANDS

Rotary cutting tool having a cutting edge formed of veined pcd

InactiveUS20120282044A1Facilitates minimal PCD removalMilling cuttersWorkpiecesMechanical engineering

Owner:KENNAMETAL INC

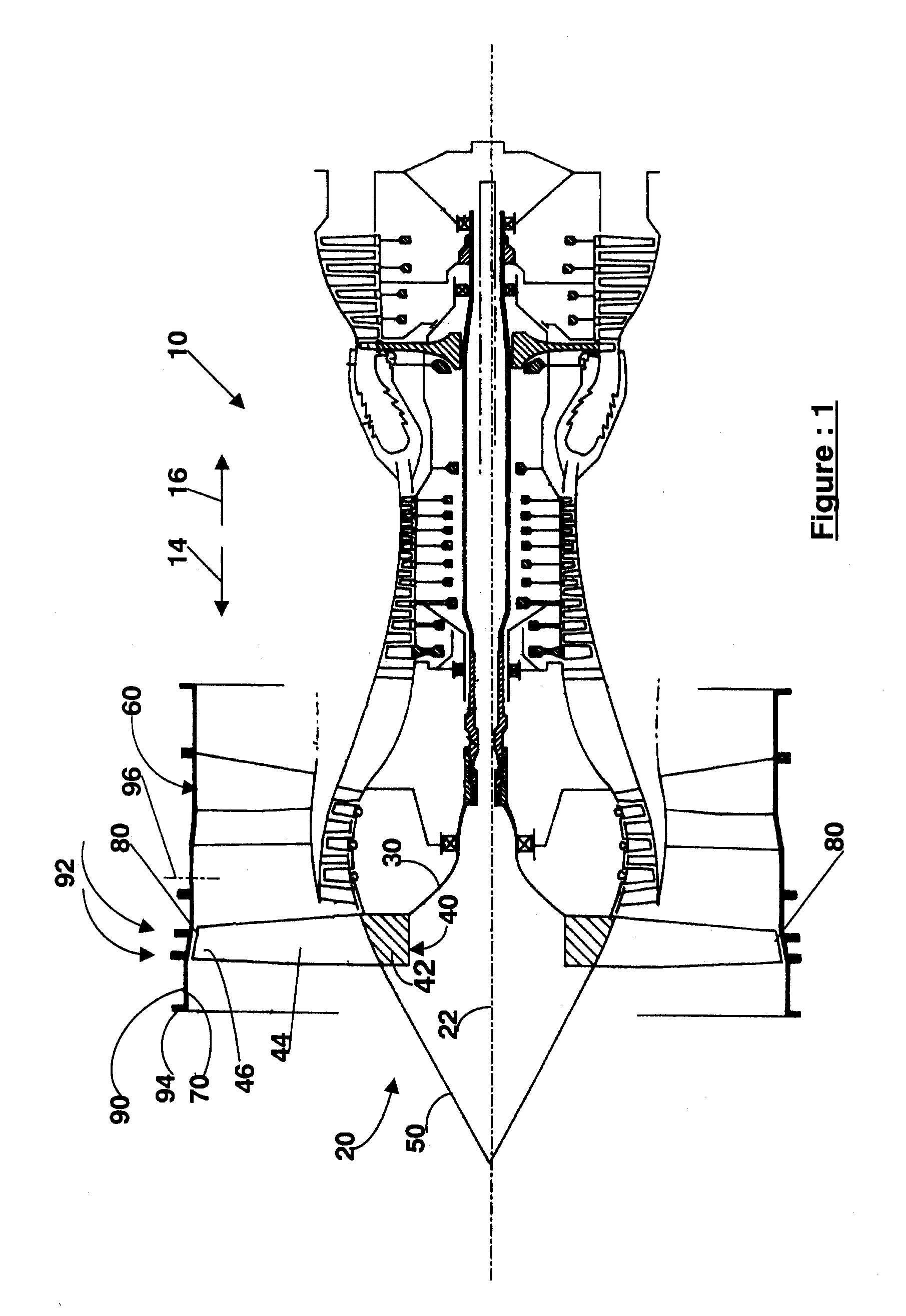

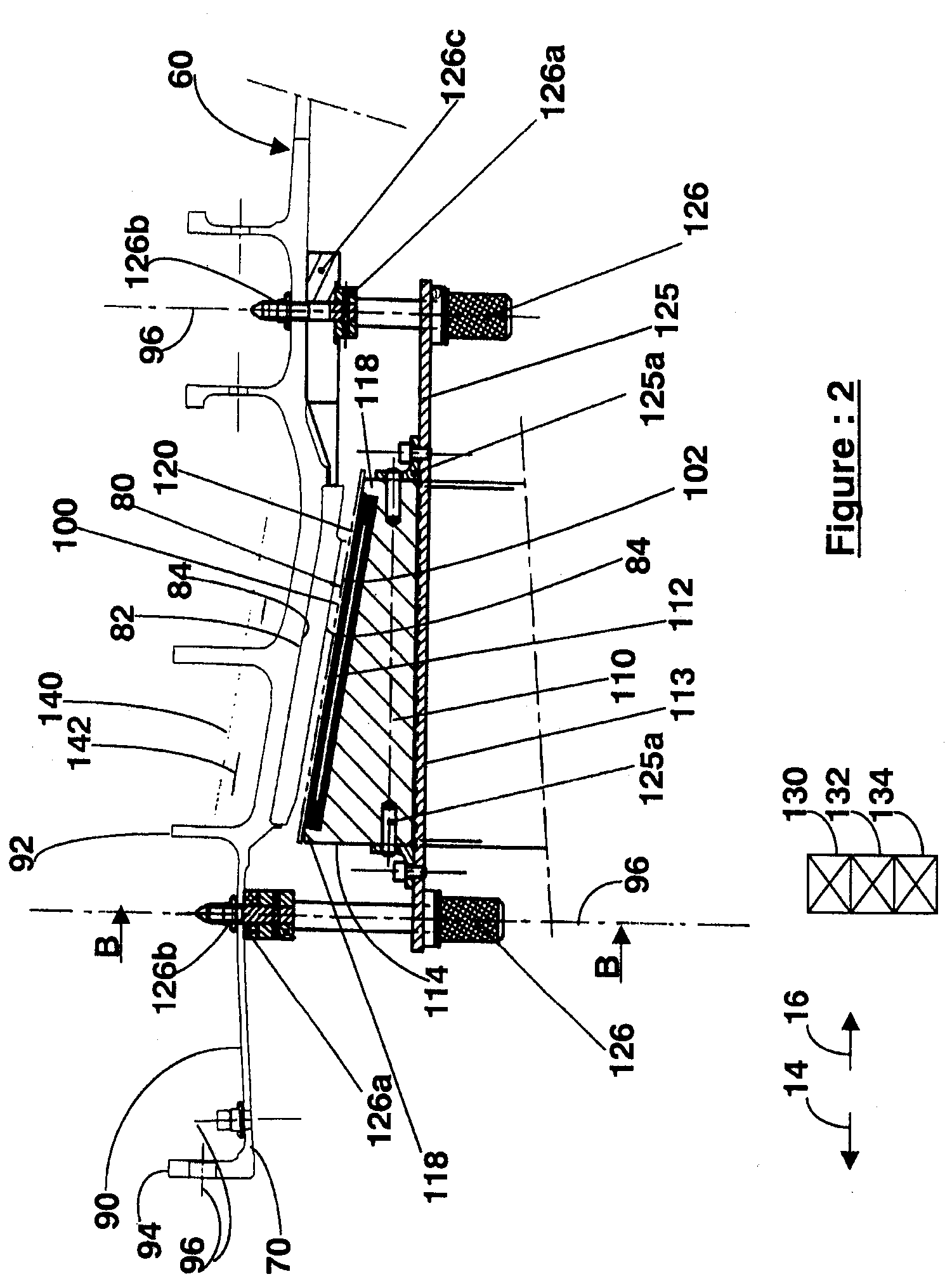

Method of replacing an abradable portion on the casing on a turbojet fan

ActiveUS7278208B2Simple and inexpensive and easy to implementBetter control over the temperature of the adhesive and the surfaces for bondingEfficient propulsion technologiesLeakage preventionAirbag deploymentTurbojet

A simple and low cost method of replacing an abradable portion on the fan casing of a turbojet includes an inside heating belt together with holding sectors therefor are put into place against the abradable portion, each holding sector including an inflatable bladder, and the abradable portion and the inside heating belt being sandwiched in full between the fan casing and the bladders, the holding sectors themselves being held in place by a plurality of straps attached to the fan casing by fixing points.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

