Patents

Literature

33results about How to "Improve drilling utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

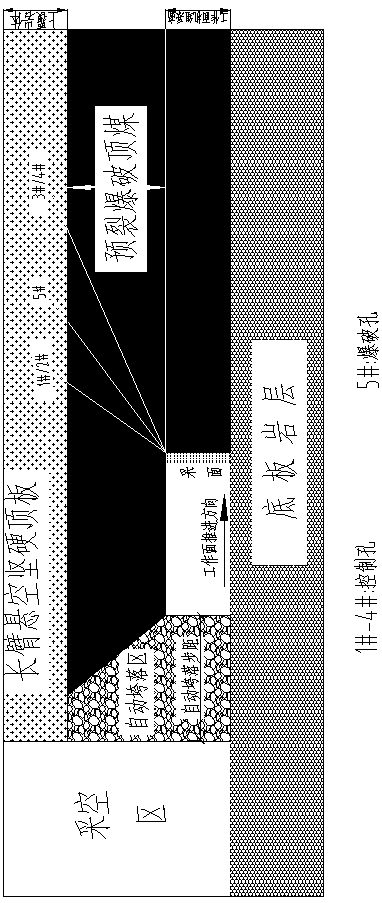

Four-period-five-purpose hole-drilling high-efficiency gas extracting process

The invention discloses a four-period-five-purpose hole-drilling high-efficiency gas extracting process, comprising the steps of: drilling a measure hole from a rock stratum tunnel wall of a coal seam top plate rock stratum tunnel to one side of the rock stratum tunnel and drilling a extracting hole from the rock stratum tunnel wall of the coal seam base plate rock stratum tunnel to a coal seam working face; performing shock blasting and / or hydrofracture to the measure hole for increasing the permeability of the coal seam, wherein the measure hole is a rock hole in the top plate or base plate rock stratum of the coal seam and positioned over or under the coal seam working face; sealing the measure hole and the extracting hole for extracting gas, and then tunneling the tunnel of the coal seam; continuously extracting the gas in the coal seam through the measure hole and / or the extracting hole when before and in stope. According to the four-period-five-purpose hole-drilling high-efficiency gas extracting process, the high-efficiency gas extraction in periods of tunneling the coal seam tunnel, and before, in and after stoping on the working face can be achieved. And simultaneously, the four-period-five-purpose hole-drilling high-efficiency gas extracting process can shield the tunneling of double coal seam tunnel of the working face.

Owner:HENAN POLYTECHNIC UNIV

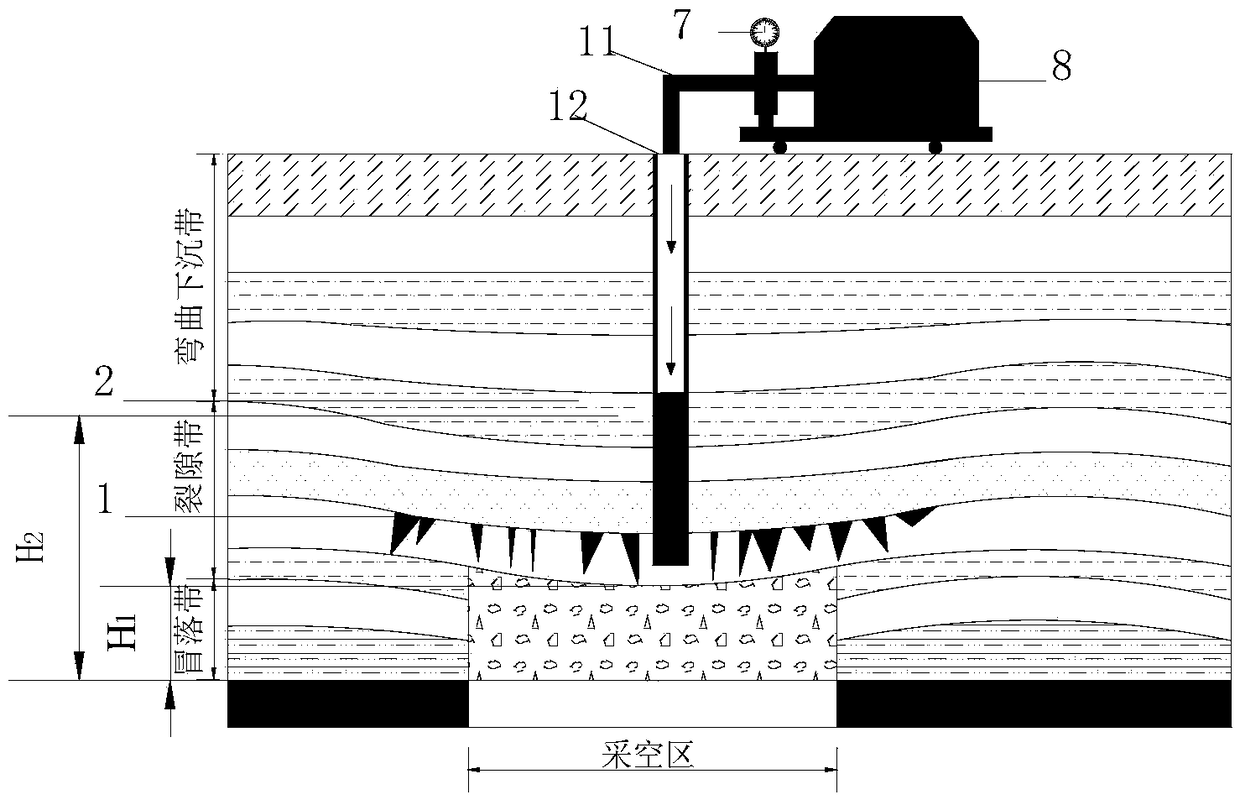

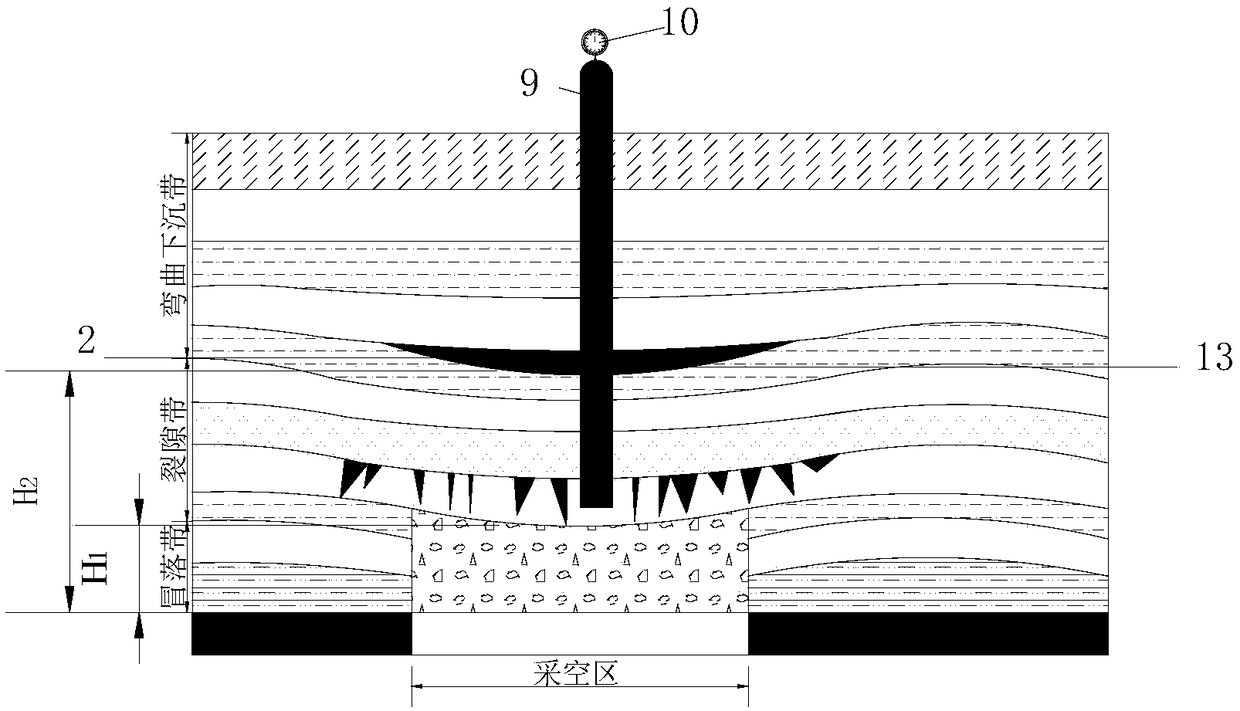

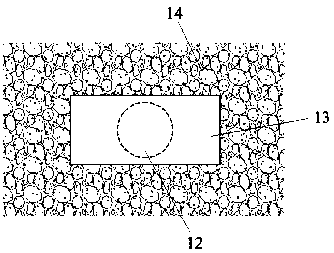

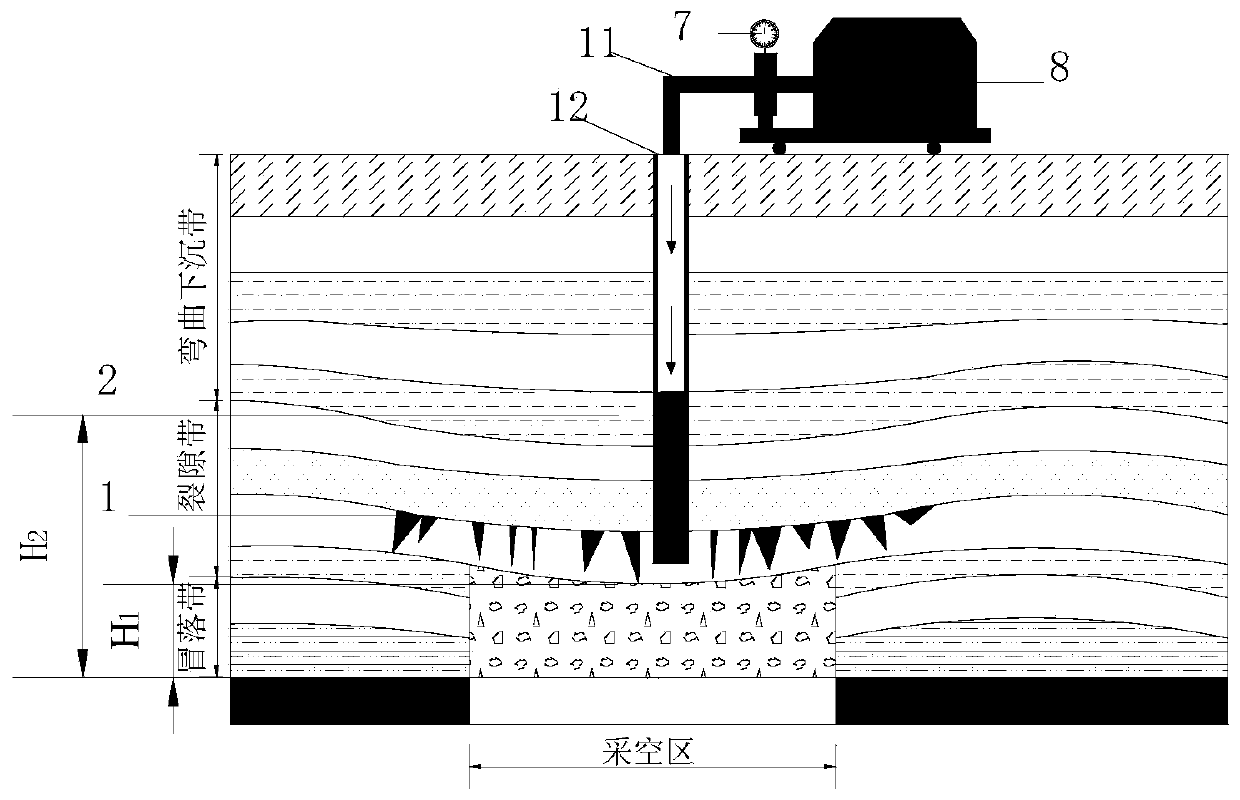

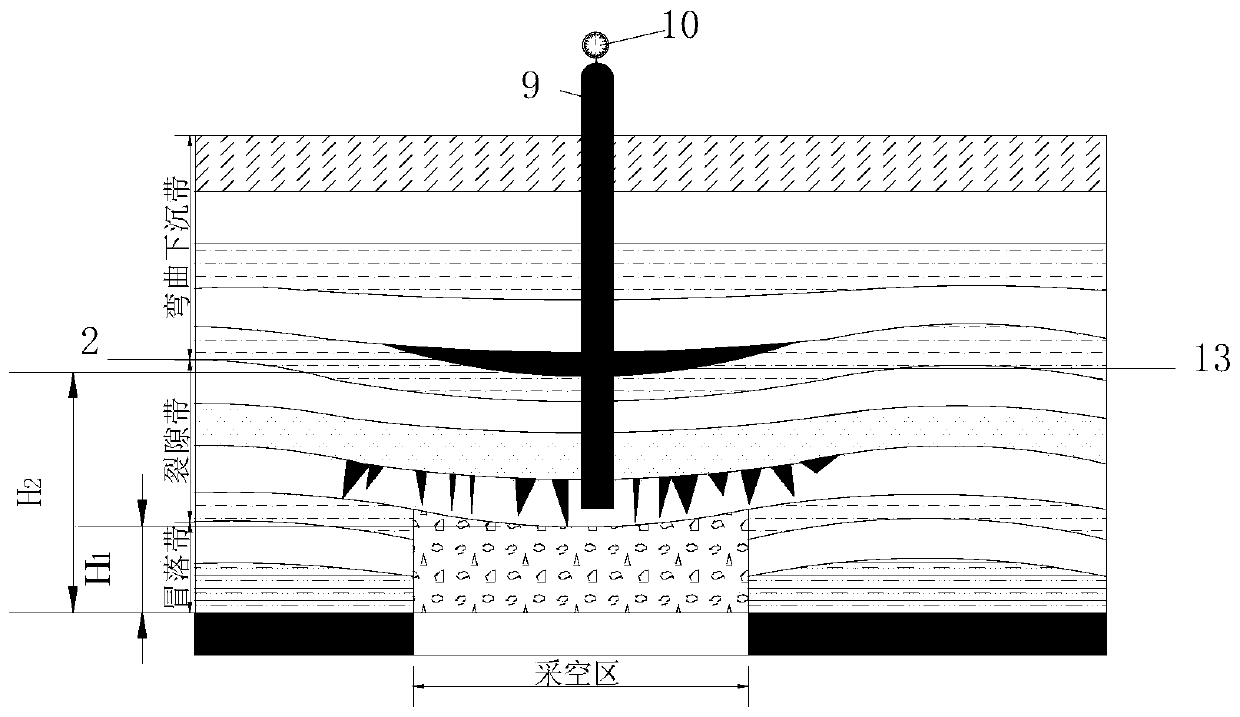

Hole multi-functionalization method for realizing water damage prevention and surface settlement control through surface borehole

InactiveCN108999634AAvoid safety hazardsThe grouting filling process is easy to controlMaterial fill-upHorizonFracture zone

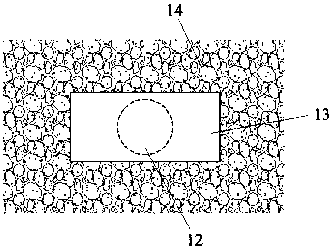

The invention discloses a hole multi-functionalization method for realizing water damage prevention and surface settlement control through a surface borehole and belongs to the coal mine green miningtechnical field. According to a grouting filling method, a single ground grouting borehole is formed downward from the ground; overlying rock located at different horizons are grouted through the grouting borehole; grouting horizons in a curved sunk zone include a low-bed-separation horizon and a high-bed-separation horizon; overlying rock fractures in a fracture zone are grouted, so that a water-blocking layer can be formed to cut off a water bursting channel of underground bed separation water damage, and therefore, secondary roof water damage can be prevented; a larger proportion of grout is adopted as the filling material of the low-bed-separation horizon so as to form a high-volume-weight rock stratum filling body; and filling bodies formed by the low-bed-separation horizon and the high-bed-separation horizon in the curved sunk zone together act on the control of surface subsidence. According to the method of the invention, a multi-horizon grouting filling project is realized through the same grouting borehole, and therefore, the utilization rate of the borehole is high, cost is low, a filling rate is improved, the subsidence-reducing rate of the surface settlement is improved, and roof water damage prevention and control is achieved.

Owner:CHINA UNIV OF MINING & TECH

Deep coal bed gas and heat co-extraction method

ActiveCN110318675AImprove breathabilityImprove permeabilityFluid removalDirectional drillingWater vaporHydraulic fracturing

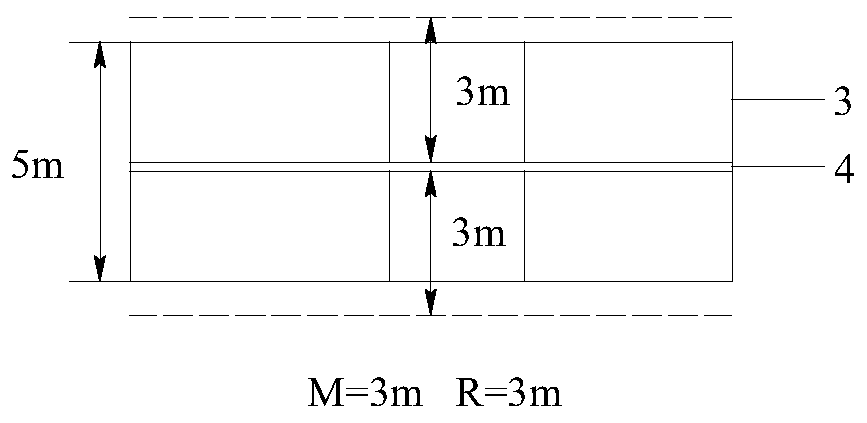

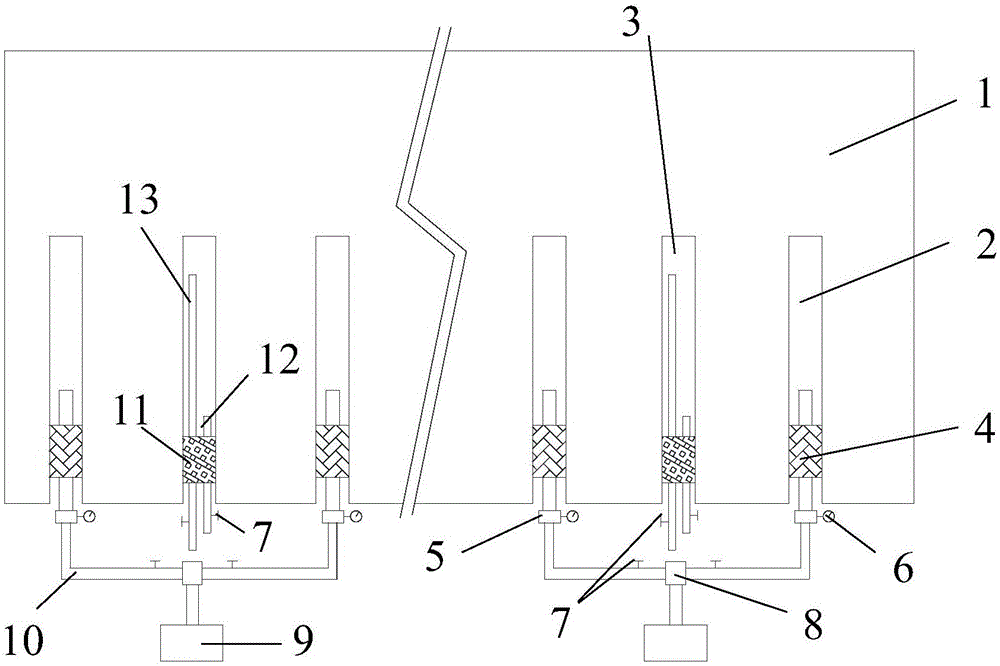

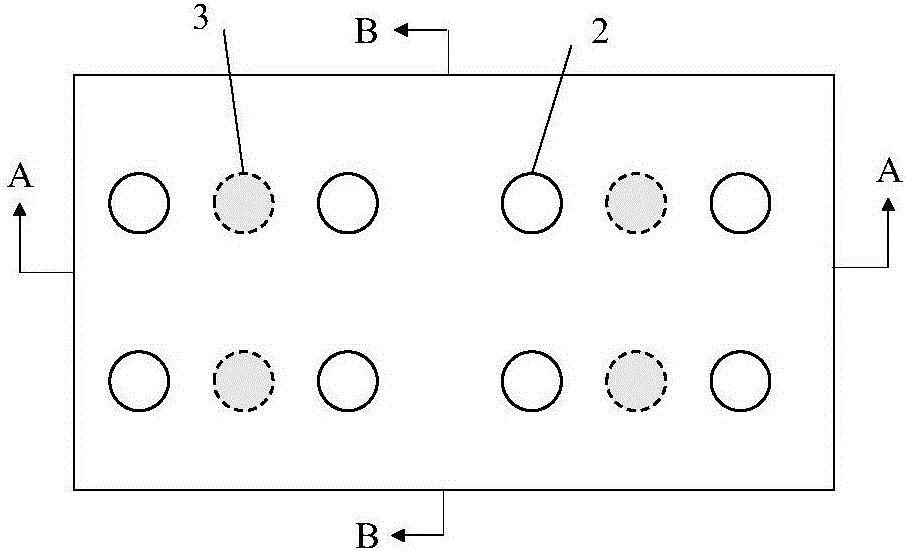

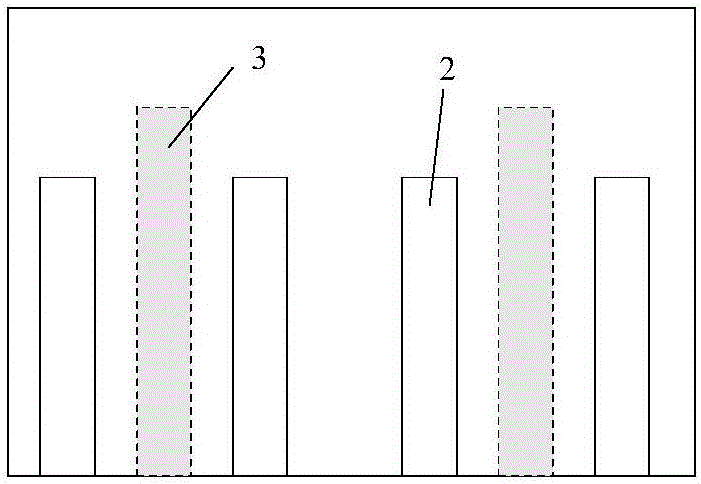

The invention discloses a deep coal bed gas and heat co-extraction method. The method comprises the steps that 1, a first vertical drilling well is constructed, a heat-preserving casing pipe is adopted for carrying out gas sealing and heat isolating protection for a well hole; 2, construction of a layering horizontal well is carried out according to the thickness of a coal bed, the layering numberK is determined according to the coal bed real thickness M and the gas drainage radius R, and K is equal to M / 2R; 3, a second vertical drilling well is constructed; 4, circumferential dispersing holes of the horizontal well are constructed, and then first extraction of gas is carried out; 5, hydraulic fracturing is carried out on all the drilled holes, a three-dimensional fracture mesh is formed,and then second extraction of the gas is carried out; 6, the first vertical drilling well serves as a water injecting well, the second vertical drilling well serves as a steam output well, the wateris injected into the deep coal bed, the principle of heat transfer is utilized for transferring geothermal energy into the water steam, and the water steam is extracted and utilized. According to themethod, gas extraction and geothermal energy exploitation can be carried out for the deep coal bed which is 1500-3000 meters, the geothermal extraction efficiency is improved, energy is saved, emission is reduced, and the geological environment problems of water and soil pollution, thermal pollution and the like are prevented.

