Phenolic resin bamboo plywood manufacturing process

A phenolic resin glue and manufacturing process technology, which is applied in the direction of flat products, wood processing appliances, household components, etc., can solve the problems of increased maintenance costs, reduced effective utilization of hot presses, easy deformation and cracks, etc., to achieve saving Removing the machining process, improving the effective utilization rate of equipment, and improving the effect of anti-deformation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

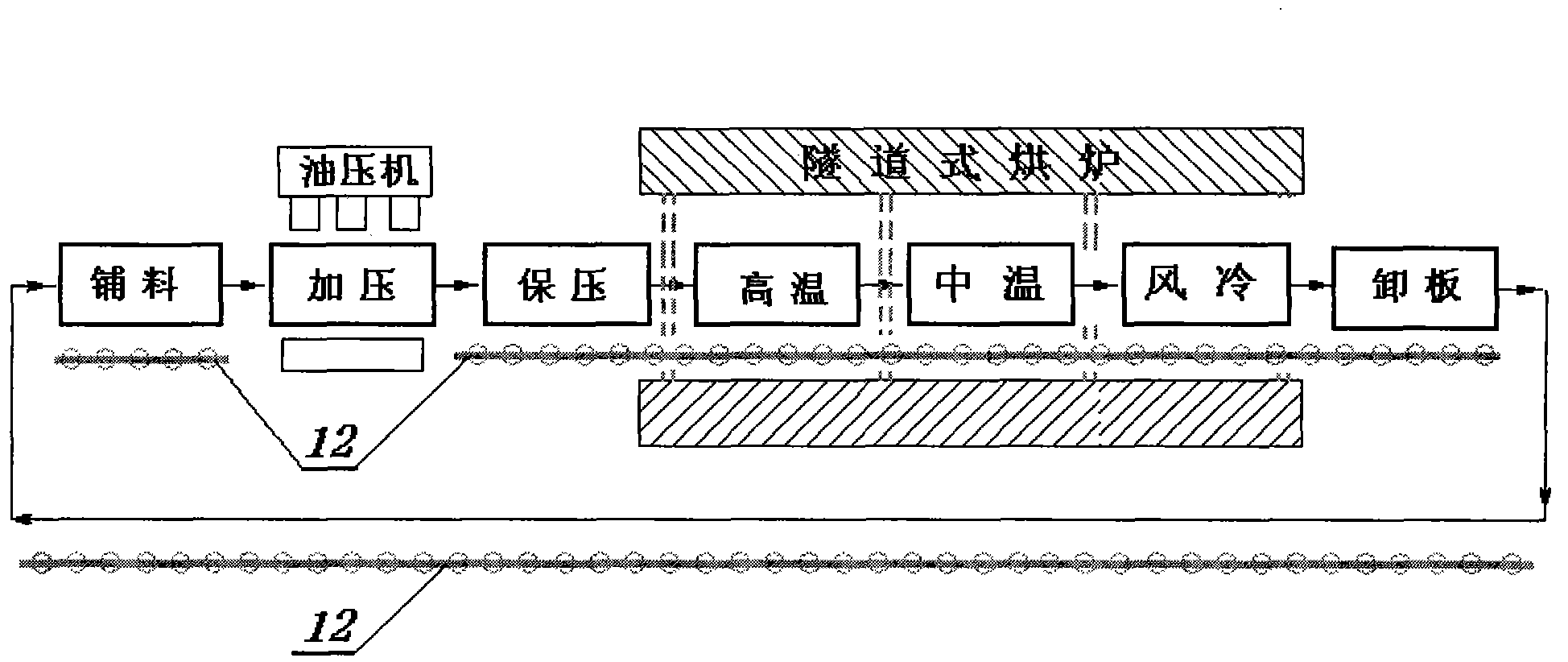

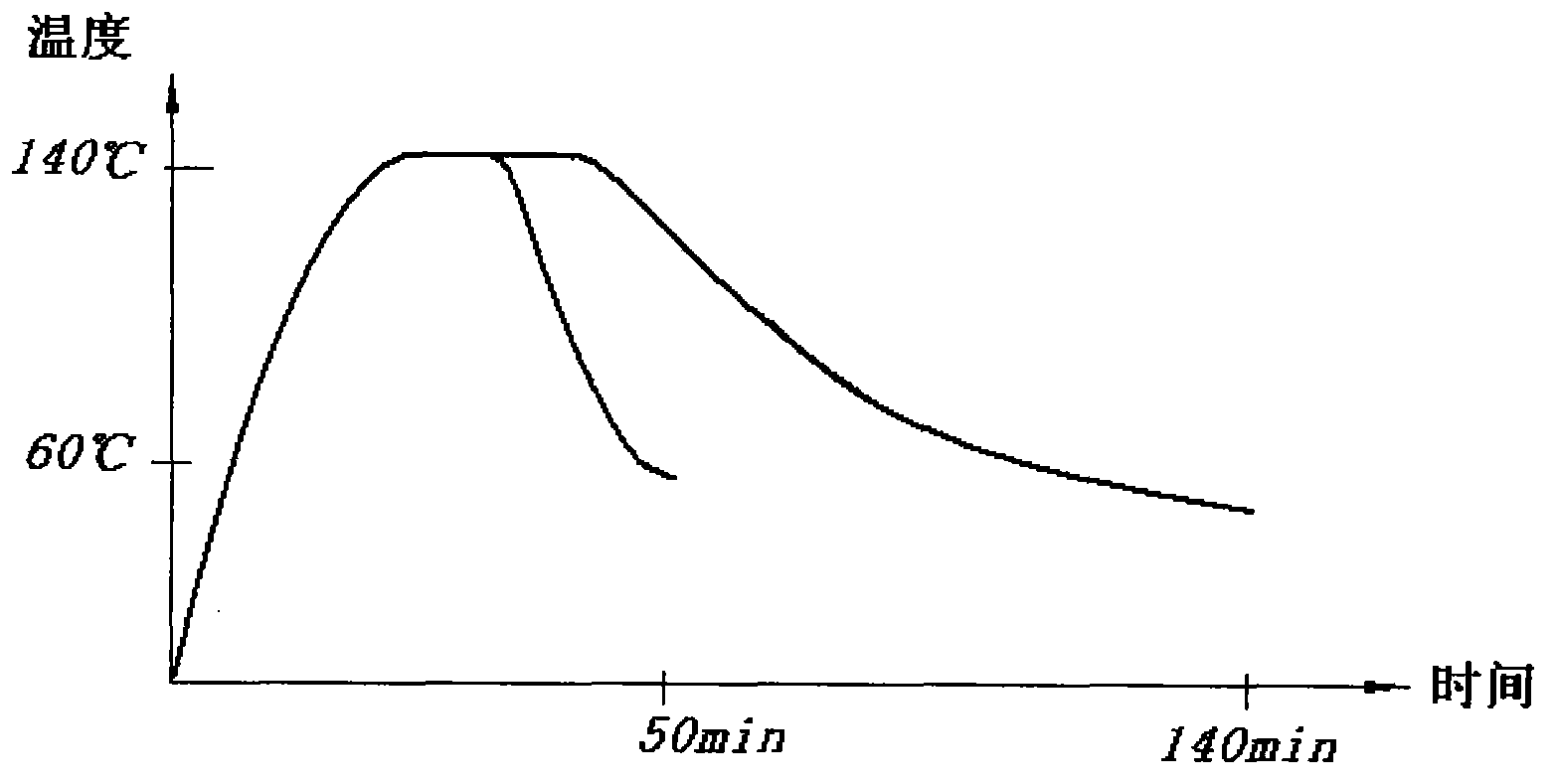

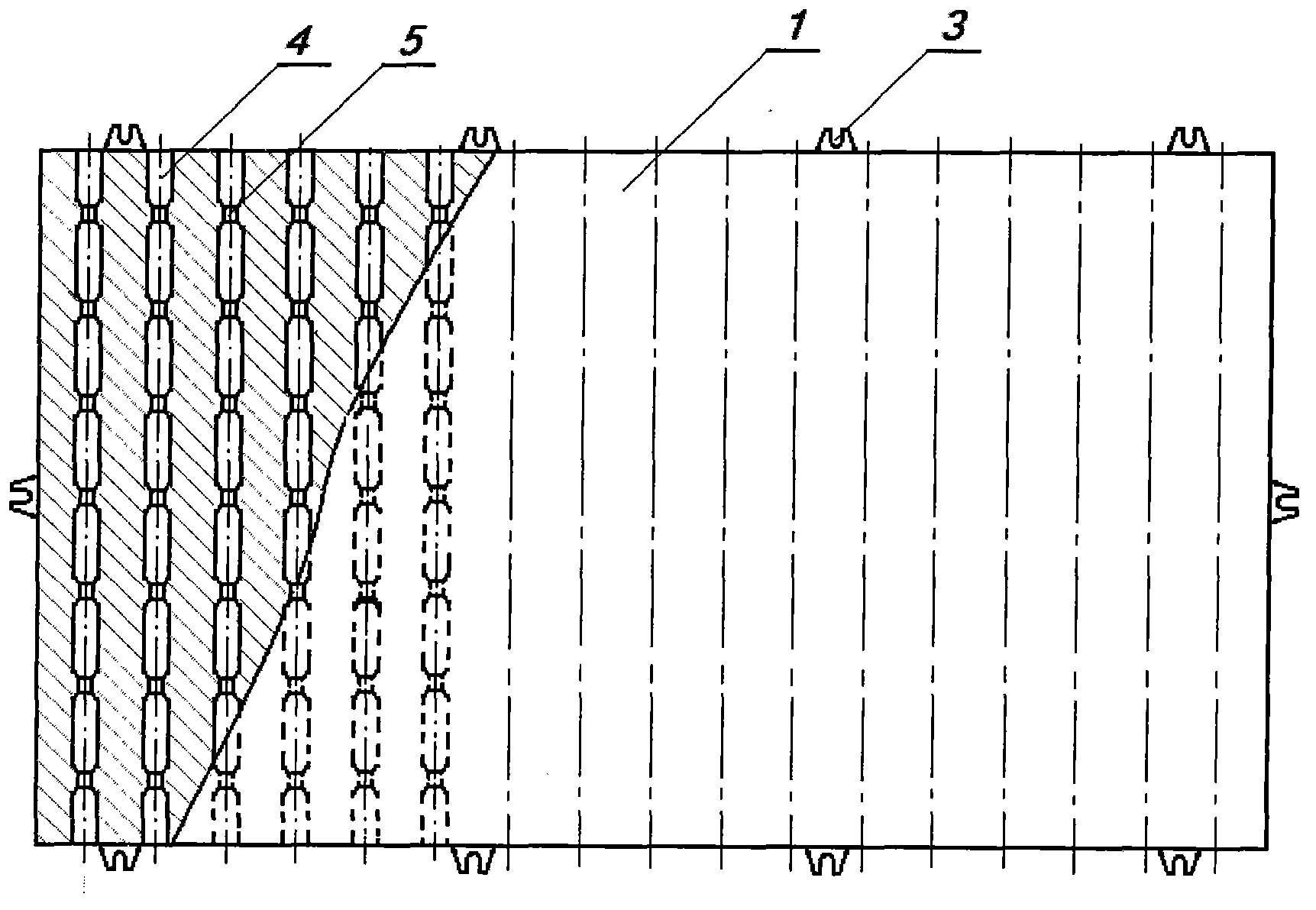

[0022] figure 1 In the process, preheat the bamboo plywood materials after pre-decomposition processing, unit drying and phenolic resin glue application to 60-80°C, and pave them on two layers of thin stainless steel plates according to the requirements for the production of bamboo plywood with different thicknesses. between them, and placed flat between a set of splints consisting of upper and lower rectangular steel plates to complete the laying process; and then transported to the hydraulic press through the roller conveyor (12) to apply high pressure, the average working pressure is 25- 32kPa / C m 2 Between, finish pressurization process; When the relative distance of upper and lower two rectangular steel plate (1,2) planes reaches the thickness of required bamboo plywood, promptly rotate each round steel pull bar (7) of lower rectangular steel plate (2) side ) to embed it into the upper fork-shaped earrings (3) corresponding to the upper rectangular steel plate (1), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com