Patents

Literature

1108results about How to "To achieve the purpose of saving energy and reducing consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frequency converting control method for refrigerator

ActiveCN102997609ASpeed up coolingReduce wasteDomestic cooling apparatusLighting and heating apparatusFrequency conversionEngineering

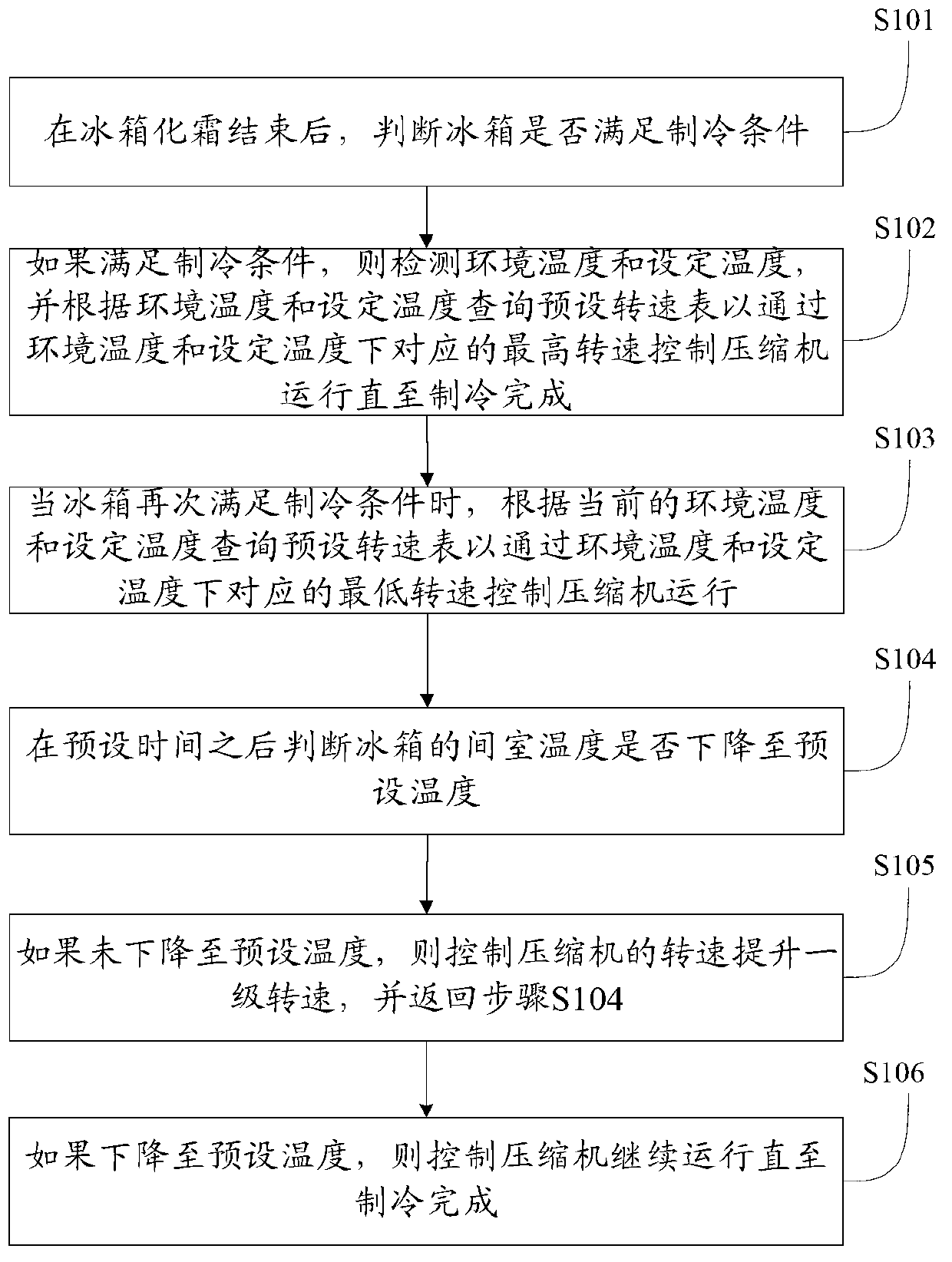

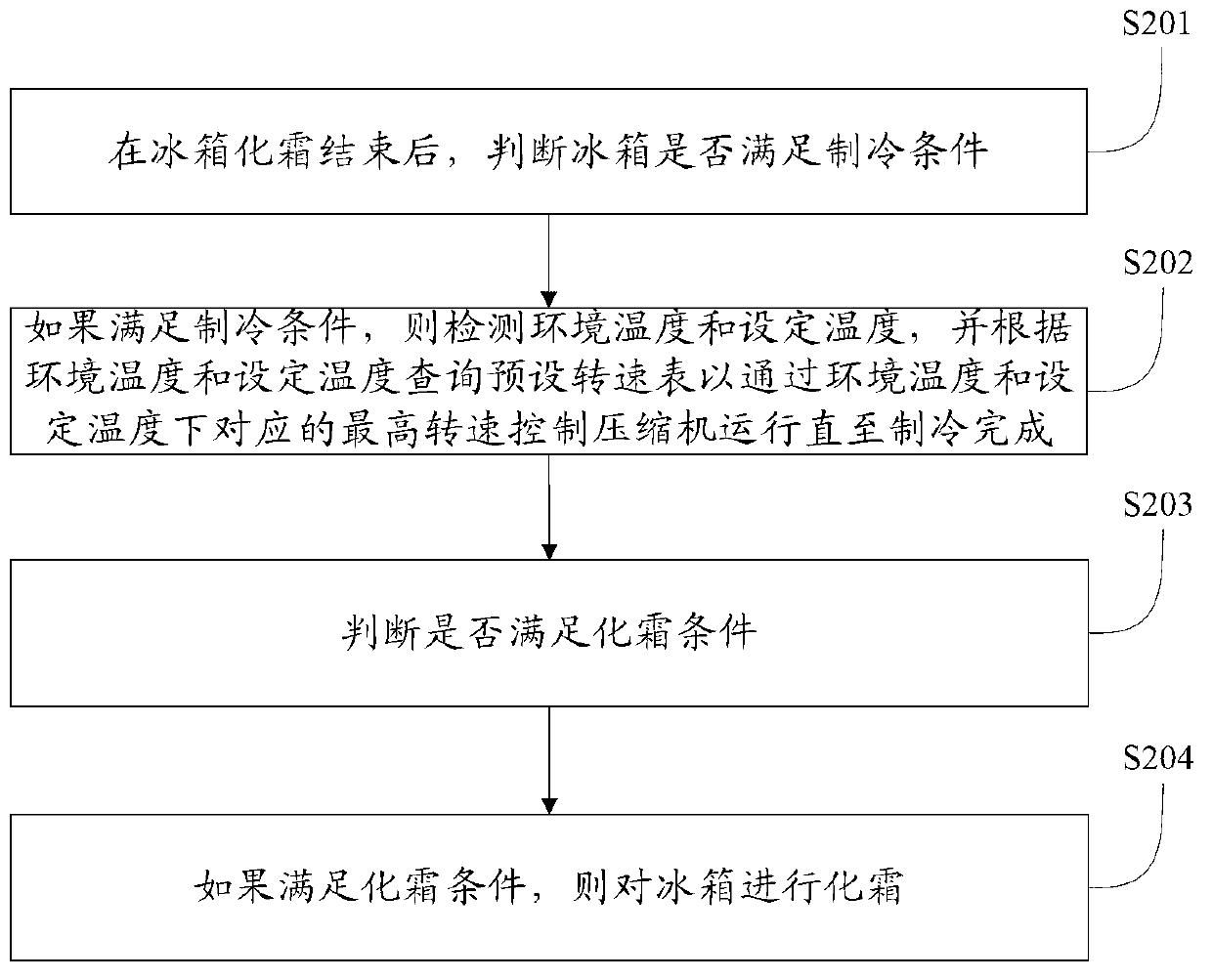

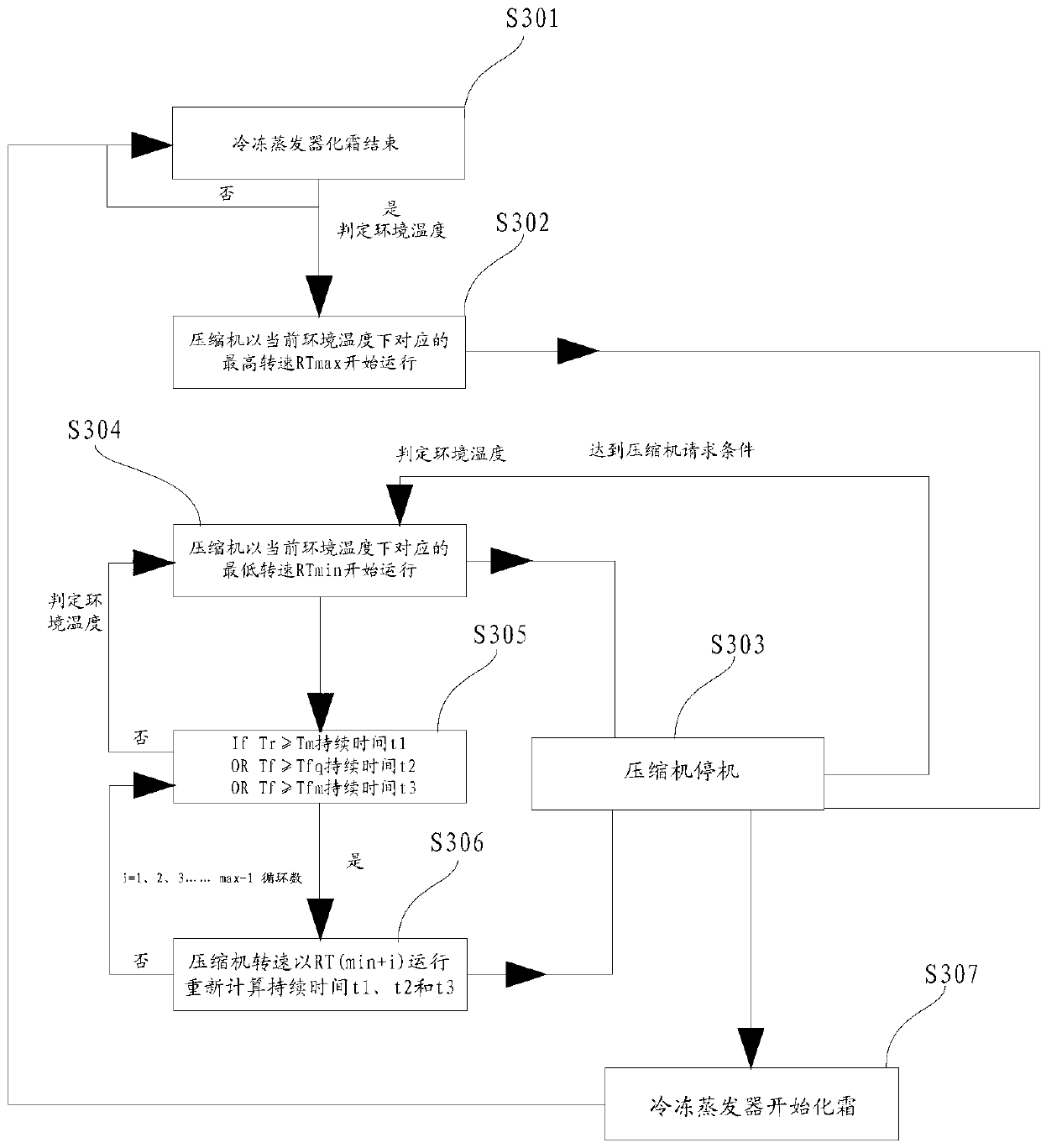

The invention provides a frequency converting control method for a refrigerator. The method includes that (1) whether the refrigerator meets a refrigeration condition or not is determined after defrosting of the refrigerator is finished; (2) if the refrigerator meets the refrigeration condition, an environment temperature and a setting temperature are detected, and a preset revolution meter is inquired so as to control the operation of a compressor at a corresponding maximum revolution speed until the refrigeration is completed; (3) when the refrigerator meets the refrigeration condition again, the operation of the compressor is controlled at a corresponding minimum revolution speed; (4) whether the compartment temperature of the refrigerator decreases to a preset temperature or not after preset time is determined; (5) if the compartment temperature of the refrigerator does not decrease to the preset temperature, the revolving speed of the compressor is increased by one level, and the step (4) is returned; and (6) if the compartment temperature of the refrigerator decreases to the preset temperature, the compressor is controlled to continue operating until the refrigeration is finished. According to the frequency converting control method for the refrigerator, the revolving speed of the compressor is continuously adjusted according to the environment temperature, interior temperatures of compartments and the like, so that the frequency conversion is achieved, the cooling speed of the refrigerator is improved, waste of cooling capacity of the compressor is reduced, and the energy consumption is lowered.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

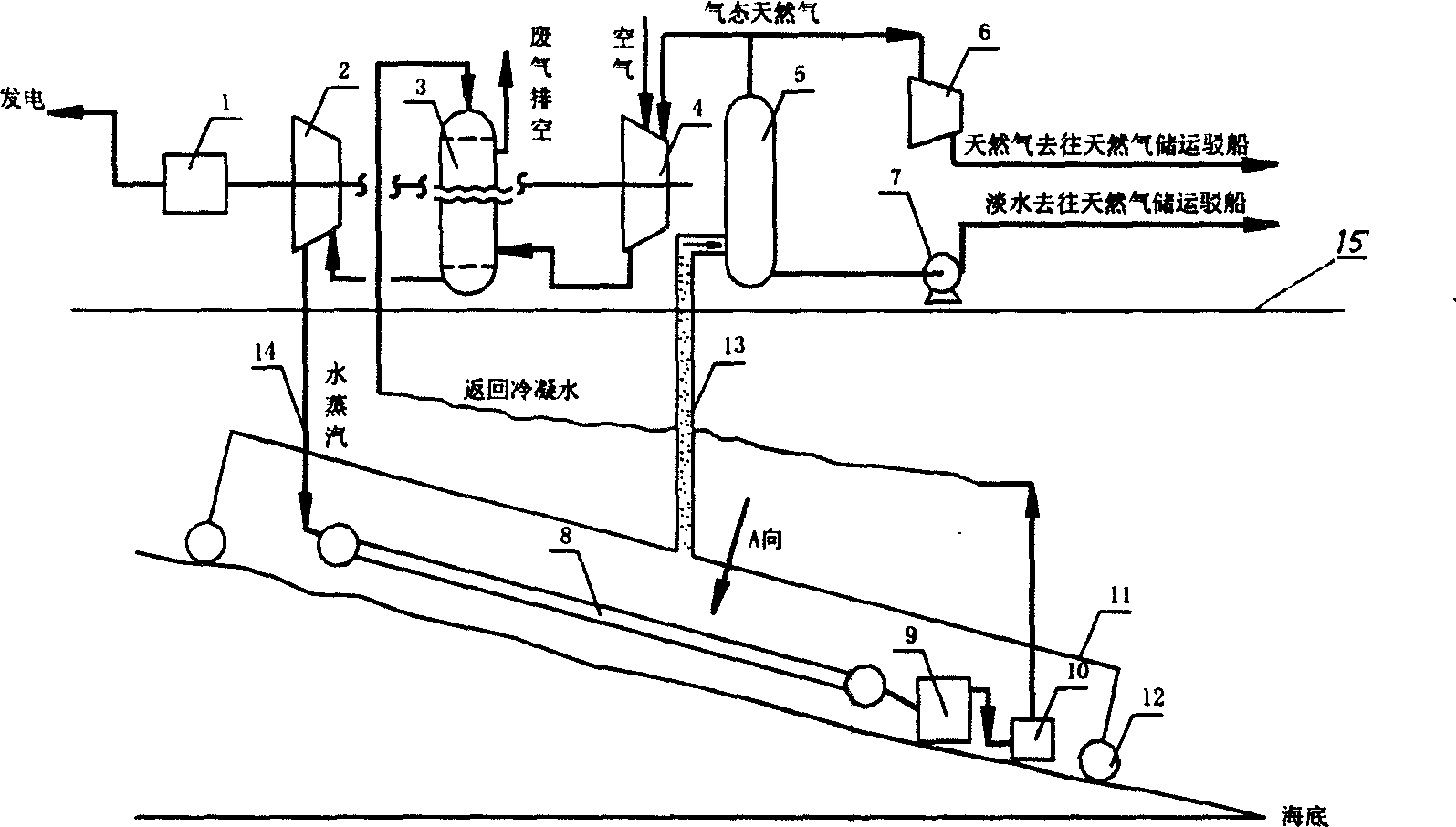

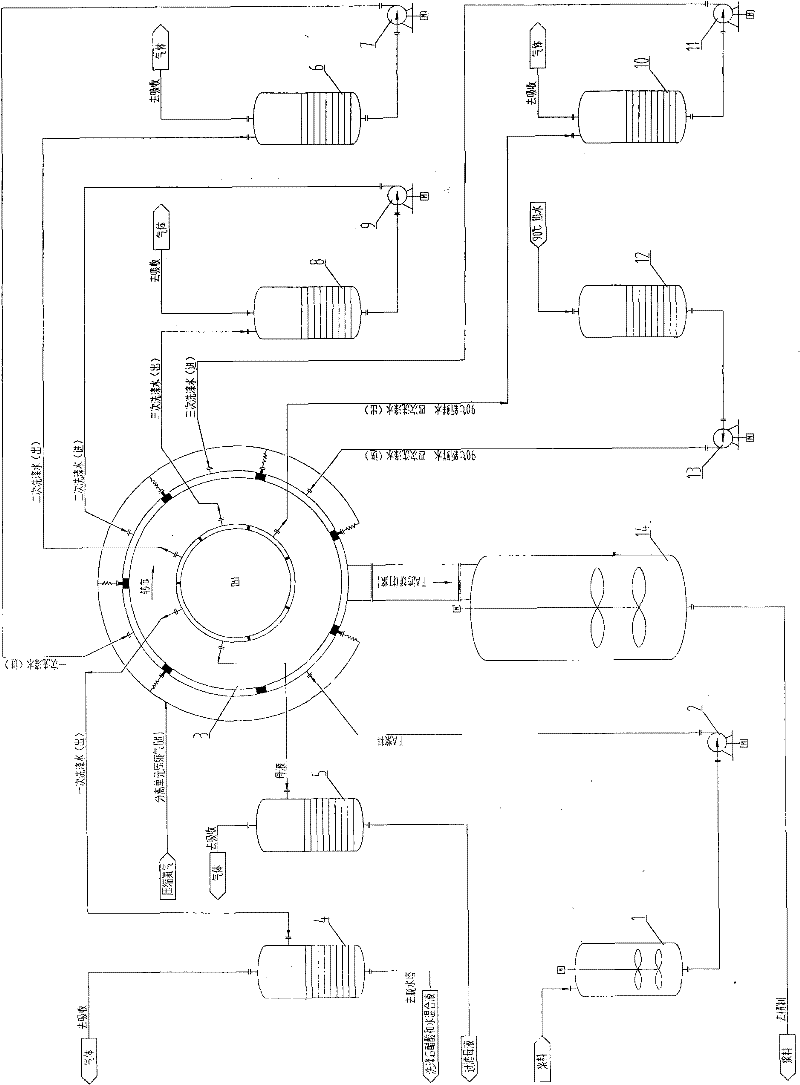

Method and system for exploiting seabed natural gas hydrates

InactiveCN1690360ALow costRealize the purpose of saving energy and reducing consumptionMechanical machines/dredgersMineral miningSubmarineNatural gas

