Patents

Literature

46results about How to "Improve uniformity of temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

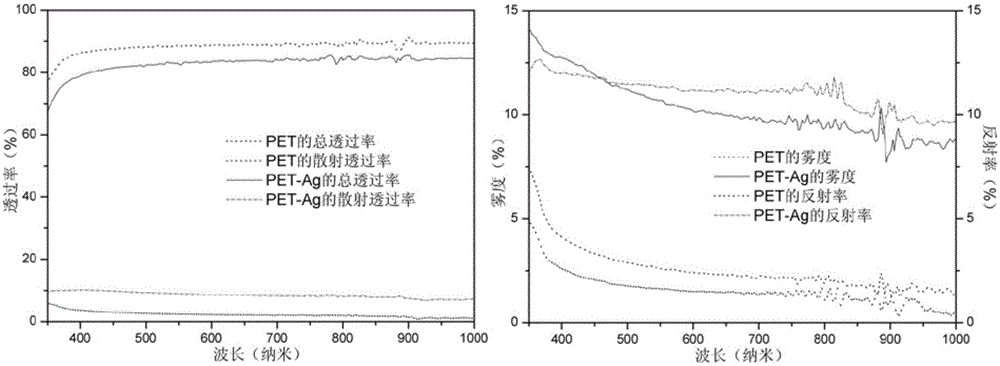

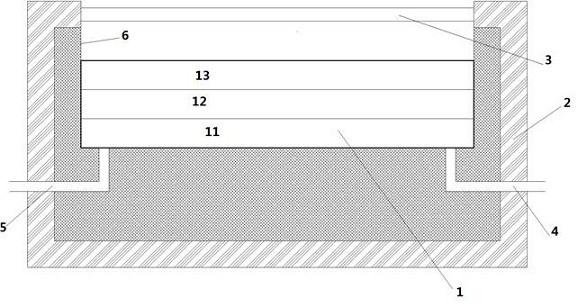

Heater based on transparent silver nanowire conducting thin film and preparation method thereof

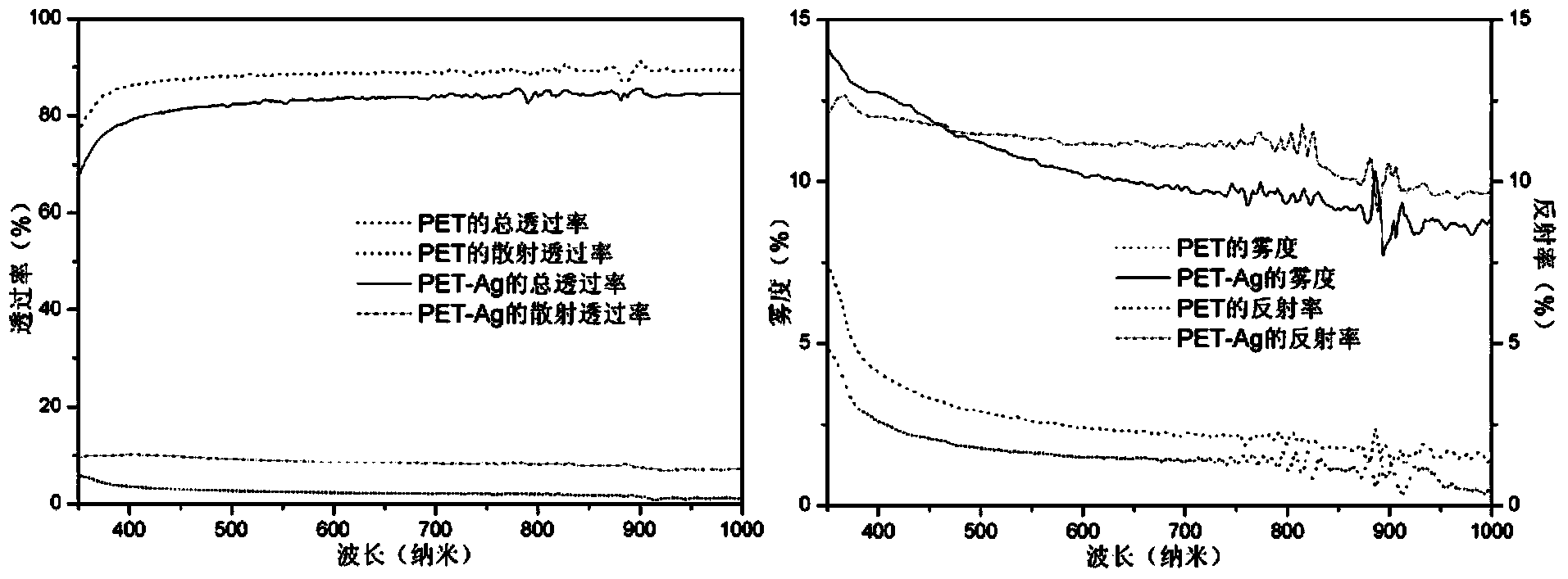

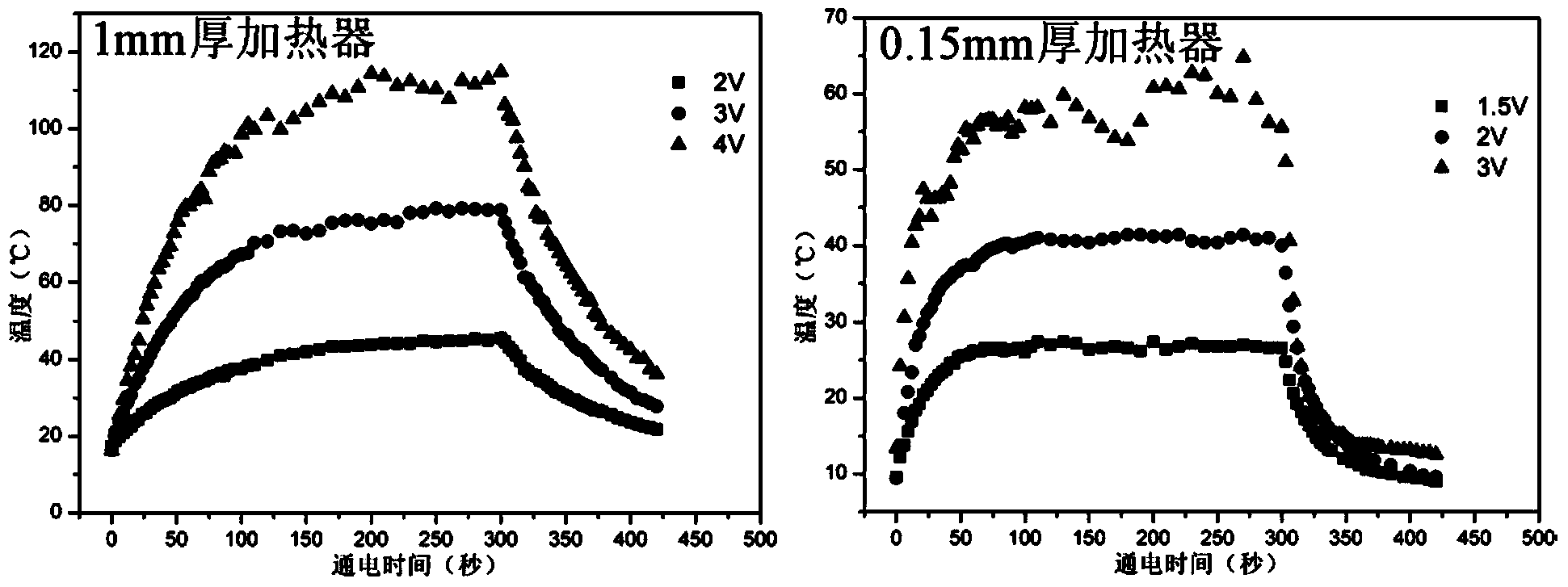

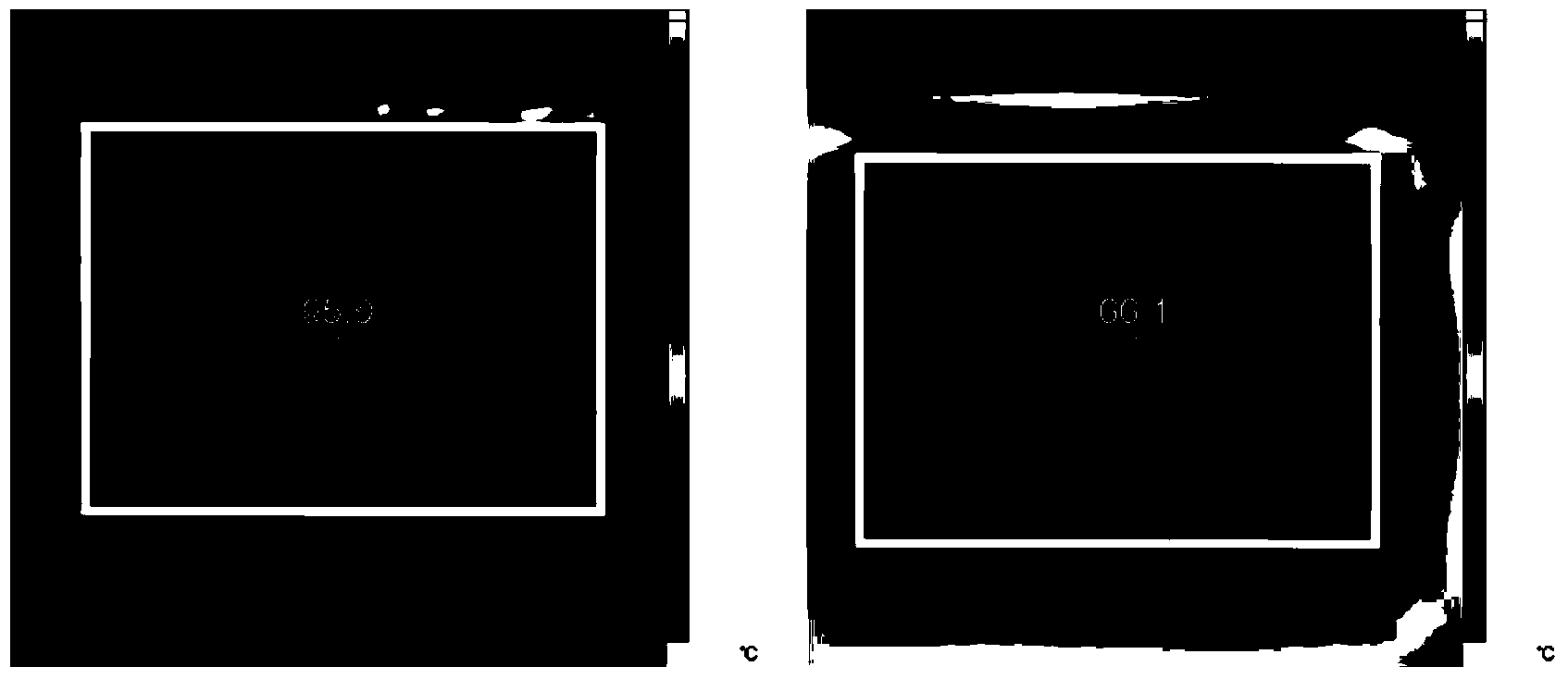

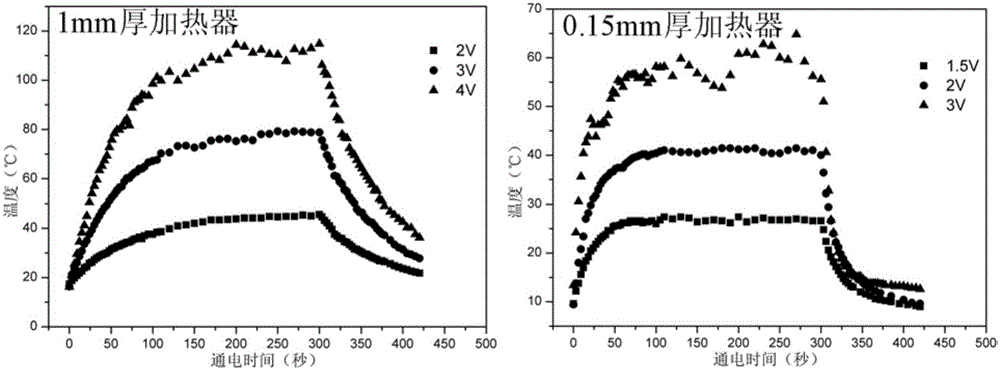

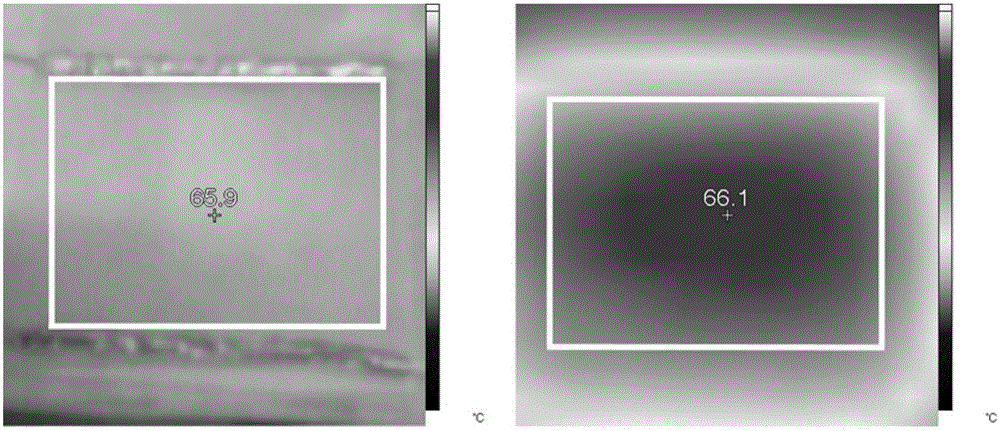

ActiveCN104053256ALow costExpand application spaceTransparent/reflecting heating arrangementsHeating element materialsHydrophilizationConductive polymer

The invention discloses a heater based on a transparent silver nanowire conducting thin film and a preparation method of the heater. The heater is simple in structure, uniform in heating and resistant to corrosion. The heater comprises a transparent substrate, the transparent conducting thin film, a conducting electrode and a protective layer. The heater is applied to defogging glass, a thermochromic substrate, a sensor substrate and the like. The preparation method of the heater comprises the steps of hydrophilization processing of the substrate, preparation of the transparent conducting thin film, preparation of the conducting electrode and preparation of the protective layer. According to the heater, silver nanowires synthesized through a low-temperature liquid phase method are used as raw materials, the transparent substrate is coated with the transparent conducting thin film through a non-vacuum non-high-temperature filming technology, the heating uniformity of the thin film is improved through technically mature and commercial conducting polymers, and the thin-layer protective film is obtained by means of liquid phase coating of cheap organic polymers. The heater is simple in structure, the raw materials are cheap, the requirement for preparation technological conditions is low, and large-scale production is facilitated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

