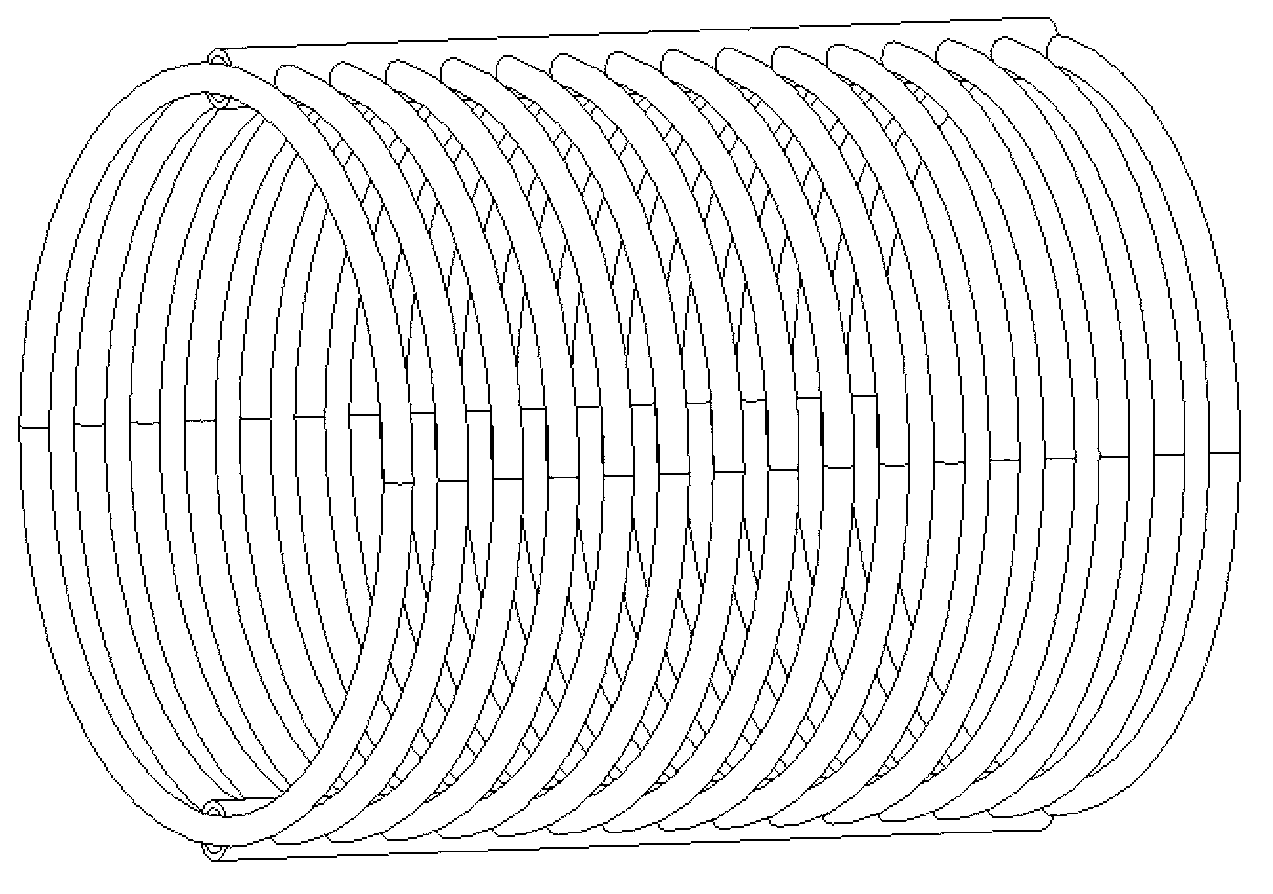

Patents

Literature

93results about How to "Improve temperature distribution uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

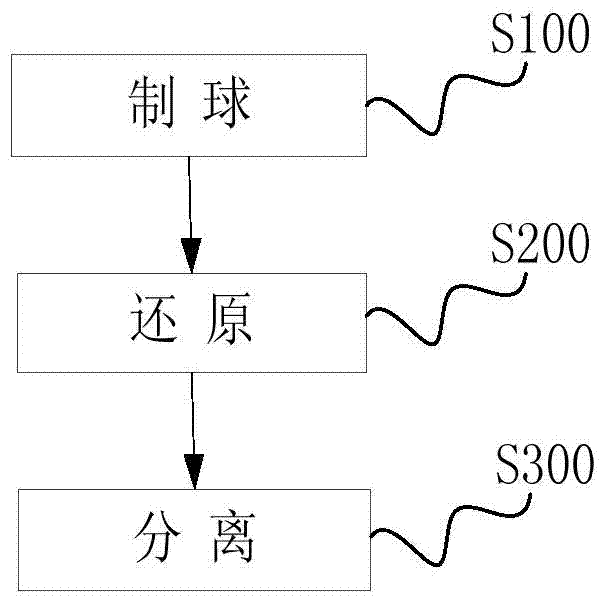

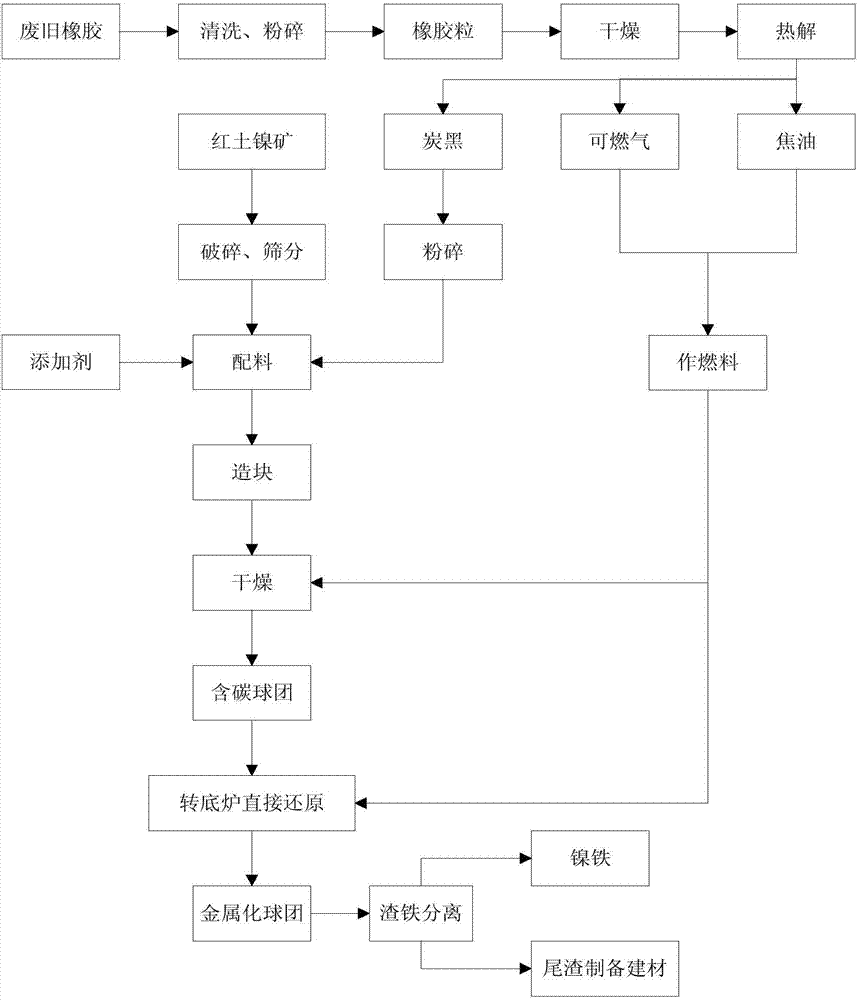

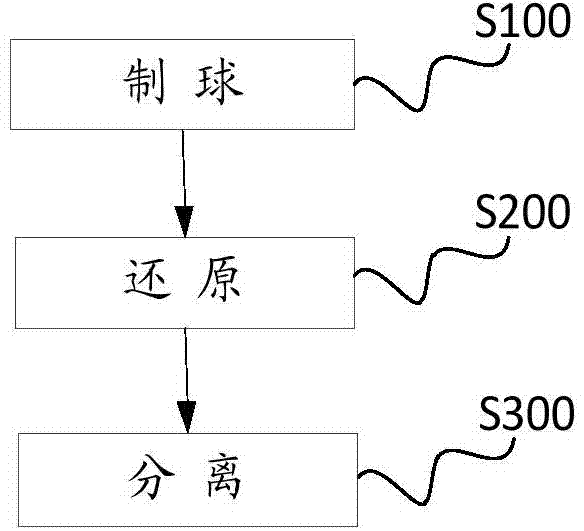

Treatment method of laterite-nickel ore

ActiveCN103667742AEffectively madeImproving the Efficiency of Reduction Roasting Laterite Nickel OreHearth type furnacesSlagHearth

The invention discloses a smelting method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, carbon black and additives; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; and carrying out slag-iron separation on the metalized pellets to obtain nickel iron and tailings. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

