Patents

Literature

115results about How to "Heating evenly and quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

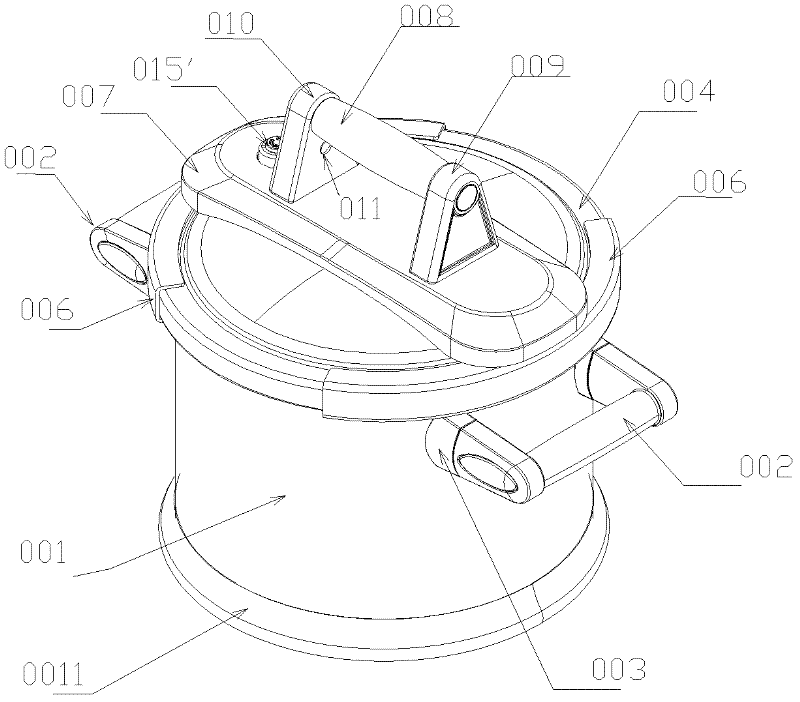

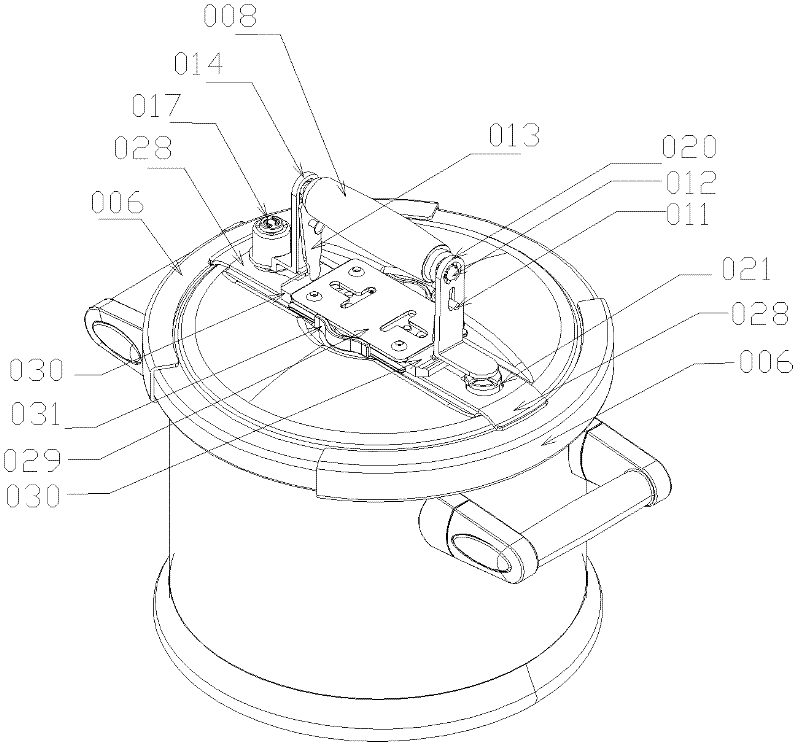

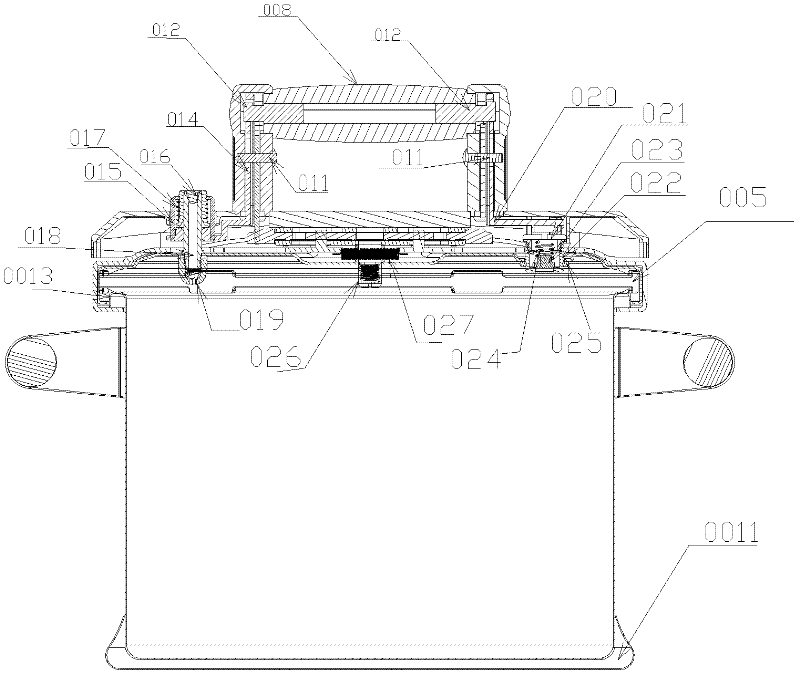

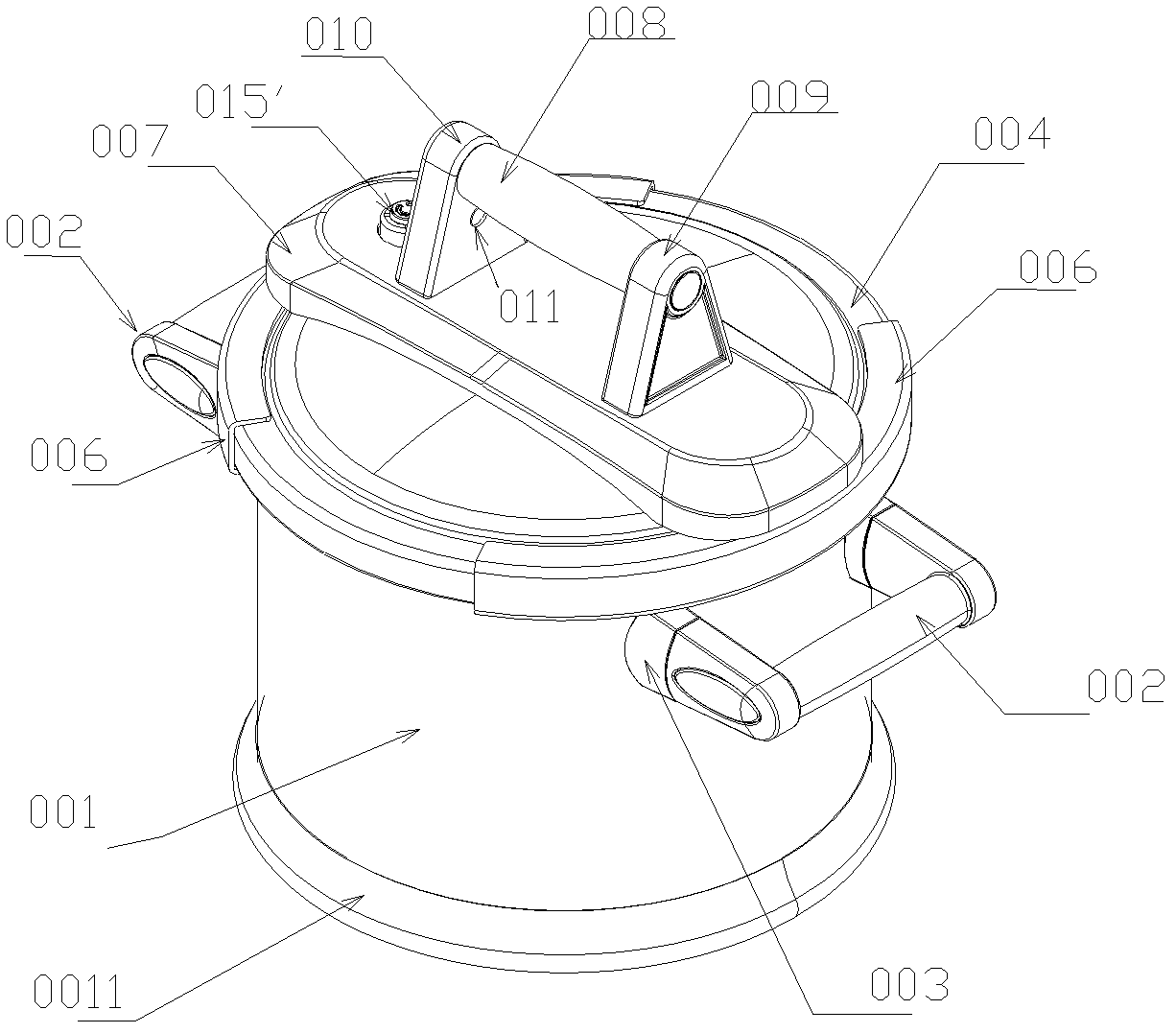

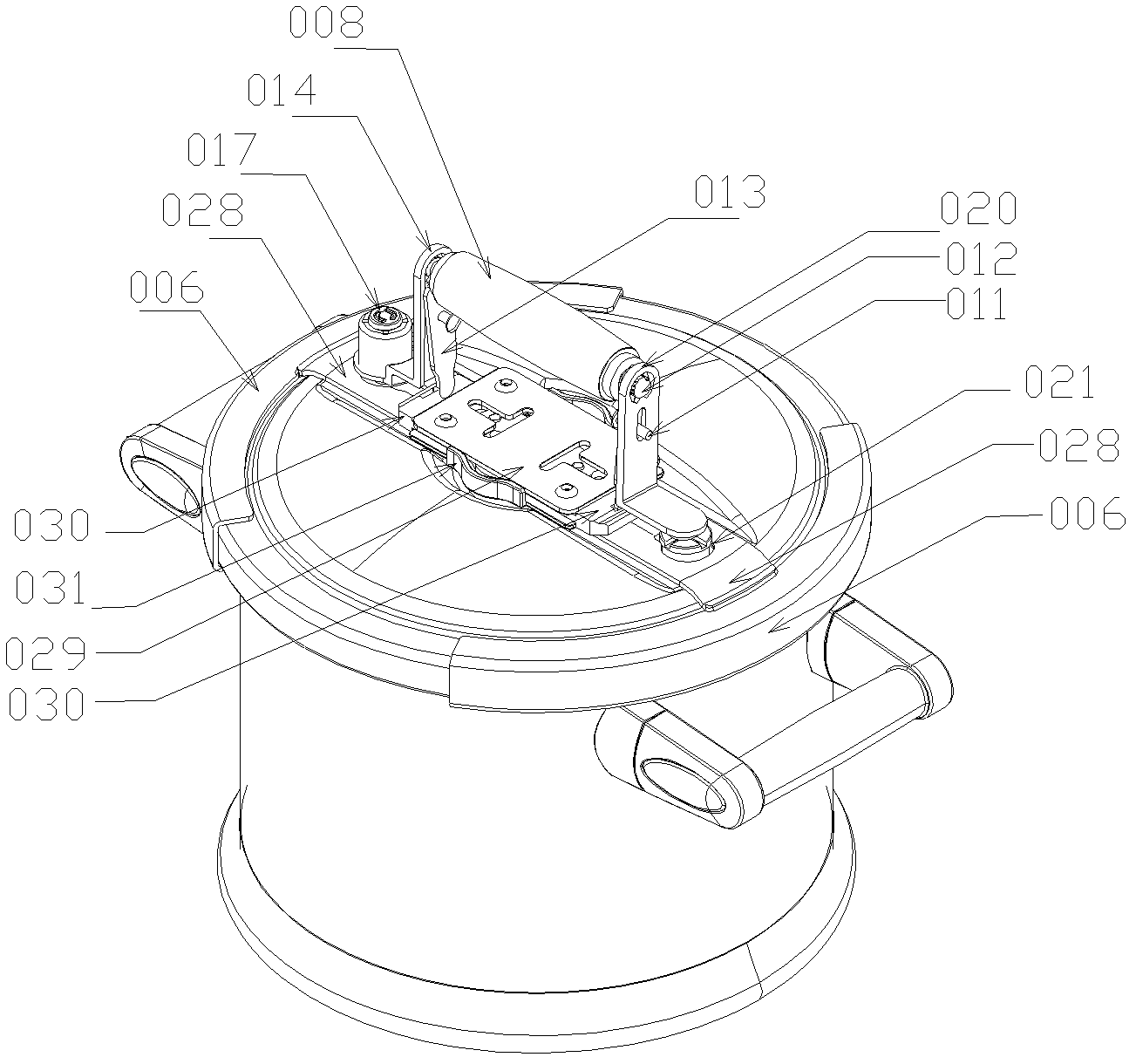

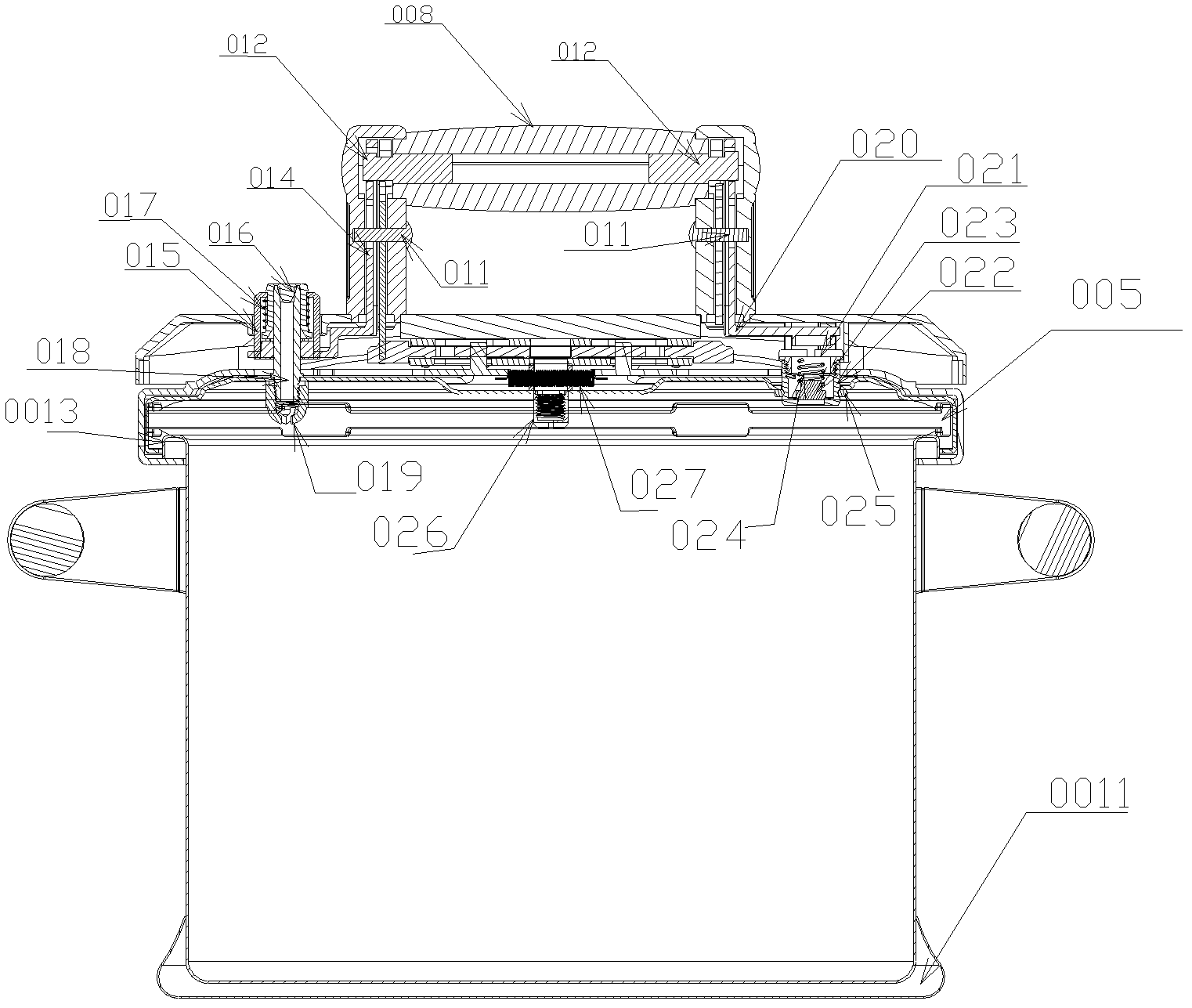

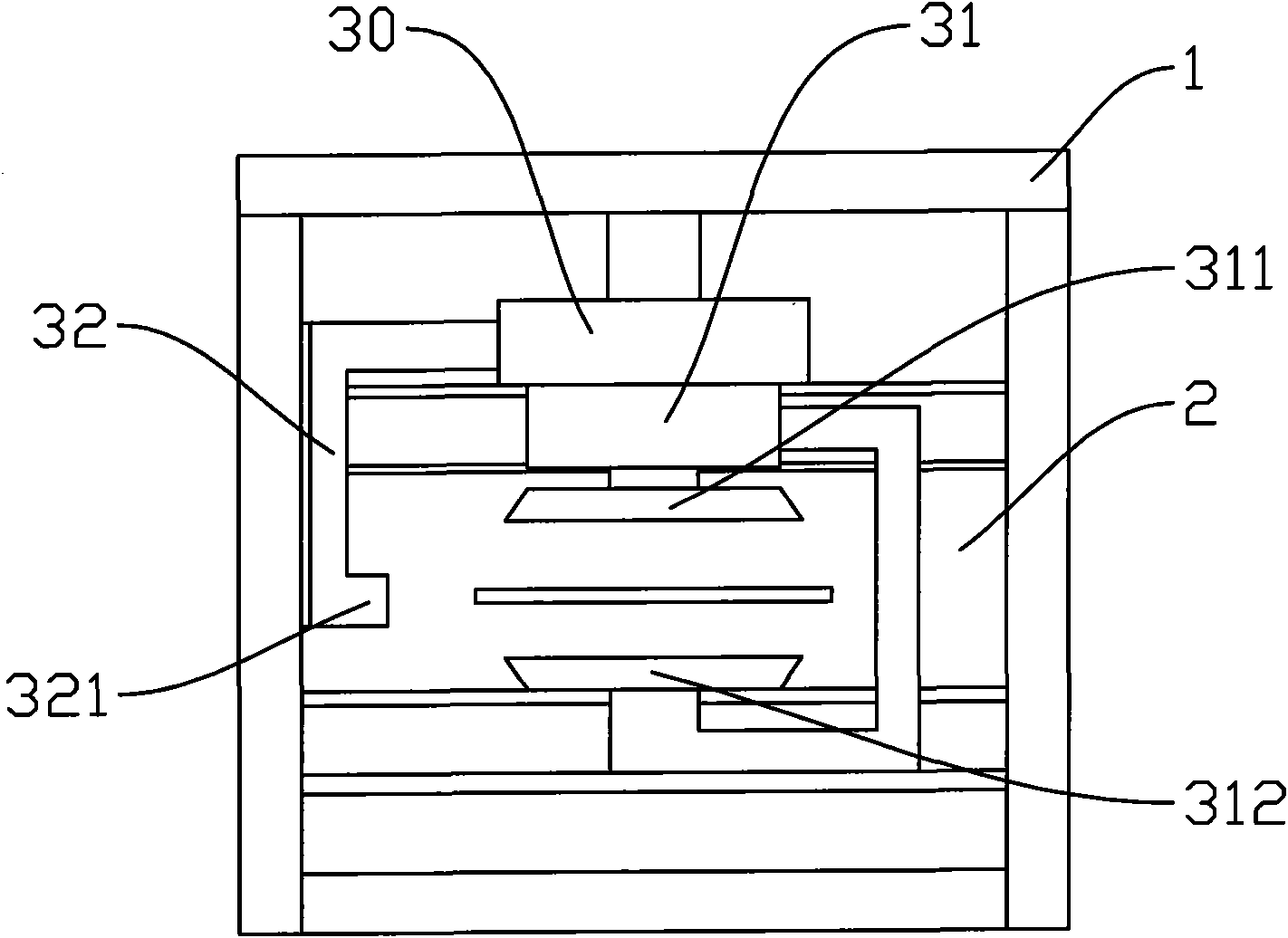

Rotating operation type pressure cooker with single handle

ActiveCN102342739ASimple structureStable structureCooking-vessel lids/coversPressure-cookersLocking mechanismClockwise

The invention discloses a rotating operation type pressure cooker with a single handle. The rotating operation type pressure cooker comprises a pot body, pot lugs, a pot cover, a movable pressure ring, a panel, a right bracket, a left bracket and a rotating handle, wherein the pot lugs are arranged on the pot body, the movable pressure ring is fixed on the pot cover, the right bracket and the left bracket are arranged on the panel, the rotating handle is arranged on the right bracket and the left bracket, the pressure ring can be opened and closed by rotating the rotating handle, a pressure sealing ring is arranged at the inner part of the pot cover, and is used for realizing the sealing between the pot cover and the pot body, and an adjusting valve and a safety pressure valve are also arranged on the pressure cooker. When the rotating operation type pressure cooker is adopted, air can be released to pressurize the adjusting valve or to return the adjusting valve to zero by rotating the rotating handle of the pot cover by a hand in a clockwise or counterclockwise manner when the pot cover is opened, the safety valve is lowered, and the pressure ring is expanded, so that the pot cover can be opened or closed. Therefore, both the handle and an operating handle of a locking mechanism serve as an operating object; and the rotating operation type pressure cooker is simple and firm in structure.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

Rotating operation type pressure cooker with single handle

ActiveCN102342739BSimple structureStable structureCooking-vessel lids/coversPressure-cookersLocking mechanismSafety valve

