Method for preparing high-purity silicon carbide powder

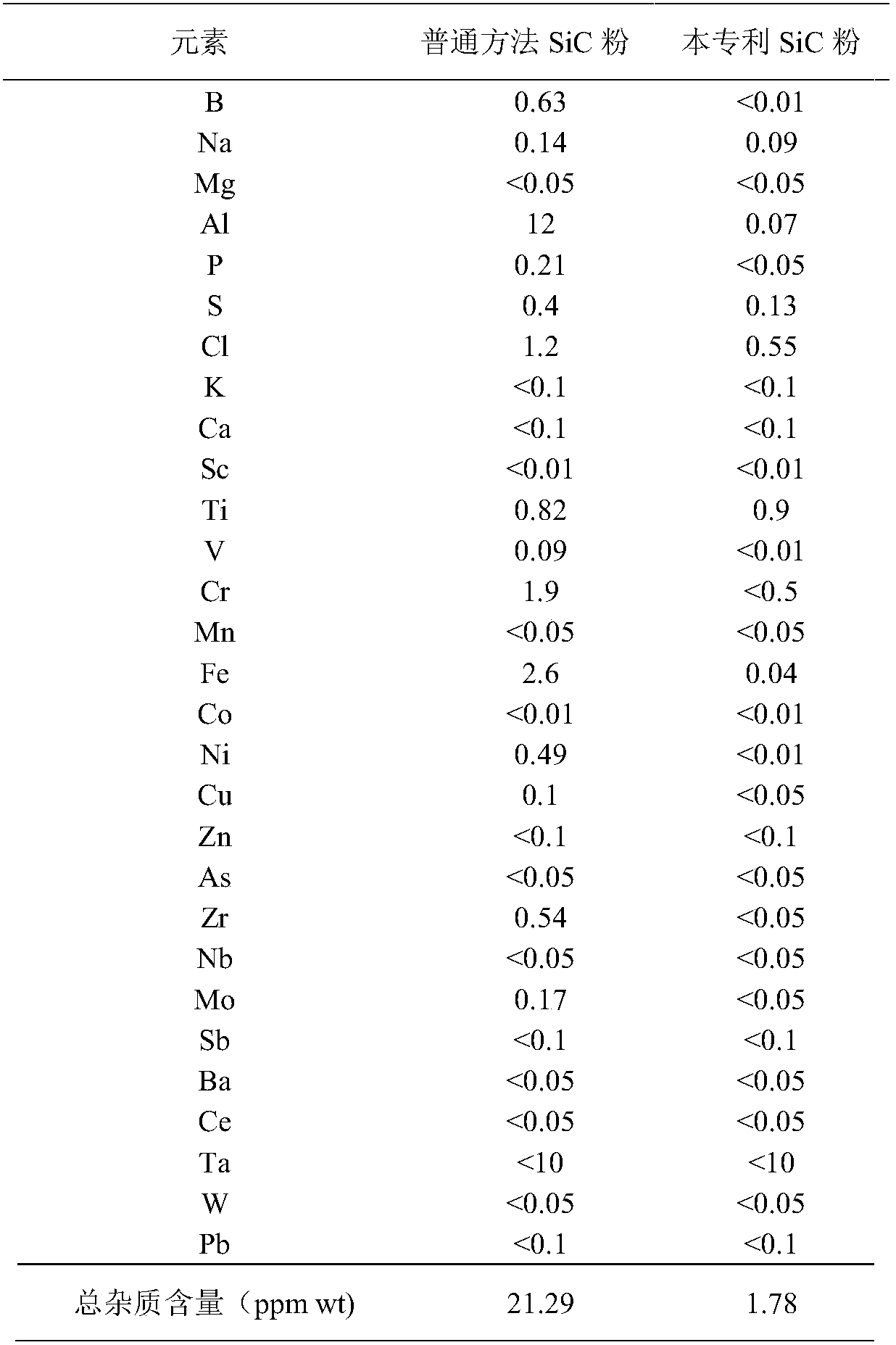

A technology of high-purity silicon carbide powder and high-purity silicon powder, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of low purity of silicon carbide powder, and achieve reduction in quantity and micropipe content, and process Simple, Purity-Enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing high-purity silicon carbide powder, the preparation method comprising the following specific steps:

[0031] (1) Provide high-purity silicon powder and high-purity carbon powder, the molar ratio of high-purity silicon powder and high-purity carbon powder is 0.9;

[0032] (2) The high-purity carbon powder is placed in a graphite crucible, then the graphite crucible and the insulation structure are placed in a heating furnace, and the heating furnace is evacuated so that the vacuum degree reaches 1×10 -4 mbar, heat up to 1000°C for degassing and purification, and last for 8 hours;

[0033] (3) At the temperature described in step (2), inert gas is injected into the heating furnace, and the temperature is slowly raised to 1800° C. for further purification. The purification time is 20 hours to obtain carbon powder with low nitrogen content and low metal impurity content and Graphite crucible and insulation structure;

[0034] (4) the high-purity carbo...

Embodiment 2

[0038] A method for preparing high-purity silicon carbide powder, the preparation method comprising the following specific steps:

[0039] (1) Provide high-purity silicon powder and high-purity carbon powder, the molar ratio of high-purity silicon powder and high-purity carbon powder is 1.2;

[0040] (2) The high-purity carbon powder is placed in a graphite crucible, then the graphite crucible and the insulation structure are placed in a heating furnace, and the heating furnace is evacuated so that the vacuum degree reaches 1×10 -4 mbar, heat up to 1500°C for degassing and purification, and last for 6 hours;

[0041] (3) At the temperature described in step (2), inert gas is injected into the heating furnace, and the temperature is slowly raised to 2300° C. to perform purification again. The purification time is 15 hours, and carbon powder and carbon powder with low nitrogen content and low metal impurity content are obtained. Graphite crucible and insulation structure;

[0...

Embodiment 3

[0046] A method for preparing high-purity silicon carbide powder, the preparation method comprising the following specific steps:

[0047] (1) Provide high-purity silicon powder and high-purity carbon powder, the molar ratio of high-purity silicon powder and high-purity carbon powder is 1.1;

[0048] (2) The high-purity carbon powder is placed in a graphite crucible, then the graphite crucible and the insulation structure are placed in a heating furnace, and the heating furnace is evacuated so that the vacuum degree reaches 1×10 -4 mbar, heat up to 1100°C for degassing and purification, and last for 10 hours;

[0049] (3) At the temperature described in step (2), inert gas is injected into the heating furnace, and the temperature is slowly raised to 1900° C. to perform purification again. The purification time is 15 hours, and carbon powder and carbon powder with low nitrogen content and low metal impurity content are obtained. Graphite crucible and insulation structure;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com