Patents

Literature

106results about How to "Increase mining rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

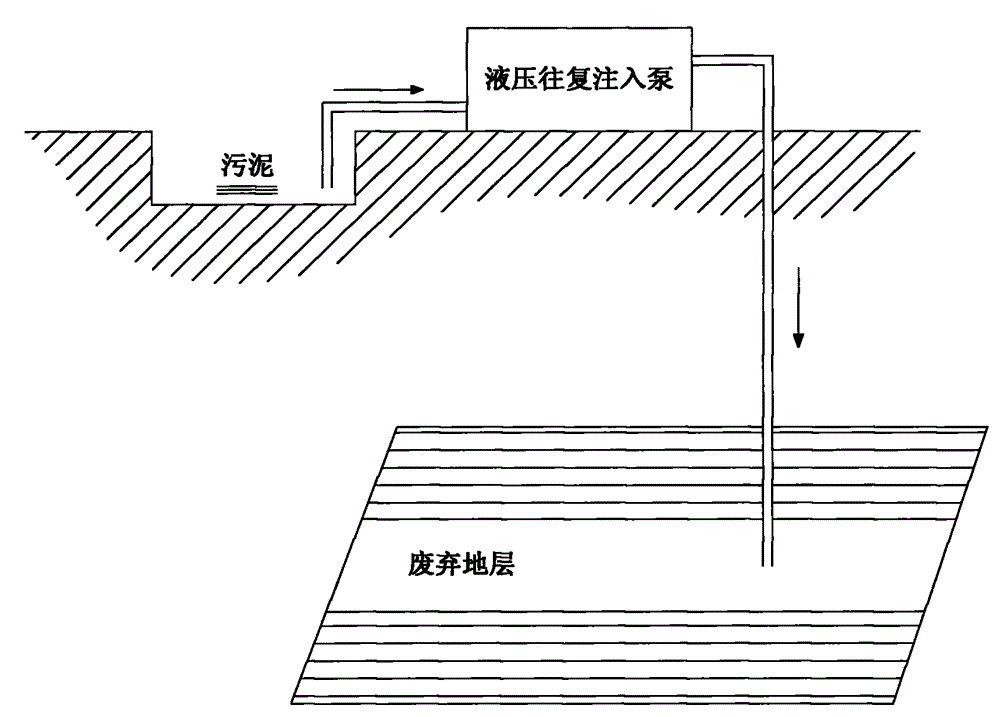

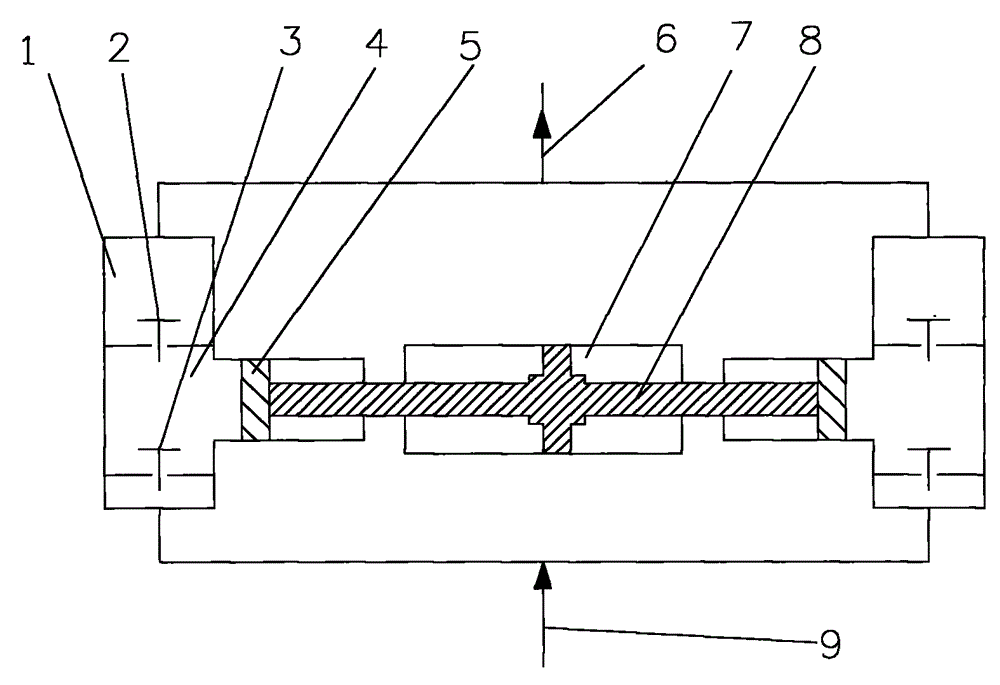

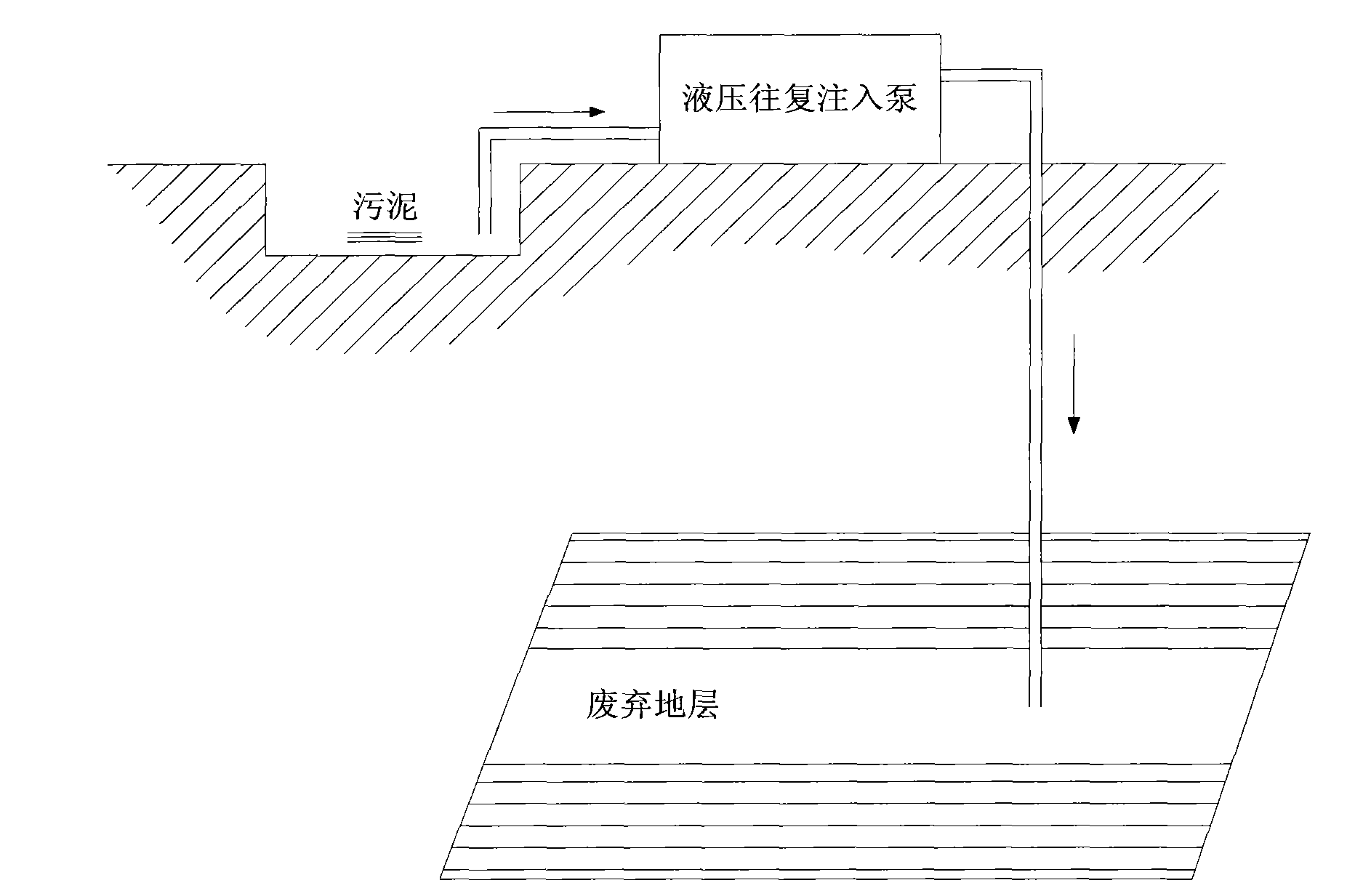

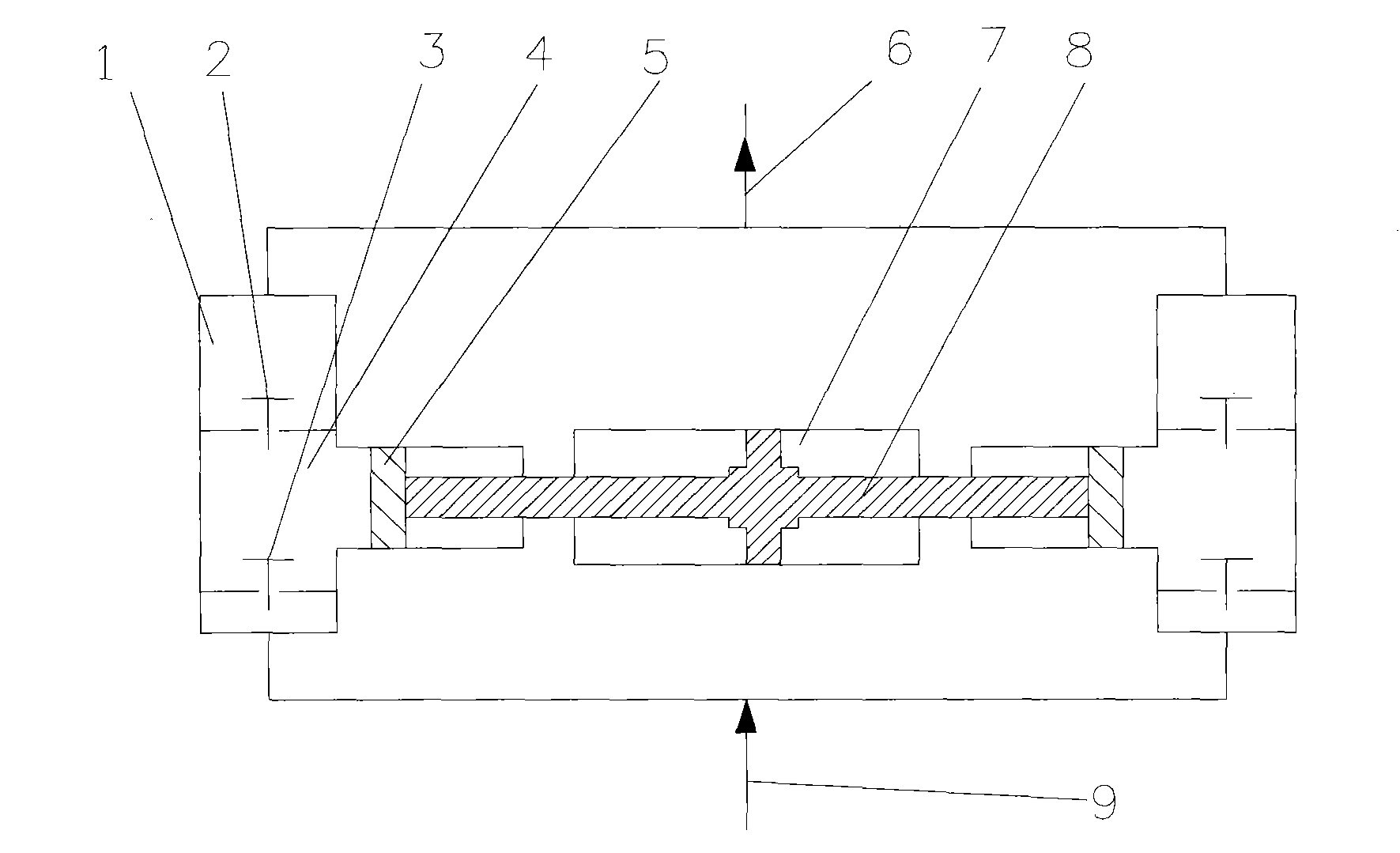

Harmless treatment method for reinjection of oil mining sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Harmless reinjection treatment method for petroleum exploitation sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

