Patents

Literature

65results about How to "High speed cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

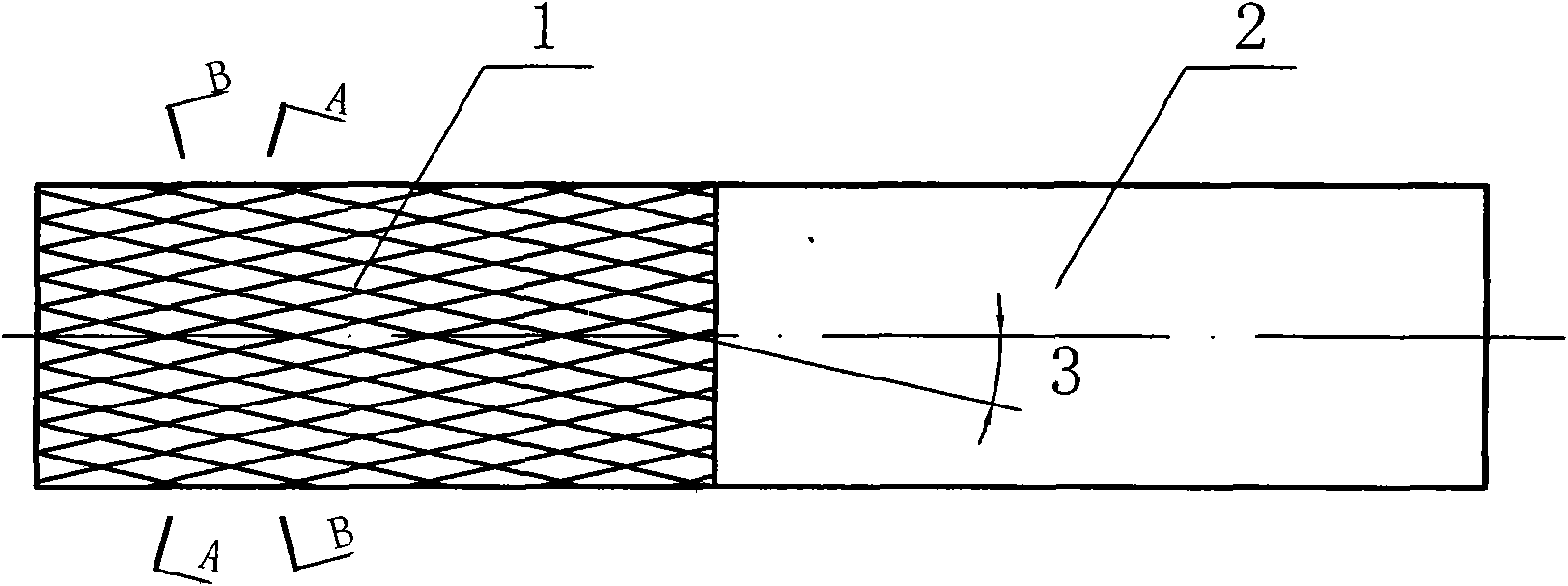

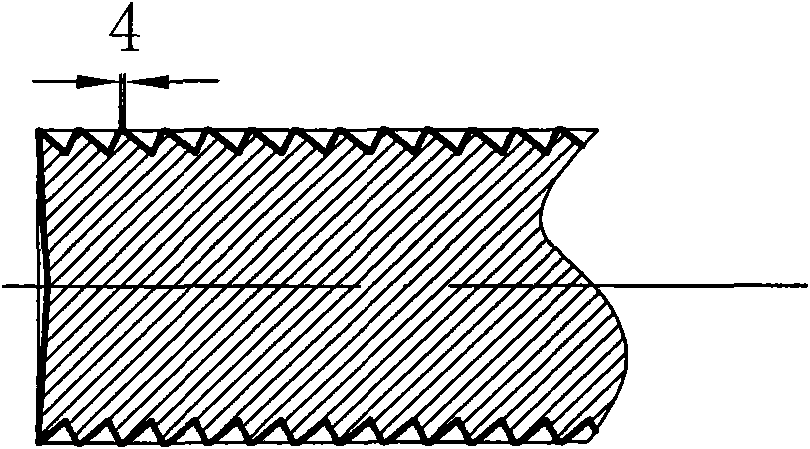

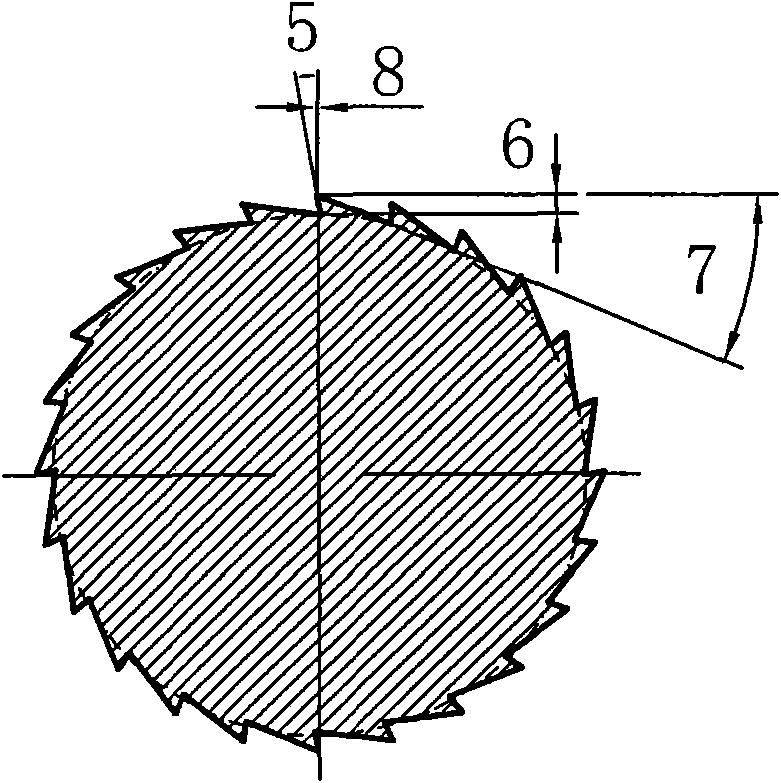

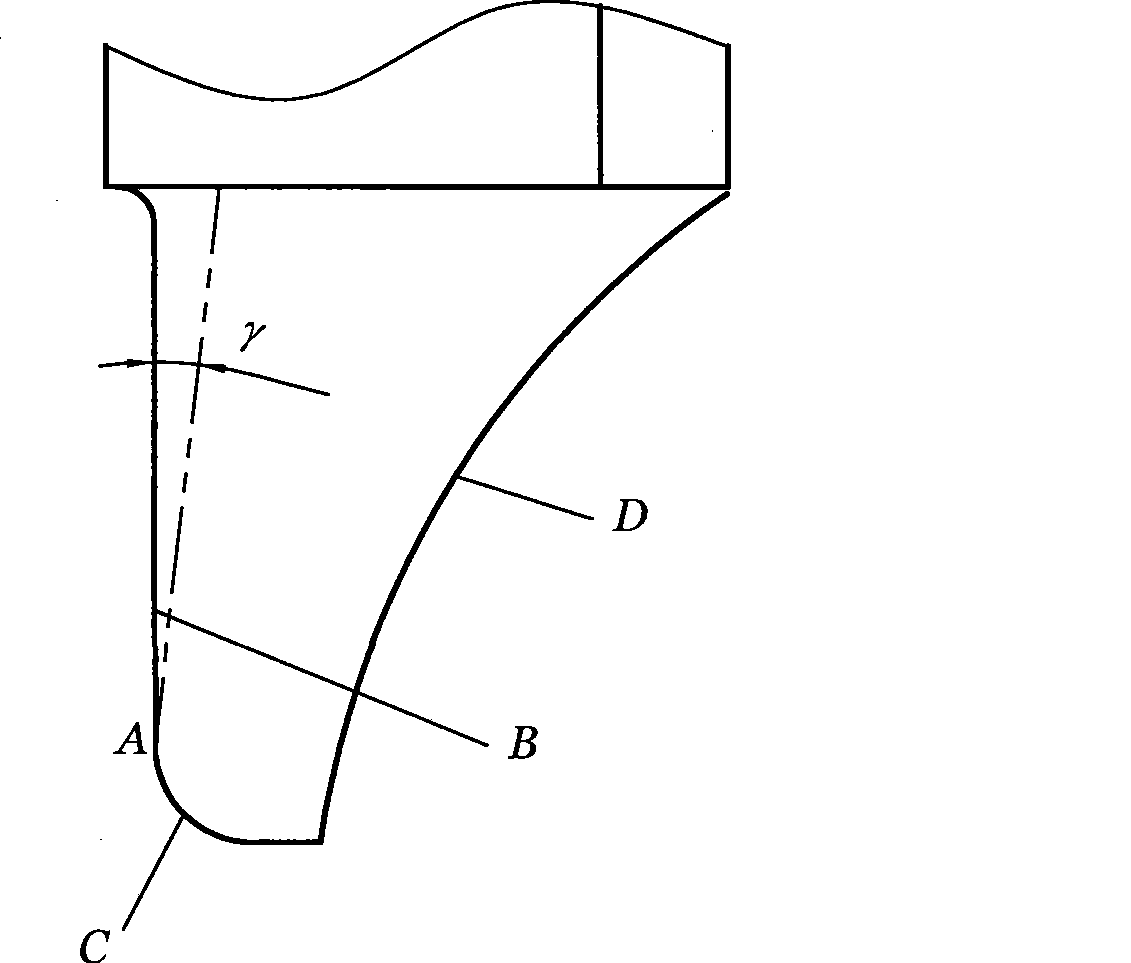

Integral carbide goldfish scale milling cutter

InactiveCN101623778AExtended service lifeImprove processing efficiencyMilling cuttersWorkpiecesGlass fiberFiber

The invention discloses an integral carbide goldfish scale milling cutter used for milling and processing composite materials such as carbon fiber, glass fiber and the like. The milling cutter of the invention comprises a milling cutter blade and a milling handle, wherein the cutting blade on the milling cutter blade is a cutting unit formed by left and right-handed rotation symmetrical staggered spiral grooves, and the number of the left spiral groove is two more than that of the right spiral groove; the length of the cutting blade of each cutting unit is 0.05-0.1mm, and the width of the rear cutter surface of the cutting blade along the cylinder surface is 0-0.01mm; the anterior angle of the cutting blade is 10-15 degrees, the front cutter surface is a straight line on a normal plane; the relief angle of the cutting blade is 20-25 degrees; the depth of the spiral cutter groove is 7-8% of the diameter of the cutter. The invention has the advantages that the cutting blade of the integral carbide goldfish scale milling cutter is composed of a plurality of cutting units and is sharp, which greatly lowers cutting resistance and realizes high speed cutting so as to obtain the effect of using milling for replacing abrading, so that the processing efficiency and the surface quality of the composite materials can be improved, and the service life of the milling cutter can be prolonged.

Owner:SHENYANG AIRCRAFT CORP

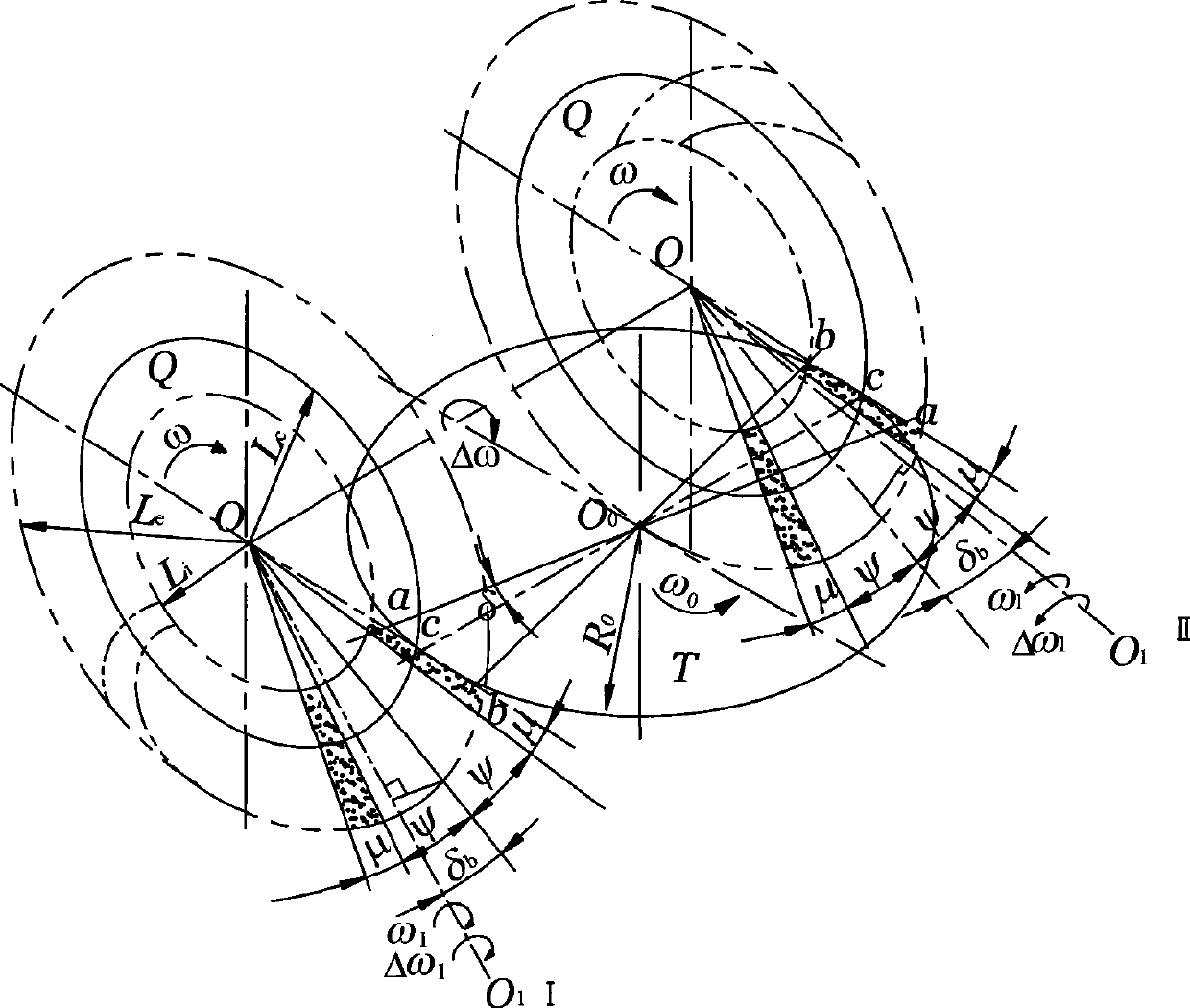

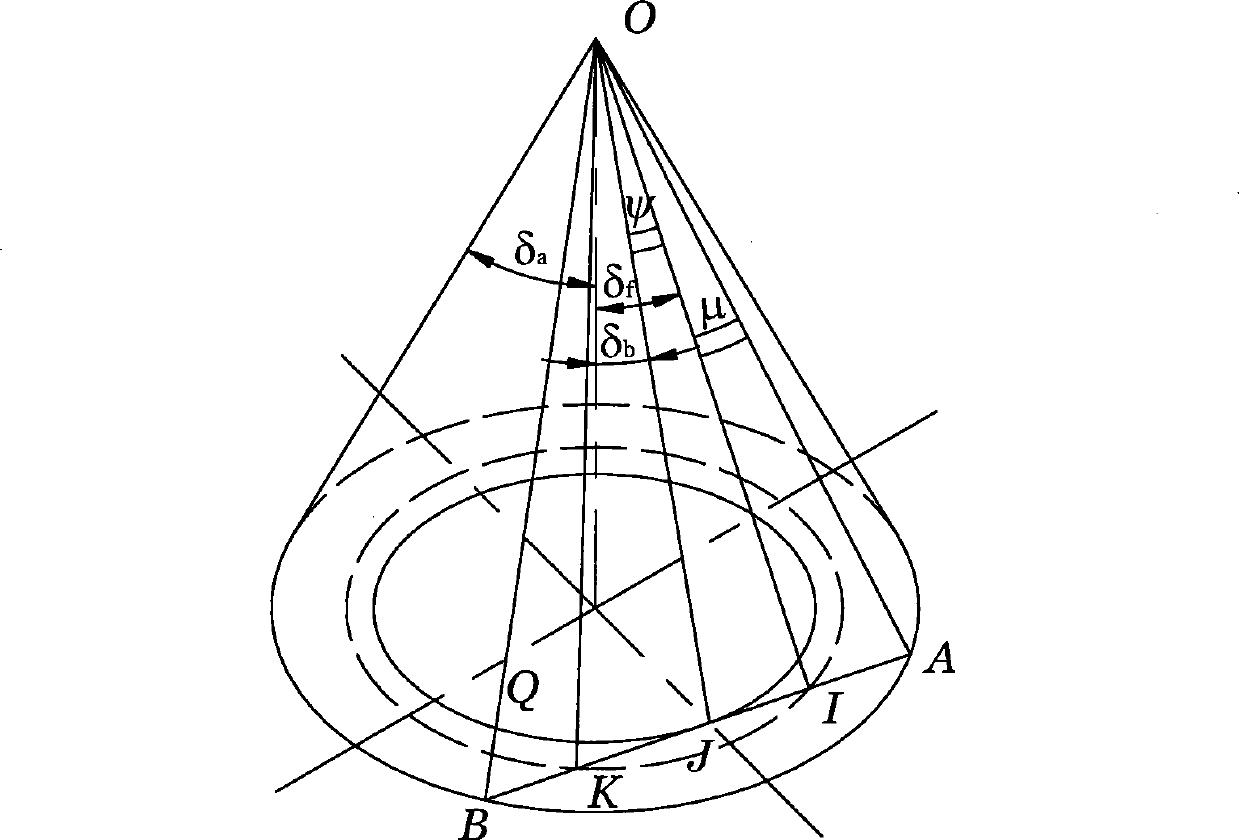

Spherical involute spiral Archimedes spiral bevel gear cutting method and machine tool

InactiveCN101391324AImprove mesh qualityEasy to controlGear teeth manufacturing toolsGear-cutting machinesEngineeringGreat circle

The invention discloses a tooth cutting method for a bevel gear with spherical involute toothed archimedes spiral teeth and a machine tool thereof. The method overcomes the disadvantages that the current tooth cutting method forms principle errors, has complex revision calculation, trial cutting and adjustment of a machine tool, and the like. The tooth cutting method adopts a machine tool with double stations and a single cutter head, which can continuously tooth dividing. When teeth are cut, the I station at one side of the cutter head completes the rough cutting of tooth sockets and the finishing cutting of the concave tooth surfaces of teeth; then the II station at the other side of the cutter head completes the finishing cutting of the convex tooth surfaces of the teeth, each cutter tooth straight edge on a cutting tooth cutter head envelopes and cuts out the side surfaces of the teeth, the circular arc edge of tooth top cuts out the tooth root, and the rough cutting concave edge cuts off the margins of the tooth sockets; and when the teeth are cut, a cutter head shaft and the tooth blank shaft are in a spatial cross position, the rotating end surface of the cutter head is perpendicular to the tangent plane of the gear blank base cone, the cutter head, the gear blank and the big circular plane of an imaginary spherical surface rotate in an uniform speed, the cutter head is in the rotary feed when cutting the teeth, and the continuous hobbling base cone toothed portion is the spiral bevel gear of Archimedes. The invention provides a machine tool, a cutter head and a cutter tooth for realizing the tooth cutting method.