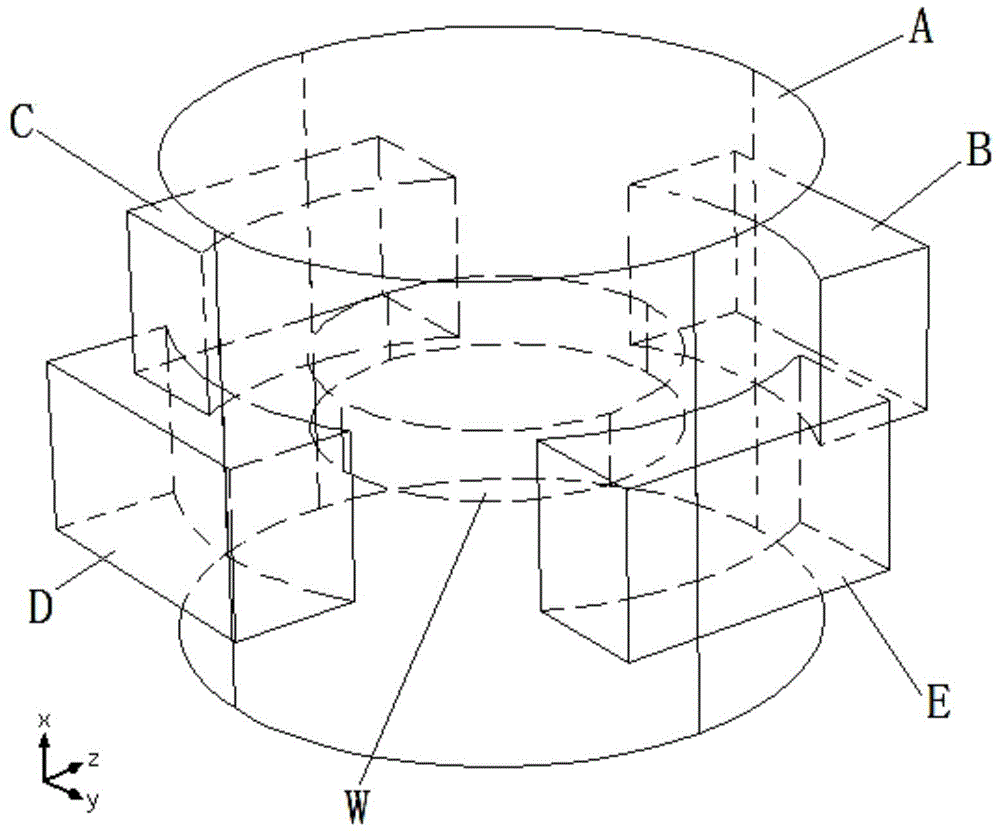

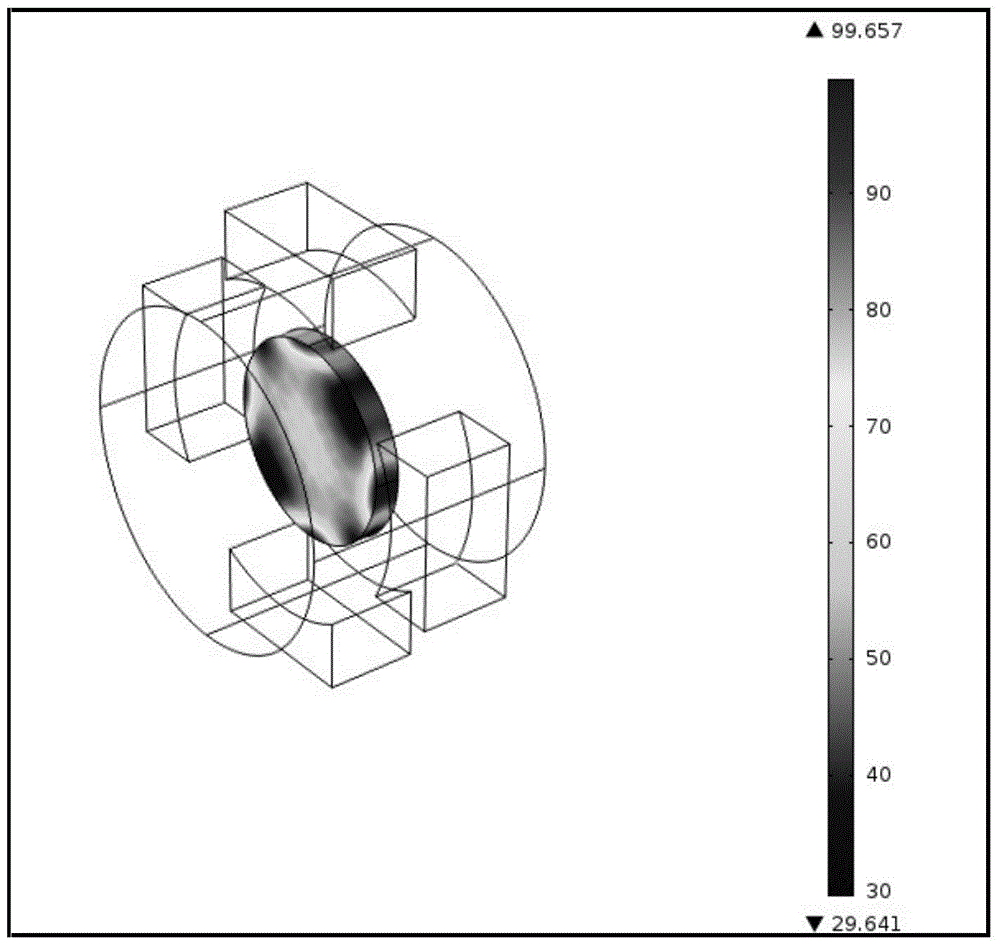

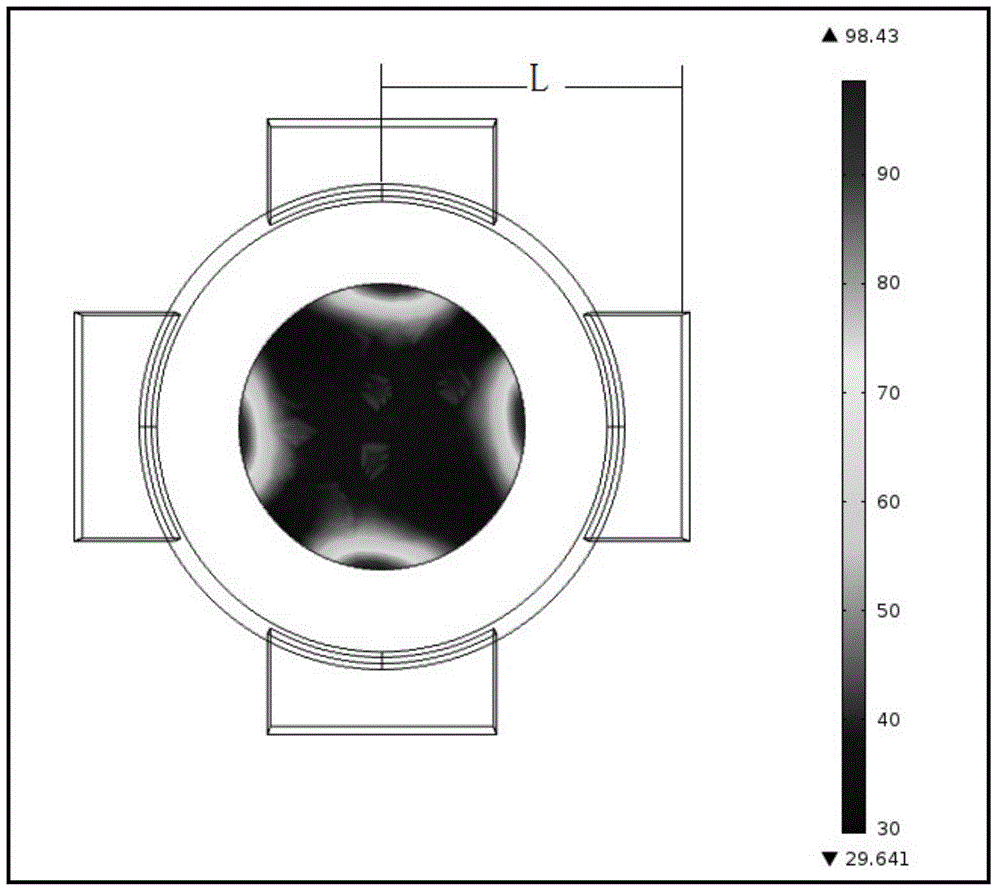

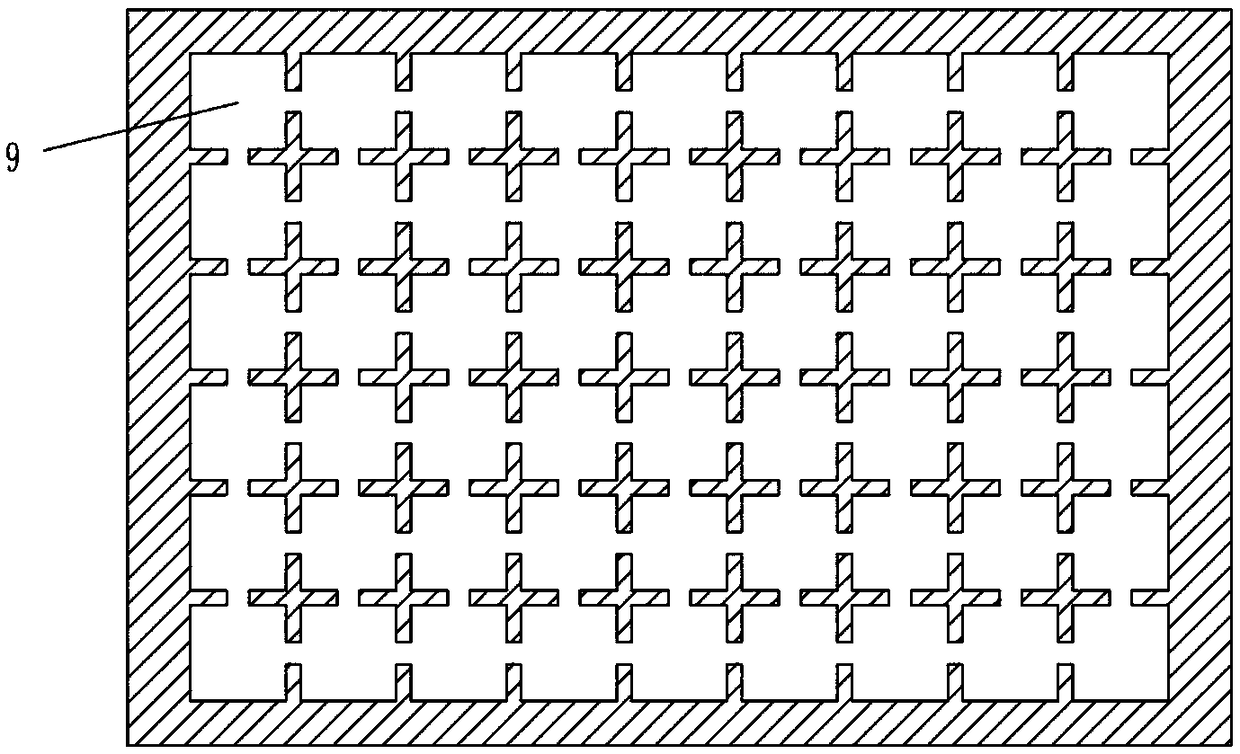

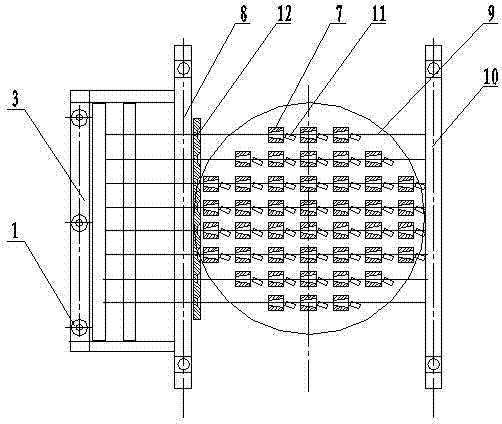

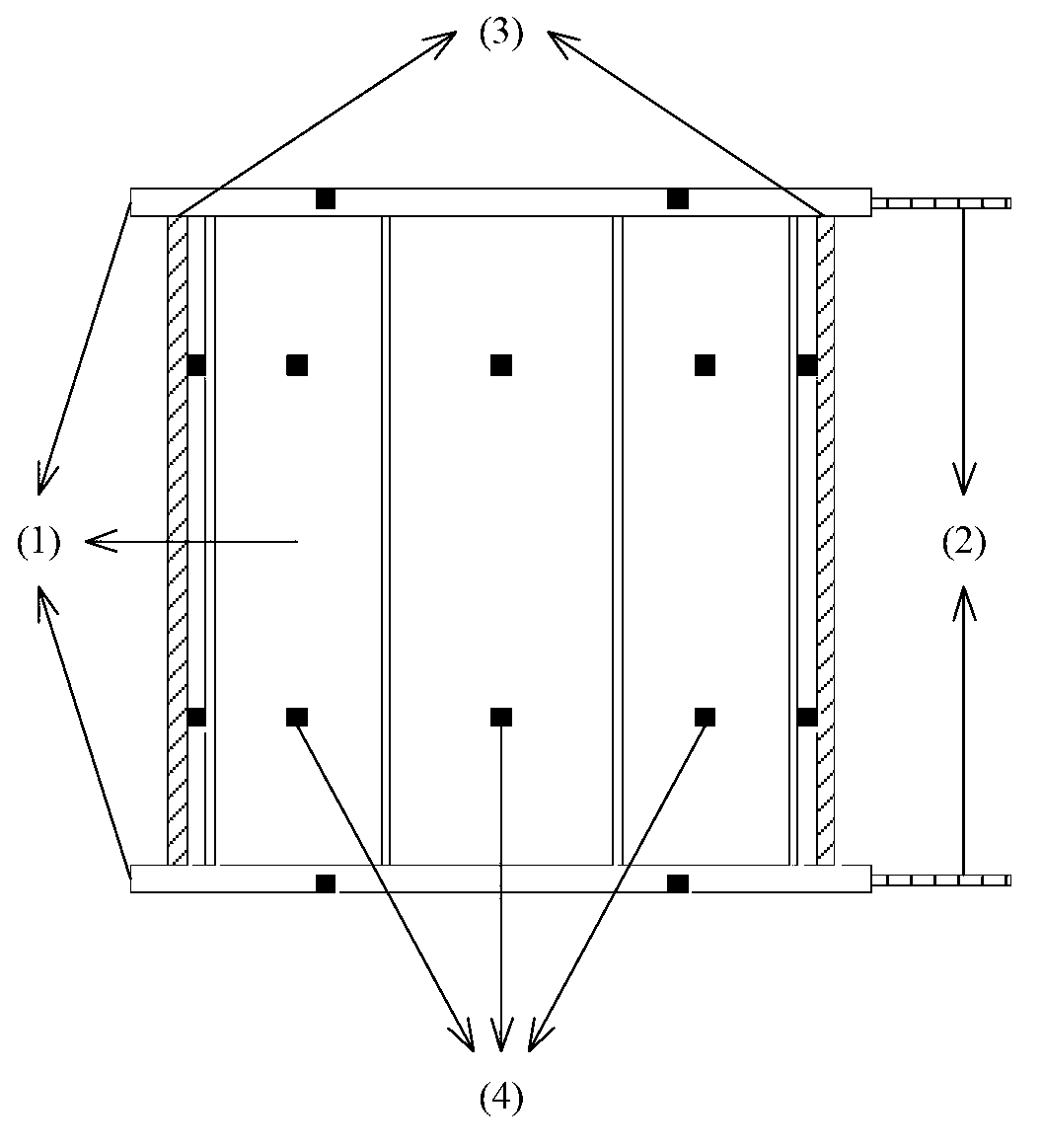

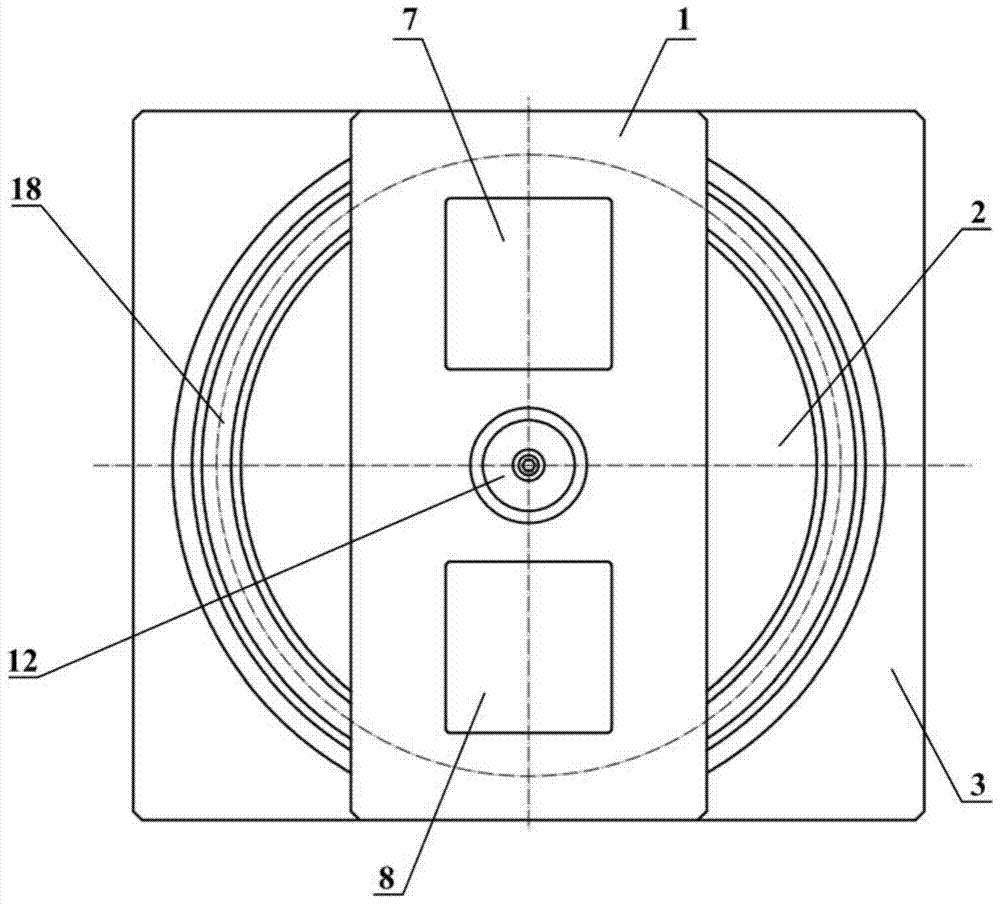

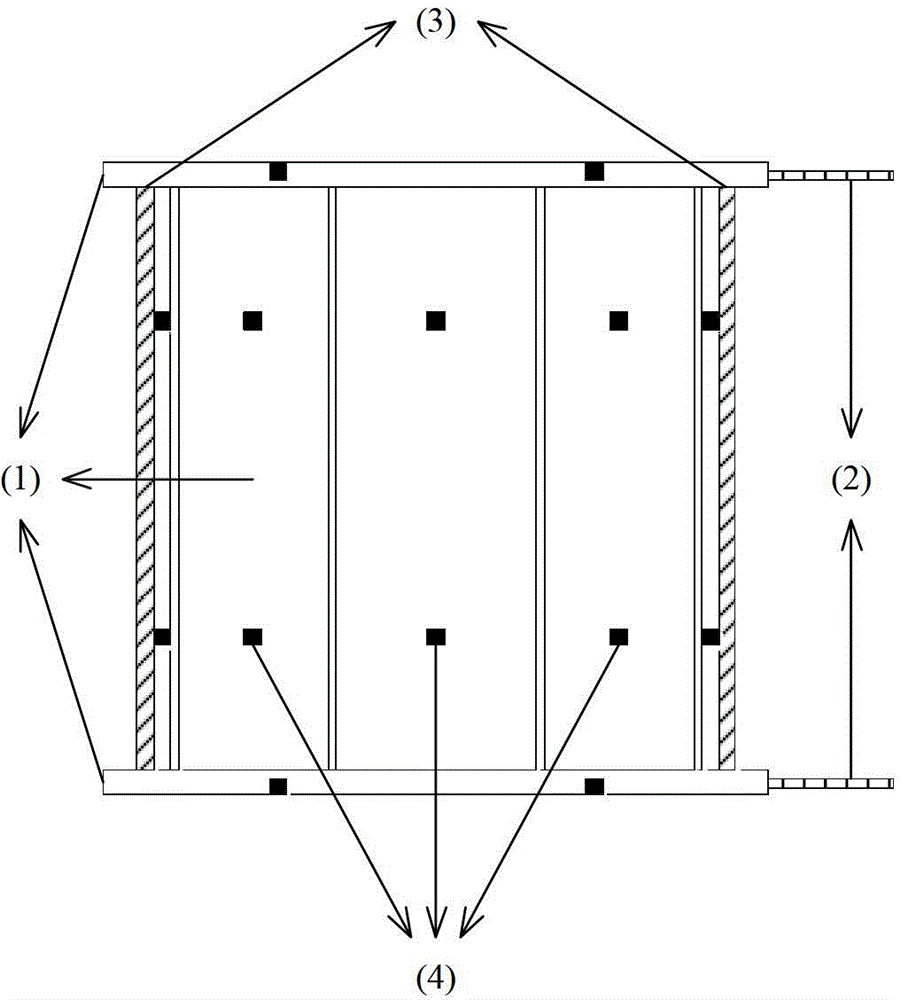

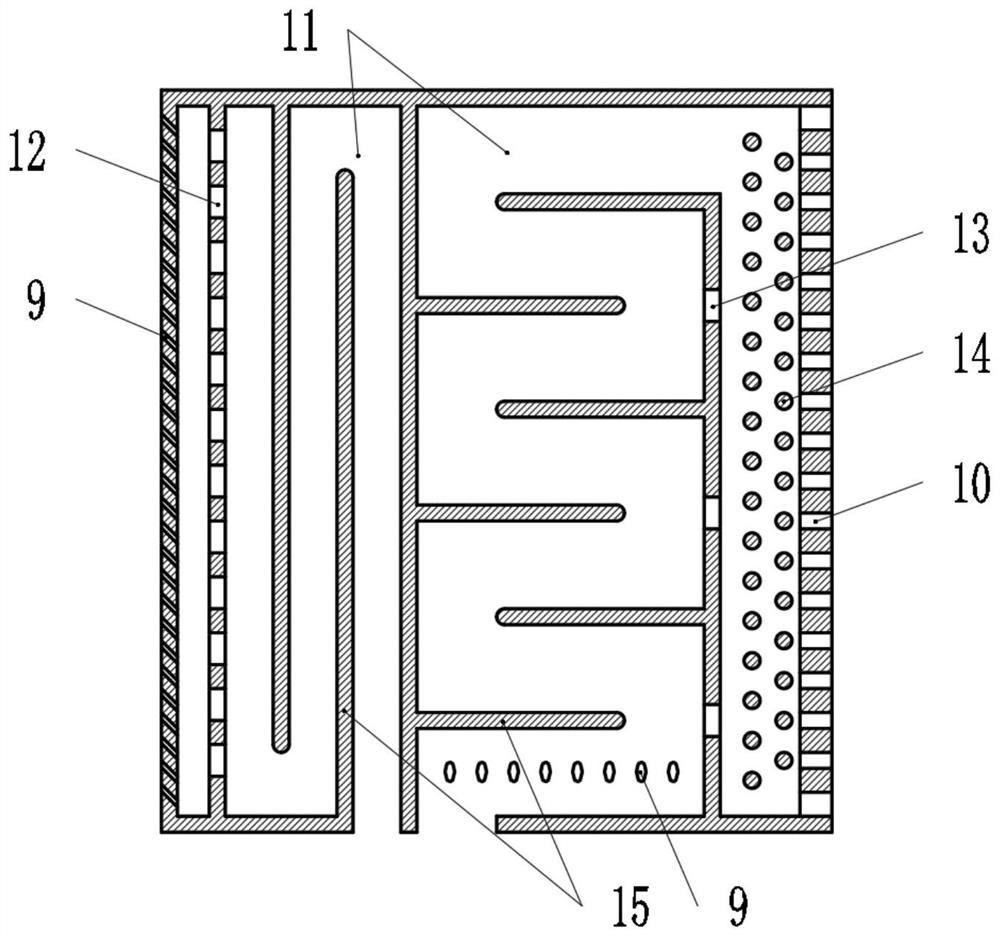

Resonant cavity for verifying wood microwave pretreatment temperature distribution

InactiveCN104797029ABreakage rateReduce the probability of ruptureMicrowave heatingHeating arrangementResonant cavityMicrowave

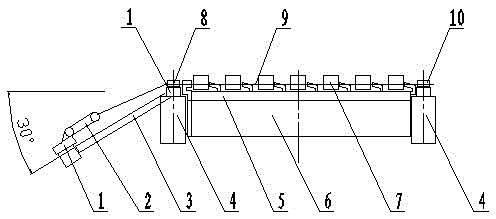

The invention discloses a resonant cavity for verifying wood microwave pretreatment temperature distribution. The resonant cavity for verifying wood microwave pretreatment temperature distribution comprises a main resonant cavity which is arranged horizontally; at least one fed-in waveguide is arranged on the main resonant cavity in the lateral direction; the main resonant cavity is connected with the fed-in waveguides; the fed-in waveguides are horizontally distributed along the direction from the center of the main resonant cavity to the outside; hollow-out openings are respectively formed in two end surfaces of each fed-in waveguide; the cross section of each fed-in waveguide is rectangular; the length direction of the rectangular cross section of each fed-in waveguide is a horizontal direction; the width direction of the rectangular cross section of each fed-in waveguide is a vertical direction; and the distance from the hollow-out opening of one end, which is far away from the center of the main resonant cavity, of each fed-in waveguide to the center of the main resonant cavity is 1.1 times greater than the length of the rectangular cross section of the fed-in waveguide. The resonant cavity for verifying wood microwave pretreatment temperature distribution has the advantages that wood microwave energy utilization rate is high, microwave energy is dispersed uniformly, temperature distribution uniformity is high, and wood breaking rate is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

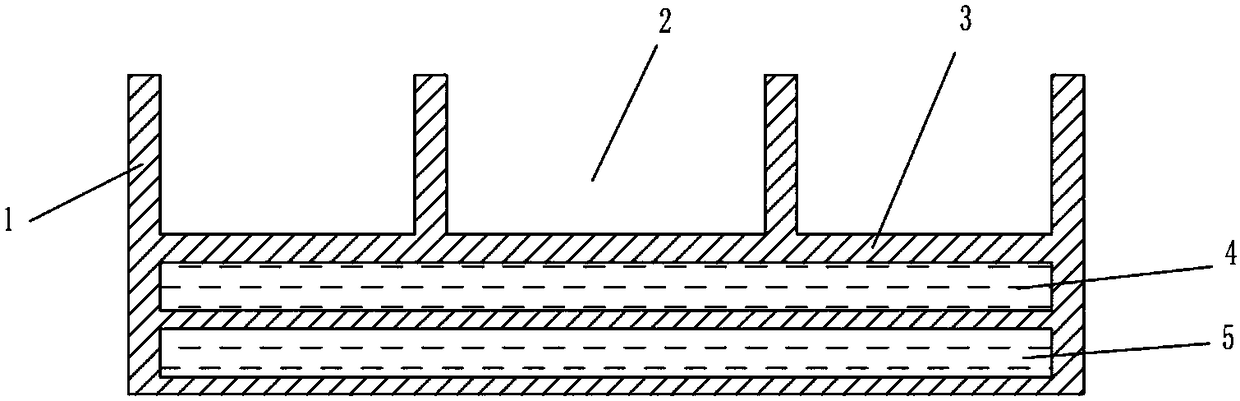

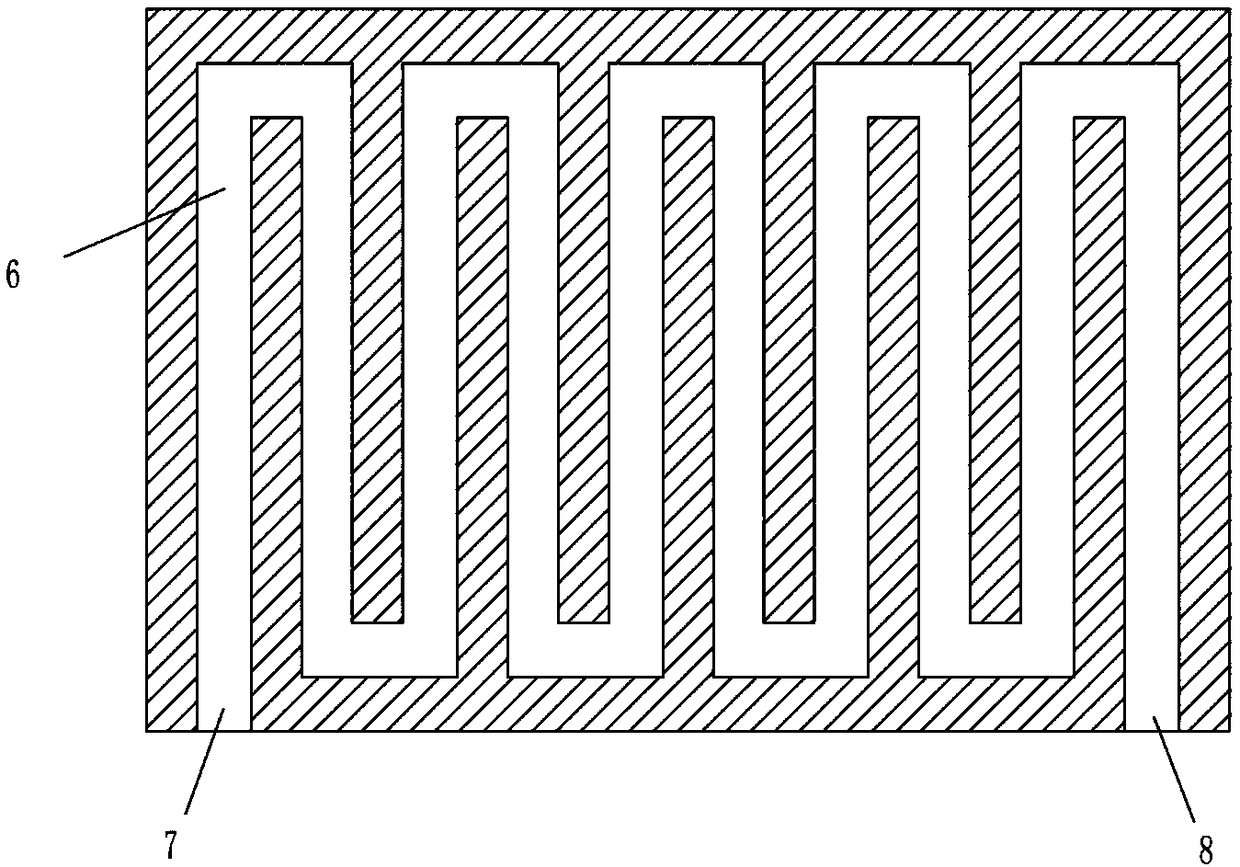

Airborne phased array antenna phase change heat storage liquid cooling heat dissipation box

InactiveCN109037882AMeet cooling needsHeat dissipation fastDe-icing/drying-out arrangementsHoneycombEngineering

The invention discloses an airborne phased array antenna phase change heat storage liquid cooling heat dissipation box, which aims to provide a phased array antenna box body with fast heat dissipation, good effect and high heat dissipation efficiency and combining liquid cooling heat dissipation and phase change heat storage. The heat dissipation box is realized through the following technical scheme: the bottom of a box body (1) is a heat dissipation base (3), the upper layer of the heat dissipation base (3) is a liquid cooling layer (4), and the lower layer is a phase change material layer (5); the liquid cooling layer is provided with an S-shaped liquid cooling flow channel, a liquid cooling inlet and a liquid cooling outlet; the phase change material layer is provided with a pluralityof honeycomb-shaped partition frame cavities enclosed between a liquid cooling layer partition plate and a box body bottom plate; the liquid cooling flow channel transfers heat out by theflow of the liquid cooling coolant; and the phase change material layer transfers heat generated by the phased array antenna to the phase change material stored in the phase change material layer by utilizing a metal partition frame connected between the partition frame cavities. The invention solves the problem that the antenna heat of the phased array antenna cannot be exported in time due to the interruption of the liquid supply under a short-time emergency condition.

Owner:10TH RES INST OF CETC

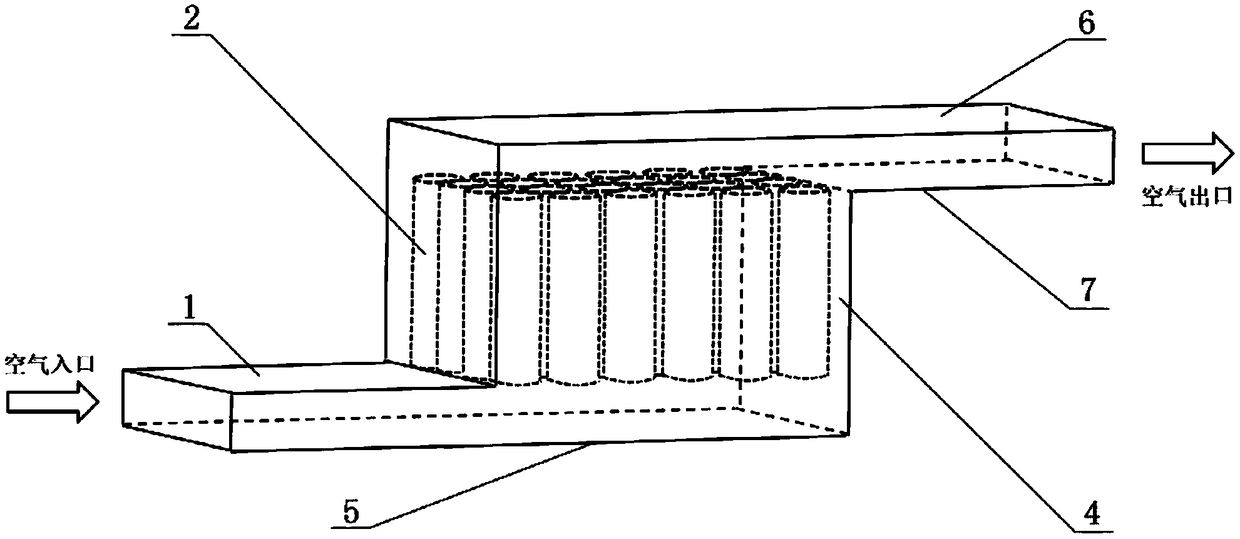

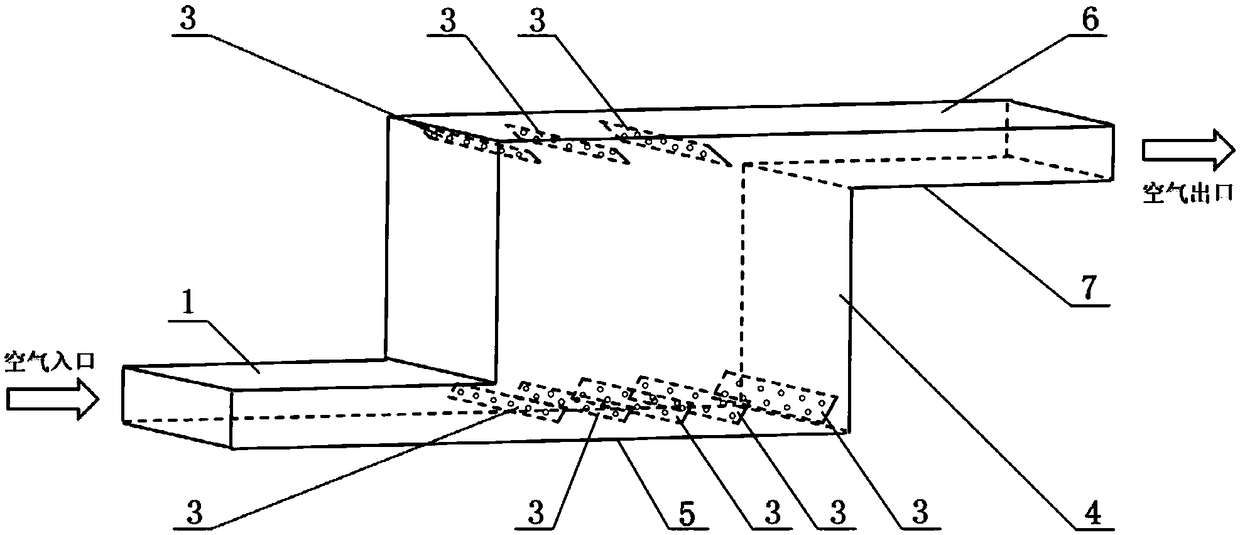

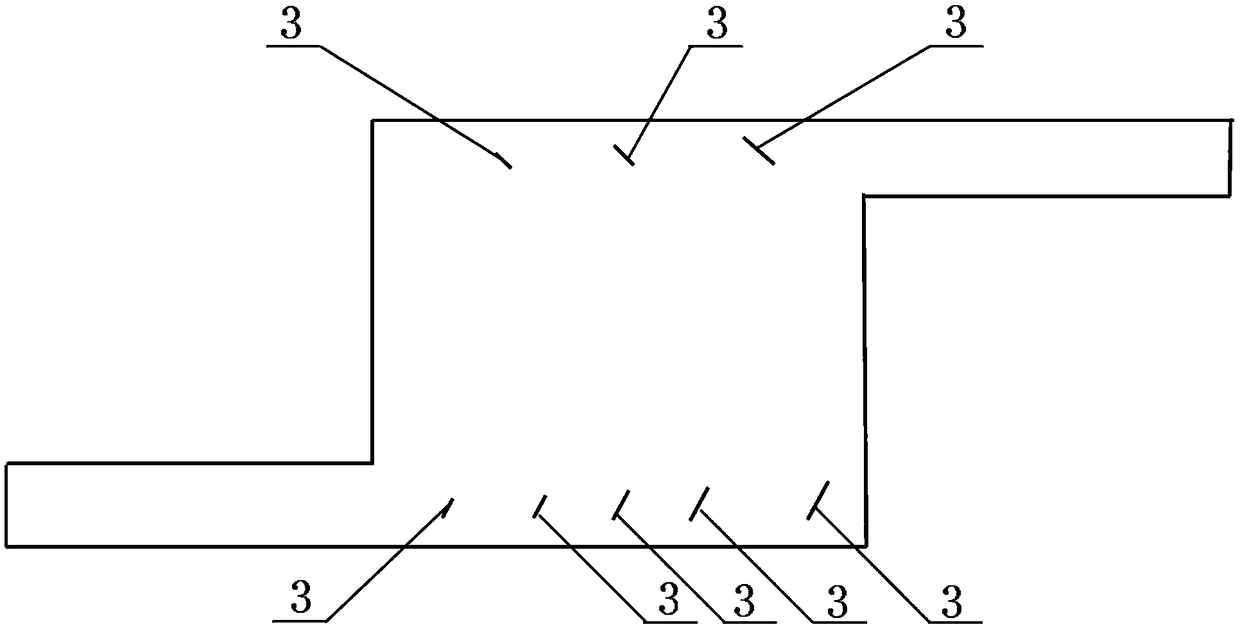

Wind cooling heat radiation structure of power battery pack

The invention provides a wind cooling heat radiation structure of a power battery pack. The heat radiation structure comprises a box body, an air inlet flow passage and an air outlet flow passage, wherein the box body is used for accommodating a power battery pack; the air inlet flow passage and the air outlet flow passage are communicated with the box body and are respectively arranged on the twoopposite side surfaces of the box body; the bottom surface of the box body is a flow guide plate; the top surface of the box body is a current collecting plate; the flow guide plate and the bottom plate of the air inlet flow passage are positioned on the same plane; the current collecting plate and the top plate of the air outlet flow passage are positioned on the same plane; a flow division sheet is arranged at one side, near the box body, of the current collecting plate and / or the flow guide plate; the flow division sheet is inclined in the fluid flowing direction; the included angle between the flow division sheet and the current collecting plate and / or the flow guide plate is greater than 0 degrees but smaller than 90 degrees. The wind cooling heat radiation structure of the power battery pack is simple and reasonable; the heat radiation problem of the battery in the parallel ventilation mode can be improved at the stable state, so that the distribution of the air fluid inside thebox body provided with the power battery pack is uniform.

