Regeneration method of decolorizing resin

A decolorizing resin and resin technology, applied in ion exchange regeneration, chemical instruments and methods, ion exchange bed cleaning/rinsing, etc., can solve problems such as high cost, large sodium chloride consumption, environmental pollution, etc., and achieve industrial application Prospects are good, the discharge of brine is reduced, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0023] Experimental example 1 Resin regeneration method of the present invention

[0024] 1. Regeneration method

[0025] Get the decolorization column (resin wherein is Rohm and Haas 98Cl, chlorine type strong base anion resin) used in the production of erythromycin by Yili Chuanning Biotechnology Co., Ltd., and regenerate according to the following method:

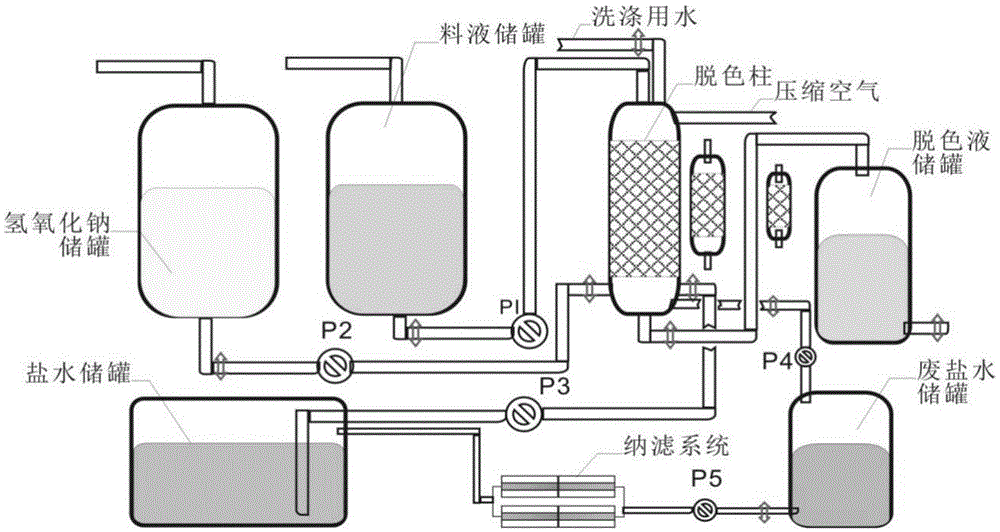

[0026] Take the decolorization column to be processed, such as figure 1 Shown, at first wash with the water of 1-2 times of volume of resin, then use P2 pump to send the sodium hydroxide solution that the concentration of 0.8 times of resin volume is 2.5% (g / g) to decolorization column from sodium hydroxide solution storage tank Clean in, then use the compressed air that pressure is 0.1 ± 0.05Mpa to push out liquid caustic soda, then wash with the water of 0.8 times of volume; Then use P3 pump to make the concentration of 0.8 times of resin volume be 8% (g / g) The sodium chloride solution is transported to the decolori...

experiment example 2

[0034] Experimental example 2 Resin regeneration method of the present invention

[0035] 1. Regeneration method

[0036] Get the decolorization column (resin wherein is Rohm and Haas 98Cl, chlorine type strong base anion resin) used in the production of erythromycin by Yili Chuanning Biotechnology Co., Ltd., and regenerate according to the following method:

[0037] Take the decolorization column to be processed, such as figure 1 Shown, at first wash with the water of 1-2 times of volume of resin, then use P2 pump to send the sodium hydroxide solution that the concentration of 1.0 times of resin volume is 4% (g / g) to decolorization column from sodium hydroxide solution storage tank Then use the compressed air with a pressure of 0.1 ± 0.05Mpa to push out the liquid caustic soda, and then wash it with 1 times the volume of water; g) The sodium chloride solution is transported to the decolorization column for static soaking and replacement of the pigment, each time for 30 minu...

experiment example 3

[0045] Experimental example 3 resin regeneration method of the present invention

[0046] 1. Regeneration method

[0047] Get the decolorization column (resin wherein is Rohm and Haas 98Cl, chlorine type strong base anion resin) used in the production of erythromycin by Yili Chuanning Biotechnology Co., Ltd., and regenerate according to the following method:

[0048] Take the decolorization column to be processed, such as figure 1Shown, at first wash with the water of 1-2 times of volume of resin, then use P2 pump to carry the sodium hydroxide solution that the concentration of 1.2 times of resin volume is 5.5% (g / g) to decolorization column from the storage tank of sodium hydroxide solution Then use the pressure of 0.1 ± 0.05Mpa compressed air to push out the liquid caustic soda, and then wash with 1.2 times the volume of water; g) The sodium chloride solution is transported to the decolorization column for static soaking to replace the pigment, each time for 80 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com