Patents

Literature

60 results about "Flow boiling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow Boiling – Forced Convection Boiling. In flow boiling (or forced convection boiling), fluid flow is forced over a surface by external means such as a pump, as well as by buoyancy effects. Therefore, flow boiling is always accompanied by other convection effects.

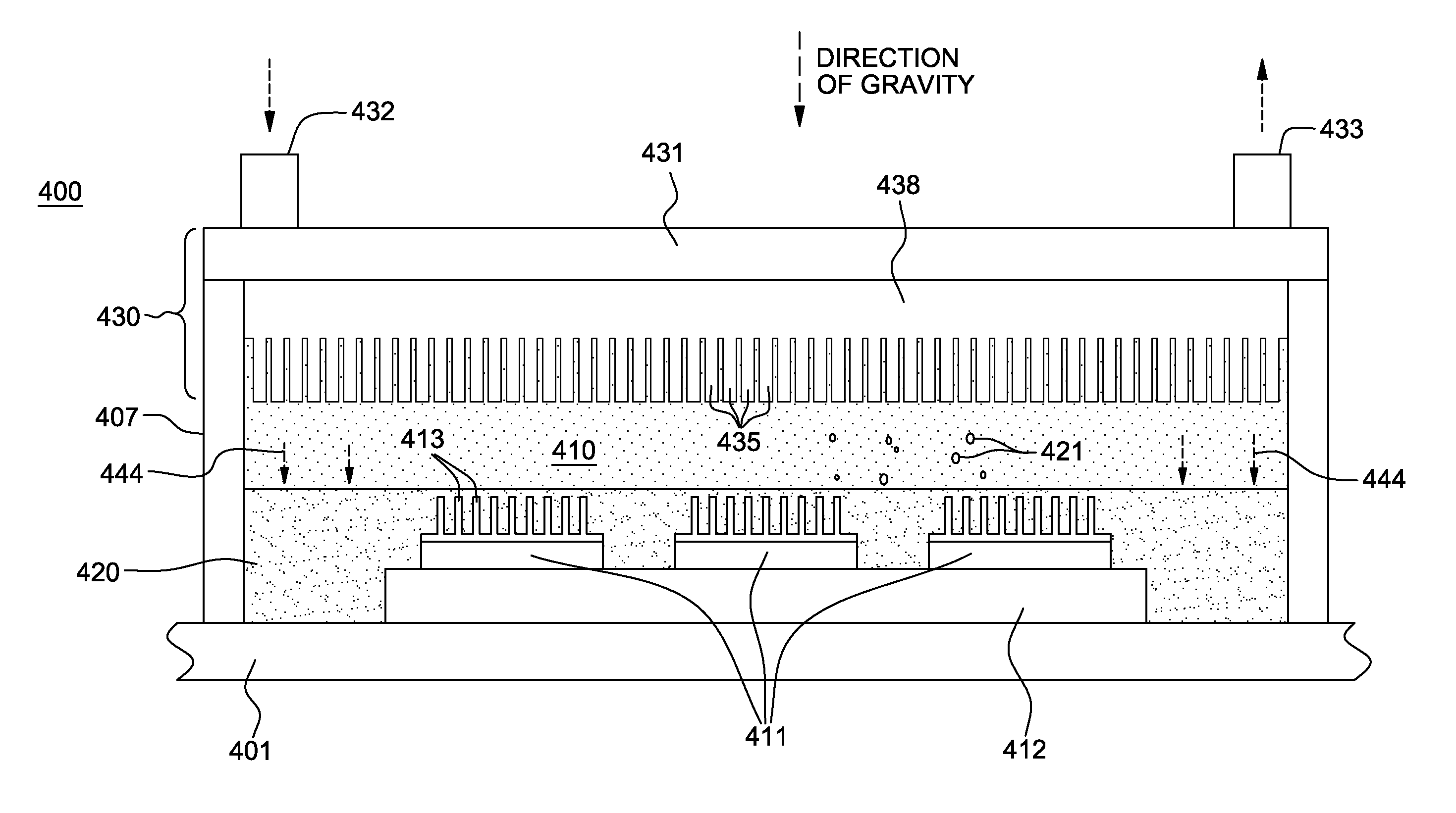

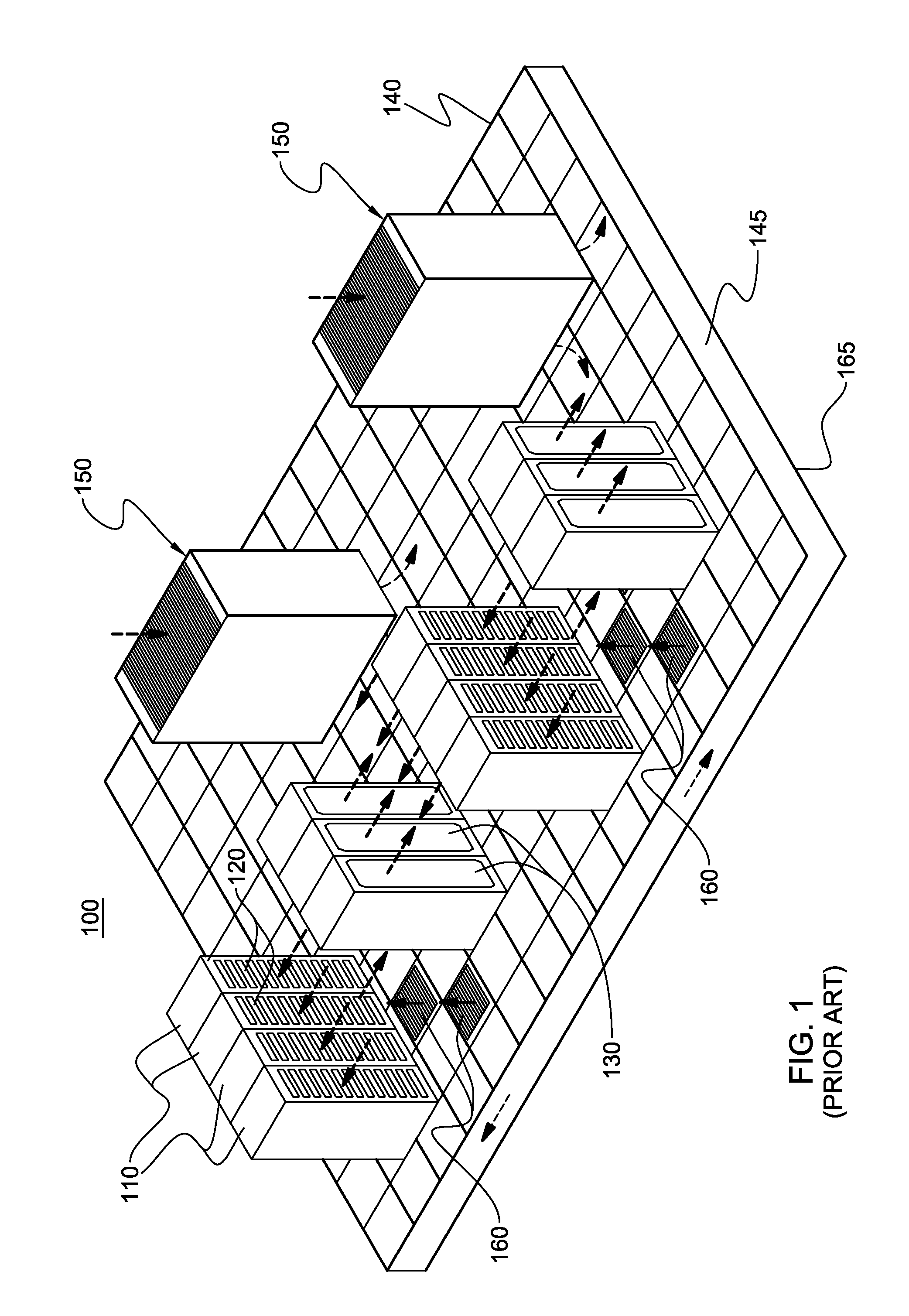

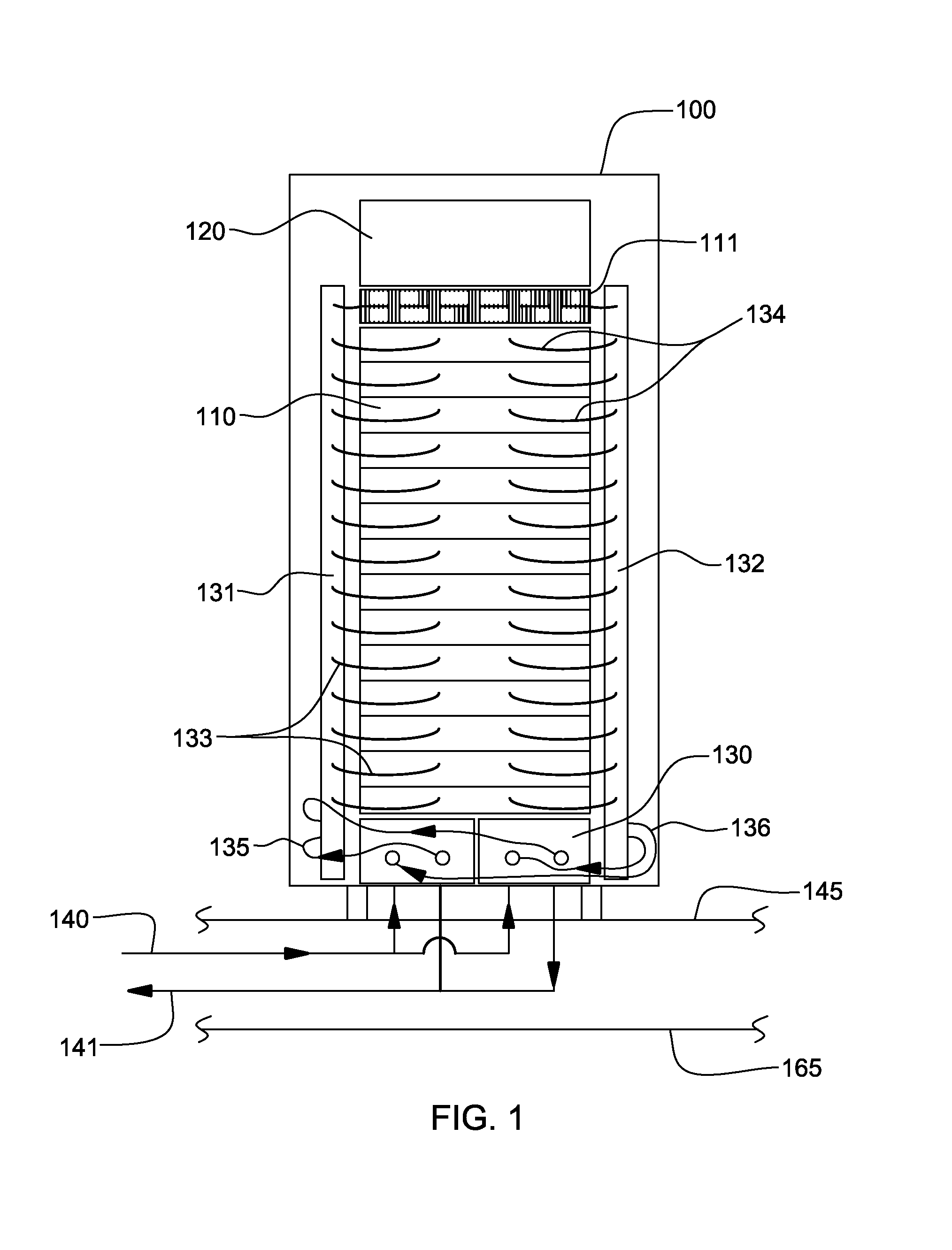

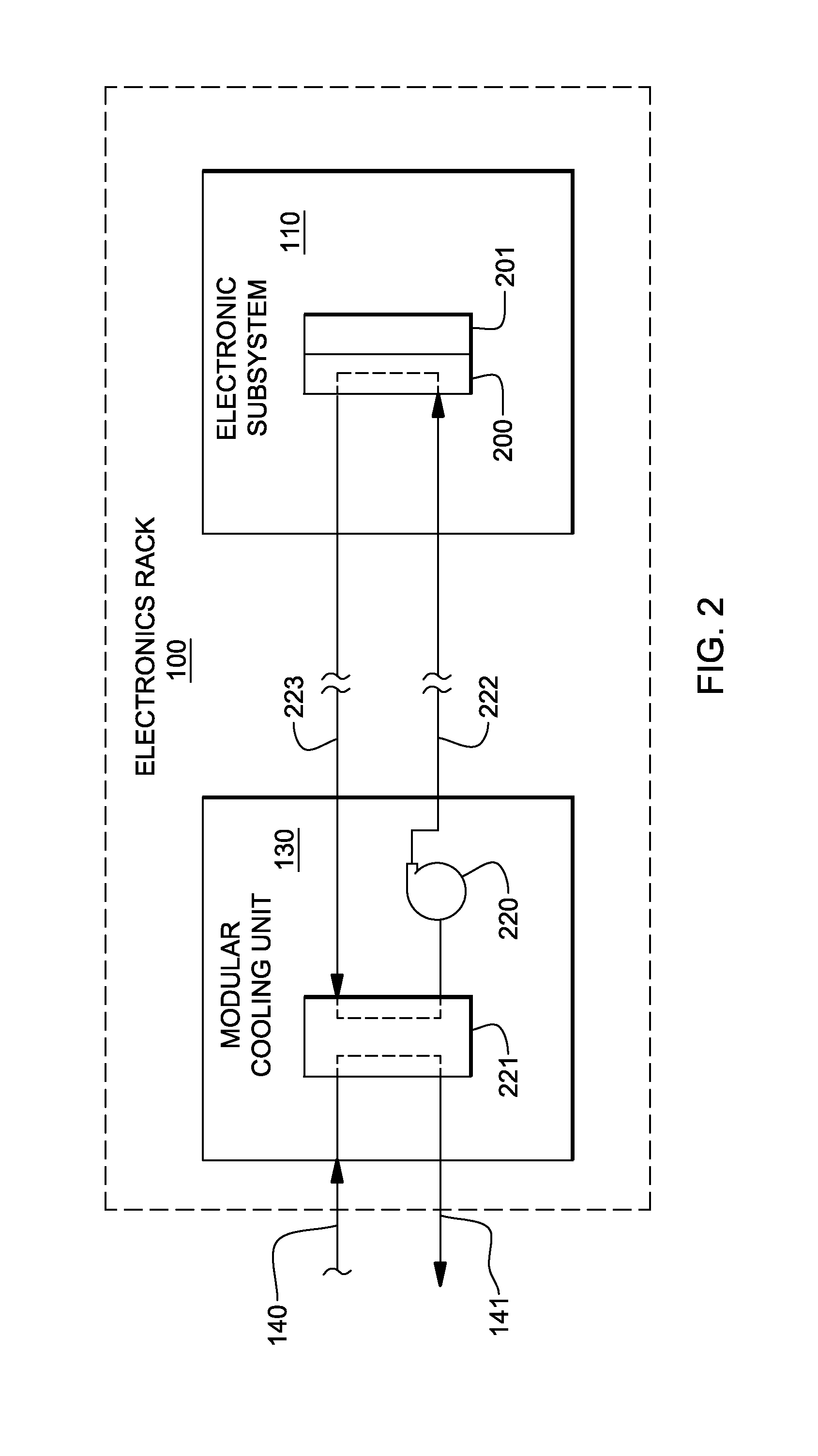

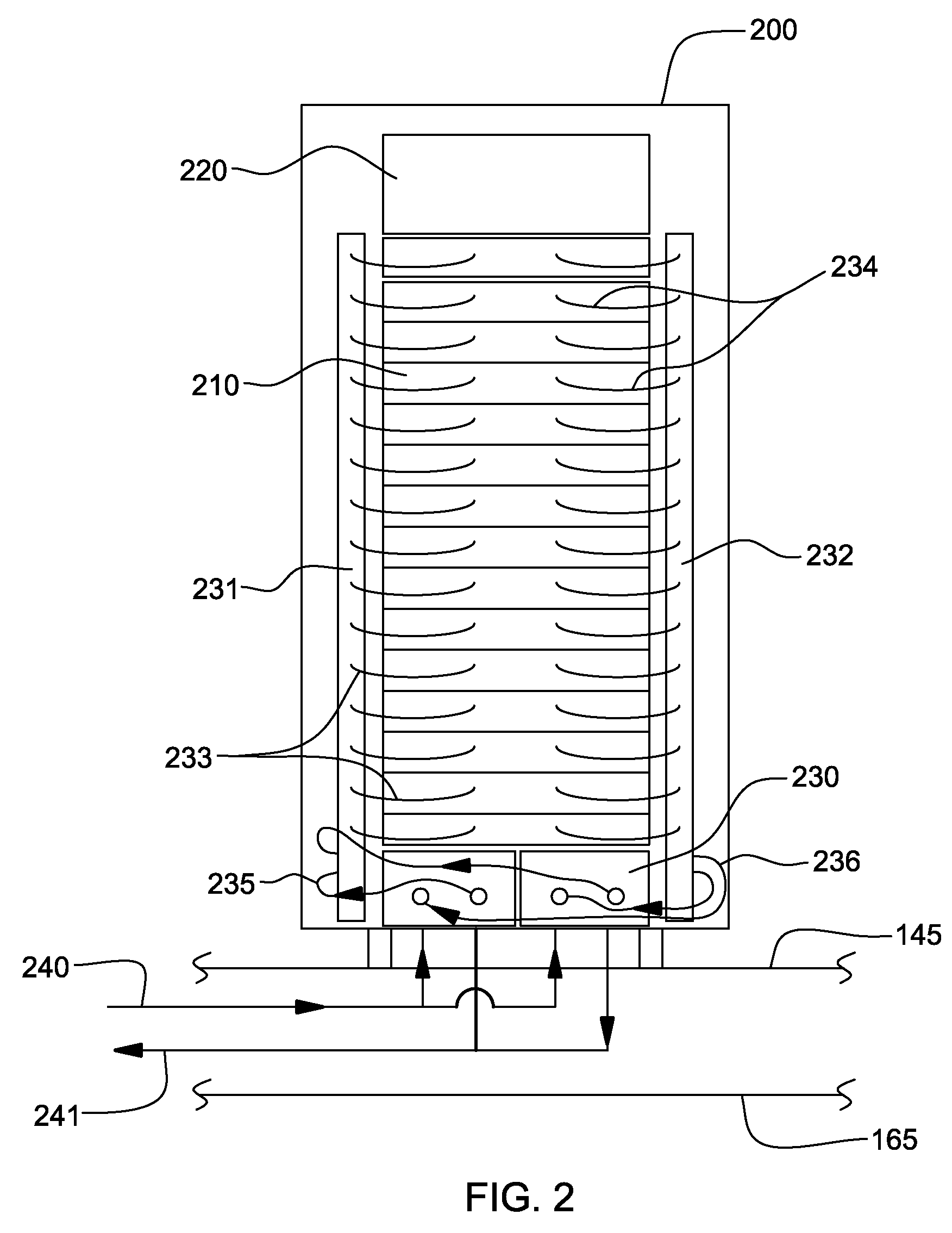

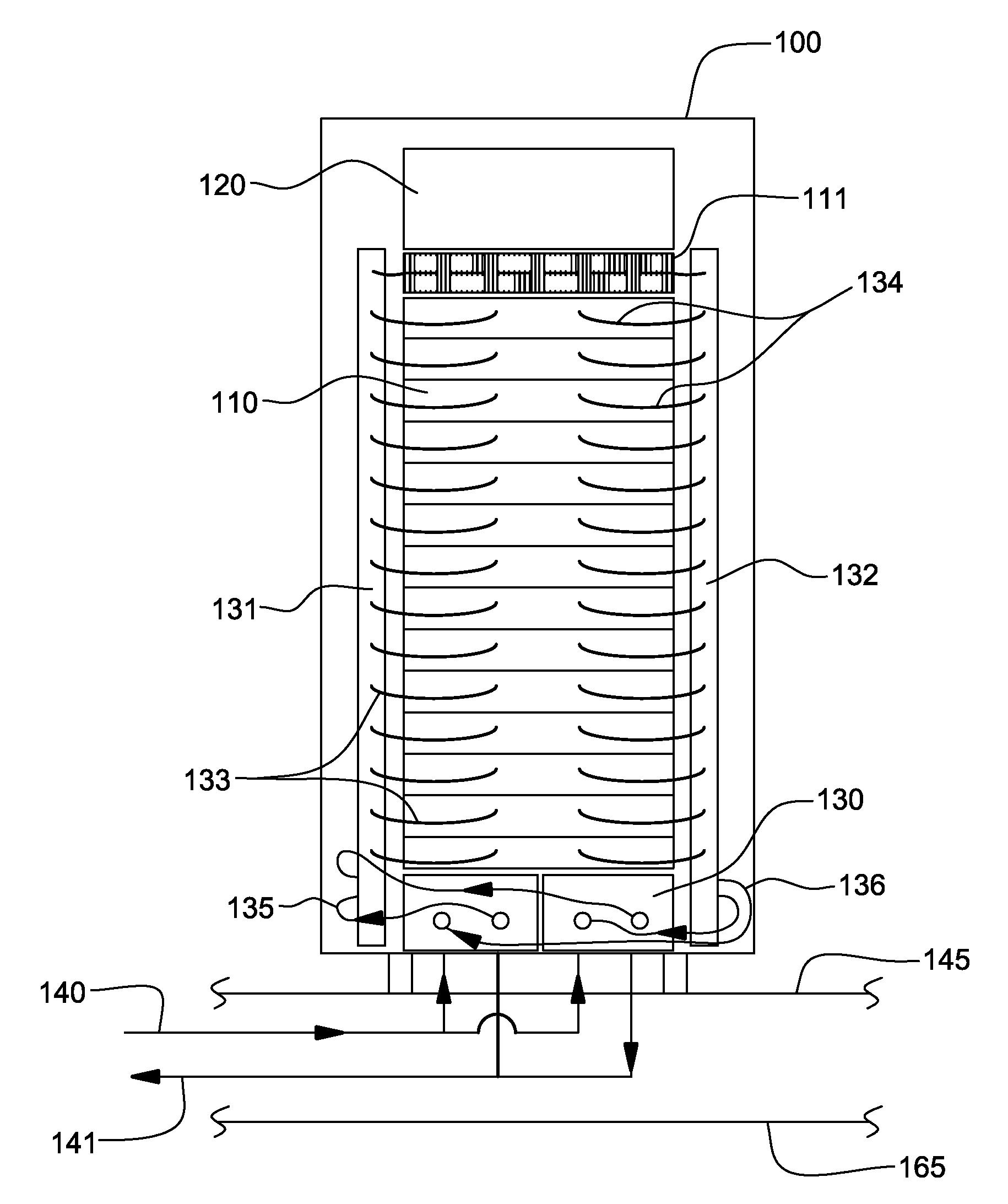

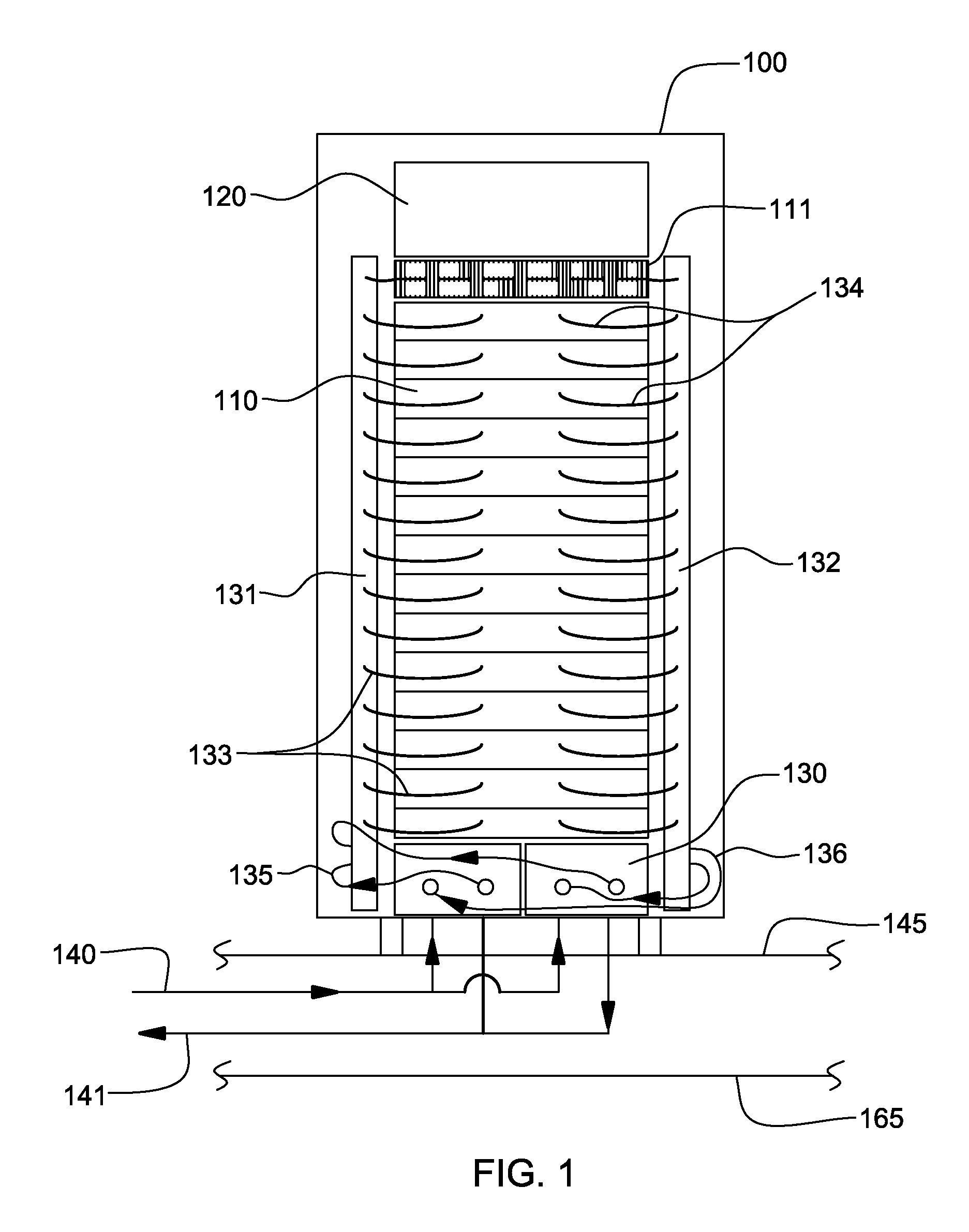

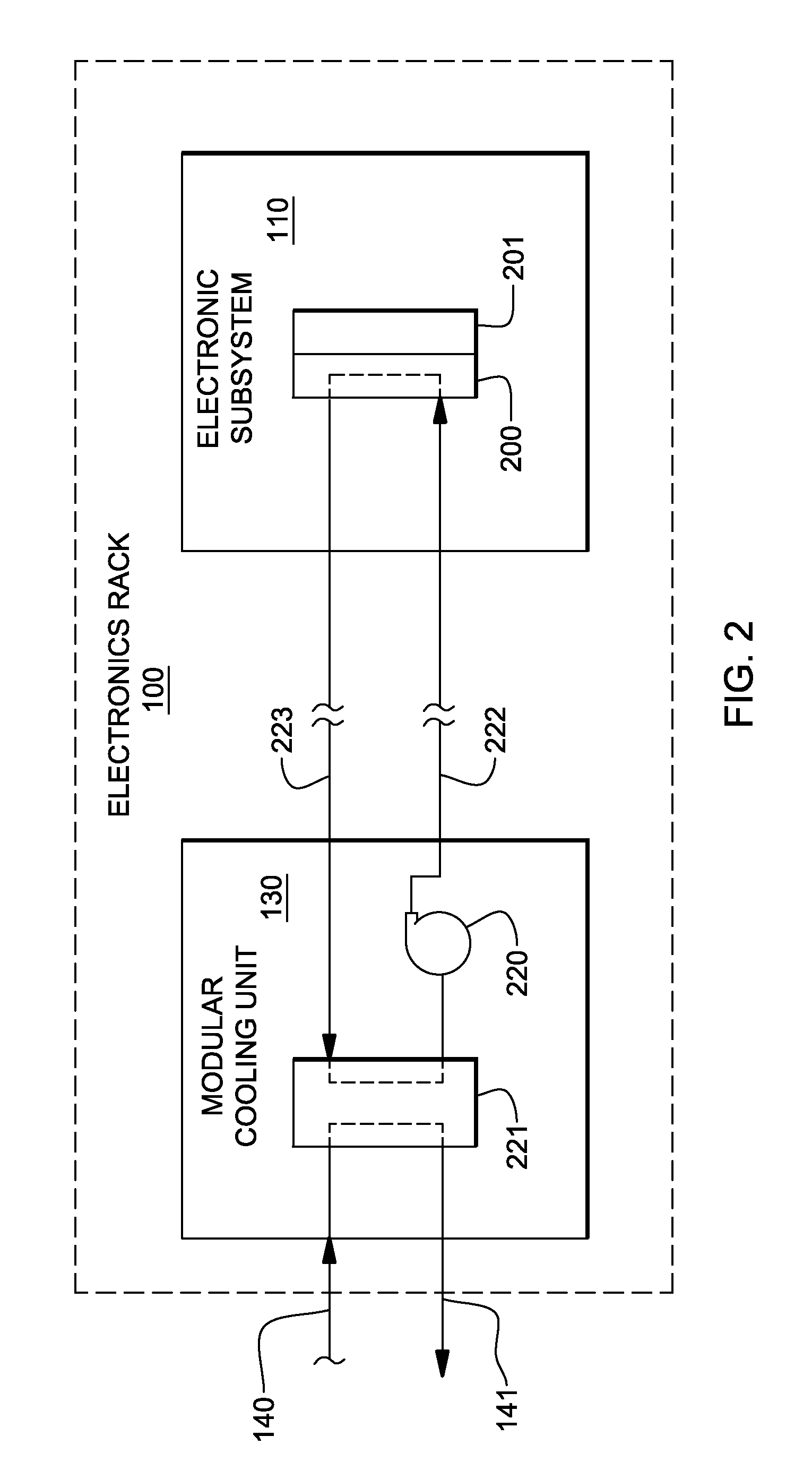

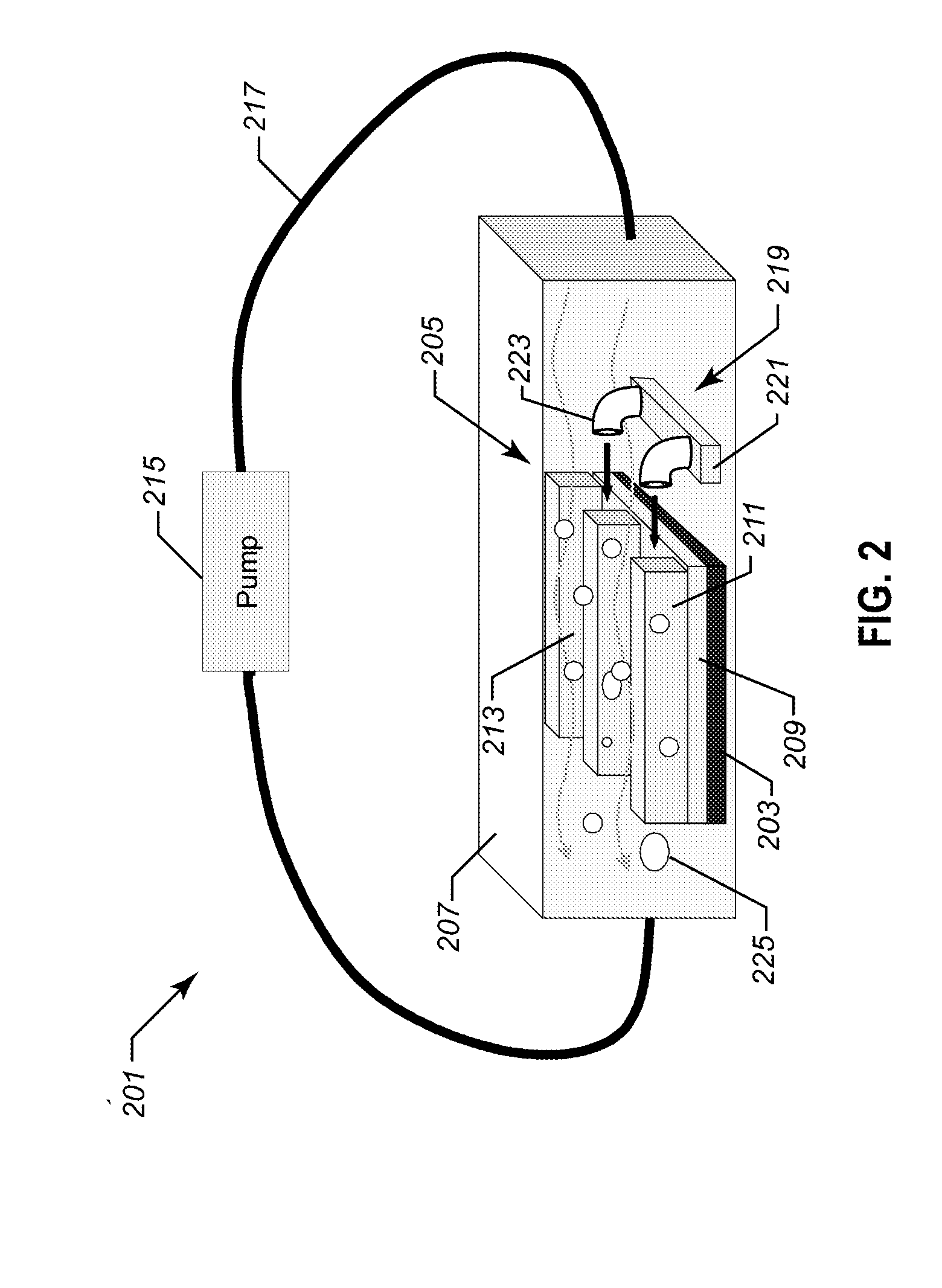

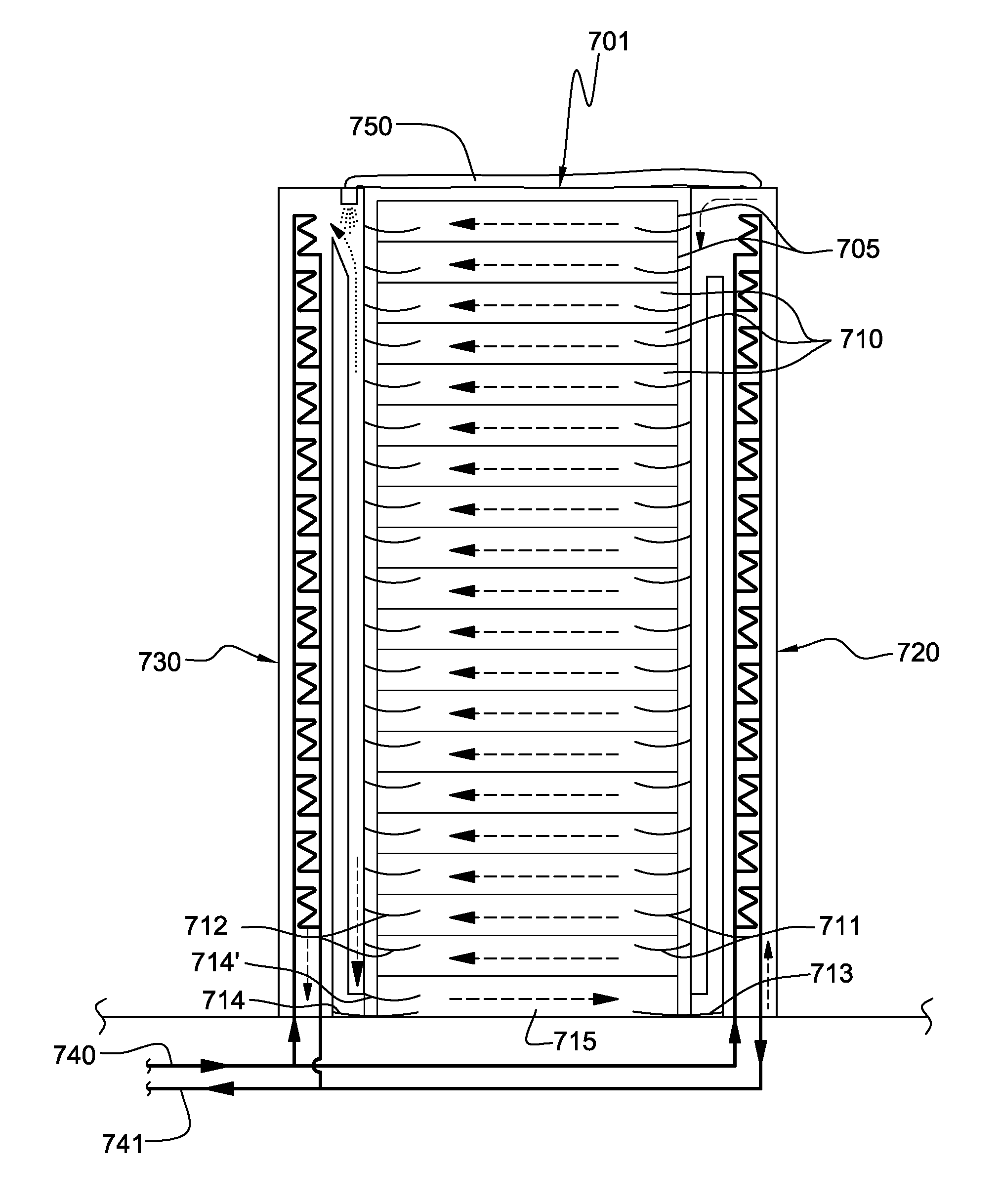

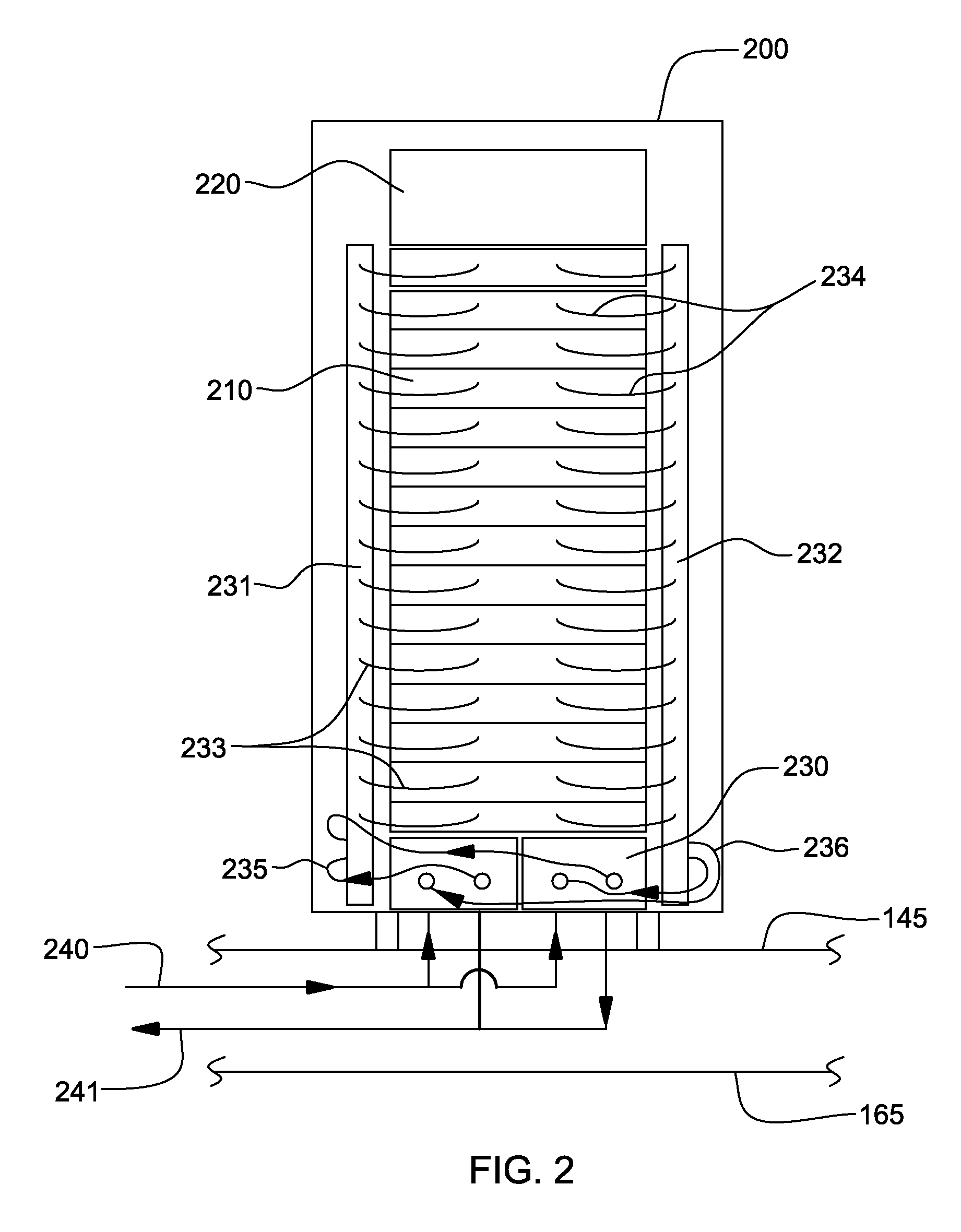

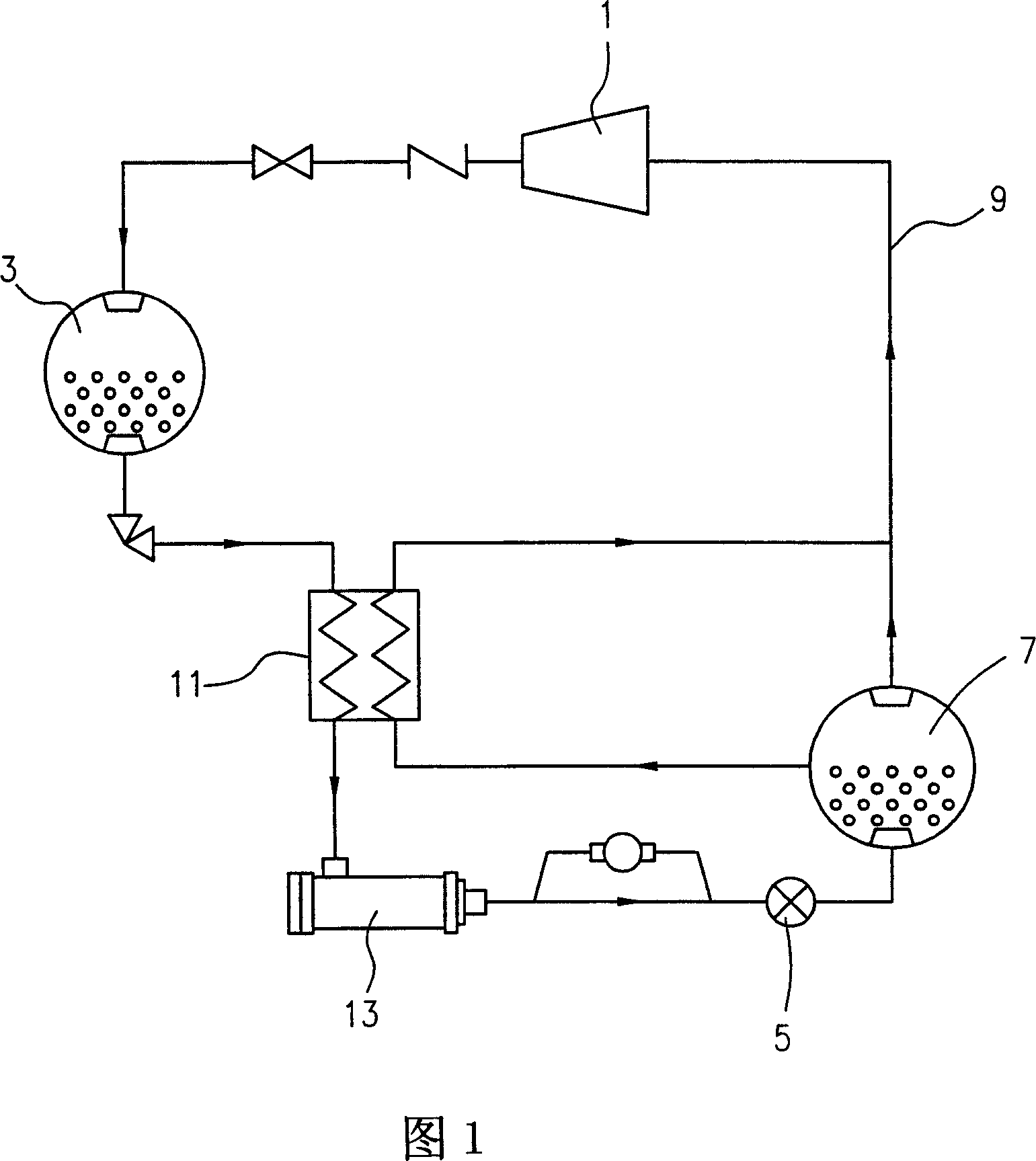

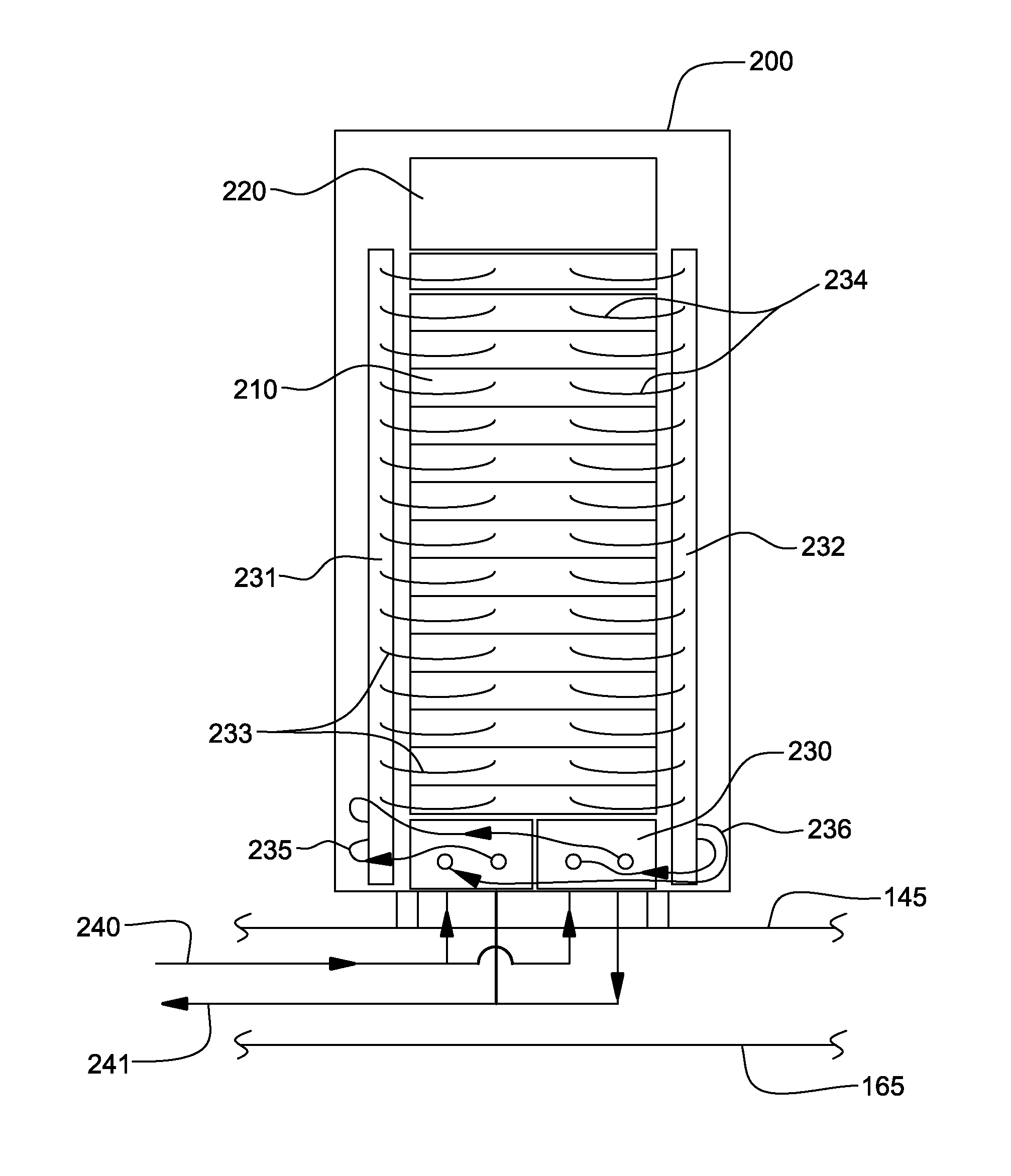

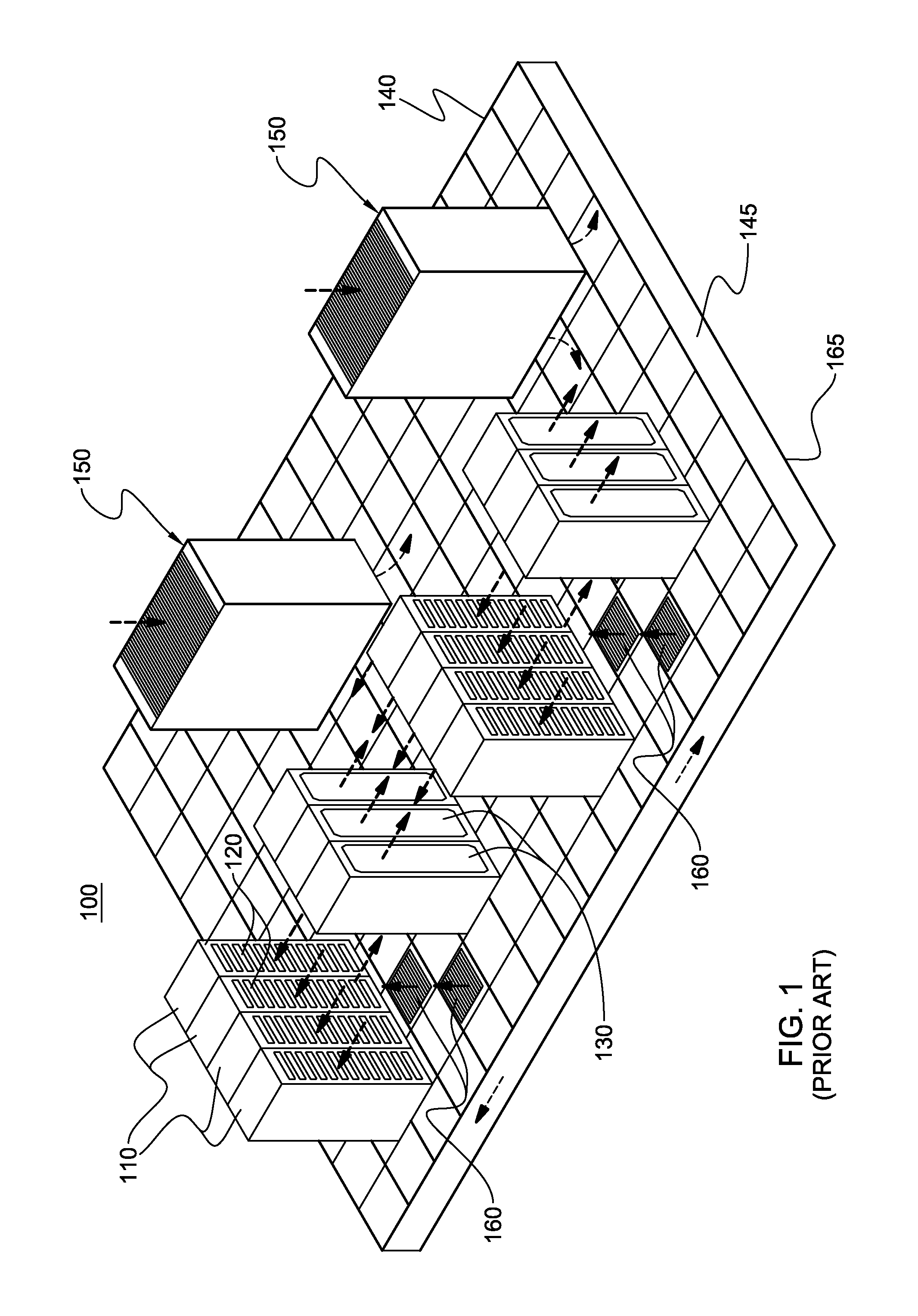

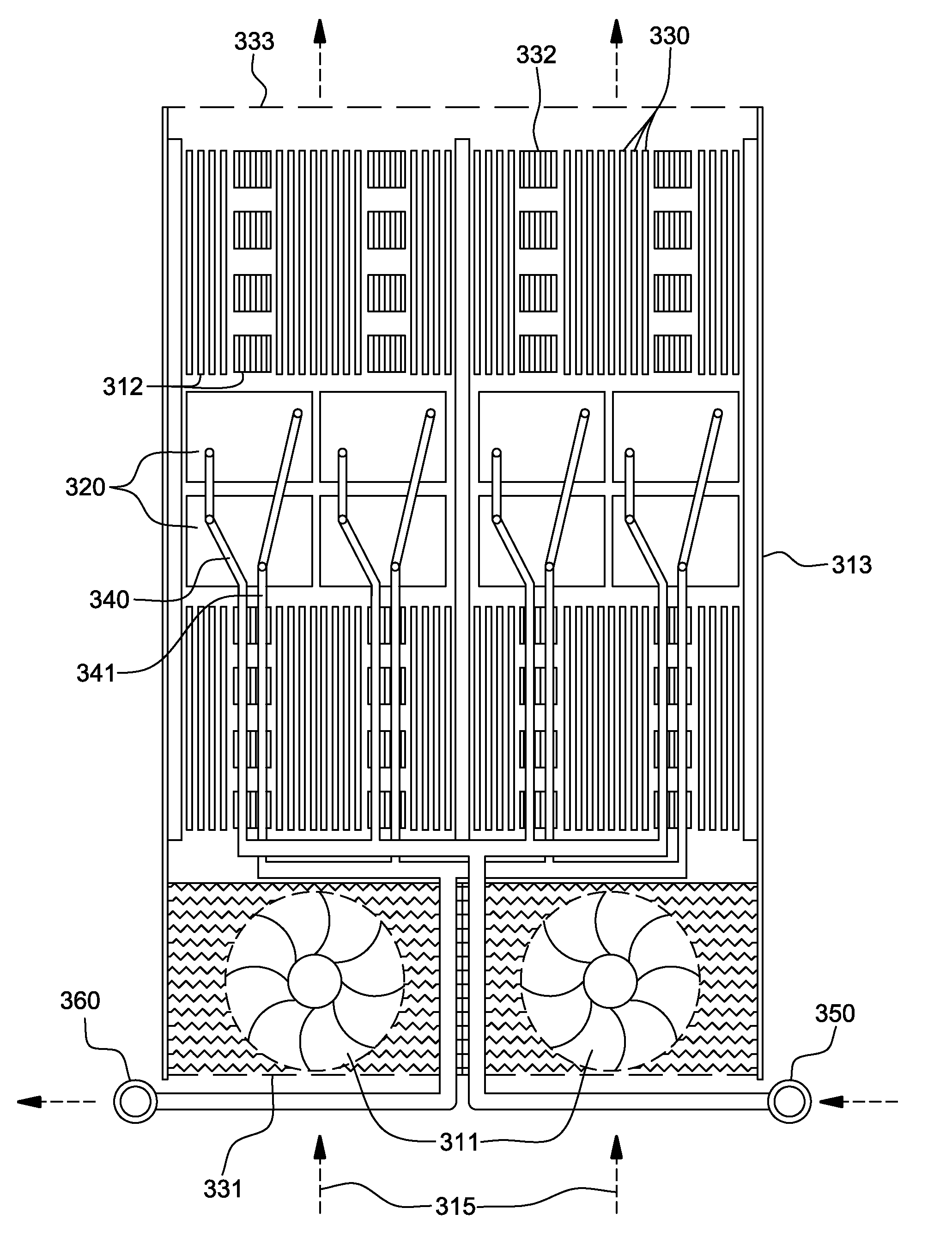

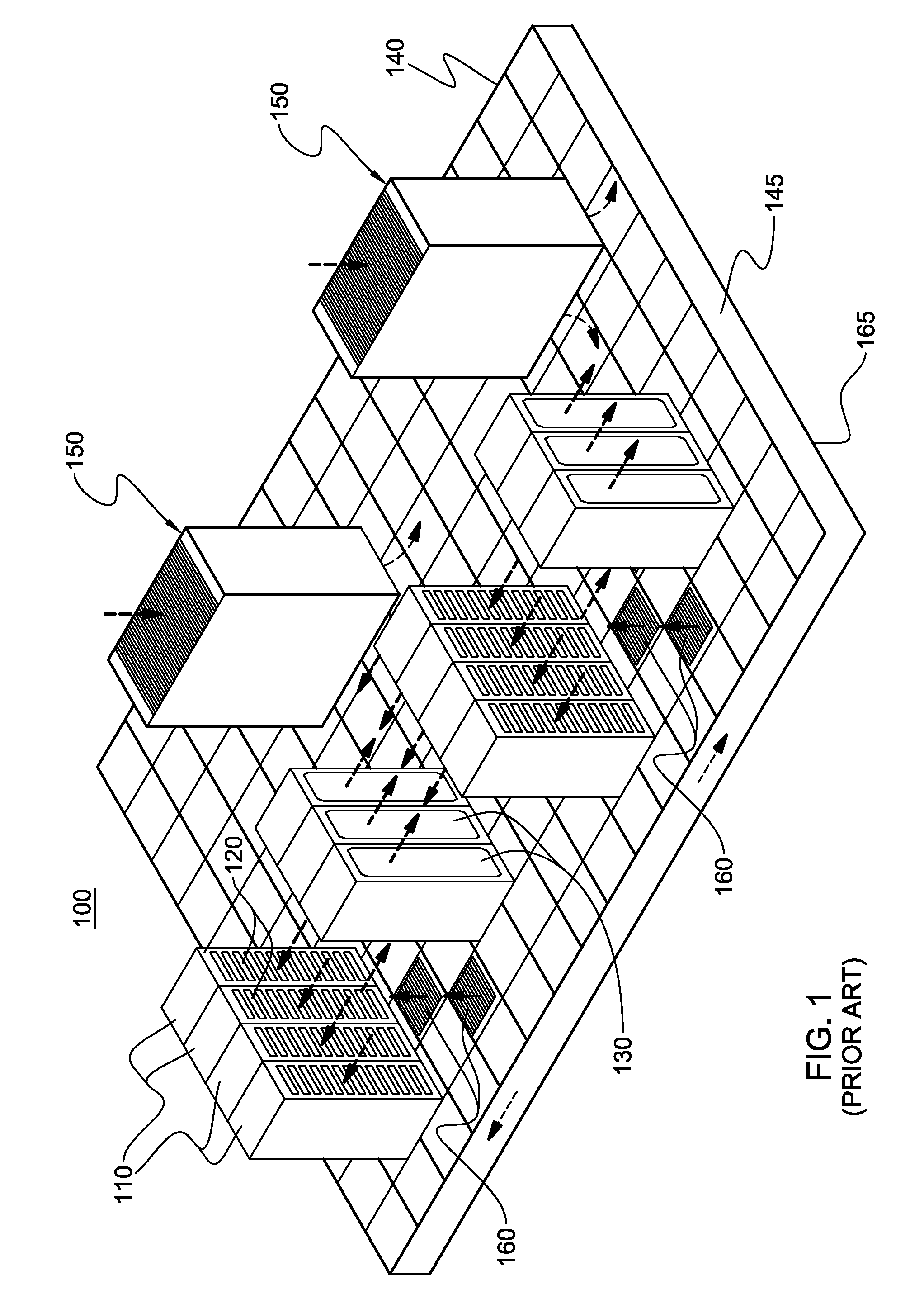

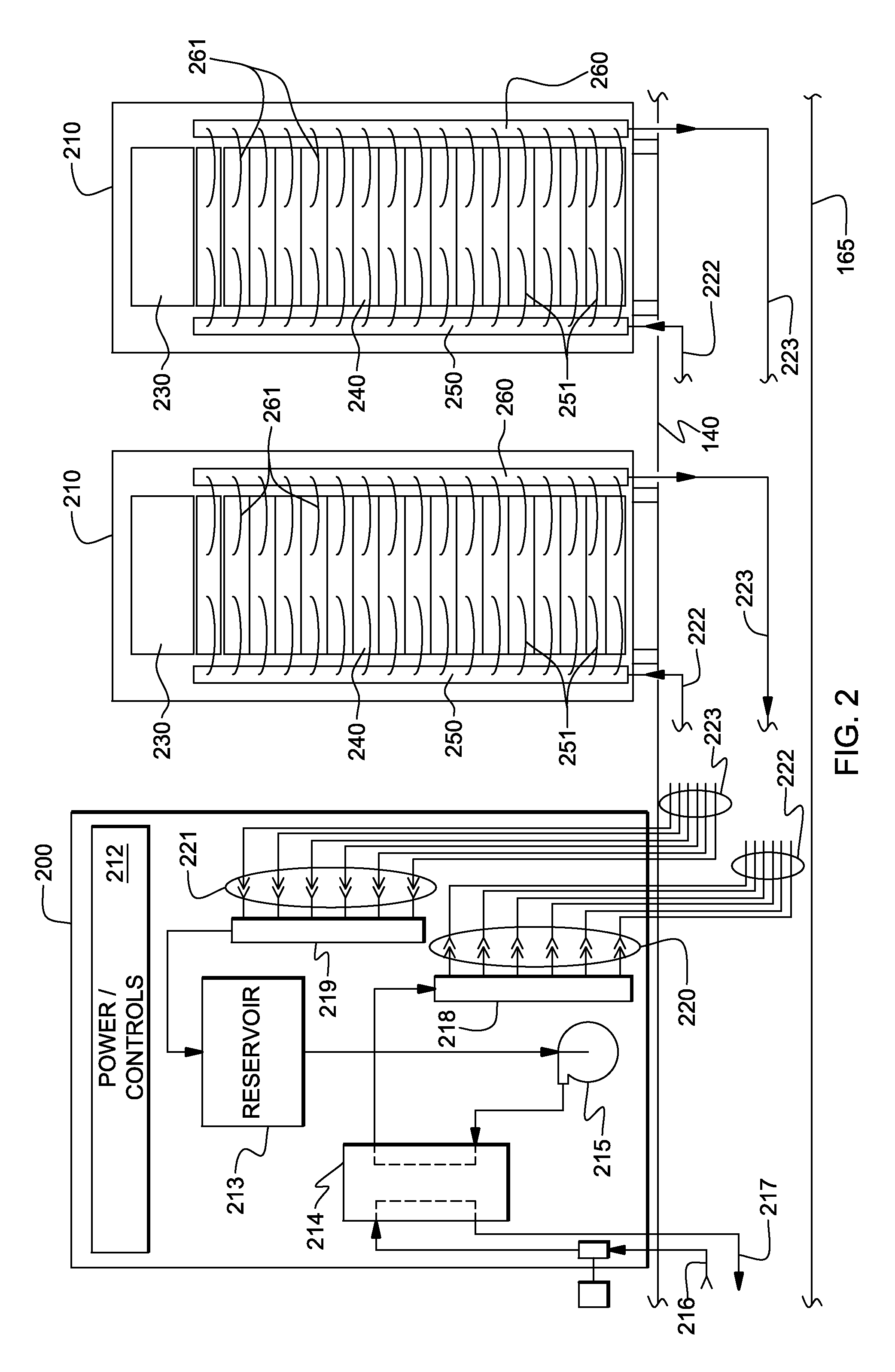

Pump-enhanced, immersion-cooling of electronic component(s)

InactiveUS20150109735A1Improve heat transfer performanceImprove fluid flowCooling/ventilation/heating modificationsDielectricElectronic component

Cooling apparatuses and methods of fabricating thereof are provided which facilitate pumped immersion-cooling of an electronic component(s). The cooling apparatus includes an enclosure having a compartment accommodating the electronic component(s), and dielectric fluid within the compartment at least partially immersing the electronic component(s). A liquid-cooled heat sink is associated with the enclosure to cool at least one cooling surface associated with the compartment, and facilitate heat transfer to the heat sink from the electronic component(s) via the dielectric fluid. A pump is disposed external to the compartment and in fluid communication therewith to facilitate pumped dielectric fluid flow through the compartment. The pumped dielectric fluid flow through the compartment enhances heat transfer from the electronic component(s) to the liquid-cooled heat sink via the cooling surface(s). In one implementation, the pumped dielectric fluid flow provides two-phase cooling to the electronic component(s) via flow boiling.

