Patents

Literature

479 results about "Nanofluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nanofluid is a fluid containing nanometer-sized particles, called nanoparticles. These fluids are engineered colloidal suspensions of nanoparticles in a base fluid. The nanoparticles used in nanofluids are typically made of metals, oxides, carbides, or carbon nanotubes. Common base fluids include water, ethylene glycol and oil.

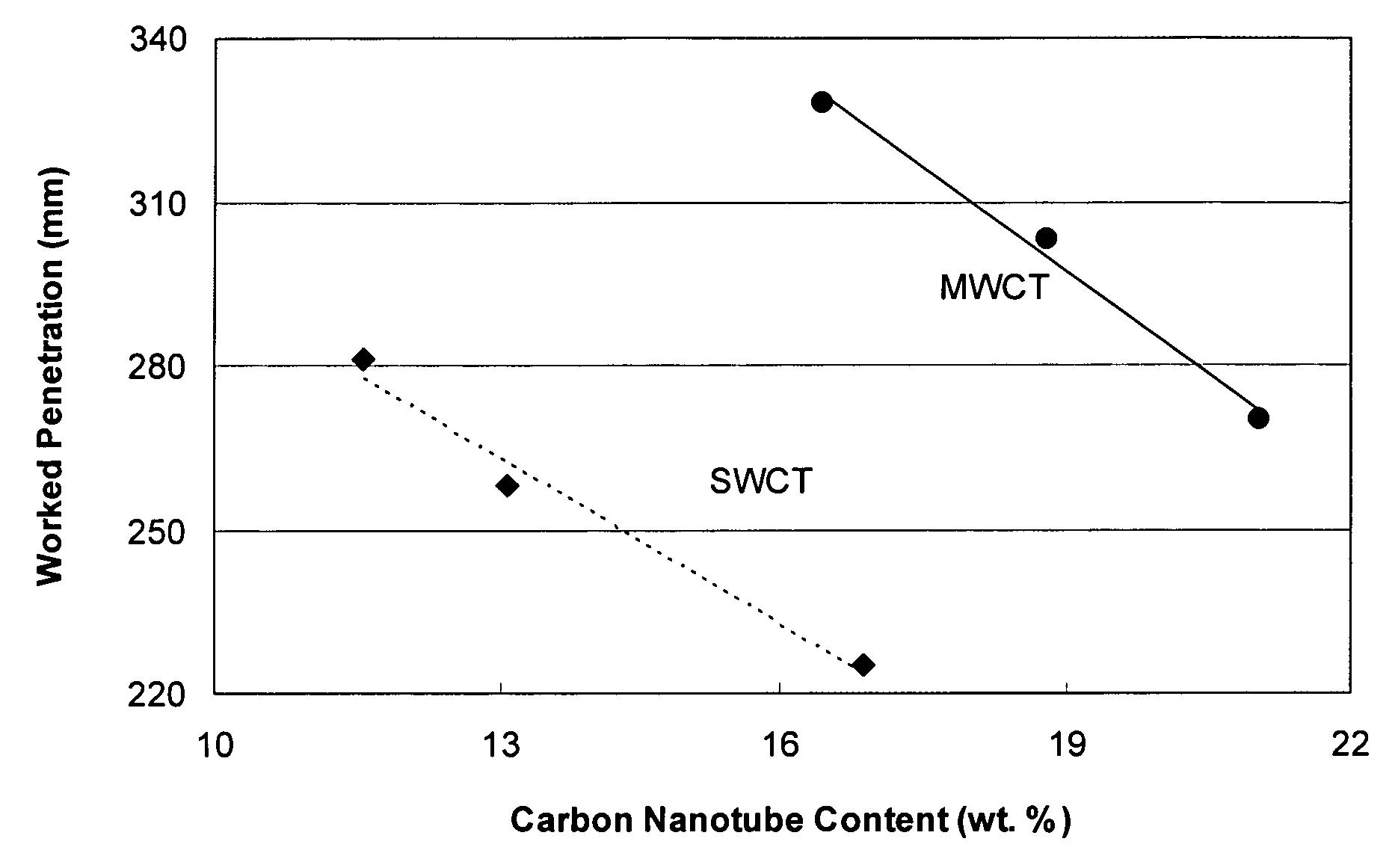

Carbon nanoparticle-containing lubricant and grease

InactiveUS20070158609A1Modulate viscosityImprove thermal conductivityMaterial nanotechnologyHeat-exchange elementsCarbon nanotubeMaterials science

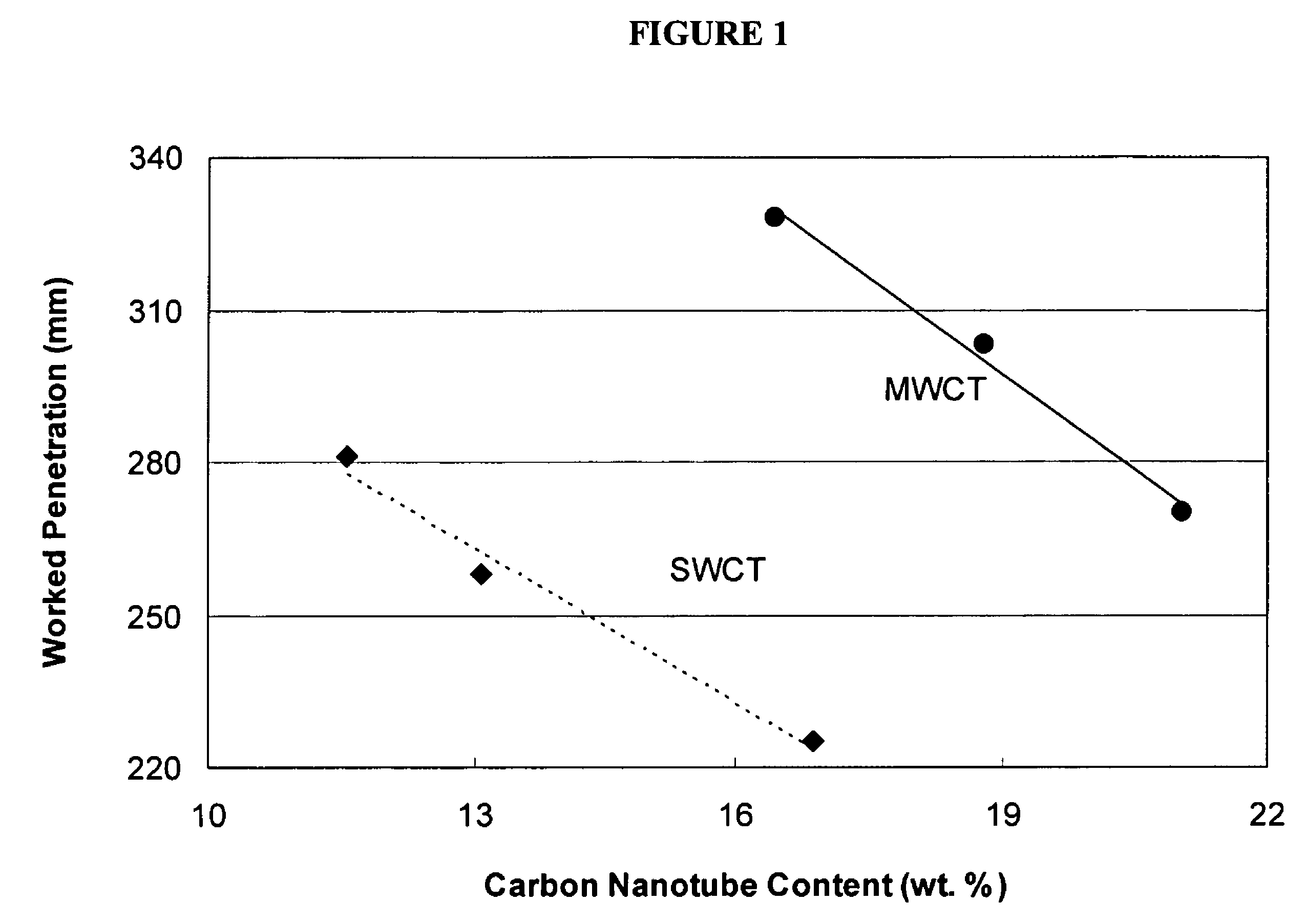

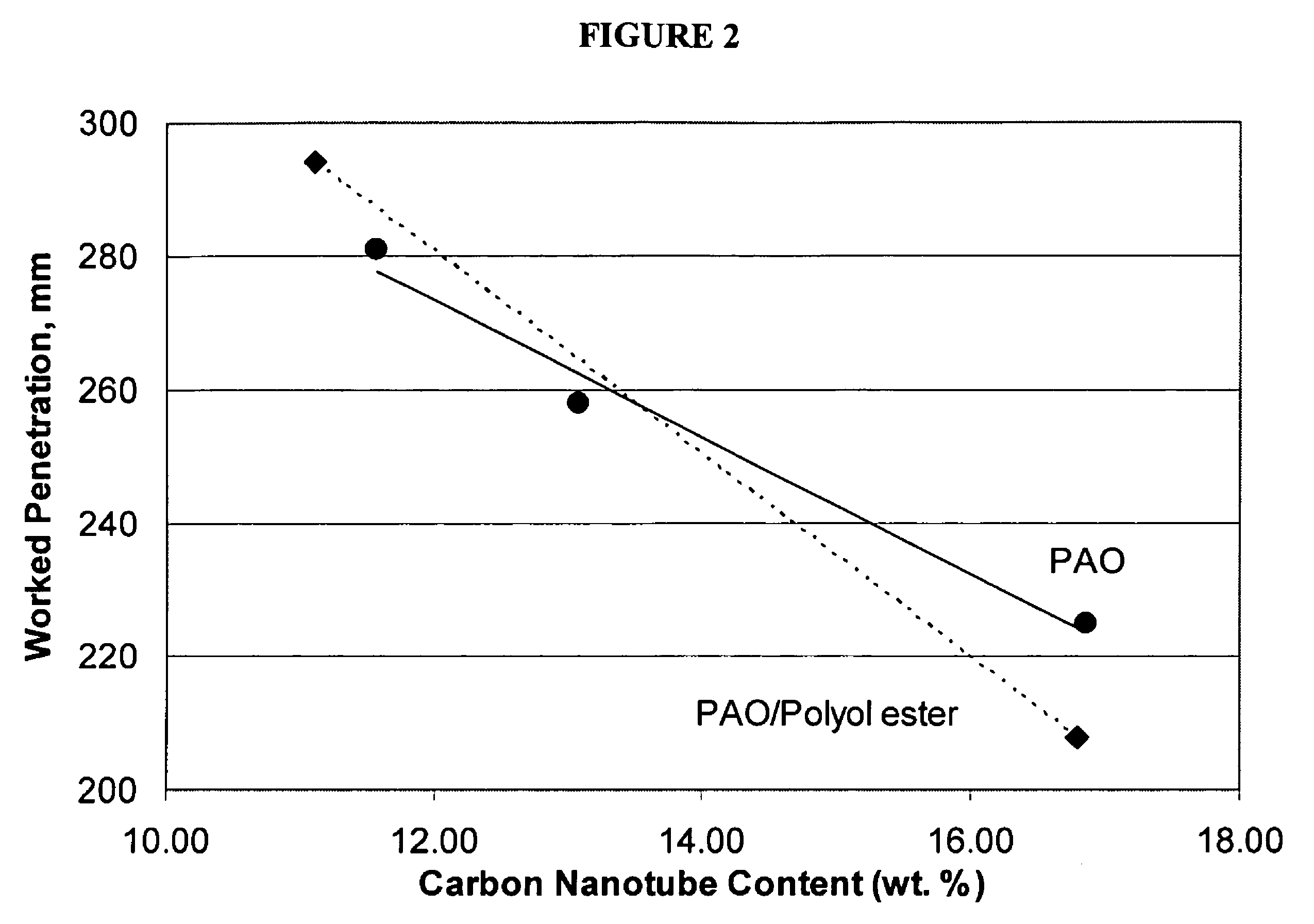

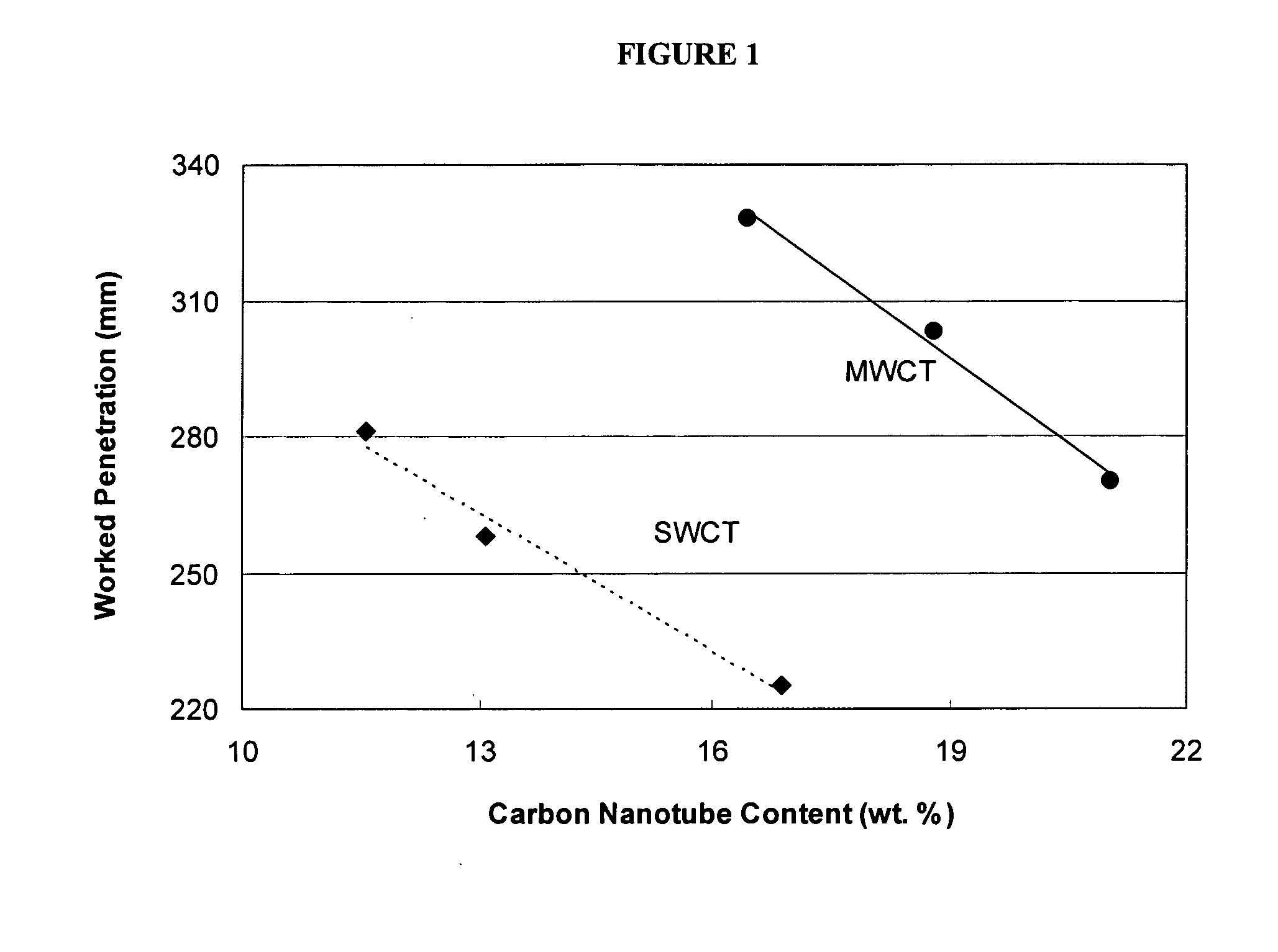

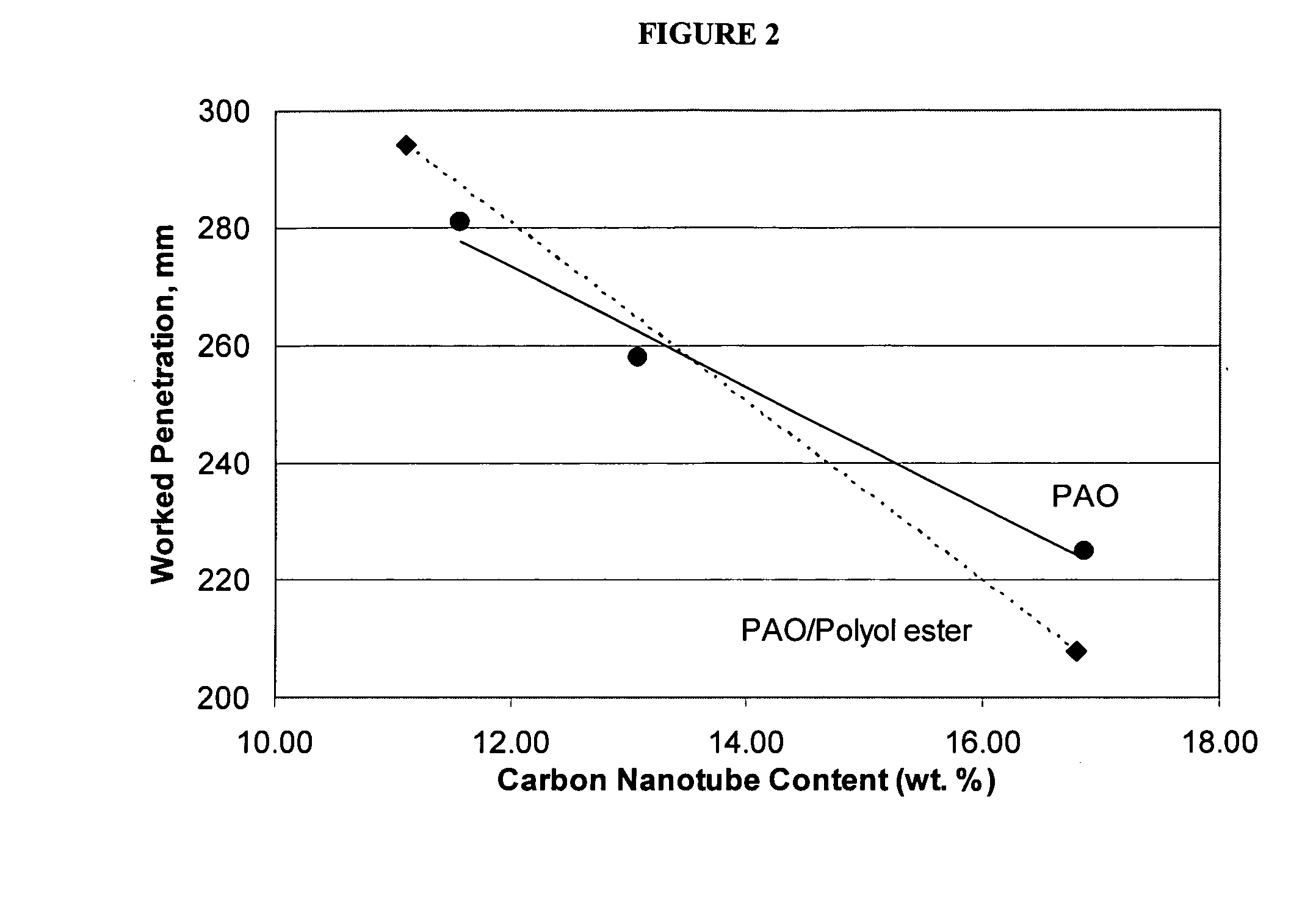

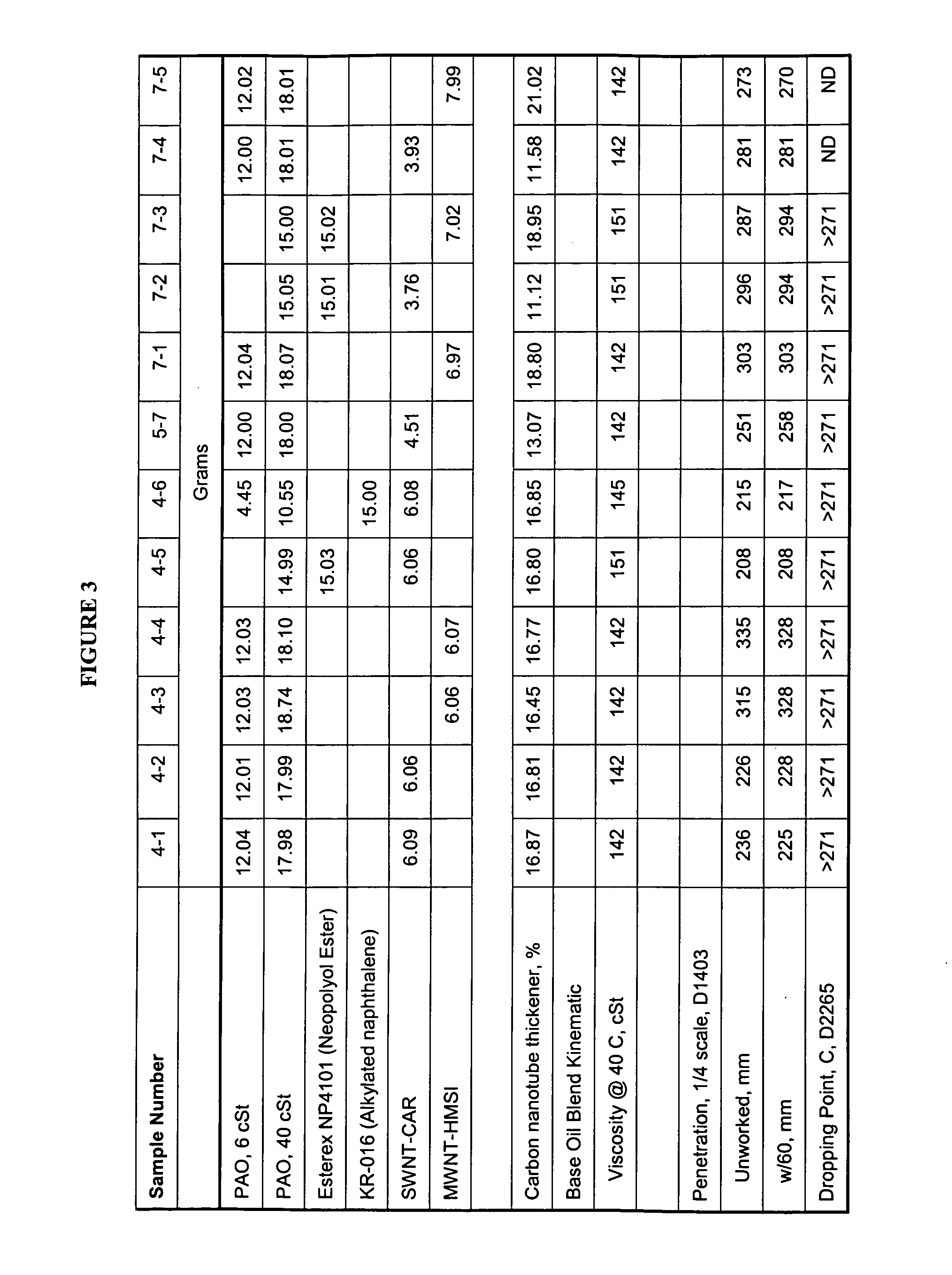

The present invention relates to processes for preparing a stable suspension of carbon nanoparticles in a thermal transfer fluid to enhance thermal conductive properties, viscosity, and lubricity. One process is to disperse carbon nanoparticles directly into a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The second process is carried out in three stages. First, carbon nanoparticles are dispersed into a volatile solvent. Then, a thermal transfer fluid, surfactants, and other additives are added into this intermediate dispersion and mixed thoroughly. At last, the volatile solvent is removed to produce a uniformly dispersed nanofluid. The third process is to disperse carbon nanoparticles at an elevated temperature into a homogeneous mixture of surfactants and other additives in a thermal transfer fluid with help of a physical agitation. The present invention also relates to compositions of carbon nanoparticle nanofluids, such as nanolubricants and nanogreases. The nanofluid of the present invention is a dispersion of carbon nanoparticles, particularly carbon nanotubes, in a thermal transfer fluid in the present of surfactants. Addition of surfactants significantly increases the stability of nanoparticle dispersion. For nanogreases, carbon nanoparticles function both as a thickener to modulate viscosity and as a solid heat transfer medium to enhance thermal conductivity and high temperature resistance.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

Carbon naoparticle-containing hydrophilic nanofluid

InactiveUS20070158610A1Stabilize nanoparticle dispersionImprove thermal conductivityHeat-exchange elementsCarbon nanotubeHydrophile

The present invention relates to a process for preparing a stable suspension of carbon nanoparticles in a hydrophilic thermal transfer fluid to enhance thermal conductive properties and other characteristics such as freezing point of an antifreeze coolant. The process involves the step of dispersing carbon nanoparticles directly into a mixture of a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The present invention also relates to the composition of a hydrophilic nanofluid, which comprises carbon nanoparticles, particularly carbon nanotubes, a hydrophilic thermal transfer fluid, and at least one surfactant. Addition of surfactants significantly increases the stability of nanoparticle dispersion.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

Carbon nanoparticle-containing hydrophilic nanofluid with enhanced thermal conductivity

ActiveUS20080302998A1Other chemical processesHeat-exchange elementsMetal oxide nanoparticlesNanofluid

The present invention relates to a nanofluid that contains carbon nanoparticles, metal oxide nanoparticles and a surfactant in a thermal transfer fluid. The present invention also relates to processes for producing such a nanofluid with enhanced thermal conductive properties.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