Owner:SHANDONG UNIV OF SCI & TECH

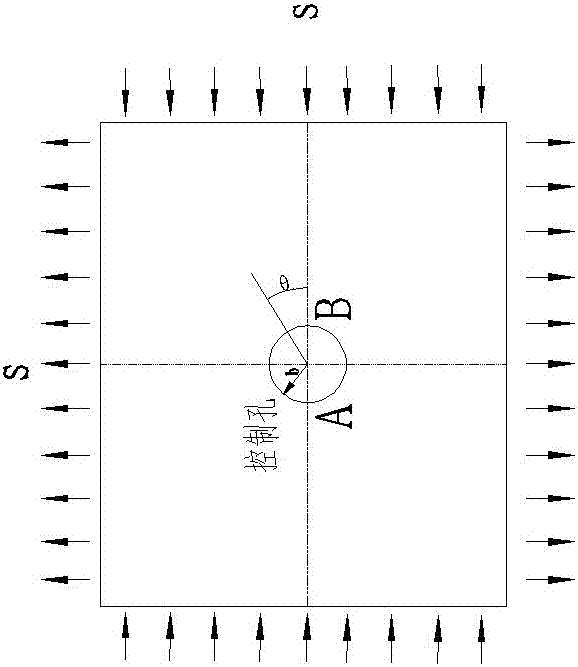

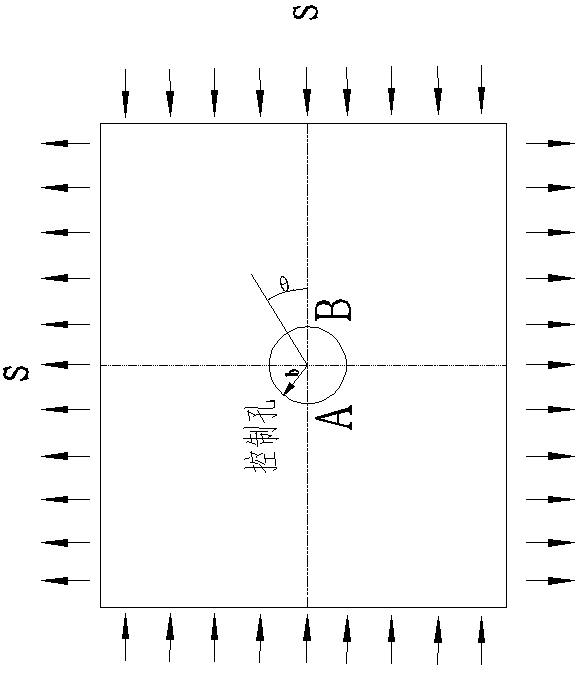

Coupling fracturing method for hard coal bed roof

ActiveCN106761740AIncrease the number of cracksImplementing Directed Complexity ExtensionsDisloding machinesFracture zoneEngineering

Provided is a coupling fracturing method for a hard coal bed roof. A drilling machine is utilized for drilling fracturing drill holes inside the hard roof till the design position, specifically, each static fracturing guide drill hole is formed between every two pulse hydraulic fracture drill holes so as to form a fracturing system; the fracture drill holes are connected to a pulse water injection pump through an isometric flow distributor with adjustable frequency, and the static fracturing drill holes are filled with static crushing agent slurry; under the action of expansion force of the static crushing agent slurry, initial cracks formed around the drill holes are monitored, released heat irradiates continuously towards the portions around the drill holes, a similarly elliptical temperature field is generated, and the elasticity modulus of a rock stratum is reduced; and under the action of hydraulic pressures of different frequencies, a fracture zone, a fatigue zone and an original stress zone are formed in the positions, around the fracture drill holes, of the rock stratum, when pressure water flows to the rock stratum bearing heat conduction along the cracks, the water and heat effect weakens the strength of the rock stratum, and the through time for crack zones among the drill holes is shortened. The method can sufficiently improve the utilization rate of the drill holes, operation is easy, and construction is safe and reliable.

Owner:CHINA UNIV OF MINING & TECH

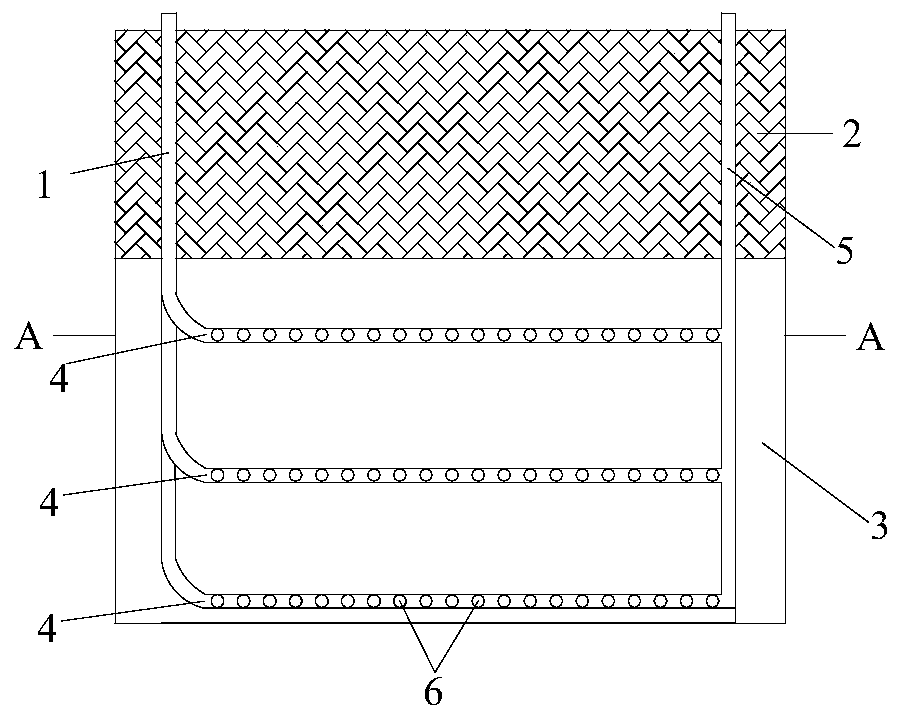

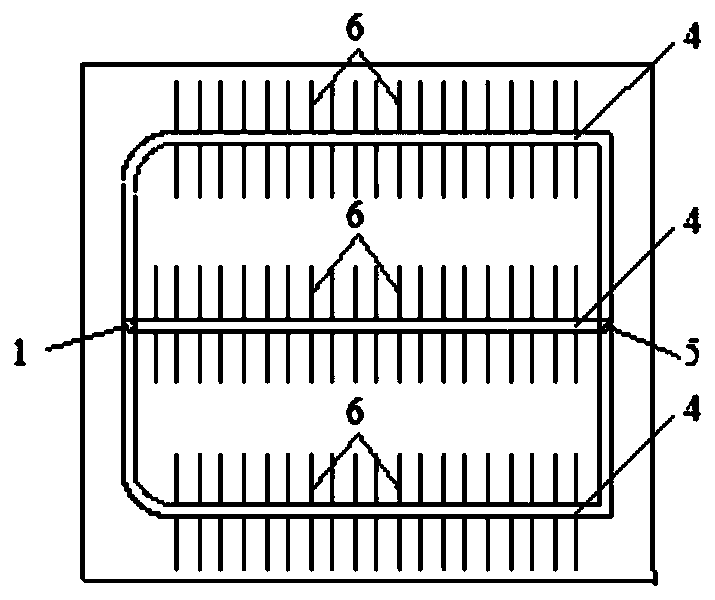

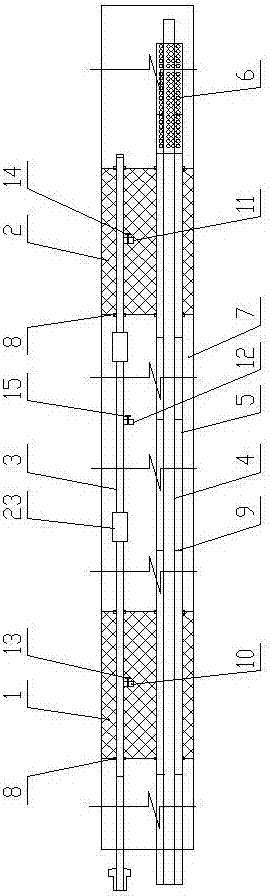

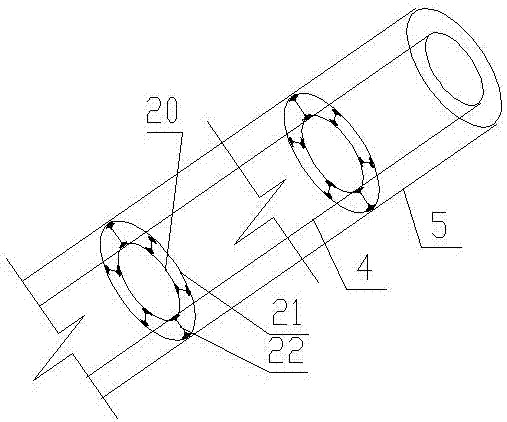

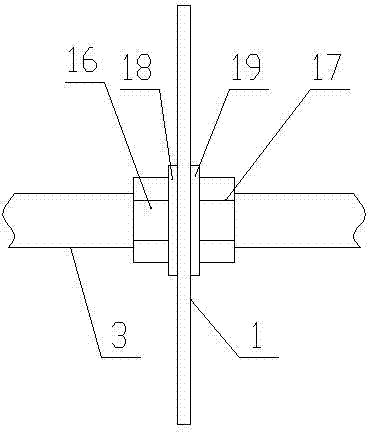

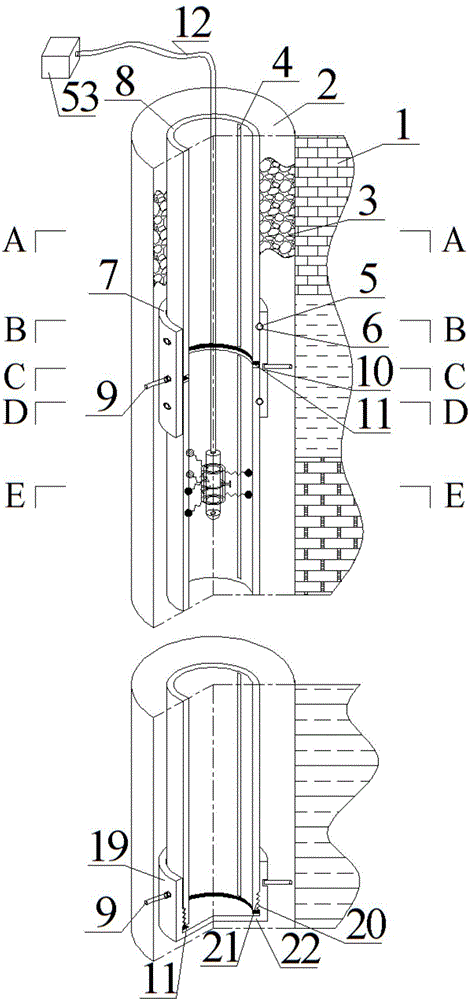

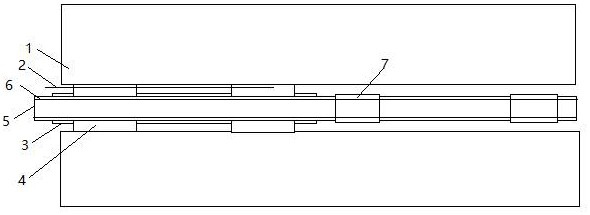

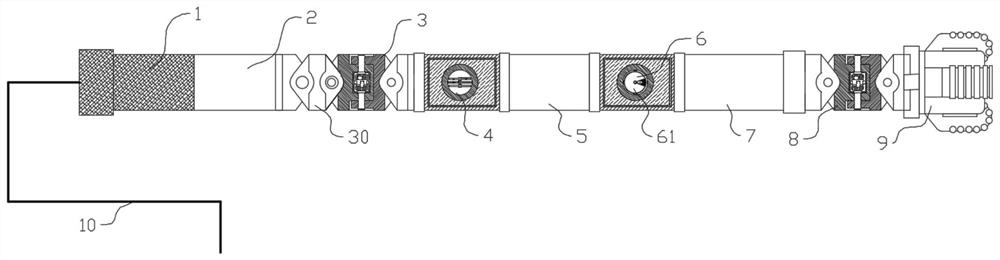

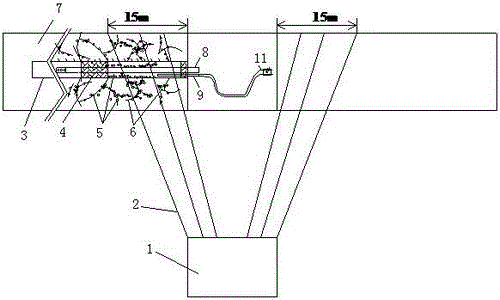

Hole-sealing, hydraulic-fracturing and gas-extraction integrated construction device and construction method thereof

ActiveCN107191172AImprove extraction efficiencyEasy extractionFluid removalGas removalThermodynamicsEngineering

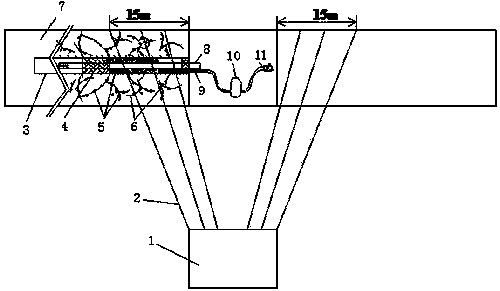

A hole-sealing, hydraulic-fracturing and gas-extraction integrated construction device comprises a first bag, a second bag, a grouting pipe, a hydraulic fracturing pipe, a gas extraction pipe and a perforated pipe. The first bag is arranged in a drilled hole and located near a hole opening, the second bag is arranged in the drilled hole and located near the hole bottom, the grouting pipe and the gas extraction pipe both sequentially penetrate through the first bag and the second bag from left to right and then extend into the hole bottom, and the left end of the perforated pipe is coaxially and fixedly connected with the right end of the gas extraction pipe. The outer diameter of the hydraulic fracturing pipe is smaller than the inner diameter of the gas extraction pipe, the hydraulic fracturing pipe is coaxially arranged in the gas extraction pipe and the perforated pipe, and the right end of the hydraulic fracturing pipe rightwards extends out of the right end of the perforated pipe. The invention further discloses a hole-sealing, hydraulic-fracturing and gas-extraction integrated construction method, that is, after a hydraulic fracturing procedure, the hole continues to be used for gas extraction; and a novel layer-penetrating fracturing-gas extraction integrated hole drilling and sealing process is provided, the good versatility of the drilled hole is guaranteed, the number of drilled holes is reduced, and the construction cost is lowered accordingly.

Owner:HENAN POLYTECHNIC UNIV

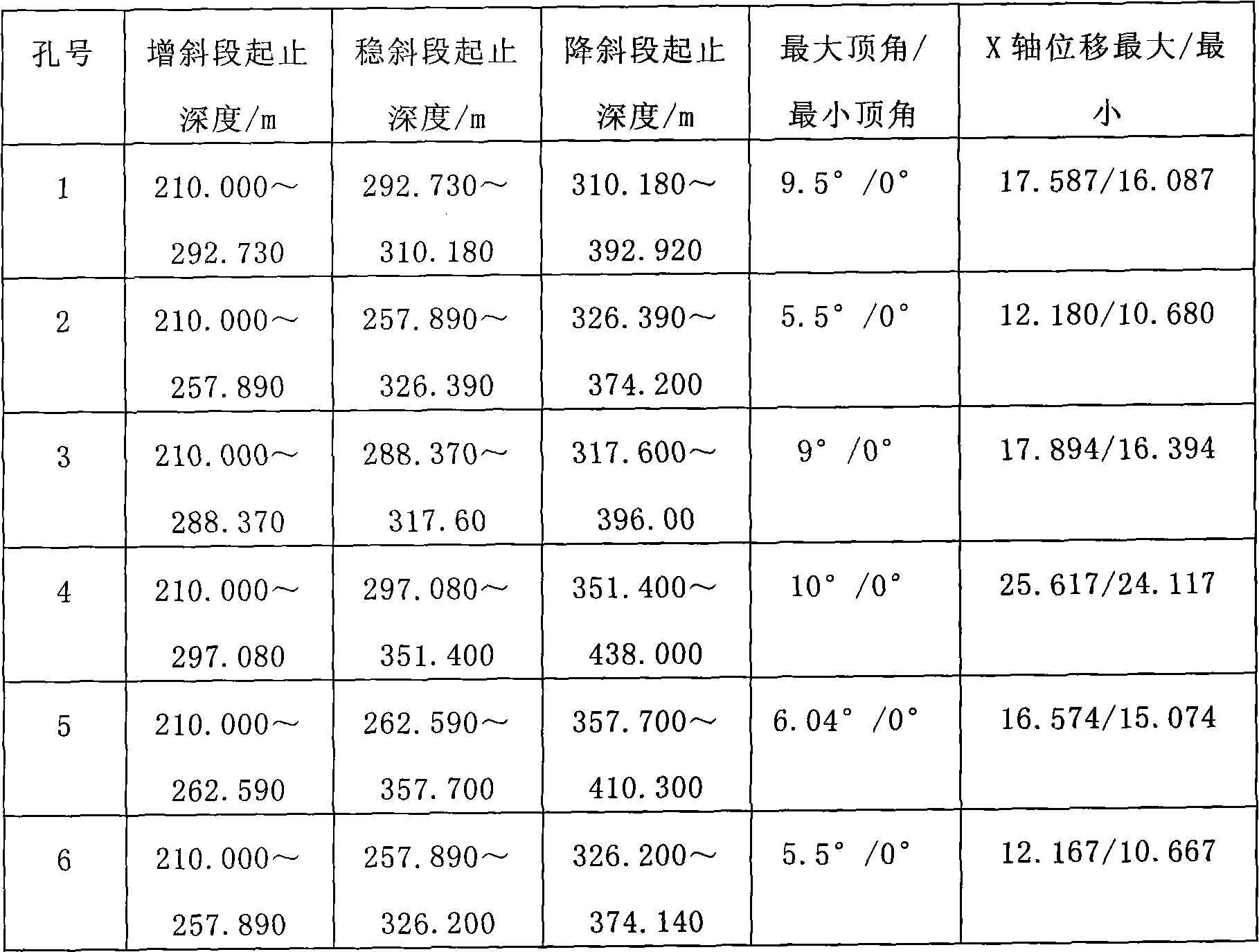

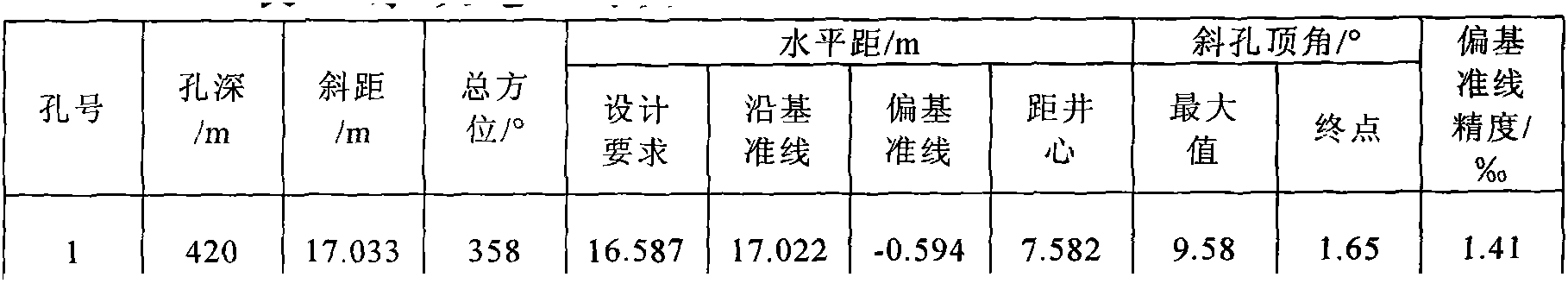

Coal engineering hole directional drilling method

InactiveCN102094580AWon't breakImprove drilling accuracyDirectional drillingCoalDirectional drilling

The invention provides a coal engineering hole directional drilling method, which mainly solves the problems of low drilling precision and complex procedure of the conventional directional drilling method. The directional drilling method is characterized by comprising the following steps of: 1, designing a drilling trace: designing the drilling trace and drilling parameters according to the requirement of engineering drilling; 2, determining special equipment, machines and devices which are required by the engineering, and combining the drilling equipment according to the requirements of all drilling stages; 3, constructing according to the trace and the parameters which are designed in the step 1, measuring the finished drilling trace by using an inclinometer after one stage is finished, analyzing whether data is the same as the designed trace, and expecting the next trace tendency; and 4, performing error correction design if error correction is needed to be performed in the step 3, repeating the content in the step 2, and cycling until the drilling is finished; and if error correction is not needed in the step 3, continuing to drill the next hole section until the drilling is finished. The coal engineering hole directional drilling method has the characteristics of high drilling precision, simple procedure, smooth drilled holes and contribution to the next work of drilling.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

