Patents

Literature

155results about How to "Will not introduce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

III-nitride substrate growing method, substrate and LED (light emitting diode)

InactiveCN102201503AWill not introduceSimple growth processSemiconductor devicesCvd grapheneLight-emitting diode

A III-nitride substrate growing method comprises the following steps: providing a copper support substrate; forming a graphene layer on the surface of the support substrate; and forming a III-nitride semiconductor layer on the surface of the graphene layer, wherein the highest growing temperature of the III-nitride semiconductor layer is lower than the melting point of copper. In the method, since graphene and III-nitride are sequentially grown on the conductive metallic copper substrate with high melting point, growth process is simple and impurities cannot be introduced in the production process.

Owner:SUZHOU NANOWIN SCI & TECH +1

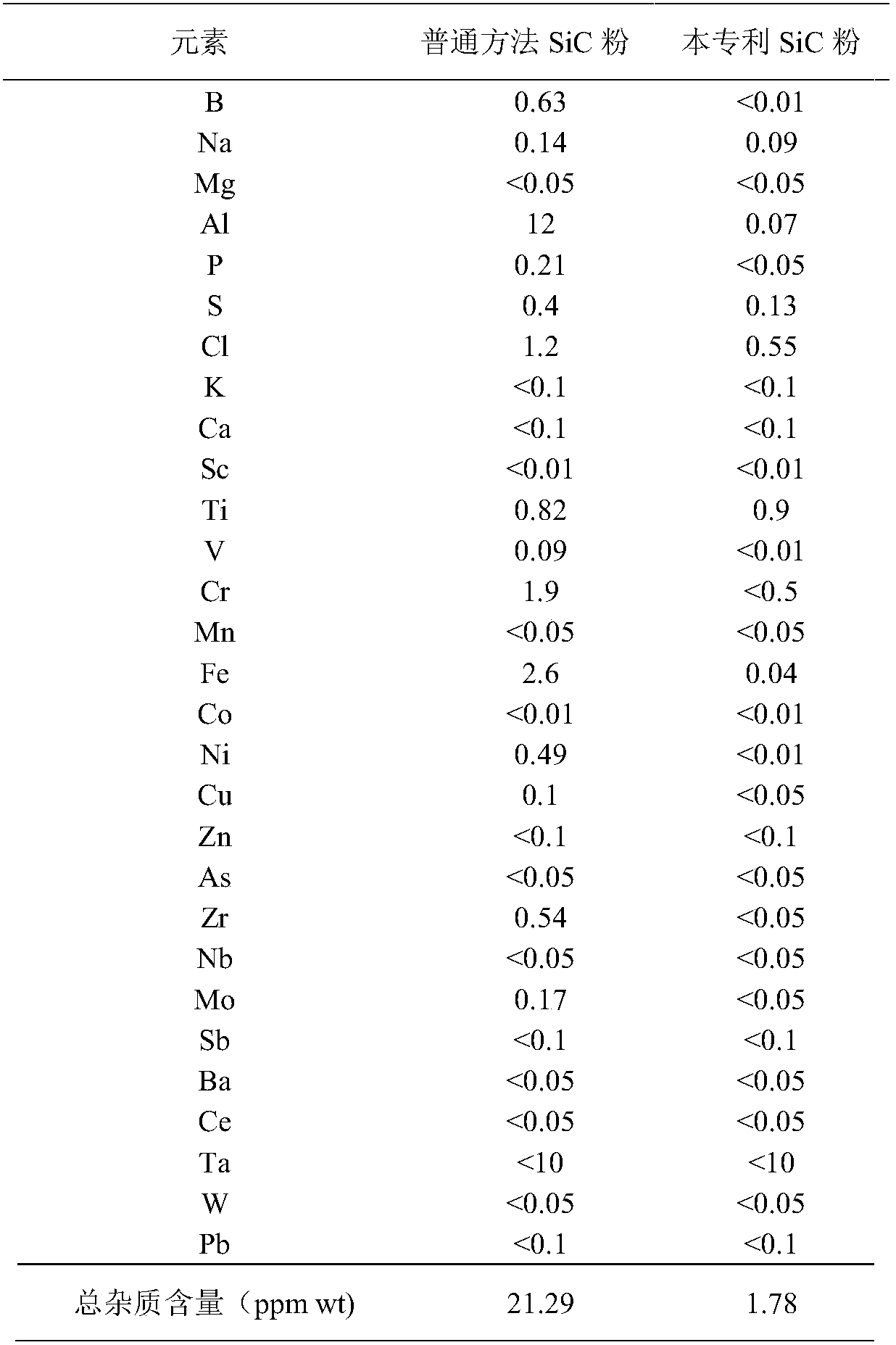

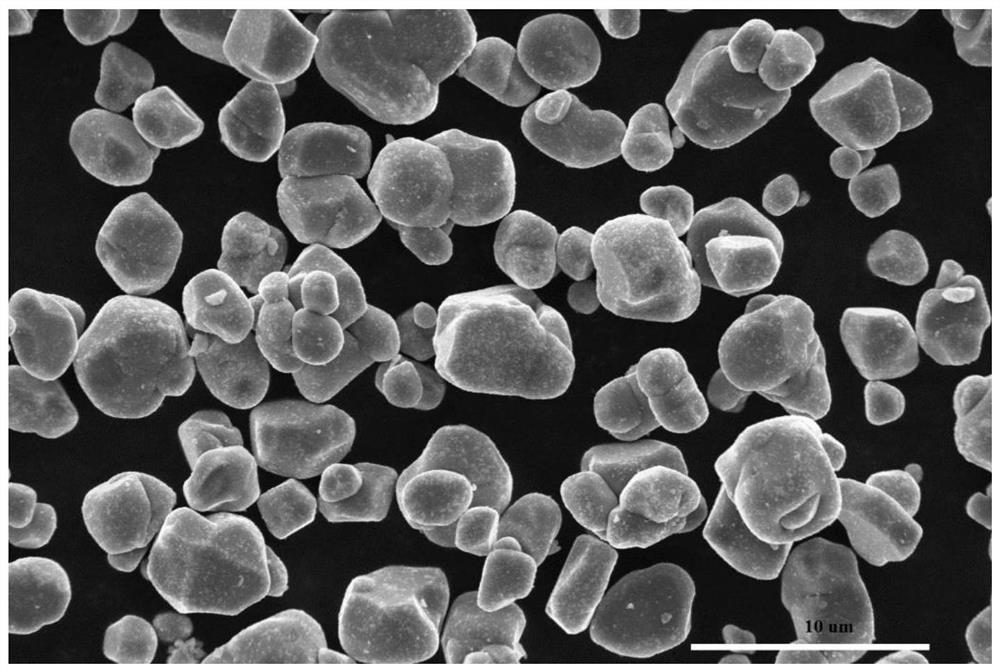

Method for preparing high-purity silicon carbide powder

InactiveCN109502589AReduce nitrogen contentLow content of metal impuritiesCarbon compoundsNitrogenPre treatment

The invention provides a method for preparing high-purity silicon carbide powder. The method is characterized by comprising the following steps: (1) selecting high-purity silicon powder and high-purity carbon powder; (2) carrying out primary purification and secondary purification on the high-purity carbon powder, a graphite crucible and a heat-insulation structure, wherein the primary purification adopts vacuum degassing purification and the secondary purification adopts high-temperature purification under inert gas; (3) putting the high-purity carbon powder subjected to the secondary purification in step (2) and the high-purity silicon powder in step (1) into the graphite crucible subjected to the secondary purification in step (2); reacting to obtain the high-purity silicon carbide powder. According to the method provided by the invention, the carbon powder, the graphite crucible and the heat-insulation structure are pre-treated, so that the nitrogen content of the high-purity carbon powder and the content of metal impurities are reduced; compared with a method of carrying out wet-process metallurgical treatment after silicon carbide is synthesized, the method is more environmentally friendly and has simpler procedures; meanwhile, impurities are not introduced from the graphite crucible and the heat-insulation structure when the silicon carbide powder is synthesized.

Owner:SICC CO LTD

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

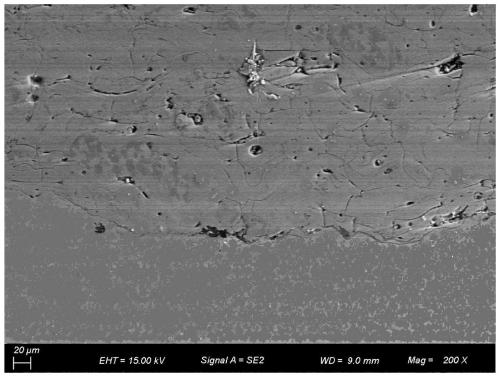

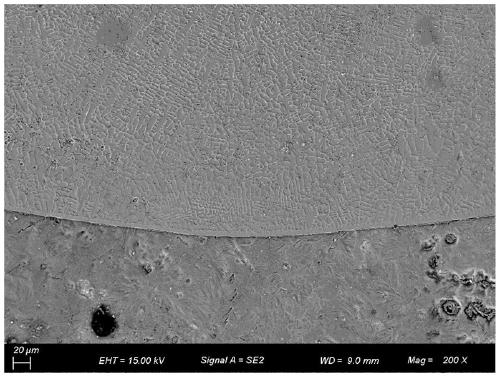

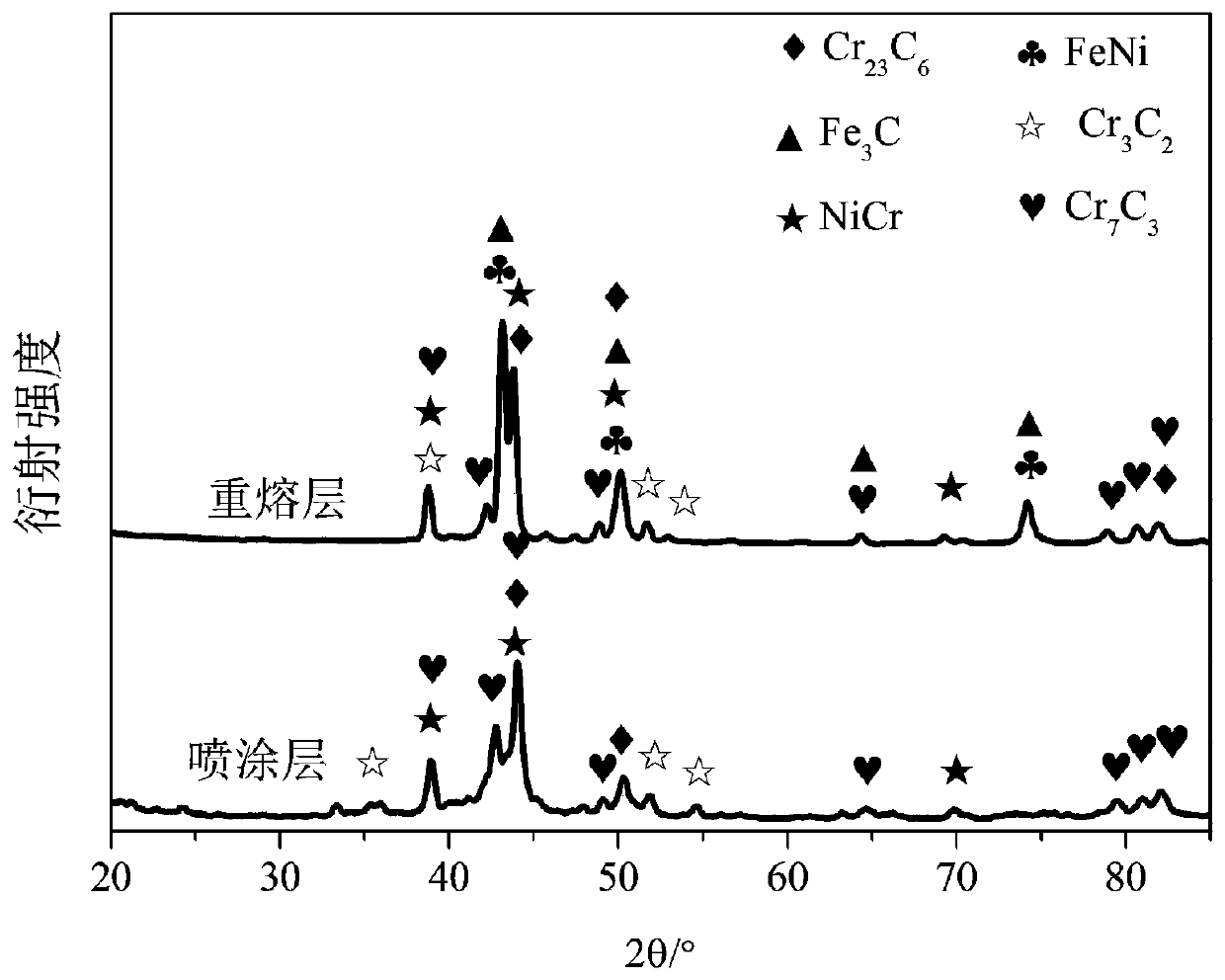

Preparation method of nickel-chromium chromium carbide wear-resistant coating

InactiveCN110079756AUniform and dense phase distributionPrevent oxidationMolten spray coatingChromium carbideWear resistant

The invention provides a preparation method of a nickel-chromium chromium carbide wear-resistant coating. The preparation method includes the following steps that 1, powder of NiCr and Cr3C2 is mixedto be uniform in proportion, and after the mixture is sintered, nickel-chromium chromium carbide powder is obtained; and 2, a nickel-chromium chromium carbide (NiCr-Cr3C2) remelted coating is prepared, wherein 1), the surface of a matrix is subjected to sand blasting pretreatment; 2), the matrix obtained after sand blasting treatment is subjected to plasma spraying; 3), a coating sample obtained after plasma spraying is subjected to preheating treatment before remelting, then a tungsten electrode argon arc welding machine is adopted for TIG remelting treatment, then heat insulation treatment after remelting is carried out, and finally the nickel-chromium chromium carbide wear-resistant remelted coating is obtained; argon is adopted as shielding gas in the TIG remelting process, wherein theTIG remelting current is 85-100 A, the argon arc length is 2 mm, the argon flow is 10 L / min, the remelting speed is 200 mm / min, and the step length is 1.5 mm. The preheating temperature and the heatinsulation temperature are both 300 DEG C, and the time is 2 hours. By means of the method, mechanical bonding between the coating and the matrix is converted into metallurgical bonding, and the mechanical performance and the wear-resistant performance of the coating are improved.

Owner:HEBEI UNIV OF TECH

Low viscosity and high performance carbon fiber spinning stock solution preparation method

ActiveCN103422187ALow viscosityImprove spinnabilityMonocomponent synthetic polymer artificial filamentSpinning solutions preparationCarbon fibersAcrylonitrile

The present invention relates to a low viscosity and high performance carbon fiber spinning stock solution preparation method, wherein problems of high molecule weight, narrow molecule weight distribution, high viscosity and poor spinnability of the polyacrylonitrile spinning stock solution prepared through the one-step method in the prior art are mainly solved with the present invention. The technical scheme comprises that the low viscosity and high performance carbon fiber spinning stock solution preparation method comprises the following steps: adopting acrylonitrile, a copolymerization monomer 1 and a copolymerization monomer 2 as copolymerization components, mixing the copolymerization components, a solvent dimethyl sulfoxide, an initiator azobisisobutyronitrile and an adjustment agent, adding the obtained material to a reactor, carrying out a reaction for 20-40 h at a temperature of 50-70 DEG C under protection of gas presenting inertia for the reaction substances, and carrying out monomer removing and deaeration to obtain the polyacrylonitrile spinning stock solution with a molecule weight of 90000-150000, molecule weight distribution of less than 3 and a viscosity of 30-90 Pa.S at a temperature of 60 DEG C. With the technical scheme, the problems in the prior art are well solved, and the preparation method can be used for industrial production of carbon fiber precursors.