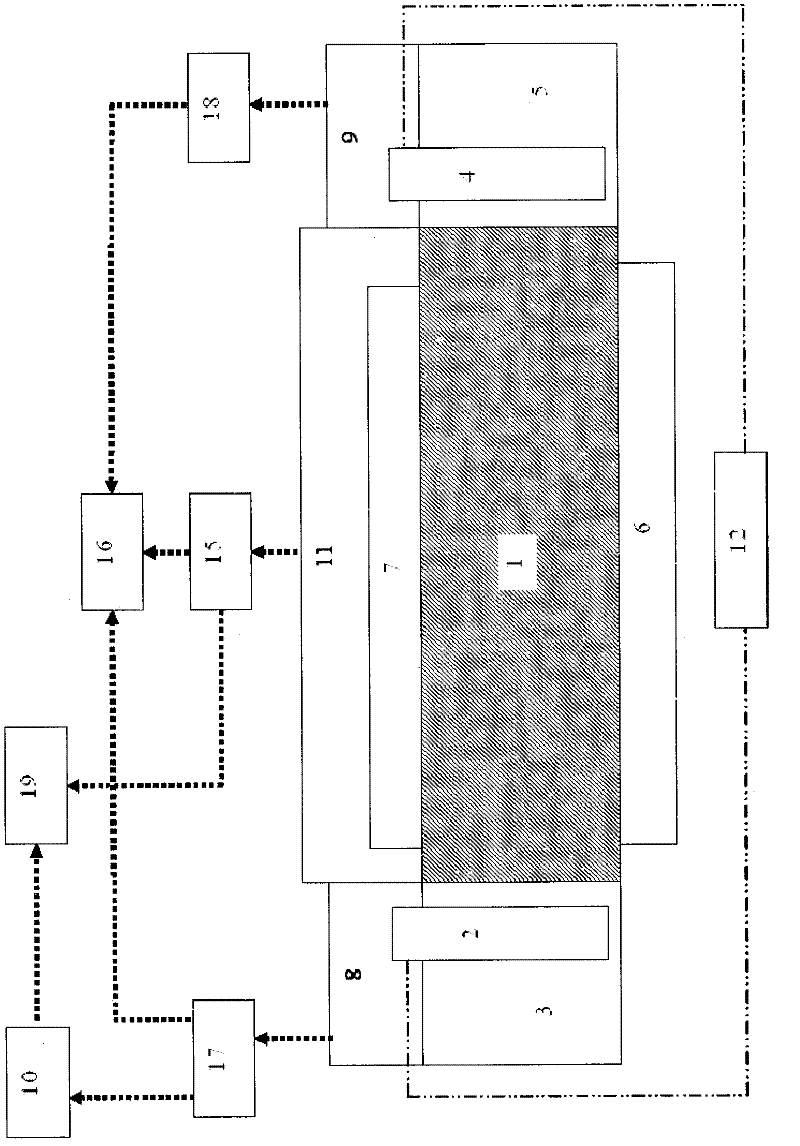

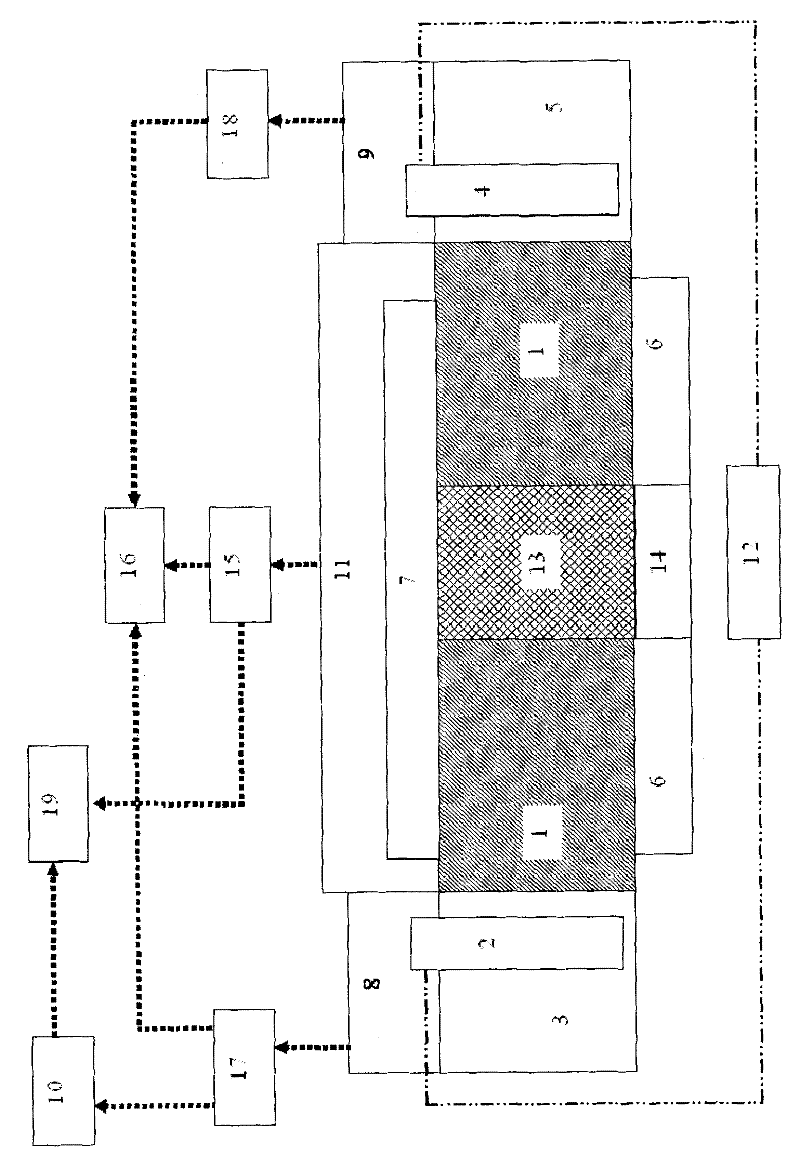

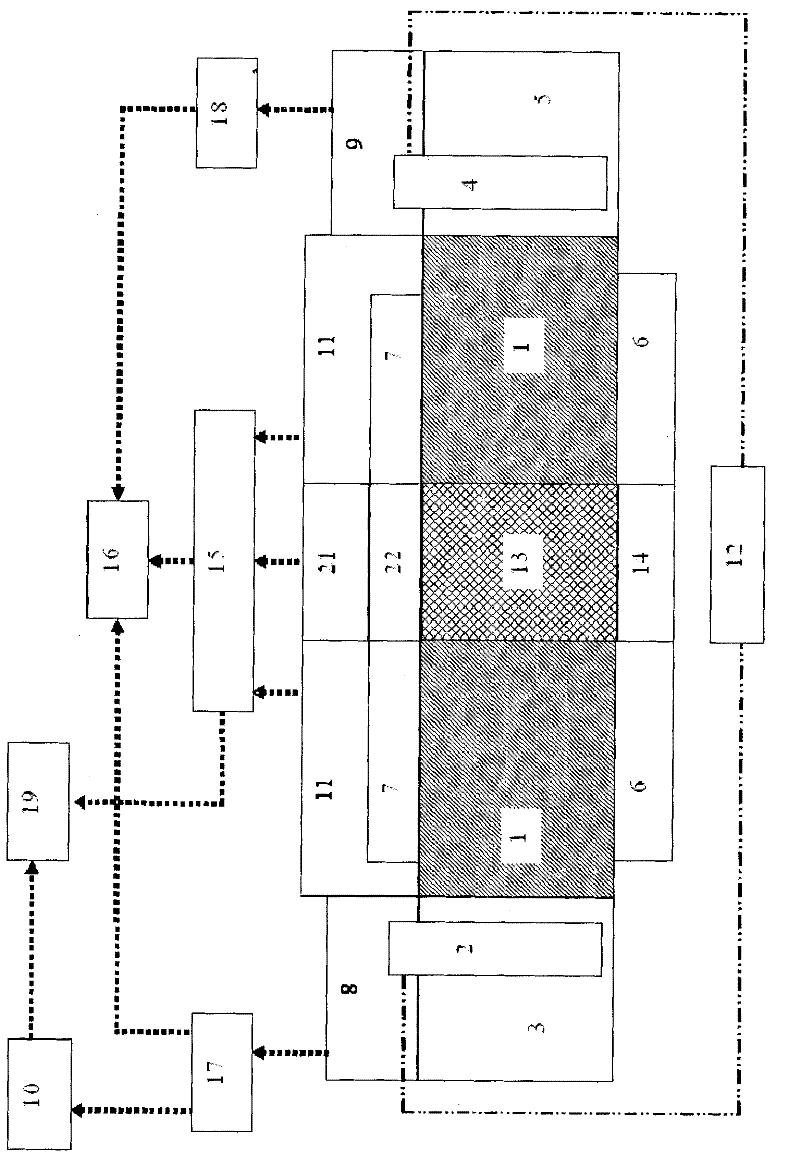

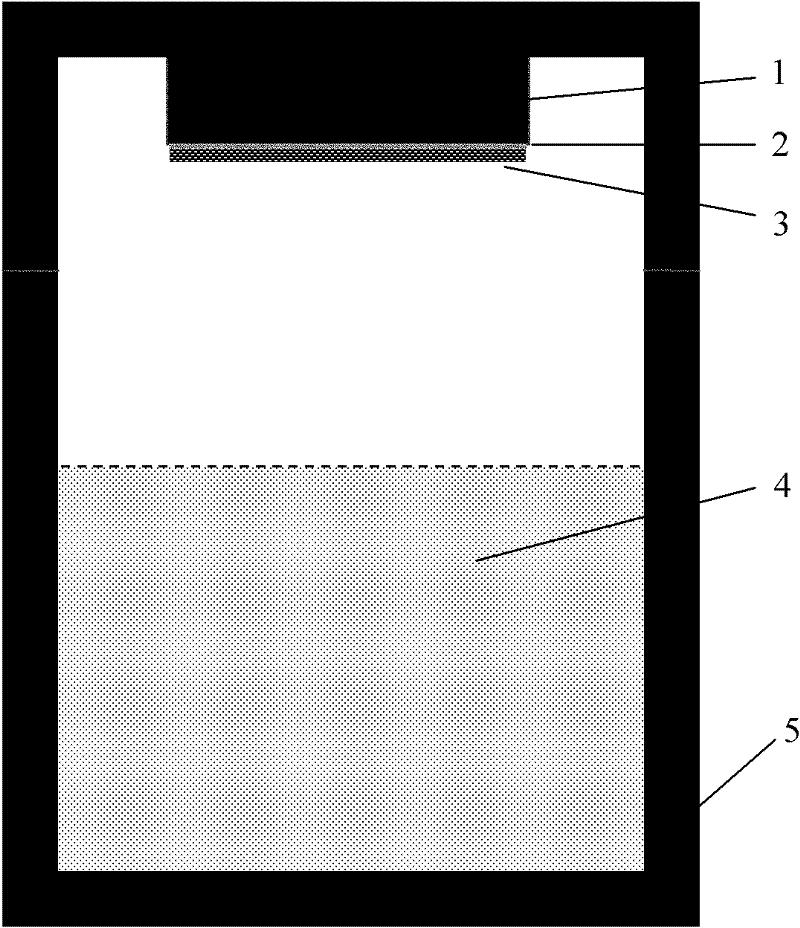

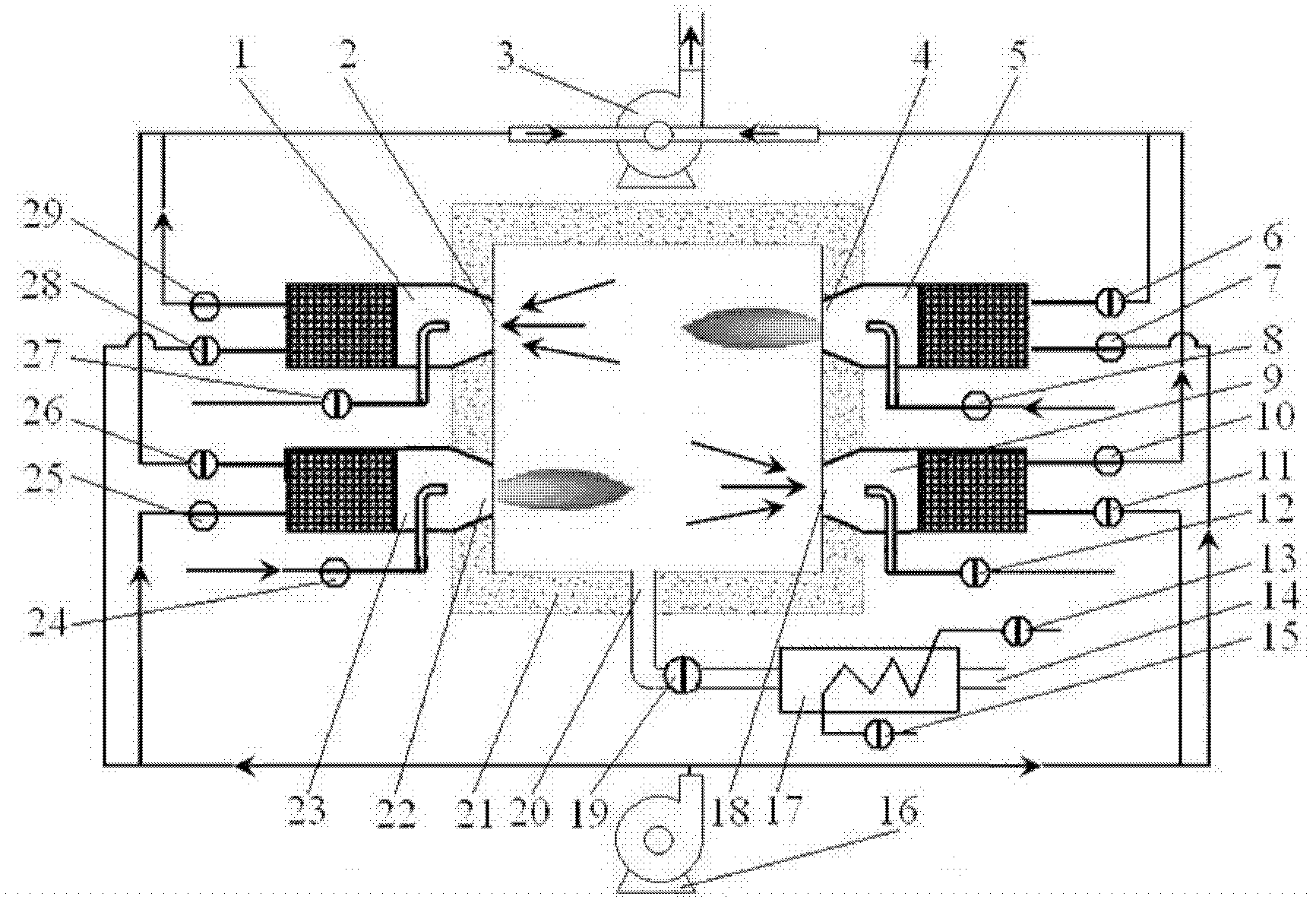

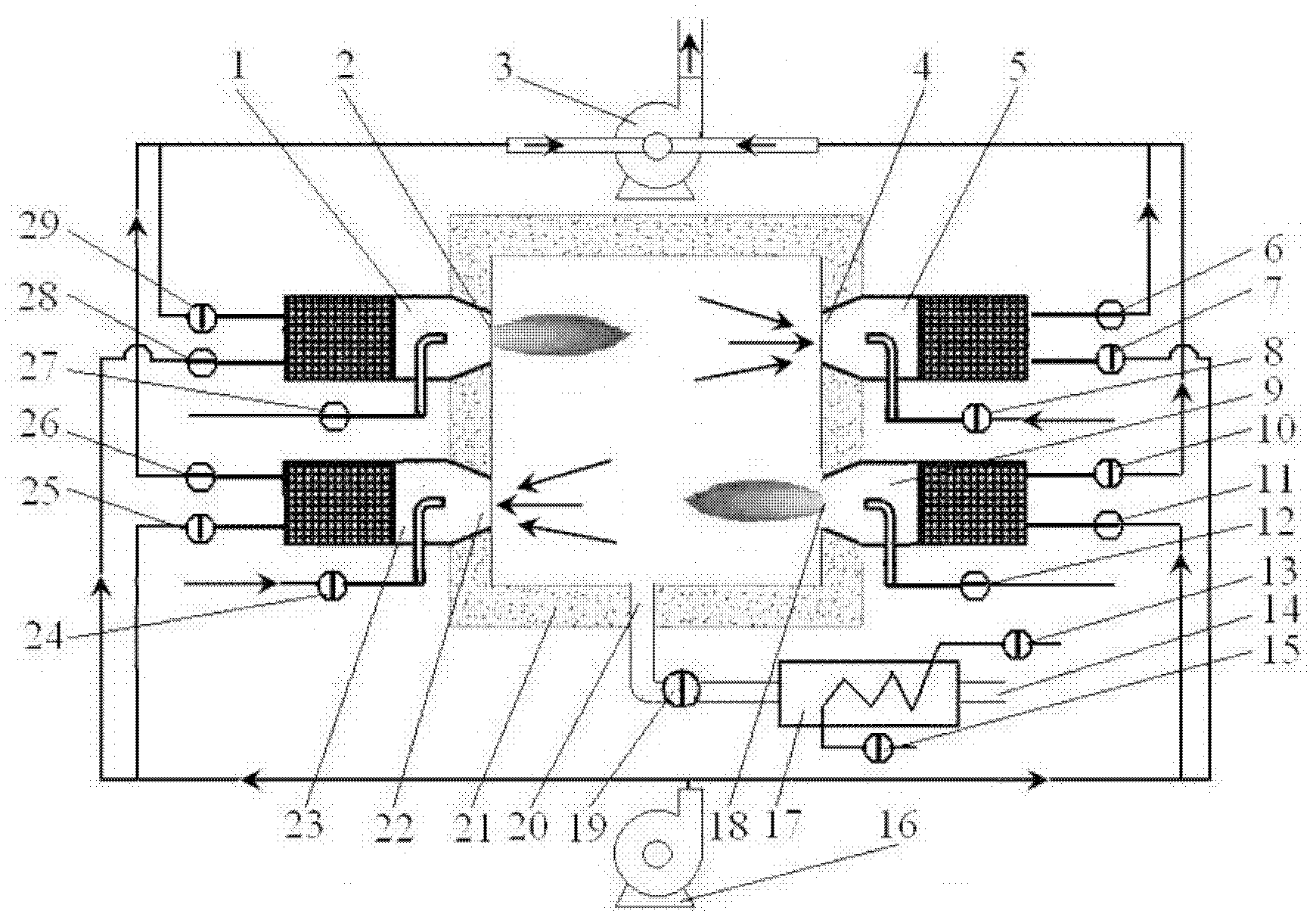

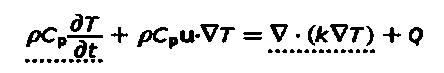

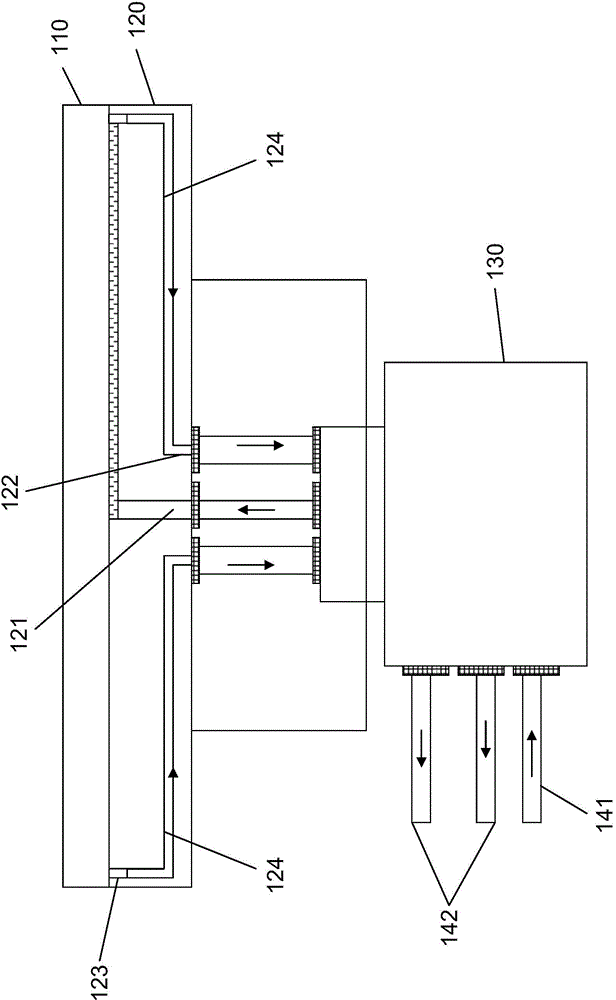

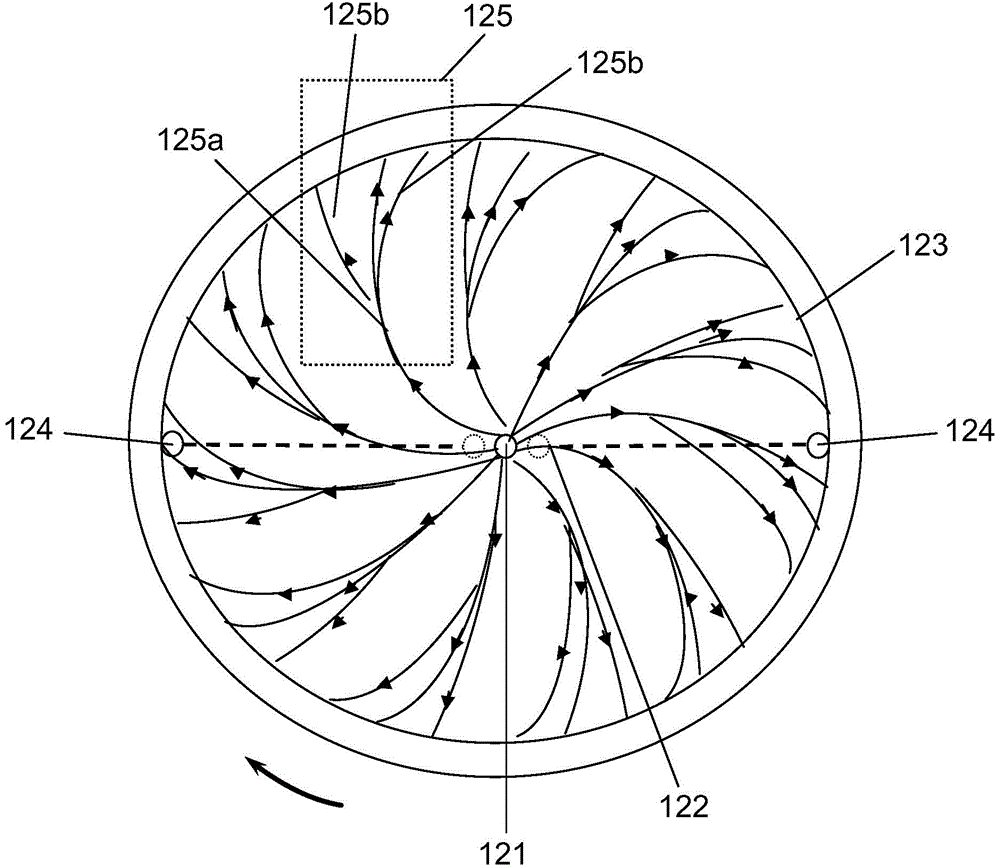

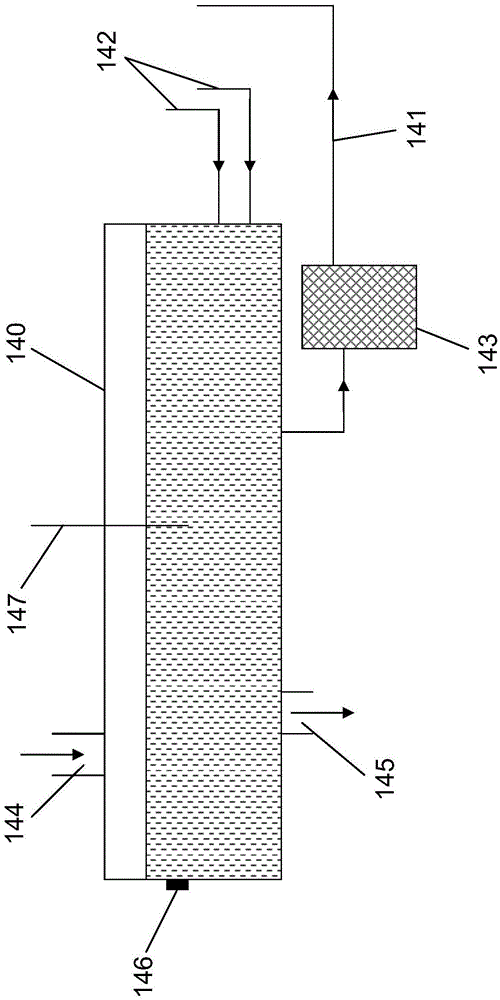

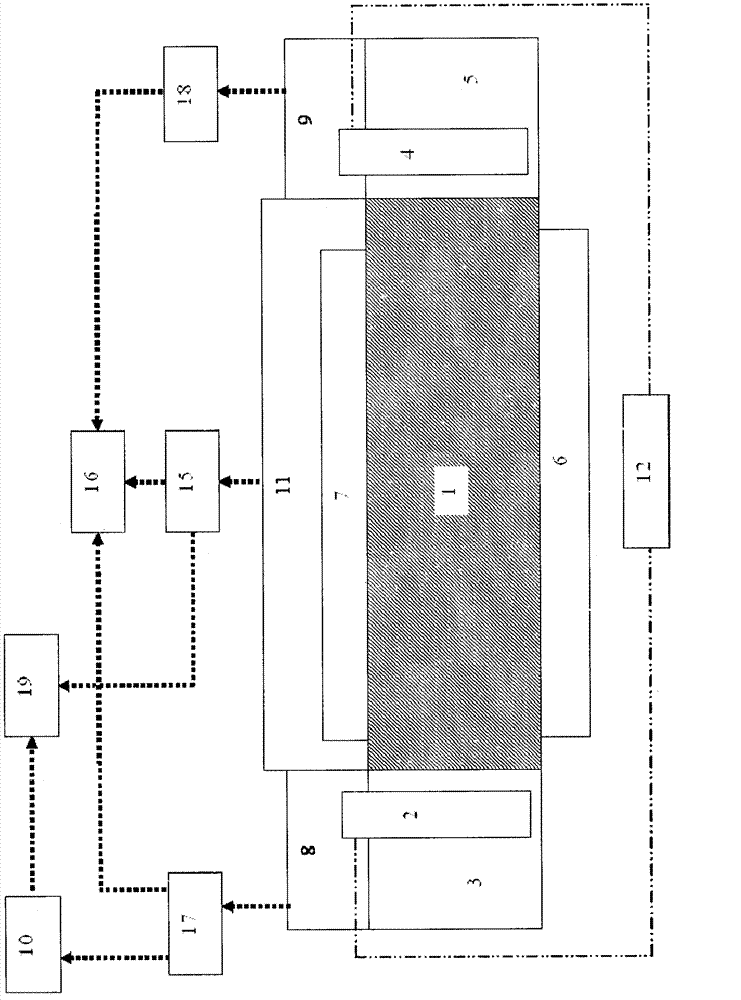

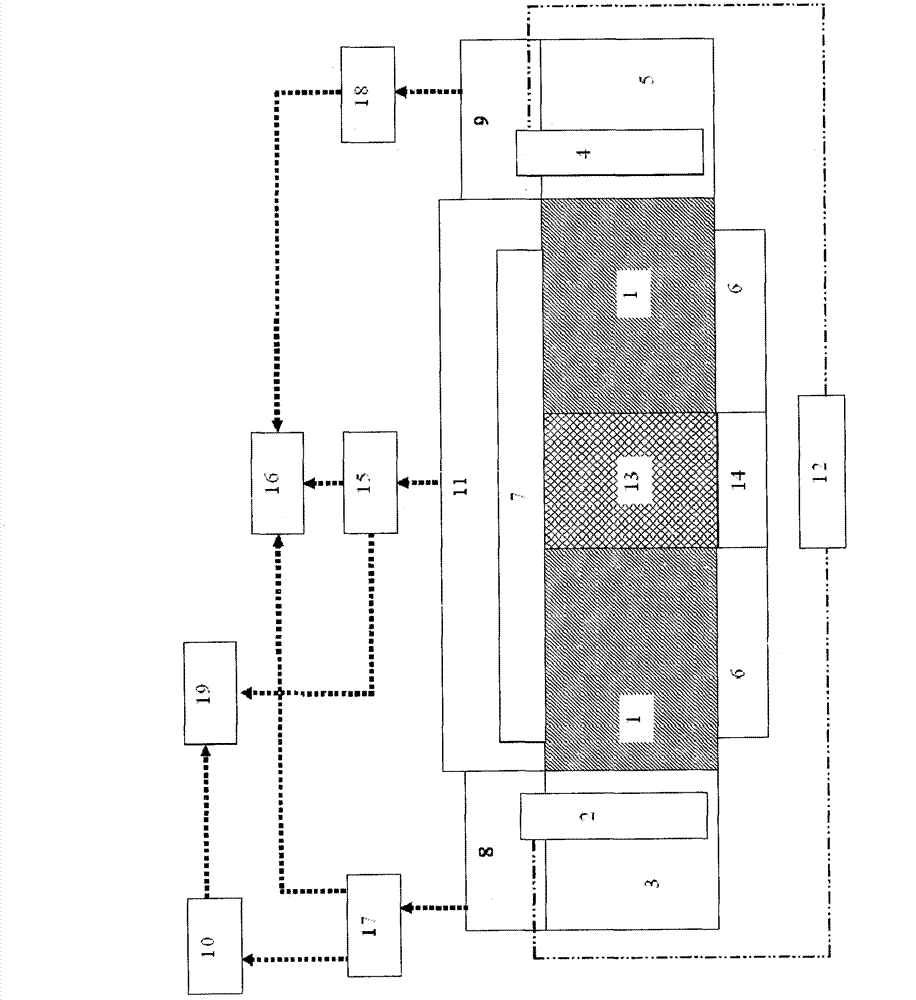

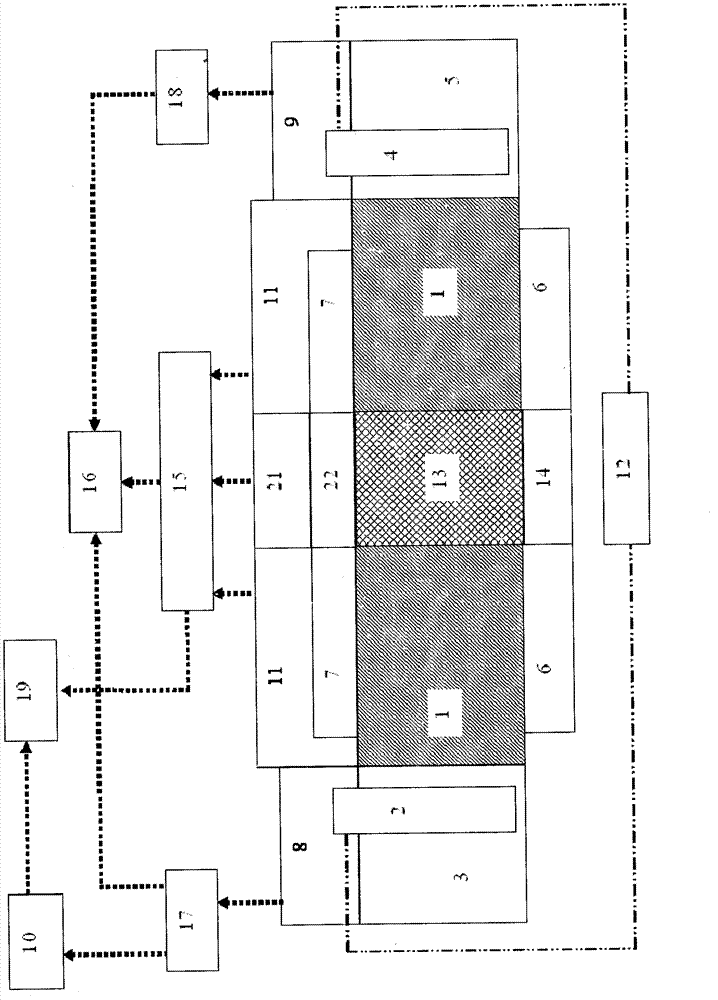

Method and device for remediating polluted soil and treating solid waste by using electric energy

InactiveCN102284474AImprove temperature distribution uniformityImprove solubilitySolid waste disposalContaminated soil reclamationSolubilityOxygen

The invention relates to a method and device for restoring polluted soil and treating solid wastes. A cathode reaction tank and an anode reaction tank are respectively arranged at the two ends of soil / solid wastes, a water supply layer is arranged at the bottom of the soil / solid wastes and contains a chemical agent which can improve the solubility of organic pollutants and heavy metals in water, and a replaceable pollutant collecting layer covers the top of the soil / solid wastes which are internally provided with a replaceable artificial focal zone. The temperature value of the soil / solid wastes is increased to dozens of degrees even hundreds of degrees by applying a high voltage and large current; volatile organic pollutants volatile from the soil / solid wastes due to a high temperature, and nonvolatile organic pollutants and the heavy metals rise to the collecting layer along with water and are left in the collecting layer after the water is evaporated; and partial heavy metal ions are transferred to the electrode tank and the artificial focal zone along the electric field direction. Hydrogen and oxygen generated at a cathode and an anode are respectively collected for burning the volatile pollutants in the collecting layer and the focal zone; and the oxygen also can be made into ozone for oxygenizing pollutants in the soil / solid wastes or be cleared out.

Owner:CHONGQING UNIV

Treatment method of laterite-nickel ore

The invention discloses a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; carrying out crushing and dry magnetic separation on the metalized pellets to obtain nickel iron granules and first tailings; and carrying out wet grinding and wet magnetic separation on the first tailings to obtain nickel iron powder and second tailings, wherein the reducer is carbon black prepared from rubber. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

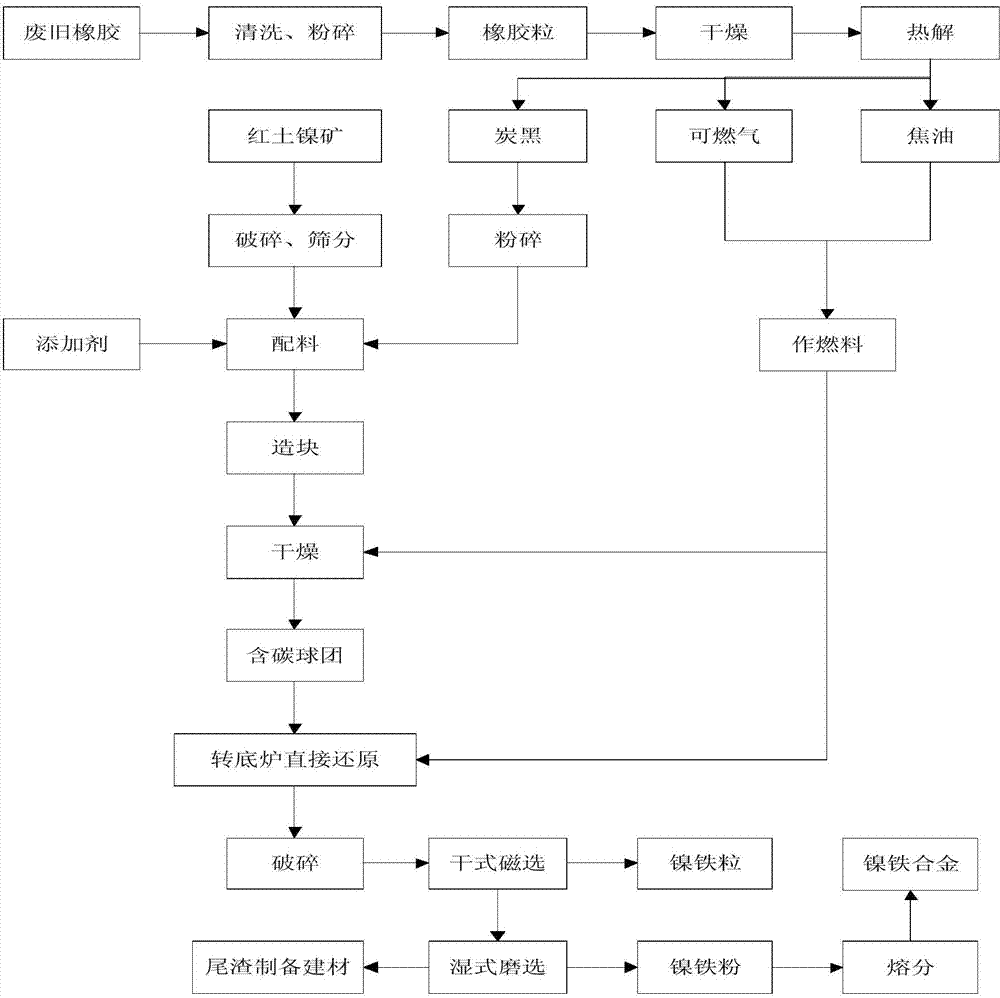

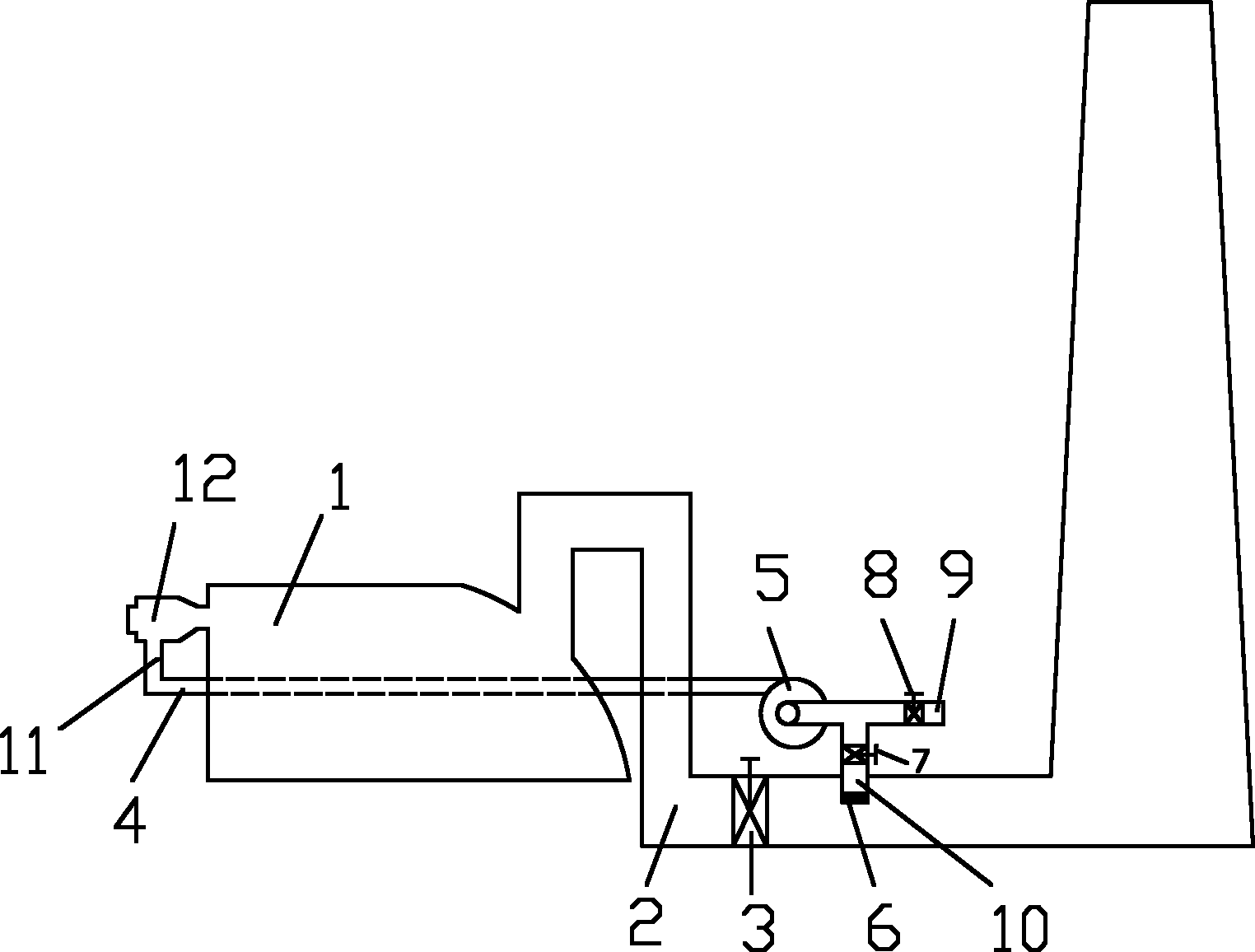

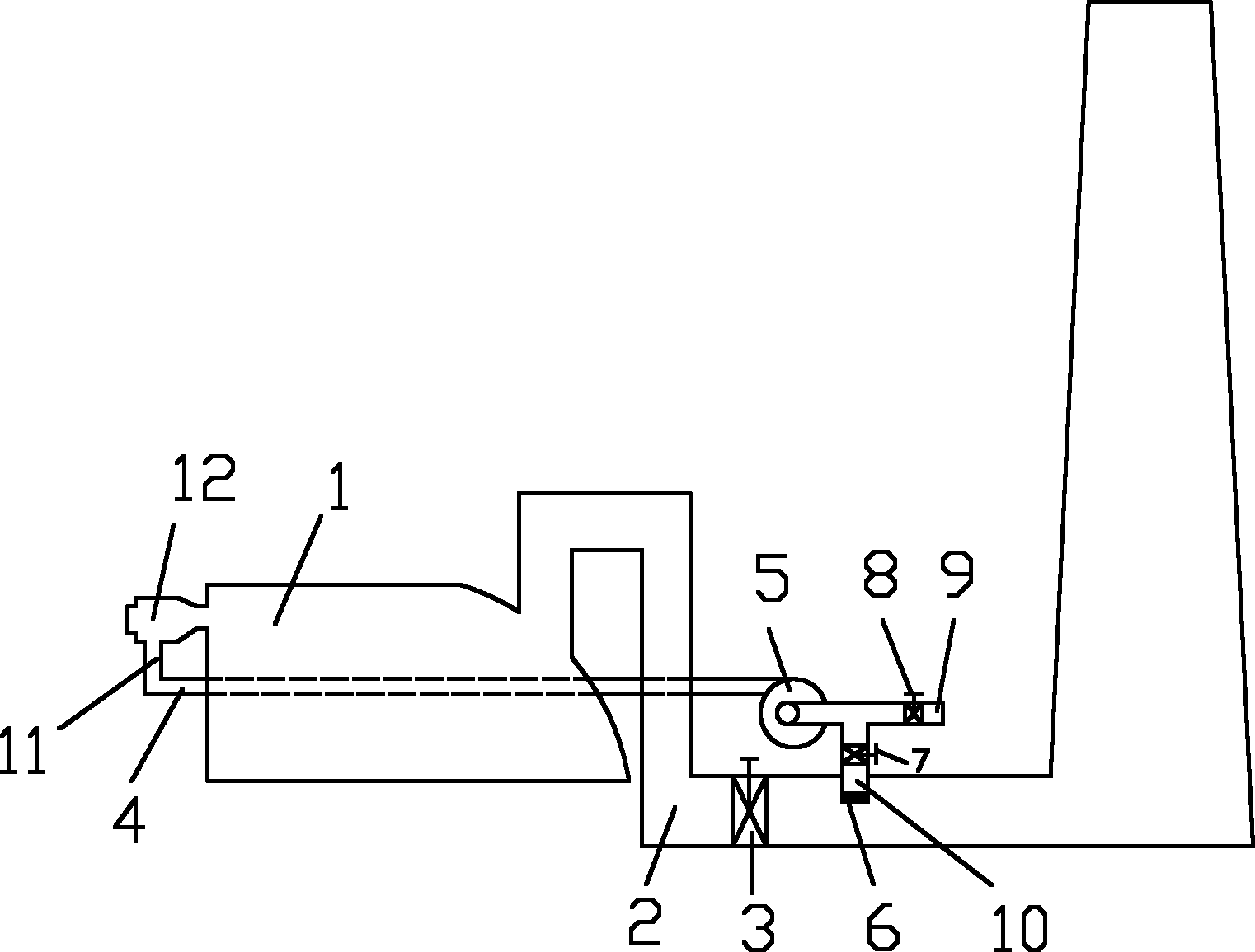

Rapid heat-treatment temperature measuring and controlling system and measuring and controlling method

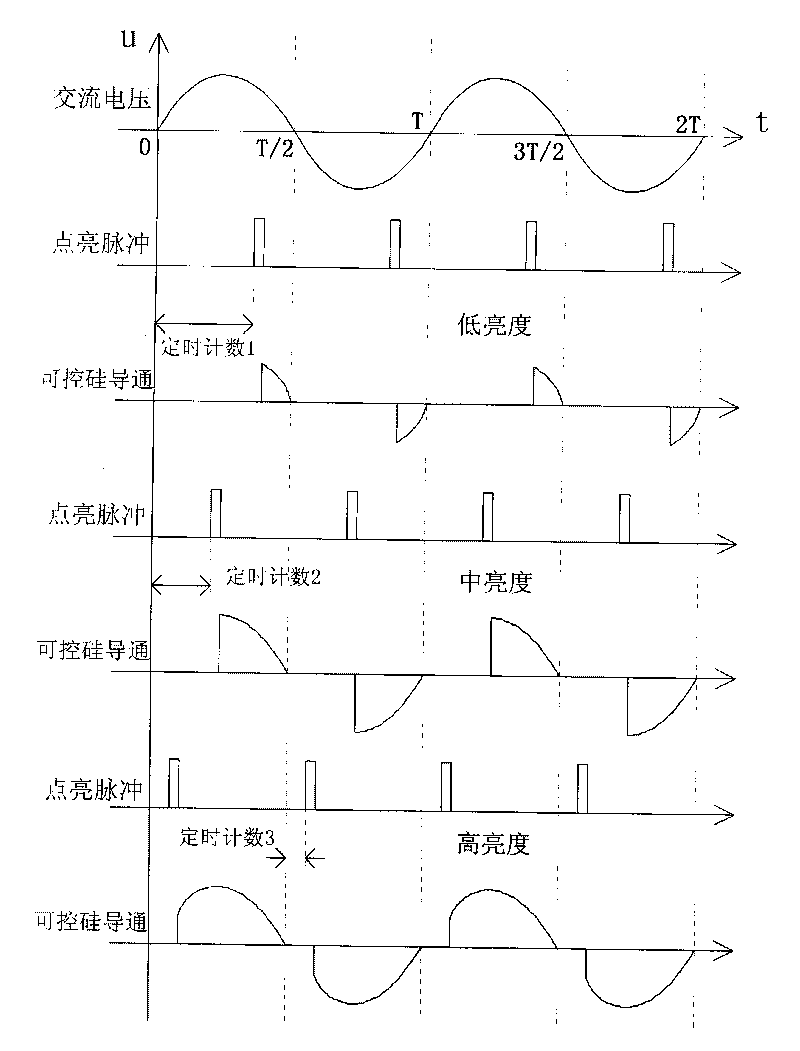

InactiveCN101727118AAccurate measurementTemperature distribution uniformity controlTemperatue controlSemiconductor/solid-state device manufacturingControl signalAlternating current

