Hot and cold dual-station rotary rapid thermal cycle injection mold and molding method

An injection mold, double-station technology, applied in the hot and cold double-station rotary rapid thermal cycle injection mold and molding field, can solve the problems of uneven heating and cooling, low thermal response efficiency of the mold, etc., to reduce energy consumption and cost , Shorten the production process of the product, and the effect of rapid and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

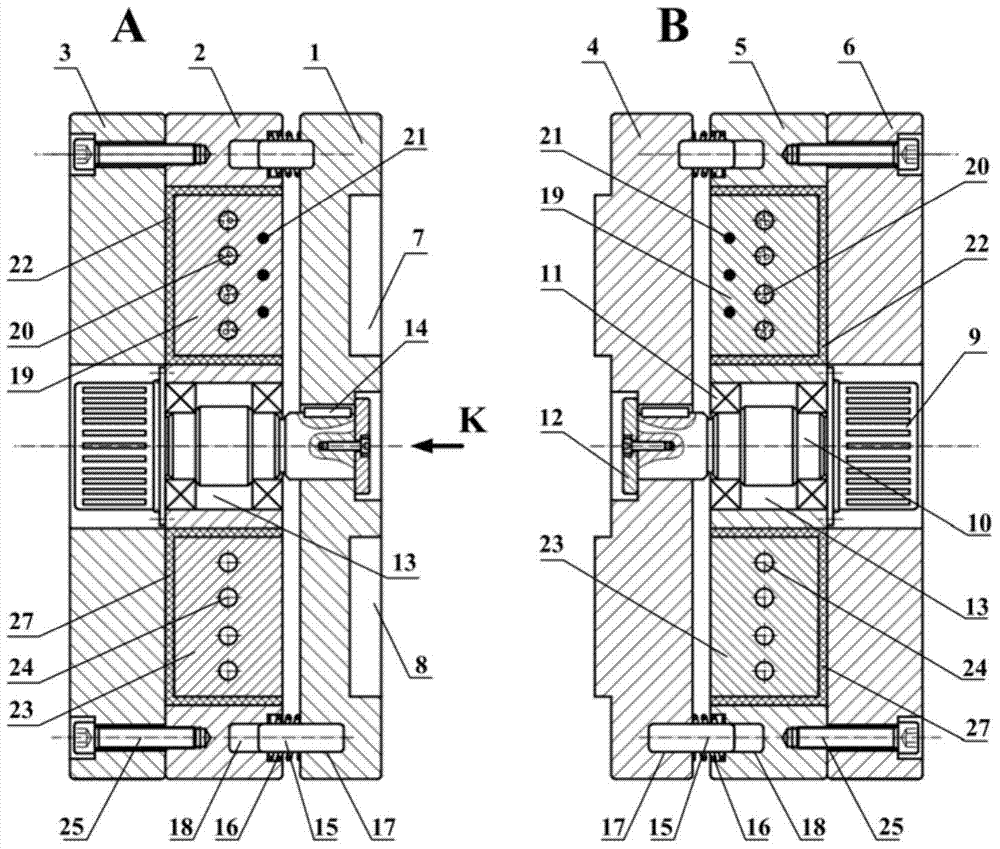

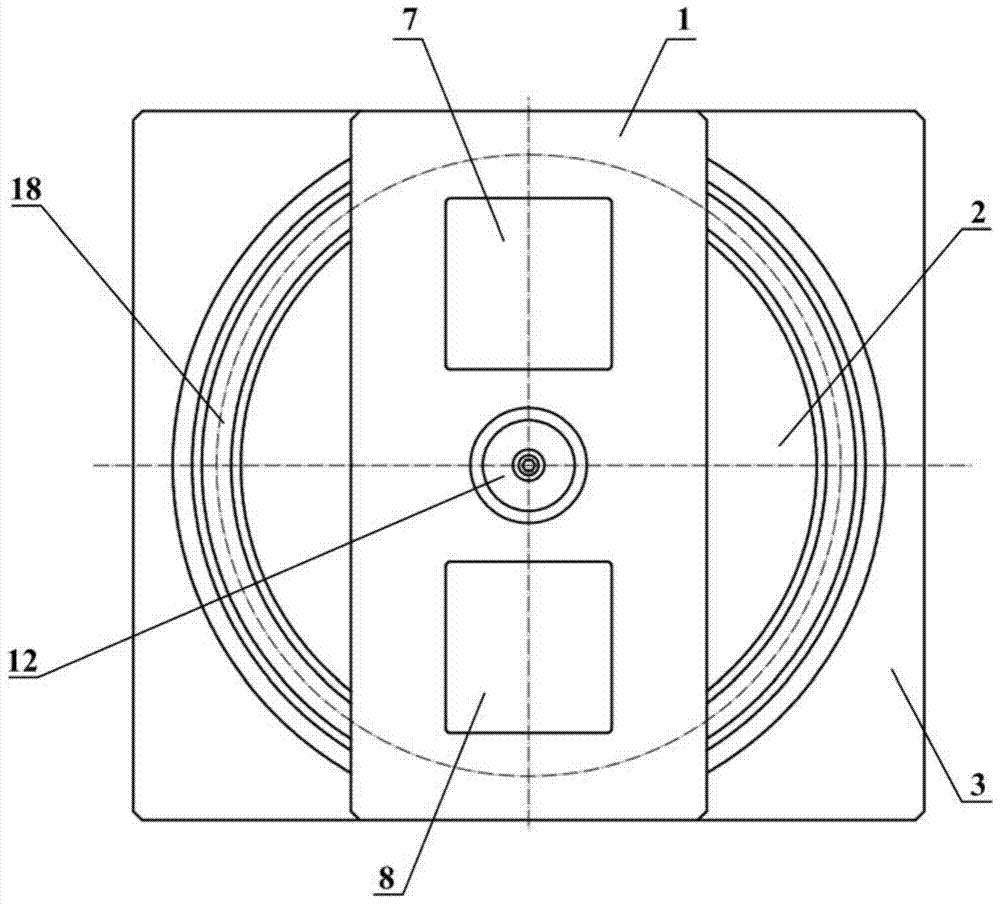

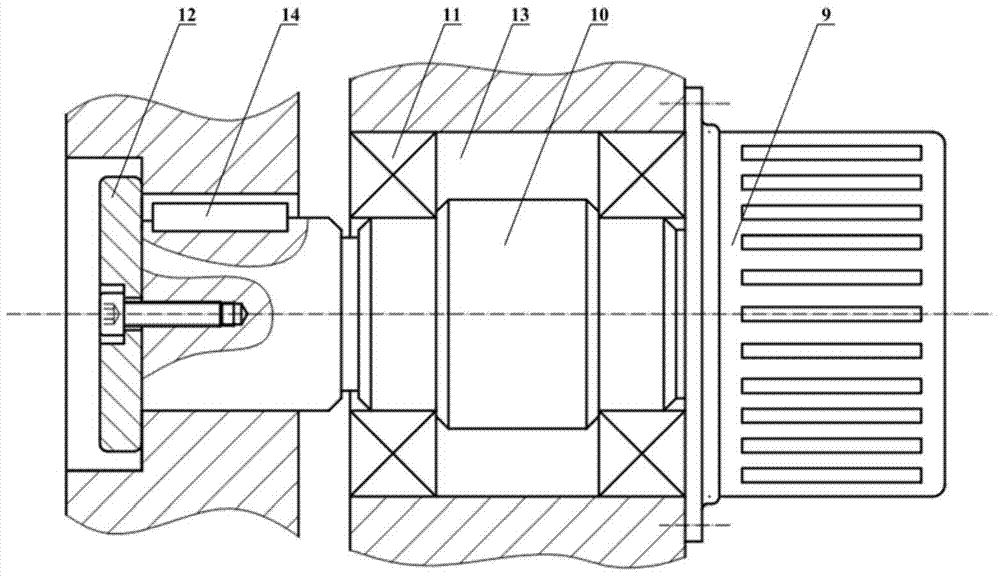

[0027] Figure 1 to Figure 3 shows the specific structure of the present invention, Figure 4a to Figure 4e The working process of the present invention is shown.

[0028] The hot and cold dual-station rotary rapid thermal cycle injection mold of the present invention includes a fixed mold assembly A and a movable mold assembly B. Fixed mold assembly A includes cavity plate 1, cavity holding plate 2, fixed mold fixing plate 3 and fixed mold rotating device that drives cavity plate 1 to rotate; movable mold assembly B includes core plate 4, core The holding plate 5, the movable mold fixed plate 6 and the movable mold rotating device that drives the core plate 4 to rotate; the front of the cavity plate 1 and the front of the core plate 4 enclose the first mold cavity 7 and the second mold mold Cavity 8, the first mold cavity 7 and the second mold cavity 8 are centrally symmetrically arranged about the rotation axis of the fixed mold rotating device and the movable mold rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com