Low-temperature BOG (Boil off Gas) gas cold energy recovering device and process

A cold energy recovery and gas technology, which is applied in the direction of heating devices, gas/liquid distribution and storage, equipment loaded into pressure vessels, etc., can solve the problem of no low-temperature BOG gas cold energy recovery and utilization, and the low recovery rate of heavy hydrocarbon separators , low recovery rate of heavy hydrocarbons, etc., to achieve the effect of improving the recovery rate of heavy hydrocarbons, wide application range, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

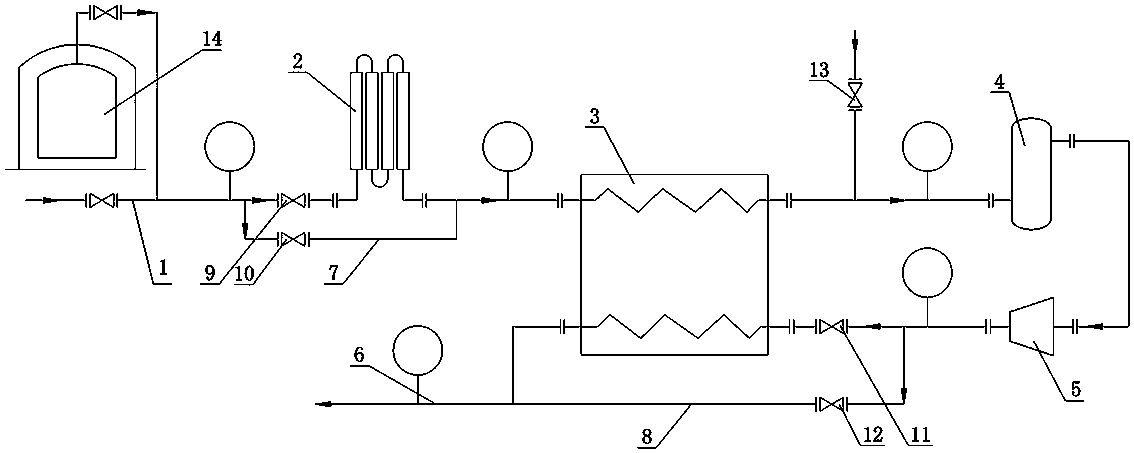

[0025] Such as figure 1 As shown, a low-temperature BOG gas cold recovery device includes a low-temperature BOG gas inlet pipe 1, a heater 2, a heat exchanger 3, a buffer tank 4, a compressor 5, a pressurized BOG gas outlet pipe 6, and a low-temperature BOG gas outlet pipe 6. The gas outlet of the inlet pipe 1 is divided into two paths, the gas outlet of the low-temperature BOG gas inlet pipe 1 is connected with the low-temperature BOG gas flow channel of the heater 2, the heat exchanger 3, and the inlet of the buffer tank 4 in sequence, and the low-temperature BOG gas enters The gas outlet of the air pipe 1 is connected to the pipeline connecting the heater 2 and the low-temperature BOG gas passage of the heat exchanger 3 through the branch pipe A7; One end of the compressor 5 is connected to the pressurized BOG gas flow channel of the heat exchanger 3 and the pressurized BOG gas outlet pipe 6 in sequence, and the other end of the compressor 5 is connected to the booster thro...

Embodiment 2

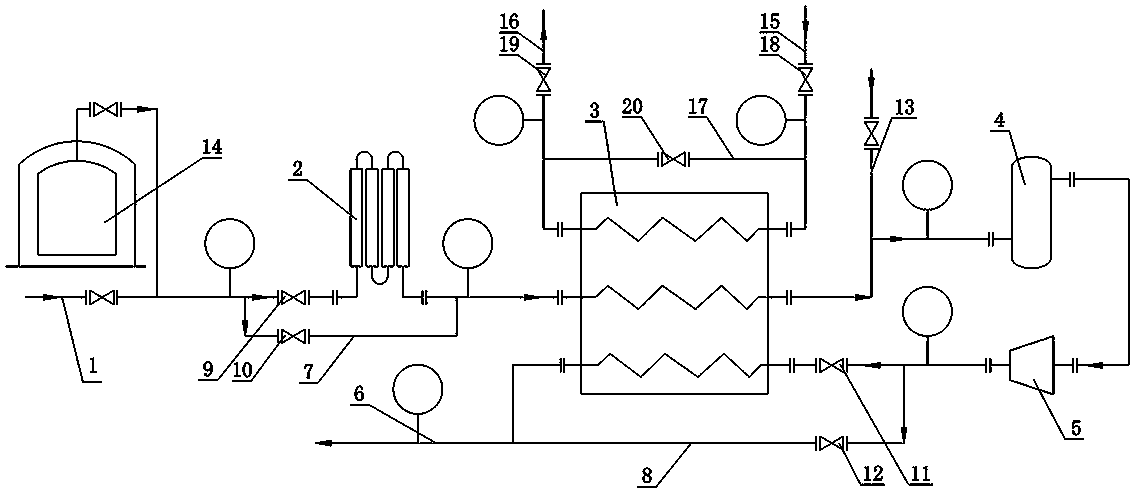

[0037] Such as figure 2 As shown, a low-temperature BOG gas cold recovery device includes a low-temperature BOG gas inlet pipe 1, a heater 2, a heat exchanger 3, a buffer tank 4, a compressor 5, a pressurized BOG gas outlet pipe 6, and a low-temperature BOG gas outlet pipe 6. The gas outlet of the inlet pipe 1 is divided into two paths, the gas outlet of the low-temperature BOG gas inlet pipe 1 is connected with the low-temperature BOG gas flow channel of the heater 2, the heat exchanger 3, and the inlet of the buffer tank 4 in sequence, and the low-temperature BOG gas enters The gas outlet of the air pipe 1 is connected to the pipeline connecting the heater 2 and the low-temperature BOG gas passage of the heat exchanger 3 through the branch pipe A7; One end of the compressor 5 is connected to the pressurized BOG gas flow channel of the heat exchanger 3 and the pressurized BOG gas outlet pipe 6 in sequence, and the other end of the compressor 5 is connected to the booster thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com