Owner:JILIN UNIV

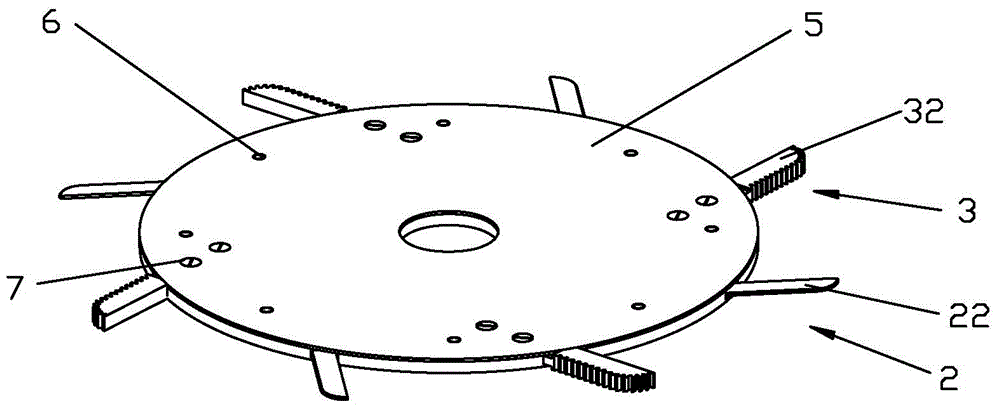

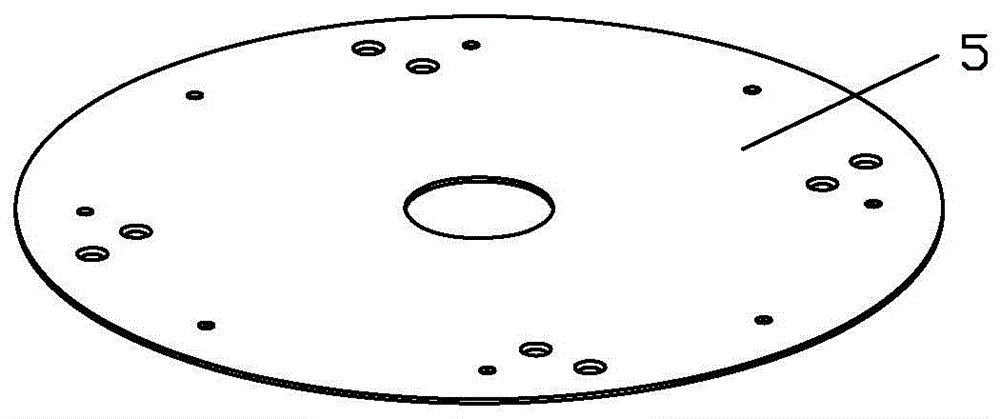

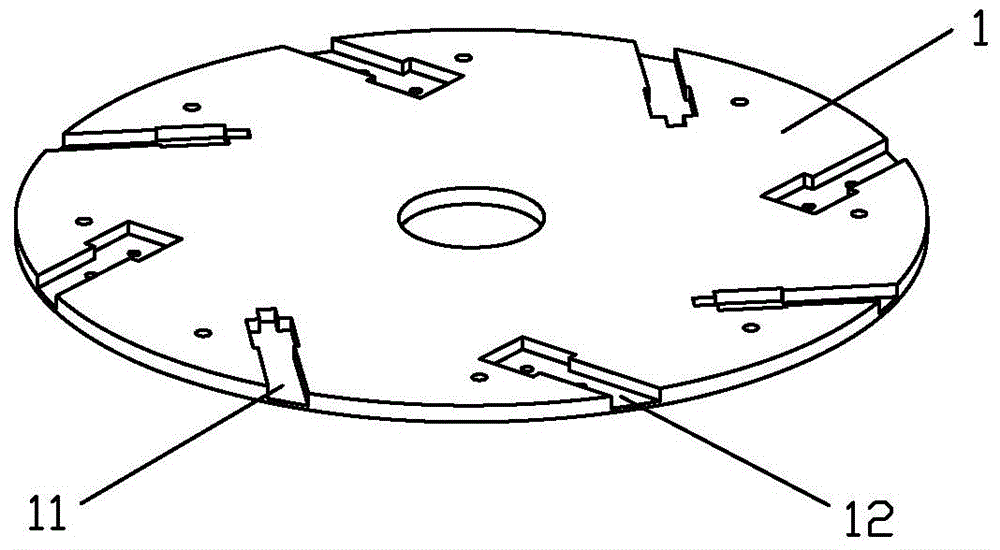

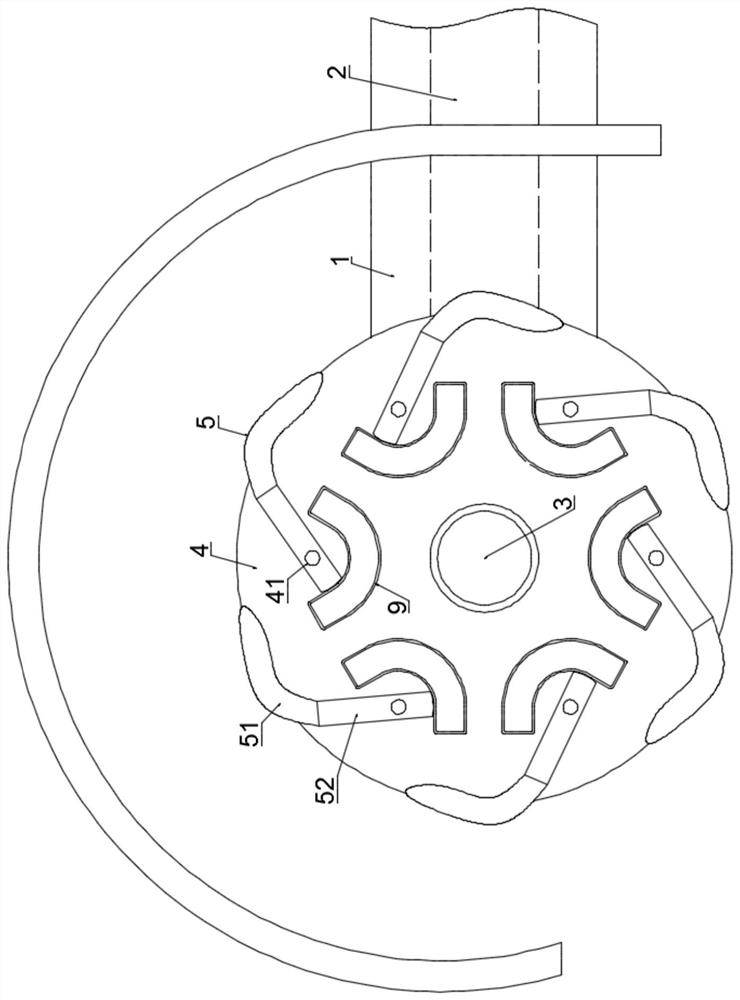

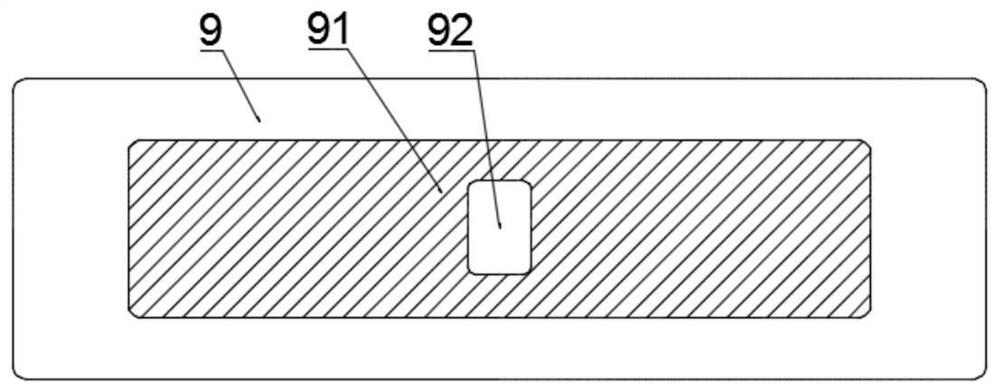

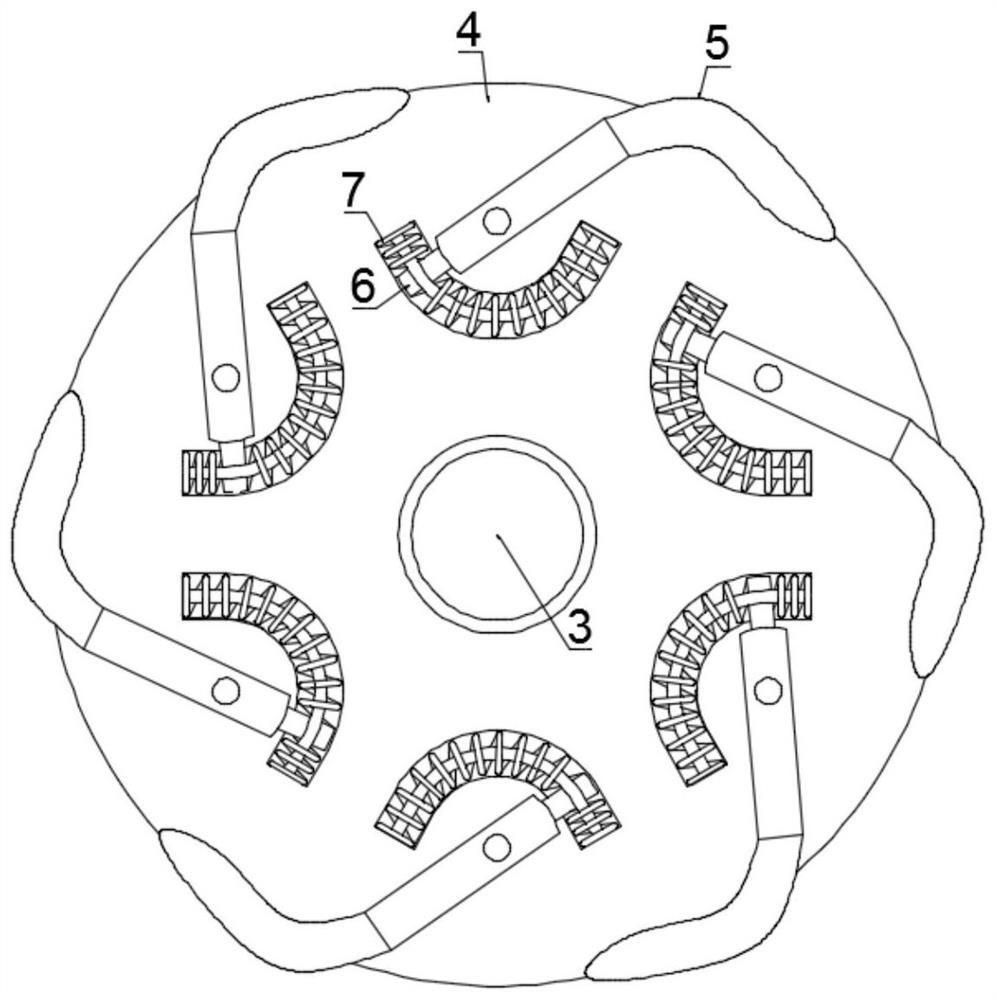

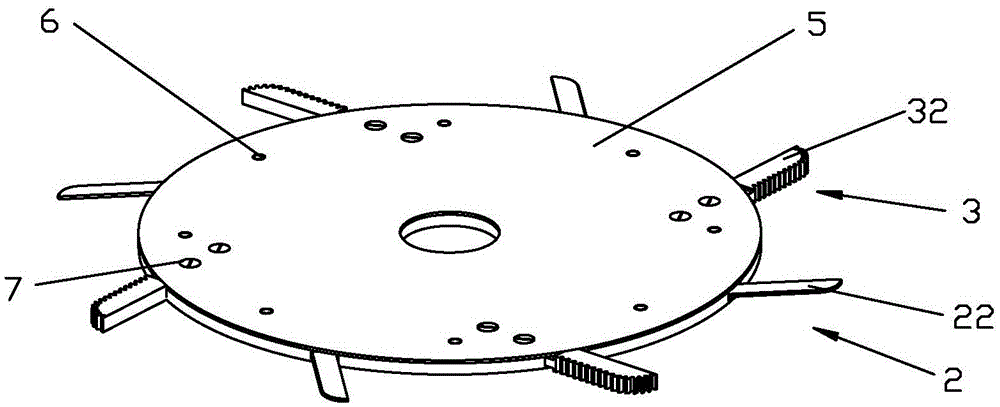

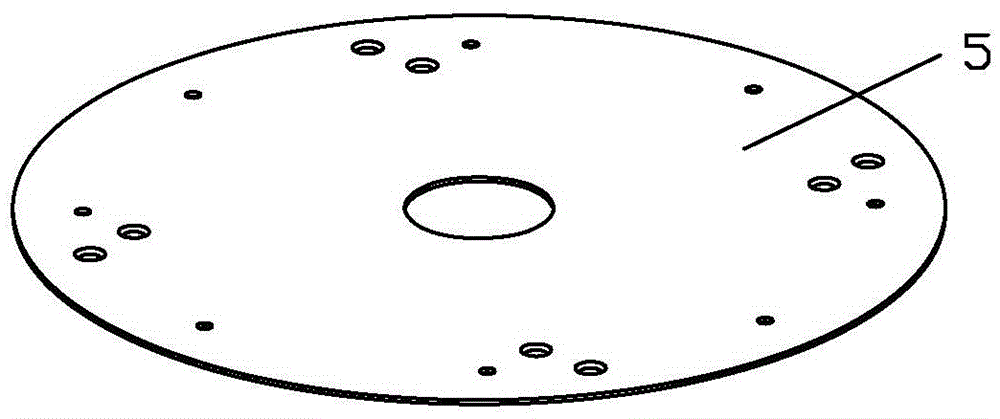

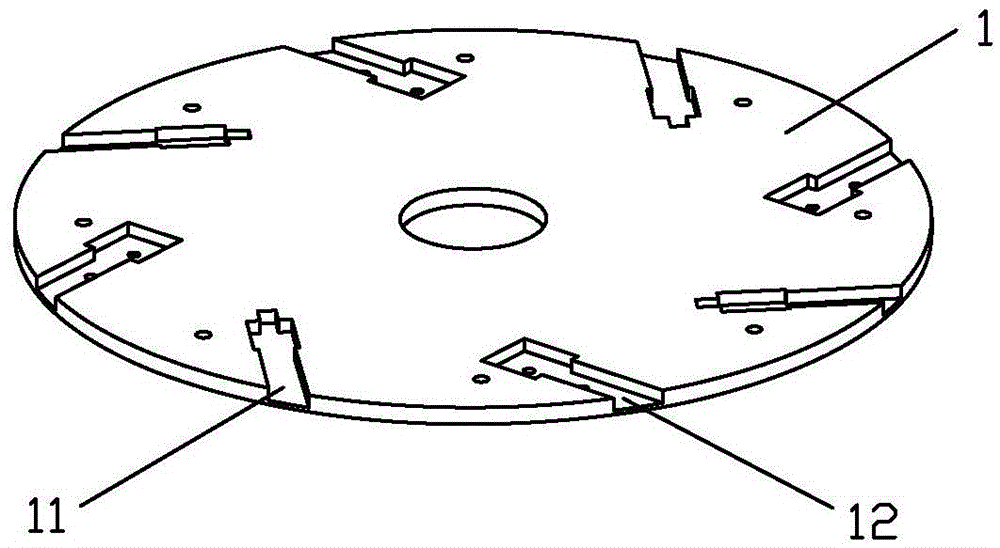

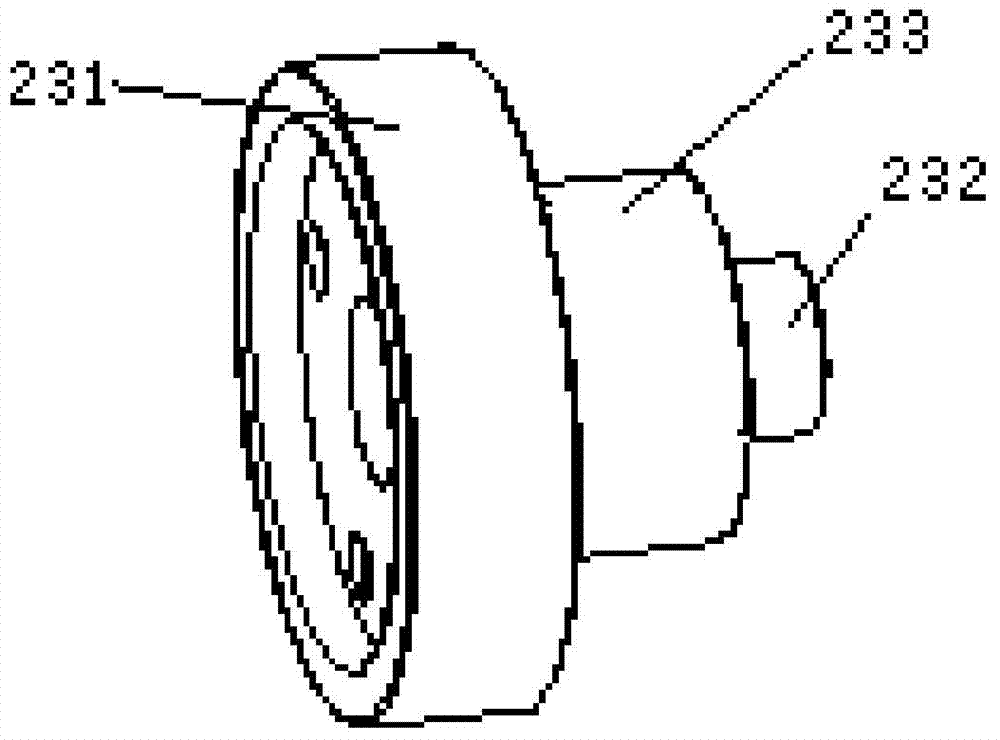

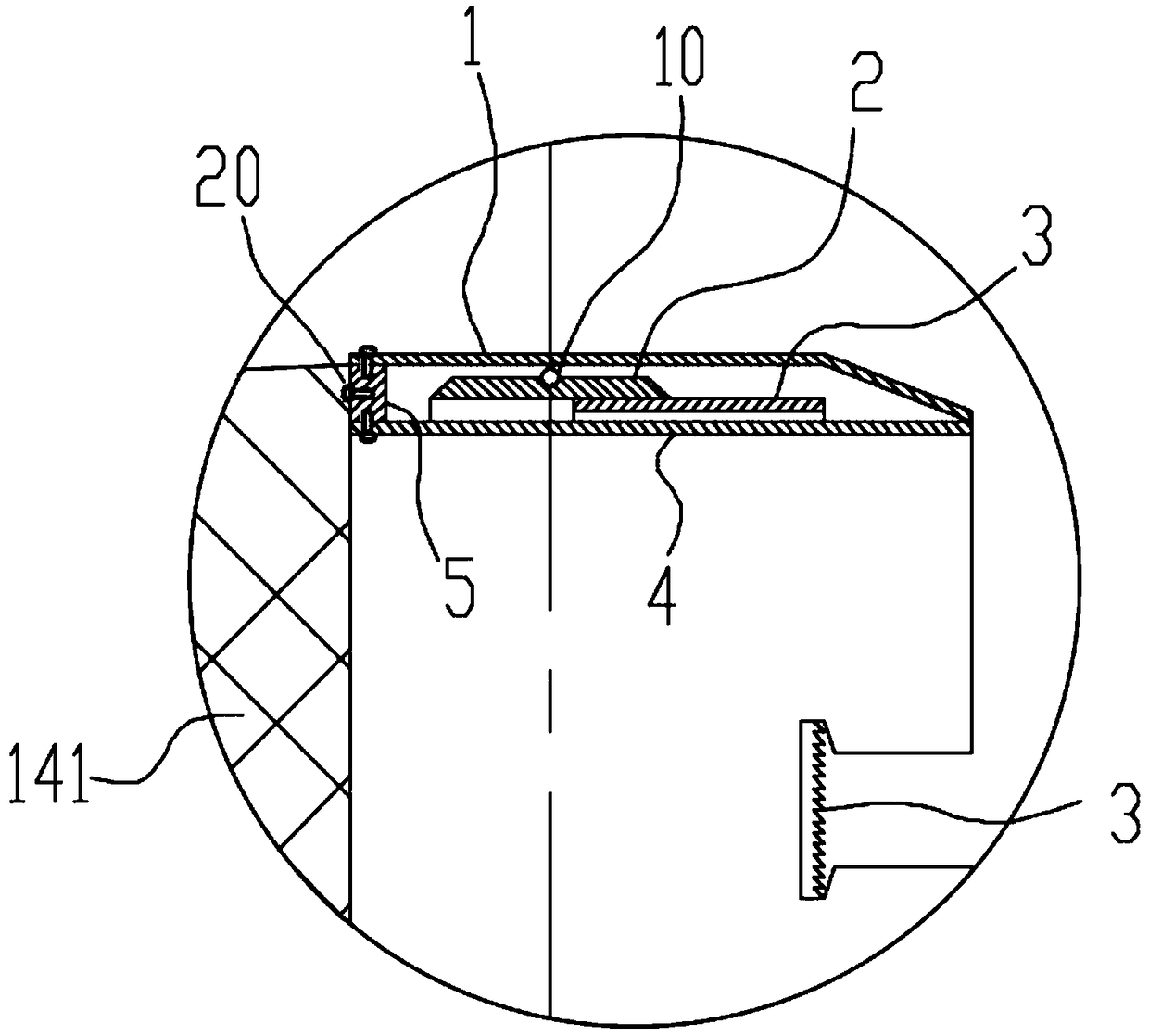

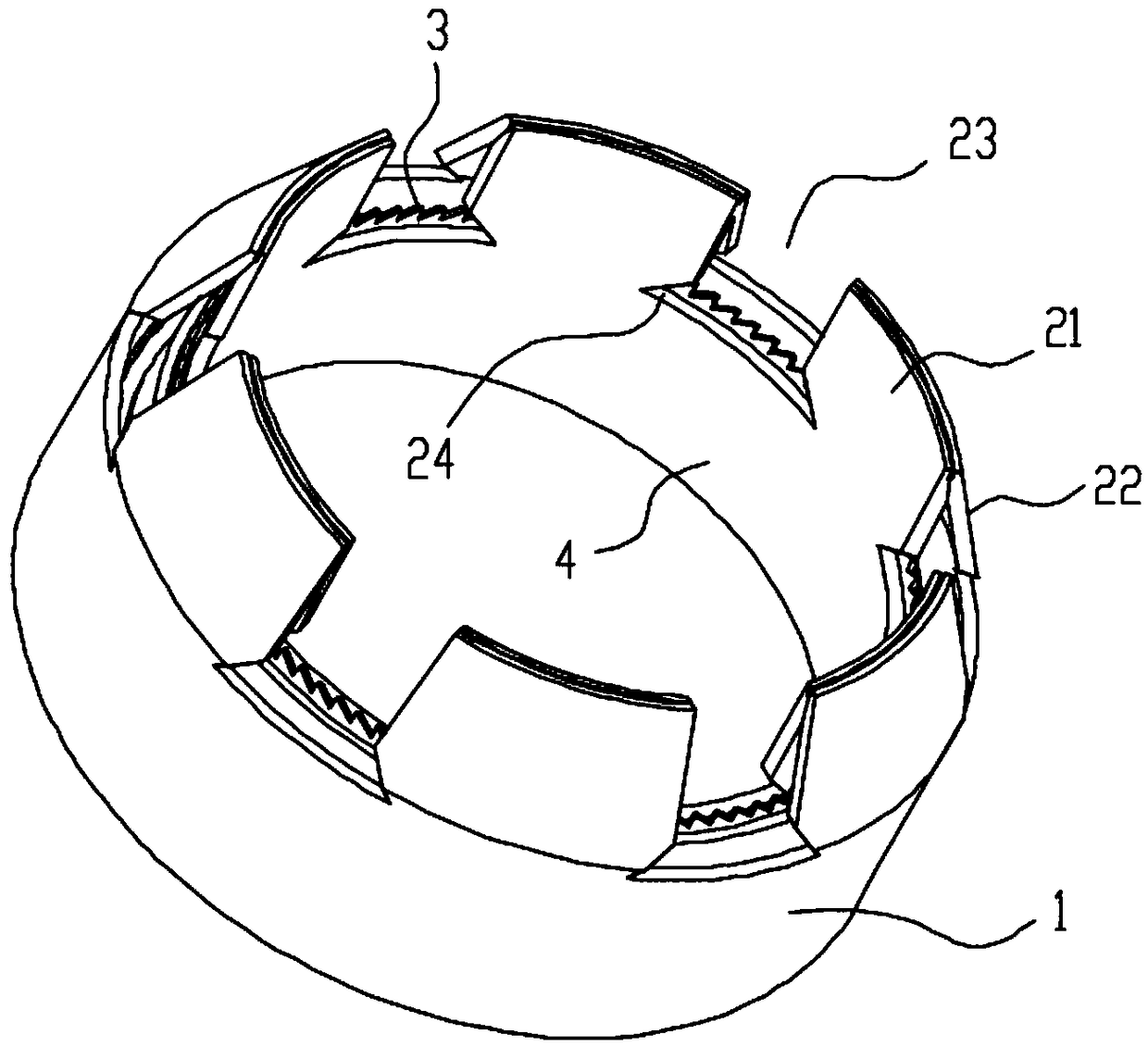

Flesh and bone cutter

The invention discloses a flesh and bone cutter which comprises a baseplate (1), flesh cutters (2), bone cutters (3) and an outer cover (5), wherein the flesh cutters (2) and the bone cutters (3) are arranged at intervals in the circumference direction along the baseplate (1) alternatively; shank parts (21) of the flesh cutters (2) are connected to the baseplate through elastic pieces (4); an included angle being 90-135 degrees is formed between the length direction of the flesh cutters (2) and the bone cutters (3) and the tangent line on which the flesh cutters (2) and the bone cutters (3) are crossed with the periphery of the baseplate (1); when the flesh cutters (2) come into contact with bones, automatic withdrawing can be realized to avoid the condition that the cutter is worn, which is caused by the fact that the bones are forcibly cut; the outer cover (5) and the baseplate (1) can be connected onto a main shaft of a motor; the flesh and bone cutter is driven by the motor to rotate to cut flesh and bones. Different cutters are automatically switched to cut bones and flesh, the synchronous mechanized cutting of bones and flesh is realized, and not only is the smoothness of flesh and bone cuts improved, but also the labor cost during the slaughtering process can be reduced.

