Patents

Literature

52results about How to "Achieve through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

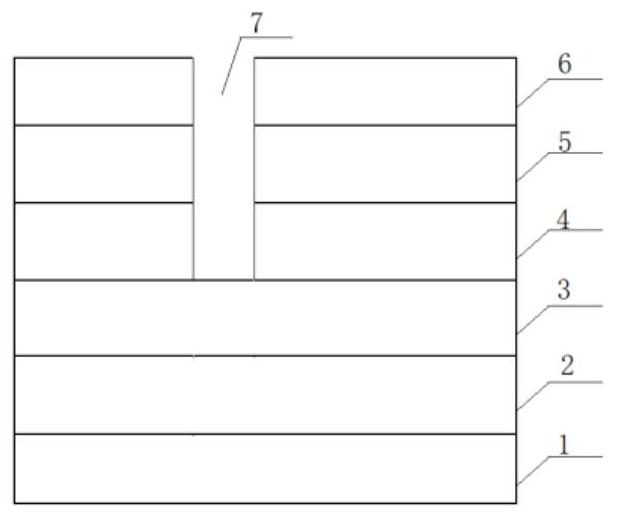

Light valve element and control method thereof and display device

InactiveCN105589252AAchieve throughImplement reflectionStatic indicating devicesNon-linear opticsDisplay deviceEngineering

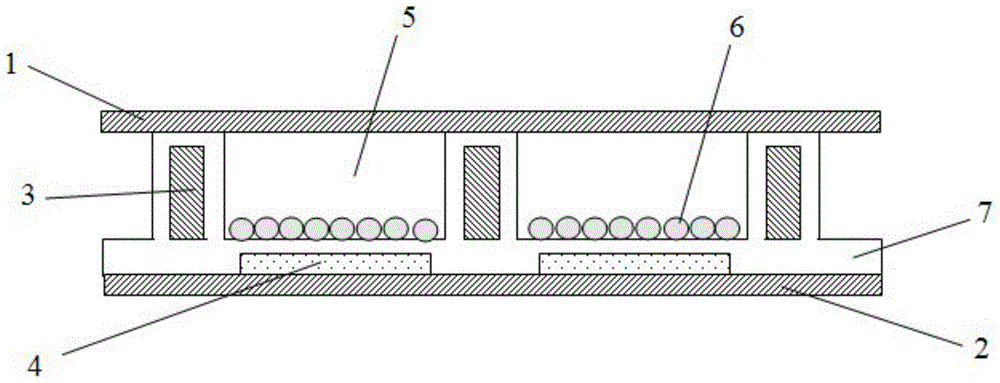

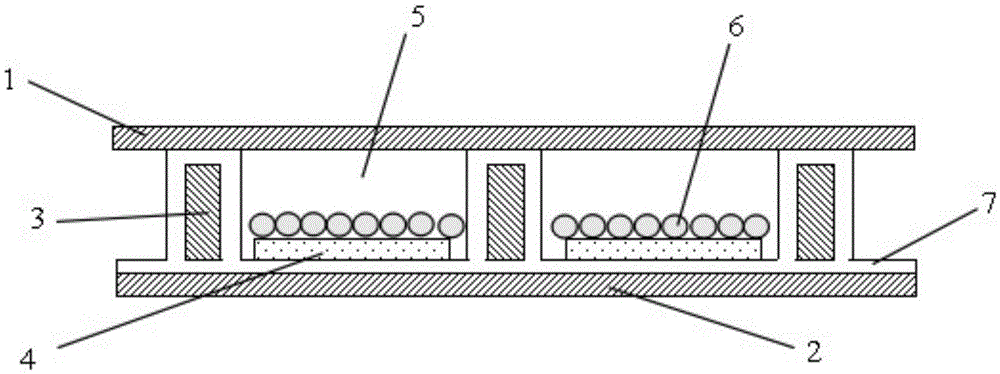

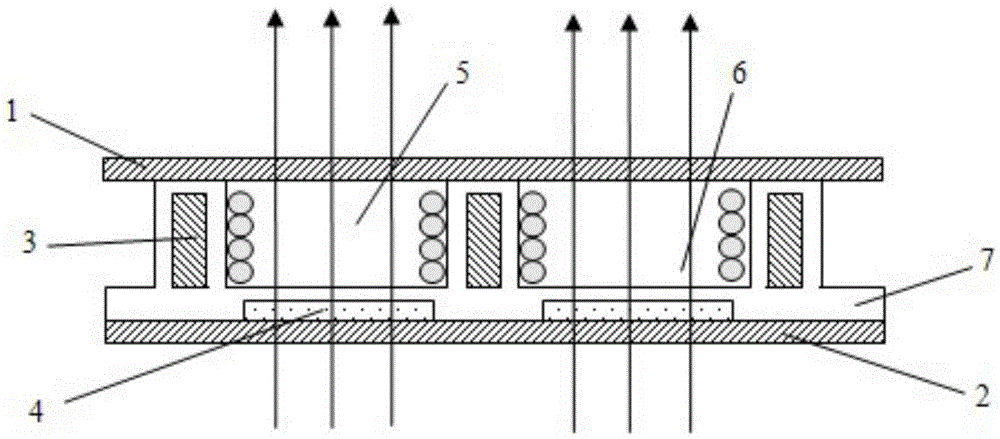

The invention provides a light valve element and a control method thereof and a display device, and belongs to the technical field of display. The problems that an existing light valve element is complex in structure, difficult to prepare, large in power consumption and high in cost can be solved. The light valve element comprises a first substrate and a second substrate which are oppositely arranged in parallel, the space between the first substrate and the second substrate are divided into multiple chambers, and first electrodes and second electrodes are arranged in each chamber, are insulated from each other and are perpendicular to each other; each chamber is filled with an electrophoretic buffer solution containing charged reflection particles, and the reflection particles can be adsorbed to the surfaces of the first electrodes or the surfaces of the second electrodes. The light valve element is simple in working principle, easy to prepare, little in power consumption, low in cost and convenient and efficient to control.

Owner:BOE TECH GRP CO LTD +1

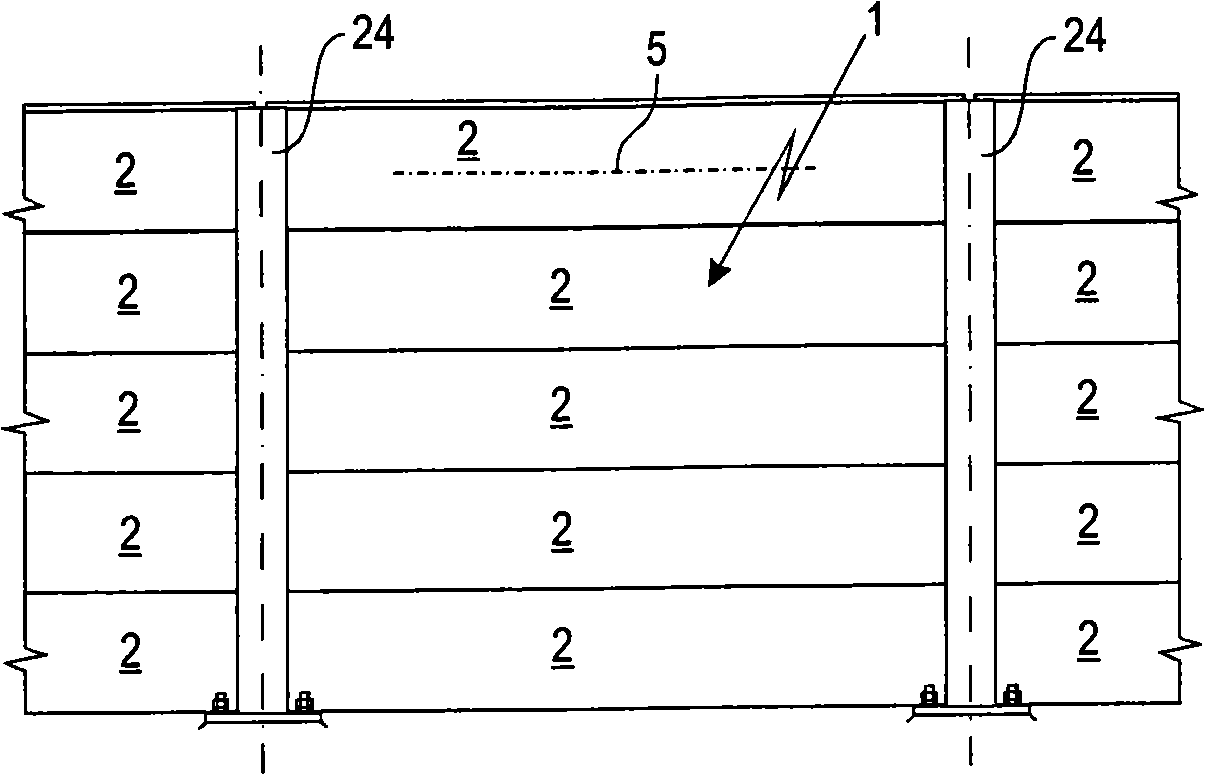

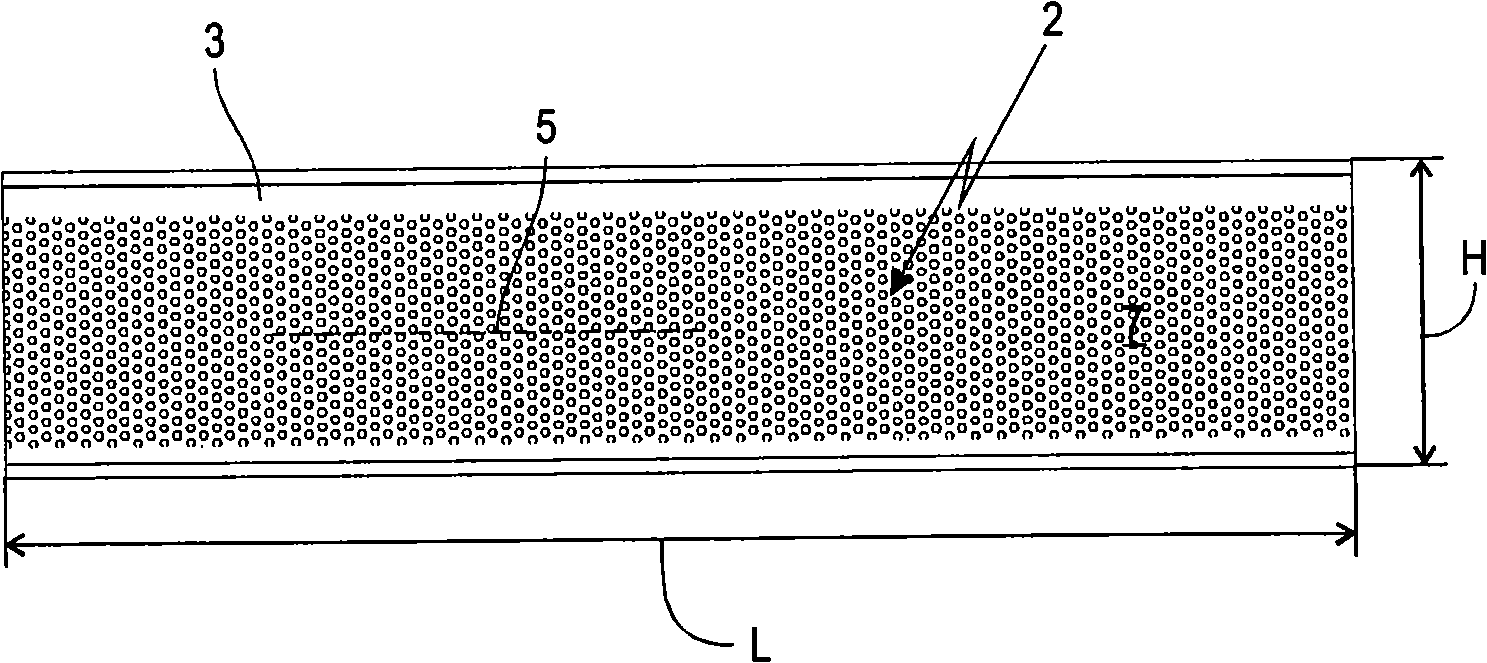

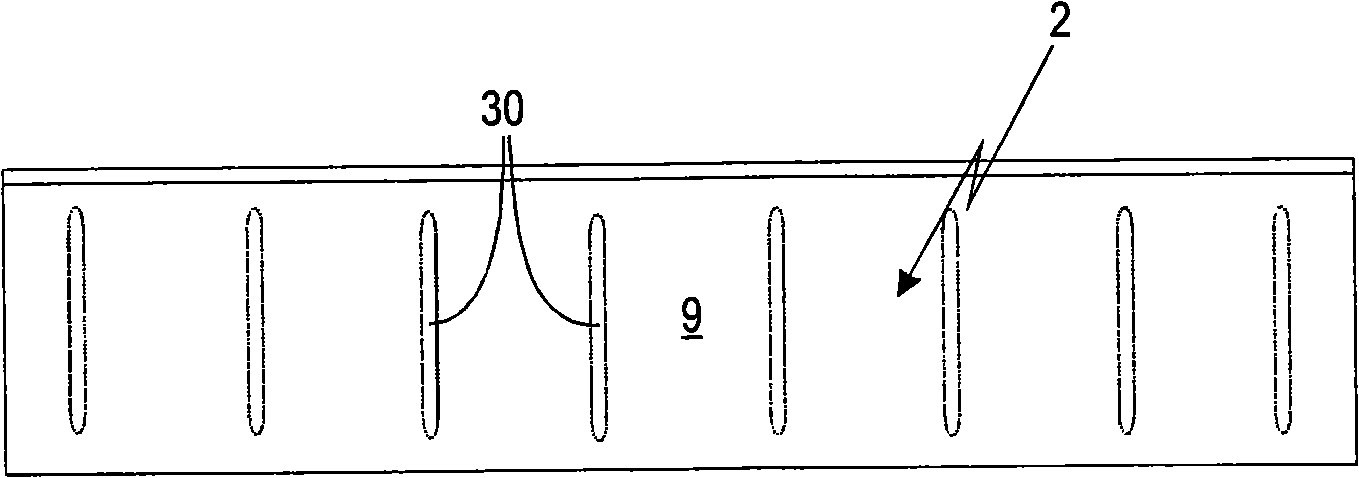

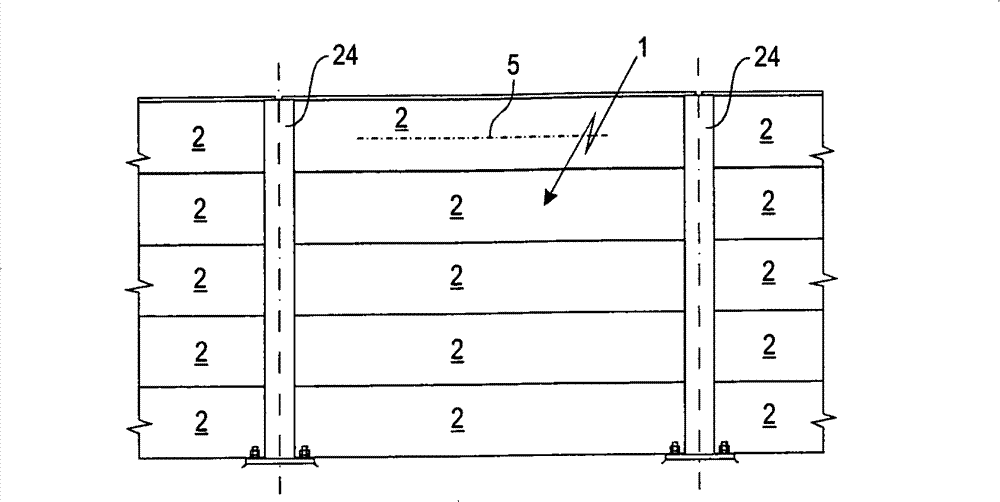

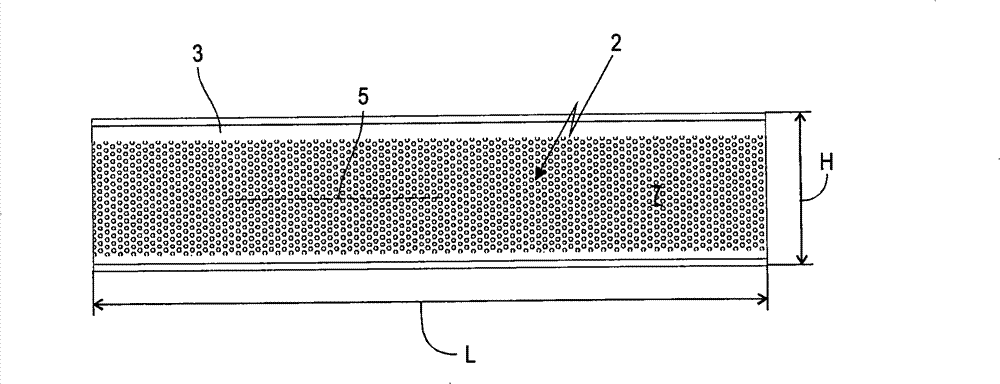

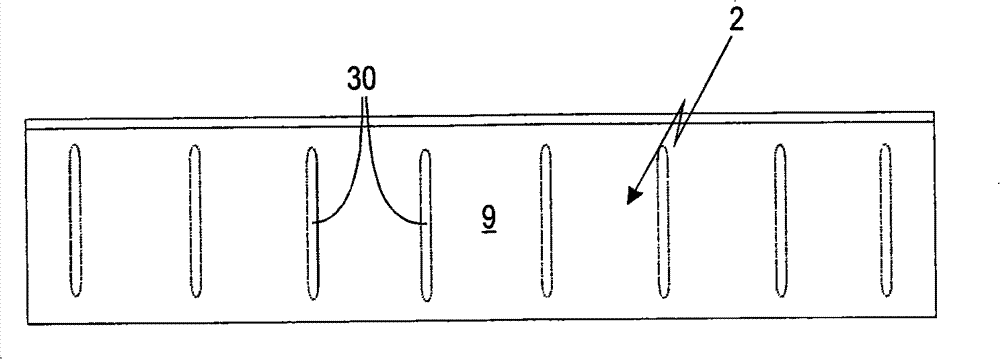

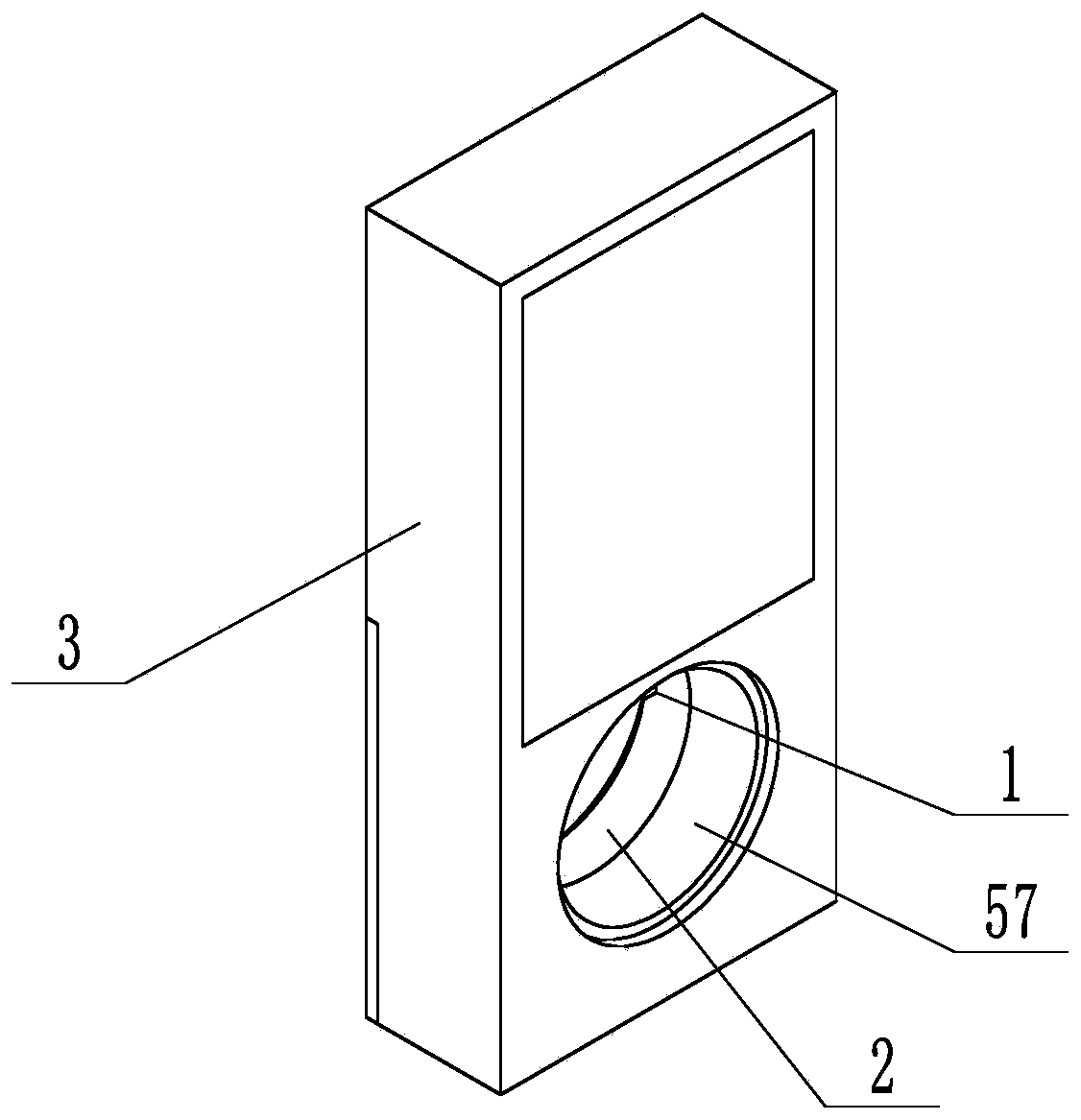

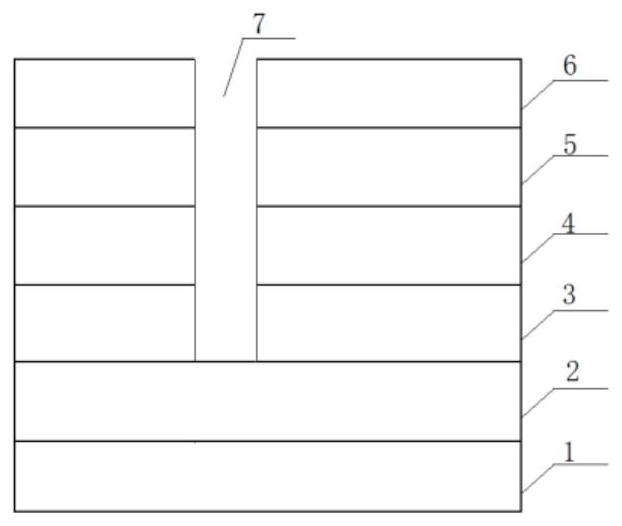

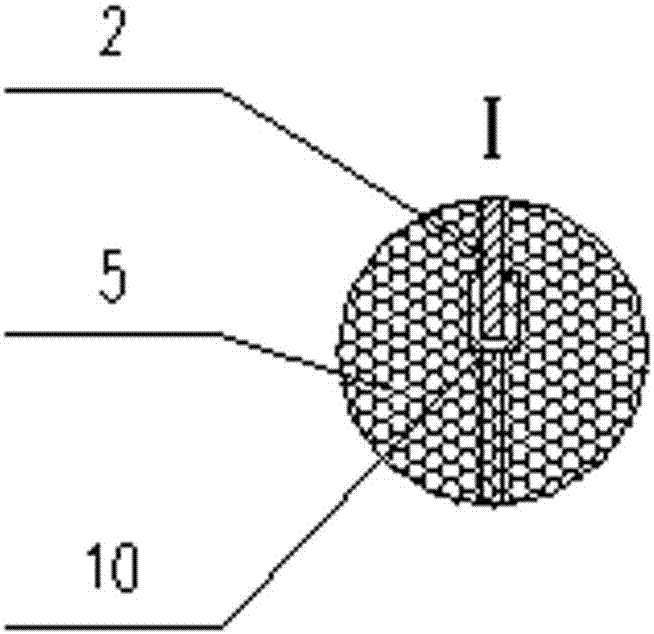

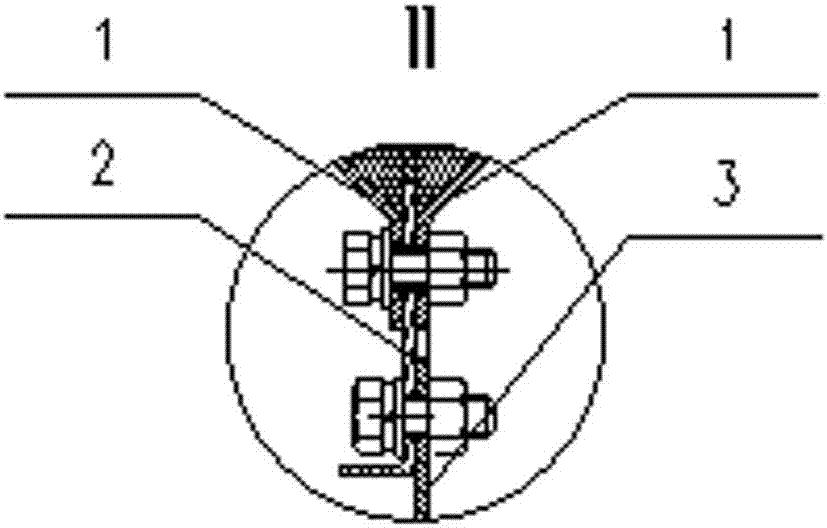

Noise barrier especially for a high-speed railway line

InactiveCN101349040AReliable Aerodynamic LoadsReliably withstands aerodynamic loadsNoise reduction constructionNoise barrierEngineering

The invention relates to an acoustic barrier especially used for high speed railway. The acoustic barrier comprises multiple acoustic insulation components (2); the acoustic insulation components (2) comprises a plate shell (3) having an acoustic insulation liner (4) and a hollow transverse section crossing the longitudinal axis (5). The surrounding walls (6, 7, 8, 9) of the plate shell (3) consist of at least on plate (10, 11) formed by folding the hollow transverse section.

Owner:旭普林工程股份公司

Noise barrier especially for a high-speed railway line

InactiveCN101349040BHollow cross-section realizationIncreasing the thicknessNoise reduction constructionNoise barrierEngineering

The invention relates to an acoustic barrier especially used for high speed railway. The acoustic barrier comprises multiple acoustic insulation components (2); the acoustic insulation components (2) comprises a plate shell (3) having an acoustic insulation liner (4) and a hollow transverse section crossing the longitudinal axis (5). The surrounding walls (6, 7, 8, 9) of the plate shell (3) consist of at least on plate (10, 11) formed by folding the hollow transverse section.

