Fixed bed counter-current regeneration device of ion exchange resin and application method of fixed bed counter-current regeneration device

An ion exchange resin, countercurrent regeneration technology, applied in ion exchange regeneration, ion exchange bed cleaning/flushing, ion exchange, etc., can solve the problems of low regeneration efficiency, large mechanical wear, large desorption liquid output, etc., and achieve economical operation. cost, achieve separation, avoid mechanical wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

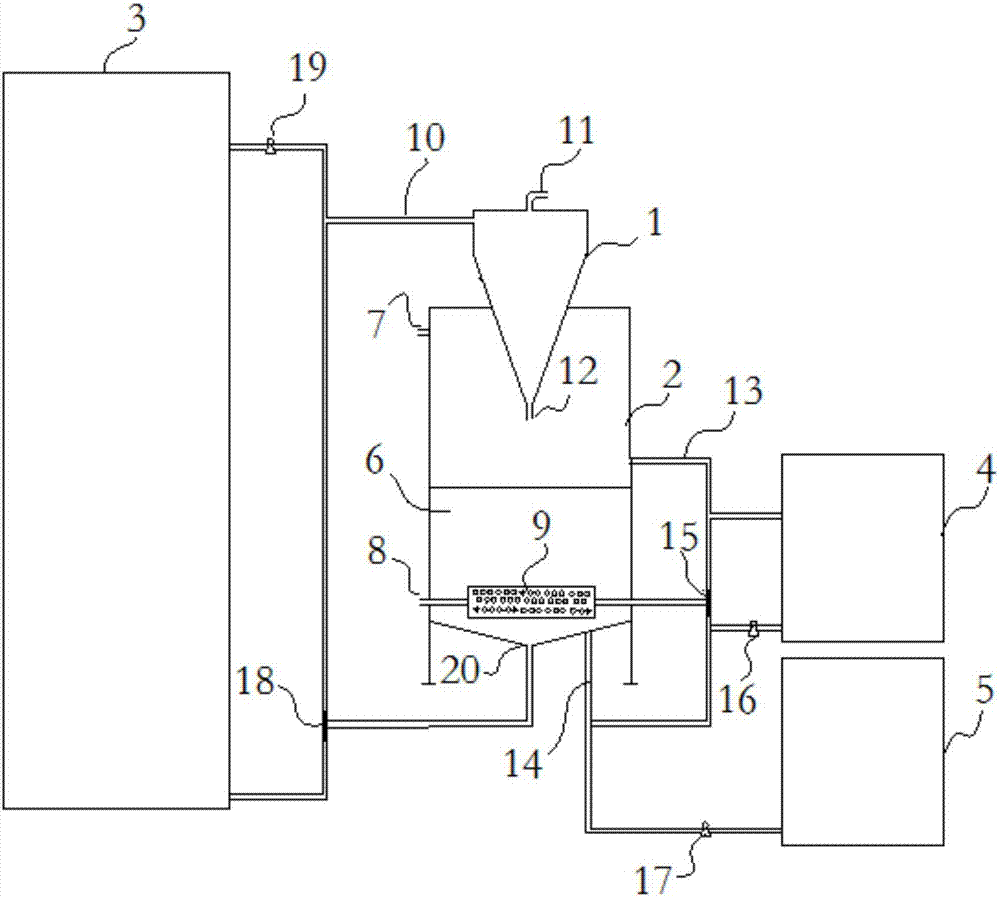

[0039] Such as figure 1 As shown, an ion exchange resin fixed bed countercurrent regeneration device in this embodiment includes a cyclone separator 1, a regeneration reactor 2, a fully mixed resin reactor 3, a desorption liquid storage tank 4 and a regeneration agent storage tank 5 , the cyclone separator 1 is placed on the top of the regeneration reactor 2, the top of the cyclone separator 1 is provided with an overflow port 11, and the upper part of the cyclone separator 1 communicates with the lower end of the fully mixed resin reactor 3 through the feed port 10, The feed port 10 is tangent to the cyclone separator 1, and the resin and water in the fully mixed resin reactor 3 are transported to the cyclone separator 1 by hydraulic pressure, and the solid-liquid separation is realized by centrifugal force. A resin inlet 12 is provided at the bottom of the cyclone separator 1 , and the resin enters the regeneration reactor 2 through the resin inlet 12 , and the remaining wat...

Embodiment 2

[0049] A kind of ion-exchange resin fixed-bed countercurrent regeneration device of the present embodiment is basically the same as embodiment 1, and further, the regeneration reactor 2 is a fiberglass material structure with a diameter of 1.5m and a height of 2m; the inner diameter of the cyclone separator 1 is 250mm, The cone angle of the lower cone of the cyclone separator 1 is 20°, the diameter of the feed inlet 10 is 75 mm, the diameter of the overflow port 11 is 100 mm, and the diameter of the resin inlet 12 is 35 mm; the resin filter 9 is two hollow tubes with closed ends. Cylinder, the diameter of the tightly wound screen around the resin filter 9 is 150 μm, and the regenerant outlet 13 is 60 cm away from the upper edge of the regeneration reactor 2 .

[0050] After the ion exchange resin is regenerated by the device, the adsorption equilibrium amount of the regenerated resin is greater than 95% of the adsorption equilibrium amount of the new resin.

Embodiment 3

[0052] An ion exchange resin fixed bed countercurrent regeneration device in this embodiment is basically the same as in Embodiment 2, except that the regeneration reactor 2 in this embodiment is a glass fiber reinforced plastic material structure with a diameter of 2.0 m and a height of 2.5 m; cyclone separation The inner diameter of the device 1 is 300mm, the cone angle of the lower cone of the cyclone separator 1 is 45°, the diameter of the feed inlet 10 is 50mm, and the diameter of the resin inlet 12 is 38mm; the resin filter 9 is 3 hollow cylinders with closed ends body, the diameter of the tightly wound mesh around the resin filter 9 is 150 μm, and the regenerant outlet 13 is 60 cm away from the upper edge of the regeneration reactor 2 .

[0053] When the present embodiment is in use, inject the fresh regenerant in the regenerant storage tank 5 (NaCl+1% NaOH solution with a mass concentration of 15%) or desorption liquid storage tank 5 into the regeneration reactor 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com