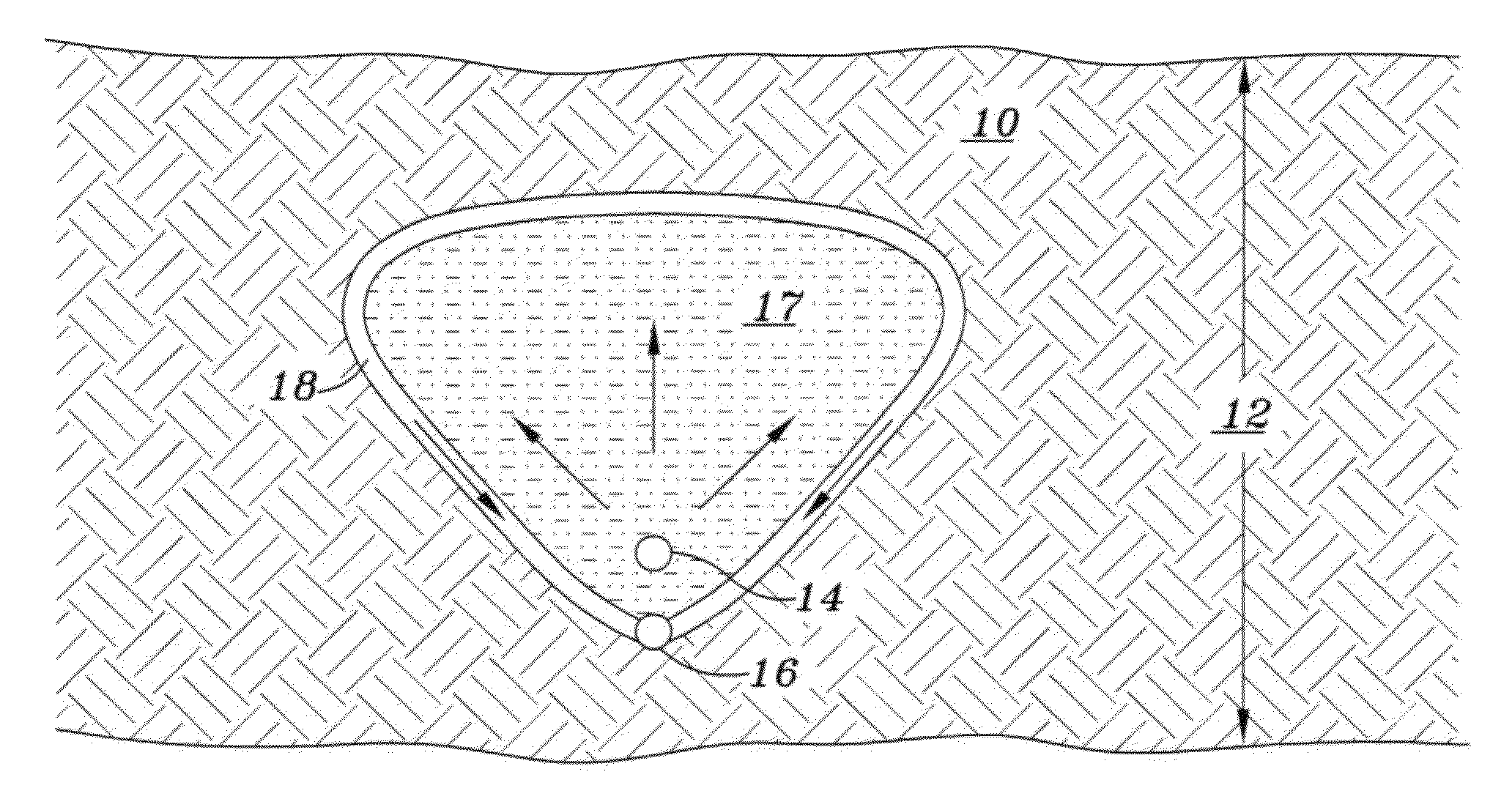

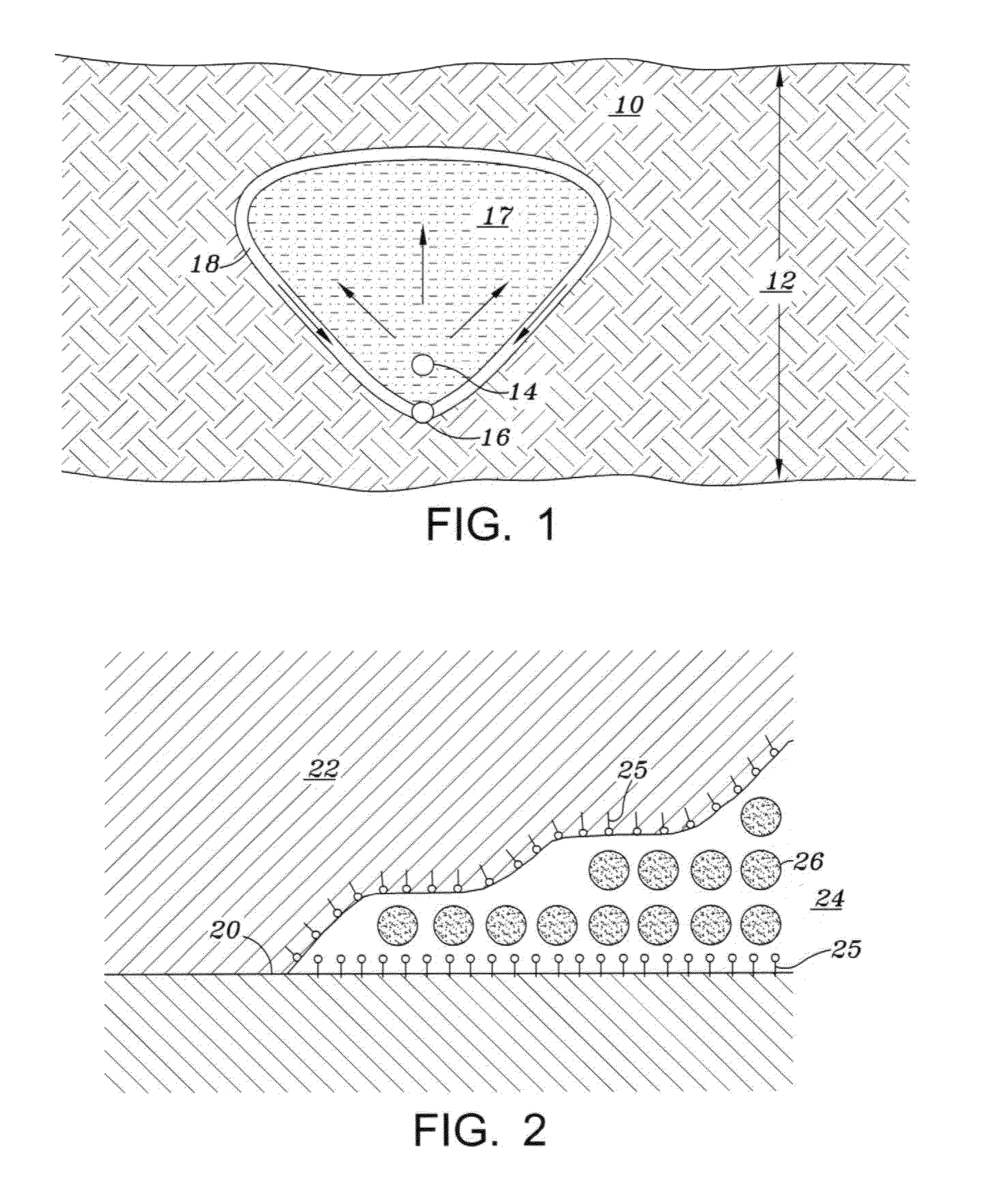

Method for Recovering Hydrocarbon from Tar Sand Using Nanofluid

InactiveUS20120255887A1Facilitated releaseFluid removalLiquid hydrocarbon mixture productionTarSlurry

Method for recovery of bitumen from tar sand is provided. An aqueous fluid containing a wetting agent and nanoparticles is injected into a first horizontal well at a temperature above reservoir temperature. Bitumen is released from sand grains and flows into a second horizontal well, where it is transported to surface. In a surface treatment facility, a slurry of tar sand is formed and surfactant and nanoparticles are added to the slurry.

Owner:FTS INT SERVICES

Carbon nanoparticle-containing nanofluid

ActiveUS7871533B1Improve thermal conductivityImprove featuresMaterial nanotechnologyOther chemical processesSolid carbonCarbon Nanoparticles

The present invention relates to compositions of a nanofluid, which comprises a thermal transfer fluid and carbon nanoparticles. The nanofluid may be hydrophilic nanofluids, such as a coolant, or hydrophobic nanofluids, such as nanolubricants or nanogreases. In particular, the present invention provides a homogenous hydrophilic nanofluid, which contains soluble carbon nanotubes in the hydrophilic thermal transfer fluid. The present invention also provides a nanogrease, which is a sustainable dispersion of solid carbon nanotubes in a hydrophobic thermal transfer fluid. The solid carbon nanotubes function as both as a thickener to modulate viscosity and as a solid heat transfer medium to enhance thermal conductivity and high temperature resistance.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

Preparation method of nanofluid for improving oil recovery

ActiveCN103937478AIncrease profitGood dispersionFluid removalDrilling compositionActive agentSurface-active agents

The invention discloses a preparation method of a nanofluid for improving oil recovery. The preparation method comprises the following steps: taking 2.0-4.0g of nanopowder, adding 60-80mL of deionized water to the nanopowder and carrying out ultrasonic dispersion at a room temperature for 30-60 minutes; dissolving 2.0g of a silane coupling agent in absolute ethyl alcohol; mixing the nano-base solution with the ethanol solution of the silane coupling agent in a three-neck boiling flask, heating while stirring to the range of 70 to 75 DEG C, reacting for 4-6 hours, filtering, washing by using an anhydrous solvent a plurality of times, and drying in a vacuum drying box at 60-70 DEG C for 12 hours to obtain modified nanoparticles; putting 0.1-0.5g of nanoparticles in the three-neck boiling flask, adding 200-300mL of water, heating to the range of 60-75 DEG C by use of a water bath, mixing a surfactant with PEG (Poly Ethylene Glycol), adding 100mL of mixed solution of the surfactant and the PEG, mechanically stirring for 6-8 hours, washing the stirred dispersion 2-3 times, adjusting the pH value to the range of 8-9, and adding deionized water to 1L, thereby obtaining the water-based nanofluid.

Owner:NORTHEAST GASOLINEEUM UNIV

Electromagnetic shielding coating material and preparation method thereof

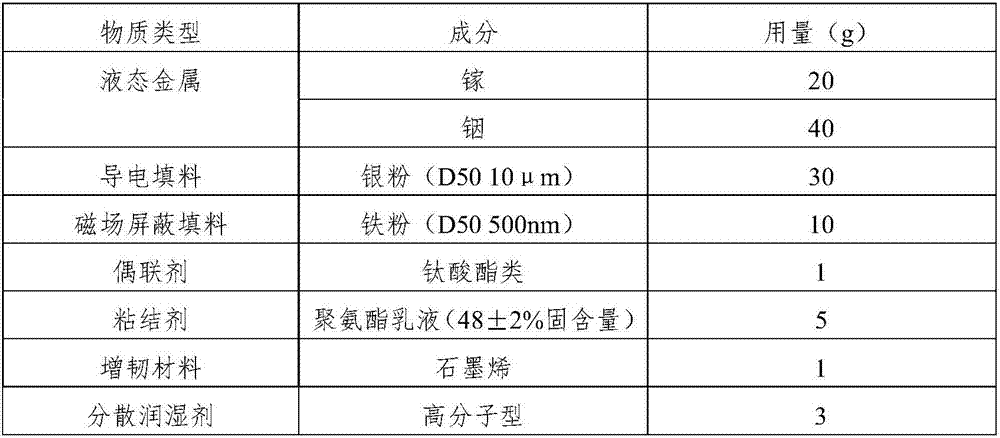

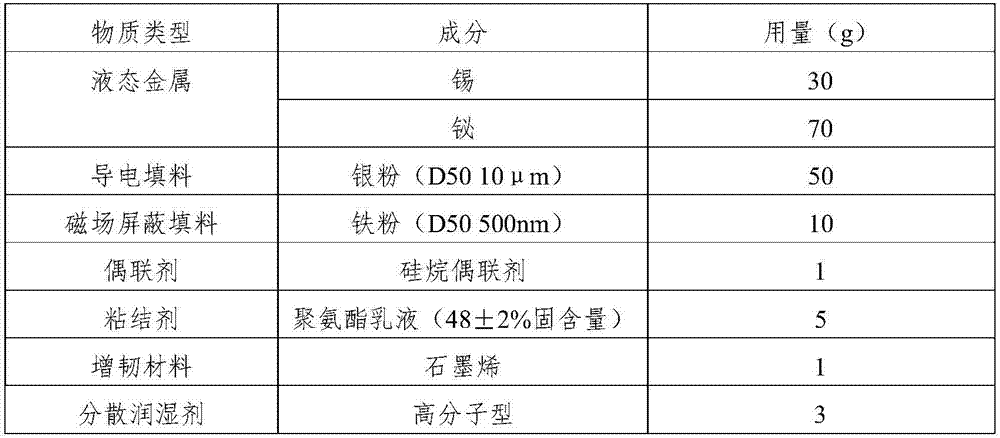

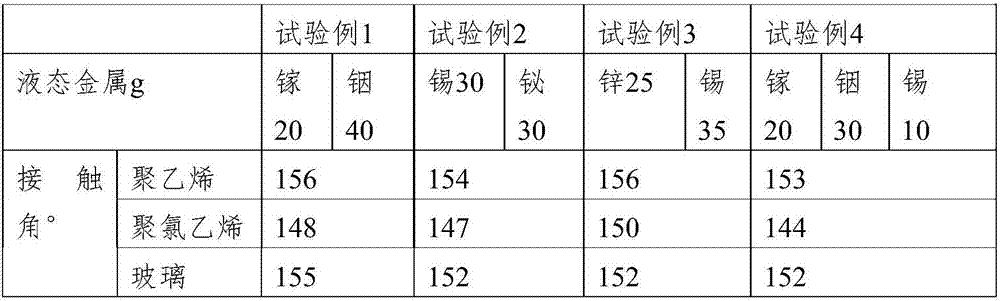

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

Method and Apparatus for Achieving Higher Cooling Rates of a Gas During Bypass Cooling in a Batch Annealing Furnace of Cold Rolling Mills

ActiveUS20120024516A1Improve cooling effectWork treatment devicesIndirect heat exchangersNanofluidAqueous medium

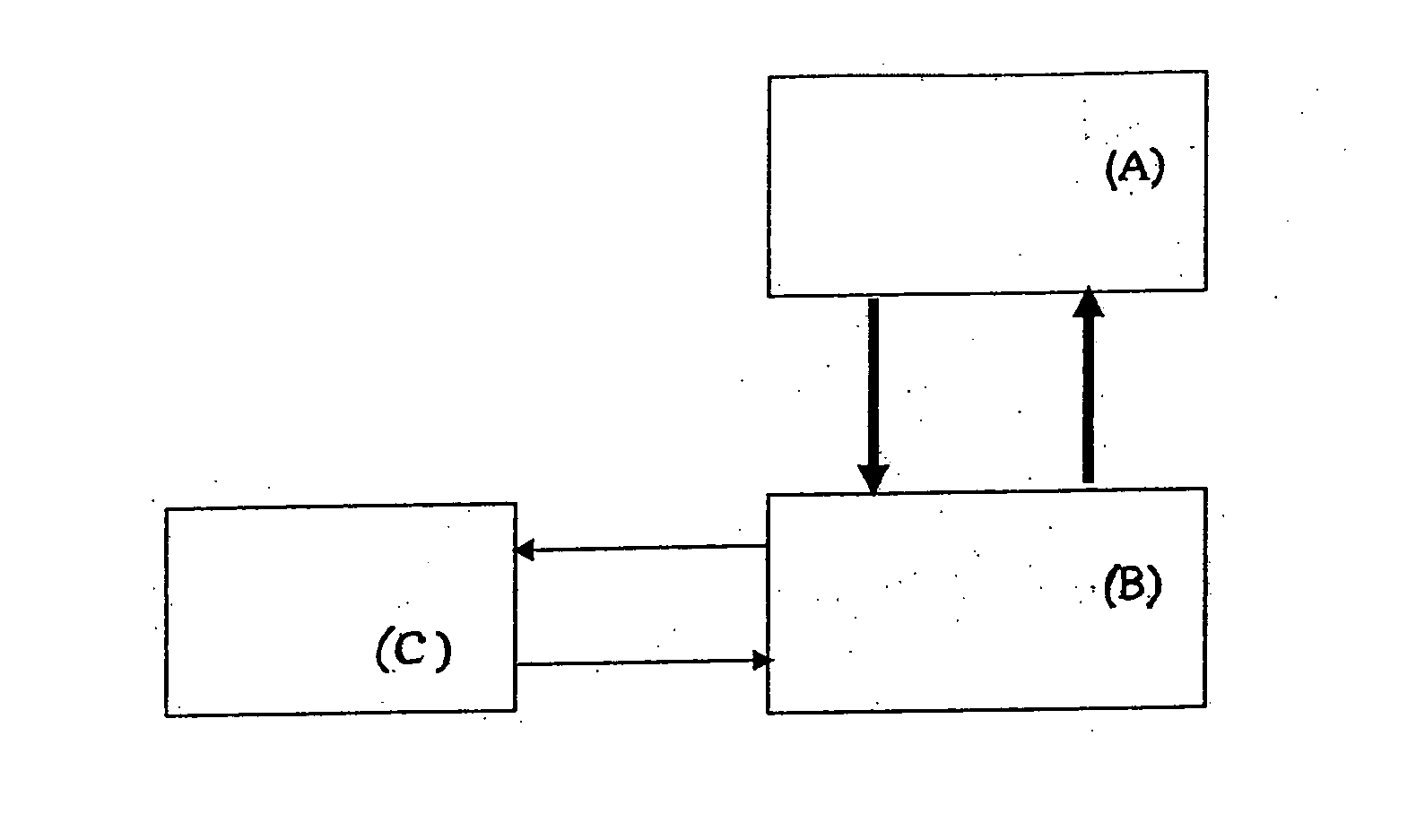

A method and apparatus to increase the cooling rate of gas used in a batch annealing furnace of cold rolling mills under bypass cooling. The invention makes use of the higher heat transfer capacities of nanocoolants developed by a high-shear mixing of nanoparticles and stabilizers in a basic aqueous medium for cooling heated hydrogen flowing through a heat exchanger during bypass cooling of the batch annealing furnace. The nanofluid is prepared in a nanofluid preparation unit.

Owner:TATA STEEL

Carbon nanoparticle-containing nanofluid

ActiveUS20110003721A1Improve thermal conductivityImprove featuresMaterial nanotechnologyOther chemical processesSolid carbonNanofluid

The present invention relates to compositions of a nanofluid, which comprises a thermal transfer fluid and carbon nanoparticles. The nanofluid may be hydrophilic nanofluids, such as a coolant, or hydrophobic nanofluids, such as nanolubricants or nanogreases. In particular, the present invention provides a homogenous hydrophilic nanofluid, which contains soluble carbon nanotubes in the hydrophilic thermal transfer fluid. The present invention also provides a nanogrease, which is a sustainable dispersion of solid carbon nanotubes in a hydrophobic thermal transfer fluid. The solid carbon nanotubes function as both as a thickener to modulate viscosity and as a solid heat transfer medium to enhance thermal conductivity and high temperature resistance.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

