Patents

Literature

160results about How to "Easy milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

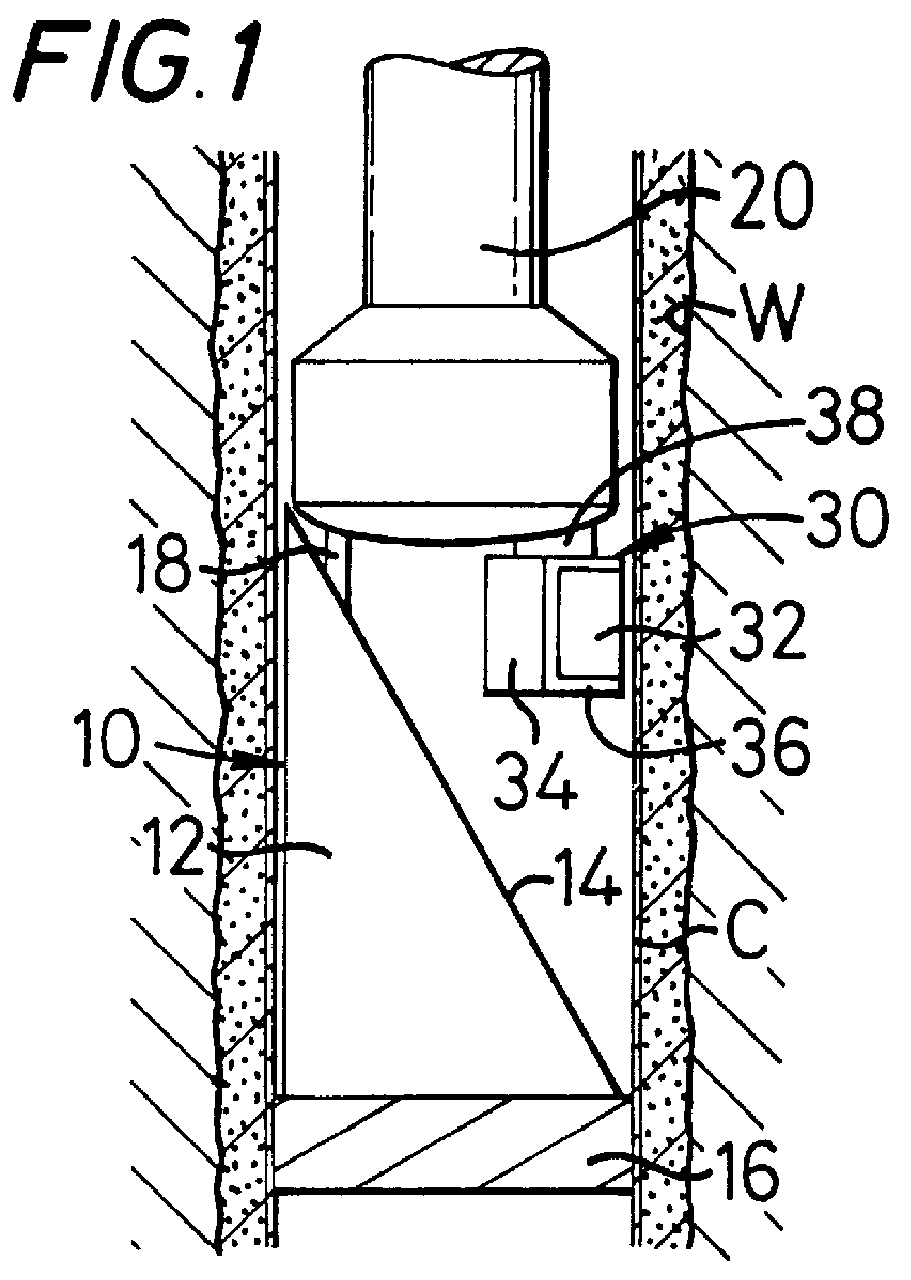

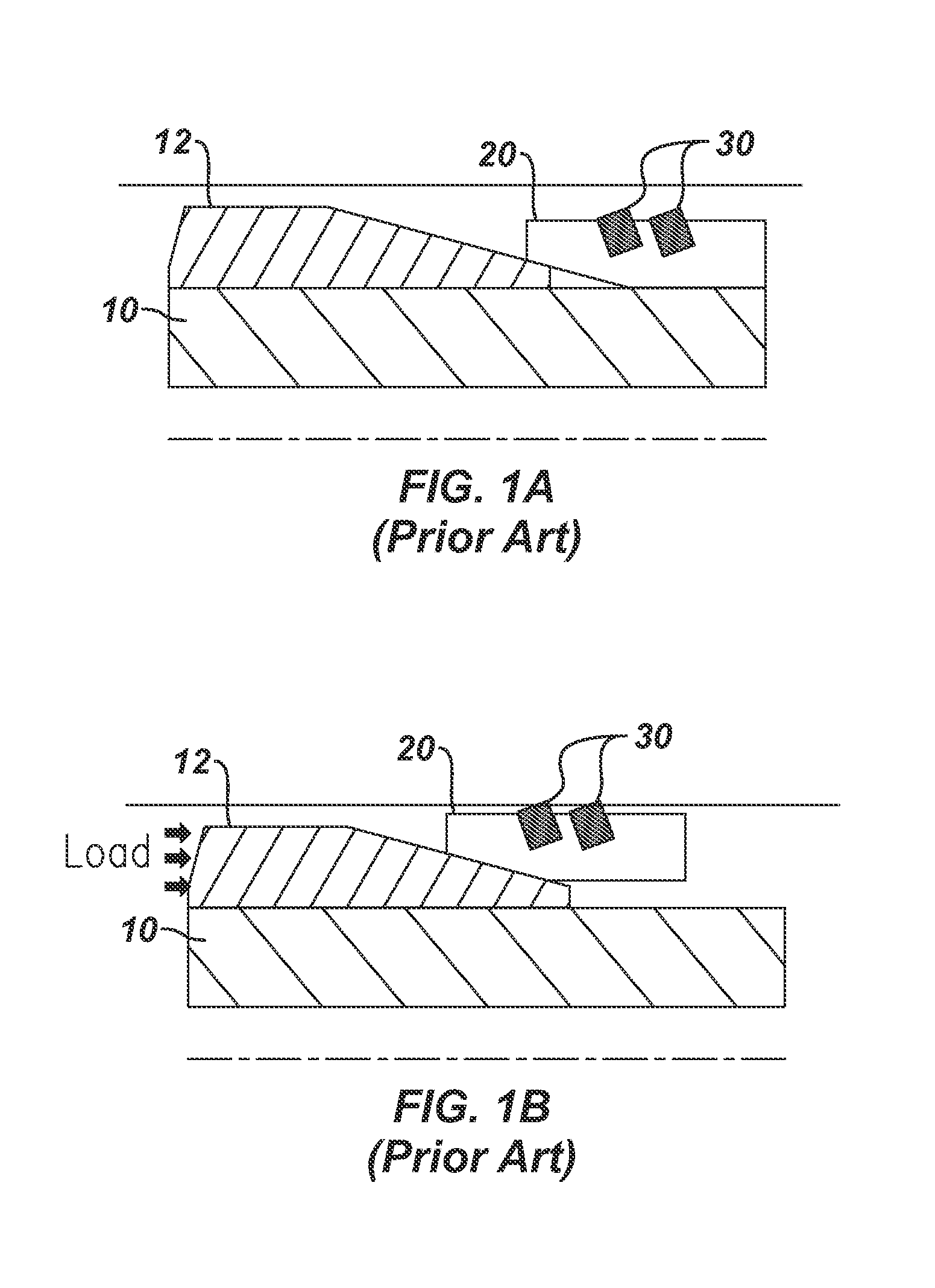

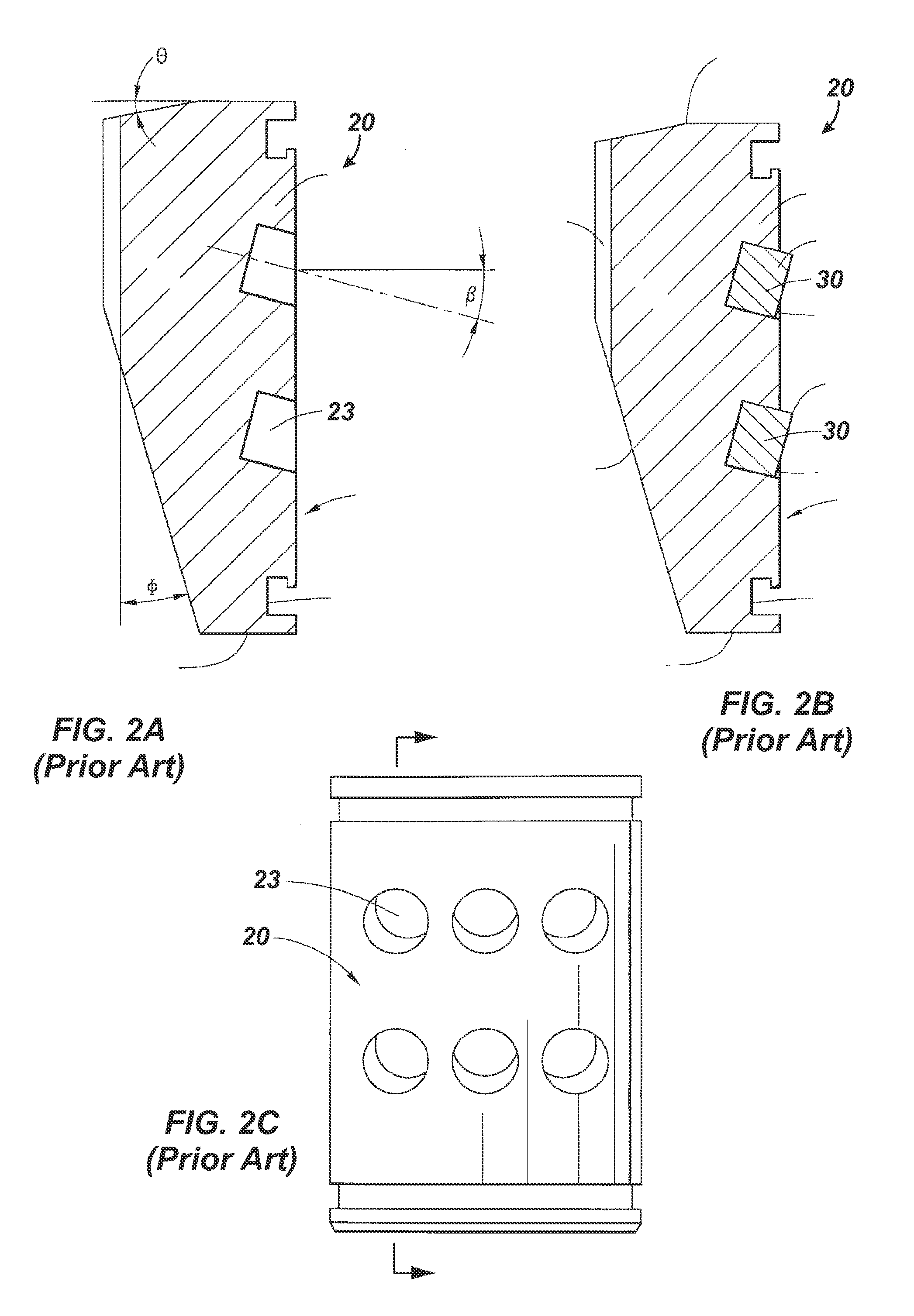

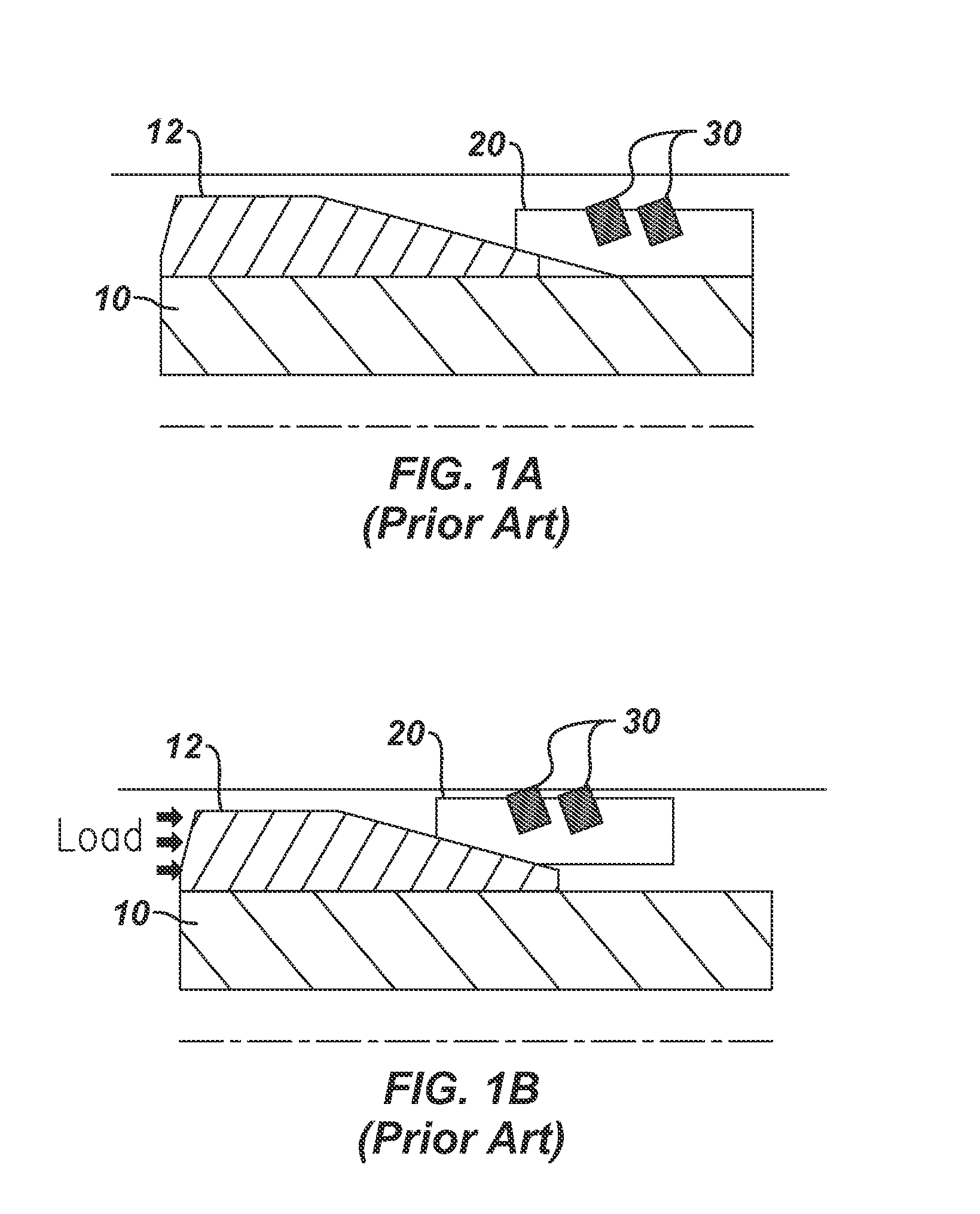

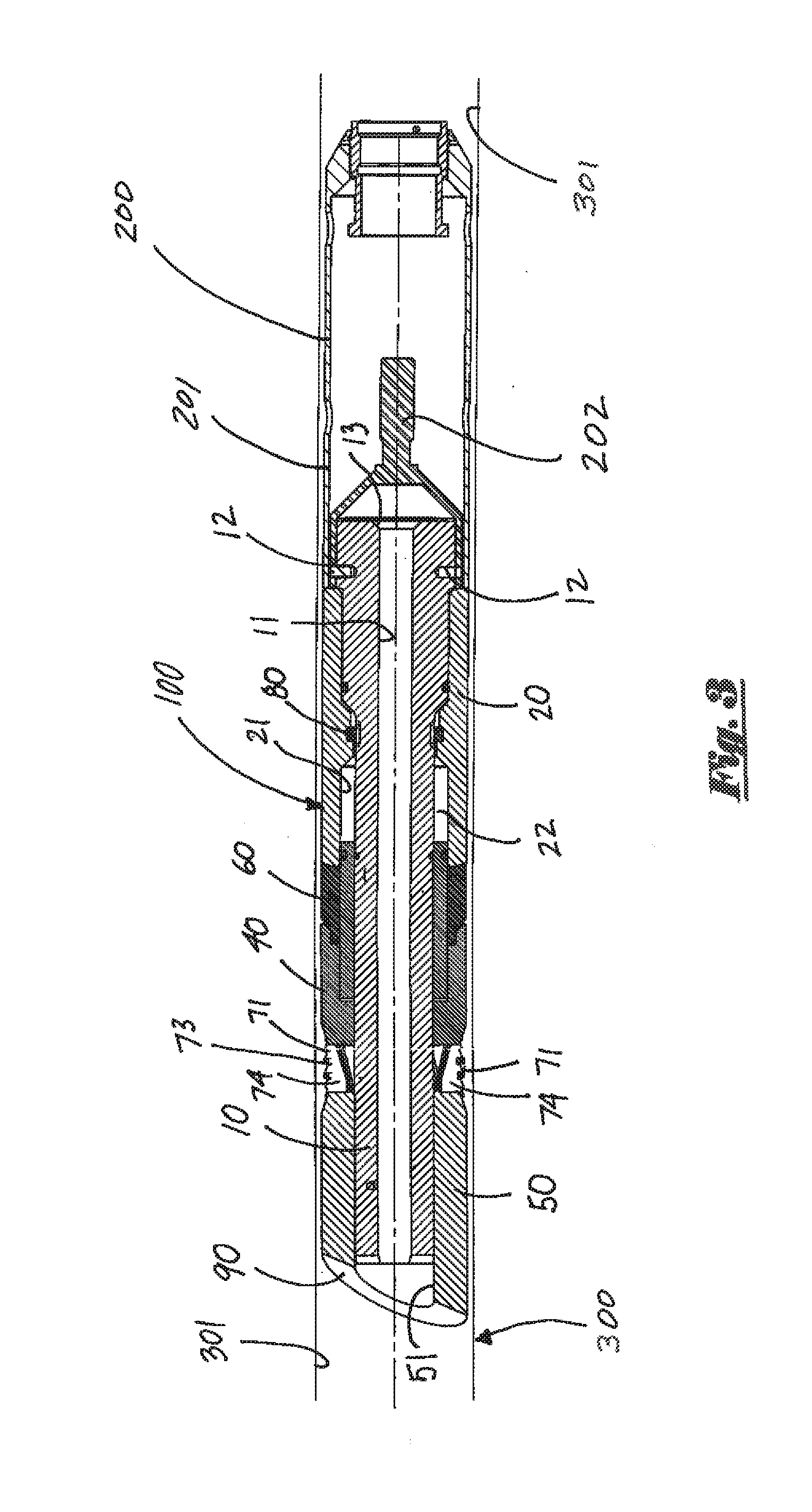

Method for window formation in wellbore tubulars

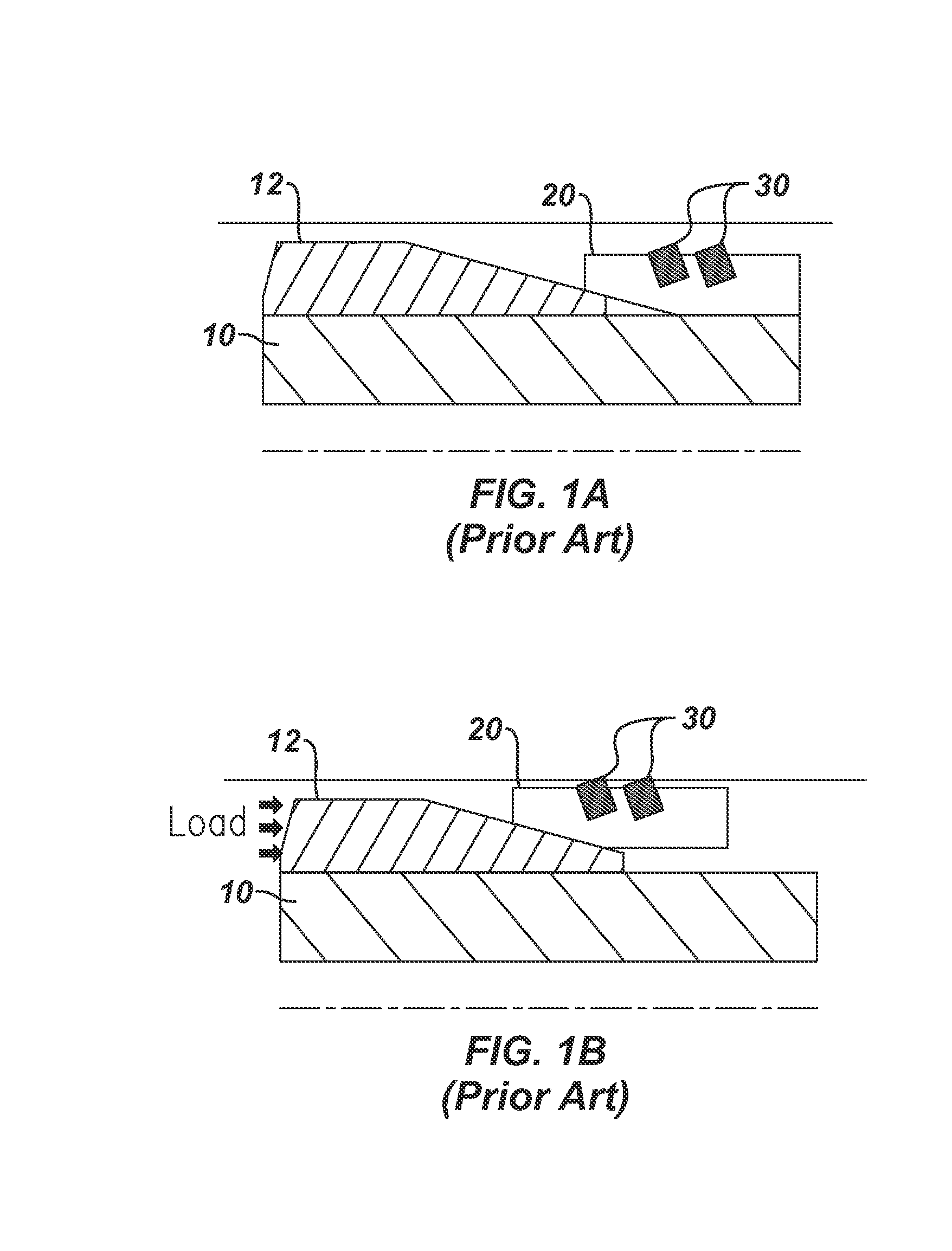

InactiveUS6024169APreventing coringEasy millingFluid removalDirectional drillingStream flowEngineering

New systems and methods have been invented for explosively forming openings, ledges, windows, holes, and lateral bores through tubulars such as casing, which openings may, in cerain aspects, extend beyond the casing into a formation through which a wellbore extends. In certain aspects openings (e.g. ledges, initial, or completed windows) in wellbore tubulars (e.g. tubing or casing) are made using metal oxidizing systems, water jet systems, or mills with abrasive and / or erosive streams flowing therethrough and / or therefrom.

