Patents

Literature

348results about "Ion exchange beds cleaning/rinsing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

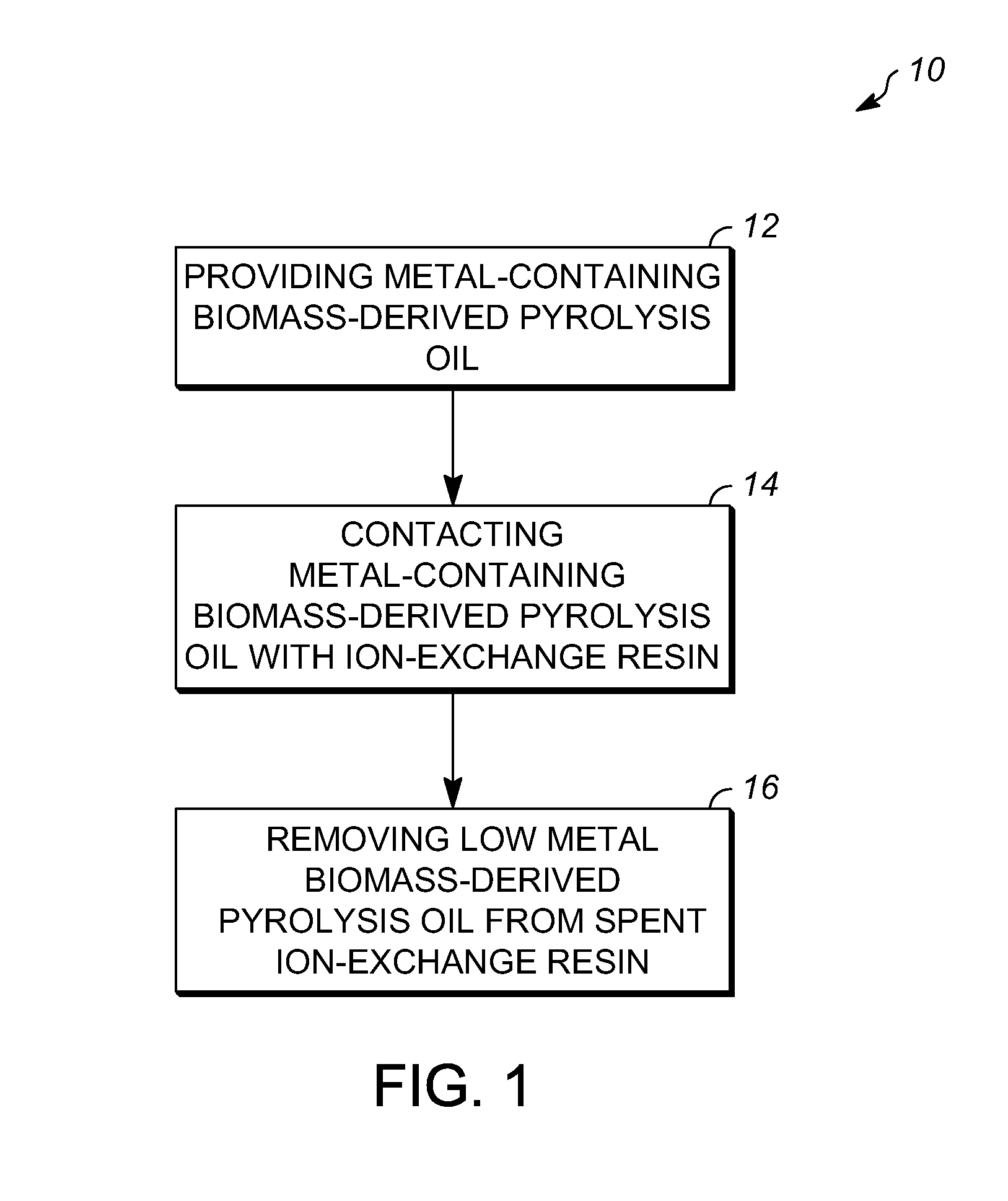

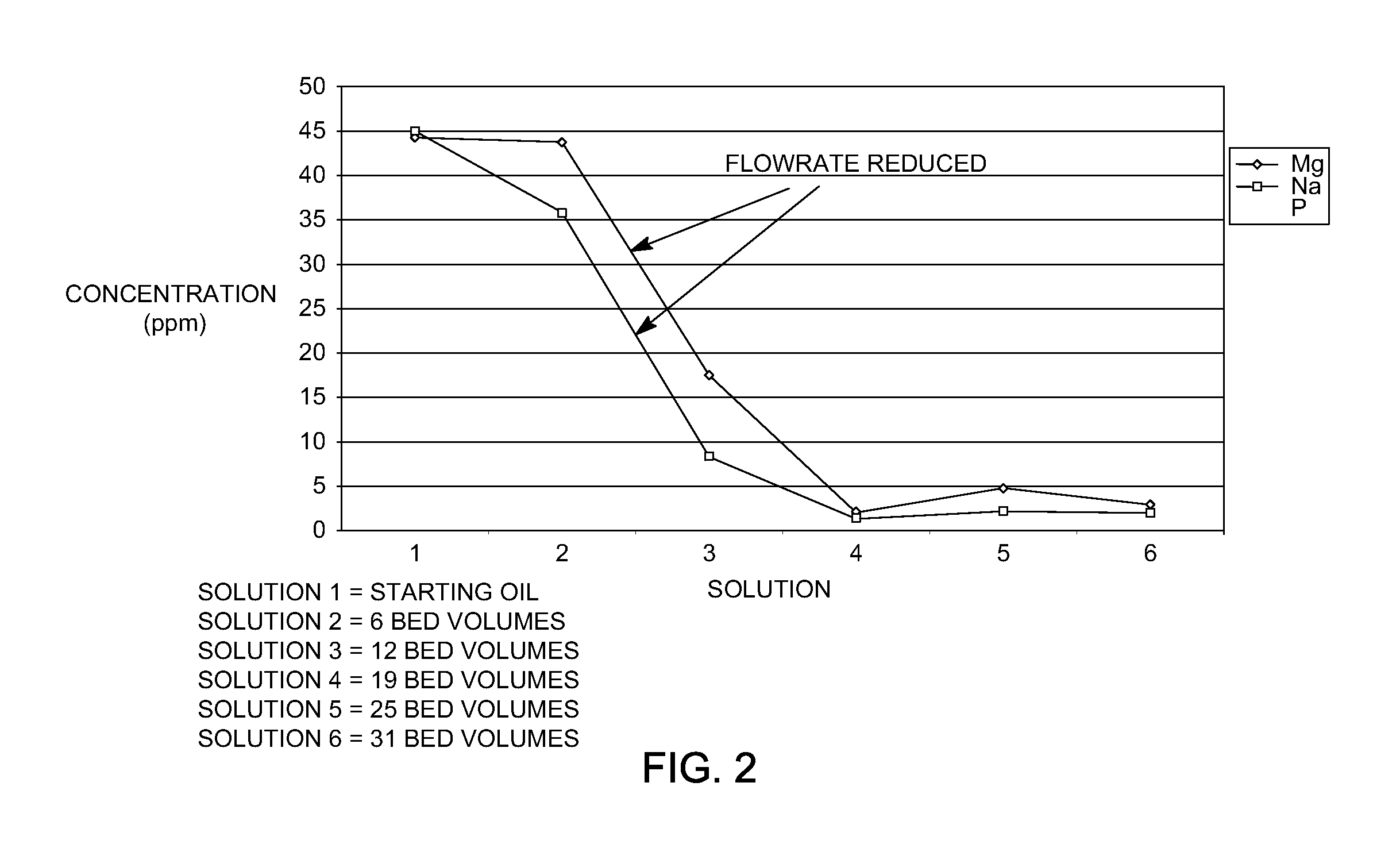

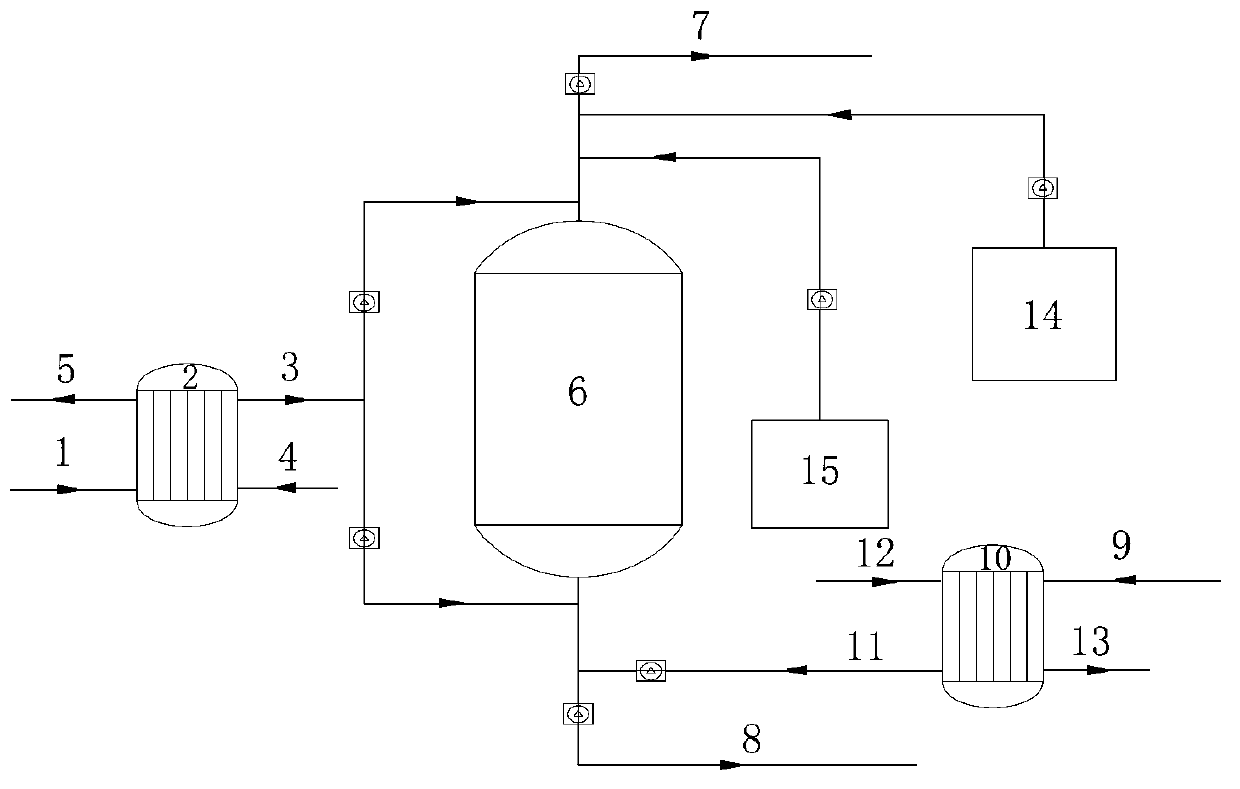

Low metal, low water biomass-derived pyrolysis oils and methods for producing the same