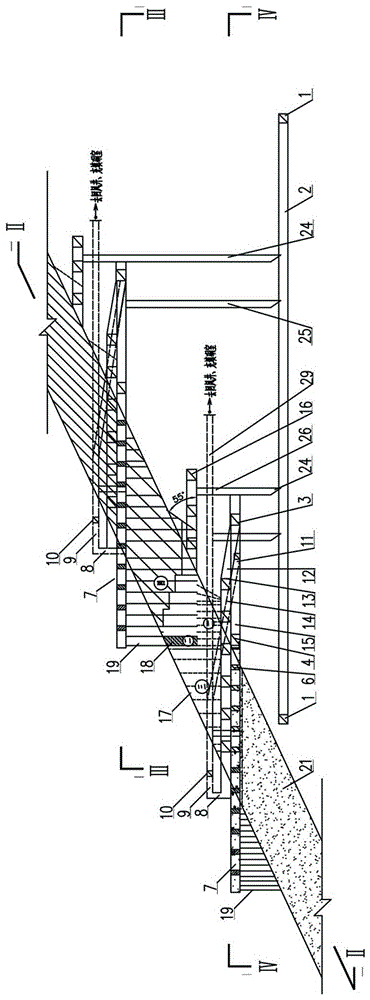

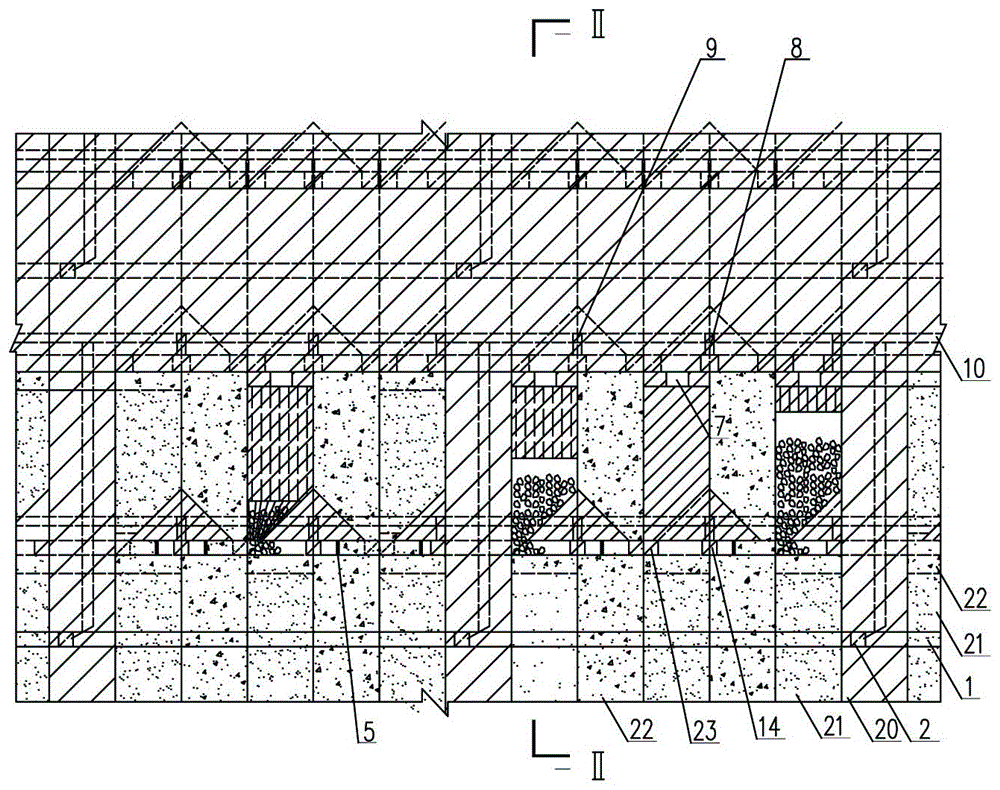

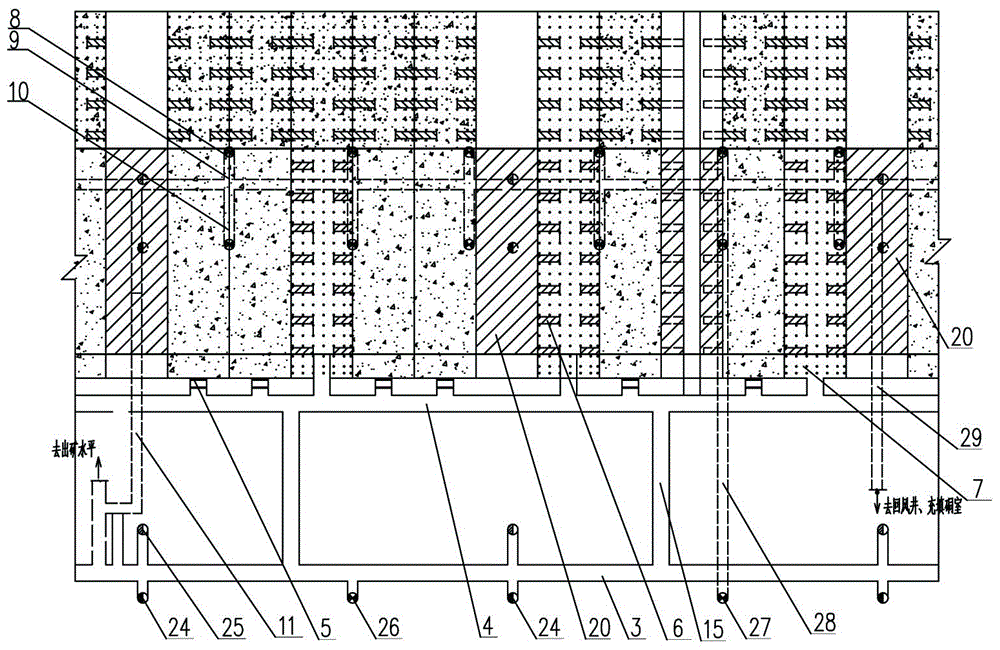

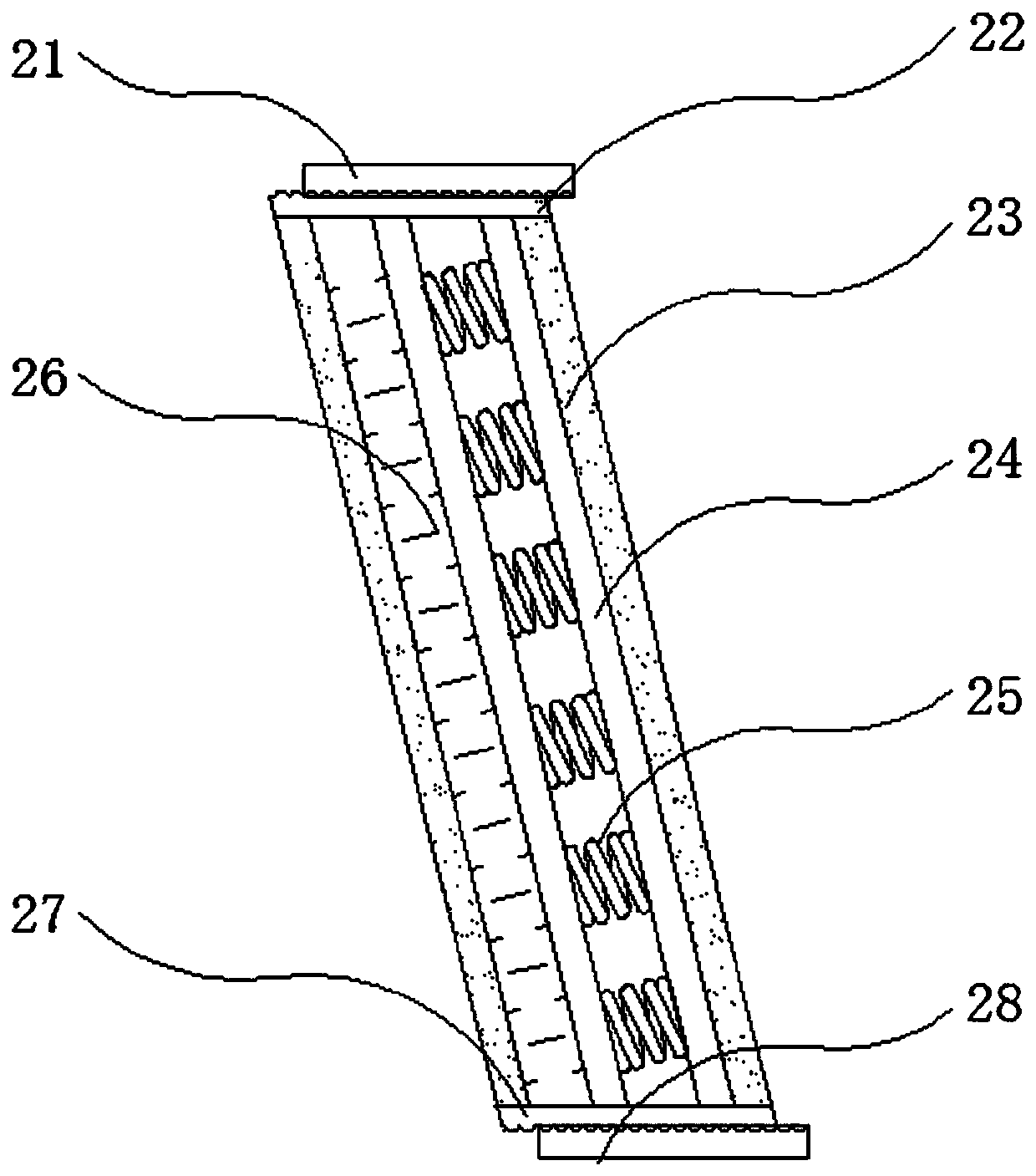

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

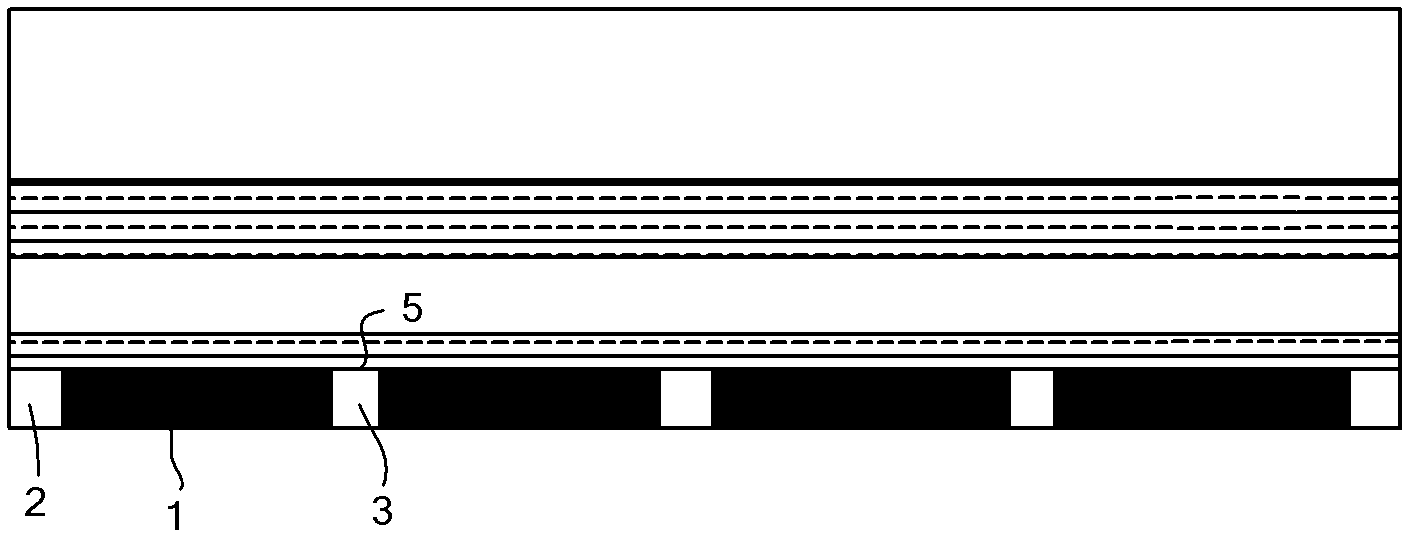

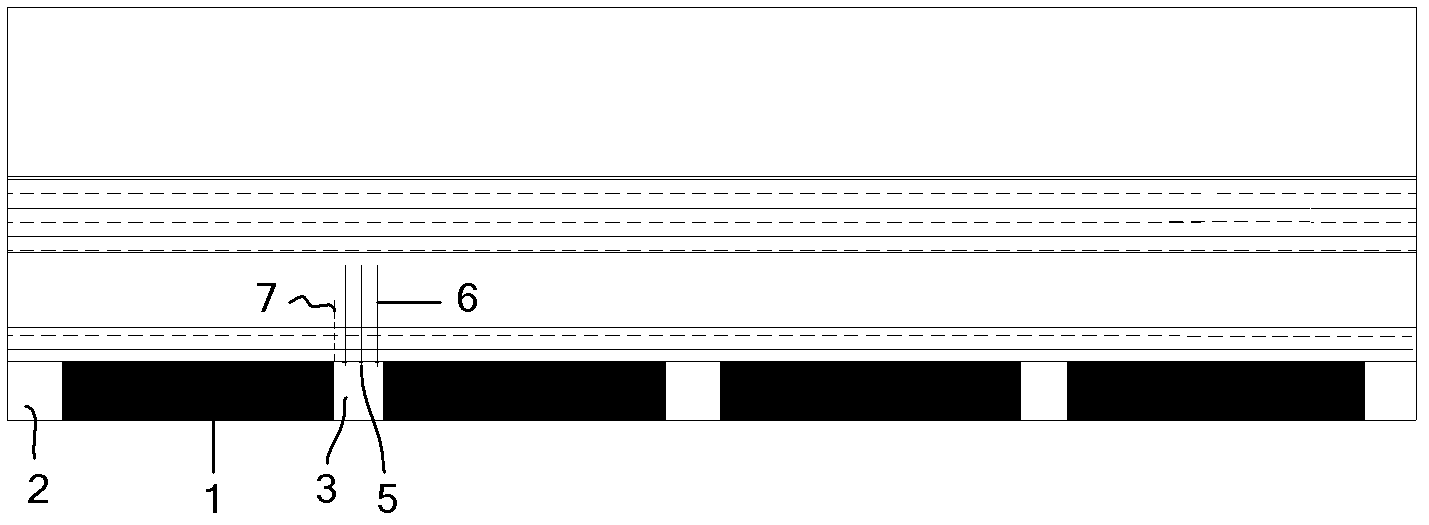

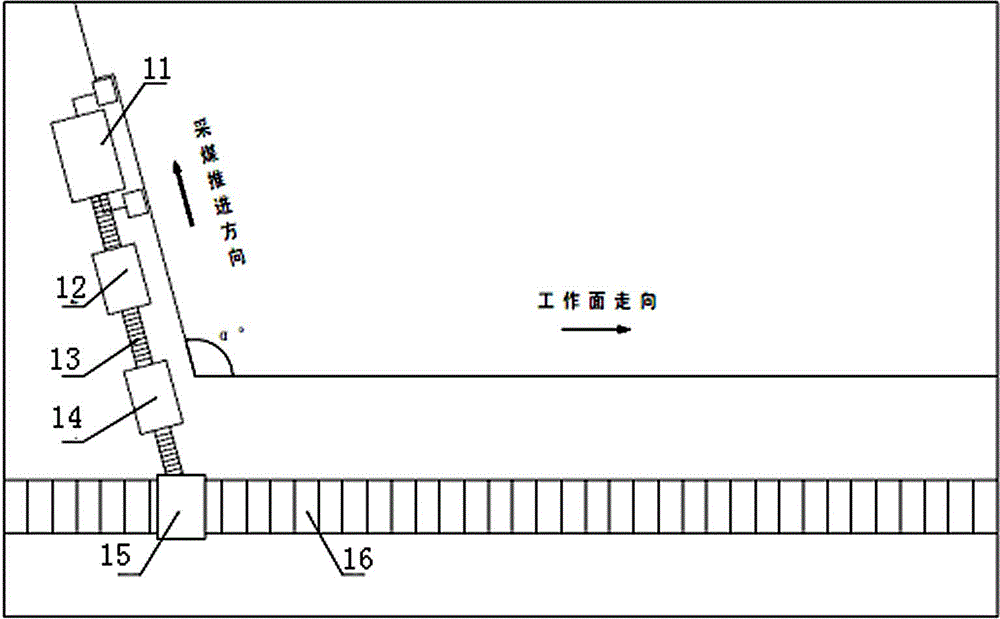

Long-wall working face coal pillar-free mining method

ActiveCN102536239AGood conditionIncrease mining rateUnderground miningSurface miningEngineeringCoal pillar

The invention discloses a long-wall working face coal pillar-free mining method which comprises the following steps of: (1) digging an upper gate road tunnel and a lower gate road tunnel; (2) reinforcing a roof plate of the lower gate road tunnel, and drilling an energy collecting hole for presplitting blasting on the roof plate; (3) recovering till that a gob is formed; (4) blasting in response to the energy collecting hole, so that a kerf is formed at the roof plate; (5) breaking and sinking a mining face, so that a new tunnel is formed; (6) taking the original lower gate road tunnel as the upper gate road tunnel of the next mining face, and digging a lower gate road tunnel opposite to the upper gate road tunnel, so that a new mining face is formed; and (7) repeating the steps (2)-(6), and continuously mining coal till that the coal bed is completely mined. Every two mining faces in the method are continuous, and can not be supported by coal pillars, so that the method is high in mining efficiency, free of long-time waiting when the tunnel is formed, and high in working efficiency.

Owner:何满潮

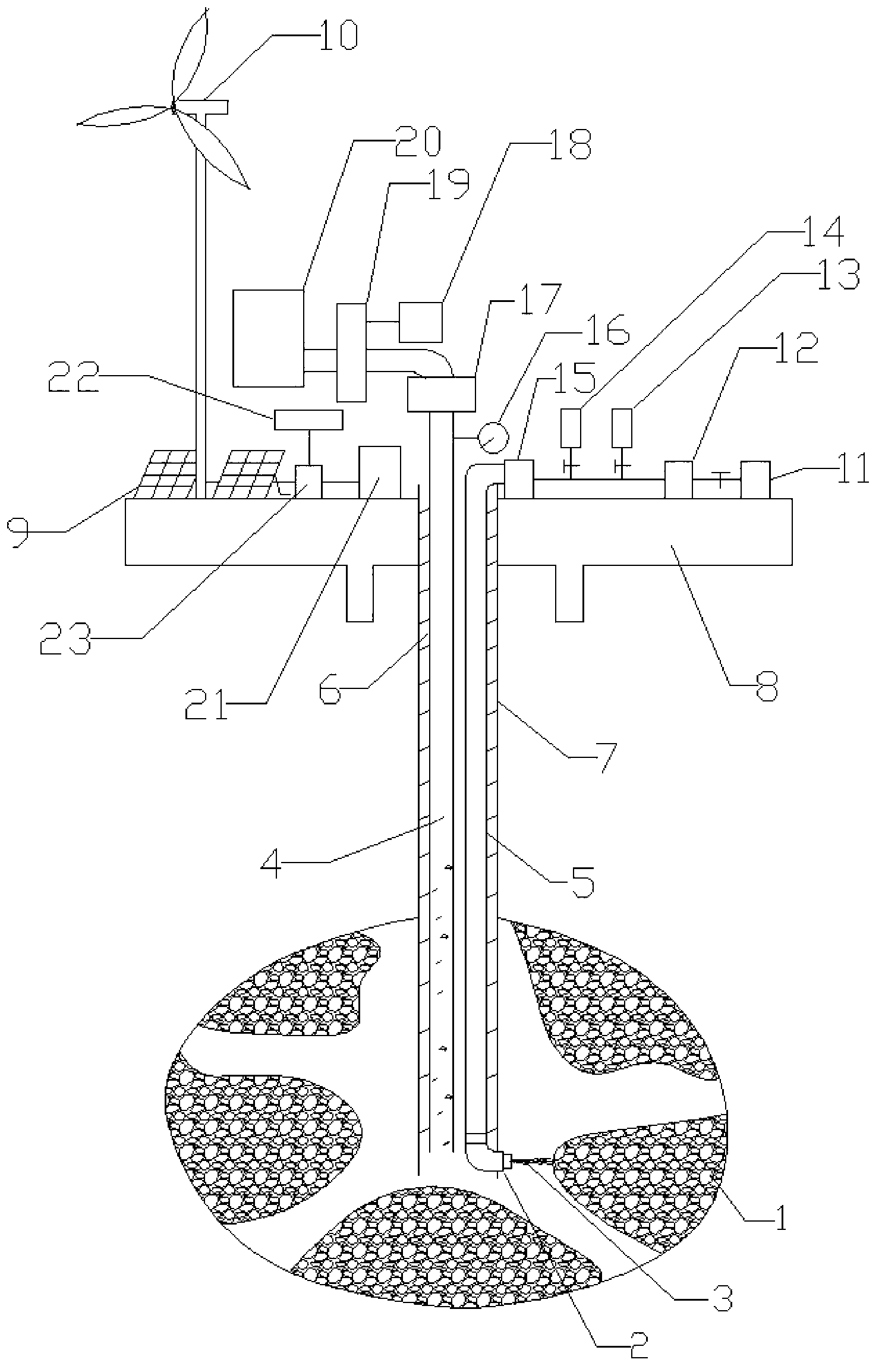

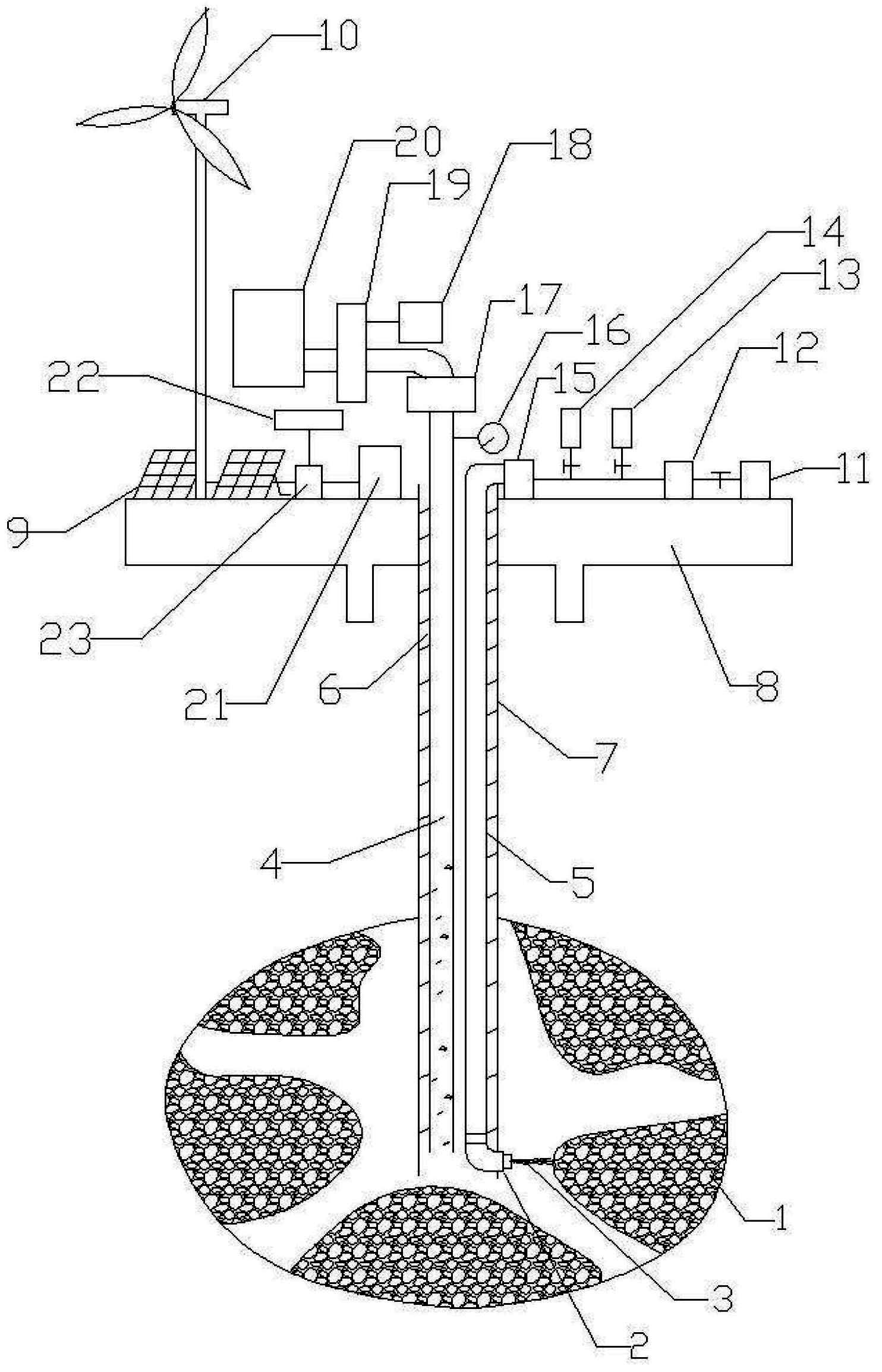

In-situ submarine natural gas hydrate exploiting device and method thereof

InactiveCN102704894AIncrease reaction rateSpeed up miningBatteries circuit arrangementsConstructionsGreenhouse gasSubmarine

The invention relates to an in-situ submarine natural gas hydrate exploiting device and a method thereof, and belongs to the technical field of exploitation of natural gas hydrates. The exploiting device comprises a solar and wind power generating system, a rotary telescopic water gun, an insulating pipeline, a conveying pipeline, a sleeve pipe, an ocean platform, a sea water pump, an electric heater, a CO2 liquid storing tank, a decomposition accelerator storing tank, a high-pressure pump, a pressure gauge, a filtering device, a water storing tank, a gas-liquid separator and a gas recovering device. A thermal activation method and a chemical reagent catalyzing method are utilized to trigger a decomposition reaction of the natural gas hydrate, and then the high-pressure CO2 jetting technology is utilized to enable the natural gas hydrate to be cut while a substitution reaction occurs. According to the invention, the natural gas hydrate is exploited by fully utilizing rich solar power and wind power in ocean areas, so that the effects of cleaning and environmental protection are realized; the thermal activation method and the chemical reagent catalyzing method are matched with the CO2 substitution method, and therefore the exploitation rate is improved, the dosage of a chemical reagent is reduced, the stability of submarine geology is protected effectively, and meanwhile the greenhouse gas is treated to a certain extent.

Owner:SHANGHAI JIAO TONG UNIV

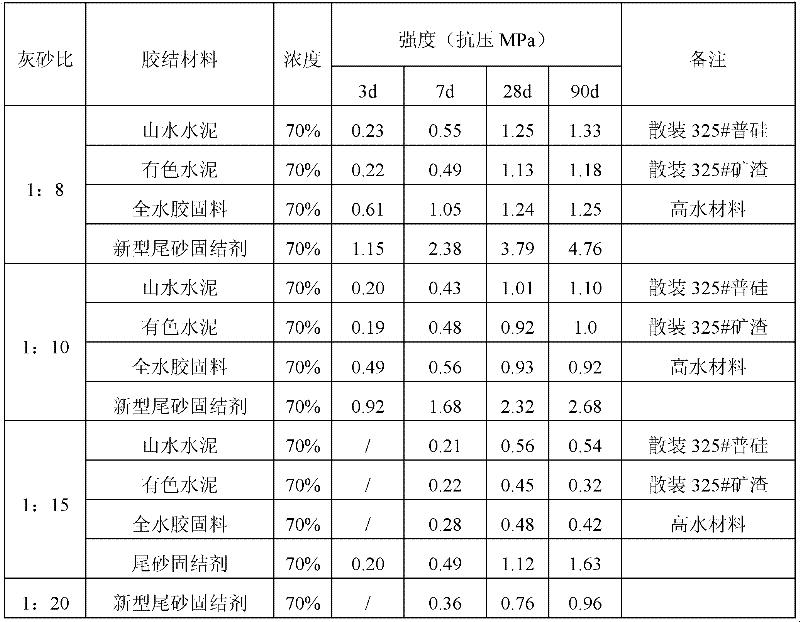

Novel tailing consolidator and preparation method thereof

The invention concretely relates to a novel tailing consolidator which uses fine powder ground from blast furnace water quenching slag as a main raw material and a preparation method of the consolidator. The consolidator is characterized in that the consolidator comprises, by mass concentration, 9 % to 17.54% of portland cement clinker, 10% to 17.54% of anhydrite, 6% to 10% of quicklime, 0.2 to 6 thousandths of Na2SO4, 0.2 to 0.5 thousandths of carboxymethyl cellulose, 5% to 10% of coal ash and 43.65% to 69.96% of the fine powder ground from the blast furnace water quenching slag. Each above component is dried by a dryer, put in a mixer to be evenly stirred, and conveyed to a bowl mill by a belt conveyer to be ground. The blast furnace slag discharged from a smeltery is used as the main raw material in the invention to reduce the cost and solve slag processing, so the consolidator has the advantages of low production cost, simple processing, and agile and convenient usage. A usage amount of the consolidator in the present invention is half or less than the usage amount of common cement under the same conditions with the same backfilling intensity.

Owner:淄博乾耀固结材料有限公司

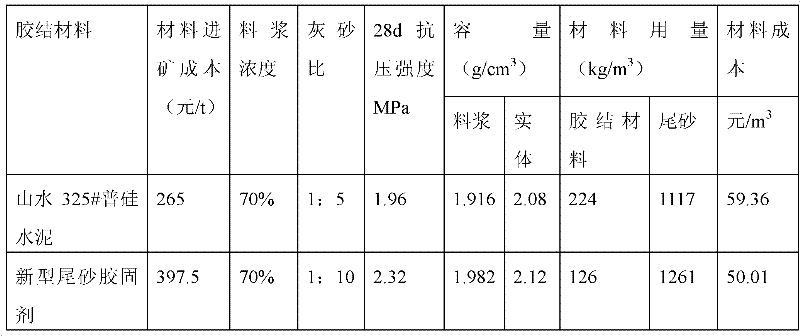

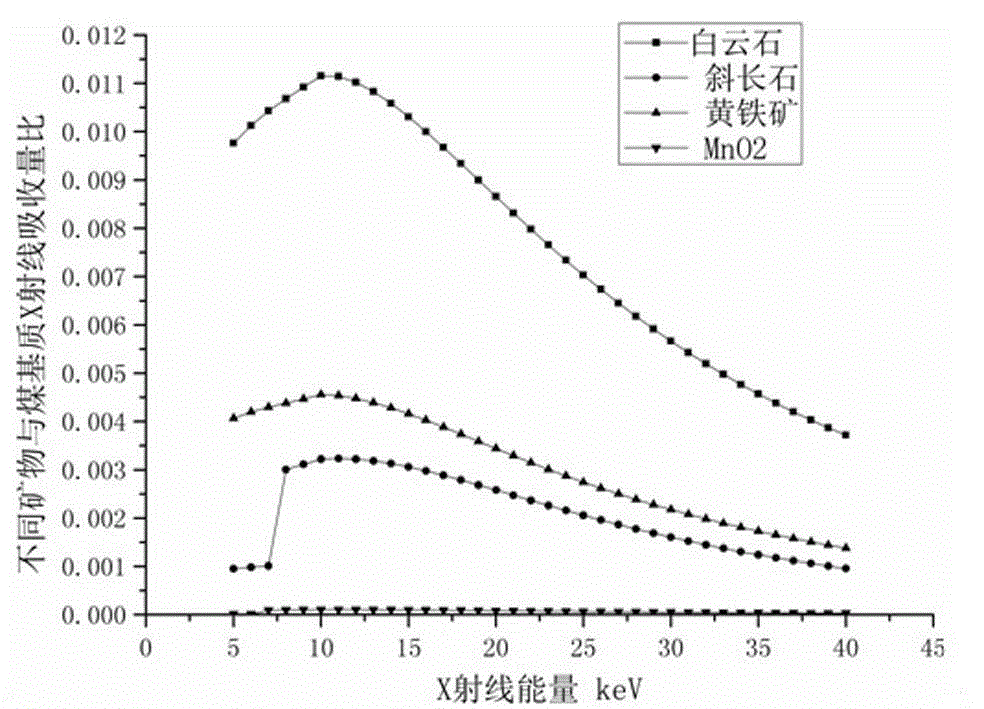

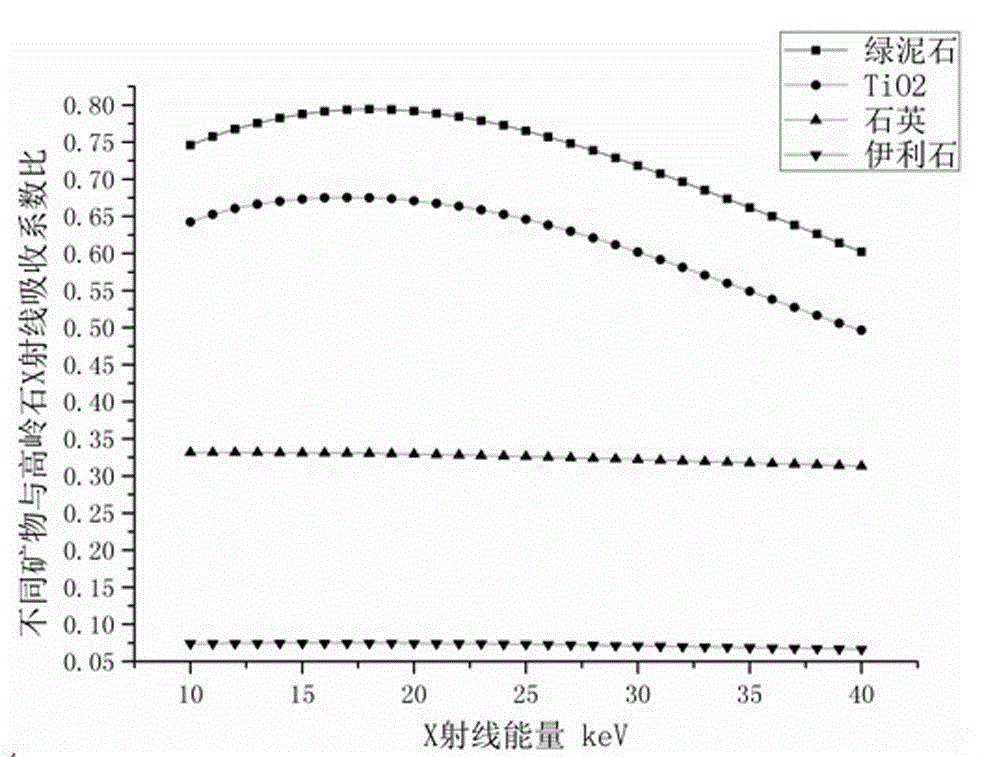

Visualization quantitative CT (Captive Test) characterization method for component distribution and physical structure of coal sample

InactiveCN102980902AHigh demands for attenuated resolutionIncrease mining rateMaterial analysis by transmitting radiationMathematical modelX-ray

The invention relates a visualization characterization technology of a coal sample, and in particular relates to a visualization quantitative CT (Captive Test) characterization method for component distribution and a physical structure of a coal sample. The visualization quantitative CT characterization method comprises the following steps of: sampling and pre-testing the coal sample; carrying out an X-ray absorption characteristic analysis on each component of a second coal sample; carrying out X-ray absorption characteristic analysis on residual minerals; carrying out a CT on the coal sample; establishing a mathematical model and carrying out a numerical analysis on CT slices; and carrying out visualization quantitative characterization. The CT characterization method provided by the invention adopts a plurality of CT data obtained by monochromatic X-ray experiment energy to carry out conjoint analysis, and detects the information of a component, dimension of which is smaller than CT resolution dimension, on a CT picture by establishing a data model on a single CT element, so that the visualization result of the component distribution characteristic and the physical structure of the coal sample is accurate.