Owner:IBM CORP

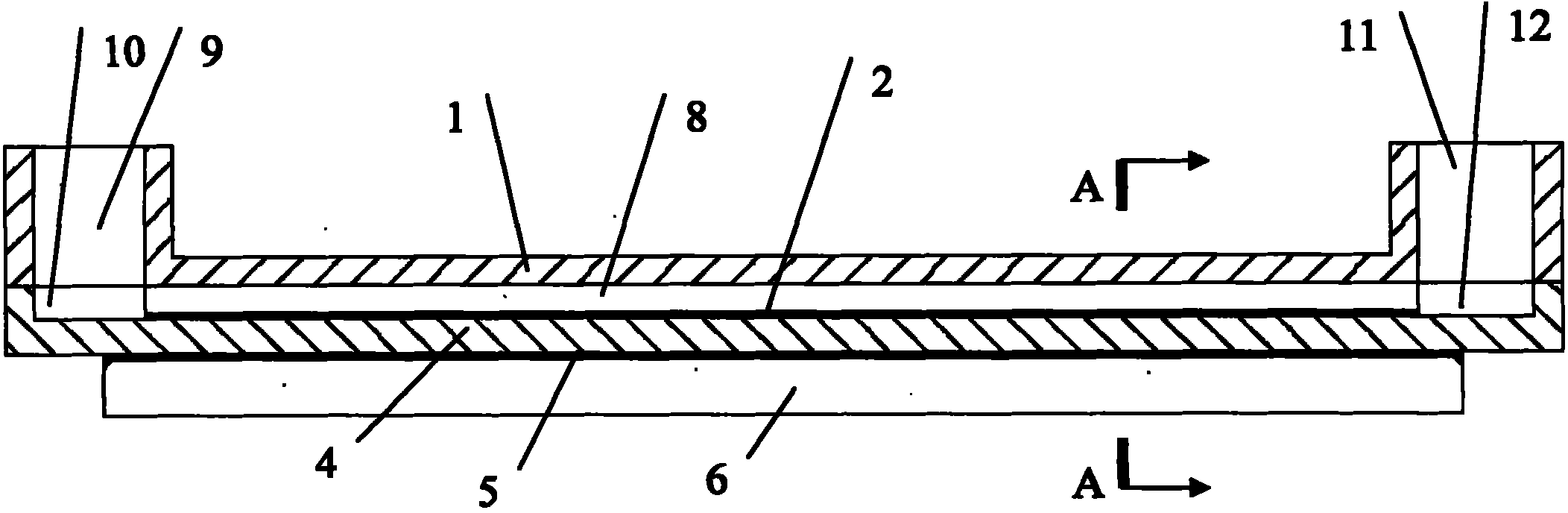

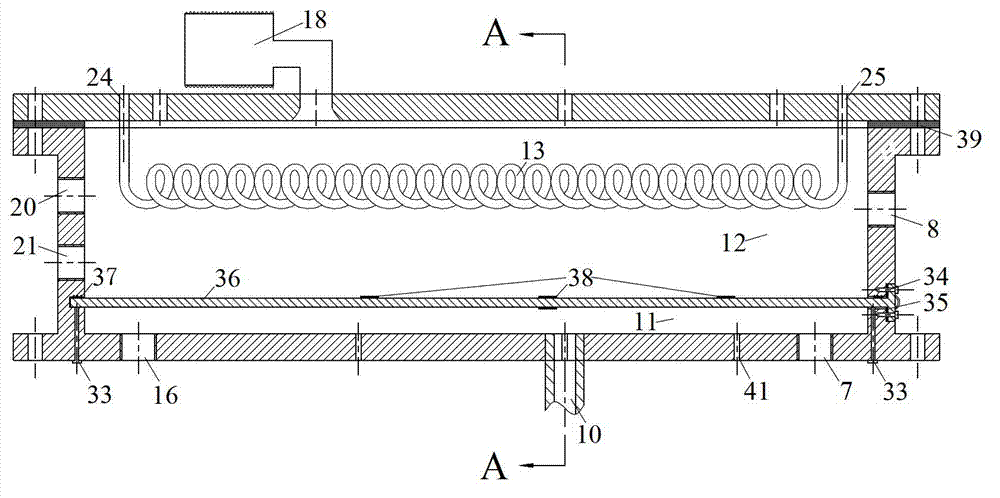

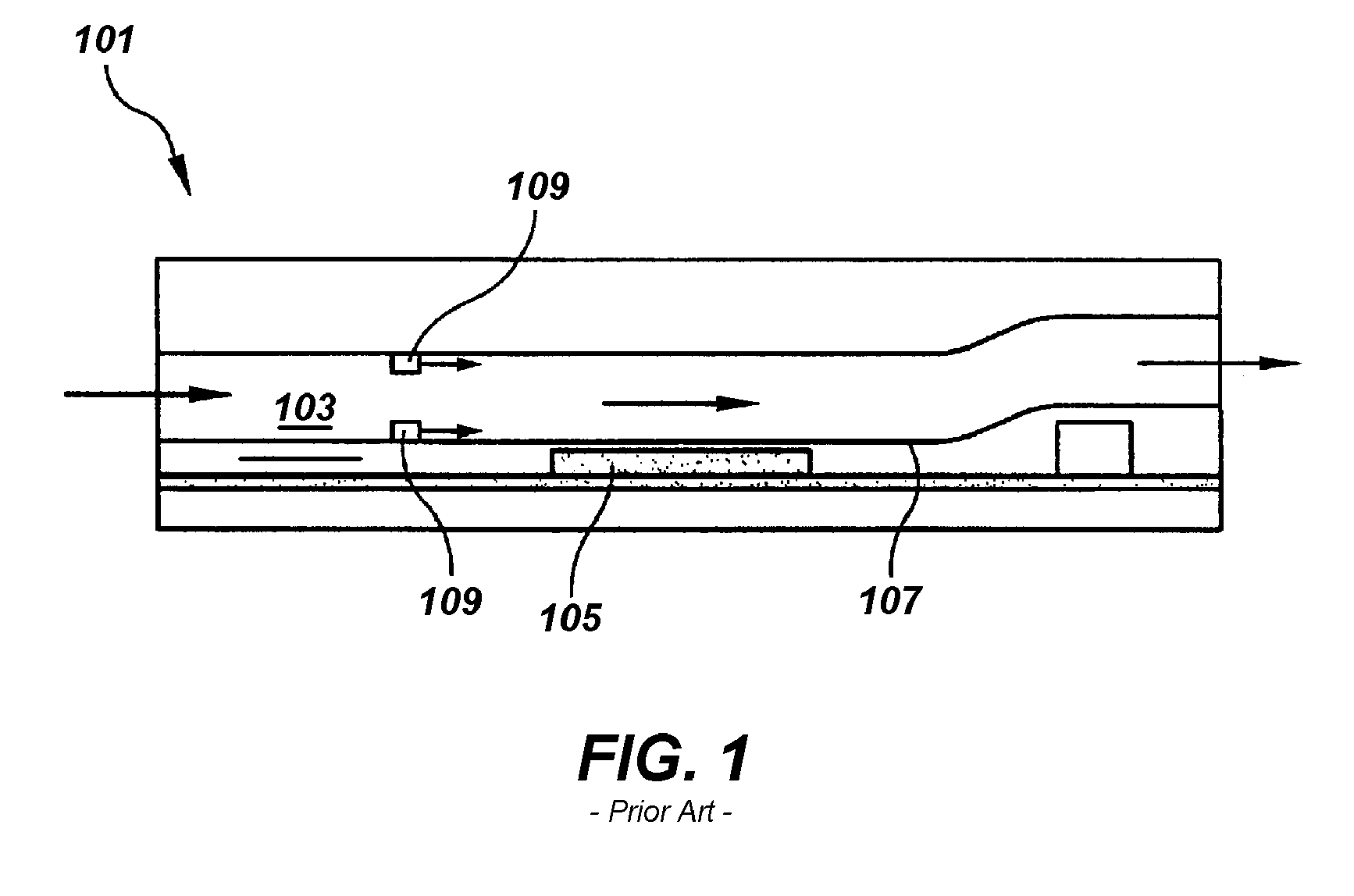

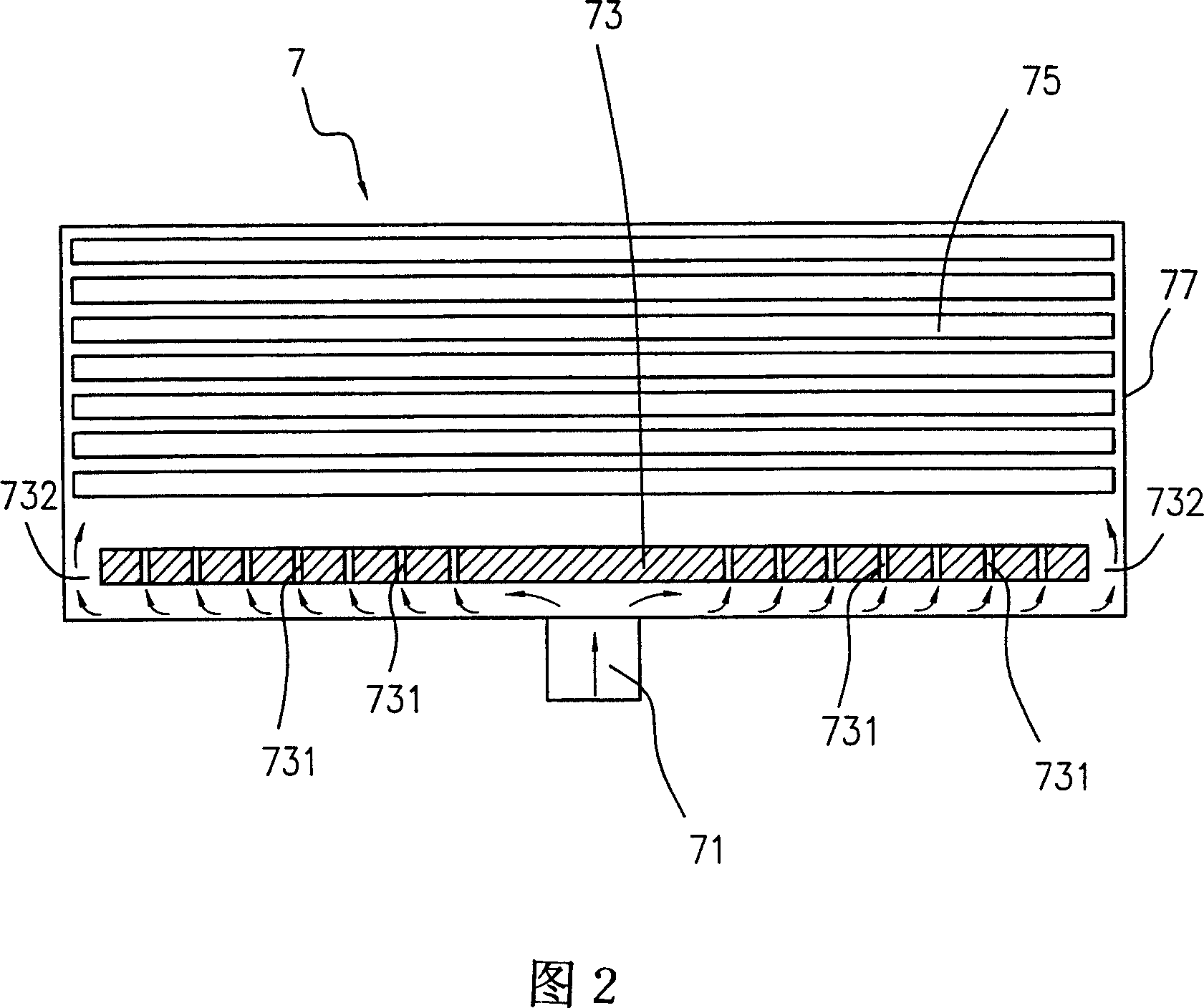

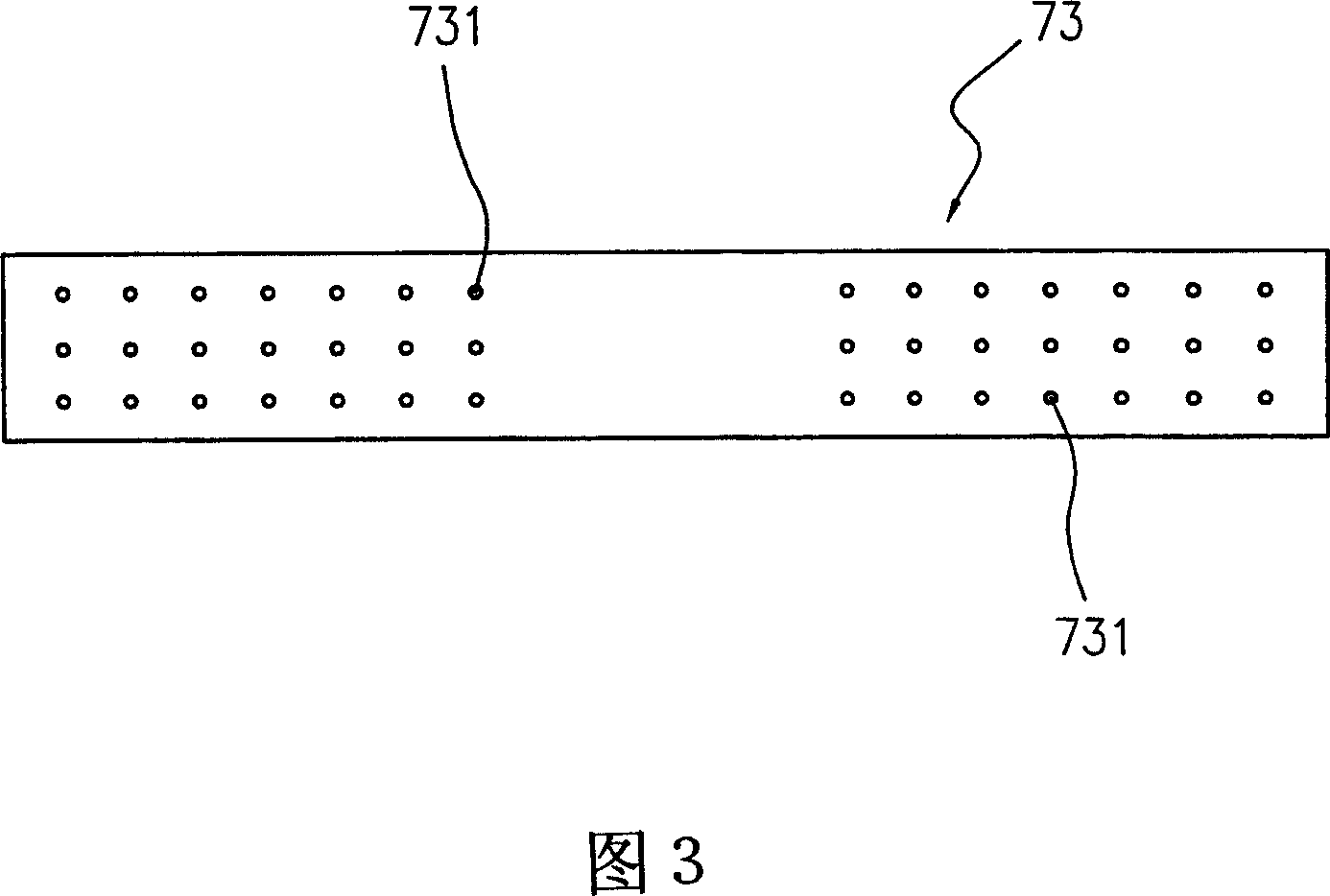

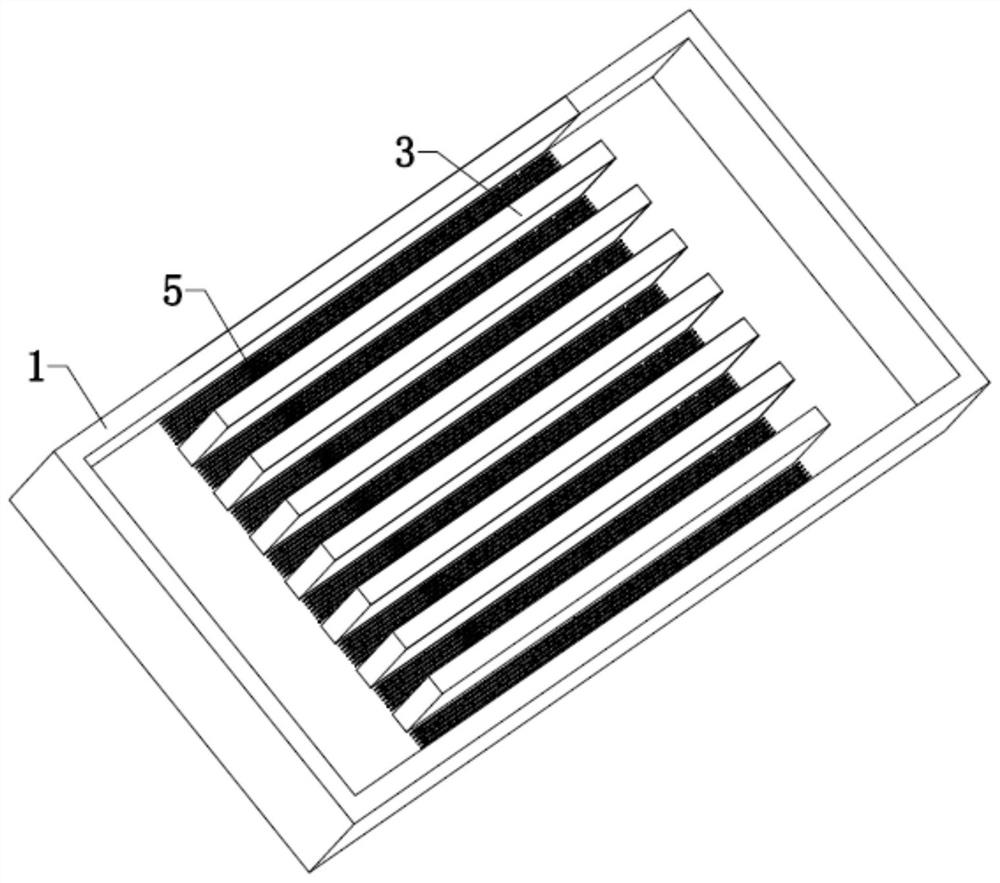

Flow boiling heat sink structure with vapor venting and condensing

ActiveUS20130027883A1Easy to disassembleImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectronic structureCoolant flow

A heat sink, and cooled electronic structure and cooled electronic apparatus utilizing the heat sink, are provided. The heat sink is fabricated of a thermally conductive structure which includes one or more coolant-carrying channels and one or more vapor-condensing channels. A membrane is disposed between the coolant-carrying channel(s) and the vapor-condensing channel(s). The membrane includes at least one vapor-permeable region, at least a portion of which overlies a portion of the coolant-carrying channel(s) and facilitates removal of vapor from the coolant-carrying channel(s) to the vapor-condensing channel(s). The heat sink further includes one or more coolant inlets coupled to provide a first liquid coolant flow to the coolant-carrying channel(s), and a second liquid coolant flow to condense vapor within the vapor-condensing channel(s).