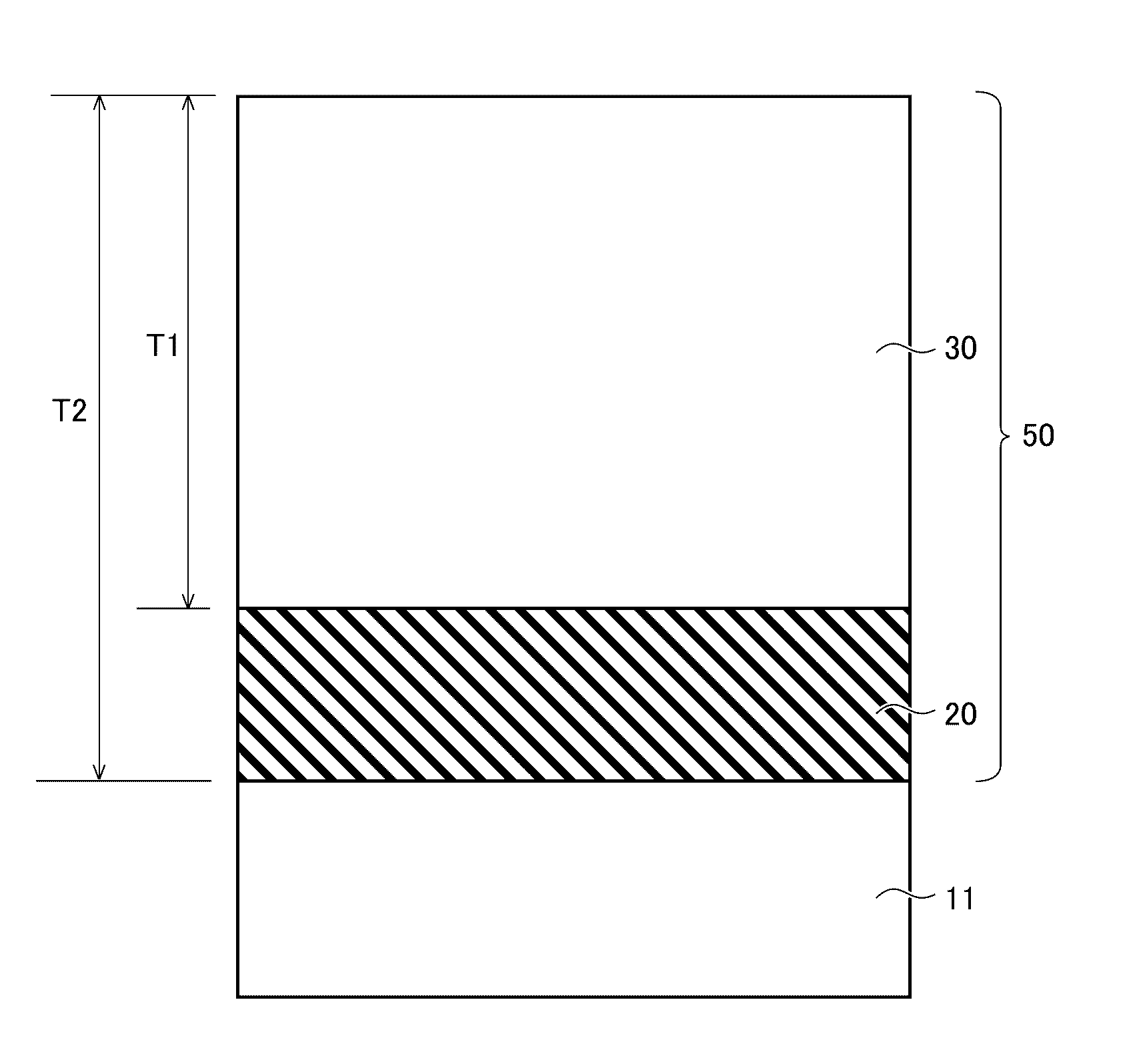

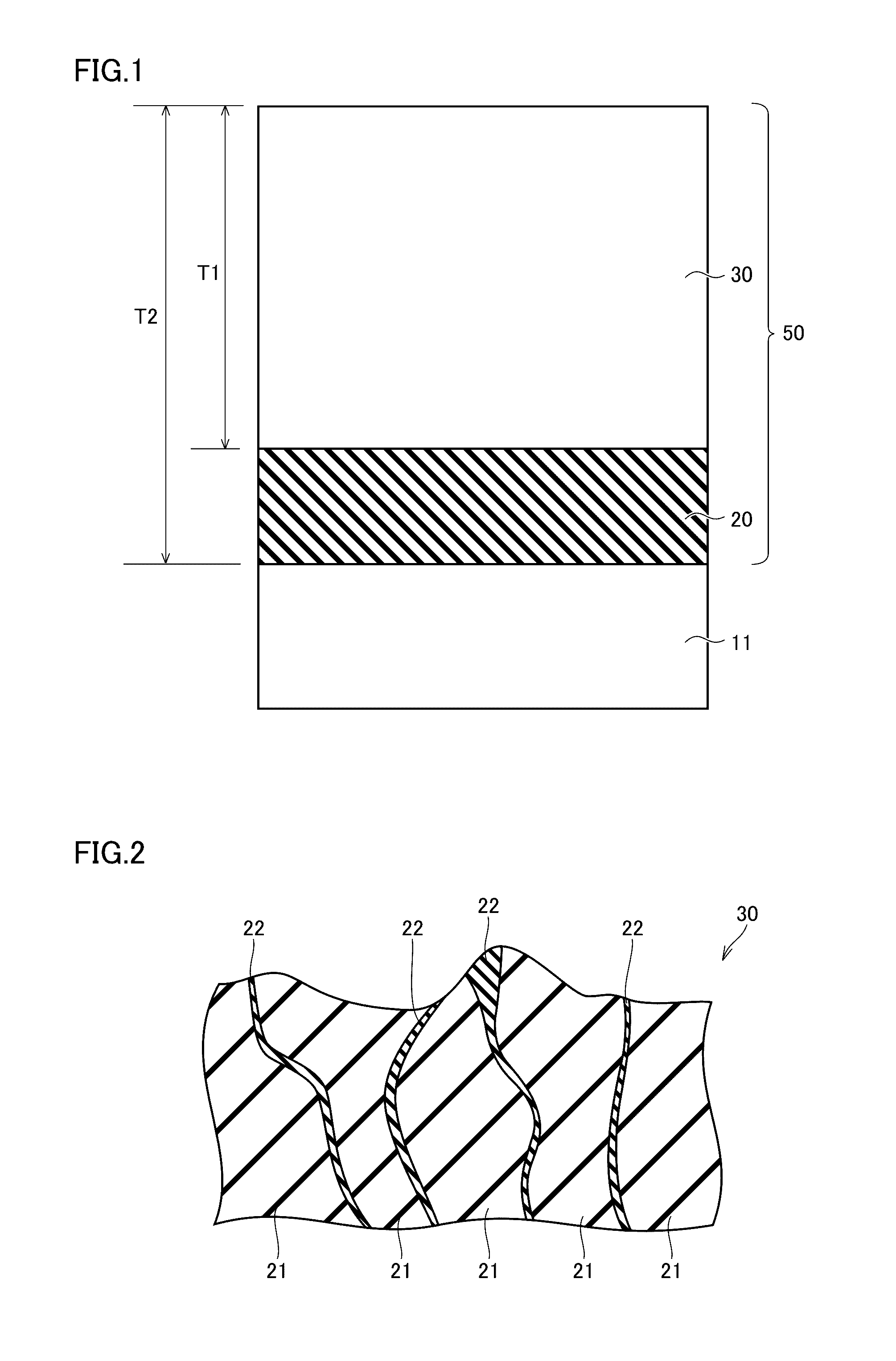

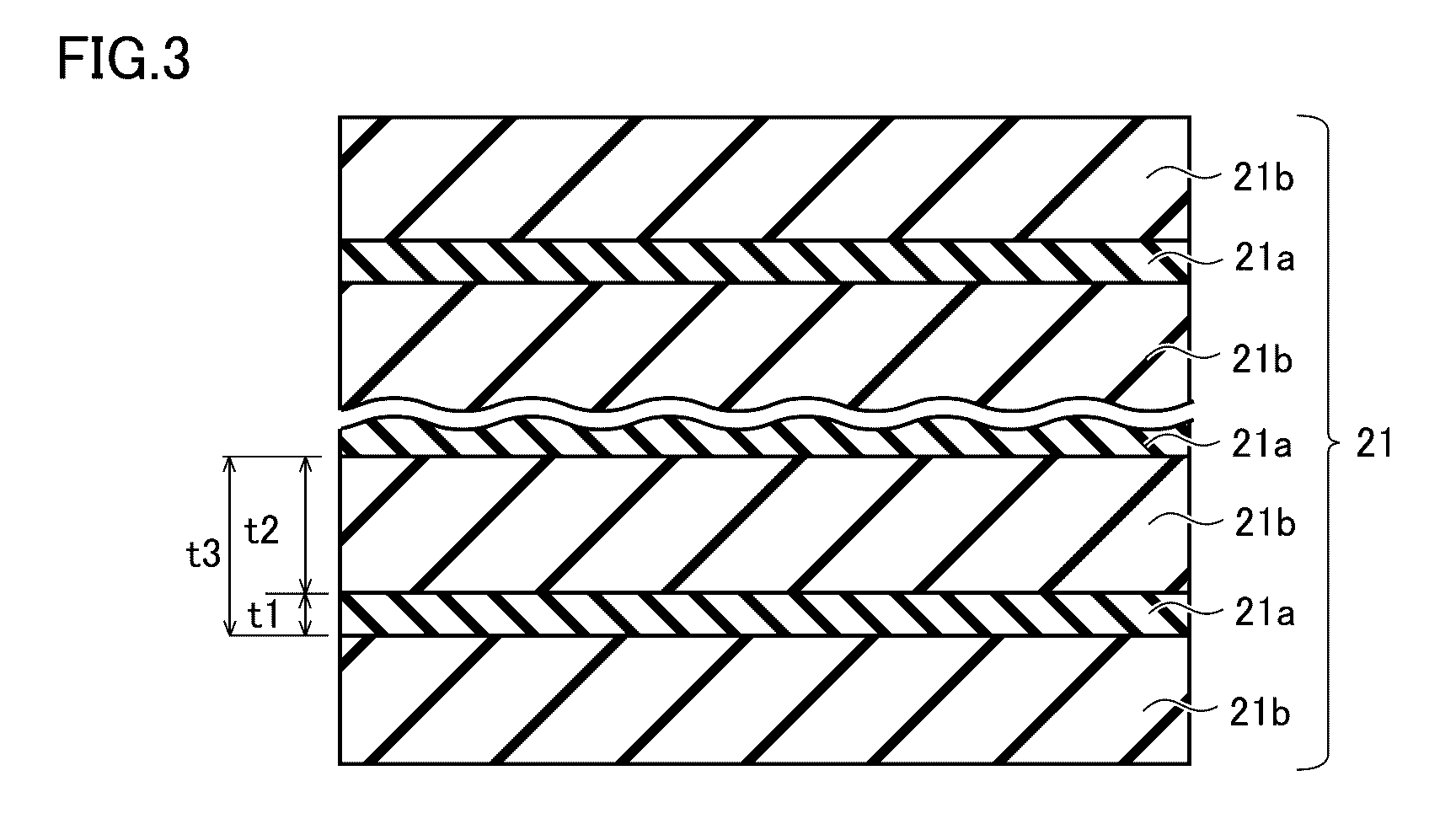

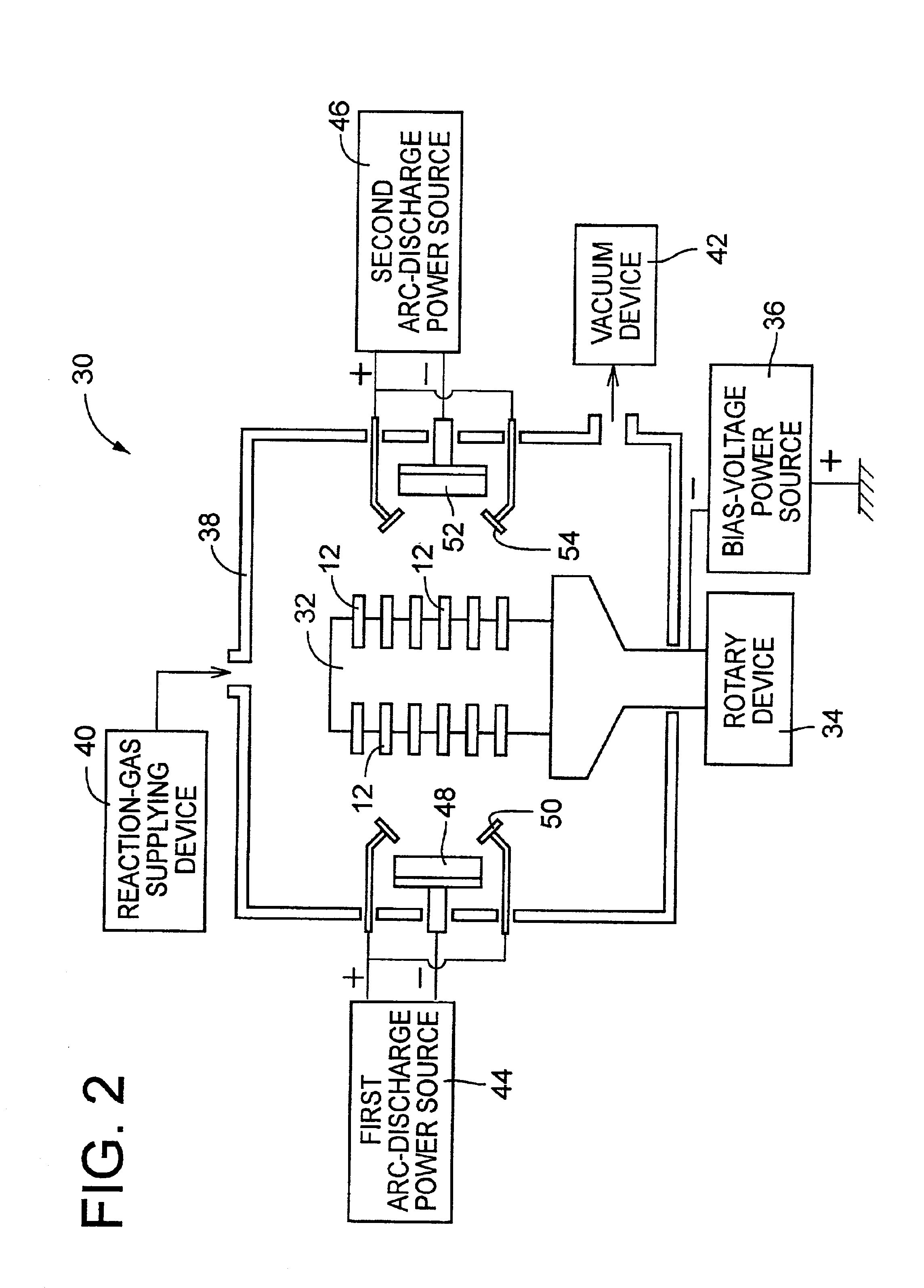

Hard coating, cutting tool, and method for producing hard coating

A hard coating includes two first crystalline phases, and a second crystalline phase containing AlN of a wurtzite-type crystal structure disposed therebetween. The two first crystalline phases each include, independently, a laminate structure having a Ti1-x1Alx1N phase having a sodium chloride-type crystal structure, and an Alx2Ti1-x2N phase having a sodium chloride-type crystal structure that are alternately stacked. An Al composition ratio x1 satisfies a relationship 0.5≦x1≦0.75, and an Al composition ratio x2 satisfies a relationship 0.75<x2≦0.95. The laminate structure includes a region in which an Al concentration periodically changes along a stacking direction of the Ti1-x1Alx1N phase and the Alx2Ti1-x2N phase. In this region, a difference between a maximum value of the Al composition ratio x2 and a minimum value of the Al composition ratio x1 is greater than 0.25.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