Owner:CHINA PETROLEUM & CHEM CORP +1

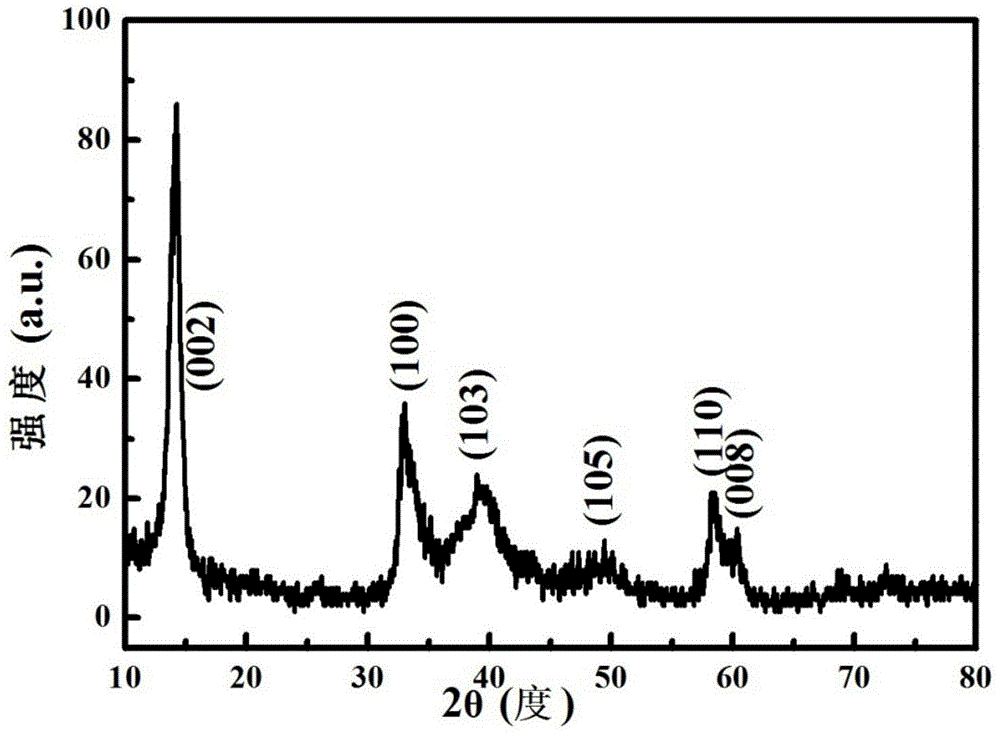

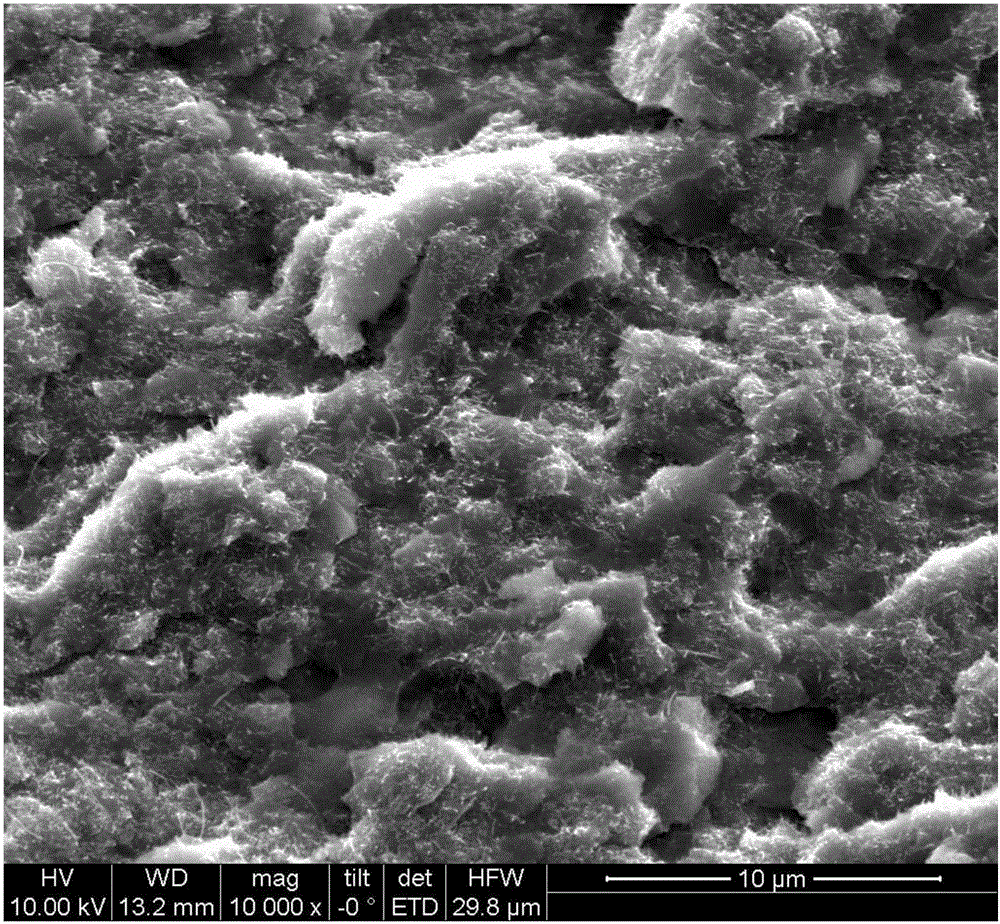

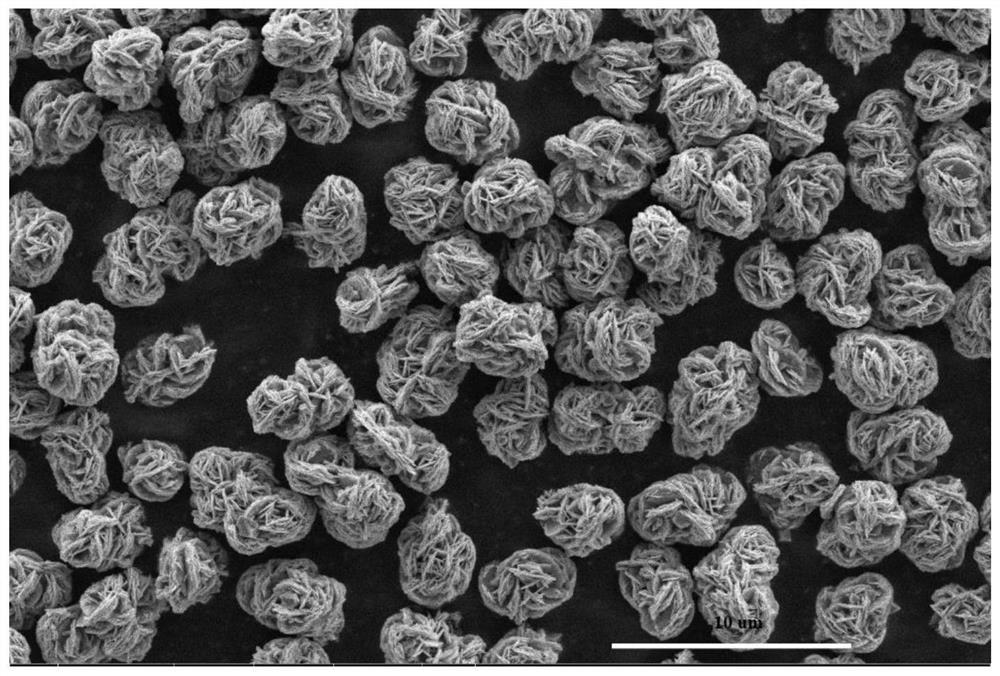

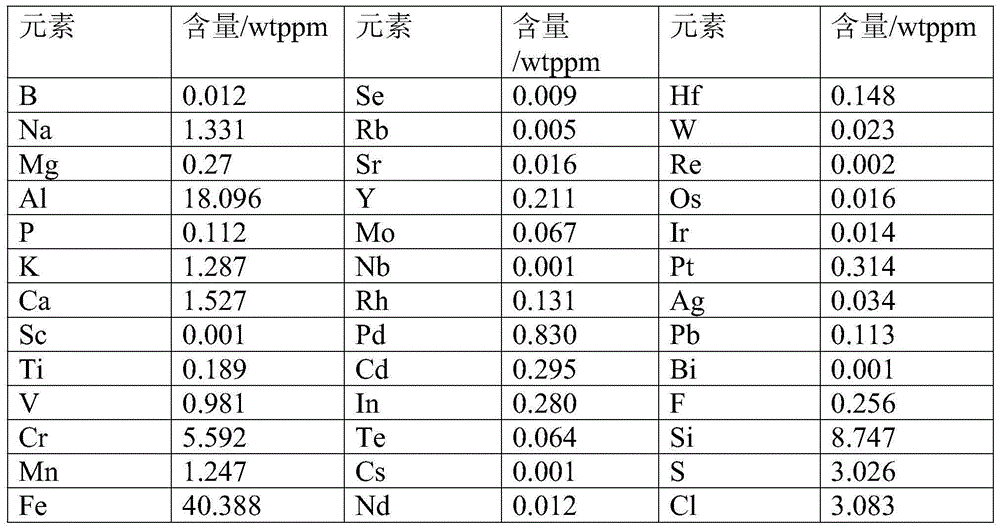

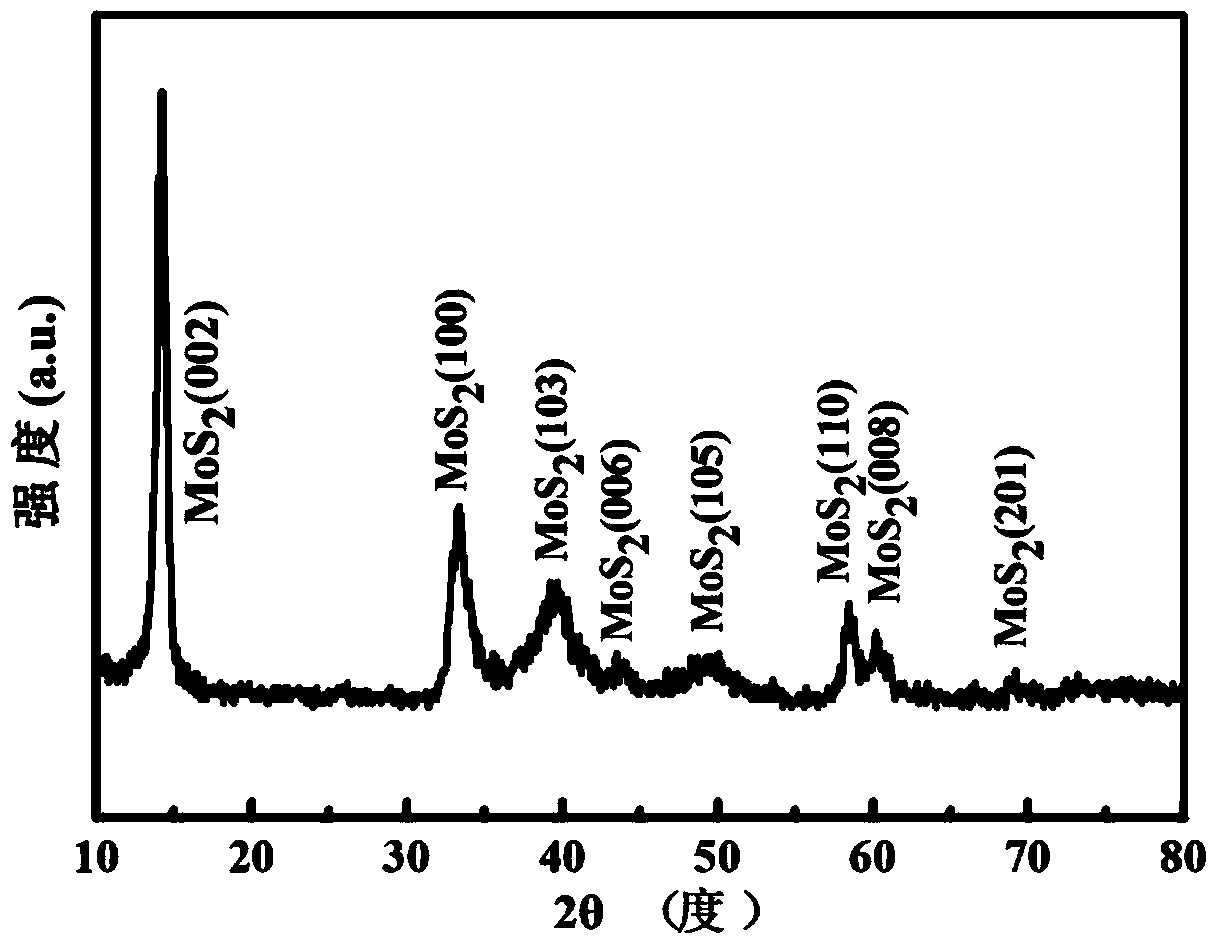

Molybdenum disulfide nano-hydrangea structural semiconductor material and preparation method thereof

InactiveCN104556230AWill not introduceSimple methodMaterial nanotechnologyMolybdenum sulfidesSodium molybdateOxalate

The invention discloses a molybdenum disulfide nano-hydrangea structural semiconductor material. The molybdenum disulfide nano-hydrangea structural semiconductor material comprises hierarchical nano-balls, wherein each nano-ball is formed by agglomerating molybdenum disulfide nano scales with the thickness of 2 to 4 nm. The invention further discloses a preparation method for the molybdenum disulfide nano-hydrangea structural semiconductor material. The molybdenum disulfide nano-hydrangea structural semiconductor material is synthesized by a one-step hydrothermal method, and is prepared by respectively dissolving sodium molybdate, thioacetamide and oxalic acid, mixing and reacting. The molybdenum disulfide nano-hydrangea structural semiconductor material and the preparation method thereof have the advantages of low cost, relatively low growth temperature and relatively high repeatability, and have a wide application prospect in the aspect of field emission.

Owner:EAST CHINA NORMAL UNIV

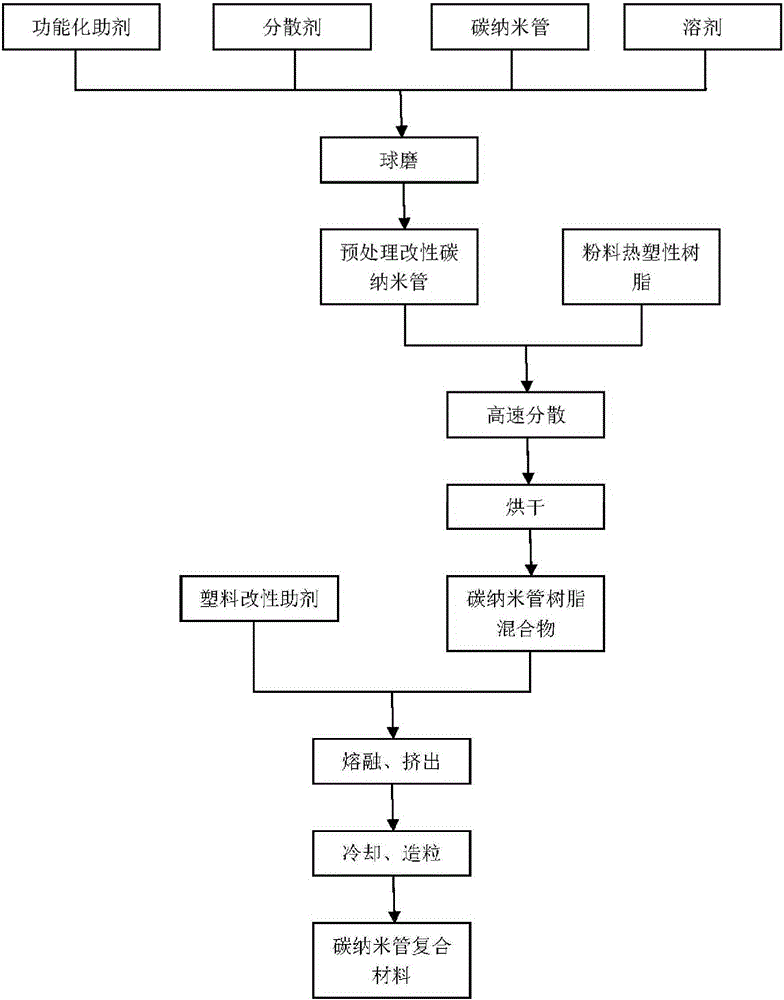

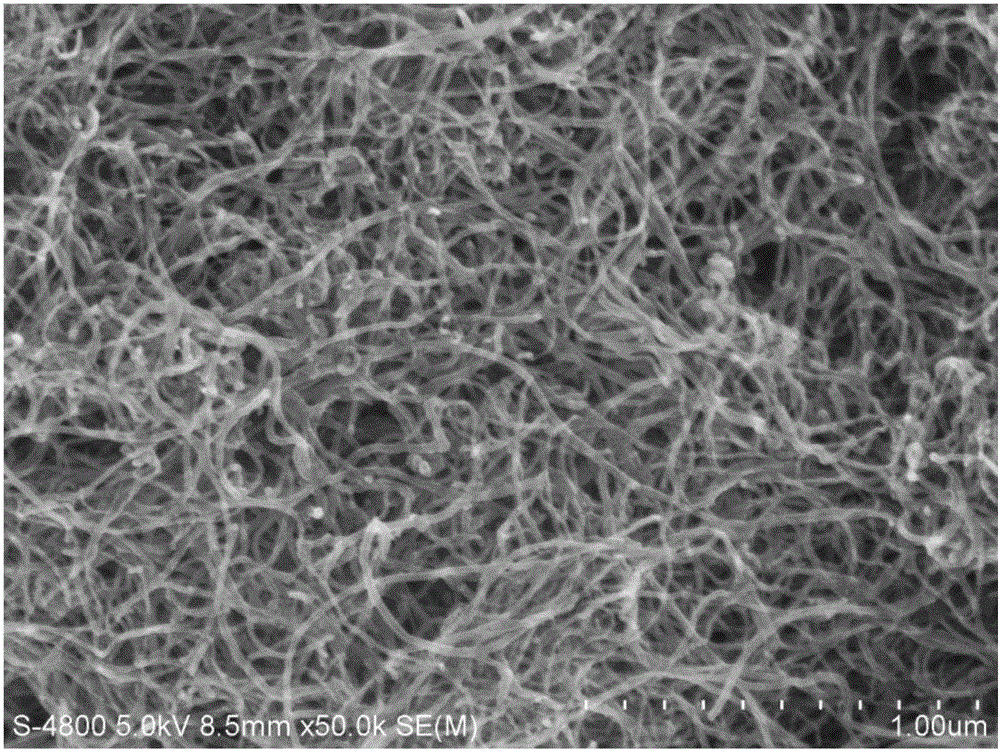

Carbon nanotube modified thermoplastic resin and preparation method thereof

The invention discloses carbon nanotube modified thermoplastic resin and a preparation method thereof. The preparation method is as follows: mixing carbon nanotubes, a functional agent, a dispersing agent and a solvent for ball milling to obtain pretreated modified carbon nanotubes; using a high speed dispersion process for fully stirring and mixing the pretreated modified carbon nanotubes and thermoplastic resin powder to obtain a stably-dispersed carbon nanotube / resin mixture; drying the carbon nanotube / resin mixture, adding a plastic modified additive, and using a double screw extruder for melt extrusion and cooling granulation to obtain the target product. Through use of carbon nanotube functionalization and pre dispersion one-step treatment process, the process is greatly simplified; at the same time, the thermoplastic resin powder is used as a raw material to obtain effective mixing and dispersion of pretreated carbon nanotube powder, and then carbon nanotube high volume filling can be realized. The preparation method has the obvious advantages of simple process, environmental protection, low cost and the like, and is an effective preparation technology of a carbon nano tube functional master batch.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Aroma improvement method for filter stick forming paper

ActiveCN102619134AIncrease aroma concentrationHarmonious smokeTobacco treatmentPaper coatingTobacco leafOrganic chemistry

The invention discloses an aroma improvement method for filter stick forming paper. The method comprises the following steps of: (1) mixing the Yunnan K326 planted in Yunnan and Yunnan Honghuadajinyuan tobacco leaves in a proportion of 1:(1-3), crushing or shredding to obtain a fragrance source, and performing normal-temperature extraction for 48 hours by use of 95-98% of ethanol solution to obtain fragrance extract; (2) performing pressure-reduced distillation of the filtrate under the conditions that the vacuum degree is 0.02-0.08MPa and the temperature is 60-85 DEG C, and separating to obtain an aromatic substance with a boiling point of 150-260 DEG C at normal pressure; and (3) coating the aromatic substance on the forming paper in a manner that the aromatic substance accounts for 0.5-4.0% of the mass of the dry forming paper. In the invention, the tobacco aromatic substance is added, and miscellaneous gas is not led in during cigarette suction so as to achieve the aims of increasing the cigarette aroma, regulating the cigarette flavor, improving the comfort and promoting the cigarette suction quality. By selecting proper fragrance and an extraction method and combining a coating method with a drying method, the invention develops a method capable of obviously increasing the aroma and effectively improving the cigarette suction quality without influencing the performance of the filter stick forming paper.