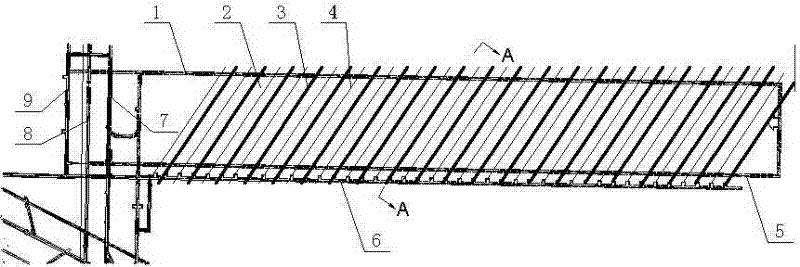

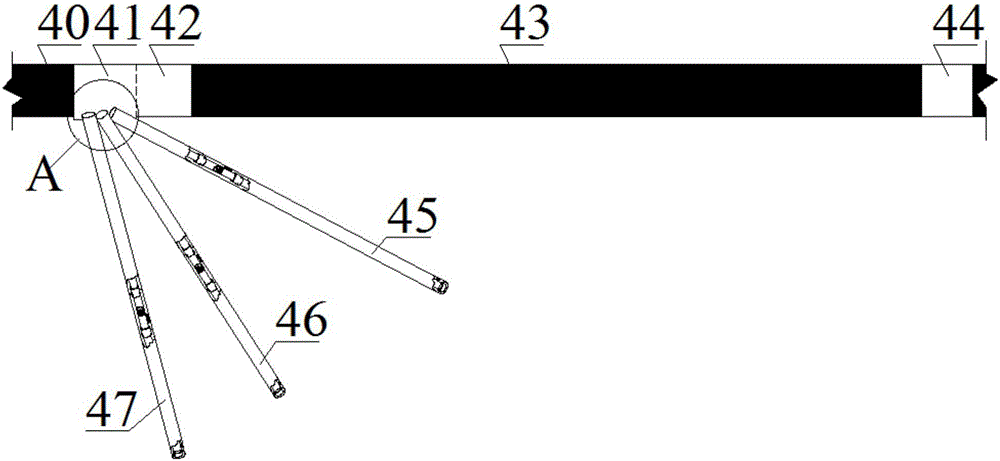

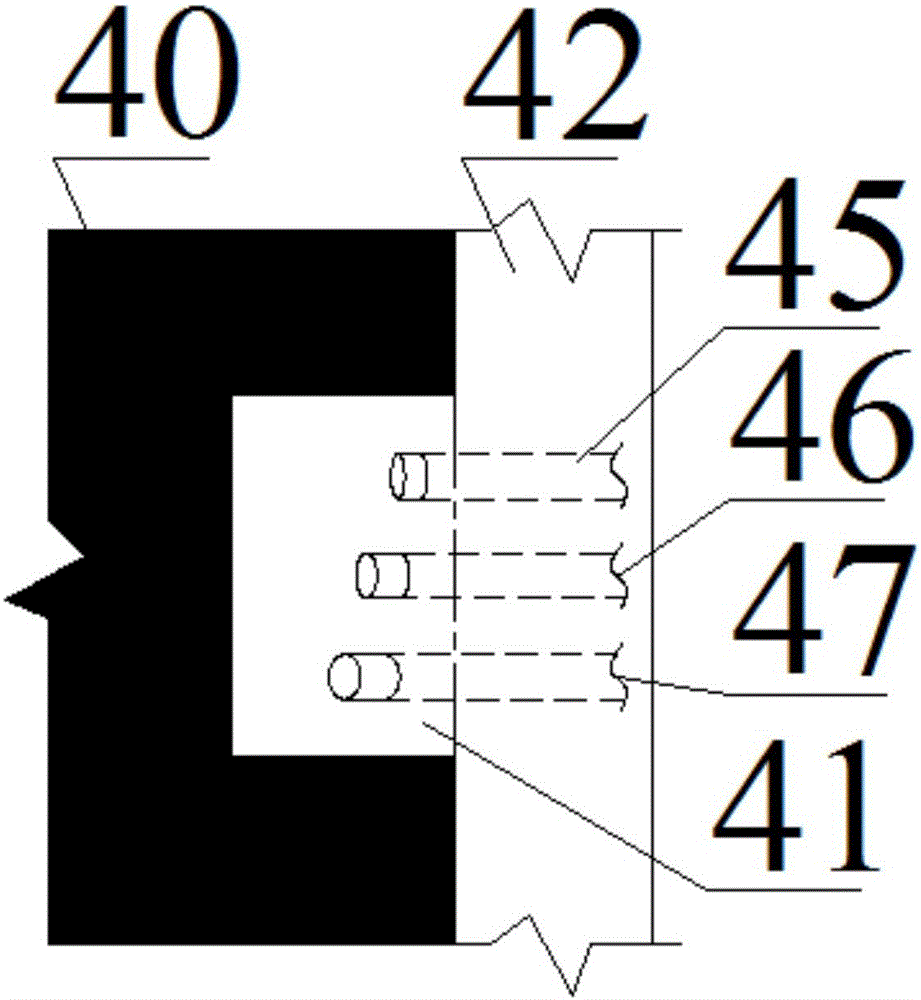

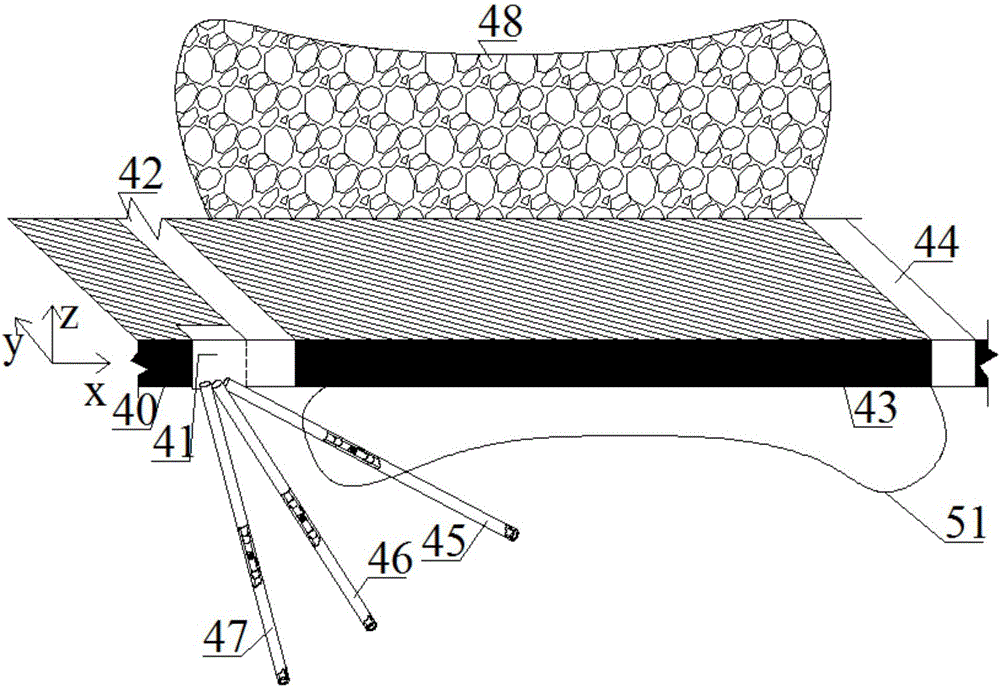

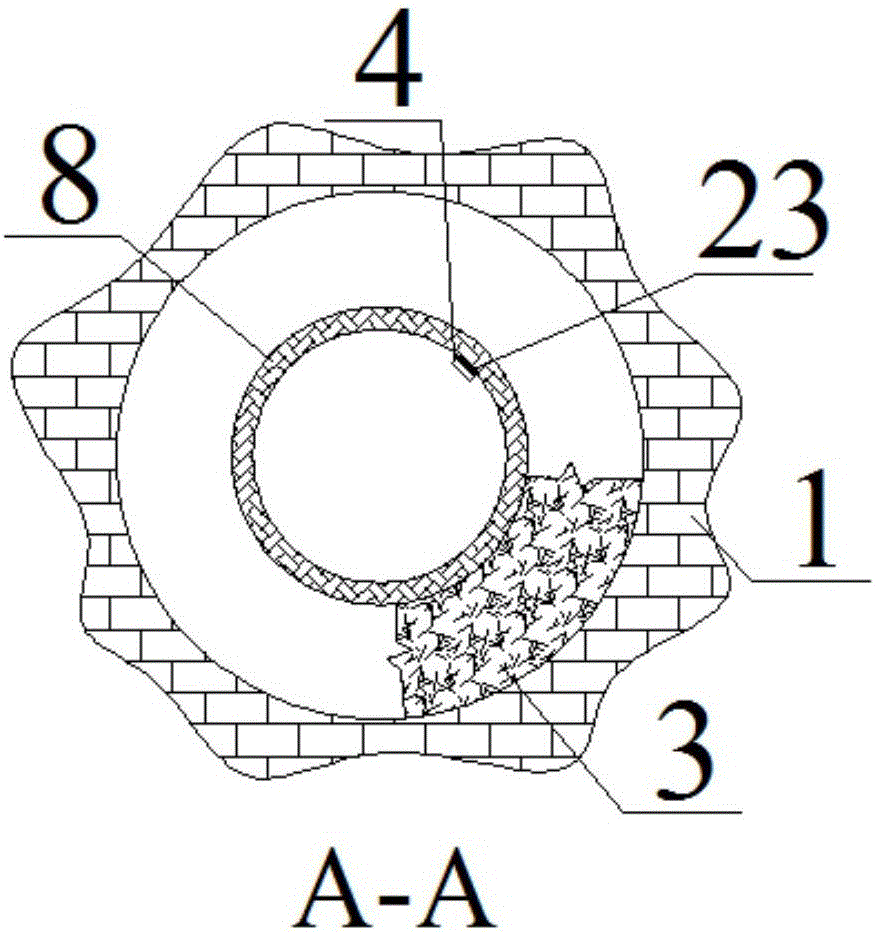

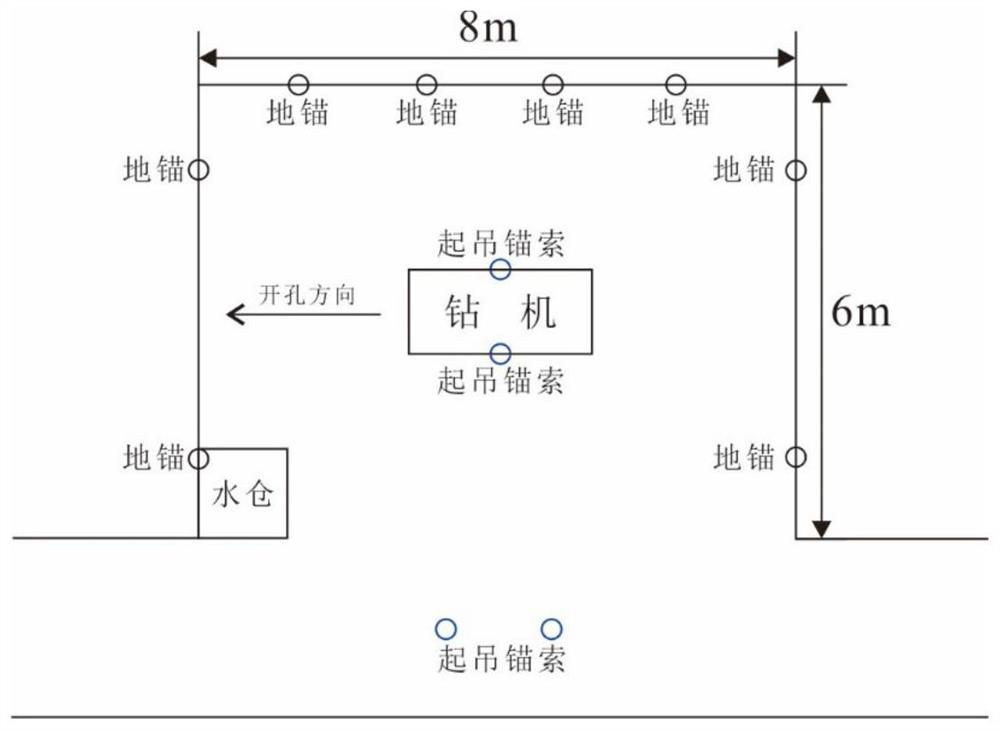

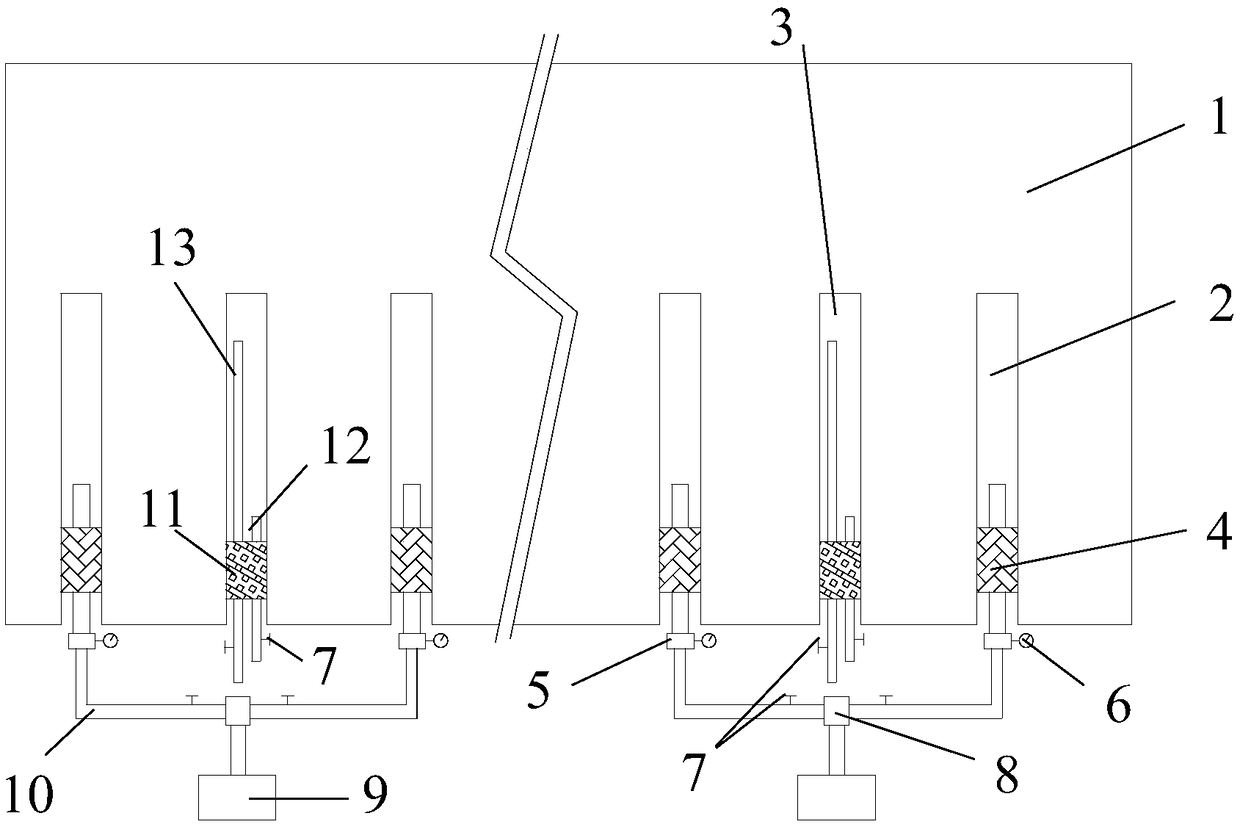

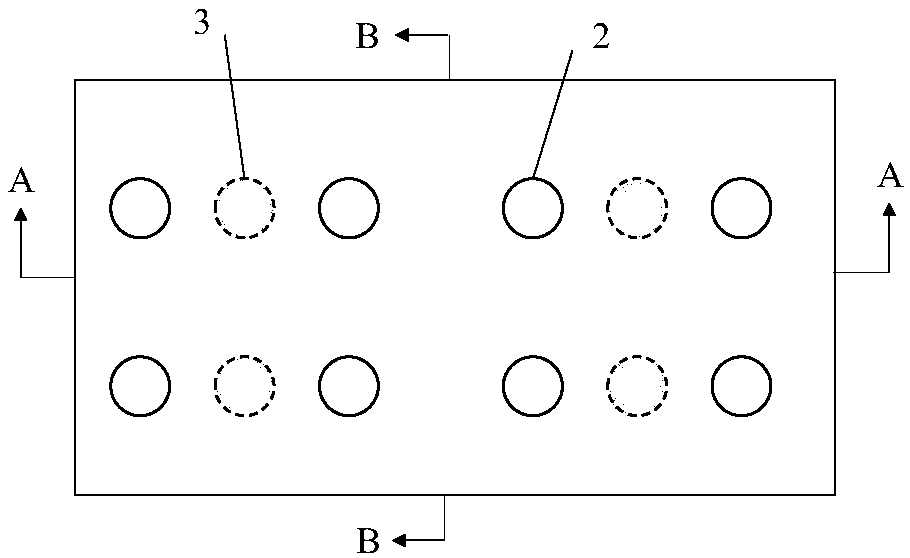

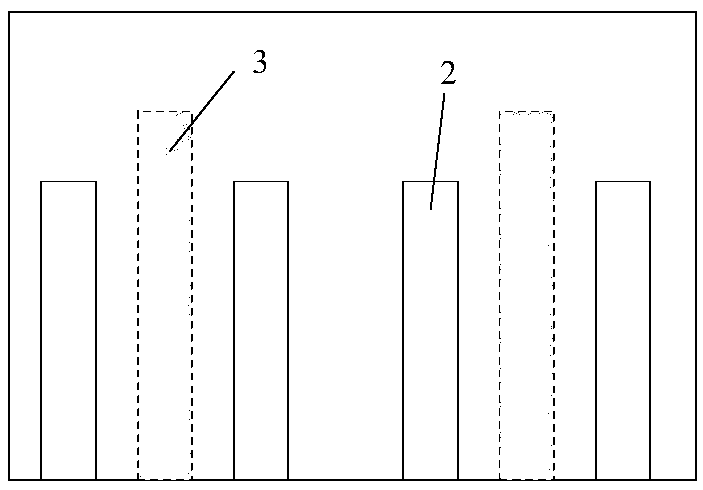

Detection system and method for monitoring fracture development of coal pillar-free gob-side entry retaining floor

ActiveCN106285628AReasonable structural designSafe and stable drillingSurveyConstructionsEngineeringCoal pillar

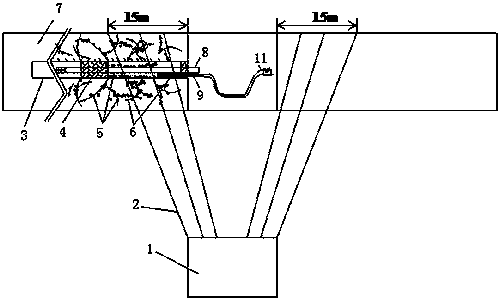

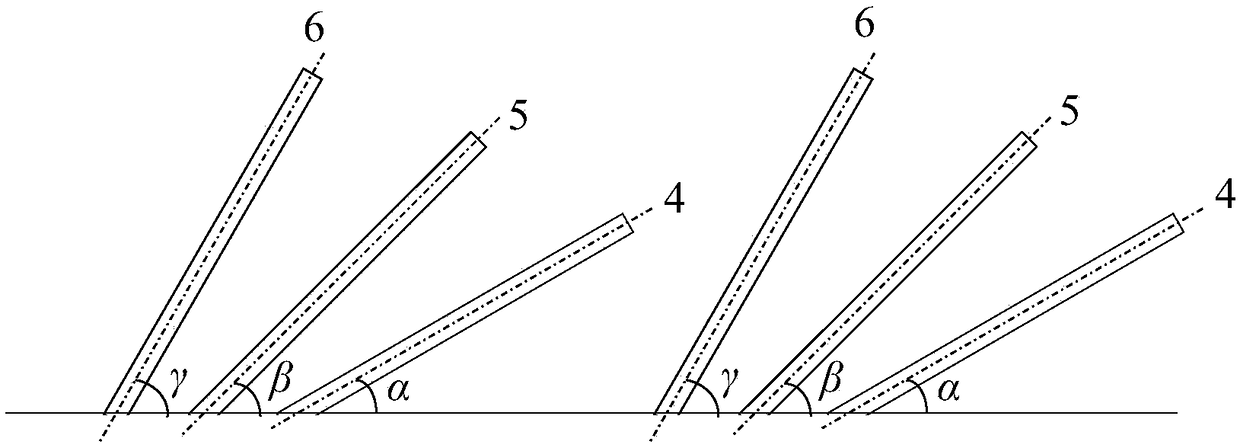

The invention relates to a detection system and a method for monitoring fracture development of a coal pillar-free gob-side entry retaining floor. The method comprises the following steps of chiseling a floor drilling field at one side of the coal pillar-free gob-side entry retaining, drilling in a floor rock layer according to different angles, gradually butting transparent hollow pipe sections by a butting sealing system, and sending into each drilling hole; grouting and anchoring a gap between each drilling hole and the corresponding transparent hollow pipe, enabling a detection positioning assembly to record the fracture of the drilling surrounding rock according to different scales of a measuring tape, performing monitoring tasks on evolution of floor mining failure rule for multiple times in different mining phases until the data is stable, and then finishing the observation. The method has the advantages that the floor small-angle drilling hole, the floor medium-angle drilling hole, and the floor large-angle drilling hole extend from the drilling field to the floor of a to-be-mined coal layer and are distributed in parallel in a stereo way; by observing the fracture condition of adjacent drilling holes in the same time and the fracture condition of the same drilling hole in different coal mining phases, the development state of the plastic failure area of the floor and the development state of the failure area of the floor after the coal bed is mined are determined, so as to provide reliable data reference for safety construction.

