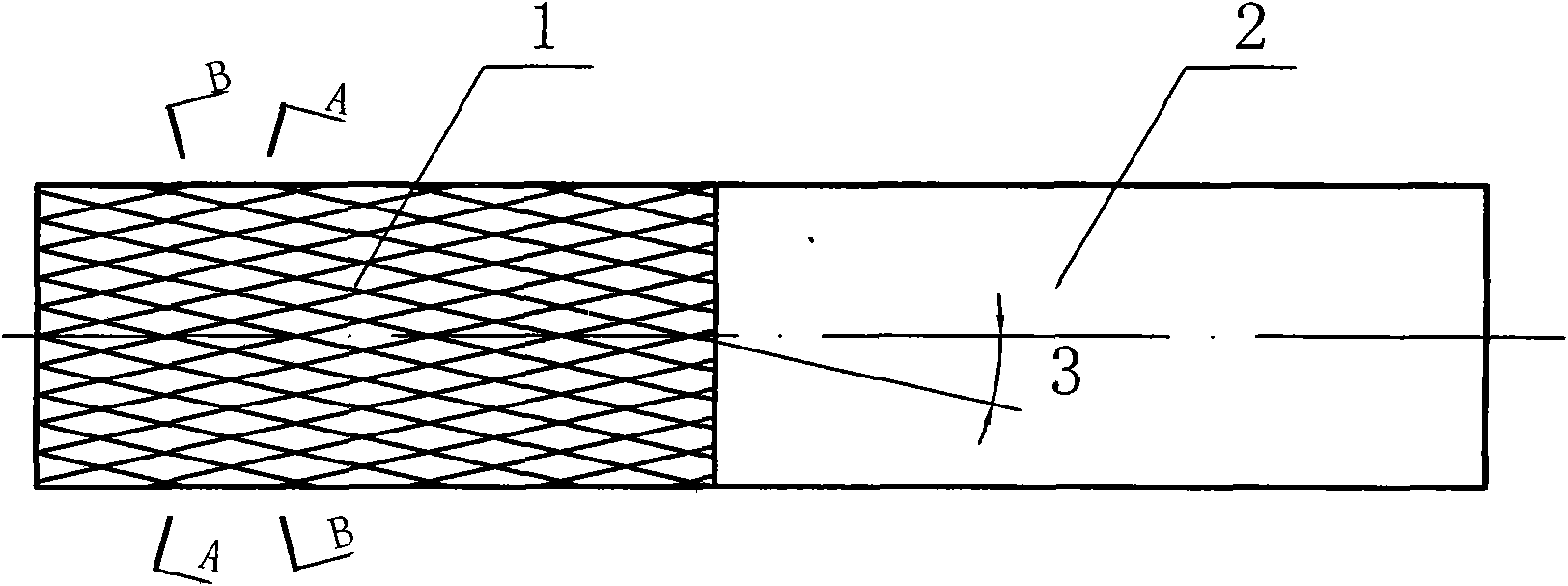

Integral carbide goldfish scale milling cutter

A technology of solid carbide and fish scales, applied in milling cutters, cutters for milling machines, milling machine equipment, etc., can solve the problems of low machining surface roughness, low machining efficiency, poor cutting performance, etc., to improve machining efficiency and Effect of surface quality, extended service life and reduced cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