Owner:SHANXI UNIV

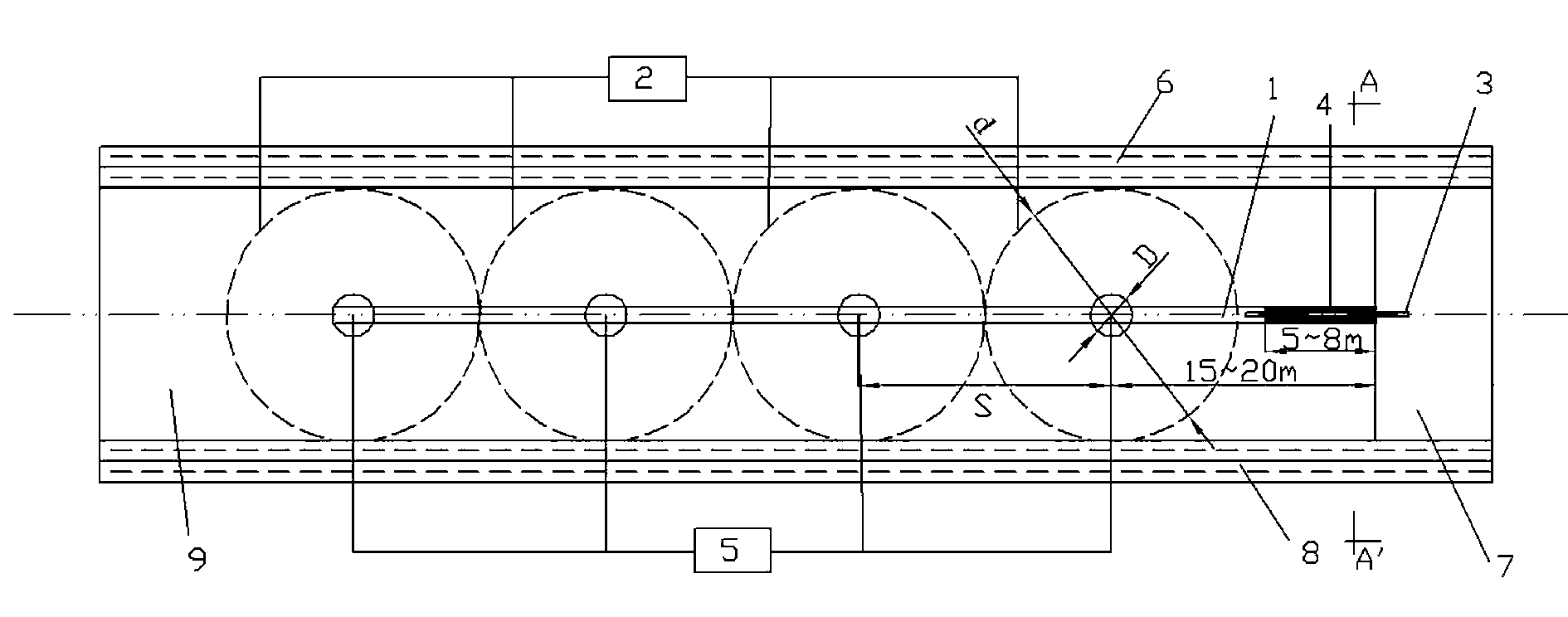

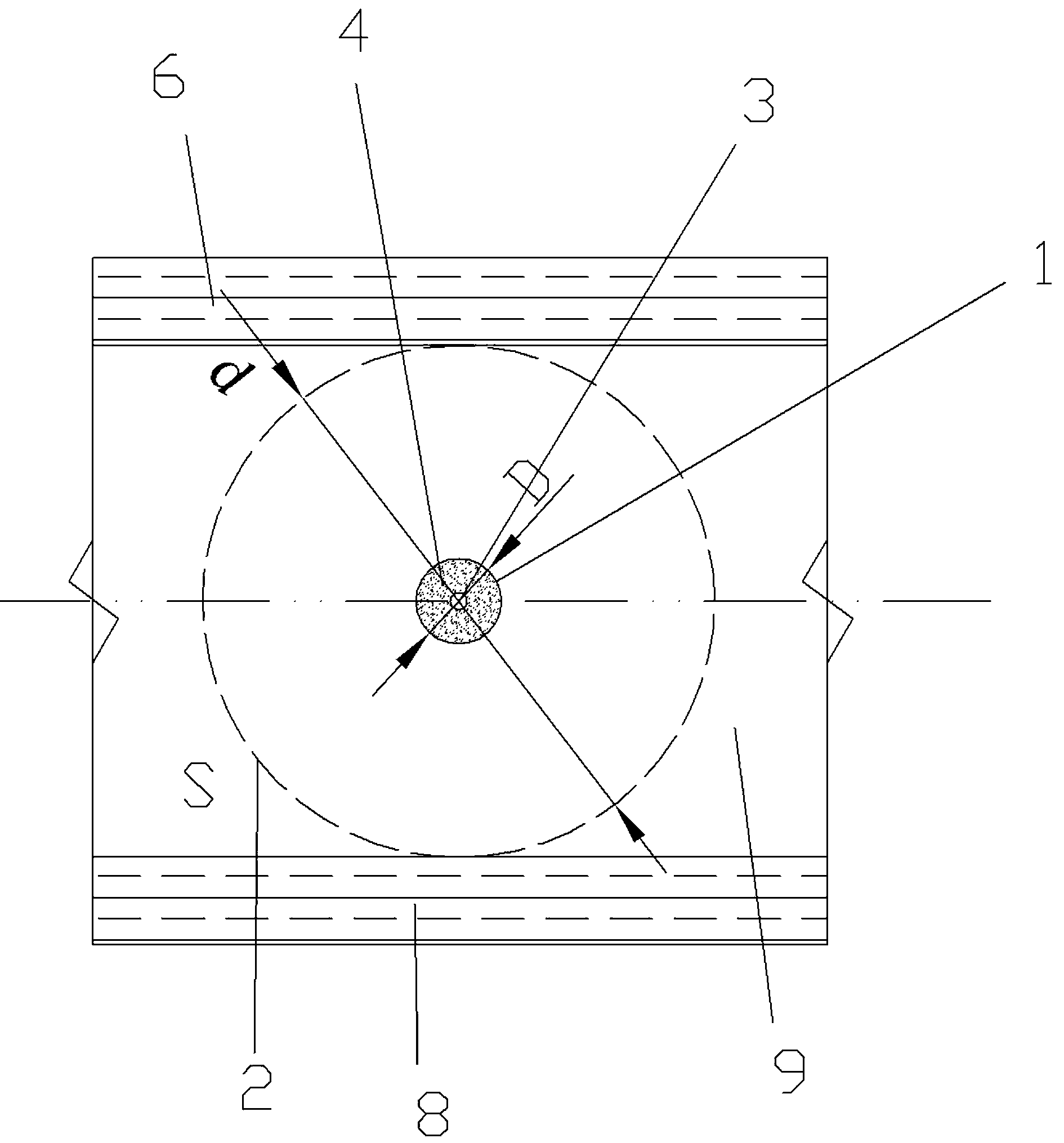

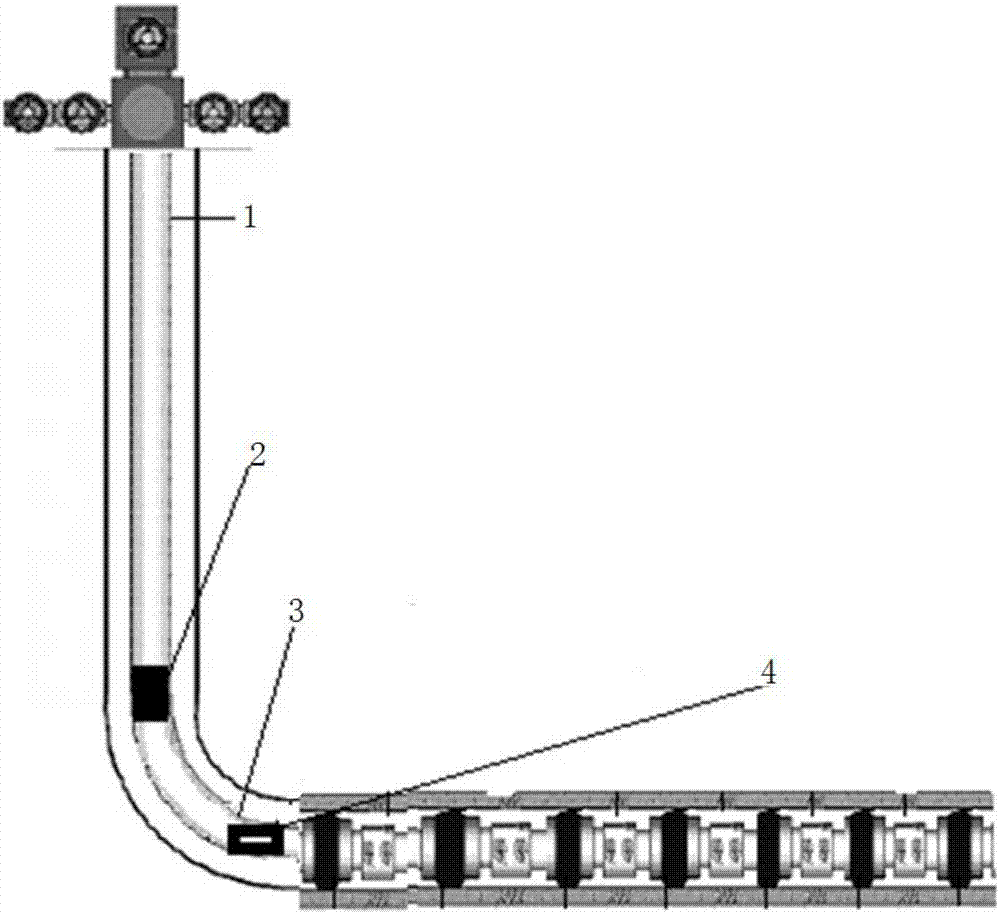

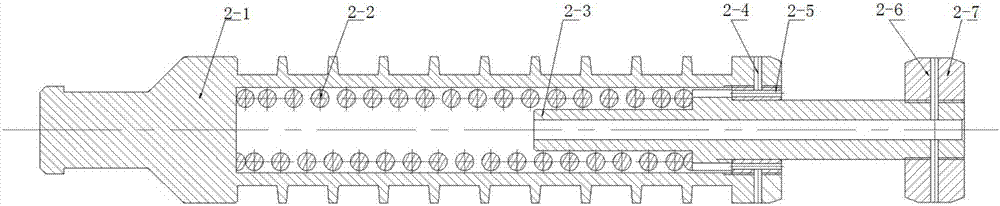

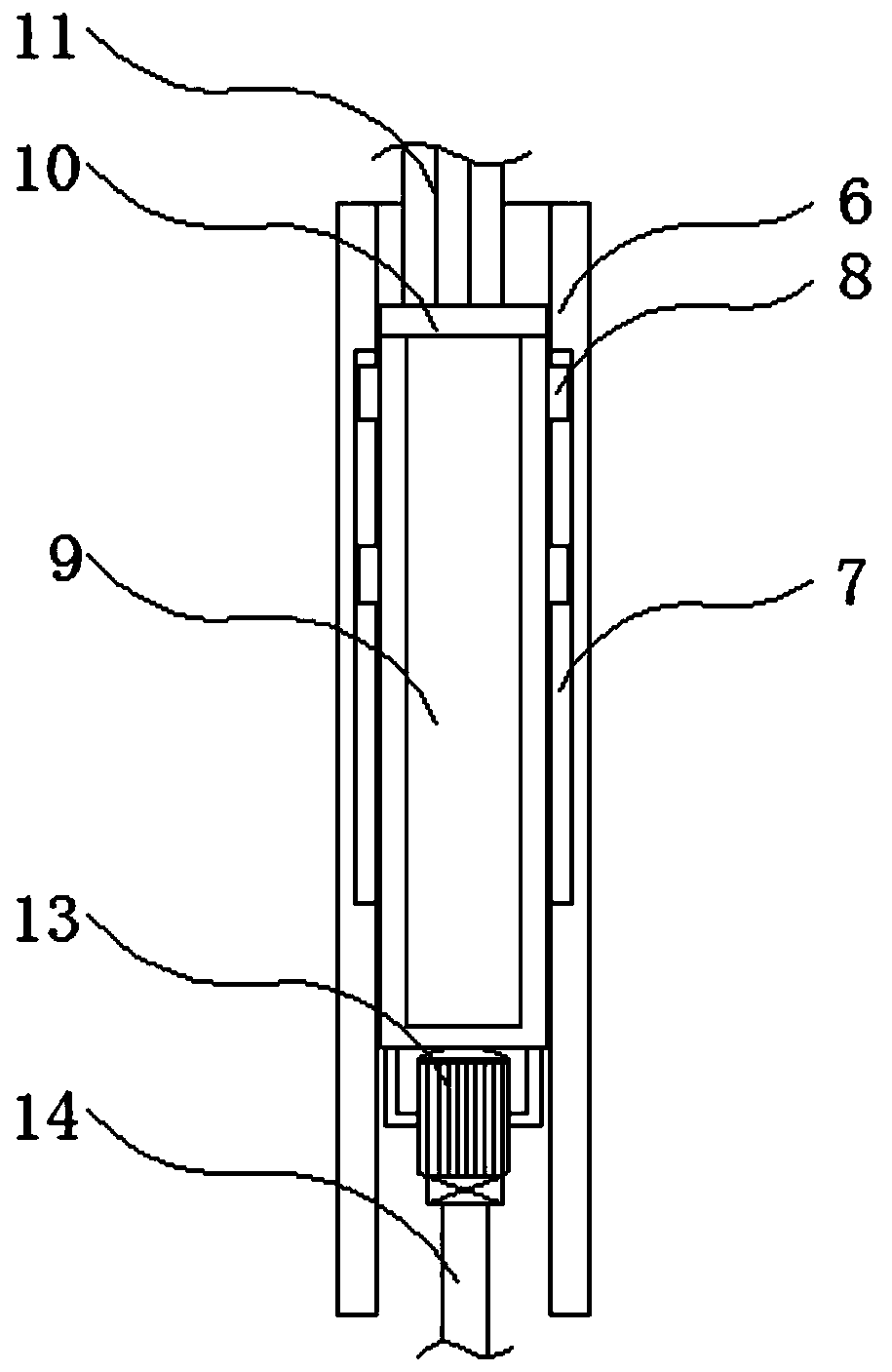

Method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building

ActiveCN103061798AImprove drilling single-hole drainage production capacityImprove extraction efficiencyDrill bitsGas removalDrill siteCoal

The invention relates to a method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building and a hydraulic mechanical drill with the diameter changed and enlarged while drilling. A coal bed bedding long borehole is combined with a cave building technology, and the permeability of low-permeable coal reservoirs and the coal bed borehole extraction capacity are improved. A hole is opened at 1 / 3 coal thickness or 1.5m upwards away from the coal heading floor on the extracting drill site coal wall of an underground coal mine along with the coal bed, the hydraulic mechanical drill with the diameter changed and enlarged while drilling performs cave building on the borehole from inside to outside successively after the borehole reaches the preset depth, and the cave diameters and distances can be calculated through formulas. Coal bed stresses around the cave are released and coal bed prior cracks are widened and lengthened after the caves are completed, tensional and shear failures occur to the coal bed, novel cracks are produced, and accordingly, the coal bed crack connectivity is increased, the permeability is improved, the coal bed methane can be depressurized and desorbed rapidly, the coal bed methane extracting efficiency is improved dramatically, and the coal bed methane extracting time is shortened.