Owner:旭普林工程股份公司

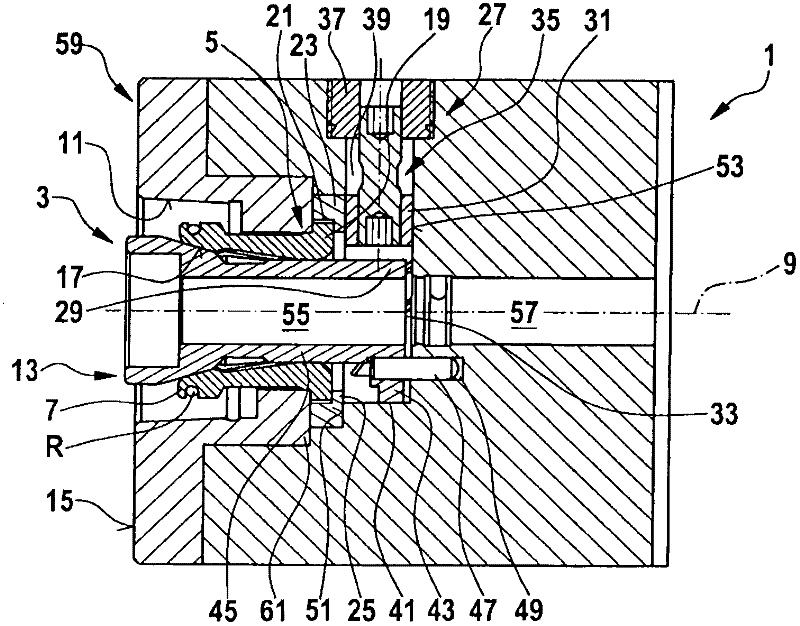

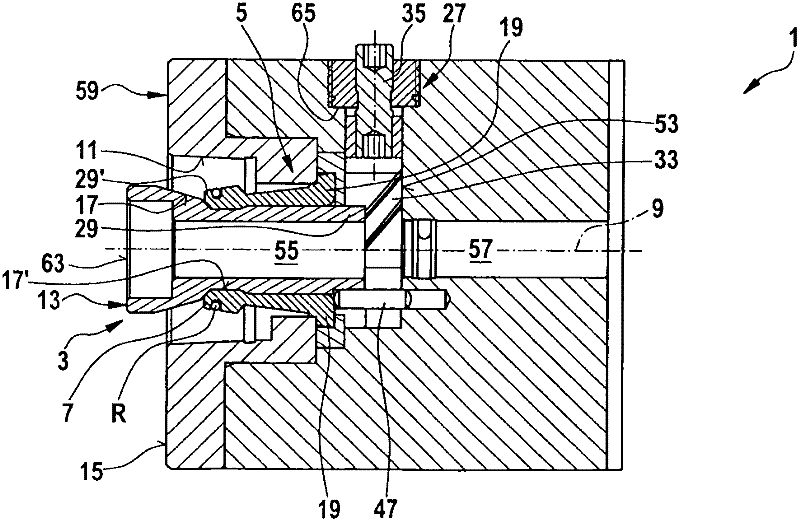

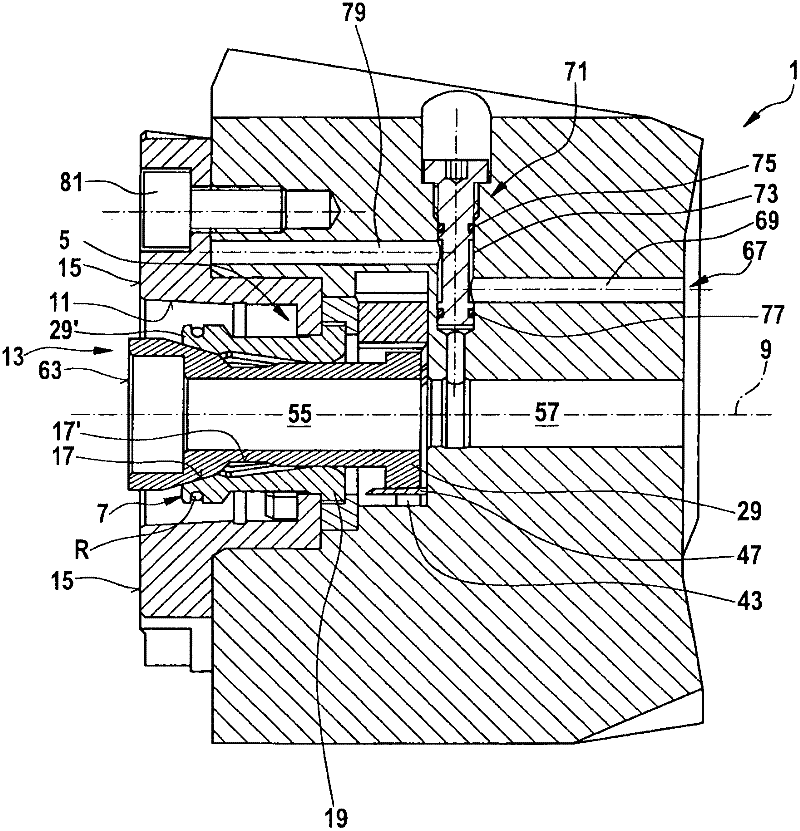

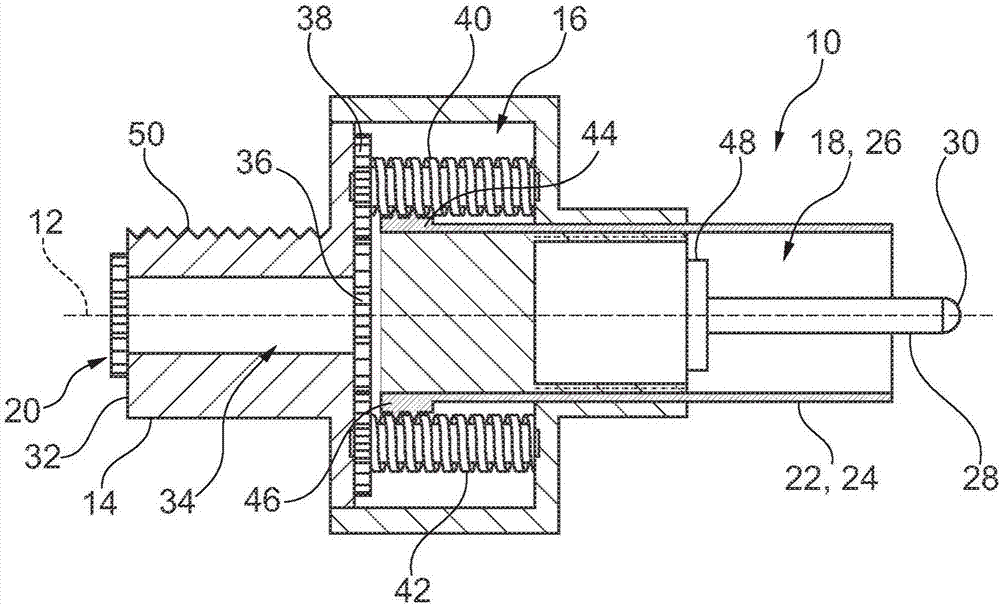

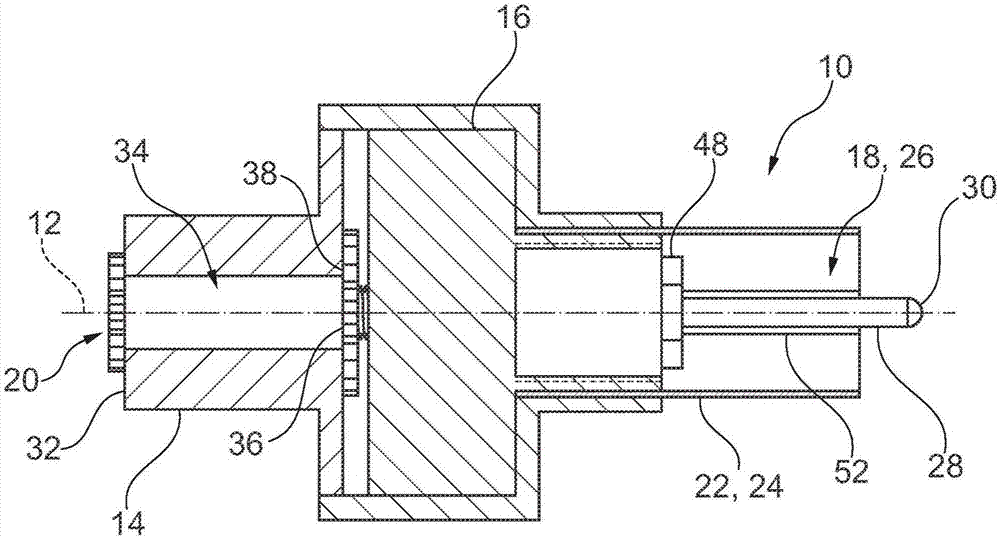

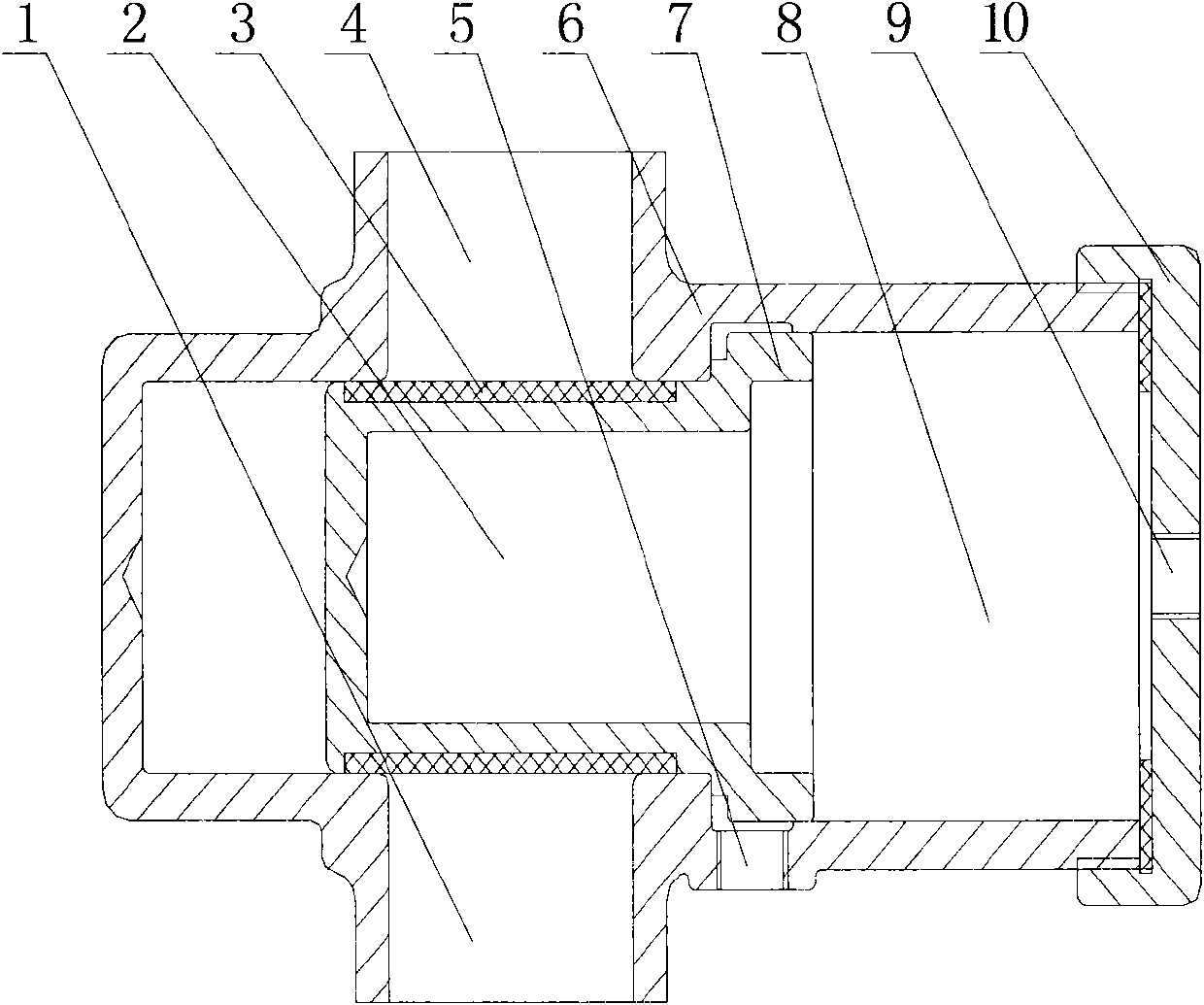

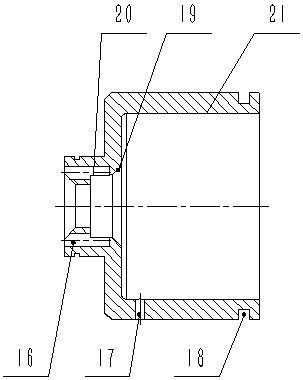

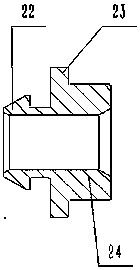

Tool holder

InactiveCN102227276AShorten the lengthAchieve flow throughLathesSleeve/socket jointsAxial displacementEngineering

The invention relates to a tool holder comprising: a hollow-shaft taper chucking device having a center axis (9), a chucking unit (7) having at least one collet chuck (7), which can be inserted into the hollow shaft of a tool, a tension rod (13) which can be moved in the direction of the center axis (9) and cooperates with the at least one collet chuck (7) such that in a first function position of the tension rod (13), the at least one collet chuck (7) is forced radially outward into a chucking position, and in a second function position of the tension rod (13), it can bend radially inward in the direction of the center axis (9) and further comprising an operating unit (27) which cooperates with the tension rod (13). According to the invention, the operating unit (27) has an operating element (31) that can be moved at an angle of preferably 90 DEG to the center axis (9) and comprises at least one operating part (33), the tension rod (13) has at least one engagement part (99), and the operating part (33) and the engagement part (99) form a wedge gear, so that the operating part (33) induces an axial displacement of the tension rod (13) with a radial displacement of the operating element (31).

Owner:MAPAL FABRIK FUER PRAEZISIONSWERKZEUGE (DE)