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

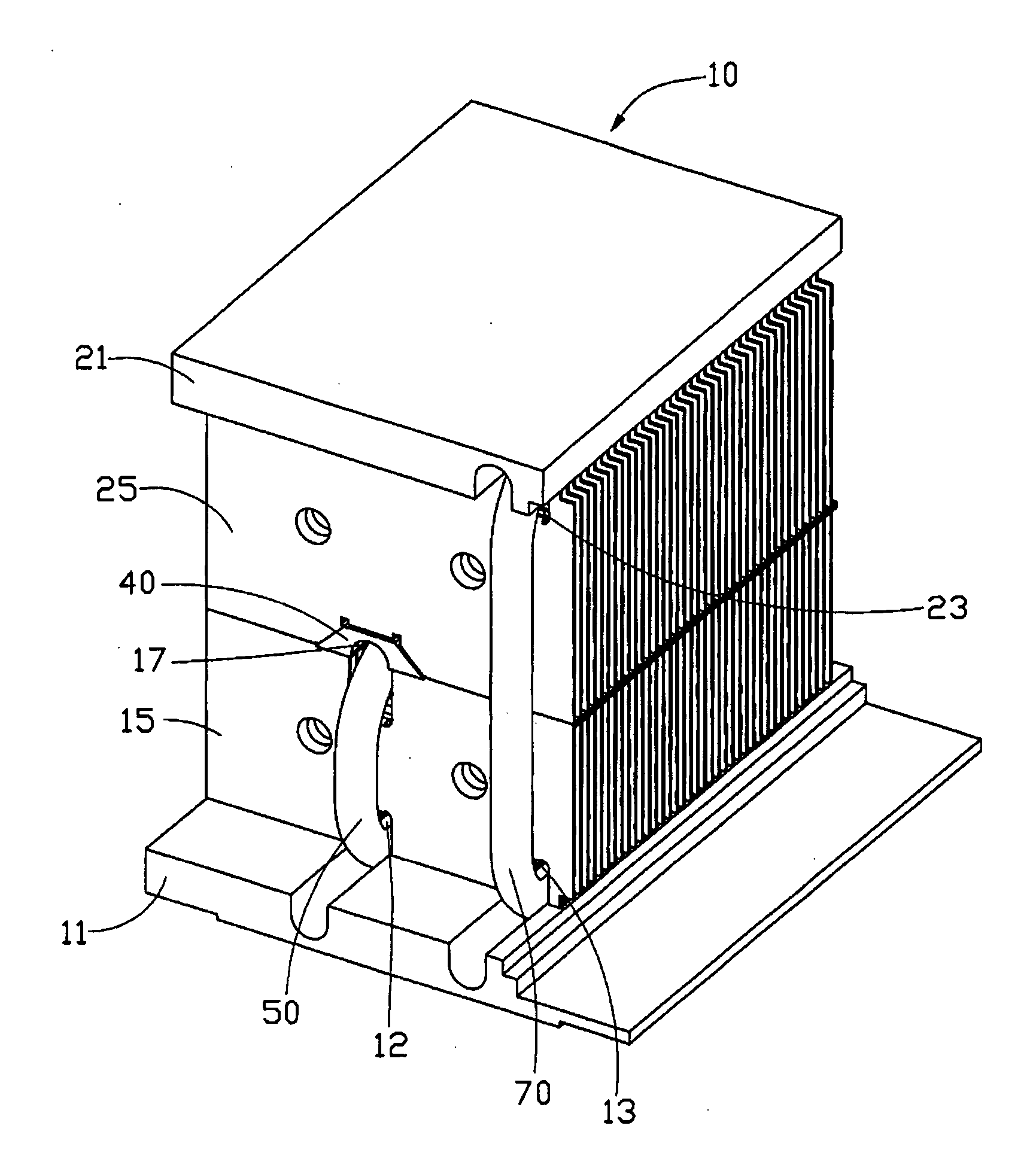

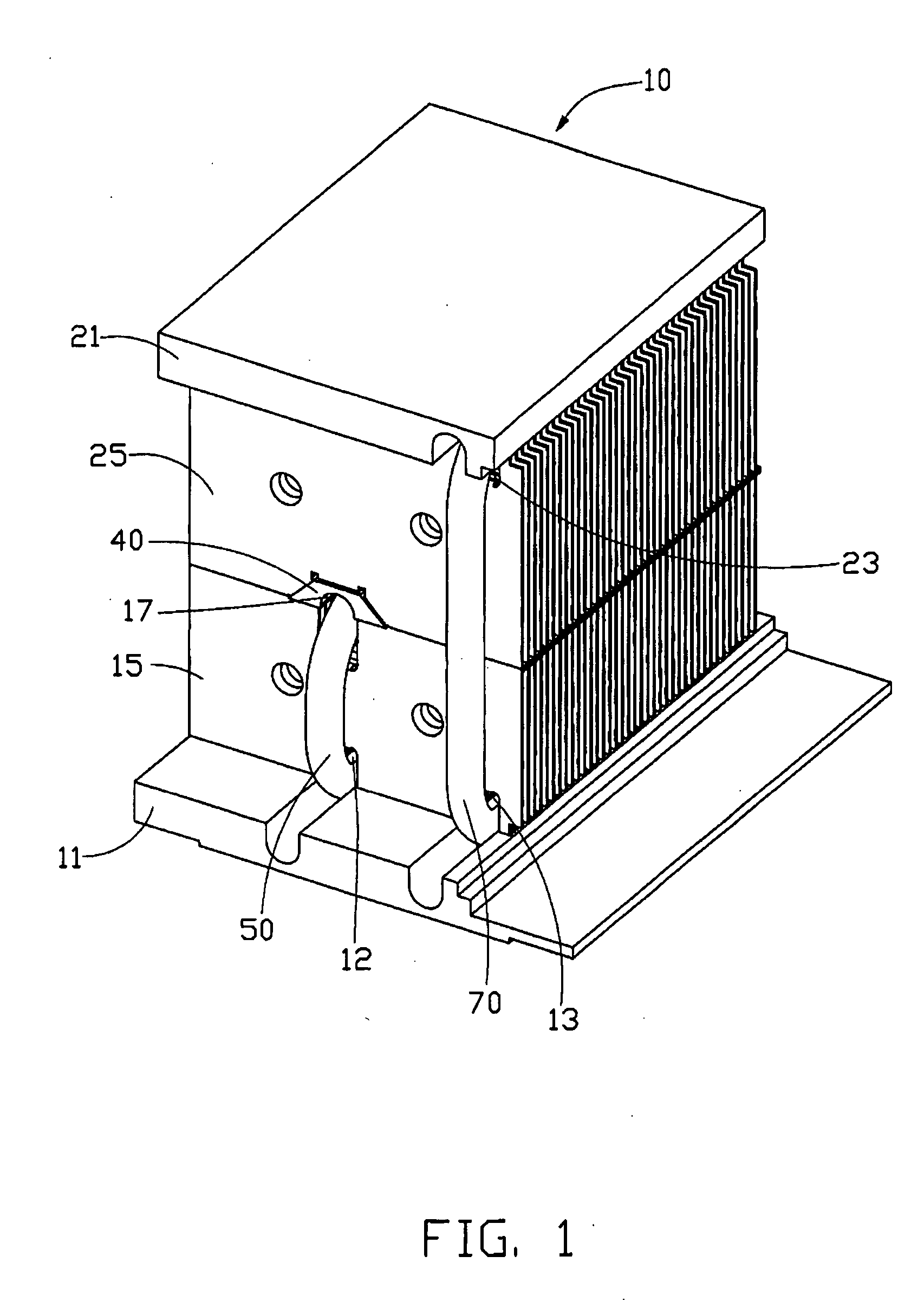

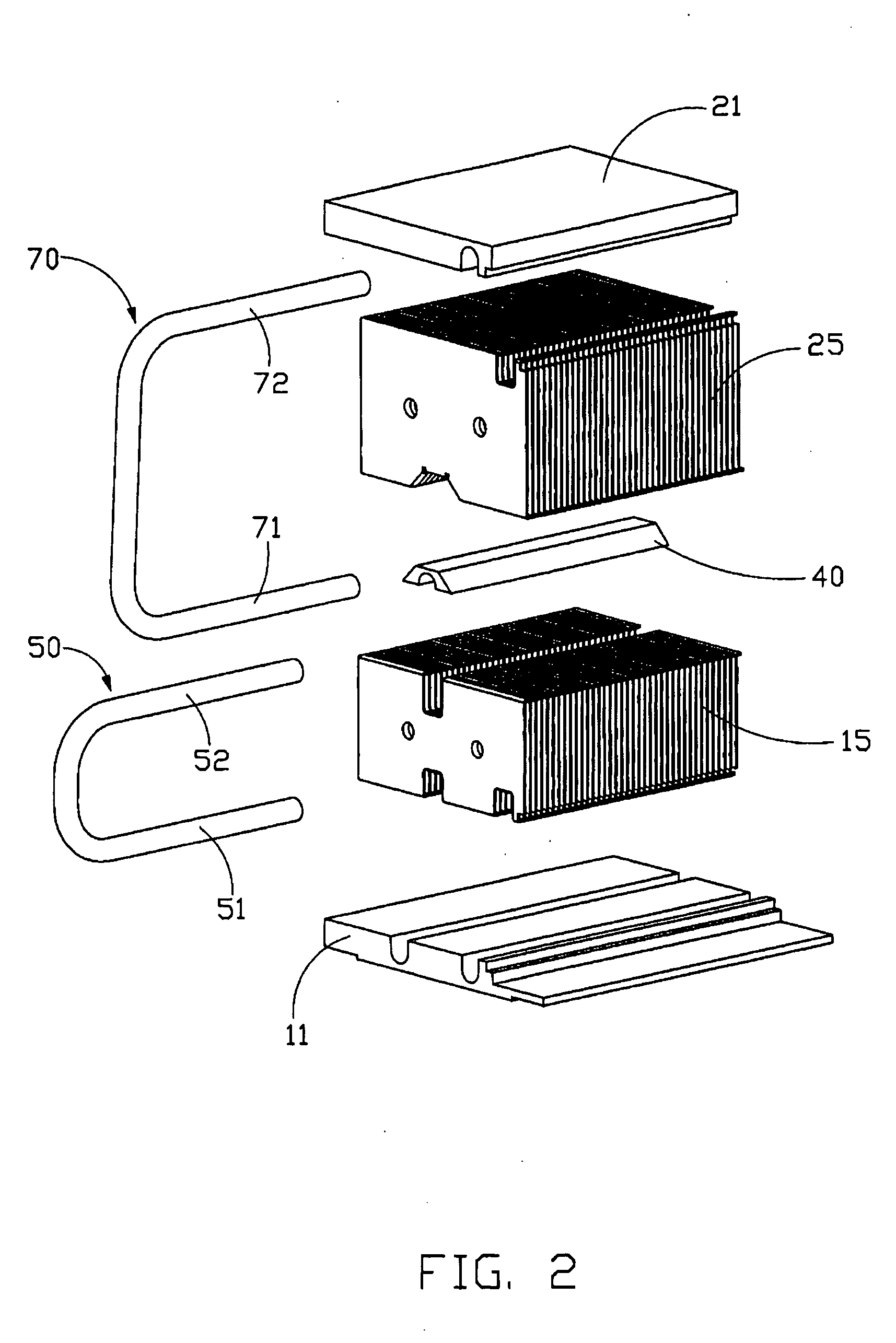

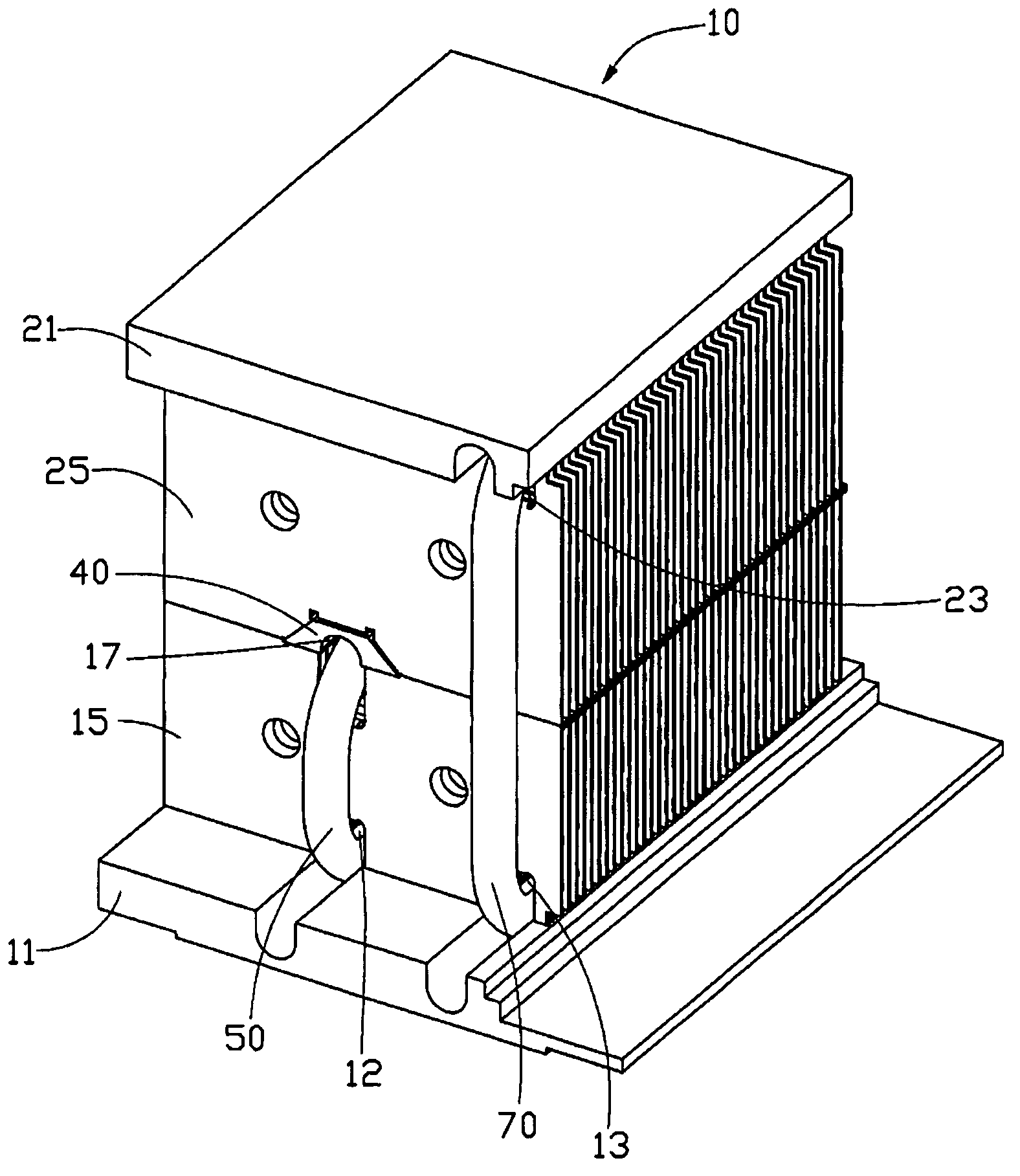

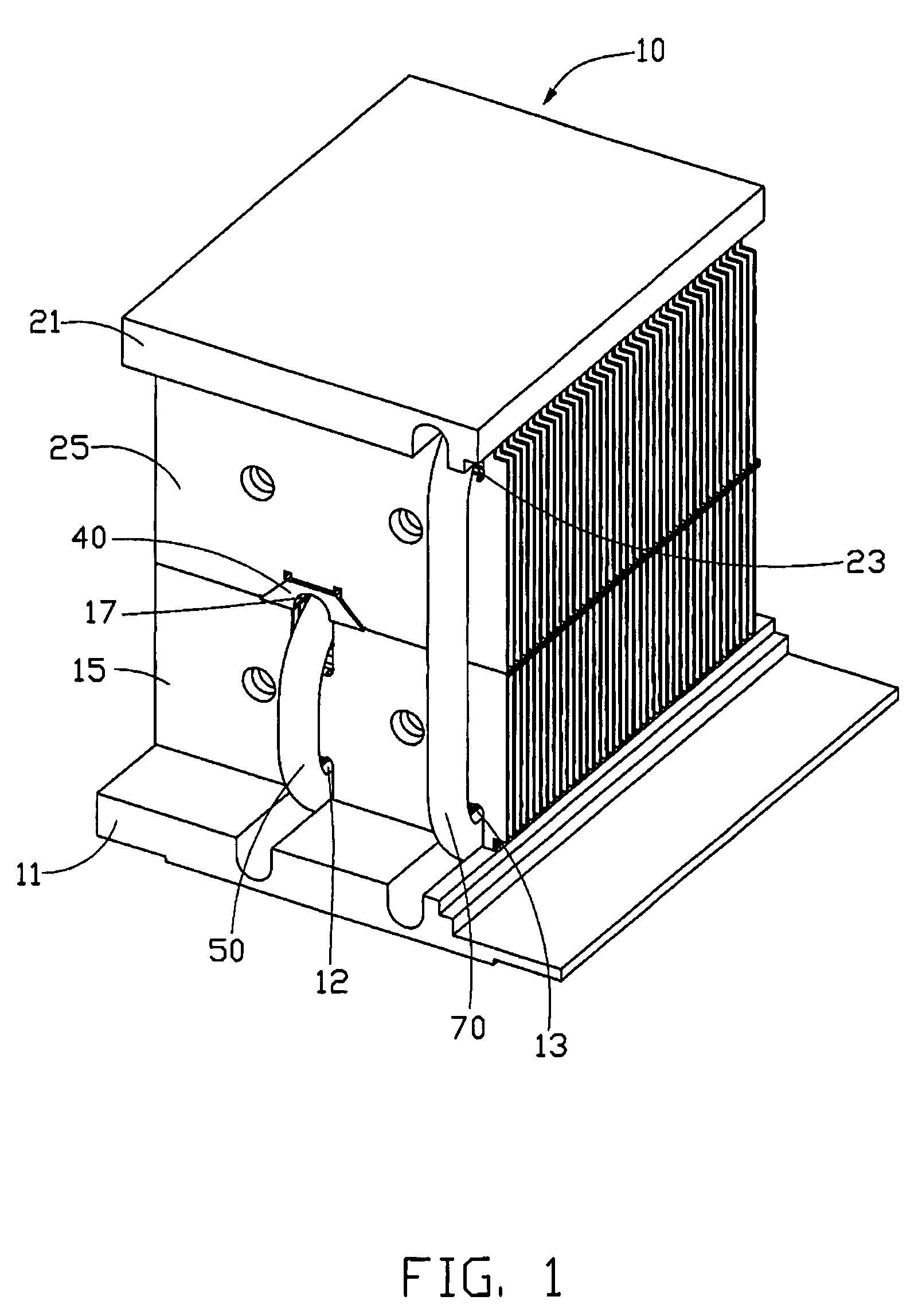

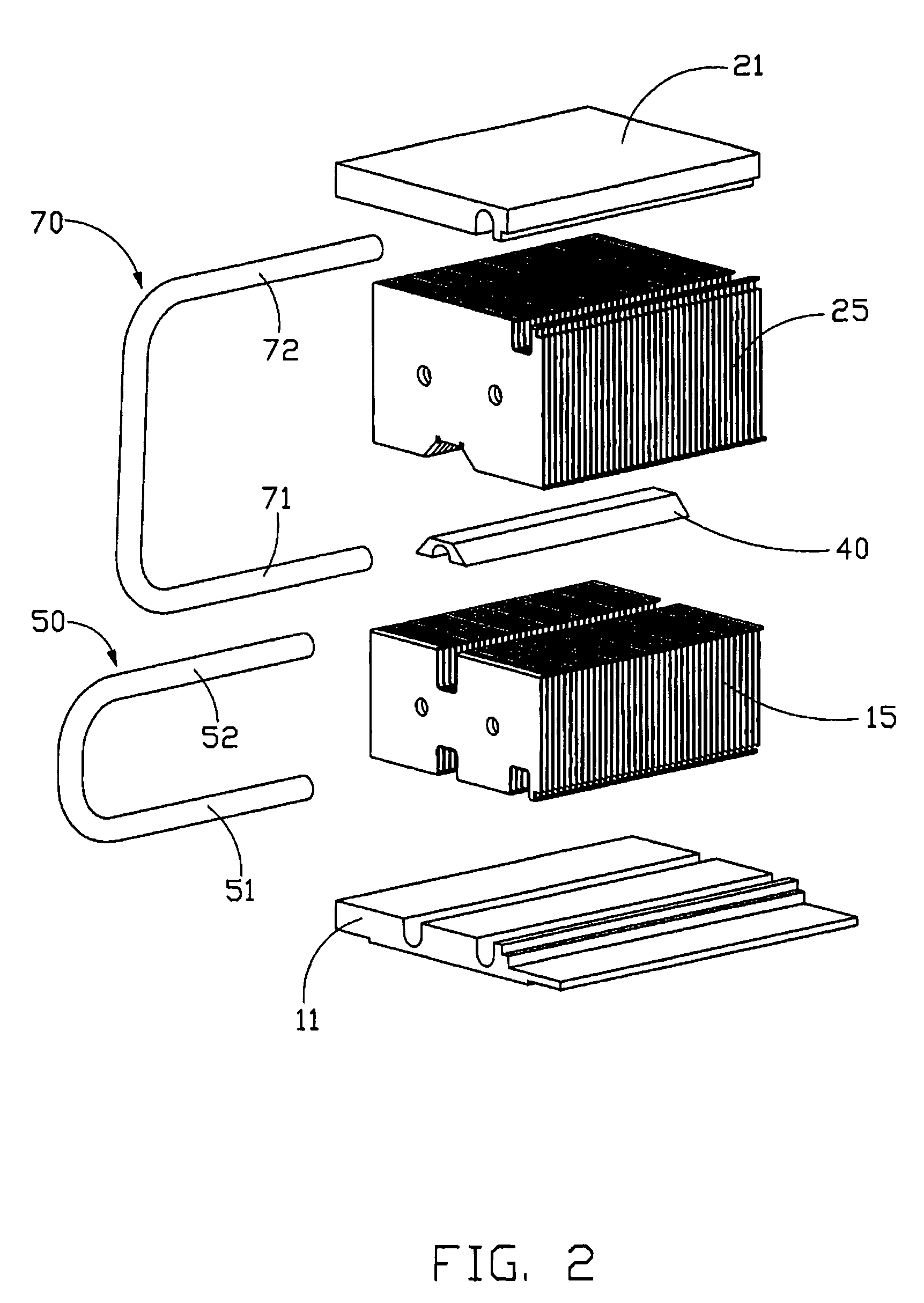

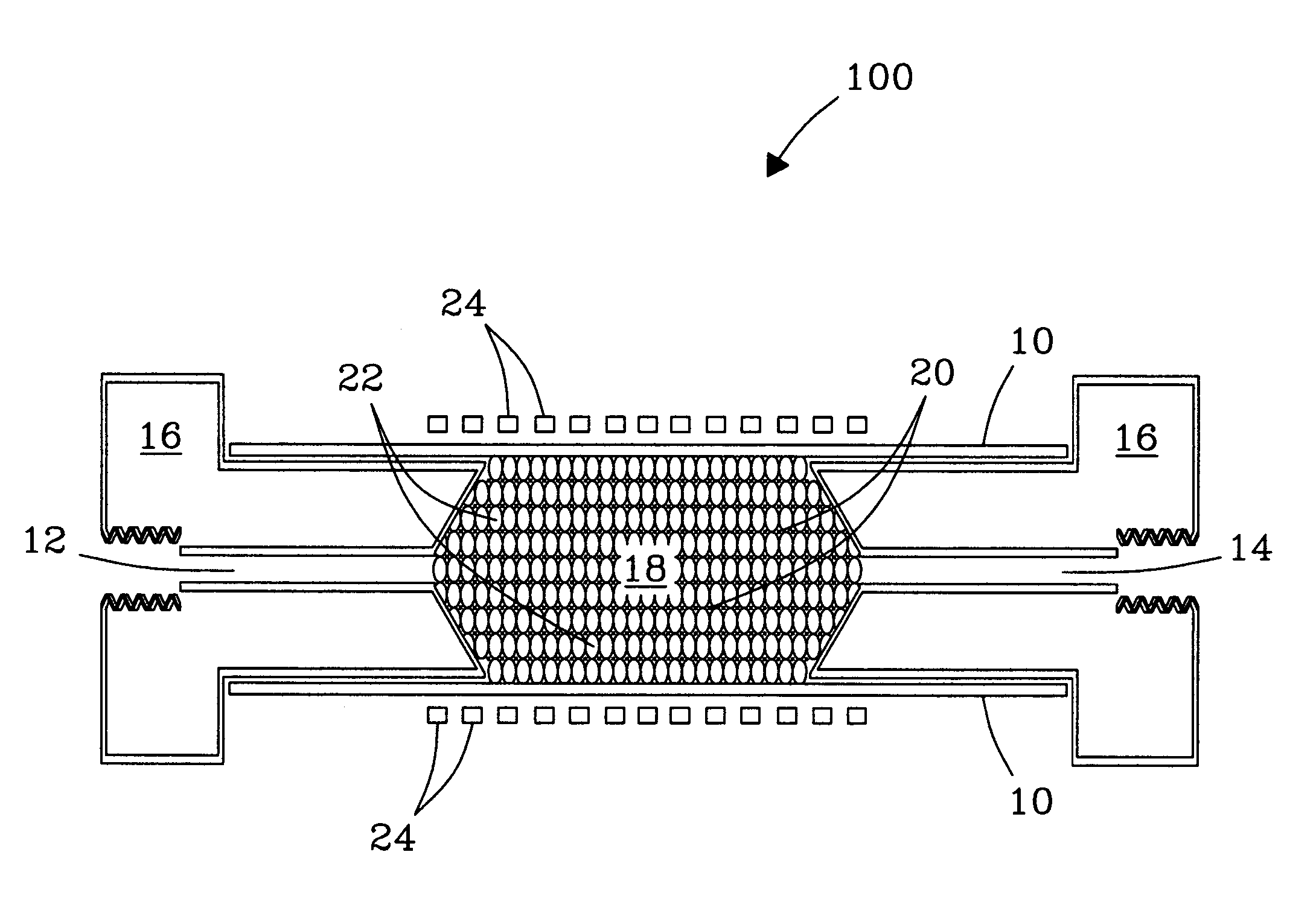

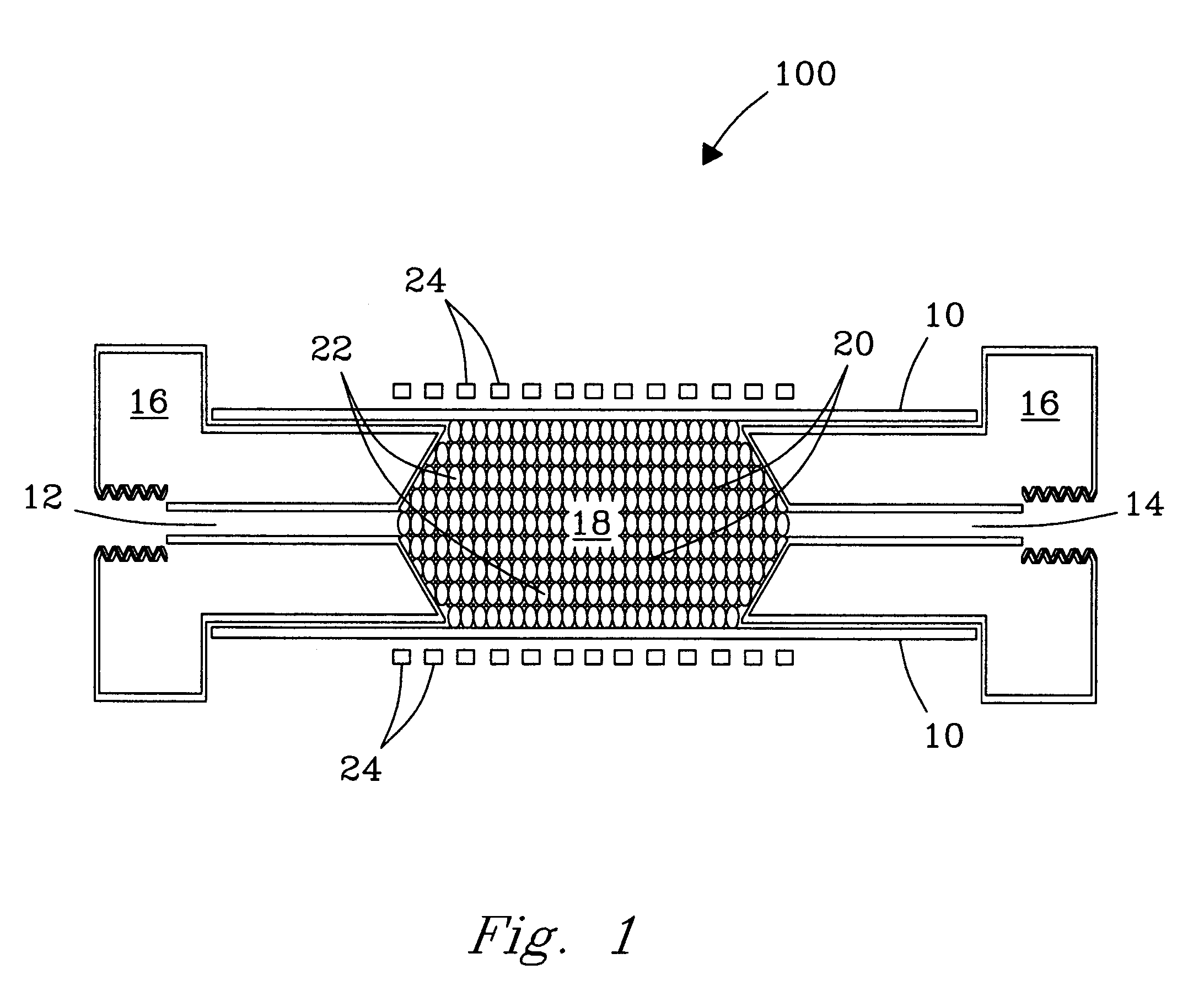

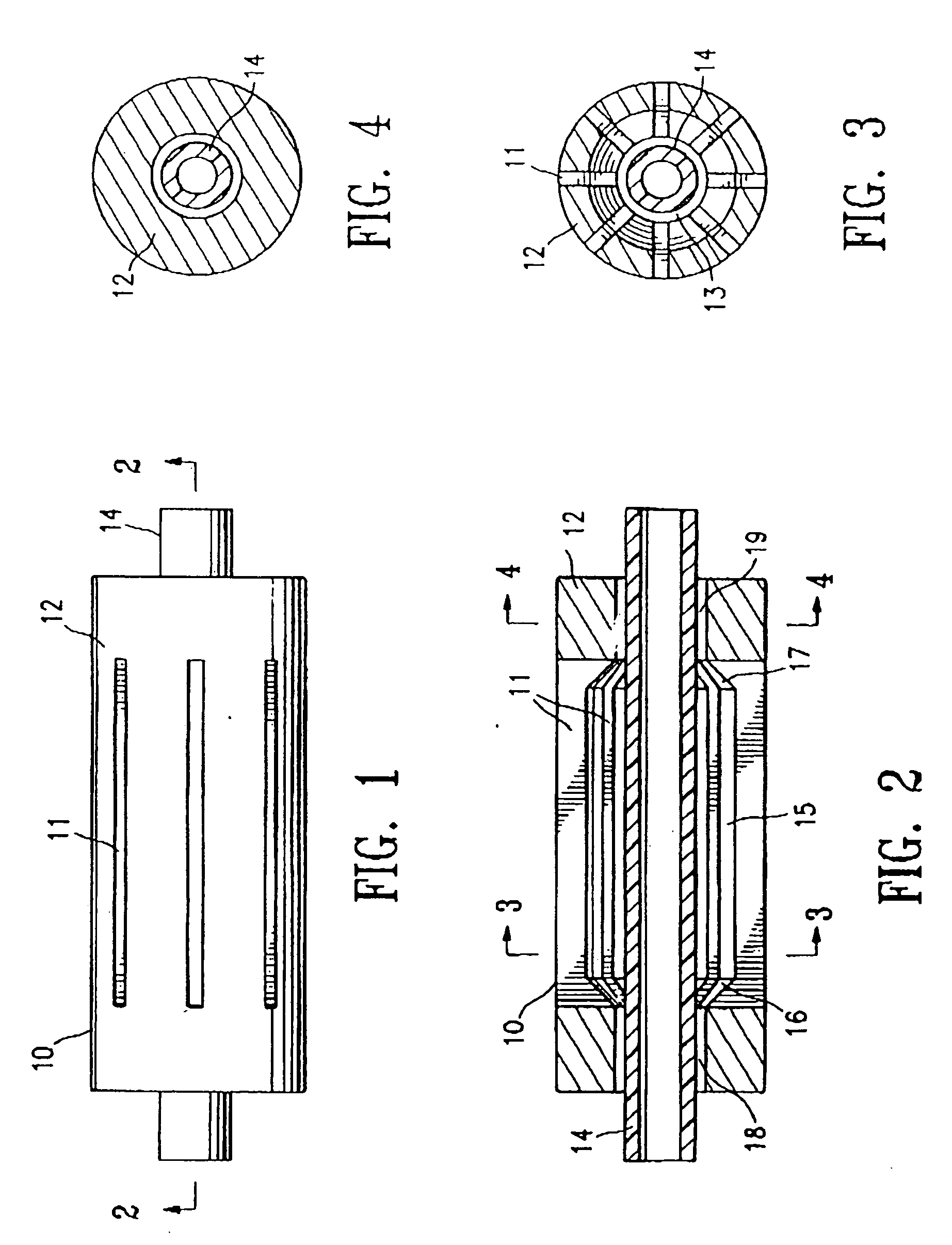

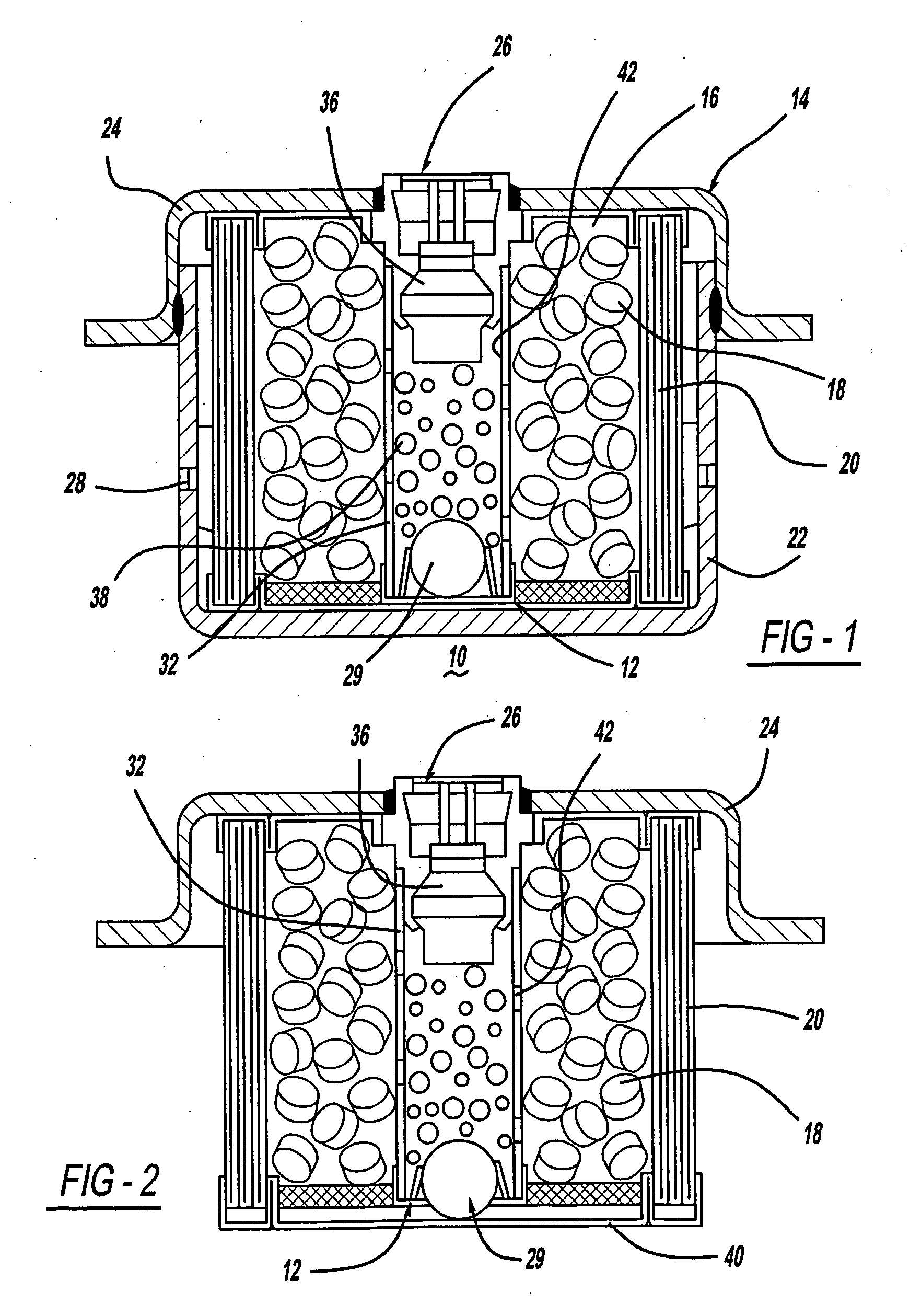

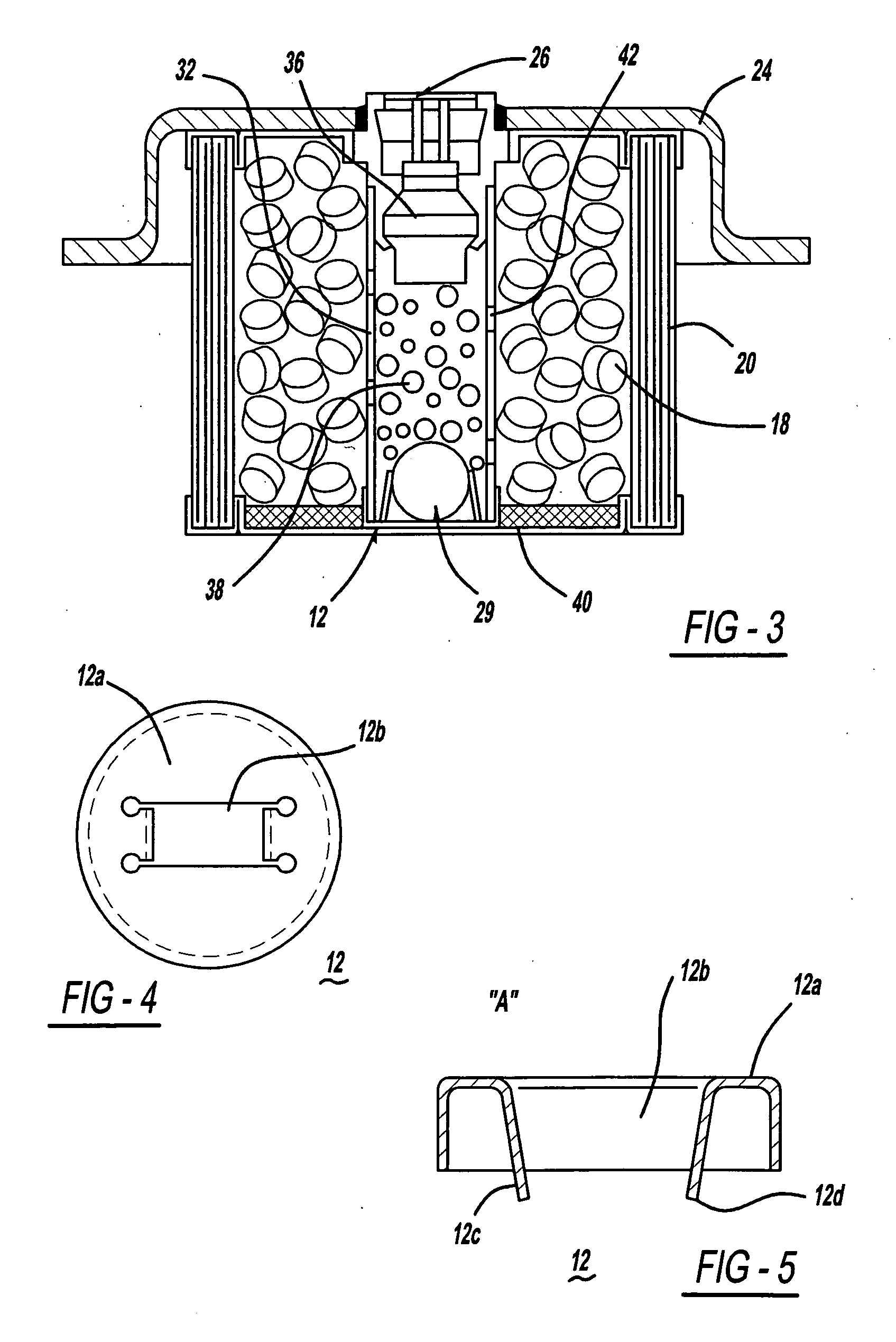

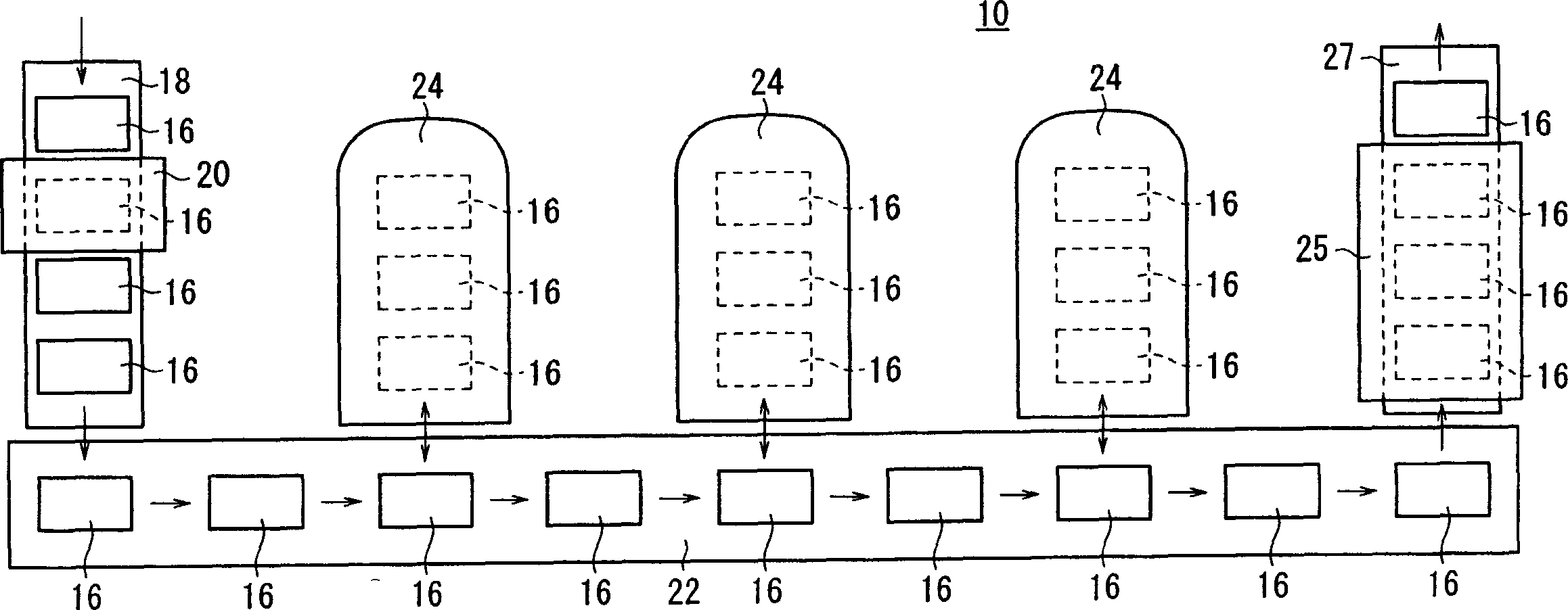

Heat dissipating device incorporating heat pipe

InactiveUS20050141198A1Distribute heat quickly and evenlyHeating evenly and quicklySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A heat dissipating device incorporating heat pipes includes a heat sink (10), a first heat pipe (50) and a second heat pipe (70). The heat sink has a first base (11), a second base (21) and a plurality of fins sandwiched between the first and second bases. Each of the heat pipes has a heat-absorption end (51, 71) and a heat-dissipation end (52, 72). The heat-absorption ends of the first and second heat pipes contact the first base of the heat sink. The heat-dissipation end of the first heat pipe is inserted in the substantial middle portion of the fins, and the heat-dissipation end of the second heat pipe is inserted between the second base and the fins.