Owner:XIAN UNIV OF SCI & TECH

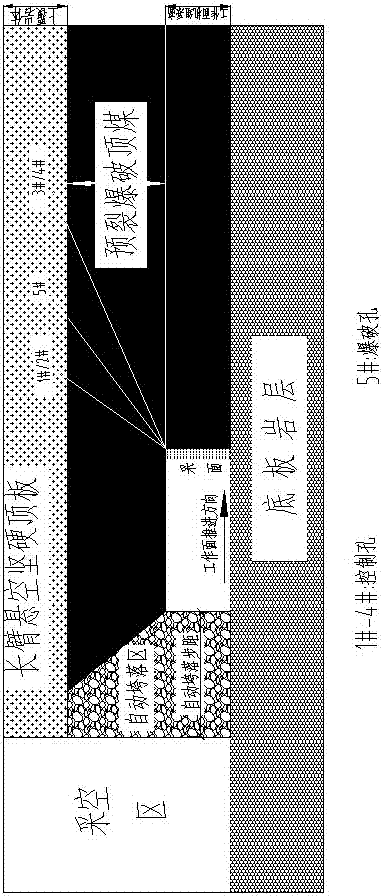

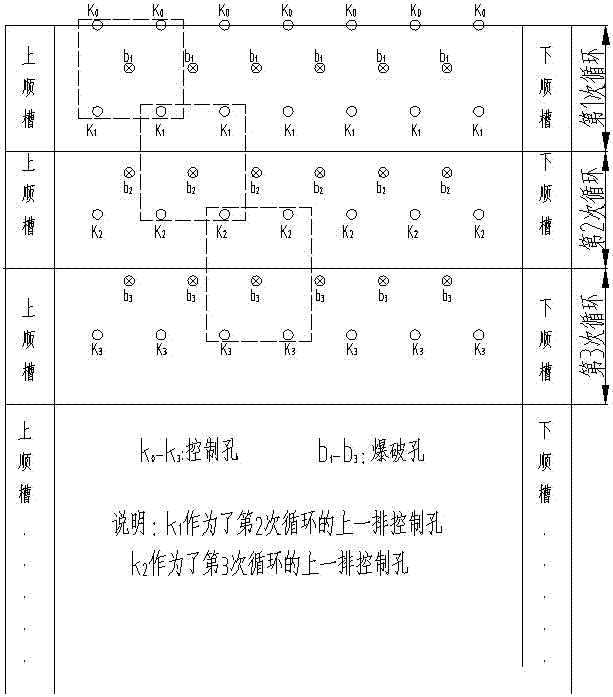

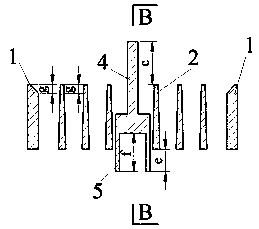

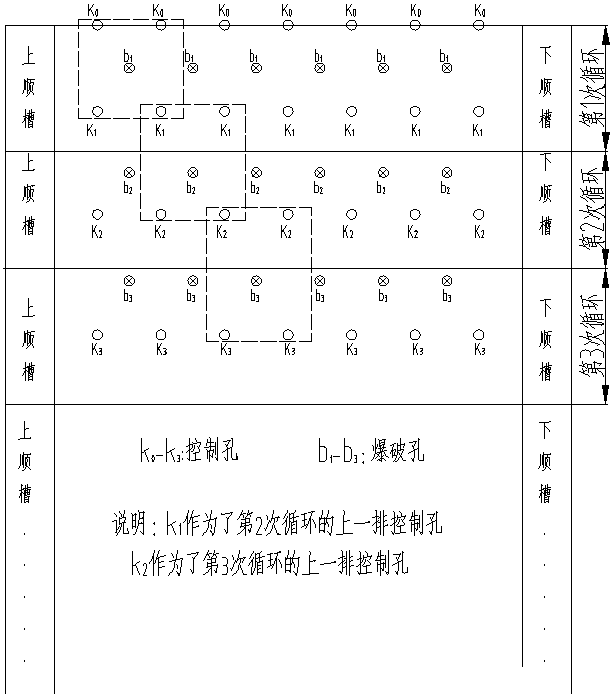

Porous control method for blasting softening of hard top plate and coal seam

InactiveCN107387085ASoften evenlySpread evenlyUnderground miningBlastingMiddle groupMechanical engineering

Disclosed is a porous control method for blasting softening of a hard top plate and a coal seam. The method comprises the following steps that a drilling arrangement scheme is determined according to the hard top plate and the coal seam at an underhole place to be blasted, that is to say, three groups of blast-holes are formed along the overall length of a working surface in an up-down parallel mode at equal intervals, wherein the uppermost group of blast-holes and the lowermost group of blast-holes are both rows of control hole groups, the middle group of blast-holes is a row of blasting hole groups, and each control hole group comprises several control holes which are formed along the overall length of the working surface in a parallel mode at equal intervals. Thus, according to the method, the overall blasting softening effects on the hard top plate and a coal body are good; by conducting blasting softening treatment on the hard coal rock mass covering at the front of the working surface in advance, the limit caving step of the top plate at the rear portion of the working surface is reduced, and puking, nicking and other accidents are prevented from occurring on a mined surface; the method has the advantages of being high in drilling hole utilization rate, low in engineering workload, high in blasting safety factor and the like and can be applied to softening and caving control of various hard top plates and coal bodies under coal mines.

Owner:HENAN POLYTECHNIC UNIV

Secondary hole sealing method for treating broken area after extraction of crossing hole

ActiveCN103758483AExtended extraction periodReduce drilling air leakageSealing/packingAir compressionHigh concentration

The invention discloses a secondary hole sealing method for treating a broken area after extraction of a crossing hole, and belongs to the methods for improving gas extraction concentration in a bedding hole. The secondary hole sealing method is especially suitable for the broken area after the extraction of the crossing hole. The bedding hole is sealed for the first time, and a first-time drilled hole sealing section is formed. Under the action of air pressure of an underground air compression system, a solid particle conveyor conveys solid particles into the bedding hole through a material blowing pipe. The underground air compression system is connected with the material blowing pipe, and air is compressed into the hole for a while. In the process of blowing the solid particles into the hole, the solid particles initially plug the fractures, caused by the crossing hole, of the broken area after the extraction around the bedding hole, and hole air leakage is reduced. The air is compressed by the underground air compression system through the material blowing pipe, the solid particles in the hole are further blown into the fractures of the broken area after the extraction, then the hole air leakage is reduced, the bedding hole high concentration gas extraction period is prolonged by more than one month, the hole use ratio is improved, and coal recovery safety is guaranteed.

Owner:CHINA UNIV OF MINING & TECH +1

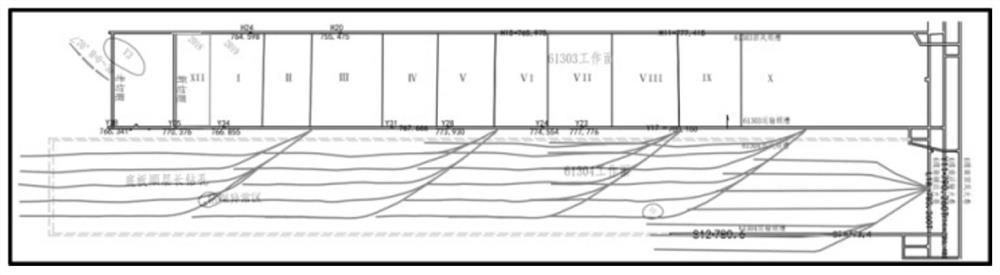

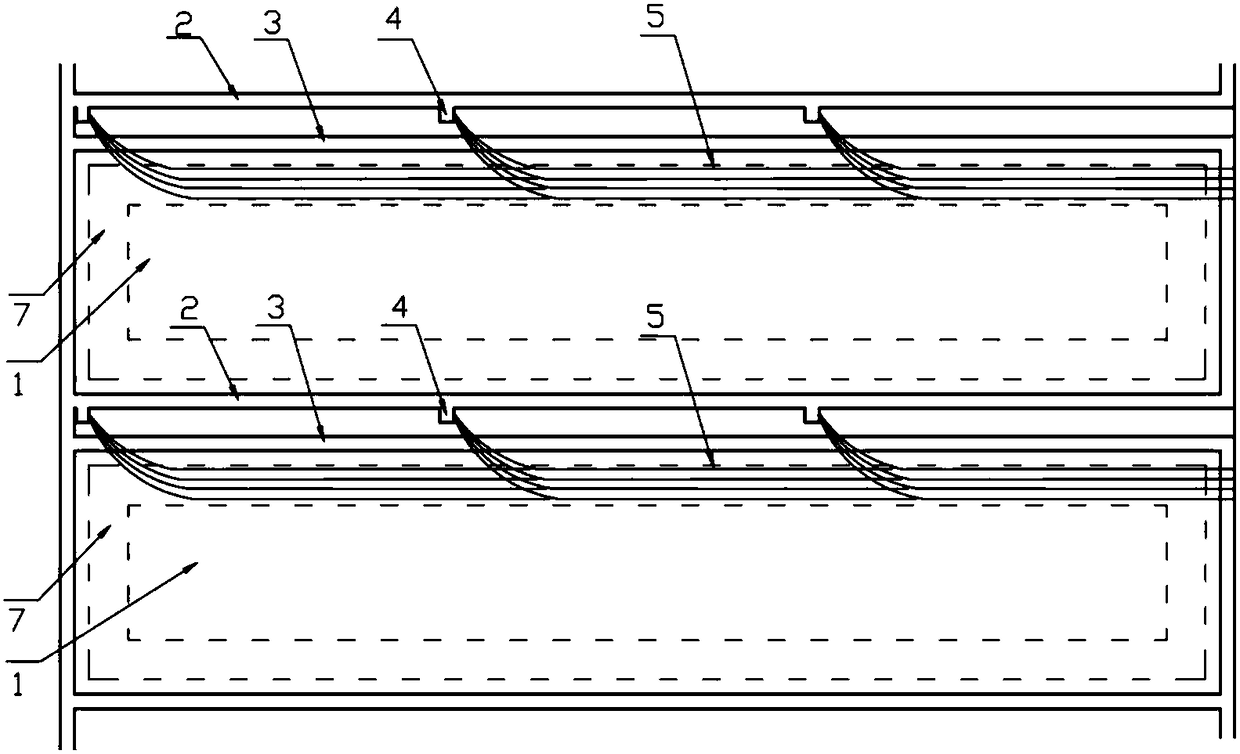

Coal face fissure zone gas extraction method

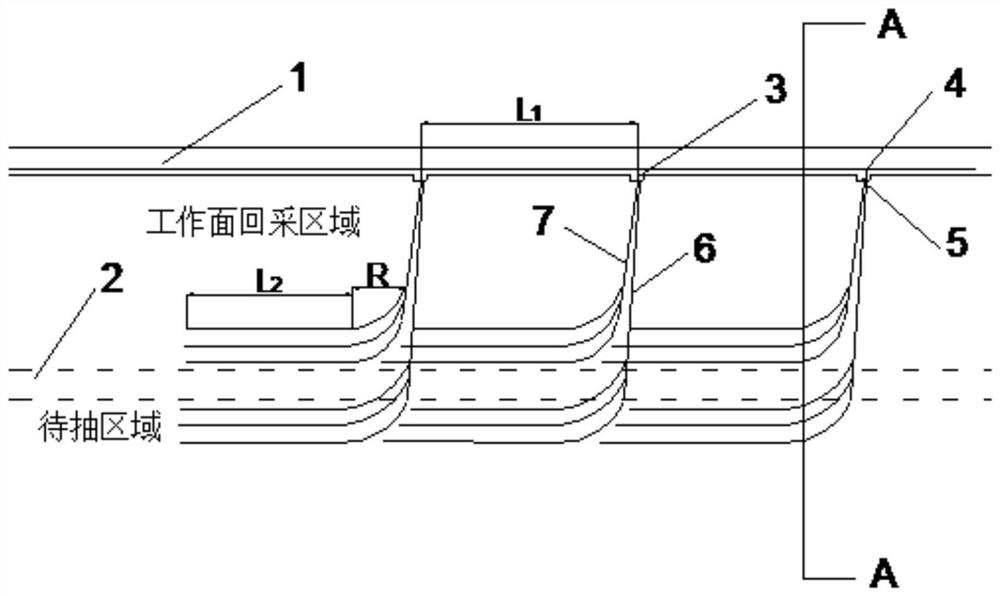

PendingCN112302704AFully pumpedShort construction periodFluid removalGas removalMining engineeringGas concentration

The invention discloses a coal face fissure zone gas extraction method. According to the principle of the coal face fissure zone gas extraction method, before working face stoping, a drill hole arrangement method is determined through goaf overlying strata movement and gas seepage research, staggered high and low fissure zone directional long drill holes along the working face trend are arranged in a drilling field in a working face air return gate road, a main hole section of the high-position drill hole extends within the range of 30 m above a goaf formed after stoping of the working face, the low-position drill hole sinks properly at the position of the working face, a low negative pressure balanced extraction mode is adopted for the low-position drill hole, a high negative pressure balanced extraction mode is adopted for the high-position drill hole, and gas in a fissure zone and the goaf after stoping of the working face is extracted. According to the method, gas in the coal facefissure zone can be fully extracted, the gas concentration in the upper corner and the return air flow of the stoping face is reduced, meanwhile, the effect of treating goaf gas is achieved, gas treatment of the working face is achieved, and safe stoping of the coal face is guaranteed.

Owner:山西汾西矿业(集团)有限责任公司双柳煤矿

A detection system and method for monitoring the development of floor cracks in gob-free entry retaining without coal pillars

ActiveCN106285628BReasonable structural designSafe and stable drillingSurveyConstructionsEngineeringCoal pillar

The invention relates to a detection system and a method for monitoring fracture development of a coal pillar-free gob-side entry retaining floor. The method comprises the following steps of chiseling a floor drilling field at one side of the coal pillar-free gob-side entry retaining, drilling in a floor rock layer according to different angles, gradually butting transparent hollow pipe sections by a butting sealing system, and sending into each drilling hole; grouting and anchoring a gap between each drilling hole and the corresponding transparent hollow pipe, enabling a detection positioning assembly to record the fracture of the drilling surrounding rock according to different scales of a measuring tape, performing monitoring tasks on evolution of floor mining failure rule for multiple times in different mining phases until the data is stable, and then finishing the observation. The method has the advantages that the floor small-angle drilling hole, the floor medium-angle drilling hole, and the floor large-angle drilling hole extend from the drilling field to the floor of a to-be-mined coal layer and are distributed in parallel in a stereo way; by observing the fracture condition of adjacent drilling holes in the same time and the fracture condition of the same drilling hole in different coal mining phases, the development state of the plastic failure area of the floor and the development state of the failure area of the floor after the coal bed is mined are determined, so as to provide reliable data reference for safety construction.

Owner:XIAN UNIV OF SCI & TECH

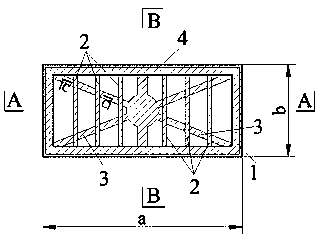

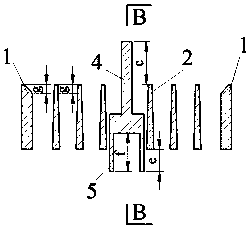

Rectangular drilling stress monitoring device and method

ActiveCN108426663AOvercome stressOvercoming utilizationConstructionsForce transducersEngineeringForce sensor

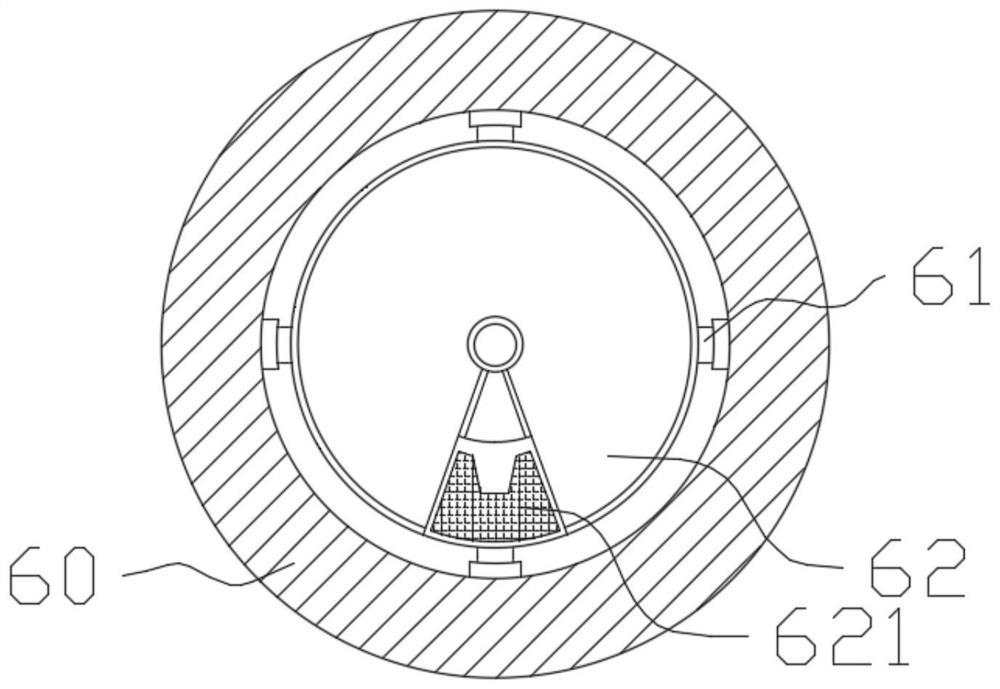

The invention provides a rectangular drilling stress monitoring device and method. The monitoring device comprises a rectangular drilling bit, a drilling pipe and a rectangular drilling stress monitor. The rectangular drilling bit includes an outer frame, and the outer frame is internally provided with forward cutters, diagonal cutters and a center guide cutter. The rectangular drilling stress monitor includes an upper cover, a lower cover, stress sensors and digital displayers. The monitoring method includes the steps of forming guide drilling holes in advance, forming rectangular drilling holes and installing the rectangular drilling stress monitor for monitoring. The monitoring device can effectively overcome the shortcomings that the test direction of traditional drilling stress gaugesis unclear and the test value is inaccurate, can accurately measure surrounding rock stress values at any angle in the vertical direction and the horizontal direction and can provide more reliable data for on-site mine pressure disaster prediction and forecast. The device and the implementation method provide a more reliable guarantee for monitoring of surrounding rock stress in coal mines in China.

Owner:SHANDONG UNIV OF SCI & TECH

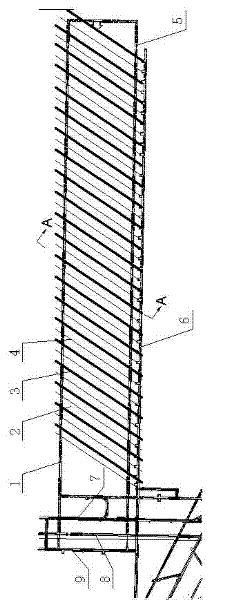

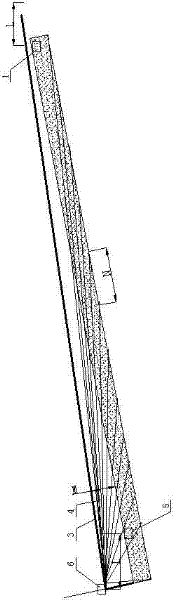

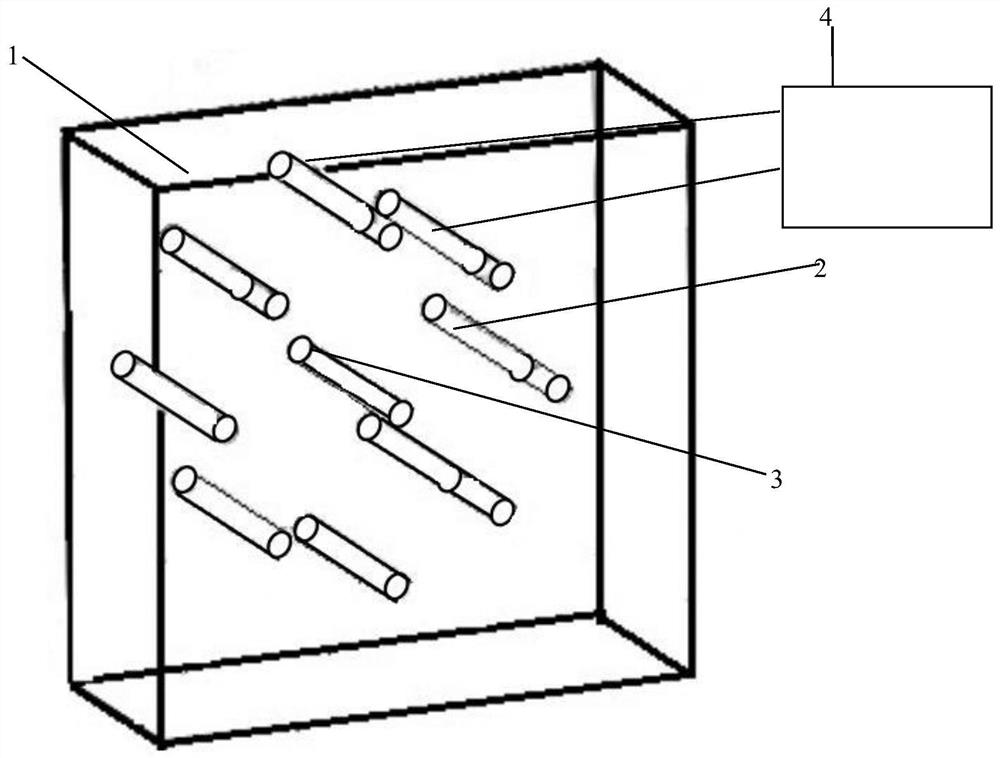

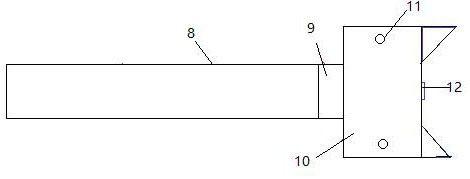

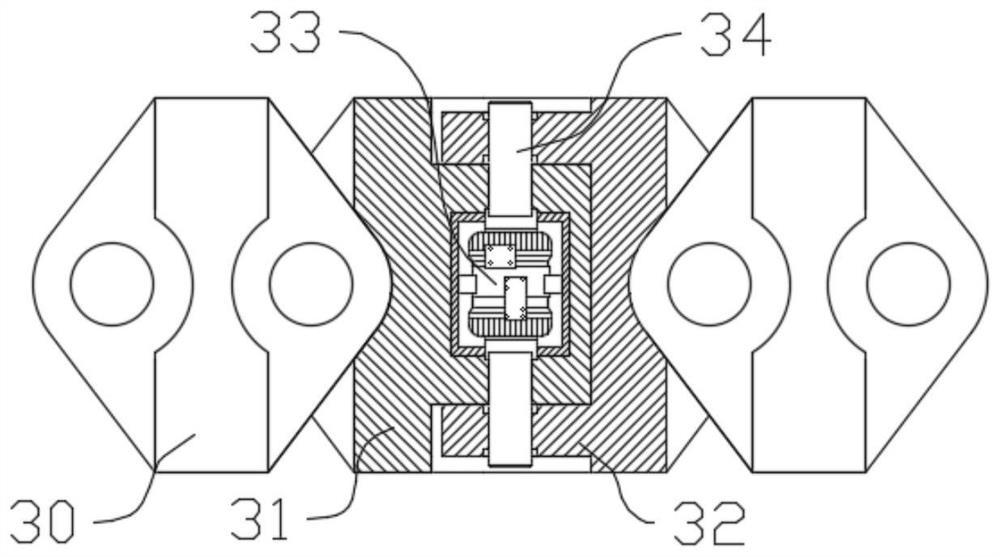

Drill hole anchoring structure for monitoring floor surrounding rock fractures and construction method thereof

ActiveCN106321001ASafe and stable drillingAvoid Drilling and Patching SituationsConstructionsBorehole/well accessoriesFailure rateButt joint

The invention discloses a drill hole anchoring structure for monitoring floor surrounding rock fractures and a construction method thereof. Transparent hollow pipes are connected in a butt joint mode section by section through butt joint sealing assemblies and a bottom sealing assembly and then fed into a drill hole; after a gap between the drill hole and the transparent hollow pipes is subjected to grouting anchoring, drill hole surrounding rock fractures at different scale positions on a measuring ruler are recorded through a detecting and positioning assembly. The rock stratum development condition in the drill hole is directly read, and the drill hole anchoring structure has the advantages of being reasonable in integral structural design, easy to construct, safe, stable, low in drilling failure rate, capable of providing clear images, capable of meeting the requirement for repeated observation and the like; the fracture positions and forms on a drill hole grouting body are directly read through the transparent hollow pipes and directly reflect the positions of floor surrounding rock fractures in the drill hole, and compared with traditional distance position data acquired indirectly, errors are greatly reduced; the drill hole in the same position is used for observing the progress of fracture development at different stages, data is real and reliable, and the position and development condition of rock stratum change can be rapidly and precisely obtained.

