Three-edge tungsten steel forming tool

A technology of forming knives and tungsten steel, which is applied in the direction of milling cutters, milling cutters, manufacturing tools, etc., can solve the problems of unguaranteed surface smoothness, unguaranteed dimensional accuracy, and limited milling speed, etc., to achieve small runout and structure Simple, the effect of increasing the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

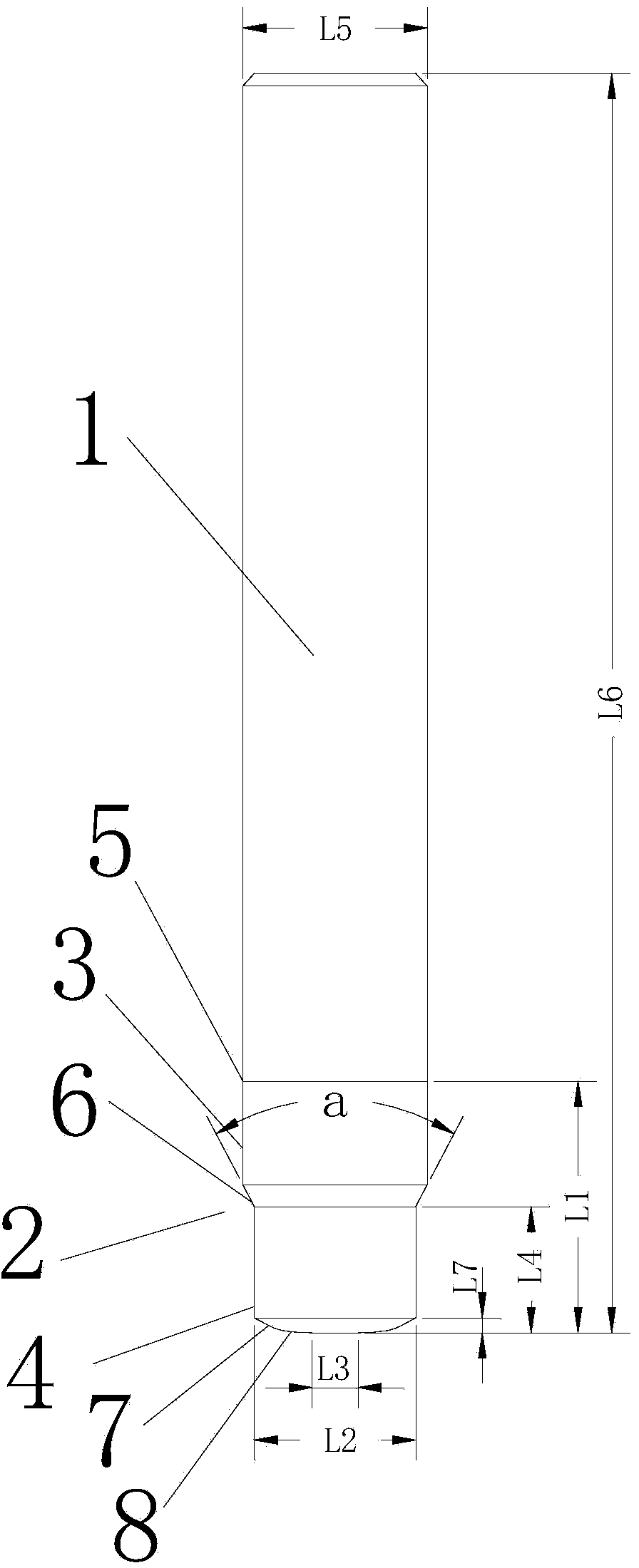

[0013] Such as figure 1 As shown, the three-edged tungsten steel forming knife, which includes a handle, is arranged at the cutting part at the bottom of the handle; the cutting part includes a neck connected to the handle, and a cutter head arranged at the bottom of the neck; The joint between the knife neck and the handle is provided with grooves, and the joint between the knife neck and the knife head is provided with chamfers; the main cutting end surface at the end of the knife head is provided with three cutting edges; the cutting edges of the three cutting edges are all The angle a of the chamfer is 60°; the length L1 of the cutting part is 10mm; the diameter L2 of the cutter head is 7mm, and the diameter L3 of the bottom end of the cutter head is 2mm; The length L4 of the cutter head is 5mm; the diameter L5 of the knife handle is 8mm; the total length L6 of the forming knife is 50mm; the distance L7 from the main cutting end face to the cutter head and its connection i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com