Owner:HON HAI PRECISION IND CO LTD

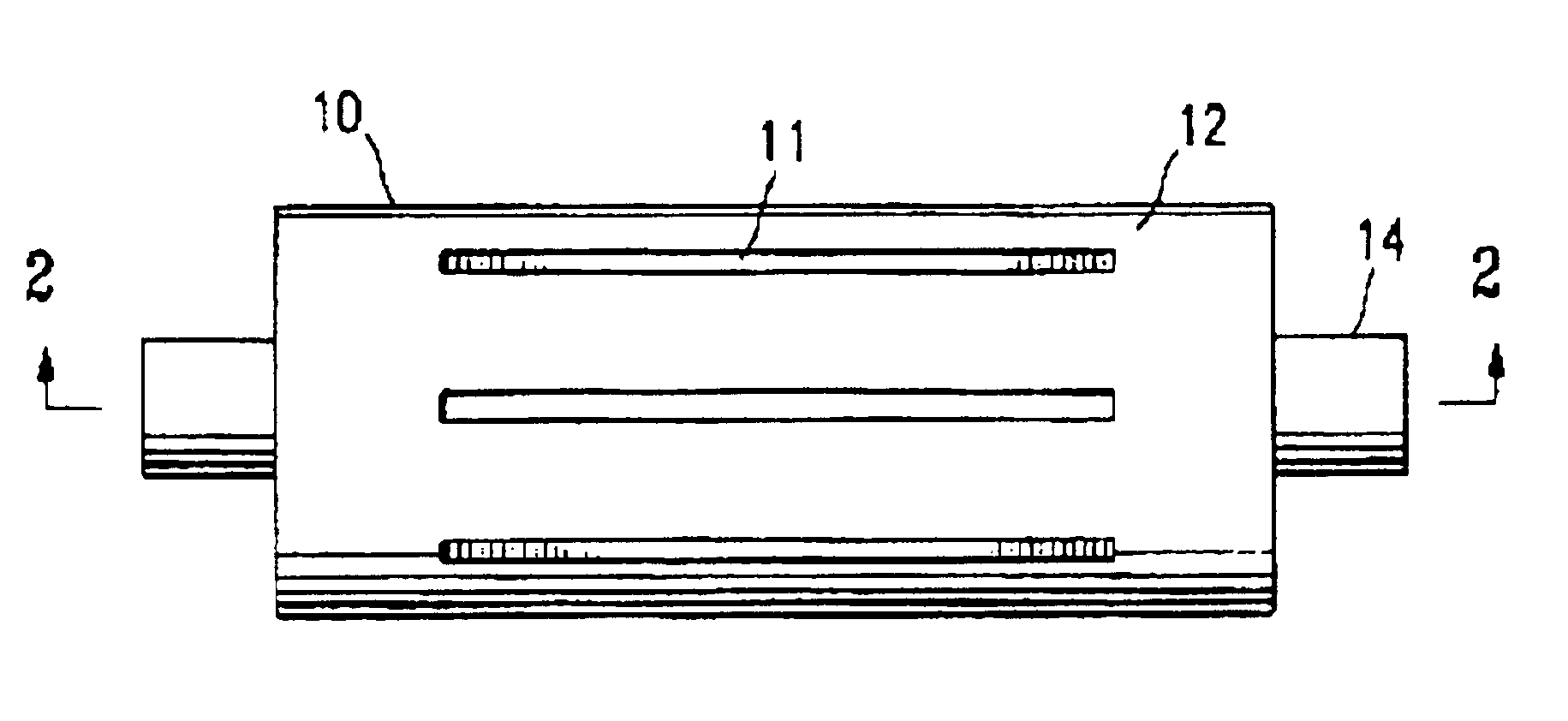

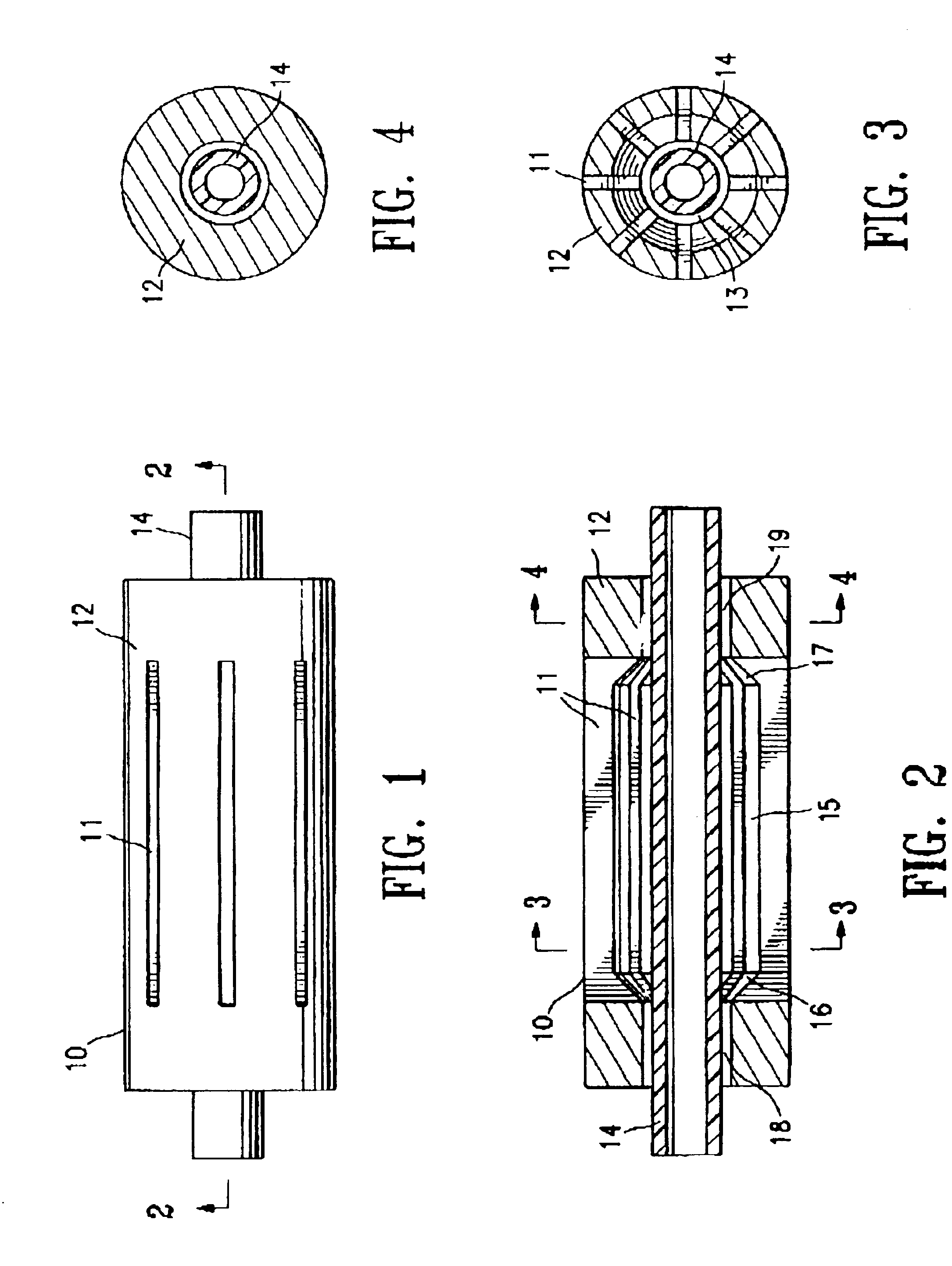

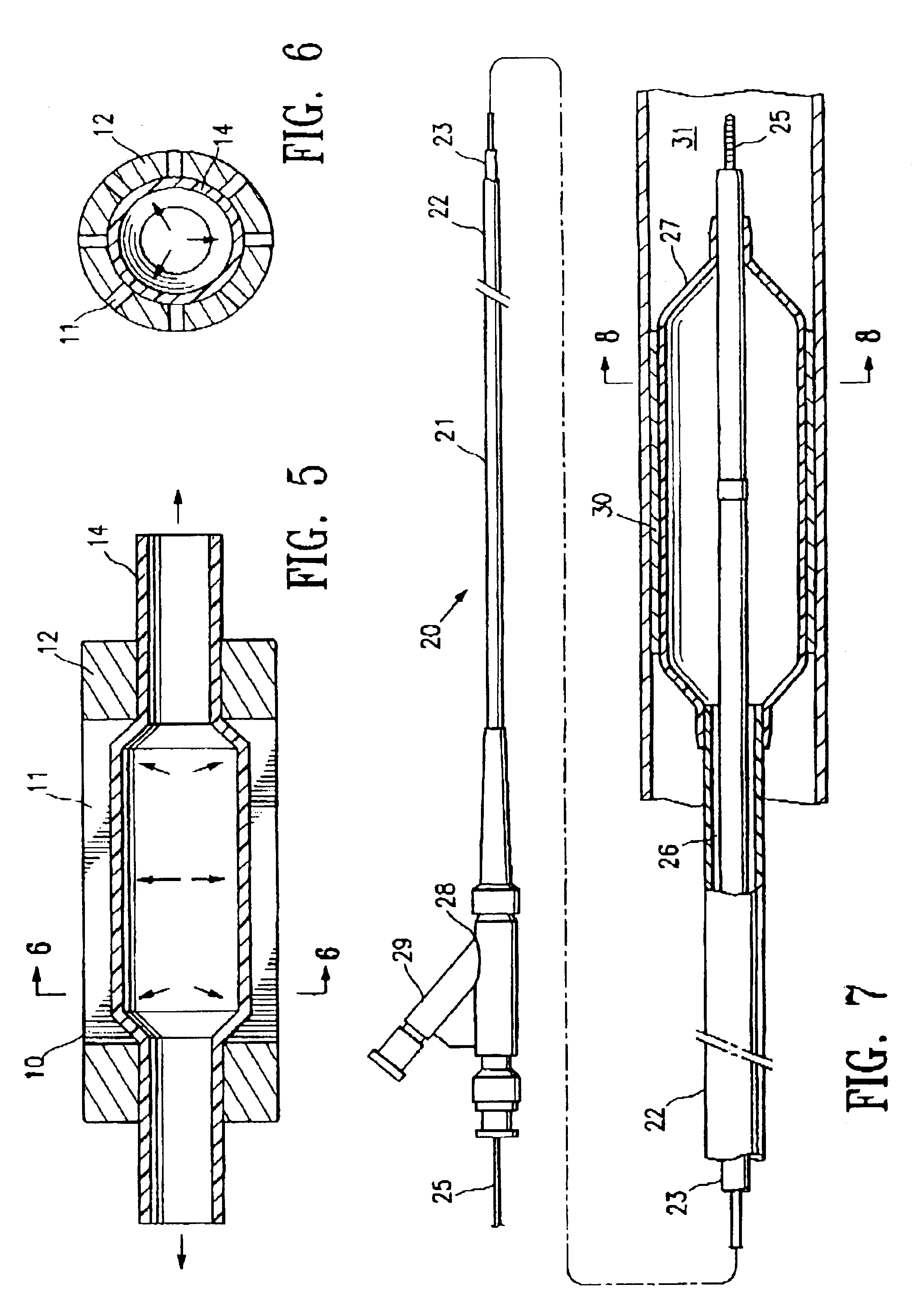

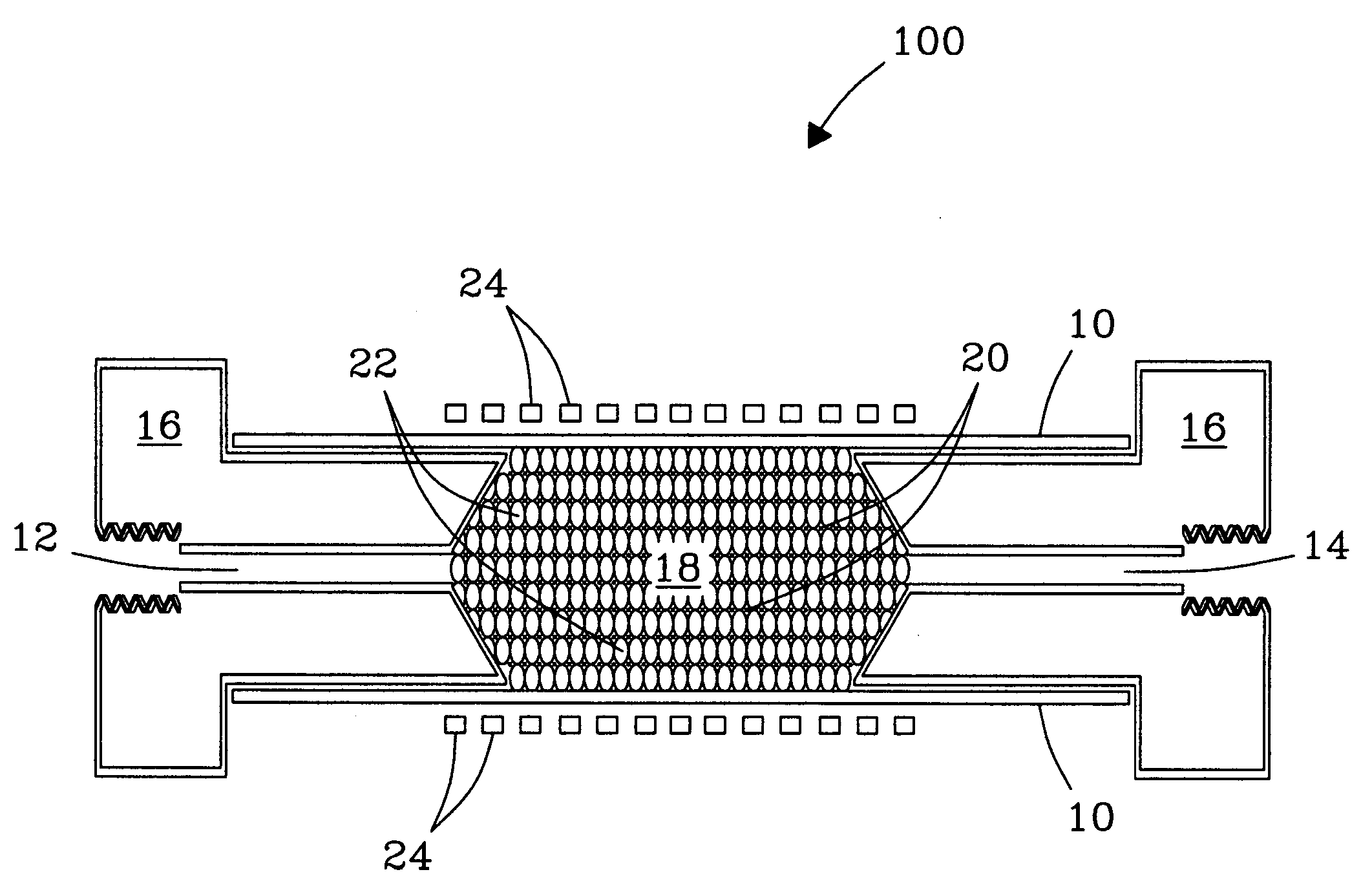

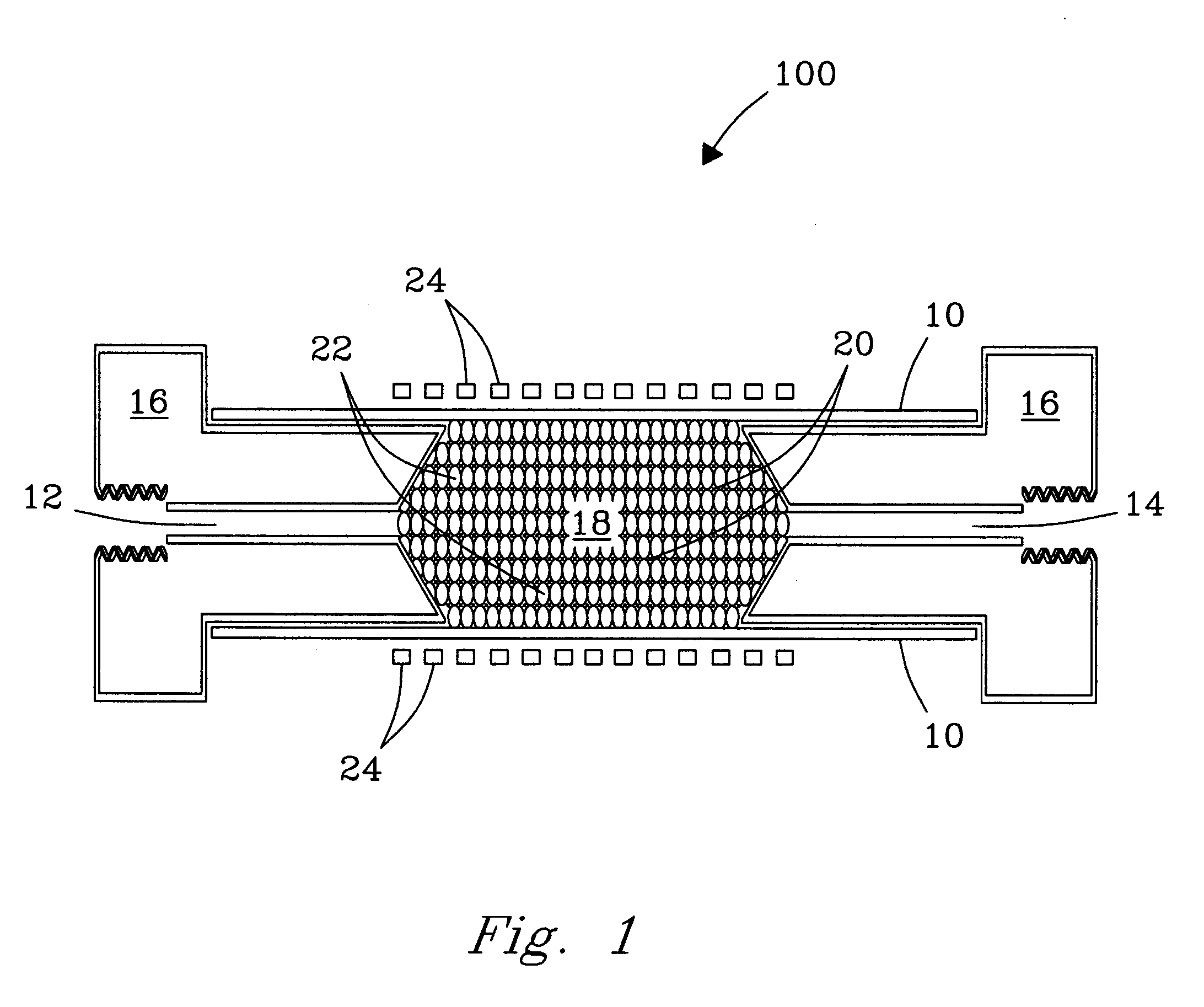

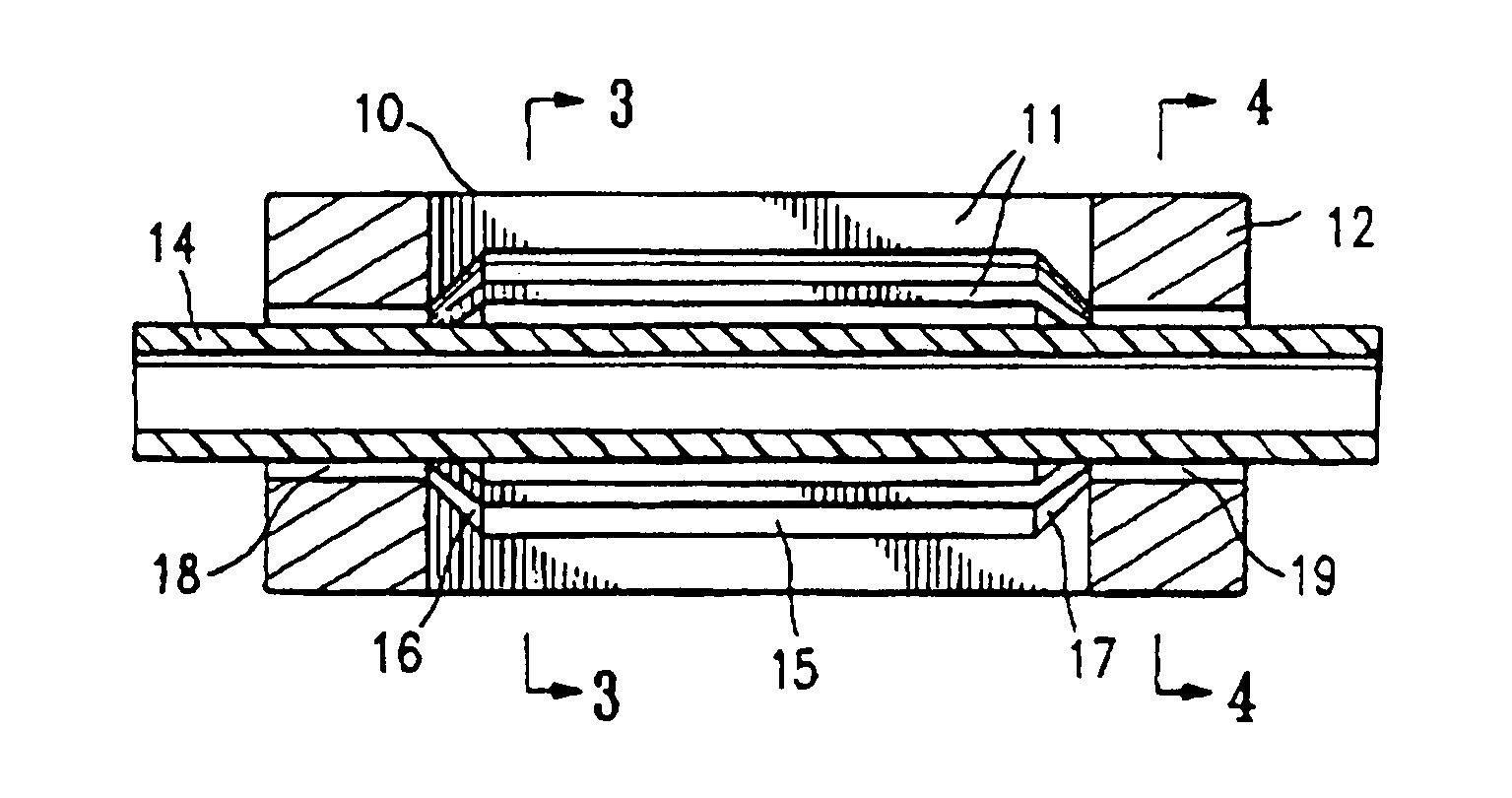

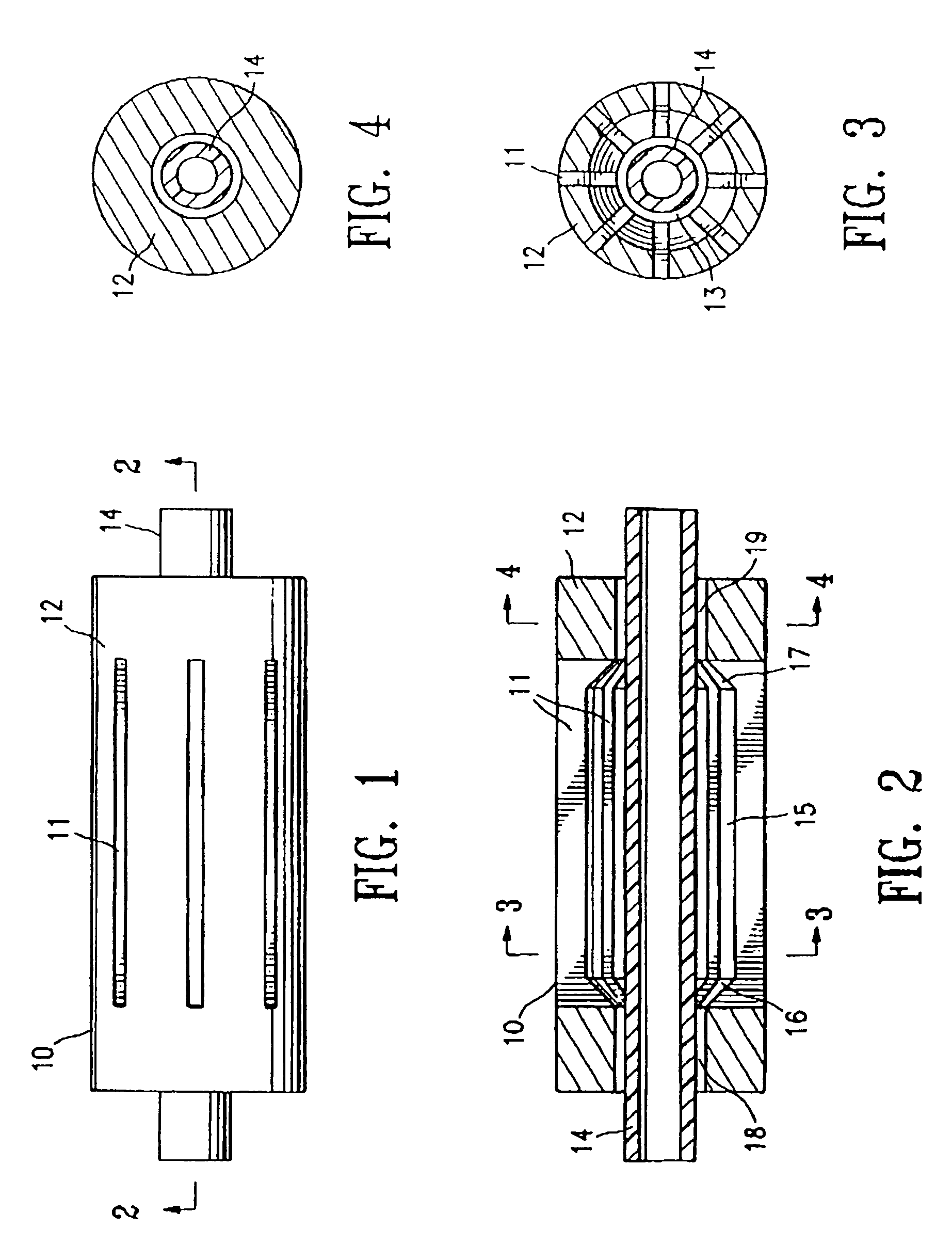

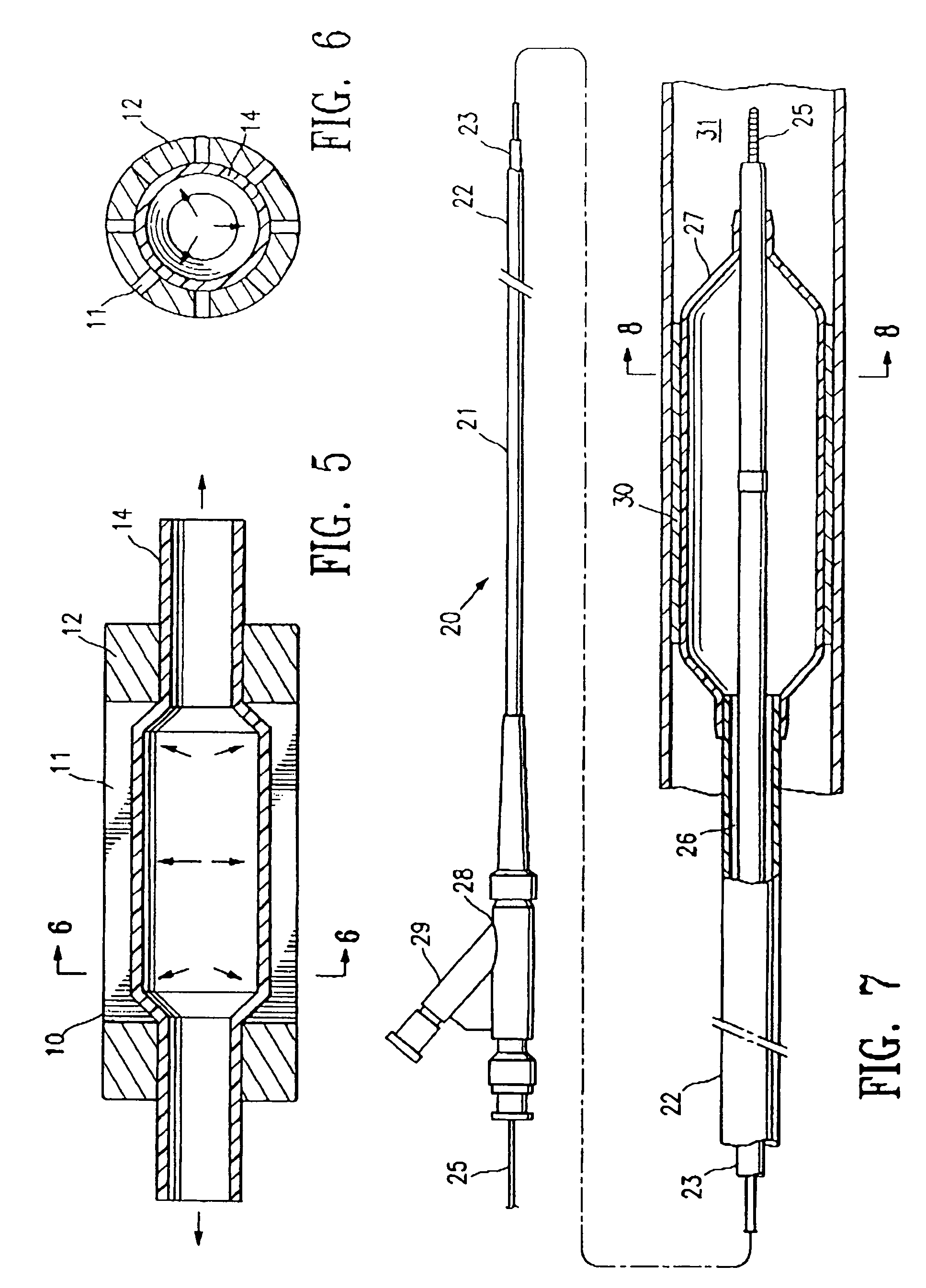

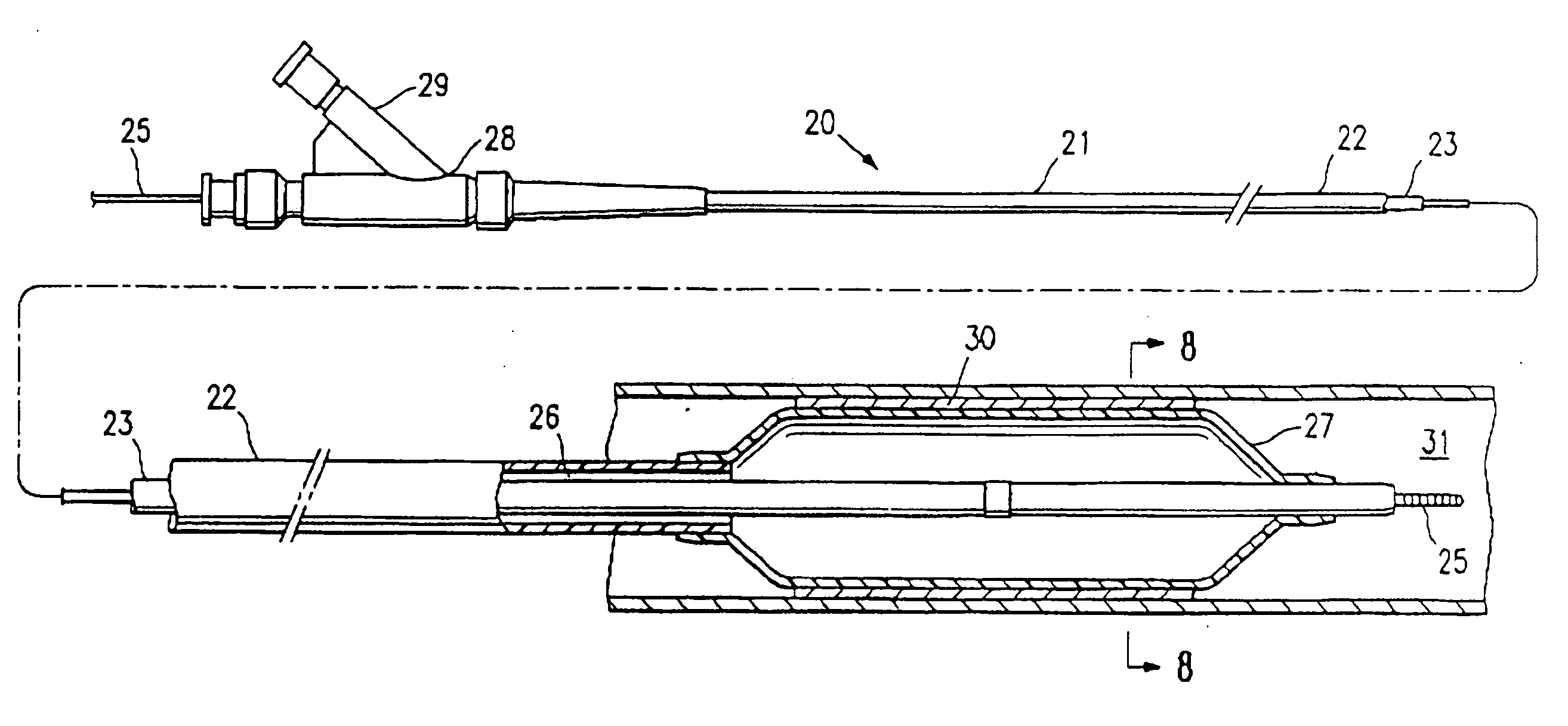

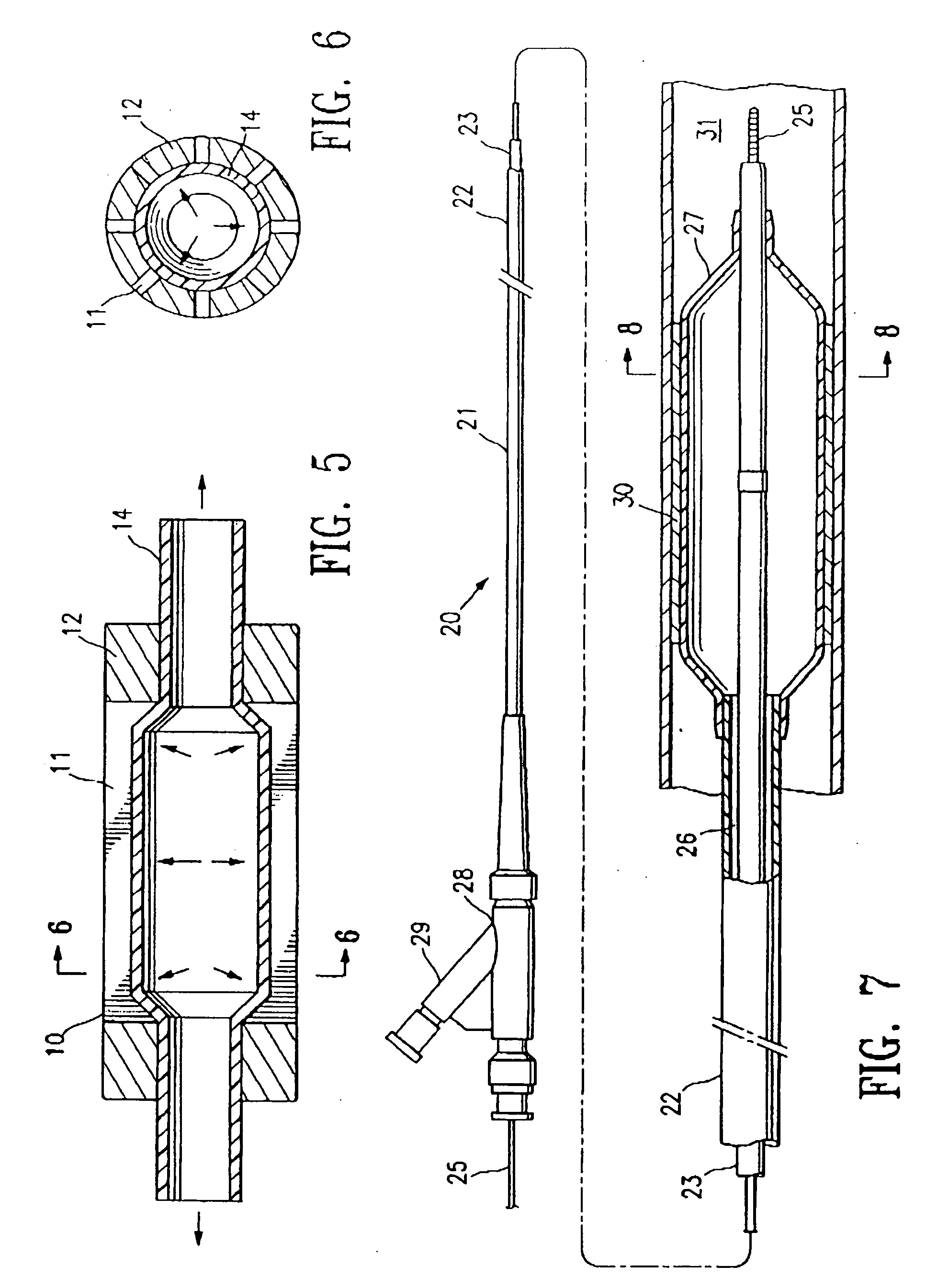

Slotted mold for making a catheter balloon

InactiveUS6863856B1Increase heatIncrease frictional resistanceTyresCeramic shaping apparatusBlow moldingMaterials science

A method of making a catheter balloon, and a balloon formed thereby, in which a polymeric tube is radially expanded in a mold having a wall with an outer surface and an inner surface defining a chamber, and having at least a section with one or more channels in the wall. The channels result in improved transfer of heat to the polymeric tube within the chamber of the mold during blow molding of the tube to form a balloon, so that the tube is heated more quickly and evenly. One aspect of the invention is directed to a balloon having sections with improved thin walls.

Owner:ABBOTT CARDIOVASCULAR

Method for synthesizing carbon-cladded ironic lithium phosphate

InactiveCN1775666AEasy to wrapHeating evenly inside and outsideCell electrodesPhosphorus compoundsPhosphateChemical measurement

The invention relates to a carbon coated lithium iron phosphate microwave-synthesizing method, relating to the preparation of anode material of a Li-ion battery. The invention weighs lithium carbonate, iron oxalate and ammonium diacid phosphate, proper amount of heat conduction agent and organic matter in chemical gauging ratio, using anhydrous alcohol as dispersant to fully grind and mix them, drying and pressing the mixture into blocks, placing the blocks in a pot holding activated carbon, and placing the pot in microwave field for irradiative heating so as to be able to make uniform- phase carbon coated lithium iron phosphate. The invention can realize carbon coating of lithium iron phosphate and more rapidly and uniformly heat the raw materials, beneficial to uniform and rapid reaction of massive raw materials. The method can shorten production cycle and reduce energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

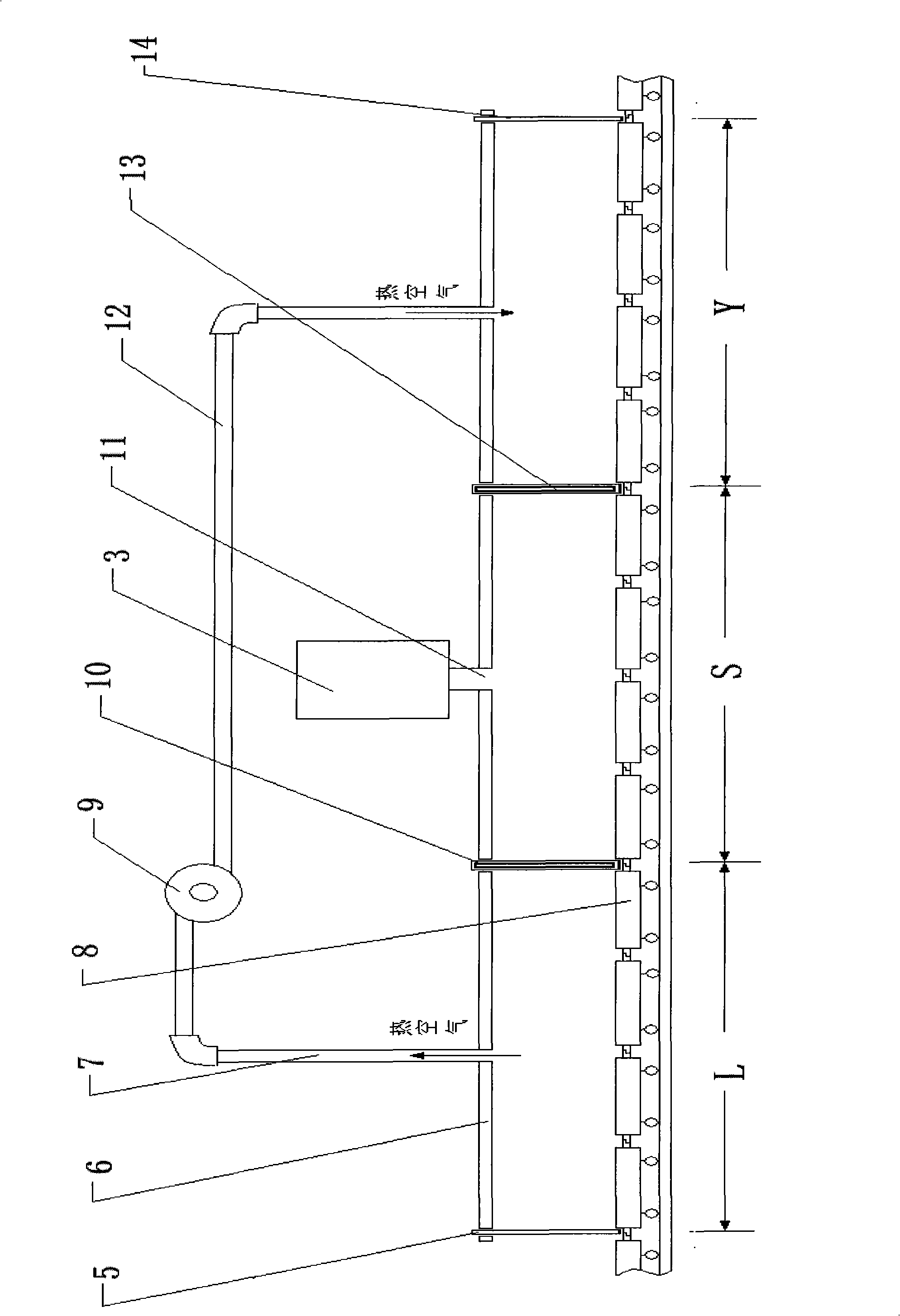

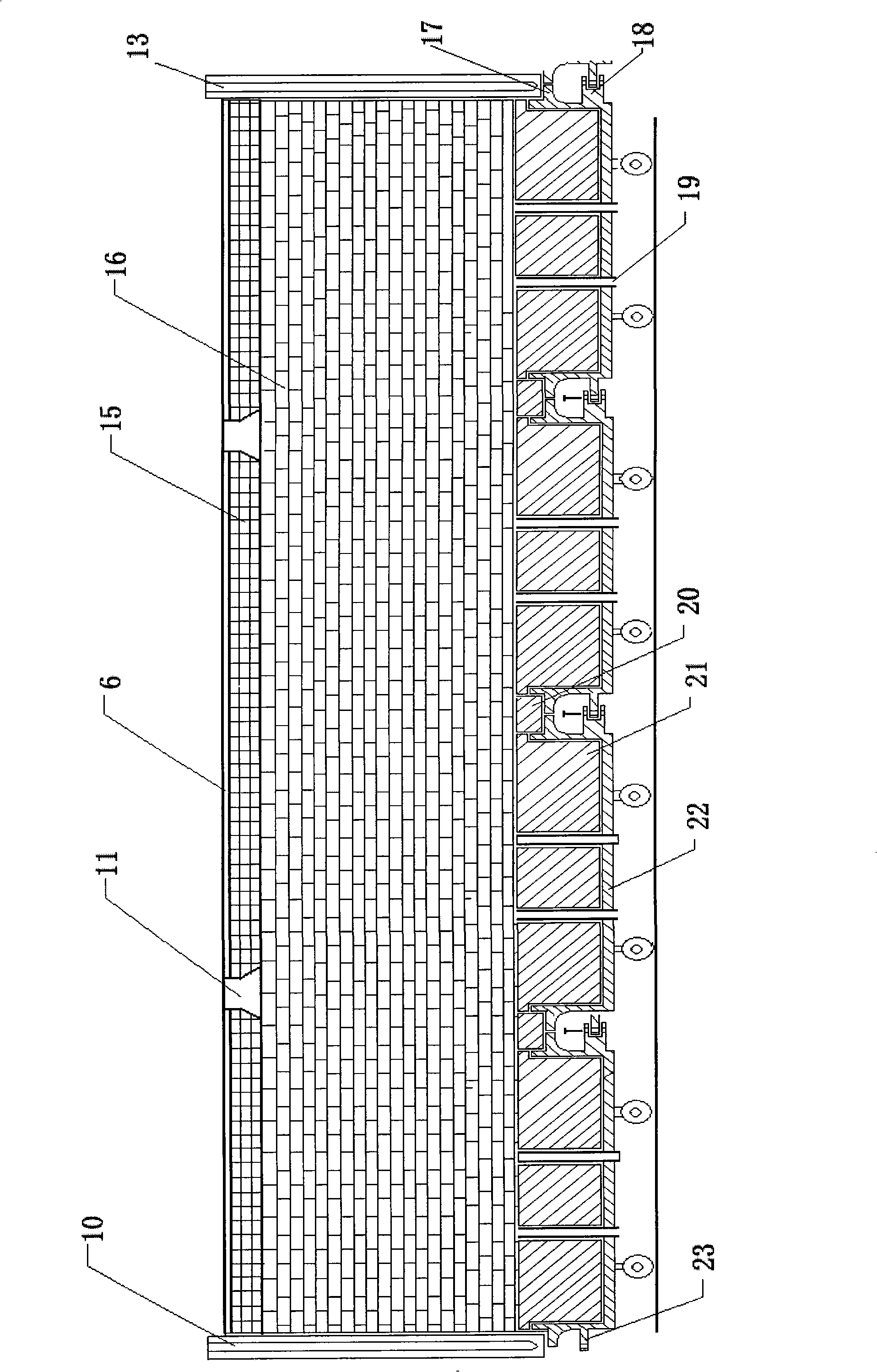

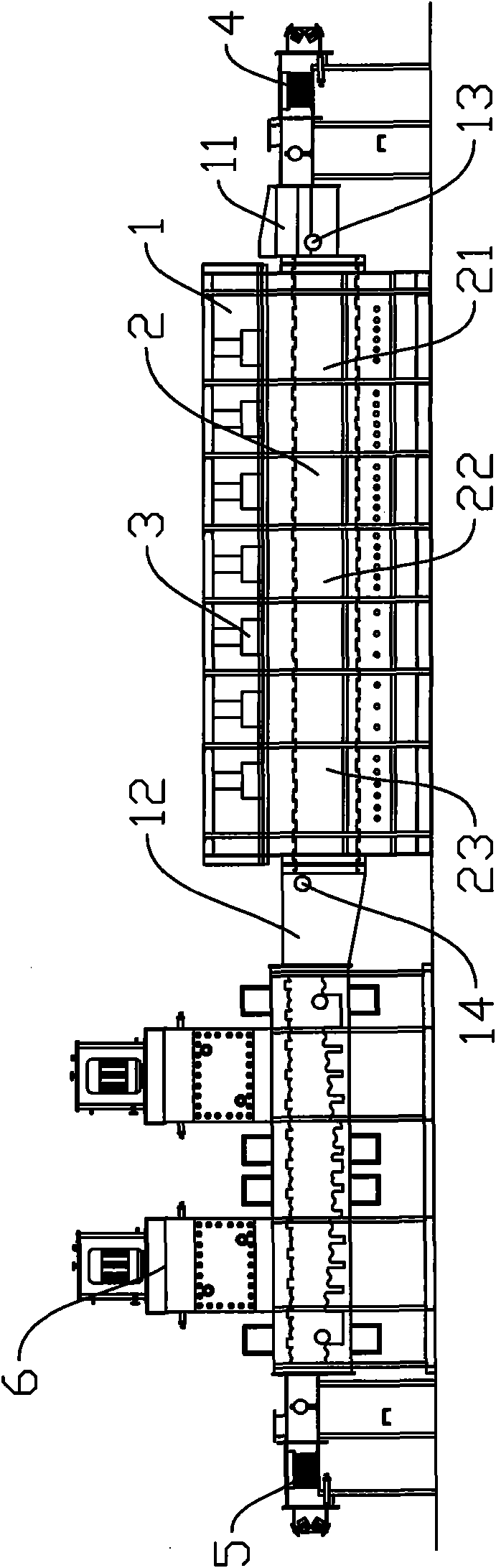

Three-section four-door long-tunnel energy-saving type microwave sintering furnace

InactiveCN101922862AHeats up quickly and evenlyIncrease temperatureFurnace typesMicrowave heatingVehicle frameProduct gas

The invention relates to a microwave sintering furnace, in particular relating to a three-section four-door long-tunnel energy-saving type microwave sintering furnace, which comprises a microwave sintering tunnel furnace, tracks and a kiln car and is characterized in that the appearance of the furnace body is in a long box structure, a base is arranged under the furnace body, two tracks are paved, the side surfaces of the furnace wall are provided with equally spaced gate slots and square sliders, and four lifting type steel doors divide the furnace chamber into a cooling section, a sintering section and a preheating section; a hot gas pumping pipeline is arranged between the cooling section and the preheating section; the top part of the tunnel furnace body is provided with a waveguide port; the kiln car is in a box-combined structure and comprises track wheels, a carframe in a steel square frame type structure, an air inlet and a heat-resisting material layer, the front and rear ends of the kiln car are respectively provided with an auricled door bracket, a connecting piece and a groove, and a kiln car group is formed by connecting 1 to 5 kiln cars; and the microwave sintering furnace also comprises three groups of servo motors controlled synchronously and driven systems. Compared with the traditional kiln furnace, the microwave sintering furnace has high heating speed, saves power by 40-50%, shortens time by 1.5h, achieves the aims of saving energy and reducing consumption and improves economic benefit.

