Patents

Literature

931results about How to "Improve fill rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

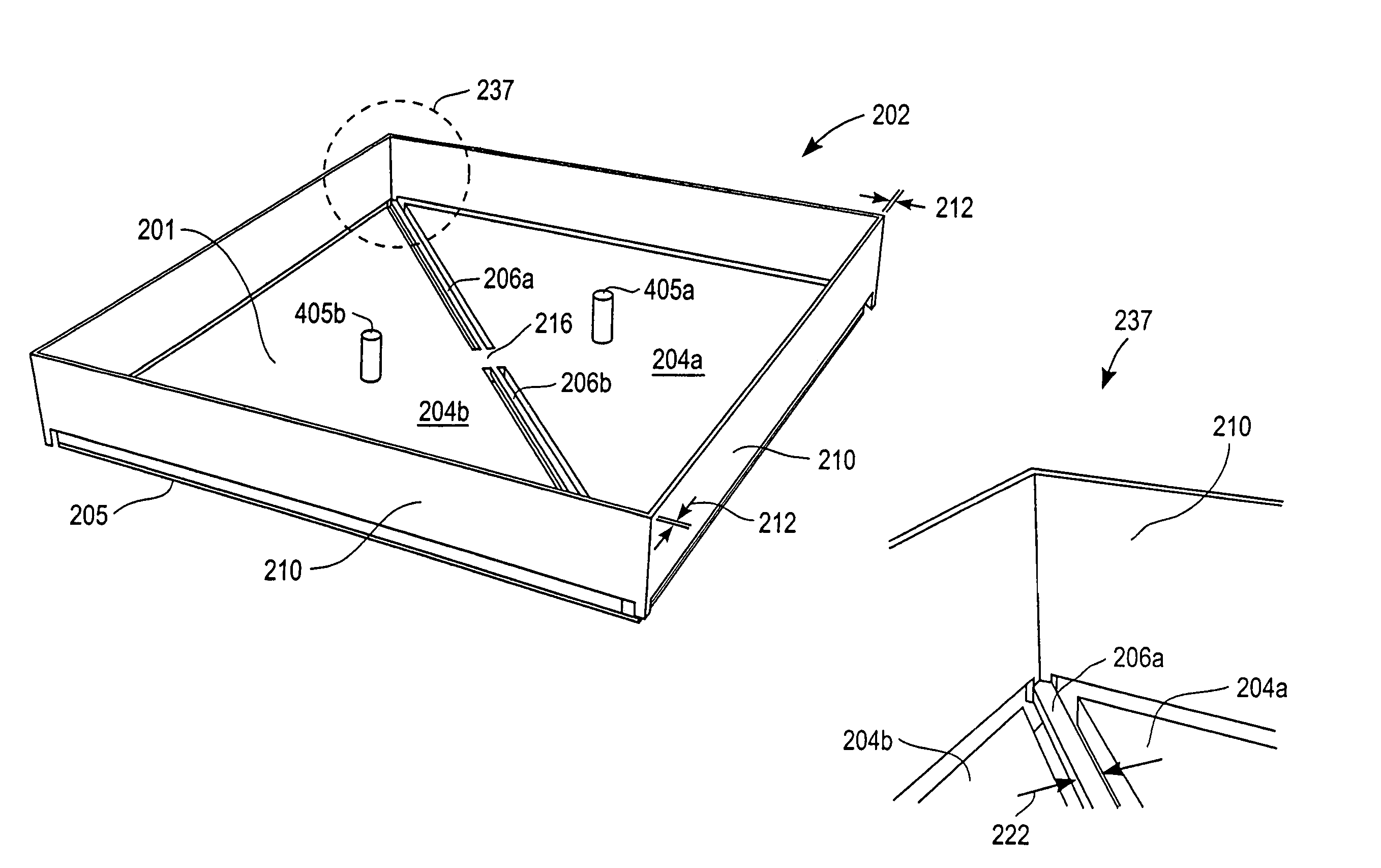

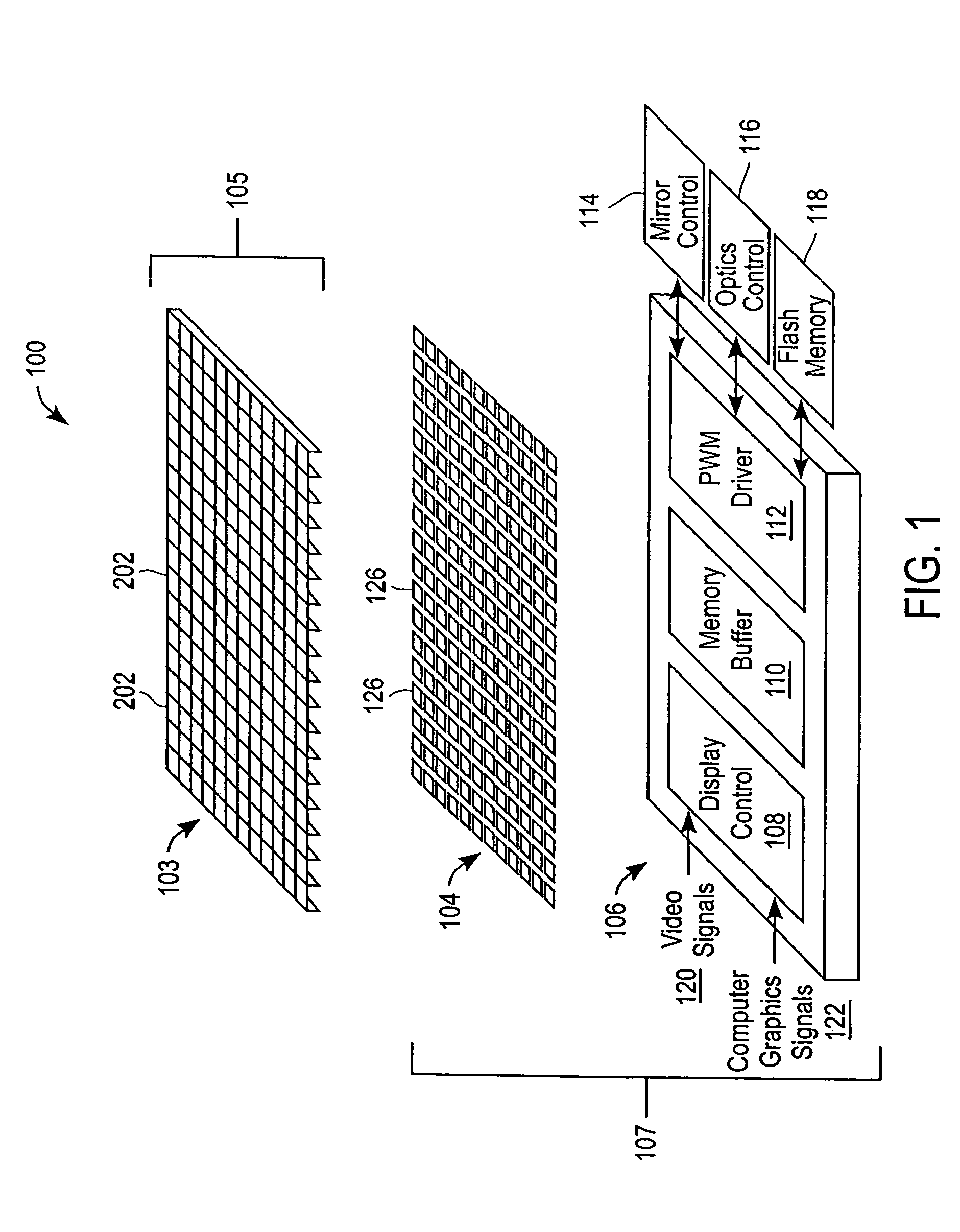

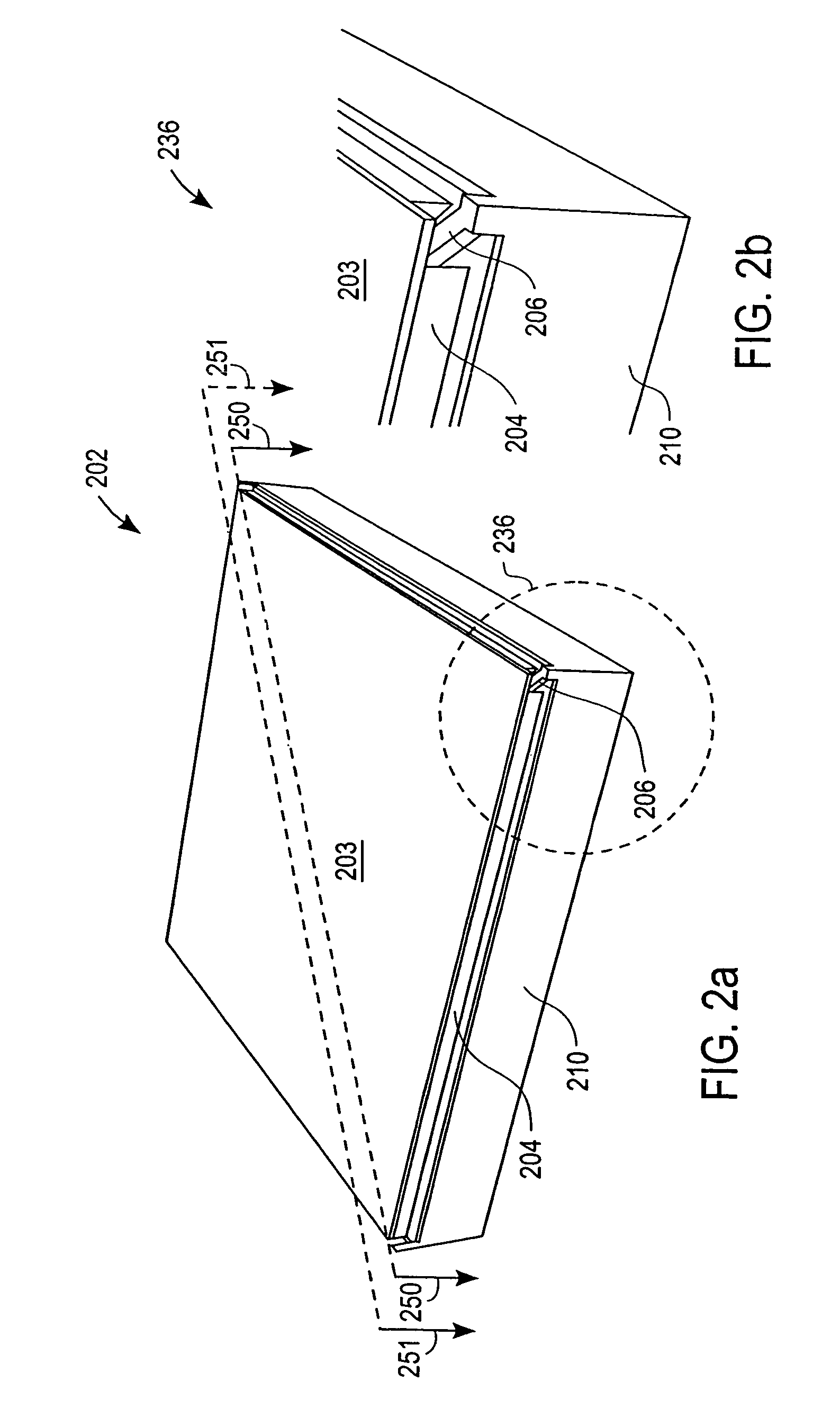

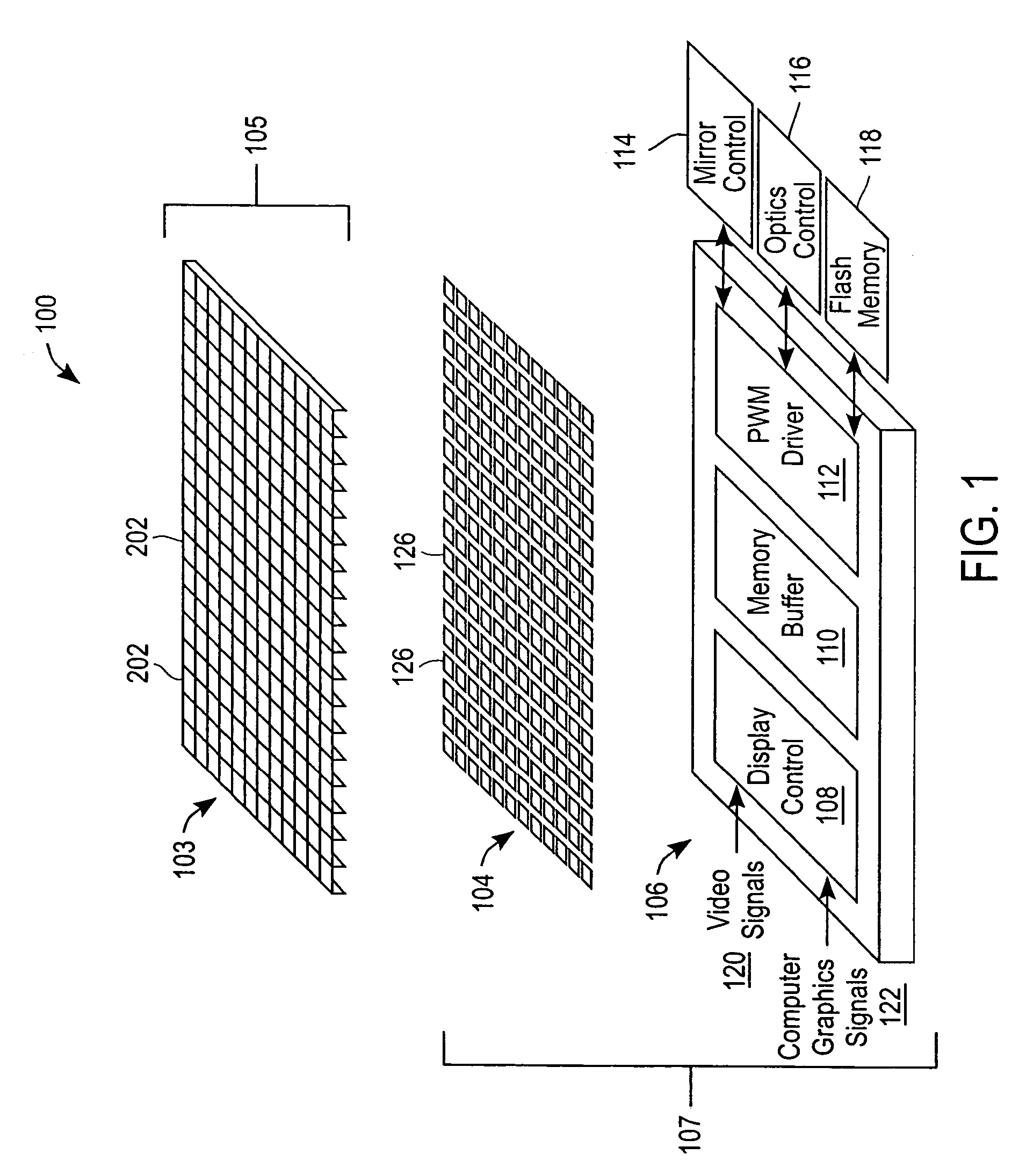

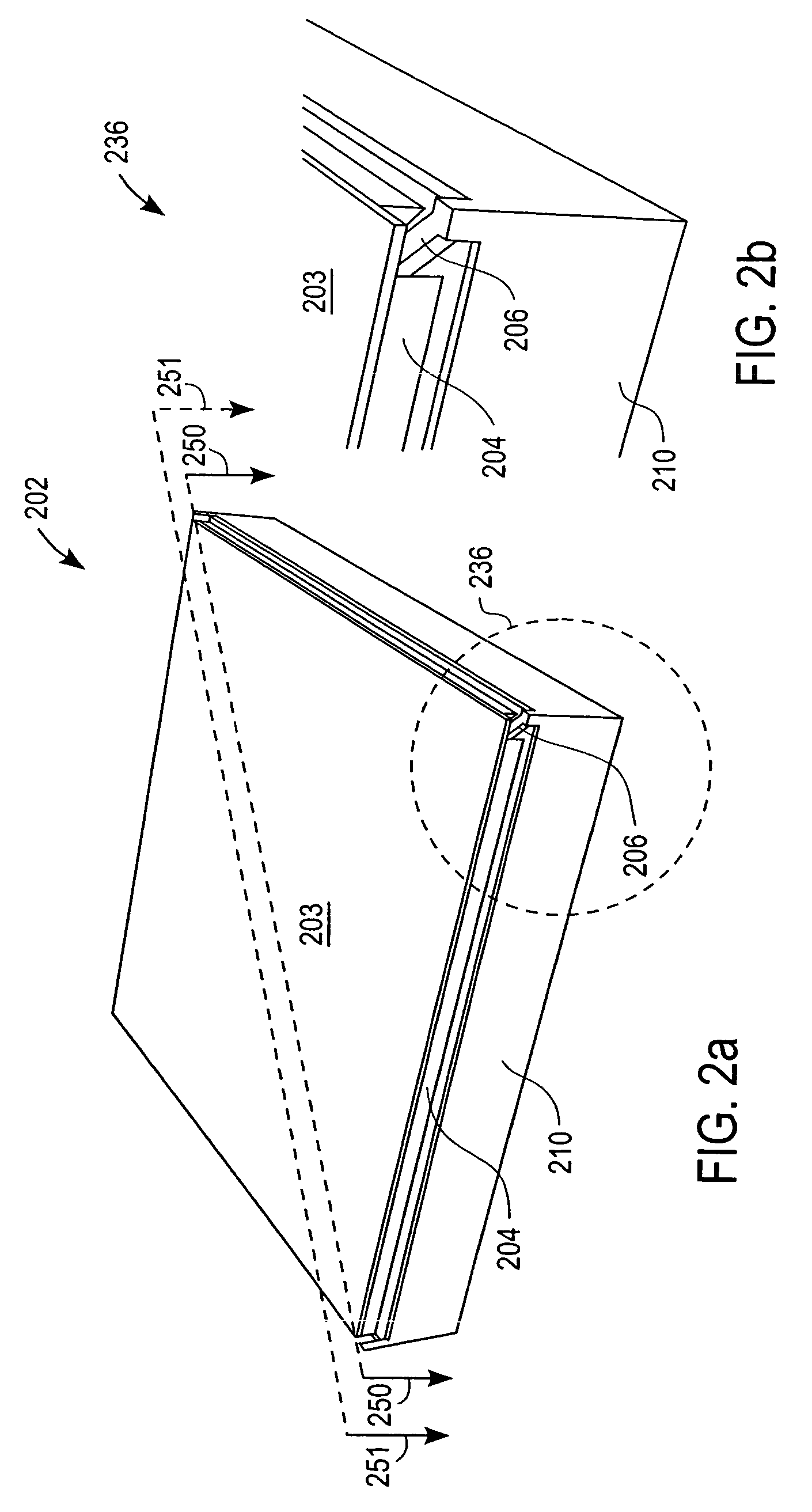

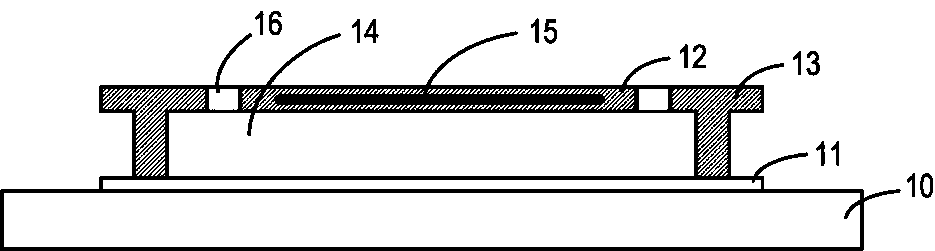

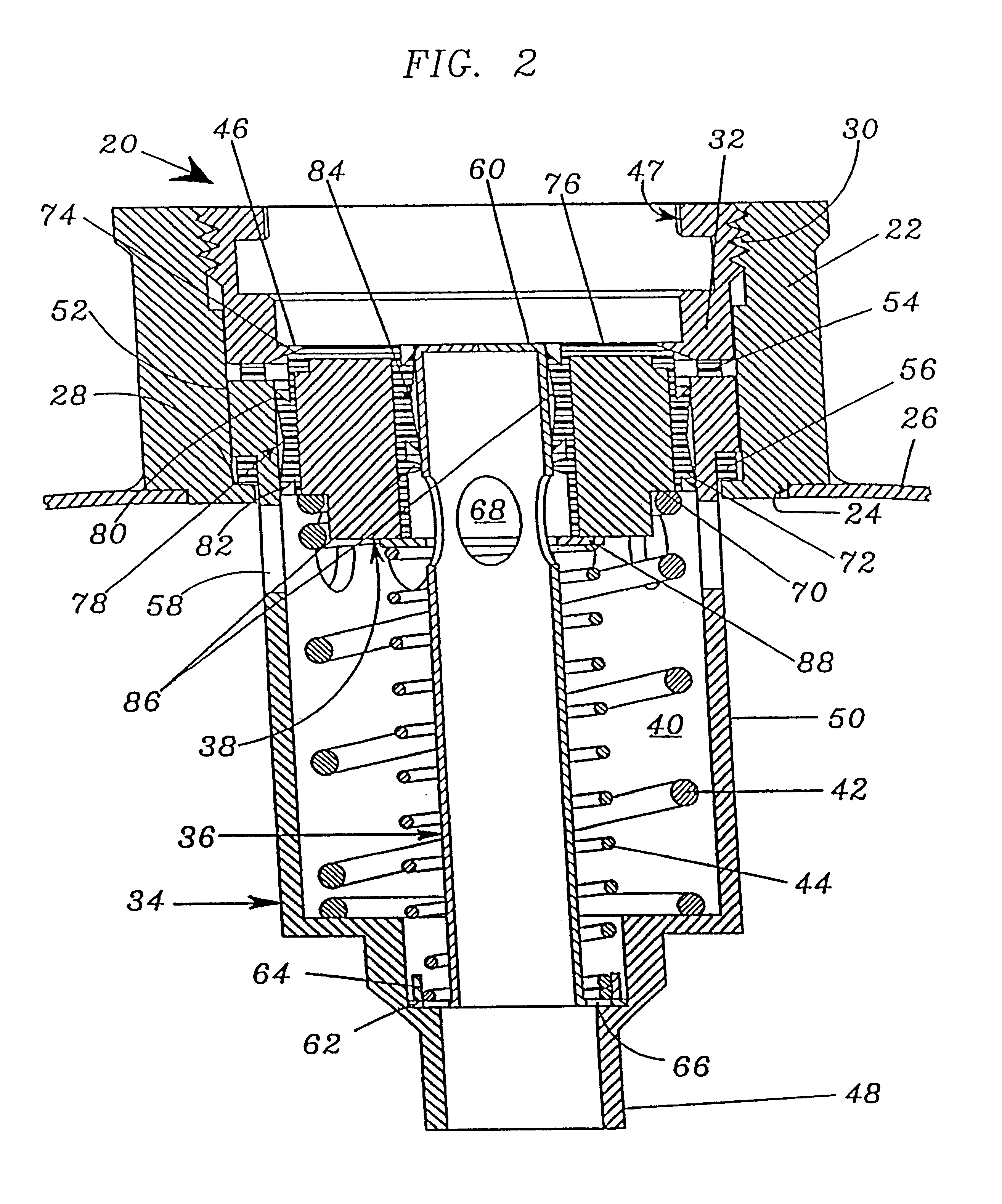

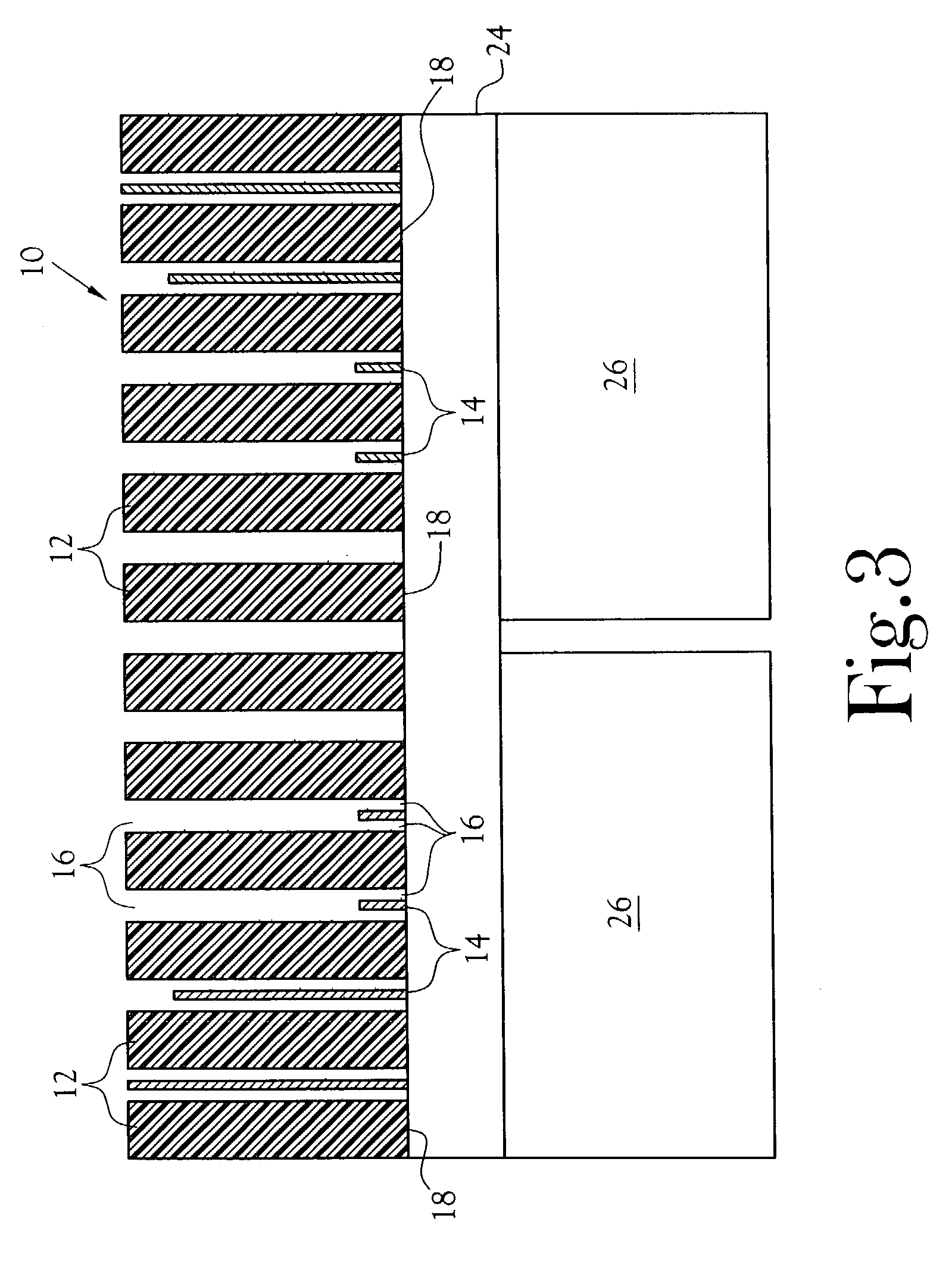

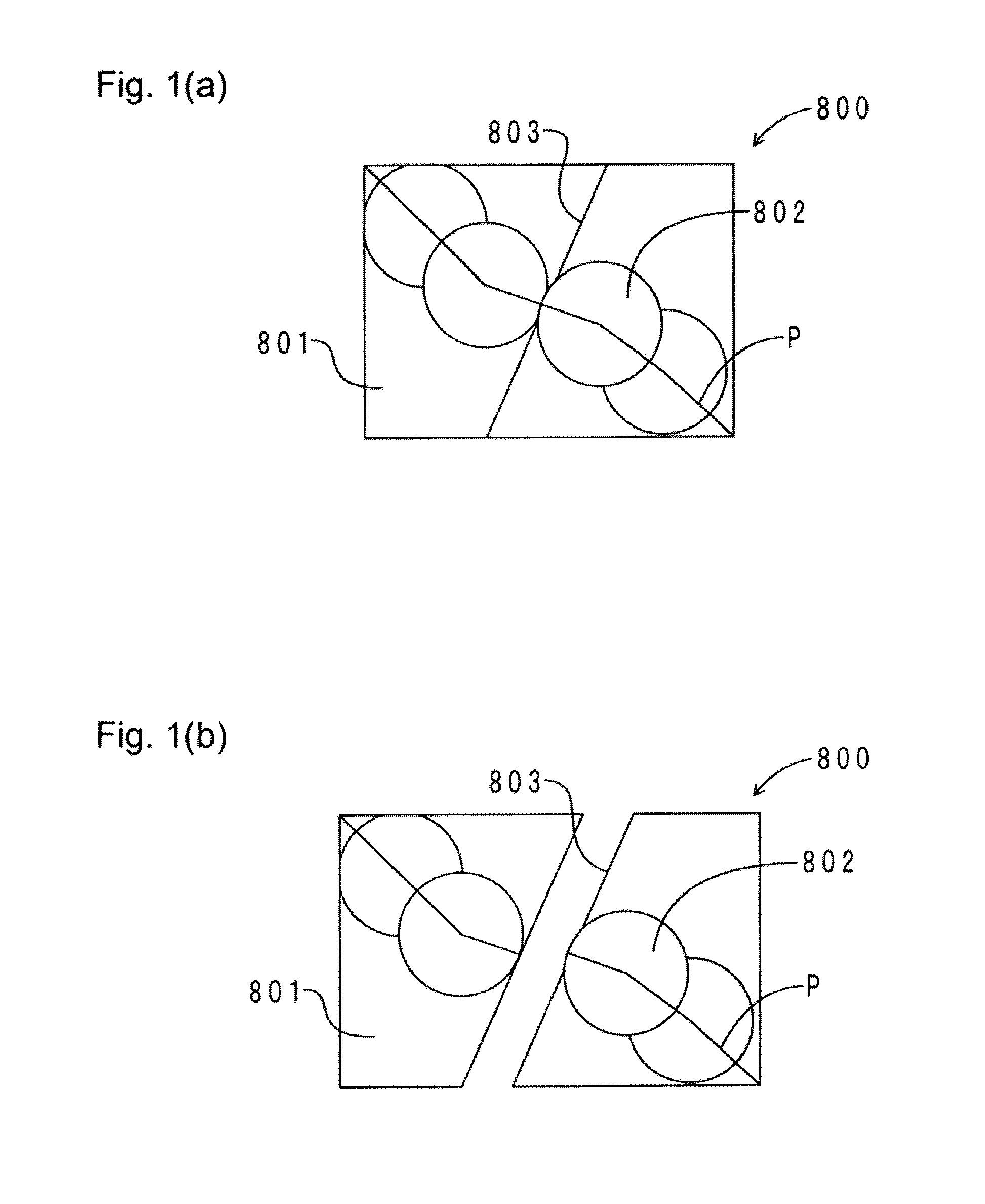

High fill ratio reflective spatial light modulator with hidden hinge

A micro mirror array having a hidden hinge that is useful, for example, in a reflective spatial light modulator. In one embodiment, the micro mirror array includes spacer support walls, a hinge, a mirror plate and a reflective surface on the upper surface of the mirror plate, the reflective surface concealing the hinge and the mirror plate. The micro mirror array fabricated from a single material.