Owner:HUAQIAO UNIVERSITY

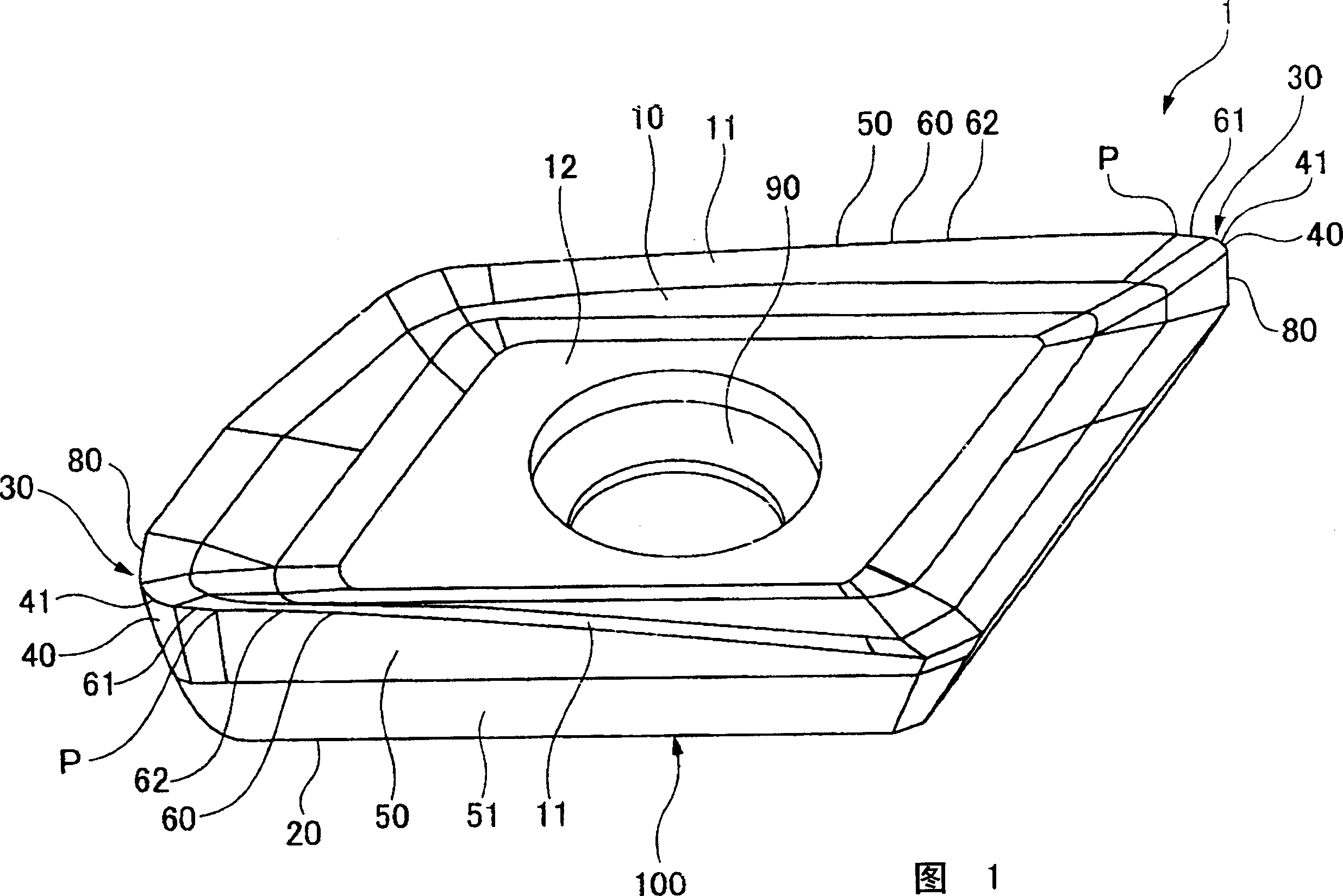

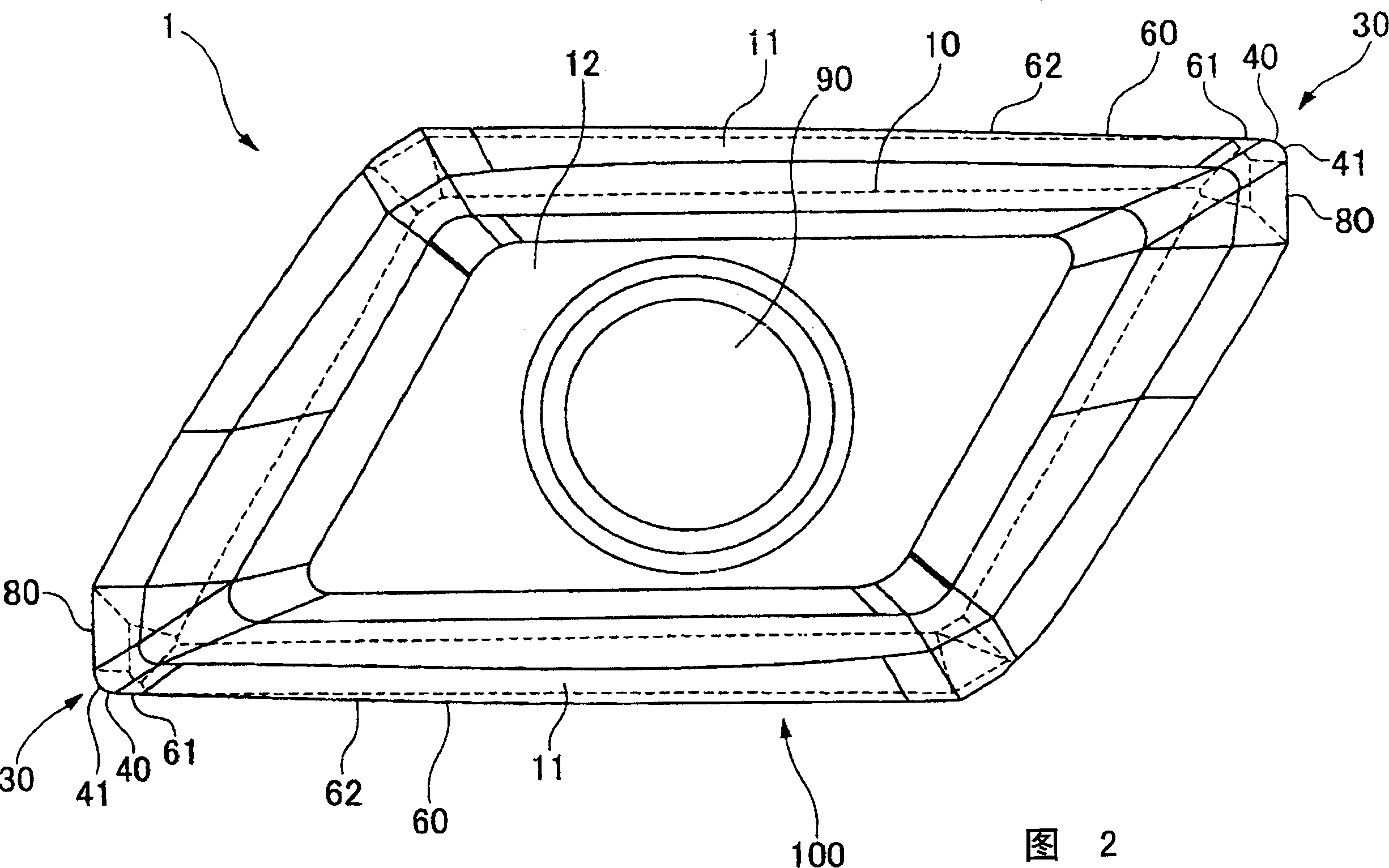

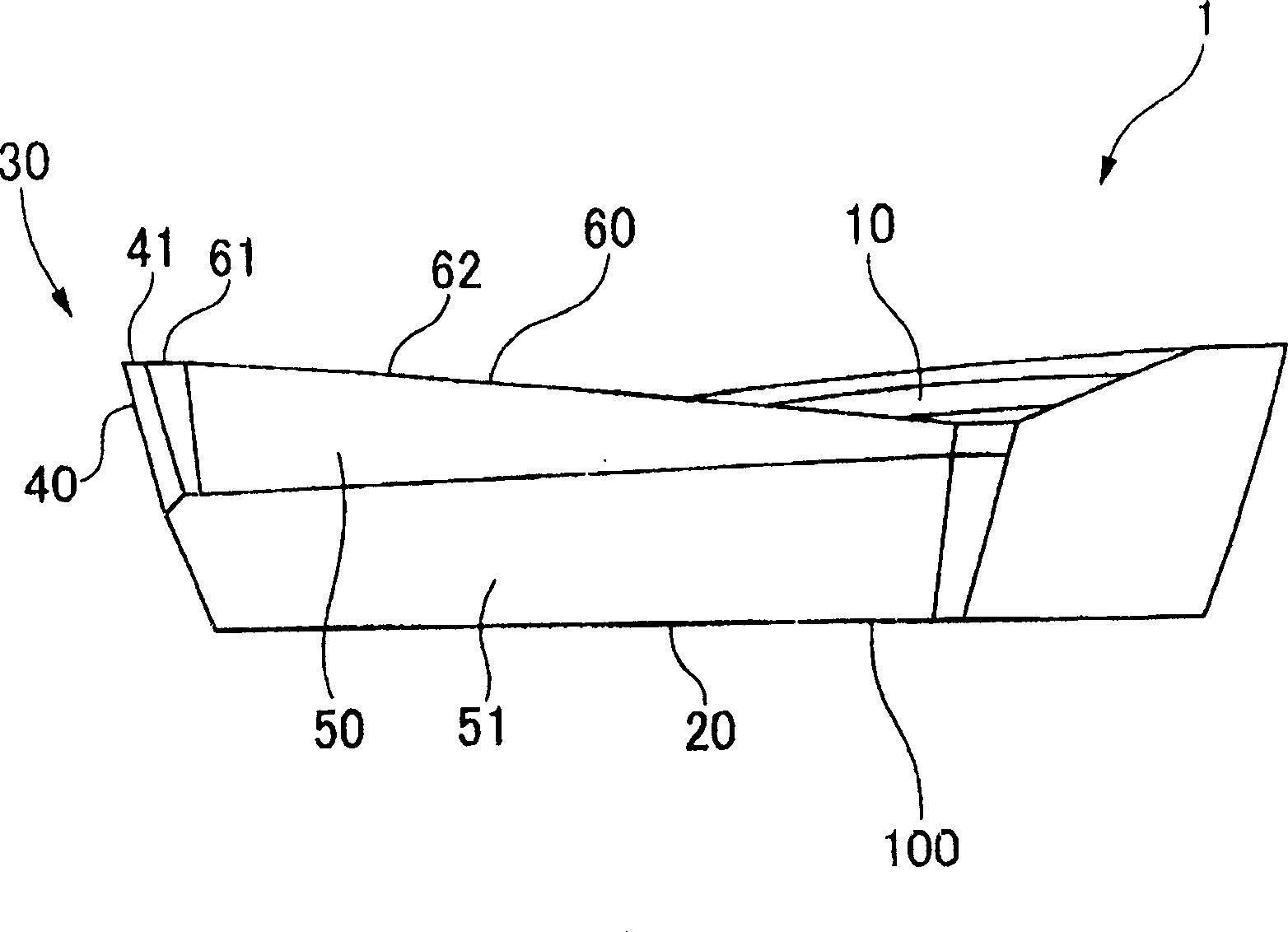

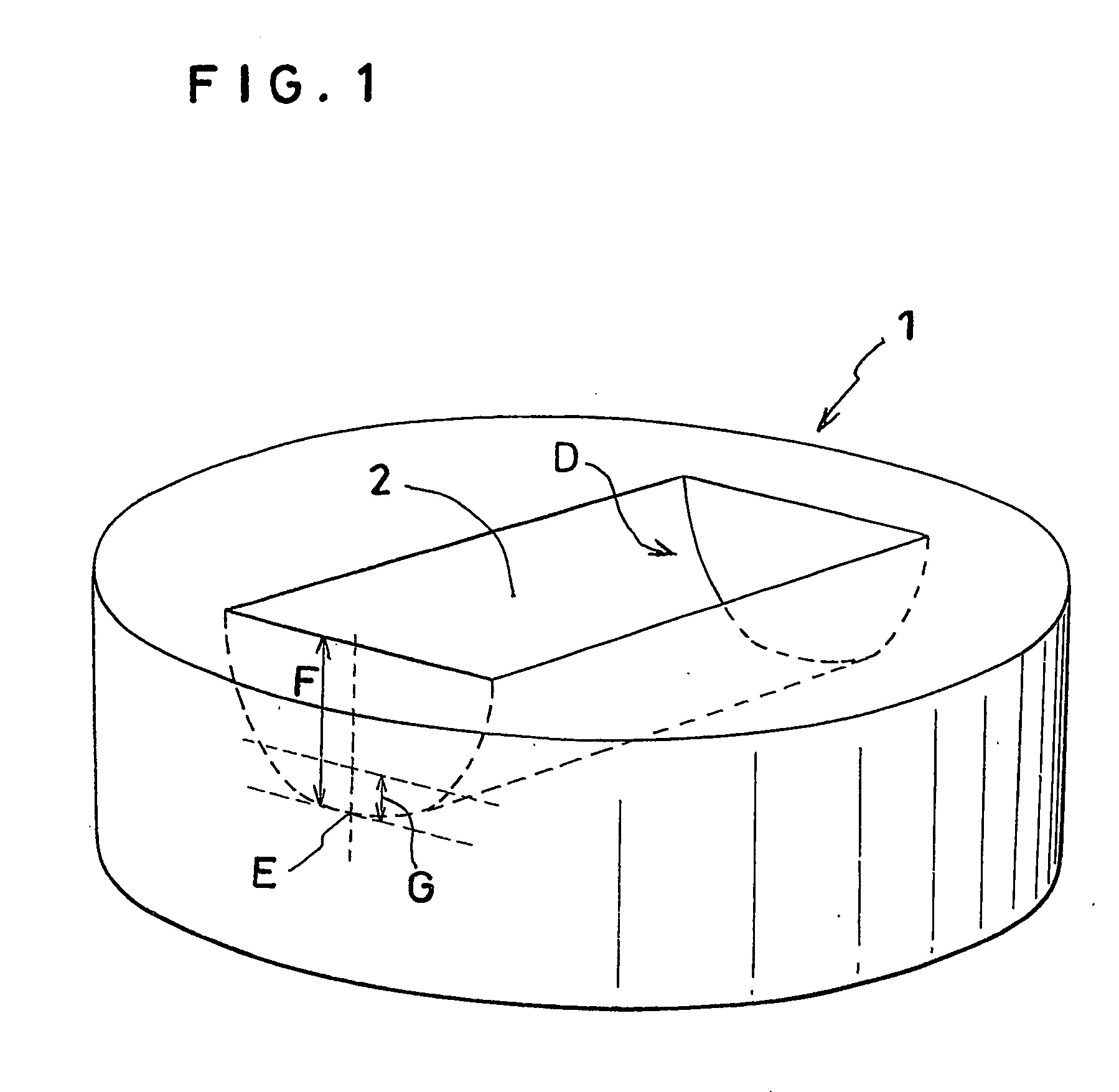

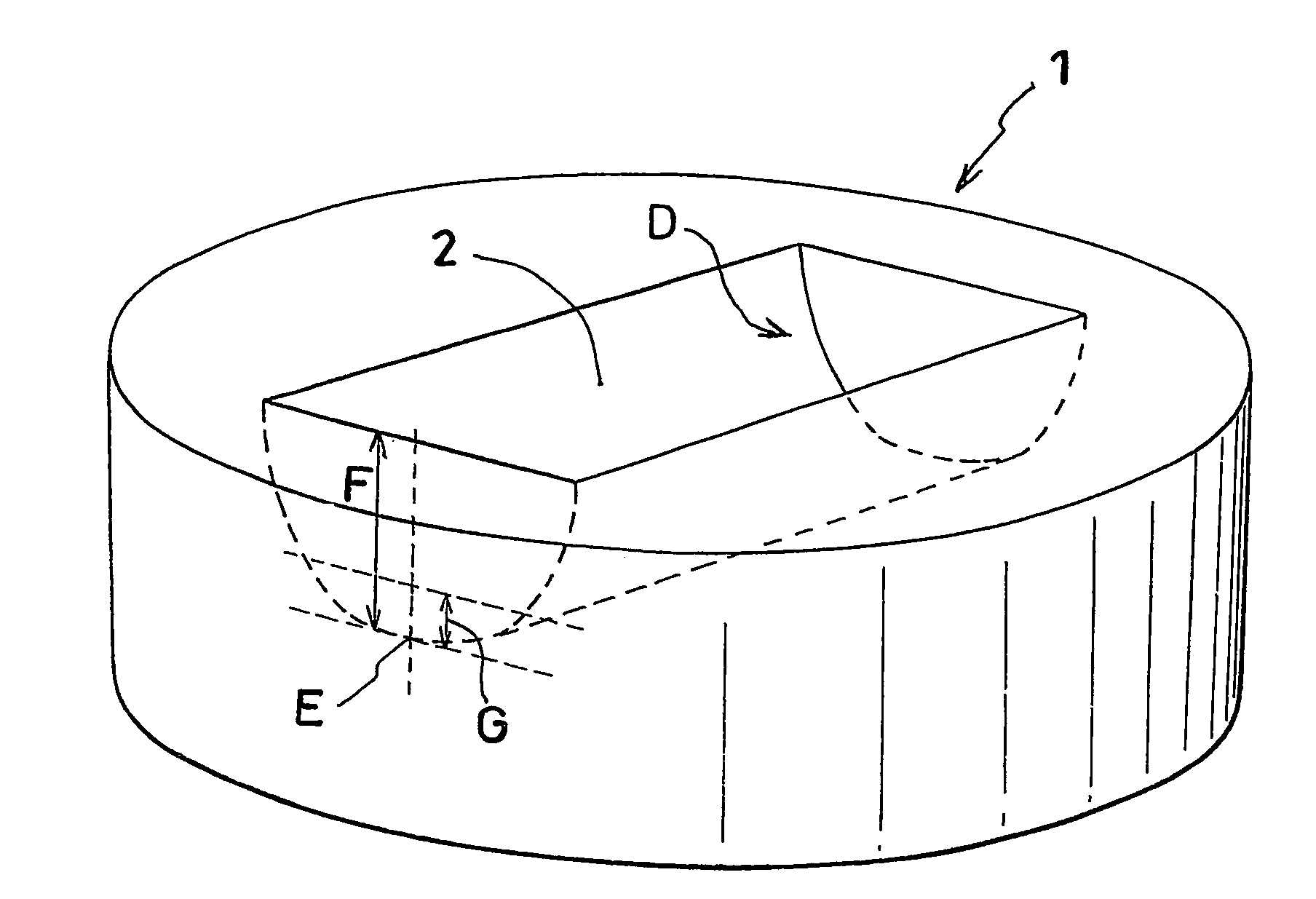

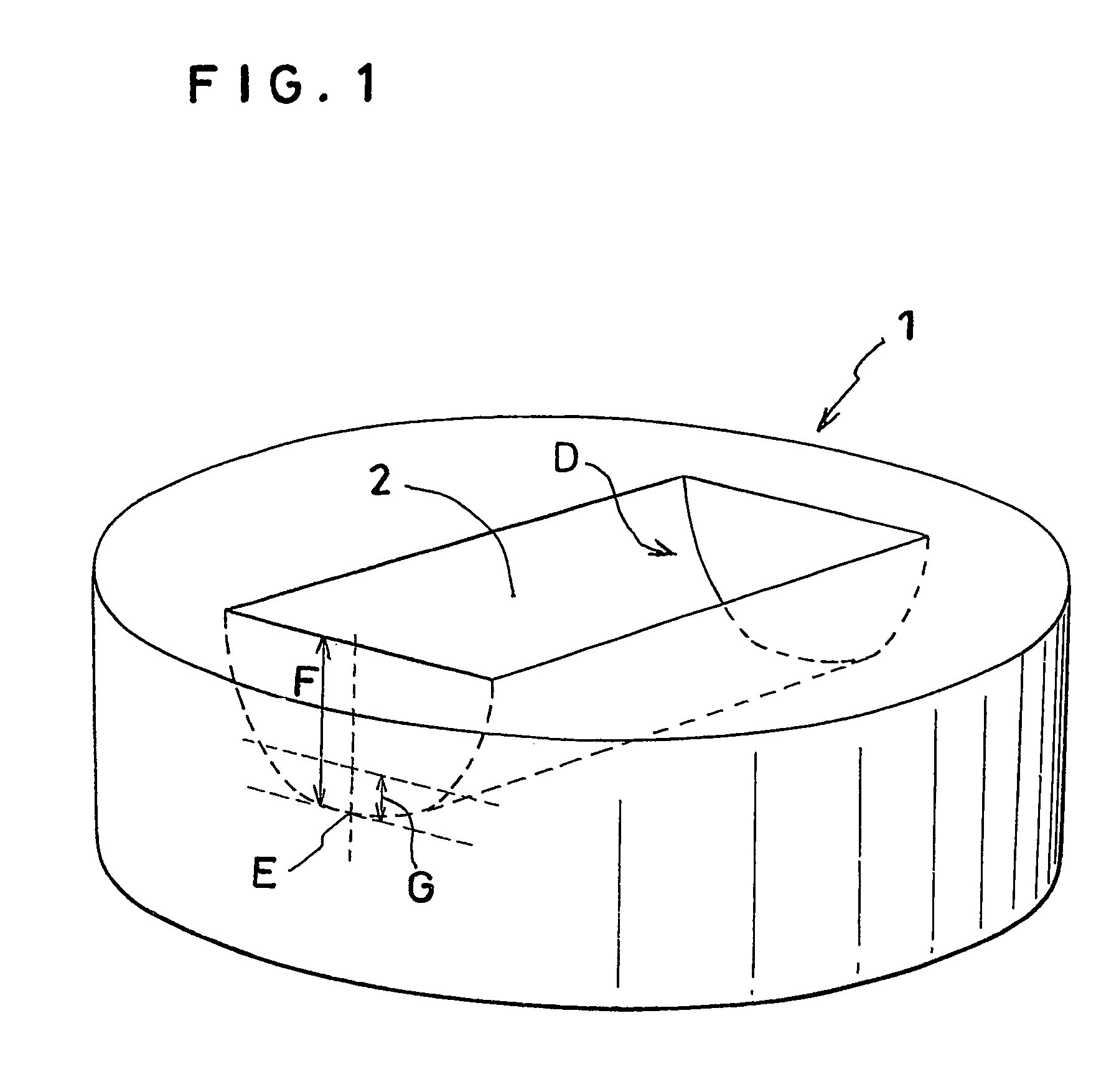

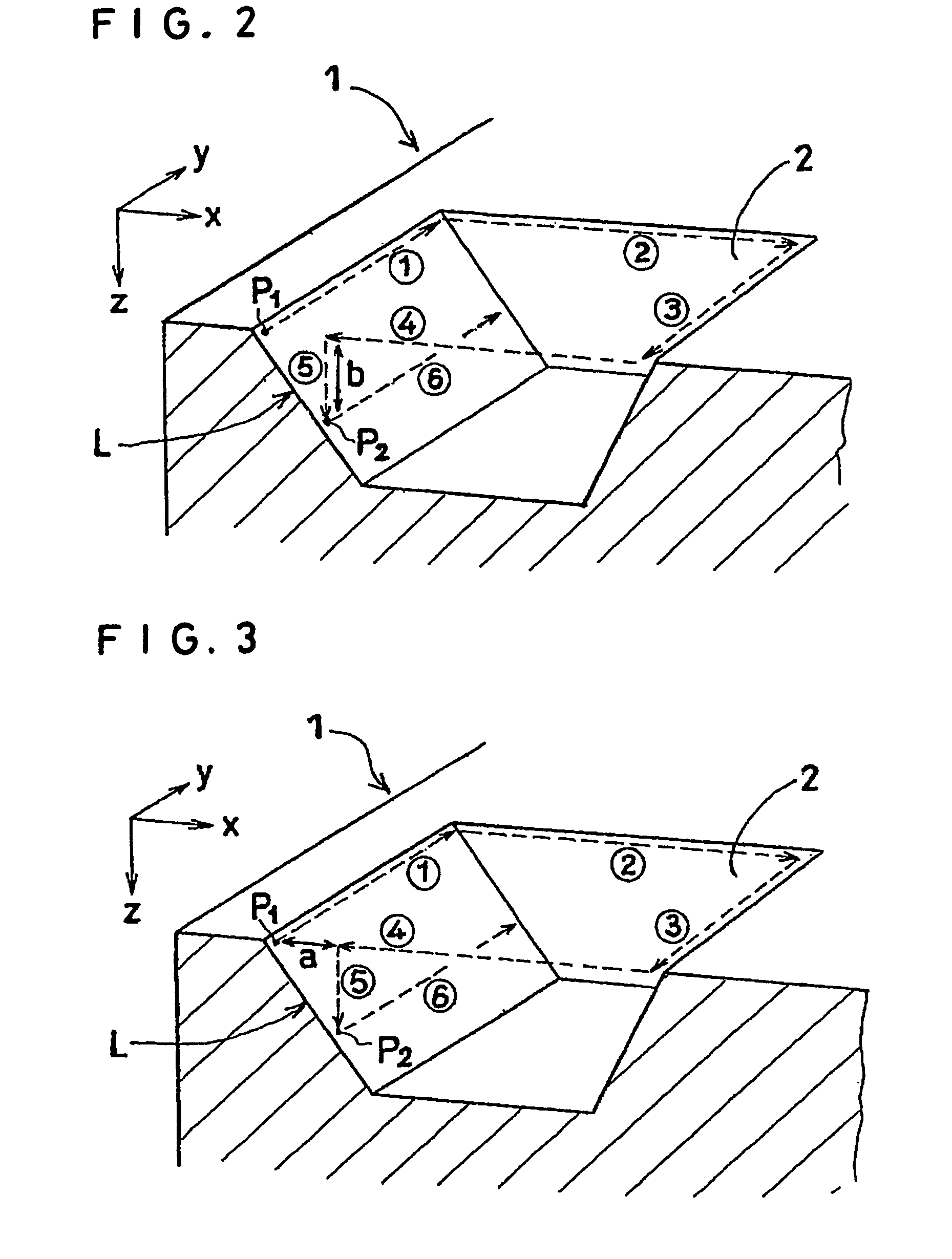

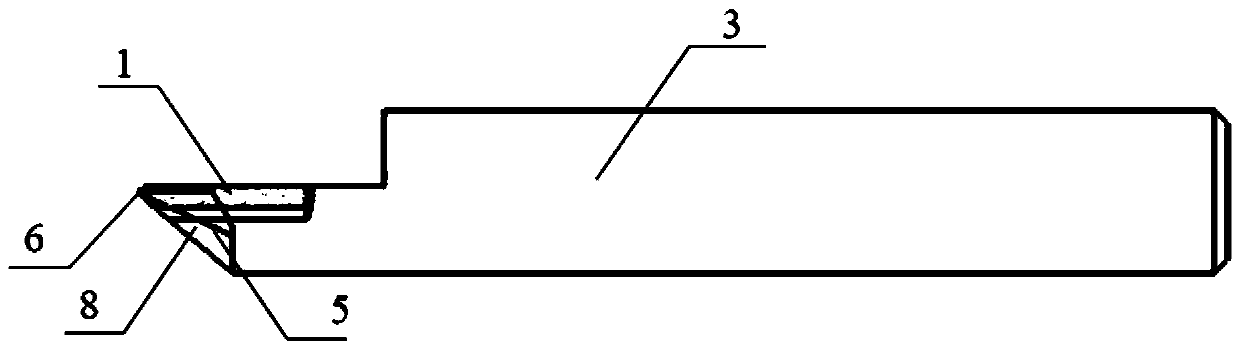

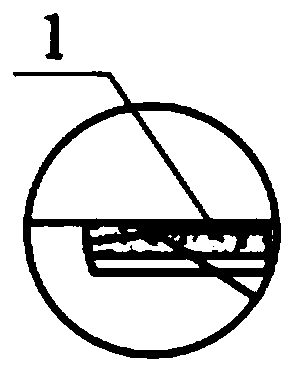

Multiple cutter blade and cutting tool

InactiveCN1443619AImprove machined surface qualityHigh speed cuttingMilling cuttersWorkpiecesRotational axisMachined surface

A throwaway insert and a cutting tool enable a high speed cutting operation for a metallic material having great ductility such as aluminum and obtaining a vertical wall with a high quality machined surface while improving chip control. The throwaway insert (1) comprises a major cutting edge (60) including a tapered cutting edge (61) connected to a cutting edge (41) of a nose portion (40), and a curved cutting edge (62) connected to an end of the tapered cutting edge (61) at a connection point (P). The curved cutting edge (62) is formed so as to extend along an imaginary cylindrical surface (S) whose center axis coincides with the axis of rotation of a tool main body (200), and tapered cutting edge (61) is formed so as to gradually curve from the imaginary cylindrical surface (S) toward the inside of the imaginary cylindrical surface (S) as the distance from the curved cutting edge (62) increases, and the distance from the nose portion (40) decreases. The throwaway insert (1) is attached to the tool main body (200) in which the surface of the distal end thereof is machined so that surface roughness thereof is less than 3.2 mu m when indicated by the Ry roughness. <IMAGE>A throwaway insert and a cutting tool enable a high speed cutting operation for a metallic material having great ductility such as aluminum and obtaining a vertical wall with a high quality machined surface while improving chip control. The throwaway insert (1) comprises a major cutting edge (60) including a tapered cutting edge (61) connected to a cutting edge (41) of a nose portion (40), and a curved cutting edge (62) connected to an end of the tapered cutting edge (61) at a connection point (P). The curved cutting edge (62) is formed so as to extend along an imaginary cylindrical surface (S) whose center axis coincides with the axis of rotation of a tool main body (200), and tapered cutting edge (61) is formed so as to gradually curve from the imaginary cylindrical surface (S) toward the inside of the imaginary cylindrical surface (S) as the distance from the curved cutting edge (62) increases, and the distance from the nose portion (40) decreases. The throwaway insert (1) is attached to the tool main body (200) in which the surface of the distal end thereof is machined so that surface roughness thereof is less than 3.2 mu m when indicated by the Ry roughness. <IMAGE>

Owner:MITSUBISHI MATERIALS CORP

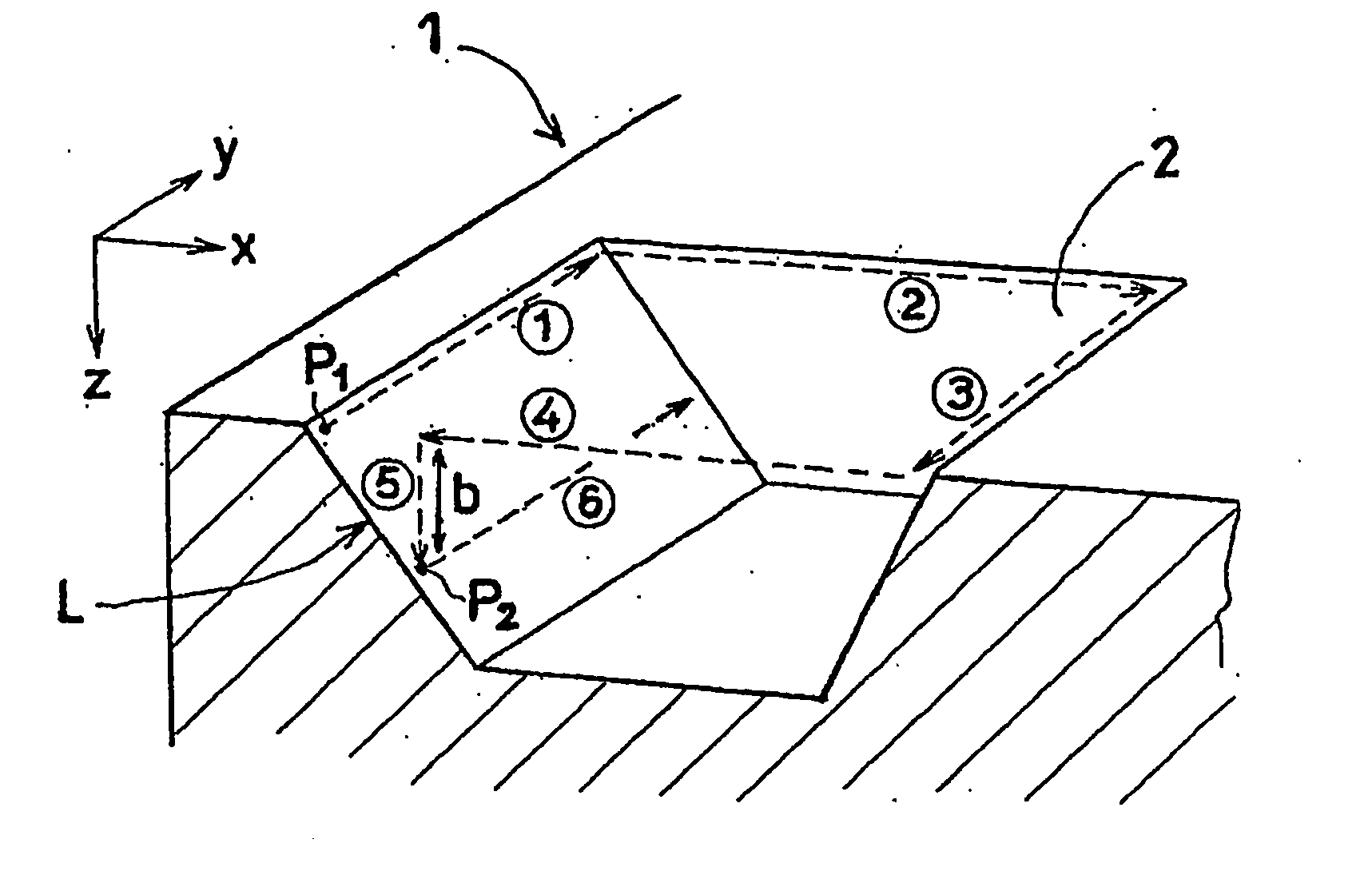

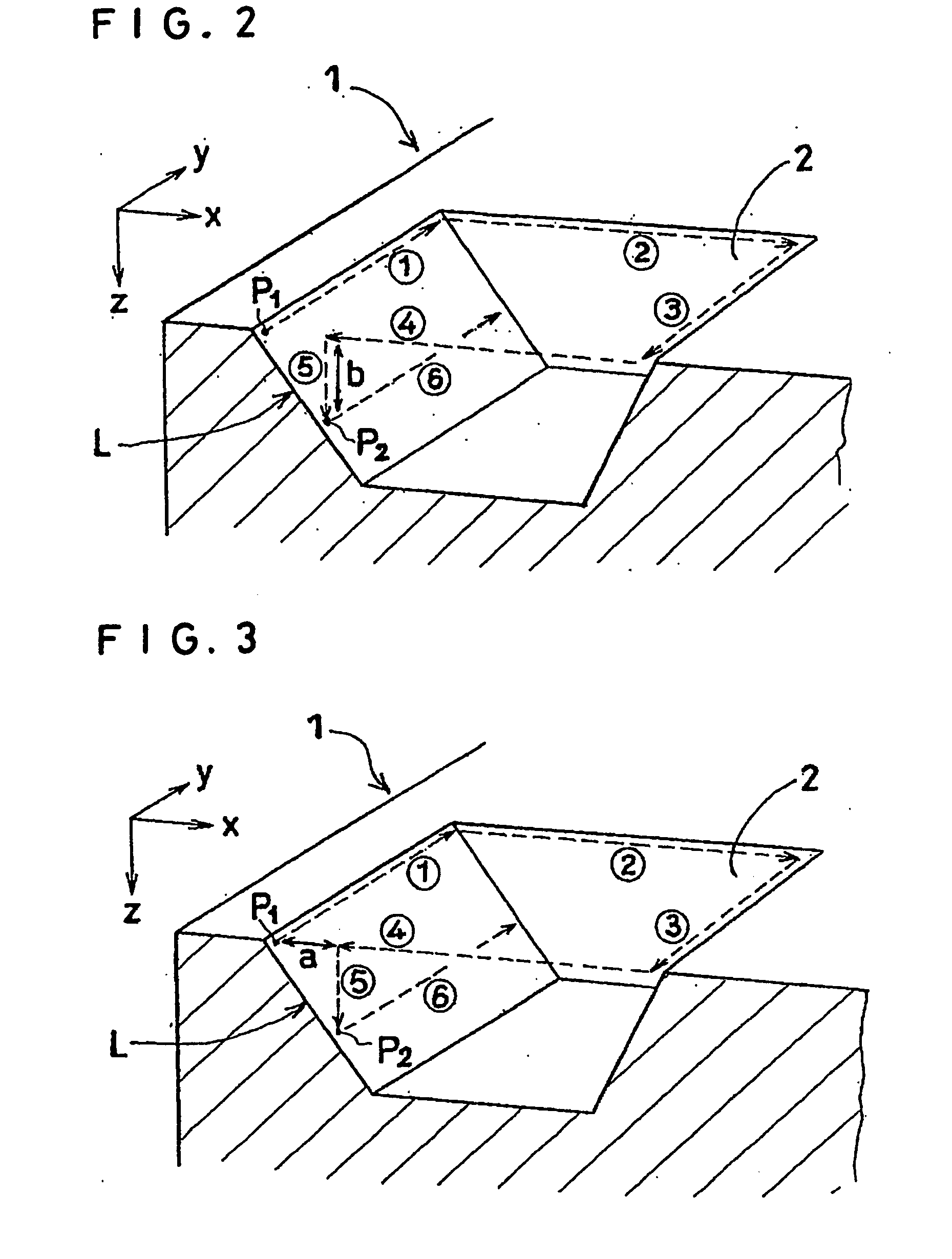

Method for Producing Forging Die, Forging Die and Forged Article

InactiveUS20070245799A1Improve working conditionsHigh speed cuttingCutting toolsMilling cuttersMilling cutterEnd mill

A forging die production method comprising a cutting step which employs, as a cutting tool, a ball end mill having a surface which has undergone a hardening treatment and in which a forging die material is cut under conditions where a length of tool extension L (mm), radius R (mm) of a cutting edge of the ball end mill, spindle speed A (rpm) and feed rate B (mm / min) satisfy (B / A)2×(L / (2×R))=0.01 to 0.05. A forging die is produced through the forging die production method. A forged article is produced through forging by use of the produced forging die.