Owner:FUJIAN WANQI SANDT CERAMICS CO LTD

Heat dissipating device incorporating heat pipe

InactiveUS7110259B2Heating evenly and quicklyDistributed quickly and evenlySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A heat dissipating device incorporating heat pipes includes a heat sink (10), a first heat pipe (50) and a second heat pipe (70). The heat sink has a first base (11), a second base (21) and a plurality of fins sandwiched between the first and second bases. Each of the heat pipes has a heat-absorption end (51, 71) and a heat-dissipation end (52, 72). The heat-absorption ends of the first and second heat pipes contact the first base of the heat sink. The heat-dissipation end of the first heat pipe is inserted in the substantial middle portion of the fins, and the heat-dissipation end of the second heat pipe is inserted between the second base and the fins.

Owner:HON HAI PRECISION IND CO LTD

Method and apparatus for concentrating vapors for analysis

ActiveUS20070180933A1Increase the rate of heatingImprove thermal conductivityComponent separationWithdrawing sample devicesImage resolutionDetection limit

An apparatus and method are disclosed for pre-concentrating gaseous vapors for analysis. The invention finds application in conjunction with, e.g., analytical instruments where low detection limits for gaseous vapors are desirable. Vapors sorbed and concentrated within the bed of the apparatus can be thermally desorbed achieving at least partial separation of vapor mixtures. The apparatus is suitable, e.g., for preconcentration and sample injection, and provides greater resolution of peaks for vapors within vapor mixtures, yielding detection levels that are 10-10,000 times better than for direct sampling and analysis systems. Features are particularly useful for continuous unattended monitoring applications.

Owner:BATTELLE MEMORIAL INST

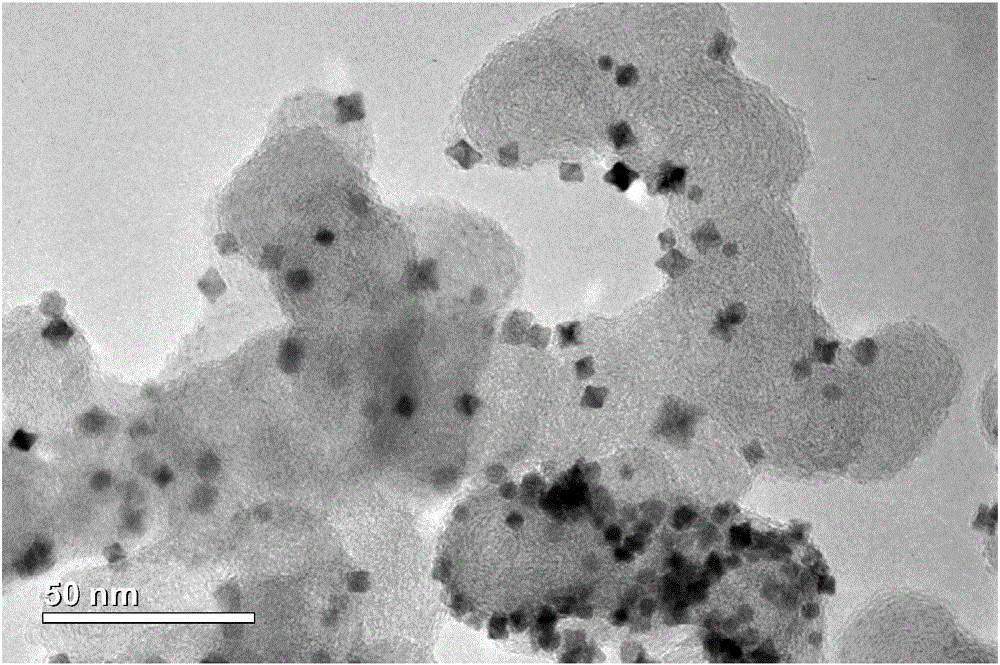

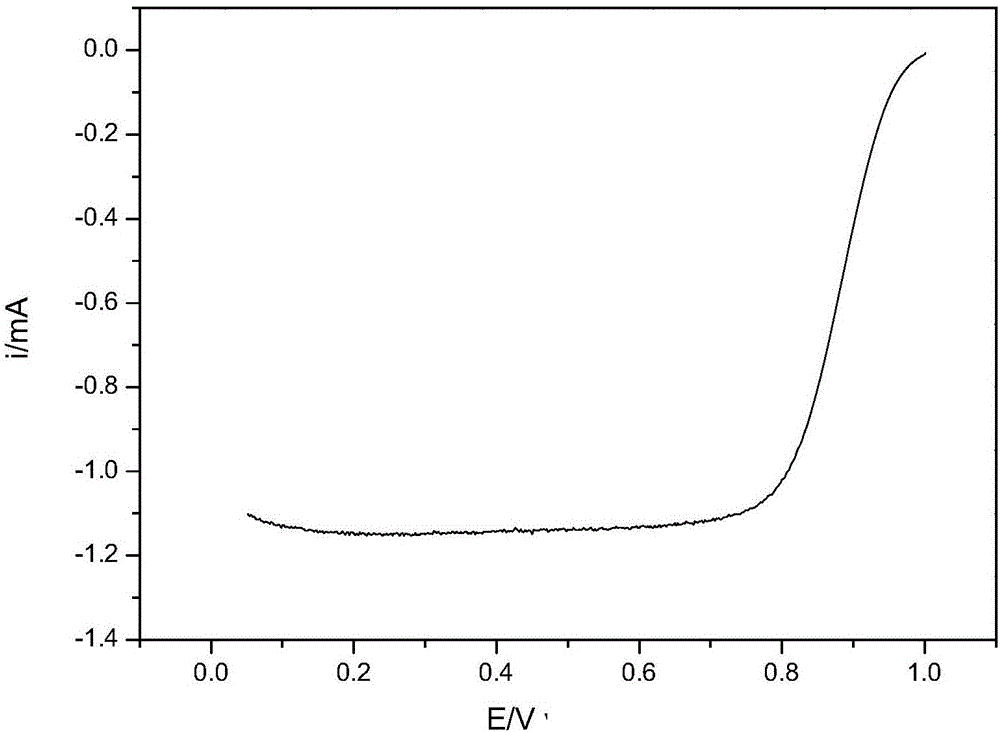

Preparation method of platinum-transition metal alloy nanometer crystals for fuel cell catalyst

InactiveCN106784903AHeating evenly and quicklyExtended reaction timeMaterial nanotechnologyCell electrodesBenzoic acidOctahedron

The invention provides a preparation method of platinum-transition metal alloy nanometer crystals for a fuel cell catalyst. The preparation method of the platinum-transition metal alloy nanometer crystals for the fuel cell catalyst includes following steps; S1, dissolving a platinum precursor, a transition metal precursor and benzoic acid in N-N dimethyl formamide so as to form a precursor mixed solution; S2, placing the precursor mixed solution in a microwave electromagnetic field to obtain the platinum-transition metal alloy nanometer crystals of octahedral shape after performing uniform heating reaction on the precursor mixed solution through microwaves. The preparation method of the platinum-transition metal alloy nanometer crystals for the fuel cell catalyst uses the characteristics of having wave-particle dualism and being capable of performing rapid, uniform and selective heating of the microwaves to continuously heat reactant during the reaction process, effectively decreases reaction time, and shortens a reaction period. Compared with a traditional synthetic process, the synthesis period is shortened by about 10 times, and reaction efficiency is greatly improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method and apparatus for concentrating vapors for analysis

ActiveUS7430928B2Increase the rate of heatingImprove thermal conductivityComponent separationWithdrawing sample devicesDetection limit

