Hole multi-functionalization method for realizing water damage prevention and surface settlement control through surface borehole

A surface subsidence and ground technology, which is applied in the directions of earthwork drilling, filling, safety devices, etc., can solve the problems of difficult construction, affecting the effect of slurry diffusion and grouting, and large amount of grouting works, and achieves a simple and feasible operation method. , The effect of strong project practicability and low grouting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

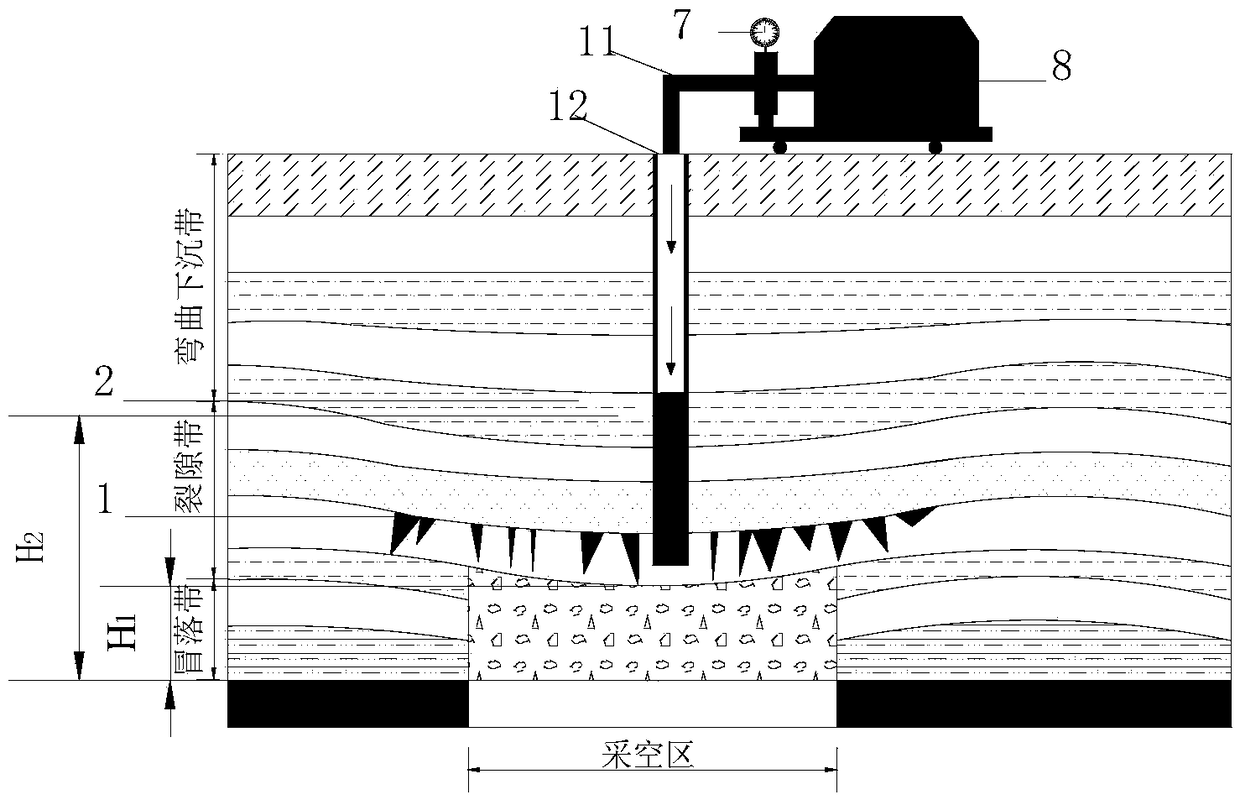

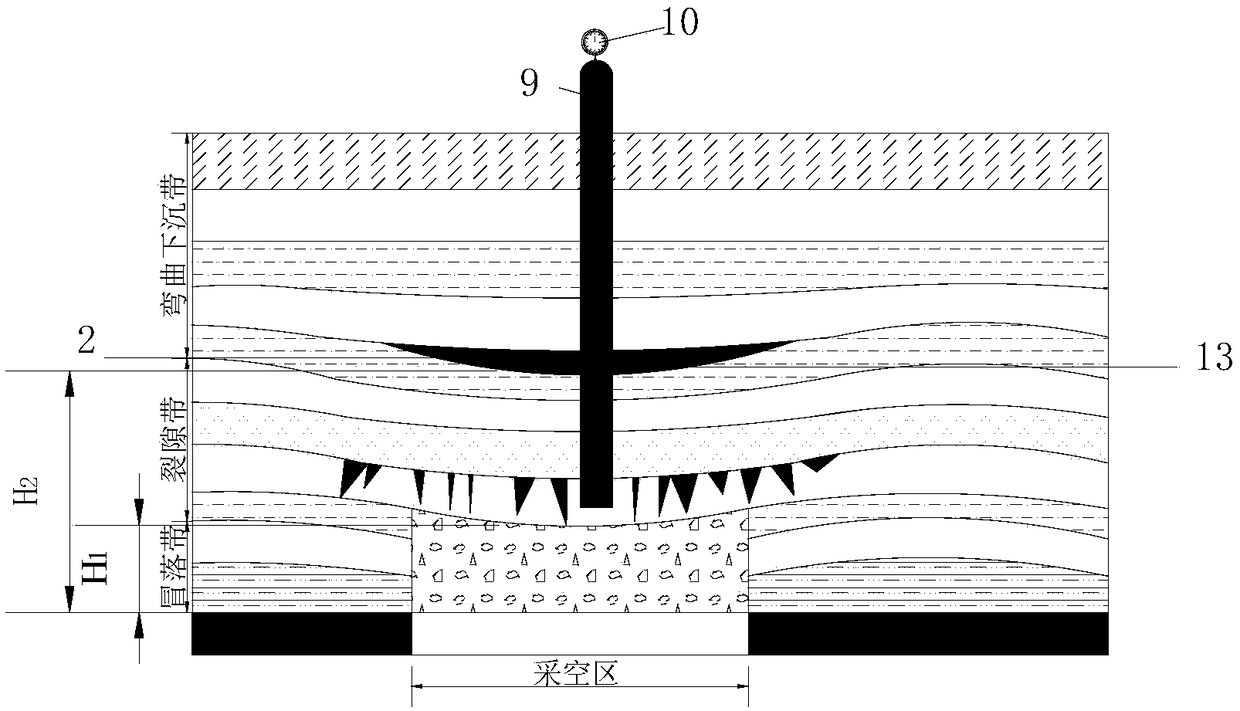

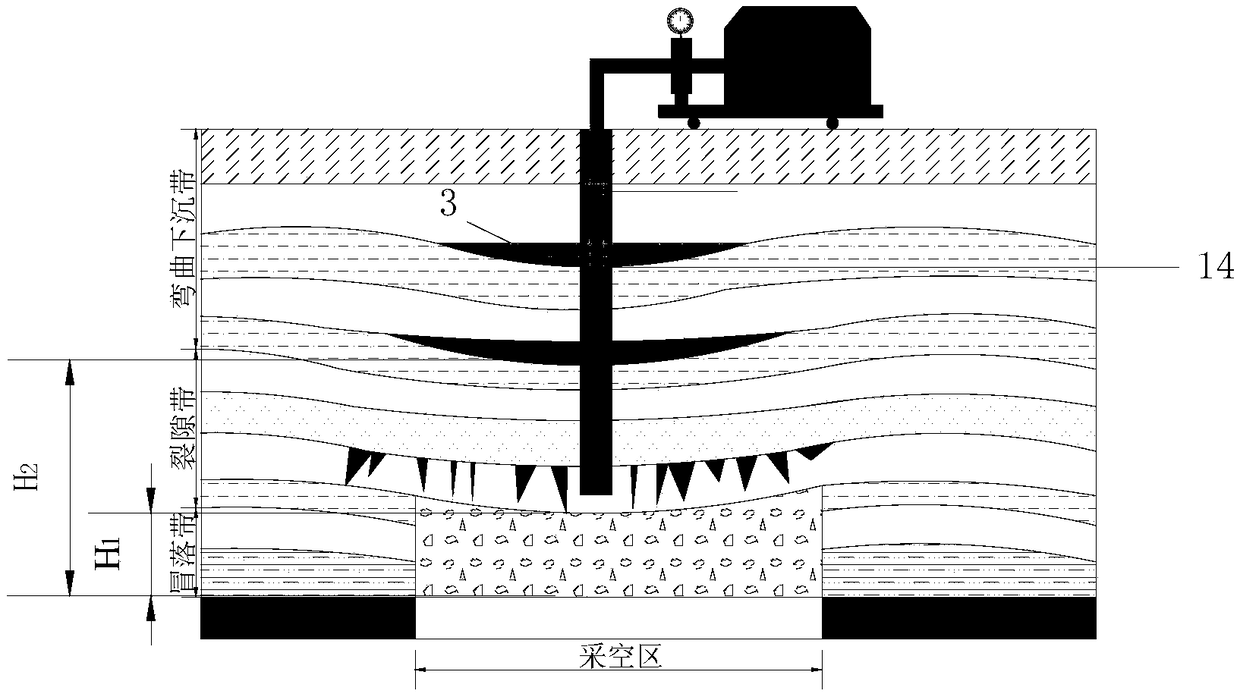

[0040] In order to make those skilled in the art understand the present invention, the specific implementation manners of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

[0041] A kind of ground drilling of the present invention realizes the multiple-purpose method of one hole of prevention and control of water damage and surface subsidence control, and described separation-layer grouting filling method comprises following 4 steps:

[0042] The first step is to determine the grouting layer

[0043] Such as Figure 1~3 As shown, the stratum lithology and rock stratum thickness displayed in the stratum information and the drilling histogram are used to determine the separation layer to be grouted. The grouting layer is mainly divided into the grouting layer 1 located in the fracture zone and two grouting layers located in the curved subsidence zone; the grouting layers located in the curved subsidence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com