Owner:WEATHERFORD TECH HLDG LLC

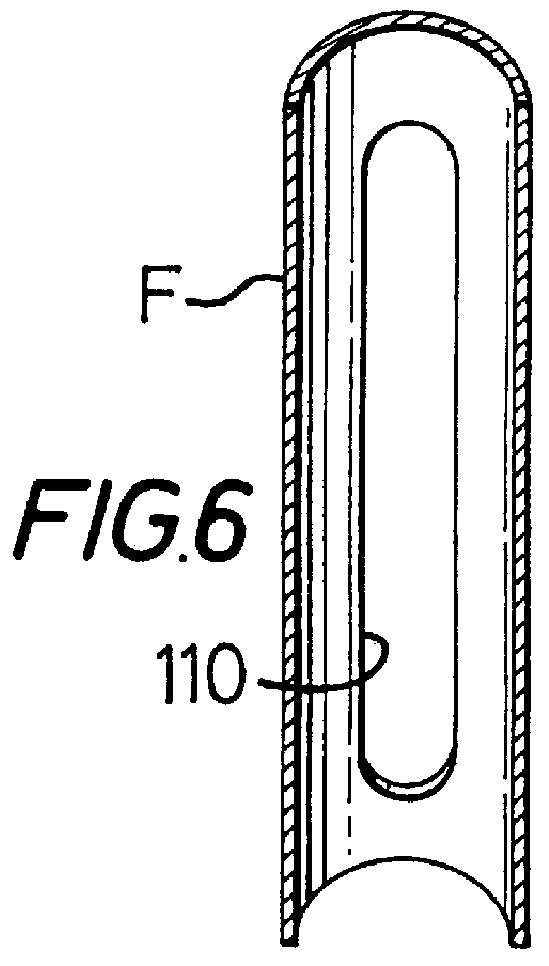

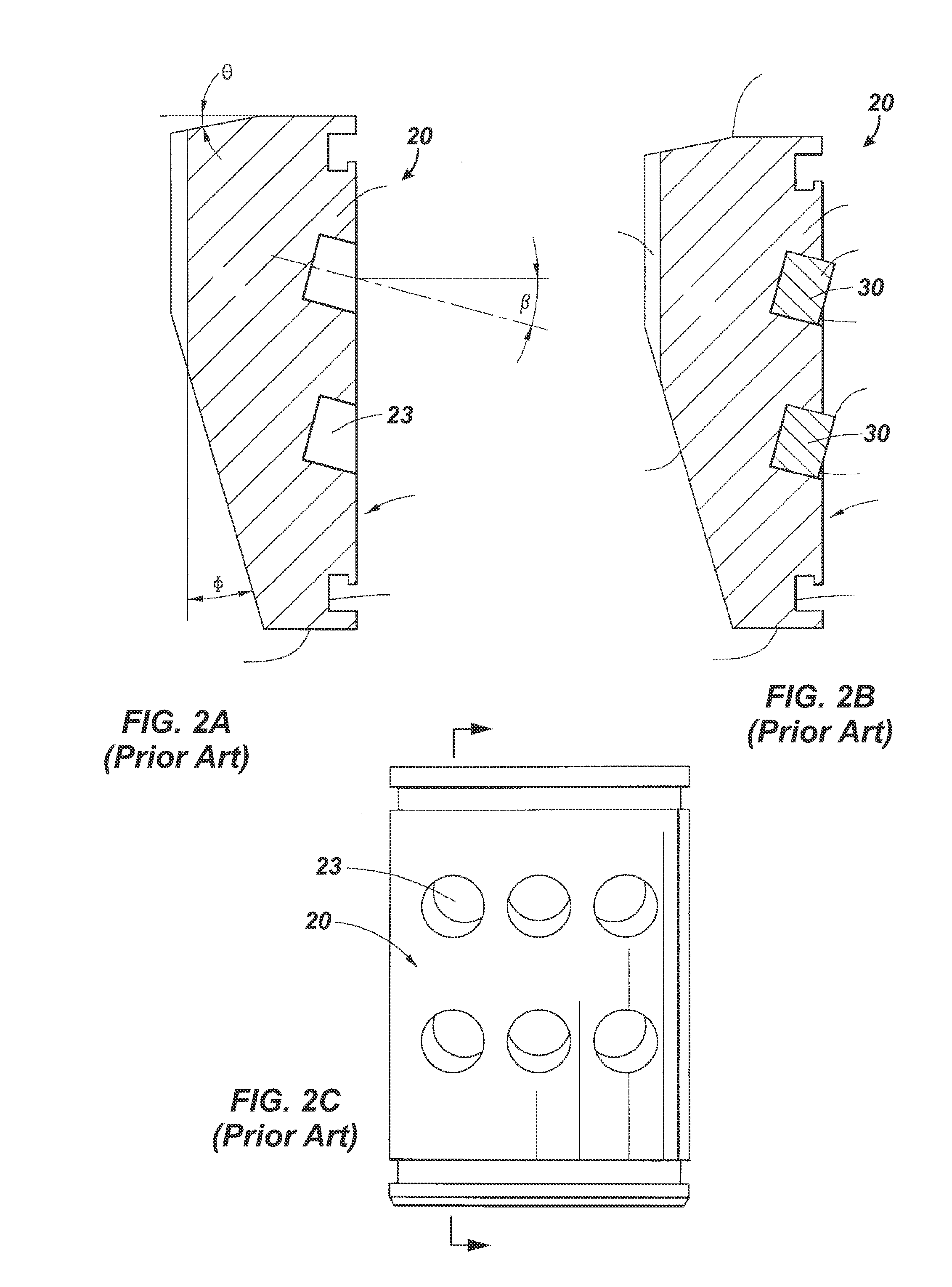

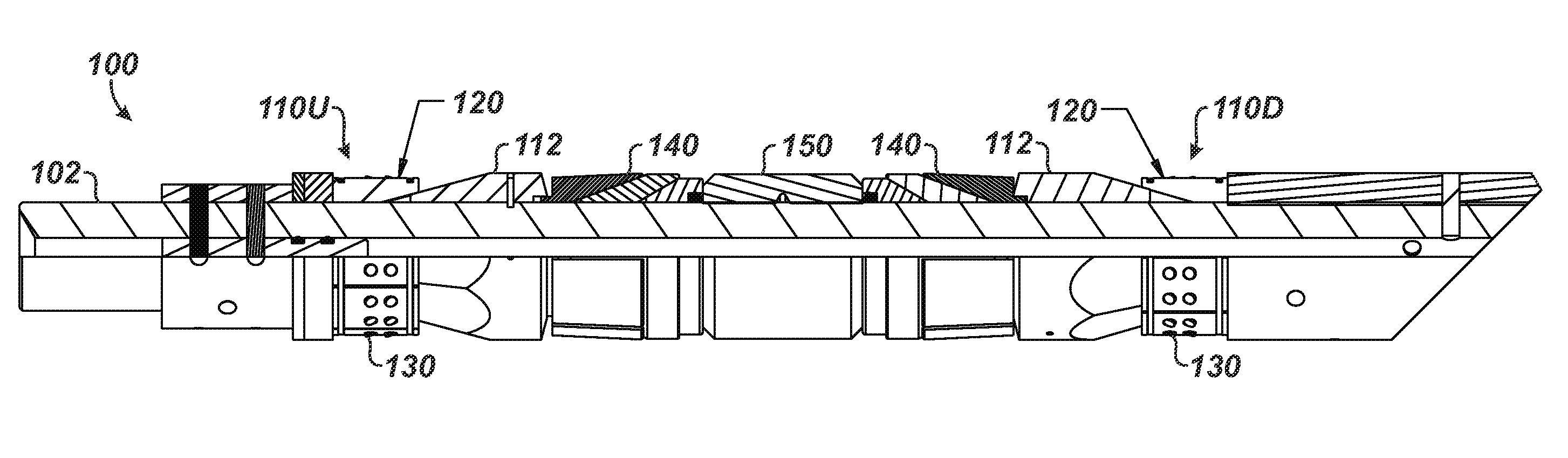

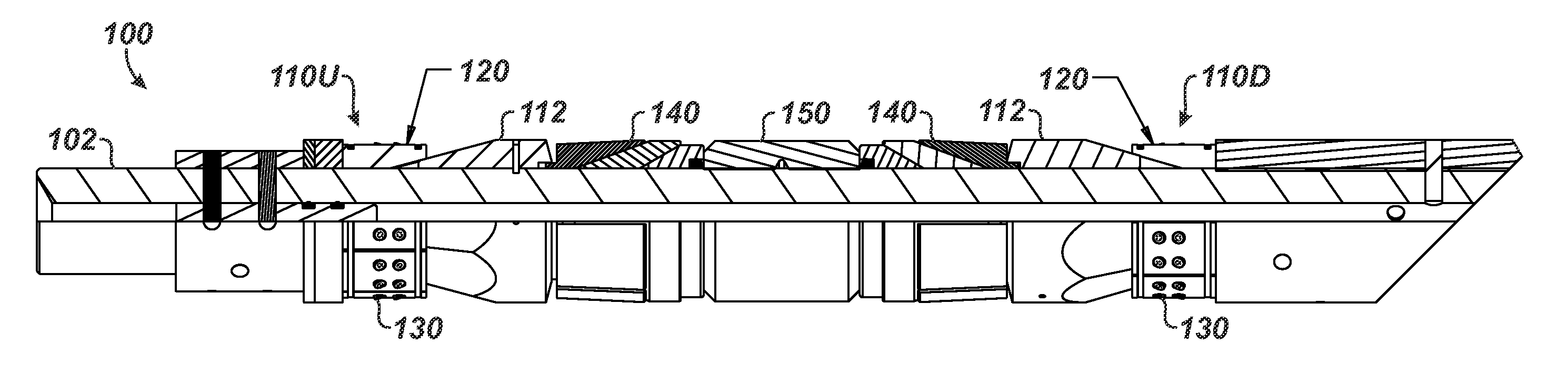

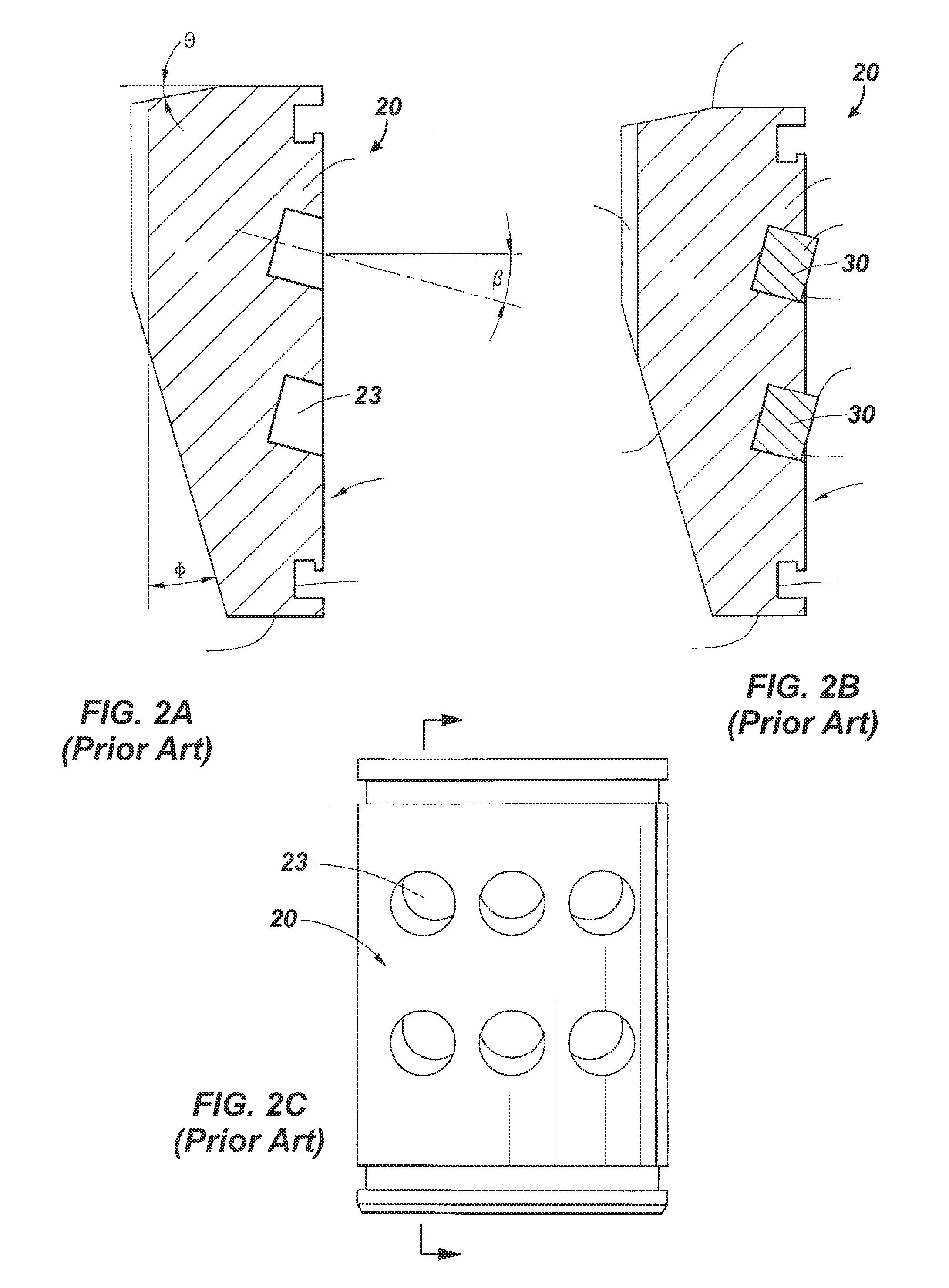

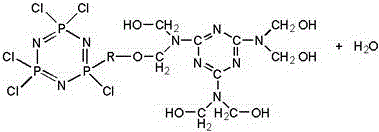

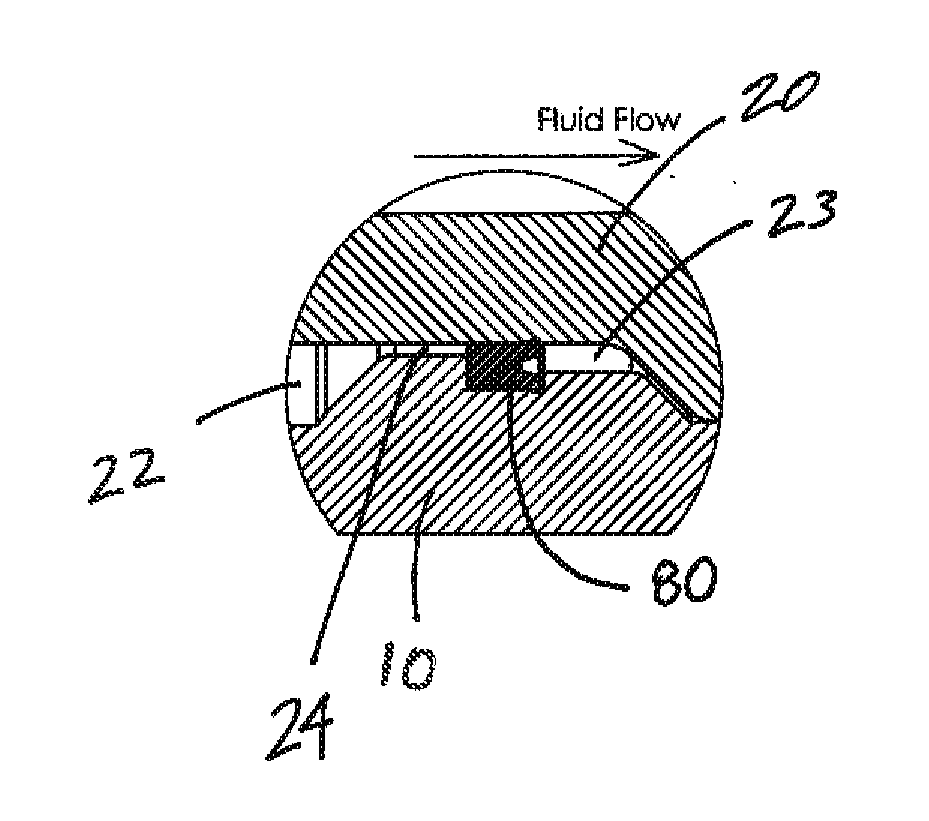

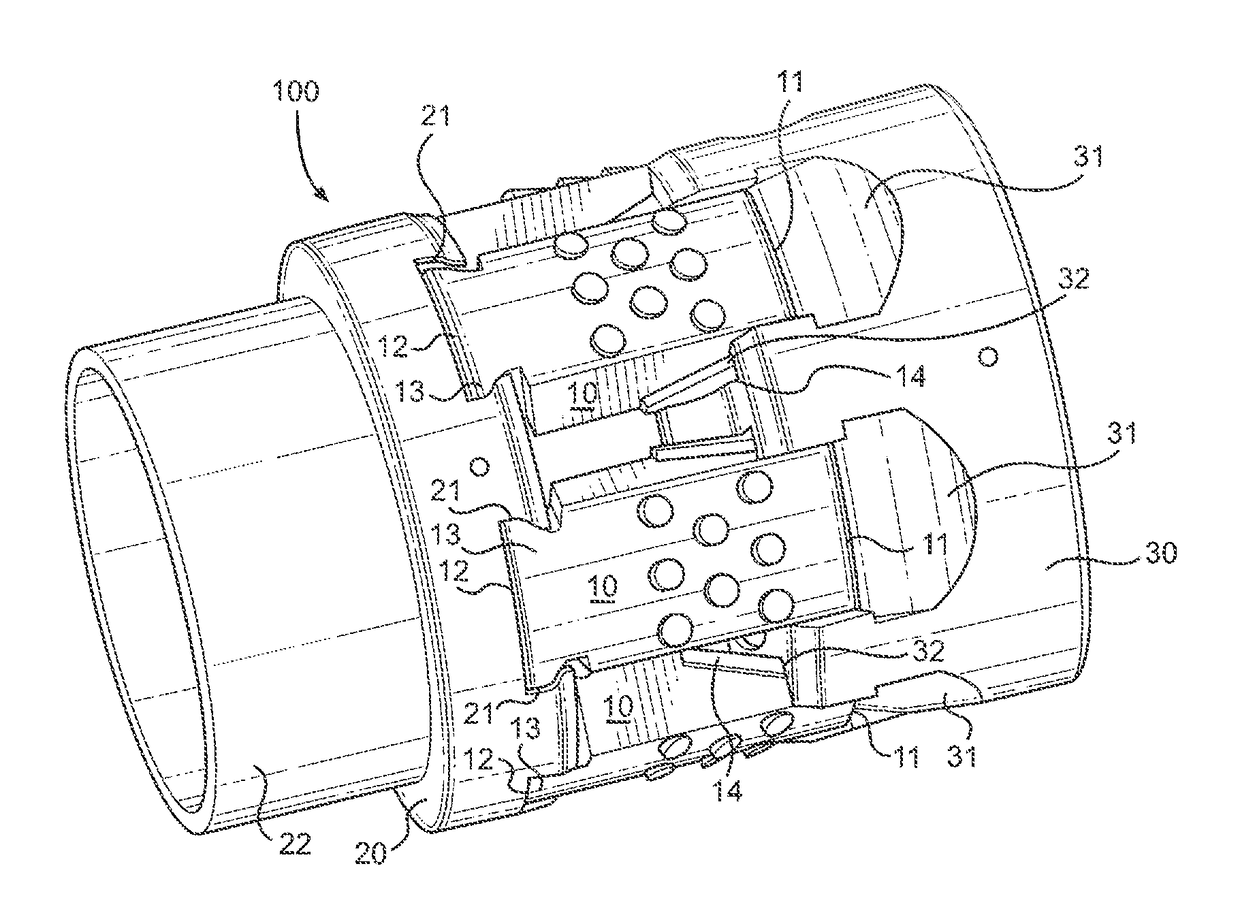

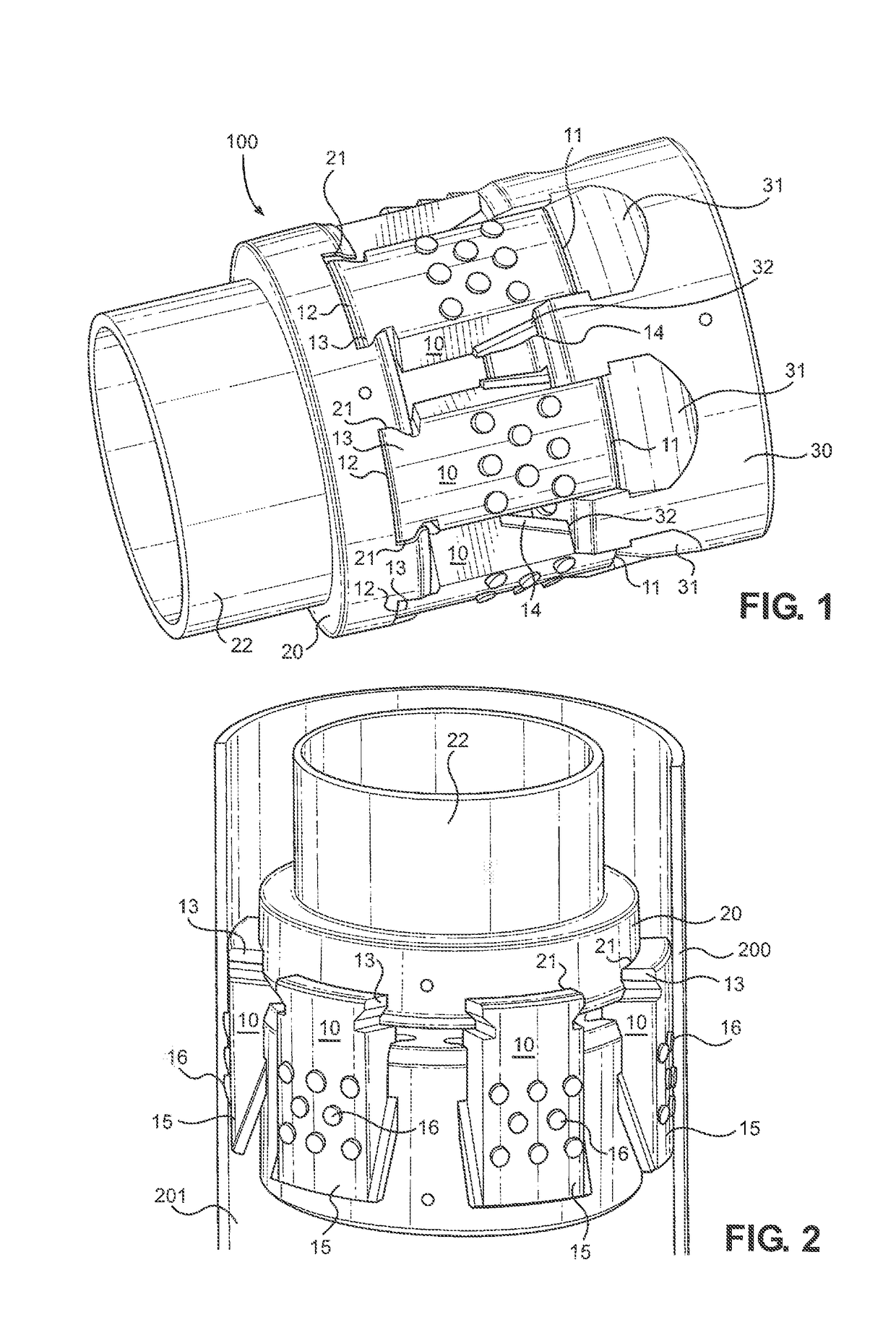

Downhole Tool Having Slip Inserts Composed of Different Materials

ActiveUS20140224477A1Reduce metal contentIncrease fluid pressureDrilling rodsFluid removalManganeseMetallic materials

A downhole tool, such as a fracture plug used during a fracture operation, installs in a downhole tubular, such as casing. The tool has a mandrel with a sealing element disposed thereon between uphole and downhole ends. Slip assemblies on the mandrel can be moved to engage the downhole tubular. The uphole assembly has inserts composed of ceramic material, and the downhole assembly has inserts composed of a metallic material. When the tool is used as a bridge plug, the uphole assembly supports the sealing element compressed, and the downhole assembly supports fluid pressure downhole of the tool. In one