Owner:BATTELLE MEMORIAL INST

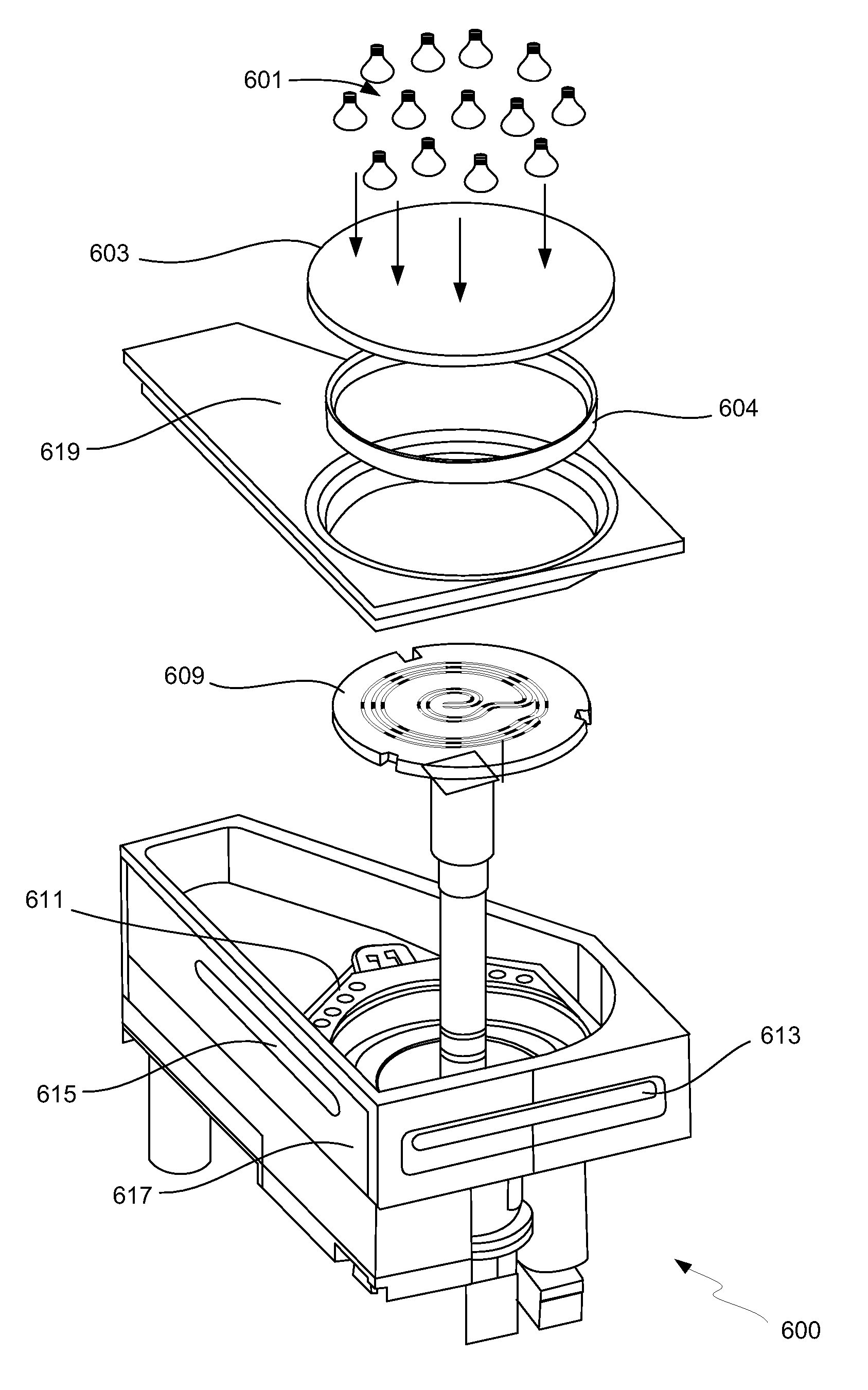

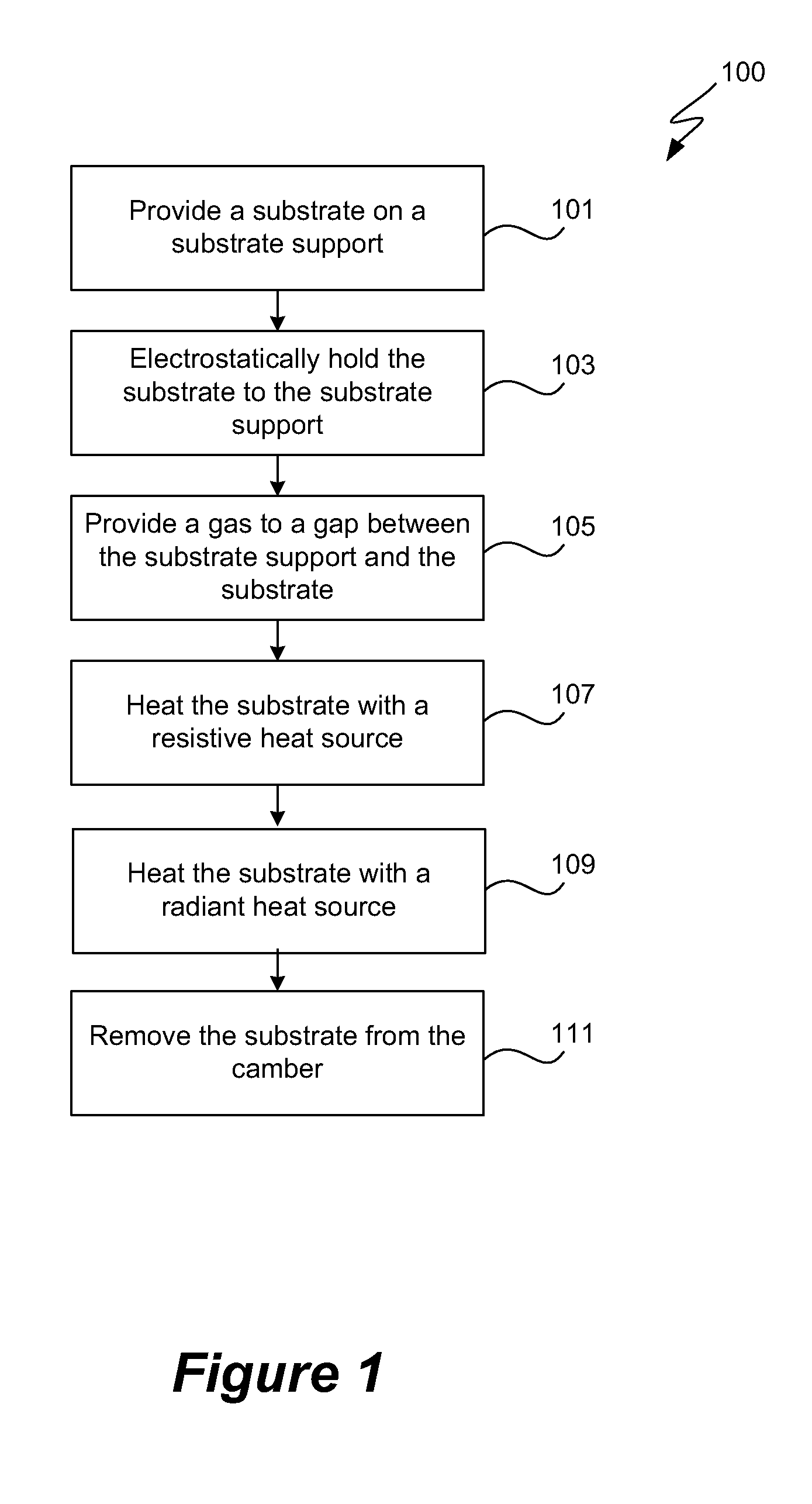

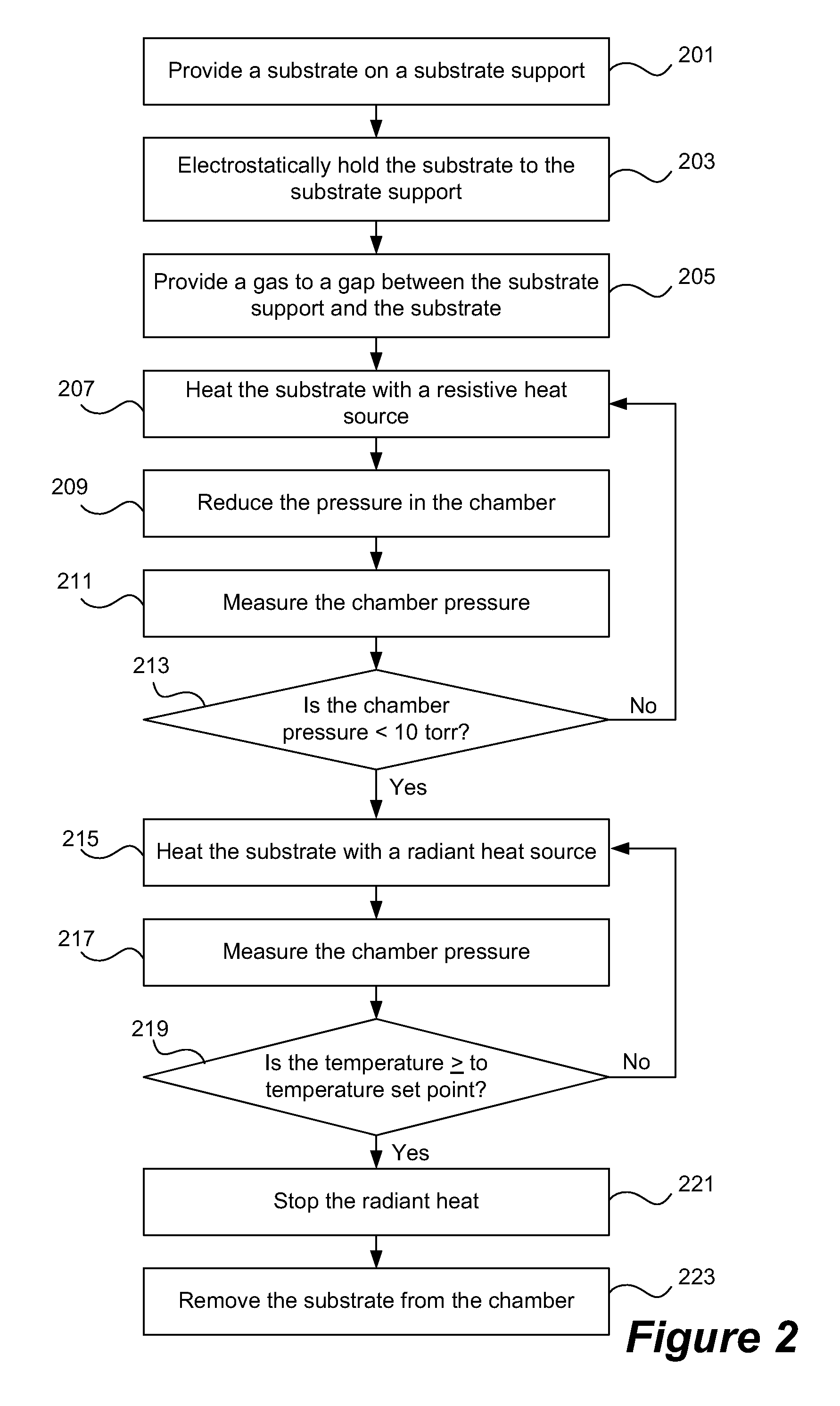

Load lock design for rapid wafer heating

ActiveUS8273670B1Heating evenly and quicklyImprove throughputSemiconductor/solid-state device manufacturingElectrostatic spraying apparatusElectrical resistance and conductanceEngineering

Owner:NOVELLUS SYSTEMS

Slotted mold for making a balloon catheter

InactiveUS7314364B2Improve heat transfer performanceHeating evenly and quicklyConfectioneryCatheterBlow moldingMedicine

A method of making a catheter balloon, and a balloon formed thereby, in which a polymeric tube is radially expanded in a mold having a wall with an outer surface and an inner surface defining a chamber, and having at least a section with one or more channels in the wall. The channels result in improved transfer of heat to the polymeric tube within the chamber of the mold during blow molding of the tube to form a balloon, so that the tube is heated more quickly and evenly. One aspect of the invention is directed to a balloon having sections with improved thin walls.

Owner:ABBOTT CARDIOVASCULAR

Slotted mold for making a balloon catheter

InactiveUS20050123640A1Improve heat transfer performanceHeating evenly and quicklySurgeryDilatorsBlow moldingMedicine

A method of making a catheter balloon, and a balloon formed thereby, in which a polymeric tube is radially expanded in a mold having a wall with an outer surface and an inner surface defining a chamber, and having at least a section with one or more channels in the wall. The channels result in improved transfer of heat to the polymeric tube within the chamber of the mold during blow molding of the tube to form a balloon, so that the tube is heated more quickly and evenly. One aspect of the invention is directed to a balloon having sections with improved thin walls.

Owner:ABBOTT CARDIOVASCULAR

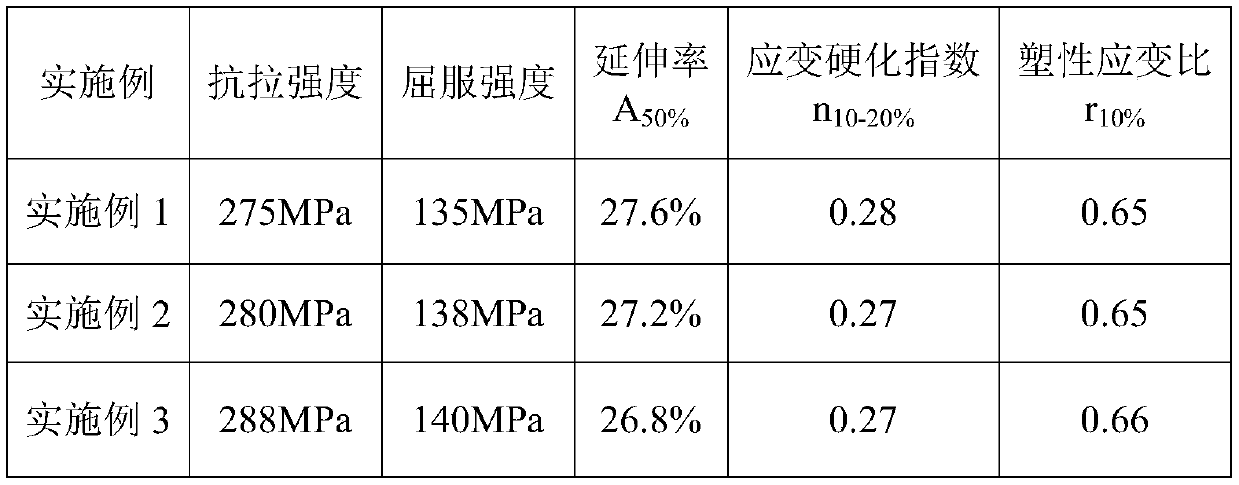

5182-O state aluminum alloy plate for automobile inner plate and production method for 5182-O state aluminum alloy plate

The invention relates to a 5182-O state aluminum alloy plate for an automobile inner plate. The 5182-O state aluminum alloy plate comprises the following raw materials in weight percentage: 0.1-0.15%of Si, 0.15-0.3% of Fe, no more than 0. 03% of Cu, 0.2-0.4% of Mn, 4.5-4.9% of Mg, 0.03-0.07% of Cr, no more than 0.1% of Zn, 0.015-0.04% of Ti and the balance Al. The production method comprises thesteps of batching; smelting and casting; ingot homogenizing heat treatment and milling surface machining; hot rolling; cold rolling; continuous and complete annealing of the finished product, wherein,the annealing furnace temperature is 420-480 DEG C, and the speed of the aluminum alloy strip in the furnace is 10-20 m / min; tension leveling line washing and withdrawing-straightening plate shape; and flying shear slicing. According to the 5182-O state aluminum alloy plate, the properties are stable, the internal texture is uniform, the machining plasticity is high, the orange peel line after stamping does not exist, and the strength is high.

Owner:河南明晟新材料科技有限公司

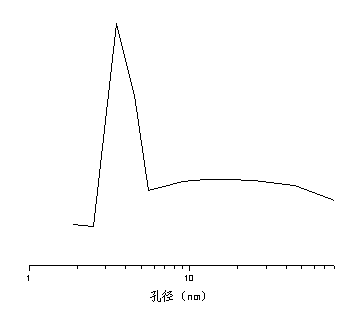

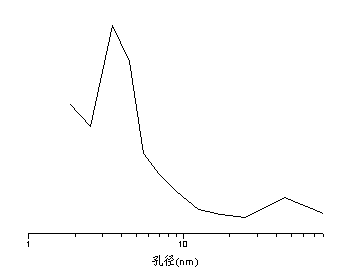

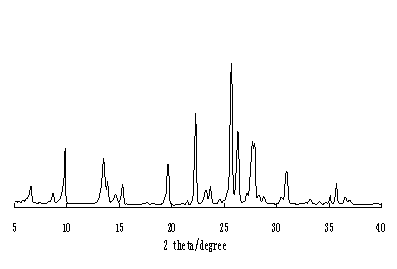

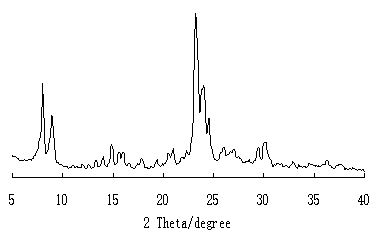

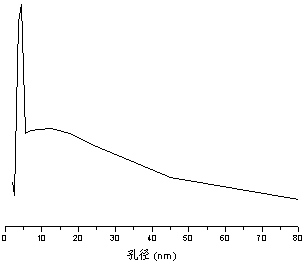

Method for preparing mesopore-micropore zeolite molecular sieve material

ActiveCN102874830AReactive centerIncrease average energyCrystalline aluminosilicate zeolitesSolution treatmentMolecular sieve

The invention discloses a method for preparing a mesopore-micropore zeolite molecular sieve material. The method comprises the following steps of: mixing an alkaline solution, an organic solvent and micropore zeolite, and performing microwave treatment; performing acid solution treatment, separating, washing and drying to obtain the mesopore-micropore zeolite. By the method, the micropore zeolite is subjected to microwave treatment in the existence of the organic solvent and the alkaline solution, so that formation of mesopores can be promoted, and micropores are efficiently converted into the mesopores and can be stabilized and protected; amorphous aluminum in a pore channel of a zeolite crystal can be eluted in the subsequent acid treatment process, so that aims of dredging the pore channel and increasing the total specific surface area are fulfilled; and the relatively complete micropores can be reserved in the mesopore-micropore zeolite, a plurality of mesopores are provided, and simultaneously, the total Brunauer, Emmett and Teller (BET) specific surface area can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

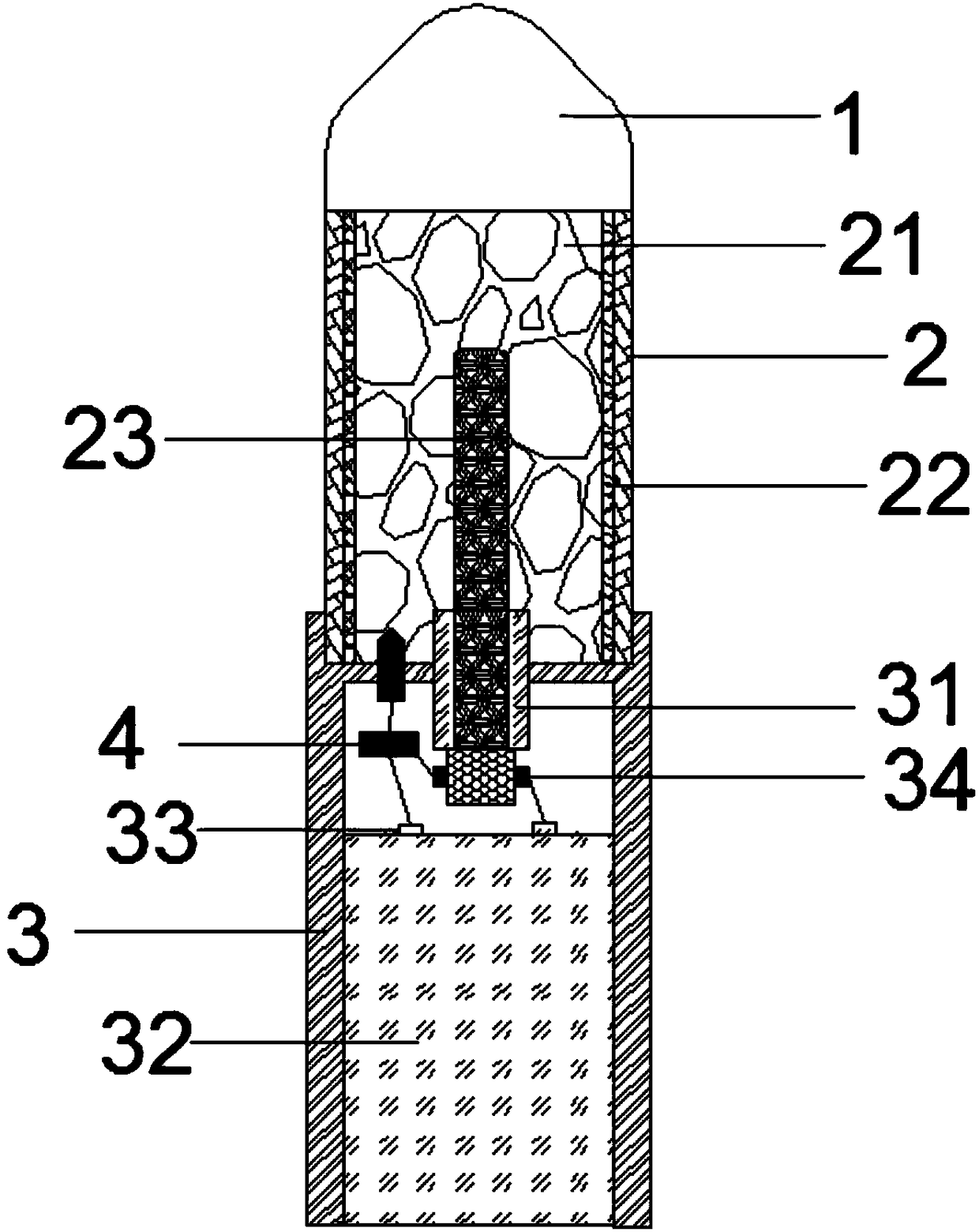

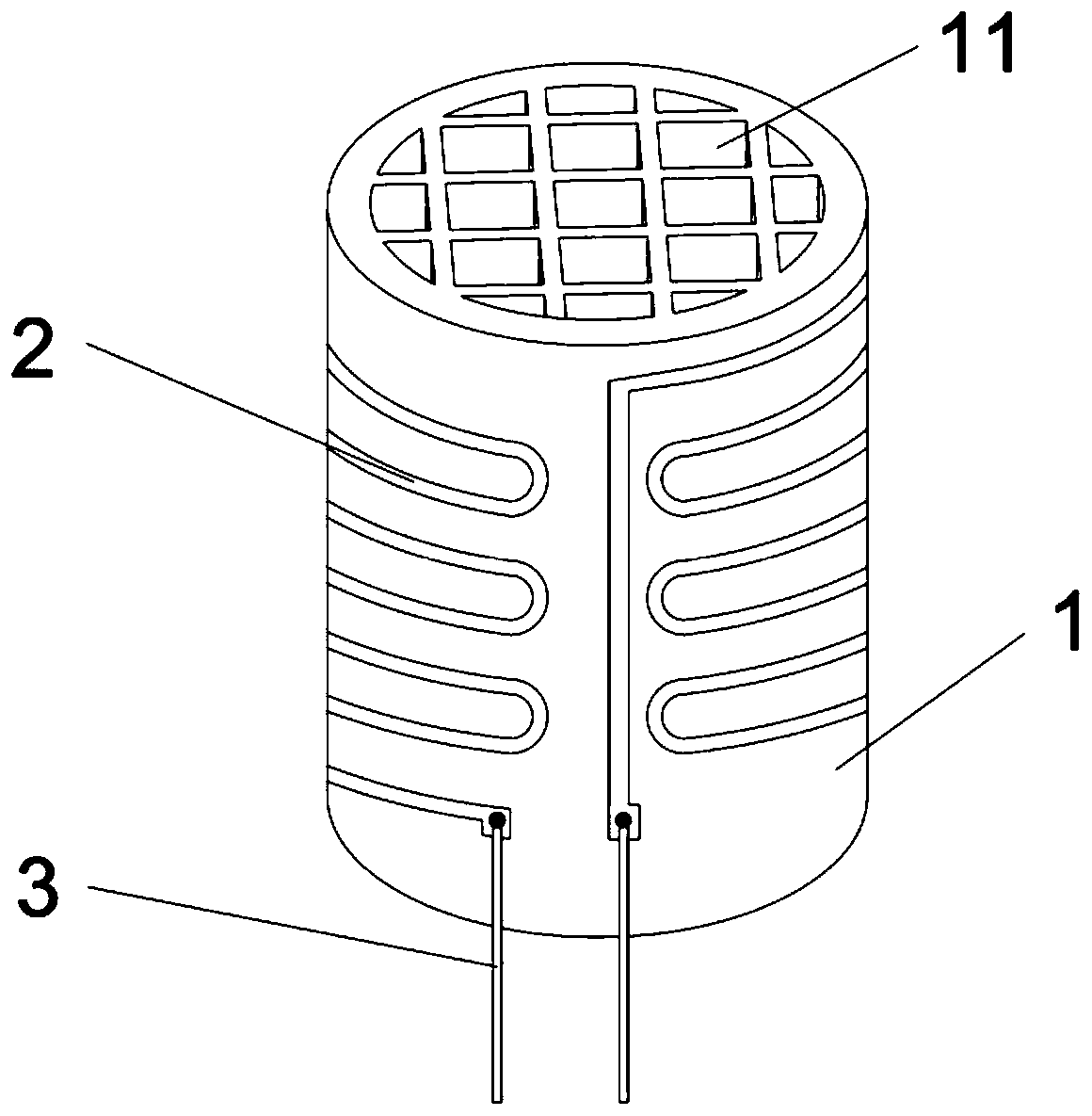

Far infrared heating electronic cigarette module

PendingCN108378426AWill not volatilize unevenlyIncrease atomization rateTobacco devicesElectricityTar

The invention provides a far infrared heating electronic cigarette module. The electronic cigarette module comprises a cigarette holder, an atomizer, a base, a far infrared heating body and a temperature regulation and control device, wherein an opening is formed in the bottom of the atomizer; a notch is formed in the top of the base; the cigarette holder is arranged on the top of the atomizer; the atomizer is mounted on the base and is filled with expanded graphite; a battery is mounted in the base; the top of the far infrared heating body extends into the atomizer; the bottom of the far infrared heating body extends into the base through the notch, and is electrically connected with the battery; one end of the temperature regulation and control device is connected with the inside of theatomizer while the other end of the temperature regulation and control device is electrically connected with the battery; and one or two far infrared reflecting layers is arranged on the inner side wall of the atomizer. The far infrared heating body is arranged in the atomizer of the electronic cigarette, far infrared rays generated by radiation can effectively penetrate through tobacco tar or a tobacco tar load, rapid and uniform heating is implemented, and meanwhile, the problem of uneven tobacco tar volatilization due to over-high local temperature can be avoided.

Owner:杭州森翼科技有限公司

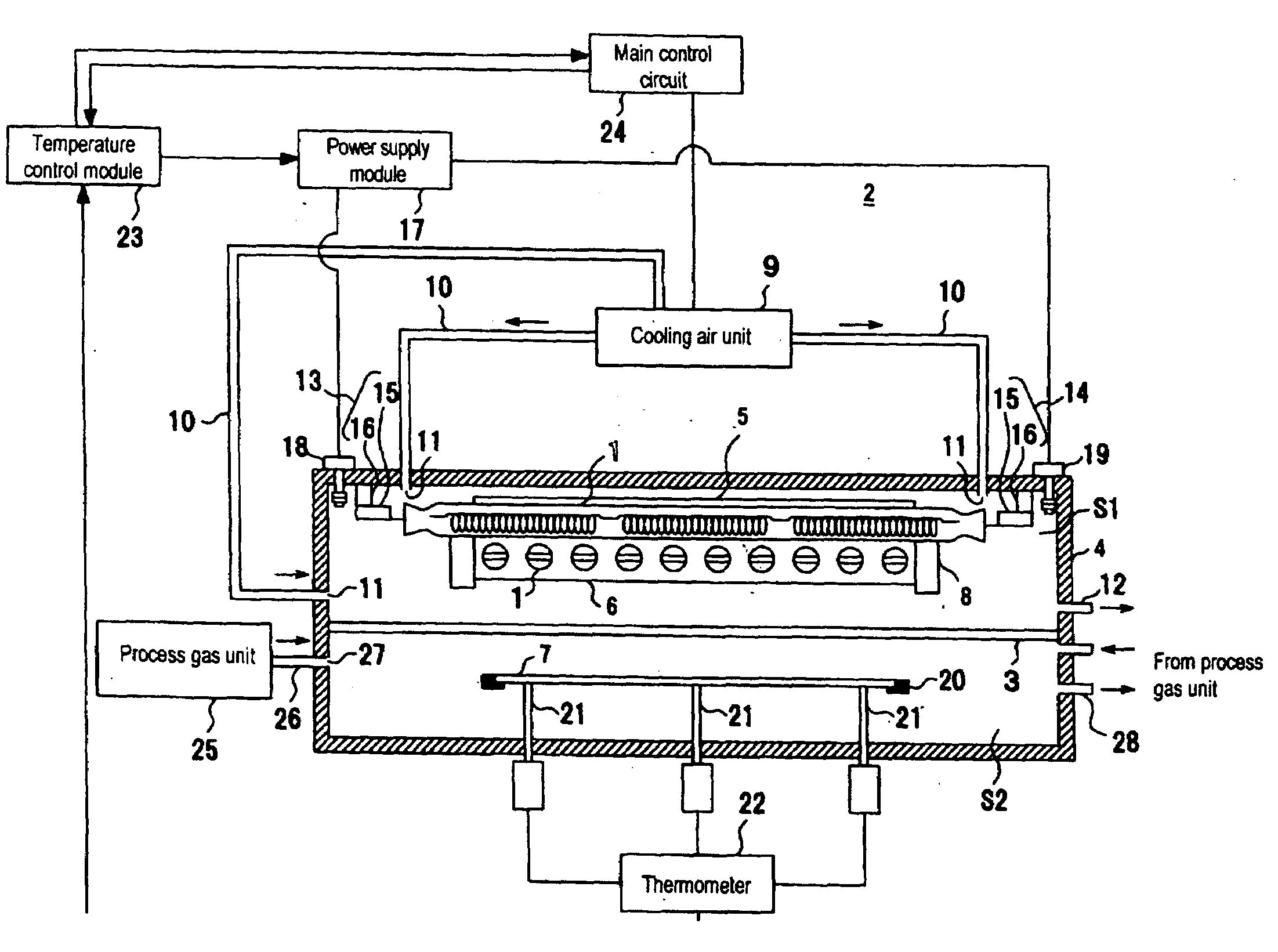

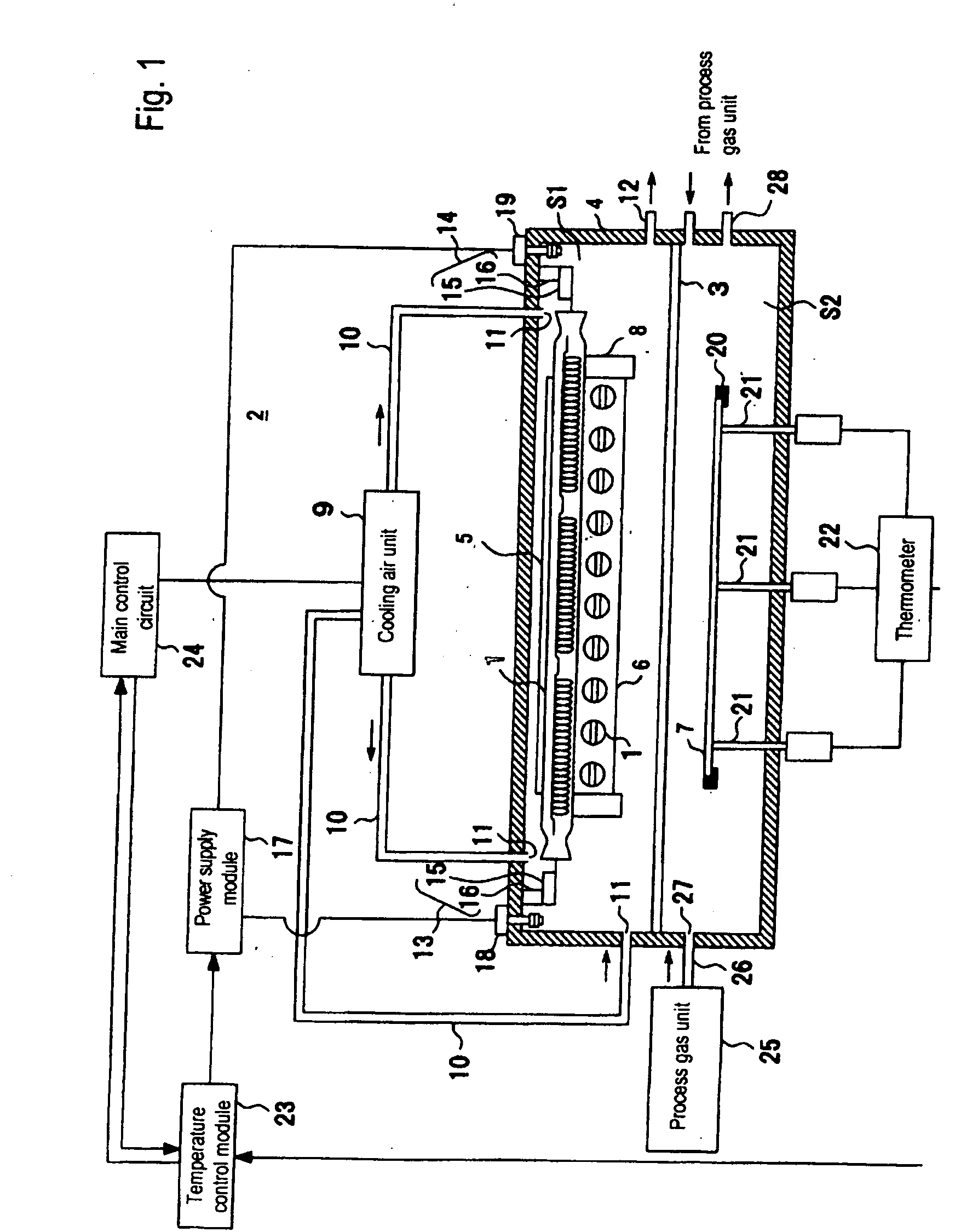

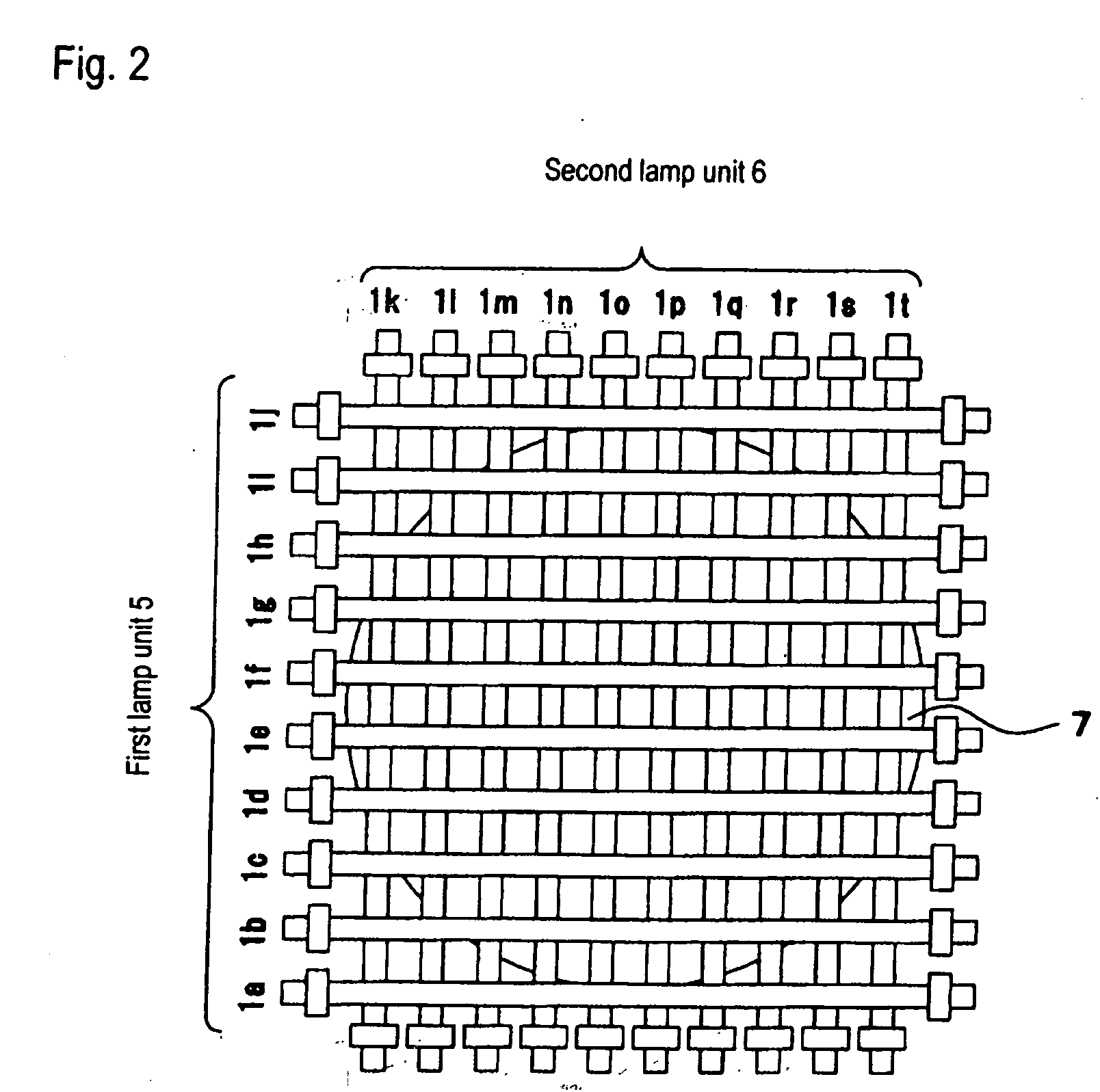

Filament lamp and heat treatment device of the light irradiation type

InactiveUS20090103905A1Increase surface areaAvoid rigidityDrying solid materials with heatLamp incadescent bodiesLight irradiationEngineering

Filament lamps whose individual filament coils can be set to specific temperatures in filament lamps that are supplied with electric power independently and to provide a heat treatment device of the light irradiation type that uses said lamps. Inside of a light emitting tube of each lamp, which has the hermetically sealed portions at each end, are multiple filament modules which have been made by linking pairs of leads which supply electrical power to both ends of coiled filaments and individual filaments that are placed so that they extend along the axis of the light emitting tube. In the electrically connected filament lamps, whose individual leads are connected to the respective electrically conductive material placed in the hermetically sealed portions, at least one of the individual filaments is made up of a single wire and at least two are made up of bundled wires with the single wire being located between the bundled wires.

