High-speed arecanut slicing device and slicing method

A slicing device and betel nut technology, applied in metal processing and other directions, can solve the problems of insecurity, low production efficiency, high cost, etc., and achieve the effects of avoiding safety accidents, improving production efficiency, and high-speed and precise cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

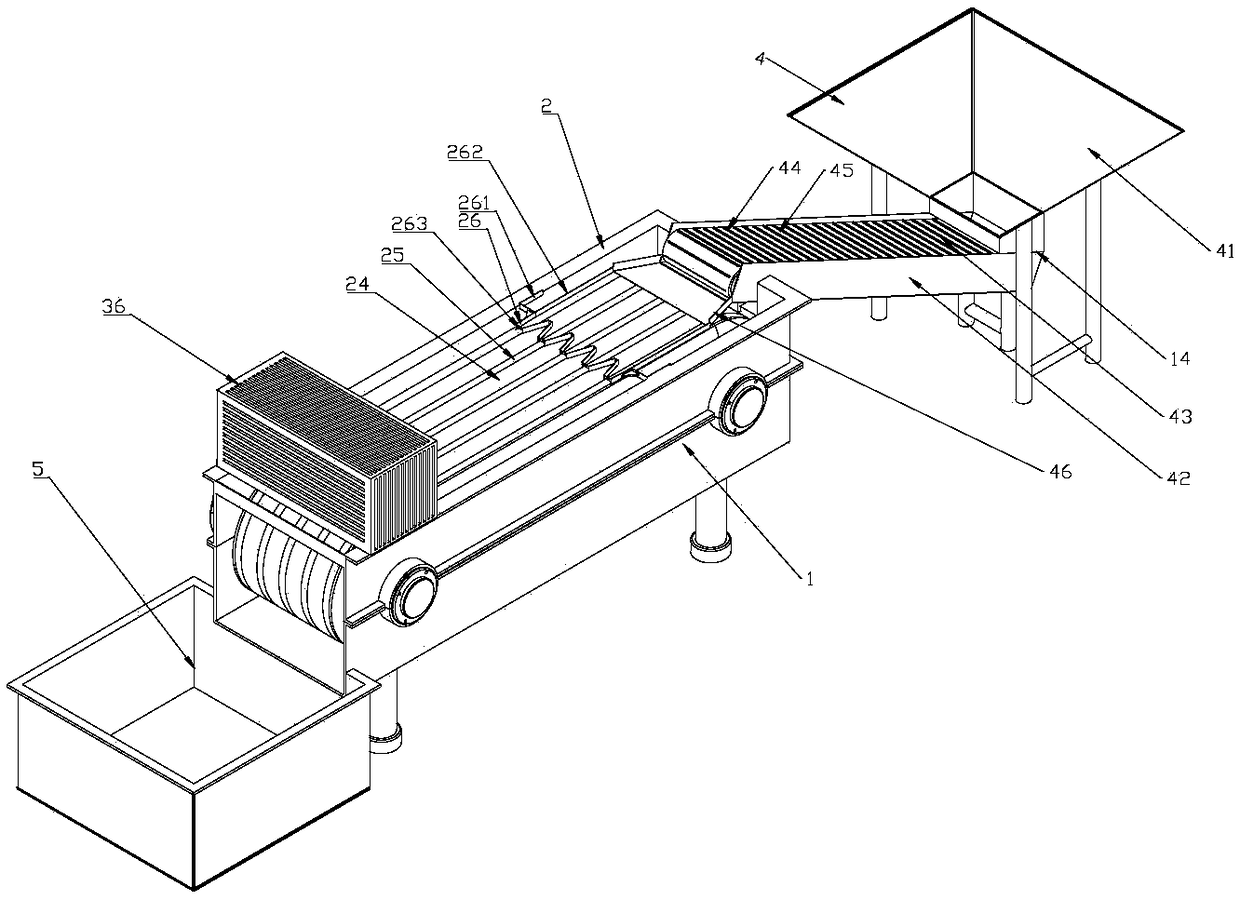

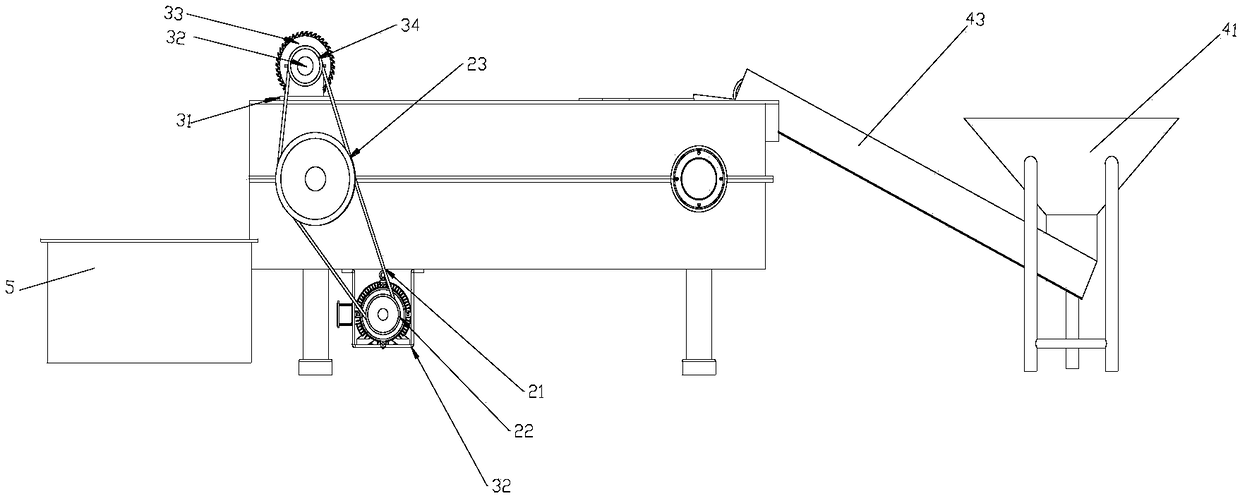

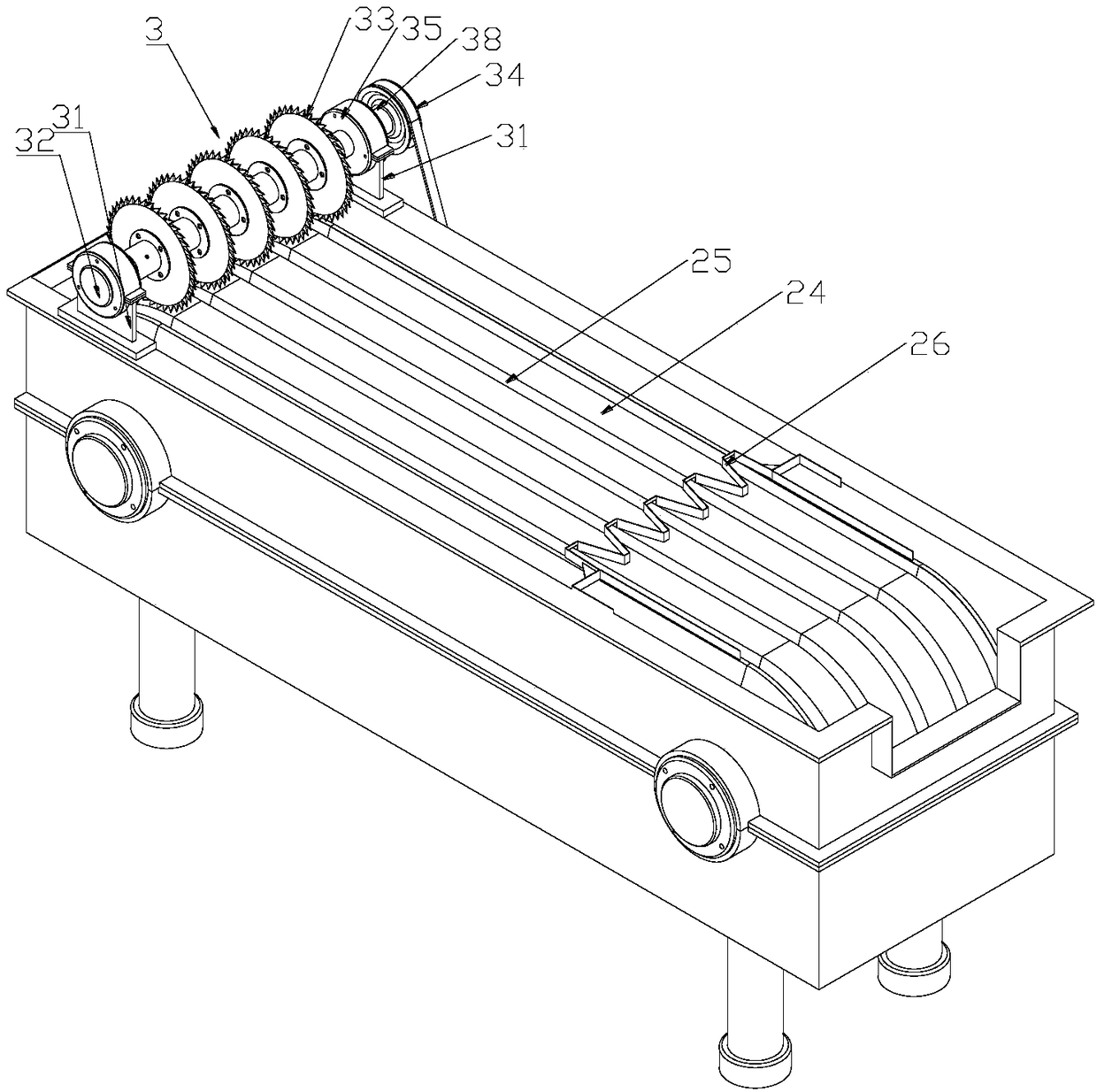

[0032] A kind of betel nut high-speed slicing device, such as Figure 1 to Figure 5As shown, it includes a transmission centering system 2 and a cutting system 3 fixed on the box base 1, and an automatic feeding system 4 that feeds materials into the transmission centering system 2. The automatic feeding system 4 is installed obliquely on the box base 1 , the automatic feeding system 4 includes a hopper 41 and a conveyor belt groove 42 connected to the outlet of the hopper 41, an inclined conveyor belt 43 is fixedly installed in the conveyor belt groove 42, and the end of the conveyor belt groove 42 is clamped at the entrance of the transmission centering system 2, The surface of the inclined conveyor belt 43 is provided with vertical baffles 44 at equidistant intervals along the conveying direction, and a trough 45 is formed between the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com