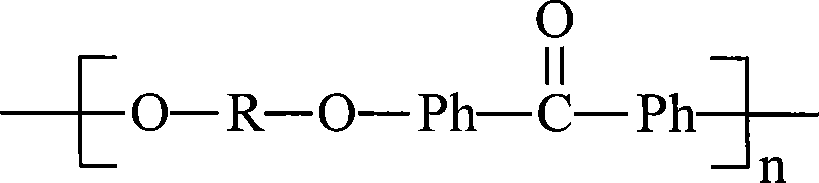

Preparation method for polyetheretherketone

A technology of polyether ether ketone and difluorobenzophenone, which is applied in the field of preparation of special functional engineering resins, can solve problems such as strong water absorption of potassium carbonate, small molecular weight, and impact on industrial production, and reduce the introduction of impurities and reaction conditions Mild, raw material reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Vacuumize the reactor equipped with mechanical stirrer, thermometer and condenser, and then fill it with high-purity nitrogen. After three times, the air in the system will be completely replaced with nitrogen. Phenylsulfone, after heating until it dissolves, add 172.2 grams of 4,4'-difluorobenzophenone (0.79 moles) to dissolve it, add 72.6 grams of biphenol (0.39 moles) to dissolve it, and add 42.9 grams of terephthalate Phenol (0.39 moles) was used to dissolve it, and the previously dried Na 2 CO 3 After crushing and sieving, accurately weigh 95.4 grams (0.9 moles) of powder and immediately add it to the reaction system, stir for 30 minutes to make it salt with diphenol and dissolve, quickly raise the temperature of the system to 190°C, and react for 30 minutes , raise the system temperature to 300°C within 10 minutes, react for 1 hour, rapidly raise the temperature to 325°C, and immediately add 1.1 grams of hydroquinone (0.01 mole) as a chain extender, increase the ...

Embodiment 2

[0020] Under the same reaction conditions as in Example 1, the mol ratio of hydroquinone and biquinone was 1: 2 when charging for the first time, and other conditions did not change, that is, when charging for the first time, hydroquinone was 28.6 grams (0.26 moles), biphenol is 96.7 grams (0.52 moles), and the experimental results are shown in Table 1.

Embodiment 3

[0022] Under the same reaction conditions as in Example 1, the mol ratio of hydroquinone and biquinone was changed to 1: 3 when charging for the first time, and other conditions did not change, that is, hydroquinone was added when charging for the first time. It is 20.9 grams (0.19 moles), and biphenol is 110 grams (0.57 moles). The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com