Owner:ZHONGBEI UNIV +1

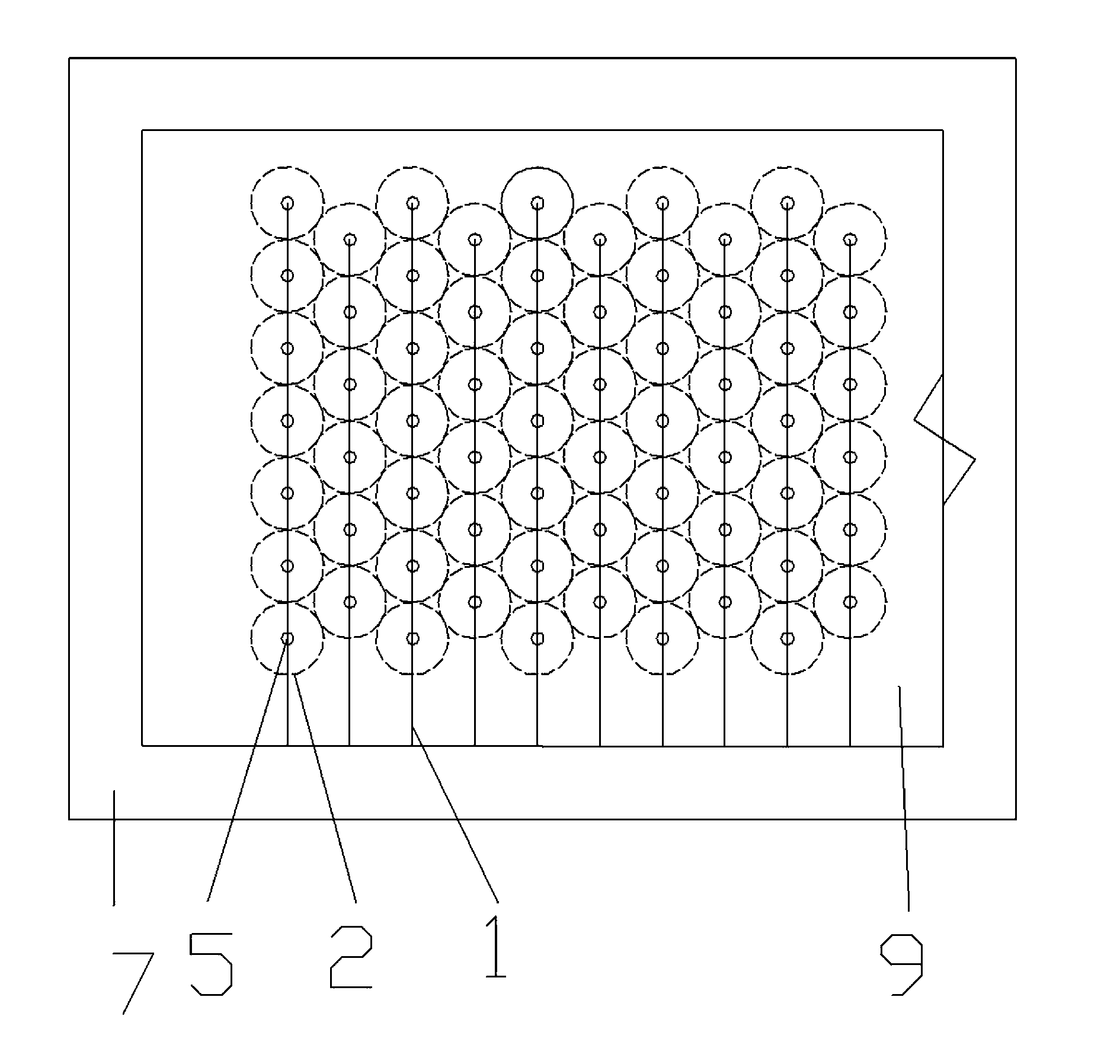

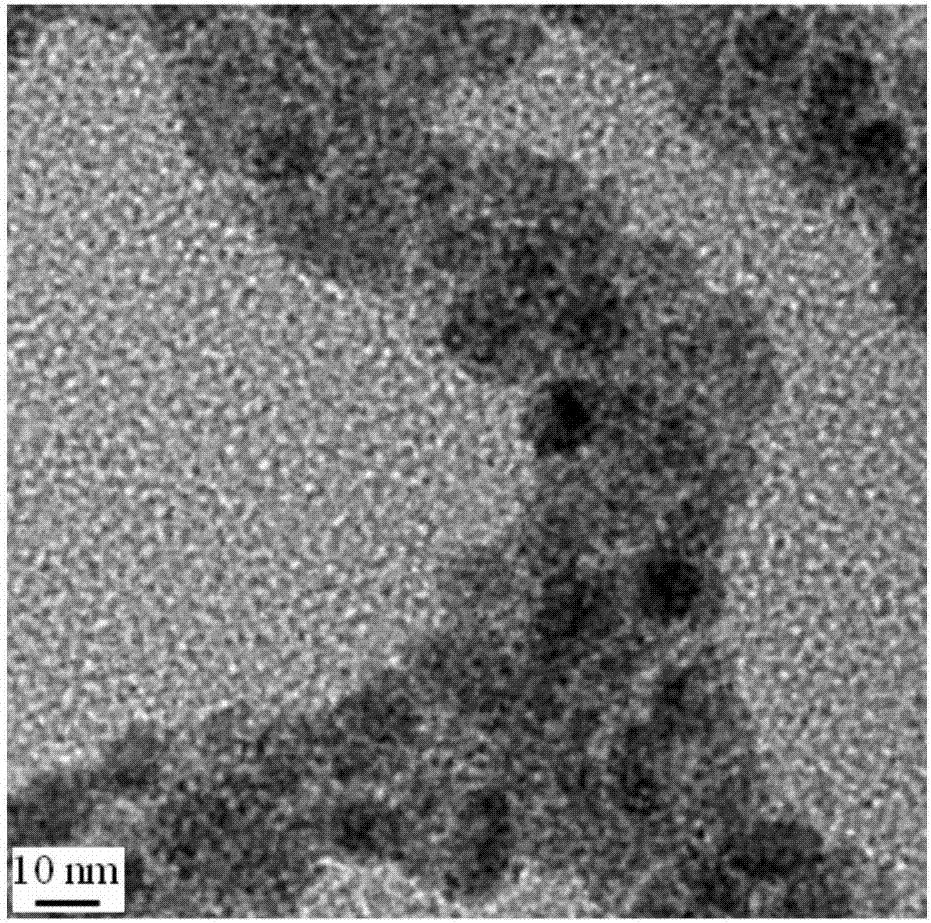

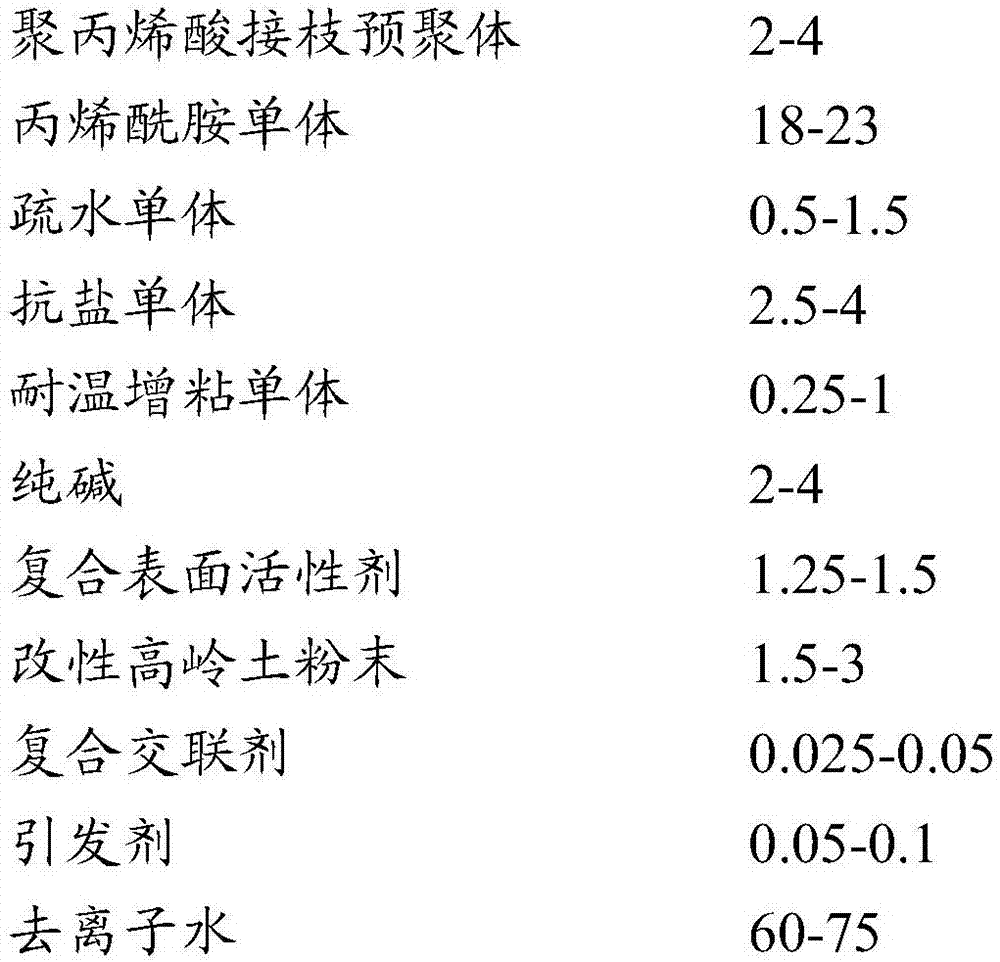

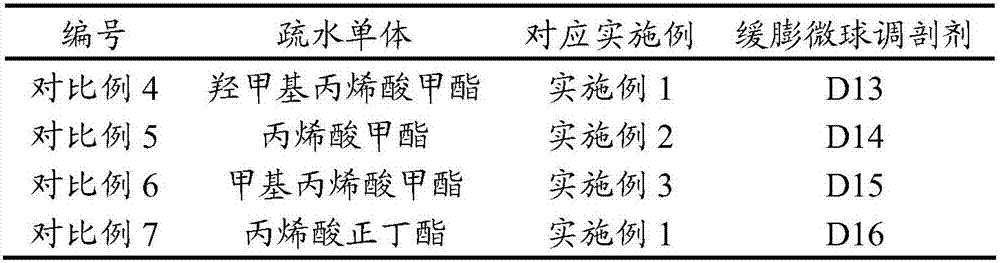

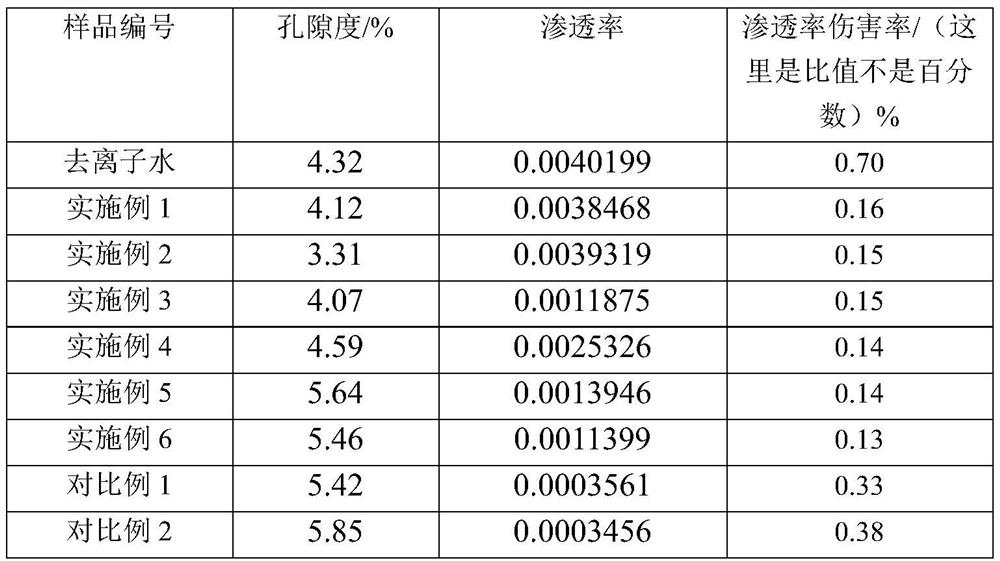

Pre-crosslinking gel retarding-swelling microsphere profile control agent and preparation method and application thereof

ActiveCN106883357AImprove temperature resistanceImprove salt toleranceDrilling compositionMicrosphereALLYL SUCROSE

The invention relates to a pre-crosslinking gel retarding-swelling microsphere profile control agent and a preparation method and application thereof. The pre-crosslinking gel retarding-swelling microsphere profile control agent comprises a polyacrylic acid grafting prepolymer, an acrylamide monomer, a hydrophobic monomer, an anti-salt monomer, a temperature-resistant tackifying monomer, pure alkaline, a composite surfactant, modified kaolin powder, a composite crosslinking agent, an initiator and deionized water. The pre-crosslinking gel retarding-swelling microsphere profile control agent has the advantages that by selecting particular components, particularly modifying multiple components, and utilizing the comprehensive synergistic and promoting functions of multiple technical features, the profile control agent with excellent result is obtained; the excellent high temperature-resistant property, high salt-resistant property, good tackifying property, plugging property and the like are realized; the good application prospect and industrial potential are realized in the field of petroleum exploitation.

Owner:DONGYING FANGLI CHEM CO LTD

Salt cavern building method based on opposite-well mining type old wells and application thereof

InactiveCN107035343AEfficient water solution miningSolve the clogging problemFluid removalFresh waterSalt mine

The invention relates to a salt cavern building method based on opposite-well mining type old wells and an application thereof, and belongs to the technical field of salt mining. The salt cavern building method comprises the following steps that (1) detection and checking are conducted on the opposite-well mining type old wells; (2) a well is drilled between the two old wells and extends to a rock salt layer; (3) pipes are downwards put, specifically, a casing pipe and a center pipe are downwards put into the drilled well, and the center pipe is sleeved with the casing pipe; (4) oil is injected between the casing pipe and the center pipe; (5) fresh water is injected from the center pipe and reaches the old wells on the two sides through old well horizontal sections to dissolve rock salt into bittern, and the bittern is discharged from the old wells on the two sides; and (6) when a cavern reaches the set volume, injection of the fresh water is stopped, and building is finished. The salt cavern building method based on the opposite-well mining type old wells achieves the comprehensive targets of horizontal section plug removal, salt mining and oil and gas storage and is suitable for being widely applied and popularized.

Owner:CHONGQING UNIV

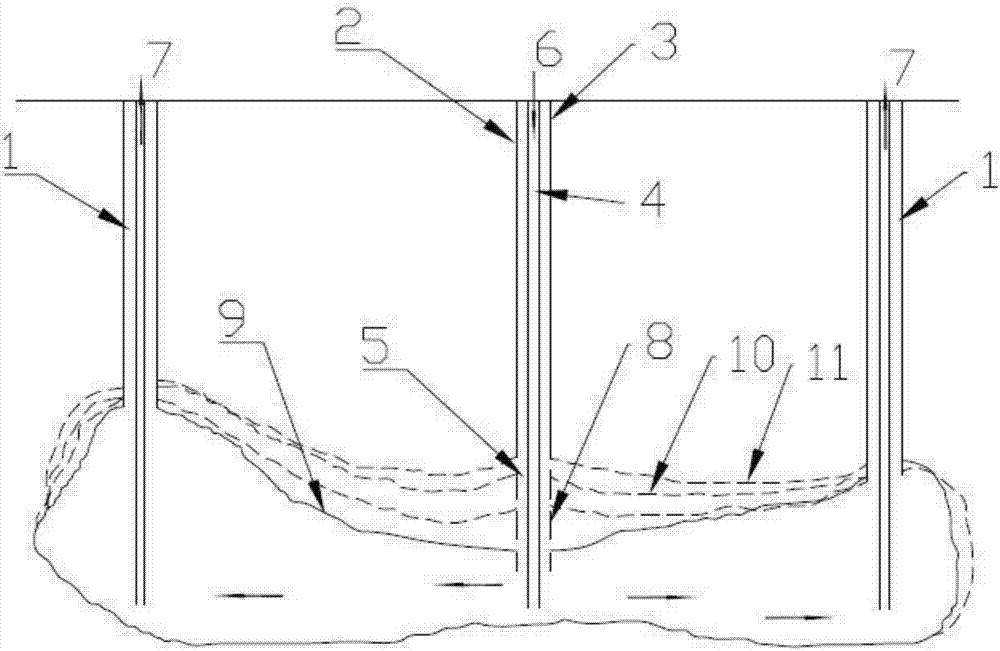

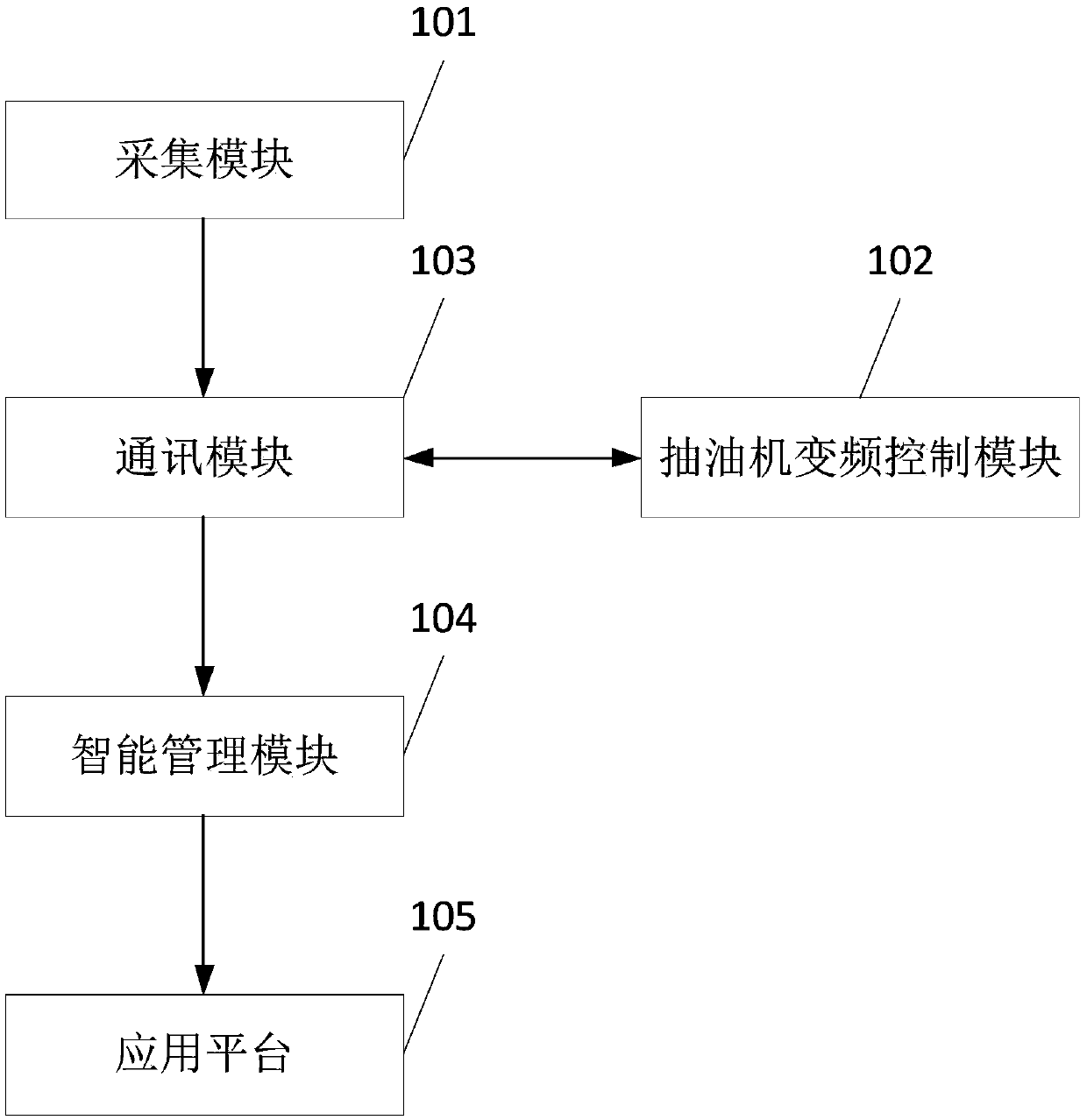

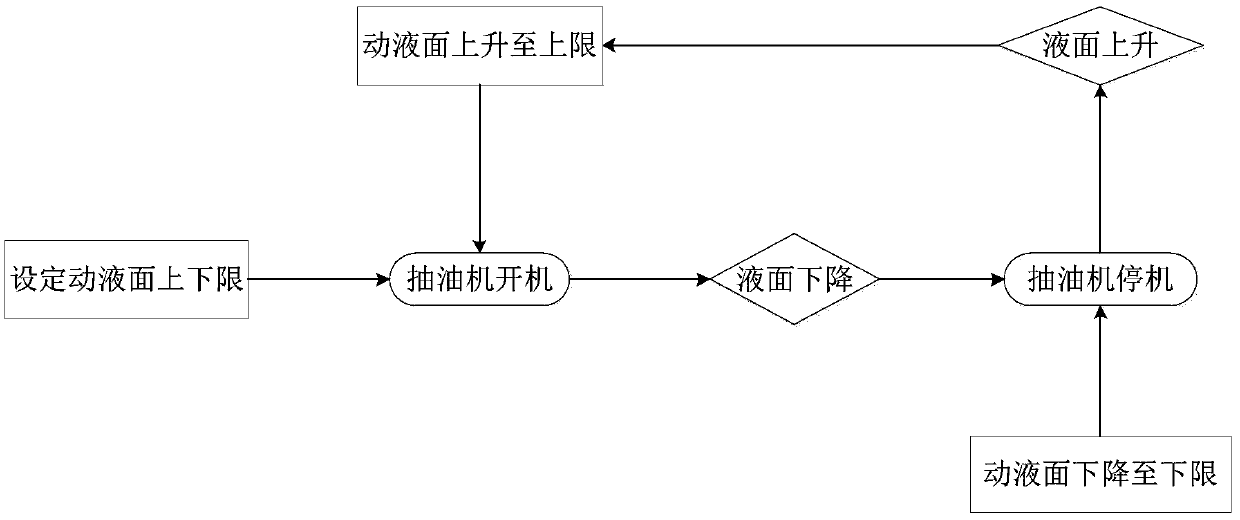

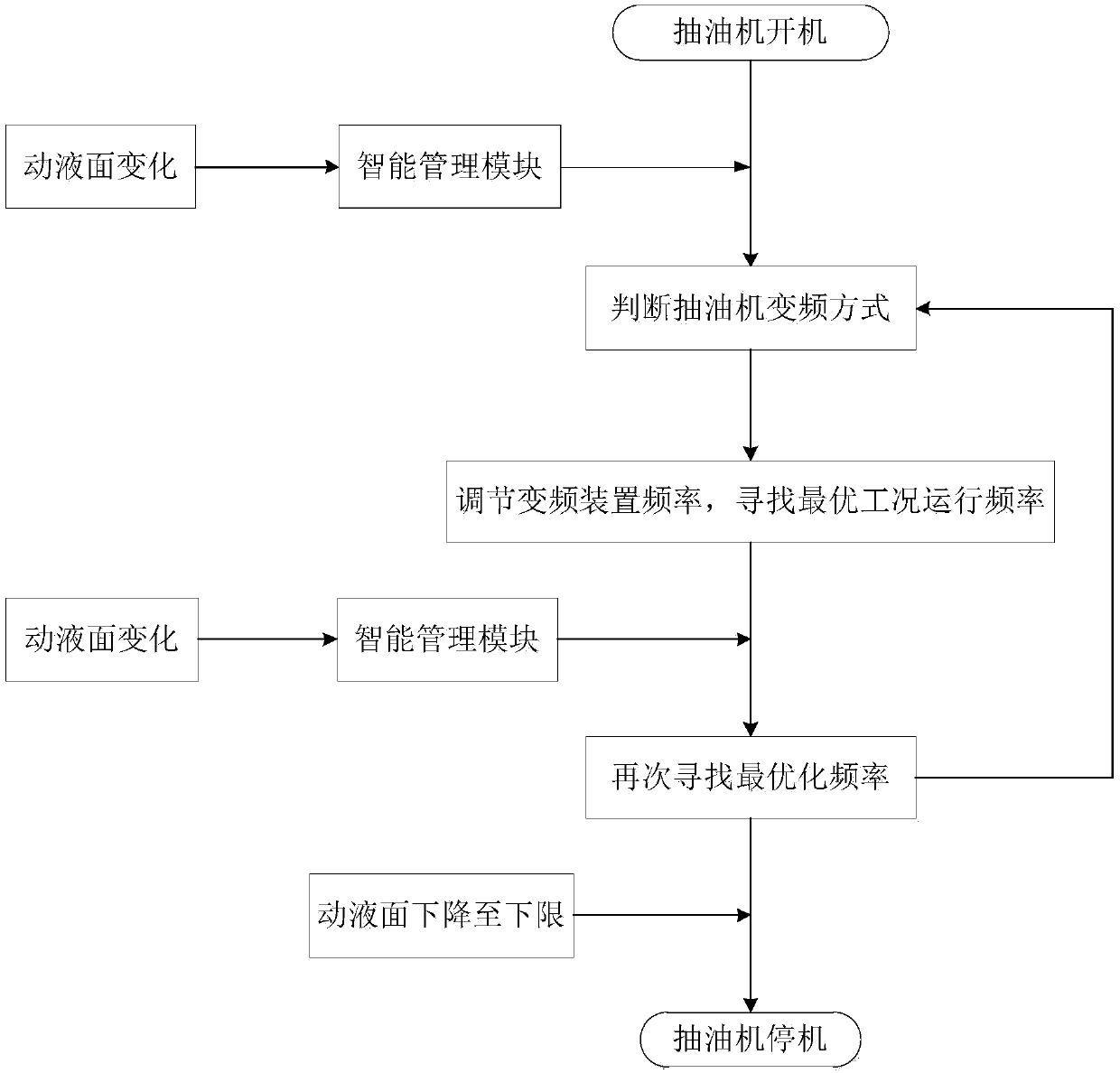

Oil well optimal control management system and method and pumping unit frequency converting control method

InactiveCN109681154ARealize real-time monitoringRealize energy saving and consumption reductionSurveyFluid removalOptimal controlEngineering

The invention discloses an oil well optimal control management system and method and a pumping unit frequency converting control method. A data collecting module of the management system conducts datacollection, an intelligent management module controls running situations of a pumping unit, monitors oil well real-time data and proposes relative control instructions and warns in advance after conducting intelligent analysis on the oil well running situations, a pumping unit frequency converting control module controls the working frequency or start-stop states of the pumping unit, an application platform is a window for showing the oil well optimal control management system in real time, a wireless communication mode is adopted, the oil-well production and running states are monitored in real time, manual inspection is replaced by electronic inspection, the manual cost is reduced, and environmental factor and manual destruction influence is reduced; a big data technology is adopted, the oil field mass data intelligent analysis requirements are met, and the fact that the real-time capability, the accuracy and the comprehensiveness of measurement data all reach 100% is ensured.