Owner:辽宁比科新能源股份有限公司 +1

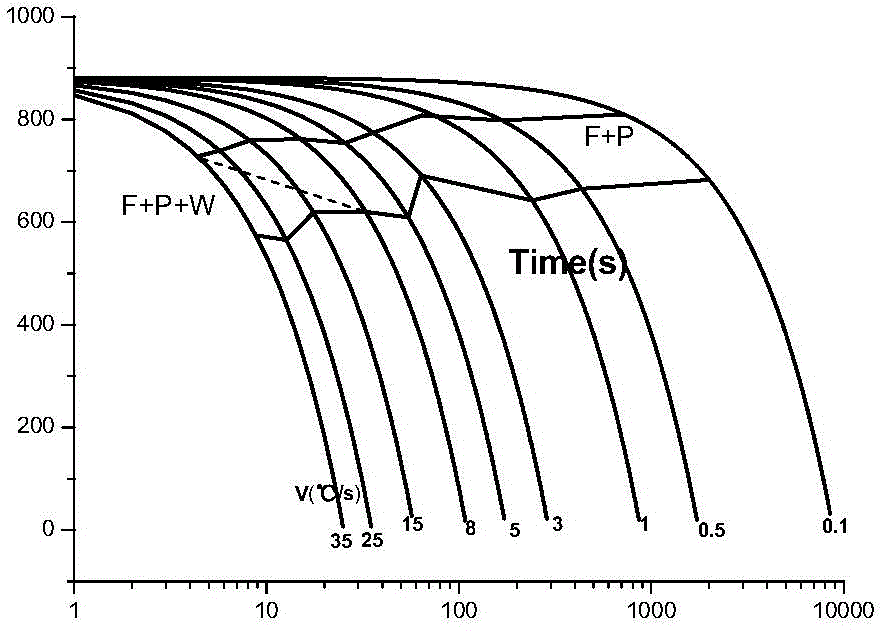

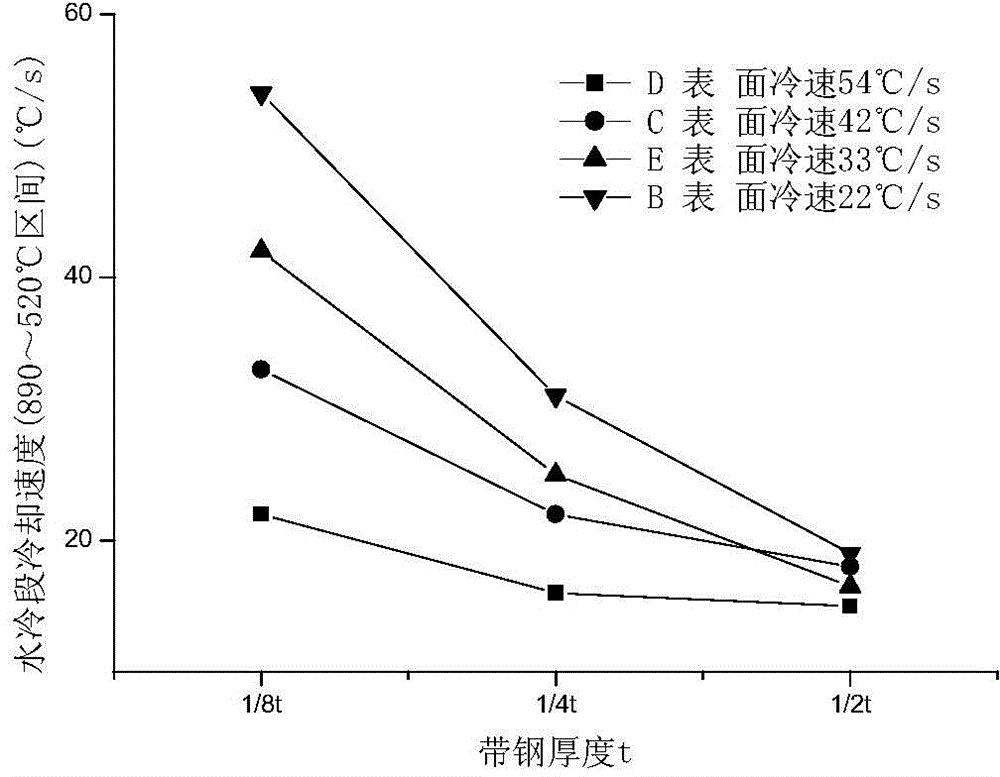

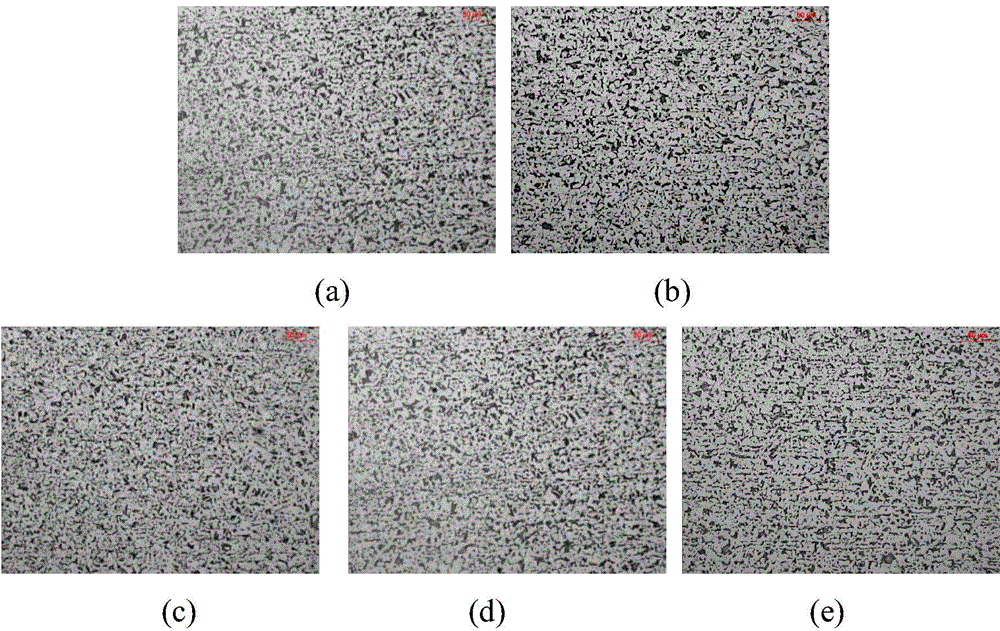

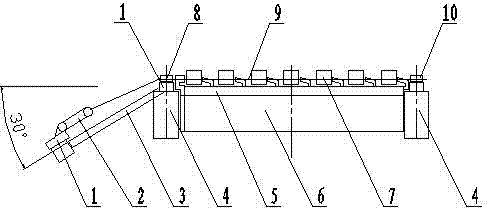

Strip steel production method for improving shape uniformity of steel cup mouth of welded gas cylinder

InactiveCN104831166AImprove uniformity of temperature distributionImprove uniformityGas cylinderLaminar cooling

The present invention relates to a strip steel production method for improving the shape uniformity of the steel cup mouth of a welded gas cylinder, which aims to solve the defect of the poor shape of the close-up part of a welded gas cylinder after the steel welding and forming process in the prior art. The heating temperature for the continuous casting blanks of welded gas cylinders is 1160 DEG C to 1240 DEG C. The continuous casting blanks are thermally insulated at the above temperature for 40 minutes to 60 minutes. During the rolling process, the cooling rate for the laminar flow is controlled within 34.1 DEG / S to 92.8 DEG / S. The quantity of the laminar cooling water on the upper surface of the strip steel is 81% to 95% the quantity of the laminar cooling water on the lower surface of the strip steel in weight percentage. The quantity of the 0-120m laminar cooling water at the head part of the strip steel is 70% to 85% the normal quantity of water in weight percentage. The quantity of the 0-120m laminar cooling water at the tail part of the strip steel is 50% to 75% the normal quantity of water in weight percentage. The quantity of the laminar cooling water at the middle part of the strip steel is equal to the normal quantity of water. According to the invention, the entire steel strip coil of a welded gas cylinder is uniform in temperature distribution, larger in crystalline grain and smaller in phase-transformation difference. The uniformity of the mechanical property in every direction and the shape uniformity of the steel cup mouth of the welded gas cylinder after the machining process are improved.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

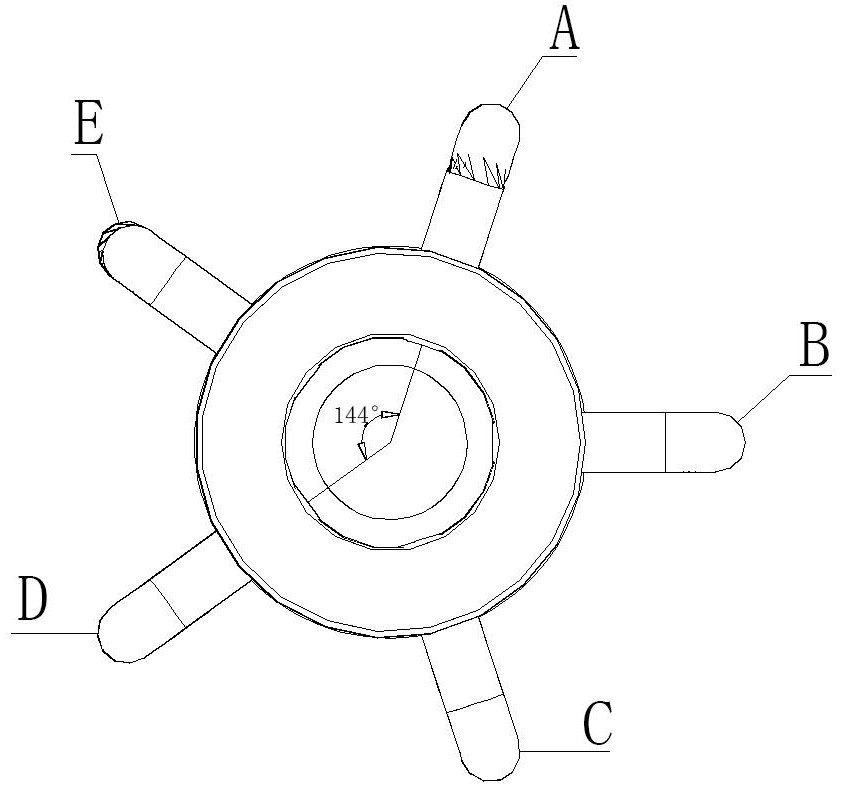

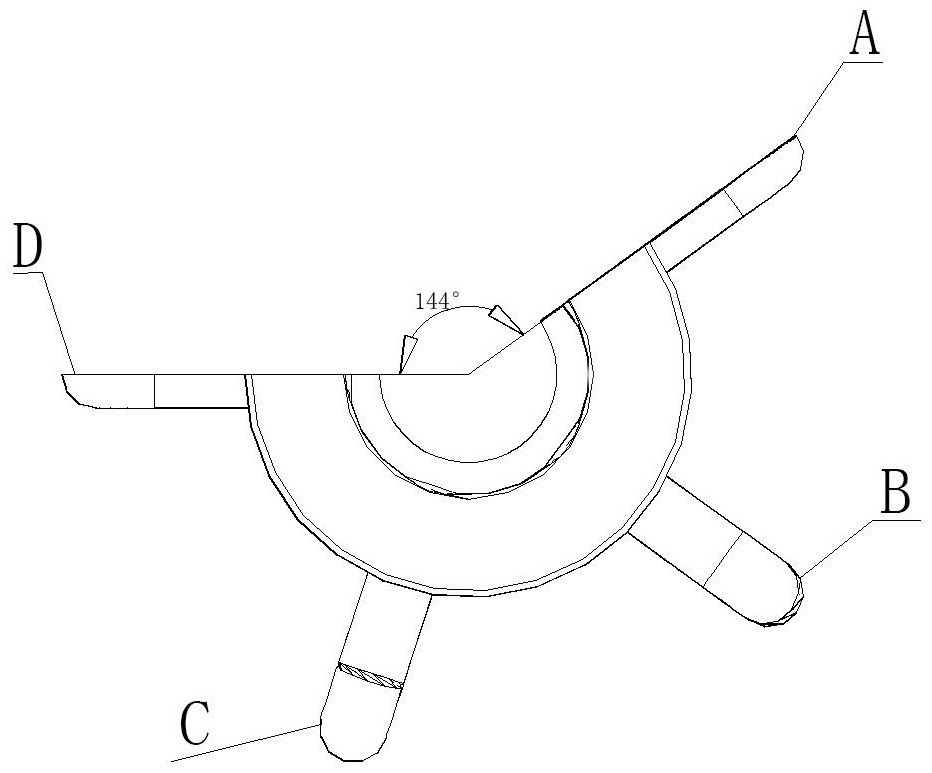

Self-oscillation jet-type mixing-increasing heat exchange air outlet device

ActiveCN111623505AIncreased diffusion areaGuaranteed heat exchange effectDucting arrangementsJet flowEngineering

The invention belongs to the technical field of air conditioning equipment mixing-increasing heat exchange, in particular to a self-oscillation jet-type mixing-increasing heat exchange air outlet device, and aims to solve the problems of fixed air outlet, poor heat exchange capability, non-uniform space temperature distribution, poor personnel comfort and the like in air outlet devices of most existing large-sized central air conditioners. The self-oscillation jet-type mixing-increasing heat exchange air outlet device comprises a main cavity and an odd number of feedback channels which are distributed on the main cavity at equal intervals, wherein the main cavity comprises a main chamber; and an air inlet and an air outlet are formed in two opposite ends of the main chamber respectively, and are in communication with each other through the main chamber. Through adoption of the mixing-increasing heat exchange air outlet device disclosed by the invention, the indoor temperature distribution uniformity is improved, and the comfort of the household living environment is improved greatly. The indoor temperature distribution is more uniform; frequent switching-on / off actions and refrigerating / heating processes of central air conditioning equipment are avoided; and the service life of the air conditioning equipment is prolonged while the running cost of the air conditioner is loweredand the electric energy is saved.

Owner:TAIYUAN UNIV OF TECH

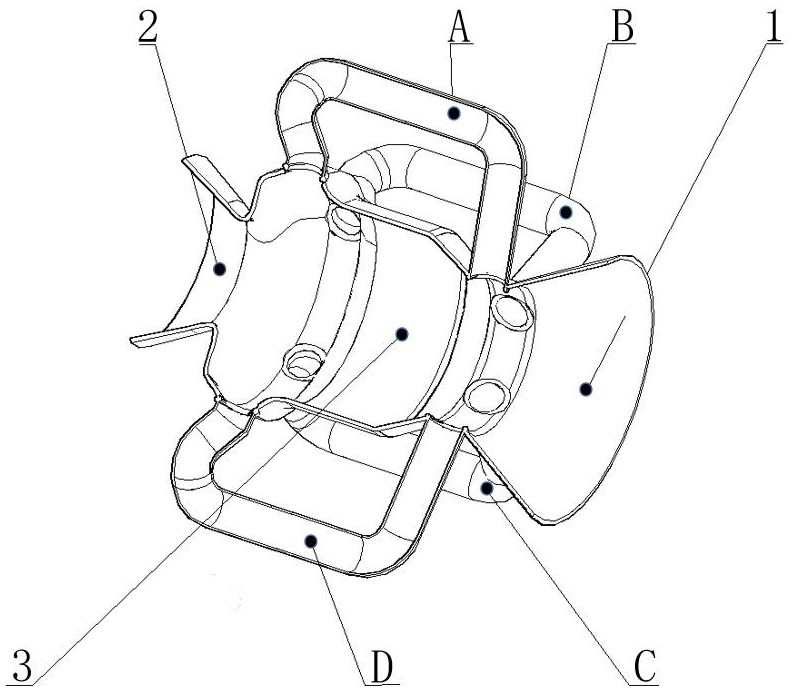

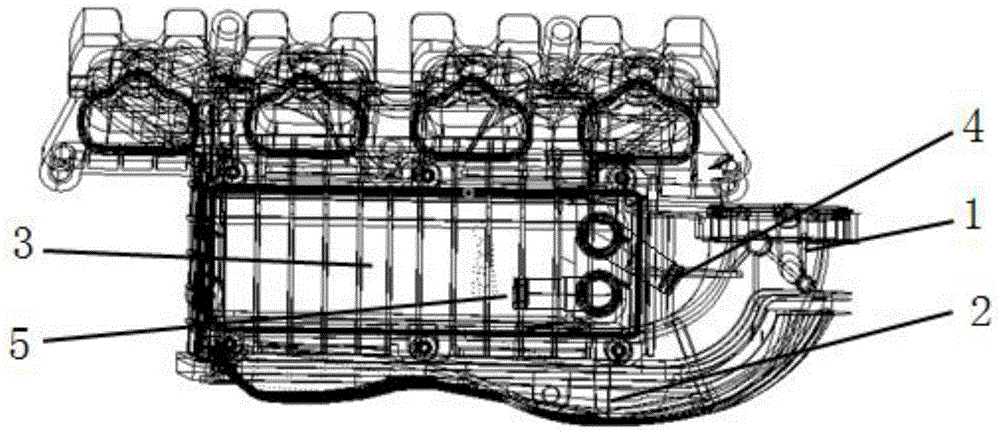

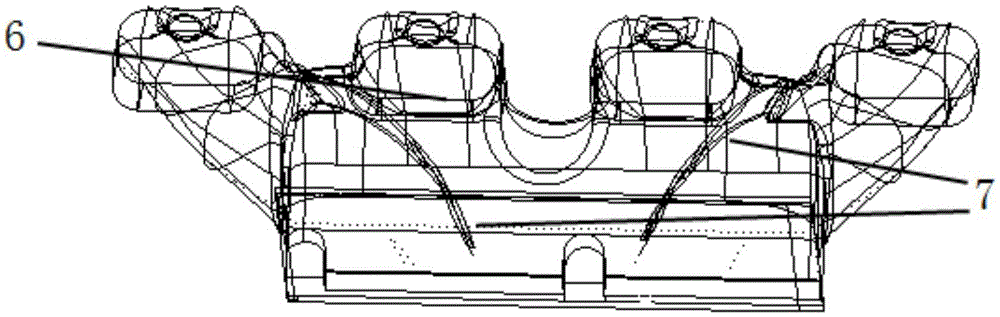

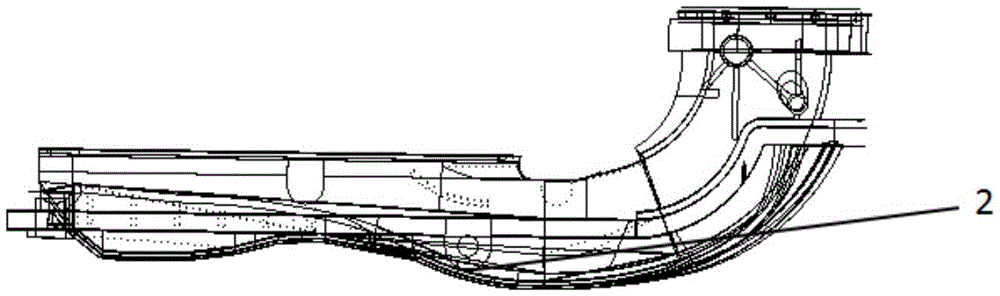

Inlet manifold integrated with intercooler

ActiveCN105673185AImprove cooling efficiencySpeed up the flowInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringIntercooler

The invention discloses an inlet manifold integrated with an intercooler. The inlet manifold comprises an inlet manifold body and the intercooler; a pressure stabilizing cavity is arranged on the inlet manifold body; the intercooler is integrated in the pressure stabilizing cavity; and the inlet manifold body further comprises an air inlet cavity communicating with the bottom face of the pressure stabilizing cavity and used for adjusting the air inlet direction and the boundary air space of the intercooler. As the appearance of the air inlet cavity of the inlet manifold integrated with the intercooler is optimized and the space of air of an edge and corner area of the intercooler is enlarged, air entering the air inlet cavity is prevented from being unevenly cooled when the boundary area space of the intercooler is small, the flowing direction of the air inlet face of the intercooler is adjusted, and accordingly flowing on the air inlet face of the intercooler is more even, and the temperature distribution evenness of the air outlet face of the intercooler is improved.