Owner:MIRADIA INC

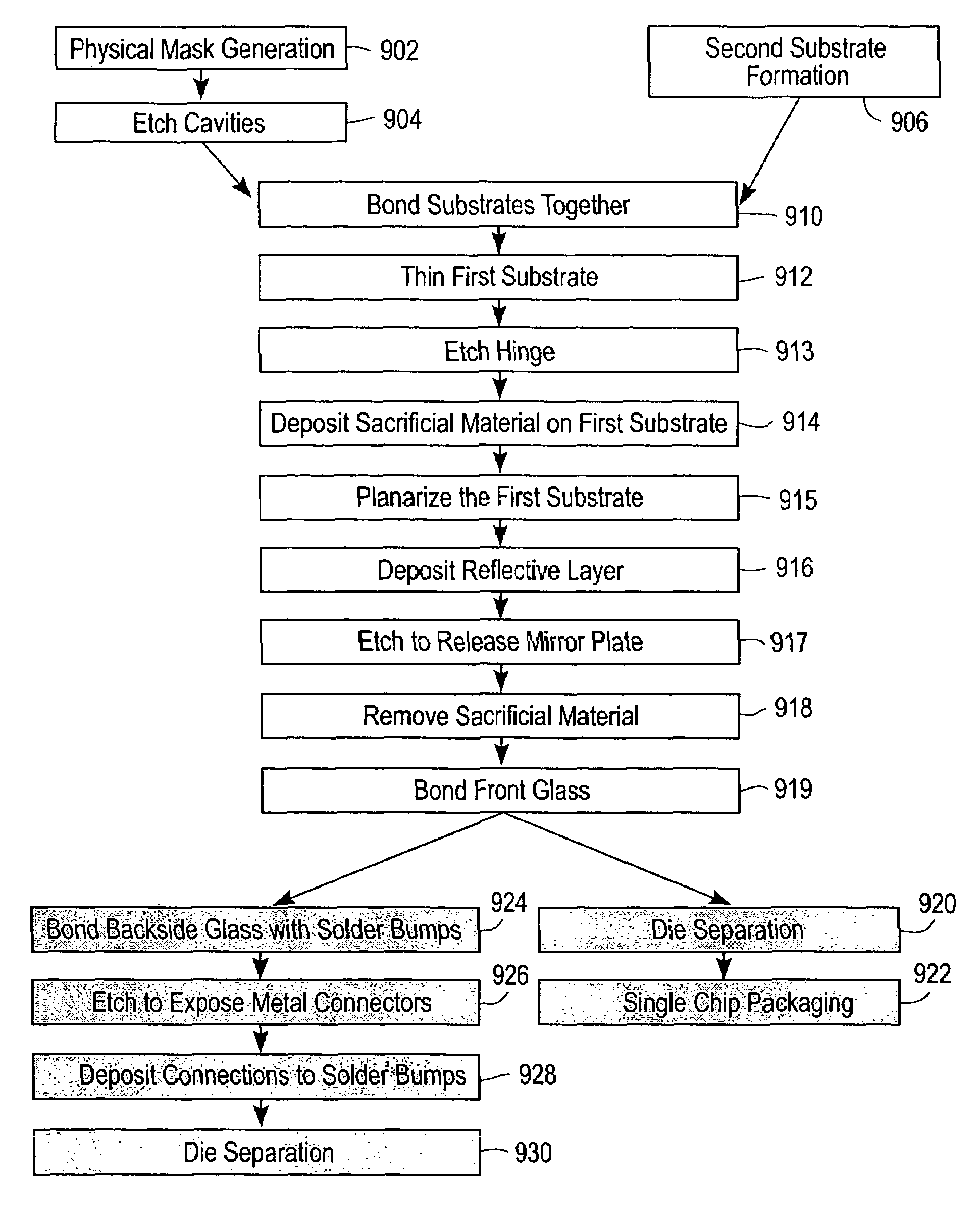

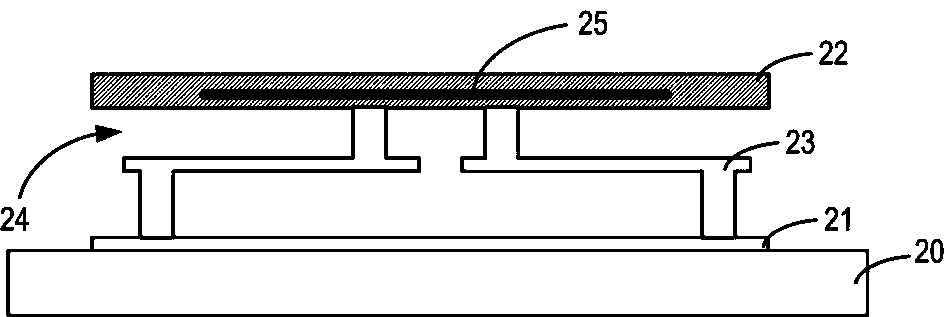

Fabrication of a high fill ratio reflective spatial light modulator with hidden hinge

InactiveUS7034984B2Easy to manufactureImprove optical efficiencySemiconductor/solid-state device manufacturingNon-linear opticsSpatial light modulatorSingle crystal

Fabrication of a micro mirror array having a hidden hinge that is useful, for example, in a reflective spatial light modulator. In one embodiment, the micro mirror array is fabricated from a substrate that is a first substrate of a single crystal material. Cavities are formed in a first side of the first substrate. Separately, electrodes and addressing and control circuitry are fabricated on a first side of a second substrate. The first side of the first substrate is bonded to the first side of the second substrate. The sides are aligned so the electrodes on the second substrate are in proper relation with the mirror plates that will be formed on the first substrate and that the electrodes will control. The first substrate is thinned to a pre-determined, desired thickness, a hinge is etched, a sacrificial material is deposited, the upper surface of the first substrate is planarized, a reflective surface is deposited to cover the hinge, a mirror is released by etching and the sacrificial layer around the hinge is removed to release the hinge so the hinge can rotate about an axis in line with the hinge.

Owner:MIRADIA INC

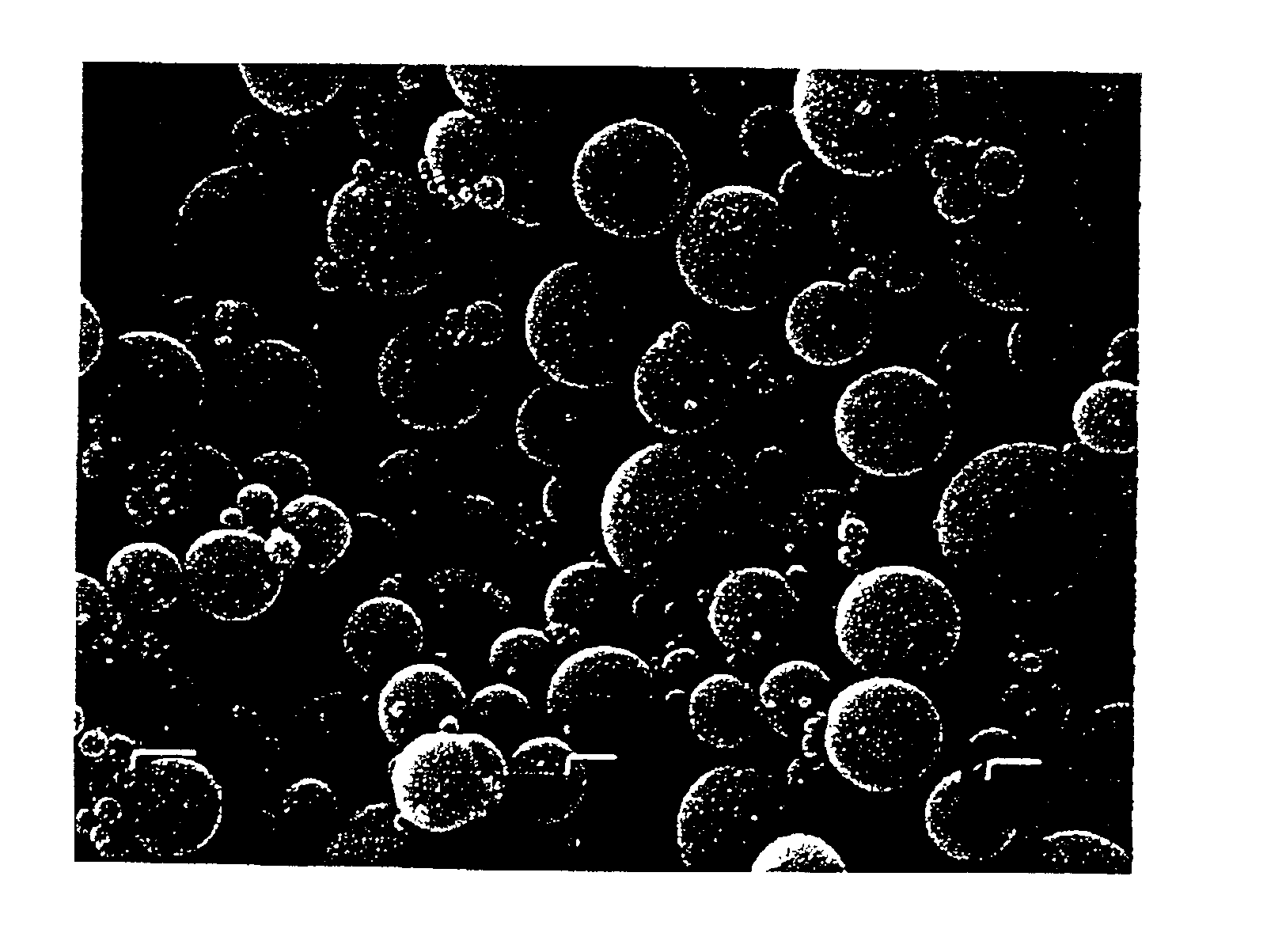

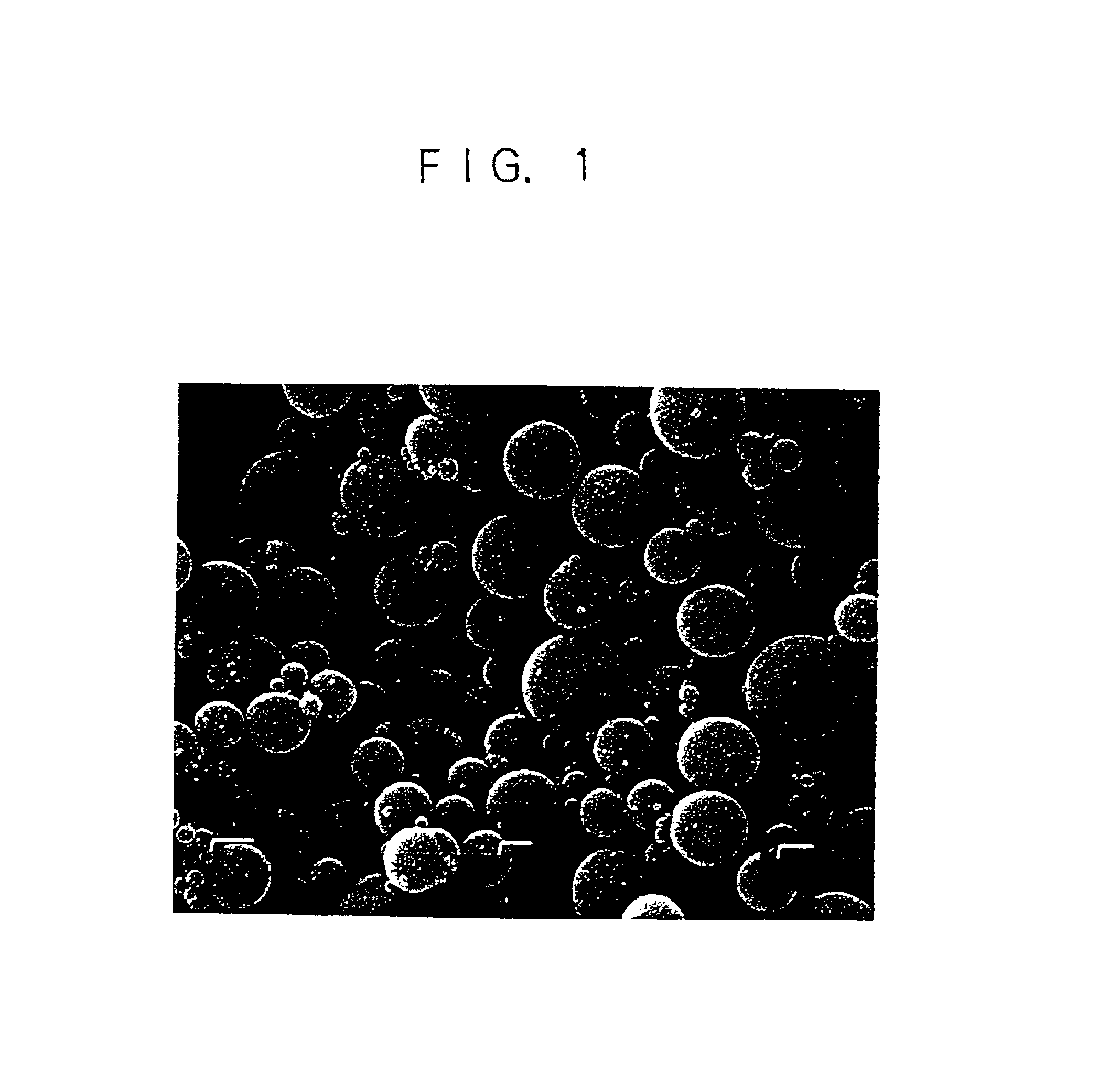

Particles for electro-rheological fluid

The present invention can provide particles for electro-rheological fluid for providing a high electro-rheological effect over a wide temperature range at low electric power consumption, and having high strength and excellent durability, not being susceptible to break-up due to the load of stress. Particles for an electro-rheological fluid of the present invention comprise spherical carbonaceous particles, obtained substantially from a solvent and a condensation product of a methylene type bond of aromatic sulfonic acid or a salt thereof.

Owner:NIPPON COKE & ENG

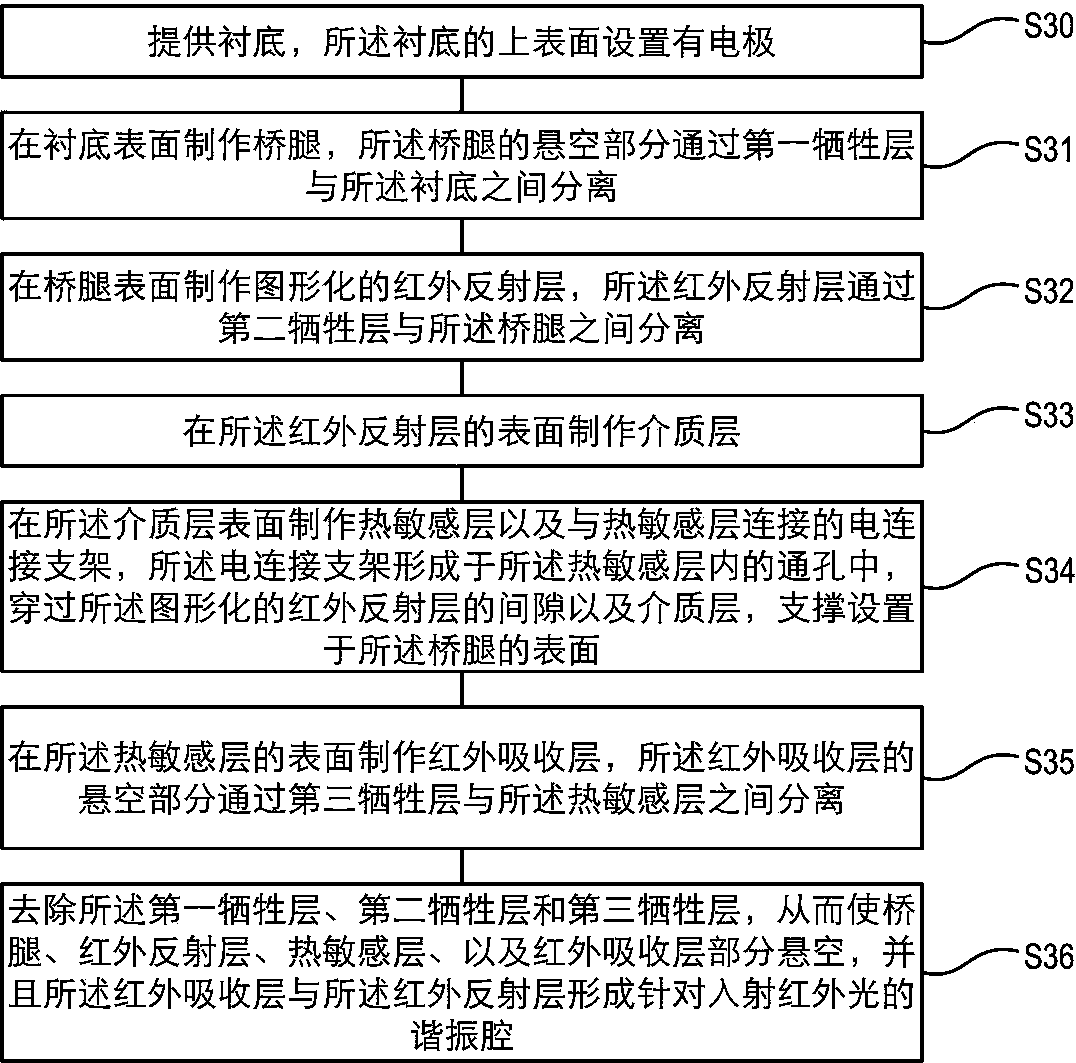

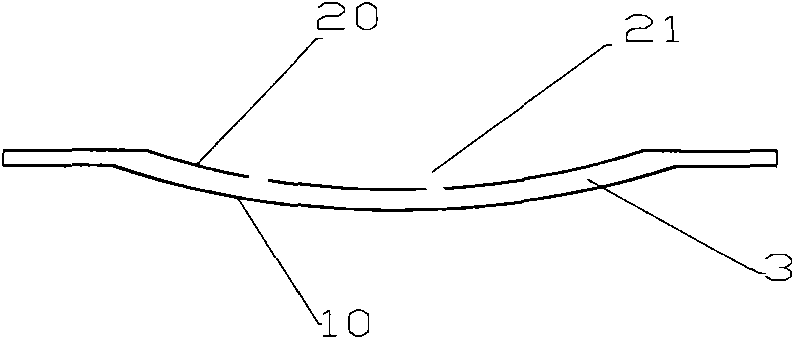

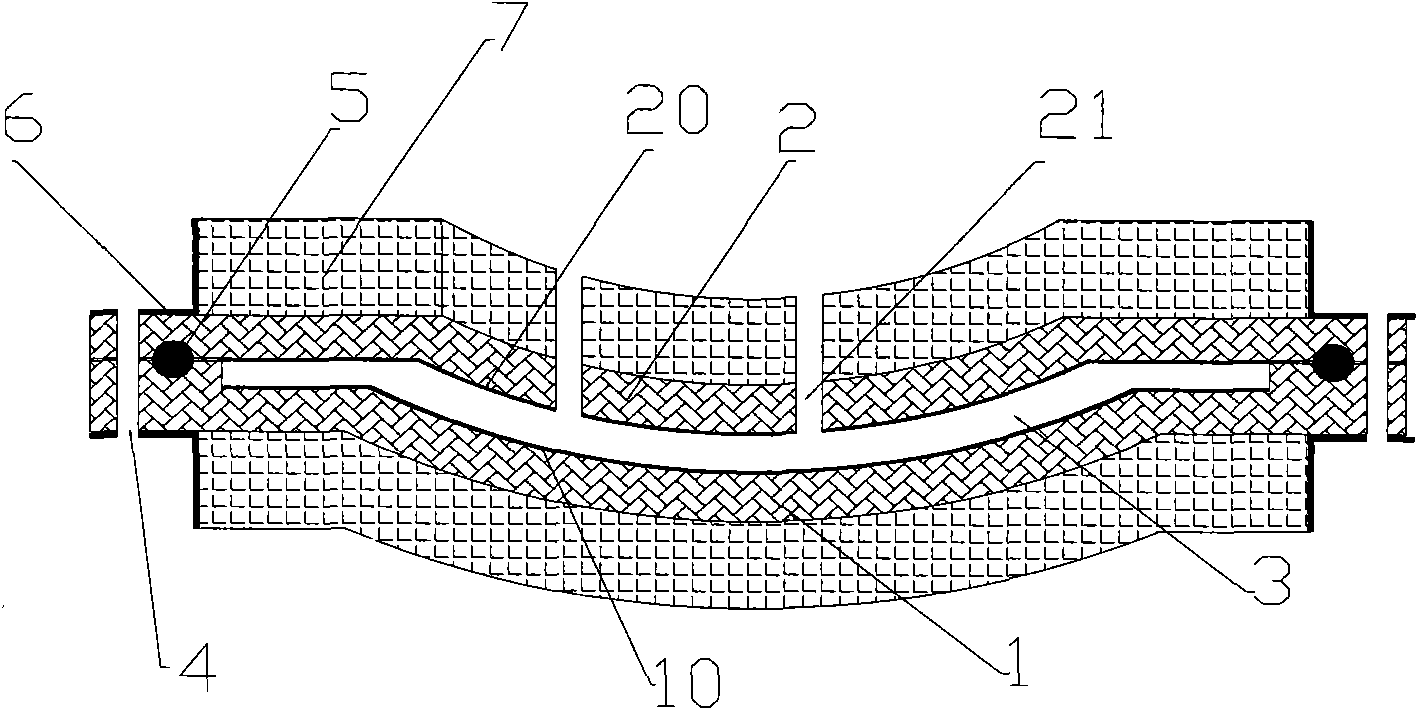

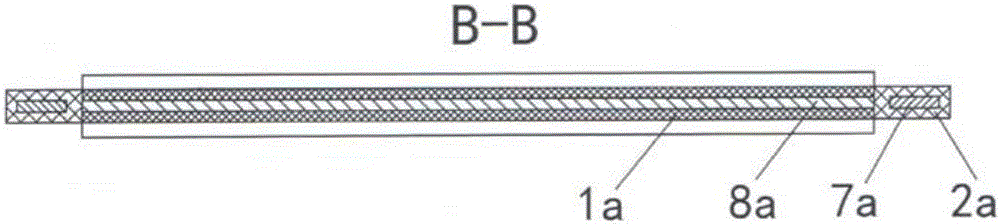

Infrared detector of microbridge structure and method for manufacturing same

ActiveCN103759838ALarge design spaceImprove infrared absorptionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesResonant cavityThermal isolation

The invention provides an infrared detector of a microbridge structure and a method for manufacturing the infrared detector of the microbridge structure. The detector comprises a reading circuit substrate, a microbridge leg, a heat sensitive layer, an infrared reflection layer and an infrared absorption layer. The infrared absorption layer is supported by and arranged above the heat sensitive layer, a resonant cavity for incoming infrared light is formed by the infrared absorption layer and the infrared reflection layer, and the microbridge leg is arranged below the infrared reflection layer and electrically connected with the reading circuit substrate. Through the structure, the infrared absorptivity of the device can be improved while thermal conductance of the device can be reduced, the filling rate of the device is improved, the defects of the resonant cavity are overcome, and thus the thermal isolation effect and the responsivity of the device are improved and the performance of the device is optimized.