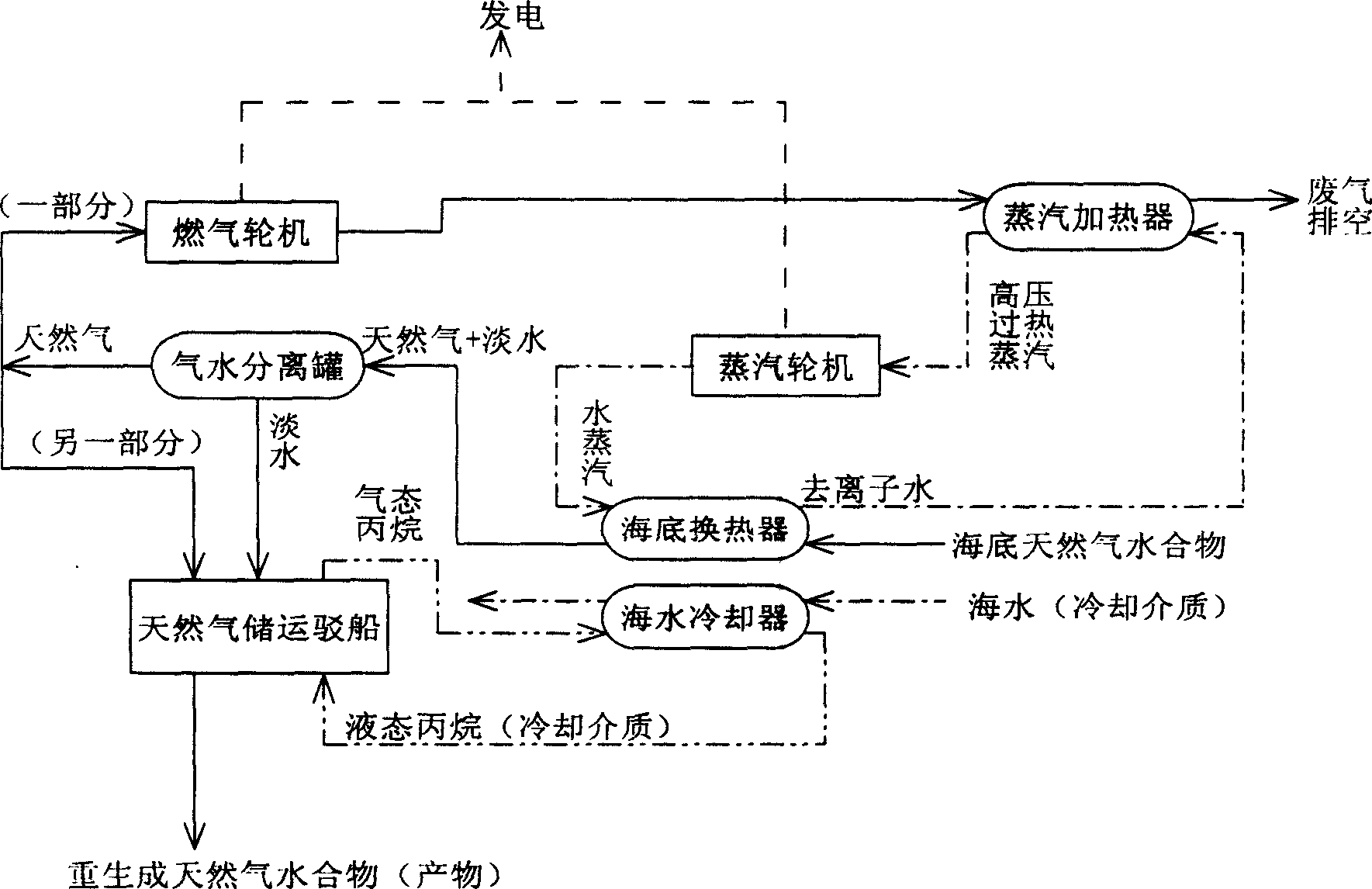

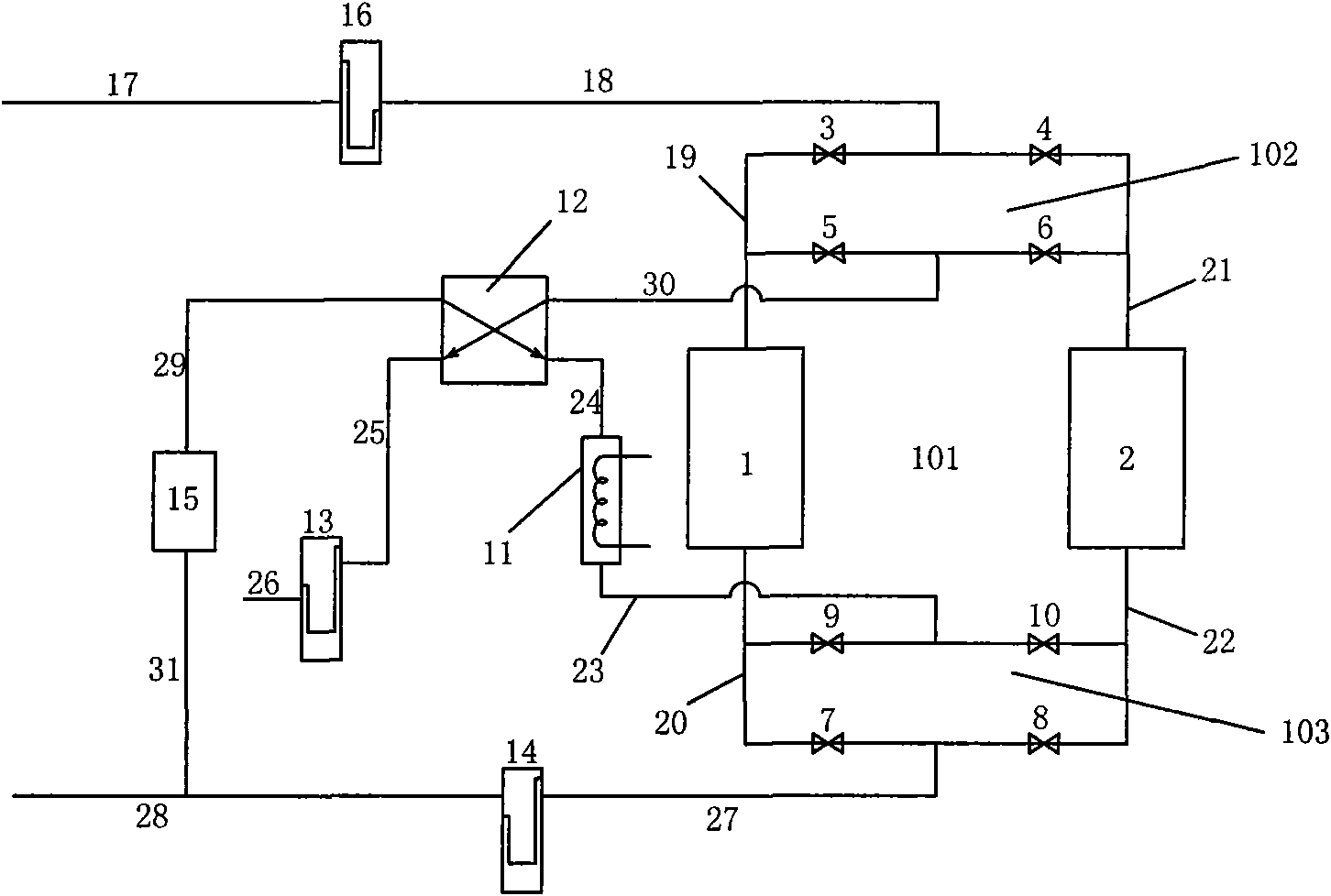

The invention relates to the recovery method and system of submarine natural gas hydrates. The method comprises: building a recovery platform of submarine natural gas hydrates; adding heating medium into the submarine heat transfer via the heat-insulating pipe to heat and melt the submarine natural gas hydrates solid for the mixture of gas and liquid, which will be lifted to the platform and separated for natural gas; attained natural gas is used as fuel of the united recycle generating system for generation, while the left as natural gas hydrates is stored in the natural gas carrying lighter which operates the storage, transportation and distribution. The system comprises: offshore platform, gas-fueled turbine, steam turbine; three-section steam heater; submarine heat transfer; methane compressor; deep well pump; submarine swash bank; and underwater controlling the movement of platform. Said invention has simple apparatus and lower cost, which can reduce the energy consumption in exploiting submarine natural gas hydrates.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

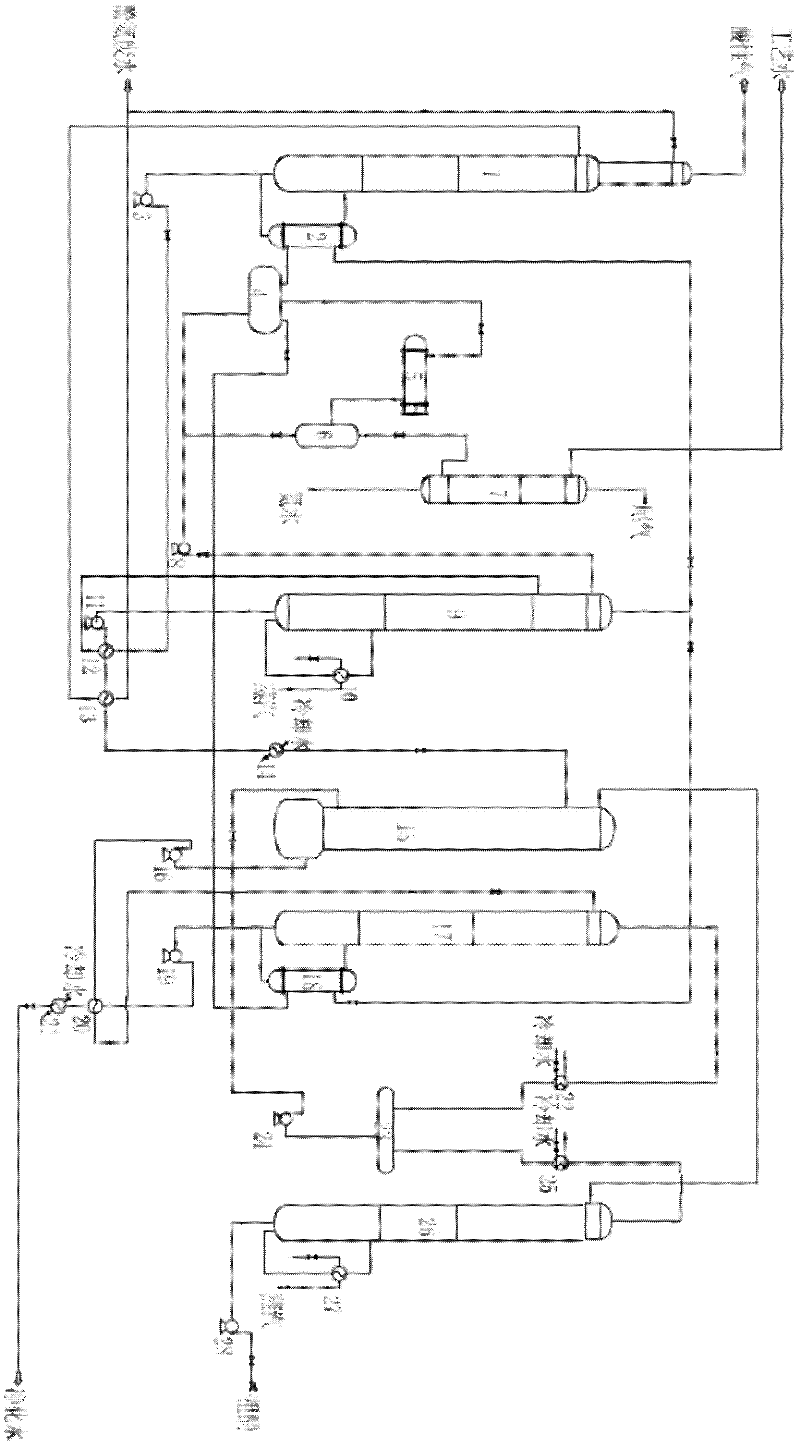

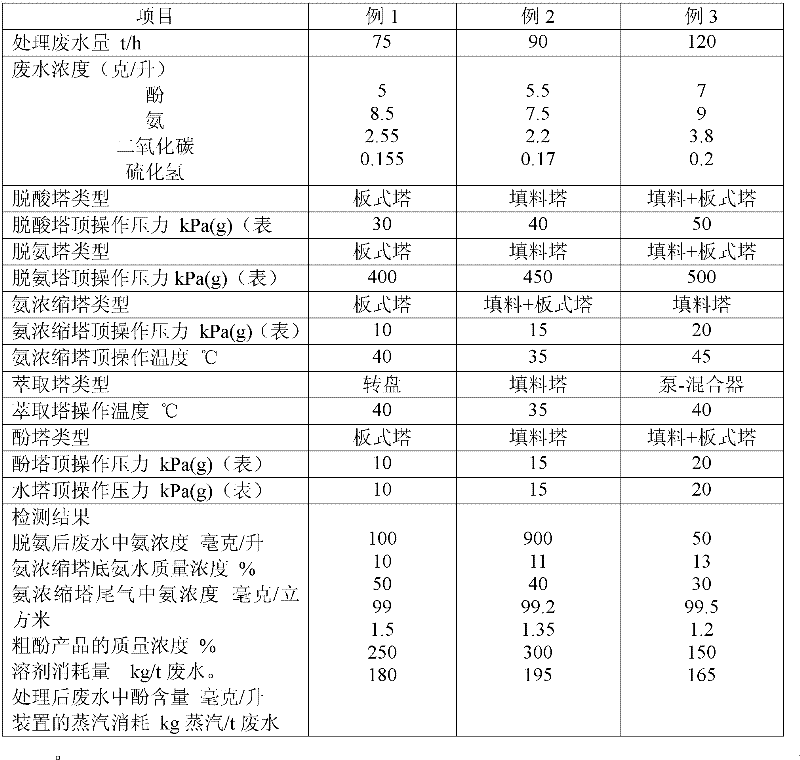

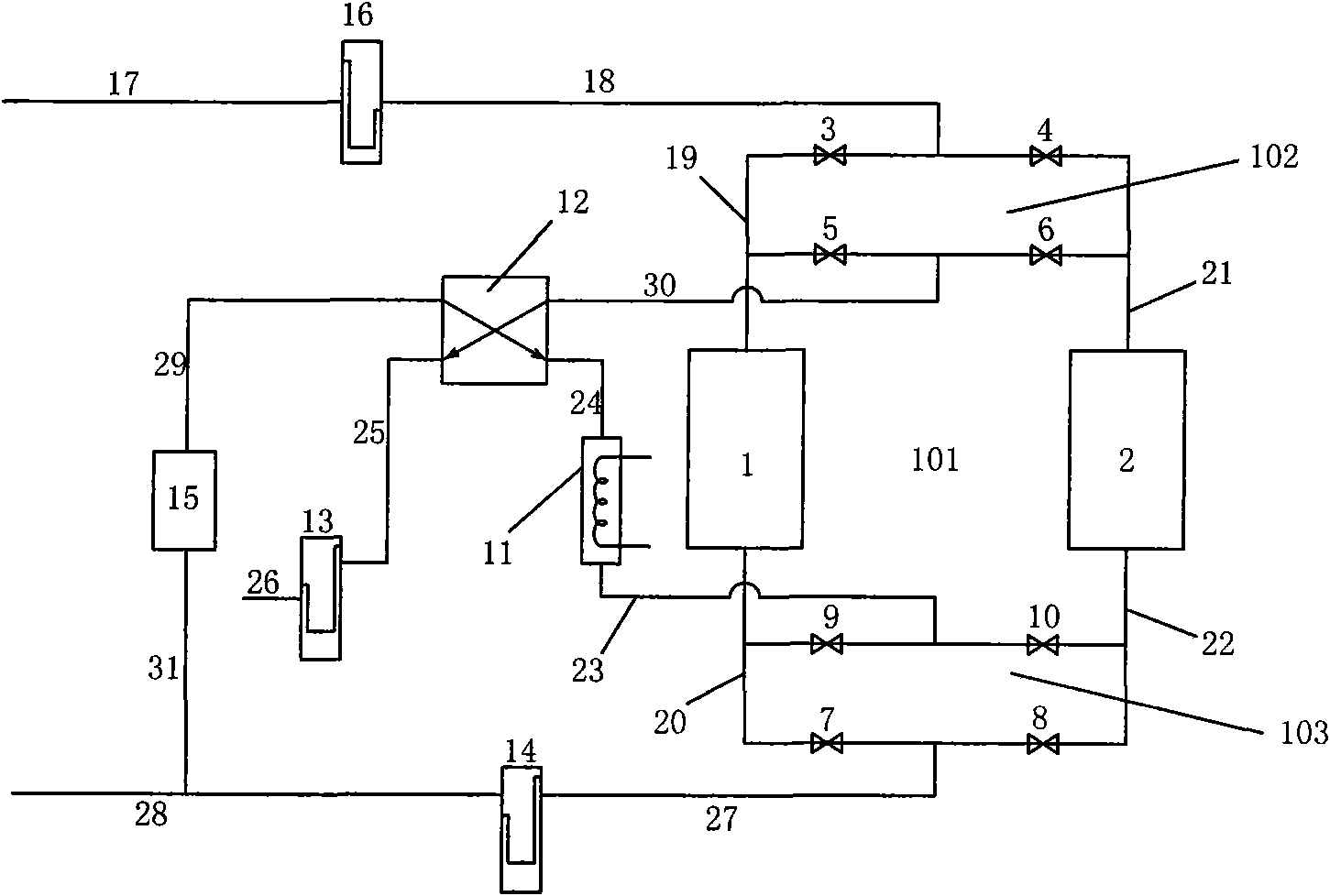

A kind of energy-saving method for recovery and treatment of phenol ammonia wastewater

InactiveCN102259943AEfficient recyclingSolve the technical problems of high energy consumptionChemical industryWater/sewage treatment by heatingCoal gasification wastewaterDifferential pressure

The invention relates to a method for treating wastewater containing phenol and ammonia, in particular to an energy-saving process for recycling the wastewater containing the phenol and the ammonia. Equipment among an acid removing tower, an ammonia removing tower and a water tower is coupled, namely a crude ammonia condenser on the top of the ammonia removing tower is taken as a reboiler of the acid removing tower and the water tower; and a differential pressure rectification technology is utilized, so that the step comprehensive utilization of a heat resource is realized, the energy consumption of wastewater treatment is reduced, and the using amount of steam and circulating water is greatly saved; particularly the equipment is coupled, the differential pressure rectification technologyis utilized and the ammonia and the phenol in the coal gasification wastewater are recycled simultaneously, so that the aims of saving energy and reducing emission in the wastewater treatment and recycling process are fulfilled. The technical problem that the energy consumption is high when the wastewater containing the phenol and the ammonia is recycled in the coal gasification process is solved; and the comprehensive utilization of energy is realized, and the method is high in social value and economic value.

Owner:TIANJIN HAOYONG CHEM TECH

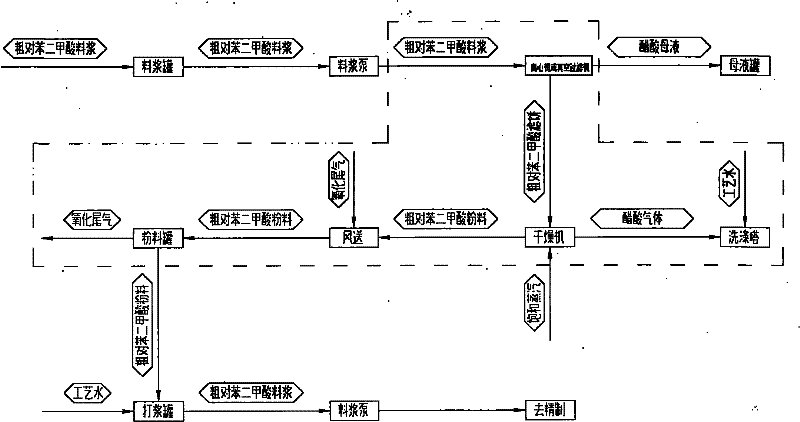

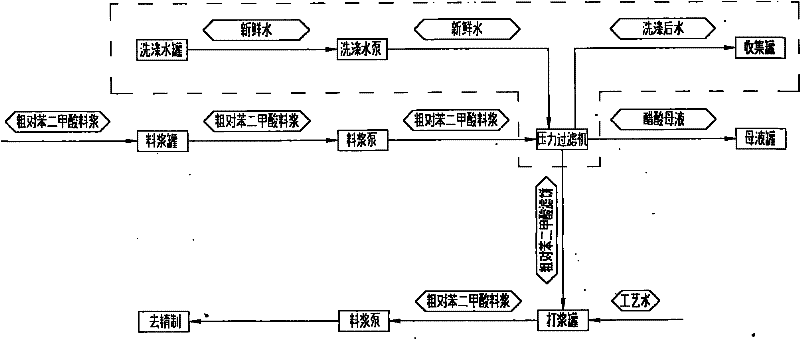

Method for filtering, washing and separating crude terephthalic acid by using oxidizing unit of fine terephthalic acid device

ActiveCN102476994AReduce in quantityShort processChemical industryCarboxylic compound separation/purificationAcetic acidFresh water

The invention relates to a method for filtering, washing and separating crude terephthalic acid by using an oxidizing unit of a fine terephthalic acid device. In the method, the aim of removing acetic acid is fulfilled by crudely filtering a crude terephthalic acid suspension and replacing acetic acid in the terephthalic acid by alternatively and repeatedly washing the crude terephthalic acid in sequence with fresh water. In the method, an integrated equipment-press filter is adopted to replace multiple sets of equipment including a vacuum centrifuge, a drier, a washing tower and a powder tank in the conventional process device, so that the equipment quantity is reduced, the flow is shortened, the process operability is enhanced, and a process for separating acetic acid from the crude terephthalic acid can be implemented in one press filter.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +2