Owner:CHERY AUTOMOBILE CO LTD

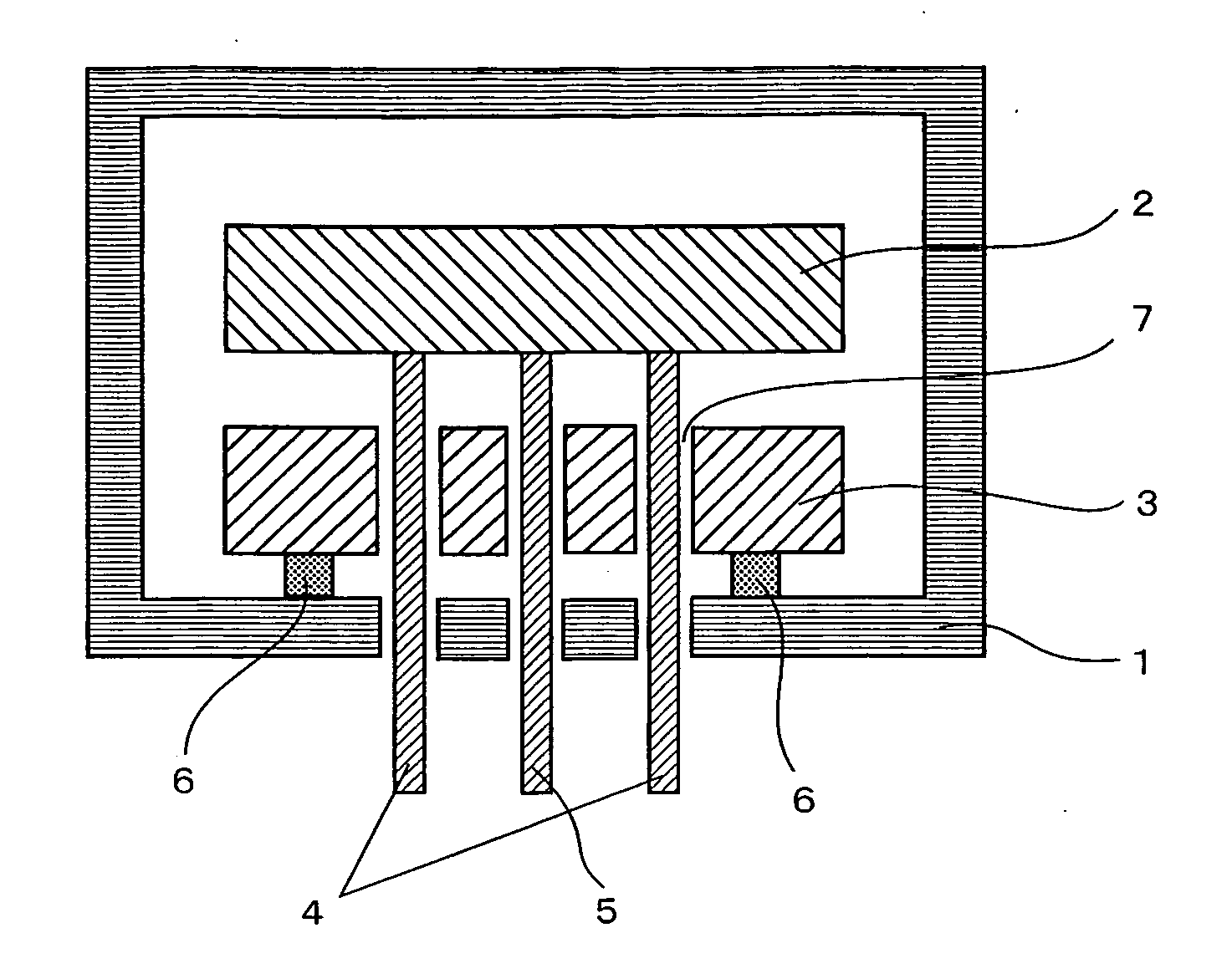

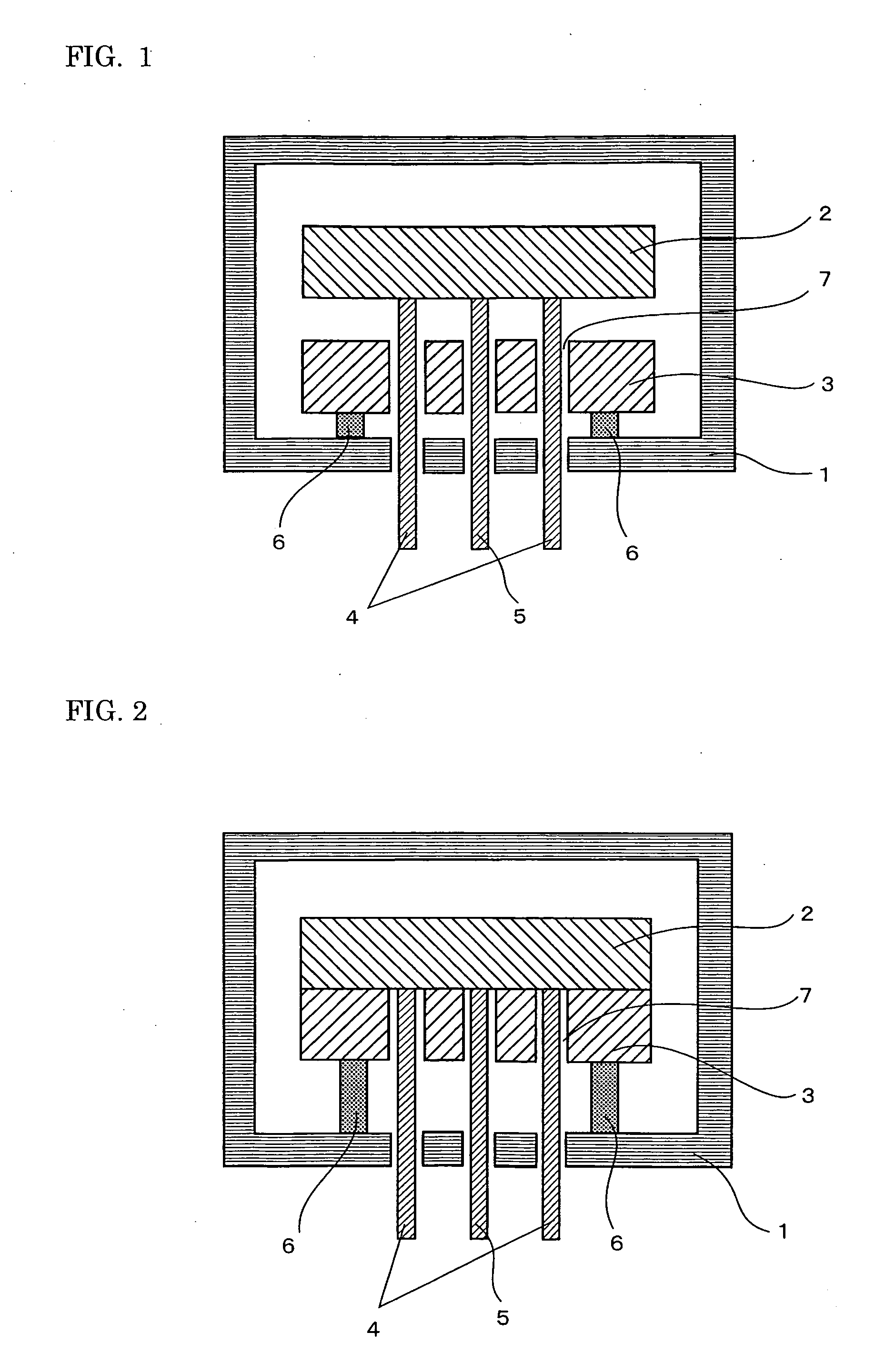

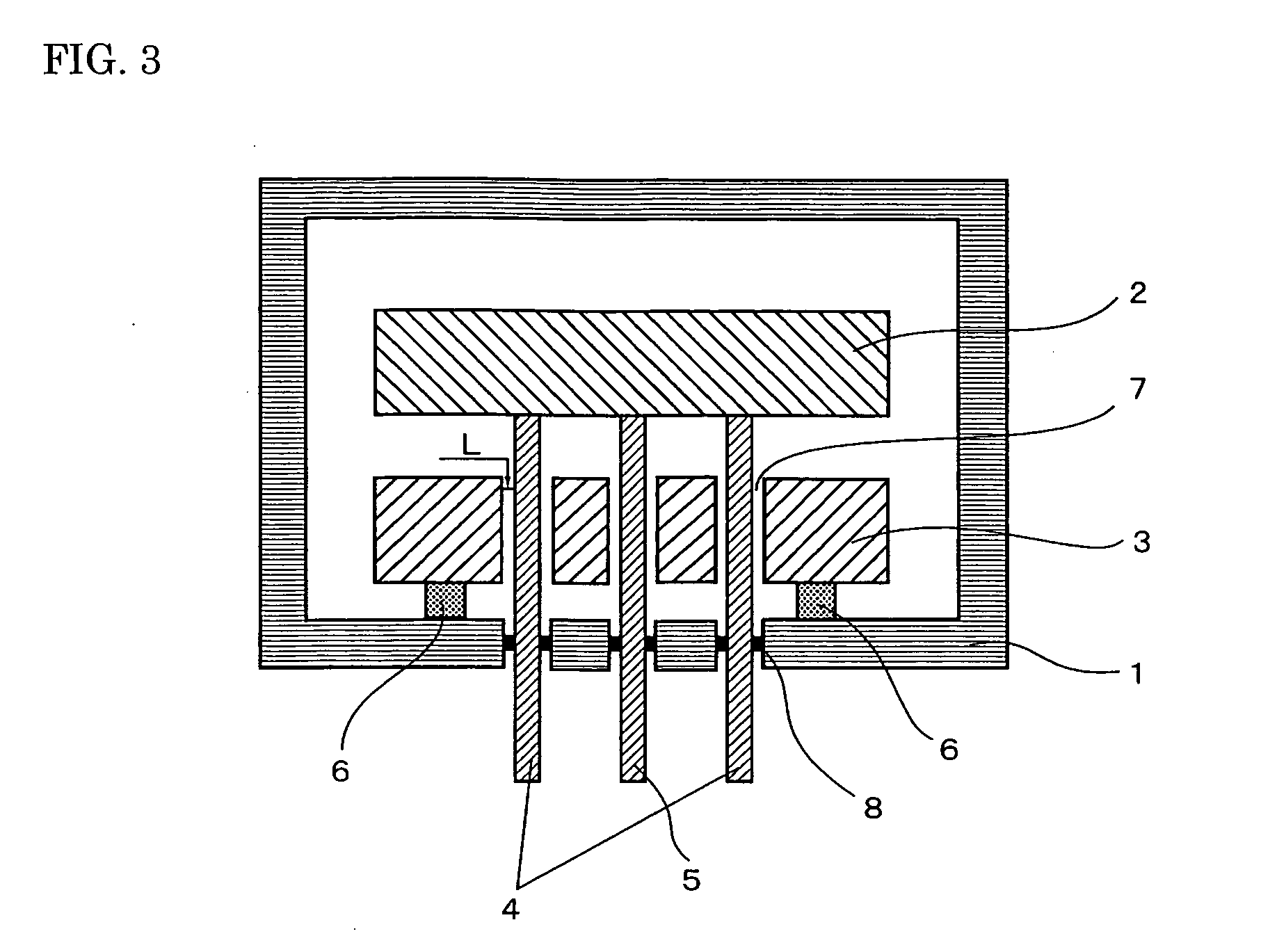

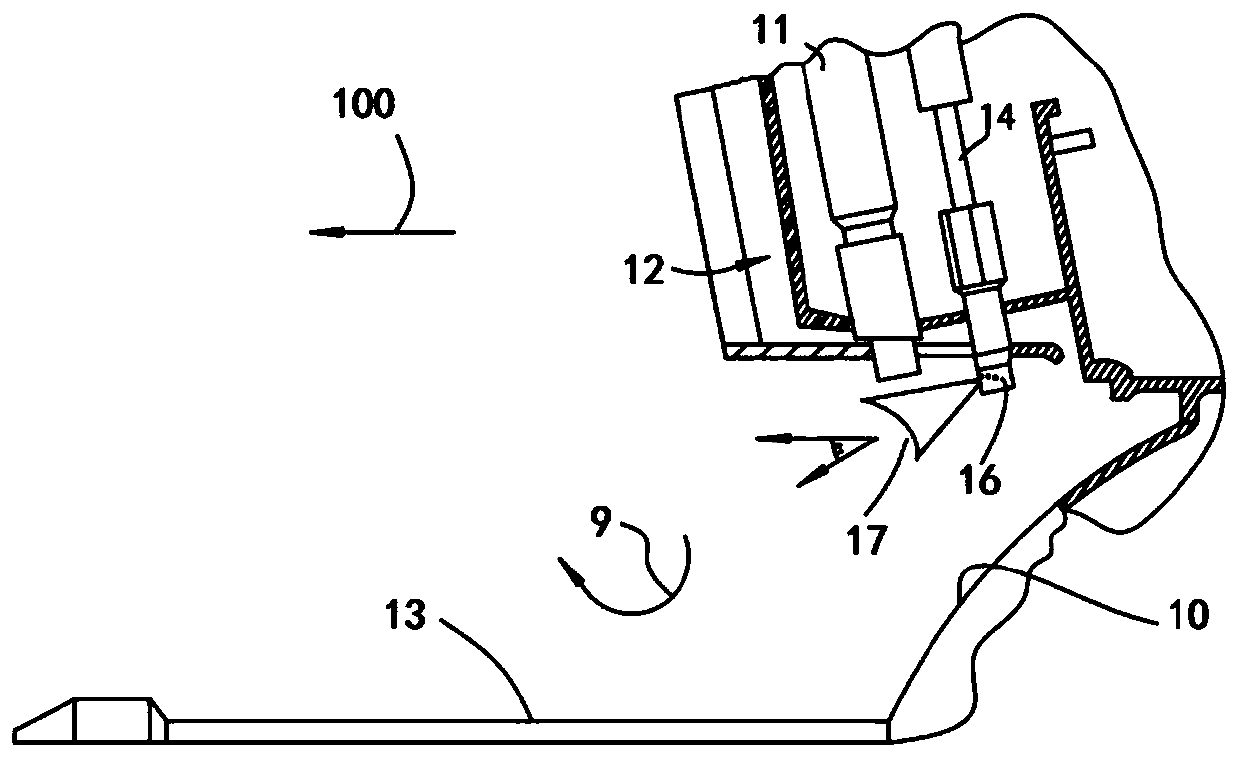

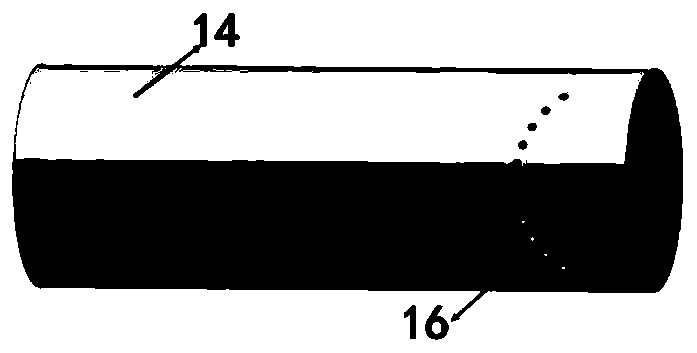

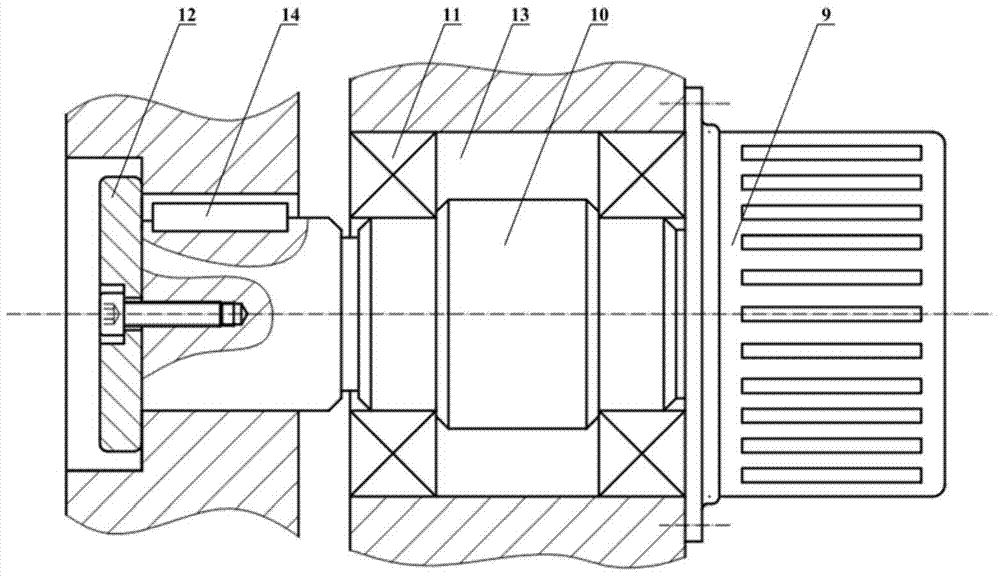

Semiconductor-producing apparatus

InactiveUS20050160988A1Increase cooling rateExcellent uniformity in temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature measurementEngineering

A semiconductor-producing apparatus increases both the cooling rate of the heater and the uniformity in the temperature distribution of the heater. The semiconductor-producing apparatus of the present invention is provided with a heater for heat-treating a semiconductor wafer and a cooling block for cooling the heater. The cooling block is provided with at least one through hole for inserting a penetrating object. The distance from the inner surface of the or each through hole to the penetrating object is at most 50 mm. The cooling block is arranged such that it can both make contact with and separate from the heater's face opposite to the face for placing the wafer. The foregoing penetrating object is a current-feeding electrode for feeding current to the heater circuit, a temperature-measuring means, or the like.

Owner:SUMITOMO ELECTRIC IND LTD

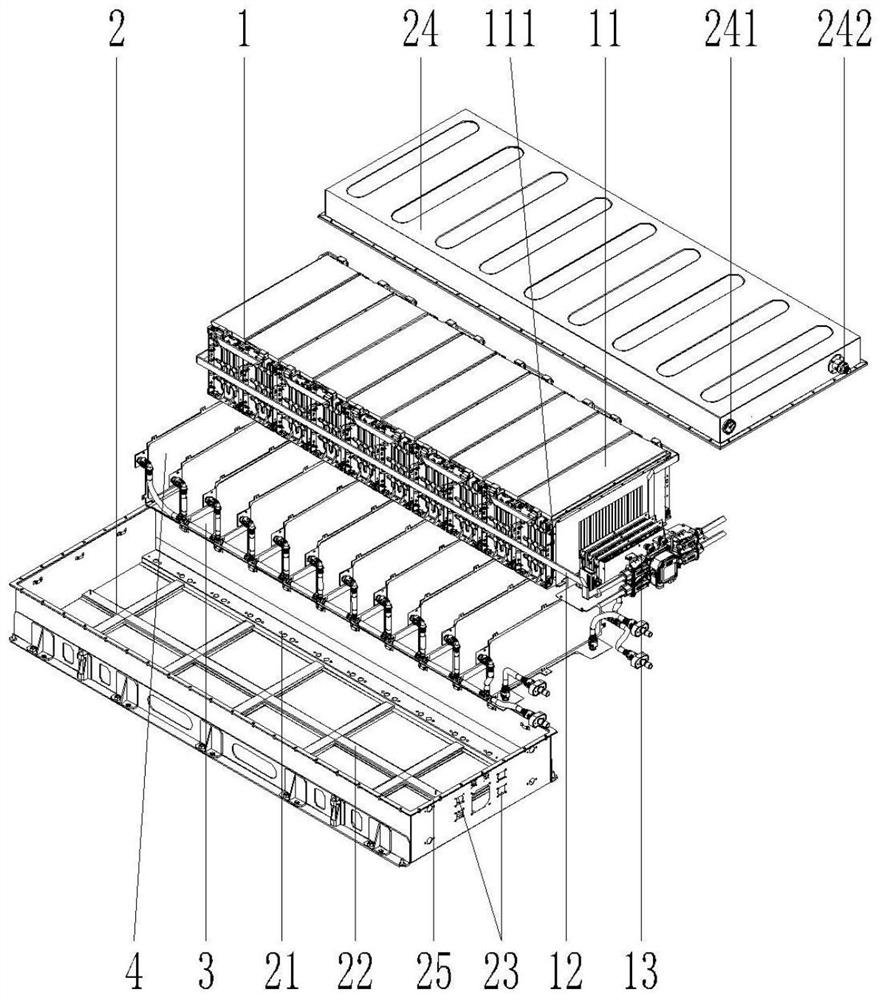

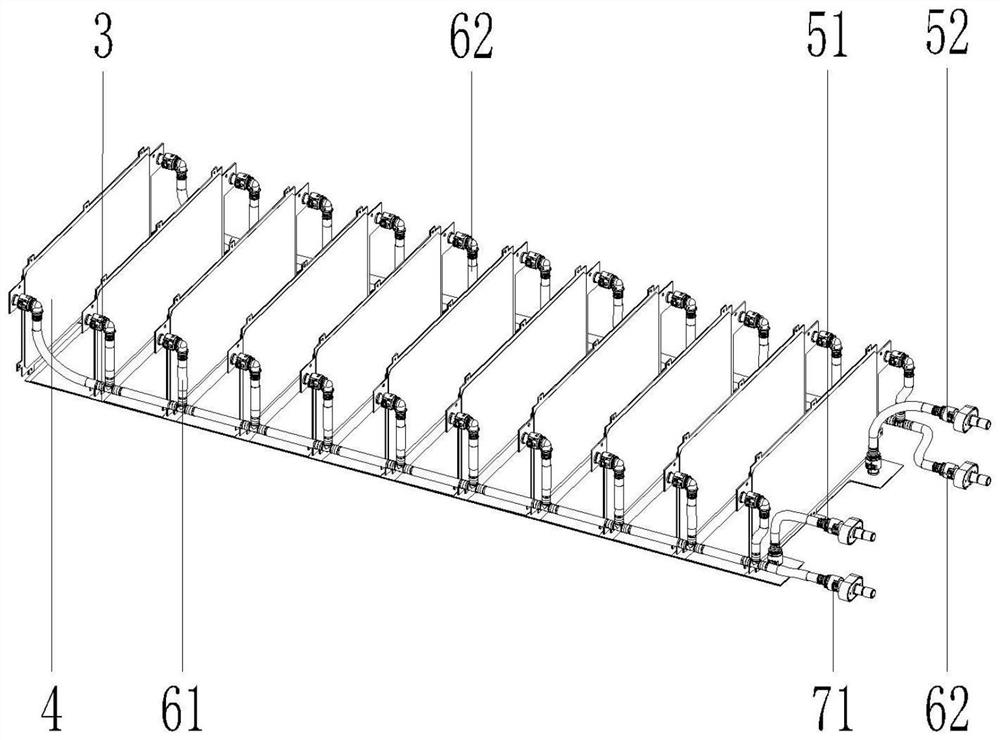

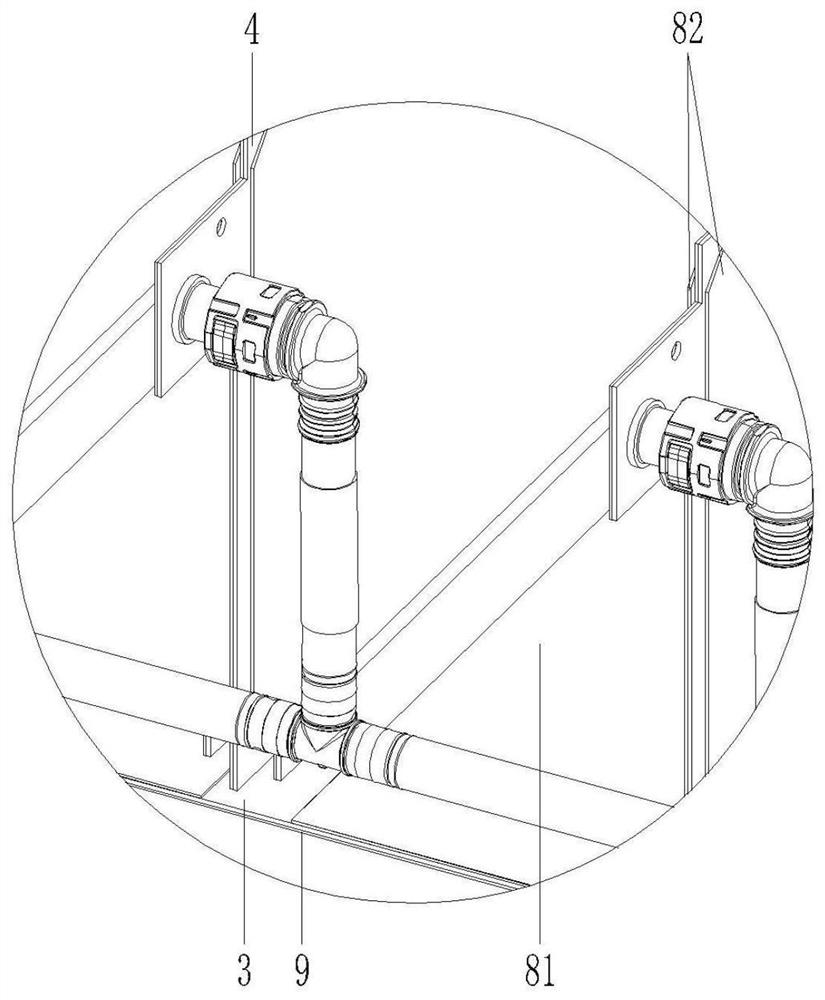

Soft package battery system with liquid cooling

PendingCN112736324ASolve the problem of limited design spaceImprove uniformity of temperature distributionSecondary cellsCharge and dischargeElectrical and Electronics engineering

The invention provides a soft package battery system with liquid cooling. The soft package battery system comprises a battery body and a battery box, wherein the battery body comprises a plurality of battery cell modules, the battery body is placed in the battery box, and a mounting gap is formed between every two adjacent battery cell modules; a liquid cooling assembly is fixed on the battery body and comprises a bottom cold plate and side cold plates, the bottom cold plate is provided with a plurality of side cold plates, and the plurality of side cold plates are inserted into the mounting gaps, so that the two side surfaces of the battery cell modules are attached to the second heat-conducting silica gel of the adjacent side cold plates, and the bottom surfaces of the battery cell modules are attached to the first heat-conducting silica gel on the bottom cold plate. Through heat dissipation of the bottoms and the side surfaces of the battery cell modules, the structural design that the plurality of side cold plates are matched with the bottom cold plate, and the design of the cold plate flow channels, the temperature distribution uniformity can be effectively improved on the premise of meeting high-rate charging and discharging, and the problem that the design space of a battery system is limited can also be solved.

Owner:FUJIAN YIDONGLI ELECTRONICS TECH CO LTD

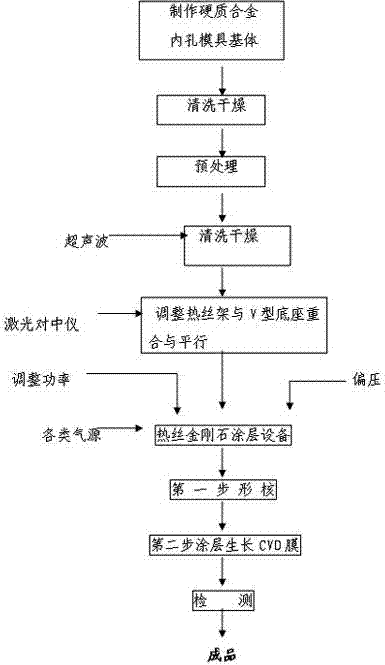

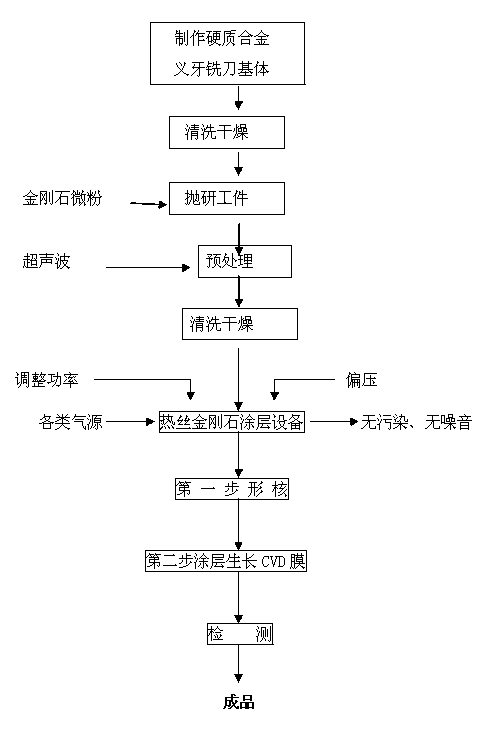

Clamp and process used for coating inner bore with diamond film

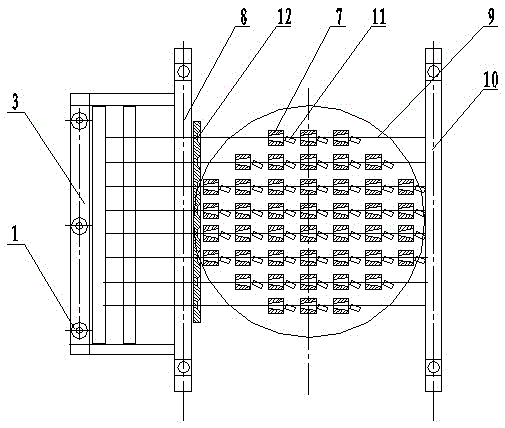

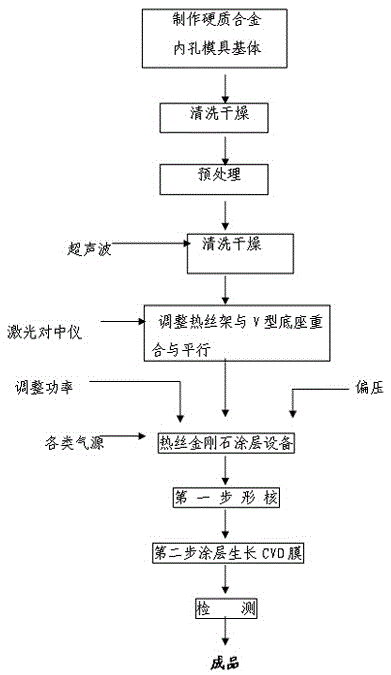

InactiveCN103834930AAutomatic Compensation for Hot Wire DrawingReduce manufacturing costChemical vapor deposition coatingPre treatmentHot filament

The invention discloses a clamp used for depositing a diamond film on an inner bore and a process for depositing the diamond film by using the clamp. The coating diamond film is deposited through cleaning, drying, pretreatment, workpiece polishing and grinding, nucleation through hot filament CVD deposition equipment, growth, etc. The diamond film deposited in the invention has the characteristics of a Vickers hardness value of HV9000, continuous, uniform and compact coating morphology and excellent heat radiation performance.