Owner:深圳市西热新技术有限责任公司

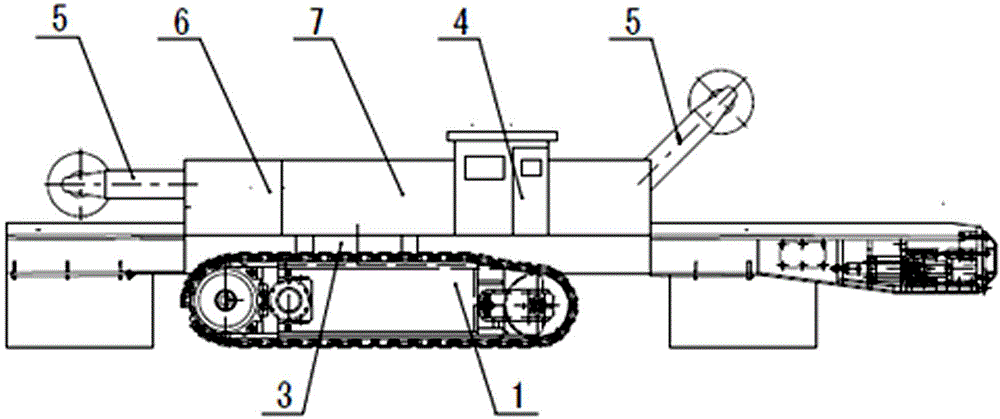

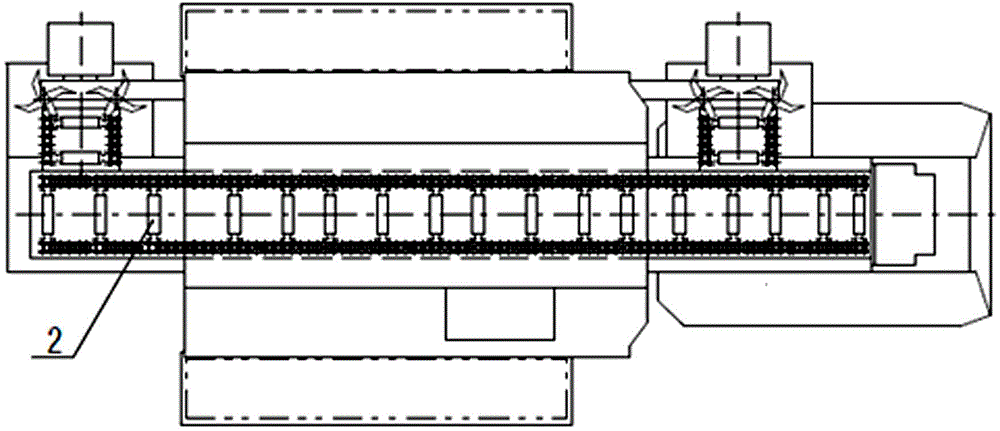

Continuous coal-mining technology for strip mine

ActiveCN104612693ASolve the problem of increasing production capacityAchieve high efficiencyOpen-pit miningCutting machinesBelt conveyorCoal mining

The invention relates to a coal mining technology, and provides a continuous coal-mining technology for strip mine so as to solve defects and shortcomings existing in an interrupt or semi-continuous coal-mining technology for strip mine at present. The method comprises the following working manner: a crawler travel type double-roller coal cutter bilaterally moves to and fro along the coal-mining propulsion direction and continuously cuts coal seam; when the coal cutter feeds every time, double rollers are raised and start to feed downwards from the upward side of coal wall; after feeding is finished, the double rollers are arranged up and down and front and back, and perform coal mining along the coal-mining propulsion direction; and mined coal is transferred to a scraper type continuous transportation set through a middle scraper conveying system at the lower part of the roller coal cutter for crushing and transferring, and finally through a discharge dolly moving along progress on a rigid rack of a working-face belt type conveyer, coal is discharged on the working-face belt type conveyer and is transported to an external conveying system. The method truly realizes continuous mining in the coal-mining propulsion direction and the working face direction, and is high in safety and reliability.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

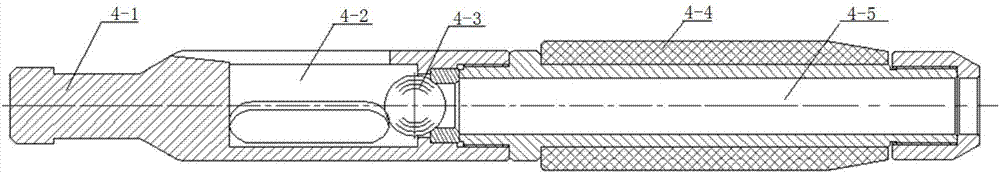

Plunger gas-lifting draining device used for horizontal gas well and production method

InactiveCN107542434AIncrease depthSimplify Downhole ToolsDrilling rodsFluid removalGas liftProcess engineering

The invention discloses a plunger gas-lifting draining device used for a horizontal gas well and a production method. The device comprises a self-buffering plunger and a uniflow device which are arranged in an oil pipe, the oil pump comprises two sections of pipelines who have different pipe diameters and are connected by a reducing short section, the self-buffering plunger is arranged in the part, which is located at the upper part of the reducing short section, of the pipeline, the uniflow device is used for controlling a gas liquid to flow unidirectionally from bottom to top and arranged inthe part, located at the lower part of the reducing short section, of the pipeline, the shaft accumulated fluid can be lifted to the upper part of the uniflow device by the own energy of the gas well, is delayed, and is lifted to the well mouth by the aid of the self-buffering plunger, and drainage production is completed. A downhole tool of an existing plunger device is simplified; the functionof gas liquid unidirectional flow is realized by the uniflow device, the structure is simple and easy to put and slave, the own lifting capacity of the gas well is effectively utilized, the shaft accumulated fluids of the horizontal gas well bottom part inclined shaft part and horizontal section are lifted, the shaft liquid column height is reduced greatly, the gas yield is increased, and the horizontal gas well draining gas production difficulty is effectively solved.

Owner:PETROCHINA CO LTD

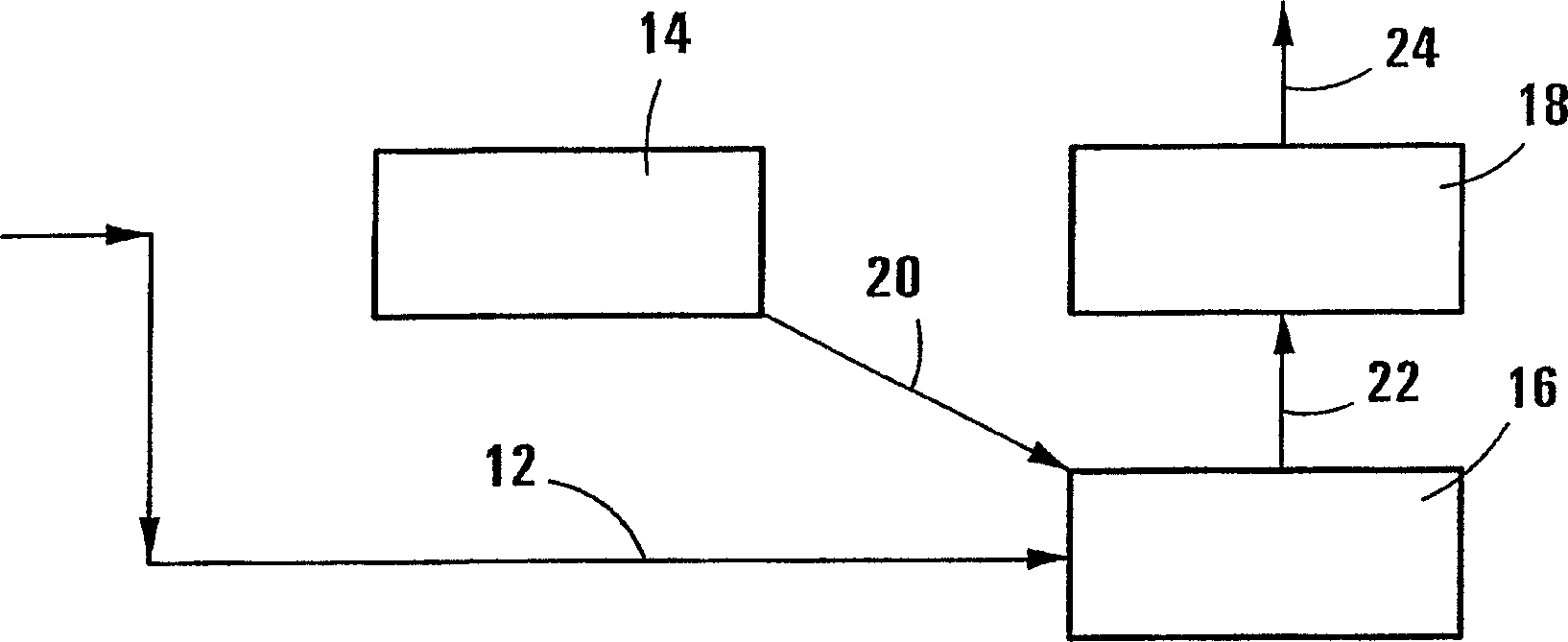

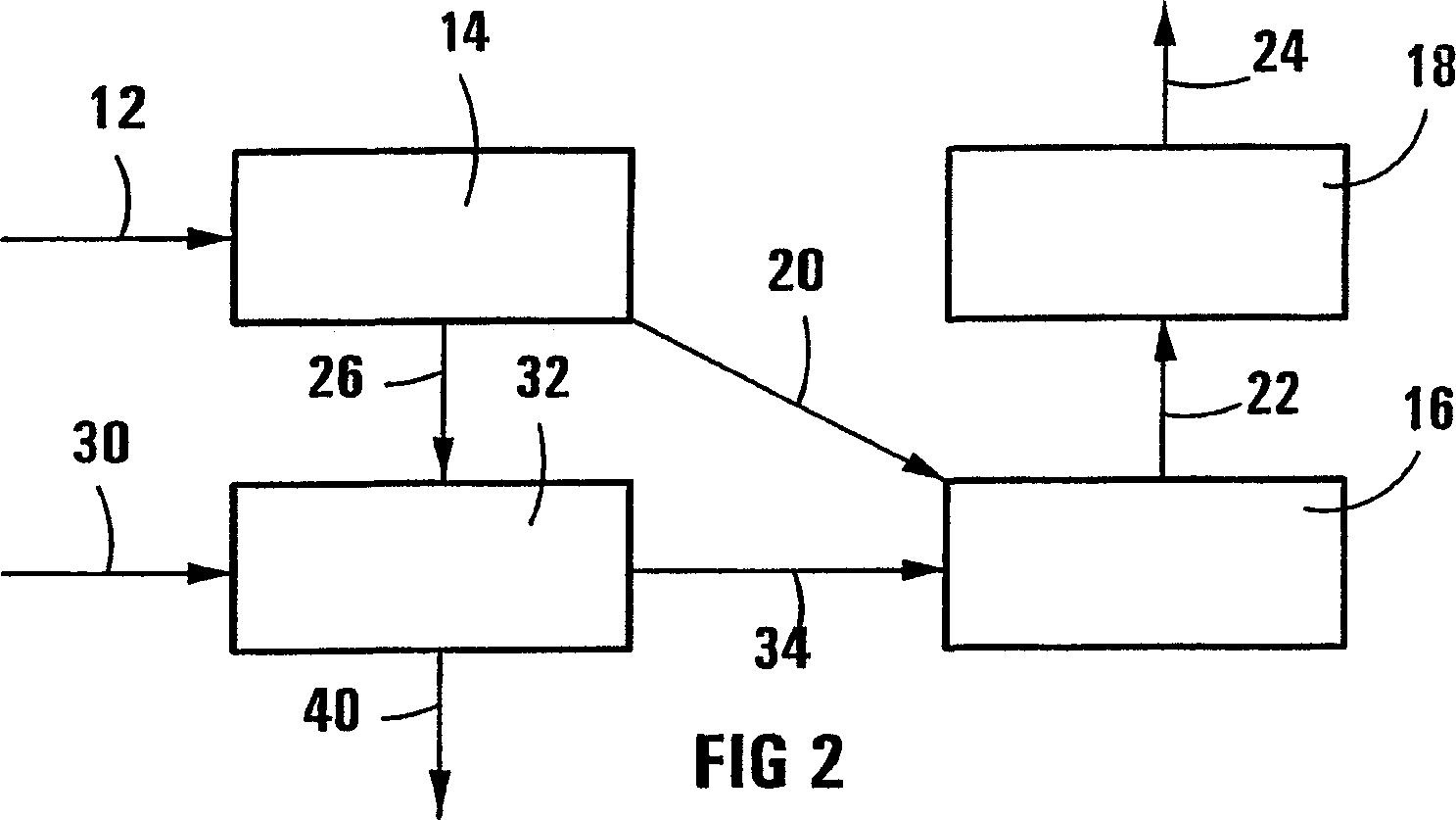

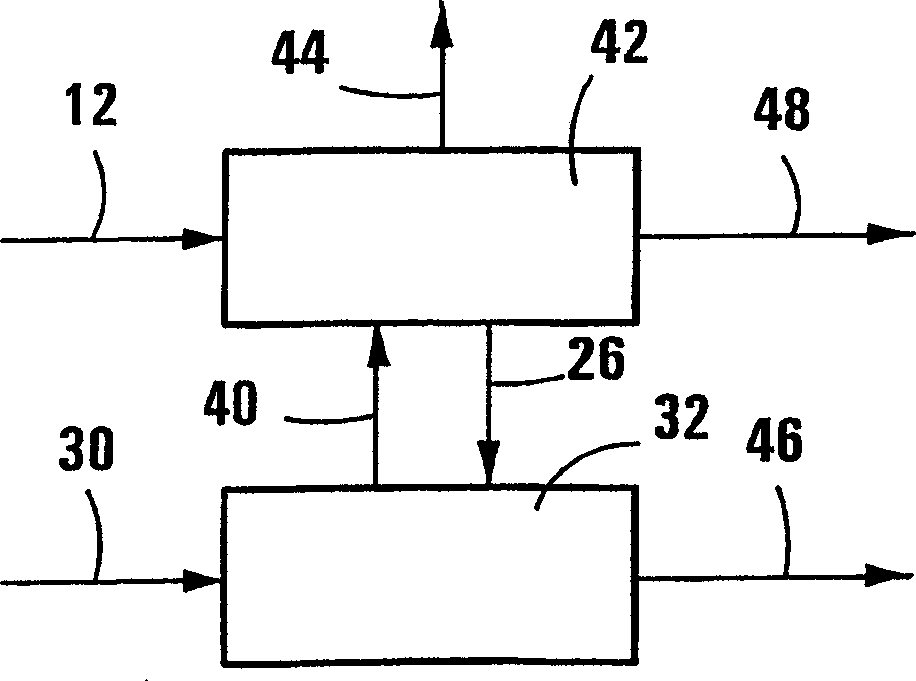

Process for recovery of oil from natural oil reservoir

InactiveCN1513079AImprove economic viabilityReduce demandSolidificationLiquefactionThermodynamicsGas to liquids

A method for recovering oil ( 24 ) from a natural oil reservoir ( 18 ) includes the steps of separating air to produce an oxygen rich stream ( 40 ) and a nitrogen rich stream ( 34 ), providing a natural gas stream ( 12 ) and feeding at least part of the oxygen rich stream ( 40 ) and the natural gas stream ( 12 ) into a gas to liquid or GTL conversion installation ( 42 ) to produce hydrocarbon products ( 44 ) and heat. The heat produced in the gas to liquid conversion installation is used to produce energy ( 20 ) to pressurize ( 16 ) the nitrogen in the nitrogen rich stream ( 34 ) to produce a pressurized nitrogen rich stream ( 22 ). The pressurized nitrogen rich stream ( 22 ) is passed into a natural oil reservoir ( 18 ) to enhance the recovery of oil ( 24 ) from the reservoir.

Owner:南非石油和天然气(私人)有限公司 +1

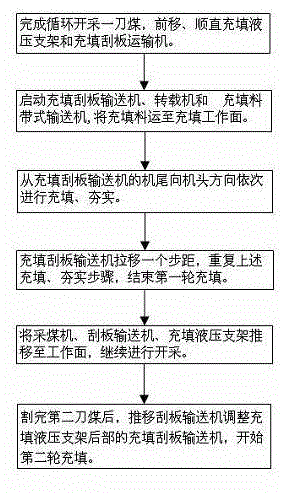

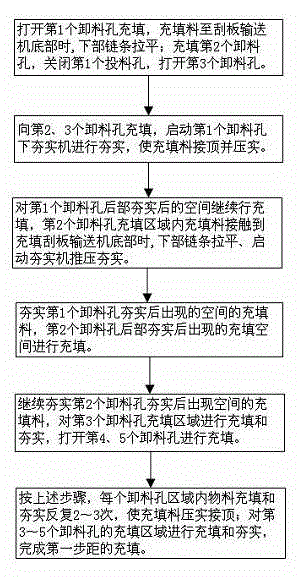

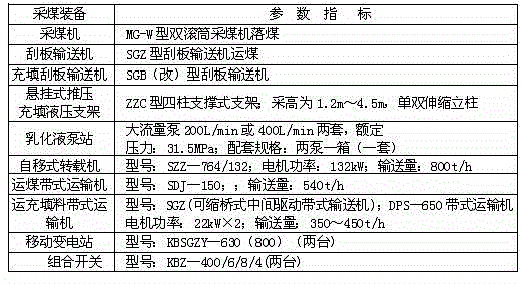

Coal mine bulk stock cut and fill mining method

InactiveCN102943689APromote recoveryExpand sourceMaterial fill-upUnderground transportCut and fillMechanical engineering

The invention relates to a coal mine bulk stock cut and fill mining method, and the mining and cutting and filling process is as follows: (1) circularly mining web on a working plane; (2) starting a cut-fill and transportation machine, and transporting the filler to the cut-fill working plane; (3) sequentially filling a first charging hole to a fifth hole on the tail part of a scraper conveyor to be compacted, repeatedly filling and compacting the filler inside each charging hole for 2 to 3 times, compacting the filler to the roof, and completing the filling of a first step; (4) pulling the filling scraper conveyor for one step, repeating the filing and compacting step, adequately filling the filler to the roof and adequately compacting the filler, and completing the filling of a first turn; (5) pushing a mining machine to the working plane, setting the coal mining step of 0.5 to 0.8m, and carrying out the mining; and (6) adjusting the cut-fill machine after second web, and carrying out the filling of a second turn. A coal mining system and a filling system are integrated through a filling hydraulic support, the mining of the work plane is synchronously carried out with the filling operation, and the integration of the mining and the filling operation is realized.

Owner:HEBEI COAL SCI RES INST

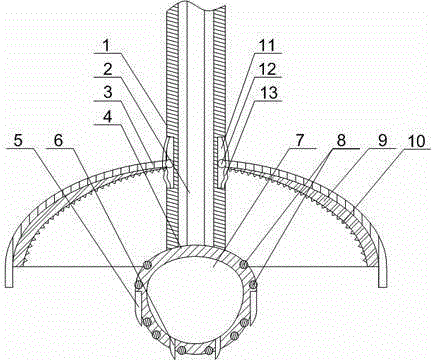

Methane hydrate collecting device for shallow stratum

The invention discloses a methane hydrate collecting device for a shallow stratum. The device comprises a gas pumping tube and a central rod; a moving block is fixed to the tail end of the central rod; a plurality of heating tubes which are connected in parallel are fixed on the outer wall of the moving block. The device further comprises a collecting cover with an arc-shaped cross section; an annular groove is formed in the outer wall of the gas pumping tube; a plurality of balls are mounted on the inner wall of a through hole; the upper side and the lower side of the collecting cover are respectively connected with the inner walls of two sides of the annular groove through elastic rubber rings; a reflecting plate is mounted on the inner wall of the collecting cover; the thickness of the reflecting plate is gradually increased from the center to two ends; a plurality of reflecting bulges with triangular longitudinal sections are arranged on the inner wall of the reflecting plate. According to the device, combustible ice can be decomposed by grades through the collecting cover and the moving block, so that the heat of the combustible ice can be slowly diffused, the combustible ice cannot be overflowed due to excessively fast decomposing while continuously pumping methane through the gas pumping tube, the influence of production of combustible ice on the environment can be avoided, and as a result, the purposes of increasing the production rate and improving the safety and reliability can be achieved.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

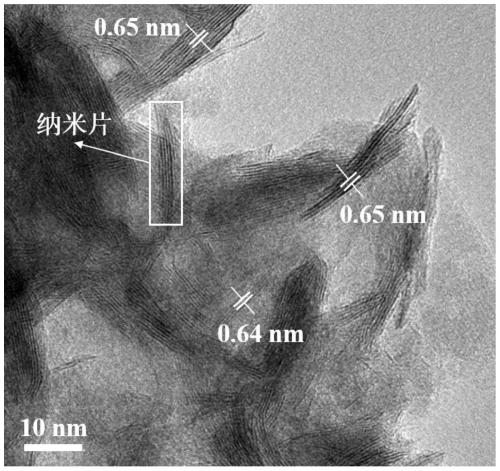

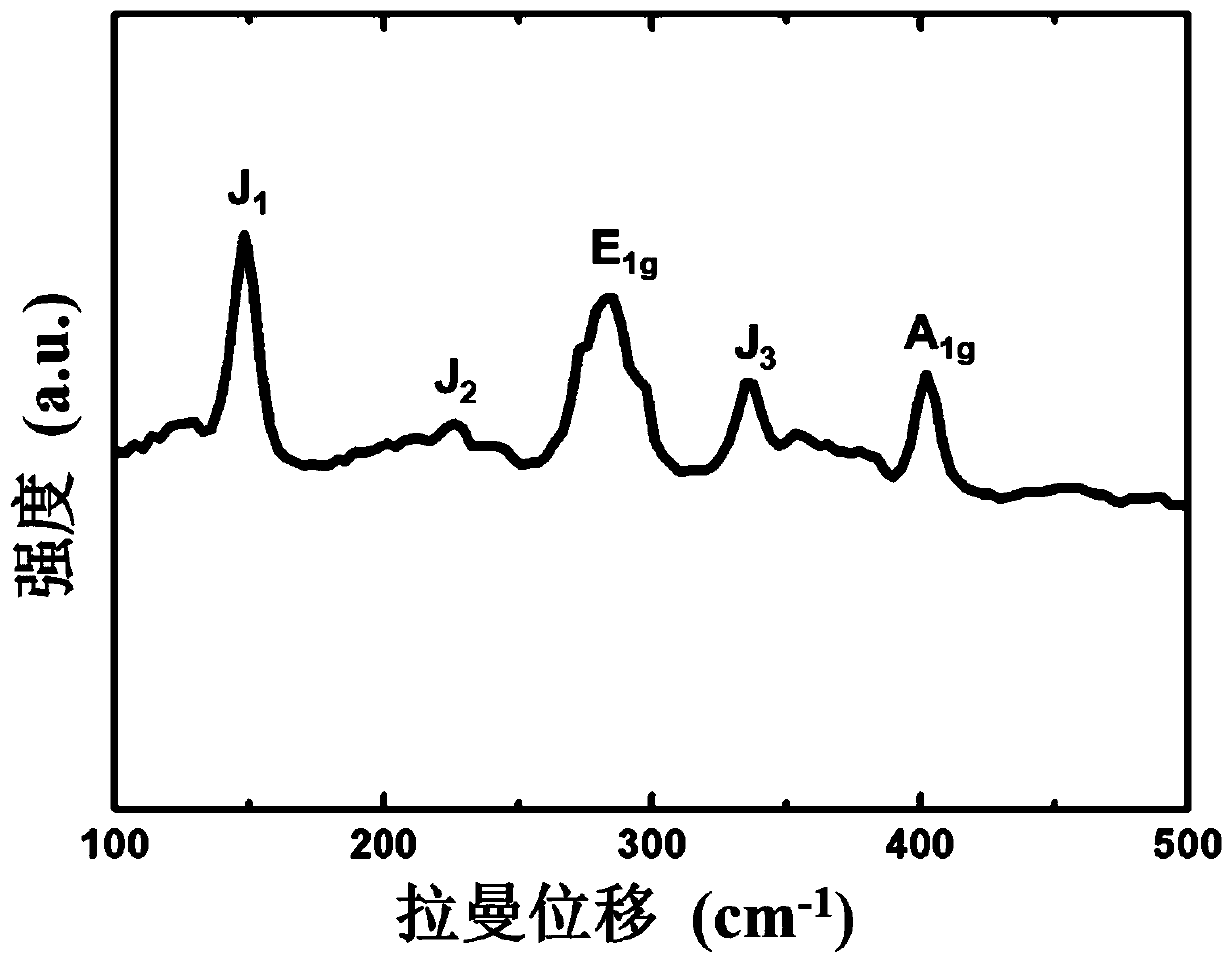

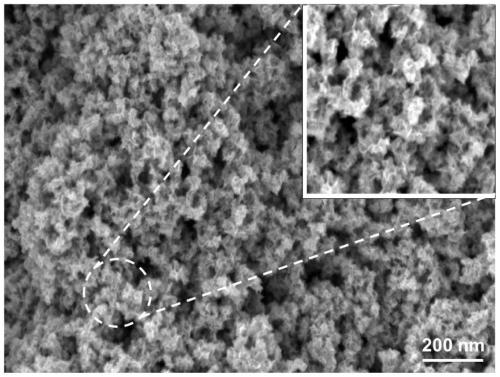

Modified MoS2 nano material and preparation method thereof

ActiveCN109943310AUniform thicknessAids in preparationMaterial nanotechnologyOrganic compound preparationNanofluidAlkyl amine

The invention provides a modified MoS2 nano material and a preparation method thereof. The modified MoS2 nano material is obtained by making an alkyl amine chain grafted onto the surface of a hydrophilic MoS2 nanosheet. The preparation method comprises the steps that a hydrophilic MoS2 nanosheet is added in an organic solution of an alkylamine compound to be stirred, and the obtained precipitationis the modified MoS2 nano material; in every 100 mL of organic solution, the amount of the hydrophilic MoS2 nanosheet is 1-10 g, and the amount of alkylamine compounds is 0.1-5 g. The invention further provides a nanofluid containing the modified MoS2 nanosheet, the hydrophilic MoS2 nanosheet used for preparing the modified MoS2 nanomaterial and a preparation method thereof. The modified MoS2 nano material can be applied to tertiary oil recovery in the oil industry by preparing the nanofluid which is an oil displacement agent solution at the low concentration, the environmental pollution in the tertiary process is greatly reduced, the production cost is lowered, and the oil recovery is increased.

