Aluminum oxide honeycomb ceramic heating element and preparation method thereof

A technology of alumina ceramic tube and honeycomb ceramics, which is applied in the field of electronic cigarettes, can solve the problems that the heating and baking effect is difficult to guarantee, the baking objects are not evenly baked, and the development and popularization are limited, and the heat conduction effect is good, good Effect of thermal conductivity and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

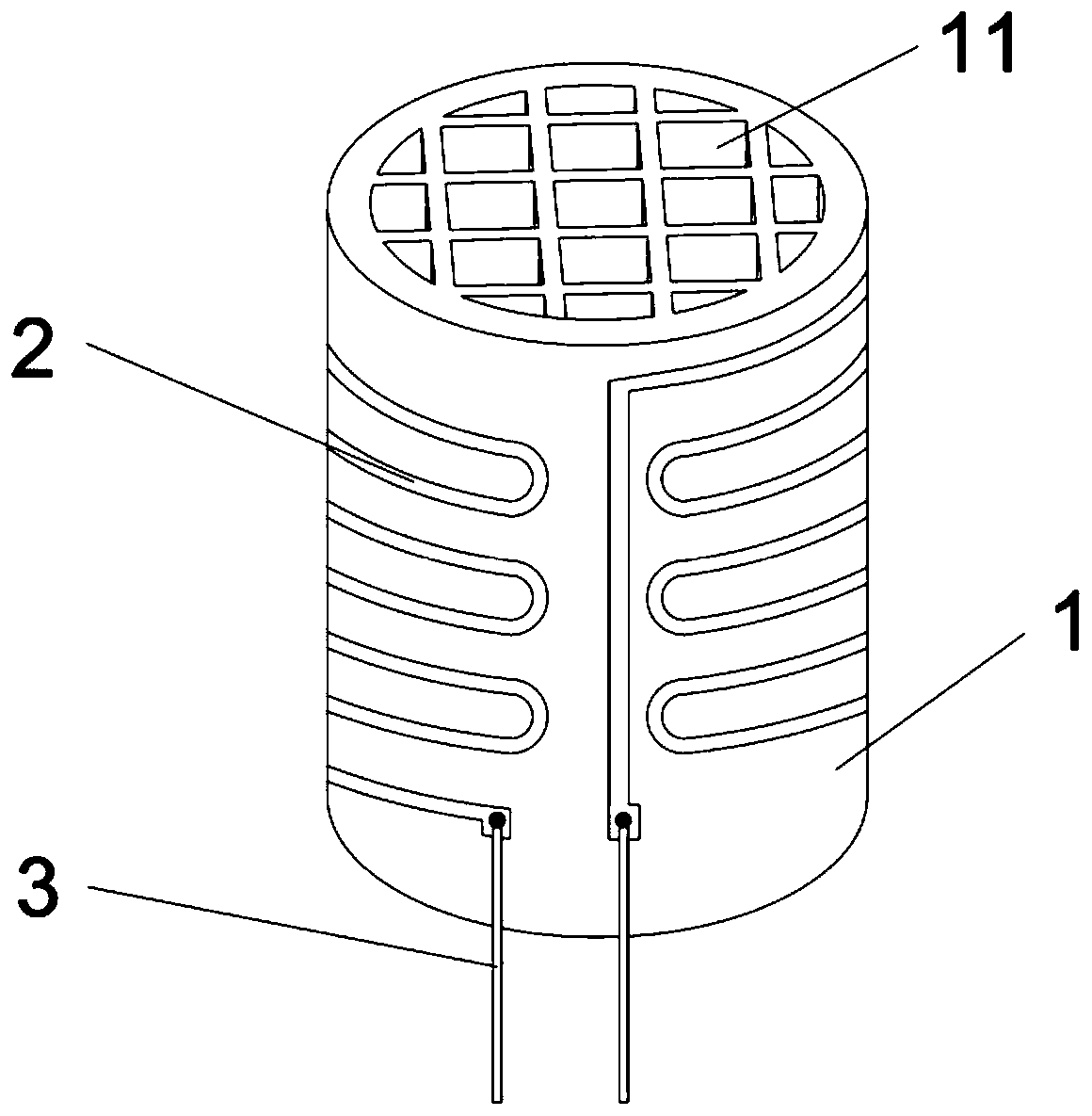

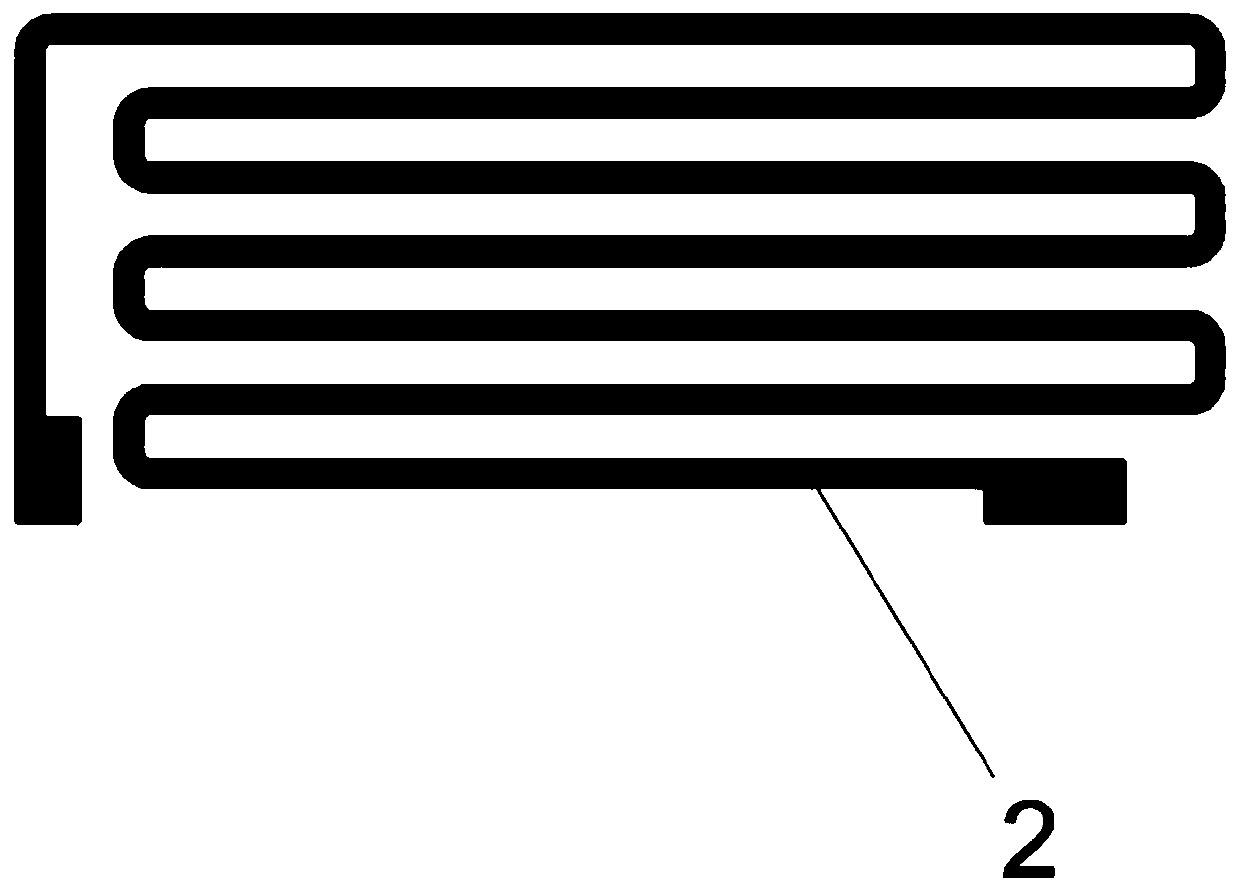

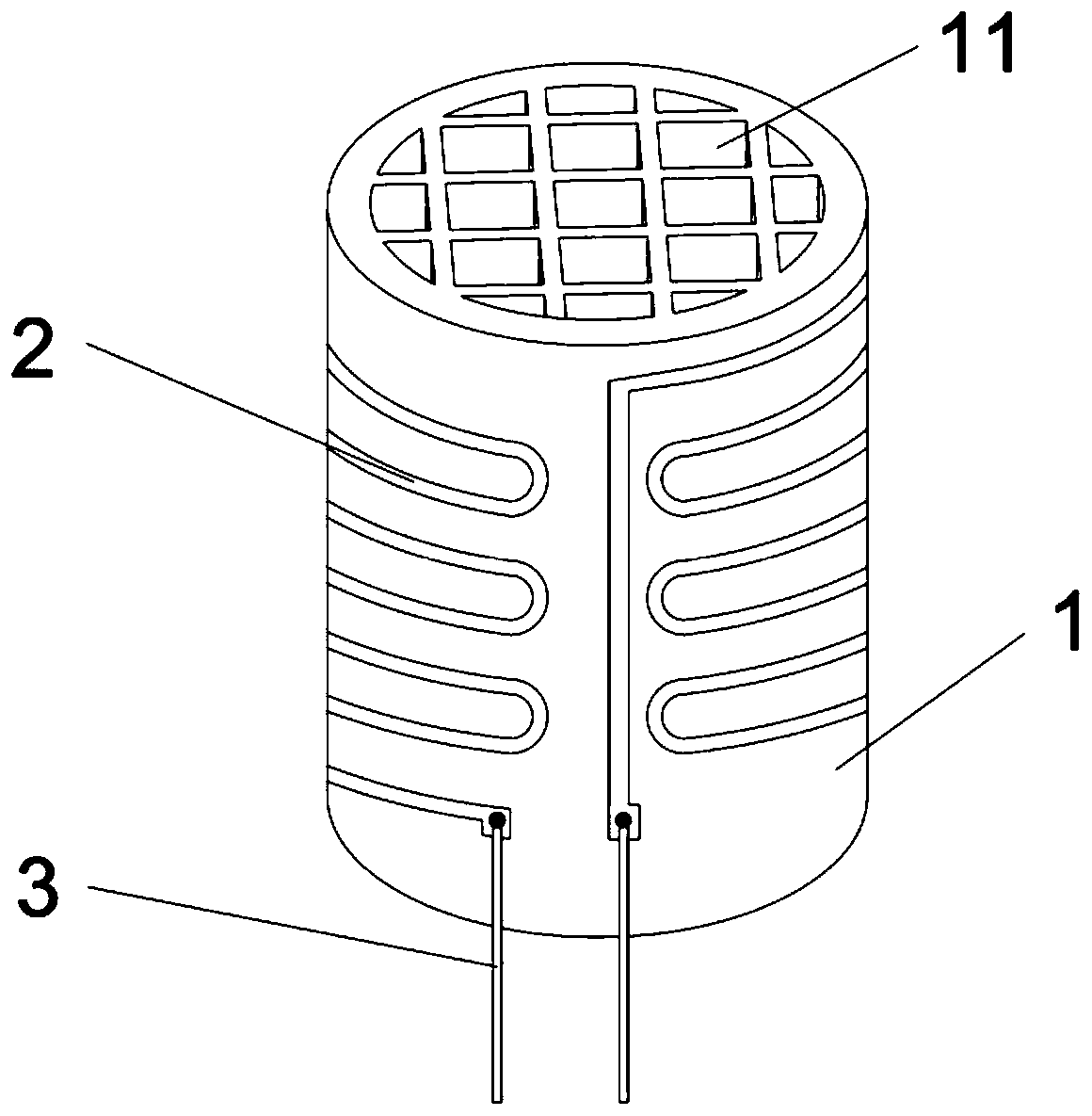

[0040] Such as Figure 1-2 As shown, an alumina honeycomb ceramic heating element and its preparation method are characterized in that: comprising an alumina honeycomb ceramic body 1, a heating printed circuit 2, and a wire 3; the center of the alumina