Owner:ZHEJIANG DALI TECH

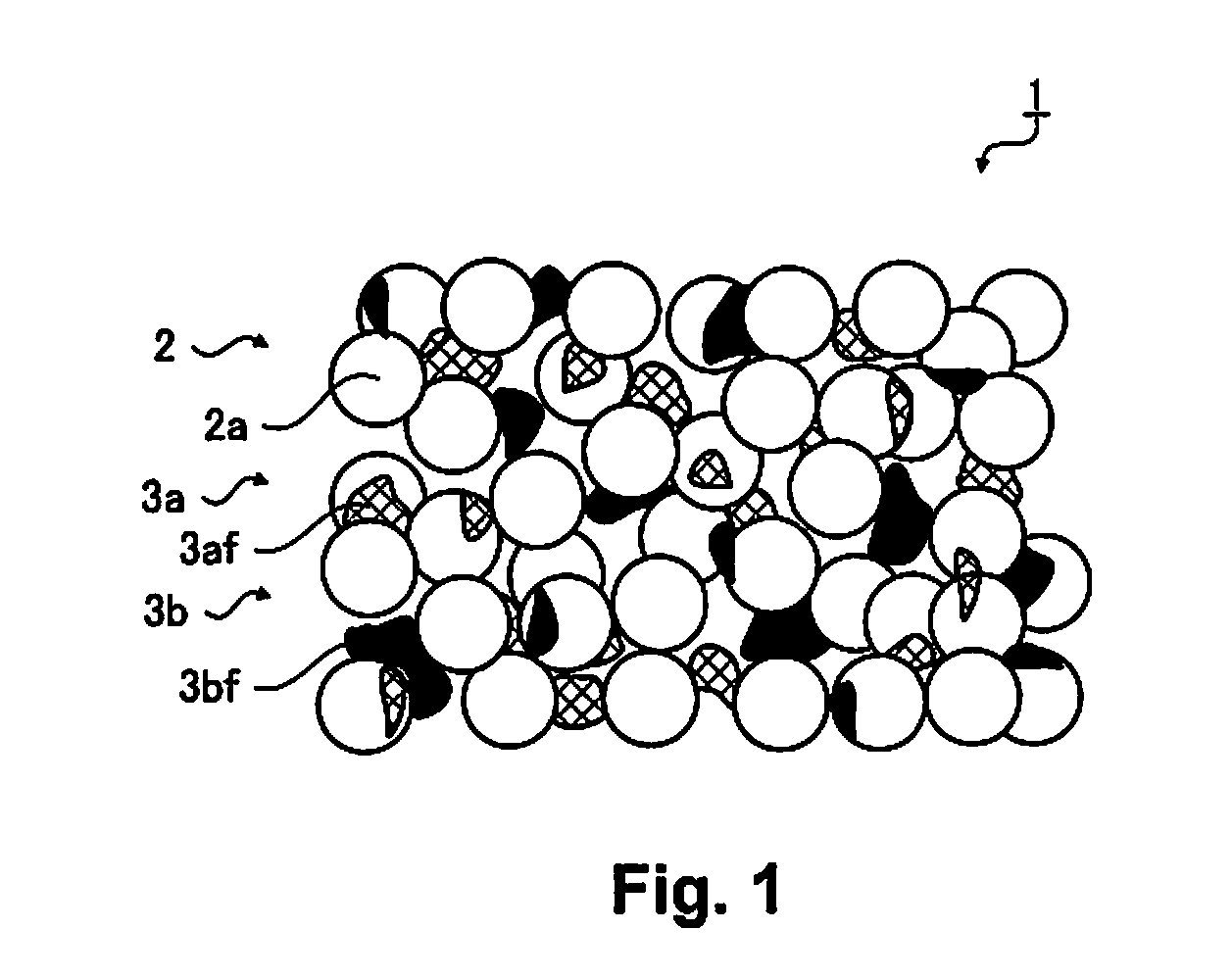

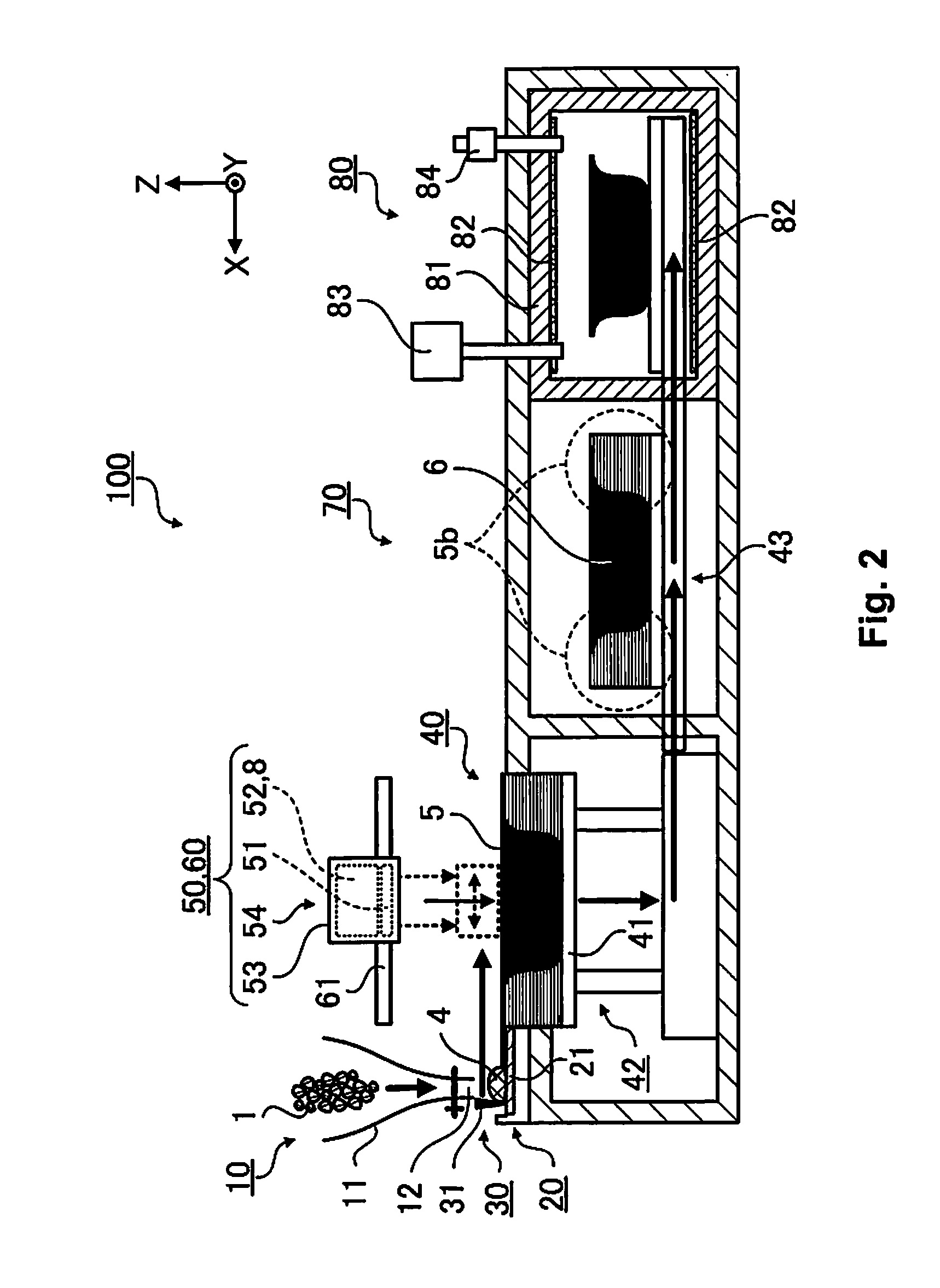

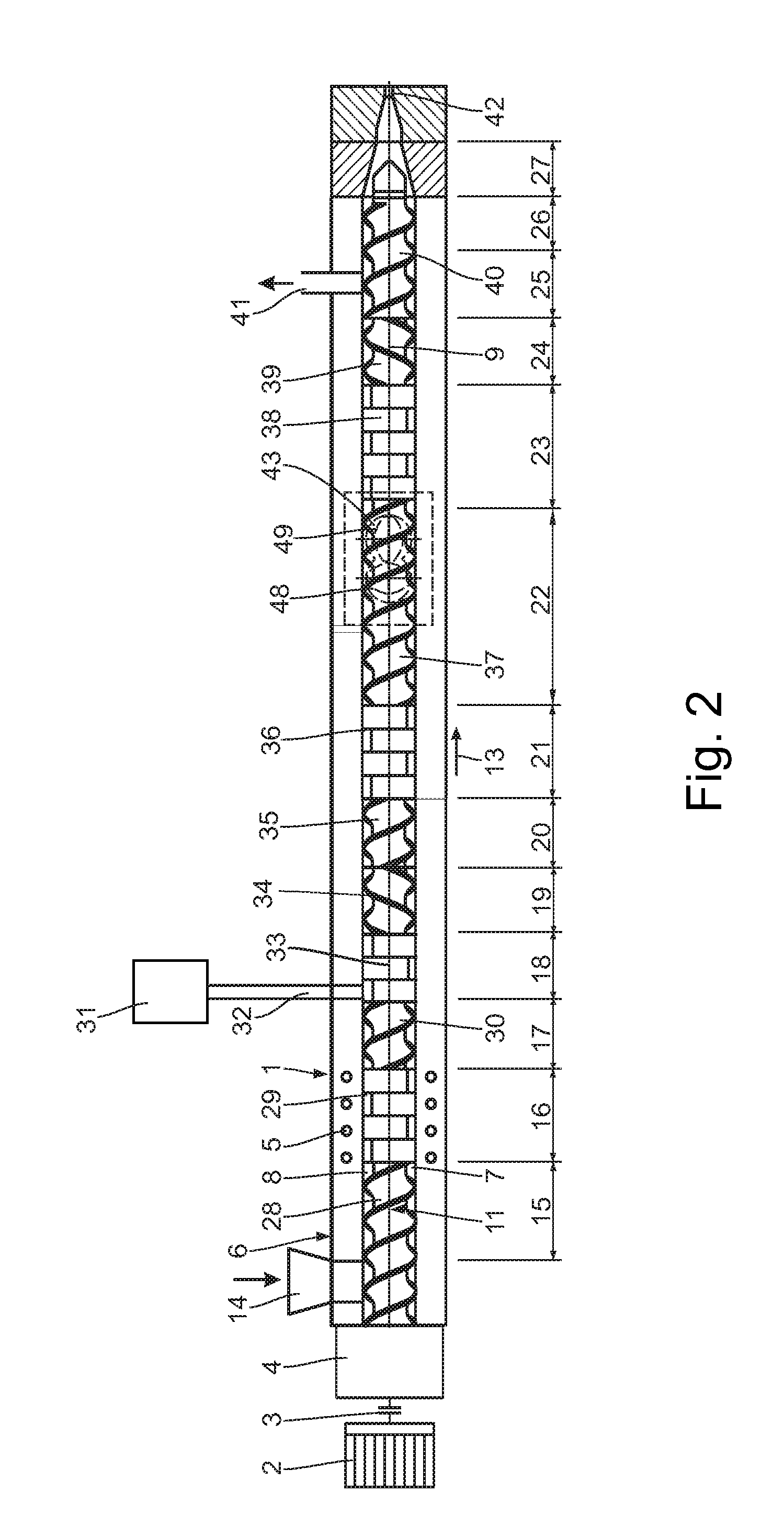

Sinter mold material, sintering and molding method, sinter mold object, and sintering and molding apparatus

InactiveUS20150224575A1Improve fill rateNon-fibrous pulp additionTransportation and packagingInorganic particleInorganic particles

A sintering and molding method includes forming a fluid mold material by heating a sinter mold material, which includes inorganic particles, a binder material and a binder material which bond together the inorganic particles, to a temperature equal to or more than the melting points of the binder materials, forming a mold layer by spreading the fluid mold material, layering a mold layer, applying UV ink to a desired region on the mold layer, forming a mold cross sectional pattern by curing the UV ink which is applied to a desired region on the mold layer, finishing a mold object by removing a region, where the UV ink is not applied, in the mold layer, carrying out heat treatment on the mold object at a temperature which is less than the initial temperature of thermal decomposition of the binder material, and carrying out sintering treatment on the mold object.

Owner:SEIKO EPSON CORP

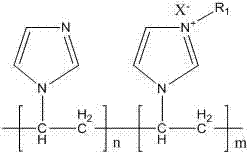

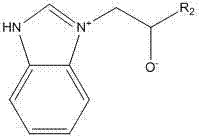

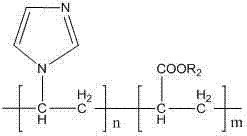

Electroplating solution and electroplating method for electroplating through holes and blind holes of circuit boards

The invention discloses an electroplating solution for electroplating through holes and blind holes of circuit boards. The electroplating solution comprises the following components: 160-180g / L of copper sulfate pentahydrate, 20-50g / L of sulfuric acid, 0.05-0.07g / L of chloride ions, 0.5-1.5g / L of accelerant, 7-30g / L of inhibitor, 10-30g / L of leveling agent and the balance of water. The electroplating solution provided by the present invention is applicable to electroplate through holes and blinds holes of circuit boards, and in particular capable of realizing simultaneously hole-filling electroplating of a through hole and a blind hole in one groove of a circuit board; as a result, the electroplating steps are reduced and the production efficiency is improved.

Owner:苏州禾川化学技术服务有限公司

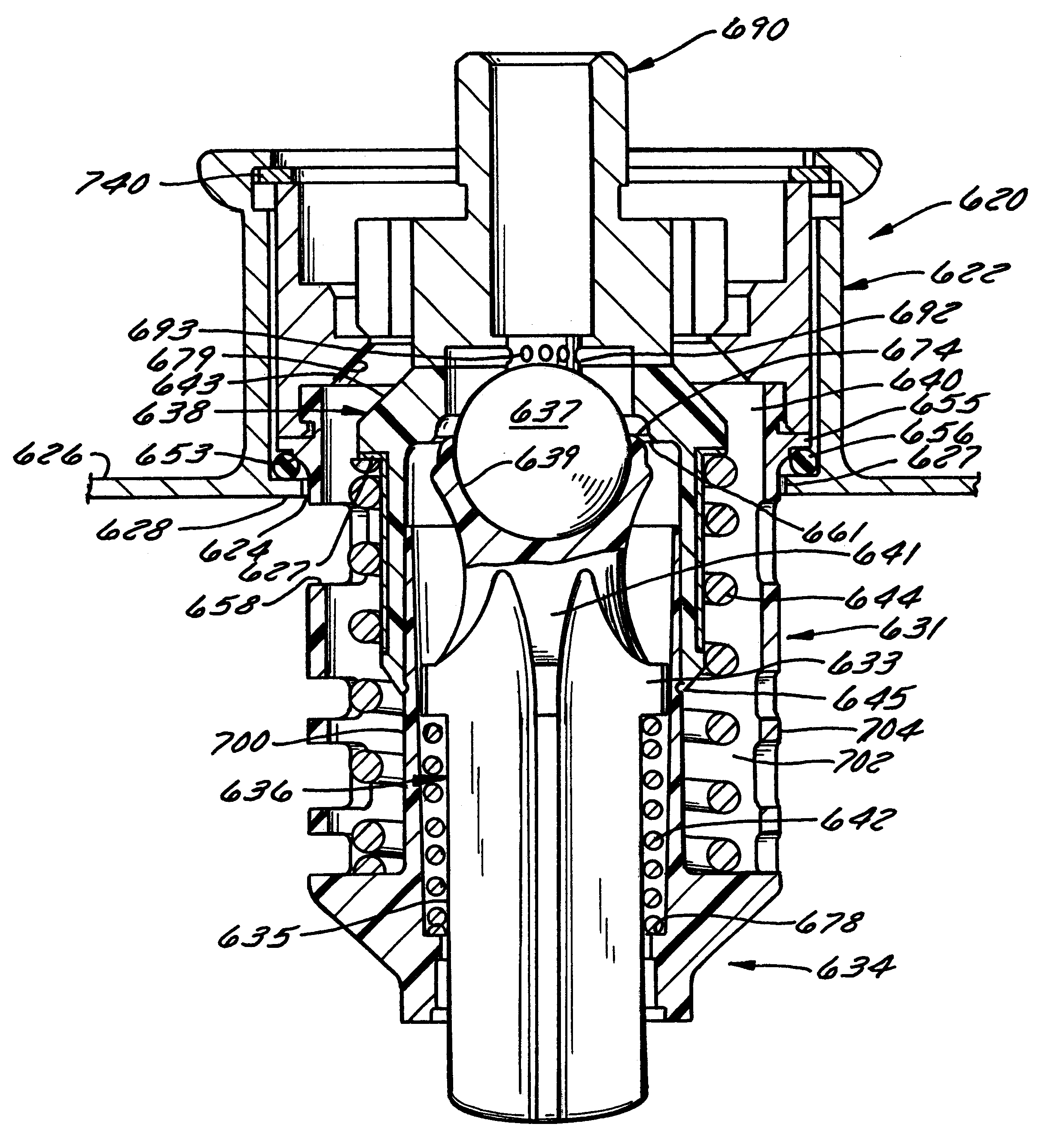

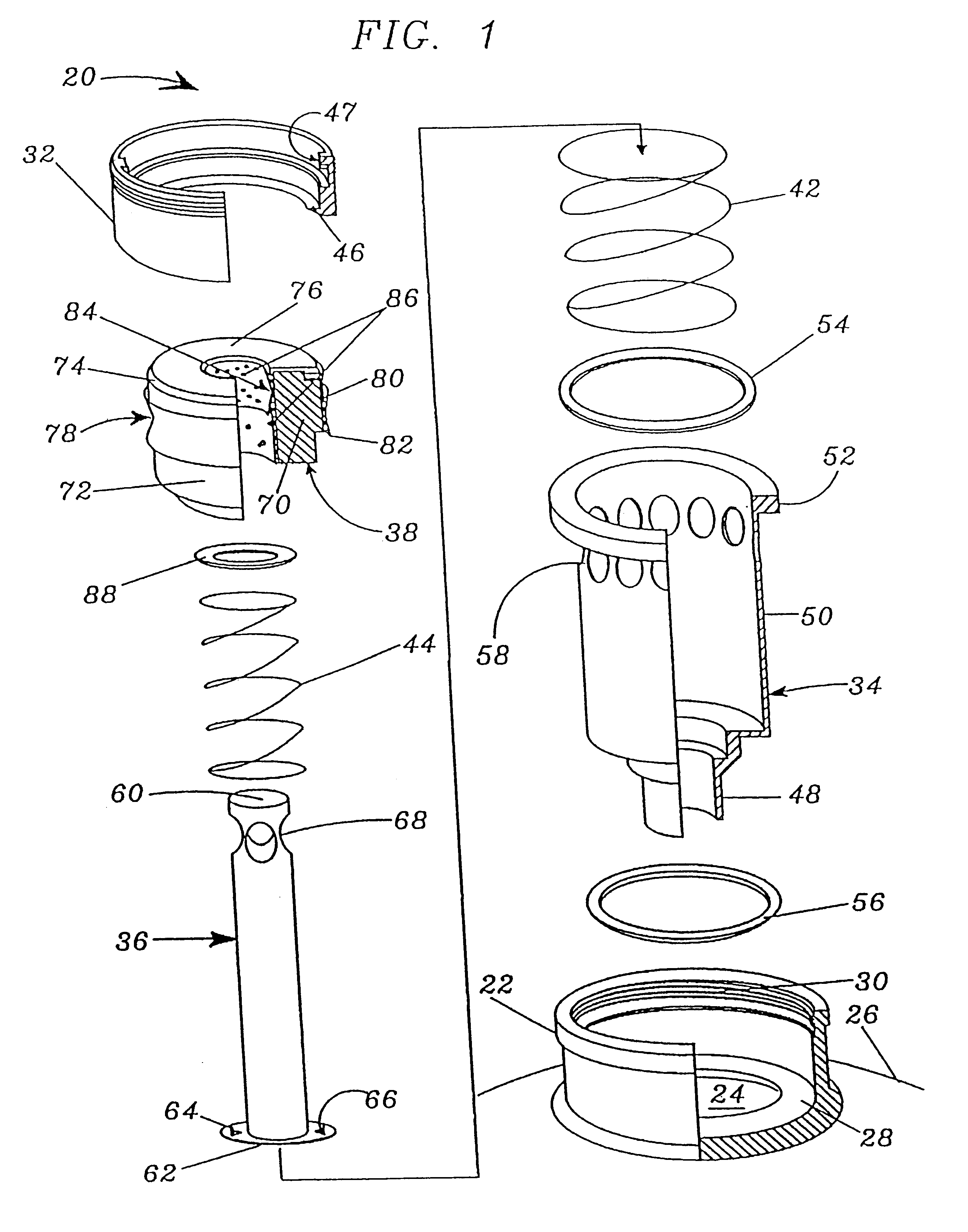

Valve assembly for controlling fluid ingress and egress from a transportable container which stores and distributes liquid under pressure

InactiveUS6286730B1Enhance self-threading natureLow costPressure pumpsLiquid transferring devicesDetentSlide plate

A valve assembly has (1) a riser pipe including a valve cup housing and portals blockable, and (2) a central tower which communicates with blockable pathways that pass both liquid and gas, and (3) a bi-directional valve member which controls separation of gas and liquid and directional flow in the chamber. A retainer assembly is provided on the outer peripheral surface of the valve cup so as to facilitate insertion of the valve cup into the container but so as to prevent the unintended removal of the valve cup from the container while still permitting selective valve cup removal when it is desired to do so. The retainer assembly preferably includes a protrusion and a pair of centering skids spaced about the outer periphery of the valve cup. The protrusion includes a radially tapered, vertical extending detent portion and a radially tapered, circumferentially extending ramp portion. The centering skids taper radially inwardly from vertically central portions thereof to the vertical end portions thereof. Upon simultaneous twisting and tilting of the valve cup relative to an annular member on the container such as the shoulder of a stub, the centering skids engage the annular member so as to take up the clearance between the valve cup and the annular member, and the protrusion ramps onto the annular member in a self-threading manner so as to circumferentially distort the valve cup and to permit the valve cup to be turned out of the container.

Owner:VENT MATIC +1

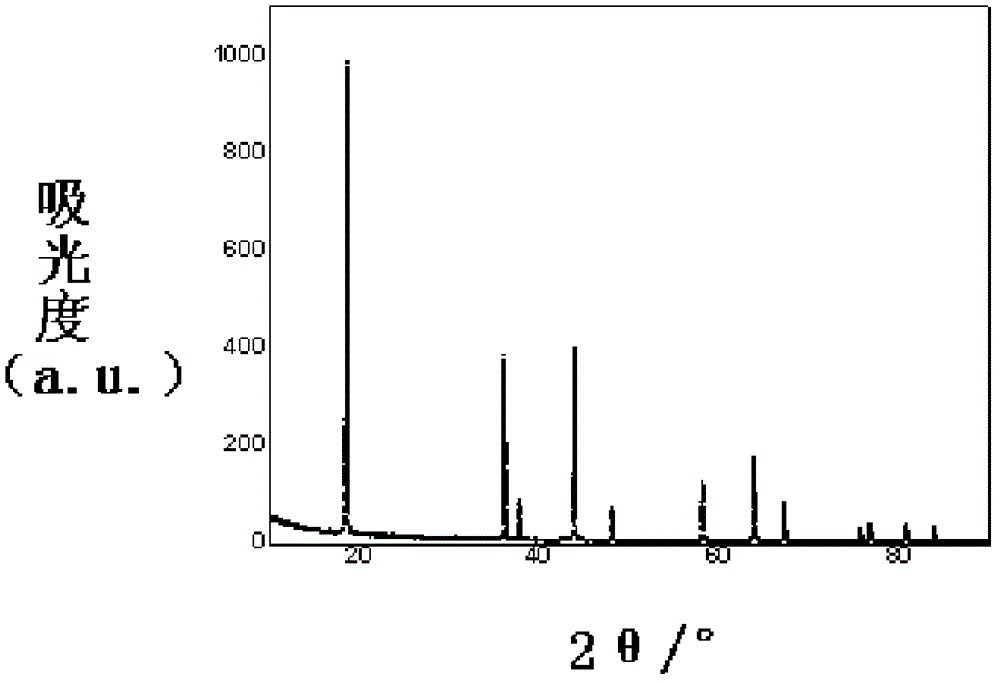

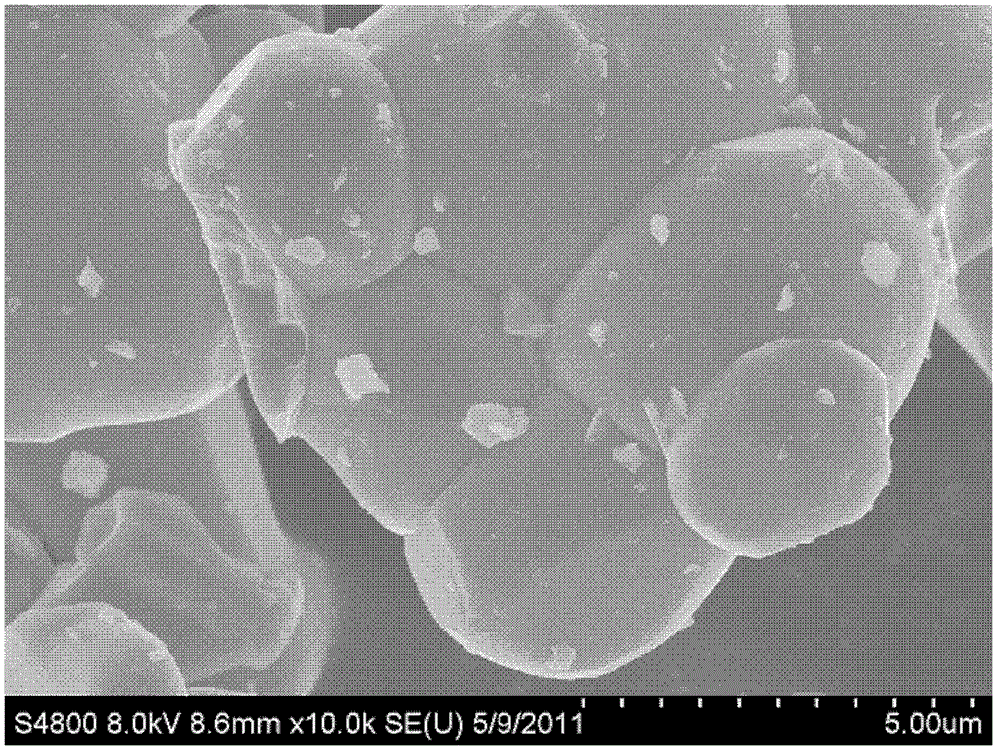

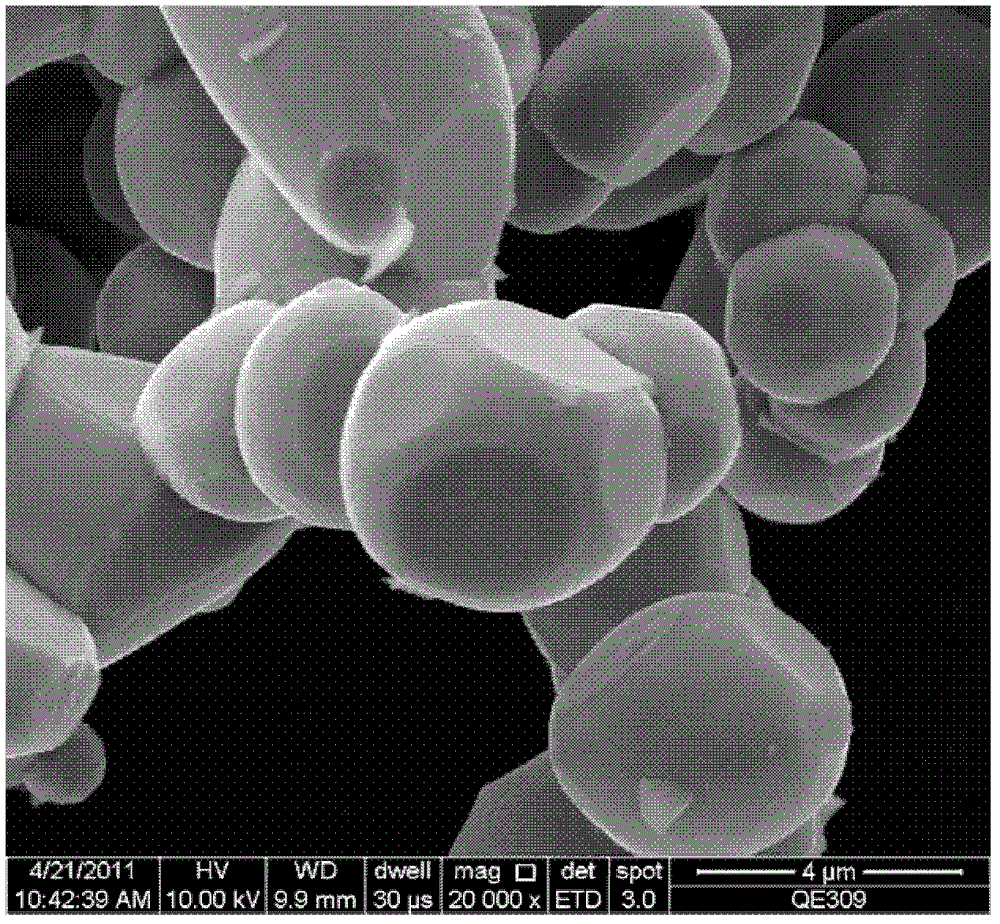

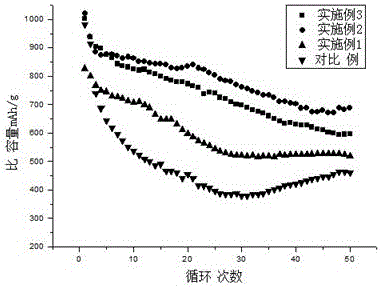

Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

ActiveCN102800840ANot easy to dissolveGood high temperature cycle performanceCell electrodesSecondary cellsTemperature cyclingLithium electrode

The invention provides a cathode material of a lithium ion battery. The cathode material is composed by the atomic ratio shown in formula (I): Lia(MxMn2-x)(O4-yZy), wherein a is greater than or equal to 0.8 and less than or equal to 1.2; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is one or more selected from Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si; and Z is one or more selected from OH, halogens, N, P, S and O. Primary particles of the cathode material have sphere-like morphologies, wherein (111) face is connected with adjacent equivalent crystal face through a curved surface having no clear edges. The invention also provides a preparation method for the cathode material of the lithium ion battery and the lithium ion battery. The cathode material provided by the invention has good high-temperature cycling performance and good filling property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

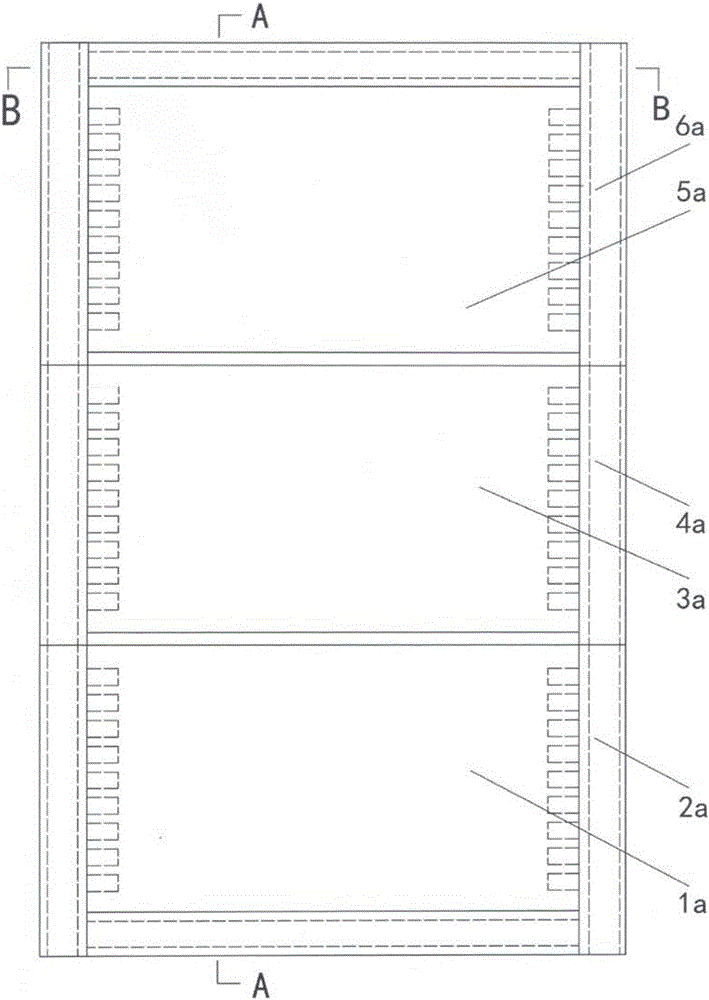

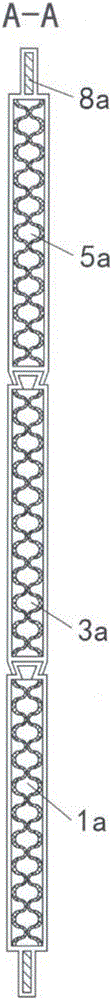

Glass steel radar cover single element and forming method thereof

InactiveCN101630774AAdjust and control thicknessFlat surfaceRadiating element housingsRadarSingle element

The invention relates to a glass steel radar cover single element and a forming method thereof. The radar cover single element is a spherical body, the periphery of which is provided with a sewing structure, wherein the spherical body is formed by assembling the inner skin and the outer skin of the glass steel with a foam core layer and the foam core layer is formed by solidifying injected polyurenthane foam glue material. The forming method comprises the following steps of: presetting a fundamental mould, and copying the female mould and the male mould of the glass steel with the same curvature based on the fundamental mould; respectively manufacturing the inner skin and the outer skin of the radar cover single element on the inner surfaces of the female mould and the male mould of the glass steel; and merging the moulds, and forming an inner cavity between the inner skin and the outer skin. The invention is characterized in that the inner skin is provided with a plurality of through holes which enter into the inner cavity; and the inner cavity is filled with polyurenthane foam glue material from the outside to the inside by the through holes and is solidified to be a foam core layer. The method has simple operation, effectively reduces the use waste of polyurenthane foam, has low cost, guarantees the consilient thickness of the inner skin and the outer skin, and can assemble the radar cover with good safety, reliability and wave permeability.