Owner:XIAN UNIV OF SCI & TECH

A combined multi-electrode high-voltage pulse discharge fragmentation hard rock device and fragmentation method

ActiveCN112044569BReduce the number of punch holesGuaranteed normal formationGrain treatmentsVoltage pulseEngineering

The invention discloses a combined multi-electrode high-voltage pulse discharge fragmentation hard rock device and a fragmentation method, which are applied to the rock mass to be crushed, including: a negative electrode, a positive electrode and a pulse power meter; the rock mass to be crushed is pre-set There are a plurality of operation holes adapted to the negative electrode and the positive electrode, and the negative electrode and the positive electrode are electrically connected to the pulse power meter; the present invention uses one negative electrode or a small number of negative electrodes Cooperate with the electrode arrangement of multiple positive electrodes to effectively avoid edge discharge.

Owner:NORTHEASTERN UNIV LIAONING

Coal roadway advanced area pre-extraction method based on directional extraction drilling cross-roadway arrangement

InactiveCN111764955AEnsure timeEnsure the effect of pre-drawingFluid removalDirectional drillingMining engineeringEconomic benefits

The invention belongs to the field of coal mine safety, and relates to a coal roadway advanced area pre-extraction method based on directional extraction drilling cross-roadway arrangement. The coal roadway advanced area pre-extraction method based on directional extraction drilling cross-roadway arrangement utilizes a directional drilling construction technology to realize the regional pre-extraction of coal seam gas in a coal roadway excavation area in advance, does not destroy the drilling extraction function during roadway excavation, can achieve the purposes of continuous and efficient extraction and multiple purposes of one hole, can effectively alleviate the situation of tight mine 'extraction and excavation' and improve the utilization rate of extraction drilling, has significant economic benefits, and is particularly suitable for single coal seam mining or high gas and outburst mines without special gas extraction roadways.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Secondary hole sealing method for underground coal mine gas drainage drill hole

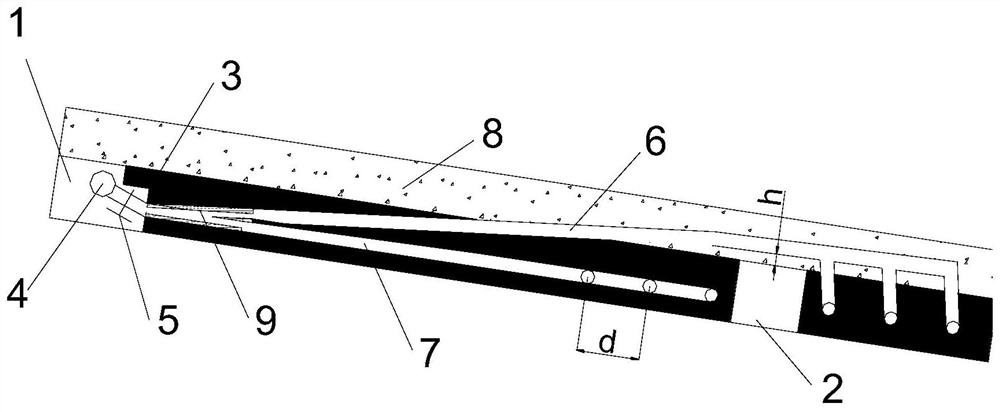

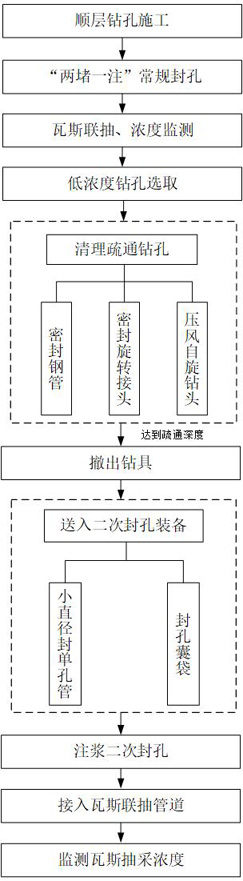

ActiveCN113756742AIncrease extraction concentrationImprove extraction efficiencyMining devicesGas removalSlagCoal

The invention discloses a secondary hole sealing method for an underground coal mine gas drainage drill hole. The secondary hole sealing method comprises the following steps that (1) a bag type grouting hole sealing device and a two-blocking one-injecting hole sealing process are adopted for implementing first-time hole sealing and continuous drainage; (2) during gas drainage, a low-concentration gas drainage drill hole is selected, and a connected gas drainage pipeline is disconnected; (3) a sealing steel pipe is connected with a compressed air self-rotating drill bit and then inserted into a first-time hole sealing pipe, a high-pressure air supply pipeline is connected, and coal slag in the hole sealing pipe and the drill hole is cleaned through the compressed air self-rotating drill bit and high-pressure air blowing; (4) the sealing steel pipe is withdrawn, and a second-time hole sealing device is plugged into the first-time hole sealing pipe to a designed position; (5) grouting is conducted on the second-time hole sealing device for implementing secondary hole sealing; and (6) a hole sealing pipe of the second-time hole sealing device is connected into the gas drainage pipeline for gas drainage. According to the secondary hole sealing method for the underground coal mine gas drainage drill hole, the application engineering cost is low, the process is relatively simple, the drainage efficiency is fully improved, the drainage time is shortened, and gas disasters are eliminated to the maximum extent.