The invention discloses a rapid heat-treatment temperature measuring and controlling system and a measuring and controlling method. The system comprises an infrared pyrometer, a standard K-shaped thermoelectric couple silicon wafer, a temperature signal processor, a thermoelectric couple thermodetector, a heating power regulator, an alternating current zero crossing detector, a timing counter, a controllable silicon control signal isolation amplifier, a controllable silicon heating source, a heating light set and a control computer. The connection relationships of the assemblies are shown as an attached drawing 1 and the whole system is uniformly coordinated by the control computer for controlling, wherein the heating power regulator is internally set in the program of the computer. The temperature measuring and controlling method comprises the steps of measuring and calibrating the temperature by using the standard thermoelectric couple, measuring the temperature by using the infrared pyrometer, controlling the adjustment of the heating power of light by using the timing counter, dividedly controlling the heating light, adjusting the distribution uniformity of the temperature and the like. The invention can carry out self-adaptive PID adjustment on the temperature, has rapid adjustment and controlling reaction and can fully-automatically achieve the rapid temperature measuring and controlling functions.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

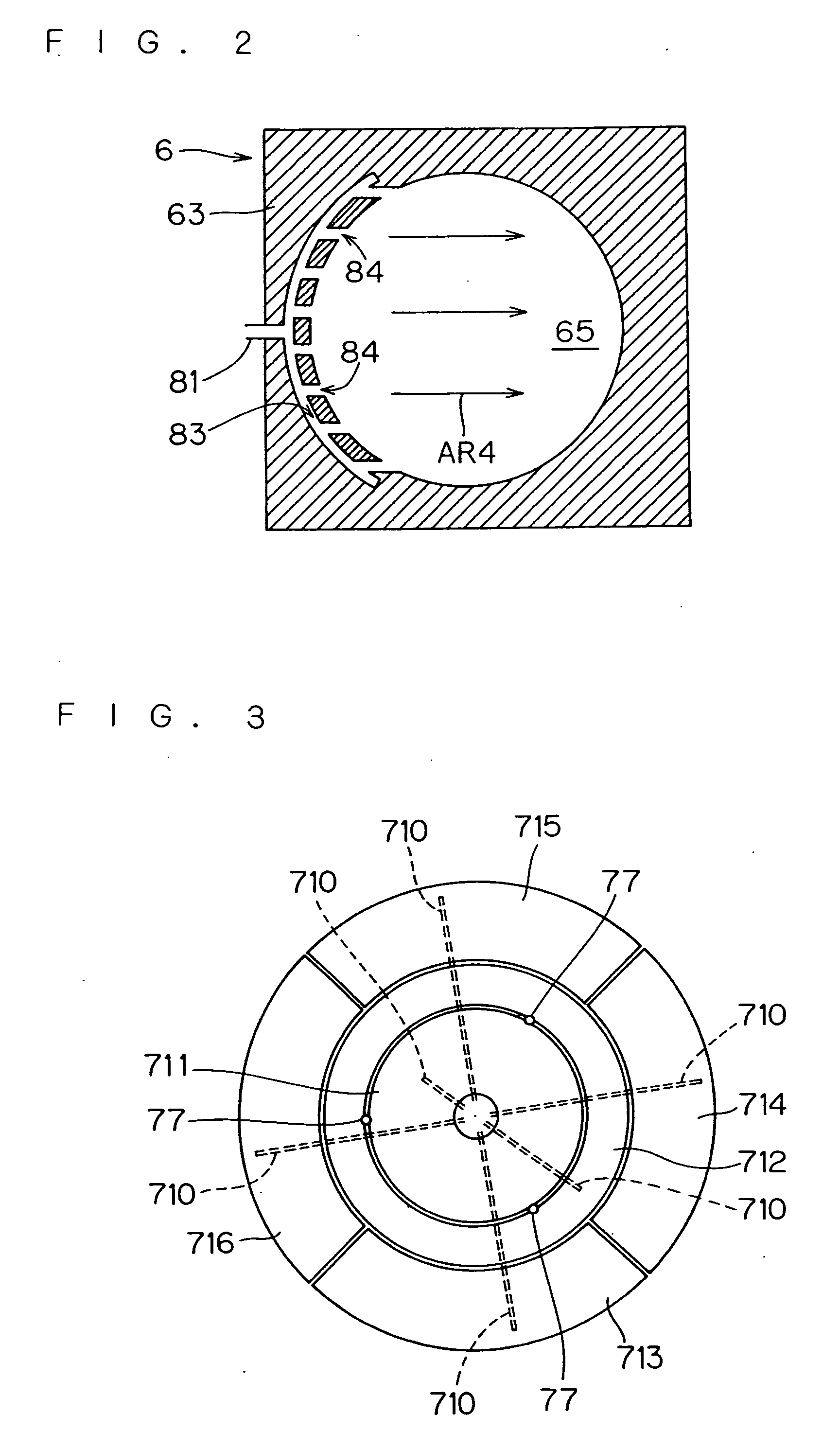

Heat treatment apparatus of light emission type

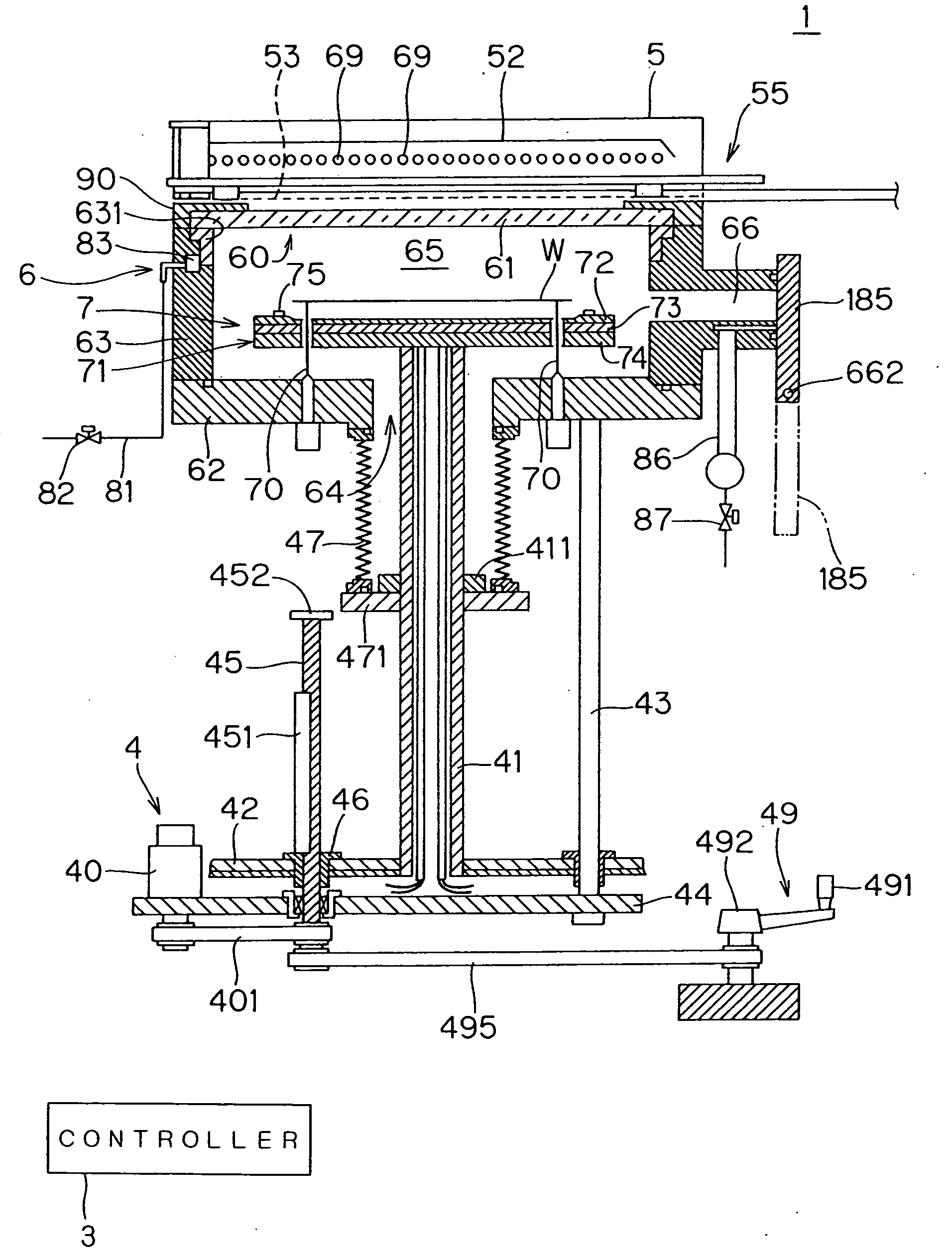

InactiveUS20060291832A1Improve temperature uniformityIncrease temperatureSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingEngineeringLight emission

A flash of light emitted from flash lamps is directed through an optical window defined by an opening provided in a clamp ring onto a semiconductor wafer. Because the opening of the clamp ring is of an elliptical configuration, the optical window defined by the clamp ring is also of an elliptical plan configuration. The clamp ring is mounted to a chamber so that opposite edge portions of the optical window facing parts of a peripheral portion of the semiconductor wafer which have a relatively low temperature if a flash of light is directed from the flash lamps through the optical window, assuming that the optical window is of a circular plan configuration, are opposite edge portions of the optical window which are located on the minor axis of the elliptical configuration. Directing the flash of light through the optical window increases the temperature of the parts of the peripheral portion having the relatively low temperature to improve the within-wafer uniformity of a temperature distribution of the semiconductor wafer during flash heating.

Owner:DAINIPPON SCREEN MTG CO LTD

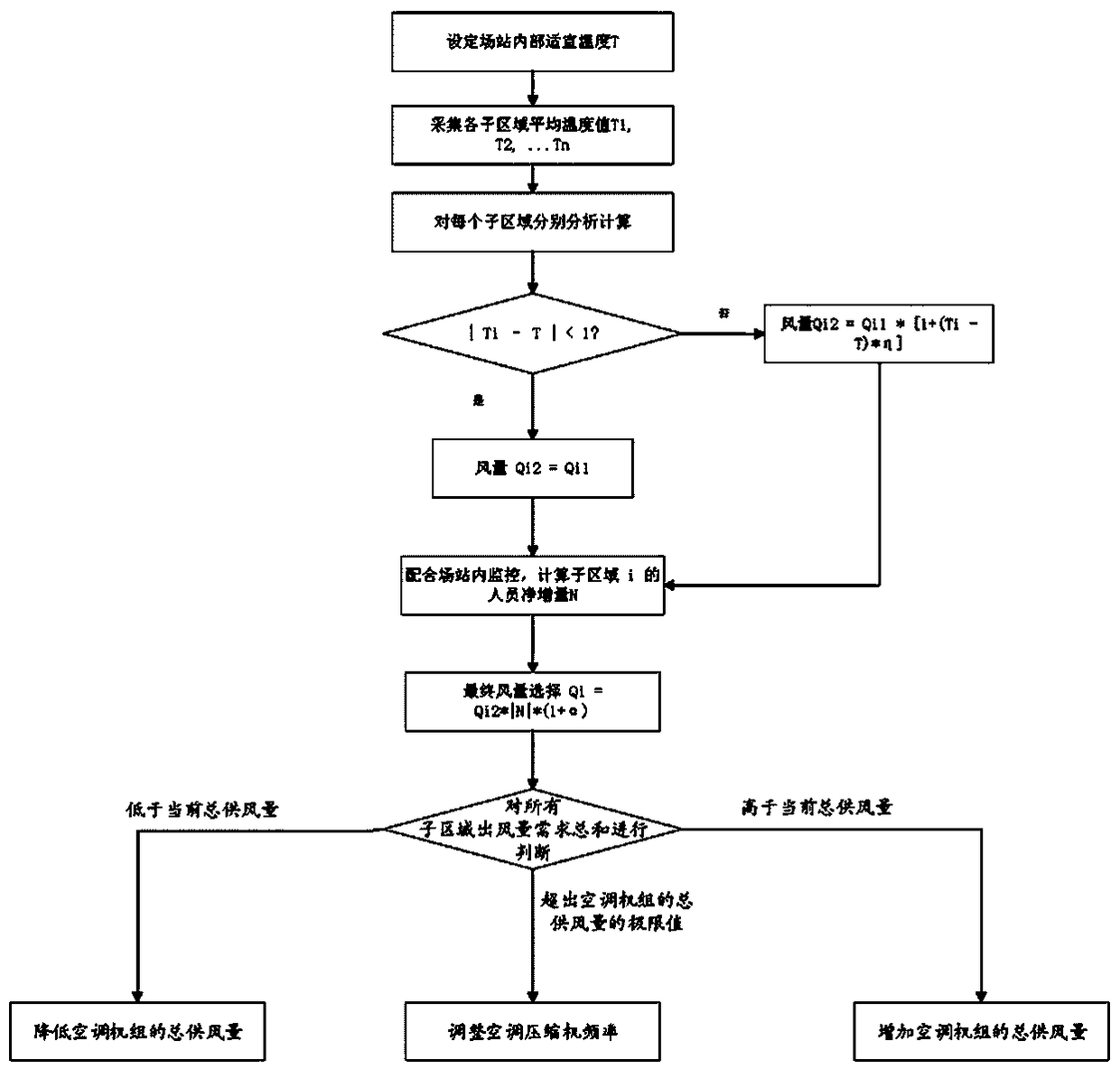

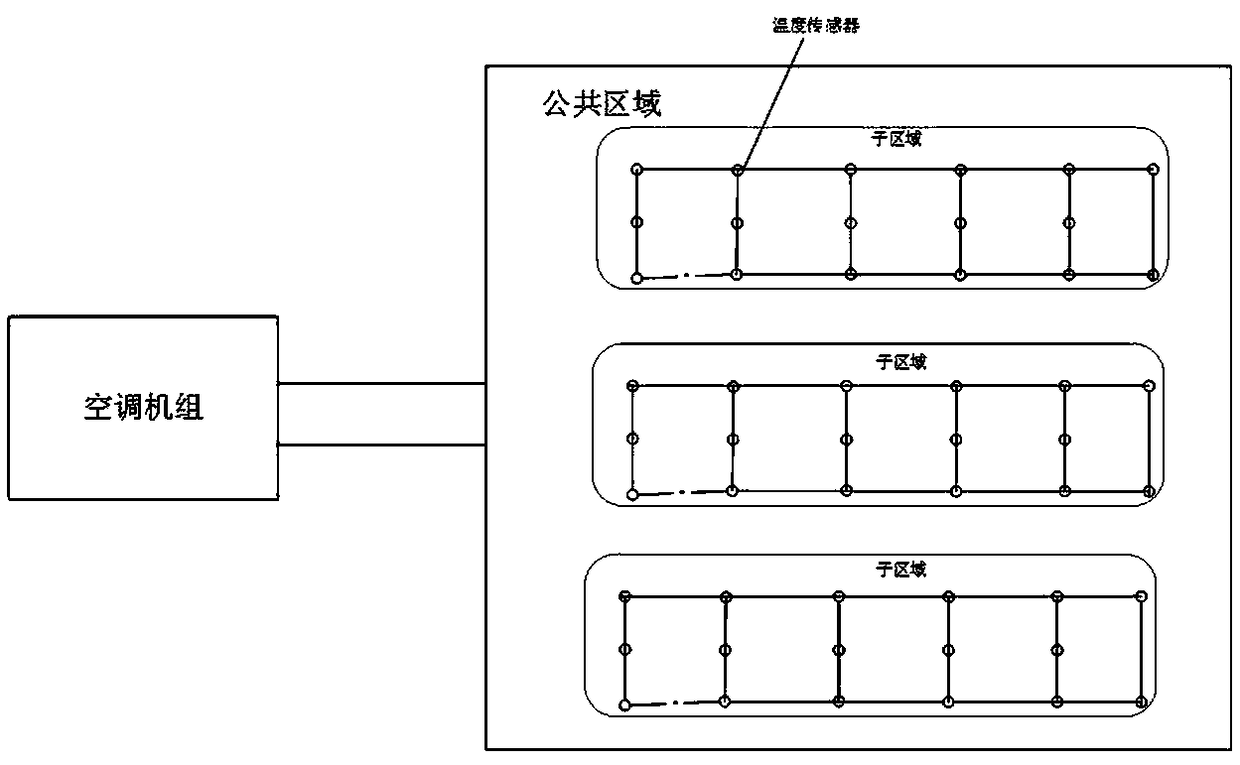

Control method used for air conditioner unit in public area and air conditioner unit

ActiveCN109210683AAchieve regulationImprove comfortMechanical apparatusEngineeringElectrical and Electronics engineering

Owner:GREE ELECTRIC APPLIANCES INC

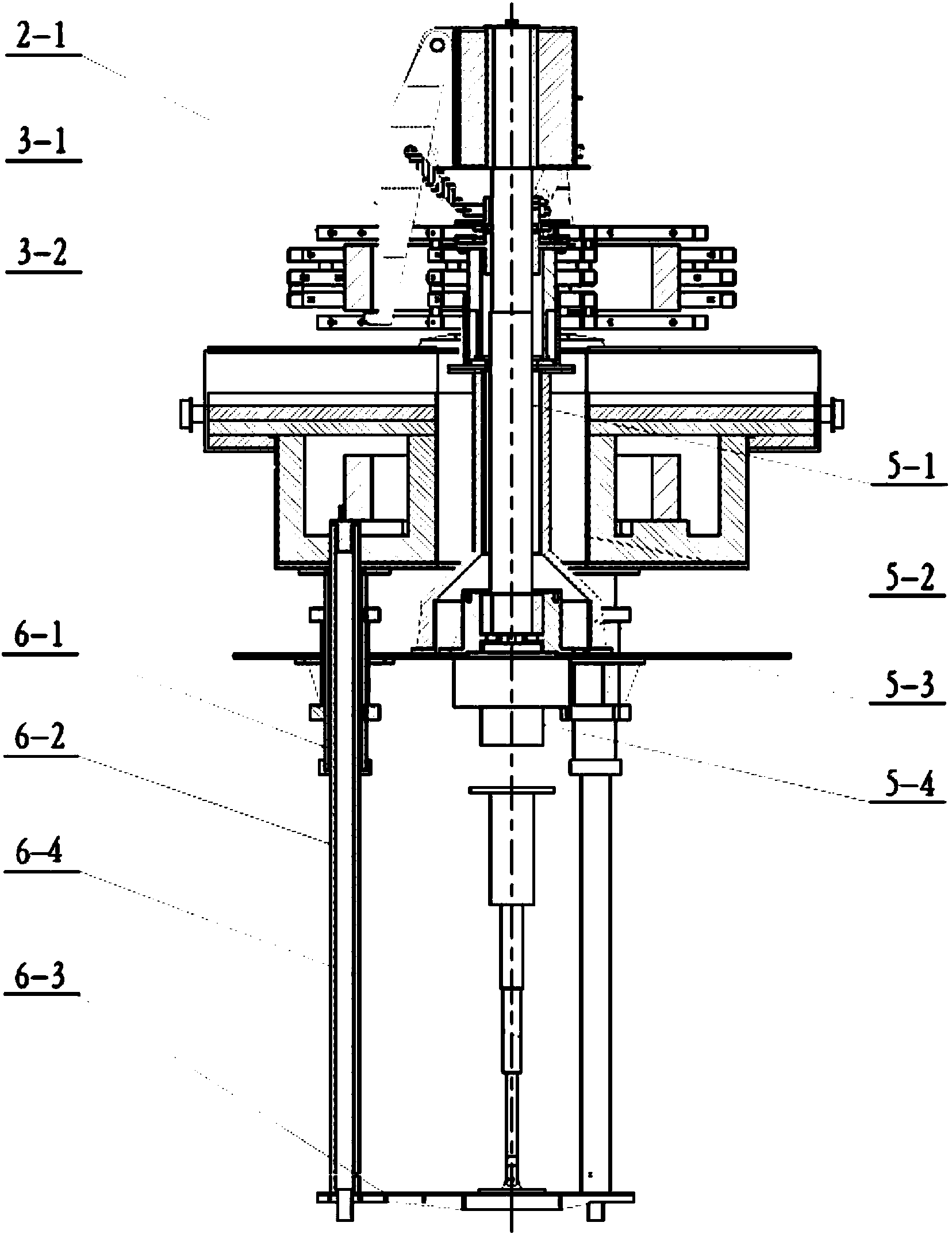

Aluminum alloy ring part spray-quenching equipment and using method thereof

ActiveCN104313274AEliminate Radial DistortionImprove performanceFurnace typesHeat treatment furnacesSupporting systemAutomatic control

Owner:CENT SOUTH UNIV

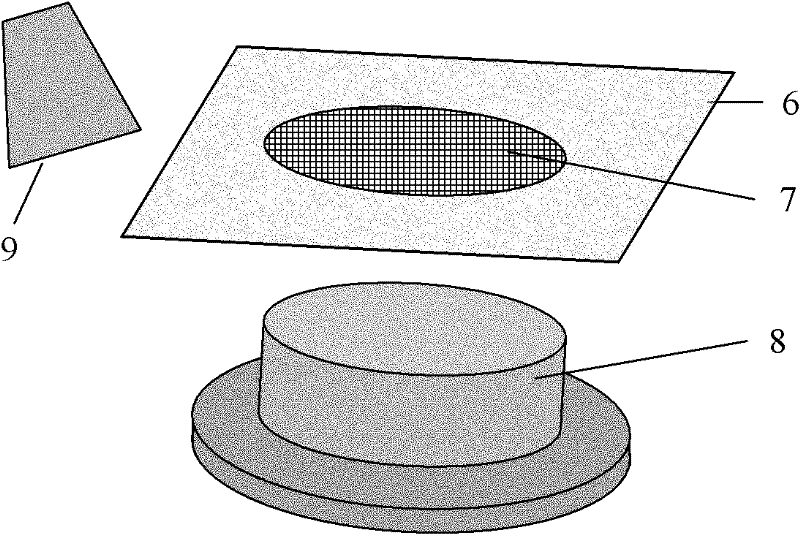

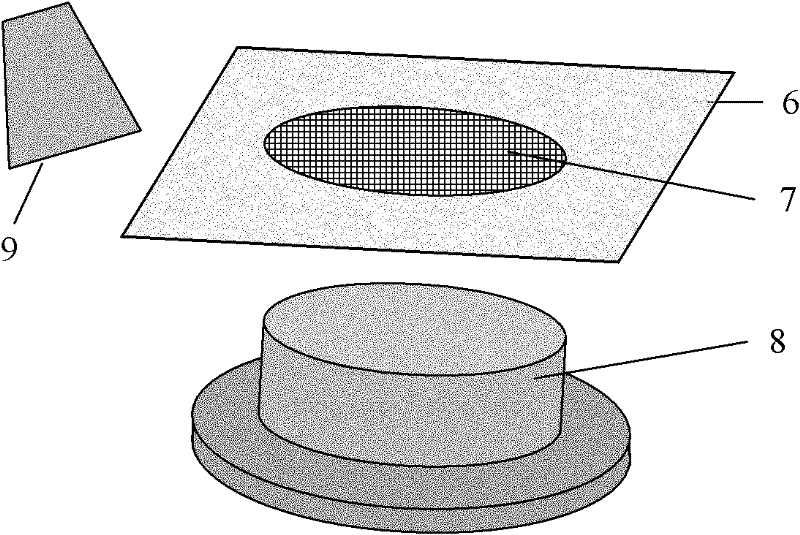

Seed crystal bonding method for growing SiC crystals

InactiveCN102534762AUniform growthQuality improvementPolycrystalline material growthFrom condensed vaporsCrystallographyAdhesive

The invention belongs to the field of crystal growth, and relates to a seed crystal bonding method for growing SiC crystals. The seed crystal bonding method for growing high-quality SiC crystal comprises the following steps of: (1) printing a silk screen; (2) bonding the seed crystals; and (3) curing an adhesive for bonding the seed crystals and a seed crystal support, wherein the thickness of the cured adhesive layer is 7-10 microns. The seed crystal bonding method for growing the high-quality SiC crystals provided by the invention can ensure uniform distribution of the thickness of the adhesive layer between the seed crystals and the seed crystal support and avoid cracking caused by non-uniform mechanical stress and heat stress; and meanwhile, the temperature gradient distribution of the seed crystals is uniform, thereby being beneficial to the uniform growth of the SiC crystals, and further improving the quality of the SiC crystals.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method and device for smelting recycled copper in reverberator

InactiveCN102061396AReduce oxygen contentFacilitate control of burning rateReverberatory furnaceCombustorCombustion

The invention discloses a method and device for smelting recycled copper in a reverberator. With the method, partial high-temperature fumes of the reverberator are directly mixed with combustion-supporting air to form a combustion-supporting gas with high temperature and low oxygen concentration, thereby improving the uniformity of temperature distribution in the reverberator, reducing local high temperature and reducing the burning loss of metal. The horizontal section of a flue gate of the reverberator is connected with a fume backflow pipe, a high temperature fan and a bypass cool air pipe to transmit a part of high temperature fume exhausted from the reverberator to a burner so that high air temperature and low oxygen concentration combustion is implemented in the reverberator and the fume backflow content accounts for 30% to 50% of the total volume of the fume in the reverberator. The method provided by the invention has the advantages of high metal recovery rate and high heat efficiency, and the device has the advantages of simple structure and reliable performance.