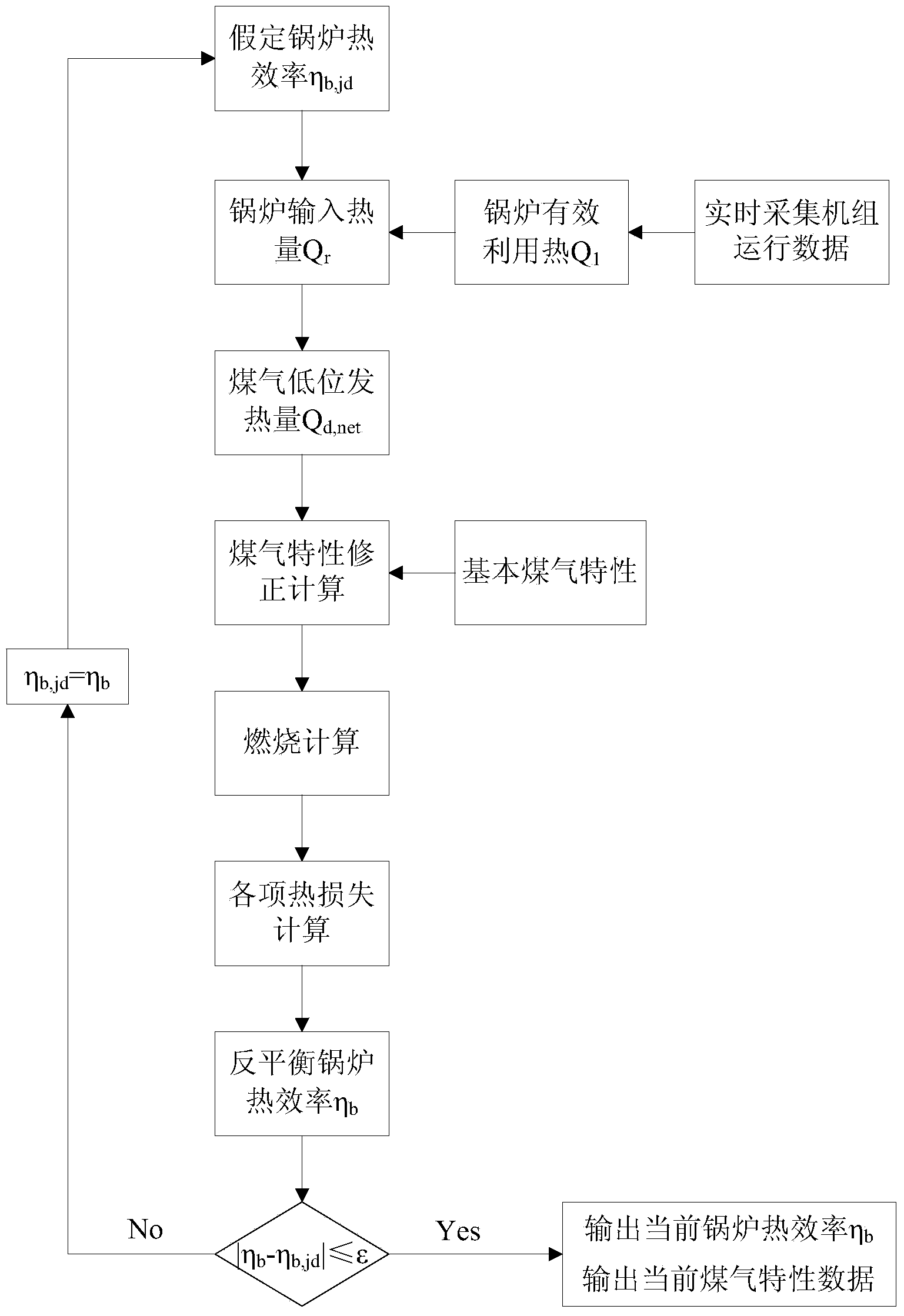

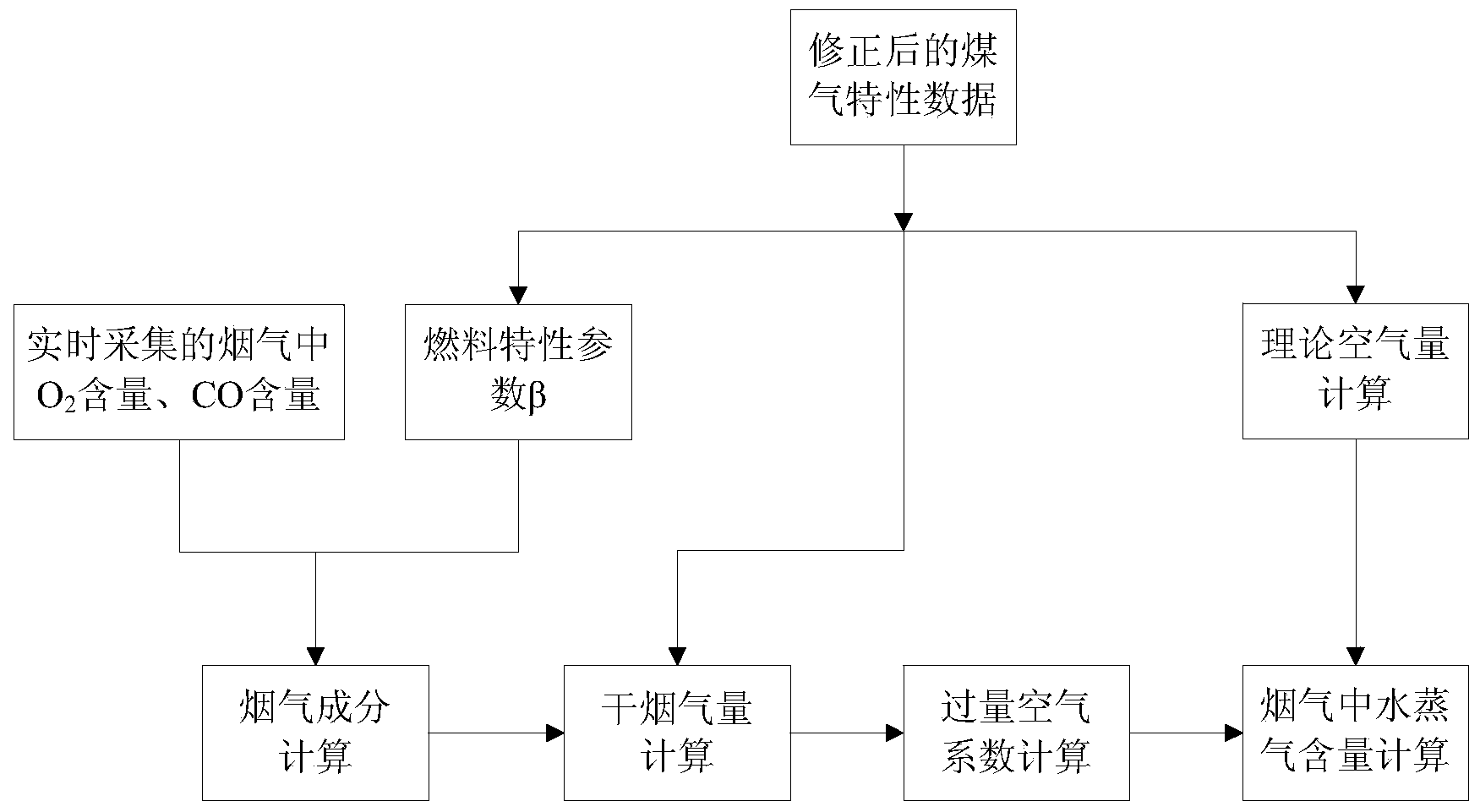

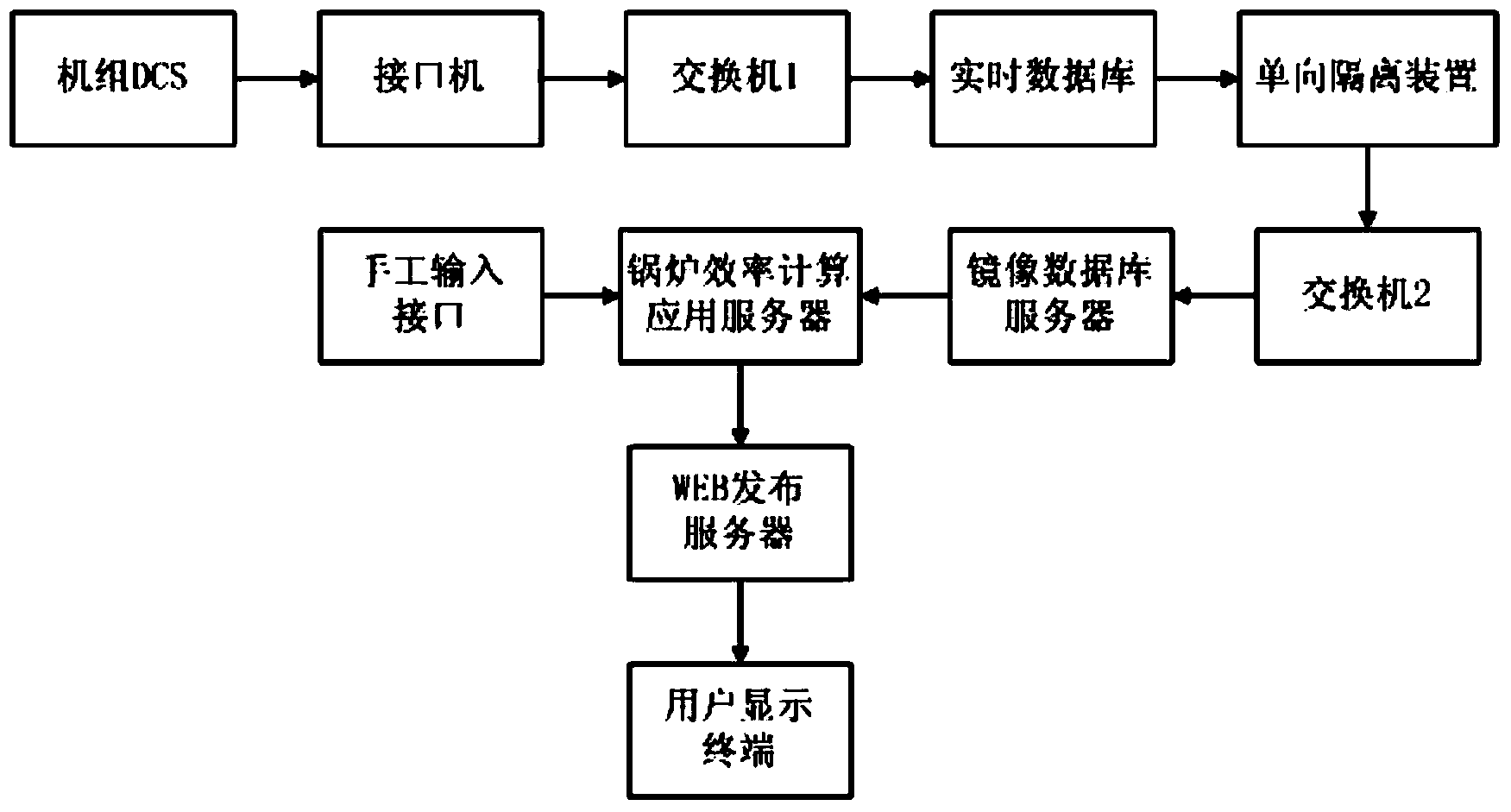

Real-time monitoring method for thermal efficiency and gas characteristics of gas boiler

ActiveCN103528846AAccurate thermal efficiencyAchieve economical operationFuel testingStructural/machines measurementOperabilityEngineering

The invention discloses a real-time monitoring method for the thermal efficiency and gas characteristics of a gas boiler. According to the method, basic gas characteristics are amended through real-time operating data of the boiler, so that real-time gas characteristics are obtained and applied to the calculation of the thermal efficiency of the gas boiler, and the real-time on-line monitoring of the thermal efficiency and the gas characteristics of the boiler is realized. The real-time monitoring method overcomes adverse effects caused by fluctuation of the gas characteristics on the calculation of the thermal efficiency of the boiler and is more accurate than a traditional method in which the thermal efficiency of the boiler is calculated by testing the gas characteristics regularly; an expensive on-line analyzer is not required to be additionally added on site, and the real-time monitoring method can be realized by fully utilizing existing conditions of a power plant and has good implementability and operability; and boiler operators can be guided by results in real time for optimization and adjustment, the economic operation of the boiler is facilitated, and the purpose of energy conservation and consumption reduction can be achieved.

Owner:HUATIAN ENG & TECH CORP MCC

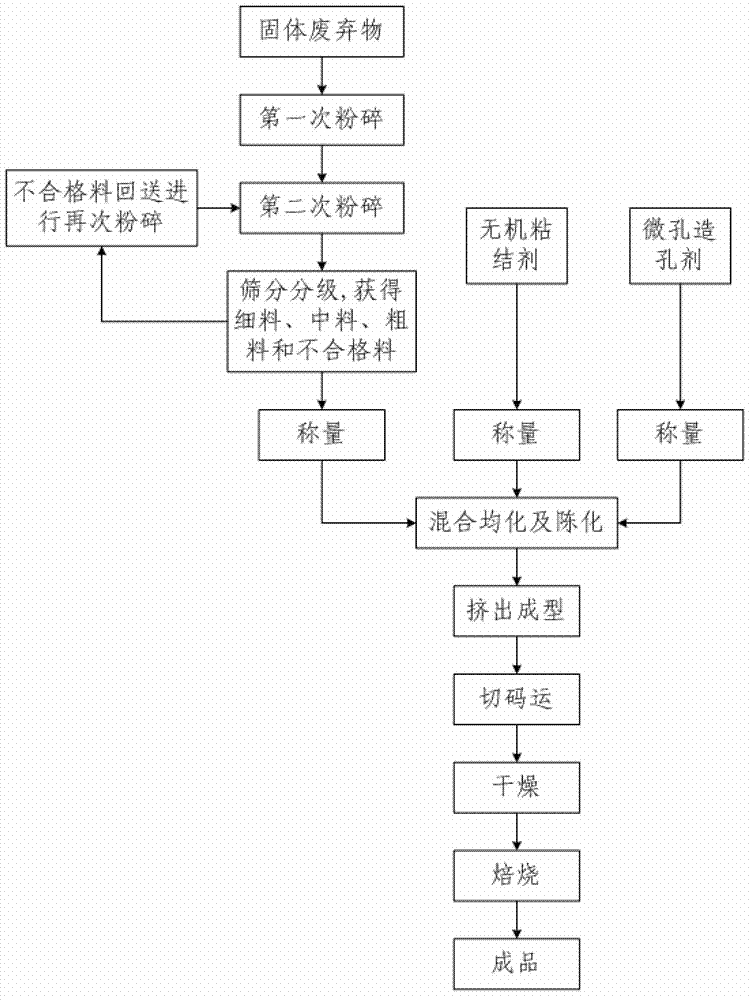

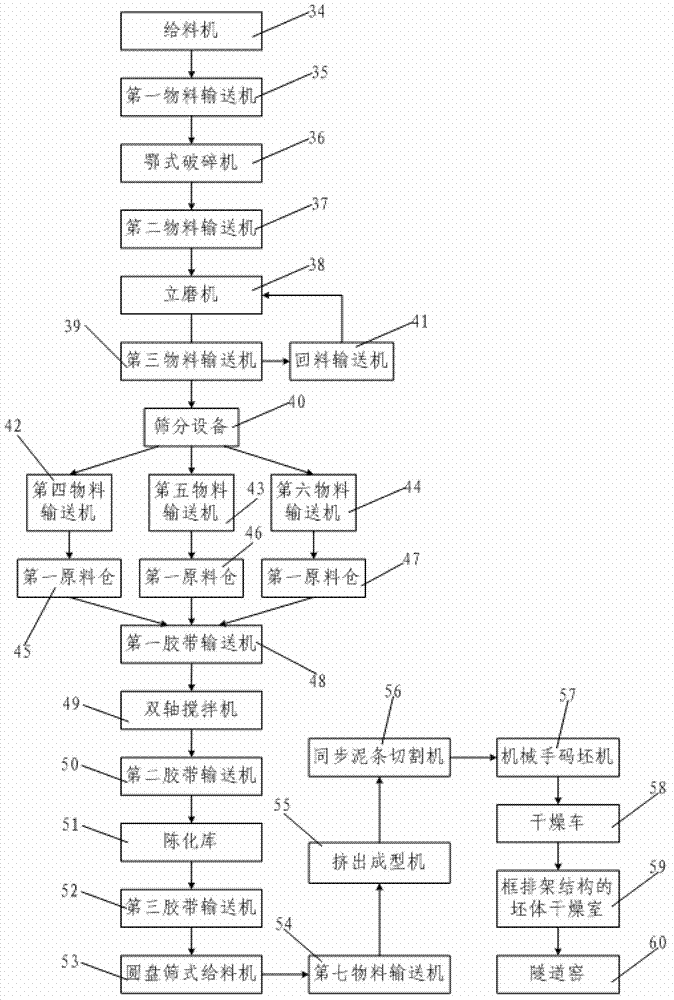

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

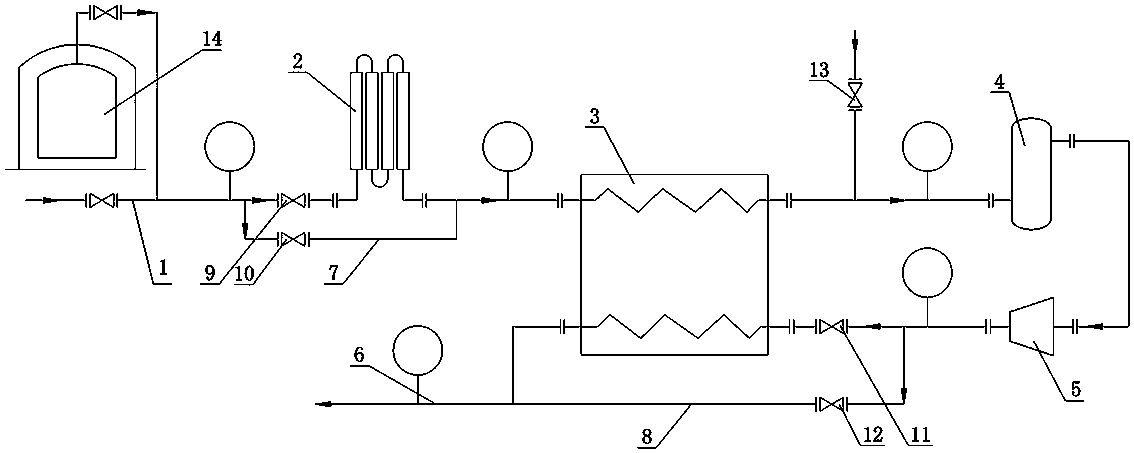

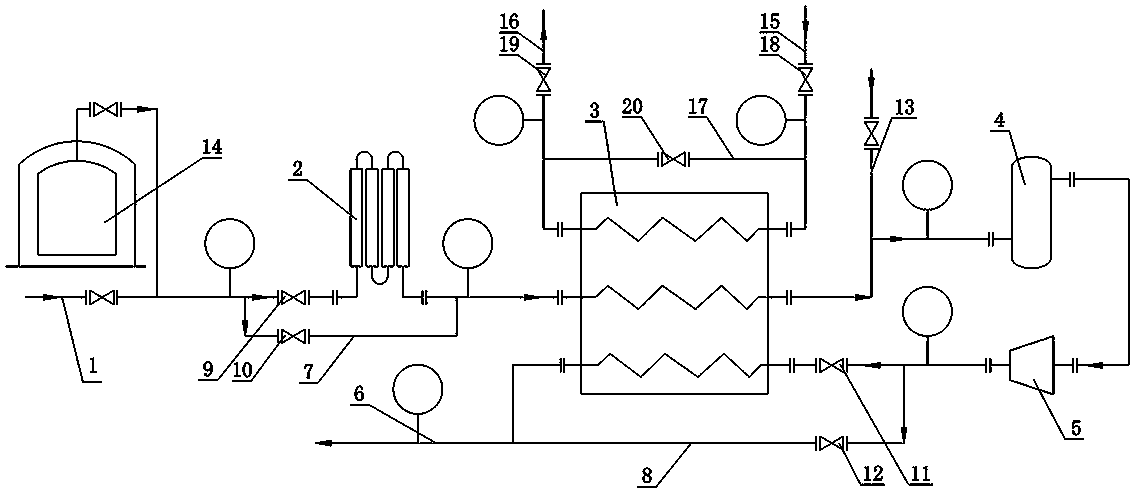

Low-temperature BOG (Boil off Gas) gas cold energy recovering device and process

ActiveCN103062620AHigh recovery rateLong runOther heat production devicesContainer discharging methodsBuffer tankMechanical engineering

The invention discloses a low-temperature BOG (Boil off Gas) gas cold energy recovering device. A low-temperature BOG gas inlet pipe (1) is sequentially connected with a heater (2), a heat exchanger (3) and a buffering tank (4) in one path, and is connected with a pipeline through a branched pipe A (7) in another path, wherein the pipeline connects the heater (2) with the heat exchanger (3); a buffering tank (4) is connected with a compressor (5); and the compressor (5) is sequentially connected with a booster BOG gas flowing channel and a booster BOG gas outlet pipe (6) of the heat exchanger (3) in one path, and is connected with the booster BOG gas outlet pipe (6) through a branched pipe B (8) in another path. The invention also discloses a cold energy recovering process. The cold energy recovering process has the beneficial effects that the gas obtained by cooling and compressing under the cold energy of the low-temperature BOG gas and the regeneration / cold blowing air before entering a heavy hydrocarbon separator are utilized, the cold and heat process mediums are fully utilized for exchanging heat, so that the energy is saved, and the consumption is reduced; and the pipeline is reasonable and simple in design; the applicable scope is wide; and the convenience is provided for conditioning.

Owner:四川蜀道装备科技股份有限公司

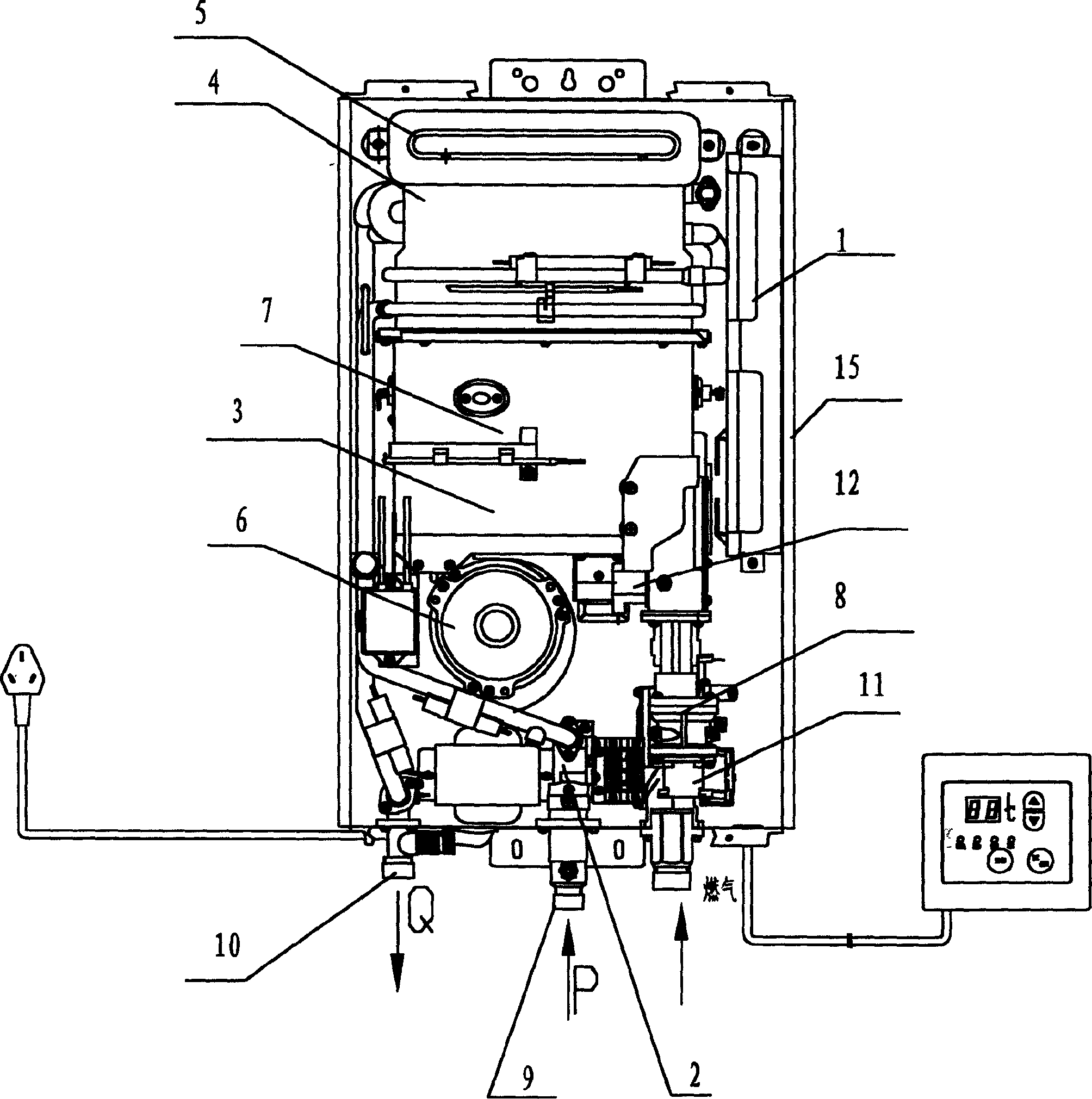

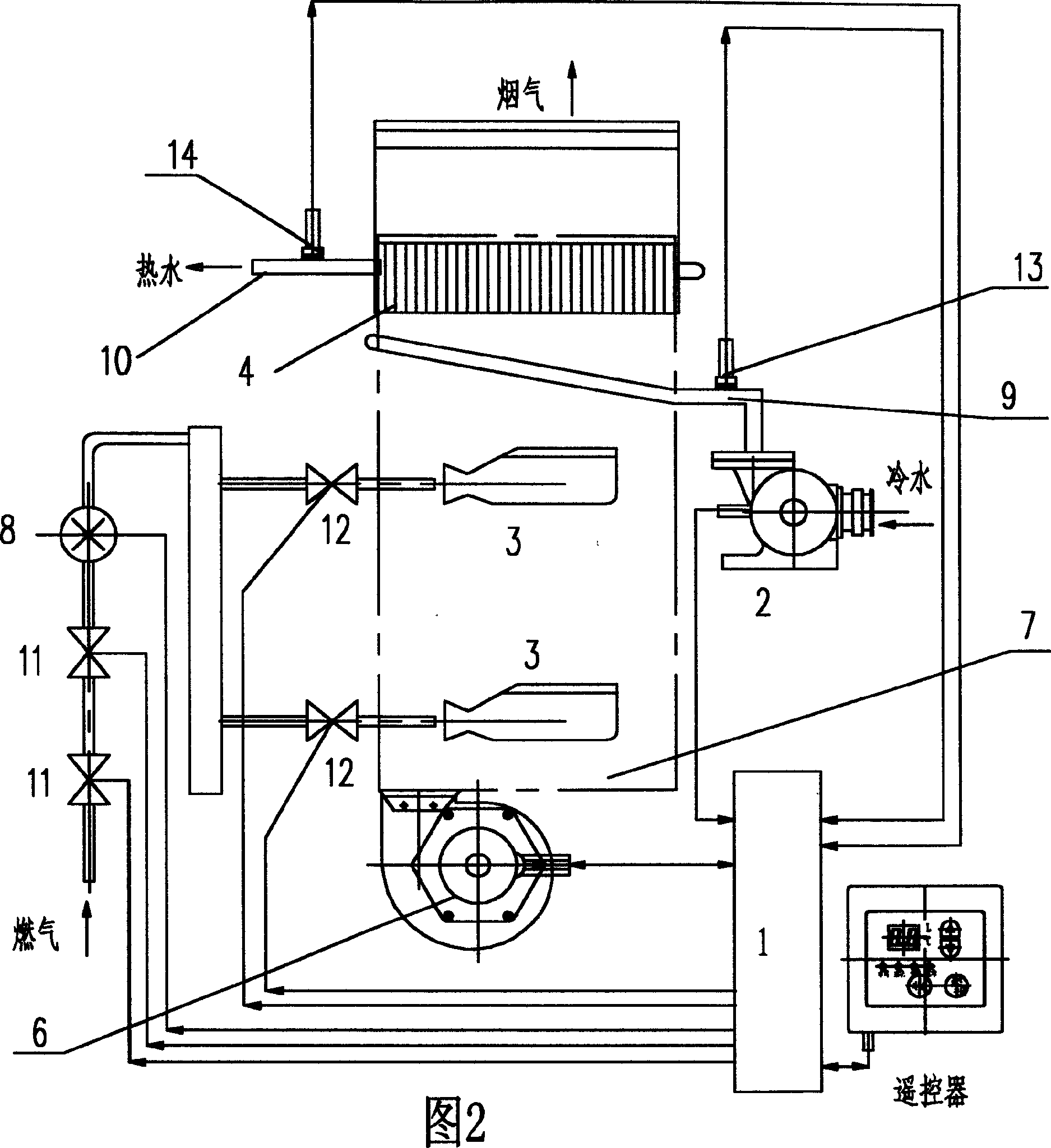

Domestic gas instantaneous water heater capable of realizing gas-air proportional control

ActiveCN1607363AIncrease the heat intensity of the fire holeReduce the size and overall size of the machineWater heatersCombustion chamberHeating efficiency

A gas-air proportion technology contains electric controller, water flow sensor, burner, heat-exchanger, smoke exhauster, combustion chamber, switch solenoid valve, casing, cold water temperature sensor in water inlet of water heater, hot water temperature sensor in water outlet of water heater, fan, proportional valve, plural sectional solenoid valves. The rotation speed of fan is automatically adjusted synchronously according to open size of proportional valve, which is proportional to heating power of burner. The heating power W= Q#-[1] x (T1-T2)K x K1 x eta, wherein the Q#-[1] is present water flow detected by water flow sensor, T1 is hot water temperature set by hot water temperature sensor, T2 is cold water temperature set by cold water temperature sensor, K is conversion coefficient, K1 is adjusting coefficient, eta is heat efficiency.

