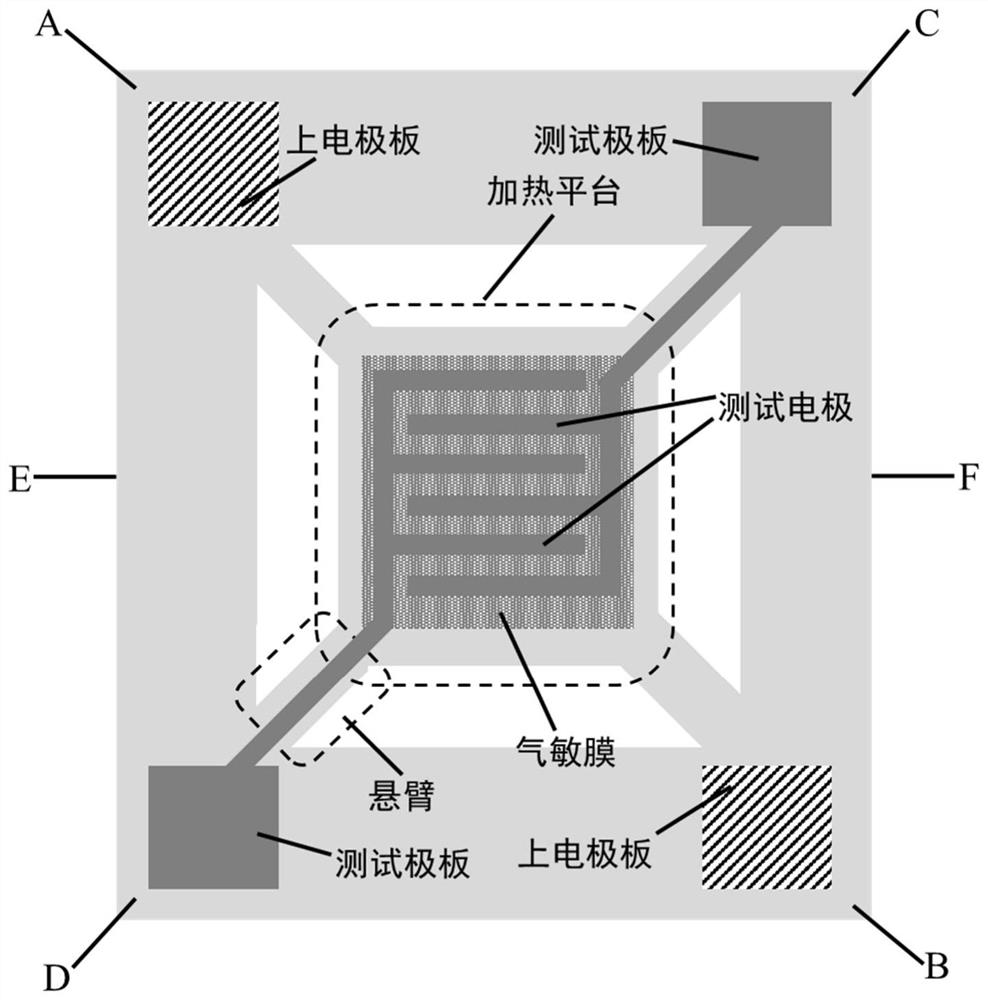

Gas sensor based on temperature compensation structure

A technology of gas sensor and temperature compensation, which is applied in the direction of microstructure technology, microstructure device, and manufacturing microstructure device, etc. MEMS gas sensor gas sensing characteristics and other issues, to achieve good temperature distribution uniformity, good temperature distribution uniformity, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