Owner:CENT SOUTH UNIV

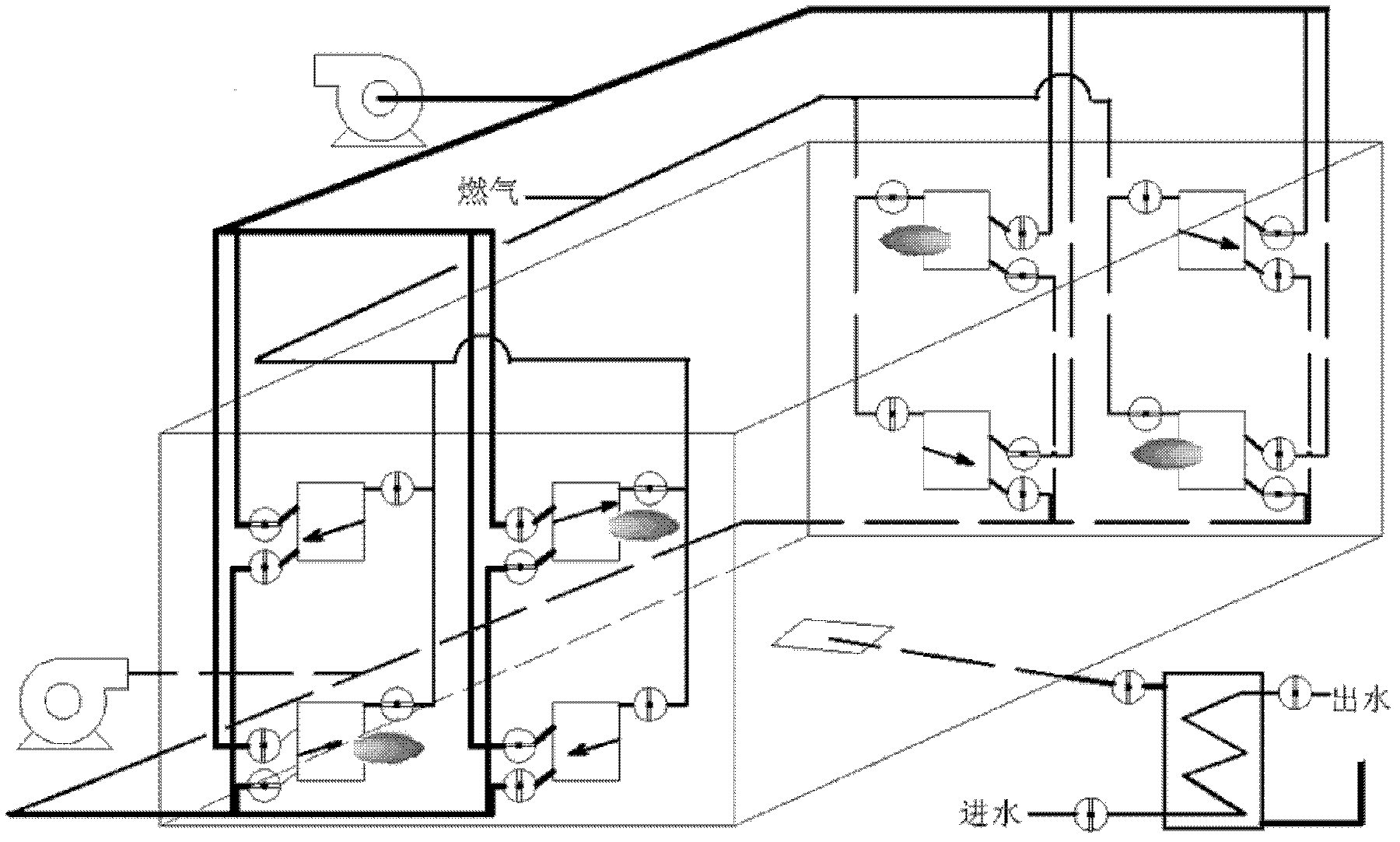

Energy-saving type shuttle type kiln

InactiveCN102564127AIncrease disturbanceUniform pressure distributionFurnace typesIncreasing energy efficiencyCombustorEngineering

The invention discloses an energy-saving type shuttle type kiln. The energy-saving type shuttle type kiln comprises a furnace body, at least one pair of heat-accumulating type combustors, a heat exchanger, corresponding valves, pipelines and a fan, wherein the combustors are arranged on the furnace body and are connected with the fan and a gas pipeline by the pipelines and the valves. When one of the combustors is in a combusting state, the other one is in a smoke-exhausting state, and the smoke stores heat in a heat-accumulating material in the combustors, and then is exhausted out of the system. When the preset time is up, the valves of the two combustors are switched, the combustor in the smoke-exhausting state is changed to be in the combusting state, and air absorbs the heat stored in the heat-accumulating material when passing through the combustor and carries the heat into a furnace so as to realize heat recovery. When a plurality of pairs of combustors are arranged, the working state of each combustor is opposite to that of the peripheral combustors so as to realize cross combustion. In the cooling process, heating and water supply are performed on the hot air by the heat exchanger on a spare flue, and the heat is absorbed by water so as to be utilized. The energy-saving type shuttle type kiln has the advantages that not only is the energy-saving effect obvious, but also the temperature distribution in the hearth is uniform, the temperature rising speed is high and the combustion temperature is high.

Owner:WUHAN ANHE ENERGY SAVING TECH

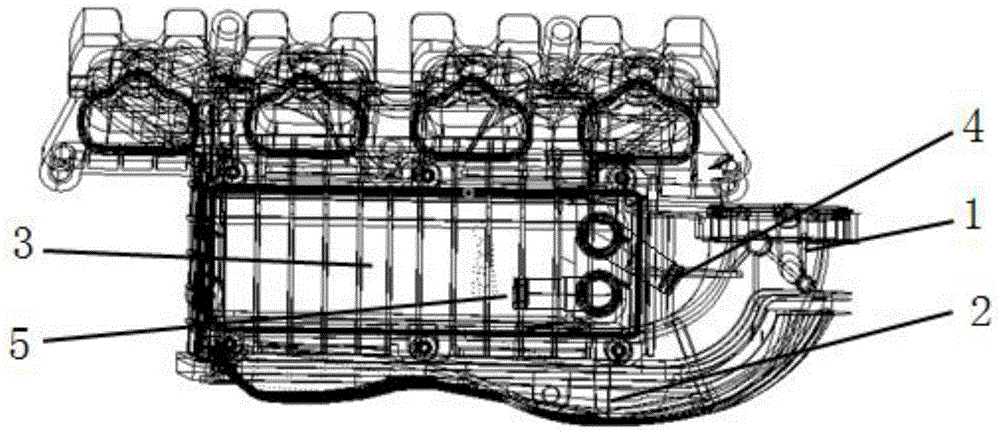

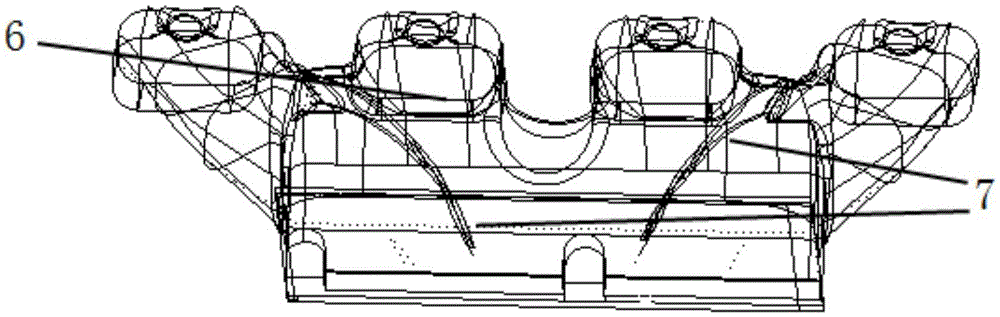

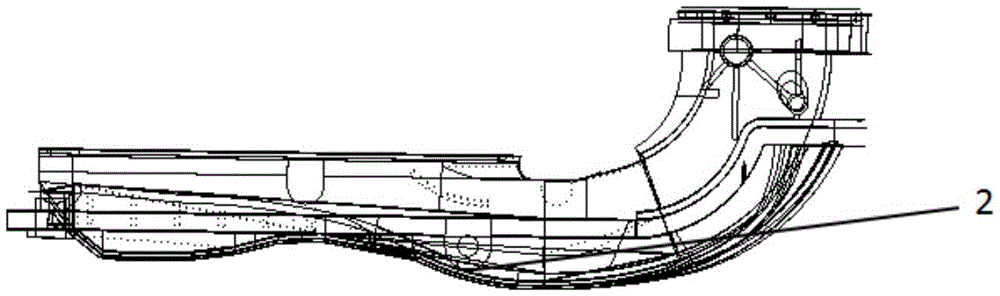

Inlet manifold integrated with intercooler

ActiveCN105673185AImprove cooling efficiencySpeed up the flowInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringIntercooler

The invention discloses an inlet manifold integrated with an intercooler. The inlet manifold comprises an inlet manifold body and the intercooler; a pressure stabilizing cavity is arranged on the inlet manifold body; the intercooler is integrated in the pressure stabilizing cavity; and the inlet manifold body further comprises an air inlet cavity communicating with the bottom face of the pressure stabilizing cavity and used for adjusting the air inlet direction and the boundary air space of the intercooler. As the appearance of the air inlet cavity of the inlet manifold integrated with the intercooler is optimized and the space of air of an edge and corner area of the intercooler is enlarged, air entering the air inlet cavity is prevented from being unevenly cooled when the boundary area space of the intercooler is small, the flowing direction of the air inlet face of the intercooler is adjusted, and accordingly flowing on the air inlet face of the intercooler is more even, and the temperature distribution evenness of the air outlet face of the intercooler is improved.

Owner:CHERY AUTOMOBILE CO LTD

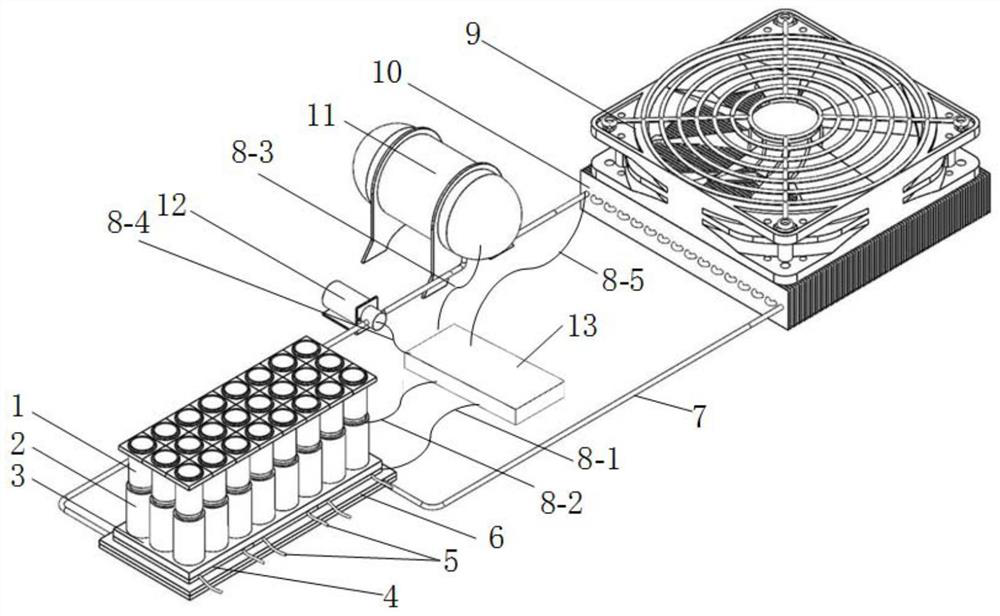

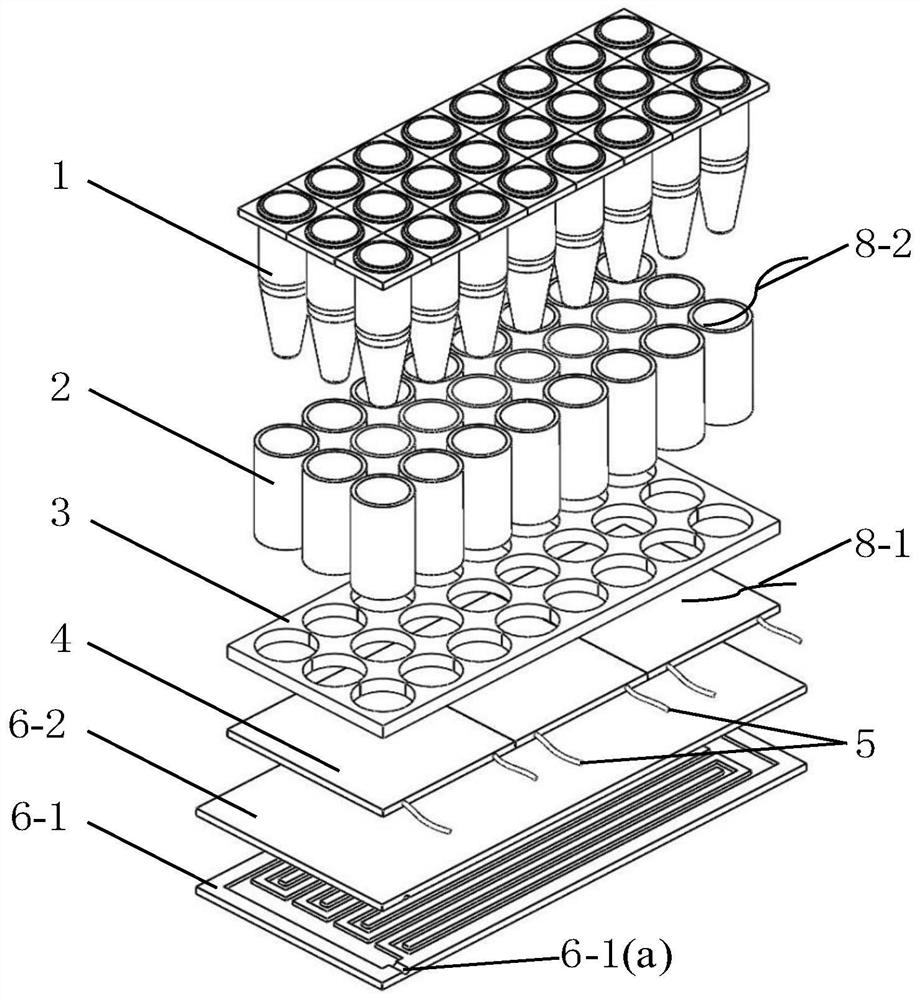

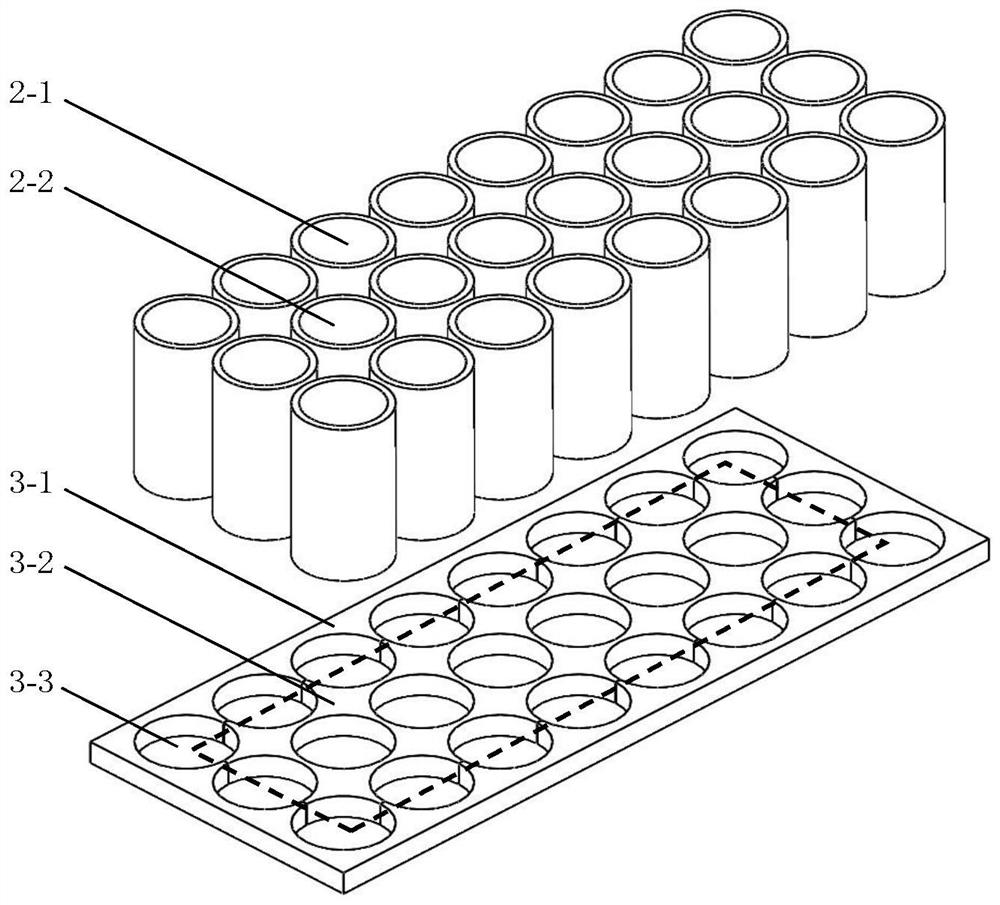

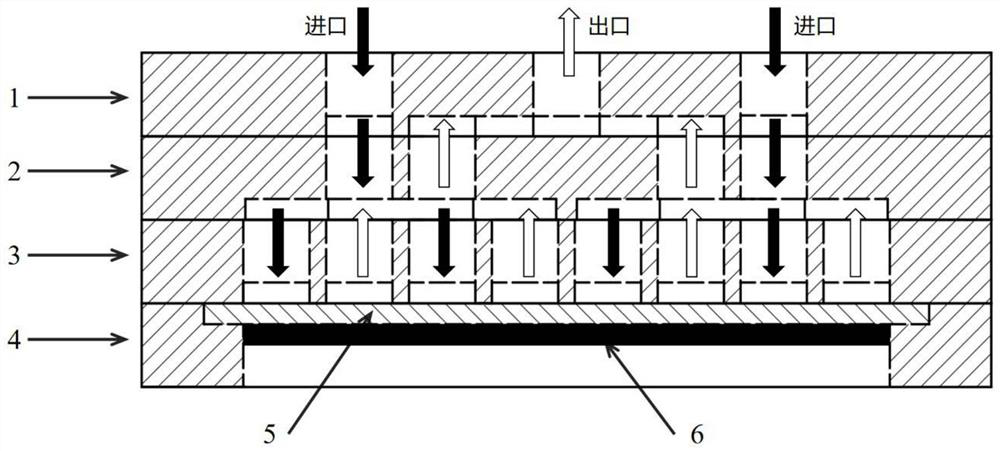

Micro-channel temperature control device and method for nucleic acid detection amplification reaction

ActiveCN112063491AImprove heat transfer effectReduce usageBioreactor/fermenter combinationsBiological substance pretreatmentsMicrocontrollerThermal insulation

The invention discloses a micro-channel temperature control device and method for a nucleic acid detection amplification reaction, and relates to a micro-channel temperature control device and method.The device comprises a nucleic acid amplification reaction module, a heating / cooling module, a micro-channel cooling module and a microcontroller module, wherein the nucleic acid amplification reaction module and the micro-channel cooling module are respectively mounted on the upper surface and the lower surface of the heating / cooling module; the nucleic acid amplification reaction module comprises a reaction plate, reaction columns and reaction tubes; the heating / cooling module is attached to the bottom of the reaction plate, and heating / cooling and temperature control of the reaction moduleare achieved through the microcontroller module; the micro-channel cooling module comprises a micro-channel plate, a micro-channel cover plate, a liquid tube, a cooling fan, a condenser, a liquid storage device and a water pump; and thermocouples are arranged at outlets of the reaction columns, a thermoelectric refrigeration sheet and the condenser and used for collecting temperature signals. Anouter-layer thermal insulation material is not used, so that the temperature distribution uniformity is improved, the cost is reduced, and the production operation convenience is improved. The power of the thermoelectric refrigeration sheet is improved and the heating / cooling rate of the reaction module is improved.

Owner:XIAMEN UNIV +1

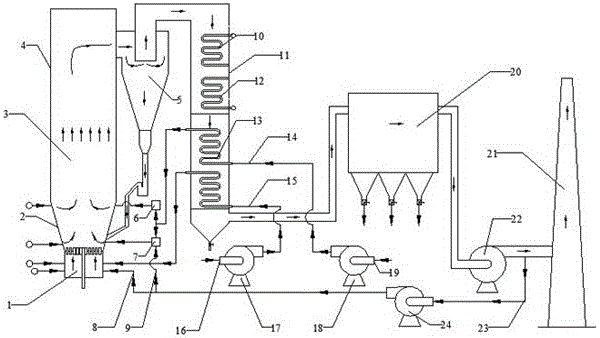

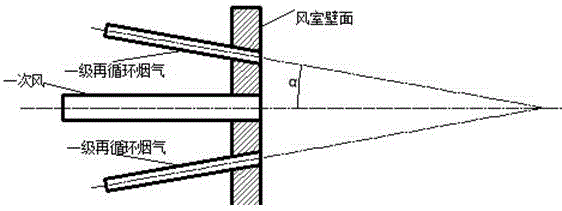

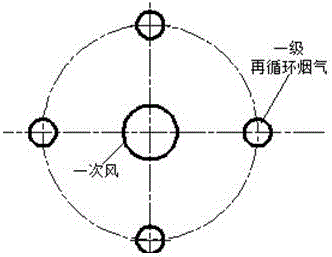

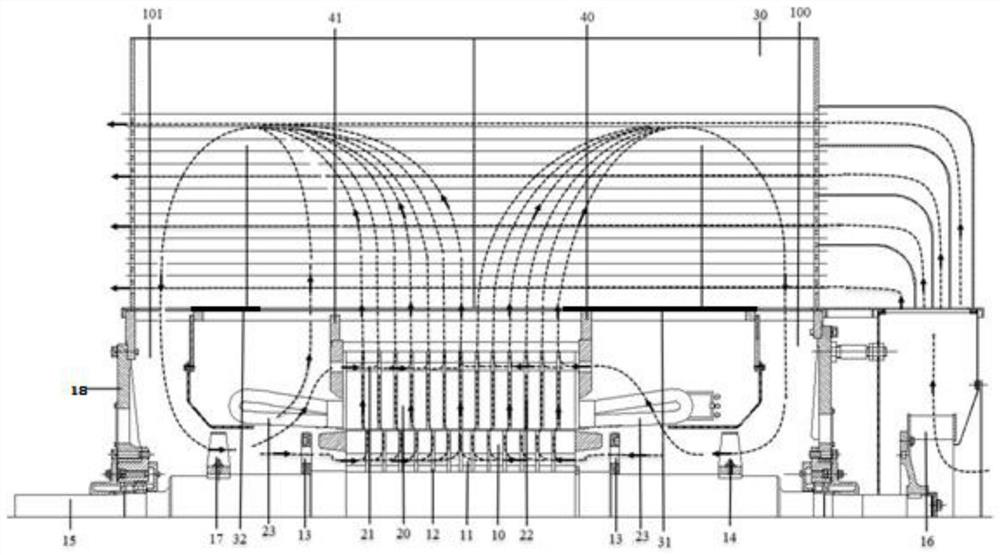

Low-nitrogen combustion device for fluidized bed boiler

ActiveCN106642090AImprove temperature distribution uniformityReduce burning intensityFluidized bed combustionStaged combustionFlue gasCoupling

The invention relates to a low-nitrogen combustion device for a fluidized bed boiler. According to the principle of oxynitride generation, through coupling of air staging and recycled flue gas staging technologies, a combustion area with three stages of the strong reducing property, the weak reducing property and oxidability is formed in the height direction of a hearth, meanwhile, the combustion intensity of a dense-phase area of the hearth is remarkably alleviated, the combustion temperature of the dense-phase area of the hearth is controlled, the distribution uniformity of the overall temperature of the hearth is improved, and generation of temperature type oxynitride is restrained; and meanwhile, generation of fuel type oxynitride is greatly lowered, and generated oxynitride can be restored into nitrogen.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

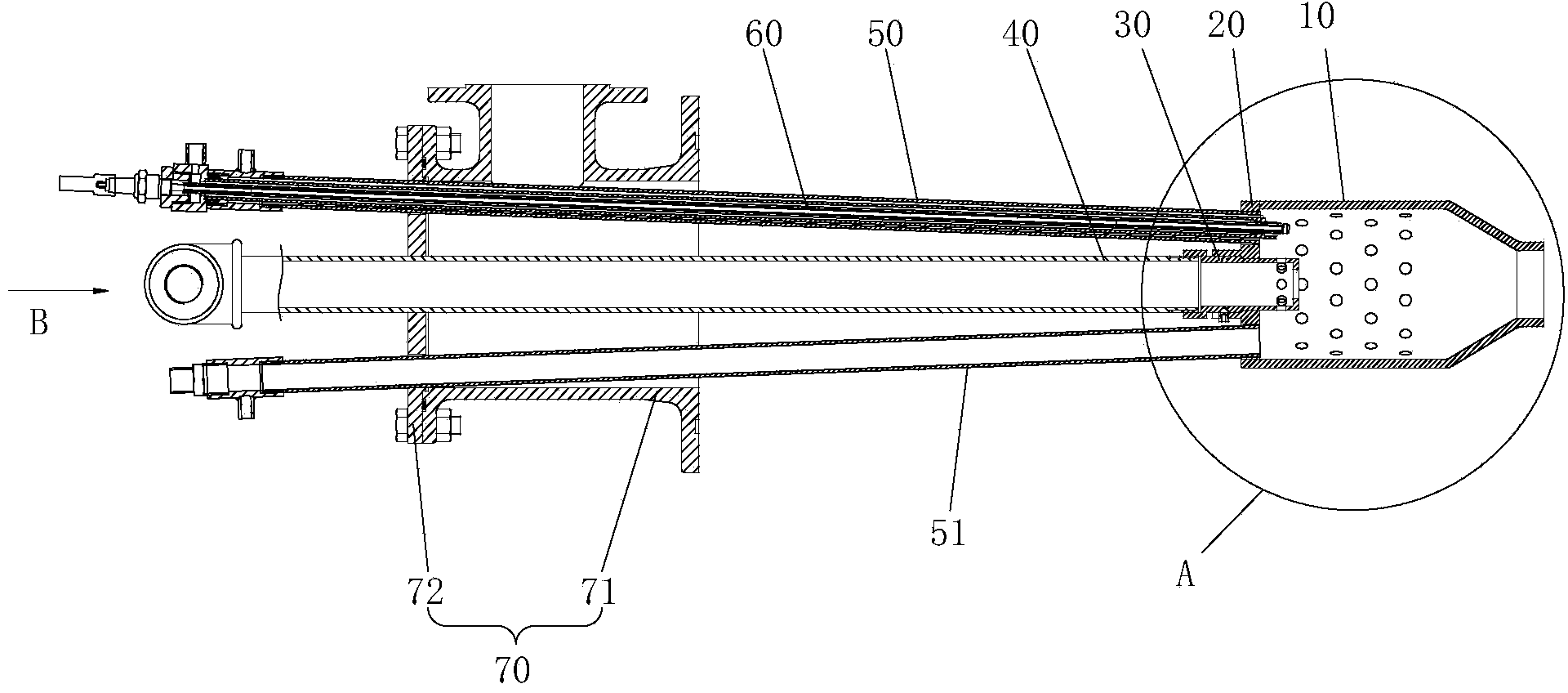

Low-calorific-value gas radiating tube burner and control method thereof

ActiveCN104266189AReduce NOx emissionsImprove temperature distribution uniformityGaseous fuel burnerSpray nozzlePollutant

The invention discloses a low-calorific-value gas radiating tube burner. The low-calorific-value gas radiating tube burner comprises a combustion chamber, an air distribution plate, a gas spraying nozzle, a gas guide tube, a first electrode guide tube, an ignition electrode and a fixing device; an inlet of the combustion chamber is provided with the air distribution plate; a combustion cavity of the combustion chamber is communicated with a radiating tube through an outlet of the combustion chamber; the air distribution plate is provided with an air inlet; the first electrode guide tube sleeves the ignition electrode; the first electrode guide tube penetrates the fixing device and the air distribution plate; the gas guide tube penetrates the fixing plate and the air distribution plate; the gas spraying nozzle is arranged at one end of the gas guide tube, wherein the end of the gas guide tube is close to the air distribution plate; the fixing device is used for fixing the low-calorific-value gas radiating tube burner into the radiating tube; the fixing device is provided with a combustion-supporting opening. The invention also provides a control method of the low-calorific-value gas radiating tube burner. According to the low-calorific-value gas radiating tube burner, the ignition stability of the burner during the application of the low-calorific-value gas is improved and meanwhile the emissions of pollutants are reduced.