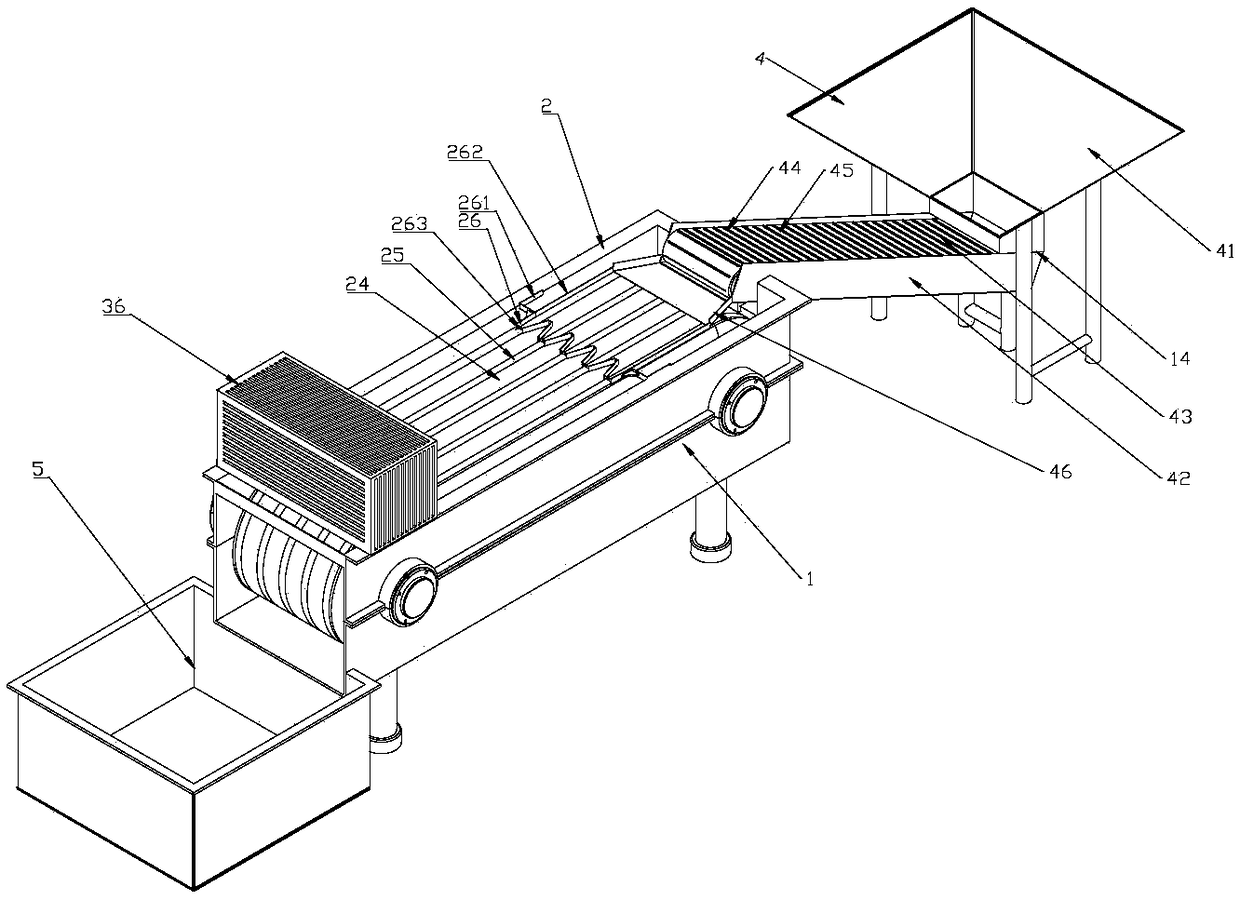

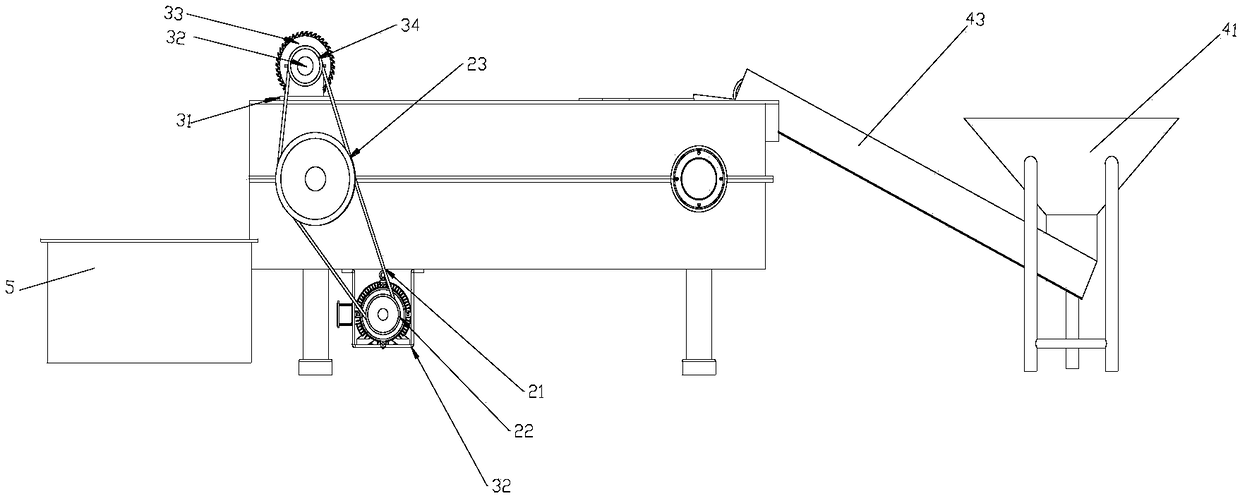

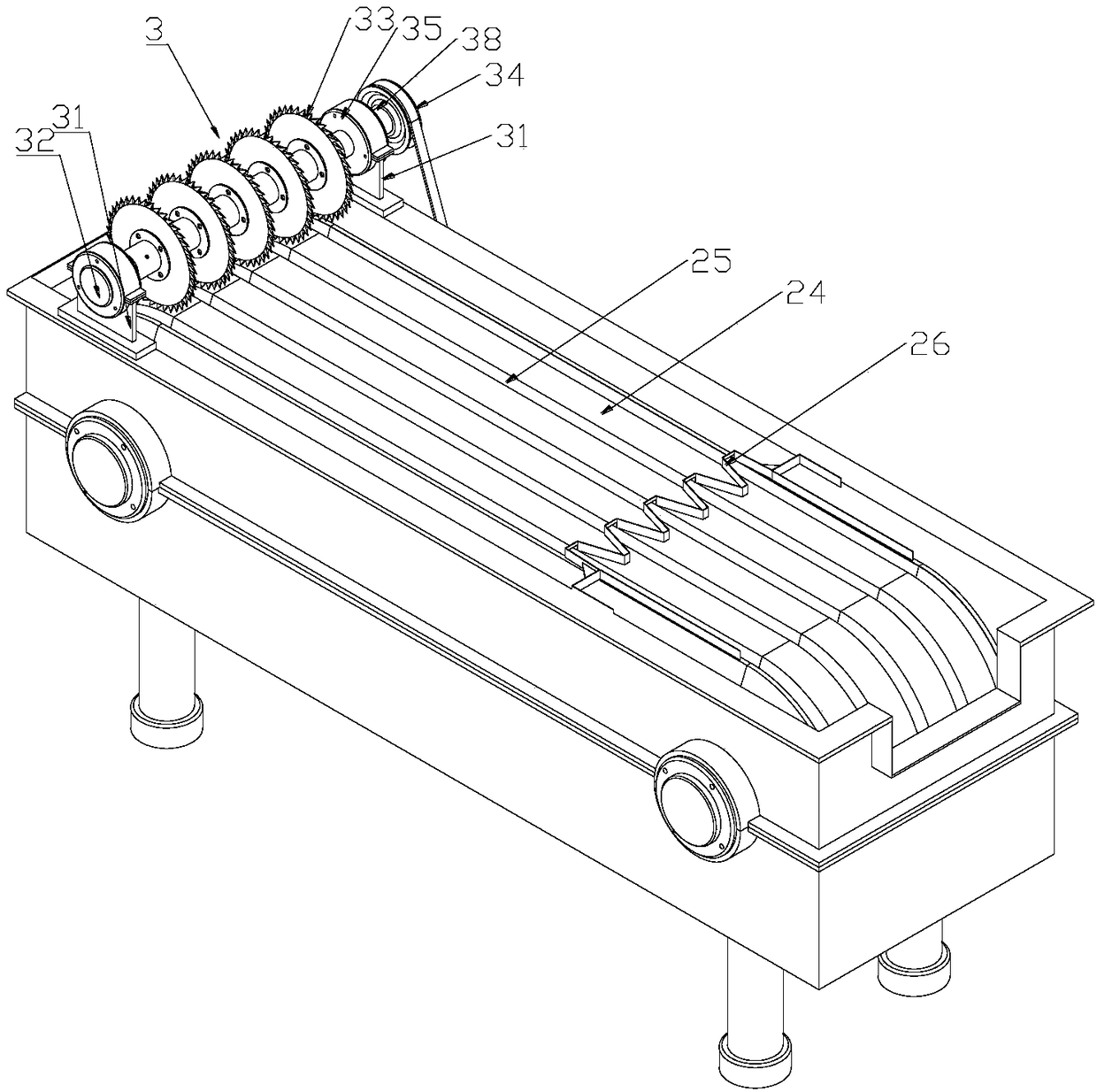

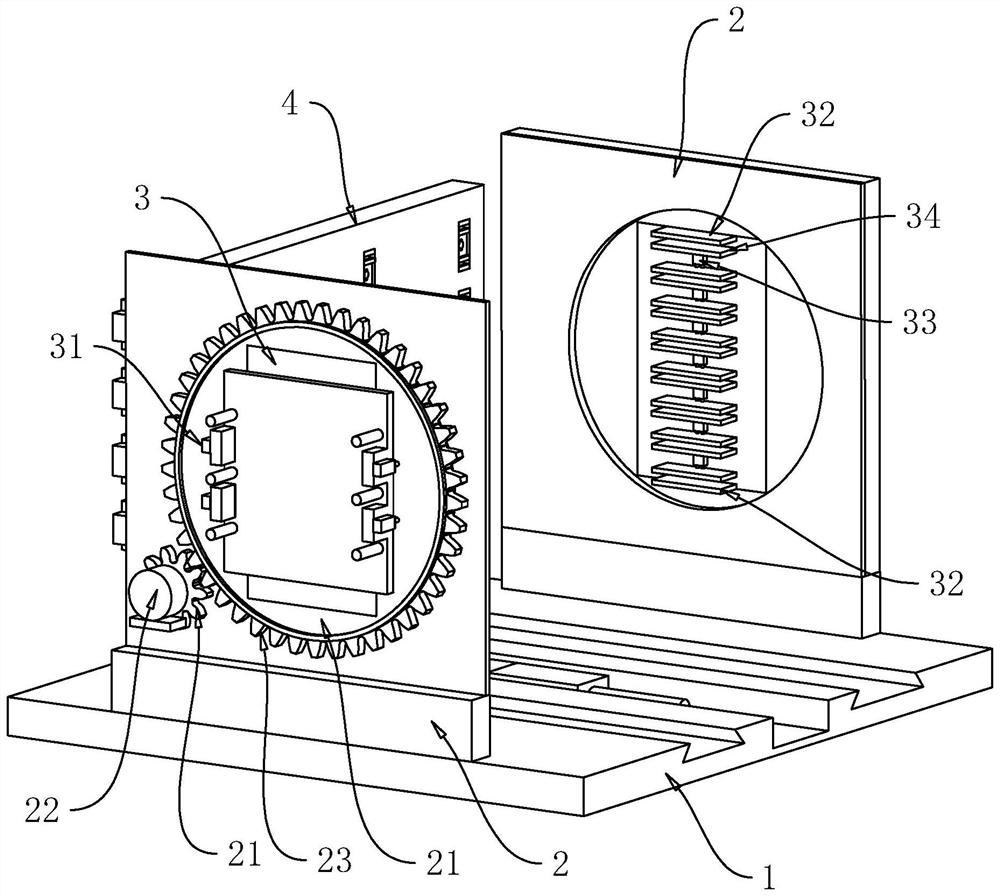

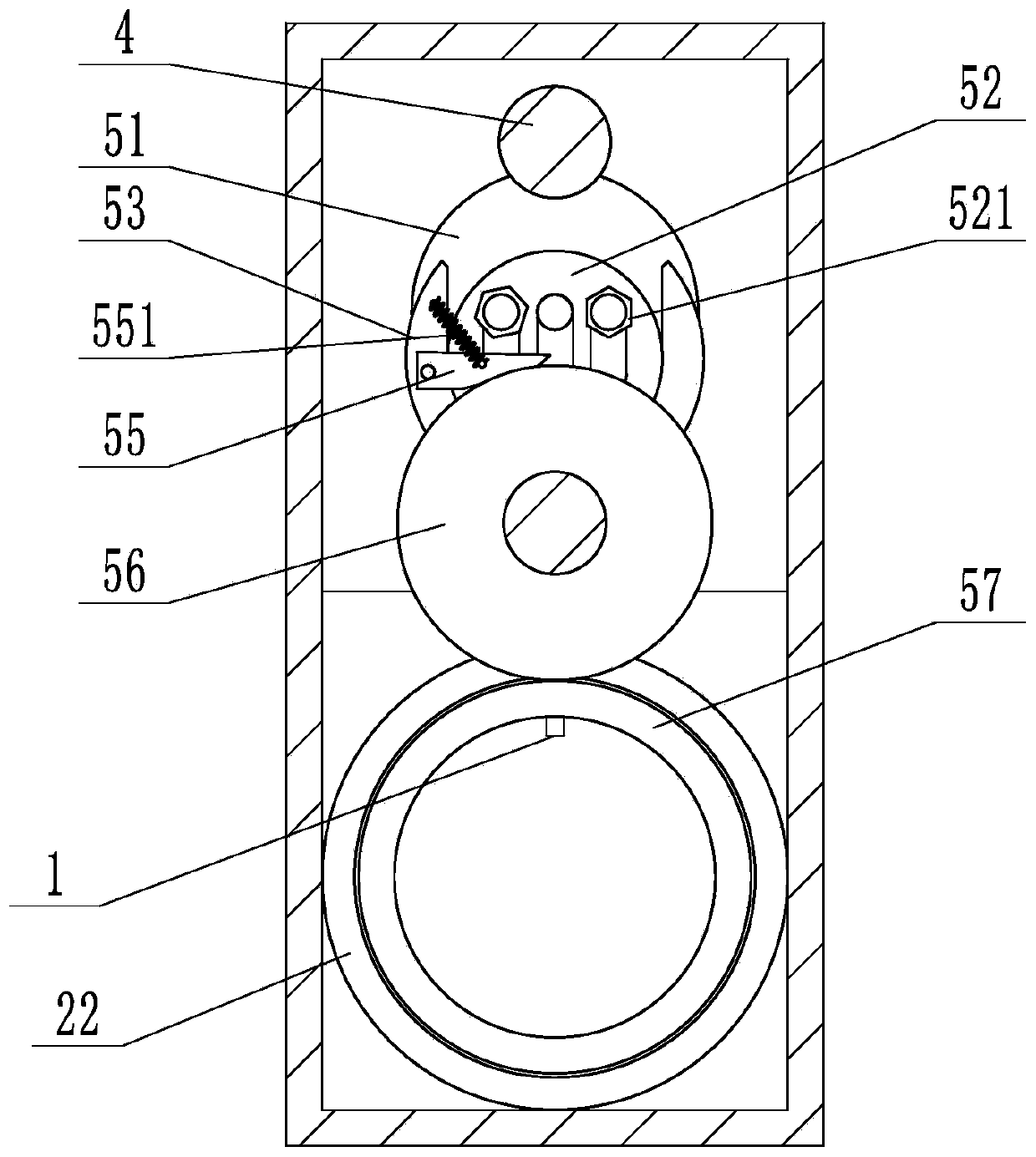

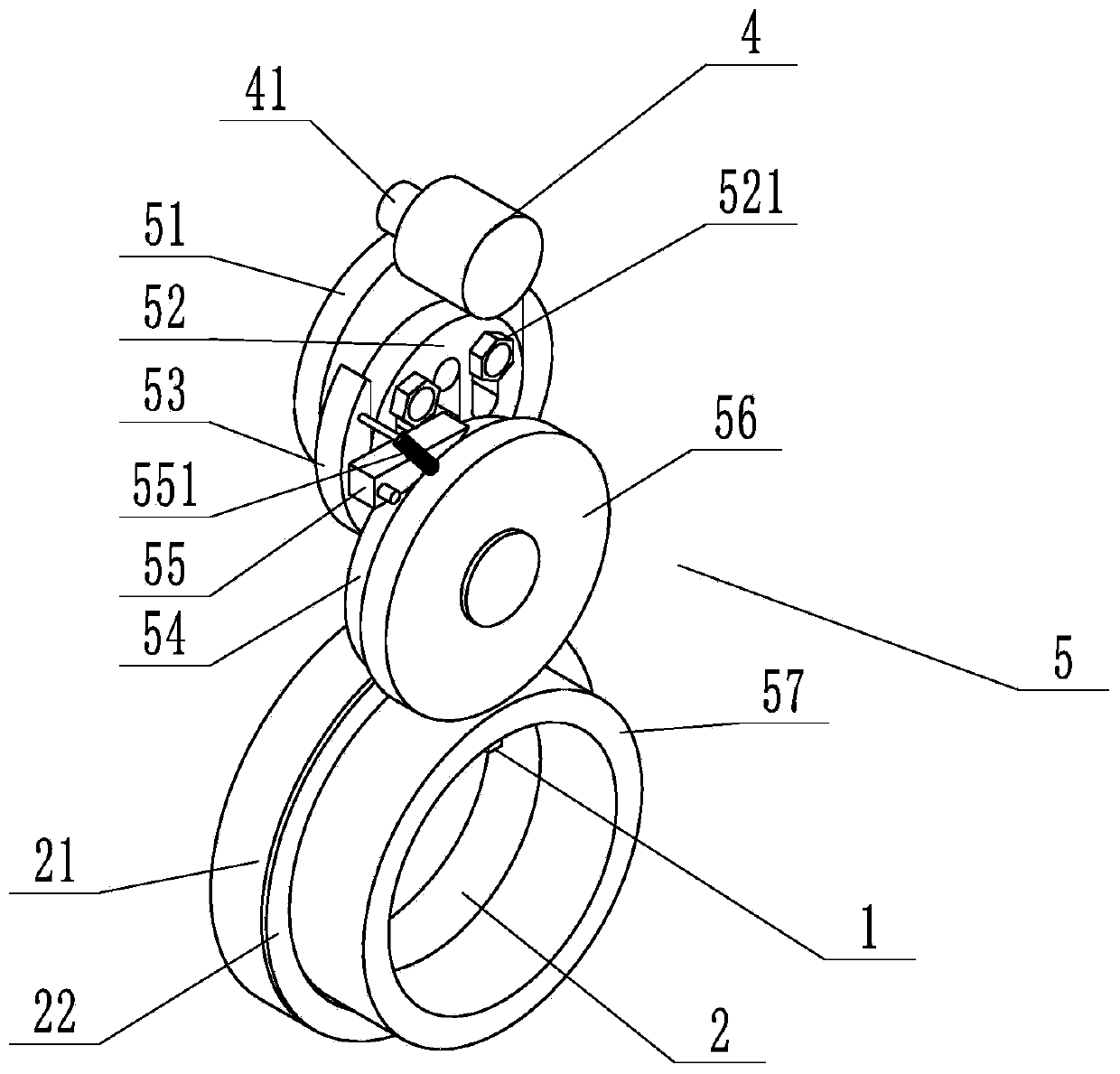

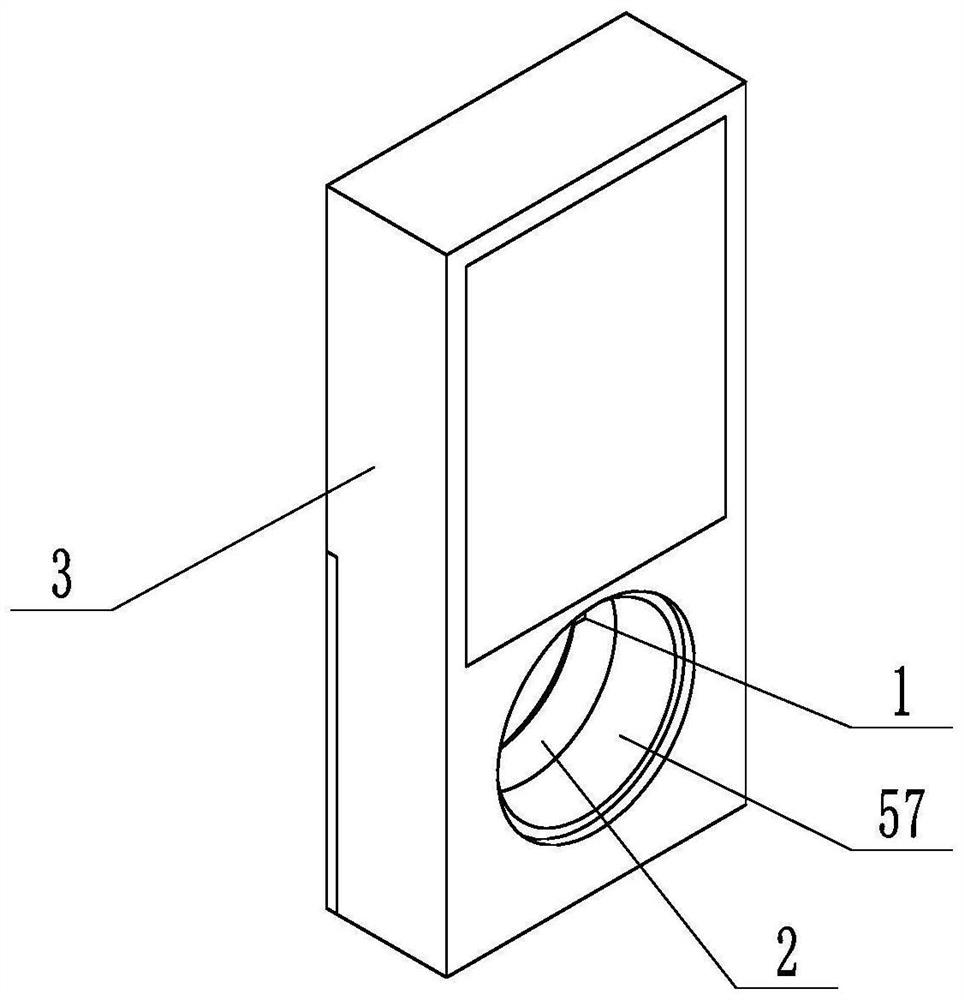

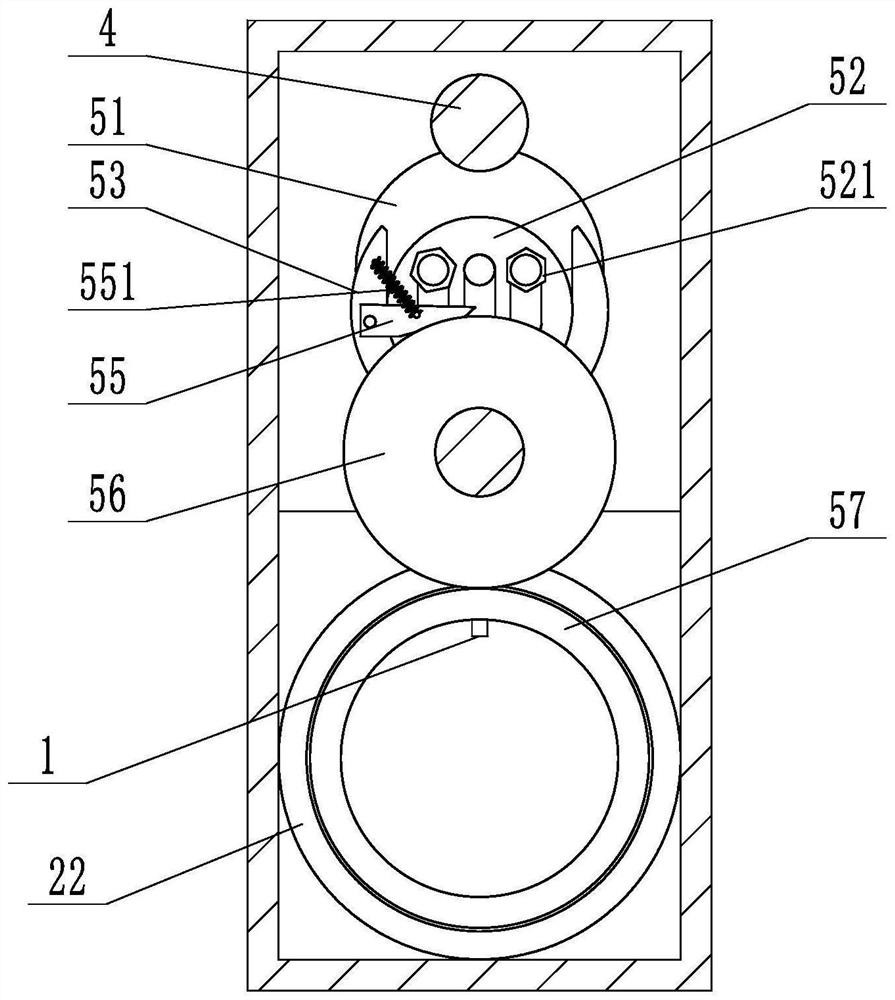

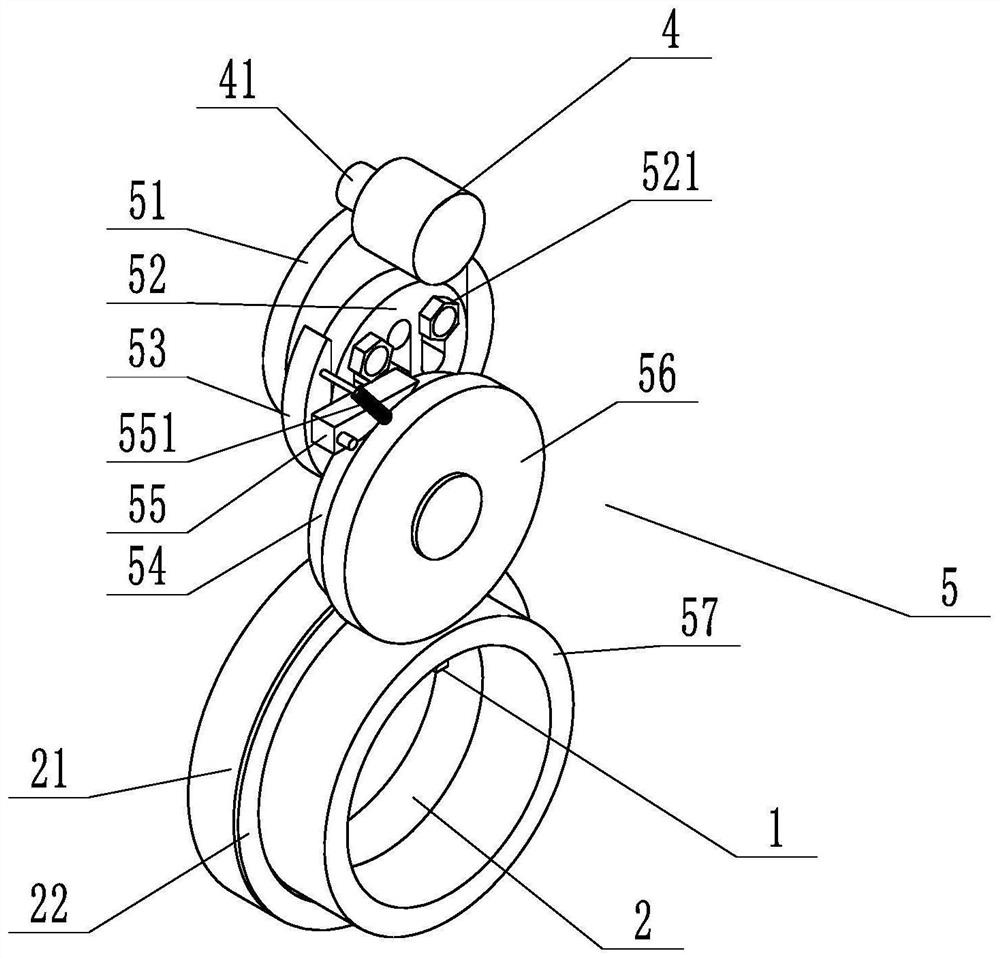

High-speed arecanut slicing device and slicing method

PendingCN108098878AHigh-speed and precise cuttingAchieve a single passMetal working apparatusEngineeringPulley

The invention discloses a high-speed arecanut slicing device comprising a conveying centering system, a cutting system and an automatic feeding system. The conveying centering system and the cutting system are fixedly arranged on a machine seat. The automatic feeding system adds materials into the conveying centering system. The conveying centering system comprises a motor, a small belt pulley, alarge belt pulley and a horizontal conveying belt in coaxial transmission with the large belt pulley. The horizontal conveying belt is provided with at least five material clamping grooves at equal intervals, and flow guide plates matched with the material clamping grooves to achieve conveying centering of materials. The flow guide plates are provided with flow limiting groove outlets. Zigzag cutters of the cutting system are separated through locating sleeves and are fixedly connected with a cutter rotary shaft. The invention further provides a high-speed arecanut slicing method. Arecanuts pass the high-speed arecanut slicing device one by one through the flow guide plates, the arecanuts are clamped by the material clamping grooves in a combined mode so as to ensure centering, additionalclamping is not needed, meanwhile, all the zigzag cutters are fixedly connected to the cutter rotary shaft through the locating sleeves, the arecanuts are sliced at the same high angular speed, thus slicing further achieves centering, and slicing efficiency is improved greatly.

Owner:WUYI UNIV

Nano-zinc oxide sun-blocking cream

InactiveCN103800269AHigh selectivityImplement reflectionCosmetic preparationsToilet preparationsAdemetionineStearate

The invention discloses nano-zinc oxide sun-blocking cream. The sun-blocking cream comprises the following components in parts by mass: 6-10 parts of zinc oxide powder with grain diameter of 100-285nm, 8-13 parts of titanium dioxide powder with grain diameter of 297-500nm, 10-30 parts of monostearate glyceride, 10-13 parts of white oil, 4-6 parts of vaseline, 4-8 parts of dehydrated sorbitan sesquioleate, 7-9 parts of cetanol, 3-7 parts of bee wax, 5-13 parts of glycerinum, 7-10 parts of deionized water, 4 parts of triethanolamine, 1-3 parts of methylparaben and 10-13 parts of traditional Chinese medicine extracted essential solution, wherein the traditional Chinese medicine extracted essential solution with mass percentage of 40 percent is prepared from Chinese angelica, polygonum multiflorum, ginseng, saffron, angelica root, cassia twig and coix seed through superfine grinding, decocting, filtering and concentrating steps.

