Automatic continuous separation system and control method for large-scale extraction and production of isoleucine

A technology of isoleucine and separation column, which is applied in the field of large-scale extraction devices for isoleucine, can solve the problems of large manual operation error, low output, and many discharge ports of fixed bed separation system, and achieves reduction of matching Equipment, reduce the cost of use, data show obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0049] A control method for any automatic continuous separation system, which includes the following steps:

[0050] 1) Set the process parameters of the system through the PLC controller;

[0051] 2) The PLC controller collects and processes the data of the flow sensor, pressure sensor and liquid level sensor in the system, and transmits it to the host computer;

[0052] 3) The operator monitors the operating status of the system and various process parameters through the host computer, and conveniently sets the operating parameters of the system according to the authorization level; including system pressure, flow rate, multi-way valve operating speed, stepping speed, System exchange time, the process position of each column in the system and the material level of each raw material tank and intermediate tank, etc.;

[0053] 4) When there is an abnormal situation in the system, the upper computer can give an alarm prompt to the operator in time, and the system is connected w...

Embodiment 3

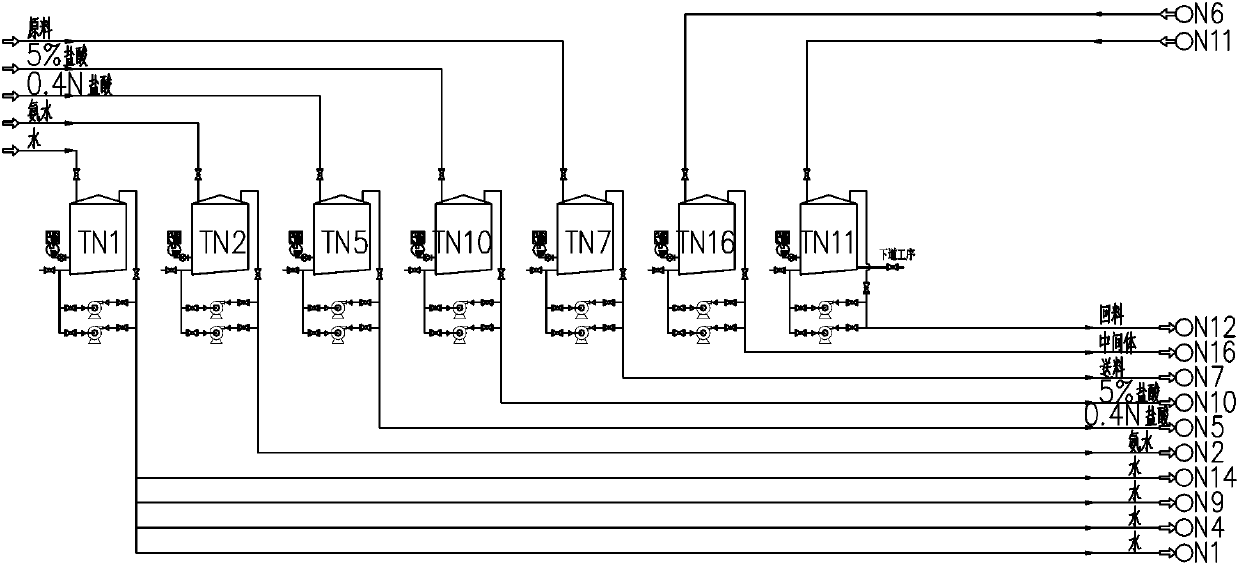

[0056] 1. The main equipment of the continuous separation system includes:

[0057] 1. Material system: ammonia water tank, water tank, raw material tank, 0.4N hydrochloric acid tank, 5.0% hydrochloric acid tank, intermediate tank, product tank and supporting centrifugal pumps for each storage tank. The valve is connected up and down with the inlet and outlet.

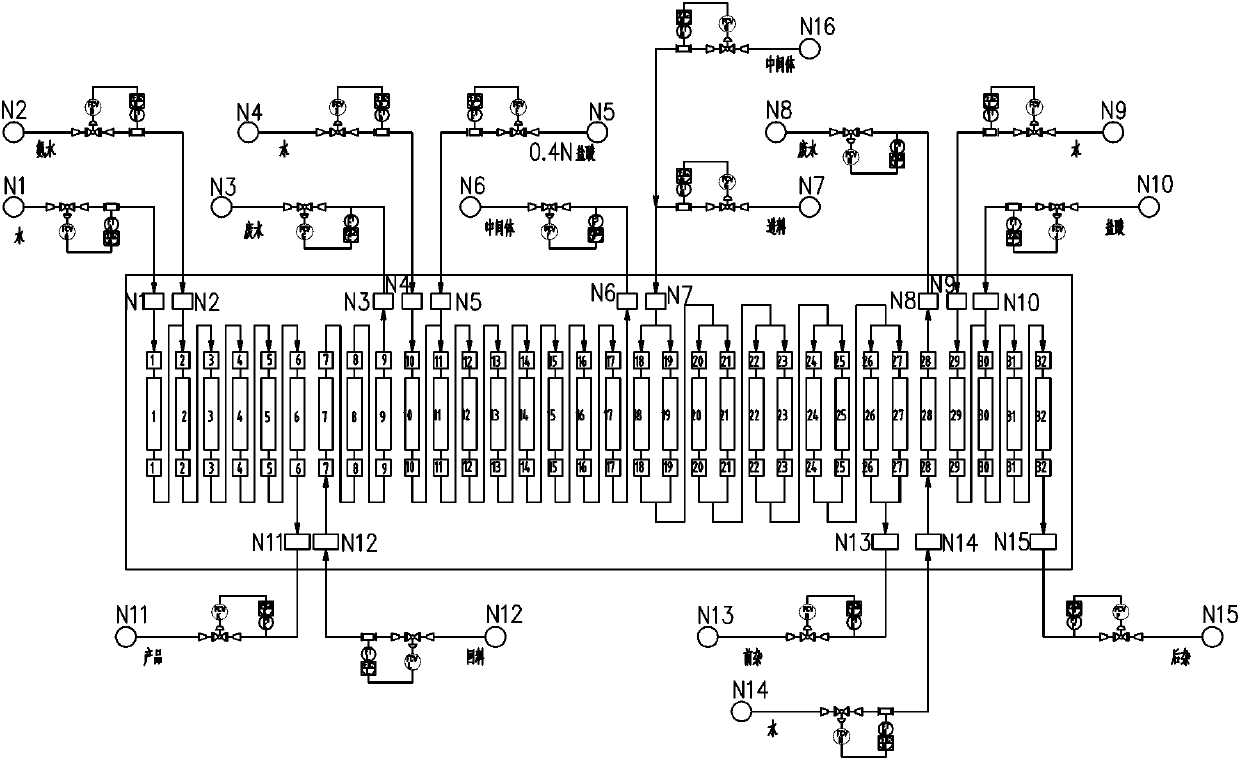

[0058] 2. IONEX multi-way valve:

[0059] 1) One DN40 IONEX multi-way valve, made of polypropylene, and corresponding O-rings, sealed, used to connect 32 inlets and 32 outlets of the resin column.

[0060] 2) 1 positioning encoder to determine the position of the IONEX valve turntable.

[0061] 3) 1 frequency converter (Danfoss brand) for controlling the rotation of IONEX valves

[0062] 4) 2 motors and reducer (380V, 50Hz) to drive IONEX valves.

[0063] 3. 32 separation columns, the resin loading capacity is about 1 to 2 tons, and the inlet and outlet of the separation columns are connected to the multi-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com