Micro-needle rib cluster array micro-channel micro heat exchanger

A technology of microchannel and heat exchanger, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of high boiling starting point, low critical heat flux density, boiling instability, etc., to reduce Boiling starting point, increasing critical heat flux, eliminating the effect of fluid boiling instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

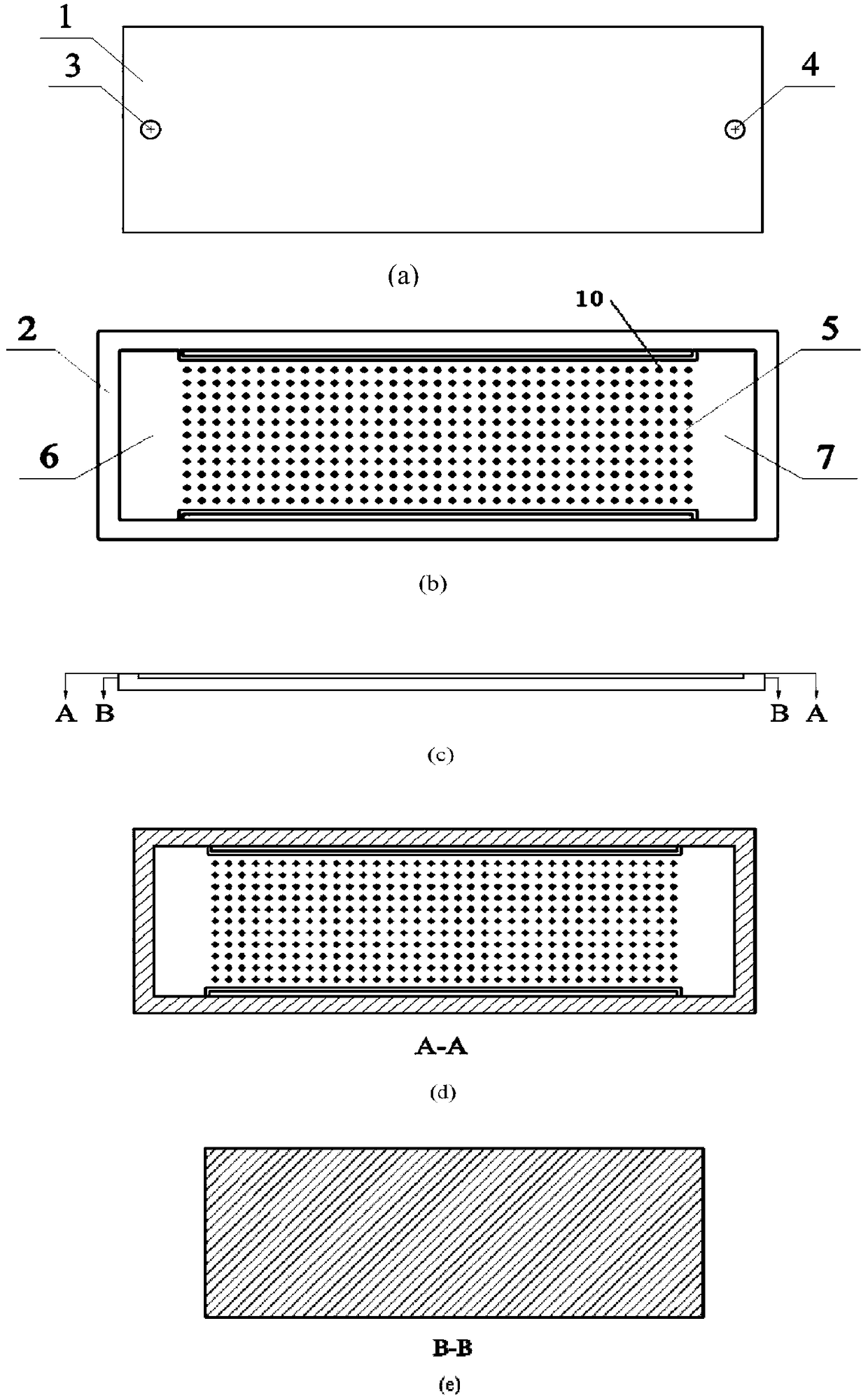

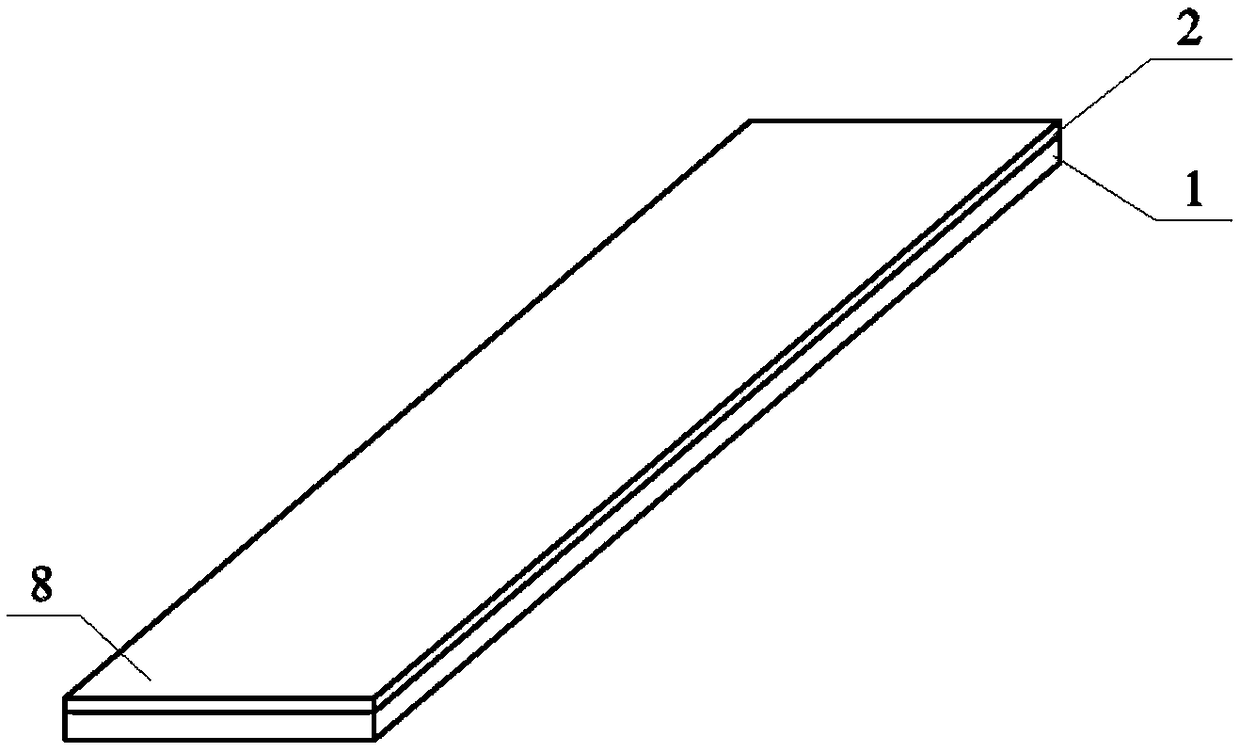

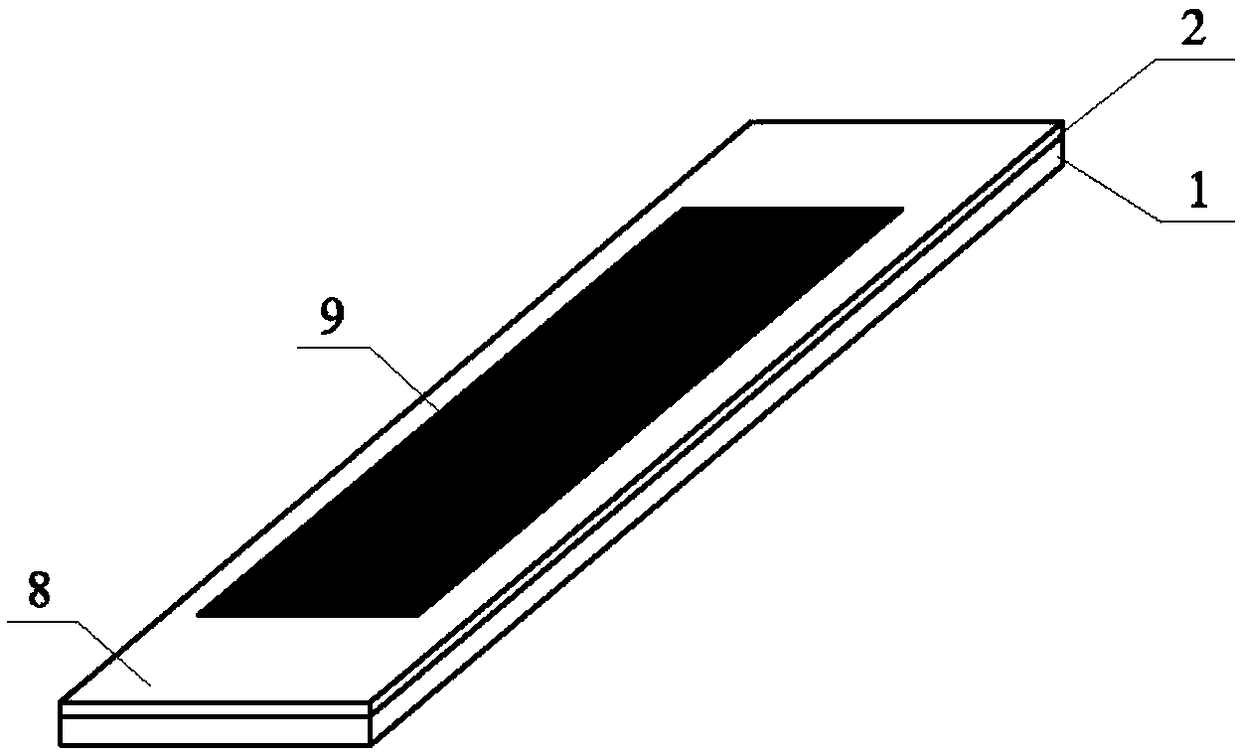

[0039] The micro-needle-fin cluster array micro-channel micro-heat exchanger consists of an encapsulation sheet 1 and a micro-channel substrate 2 . The packaging sheet is made of 7740 heat-resistant glass, the substrate is made of silicon, and the working fluid is made of acetone. Because the cost of high-power chips