Owner:山西兰花科创玉溪煤矿有限责任公司 +1

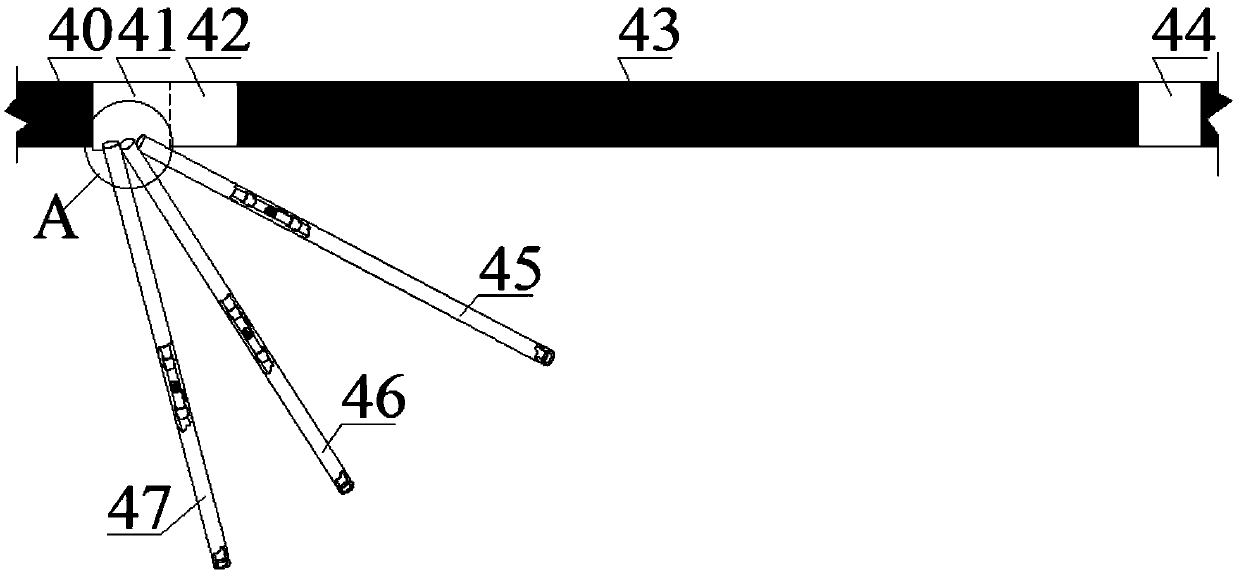

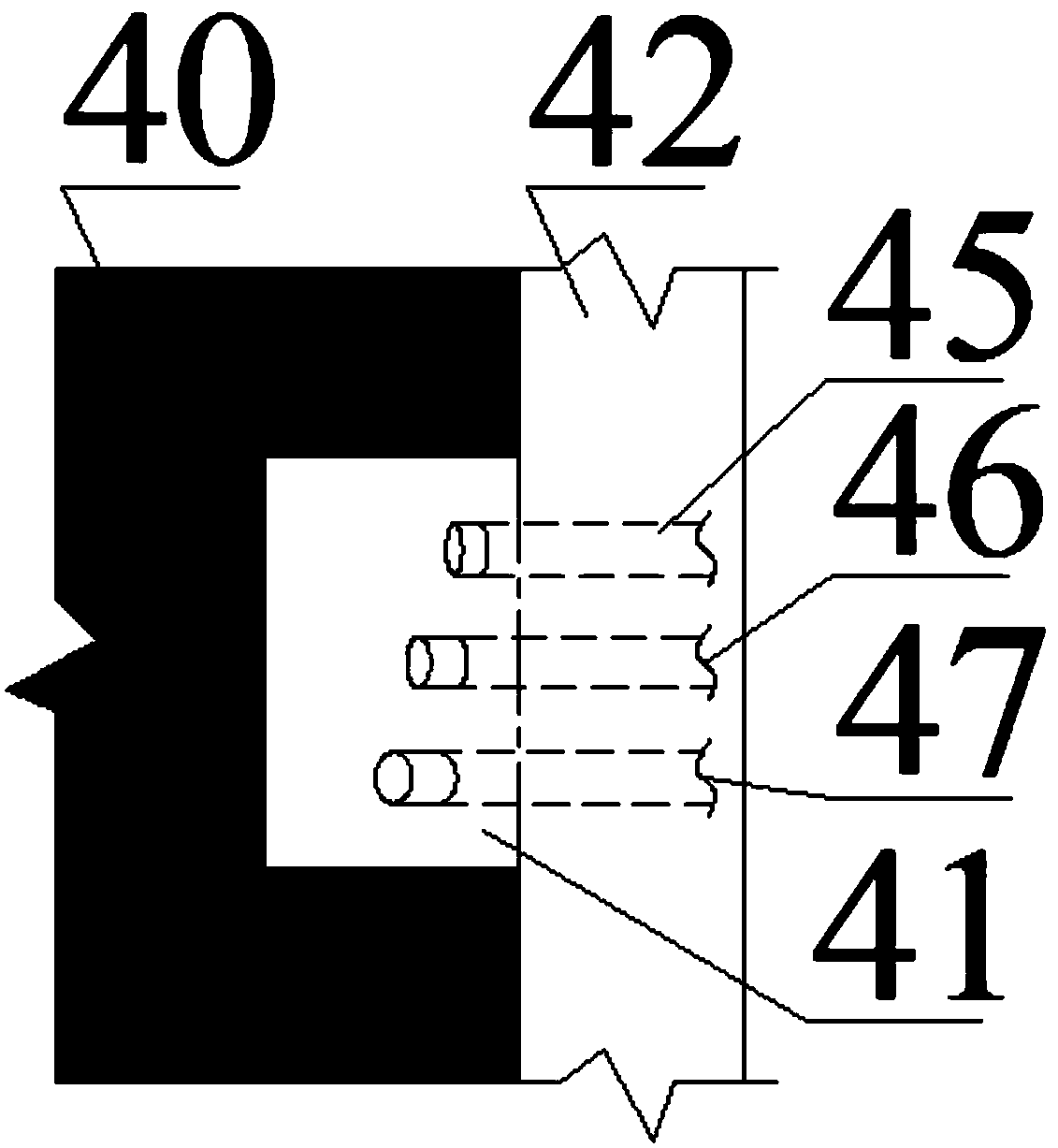

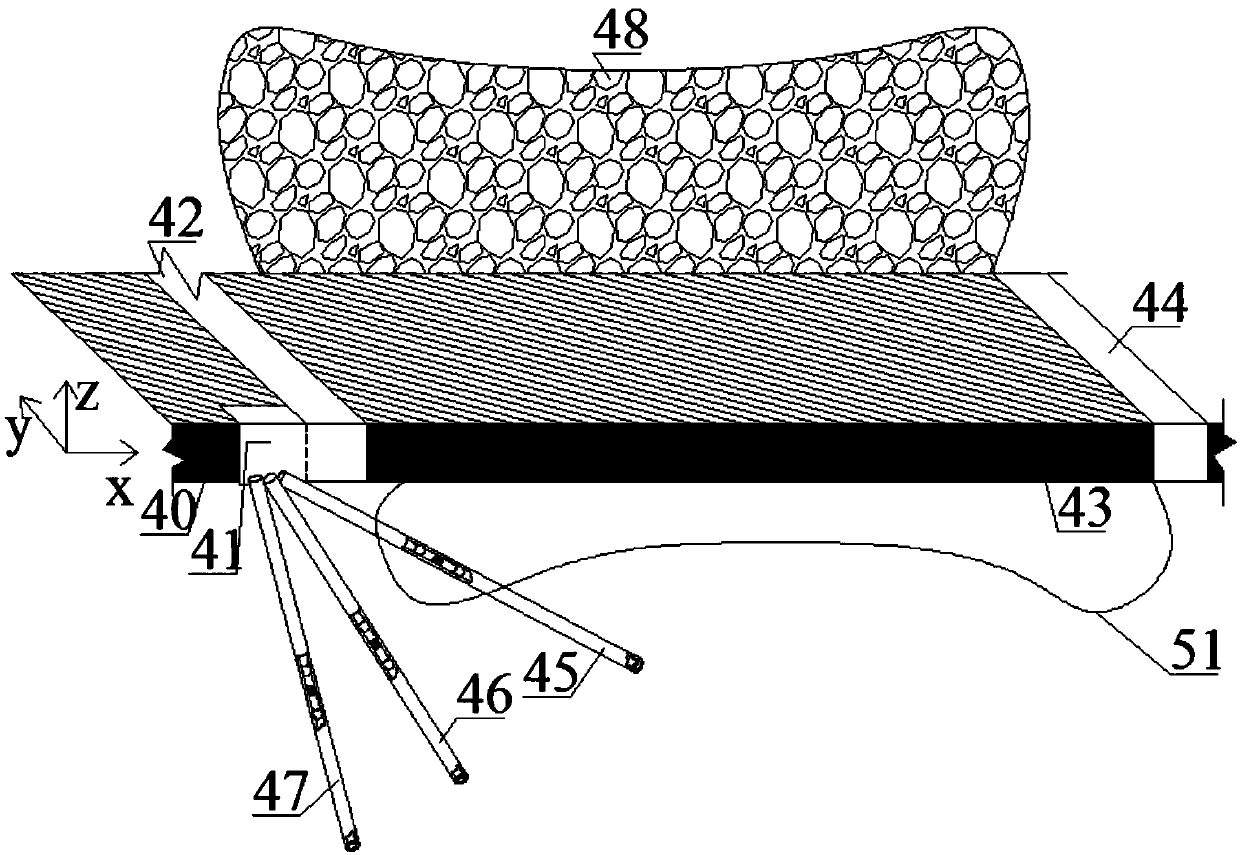

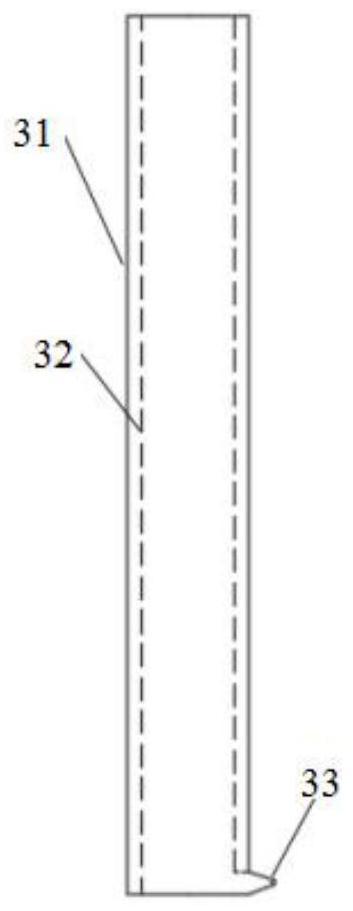

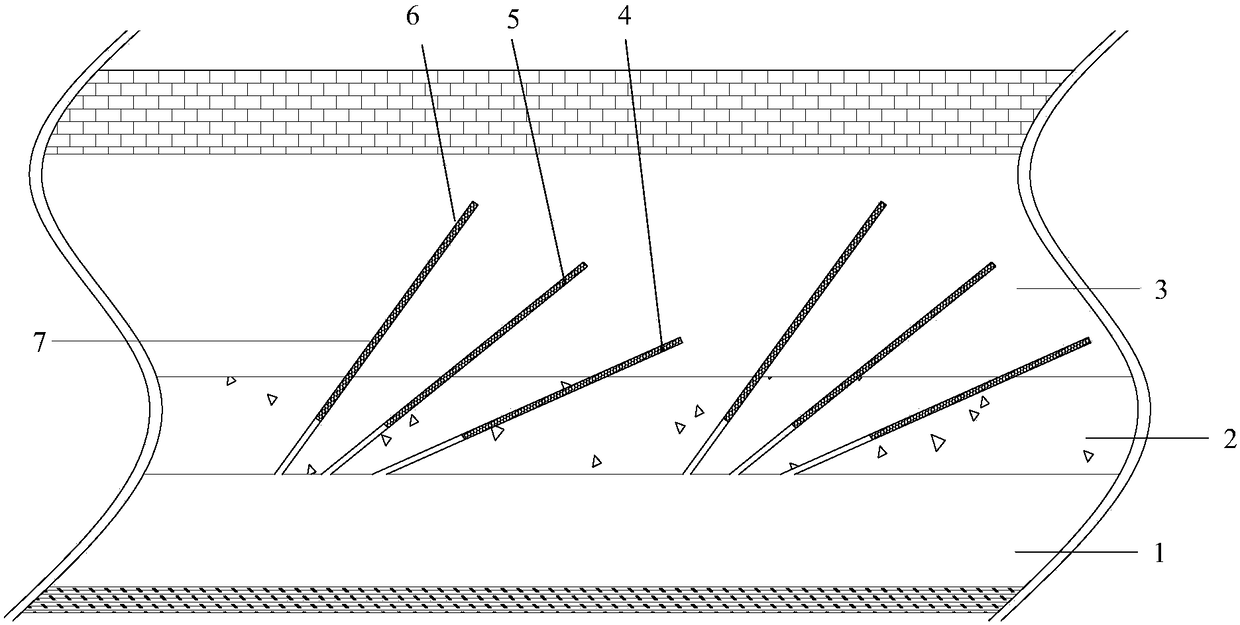

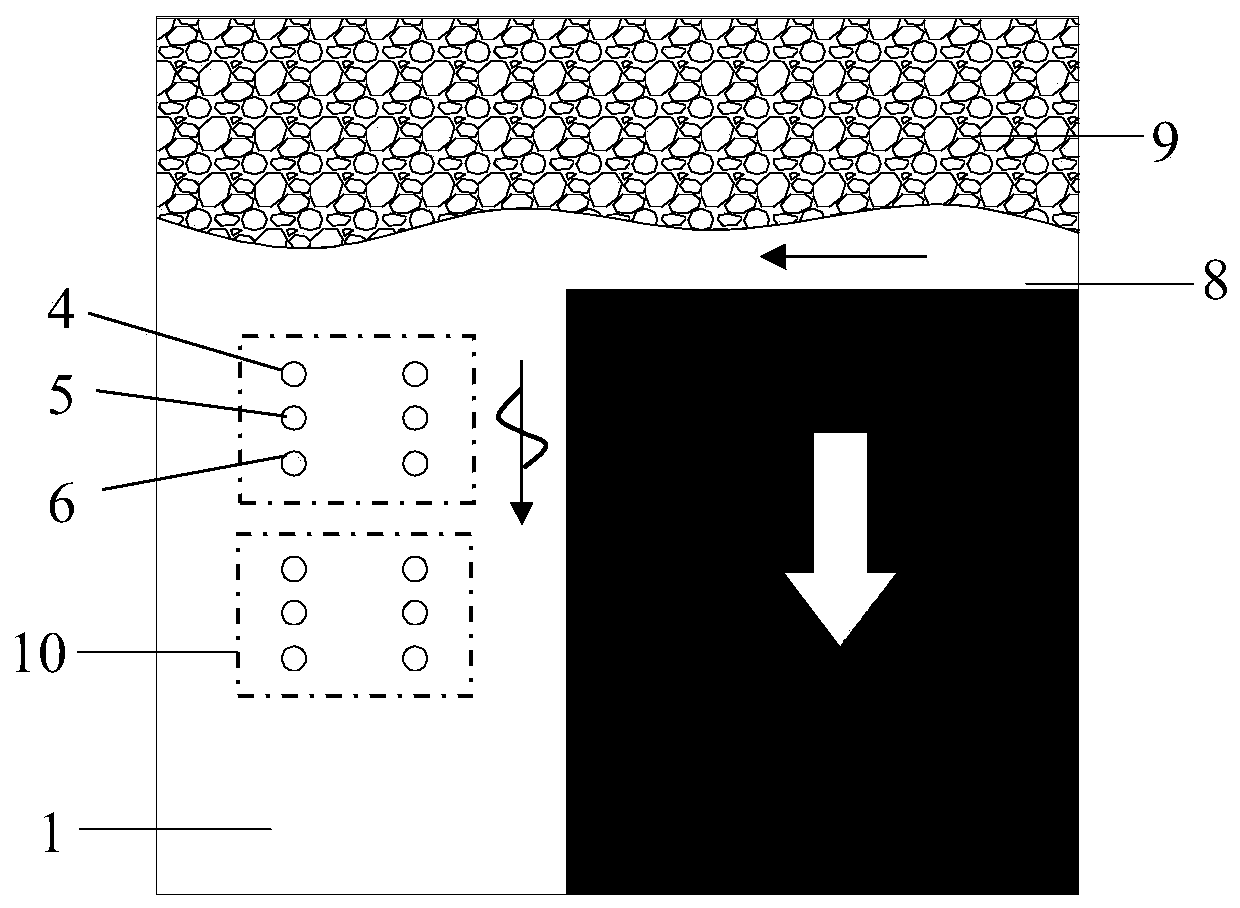

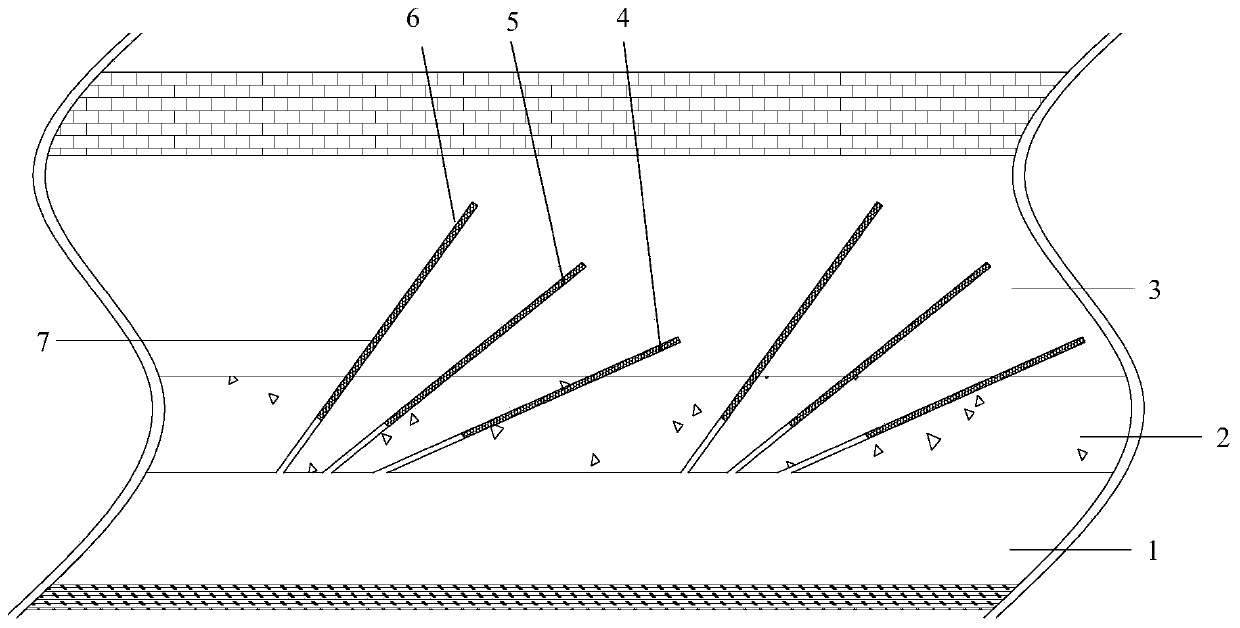

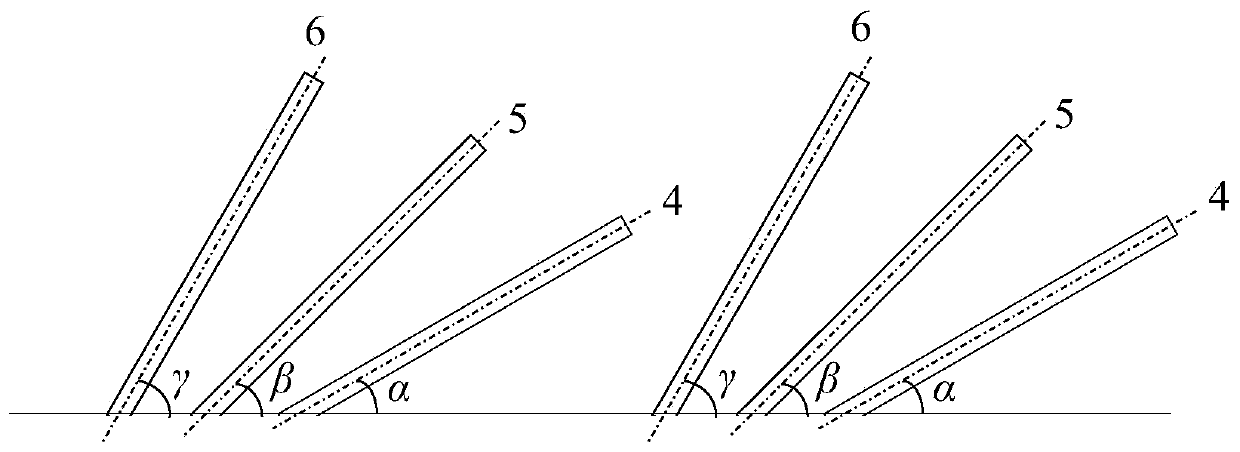

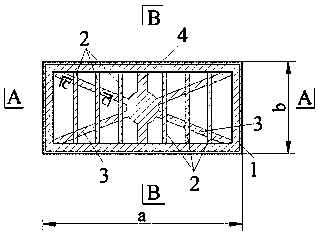

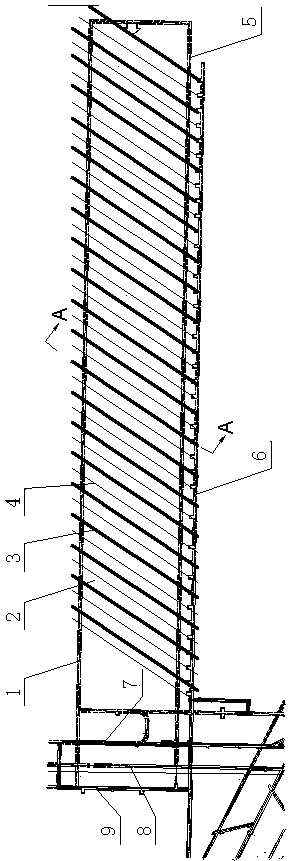

Space and time coordination control weakening method for hard coal seam roof

ActiveCN108252715AAvoid expansion stress cooling periodImprove drilling utilizationDisloding machinesUnderground miningDrill holeCoal

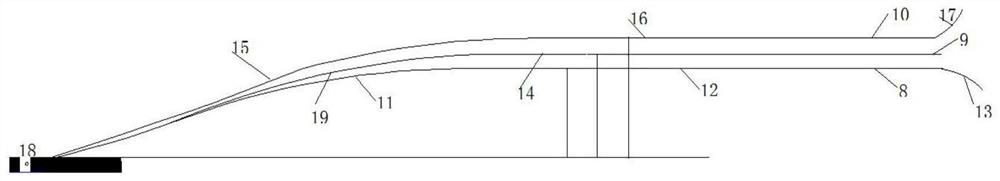

The invention discloses a space and time coordination control weakening method for a hard coal seam roof. The space and time coordination control weakening method comprises the steps that firstly, a plurality of advanced weakening fracturing drilling groups are drilled in sequence in the advance direction of the coal seam working face on the roof of a return air roadway, wherein each advanced weakening fracturing drilling group internally comprises a first row of fracturing drill holes, a second row of fracturing drill holes and a third row of fracturing drill holes which are arranged in sequence in the advance direction of the coal seam working face, and all the three rows of fracturing drill holes are inclined at different angles towards the direction of a goaf; and when the coal seam working face advances to the position of the advanced weakening fracturing drilling groups, the three rows of fracturing drill holes are filled with static crushing agent cartridges in sequence to realize gradual fracturing weakening of the roof rock layer. According to the method, the best effect of the cartridges is achieved by using the free surface to create a free face or a weakening layer, ''gradual weakening + overall fracture '' is achieved, and the space and time coordination fracturing of the drill holes with different tilt angles of the roof is realized, so that the roof caving efficiency is enhanced. The space and time coordination control weakening method for the hard coal seam roof is simple in structure, and the fracturing effect is good.

Owner:CHINA UNIV OF MINING & TECH

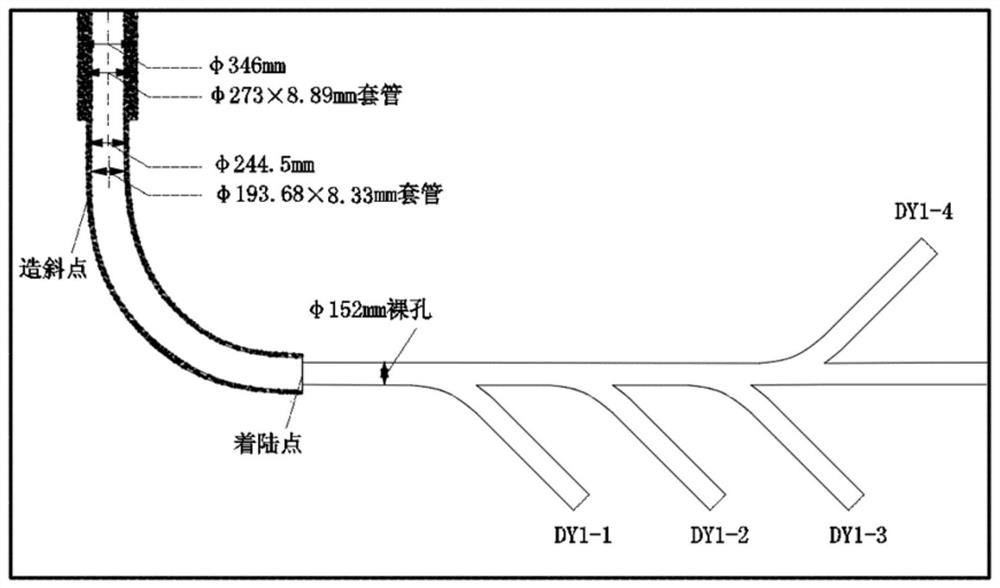

Ground-underground combined exploration and treatment method for mine geological anomalous body

InactiveCN113464203AImprove elimination effectEffective blockingMining devicesDirectional drillingDirectional drillingGeophysics

The invention discloses a ground-underground combined exploration and treatment method for a mine geological anomalous body. The method comprises the following steps of 1, exploration, wherein the position of the geological anomalous body is determined, that the geological anomalous body is communicated with gray water is determined, and the water burst risk exists, wherein 1.1 mine underground exploration is conducted, 1.2 three-dimensional seismic exploration is conducted, an anomalous area is delineated, and 1.3 ground exploration is conducted mainly by drilling a hole, and a three-opening well body structure is adopted for the drilled hole; and 2, treatment, wherein 2.1 ground treatment is conducted, and 2.2 underground treatment is conducted. According to the ground-underground combined exploration and treatment method for the mine geological anomalous body, directional drilling of the ground and directional long drilling of an underground bottom plate along the layer are combined according to engineering practice, exploration and treatment of the mine geological anomalous body are conducted, the effects that the exploration and treatment time is advanced, the exploration and treatment space range is large, the exploration accuracy is high, the overall elimination effect of water damage hidden danger is good, a water guide fracture channel is effectively blocked, and the treatment effect is obvious are achieved.

Owner:鄂尔多斯市华兴能源有限责任公司 +2

A spatio-temporal collaborative control weakening method for hard coal seam roof

ActiveCN108252715BAvoid expansion stress cooling periodImprove drilling utilizationDisloding machinesUnderground miningEngineeringCoal

The invention discloses a space and time coordination control weakening method for a hard coal seam roof. The space and time coordination control weakening method comprises the steps that firstly, a plurality of advanced weakening fracturing drilling groups are drilled in sequence in the advance direction of the coal seam working face on the roof of a return air roadway, wherein each advanced weakening fracturing drilling group internally comprises a first row of fracturing drill holes, a second row of fracturing drill holes and a third row of fracturing drill holes which are arranged in sequence in the advance direction of the coal seam working face, and all the three rows of fracturing drill holes are inclined at different angles towards the direction of a goaf; and when the coal seam working face advances to the position of the advanced weakening fracturing drilling groups, the three rows of fracturing drill holes are filled with static crushing agent cartridges in sequence to realize gradual fracturing weakening of the roof rock layer. According to the method, the best effect of the cartridges is achieved by using the free surface to create a free face or a weakening layer, ''gradual weakening + overall fracture '' is achieved, and the space and time coordination fracturing of the drill holes with different tilt angles of the roof is realized, so that the roof caving efficiency is enhanced. The space and time coordination control weakening method for the hard coal seam roof is simple in structure, and the fracturing effect is good.

Owner:CHINA UNIV OF MINING & TECH

One-hole multi-purpose method for ground drilling to realize water damage prevention and surface subsidence control

InactiveCN108999634BAvoid safety hazardsThe grouting filling process is easy to controlMaterial fill-upHorizonFracture zone

The invention discloses a hole multi-functionalization method for realizing water damage prevention and surface settlement control through a surface borehole and belongs to the coal mine green miningtechnical field. According to a grouting filling method, a single ground grouting borehole is formed downward from the ground; overlying rock located at different horizons are grouted through the grouting borehole; grouting horizons in a curved sunk zone include a low-bed-separation horizon and a high-bed-separation horizon; overlying rock fractures in a fracture zone are grouted, so that a water-blocking layer can be formed to cut off a water bursting channel of underground bed separation water damage, and therefore, secondary roof water damage can be prevented; a larger proportion of grout is adopted as the filling material of the low-bed-separation horizon so as to form a high-volume-weight rock stratum filling body; and filling bodies formed by the low-bed-separation horizon and the high-bed-separation horizon in the curved sunk zone together act on the control of surface subsidence. According to the method of the invention, a multi-horizon grouting filling project is realized through the same grouting borehole, and therefore, the utilization rate of the borehole is high, cost is low, a filling rate is improved, the subsidence-reducing rate of the surface settlement is improved, and roof water damage prevention and control is achieved.