particular embodiment, the metallic material is a powdered metal material, such as a sintered-hardened powdered metal steel having a balance of iron, an admixture of carbon, and alloy components of molybdenum, chromium, and manganese.

Owner:WEATHERFORD TECH HLDG LLC

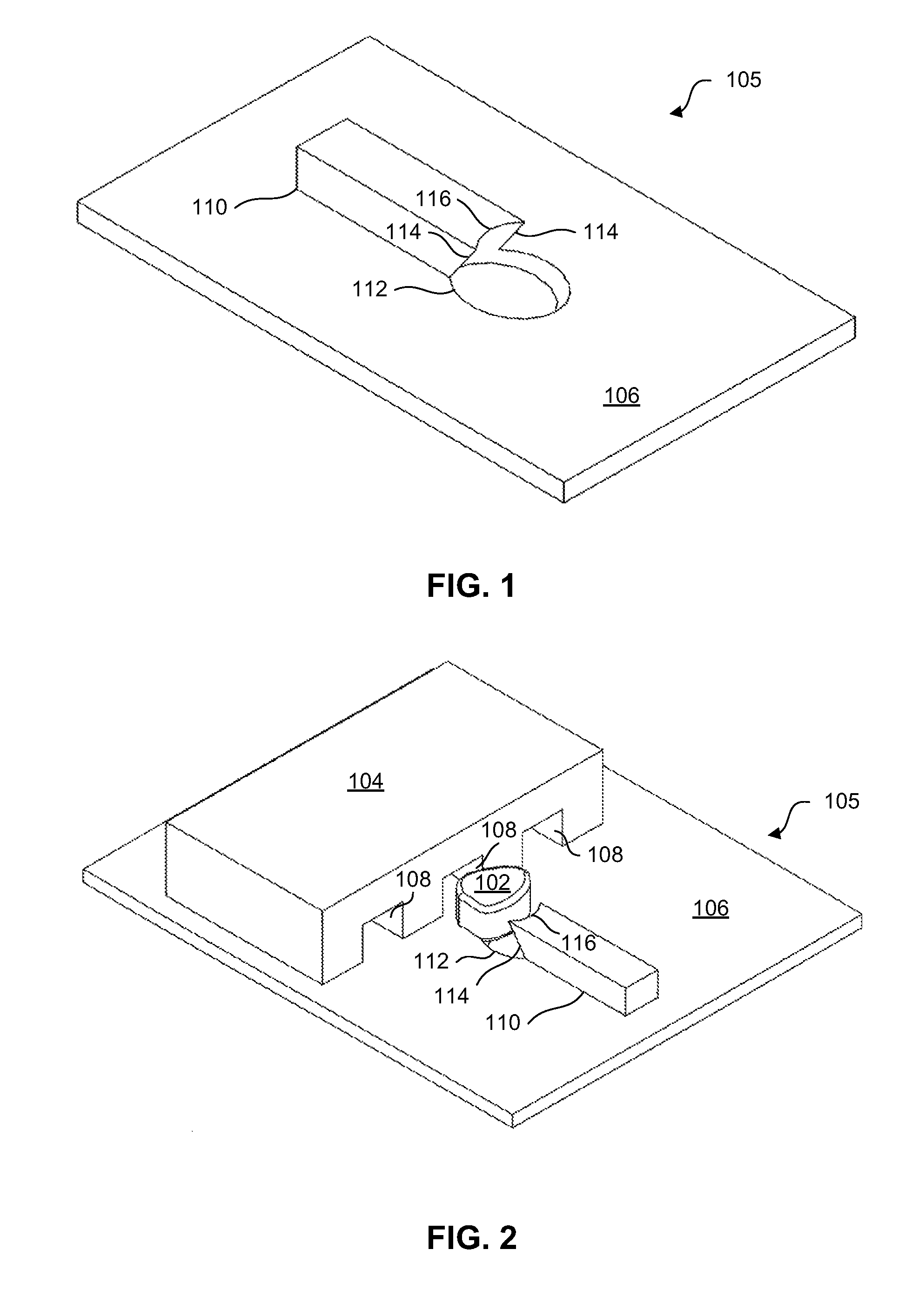

Apparatus for milling material

ActiveUS20070164137A1Easy millingSolid waste disposalGrain treatmentsMechanical engineeringEngineering

An apparatus for milling material is disclosed. The apparatus may include a base surface. The base surface may include a first cutting tooth for milling the material. The base surface may include a first aperture of a predetermined diameter. The first aperture may be disposed adjacent the first cutting tooth so that material of less than the predetermined diameter may pass through the first aperture. The apparatus may include a trimming member. The trimming member may include a first rib for interfacing with the first cutting tooth to facilitate the milling of the material. The base surface and the trimming member may move relative to each other. The base surface and the trimming member may interface to mill material placed on the base surface.