Owner:WISDRI WUHAN WIS IND FURNACE

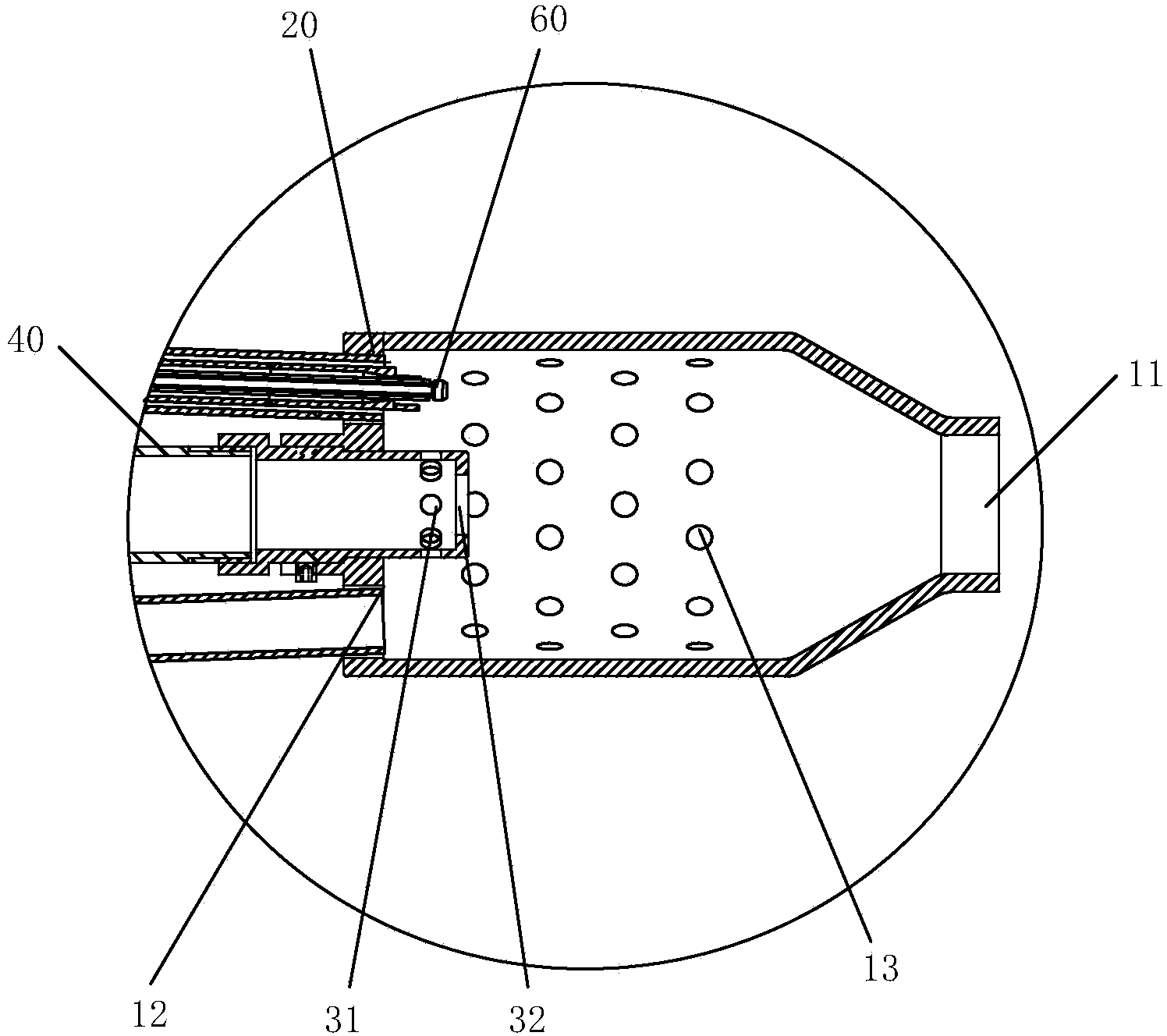

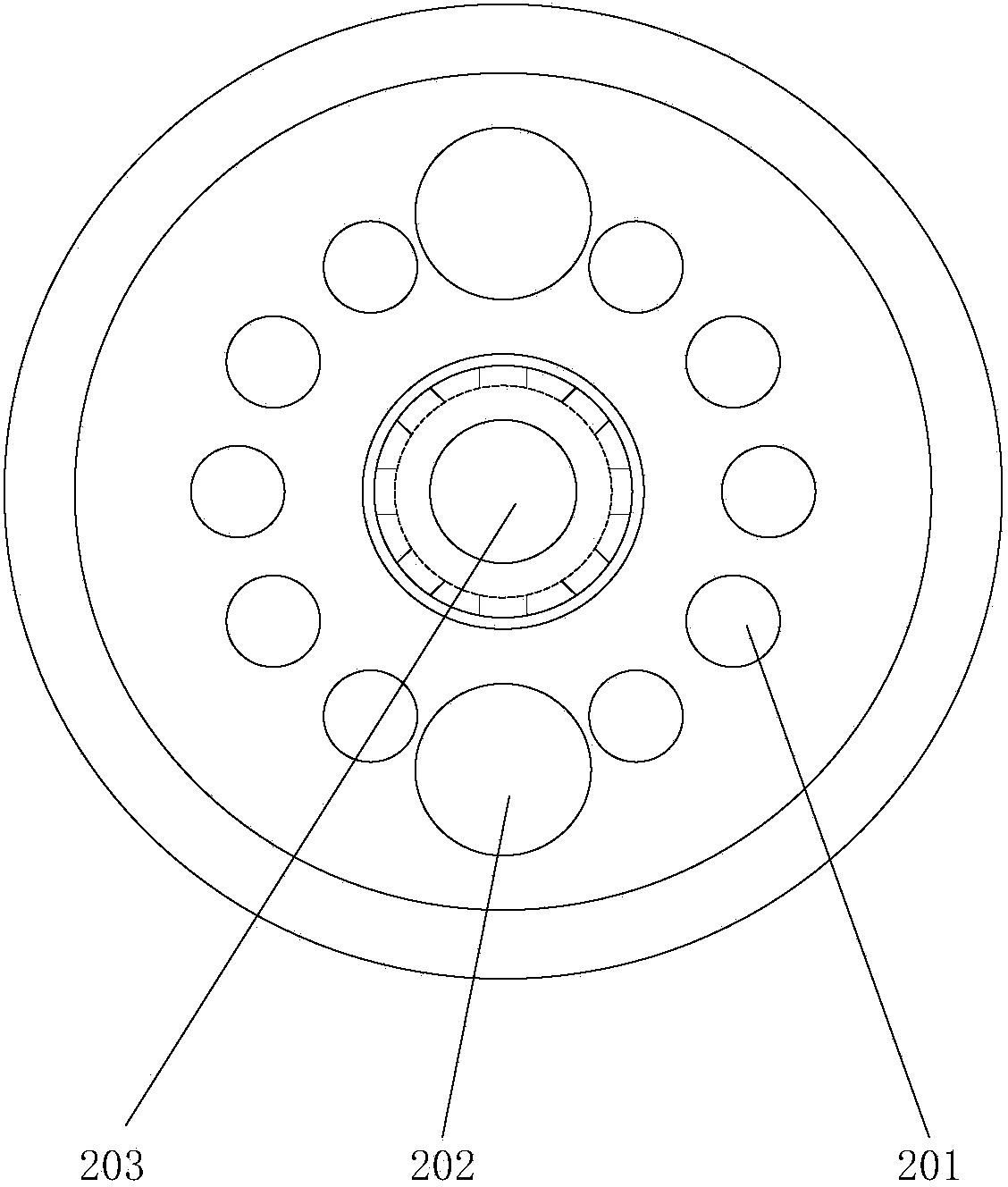

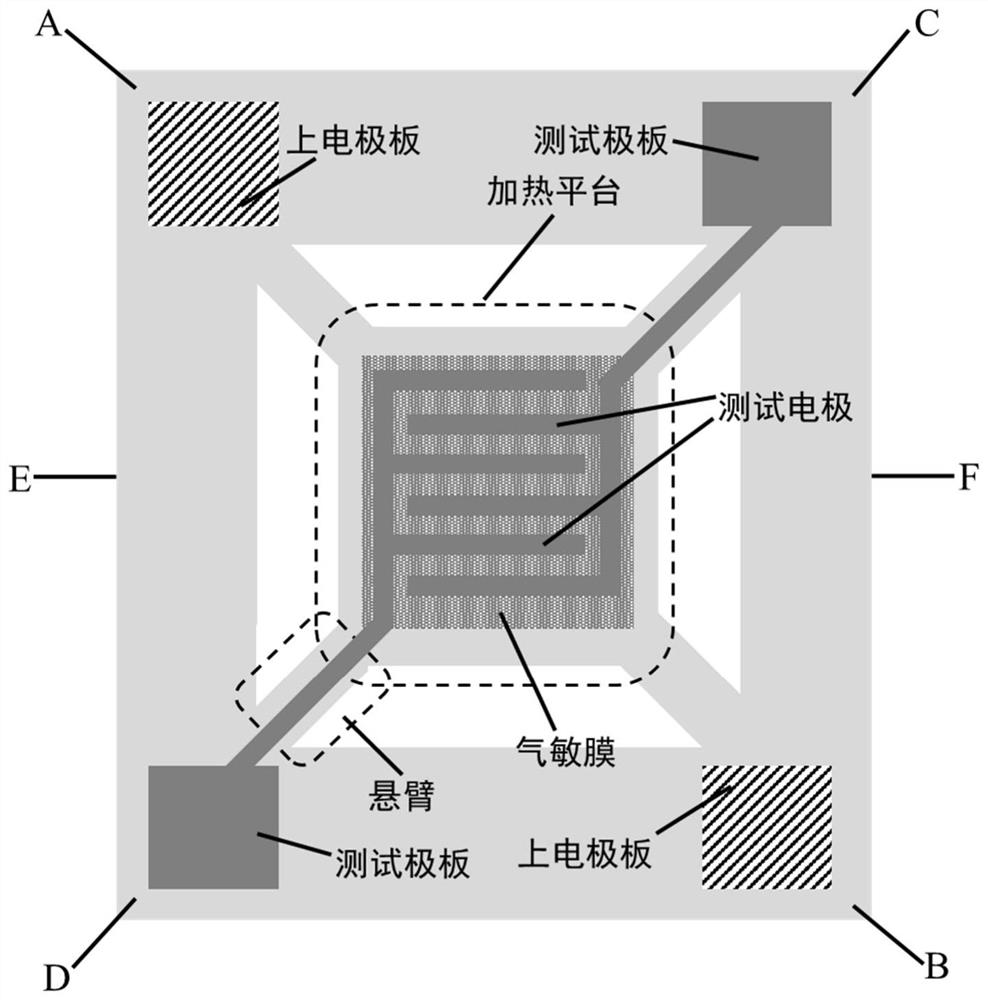

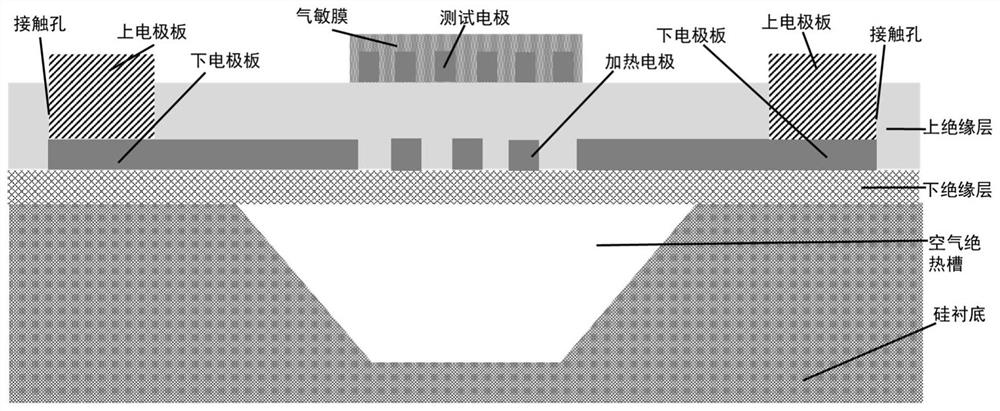

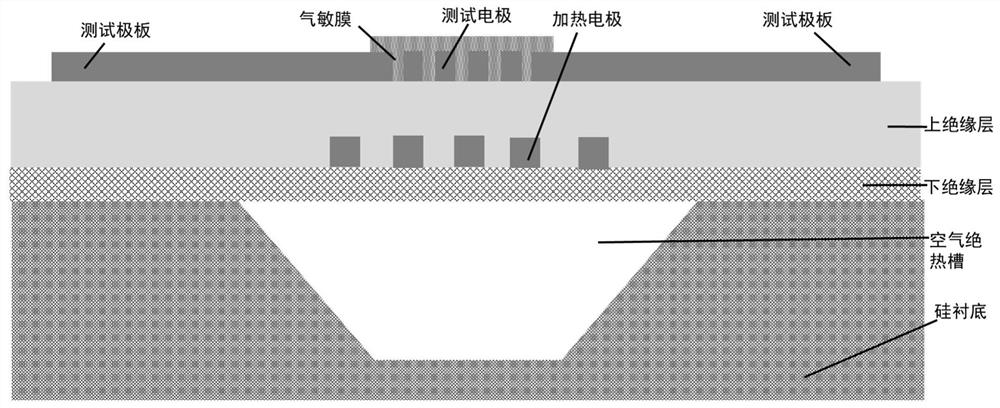

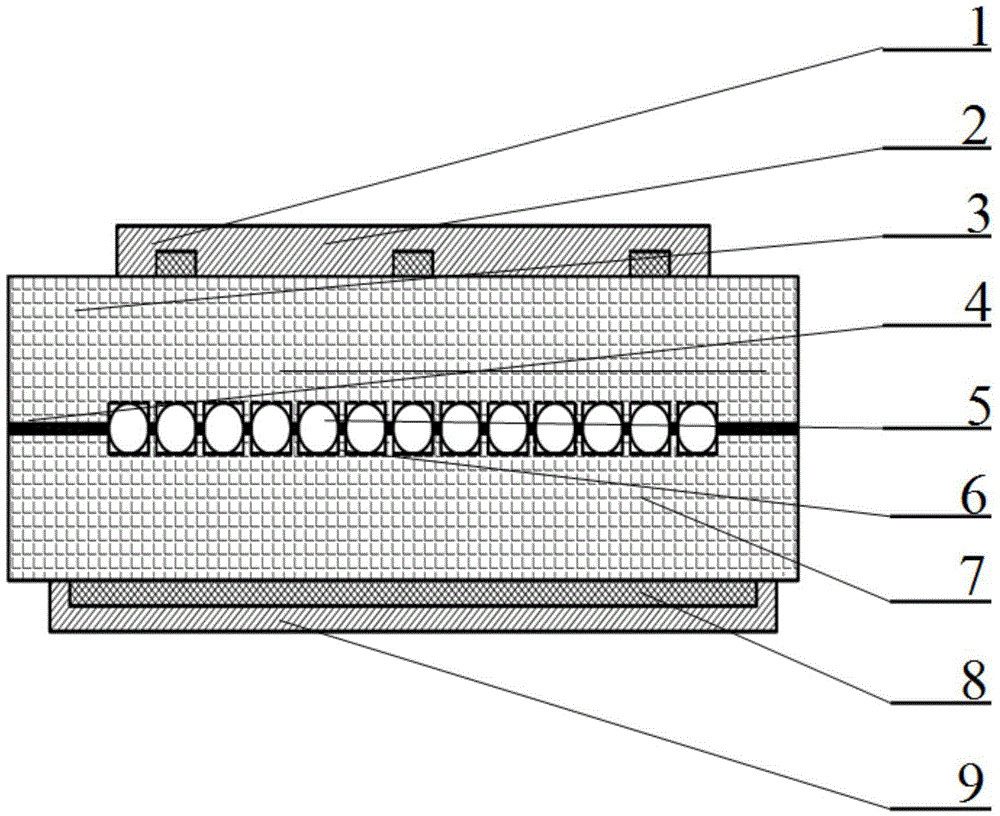

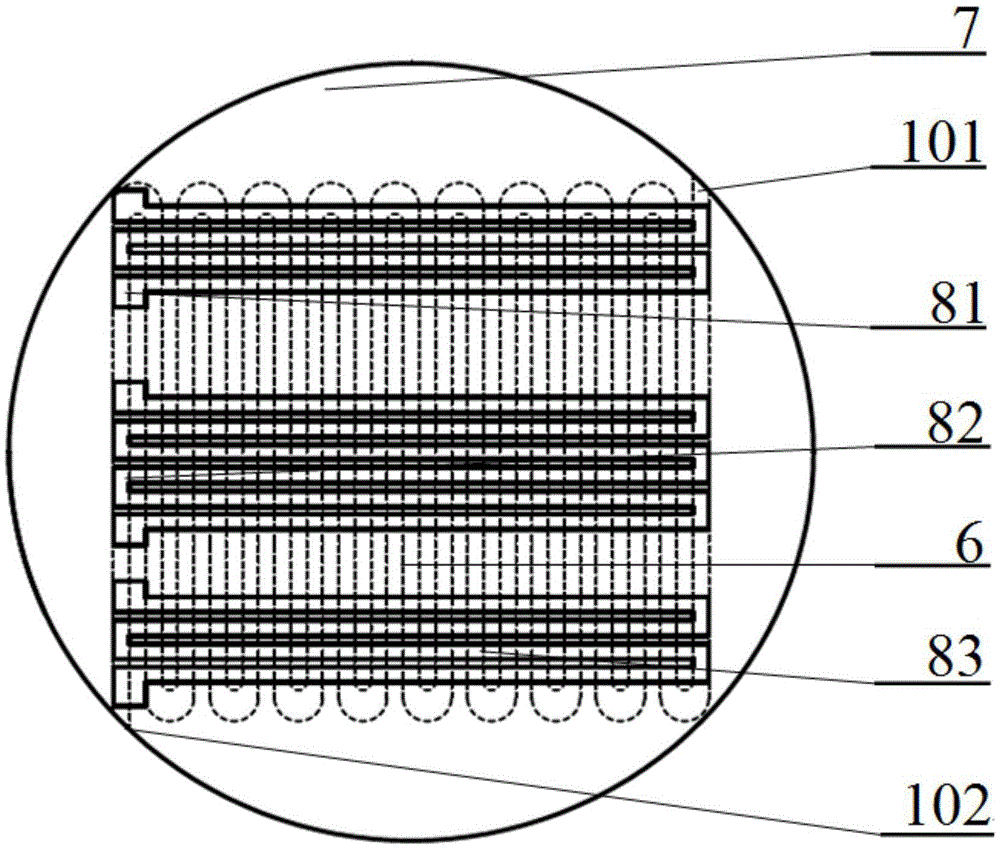

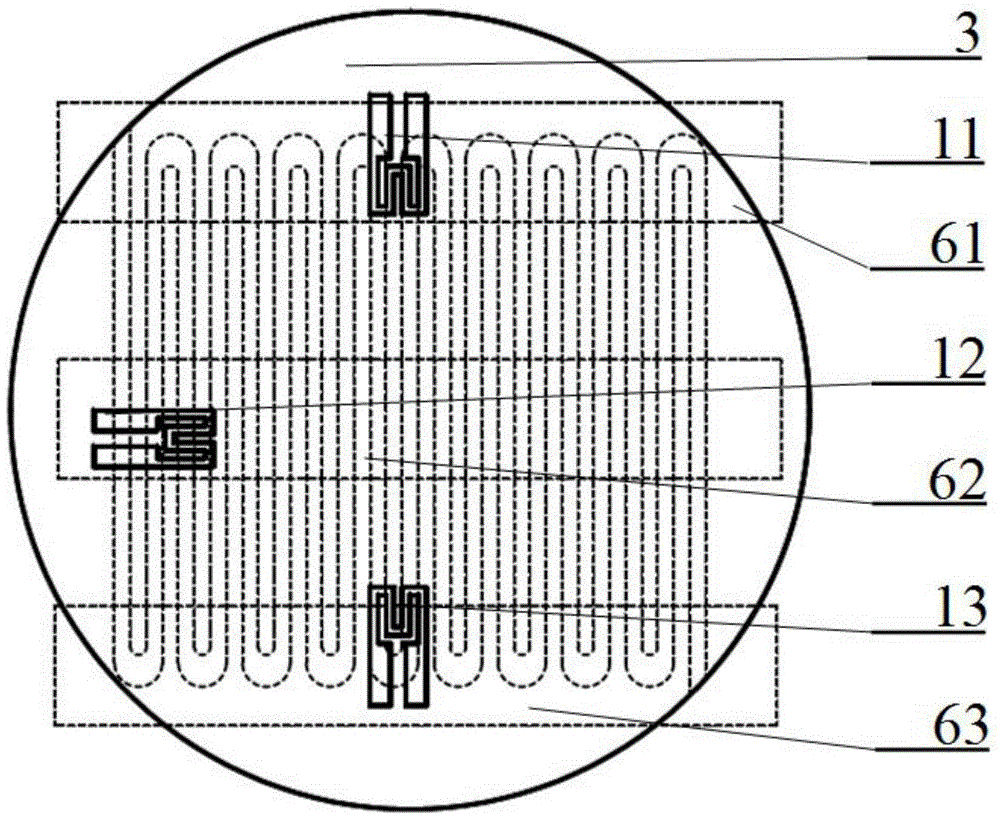

Gas sensor based on temperature compensation structure

ActiveCN111689457AImprove uniformity of temperature distributionIncrease resistanceTelevision system detailsImpedence networksInsulation layerThermal break

The invention discloses a gas sensor based on a temperature compensation structure. The problem that an existing gas sensor is uneven in temperature distribution is mainly solved. The gas sensor comprises a silicon substrate (1), a lower insulating layer (2), a temperature compensation structure heating electrode (3), an upper electrode plate (9), a lower electrode plate (4), an upper insulating layer (5), a covering layer (6), a protective layer (7), a test electrode (8), a test electrode plate (10), a heating platform (15), a cantilever (16) and a gas sensitive film (17), wherein an air heatinsulation groove (11) is formed in the silicon substrate through corrosion, a through hole array (12) and an air heat insulation layer (13) are arranged in the middle of the covering layer, a contact hole (14) is formed between the lower electrode plate and the upper electrode plate, and the heating electrode of the temperature compensation structure is composed of m circles of electrodes of which the thicknesses are gradually reduced from inside to outside. The gas sensor is uniform in temperature distribution and low in power consumption, and can be used for monitoring chemical gas in thefields of chemical production and safe home furnishing.

Owner:XIDIAN UNIV

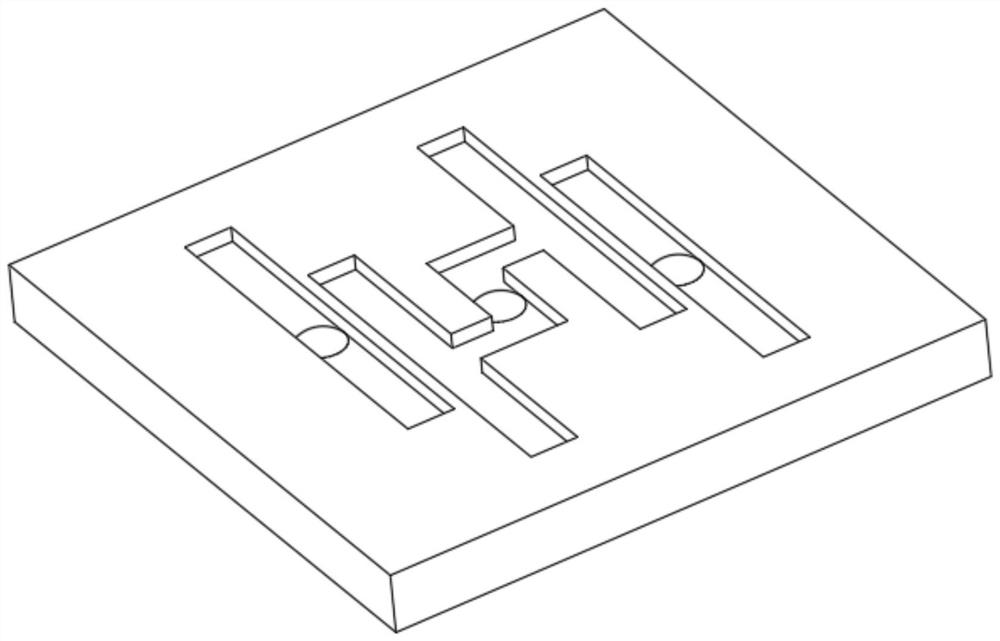

Three-temperature-region channel embedded continuous flow laminated PCR (polymerase chain reaction) chip

InactiveCN104893954AReduce generationImprove temperature distribution uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsPcr chipElectricity

The invention provides a three-temperature-region channel embedded continuous flow laminated PCR (polymerase chain reaction) chip. Temperature measurement electrodes are arranged on the upper surface of an upper substrate; heating electrodes are arranged on the lower surface of a lower substrate; the upper substrate and lower substrate are bonded to form an integral body; and the reaction channels are formed by splicing grooves which are symmetrically etched on the lower surface of the upper substrate and the upper surface of the lower substrate. The substrates are divided into three different regions at certain intervals according to three different reaction regions of PCR, and the reaction solution continuously flows through the three different regions to complete the reaction; and in one reaction region, the temperature distribution uniformity is higher, and no repeated rise and fall of the temperature are needed, thereby shortening the total reaction time and saving the time. The reaction channels are symmetrically arranged on the upper and lower surfaces, so that the distance between the temperature measurement elements and the reaction solution becomes shorter, and the temperature measurement accuracy is higher. The fine hoses in the reaction channels restrict the reaction solution, thereby reducing the generation of bubbles.