Owner:侯吉瑞

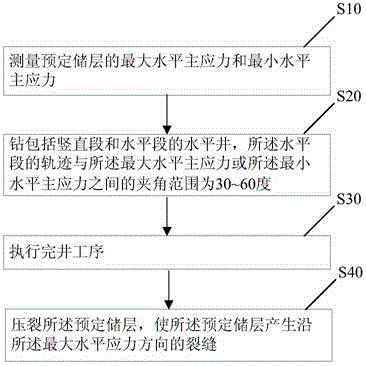

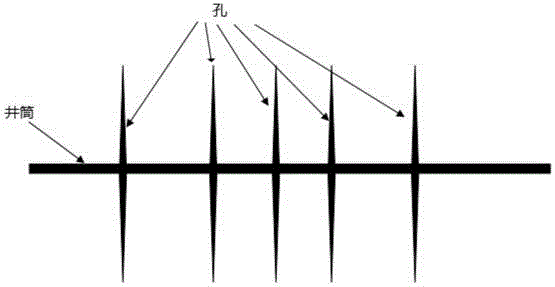

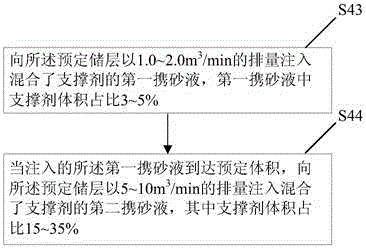

Reservoir reforming method

InactiveCN104594869ABest empirical completenessGood fracture oil conduction effectFluid removalDirectional drillingHorizontal stressDesign stage

The invention provides a reservoir reforming method. The reservoir reforming method includes the steps that the maximum horizontal principle stress and the minimum horizontal principle stress of a predetermined reservoir are measured; a horizontal well comprising a vertical section and a horizontal section is drilled, wherein the included angle between the track of the horizontal section and the maximum horizontal principle stress or the minimum horizontal principle stress ranges from 30 degrees to 60 degrees; a well completion procedure is executed; the predetermined reservoir is cracked so that a crack can be formed in the predetermined reservoir in the direction of the maximum horizontal stress. At the initial design stage, in consideration of the possible extension direction of the crack when the reservoir is cracked, the included angle between the extension direction of the horizontal section and the maximum horizontal principle stress or the minimum horizontal principle stress of the predetermined reservoir is made to range from 30 degrees to 60 degrees, so that the horizontal well has good experience completeness and a good oil-guiding effect of the crack, and then the oil and gas production rate is easily increased.

Owner:PETROCHINA CO LTD

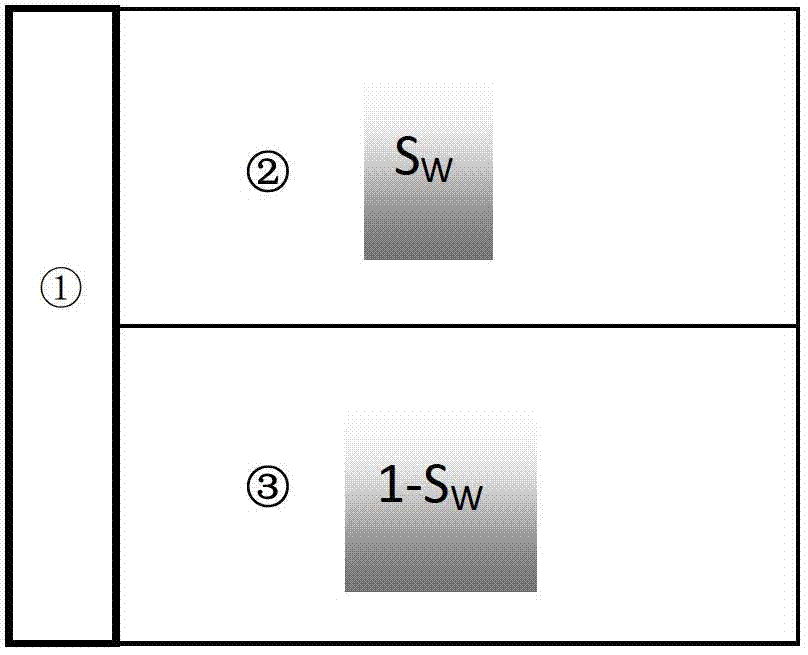

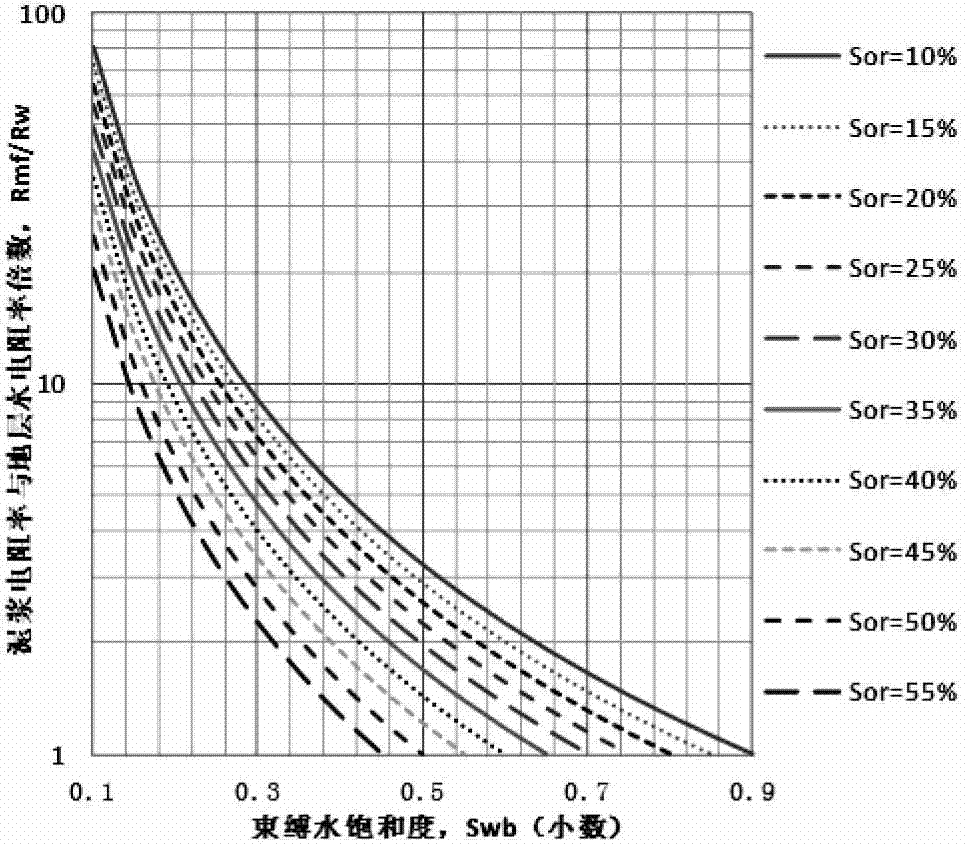

Method for fast recognizing low-resistivity oil and gas reservoirs through optimizing drilling mud

ActiveCN103046923AImprove recognition rateIncrease mining rateBorehole/well accessoriesElectrical resistance and conductanceWell drilling

The invention belongs to a method for recognizing oil and gas reservoirs in oil exploration and development and particularly relates to a method for fast recognizing a low-resistivity zone through optimizing drilling mud to determine oil content. The method includes optimizing drilling mud parameters according to drilling coring materials in a zone to be detected and earth's surface physical materials, establishing evaluation to form a drilling mud resistivity model of the low-resistivity zone; and detecting the drilling mud resistivity value of the zone to be detected and recognizing the process of the low-resistivity oil and gas reservoirs through combining the model, wherein Rmf>KRw in the drilling mud resistivity model. By means of the method, the recognition rate of the low-resistivity oil and gas reservoirs can be improved, therefore the exploitation rate of the low-resistivity oil and gas reservoirs can be improved, and exploratory and development costs can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

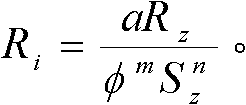

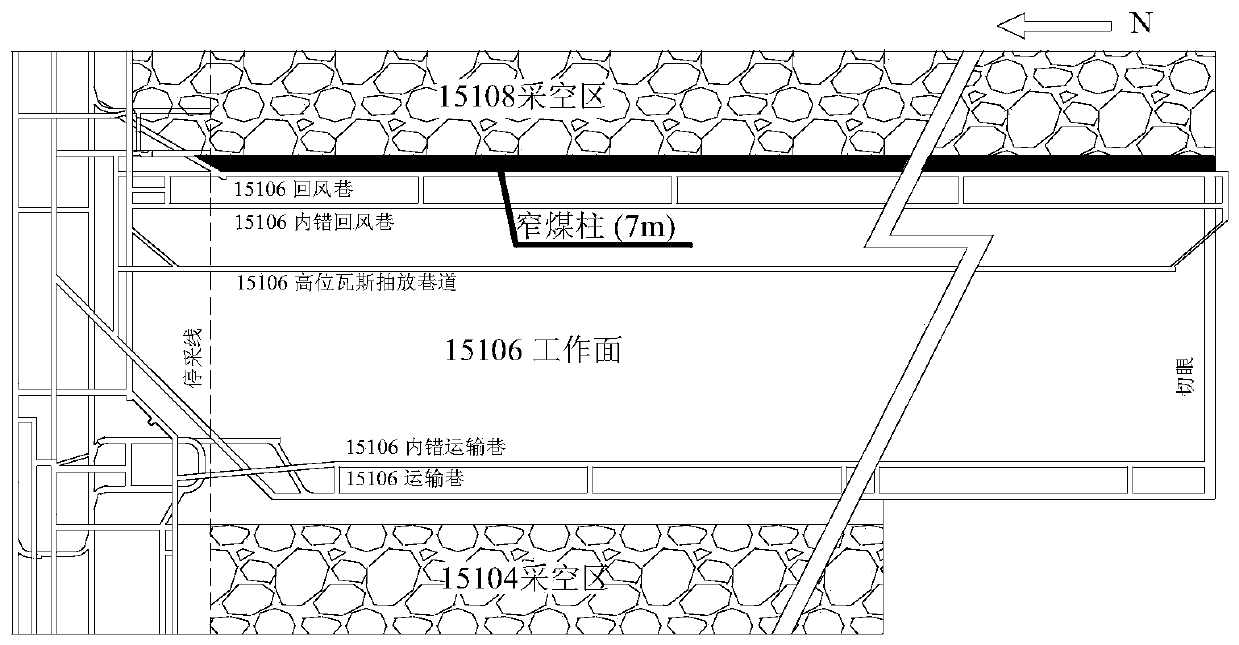

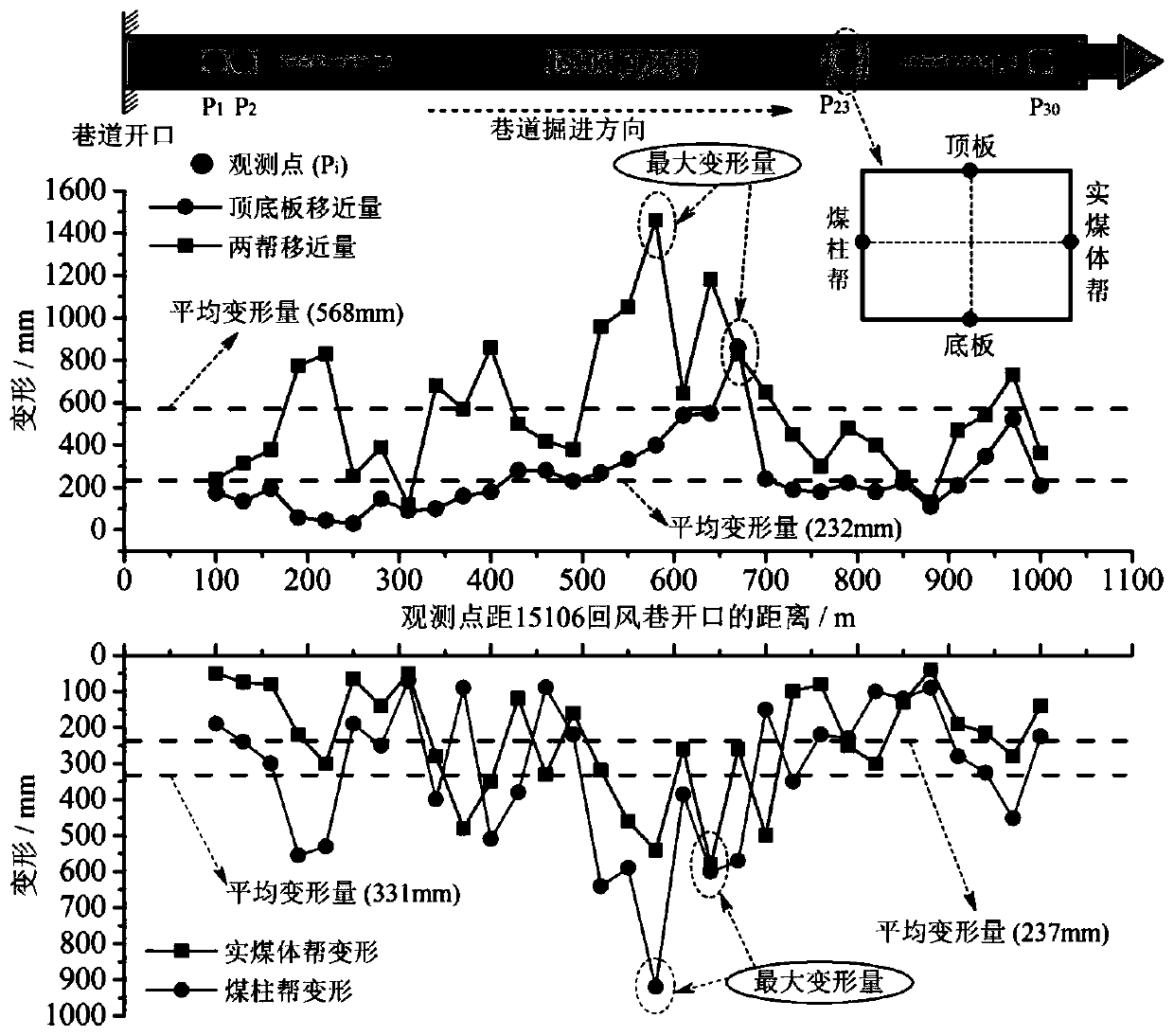

Reasonable width determination method for gob-side entrydriving narrow coal pillar based on fracture evolution

ActiveCN110397470AEffective isolationIncrease mining rateUnderground miningFluid removalPre stressDistribution characteristic

The invention discloses a reasonable width determination method for a gob-side entrydriving narrow coal pillar based on fracture evolution. The method comprises the following five steps: observing roadway deformation and coal pillar fracture distribution characteristics on site; establishing a UDEC-Trigon numerical model to match with on-site condition to determine model parameters; reversing an evolution rule of fractures in different coal pillar widths; determining the reasonable coal pillar width fracture evolution penetration; and finally providing a high pre-stressed anchor and anchor cable technology to control stability of the coal pillar. By adopting a damage factor for quantifying assessment of fracture evolution penetration to finally determine the optimum reasonable width of thegob-side entrydriving narrow coal pillar, inner fractures of the coal pillar in a service period are not penetrated, and gas in a goaf can be isolated effectively while the coal pillar is carried stably.

Owner:CHINA UNIV OF MINING & TECH +1

Method for redevelopment of junked drowned oil field

InactiveCN1664306AEasy to masterIncrease mining rateFluid removalSealing/packingGeomorphologyOil field

The invention relates to a method to explore the oil field that has been rejected by flood. It includes the following steps: applying part gelate water shut off to the original water injection well, and forcing the water flowing along the portrait direction and the radial direction; applying gelate water shut off to the water flooded layer of the original production well; taking large cubic capacity pumping draining to the original production well until emptying the seeper; injecting high pressure intensified water into the original flooded oil well and the quantity is 3-5 times of the normal injecting rate; adopting pumping method to the oil field that can not flow; adjusting the output proportion and the speed to realize producing steadily.

Owner:胡振起

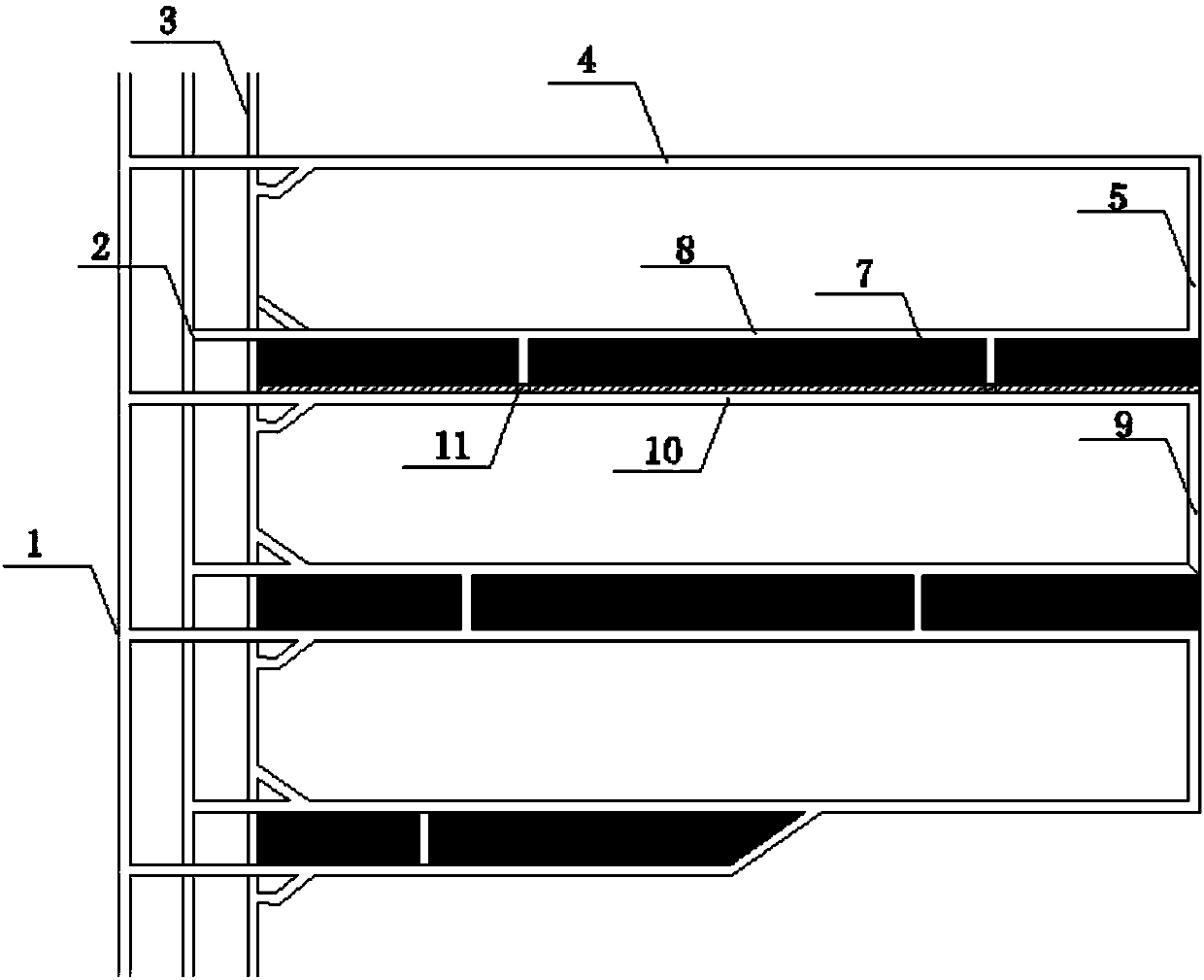

Remained small coal pillar comprehensive mechanized coal mining supporting structure and construction method

PendingCN107905807APrevent intrusionAvoid roof fall accidentsUnderground chambersUnderground miningEngineeringCoal pillar

The invention discloses a remained small coal pillar comprehensive mechanized coal mining supporting structure and a construction method. The remained small coal pillar comprehensive mechanized coal mining supporting structure and the construction method comprises a narrow coal pillar arranged between a current stope working face and an adjacent stope working face, one side of the narrow coal pillar is provided with a filling body, and the adjacent stope working face is also provided with a roof presplitting cutting line; the construction method of the remained small coal pillar comprehensivemechanized coal mining comprises the following steps that before the coal mining, an air return way, a haulage gate, and an auxiliary haulage gate are constructed; the roof presplitting cutting line of the current stope working face is constructed in the auxiliary haulage gate; then the filling body is constructed synchronously with a head coal mining. The remained small coal pillar comprehensivemechanized coal mining supporting structure and the construction method solves the problems of gangue darting into a lane in a worked out section, roof bolting accident of the auxiliary transport chute, and the leakage of the narrow coal pillar in the current stope working face; and the mining influence to the auxiliary transport chute caused by the stope working face is weakened, cost of maintenance of the lane is reduced, and recovery coefficient of coal resource is enhanced; and the remained small coal pillar comprehensive mechanized coal mining supporting structure and the construction method can be applied to most geological mining conditions and has a great significance to promote and achieve safe and efficient mining of coal mine.

