Modified MoS2 nano material and preparation method thereof

A nano-material and modification technology, applied in the field of modified MoS2 nano-material and its preparation, can solve the problems of low oil recovery, high cost, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

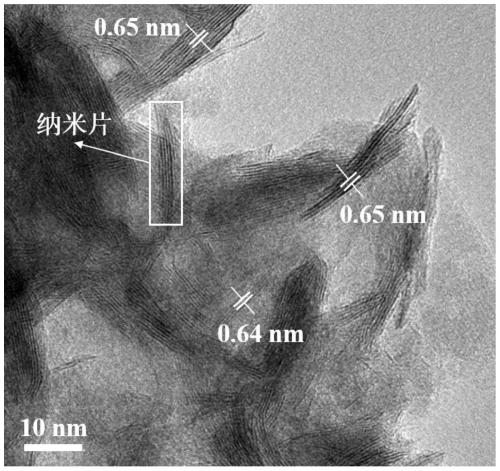

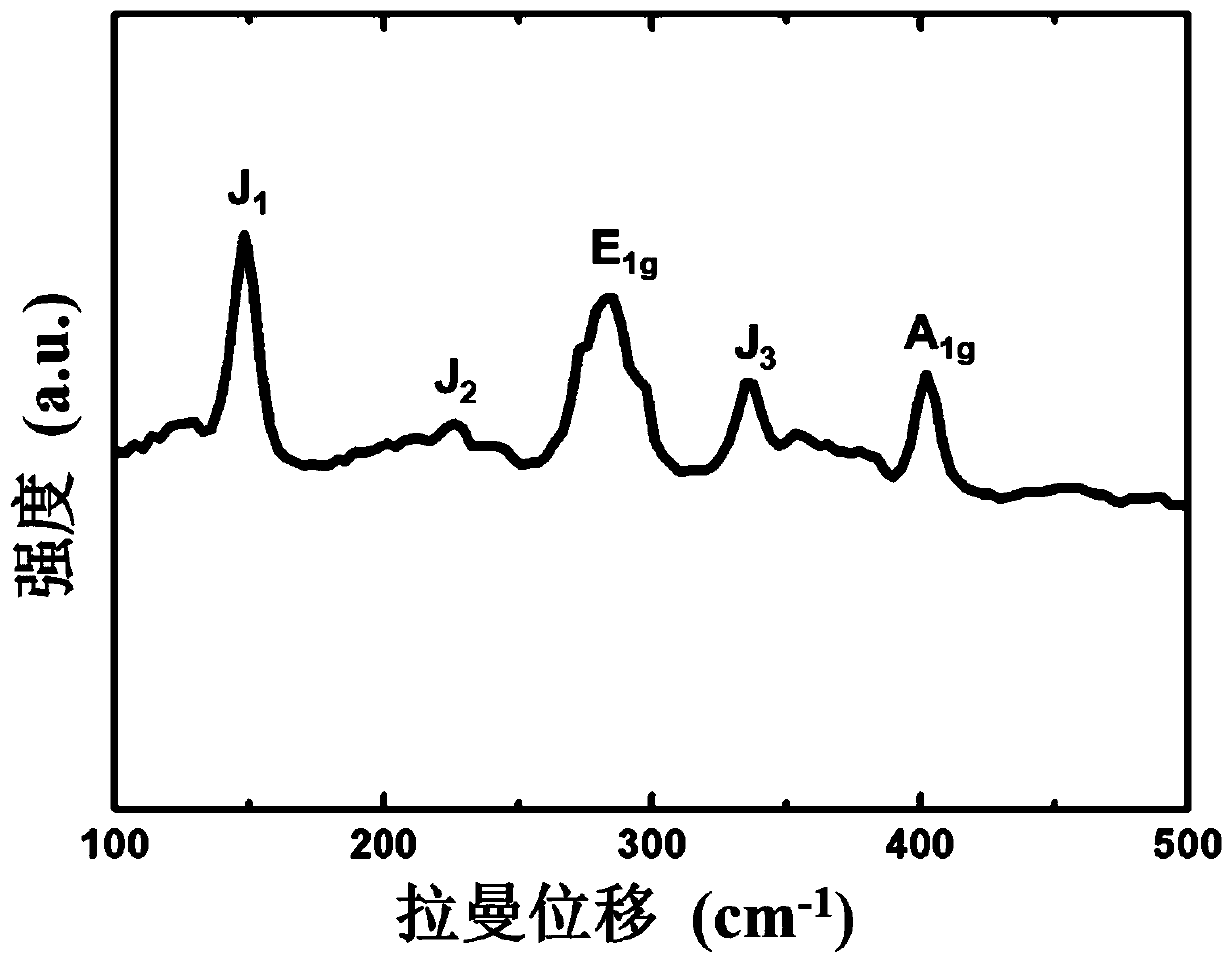

[0080] This embodiment provides a kind of hydrophilic MoS 2 Nanosheets, the specific preparation method is as follows:

[0081] 1) ammonium molybdate, potassium thiocyanate and potassium borohydride are added in water to obtain a reaction mixture, wherein, in every 100mL of water, the amount of ammonium molybdate is 70mmol, the amount of potassium thiocyanate is 140mmol, and the amount of potassium borohydride is 1mol;

[0082] 2) Put the reaction mixture into a hydrothermal reaction kettle, heat the hydrothermal reaction kettle with an oil bath, and stir the above reaction mixture at a speed of 450 rpm for 1-3 hours at a pressure of 3 bar and a temperature of 200°C;

[0083] 3) Then the above reaction mixture was continued to react at 180°C for 12 hours under 3 bar pressure, the obtained precipitate was cooled to room temperature, washed with water and ethanol, and then dried at 80°C to obtain hydrophilic MoS 2 Nanosheets.

[0084] This embodiment further provides a modifi...

Embodiment 2

[0096] Preparation of nanofluid a: the obtained modified MoS 2 The nanomaterials were mixed with the stabilizer polyvinylpyrrolidone in deionized water; among them, every 100mL of deionized water, the modified MoS 2 The quality of the nanomaterial is 500ppm (ie 0.05wt.%), the quality of the stabilizer is 1000ppm, and the nanofluid is named as a.

