Method for preparing ruthenium powder for target materials from ruthenium trichloride

A technology of ruthenium trichloride and ruthenium powder, which is applied in the field of preparation of precious metal powder, can solve the problems of complex operation, reduced chlorine content of ruthenium powder, and cannot be removed, and achieves the effects of simple process, low impurity content, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

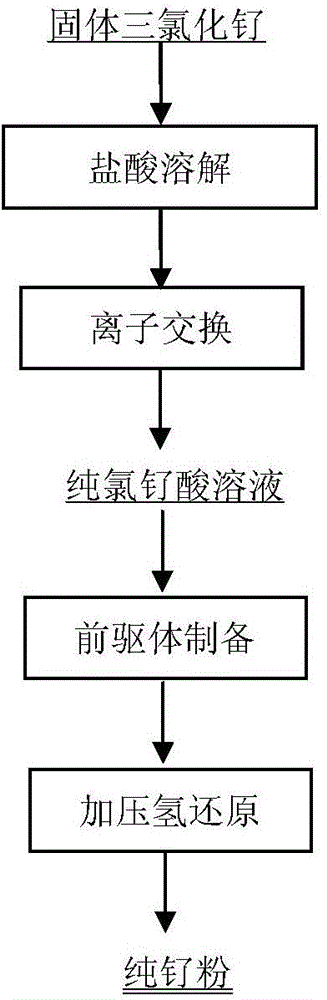

[0018] Embodiment 1, see attached figure 1 , dissolving solid ruthenium trichloride with 6-12mol / L hydrochloric acid to obtain a ruthenium chloride solution, passing the resulting solution through a cation exchange resin to remove cationic impurities to obtain a pure ruthenium solution, adding sodium hydroxide to the obtained pure ruthenium solution to generate hydrogen Precipitate ruthenium oxide, add deionized water to slurry, adjust the pH value to 9, and obtain the precursor of ruthenium powder, place the obtained precursor in a high-pressure reactor, heat to 180 ° C, and feed hydrogen to maintain a partial pressure of 2 MPa for 6 hours. Solid-liquid separation, fully washed with deionized water, and vacuum drying at 120°C to obtain pure ruthenium powder.

Embodiment 2

[0019] Embodiment 2, see attached figure 1 , dissolving solid ruthenium trichloride with 6-12mol / L hydrochloric acid to obtain a ruthenium chloride solution, passing the resulting solution through a cation exchange resin to remove cationic impurities to obtain a pure ruthenium solution, adding sodium hydroxide to the obtained pure ruthenium solution to generate hydrogen Precipitate ruthenium oxide, add deionized water to slurry, adjust the pH value to 10, and obtain the precursor of ruthenium powder, place the obtained precursor in a high-pressure reactor, heat to 200°C, and pass in hydrogen to maintain a partial pressure of 1.5 MPa for 6 hours. , solid-liquid separation, fully washed with deionized water, and vacuum-dried at a temperature of 120 ° C to obtain pure ruthenium powder.

Embodiment 3

[0020] Embodiment 3, see attached figure 1 , dissolving solid ruthenium trichloride with 6-12mol / L hydrochloric acid to obtain a ruthenium chloride solution, passing the resulting solution through a cation exchange resin to remove cationic impurities to obtain a pure ruthenium solution, adding sodium hydroxide to the obtained pure ruthenium solution to generate hydrogen Precipitate ruthenium oxide, add deionized water to slurry, adjust the pH value to 10, and obtain the precursor of ruthenium powder, place the obtained precursor in a high-pressure reactor, heat to 220°C, and pass in hydrogen to maintain a partial pressure of 1.2MPa for 8 hours , solid-liquid separation, fully washed with deionized water, and vacuum-dried at a temperature of 120 ° C to obtain pure ruthenium powder.