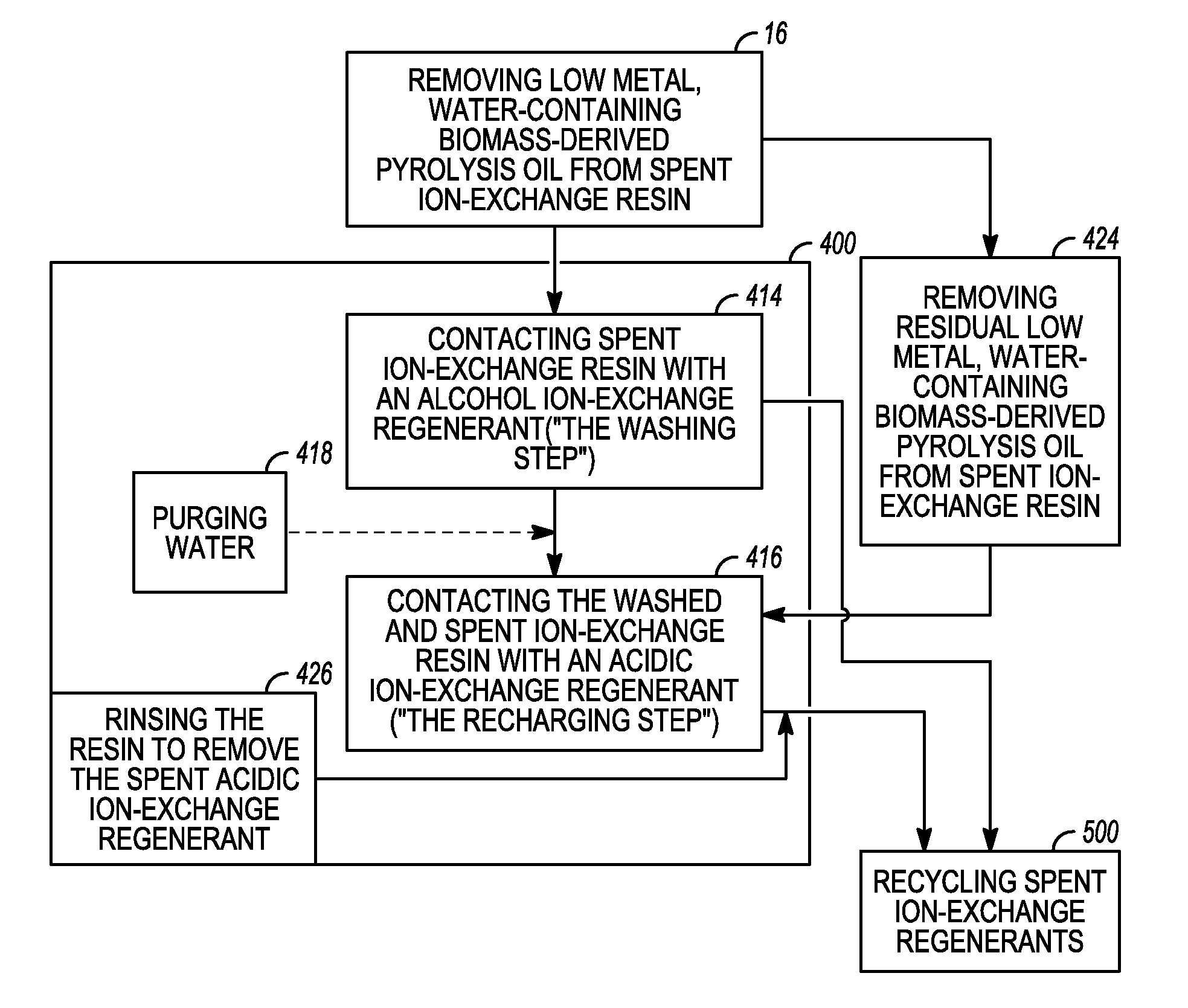

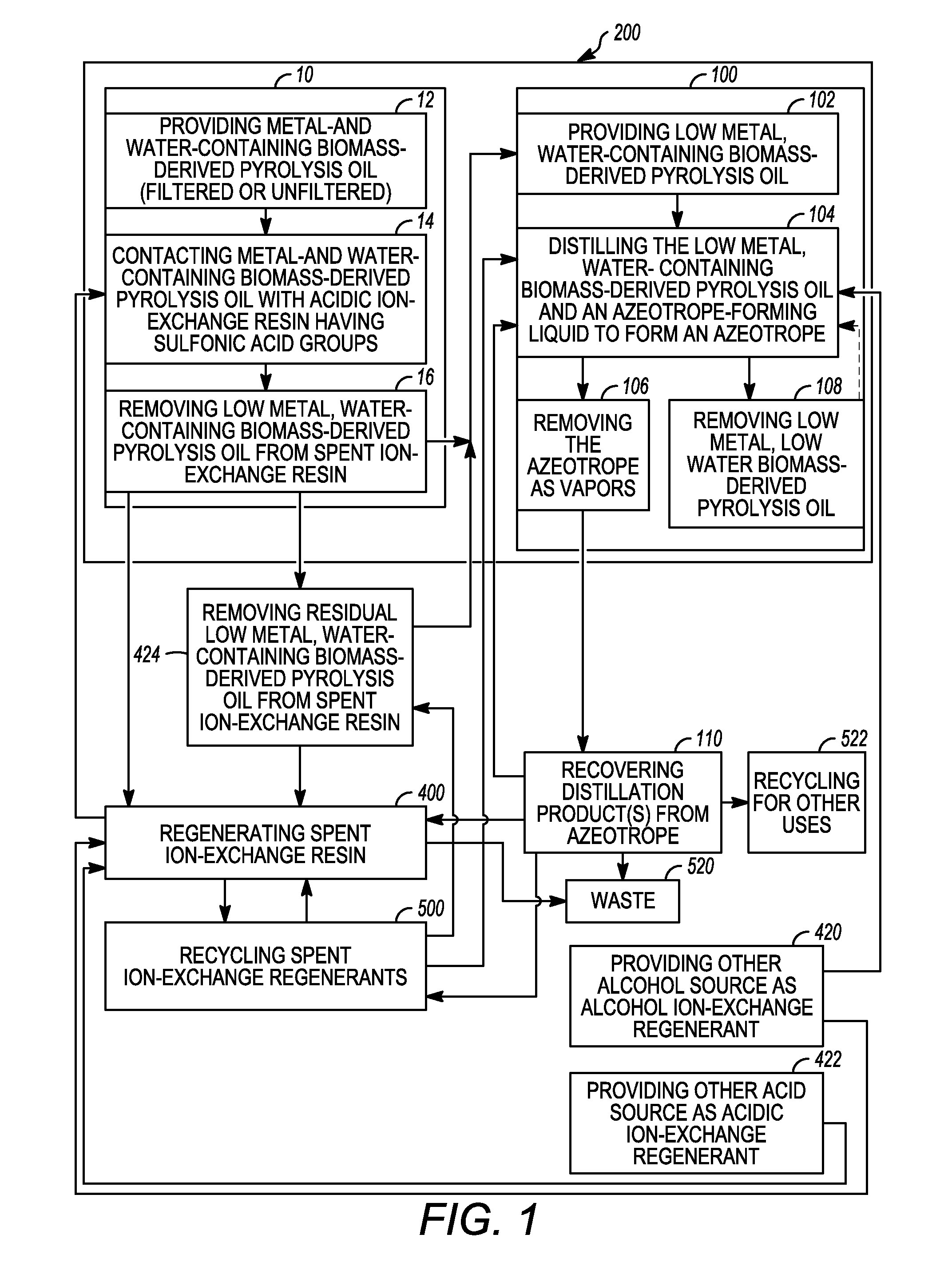

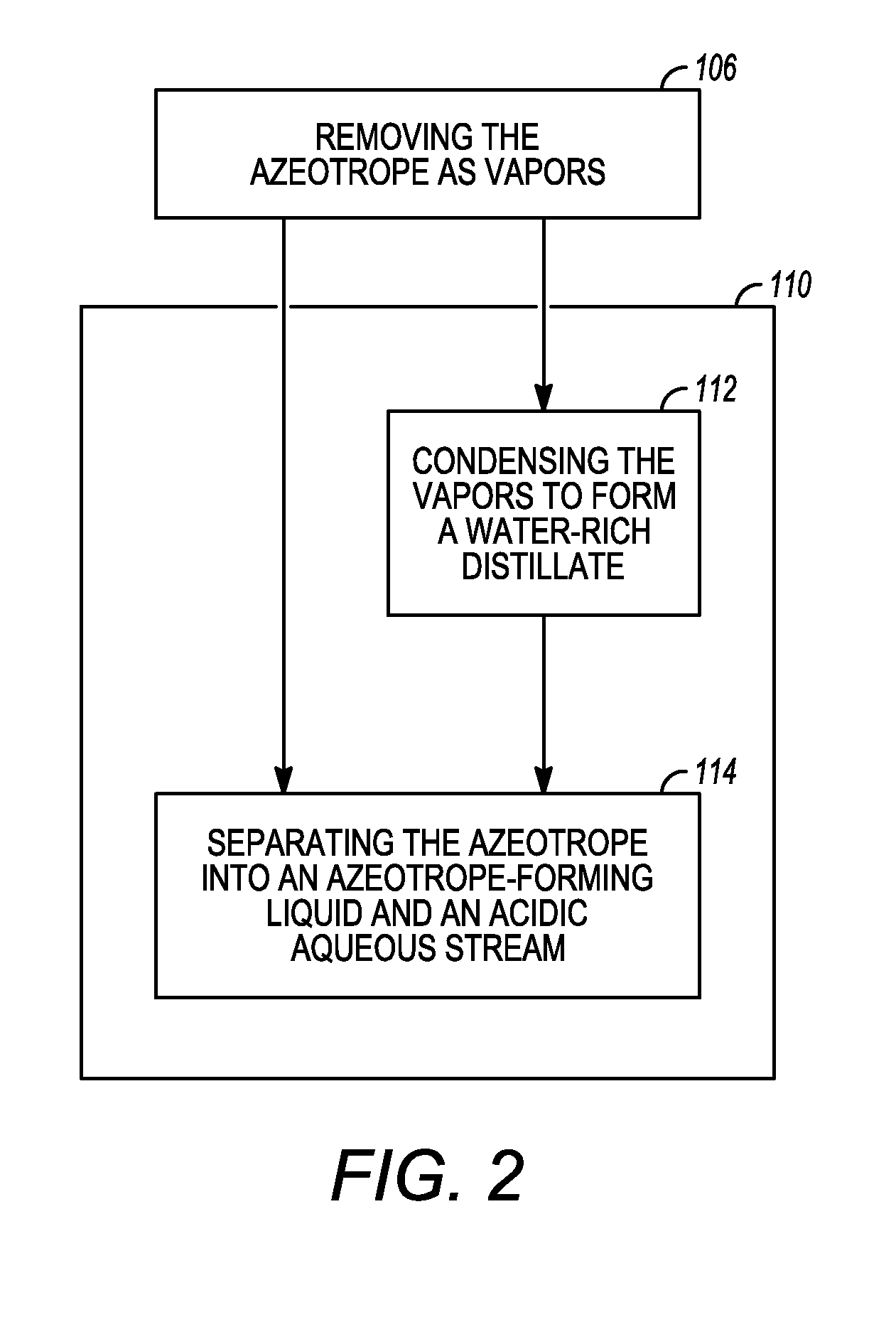

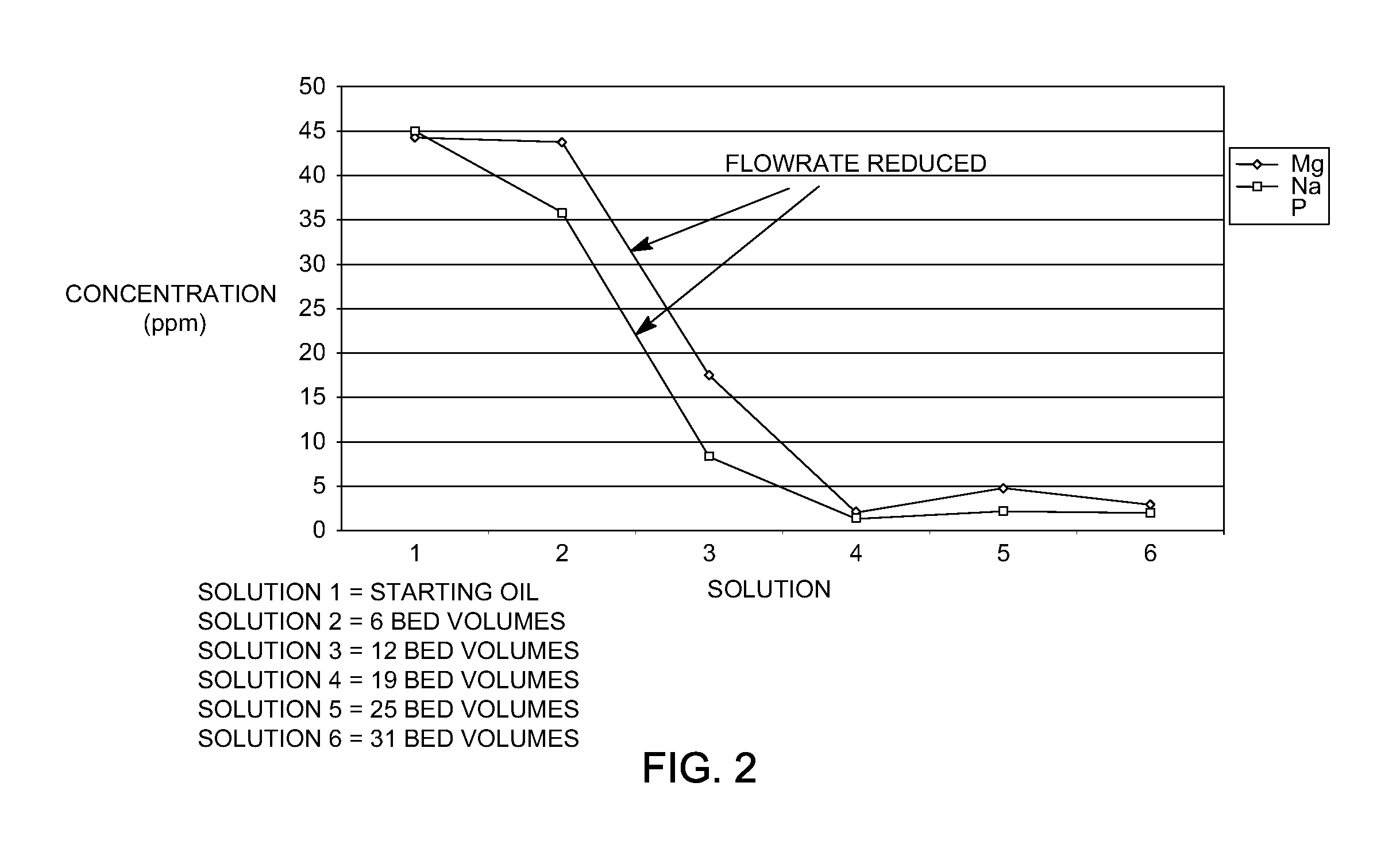

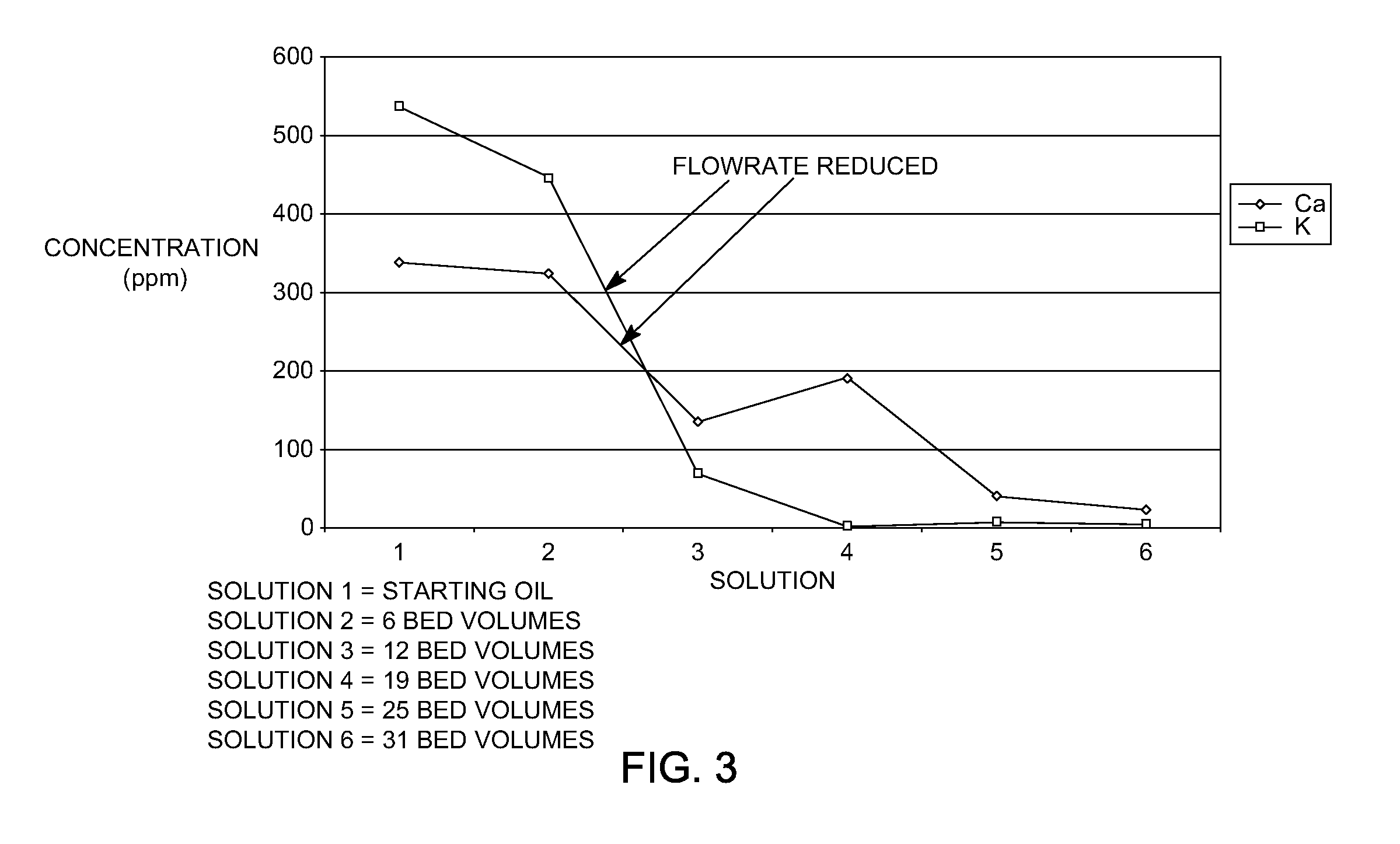

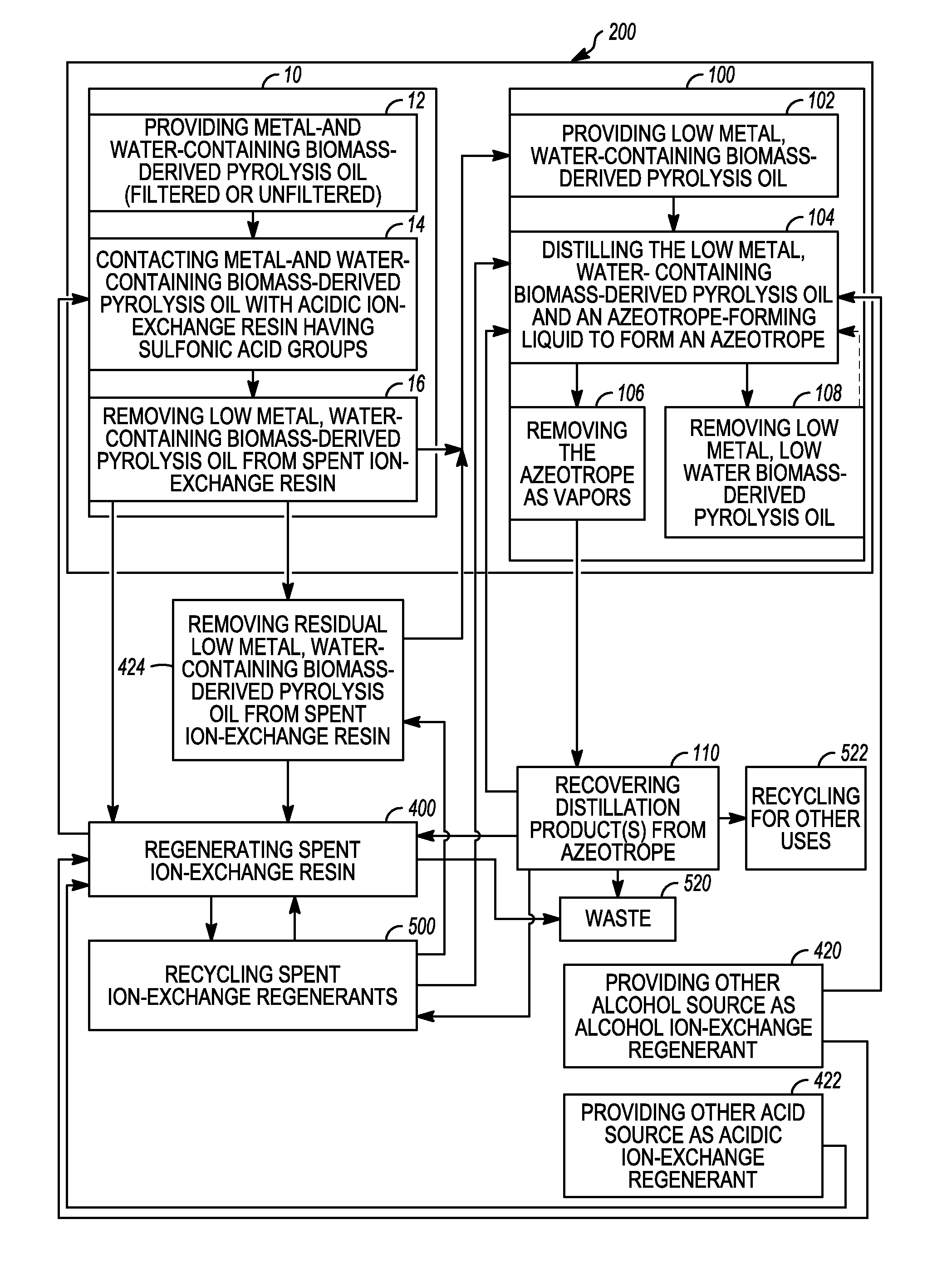

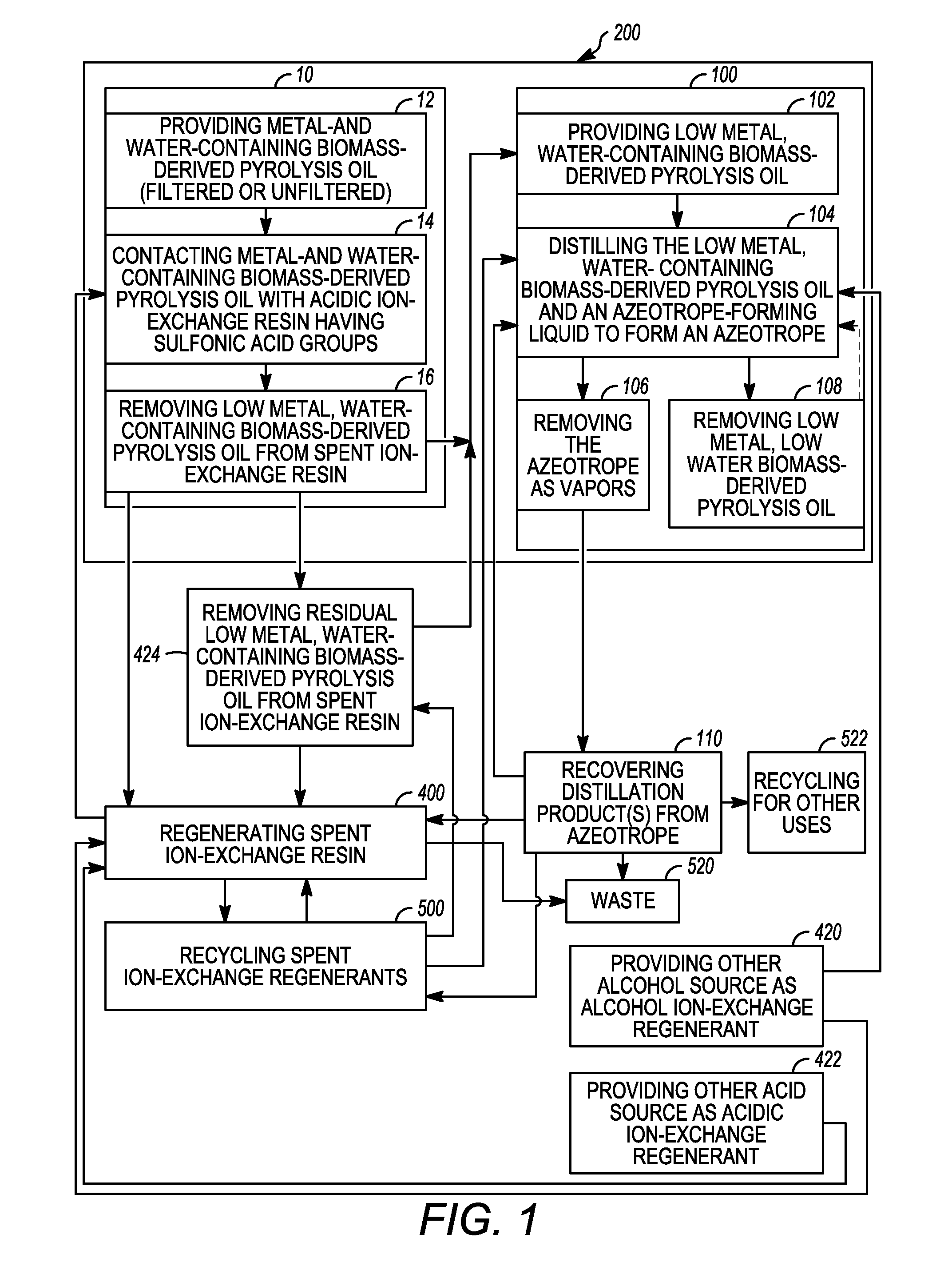

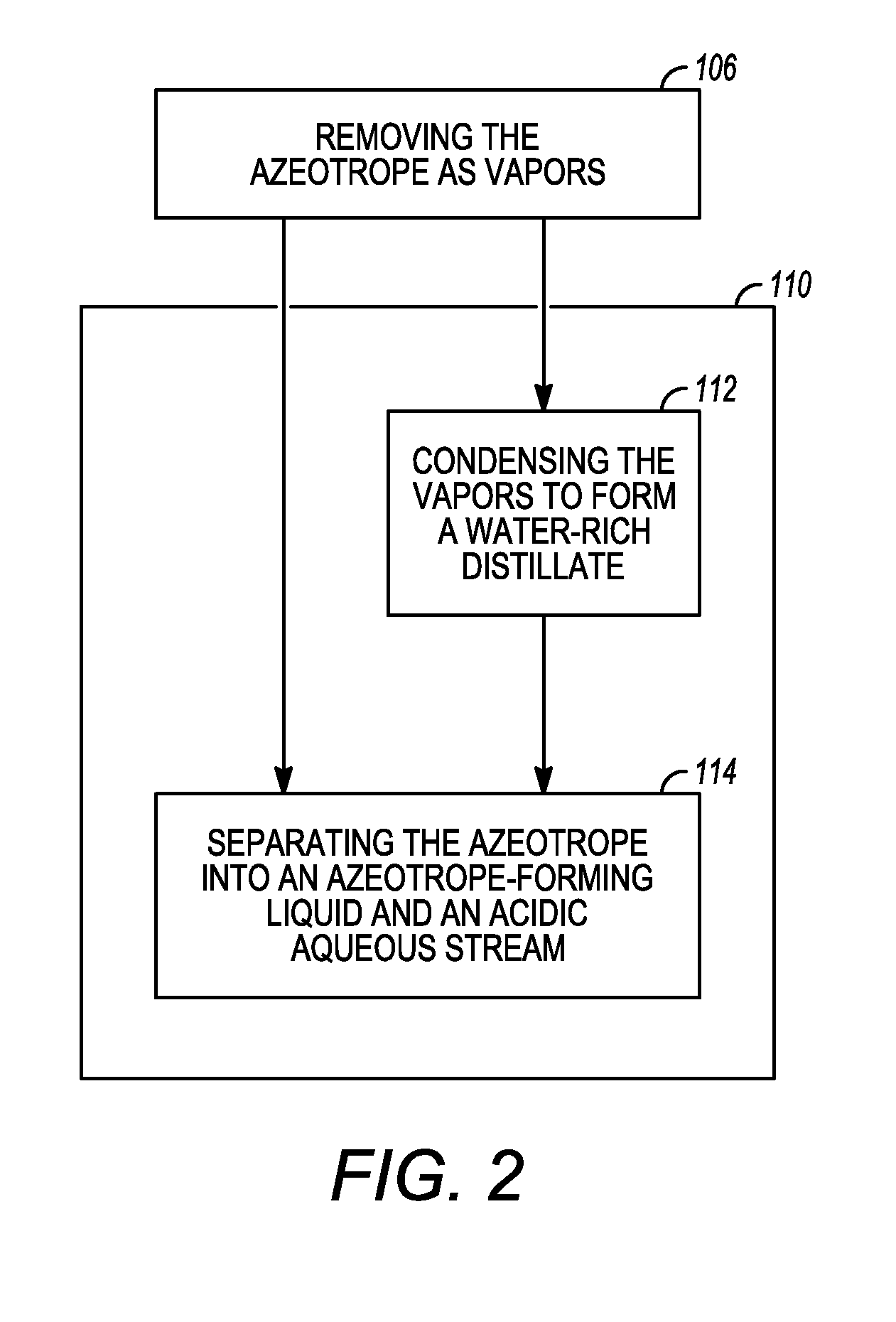

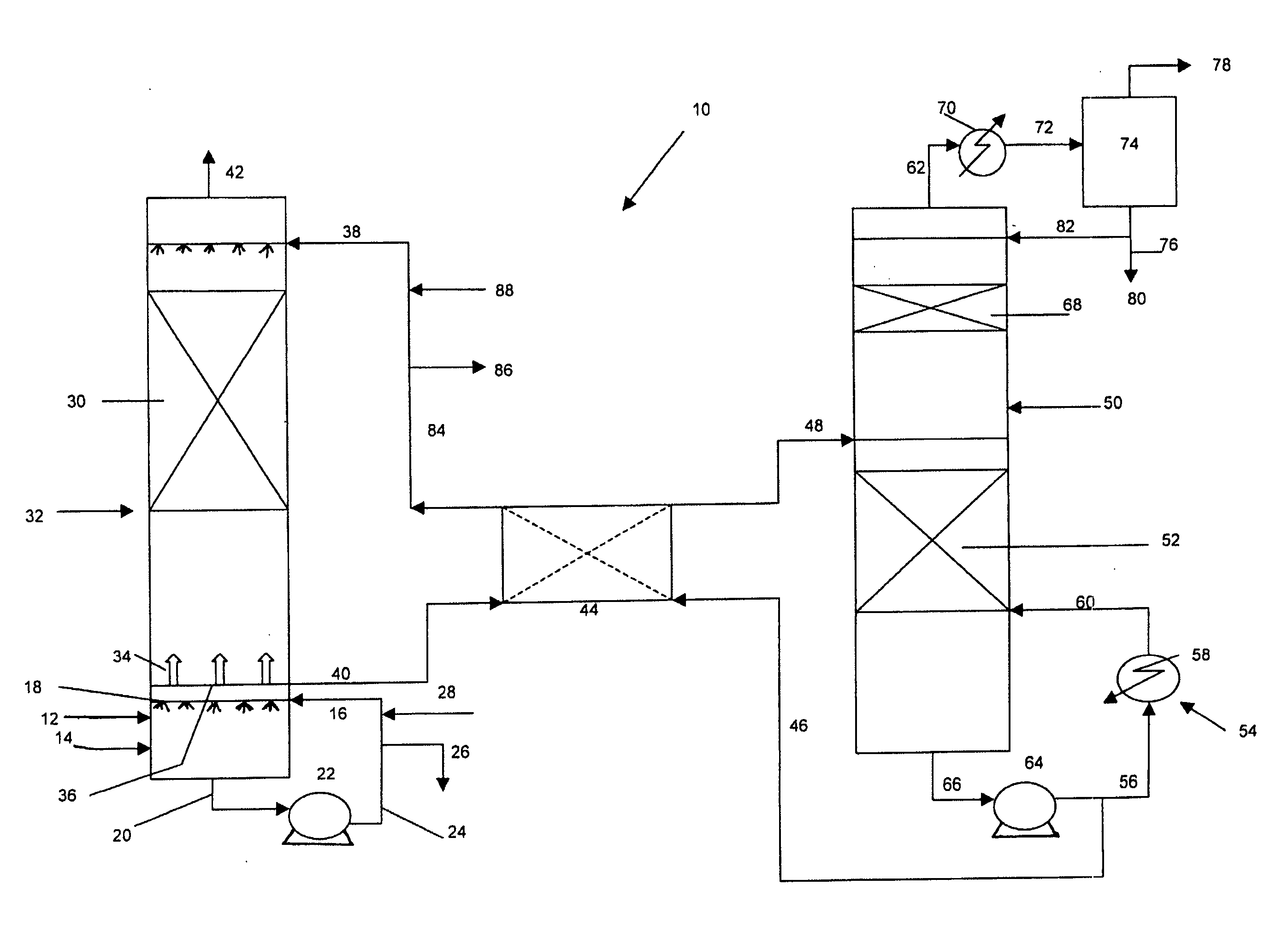

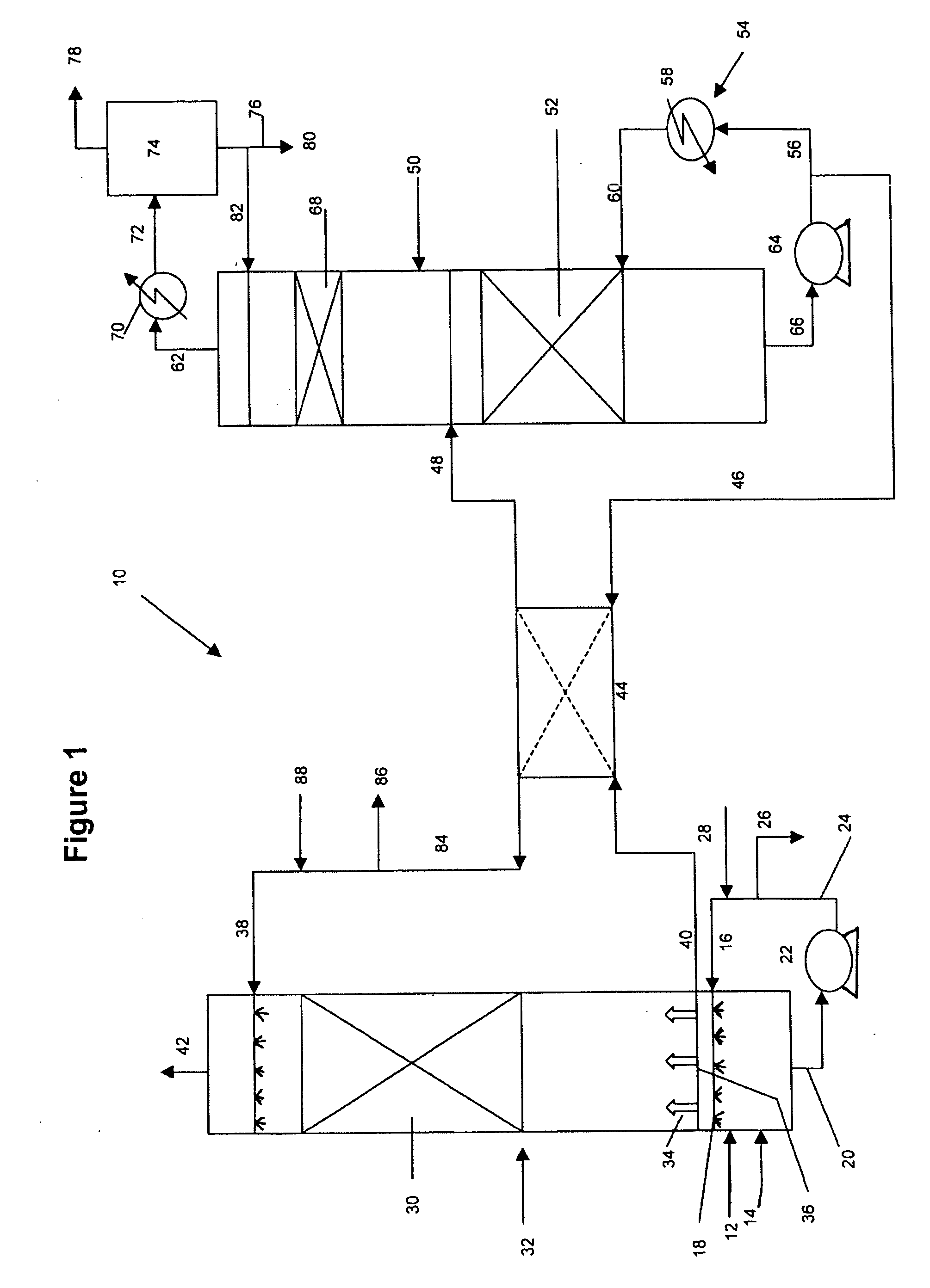

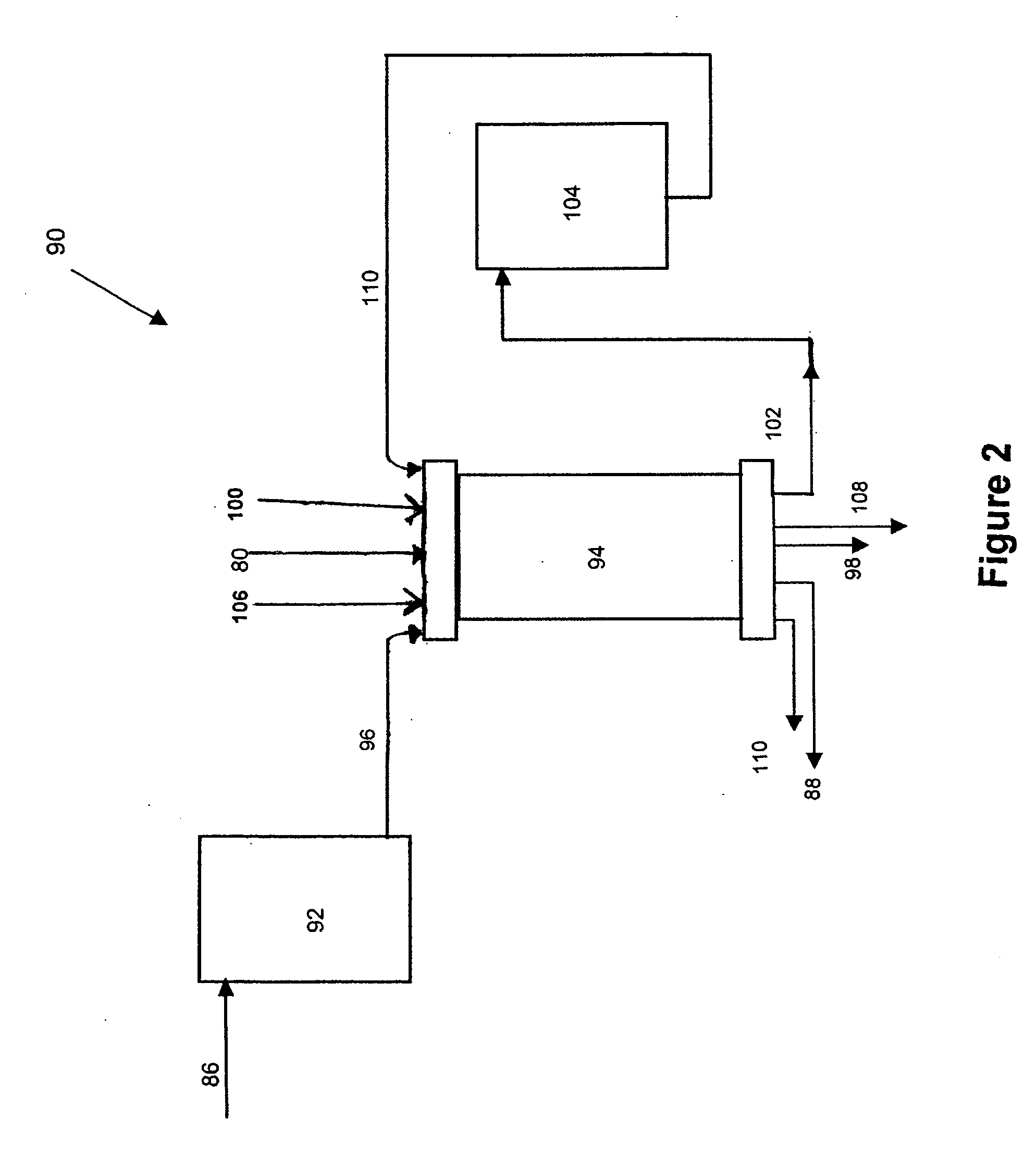

Low metal, low water biomass-derived pyrolysis oils and methods for producing the same are provided. Metal- and water-containing biomass-derived pyrolysis oil is contacted with an acidic ion-exchange resin having sulfonic acid groups to produce a low metal, water-containing biomass-derived pyrolysis oil. The low metal, water-containing biomass-derived pyrolysis oil is removed from the spent ion-exchange resin after ion-exchange. The low metal, water-containing biomass-derived pyrolysis oil is distilled to produce a low metal, low water biomass-derived pyrolysis oil and a distillation product. The distillation product comprises one or both of an alcohol ion-exchange regenerant and an acidic ion-exchange regenerant which may be used to regenerate the spent ion-exchange resin. The regenerated acidic ion-exchange resin may be recycled. The spent alcohol and acid ion-exchange regenerants may be recovered and recycled.