Owner:USHIO DENKI KK

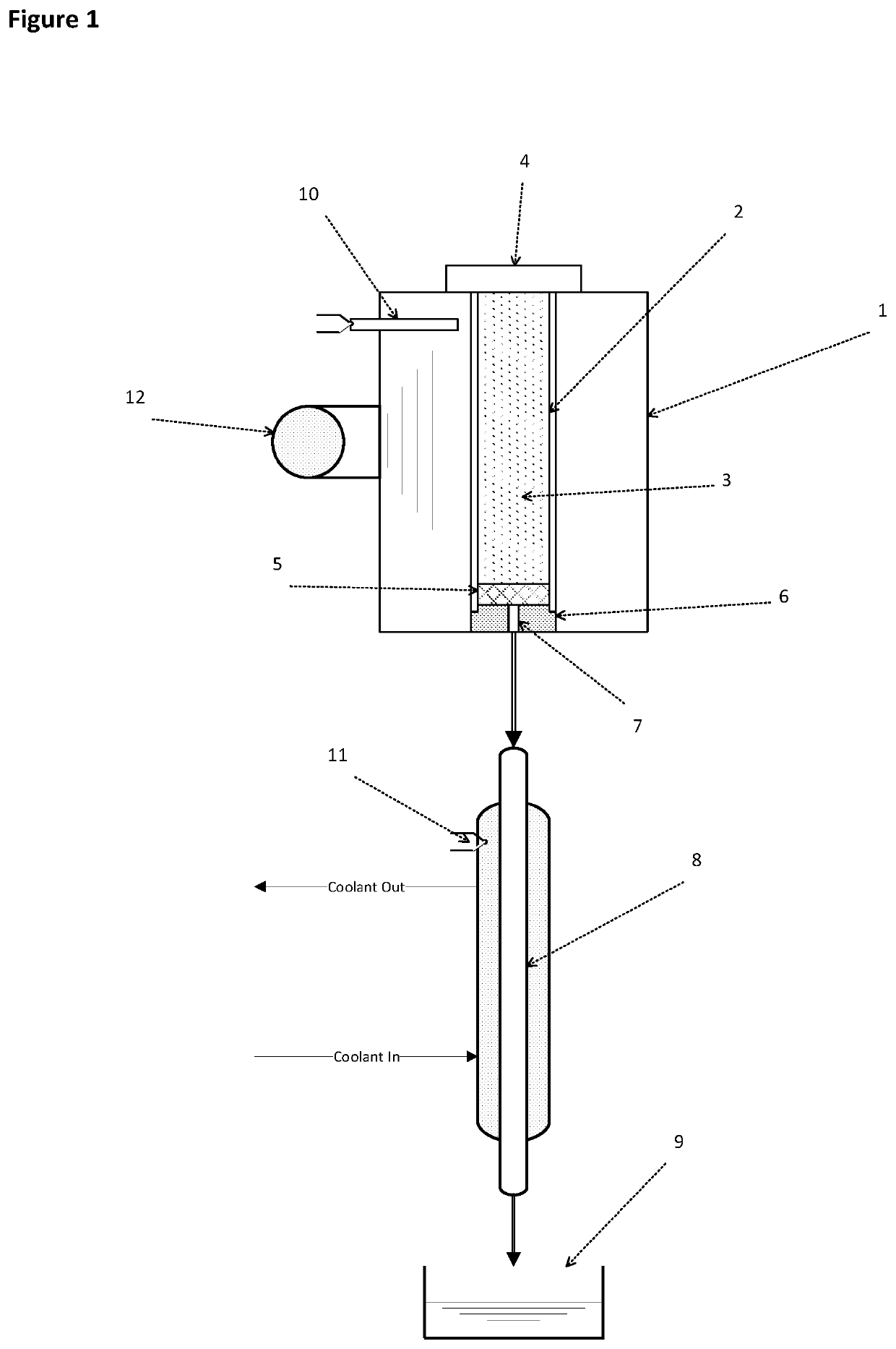

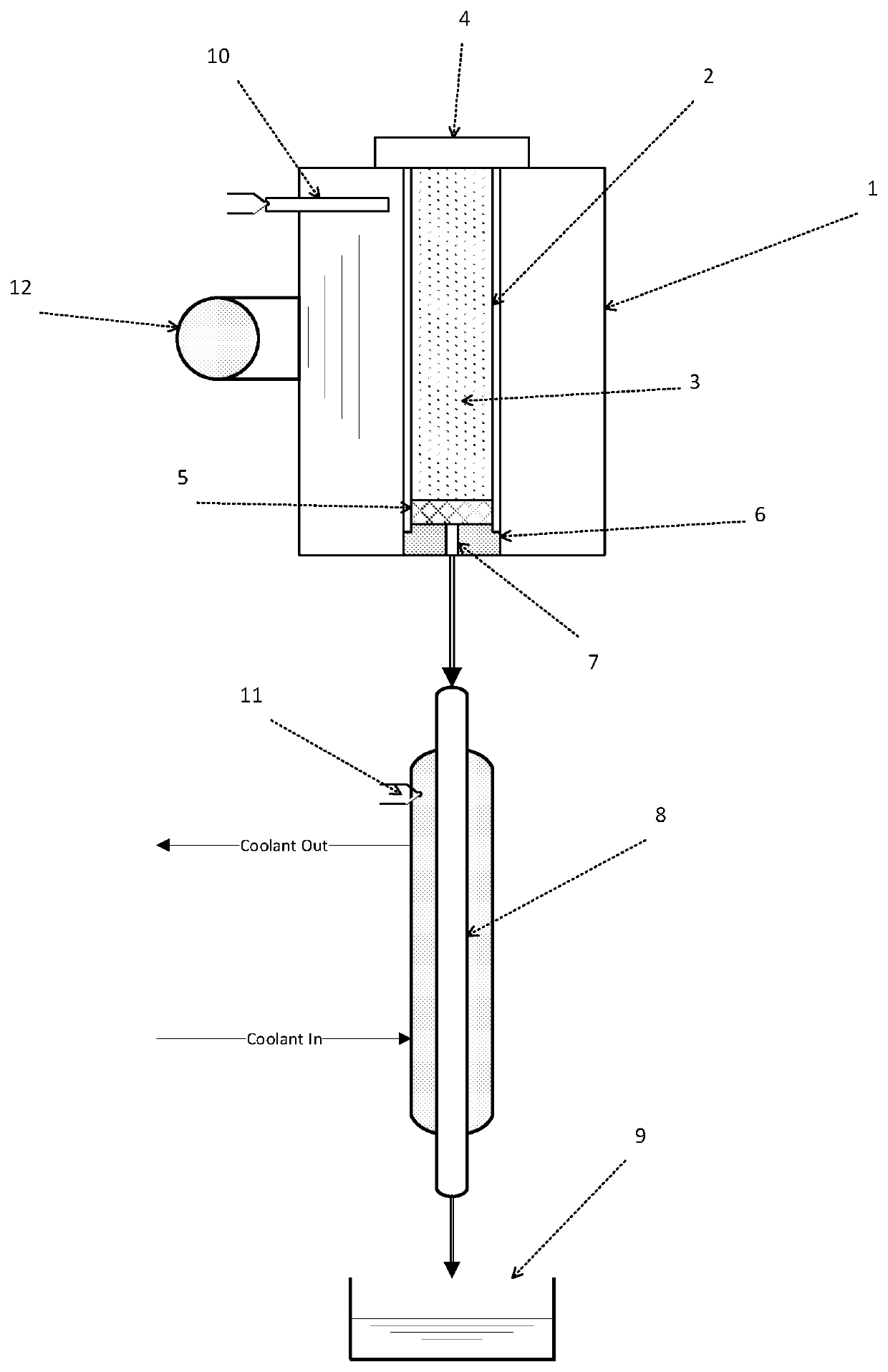

Rapid botanical oil distillation device utilizing microwave agent

ActiveUS20200080021A1Rapidly and evenly heatRapidly and evenly and materialNervous disorderEnergy modified materialsVegetable oilPhysical chemistry

Various aspects of the disclosure relate to methods and systems for extracting plant oil from plant material. A system may comprise a microwave emitter, an extraction chamber, and a cooling chamber. Microwave radiation emitted by the microwave emitter may dielectrically heat a microwave absorbing agent, which may heat the plant oil of the plant material. Plant oil of the plant material may be volatized in the extraction chamber and may be directed into the cooling chamber to be condensed.

Owner:NATURAL EXTRACTION SYST LLC

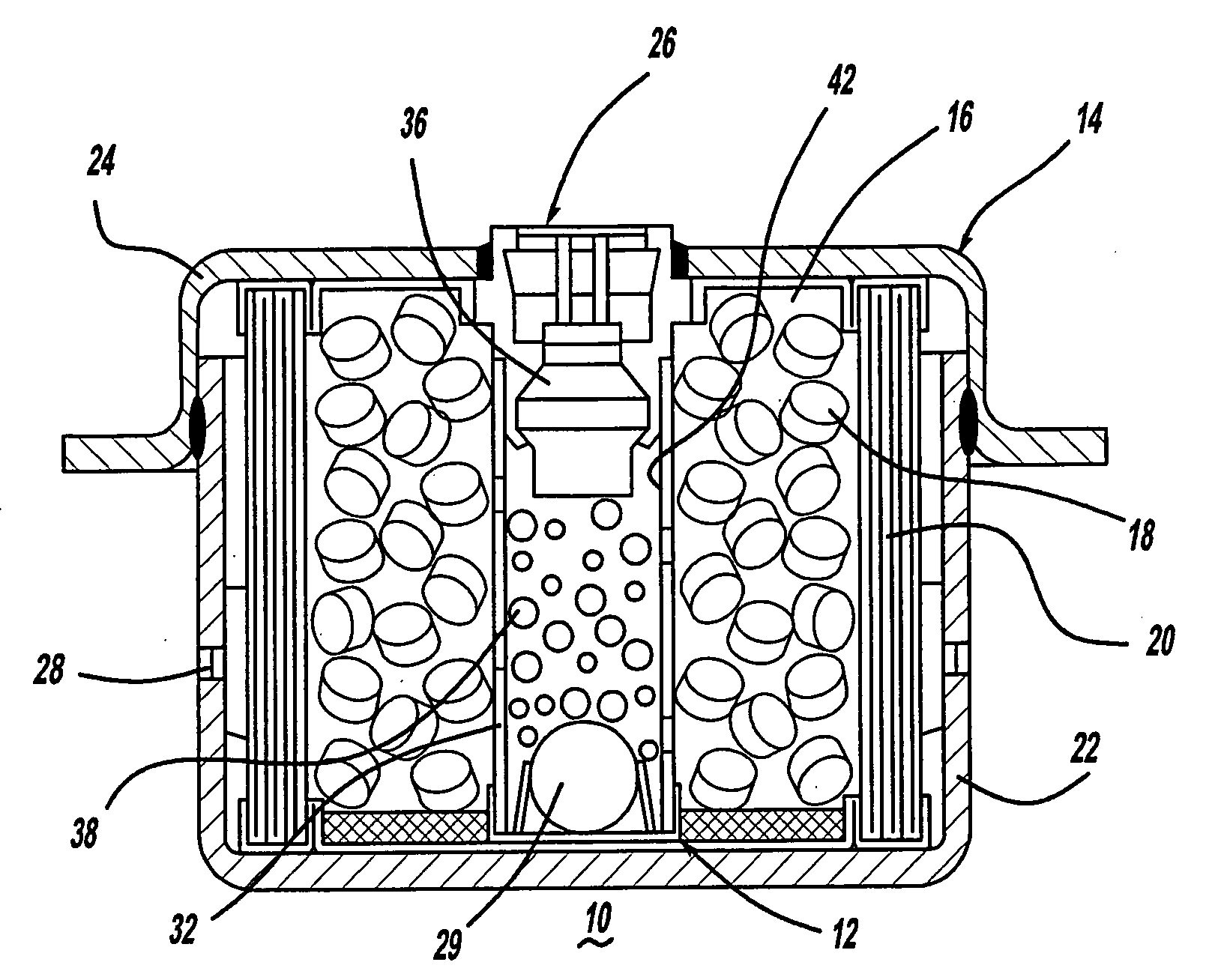

Inflator with an auto-ignition cradle

InactiveUS20080122207A1Facilitates assured contactHeating evenly and quicklyPedestrian/occupant safety arrangementAuto ignitionAerospace engineering

A gas generating system includes an inflator that contains an auto-ignition cradle containing an auto-ignition composition. The cradle operatively and thermodynamically communicates with the exterior of the inflator and also resiliently contains the auto-ignition composition, thereby maximizing the ignitability of the auto-ignition composition in the event of a fire.

Owner:TK HLDG

Method for modifying ZSM-5 zeolite material

ActiveCN102874841AMesoporous specific surface area is highMesoporous structure intactPentasil aluminosilicate zeoliteMicrowaveOrganic solvent

The invention discloses a method for modifying a ZSM-5 zeolite material. The method comprises the following steps of: mixing an alkaline solution, an organic solvent and ZSM-5 zeolite in a certain ratio, and performing microwave treatment; and performing acid treatment, separating, washing and drying to obtain the mesopore-micropore ZSM-5 zeolite. By the method, the ZSM-5 zeolite is subjected to microwave treatment in the existence of the organic solvent and the alkaline solution, so that formation of mesopores can be promoted, and micropores are efficiently converted into the mesopores and can be stabilized and protected; amorphous aluminum in a pore channel of a zeolite crystal can be eluted in the subsequent acid treatment process, so that aims of dredging the pore channel and increasing the total specific surface area are fulfilled; and the relatively complete micropores can be reserved in the ZSM-5 zeolite, a plurality of mesopores are provided, and simultaneously, the total Brunauer, Emmett and Teller (BET) specific surface area can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

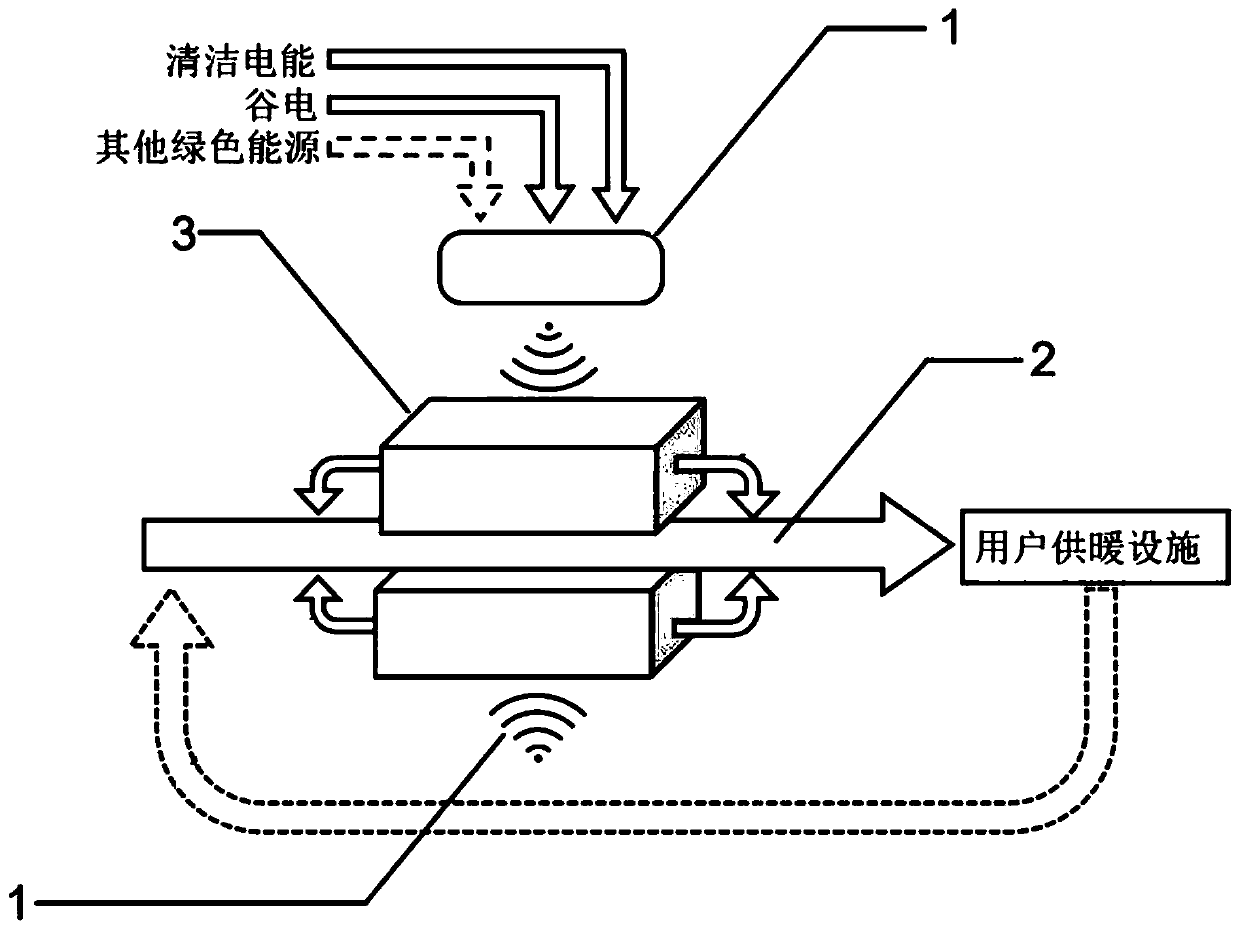

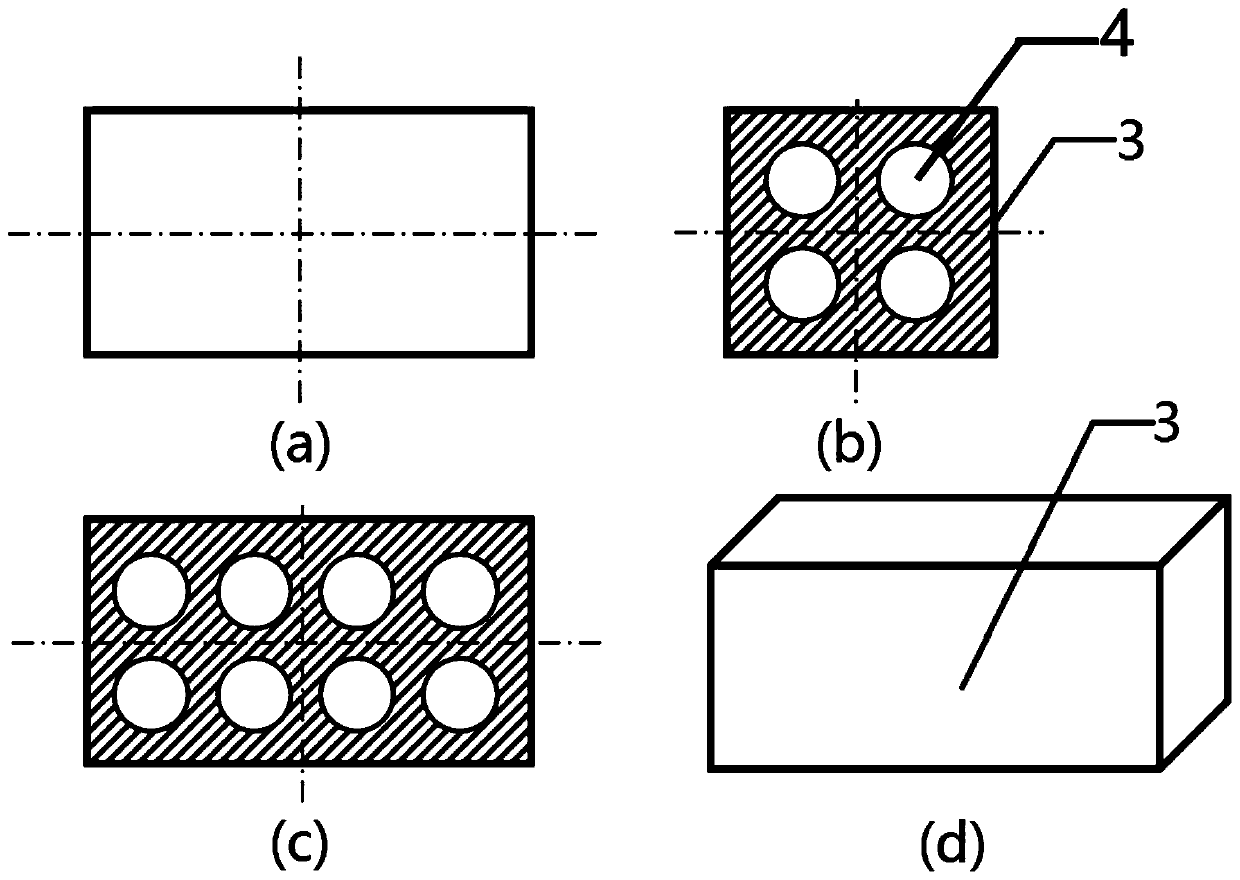

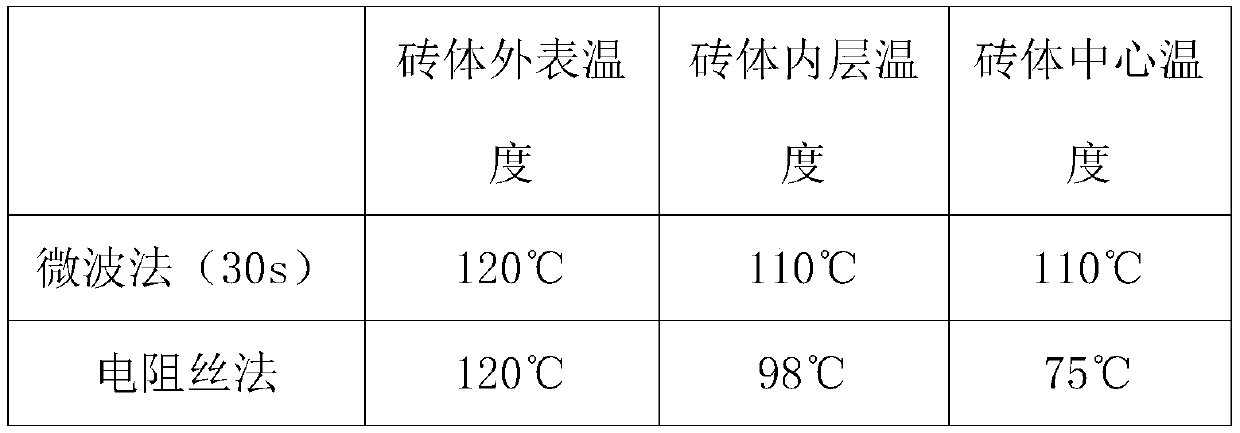

Composite material based on microwave heating, heat storage system and operation method thereof

InactiveCN110345542ASmall heating is convenientLow costCentral heating with accumulated heatHeat storage plantsElectricityMicrowave

The invention discloses a composite material based on microwave heating, a heat storage system and an operation method thereof. The composite material comprises a heat storage phase change material and a wave absorption material, wherein the mass ratio of the heat storage phase change material to the wave absorption material is 1 to (0.01-0.02); the heat storage phase change material and the waveabsorption material are heated, melted or mixed to prepare the composite material; and heat storage temperature of the composite material heated by microwave is 91-607 DEG C. According to the heat storage system, new energy or off-peak electricity is used for supplying power to a microwave system; the microwave environment is used for heating the composite material and storing heat; the heated heat is supplied to user sides through circulation heating water; the heat storage system is green and environmentally friendly, is low in cost and rapid in heat storage, and is taken as an extremely promising new mechanism.

Owner:XI AN JIAOTONG UNIV

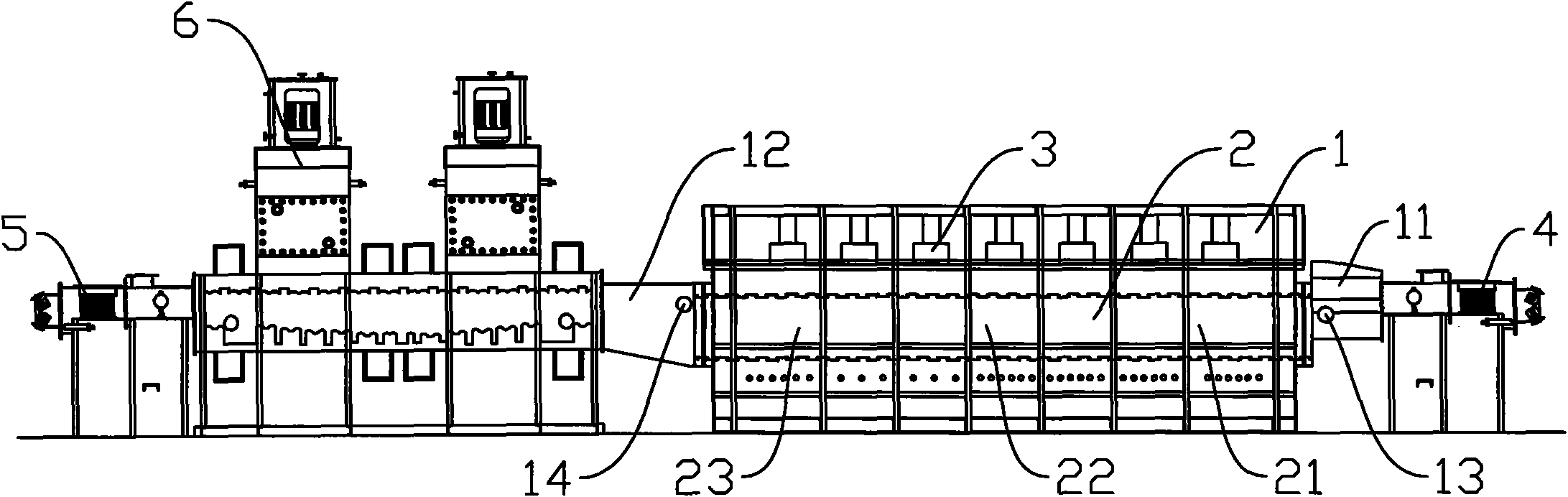

Continuous annealing furnace

InactiveCN101914736AFast heatingHeating evenlyFurnace typesHeat treatment furnacesHearthContinuous annealing

The invention discloses a continuous annealing furnace, which comprises a furnace body, wherein a feed inlet is arranged on the front end of the furnace body; a discharge opening is arranged on the rear end of the furnace body; a hearth in which material strips are heated is formed in the furnace body; when the furnace operates, the hearth is filled with a protective atmosphere; the front end of the hearth is provided with a tension roll I; the rear end of the hearth is provided with a tension roll II; a circulating fan assembly is arranged on the furnace body; and under the tension actions of the tension roll I and the tension roll I, the material strips floats when blown by high-speed air flow blown out by the circulating fan assembly. The furnace is simple and practical; and the furnace has the advantages of high heating speed, high efficiency, uniform heating temperature, fine grains, easily-controllable performance, complete surface, high equipment automation and the like, so demands of domestic and overseas markets can be satisfied and China-made continuous annealing furnace equipment can be realized.

Owner:ZHEJIANG HAODA IND FURNACE

Cooking method

InactiveUS20180177339A1Heating evenly and quicklyGood effectCooking vessel constructionsAdditive ingredientBarrel Shaped

The present invention provides a cooking method, comprising the following steps:(1) feeding cooking ingredients into a barrel-shaped pot body;(2) controlling the pot body to rotate at a first rotating speed which is lower than a critical rotating speed and which enables cooking ingredients to, driven by the pot body, rotatingly ascend and then fall down; wherein the cooking ingredients are controlled to rotate, along with the pot body(3) controlling the pot body to rotate at a second rotating speed which is greater than or equal to a critical rotating speed, enabling cooking ingredients to attach to the pot body and rotate along with the pot body and then fall down.The cooking method of the present invention not only achieves rapid and uniform heating of cooking ingredients, but also effectively improves cooking productivity.