Owner:CHINA UNIV OF MINING & TECH

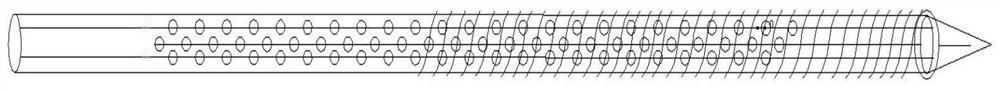

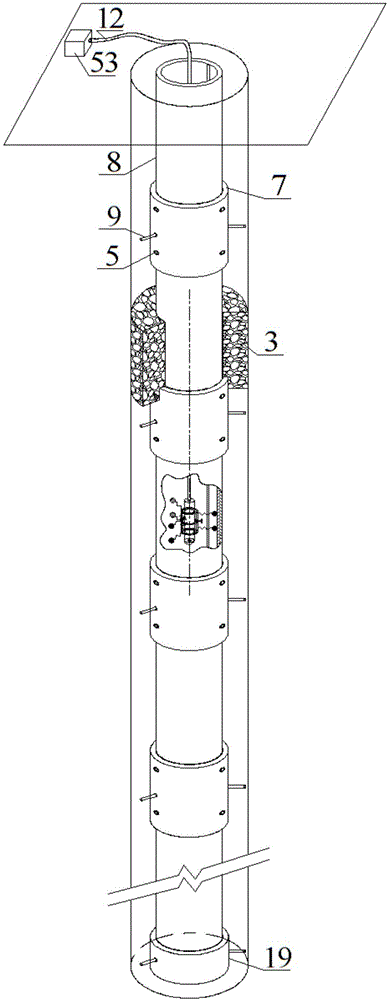

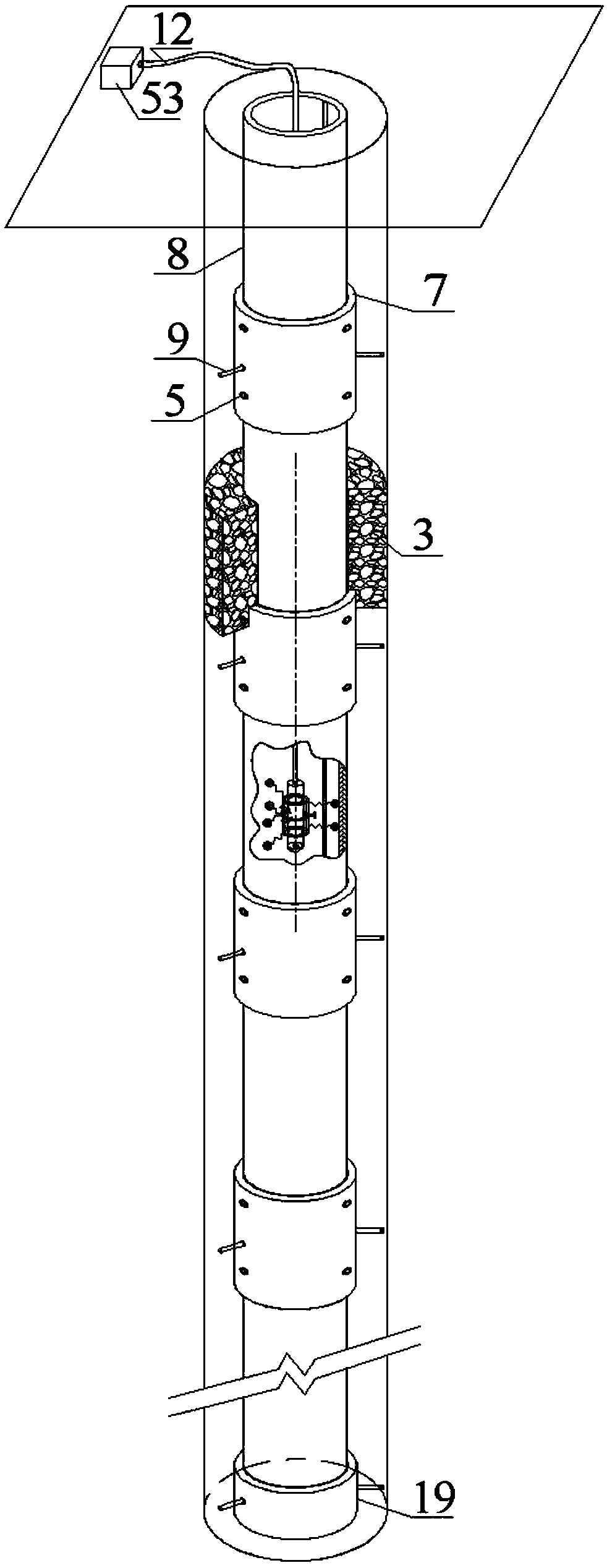

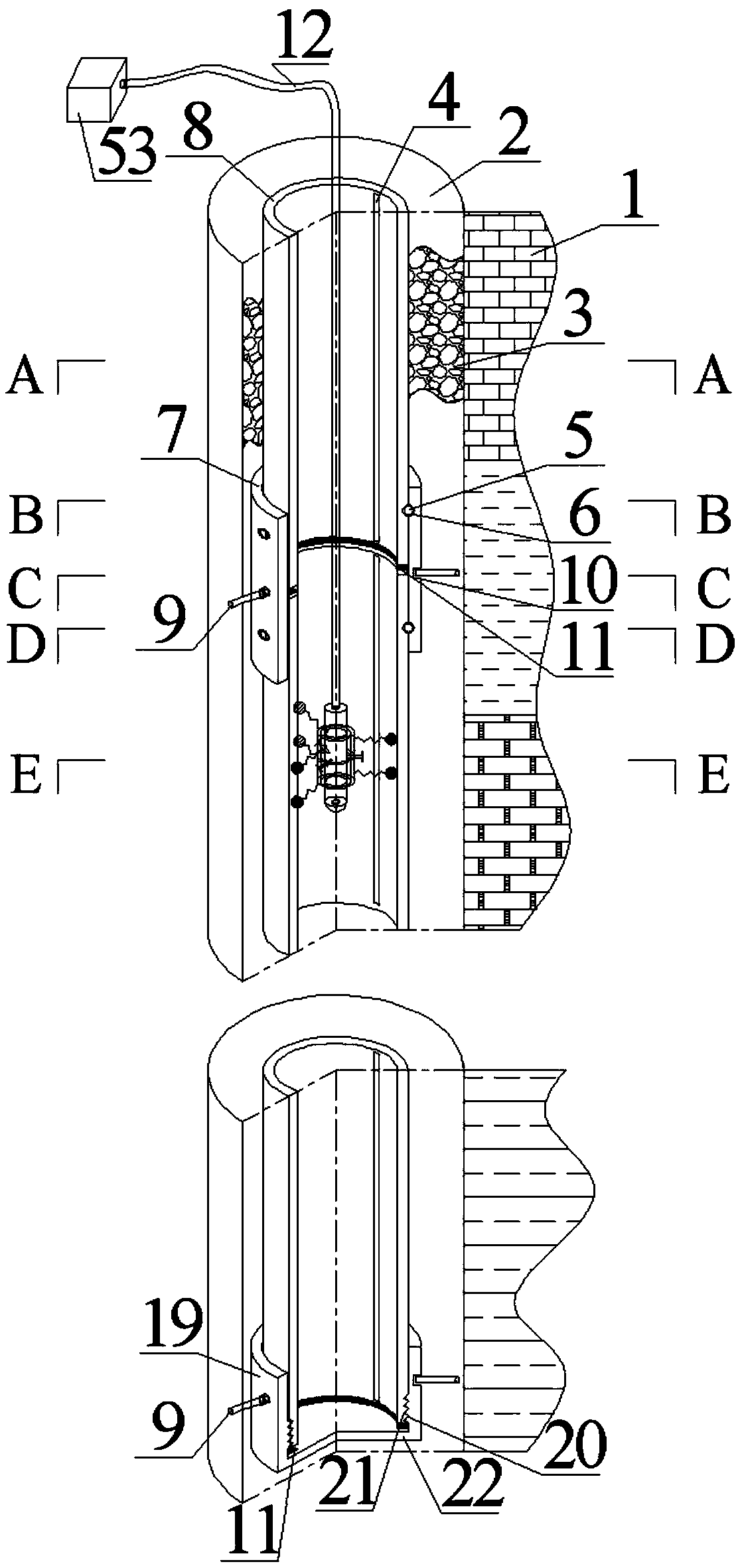

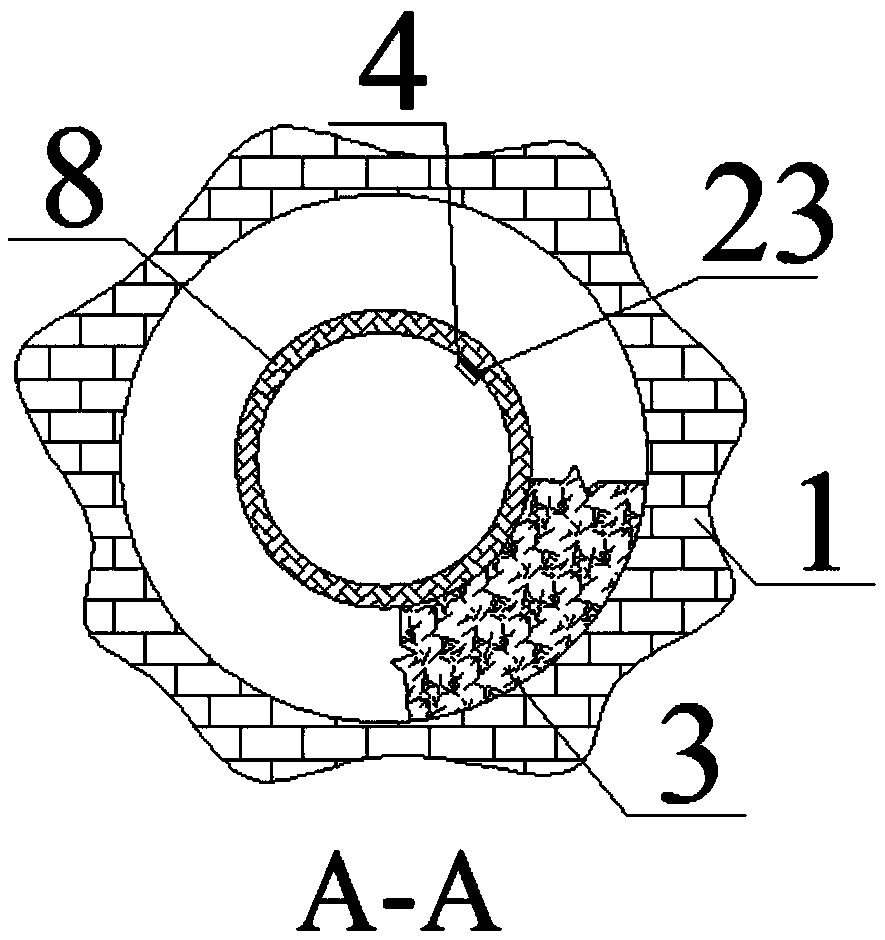

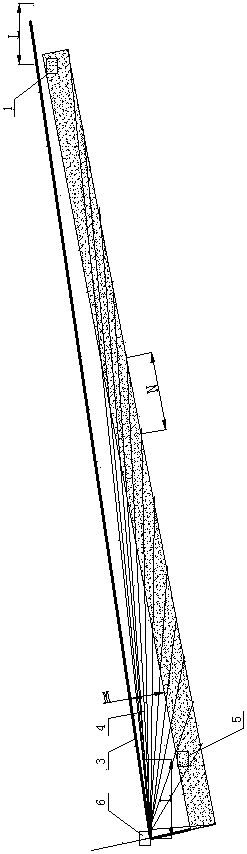

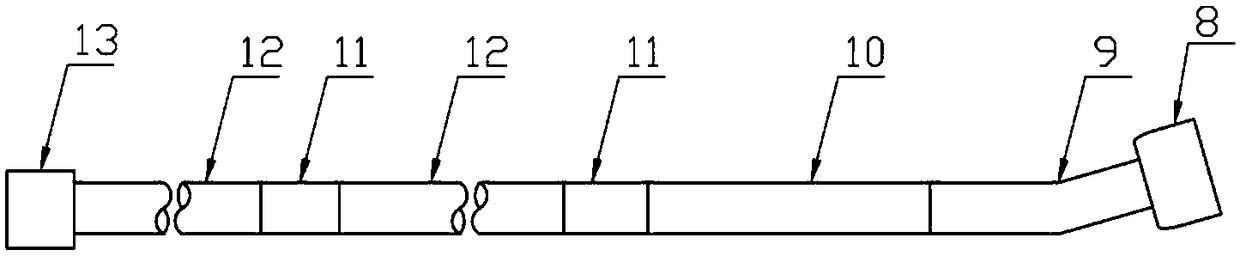

Complex roof rock stratum high-position directional long drill hole construction device

PendingCN112901073AShorten the production cycleIncrease layout costSurveyDirectional drillingDrill holeGeotechnical engineering

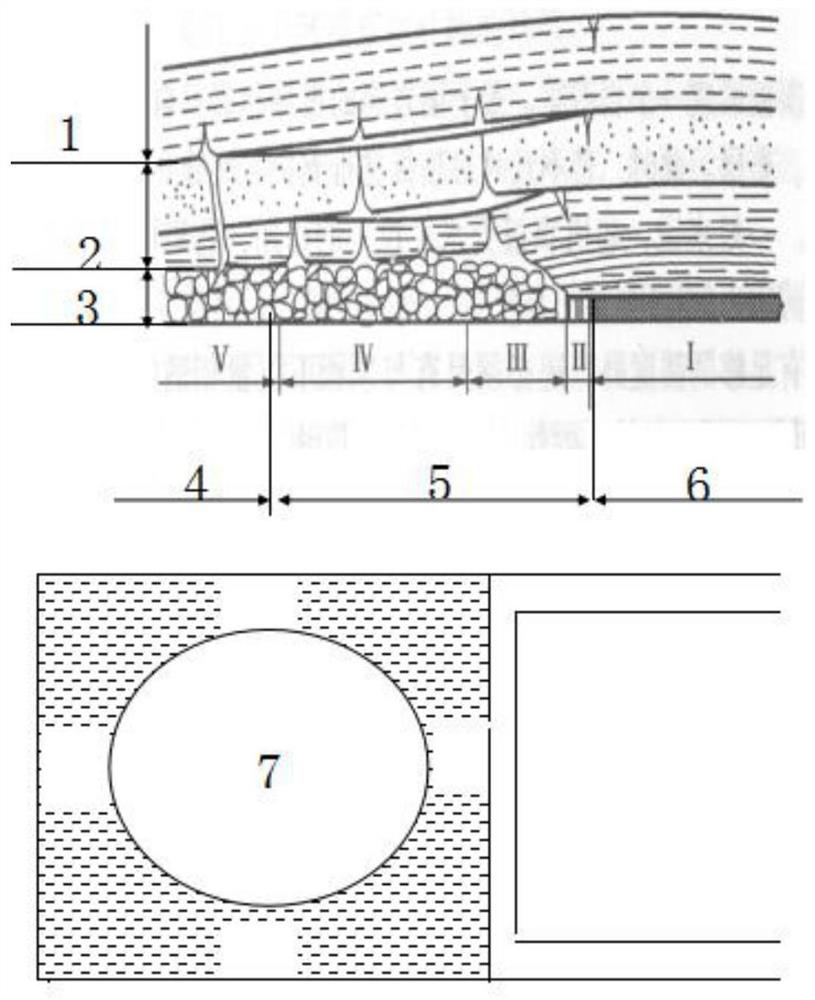

The invention discloses a complex roof rock stratum high-position directional long drill hole construction device. The complex roof rock stratum high-position directional long drill hole construction device is characterized by comprising a water feeder, a drill rod, a first steering stub, a first measuring exploring tube, an upper non-magnetic drill rod, a second measuring exploring tube, a lower non-magnetic drill rod, a second steering stub and a drill bit, wherein one end of the water feeder is connected to the drill rod; the drill rod is connected to the first measuring exploring tube through the first steering stub; the first measuring exploring tube is connected to the upper non-magnetic drill rod; the upper non-magnetic drill rod is connected to the lower non-magnetic drill rod through the second measuring exploring tube; the lower non-magnetic drill rod is connected to the second steering stub; and the drill bit is arranged at one end of the second steering stub; and the other end of the water feeder is provided with a communication cable.

Owner:HENAN POLYTECHNIC UNIV

A rectangular drilling stress monitoring device and monitoring method

ActiveCN108426663BHigh measurement accuracyEasy to determine the direction of stress monitoringConstructionsForce transducersStress sensorForce sensor

The invention provides a rectangular drilling stress monitoring device and method. The monitoring device comprises a rectangular drilling bit, a drilling pipe and a rectangular drilling stress monitor. The rectangular drilling bit includes an outer frame, and the outer frame is internally provided with forward cutters, diagonal cutters and a center guide cutter. The rectangular drilling stress monitor includes an upper cover, a lower cover, stress sensors and digital displayers. The monitoring method includes the steps of forming guide drilling holes in advance, forming rectangular drilling holes and installing the rectangular drilling stress monitor for monitoring. The monitoring device can effectively overcome the shortcomings that the test direction of traditional drilling stress gaugesis unclear and the test value is inaccurate, can accurately measure surrounding rock stress values at any angle in the vertical direction and the horizontal direction and can provide more reliable data for on-site mine pressure disaster prediction and forecast. The device and the implementation method provide a more reliable guarantee for monitoring of surrounding rock stress in coal mines in China.

Owner:SHANDONG UNIV OF SCI & TECH

A drilling and anchoring structure for monitoring cracks in the surrounding rock of the floor and its construction method

ActiveCN106321001BSafe and stable drillingAvoid Drilling and Patching SituationsConstructionsBorehole/well accessoriesFailure rateButt joint

The invention discloses a drill hole anchoring structure for monitoring floor surrounding rock fractures and a construction method thereof. Transparent hollow pipes are connected in a butt joint mode section by section through butt joint sealing assemblies and a bottom sealing assembly and then fed into a drill hole; after a gap between the drill hole and the transparent hollow pipes is subjected to grouting anchoring, drill hole surrounding rock fractures at different scale positions on a measuring ruler are recorded through a detecting and positioning assembly. The rock stratum development condition in the drill hole is directly read, and the drill hole anchoring structure has the advantages of being reasonable in integral structural design, easy to construct, safe, stable, low in drilling failure rate, capable of providing clear images, capable of meeting the requirement for repeated observation and the like; the fracture positions and forms on a drill hole grouting body are directly read through the transparent hollow pipes and directly reflect the positions of floor surrounding rock fractures in the drill hole, and compared with traditional distance position data acquired indirectly, errors are greatly reduced; the drill hole in the same position is used for observing the progress of fracture development at different stages, data is real and reliable, and the position and development condition of rock stratum change can be rapidly and precisely obtained.

Owner:XIAN UNIV OF SCI & TECH

A Secondary Hole Sealing Method for Dealing with the Fractured Area of Drilling Through Layers

ActiveCN103758483BExtended extraction periodReduce drilling air leakageSealing/packingHigh concentrationAir compression

The invention discloses a secondary hole sealing method for treating a broken area after extraction of a crossing hole, and belongs to the methods for improving gas extraction concentration in a bedding hole. The secondary hole sealing method is especially suitable for the broken area after the extraction of the crossing hole. The bedding hole is sealed for the first time, and a first-time drilled hole sealing section is formed. Under the action of air pressure of an underground air compression system, a solid particle conveyor conveys solid particles into the bedding hole through a material blowing pipe. The underground air compression system is connected with the material blowing pipe, and air is compressed into the hole for a while. In the process of blowing the solid particles into the hole, the solid particles initially plug the fractures, caused by the crossing hole, of the broken area after the extraction around the bedding hole, and hole air leakage is reduced. The air is compressed by the underground air compression system through the material blowing pipe, the solid particles in the hole are further blown into the fractures of the broken area after the extraction, then the hole air leakage is reduced, the bedding hole high concentration gas extraction period is prolonged by more than one month, the hole use ratio is improved, and coal recovery safety is guaranteed.

Owner:CHINA UNIV OF MINING & TECH +1

A coupling fracturing method for hard coal seam roof

ActiveCN106761740BIncrease the number of cracksImplementing Directed Complexity ExtensionsDisloding machinesFracture zoneSlurry

Provided is a coupling fracturing method for a hard coal bed roof. A drilling machine is utilized for drilling fracturing drill holes inside the hard roof till the design position, specifically, each static fracturing guide drill hole is formed between every two pulse hydraulic fracture drill holes so as to form a fracturing system; the fracture drill holes are connected to a pulse water injection pump through an isometric flow distributor with adjustable frequency, and the static fracturing drill holes are filled with static crushing agent slurry; under the action of expansion force of the static crushing agent slurry, initial cracks formed around the drill holes are monitored, released heat irradiates continuously towards the portions around the drill holes, a similarly elliptical temperature field is generated, and the elasticity modulus of a rock stratum is reduced; and under the action of hydraulic pressures of different frequencies, a fracture zone, a fatigue zone and an original stress zone are formed in the positions, around the fracture drill holes, of the rock stratum, when pressure water flows to the rock stratum bearing heat conduction along the cracks, the water and heat effect weakens the strength of the rock stratum, and the through time for crack zones among the drill holes is shortened. The method can sufficiently improve the utilization rate of the drill holes, operation is easy, and construction is safe and reliable.

Owner:CHINA UNIV OF MINING & TECH

A four-period-five-purpose hole-drilling high-efficiency gas extracting process

Owner:HENAN POLYTECHNIC UNIV

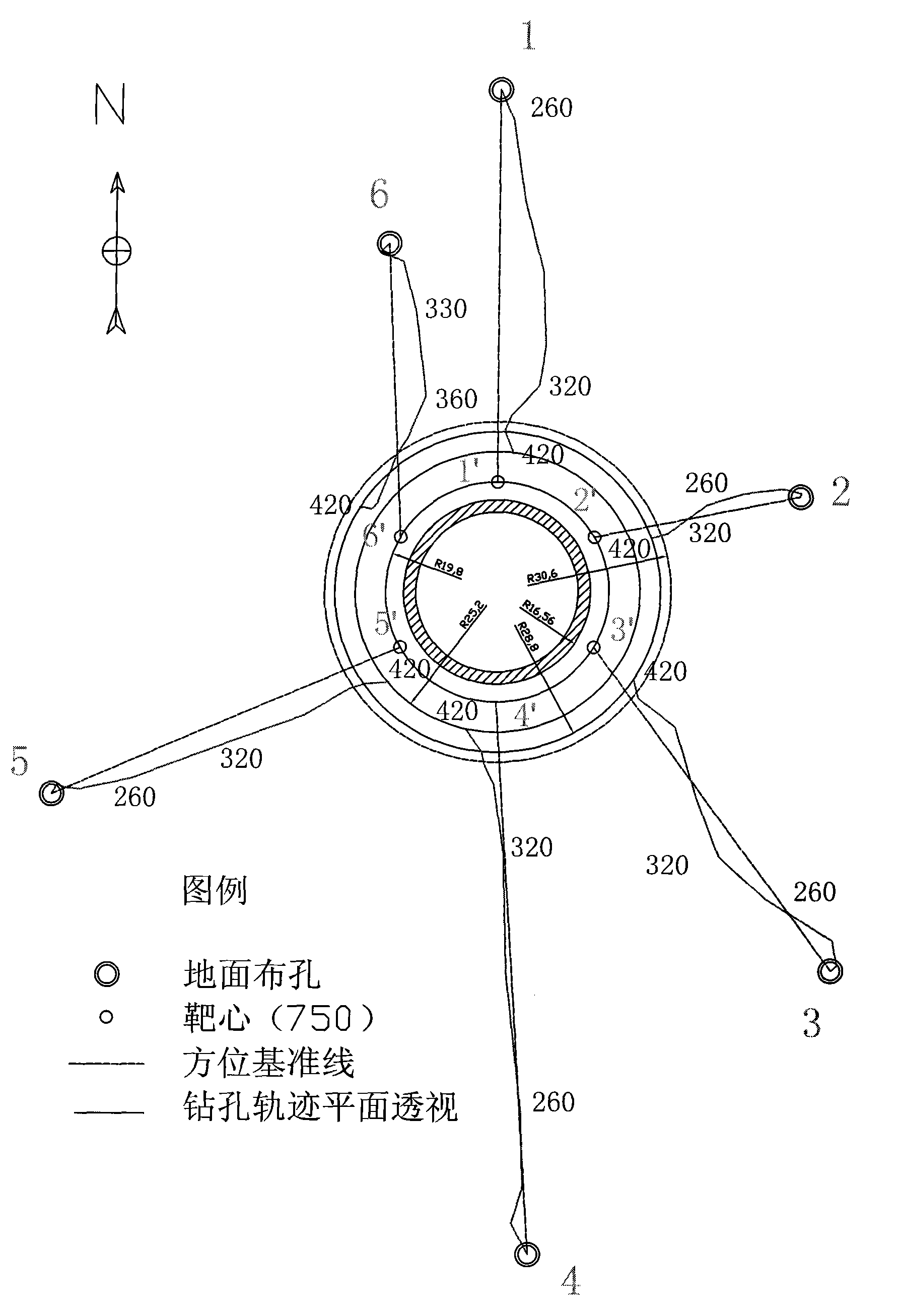

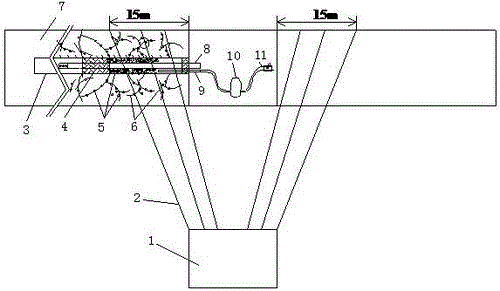

Construction method of directional hole in upward penetration layer on top plate for gas drainage in underground coal mine

ActiveCN106285477BSave recovery preparation periodLarge hole diameterDrill bitsDirectional drillingFracture zoneDrill site

The invention relates to a method for constructing a directional hole in an upward penetration layer on an underground mining gas drainage roof of a coal mine. The present invention utilizes the drilling field that has been excavated into the air roadway at the adjacent working face of the working face to be mined, and utilizes equipment such as pilot directional drilling tools and impact compound reaming drilling tools, and adopts multi-stage rotary reaming technology, sliding directional drilling technology, and composite drilling technology. Directional drilling technology and percussion compound reaming technology drilled to obtain directional holes on the roof through the layer, so that they can enter the roof mining fracture zone and abscission zone in advance, and extend for a long distance and large diameter. After the drilling construction, when the working face to be mined is recovered, the upward fissures formed by the mining on the roof layer are connected with the directional holes in the upward penetration layer on the roof. The use of dynamic gas drainage solves the shortcomings of the current mining gas drainage drilling, such as small hole diameter, short extension distance of the fissure zone, low drilling efficiency, high cost, and long construction period, and improves the effect of mining gas drainage.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