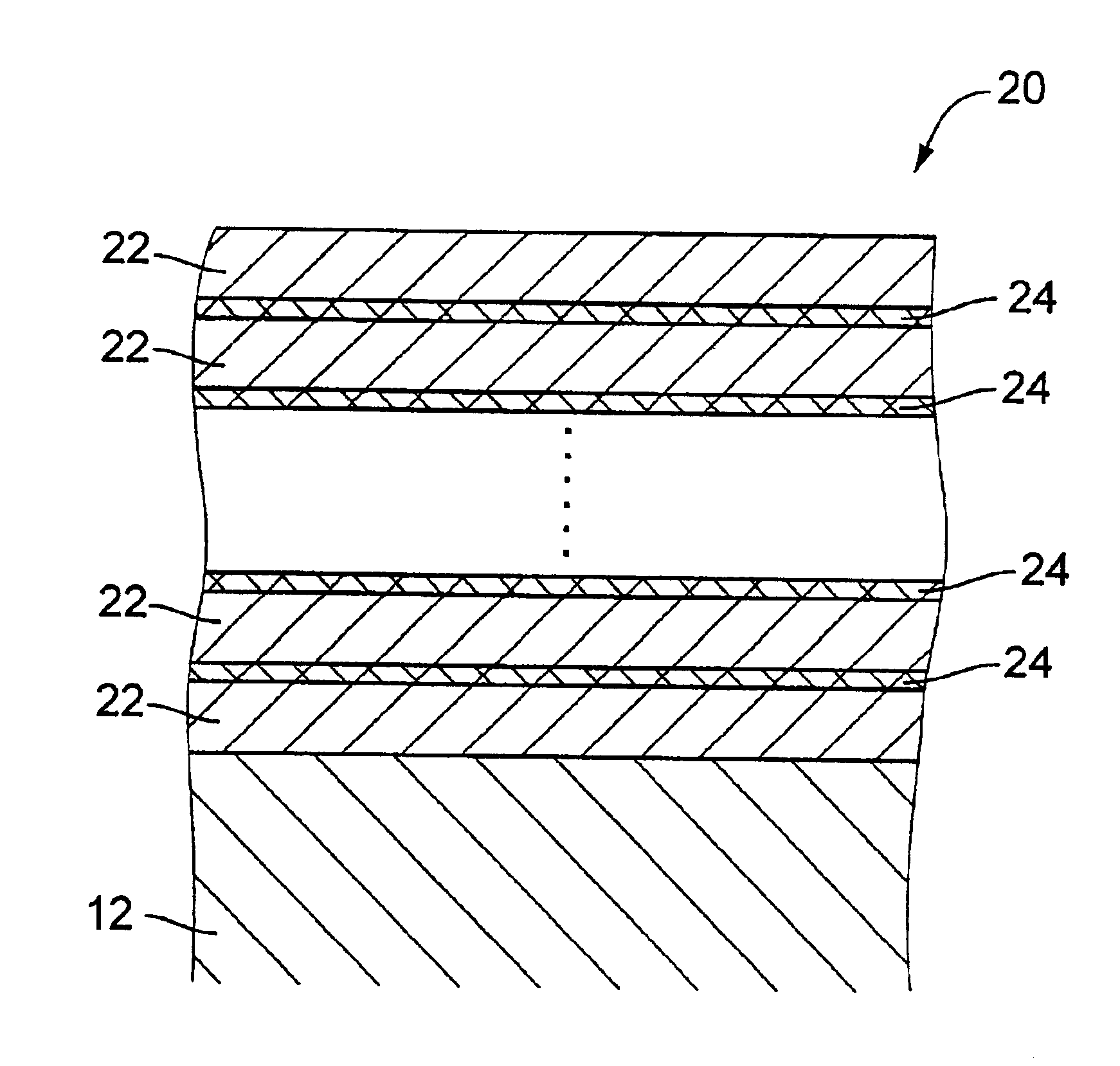

Hard multilayer coating, hard multilayer coated tool including the hard multilayer coating, and method of forming the hard multilayer coating

InactiveUS7008688B2Improve wear resistanceHigh hardnessMilling cuttersVacuum evaporation coatingComposite materialCoating

A hard multilayer coating which is to be disposed on a surface of a substrate, including at least one first coating layer and at least one second coating layer which are alternately superposed on each other, wherein each of the at least one first coating layer consists of (Tix Al1-x) (Cy N1-y) wherein 0.20≦x≦0.60, 0≦y≦0.5, while each of the at least one second coating layer includes CrN, and wherein one of the at least one first coating layer constitutes an outermost layer of the hard multilayer coating.