Owner:HUA XIAOLING

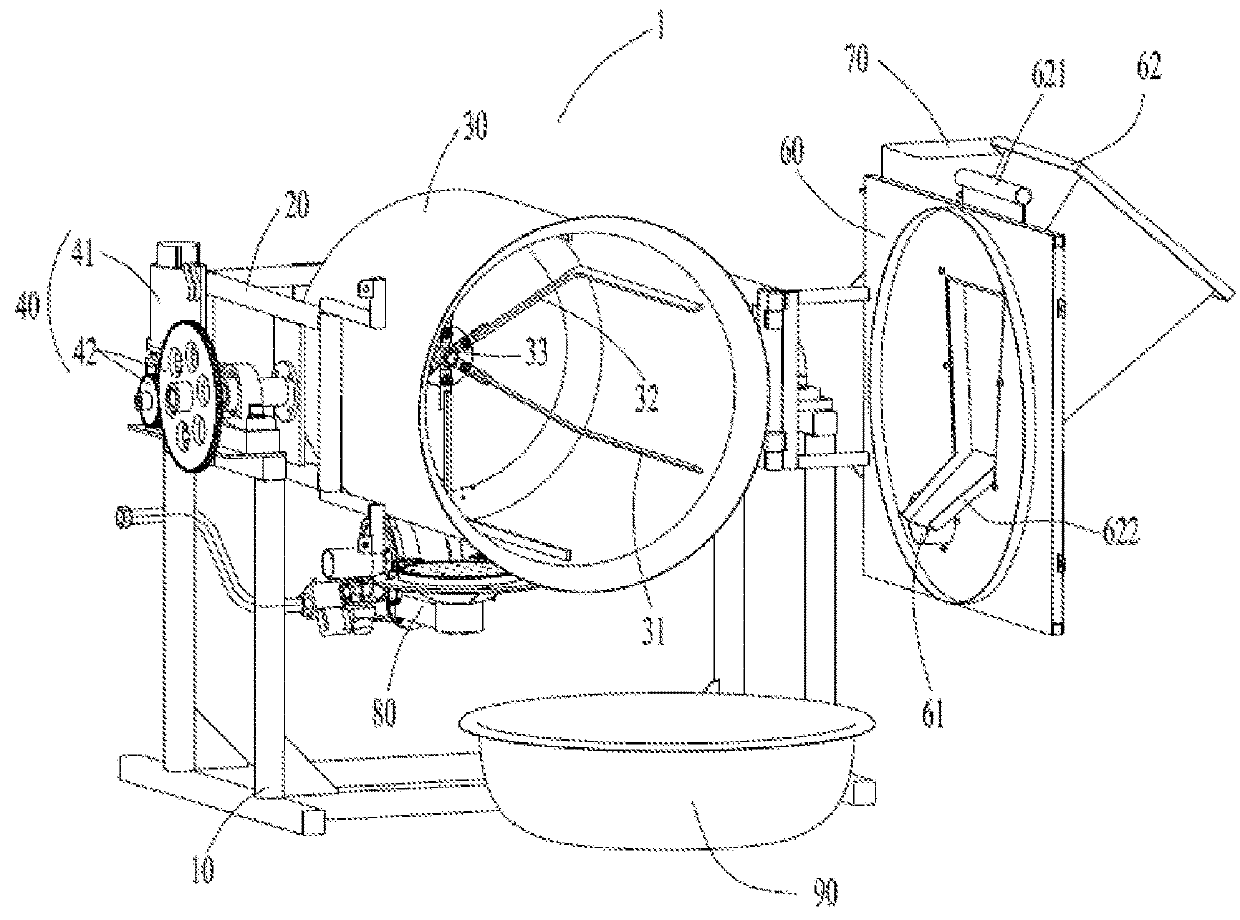

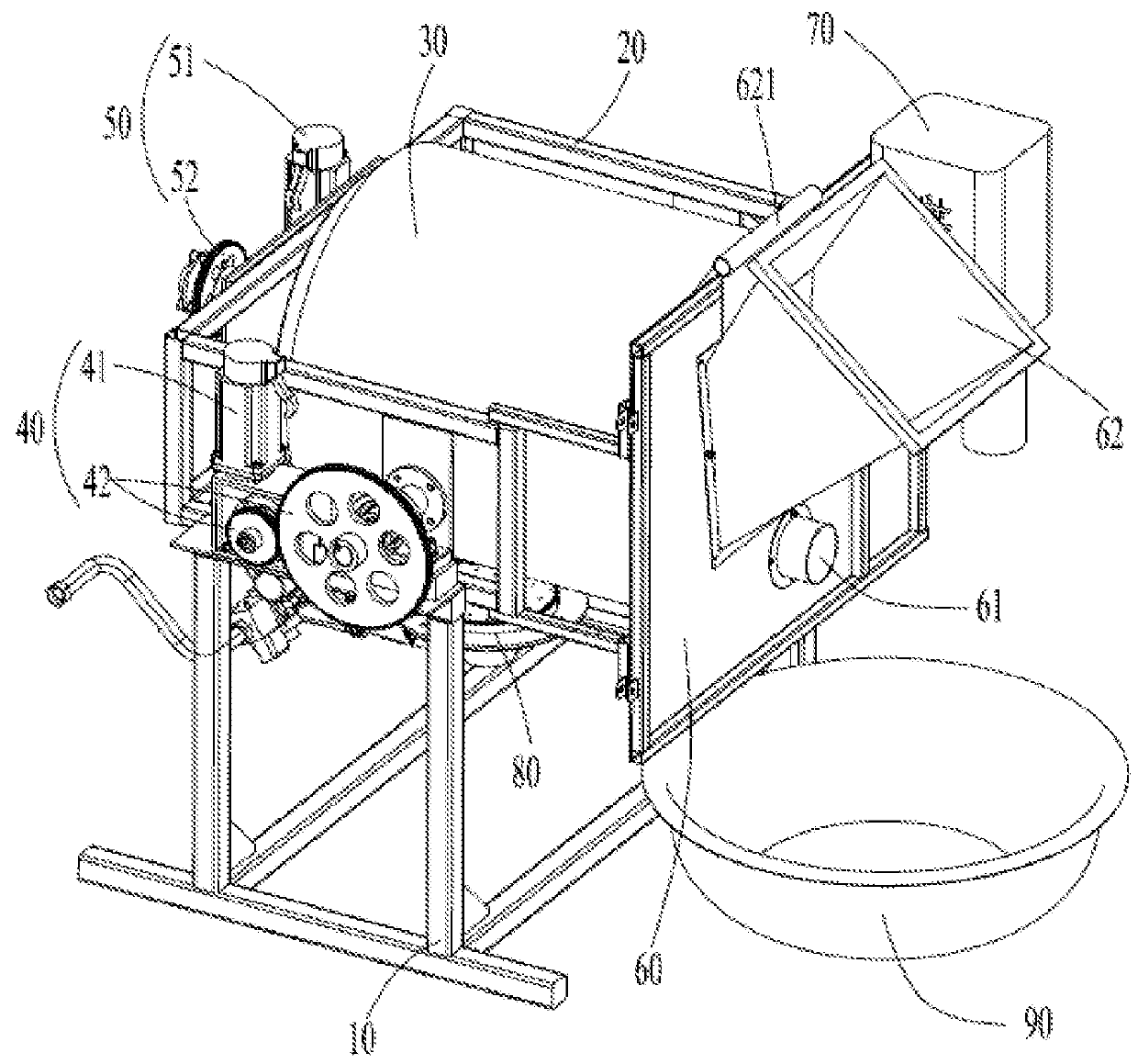

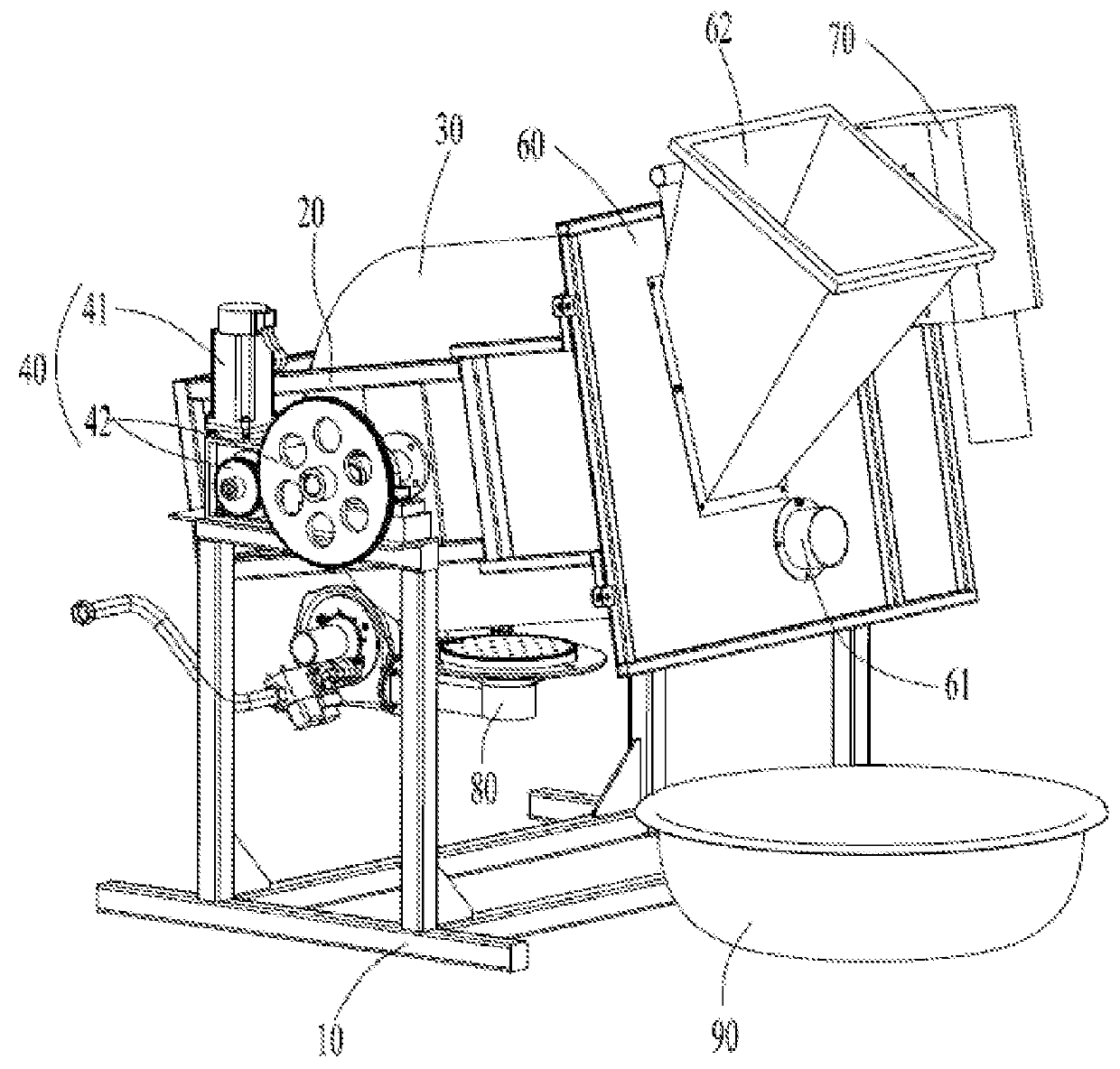

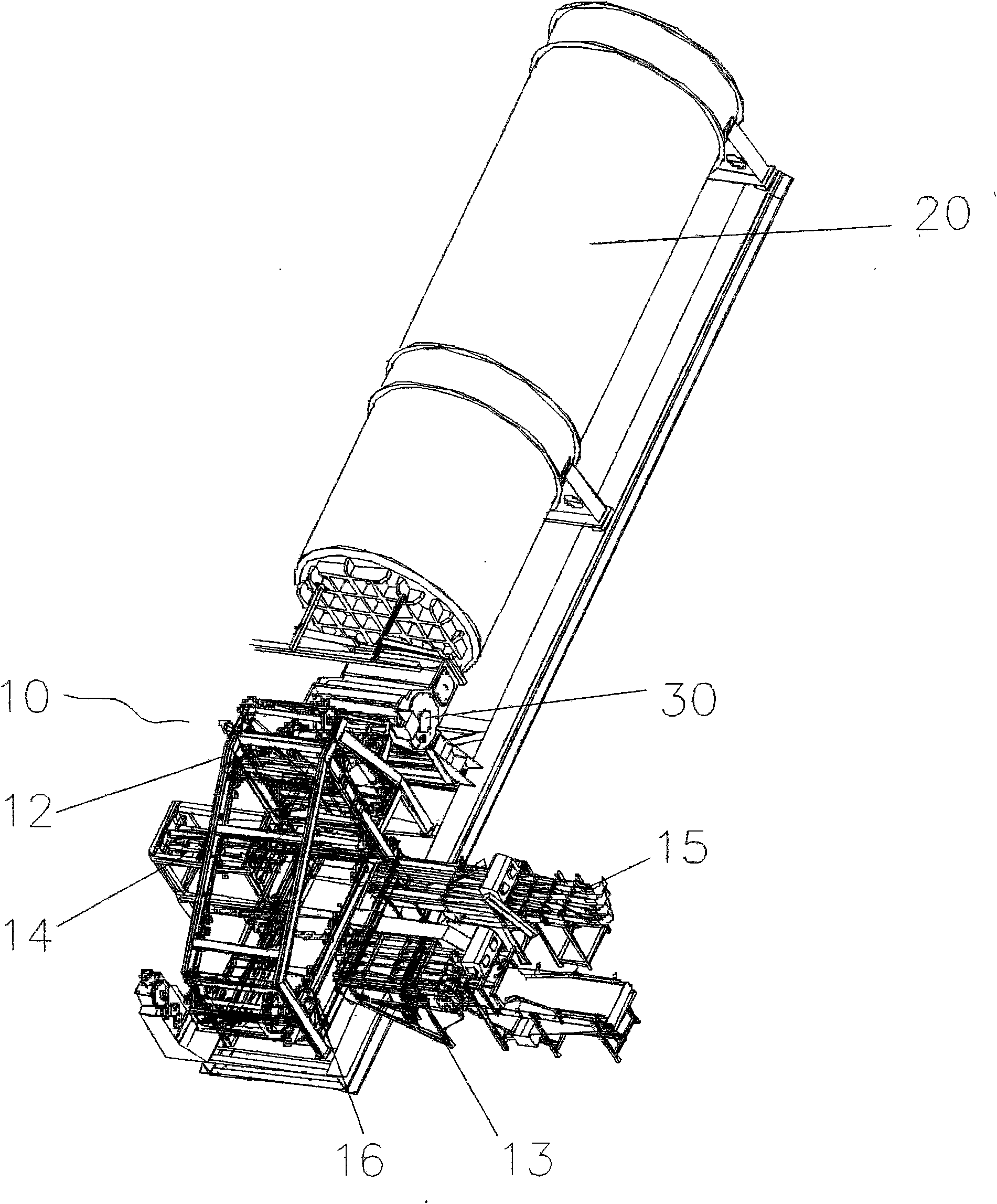

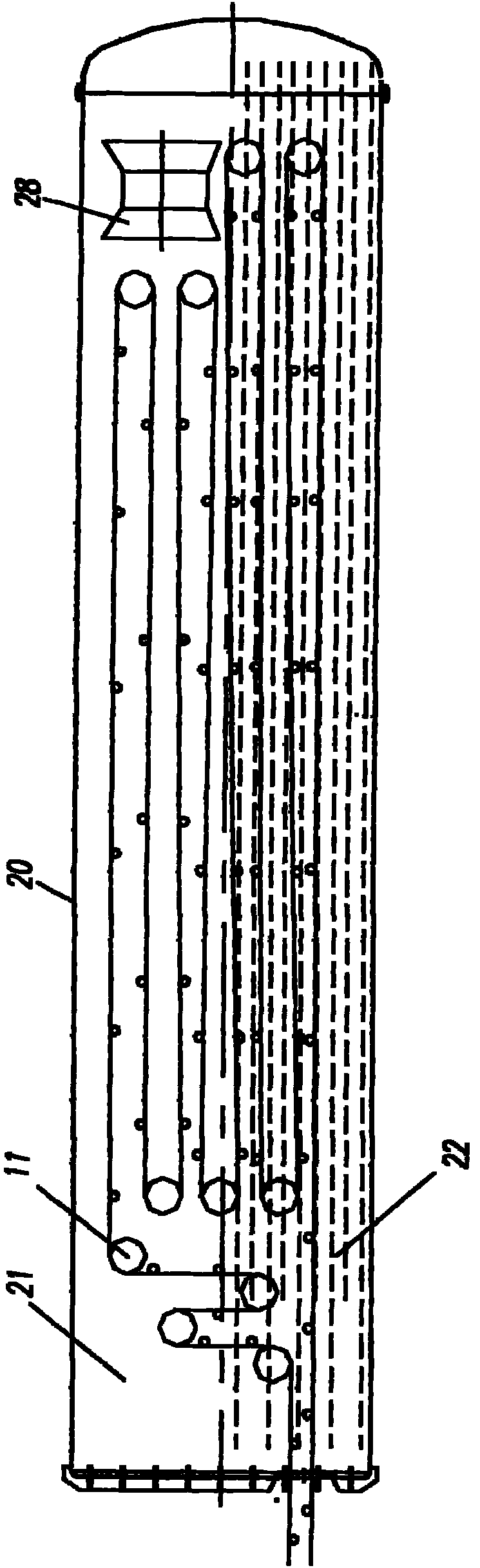

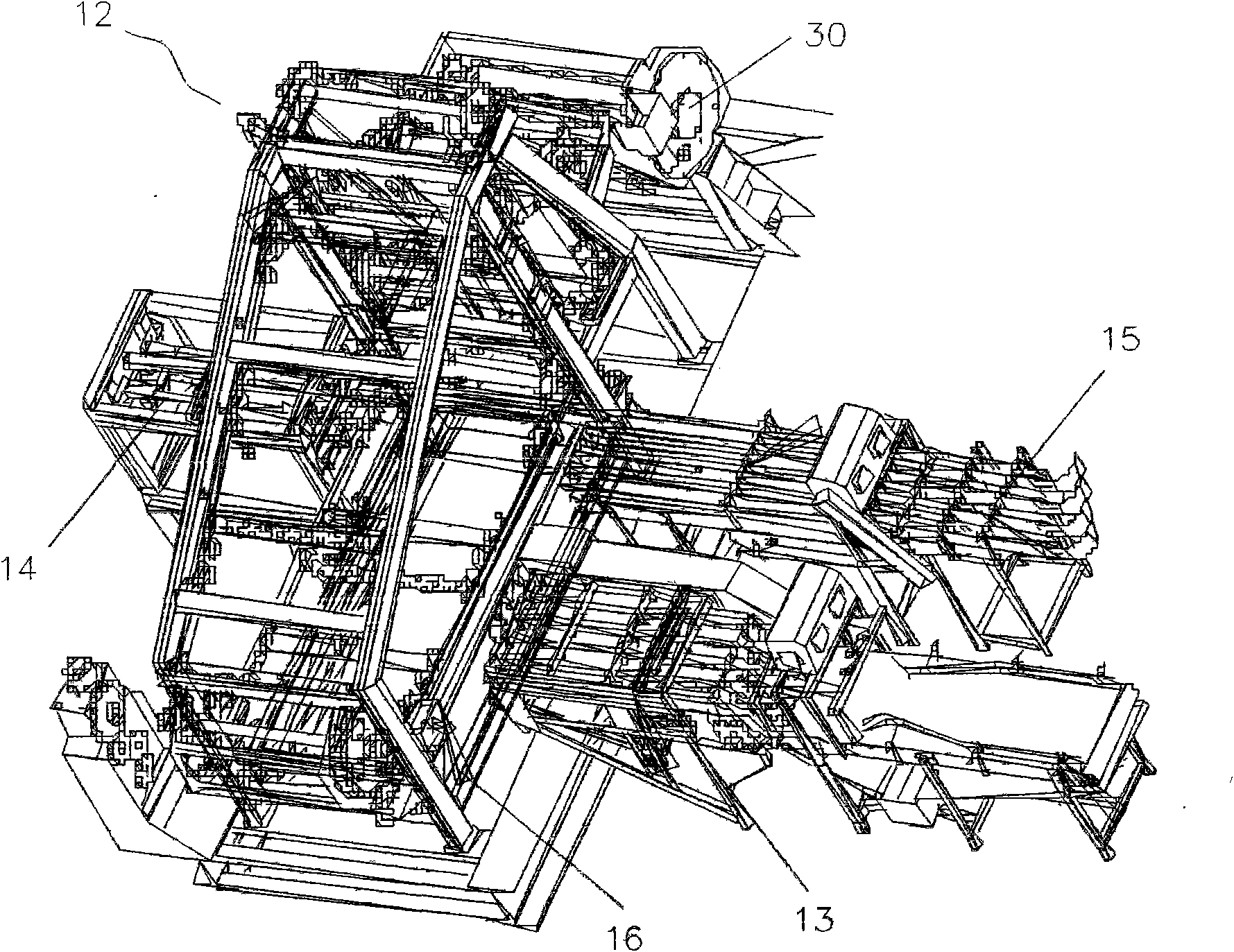

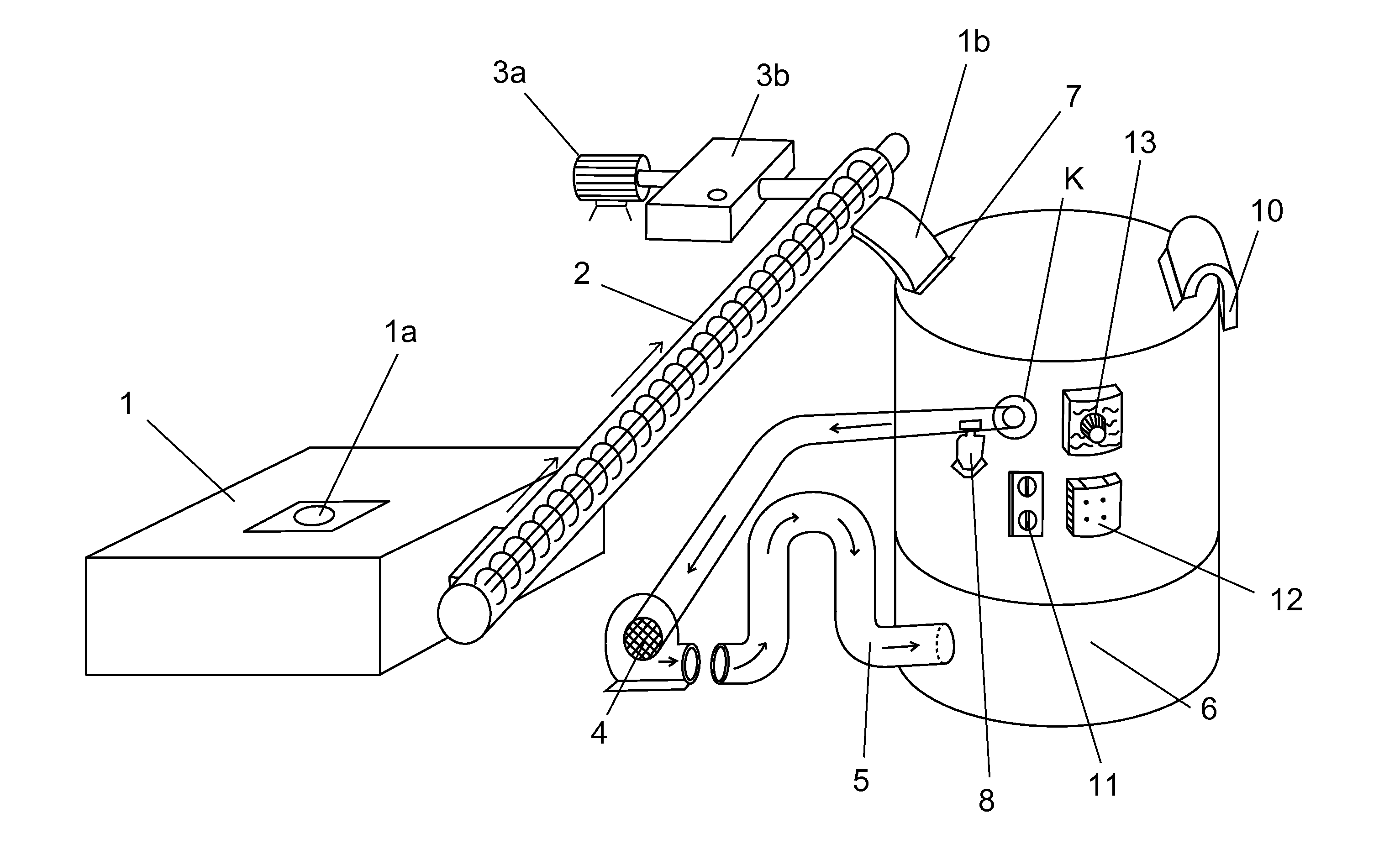

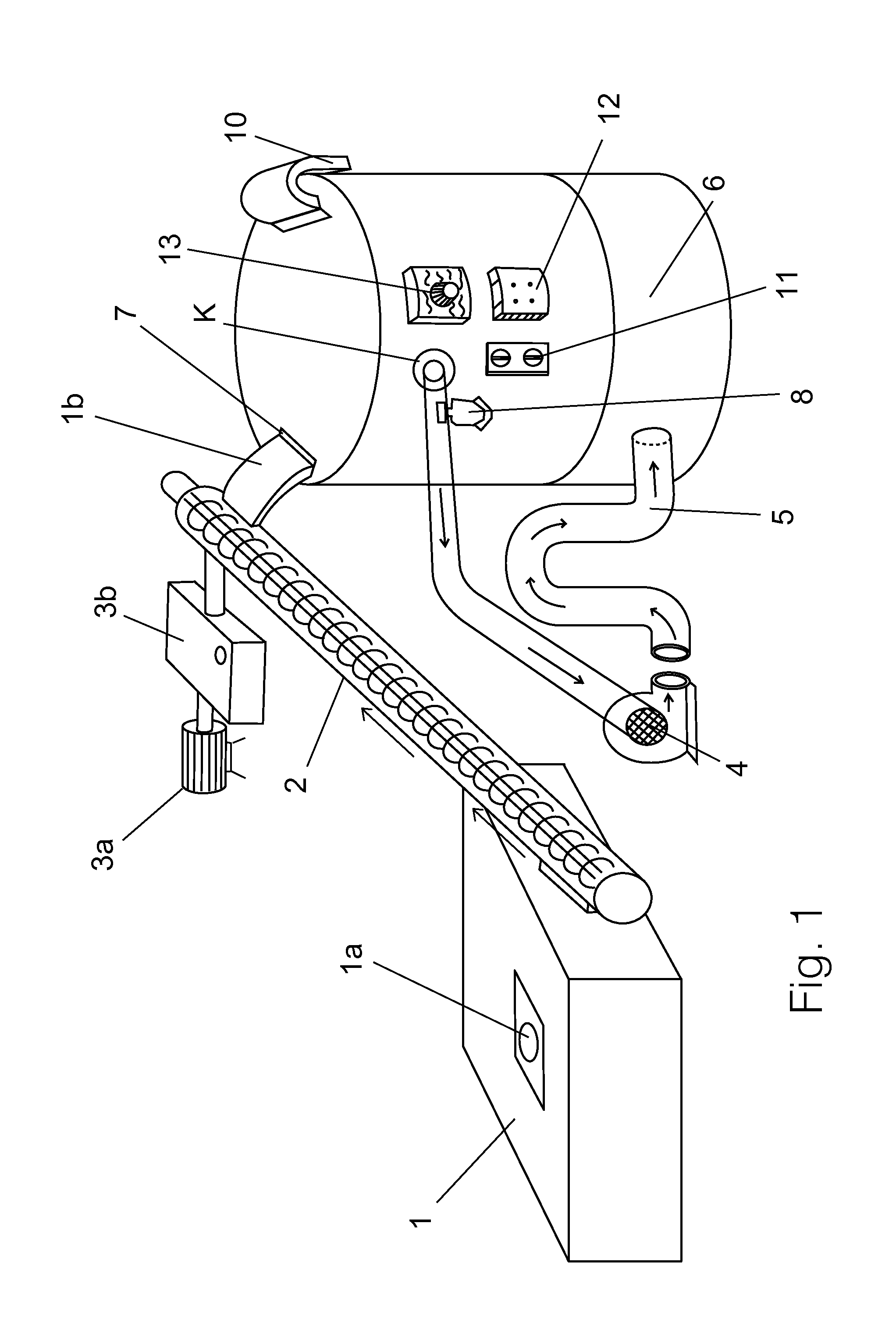

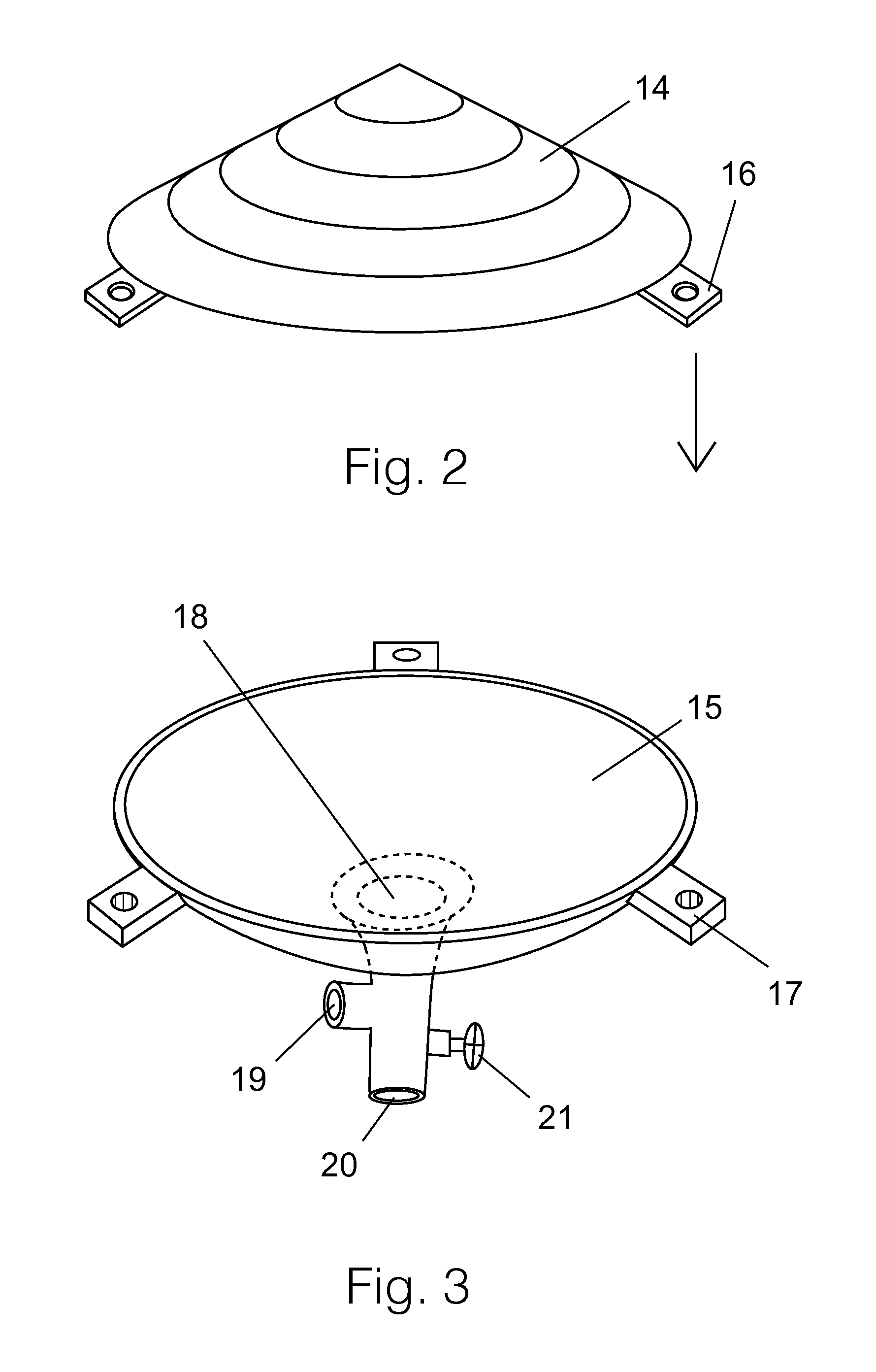

Organic waste cracking and fractionating device and method

InactiveCN102776016AEvenly heatedGood raw material adaptabilityLiquid hydrocarbon mixture productionProduct gasEnergy consumption

The invention discloses an organic waste cracking and fractionating device and method. The organic waste cracking and fractionating device comprises a feeding device (1), a rotational cracking furnace (2), a gas-solid separator (4), a rectifying tower (5), a built-in condenser (6), a condenser (7), a receiving tank (8) and a combustible gas liquid sealing tank (9). The organic waste cracking and fractionating method comprises the following steps of: feeding organic waste into the rotational cracking furnace (2), recycling gas carbon residue after thermal cracking, separating solids such as charcoal by virtue of a discharging bin, feeding gas of the gas-solid separator (4) into the rectifying tower (5), feeding the gas into the receiving tank (8), and feeding non-condensable into a combustion system. The organic waste cracking and fractionating device and method disclosed by the invention have the advantages that raw materials are not required to be smashed, no fine screening is required, a guarantee that the raw materials are uniformly heated and quickly cracked is realized, noneffective condensation reaction is reduced, the energy consumption is reduced, the raw fuel stock refining process is simplified, and an oil product has the advantages of good colour and lustre and high added value.