Owner:SHANGHAI JIAO TONG UNIV

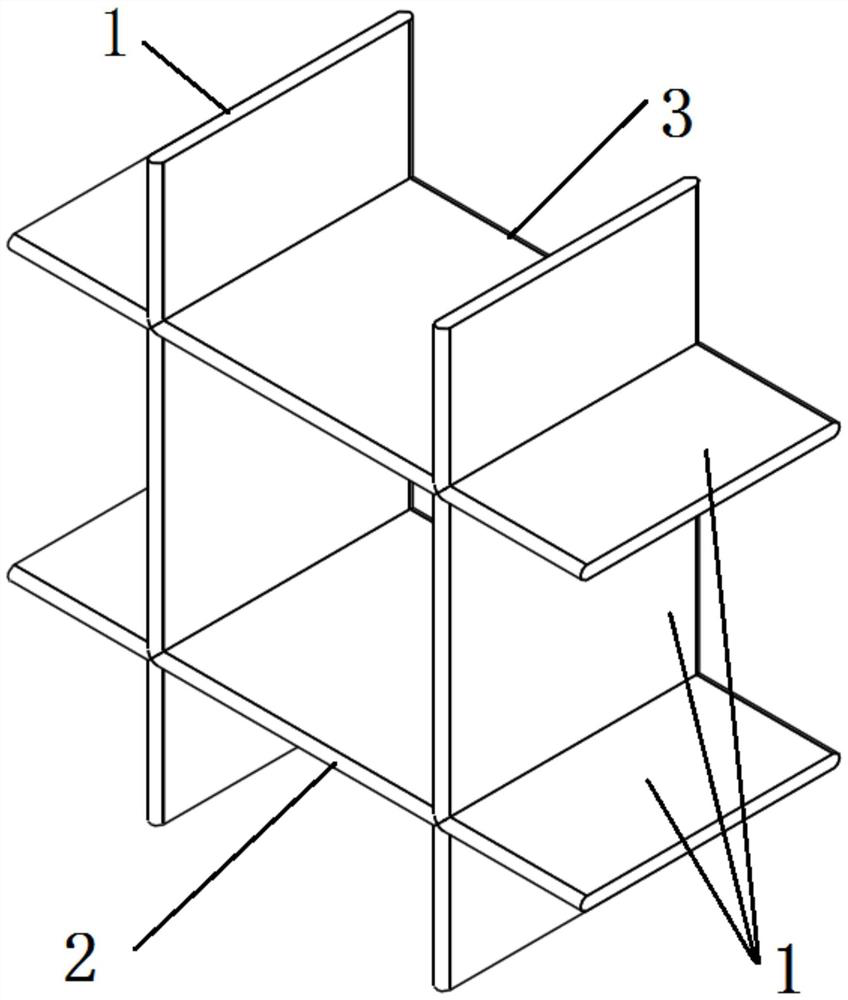

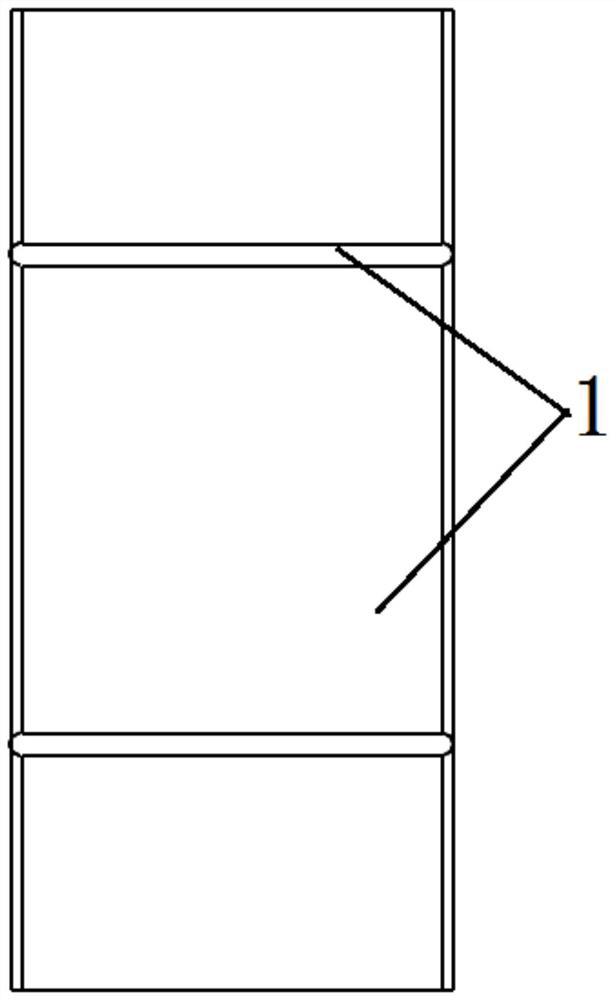

Grid rudder and aircraft

PendingCN111731467AThe absolute value of the slope of the tangent line decreases continuouslyReduce structural strengthAircraft controlFlight vehicleRudder

The invention provides a grid rudder and an aircraft. The grid rudder comprises a plurality of partition plates which are connected with each other and form a grid structure; wherein each partition plate is oppositely provided with a windward side and a leeward side along the two ends of the intersection line of the partition plates, at least one part of the windward side is provided with a notch,and the absolute value of the tangent slope of the outer surface where the notch is located is continuously reduced along the direction from the windward side to the leeward side, a flow guide curvedsurface is formed at the windward side, square arrangement at the windward side is avoided, and under hypersonic speed environment, on one hand, differential pressure resistance and friction resistance are reduced, power efficiency is improved, the total heat generated by heating of the windward side is reduced, and the structural strength of materials of the grid structure is guaranteed; on theother hand, the condition of local high heat generated by protruding parts such as edges and corners under the condition of airflow friction is improved, the aerodynamic heat of the grid structure isreduced, the thermal environment distribution of the grid structure is improved, and the temperature distribution uniformity is improved, so that the structural thermal stress is reduced, and the strength performance is optimized.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

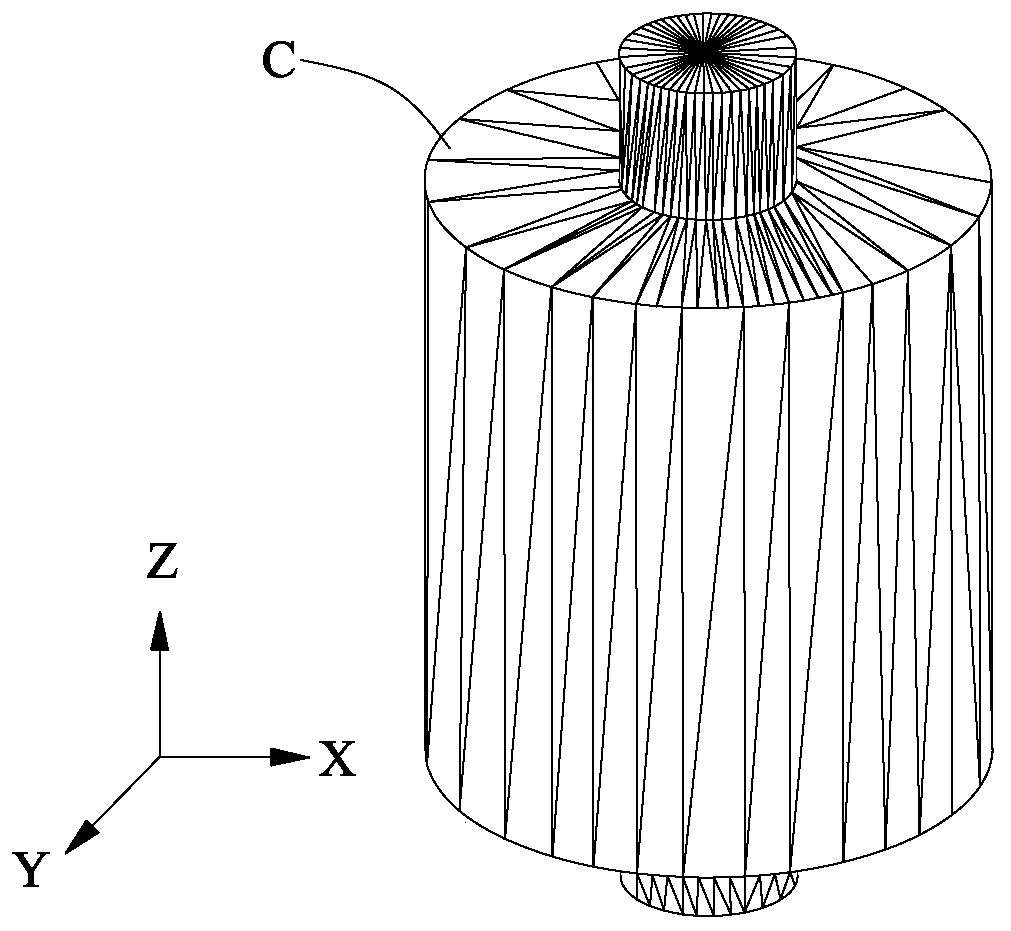

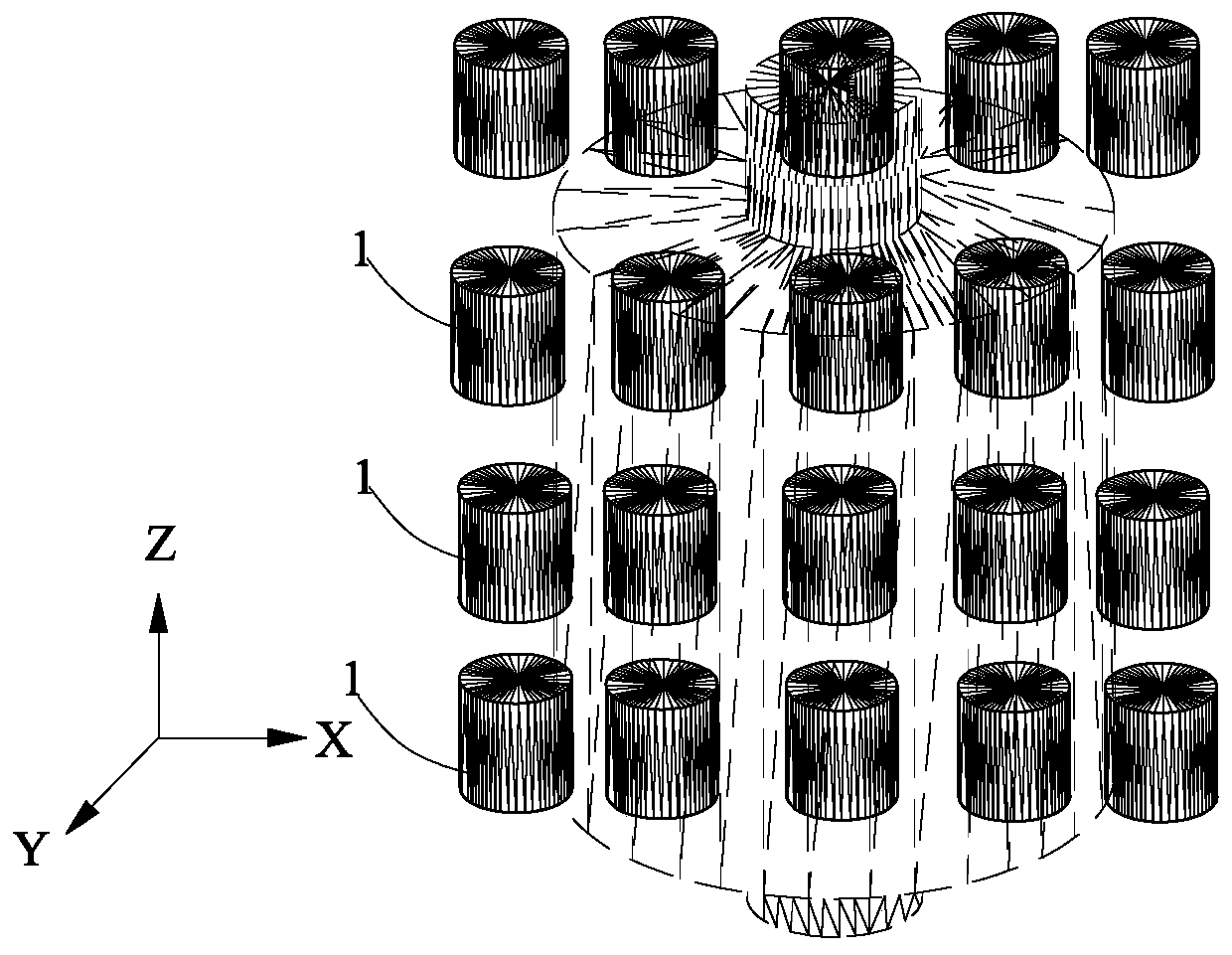

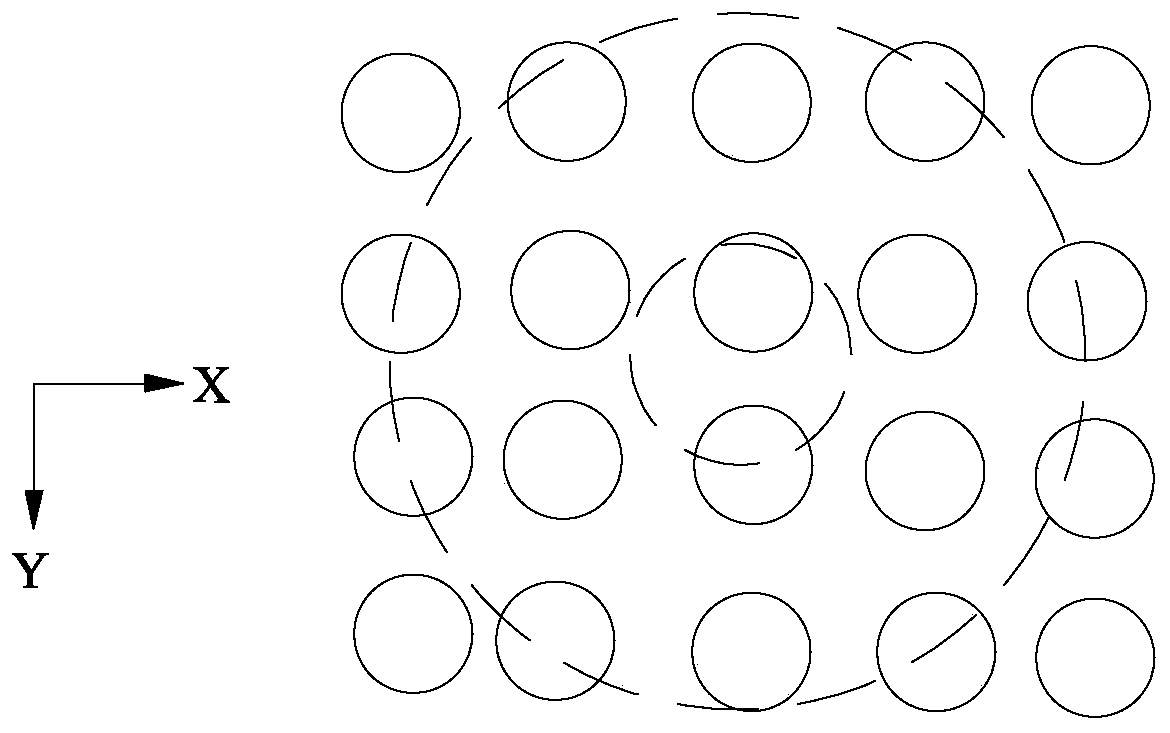

Design method of smooth inner cavity of hollow casting mold or hollow sand core

ActiveCN111085667AReduce crackingAvoid crackingAdditive manufacturing apparatusFoundry mouldsModelSimCasting mold

The invention provides a design method of a smooth inner cavity of a hollow casting mold or a hollow sand core. The design method comprises the steps of modeling standard blocks, and then outputting an STL formatted file, wherein the surfaces of the constructed standard blocks are smooth; outputting the STL formatted file of the casting mold or the sand core in modeling software; reading the STL formatted file of the standard blocks, and scaling the size of the corresponding direction of the standard blocks; reading the STL formatted file of the casting mold or the sand core; putting the scaled standard blocks in an array; determining the relation between the outline of the standard blocks and the outline of the casting mold or the sand core in each perpendicular cross section of an X axis, a Y axis and a Z axis; determining the distance between the outline of the casting mold or the sand core and the outline of each standard block; and reversing normals of all triangular patches of the standard blocks which are reserved ultimately, and adding the reversed standard blocks to the STL formatted file of the casting mold or the sand core so as to generate the STL formatted file of thehollow casting mold or the hollow sand core with the smooth inner cavity.

Owner:TSINGHUA UNIV +1

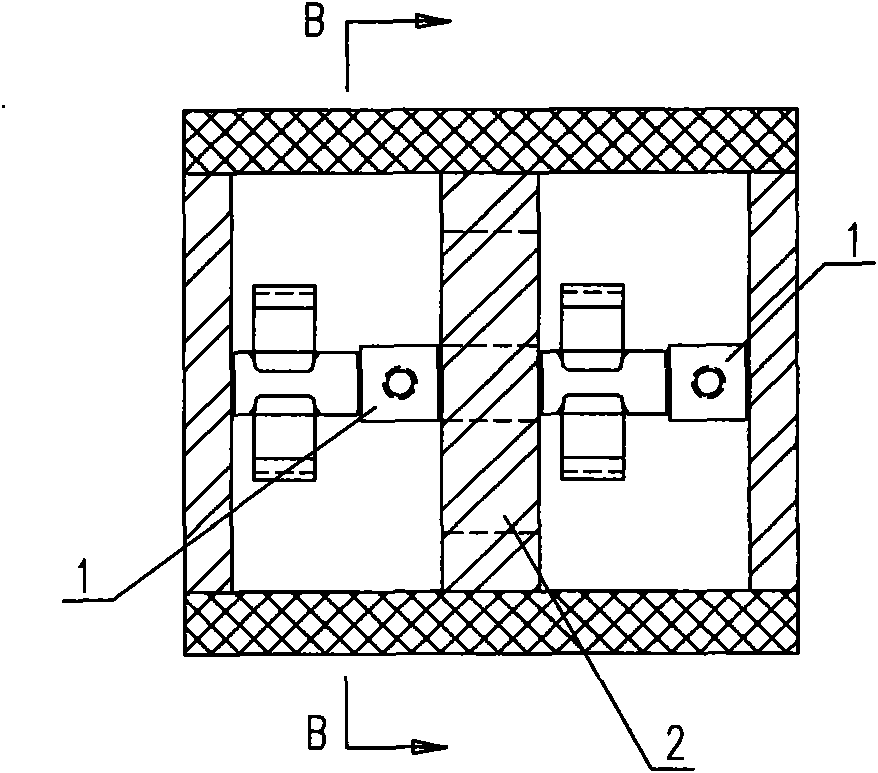

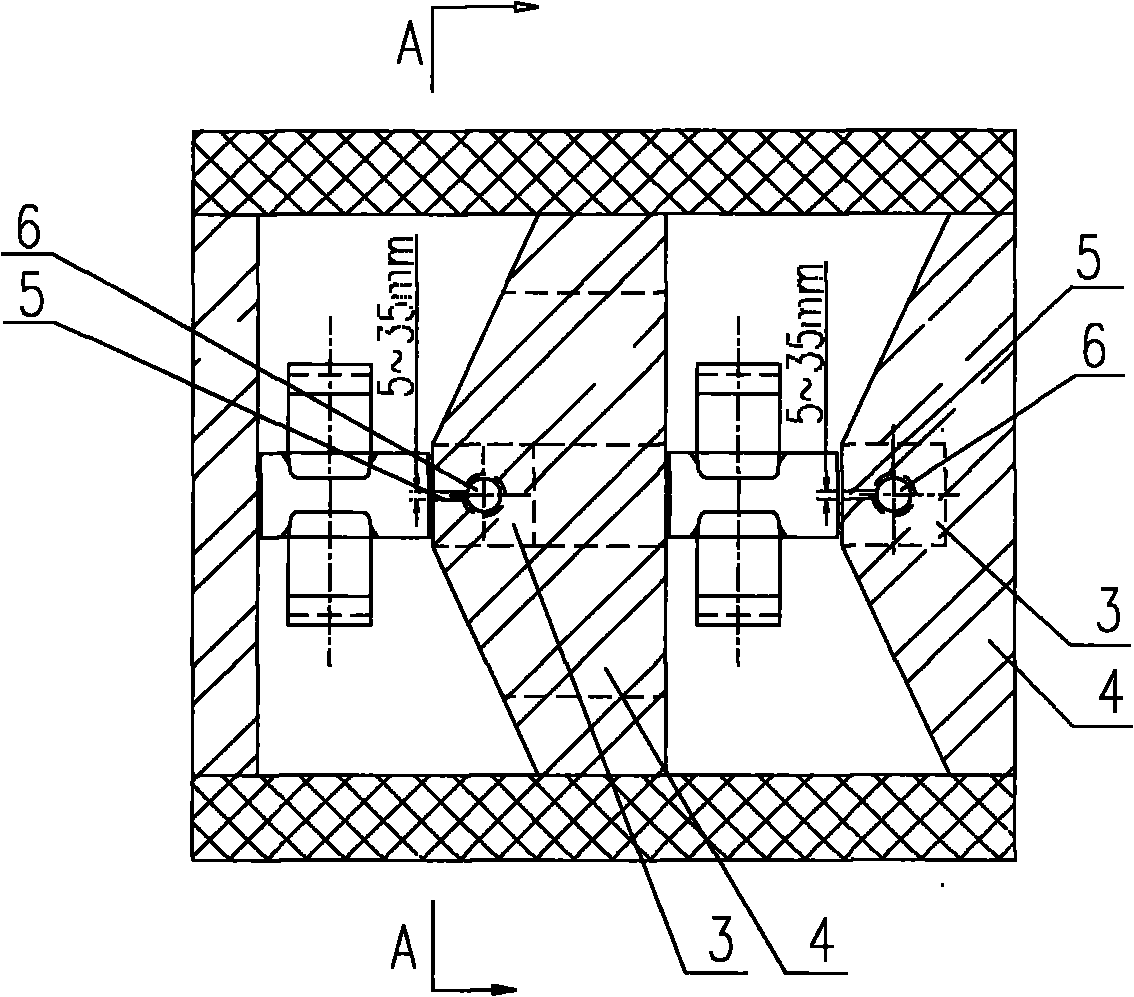

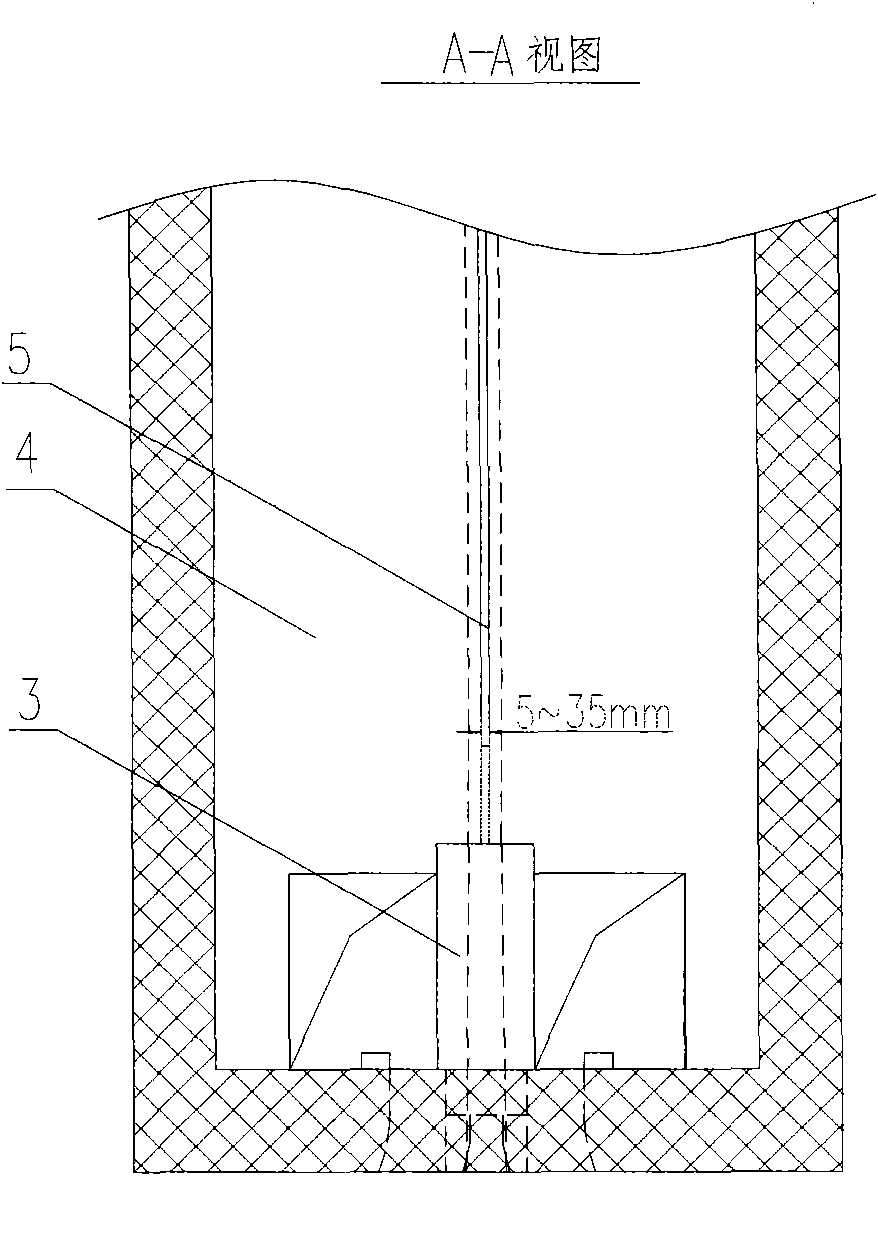

Coke oven combustion chamber flue with optimized structure

InactiveCN101906307ALimit the rate of diffusionReduce contact areaCombustible gas coke oven heatingCoke oven detailsBrickCombustion chamber

The invention relates to the field of combustible gas downdraft coke ovens, in particular to a coke oven combustion chamber flue with an optimized structure. The flue comprises tubular bricks and a partition wall, and is characterized in that: the flue is realized by lengthening the travel of a combustible gas in the flue and forming a combustible gas passage in the flue along the travel, wherein the partition wall and the tubular bricks form a semi-enclosed structure along a horizontal direction; the partition wall is provided with a gas flow passage above the tubular bricks along a vertical direction; and the gas flow passage is provided with a groove-shaped gap with the width of between 10 and 35mm and the height of between 10 and 10,000mm. Compared with the prior art, the flue has the advantages that: because a gas outlet has a narrow groove structure, the diffusion speed of the gas is limited; the contact area of the gas and a combustion-supporting gas at the bottom of the flue is reduced, so the combustible gas is diffused from bottom to top along the groove-shaped gap, the combustion-supporting gas is excessively distributed in the flue and the flame is elongated, which is favorable for improving the uniformity of the temperature distribution in the flue; and meanwhile, because the partition wall becomes wider, the structural strength of a coke oven combustion chamber can also be improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

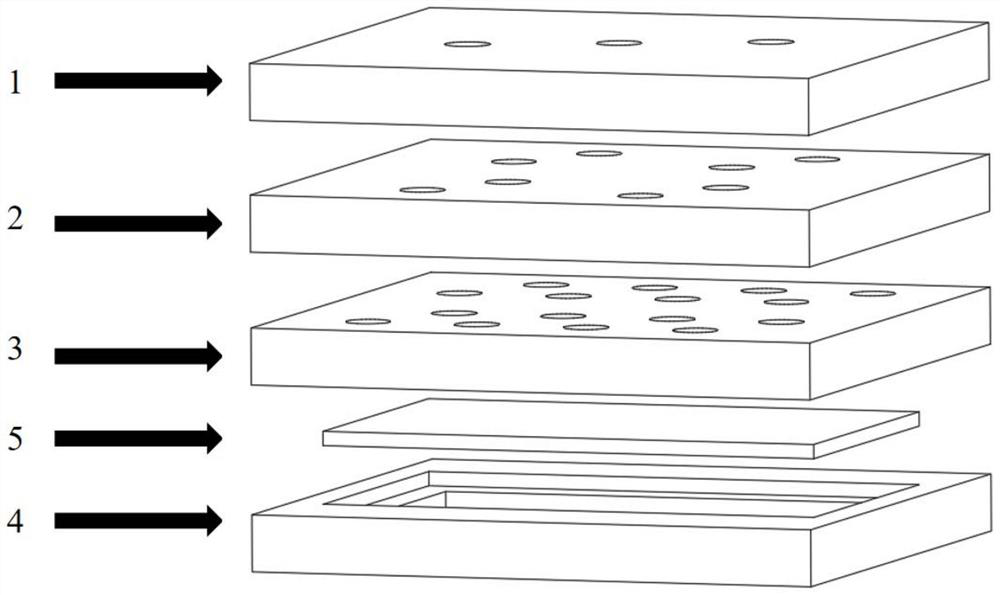

Hierarchical manifold micro-channel heat dissipation device

PendingCN114141733AAvoid Flow Dead ZonesAvoid the problem of premature dry burningSemiconductor/solid-state device detailsSolid-state devicesHeat fluxThermodynamics

The invention discloses a graded manifold micro-channel heat dissipation device. The graded manifold micro-channel heat dissipation device mainly comprises a first-stage micro-channel, a second-stage micro-channel, a third-stage micro-channel and a bottom plate part. The four layers of channels are packaged through the bonding technology, working medium inlets and working medium outlets are located in the top, and the number of the micro-channels and the number of the manifold channels can be increased according to the heat exchange area. A heat exchange working medium flows into the third-stage micro-channel through the first-stage micro-channel and the second-stage micro-channel, is split into the last eight inlets from the first two inlets and flows to the surface of the analog chip, and the temperature distribution uniformity of the surface of the analog chip is improved through uniform distribution of the working medium. And the working medium after heat exchange is converged into the first-stage micro-channels through the third-stage micro-channels and the second-stage micro-channels, and finally is converged to an outlet in the middle through the two first-stage micro-channels to flow out. The flow channel is segmented into a plurality of micro-channel units, the flow length is shortened, so that the pressure drop is reduced, a thermal boundary layer is difficult to develop in the micro-channel, and the heat exchange coefficient is increased and the total thermal resistance is reduced. The device has the advantages of being small in occupied area, low in power consumption and high in heat dissipation capacity, and can be used for meeting the heat dissipation requirement exceeding the heat flux density.