Owner:RASEKHI HOUSHANG

Downhole tool having slip inserts composed of different materials

ActiveUS9416617B2Reduce metal contentIncrease fluid pressureDrilling rodsSealing/packingMetallic materialsManganese

A downhole tool, such as a fracture plug used during a fracture operation, installs in a downhole tubular, such as casing. The tool has a mandrel with a sealing element disposed thereon between uphole and downhole ends. Slip assemblies on the mandrel can be moved to engage the downhole tubular. The uphole assembly has inserts composed of ceramic material, and the downhole assembly has inserts composed of a metallic material. When the tool is used as a bridge plug, the uphole assembly supports the sealing element compressed, and the downhole assembly supports fluid pressure downhole of the tool. In one particular embodiment, the metallic material is a powdered metal material, such as a sintered-hardened powdered metal steel having a balance of iron, an admixture of carbon, and alloy components of molybdenum, chromium, and manganese.

Owner:WEATHERFORD TECH HLDG LLC

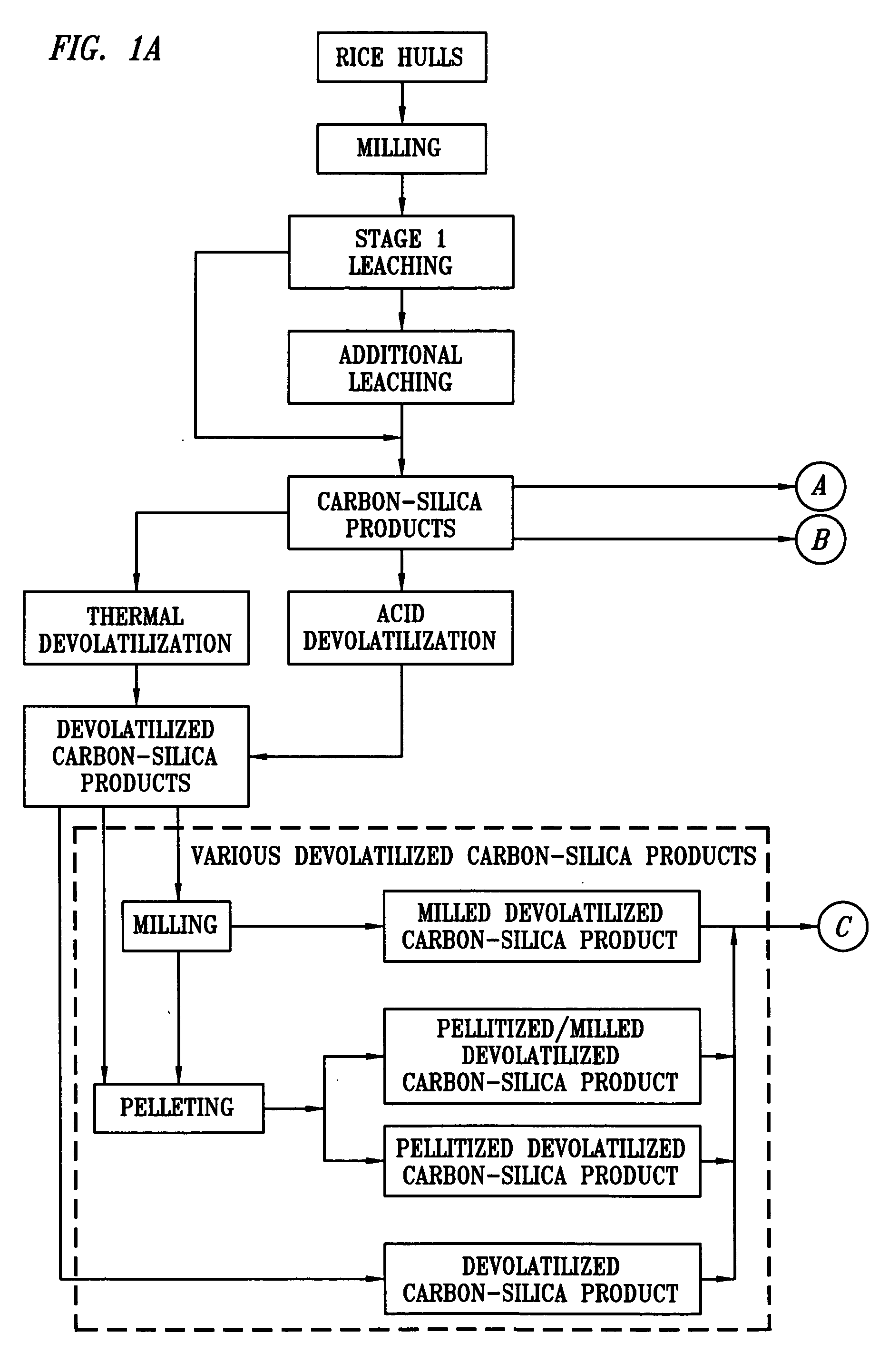

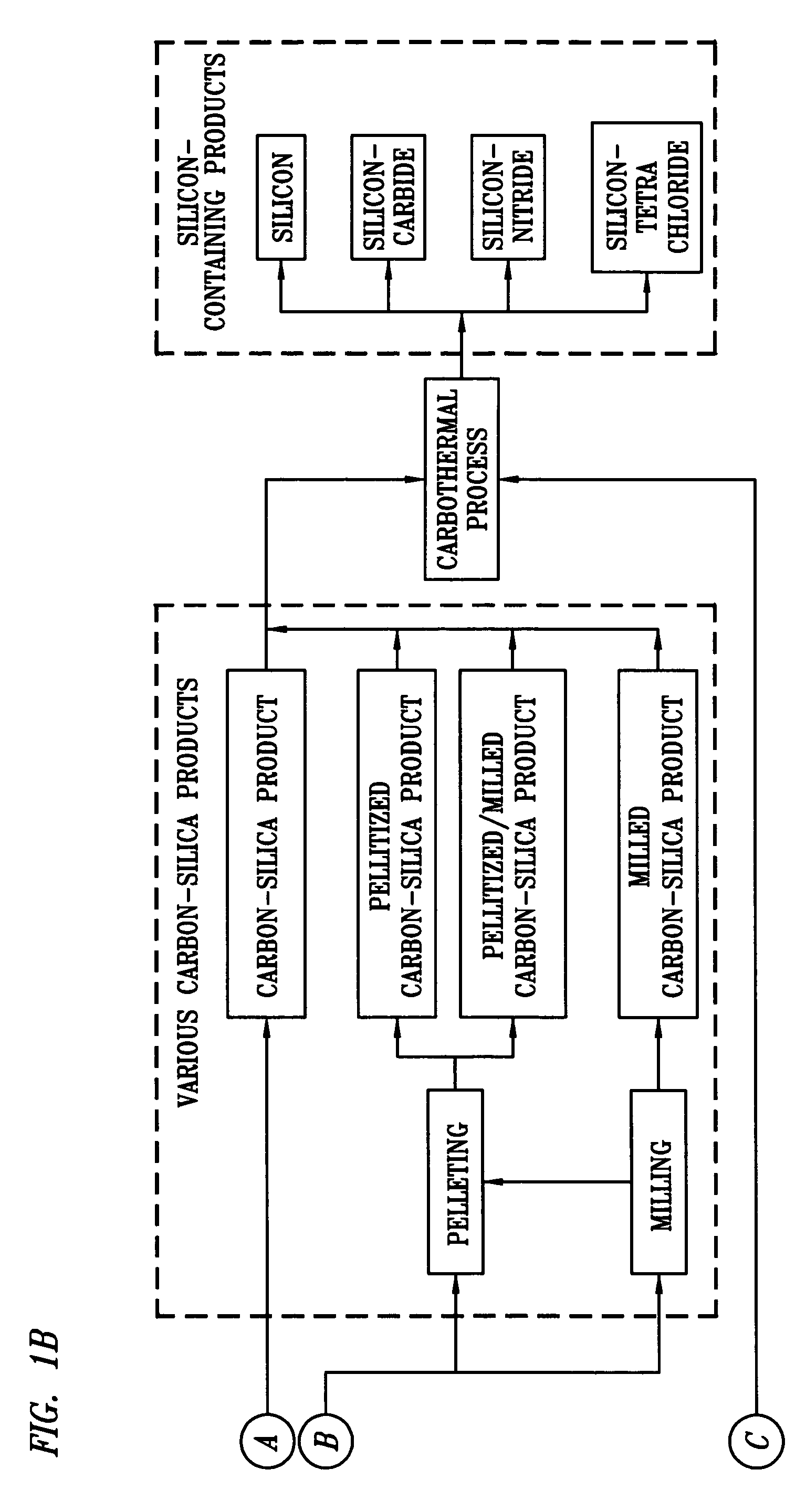

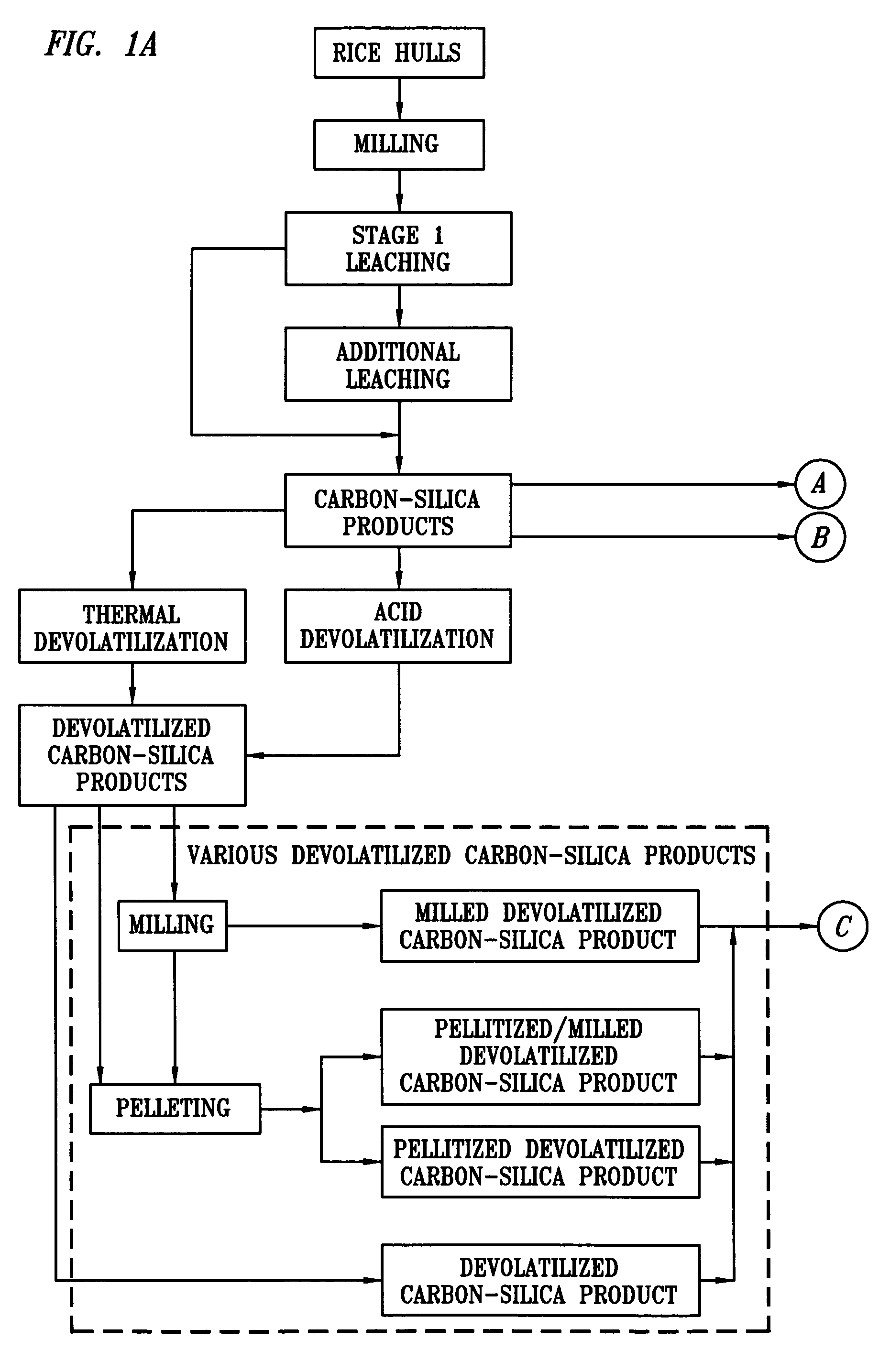

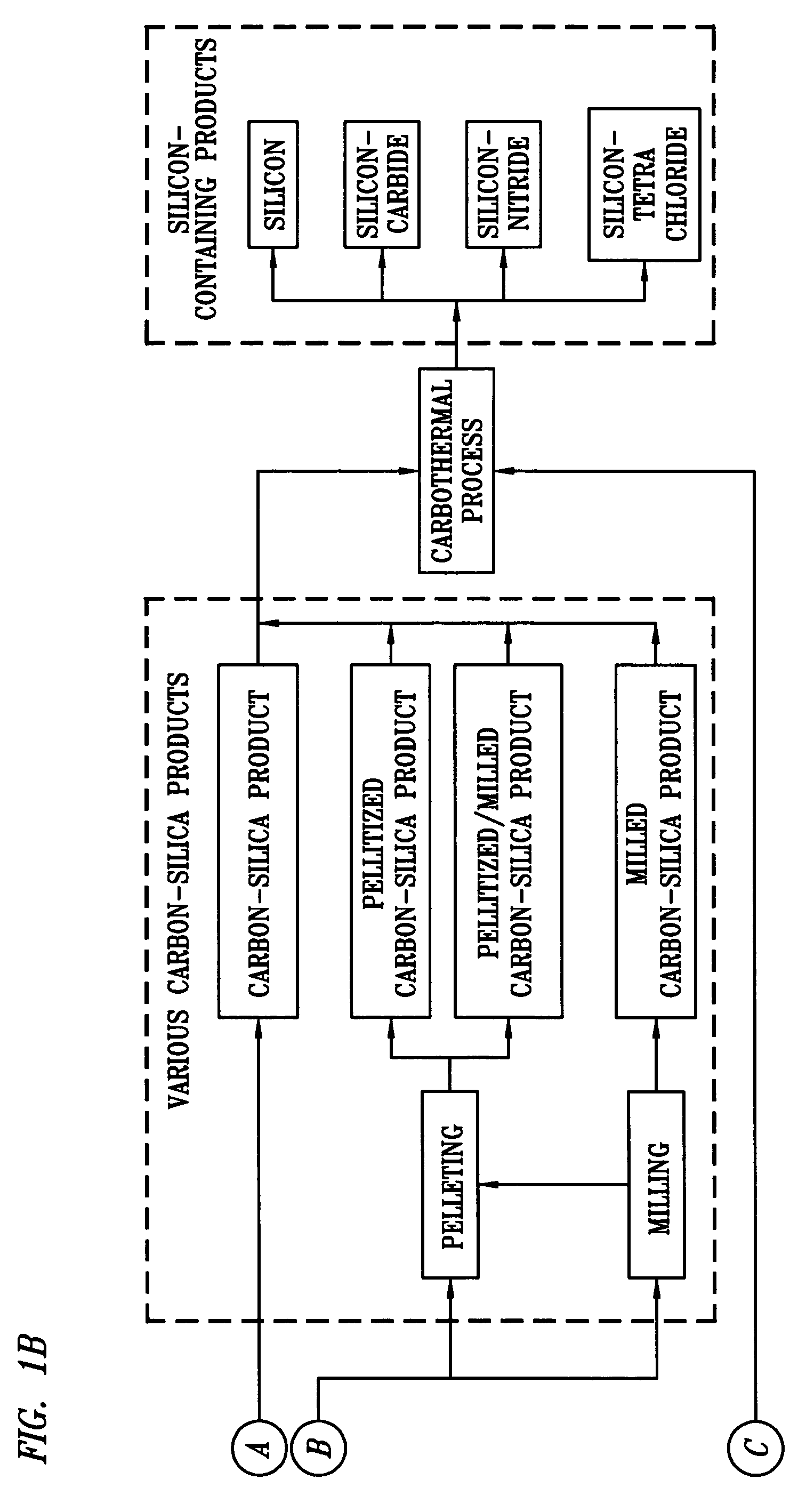

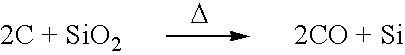

Composition and method for making silicon-containing products

ActiveUS20050227868A1Increase throughputSave energyNitrogen compoundsOther chemical processesPorositySilicon dioxide

A method for producing carbon-silica products from silica-containing plant matter such as rice hulls or straw by leaching with sulfuric acid to remove non-silica minerals and metal while adjusting the mole ratio of fixed carbon to silica in the resultant product. The carbon and silica are intimately mixed on a micron or submicron scale and are characterized by high purity and reactivity, small particle size, high porosity, and contain volatile carbon that can be used as a source of energy for the production of silicon-containing products from the carbon-silica products. High purity silicon-containing products made from the carbon-silica products of the invention are also disclosed.