Owner:IBM CORP

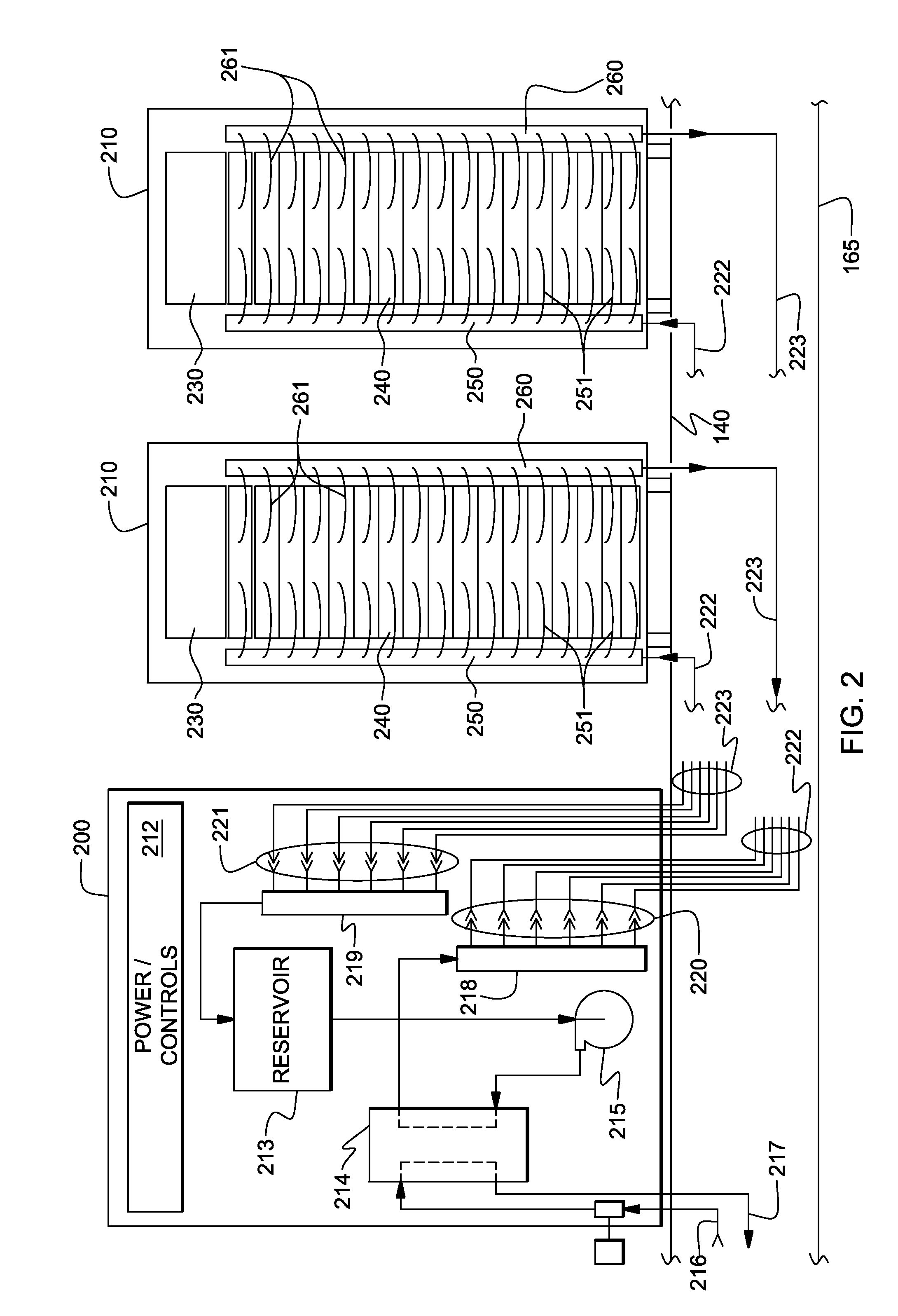

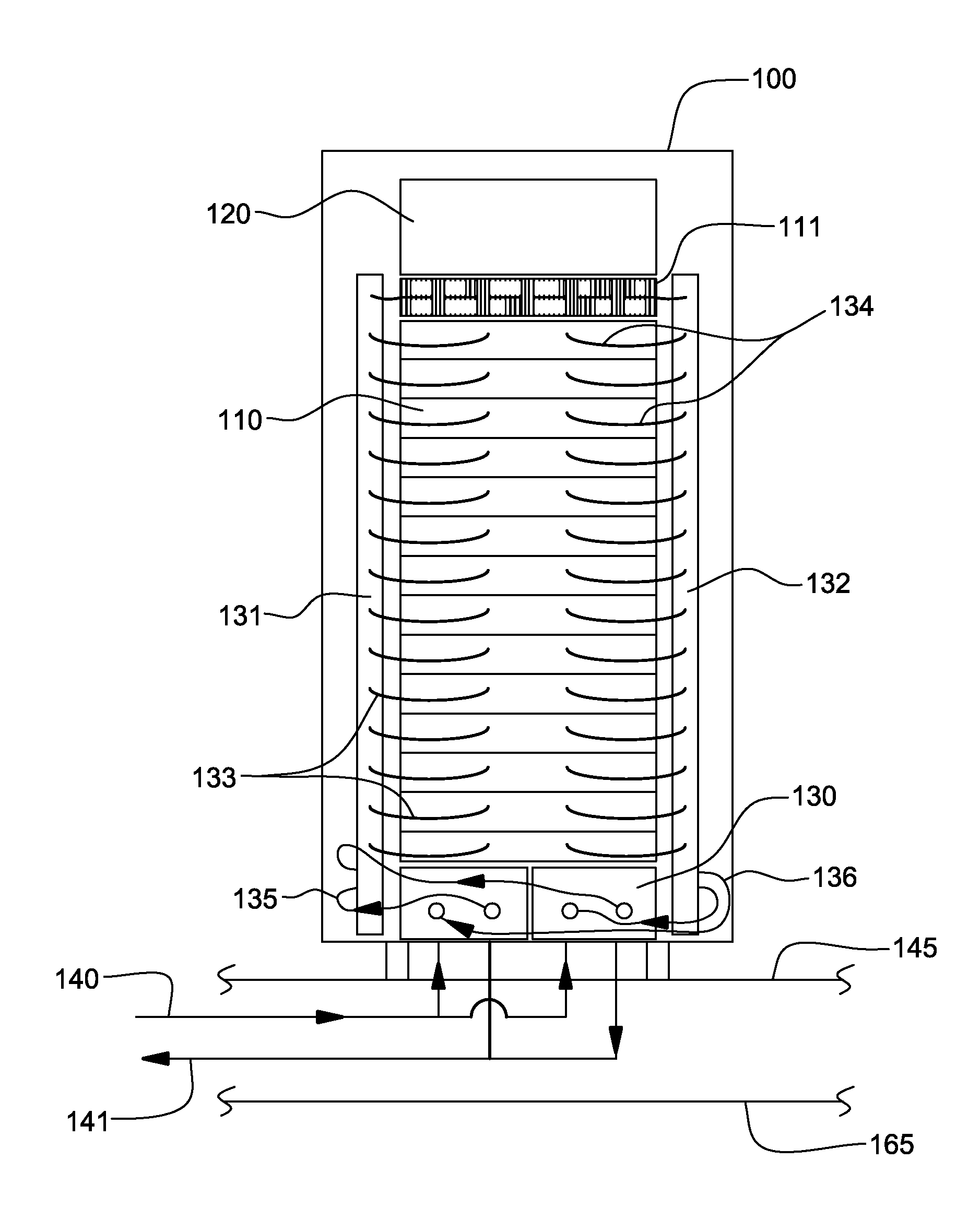

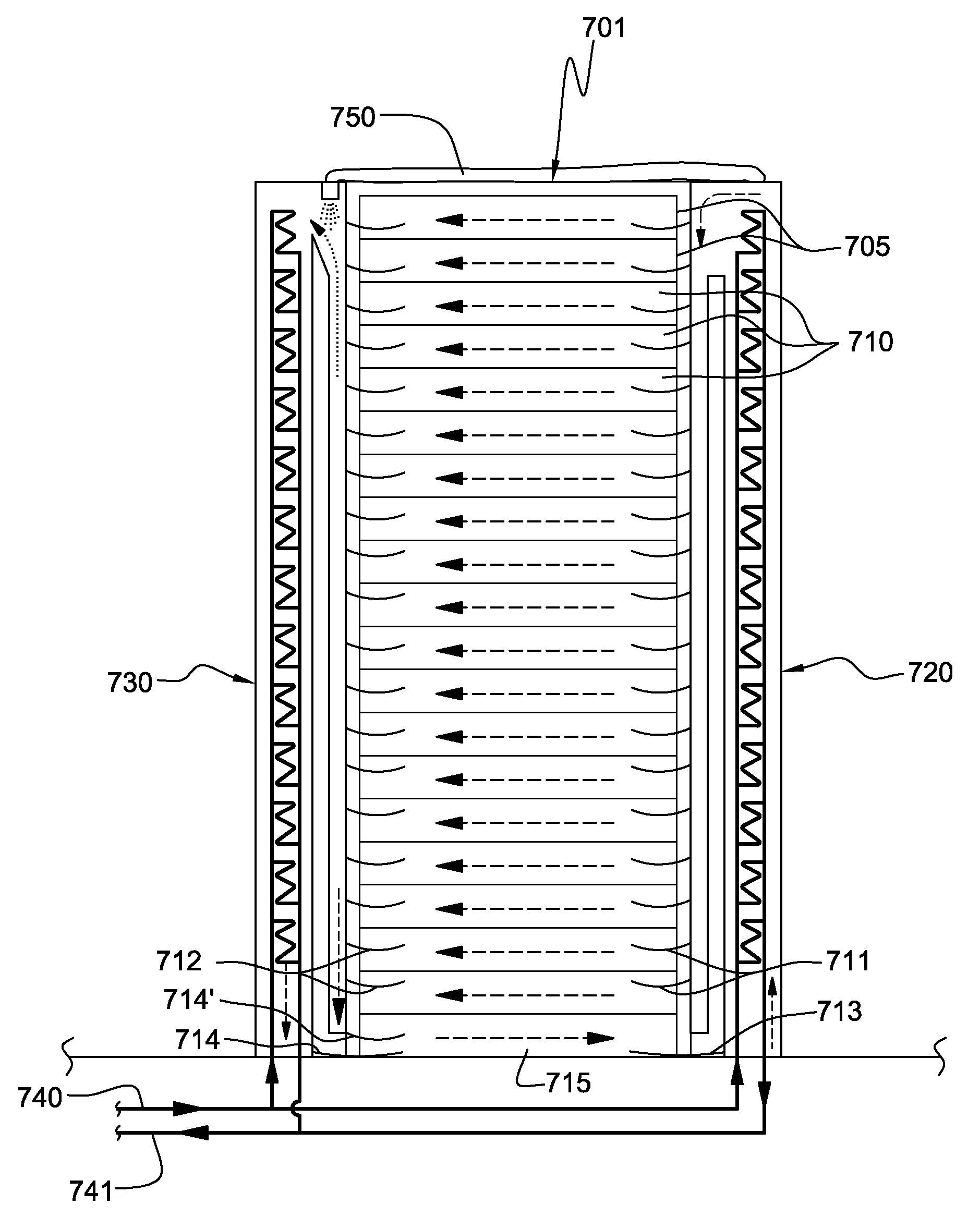

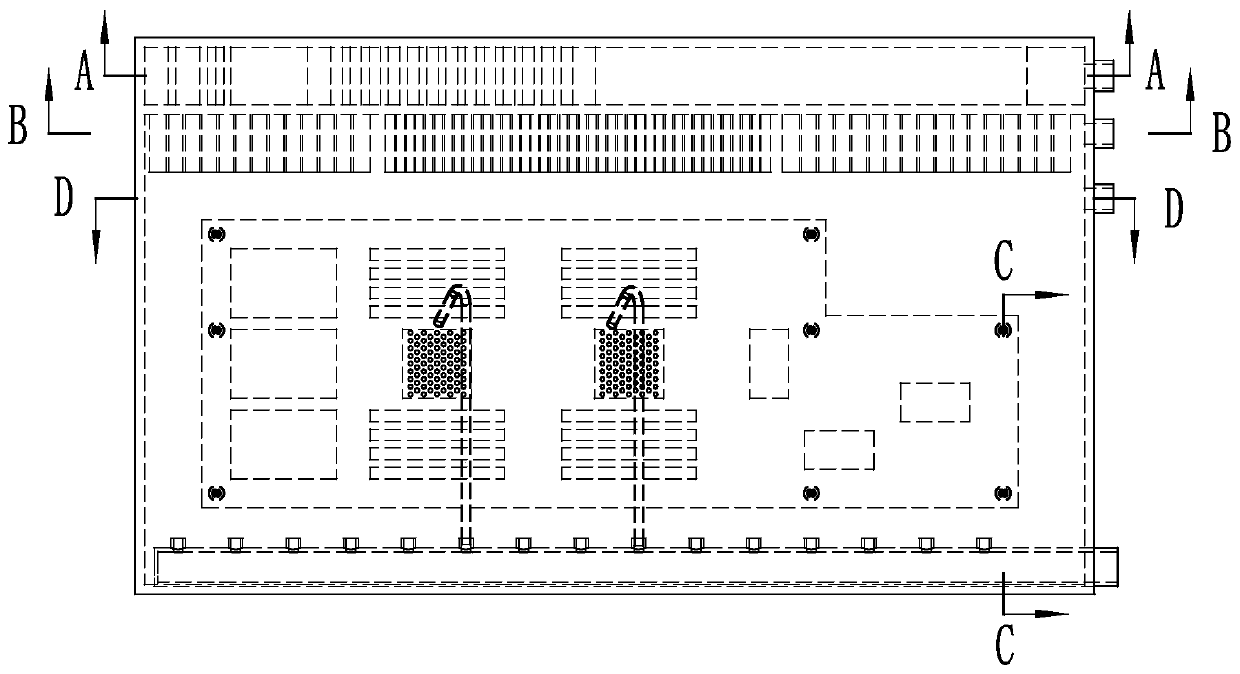

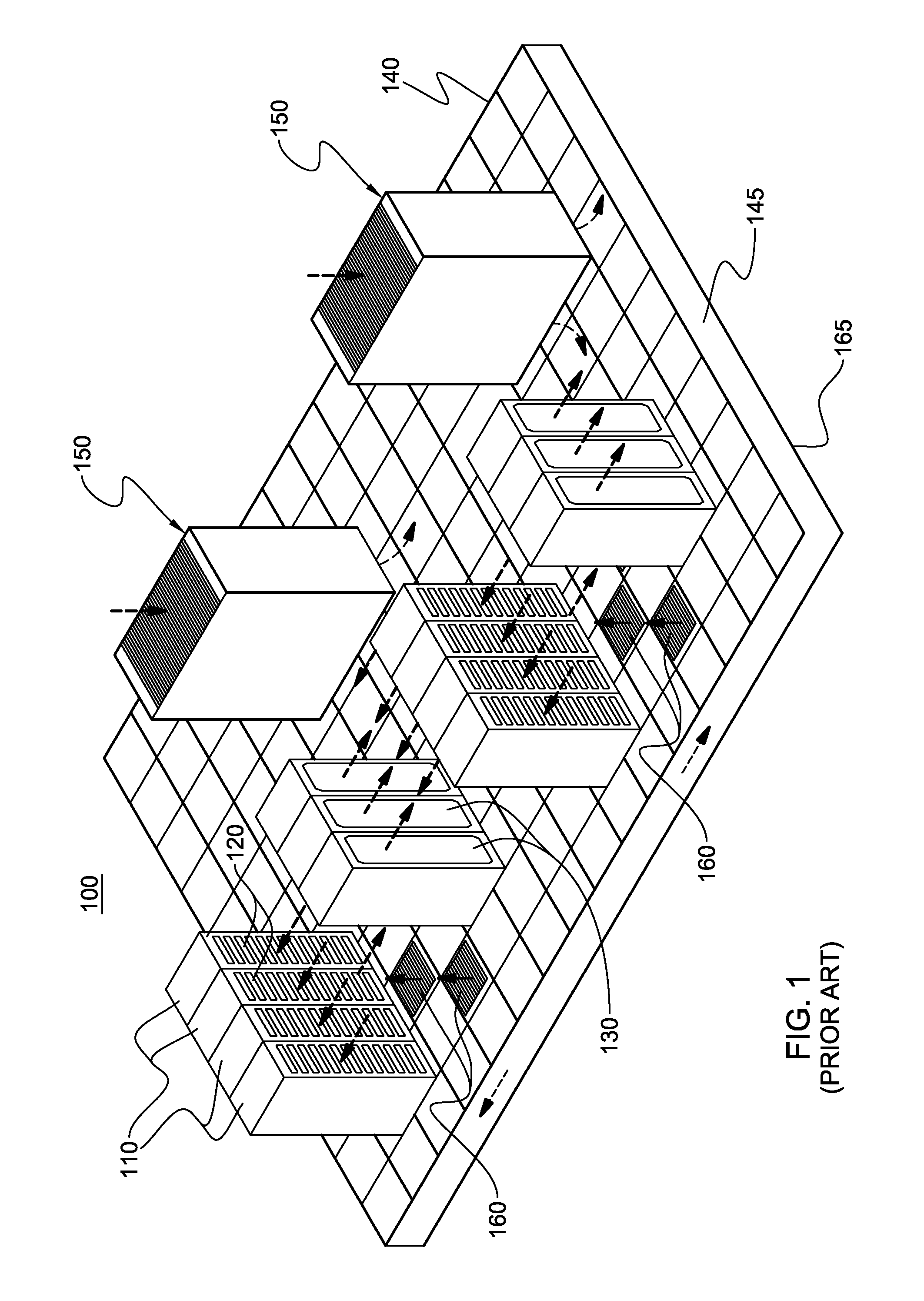

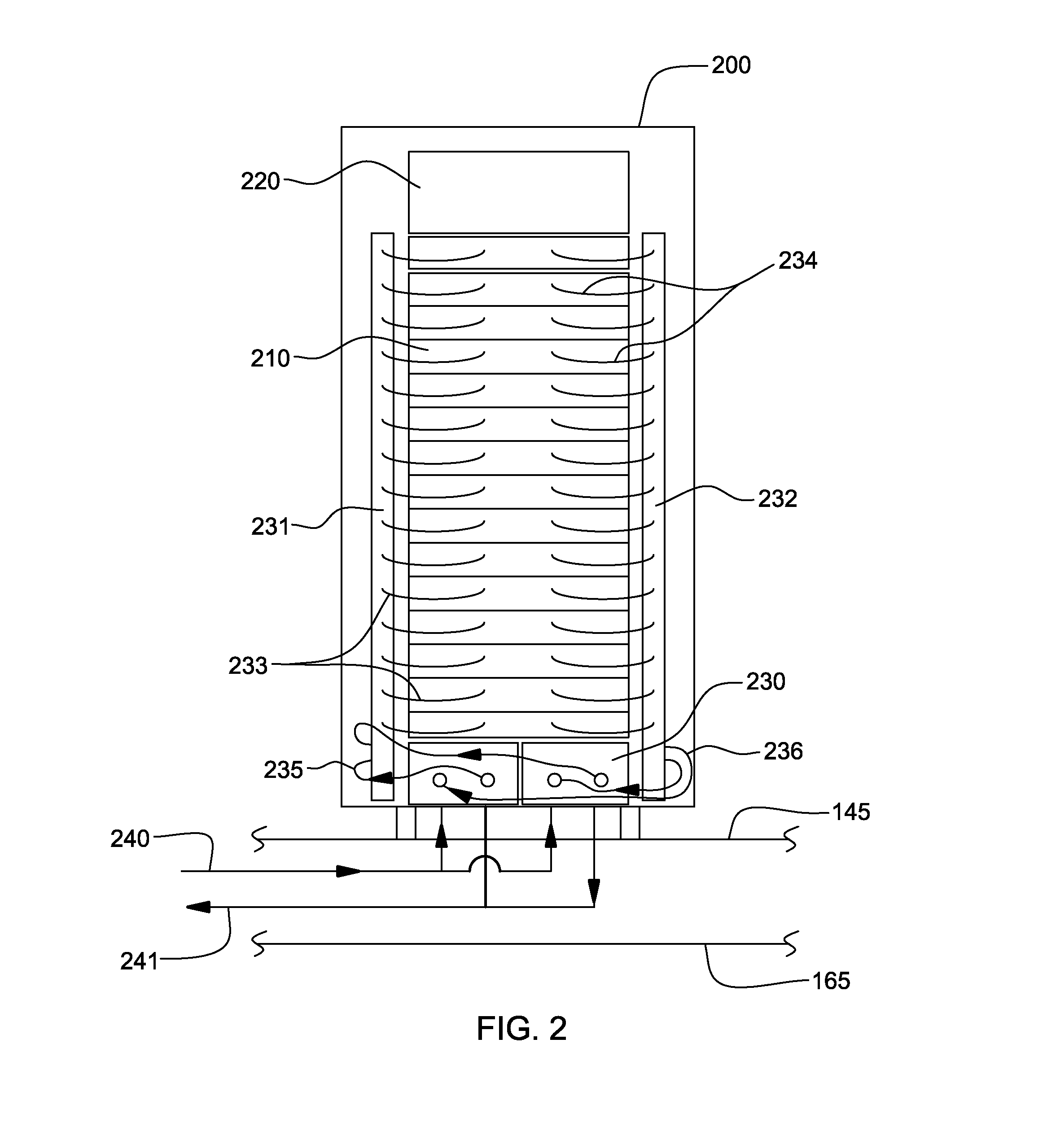

Sectioned manifolds facilitating pumped immersion-cooling of electronic components

InactiveUS8964391B2Improve cooling effectPromote circulationDomestic cooling apparatusDigital data processing detailsElectronic componentFlow boiling

Cooling methods are provided for facilitating pumped immersion-cooling of electronic components. The cooling method includes: providing a housing forming a compartment about one or more components, and providing a supply manifold, a return manifold, and coupling a coolant loop coupling in fluid communication the supply and return manifolds and the housing. Coolant flowing through the coolant loop flows through the compartment of the housing and, at least partially, immersion-cools the component(s) by flow boiling. A pump facilitates circulation of coolant within the loop, and a coolant bypass line is coupled between the supply and return manifolds. The return manifold includes a mixed-phase manifold section, and the bypass line provides coolant from the supply manifold directly to the mixed-phase manifold section. Coolant flows from the coolant bypass line into the mixed-phase manifold section in a direction counter to the direction of any coolant vapor flow within that manifold section.

Owner:INT BUSINESS MASCH CORP

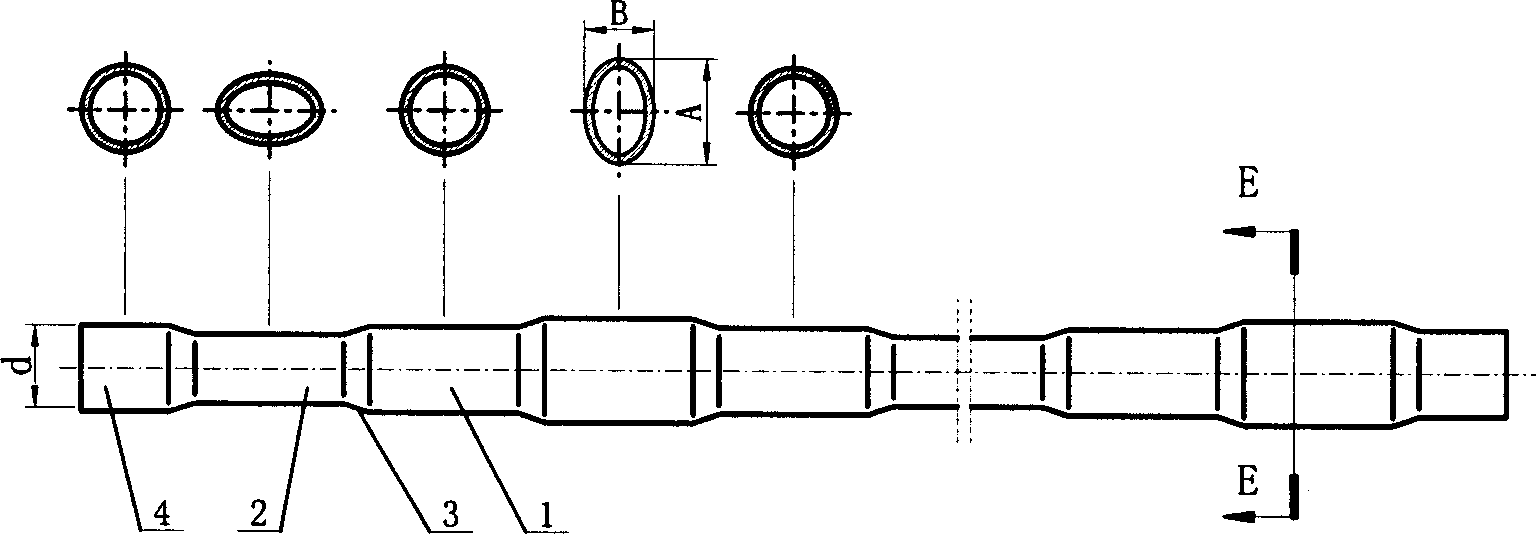

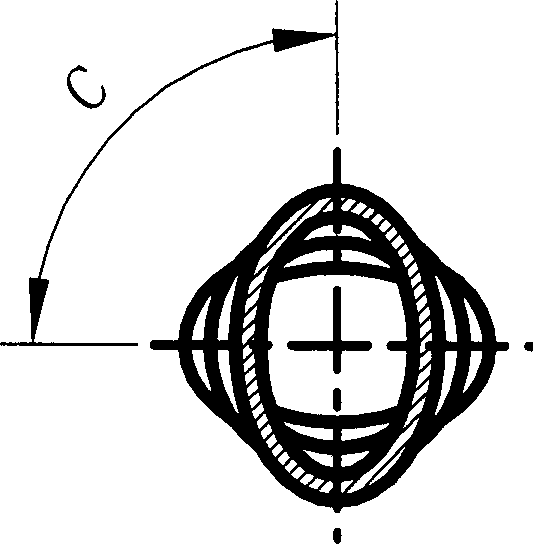

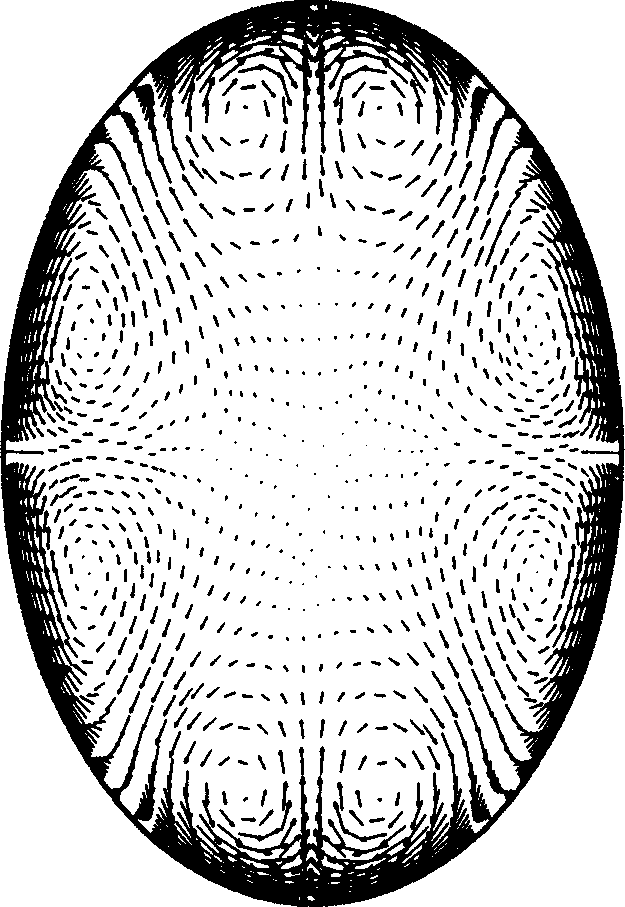

Intensified heat exchange tube with intersectional zoomed sections of circle-ellipse

Owner:TSINGHUA UNIV

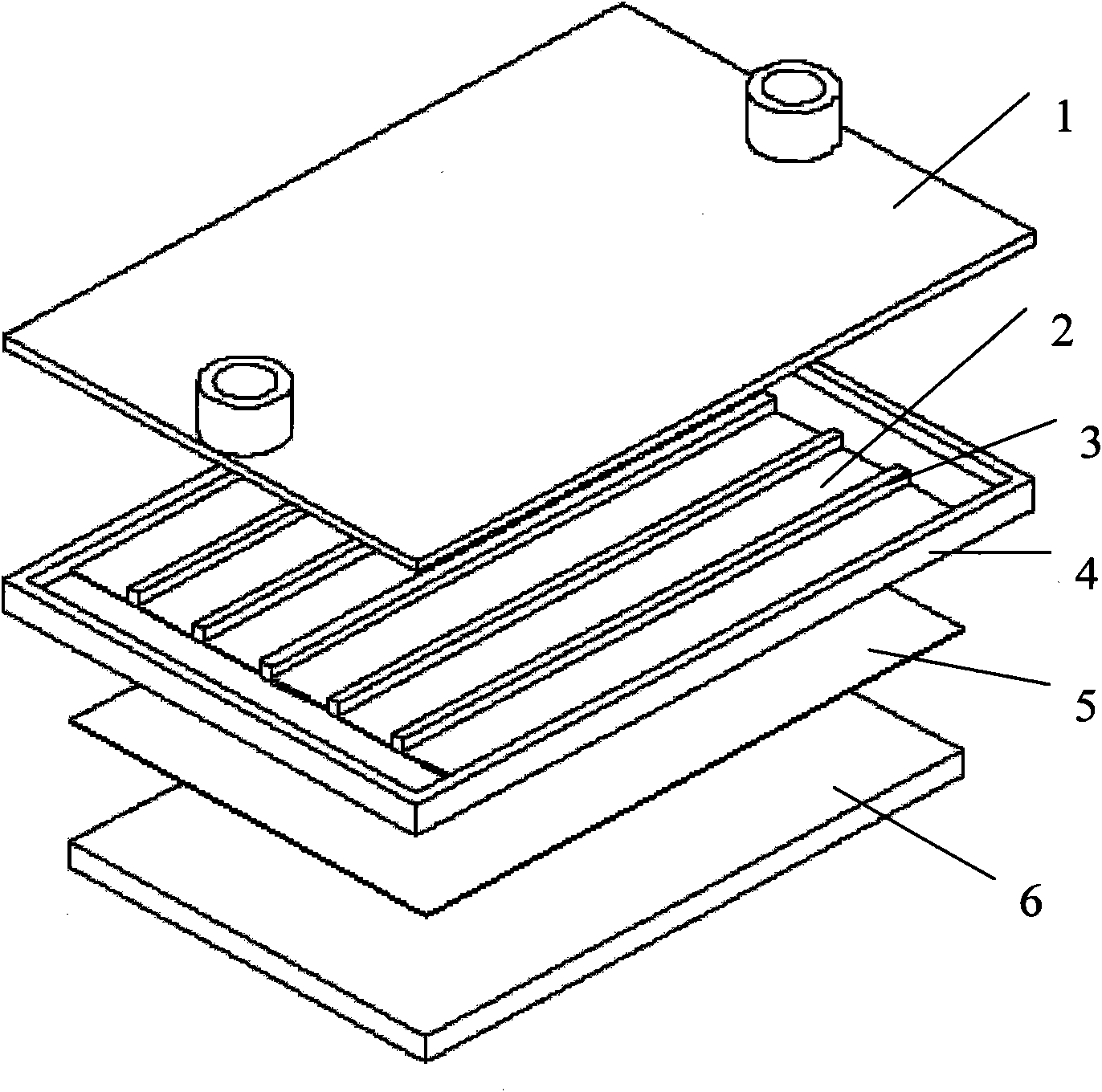

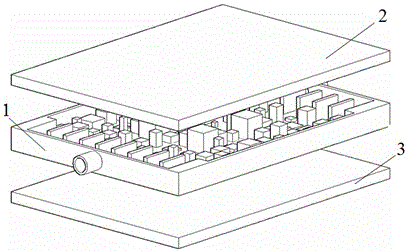

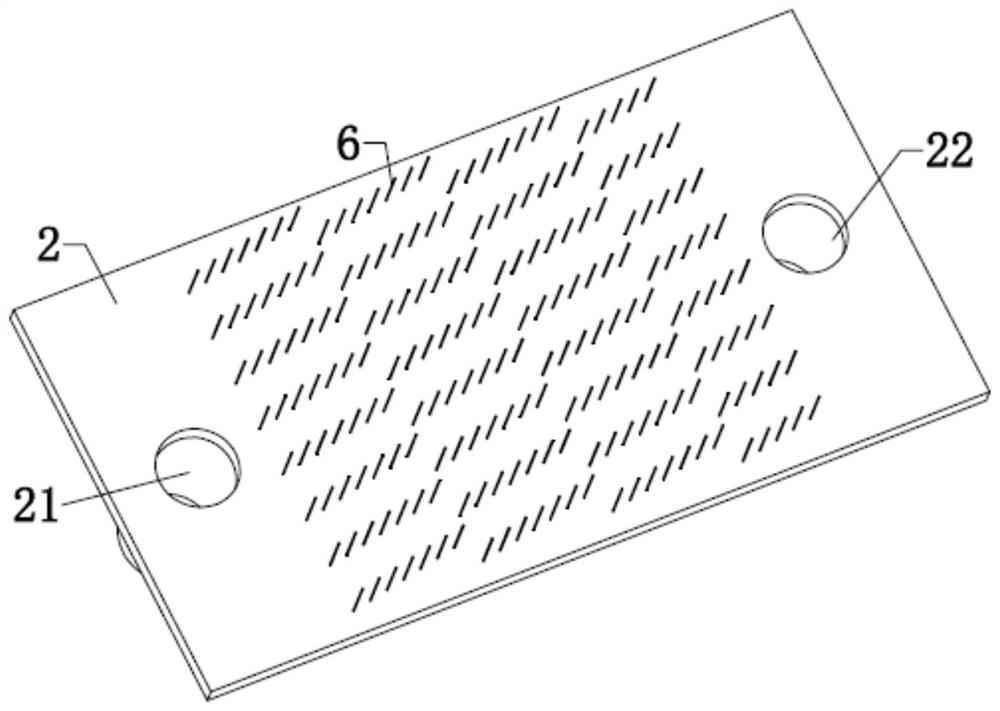

Evaporator for cooling chip and manufacture method thereof

InactiveCN101894812AMeet compactness requirementsImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesHeat transmissionEngineering

The invention relates to an evaporator for cooling a chip and a manufacture method thereof. The evaporator combines a micro-porous surface coat with a plurality of small-scale passageways. An evaporator main body consists of an upper cover plate and a lower base plate. The two ends of the upper cover plate of the evaporator are provided with a cooling liquid inlet and a cooling liquid outlet. The two ends of the lower base plate of the evaporator are respectively provided with an empty cavity; and the lower base plate is machined with a plurality of parallel ribs to form into the plurality of parallel small-scale passageways for flowing cooling liquid. The bottom surface of each small-scale passageway is coated with a layer of micro-porous surface coat for greatly intensifying the boiling phase-change heat transmission of the cooling liquid. The evaporator is glued with a heating electronic chip through a layer of heat-conductive silicone grease, heats up the cooling liquid which flows the passageways therein, absorbs the dissipated power of the electronic chip in the form of flowing boiling heat transmission, has the characteristics of small flow resistance, compact structure and low cost, has strong cooling performance, and is applied to cooling the electronic chip with high dissipated power.

Owner:EAST CHINA UNIV OF SCI & TECH

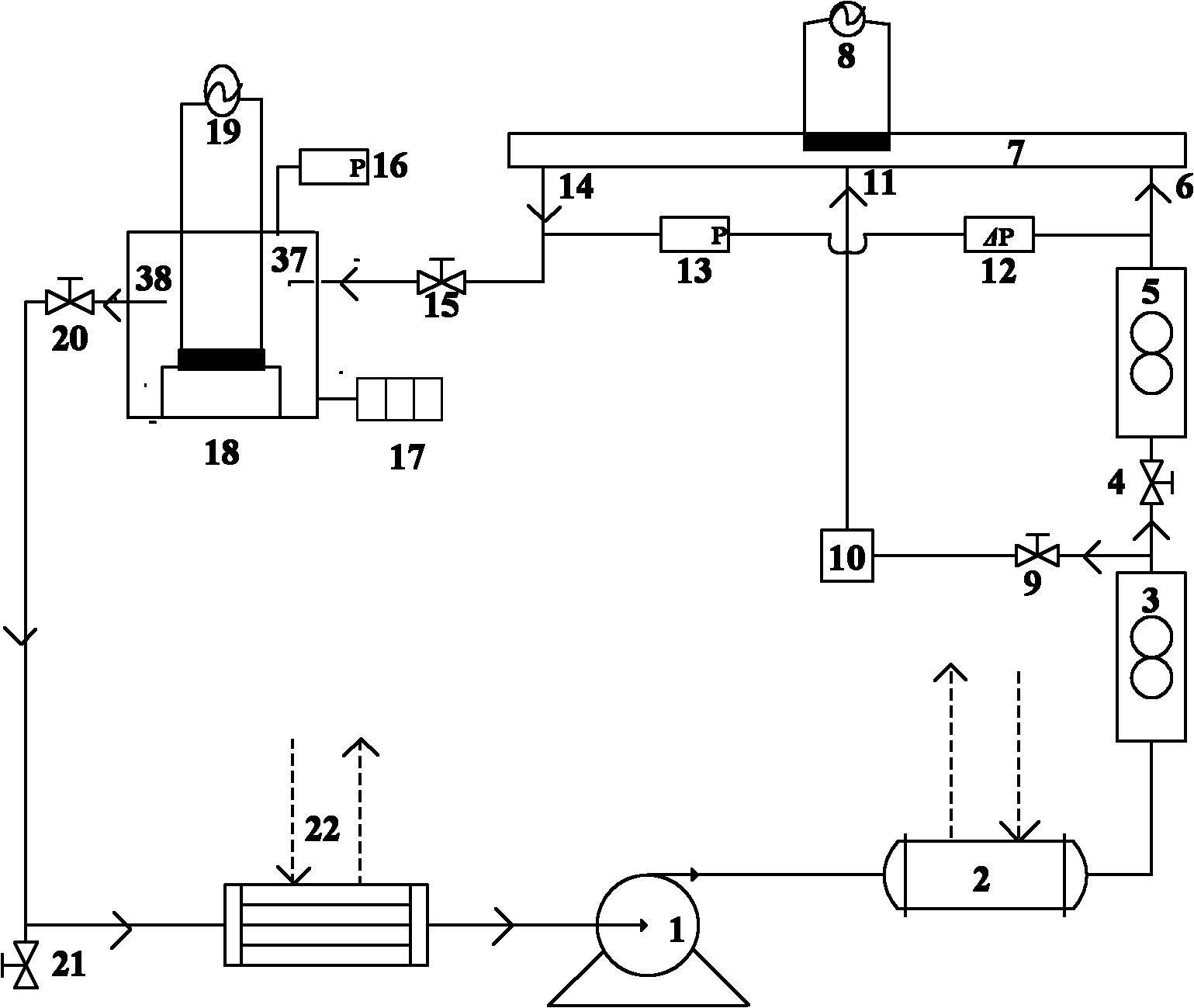

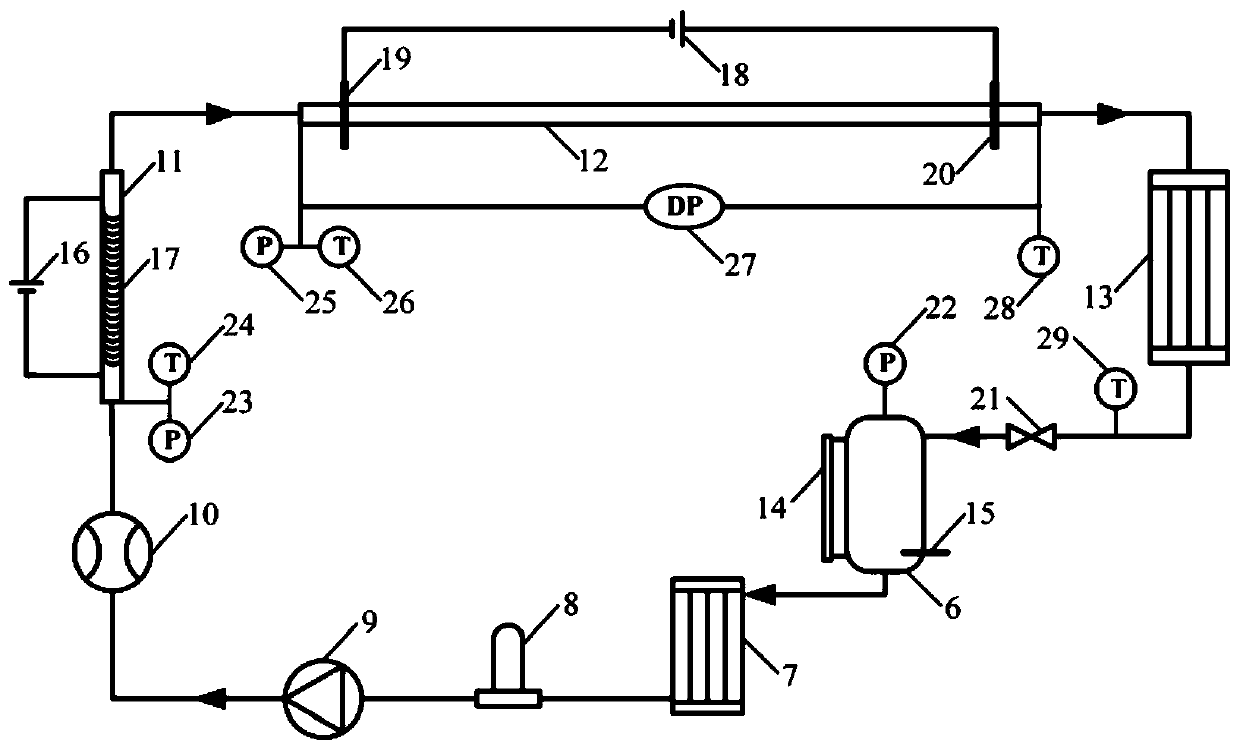

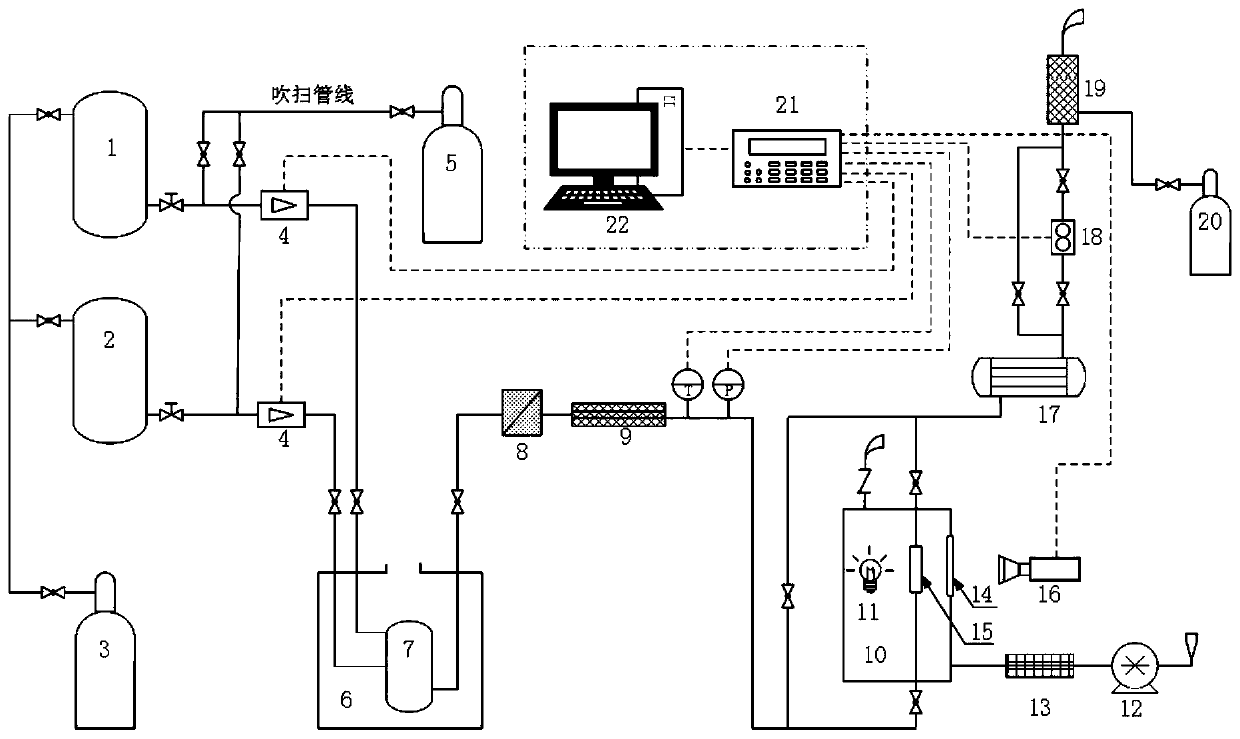

Multi-factor width parameter nanofluid heat transfer characteristic experimental system and experimental method

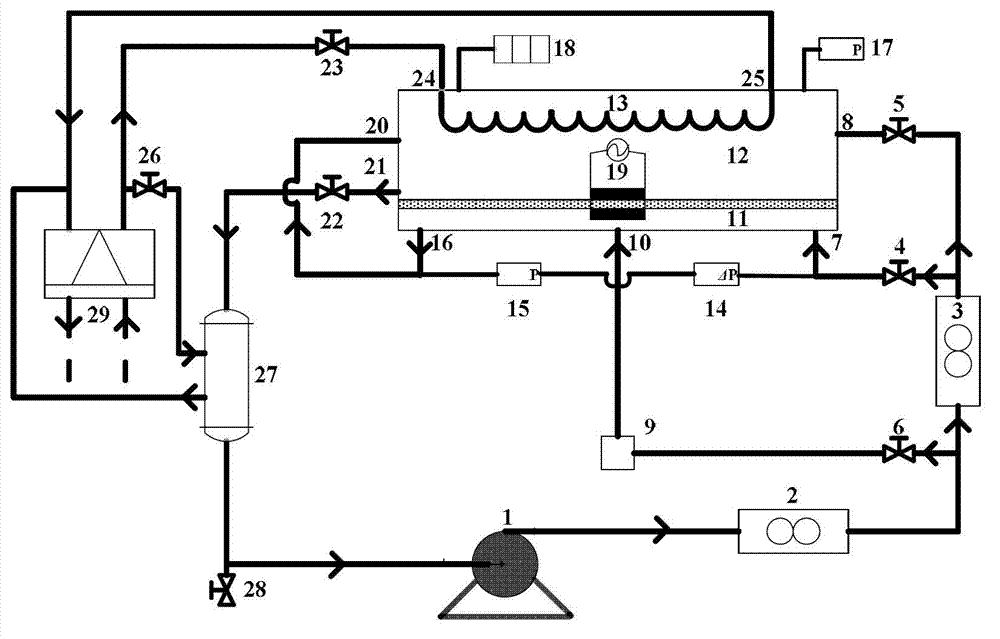

The invention discloses a multi-factor width parameter nanofluid heat transfer characteristic experimental system and an experimental method. The system comprises three parts, namely an experimental loop, a pressure control loop and a cooling loop, wherein the experimental loop is composed of an ultrasonic oscillator, a circulating main pump, a heat regenerator, a mass flow meter, a preheating section, an experimental section, a data acquisition system and an electric heating system; the pressure control loop is composed of a high-pressure nitrogen and gas-liquid header and a safety valve; andthe cooling loop is composed of a cooling tower, a circulating pump and a cooling jacket. According to the experimental system, single-phase heat convection, flow boiling heat exchange and critical heat flux experimental researches under multi-factor and width parameter conditions can be performed aiming at nanofluid of different components under the condition that the stability of the nanofluidis maintained. The invention further provides an experimental method. The stability of the nanofluid is ensured, the influence of a dispersing agent or other additives is avoided, and the influence factors and mechanisms of the single-phase heat convection, flow boiling heat exchange and critical heat flux of the nanofluid can be conveniently researched.