Owner:CHINA TOBACCO GUANGDONG IND +1

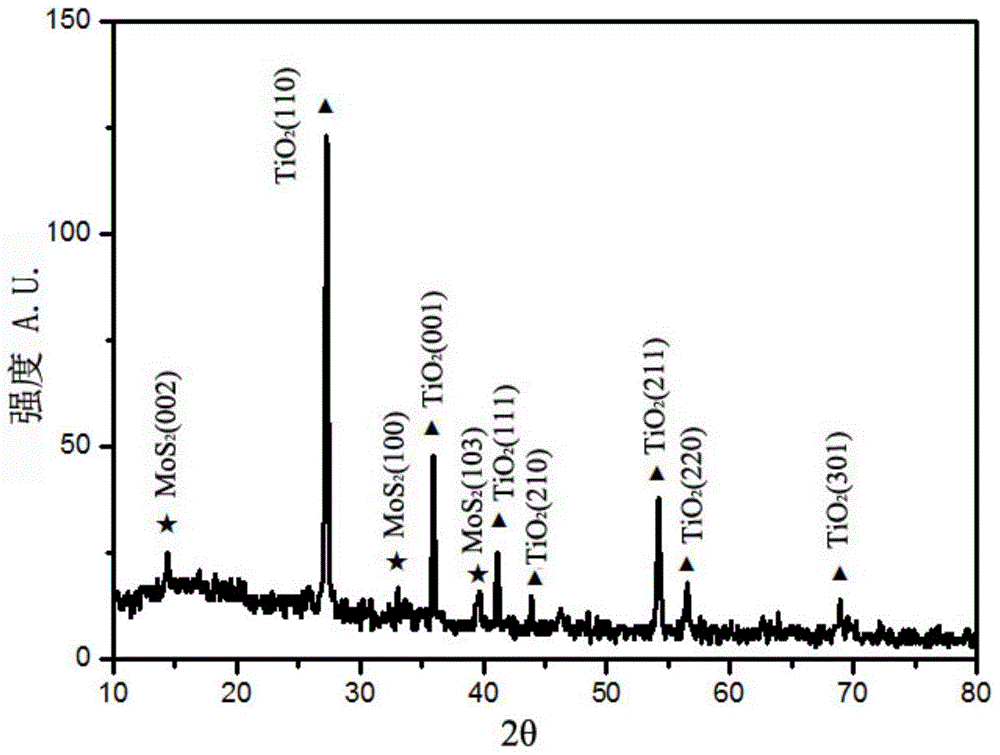

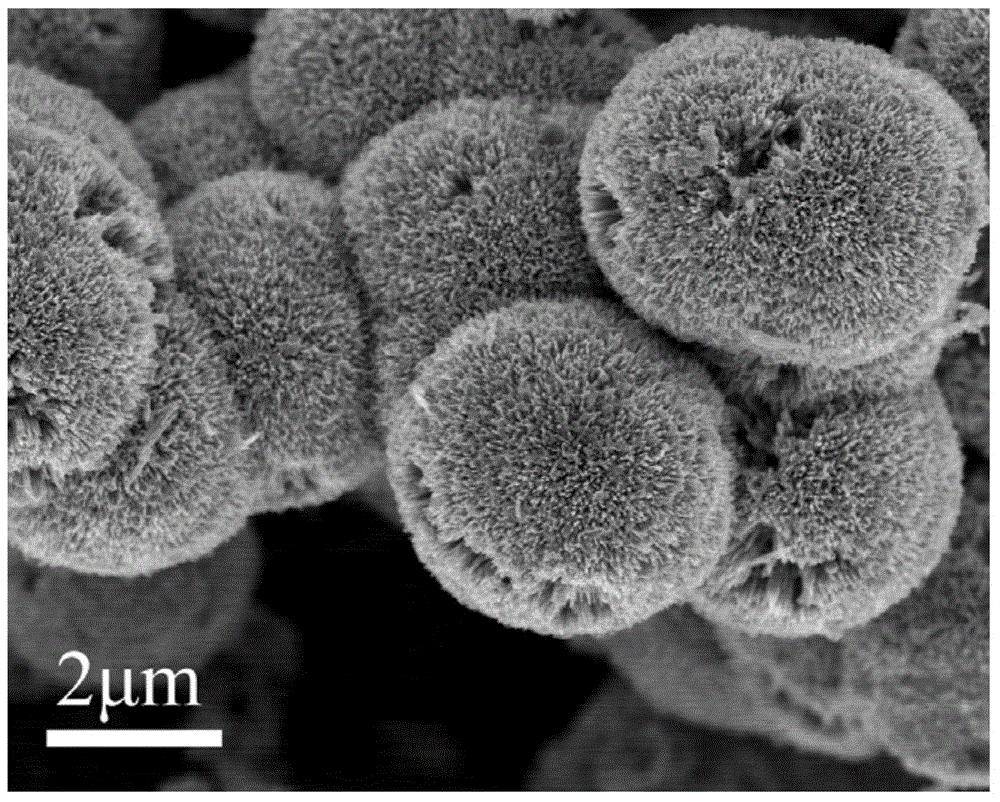

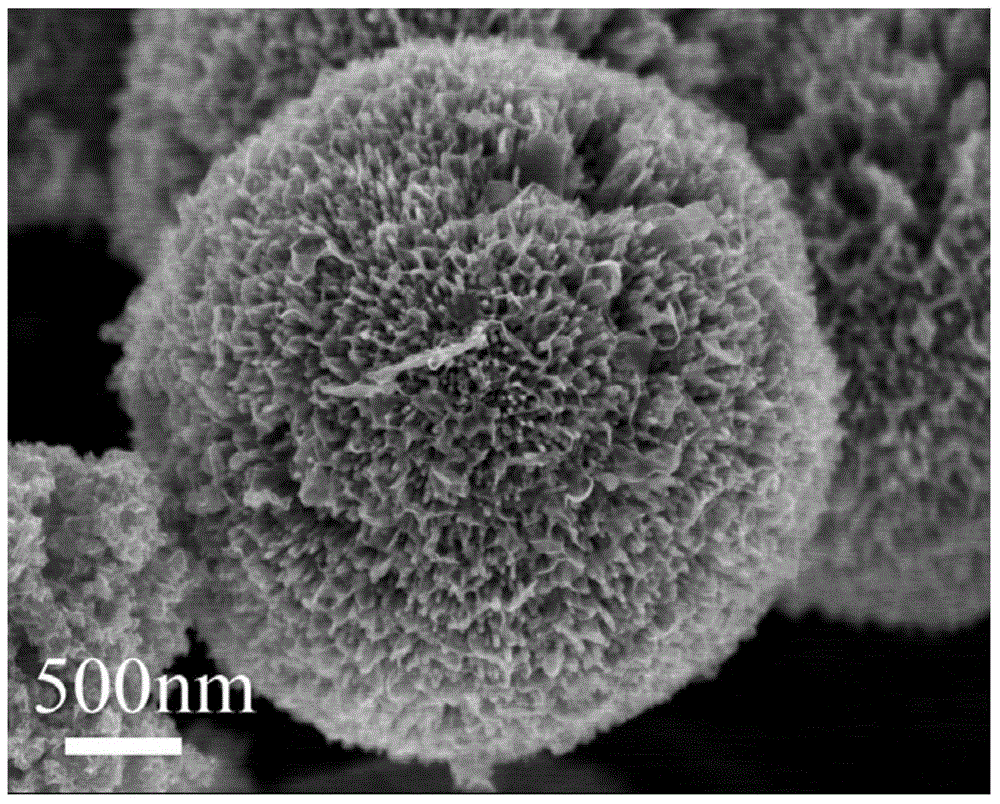

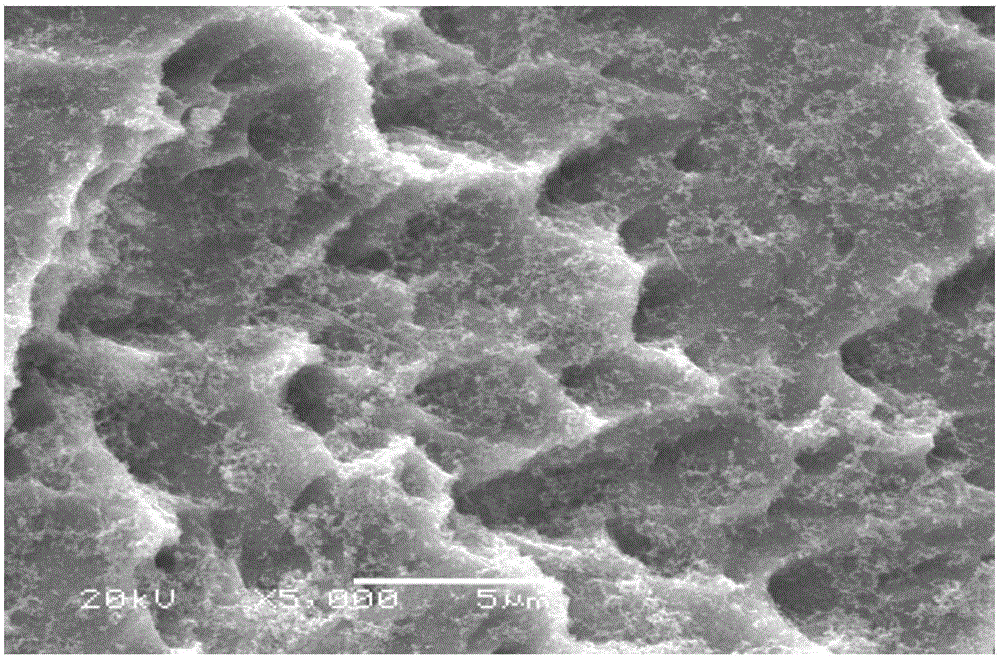

Wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material and preparation method thereof

InactiveCN104437555AGuaranteed vacuum environmentWill not introducePhysical/chemical process catalystsHeterojunctionPhoto catalytic

The invention discloses a wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material. The wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material contains MoS2 nanosheets and TiO2 dandelion nanospheres, wherein the MoS2 nanosheets penetrate through the space among nanorods on the TiO2 dandelion nanospheres uniformly and can be stably combined with gaps among the nanorods,. The invention also discloses a method for preparing the wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material by a two-step solvent method. The wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material and the method have the advantages that the preparation operation is simple, the yield is high and the cost is low, and the wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material has great potential and wide application prospect in the fields of photo-catalytic industrial wastewater and field emission.

Owner:EAST CHINA NORMAL UNIV

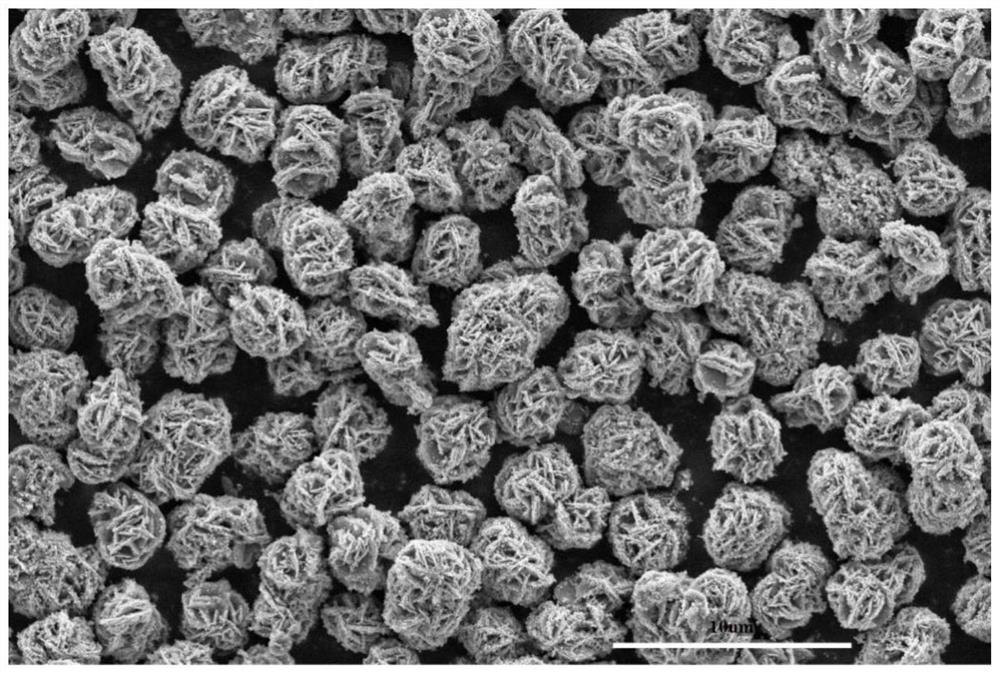

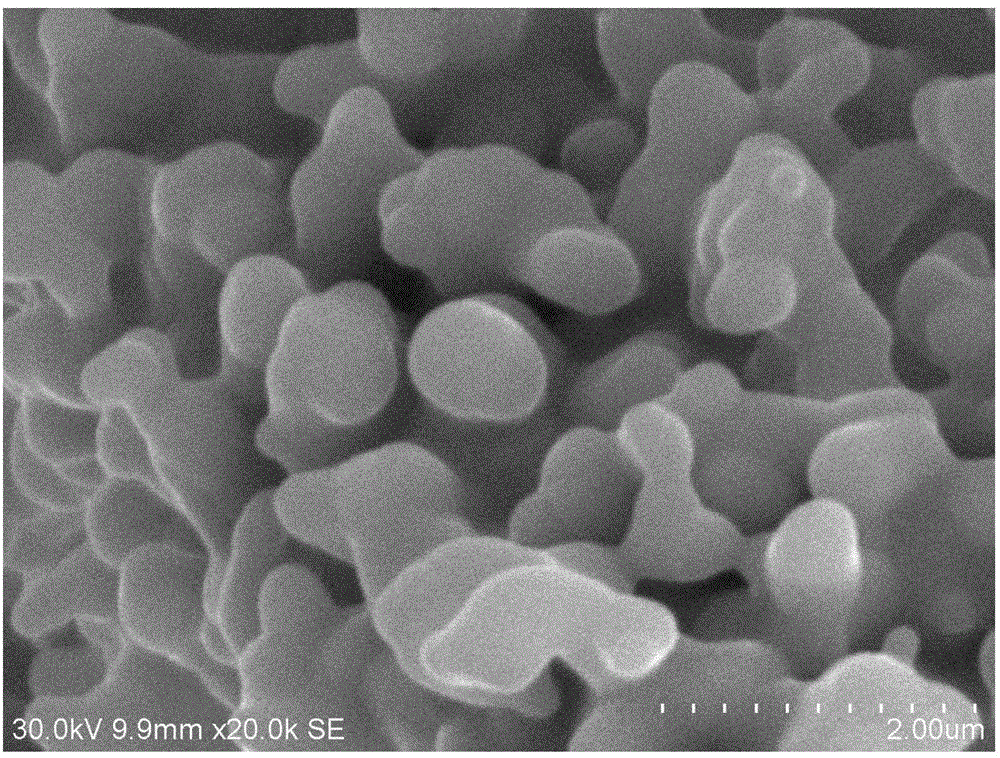

Massproduction method of single crystal cobalt-free lithium-rich manganese-based binary material precursor

PendingCN112158889ALow costLow raw material costCell electrodesManganese compoundsNickel saltLiquid ammonia

The invention discloses a mass production method of a single crystal cobalt-free lithium-rich manganese-based binary material precursor. The method comprises: 1, preparing a solution A from a nickel salt and a manganese salt, and adopting a NaOH solution as a precipitating agent B, ammonia water as a complexing agent C and a sodium sulfite solution as a reducing agent D; 2, preparing a base solution, introducing N2, enabling the pH value of the base solution to 11-13 by using ammonia with the concentration of 3-10 g / L, and stirring at a temperature of 30-60 DEG C under a stirring speed of 200-500 rpm; step 3, adding the solution A, a solution B, a solution C and a solution D into a reaction kettle at the same time, and keeping the pH at 10-12, the concentration of supernatant liquid ammonia at 3-10 g / L, the temperature at 30-60 DEG C and the stirring speed at 200-500 rpm; and 4, stopping feeding after D50 reaches the target particle size, and carrying out centrifugal washing, drying, screening, iron removal and packaging to obtain the single-crystal cobalt-free lithium-rich manganese-based binary material precursor.