[0097] Preparation of nanofluid b: The steps for preparing nanofluid b are the same as those for nanofluid a, except that the modified MoS 2 The quality of the nanometer material is 1000ppm (ie 0.1wt.%), the quality of the stabilizer is 100ppm, and the stabilizer is sodium polystyrene sulfonate.

[0098] Preparation of nanofluid c: The steps for preparing nanofluid c are the same as those for nanofluid a, except that the modified MoS 2 The quality of the nanometer material is 50ppm (ie 0.005wt.%), the quality of the stabilizer is 50ppm, and the stabilizer is an alkyl polyoxyethylene ether.

[0099] Preparation of nanofluid c-1: Th...

Embodiment 3

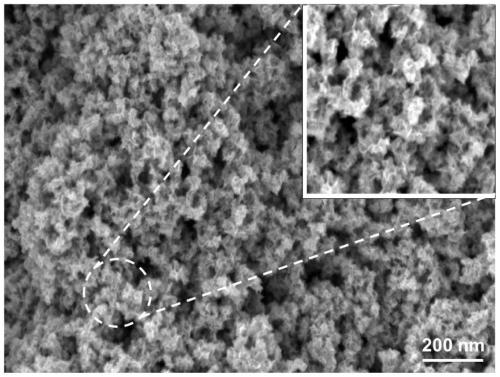

[0129] This example provides a modified MoS 2 Nanomaterials, the specific preparation method is as follows:

[0130] 1) the hydrophilic MoS provided by embodiment 1 2 The nanosheets were added to the absolute ethanol solution of butylamine, and stirred at 60 rpm for 15 hours at 25°C to obtain precipitation; among them, in every 100mL of absolute ethanol, the hydrophilic MoS 2 The amount of nanosheets is 5g, and the amount of butylamine is 1g;

[0131] 2) Wash the precipitate obtained in step 1) with water and ethanol, and then dry it at 80°C for about 6 hours to obtain modified MoS 2 nanomaterials.

[0132] Table 4 Analysis and summary of core displacement experiments under various core permeability and oil viscosity

[0133]

[0134] Test the modified MoS of this example 2 The performance of nanomaterials to enhance oil recovery, the specific process is as follows: Figure 12 The displacement experiments were carried out in the displacement equipment shown. The core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com