Owner:UOP LLC

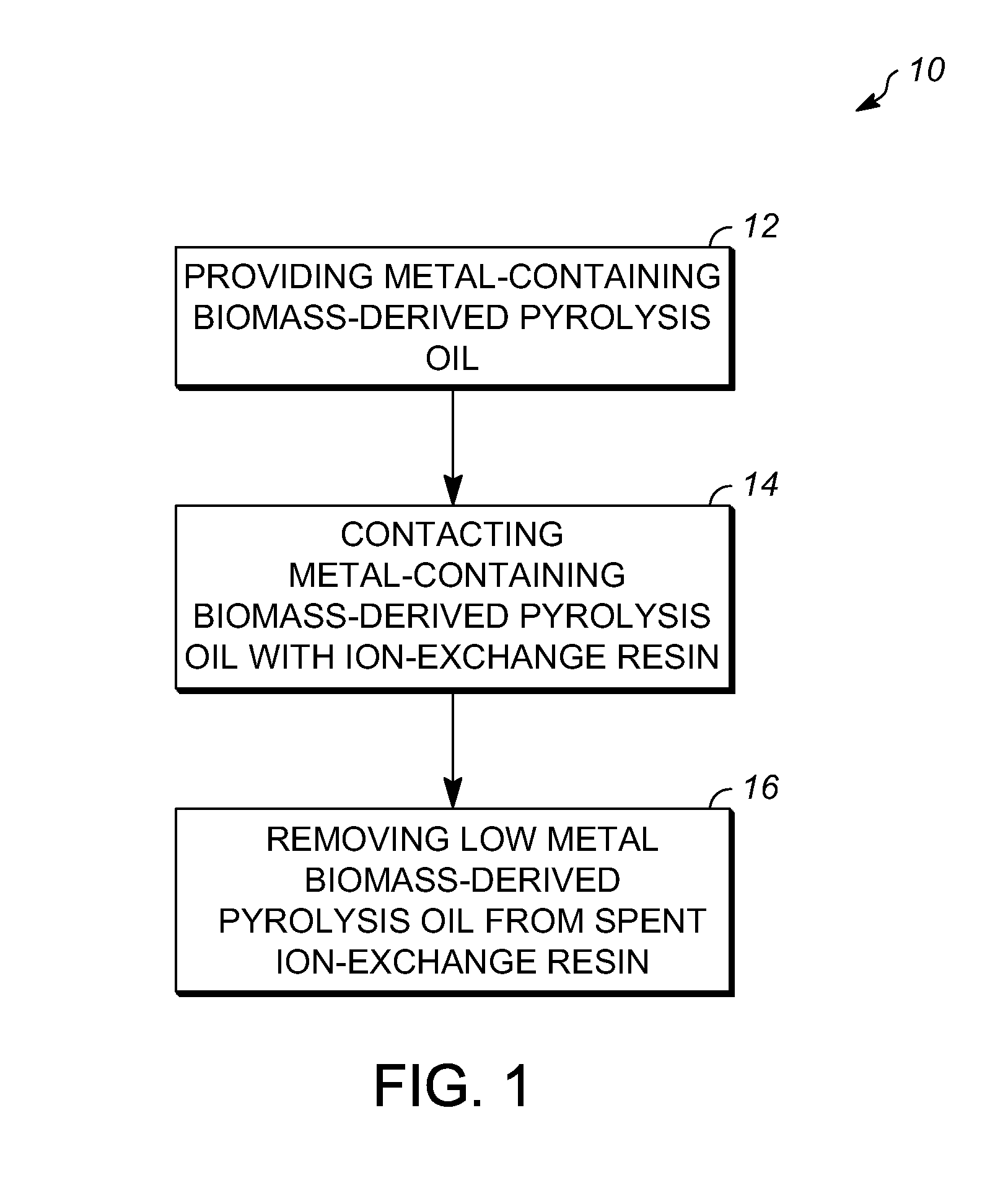

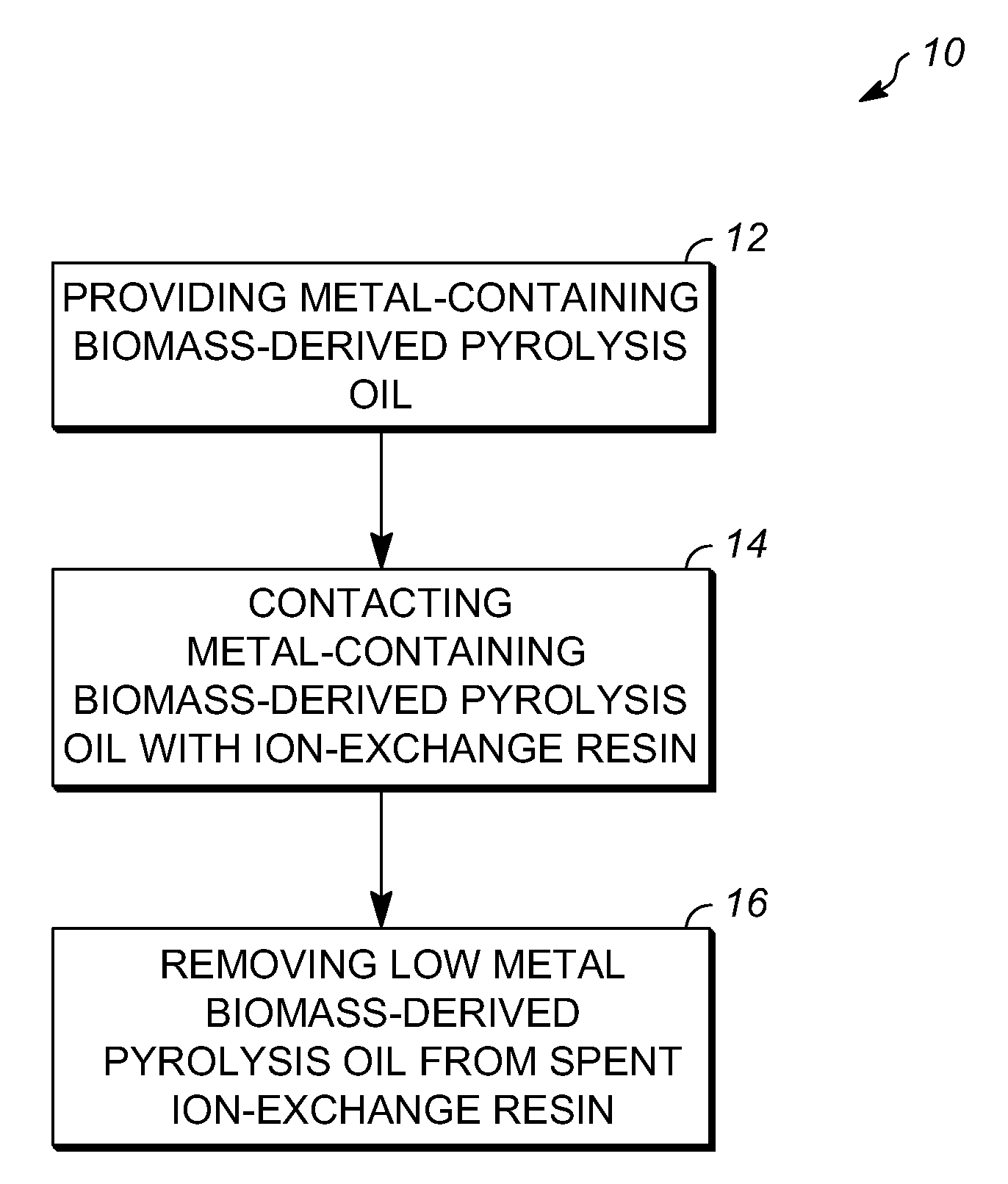

Low metal biomass-derived pyrolysis oils and processes for producing the same

Low metal biomass-derived pyrolysis oils and processes for producing the same are provided. Low metal biomass-derived pyrolysis oil is produced by a process of contacting metal-containing biomass-derived pyrolysis oil with an acidic ion-exchange resin having sulfonic acid groups. Low metal biomass-derived pyrolysis oil is removed from spent acidic ion-exchange resin after ion-exchange.

Owner:UOP LLC

Separation of radium and rare earth elements from monazite

InactiveUS20100018347A1Efficiently recoversEfficient separationIon-exchange process apparatusAnion exchanger materialsRare-earth elementDecay product

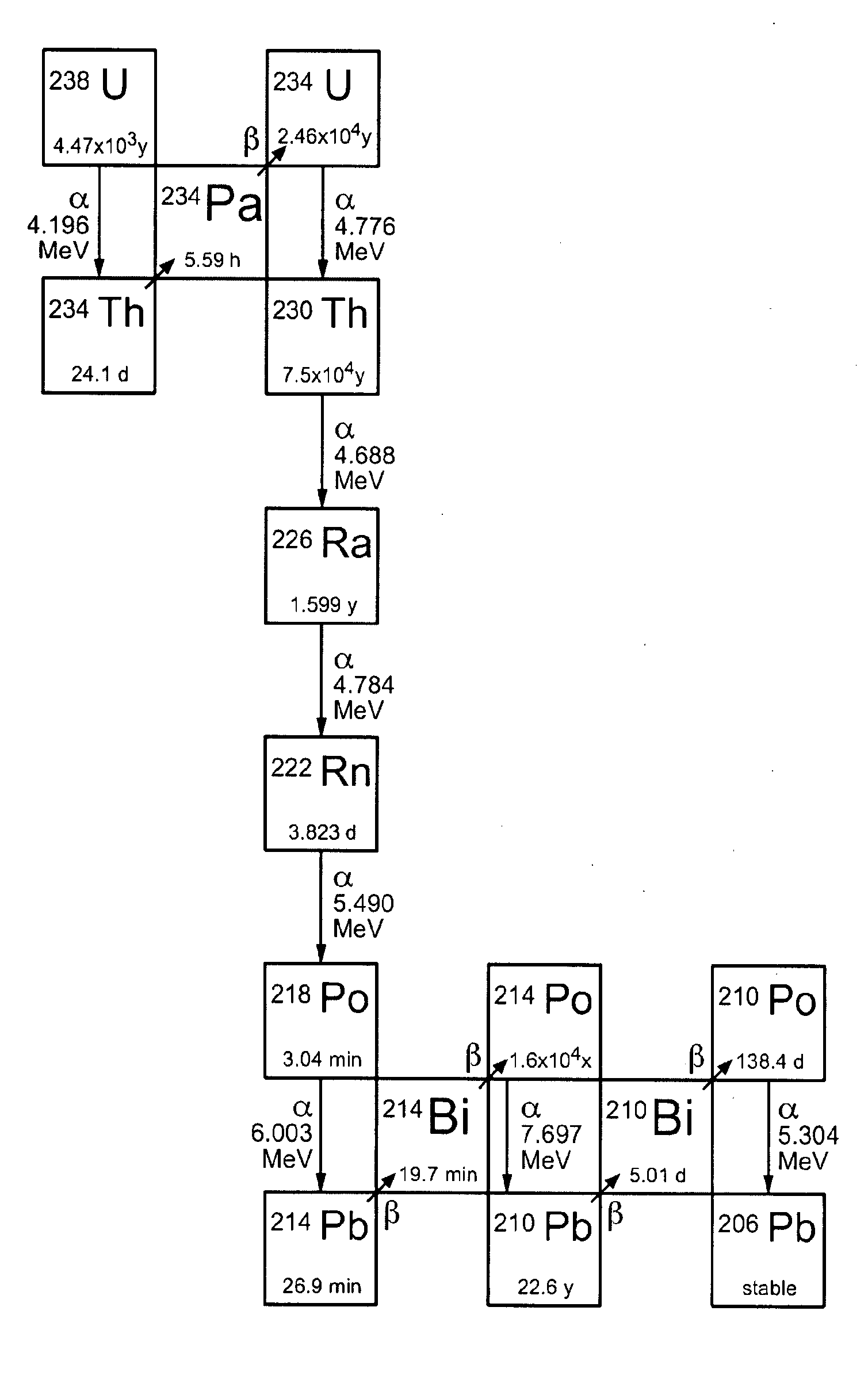

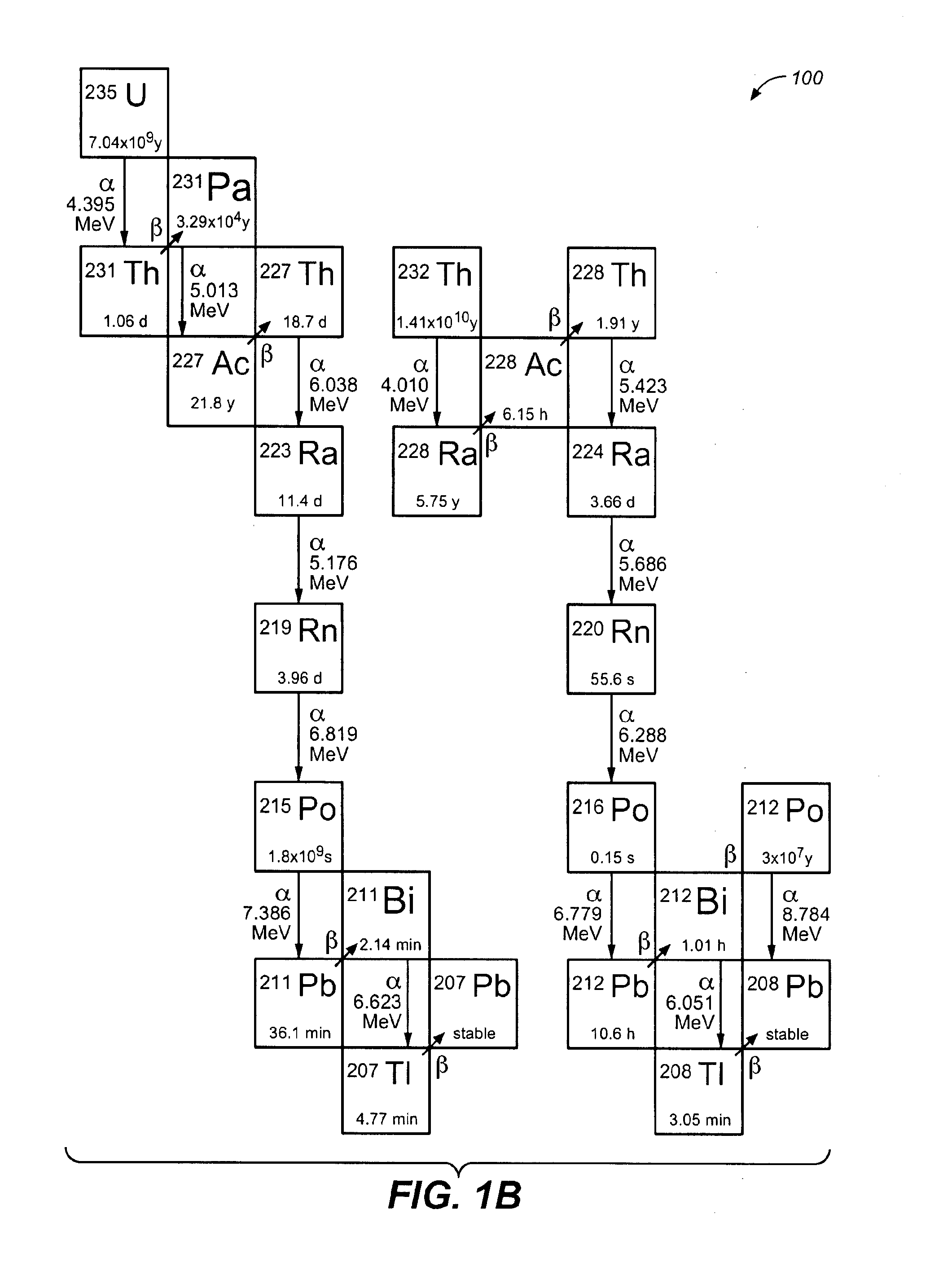

A method of chemically extracting radium-228, rare earth metals, thorium, the decay products of thorium, and phosphates from thorium-containing ores. The method involves breaking thorium-containing ore into fragments, wetting the fragments with a concentrated strong acid to make a slurry, heating the slurry, passing the heated solution through a first anion exchange column, retaining metals and radium-228 captured on the resin, allowing the radium-228 ions to decay to actinium-228, purifying the actinium-228 fraction, sending the actinium-228 fraction through a capture column, eluting the captured thorium-228 with acid, removing radium from the solution, retaining the radium-228 fraction for isomer in-growth, retaining decay products from the radium-228, separating the REEs from the process stream; and eluting and retaining the REEs.

Owner:HOLDEN CHARLES S +1

Ion exchange regeneration and upw treatment system

ActiveUS20060021944A1Solid sorbent liquid separationWater/sewage treatment by ion-exchangeIon exchangeBottle

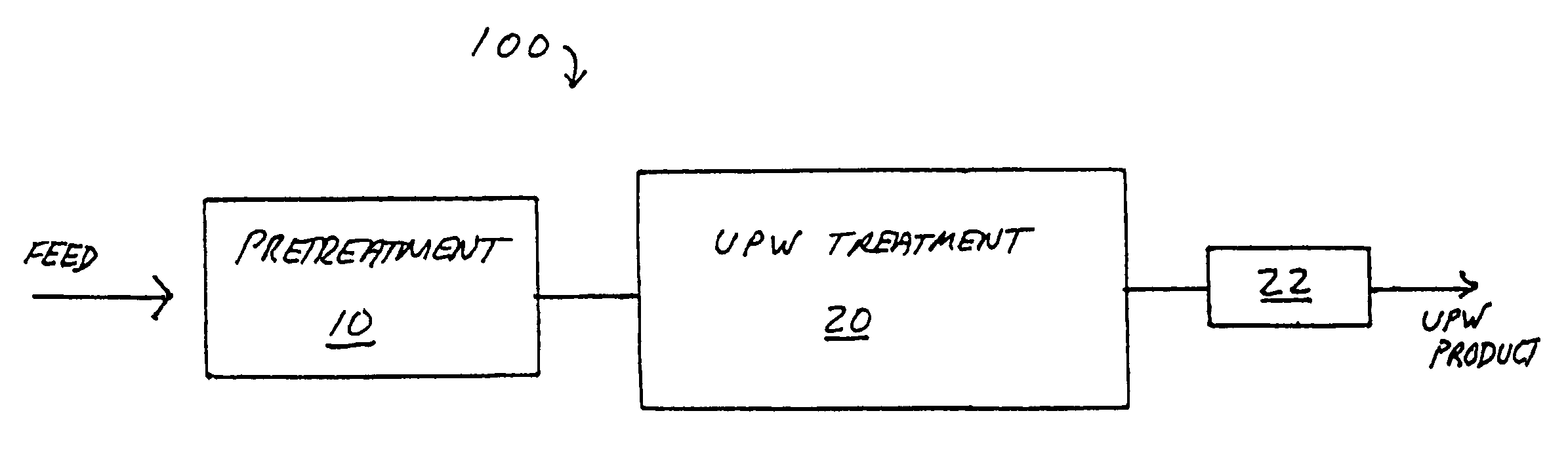

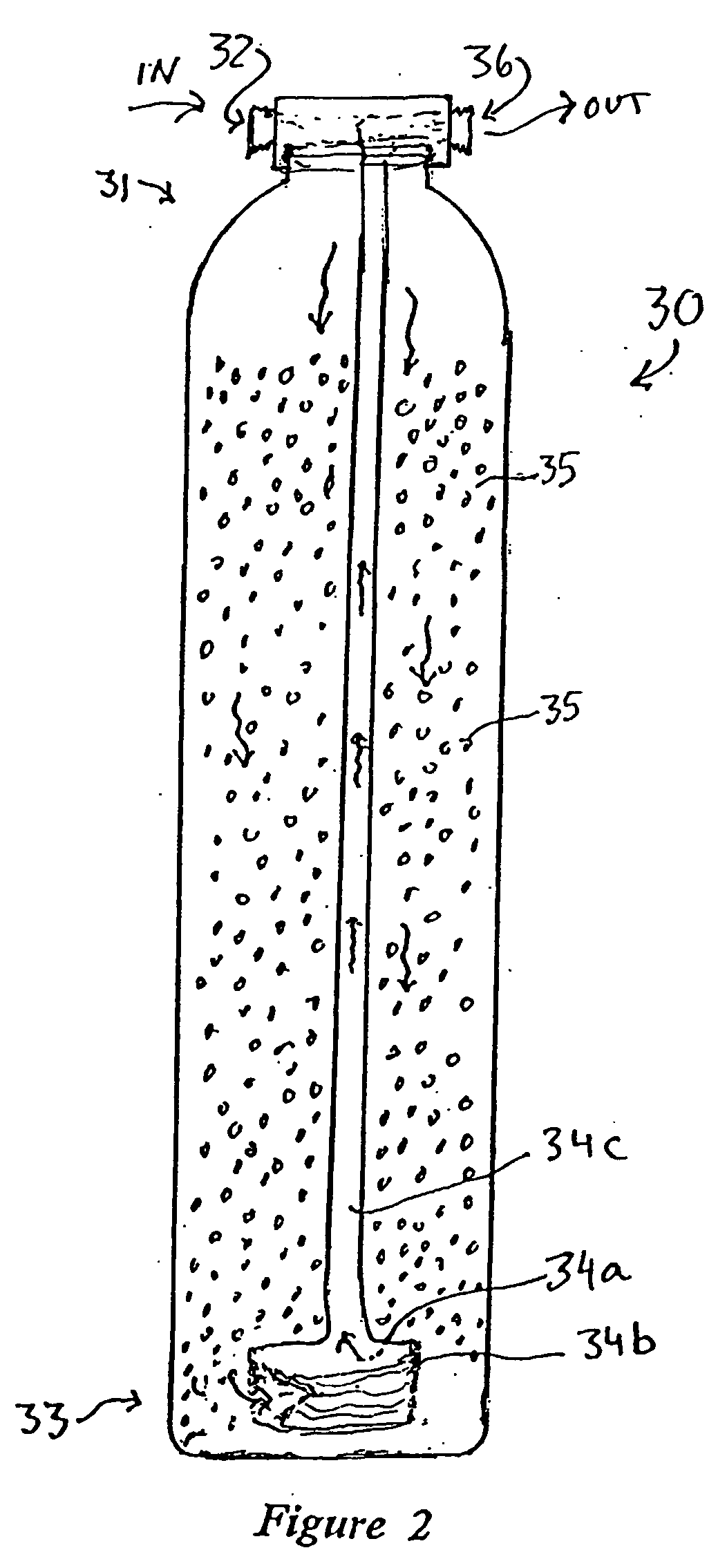

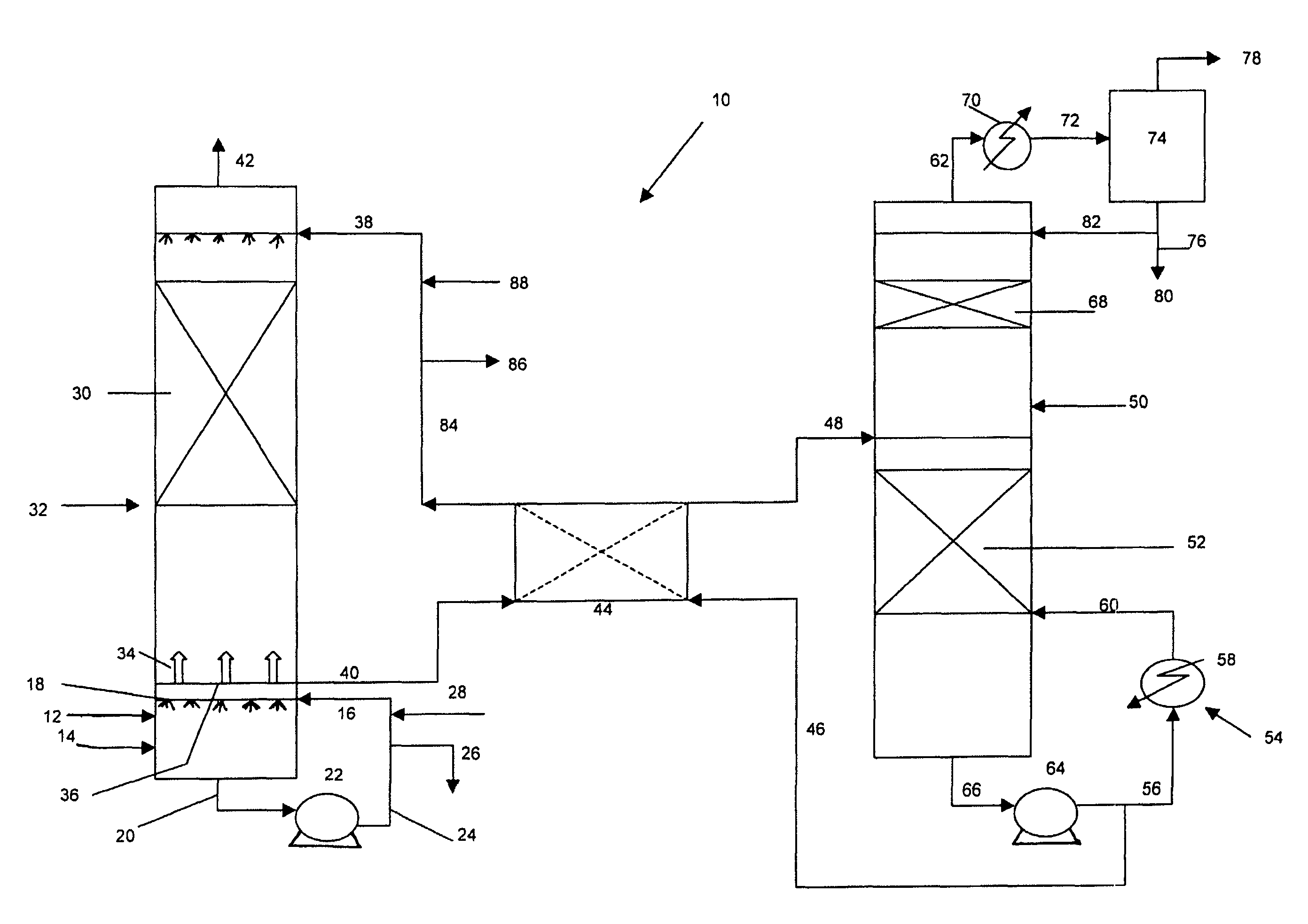

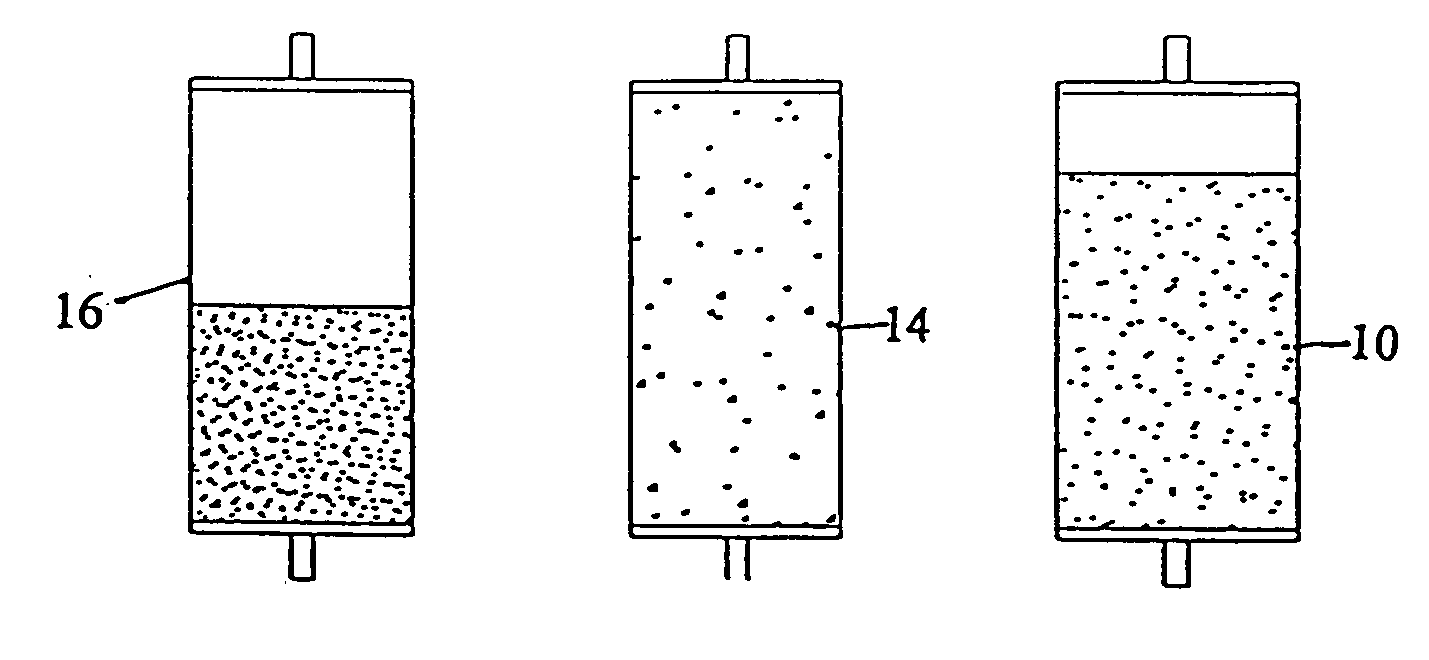

An improved process for regenerating ion exchange resin, includes a regeneration step of displacing captured ions from the resin to regenerate its ion-capture functionality, followed by one or more fluid-employing post-regeneration steps such as a fluid displacement or rinse, a fluid transport or mixing, and a rinse down to quality. To avoid problems of early leakage of weakly held ions such as boron, the post-chemical or postdisplacement steps use water that is essentially free of boron, or otherwise avoid localized contamination in the regenerated resin which is used in bottles or beds (30). A two-stage polish may be operated with modified lead / lag bottles. A detector (D) for an indicator condition (conductivity, silica breakthrough) between stages determines when to shift the lag bottle forward, and periodically both bottles are replaced.