Owner:SI OPTIONS LLC

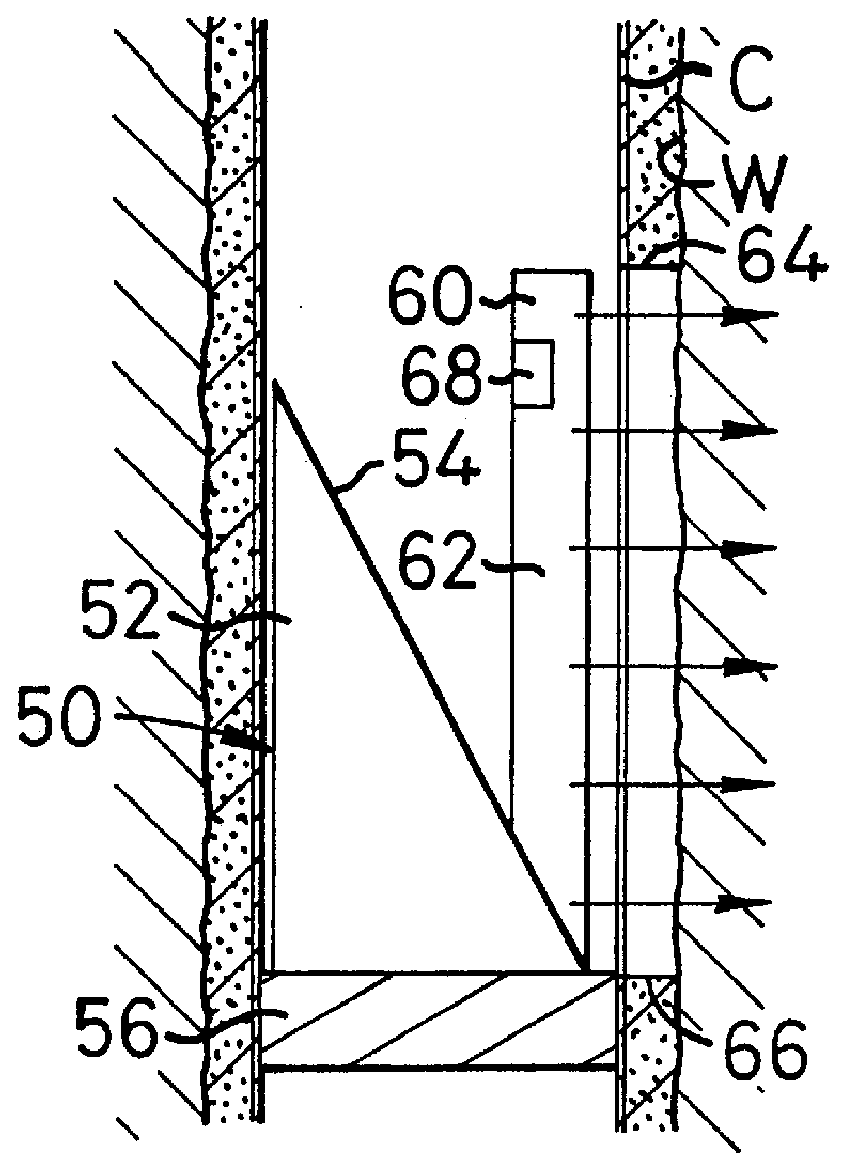

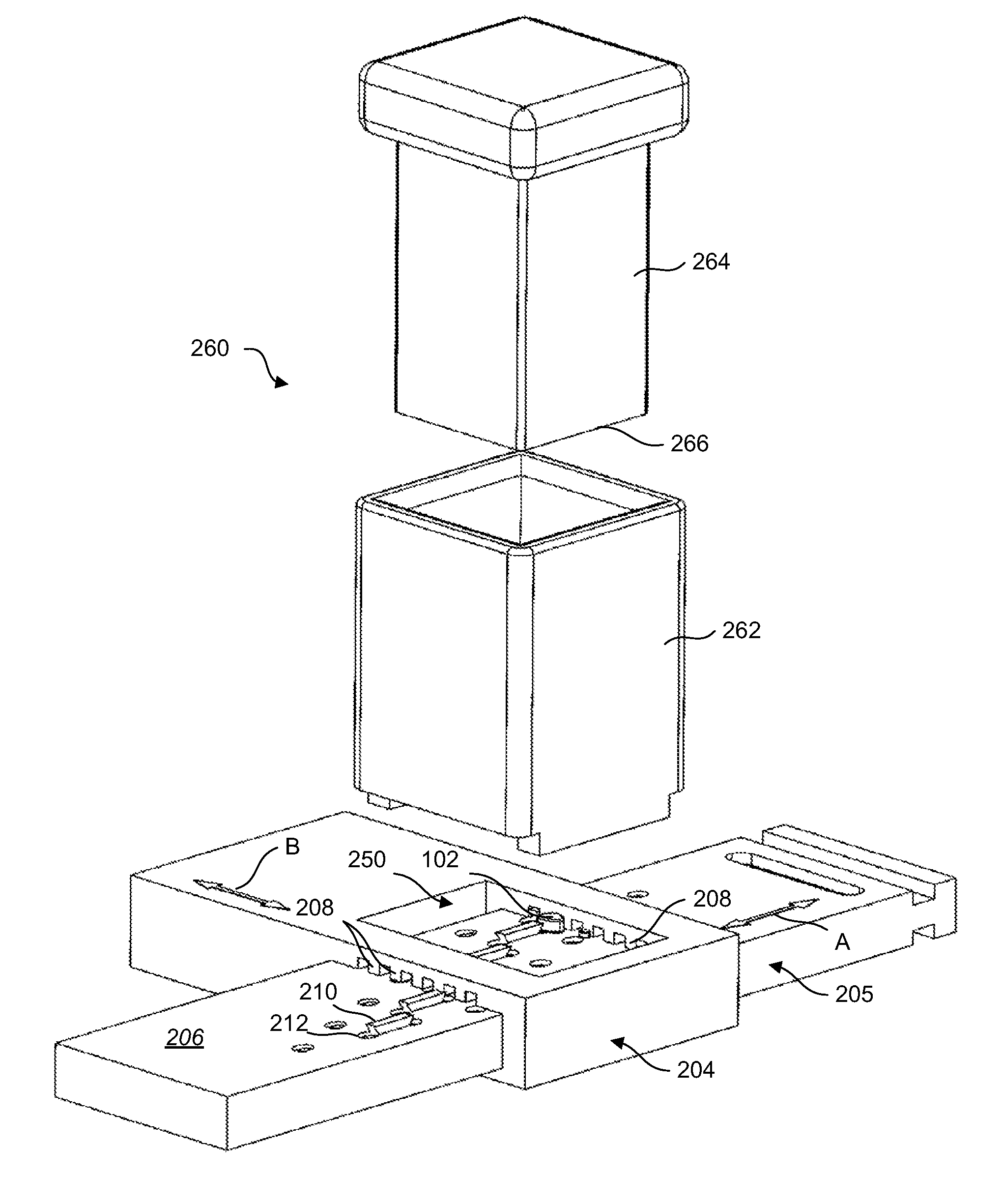

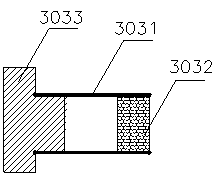

Inserts Having Geometrically Separate Materials for Slips on Downhole Tool

ActiveUS20150368994A1Reduce metal contentEasy millingFluid removalSealing/packingEngineeringFluid pressure

A downhole tool, such as a fracture plug used during a fracture operation, installs in a downhole tubular, such as casing. The tool has a mandrel with a sealing element disposed thereon between uphole and downhole ends. Slip assemblies on the mandrel can be moved to engage the downhole tubular. When the tool is used as a bridge plug, the uphole assembly supports the sealing element compressed, and the downhole assembly supports fluid pressure downhole of the tool. The slip assemblies have inserts composed of at least two materials that are different from one another and are geometrically separate from one another. In addition or as an alternative, the slip assemblies can be composed of at least two different materials that are geometrically separate from one another.

Owner:WEATHERFORD TECH HLDG LLC

Wheat variety 25R54

ActiveUS6989480B2Increase grain yieldIncrease resistanceOther foreign material introduction processesFermentationTriticeaeBiology

A wheat variety designated 25R54, the plants and seeds of wheat variety 25R54, methods for producing a wheat plant produced by crossing the variety 25R54 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety 25R54 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety 25R54. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety 25R54 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

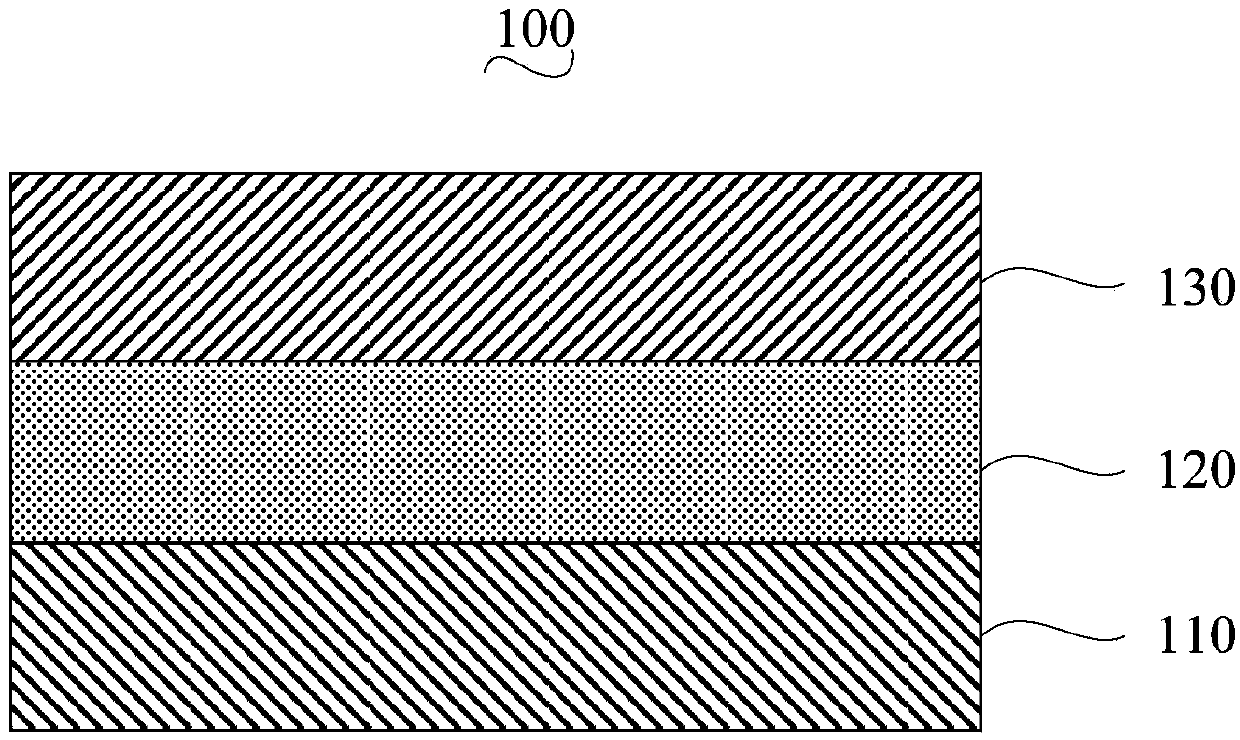

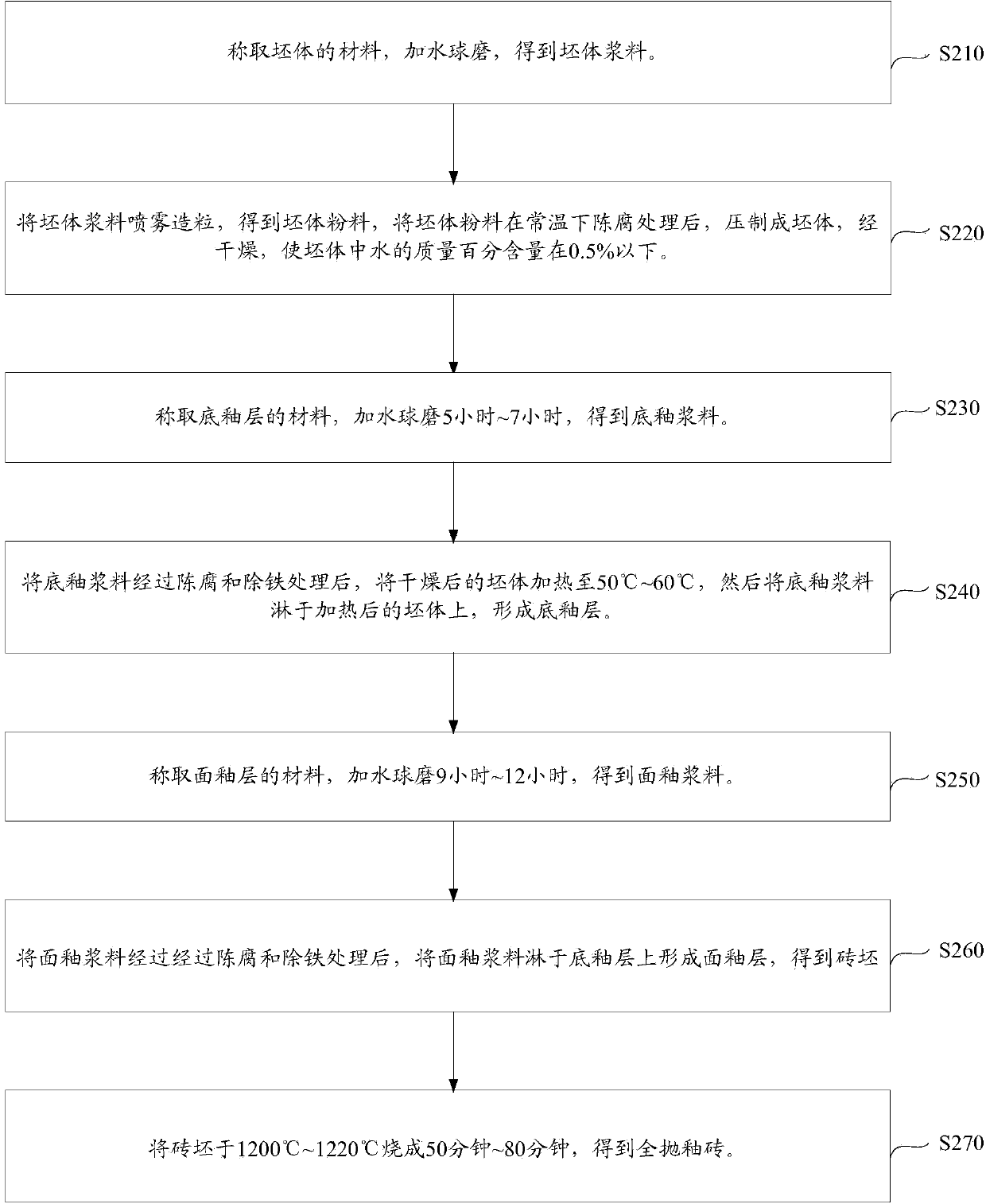

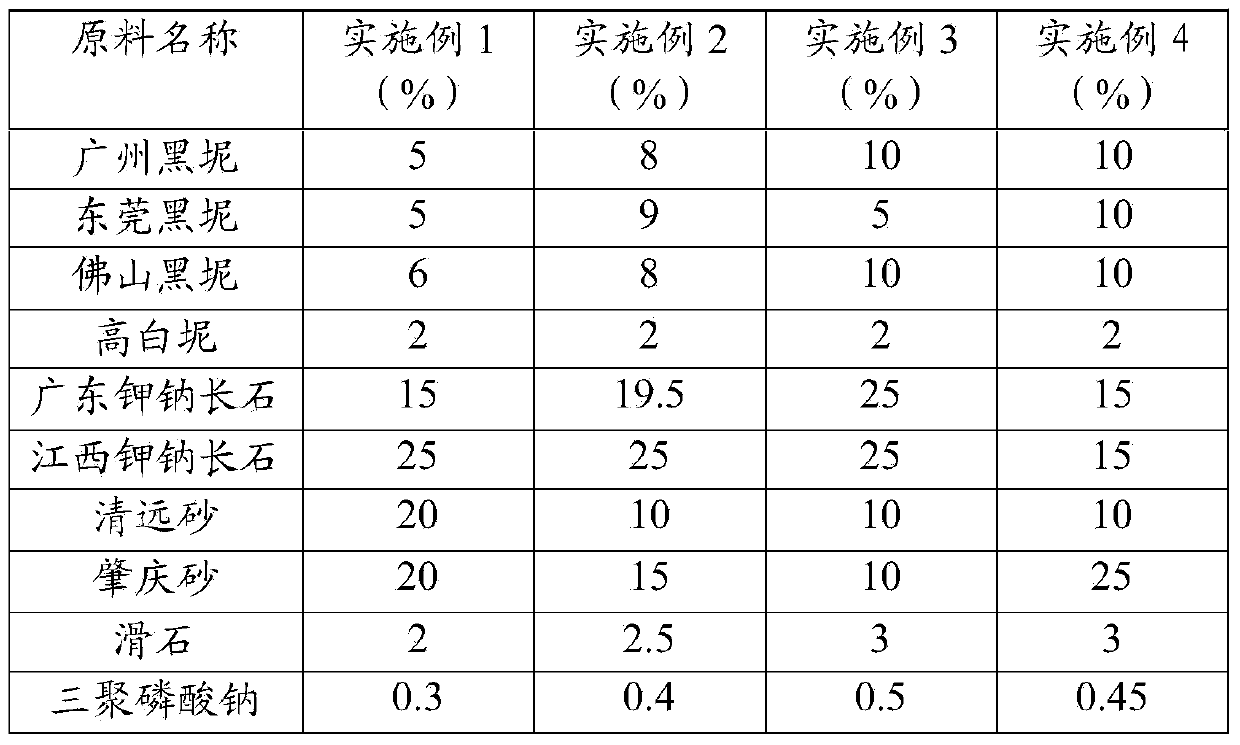

Full-glazed tile and preparation method thereof

The invention relates to a full-glazed tile. A base glaze layer is prepared from the following raw materials in percentage by weight: 15-25% of sodaclase, 5-12% of kaolin, 1-8% of aluminium hydroxide, 25-35% of quartz, 5-15% of talc, 15-20% of zirconium silicate, 0.3-1% of sodium tripolyphosphate and 4-5% of wollastonite; a cover glaze layer is prepared from the following raw materials in percentage by weight: 15-25% of sodaclase, 8-12% of kaolin, 5-9% of aluminium hydroxide, 5-15% of talc, 0.3-1% of sodium tripolyphosphate, 10-25% of potassium feldspar, 3-5% of zinc oxide, 8-20% of wollastonite and 5-18% of dolomite. The whiteness of the full-glazed tile can reach more than 80 degrees. The invention also provides a preparation method of the full-glazed tile.