Owner:JINGMEN GEM NEW MATERIAL

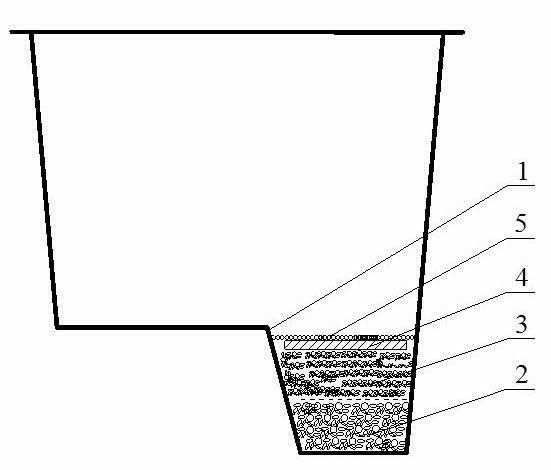

Spheroidizing treatment technology by rush-in method

The invention relates to a spheroidizing treatment technology by rush-in method, comprising the following steps: adding a nodulizer and an inoculant successively in a ladle pit or a dam; using a ductile iron plate to cover the nodulizer and the inoculant; scattering a covering agent on the ductile iron plate; dumping molten iron into the ladle; scattering a slag collecting agent after the spheroidizing reacts sufficiently, and removing the slag. By covering the nodulizer and the inoculant with the ductile iron plate and the covering agent successively, the covering agent containing perlite expands rapidly under the condition of instantaneous high-temperature to form a protective layer, so that the temperature of the spheroidizing reaction is reduced, the time of the spheroidizing reaction is prolonged and the spheroidization effect is improved.

Owner:JIANGLING MOTORS

Preparation method of full-compact nanometer compound rare earth permanent magnetic material

ActiveCN101345108AEvenly distributedWill not introduceInorganic material magnetismRare earthCompound (substance)

The invention provides a preparation method of full-density nanometer composite rare earth permanent magnetic material, comprising the process steps as follows: (1) non-crystal nanometer rare earth permanent magnetic powder is put into a reaction chamber where inert gas is pumped into so as to eliminate air in the reaction chamber; subsequently, the inert gas is taken as carrier gas; pentacarbonyl iron steam is brought into the reaction chamber and carries out chemical vapour deposition under the vibration condition; the pentacarbonyl iron steam is decomposed so as to generate elementary substance Fe which is deposited on the surface of the rare earth magnetic powder so as to form the rare earth permanent magnetic powder / elementary substrate Fe composite magnetic powder; (2) the rare earth permanent magnetic powder / elementary substrate Fe composite magnetic powder is put into a discharging plasma sintering device or an induction sintering device so as to carry out vacuum pressurization sintering, thus obtaining the full-density nanometer composite rare earth permanent magnetic material. The method of the invention can not only prepare the full-density nanometer dual-phase composite magnetic body with high performance, but also has simple technology and low cost.

Owner:SICHUAN UNIV

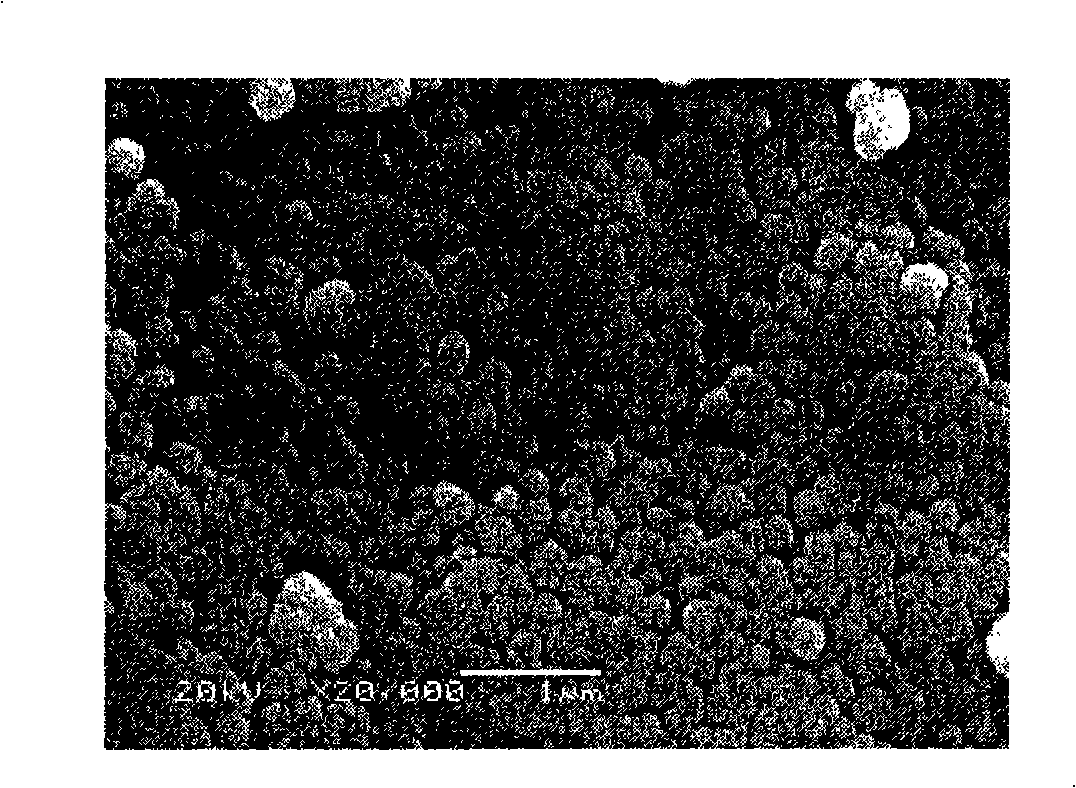

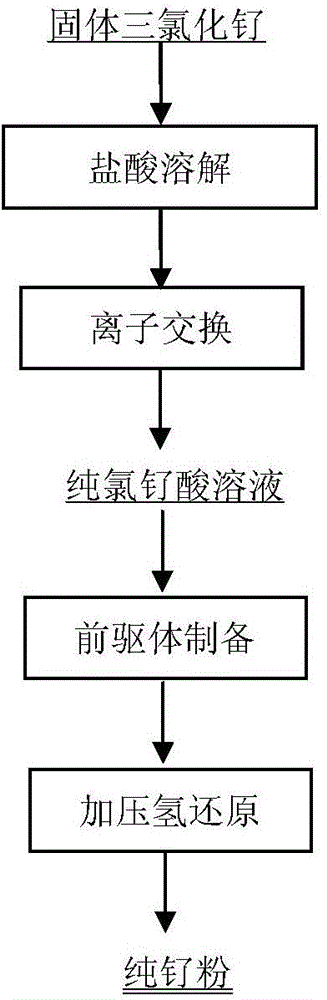

Method for preparing ruthenium powder for target materials from ruthenium trichloride

The invention discloses a method for preparing ruthenium powder for target materials from ruthenium trichloride. The method comprises the following steps of (1) dissolving: solid ruthenium trichloride is dissolved by hydrochloric acid to obtain a chlororuthenite solution; (2) ion exchange purification: the solution obtained in the step (1) is subjected to positive ion impurity removal through ion exchange resin to obtain a pure ruthenium solution; (3) precursor preparation: alkali is added into the pure ruthenium solution to generate ruthenium oxide hydrate precipitates, deionized water is continuously added for pulpifying, the pH value is regulated, and ruthenium powder precursors are obtained; and (4) pressurization hydrogen reduction: the precursors obtained in the step (3) are placed into a high-pressure reaction kettle and are heated, hydrogen gas is introduced, certain hydrogen partial pressure is maintained for carrying out reduction, solid-liquid separation is carried out, the deionized water is used for sufficiently washing the materials, and pure ruthenium powder is obtained after the vacuum drying. The method provided by the invention has the advantages that the process is simple, the impurity content of the ruthenium powder is low (lower than 100ppm), the direct yield is greater than 99 percent, the microcosmic micro appearance of the obtained ruthenium powder is in a spherical shape, the granularity is 2 to 5 mum, and the method conforms to the production requirements of ruthenium target materials.