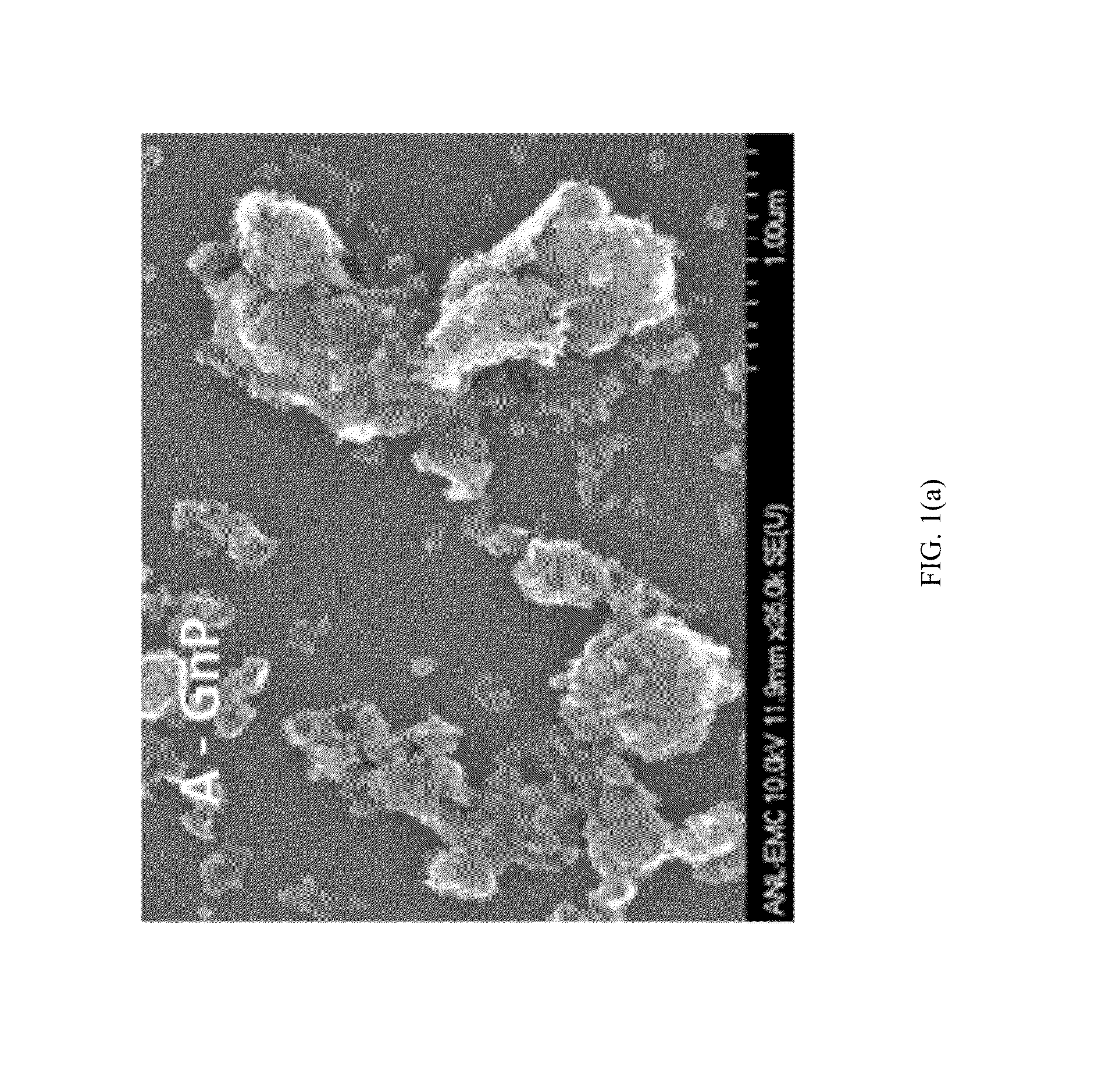

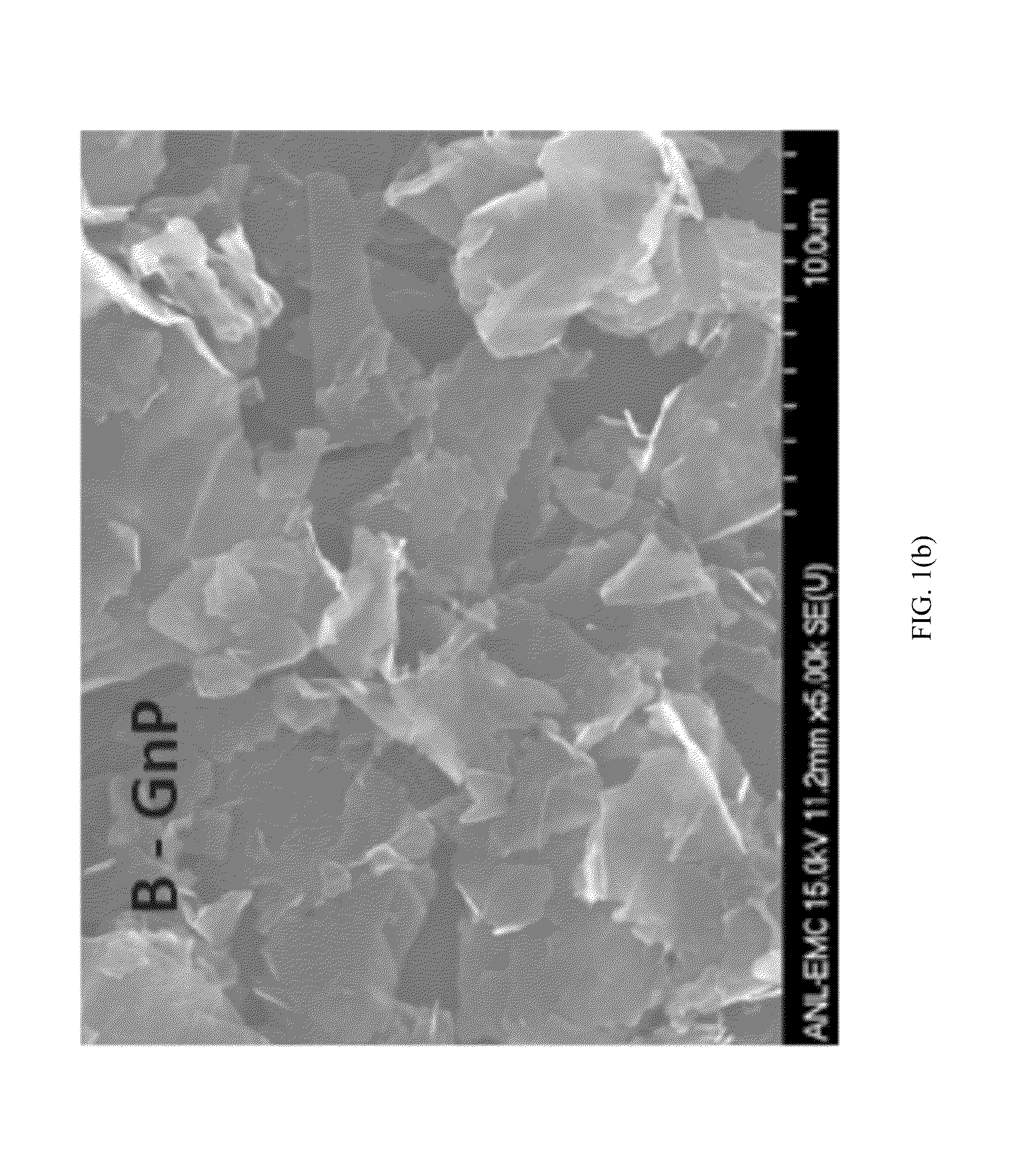

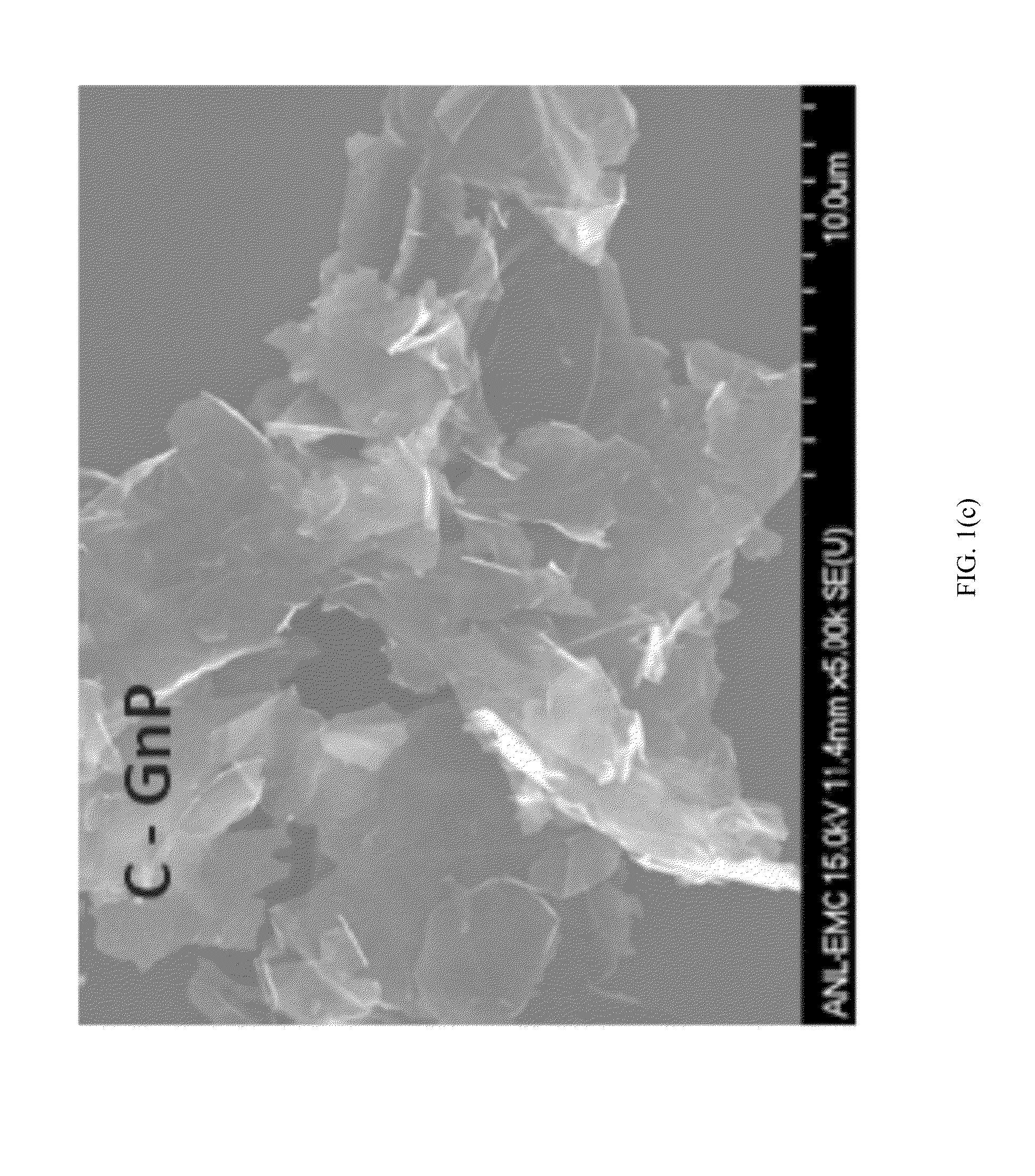

Advanced thermal properties of a suspension with graphene nano-platelets (GNPS) and custom functionalized f-gnps

InactiveUS20140312263A1Improve thermal performanceMinimal negative mechanical effectHeat-exchange elementsPower electronicsElectric power

A method for producing nanofluids with multilayered graphene nanoplatelets for providing improved heat transfer coolant fluids. A method for optimizing the concentration of nanoplatelets based on their morphology that allows achieving high thermal conductivity and low viscosity thus resulting in high heat transfer coefficient. A method is provided to functionalize as received graphene nanoplatelets by oxidaitively treating the multilayered graphene / nanothin graphite to generate highly dispensable nanoparticles for suspension in polar fluids for cooling thermal sources, such as power electronics and other heat transfer cooling applications.

Owner:UCHICAGO ARGONNE LLC

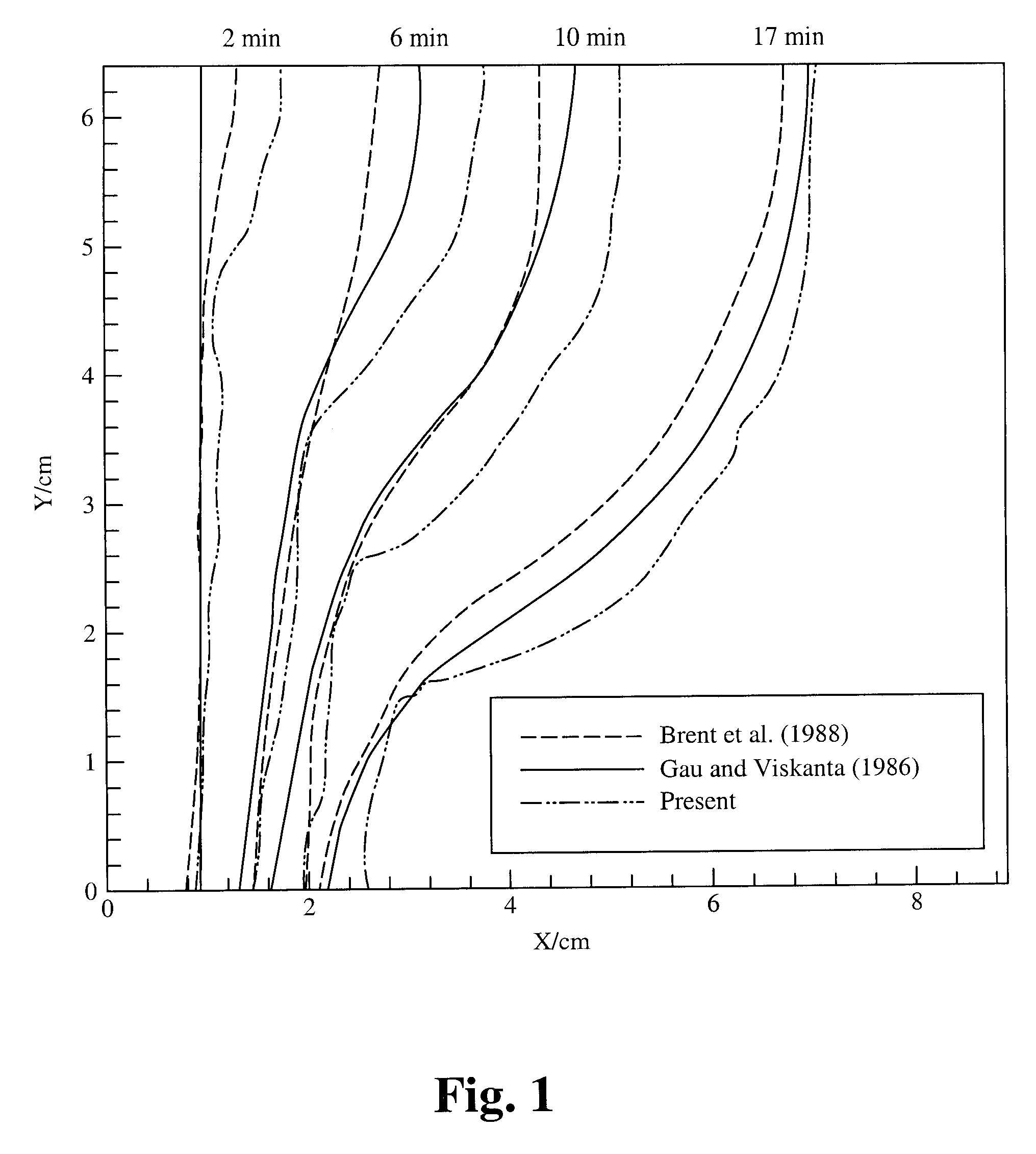

Nanoparticle-enhanced phase change materials (NEPCM) with great potential for improved thermal energy storage

InactiveUS20090236079A1Increased heat release rateFunction increaseMaterial nanotechnologyHeat storage plantsThermal energyThermal energy storage

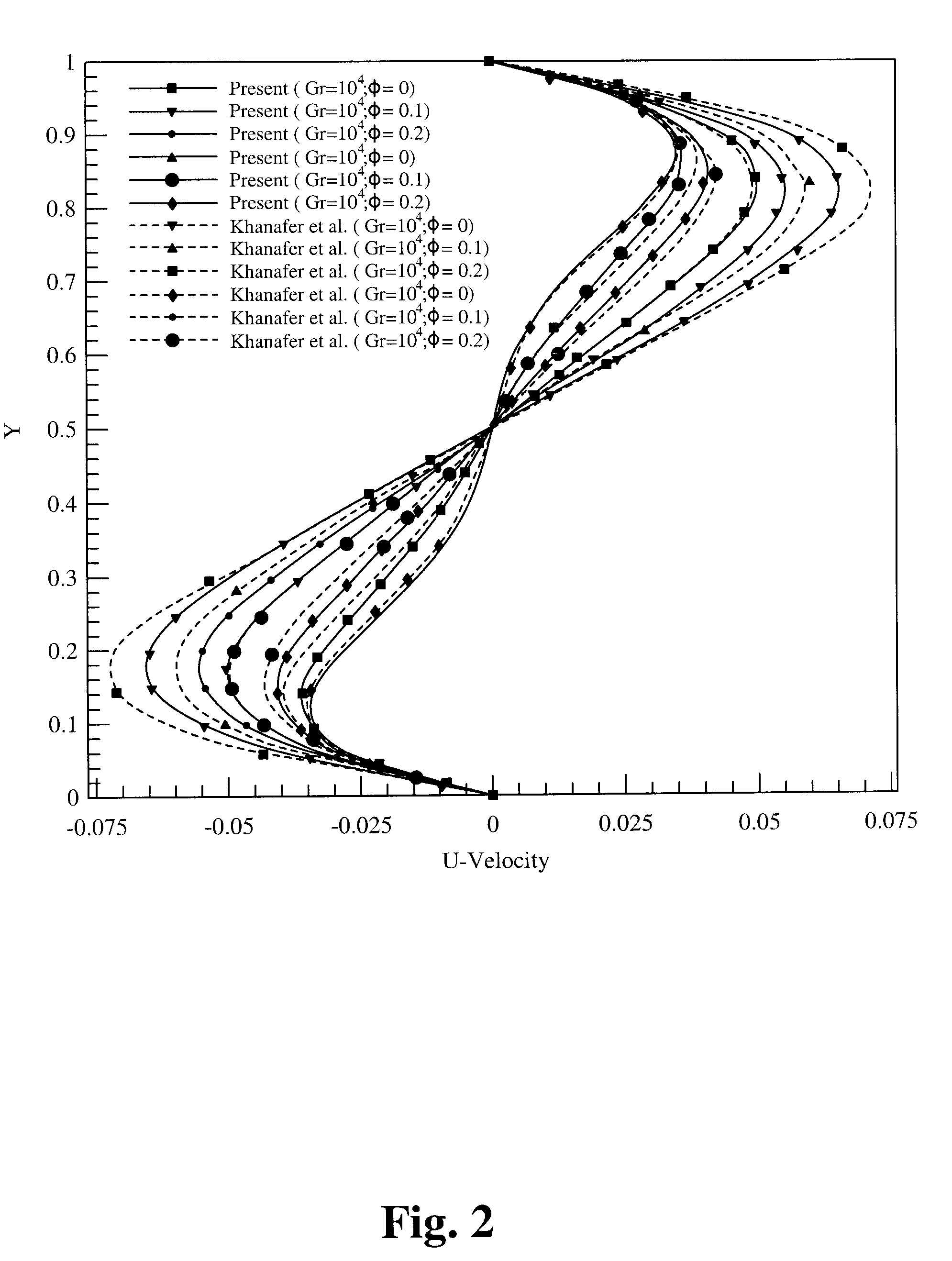

Improved functionality of phase change materials (PCM) through dispersion of nanoparticles is described. The resulting nanoparticle-enhanced phase change materials (NEPCM) exhibit enhanced thermal conductivity in comparison to the base material. Starting with steady state natural convection within a differentially-heated square cavity that contains a nanofluid (water plus copper nanoparticles), the nanofluid is allowed to undergo solidification. Partly due to increase of thermal conductivity and also lowering of the latent heat of fusion, higher heat release rate of the NEPCM in relation to the conventional PCM is observed. The predicted increase of the heat release rate of the NEPCM is a clear indicator of its great potential for diverse thermal energy storage applications.

Owner:AUBURN UNIV

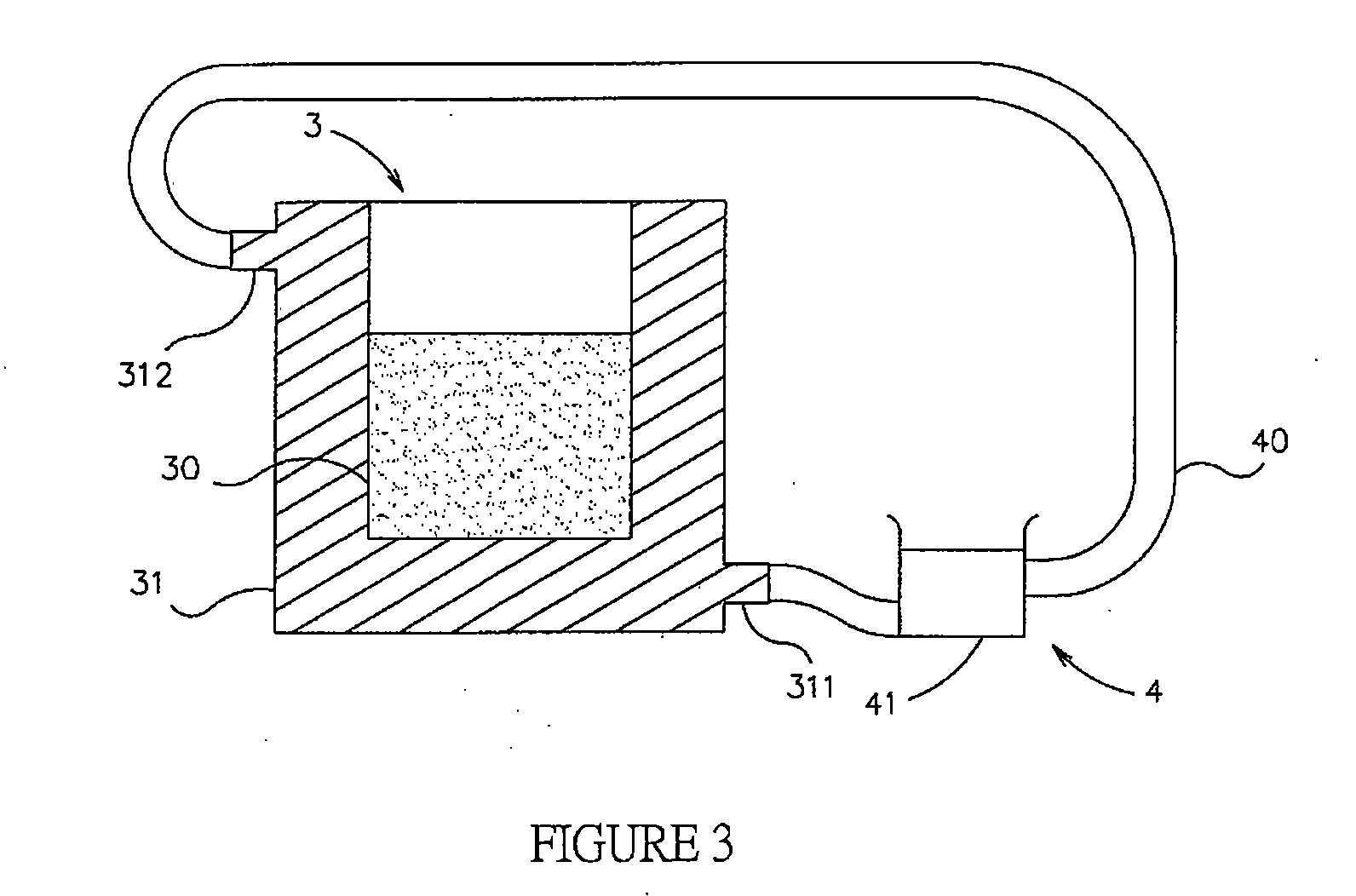

Heat pipe and manufacturing method thereof

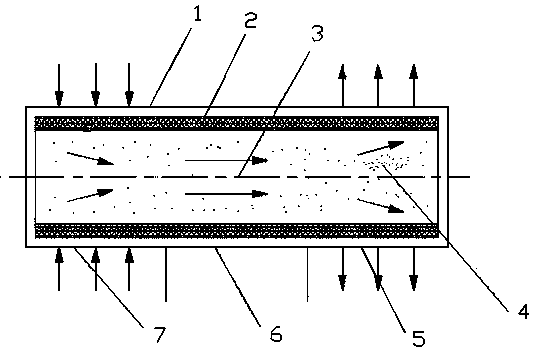

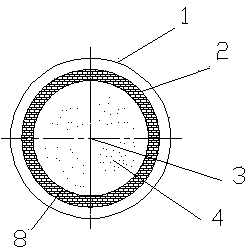

InactiveCN103994682AImprove heat transfer efficiencySolve the problem of insufficient heat dissipation capacity of high heat fluxIndirect heat exchangersHeat exchange apparatusWater basedThermal insulation

The invention discloses a heat pipe and a manufacturing method of the heat pipe. The heat pipe and the manufacturing method of the heat pipe can achieve cooling of electronic devices and a device. According to the heat pipe, a pipe shell is arranged on the outermost portion, a steam chamber is formed in the innermost portion, the steam chamber is divided into an evaporation segment, a thermal insulation segment and a condensation segment in the axial direction of the steam chamber, the thermal insulation segment is arranged in the middle, the evaporation segment and the condensation segment are arranged at the two ends respectively, a cylindrical capillary liquid absorption core layer formed by a multi-hole foamy copper liquid absorption core is closely attached to the inner wall of the pipe shell, holes in the multi-hole foamy copper liquid absorption core are different in hole diameter, a silk screen supporting frame is closely attached to the inner wall of the capillary liquid absorption core layer, the steam chamber is filled with a metal oxide water-based nanofluid working medium, the volume of the nanofluid working medium is 40% to 60% that of the evaporation segment, and metal oxide is aluminum oxide or copper oxide or silicon dioxide. According to the heat pipe and the manufacturing method of the heat pipe, nanofluid and multi-hole foamy copper are combined in the heat pipe, and the heat transfer efficiency of the heat pipe is improved.

Owner:JIANGSU UNIV OF SCI & TECH

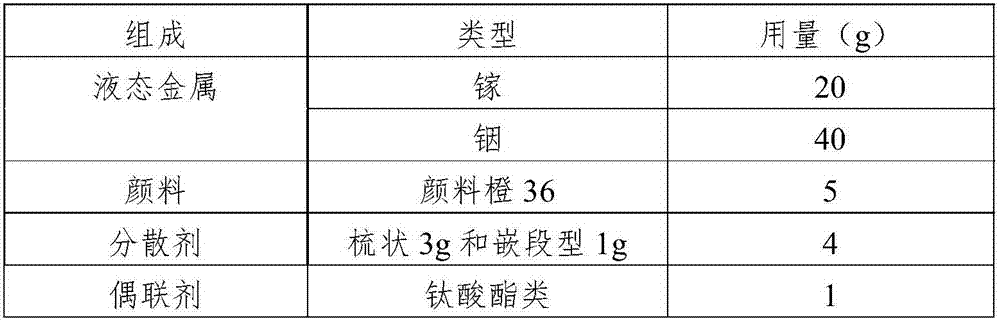

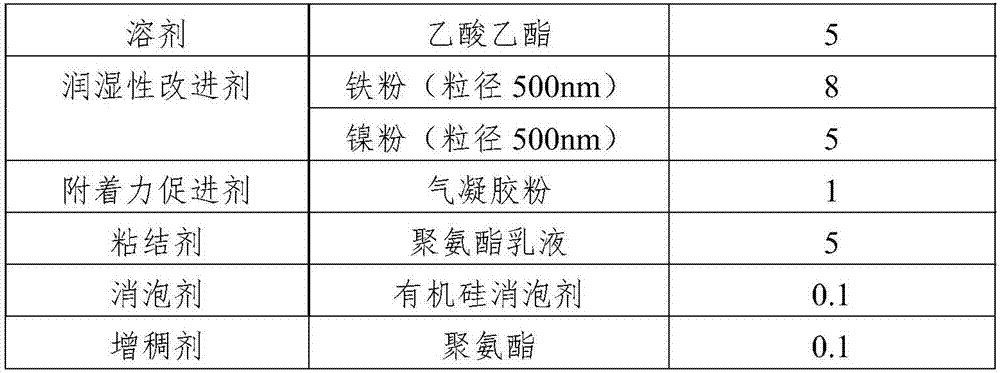

Colored liquid metal printing ink and preparation method thereof

The invention provides colored liquid metal printing ink. The printing ink is prepared from, in percentage by weight, 40%-70% of liquid metal, 2%-10% of pigment, 10%-30% of a wettability improver, 1%-5% of a dispersant, 0.5%-3% of a coupling agent, 1%-10% of a binder, 0.5%-3% of an adhesion promoter, 1%-5% of a solvent and the balance of other aids, wherein the liquid metal is a conductive nanofluid formed by low-melting-point metal or alloy or metal nanoparticles with the melting point being 300 DEG C or below and a fluid dispersant. The concept and the preparation method of the colored liquid metal printing ink are proposed for the first time, the existing application method that pigment powder is directly adopted in liquid metal is changed, color paste rather than pigment is adopted to provide colors for the liquid metal, and the color saturation and stability of a colored liquid metal composite are further improved, so that the composite has both good conductivity of liquid metal and rich colors of pigment.

Owner:BEIJING DREAM INK TECH CO LTD

Carbon nanoparticle-containing hydrophilic nanofluid with enhanced thermal conductivity

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

Compound gas hydrate generation accelerant and preparation method thereof

ActiveCN104437290AHigh thermal conductivityStable suspension characteristicsPressurized chemical processGaseous fuelsActive agentPhysical chemistry

The invention relates to a gas hydrate, in particular to a compound gas hydrate generation accelerant and a preparation method thereof. The accelerant is a mixed solution formed by dissolving nano dispersed particles and a gemini surfactant in water, wherein the nano dispersed particles are nano graphene particles, the purity degree (the mass fraction) of the nano dispersed particles is 99%, and the fineness of the nano dispersed particles ranges from 20 nm to 60 nm; the gemini surfactant adopts dimethylene-1,2-double (dodecyl dimethyl ammonium bromide)-C12-2-122Br-1; by taking the mixed solution as the total amount, in the prepared mixed solution, the concentration of the nano graphene particles is controlled from 0.08% to 1.2%, the concentration of the gemini surfactant is controlled from 0.03% to 0.1%, and the balance is water. The accelerant can be used to enhance the gas hydrate from the two processes of heat transmission and mass transfer in the generation process of the gas hydrate, reduces the induction time for gas hydrate generation, and improves generation efficiency of the gas hydrate; a nanofluid is more stable and has low possibility of coagulation under the compound condition of the nano dispersed particles and the gemini surfactant.