Owner:广州锦盈新型材料有限公司

Apparatus for milling material

Owner:RASEKHI HOUSHANG

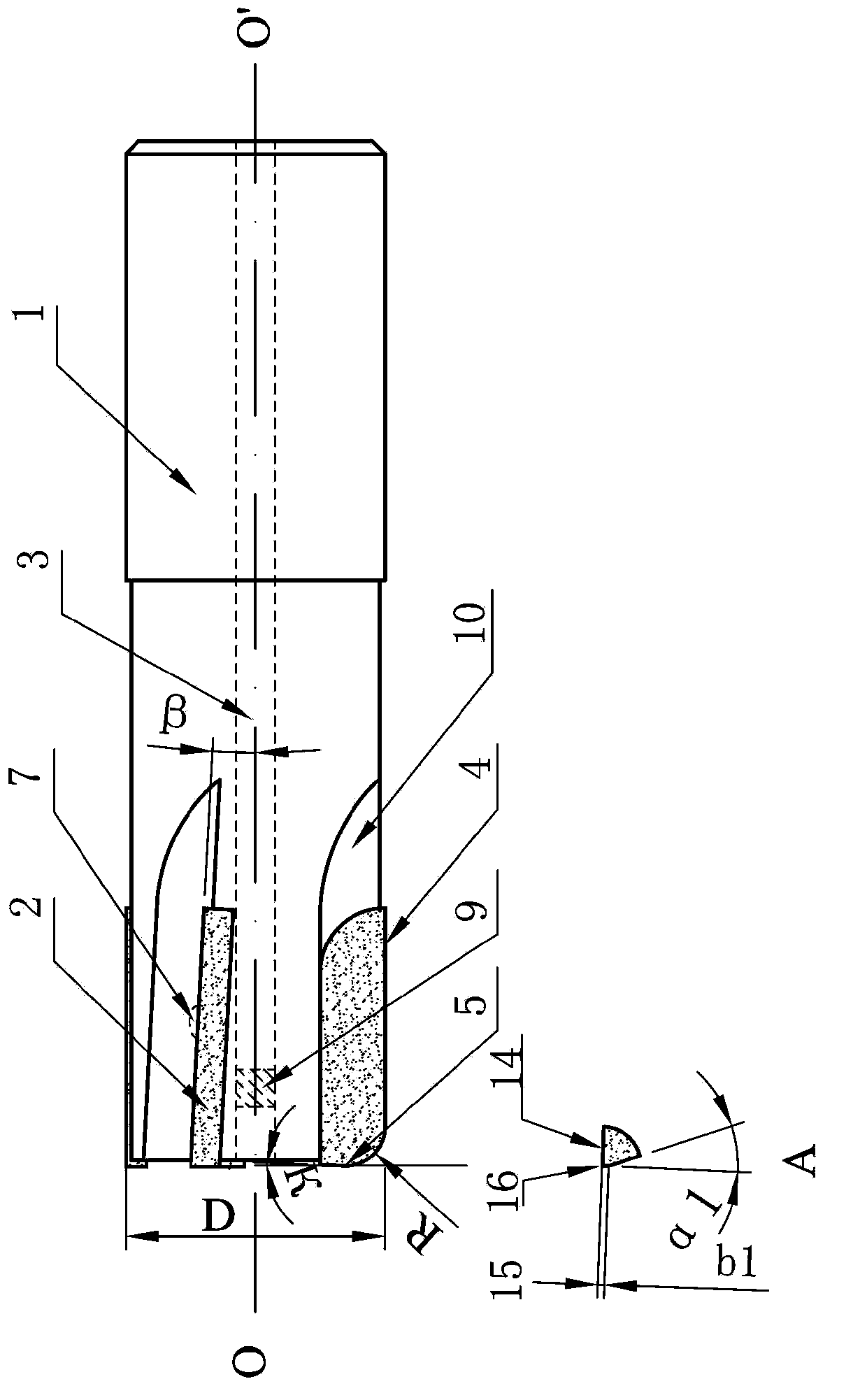

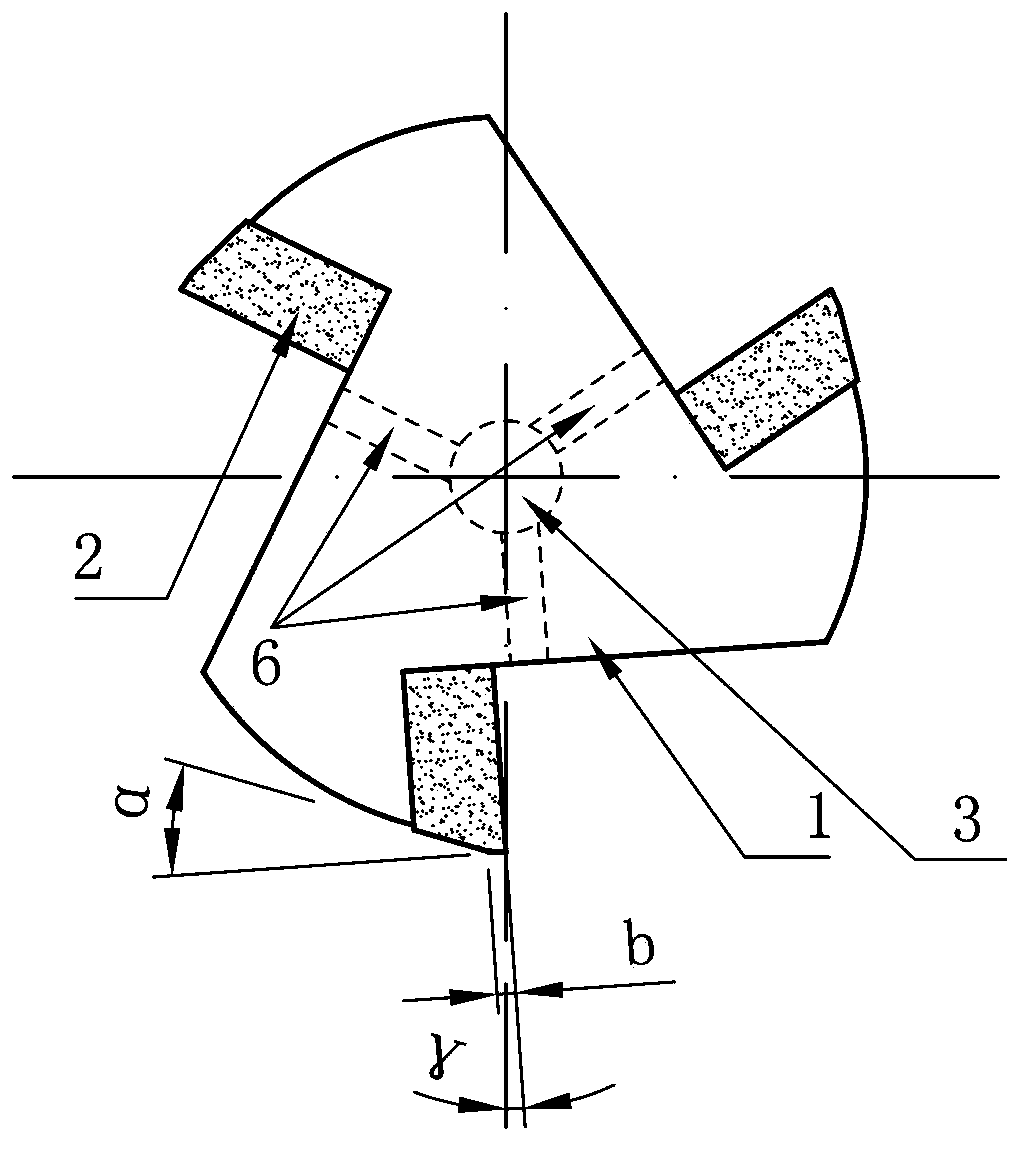

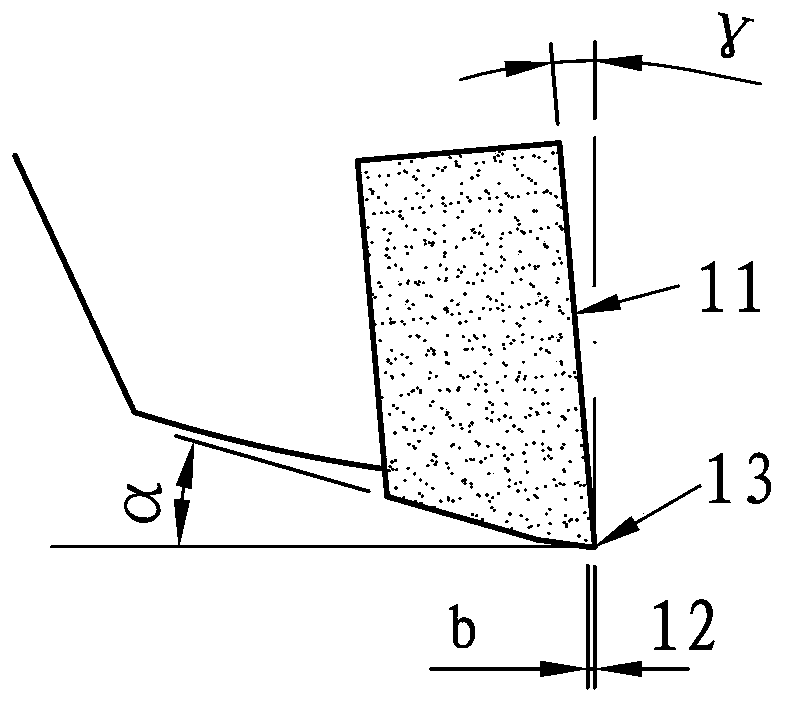

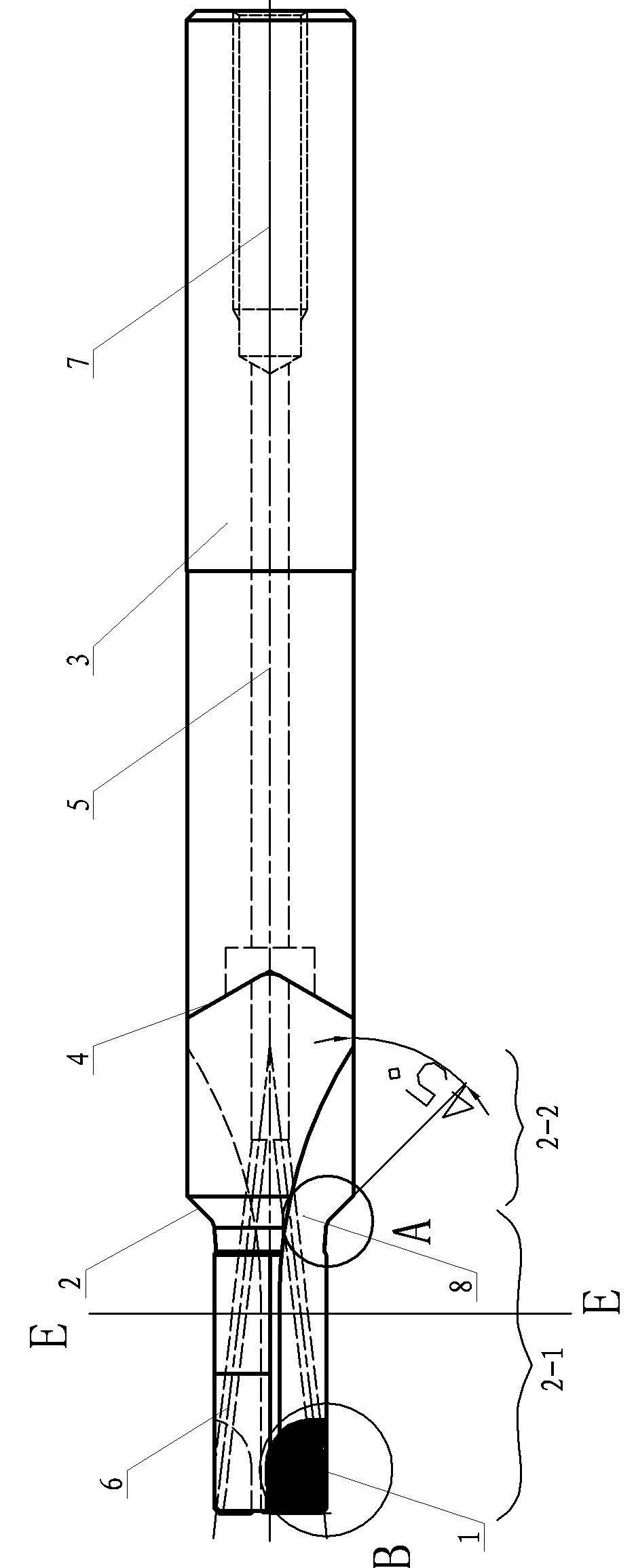

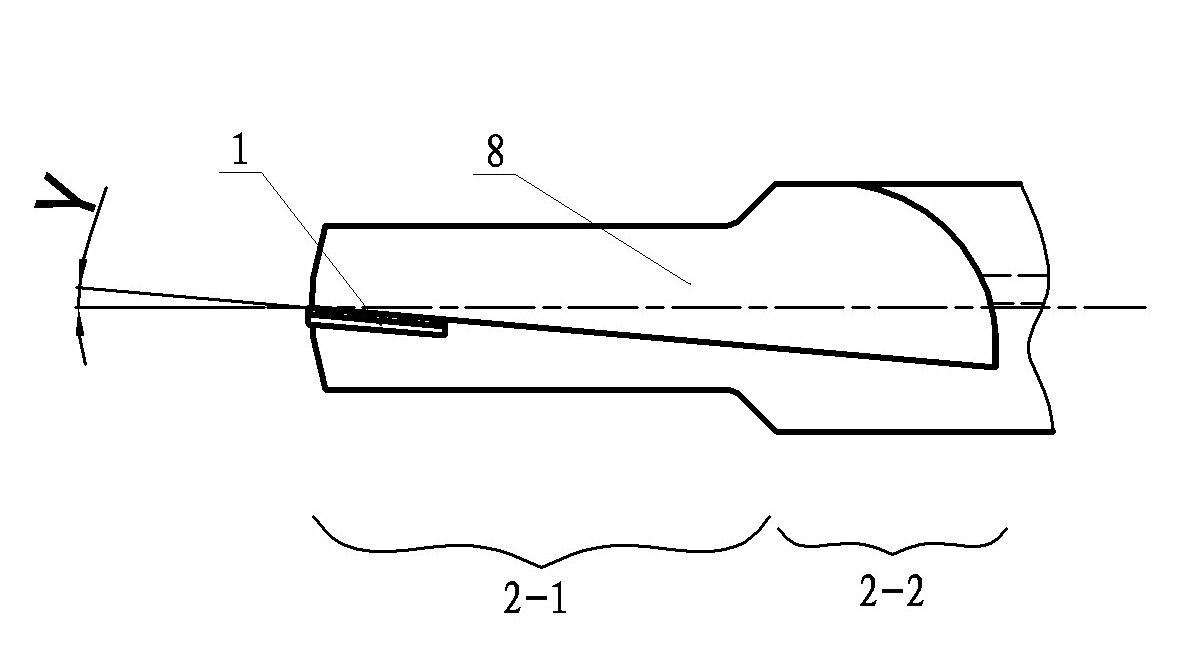

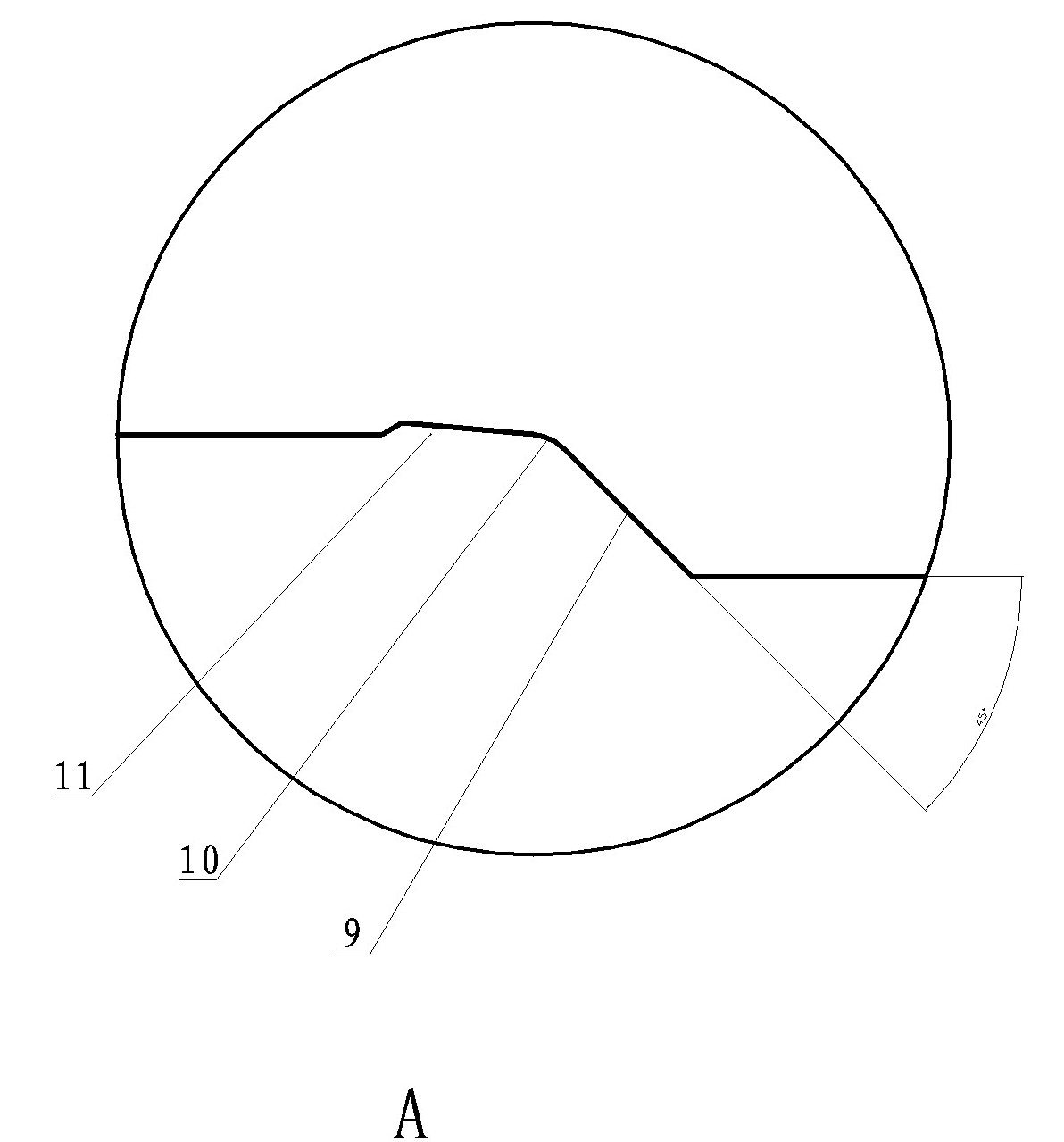

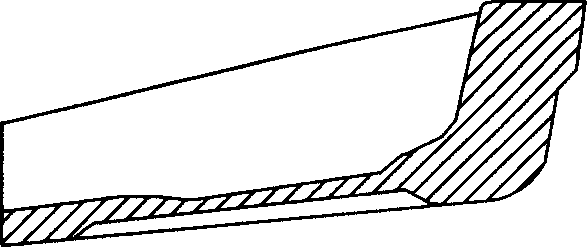

Polycrystalline diamond milling cutter

ActiveCN103658795AEasy millingSolve the sticky knife problemMilling cuttersMilling cutterPolycrystalline diamond

The invention provides a milling cutter which is used for processing a forming surface and can rotate around a central axis. The milling cutter comprises a rigid cutter body (1), polycrystalline diamond blades (2) respectively fixed on tooth bases as well as a cooling structure, wherein the cutter body is provided with at least two tooth bases (10) which are parallelly arranged at an interval; the polycrystalline diamond blades (2) can axially extend and can exceed the tail end of the rigid cutter body (1) so as to form end teeth (4), and the outmost radial sides of the polycrystalline diamond blades can limit circumference teeth (3); the cooling structure comprises a main cooling channel (3) formed in the cutter body and cooling holes (6,8) which are communicated with the main cooling channel (3) and can supply a cooling fluid to the blades (2).

Owner:JUNTEC ULTRA HARD TOOLS CO LTD

Equal-length glass tube batch production cutting device

InactiveCN106495457AReduce workloadReduce time for step-by-step processingEdge grinding machinesGlass severing apparatusBatch productionEngineering

The invention provides an equal-length glass tube batch production cutting device which comprises a base and a lift plate. A pad plate is slidably connected to the lift plate, rollers are arranged on the pad plate, a clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism, the first clamping mechanism comprises a first motor and a first transmission rod, the cutting mechanism comprises a support and a cutter arranged on the support, a first arc connection plate and a second arc connection plate are arranged on the support, the milling mechanism comprises a side wall and a milling cutter slidably connected with the side wall, and a sliding plate is slidably connected to the pad plate. By using the equal-length glass tube batch production cutting device, cutting and milling of equal-length glass tubes can be completely efficiently, staff's manual operation during the entire process is omitted, potential safety hazards of staff are reduced, production efficiency is improved, and machining cost is reduced.

Owner:天津南玻节能玻璃有限公司

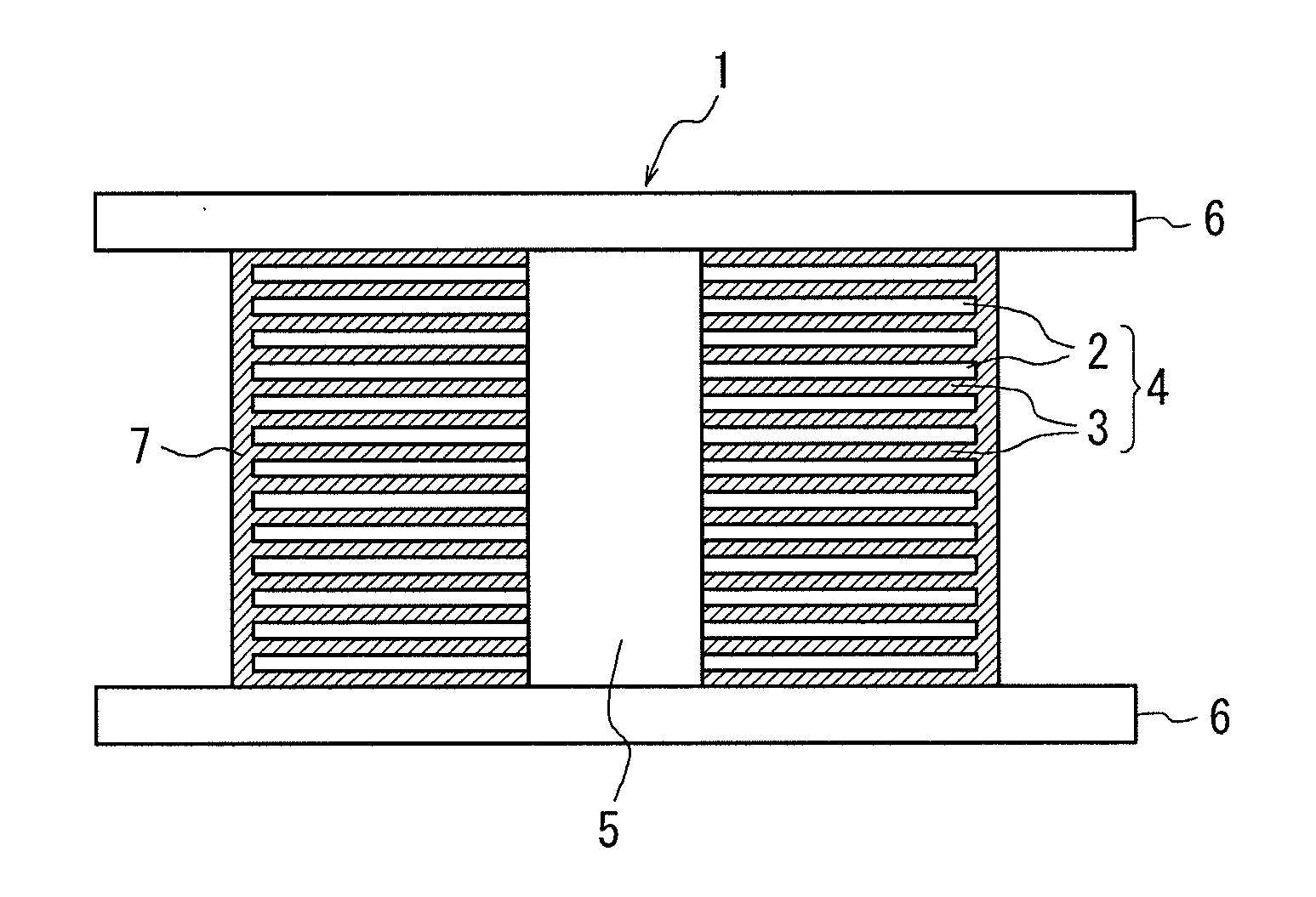

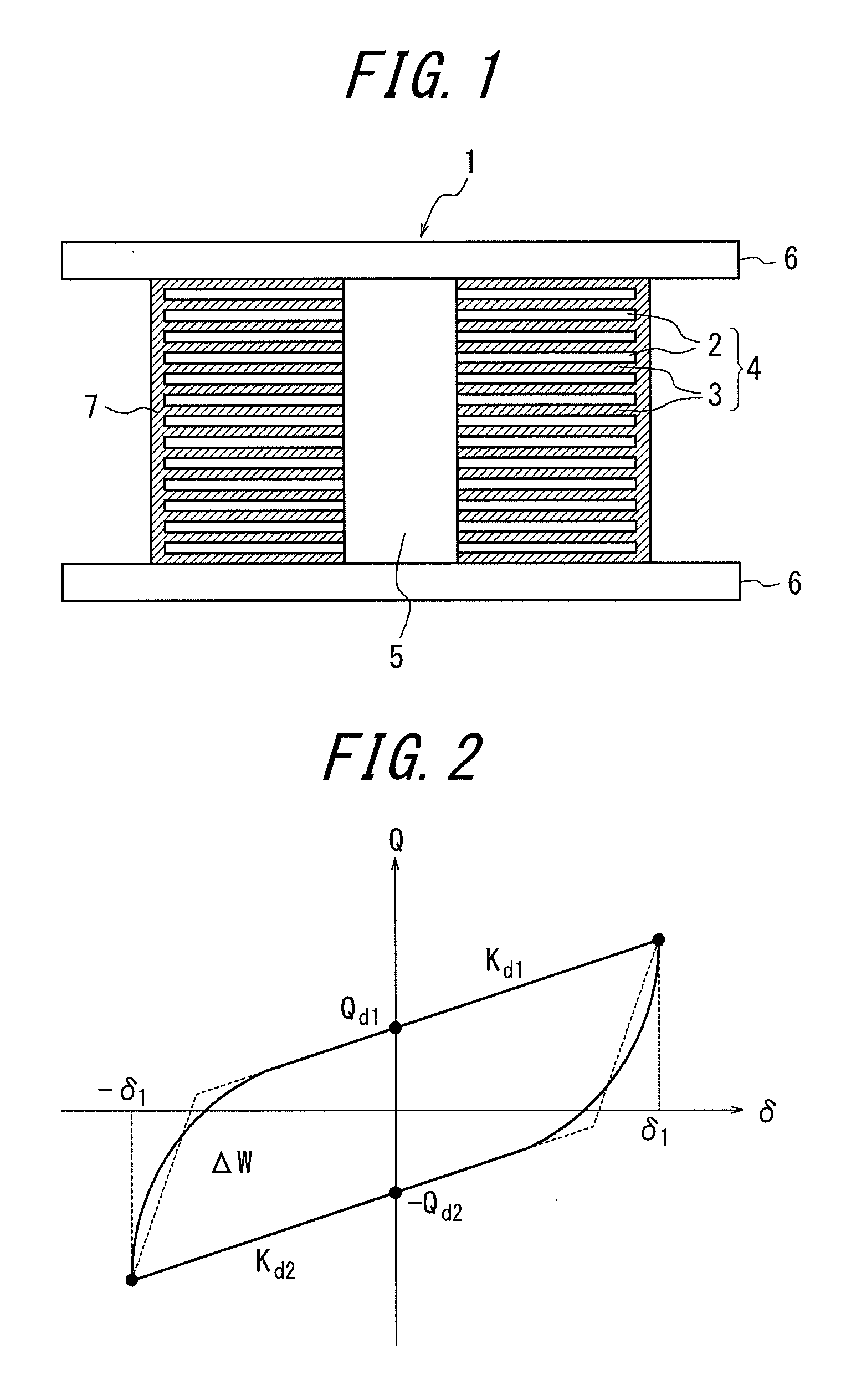

Composition for plug in base-isolated structure, plug for base-isolated structure and base-isolated structure

InactiveUS20100255233A1High viscosityFluid resistance becomes largeNon-rotating vibration suppressionSynthetic resin layered productsElastomerEngineering

This invention relates to a composition for plug in a base-isolated structure capable of providing a plug for base-isolated structure having sufficient damping performance, displacement following property and the like, and more particularly to a composition for plug in a base-isolated structure characterized by including powder and an elastomer composition formed by compounding an elastomer component with a reinforcing filler.