Owner:KUNMING INST OF PRECIOUS METALS

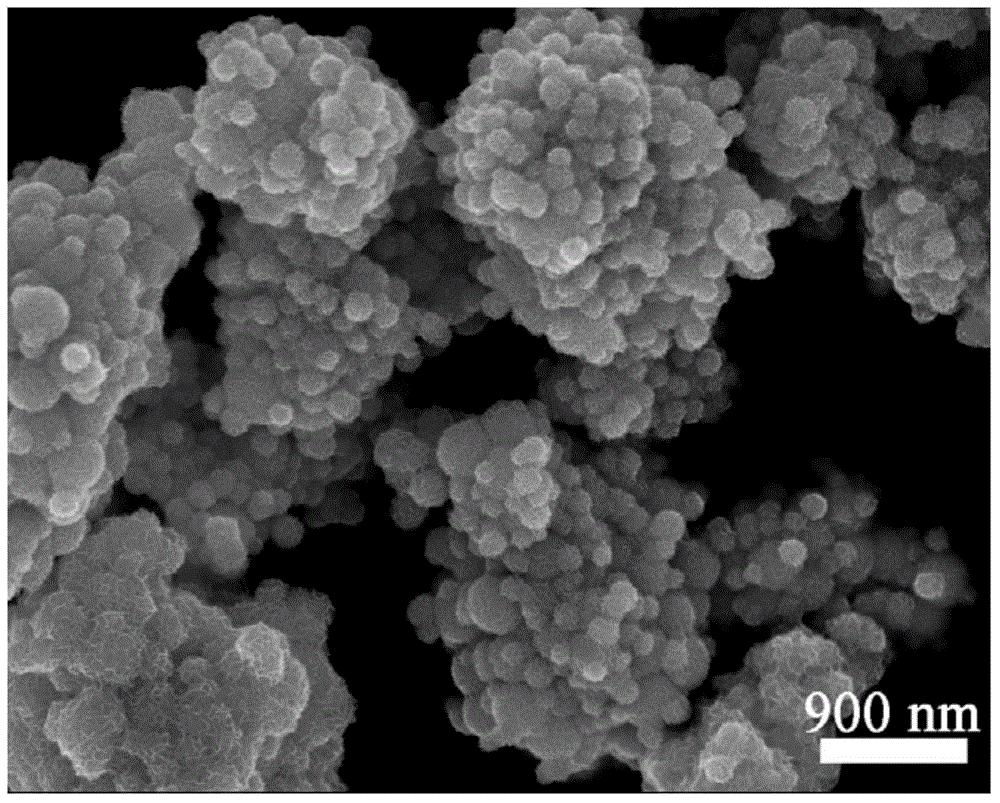

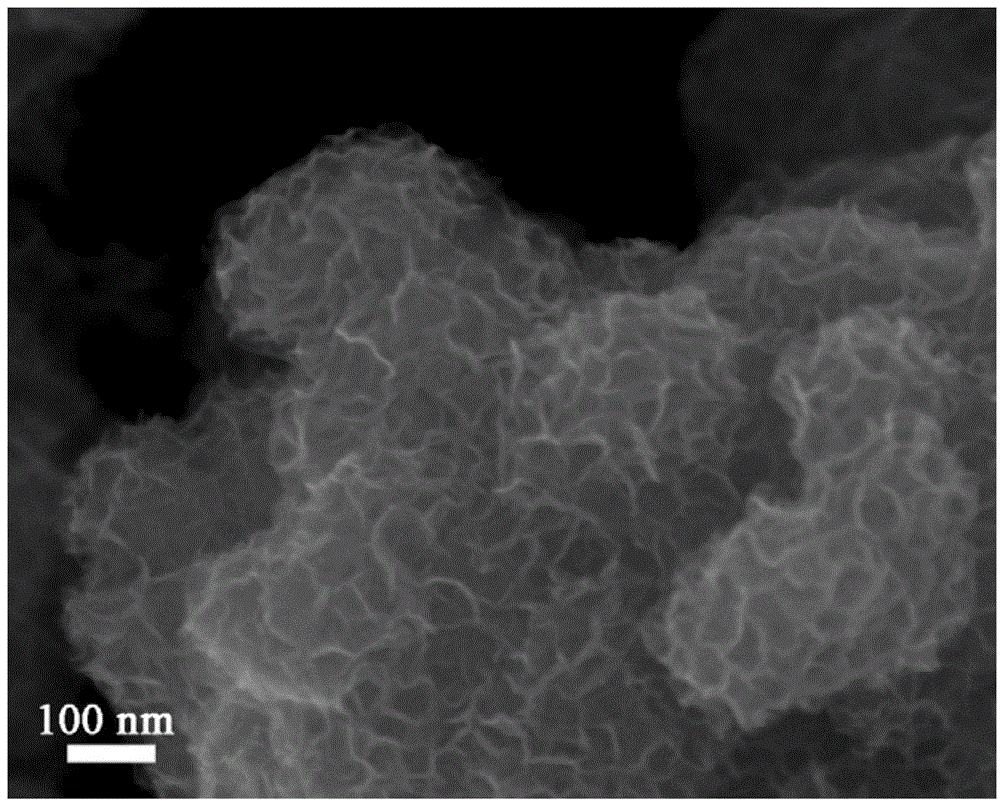

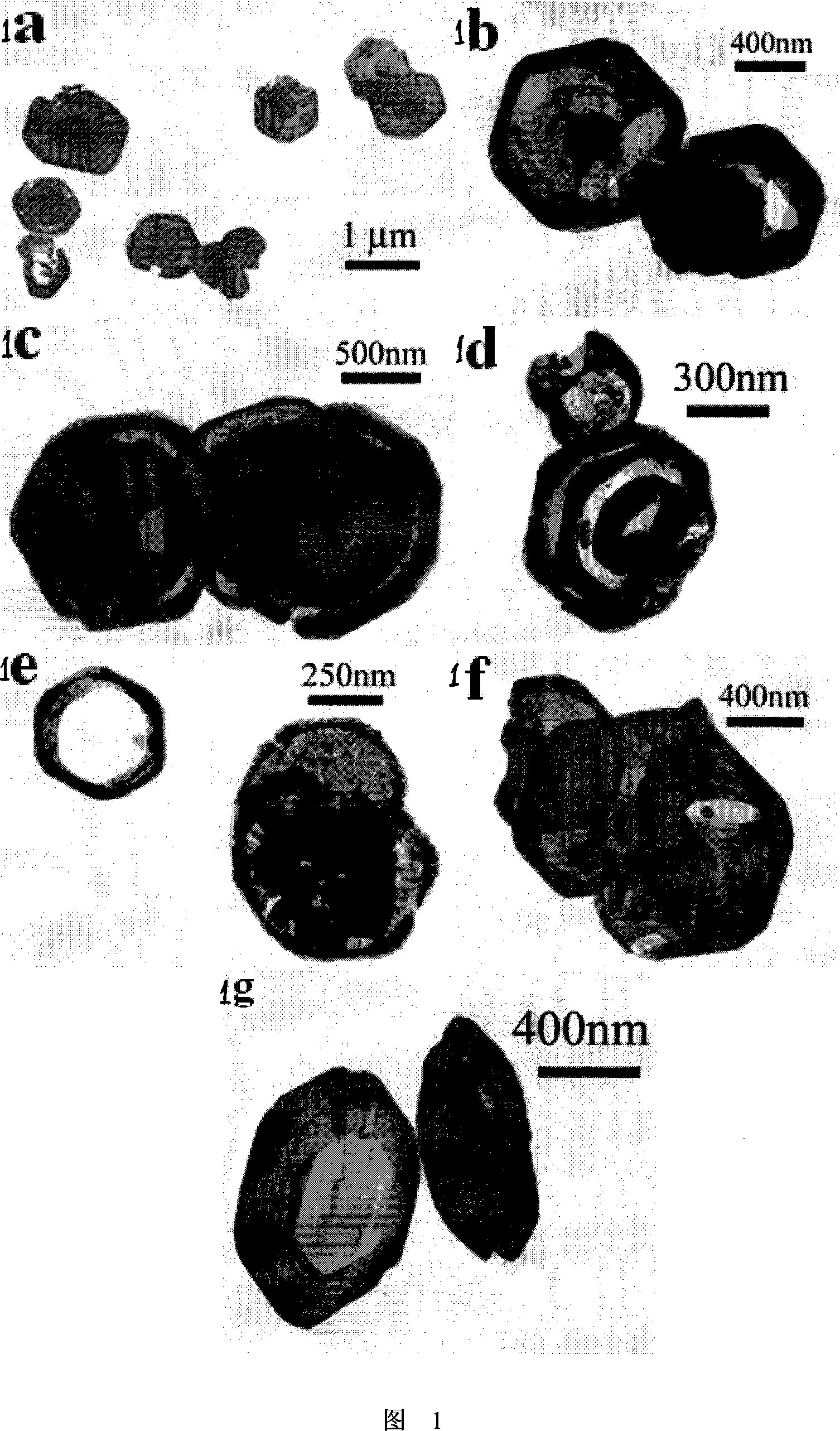

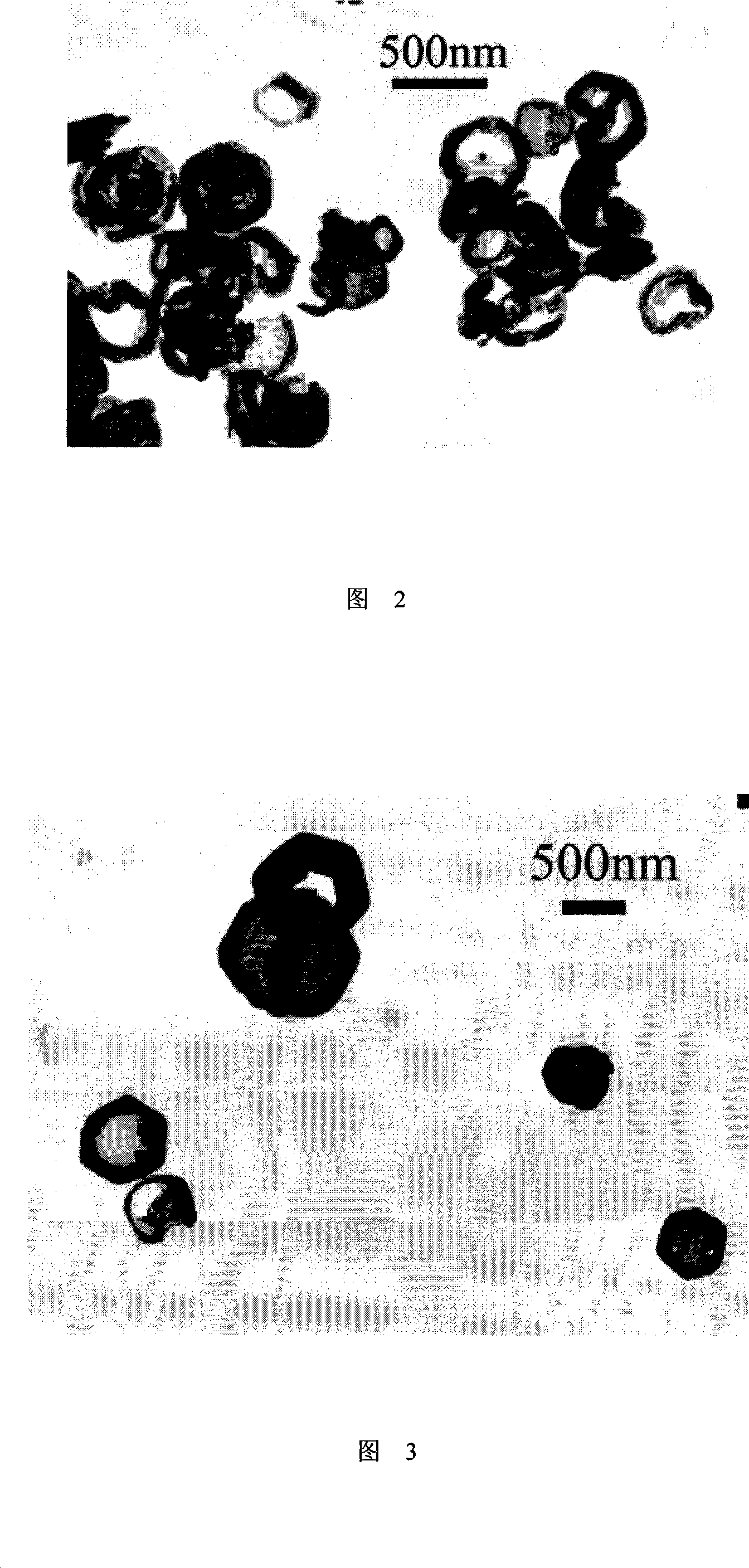

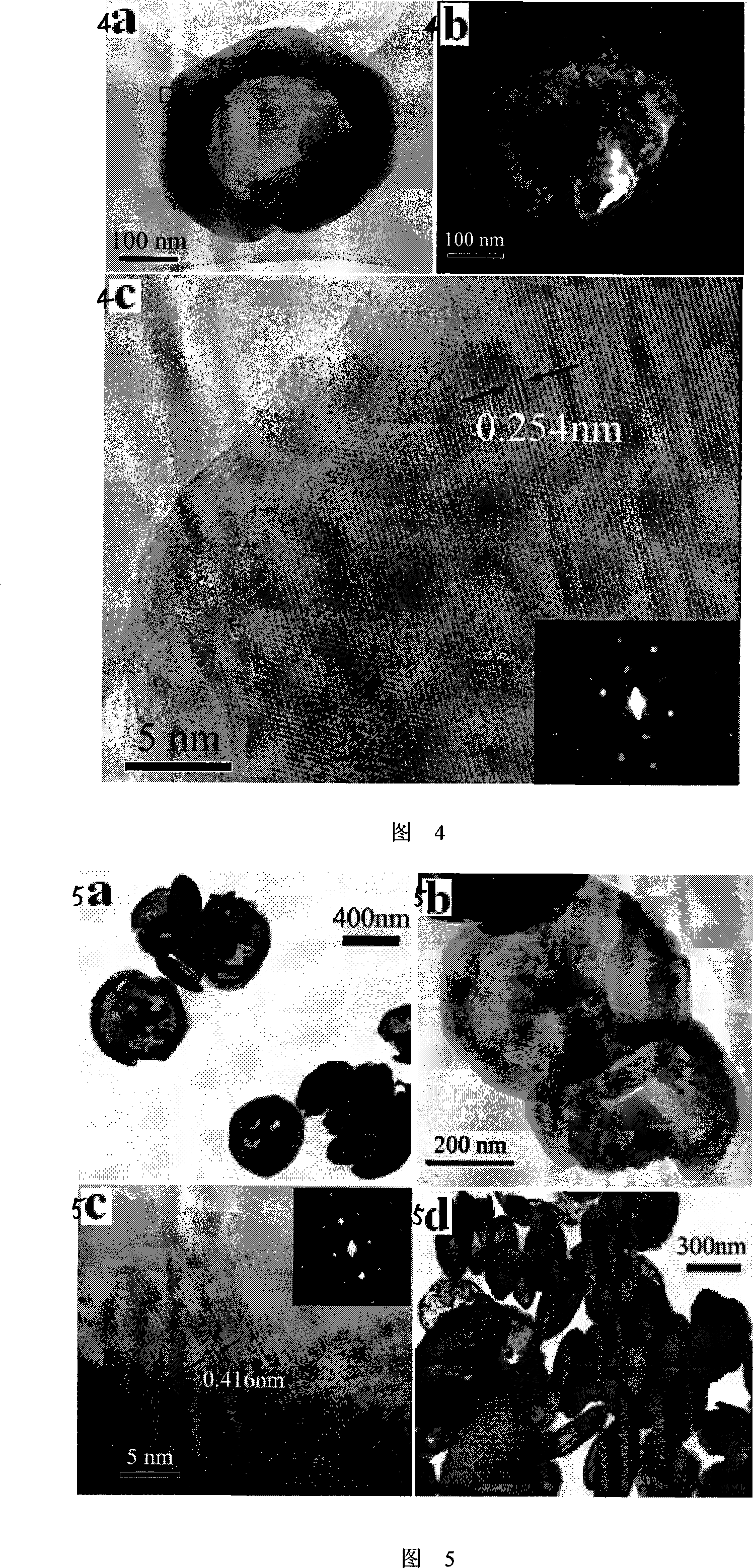

Nanosphere encapsulated MoS2 micron hollow sphere structure semiconductor material and preparation method thereof

InactiveCN104192908ASimple methodThe method is simpleMaterial nanotechnologyMolybdenum sulfidesMicron scaleIndustrial waste water

The invention discloses a nanosphere encapsulated MoS2 micron hollow sphere structure semiconductor material. The nanospher encapsulated MoS2 micron hollow sphere structure semiconductor material comprises MoS2 micron-scale spheres and MoS2 nano scale spheres, wherein the nano scale spheres are uniformly dispersed and grown on the surface of the micron scale spheres; the MoS2 micron scale spheres are hollow and have thin spherical shells, the nano scale spheres are of an onion-like structure and are formed by nesting the spherical shells layer by layer, and the small part at the center of structure is hollow. The invention also discloses a preparation method of the nanosphere encapsulated MoS2 micron hollow sphere structure semiconductor material. A MoS2 spherical structure with two diameters can be prepared by only adopting a one-step hydro-thermal method. The preparation method of the nanosphere encapsulated MoS2 micron hollow sphere structure semiconductor material has the advantages of less product impurities and low preparation cost, and is simple to prepare. The nanosphere encapsulated MoS2 micron hollow sphere structure semiconductor material has great development potential in the fields of photocatalysis on industrial waste water and field emission.

Owner:EAST CHINA NORMAL UNIV

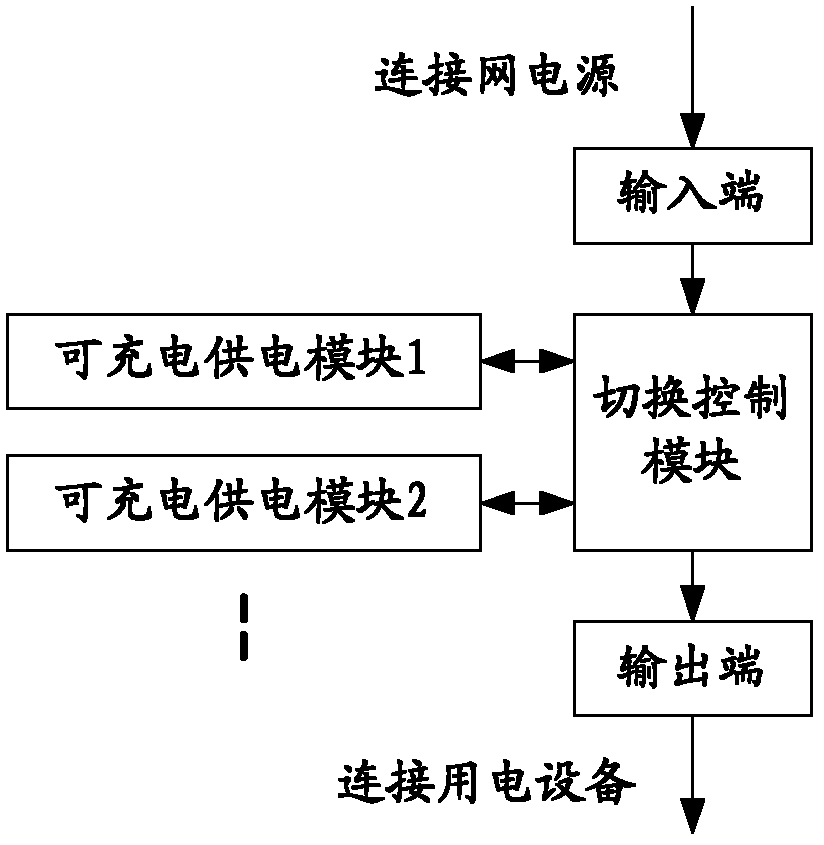

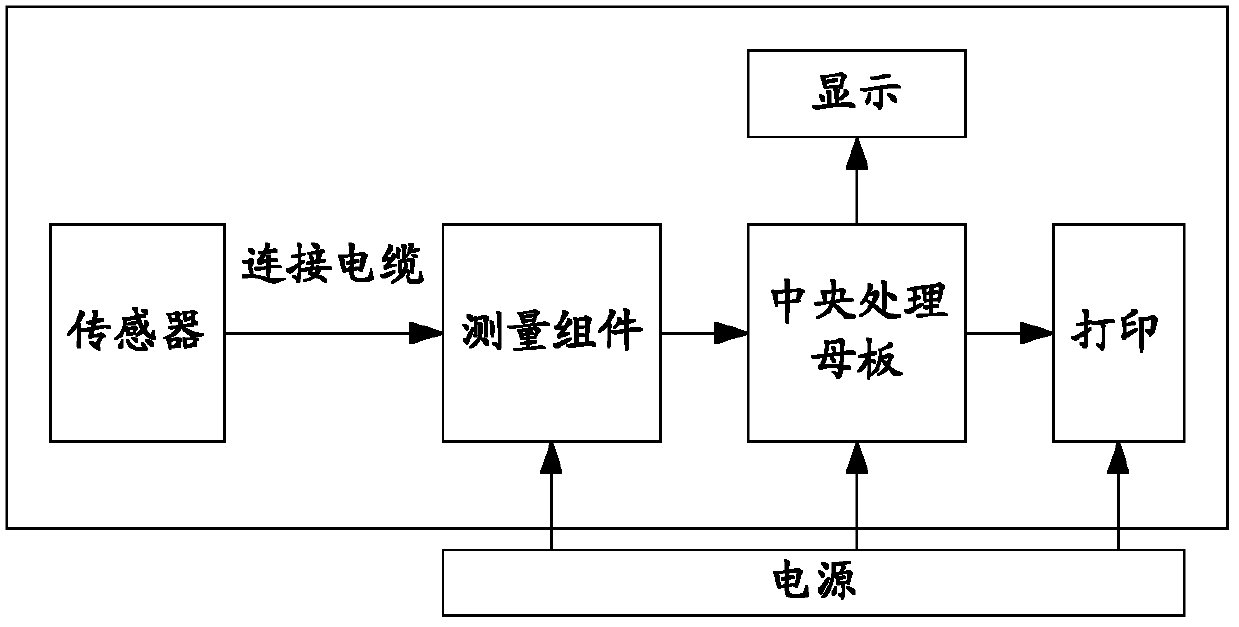

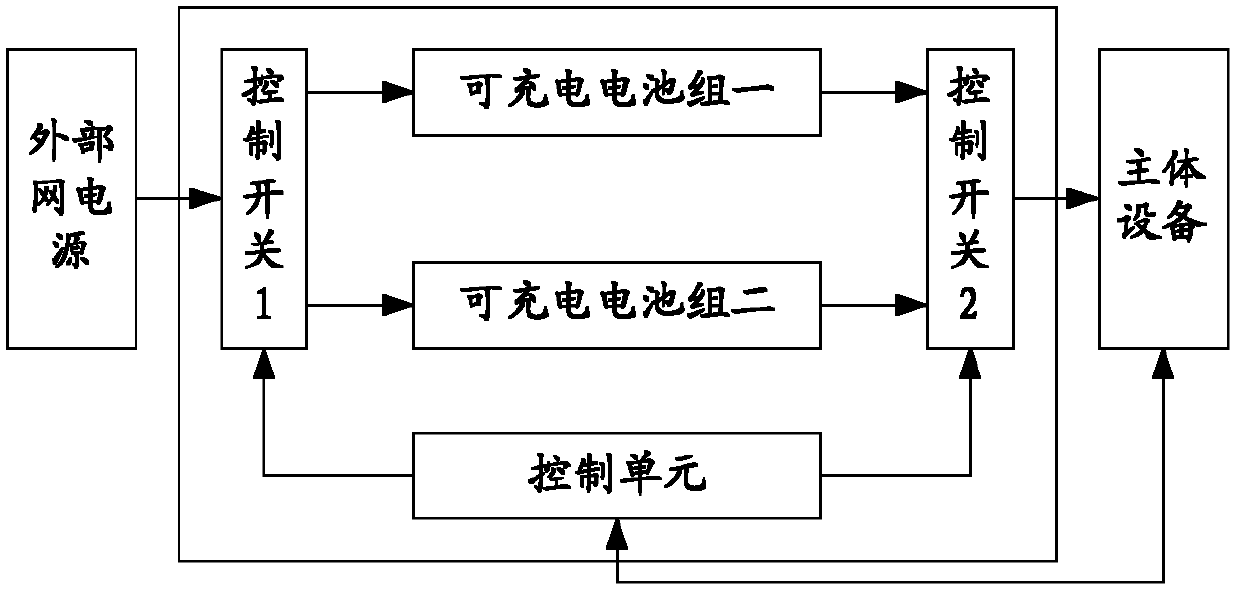

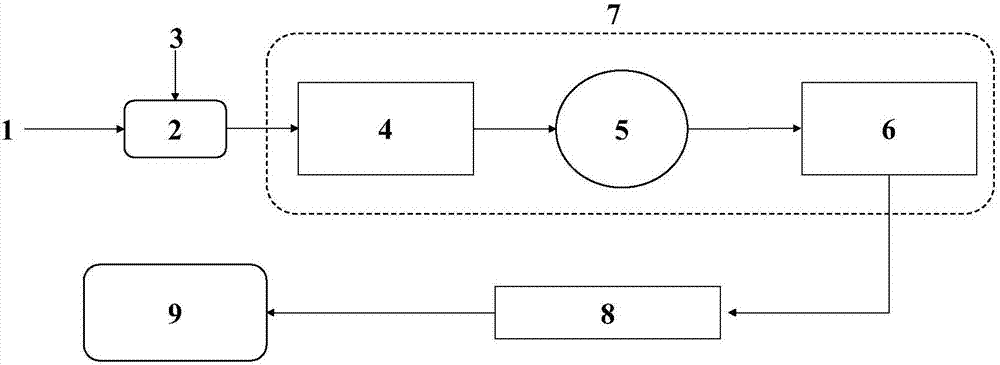

Power source for medical equipment and power supply method for same

ActiveCN103296744AReduce distractionsWill not introduceEmergency power supply arrangementsElectricityEngineering

The invention discloses a power source for medical equipment. The power source for the medical equipment comprises an input end which is connected with a grid electricity power source, an output end which supplies power to the medical equipment, at least two chargeable power supply modules and a switching control module, wherein the switching control module controls the two chargeable power supply modules to be connected with the output end and the input end, so that the chargeable power supply module which is connected with the output end is made to be isolated from the chargeable power supply module which is connected with the input end. The invention further discloses a power supply method for the medical equipment. According to the power source for the medical equipment, one of the chargeable power supply modules is adopted to supply power, the chargeable power supply module is isolated from the grid electricity power source when executing power supply, and therefore interference of the grid electricity power source to the medical equipment is reduced.