Owner:陆燕

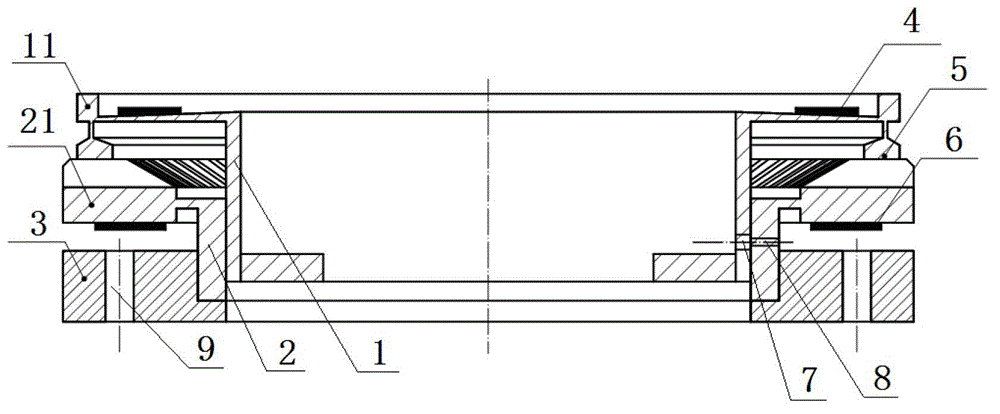

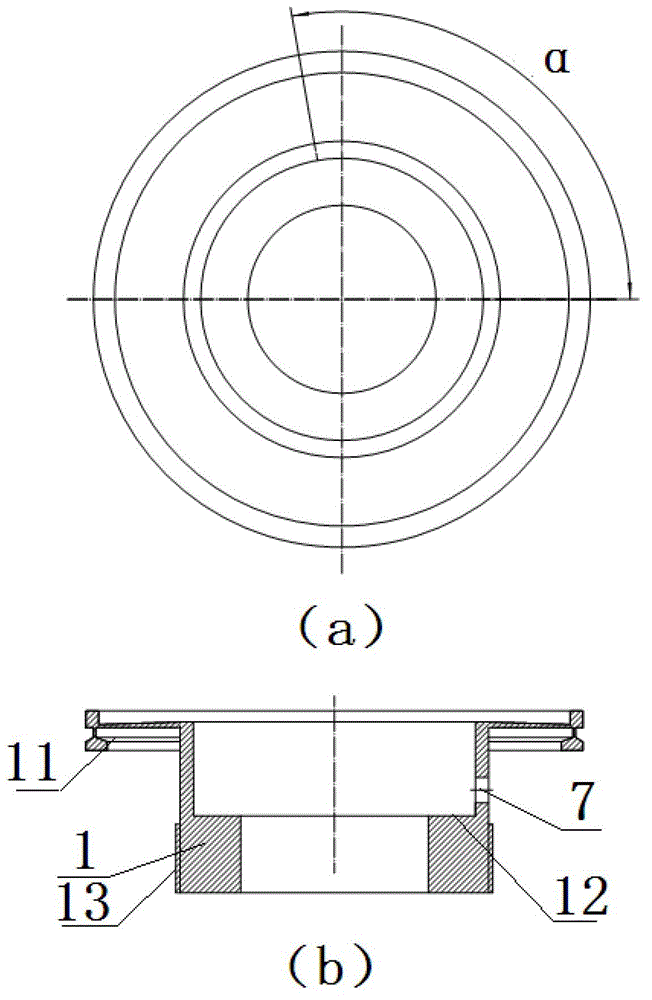

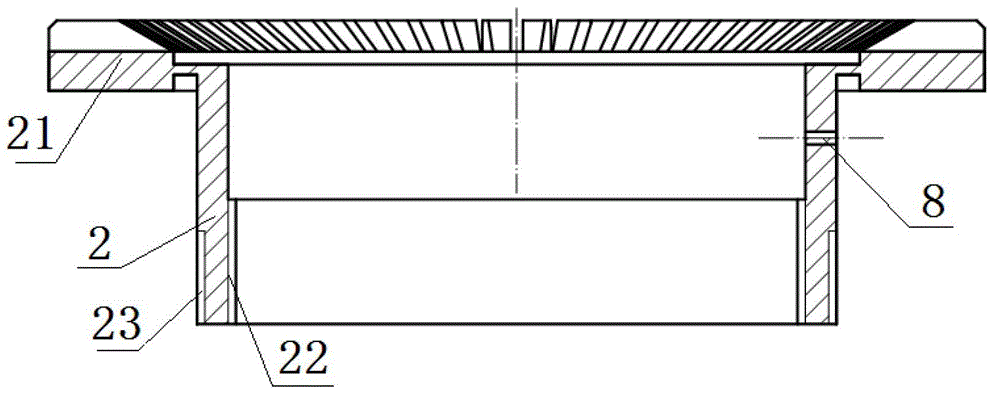

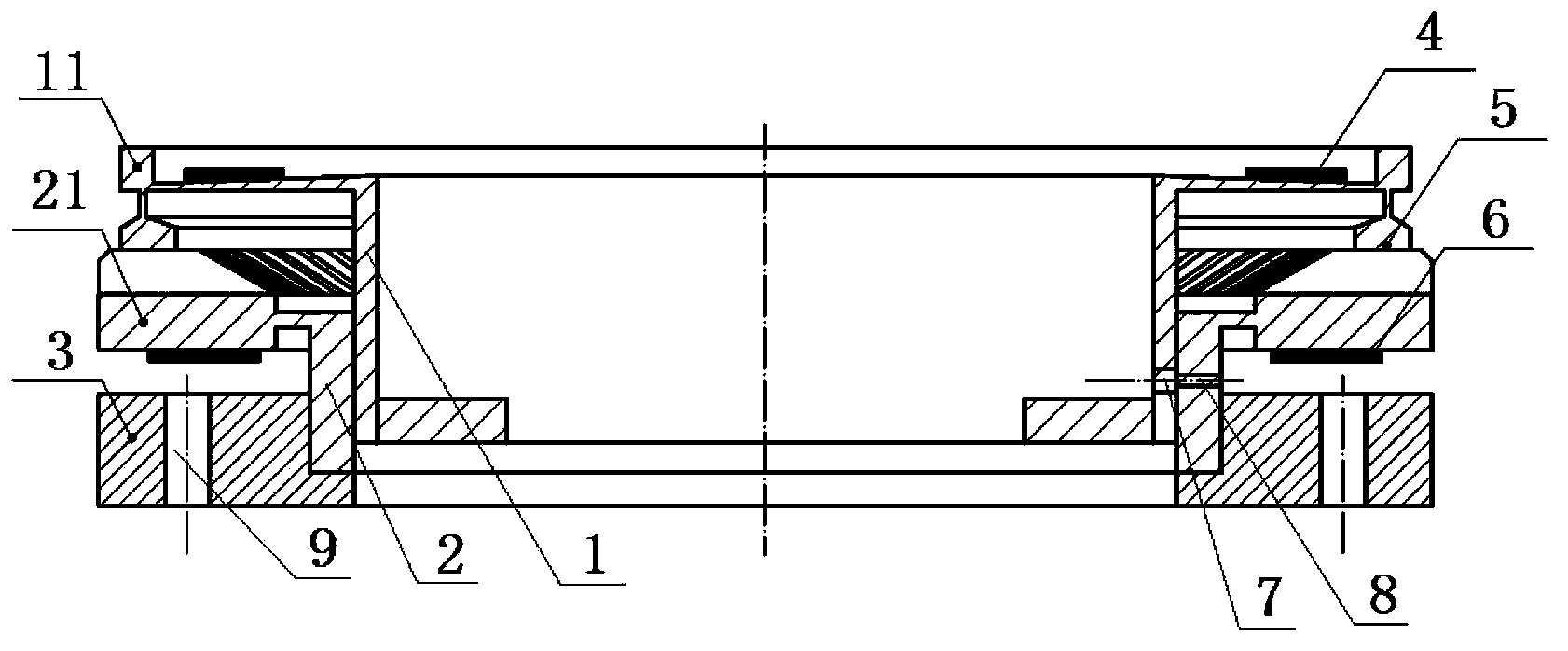

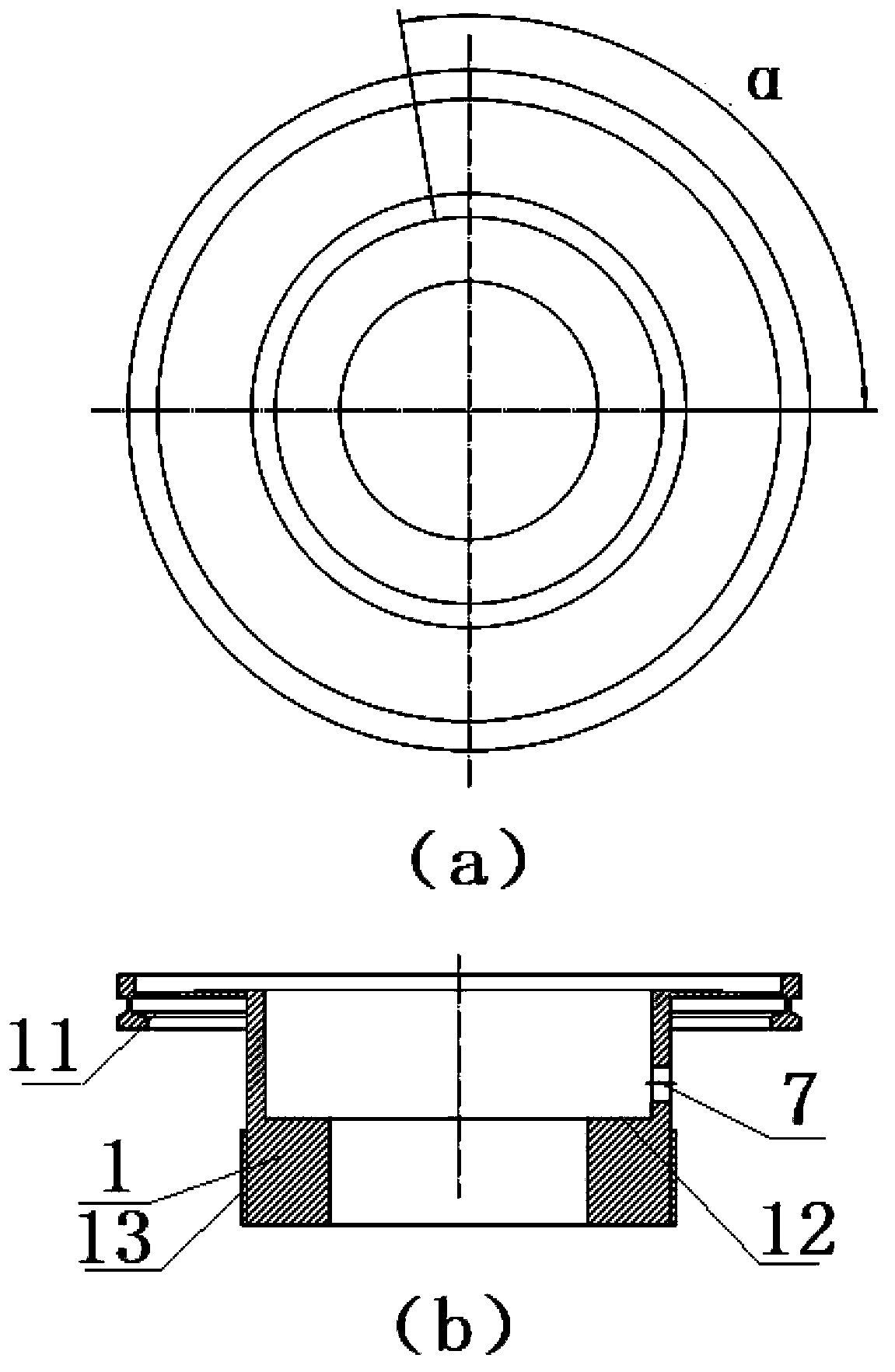

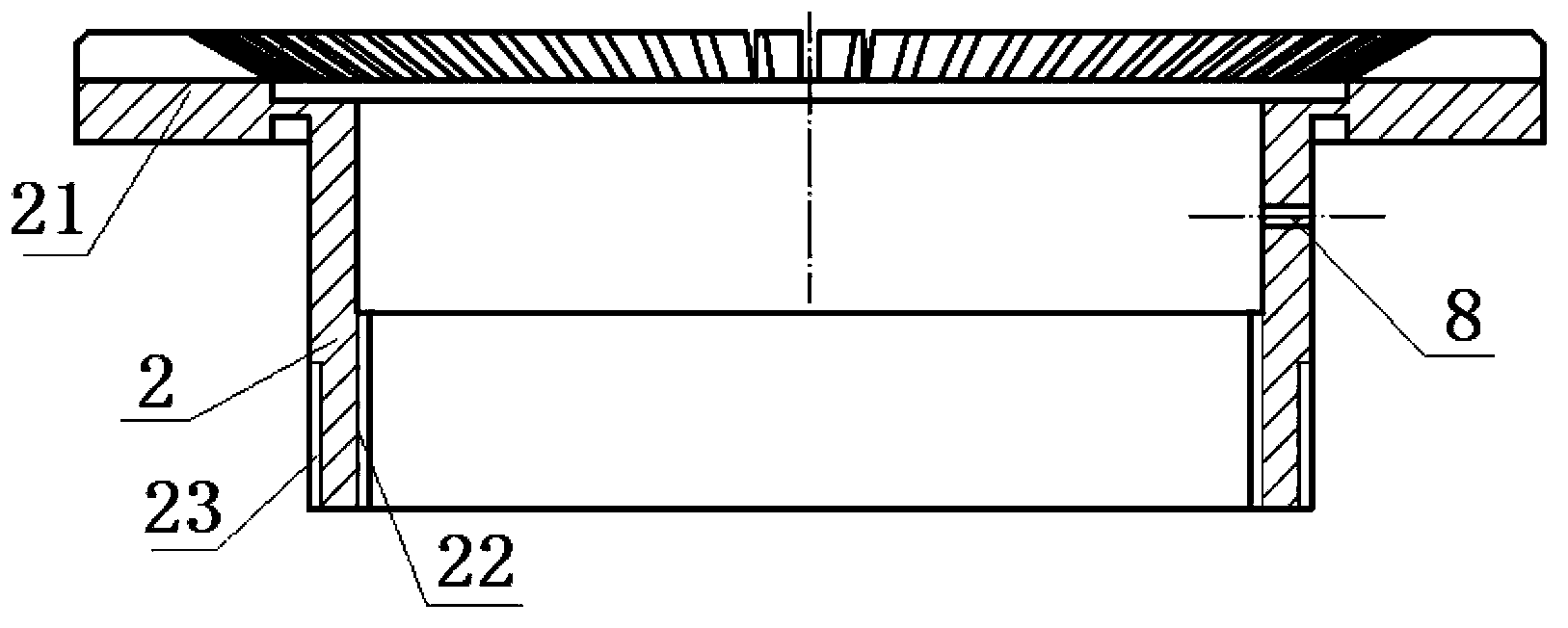

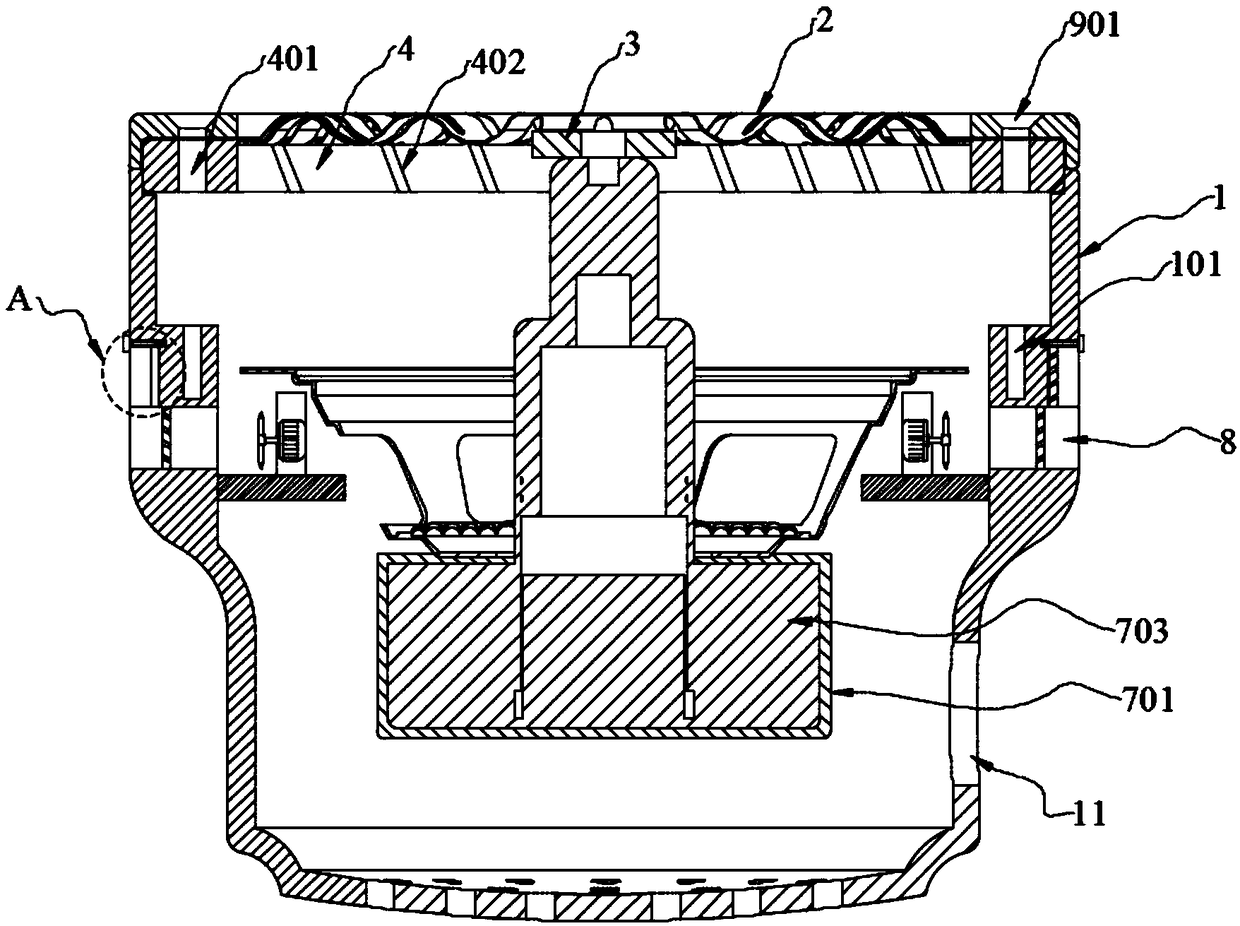

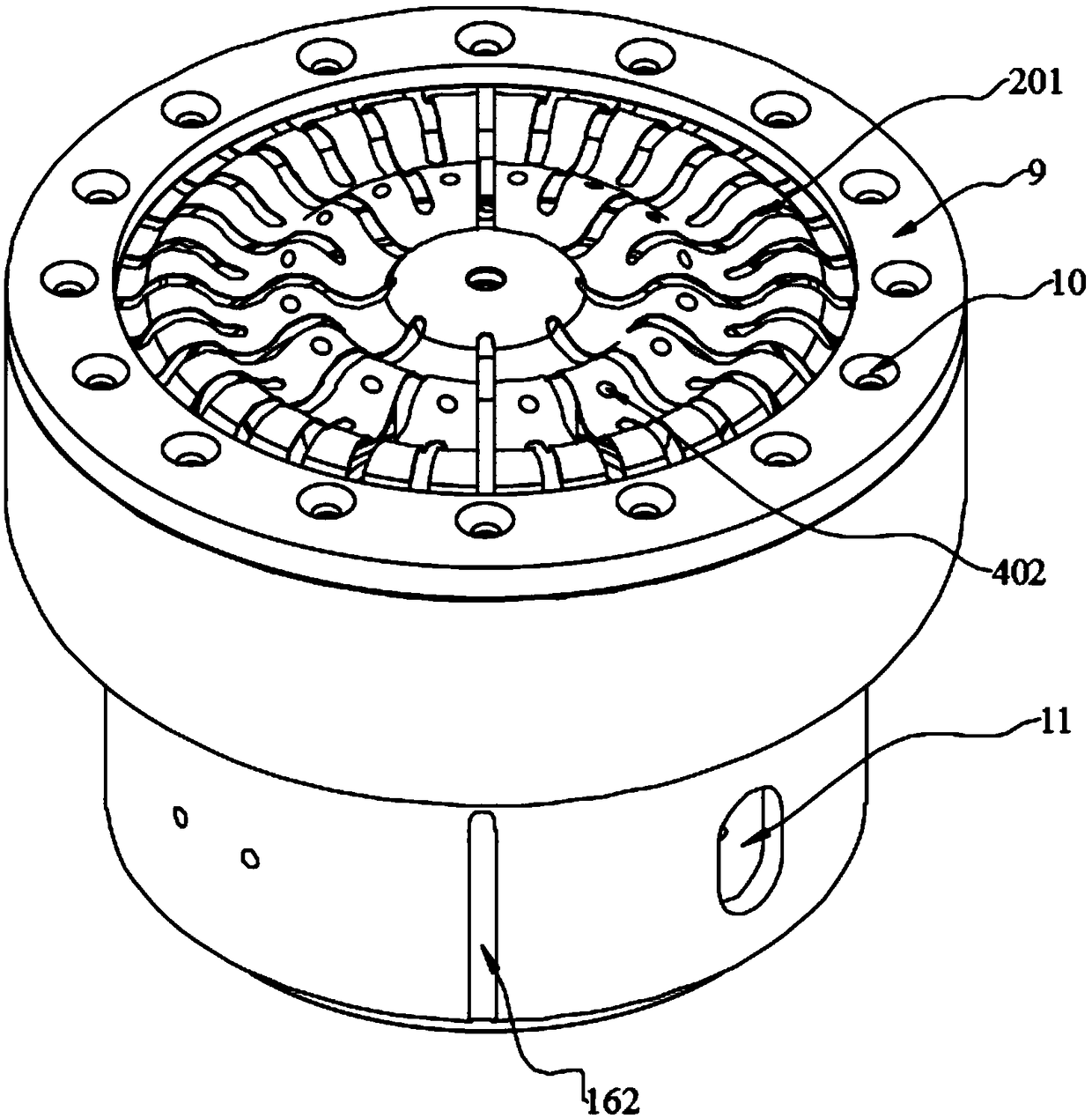

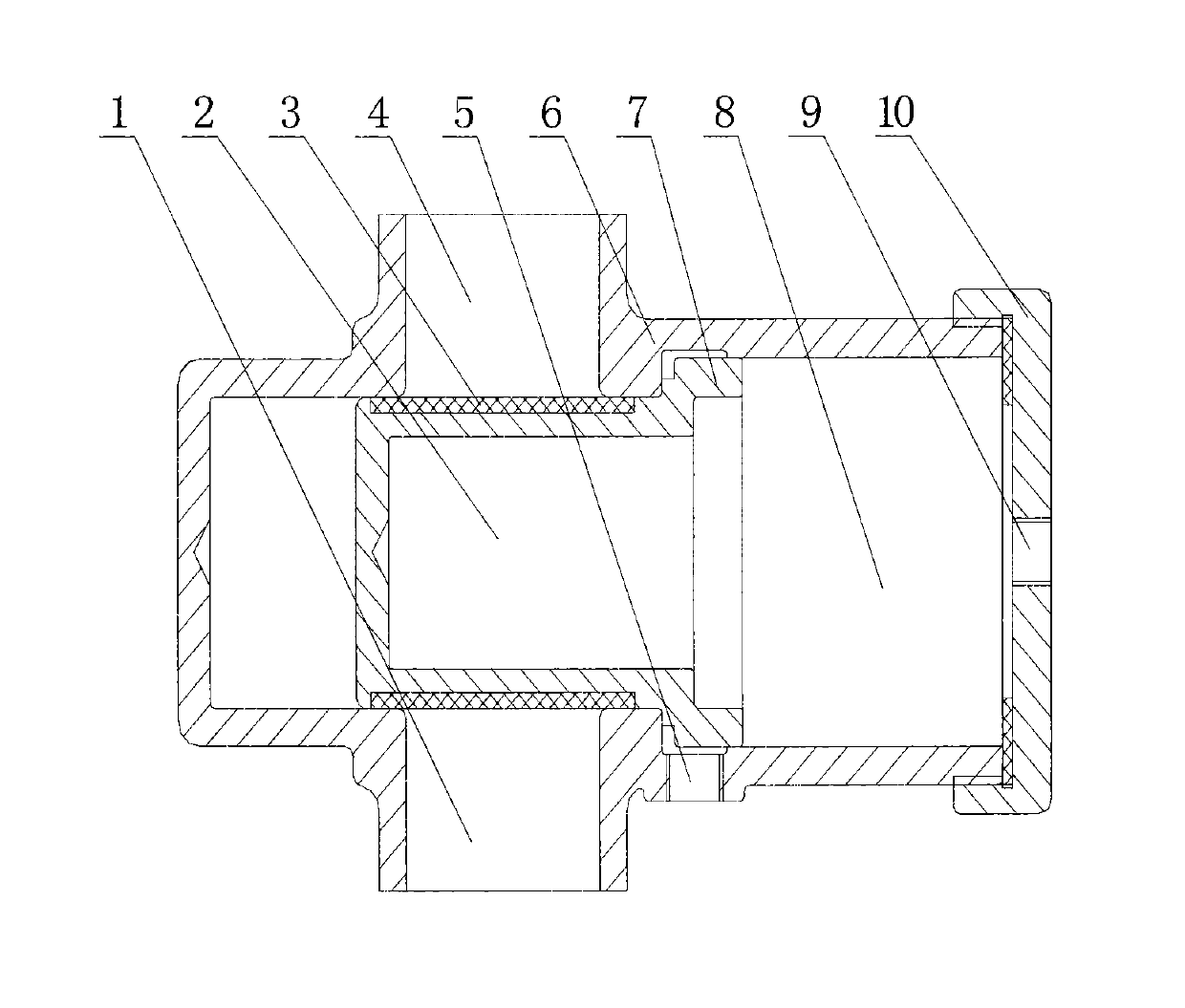

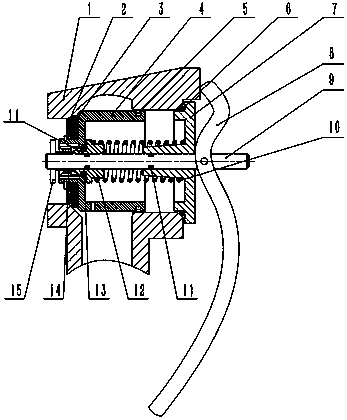

Threaded hollow revolution type travelling wave ultrasound motor

InactiveCN102751906ALarge hollow diameterLarge output torquePiezoelectric/electrostriction/magnetostriction machinesStatorEngineering

The invention relates to a threaded hollow revolution type travelling wave ultrasound motor used for adjusting a diaphragm. The diaphragm comprises a diaphragm fixing ring and a diaphragm moving ring provided with a connecting rod, and the threaded hollow revolution type travelling wave ultrasound motor provided by the invention comprises a base, a piezoelectric ceramic piece, a friction material layer, a damping material layer as well as a stator shaft and a rotor shaft which are arranged in a hollow manner along an axis. The threaded hollow revolution type travelling wave ultrasound motor provided by the invention has the advantages that the infliction preliminary pressure is large, the regulation precision is high, the installation is convenient, the structure is simple, the torque output is large, and meanwhile, the threaded hollow revolution type travelling wave ultrasound motor is used for a diaphragm adjusting system. The threaded hollow revolution type travelling wave ultrasound motor provided by the invention is also suitable for a precision optical system which needs high diaphragm adjusting precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

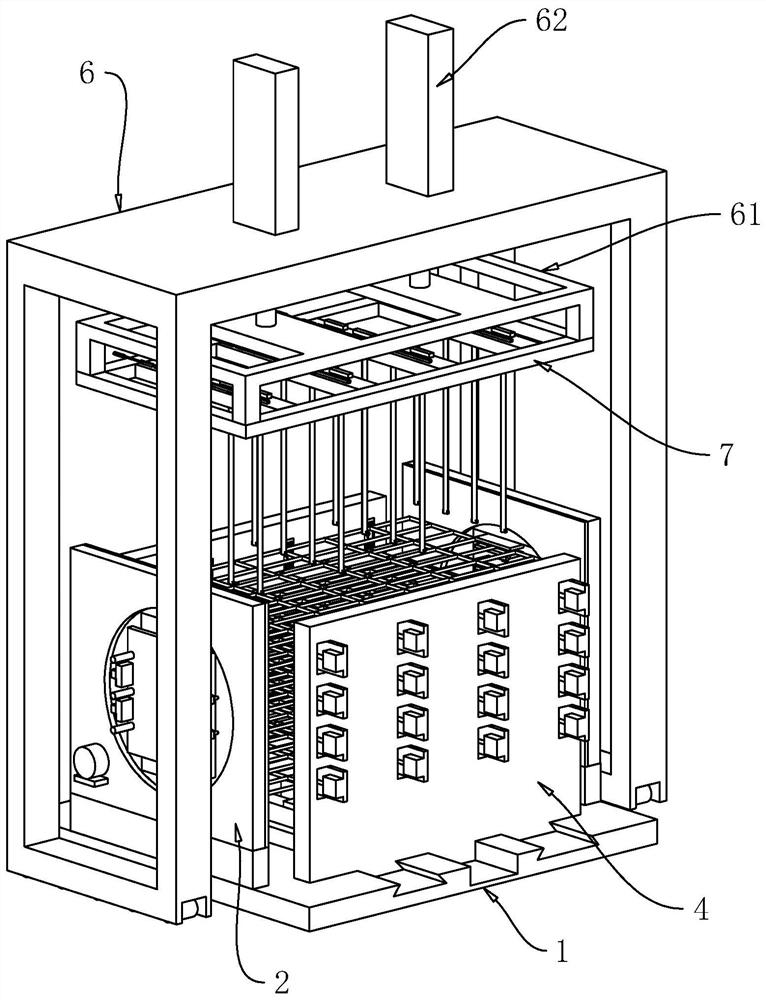

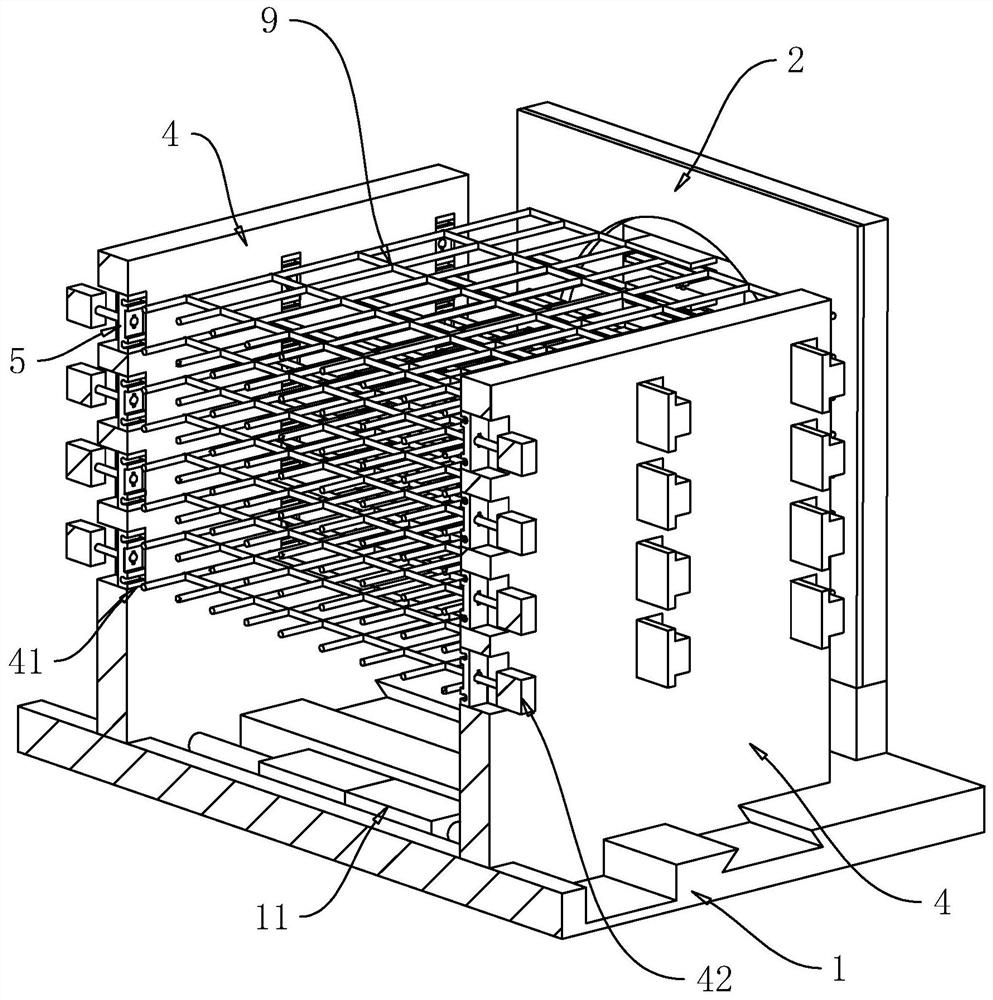

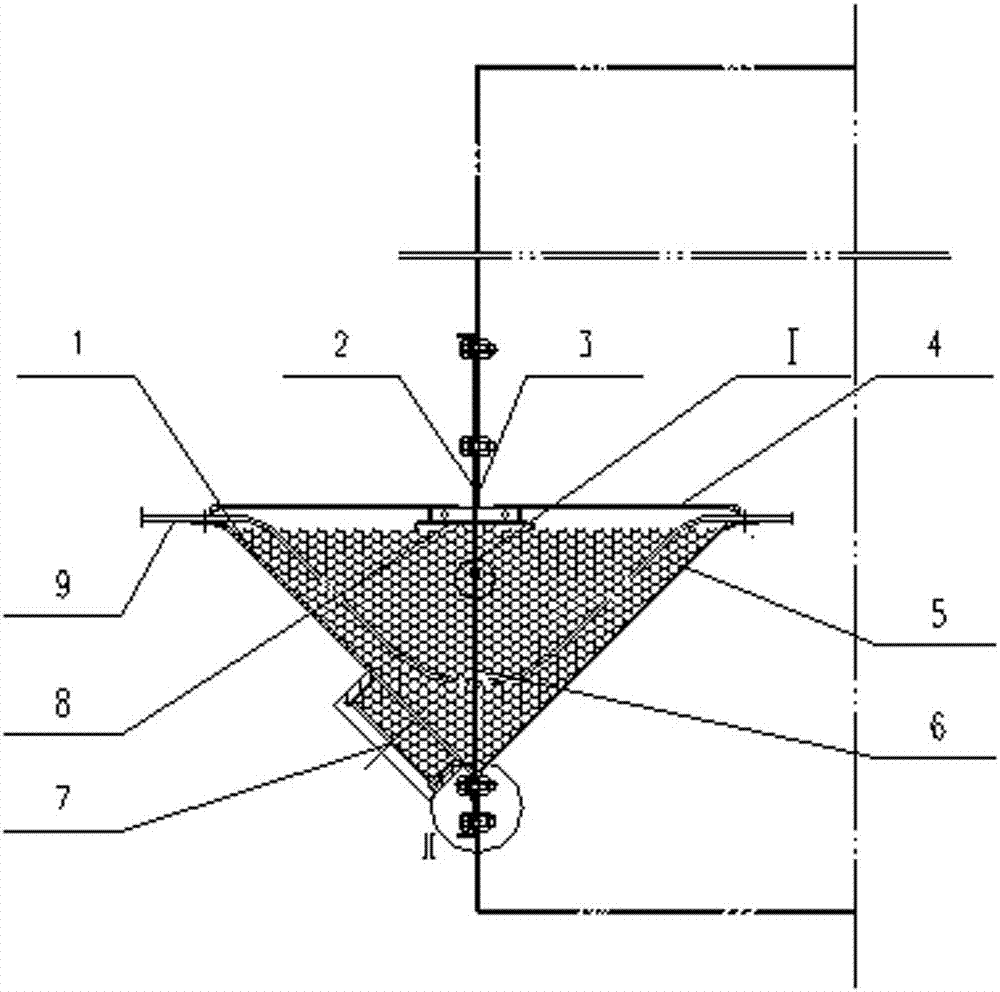

Hanging net assembling system of concrete prefabricated mold

The invention relates to a hanging net assembling system of a concrete prefabricated mold. The hanging net assembling system comprises a bottom frame, movable frames are arranged at the two ends of the bottom frame correspondingly, fixed plates are fixedly connected to the two ends of each of the sides, close to each other, of the movable frames correspondingly, multiple bidirectional cylinders are arranged between every two corresponding fixed plates, and telescopic rods of each bidirectional cylinders face the two corresponding fixed plates correspondingly and are fixedly connected with movable plates correspondingly. Sliding frames are vertically arranged on the two sides of the bottom frame correspondingly, multiple containing grooves are formed in the positions, corresponding to the length-direction middles of the corresponding bidirectional cylinders, of each of the sides, close to each other, of the two sliding frames, vertically-arranged fixing pieces can be contained in the containing grooves, clamping grooves are formed in the two ends of each of the sides, close to each other, of the fixing pieces correspondingly, and a through hole is formed in the middle of each fixing piece. The sides, away from each other, of the sliding frames are fixedly connected with push cylinders capable of pushing the fixing pieces in the containing grooves to move in the direction close to each other correspondingly. The hanging net assembling system has the effects that the fixing pieces and a reinforcing mesh can be conveniently installed, and the working efficiency can be improved.