Owner:VATTI CORP LTD

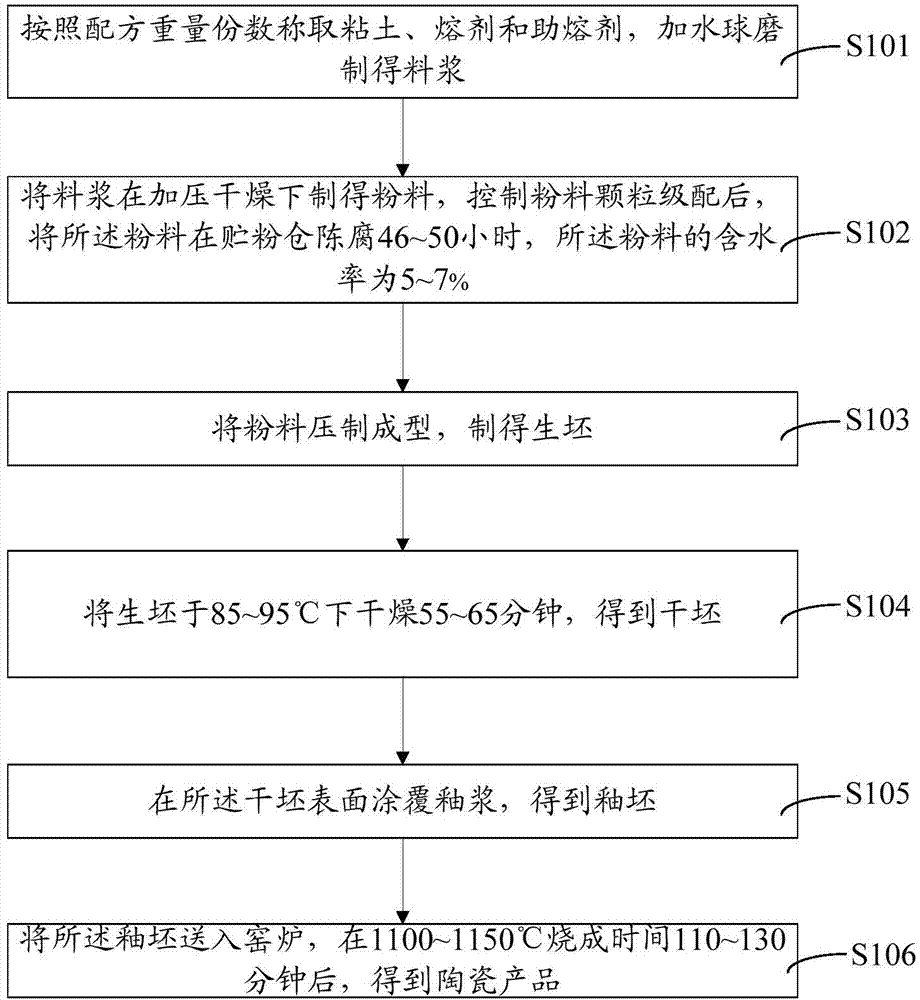

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

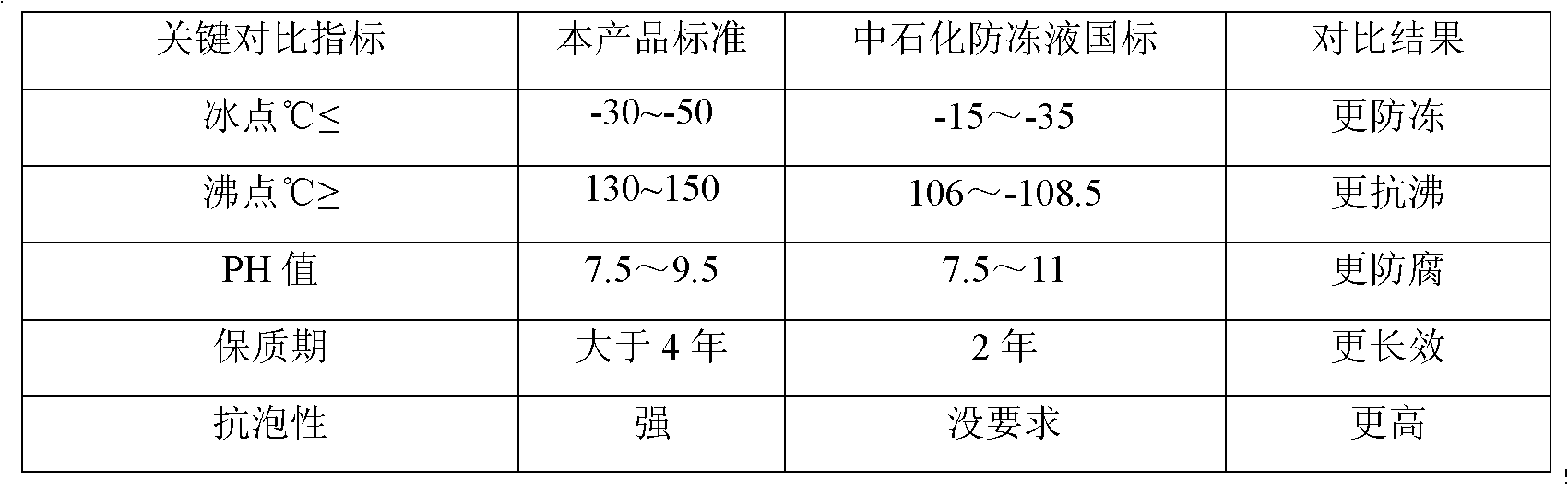

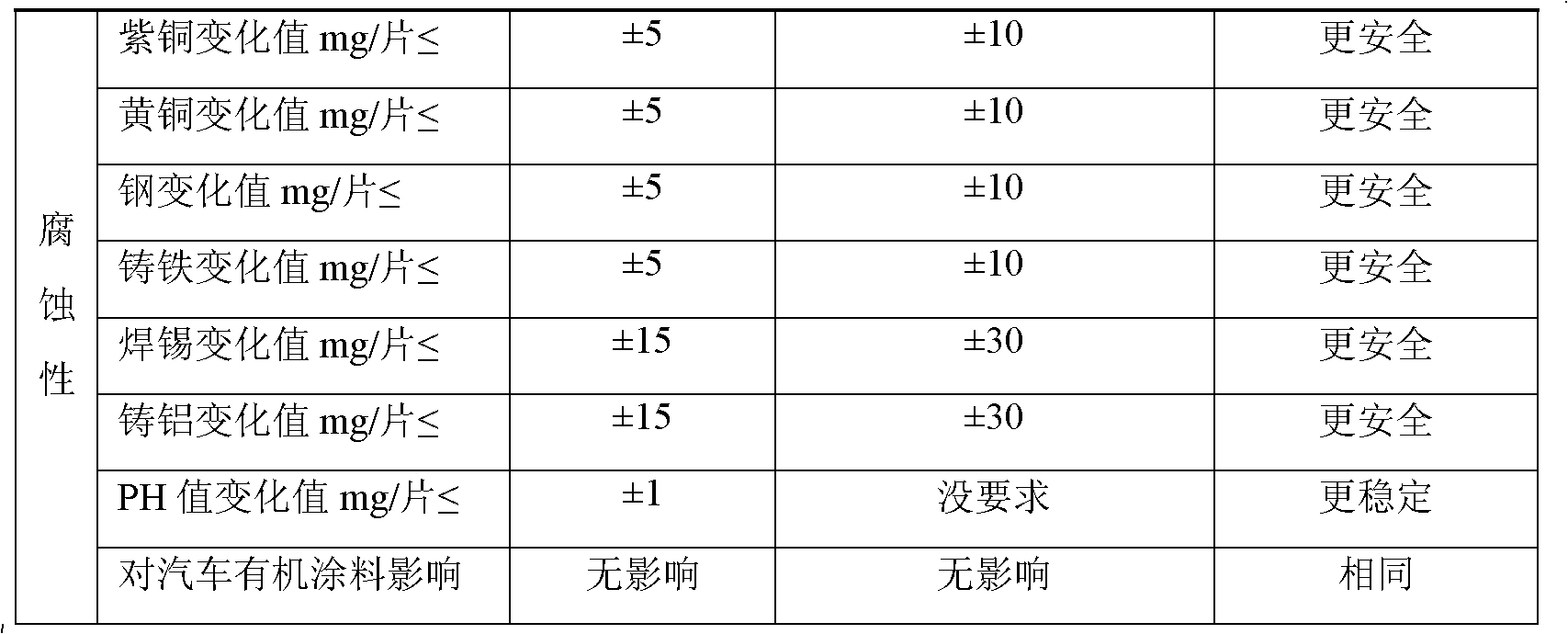

Non-aqueous coolant for engine

ActiveCN102002347AStable pHImprove antifreeze effectHeat-exchange elementsOctanoic AcidsPhosphoric acid

The invention relates to a non-aqueous coolant for an engine, which is characterized by comprising the following components in percent by weight: 10-80 percent of ethylene glycol, 10-80 percent of propylene glycol, 5-20 percent of polyol, 0.1-0.8 percent of phosphate-molybdate, 0.2-0.9 percent of silicate ester, 0.1-1 percent of 4-methyl 1H-benzotriazole, 0.2-0.8 percent of citric acid, 0.2-1 percent of sebacic acid, 0.1-1 percent of octanoic acid, 0.4-1.2 percent of citrate and 0.01-0.2 percent of cosolvent. The non-aqueous coolant has freezing point of -30--50 DEG C and boiling point of 130-150 DEG C, and ensures that the cold start of the engine is realized in cold weather; meanwhile, the working temperature of the engine is improved to 95-150 DEG C from the original 85-95 DEG C. The non-aqueous coolant belongs to a non-aqueous system, avoids electrochemical corrosion, and is a buffer system with pH of 7.5-9.5; and the added relevant auxiliaries have active corrosion resistance on aluminum and aluminum alloy and copper.

Owner:HEFEI UNIV OF TECH

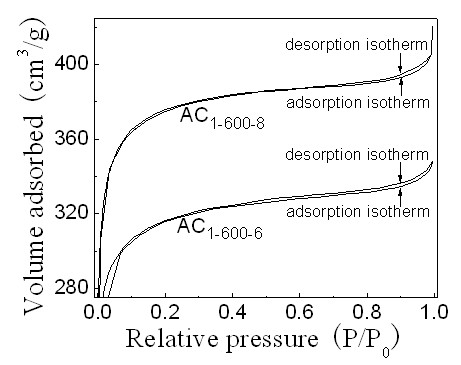

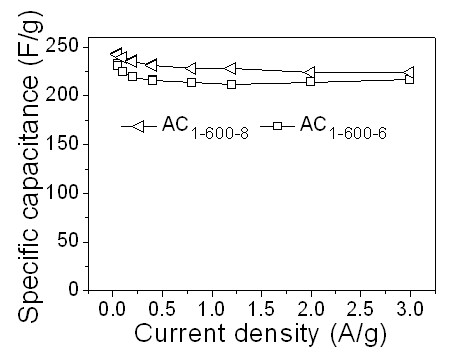

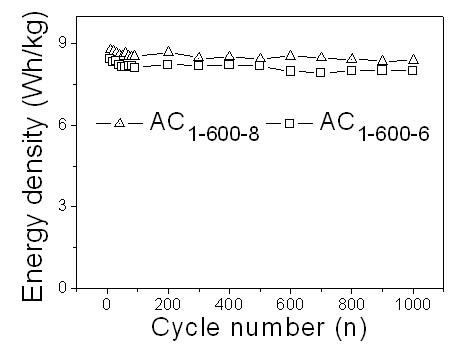

Preparation method of activated carbon material for electrochemical capacitor

The invention discloses a preparation method of an activated carbon material for an electrochemical capacitor and belongs to the technical field of carbon material and microwave chemistry. The preparation method comprises the following steps of: using peanut shells as a raw material, processing the peanut shells by using a KOH solution and a potassium hydroxide alkali solution, transferring the peanut shells processed by the potassium hydroxide alkali solution into a corundum crucible, placing the corundum crucible into a microwave reactor for microwave heating and activation to obtain the activated carbon material for an electrochemical capacitor. According to the method, with peanut shells as a carbon source and potassium hydroxide as an activator, the activated carbon material is prepared by microwave-assisted heating of the potassium hydroxide activated peanut shells. The activated carbon material prepared by the preparation method is characterized in that its specific surface area is 990-1277m<2> / g, total pore volume is 0.47-0.63cm<3> / g, and the yield is 14.2-24.4%. The activated carbon material, which is prepared as an electrode material for an electrochemical capacitor, hasgood stability and excellent comprehensive performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

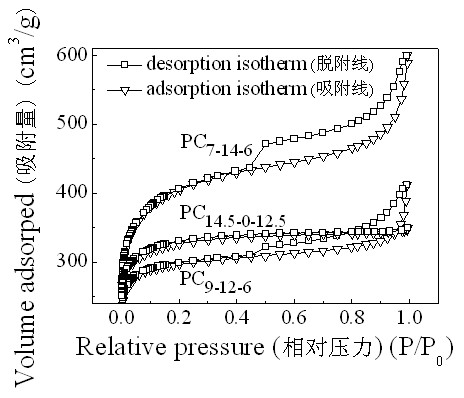

Method for preparing porous carbon material by using magnesium oxide template in cooperation with activation of potassium hydroxide

The invention discloses a method for preparing a porous carbon material by using a magnesium oxide template in cooperation with the activation of potassium hydroxide, and belongs to the technical field of carbon materials and microwave chemistry. The method comprises the following steps of: grinding coal tar pitch serving as a carbon source, nano magnesium oxide serving as a template and the potassium hydroxide serving as an activating agent; transferring the mixture to a corundum crucible; and putting into a microwave reactor, performing one-step microwave heating activation, and thus obtaining the porous carbon material for an electrochemical capacitor, wherein the specific surface area of the obtained porous carbon material is between 439 and 1,394m<2> / g, the total pore volume is between 0.23 and 0.94cm<3>, the average pore size is between 1.95 and 3.36mm, the ratio of the volume of a non-micro pore to the total pore volume is between 26.1 and 86.2 percent, and the porous carbon yield is between 37.8 and 84.9 percent. The invention has the advantages that: the method is quick and energy-saving; and the prepared porous carbon is used as an electrode material of the electrochemical capacitor and has extremely high stability and high comprehensive performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

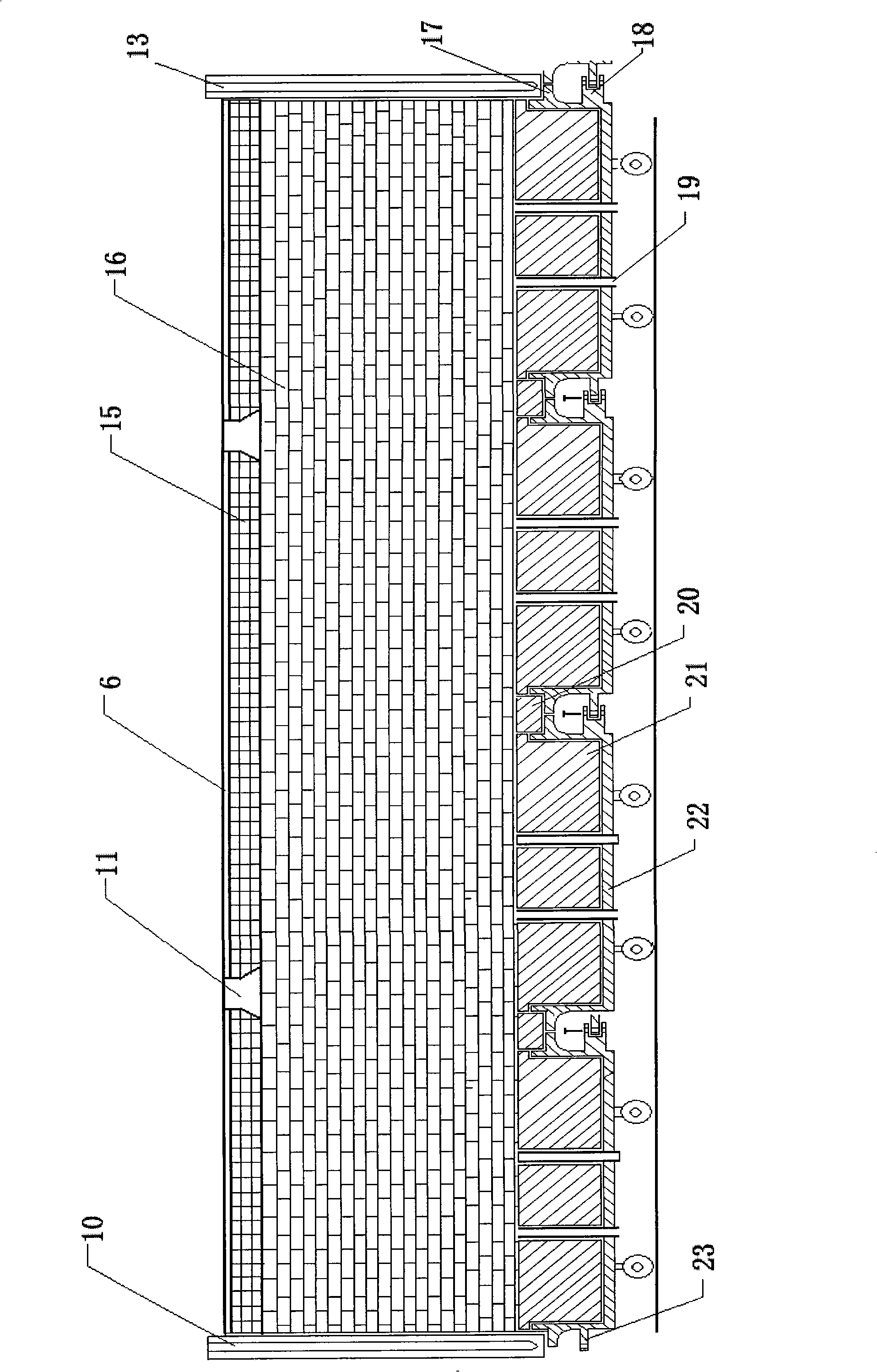

Three-section four-door long-tunnel energy-saving type microwave sintering furnace

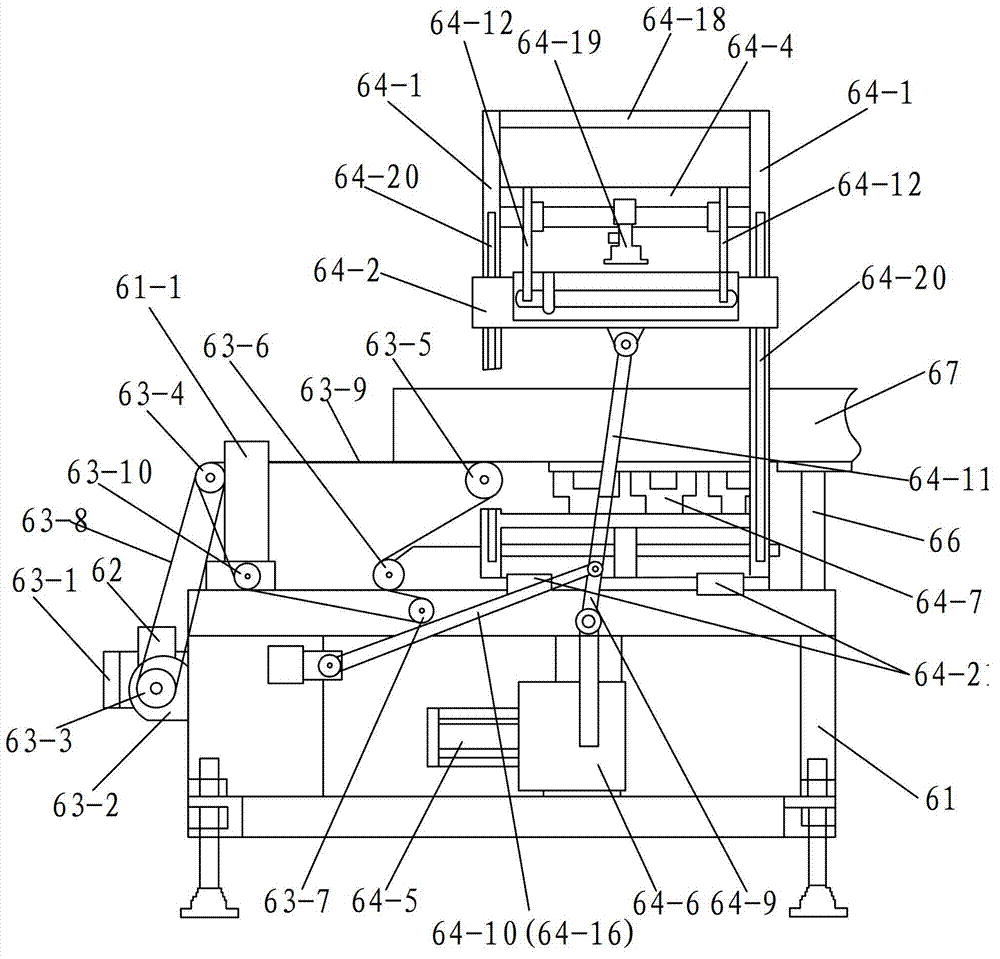

InactiveCN101922862AHeats up quickly and evenlyIncrease temperatureFurnace typesMicrowave heatingVehicle frameProduct gas

The invention relates to a microwave sintering furnace, in particular relating to a three-section four-door long-tunnel energy-saving type microwave sintering furnace, which comprises a microwave sintering tunnel furnace, tracks and a kiln car and is characterized in that the appearance of the furnace body is in a long box structure, a base is arranged under the furnace body, two tracks are paved, the side surfaces of the furnace wall are provided with equally spaced gate slots and square sliders, and four lifting type steel doors divide the furnace chamber into a cooling section, a sintering section and a preheating section; a hot gas pumping pipeline is arranged between the cooling section and the preheating section; the top part of the tunnel furnace body is provided with a waveguide port; the kiln car is in a box-combined structure and comprises track wheels, a carframe in a steel square frame type structure, an air inlet and a heat-resisting material layer, the front and rear ends of the kiln car are respectively provided with an auricled door bracket, a connecting piece and a groove, and a kiln car group is formed by connecting 1 to 5 kiln cars; and the microwave sintering furnace also comprises three groups of servo motors controlled synchronously and driven systems. Compared with the traditional kiln furnace, the microwave sintering furnace has high heating speed, saves power by 40-50%, shortens time by 1.5h, achieves the aims of saving energy and reducing consumption and improves economic benefit.

Owner:FUJIAN WANQI SANDT CERAMICS CO LTD

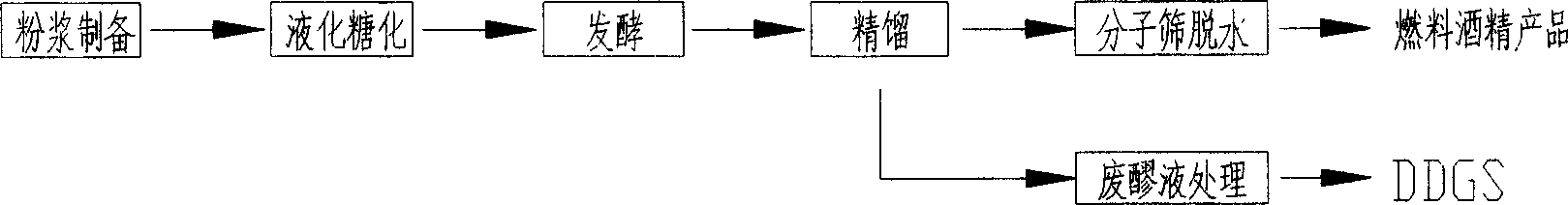

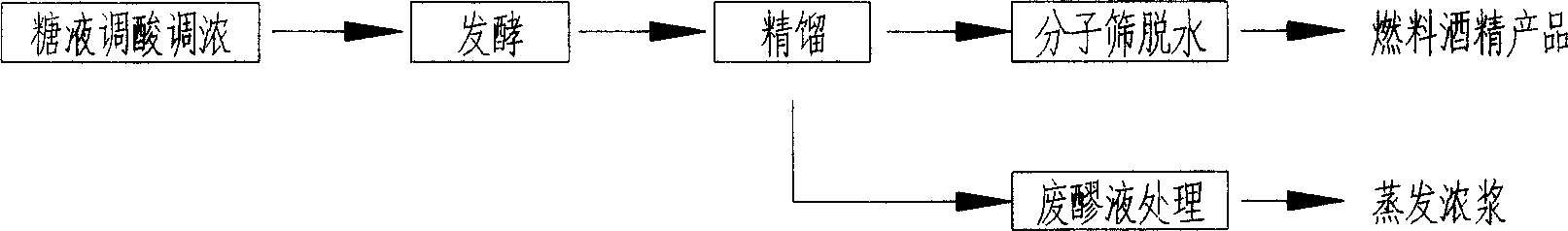

Production of alcohol fuel

InactiveCN1644703AGuaranteed dehydration effectDoes not consume external heatBiofuelsLiquid carbonaceous fuelsAlcohol fuelDistillation

Alcohol fuel can be produced by: treating raw materials, fermenting, refining, molecular sieve adsorption dewatering, and waste liquid treating. A thermal coupling is used to connect dewatering and condense distilling procedures, i.e., gas alcohol from refining process is fed to molecular adsorption dewatering process after thermal coupling condensation and distillation. Heat energy released from cold condensation is used as heat energy for distillation. None of energy is needed any more. The raw materials may be corn, rice, wheat, Chenese sorghum, dry sweet potato, cassawa, sugarcane juice, sugarbeet juice, or green cyrup, etc.