Owner:SHENZHEN WEITUOLI MEDICAL ELECTRONICS

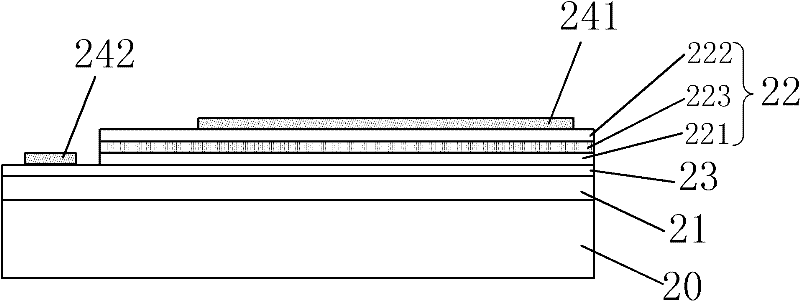

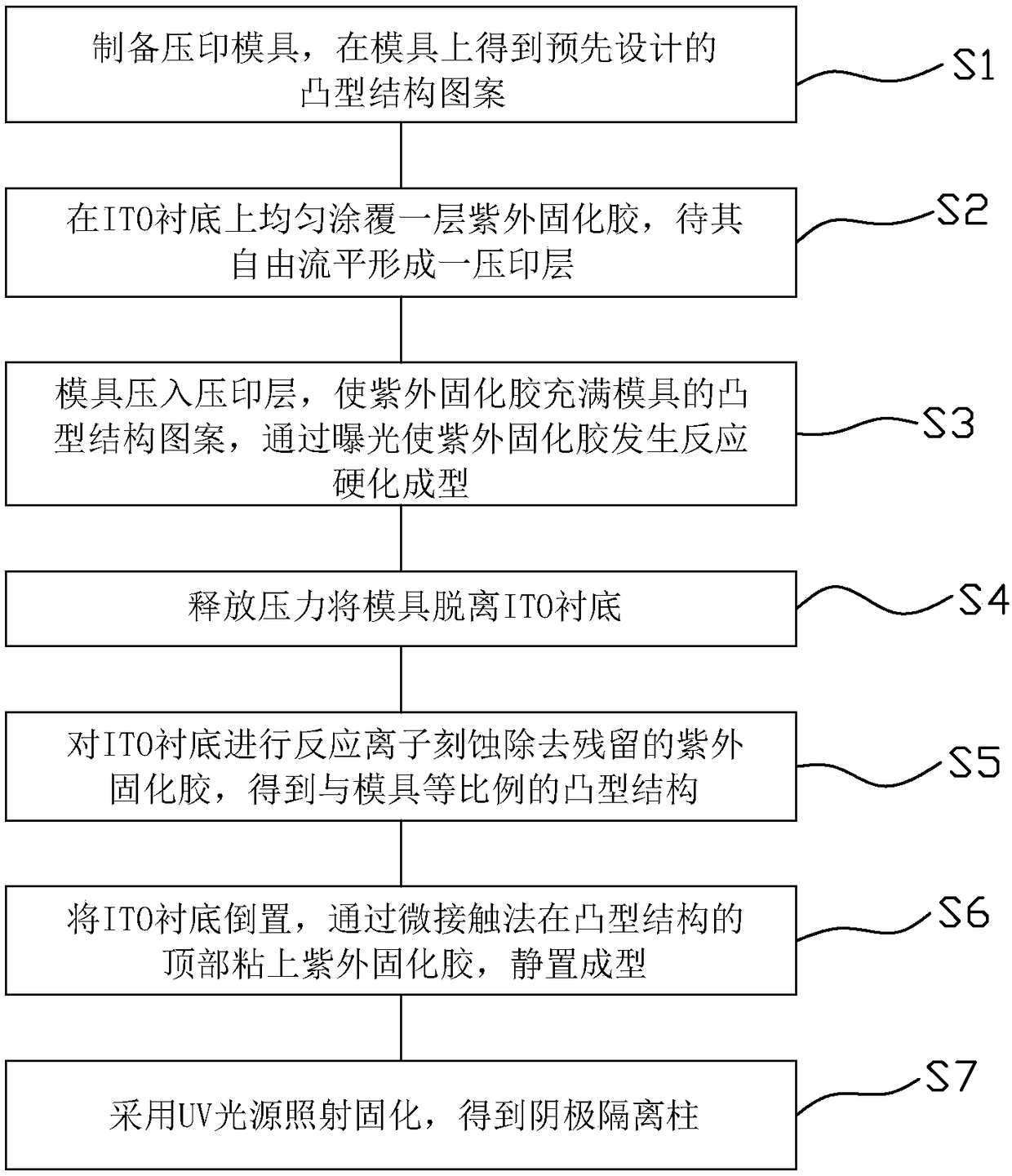

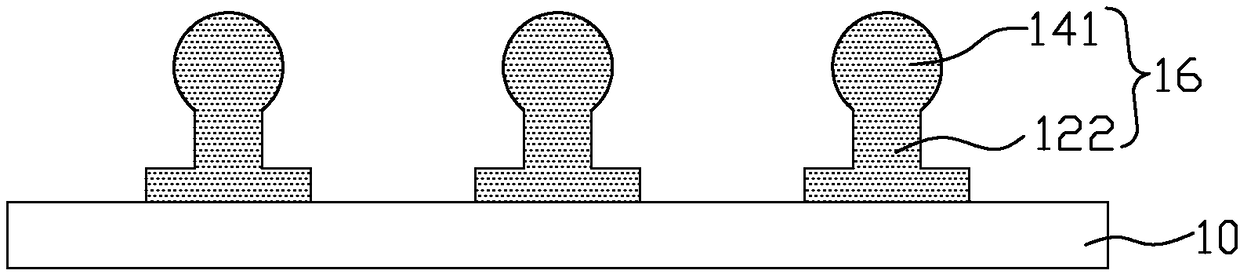

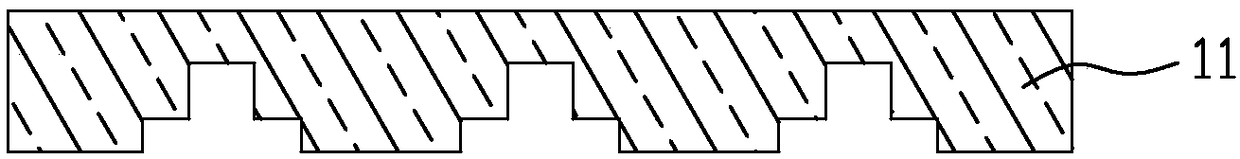

Preparation method of cathode isolation column of organic light emitting display

ActiveCN108539054ASimple processWill not introduceSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureImage resolution

The invention discloses a preparation method of a cathode isolation column of an organic light emitting display (OLED). The preparation method comprises the following steps: firstly, preparing a coining mold, and obtaining a predesigned convex structural pattern on the mold; uniformly applying a layer of ultraviolet solidification glue on an ITO substrate, and allowing the ultraviolet solidification glue to freely flow to be flat and form a coining layer; pressing the mold in the coining layer, filling the convex structural pattern of the mold with the ultraviolet solidification glue, and through exposure, enabling the ultraviolet solidification glue to have a reaction to be hardened and formed; releasing pressure to separate the mold from the ITO substrate; performing reactive ion etchingon the ITO substrate to remove remained ultraviolet solidification glue, and obtaining a convex structure of which the ratio is the same as that of the mold; inverting the ITO substrate, adhering theultraviolet solidification glue to the top of the convex structure through a micro contact method, and performing standing forming; and performing irradiation solidification with an UV light source,so as to obtain the cathode isolation column. According to the preparation method disclosed by the invention, an ultraviolet coining technology is adopted, so that the cathode isolation column is prepared under room temperature and constant pressure; the preparation method is simple in technology and few in steps, and besides, moisture cannot be introduced; the device life of the OLED is greatly prolonged; and the pixel resolution is obviously increased.

Owner:SUZHOU WEIYEDA TOUCH TECH +2

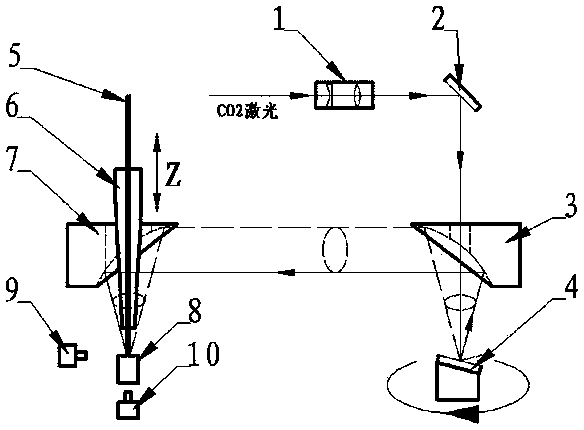

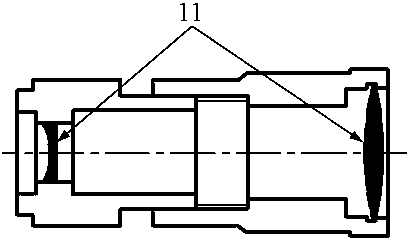

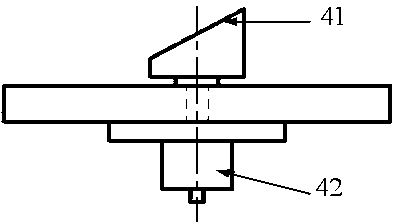

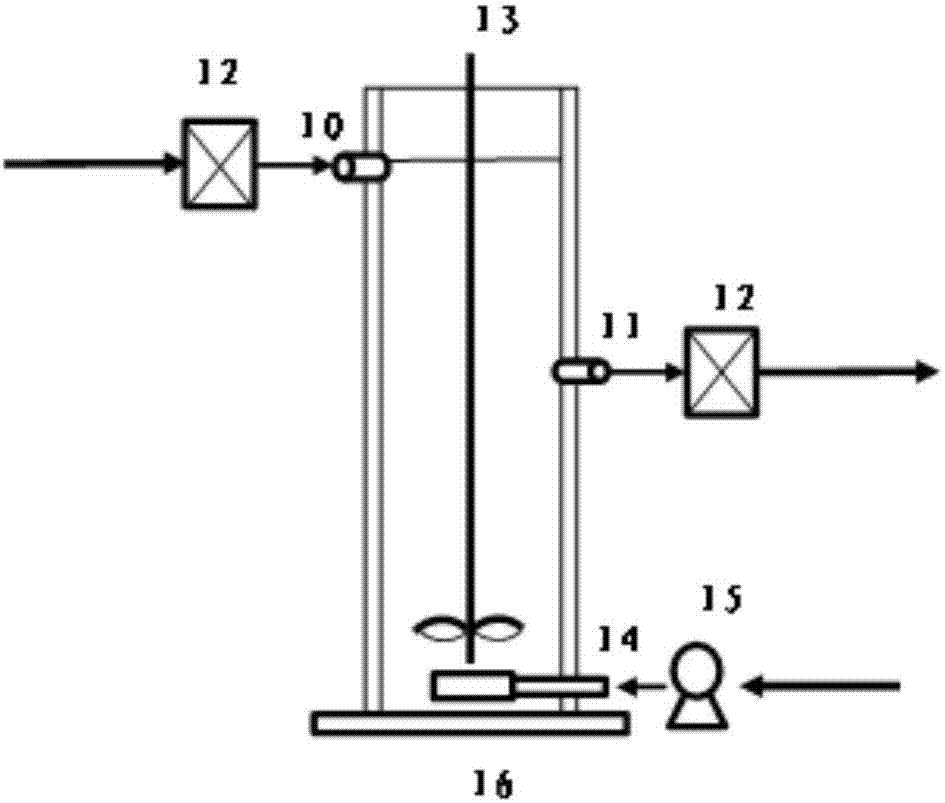

Device and method for welding optical fibre and end cap

The invention relates to a device and a method for welding an optical fibre and an end cap. The device comprises the following components: a beam expansion and collimation lens (1) used for carrying out beam expansion and collimation on a laser emitted by a laser emitter, a reflector (2) used for reflecting and reversing the laser emitted out of the beam expansion and collimation lens (1), a rotary reflector (4) used for reflecting the laser reflected by the reflector (2) into a conical light beam, an off-axis parabolic reflector I (3) used for reflecting the conical light beam reflected and expanded by the rotary reflector (4) again into an annular light beam, and an off-axis parabolic reflector II (7) used for focusing the annular light beam reflected by the off-axis parabolic reflector I (3) on the welded portion of the optical fibre (5) and the quartz end cap (8). The device and the method for welding the optical fibre and the end cap are convenient to apply and weld, and good in welding effect.

Owner:JIANGSU FASTEN OPTOELECTRONICS TECH

Method for producing cerium fluoride hollow nanostructured material

InactiveCN101172637AMeet the concentrationLow priceNanostructure manufactureFluoride preparationSucroseHigh pressure

A method for preparing hollow cerium fluoride nanometer structure material comprises the steps as follows: the oscillating reaction adopts potassium bromate, sodium bromate-organic acid or sugar-cerium-sulphuric acid, with the consistence of 0.06 plus or minus 0.04, 0.06 plus or minus 0.04, 0.02 plus or minus 0.02 and 0.6 plus or minus 0.4mol / L respectively; Naf is adopted as the fluorin source with consistence of 0.1 to 0.5mol / L; the preparative process of hydro-thermal reaction is performed under the temperature of 110 to 170 DEG C. The cerium source can be K7Ce6F31 powder, ammonium ceric nitrate or ceric ammonium sulfate; the organic acid or the sugar can use the organic matter such as propane diacid, oxalic acid, sucrose and glucose to replace the citric acid. The preparation of the hollow cerium fluoride nanometer structure material needs 12 to 100 hours in a high pressure kettle having polyfluortetraethylene as the lining. Furthermore, the invention prepares the hollow cerium fluoride nanometer structure materials with hexagonal or circular section respectively by controlling the temperature of the hydro-thermal reaction.