Owner:武汉世纪中航超强金刚石膜高科技有限公司

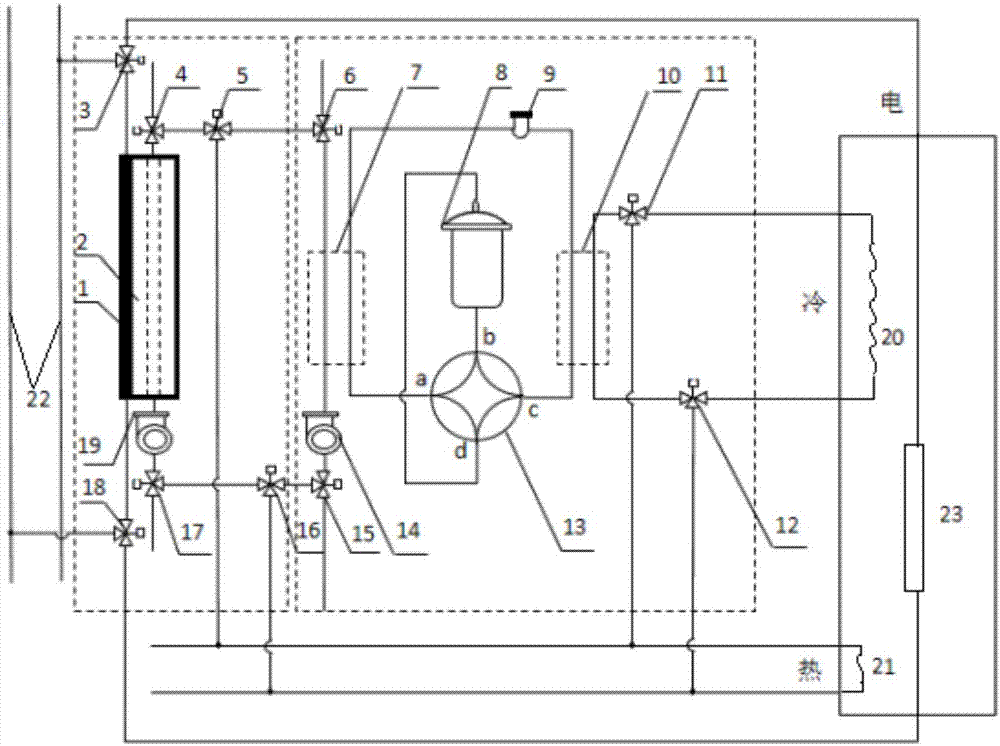

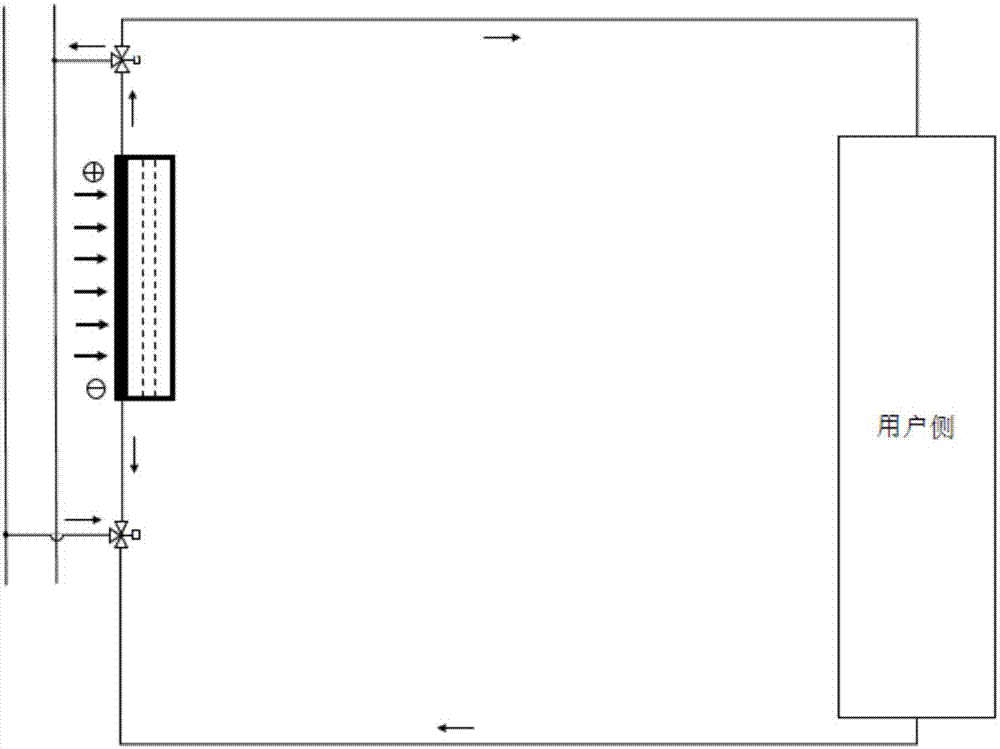

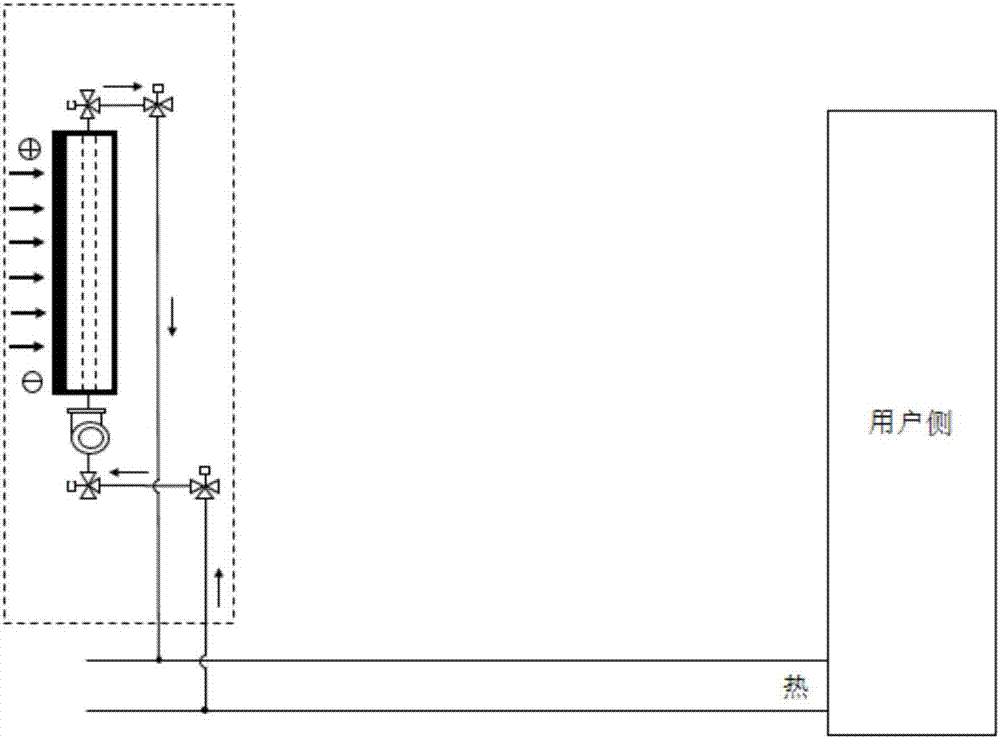

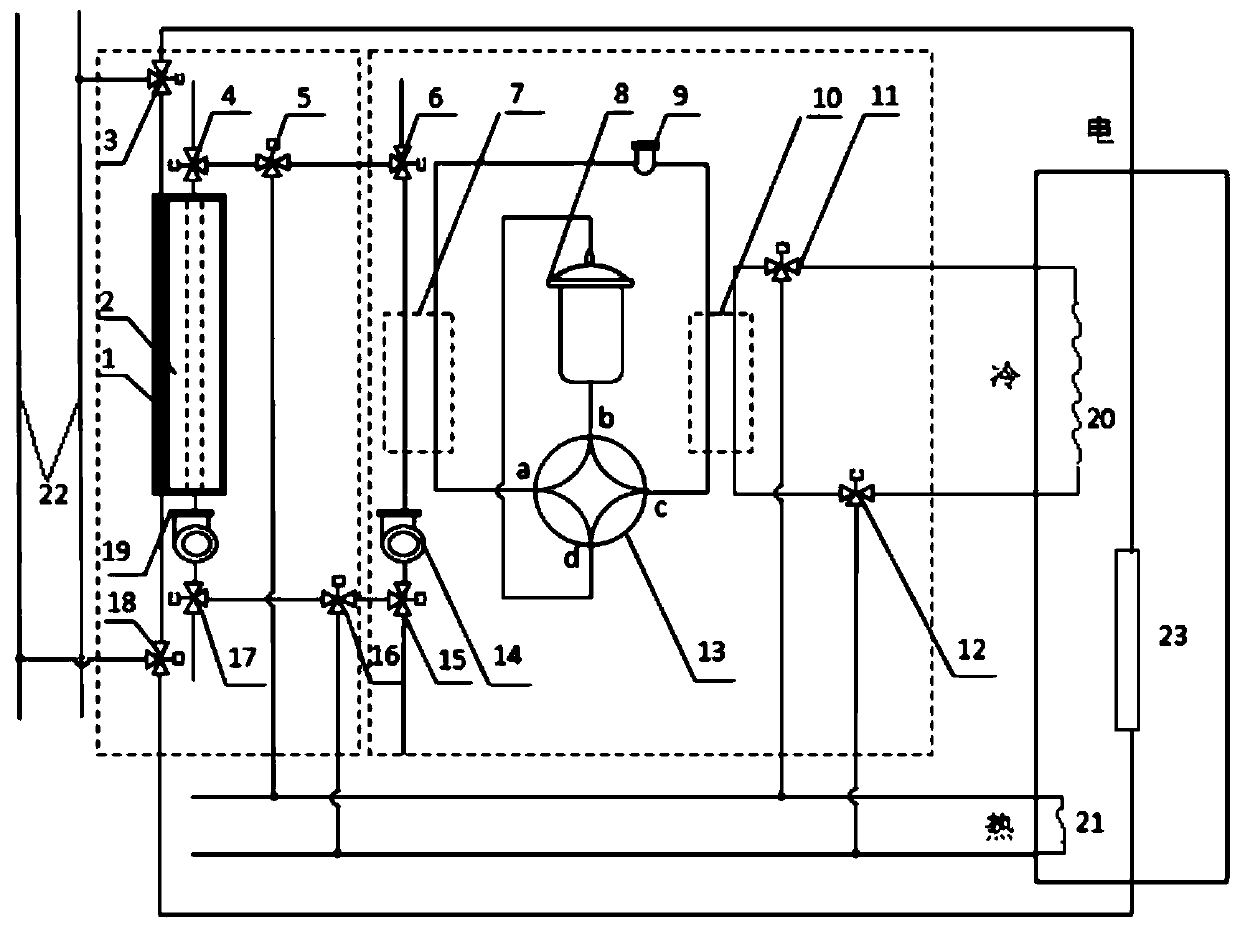

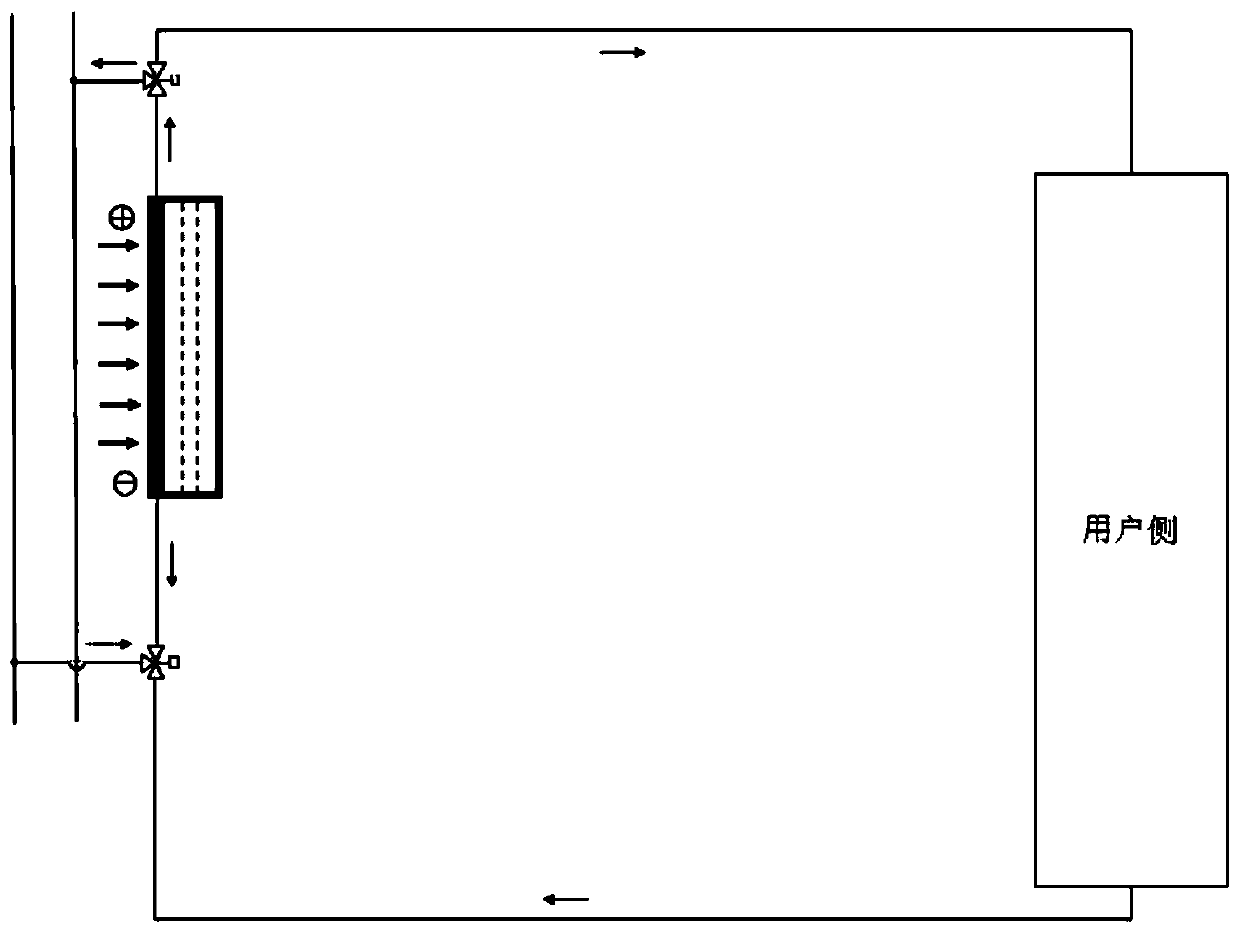

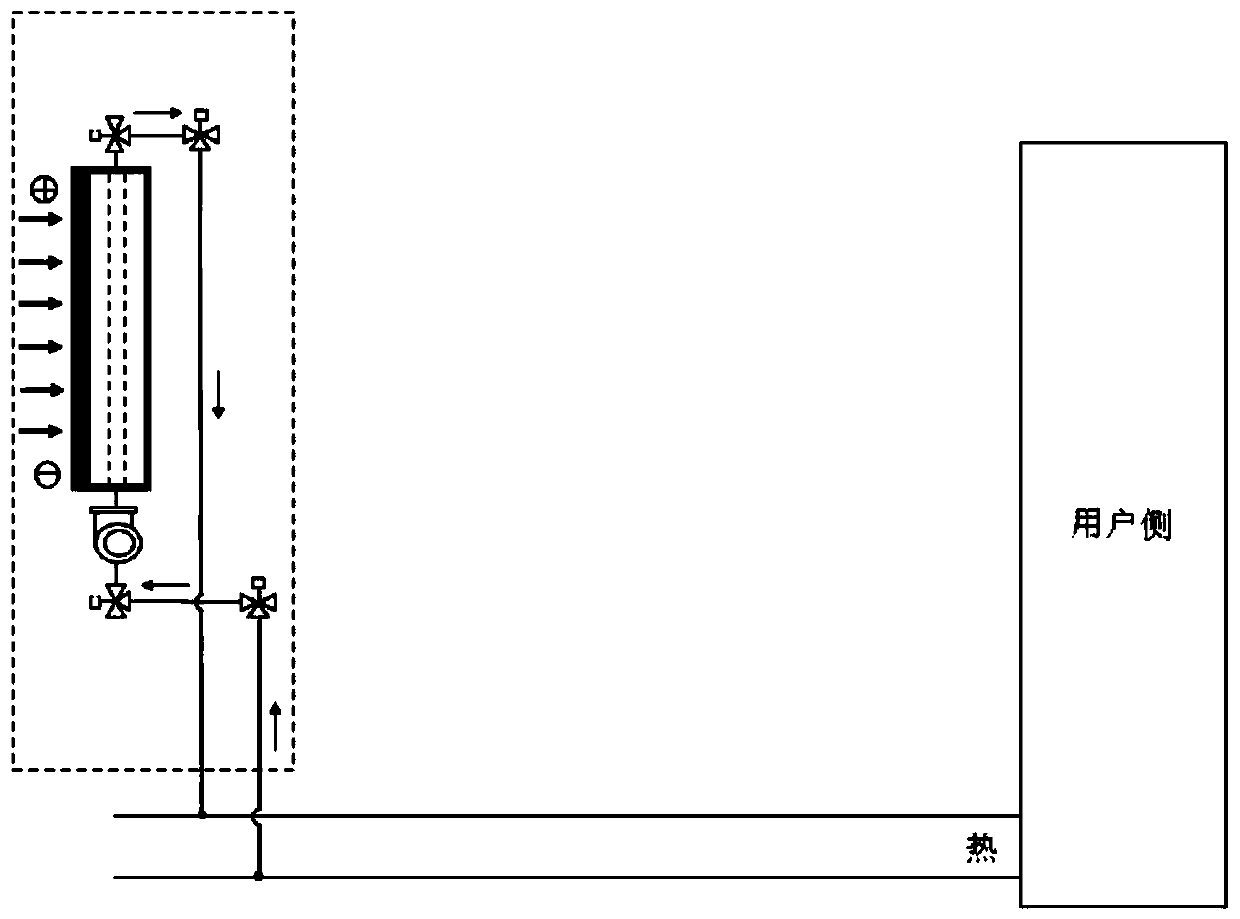

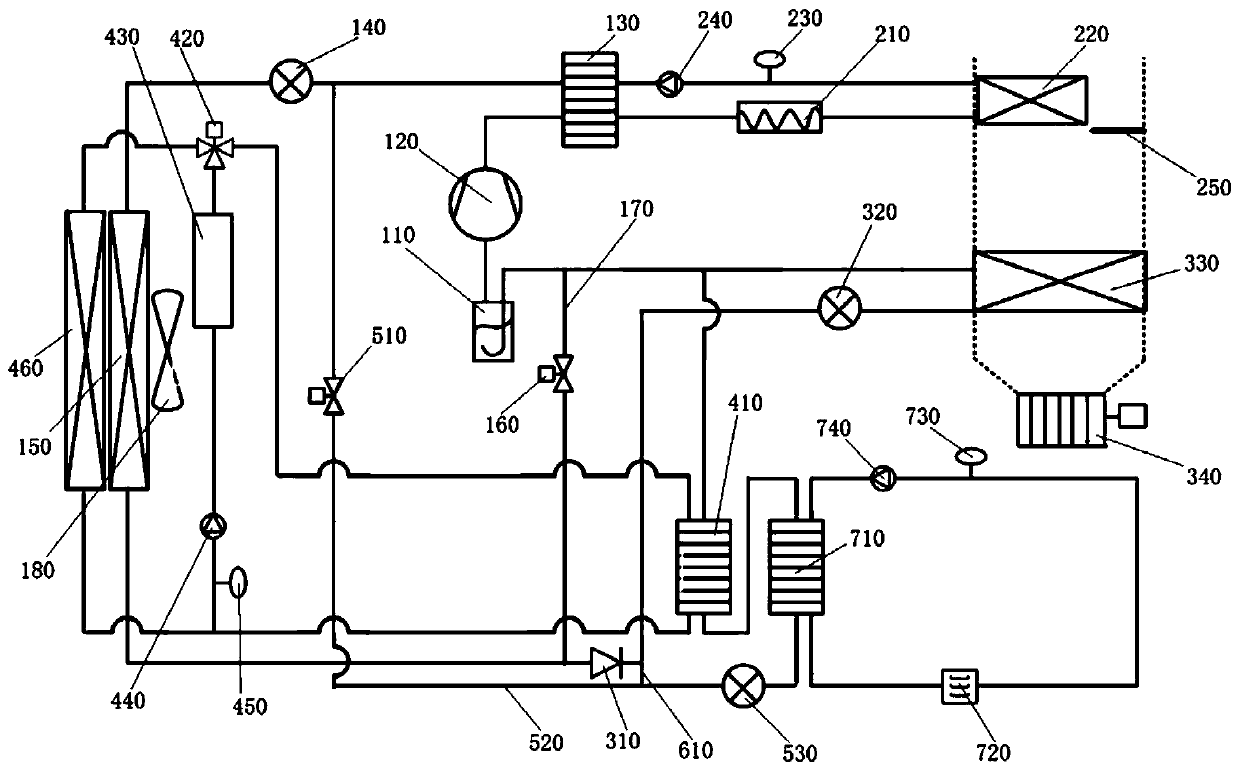

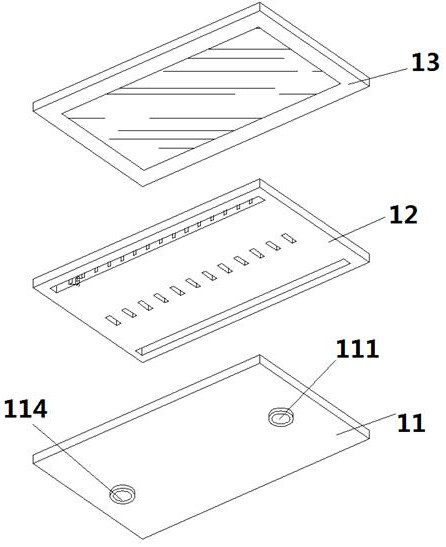

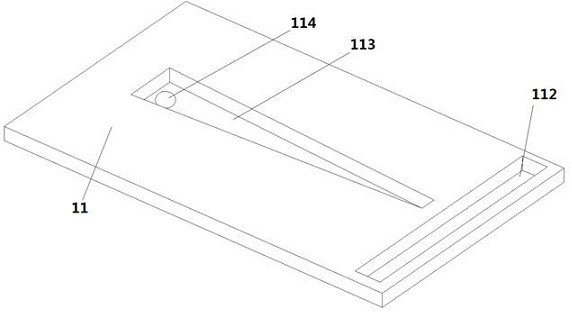

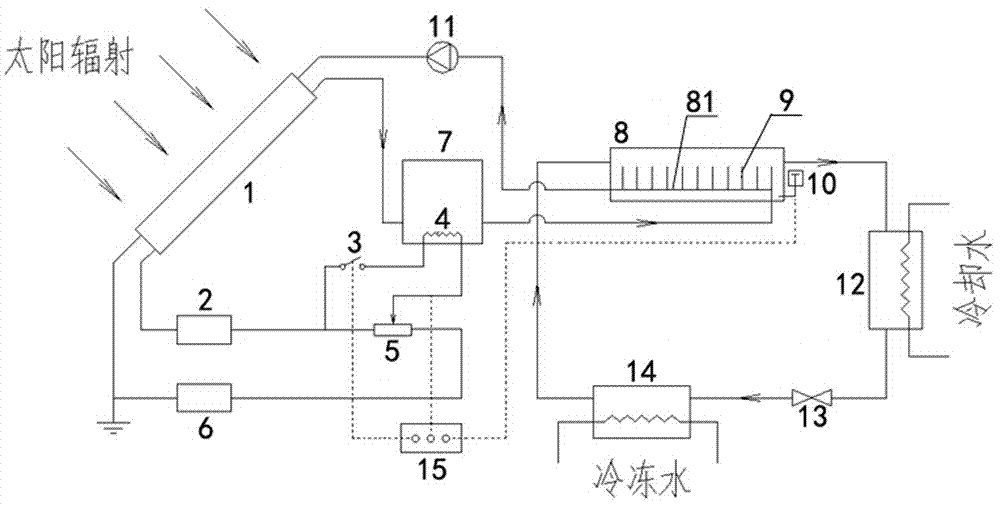

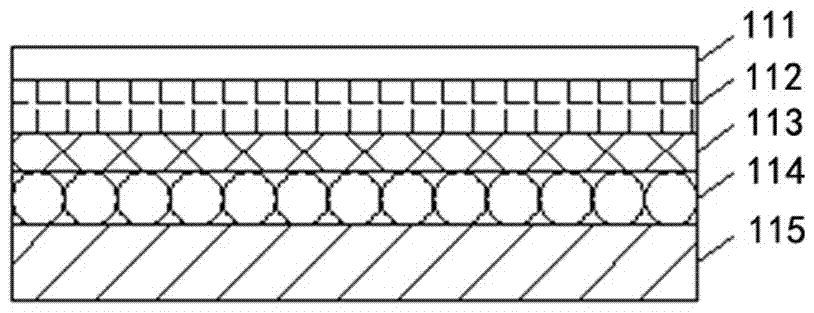

Compound energy system capable of achieving solar photovoltaic combined cold, heat and power supply

ActiveCN107461954AImprove uniformity of temperature distributionLarge cooling capacityEvaporators/condensersPhotovoltaicsEngineeringSolar cell

The invention relates to a compound energy system capable of achieving solar photovoltaic combined cold, heat and power supply. The compound energy system comprises a solar cell temperature control power supply and heat supply unit and a heat pump unit; the solar cell temperature control power supply and heat supply unit comprises a power supply subunit and a heat supply subunit, the power supply subunit communicates with a subscriber circuit and a power grid, the heat supply subunit is connected with the heat pump unit, a heat consumer unit and tap water, and the heat pump unit is connected with the heat consumer unit and the tap water. Compared with the prior art, the compound energy system has the advantages that solar photovoltaics, optothermal and a heat pump are combined, the application range of solar energy is widened, combined cold, heat and power supply compound energy utilization integrating solar cell power generation, heating and refrigerating is achieved, the comprehensive utilization efficiency of solar energy is improved, and the cold-heat-power multi-form energy source requirements of a building are met.