Owner:SHAANXI COAL & CHEM TECH INST

Earth surface rock breaking multi-position rotary drill machine for oil exploitation

InactiveCN109519119AIncreased drilling and extraction efficiencyIncreases the rate of oil extractionEarth drilling toolsDrilling rodsDrive motorEngineering

The invention discloses an earth surface rock breaking multi-position rotary drill machine for oil exploitation. The earth surface rock breaking multi-position rotary drill machine includes a fixed plate, a movable groove, a first fixing strip and an embedding groove. A supporting rod is fixedly welded to the outer wall of the fixed plate, a sliding block is mounted on the inner wall of a slidinggroove, a driving motor is mounted at the tail end of a movable rod, the output end of the driving motor is in flange connection with a rotating shaft, the first fixing strip is fixedly welded to thetail end of the fixed plate, a first mounting strip is mounted below the first fixing strip, the lower end of the first mounting strip is in screw connection with an anti-collision strip, the inner wall of the anti-collision strip is provided with a damping pad, and the embedding groove is disposed on the edge of the inner wall of the first mounting strip. The supporting rod in the earth surface rock breaking multi-position rotary drill machine for oil exploitation has a stabilizing and balancing function, the effect of fixedly supporting the whole machine can be achieved, and because a hydraulic pump and the driving motor generate a certain amplitude during the working process, a damping rod can have effects of damping on the amplitude.

Owner:广州科奥信息技术有限公司

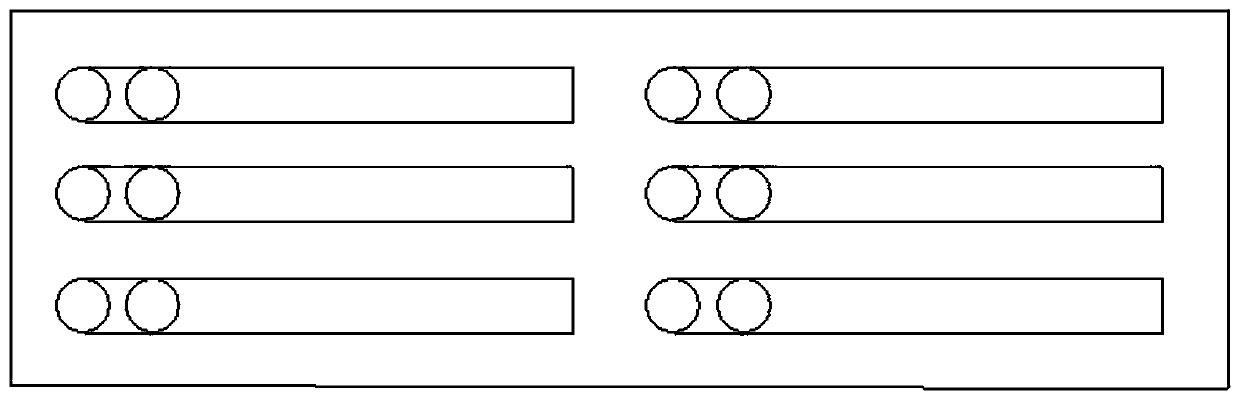

Transient electromagnetic underground detecting instrument

InactiveCN103091719ADetection depth is farLong detection distanceElectric/magnetic detection for well-loggingExplosive atmospheresPower flow

The invention relates to a transient electromagnetic underground detecting instrument which comprises a main engine, a transmitter, a power supply, a transmitting coil and a receiving coil. The main engine sends operational orders to the transmitter through a main engine connecting line. A power supply adjusting plate, a current plate and a transmitting plate are arranged in the transmitter. The power supply is a large current power supply, and total voltage provided by the large current power supply is 24 volt(V)-36V. Length of the transmitting coil is 6m-10m, and transmitted power is improved. The power supply adjusting plate, the current plate and the transmitting plate arranged in the transmitter are integrated to form an integrated transmitting plate, and a size of the transmitter is reduced. The transmitter is provided with an explosive-proof cavity and a connecting line cavity, the power supply and the integrated transmitting plate are arranged in the explosive-proof cavity, and explosive atmospheres in an outside world and a launcher with large current are isolated to guarantee using safety. The explosive-proof cavity is composed of an explosive-proof shell body, materials of the explosive-proof shell body are acrylonitrile butadiene styrene (ABS) engineering plastics which accord with coin mine safety requirements, weight of the transmitter is reduced, and exploration efficiency is improved largely.

Owner:武汉地大华睿地学技术有限公司

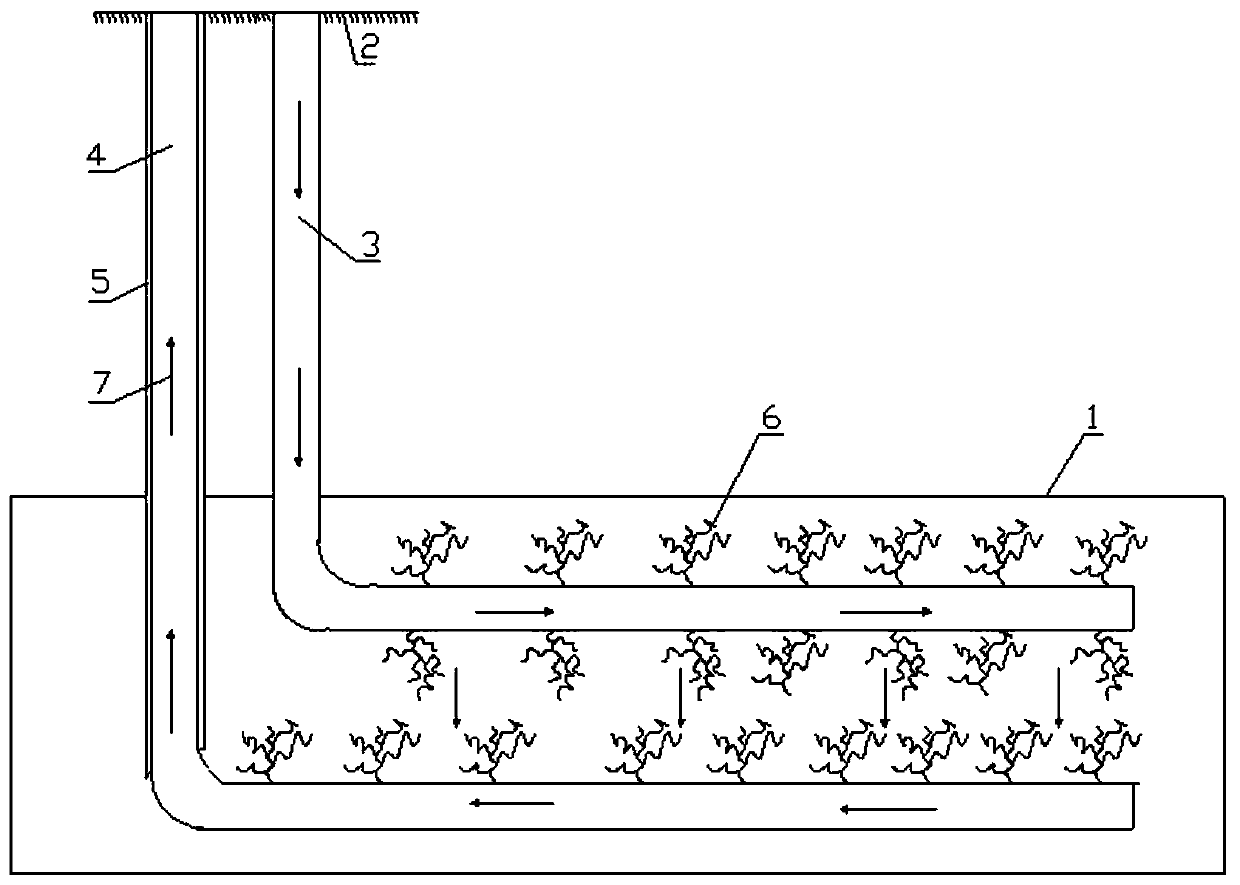

Method for developing hot dry rock geothermal resources through using gravity drainage technology

InactiveCN111022014AHigh compressive strengthReduced compressive strengthSurveyGeothermal energy generationThermodynamicsWell drilling

The invention provides a method for developing hot dry rock geothermal resources through using a gravity drainage technology. The method comprises the three steps of injection-production well design and well drilling, inter-well fracturing communication and high-pressure water injection production. In the well drilling stage, vertical fracturing and longitudinal communication are carried out on anupper horizontal well and a lower horizontal well which are parallel to each other, so that the upper injection-production horizontal well and the lower injection-production horizontal well meet therequirements of flow communication and pressure communication; in the production stage, low-temperature water is injected into an upper injection well and then subjected to sufficient heat exchange with a stratum, so that high-temperature water is extracted from a lower production well, extracted heat energy is comprehensively utilized for power generation and the like, and the treated water is circularly injected back into a dry hot rock stratum. According to the technical scheme, the gravity settling principle and a method for improving the heat exchange efficiency through crack auxiliary fluid flowing are combined, and the development efficiency of the hot dry rock geothermal resources can be greatly improved.

Owner:SOUTHWEST PETROLEUM UNIV

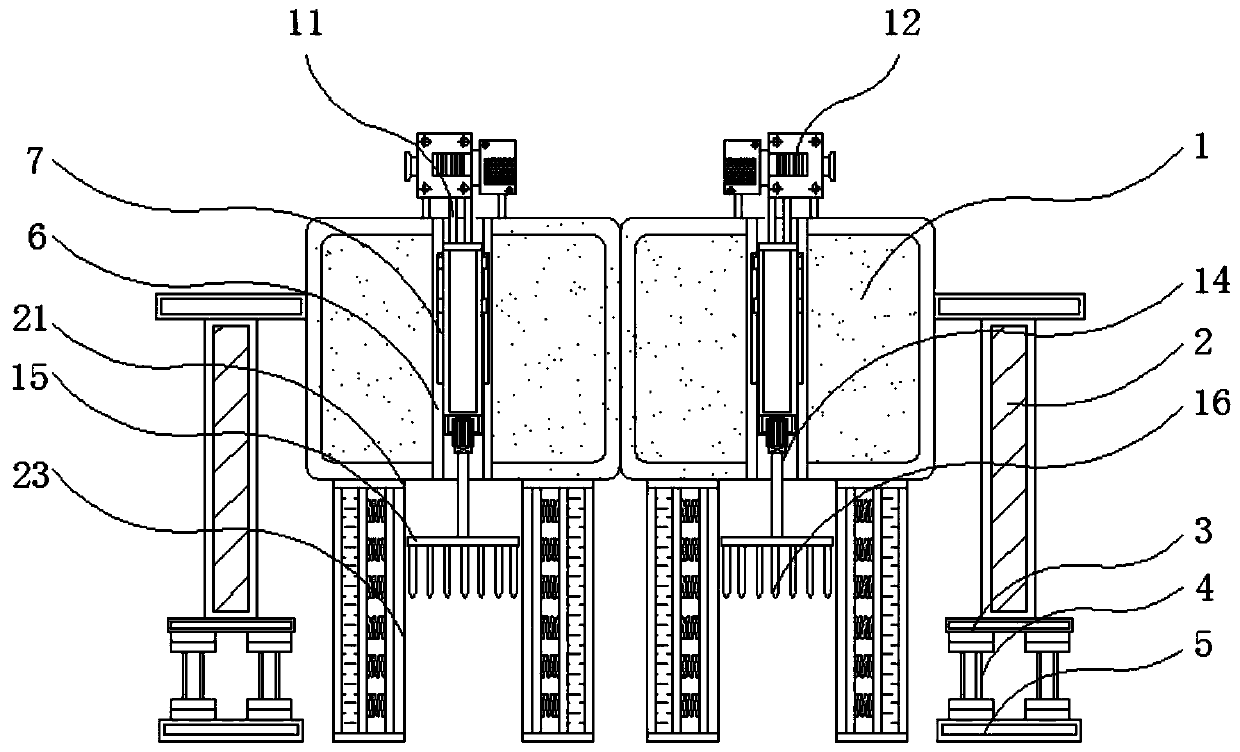

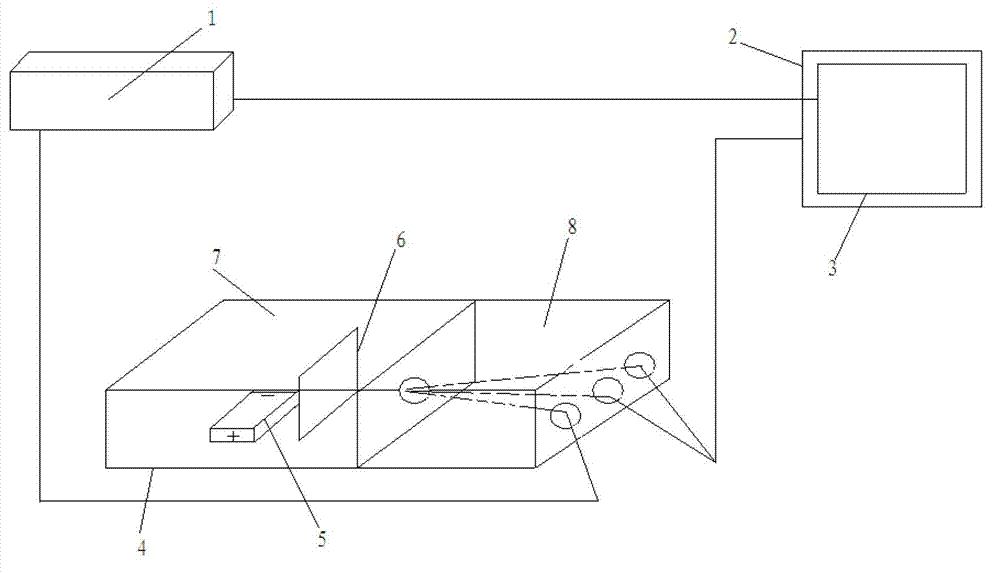

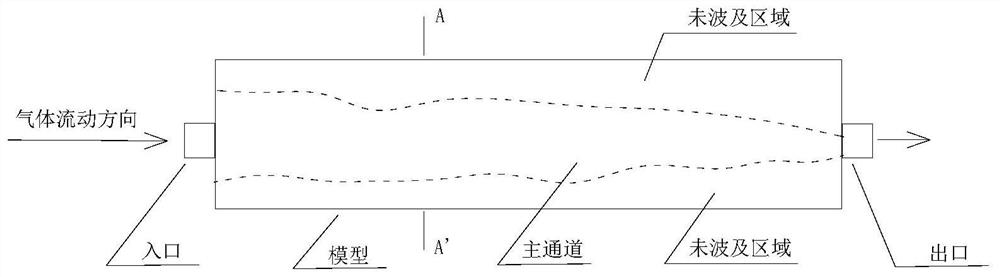

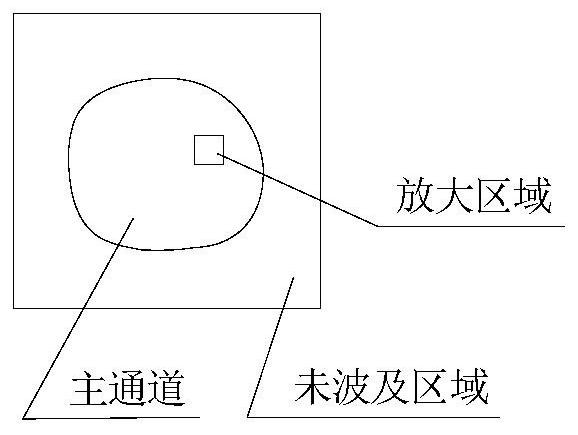

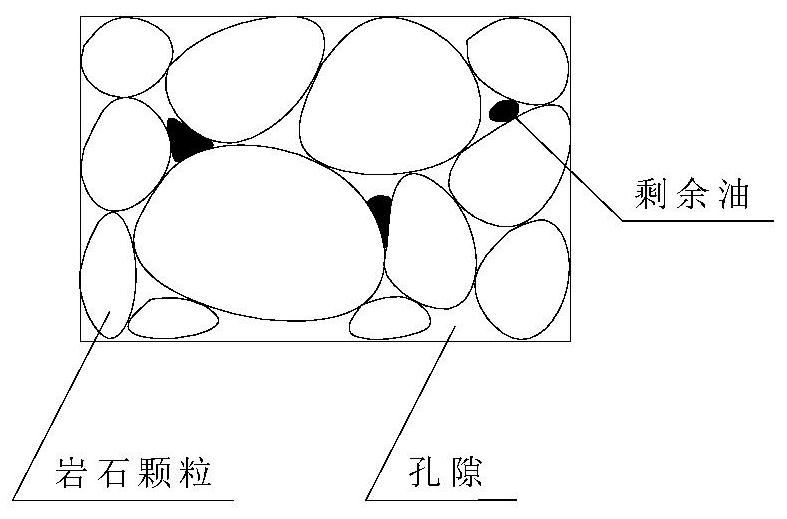

Experimental device for improving gas injection recovery ratio through low-frequency voltage transformation

ActiveCN112627783AIncrease mining rateMaterial analysis using sonic/ultrasonic/infrasonic wavesFluid removalUltrasound attenuationUltrasonic attenuation

The invention provides an experimental device for improving the gas injection recovery ratio through low-frequency voltage transformation. The experimental device comprises a rock model, an autoclave, a low-frequency voltage transformation device, an ultrasonic transmitting and receiving device and a gas injection oil displacement device, wherein the rock model is located in the autoclave and simulates an actual oil reservoir stratum; a low-frequency voltage transformation well and an ultrasonic probe are arranged in the rock model; a hole is formed in the lower section of the low-frequency voltage transformation well and communicates with an actual oil reservoir simulated by the rock model; the ultrasonic probe is connected with the ultrasonic transmitting and receiving device; the gas saturation change process is monitored through the change of the ultrasonic attenuation amplitude; the low-frequency voltage transformation device is used for changing the distribution state of remaining oil in the rock model; and the gas injection oil displacement device conducts gas injection oil displacement after the rock model reaches the oil saturation state and the distribution state of the remaining oil is changed, and the improvement rate of the gas injection recovery ratio is determined according to two times of gas injection oil displacement. According to the scheme, pressure change is caused between an injection well and a production well, the remaining oil in oil reservoir pores is affected by pressure, and therefore the recovery rate of the remaining oil is increased.