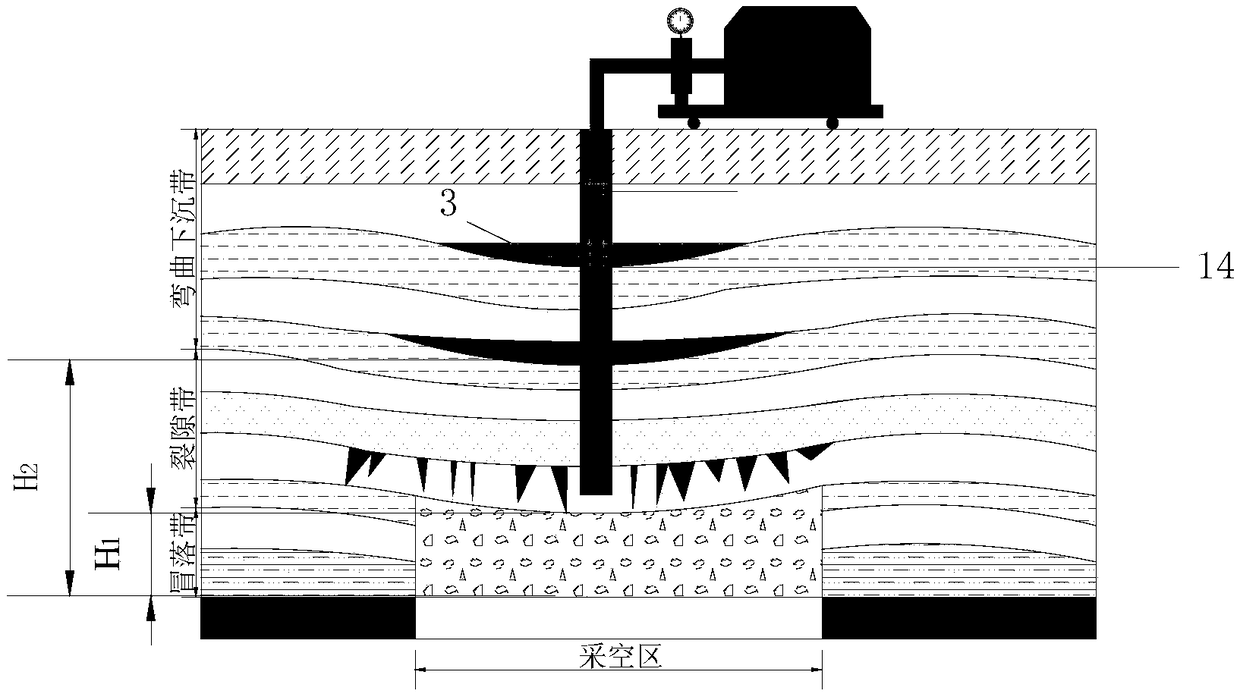

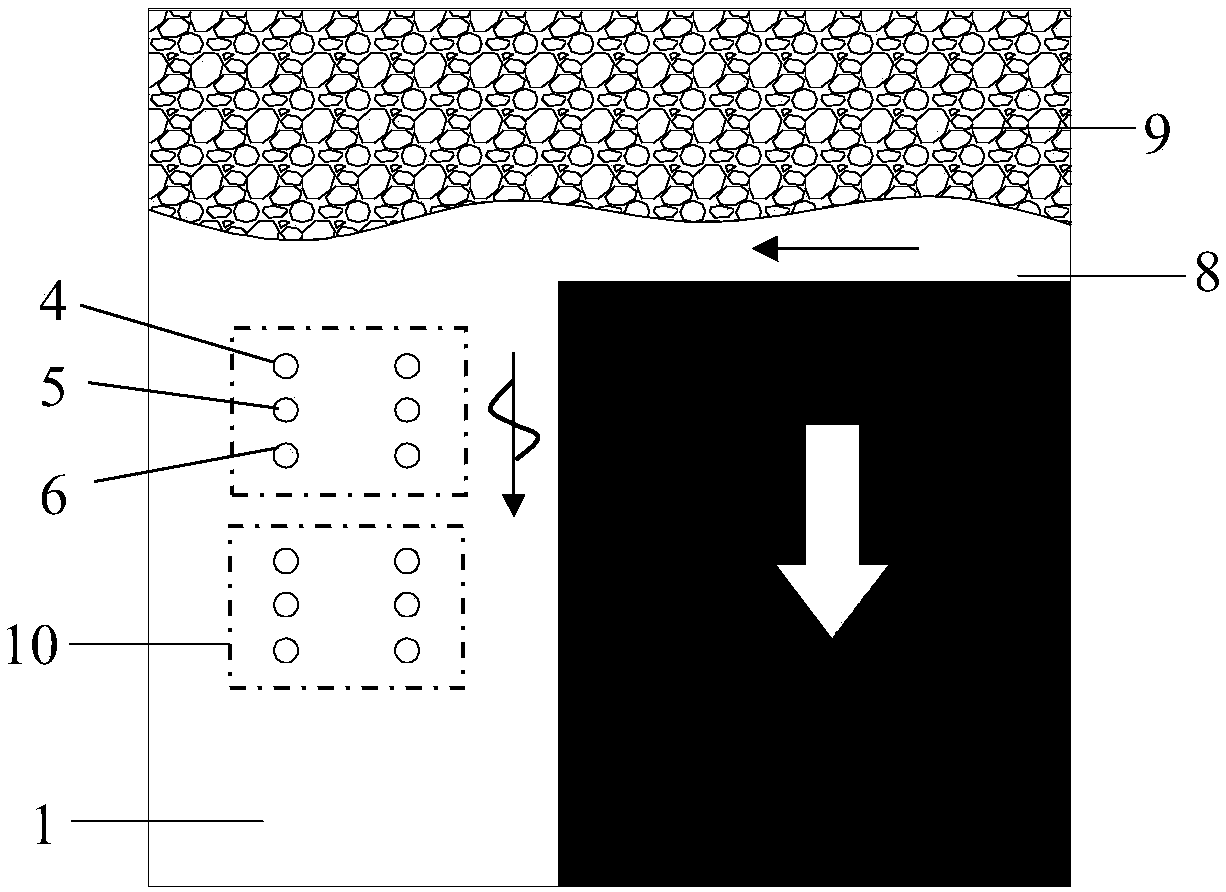

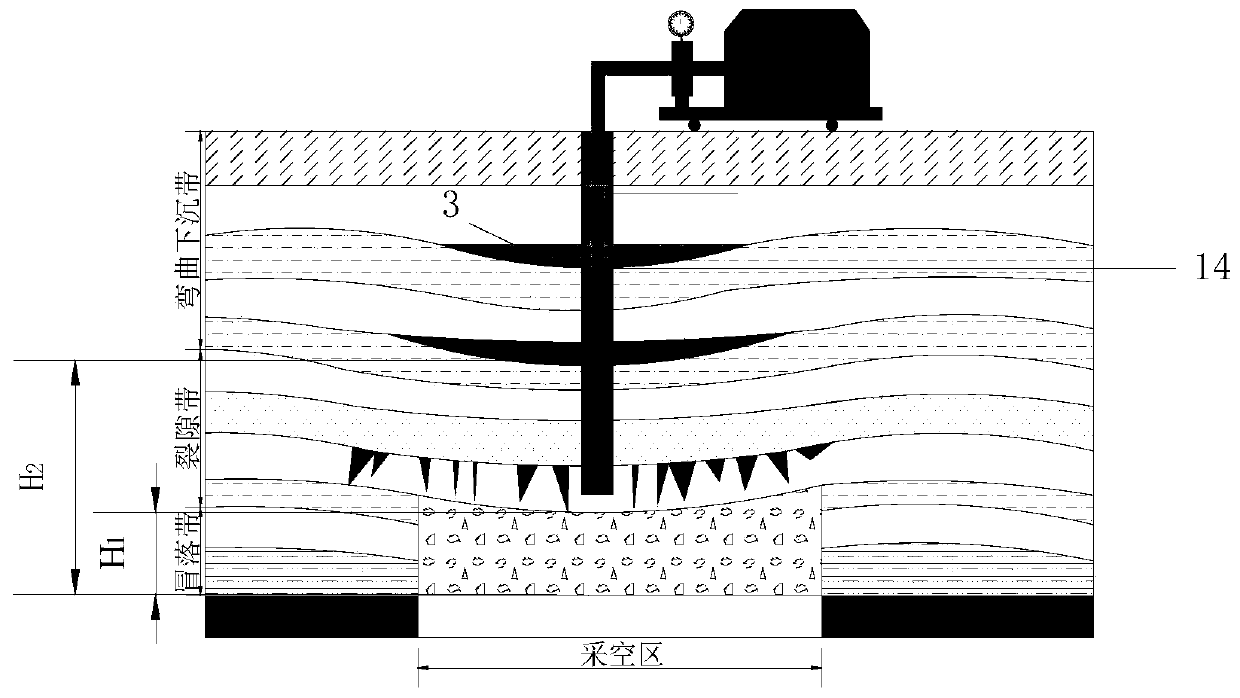

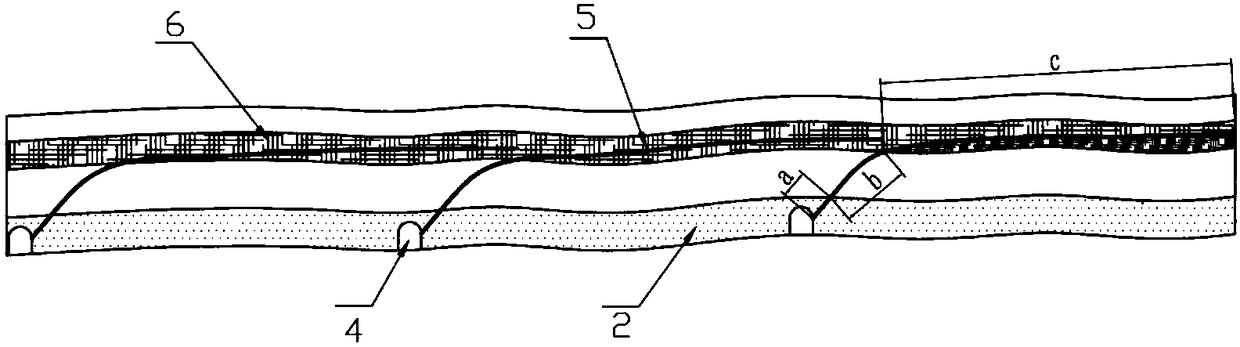

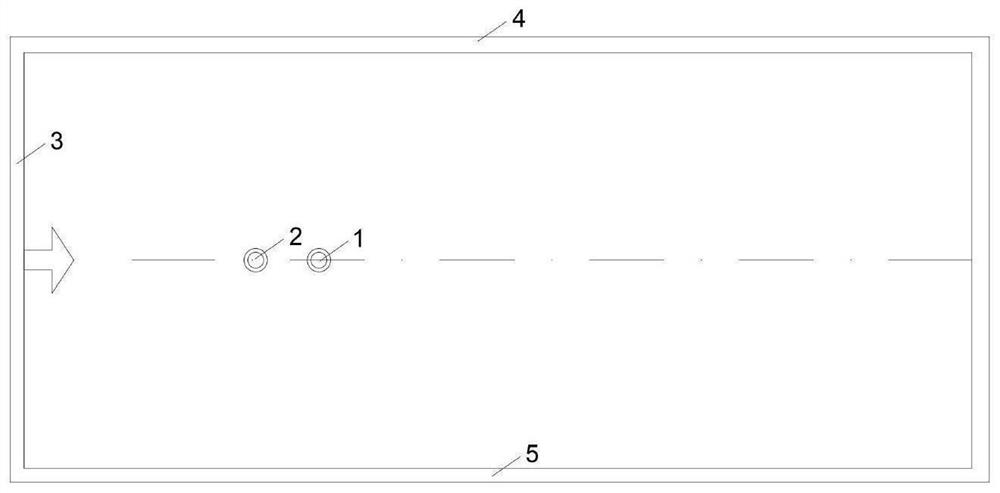

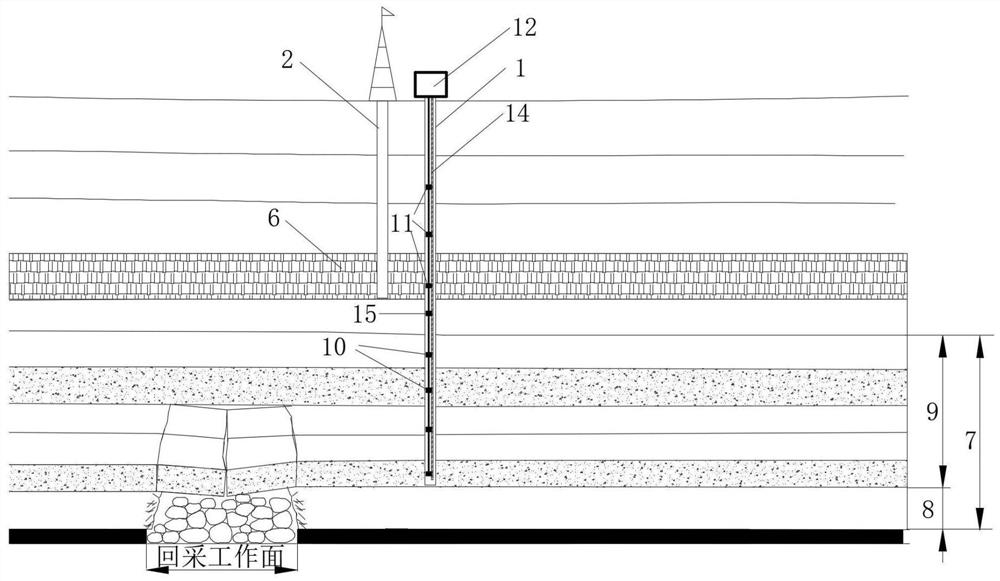

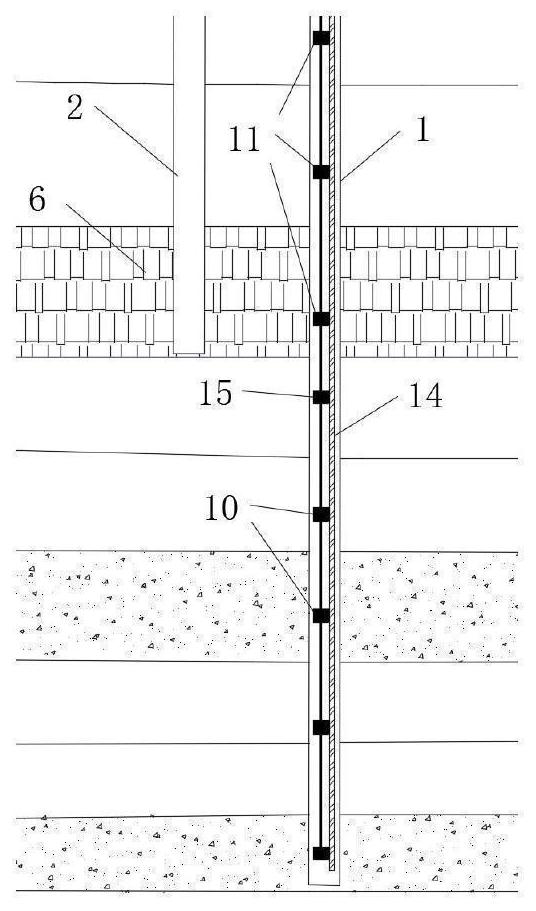

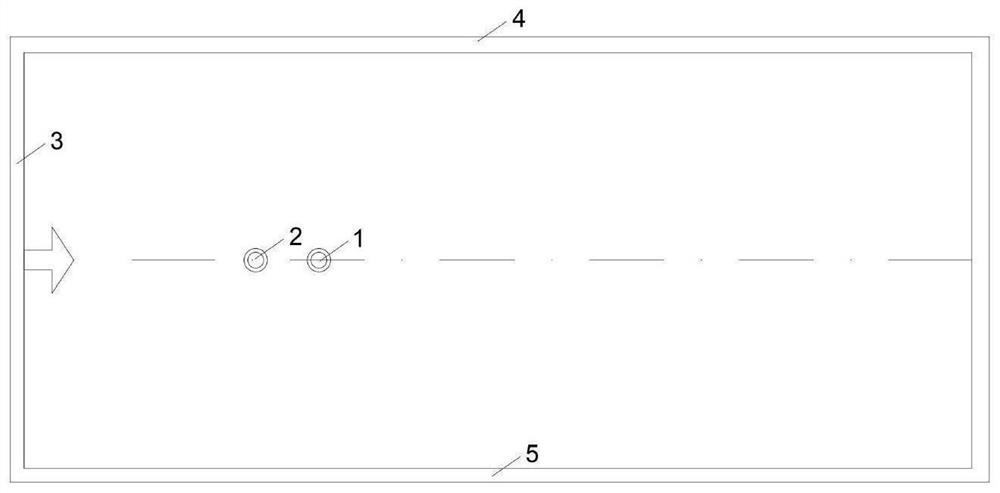

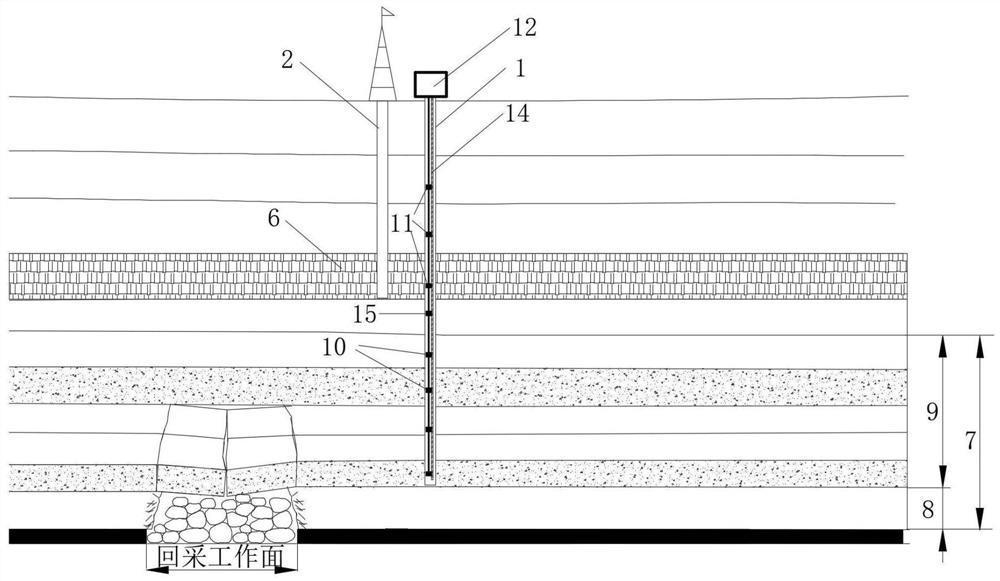

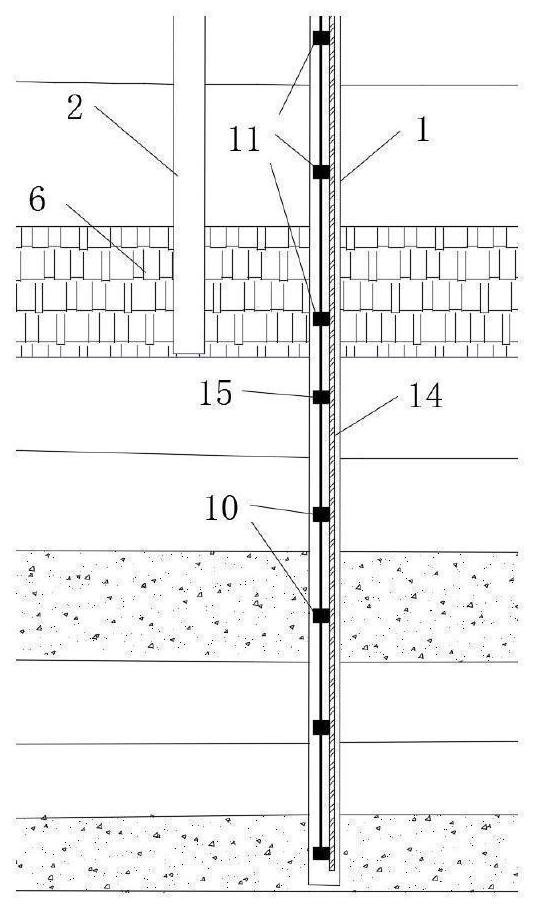

Ground double-hole combined anti-water inrush method based on overlying rock movement monitoring and delaminated water release

ActiveCN113685132BPreventing Water Inrush DisastersEvacuation scienceSurveyConstructionsSoil scienceEarth surface

The invention discloses a ground double-hole joint water inrush prevention method for monitoring the movement of overlying rock and releasing the detached layer water, which is suitable for the treatment of the overlying detached layer flood after the mining of the strata rich in water. In the middle of the working face corresponding to the ground surface along the strike, two adjacent drill holes for monitoring the movement of rock formations and drilling holes for releasing water from the layer are constructed, and the drilling holes for monitoring movement of rock formations are arranged to monitor the internal movement information of the overlying rock strata during the mining process of the working face. Development of detachment layer, detachment of detachment water Drilling is based on the timing of detachment generation fed back by the monitoring of rock stratum movement inside the drill hole, and drilling and penetration are carried out to achieve staged and controlled detachment layer of water to prevent water inrush on the working face. By monitoring the changes of the arrangement of measuring points in the upper and lower layers of the aquifer bottom interface, the drilling depth, water drainage and penetration holes are guided. Through the combination of the internal movement monitoring drilling of the rock formation and the separation water drainage drilling, the utilization rate of the separation water drainage drilling can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

A softening method of hard roof and coal seam controlled blasting

Disclosed is a porous control method for blasting softening of a hard top plate and a coal seam. The method comprises the following steps that a drilling arrangement scheme is determined according to the hard top plate and the coal seam at an underhole place to be blasted, that is to say, three groups of blast-holes are formed along the overall length of a working surface in an up-down parallel mode at equal intervals, wherein the uppermost group of blast-holes and the lowermost group of blast-holes are both rows of control hole groups, the middle group of blast-holes is a row of blasting hole groups, and each control hole group comprises several control holes which are formed along the overall length of the working surface in a parallel mode at equal intervals. Thus, according to the method, the overall blasting softening effects on the hard top plate and a coal body are good; by conducting blasting softening treatment on the hard coal rock mass covering at the front of the working surface in advance, the limit caving step of the top plate at the rear portion of the working surface is reduced, and puking, nicking and other accidents are prevented from occurring on a mined surface; the method has the advantages of being high in drilling hole utilization rate, low in engineering workload, high in blasting safety factor and the like and can be applied to softening and caving control of various hard top plates and coal bodies under coal mines.

Owner:HENAN POLYTECHNIC UNIV

Ground double-hole combined water inrush prevention method for overlying strata movement monitoring and bed separation water drainage

ActiveCN113685132AEvacuation scienceImprove drilling utilizationSurveyConstructionsDrill holeSoil science

The invention discloses a ground double-hole combined water inrush prevention method for overlying strata movement monitoring and bed separation water drainage. The ground double-hole combined water inrush prevention method is suitable for treatment of overlying separation flood after mining of a water-rich stratum mine and comprises the steps that a rock stratum movement monitoring drill hole and a bed separation water drainage drill hole which are adjacent to each other are constructed in the middle of a working face along the trend corresponding to the earth surface, the rock stratum movement monitoring drill hole is formed to monitor internal movement information of an overlying rock stratum in the working face mining process, and the bed separation development condition is mainly mastered; and the bed separation water drainage drill hole is used for drilling and penetrating holes based on the bed separation generation time fed back by rock stratum movement monitoring in the arranged rock stratum movement monitoring drill hole, drilling and hole penetration are carried out, bed separation water is drained in a staged and controlled mode, and water inrush of the working face is prevented. The drilling depth, drainage and hole penetration of the bed separation water drainage drill hole are guided by monitoring the change of the measuring points arranged in the upper rock stratum and the lower rock stratum of the bottom interface of an aquifer. The utilization rate of the bed separation water drainage drill holes is effectively improved through combination of the mobile monitoring drill holes in the rock stratum and the bed separation water drainage drill holes.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com