Owner:XI AN JIAOTONG UNIV

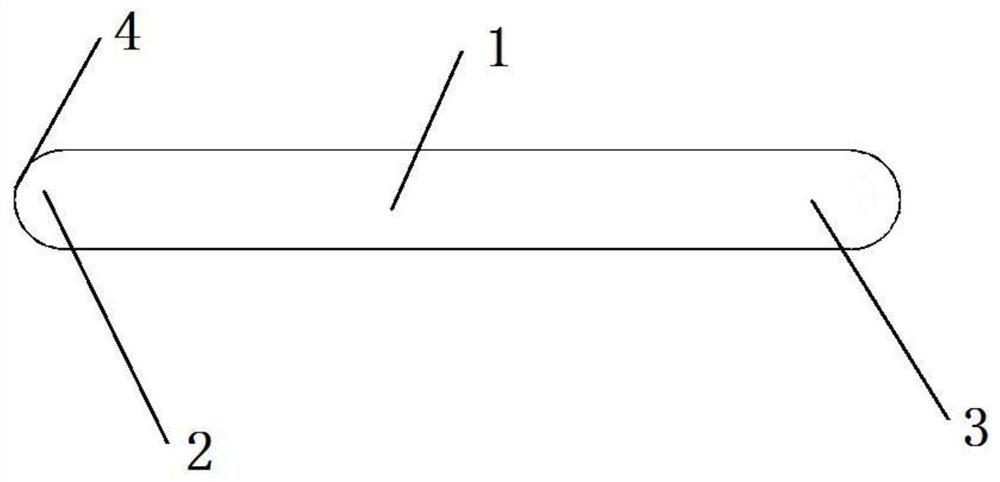

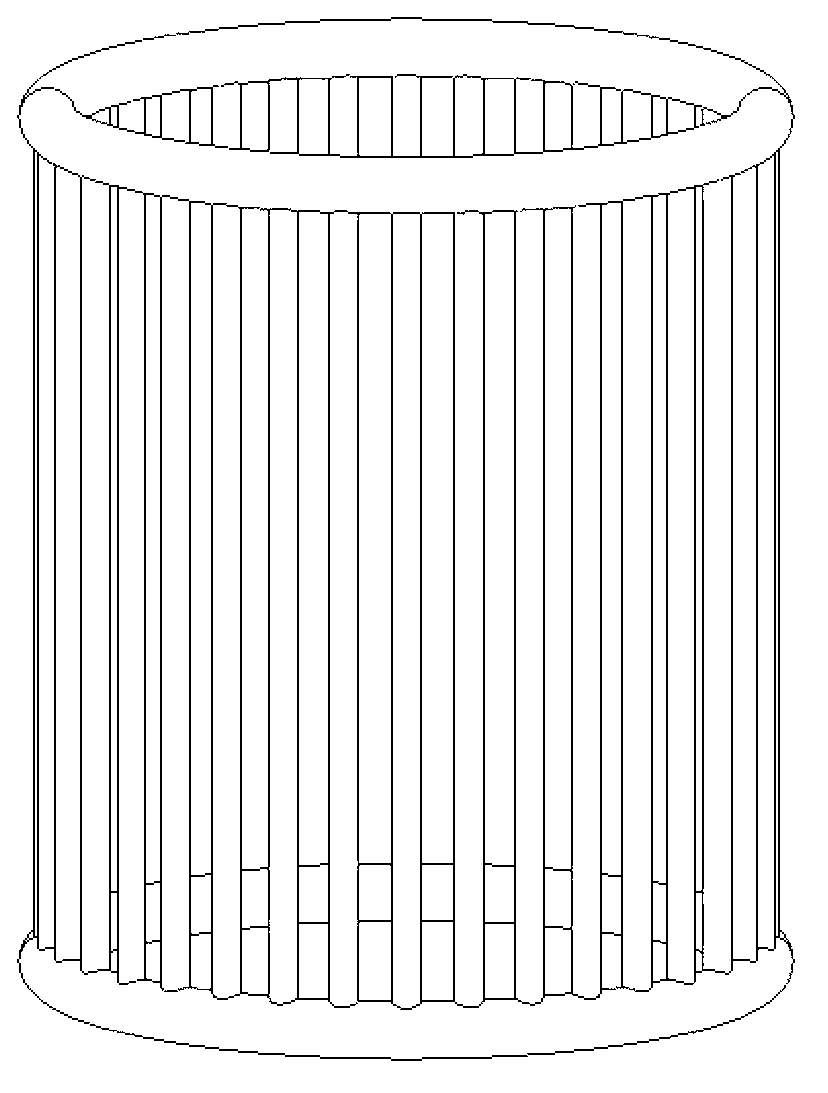

Noise reduction method for molecule-electronics induction type linear speedometer based on heat conduction structure

ActiveCN104409072AReduce temperature differenceReduce the temperatureSound producing devicesElectrolytic agentThermal insulation

The invention relates to a noise reduction method for a molecule-electronics induction type linear speedometer based on a heat conduction structure, and belongs to the technical field of noise processing. According to the noise reduction method for the molecule-electronics induction type linear speedometer based on the heat conduction structure, a multi-tube / single-tube (helix tube) heat conduction structure is adopted, and self noise is restrained. The noise reduction method relates to the multi-heat-tube or single-heat-tube structures, wherein multiple heat tubes or single heat tubes can be of straight-tube structures or multiple spiral structures / single spiral structures; the heat tubes are placed in a reaction cavity of the molecule-electronics induction type linear speedometer; a thermal insulation interlayer is arranged outside the reaction cavity; and the design of a reaction cavity structure, of the single cylindrical reaction cavity structure and the multi-tube / single-tube (helix tube) heat conduction structure, of the molecule-electronics induction type linear speedometer is adopted. The temperature distribution uniformity of electrolytes in the cavity is effectively improved; electrolyte internal heat conduction transition process caused by uneven temperature distribution of the molecule-electronics induction type linear speedometer is shortened; and the self noise caused by uneven temperature distribution of the molecule-electronics induction type linear speedometer is reduced. By means of the noise reduction method, the signal to noise ratio of the molecule-electronics induction type linear speedometer is fundamentally improved; and a great help is provided for improving performance indexes.

Owner:JILIN UNIV

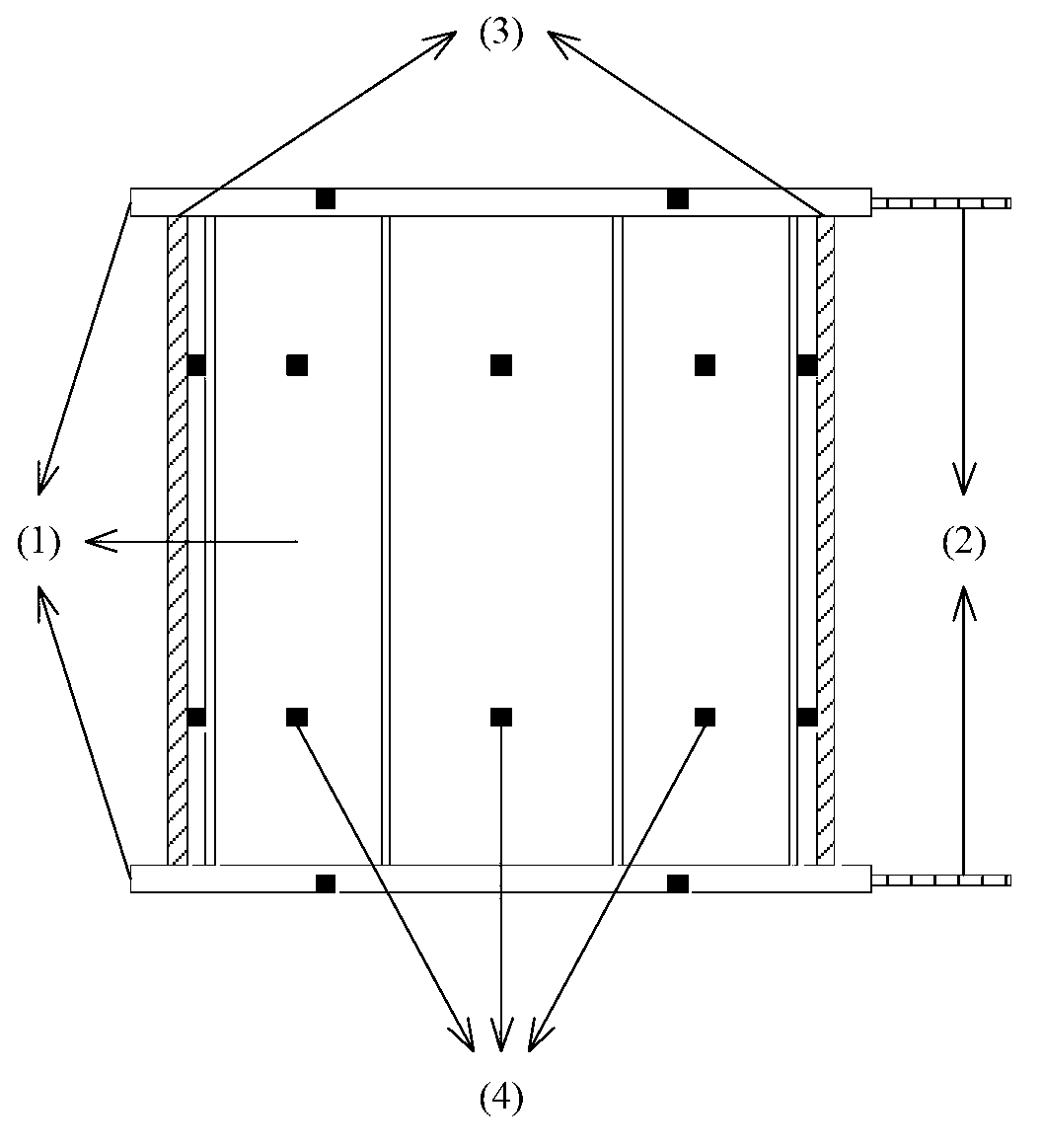

Aluminum-made vertical heat sink device with high temperature distribution uniformity

InactiveCN103008041AStrong black adhesionImprove temperature distribution uniformityHeating or cooling apparatusEnclosures/chambersCooling effectPrism

The invention discloses an aluminum-made vertical heat sink device with high temperature distribution uniformity. The heat sink device consists of fin tube array sides, a metal corrugated soft pipe, a plurality of thermal insulating material layers and a temperature acquisition system, wherein an eight-prism-shaped side surface is formed by eight fin tube array sides being 460mm*1160mm; two fin tube array sides being 1120mm*1200mm are respectively used as the top surface and the bottom surface of the heat sink device; the metal corrugated soft pipe is connected with the surfaces so as to integrate an inner cavity of the whole heat sink device; thermistors in the temperature acquisition system are adhered to the outer surface of the heat sink device; and the plurality of thermal insulating material layers are wrapped at the outermost surface of the device. The aluminum-made vertical heat sink device has the advantages of good temperature distribution uniformity, good cooling effect, rapid cooling speed, small size, convenience in operation and maintenance, and the like, and has a good practical value and an application prospect in the field of space technologies.

Owner:BEIHANG UNIV

Polishing disk and cooling device thereof

ActiveCN105290956AReduce the temperatureImprove temperature distribution uniformityLapping toolsReturn channelWaste management

The invention discloses a cooling device of the polishing disk. The cooling device is applied to the polishing disk and comprises a cooling water inlet, cooling water outlets, an annular liquid return tank, liquid return channels and cooling water grooves. The cooling water inlet and the cooling water outlets are formed in the polishing disk. The annular liquid return tank and the liquid return channels are formed in the polishing disk, one end of each liquid return channel is communicated with the liquid return tank, and the other ends of the liquid return channels are communicated with the cooling water outlets. The cooling water grooves are formed in the polishing disk and located in the area, wrapped by the liquid return tank, of the polishing disk, and the cooling water grooves are evenly distributed in a branch shape. Each cooling water groove comprises a main groove body and side groove bodies, wherein one end of the main groove body is communicated with the cooling water inlet, the other end of the main groove body is communicated with the liquid return tank, one ends of the side groove bodies are communicated with the main groove body, and the other ends of the side groove bodies are communicated with the liquid return tank. The invention further discloses the polishing disk with the cooling device.

Owner:ACM RES SHANGHAI

Battery pack heat exchange system and electric vehicle

InactiveCN108172927AGuaranteed rangeEnsure safetySecondary cellsElectric vehicle charging technologyEngineeringElectric vehicle

The present invention provides a battery pack heat exchange system and an electric vehicle, pertaining to the technical field of new energy sources. The battery pack heat exchange system comprises multiple heat exchange devices, a total water inlet pipe and a total water outlet pipe. The multiple heat exchange devices are arranged corresponding to multiple batteries in a battery pack one by one, and each heat exchange device comprises a water inlet and a water outlet. The multiple water inlets are all connected with the total water inlet pipe, and the multiple water outlets are all connected with the total water outlet pipe, so that the multiple heat exchange devices are connected in parallel. Each heat exchange device is arranged under each single battery, the multiple heat exchange devices are connected in parallel, and when the heat exchange is needed, each heat exchange device performs heat exchange independently, so that the mutual contamination between the heat exchange devices is reduced, and the heat exchange of the battery pack is more even. The electric vehicle comprises the battery pack heat exchange system. The battery pack heat exchange system and the electric vehiclecan solve the technical problem of uneven temperature control among single batteries in the battery pack.

Owner:SHANGHAI HUAPU AUTOMOBILE CO LTD +1

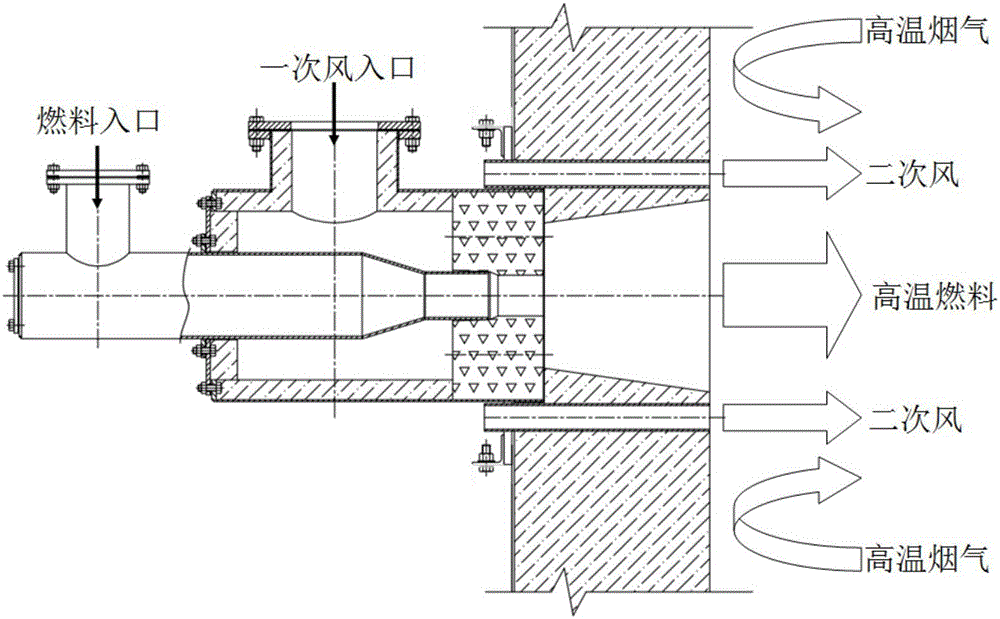

Staged oxygen-enriched flameless combustion gas burner and its control method

ActiveCN104235849BUnlimited calorific valueEfficient use ofIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHeating furnace

The invention discloses a grading oxygen-enriched flameless combustion gas burner which comprises a burner shell, an air distribution plate, a pre-combustion chamber, secondary air spray pipes and a fuel spray pipe. The wall of a heating furnace is provided with a channel penetrating through the wall, the burner shell is arranged on one side of the channel, the pre-combustion chamber is formed in space in the channel, the burner shell is provided with a combustion-supporting air channel, the fuel spray pipe is provided with a fuel channel, the air distribution plate is provided with a primary air inlet and a fuel inlet, the secondary air spray pipes are arranged and provided with secondary air channels used for introducing oxygen-enriched air or air into a hearth of the heating furnace, the secondary air spray pipes penetrate through the wall of the heating furnace, and the secondary air channels are communicated with the hearth of the heating furnace. The grading oxygen-enriched flameless combustion gas burner optimizes temperature distribution in the furnace and meanwhile reduces emission of NOx.

Owner:WISDRI WUHAN WIS IND FURNACE

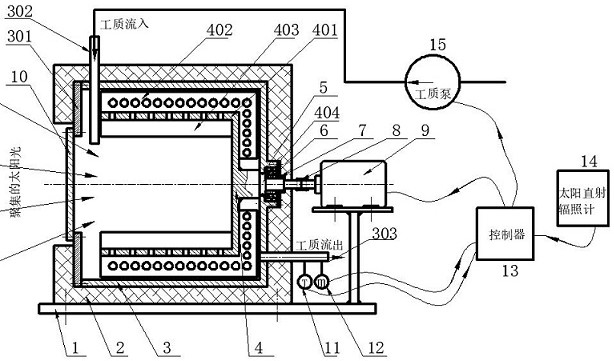

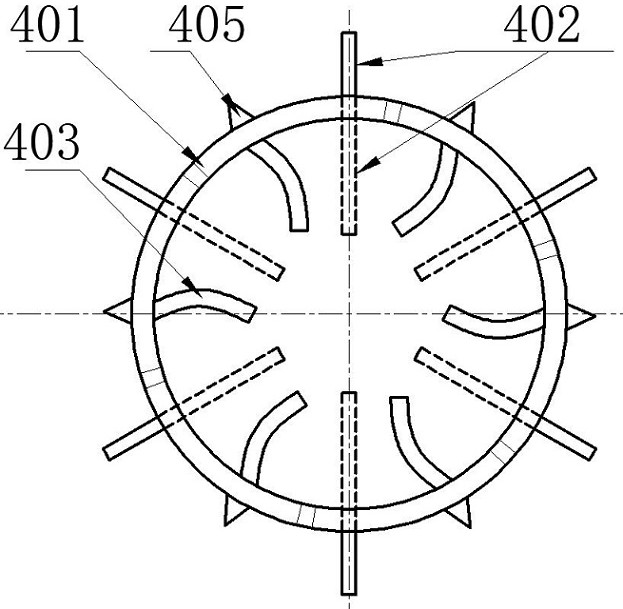

Volumetric solar cavity heat absorber with rotary heat absorbing body

InactiveCN113294919AImprove temperature distribution uniformityEnhanced convective heat transfer intensitySolar heating energySolar heat collector controllersGlass coverDrive shaft

The invention discloses a volumetric solar cavity heat absorber with a rotary heat absorbing body. The volumetric solar cavity heat absorber is composed of an outer barrel, the heat absorbing body, a glass cover plate, a motor, a controller, a temperature sensor and the like, wherein the heat absorbing body is composed of a heat absorbing main body in a concave cavity shape, a plurality of outer fins arranged on the outer side surface and the outer bottom surface of the heat absorbing main body, a plurality of inner fins arranged on the inner side surface of the heat absorbing main body and a transmission shaft arranged at the bottom of the heat absorbing main body; the inner surface of a concave cavity of the heat absorbing main body absorbs sunlight; a plurality of through holes are formed in the side wall and the bottom of the heat absorbing main body and the outer fins; and the transmission shaft is matched with a stepped hole in the bottom of the outer barrel through the shaft surface of the transmission shaft and an installed bearing, and the tail end of the transmission shaft is fixedly connected with an output shaft of the motor through a connecting sleeve. The motor is controlled to drive the heat absorbing body to rotate, so that the convective heat exchange intensity of the heat absorbing body and a heat transfer working medium is improved, the working temperature distribution of the heat absorbing body and the distribution uniformity of absorbed solar energy are improved, and safe, reliable and efficient operation of the solar heat absorber achieved.

Owner:HUNAN UNIV OF SCI & TECH

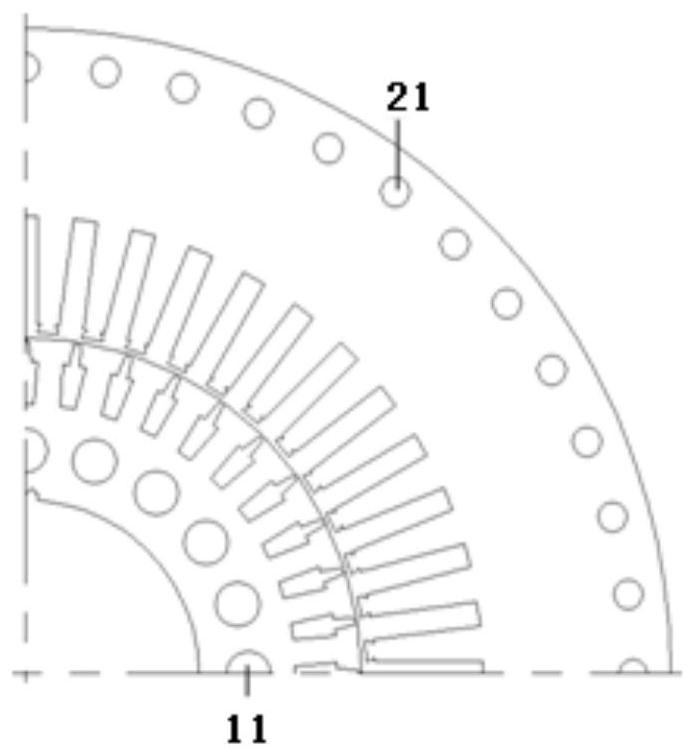

Motor

ActiveCN112072855AAxial temperature difference is smallLarge air volumeMagnetic circuit rotating partsElectric machinesAir volumeElectric machinery

The invention discloses a motor. A sealing part is arranged on a cooling bottom plate at the cooling medium inlet end of an outer air path, so that airflow driven by an inner fan enters through an airinlet duct and can only enter a cooling cover through a rotor and a stator to force a cooling medium to enter the stator to cool the stator, the air volume of a straight-section winding is increased,the temperature difference between the cooling straight section winding and the cooling end winding is reduced, the axial temperature difference of the stator is reduced, the temperature distributionuniformity is improved, the hot spot temperature difference of the windings is reduced, and the motor operation reliability is improved; the air volume is reasonably distributed, the temperature difference between the temperature entering a motor body through the shaft extension side of a cooling assembly and the non-shaft side is reduced, the temperature uniformity of the two sides of the motoris improved, and meanwhile the cooling effect of a stator is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

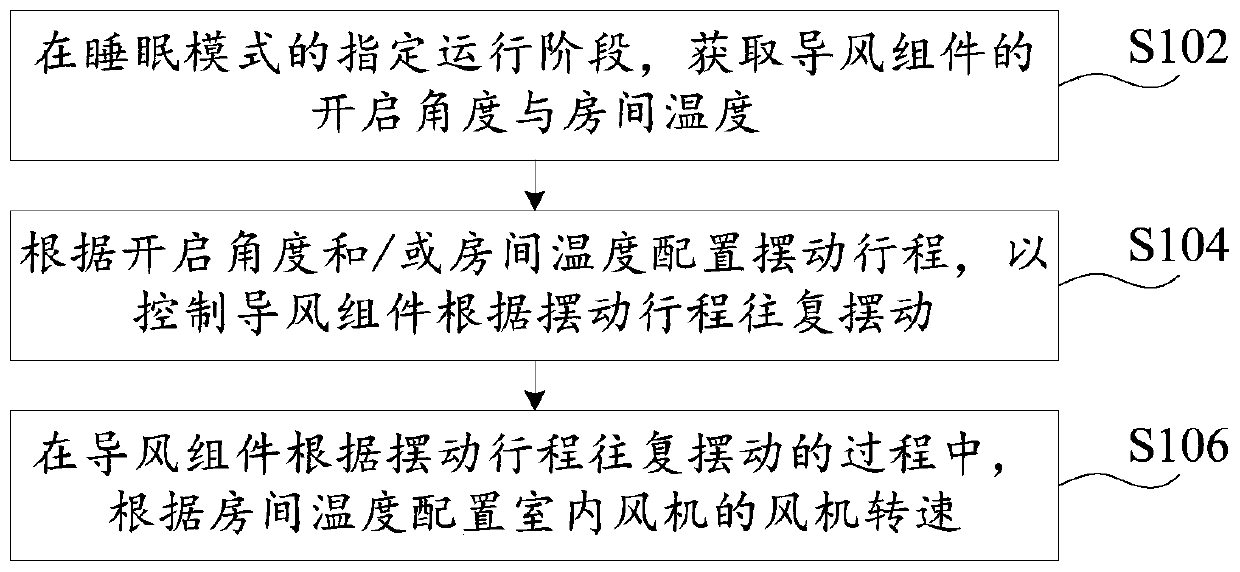

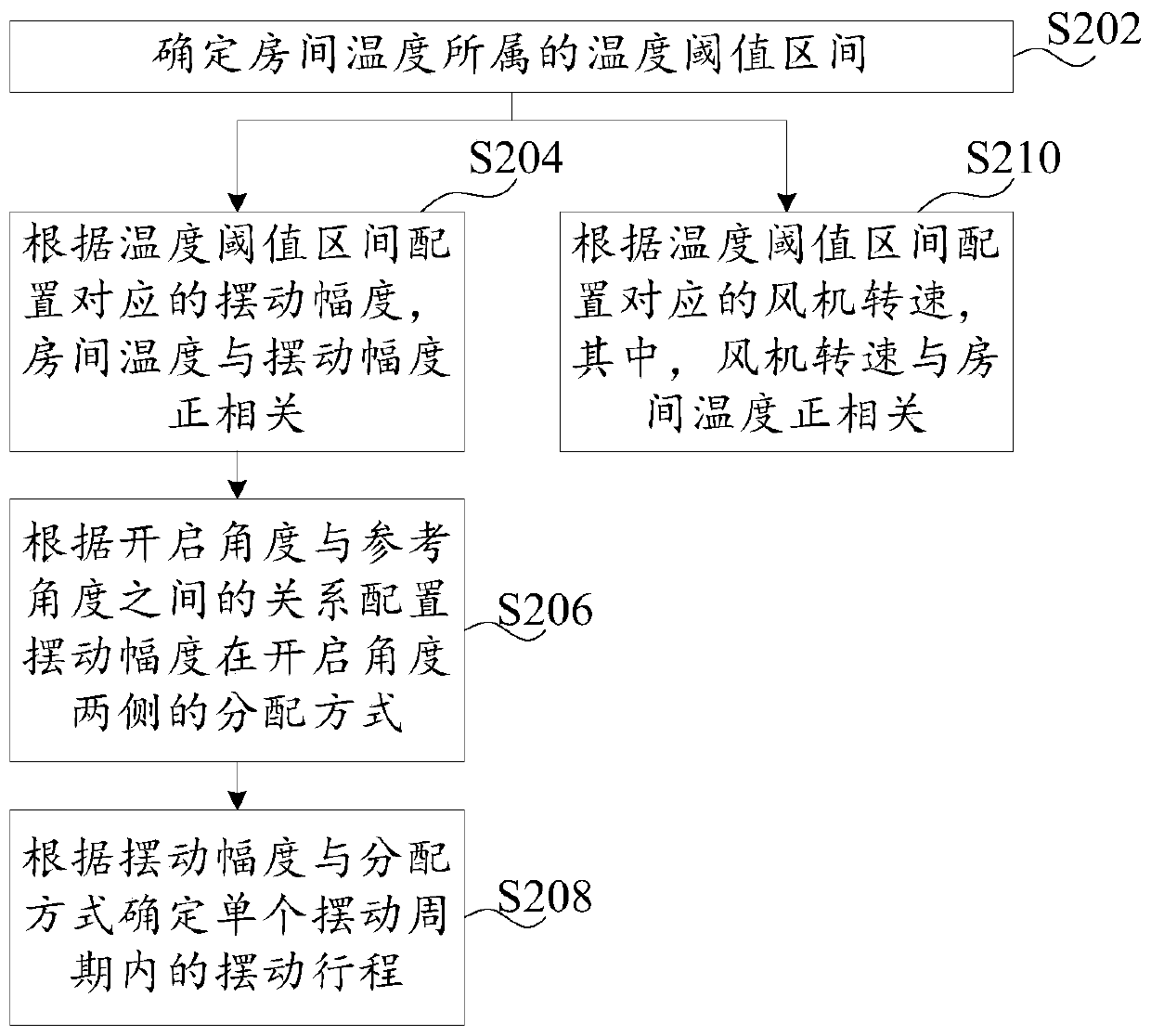

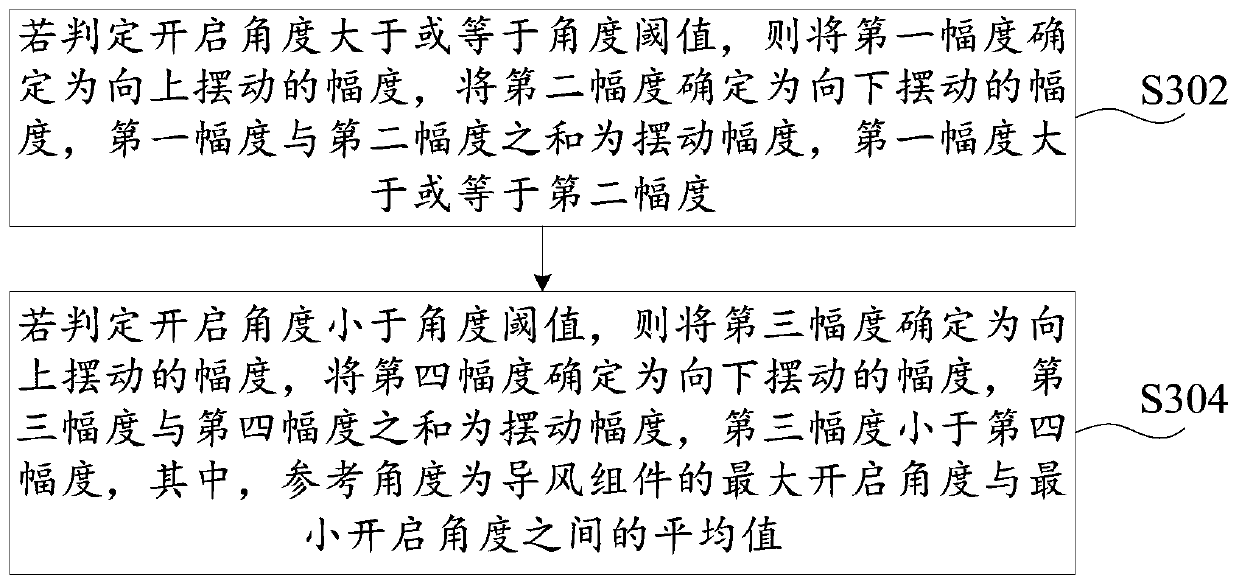

Operation control method, operation control device, air conditioner and storage medium