Owner:OSG

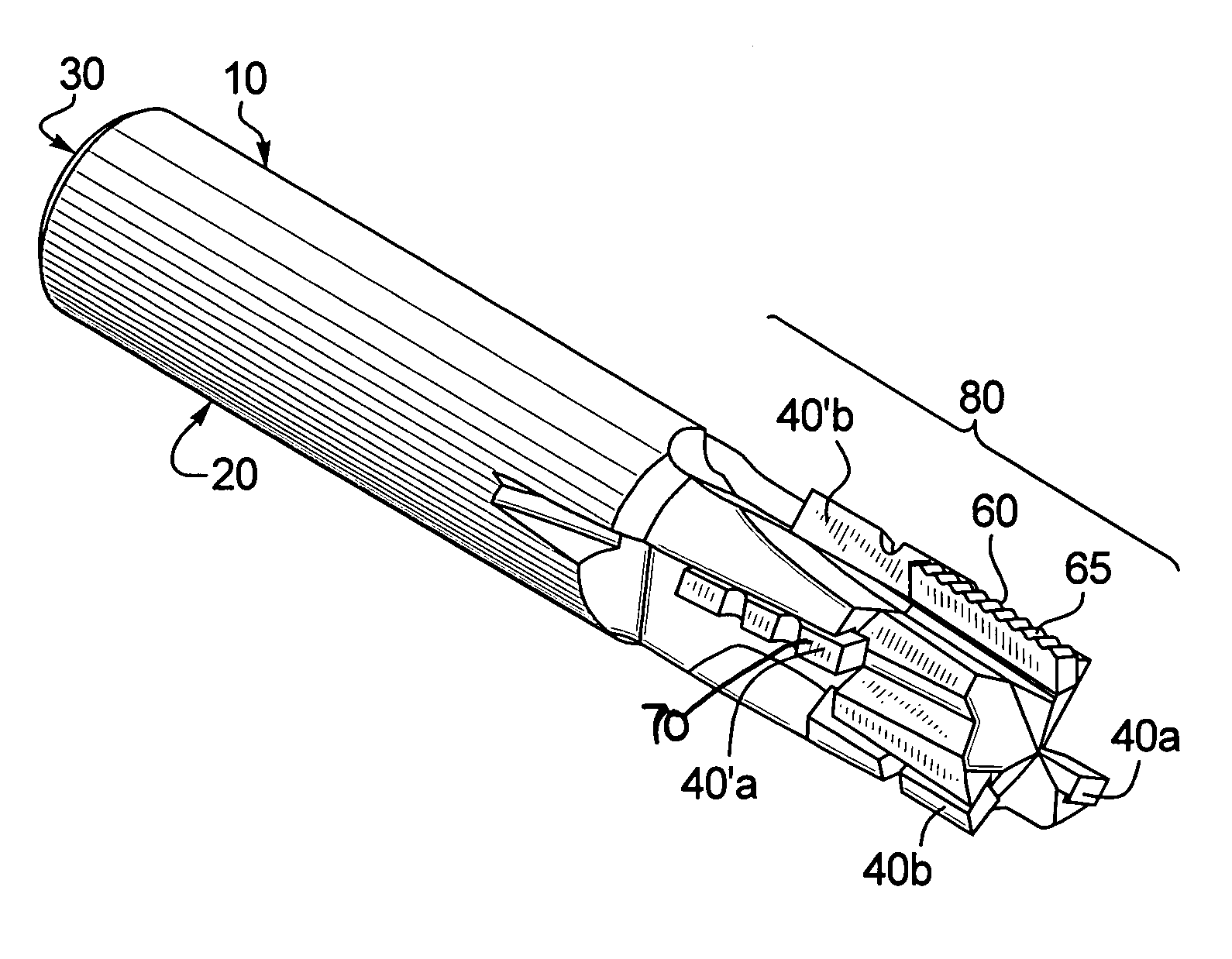

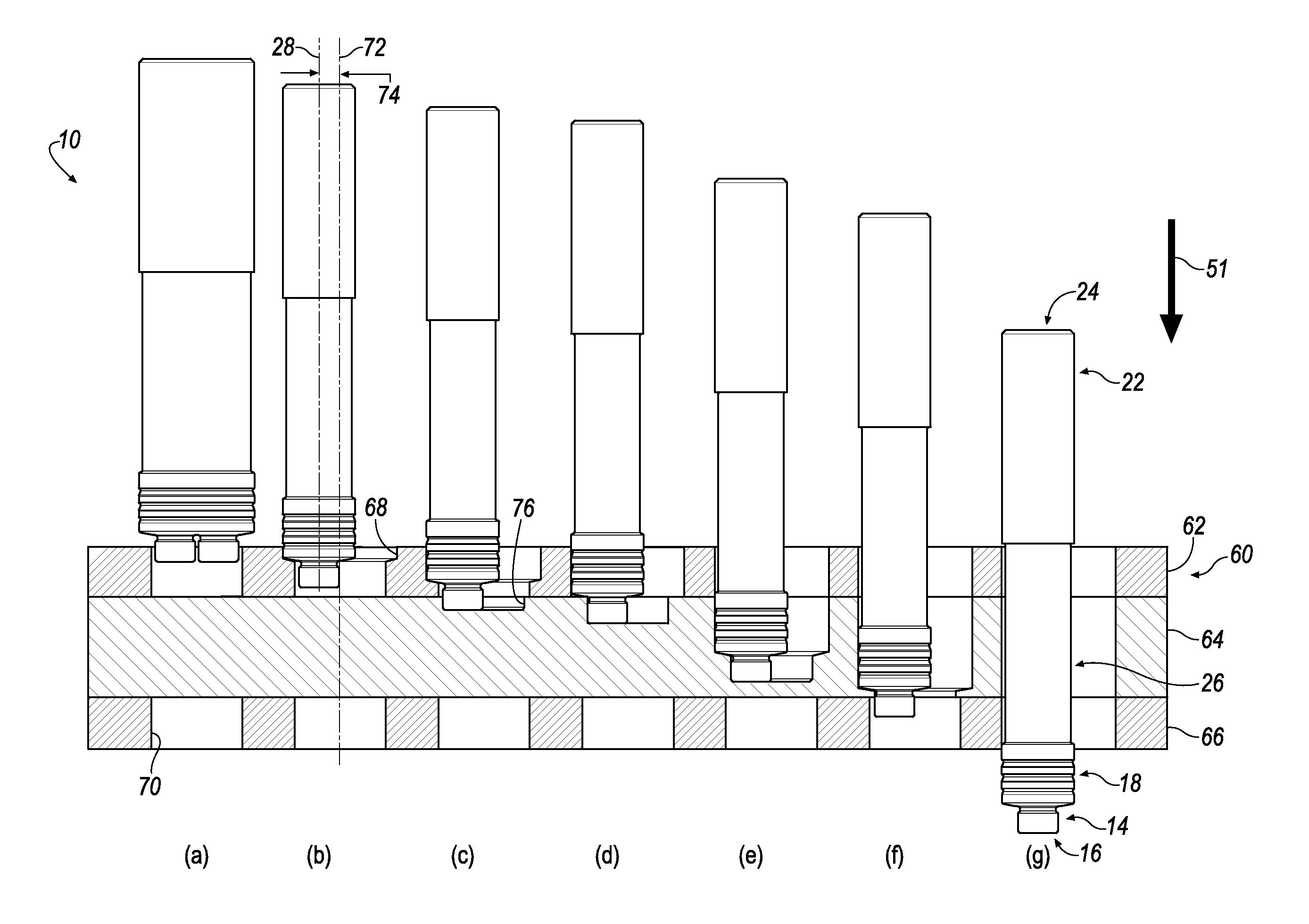

Segmented orbital drill

ActiveUS20120219371A1Improve tool lifeIncreased tool wearTransportation and packagingMilling cuttersClassical mechanicsStructural engineering

A segmented orbital drill includes a segmented portion with a semi-finishing cutting portion and a plurality of finishing cutting portions. The semi-finishing cutting portion and finishing cutting portions are separated by grooves formed by a front wall and a rear wall. The segmented portion allows for a fresh cutting edge (i.e., rear wall of the groove) to be revealed as the orbital drill wears in the axial direction. The segmented portion also causes less contact with the workpiece, which reduces power consumption and minimizes deflection of the orbital drill. The segmented orbital drill also includes an optional pilot at one end of the drill, and a clearance neck portion between a shank and the segmented portion. A method of machining a workpiece using the segmented orbital drill is also disclosed.