Owner:BL TECH INC

Low metal, low water biomass-derived pyrolysis oils and methods for producing the same

Low metal, low water biomass-derived pyrolysis oils and methods for producing the same are provided. Metal- and water-containing biomass-derived pyrolysis oil is contacted with an acidic ion-exchange resin having sulfonic acid groups to produce a low metal, water-containing biomass-derived pyrolysis oil. The low metal, water-containing biomass-derived pyrolysis oil is removed from the spent ion-exchange resin after ion-exchange. The low metal, water-containing biomass-derived pyrolysis oil is distilled to produce a low metal, low water biomass-derived pyrolysis oil and a distillation product. The distillation product comprises one or both of an alcohol ion-exchange regenerant and an acidic ion-exchange regenerant which may be used to regenerate the spent ion-exchange resin. The regenerated acidic ion-exchange resin may be recycled. The spent alcohol and acid ion-exchange regenerants may be recovered and recycled.

Owner:UOP LLC

Regeneration of ion exchangers that are used for salt removal from acid gas capture plants

ActiveUS7776296B2Large volumeEfficiently recover the amine after the loading step can be minimizedDispersed particle separationHydrogen sulfidesIon exchangeIon-exchange resin

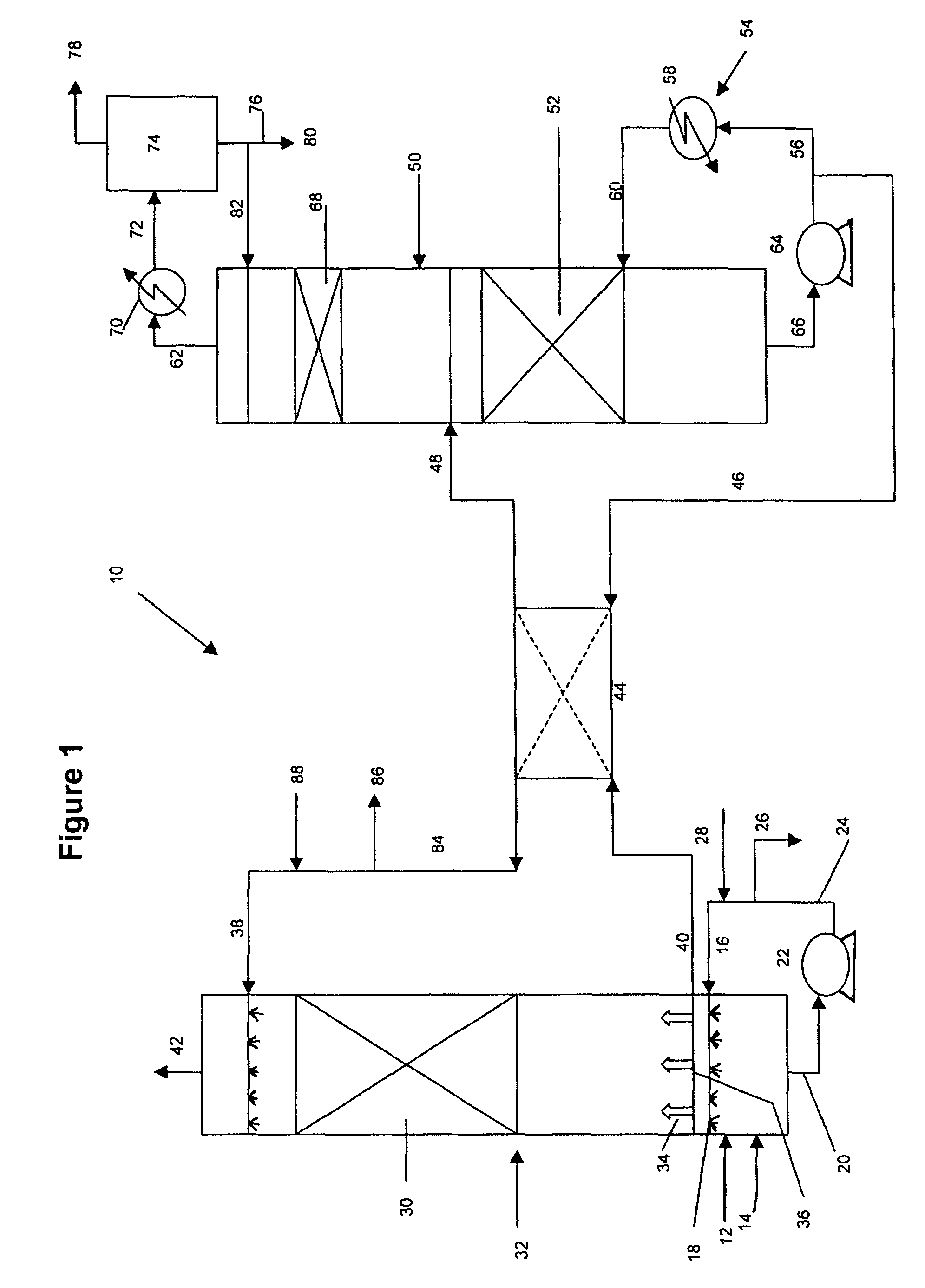

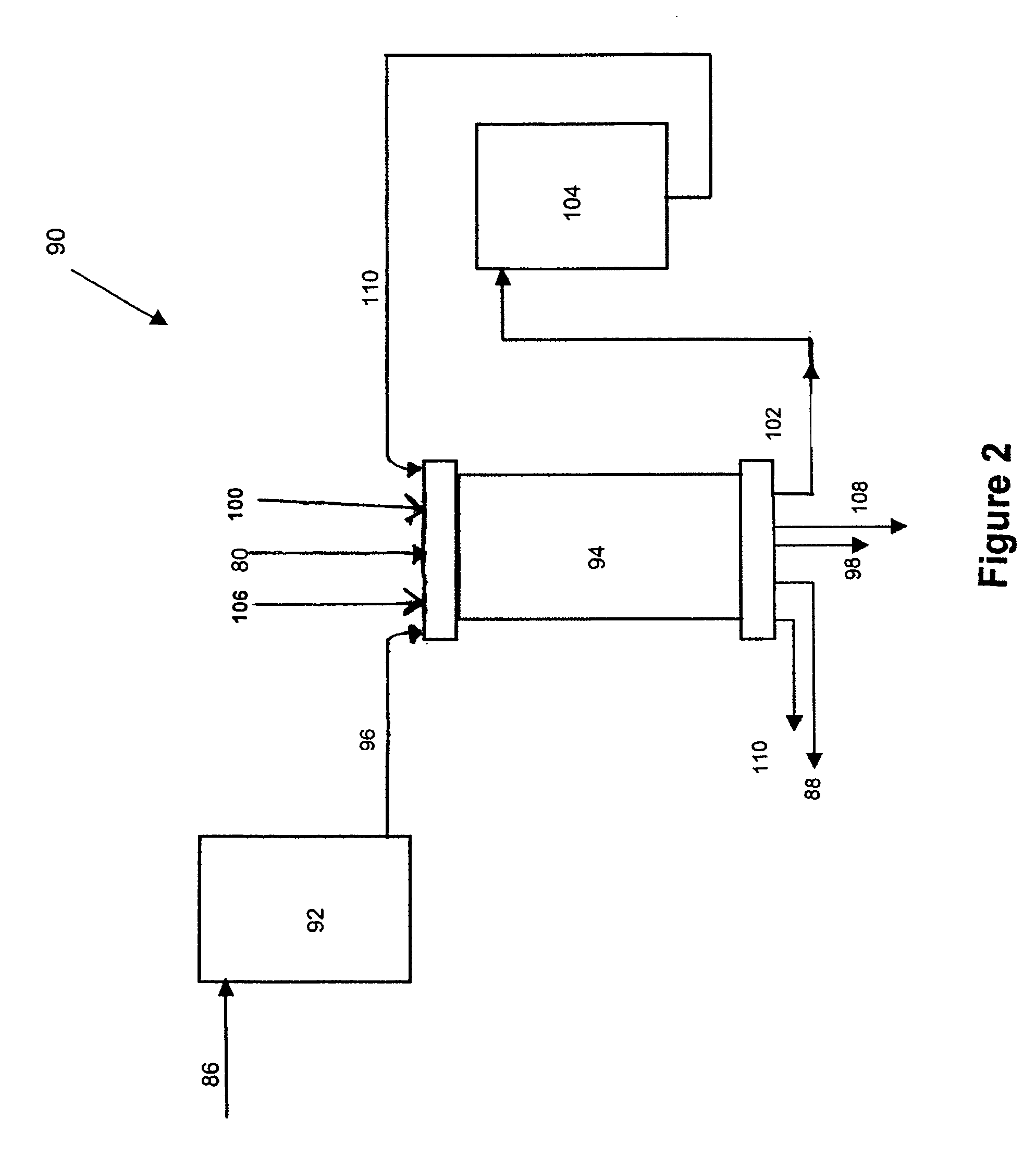

A process for the removal of an amine capturable gas from a feed gas stream using an amine solvent, the process comprises (a) contacting the feed gas stream with a lean amine solvent to form a rich amine solvent, wherein heat stable salts are present in the rich amine solvent; (b) stripping amine capturable gas from the rich amine solvent to form the lean amine solvent and an overhead reflux stream; (c) periodically contacting at least a portion of one or both of the lean amine solvent and the rich amine solvent with an anion exchange resin to form a first heat stable salt lean amine solvent; (d) periodically regenerating the anion exchange resin, wherein during the regeneration of the anion exchange resin, at least a portion of the reflux stream is used to wash the amine solvent from the anion exchange resin to produce a second heat stable salt lean amine solvent; and, (e) recycling at least a portion of the first and the second heat stable salt lean amine solvent for use in capturing the amine capturable gas from the feed gas.

Owner:SHELL OIL CO

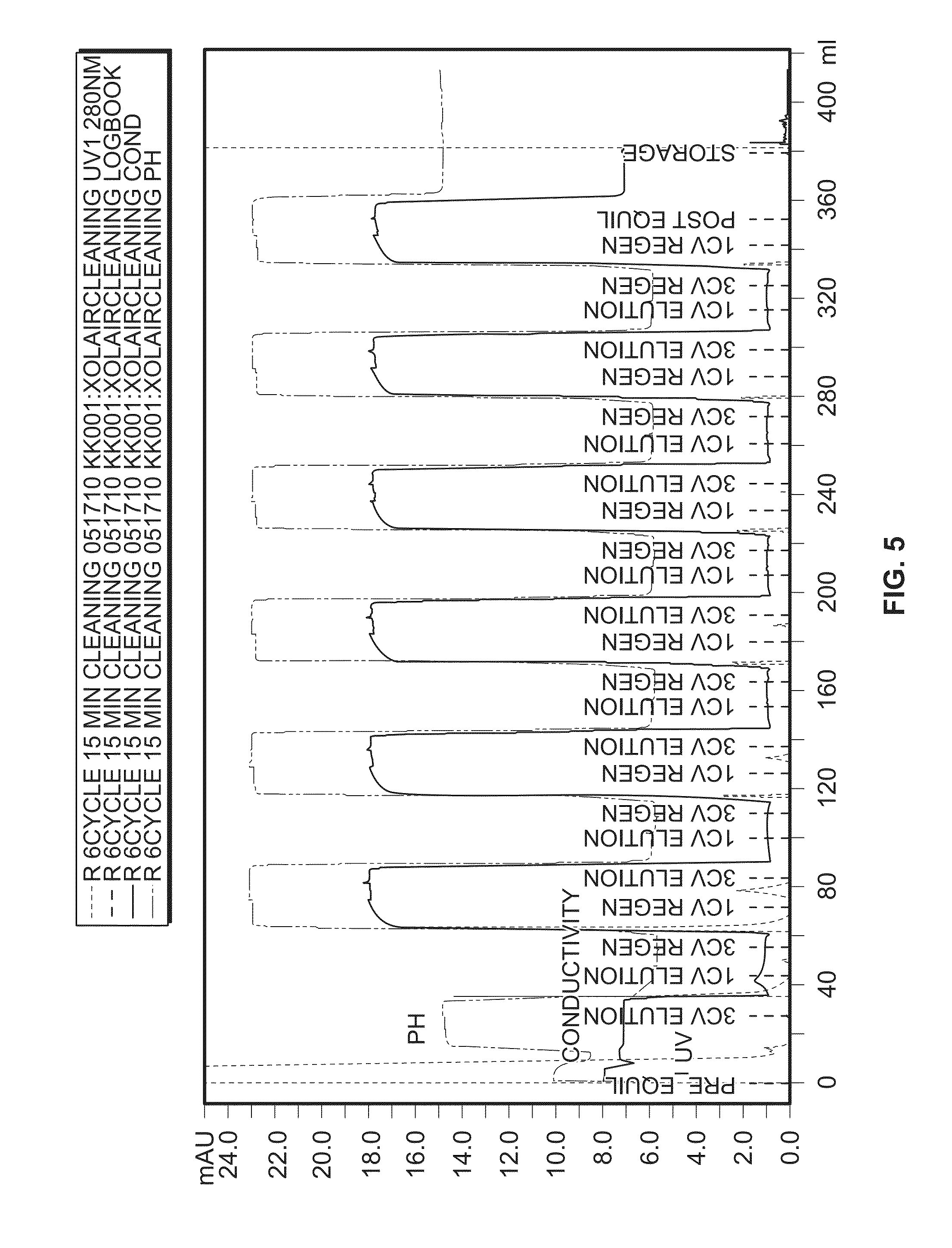

Method for chromatography reuse

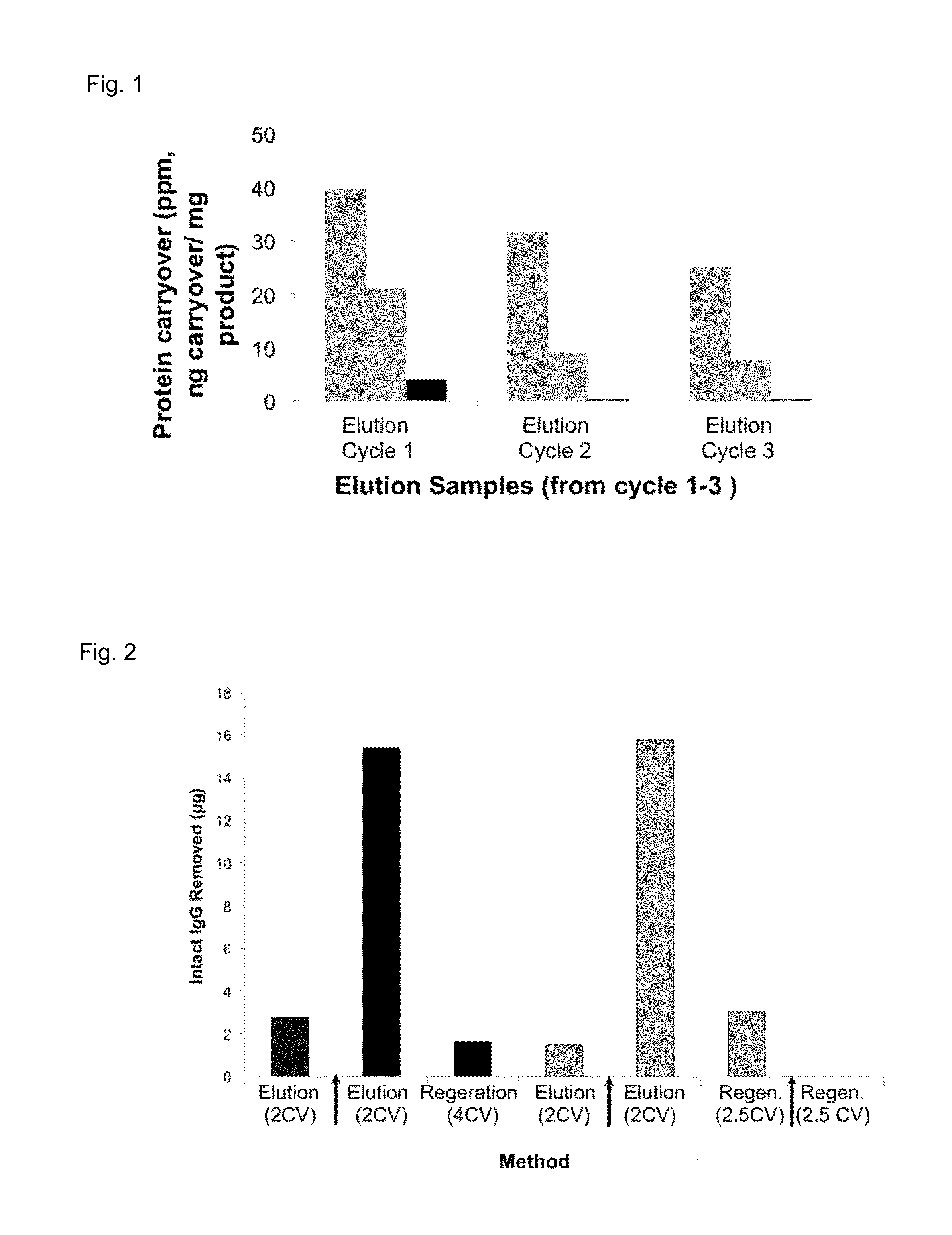

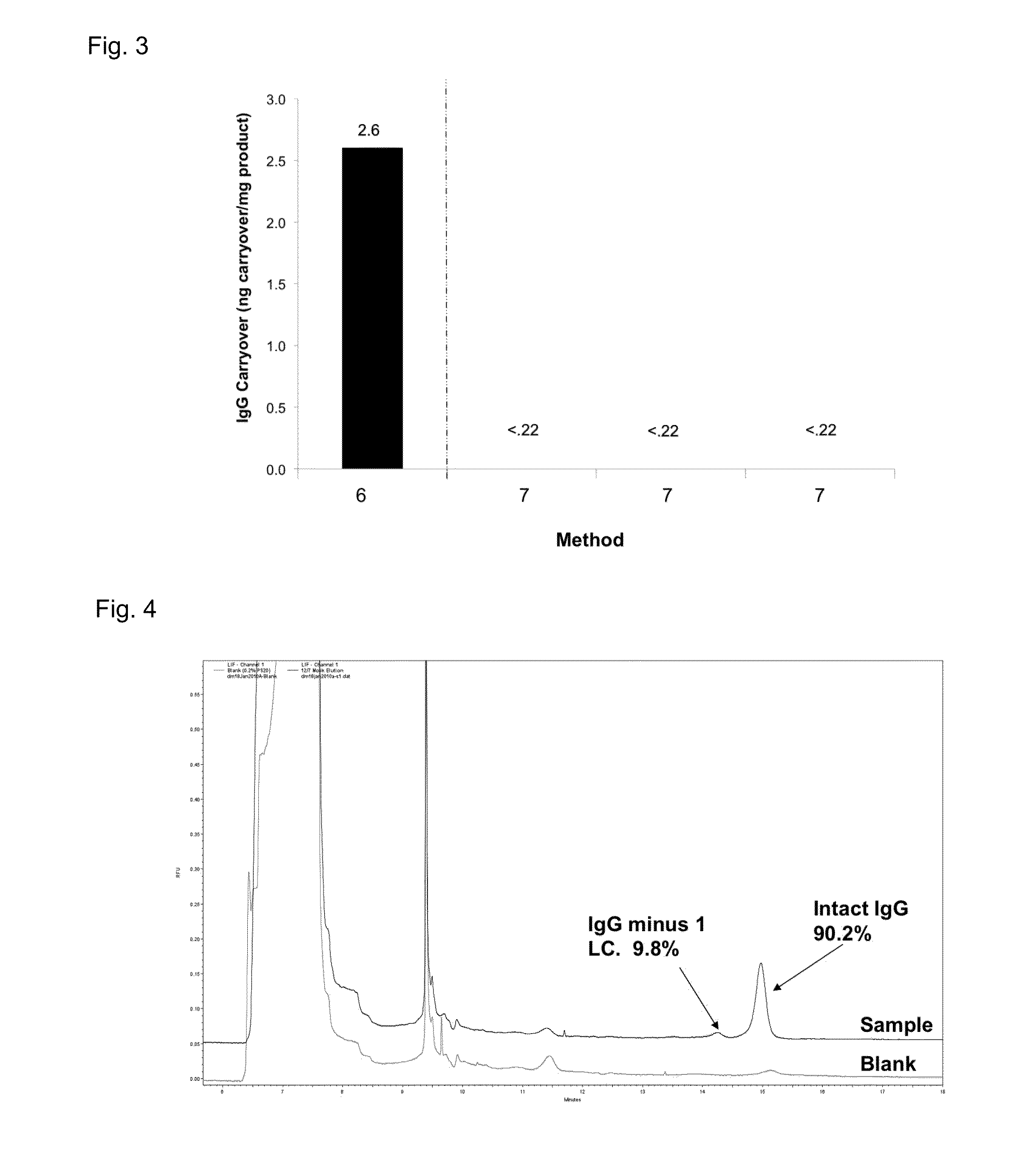

InactiveUS20150093800A1Easy to cleanIon-exchange process apparatusPeptide preparation methodsChromatography columnChemistry

The present invention provides methods for cleaning or regenerating a chromatography materiel for reuse. The methods of the invention can be used for cleaning or regenerating chromatography columns for reuse in the large-scale manufacture of multiple polypeptide products.