Owner:XI AN JIAOTONG UNIV

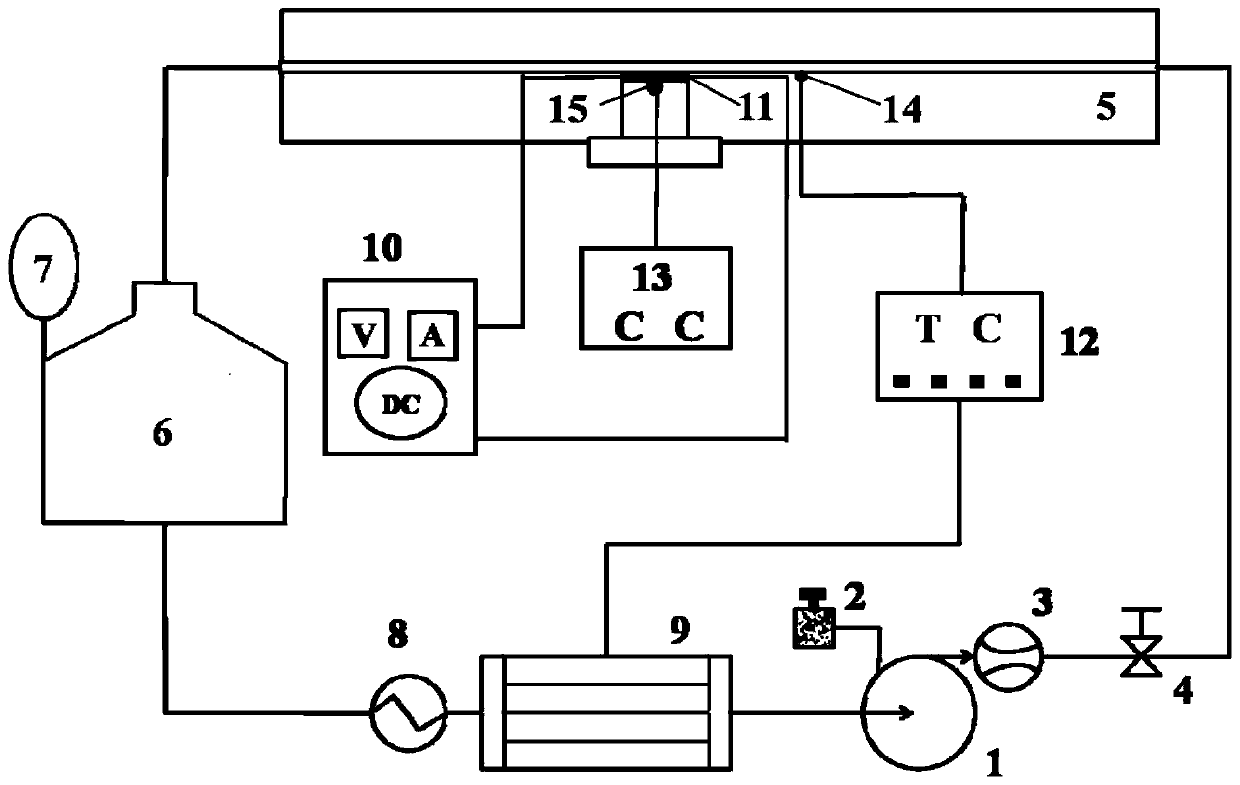

Composite electronic chip cooling and boiling heat transfer enhancement experiment device

InactiveCN103033535AReduce superheatGuaranteed contactMaterial heat developmentSmall footprintEngineering

The invention relates to a composite electronic chip cooling and boiling heat transfer enhancement experiment device, which comprises a peripheral pump, wherein the outlet of the peripheral pump is connected with a total flow meter inlet; a total flow meter outlet is divided into two paths, one path passes through a jet branch to enter the flow jet segment of a composite boiling experiment box, and the other path is further divided into two paths; one path passes through a transverse flow branch to enter the flow jet segment of the composite boiling experiment box, and the outlet of the flow jet segment of the composite boiling experiment box is connected with the boiling segment of the composite boiling experiment box; the other path directly enters the boiling segment of the composite boiling experiment box, and the outlet of the boiling segment of the composite boiling experiment box is connected with the inlet of a heat transfer device; the outlet of the heat transfer device is connected with the peripheral pump; and a circle is completed. The device combines the advantages of pool boiling, pure flow boiling, pure jet impact boiling and flow jet composite boiling heat transfer, and has the advantages of flexibility in operation, simplicity in control, small occupied area and short experimental period.

Owner:XI AN JIAOTONG UNIV

Flow boiling heat sink with vapor venting and condensing

InactiveUS20130070420A1Mechanical energy handlingModifications using liquid coolingSteam condensationCoolant flow

A method is provided for facilitating extraction of heat from a heat-generating electronic component. The method includes providing a heat sink, the heat sink including a thermally conductive structure which has one or more coolant-carrying channels and one or more vapor-condensing channels. A membrane is disposed between the coolant-carrying channel(s) and the vapor-condensing channel(s). The membrane includes at least one vapor-permeable region, at least a portion of which overlies a portion of the coolant-carrying channel(s) and facilitates removal of vapor from the coolant-carrying channel(s) to the vapor-condensing channel(s). The heat sink further includes one or more coolant inlets coupled to provide a first liquid coolant flow to the coolant-carrying channel(s), and a second liquid coolant flow to condense vapor within the vapor-condensing channel(s).

Owner:INT BUSINESS MASCH CORP

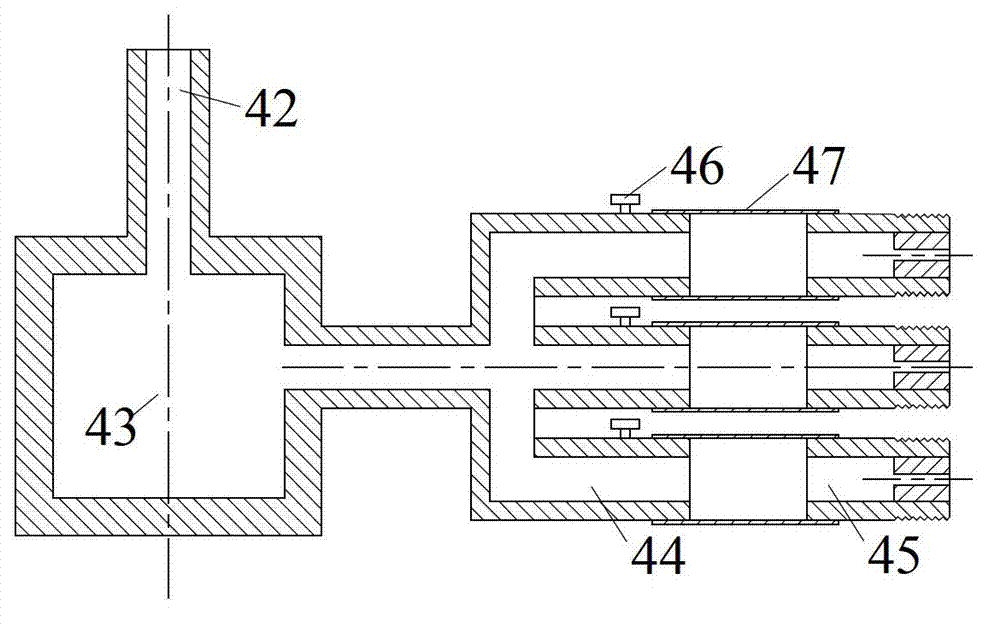

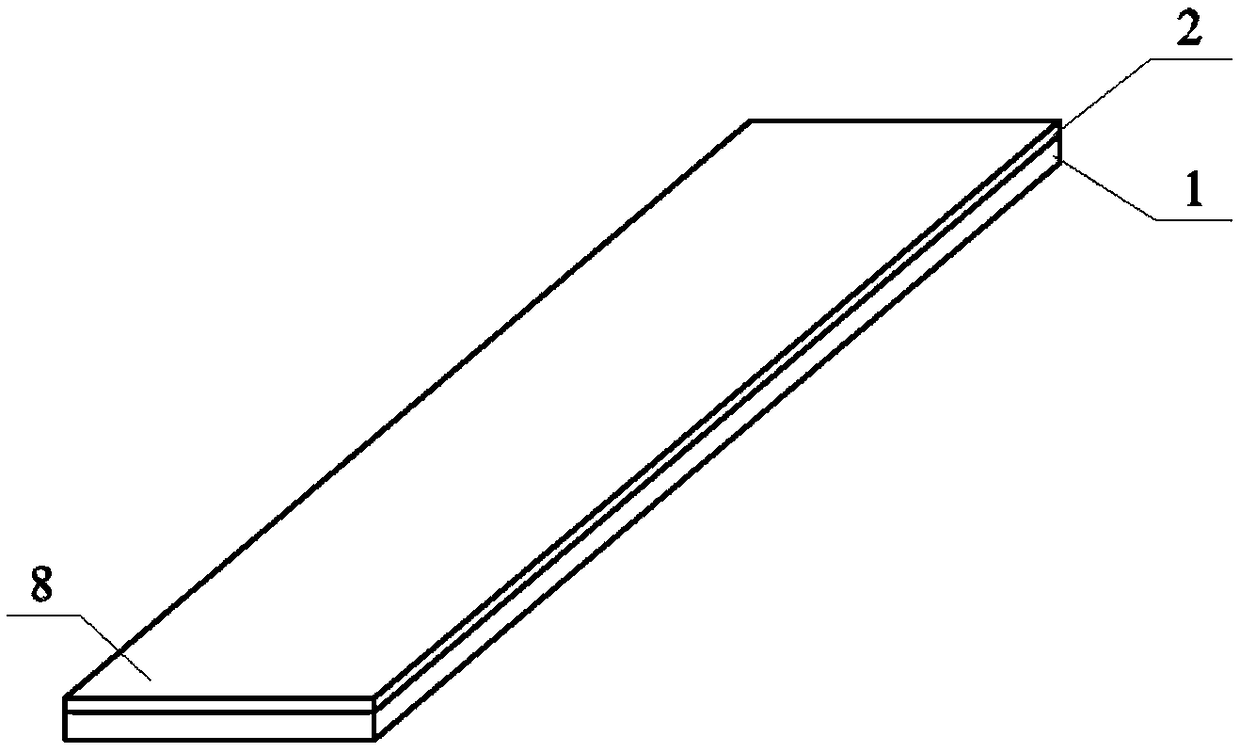

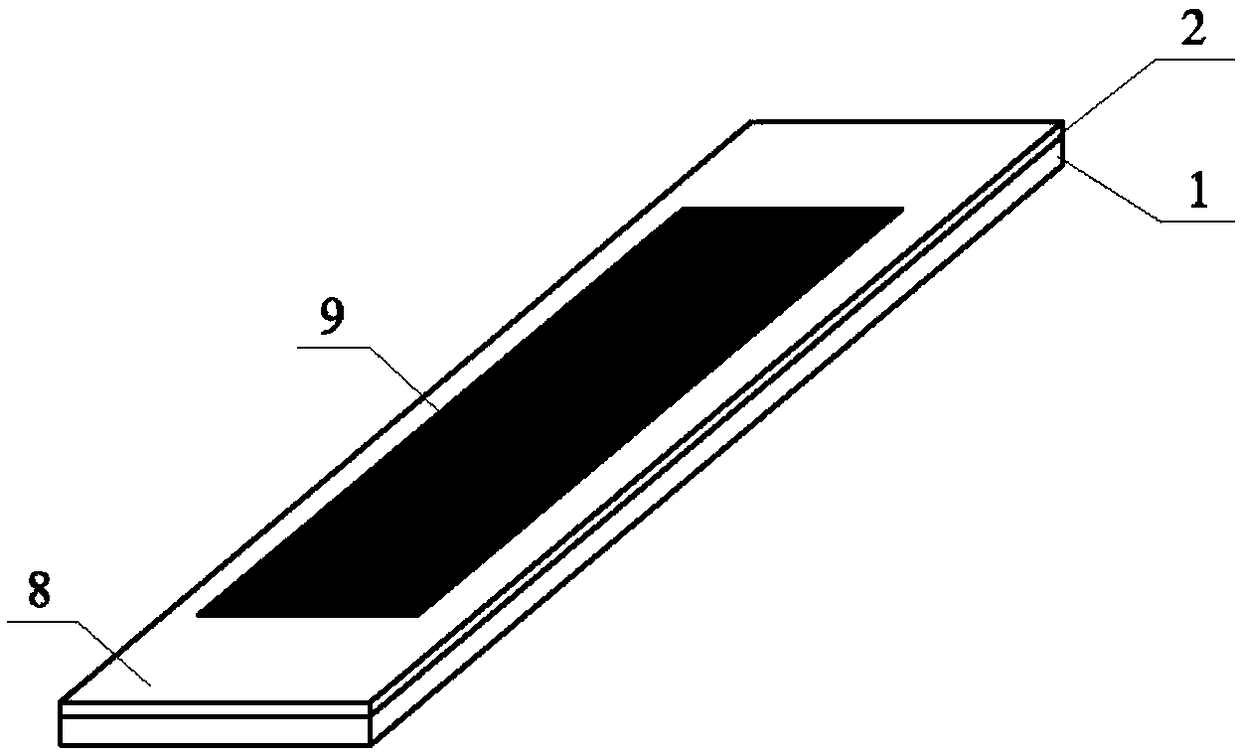

Flowing boiling micro-miniature heat exchanger

ActiveCN106061199AUniform temperatureExtend your lifeCooling/ventilation/heating modificationsEngineeringHeat transfer efficiency

The invention discloses a flowing boiling micro-miniature heat exchanger, which comprises a heat exchanger casing, a heat exchange structure passage, an inlet passage and an outlet passage, wherein the heat exchange structure passage is arranged in the heat exchanger casing; and the inlet passage and the outlet passage are arranged at the two ends of the heat exchange structure passage. The flowing boiling micro-miniature heat exchanger is characterized in that the inlet passage consists of a condensing medium input opening, a flow storage pool and an inlet flow division passage; the flow storage pool is connected between the condensing medium input opening and the inlet flow division passage; the outlet passage consists of a condensing medium output opening and an outlet flow division passage; a micro rib column group and support columns are arranged in the heat exchange structure passage; the micro rib column group consists of micro rib columns; the cross section dimension of the micro rib columns conforms to the fractal Brownian motion features; the micro rib columns are in planar distribution; the height of the micro rib columns meets the normal distribution; and the support columns are distributed in the center of the micro rib column group in an array mode. The flowing boiling micro-miniature heat exchanger has the advantages that the heat transfer efficiency is high; the flowing resistance loss is small; the surface temperature of the heat exchanger is uniform; the work is stable; and the service life is long.

Owner:SOUTHEAST UNIV

Synthetic Jet Ejector for Augmentation of Pumped Liquid Loop Cooling and Enhancement of Pool and Flow Boiling

InactiveUS20100263838A1Semiconductor/solid-state device detailsSolid-state devicesLiquid mediumThermal management system

Owner:NUVENTIX

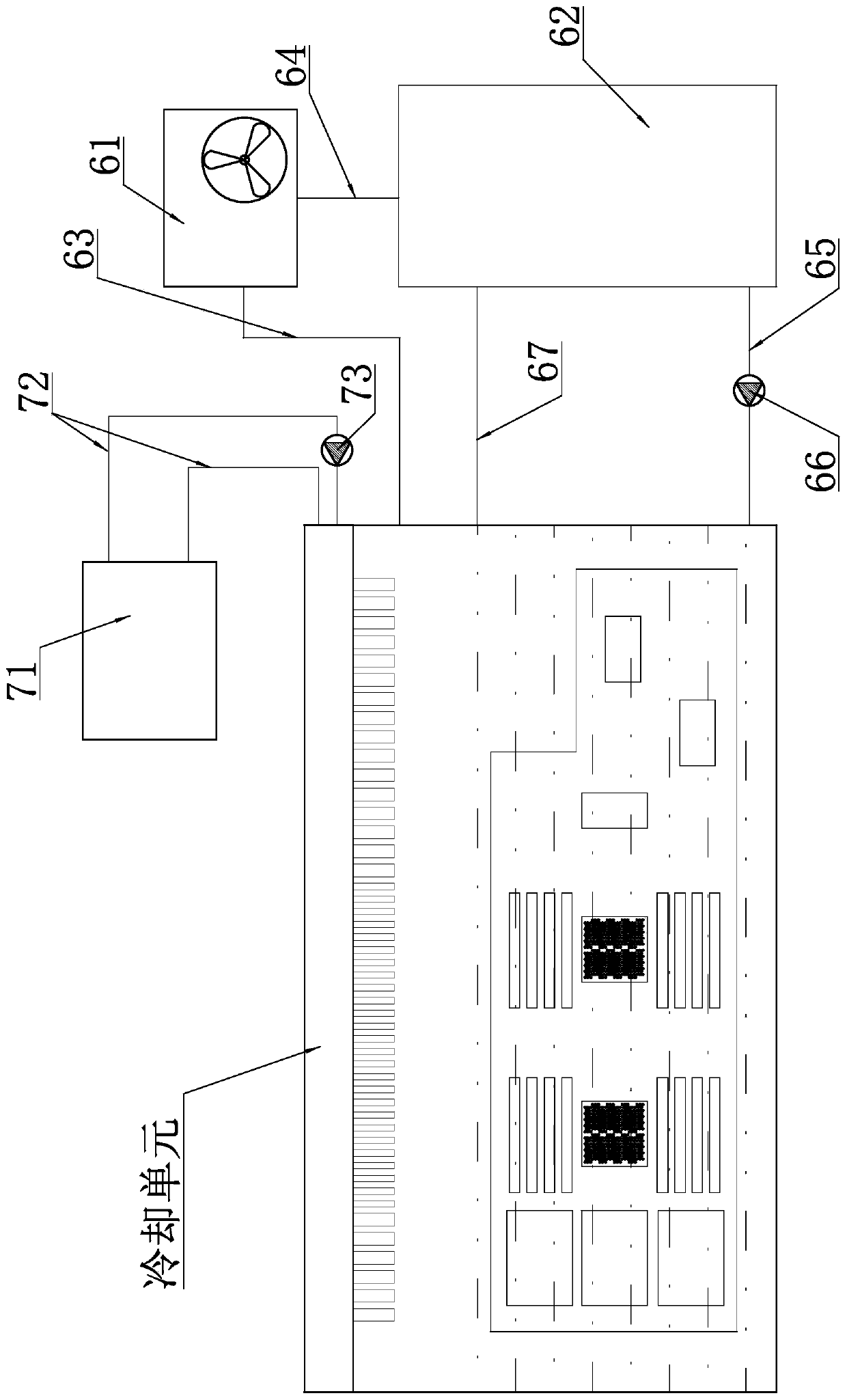

Flowing boiling immersion type liquid cooling device

ActiveCN111352489AAchieve normal operationReduce dosageDigital data processing detailsLiquid storage tankCirculator pump

The invention discloses a flowing boiling immersion type liquid cooling device, and relates to the technical field of server hardware equipment. The device comprises a cooling unit, the cooling unit comprises a square box body, and the box body is filled with cooling liquid capable of generating phase change. A mainboard is fixedly arranged on a left side plate and / or a right side plate of the boxbody, and the mainboard is immersed in the cooling liquid. An air return port, an overflow port and a liquid inlet pipe are sequentially arranged on a front side plate of the box body from top to bottom, wherein the air return port is connected with an inlet of an air-cooled condenser, an outlet of the air-cooled condenser is connected with a first inlet of the liquid storage tank, the overflow port is connected with a second inlet of the liquid storage tank, an outlet of the liquid storage tank is connected with the liquid inlet pipe through a liquid inlet pipeline, and a first circulating pump is arranged on the liquid inlet pipeline. According to the system, the use amount of cooling liquid is effectively reduced, the size of the whole equipment is reduced, the fluidity of the coolingliquid is improved, and then the heat dissipation effect is improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

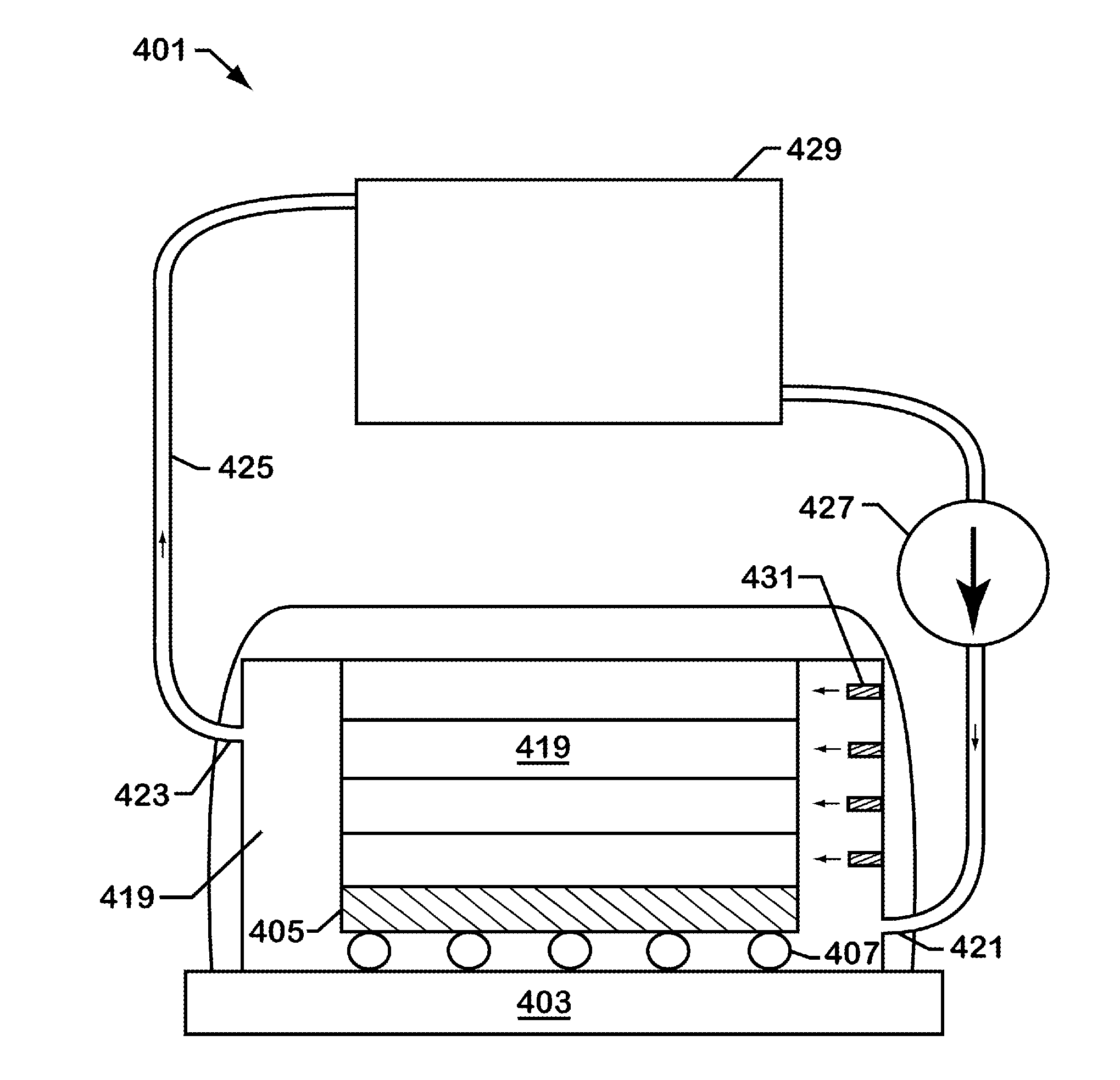

Sectioned manifolds facilitating pumped immersion-cooling of electronic components

ActiveUS8964390B2Promote circulationImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringFlow boiling

Cooling apparatuses and methods are provided for facilitating pumped immersion-cooling of electronic components. The cooling apparatus includes a housing forming a compartment about one or more components, a supply manifold, a return manifold, and a coolant loop coupling in fluid communication the supply and return manifolds and the housing. Coolant flowing through the coolant loop flows through the compartment of the housing and at least partially immersion-cools the component(s) by flow boiling. A pump facilitates circulation of coolant within the loop, and a coolant bypass line is coupled between the supply and return manifolds. The return manifold includes a mixed-phase manifold section, and the bypass line provides coolant from the supply manifold directly to the mixed-phase manifold section. Coolant flows from the coolant bypass line into the mixed-phase manifold section in a direction counter to the direction of any coolant vapor flow within that manifold section.