Owner:TIANJIN UNIV

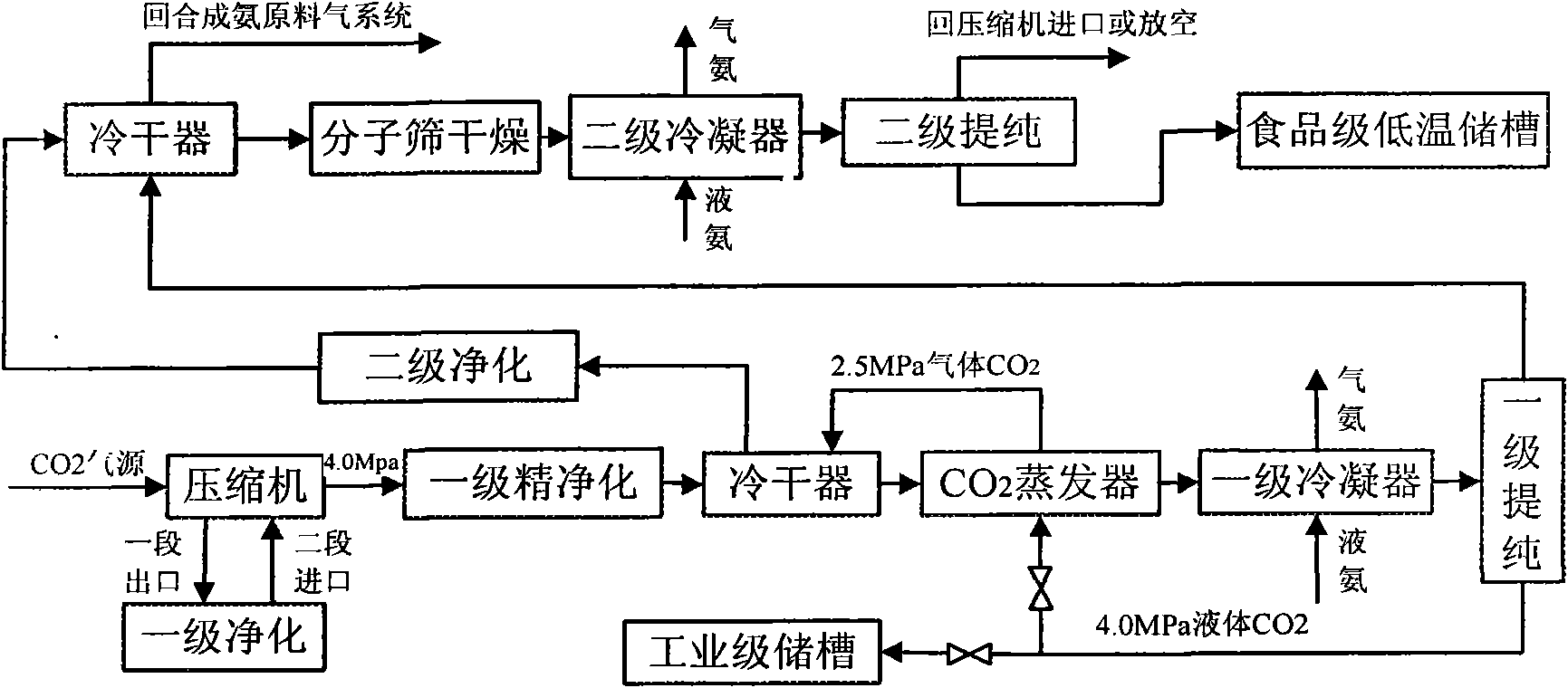

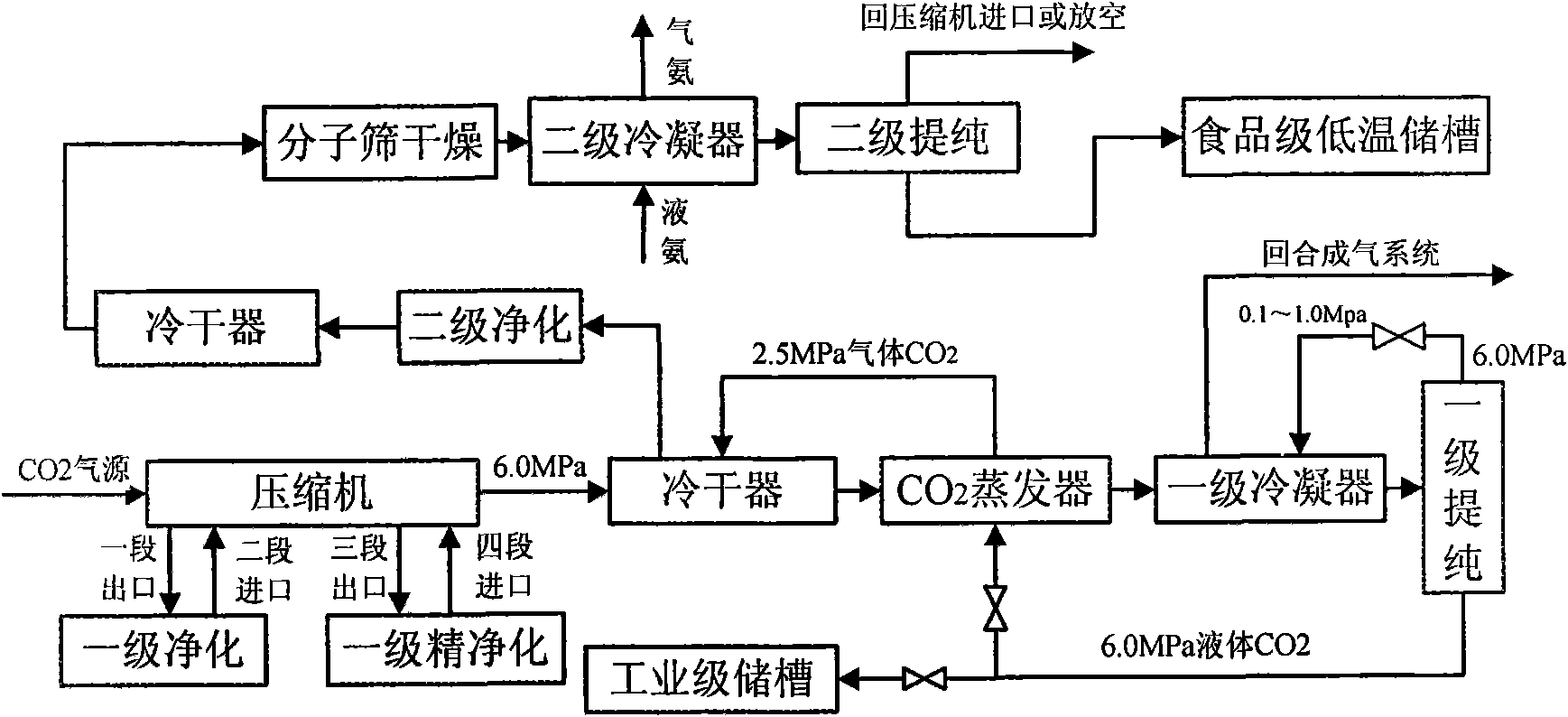

Method for coproducing or singly producing food grade carbon dioxide and industrial grade carbon dioxide by utilizing industrial waste gas

ActiveCN101538040AHigh recovery rateReduce ventingCarbon compoundsChemical industryEnergy consumptionToxic industrial waste

Owner:重庆川茂化工科技有限公司

Zirconium oxide plasticizing mullite ceramic material and preparation method thereof

The invention relates a zirconia-toughened mullite ceramic material and manufacturing method thereof, which is manufactured through modern toughening and strengthening technologies with zirconium silicate and Alpha-aluminum oxide as a substrate, yttrium oxide, magnesium oxide, calcium oxide and titanium oxide as a mineralizer, and mullite as a seed crystal. The material is toughened and strengthened through the modifying treatment and the green compact has good uniformity and compactness with the aid of an isostatic pressing. The sintering process is completed within one time in the shuttle kiln under normal pressure and high temperature conditions, having a uniform temperature and low cost. Compared with an aluminum oxide ceramic material, the invention has advantages of high strength, high tenacity, high wear resistance and simple process; the dramatic reduction of sintering temperature can achieve the purpose of energy efficiency.

Owner:湖南泰鑫瓷业有限公司

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

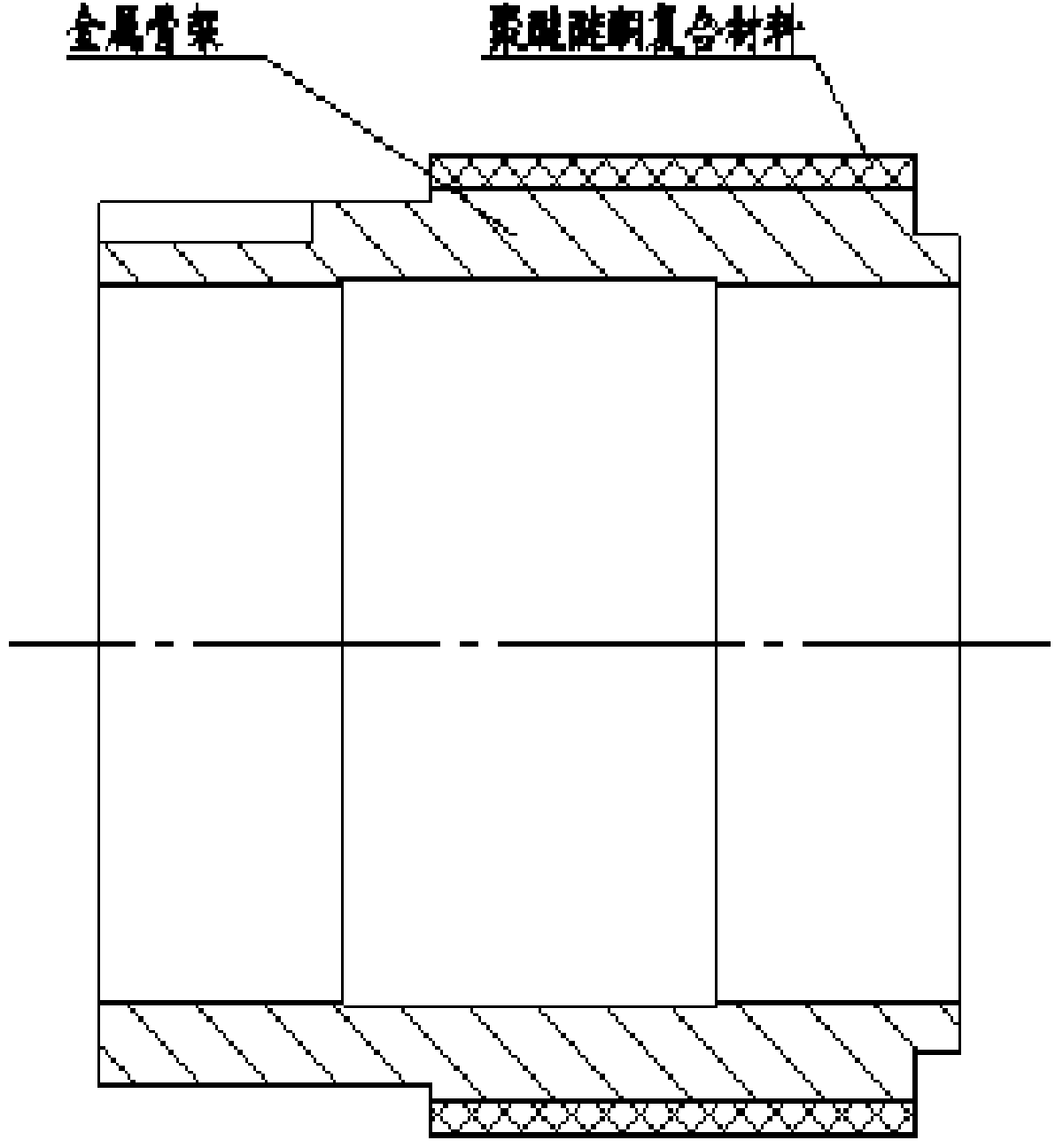

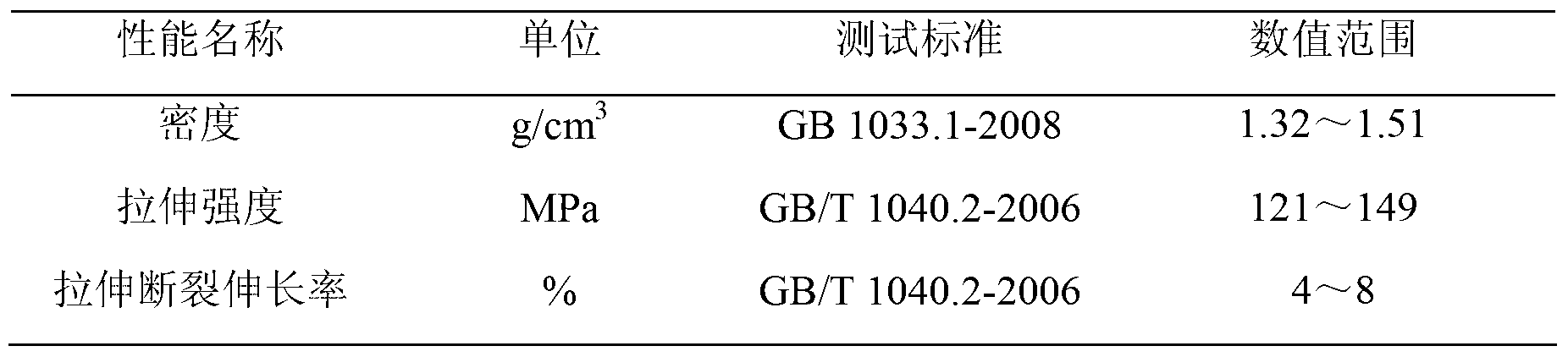

Wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material

The invention discloses a wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material. The poly (ether-ether-ketone) composite material comprises the following raw materials in parts by weight: 71-83 parts by weight of poly (ether-ether-ketone) resin, 5-10 parts by weight of suspension polytetrafluoroethylene resin, 7-12 parts by weight of carbon fiber powder and 5-7 parts by weight of aluminum oxide powder, as well as a silane coupling agent with the adding quantity of 0.8-1.5% of the weight of the aluminum oxide powder. The poly (ether-ether-ketone) composite material disclosed by the invention has the performance characteristics of wear resistance, high strength, self-lubrication, light weight, corrosion resistance and the like, is used for replacing a hard alloy and a metal framework to assemble a novel sliding bearing, effectively reduces the cost and weight of a bearing product (the weight is reduced by 30%) under the situation of meeting the requirements for service life, and can obviously reduce the power consumption and noise of a pump and achieve the purposes of saving energy and reducing consumption.

Owner:HEFEI GENERAL MACHINERY RES INST

Antibacterial spandex fiber and preparation method thereof

InactiveCN104726961AWith antibacterial functionEasy to useWet spinning methodsConjugated synthetic polymer artificial filamentsAntioxidantAntibacterial agent

The invention discloses an antibacterial spandex fiber and a preparation method thereof. The antibacterial spandex fiber is prepared by combining a wrapper and a core part, wherein the section of the fiber is solid; the material of the core material is a polyurethane slice for melt spinning; the wrapper comprises the following raw materials in percentage by mass: 0.1-0.2% of a silver ion compound, 0.1-0.5% of an ultraviolet screening agent, 0.1-0.55 of an antioxidant,0.2-1.0% of a lubricant, 0.1-0.5% of a matting agent and 97.3-99.4% of fiber forming aggregate. The preparation method of the antibacterial spandex fiber comprises the following steps: 1 manufacturing an antibacterial spandex core part by a melt spinning technique according to the formula ratio; 2 manufacturing an antibacterial spandex wrapper by a wet-dry spinning technology according to the ratio; and 3 spinning by wet-dry spinning equipment and process through a special spinneret assembly, and thus preparing the antibacterial spandex fiber by a special coagulating bath. The preparation method of the antibacterial spandex fiber is simple in process; the antibacterial agent is low in amount, economical and practical; and the prepared antibacterial spandex fiber is stable and uniform in performance, broad-spectrum antibacterial and lasting in antibacterial effect.

Owner:ZHEJIANG HUAFENG SPANDEX

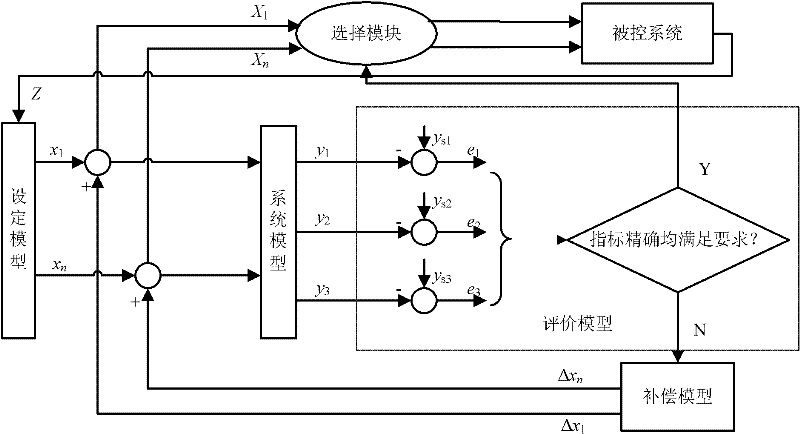

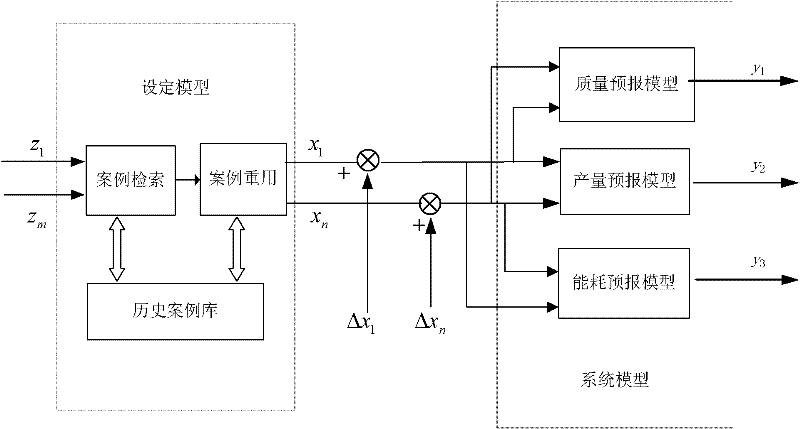

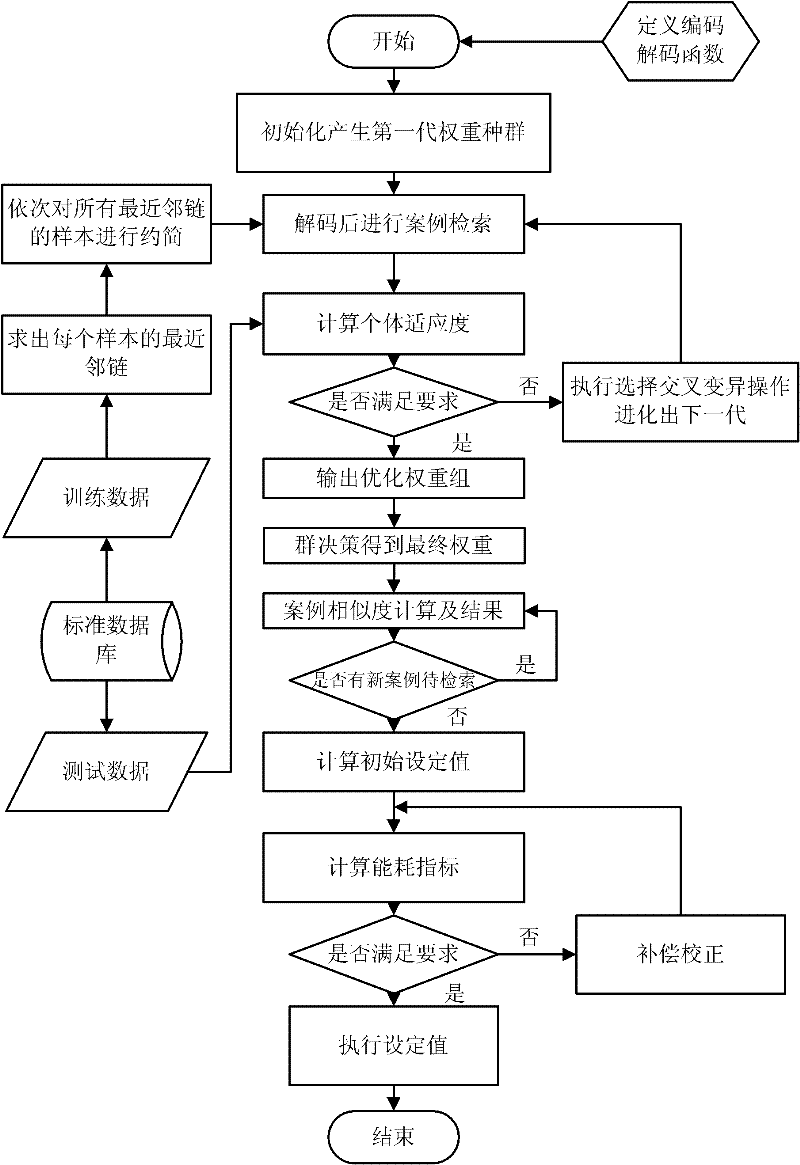

Multi-target evaluation optimization method based on group decision making retrieval strategy

InactiveCN102540879ARealize rationality evaluationQuality improvementAdaptive controlImage retrievalPhase retrieval

The invention discloses a multi-target evaluation optimization method based on a group decision making retrieval strategy and a multi-target evaluation structure for the optimization calculation of set values. The method comprises the following steps of: defining an encoding function; randomly assigning weights for initialization; performing case retrieval after decoding; calculating individual adaptability; judging whether the accuracy meets requirements or not (outputting optimized weights if the accuracy meets the requirements, otherwise, performing the case retrieval again); obtaining final weights by adopting group decision making; calculating case similarity to obtain new retrieval results; judging whether new cases to be retrieved exist or not; calculating product quality, product yield and an energy consumption index within a unit time; evaluating the set values; judging whether to perform compensation and correction on the set values or not; and outputting final set values. The method and the structure are applied to control over the roasting process of a shaft furnace in the metallurgical industry; the rationality of the set values can be evaluated; the quality of roasted ore is improved by 2 percent, the yield of the roasted ore is improved by 4 percent, and energy consumption is reduced by 5 percent; and optimal target values of production indexes are realized, the quality of the roasted ore is improved, gas consumption in a production process is reduced, and the aims of energy saving and consumption reduction are fulfilled.