Owner:北京中清绿智科技有限公司

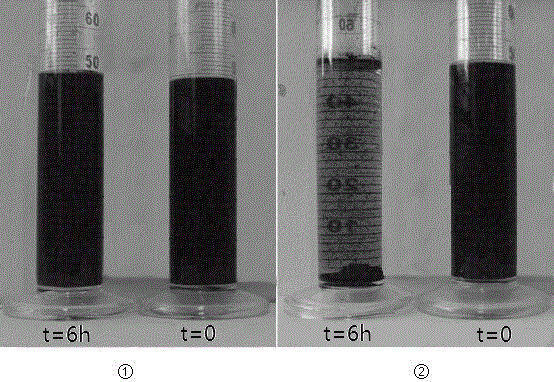

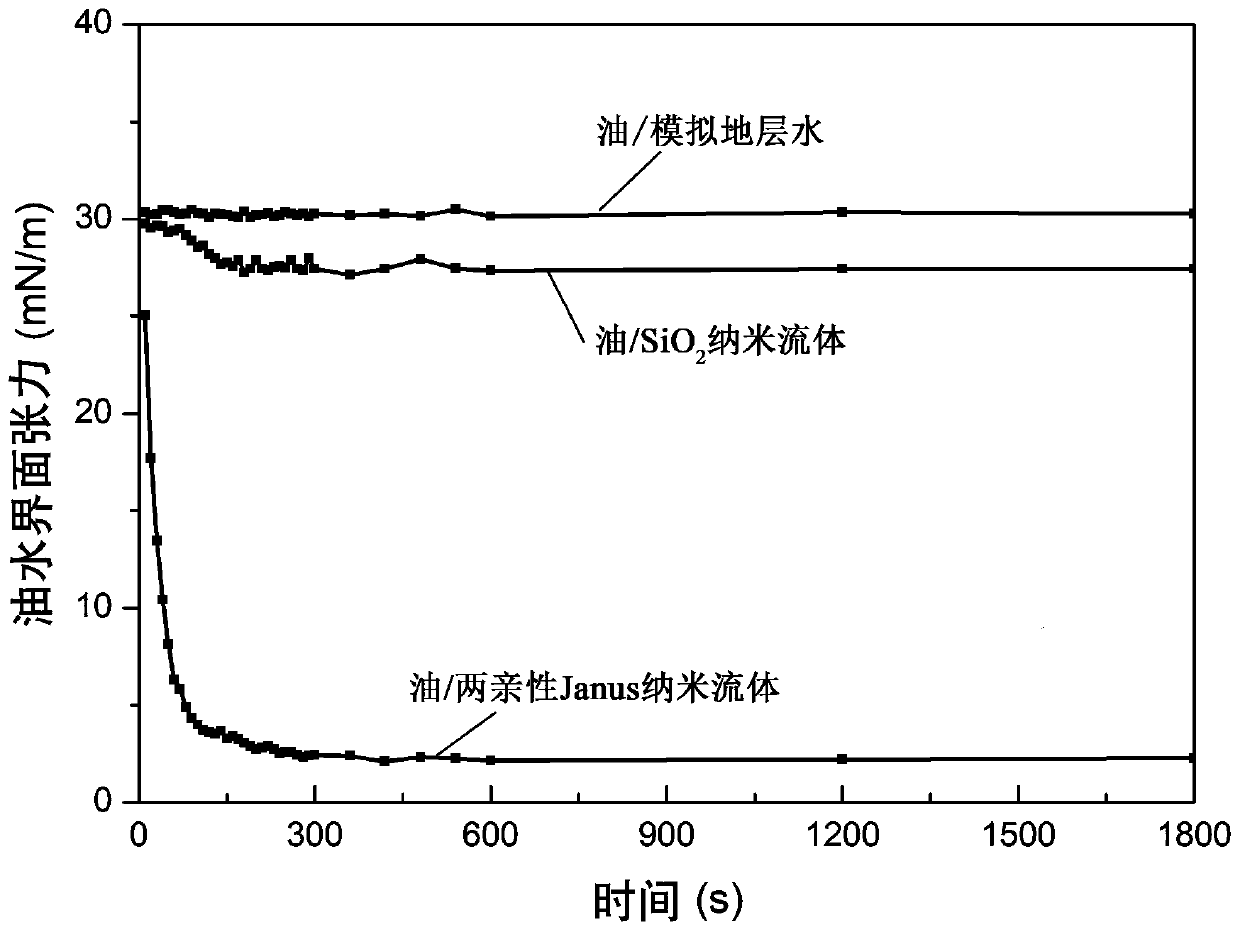

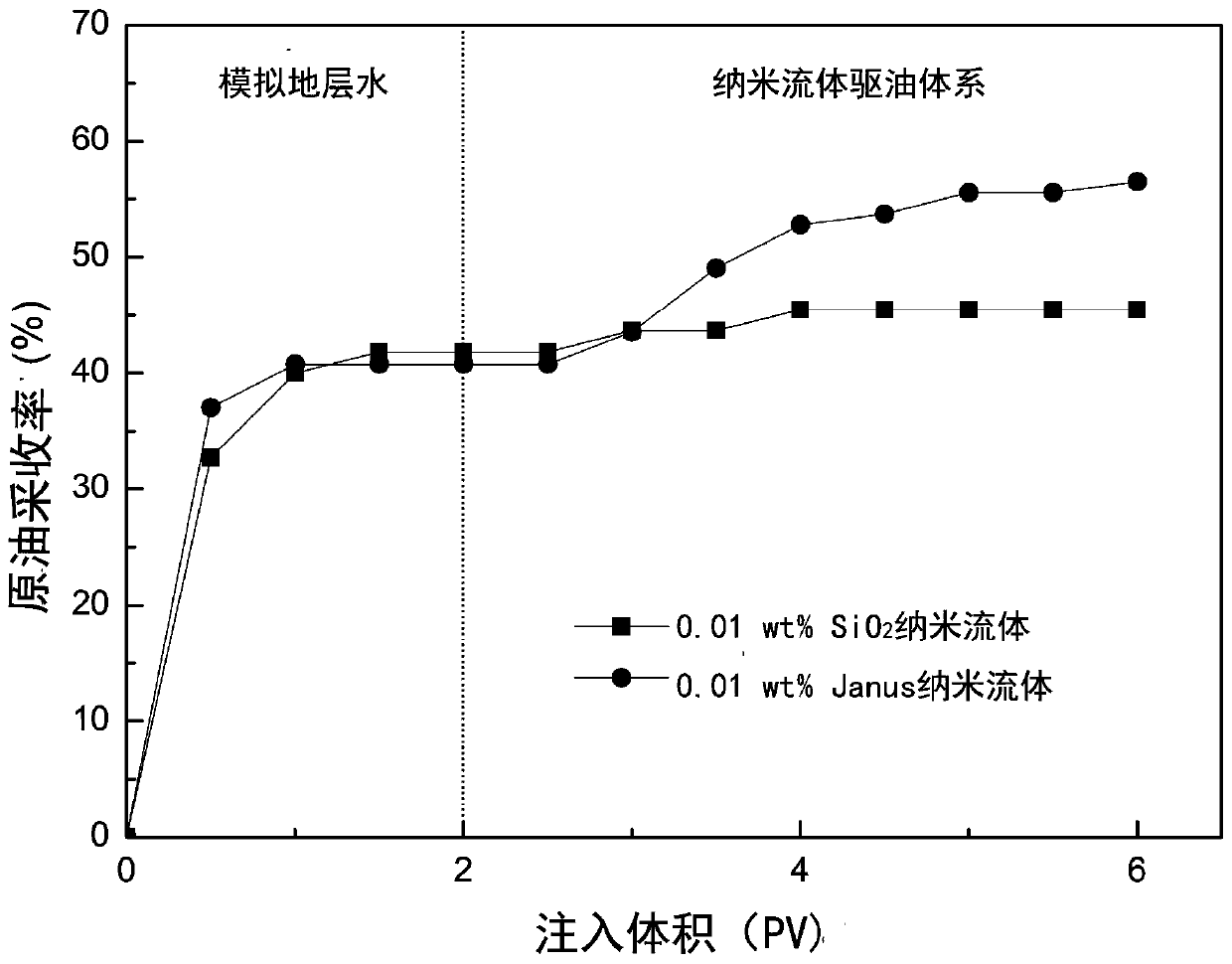

Amphiphilic Janus nano particle and preparation method and application thereof

InactiveCN111303853AThe synthesis steps are simpleGood interfacial propertiesDrilling compositionParaffin waxPtru catalyst

The invention provides an amphiphilic Janus nano particle and a preparation method and application thereof. The preparation method comprises the following steps: dispersing silicon dioxide nanoparticles in water to obtain a dispersion liquid, mixing the dispersion liquid and liquid paraffin, heating and stirring in a water bath to form a Pickering emulsion, cooling to obtain small wax balls, adding a silane coupling agent into the small wax balls for modification to obtain modified small wax balls, mixing the modified small wax balls, an amidation catalyst and C12-C18 saturated fatty acid, andcarrying out an amidation reaction process to obtain organic hydrophobic chain grafted oil-water amphiphilic nanoparticles, and removing paraffin in the organic hydrophobic chain grafted oil-water amphiphilic nanoparticles to obtain the amphiphilic Janus nano particles. When the surfactant is used as an oil-displacing agent, oil-water interfacial tension can be effectively reduced at low concentration, rock wettability is changed, oil-displacing efficiency of nanofluid is remarkably improved, economic cost is reduced, and the surfactant has a wide application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

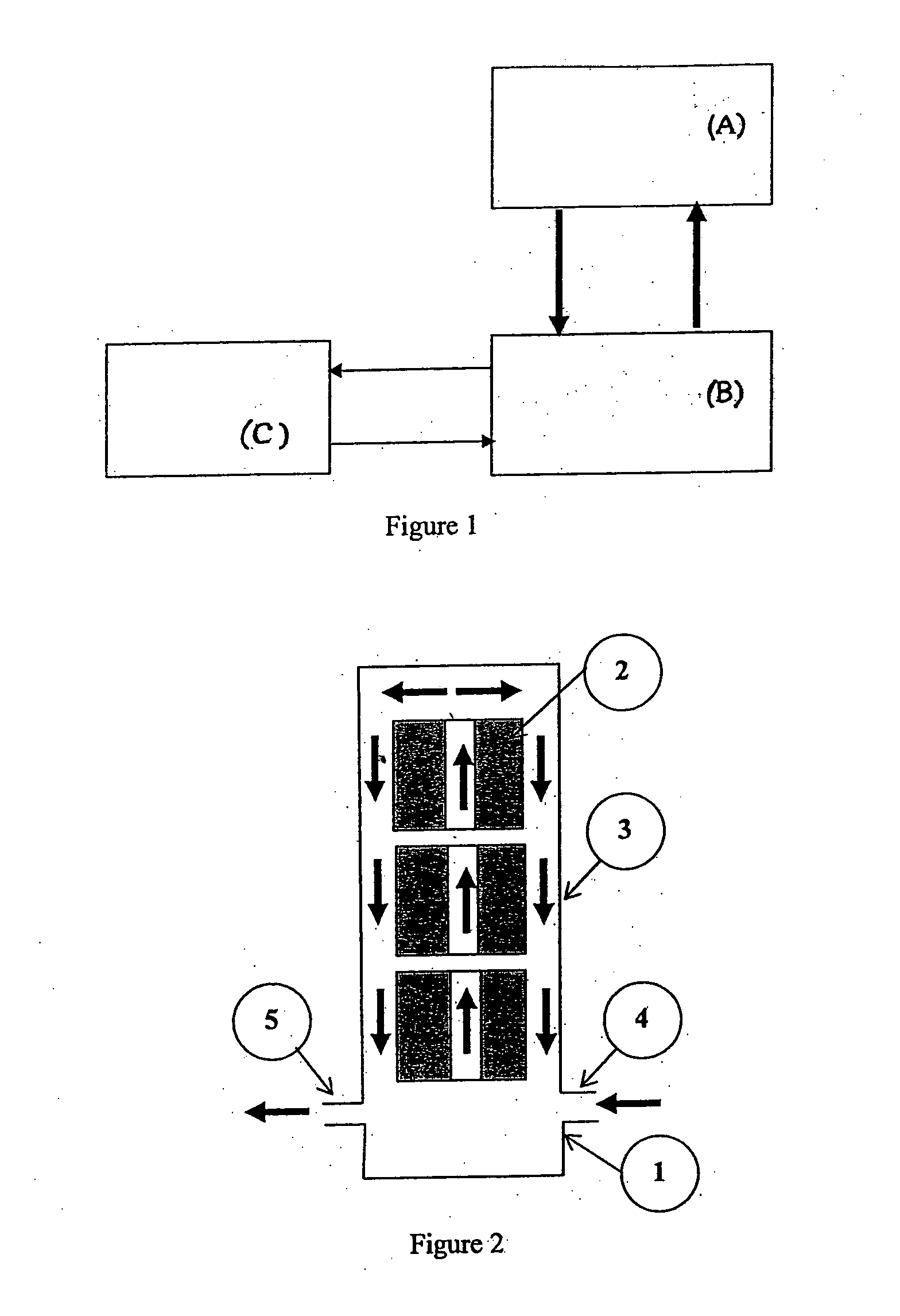

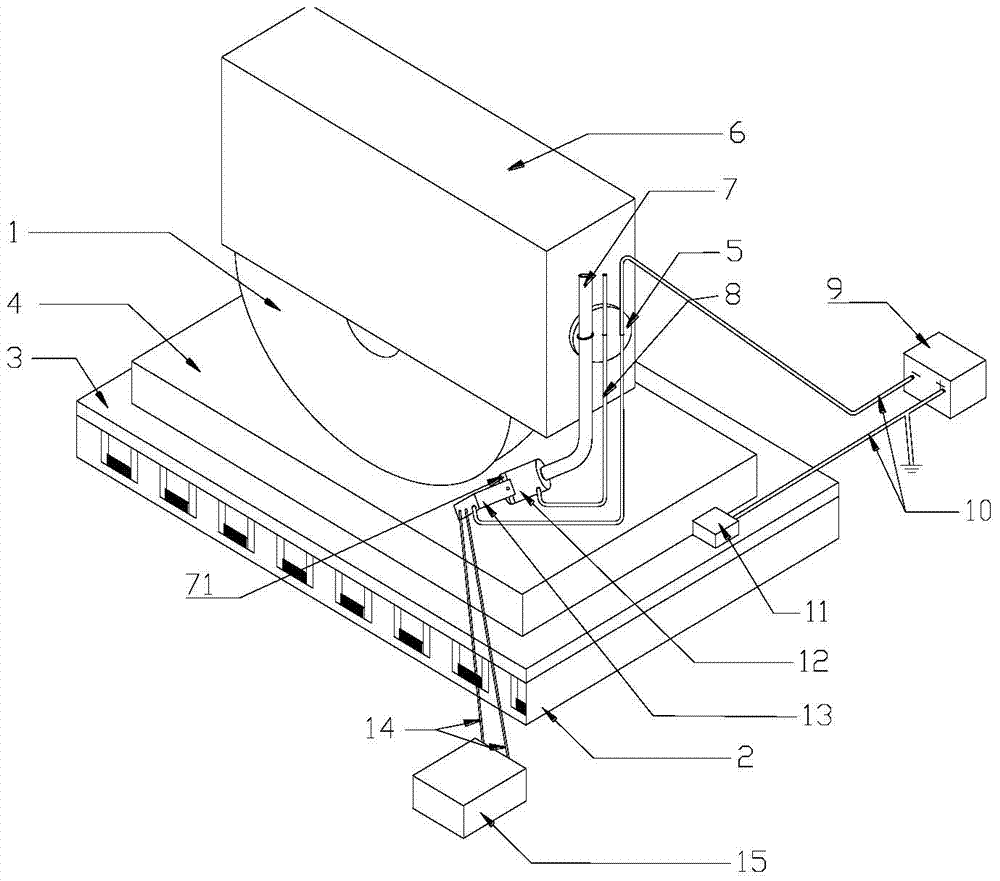

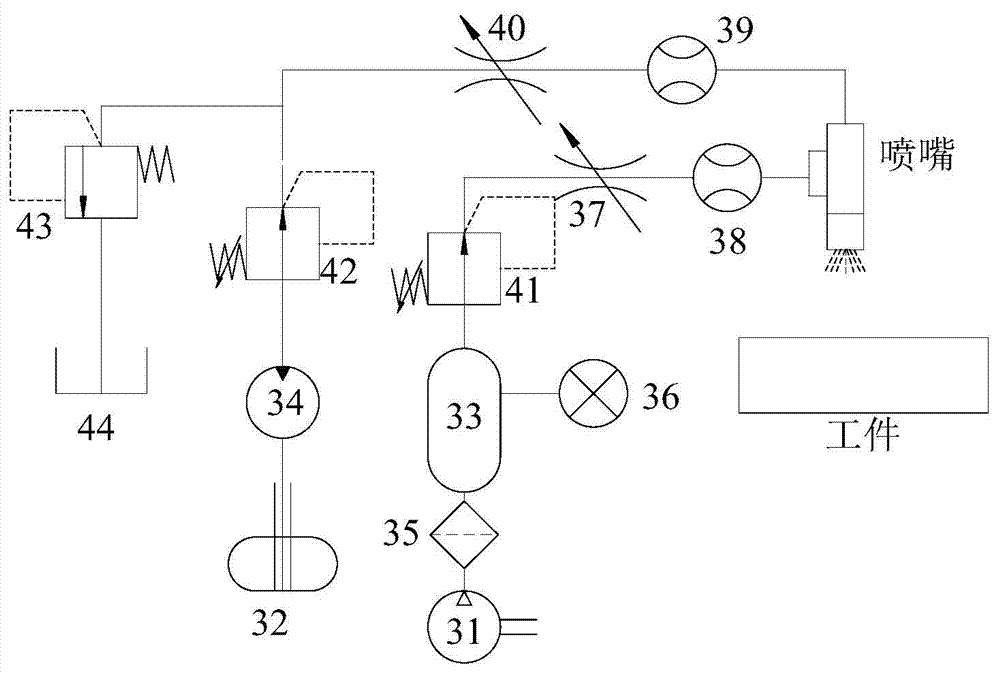

Conveying capacity controllable nano particle jet flow minimal quantity lubrication grinding device in enhanced magnetoelectricity field

ActiveCN103612207AViolent avalancheImprove charging capacitySpray discharge apparatusGrinding/polishing safety devicesMachined surfaceCorona discharge

The invention relates to a conveying capacity controllable nano particle jet flow minimal quantity lubrication grinding device in an enhanced magnetoelectricity field. Through adding of a magnetic field on the periphery of a corona zone, the charge capacity of liquid drops is increased. The device comprises a spray nozzle, a nano particle liquid feeding system, a gas supply system, a high-voltage DC electrostatic generator, an adjustable high voltage DC power supply and a magnetic field forming device. The high-voltage DC electrostatic generator and the magnetic field forming device are arranged outside the spray nozzle. The spray nozzle is connected with the nano particle liquid feeding system and the gas supply system. The high-voltage DC electrostatic generator is connected with the negative pole of the adjustable high voltage DC power supply. The positive pole of the adjustable high voltage DC power supply is connected with a workpiece power-up device which is used for being attached to a non-machined surface of a workpiece, and consequently a negative corona discharge form is formed. The magnetic field forming device is arranged on the periphery of the corona zone with electrostatic discharge. Nanofluid grinding fluid is sprayed out of a spray head of the spray nozzle and is atomized to be the liquid drops, and at the same time, the liquid drops are charged under the action of the high-voltage DC electrostatic generator and the magnetic field forming device and then are fed into a grinding region.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