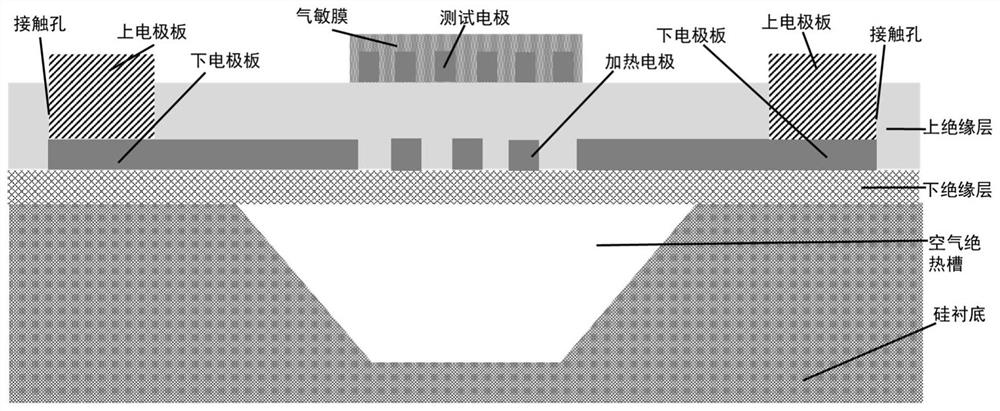

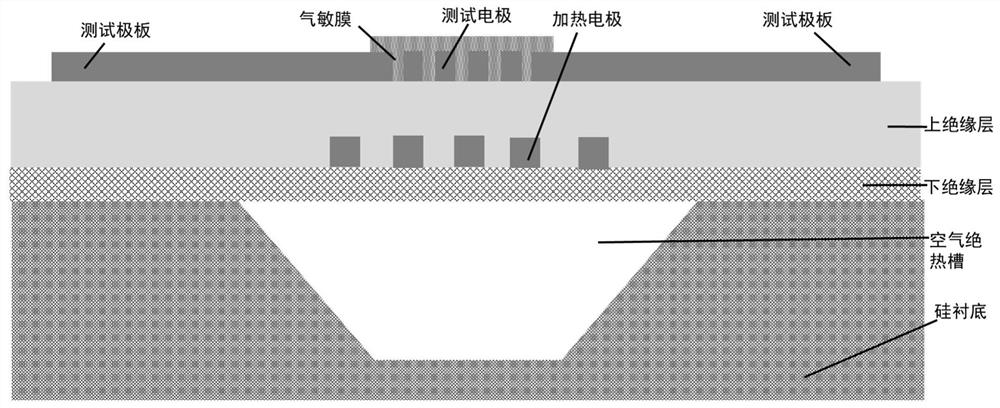

[0070] Embodiment 1: The thickness h of p-type (100) silicon wafers is made to be 200 μm, the number of circles m of the temperature compensation structure heating electrode is 3, and the third circle of electrodes E 3 Thickness D 3 0.2μm, the second circle electrode E 2 Thickness D 2 0.6μm, the first ring electrode E 1 Thickness D 1 A gas sensor based on a temperature-compensated structure of 1 μm.

[0071] Step 1, making the lower insulating layer on the silicon substrate, such as Figure 10 a.

[0072] A layer of thickness t is grown on a silicon substrate by thermal oxidation d 1µm SiO 2 The insulating medium forms the lower insulating layer.

[0073] Step 2, making a temperature compensation structure heating electrode and lower electrode plate on the lower insulating layer, such as Figure 10 b.

[0074] 2a) Make a mask on the lower insulating layer for the first time, using electron beam evaporation technology, that is, when the degree of vacuum is less than 1...

Embodiment 2

[0102] Embodiment 2: The thickness h of p-type (100) silicon wafers is made to be 300 μm, the number of turns m of the temperature compensation structure heating electrode is 4, and the fourth turn electrode E 4 Thickness D 4 0.5μm, the third ring electrode E 3 Thickness D 3 0.8μm, the second circle electrode E 2 Thickness D 2 1.1μm, the first ring electrode E 1 Thickness D 1 A gas sensor based on a temperature-compensated structure of 1.4 μm.

[0103] Step 1, making a lower insulating layer on the silicon substrate, such as Figure 10 a.

[0104] A layer of thickness t is grown on a silicon substrate by thermal oxidation d 2µm SiO 2 The insulating medium forms the lower insulating layer.

[0105] Step 2, making a temperature compensation structure heating electrode and lower electrode plate on the lower insulating layer, such as Figure 10 b.

[0106] 2.1) Make a mask on the lower insulating layer for the first time, and use electron beam evaporation technology to...

Embodiment 3

[0144] Embodiment 3: The thickness h of p-type (100) silicon wafers is made to be 500 μm, the number of turns m of the temperature compensation structure heating electrode is 5, and the fifth circle electrode E 5 Thickness D 5 1.2μm, the fourth ring electrode E 4 Thickness D 4 1.4μm, the third ring electrode E 3 Thickness D 3 1.6μm, the second circle electrode E 2 Thickness D 2 1.8μm, the first ring electrode E 1 Thickness D 1 A gas sensor based on a temperature-compensated structure of 2 μm.

[0145] Step A, making a lower insulating layer on the silicon substrate, such as Figure 10 a.

[0146] A layer thickness t is grown on the silicon substrate by thermal oxidation d 5µm SiO 2 The insulating medium forms the lower insulating layer.

[0147] Step B, making a temperature compensation structure heating electrode and lower electrode plate on the lower insulating layer, such as Figure 10 b.

[0148] First, make a mask on the lower insulating layer for the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com