Owner:GENENTECH INC

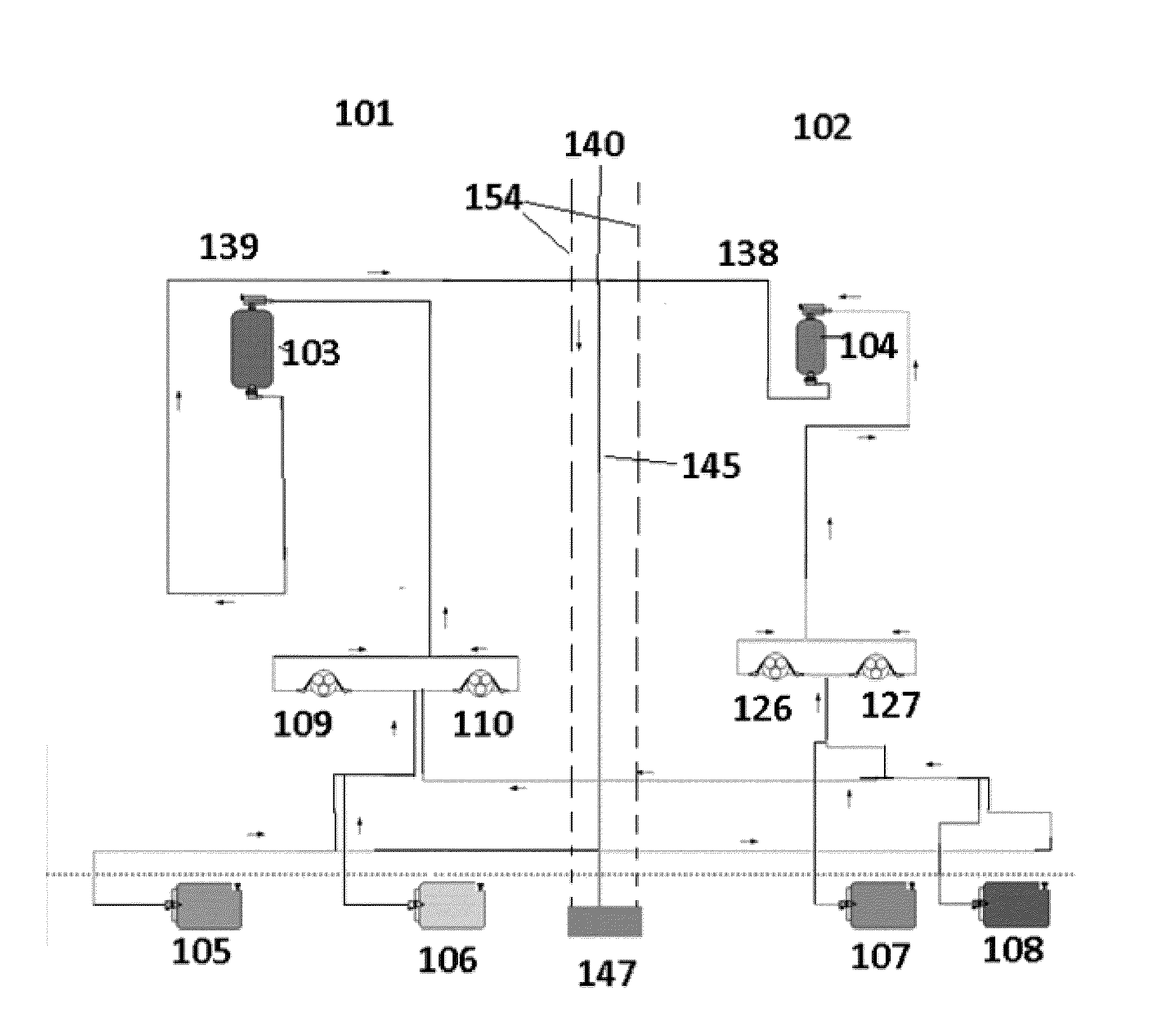

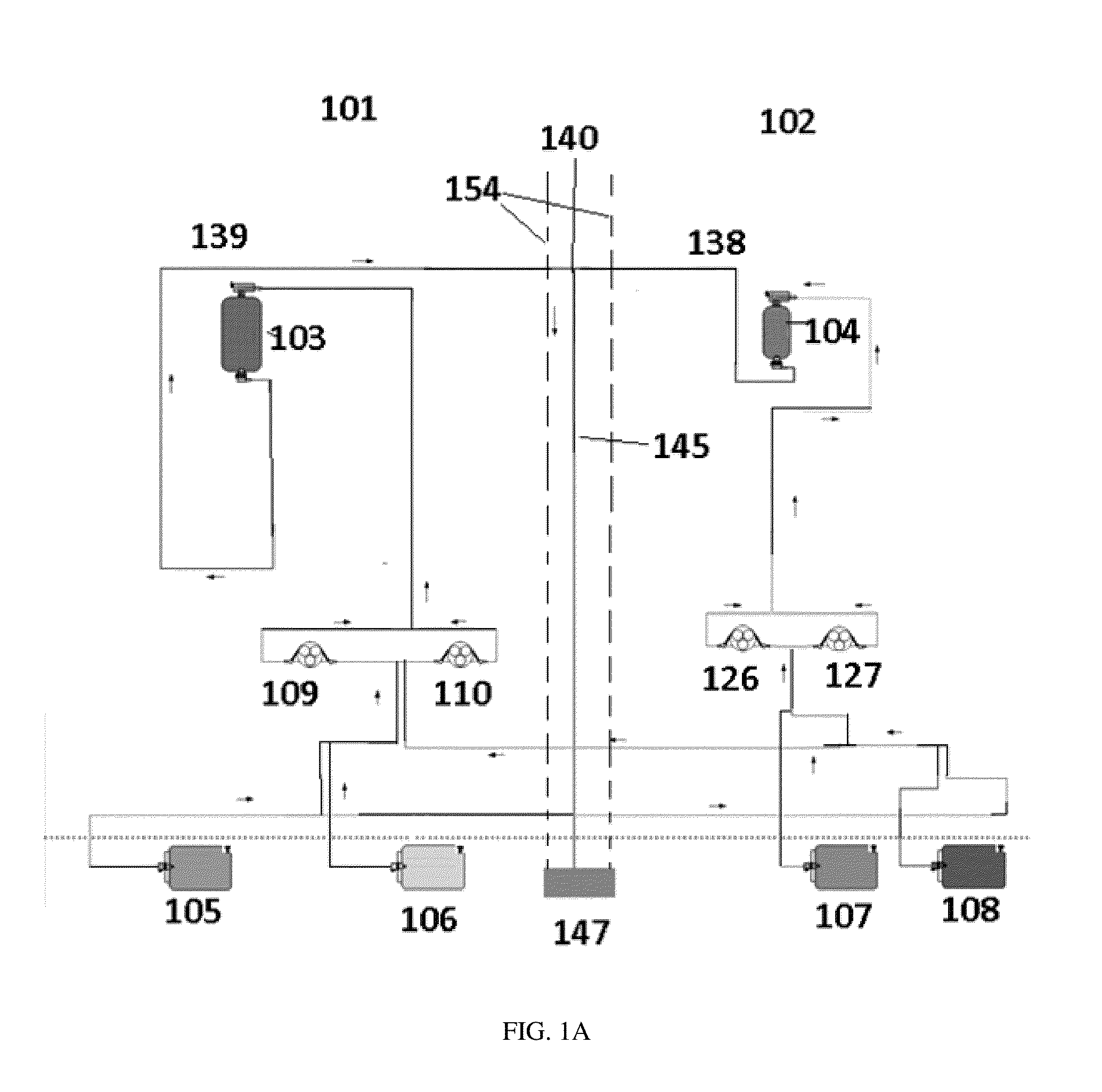

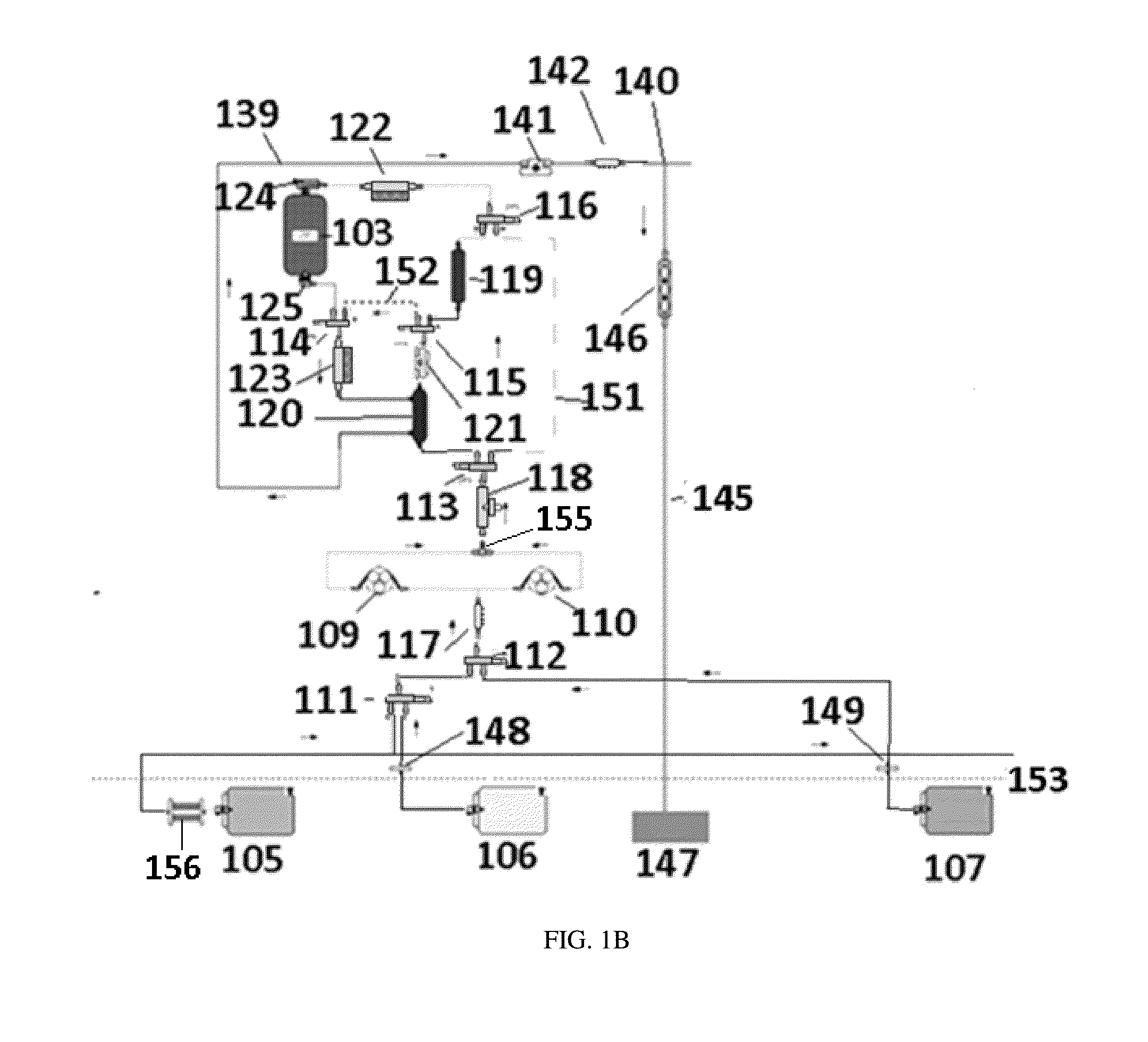

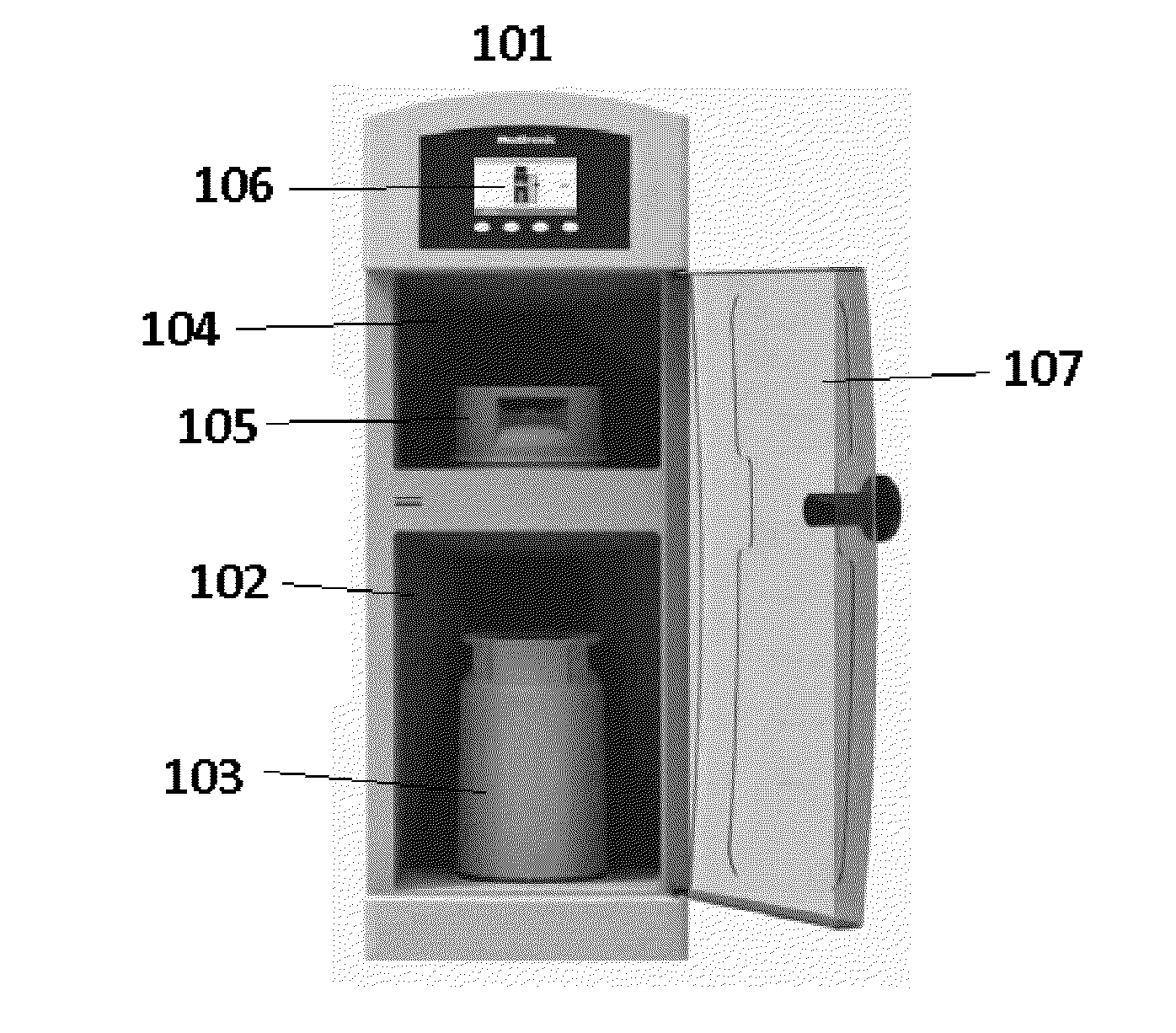

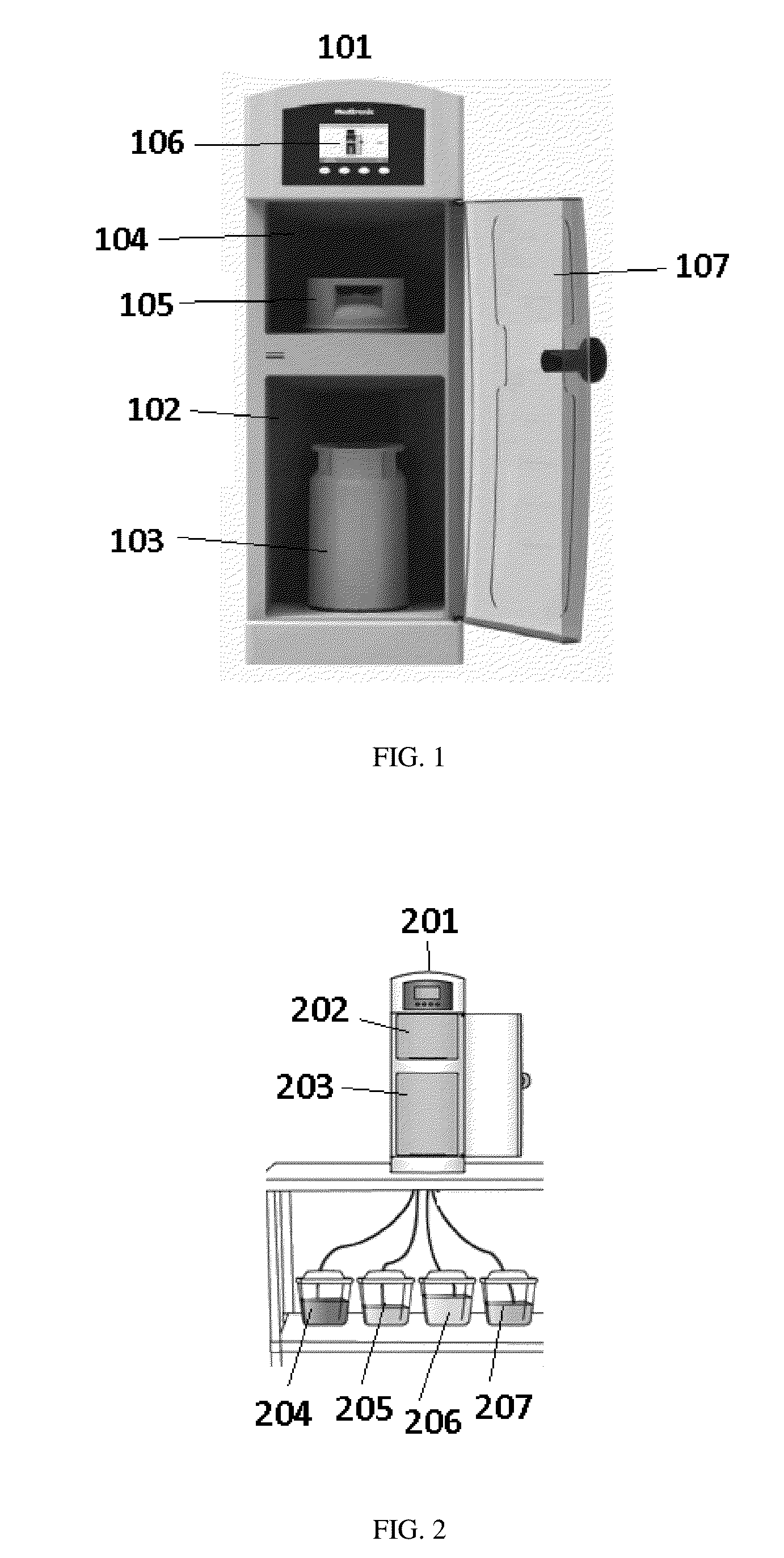

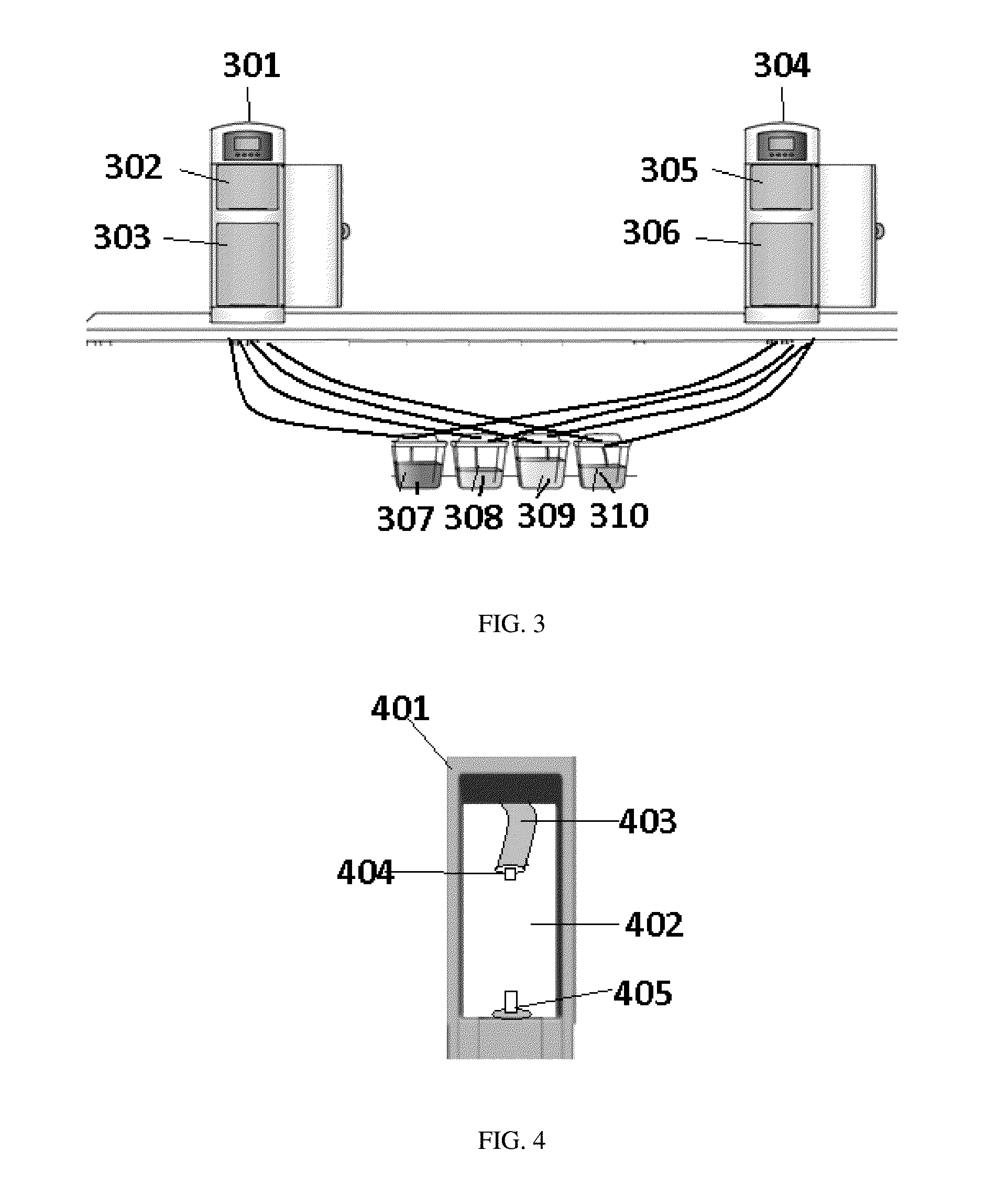

Zirconium phosphate and zirconium oxide recharging flow paths

Systems and methods for recharging zirconium phosphate and zirconium oxide are provided. The systems and methods provide for recharging of the zirconium phosphate and zirconium oxide in reusable sorbent modules. The systems and methods include recharging flow paths for recharging zirconium phosphate independently or concurrently.

Owner:MOZARC MEDICAL US LLC

Regeneration of ion exchangers that are used for salt removal from acid gas capture plants

ActiveUS20070213415A1Speed up the processLarge volume of waterDispersed particle separationHydrogen sulfidesRefluxIon exchange

A process for the removal of an amine captureable gas from a feed gas stream using an amine solvent, the process comprises (a) contacting the feed gas stream with a lean amine solvent to form a rich amine solvent, wherein heat stable salts are present in the rich amine solvent; (b) stripping amine captureable gas from the rich amine solvent to form the lean amine solvent and an overhead reflux stream; (c) periodically contacting at least a portion of one or both of the lean amine solvent and the rich amine solvent with an anion exchange resin to form a first heat stable salt lean amine solvent; (d) periodically regenerating the anion exchange resin, wherein during the regeneration of the anion exchange resin, at least a portion of the reflux stream is used to wash the amine solvent from the anion exchange resin to produce a second heat stable salt lean amine solvent; and, (e) recycling at least a portion of the first and the second heat stable salt lean amine solvent for use in capturing the amine captureable gas from the feed gas.

Owner:SHELL OIL CO

Low metal biomass-derived pyrolysis oils and processes for producing the same

Low metal biomass-derived pyrolysis oils and processes for producing the same are provided. Low metal biomass-derived pyrolysis oil is produced by a process of contacting metal-containing biomass-derived pyrolysis oil with an acidic ion-exchange resin having sulfonic acid groups. Low metal biomass-derived pyrolysis oil is removed from spent acidic ion-exchange resin after ion-exchange.

Owner:UOP LLC

Method for on-line recovery of ion exchange resin

ActiveCN102989529AEnable Online RecoveryExtend the life cycleIon exchange beds cleaning/rinsingPhysical chemistryIon exchange

The invention discloses a method for the on-line recovery of ion exchange resin. The method for the on-line recovery of ion exchange resin is carried out in an ion exchanger and comprises the following steps: flushing the ion exchange resin by using desalted water so as to remove dust and suspended matters in the ion exchange resin; backflushing the flushed resin by using acid so as to remove metal ions which are adsorbed by the ion exchange resin; soaking the resin by using a mixed solution 5-7% Na2SO4 and 8-10% NaOH so as to remove organic matters in the ion exchange resin; and NaOH solution is used to regenerate the ion exchange resin. The method for the on-line recovery of ion exchange resin can realize the on-line recovery of the ion exchange resin and has good recovery effect, the recovery solution cost is reduced, and the use cycle of the ion exchange resin is prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for processing dimethylamine waste water by ion-exchange method

InactiveCN101337707AReduce processing costsRealize green and harmless treatmentWater contaminantsWaste water treatment from animal processingHigh concentrationFiltration

A method for treating dimethylamine wastewater by using the ion exchange technique comprises the following steps: performing ion exchange to wastewater, from which suspended substances have been removed by filtration, and strong acid cations at the temperature of 10-90 DEG C; absorbing dimethylamine to saturation by resin, and then eluting dimethylamine by using an inorganic acid solution at the concentration of 0.1-8M to regenerate resin. The method can ensure that the removal rate of dimethylamine from wastewater is equal to or higher than 96%, so as to cause wastewater to be emitted according to the emission standard or to be recycled; and the eluted dimethylamine forms high-concentration dimethylamine salt, which can be recycled. The method has the advantages of simple process, convenient operation, low treatment cost, and no secondary pollution, thus realizing harmless green treatment of dimethylamine wastewater.

Owner:HEFEI UNIV OF TECH

Ion exchange process

InactiveUS20050194319A1Simple and cost-effectiveWater treatment parameter controlSpecific water treatment objectivesSaline waterWastewater

An ion exchange process for treating waste water having caustic materials, uses a bed of cation exchange resin beads to which the waste water is added. Thereafter the bed of beads is allowed to absorb the caustic materials in a brine until the resin is exhausted. The bed having retained organic matter is regenerated by rinsing the bed with water to remove substantially all the organic matter; draining any remaining rinse water; adding water and allowing it to pass through the bed and exit therefrom; mixing the exiting water with acid to form a dilute acid; and adding this dilute acid to the bed until the water exiting the bed has substantially the same pH as the dilute acid entering the bed.

Owner:WEGNER PAUL

Ion exchange resin regeneration method

InactiveCN101224436ASolve the problem of pressure cakingShort operating cycleIon exchange beds cleaning/rinsingDesorptionIon exchange

The invention relates to a regeneration method for an ion exchange resin, wherein, the ion exchange resin includes a cation exchange resin and an anion exchange resin. The method mainly comprises two steps that: a desorption solution is introduced into an ion exchange column containing ion exchange resin for removing the impurity ions absorbed on or firmly combined with the resin; a regeneration solution counter current is introduced into the ion exchange column for restoring the ion exchange ability of the ion exchange resin. The desorption solution and the regeneration solution adopts forward current and counter current modes respectively to be introduced into the ion exchange column one after another. By adopting the combining mode of forward and counter currents, the regenerated ion exchange resin can be effectively dispersed and equally dispersed in the ion exchange column, thus improving the column efficiency of the column exchange column and good for environment at the same time of reducing energy consumption and production cost.

Owner:张剑秋 +1

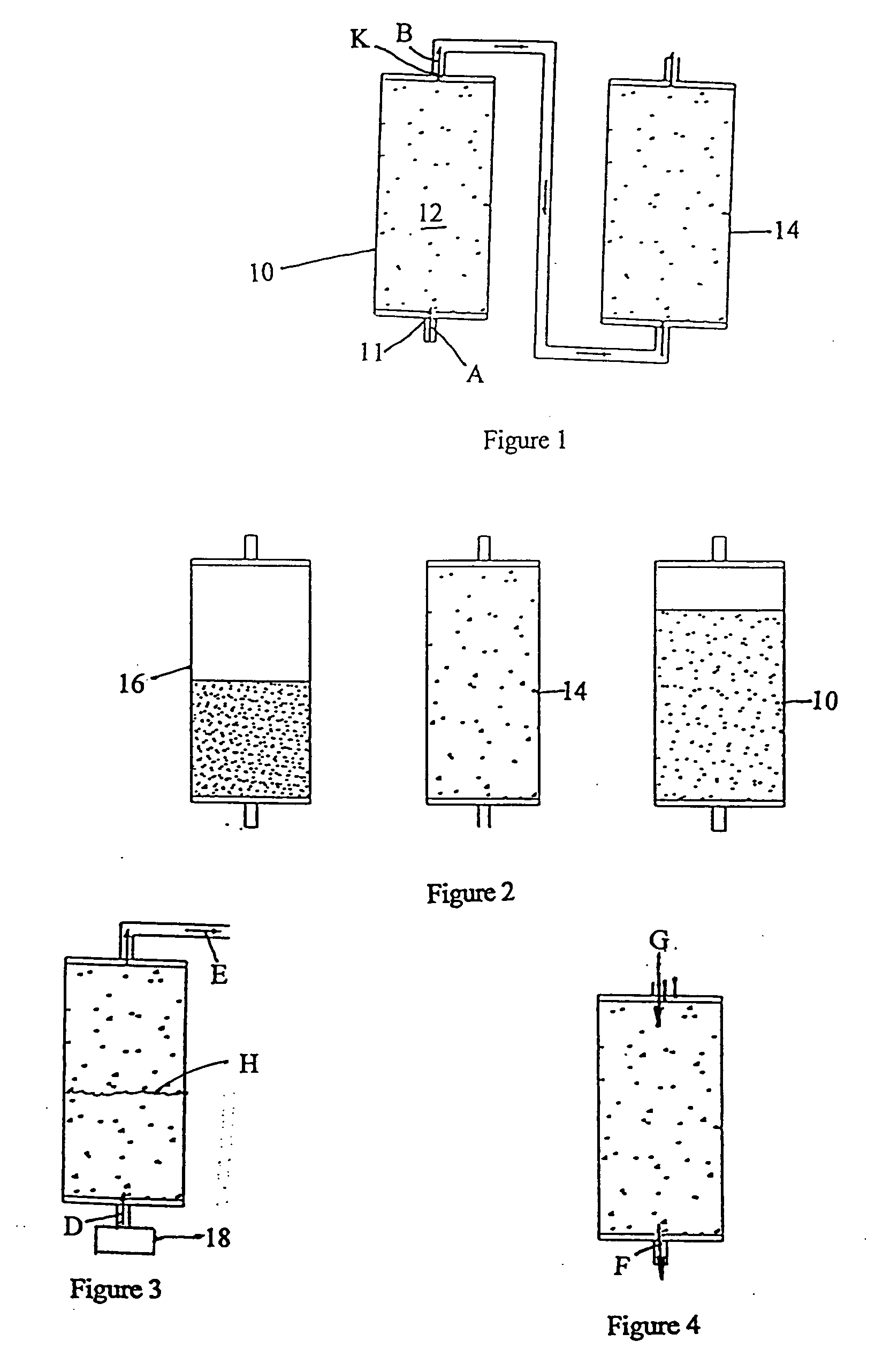

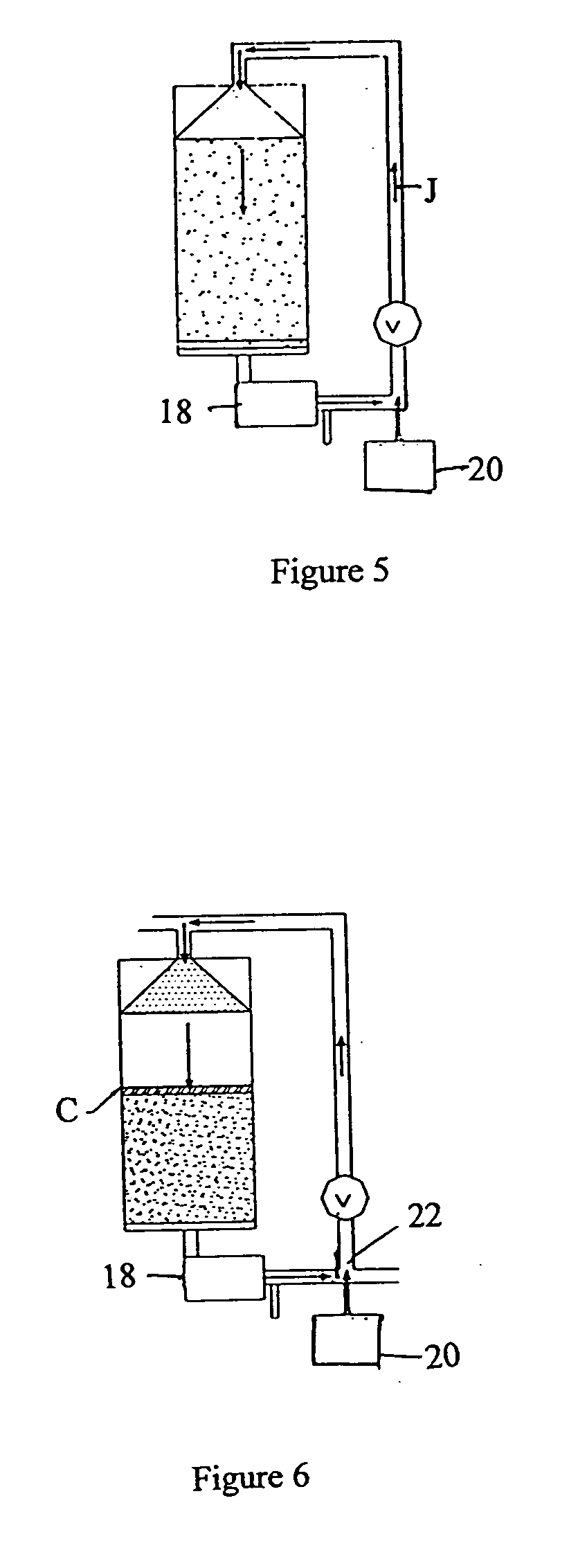

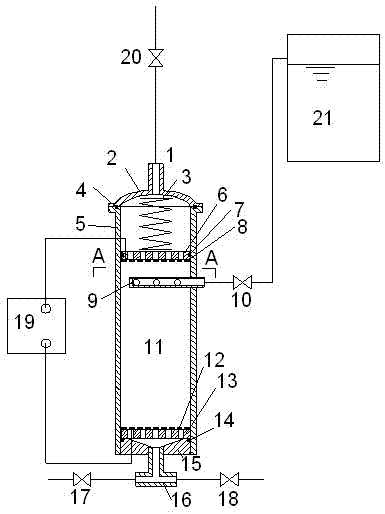

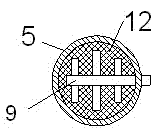

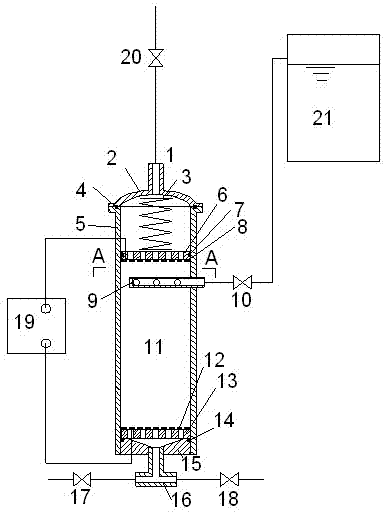

Membraneless electrodeionization method and system thereof, capable of directly exhausting oxygen gas and hydrogen gas outwards are