Owner:BRIDGESTONE CORP

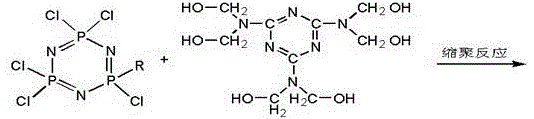

Impregnated paper finished OSB composite floor and preparation method

ActiveCN105464335ALow costGood value for moneyAldehyde/ketone condensation polymer adhesivesFlooringPulp and paper industryUltimate tensile strength

The invention relates to a plate, in particular to an impregnated paper finished OSB composite floor and a preparation method. The impregnated paper finished OSB composite floor sequentially comprises an OSB base material layer, a veneer layer, a buffer paper layer, a balance paper layer and a sprayed decorative paper layer from bottom to top. The longitudinal static bending intensity of the OSB base material layer is larger than or equal to 50 MPa, and the water absorption thickness swelling rate of the OSB base material layer is smaller than or equal to 12%. The veneer layer is a poplar bleached veneer, and the thickness ranges from 0.6 mm to 1.2 mm. The buffer paper layer is impregnated kraft paper with the thickness of 0.4 mm to 0.6 mm, and the glue quantity is 80% or above. The weight of the balance paper layer ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The weight of the sprayed decorative paper ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The impregnated paper finished OSB composite floor has high environment friendliness, stability and water resistance.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for preparing conductive powder by recoating aluminum-doped nano zinc oxide with aluminum

InactiveCN103570056AImprove dispersionSmall particle sizeMaterial nanotechnologyZinc oxides/hydroxidesIonNano zinc oxide

The invention discloses a method for preparing conductive powder by recoating aluminum-doped nano zinc oxide with aluminum. The method comprises the following steps: firstly, preparing aluminum-doped zinc oxide powder; secondly, coating the aluminum-doped zinc oxide powder with an aluminum-containing film; finally, mixing the coated aluminum-doped zinc oxide powder with zinc powder, grinding, and calcining in an inert gas atmosphere to obtain the conductive powder. The method has the advantages that the zinc oxide conductive powder is prepared through primary aluminum doping and secondary aluminum coating, the primary aluminum doping improves the whiteness and the water dispersion of the nano zinc oxide and reduces the particle size of the nano zinc oxide, and the secondary aluminum coating further increases the defect concentration of zinc oxide crystals and improves the conductivity of the nano zinc oxide; the aluminum-doped zinc oxide is coated with a thin oxide film, so that zinc ions in water are unlikely to dissolve out, and the ball milling process of the zinc powder and the aluminum-doped zinc oxide is facilitated; the prepared conductive powder is high in conductive ability, small in particle size, light in color, wide in sources of raw materials, low in production cost, simple in preparation method, high in security, relatively light in environmental pollution, and suitable for industrial mass production.