Owner:PETROCHINA CO LTD

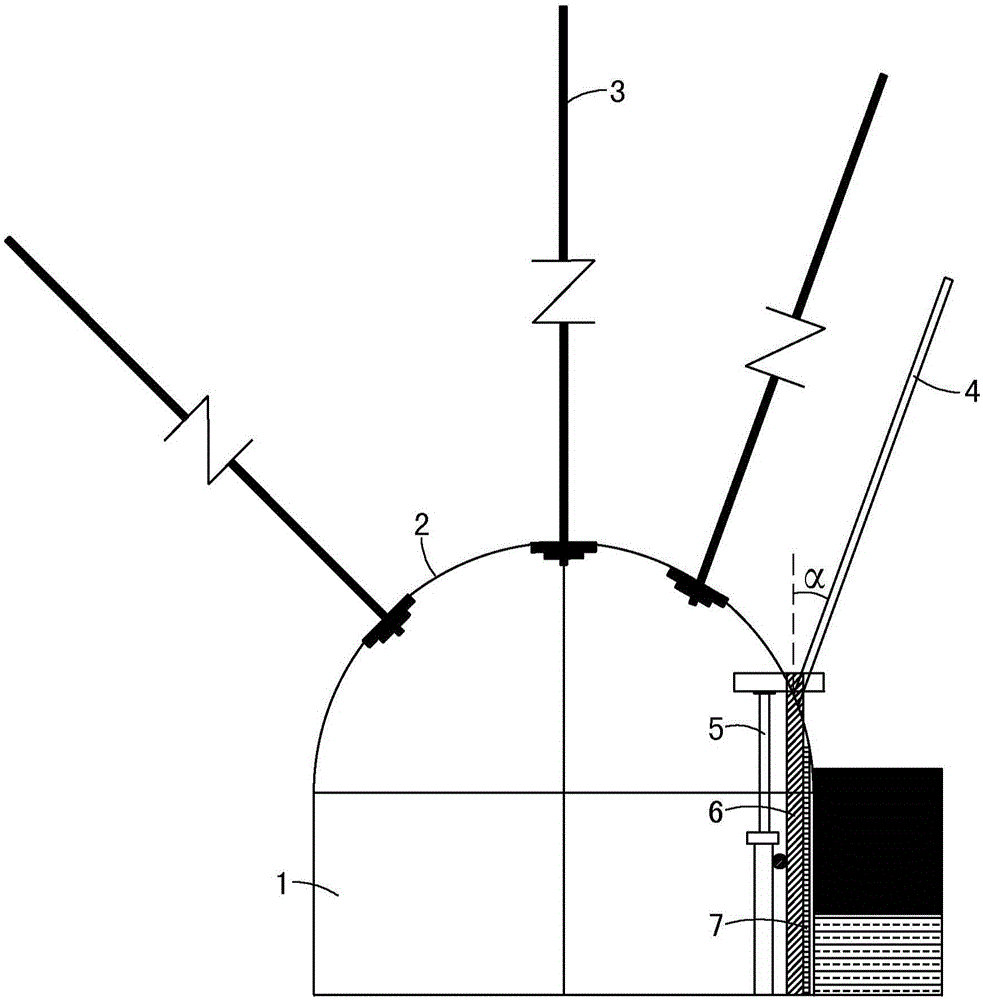

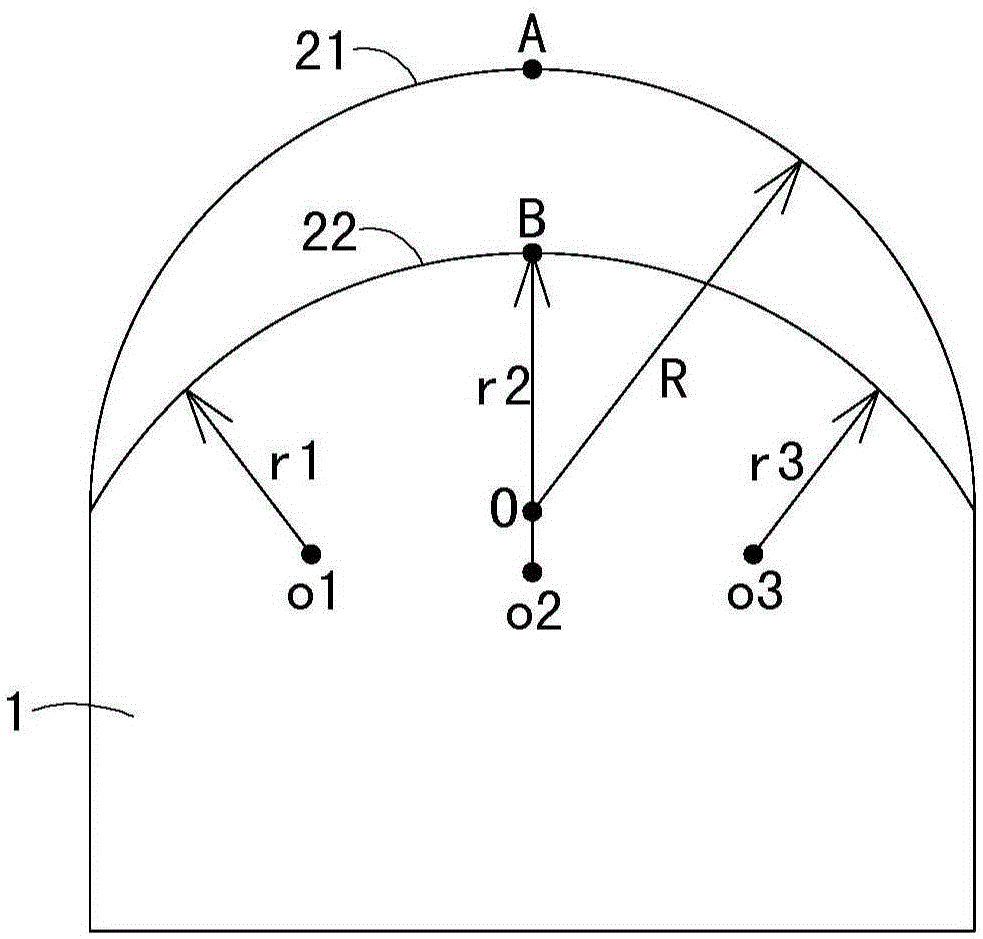

Anti-collapse structure beside roadway based on breaking roof 110 construction method

ActiveCN105134216AImprove securityGuaranteed Fall DirectionUnderground chambersUnderground miningStructural engineeringCoal pillar

The invention discloses an anti-collapse structure beside a roadway based on a breaking roof 110 construction method. The anti-collapse structure is applied to the 110 construction method. One working face of the 110 construction method corresponds to the roadway, no coal pillar needs to be reserved, and the roadway is retained after mining roof cutting and pressure relieving of the roadway are completed on the previous working face. Moreover, a top plate of the roadway is arched. Directional joint cutting is conducted on one side of the top plate of the roadway, and the joint cutting angle is 15-20 degrees. According to the anti-collapse structure beside the roadway, when underground mining is conducted, one working face corresponds to the roadway, and no coal pillar needs to be reserved, so that resources are saved and the coefficient of mining is increased. Besides, the top plate of the retained roadway is arched, so that the safety is improved; the safety of the coal mining working face is guaranteed. In addition, the joint cutting angle is 15-20 degrees, the caving direction of the top plate after roof cutting can be effectively guaranteed, and the influence on roadway retaining by top plate caving is reduced to the greatest extent.

Owner:何满潮

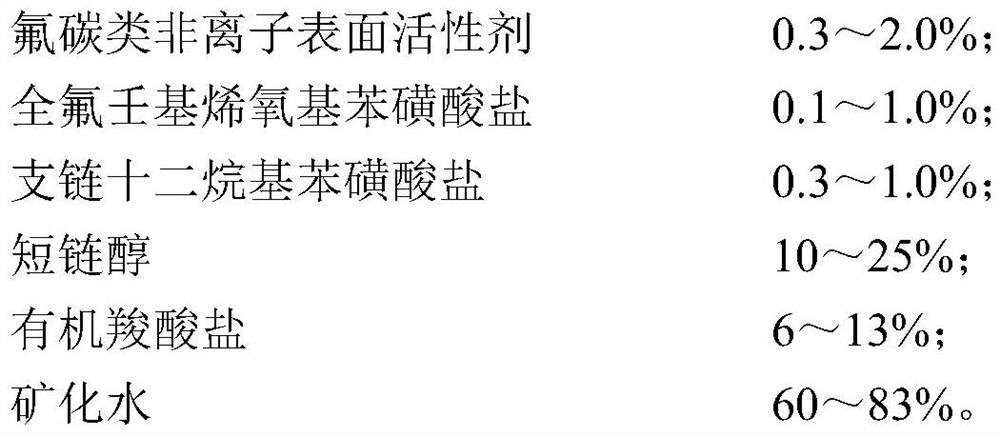

Temperature-resistant high-efficiency tight gas reservoir fracturing waterproof locking agent and application thereof

ActiveCN113308236AHigh temperature resistanceExcellent table/interface performanceDrilling compositionActive agentCarboxylic acid

The invention discloses a temperature-resistant high-efficiency tight gas reservoir fracturing waterproof locking agent which comprises the following components in percentage by mass: 0.3-2.0% of a fluorocarbon nonionic surfactant, 0.1-1.0 % of perfluorononyl alkenyloxy benzene sulfonate; 0.3-1.0% of branched chain dodecyl benzene sulfonate; 10-25 % of short-chain alcohol; 6-13% of an organic carboxylate; and 60-83% of mineralized water. The waterproof locking agent has the advantages of being high in temperature resistance, small in solution particle size, excellent in surface / interface performance, good in wettability, low in use concentration and high in water-blocking-resistant capacity; the surface tension of an aqueous solution with the concentration being 0.2-0.5% is smaller than 21 mN / m, the solution particle size is smaller than 40 nm, and the water-blocking-resistant capacity is larger than 85%; and the waterproof locking agent has a huge application prospect in tight gas fracturing synergistic exploitation. The invention also discloses an application of the waterproof locking agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

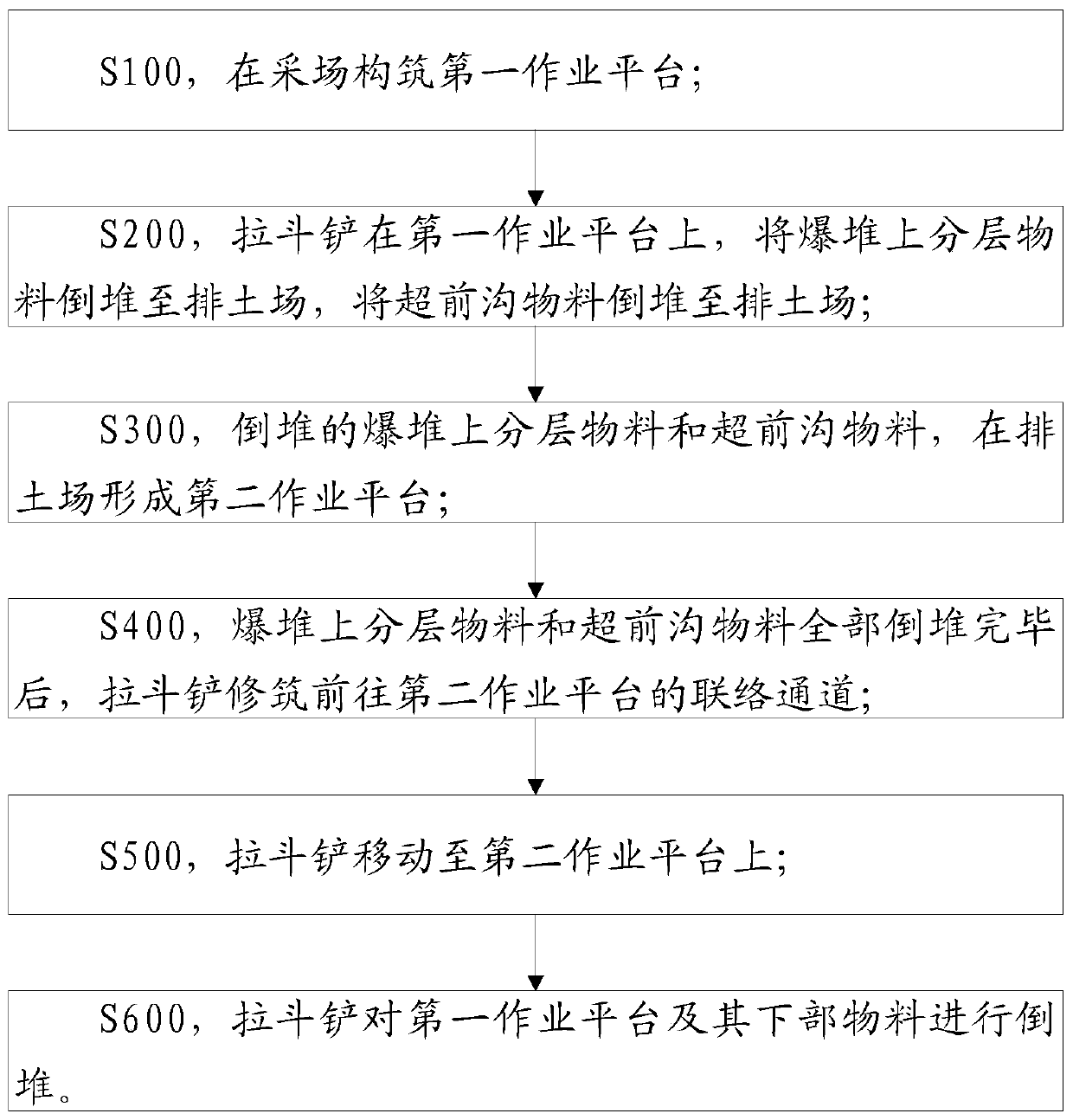

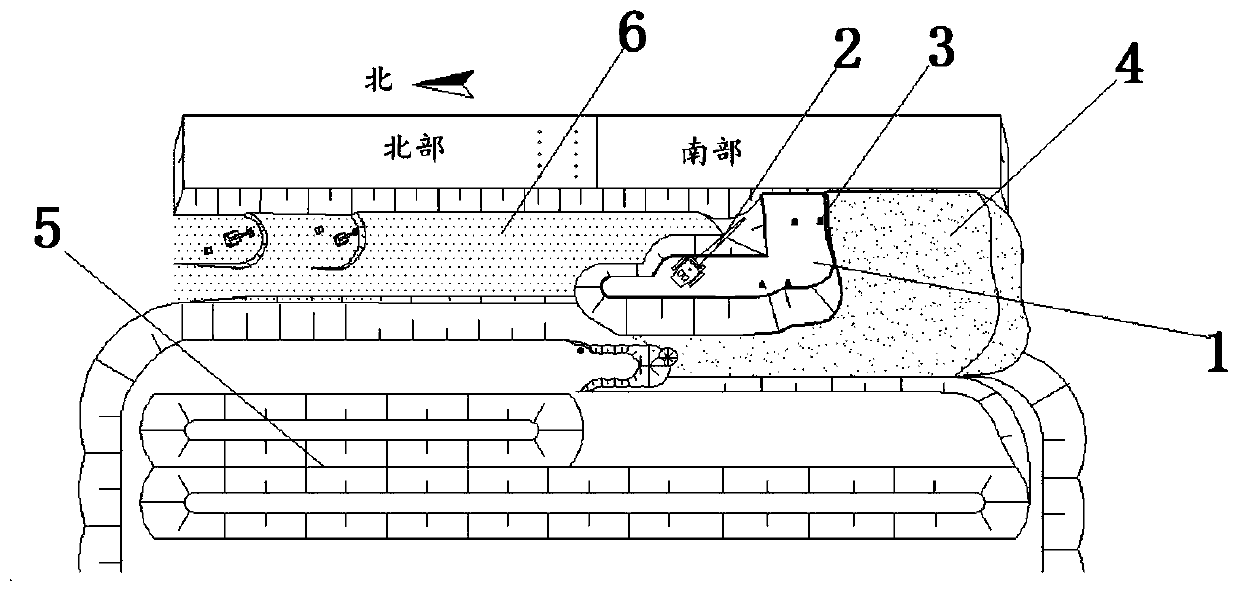

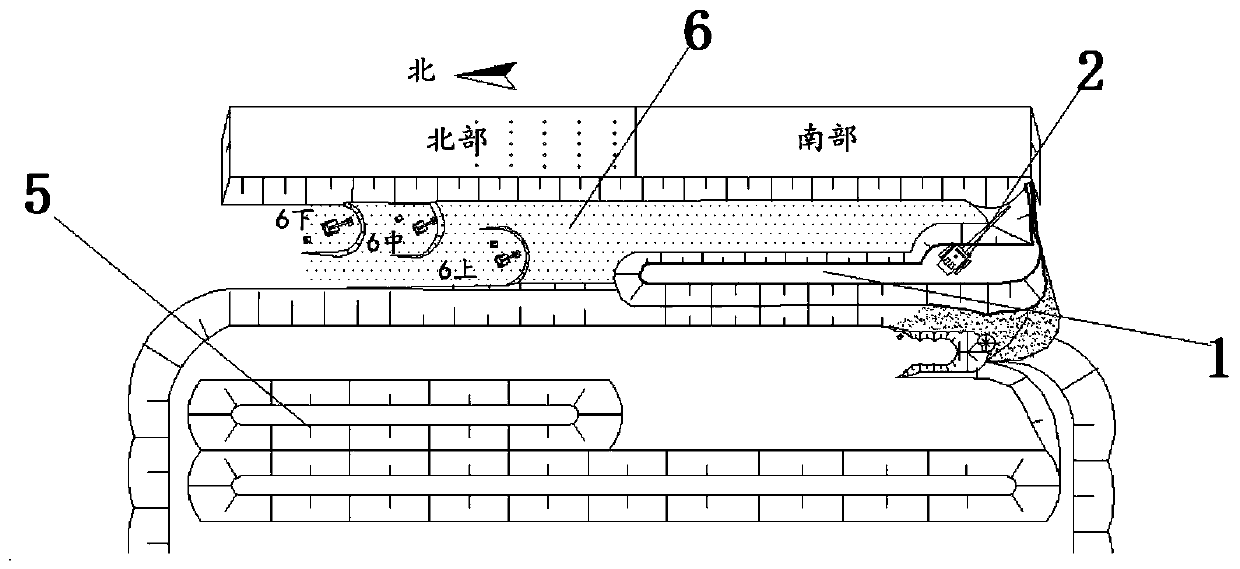

Drag bucket forklift operating method

InactiveCN110700837AReduced Quantity RequirementsLarge operating radiusOpen-pit miningWaste dumpEngineering

An embodiment of the invention discloses a drag bucket forklift operating method. The drag bucket forklift operating method comprises the steps that a first operating platform is built on the stope; adrag bucket forklift is located on the first operating platform, pushes layered materials on a blasting muck pile to a waste dump in an overcast mode and pushes leading ditch materials to the waste dump in an overcast mode; the pushed layered materials on the blasting muck pile and the pushed leading ditch materials are combined to form a second operating platform on the waste dump; after the pushed layered materials on the blasting muck pile and the pushed leading ditch materials are completely pushed in an overcast mode, the drag bucket forklift constructs a connection channel for the second operating platform; the drag bucket forklift moves to the second operating platform; and the drag bucket forklift pushes the first operating platform and materials at the bottom of the first operating platform in an overcast mode. By the use of the drag bucket forklift operating method, the operation that drag bucket forklifts are arranged on the stope and the waste dump is not required any longer, the requirement for the number of the drag bucket forklifts can be reduced, the operating radius of the drag bucket forklift is increased, the operating capacity of the drag bucket forklift is improved, the purchase cost is reduced, the exploitation quantity is increased, and the exploitation rate is improved.

Owner:SHENHUA ZHUNGER ENERGY

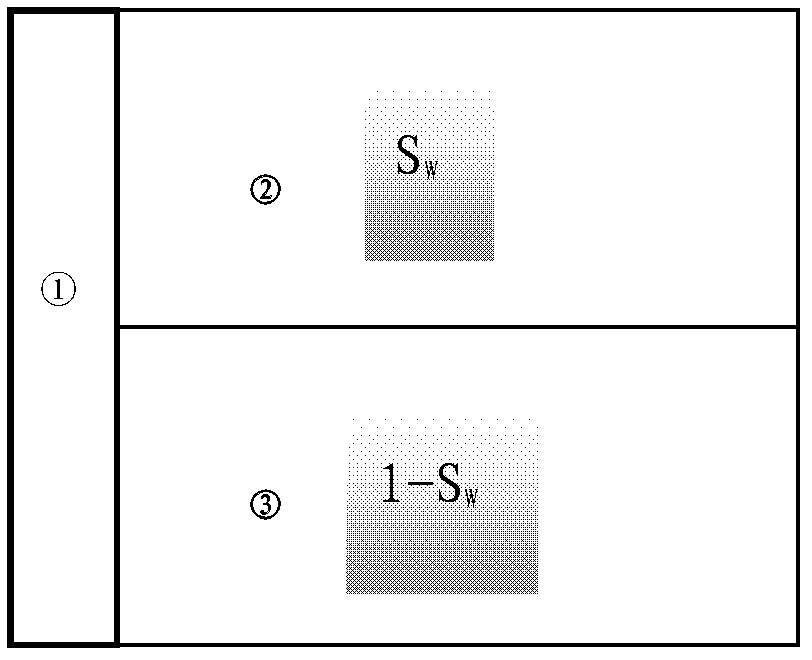

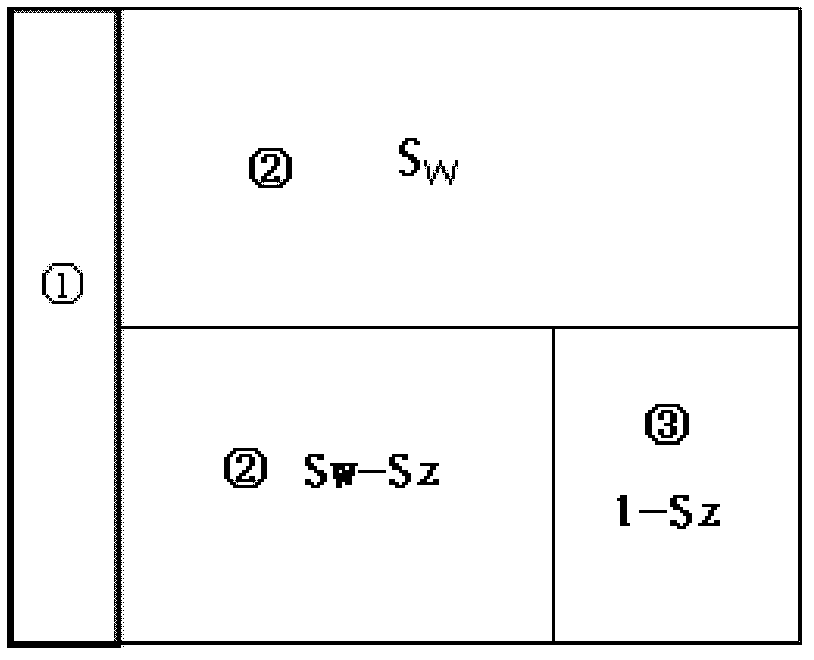

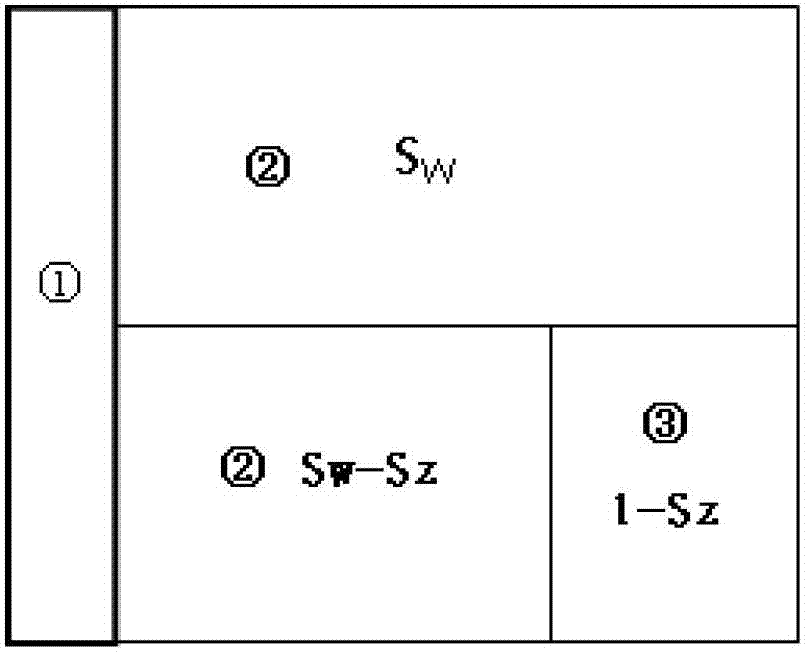

Method of judging low-resistivity annulus formed in formation

ActiveCN103590822AImprove recognition rateIncrease mining rateBorehole/well accessoriesElectrical resistance and conductanceRock core

The invention belongs to the technical field of petroleum exploration and development, in particular to an oil and gas reservoir recognition method applied to qualitatively analyzing existence of oil reservoirs through detection data, and provides a method of judging a low-resistivity annulus formed in a formation. The method includes: acquiring core data and determining irreducible water saturation Swb and residual oil saturation Sor of a core; acquiring a ratio of drilling fluid resistivity Rmf and formation water resistivity Rw according to the irreducible water saturation Swb and residual oil saturation Sor of the core; detecting a target formation to acquire the formation water resistivity Rw and the drilling fluid resistivity Rmf; if an actual physical value is larger than a calculated value, determining the low-resistivity annulus is formed. Through the application of the method in low-resistivity oil and gas fields, efficiency of exploiting low-resistivity oil and gas reservoirs can be improved effectively, the low-resistivity oil and gas reservoirs are recognized visually and quickly, exploration cost is reduced, and economic benefit is increased. As China possesses many low-resistivity oil and gas reservoirs, the method has promising application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com