Mildewproof, mothproof and bacteriostatic straw plate and preparation method thereof

A straw board, insect-proof technology, applied in the direction of flat products, other household appliances, wood processing appliances, etc., can solve the problems of the bonding strength not meeting the standard requirements, harming human health, excessive formaldehyde content, etc., and achieving convenient transportation and construction and installation. , Improve the effect of anti-deformation strength and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

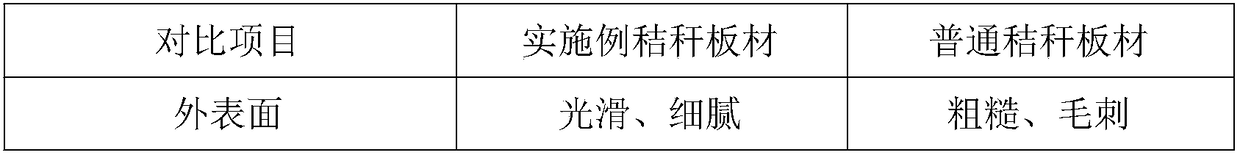

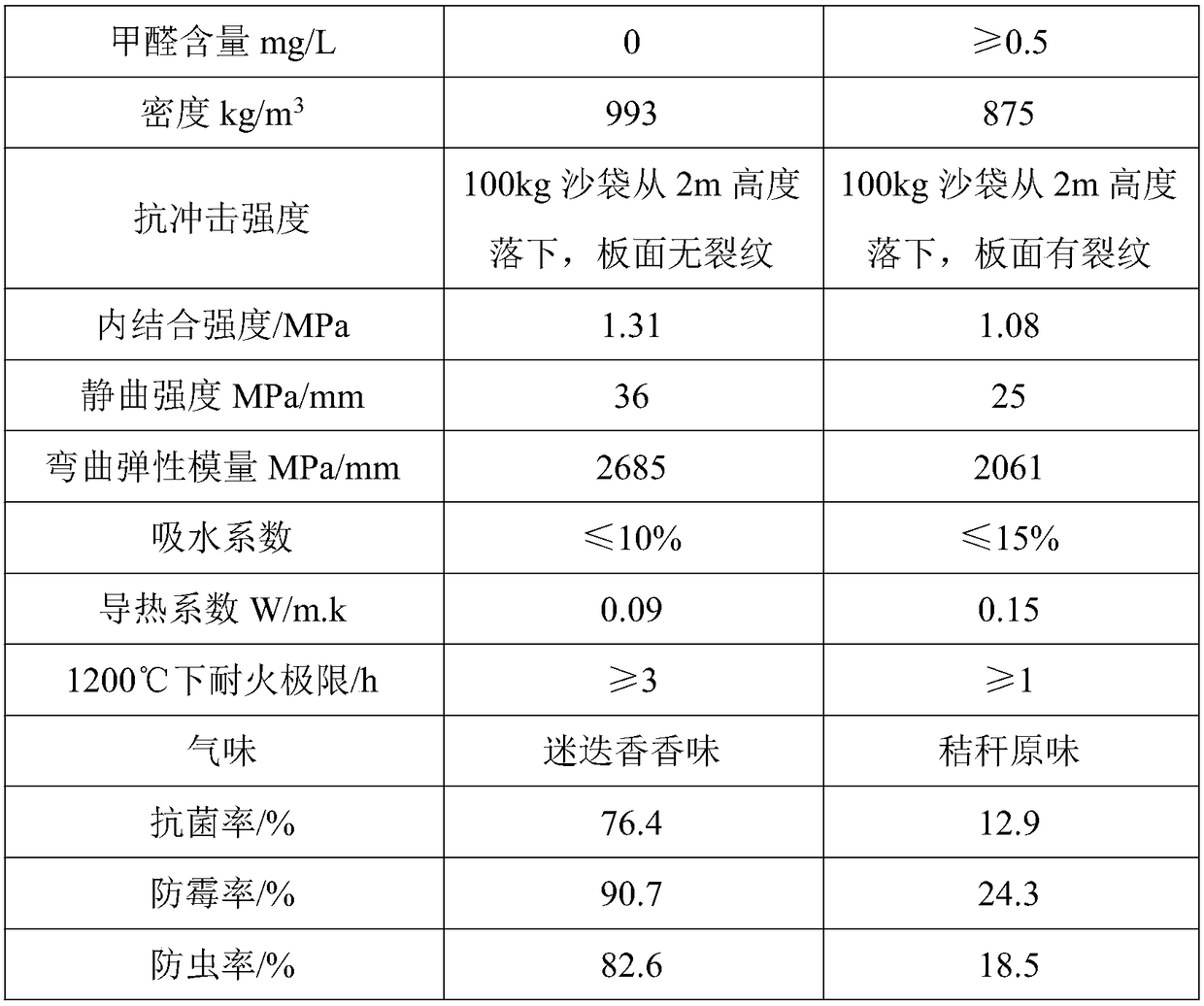

Examples

Embodiment

[0032] A preparation method of anti-mildew, insect-proof and anti-bacterial straw board includes the following steps:

[0033] (1) Wash the crop stalks with clean water, then dry them to a water content of 15%, and pulverize them into 3mm particles with a pulverizer to obtain smashed straws;

[0034] (2) Soak the straw crushed material with 2% sodium hydroxide solution, soak it for 60 minutes at a temperature of 40°C and an ultrasonic power of 300W, and wash with deionized water until the washing liquid is neutral. After drying, it is soaked in a sulfuric acid solution with a mass fraction of 40%, soaked at a temperature of 35°C for 40 minutes, washed with deionized water until the washing solution is neutral, and dried to obtain straw fibers;

[0035] (3) Mix the straw fiber, rosemary powder, bamboo charcoal fiber, expanded vermiculite, and diatomaceous earth according to the weight ratio, add deionized water, send it to the disc mill for 4 hours, take it out under the microwave pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com