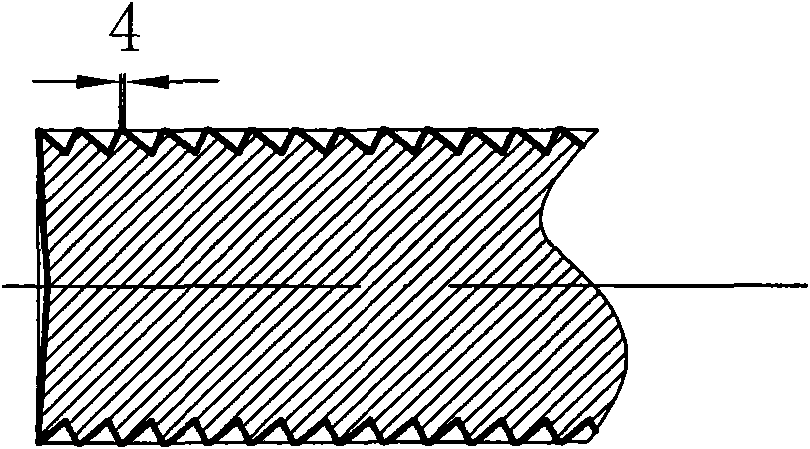

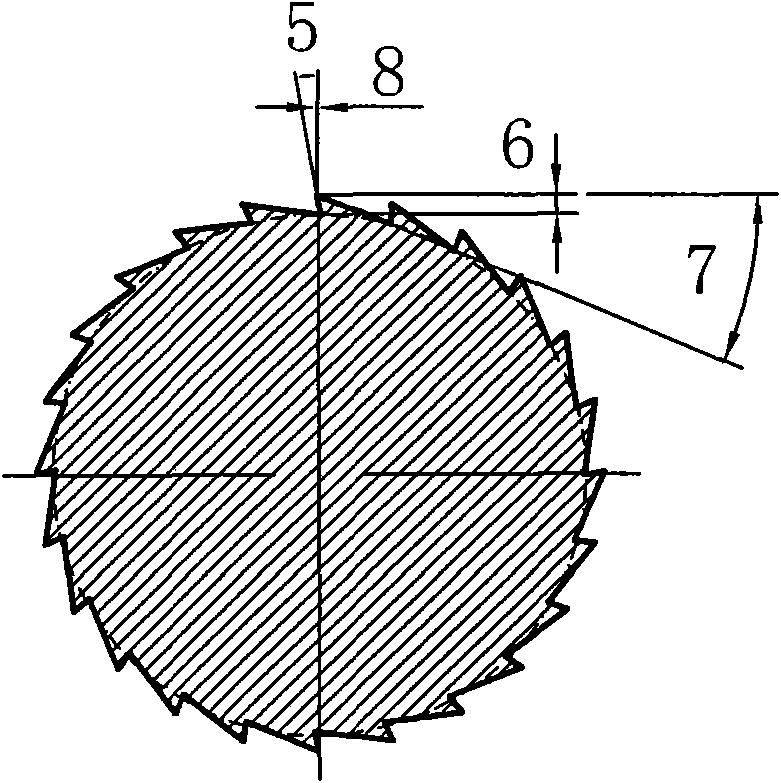

[0011] Example 1: Solid carbide fish scale milling cutter, blade diameter Φ16mm, including milling cutter blade and milling cutter shank, characterized in that the cutting edge on the milling cutter blade is composed of left-handed and right-handed symmetrical spiral grooves for cutting unit, the left helical groove is 2 more than the right helical groove; the length of the main cutting edge of each cutting unit is made 0.05, the flank surface of the cutting edge is made 0-0.01mm along the width of the cylindrical surface; the rake angle of the cutting edge is made 12°, The rake face is a straight line on the normal section; the cutting edge relief angle is made 24°; the spiral groove depth is made 1.2mm of the tool diameter.

example 2

[0012] Example 2: Solid carbide fish scale milling cutter, blade diameter Φ16mm, including milling cutter blade and milling cutter shank, characterized in that the cutting edge on the milling cutter blade is composed of left-handed and right-handed symmetrical spiral grooves for cutting Unit, the left helical groove is 2 more than the right helical groove; the length of the main cutting edge of each cutting unit is made 0.1mm, the flank surface of the cutting edge is made 0~0.01mm along the width of the cylindrical surface; the rake angle of the cutting edge is made 10° , The rake face is a straight line on the normal section; the cutting edge relief angle is made 20°; the spiral sipe depth is made 1.2mm of the tool diameter.

example 3

[0013] Example 3: Solid carbide fish scale milling cutter, blade diameter Φ16mm, including milling cutter blade and milling cutter shank, characterized in that the cutting edge on the milling cutter blade is composed of left-handed and right-handed symmetrical spiral grooves for cutting unit, the left helical groove is 2 more than the right helical groove; the length of the main cutting edge of each cutting unit is made 0.05 ~ 0.1mm, the flank surface of the cutting edge is made 0 ~ 0.01mm along the width of the cylindrical surface; the rake angle of the cutting edge is made 15°, the rake face is a straight line on the normal section; the cutting edge relief angle is made 25°; the spiral groove depth is made 1.2mm of the tool diameter.

[0014] Integral carbide fish scale milling cutter, the cutting edge is composed of many cutting units, the cutting edge is sharp, which greatly reduces the cutting resistance, and can achieve high-speed cutting, achieving the effect of milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com