ActiveCN102583646AWon't enterAvoid accumulationWater/sewage treatment by ion-exchangeIon exchange beds cleaning/rinsingIonHeavy metals

The invention discloses a membraneless electrodeionization method and a system thereof, which are capable of directly exhausting oxygen gas and hydrogen gas outwards. A gas exhaust opening is connected with a gas exhaust valve; a spring, an upper porous support plate, an upper electrode, a water distributor with micropores, a lower electrode and a lower porous support plate are sequentially placed in an insulated cavity body from the top to the bottom; an outlet of the water distributor is connected with a water purification box via a water purification valve; ion exchange resin is filled between the two electrodes; the upper electrode is fixed on the lower surface of the upper porous support plate, and the lower electrode is fixed on the upper surface of the lower porous support plate; atop cover is sealed with a cylinder-shaped housing, and a bottom cover is sealed with the lower end surface of the cylinder-shaped housing; the upper porous support plate is sealed with the upper endsurface of the cylinder-shaped housing; and the two electrodes are respectively connected with a direct current power source. In a regeneration process, gas produced on the two electrodes is exhausted outwards from the two ends of a membraneless electrodeionization device, so that gas products cannot be accumulated in a resin layer. The membraneless electrodeionization method and the system thereof are suitable for the preparation of high purity water, the purification of electroplating and rinsing wastewater containing heavy metal ions, and the like, and the treatment of other water and wastewater, which aims for ionic impurity removal.

Owner:浙江泽众环保科技有限公司

Recharger for recharging zirconium phospahte and zirconium oxide modules

Systems and methods for recharging zirconium phosphate and zirconium oxide in reusable sorbent modules are provided. The systems and methods provide for recharging any combination of zirconium phosphate and / or zirconium oxide sorbent modules. The systems and methods also provide for linkage of multiple rechargers for sharing of infrastructure.

Owner:MOZARC MEDICAL US LLC

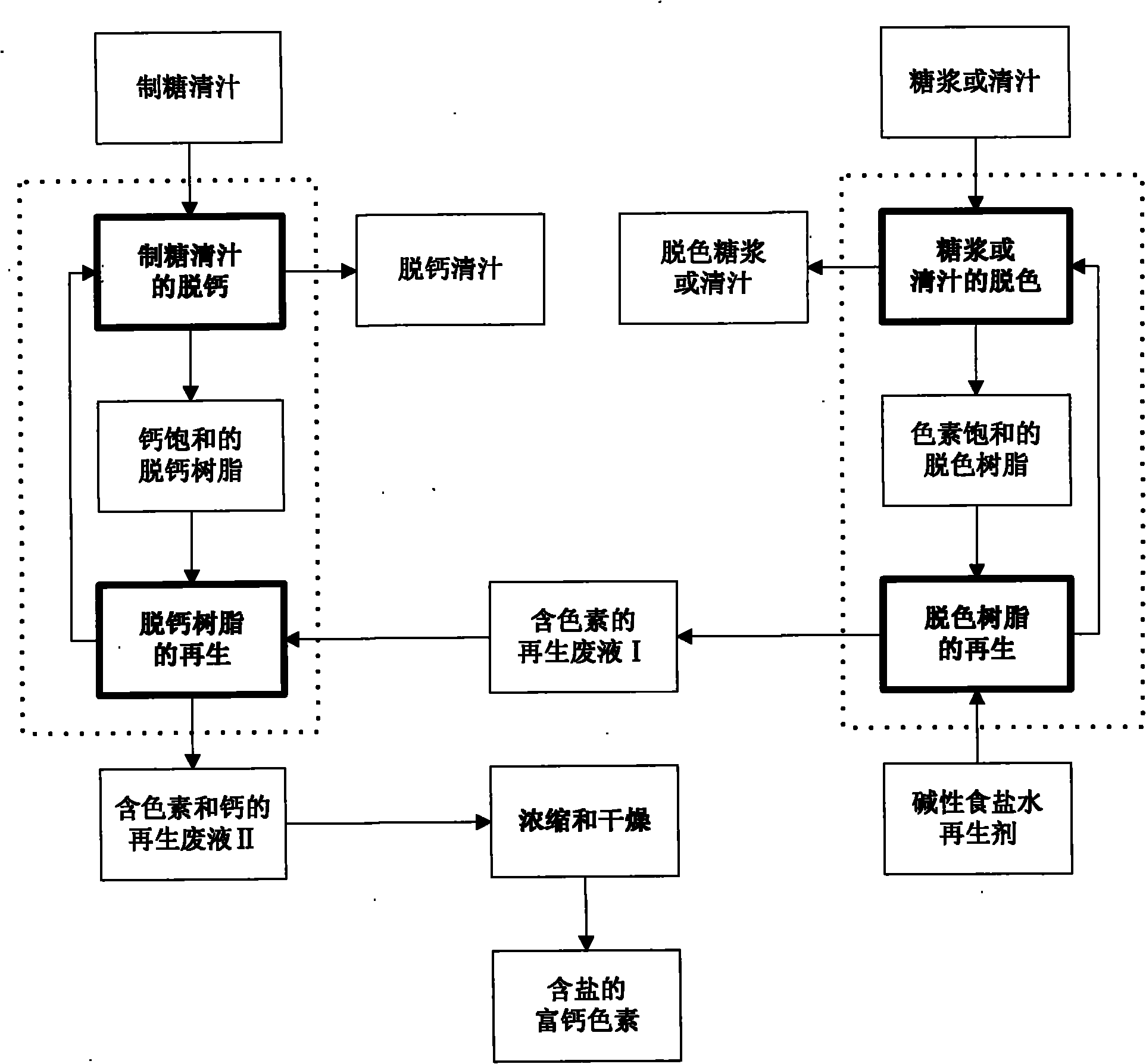

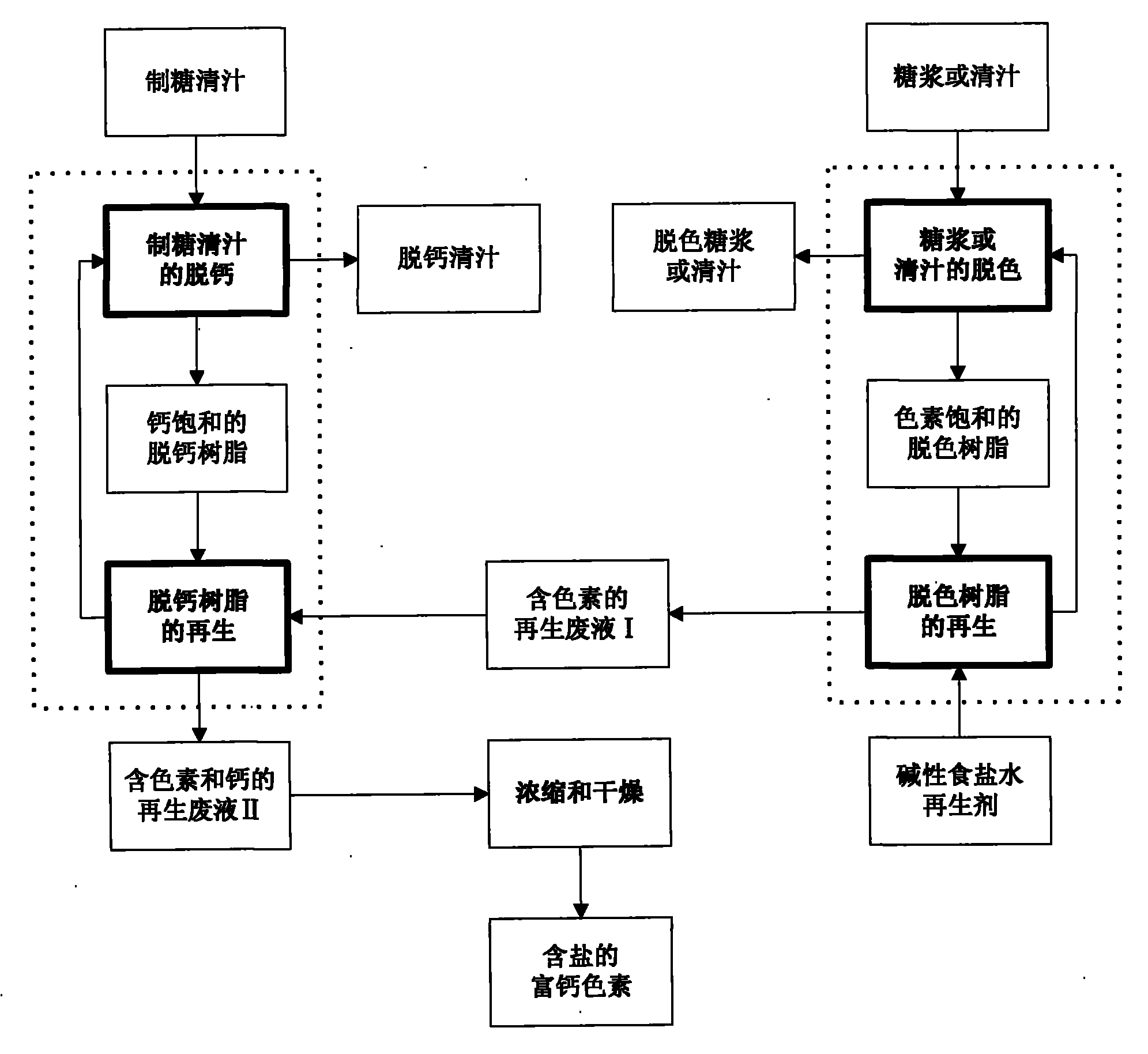

Method for regenerating sugar making decolorized and decalcified resin and method for recycling regeneration waste liquid

ActiveCN102031315AEmission reductionHigh regeneration ratePurification using ion-exchange materialsNatural dyesLiquid wasteEvaporation

The invention discloses a method for regenerating sugar making decolorized and decalcified resin, which comprises the following steps of: (1) decolorizing syrup or clear juice to obtain decolorized resin and decolorized syrup or clear juice; (2) regenerating the decolorized resin to obtain regenerated decolorized resin and decolorized resin regeneration waste liquid I; (3) decalcifying sugar making clear juice to obtain decalcified resin and decalcified clear juice; and (4) regenerating the decalcified resin, namely regenerating the decalcified resin by using the regeneration waste liquid I to obtain regenerated decalcified resin and decalcified resin regeneration waste liquid II. The invention also discloses a method for recycling the regeneration waste liquid II, which is used for preparing a calcium-rich pigment with anti-oxidation activity. The method is suitable for the cleaning or clarifying process of the syrup (juice) in a beet or cane sugar factory, is particularly suitable for decolorizing and decalcifying the sugar making clear juice and the syrup, has the main characteristics of reducing the using amount of a regenerant and the scaling of an evaporator, saving the evaporation energy of an evaporating pot, recycling non-sugar components in the syrup (juice), such as the pigment, calcium and the like, along with safe processing technology, and is environmental-friendly.

Owner:广东华糖实业有限公司

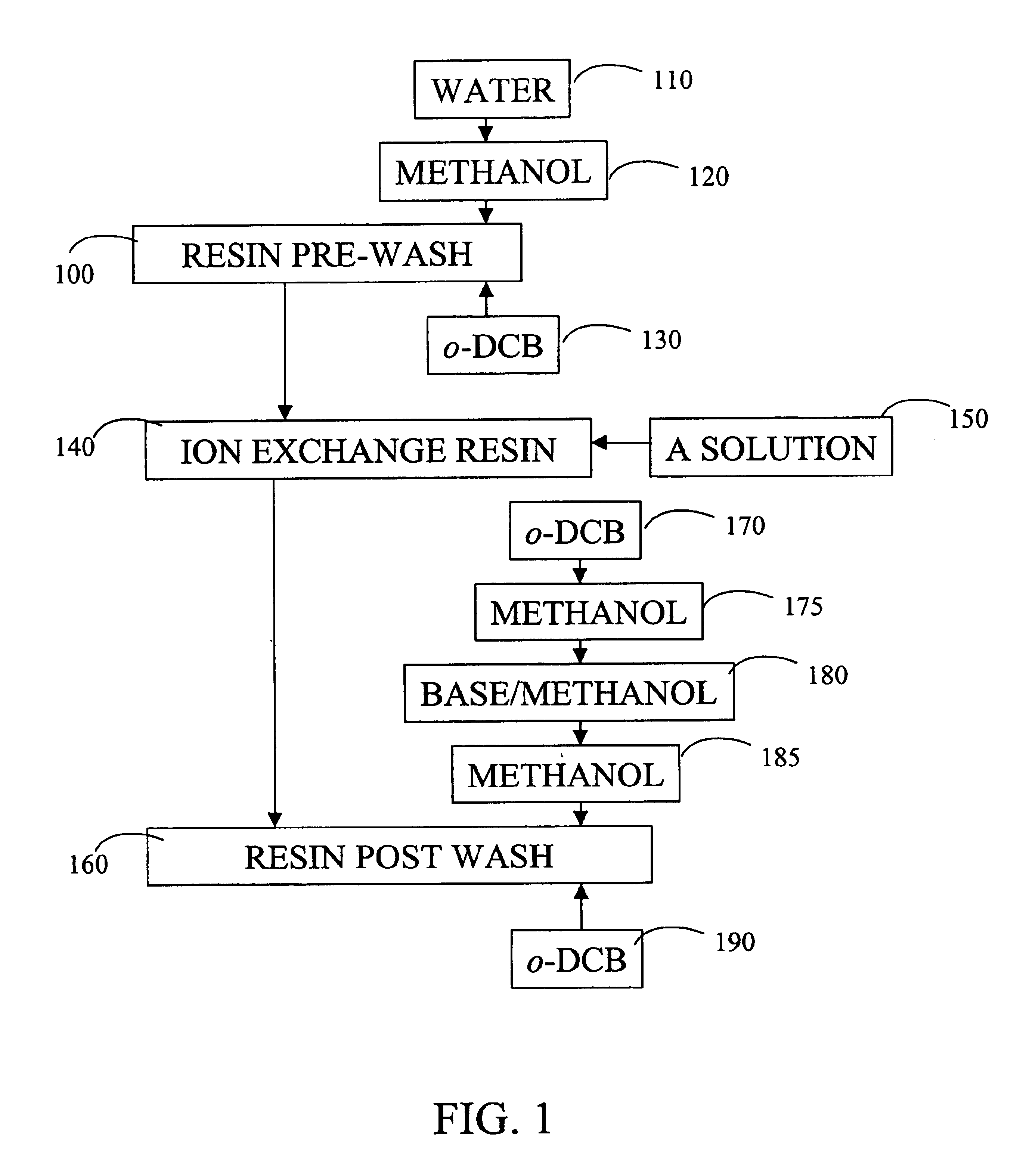

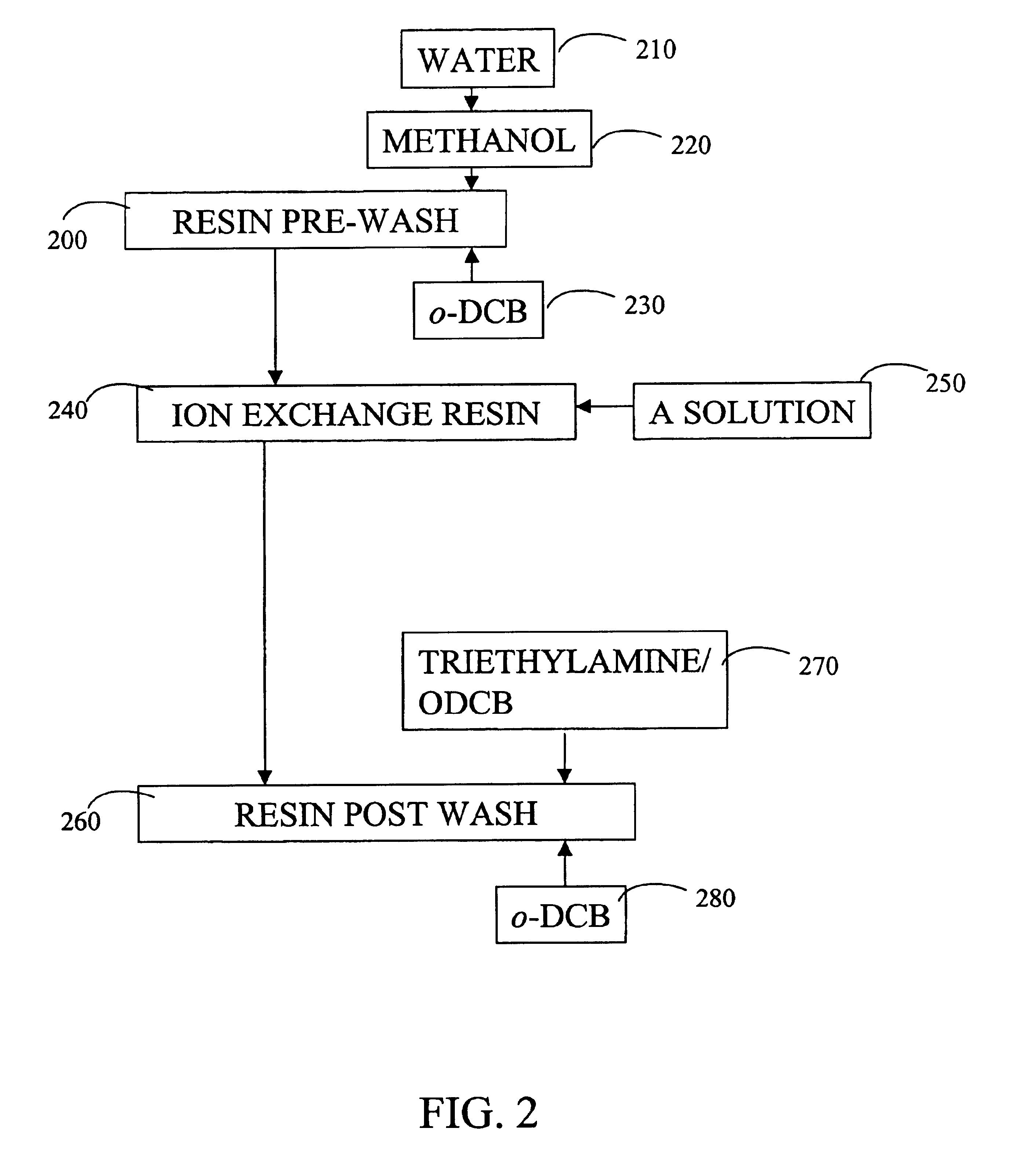

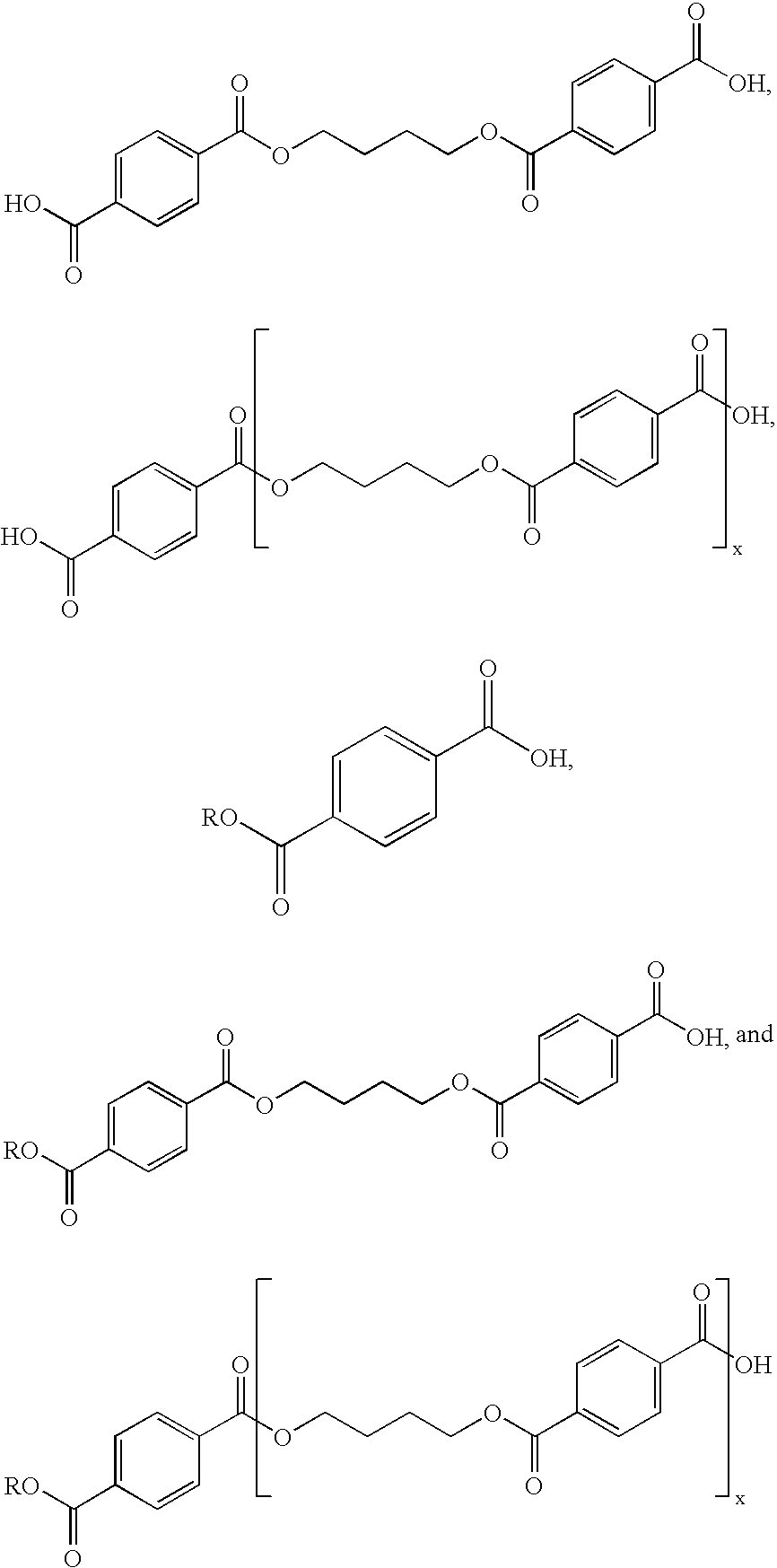

Purification of macrocyclic oligoesters

InactiveUS6962968B2Readily availableEfficient and economicalOrganic anion exchangersIon exchange beds cleaning/rinsingPolyesterEndcapping

Acid impurities, such as carboxylic acid-terminated polymers, are removed from macrocyclic oligoesters with ion exchange resins, resulting in macrocyclic oligoesters that are substantially free of acid impurities. The ion exchange resins can be regenerated anew and reused by washing the resins with various wash solutions. Macrocyclic oligoesters substantially free of acid impurities polymerize to much higher molecular weight polyesters than macrocyclic oligoesters containing acid impurities.

Owner:CYCLICS CORP

Preparation of weak acid cation exchange resins

InactiveUS20020193453A1Improve efficiencyEfficient removalCation exchanger materialsWater/sewage treatment by ion-exchangeWater treatment systemPotable water

An improved process for cleaning weak acid cation exchange resin intermediates resulting in finished weak acid resins providing enhanced performance of mixed-bed water-treatment systems is disclosed. The cleaning process involves selected steam treatment during the manufacturing process of the resins and is applicable to weak acid cation exchange resins in general that are used as components in potable water treatment systems, such as cartridge-water-pitcher systems.