Owner:BEIJING UNIV OF TECH

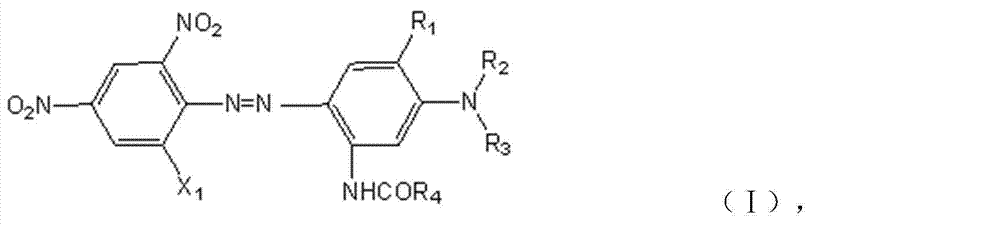

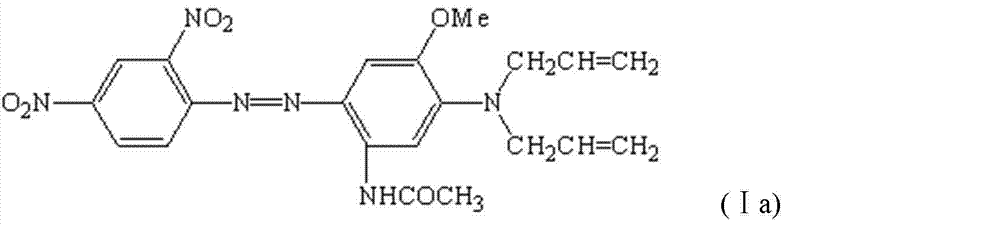

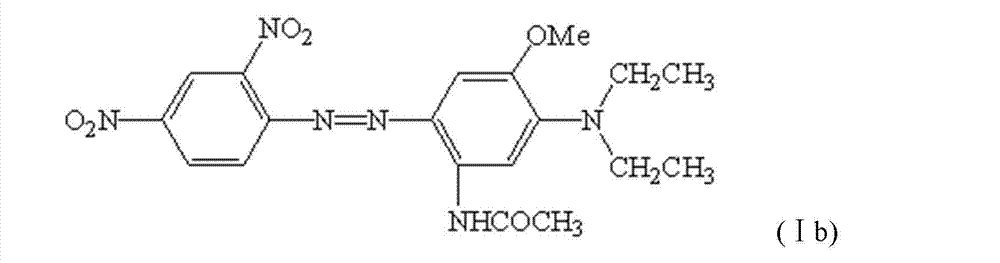

Dispersed dye mixture and application thereof

ActiveCN103113758AIncrease coverageGood compatibilityOrganic dyesDyeing processDisperse dyePhotochemistry

The invention relates to the technical field of dispersed dyes. In order to solve the problem that the dyes having a 2,4-dinitraniline structure are all poor in light fastness, the invention provides a dispersed dye mixture which is prepared by the step of mixing component A and component B, wherein the weight percentage of the component A is 10-92%. The 2,4-dinitraniline is used for synthesizing the dye so that the big problem which is always evaded in the industry is solved in a compounding and synergic way; as a result, a dye composition which is good in deep dyeing effect and excellent in light fastness can be obtained while the cost of the color matching dyes is greatly reduced.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

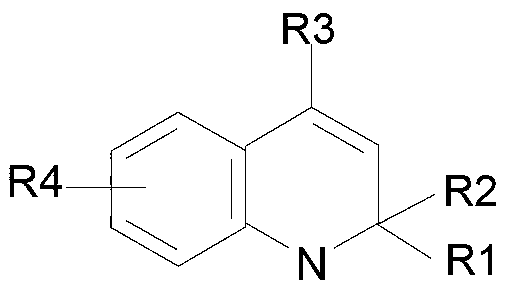

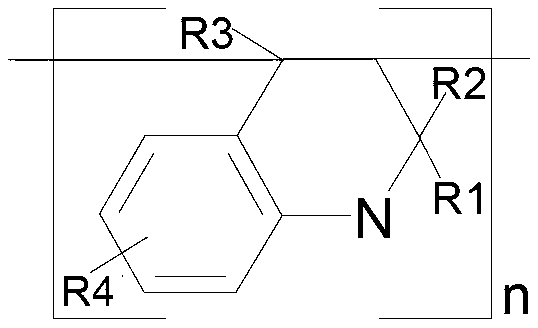

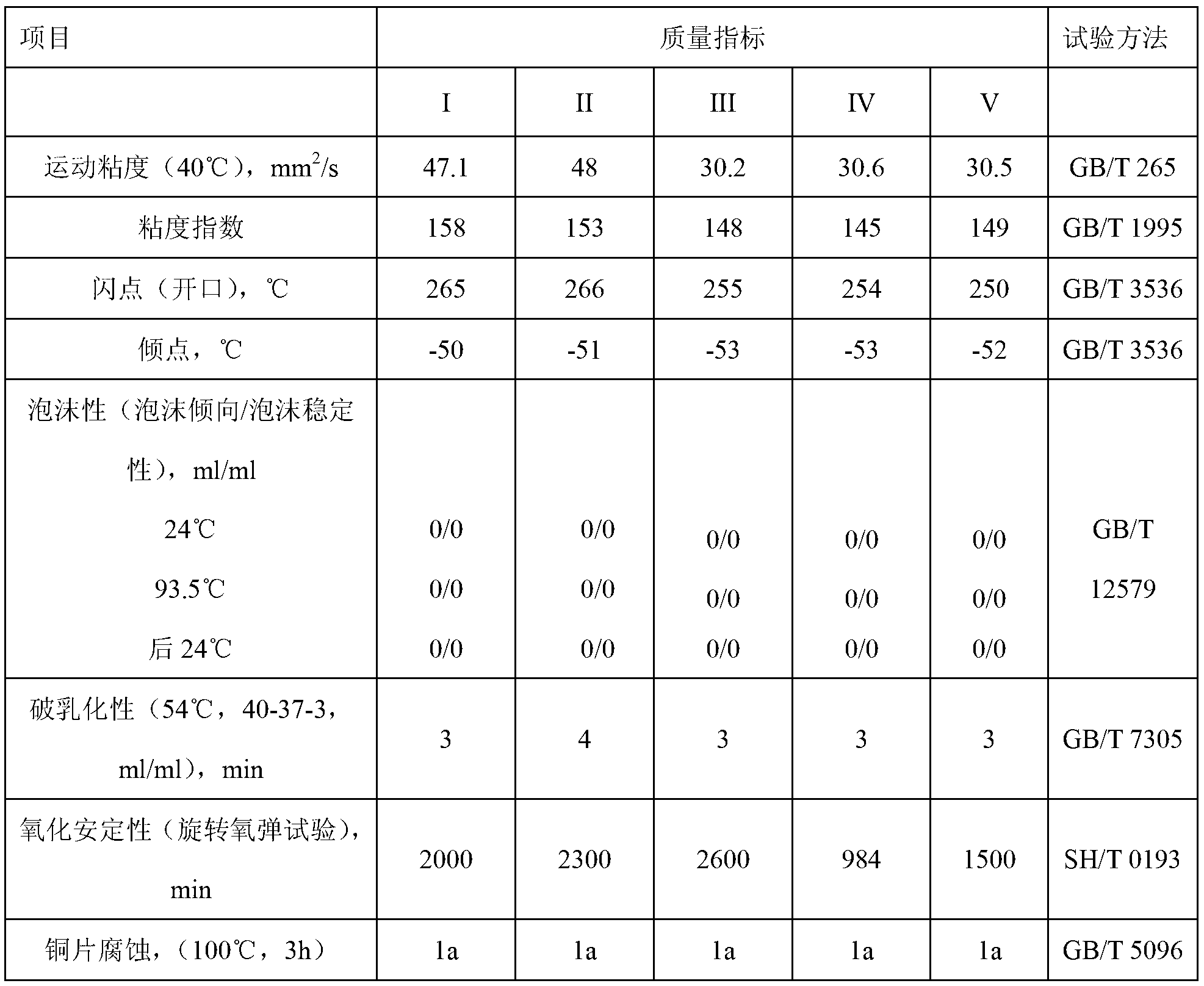

Air compressor oil composition and preparation method thereof

ActiveCN103194303AExtended service lifeImprove performanceHeat-exchange elementsLubricant compositionAntioxidantOxidation stability

The invention provides an air compressor oil composition and a preparation method thereof. The air compressor oil composition comprises polyether oil base oil or polyether oil and ester oil mixture base oil, a 2,2,4-trialkyl-1,2-dihydroquinoline antioxidant and a metal deactivator. Compared with the known air compressor oil composition, the air compressor oil composition has excellent oxidation stability, excellent comprehensive performance and a simple preparation method, and is particularly suitable for a screw air compressor.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

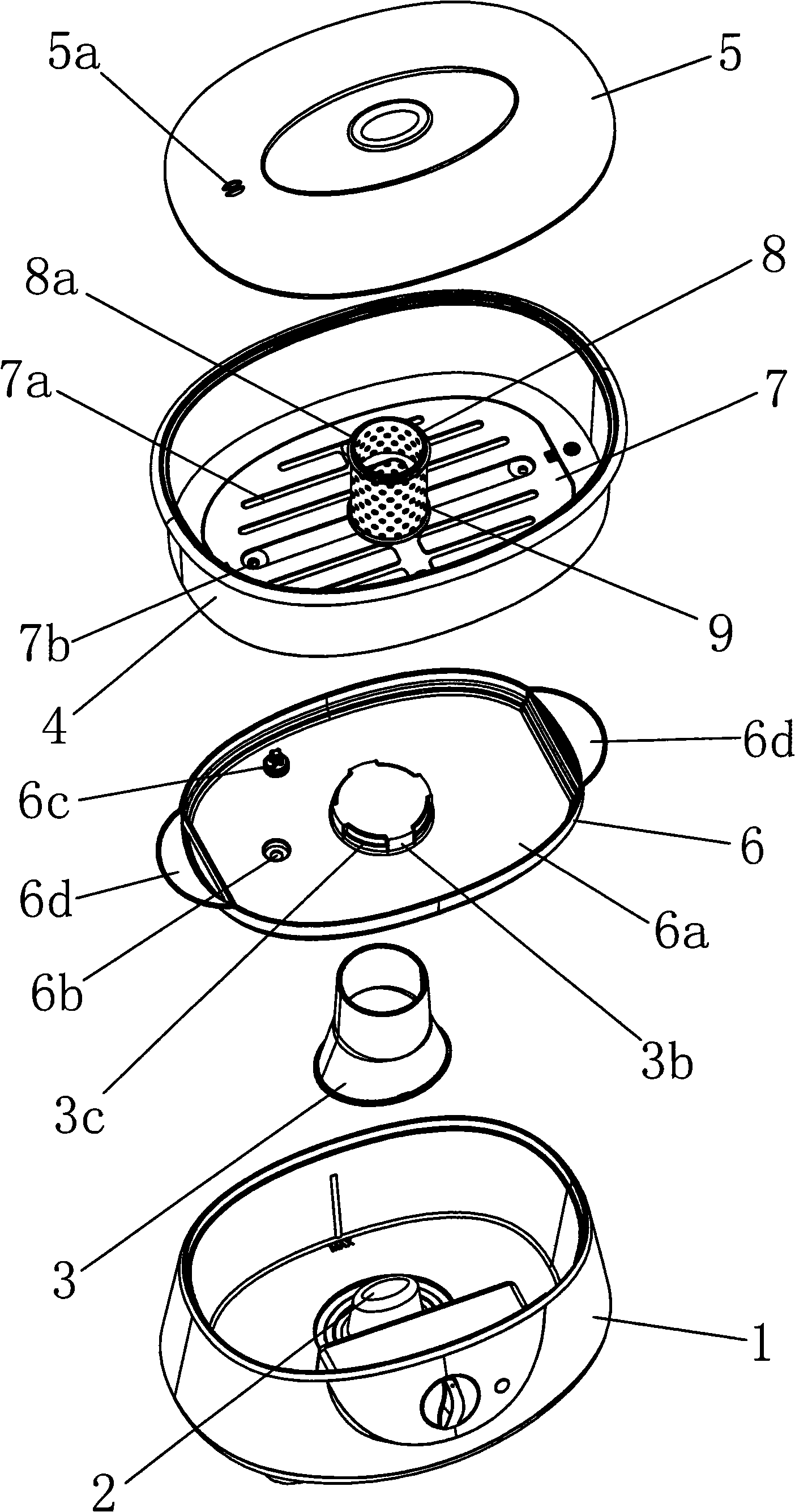

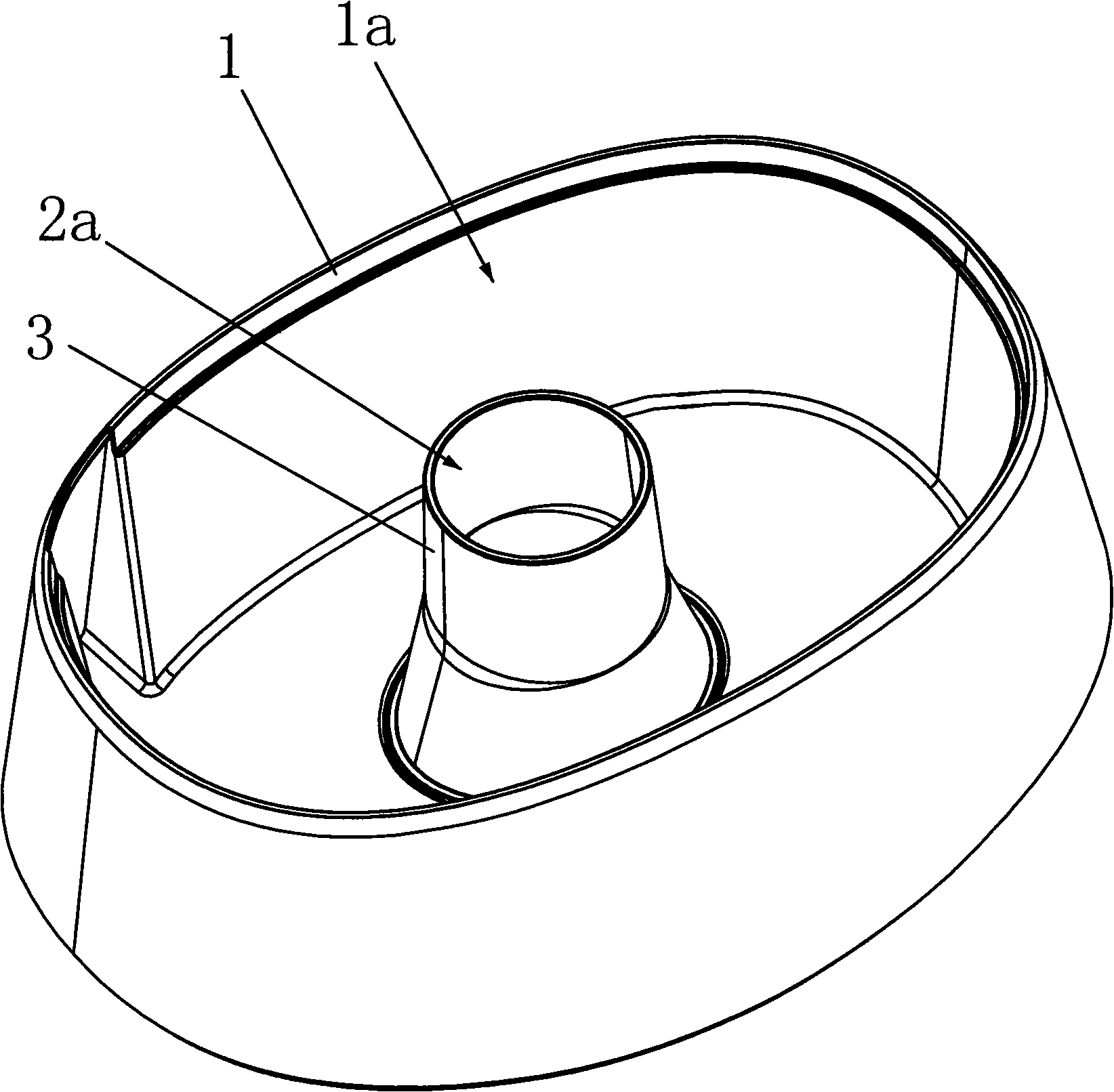

Energy-saving consumption-reducing electric steamer

InactiveCN101357039AOccurs continuouslyImprove heating efficiencySteam cooking vesselsWater savingThermal energy

The invention relates to the field of electric steam cooker, in particular to an electric steam cooker which can save the energy and reduce the dissipation. The electric steam cooker comprises a water storing vessel, a steaming layer and a top cover; the electric steam cooker is internally provided with a steam quick generation device, a non-mixed flour device, and a usable water circulation device; the water storing vessel, a separation cover and a heating body which is enclosed inside the separation cover form the steam quick generation device; the steam quick generation device can continuously and quickly generate the steam, has high heating efficiency, high utilization ratio of the heat energy and low energy dissipation; the separation layer and a steam guiding column form the non-mixed flour device; when various foods are steamed and cooked in a disposable way, mixed flour phenomena is not generated inside all steaming layers, thus enlarging the application range of the electric steam cooker; the top cover, the steaming layer, a water collecting layer and the water storing vessel form the usable water circulation device; the usable water circulation device recycles and reuses the condensed water, thus achieving the objects of saving the water and the energy and reducing the energy dissipation.