Owner:SHOWA DENKO KK

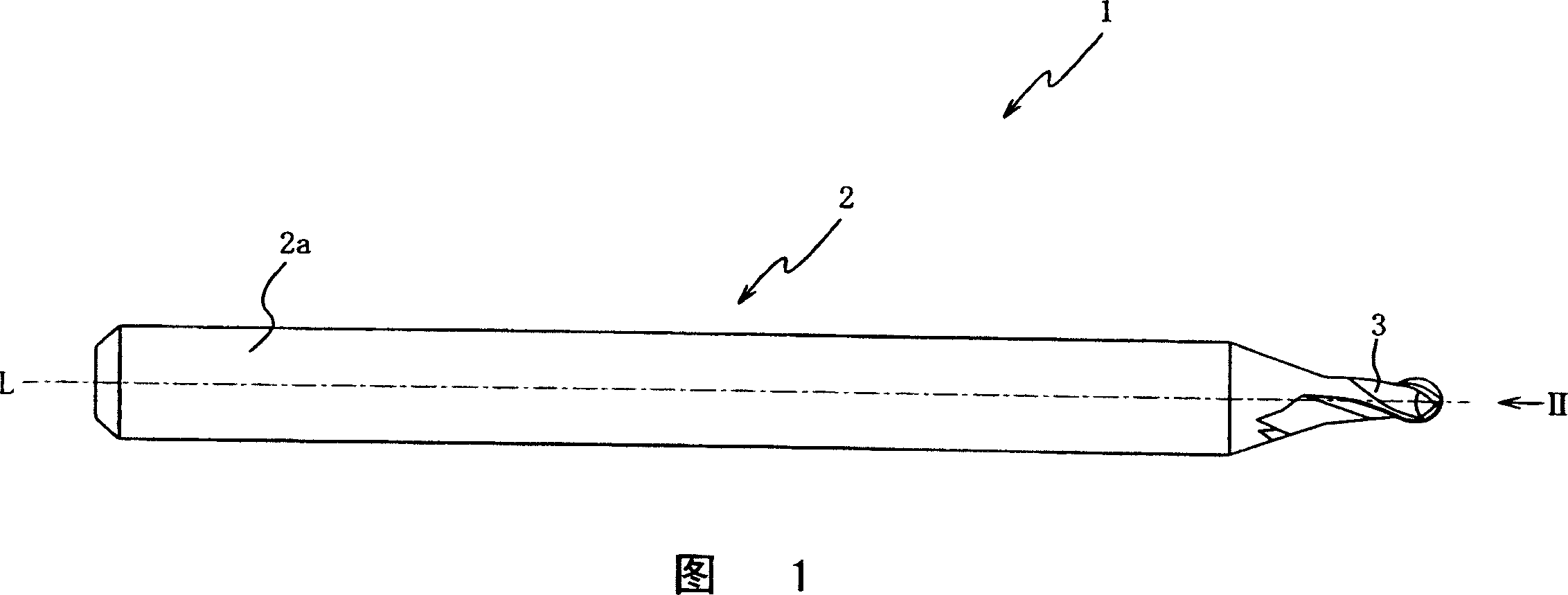

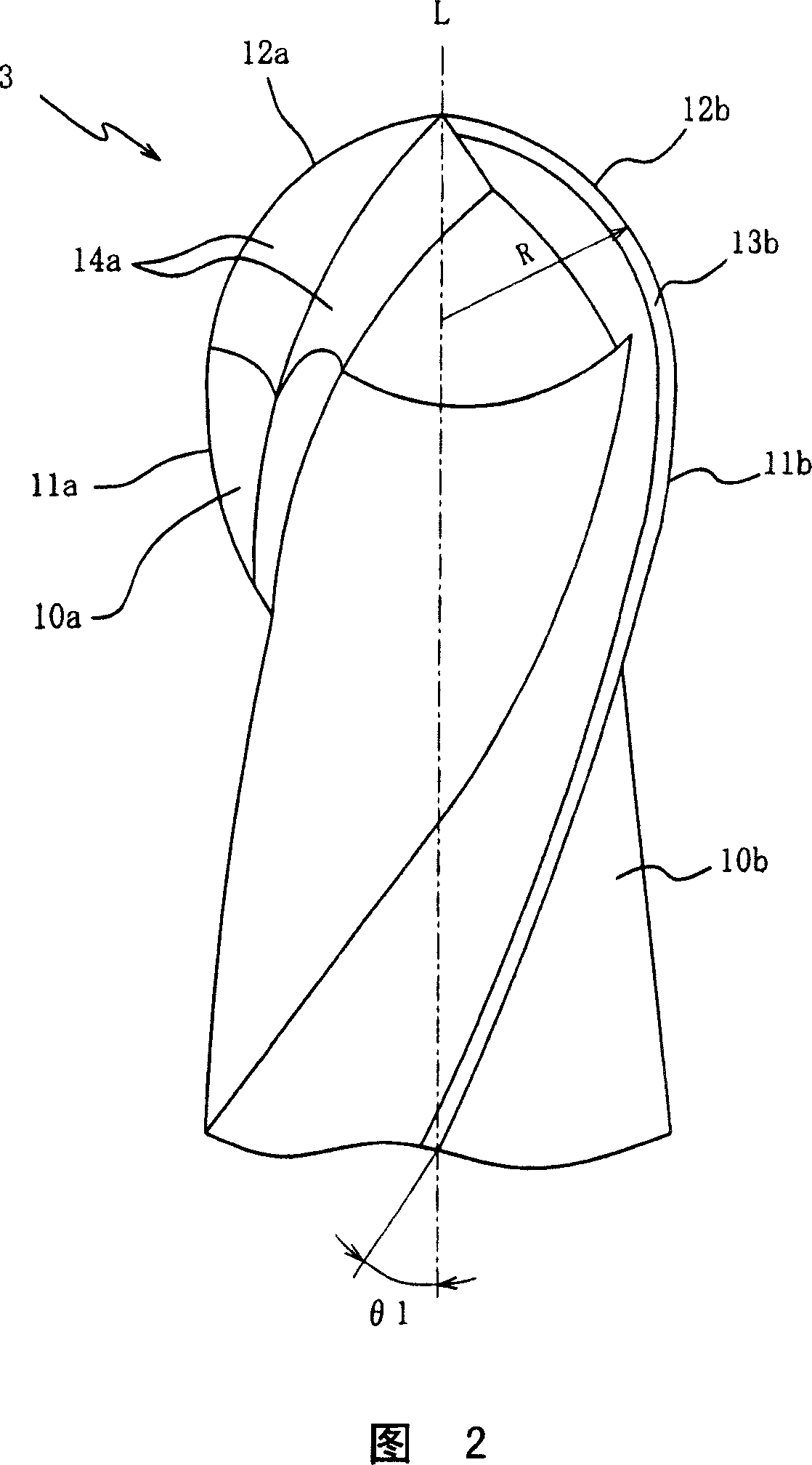

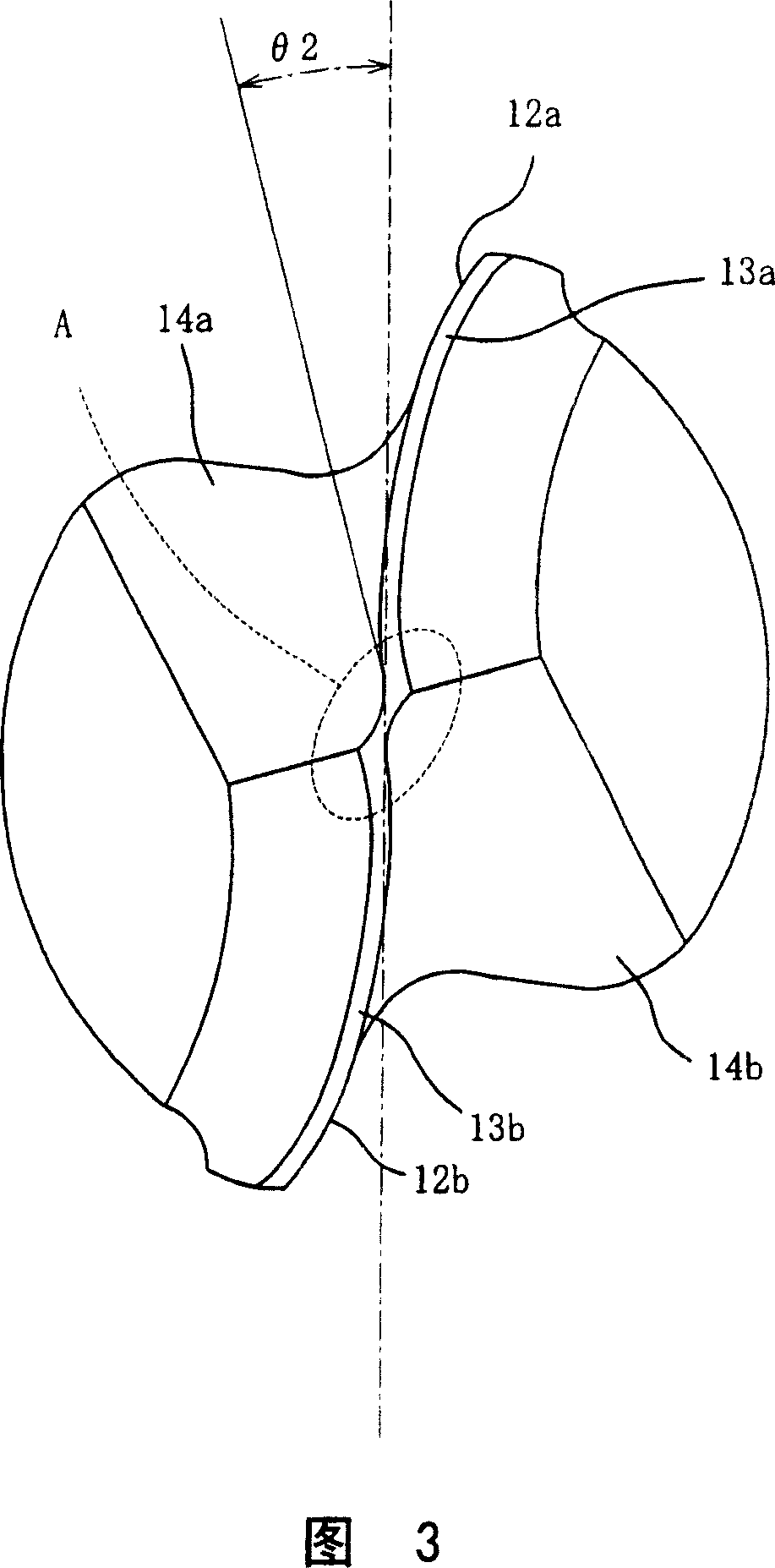

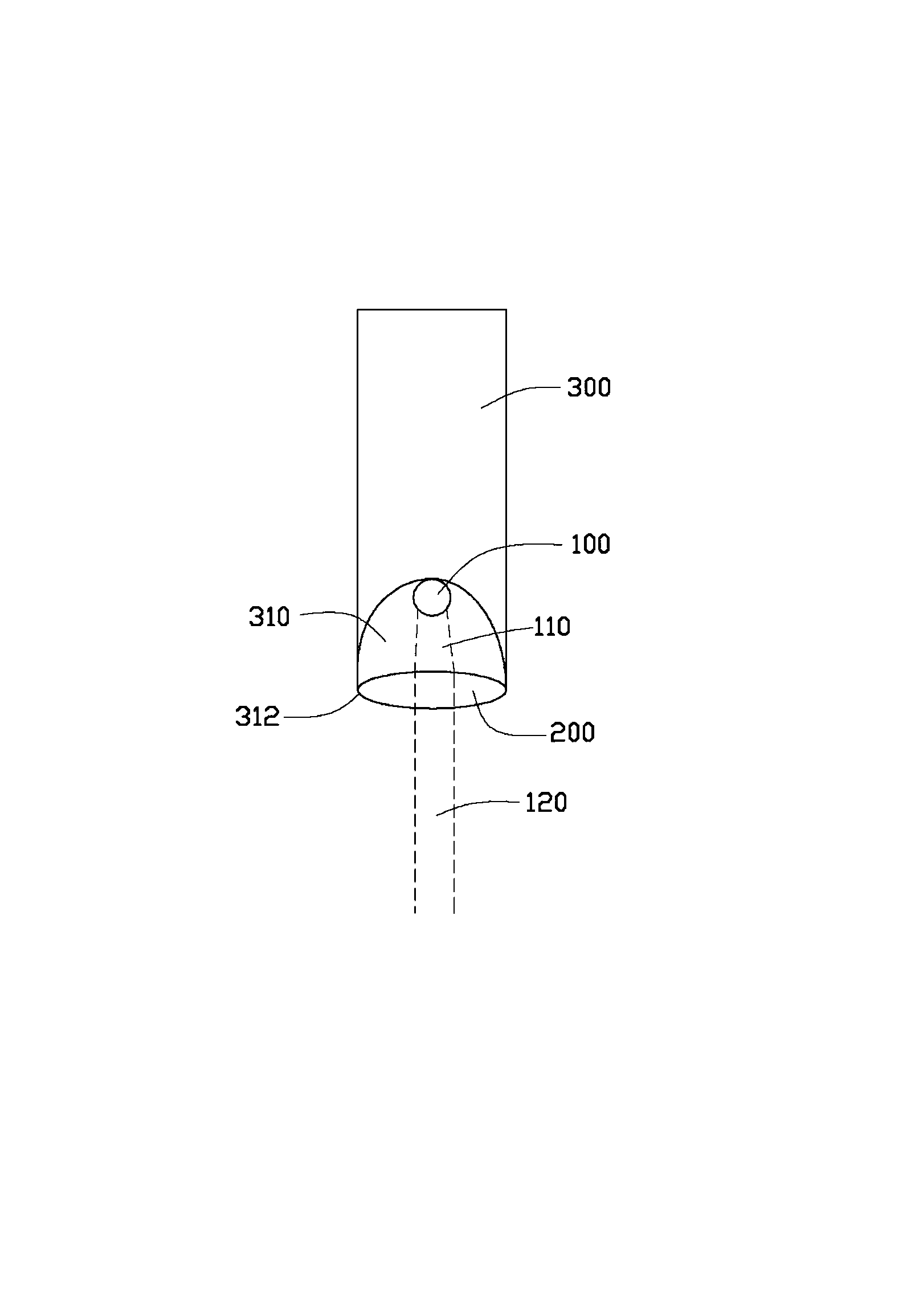

Ball end mill

InactiveCN1942277AHigh speed cuttingImprove processing efficiencyMilling cuttersWorkpiecesMilling cutterHardness

A ball end mill enabling an increase in machining efficiency, wherein a pair of roughly semi-spherical ball edges (12a) and (12b) are formed on an edge part (3) at the tip thereof symmetrically with respect to the axis thereof, and the area of the edge part (3) including at least the ball edges (12a) and (12b) is formed of a hard sintered body (PCBN). Also, the faces of the ball edges (12a) and (12b) are formed by spiral gashes (14a) and (14b), and the helix angles of the spiral gashes (14a) and (14b) are formed at approximately 20 DEG. Since the ball edges (12a) and (12b) are formed of the hard sintered body having high hardness characteristic and formed in a twisted shape, the ball end mill can cut with a large depth of cut and at high speeds to increase the machining efficiency of the ball end mill.

Owner:OSG

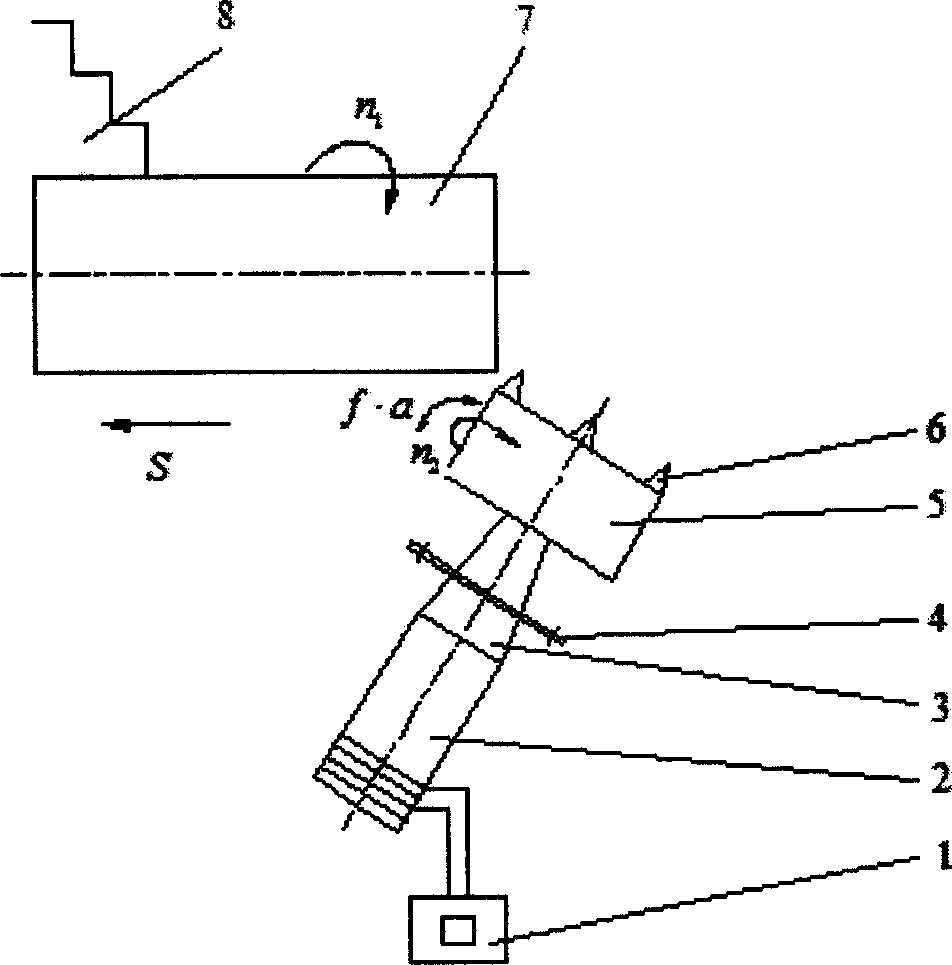

Ultrasonic torsional vibration turning-milling system and method

InactiveCN101020245AShort chipsEasy automatic chip removalMilling equipment detailsDriving apparatusMilling cutterEngineering

The present invention discloses one kind of ultrasonic torsional vibration turning-milling system and method. In the turning-milling process, the resultant motion of the rotation of the milling cutter, the rotation of the workpiece, the axial feeding of the milling cutter shaft, the radial feeding of the milling cutter and the ultrasonic torsional vibration of the milling cutter is adopted to complete the cutting of the workpiece. The ultrasonic torsional vibration of the milling cutter is generated with ultrasonic torsional vibration devices arranged radially along the workpiece. The present invention has the advantages of easy elimination of scraps, high machining precision, etc.

Owner:HANGZHOU DIANZI UNIV

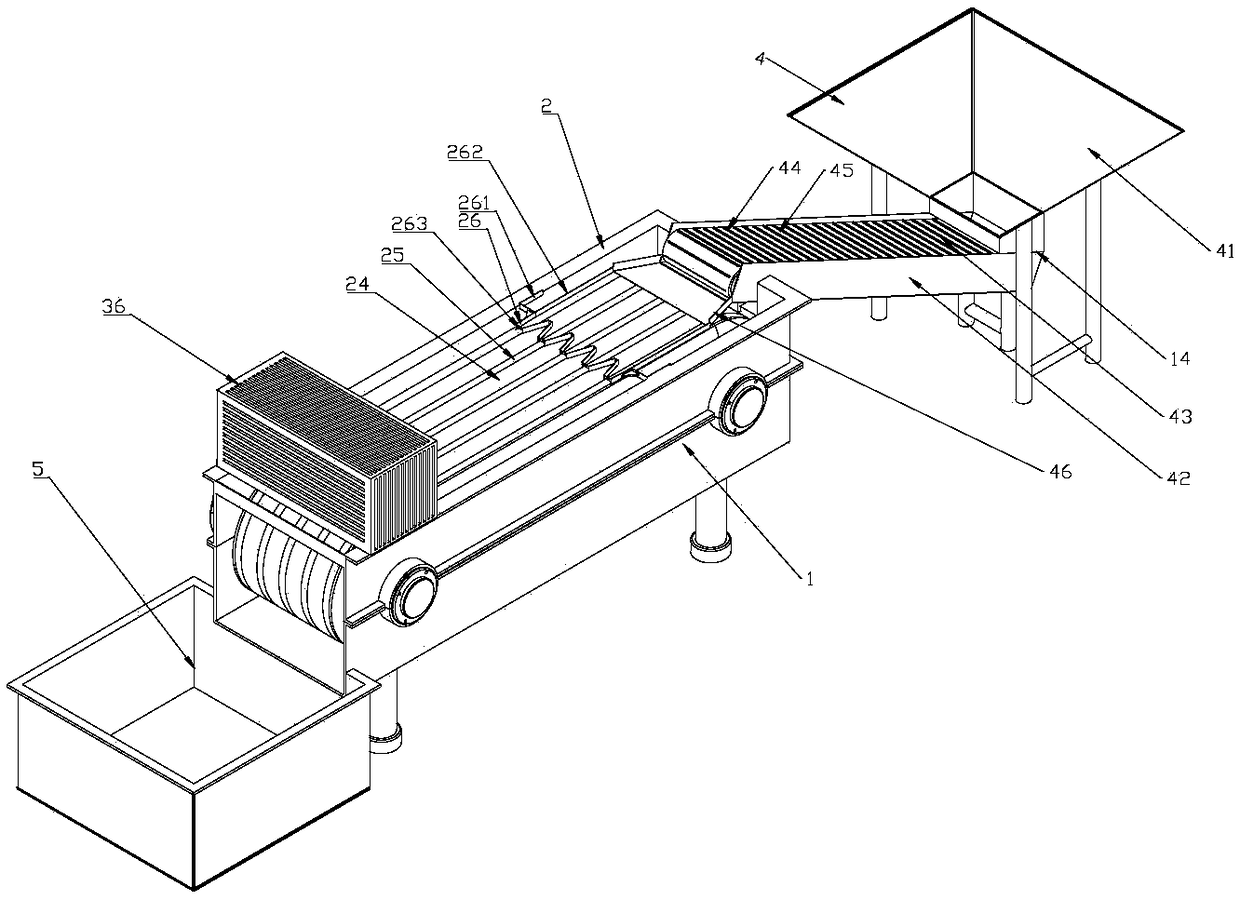

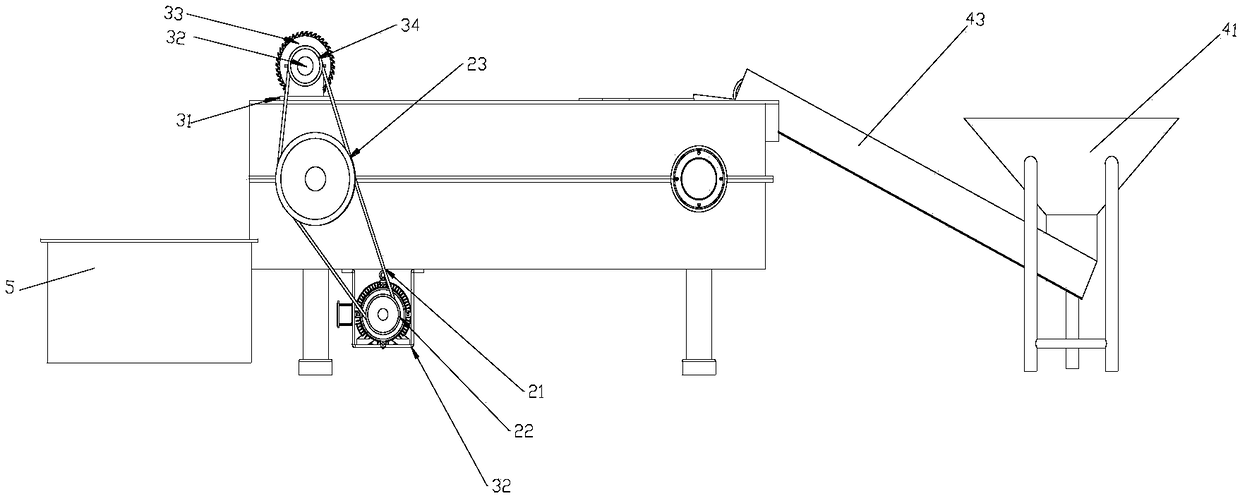

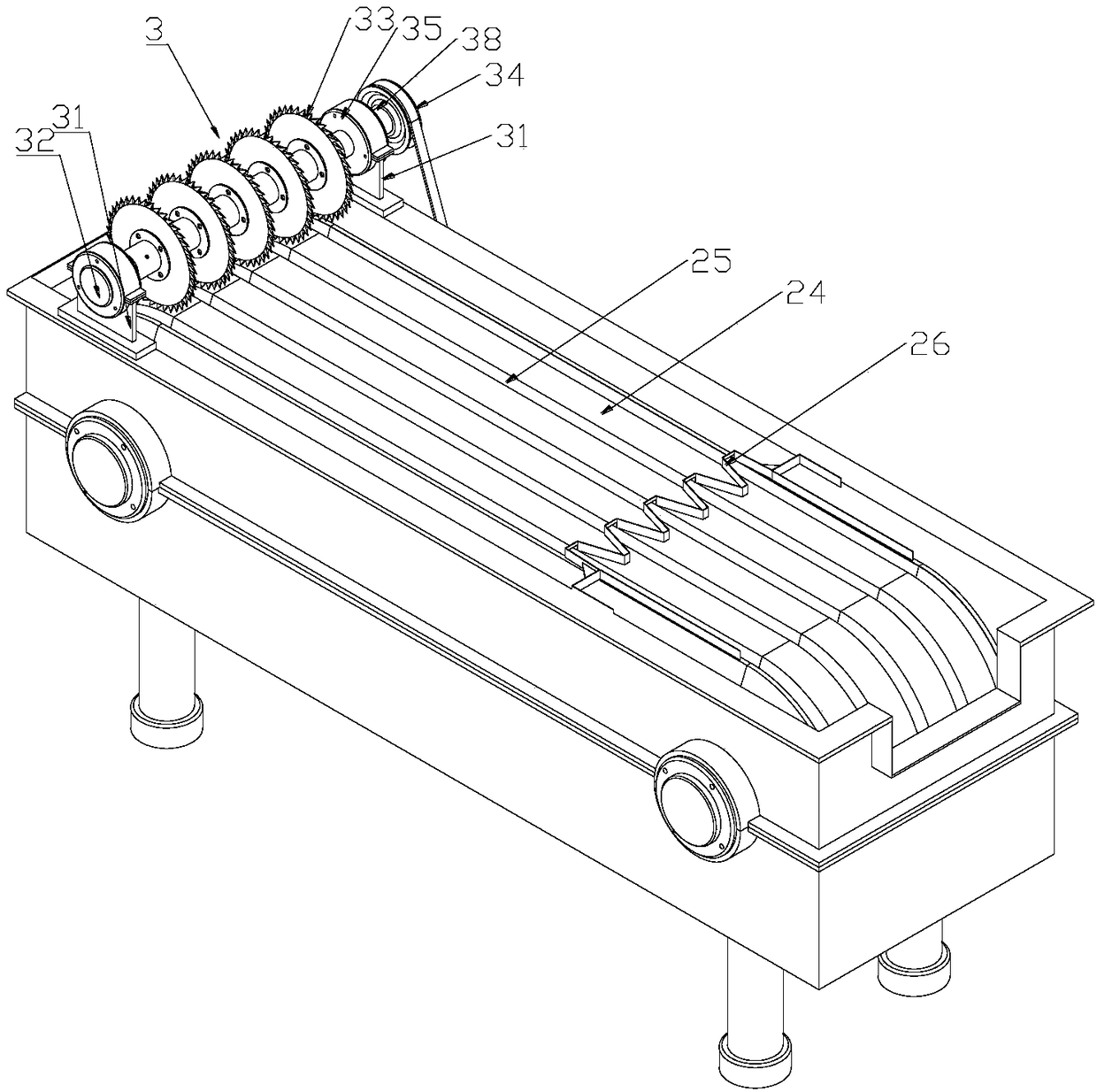

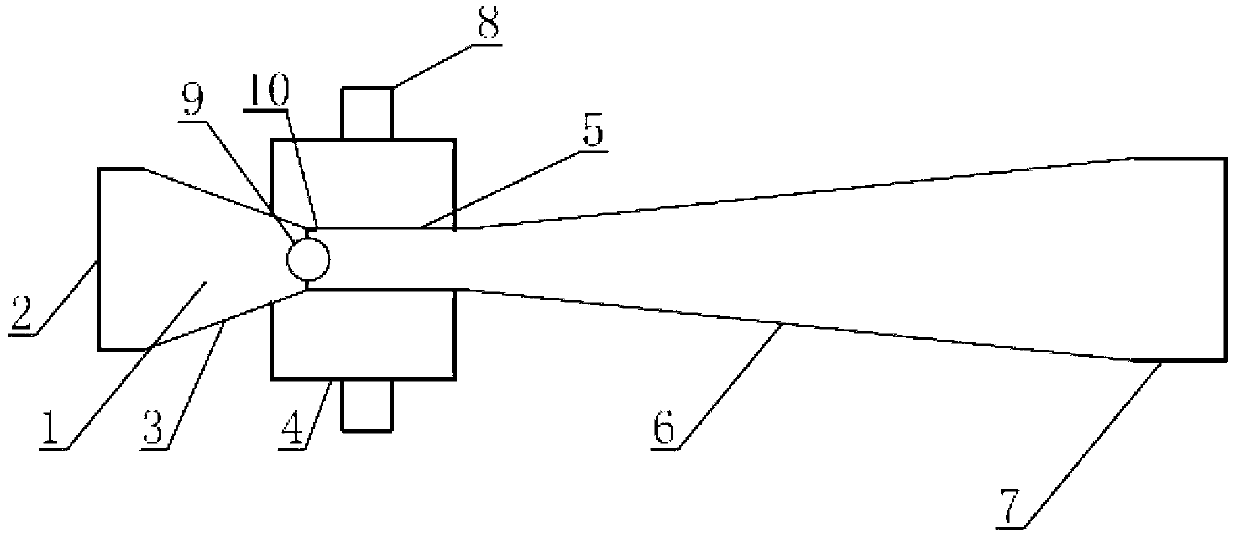

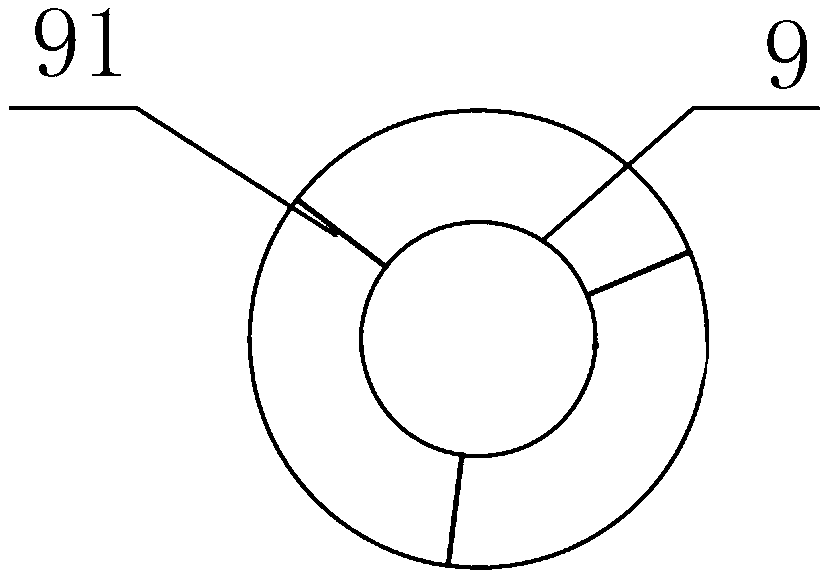

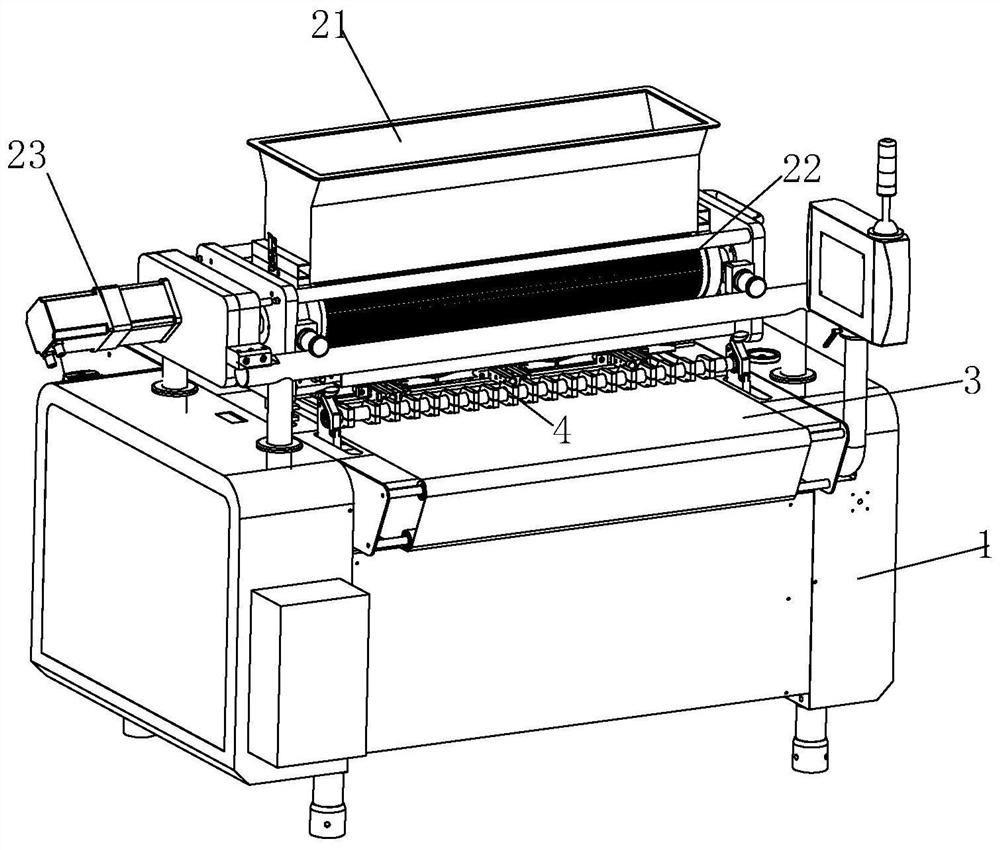

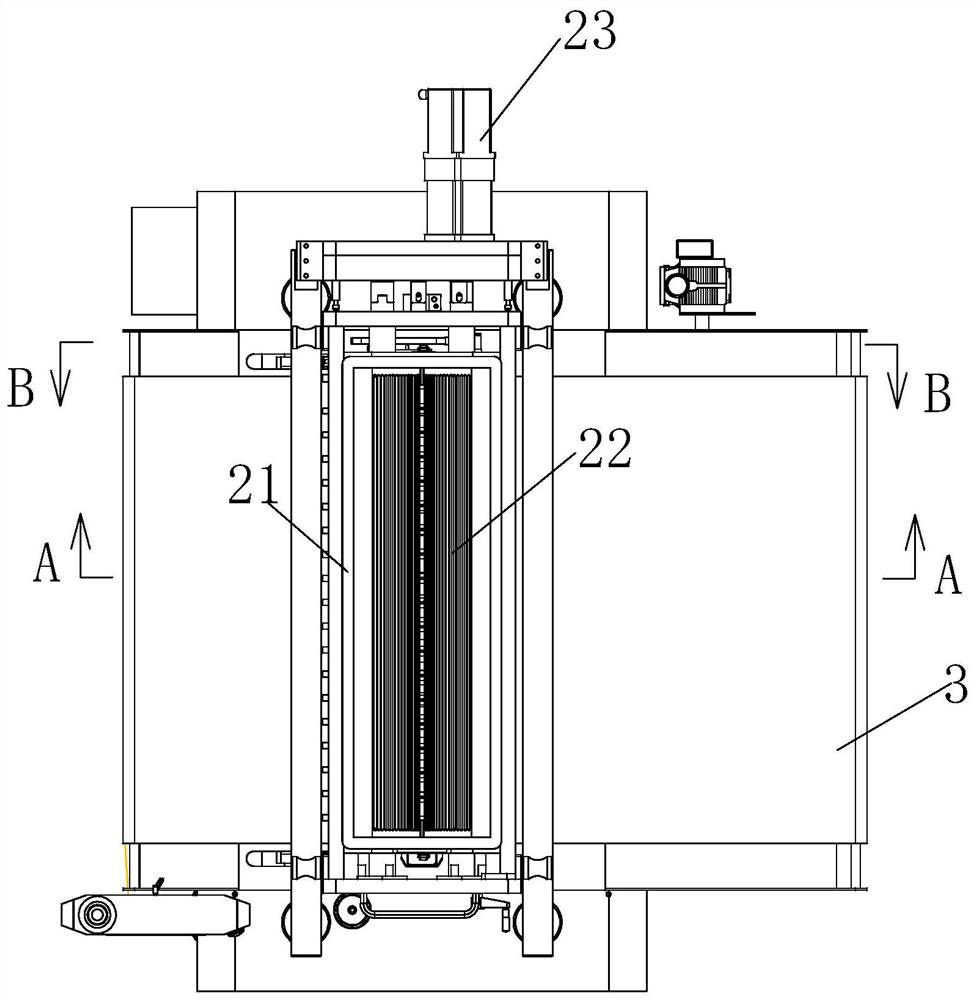

High-speed arecanut slicing device and slicing method

PendingCN108098878AHigh-speed and precise cuttingAchieve a single passMetal working apparatusEngineeringPulley

The invention discloses a high-speed arecanut slicing device comprising a conveying centering system, a cutting system and an automatic feeding system. The conveying centering system and the cutting system are fixedly arranged on a machine seat. The automatic feeding system adds materials into the conveying centering system. The conveying centering system comprises a motor, a small belt pulley, alarge belt pulley and a horizontal conveying belt in coaxial transmission with the large belt pulley. The horizontal conveying belt is provided with at least five material clamping grooves at equal intervals, and flow guide plates matched with the material clamping grooves to achieve conveying centering of materials. The flow guide plates are provided with flow limiting groove outlets. Zigzag cutters of the cutting system are separated through locating sleeves and are fixedly connected with a cutter rotary shaft. The invention further provides a high-speed arecanut slicing method. Arecanuts pass the high-speed arecanut slicing device one by one through the flow guide plates, the arecanuts are clamped by the material clamping grooves in a combined mode so as to ensure centering, additionalclamping is not needed, meanwhile, all the zigzag cutters are fixedly connected to the cutter rotary shaft through the locating sleeves, the arecanuts are sliced at the same high angular speed, thus slicing further achieves centering, and slicing efficiency is improved greatly.