Owner:北京玻钢院复合材料有限公司

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

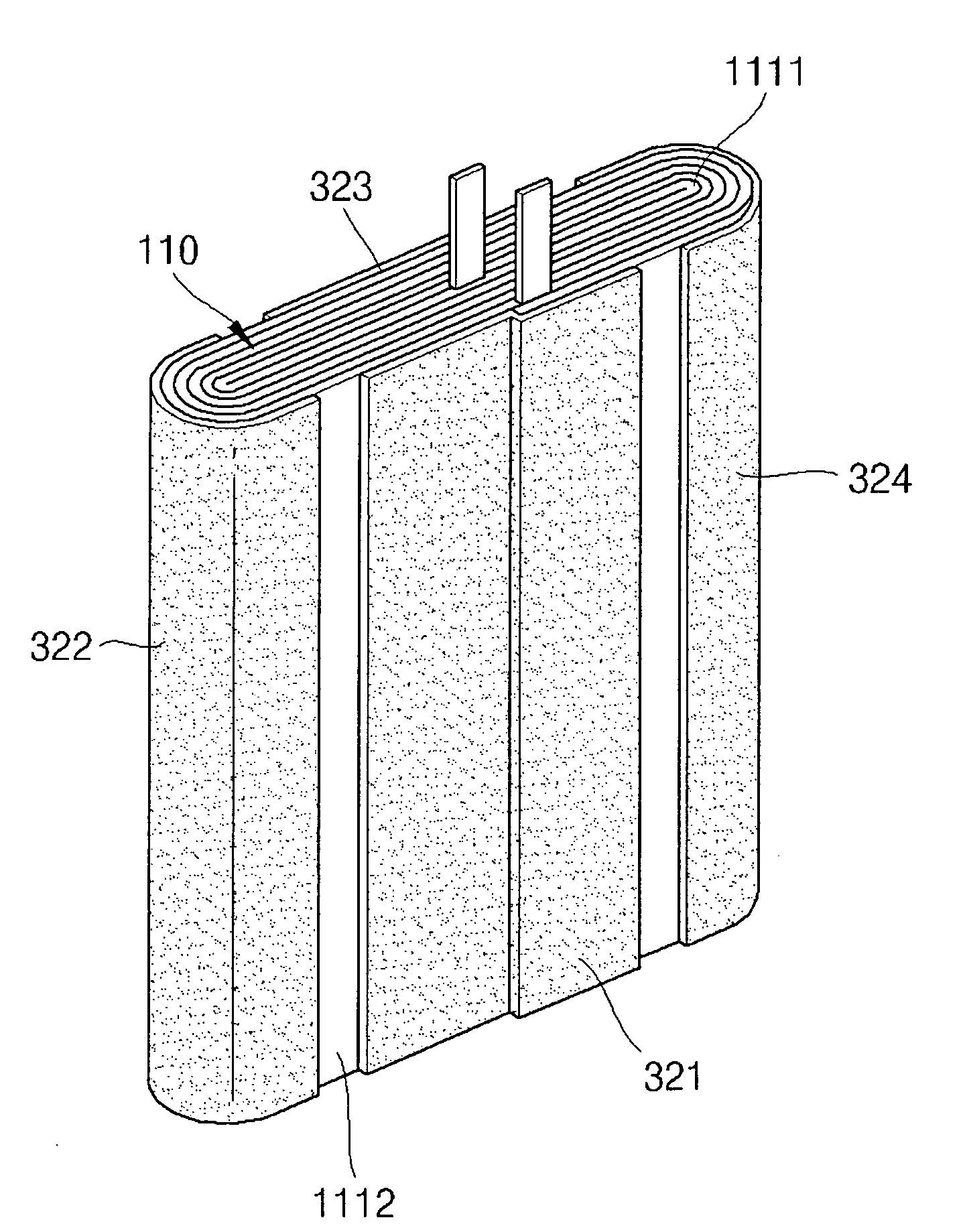

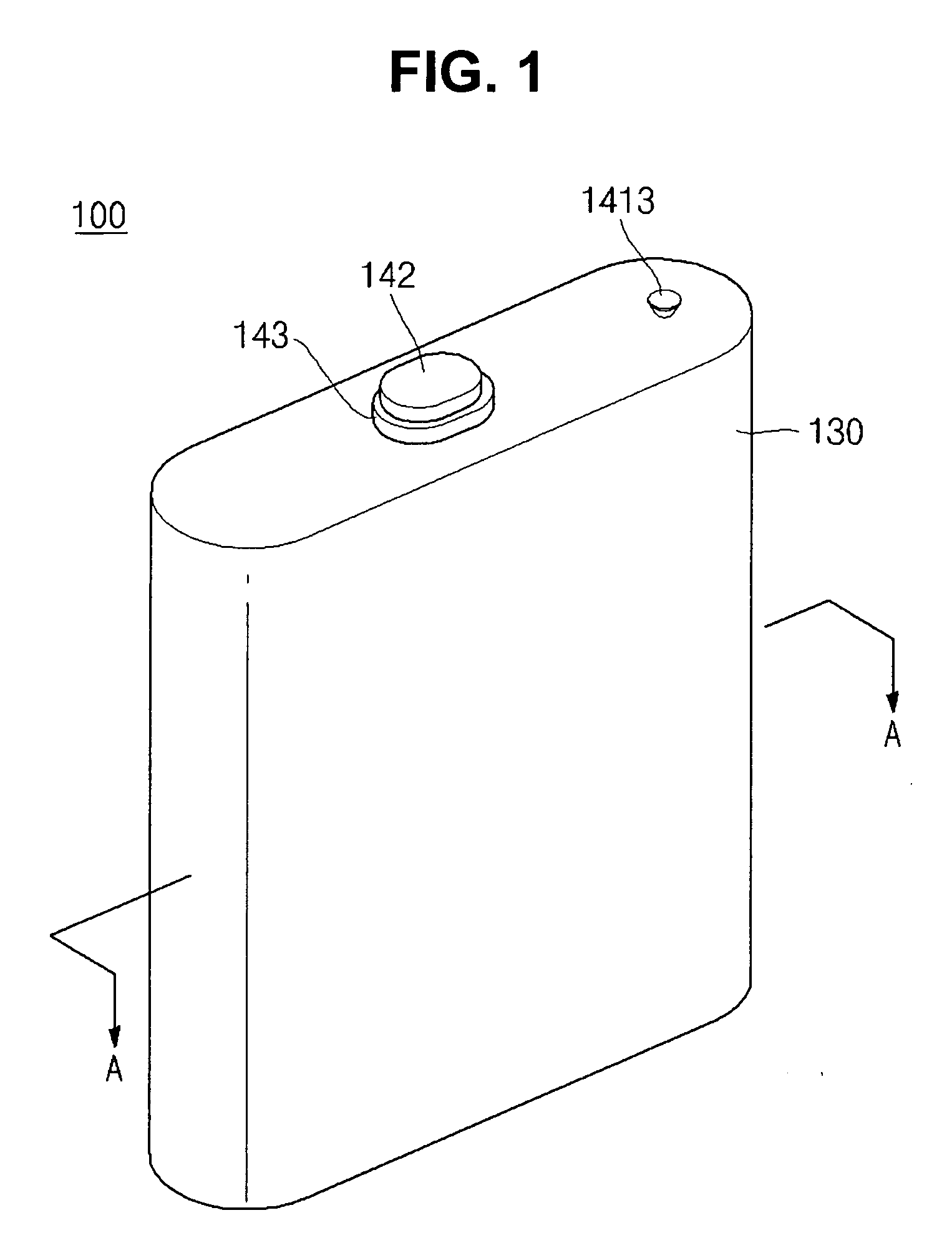

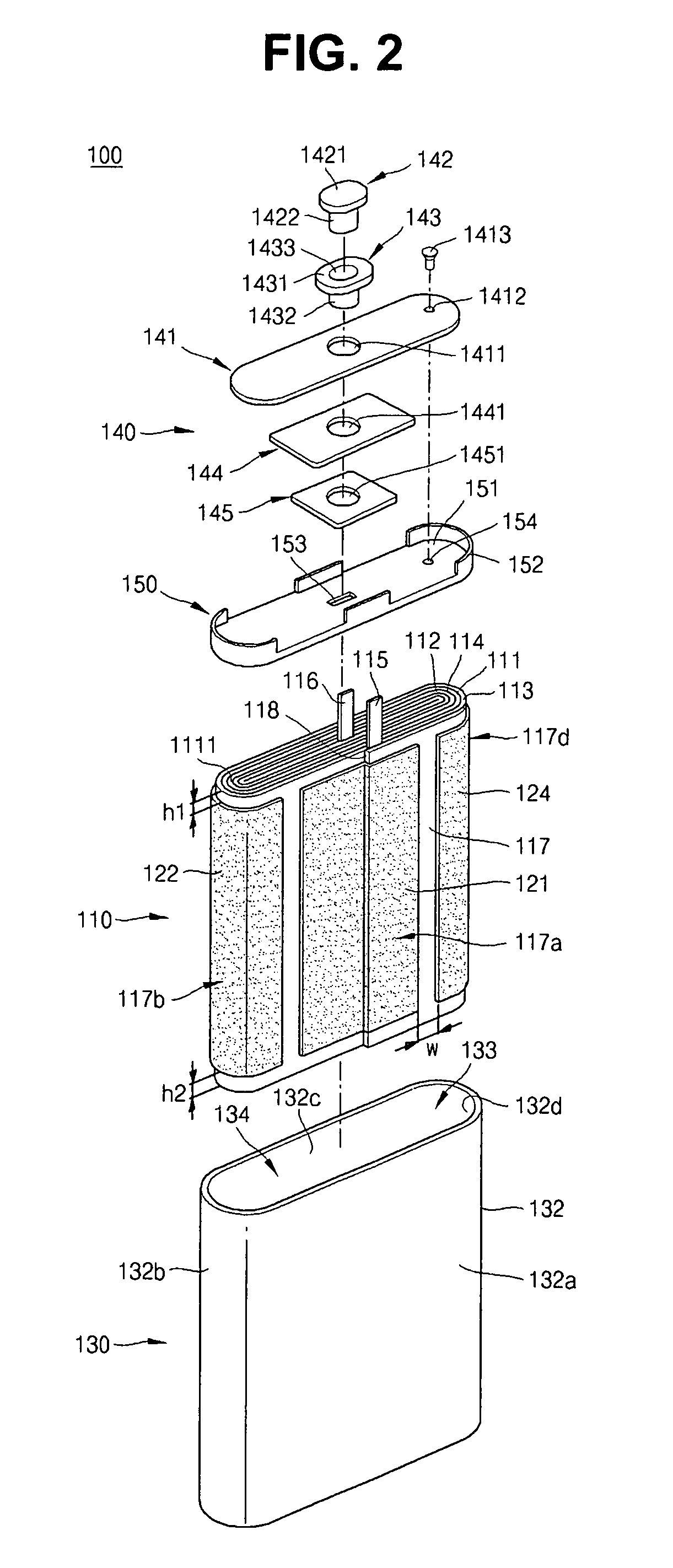

Secondary battery

InactiveUS20100035132A1Shape can not be easilyIncrease heat radiationFinal product manufactureCell electrodesBiomedical engineeringElectrode

A secondary battery includes an electrode assembly in which a first electrode plate, a separator, and a second electrode assembly are sequentially stacked forming a stack and is wound about one edge of the stack, and a plurality of finishing tapes attached to the outer surface of the electrode assembly and spaced apart from each other along the winding direction of the electrode assembly.

Owner:SAMSUNG SDI CO LTD

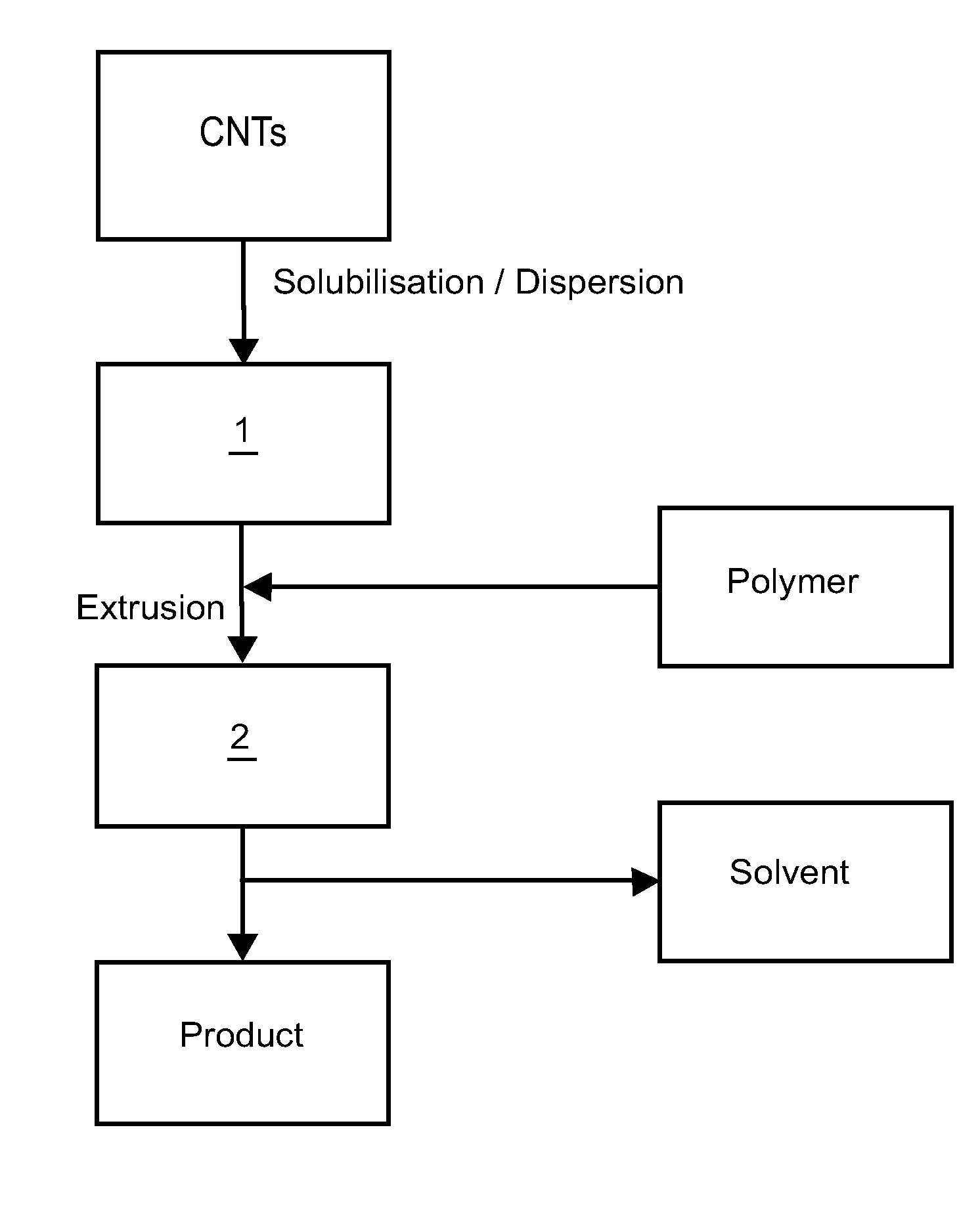

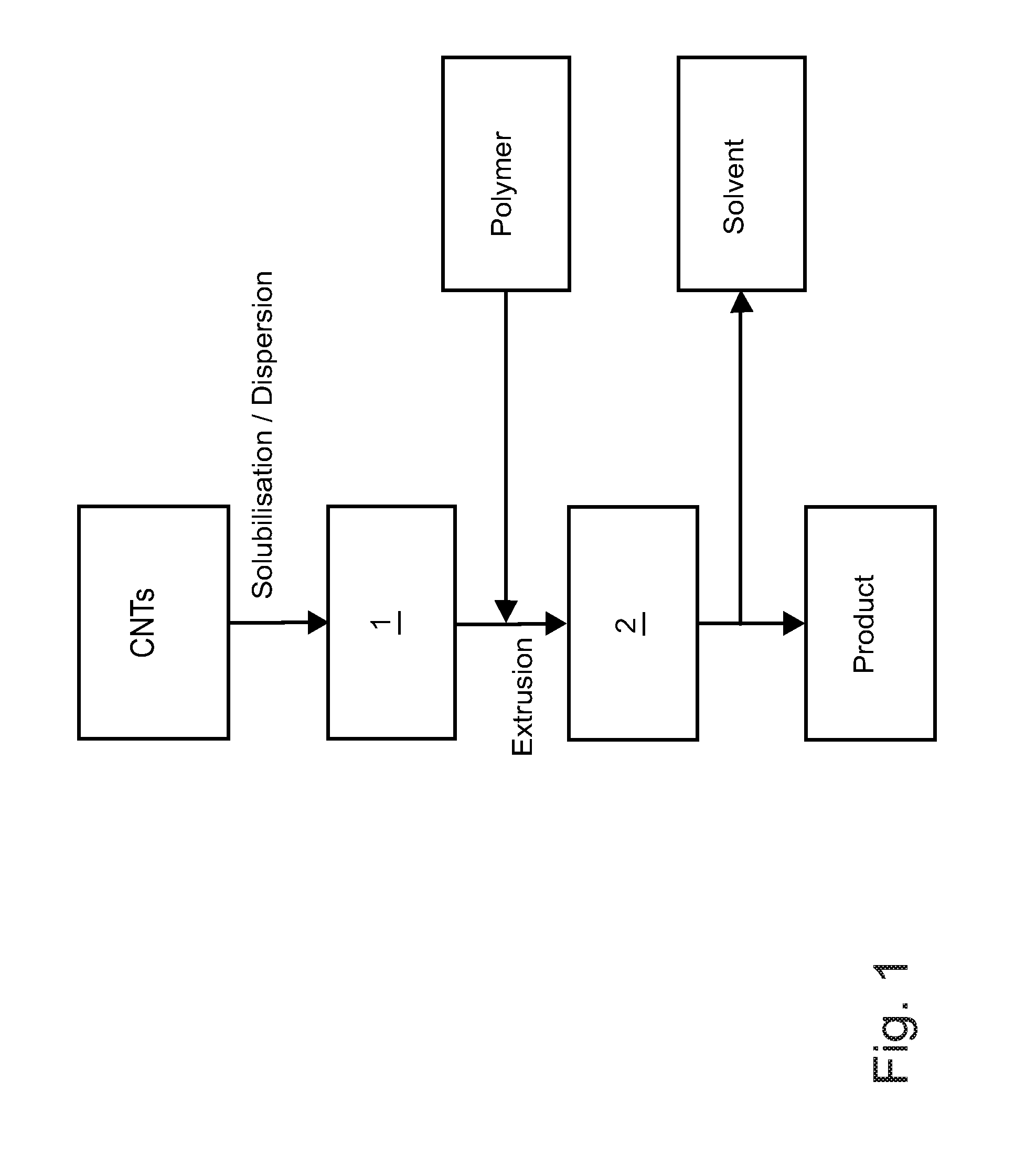

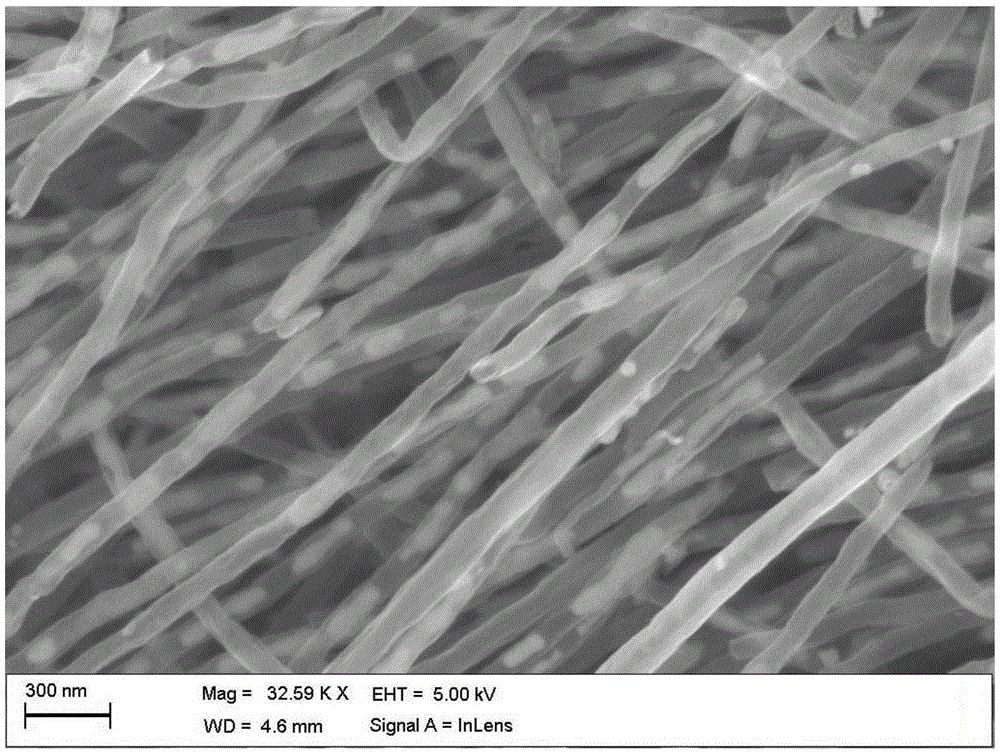

METHOD FOR PRODUCING COMPOSITE MATERIALS BASED ON POLYMERS AND CARBON NANOTUBES (CNTs), COMPOSITE MATERIALS PRODUCED IN THIS WAY AND USE THEREOF

InactiveUS20120292578A1Improve fill ratePromote reproductionMaterial nanotechnologyNon-metal conductorsPolymer scienceCarbon nanotube

The invention relates to a method for producing composite materials based on at least one polymer and carbon nanotubes (CNTs), and to composite materials obtained in this manner and the use thereof.

Owner:BACHER ALEXANDER +12

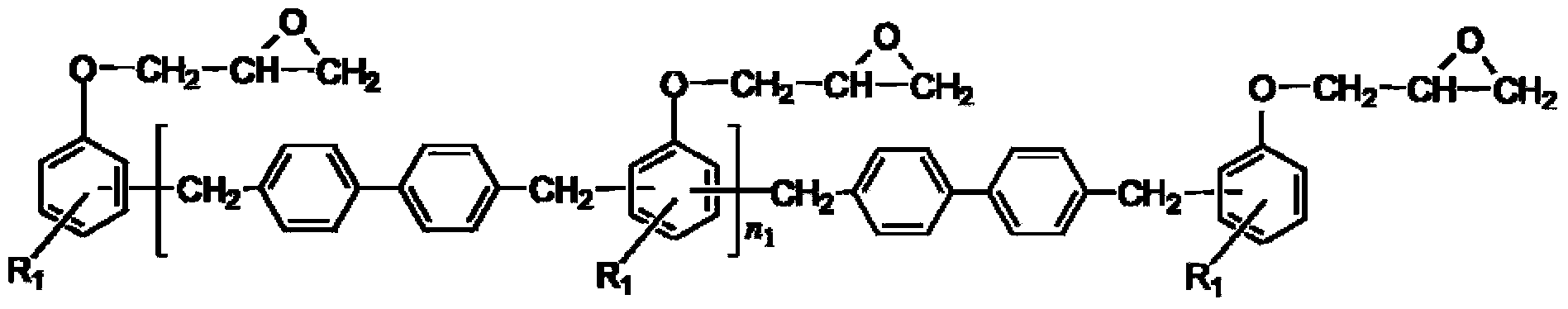

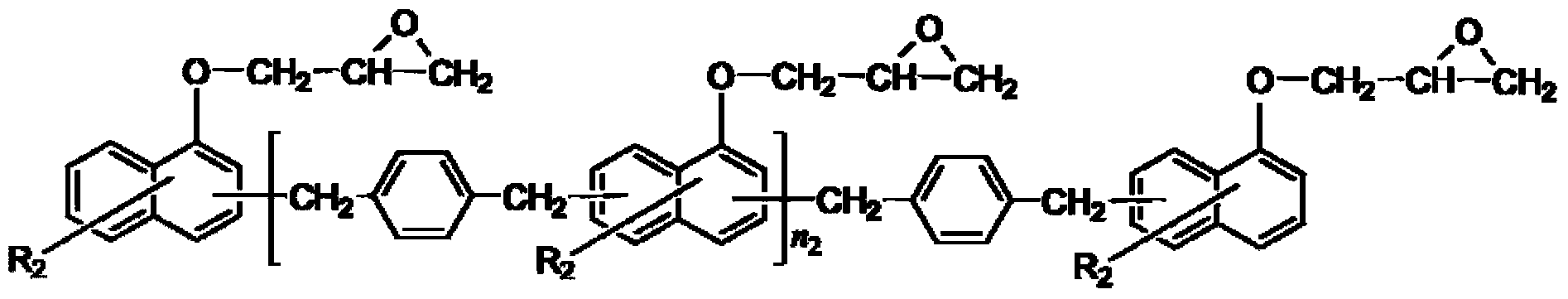

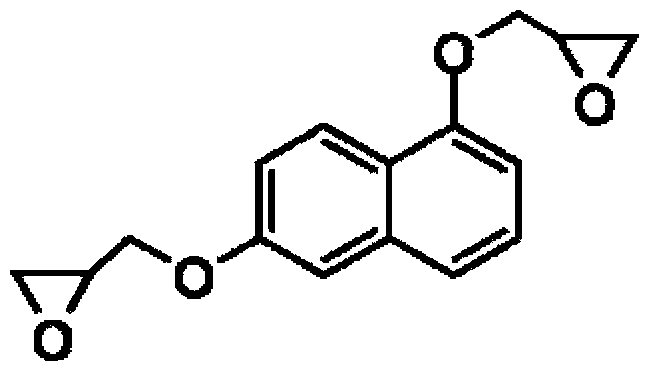

Resin composition used for forming dielectric layer of dielectric substrate for antenna and application of resin composition

ActiveCN103351578ASmall coefficient of thermal expansionLittle change in thicknessSynthetic resin layered productsMetal layered productsEpoxyDielectric substrate

The invention relates to a resin composition used for forming a dielectric layer of a dielectric substrate for an antenna. The resin composition comprises (A), epoxy resin containing a naphthalene nucleus or diphenyl structure, (B), any one of or a mixture of at least two of tri(4-hydroxyphenyl) methane type epoxy resin, o-cresol type novolac epoxy resin and phenol type novolac epoxy resin, (C), a resin fusion viscosity modifier, and (D), spherical ceramic powder after presintering treatment. With the adoption of the resin composition, the obtained dielectric substrate has a high dielectric constant, high peeling strength, a low thermal expansion coefficient and very good thickness consistency, and can meet a performance requirement of the high dielectric constant antenna substrate.