honeycomb ceramic body 1 is provided with a porous channel 11; The heating printed circuit 2 is arranged around the outer surface of the alumina honeycomb ceramic body 1; the first end of the heating printed circuit 2 is provided with a wire 3;

[0041] The preparation method of the alumina honeycomb ceramic heating element comprises the following steps:

[0042] Step 1: Preparation of alumina ceramic tube mud: add in 100 parts by weight of nano-alumina powder, 0.04 parts by weight of Mg(NO 3 ) 2 ·6H 2 O, 0.04 parts by weight ZrOCl 2 ·8H 2 O, 0.01 parts by weight Y (NO 3 ) 3 ·6H 2 O, 2.4 parts by weight of oleic acid, 1.2 parts by weight of polyethylene glycol 600, 14 parts by weight of high-purity ethyl cellulose ether ...

Embodiment 2

[0057] Such as Figure 1-2 As shown, an alumina honeycomb ceramic heating element and its preparation method are characterized in that: comprising an alumina honeycomb ceramic body 1, a heating printed circuit 2, and a wire 3; the center of the alumina honeycomb ceramic body 1 is provided with a porous channel 11; The heating printed circuit 2 is arranged around the outer surface of the alumina honeycomb ceramic body 1; the first end of the heating printed circuit 2 is provided with a wire 3;

[0058] The preparation method of the alumina honeycomb ceramic heating element comprises the following steps:

[0059] Step 1: Preparation of alumina ceramic tube mud: add in 100 parts by weight of nano-alumina powder, 0.02 parts by weight of Mg(NO 3 ) 2 ·6H 2 O, 0.05 parts by weight ZrOCl 2 ·8H 2 O, 0.015 parts by weight Y (NO 3 ) 3 ·6H 2 O, 2 parts by weight of oleic acid, 1.5 parts by weight of polyethylene glycol 600, 8 parts by weight of high-purity ethyl cellulose ether an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com