Owner:青岛天利兴达新型建材有限公司

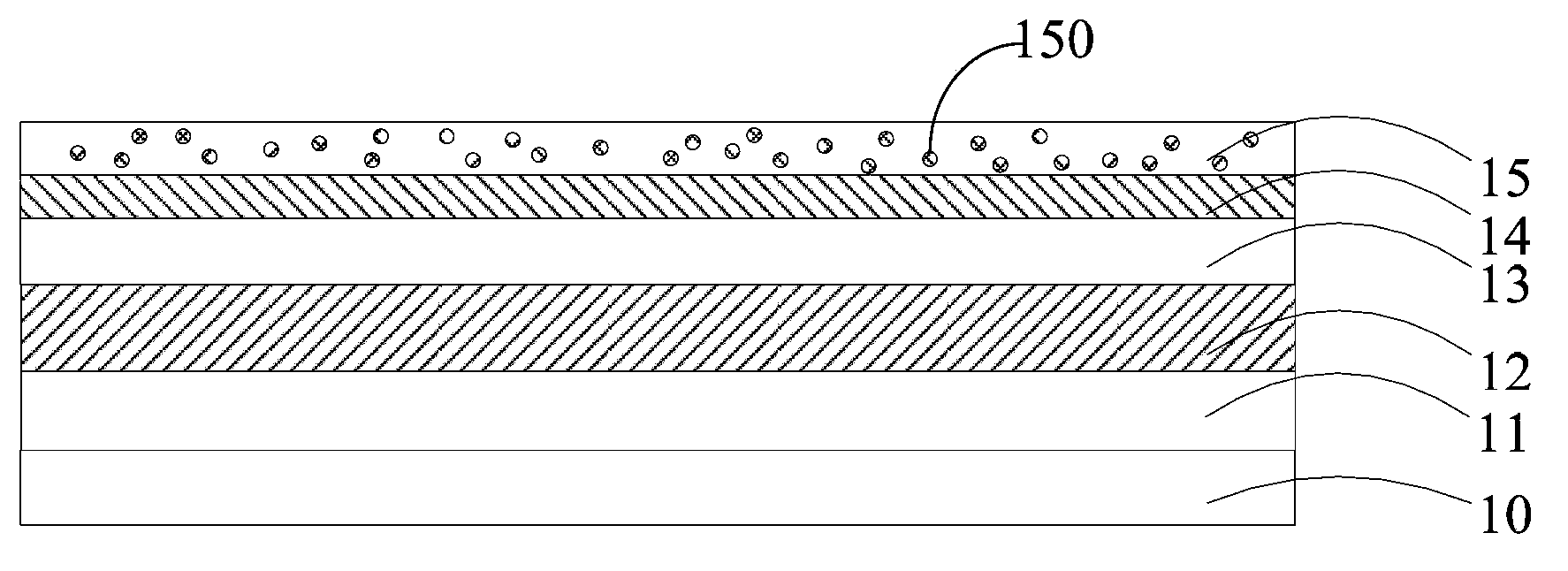

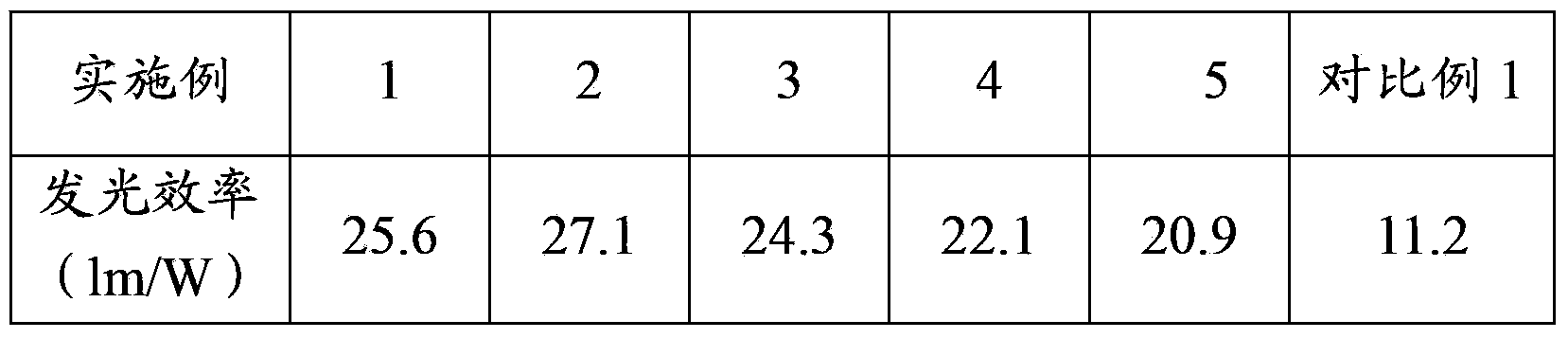

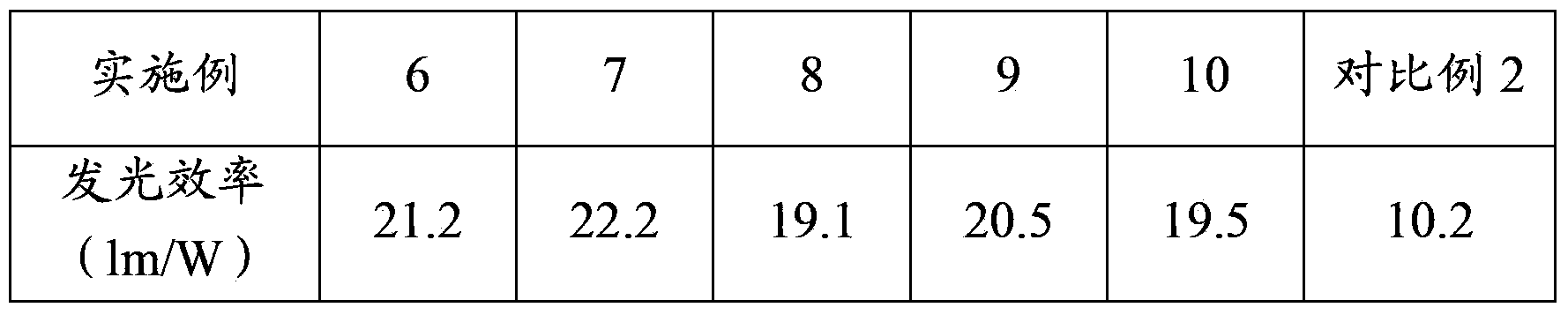

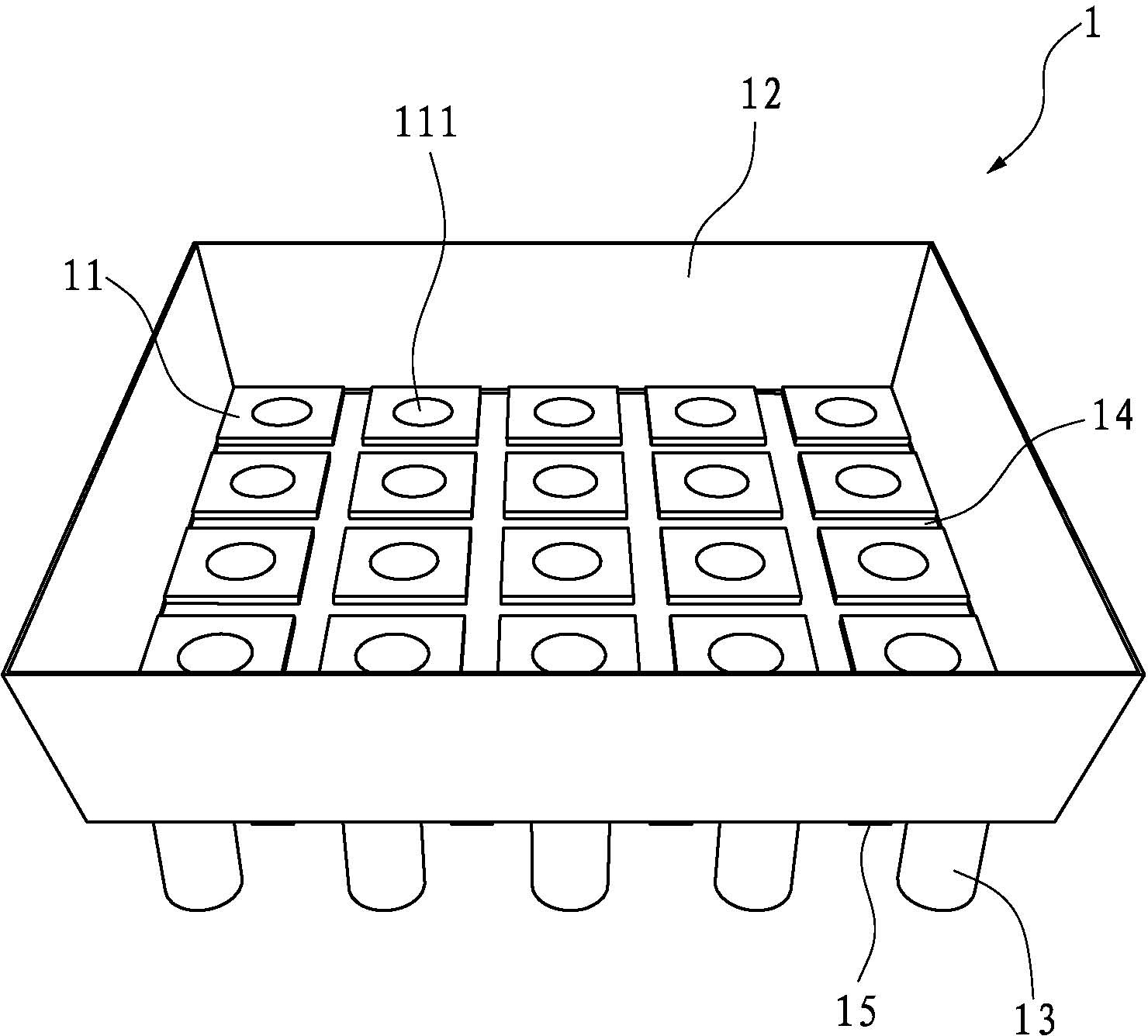

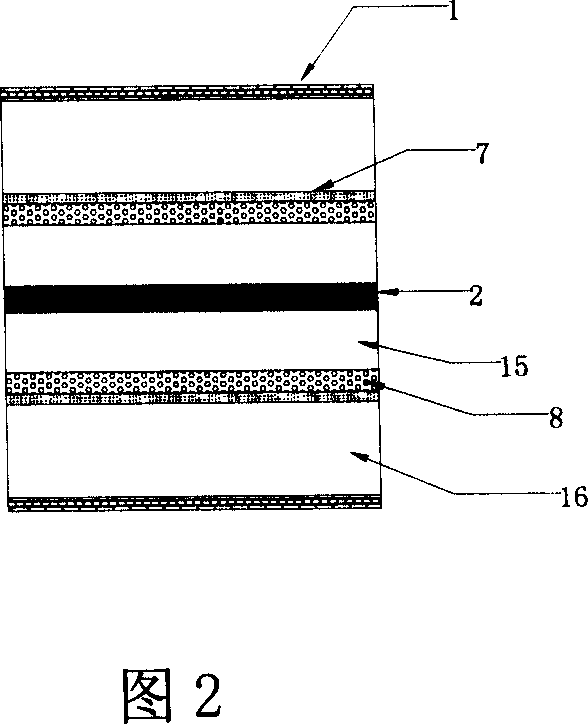

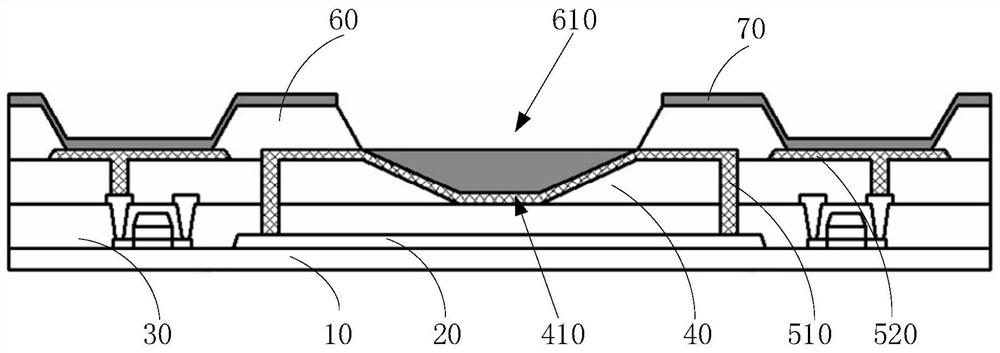

Organic light emission diode device and fabrication method thereof

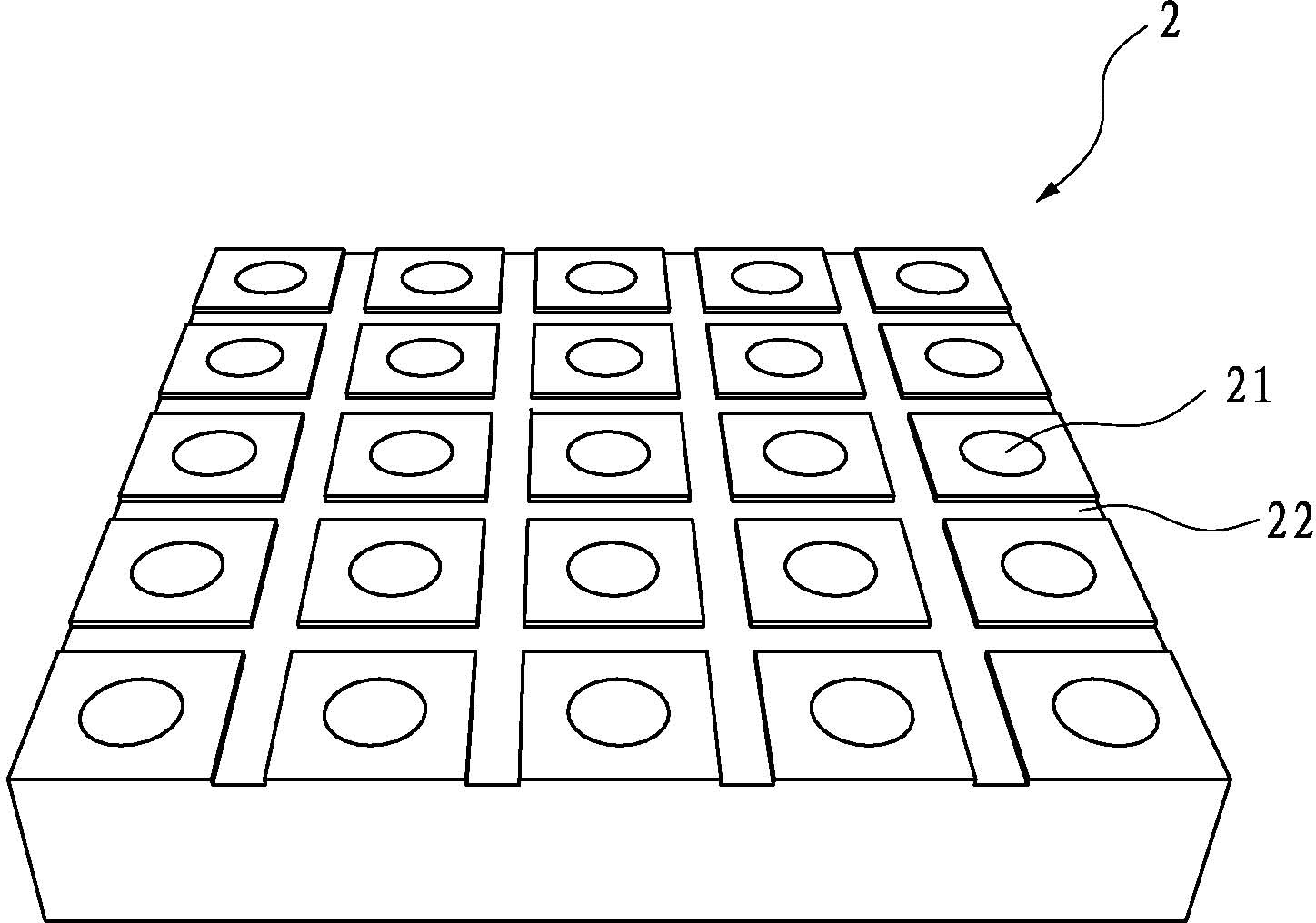

InactiveCN104218173AImprove light extraction efficiencyGood light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereMixed materials

The invention provides an organic light emission diode device. The organic light emission diode device comprises a substrate and an anode, a light emission functional layer and a cathode which are sequentially laminated on the substrate, a light matching layer and a light extraction layer are sequentially arranged on the surface of the cathode, the material of the light extraction layer comprises nanoparticles and a polymer material, the nanoparticles are ceramic or high-polymer material particles with the grain size of 50 to 1,500 nanometers, the polymer material is a heat cured polymer or photo cured polymer material, the thickness of the light extraction layer is 10 to 100 micrometers, the material of the light matching layer is a mixed material formed by metal and an organic material, the metal is silver, aluminum or magnesium, and the organic material is N,N'-diphenyl-N,N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-diamine, copper phthalocyanine or 8- hydroxyquinoline aluminum. The luminous efficiency of the cathode of the organic light emission diode device is high, so that the luminous efficiency of the device is improved. The invention also provides a fabrication method of the organic light emission diode device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

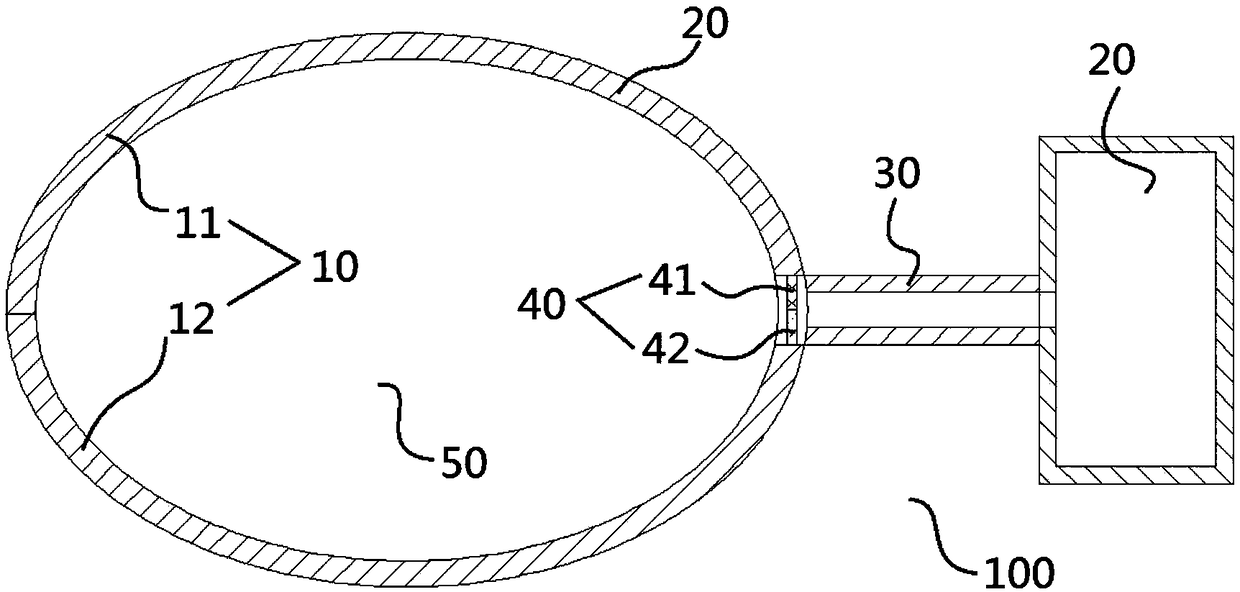

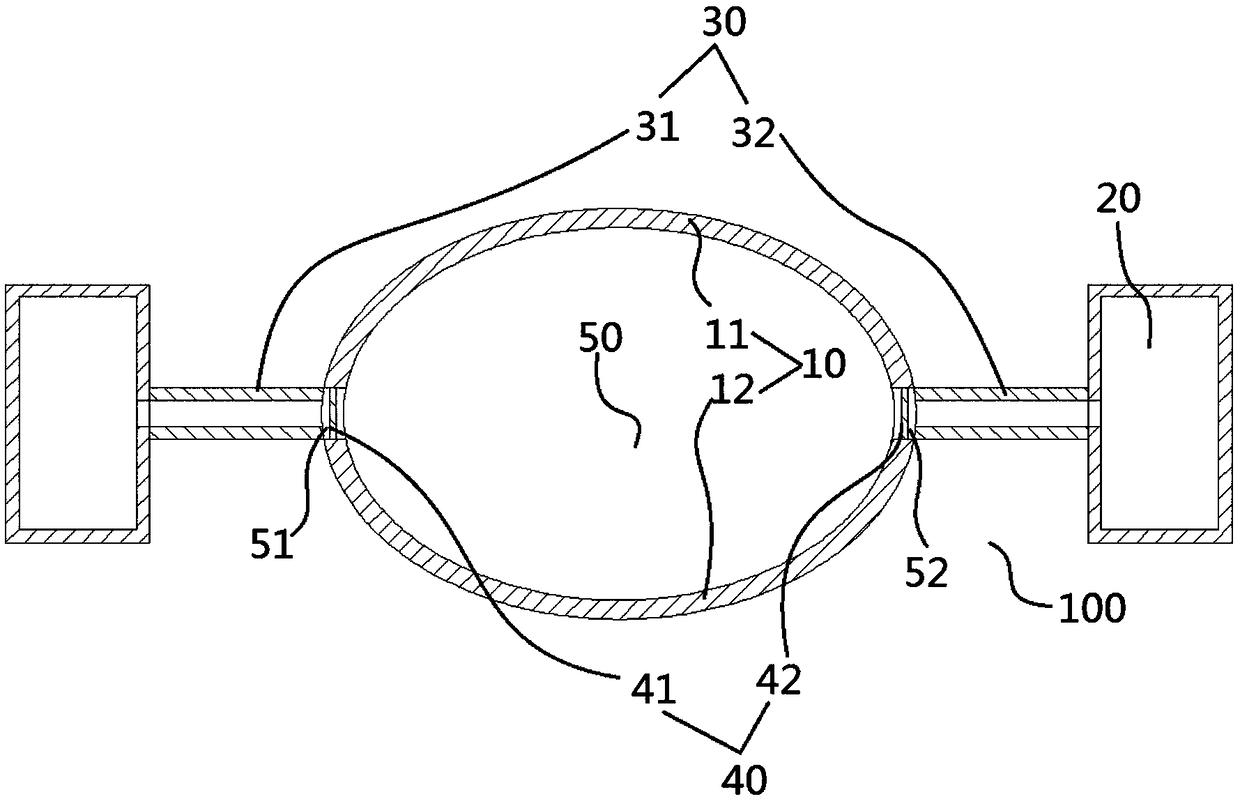

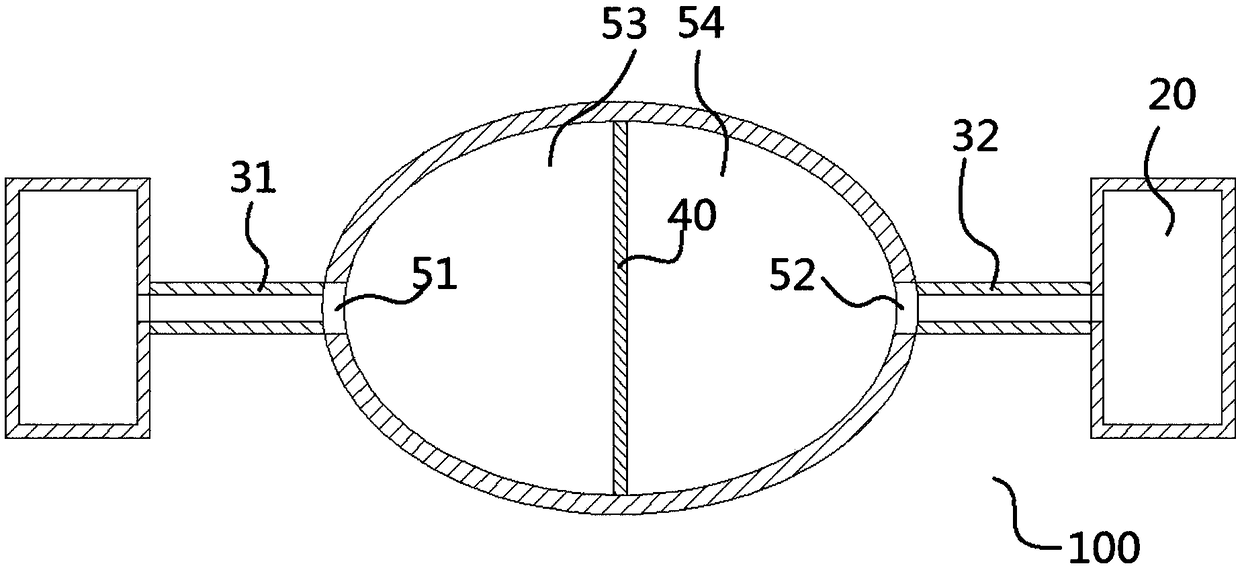

Lens focusing mechanism

The invention provides a lens focusing mechanism comprising an elastic lens surface, a liquid storage chamber, a connecting pipe and a permeable membrane, wherein an accommodating chamber is defined in the elastic lens surface, and at least two liquids which are not mutually dissolved and have different refractive indexes are in the accommodating chamber; the liquid storage chamber is disposed onthe outer side of the elastic lens surface and communicated with the accommodating chamber; one end of the connecting pipe is communicated with the liquid storage chamber, and the other end of the connecting pipe is communicated with the accommodating chamber; and the permeable membrane is arranged between the connecting pipe and the accommodating chamber. According to the lens focusing mechanism,by utilizing the structure of combining the elastic lens surface, the liquid storage chamber, the connecting pipe and the permeable membrane, flexible focusing can be achieved, and the lens focusingmechanism has the advantages of having a wide focusing range, being convenient to use and facilitating processing and production.