Owner:江苏生益特种材料有限公司

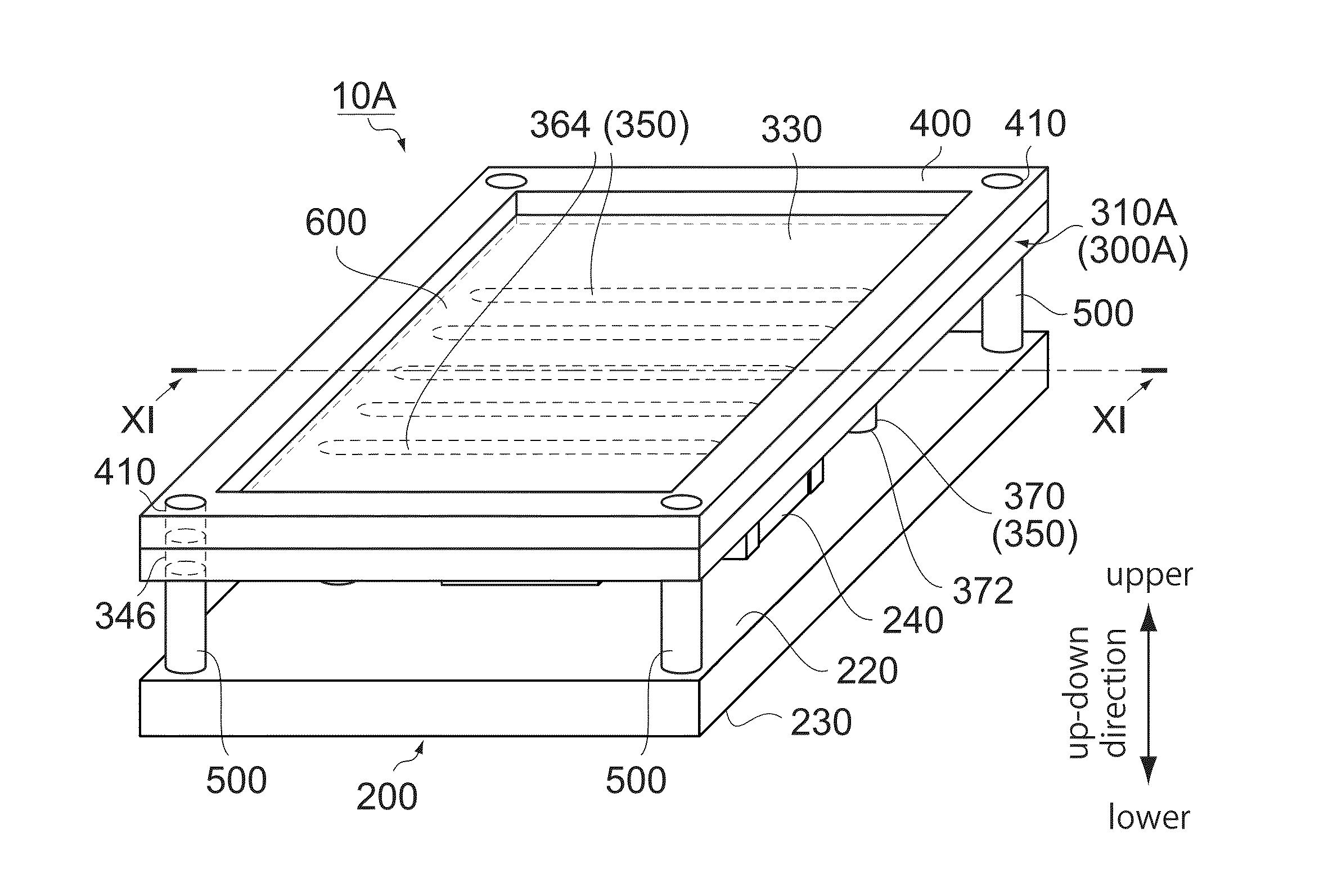

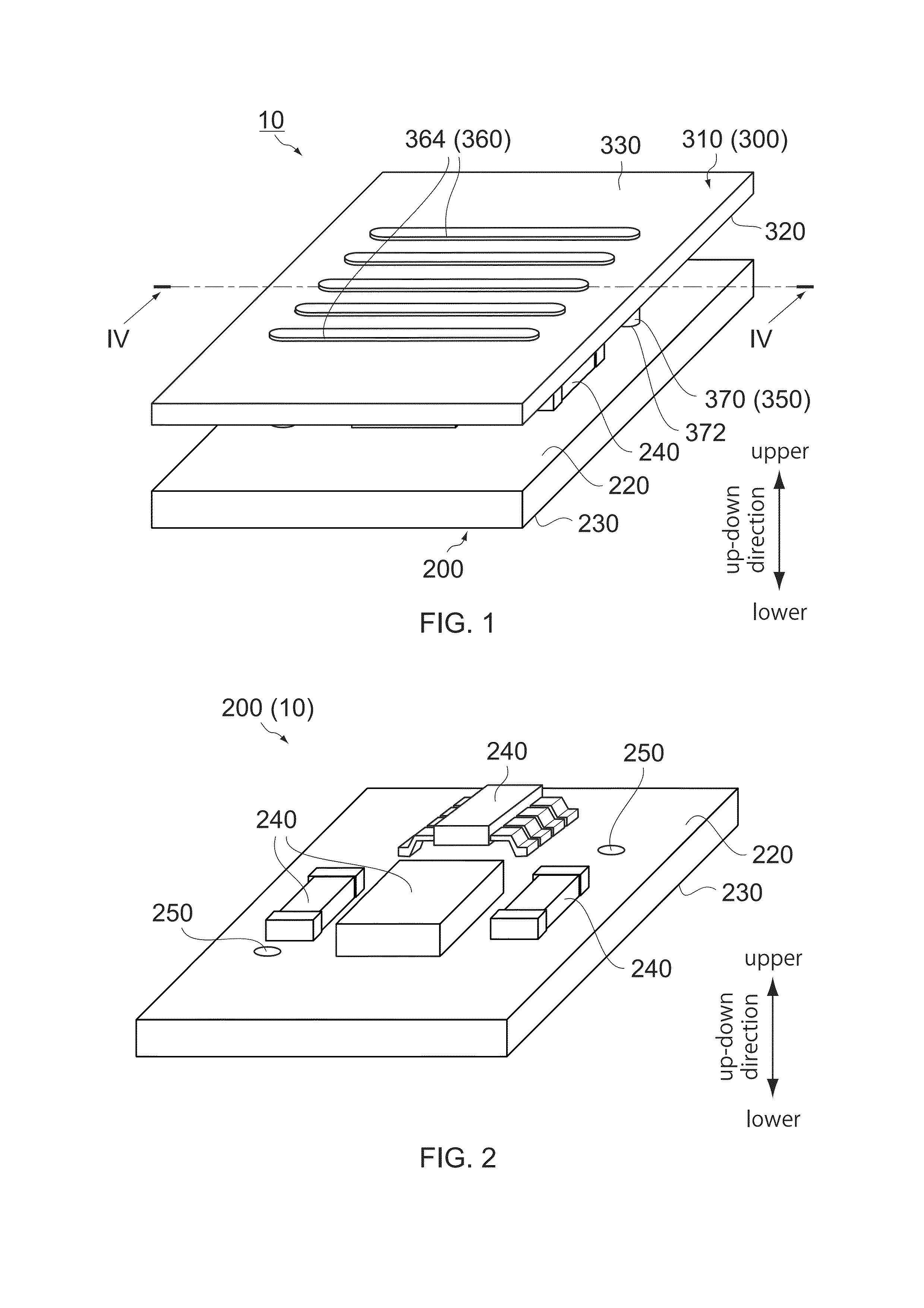

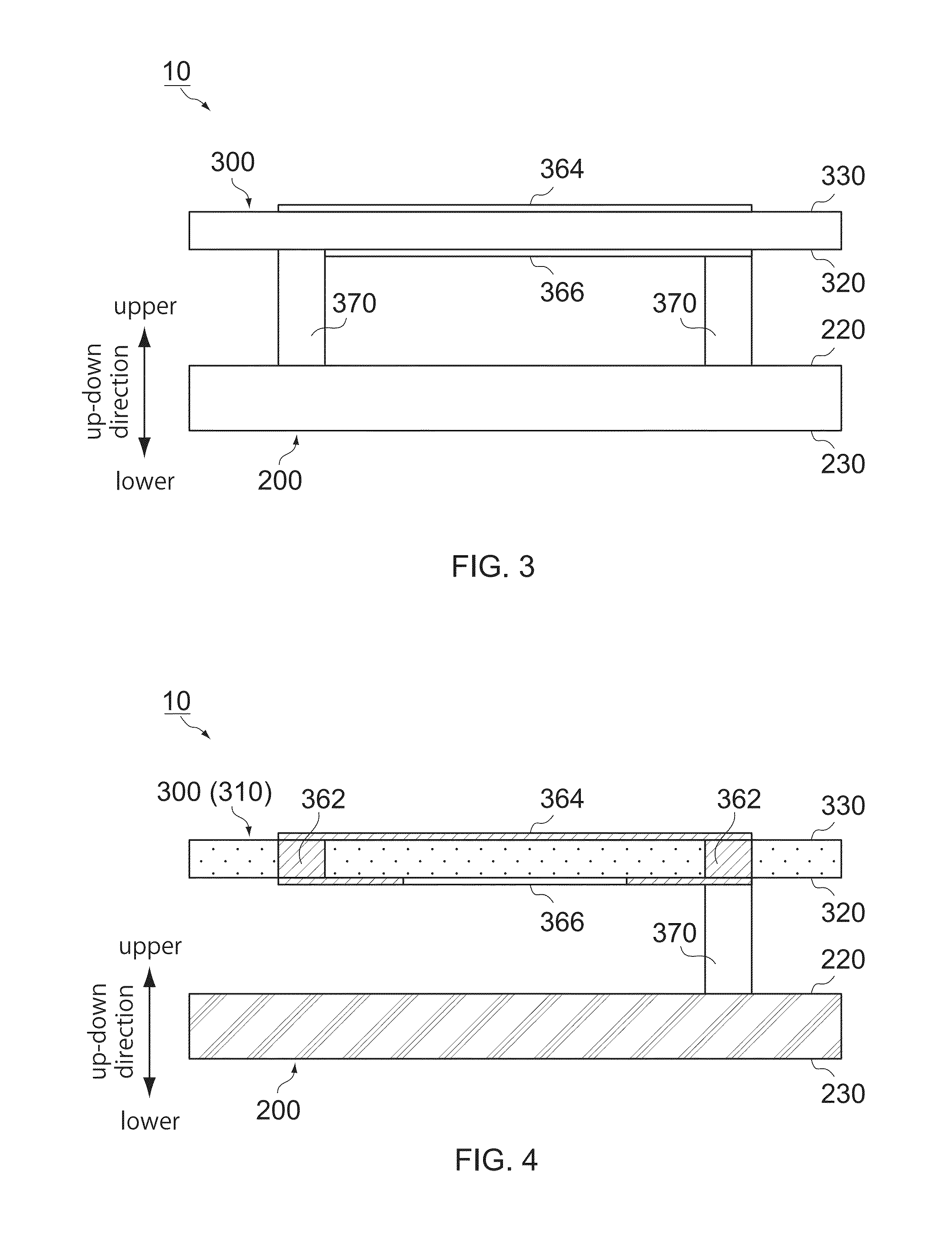

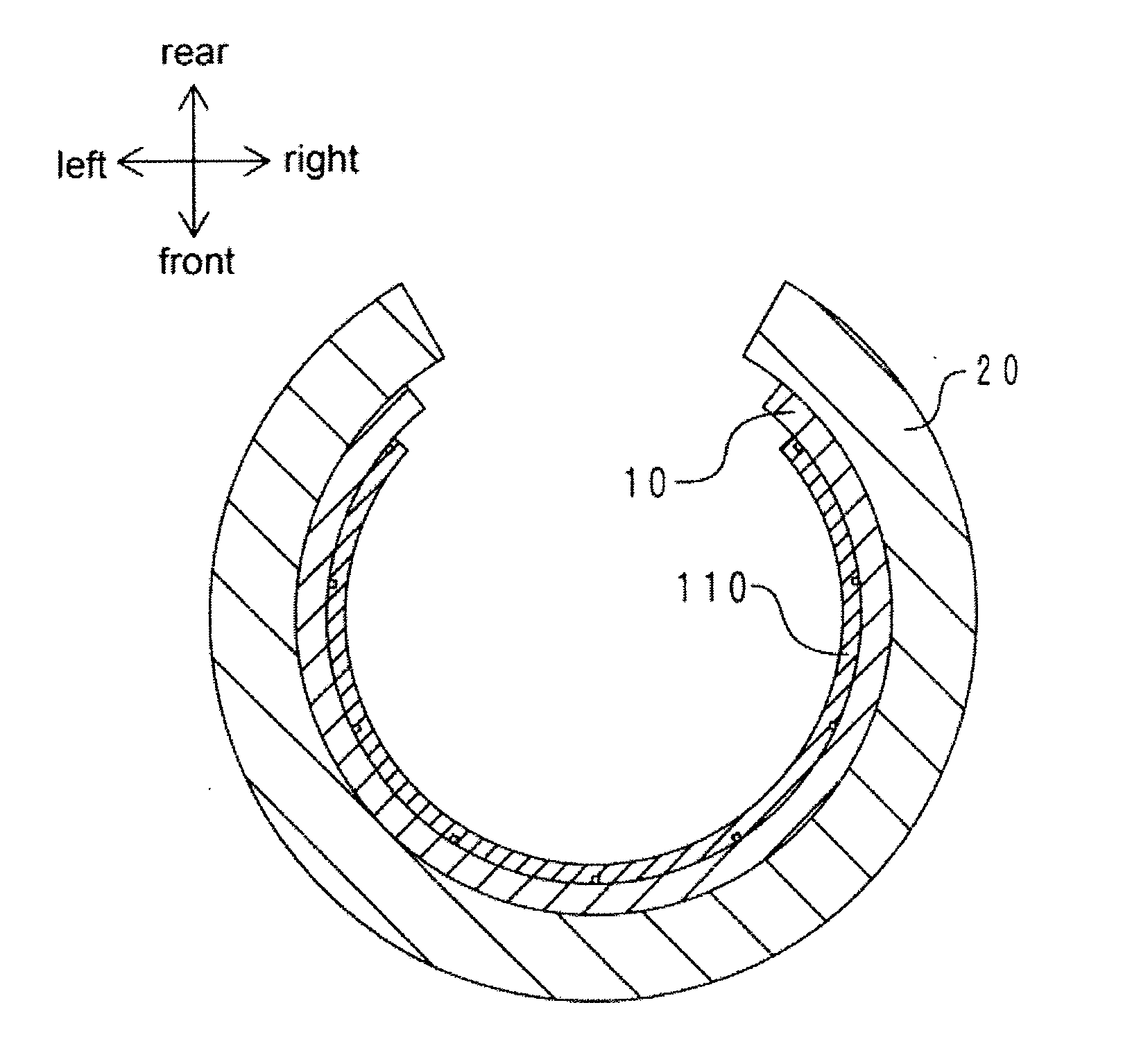

Magnetic core, inductor and module including inductor

ActiveUS20140218147A1Simple structureEffective coolingTransformers/inductances coolingTransformers/inductances coils/windings/connectionsInductorInductance

A module comprises a circuit board and an inductor. The circuit board has a facing surface and a rear surface which are located at opposite sides to each other in an up-down direction. The inductor has a magnetic core and a coil. The magnetic core is made of a soft magnetic metal material. The magnetic core has a facing surface and a radiating surface which are located at opposite sides to each other in the up-down direction. The facing surface of the magnetic core is arranged to face the facing surface of the circuit board in the up-down direction. The radiating surface of the magnetic core is arranged to be radiatable heat outward. The coil has a coil portion and a connection end. The coil portion winds, at least in part, the magnetic core. The connection end is connected to the facing surface of the circuit board.

Owner:TOKIN CORP

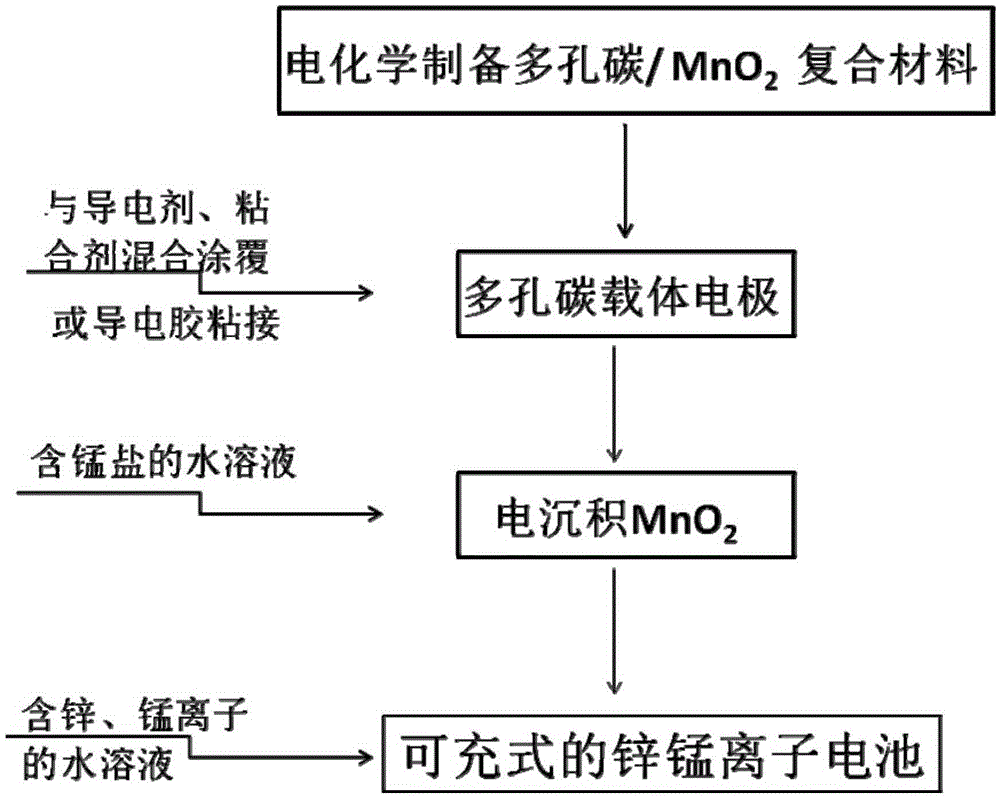

Porous carbon/manganese dioxide composite electrode, preparation method of porous carbon/manganese dioxide composite electrode and rechargeable zinc-manganese ion battery

ActiveCN105390697AControl particle sizeControl distribution densityCell electrodesFinal product manufactureSupporting electrolyteElectrolytic agent

The invention relates to a porous carbon / manganese dioxide composite electrode, a preparation method of the porous carbon / manganese dioxide composite electrode and a rechargeable zinc-manganese ion battery, and belongs to the technical field of electrochemistry. Porous carbon with high specific surface area and favorable electric conductivity is taken as a carrier electrode; the carrier electrode is electrolyzed in flowing water solution which contains a manganous salt precursor and a supporting electrolyte; and manganese dioxide is deposited on the surface of the porous carbon. Through selecting the concentration of the manganous salt as well as the concentration, pH value, current, temperature and time of the supporting electrolyte in the electric deposition process, a porous carbon / manganese dioxide composite is prepared, so that the regulation and control of the particle size and distribution density of the manganese dioxide are realized, and the active substance utilization rate of the manganese dioxide is improved. By taking the obtained porous carbon / manganese dioxide composite as the electrode, and by using the water solution containing zinc and manganese ions as electrolyte to assemble secondary batteries, the specific capacity of the electrode is above 200mAh / g and the electrode has the characteristics of being high in capacity and long in service life. The preparation method is easy to operate, green and environmental.