Owner:SHANGHAI JIAO TONG UNIV

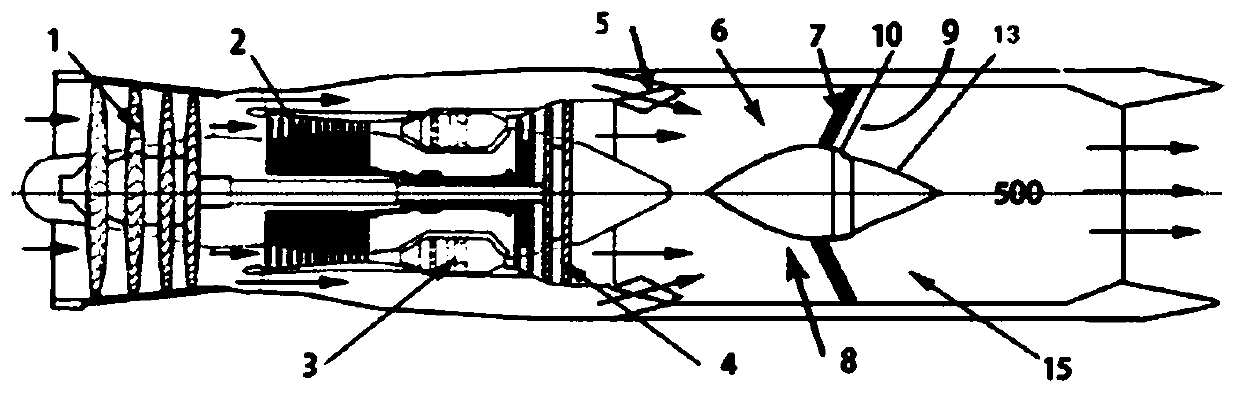

Direct-injection type fan-shaped nozzle applied to cavity structure of afterburner

ActiveCN111306577AImproved circumferential cross-fire performanceImprove combustion stabilityContinuous combustion chamberCombustion chamberAerosolize

The invention discloses a direct-injection type fan-shaped nozzle applied to a cavity structure of an afterburner, relates to the direct-injection type fan-shaped nozzle which is installed in the cavity of the afterburner and used for enhancing fire stabilization performance and flame connection performance, and belongs to the field of aeroengines. According to the direct-injection type fan-shapednozzle applied to the cavity structure of the afterburner, a plurality of direct-injection type spray holes distributed in a certain shape are formed in the bottom end of each oil injection rod and used for spraying fuel into the cavity structure in the afterburner, the fuel forms a fan-shaped oil mist annular surface after being sprayed and atomized through the shape of the holes, the fan-shapedoil mist surfaces of every two adjacent oil injection rods intersect, and an oil mist ring concentric with a casing is formed in the cavity structure. The fuel atomization effect is enhanced, the circumferential flame connection performance is enhanced, and the combustion efficiency is improved. The direct injection type fan-shaped nozzle is small in machining difficulty, high in machining precision and small in nozzle hole diameter, so that the fuel atomization effect is good, and the overall performance of the afterburner is greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

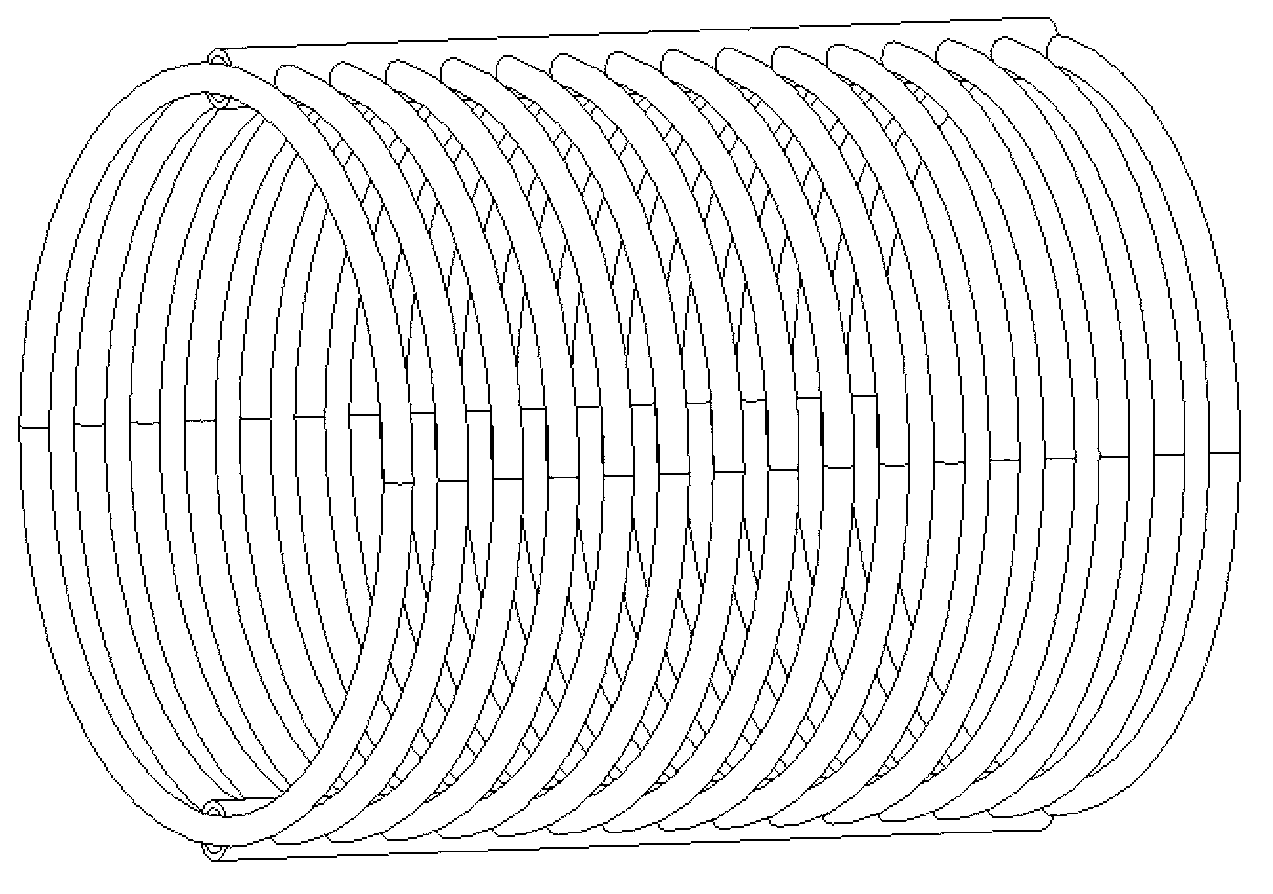

Aluminum-made vertical heat sink device with high temperature distribution uniformity

InactiveCN103008041AStrong black adhesionImprove temperature distribution uniformityHeating or cooling apparatusEnclosures/chambersCooling effectPrism

The invention discloses an aluminum-made vertical heat sink device with high temperature distribution uniformity. The heat sink device consists of fin tube array sides, a metal corrugated soft pipe, a plurality of thermal insulating material layers and a temperature acquisition system, wherein an eight-prism-shaped side surface is formed by eight fin tube array sides being 460mm*1160mm; two fin tube array sides being 1120mm*1200mm are respectively used as the top surface and the bottom surface of the heat sink device; the metal corrugated soft pipe is connected with the surfaces so as to integrate an inner cavity of the whole heat sink device; thermistors in the temperature acquisition system are adhered to the outer surface of the heat sink device; and the plurality of thermal insulating material layers are wrapped at the outermost surface of the device. The aluminum-made vertical heat sink device has the advantages of good temperature distribution uniformity, good cooling effect, rapid cooling speed, small size, convenience in operation and maintenance, and the like, and has a good practical value and an application prospect in the field of space technologies.

Owner:BEIHANG UNIV

Heater based on silver nanowire transparent conductive film and preparation method thereof

ActiveCN104053256BLow costExpand application spaceTransparent/reflecting heating arrangementsHeating element materialsHydrophilizationConductive polymer

The invention discloses a heater based on a transparent silver nanowire conducting thin film and a preparation method of the heater. The heater is simple in structure, uniform in heating and resistant to corrosion. The heater comprises a transparent substrate, the transparent conducting thin film, a conducting electrode and a protective layer. The heater is applied to defogging glass, a thermochromic substrate, a sensor substrate and the like. The preparation method of the heater comprises the steps of hydrophilization processing of the substrate, preparation of the transparent conducting thin film, preparation of the conducting electrode and preparation of the protective layer. According to the heater, silver nanowires synthesized through a low-temperature liquid phase method are used as raw materials, the transparent substrate is coated with the transparent conducting thin film through a non-vacuum non-high-temperature filming technology, the heating uniformity of the thin film is improved through technically mature and commercial conducting polymers, and the thin-layer protective film is obtained by means of liquid phase coating of cheap organic polymers. The heater is simple in structure, the raw materials are cheap, the requirement for preparation technological conditions is low, and large-scale production is facilitated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

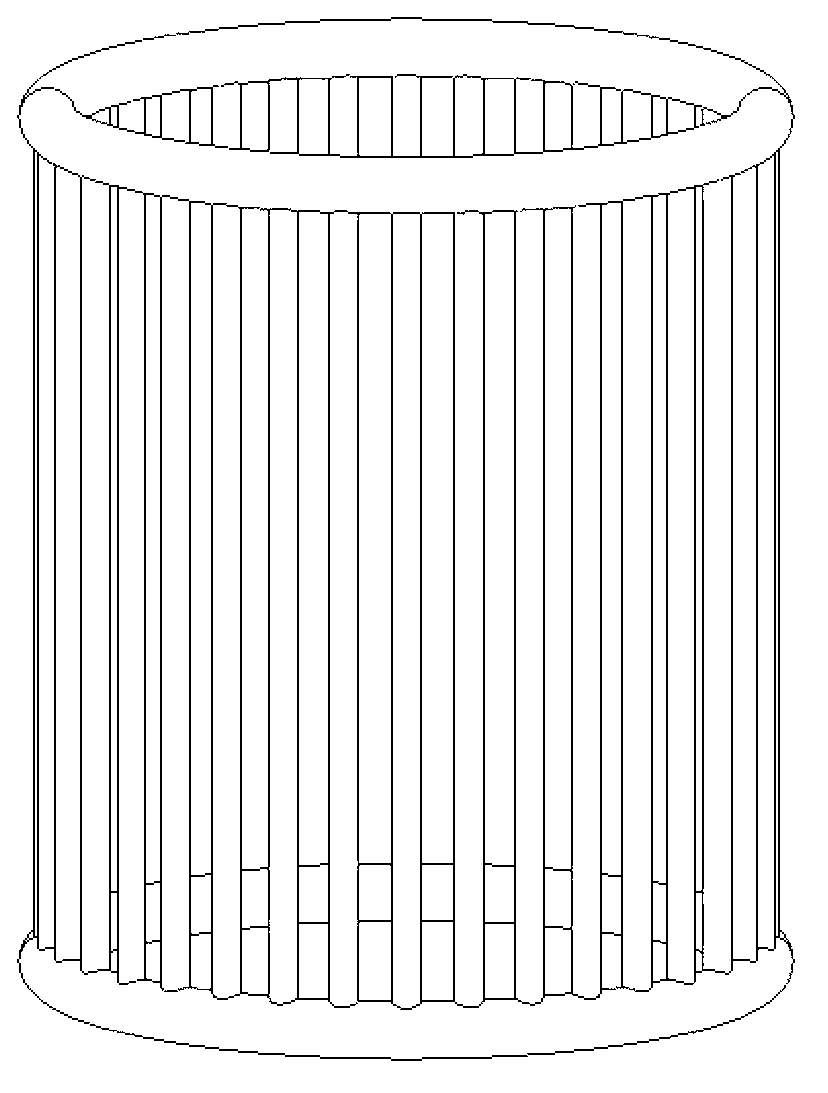

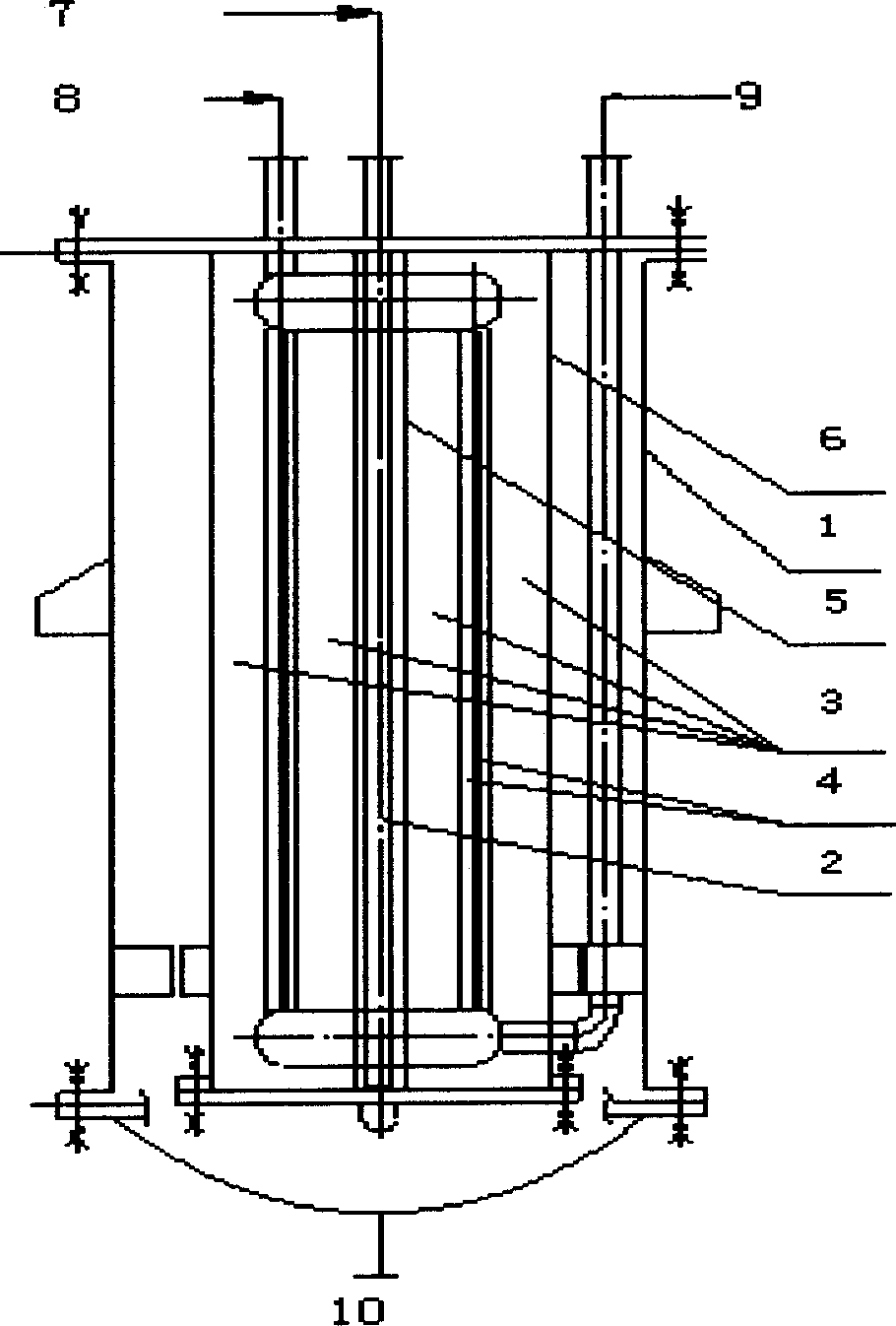

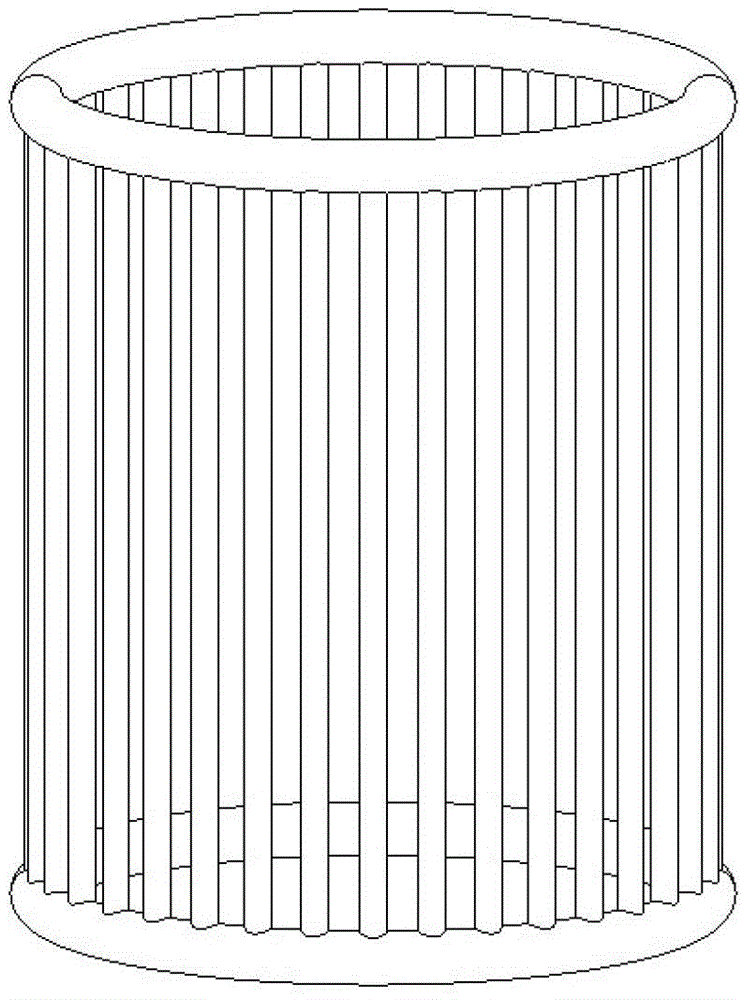

Radial reactor for preparing ethylene (propylene) carbonate

ActiveCN1861561AImprove uniformityRadial runner shortProductsReagentsProcess engineeringHigh selectivity

A radial reactor for preparing vinyl (or propenyl) carbonate has a central feeding pipe with perforated wall, concentric internal and external cylinders with pinholes, catalyst bed between said internal and external cylinders, and U-shaped tube in catalyst bed. Its advantages are high utilization rate and long service life of catalyst, high conversion rate of epoxy ethane and high selectivity.

Owner:PETROCHINA CO LTD

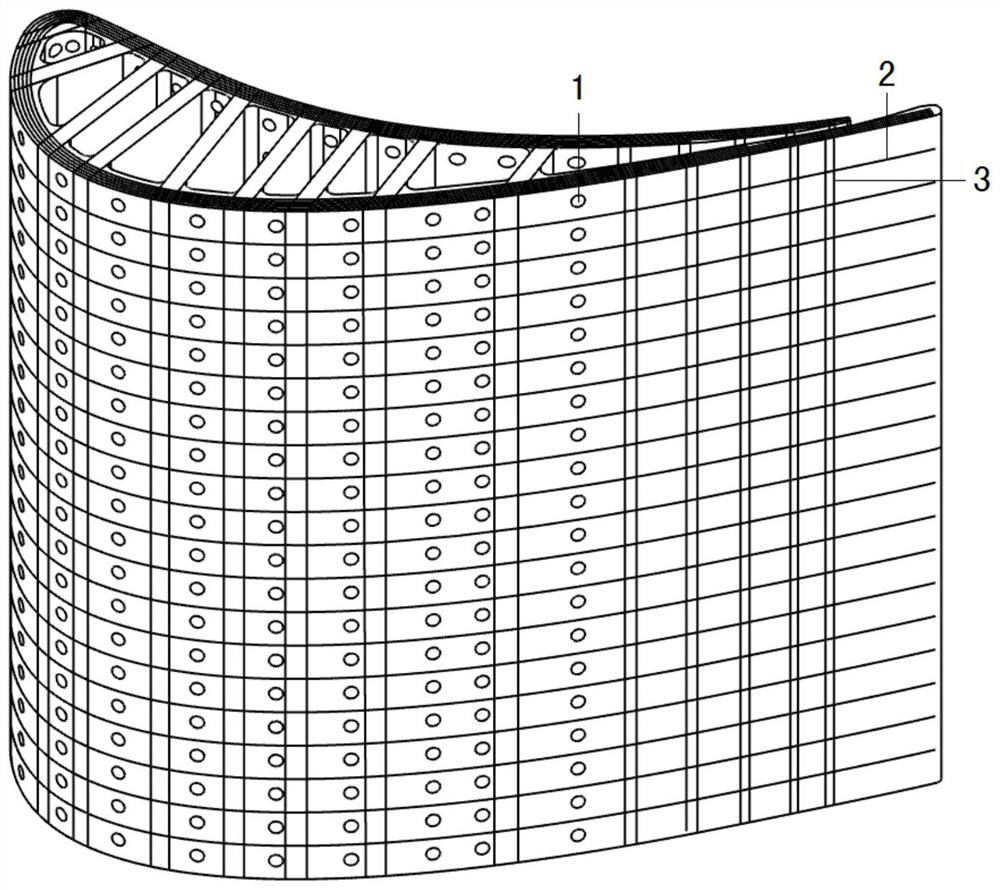

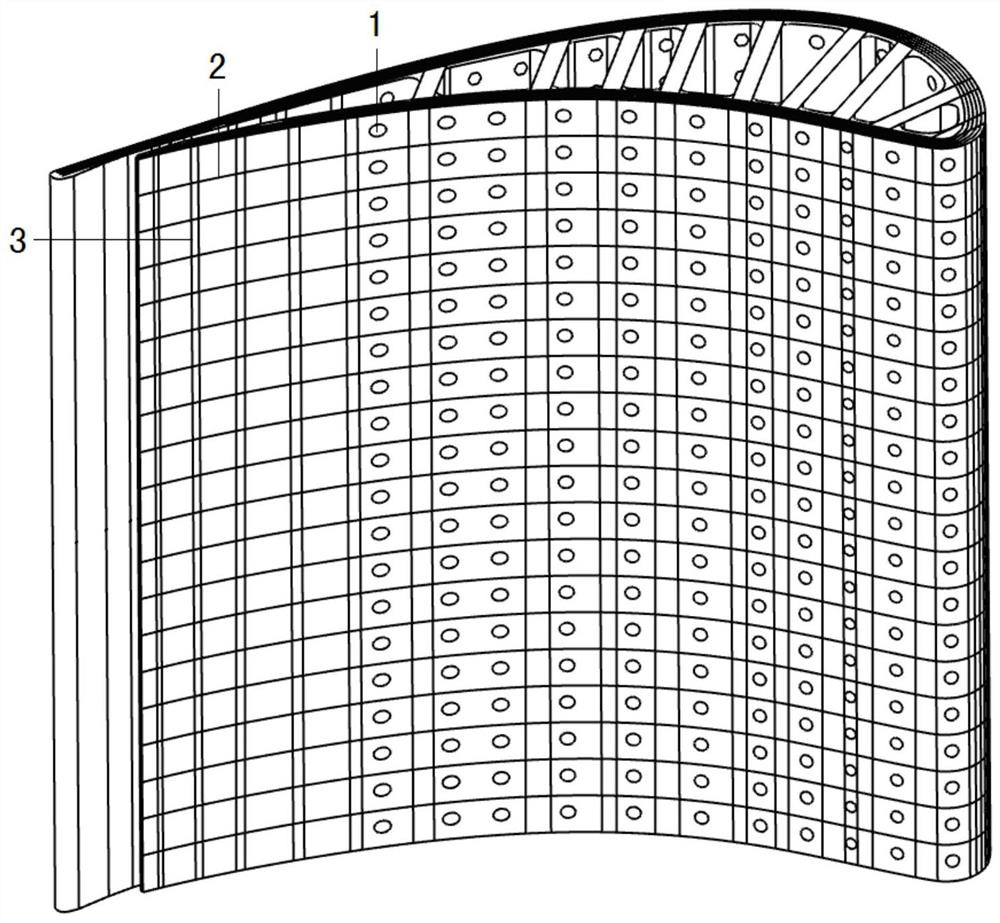

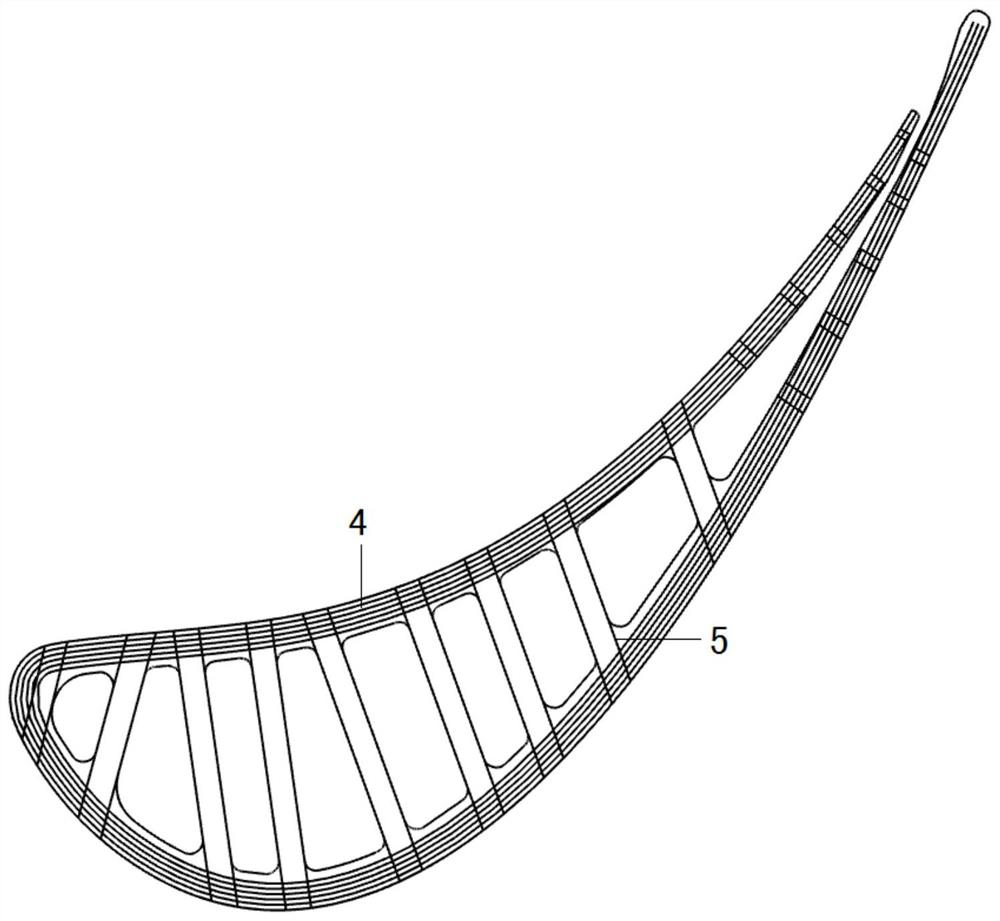

Turbine blade with three-dimensional mesh woven fibers

ActiveCN112160797AImprove mechanical propertiesImprove thermal conductivityBlade accessoriesEfficient propulsion technologiesFiberTurbine blade

The invention provides a turbine blade with three-dimensional mesh woven fibers. The three-dimensional mesh woven fibers are added to the wall surface and the interior of the turbine blade, wherein onthe wall surfaces of a suction surface and a pressure surface of the turbine blade, the fibers are distributed around an air mold hole, and the fibers comprise wall surface transverse fibers and wallsurface vertical fibers; on a blade grid plane without the air mold hole of the turbine blade, the fibers comprise first internal transverse fibers and first internal longitudinal fibers; the first internal longitudinal fibers penetrate through the wall surface of the suction surface or the pressure surface and are connected with cross intersection points of the wall surface transverse fibers andthe wall surface vertical fibers; on the blade grid plane with the air mold hole of the turbine blade, no fibers are distributed on the inner wall of the air mold hole, and the fibers are only distributed on the periphery of the air mold hole; the fibers comprise second internal transverse fibers and second internal longitudinal fibers, and the second internal transverse fibers and the second internal longitudinal fibers are located in ribs and penetrate through the cross sections of the whole ribs to form a ladder-shaped fiber net; the fibers at the tail edge of the turbine blade penetrate through the inner wall surface and the outer wall surface to be distributed; and the internal vertical fibers are distributed in the ribs of the turbine blade in the blade height direction.