Owner:INT BUSINESS MASCH CORP

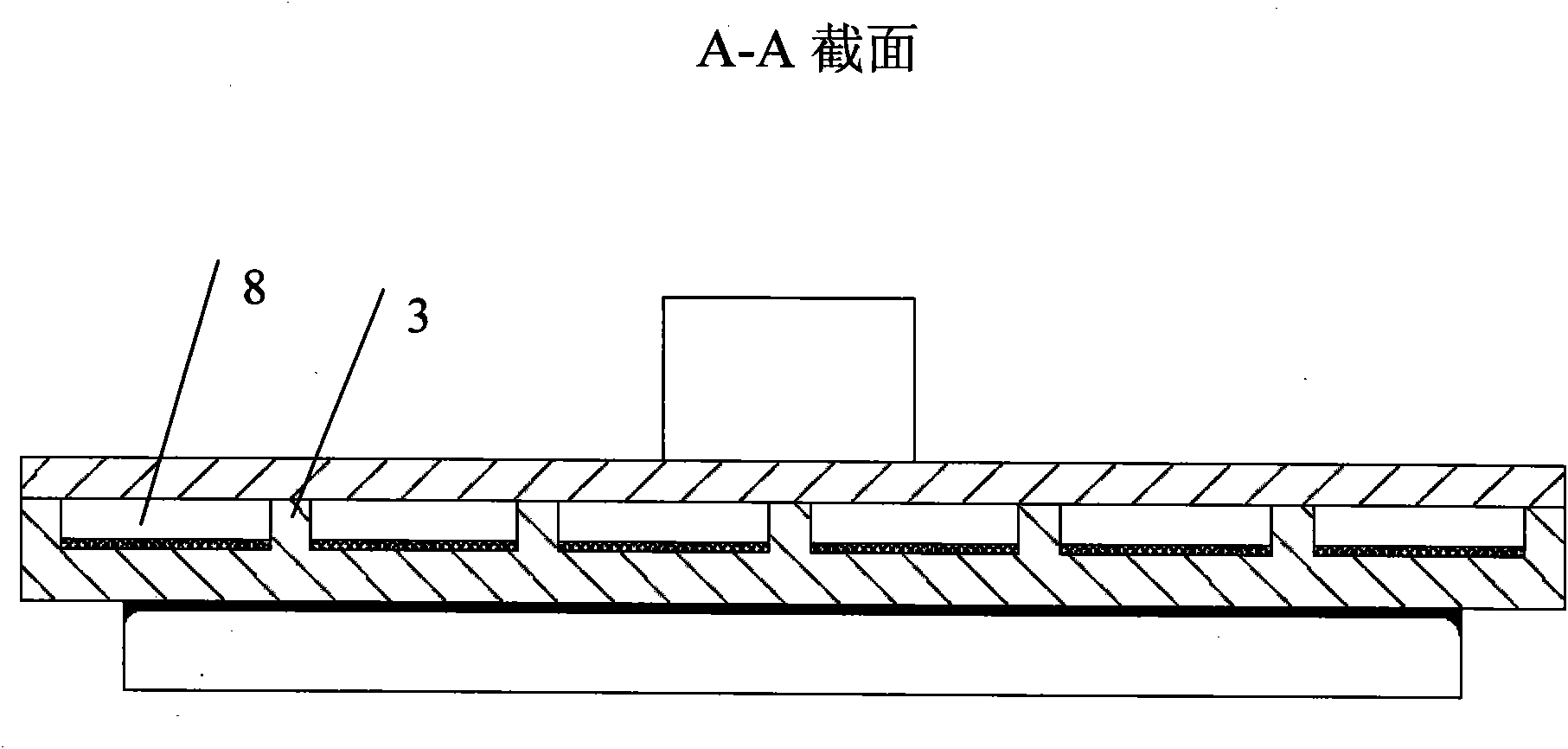

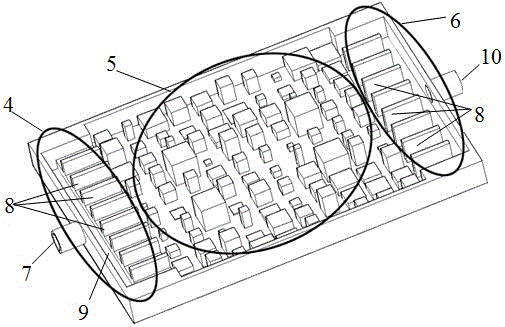

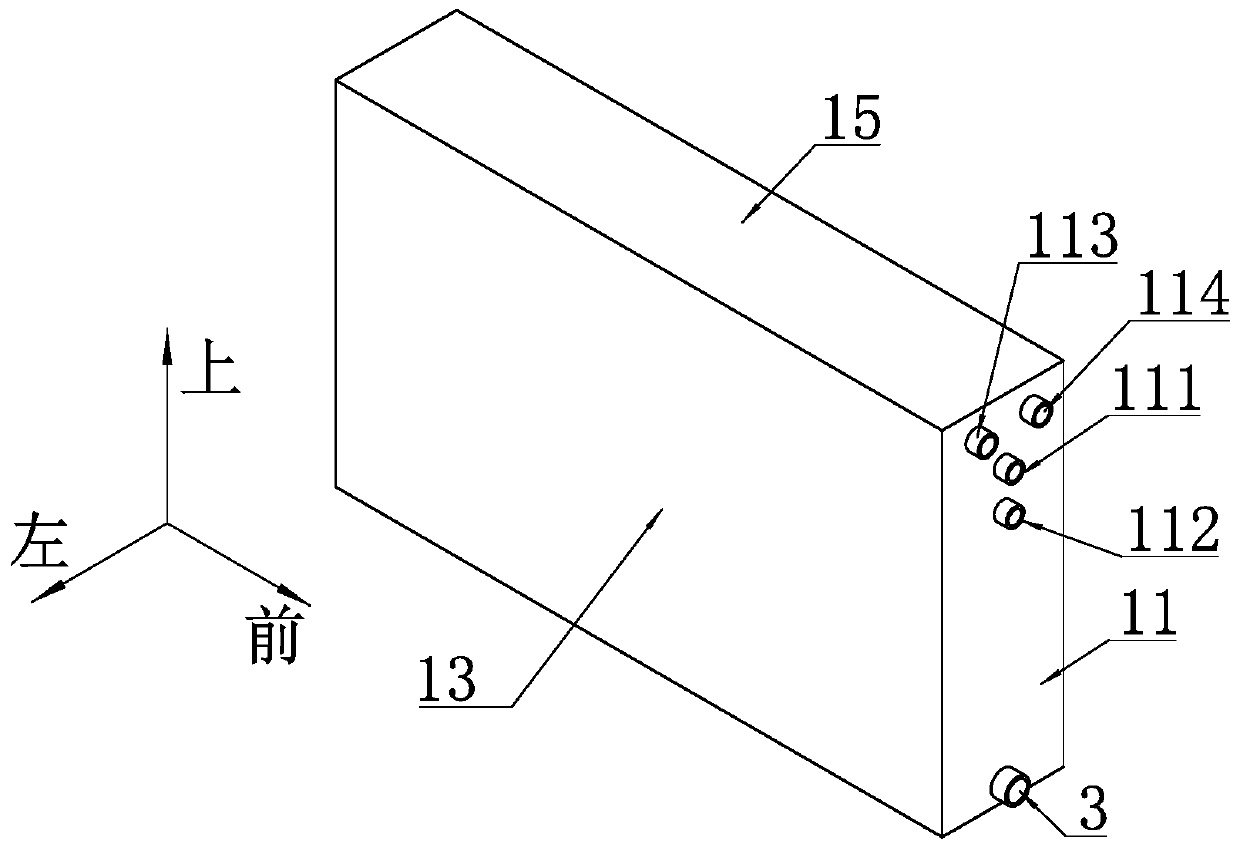

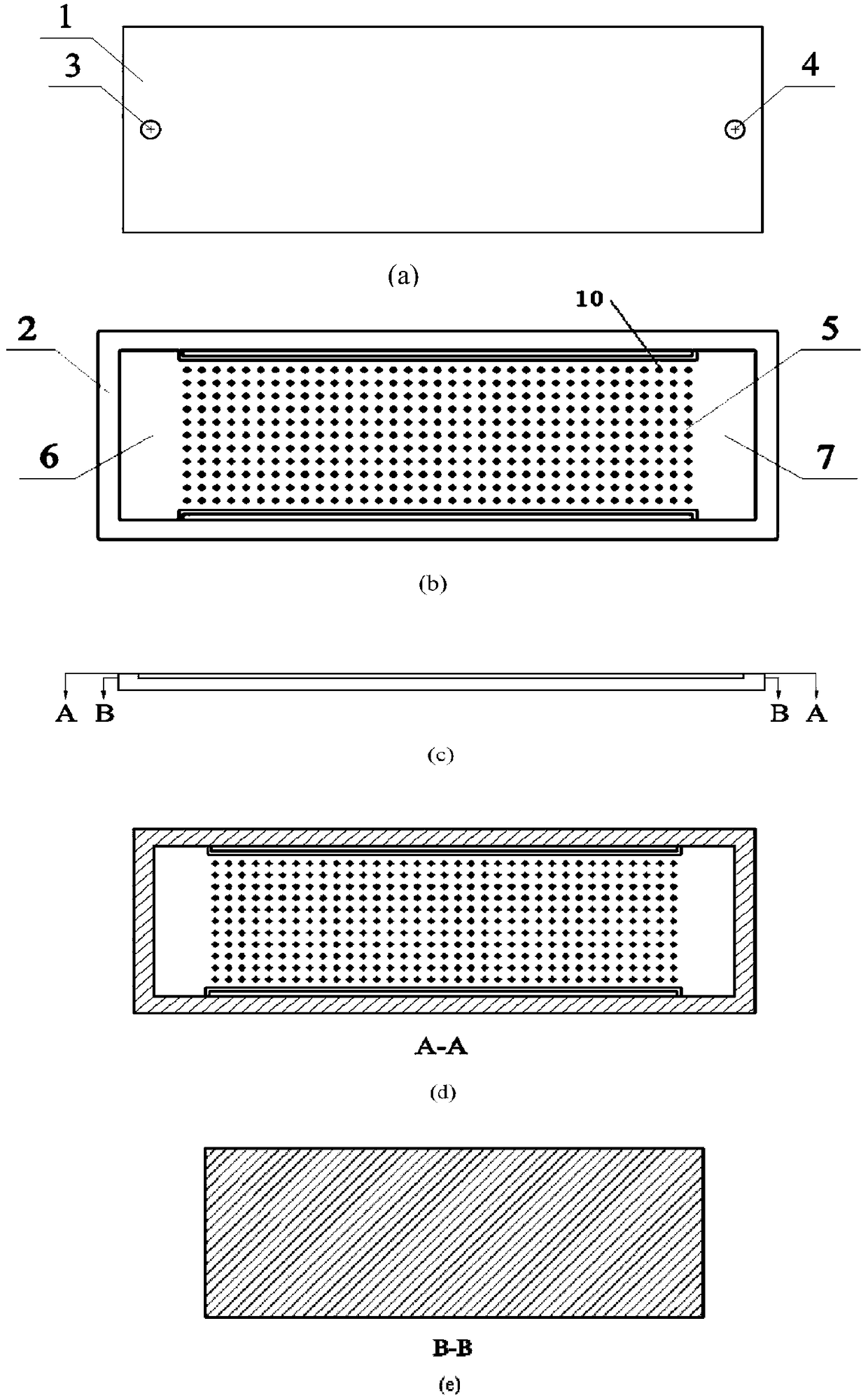

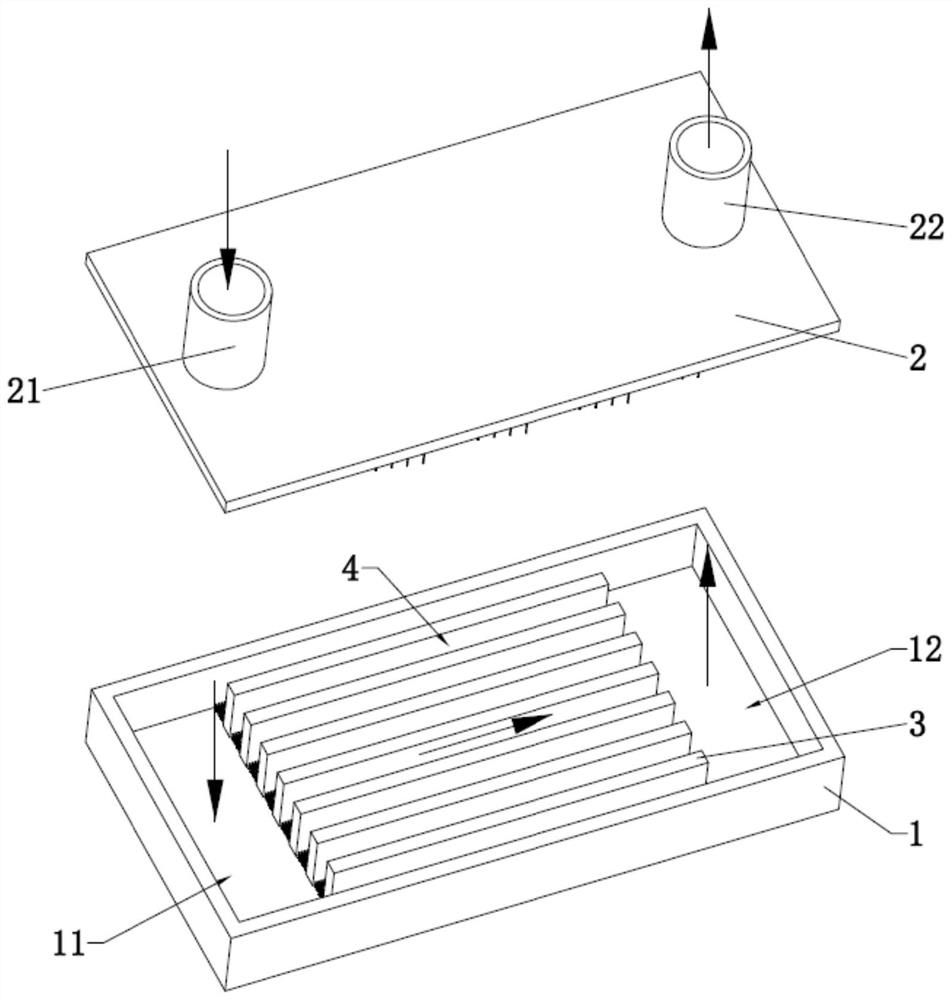

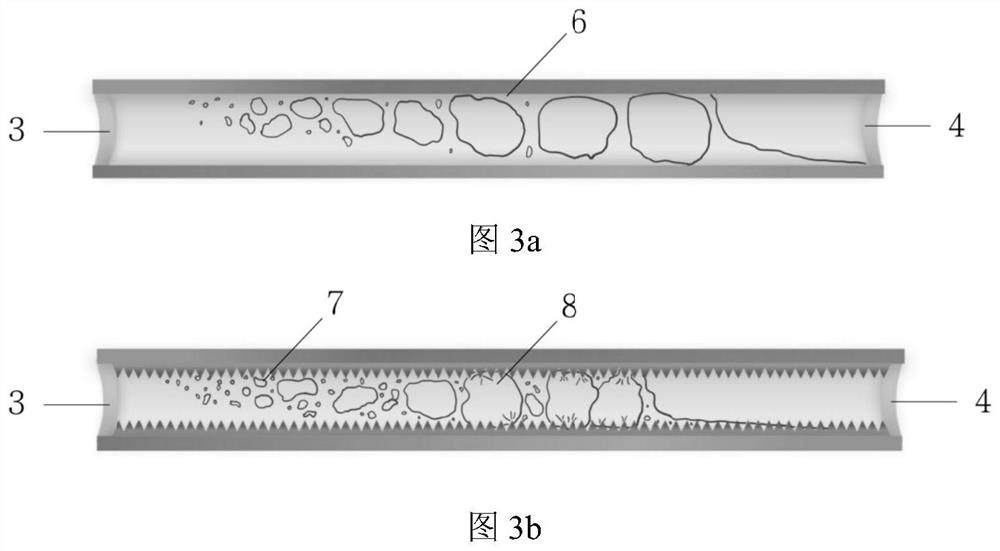

Micro-needle rib cluster array micro-channel micro heat exchanger

PendingCN109378303AIncrease disturbanceIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesEnhanced heat transferEngineering

A micro-needle rib cluster array micro-channel micro heat exchanger belongs to the field of enhanced heat transfer of microelectronic technology. The micro-needle rib cluster array micro-channel microheat exchanger comprises a packaging sheet (1) and a substrate (2) which are successively stacked and packaged together. A fluid inlet (3) and a fluid outlet (4) connected to an external pipeline aredisposed on the packaging sheet (1). A micro-needle rib cluster array micro-channel (5), an inlet reservoir (6) and an outlet reservoir (7) are processed on the front side of the substrate. The micro-needle rib cluster elements in a micro-needle rib cluster array are arranged successively. The X-direction spacing L, the Y-direction spacing Lb, and the X-direction structure size La and Y-directionstructure size H of the micro-needle rib cluster unit all can be optimized according to actual needs and achieved by MEMS processing technology. Compared with a general micro-channel micro heat exchanger, the micro-needle rib cluster array micro-channel micro heat exchanger can meet the heat dissipation of a large-power electronic chip, has the advantages of low boiling initial point wall temperature, low flow boiling pressure drop, and high temperature distribution uniformity on the chip. A high thermal flow electronic device enables efficient thermal management.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

A multifunctional electronic chip cooling and boiling enhanced heat transfer experimental device

InactiveCN102279205AFlexible operationEasy to controlMaterial heat developmentElectrical testingEngineeringSmall footprint

A multifunctional electronic chip cooling and boiling enhanced heat exchange experimental device, comprising a vortex pump, the outlet of the vortex pump is connected to the inlet of a heater, the outlet of the heater is connected to the inlet of a total flowmeter, and the outlet of the total flowmeter is divided into two paths, one of which passes through a cross-flow branch. The back of the road enters the pure flow section, and the other road enters the pure flow section after passing through the injection branch. The outlet of the pure flow section is connected to the inlet of the boiling section of the pool. The outlet of the boiling section of the pool is divided into two paths. The inlet of the condenser is connected to the inlet of the vortex pump, and the outlet of the condenser is connected to the inlet of the vortex pump to complete a cycle, which combines the advantages of pool boiling, pure flow boiling and jet impingement boiling heat transfer, and removes some repetitive equipment and operation processes. Advantages of small land area.

Owner:XI AN JIAOTONG UNIV

Heat exchanger

InactiveCN1979072AImprove liquidityImprove heat exchange efficiencyStationary conduit assembliesHeat exchanger casingsPlate heat exchangerEngineering

The invention relates to a heat exchanger that sets at least a distribution diversion baffle at secondary refrigerant intake end of evaporator. By setting diversion mouths at two sides of baffle, the liquid secondary refrigerant would be sent to the intake baffle of evaporator and could be equally flowing into evaporator to increase flow effect in evaporator. Flow boiling effect would be formed in heating pipe to improve heat exchanging benefit of evaporator, and decrease heating pipe quantity. The producing cost would be lowered.

Owner:TECO ELECTRIC AND MACHINERY

Phase change heat exchanger

InactiveCN112797827AAvoid instability or even blockageReduce superheatIndirect heat exchangersHeat exchanger casingsEngineeringHeat sink

The invention relates to the technical field of heat dissipation and heat exchangers, and discloses a phase change heat exchanger. The phase change heat exchanger comprises a body, a cover plate and a heat dissipation assembly. The heat dissipation assembly comprises a plurality of heat dissipation parts, the adjacent heat dissipation parts are arranged at intervals to form micro-channels, a plurality of first pin fins are arranged in each micro-channel, and the micro-channels are combined to form a micro-channel area. The body comprises an inlet cavity and an outlet cavity, and the inlet cavity communicates with the outlet cavity through the micro-channel area. The cover plate is provided with an inlet pipe and an outlet pipe, the inlet pipe communicates with the inlet cavity, and the outlet pipe communicates with the outlet cavity. A brand-new micro-channel heat sink is provided mainly from the angles of increasing vaporization cores and enhancing the turbulence degree of fluid in the micro-channels, that is, pin fin structures are arranged on the upper bottom surfaces and the lower bottom surfaces of the micro-channels, so that the flowing boiling stability in the heat exchanger is enhanced, and the cooling and temperature equalizing effects of the heat sink are greatly improved.

Owner:GUANGDONG INST OF SEMICON IND TECH

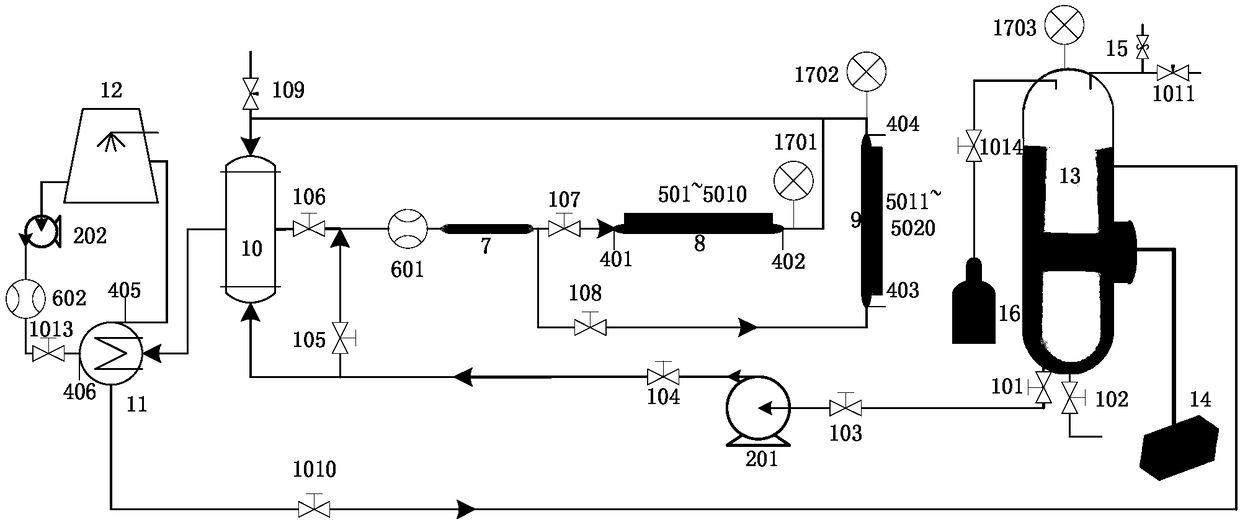

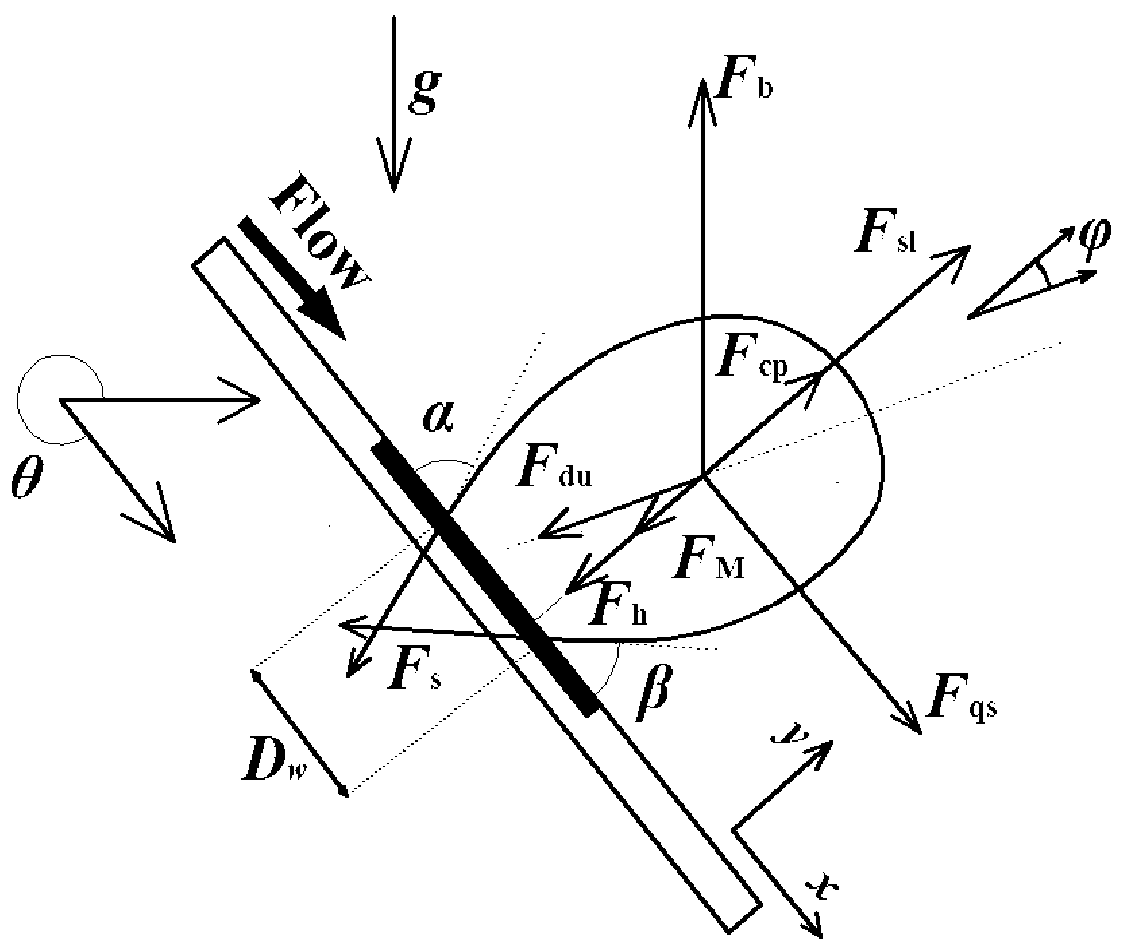

Flow boiling critical heat flux experimental device under super-gravity

ActiveCN110044953AAccurate measurementRadiation pyrometryMaterial thermal conductivityHeat flowThermodynamics

The invention discloses a flow boiling critical heat flux experimental device under super-gravity, which is mainly used for measuring the critical heat flux density of flow boiling under the super-gravity. The flow boiling critical heat flux experimental device under the super-gravity comprises a fluid circulation module, a critical heat flux measurement module and a super-gravity simulation platform; and the fluid circulation module is fixed on the super-gravity simulation platform. Super-gravity of different sizes and directions is realized by adjusting a motor frequency and an arrangement form of experimental pipes. The experimental pipe is heated through a direct energization manner, the system pressure is regulated by a heater in a liquid storage tank, and the flow rate is regulated by a pump. During the experiment, when the pressure, flow, dryness or temperature reaches set values, the heating power of the experimental pipe is slowly increased until the CHF is reached; and then the super-gravity is increased and the experiment is repeated. The invention realizes the accurate measurement of the flow boiling CHF under the super-gravity, and obtains the CHF and the correspondingtemperature in different super-gravity sizes and directions, which can be used for exploring the occurrence mechanism of the CHF under the super-gravity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

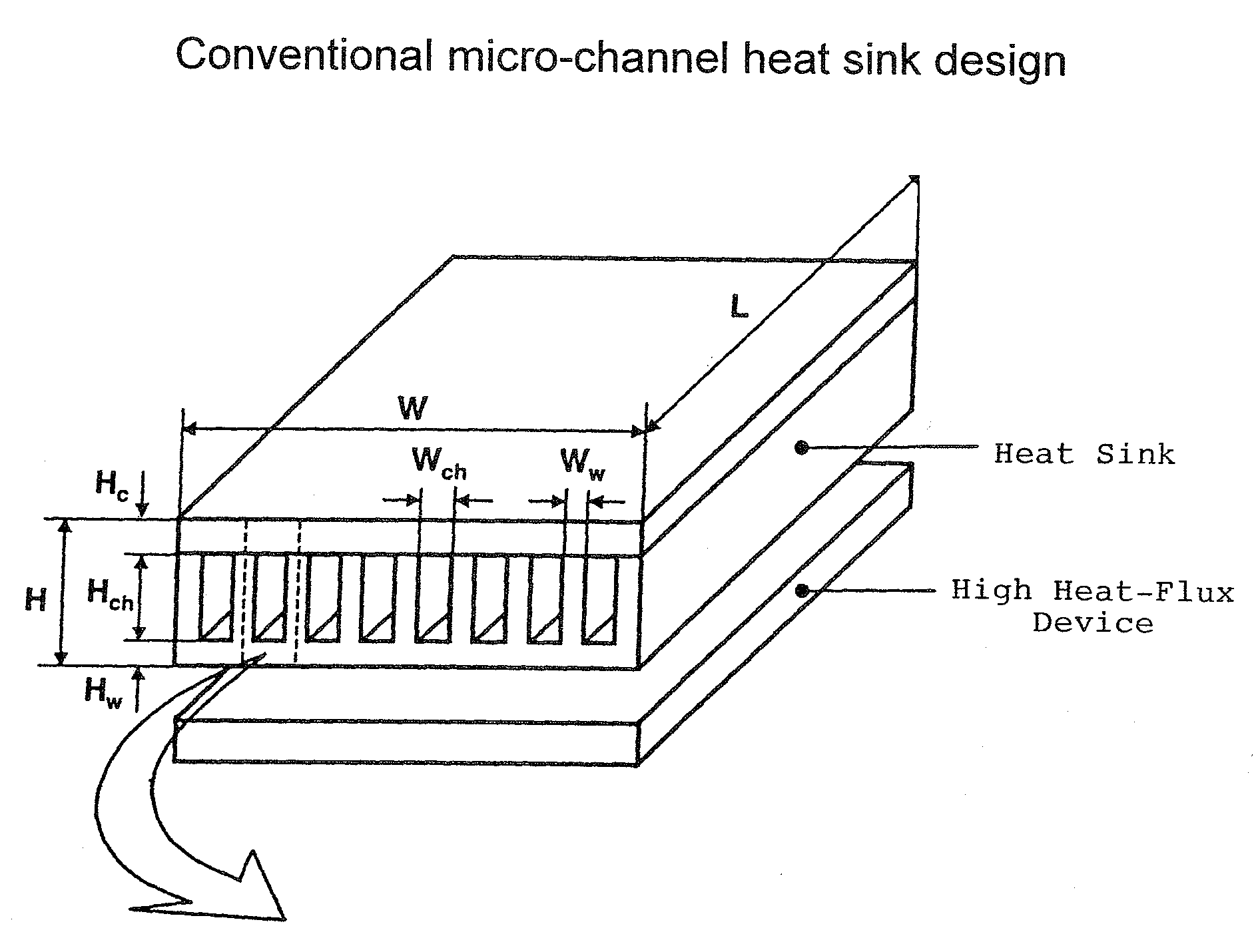

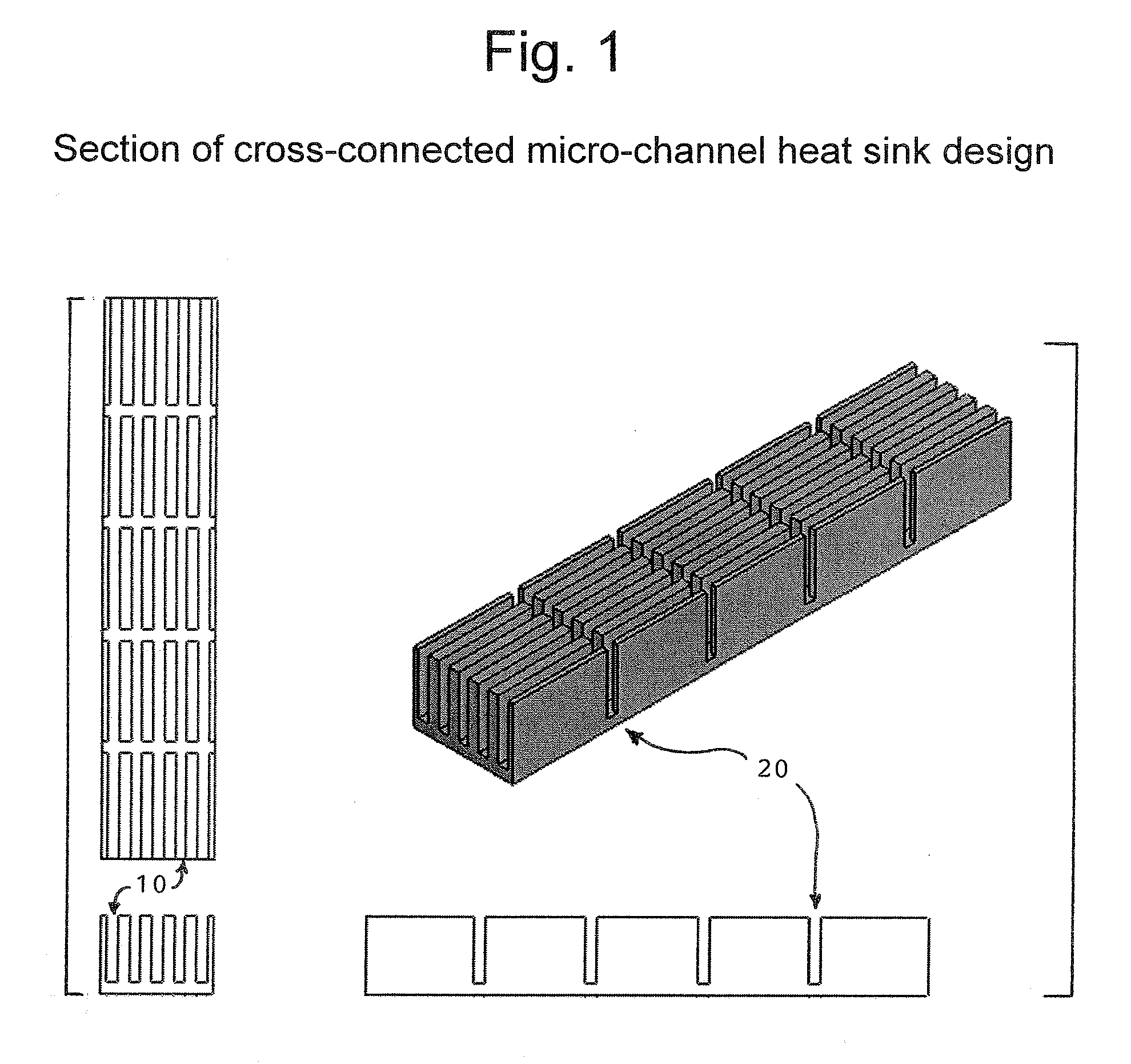

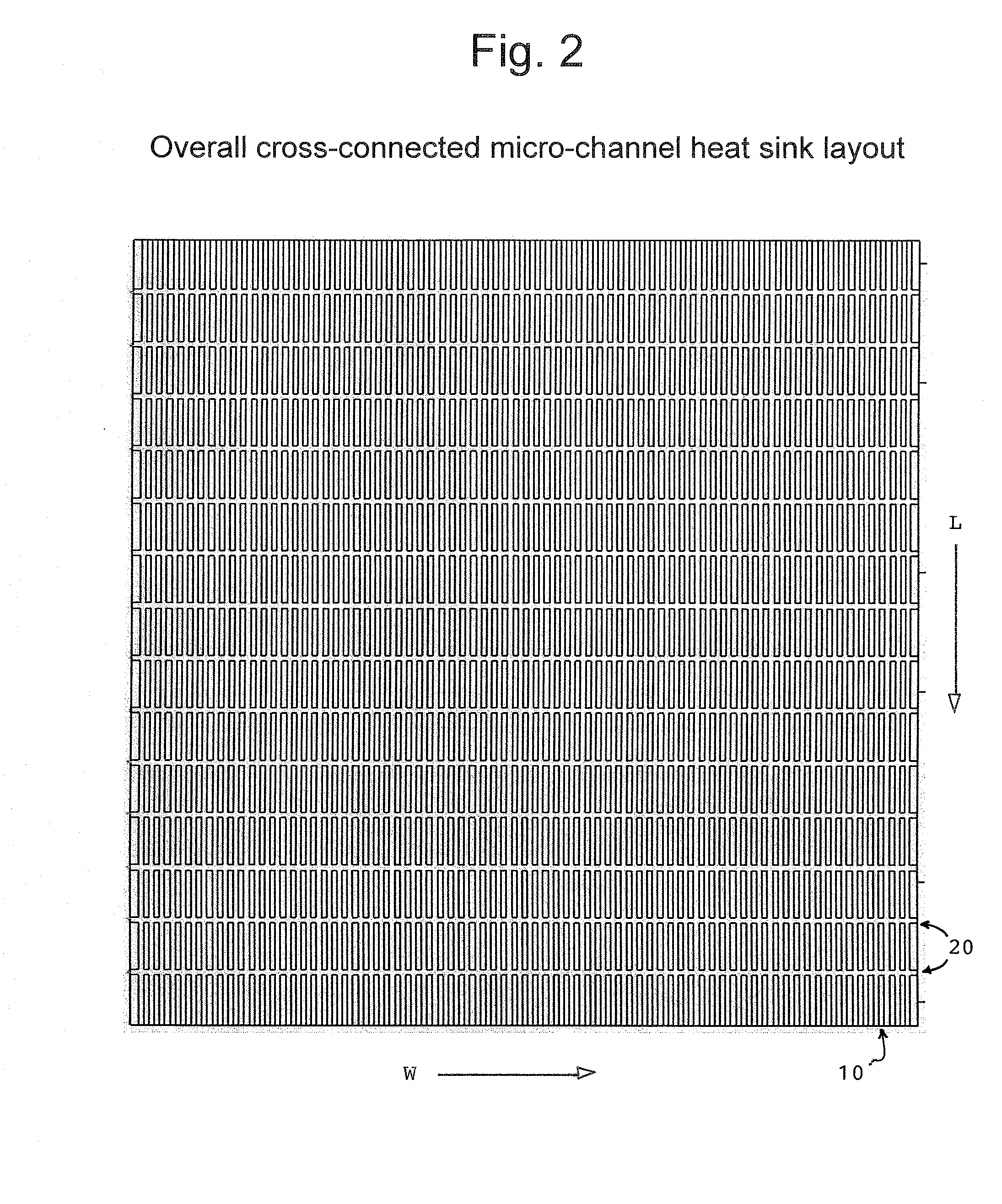

Two-phase cross-connected micro-channel heat sink

InactiveUS20090139701A1Uniform pressure fieldUniform pressureSemiconductor/solid-state device detailsSolid-state devicesCross connectionFlow boiling

An improved two-phase micro-channel heat sink has a plurality of flow micro-channels extending in parallel in a longitudinal direction for accommodating a flow of liquid coolant therein, and a plurality of cross-connected micro-channels extending in parallel in a transverse direction formed at regular intervals along the longitudinal direction for cross-connecting with the flow micro-channels. The cross-connected micro-channels enable a uniform pressure field to be maintained for two-phase flow boiling of liquid coolant in the heat sink. In a preferred embodiment, the heat sink contains flow micro-channels with width of 100 μm, wall thickness of 100 μm, and height of 600 μm, and cross-connected micro-channels of similar width and height cut at 1 mm intervals along the flow direction.

Owner:UNIV OF HAWAII

Sectioned manifolds facilitating pumped immersion-cooling of electronic components

ActiveUS20140124167A1Promote circulationFacilitate vapor flowAir heatersIndirect heat exchangersNuclear engineeringFlow boiling

Cooling apparatuses and methods are provided for facilitating pumped immersion-cooling of electronic components. The cooling apparatus includes a housing forming a compartment about one or more components, a supply manifold, a return manifold, and a coolant loop coupling in fluid communication the supply and return manifolds and the housing. Coolant flowing through the coolant loop flows through the compartment of the housing and at least partially immersion-cools the component(s) by flow boiling. A pump facilitates circulation of coolant within the loop, and a coolant bypass line is coupled between the supply and return manifolds. The return manifold includes a mixed-phase manifold section, and the bypass line provides coolant from the supply manifold directly to the mixed-phase manifold section. Coolant flows from the coolant bypass line into the mixed-phase manifold section in a direction counter to the direction of any coolant vapor flow within that manifold section.