Owner:中国人民解放军军事科学院防化研究院

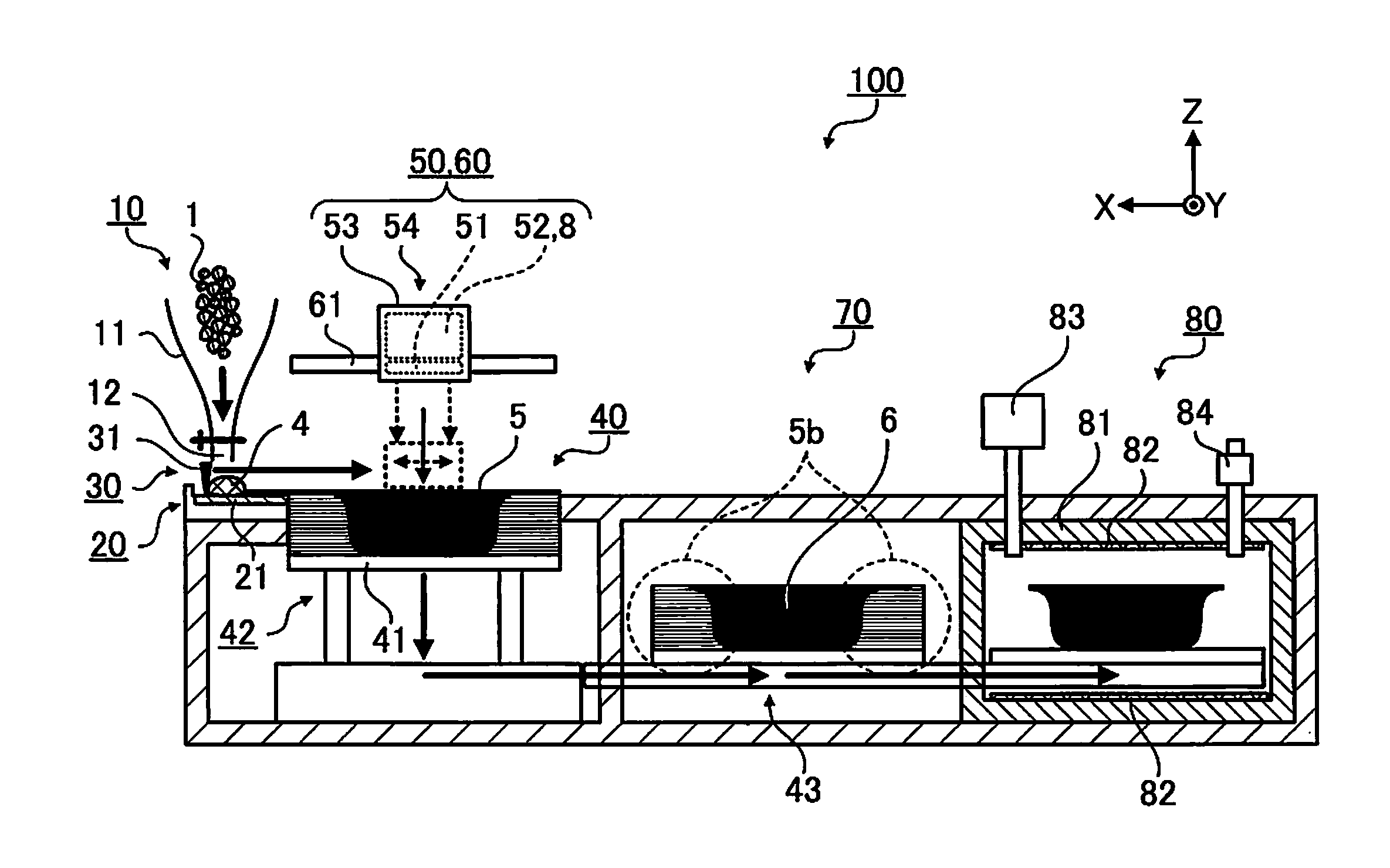

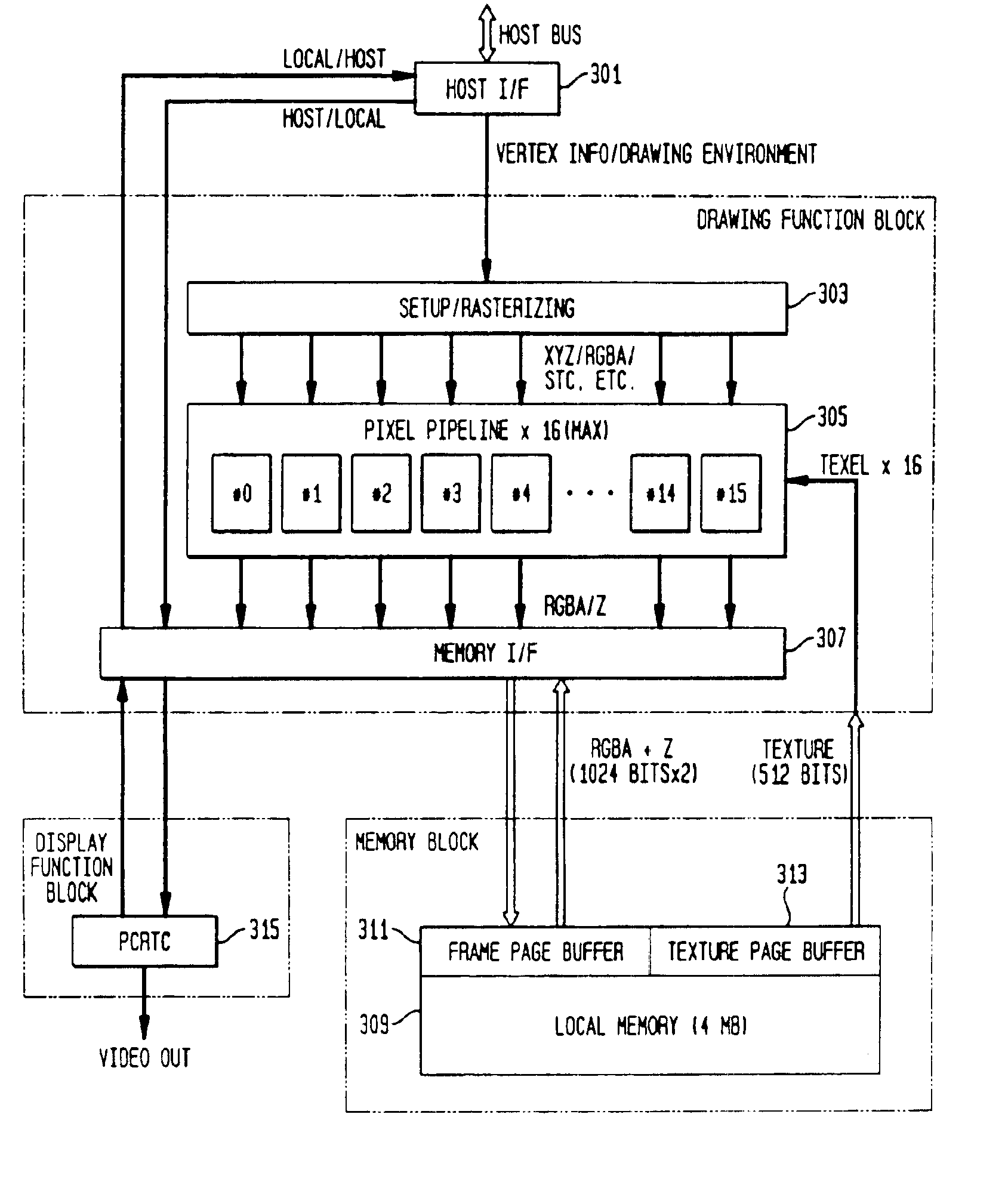

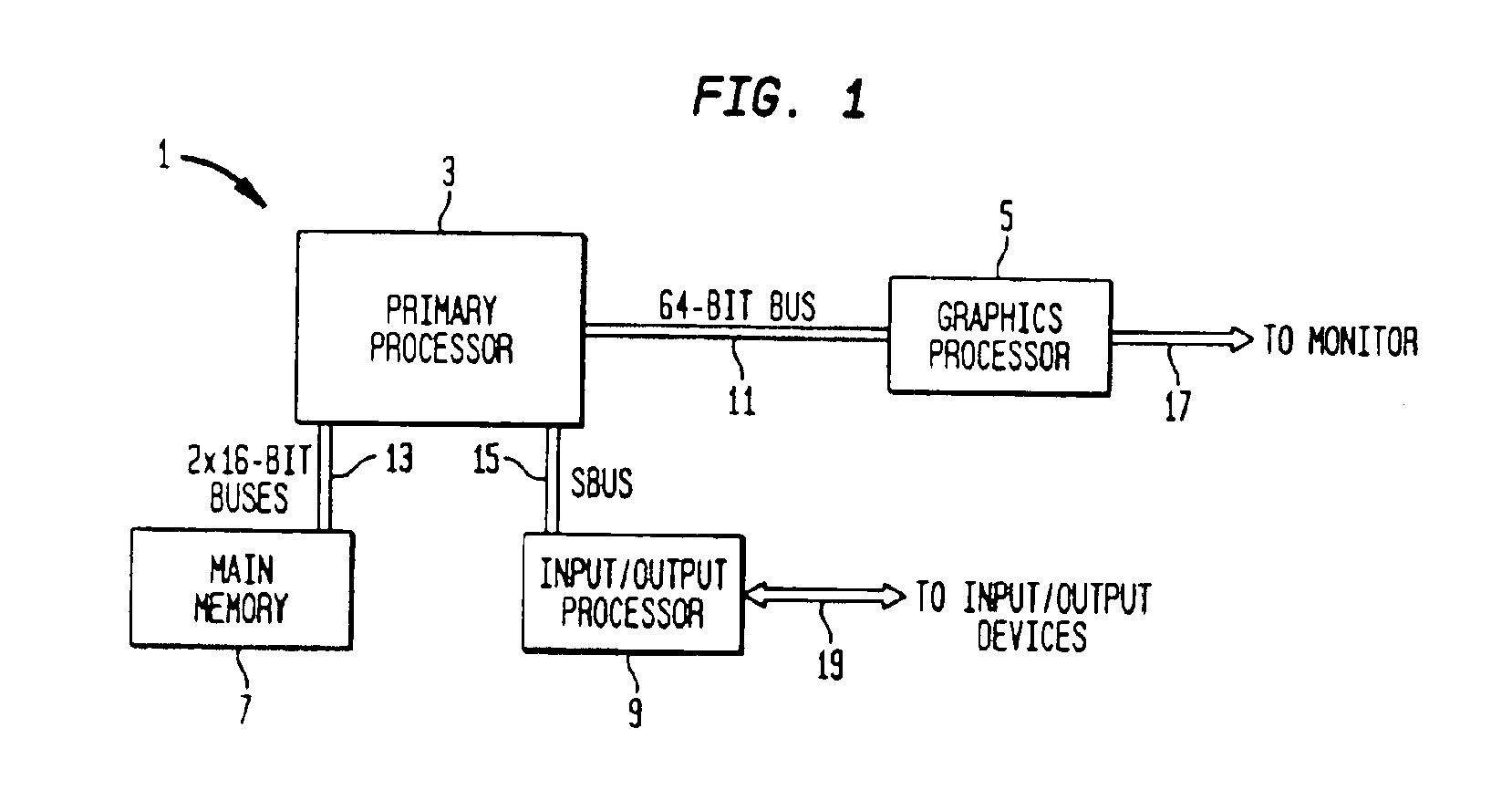

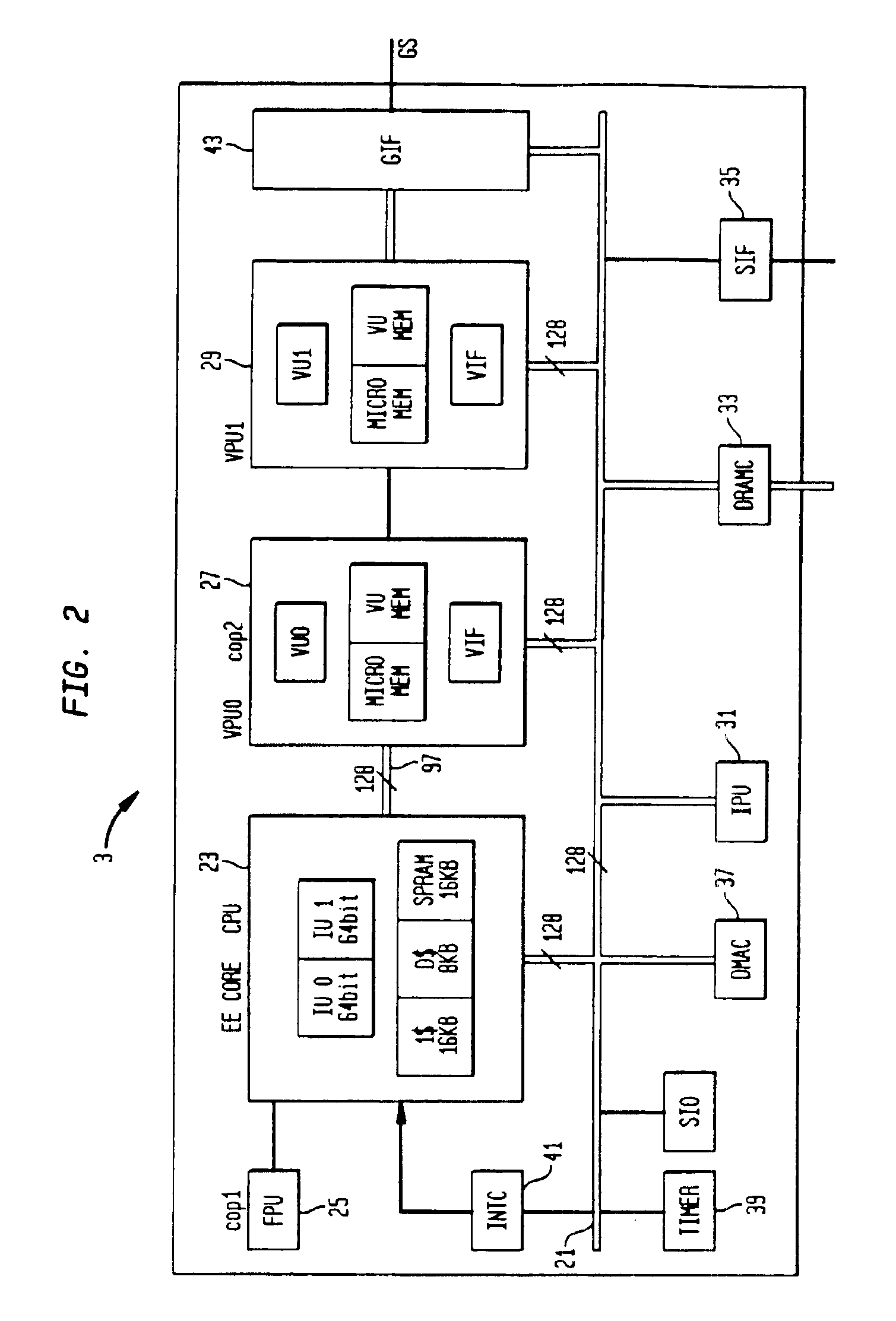

Game system with graphics processor

InactiveUS6891544B2Reduce data volumeHide main memory latencyIndoor gamesDigital computer detailsFill rateData stream

The present invention relates to the architecture and use of a computer system optimized for the efficient modeling of graphics. The computer system has a primary processor and a graphics processor. The primary processor has two vector processor units within it, one which is closely connected to central processor unit. Simultaneously performing complex modeling calculations on the first vector processor and CPU, and geometry transformation calculations on the second vector processor, allows for efficient modeling of graphics. Furthermore, the graphics processor is optimized to rapidly switch between data flows from the two vector processors. In addition, the graphics processor is able to render many pixels simultaneously, and has a local memory on the graphics processor chip that acts as a frame buffer, texture buffer, and z buffer. This allows a high fill rate to the frame buffer.

Owner:SONY COMPUTER ENTERTAINMENT INC

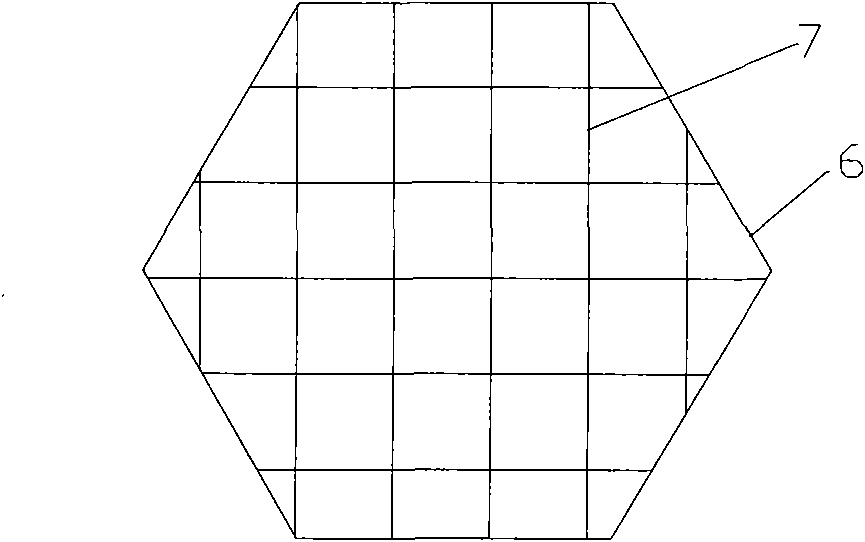

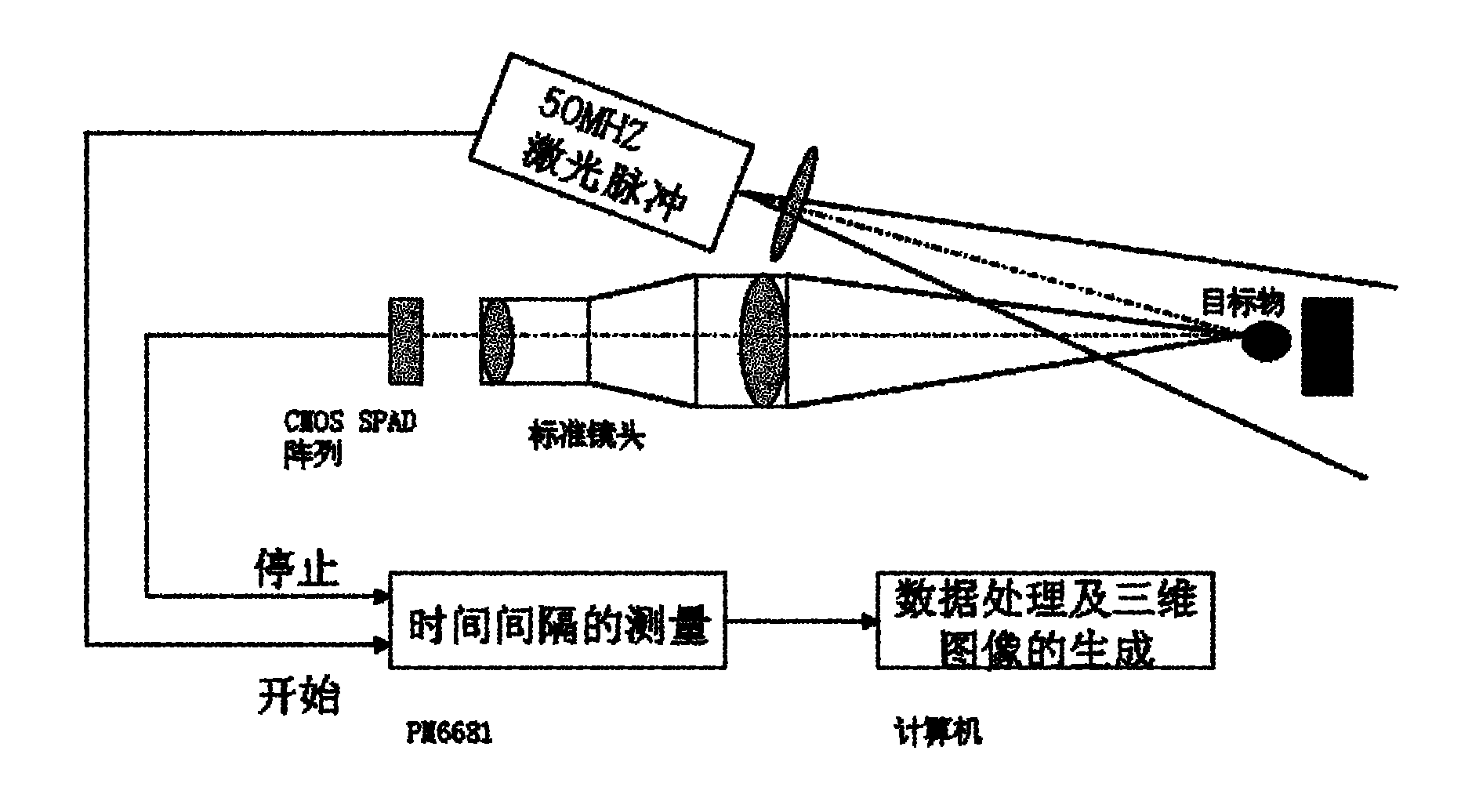

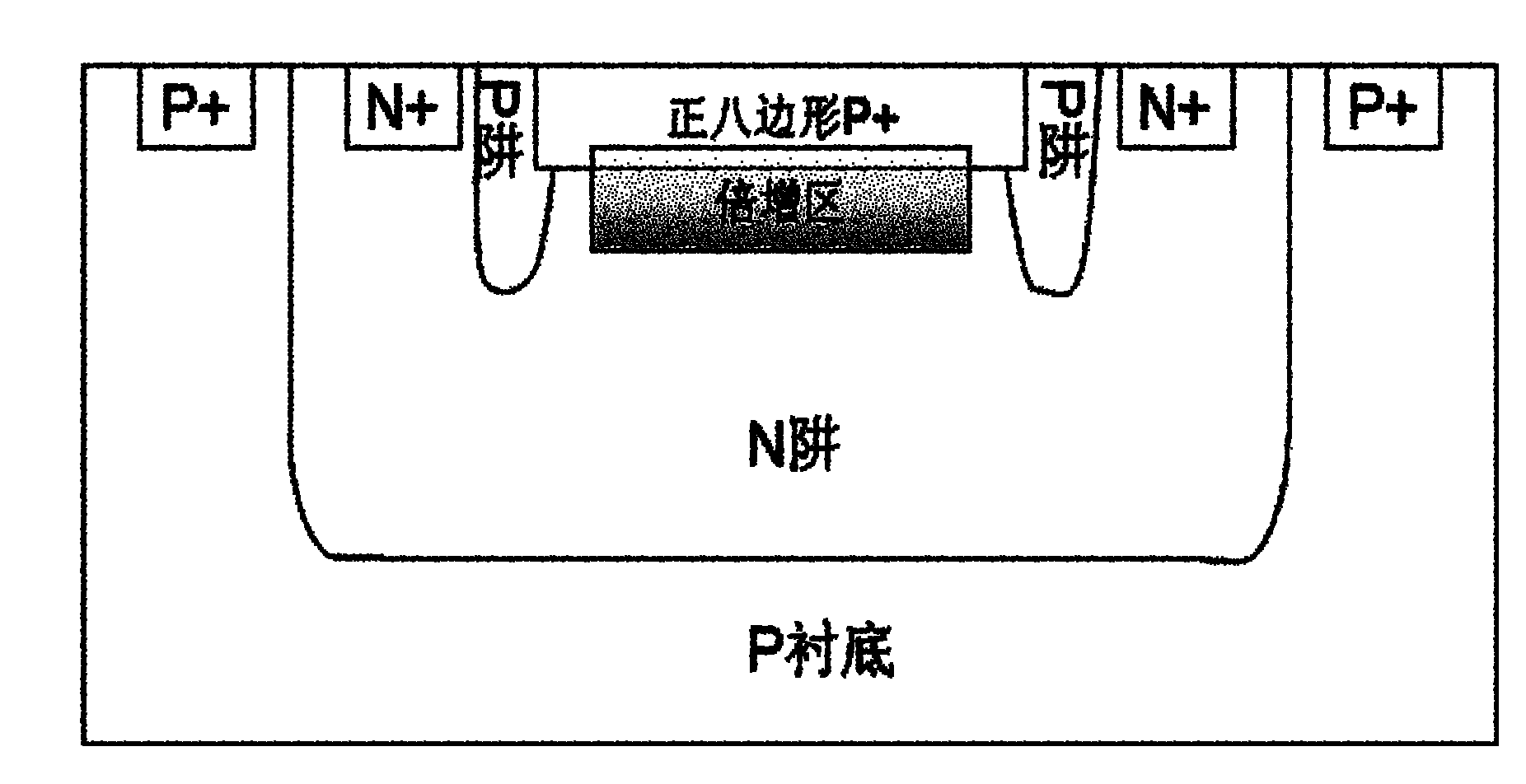

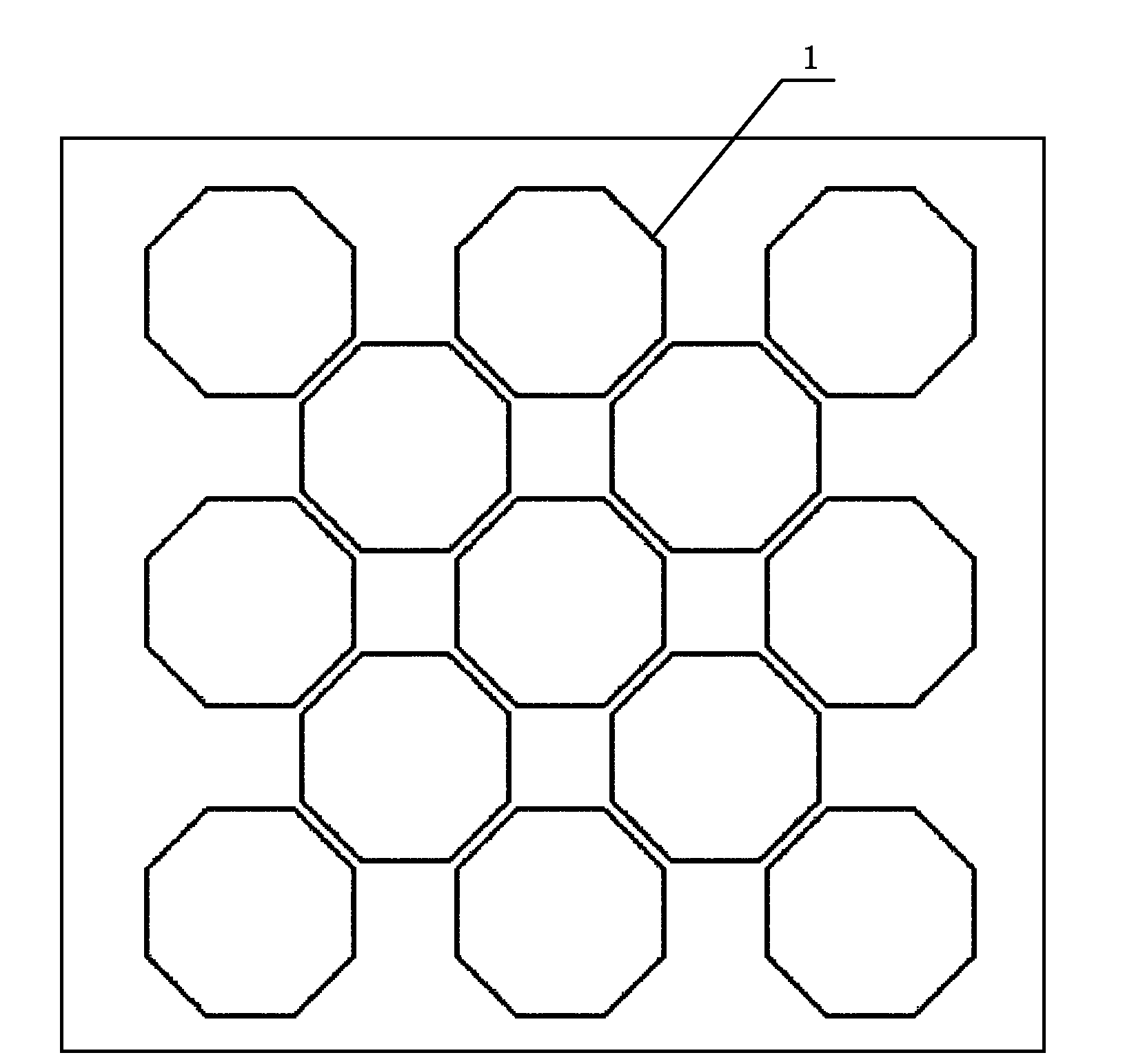

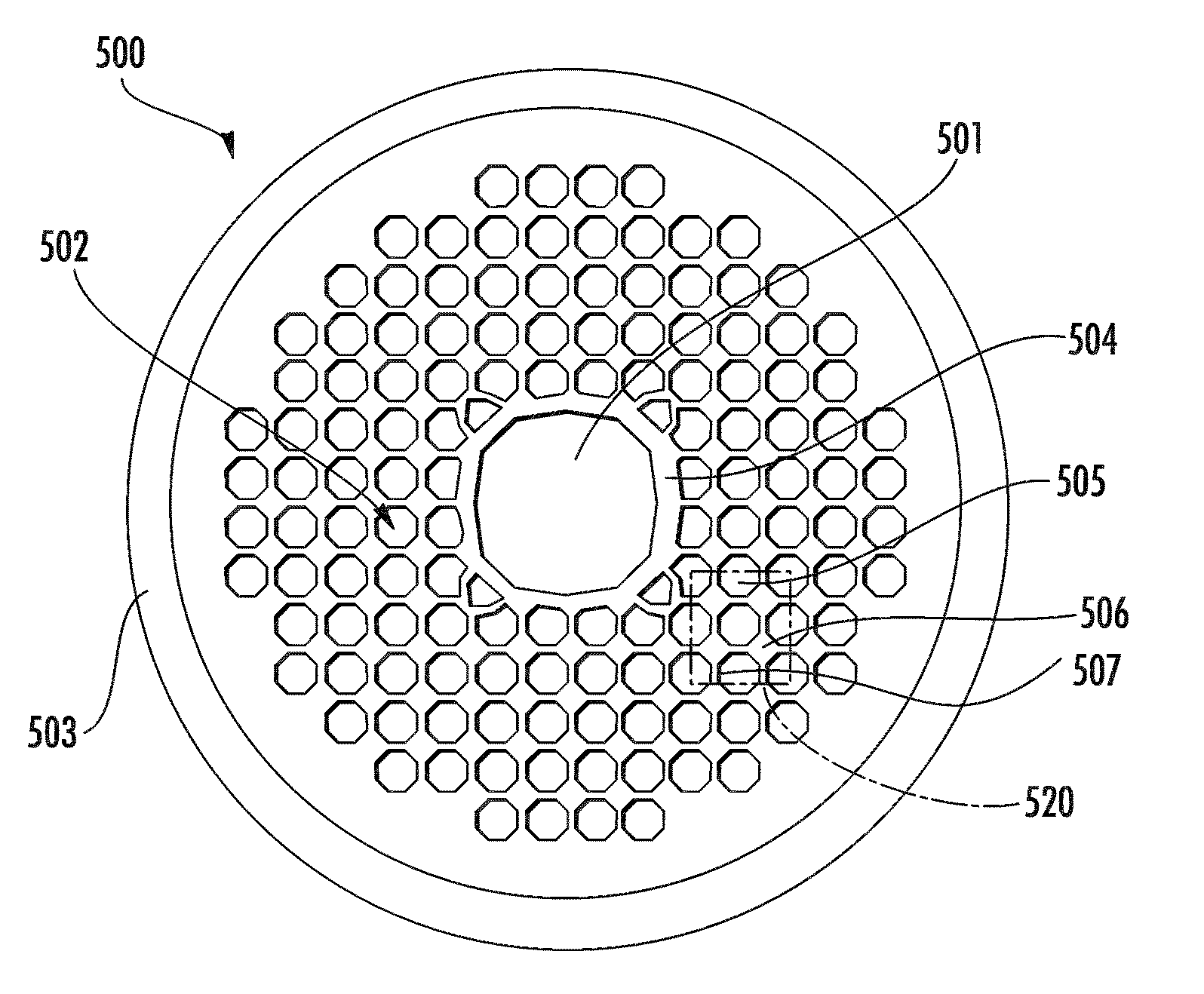

Single-photon avalanche diode and three-dimensional CMOS (Complementary Metal Oxide Semiconductor) image sensor based on same

InactiveCN101931021AImprove uniformityFully magnifiedTelevision system detailsFinal product manufactureHorizontal and verticalElectron

The invention belongs to the technical field of electronic technologies and photoelectronic imaging technologies, in particular relates to a single-photon avalanche diode and a three-dimensional CMOS (Complementary Metal Oxide Semiconductor) image sensor based on the diode. The single-photon avalanche diode of the invention improves the traditional rectangular photosensitive PN junction into a regular octagon and can conveniently and simply weaken edge breakdown and improve gain uniformity. A two-dimensional pixel array of the three-dimensional CMOS image sensor based on the diode comprises unit pixels of the regular octagon-shaped single-photon avalanche diode and is arrayed in a honeycomb-shape, thereby being convenient for interpolation and improving resolution in horizontal and vertical direction.