Owner:FOSHAN OUTEKELANG TECH CO LTD

Threaded hollow revolution type travelling wave ultrasound motor

InactiveCN102751906BAchieve throughLarge hollow diameterPiezoelectric/electrostriction/magnetostriction machinesHigh diaphragmEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

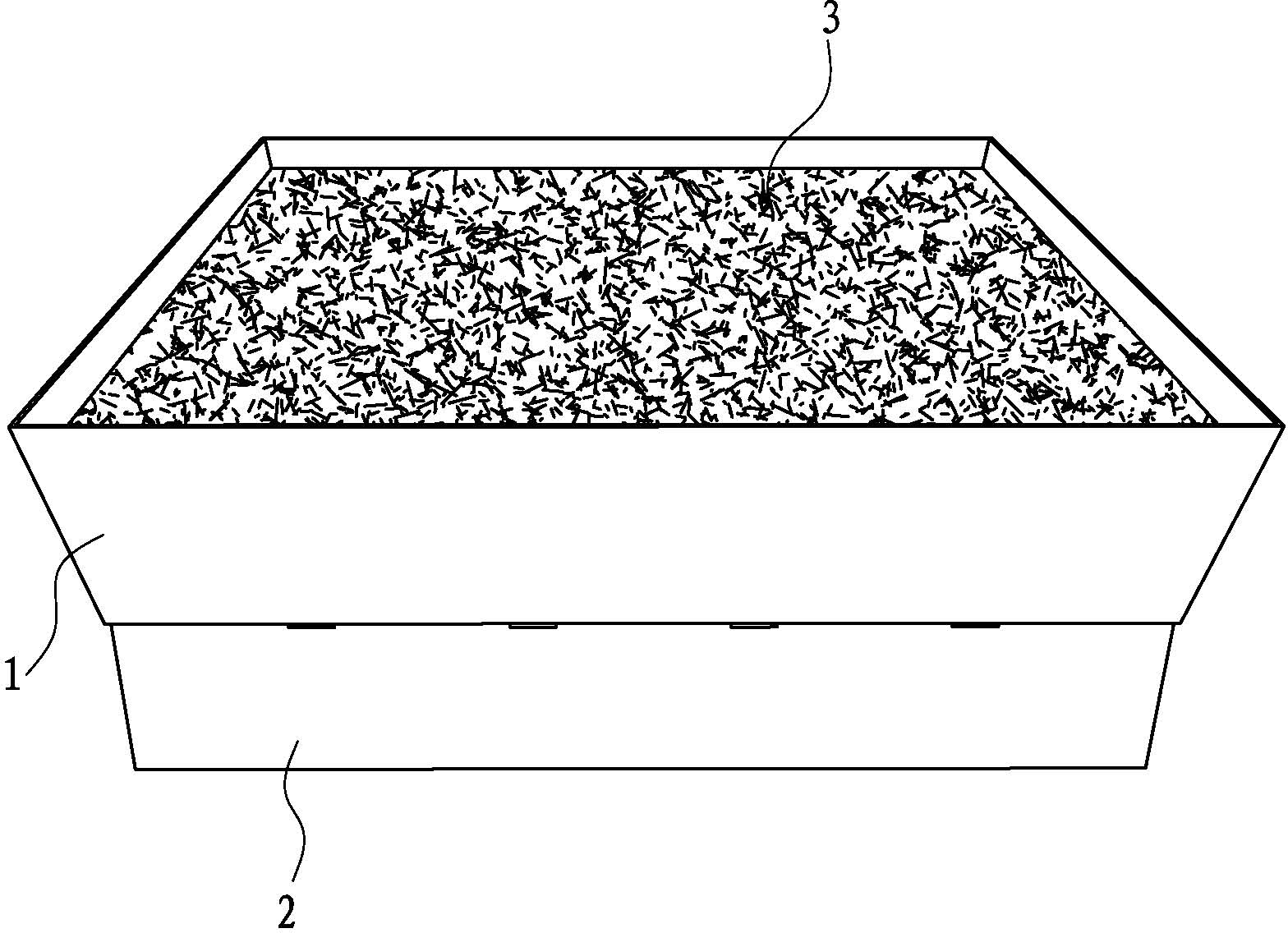

Water surface floating vessel

ActiveCN102177837AIncrease buoyancyShock resistanceAgriculture gas emission reductionCultivating equipmentsMarine engineeringBuoyancy function

The invention discloses a water surface floating vessel. The vessel mainly comprises a vessel body and a heavy floating disk, wherein the heavy floating disk is fixedly connected to the outer bottom surface of the vessel body; the vessel body consists of a bottom plate, an encircling plate and a plurality of root penetrating columns; the encircling plate is arranged along the edge of the bottom plate, and forms an upward opening accommodating space together with the inner bottom surface of the bottom plate; and the plurality of root penetrating columns are fixedly connected to the outer bottom surface of the bottom plate, and pipe cavities of the root penetrating columns pass through the bottom plate. Due to the heavy floating disk arranged on the vessel body and the pipeline type root penetrating columns at the bottom of the vessel body, the vessel body can be supported and float on the water surface by the structure design, root systems of plants planted in the vessel body can pass through the pipe cavities of the root penetrating columns and enter water. The arch bucket shaped vessel body can reinforce the buoyancy of the water surface, can resist impact of water wave and storm, and floats stably.

Owner:厦门中卉生态景观有限公司

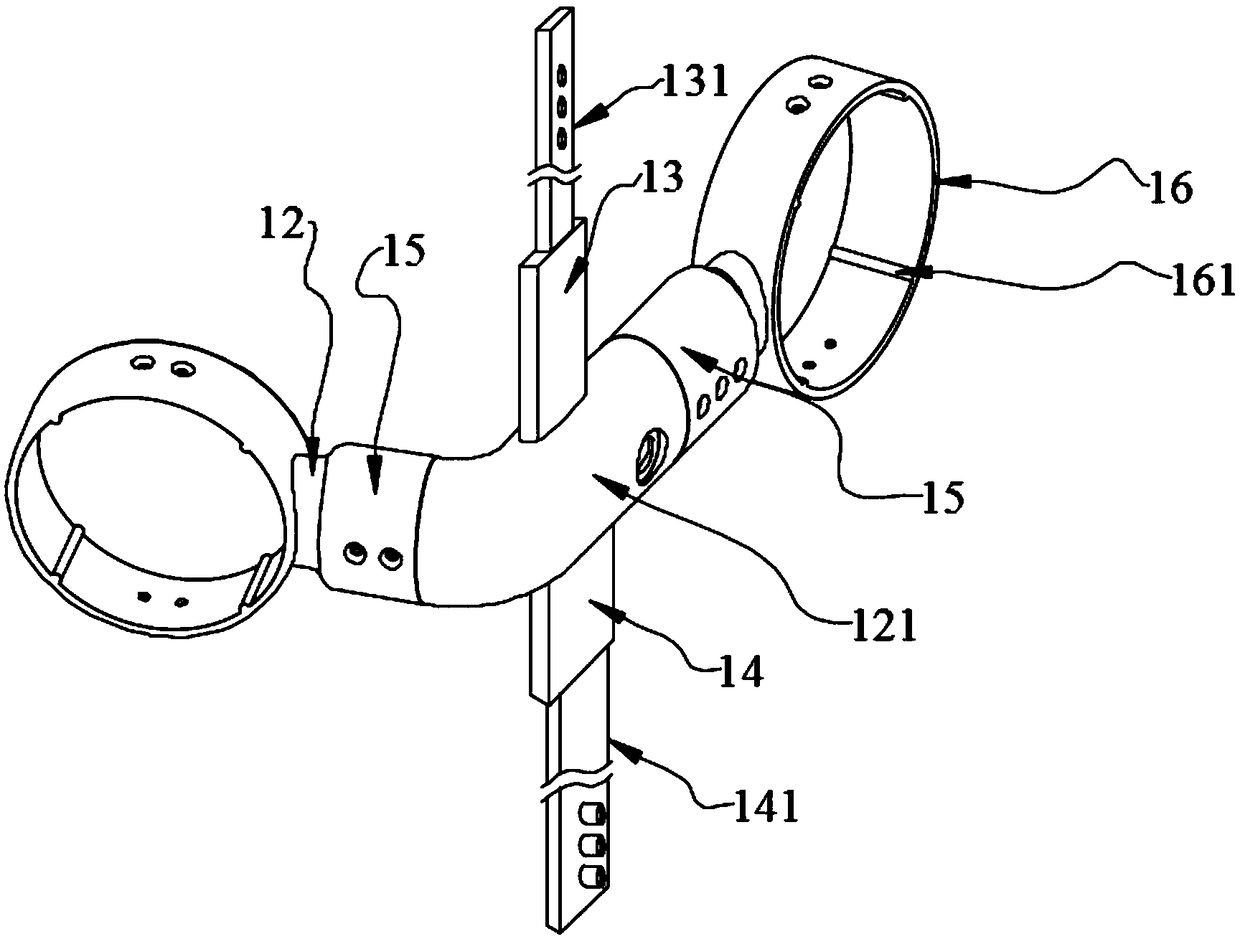

Conveniently adjusted magnetic resonance therapeutic device

PendingCN108836809AAdjust the connection lengthAchieve rotationVibration massageGenitals massageTherapeutic DevicesResonance

The invention discloses a conveniently adjusted magnetic resonance therapeutic device, and belongs to the technical field of medical devices. The device is used for solving the problem that a magneticresonance therapeutic head of a current magnetic resonance therapeutic instrument cannot be finely adjusted. The conveniently adjusted magnetic resonance therapeutic device comprises a hollow connecting handle, wherein the two ends of the connecting handle are connected with clamping rings respectively, and the clamping rings are internally provided with magnetic resonance therapeutic heads; thedevice is characterized in that the connecting handle comprises a holding area in the middle and connecting areas located at the two radial sides of the holding area, the connecting areas of the connecting handle are sleeved with handle covers respectively, a plurality of first adjusting holes are formed in the two ends of the connecting handle, second adjusting holes mutually matched with the first adjusting holes are formed in the handle covers, the first adjusting holes and the second adjusting holes are fixed by inserting bolts, the ends, close to the clamping rings, of the handle covers are provided with first wiring holes, the periphery of each first wiring hole is provided with a turntable, each turntable is provided with at least two connecting rings, and the connecting rings are mutually connected with the clamping rings.

Owner:ZHENGZHOU RENHUI MEDICAL EQUIP

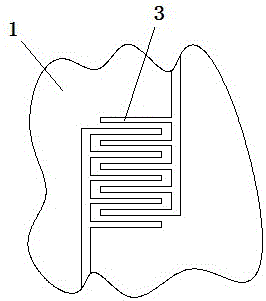

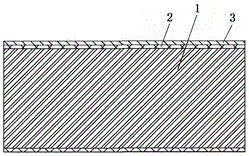

Transparent interdigital electrode for photoelectrocatalysis and processing method thereof

ActiveCN106098383AAchieve throughImprove utilizationLight-sensitive devicesMaterial electrochemical variablesElectric signalMaterials science

The invention provides a transparent interdigital electrode for photoelectrocatalysis and a processing method thereof. The interdigital electrode comprises a substrate, a buffer layer and a conducting layer in sequence from bottom to top, wherein the substrate is made of a transparent material; and the conducting layer is a metal layer. The transparent interdigital electrode for photoelectrocatalysis provided by the invention has the advantages of good conductivity, stable electric signal base line, high photoelectrocatalysis efficiency and repeated use.

Owner:HUIZHOU LEADAO ELECTRONICS MATERIAL

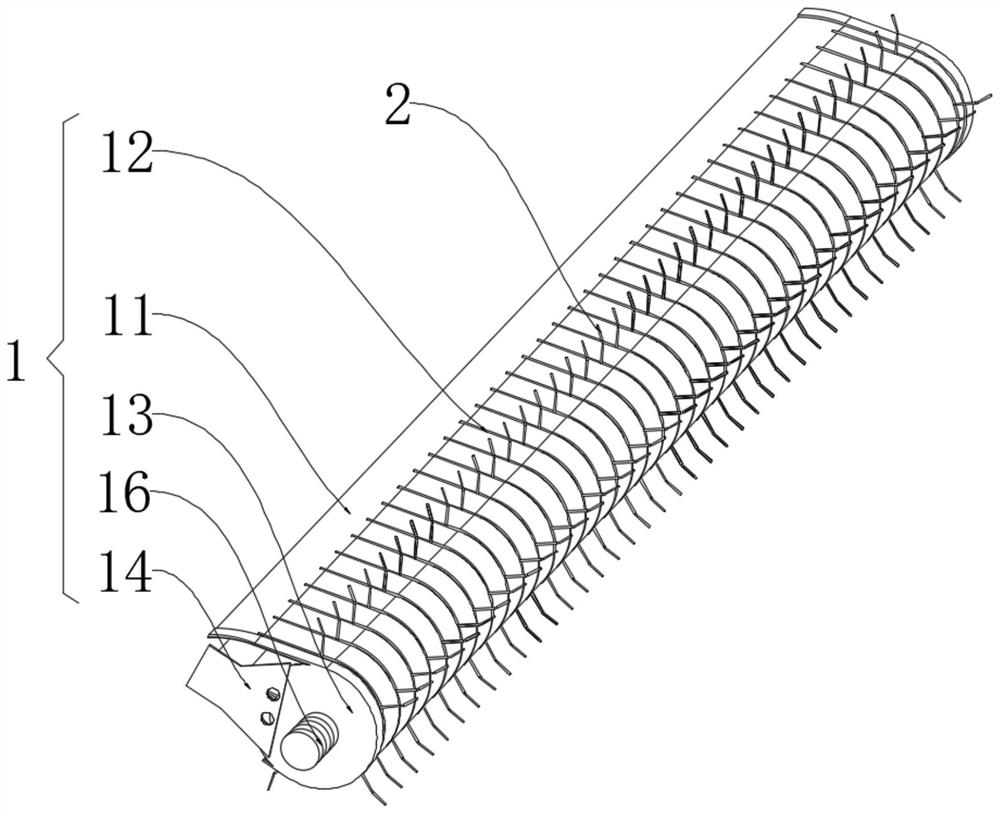

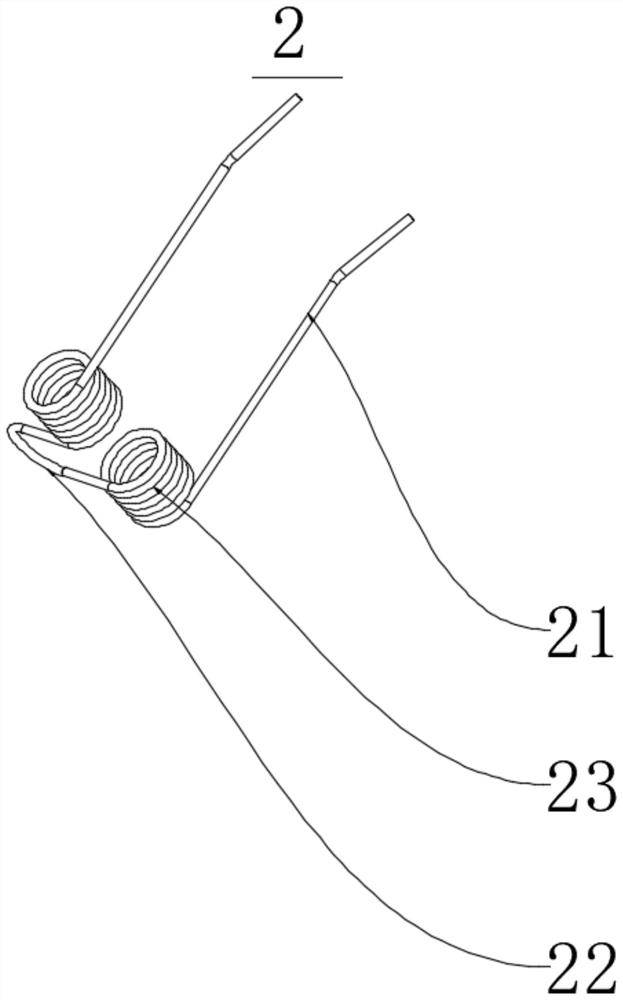

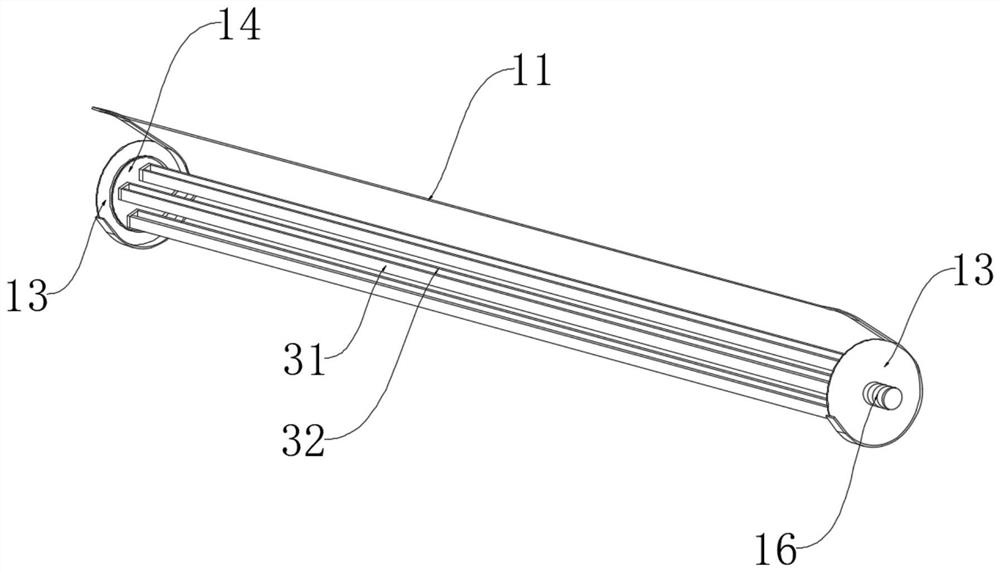

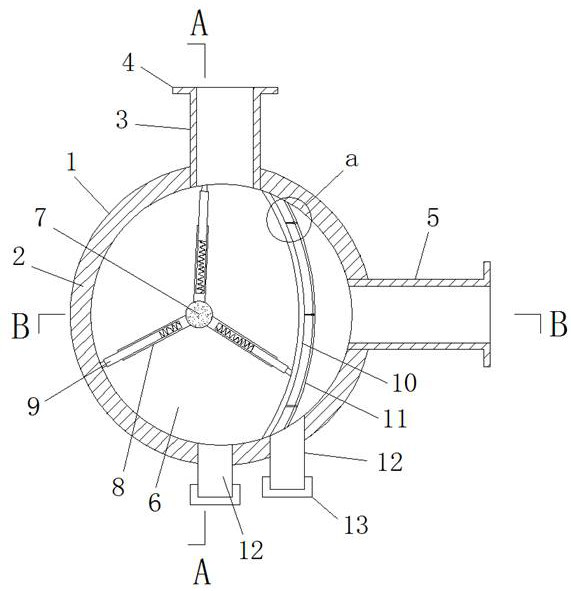

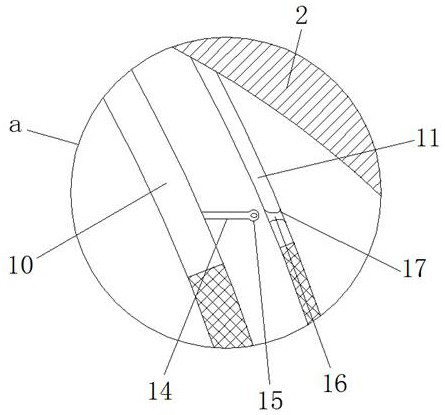

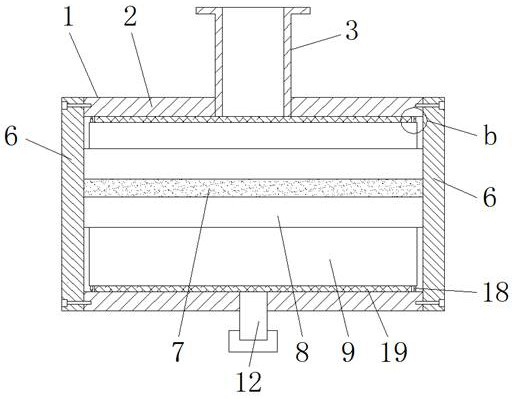

Five-axis retainer-free and cam-free integral pickup

The invention relates to a five-axis retainer-free and cam-free integral pickup, which comprises a protection assembly (1), an elastic assembly (2) and a driven assembly (3), wherein the protection assembly (1) comprises a connecting plate (14), two ends of the driven assembly (3) are respectively connected with the connecting plate (14), and the elastic assembly (2) is detachably mounted on the driven assembly (3). The two ends of the driven assembly are connected with the connecting plates respectively, the elastic assembly is detachably installed on the driven assembly, disassembly and installation can be convenient, the balance performance of the product is improved in the aspect of manufacturing, and the structure of the product is more stable.

Owner:南通瑞斯电子有限公司

Paddle type filtering and conveying type oil exploitation all-in-one machine

InactiveCN112090141AAvoid cloggingAchieve vibrationFluid removalMoving filtering element filtersMachineBrush

The invention discloses a paddle type filtering and conveying type oil exploitation all-in-one machine which comprises a filtering machine, a filtering barrel, an oil inlet pipe, a flange plate, an oil outlet pipe, a sealing cover plate, a rotating rod, a first paddle, a second paddle, a supporting wheel, a brush and a spring, the filtering machine is provided with the filtering barrel, and the oil inlet pipe is welded to the top of the filtering barrel; and the oil outlet pipe is welded to the side portion of the filtering barrel, the first paddle is welded to the outer side of the rotating rod, the slidable second paddle is arranged on the first paddle, supporting wheels are fixed to the two sides of the outer end of the second paddle, and meanwhile brushes are arranged at the positions,on the inner sides of the two supporting wheels, of the outer end of the second paddle. According to the paddle type filtering and conveying type oil exploitation all-in-one machine, when crude oil is filtered, the filtering net can be cleaned, blocking of the filtering net is avoided, through arrangement of double-layer filtering, vibration of the double-layer filtering net can be achieved whenthe paddles rotate, impurities on the filtering net brushed by the brush fall off, and blocking of the filtering net is effectively avoided.

Owner:韩世强

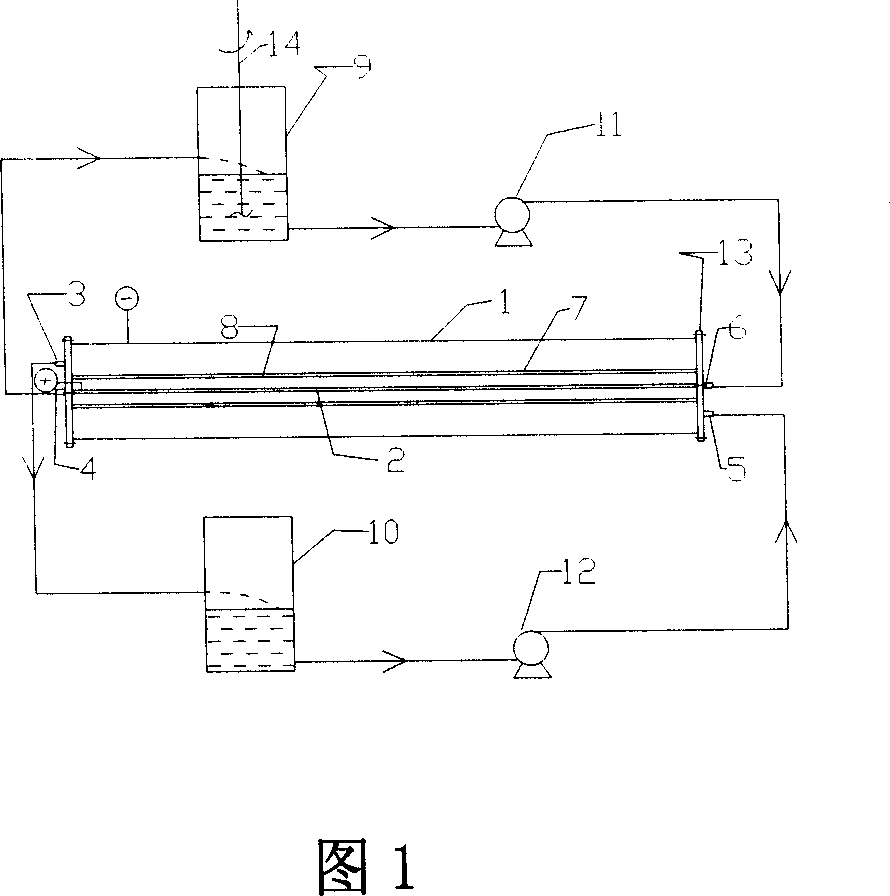

Device for leaching gold mine by electrochemistry oxidation method

InactiveCN101054624AAvoid mechanical wearOvercome the disadvantages of direct application of ion exchange membranesProcess efficiency improvementElectrolysisMechanical wear

The invention is a method of extracting refractory gold ore by electrochemical oxidation method which produces oxidant and disposes refractory gold ore in situ, comprising dividing the electrobath into cathode and anode sections by membrane elements composed of inorganic ceramic membrane and ion exchange membrane. The anode section, anode material liquid groove and cathode section, cathode material liquid groove respectively form two absolute material liquid circulating system. The invention uses the characteristic of the inorganic ceramic membrane such as corrosion stability, acid and alkali resistance to effective prevent the mechanical wear of the ion exchange membrane owing to not directly applying ion exchange membrane.