Owner:IBM CORP

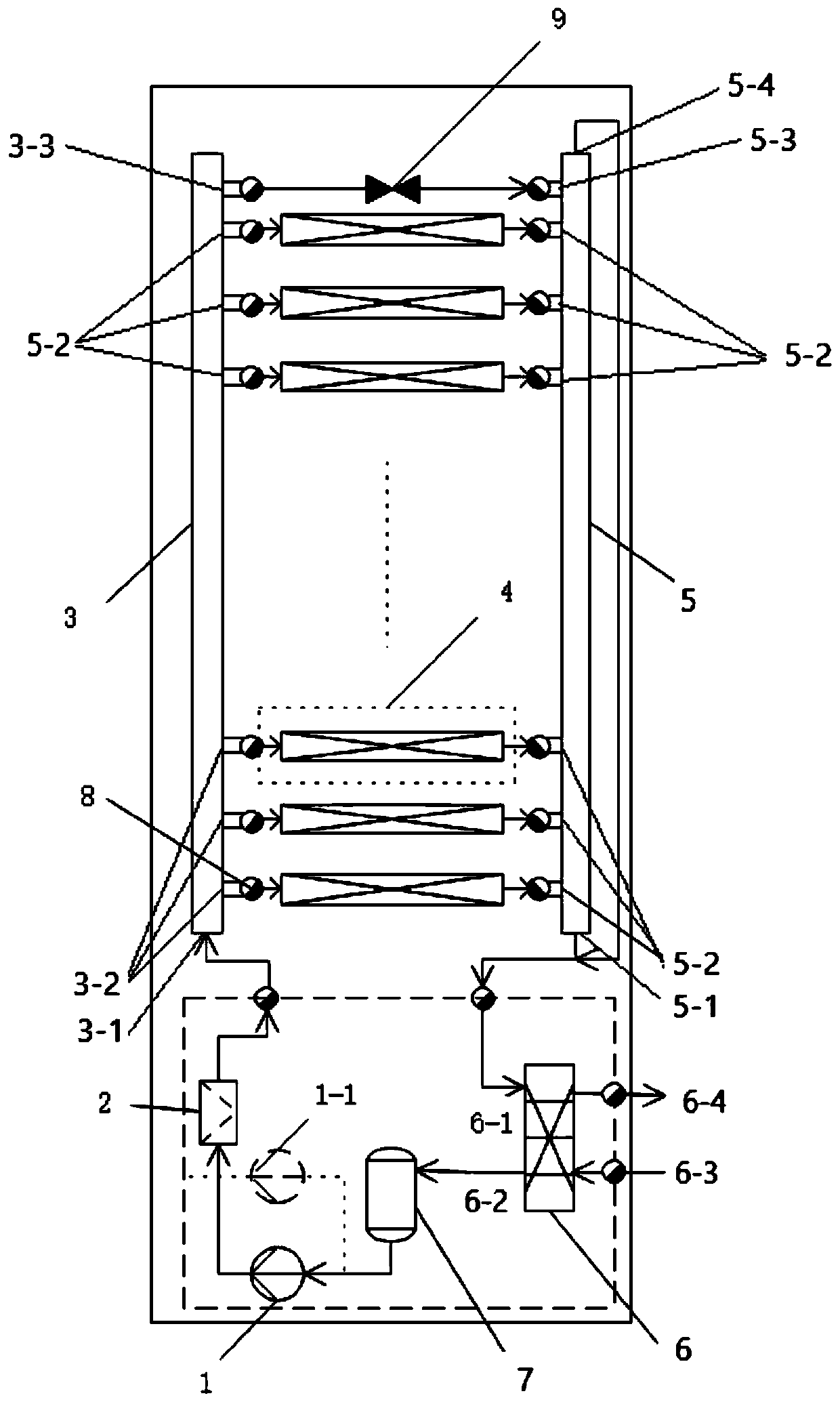

Pump-driven two-phase loop heat dissipation system for high-power-density cabinet

ActiveCN110278691AAvoid hotspotsIncrease profitModifications using liquid coolingEnergy efficient computingLiquid storage tankEngineering

The invention discloses a pump-driven two-phase loop heat dissipation system for a high-power-density cabinet. The system comprises a refrigerant liquid storage tank, a pump, a filter, a flow dividing pipe, a plurality of server heat dissipation units, a collecting pipe and a heat exchanger which are sequentially communicated. The heat exchanger and the refrigerant liquid storage tank are communicated to form a circulation loop, and the flow dividing pipe comprises a liquid inlet port, a plurality of first flow dividing ports and a plurality of second flow dividing ports; the collecting pipe comprises a main outlet, a plurality of first collecting ports, a plurality of second collecting ports and a plurality of auxiliary outlets, wherein the first collecting ports, the second collecting ports and the auxiliary outlets are arranged from bottom to top in a layered mode, the second collecting ports are connected through one-way valves, and local resistance elements are arranged at the front ends of liquid inlets of all the server heat dissipation units. According to the invention, the system can achieve the cooling of main heating elements of the server, effectively solves the problem of local hot spots of the server and a cabinet, remarkably improves the power density of the server in a single cabinet by utilizing the micro-channel flow boiling heat exchange technology, and reduces the noise of a cooling fan of the cabinet.

Owner:BEIHANG UNIV

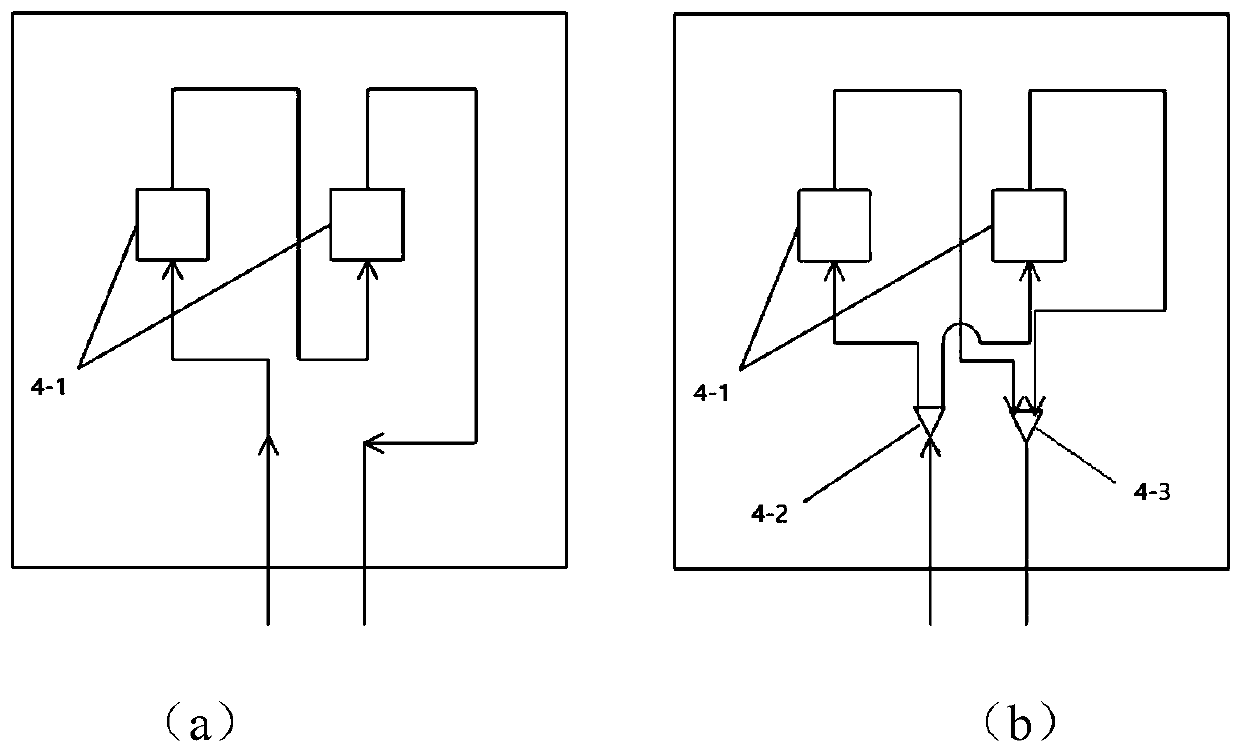

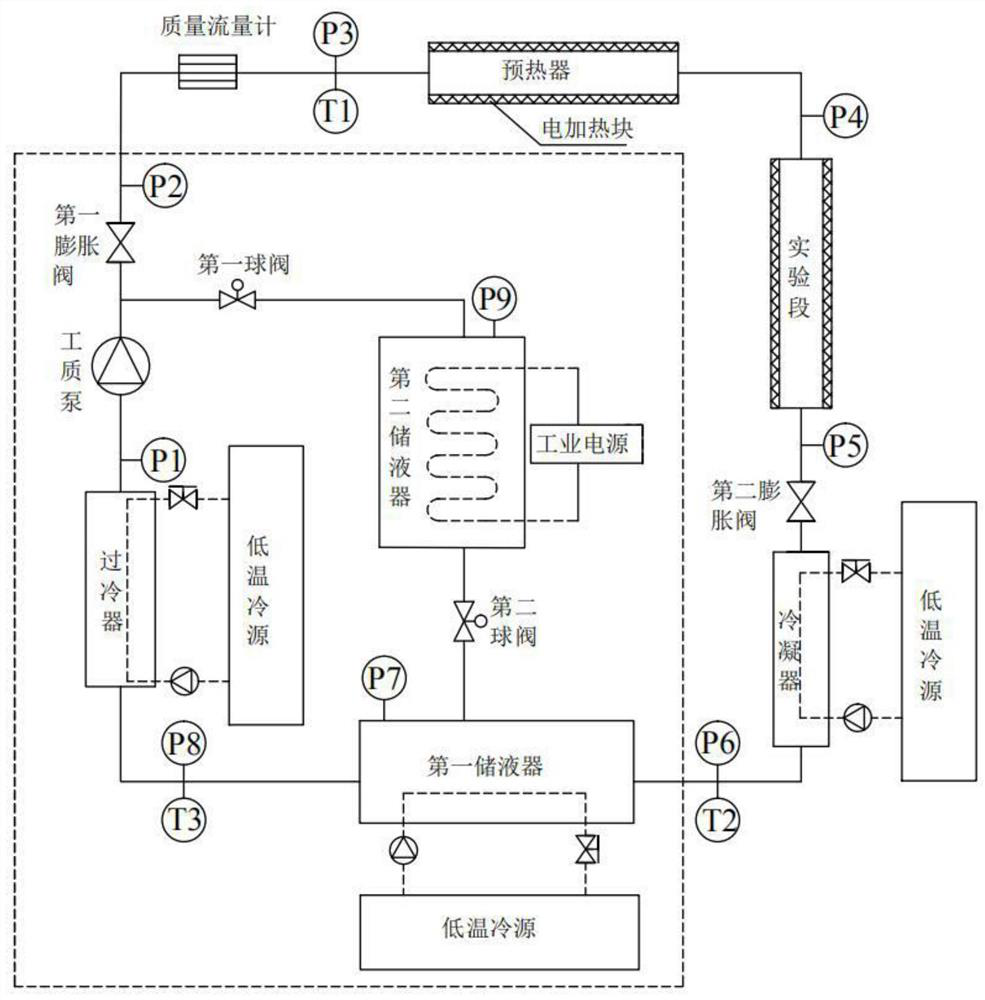

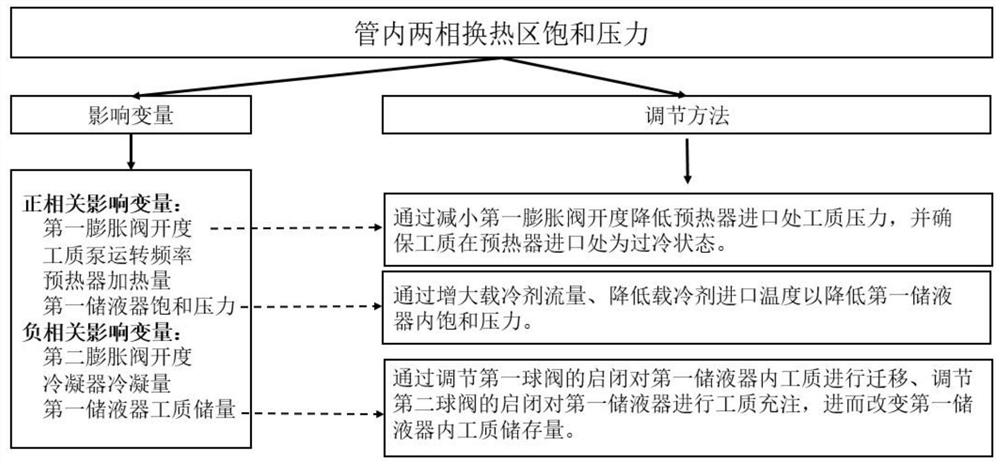

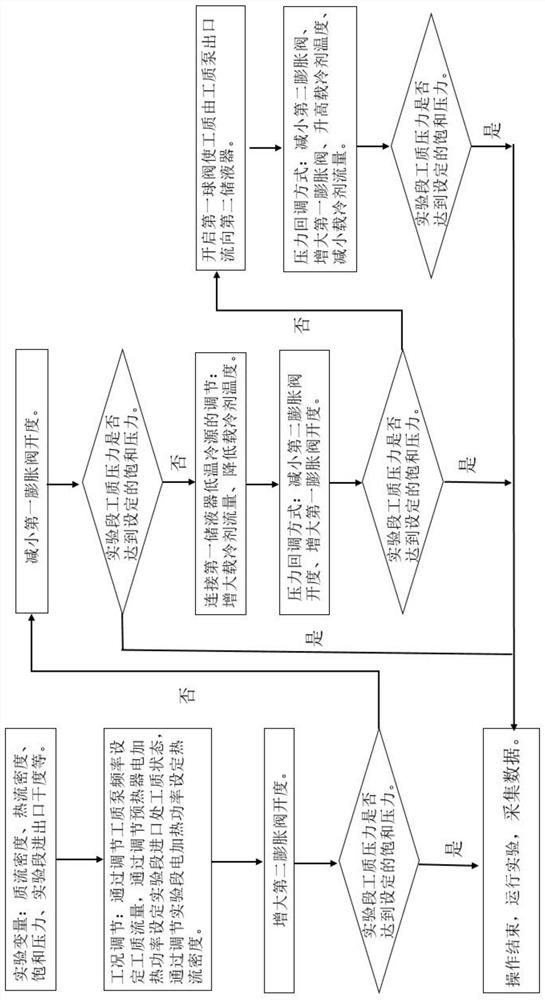

In-pipe two-phase flow boiling heat transfer test system and control method thereof

PendingCN112924487AEasy accessControl working fluid storageMaterial heat developmentFlow boiling heat transferCondenser (heat transfer)

The invention relates to the technical field of heat exchange testing, and concretely relates to an in-pipe two-phase flow boiling heat exchange testing system and a control method thereof. The test system sequentially comprises a working medium pump, a mass flow meter, a preheater, an experiment section, a second expansion valve, a condenser, a first liquid storage device and a subcooler, the first liquid storage device, the subcooler and the condenser are all connected with a low-temperature cold source, and the test system is characterized in that the first expansion valve is further arranged between the working medium pump and the mass flow meter, the test system further comprises a second liquid storage device, one end of the second liquid storage device is communicated with a pipeline between the working medium pump and the first expansion valve through a first ball valve, and the other end of the second liquid storage device is communicated with the first liquid storage device through a second ball valve. According to the scheme, the influence of the working medium flow fluctuation on the experimental parameter measurement precision can be effectively reduced, and the experimental test range can be expanded and the control precision of the working condition environment can be improved on the premise of the existing equipment component capability.

Owner:浙大宁波理工学院

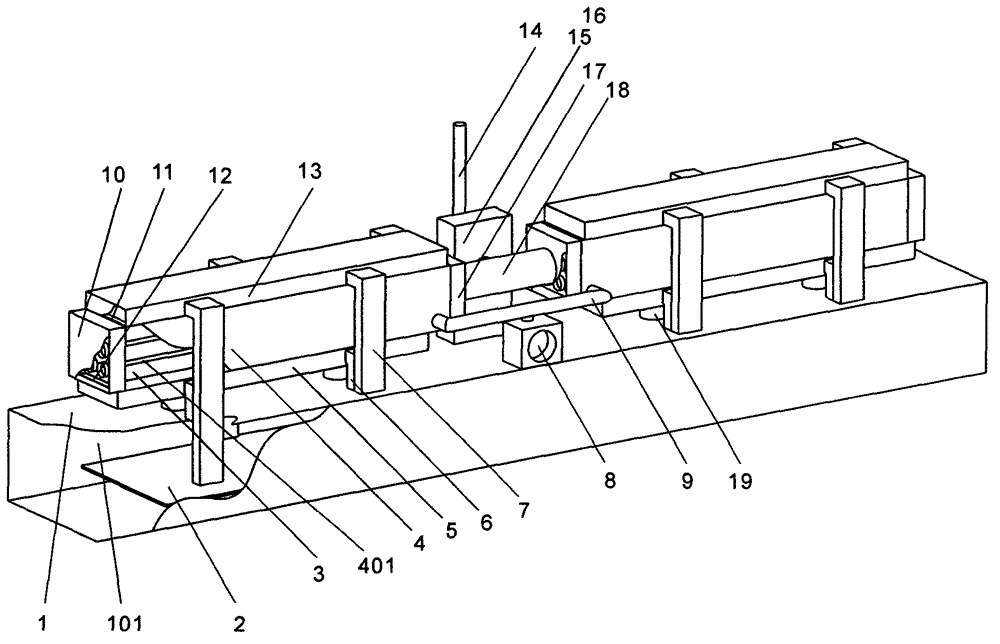

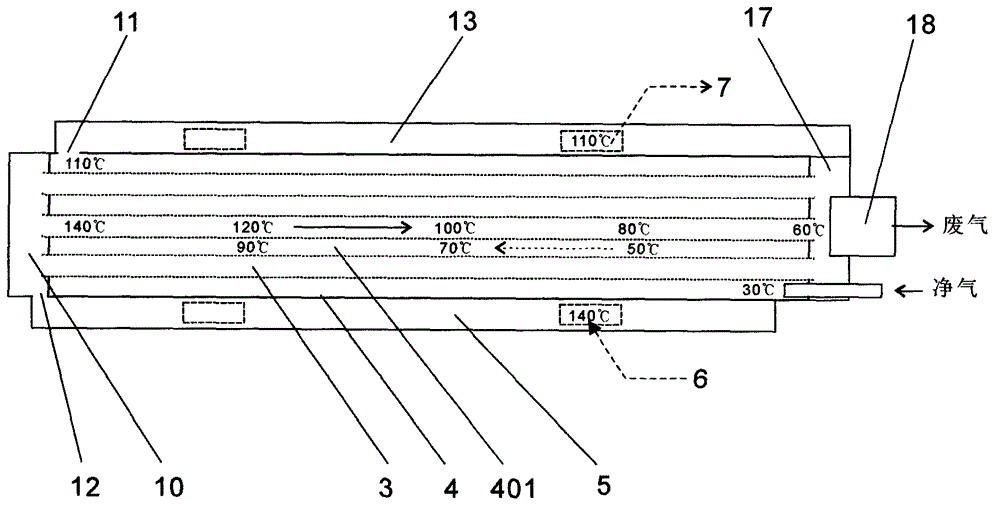

Waste gas heat recovery and purification device for setter

ActiveCN105483965AShorten the lengthSimple structureOther heat production devicesUsing liquid separation agentFresh airFlow boiling

The invention discloses a waste gas heat recovery and purification device for a setter. The device comprises heat exchange cases arranged above the setter and heat exchange tube stacks in the heat exchange cases, wherein waste gas chambers are arranged at the front and rear ends of the heat exchange tube stacks; clean gas collection passages are arranged above the heat exchange cases; the front ends of the clean gas collection passages are communicated with heat exchange chambers in the heat exchange cases; clean gas inlet pipes are arranged on the lateral surfaces of the clean gas collection passages, and penetrate through the top of the setter to be inserted into the upper parts of heaters; waste gas collection passages are arranged below the heat exchange cases; the front ends of the waste gas collection passages are communicated with the front-end waste gas chambers; the lateral surfaces of the waste gas collection passages are communicated with openings in the top of the setter through waste gas collection pipes; the hot waste gas of the rear-end waste gas chambers is exhausted into gas flow boiling dust removal purification cases for treatment through waste gas exhaust motors, and then is discharged into the air; blower motors are arranged at the tail ends of the heat exchange cases to introduce fresh air. The device is simple in structure, large in heat exchange area, high in heat exchange efficiency, difficult to block and low in failure rate, the tubes have large diameters, fewer bends and small lengths, hot gas can be internally circulated, and waste gas emission is avoided by such an ideal structure, so that remarkable energy saving and emission reduction effects, low cost and high benefits are achieved.

Owner:广东联和环保科技有限公司

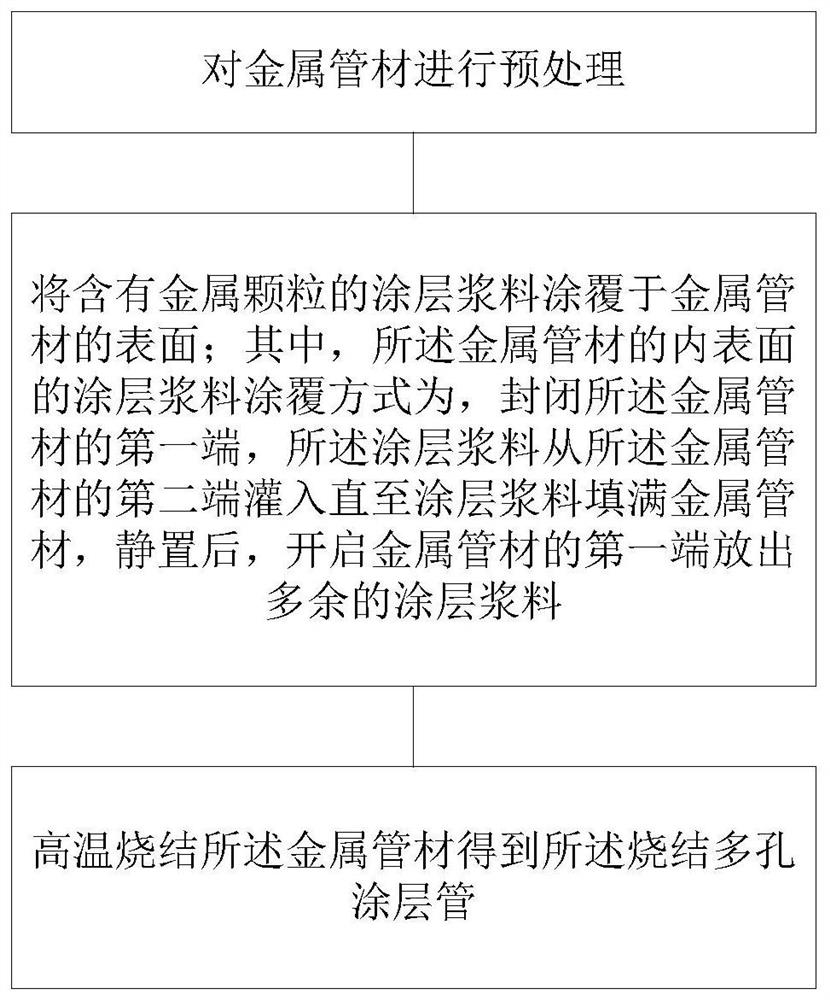

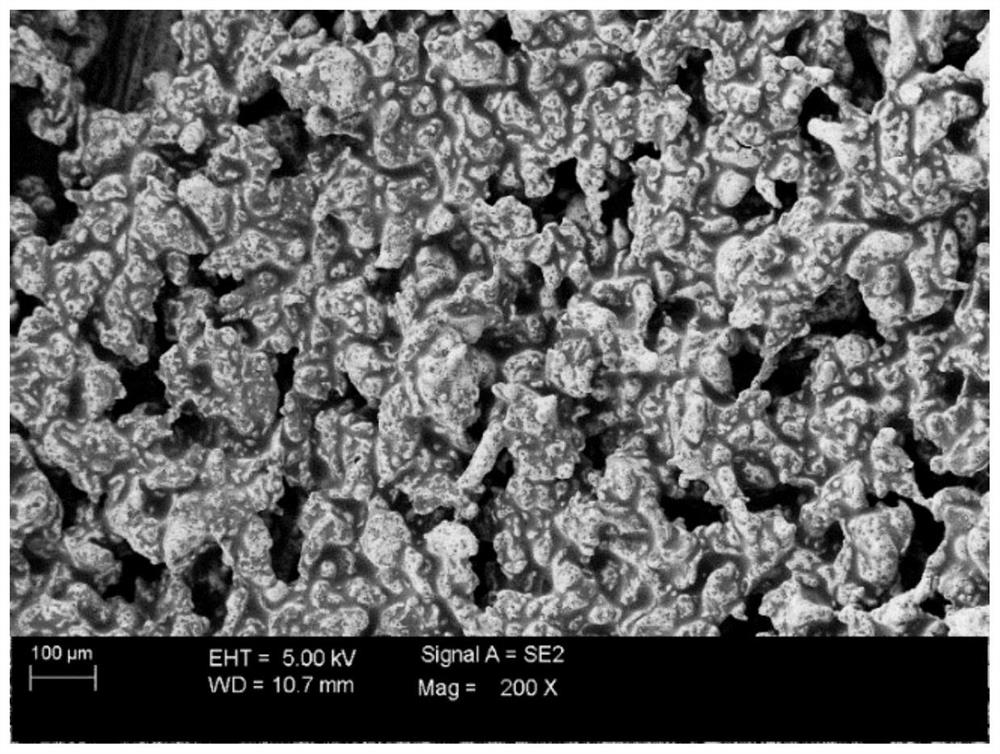

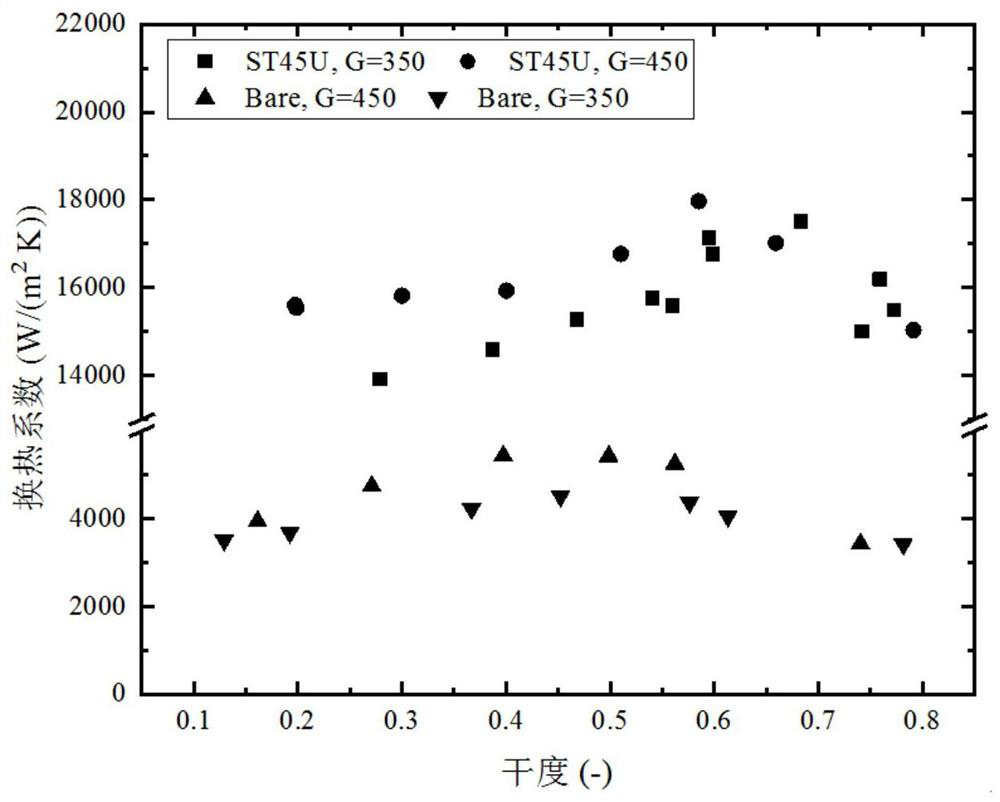

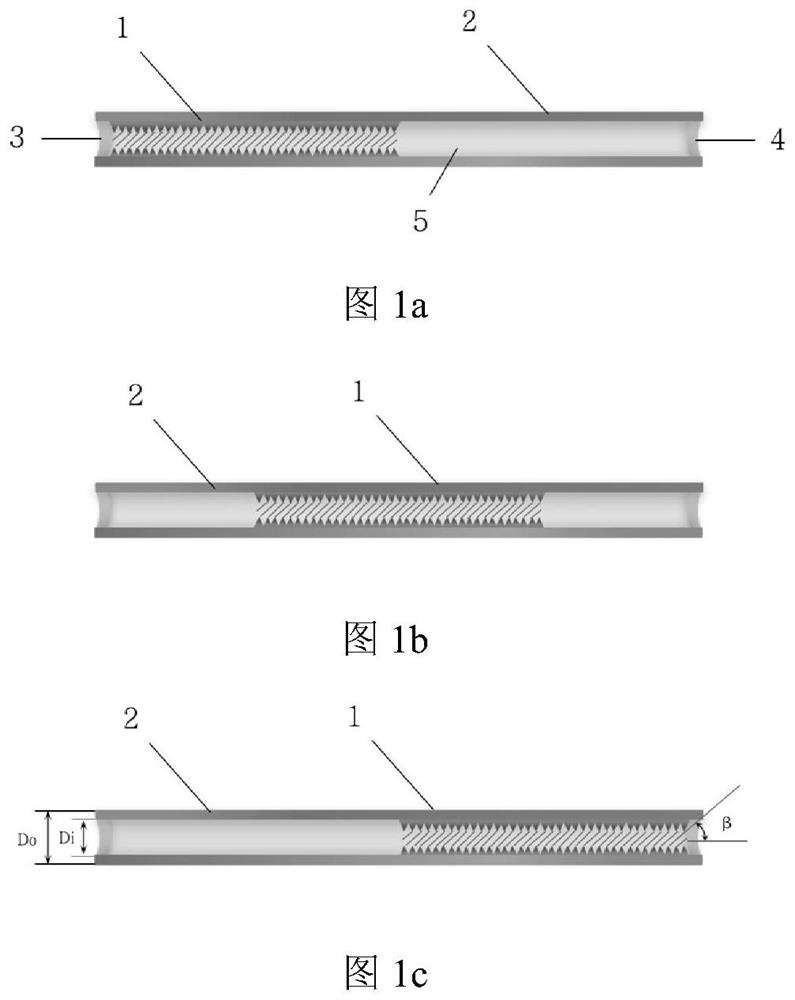

Sintered porous coating pipe for strengthening flow boiling and preparation method of sintered porous coating pipe

ActiveCN113621962AEase of mass productionEven distribution of metal particlesMetallic material coating processesHeat transfer modificationFlow boiling heat transferMicro nano

The invention discloses a preparation method of a sintered porous coating pipe for strengthening flow boiling. The preparation method comprises the following steps: coating the surface of a metal pipe with coating slurry containing metal particles, and sintering the metal pipe at high temperature to obtain the sintered porous coating pipe, wherein the coating mode of the coating slurry on the inner surface of the metal pipe is that the first end of the metal pipe is closed, the coating slurry is injected from the second end of the metal pipe until the metal pipe is filled with the coating slurry, and after standing, the first end of the metal pipe is opened to discharge redundant coating slurry. The preparation method is lower in cost, large-scale production of the sintered porous coating pipe is facilitated, the prepared sintered porous coating pipe is provided with the micro-nano porous metal coating which is uniform in metal particle distribution and firm and does not fall off, the flow boiling heat transfer coefficient in the pipe can be increased by multiple times, and the method has wide application prospects in the fields of nuclear energy, aerospace, high-power device heat dissipation and the like.

Owner:中国空气动力研究与发展中心设备设计与测试技术研究所

Pump-enhanced, immersion-cooling of electronic component(s)

Cooling apparatuses and methods of fabricating thereof are provided which facilitate pumped immersion-cooling of an electronic component(s). The cooling apparatus includes an enclosure having a compartment accommodating the electronic component(s), and dielectric fluid within the compartment at least partially immersing the electronic component(s). A liquid-cooled heat sink is associated with the enclosure to cool at least one cooling surface associated with the compartment, and facilitate heat transfer to the heat sink from the electronic component(s) via the dielectric fluid. A pump is disposed external to the compartment and in fluid communication therewith to facilitate pumped dielectric fluid flow through the compartment. The pumped dielectric fluid flow through the compartment enhances heat transfer from the electronic component(s) to the liquid-cooled heat sink via the cooling surface(s). In one implementation, the pumped dielectric fluid flow provides two-phase cooling to the electronic component(s) via flow boiling.