Owner:KENNAMETAL INC

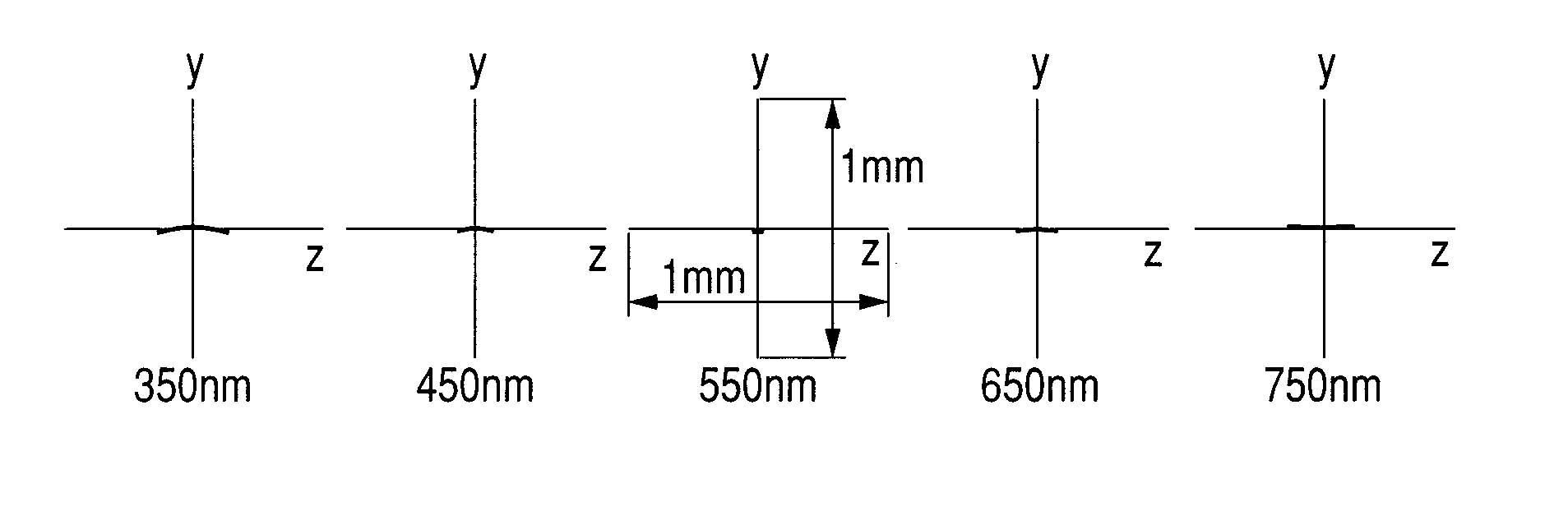

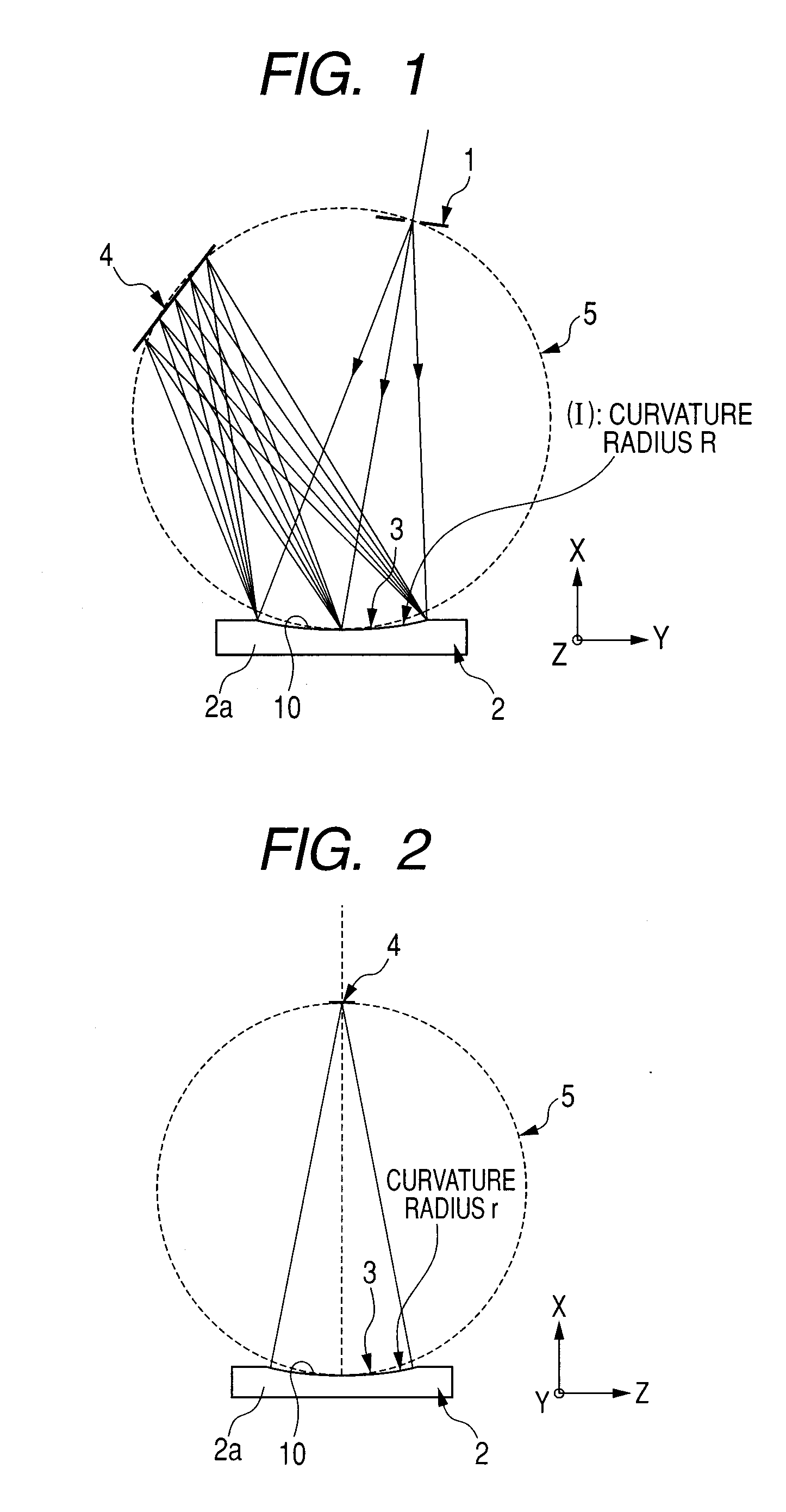

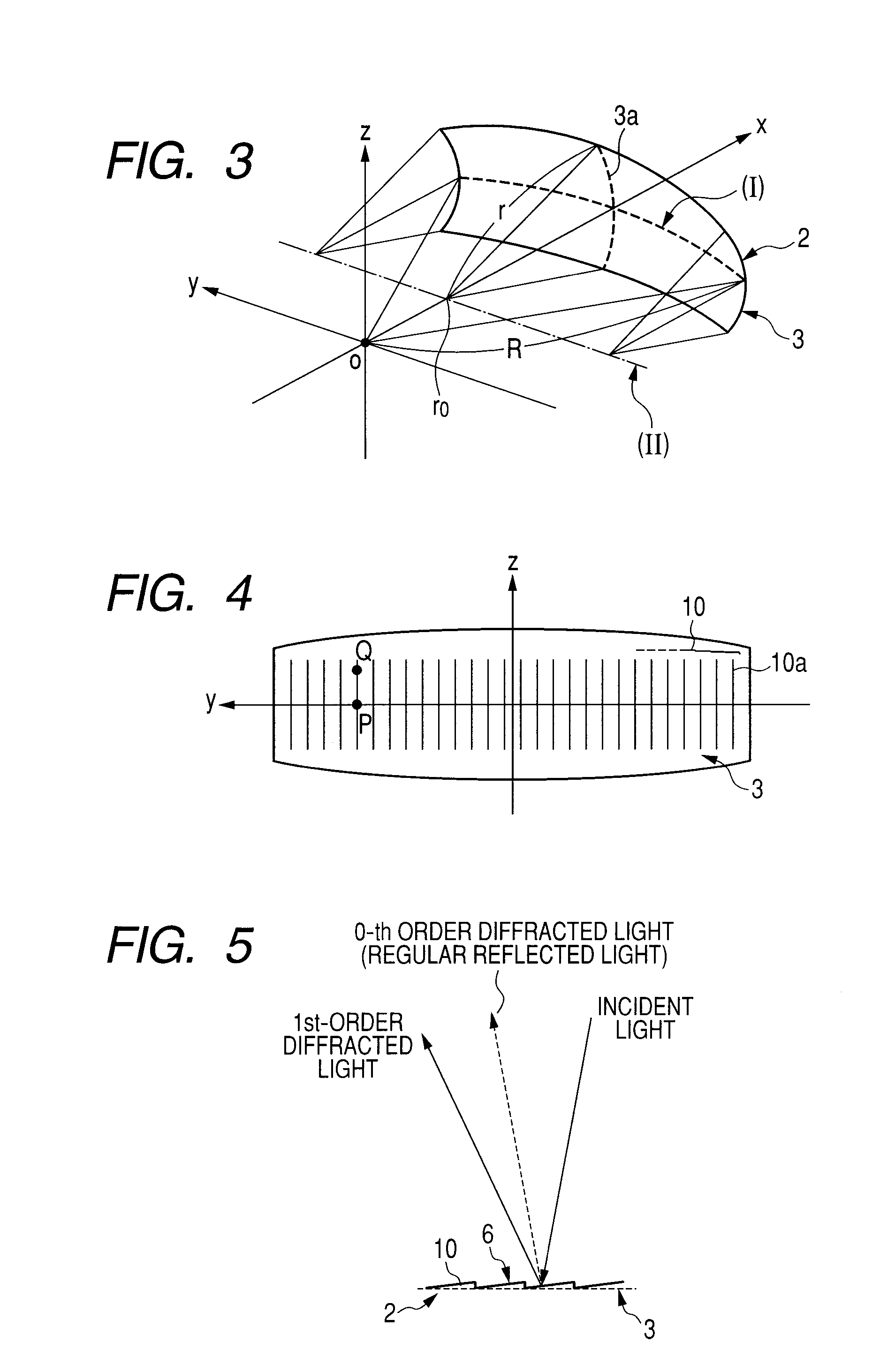

Diffraction element, manufacturing method for diffraction element, and spectrometer using the same

ActiveUS20100284084A1Accurate diffractionAvoid intensityRadiation pyrometrySpectrum investigationLight beamFlare

Objects are to obtain a highly accurate diffraction element that may prevent an intensity decrease of a light beam entering a light receiving unit without a decrease in diffraction efficiency and without a problem of flare or the like, a manufacturing method for the diffraction element, and a spectrometer using the same. A diffraction element (2) includes a diffraction grating formed on a substrate having a curved surface. In the diffraction element (2), the curved surface (3) has an anamorphic shape formed by pivoting a curved line (I) in a plane about a straight line (II) in the same plane serving as a rotation axis, and gratings (10a) of the diffraction grating (10) exist in cross sections orthogonal to the rotation axis.