Owner:NANJING UNIV

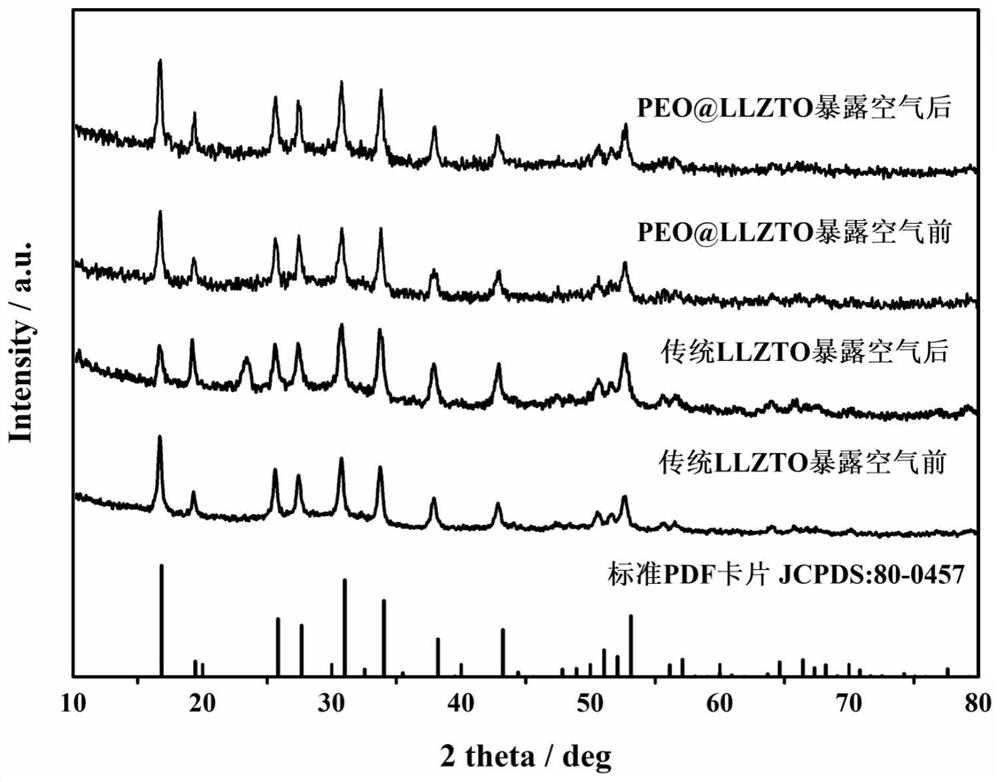

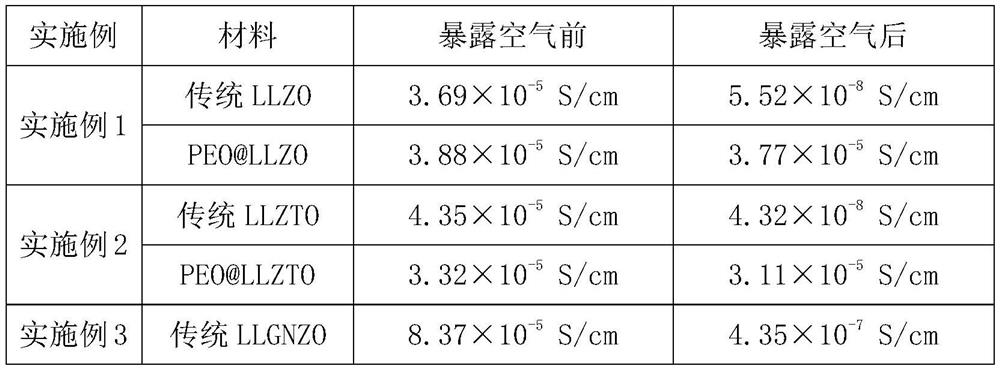

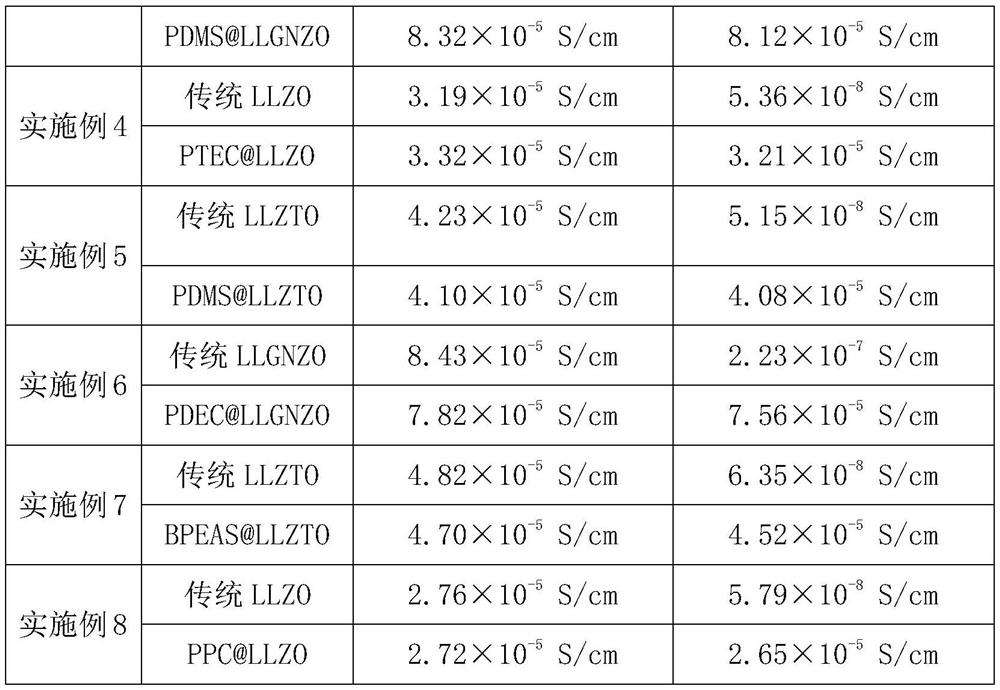

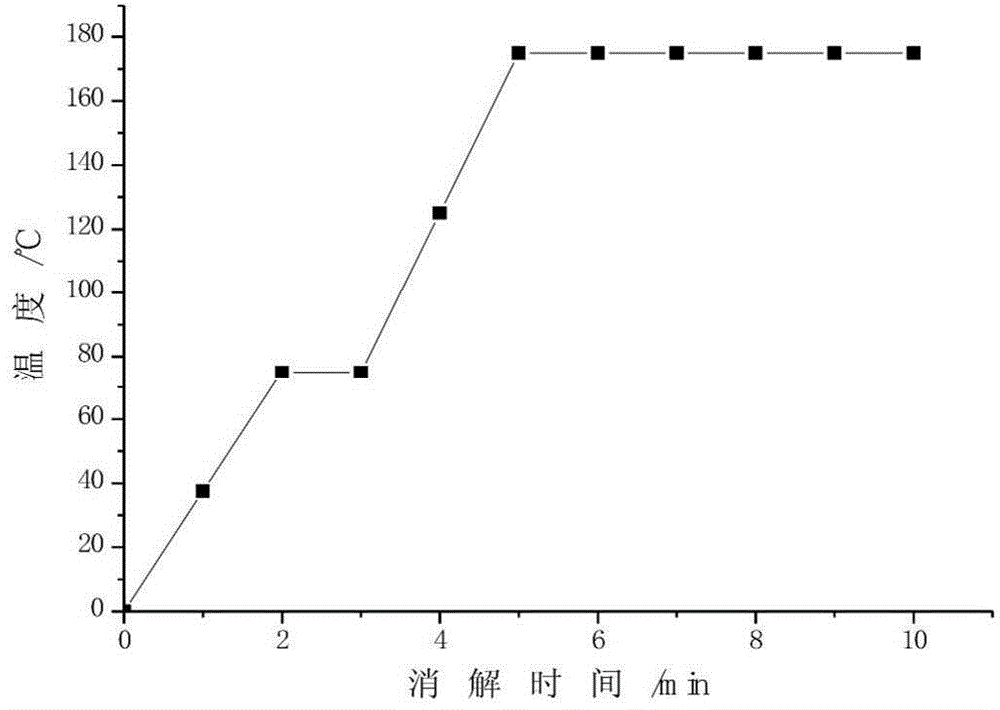

Surface treatment method for garnet type solid electrolyte

ActiveCN112290082ACoated evenlyWill not introduceElectrolytesLi-accumulatorsSolid state electrolyteConductive polymer

The invention belongs to the technical field of solid electrolyte preparation, and particularly relates to a surface treatment method for a garnet-type solid electrolyte. The method comprises the following steps: pretreating a garnet electrolyte powder material, and forming an ion conductive polymer coating layer with the thickness of 1-50 nm on the surface of the garnet electrolyte powder material by adopting a spray drying technology. According to the method disclosed by the invention, adverse reaction between the garnet solid electrolyte and air is prevented, the generation of surface impurities is inhibited, and meanwhile, the ionic conductivity of the electrolyte is not deteriorated, so that the electrolyte can keep high stability and electrochemical performance in the storage and useprocesses.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

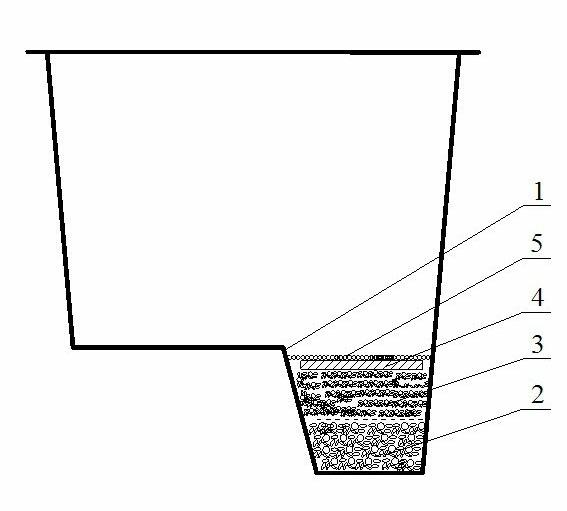

Lake endogenesis control brick and use method thereof

ActiveCN104445627AReduce disturbanceImprove adsorption capacityWater contaminantsTreatment with aerobic and anaerobic processesIron saltsBrick

The invention provides a lake endogenesis control brick and a use method thereof. The brick is prepared by steps as follows: (1), bottom sediment of a lake is taken, and content of iron and phosphorus in the bottom sediment is measured; (2), iron salt is added to the bottom sediment and mixed; (3), a mixture obtained from step (2) is air-dried, and a green brick is prepared from the mixture when the moisture content is 50 wt%-60 wt% after air-drying; (4), the green brick is dried in the shade for 2-3 days and then sintered; (5), a plurality of planting holes are punched in the sintered brick; and (6), submerged plants are planted in the planting holes, and the lake endogenesis control brick is obtained. After the lake endogenesis control brick is placed in the lake, the shearing force of bottom water and disturbance of water flowing to sediment can be reduced, so that release of nutrient salt suspended on the sediment is reduced, the chemical property of the sediment-water interface can be effectively improved by adjusting iron-phosphorus ratio of the sediment water interface, stability of phosphorus in the sediment is improved, and the planting and amplification capability of the submerged plants is enhanced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

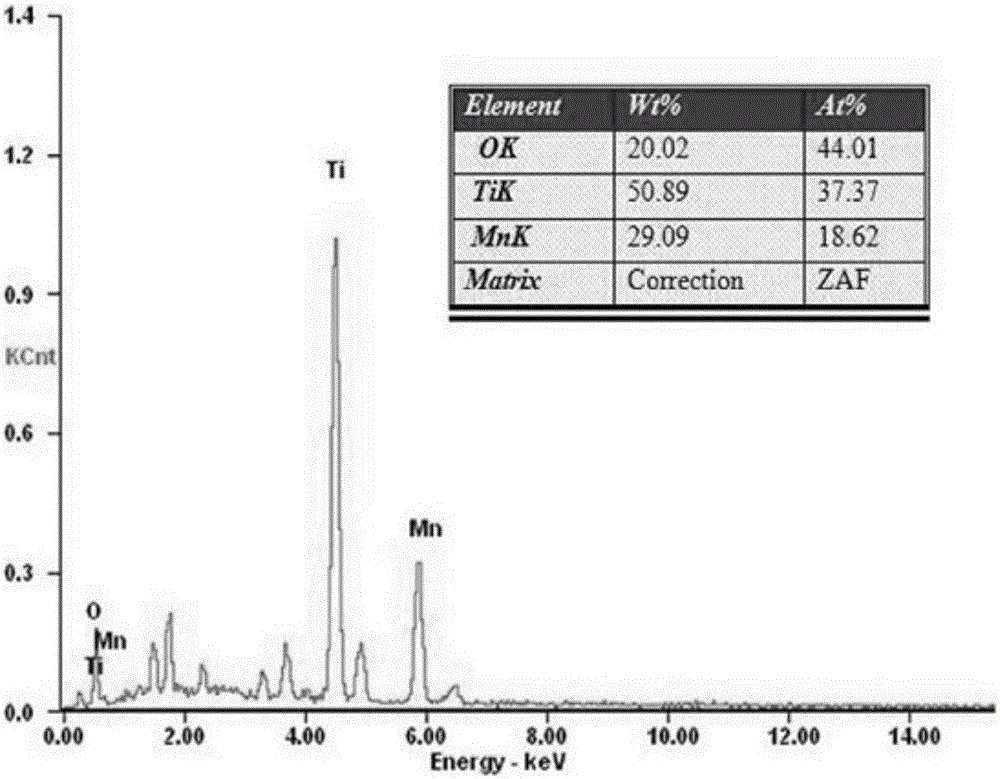

Titanium-based composite anode and preparing method and application thereof

ActiveCN105154915AThe process steps are simpleReduce energy consumptionElectrodesTitaniumSURFACTANT BLEND

The invention discloses a titanium-based composite anode which comprises a titanium substrate, a compact protection middle layer and an active surface layer. The compact protection middle layer is a titanium dioxide layer, and the titanium dioxide layer and the active surface layer are synchronously generated in an in-situ manner. A preparing method for the titanium-based composite anode comprises the following steps that firstly, the titanium substrate is polished and cleaned for standby use; secondly, the cleaned titanium substrate is arranged in a mixed solution of surfactant and metal salt with a strong oxidizing property, the pH value of the mixed solution is regulated to be 4-7, a reaction is carried out through heating, and a titanium-based composite anode precursor is obtained; and thirdly, the titanium-based composite anode precursor is roasted, and the titanium-based composite anode is obtained. In the titanium-based composite anode, the titanium dioxide layer and the active surface layer are synchronously generated in the in-situ manner, the composite anode is prepared through only one step, so that the technological steps are simple, and energy consumption is low. The titanium dioxide layer synchronously generated in the in-situ manner is very compact, further oxidation of the substrate can be restrained, and the catalytic activity of the active surface layer generated on the surface is high.

Owner:CENT SOUTH UNIV

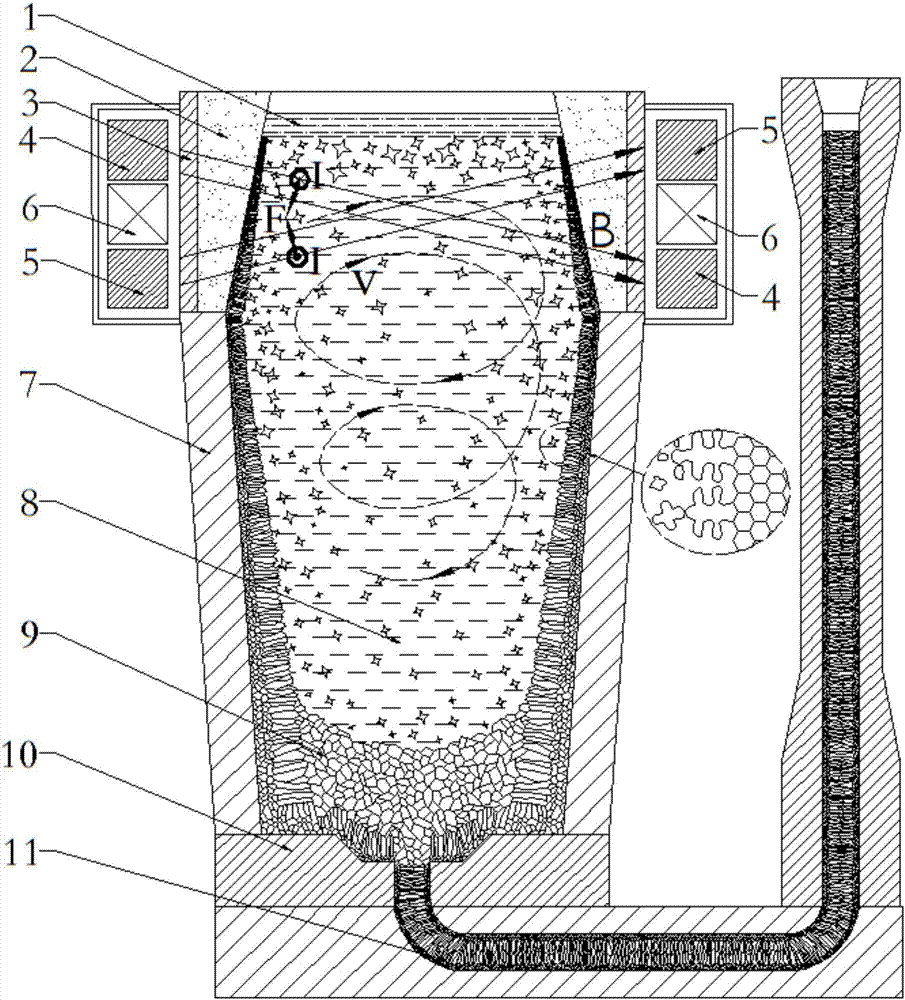

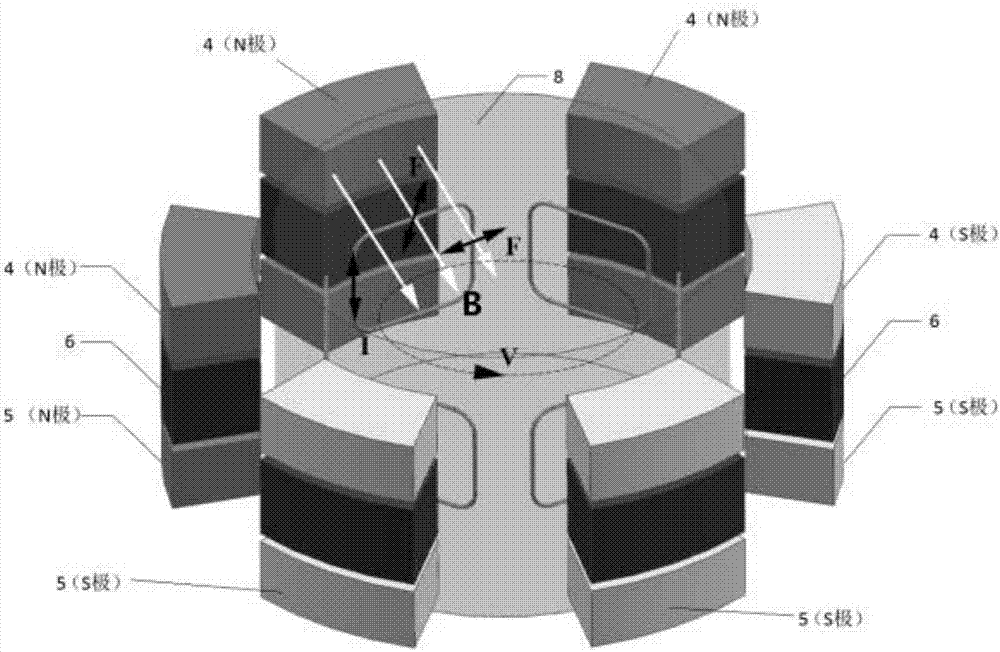

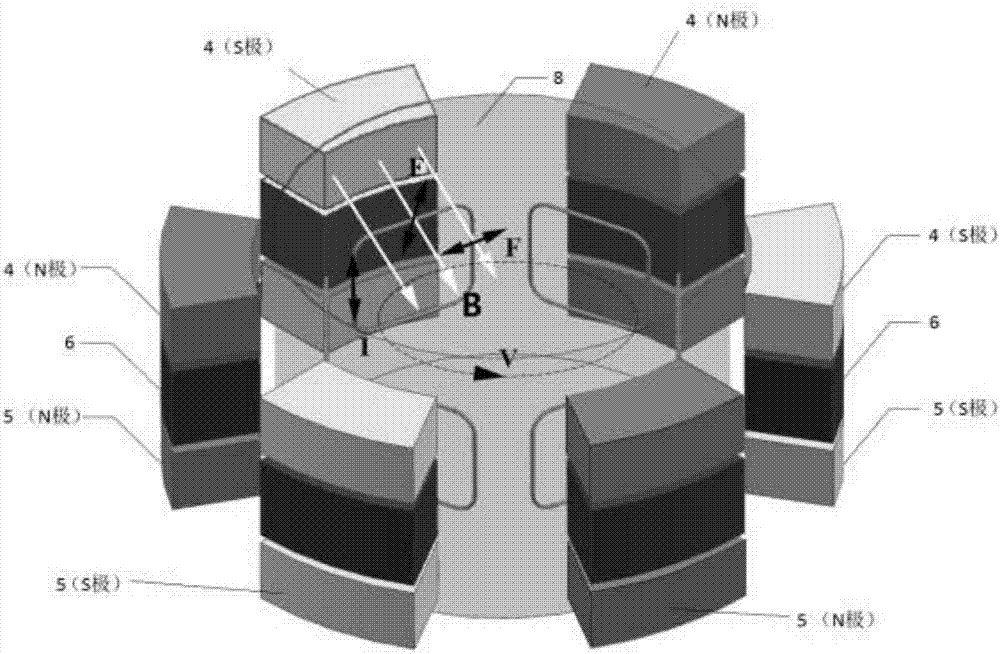

Method and device for homogenizing large ingot solidification structure by combining static magnetic field with rotating magnetic field

The invention discloses a method and device for homogenizing a large ingot solidification structure by combining a static magnetic field with a rotating magnetic field. Through the electromagnetic oscillation effect generated by a combined magnetic field and the rotational flow induction stirring effect of the rotating magnetic field, nucleation is promoted, dendritic crystal tips are crushed, crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, and therefore the method and the device are used for the large ingot casting process. When metal melt is solidified, the static magnetic field and the rotating magnetic field are exerted to a heat preservation riser in a combined mode according to the characteristics that metal liquid at an ingot mould riser is solidified lastly, the riser wall and the metal liquid surface are easy to nucleate first, and the rotating magnetic field and the static magnetic field can easily permeate a riser material, the metal liquid in the heat preservation riser is effectively oscillated and stirred, and the metal liquid in the riser is delivered into the metal liquid at the center of an ingot mould through oscillating and rotational flow stirring; the dendritic crystal tips are crushed, the crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, a compact, homogenized and crystal grain-refined large ingot is obtained, and therefore the subsequent machining performance and service performance of the large ingot are improved.