is very expensive, this embodiment uses simulated heat sources instead of chips for performance testing experiments. The simulated heat source adopts Pt platinum metal serpentine heating film. After design optimization, the heating film can generate heat evenly, simulating the heat generation of high-power chips. The input voltage of the platinum heating film can be determined according to the heat generated by the chip.

[0040] Such as image 3 As shown, a uniform serpentine Pt platinum metal film with a thickness of 100 nanometers is plated on the back of the silicon substrate through the coating technology, and the heat generated after power-on simulates th...

Embodiment 2

[0042] The micro-needle-fin cluster array micro-channel micro-heat exchanger consists of an encapsulation sheet 1 and a micro-channel substrate 2 . The packaging sheet is made of 7740 heat-resistant glass, the substrate is made of silicon, and the working fluid is made of acetone. Because the cost of high-power chips is very expensive, this embodiment uses simulated heat sources instead of chips for performance testing experiments. The simulated heat source adopts Pt platinum metal serpentine heating film. After design optimization, the heating film can generate heat evenly, simulating the heat generation of high-power chips. The input voltage of the platinum heating film can be determined according to the heat generated by the chip.

[0043] Such as image 3 As shown, a uniform serpentine Pt platinum metal film with a thickness of 100 nanometers is plated on the back of the silicon substrate through the coating technology, and the heat generated after power-on simulates th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com