Owner:XIANGTAN UNIV

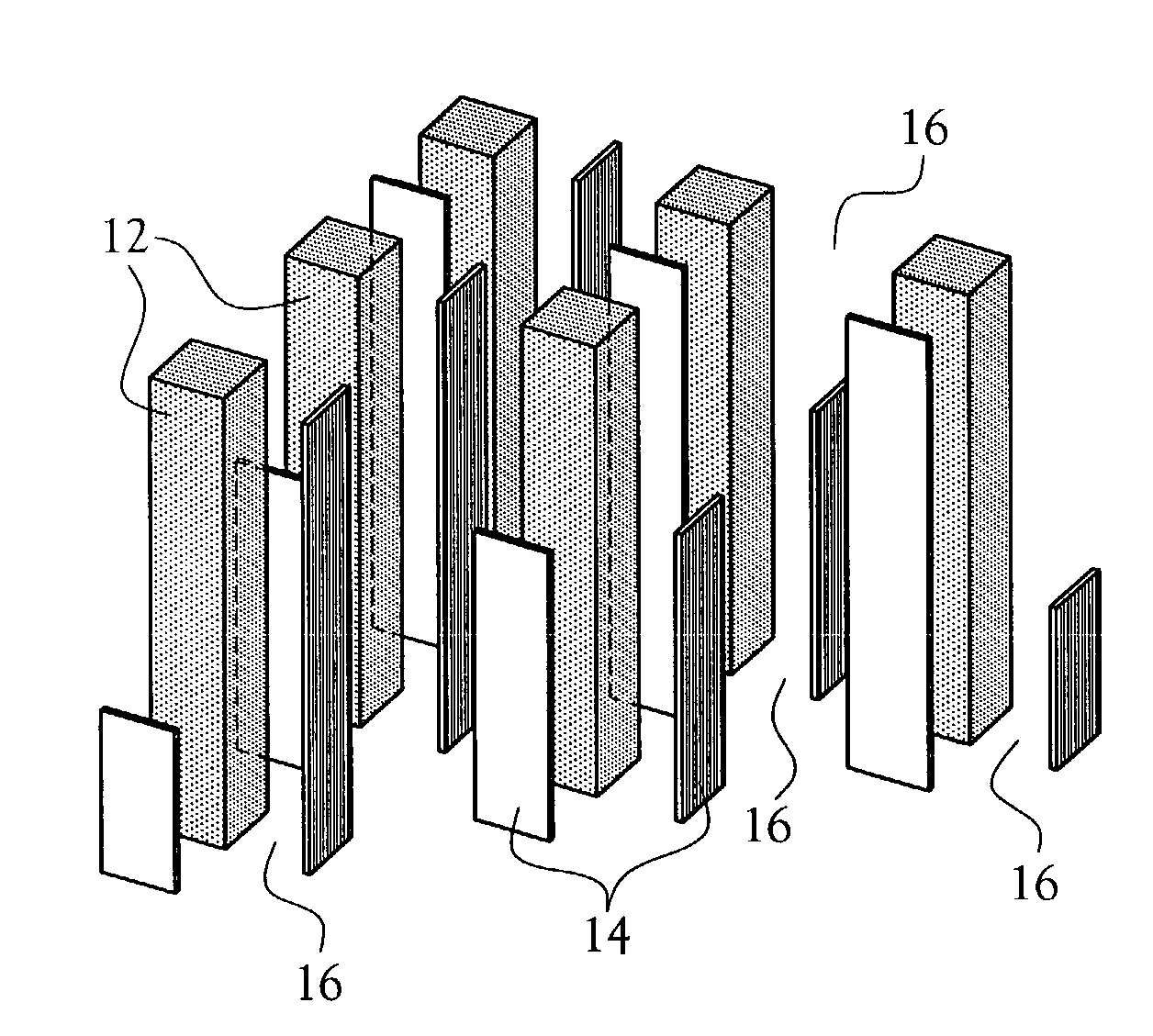

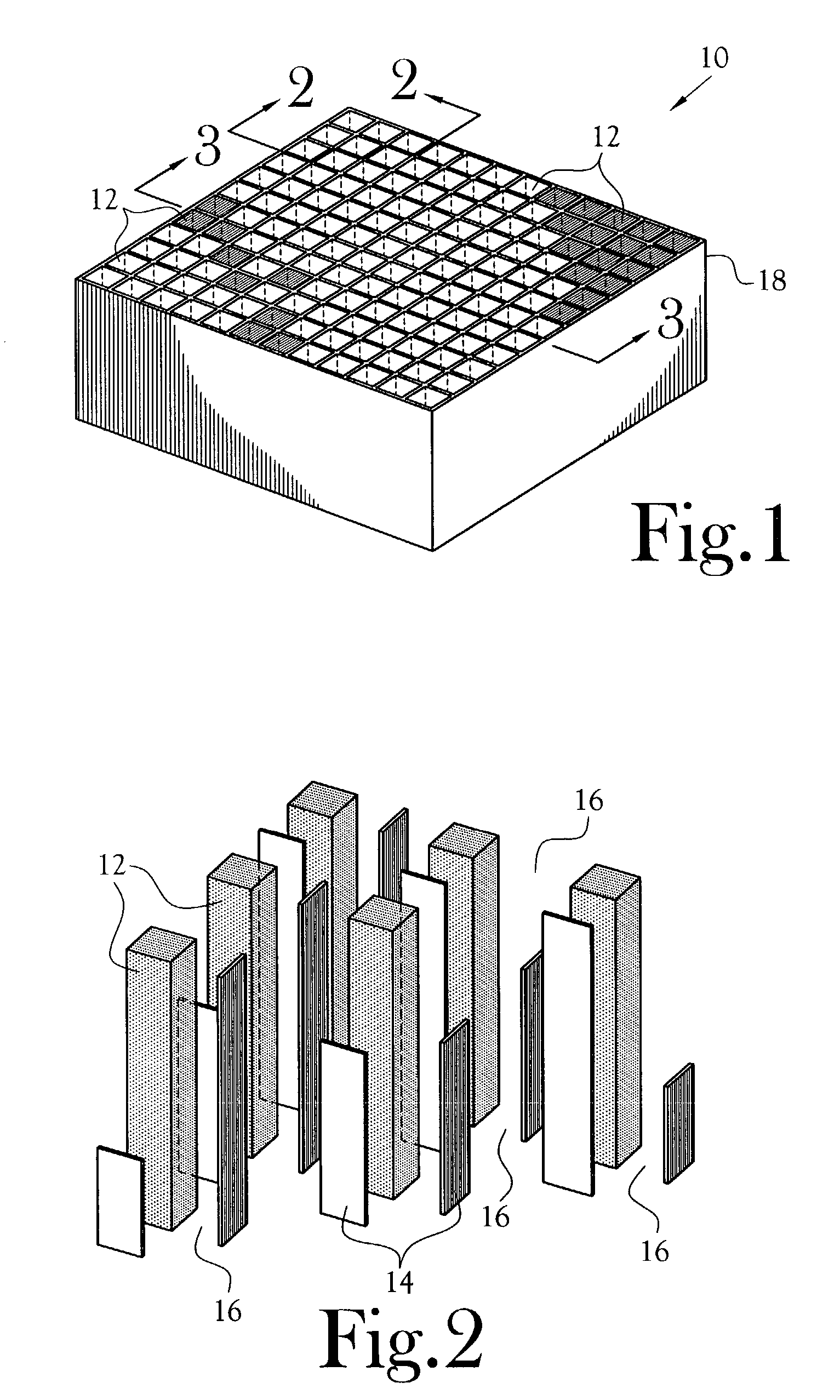

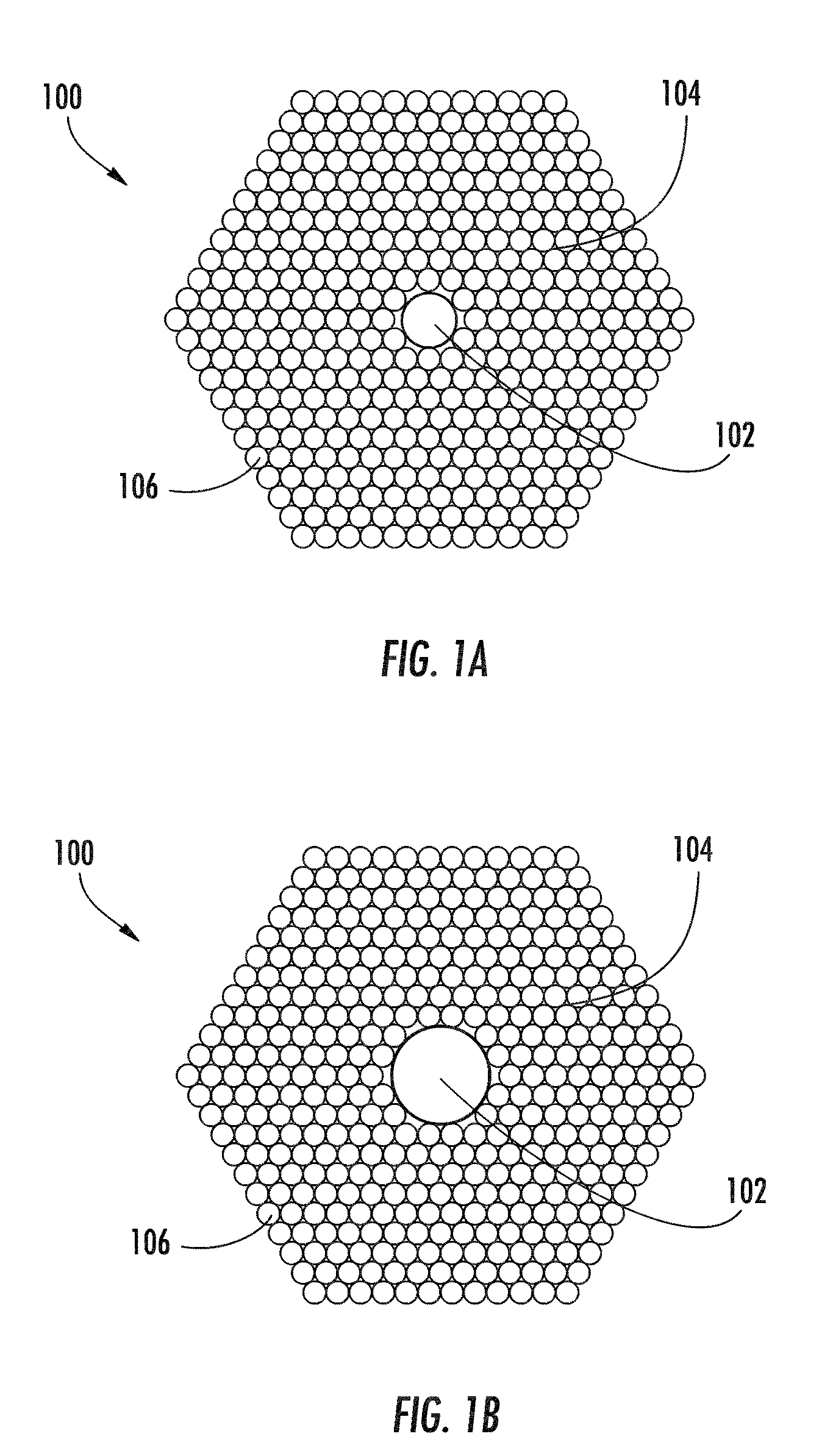

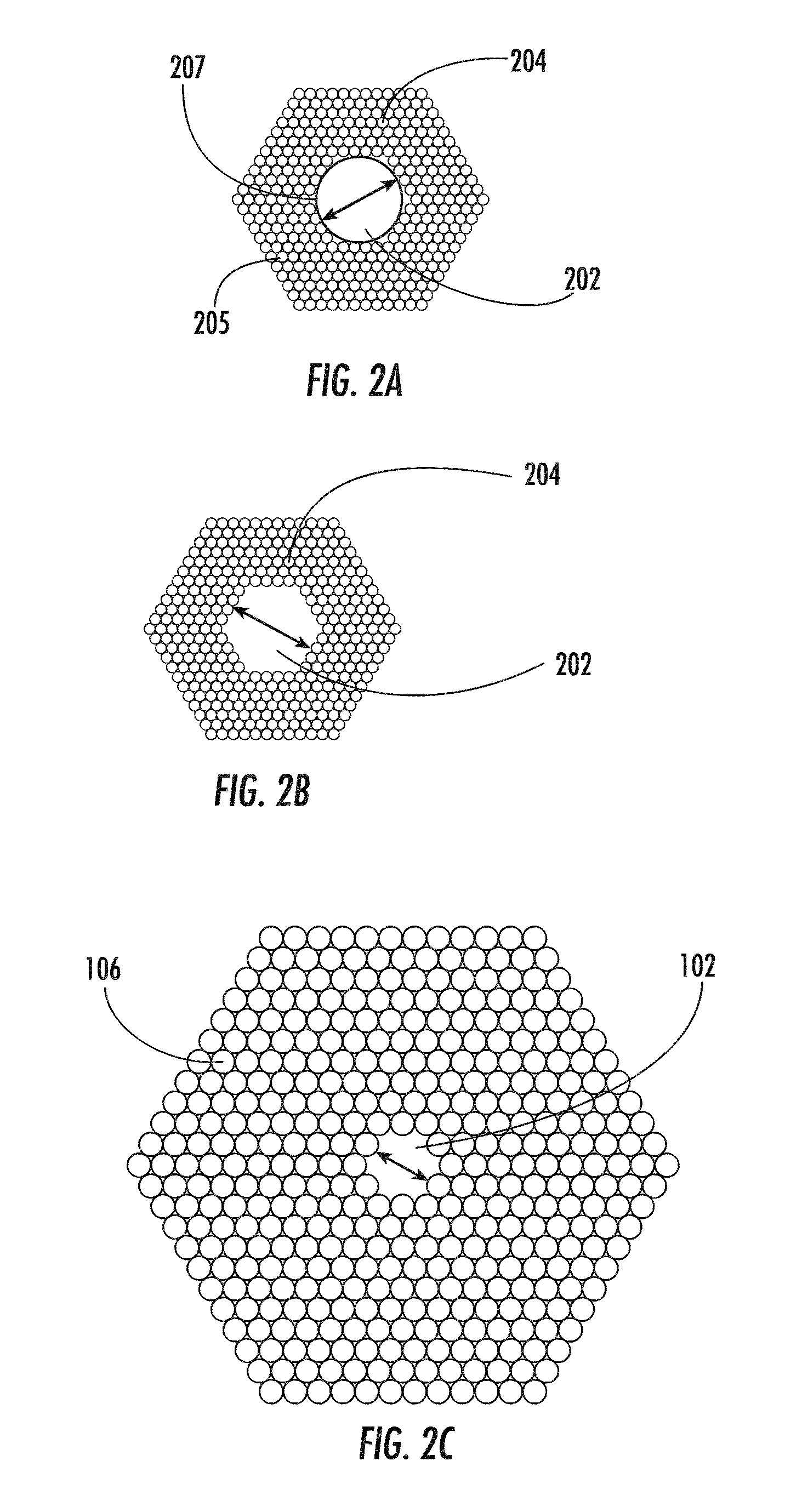

Detector array using internalized light sharing and air coupling

InactiveUS7019297B2Efficient and consistent and accurate and cost-effective processEliminate needAdditive manufacturing apparatusMaterial analysis by optical meansCouplingCombined use

A method for fabricating an array adapted to receive a plurality of scintillators for use in association with an imaging device. The method allows the creation of a detector array such that location of the impingement of radiation upon an individual scintillator detector is accurately determinable. The array incorporates an air gap between all the scintillator elements. Certain scintillators may have varying height reflective light partitions to control the amount of light sharing which occurs between elements. Light transmission is additionally optimized by varying the optical transmission properties of the reflective light partition, such as by varying the thickness and optical density of the light partitions. In certain locations, no light partitions exist, thereby defining an air gap between those elements. The air gap allows a large increase in the packing fraction and therefore the overall sensitivity of the array.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Copper plating solution for PCB (printed circuit board) blind holes, as well as preparation method and plating method of copper plating solution

InactiveCN103572336AReduce internal stressHigh filling ratePrinted element electric connection formationCopper platingPrinted circuit board

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB blind holes, as well as a preparation method and a plating method of the copper plating solution. Each liter of the copper plating solution comprises the following components according to contents: 100-300g of copper sulfate pentahydrate, 50-200g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is (1.5-2): 1. The plating method comprises the following steps: putting a PCB with blind holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a hole-filling rate as high as 97% above, and is dense, smooth, voidless, seamless, low in surface sediment thickness, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

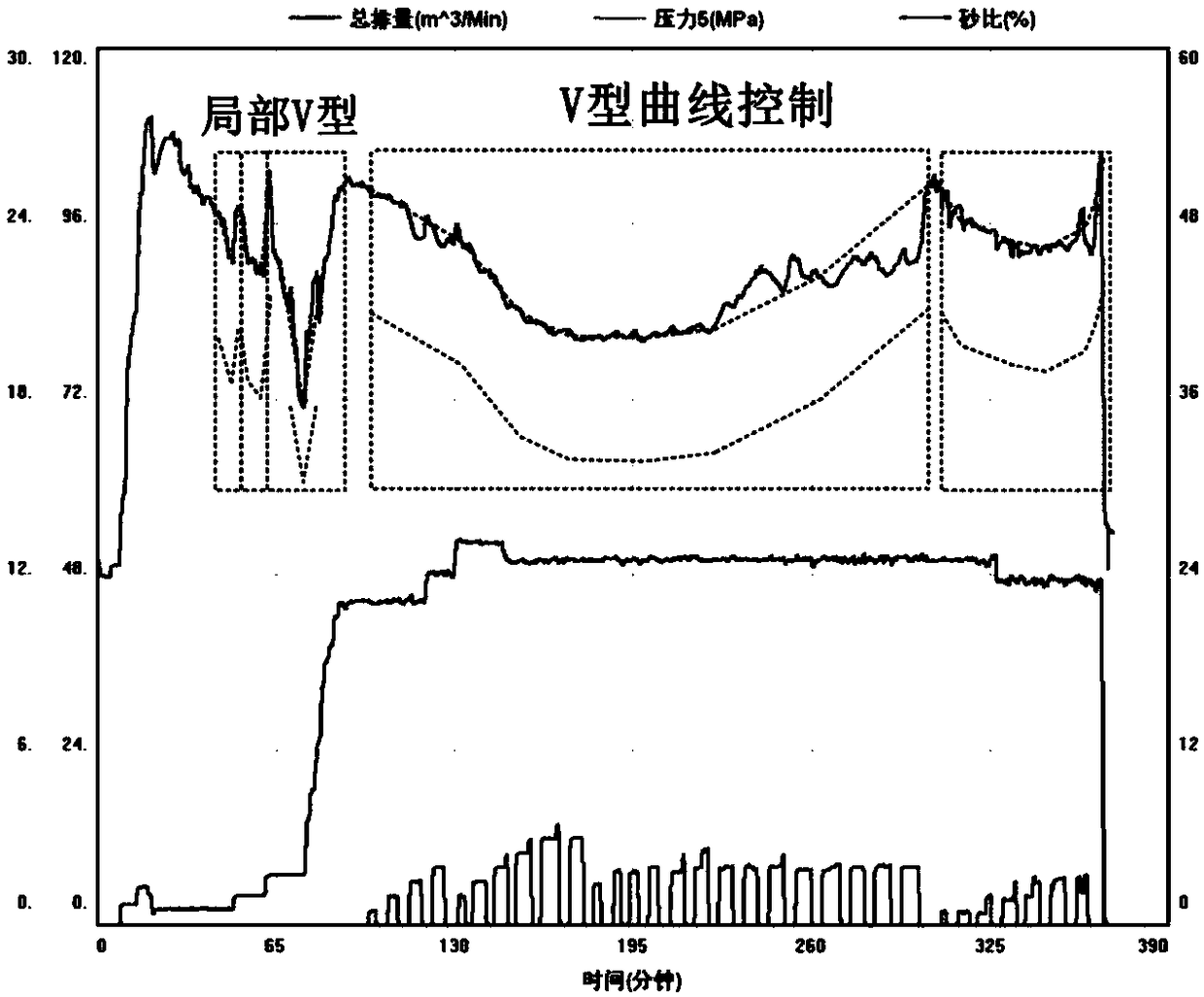

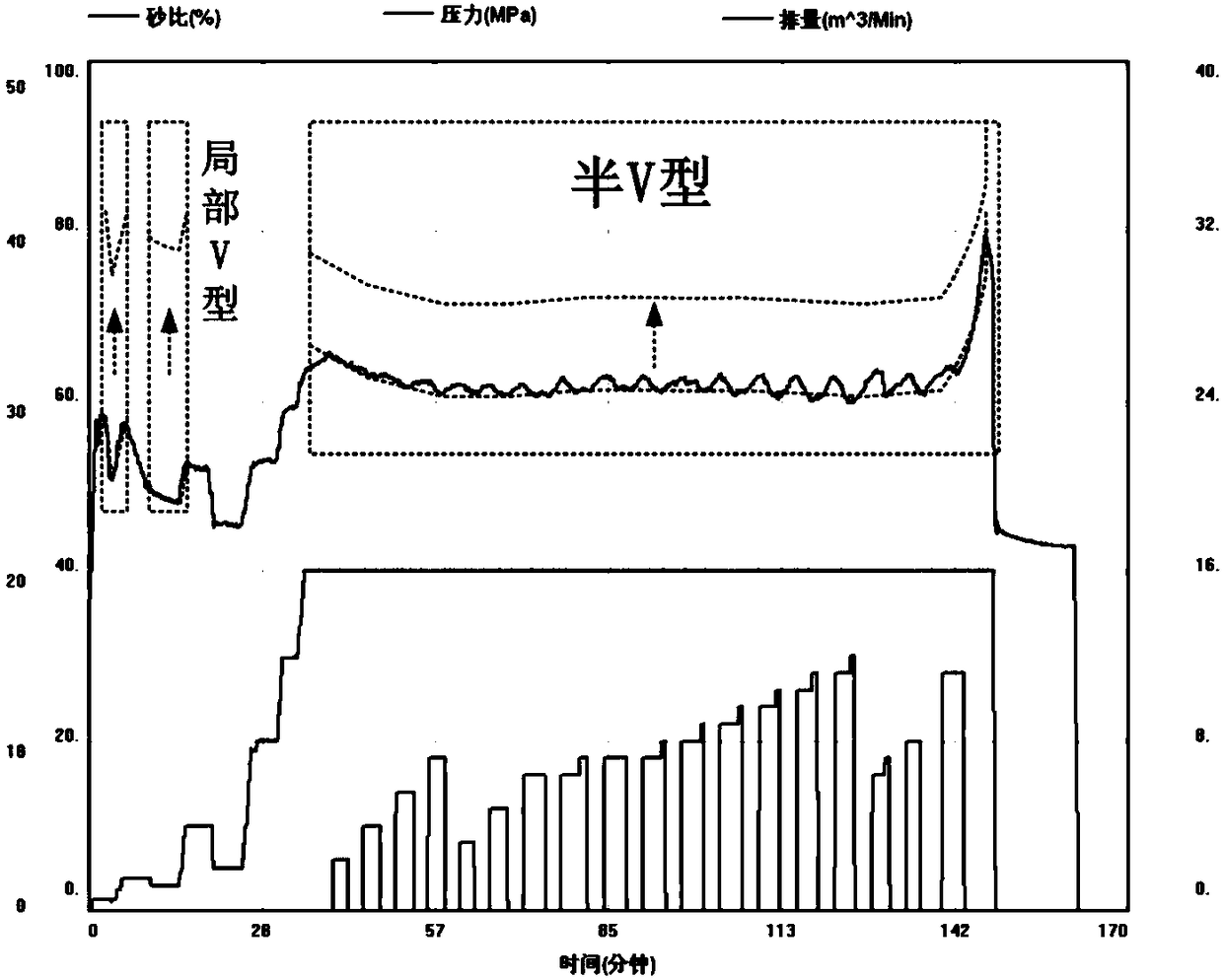

Fracturing method for deep shale gas through V-shaped pressure curve

ActiveCN109113703AIncrease the effective transformation volumeImprove fill rateFluid removalLiquid ratioPressure curve

The invention discloses a fracturing method for deep shale gas through a V-shaped pressure curve. The fracturing method comprises the steps of (1) key reservoir parameter evaluation, (2) optimizationof fracture parameters and fracturing construction parameters, (3) perforation position determination and perforation operation, (4) acid pretreatment, (5) variable-displacement and low-viscosity slick water joint forming construction, (6) powder pottery construction for adding different sand liquid ratios into low-viscosity slick water, (7) medium-particle-size proppant construction for adding different sand liquid ratios into medium-viscosity slick water, (8) high-viscosity gel and large-particle-size carrying proppant construction, and (9) displacing operation. According to the fracturing method, complexity of fracturing fractures of the deep shale gas is improved, the filling ratios of systems with different scales of fractures such as near wells, far wells, main fractures and micro-fractures are increased, the effective stimulation volume of the deep shale gas is increased, and the yield increasing and stabilizing effects after pressure are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microwave modification method of plant fiber and application thereof

InactiveCN101725032AIncrease polarityHigh tensile strengthPhysical treatmentVegetal fibresFiberFilling materials

The invention discloses a microwave modification method of plant fiber and application thereof. The method comprises the steps of: firstly smashing the plant fiber; preprocessing the smashed plant fiber with coupling agent; and processing the preprocessed plant fiber by means of microwave radiation, so that the coupling agent is grafted at the surface of the plant fiber to obtain the microwave-modified plant fiber, wherein the microwave-modified plant fiber can be used as filling material of composite material for the field of high molecular material. The modification method is environment-friendly, and has no pollution, low production cost and remarkable economic benefit; and the microwave-modified plant fiber has obvious polarity change, wherein the nonpolarity is obviously enlarged, thereby obviously improving the interface consistency with non-polarity high molecule substances and improving the combination property of the composite material.

Owner:JINAN UNIVERSITY

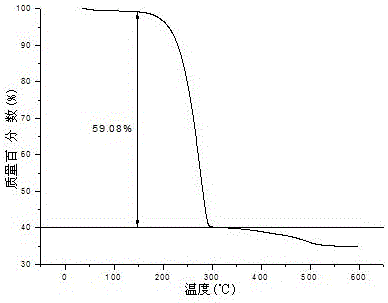

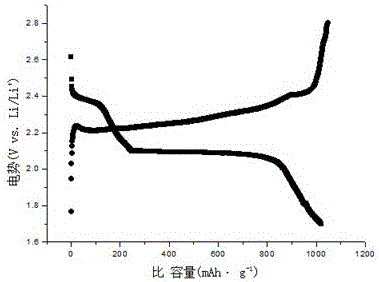

Halloysite-based positive electrode material of lithium-sulfur battery and preparation method for positive electrode material

ActiveCN105932235AIncrease inner diameterImprove fill rateMaterial nanotechnologyCell electrodesAcid etchingHalloysite

The invention relates to a positive electrode material of a lithium-sulfur battery and a preparation method for the positive electrode material, wherein the positive electrode material takes halloysite as a sulfur carrier; the preparation method comprises the steps of enlarging the inner diameter of the tube cavity of the halloysite by acid etching; then filling the tube cavity of the halloysite with sulfur by a liquid phase chemical deposition method and a thermal processing two-step method to form a halloysite / sulfur composite material; and then preparing and obtaining the halloysite-based lithium-sulfur battery positive plate. The halloysite is large in specific surface area, high in adsorption capacity and unique in the micropore structure, so that polysulfide generated in the charging-discharging process of the lithium-sulfur battery can be limited in the tube cavity of the halloysite, the volume expansion of sulfur in the charging-discharging process is restrained, and the capacity and the cycling stability of the battery are greatly improved; in addition, the preparation process is simple; and in addition, the halloysite nanotube is a natural environment-friendly material, low in cost and easily available, so that the industrial production of the lithium-sulfur battery can be realized conveniently.

Owner:BEIJING UNIV OF CHEM TECH

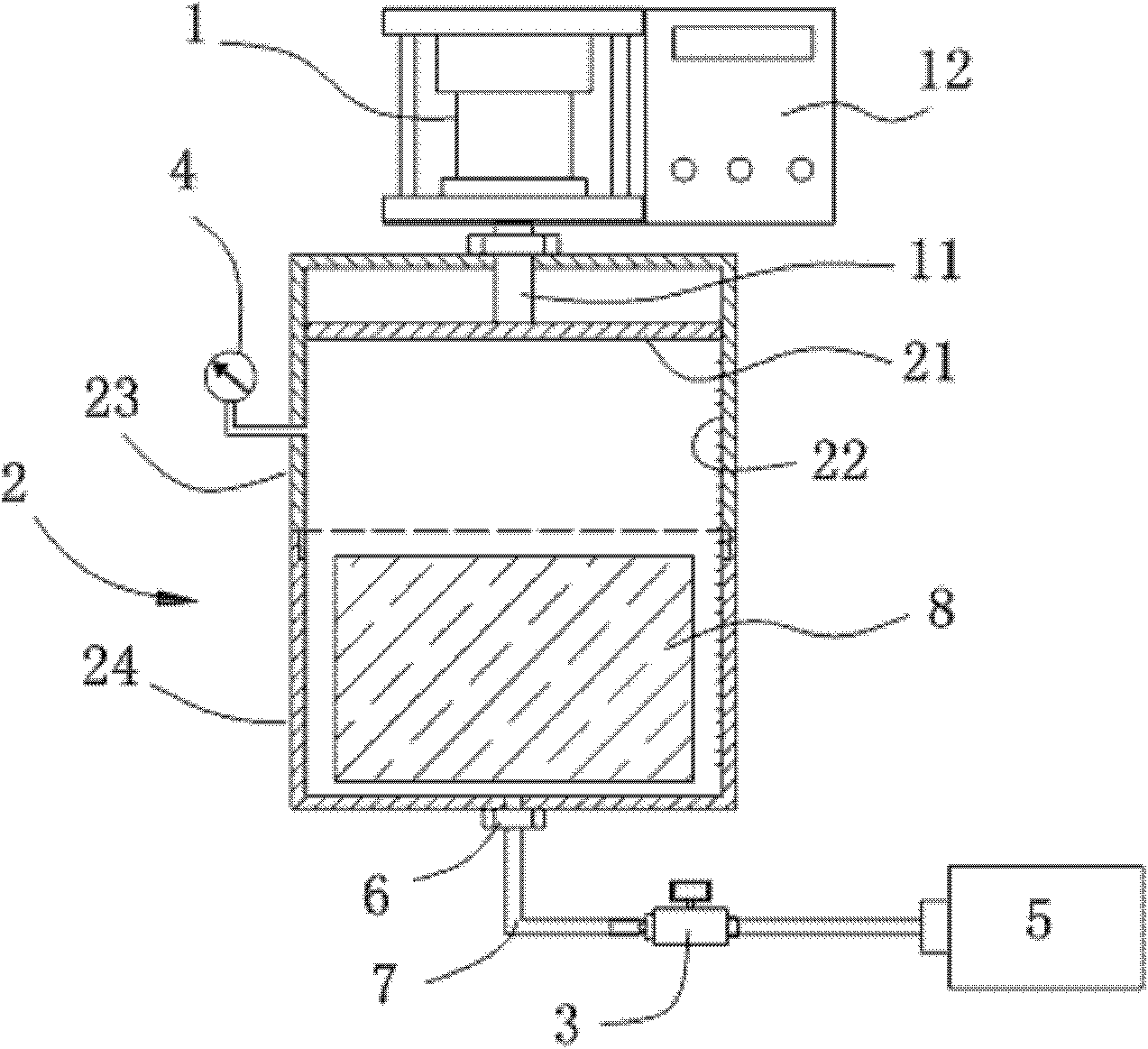

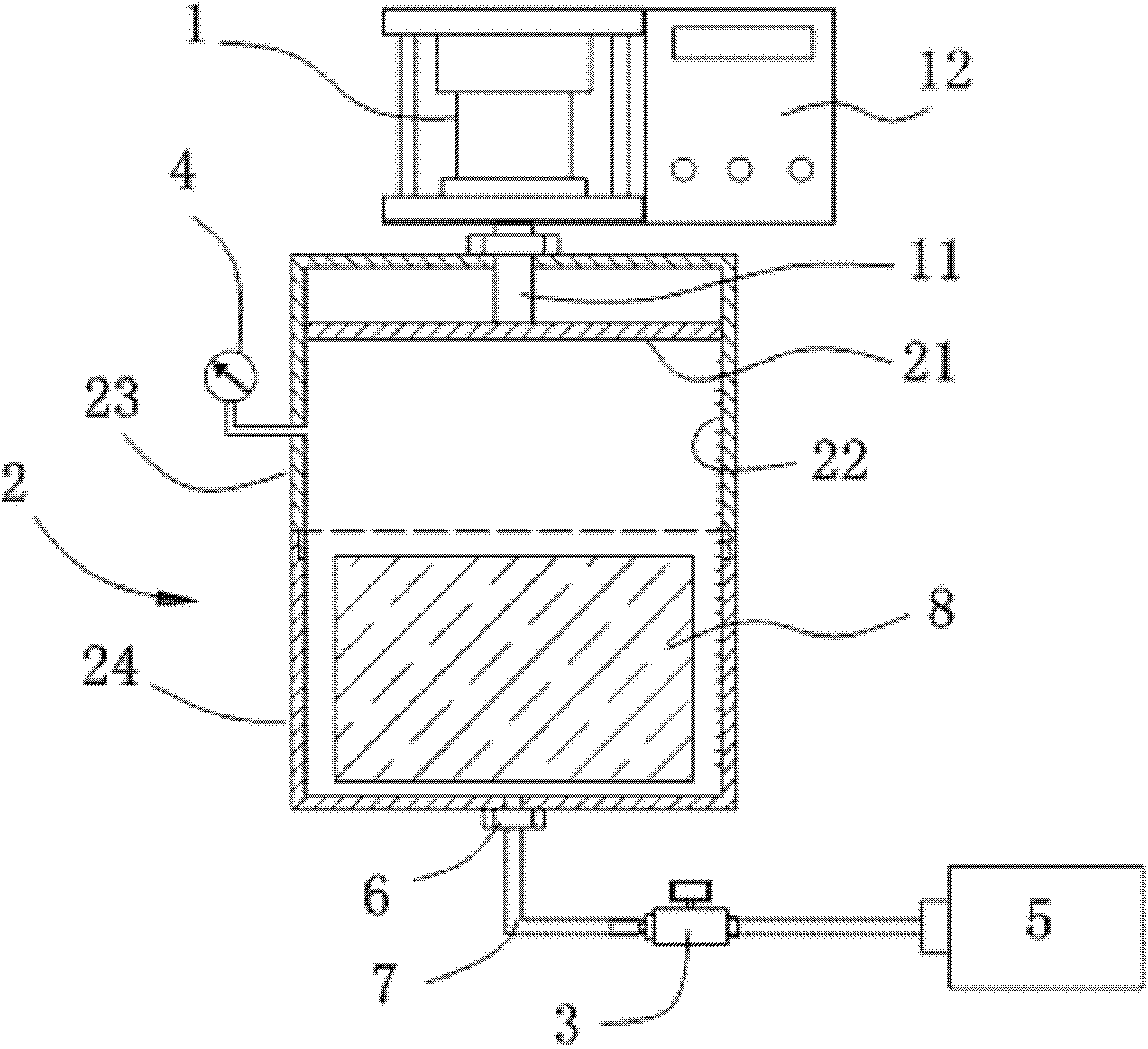

Test method for porosity of asphalt mixture, and apparatus thereof

ActiveCN102359930AExtended closure timeImprove solubilityPermeability/surface area analysisPorosityHydraulic cylinder

The present invention relates to a test method for porosity of an asphalt mixture, and an apparatus thereof. With the present invention, the volumes of the pore with an opening and the pore with a semi-opening can be determined. The test apparatus mainly comprises a sealed container, a pressurization device of the sealed container, a hydraulic cylinder, a water pump and a flow control valve. The sealed container is provided with a pressurization piston. A piston rod of the hydraulic cylinder is connected with the pressurization piston arranged inside the sealed container. The flow control valve is connected between a water inlet of the sealed container and the water pump. The test method comprises that: a specimen is sealed with a thin film, and is placed in the sealed container; with thehydraulic cylinder, the piston inside the container is pushed, such that the air pressure in the container is increased to more than two standard atmospheric pressures; water is slowly injected to the container until the height of the water is the preset height, and the water injecting amount is recorded as L1; the specimen is taken, and the thin film is removed, then the specimen is placed in the container again; under the same air pressure condition, water is slowly injected in the container, and the water injecting amount is recorded as L2; the difference between the two water injecting amount is the amount that the water enters the inner pores of the specimen, and the porosity of the specimen can be calculated, wherein the difference is calculated by the following formula, L2-L1.

