Conveying capacity controllable nano particle jet flow minimal quantity lubrication grinding device in enhanced magnetoelectricity field

A nano-particle and micro-lubrication technology, which is applied in electrostatic spraying devices, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as increasing electrostatic voltage, achieve enhanced air ionization, fully charged particles, and Effect of halo voltage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

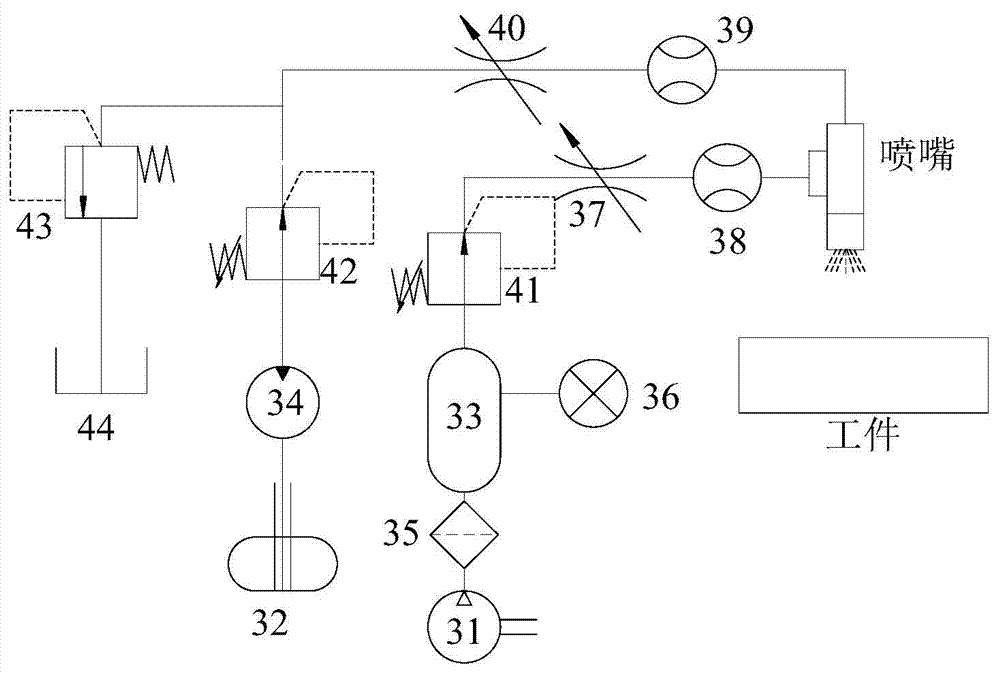

Method used

Image

Examples

Embodiment 1

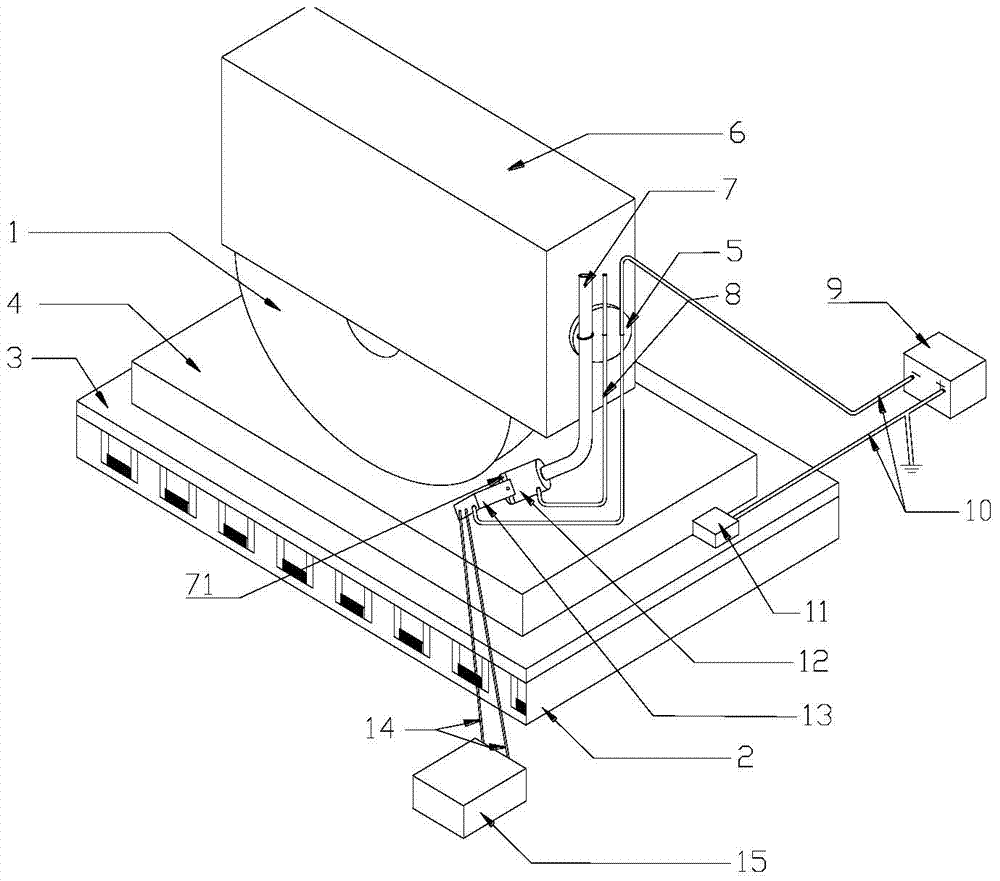

[0079] The first embodiment of the present invention is figure 1 and Figures 3 to 17 As shown, it is about a magnetic-enhanced electric field-induced nanoparticle jet droplet charging mechanism and a controllable and orderly transport of the droplet, a micro-lubrication grinding process method and equipment.