Owner:BOHLING JAMES CHARLES +1

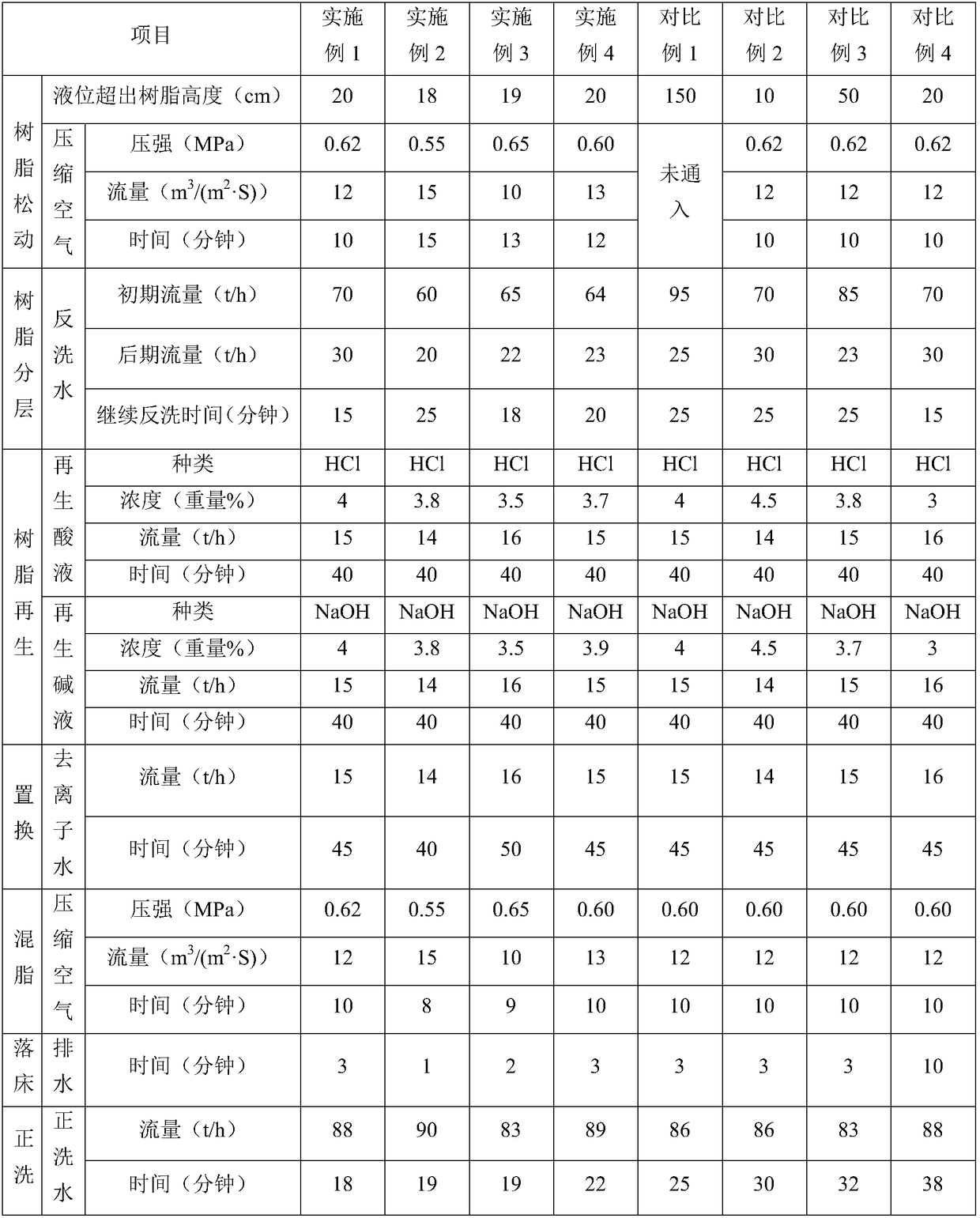

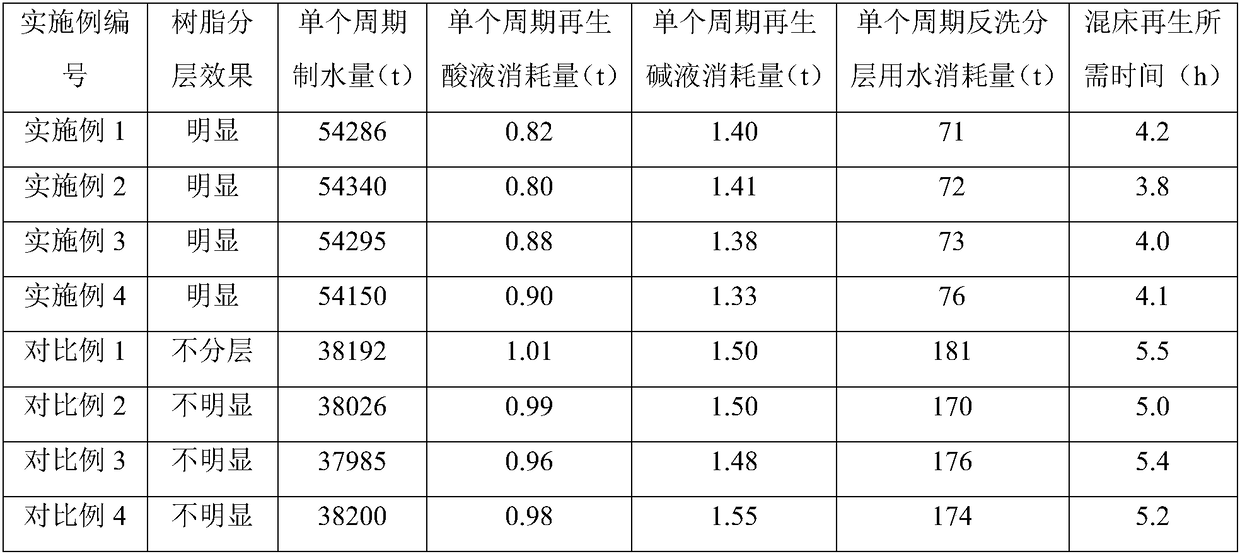

Resin regeneration method of condensate polishing high tower separation method regeneration system

InactiveCN105618163AEmission reductionEasy to controlIon exchange beds cleaning/rinsingWastewaterEngineering

The invention relates to a resin regeneration method of a condensate polishing high tower separation method regeneration system. The resin regeneration method comprises the following steps: (1) separation regeneration process of resin; (2) conveying of the resin; (3) scrubbing and regeneration of the resin; and (4) mixing of the resin for later use. The resin regeneration method has the advantages that the control is facilitated, the cost is saved, and the discharge of acid-alkali wastewater is reduced.

Owner:江阴市尚时环境工程有限公司

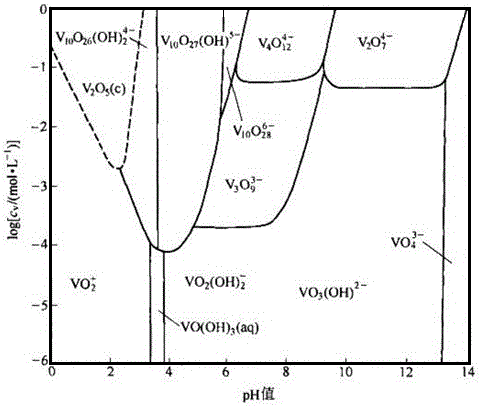

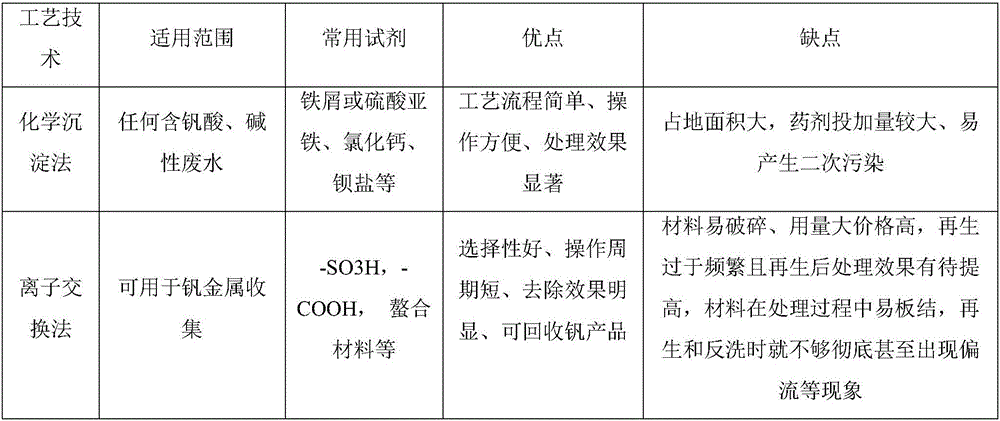

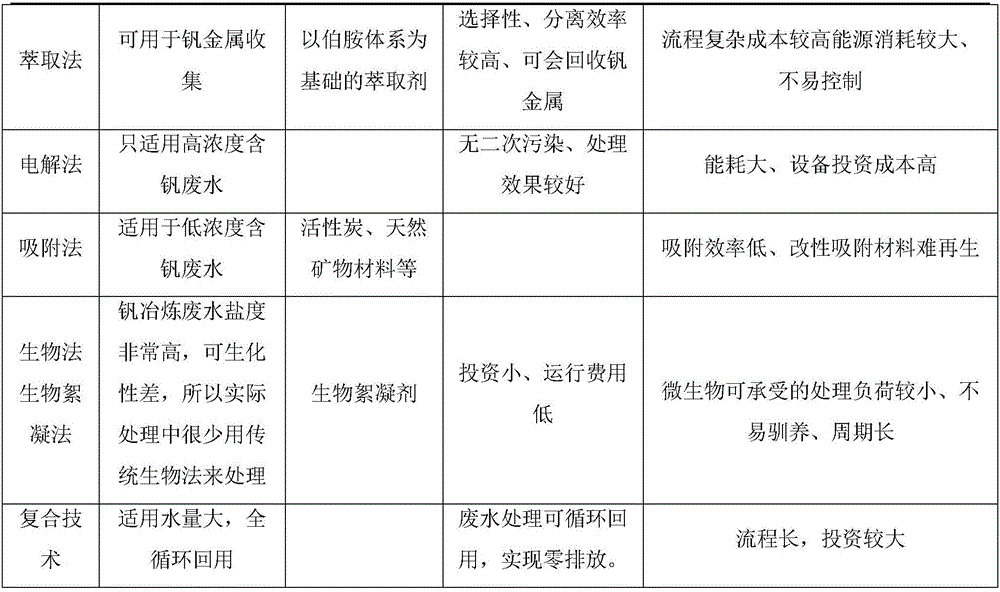

Process for purifying and treating vanadium-containing wastewater in advanced manner and process for recycling vanadium and chromium

ActiveCN105753219ALow costWater contaminantsTreatment involving filtrationEnvironmental resistanceIon-exchange resin

The invention relates to a process for purifying and treating vanadium-containing wastewater in an advanced manner and a process for recycling vanadium and chromium, and belongs to the field of sewage treatment.The process for purifying and treating the vanadium-containing wastewater in the advanced manner includes regulating a pH (potential of hydrogen) value of the vanadium-containing wastewater until the pH value reaches 4-6, sequentially adsorbing the vanadium-containing wastewater by the aid of resin A and resin B which are used as adsorption media; draining tail liquid which reaches standards and is obtained after the vanadium-containing wastewater is adsorbed.The resin A is chelating ion exchange resin; the resin B is macroporous weakly basic anion exchange resin with polyamine.The processes have the advantages that the process for purifying and treating the vanadium-containing wastewater is a novel, efficient and low-cost technology for treating heavy metal wastewater, the requirement on harmlessness and resource recovery (valuable heavy metal recycling) of the vanadium-containing wastewater and the requirement on water recycling and reusing can be simultaneously met, the processes are novel environment-friendly emission reduction and resource recycling technologies, 'cleaner production' standards implemented for vanadium metallurgy and vanadium application industries can be improved, and the processes have obvious economic and social benefits.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST +1

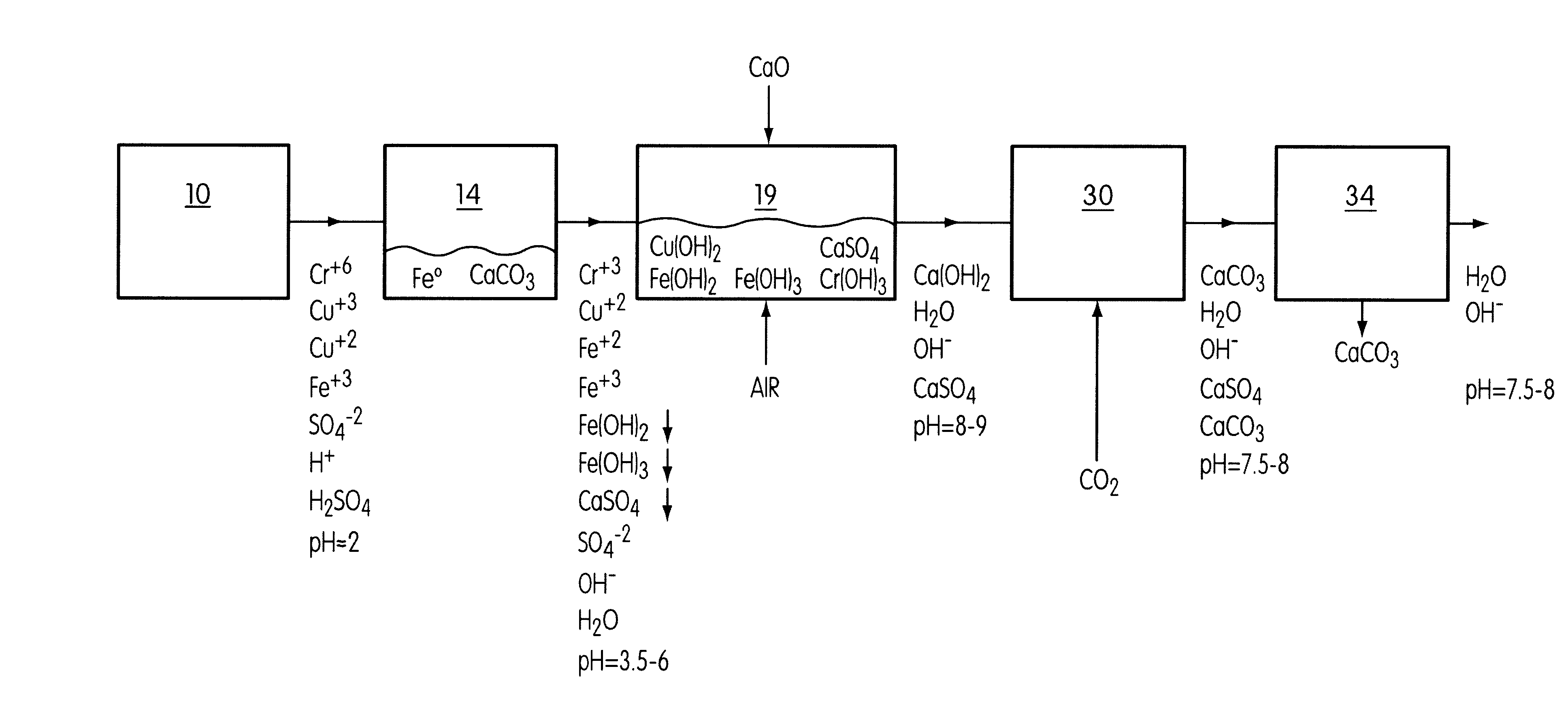

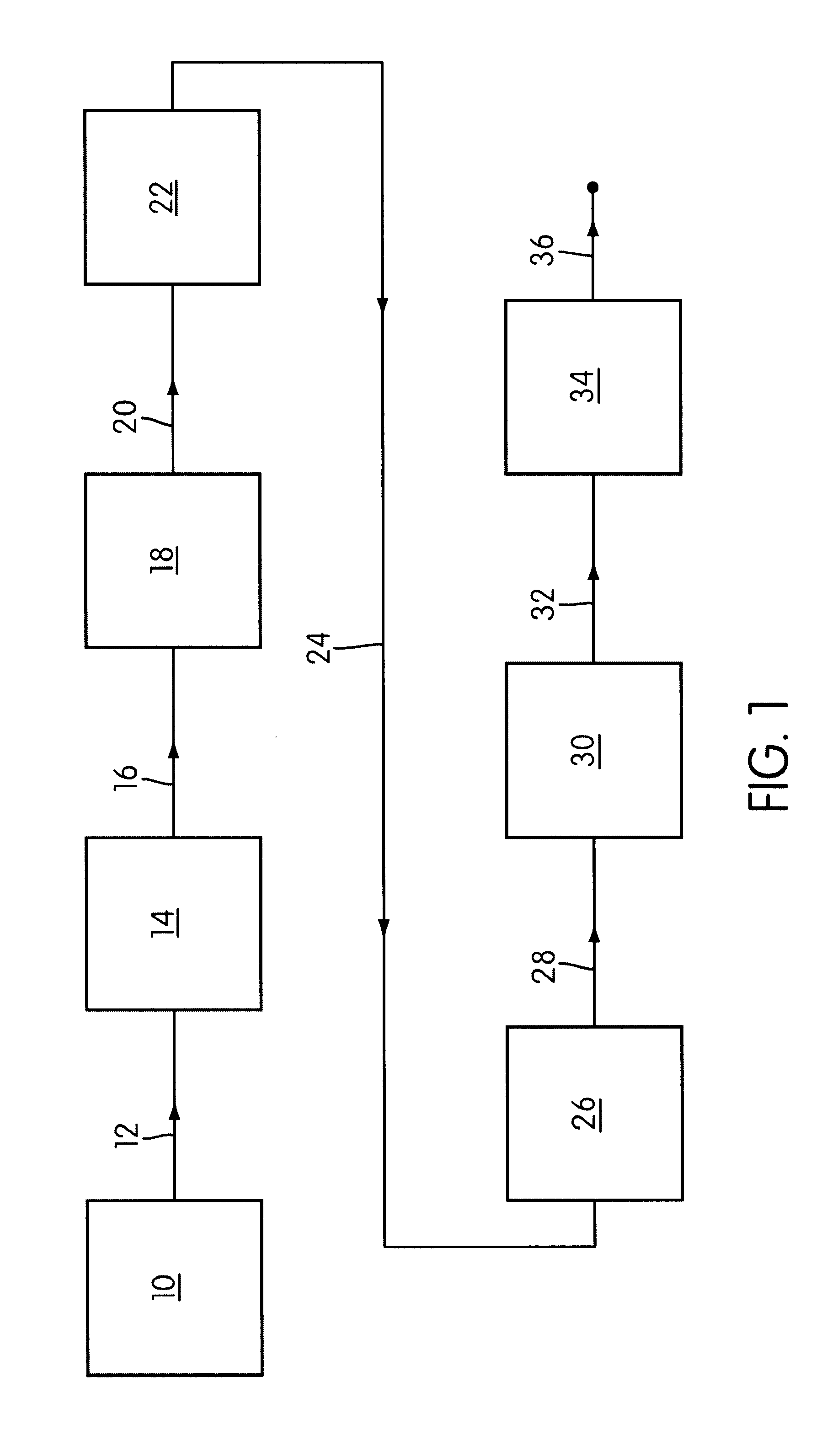

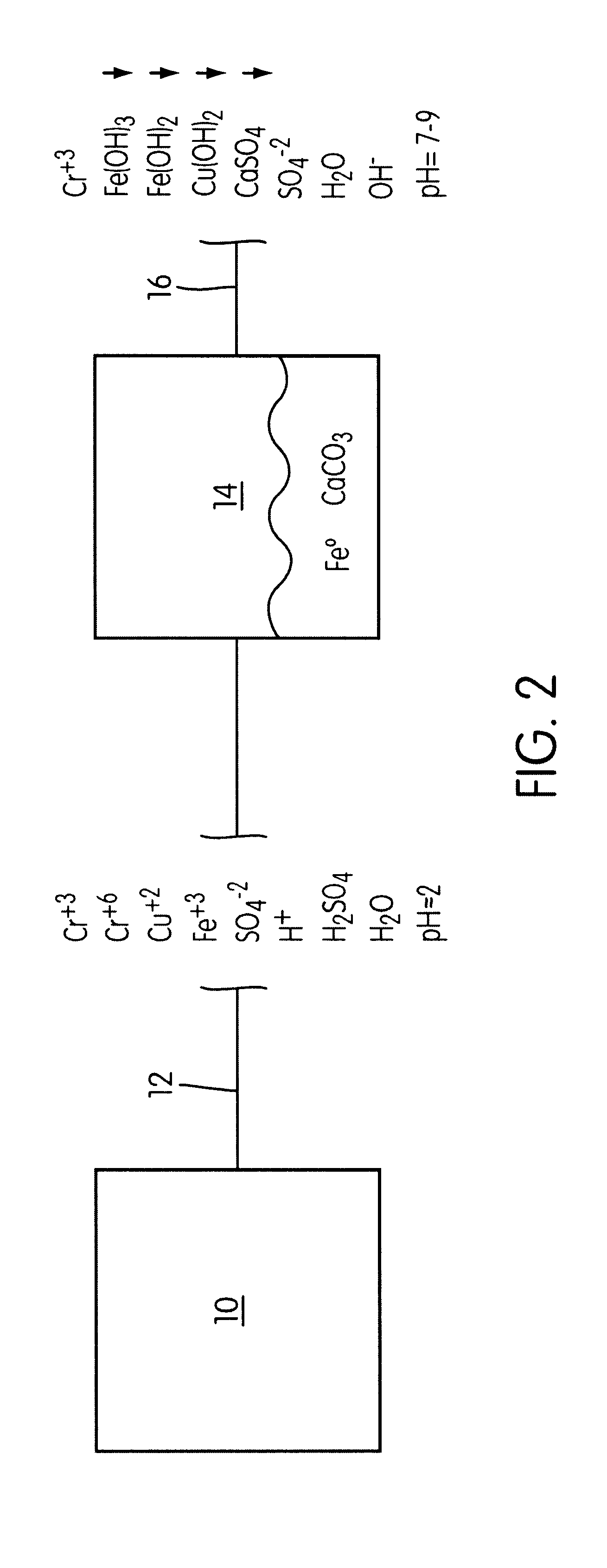

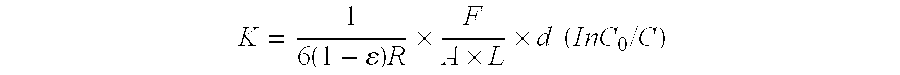

Process and system for treating the discharge stream from an ion exchanger

A method is disclosed for treating a flushing solution from an ion exchanger used in electroplating operations by co-precipitating or selectively precipitating out metal hydroxides derived from metal ions from the structures being plated in the electroplating bath, metal ions from the electrodes use in the electroplating bath and metal ions from the plating metal used in the electroplating bath, and a pH raising agent having a cation with a valence of at least 2. After the metals are precipitated out of the flushing solution, the flushing solution is aerated with carbon dioxide to precipitate out the cation from the pH raising agent as a carbonate. The carbonate precipitate is removed from the flushing solution and the resulting solution consists essentially of water that may be recycled for use in the electroplating plant or safely discharged into the environment.

Owner:CWS PARTS +1

Method for regenerating ion exchange resin based on fluidized bed

InactiveCN103551210AExtend the switching periodReduce consumptionIon exchange beds cleaning/rinsingFluidized bedIon exchange

The invention relates to a method for regenerating an ion exchange resin based on a fluidized bed, and in particular relates to a method for regenerating ion exchange resin, which forms the fluidized bed from analytical liquid, regenerating liquid, cleaning liquid and ion exchange resin in a caprolactam production process to improve the regeneration efficiency and reduce cost. Compared with the prior art, the method can prolong the switching period of an ion exchange resin tower, reduce material and energy consumption, and reduce the emission quantity of wastewater. By implementing the method, the ion exchange resin tower need not to be transformed, the operation is simple and practical, and the economical and environment-friendly benefits are remarkable. The method has a good popularization and application space.

Owner:CHINA PETROLEUM & CHEM CORP

Method for recovering activity of ion exchanger and agent for use in recovering activity of anion exchanger

InactiveUS20050029087A1Deionization capacityNegatively chargedElectrolysis componentsVolume/mass flow measurementAmmonium compoundsIon-exchange membranes

A performance-lowered ion exchanger hard to recover in performance by the conventional regeneration (ion exchange resin, ion exchange membrane, or the like) is endowed with the same electric charge as the electric charge of the ion exchanger. A performance-lowered ion exchanger hard to recover in performance by the conventional regeneration owing to adsorption thereon of a charged substance is endowed with an electric charge opposite to that of the charged substance. According to the foregoing operations, the ion exchangers are recovered in performance. At least one compound selected from among organic amine compounds and organic ammonium compounds, which are capable of being endowed with an electric charge through dissociation thereof in solution, is preferably used as a rejuvenation agent for an anion exchanger.

Owner:ORGANO CORP

Method for regenerating desalting mixed bed

ActiveCN108178240AShort regeneration timeIncrease water productionSpecific water treatment objectivesWater/sewage treatment by ion-exchangePower stationWater production

The invention relates to the field of chemical water production in power plants, and discloses a method for regenerating a desalting mixed bed. In the method, the liquid level in a mixed bed tank reduces to the top of a resin layer before the resin layer is subjected to hydrodynamic backwashing layering, and compressed air is introduced into the mixed bed tank to perform air washing, so the resinis effectively loosened, the water injection pressure of the subsequent backwashing step is reduced, the backwashing layering effect is enhanced, the backwashing layering time is significantly shortened, and the consumption of backwashing water in the resin backwashing layering process is reduced. After the resin is backwashed with water, the control of the concentrations and the flow amounts of aregeneration alkali solution and a regeneration alkali solution can significantly reduce the consumptions of the regeneration alkali solution and the regeneration alkali solution in the resin regenerating process and greatly shortens the regeneration time of the desalting mixed bed. The water production volume of the desalting mixed bed in a single period is high, and the outlet water of the regenerated desalting mixed bed has excellent quality.