Owner:西安公路养护技术工程研究中心有限公司

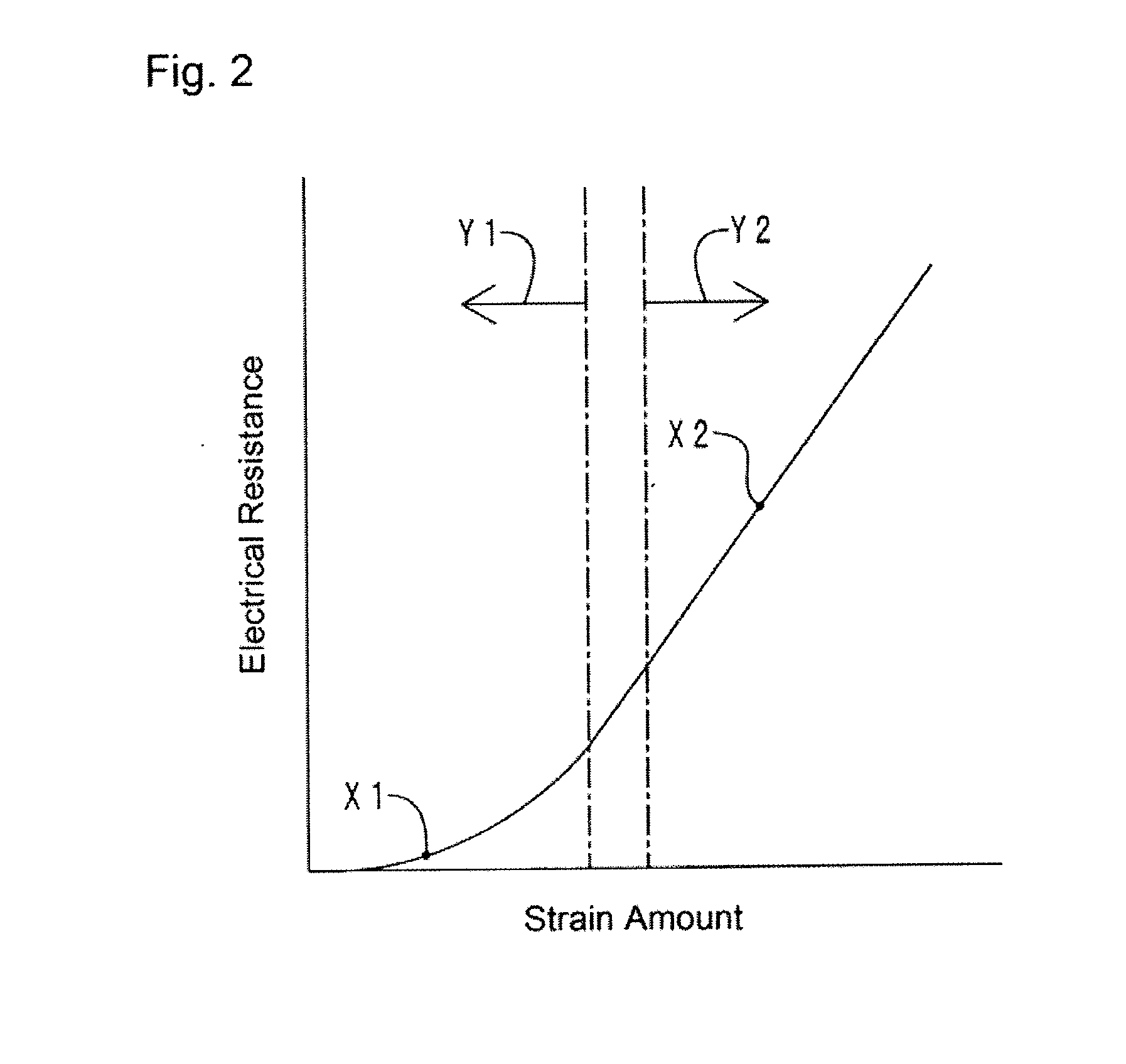

Distortion sensor and deformed shape measuring method

ActiveUS20110307214A1Easily and dynamically measureAccurately calculateForce measurementDigital computer detailsDistortionFiller particle

Provided are a bending sensor that is less dependent on an input speed of a strain and in which a response delay is unlikely to occur, and a deformed shape measurement method using the bending sensor. The bending sensor is configured to include a base material; a sensor body arranged on a surface of the base material and containing a matrix resin and conductive filler particles filled in the matrix resin at a filling rate of 30% by volume or more, and in which three-dimensional conductive paths are formed by contact among the conductive filler particles, and electrical resistance increases as an deformation amount increases; an elastically deformable cover film arranged so as to cover the sensor body; and a plurality of electrodes connected to the sensor body and capable of outputting electrical resistances. In the sensor body, cracks are formed in advance in such a direction that the conductive paths are cut off during a bending deformation.

Owner:TOKAI RUBBER IND LTD

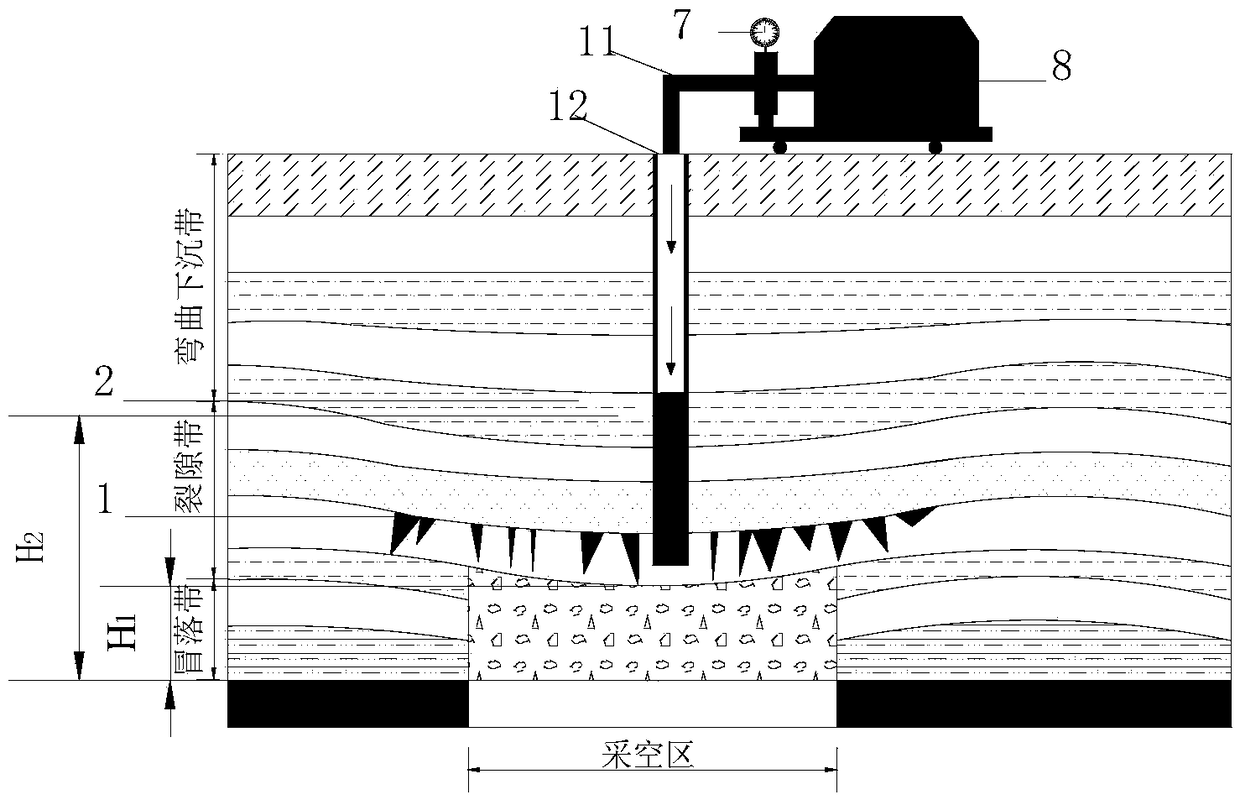

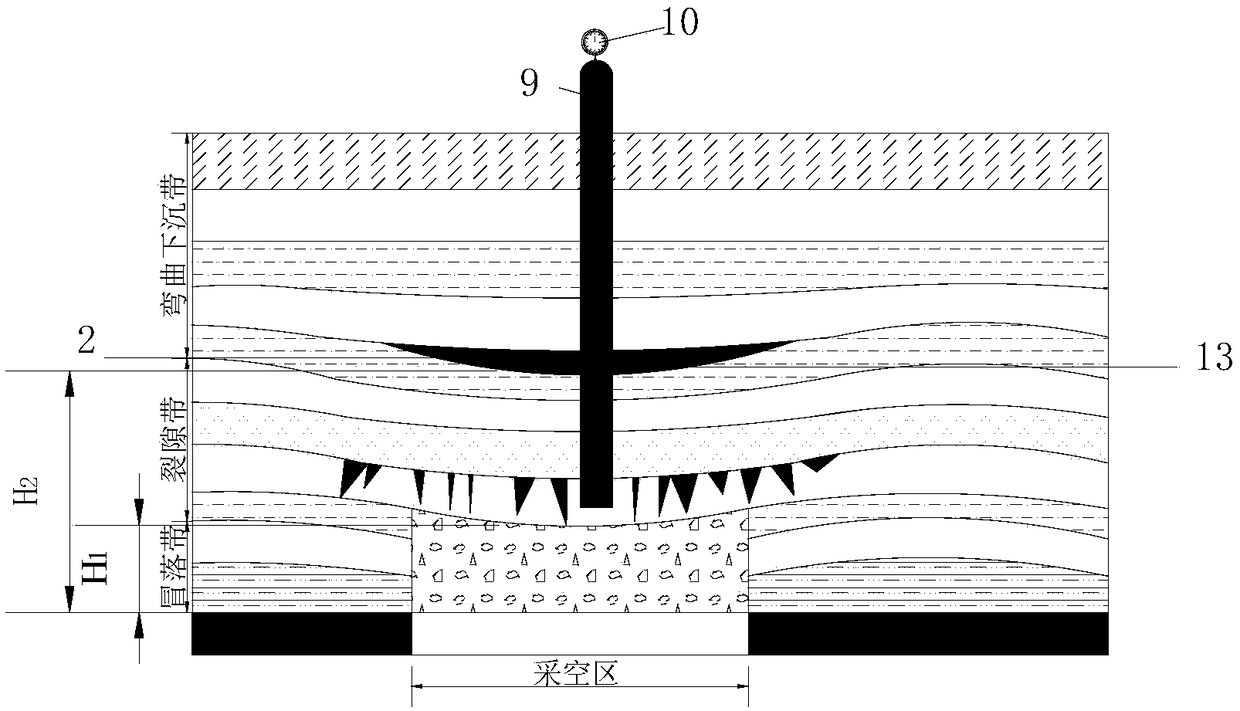

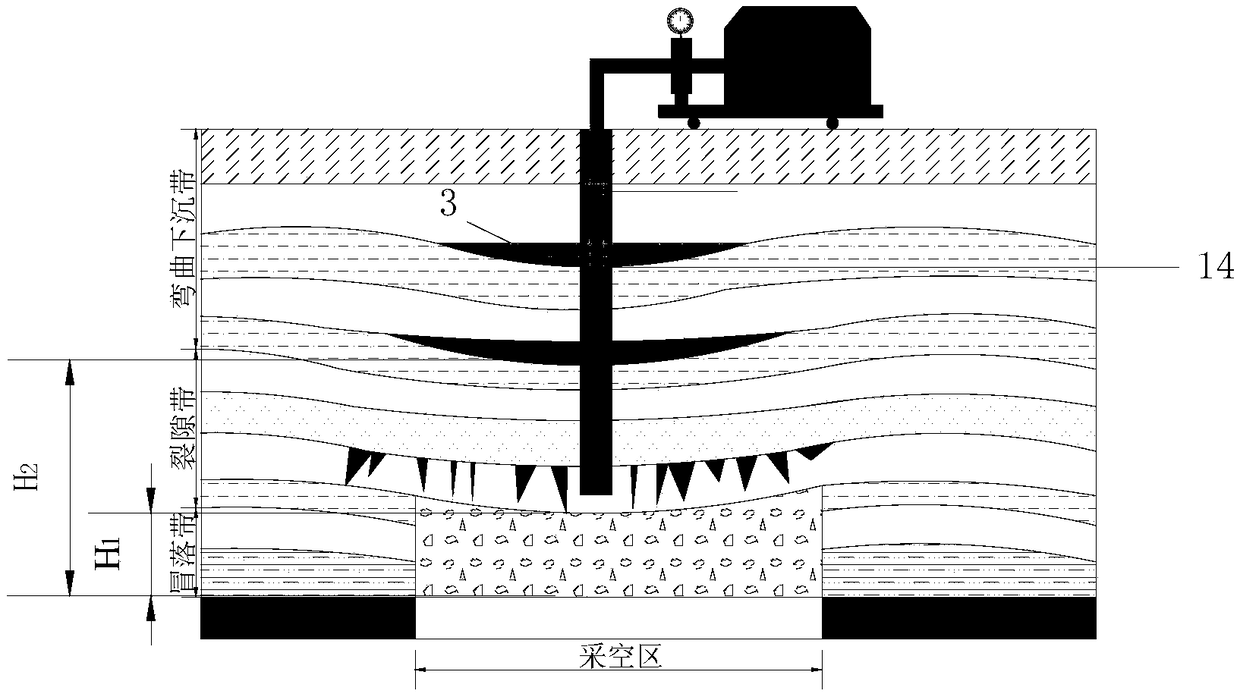

Hole multi-functionalization method for realizing water damage prevention and surface settlement control through surface borehole

InactiveCN108999634AAvoid safety hazardsThe grouting filling process is easy to controlMaterial fill-upHorizonFracture zone

The invention discloses a hole multi-functionalization method for realizing water damage prevention and surface settlement control through a surface borehole and belongs to the coal mine green miningtechnical field. According to a grouting filling method, a single ground grouting borehole is formed downward from the ground; overlying rock located at different horizons are grouted through the grouting borehole; grouting horizons in a curved sunk zone include a low-bed-separation horizon and a high-bed-separation horizon; overlying rock fractures in a fracture zone are grouted, so that a water-blocking layer can be formed to cut off a water bursting channel of underground bed separation water damage, and therefore, secondary roof water damage can be prevented; a larger proportion of grout is adopted as the filling material of the low-bed-separation horizon so as to form a high-volume-weight rock stratum filling body; and filling bodies formed by the low-bed-separation horizon and the high-bed-separation horizon in the curved sunk zone together act on the control of surface subsidence. According to the method of the invention, a multi-horizon grouting filling project is realized through the same grouting borehole, and therefore, the utilization rate of the borehole is high, cost is low, a filling rate is improved, the subsidence-reducing rate of the surface settlement is improved, and roof water damage prevention and control is achieved.

Owner:CHINA UNIV OF MINING & TECH

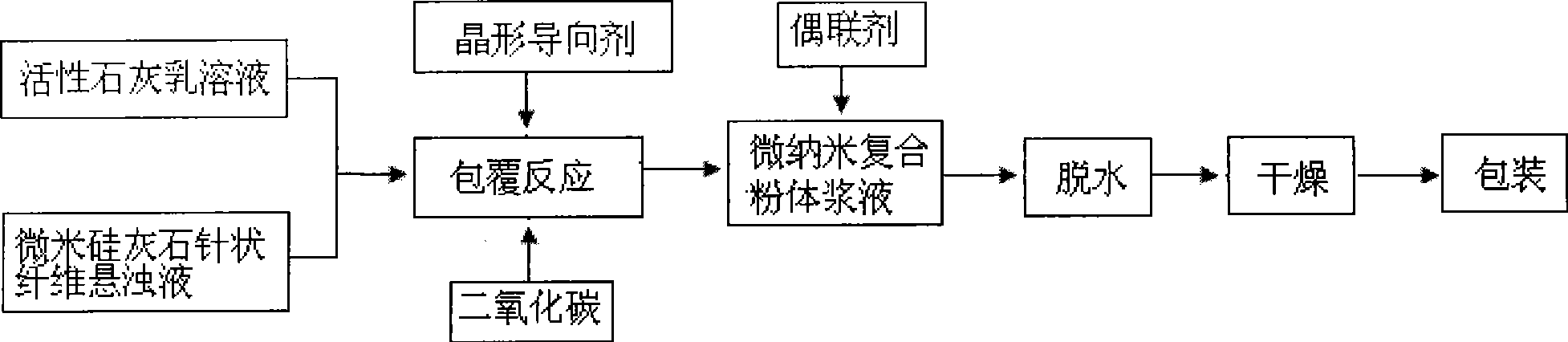

Grammite raphioid fibre crystal-nano calcium carbonate micro-nano composite powder material and production method

InactiveCN101498052AHigh surface energyHigh chemical activityPolycrystalline material growthAfter-treatment detailsMicro nanoFiber crystal

The invention relates to a surface modified product of an acicular wollastonite crystal and a production method thereof. The product is micro-nano composite powder by coating a nanometer calcium carbonate crystal on the surface of the acicular wollastonite fiber crystal. The method comprises the following steps: firstly, preparing an active lime milk solution and an acicular wollastonite fiber solution; compounding the two solutions into a suspension; adding a crystalline directing agent to the suspension and filling CO2 gas for a coating reaction so that the nanometer calcium carbonate crystal gradually grows on the surface of an acicular aedelforsite fiber, and the micro-nano composite powder by coating a nanometer calcium carbonate crystal on wollastonite is obtained; and coating a layer of coupling agent on the surface of the micro-nano composite powder to obtain the acicular wollastonite fiber crystal-nanometer calcium carbonate crystal-coupling agent composite powder material. The product keeps the superior characteristics of the acicular wollastonite crystal and the nanometer calcium carbonate crystal, improves the surface energy and the chemical activity of wollastonite composite particles and can be well stuck with organic polymers so as to form a favorable interface and improve the bonding force between fillings and basal bodies, such as plastics, pulp, and the like.

Owner:颜鑫 +3

Combined rubber-plastic corrugated board and RFID circulation box manufactured from corrugated board

ActiveCN106081300AConvenient shipmentImprove buffering effectContainer decorationsLevel indicationsLogistics managementShortest distance

The invention provides a combined rubber-plastic corrugated board and an RFID circulation box manufactured from the corrugated board and belongs to the field of packaged product transporting and logistics conveying equipment. Rubber-plastic corrugated spliced panels are re-combined into the circulation box, or rubber-plastic corrugated non-spliced panels can be directly combined into the circulation box, and an information module composed of a GPS chip, an RFID chip for information storage and exchange and an electronic lock is arranged. The circulation box serves as an informationalized material carrier, has modularized, standardized and informationalized characteristics, and achieves good buffering performance. The circulation box is applied to various procedures inside enterprises, between the enterprises and e-commerce distribution centers, between the e-commerce distribution centers and express companies, between outside-city long distance and inside-city short distance of the express companies and standardization and universality of express delivery men, automatic carrying, stacking and vehicle loading and transporting are convenient, and the remarkable advantages of being high in use efficiency and safety are achieved.

Owner:章军

Wide bandwidth, low loss photonic bandgap fibers

InactiveUS20100247046A1Improves air filling fractionReduce lossOptical fibre with polarisationOptical articlesEngineeringTransmission loss

Various embodiments described herein comprise hollow core (HC) photonic bandgap fibers (PBGF) with a square lattice (SQL). In various embodiments the, HC SQL PBGF includes a cladding region comprising 2-10 layers of air-holes. In various embodiments, the HC SQL PBGF can be configured to provide a relative wavelength transmission window Δλ / λc larger than about 0.35 and minimum transmission loss in a range from about 70 dB / km to about 0.1 dB / km. In some embodiments, the HC SQL PBGF fiber can be a polarization maintaining fiber. Methods of fabricating such fibers are also disclosed herein along with some examples of fabricated fibers. Various applications of such fibers are also described herein.

Owner:IMRA AMERICA

High-performance silicon-based wave absorbing material and preparation method thereof

InactiveCN102585507AExcellent electrical propertiesImprove physical propertiesOther chemical processesAviationAging resistance

The invention relates to a high-performance silicon-based wave absorbing material and a preparation method thereof. The high-performance silicon-based wave absorbing material comprises the following raw materials in percentage by weight: 12-16 percent of silicon rubber, 0.005-1 percent of a silane coupling agent, 0.6-1.2 percent of a vulcanizing agent, 3-5 percent of a flame retardant and 76.8-84.4 percent of an absorbent. The method comprises the following steps of: drying the absorbent, and grading the particle diameter of the absorbent; coating the absorbent; and mixing. The high-performance silicon-based wave absorbing material disclosed by the invention has excellent electric and physical properties, aging resistance, high and low temperature resistance and the like, and can be applied to military electronic equipment such as aviation, space flight, naval vessels and the like, working stations, computers, data communication, communication equipment and the like.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

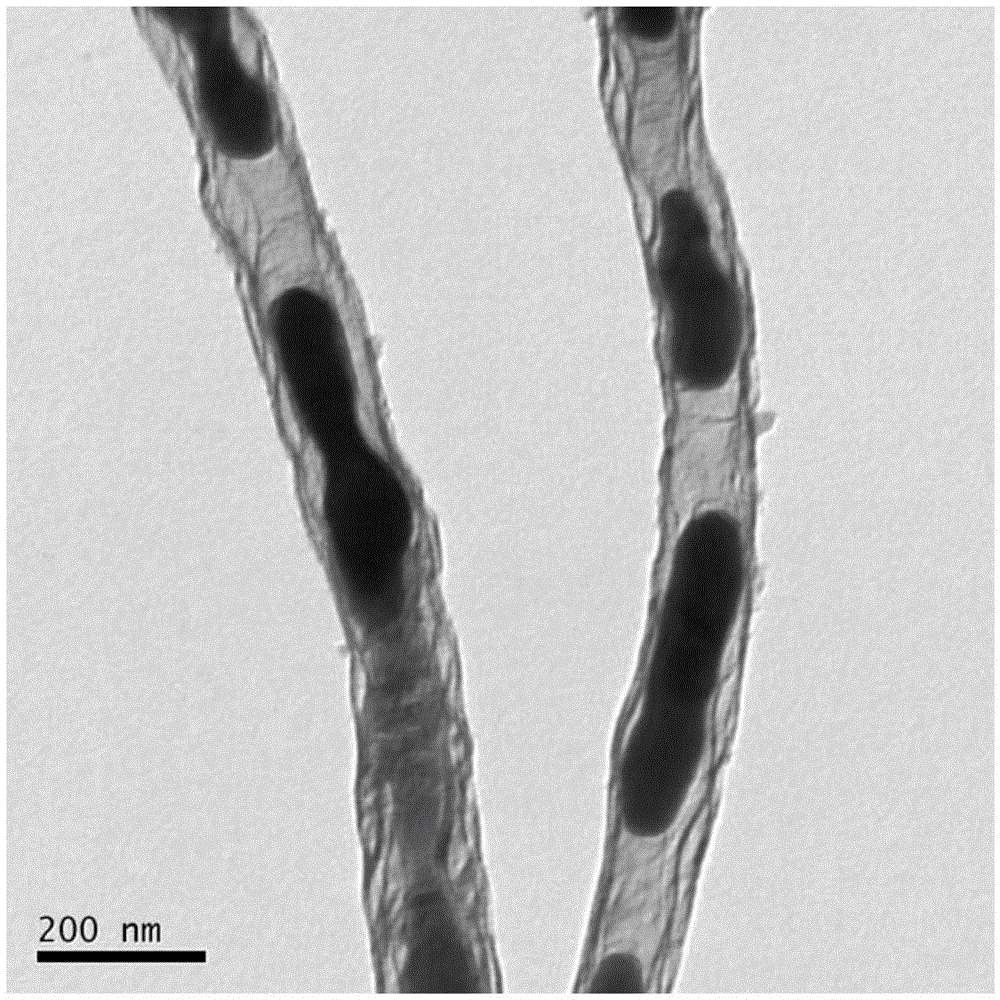

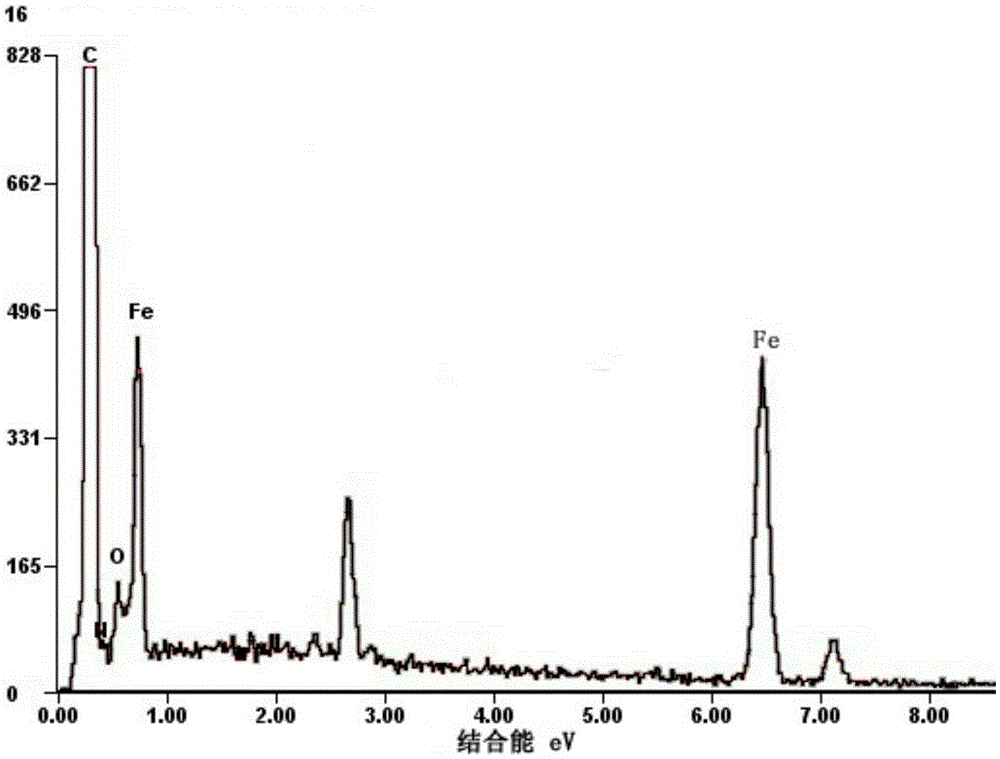

Method for in-situ preparation of iron carbide filled doped carbon nanotube

InactiveCN105271229AHigh iron filling rateIncrease productionMaterial nanotechnologySimple Organic CompoundsTube furnace

The invention discloses a method for in-situ preparation of an iron carbide filled doped carbon nanotub. The method includes: mixing an iron salt, a cyanamide nitrogenous organic compound precursor and a doping precursor evenly, then conducting high temperature pyrolysis in a tube furnace, and carrying out pickling to remove impurities, thus obtaining the iron carbide filled doped carbon nanotub. Compared with the traditional method, the method provided by the invention uses cheap precursor, reaches high utilization ratio, lower equipment requirement, improves the safety of the preparation process, and can be used for large-scale preparation, The prepared iron carbide filled doped carbon nanotub has uniform size, iron carbide is filled evenly, the filling content is high, and the product yield is high.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com