Device for leaching gold mine by electrochemistry oxidation method

An oxidation method and electrochemical technology, applied in the direction of improving process efficiency, etc., can solve the problems of shortened membrane operating life, limited industrial application, mechanical damage, etc., and achieve the effect of simple equipment, convenient operation, and prevention of mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

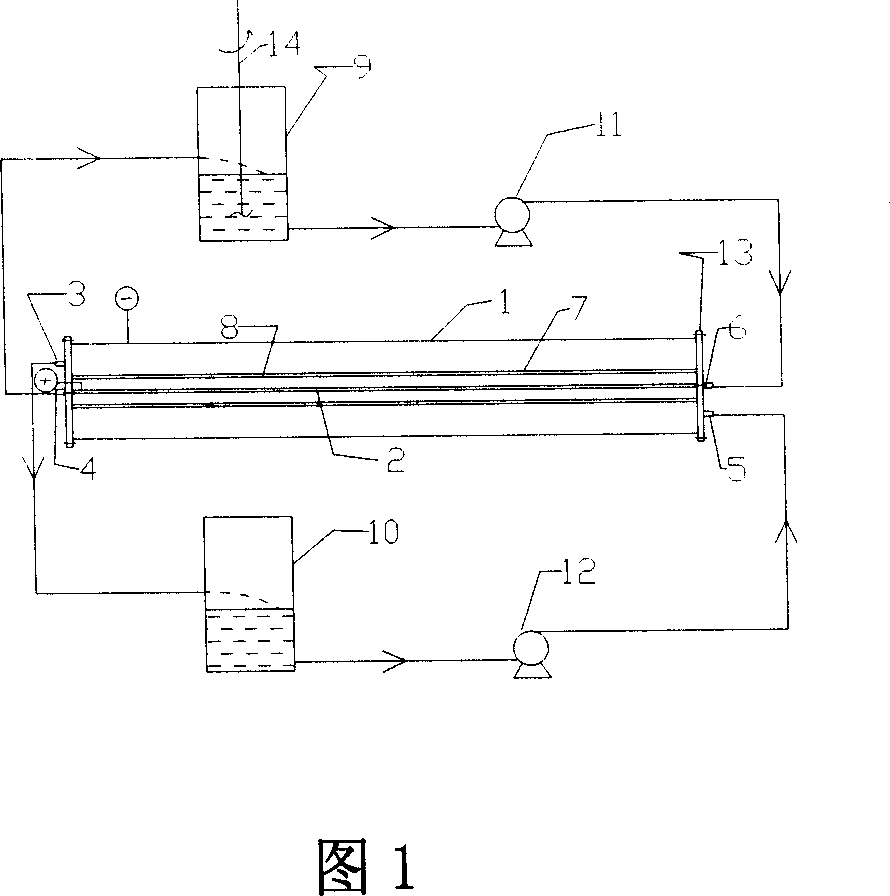

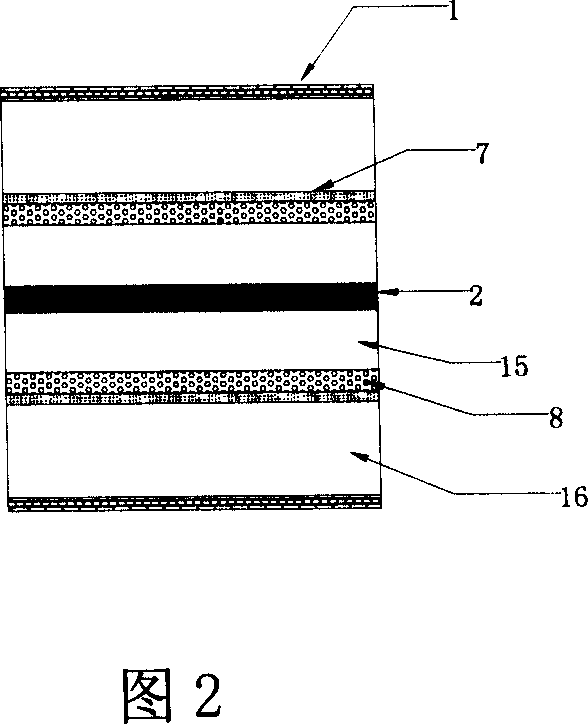

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0013] In this equipment, the anode liquid tank 9 is connected to the water inlet of the anode magnetic circulation pump 11, the water outlet of the anode magnetic circulation pump 11 is connected to the anolyte water inlet 6 of the electrolytic cell through a pipeline, and the anolyte water outlet 4 of the electrolytic cell is passed through The pipeline is connected with the anode feed liquid tank 9 again. The stirring blade 14 is installed at the opening of the cover of the anode feed tank 9 .

[0014] The cathode feed liquid tank 10 is connected with the water inlet of the cathode magnetic circulation pump 12, and the water outlet of the cathode magnetic circulation pump 12 is connected with the catholyte water inlet 5 of the electrolyzer through a pipeline, and the catholyte water outlet 3 of the electrolyzer is connected with the cathode throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com