Owner:GUANGDONG LUBY ELECTRONICS

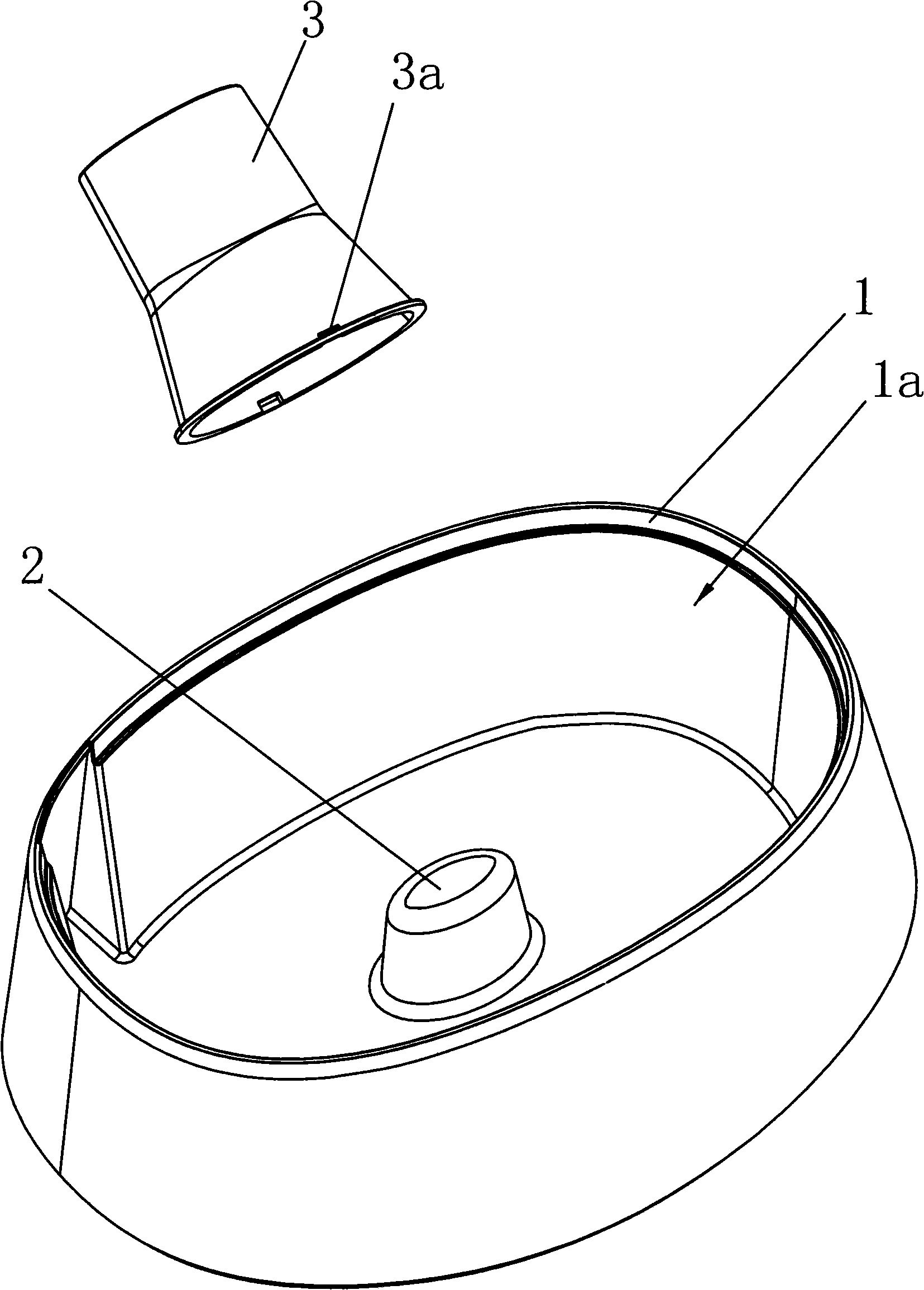

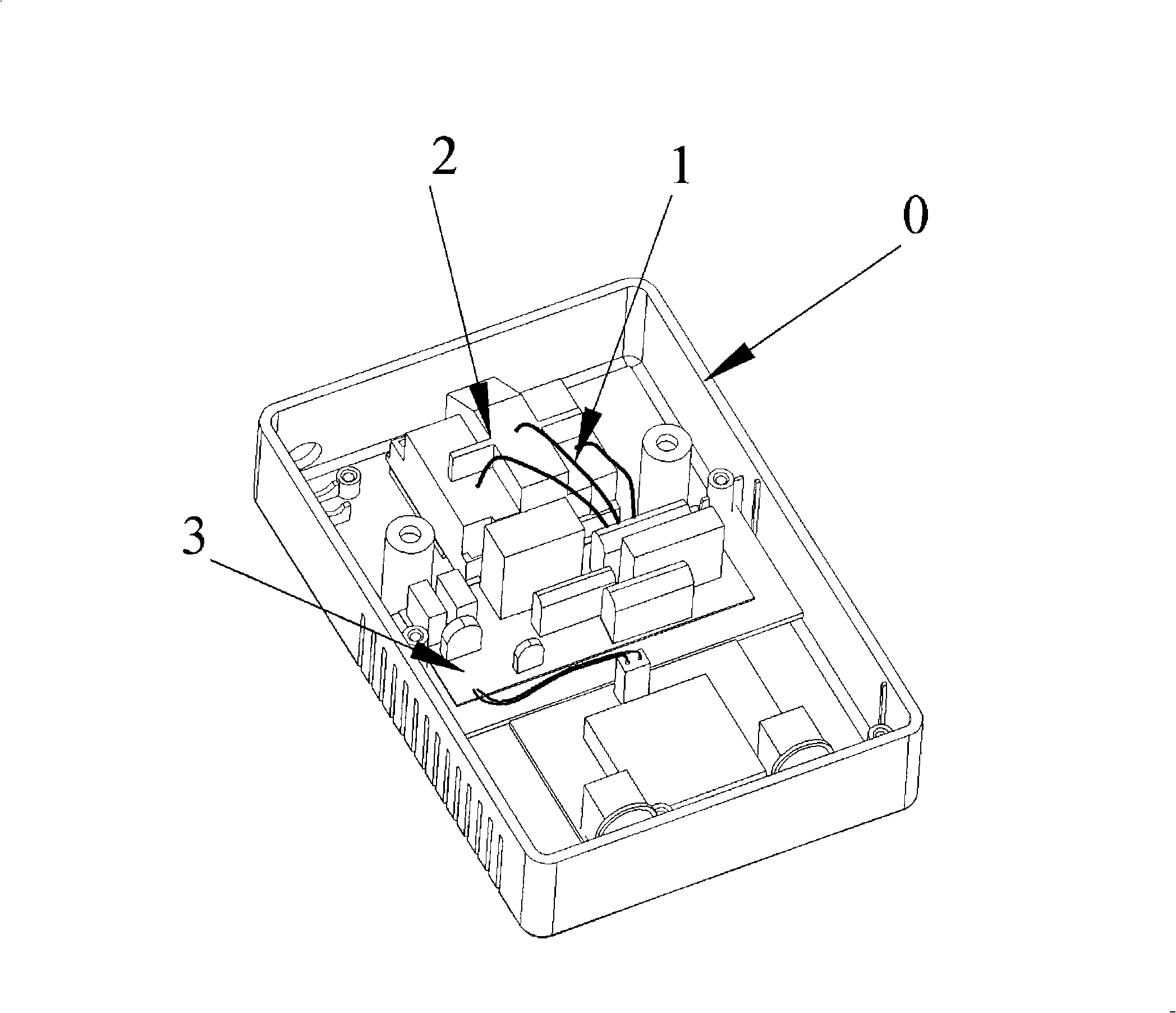

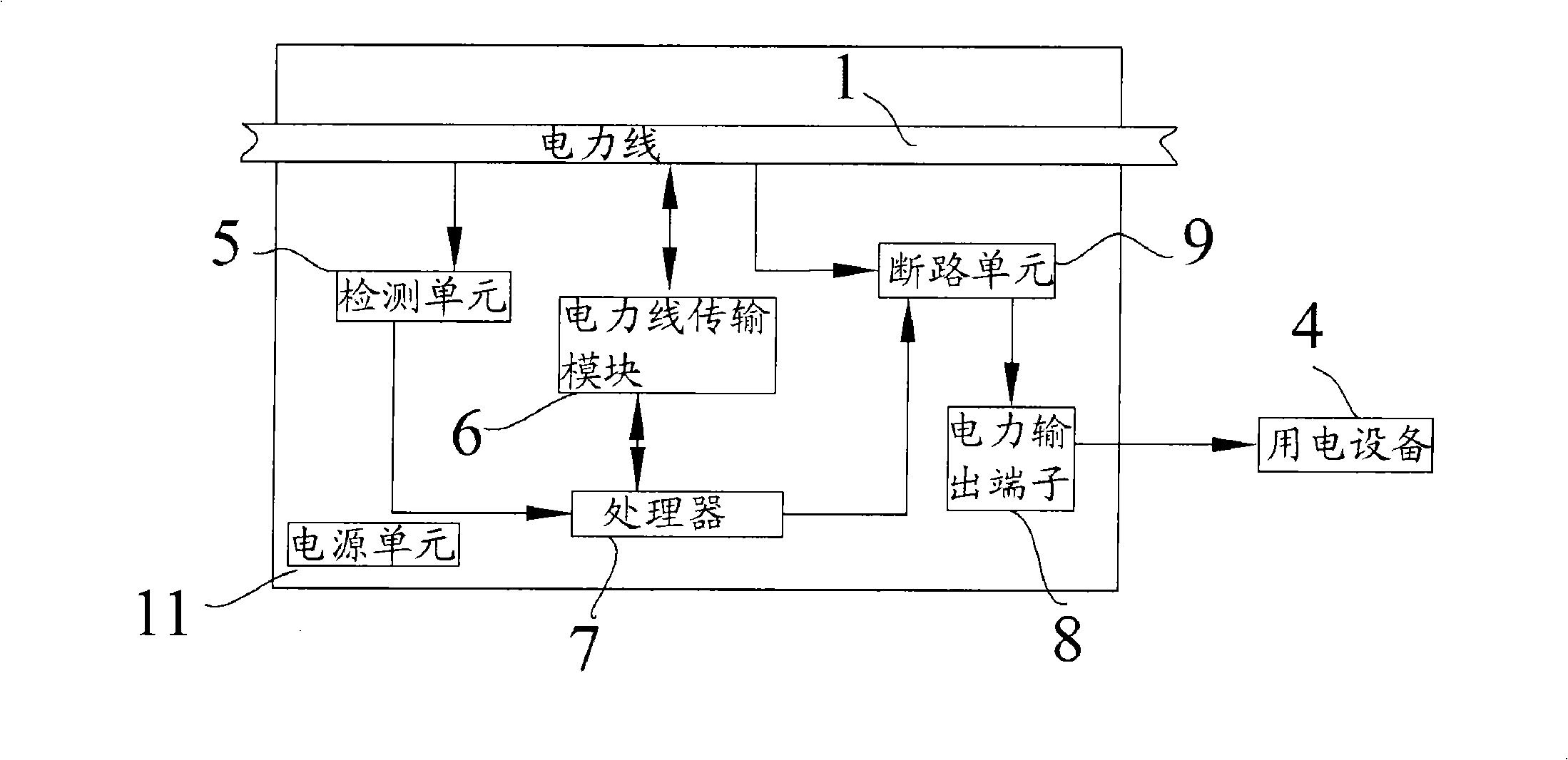

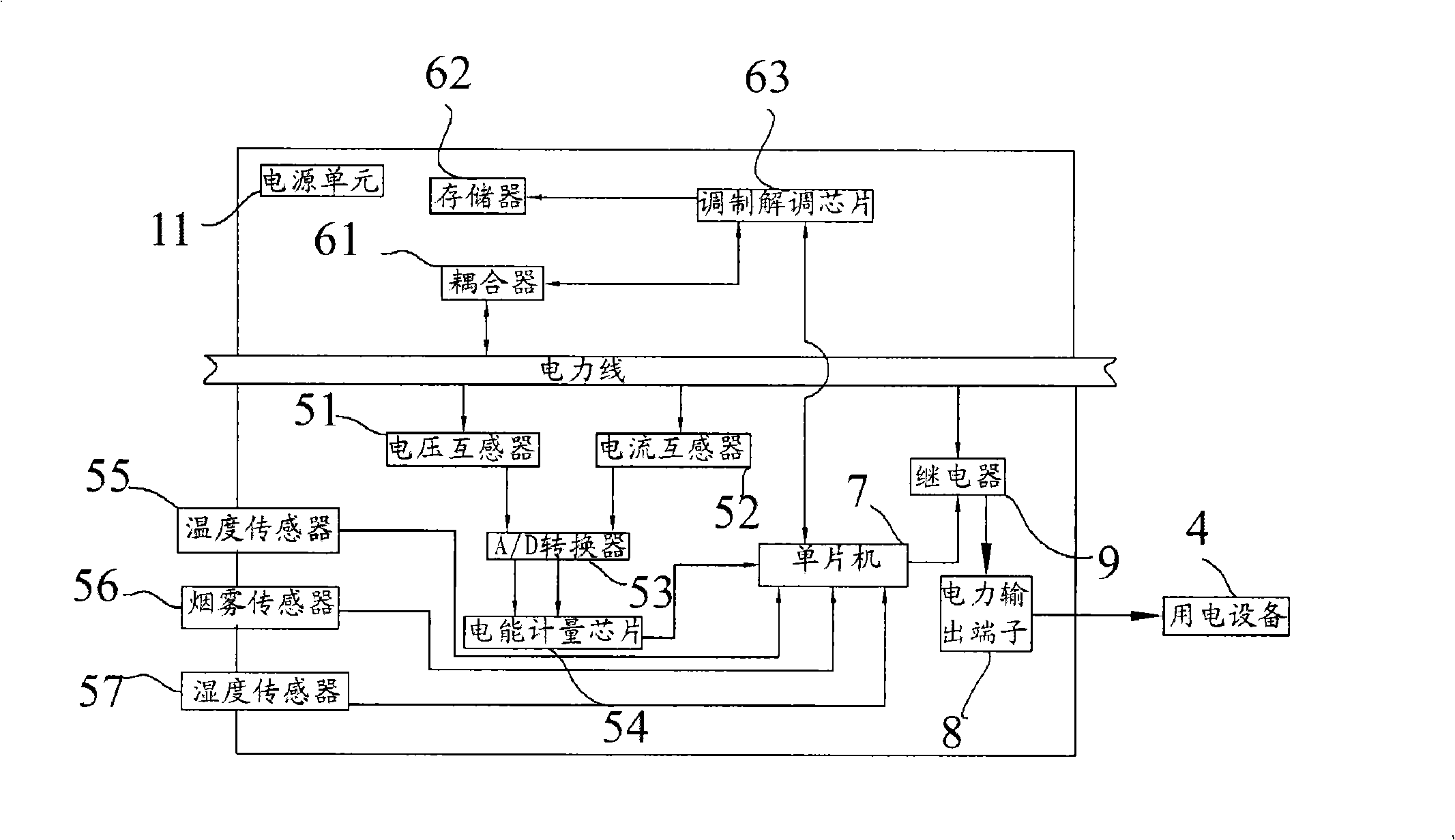

Energy conservative monitoring plug

InactiveCN101291031ARealize real-time monitoringAvoid wastingComputer controlCoupling device detailsData informationComputer module

The invention provides an energy-efficient monitoring socket. The socket comprises a socket body connected with a power line, and a power output terminal is arranged on the socket body and is used for the combination with a plug of an electric appliance. The socket also comprises a detection unit, a processor, a power line transmission module and a circuit break unit, wherein the detection unit detects the instantaneous power consumption parameters of the corresponding power terminal; the processor receives the instantaneous power consumption parameters and sends out control commands according to preset data; the power line transmission module is connected with the processor, sends out data information through the power line, and receives instructions of an upper computer; the circuit break unit is arranged between the power line and the power output terminal, receives the control commands of the processor, and cuts off the power output of the power output terminal.

Owner:北京意科能源技术有限公司

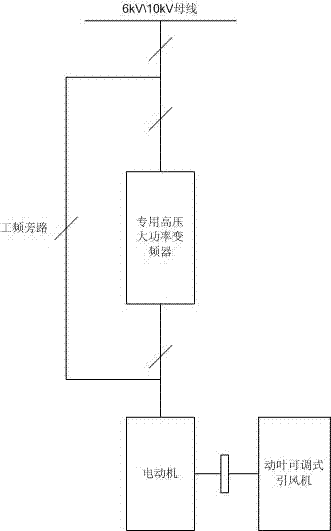

Variable frequency energy-saving system for movable blade adjustable type induced draft fan

ActiveCN104329281AImprove securityImprove reliabilityPump controlNon-positive displacement fluid enginesControl theoryCircuit breaker

The invention particularly discloses a variable frequency energy-saving system for a movable blade adjustable type induced draft fan. By optimizing the operating and regulating mode of the movable blade adjustable type induced draft fan of existing new and in-service thermal power plant boilers and utilizing a special movable blade adjustable type induced draft fan high-voltage high-power frequency converter to drive the movable blade adjustable type induced draft fan, the movable blade adjustable type induced draft fan not only can fulfill the aims of saving energy and reducing consumption, but also can improve integral operation reliability of the system. The invention aims to configure the variable frequency energy-saving system for the movable blade adjustable type induced draft fan between a power supply circuit breaker and an electric motor on the basis that the connection mode of the conventional movable blade adjustable type induced draft fan is unchanged; by switching of power frequency and variable frequency loops, four operating modes of the movable blade adjustable type induced draft fan can be implemented, i.e. after the energy-saving system is utilized, not only can variable frequency speed governing operation of the movable blade adjustable type induced draft fan at a high-efficiency economic working point be implemented, but also the power frequency fixed-speed regulating mode of an original movable blade adjustable type induced draft fan system before transformation is retained.

Owner:DONGFANG HITACHI CHENGDU ELECTRICAL CONTROL EQUIP CO LTD

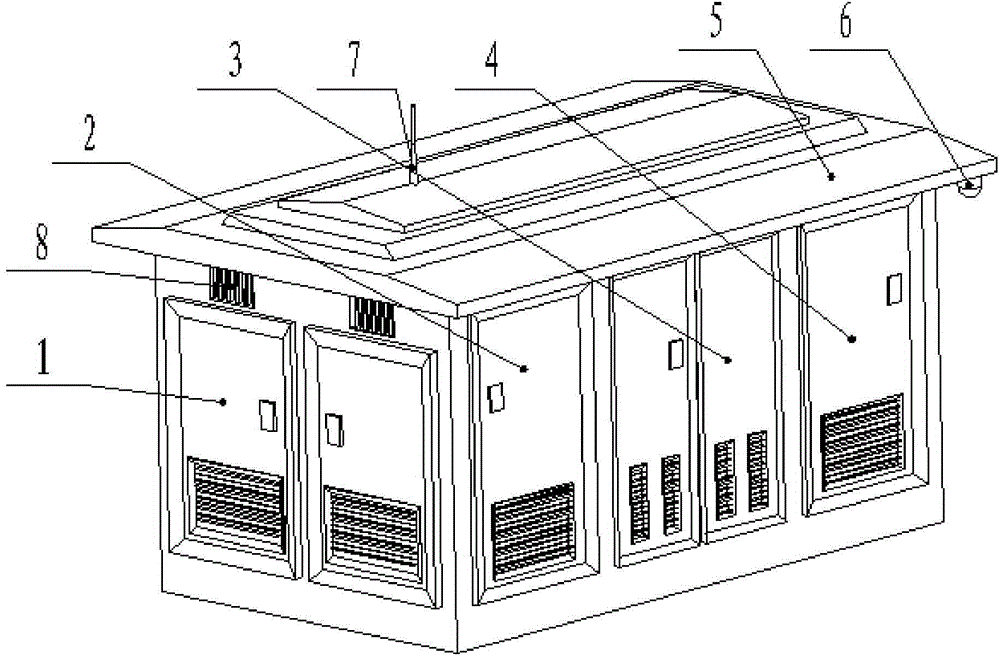

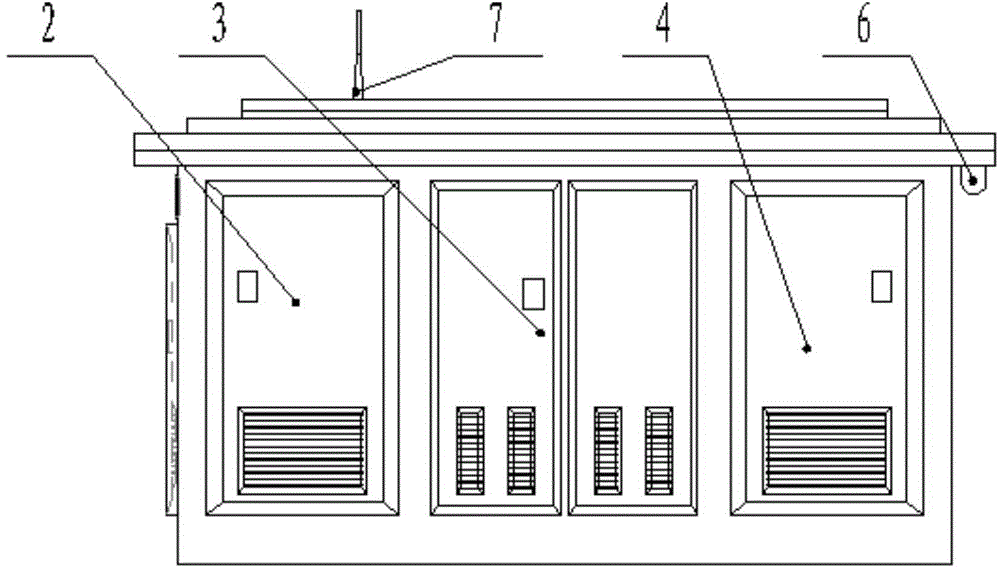

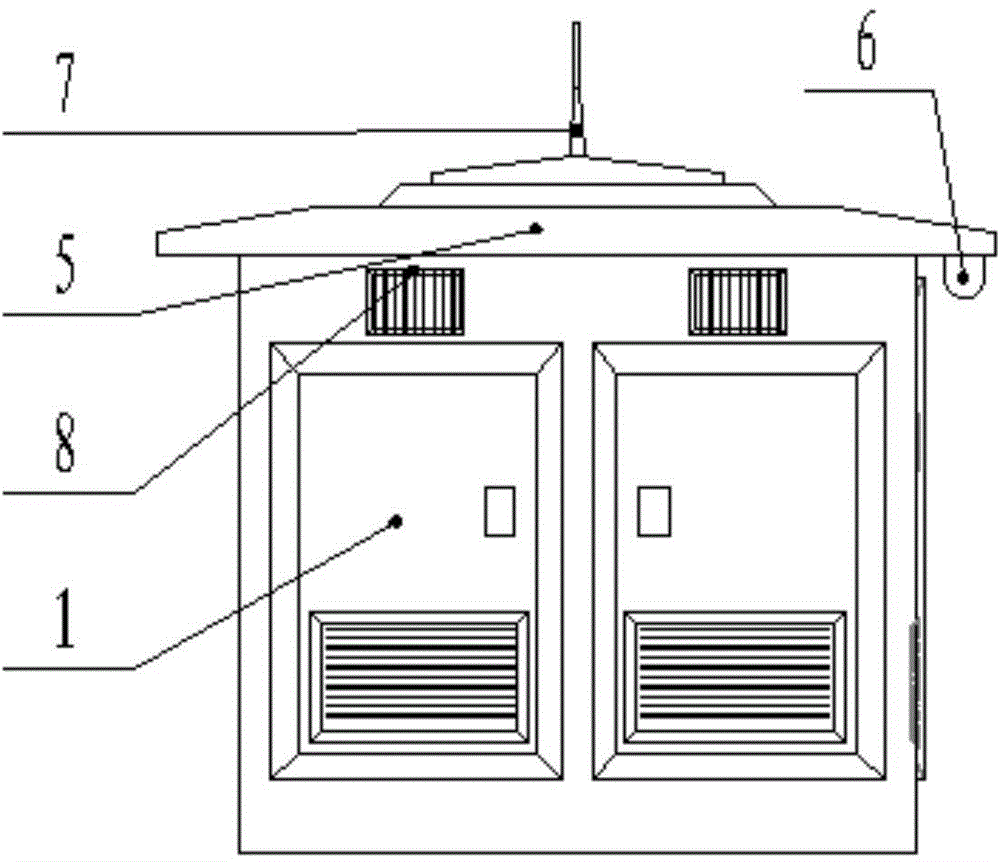

Energy-saving box type outdoor substation

InactiveCN104821503ASafe and reliable performanceImprove work efficiencyCircuit arrangementsSubstation/switching arrangement casingsCapacitancePower grid

The invention belongs to the power transmission and transformation equipment field and relates to an energy-saving box type outdoor substation. The substation comprises a top cover and a box body; the box body is divided into a high-voltage chamber, a transformer chamber and a low-voltage chamber. The energy-saving box type outdoor substation further comprise an intelligent controller; the intelligent controller is connected with a low-voltage chamber power transmission line through a power source input cable; the high-voltage chamber is provided with a high-voltage entering cabinet, a high-voltage metering cabinet, a high-voltage ring main unit and a high-voltage outgoing cabinet; the low-voltage chamber is provided with a low-voltage entering cabinet, a high-voltage reactive power automatic compensation capacitor cabinet and a low-voltage outgoing cabinet; and a transformer arranged in the transformer chamber is an on-load automatic capacitance adjustment power distribution transformer. The energy-saving box type outdoor substation is safe, reliable, energy-saving and efficient. With the energy-saving box type outdoor substation adopted, a power factor as well as the power supply efficiency and voltage quality of a system can be improved, and line loss can be decreased, and distribution line cost can be decreased, and electric energy can be saved, and the occupancy of a power grid and the no-load reactive loss and active loss of the transformer can be decreased, and capacity increasing cost and operation cost can be saved, and saving energy and consumption reduction can be realized, and great economic benefits and social benefits can be brought about.