[0080] Such as figure 1As shown, in the first embodiment, an insulating plate 3 is covered on the workbench 2 of the grinding machine (this new material can be magnetically conductive but not conductive, so as to ensure the installation of the workpiece 4 and the connection between the nozzle 12 and the workpiece. 4 to form a stable electric field). Place the workpiece 4 on the insulating plate 3, clamp and position the workpiece 4 when the grinder is magnetized, and attach the magnetic chuck 5 to the side of the grinding wheel cover 6 to fix the nanofluid delivery serpentine tube 8 and the compressed air delivery serpentine tube 7 And the negative lead in the electr...

Embodiment 2

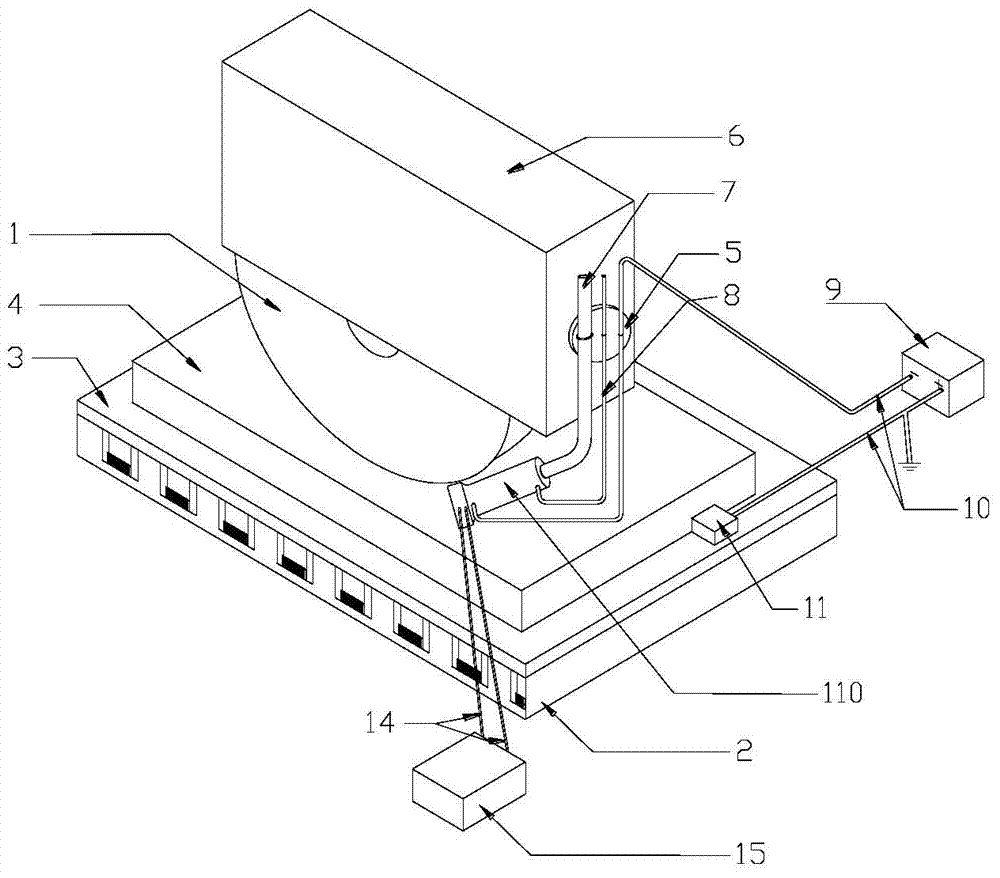

[0087] figure 2 to 5 and Figures 18 to 22 As the second embodiment of the present invention, in the second implementation, the nozzle 12 and the electromagnetic device 13 in the first embodiment are replaced with an integral nozzle 110 .

[0088] Such as figure 2 As shown, an insulating plate 3 is covered on the workbench 2 of the grinding machine (this new material can be magnetically conductive, but not conductive, so that it can not only ensure the installation of the workpiece but also ensure the formation of a stable electric field between the nozzle and the workpiece). Place the workpiece 4 on the insulating plate 3, clamp and position the workpiece 4 when the grinder is magnetized, and attach the magnetic chuck 5 to the side of the grinding wheel cover 6 to fix the nanofluid delivery serpentine tube 8 and the compressed air delivery serpentine tube 7 And the negative lead in the electrode high voltage lead 10. One end of the nanofluid delivery serpentine tube 8 is...

Embodiment 3

[0094] The third embodiment of the present invention is as figure 1 , image 3 to 5, Figure 6 , Figure 7 , Figures 9 to 16 and Figure 23 As shown, in the third embodiment of the present invention, except that the arrangement of the electrodes and the design of the nozzle are different from the first embodiment, other designs are the same as the first embodiment. In the third embodiment, the method of adding the discharge electrodes is changed. The electrode slot 68 on the electrode chuck 51 in the original first embodiment is no longer arranged in the L-shaped needle-shaped electrode I83. In the third embodiment, the electrode The chuck 51 is only used as a cover of the magnetic case 52 . In embodiment three, the shower nozzle 18 in embodiment one has been redesigned, and the design scheme is as follows Figure 23 As shown, the nozzle 18 in the original first embodiment is split into two parts, the nozzle body 111 and the electrode nozzle I 112, and the nozzle body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com