Owner:CHINA SHENHUA ENERGY CO LTD +2

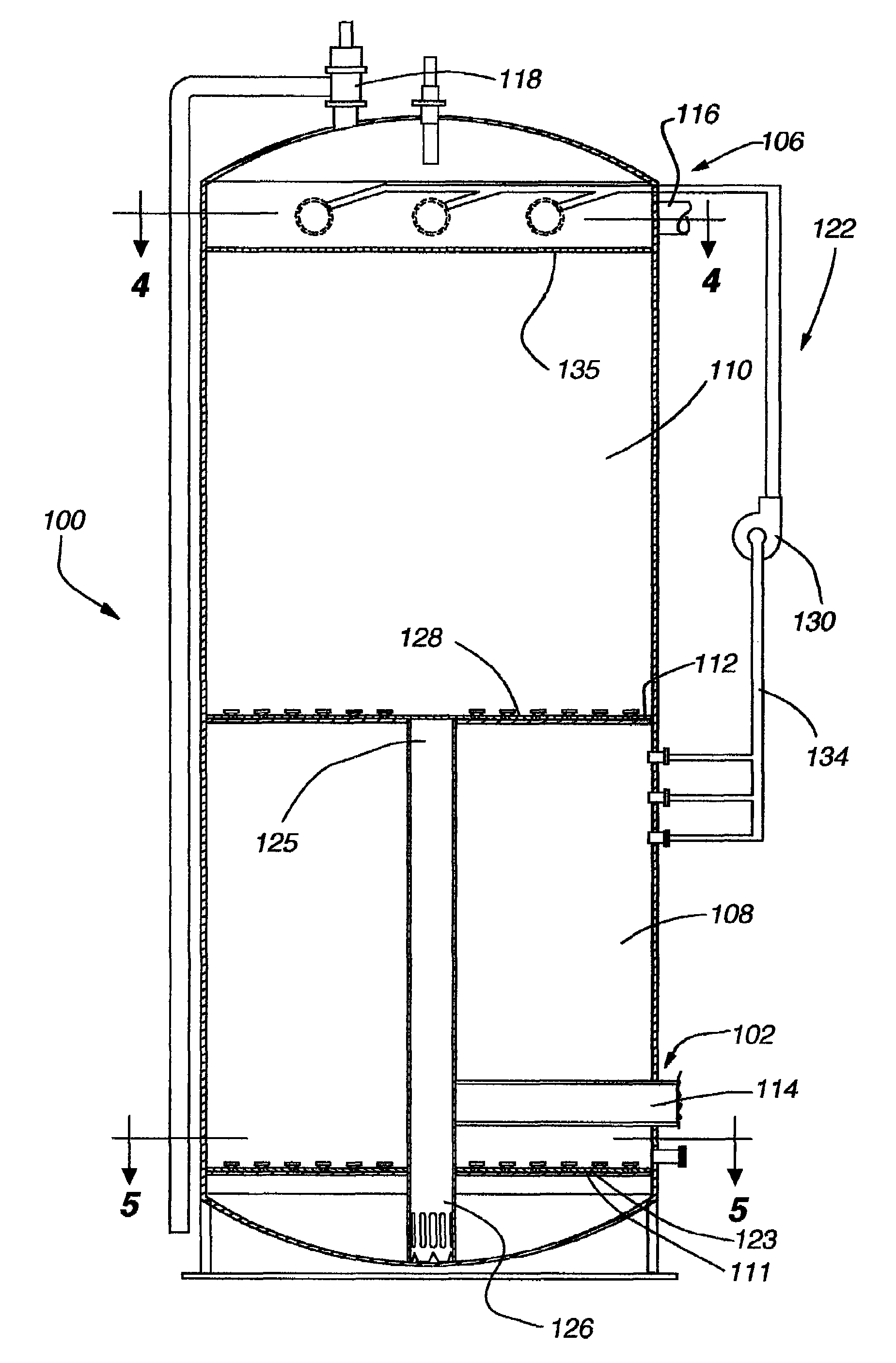

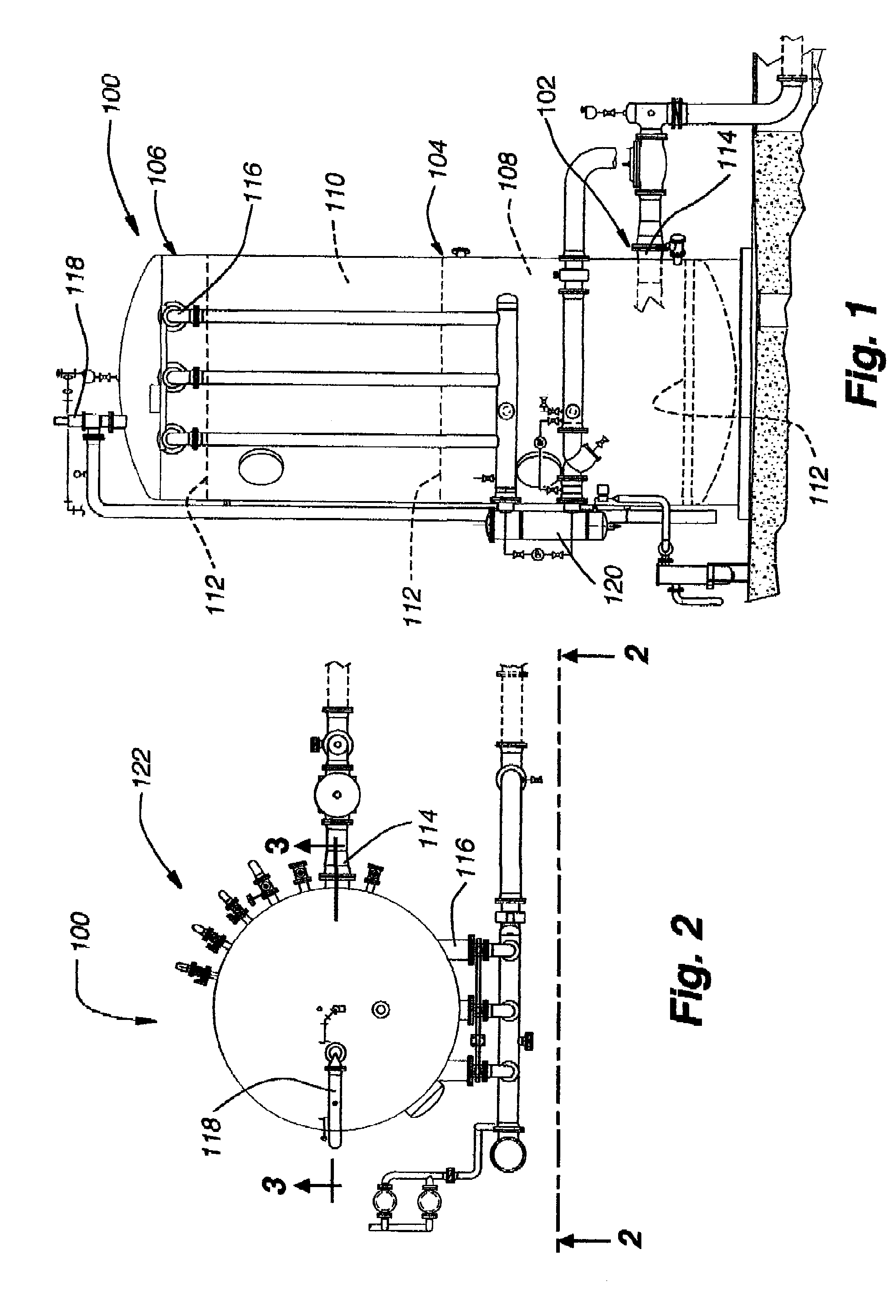

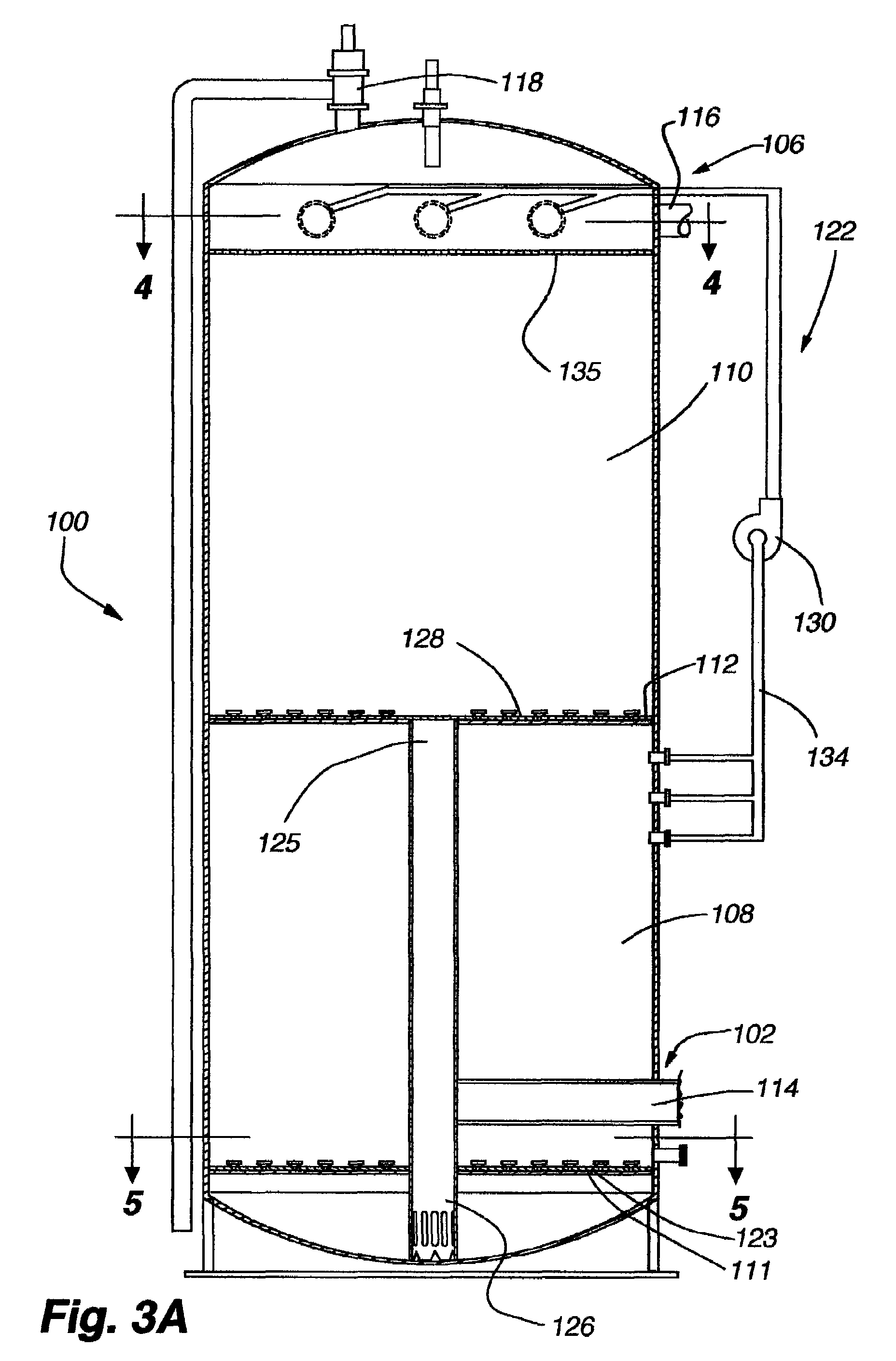

System and apparatus for purging absorptive materials used in the removal of contaminates from an aqueous medium

ActiveUS7520987B1Limit back-pressure build-upSignificant costWater treatment parameter controlSpecific water treatment objectivesParticulatesAqueous medium

Methods, systems and apparatus are provided for purging an adsorptive material of entrapped particulates. Methods, systems and apparatus rely upon a reverse loop for reversing the flow of medium within an adsorption material, allowing particulates caught within the adsorption material to be preferentially moved through and out of the adsorption material.

Owner:WRT INT

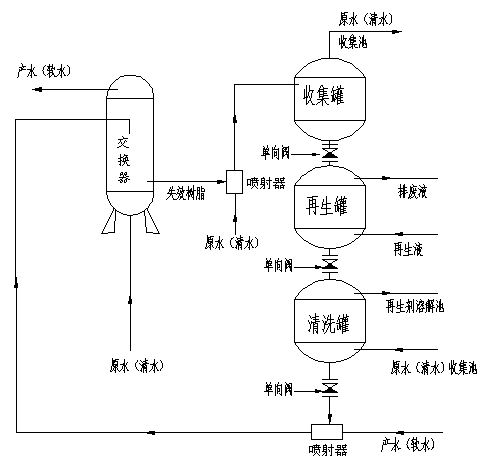

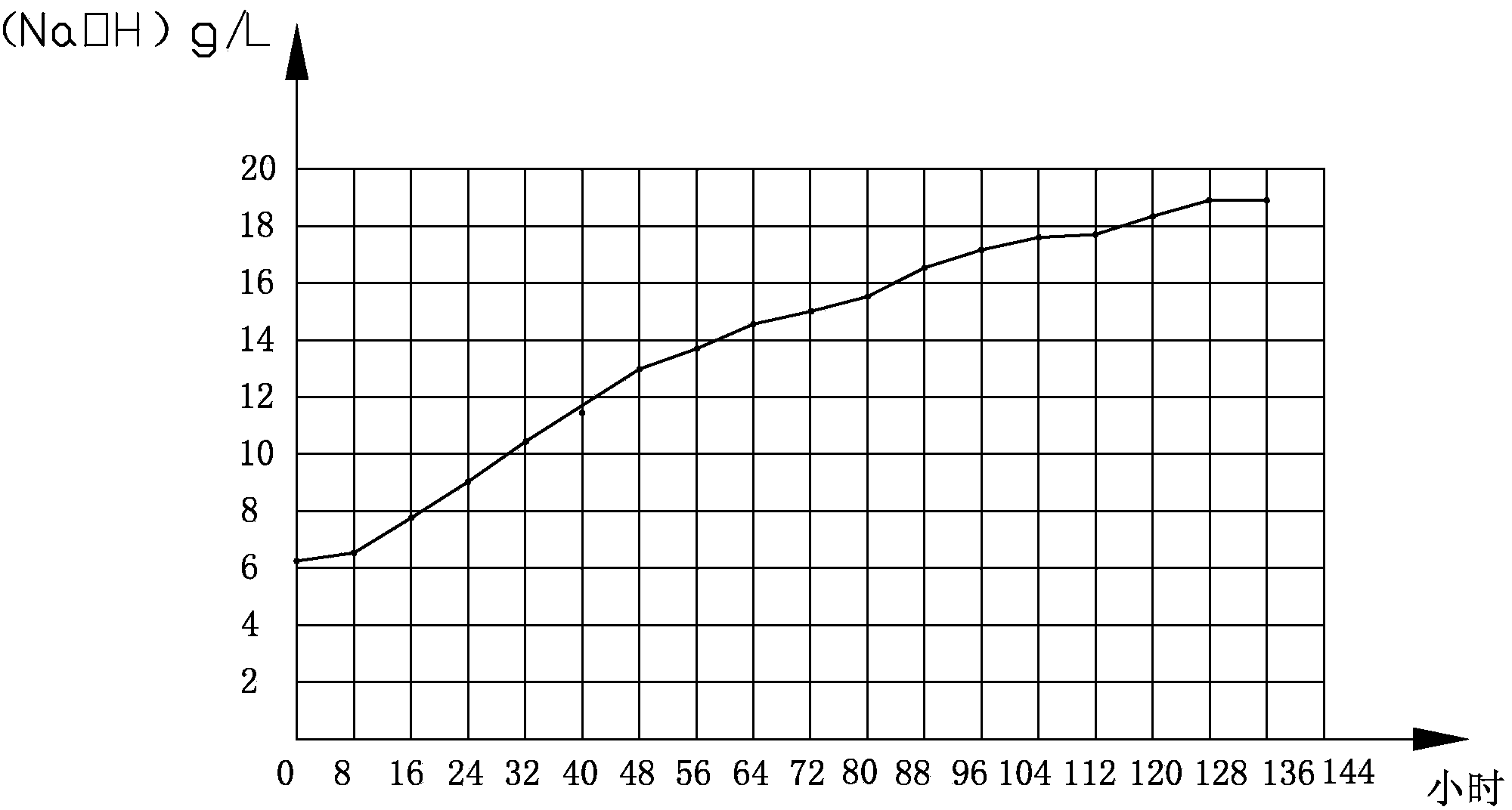

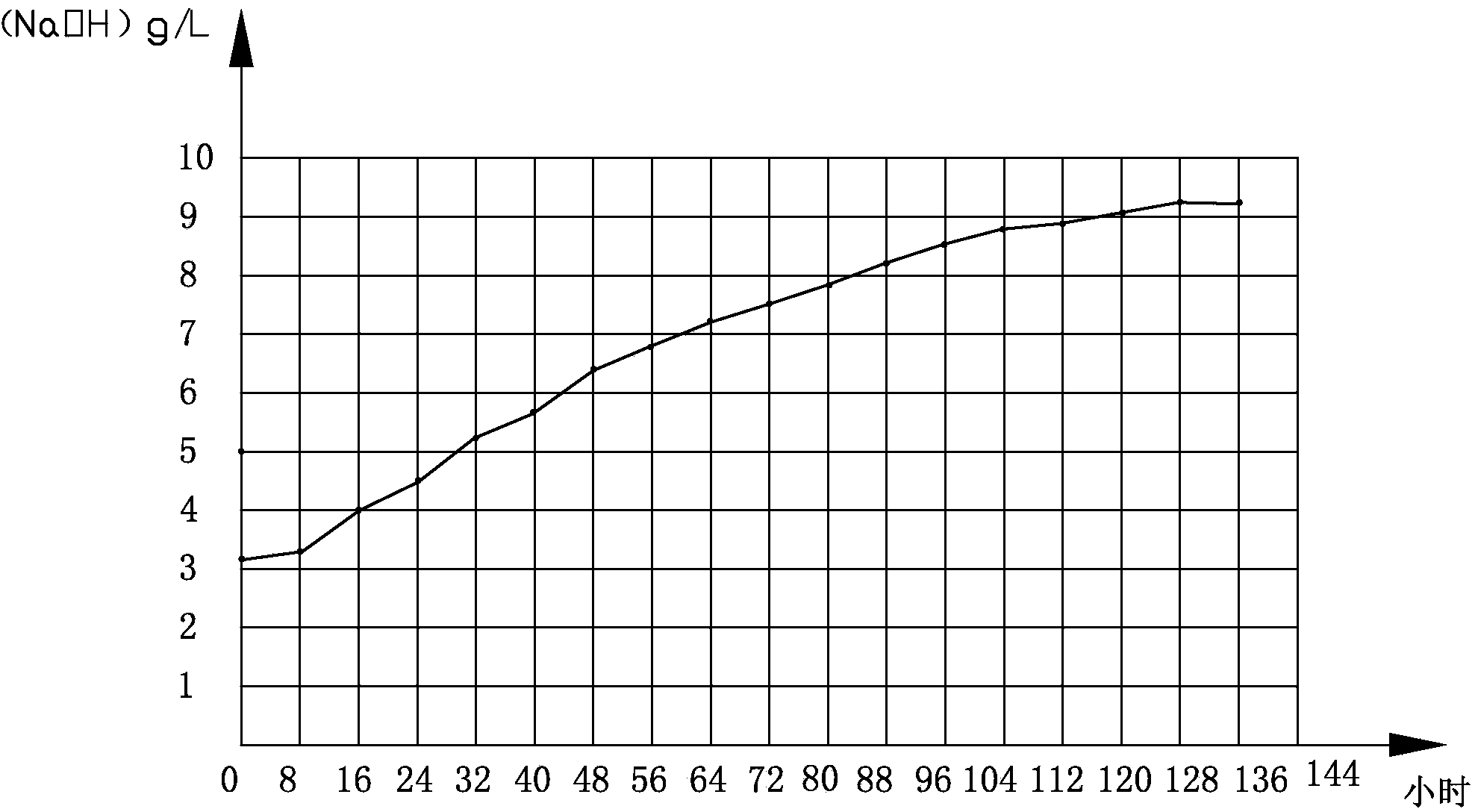

Extracorporeal upflow regeneration process for ion exchange resin

ActiveCN104003478ADoes not affect productionRealize continuous productionWater/sewage treatment by ion-exchangeIon exchange beds cleaning/rinsingWater flowIon exchange

The invention provides an extracorporeal upflow regeneration process for ion exchange resin. The process includes the following steps that firstly, soft water is produced, and meanwhile exhausted resin is continuously discharged from the lower portion of an ion exchanger; secondly, the exhausted resin is conveyed to a gathering tank through injection, conveying fluid is drained from the upper portion of the gathering tank, and the exhausted resin is discharged from the bottom of the gathering tank and enters a regeneration tank; thirdly, regeneration fluid flows into the lower portion of the regeneration tank, upflow regeneration is conducted on the exhausted resin, and regenerated resin is discharged from the bottom of the regeneration tank and enters a cleaning tank; fourthly, water flows into the lower portion of the cleaning tank, the regeneration fluid left on the regenerated resin is reversely cleaned away, and the cleaned regenerated resin is discharged from the bottom of the cleaning tank and is conveyed back to the ion exchanger through injection. According to the process, the soft water can be continuously produced, energy consumption is reduced, and the equipment utilization rate is increased.

Owner:CHENGDU GRACE FIBER +1

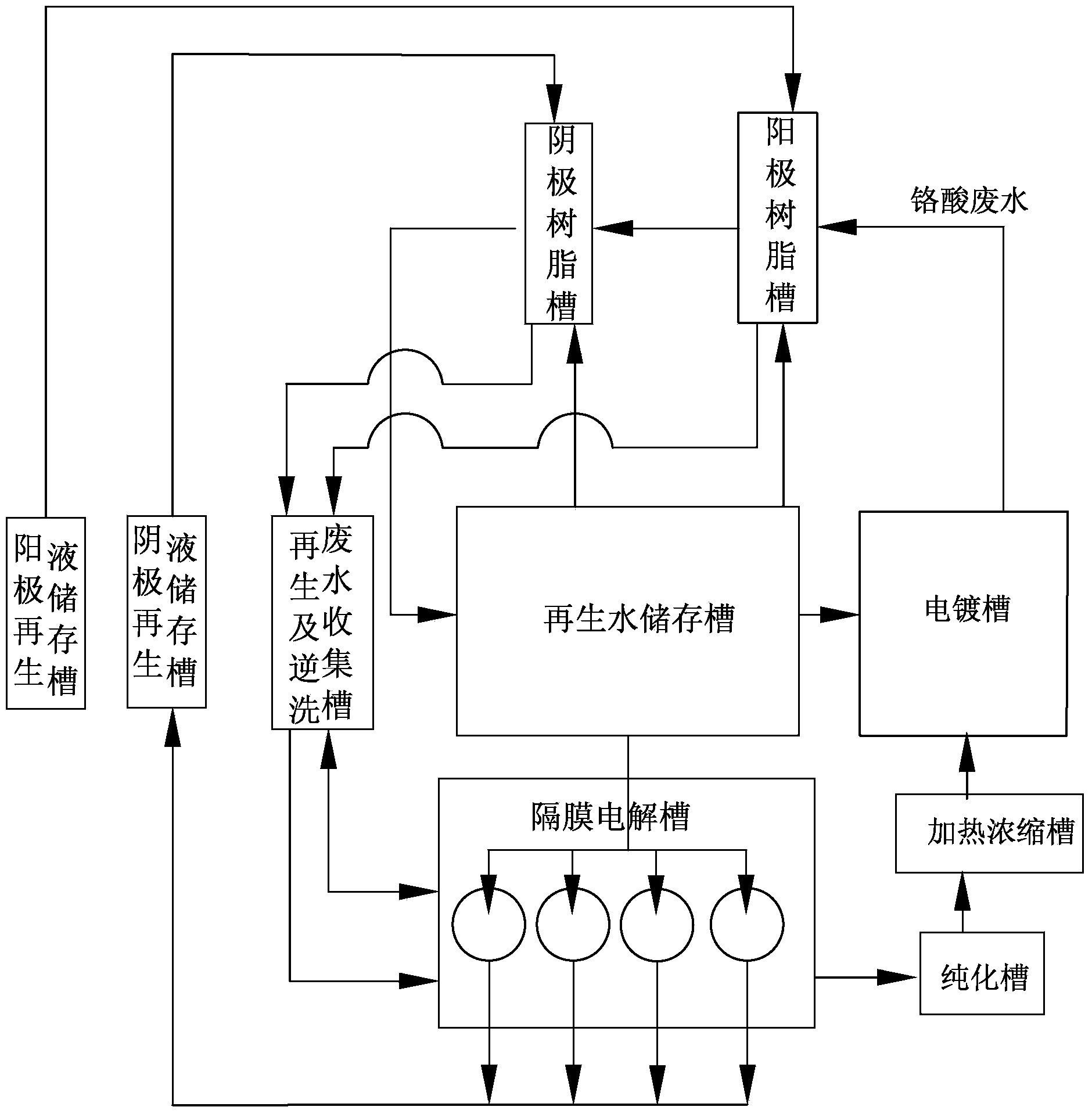

Chromic acid wastewater treatment method and system

InactiveCN103833167AReduce wasteReduce investmentIon-exchange process apparatusWater/sewage treatment by ion-exchangeLiquid wasteWater storage tank

The invention discloses a chromic acid wastewater treatment method which comprises the following steps: performing ion exchange on chromic acid wastewater and anion and cationic resins, and treating wastewater generated by backwashing and regenerating the anion and cationic resins with saturated exchange capacity in a diaphragm electrolytic cell. The invention also discloses a chromic acid wastewater treatment system used for treating the chromic acid wastewater generated in a production system. The chromic acid wastewater treatment system comprises an anode resin tank, a cathode resin tank, a regenerating and backwashing wastewater collection tank, a reclaimed water storage tank, the diaphragm electrolytic cell, a purification tank, a cathode regenerated liquid storage tank and an anode regenerated liquid storage tank, wherein the diaphragm electrolytic cell is used for performing electrolytic treatment on the mixed waste liquid and comprises a cell body, an ion diaphragm is arranged in the cell body, and the cell body is separated into an inner cell and an outer cell through the ion diaphragm; a cathode plate is arranged in the inner cell; an anode plate is arranged in the outer cell; the cathode regenerated liquid storage tank is used for storing a strong base solution; the liquid inlet of the production system is respectively connected with the regenerated water storage tank and the purification tank; the chromic acid wastewater outlet of the production system is respectively connected with each anode resin tank. The chromic acid wastewater treatment method and system are used for occasions of generating chromic acid wastewater in electroplating industry and the like.

Owner:黄运富

Weak-acid cation exchange resin preparation

InactiveCN1389296ACation exchanger materialsMolecular sieve catalystsWater treatment systemPotable water

An improved process for cleaning weak acid cation exchange resin intermediates resulting in finished weak acid resins providing enhanced performance of mixed-bed water-treatment systems is disclosed. The cleaning process involves selected steam treatment during the manufacturing process of the resins and is applicable to weak acid cation exchange resins in general that are used as components in potable water treatment systems, such as cartridge-water-pitcher systems.

Owner:ROHM & HAAS CO

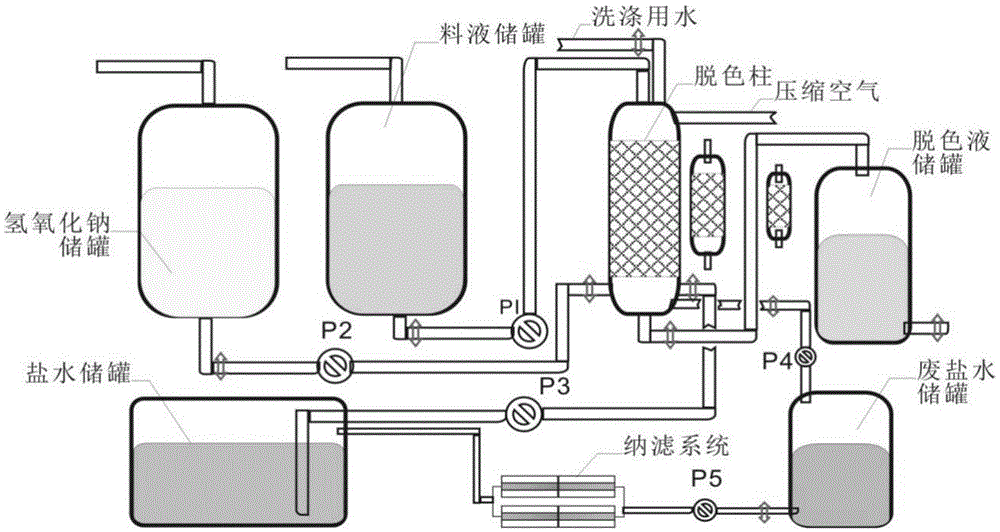

Regeneration method of decolorizing resin

InactiveCN105618164AGuaranteed regeneration effectEmission reductionIon exchange beds cleaning/rinsingRecovery methodSaline water

The invention discloses a regeneration method of decolorizing resin. The method comprises the following steps: firstly, cleaning a decolorizing resin column with fresh water with the volume being 1 to 2 times of that of the resin, then cleaning the decolorizing resin column with sodium hydroxide solution, pushing out liquid sodium hydroxide with compressed air, and then washing with water; secondly, leading in sodium chloride solution, soaking, then pushing out the sodium chloride solution with compressed air, repeating the process for 1 to 3 times, and finally washing with water. The invention further provides a recovery method of effluent brine during the regeneration process. The regeneration method can guarantee the regeneration effect of resin under the condition that the use level of sodium chloride is greatly reduced, greatly reduces the production cost, further reduces the discharge of brine, is environment-friendly, and has a very good industrial application prospect.

Owner:YILI CHUANNING BIOTECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com