Owner:SHANGHAI UNIV

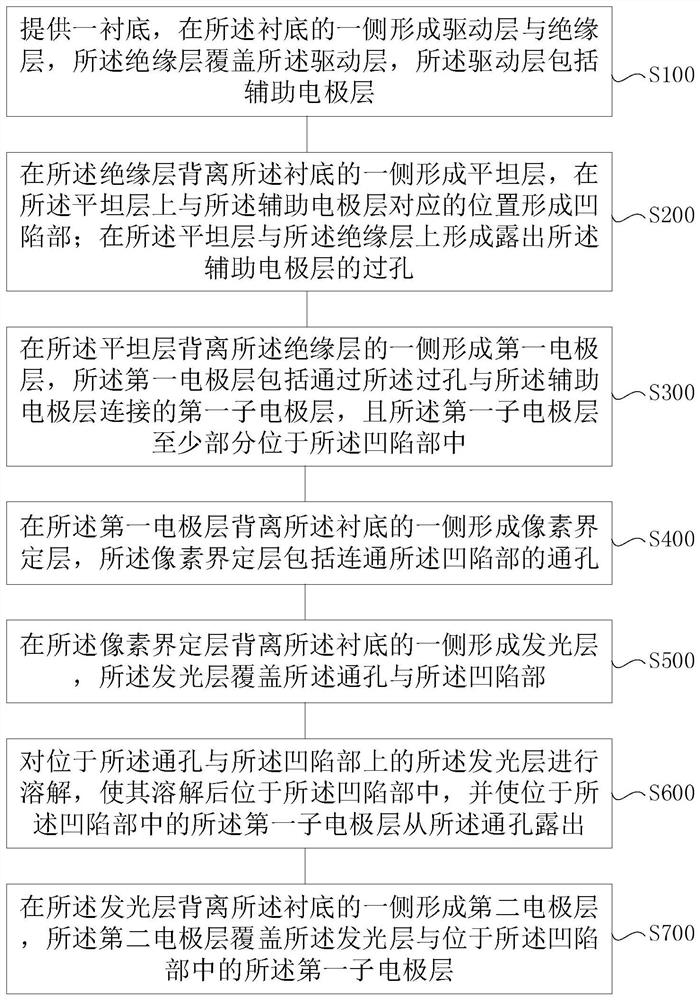

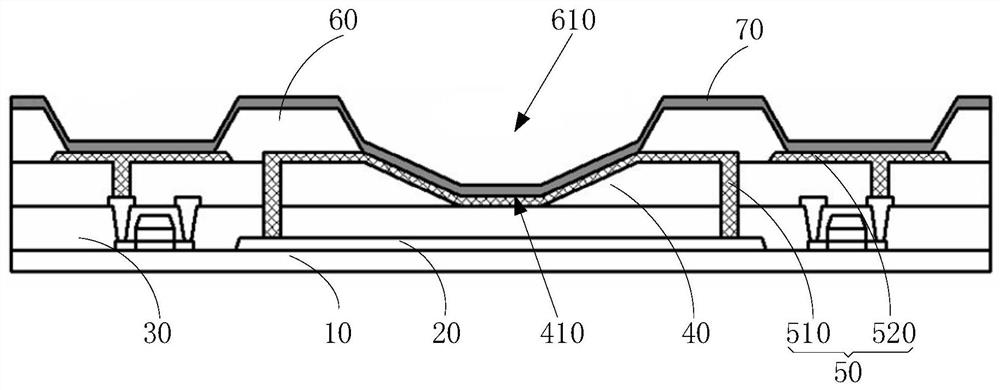

Manufacturing method of display substrate, display substrate, display panel and display device

ActiveCN112038506AAchieve throughSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a manufacturing method of a display substrate, the display substrate, a display panel and a display device. The manufacturing method comprises the steps that a driving layer comprising an auxiliary electrode layer and an insulating layer covering the driving layer are formed on one side of a substrate; a flat layer is formed on the side, deviating from the substrate, of the insulating layer, and a concave part is formed in the position, corresponding to the auxiliary electrode layer, of the flat layer; via holes for exposing the auxiliary electrode layer are formed onthe flat layer and the insulating layer; a first electrode layer is formed on one side, deviating from the insulating layer, of the flat layer, wherein the first electrode layer comprises a first sub-electrode layer which is connected with the auxiliary electrode layer and at least partially located in the concave part; a pixel defining layer comprising a through hole communicated with the concavepart is formed on one side, deviating from the substrate, of the first electrode layer; a light-emitting layer is formed on one side, deviating from the substrate, of the pixel defining layer, wherein the light-emitting layer covers the through hole and the concave part; and the light-emitting layer on the through hole and the concave part is dissolved, the dissolved light-emitting layer is located in the concave part, and the first sub-electrode layer located in the concave part is exposed out of the through hole.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

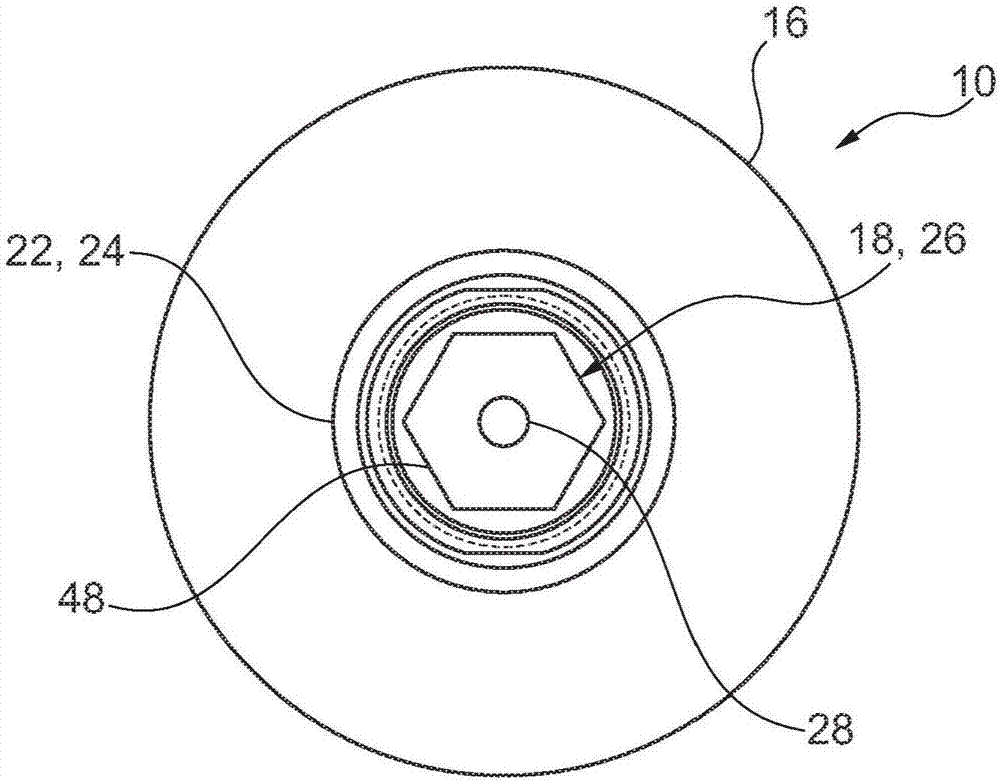

Measurement device for a machine tool and corresponding machine tool

ActiveCN107427982AImprove protectionAchieve throughAuxillary equipmentMeasurement/indication equipmentsMeasurement deviceEngineering

The invention relates to a measurement device (10) for machine tool having a tool drive (20), the measurement device (10) comprising a measurement head (18). According to the invention, it is provided that the measurement device (10) comprises a displaceably mounted protective cover (22) which is driven by the tool drive (20) and displaceable in such a way that said protective cover (22) selectively covers or uncovers the measurement head (26) for measuring. The invention further relates to a machine tool comprising such a measurement device (10).

Owner:SCHAEFFLER TECH AG & CO KG

Neck radiotherapy device

ActiveCN109966660AImprove the effect of radiotherapyReduce damage rateX-ray/gamma-ray/particle-irradiation therapyGear wheelDrive shaft

The invention discloses a neck radiotherapy device, which comprises a radiotherapy device body, a barrel, a chamber, a motor and a transmission mechanism. The barrel is rotationally mounted in the chamber, the radiotherapy device body is fixedly arranged on the inner side of the barrel, and the motor is fixedly arranged in the chamber. A first gear is arranged on a driving shaft of the motor and drives the barrel to intermittently rotate through the transmission mechanism. The neck radiotherapy device has advantages that direction adjustment of the radiotherapy device can be realized through continuous rotation of the radiotherapy device so as to realize radiotherapy of the neck in different directions, and intermittent rotation of the radiotherapy device can be realized so as to improve radiotherapy effects.

Owner:QINGDAO CENT HOSPITAL

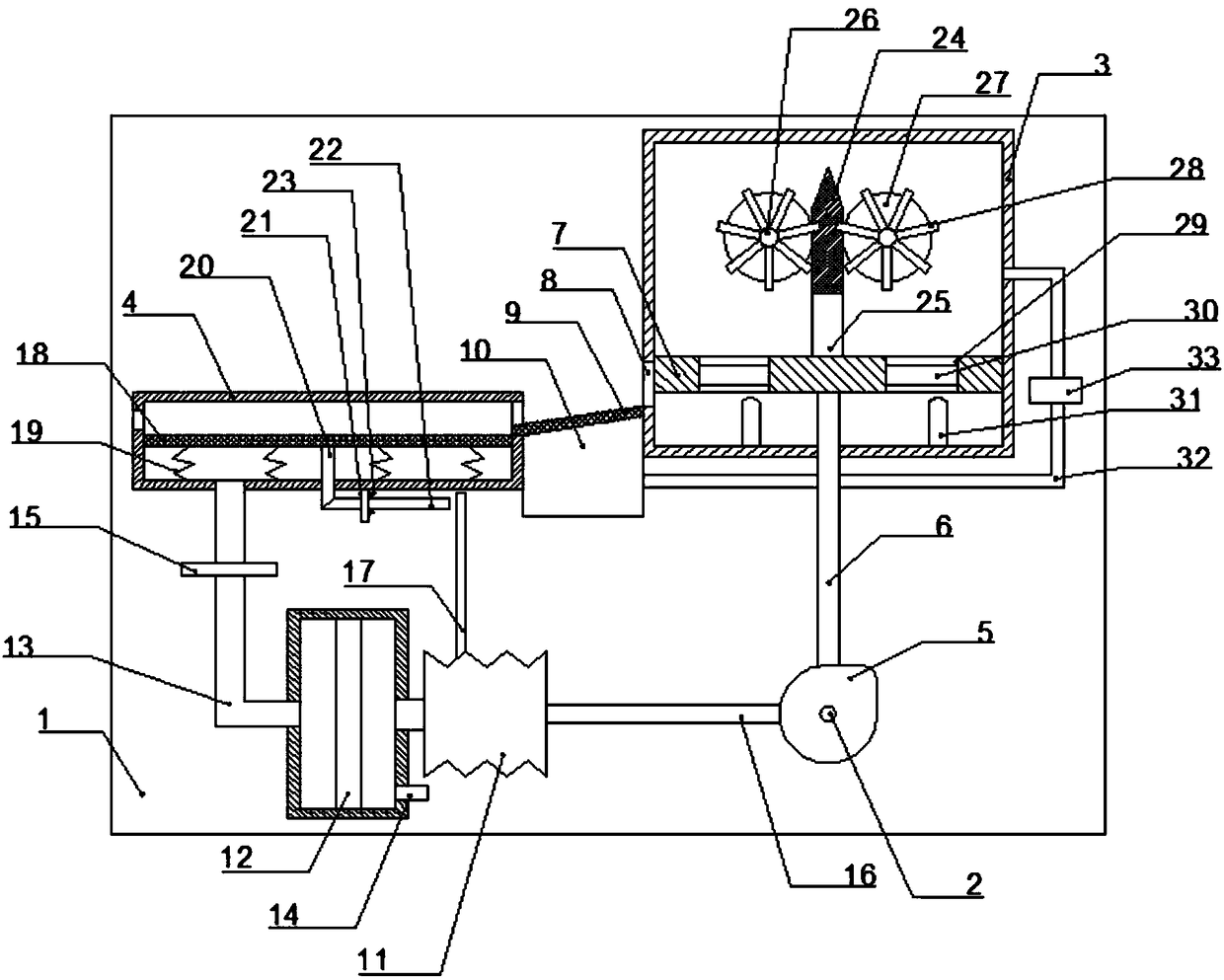

Sterilizing device for wine bottle

PendingCN108578722AShorten the processing chainImprove processing efficiencyHollow article cleaningDrying gas arrangementsMechanical engineeringWine bottle

The invention discloses a sterilizing device for a wine bottle. The sterilizing device comprises a base, wherein the base is provided with a power mechanism, a cleaning mechanism, a heating mechanismand a sterilizing box, the power mechanism can drive the cleaning mechanism to clean the wine bottle and drive the heating mechanism to generate hot air flow and introduce the hot air flow into the sterilizing box, the sterilizing box is internally provided with a vibration net, a first spring is arranged between the vibration net and the inner bottom of the sterilizing box, the bottom of the vibration net is provided with a first oblique wedge penetrating through the sterilizing box, the bottom of the sterilizing box is provided with a guide block, the guide block is slidably connected with asecond oblique wedge propping against the first oblique wedge, a second spring is arranged between the second oblique wedge and the guide block, and the heating mechanism can squeeze the second oblique wedge intermittently. The problem of low processing efficiency due to a long wine bottle processing process in the prior art is mainly solved.

Owner:重庆技嘉模具有限公司

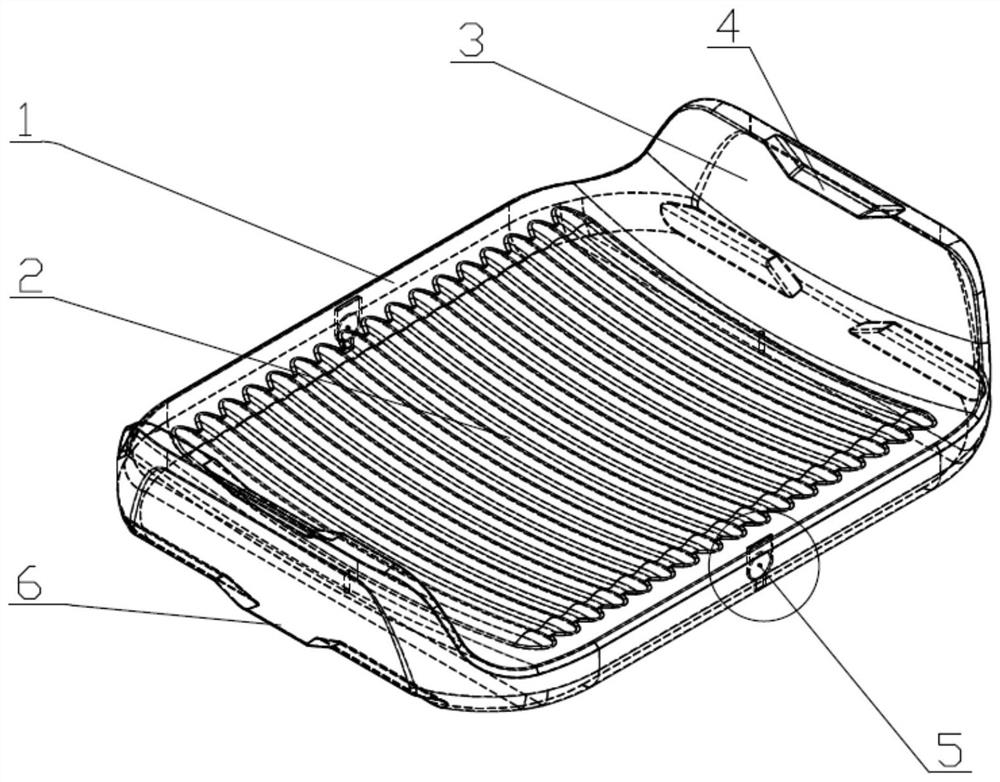

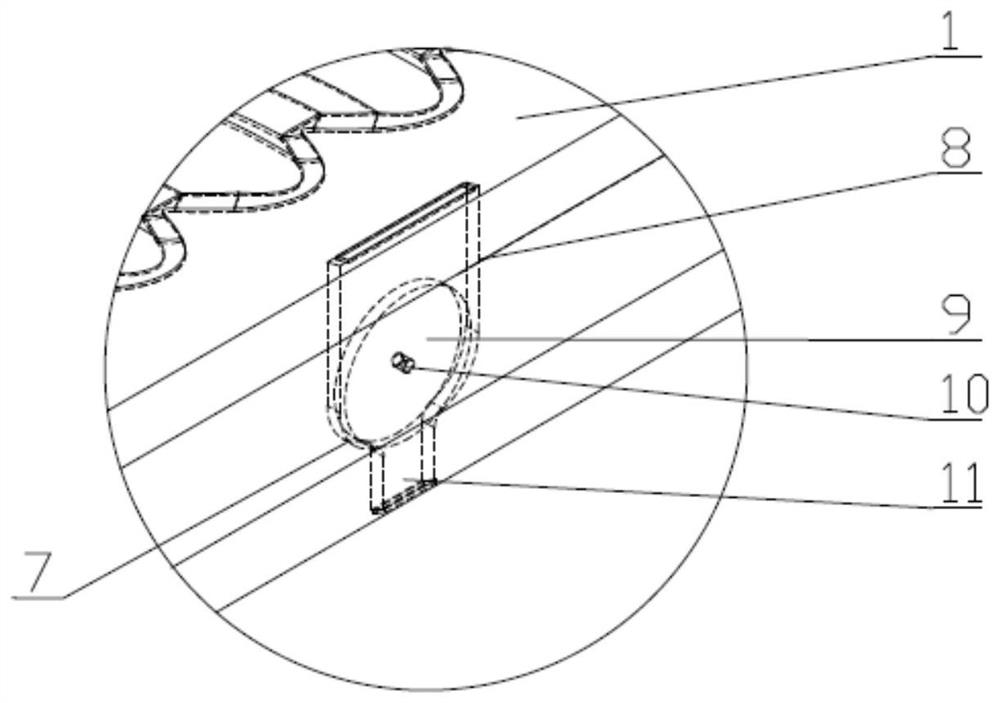

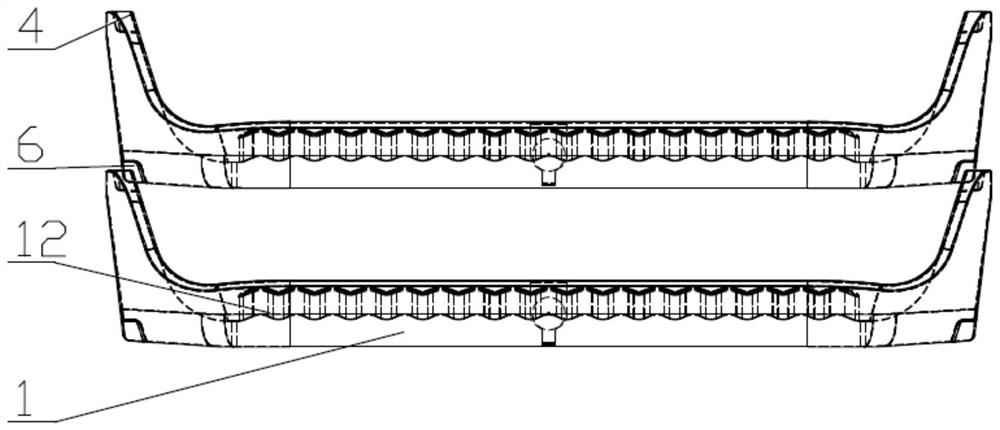

A foamed plastic tray coated with wear-resistant coating

ActiveCN110697206BImprove wear resistanceImprove wear performanceRigid containersCoated surfaceWear resistance

The invention discloses a foamed plastic tray coated with a wear-resistant coating, and belongs to the technical field of airport luggage conveying equipment. The foamed plastic tray comprises a corepart and the surface wear-resistant coating, wherein the core part is made of foamed plastic; the outer side of the core part is coated with the surface wear-resistant coating; a chip is arranged in the core part, the core part is provided with a chip fixing structure; and V-shaped stacking structures are arranged at the two ends of the tray. According to the foamed plastic tray, the core part adopts the foamed plastic as a body, the core part material comprises but is not limited to foamed hard PU, foamed PP, foamed PVC, EPP and other foamed plastic, then the wear-resistant coating is sprayedon the surface, the surface wear-resistant coating material comprises but is not limited to polyurea coating, wear-resistant polyurethane and the like, so that the wear resistance of the luggage trayis improved; and compared with the prior art, the overall weight of the tray is reduced, the wear resistance of the tray in the high-speed movement process is improved, the side surface of the tray is prevented from being worn or even broken, and the service life of the tray is prolonged.

Owner:CIVIL AVIATION LOGISTICS TECH

Pneumatic piston sewage valve

InactiveCN101769382AMeet the requirements of high-speed flowAchieve throughOperating means/releasing devices for valvesLift valveEngineeringPiston

The invention relates to a pneumatic sewage valve, in particular to a pneumatic piston sewage valve which is provided with a valve body. A sewage inlet and a sewage outlet are arranged on the valve body. A through runner is arranged between the sewage inlet and the sewage outlet. A piston chamber intersecting with the runner is arranged in the valve body. A piston is arranged in the piston chamber. The diameter of the piston is larger than the diameter of the runner. A step-shaped spacer ring is arranged at the rear end of the piston. Control ports are arranged on the piston chamber on the two sides of the spacer ring. Since the through runner is arranged between the sewage inlet and the sewage outlet, the requirement of high-speed sewage flow is satisfied; and since the piston chamber intersecting with the runner is arranged in the valve body, the piston is arranged in the piston chamber, the diameter of the piston is larger than the diameter of the runner, the step-shaped spacer ring is arranged at the rear end of the piston and the control ports are arranged on the piston chamber on the two sides of the spacer ring, the valve is not apt to be blocked by impurities in sewage, leakage is not apt to occur, the closing speed is fast, the high-speed instant passage and cut-off of the sewage can be realized, the valve can be used normally in places requiring the valve to be opened and closed rapidly and frequently, and the valve is suitable for sewage discharge.

Owner:SHANDONG SHUANGLUN

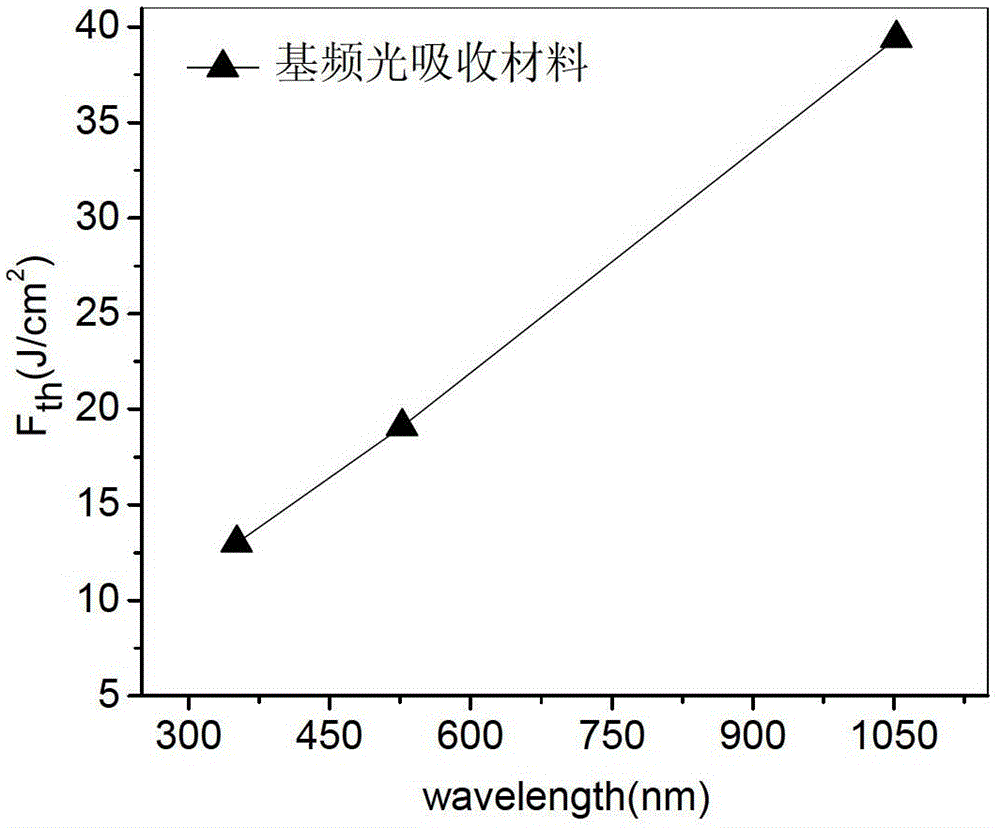

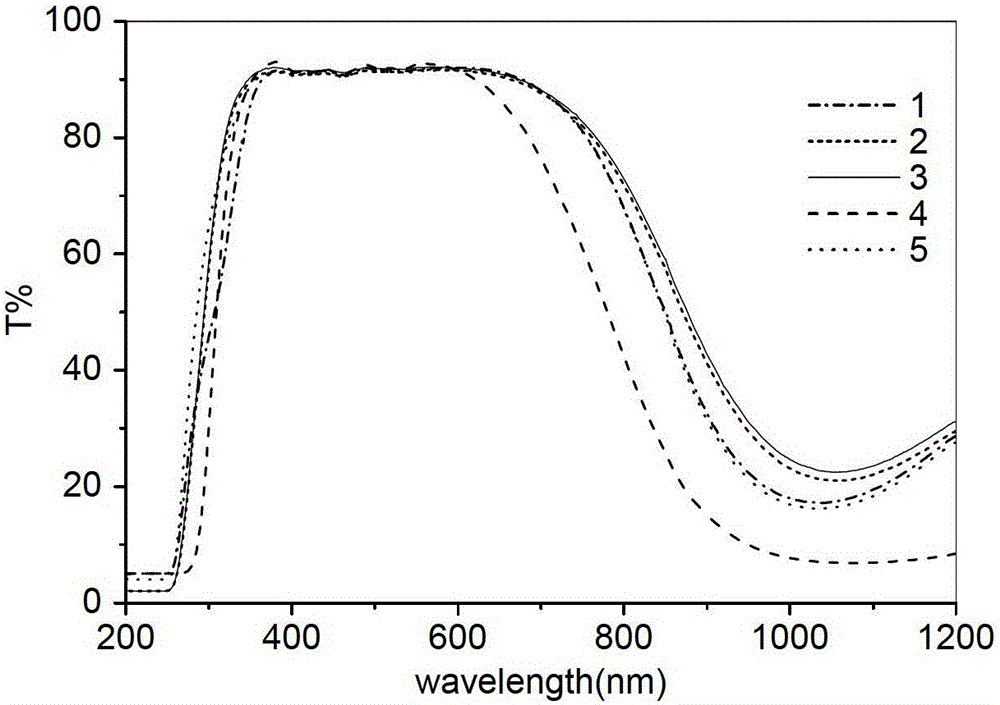

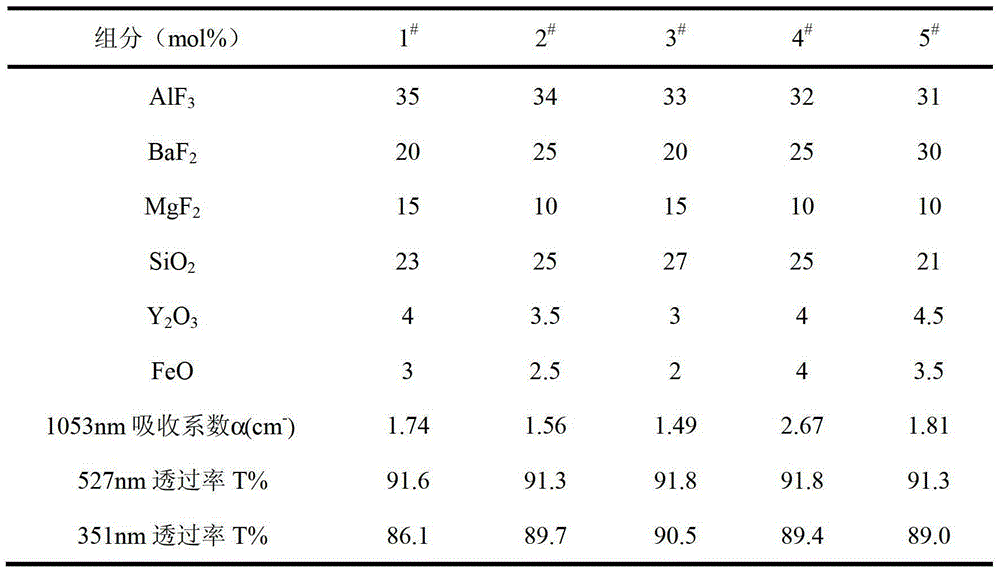

A kind of preparation method of high damage threshold fundamental frequency light absorption material