Owner:WUYI UNIV

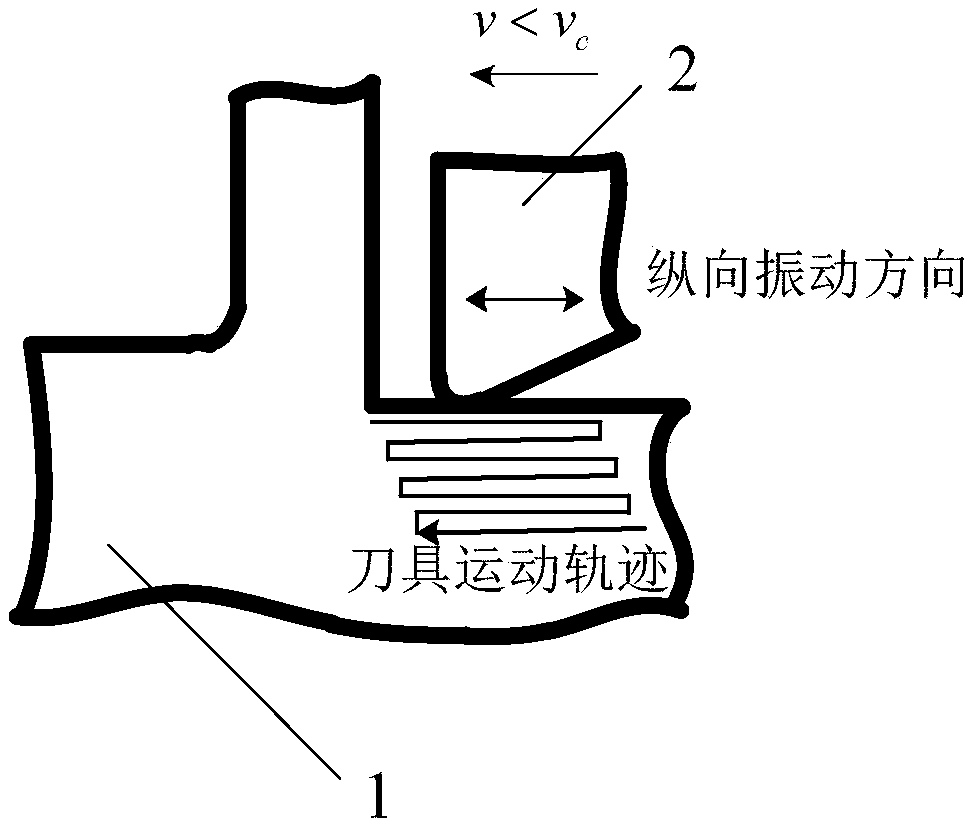

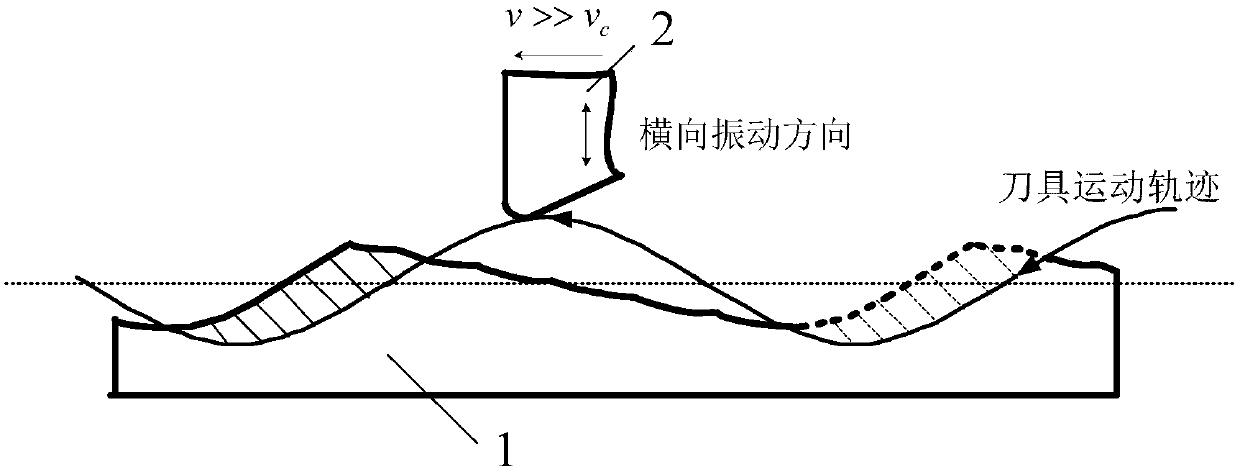

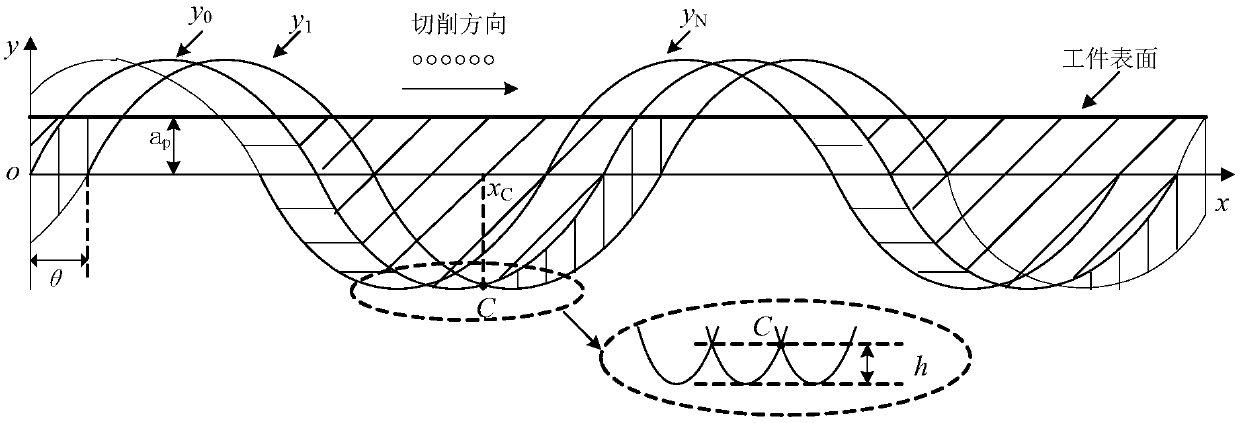

High-speed separation ultrasonic vibration cutting control method

ActiveCN108052074ARegular dislocation overlapArranged regularlyAutomatic control devicesFeeding apparatusSonificationPhase difference

The invention relates to a high-speed separation ultrasonic vibration cutting control method which, by using an ultrasonic vibration cutting device including a closed-loop DDS, controls a cutter to achieve vibration including the vibration in the direction perpendicular to the cutting speed direction in a cutting process, and simultaneously controls a phase difference of the motion trajectories oftwo adjacent cutters in the cutting direction so as to causes pits caused by the lateral vibration in the motion trajectories of the two adjacent cutters to be staggered and overlapped, thereby reducing the deterioration of the surface roughness caused by the vibration perpendicular to the cutting speed direction. Since the ultrasonic vibration includes a component perpendicular to the cutting speed direction, the cutting speed is not limited by an ultrasonic vibration cutting separating condition and thus high-speed ultrasonic vibration cutting can be achieved. By controlling the phase difference, it is possible to simultaneously satisfy the high speed cutting and the surface roughness.

Owner:BEIHANG UNIV

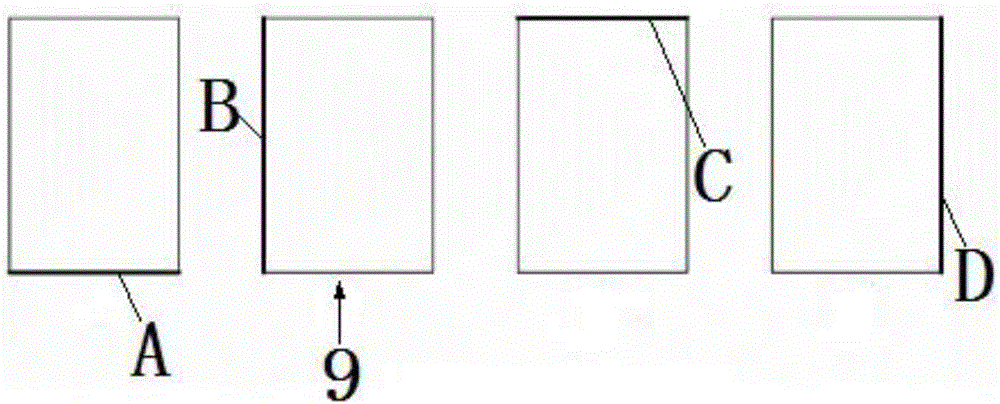

Method for quickly dismantling failure zones of rock-fill dam concrete faceplate

ActiveCN106284187AHigh cutting performanceSmooth runningBuilding repairsHydraulic engineering apparatusSurface platePollution

The invention discloses a method for quickly dismantling failure zones of a rock-fill dam concrete faceplate. The method comprises the following steps that according to the failure condition of the concrete faceplate, the dismantling zones of the concrete faceplate are delimited; the concrete faceplate is divided into multiple concrete blocks to be cut by size; and a hydraulic wall sawing system is used for cutting the concrete blocks to be cut from bottom to top. By means of the method, the defects that the dismantling efficiency of rock-fill dam concrete faceplates is low, the dismantling range is hard to control, and the environmental friendliness is poor in the prior art are overcome. The method has the advantages that the cutting speed is high; cut surfaces are smooth and neat; cutting positions are accurate; a dam body and faceplates not dismantled are not damaged; the construction cost is moderate; operation is convenient; pollution is avoided; and noise is low.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Method for producing forging die, forging die and forged article

InactiveUS7930954B2Efficient productionSimple working processCutting toolsMilling cuttersMilling cutterEnd mill

A forging die production method comprising a cutting step which employs, as a cutting tool, a ball end mill having a surface which has undergone a hardening treatment and in which a forging die material is cut under conditions where a length of tool extension L (mm), radius R (mm) of a cutting edge of the ball end mill, spindle speed A (rpm) and feed rate B (mm / min) satisfy (B / A)2×(L / (2×R))=0.01 to 0.05. A forging die is produced through the forging die production method. A forged article is produced through forging by use of the produced forging die.

Owner:SHOWA DENKO KK

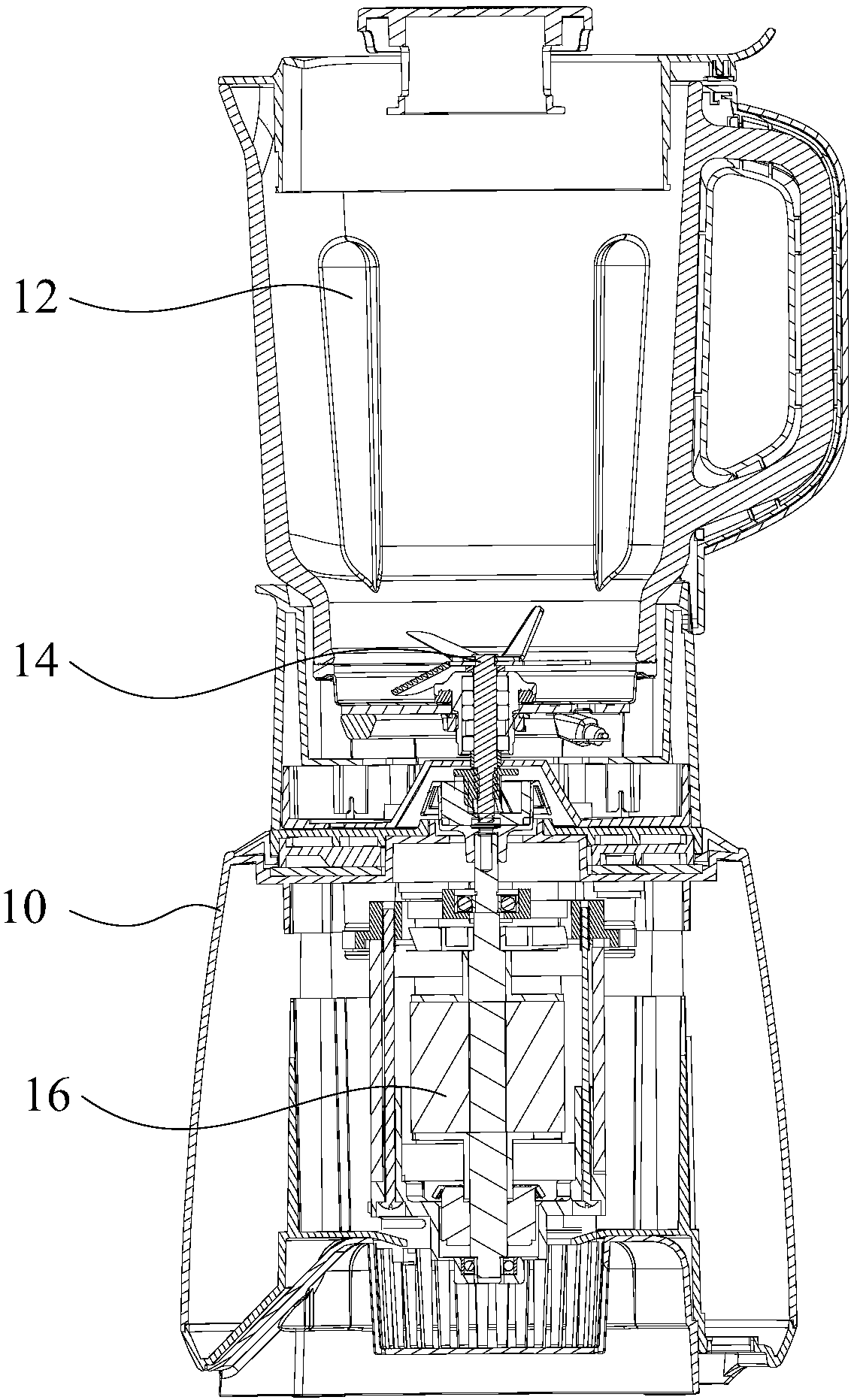

Food processor

InactiveCN109199153AReduce speedGuaranteed crushing effectMagnetic circuit rotating partsKitchen equipmentPermanent magnet synchronous motorEngineering

The invention provides a food processor, comprising: a machine base having a receiving cavity; a cup body, with the cross-sectional area of the top end of the cup body being larger than the cross-sectional area of the lower end of the cup body, the cup body being arranged on the frame, and a spoiler rib being arranged on the inner wall of the cup body; a stirring assembly one end of which extendsinto the inside of the cup body, and the other end of which is connected with a permanent magnet direct current motor; a permanent magnet dc motor disposed in the accommodation chamber, wherein the speed range of the permanent magnet dc motor is from 10000 rpm to 18000 rpm. By keeping the rotational speed of the permanent magnet dc motor between 10000 rpm and 18000 rpm, As a result, when too manyingredients are added to the food processor, namely when the load is large, the speed of the permanent magnet dc motor will not be lower than 10000rpm, which effectively ensures the crushing effect ofthe food materials, and when the load is small, the speed of the permanent magnet dc motor will not exceed 18000rpm, which effectively reduces the noise of the food processor and improves the user experience.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

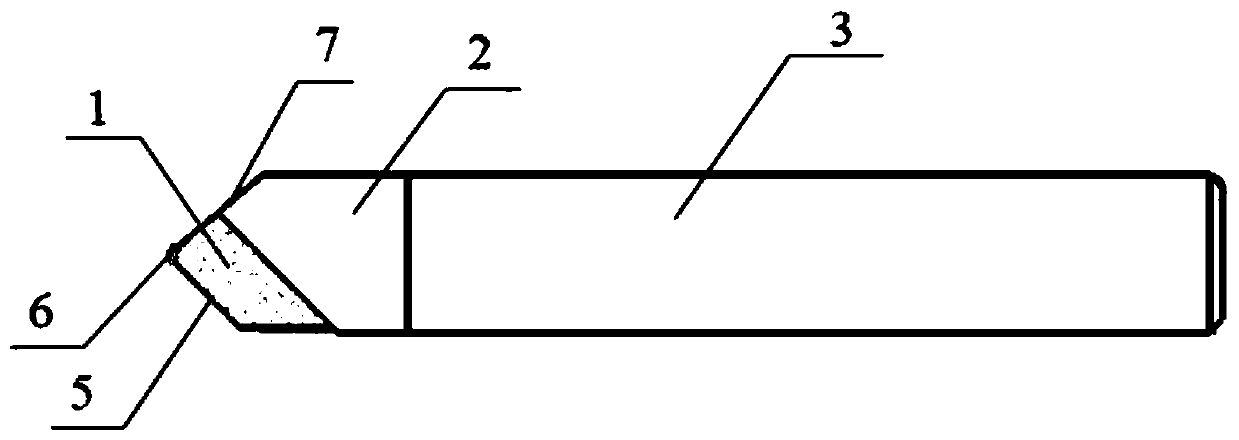

Efficient disc type ditcher

InactiveCN112154744AAvoid collisionAvoid damagePlantingSoil-shifting machines/dredgersDrive shaftAgricultural engineering

The invention discloses an efficient disc type ditcher, and relates to the technical field of agricultural machines. The efficient disc type ditcher comprises a rack, a driving assembly is fixedly connected to the middle of the rack, driving shafts are coaxially and fixedly connected to the output ends of the two ends of the driving assembly, and the two ends of the two driving shafts are rotationally connected to the rack; and ditching cutter discs are fixedly and coaxially connected to the middles of the driving shafts, and a plurality of ditching curved knives are connected to the faces, away from each other, of the two ditching curved knives. Compared with a traditional disc-type ditcher which needs an ultra-low-speed large-torque driving assembly for driving, the disc type ditcher hasthe advantages that when hard soil and stones are encountered during excavating, instantaneous acting force between the ditching curved knives and the ditching cutter discs can be effectively reduced, tree roots or other obstacles hooking the ditching curved knives can be cut and broken, so that peak torque between the ditching curved knives and the ditching cutter discs is reduced, a driving assembly with higher rotating speed can be selected, the rotating speed of the ditching cutter discs is increased, and the excavation efficiency of the disc type ditcher is improved.

