Gasification system of oxygen-enriched biomass circulating fluidized-bed

A technology of circulating fluidized bed and gasification system, which is applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry. Large-scale industrial application and other issues, to achieve the effect of increasing heat transfer and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

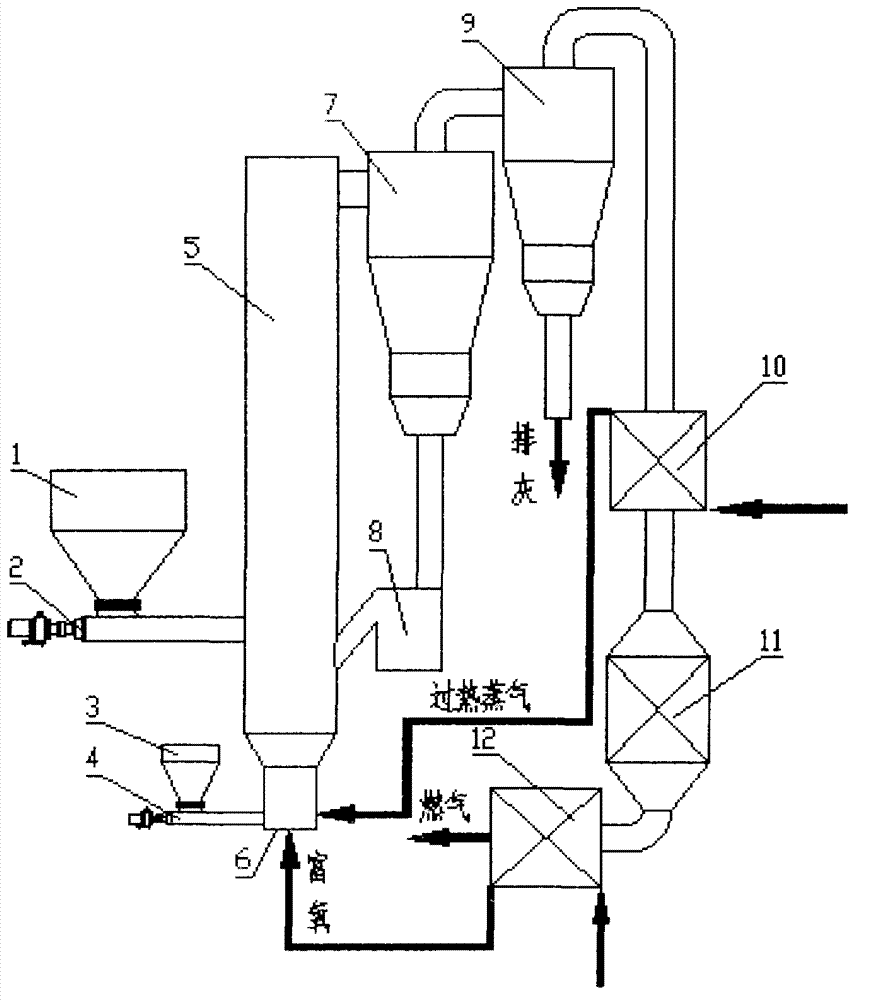

[0025] The preheating temperature of the oxygen-enriched air is 351°C. The preheated high-temperature oxygen-enriched air enters from the bottom of the gasification furnace 5, and wood chips with a water content of 18% are fed from the middle and lower part of the gasification furnace 5 through the feeding screw conveyor 2. High-efficiency gasification reaction occurs between medium biomass and high-temperature oxygen-enriched air. The high-temperature gas from gasification furnace 5 passes through cyclone separator 7 and then passes through cyclone dust collector 9, superheater 10, waste heat boiler 11 and preheater 12, The obtained temperature is 420°C and the calorific value is 10800kj / Nm 3 high-quality gas.

Embodiment 2

[0027] The preheating temperature of oxygen-enriched air is 323°C. The preheated high-temperature oxygen-enriched air enters from the bottom of gasification furnace 5, and wood chips with a water content of 10% are fed from the middle and lower part of gasification furnace 5 through feeding screw conveyor 2. High-efficiency gasification reaction occurs between medium biomass and high-temperature oxygen-enriched air. The high-temperature gas coming out of gasifier 5 passes through cyclone separator 7 and then passes through cyclone dust collector 9, superheater 10, waste heat boiler 11 and preheater 12, The obtained temperature is 431°C and the calorific value is 11500kj / Nm 3 high-quality gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com