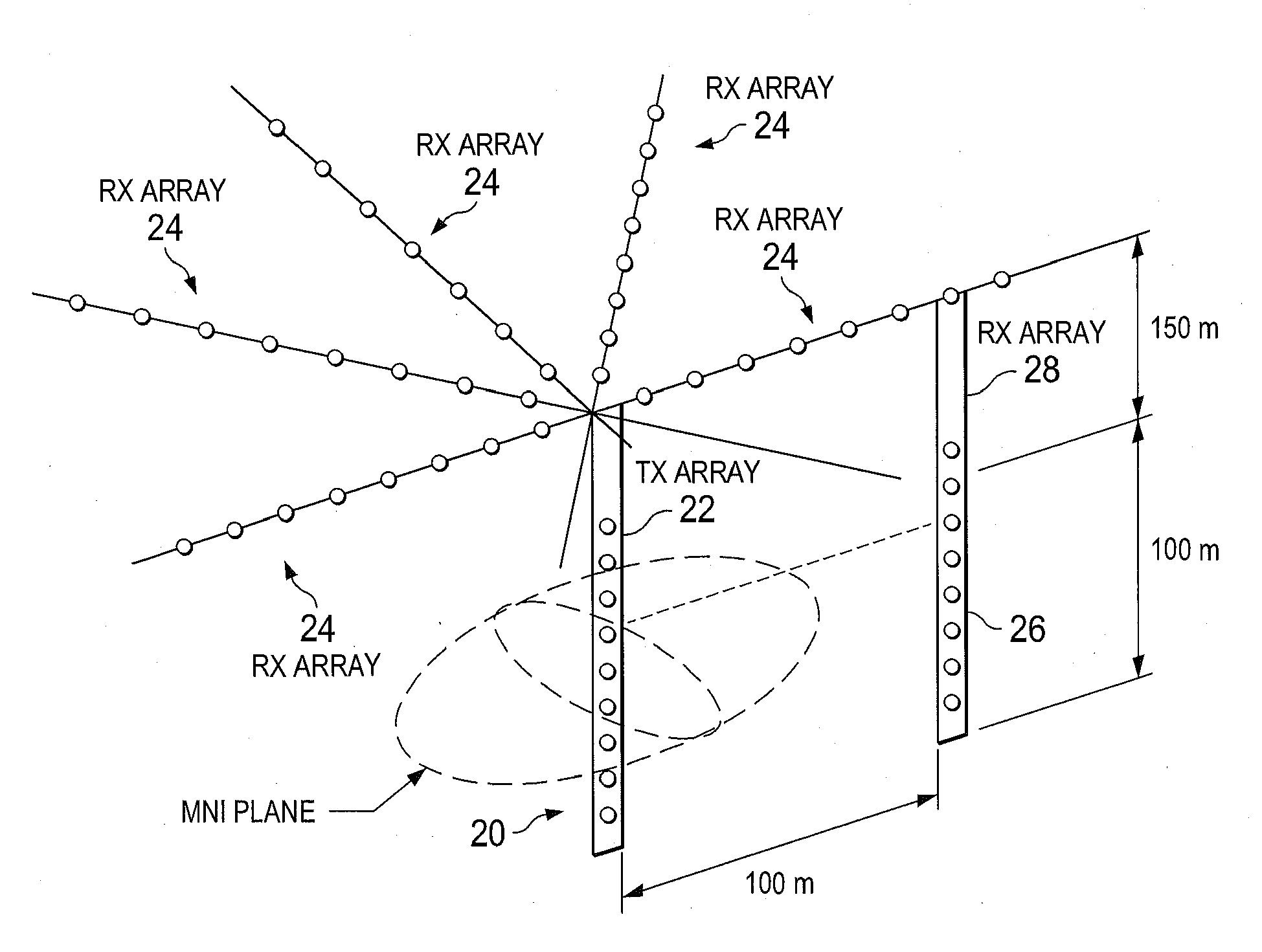

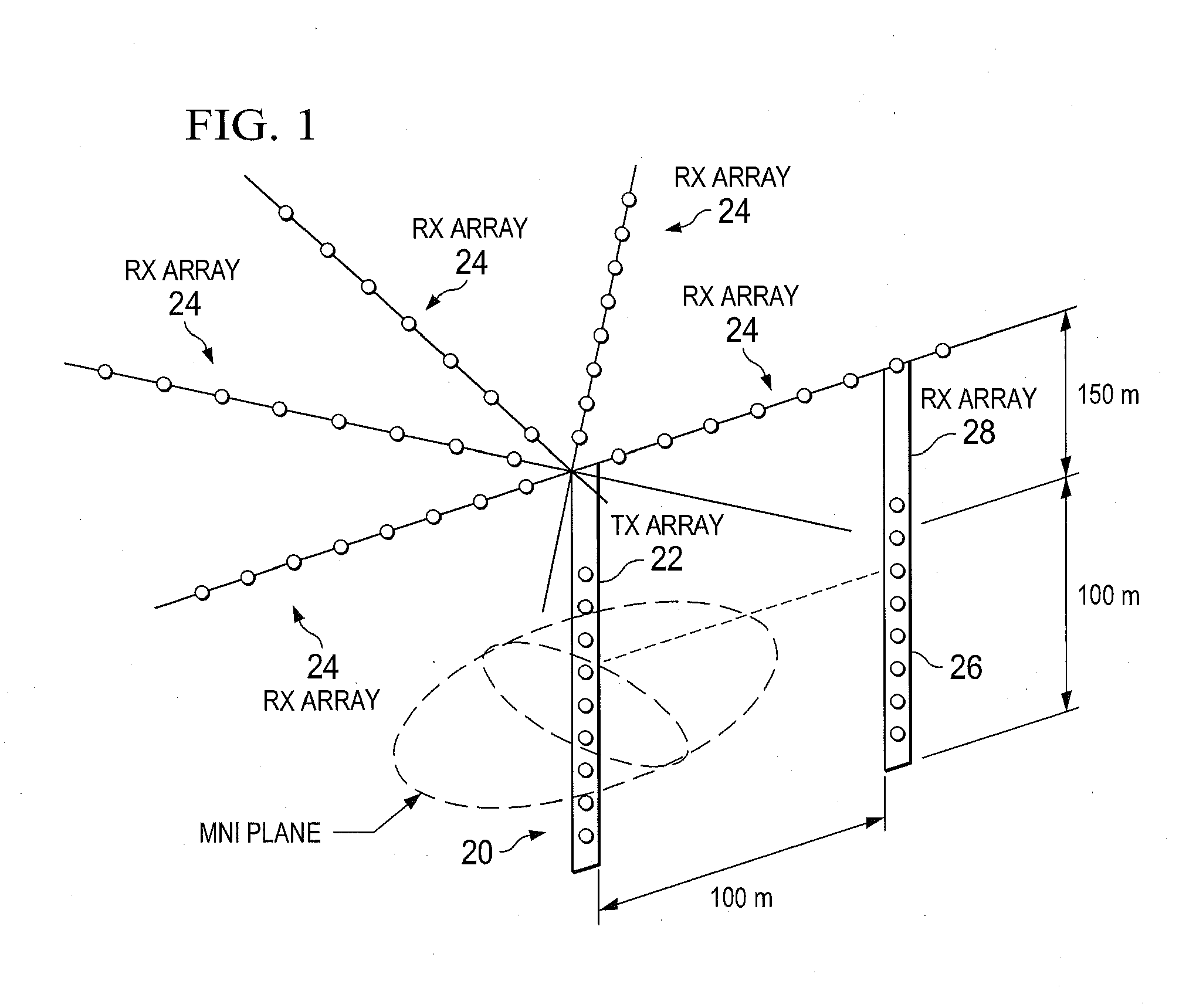

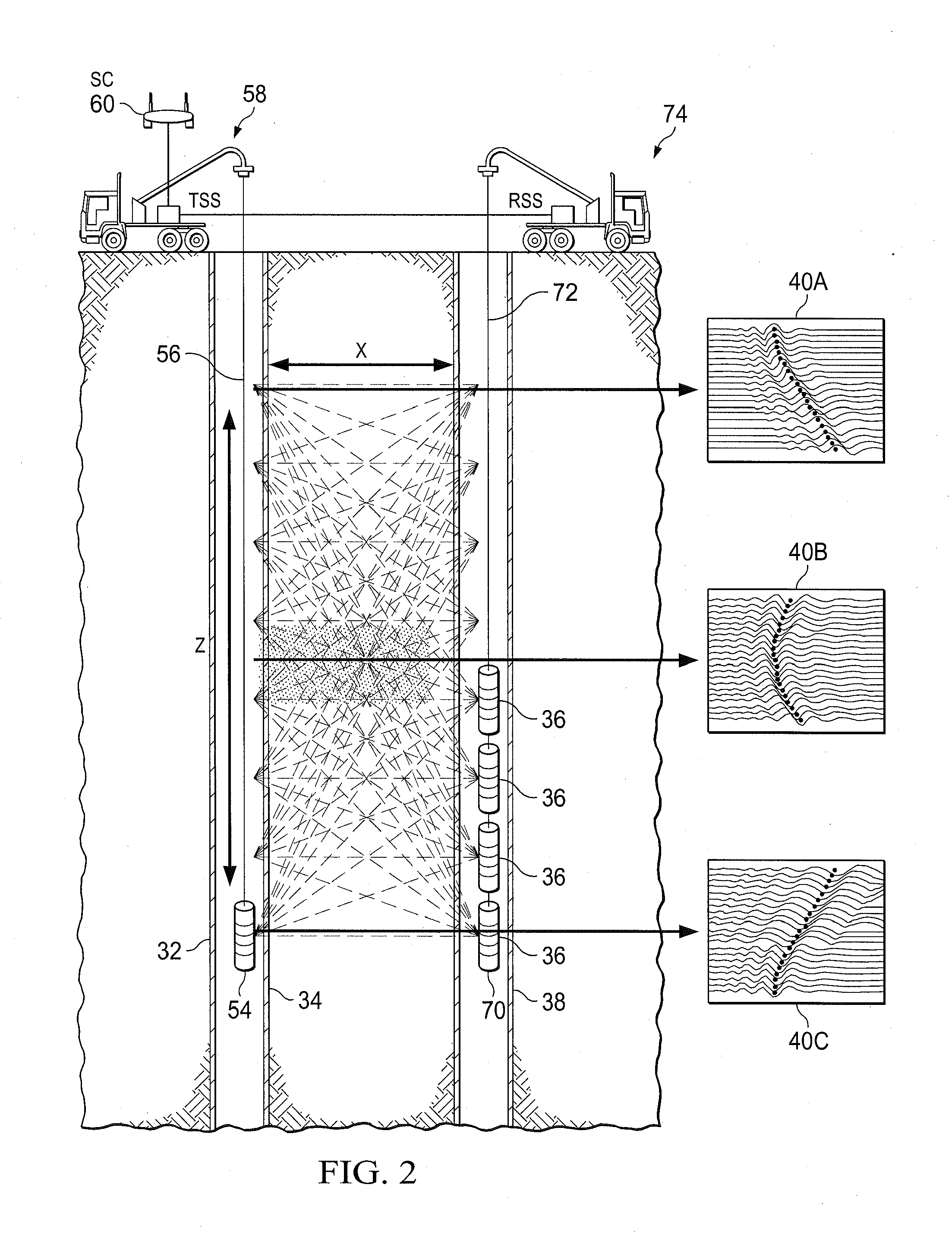

Super-Resolution Formation Fluid Imaging

ActiveUS20130146756A1Electric/magnetic detection for well-loggingDetection using electromagnetic wavesLow noiseOversampling

Cross-well electromagnetic (EM) imaging is performed using high-power pulsed magnetic field sources, time-domain signal acquisition, low-noise magnetic field sensors, spatial oversampling and super-resolution image enhancement and injected magnetic nanofluids. Inter-well images are generated mapping electromagnetic (EM) signal speed (group velocity) rather than conductivity maps. EM velocity maps with improved resolution for both native and injected fluids are provided.

Owner:SAUDI ARABIAN OIL CO

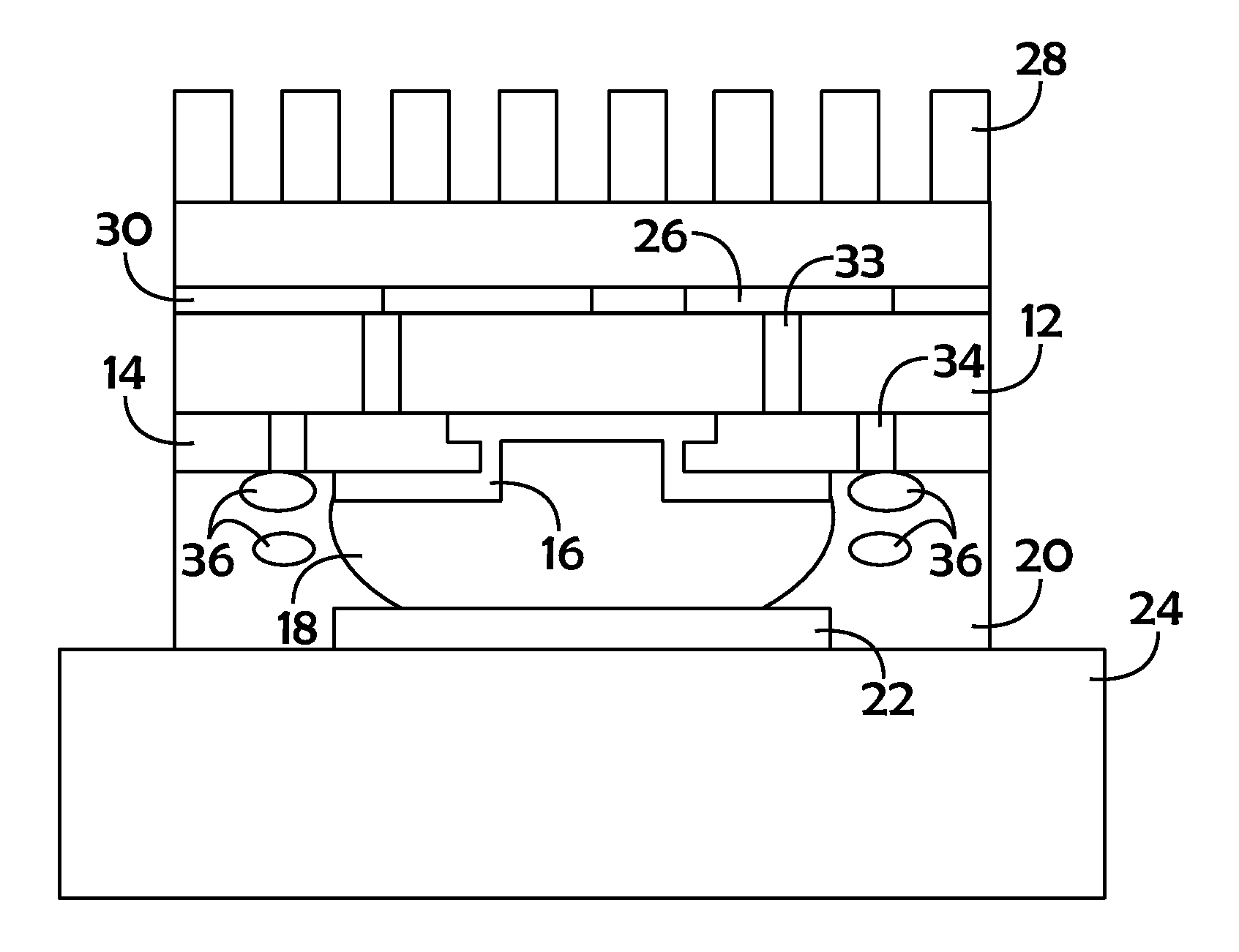

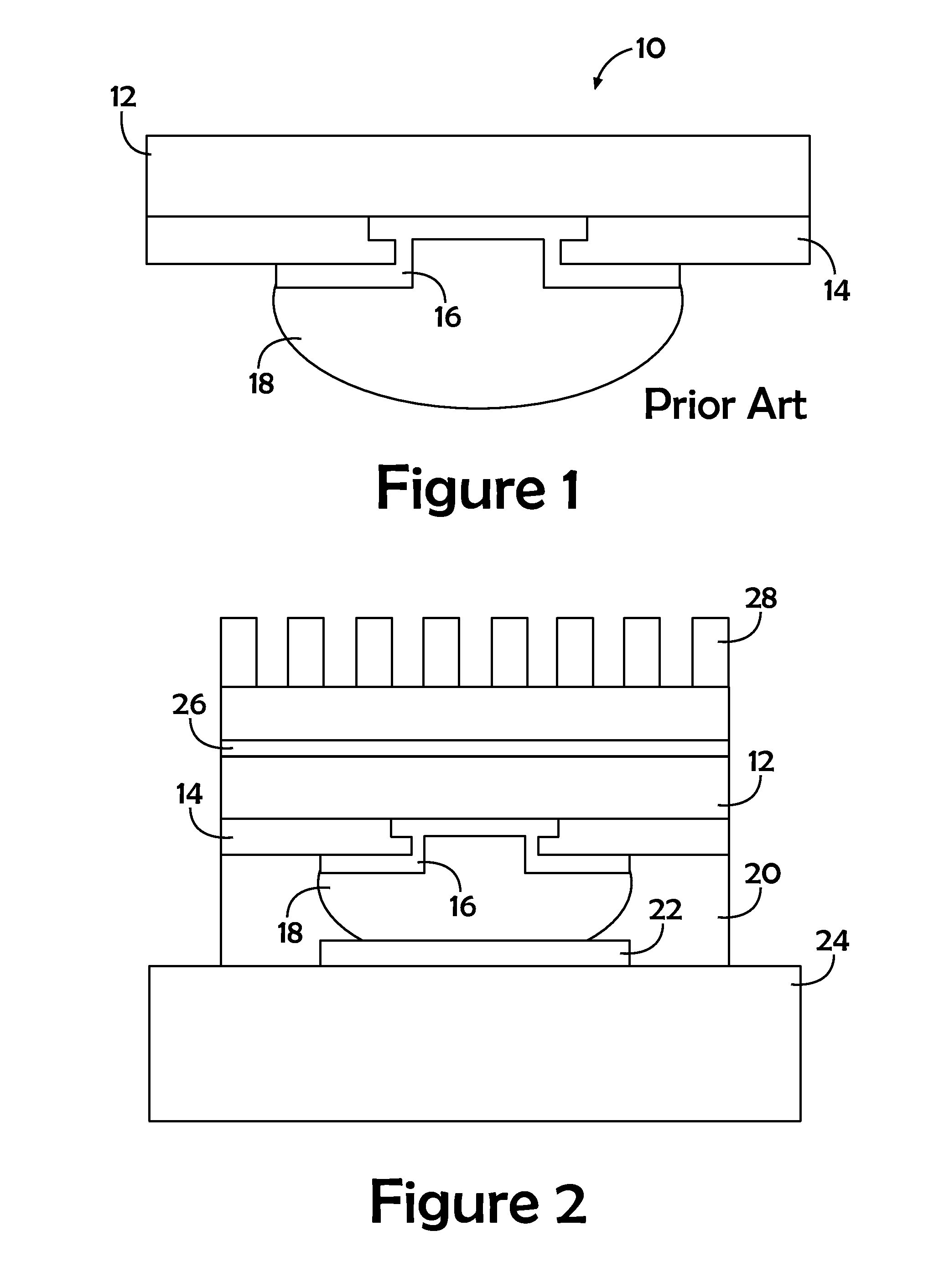

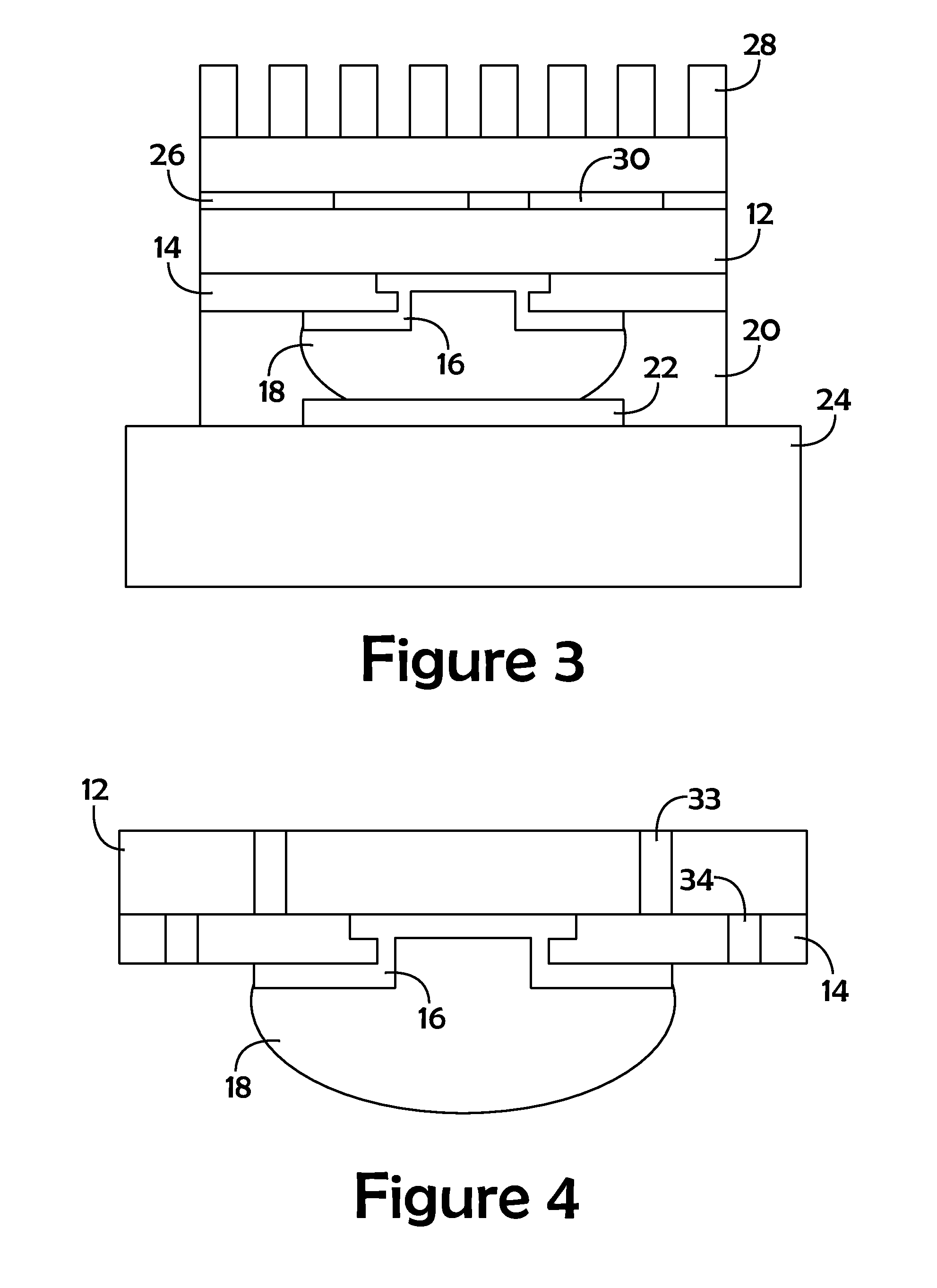

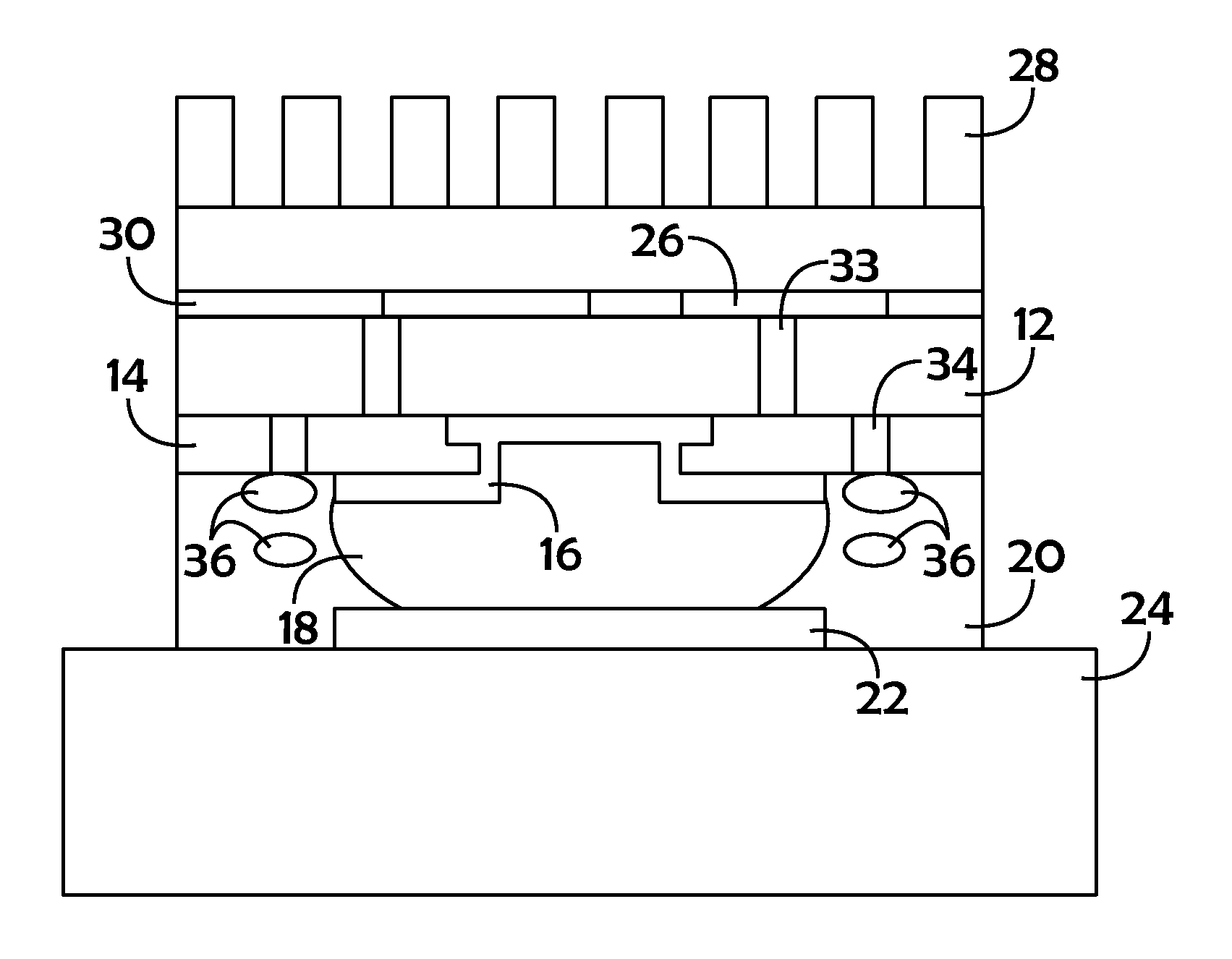

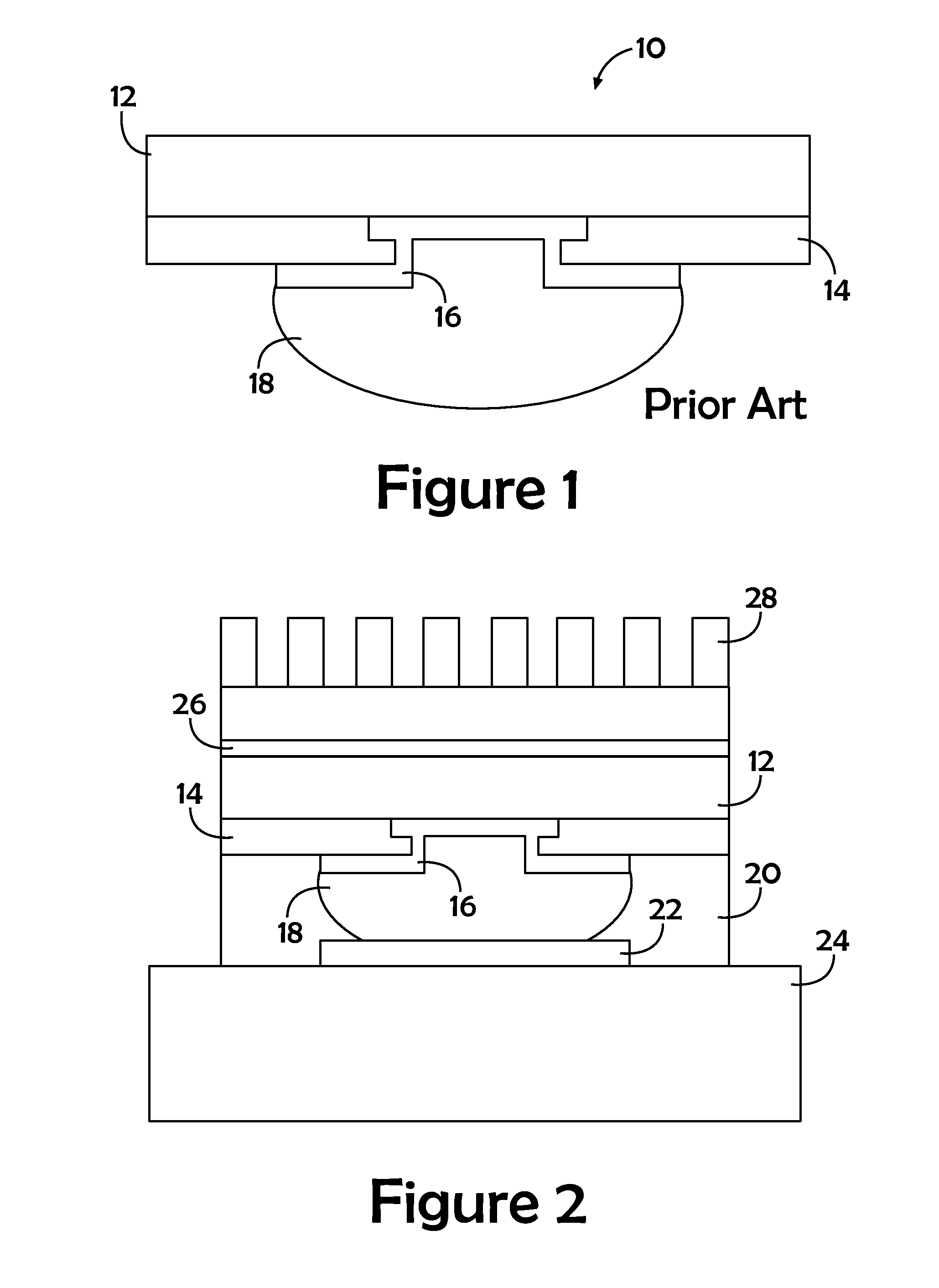

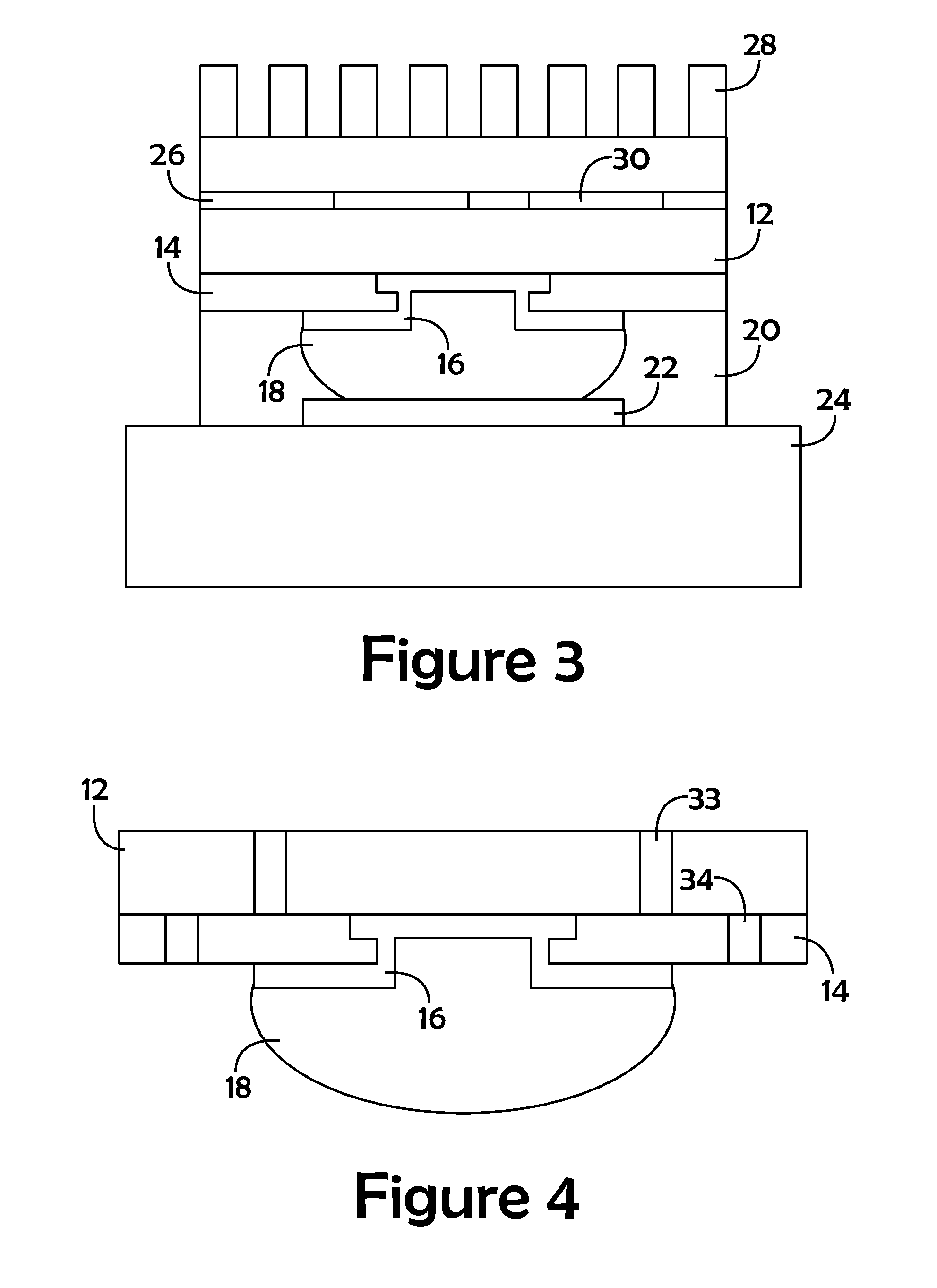

Anti-tamper microchip package based on thermal nanofluids or fluids

InactiveUS20120068326A1Improve artImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesNanofluidEngineering

A tamper-resistant microchip package contains fluid- or nanofluid-filled capsules, channels, or reservoirs, wherein the fluids, either alone or in combination, can destroy circuitry by etching, sintering, or thermally destructing when reverse engineering of the device is attempted. The fluids are released when the fluid-filled cavities are cut away for detailed inspection of the microchip. Nanofluids may be used for the sintering process, and also to increase the thermal conductivity of the fluid for die thermal management. Through-vias and micro vias may be incorporated into the design to increase circuitry destruction efficacy by improving fluid / chip contact. Thermal interface materials may also be utilized to facilitate chip cooling.

Owner:I3 ELECTRONICS

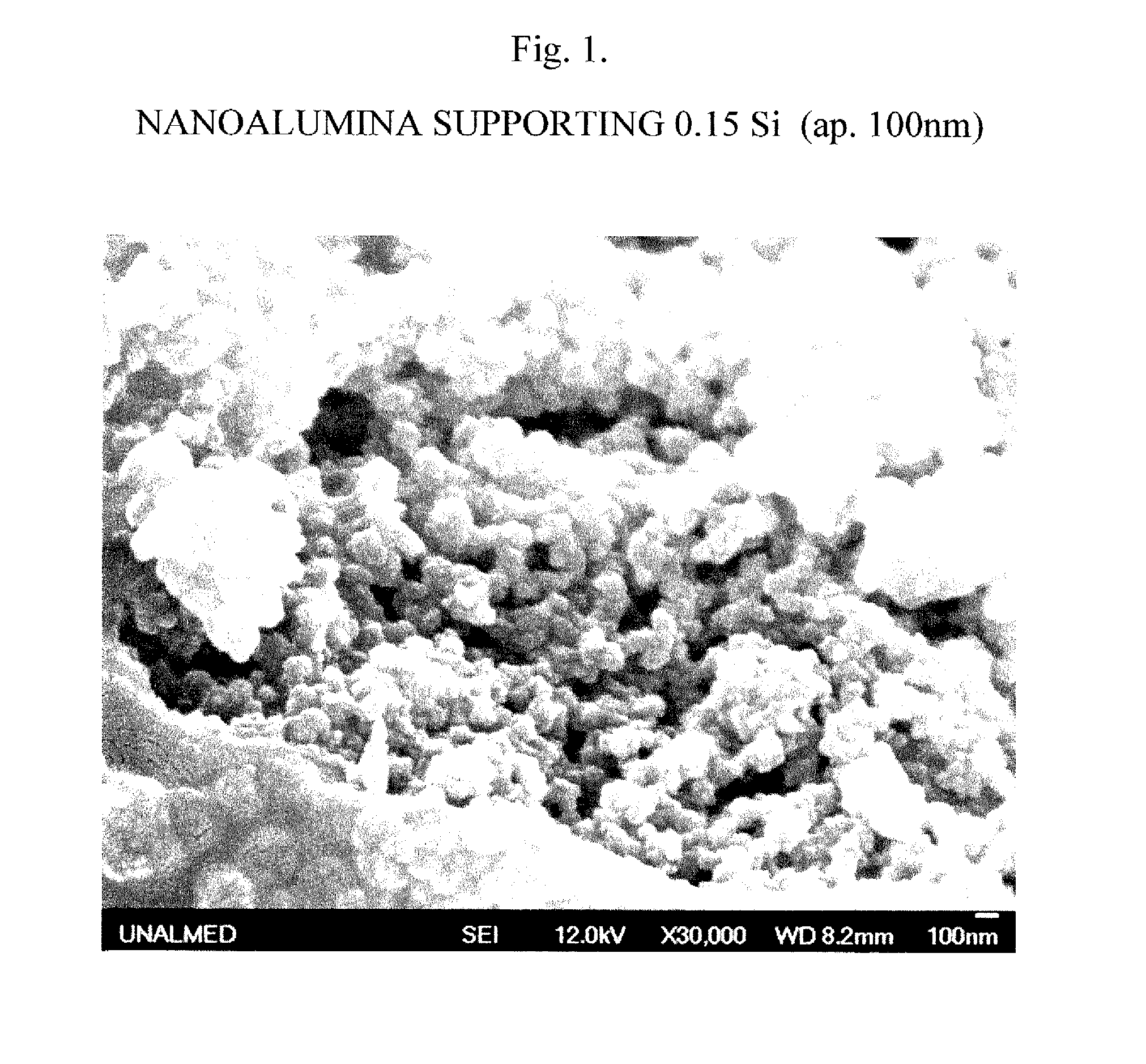

Nanofluids for oil recovery from tight light oil reservoirs and methods of their use

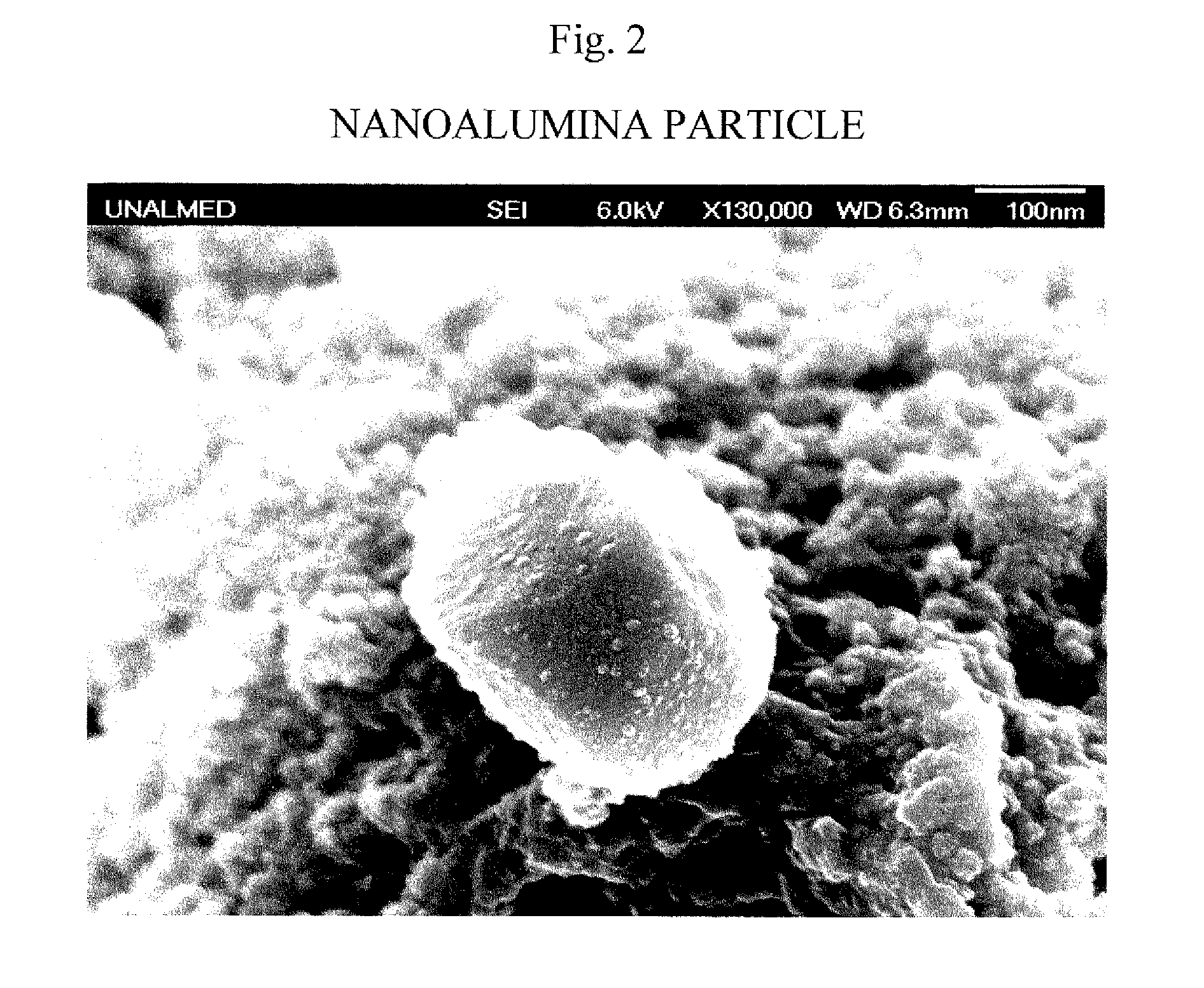

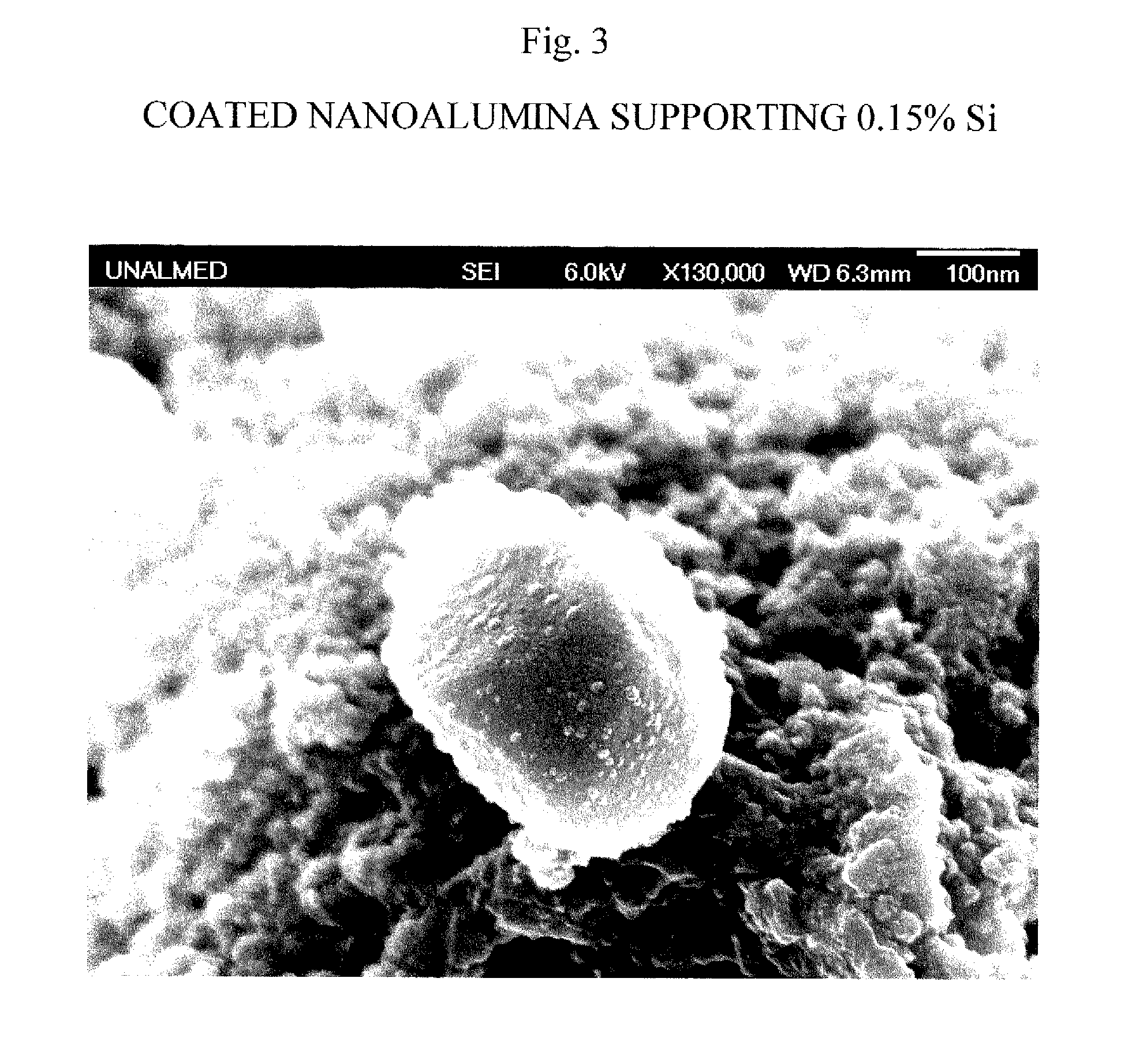

Novel nanoparticle catalysts comprising alumina nanoparticles doped with silicon, nanofluids containing the nanoparticle catalysts, processes for their preparation, as well as methods of their use in treating light tight oil wells having fractures and the oils produced by the wells post are disclosed. The novel nanocatalysts are useful, inter alia, improving well production, extending the time between fracturings, reducing well treatment costs associated with improving well production and or reducing equipment down time.

Owner:PETRORAZA

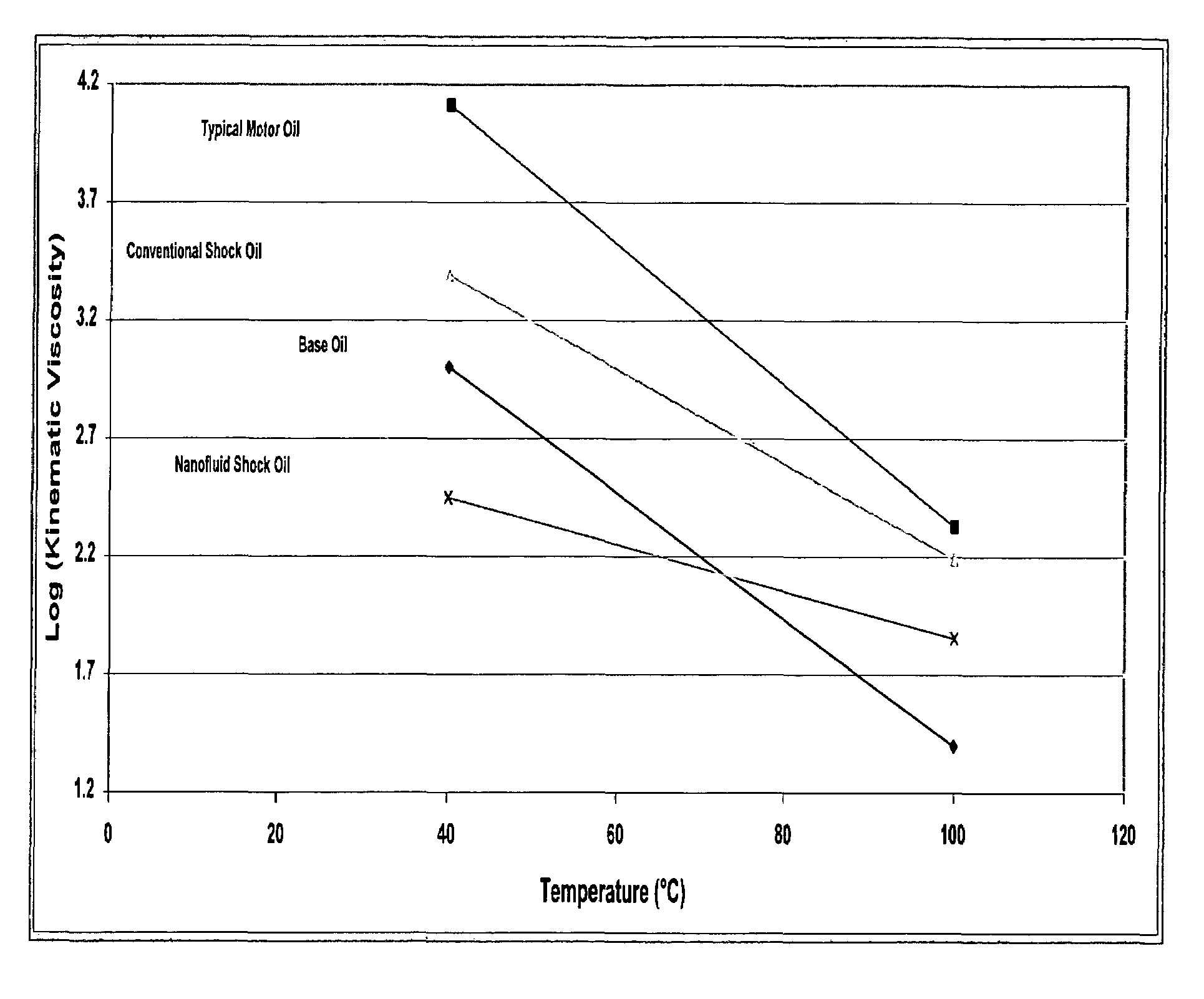

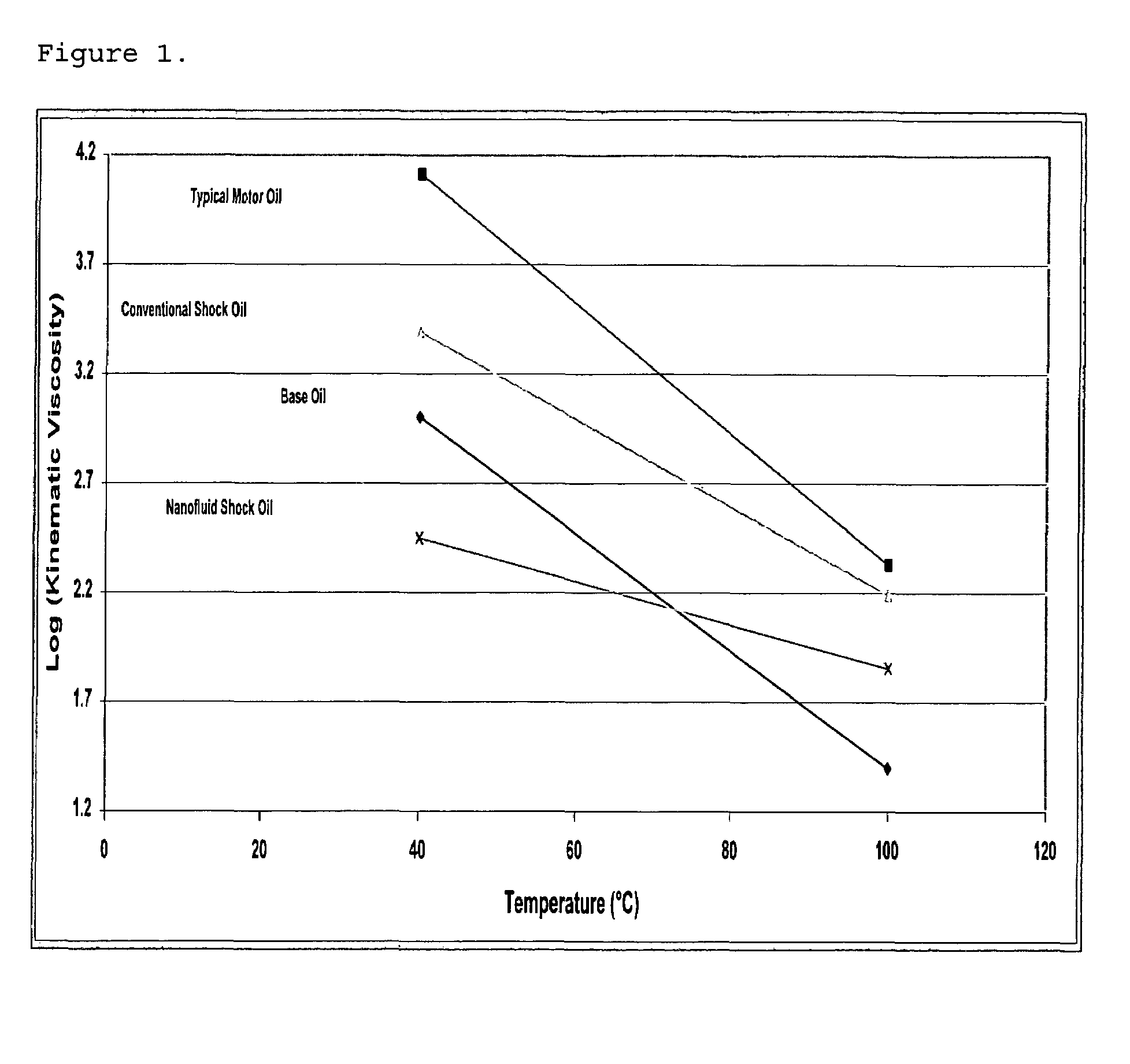

Shock absorber fluid composition containing nanostructures

The introduction of nanostructures in a liquid provides a means for changing the physical and / or chemical properties of the liquid. Improvements in heat transfer, electrical properties, viscosity, and lubricity can be realized upon dispersion of nanotubes in liquids. Stable dispersions of nanostructures are described and surfactants / dispersants are identified which can disperse nanostructures in petroleum liquid medium. The appropriate dispersant is chosen for the selected nanostructure material and the oil based medium and the dispersant is dissolved into the liquid medium to form a solution. The nanostructure is added to the dispersant containing the solution with agitation, ultrasonication, and / or combinations thereof. Nanostructures dispersed in a fluid form a nanofluid utilized as a shock absorber oil whereby the nanostructures serve to improve the viscosity index of the fluid or more particularly the shock absorber oil in the form of a lubricant additive.