Owner:SHENYANG AEROSPACE UNIVERSITY

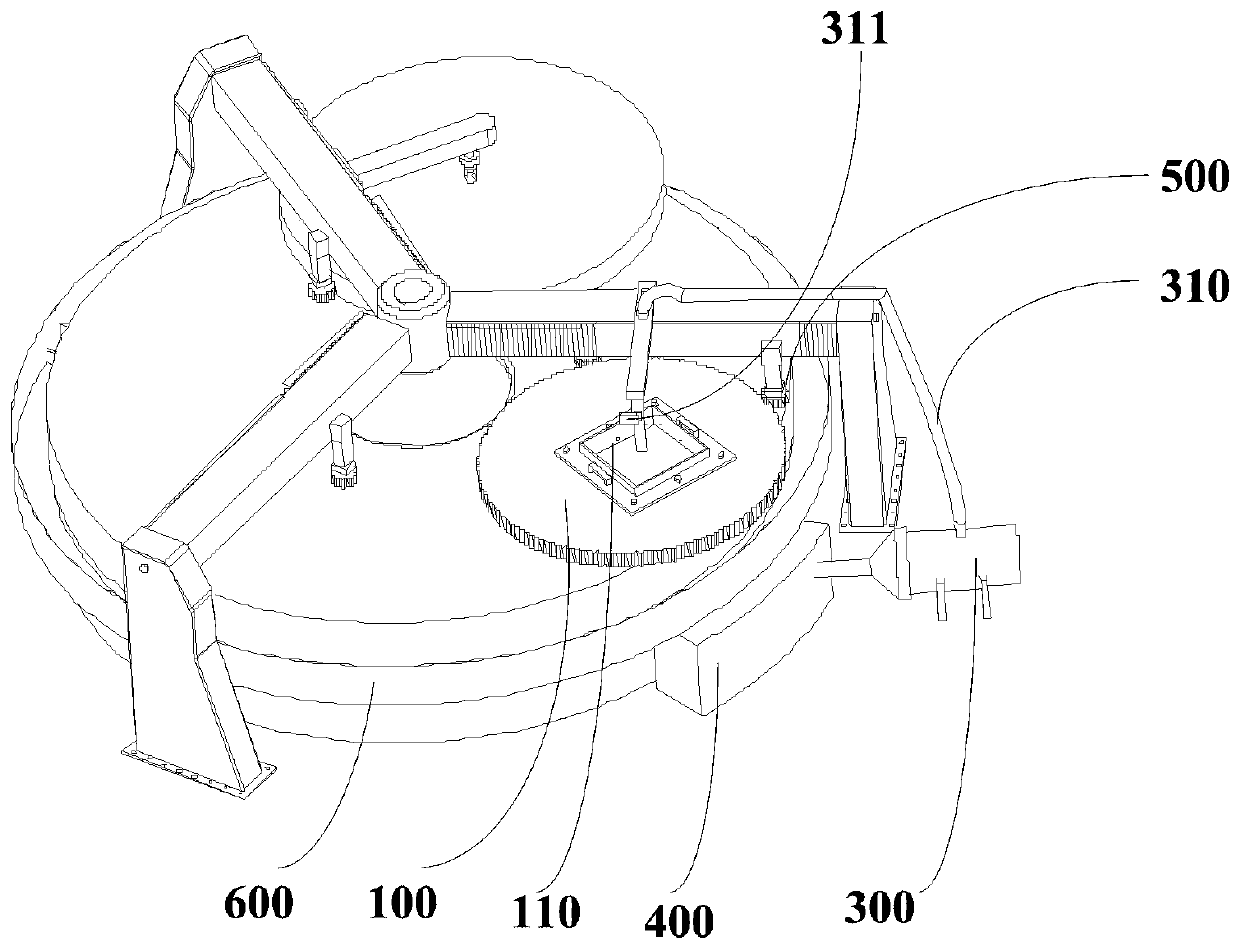

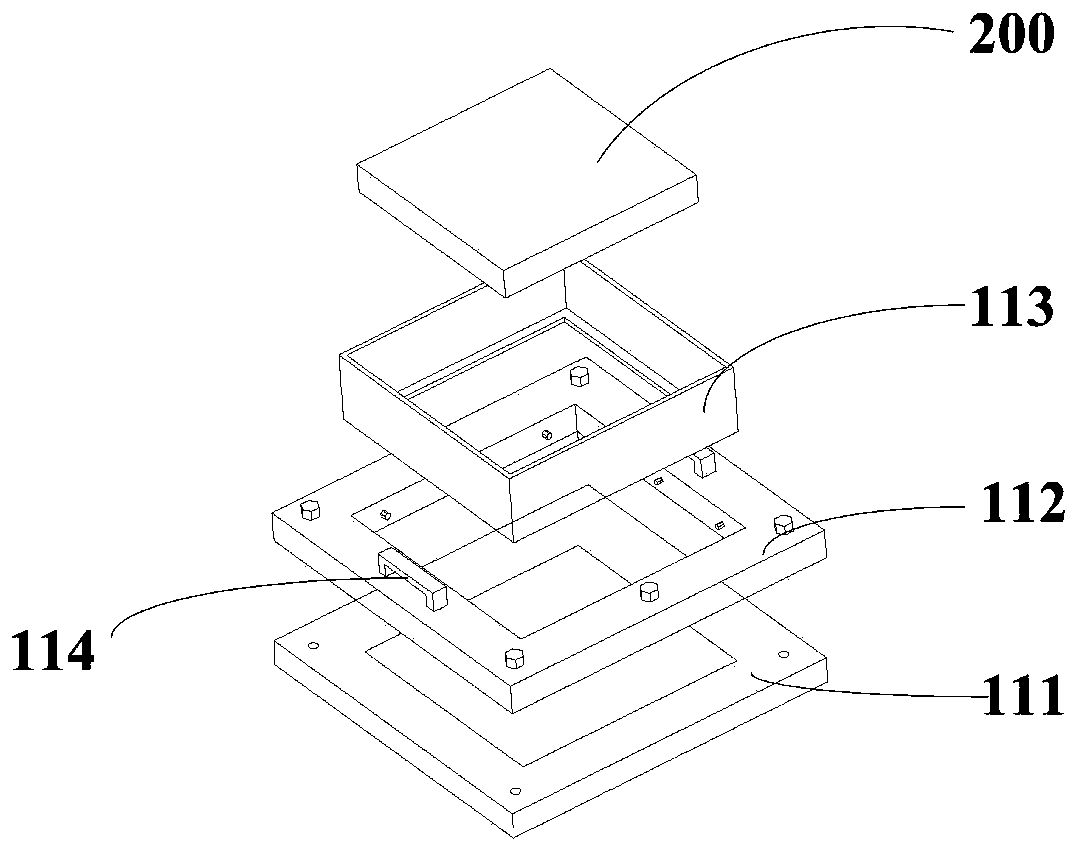

Full-caliber polishing immersing type element machining device and method and polishing machine

PendingCN110153839AImprove uniformity of temperature distributionReduce distortionOptical surface grinding machinesGrinding/polishing safety devicesEngineeringMachining

The invention relates to a full-caliber polishing immersing type element machining device and method and a polishing machine. The full-caliber polishing immersing type element machining device comprises a workpiece disc and a polishing liquid conveying pump, wherein an immersing chamber is defined at the middle portion of the workpiece disc and used for immersing an element during machining, the liquid outlet end of the polishing liquid conveying pump is connected to the upper portion of the immersing chamber through a polishing liquid conveying pipe for polishing liquid spraying, and the liquid inlet end of the polishing liquid conveying pump is connected with a polishing liquid storage barrel. It can be known from the above technical scheme that compared with the prior art, the full-caliber polishing immersing type element machining device is provided, the element is placed in the immersing chamber, the polishing liquid conveying pump supplies liquid, the polishing liquid flows in from the top of the immersing chamber, the polishing liquid and various surfaces of the element during machining conduct heat, temperature distribution uniformity in the element can be better improved,and deformation caused by uneven temperature distribution is reduced.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

A composite energy system of solar photovoltaic combined cooling, heating and power supply

ActiveCN107461954BImprove uniformity of temperature distributionLarge cooling capacityEvaporators/condensersPhotovoltaicsThermodynamicsElectrical battery

The invention relates to a compound energy system capable of achieving solar photovoltaic combined cold, heat and power supply. The compound energy system comprises a solar cell temperature control power supply and heat supply unit and a heat pump unit; the solar cell temperature control power supply and heat supply unit comprises a power supply subunit and a heat supply subunit, the power supply subunit communicates with a subscriber circuit and a power grid, the heat supply subunit is connected with the heat pump unit, a heat consumer unit and tap water, and the heat pump unit is connected with the heat consumer unit and the tap water. Compared with the prior art, the compound energy system has the advantages that solar photovoltaics, optothermal and a heat pump are combined, the application range of solar energy is widened, combined cold, heat and power supply compound energy utilization integrating solar cell power generation, heating and refrigerating is achieved, the comprehensive utilization efficiency of solar energy is improved, and the cold-heat-power multi-form energy source requirements of a building are met.

Owner:SHANGHAI JIAOTONG UNIV

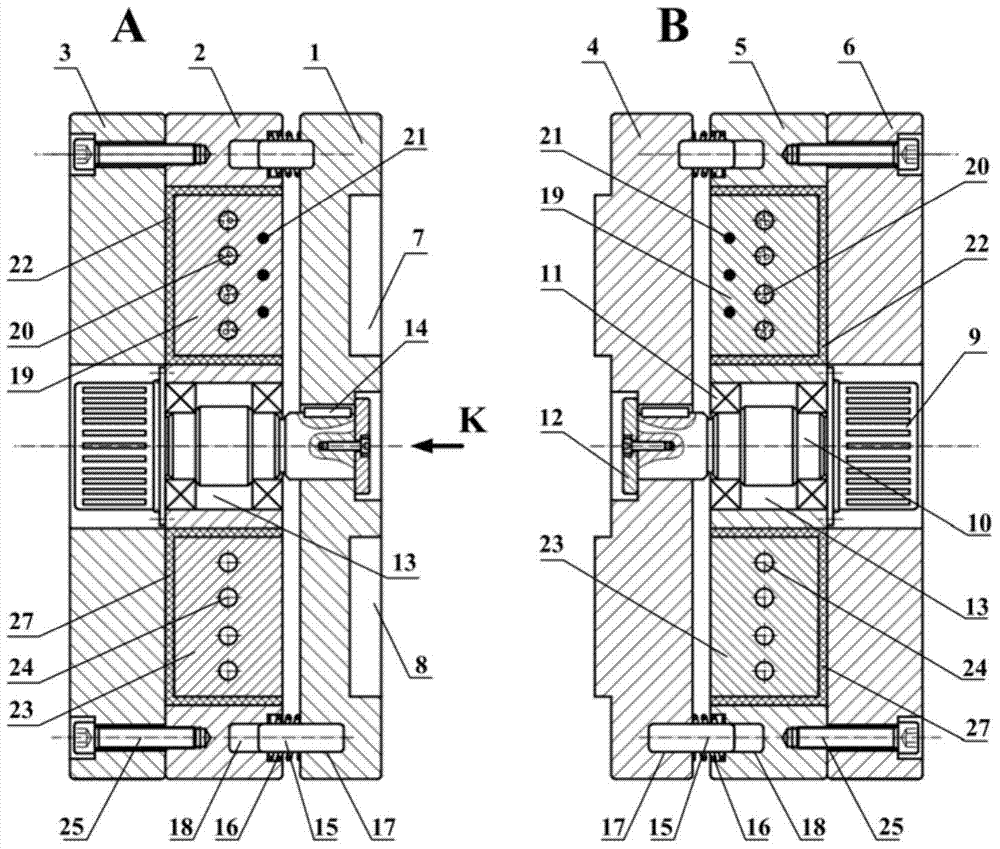

Hot and cold dual-station rotary rapid thermal cycle injection mold and molding method

ActiveCN104859105BIncrease productivityImprove Thermal Response EfficiencyEngineeringInjection moulding

The invention provides a hot-and-cold double-station rotary rapid heat cycle injection mould, comprising a fixed mould module and a movable mould module. The fixed mould module comprises, arranged in sequence, a cavity plate, a cavity retaining plate, a fixed mould fixing plate and a fixed mould rotating device driving the cavity plate to rotate on the cavity retaining plate; the movable mould module comprises, arranged in sequence, a core plate, a core retaining plate, a movable mould fixing plate and a movable mould rotating device driving the core plate to rotate on the core retaining plate; the front surface of the cavity plate and the front surface of the core plate define two mould cavities through enclosure; and a heating device and a cooling device are arranged in both the cavity retaining plate and the core retaining plate, and in a closed state of the mould, the heating device heats one of the two mould cavities while the cooling device cools the other of the two mould cavities. The invention also provides a hot-and-cold double-station rotary rapid heat cycle injection moulding method using the mould. The mould and method provided by the invention have high heating and cooling rates and high production efficiency, enables good temperature homogeneity to be obtained on the surface of the cavities and are convenient for industrial application.

Owner:SOUTH CHINA UNIV OF TECH

Heat pump air conditioning system and vehicle

PendingCN110186222AAchieve defrostingOptimize layoutMechanical apparatusAir-treating devicesEngineeringRecuperator

The invention relates to the technical field of vehicle manufacturing, in particular to a heat pump air conditioning system and a vehicle. The heat pump air conditioning system comprises a heat pump air conditioning unit, a heating piece cooling unit, a battery cooling unit and a first pipeline, wherein the heat pump air conditioning unit comprises an outdoor heat exchanger; the heating piece cooling unit comprises a heating piece cooling plate and a first heat exchanger which are connected with each other and form a loop; the battery cooling unit comprises a battery cooling plate and a secondheat exchanger which are connected with each other and form a loop; the first heat exchanger and the second heat exchanger are connected in series through the first pipeline, and the first pipeline is connected with the outdoor heat exchanger in parallel. According to the heat pump air conditioning system, the problem that in the prior art, the heat generated by a heating device can be recycled or cooled, the number of valves in the system is more and the corresponding joint is more, so that the risk of refrigerant leakage of the system is increased are avoided.

Owner:ZHEJIANG YINLUN MACHINERY

Flat plate type solar heat collector with elastic heat dissipation body

InactiveCN114294839AEnhanced descalingImprove spoiler effectSolar heating energyFluid circuit connectionsThermodynamicsEnhanced heat transfer

The flat plate type solar heat collector comprises a heat absorption plate, a shell, a transparent cover plate and a heat preservation material, the transparent cover plate is arranged at the top of the shell, the heat absorption plate is arranged in the shell, and the heat preservation material is arranged in the inner side face of the shell so that a heat preservation space can be formed in the shell; a plurality of heat dissipation bodies extending downwards from the lower side are arranged on the inner side face of the upper portion of the heat absorption plate, gap flow paths for fluid to flow are arranged among the heat dissipation bodies, and the heat dissipation bodies are of elastic structures. According to the flat plate type solar heat collector of a novel structure, the heat dissipation body can be scoured when fluid flows through the elastic structure, the heat dissipation body can swing in a pulsating mode, and therefore descaling and vibration are promoted to cause the turbulent flow effect, and heat transfer can also be enhanced.

Owner:ZHONGBEI UNIV

A Solar Adsorption Refrigeration System Driven by Photovoltaic Photothermal Combination to Enhance Heat Exchange

ActiveCN105222397BNovel structureIngenious ideaMechanical apparatusEnergy efficient heating/coolingElectrical batteryEngineering

Owner:山西桑尼洛英能源科技有限公司

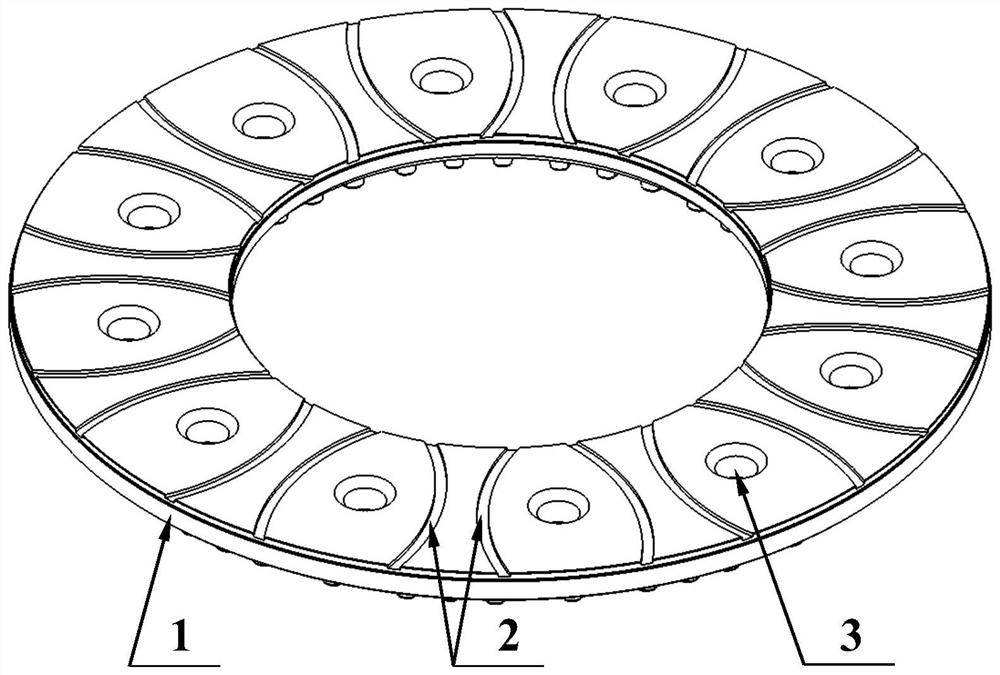

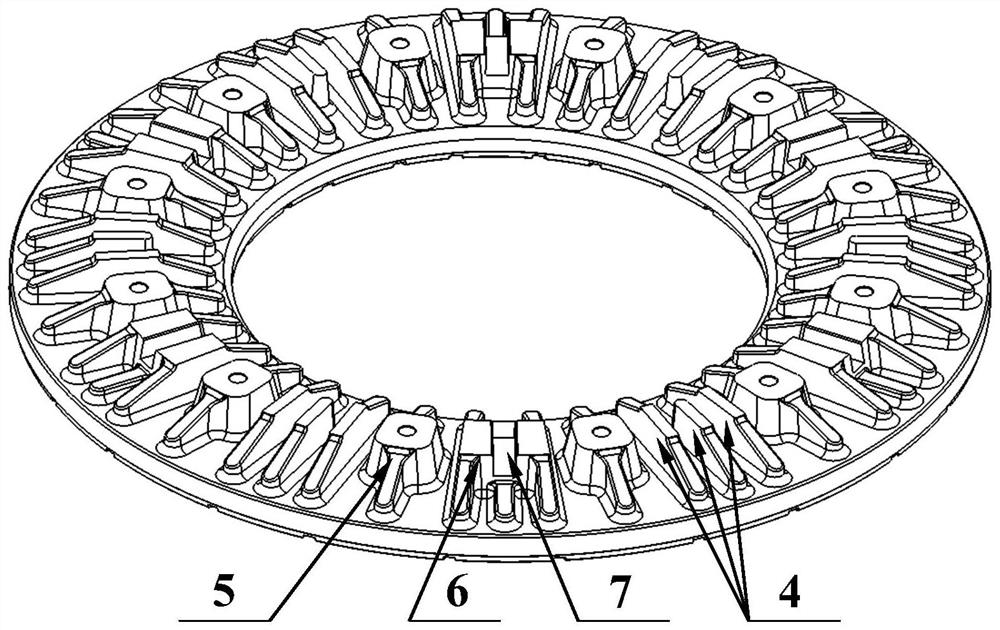

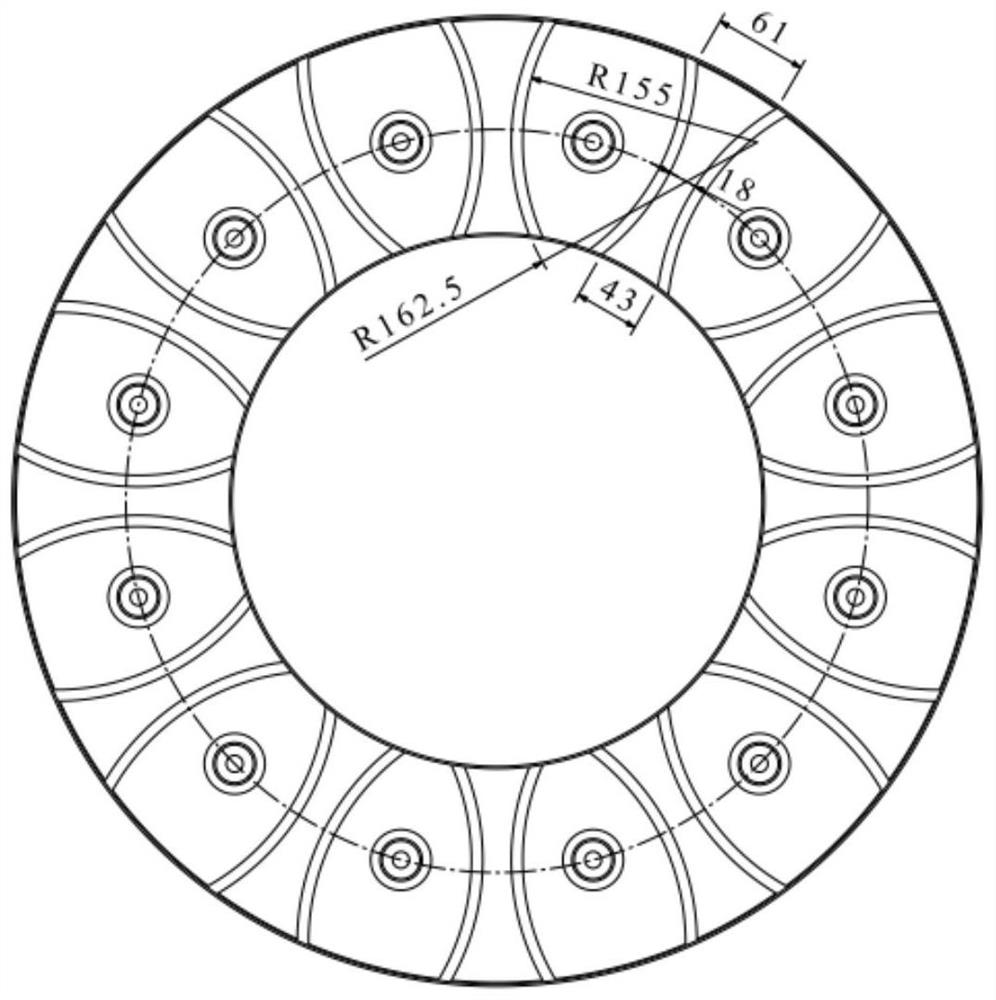

Friction surface microstructure scratch-resistant brake disc body

PendingCN114673742AReduce scratchesImprove uniformity of temperature distributionBraking discsBrakePhysics

The friction surface microstructure scratch-resistant brake disc body comprises a friction ring, bolt holes are evenly distributed in the friction ring in the circumferential direction, a plurality of through chip removal scratch-resistant grooves are formed in the friction surface of the friction ring, and the chip removal scratch-resistant grooves are symmetrically formed in the two sides of each bolt hole in pairs; the two ends of the chip removal scratch-resistant groove extend to the inner edge and the outer edge of the friction ring respectively, and the chip removal scratch-resistant groove passes through a high vertical deformation area (instantaneous high heat area) of the friction ring in a long path. The chip removal scratch-resistant grooves distributed on the friction surface of the disc body can discharge friction chips and block scratches, so that local heat dissipation is improved, and the temperature distribution uniformity of the disc body is improved.