Owner:CANON KK

Ti(C,N) base metal ceramic and preparation method thereof

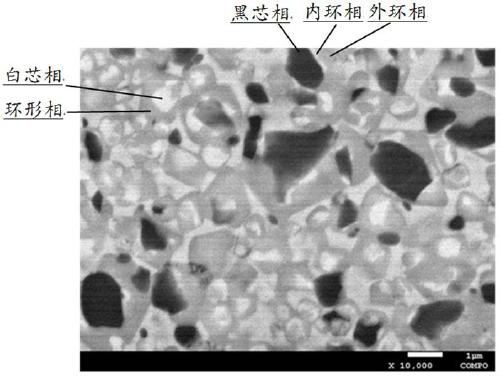

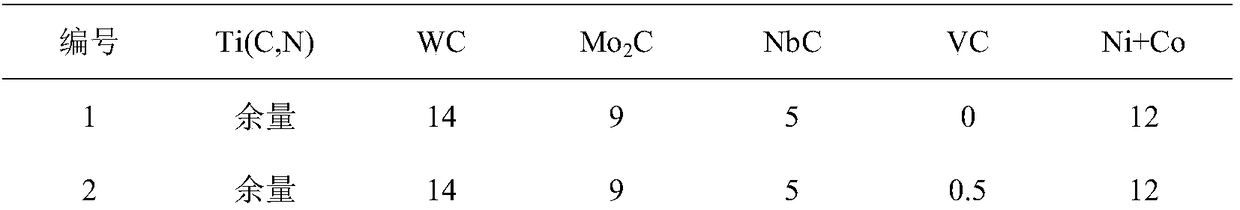

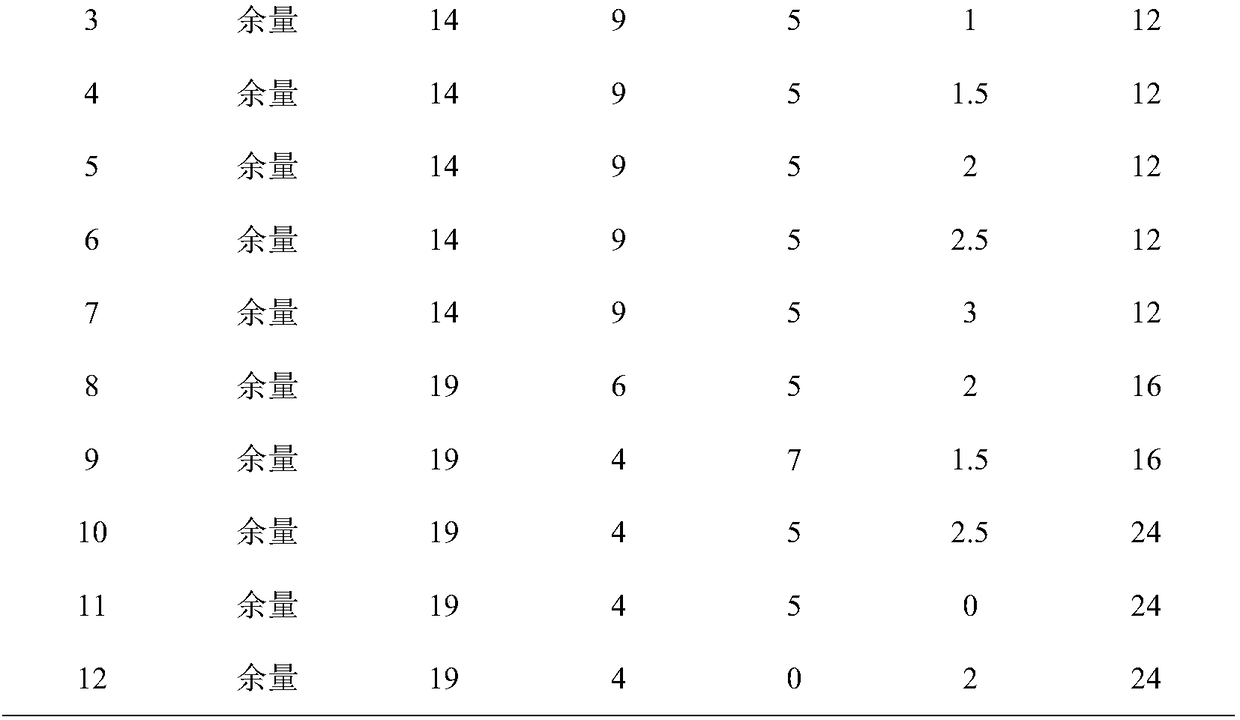

ActiveCN108950342AAdjust machinabilityMachinability satisfactionMilling cuttersWorkpiecesTitanium carbonitrideMolybdenum carbide

The invention discloses Ti(C,N) base metal ceramic and a preparation method thereof. Raw materials of the metal ceramic comprise titanium carbonitride Ti(0.5 of C and 0.5 of N), tungsten carbide WC, molybdenum carbide / molybdenum Mo2C / Mo, niobium carbide NbC, vanadium carbide VC, cobalt Co and nickel Ni powder, wherein the content of NbC ranges from 3 wt% to 15 wt%, the VC content is 0.3-3%, and the VC content changes along with the content of NbC. Hard phases formed by the materials are of two core-ring structures, one structure is a ring-shaped phase structure containing typical black core phases and inner ring phases, or outer ring phases and black core phases, and the other structure is a ring-shaped phase structure containing white core phases. The total credit of the black core phasesin the ring-shaped phase structure containing the black core phases and the inner ring phases, or the outer ring phases and the black core phases is 10-20%, the total credit of the inner ring phasesis 0.5-2%, and the total credit of the white core phases in the ring-shaped structure containing the white core phases is 5-10%. Chemical components of some or all white core phases are different fromthose of the inner ring phases, and the content of the Nb element in some or all white core phases is 30-40 wt% higher than the content of the Nb element in the inner ring phases. The Ti(C,N) base metal ceramic has thermal shock resistant performance and cutting performance.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com