Owner:SHANGHAI UNIV

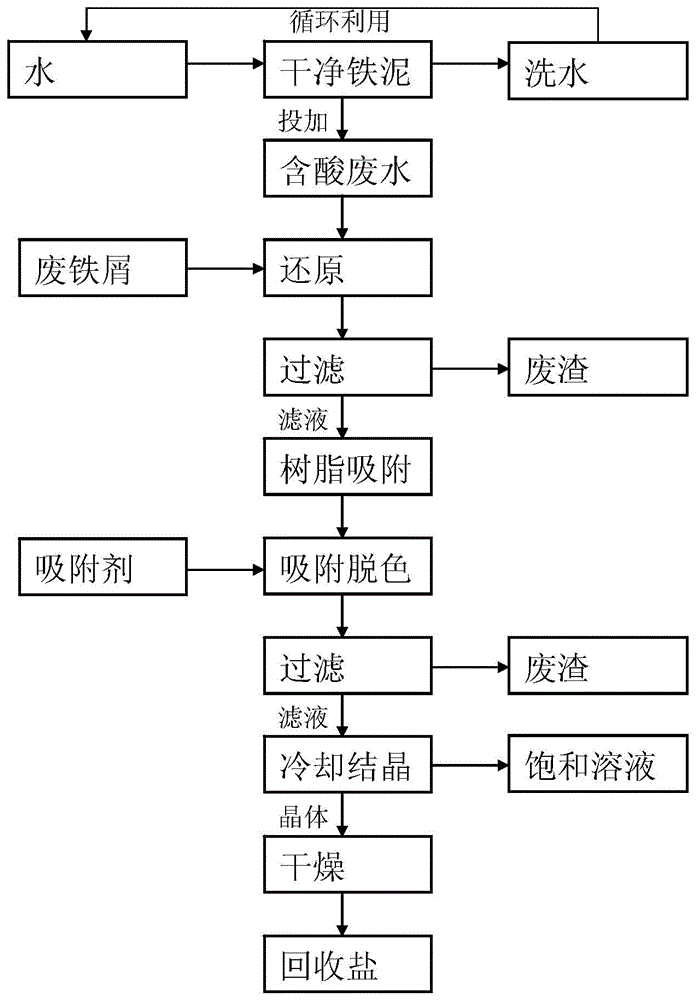

Comprehensive treatment method for organic acid-containing wastewater and iron mud

ActiveCN104445756ATake advantage ofLow equipment requirementsMultistage water/sewage treatmentIron sulfatesLiquid wasteIron sulfate

The invention discloses a comprehensive treatment method for organic acid-containing wastewater and iron mud. The comprehensive treatment method comprise the steps of firstly, adding iron mud into organic acid-containing wastewater, reacting by stirring at the temperature of 40-70 DEG C until the pH value is up to 0.5-3, and then, stopping adding the iron mud; then, adding waste scrap iron and active carbon powder, reacting by stirring, stopping adding until trivalent iron is completely reduced, keeping the pH value of the solution at 1-5, and filtering to obtain a supernatant solution I; and treating the supernatant solution I through the steps (3-a) and (3-b) according to any sequence to obtain a treating solution, and then, recycling iron sulfate heptahydrate through cooling crystallization, wherein the step (3-a) is realized by filtering by using an ultrafiltration membrane and / or carrying out adsorption treatment by using naphthalenesulfonic acid resin, and the step (3-b) is realized by filtering after adsorbing by using an adsorbent. The comprehensive treatment method disclosed by the invention can be used for realizing comprehensive treatment on solid wastes and liquid wastes through mixing the organic acid-containing wastewater and the iron mud generated in the same product production process, can also be used for recycling high-purity iron sulfate heptahydrate and is simple in process, low in treatment cost and easy to popularize.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Preparation method for high-purity vanadyl sulfate solution

ActiveCN105355955AReduce manufacturing costSimple processRegenerative fuel cellsElectrolytesVanadyl sulfateHydrometallurgy

The invention belongs to the field of wet-process metallurgy, and mainly relates to a preparation method for a high-purity vanadyl sulfate solution. The preparation method for the high-purity vanadyl sulfate solution provided by the invention comprises the following steps: a), oxidation of Fe2+; b), removal of Fe3+; c), removal of chromium ions and preparation of oxovanadium hydroxide; and d), preparation of the high-purity vanadyl sulfate solution, wherein the rough vanadyl sulfate solution is the vanadyl sulfate solution with the chromium content of greater than or equal to 550.3 mg / L and the iron content of greater than or equal to 269.6 mg / L. The chromium content is less than or equal to 0.002% and the iron content is less than or equal to 0.0027 g / L in the vanadyl sulfate solution prepared by the method.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Environmental-protection high-fire-retardant cable insulation material and preparation method thereof

The invention provides an environmental-protection high-fire-retardant cable insulation material, which comprises 30 to 50 parts of EVA (ethylene vinyl acetate) copolymer, 20 to 50 parts of methyl vinyl silicone rubber, 4 to 6 parts of glass powder, 10 to 15 parts of nitrogen-phosphorus flame retardant, 2 to 7 parts of compatilizer, 1 to 5 parts of antioxygen, 1 to 5 parts of vulcanizing agent and 1 to 5 parts of cross-linking agent in parts by mass, wherein the nitrogen-phosphorus flame retardant is the nitrogen-phosphorus flame retardant of which the surface is activated by silane or titanate. The cable insulation material provided by the invention avoids the use of the traditional organic halide flame retardant, does not contain halogen, has higher flame retardant property and is excellent in strength.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

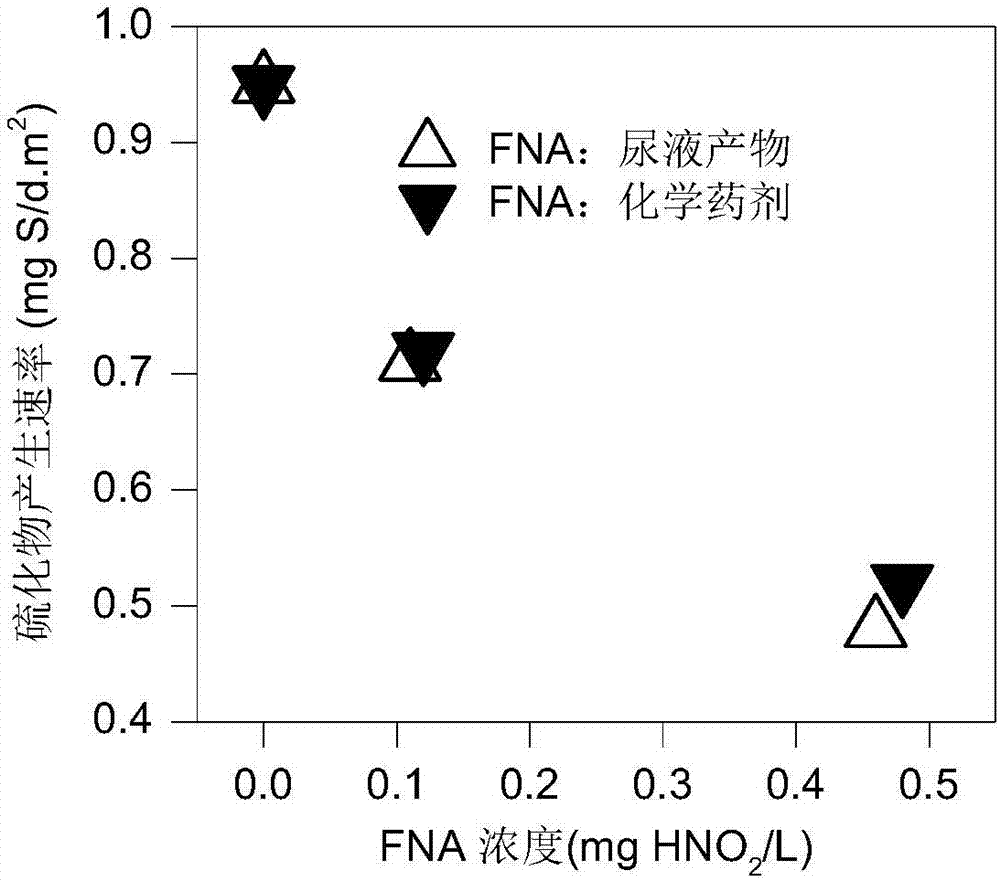

Treatment system and treatment method for controlling pipeline corrosion stink

ActiveCN106986447ARealize resourcesTo achieve the effect of corrosion and odor controlSpecific water treatment objectivesSustainable biological treatmentSewageSanitary sewer

The invention provides a treatment system and method for controlling pipeline corrosion stink. The treatment system comprises a urine storage tank, a free nitrous acid reaction tank and a free nitrous acid dosing system which are sequentially connected, wherein the urine storage tank is used for in-situ collection and urine hydrolysis, the free nitrous acid reaction tank is used for preparing free nitrous acid solution from hydrolyzed urine through nitrosation, and the free nitrous acid dosing system is used for realizing contact of the free nitrous acid solution and a pipeline. The treatment system and method have the advantages of simple structure, convenience in operation, stable effect and the like, and have a quite wide application prospect in source separating reclamation, sewage pipeline operation optimization management and the like.

Owner:TSINGHUA UNIV

Method for treating nickel and cadmium impurities in cobalt sulfate solution

InactiveCN109022822AGood removal effectWill not introduceProcess efficiency improvementKeroseneNickel cadmium

The invention discloses a method for treating nickel and cadmium impurities in cobalt sulfate solution. The method includes the steps that (1) the pH value of cobalt sulfate raw material liquid is adjusted; (2) P507 nickel soap is prepared, an extraction agent P507 and a diluent sulfonated kerosene are mixed, industrial NaOH (concentration being 30% or 45%) and nickel soap anterior liquid are usedin sequence for counter current extraction, and the formed organic phase is the P507 nickel soap; (3) extraction is conducted, the P507 nickel soap is used for extracting cobalt and cadmium; (4) washing is conducted, the dilute hydrochloric acid is used to wash nickel and cadmium; and (5) back extraction is conducted, and back extraction is conducted with the dilute hydrochloric acid or dilute sulfuric acid to produce cobalt chloride or cobalt sulfate solution. By means of the method, the nickel and cadmium impurities can be effectively removed from the cobalt sulfate solution, the process issimple and reliable, the maneuverability is high, the nickel, cadmium and other impurities removal effect is high, other impurities cannot be introduced, and the better economic value is achieved.

Owner:JINCHUAN GROUP LIMITED

Method for separating different sizes of alpha aluminum oxide nano-particles

The invention discloses a technology for separating different sizes of alpha aluminum oxide nano-particles. The separation method adopts mineral acid solutions, most preferably hydrochloric acid, with different concentrations to separate different sizes of alpha aluminum oxide nano-particles. The method comprises the steps as follows: the alpha aluminum oxide nano-particles are dispersed in hydrochloric acid with different concentrations to obtain different sizes of alpha aluminum oxide nano-particles through separation, wherein during separation processing, the concentration of the used diluted hydrochloric acid is 0-1.25 M; the ratio of the amount of the diluted hydrochloric acid to the to-be-processed alpha aluminum oxide nano-particles is 0.5-4.0 ml / g; and during separation of the particles in supernatant, the concentration of the hydrochloric acid in the supernatant is required to be adjusted to 2.0-10.0 M by concentrated hydrochloric acid. The method is quite simple, can separate alpha aluminum oxide nano-particle powder according to different sizes very conveniently, cannot introduce impurities in a separation process, cannot produce pollution, and can be applied widely in the industry.

Owner:LANZHOU UNIVERSITY

Method for washing silicon wafer by organic solvent

InactiveCN102806217AReduce reflectivityWill not introduceCleaning using liquidsAqueous solutionImpurity ions

The invention discloses a method for washing a silicon wafer by an organic solvent, and relates to a silicon wafer washing technology. The method, in sequence, comprises the following steps: (a) after taking the silicon wafer from a mortar liquid; immediately putting the silicon wafer into hot water at 50-100 DEG C; and ultrasonically washing the silicon wafer for 10-30 minutes; and (b) putting the silicon wafer into an organic washing liquid YB and ultrasonically washing the silicon wafer for more than 30 minutes at 30-75 DEG C, wherein the organic washing liquid YB is an aqueous solution with organic ethanol and acetone as a solute; and the frequency of ultrasonic waves is 28-40 kHz; and the power is 2500-3000 W. The method for washing the silicon wafer by the organic solvent, disclosed by the invention, has the advantages as follows: smudges on the surface of the silicon wafer can be easily washed and the original mechanical damage layer of the silicon wafer is kept. It is shown by detection that the reflectivity of the silicon wafer is further reduced by about 2% in the later section of the texture acid-etching process. The washing efficiency is increased without introducing impurity ions; and washing cost and pollution are reduced.

Owner:ANYANG PHOENIX PHOTOVOLTAIC TECH +1

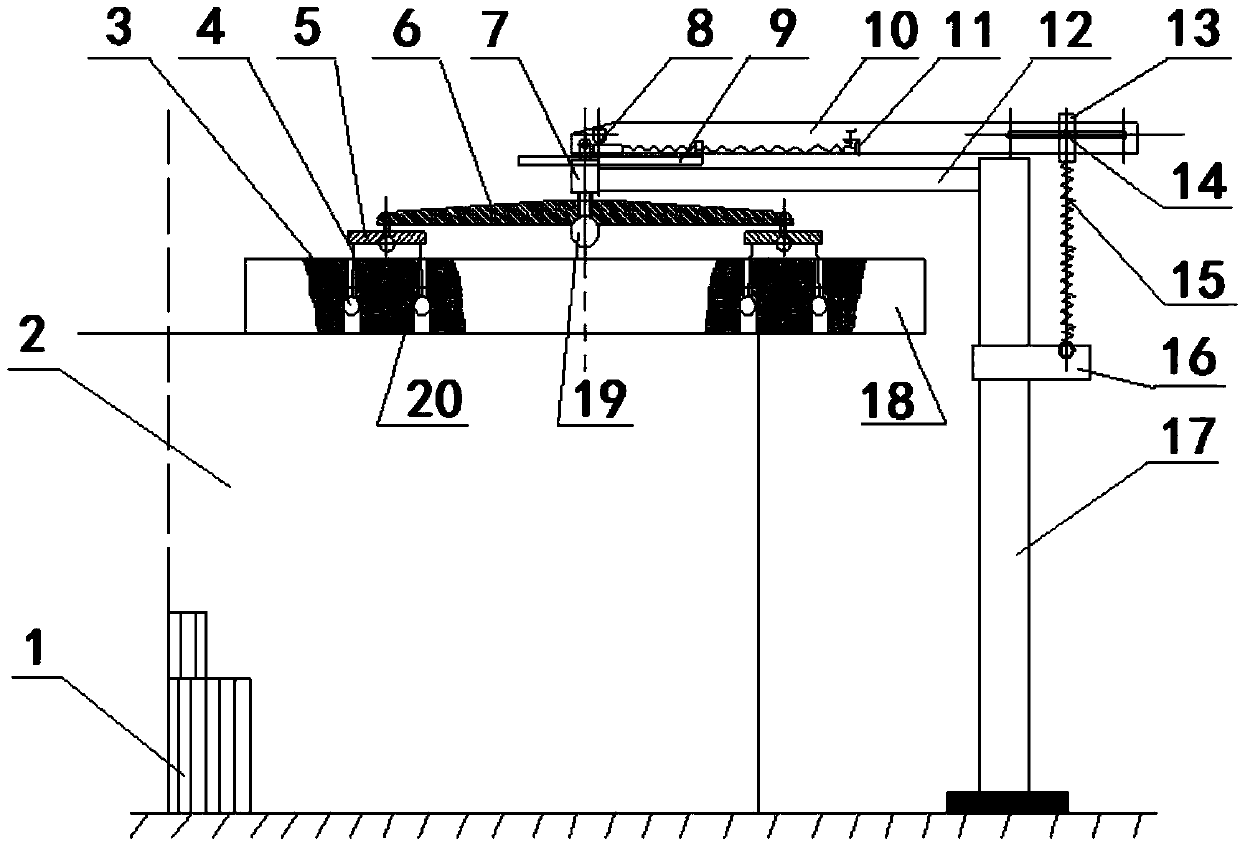

Calibration disc unloading and load-transferring device of large ring polishing machine

ActiveCN103722464ARealize pollution-free bearingImprove securityOptical surface grinding machinesEngineeringSpherical joint

The invention provides a calibration disc unloading and load-transferring device of a large ring polishing machine and relates to a calibration disc unloading and load-transferring device which is used for assisting surface precision polishing on the large ring polishing machine and large in weight. The calibration disc unloading and load-transferring device mainly comprises a tensile force adjusting spring for providing power, wherein the spring is connected with one end of a lever through a pin, a supporting point is arranged at the other end of the lever, a cross-shaped knife edge, a hanging bracket and a spherical joint are sequentially arranged under the supporting point, and the spring tensile force acts on the hanging bracket through the cross-shaped knife edge. The hanging bracket is of a multiple-jaw-shaped structure, a distribution disc is arranged on each extending jaw arm, each distribution disc pulls a copper sleeve inlayed in a calibration disc through a steel wire and a pulling steel ball, and accordingly the tensile force is transferred to the calibration disc. The calibration disc unloading and load-transferring device can achieve mechanized operation of calibration disc unloading and load transferring of the large ring polishing machine, reduce the labor intensity of workers and improve the working efficiency, is simple in structure and convenient to operate, greatly improves the safety in the calibration disc unloading and load transferring process and avoids outside impurities.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com