Owner:湖州海明机械科技有限公司

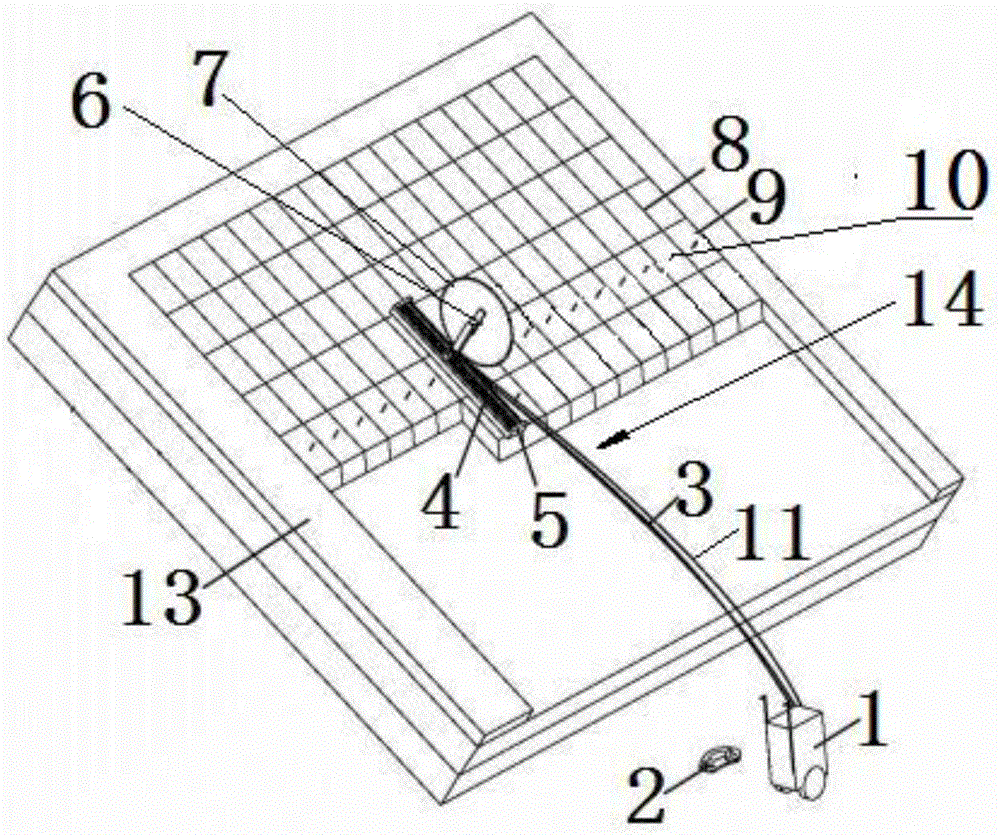

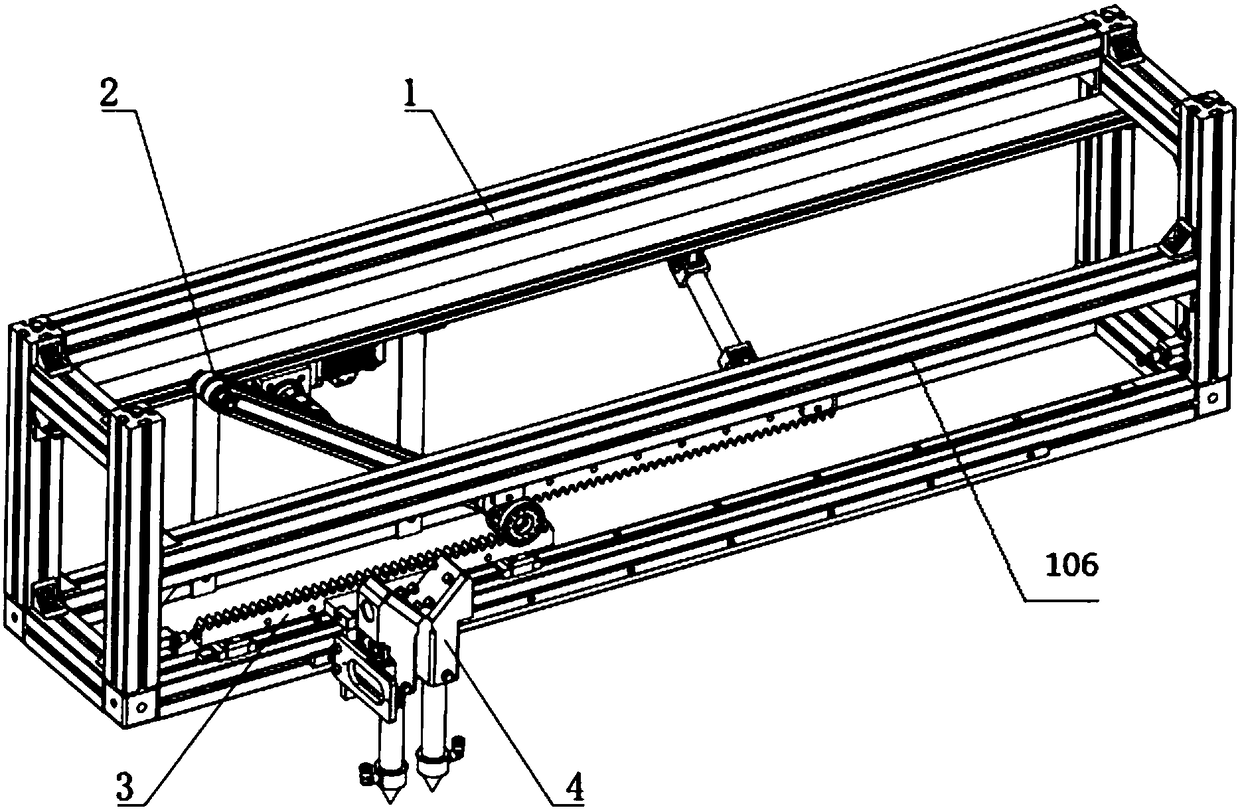

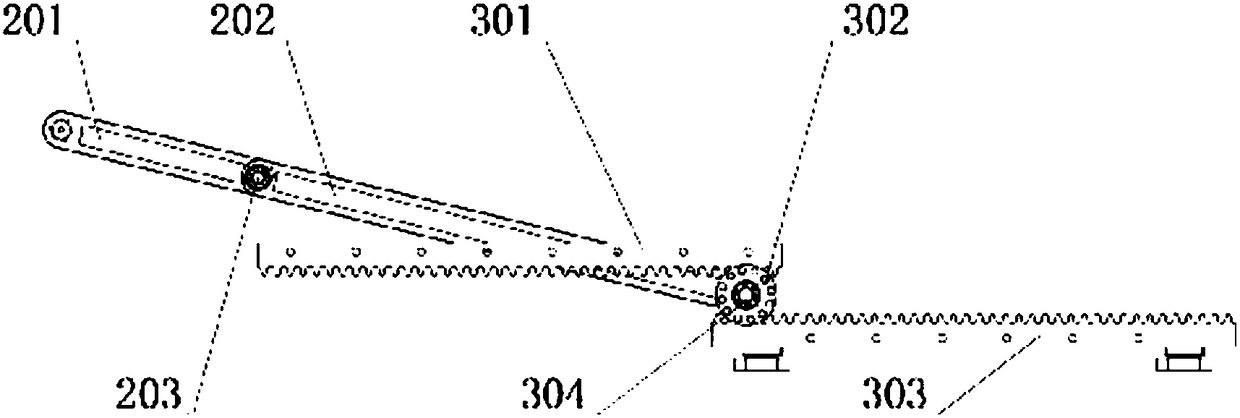

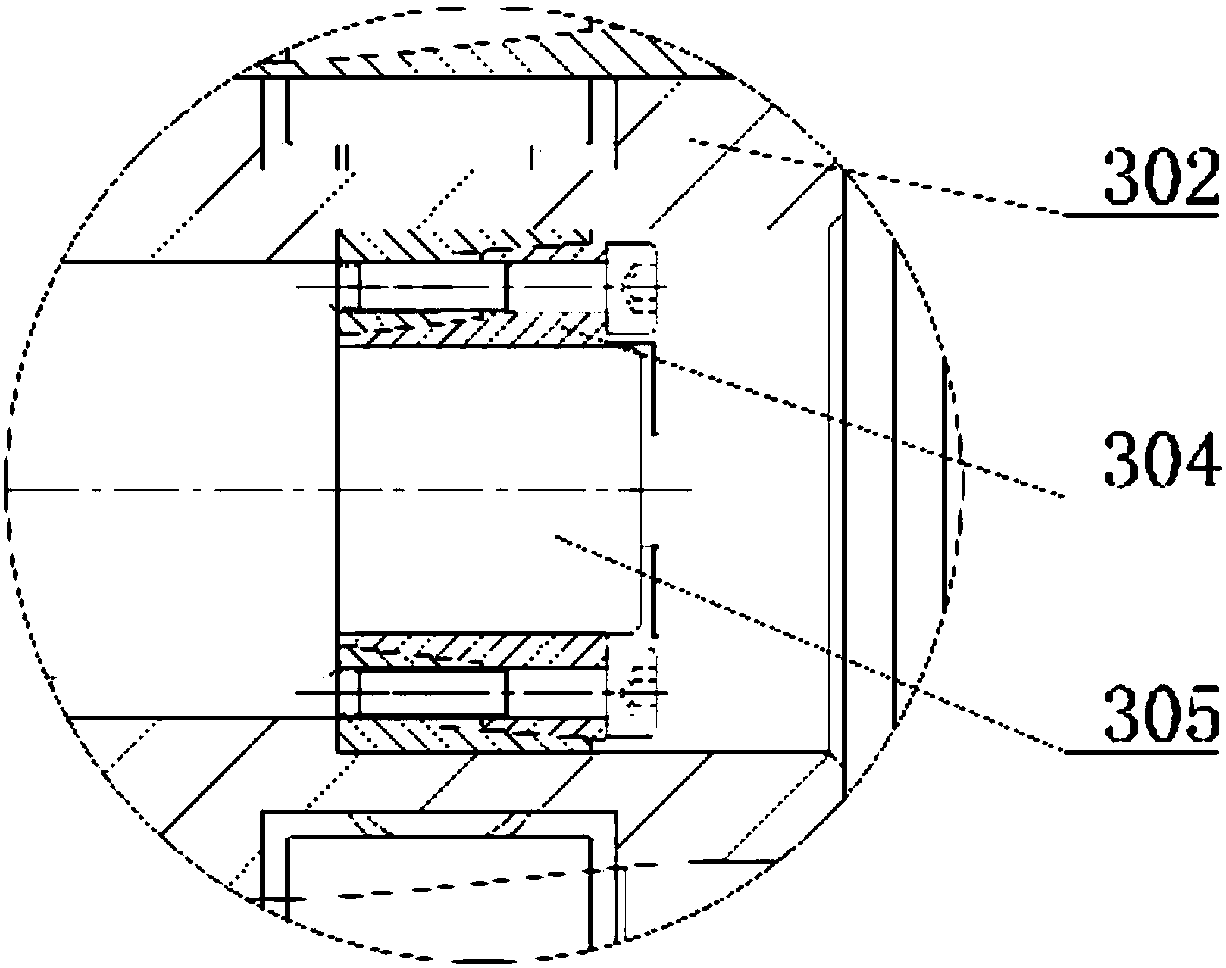

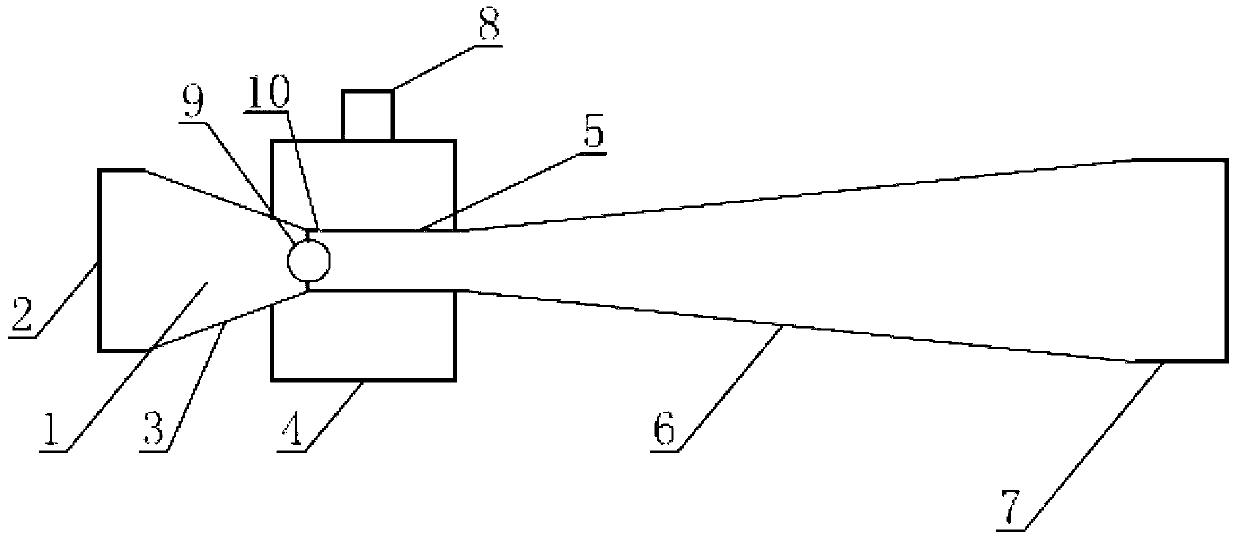

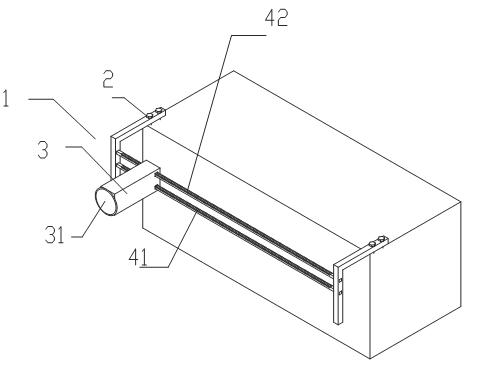

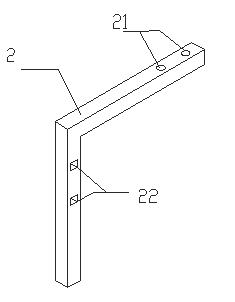

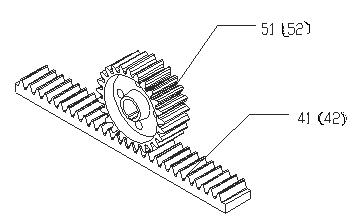

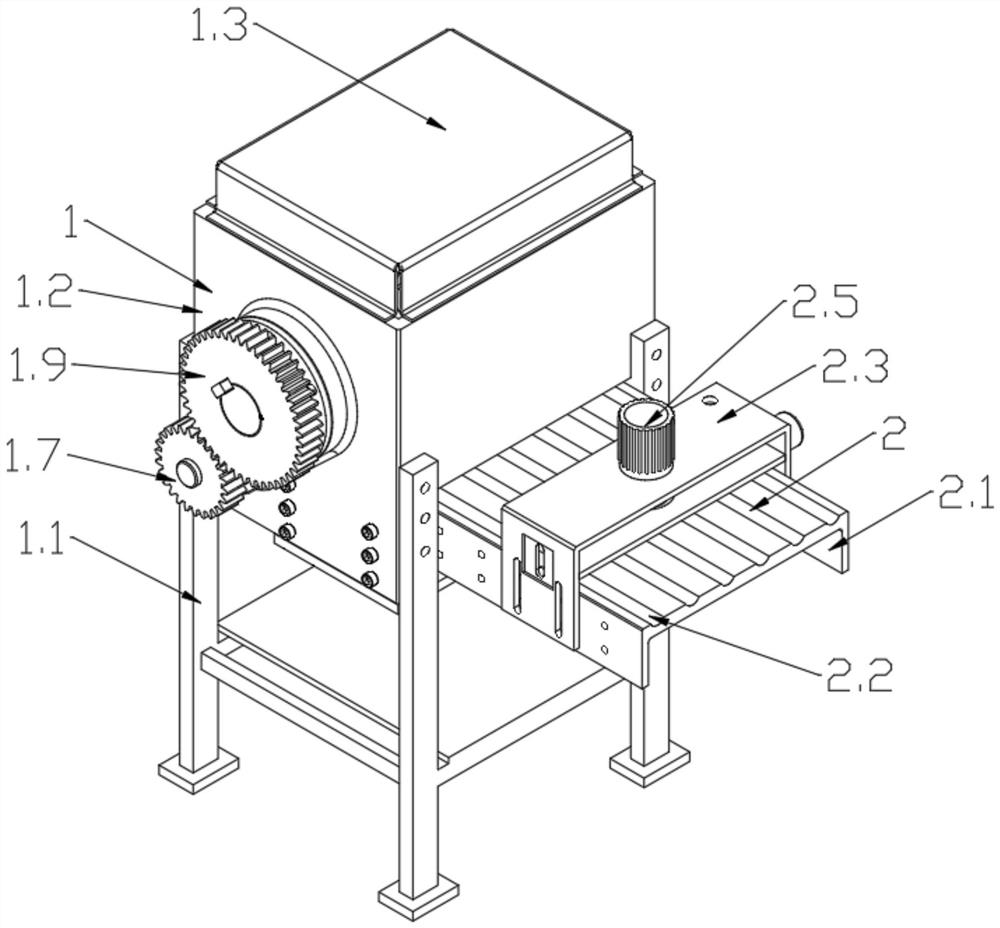

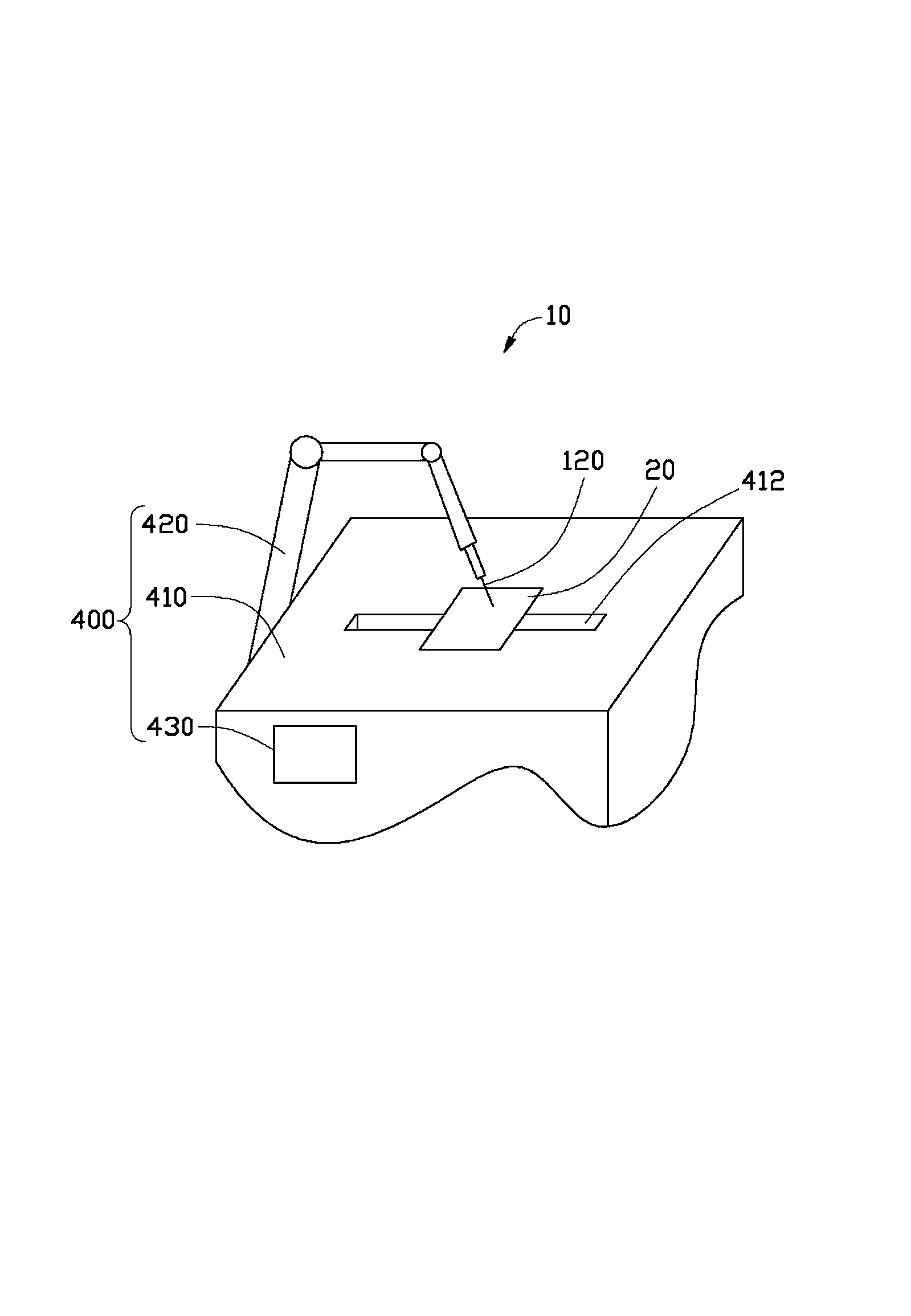

Large-format laser high-speed machining mechanism

InactiveCN108500450ASimple and reliable structureMovement runs smoothlyLaser beam welding apparatusLaser processingMachining

The invention belongs to laser machining technology, and particularly relates to a large-format laser high-speed machining mechanism. The large-format laser high-speed machining mechanism comprises aframe body. The frame body is provided with a drive stepping motor, a bias slider-crank mechanism, a linear differential motion travel multiplying mechanism and a laser processing head. The bias slider-crank mechanism comprises a crank and a connecting rod, wherein the crank is connected with the drive stepping motor, and the connecting rod is hinged to the crank. The linear differential motion travel magnifying mechanism comprises a fixedly-arranged fixed rack, a sliding rack and a rolling wheel which is engaged with the fixed rack and the sliding rack, the rolling wheel is connected with theend portion of the connecting rod, the fixed rack and the sliding rack are arranged in parallel, the rolling wheel is arranged between the fixed rack and the sliding rack, the rolling wheel does reciprocating rectilinear motion relative to the fixed rack, and the sliding rack is fixedly connected with the laser machining head. By means of the large-format laser high-speed machining mechanism, high-speed and high-precision batch welding, cutting and nicking of large-format workpieces can be achieved, and the laser machining efficiency can be remarkably improved.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Stone carver

PendingCN110076915AExtend your lifePrevent crashStone-like material working toolsPolycrystalline diamondHardness

The invention relates to the technical field of stone machining carving, in particular to a stone carver. The stone carver comprises a hard alloy carver bar and a polycrystalline diamond carver bit. The carver bit and the carver bar are connected and fixed in a welded manner, a carver pit of a quadrilateral skewed slot structure is formed in the carver bar, the shape of the carver bit and the shape of the carver pit are complementary, the carver bit is obliquely welded into the carver pit through the welding technology of the carver bit and the carver bar, and the stone carver is formed. The stone carver is composed of the polycrystalline diamond carver bit and the hard alloy carver bar, the carver bit is made of high-hardness polycrystalline diamond, and the therefore service life of thecarver can be greatly prolonged; the carver pit is in skew slot design, the carver bit of the carver is parallel to one supporting surface of the carver pit, during use of the carver, higher supporting force can be provided, and chipping of a cutting edge of the carver bit can be effectively avoided; and meanwhile the carver can cut workpieces at a high speed due to the high-hardness attribute ofthe polycrystalline diamond, abrasion of the cutting edge is slow, and the machining efficiency and the machining precision of the stone carver can be improved.

Owner:LANGFANG SUPOWER DIAMOND TECH

Efficient energy-saving jet aerator

ActiveCN103342420AImprove mass transfer efficiencyImprove inhalation capacityTreatment using aerobic processesWater aerationWater flowEngineering

The invention discloses an efficient energy-saving jet aerator which comprises a water flow inlet pipe, a reducing pipe, a hollow throat, an increasing pipe and a gas-liquid mixed outlet pipe, wherein the diameter of the hollow throat is less than that of the water flow inlet pipe and the gas-liquid mixed outlet pipe, the hollow throat is connected with the water flow inlet pipe through the reducing pipe and is connected with the gas-liquid mixed outlet pipe through the increasing pipe, an admission port is arranged on the outer wall of the hollow throat, and a water flow cutter is fixedly arranged at the connection of the reducing pipe and the hollow throat. The aerator disclosed by the invention has the beneficial effects that the water flow cutter is arranged in a pipeline to increase the gas-liquid contact area, and in equal pressure drop, the admission amount is greatly improved, and meanwhile, the shearing effect is further enhanced. The admission port is designed, so that gas paste is easier to be sheared by a high speed shearing water flow so as to obtain a better mass-transfer effect, and therefore, smaller bubbles are cut, and the dissolving efficiency is higher.

Owner:SHENZHEN CLEAR SCI & TECH

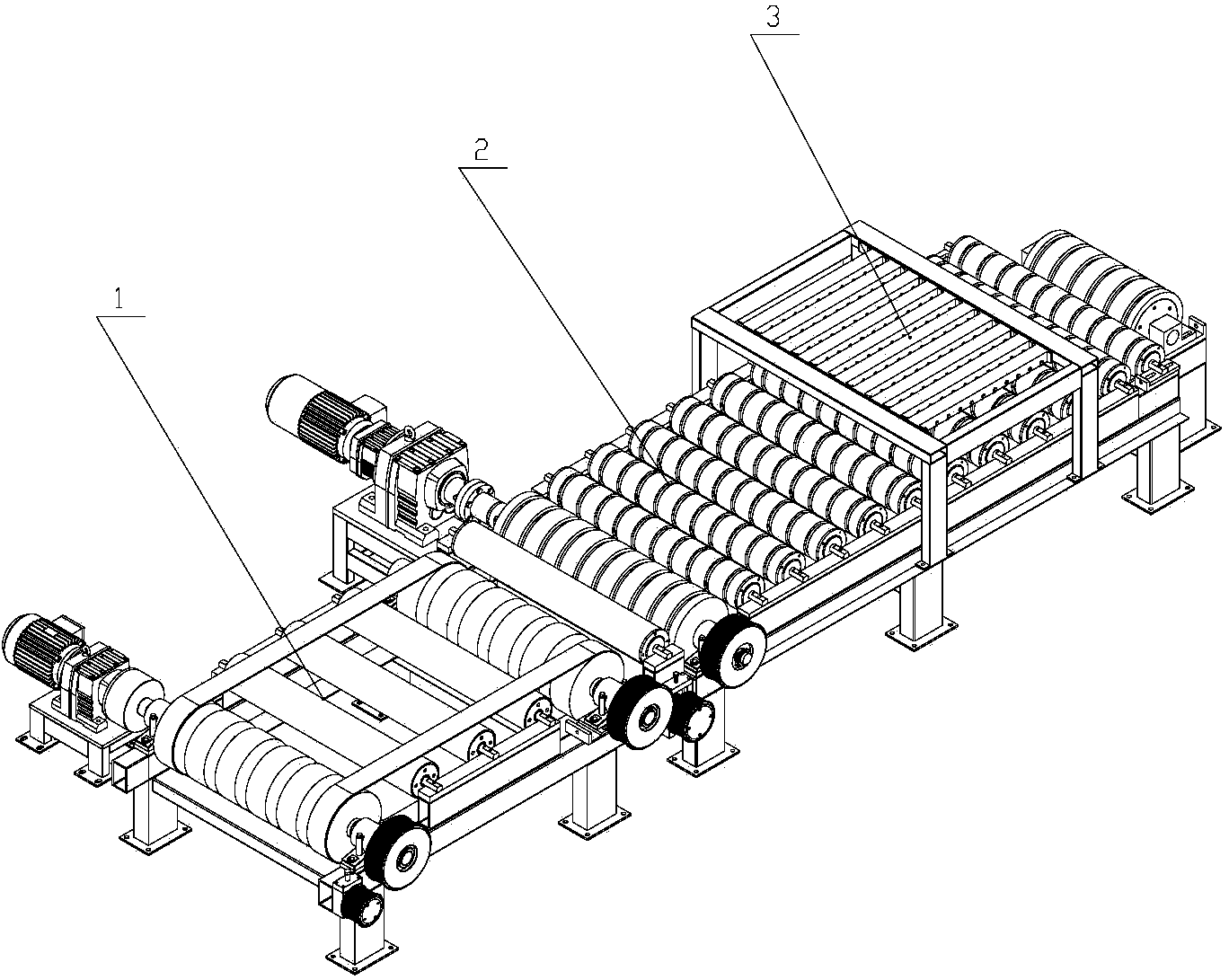

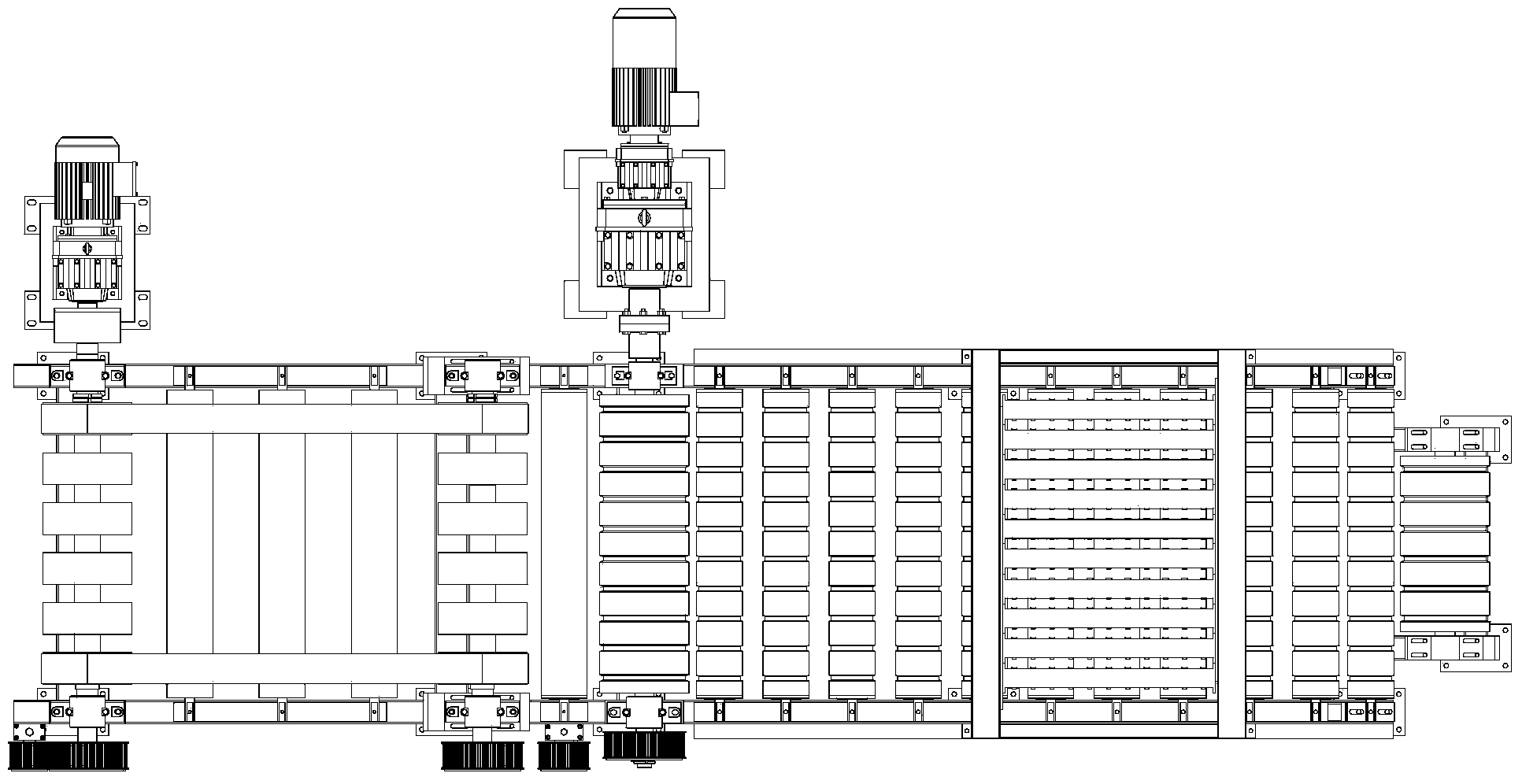

Building block cutting, feeding and conveying mechanism

ActiveCN103878873AGuaranteed to liftExpand the scope of useCeramic shaping apparatusRoller-waysFixed frameEngineering

The invention discloses a building block cutting, feeding and conveying mechanism which comprises a conveying mechanism, a feeding mechanism and a first compressing mechanism. The tail end of the conveying mechanism is fixed to the front end of the feeding mechanism; the first compressing mechanism is mounted above the feeding mechanism; the conveying mechanism comprises a conveying mechanism frame, a conveying motor fixing frame, a gear motor, a first roller and a first synchronous belt pulley, the feeding mechanism comprises a motor fixing frame, a motor, a transitional roller, a driving roller, a second compressing mechanism, a feeding mechanism frame, a first tension roller and a second tension roller, the second tension roller is arranged at the tail end of the feeding mechanism frame, the first compressing mechanism comprises compressing wheel fixing plates, compressing wheel frames and compressing wheels, and the bottoms of the compressing wheel frames are mounted on supporting steel angles of the feeding mechanism frame; the compressing wheels are connected onto the compressing wheel fixing plates by shafts, and rolling surfaces of the compressing wheels are positioned above first supporting rollers. The building block cutting, feeding and conveying mechanism has the advantages that by the aid of the building block cutting, feeding and conveying mechanism, building blocks can be continuously and stably cut, can be assuredly thoroughly cut and can be quickly conveyed after being cut, accordingly, the efficiency can be improved, and the labor intensity of staffs can be relieved.

Owner:湖州优研知识产权服务有限公司

Scraping device of insulating telegraph pole

The invention discloses a scraping device of an insulating telegraph pole. The device comprises a rack, a die cylinder, a feed pipe, a rotary cover, a compressed spring, a scraper, a hollow shaft, a nut, a belt pulley, and a machine body. The machine body is arranged on the rack. One end of the hollow shaft extends out of the machine body, and the scraper is fixed on one end of the hollow shaft. The hollow shaft is provided with the belt pulley. The left side of the belt pulley is provided with a round nut. The round nut is screwed in threads on the shaft to realize fastening. One side of thescraper is provided with a cylindrical die cylinder. The outer end of the die cylinder is screwed with the round rotary cover. The feed pipe is connected between the die cylinder and the rack. The scraping device effectively ensures good coaxiality of the insulating telegraph pole and a scraper axis, and can scrape oxide skin on the surface of the insulating telegraph pole in high speed, and feedspeed of the insulating telegraph pole is fast, and thickness of cut surface scale is uniform.

Owner:徐菁涵

Flesh Cutting Knife

ActiveCN104057479BReduce wearImprove the finishMetal working apparatusElectric machineryBiomedical engineering

The invention discloses a flesh and bone cutter which comprises a baseplate (1), flesh cutters (2), bone cutters (3) and an outer cover (5), wherein the flesh cutters (2) and the bone cutters (3) are arranged at intervals in the circumference direction along the baseplate (1) alternatively; shank parts (21) of the flesh cutters (2) are connected to the baseplate through elastic pieces (4); an included angle being 90-135 degrees is formed between the length direction of the flesh cutters (2) and the bone cutters (3) and the tangent line on which the flesh cutters (2) and the bone cutters (3) are crossed with the periphery of the baseplate (1); when the flesh cutters (2) come into contact with bones, automatic withdrawing can be realized to avoid the condition that the cutter is worn, which is caused by the fact that the bones are forcibly cut; the outer cover (5) and the baseplate (1) can be connected onto a main shaft of a motor; the flesh and bone cutter is driven by the motor to rotate to cut flesh and bones. Different cutters are automatically switched to cut bones and flesh, the synchronous mechanized cutting of bones and flesh is realized, and not only is the smoothness of flesh and bone cuts improved, but also the labor cost during the slaughtering process can be reduced.

