Preparation method of platinum-transition metal alloy nanometer crystals for fuel cell catalyst

An alloy nanocrystal and transition metal technology, applied in the field of nanomaterials, can solve problems such as low synthesis efficiency, and achieve the effects of shortening the synthesis cycle, accelerating the reaction time, and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing platinum-transition metal alloy nanocrystals for fuel cell catalysts, comprising the steps of:

[0018] S1, dissolving the platinum precursor, transition metal precursor, and benzoic acid in N-N dimethylformamide to form a precursor mixed solution;

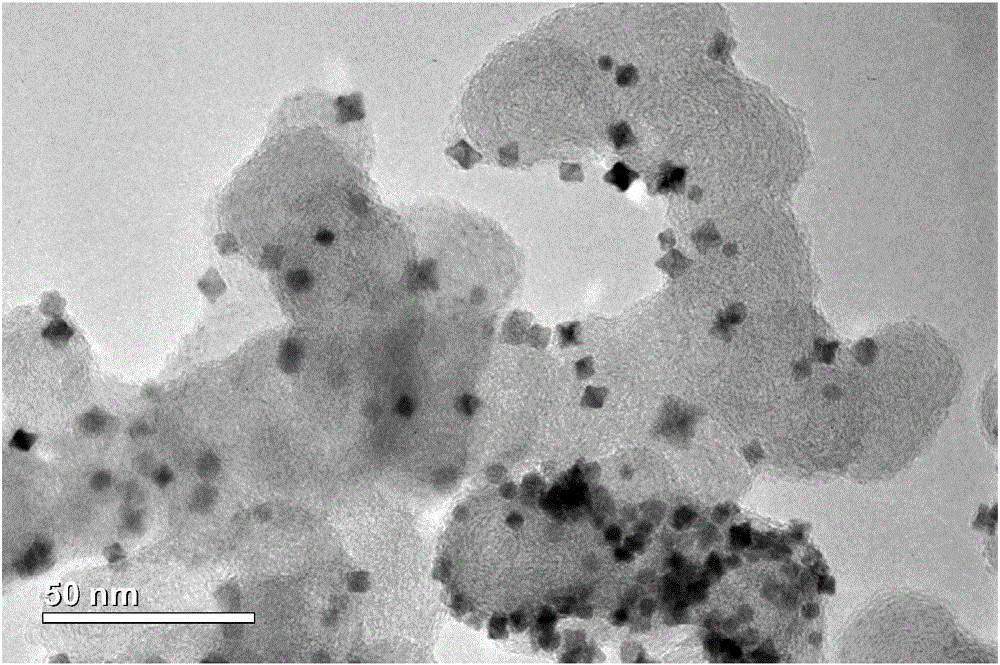

[0019] S2. Place the precursor mixed solution in a microwave electromagnetic field, and after the microwave acts on the precursor mixed solution to uniformly heat and react, an octahedral platinum-transition metal alloy nanocrystal is obtained.

[0020] Microwave is a kind of electric wave with a frequency of 300MHz to 300GHz. It has wave-particle duality, and it can heat objects rapidly, uniformly and selectively. This is because the polar orientation of polar molecules under the action of microwaves changes with the change of the external electric field, resulting in the spin motion effect of polar molecules. At this time, the field energy of the microwave field is converted into the heat energy of ...

Embodiment 1

[0045] Configure the precursor solution: dissolve 31.46 mg of platinum acetylacetonate, 51.38 mg of nickel acetylacetonate and 122 mg of benzoic acid in 20 mL of N-N-dimethylformamide (DMF) at room temperature, and stir well to form a uniform and transparent solution. After the precursor was completely dissolved, 83.7 mg of carbon black (XC 72) was added, and stirred sufficiently at room temperature to form a suspension.

[0046] Microwave heating: Add the above suspension into a 30mL quartz tube, put it into a CEM DISCOVER ring-focused single-mode microwave synthesis system, adjust the parameters until the temperature rises to 120°C, keep it warm for 12h and keep stirring.

[0047] Centrifugation and cleaning: Centrifuge the reaction solution obtained by microwave synthesis at 8000rpm for 10 minutes to obtain platinum-nickel alloy nanocrystals, then wash these nanocrystals in a mixture of water and ethanol three times, and obtain PtNi alloy loaded on carbon black after drying...

Embodiment 2

[0050] Pre-body solution: Dissolve 19.67mg of platinum acetylacetonate, 25.69mg of nickel acetylacetonate and 61.06mg of benzoic acid in 17mL of N-N-dimethylformamide (DMF) at room temperature, stir well to form a uniform transparent The solution.

[0051] Microwave heating: Add the above solution into a 30mL quartz tube, put it into a CEM DISCOVER ring-focused single-mode microwave synthesis system, adjust the parameters to raise the temperature to 180°C, keep it warm for 4 hours and keep stirring.

[0052] Loaded graphene: Sonicate the reaction solution obtained by microwave synthesis for 10 minutes in an ultrasonic cell disruptor, add 52.33 mg of graphene, and then ultrasonicate in an ultrasonic cell disruptor for 30 minutes.

[0053] Centrifugation and cleaning: Centrifuge the ultrasonically crushed suspension at 10,000 rpm for 5 minutes to obtain PtNi alloy nanocrystals, then wash these nanocrystals three times in a mixture of water and ethanol, and obtain PtNi alloys loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com