ActiveCN110701751AImprove uniformityImprove comfortMechanical apparatusLighting and heating apparatusControl engineeringRoom temperature

The invention provides an air conditioner, an operation control method of the air conditioner, an operation control device of the air conditioner and a readable storage medium, wherein the operation control method of the air conditioner comprises the following steps of obtaining the opening angle and the room temperature of an air guide assembly at a specified operation stage; and configuring a swinging stroke according to the opening angle and / or the room temperature so as to control the air guide assembly to swing in a reciprocating way according to the swinging stroke. By executing the technical scheme, on one hand, the uniformity of the temperature in a room can be improved; on the other hand, the airflow disturbance in the room can be increased; and the body feeling comfort of users is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Method and device for restoring polluted soil and treating solid wastes by utilizing electric energy

InactiveCN102284474BImprove temperature distribution uniformityImprove solubilitySolid waste disposalContaminated soil reclamationSolubilityOxygen

The invention relates to a method and device for restoring polluted soil and treating solid wastes. A cathode reaction tank and an anode reaction tank are respectively arranged at the two ends of soil / solid wastes, a water supply layer is arranged at the bottom of the soil / solid wastes and contains a chemical agent which can improve the solubility of organic pollutants and heavy metals in water, and a replaceable pollutant collecting layer covers the top of the soil / solid wastes which are internally provided with a replaceable artificial focal zone. The temperature value of the soil / solid wastes is increased to dozens of degrees even hundreds of degrees by applying a high voltage and large current; volatile organic pollutants volatile from the soil / solid wastes due to a high temperature, and nonvolatile organic pollutants and the heavy metals rise to the collecting layer along with water and are left in the collecting layer after the water is evaporated; and partial heavy metal ions are transferred to the electrode tank and the artificial focal zone along the electric field direction. Hydrogen and oxygen generated at a cathode and an anode are respectively collected for burning the volatile pollutants in the collecting layer and the focal zone; and the oxygen also can be made into ozone for oxygenizing pollutants in the soil / solid wastes or be cleared out.

Owner:CHONGQING UNIV

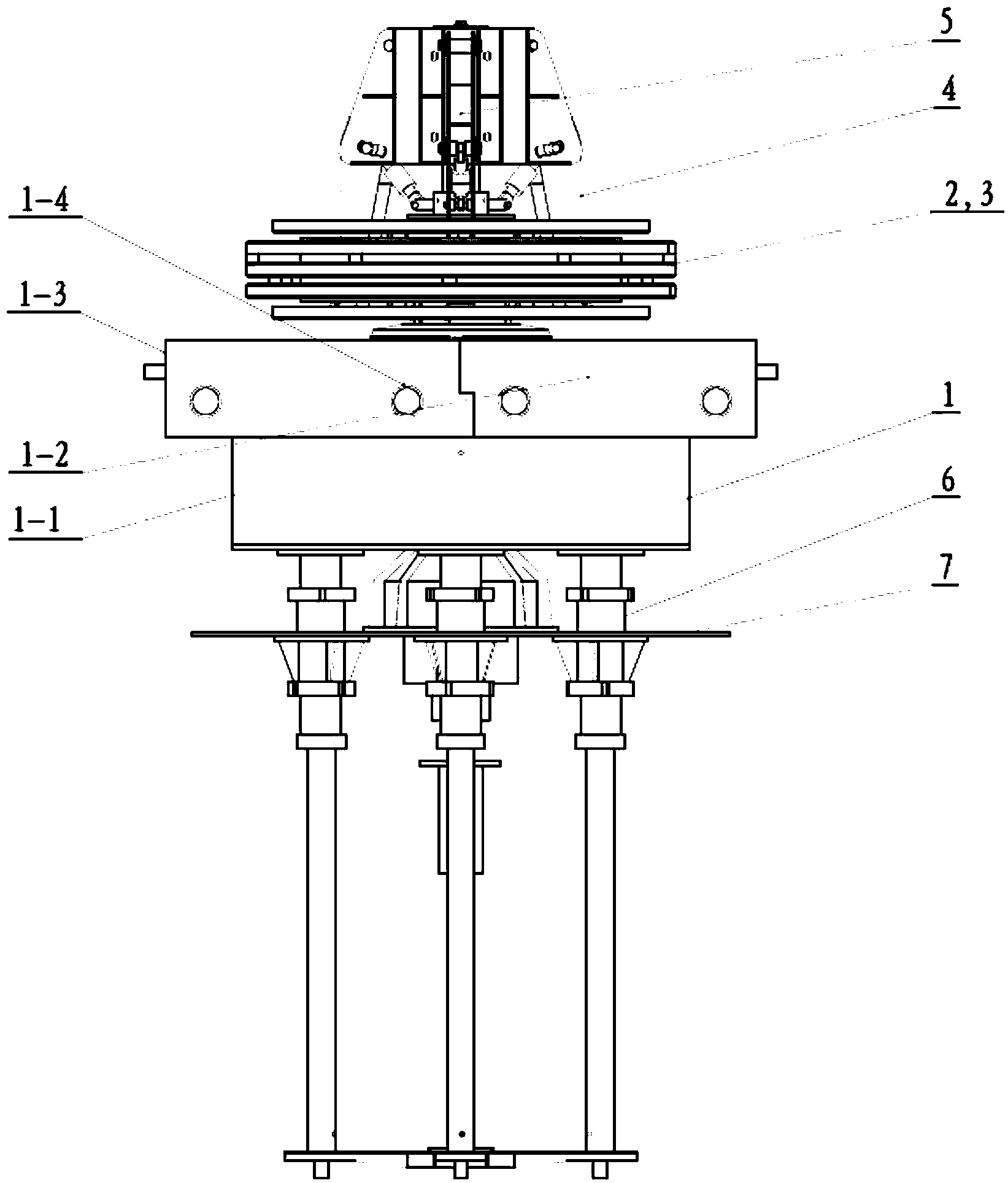

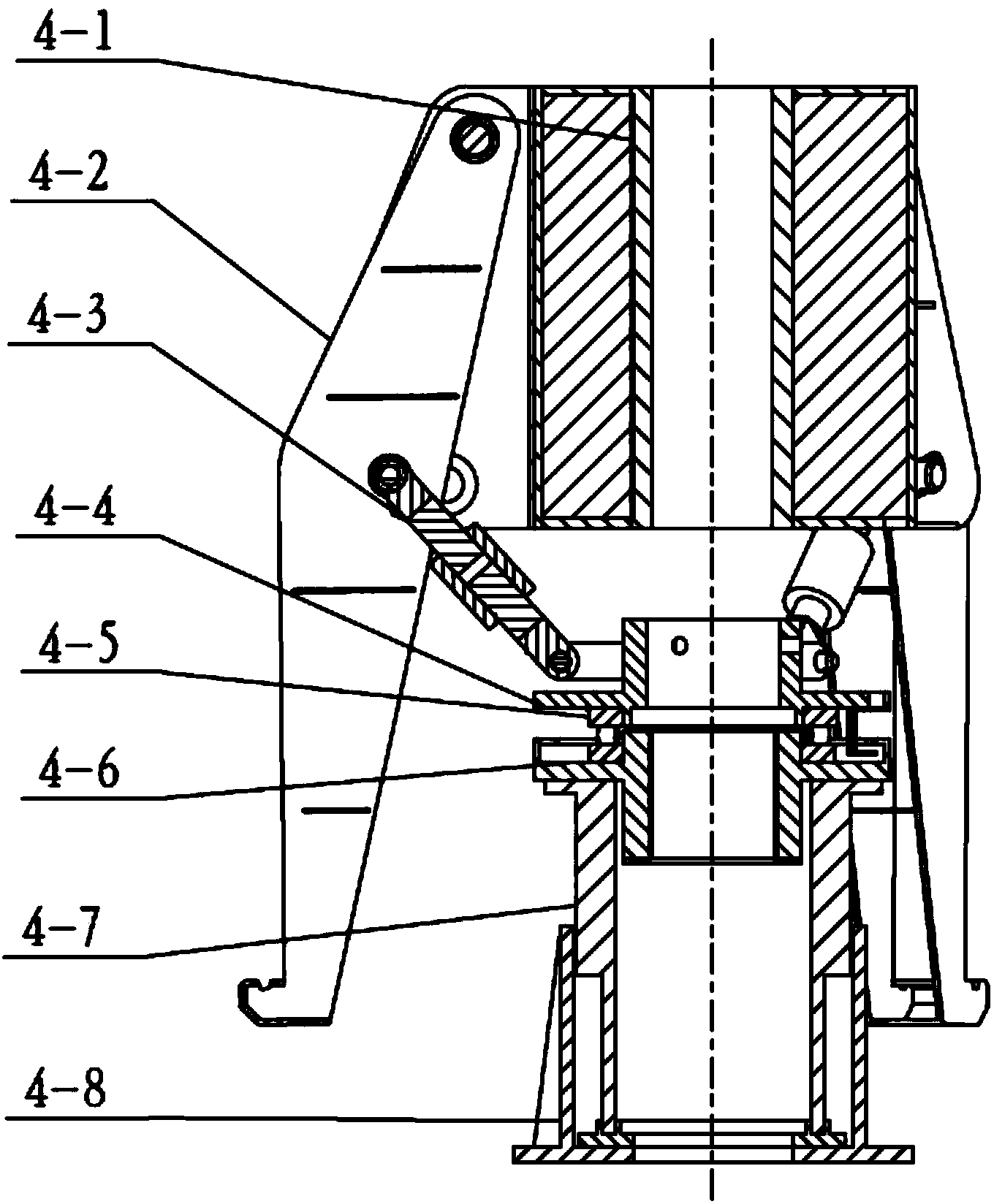

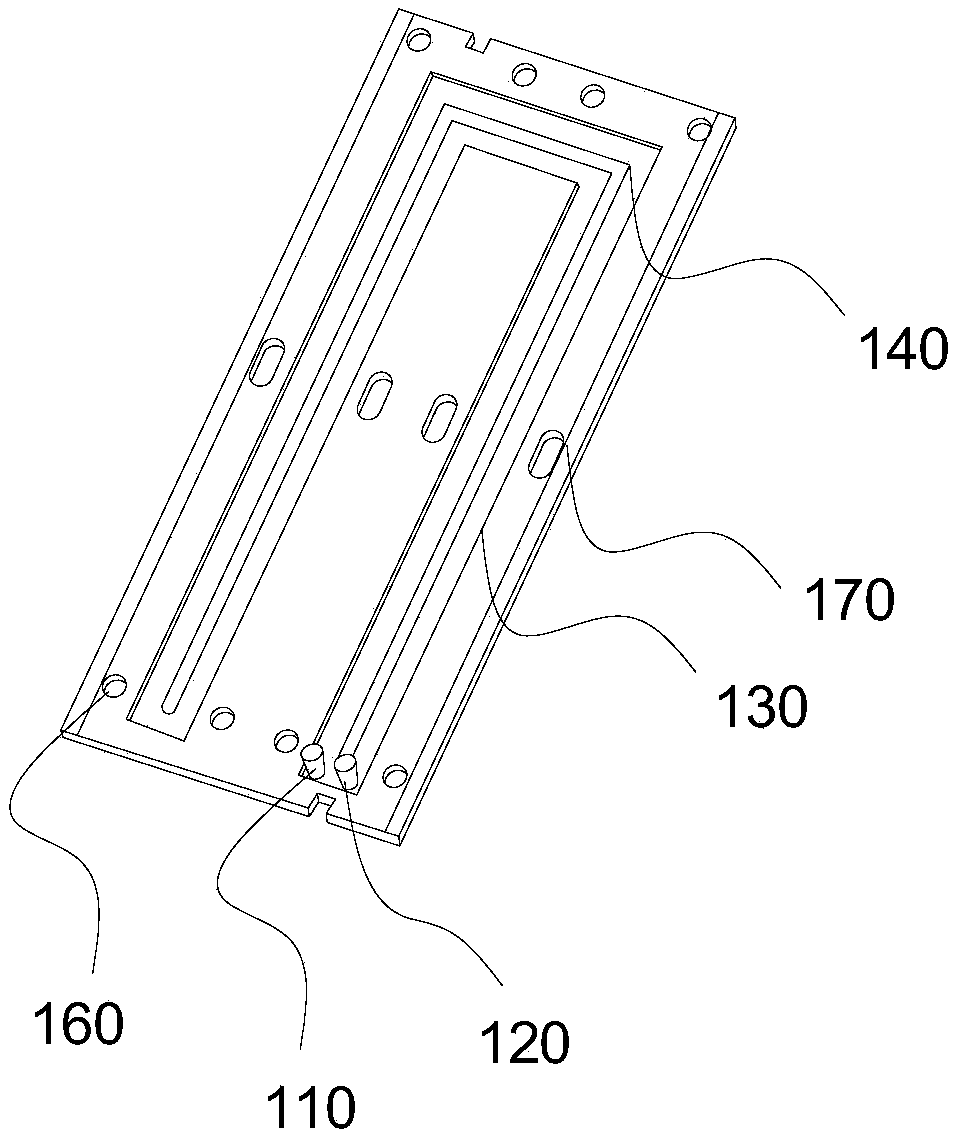

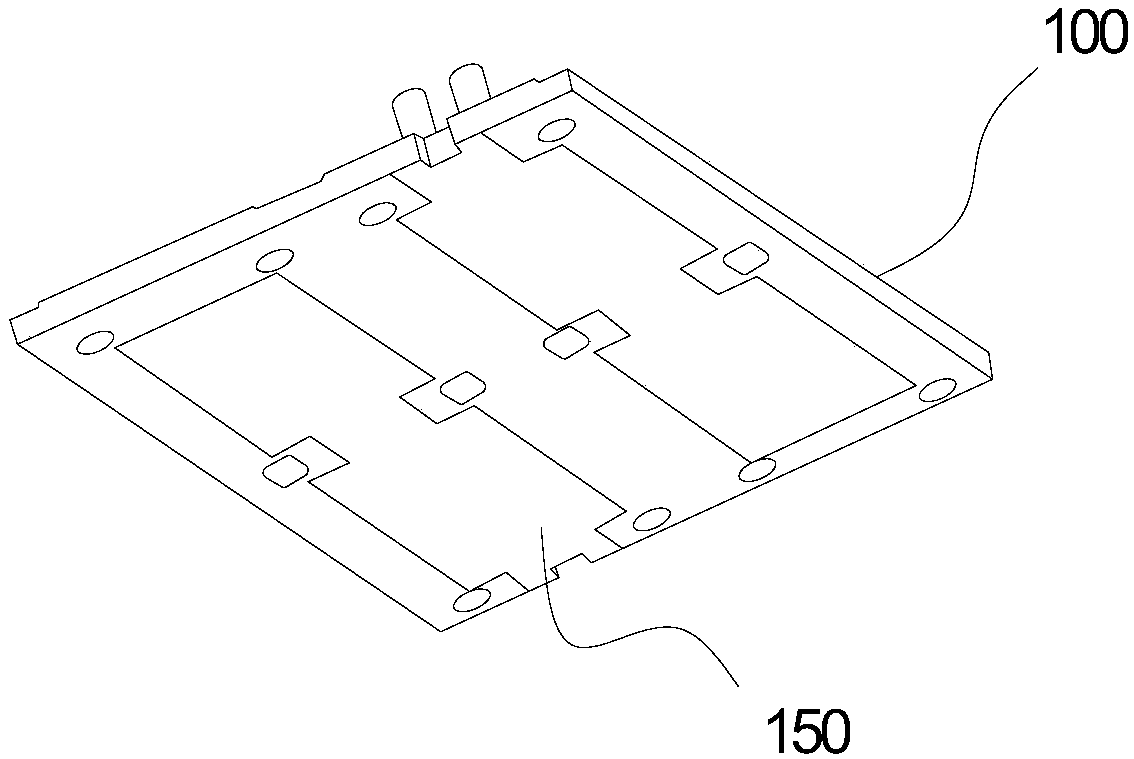

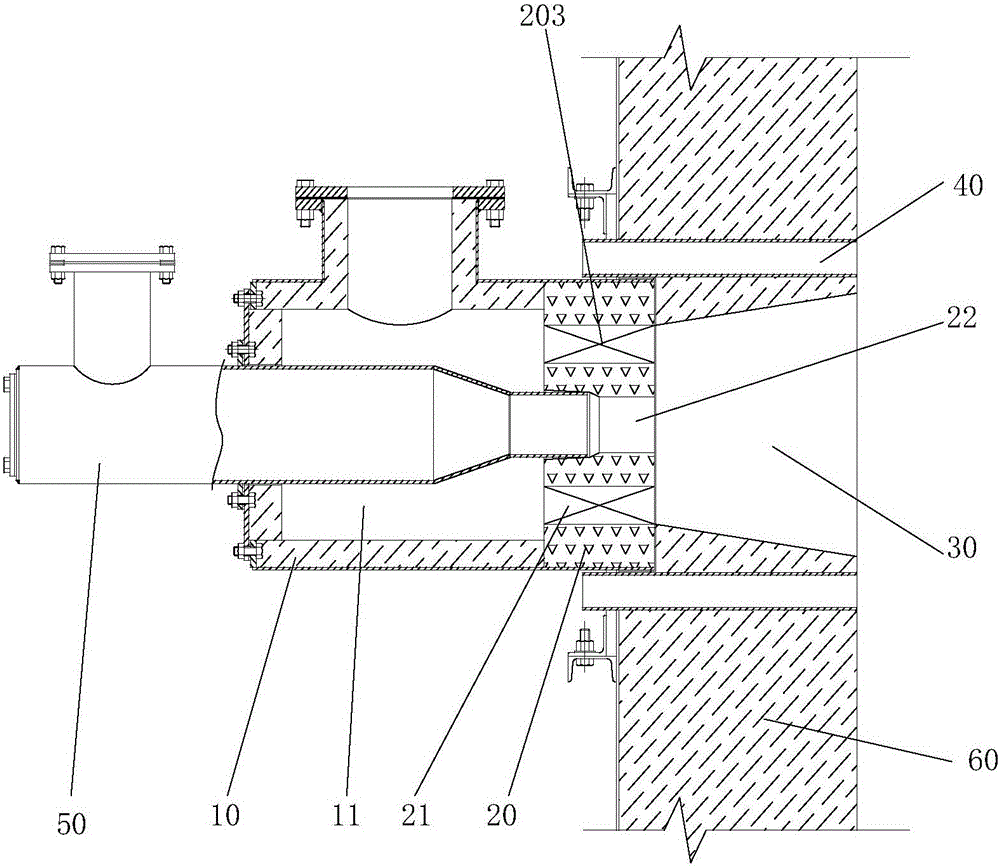

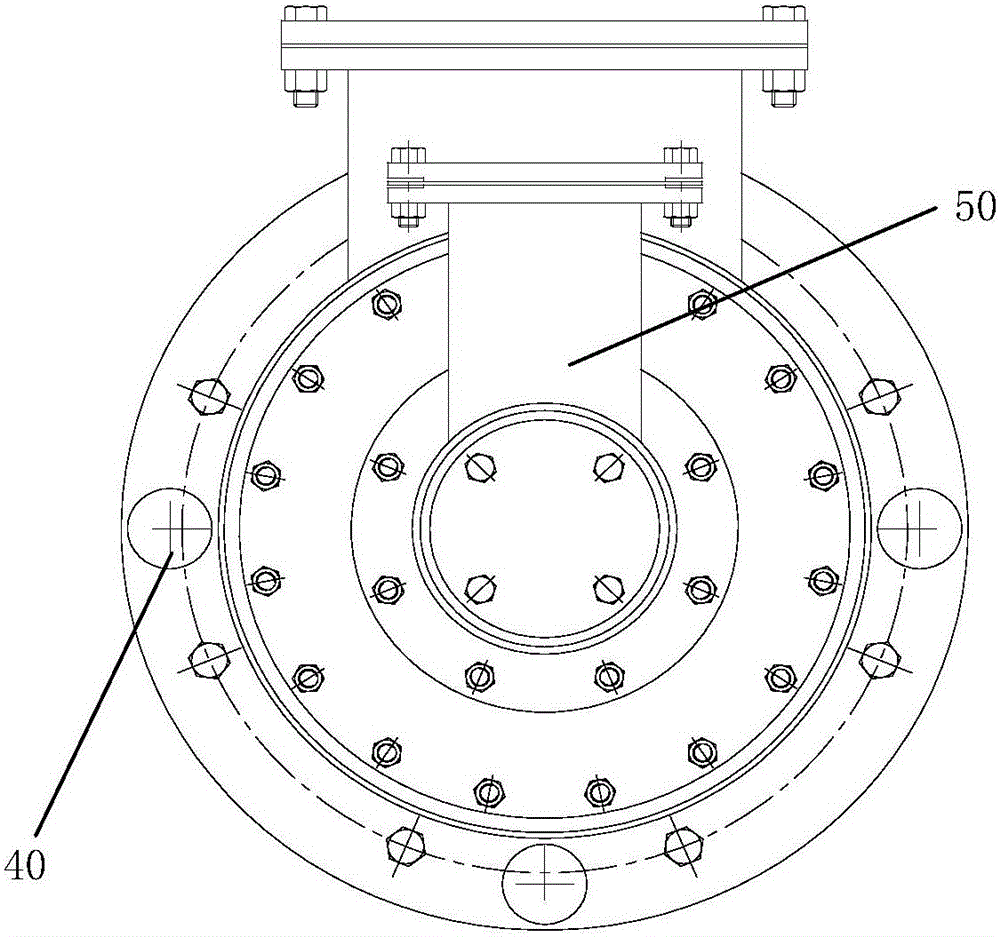

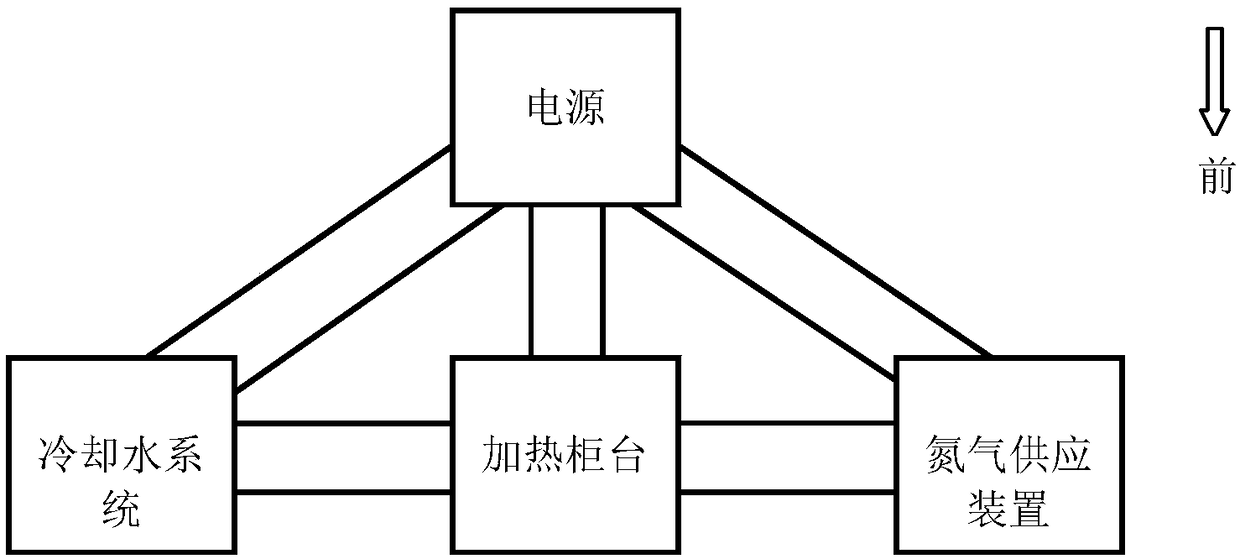

A sheet metal heating system for hot stamping experiments

ActiveCN106238587BReal-time control of heating speedReal-time control of heating temperatureShaping toolsMetal-working feeding devicesHot stampingLoop control

The invention relates to a plate heating system for a hot stamping experiment and belongs to the technical field of hot stamping. The plate heating system for the hot stamping experiment is composed of a power source, a cooling water system, a nitrogen gas supply device and a heating counter. According to the plate heating system, control over the plate heating temperature and heating speed can be achieved through a built-in closed-loop control program. A flat plate type inductor is used for heating plates so that heating efficiency can be improved. A transmission device is arranged to be used for eliminating the phenomenon that gaps between copper pipes of the flat plate type inductor cause non-uniform heating of plates. A special pushing device is arranged to be used for pushing heated high-temperature plates out of a heating box, and plates are convenient to take. The heating system can meet the performance requirement of hot stamping for the heating system, is convenient to use and has broad application prospects.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com