Owner:HUAQIAO UNIVERSITY

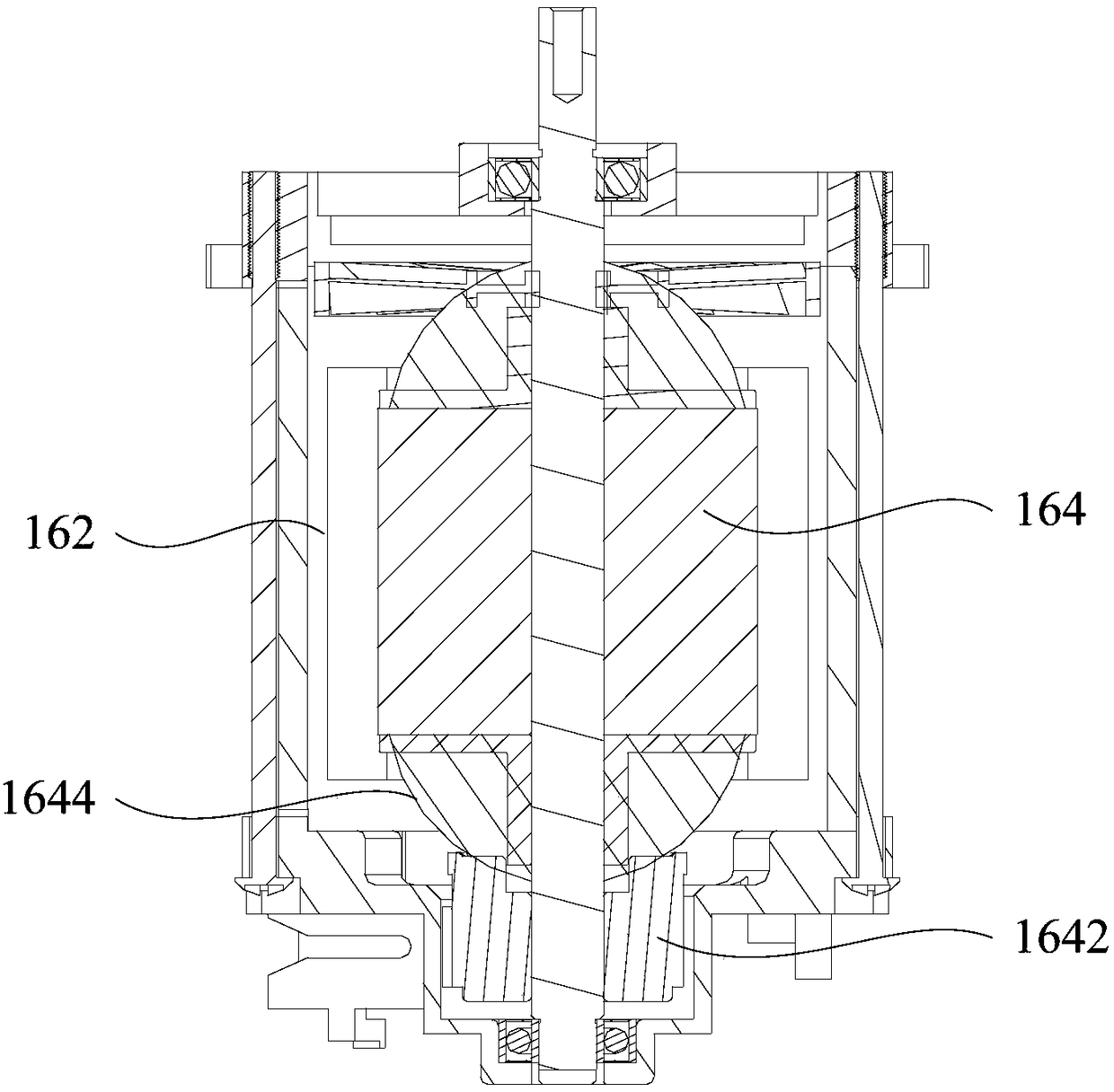

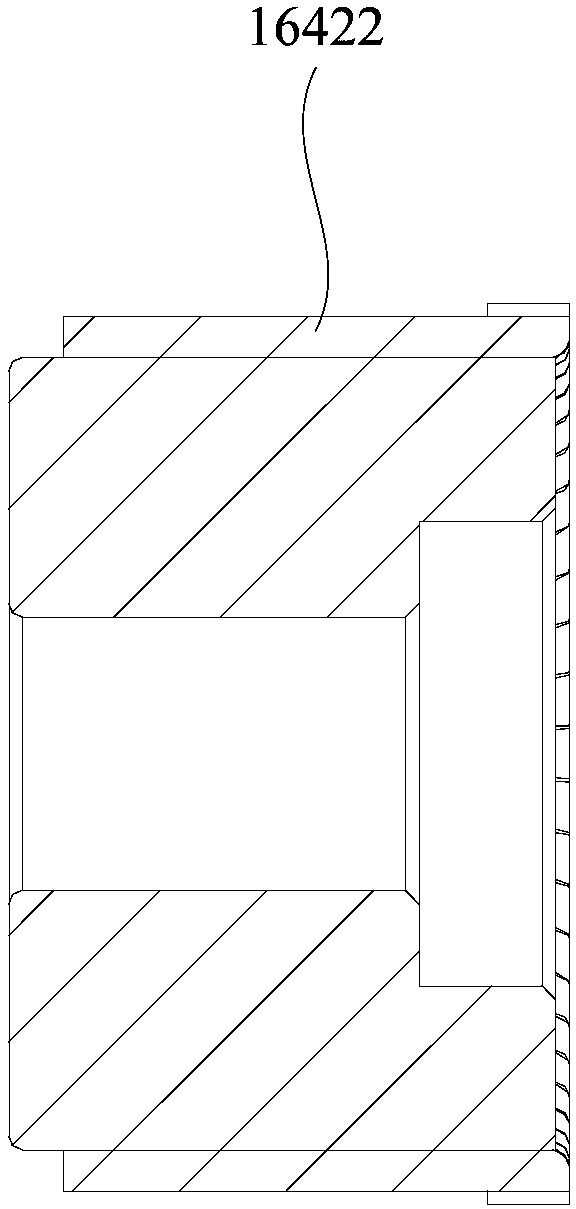

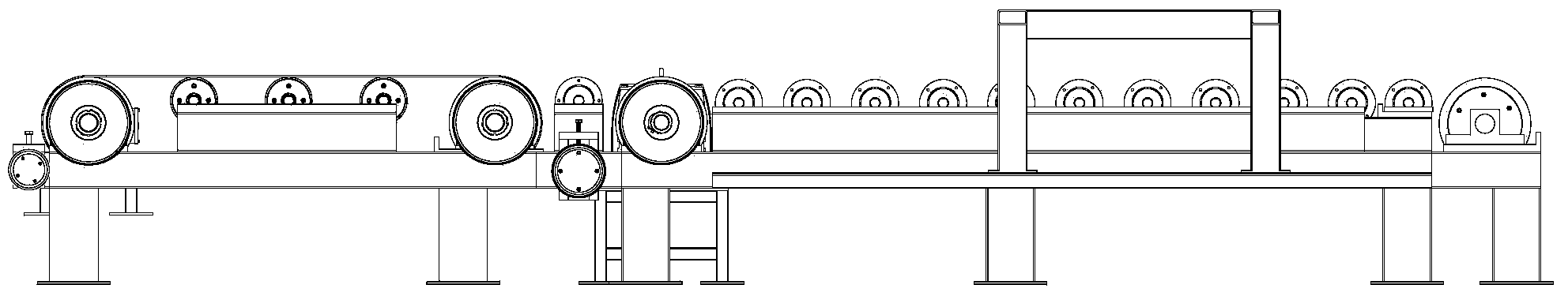

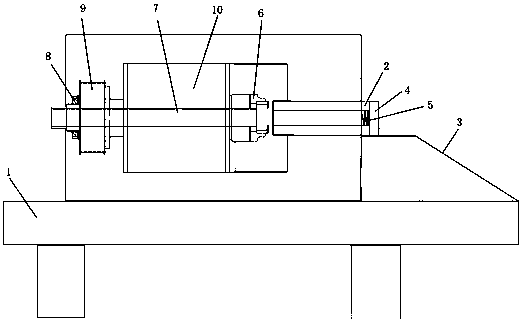

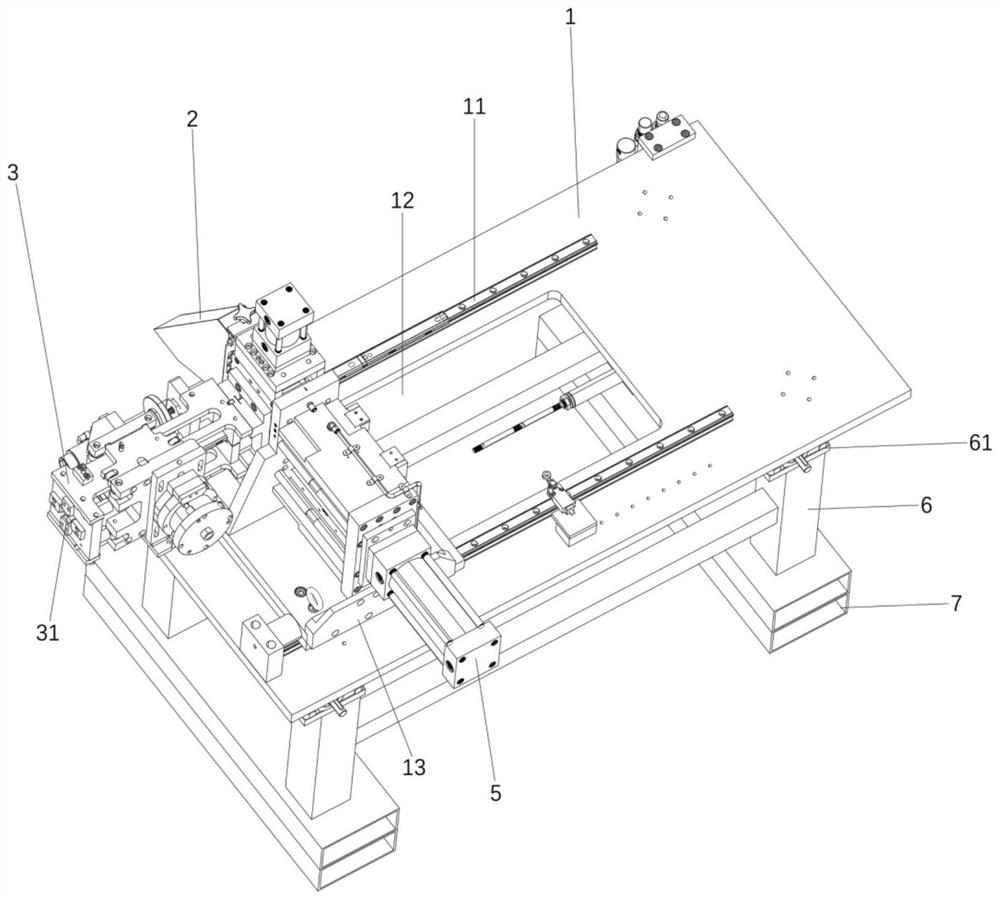

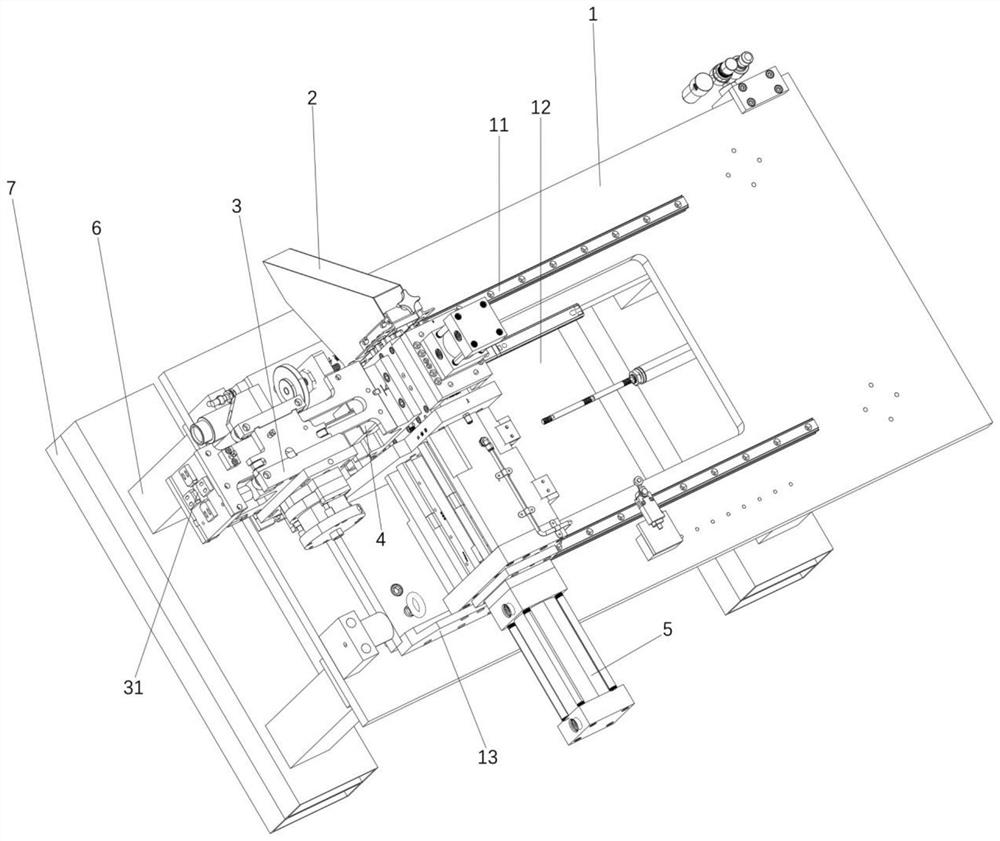

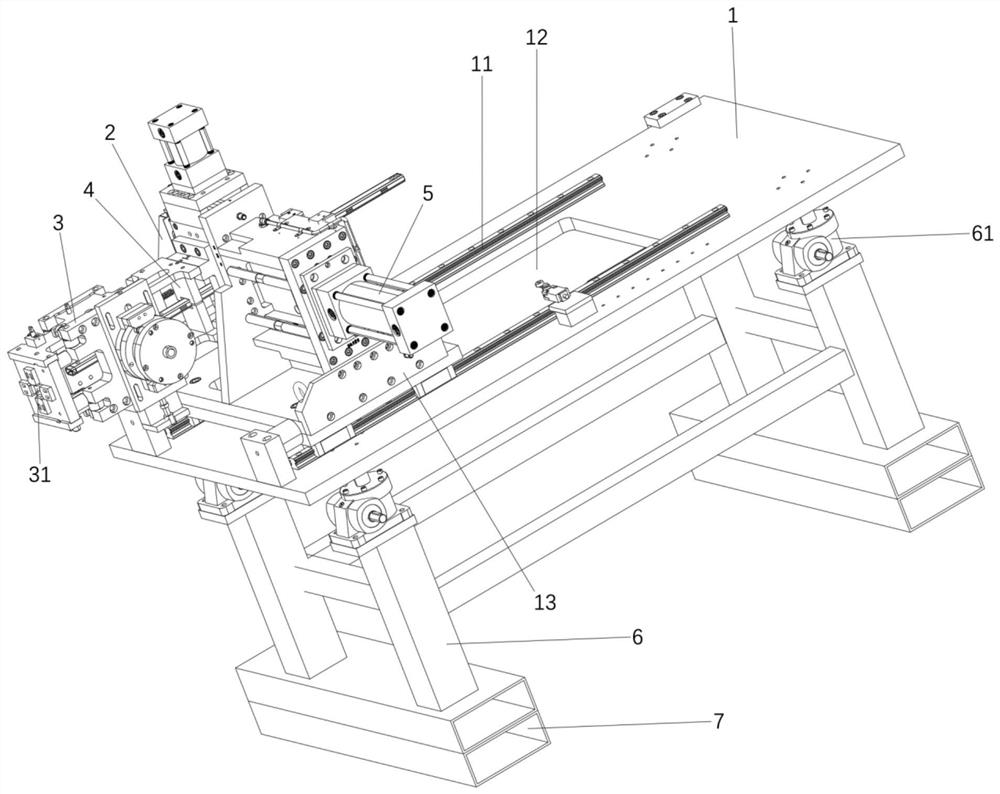

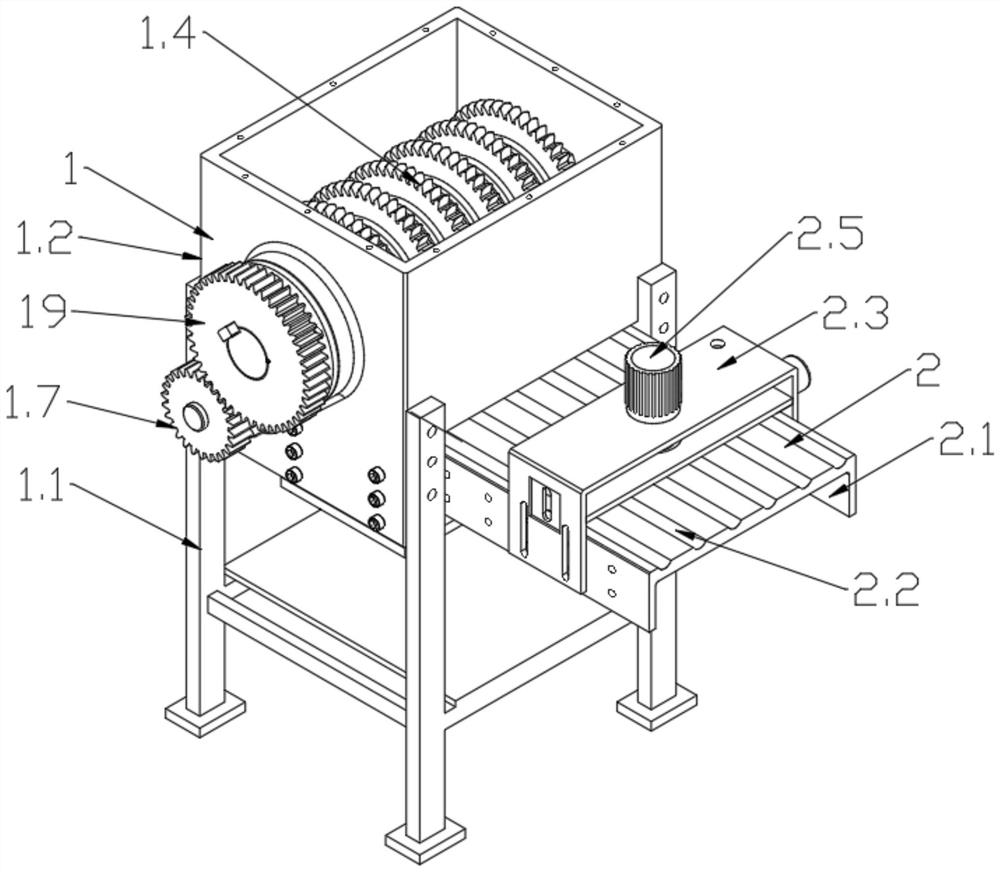

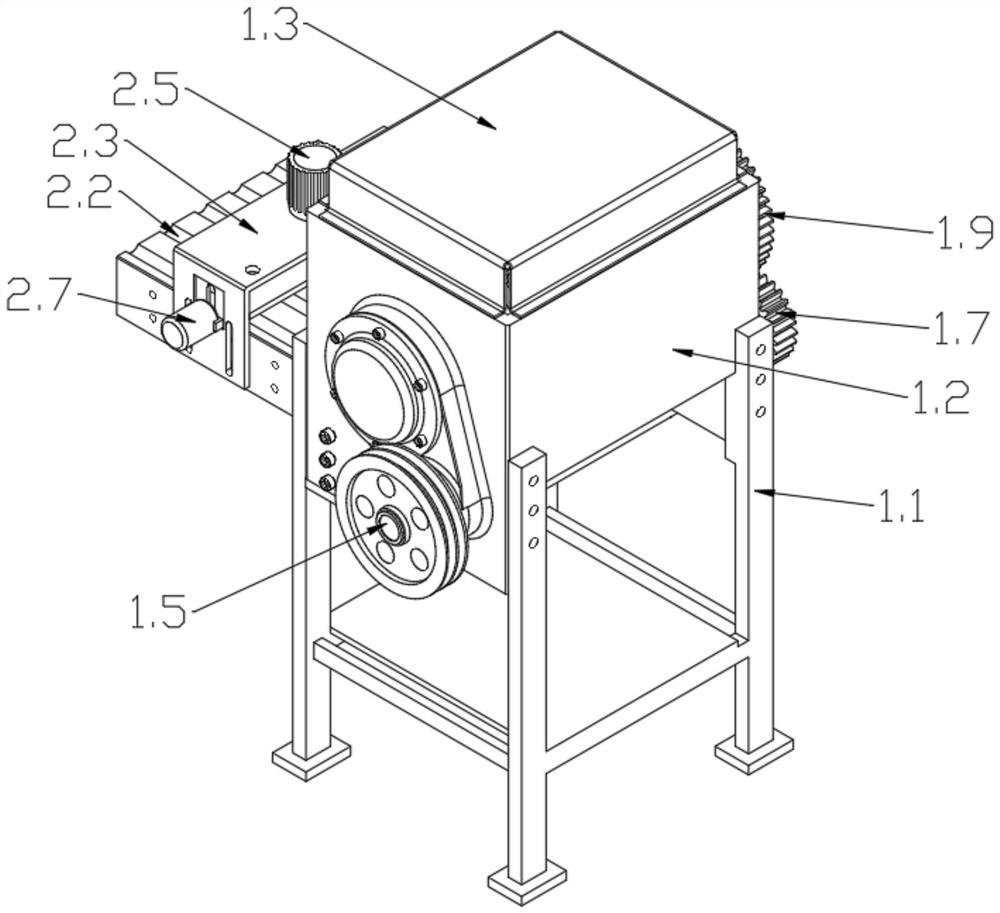

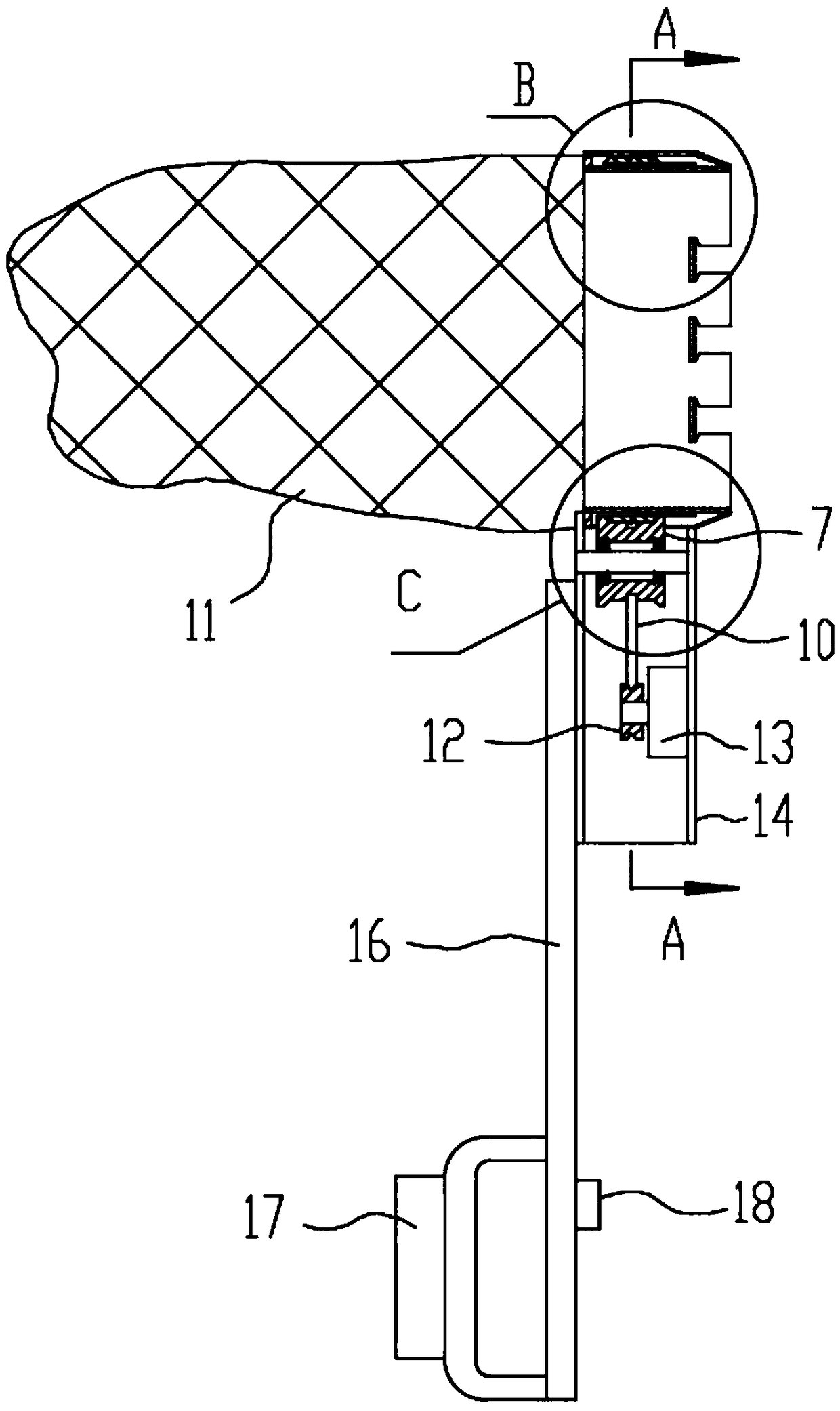

High-speed cutting device for rolling parts

PendingCN112692363ASolve glitchesCut high speedLarge fixed membersMetal working apparatusMechanical engineeringPhysics

The invention discloses a high-speed cutting device for rolling parts. The high-speed cutting device comprises a pedestal, a discharging system, a feeding system, a pressing system and a cutting system, wherein an open groove penetrating through the pedestal is formed in the pedestal; sliding rails are arranged on the two sides of the open groove; a sliding base is mounted on the sliding rails; the pressing system and the feeding system are mounted on the sliding base and fixed; the pressing system comprises a first clamping piece and a second clamping piece; a clamping hole is formed between the end of the first clamping piece and the end of the second clamping piece; a feeding port is formed in the end of the feeding system and communicates with the clamping hole; the cutting system is arranged on one side of the pressing system; and the discharging system is mounted at the end of the cutting system. By adoption of the high-speed cutting device for the rolling parts, the problem that burrs exist after the rolling parts are cut off is solved, high-speed cutting can be achieved, and the production efficiency is improved; and high-speed cutting in the online state is achieved.

Owner:博瑞孚曼机械科技(苏州)有限公司

Shearing unit with humidity control

InactiveCN102277716AImprove stabilityReduce the temperatureSevering textilesAuxiliary memorySpray nozzle

The invention discloses a shearing device with a humidity control device. The shearing device includes a fixed bracket and a cutter head. The cutter head includes a disc blade. The cutter head also includes a Atomizing nozzles for the local ambient humidity of the disc blades described above. The fixed bracket is provided with a main slide rail and an auxiliary slide rail, the inside of the cutter head is provided with a main gear and an auxiliary gear, the main gear is meshed with the main slide rail, and the auxiliary gear is Engage with the auxiliary slide rail described above. The cutter head also includes a humidity sensor. The shearing device for the loom of the present invention utilizes the double slide rail design of the main slide rail and the auxiliary slide rail, which greatly increases the stability of the cutter head and realizes high-speed cutting of the cloth. At the same time, the cutting device utilizes controllable fog The spray head can provide a suitable humidity environment for the cloth to be cut, and at the same time can reduce the temperature of the blade head, making the cutting more neat.

Owner:许同永

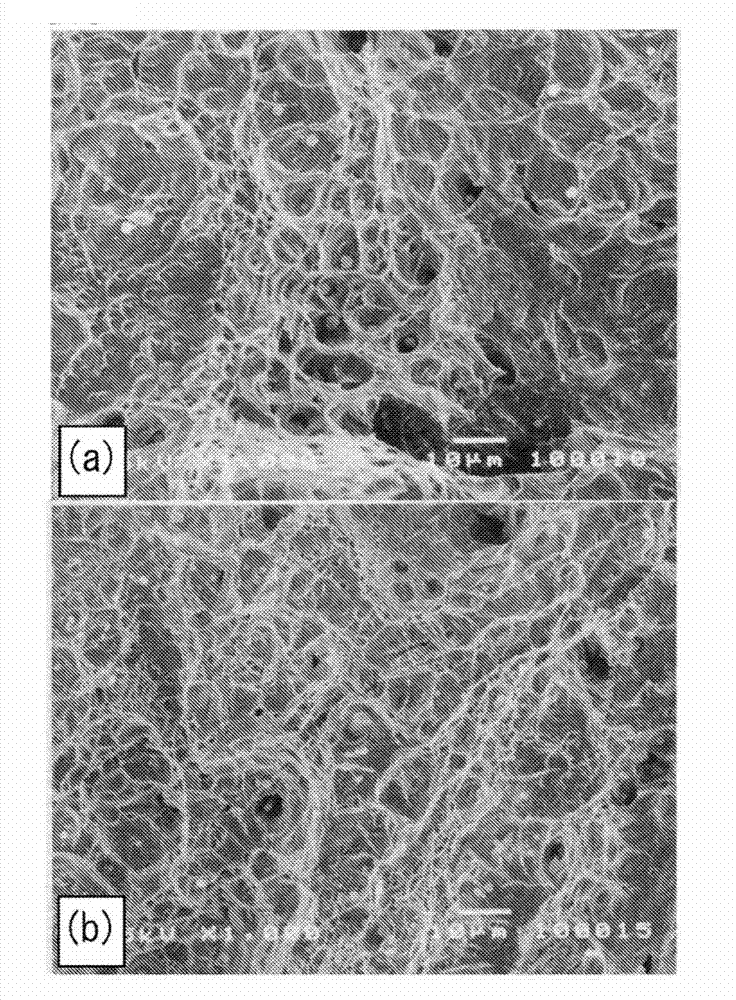

Aluminium alloy easy to be cut at high speed and its prepn

InactiveCN1772933AChip breaking is convenientHigh dimensional accuracyMaterials scienceAluminium alloy

The present invention is aluminum alloy easy to be cut at high speed and its preparation, and belongs to the field of aluminum alloy material. The aluminum alloy easy to be cut at high speed has Fe 0.7-7.0 wt% and Bi 0.2-5.0 wt%, or Fe 0.7-7.0 wt% and Pb 0.2-5.0 wt%, or Fe 0.9-7.0 wt%, Bi 0.2-5.0 wt% and Pb 0.2-5.0 wt% added. It has excellent cutting performance and high cutting efficiency.