Owner:INT BUSINESS MASCH CORP

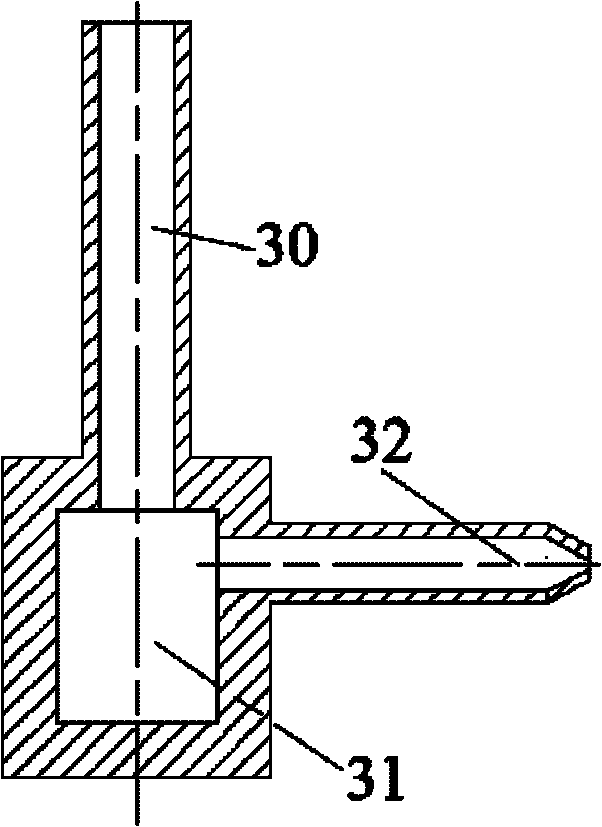

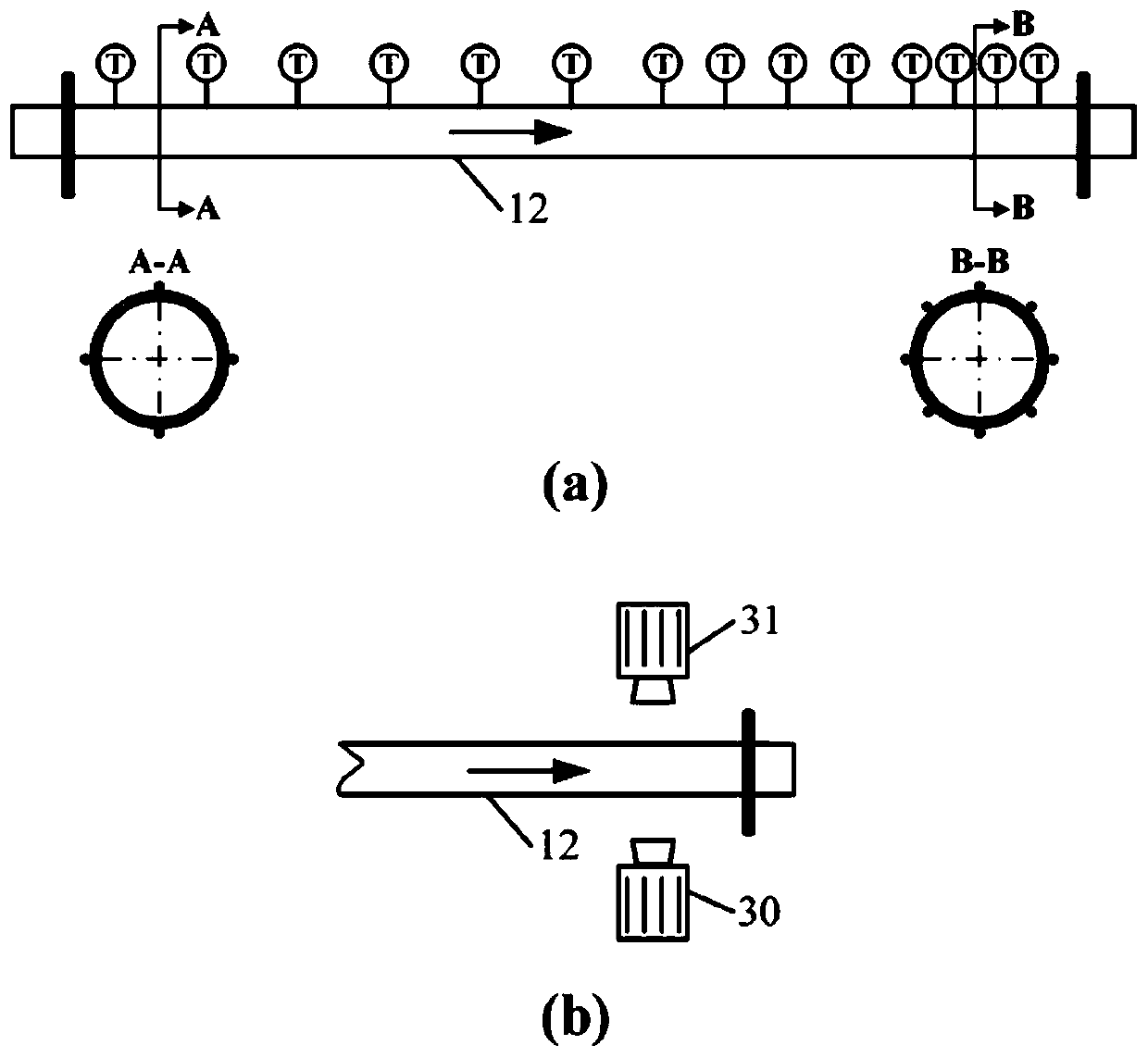

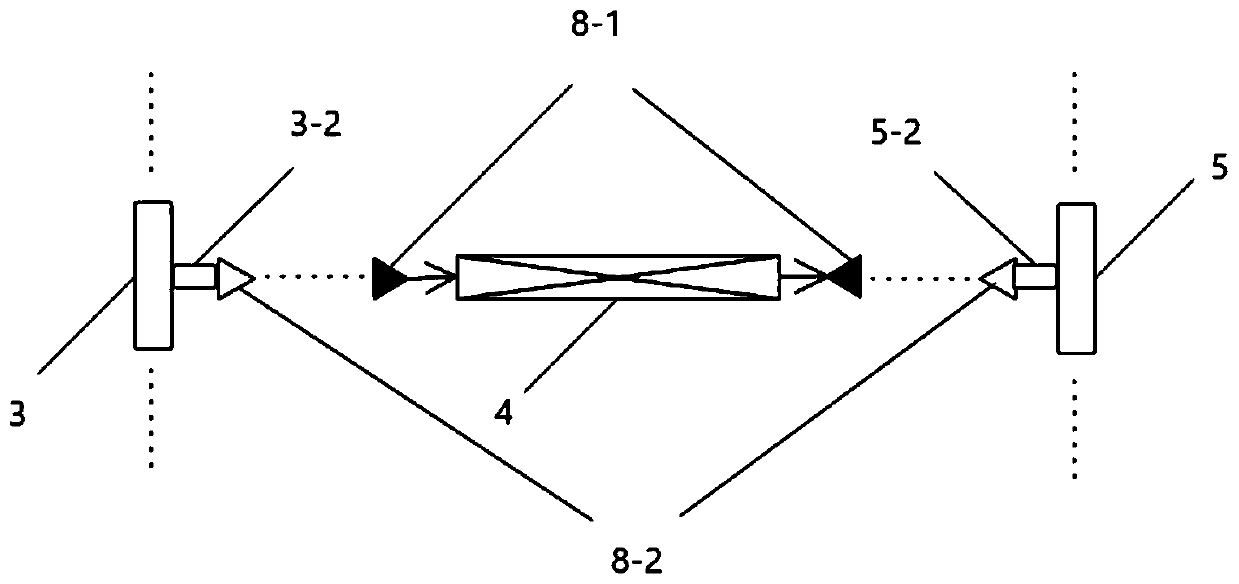

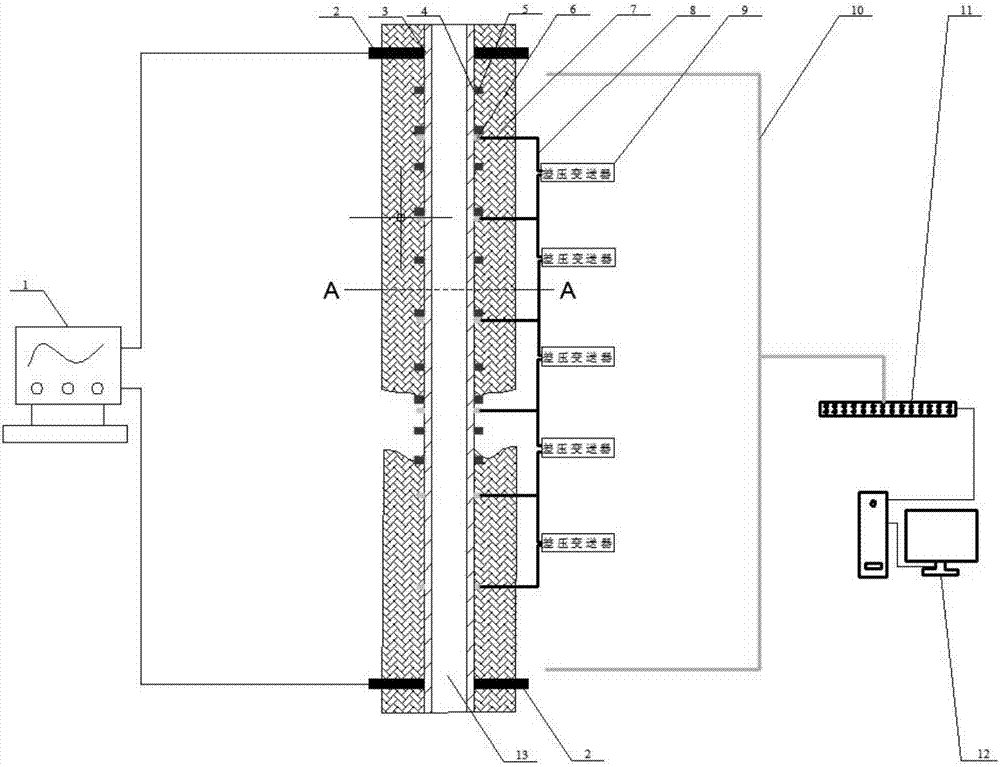

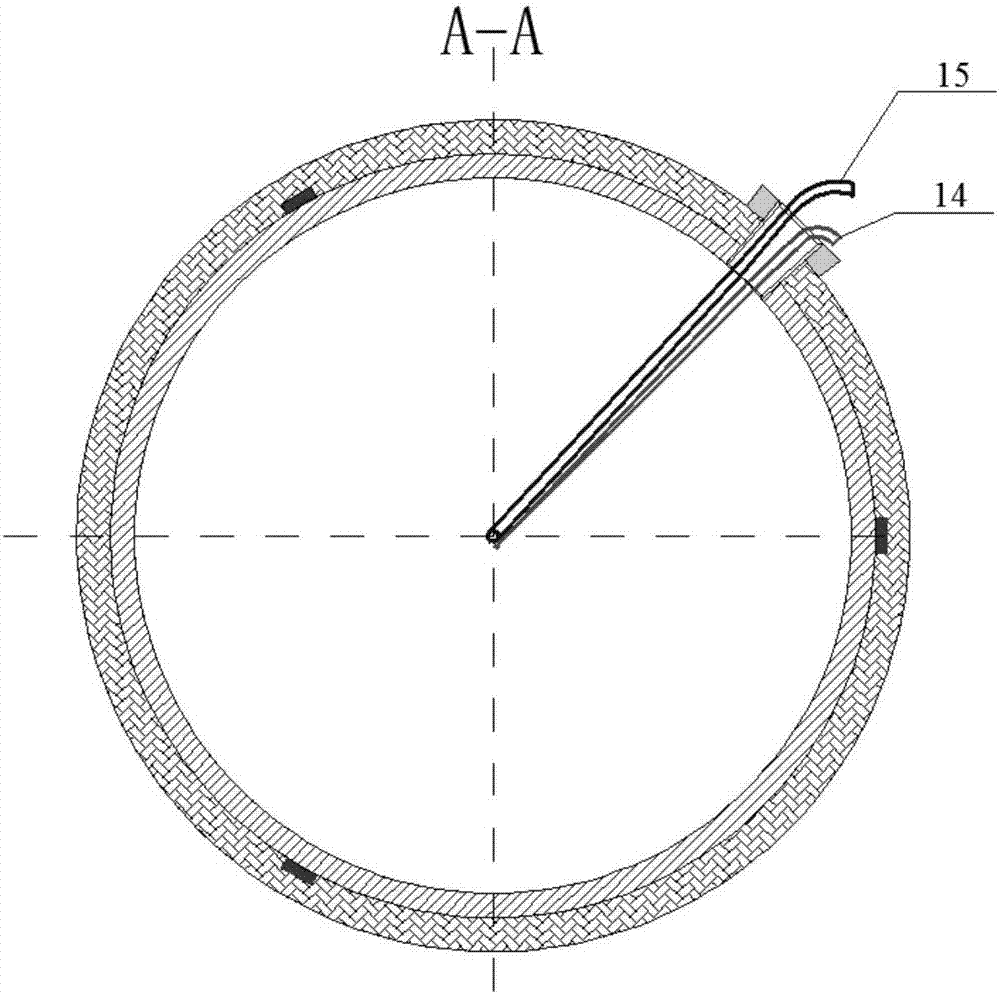

Experimental device for evaporating and post-evaporating thermotechnical hydraulic characteristics during in-tube flow boiling and evaporation judging method

ActiveCN107014860AConvenient researchFlow heat transfer effectMaterial heat developmentVertical tubeEvaporation

The invention provides an experimental device for evaporating and post-evaporating thermotechnical hydraulic characteristics during in-tube flow boiling and an evaporation judging method. The device comprises a vertical tube experimental section, an electric heater and a control system thereof, a heating electrode and a data acquisition system. The device is characterized in that electrodes are separately mounted on the upper and lower ends of the vertical tube experimental section, the electrodes are connected to the electric heater, a heat resistor is mounted on the outer wall of the vertical tube experimental section, a pressure sensor and an optical fiber probe are mounted in the vertical tube experimental section, measuring holes are formed in the vertical tube experimental section in a spaced manner, a pressure difference transmitter is mounted between two adjacent measuring holes, and the heat resistor, the pressure sensor, the optical fiber probe and the pressure different transmitters are connected to the data acquisition system. By pre-judging an evaporating position to perform an experiment to obtain related data, experiment researches on evaporating and post-evaporating thermotechnical hydraulic characteristics in an in-tube flow boiling process are realized.

Owner:HARBIN ENG UNIV

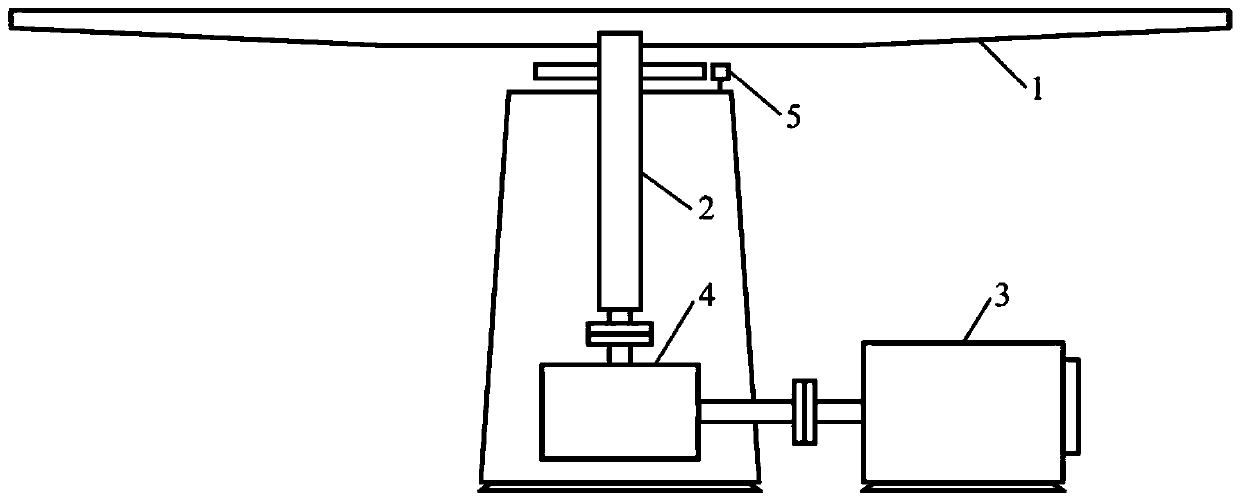

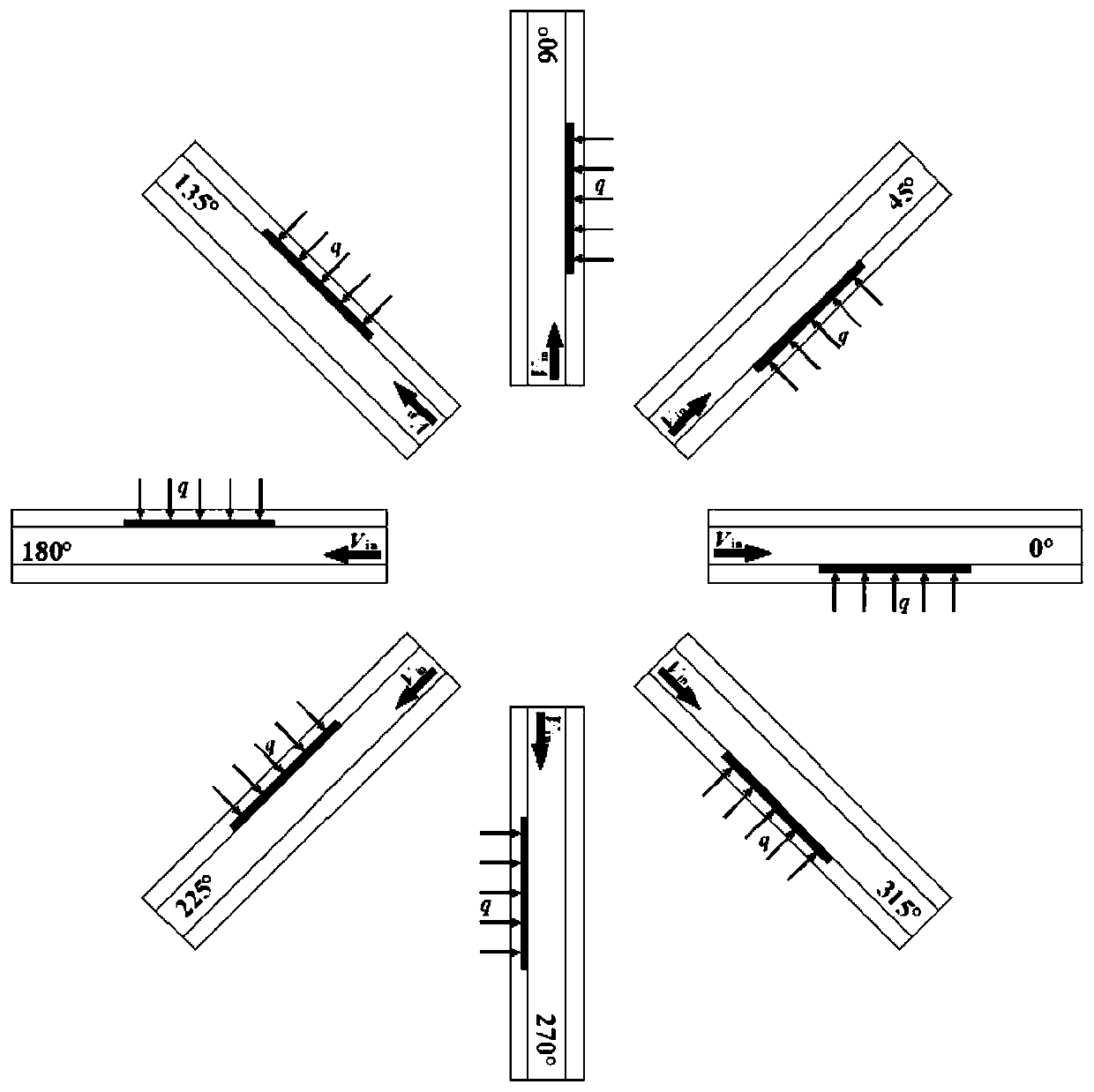

Ground simulative experiment device and method for micro-gravity flow boiling critical heat flux density

ActiveCN110320230AImprove economyEasy to replaceInvestigating phase/state changeTemperature controlFlow boiling heat transfer

The invention discloses a ground simulative experiment device and method for micro-gravity flow boiling critical heat flux density, and the device comprises a test tube, a flow regulating valve, a flow meter, a pump, a condenser, a pre-heater, a buffer tank, a speed regulator, a voltage stabilizer, a temperature controller, a heating surface, a power supply and a temperature collector. The simulative experiment method is that the critical heat flux density of the flow boiling heat transfer under microgravity conditions can be replaced by the critical heat flux density range measured under normal gravity conditions and corresponding to the experimental conditions that theta is equal to 315 degrees and theta is equal to 135 degrees. The ground simulative experiment device and method for micro-gravity flow boiling critical heat flux density provided by the invention, compared with the direct micro-gravity experiment and traditional ground simulation method, are rather simple in device structure, very convenient to operate and good in economy, can satisfy experimental test of different experiment conditions, can accurately, conveniently and economically simulate the critical heat fluxdensity under microgravity conditions on the ground, and significantly expand the application range compared with the conventional simulation method.

Owner:XI AN JIAOTONG UNIV

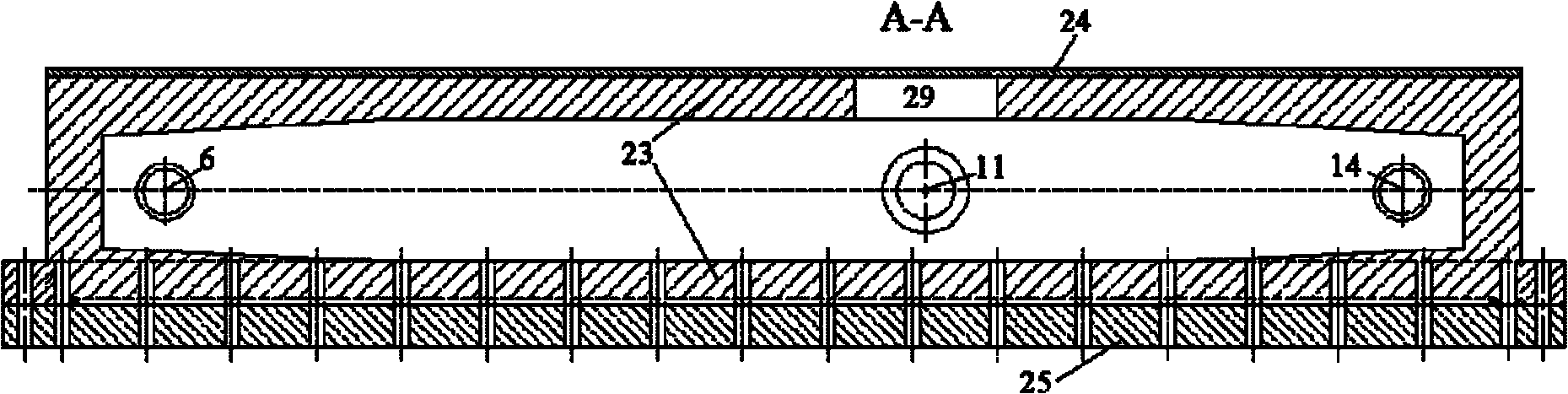

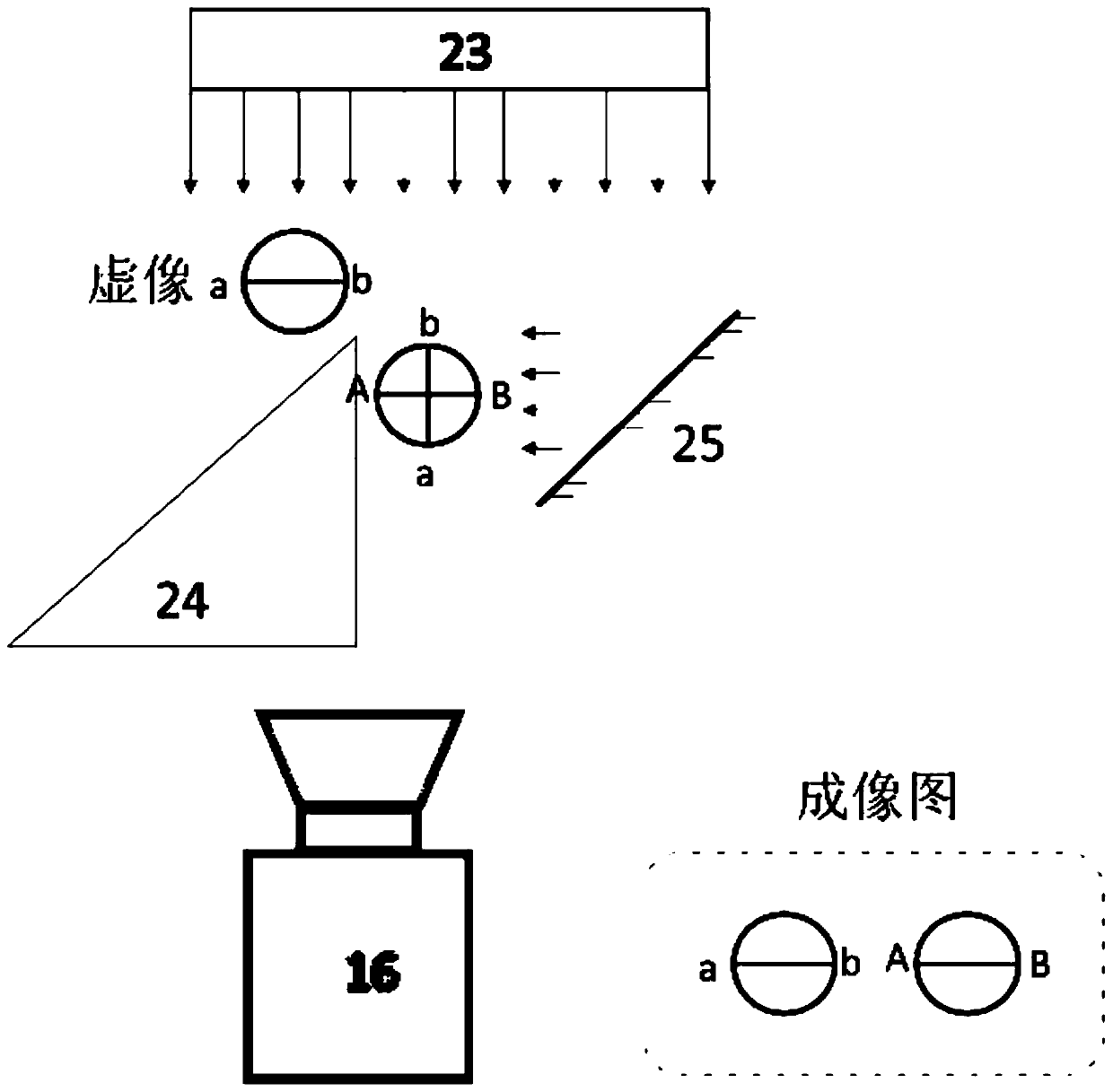

Test device and method for observing behavior of flowing boiling bubbles in micro-channel

InactiveCN111289518AConvenient researchEasy to operateHydrodynamic testingInvestigating moving fluids/granular solidsFlow boiling heat transferLiquid storage tank

The invention discloses a test device and method for observing the behavior of flowing boiling bubbles in a micro-channel, which belongs to the field of physical measurement. The device comprises a camera, a mass flow meter and a liquid preparation device, wherein the camera is arranged outside a drying box and can observe the interior of the drying box, and a light source is also arranged in thedrying box; the micro-channel is arranged in the drying box; the liquid preparation device is communicated with the micro-channel, the mass flow meter is connected to the liquid preparation device, and the mass flow meter is connected to the server; the liquid preparation device comprises a mixing tank and a plurality of liquid storage tanks, the plurality of liquid storage tanks are communicatedwith the mixing tank, and the mixing tank is communicated with one end of the channel; and the other end of the micro-channel is also communicated with an emptying mechanism. The device can solve theproblem that a test device for researching flowing boiling heat exchange and bubble dynamic characteristics of a non-azeotropic mixed working medium in a micro-channel does not exist at present.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Hydrocarbon hydrogenation method with up-flow bed layer and fixed bed operated in series

The invention discloses a hydrocarbon hydrogenation method with an up-flow bed layer and a fixed bed operated in series. The method is particularly suitable for the deep hydro-conversion process of medium and low-temperature coal tar containing a moderate quantity of hydrogenolytic metal compounds. A reaction product in an up-flow pre-hydrogenation reaction area R11 contains particles, and particles of predetermined granularity are intercepted in series by a particle intercepting bed arranged in a pre-hydrogenation reaction area R12 of a fixed bed, so that the quantity of particles filling a catalyst bed layer of the fixed bed in a deep hydro-upgrading process R2 for processing an R12 reaction product is reduced. The up-flow pre-hydrogenation reaction area R11 can be an up-flow micro-expansion bed, an up-flow suspension bed, an up-flow boiling bed, an up-flow fixed bed, an up-flow bubbling bed and the like. The porosity or gap equivalent diameter of the catalyst bed layer of the fixed bed in the pre-hydrogenation reaction area R12 is smaller than the porosity or gap equivalent diameter of the catalyst bed layer of the fixed bed in the deep hydro-upgrading process R2.

Owner:何巨堂

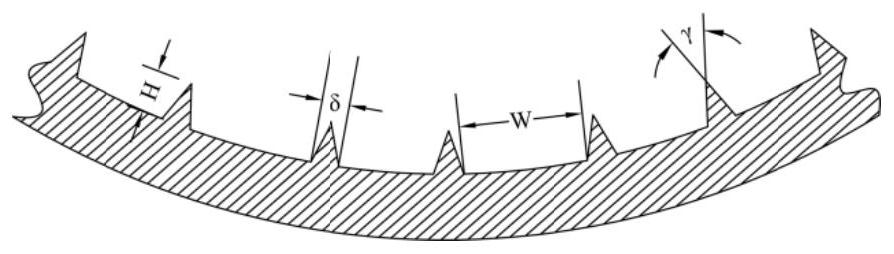

Segmented combined type inner finned tube device for strengthening flow boiling heat exchange

PendingCN114166061AImprove utilization efficiencyImprove heat transfer effectHeat transfer modificationTubular elementsFlow boiling heat transferThermodynamics

The invention discloses a segmented combined type inner finned tube device for strengthening flow boiling heat exchange, which is characterized in that a finned tube is at least divided into two sections, one section is arranged as a threaded micro-fin pipeline, the other section is arranged as a smooth pipeline, the finned tube is internally provided with a gas-liquid two-phase circulation channel, and the gas-liquid two-phase circulation channel is arranged in the finned tube. One end of the finned tube is a fluid inlet of the finned tube, and the other end of the finned tube is a fluid outlet. According to the segmented combined pipeline formed by combining the threaded pipe and the smooth pipe, the heat exchange performance is optimized by adjusting the arrangement of threads according to the flow pattern characteristics; meanwhile, the situation that the requirements for the heat exchange capacity are different exists in the actual life, all-smooth pipes or all-threaded pipes do not have flexible adjustability for the heat exchange effect, and a mode for controlling the heat exchange capacity is provided for people through the segmented combined type pipeline.

Owner:DONGHUA UNIV

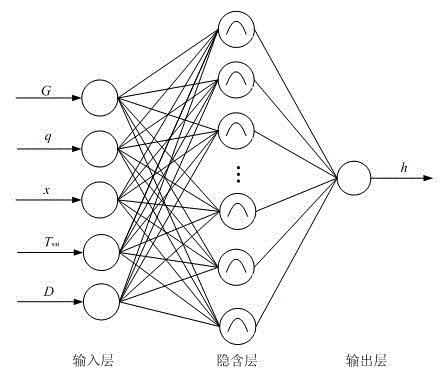

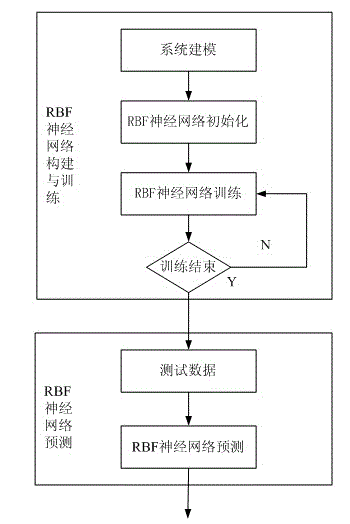

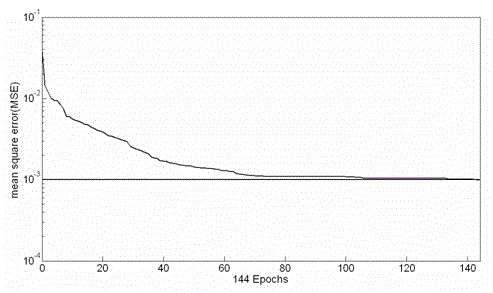

Radial basis function (RBF) neural network-based boiling heat exchanging prediction method

ActiveCN102419827BGood correlationAccurate flow boiling heat transferNeural learning methodsNerve networkPredictive methods

The invention provides a radial basis function (RBF) neural network-based boiling heat exchanging prediction method, in particular a radial basis neural network-based boiling heat exchanging prediction method of mixed medium flowing inside a horizontal plain tube, and the method comprises the following steps that: collecting data, determining input and output vectors of a network, preprocessing data, training and testing an RBF neural network, utilizing the neural network after being trained for prediction to obtain the predicted flowing boiling heat exchanging coefficient, and realizing the prediction of boiling heat exchange of the mixed medium flowing inside the horizontal plain tube. Due to the adoption of the method, the complicated internal mechanism for analyzing a mixed medium flowing boiling heat exchanging process can be avoided, the experimental times can be reduced, the flowing boiling heat exchanging of the mixed medium can be correctly and rapidly predicted through the simulation test of a computer, the precision is remarkably improved compared to a traditional correlation way, and a good instruction significance on predicting the performance and optimizing the structure of a tube-type heat exchanger in a mixed medium refrigerating system can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com