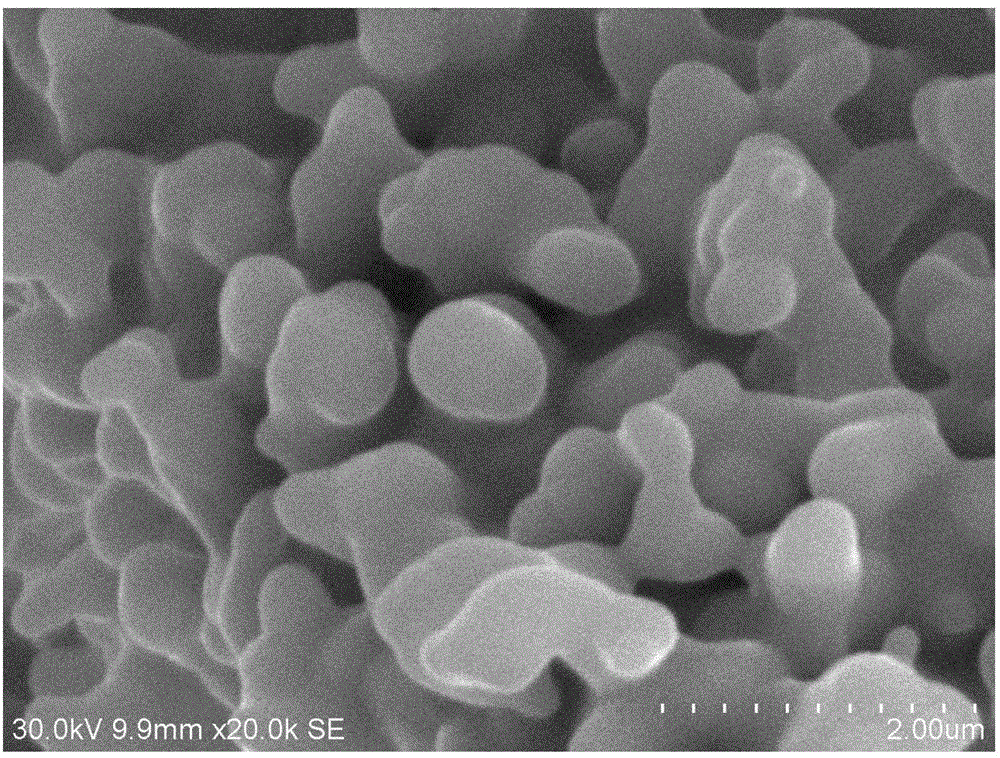

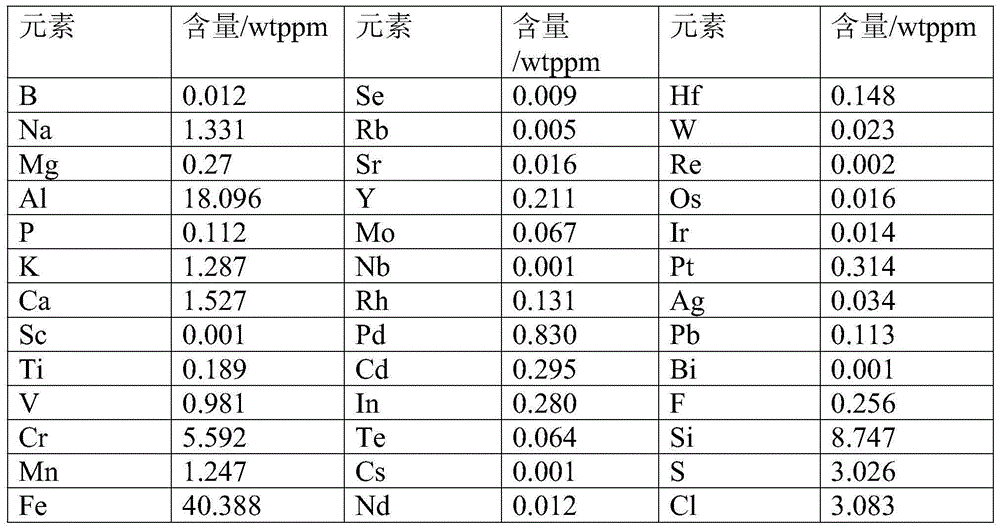

[0021] The ruthenium powder prepared by the present invention was analyzed by GDMS, and the results are shown in Table 1 below.

[0022] Table 1 GDMS impurity analysis results of ruthenium powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com