Owner:卫品官

Cutting equipment for plastic particle processing

InactiveCN114633395AUniform particle size and shapeUniform shape and sizeMetal working apparatusDrive shaftGear wheel

The cutting equipment for plastic particle processing comprises a cutting device and a feeding device, the cutting device comprises a mounting frame, a cutting box and cutting gears, the cutting box is mounted at the upper end of the mounting frame, and a first transmission shaft is fixedly sleeved with the multiple cutting gears in the circumferential direction; the two ends of the first transmission shaft are rotationally installed in the cutting box through bearings correspondingly, and a first transmission wheel is installed at the end, extending to the outer side of the cutting box, of the first transmission shaft. The plastic wire cutting device has the beneficial effects that a plurality of cutting gears are arranged to be inserted into a first transmission shaft in a penetrating mode, a first transmission wheel at the end of the first transmission shaft is driven to drive the cutting gears to rotate, tooth blades on the cutting gears are matched with cutting grooves formed in a feeding plate, and plastic wires in the cutting grooves are cut; due to the fact that the tooth pitches between the tooth blades of the cutting gear are equal, the manufactured plastic wire particles are uniform in size and shape, the cutting gear is provided with the multiple tooth blades, and the phenomenon that the cutting effect is reduced after long-time work is avoided.

Owner:林佳鸿

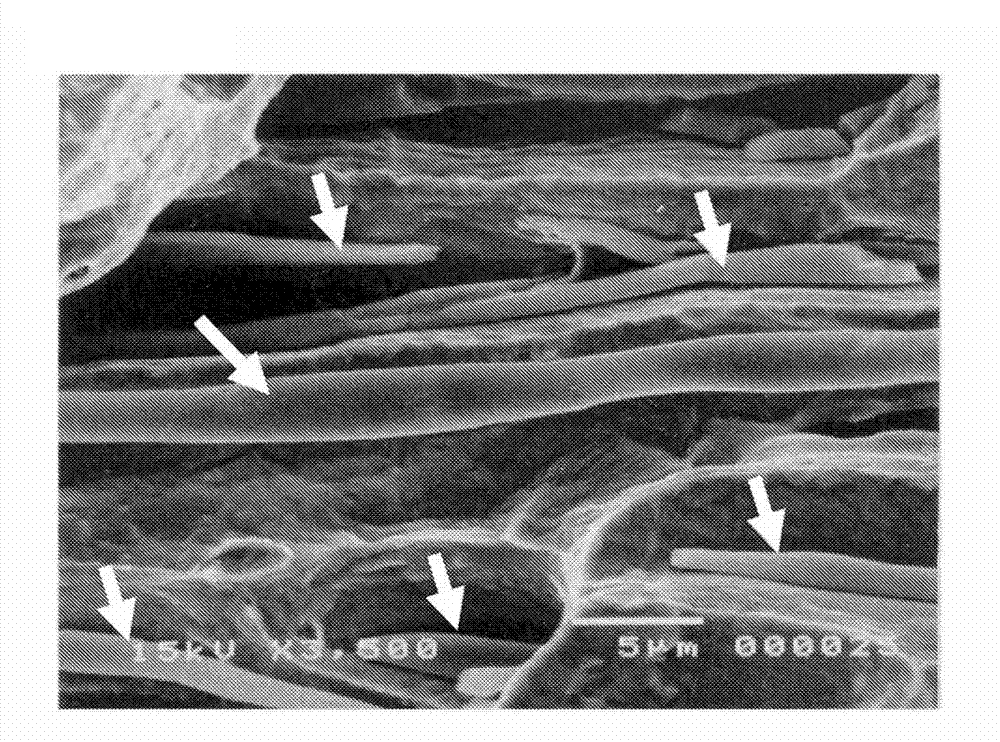

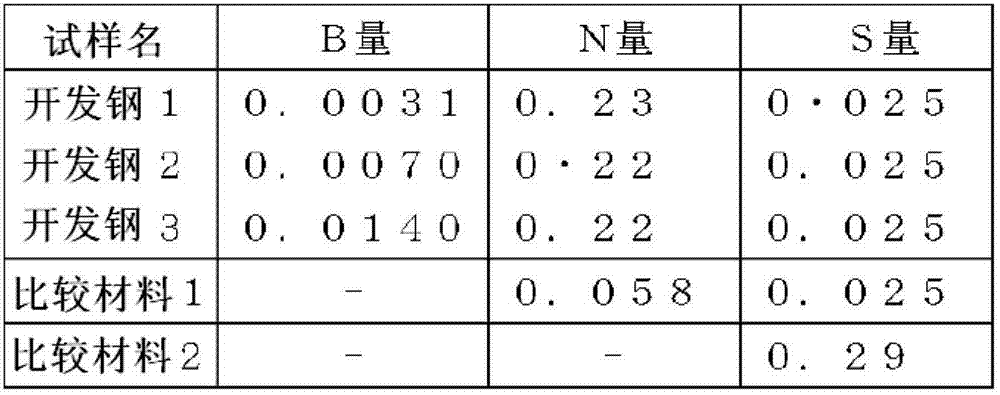

Free-cutting stainless-steel material for precision processing and process for producing same

InactiveCN102906290AMeet friendlinessSave powerFurnace typesHeat treatment furnacesSolid solutionMaterials science

Provided are a free-cutting stainless-steel material for precision processing which can satisfy all of excellent cutting precision, cuttability, corrosion resistance, and environmental preservation at the same time and a process for producing the stainless-steel material. The free-cutting stainless-steel material for precision processing is a material to be formed by cutting on the order of micrometer, and is characterized by containing a material for imparting cutting workability which is constituted of h-BN grains and has been dispersed as primary particles in the steel. The process for producing a free-cutting stainless-steel material for precision processing is characterized by heating a free-cutting stainless-steel material for precision processing in which h-BN grains have been precipitated, thereafter quenching the material to eliminate the h-BN grains through formation of a solid solution thereof, and then tempering the material to thereby precipitate h-BN grains again which are evenly dispersed in the material.

Owner:NAT INST FOR MATERIALS SCI

Sapphire cutting device

InactiveCN103567642ALow costHigh speed cuttingWelding/soldering/cutting articlesLaser beam welding apparatusOptoelectronicsLaser cutting

The invention provides a sapphire cutting device. The sapphire cutting device comprises an ultraviolet laser source and a collimating lens, wherein the ultraviolet laser source is used for sending out a laser beam; the collimating lens is used for converging the laser beam into a parallel laser beam; the parallel laser beam is used for cutting sapphire; the working wavelength range of the ultraviolet laser source is 200-400 nm. Thus, the cost can be reduced since the ultraviolet laser source and the collimating lens with lower cost are adopted for replacing diamond with higher cost. In addition, laser cutting can realize high-speed cutting, and the efficiency is improved.

Owner:SCIENBIZIP CONSULTINGSHENZHENCO

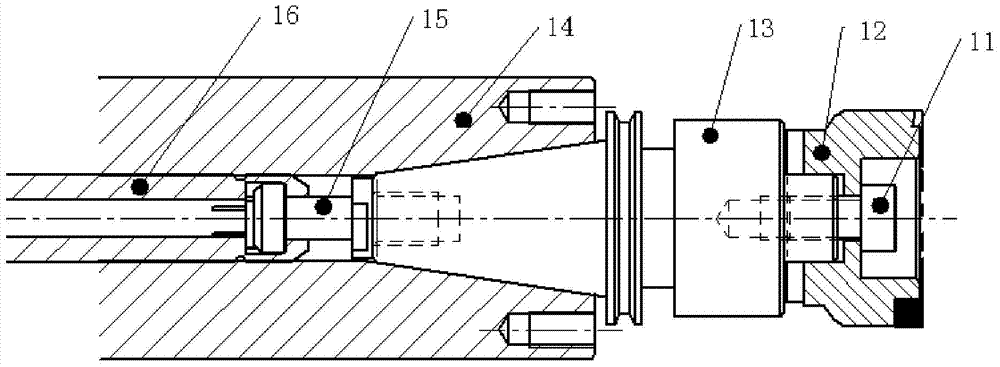

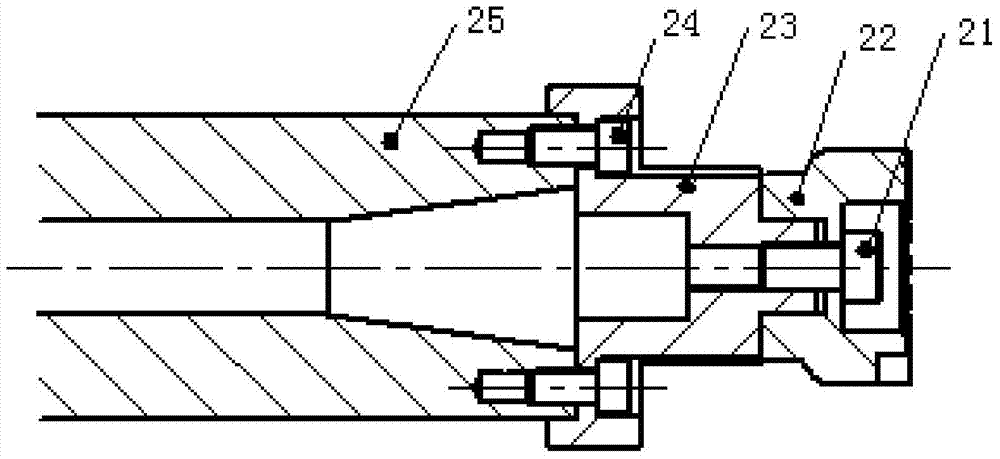

Connection tool of face milling cutter

InactiveCN104741677AWill not destroy positioning accuracyImprove connection rigidityMilling cuttersMilling cutterEngineering

The invention discloses a connection tool of a face milling cutter. The connection tool is in a three-grade ladder shaft structure, and specifically comprises a large shaft connected with a machine tool main shaft, a small shaft connected with a cutterhead, and a middle shaft connecting the large shaft with the small shaft, wherein a positioning seam allowance which is adapted and positioned with the end face of the machine tool main shaft and the external circle is formed in the outer end of the large shaft. According to the connection tool of the face milling cutter, the end face of the main shaft is positioned with the external circle so that the system connection rigidity is relatively good, and the machining quality and high-speed cutting can be improved. Furthermore, only a cutter needs to be detached at ordinary times and the connection tool does not need to be detached, so that the positioning precision of the main shaft and the connection tool is not damaged; and in addition, the installation of the face milling cutter is unrelated to a tapered hole and a tensioning mechanism, so that the tapered hole and the tensioning mechanism do not need to be repaired and a machine tool is prevented from being overhauled.

Owner:GUANGXI YUCHAI MASCH CO LTD

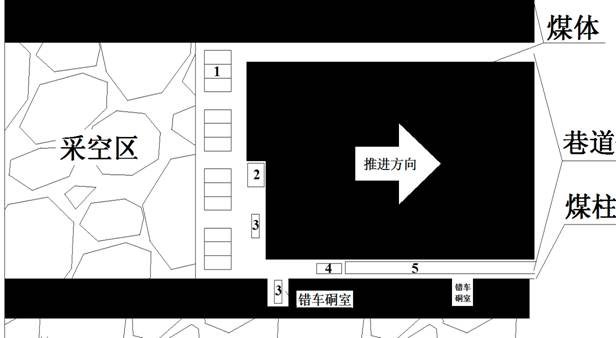

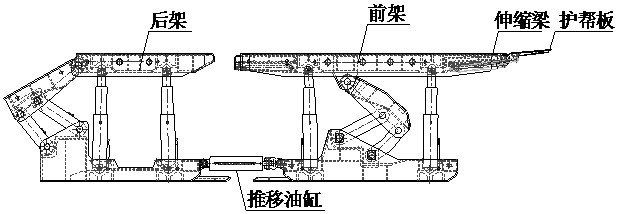

Efficient mining method for long-wall type thin coal seam and medium-thickness coal seam

InactiveCN113586056AEfficient miningHigh speed cuttingUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses an efficient mining method for a long-wall type thin coal seam and a medium-thickness coal seam, and relates to the technical field of coal mining. The method comprises the following steps that a coal mining working face is arranged; coal breaking is carried out through a continuous coal mining machine, wherein a roller of the continuous coal mining machine is lifted, and is cut into a coal body, the roller is from top to bottom until reaching a bottom plate, a top plate and the bottom plate are flat to complete one-knife cutting of coal, then the roller is lifted again, and cutting is circularly and repeatedly carried out cutting until the roller reaches the end part of another roadway to complete one-cycle cutting of the working surface; the coal is loaded by means of the continuous coal mining machine; the coal is conveyed; supporting is carried out, wherein a shield type self-moving hydraulic support is used for working face supporting, and when the shield type self-moving hydraulic support is propelled and moved in the roadway direction, the top plate is supported by two hydraulic supports in one supporting unit, and another hydraulic support descends and moves forward; and a goaf is treated. According to the method, gangue is not cut in the 0.8-1.5 m coal seam, the coal cutting speed reaches 10-20 m / min or above, the requirement for the thickness of the coal seam is met, and efficient mining and high-speed propelling are guaranteed.

Owner:CCTEG COAL MINING RES INST +6

Bearingless fruit picking device for high branches

The invention discloses a bearingless fruit picking device for high branches. The device includes a retractable rod, an outer sleeve and an inner sleeve which are sleeved with each other coaxially arearranged at the front end of the retractable rod, and annular saw webs are arranged between the outer sleeve and the inner sleeve; notches are uniformly formed in the upper end openings of the innerand outer sleeves; triangular grooves are formed in the side walls of the bottom surfaces of the notches; the bottom surfaces of the triangular grooves are flush with the bottom surfaces of the notches; the upper end faces of the annular saw webs are higher than the bottom surfaces of the notches and lower than the top surfaces of the triangular grooves; a rotatably annular rope wheel is arrangedat the lower ends of the annular saw webs; the rope wheel is meshed with supporting wheels on the two sides behind the rope wheel; a driving wheel connection motor is arranged on the retractable rod and connected with a storage battery and a power source switch; an annular driving rope is arranged among the rope wheel, the supporting wheels and a driving wheel; the driving rope winds around the driving wheel for at least one circle, then winds around the supporting wheels for at least one circle and then entangles itself with the rope wheel; a net bag is arranged at the bottom of the inner sleeve. The picking efficiency is high, precise positioning can be achieved, more convenience is provided for picking, the structure is small, and the device is suitable for operation under dense branches.

Owner:李佳馨

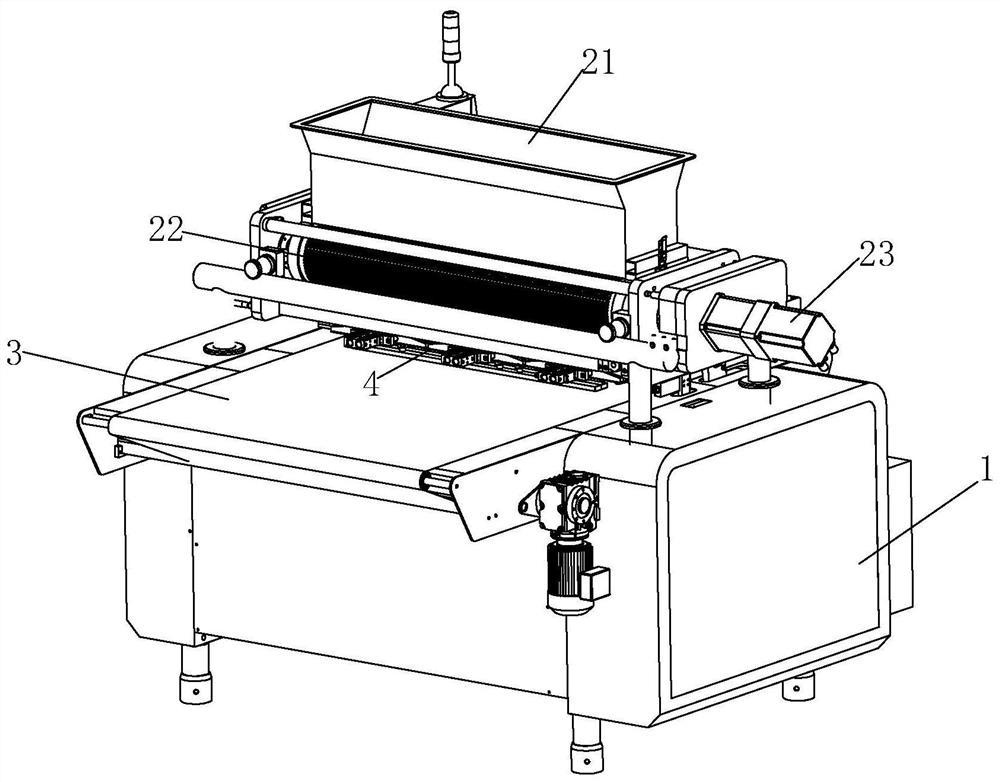

Cookie machine integrating knife cutting and line cutting

ActiveCN112450246AReduce manufacturing costHigh speed cuttingDough shaping and cutting apparatusElectric machineryKnife cuts

The invention relates to a cookie machine integrating knife cutting and line cutting. The cookie machine comprises a frame; the frame is provided with a dough discharging base, a line cutting mechanism and a knife cutting mechanism; the line cutting mechanism includes a line cutting motor, front-back swing arms, a cutting line rotating shaft, a lifting swing arm, a cutting line and a plurality ofcutting line bases; the front-back swing arms are rotationally arranged on the frame with the axis in the horizontal direction as a rotating shaft; the cutting line rotating shaft is horizontally arranged and is rotationally arranged at the upper ends of the front-back swing arms; the plurality of cutting line bases are arranged on the cutting line rotating shaft in the length direction of the cutting line rotating shaft; the line cutting motor is arranged on the frame, and drives the front-back swing arms to swing front and back in a reciprocating manner and drives the lifting swing arm to ascend and descend in a reciprocating manner. The cookie machine of the invention is provided with both the knife cutting mechanism and the line cutting mechanism, so that the cookie machine integratesknife cutting and line cutting; the cookie machine can meet the cutting process of different cookies, has low production cost, and can be suitable for cutting different cookie blanks.

Owner:广东顺德华机机械实业有限公司

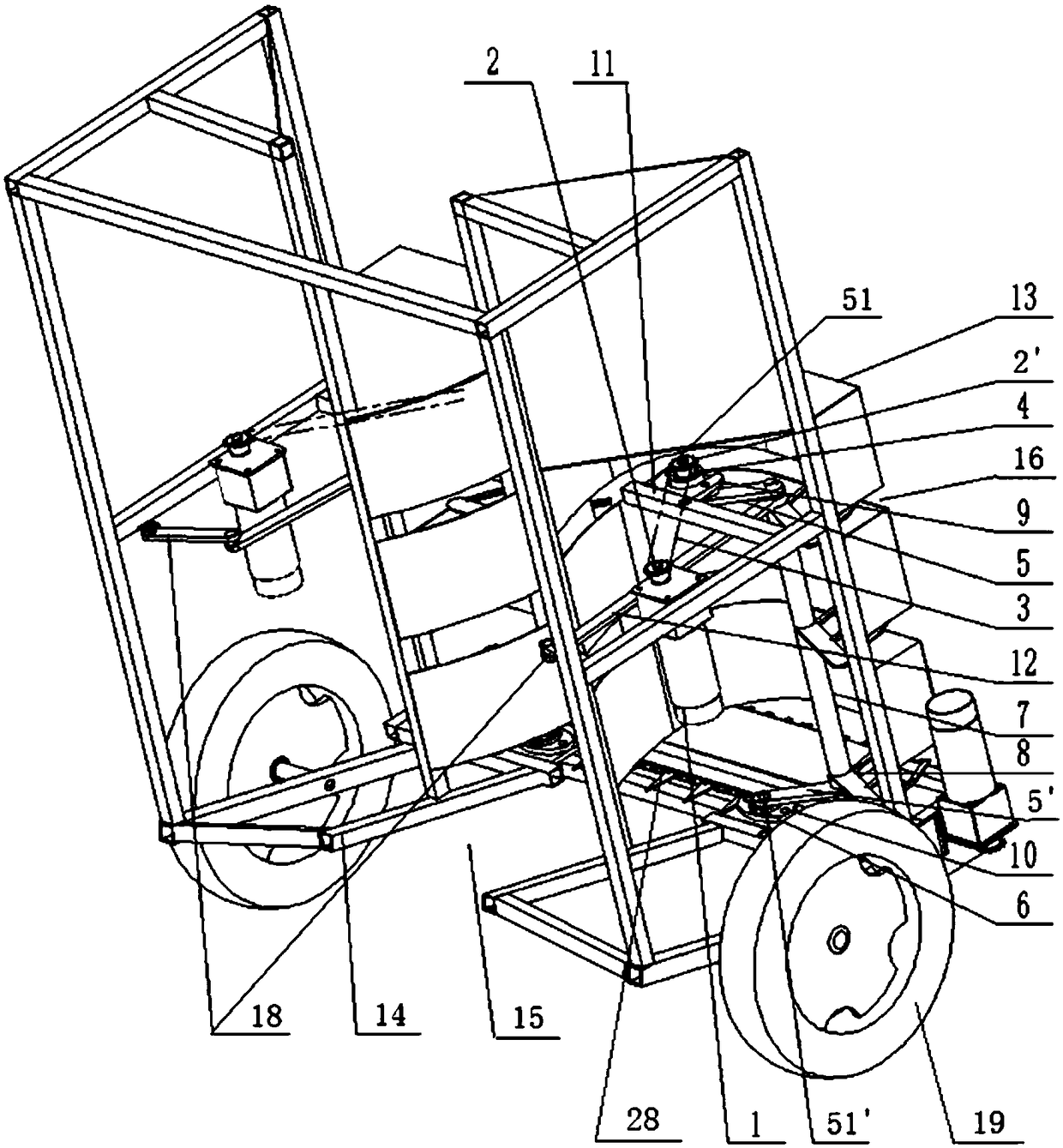

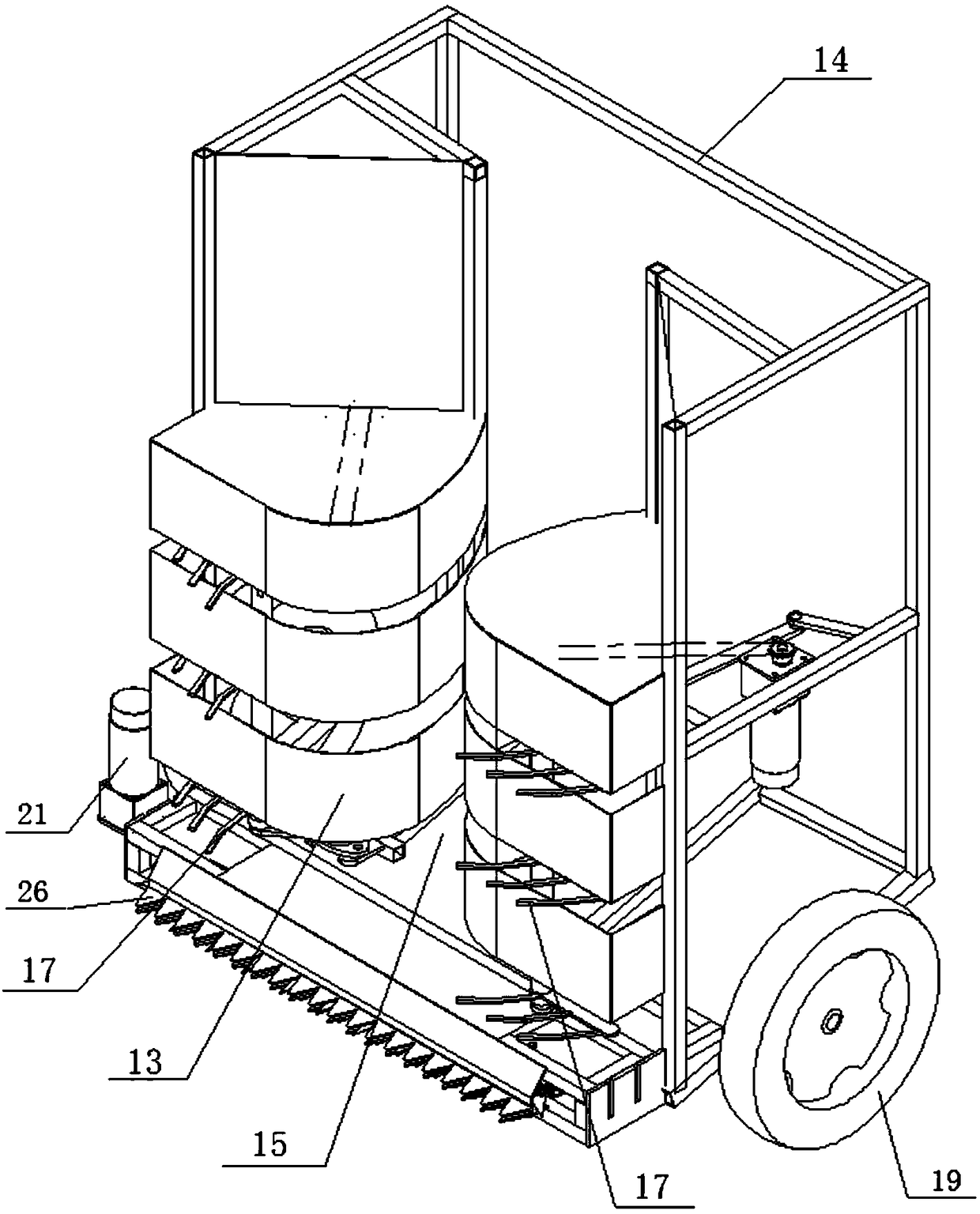

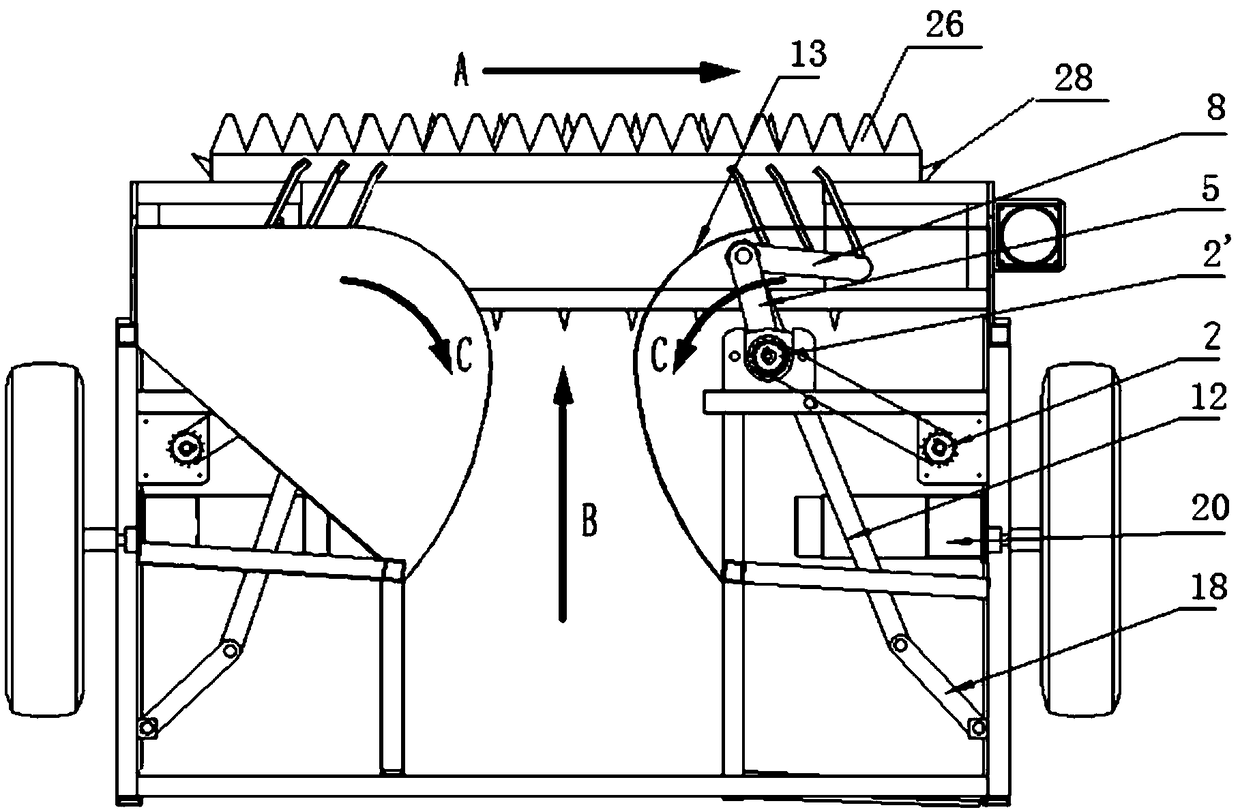

Electric oilseed rape circulating cutting and airing machine allowing middle laying

InactiveCN108848880APlay a guiding rolePlay a guiding role to achieve the purpose of laying in the middleMowersAgricultural undercarriagesMechanical engineeringMultiple layer

The invention discloses an electric oilseed rape circulating cutting and airing machine allowing middle laying. The machine comprises a walking mechanism, a cutting mechanism and a cereal poking and laying mechanism. The cereal poking and laying mechanism comprises multiple layers of cereal guiding plates (13) arranged on the two sides of a rack, cereal poking gaps (16) are reserved among all thelayers of cereal guiding plates, and a laying space (15) is reserved between the cereal guiding plates on the two sides; rotation supporting mechanisms are arranged on the portions, behind the cerealguiding plates on the two sides, of the rack respectively, and comprise first cranks (5) and second cranks (5'), wherein the front ends of the first cranks (5) are pivoted to the rack, and the rear ends of the second cranks (5') are pivoted to the rack; the rear ends of the first cranks are pivoted to one end of a supporting component (7), the other end of the supporting component (7) is pivoted to the front ends of the second cranks, multiple poking rods (8) are fixedly arranged in the middle of the supporting component, and poking fingers (17) are installed on all the poking rods and are opposite to the gaps of cereal poking. When the first cranks behind the cereal guiding plates on the two sides drive the supporting component to rotate, the poking fingers on the two sides intermittentlyextend out the gaps of cereal poking respectively to form an encircle and opposite-embracing state, and then retreat into the cereal guiding plates.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com