Owner:昆明湘云衡电气设备有限公司

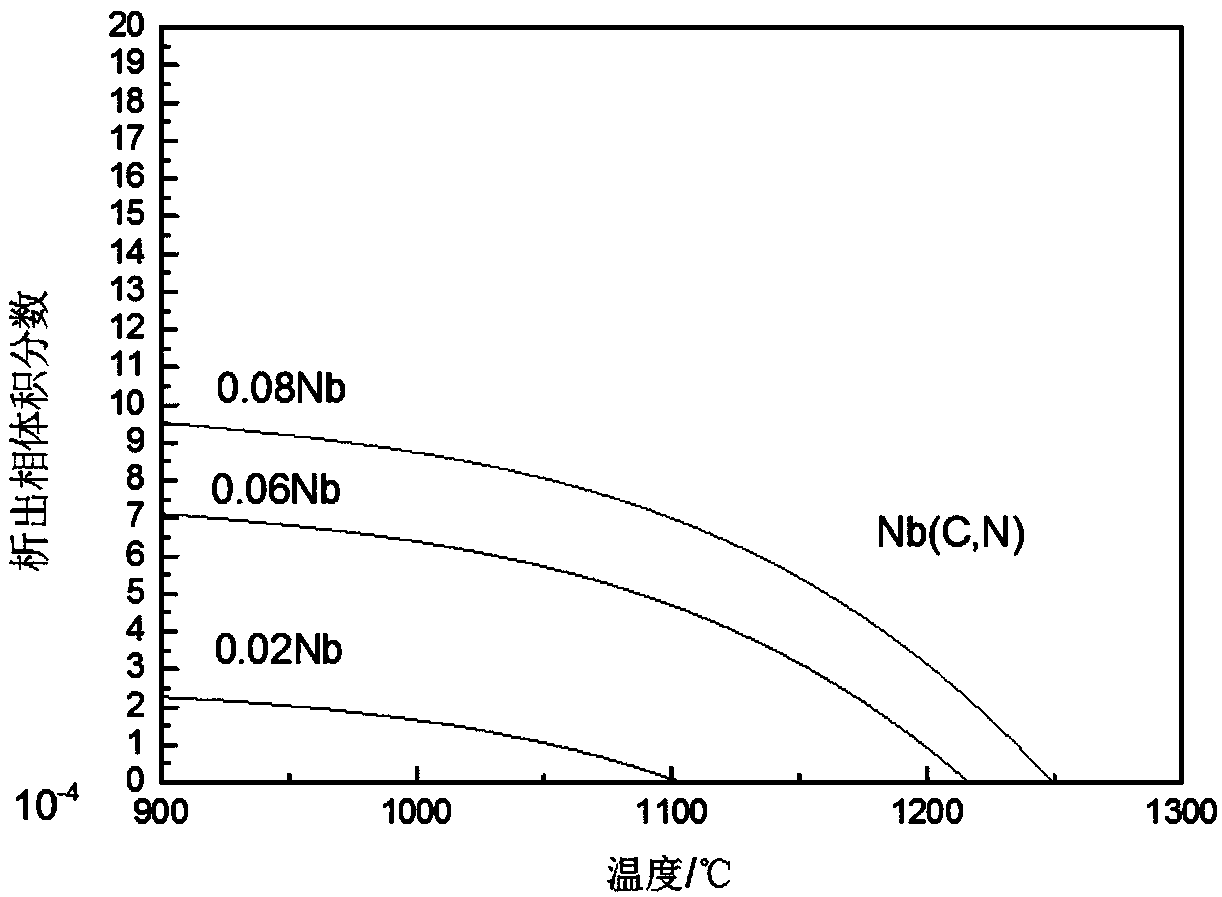

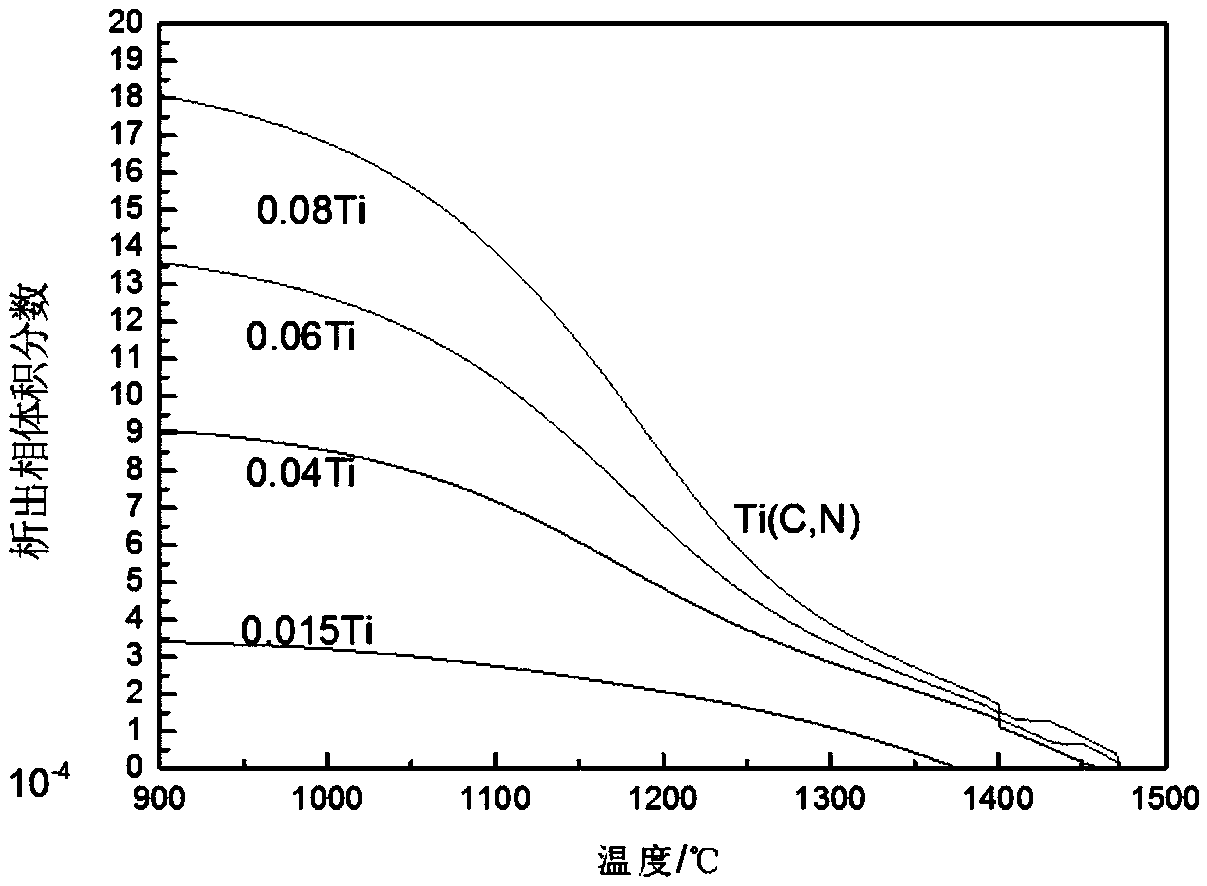

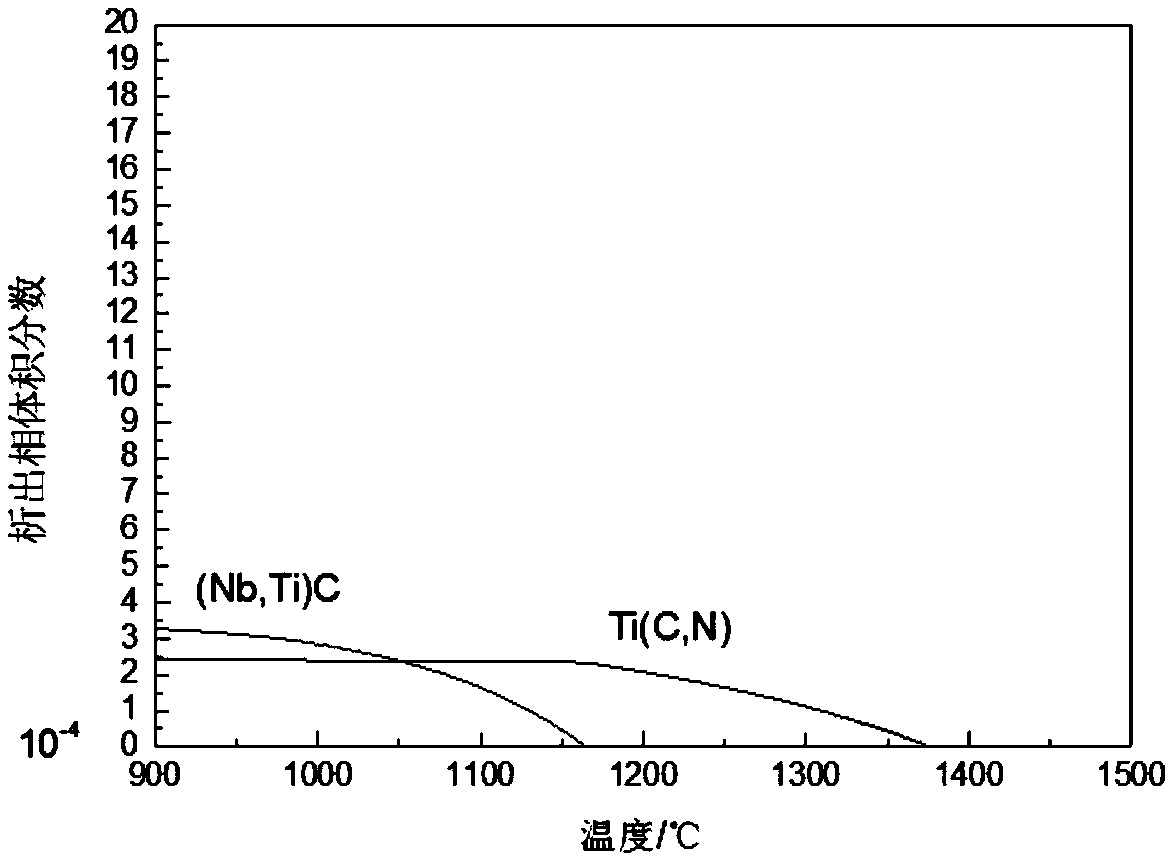

Steel for Nb-Ti composite microalloyed high-temperature vacuum carburizing heavy-duty gear

ActiveCN108866439AIncrease carburizing temperatureIncrease productivitySolid state diffusion coatingAustenite grainMetallurgy

The invention relates to steel for an Nb-Ti composite microalloyed high-temperature vacuum carburizing heavy-duty gear. The steel is prepared from the following components in percentage by mass: 0.15-0.23 percent of C, 0.10-0.40 percent of Si, 0.45-0.90 percent of Mn, 1.50-1.80 percent of Cr, 1.40-1.70 percent of Ni, 0.15-0.55 percent of Mo, 0.02-0.08 percent of Nb, 0.015-0.08 percent of Ti, smaller than or equal to 0.020 percent of P, smaller than or equal to 0.020 percent of S and the balance of Fe and inevitable impurities. For the steel provided by the invention, by adopting a composite microalloying manner, adding Nb and Ti microalloy elements and controlling the contents of the Nb and Ti microalloy elements, a precipitated phase is utilized to pin a crystal boundary to inhibit coarsening and growth of austenite grains in the high-temperature vacuum carburizing process, increase of the steel carburizing temperature of the heavy-duty gear is realized, the gear carburizing heat treatment process time is effectively shortened, the energy consumption is greatly lowered, and the production cost of the gear is saved.

Owner:NORTHEASTERN UNIV

Adsorption type high pressure natural gas dehydration process and device

InactiveCN101899341AReduce the temperatureImprove cooling effectDispersed particle separationGaseous fuelsNatural gas dehydrationProduct gas

The invention provides an adsorption type high pressure natural gas dehydration process and a device, and the Joule-Thomson effect is utilized for converting the pressure loss during the process of reducing the pressure of high pressure natural gas into cold energy of low-temperature gas flow, thereby carrying out heat exchange on the cold gas flow and hot gas flow, cooling the hot gas flow, increasing the temperature of the cold gas flow, effectively reducing the energy loss, simplifying equipment and saving energy. The method comprises three steps of adsorption, regeneration and switching, and the device increases a pressure reducing valve and a heat exchanger for treatment of finished product gas, thereby not using a cooling fan during the cooling process, saving electrical energy, avoiding troubles caused by explosion prevention of a motor and being safe and energy-saving.

Owner:XIAN UNIONFILTER PURIFICATION EQUIP

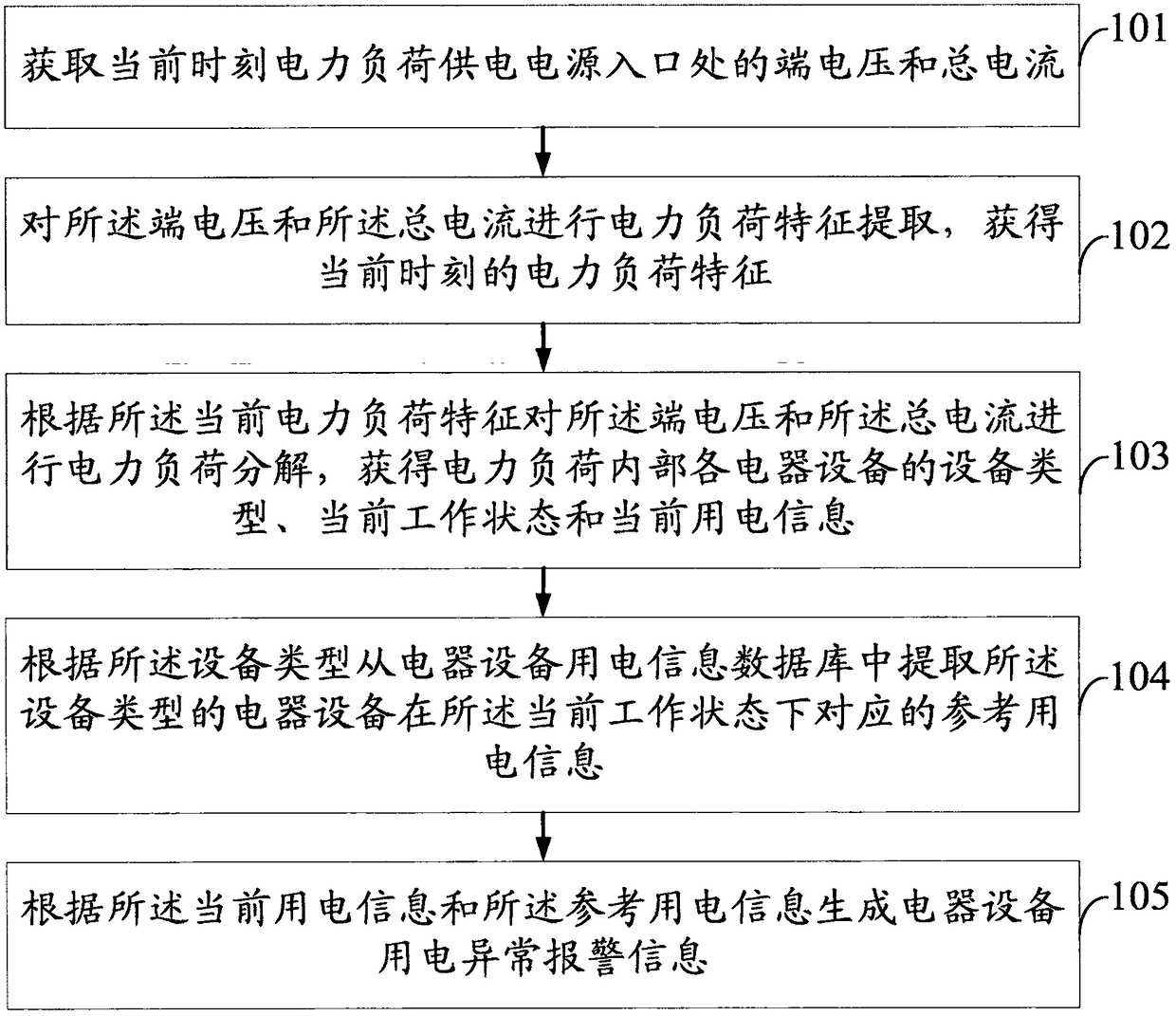

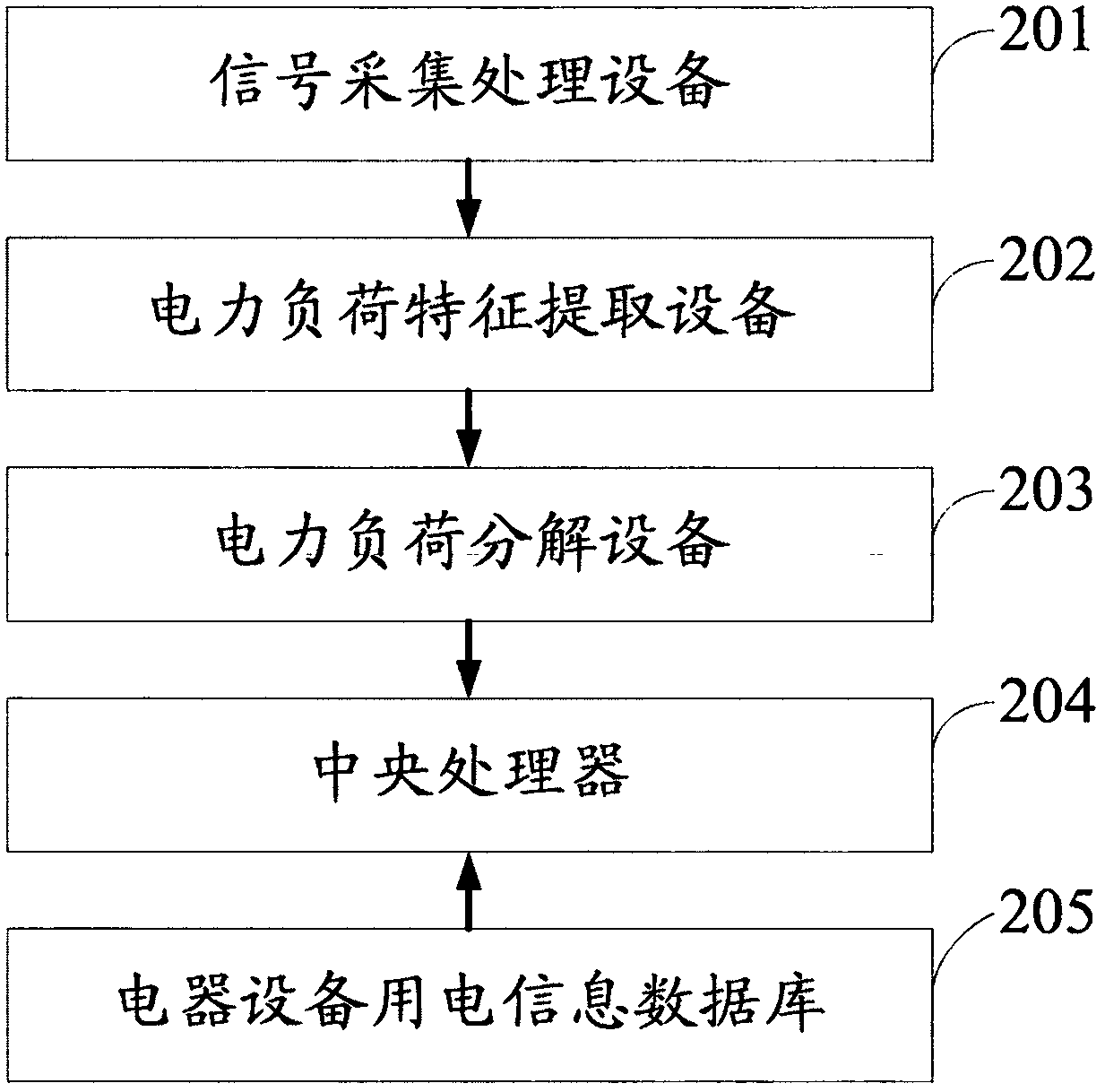

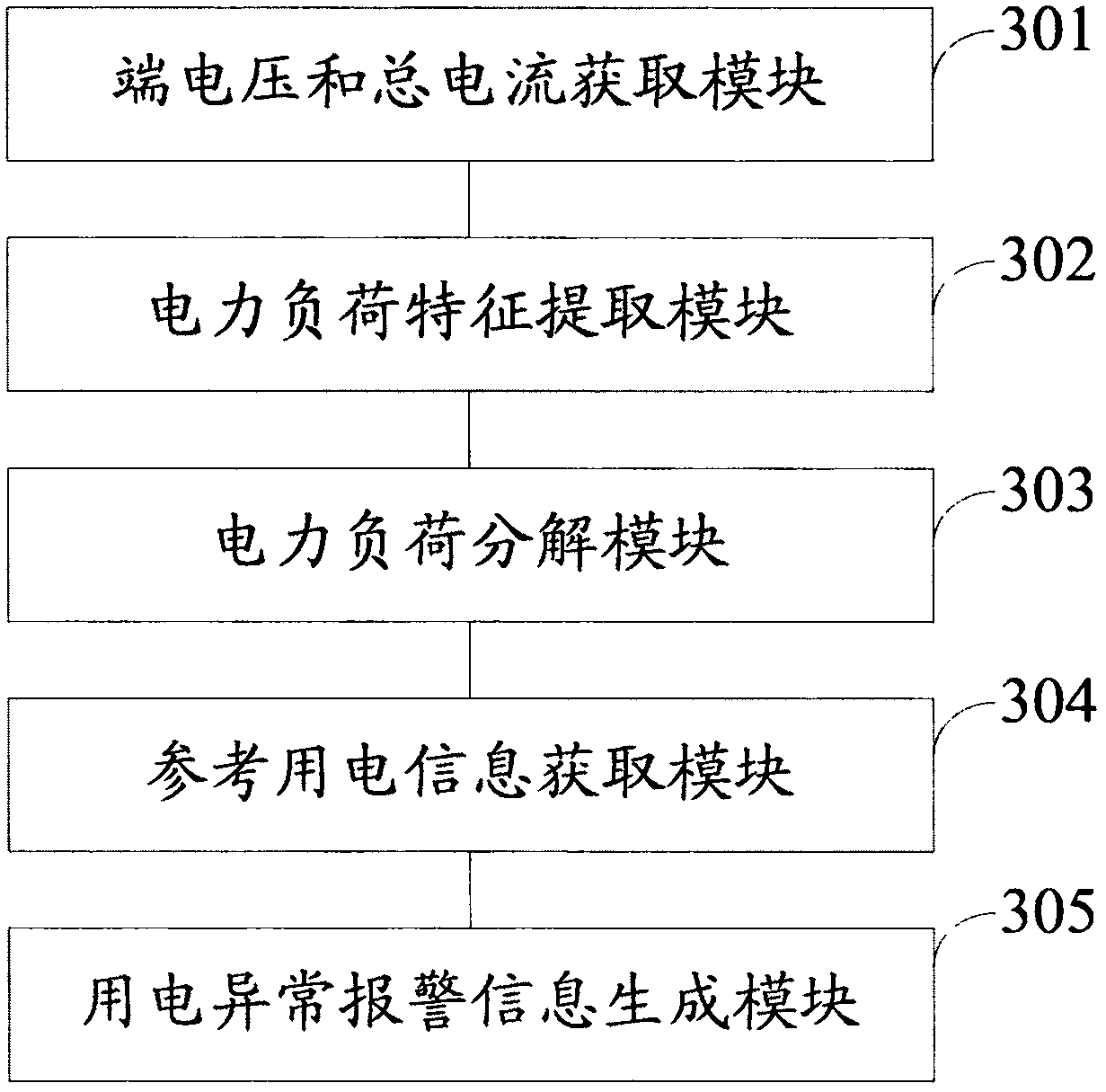

Non-invasive method and system for monitoring electric load alarm

InactiveCN109239494ACheck in timeReduce spendingElectric devicesElectrical testingDecompositionTerminal voltage

The invention discloses a non-invasive method and a system for monitoring an electric load alarm. The method comprises the following steps: obtaining a terminal voltage and a total current at the inlet of an electric load power supply at the current moment; performing electric load characteristic extraction on the terminal voltage and the total current to obtain an electric load characteristic atthe current moment; performing electric load decomposition on the terminal voltage and the total current according to the current electric load characteristic; obtaining a type, a current working state and current electric consumption information of each electrical equipment in the electric load; and generating electric consumption abnormal alarm information of the electrical equipment according to the current electric consumption information and a reference electric consumption information. Once any of the current electric consumption information of the electrical equipment is abnormal, the system can timely discover it and give an alarm. Users can timely view and process the abnormal condition according to the type, the current working state and the abnormal electric consumption information of the electrical equipment with abnormal electric consumption in the abnormal electric consumption alarm information of the electrical equipment.

Owner:无锡风繁伟业科技有限公司

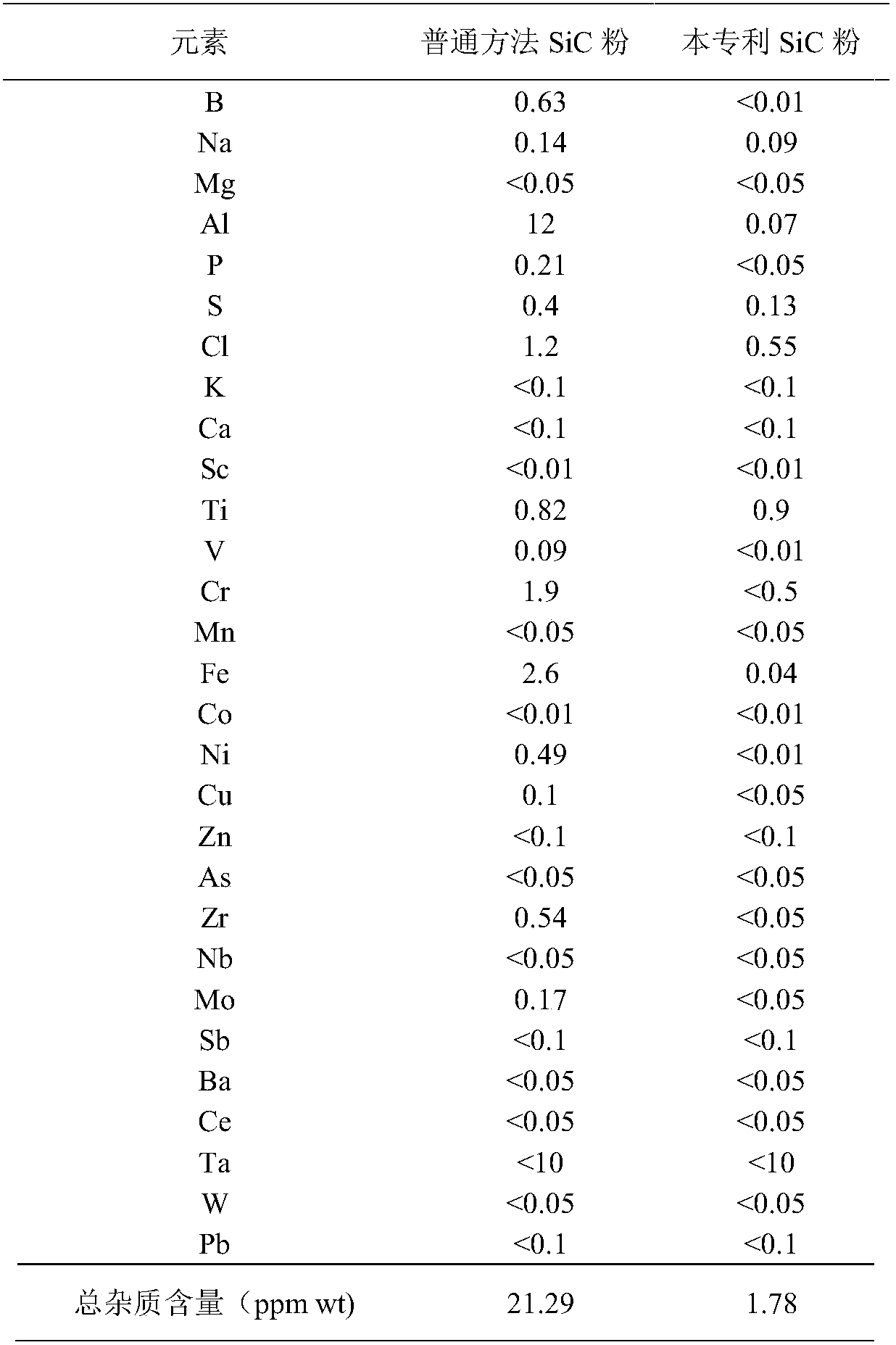

Method for preparing high-purity silicon carbide powder

InactiveCN109502589AReduce nitrogen contentLow content of metal impuritiesCarbon compoundsNitrogenPre treatment

The invention provides a method for preparing high-purity silicon carbide powder. The method is characterized by comprising the following steps: (1) selecting high-purity silicon powder and high-purity carbon powder; (2) carrying out primary purification and secondary purification on the high-purity carbon powder, a graphite crucible and a heat-insulation structure, wherein the primary purification adopts vacuum degassing purification and the secondary purification adopts high-temperature purification under inert gas; (3) putting the high-purity carbon powder subjected to the secondary purification in step (2) and the high-purity silicon powder in step (1) into the graphite crucible subjected to the secondary purification in step (2); reacting to obtain the high-purity silicon carbide powder. According to the method provided by the invention, the carbon powder, the graphite crucible and the heat-insulation structure are pre-treated, so that the nitrogen content of the high-purity carbon powder and the content of metal impurities are reduced; compared with a method of carrying out wet-process metallurgical treatment after silicon carbide is synthesized, the method is more environmentally friendly and has simpler procedures; meanwhile, impurities are not introduced from the graphite crucible and the heat-insulation structure when the silicon carbide powder is synthesized.

Owner:SICC CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com