Owner:VGP IPCO LLC

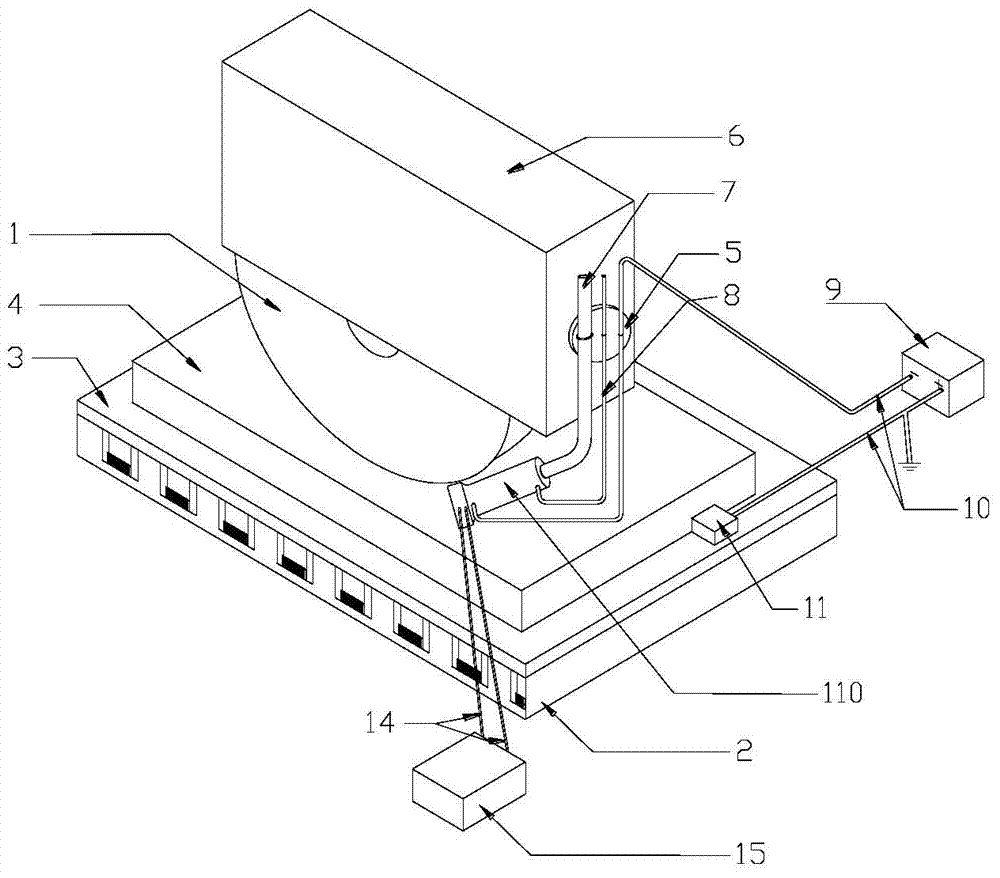

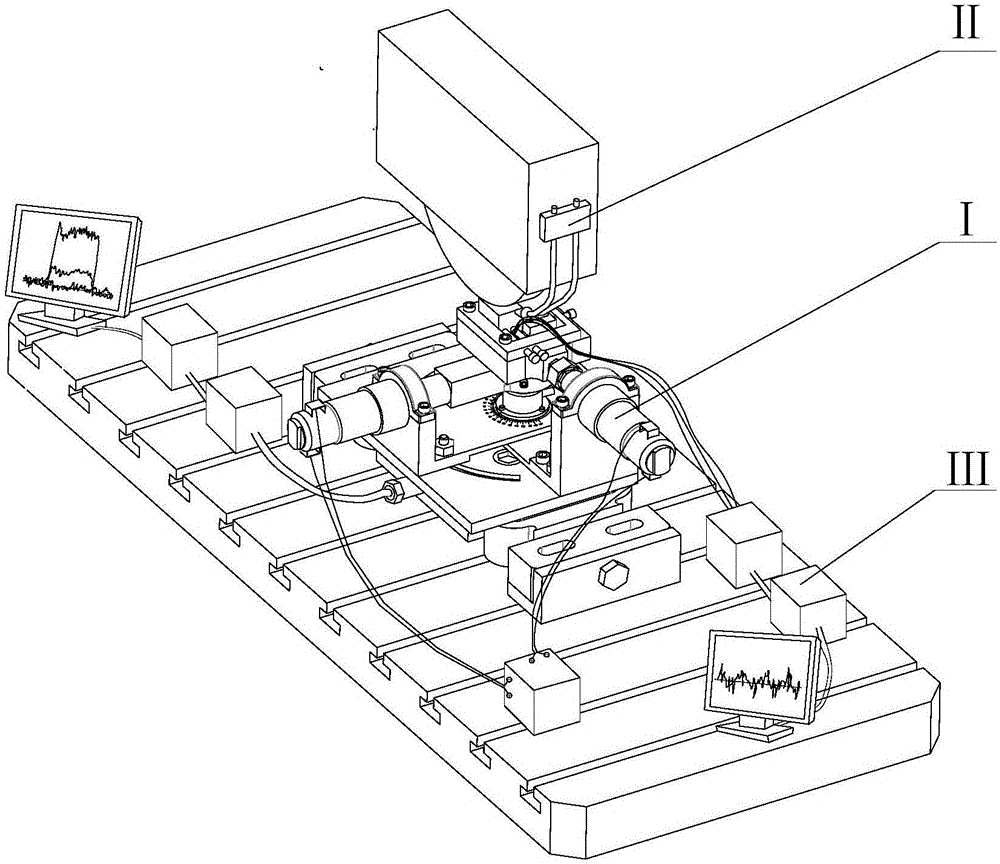

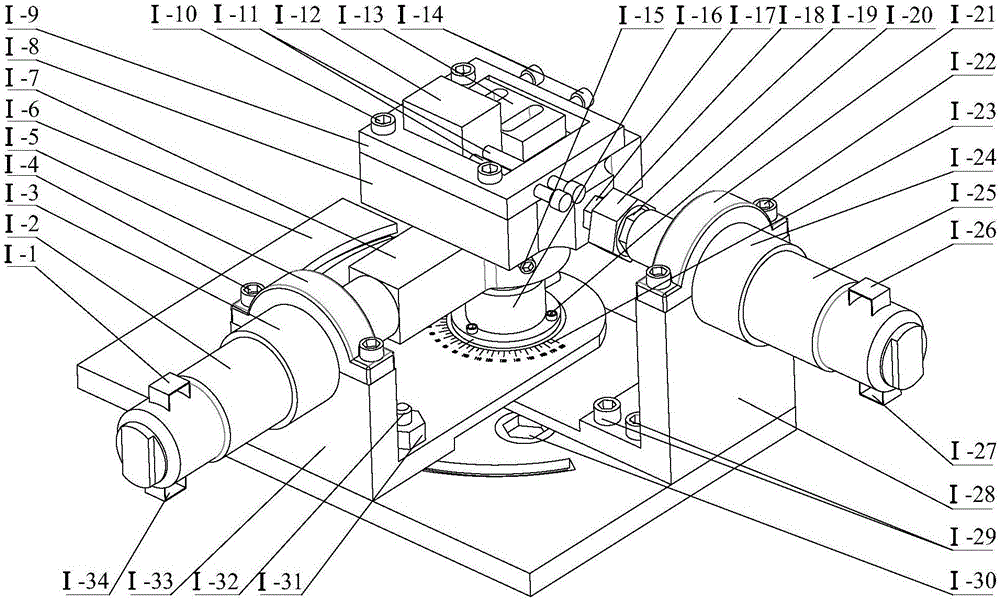

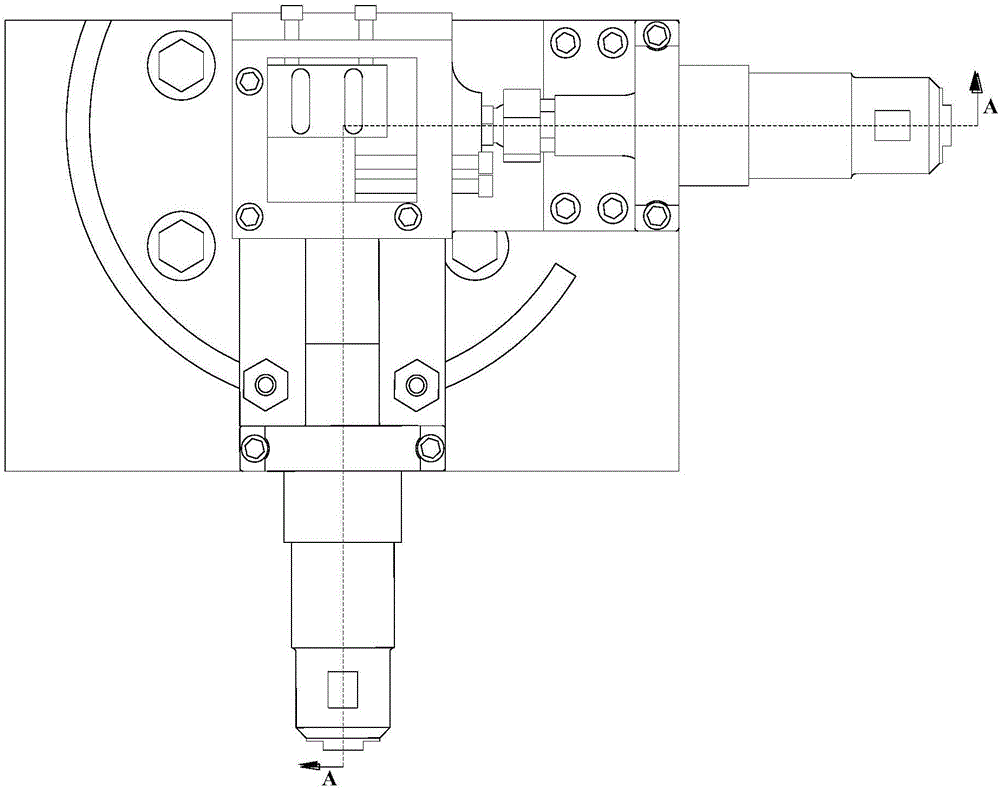

Multi-angle two-dimensional ultrasonic vibration-assisted nanofluid minimized quantity lubricating and grinding device

ActiveCN106181596AImprove surface qualityDifferent grinding effectsGrinding feed controlGrinding/polishing safety devicesThermal injuryCoupling

The invention discloses a multi-angle two-dimensional ultrasonic vibration-assisted nanofluid minimized quantity lubricating and grinding device. The device comprises a workpiece clamp for clamping a workpiece and a grinding wheel for grinding the workpiece, wherein the workpiece clamp is connected to a two-dimensional ultrasonic vibrating device so as to maintain the degree of sharpness of the cutting edge of the grinding wheel and reduce the surface grinding temperature of the workpiece; an injection mechanism for injecting a nanofluid to the workpiece is arranged on one side of the grinding wheel to form coupling of two-dimensional ultrasonic vibration and nanofluid minimized quantity lubrication and grinding. The device applies a variable-angle two-dimensional ultrasonic vibration technology to grinding, and different combined vibrating directions are generated by adjusting the angles of two ultrasonic vibrators, so that the relative movement tracks of abrasive particles and the workpiece are changed. The grinding force and the grinding temperature are detected in real time through a force measuring device and a temperature measuring device, and meanwhile, the device is matched with nanofluid minimized quantity lubrication, so that the machining quality of the workpiece is further improved, and the thermal injury of the workpiece is avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

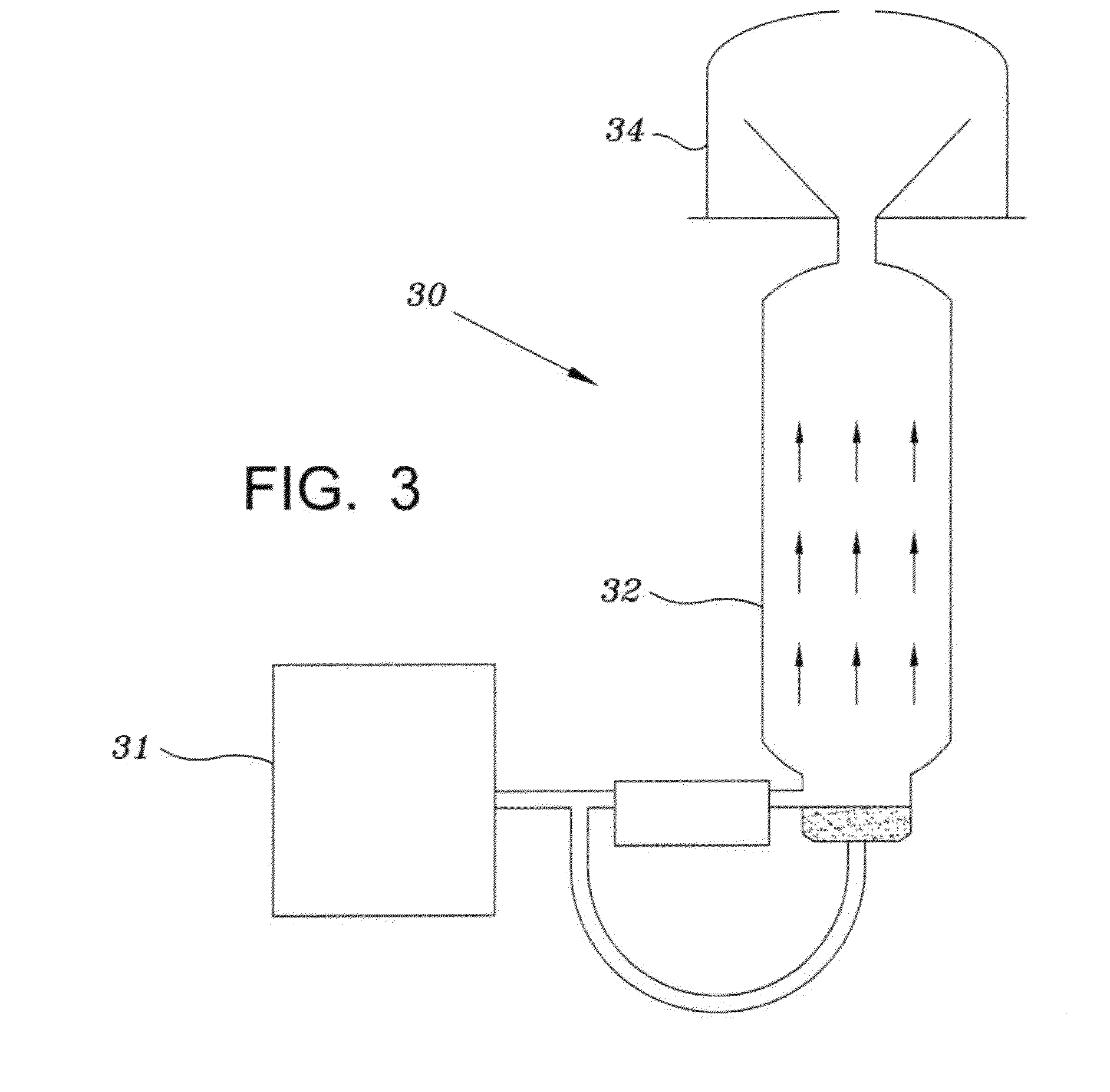

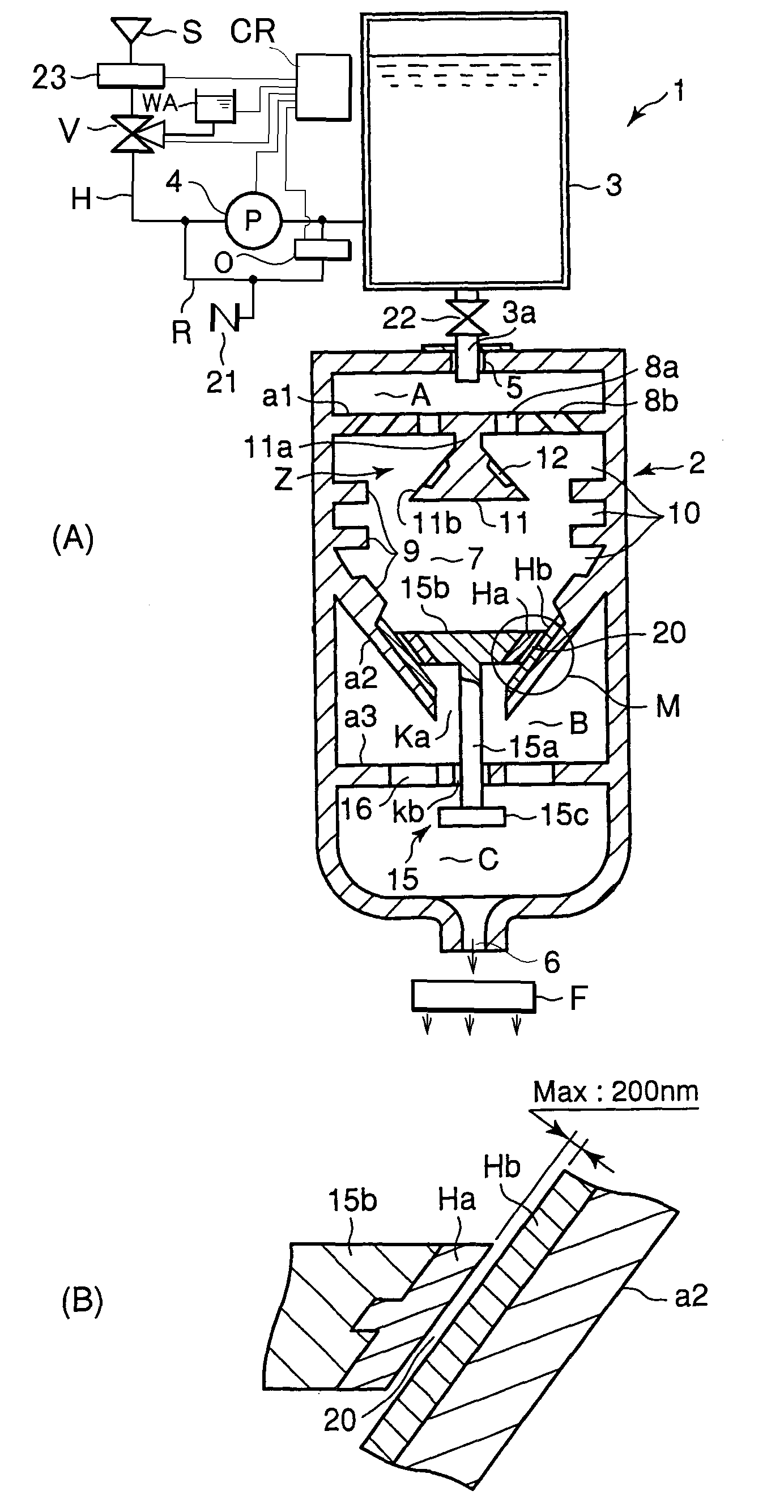

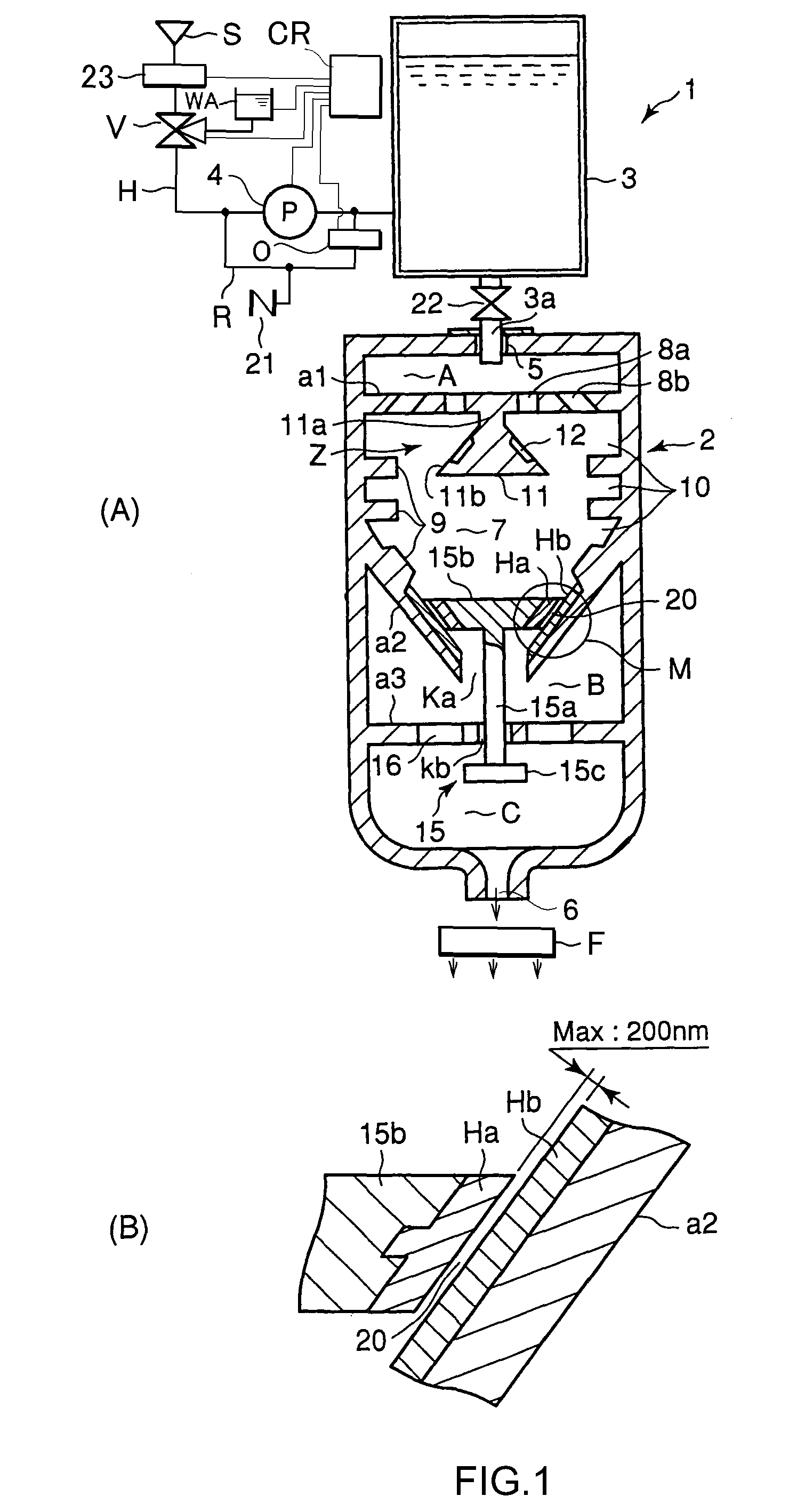

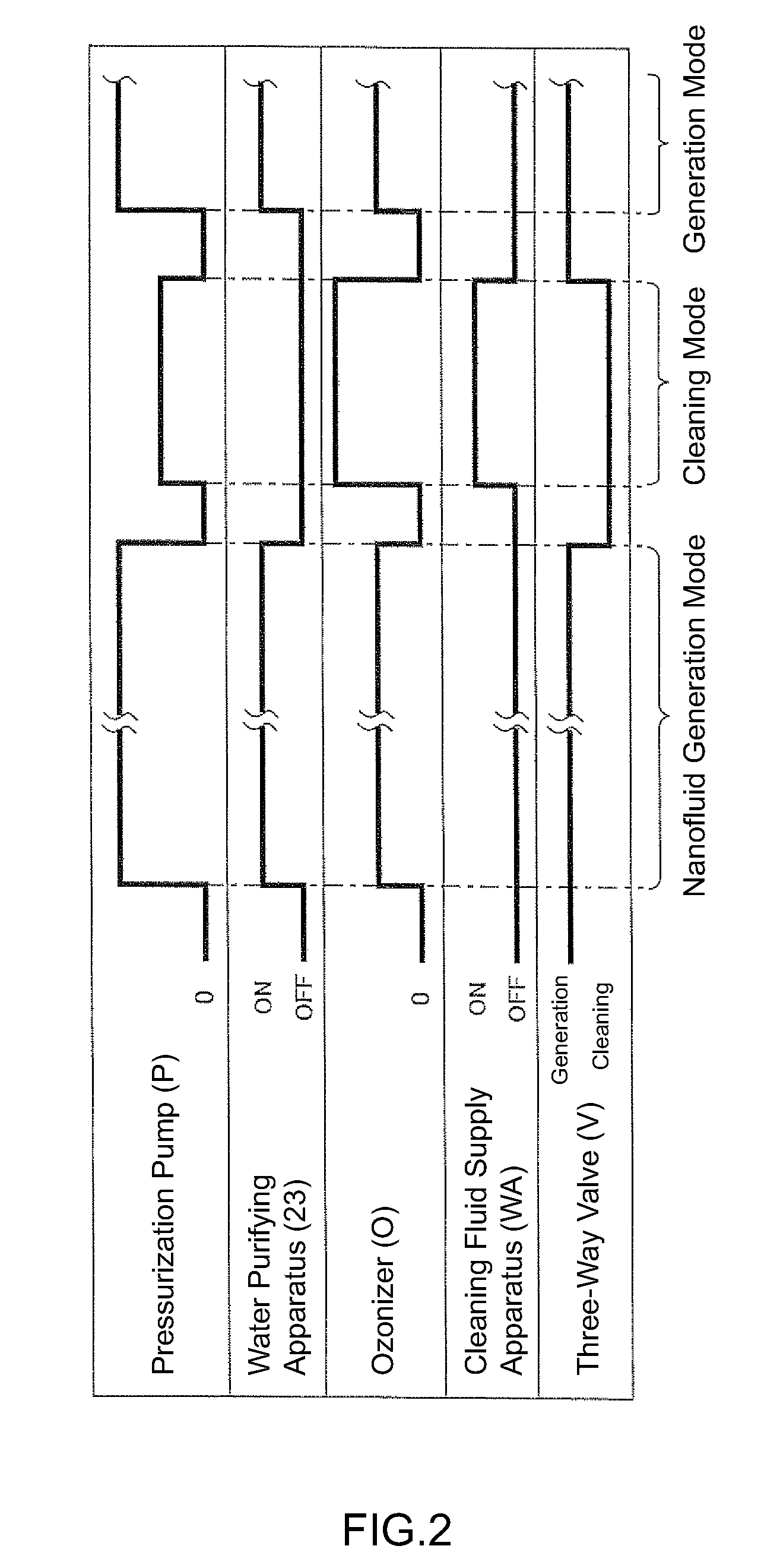

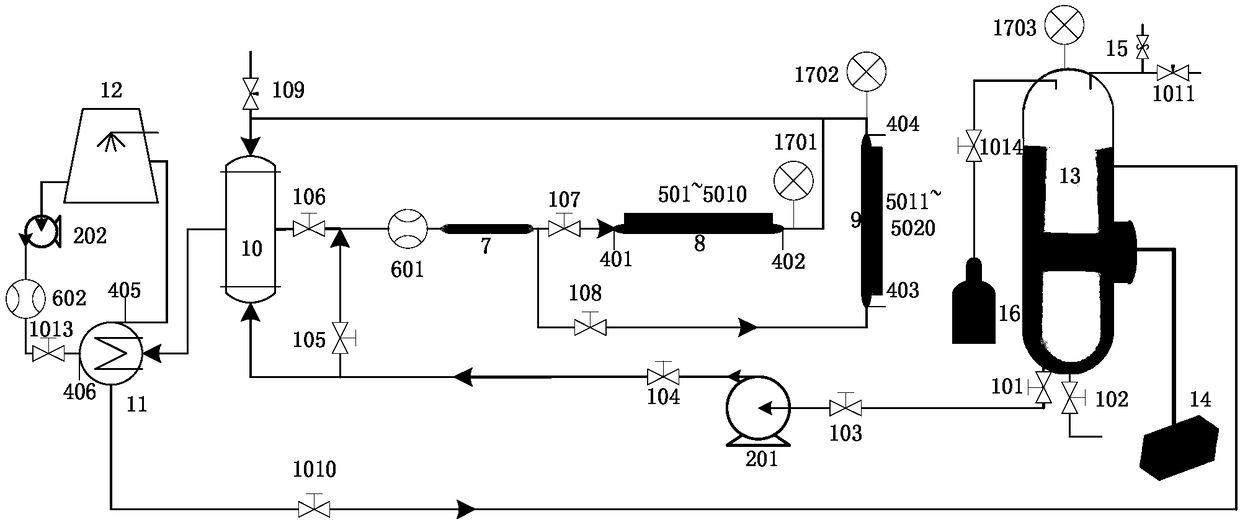

Nanofluid Production Apparatus and Method

InactiveUS20100010422A1Simple and inexpensive structureEasy to useFlow mixersUsing liquid separation agentNanofluidProcess engineering

The object of the invention is to provide an apparatus and a method for generating a large amount of nanofluid continuously and stably with a relatively simple, inexpensive and easy-to-use structure, and for efficiently performing an intra-apparatus cleaning operation to substantially reduce the nanofluid manufacturing cost.A nanofluid generating apparatus 1 for generating nanofluid containing nanobubbles, wherein the nanobubbles are gas bubbles with diameter less than 1 μm, comprises a gas-liquid mixing chamber 7, comprising a turbulence generating mechanism for forcibly mixing supplied gas and liquid by generating turbulence, and a nano-outlet 20 for discharging the gas-liquid mixture fluid to outside of the gas-liquid mixing chamber to generate nanofluid; a gas-liquid supply apparatus 21, 23, . . . for supplying gas and liquid to the gas-liquid mixing chamber 7; a pressurization pump for applying pressure to the gas and liquid; and a control unit CR for controlling operations of the pressurization pump 4 and the gas-liquid supply apparatus. The control unit CR controls the gas-liquid supply apparatus and the pressurization pump 4 to switch between a nanofluid generation mode and a cleaning mode for cleaning the inside of the gas-liquid mixing chamber 7.