InactiveCN103265174BAchieve separationAvoid damageGlass shaping apparatusGlass productionBeam splitterPrism

The invention provides a preparation method of a fundamental frequency light absorbing material with high damage threshold. The method comprises the following steps: 1) preparing raw materials and molar ratio; 2) adding uniformly mixed raw powder to a crucible and fusing; 3) after cooling molten glass, injecting the glass to a mould to form; and 4) annealing the glass to obtain the fundamental frequency light absorbing glass with high damage threshold. According to the material prepared by the invention, the damage problem that rasters, spectroscopic films and beam splitter prisms split light under intense laser, so that the loading capacity of a laser is improved. The material is highly transparent in near ultraviolet band and has good glass forming property, and meanwhile further has high laser-damaged threshold, so that the material can be used as the fundamental frequency light absorbing material used in the field of intense laser.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

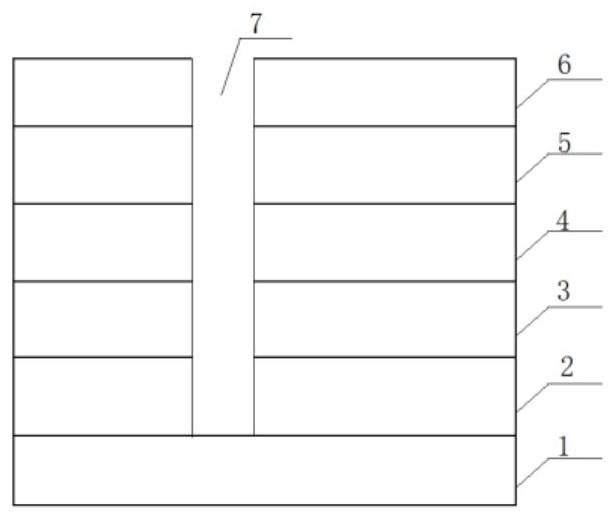

Semitransparent hollow perovskite solar cell and preparation method thereof

PendingCN112382727AAchieve throughRealized areaFinal product manufactureSolid-state devicesPerovskite solar cellSolar battery

The invention discloses a semitransparent hollow perovskite solar cell and a preparation method thereof. The cell is a positive cell structure or an inverted cell structure, the positive cell structure sequentially comprises a transparent glass layer, a bottom electrode layer, an electron transport layer, a perovskite layer, a hole transport layer and a top electrode layer from bottom to top, andthe inverted cell structure sequentially comprises a transparent glass layer, a bottom electrode layer, a hole transport layer, a perovskite layer, an electron transport layer and a top electrode layer from bottom to top. The cell is provided with a plurality of semi-hollow holes, and the semi-hollow holes at least penetrate through the top electrode layer, the hole transport layer and the perovskite layer of the positive cell structure, or penetrate through the top electrode layer, the electron transport layer and the perovskite layer of the inverted cell structure. The preparation method canbe used for preparing the full-spectrum semitransparent perovskite solar cell and can be used for simply, conveniently and efficiently manufacturing the full-spectrum semitransparent perovskite solarcell.

Owner:WUHAN UNIV OF TECH

Valve mechanism

PendingCN108240550ARelieve pressureExtended service lifeOperating means/releasing devices for valvesLift valvePiston ringMechanical engineering

The invention discloses a valve mechanism. The valve mechanism comprises a valve body, and a valve element assembly is installed at an outlet of the valve body; the valve element assembly is installedin the middle of a spindle in a sleeving mode, one end of the spindle is provided with a handle, and the other end of the spindle is provided with a stopping portion used for cooperating with the handle to push the valve element assembly to move; and the valve element assembly comprises a main valve element, the main valve element is provided with a liquid filling hole and an overflow hole, the valve element assembly further comprises a pressure relieving valve element used for communicating with the liquid filling hole and the overflow hole to complete pressure relieving and a spring used for supporting the pressure relieving valve element, the pressure relieving valve element is located in the main valve element, one end of the spring abuts against the pressure relieving valve element,and the other end of the spring abuts against a sealing cover installed on the valve body. The valve mechanism has the characteristics of being simple and compact in structure and convenient to use. When the valve mechanism frequently moves back and forth, the service life of the valve element is mainly prolonged through friction between a piston ring and a valve body.

Owner:XINXING HEAVY IND HUBEI 3611 MECHANICAL

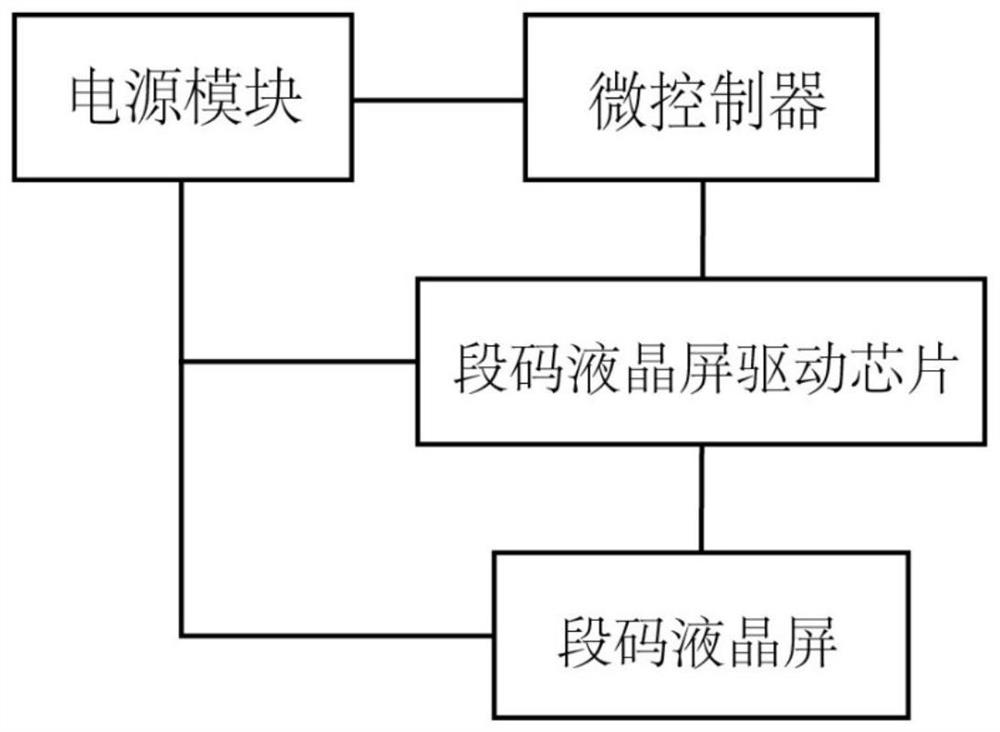

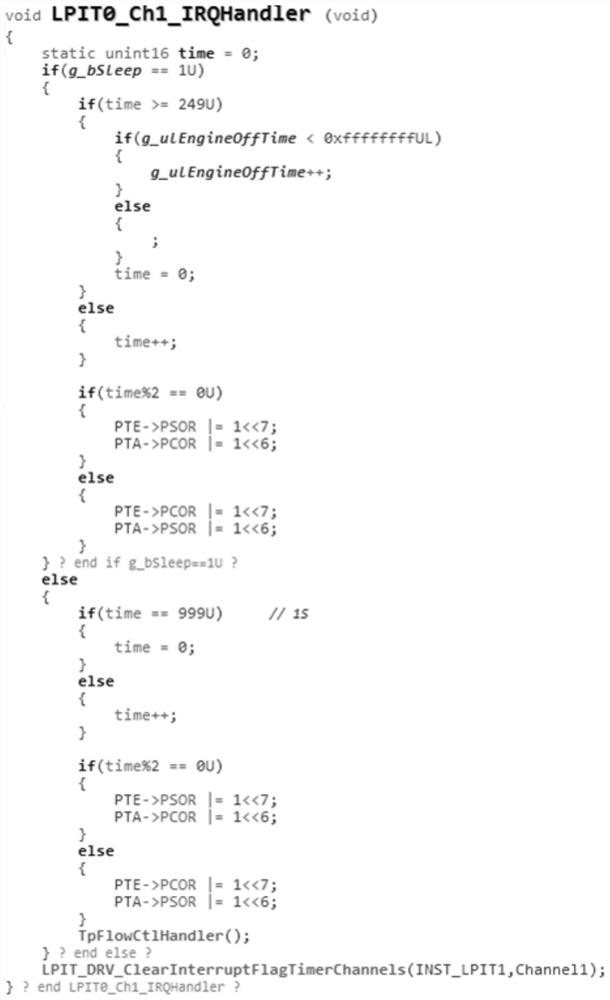

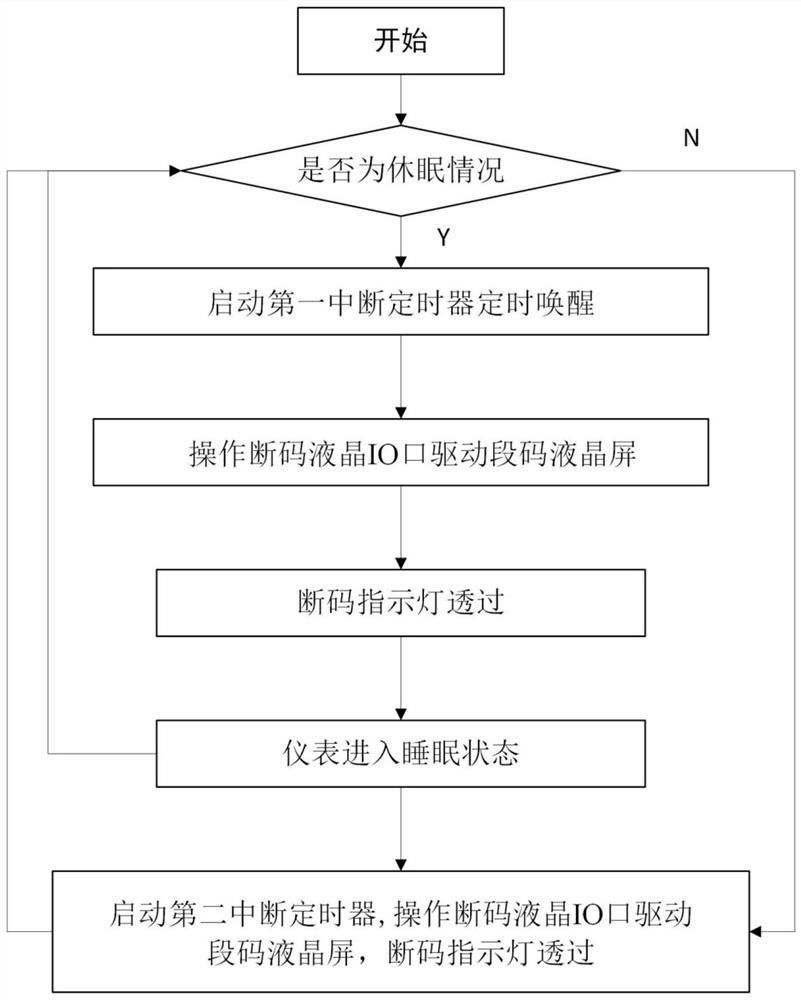

Low-power-consumption driving system and method for full-segment-code instrument indicator lamp

ActiveCN112731834AAchieve throughProgramme controlComputer controlMicrocontrollerLow power dissipation

The invention provides a low-power-consumption driving system and method for a full-segment-code instrument indicator lamp. The system comprises a power module, a microcontroller, a segment-code liquid crystal screen driving chip and a segment-code liquid crystal screen. The power supply module is connected with the microcontroller, the segment code liquid crystal screen driving chip and the segment code liquid crystal screen, and the microcontroller is connected with the segment code liquid crystal screen driving chip; the microcontroller is used for controlling the segment code liquid crystal screen driving chip, the segment code liquid crystal screen driving chip, the broken code indicating lamp used for driving the segment code liquid crystal screen, and the power supply module, and is used for supplying power to each module. According to the invention, under the condition that the instrument is dormant, the system can be awakened regularly, the broken code liquid crystal IO port is operated, and the liquid crystal indicator light is transmitted.

Owner:CHONGQING DELCO ELECTRONICS INSTR

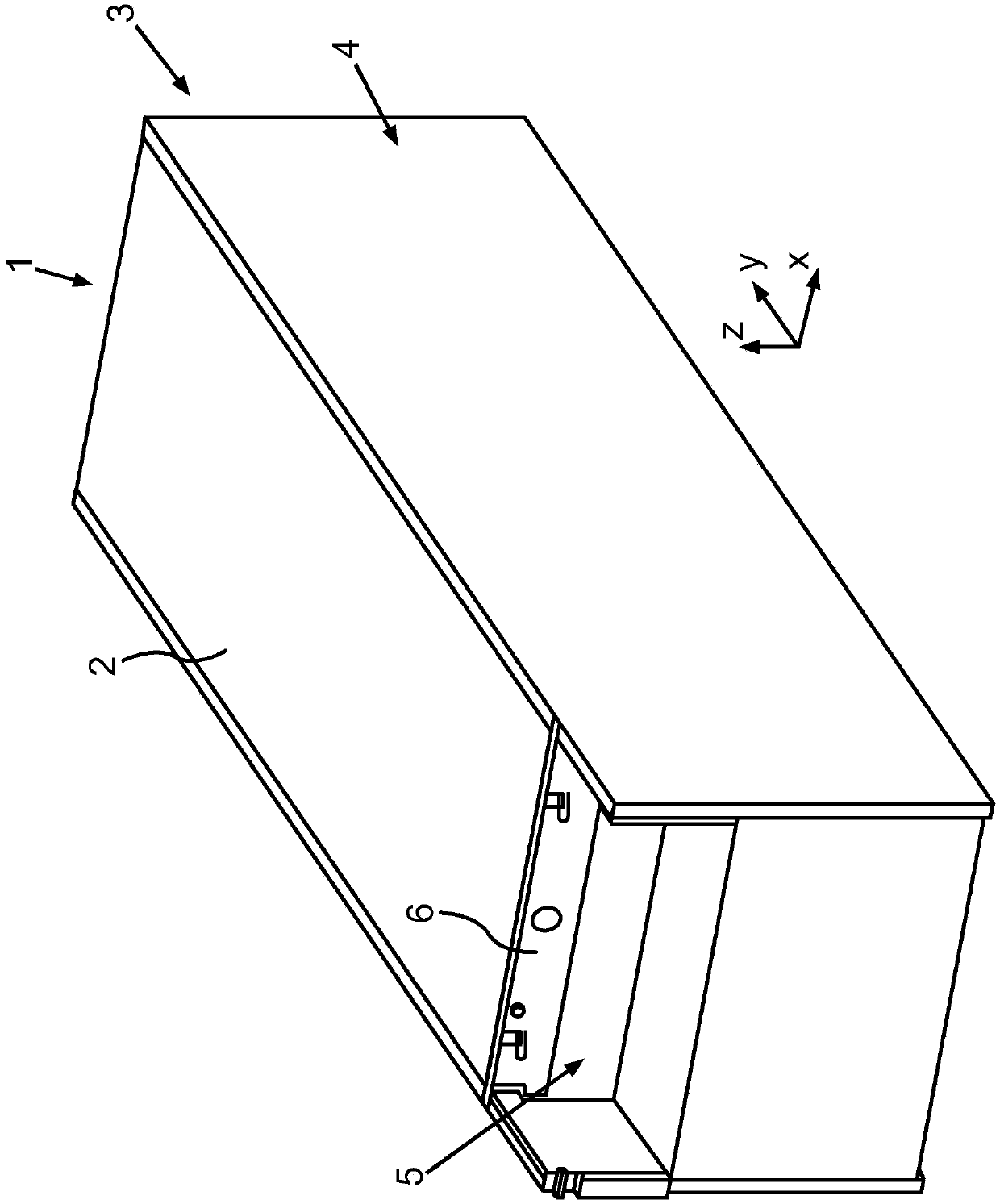

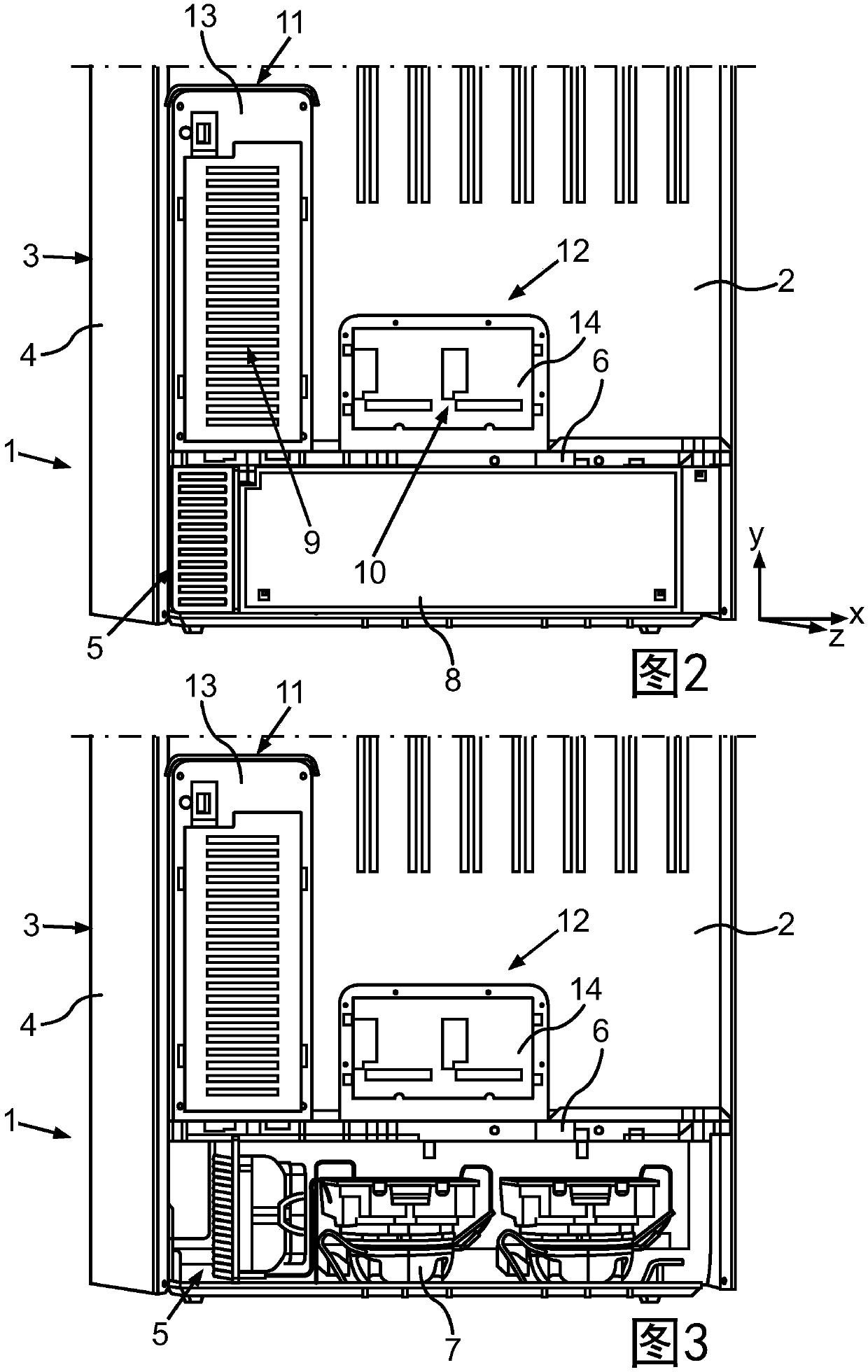

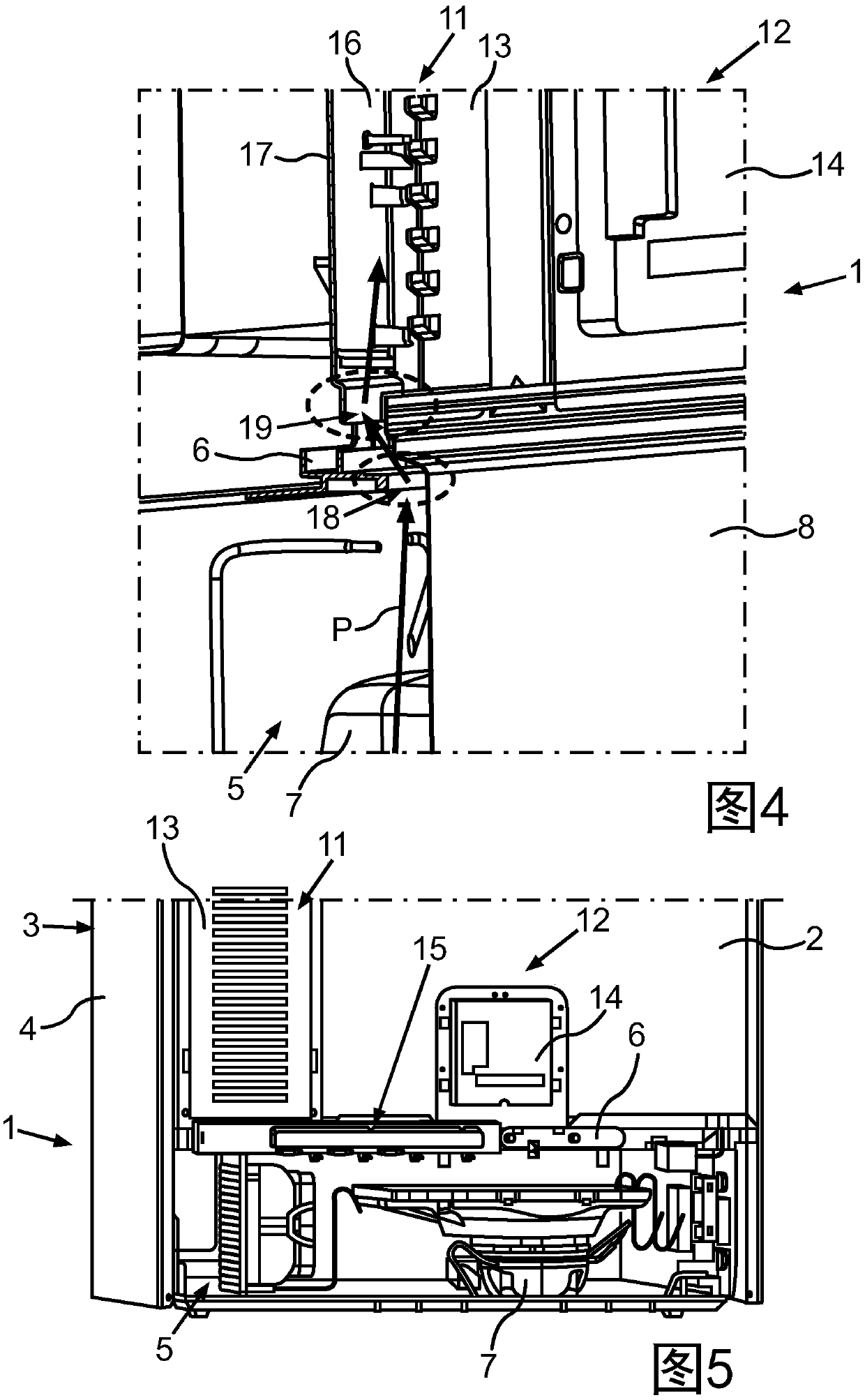

Domestic refrigeration appliance containing a cover for a gap between a foam crossmember and an electronics box

ActiveCN109631479ASave spaceReduce weightLighting and heating apparatusInsulation for cooling apparatusIntermediate spaceElectronics

A domestic refrigeration appliance (1) contains a housing (3) in which a receiving space for food is configured, a machinery compartment (5), and an electronics box (9, 10) which is arranged above themachinery compartment (5) in the housing (3). The machinery compartment (5) is separated in the upward direction by a foam cross-member (6) from an intermediate space (26) of the housing (3) filled with a thermally insulating material at least in regions. A gap (19) is formed between the foam cross-member (6), and an interior (16) of the electronics box (9, 10). A cover element (15) is arranged in the gap (19) such that a flow of media (P) is blocked from the machinery compartment (5) into the interior (16) of the electronics box (9, 10).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

A neck radiotherapy device

ActiveCN109966660BImprove the effect of radiotherapyReduce damage rateX-ray/gamma-ray/particle-irradiation therapyGear driveGear wheel

The invention discloses a radiotherapy device for the neck, which includes a radiotherapy device, a drum, a box body, a motor and a transmission mechanism. The motor is fixedly arranged in the box body, and the driving shaft of the motor is provided with a first gear, and the first gear drives the drum to rotate intermittently through a transmission mechanism. The invention can not only realize the continuous rotation of the radiotherapy equipment to adjust the direction of the radiotherapy equipment, perform radiotherapy to different directions of the neck, but also make the radiotherapy equipment rotate intermittently to improve the effect of radiotherapy.

Owner:QINGDAO CENT HOSPITAL

Fully assembled bulk fiber optic cable over-the-wall device

ActiveCN104678526BEasy to installQuick installationOptical fibre/cable installationElectromagnetic shieldingEngineering

The invention relates to a completely-assembled optical cable batch wall passing device, which comprises a pair of symmetric half casings, a pair of symmetric upper cover plates, a partition plate and highly-conductive shielding and sealing particles, wherein a hole through which optical cables penetrate is formed in the middle lower part of the partition plate; the pair of symmetric half casings are fixed on the two sides of the partition plate to form a shielding casing through flanges; the hole through which the optical cables penetrate is positioned in the shielding casing; the highly-conductive shielding and sealing particles are arranged in the shielding casing; the pair of symmetric upper cover plates are arranged at an upper opening of the shielding casing through support plates fixed on the partition plate; the pair of symmetric half casings, the pair of symmetric upper cover plates and the partition plate are made from highly-conductive metal plates. The completely-assembled optical cable batch wall passing device has the benefits of (1) convenience and high speed in mounting and high reliability; (2) capability of high-electromagnetic shielding performance optical signal transmission.

Owner:NORTHERN ENG DESIGN & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com