Owner:NANJING CRRC PUZHEN HAITAI BRAKE EQUIP CO LTD +1

Aluminum-made vertical heat sink device with high temperature distribution uniformity

InactiveCN103008041BImprove temperature distribution uniformityImprove uniformity of temperature distributionHeating or cooling apparatusEnclosures/chambersElectrical resistance and conductanceCooling effect

The invention discloses an aluminum-made vertical heat sink device with high temperature distribution uniformity. The heat sink device consists of fin tube array sides, a metal corrugated soft pipe, a plurality of thermal insulating material layers and a temperature acquisition system, wherein an eight-prism-shaped side surface is formed by eight fin tube array sides being 460mm*1160mm; two fin tube array sides being 1120mm*1200mm are respectively used as the top surface and the bottom surface of the heat sink device; the metal corrugated soft pipe is connected with the surfaces so as to integrate an inner cavity of the whole heat sink device; thermistors in the temperature acquisition system are adhered to the outer surface of the heat sink device; and the plurality of thermal insulating material layers are wrapped at the outermost surface of the device. The aluminum-made vertical heat sink device has the advantages of good temperature distribution uniformity, good cooling effect, rapid cooling speed, small size, convenience in operation and maintenance, and the like, and has a good practical value and an application prospect in the field of space technologies.

Owner:BEIHANG UNIV

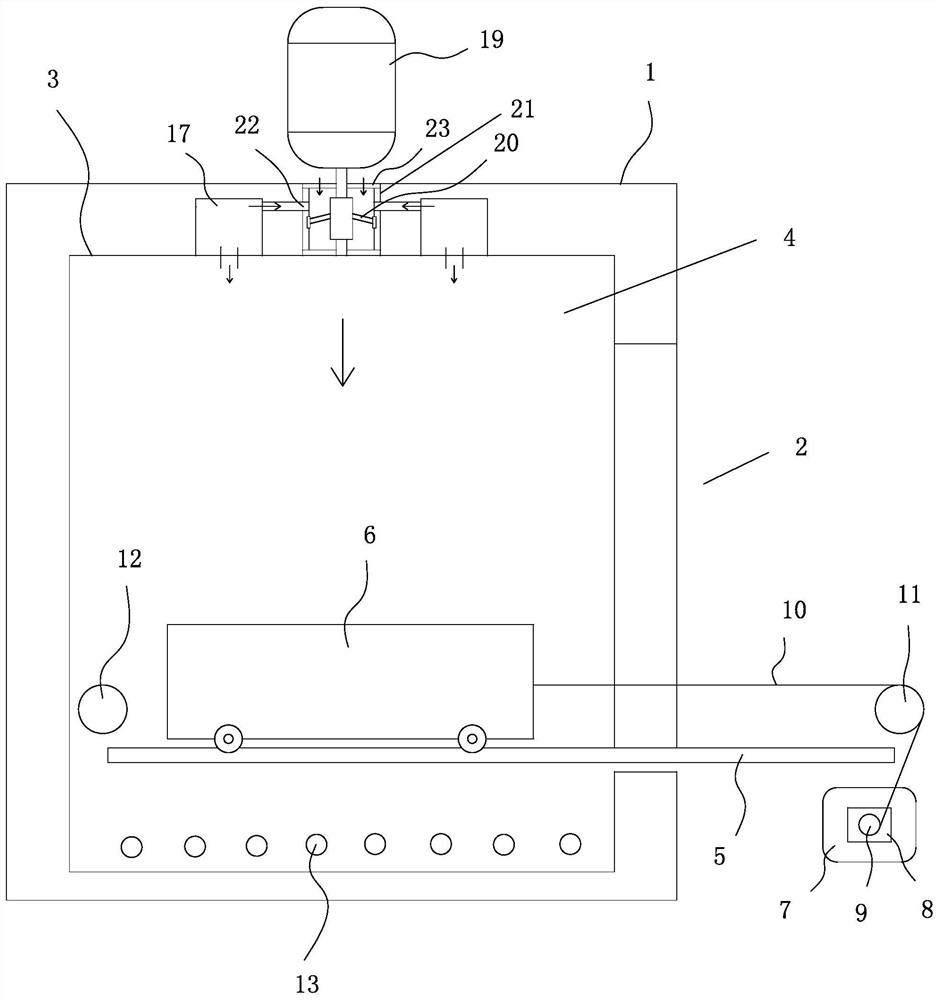

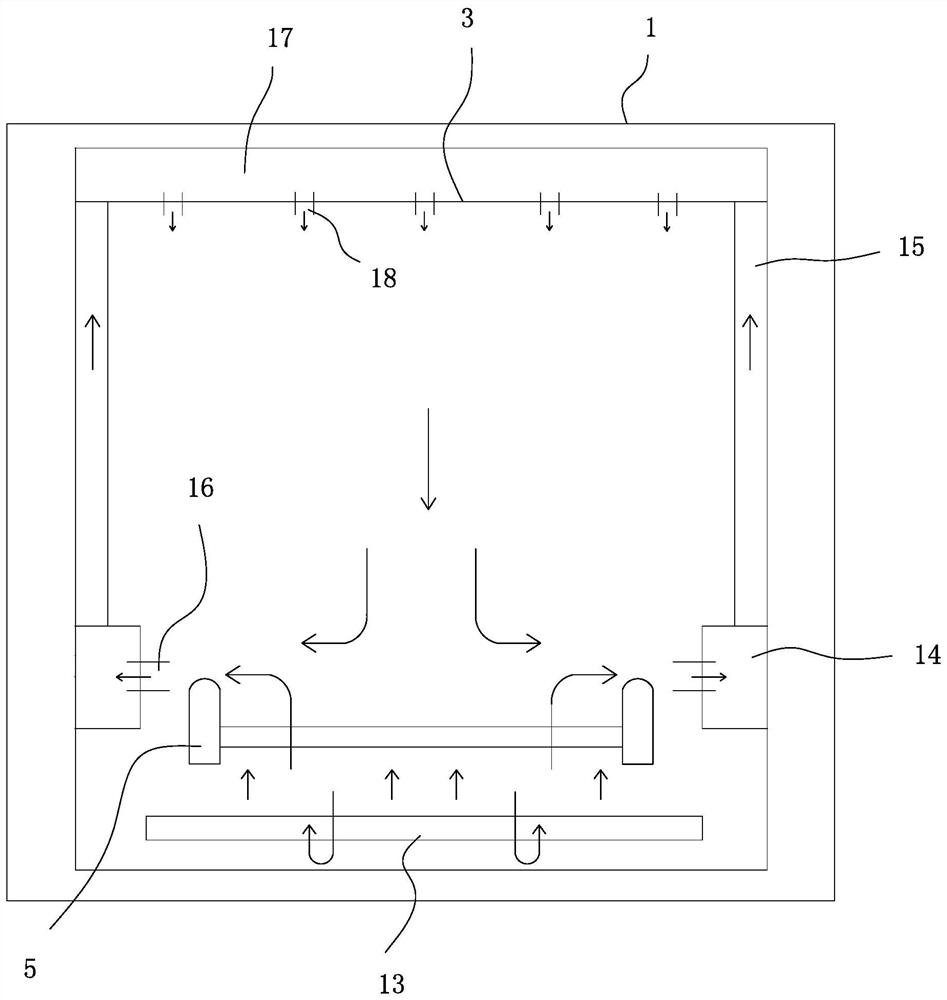

An energy-saving and environment-friendly annealing furnace

ActiveCN111235374BImprove uniformity of temperature distributionReduce consumptionFurnace typesHeat treatment furnacesThermodynamicsMechanics

The invention relates to the field of metal annealing equipment, in particular to an energy-saving and environment-friendly annealing furnace. The first driving device on the body, the furnace body has an opening, the opening is provided with a furnace door, the furnace body is provided with a heat shield, and a working room with a certain space is formed in the heat shield, There is a guide rail in the working room, one end of which extends outward through the opening, and at least two flow passages are arranged side by side between the heat shield and the furnace body along the left and right directions, and the heat shield is located at each flow passage. All are provided with ventilation holes communicating with the working chamber, the upper ends of the longitudinal air guiding hoods are communicated with each flow channel, the first driving device is arranged on the upper part of the furnace body, and the output end of the first driving device passes through The heat shield enters the working chamber and is equipped with an axial exhaust fan.

Owner:泉州柏洋精密机械制造有限公司

A jig and process for inner hole coating diamond film

InactiveCN103834930BAutomatic drawingExtension elongation compensationChemical vapor deposition coatingHardnessPre treatment

The invention discloses a clamp used for depositing a diamond film on an inner bore and a process for depositing the diamond film by using the clamp. The coating diamond film is deposited through cleaning, drying, pretreatment, workpiece polishing and grinding, nucleation through hot filament CVD deposition equipment, growth, etc. The diamond film deposited in the invention has the characteristics of a Vickers hardness value of HV9000, continuous, uniform and compact coating morphology and excellent heat radiation performance.

Owner:武汉世纪中航超强金刚石膜高科技有限公司

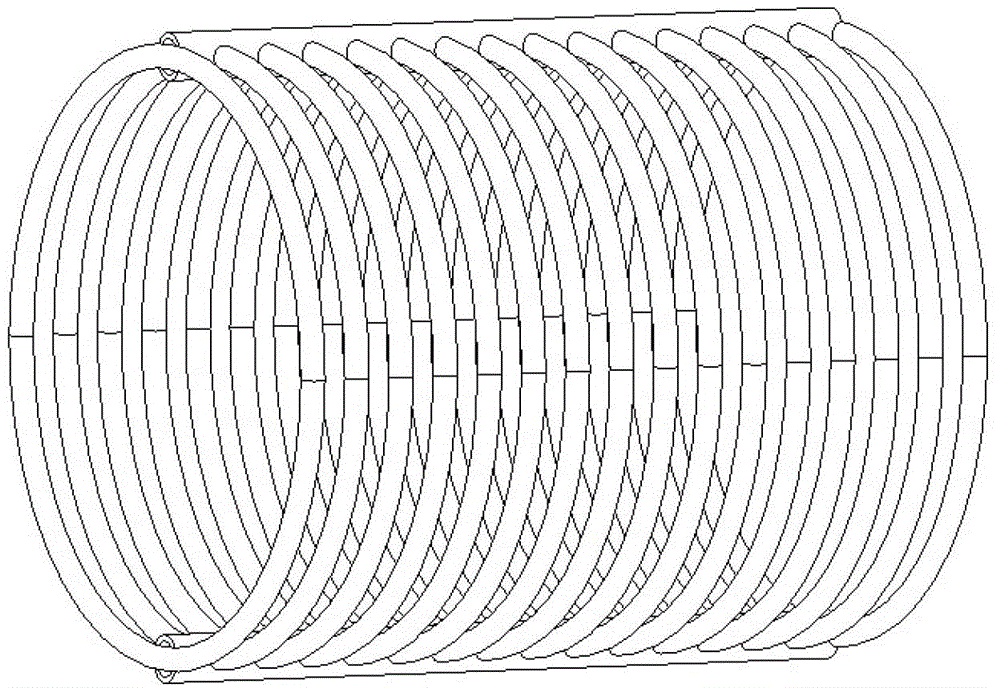

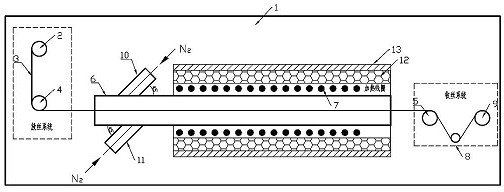

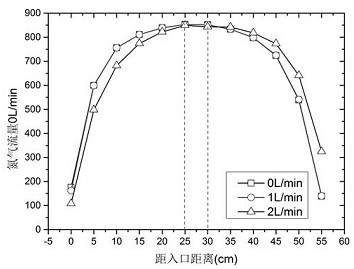

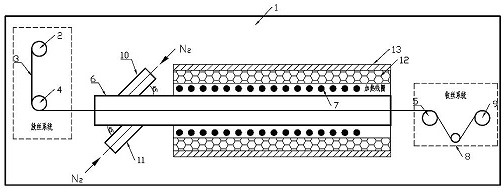

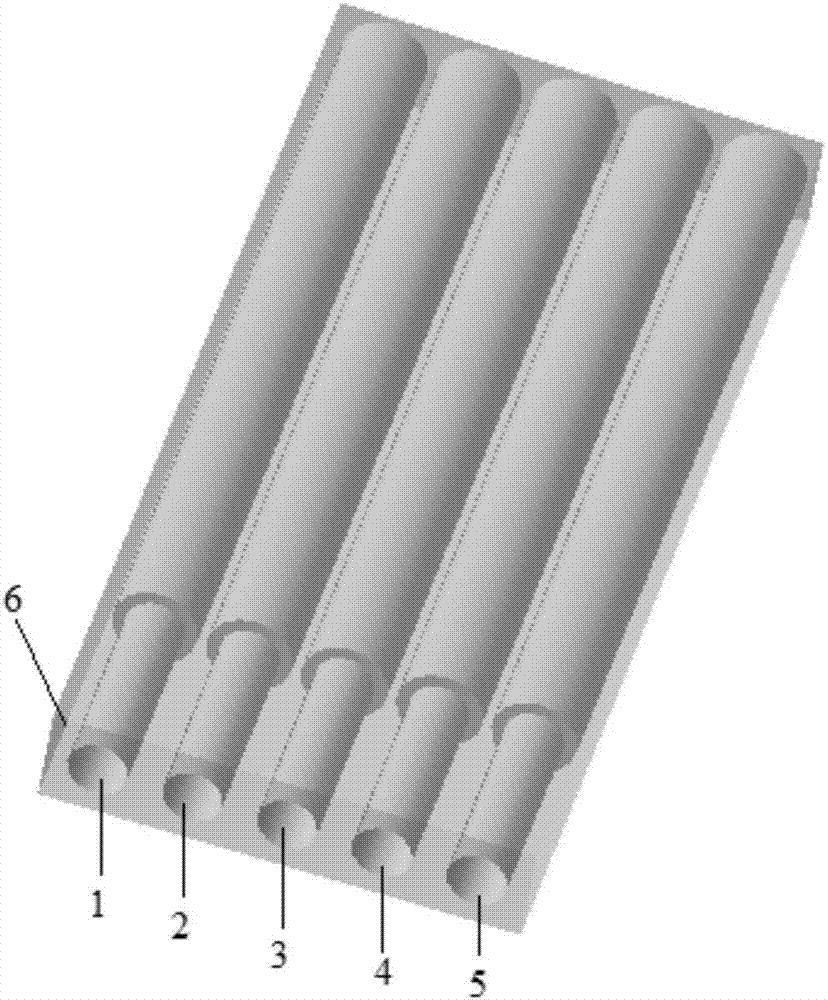

Large-strain nickel-chromium alloy ultrafine filament monofilament continuous annealing device

ActiveCN113957363APlastic deformation performance recoverySolve surface oxidationNuclear energy generationFurnace typesTemperature controlInsulation layer

The invention discloses a large-strain nickel-chromium alloy ultrafine filament monofilament continuous annealing device which comprises a filament unwinding system arranged at the front end, a filament winding system arranged at the rear end and a temperature control system arranged between the filament unwinding system and the filament winding system. The temperature control system comprises a quartz tube, a heating ring arranged outside the quartz tube and a heat insulation layer arranged outside the heating ring; the wire unwinding system and the wire winding system are matched to enable a superfine NiCr alloy wire in the drawing state to pass through the quartz tube at a constant speed; and a first gas inlet forming an angle of 45 degrees with the quartz tube and a second gas inlet forming an angle of 225 degrees with the quartz tube are formed in the front end of the quartz tube. Nitrogen is introduced into the first gas inlet and the second gas inlet respectively, so that effective annealing temperature fields which are symmetrically distributed are formed in the quartz tube. According to the method, the plastic deformation performance of the large-strain NiCr alloy wire in the drawing state can be recovered, the temperature distribution uniformity of a heat treatment area can be effectively improved, and the surface oxidation problem in the annealing process of the alloy wire can be solved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

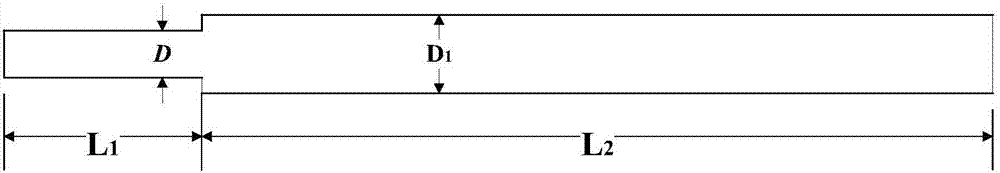

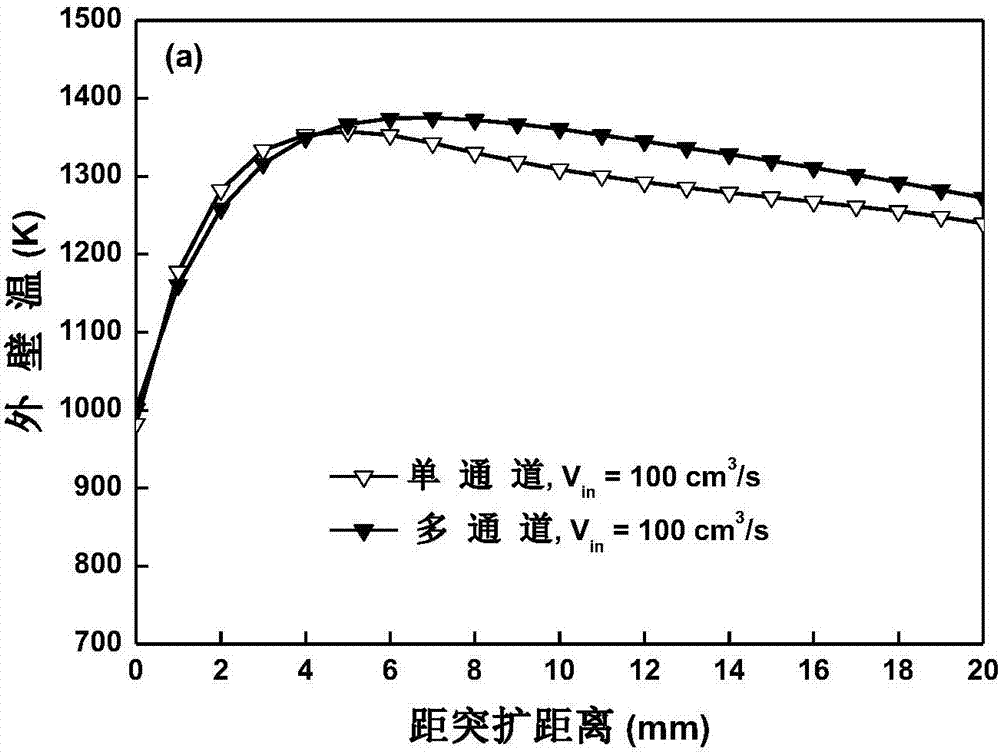

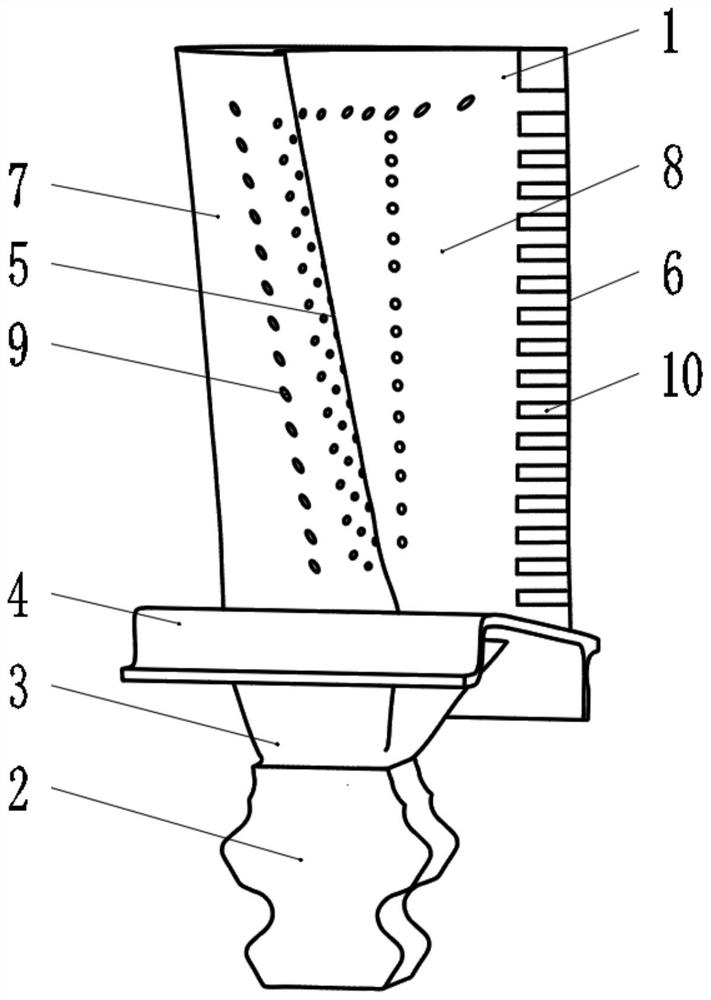

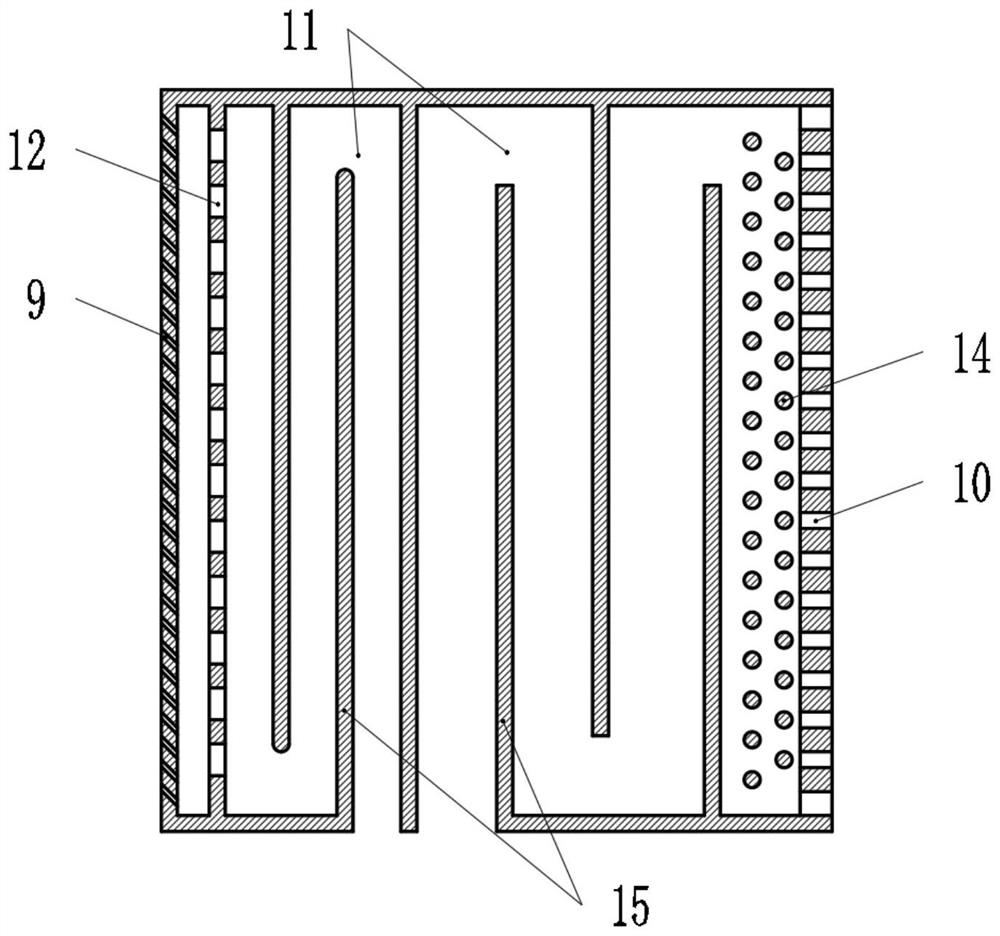

A multi-channel burner

InactiveCN105864766BRaise the surface radiation temperatureImprove uniformityPV power plantsPhotovoltaic energy generationCombustorCombustible gas

The invention discloses a multi-channel combustor. The multi-channel combustor comprises a plurality of parallel combustion channels, wherein central lines of the plurality of combustion channels are parallel to each other and are positioned on the same plane; each combustion channel comprises a first channel section and a second channel section; the sectional area of a channel part, in the direction vertical to the central line of each combustion channel, of each first channel section, is less than the sectional area of the channel part, in the direction vertical to the central line of each combustion channel, of the corresponding second channel section; combustible gas can combust through the combustion channels; the central lines of every two of the plurality of combustion channels have the same spacing. According to the multi-channel combustor, the surface temperature is high, and the temperature uniformity is high; photons can be radiated to a photovoltaic generating device to enable thermophotovoltaic generating effect, thus improving the comprehensive energy conversion efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A turbine blade with transverse meandering and alternately shortening and shortening channels inside

ActiveCN110863864BIncrease heat absorptionReduce the temperatureBlade accessoriesMachines/enginesCold airSuction force

Owner:SHENYANG AEROSPACE UNIVERSITY

Preparation method of milling cutter with diamond coating for processing pure titanium porcelain teeth and zirconium dioxide false teeth

ActiveCN103741114AImprove cooling effectImprove uniformity of temperature distributionEfficient propulsion technologiesChemical vapor deposition coatingTitaniumHot filament

The invention discloses a preparation method of a milling cutter with a diamond coating for processing pure titanium porcelain teeth and zirconium dioxide false teeth. The preparation method comprises the following steps of cleaning, drying, performing pretreatment, polishing and grinding a workpiece, nucleating by a hot wire CVD (chemical vapor deposition) device, growing and depositing a coating diamond thin film. According to the preparation method disclosed by the invention, the phenomena of difficult cutting, fast abrasion of the cutter, blade breaking, blade sticking and the like of a titanium alloy, zirconium dioxide and other difficult-to-process materials in cutting processes can be eliminated.

Owner:武汉世纪中航超强金刚石膜高科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com