Owner:WATANABE SADATOSHI

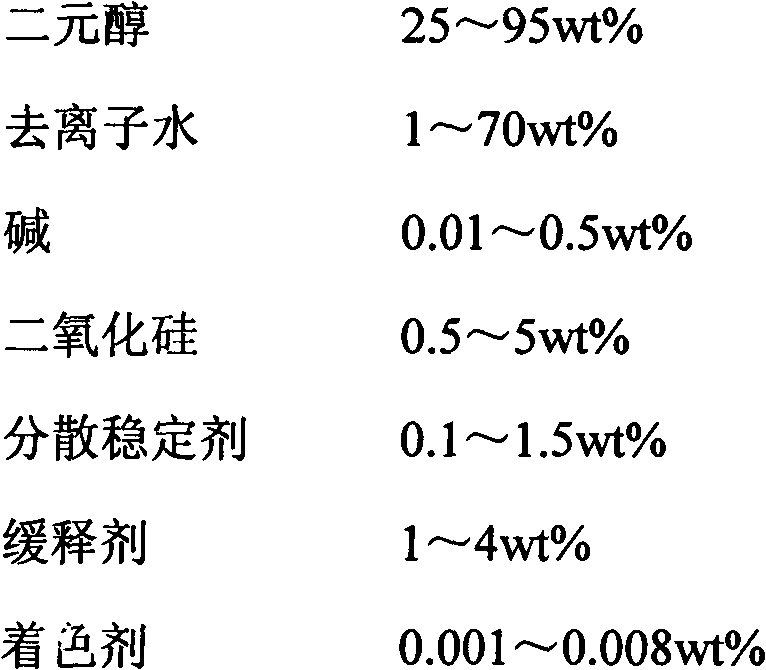

Preparation method of nanofluid cooling liquid and nanofluid cooling liquid prepared by same

The invention discloses a preparation method of nanofluid cooling liquid and the nanofluid cooling liquid prepared by the same. The preparation method comprises the following steps of: uniformly mixing dibasic alcohol, de-ionized water and alkali to obtain basic liquid; adding ethyl silicate into the basic liquid and hydrolyzing the mixture to obtain nanofluid containing silicon dioxide nanoparticles; and adding a dispersion stabilizer, a corrosion inhibitor and a coloring agent into the nanofluid to obtain the nanofluid cooling liquid. The preparation method provided by the invention has the characteristics of simple equipment and process, mild conditions, high raw material utilization rate, low cost, easiness for large-scale production and the like. The prepared nanofluid cooling liquid has high stability and high heat exchange capacity.

Owner:青岛康普顿石油化工有限公司 +1

Alignment of Carbon Nanotubes Comprising Magnetically Sensitive Metal Oxides in Nanofluids

ActiveUS20120235080A1Reduce amountHigh trafficMaterial nanotechnologyMagnetic liquidsCarbon nanotubeNanofluid

The present invention is a nanoparticle mixture or suspension or nanofluid comprising nonmagnetically sensitive nanoparticles, magnetically sensitive nanoparticles, and surfactant(s). The present invention also relates to methods of preparing and using the same.

Owner:SOUTH DAKOTA BOARD OF REGENTS +1

A method for preparing carbon nanofluid

InactiveUS20070253888A1Improve thermal conductivityMaterial nanotechnologyStationary conduit assembliesCarbon nanotubeNanofluid

The present invention provides a method for preparing a carbon nanofluid. The method includes providing a base fluid, providing a number of carbon nanotubes, combining the carbon nanotubes with the base fluid, dispersing the carbon nanotubes substantially evenly in the base fluid through a physical agitation operation, and cooling a system performing the physical agitation operation during the physical agitation operation. The present invention also provides a carbon nanofluid capable of serving as a heat transfer fluid. The carbon nanofluid includes about 99.8 to about 98% by volume of a base fluid, and from about 0.2 to about 2.0% by volume of functionalized carbon nanotubes substantially evenly-dispersed in the base fluid.

Owner:IND TECH RES INST

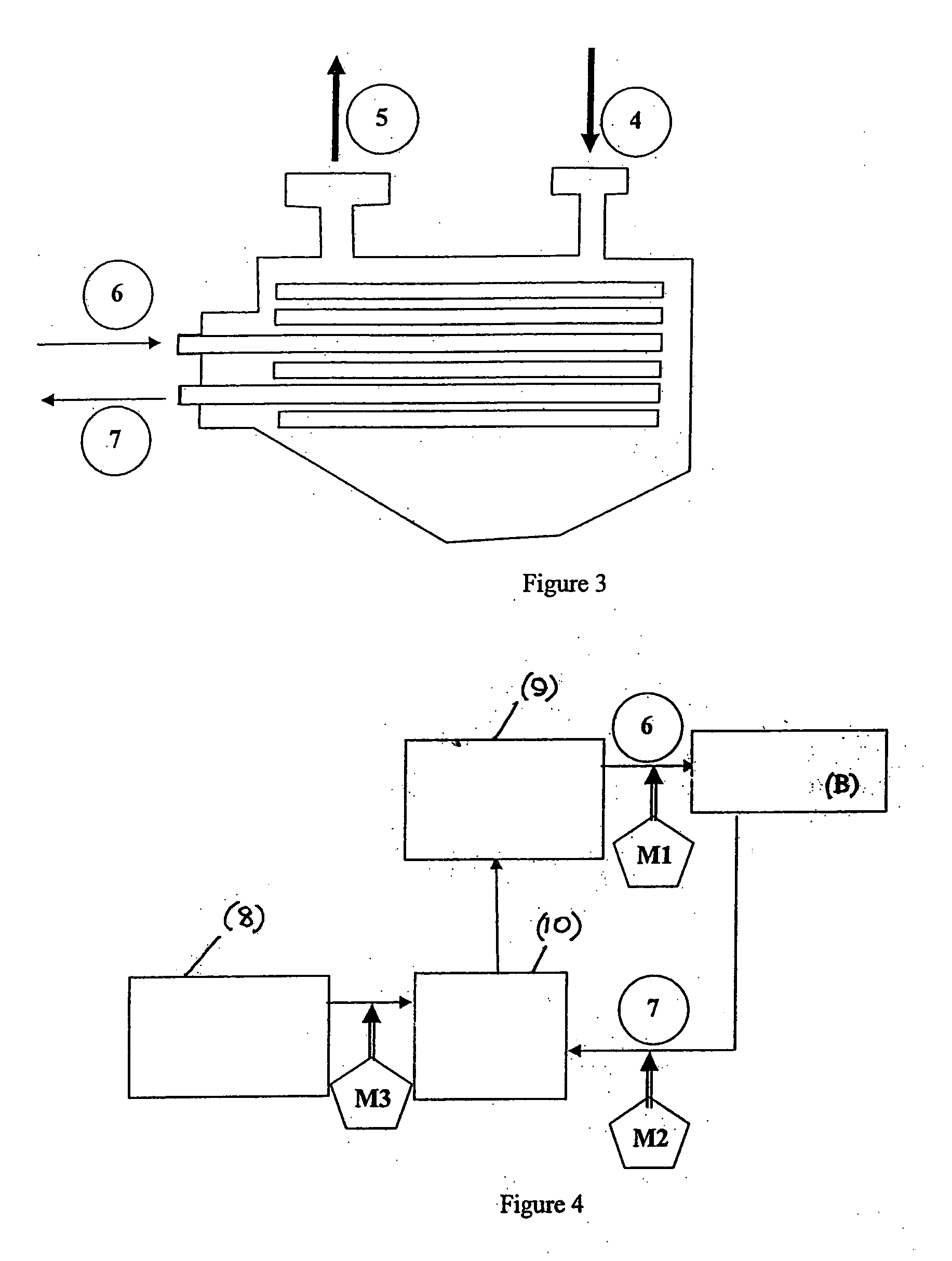

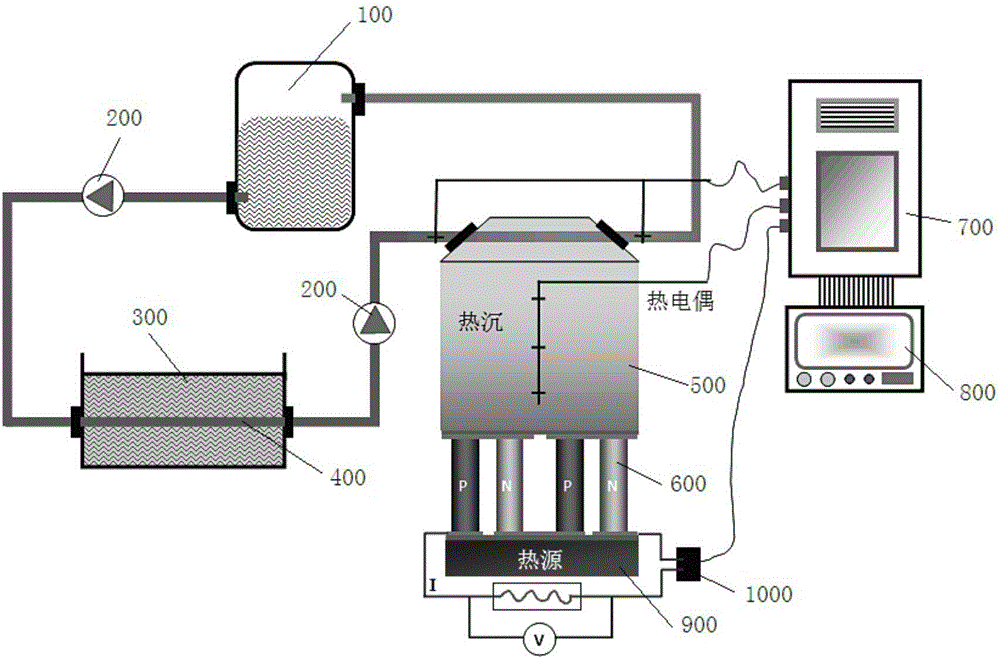

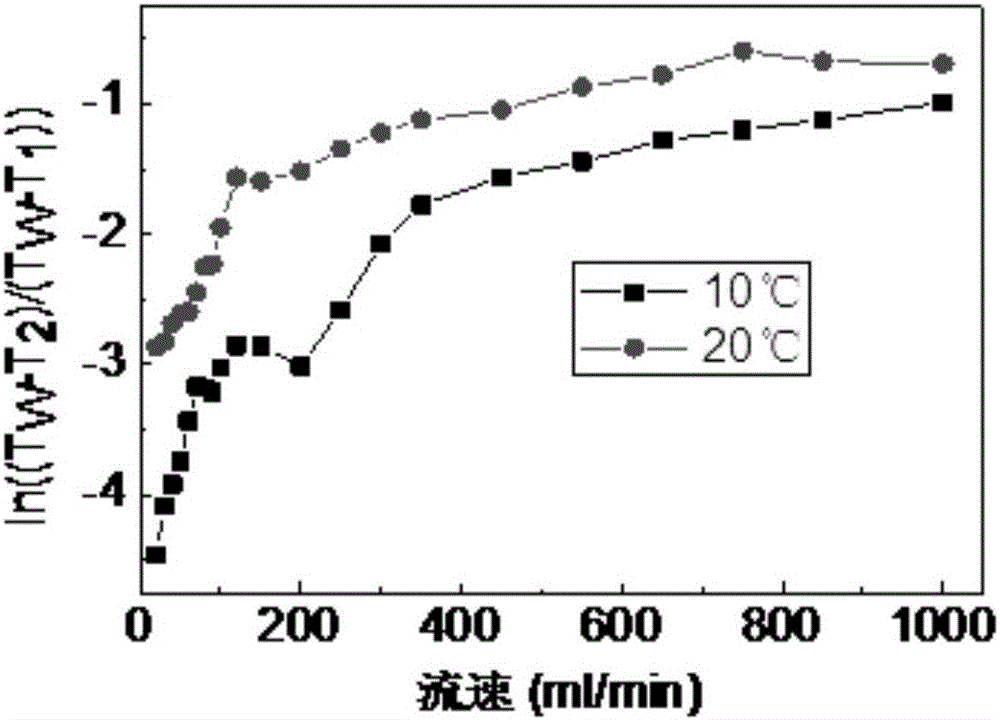

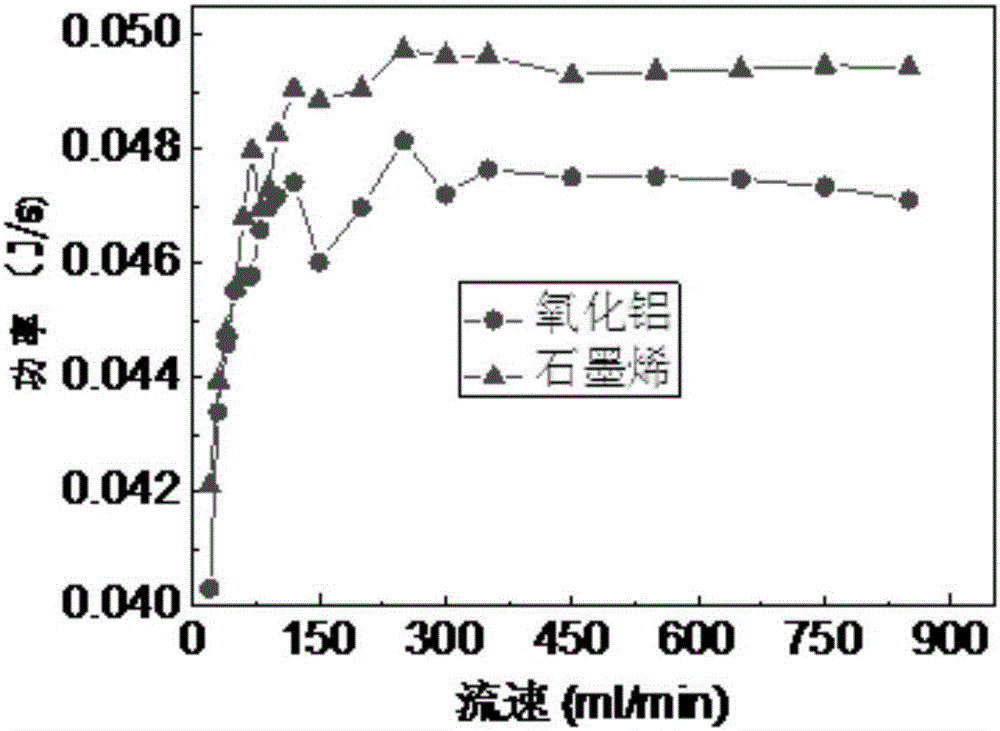

System and method for synchronously testing nanofluid heat transfer coefficient and influence rule thereof on power generation efficiency of thermoelectric generation system

ActiveCN106198616AReduce measurement errorImprove accuracyMaterial heat developmentPower measurement by thermal methodsPeristaltic pumpWater baths

The invention relates to a system and a method for synchronously testing nanofluid heat transfer coefficient and influence rule thereof on the power generation efficiency influence rule of a thermoelectric generation system. The system mainly comprises a liquid storage tank, a peristaltic pump, a cold water bath, a copper pipe, a heat sink, a thermoelectric device, a heat source, a plurality of groups of thermocouples, a data acquirer, a computer control terminal and the like. The method comprises the following steps: measuring the temperature T1, T2 and T3 of nanofluid entering the inlet end of the cold water bath, at the distance away from the inlet end by 20-30cm and in the cold water bath, calculating the intensified convection heat transfer performance of the nanofluid according to constant-temperature boundary conditions. Heat carried by the nanofluid is estimated by distributing the thermocouples on the heat sink from top to bottom, and the thermoelectric conversation efficiency under differnet nanofluid working conditions can be obtained by combining the conversation power of the thermoelectric devices. The synchronous testing on the intensified heat transfer coefficient of nanofluid under different working conditions, and the influence of the intensified heat transfer coefficient of nanofluid under different working conditions on the cooling effect of the cold end of the thermoelectric devices as well as the influence on the conversation efficiency can be realized, the measurement errors can be decreased, and the testing accuracy can be improved.

Owner:江苏南通创源材料科技有限公司

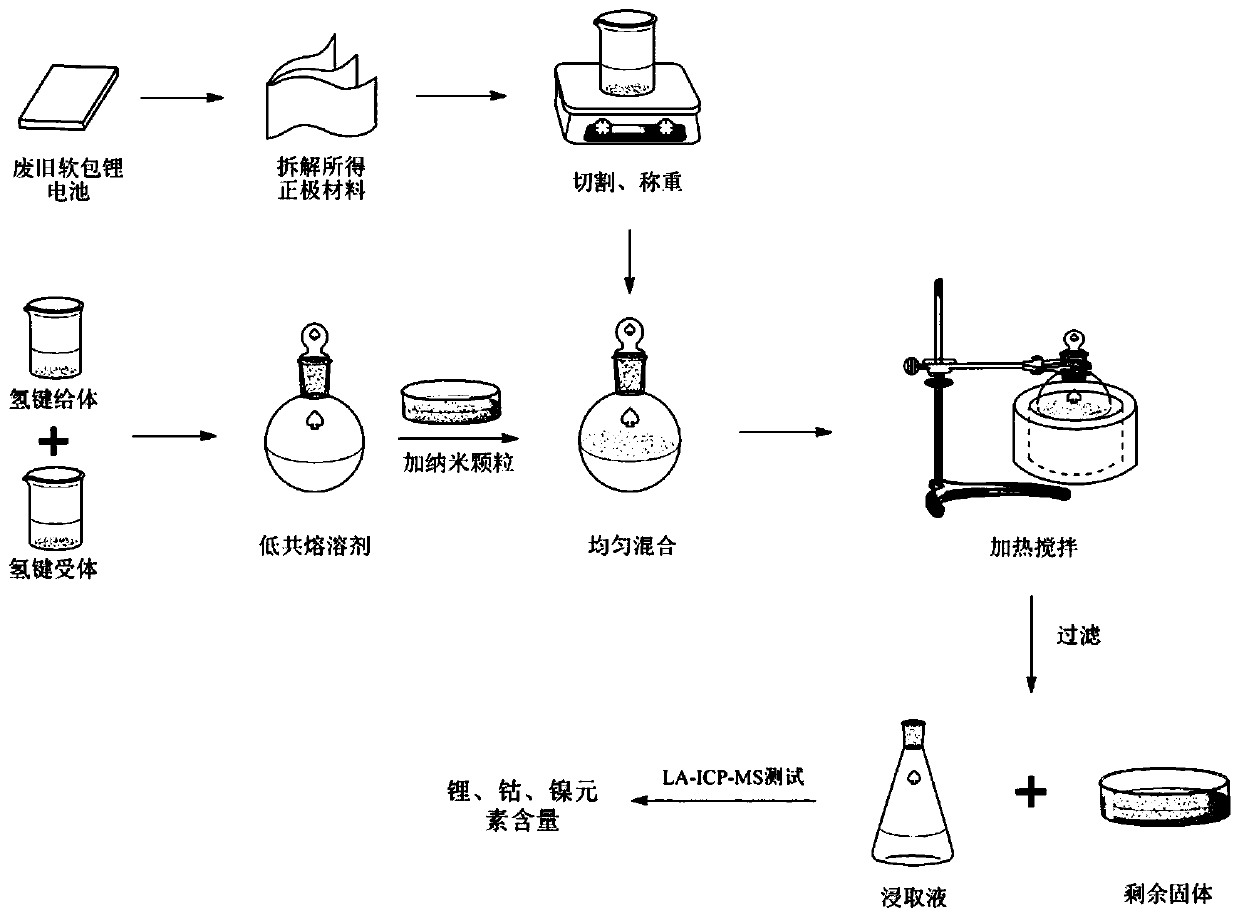

Method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid

ActiveCN111074074AWide range of sourcesShorten the timeWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryNanofluid

The invention discloses a method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid. The method mainly comprises the following several steps that (1) a dispersing agent and nano particles are sequentially added into a deep-eutectic solvent, and nanofluid with the deep-eutectic solvent as base fluid is prepared through stirring and ultrasonic treatment;(2) waste lithium ion batteries are disassembled after being completely discharged, and anode plates are obtained through separation; and (3) the anode plates are added into a prepared deep-eutecticsolvent nanofluid solution, stirring is carried out for 24-72 h under the temperature ranging from 25 DEG C to 220 DEG C, filtering is carried out, and the contents of valuable metal elements nickel,cobalt and lithium in the reacting solution are detected. The deep-eutectic solvent nanofluid is used for recycling the lithium ion battery anode materials, the process is simple, the recovery rate ofvaluable metal is high, and application and popularization are easy.

Owner:CHINA UNIV OF MINING & TECH

Anti-tamper microchip package based on thermal nanofluids or fluids

InactiveUS8288857B2Improve artImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringNanofluid

A tamper-resistant microchip package contains fluid- or nanofluid-filled capsules, channels, or reservoirs, wherein the fluids, either alone or in combination, can destroy circuitry by etching, sintering, or thermally destructing when reverse engineering of the device is attempted. The fluids are released when the fluid-filled cavities are cut away for detailed inspection of the microchip. Nanofluids may be used for the sintering process, and also to increase the thermal conductivity of the fluid for die thermal management. Through-vias and micro vias may be incorporated into the design to increase circuitry destruction efficacy by improving fluid / chip contact. Thermal interface materials may also be utilized to facilitate chip cooling.

Owner:I3 ELECTRONICS

Multi-factor width parameter nanofluid heat transfer characteristic experimental system and experimental method

The invention discloses a multi-factor width parameter nanofluid heat transfer characteristic experimental system and an experimental method. The system comprises three parts, namely an experimental loop, a pressure control loop and a cooling loop, wherein the experimental loop is composed of an ultrasonic oscillator, a circulating main pump, a heat regenerator, a mass flow meter, a preheating section, an experimental section, a data acquisition system and an electric heating system; the pressure control loop is composed of a high-pressure nitrogen and gas-liquid header and a safety valve; andthe cooling loop is composed of a cooling tower, a circulating pump and a cooling jacket. According to the experimental system, single-phase heat convection, flow boiling heat exchange and critical heat flux experimental researches under multi-factor and width parameter conditions can be performed aiming at nanofluid of different components under the condition that the stability of the nanofluidis maintained. The invention further provides an experimental method. The stability of the nanofluid is ensured, the influence of a dispersing agent or other additives is avoided, and the influence factors and mechanisms of the single-phase heat convection, flow boiling heat exchange and critical heat flux of the nanofluid can be conveniently researched.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com