Owner:河南星火生物能源有限公司

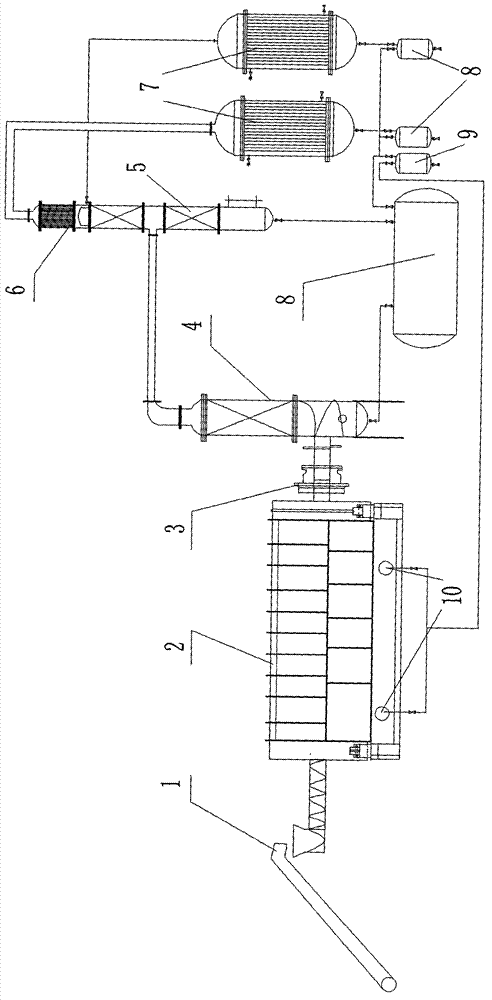

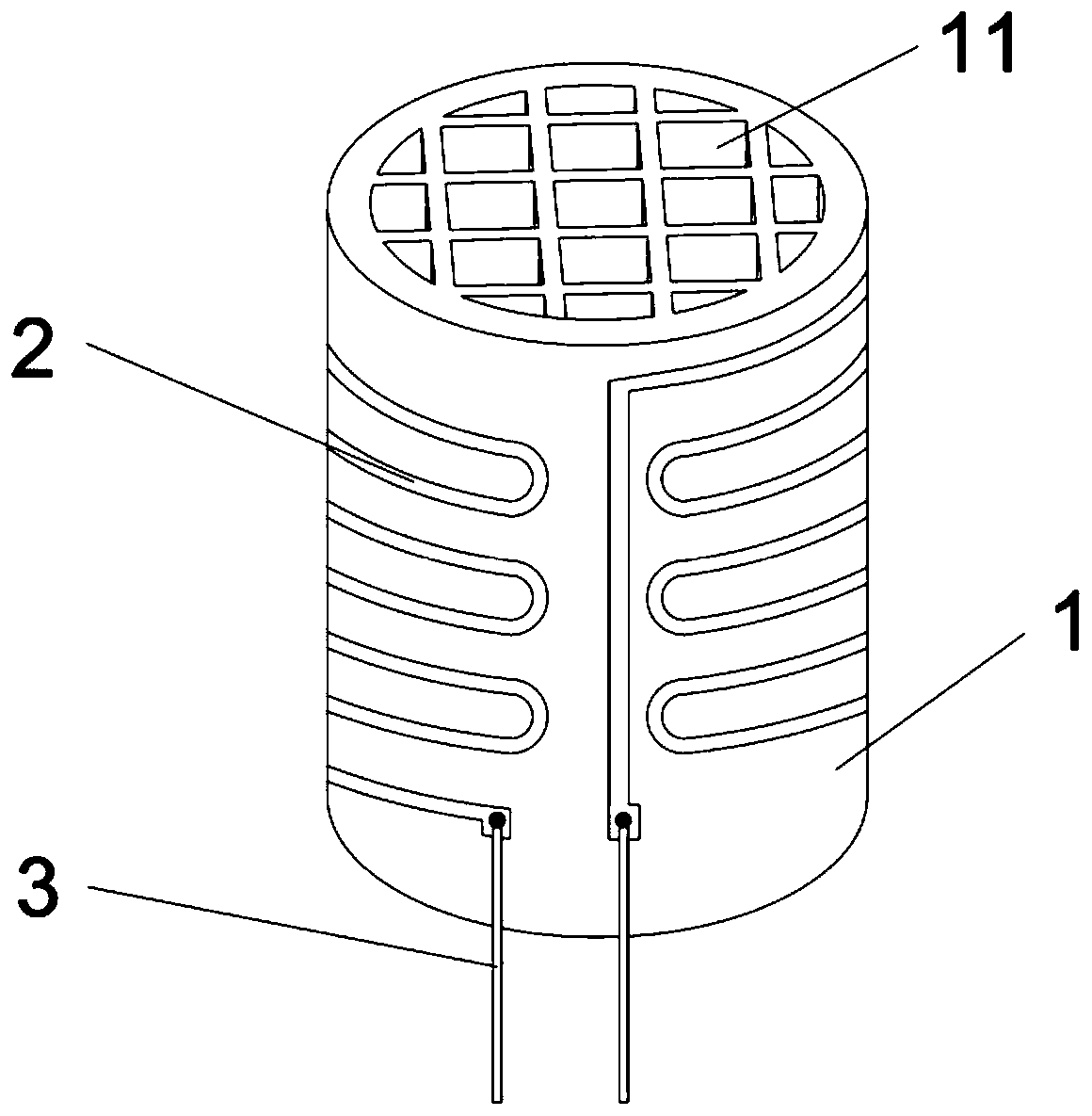

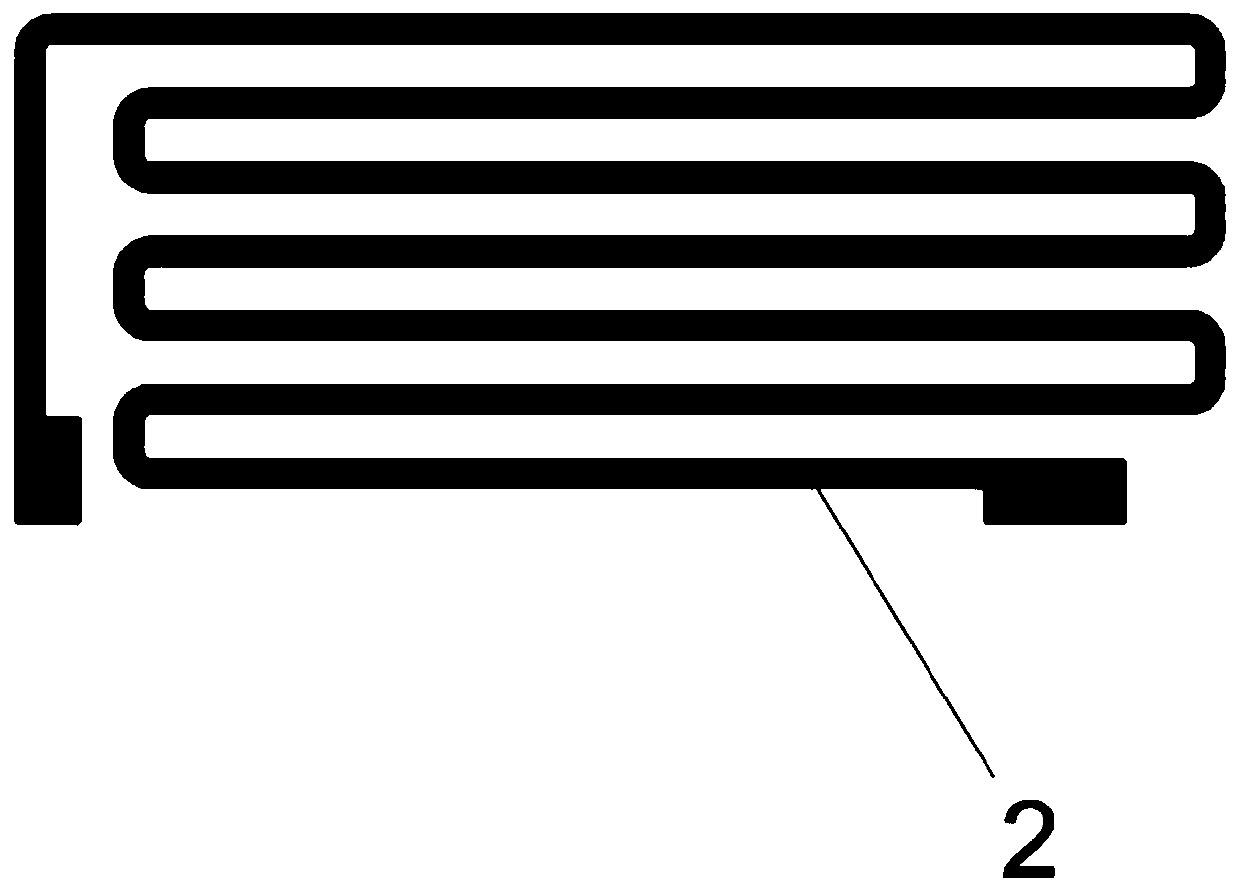

Aluminum oxide honeycomb ceramic heating element and preparation method thereof

ActiveCN110022622AImprove thermal conductivitySmall wall thicknessTobacco devicesHeating element materialsHigh heatAluminium oxide

The invention provides an aluminum oxide honeycomb ceramic heating element and a preparation method thereof. The aluminum oxide honeycomb ceramic heating element comprises an aluminum oxide honeycombceramic, a heating printed circuit and wires, wherein the heating printed circuit is arranged around the outer surface of the aluminum oxide honeycomb ceramic; and the front and tail ends of the heating printed circuit are provided with the wires. The aluminum oxide honeycomb ceramic heating element provided by the invention has good heating efficiency, high heat conduction rate and good compactness, air can be heated quickly, the aluminum oxide honeycomb ceramic heating element is energy-saving and power-saving, and simultaneously, smoke particles cannot be adsorbed, and the aluminum oxide honeycomb ceramic heating element is free of abnormal odor.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

Continuous secondary sterilization machine

InactiveCN101884796AImprove the bactericidal effectRapid sterilizationFood preservationLavatory sanitoryEngineeringAutomation

The invention discloses a continuous secondary sterilization machine, at least comprising a conveying device and a sterilization device. The machine also comprises a water-tightseal device and an external steam circulation system, wherein the water-tightseal device is arranged at the opening of the sterilization device; the conveying device enters and exits the sterilization device through the water-tightseal device; the part of the conveying device, which is positioned inside the sterilization device and carries out continuous conveying is an internal transmission mechanism, and the part of the conveying device, which is positioned outside the sterilization device and carries out clearance halt type conveying, is an outer transmission mechanism; and the external steam circulation system provides sterilizing steam to the inside of the sterilization device. The machine of the invention ensures the secondary sterilization process to be continuous, removes mass heavy manual work, realizes full automation, and greatly improves the production efficiency.

Owner:上海伊本轻工机械有限公司

Microwave Dryer and Microwave Drying Method

InactiveUS20130091722A1Optimal drying resultMinimum energy consumptionDrying solid materials with heatGarbage dryingMicrowavePulp and paper industry

A microwave dryer and a microwave drying method are provided to evaporate water by using the penetrability of microwave. A wind screen (14) arranged in a dryer body (6) is used as a heat storage body to store heat temporarily when the material in the dryer body (6) is heated. Hot air in the dryer body (6) is extracted by an air discharging system and redelivered to the dryer body (6) from the bottom of the dryer. The specific weight of the material after water is evaporated is reduced, so the dried material can be carried out of the dryer body (6) if enough wind power is provided.

Owner:LAM KWOK FAI

Rapid botanical oil distillation device utilizing microwave agent

ActiveUS11021674B2Heating evenly and quicklyNervous disorderEnergy modified materialsVegetable oilPhysical chemistry

Owner:NATURAL EXTRACTION SYST LLC

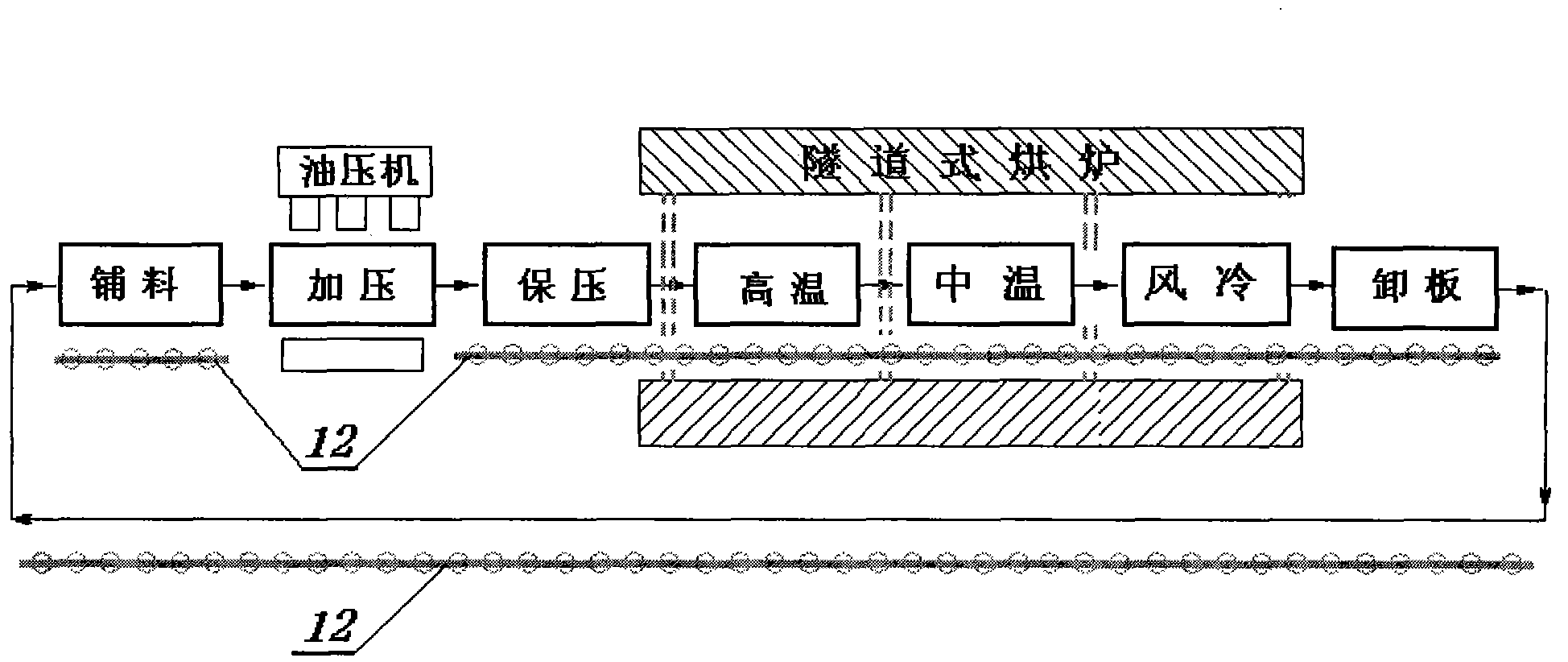

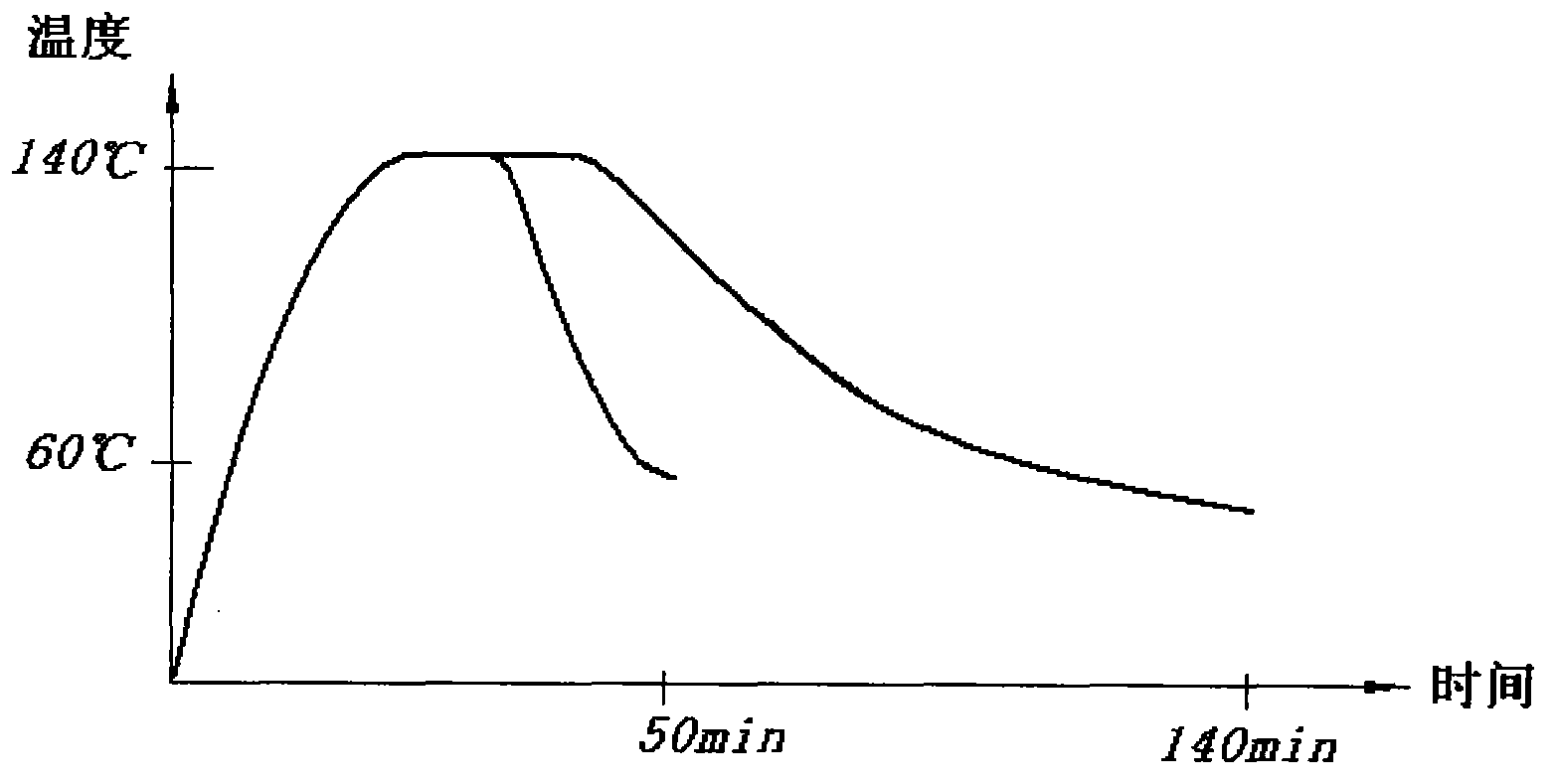

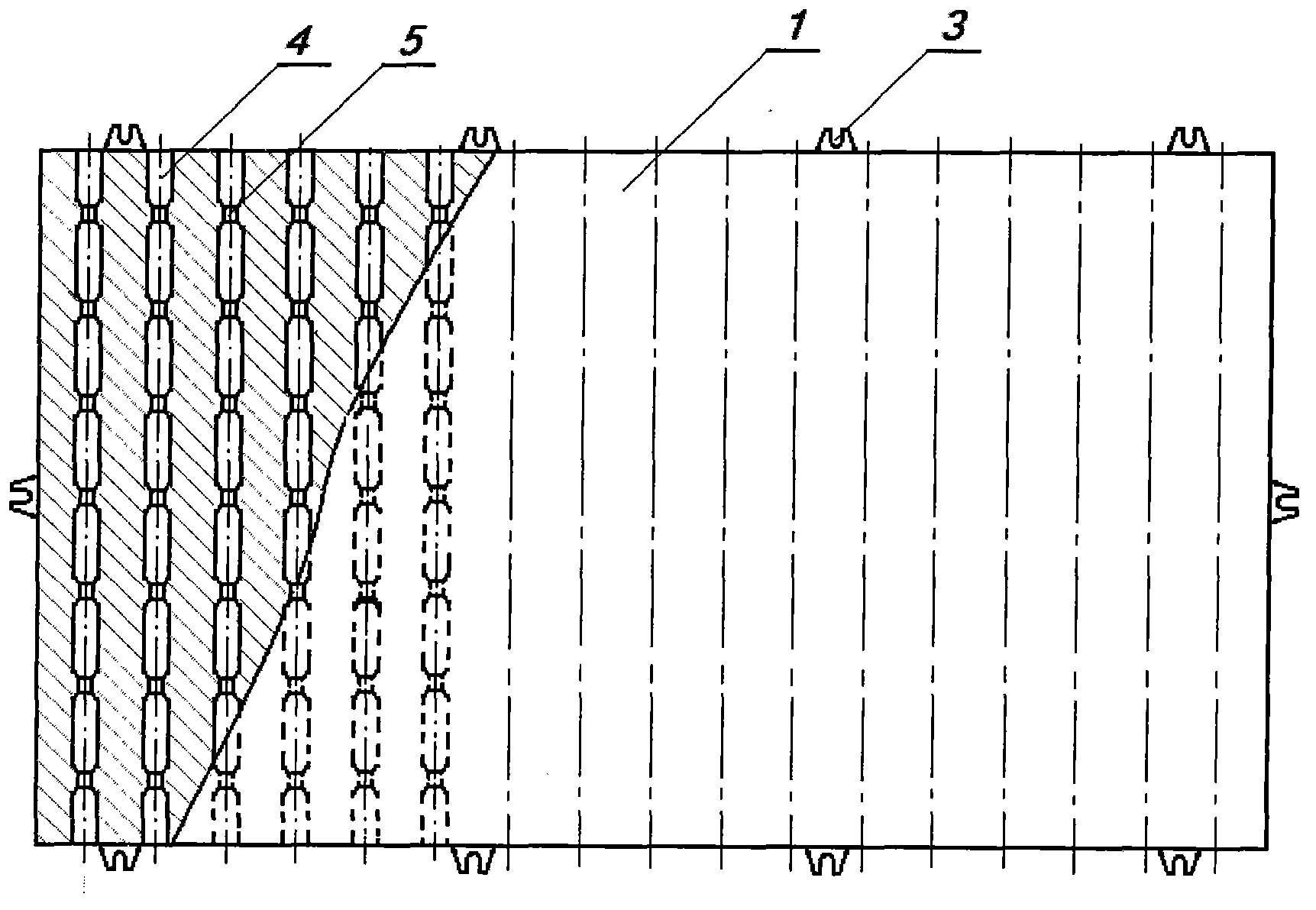

Phenolic resin bamboo plywood manufacturing process

InactiveCN102837349AIncreased deformation resistanceUniform and rapid pressure moldingWood working apparatusFlat articlesDecompositionPhenol formaldehyde resin

The invention provides a novel and continuous phenolic resin bamboo plywood manufacturing process; the preliminary bamboo decomposition and processing as well as unit desugaring and drying and phenolic resin glue application stages are the same with those of a bamboo plywood production process of the prior art, while the pressurization, the formation, the curing, the heating and the pressure maintenance of bamboo plywood materials are carried out on different equipment, wherein the pressurization of the bamboo plywood materials is carried out on a press on which no heat source needs to be fed in; meanwhile, a special clamp is adopted to maintain the pressure; the formation and the curing of the bamboo plywood materials are carried out in a tunnel-type baker; and a roller conveying device continuously conveys the bamboo plywood during a pressure maintenance process, so that the technical practice in the hot pressing and formation and curing stages in the bamboo plywood production is changed with less investment.

Owner:浙江晨峰模板有限公司

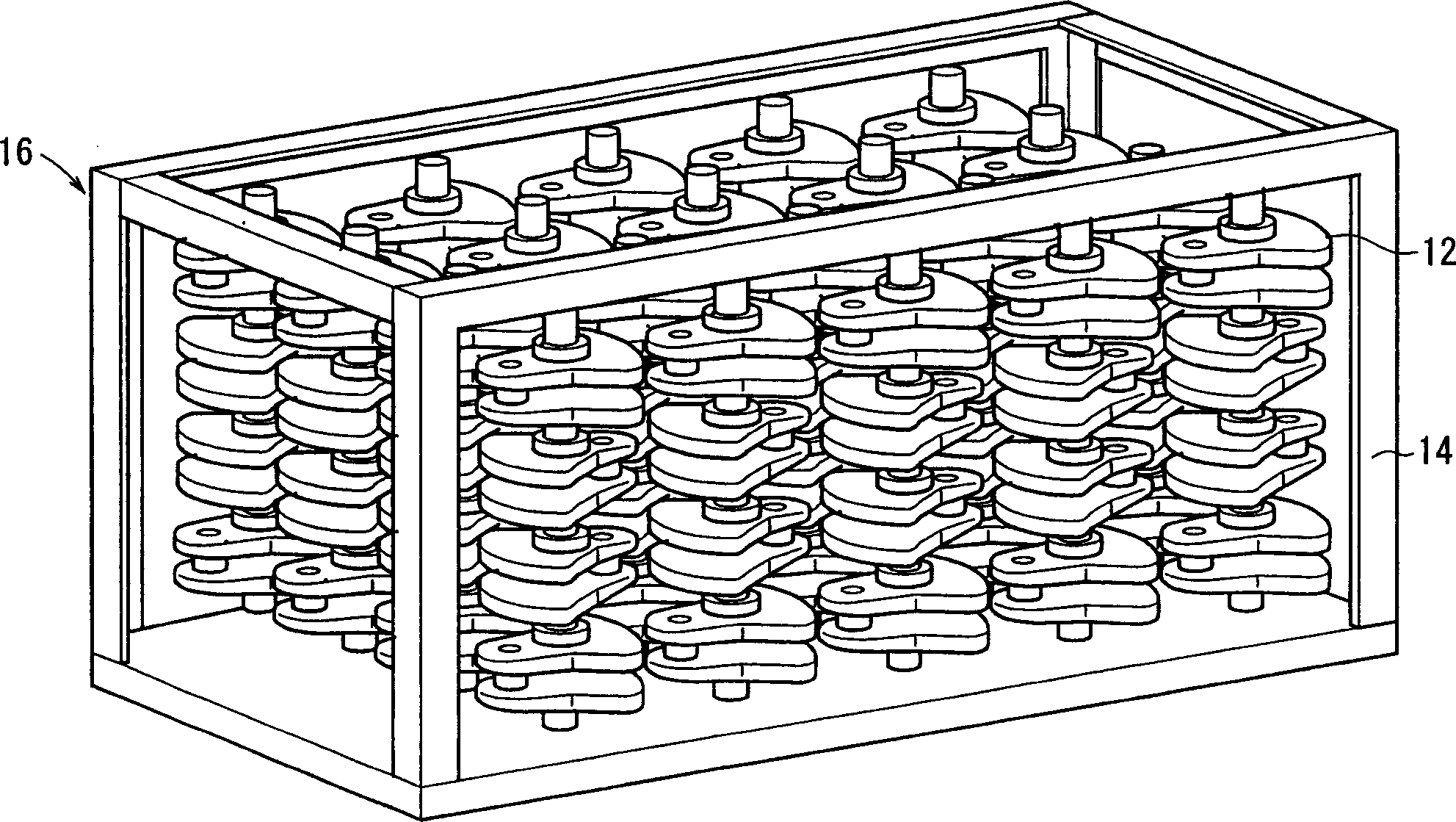

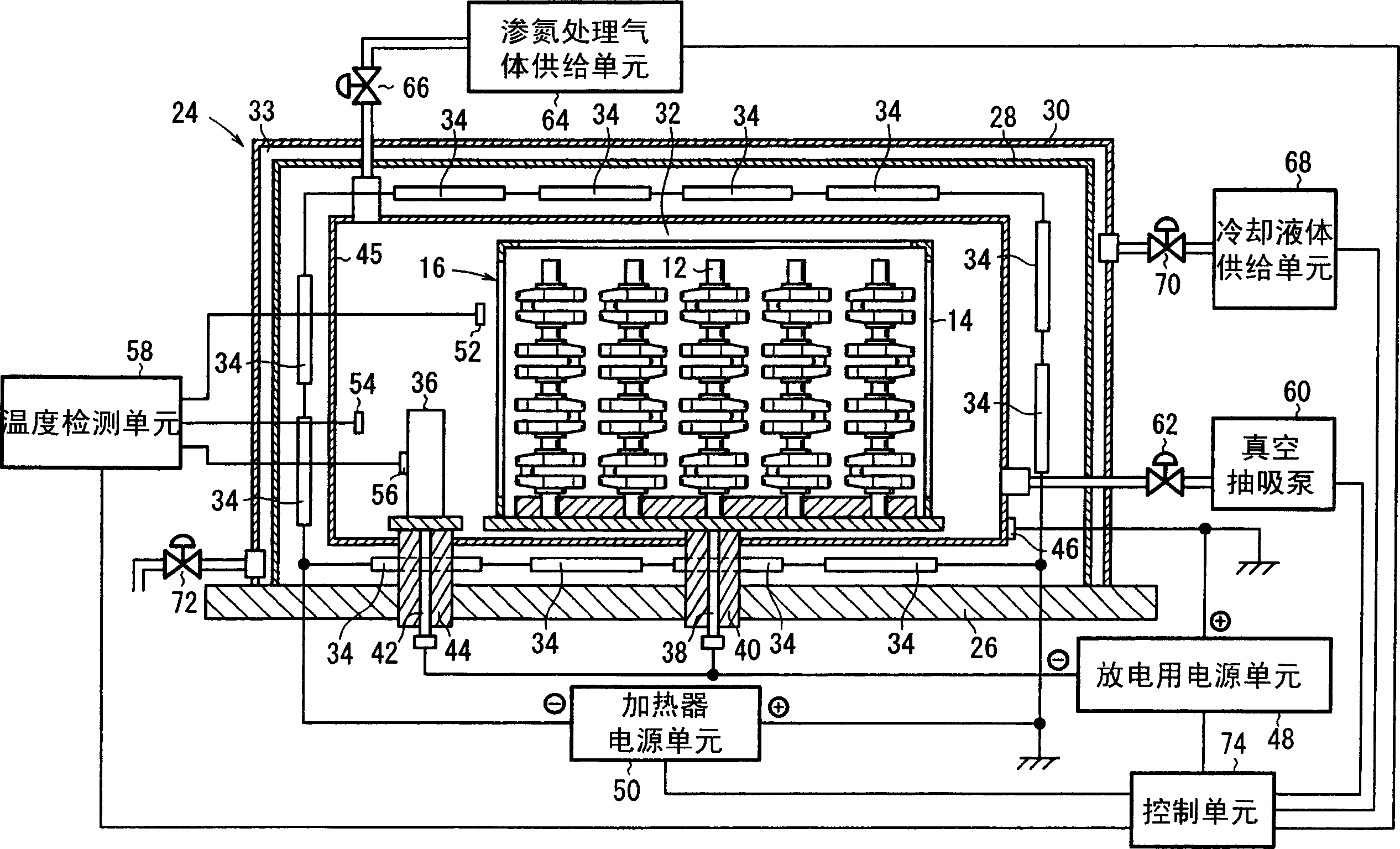

Nitriding method and device

InactiveCN1826422AHeating evenly and quicklyVacuum evaporation coatingSputtering coatingElectricityPulse voltage

A pulse voltage having a frequency of 15 kHz is applied from a discharging power supply unit (48) to between a crankshaft (12) and an electrode plate (45) at a current density of 2.5 mA / cm2 to generate a glow discharge and an electric heater (34) is driven at a 40% output (64 kW / kg) to heat the crankshaft (12) to up to 400 DEG C, and then heating is continued with the current density of a glow discharge set at 0.5 mA / cm2 and the output of the electric heater (34) set at 90% (144 kW / kg), thereby effecting nitriding at a desired nitriding temperature.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com