Owner:JIANGSU DONGTAI FINE CHEM

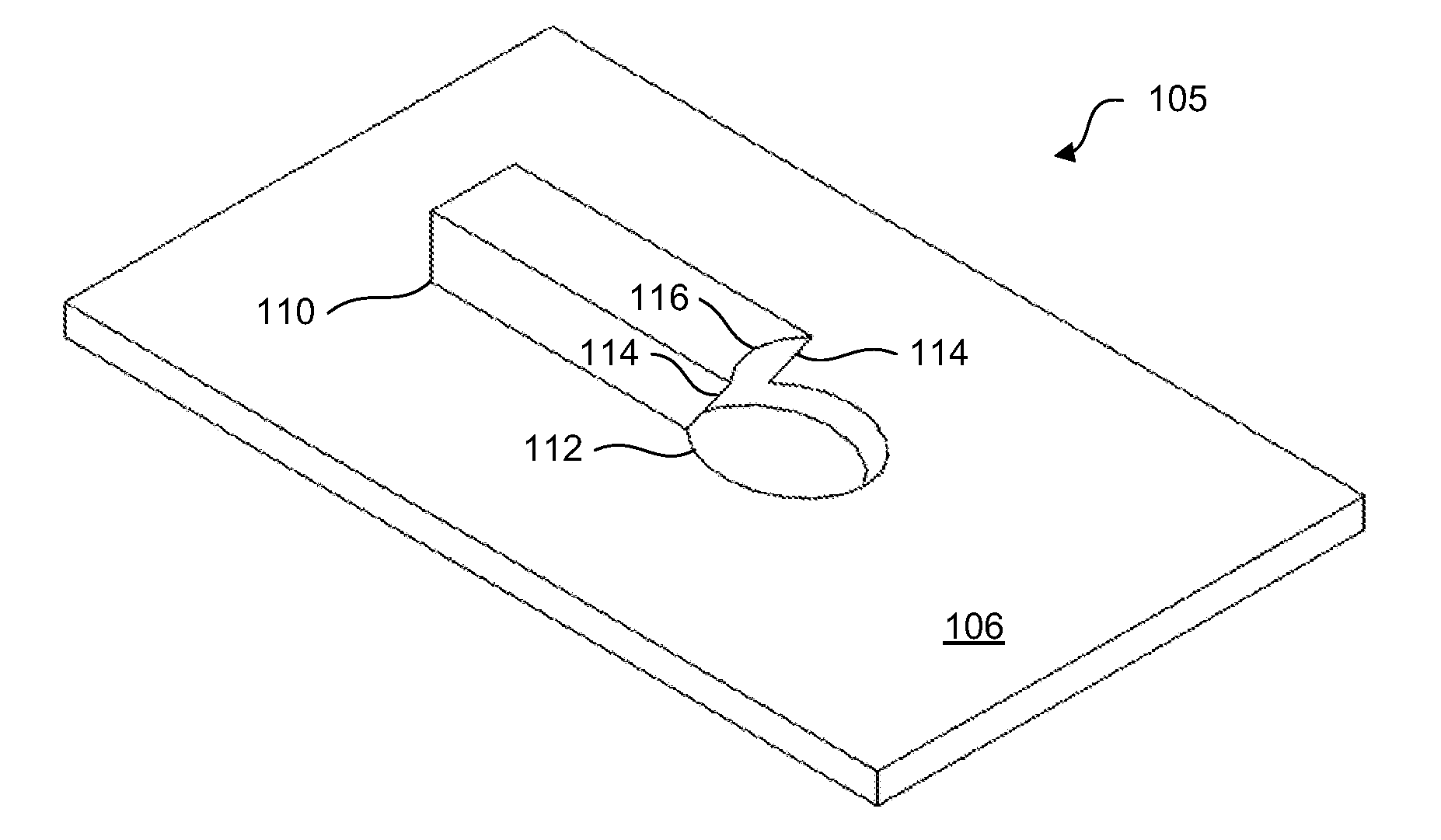

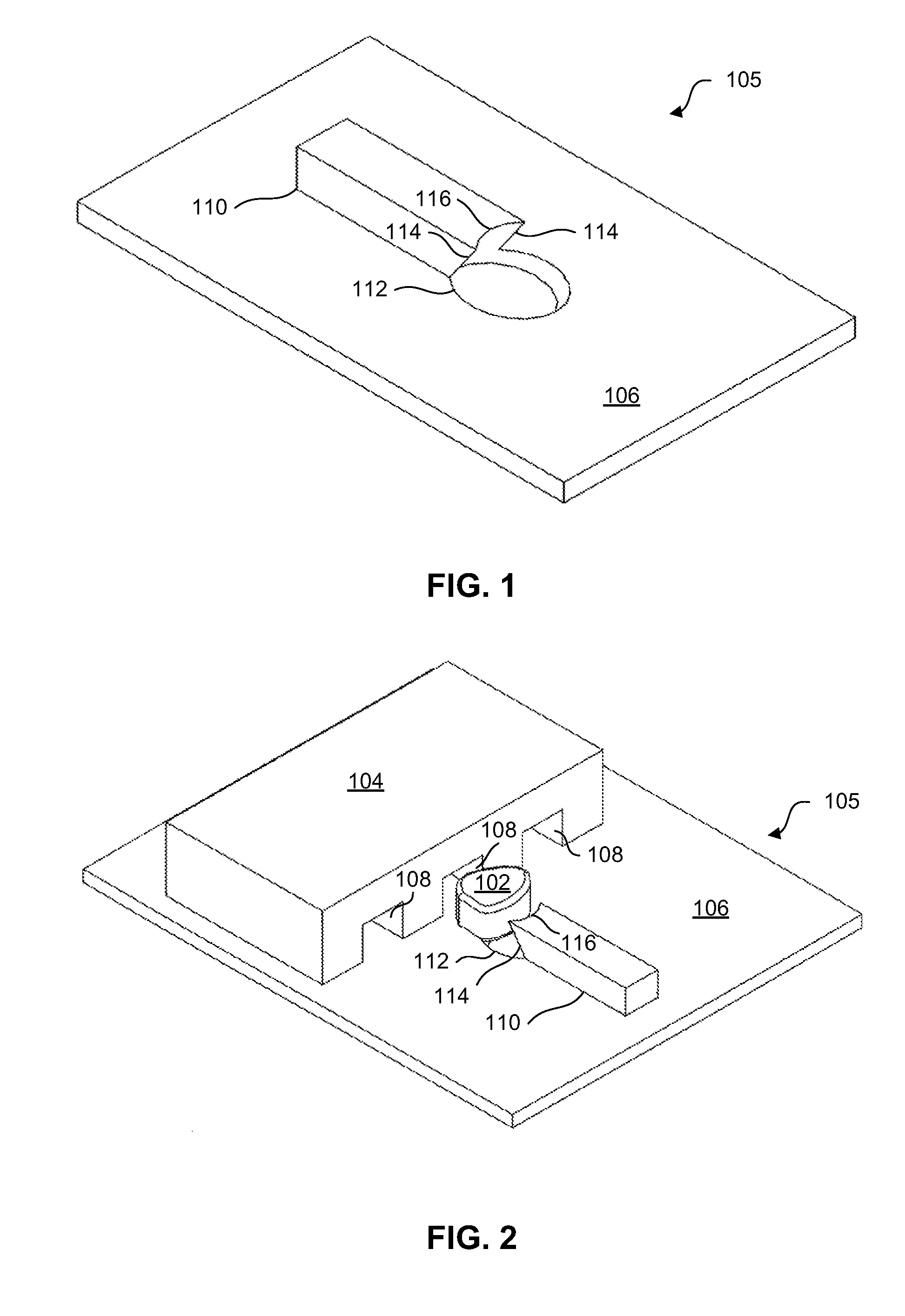

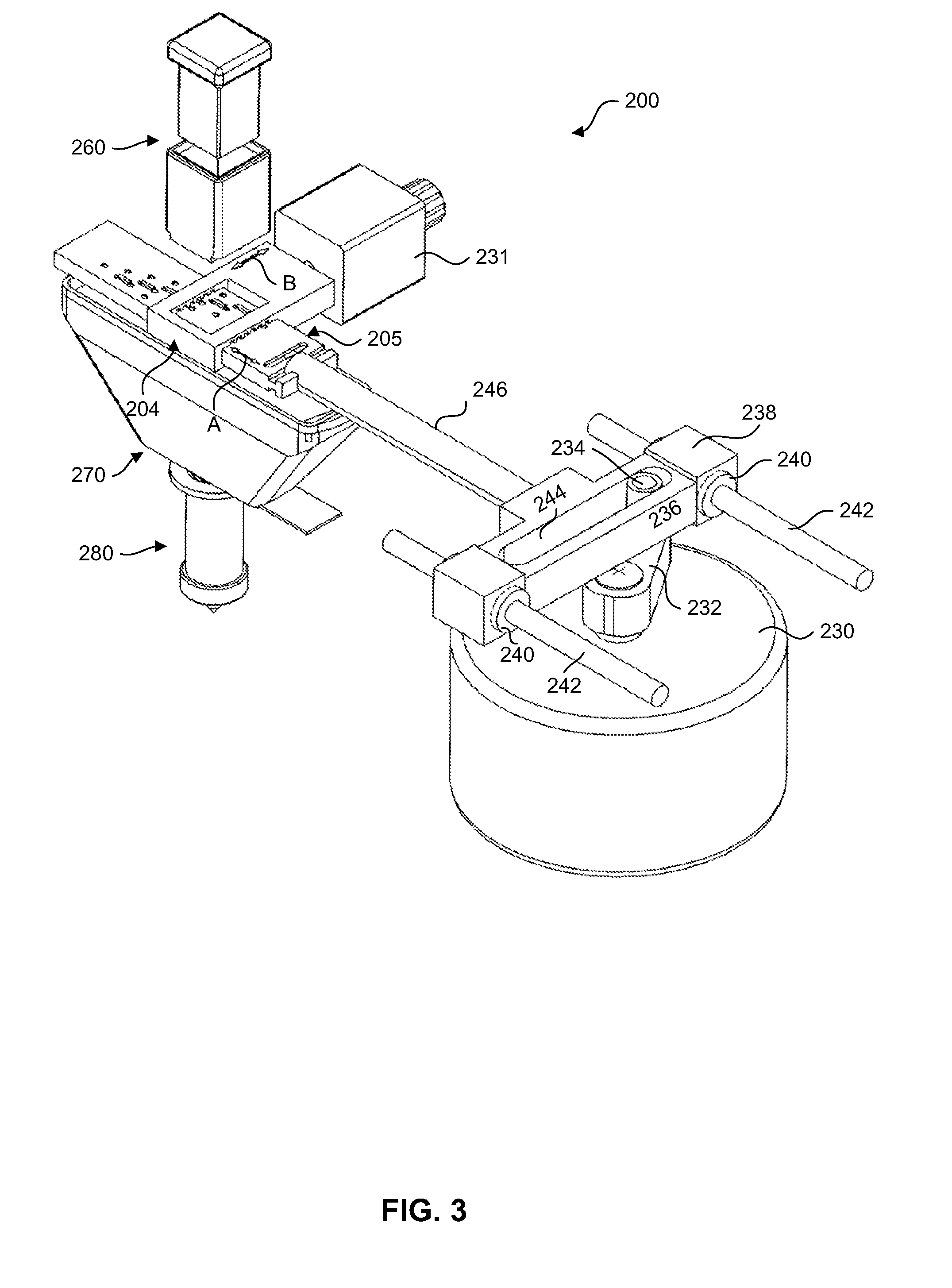

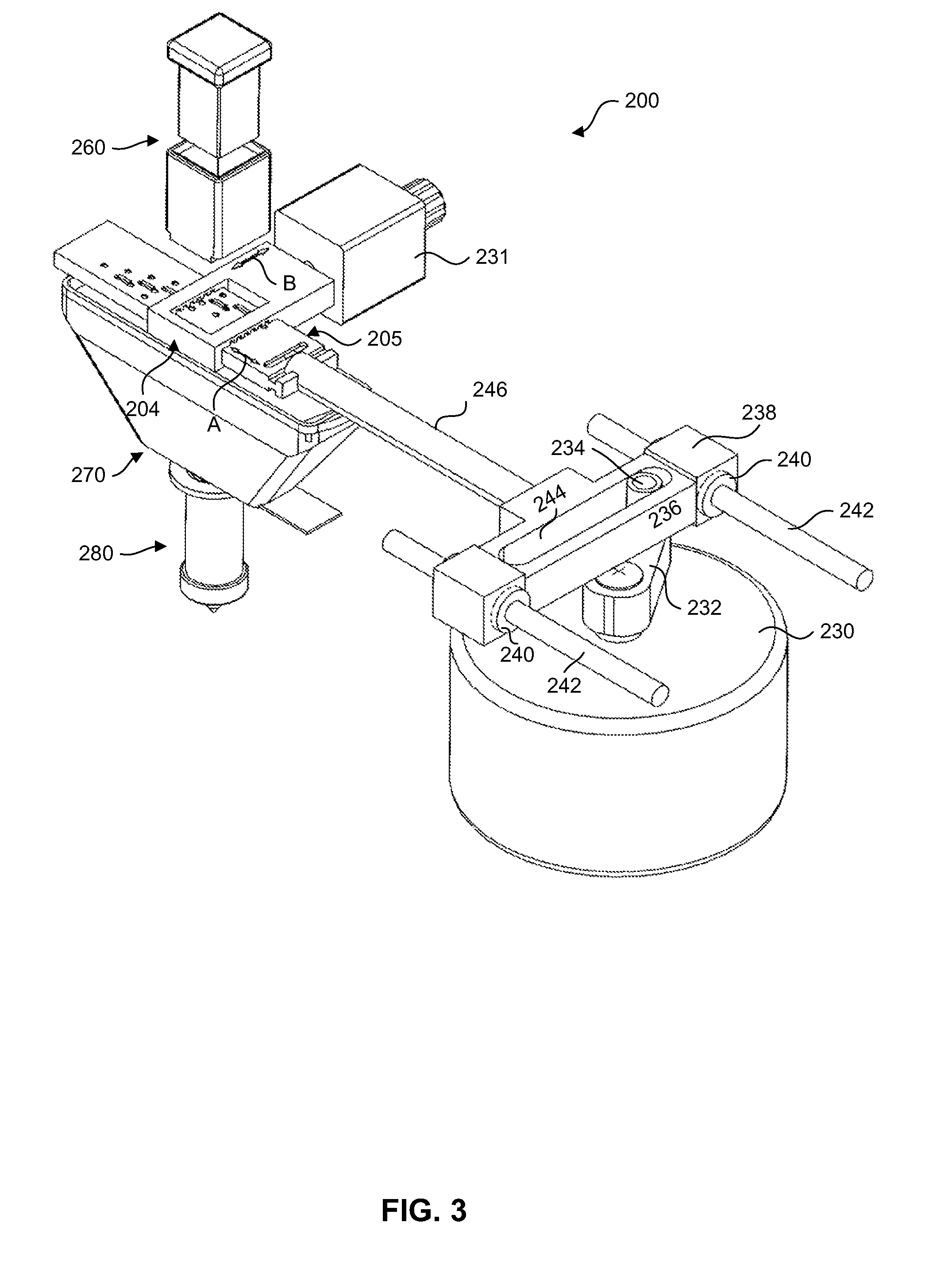

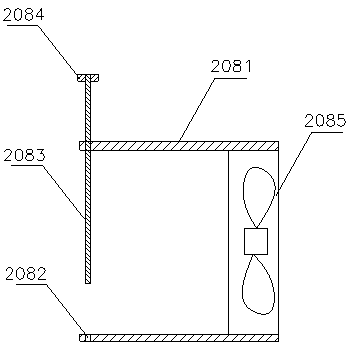

Wellbore composite plug assembly

InactiveUS20150013965A1Easy and efficientAvoid flowFluid removalSealing/packingEngineeringMetallic materials

A down hole tool assembly can be installed at a desired location within a subterranean wellbore that is capable of isolating one portion of the wellbore from another, while sealing fluid pressure within the wellbore from at least one direction. The plug assembly can include components constructed of non-metallic material that can be drilled, milled or mechanically broken up more quickly and efficiently than conventional wellbore plugs.

Owner:DRILSEAL L L C

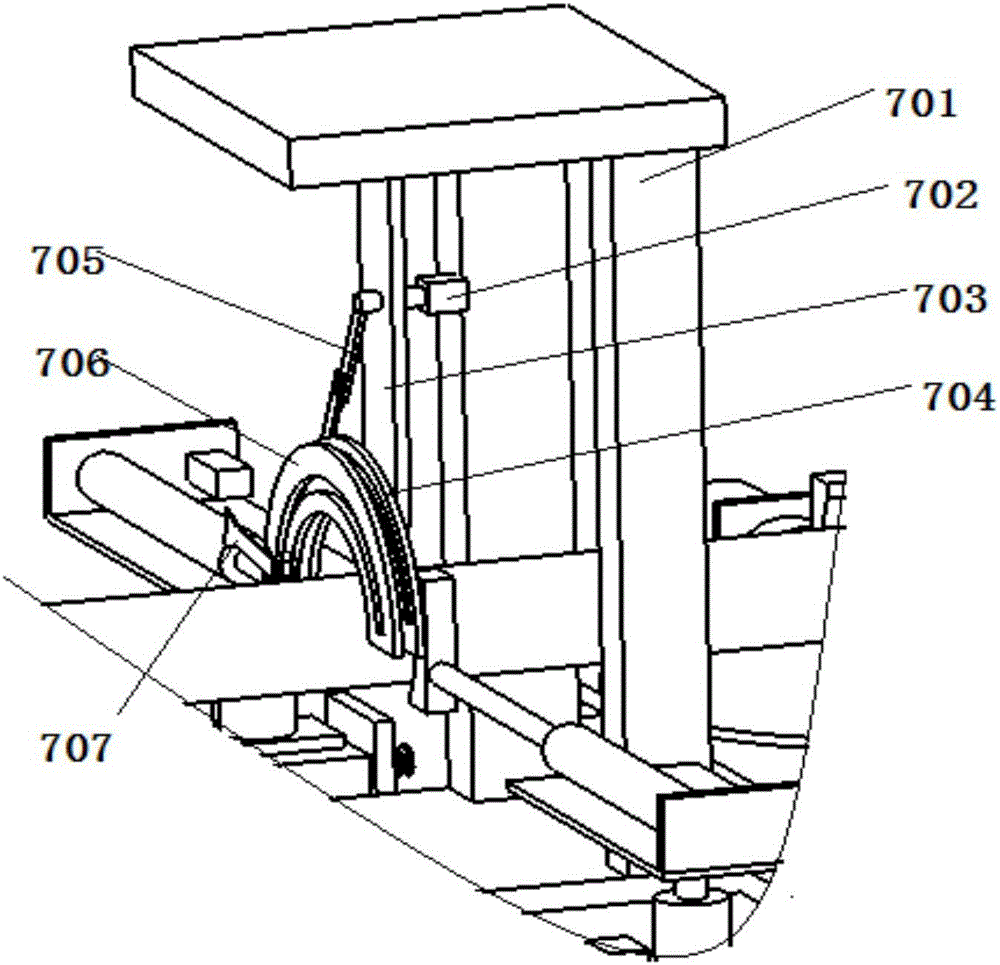

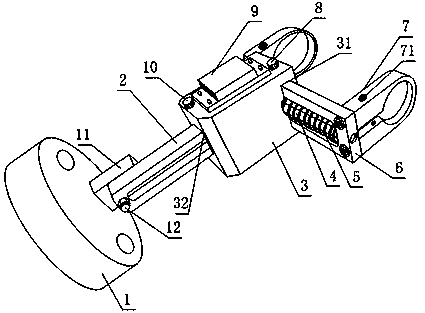

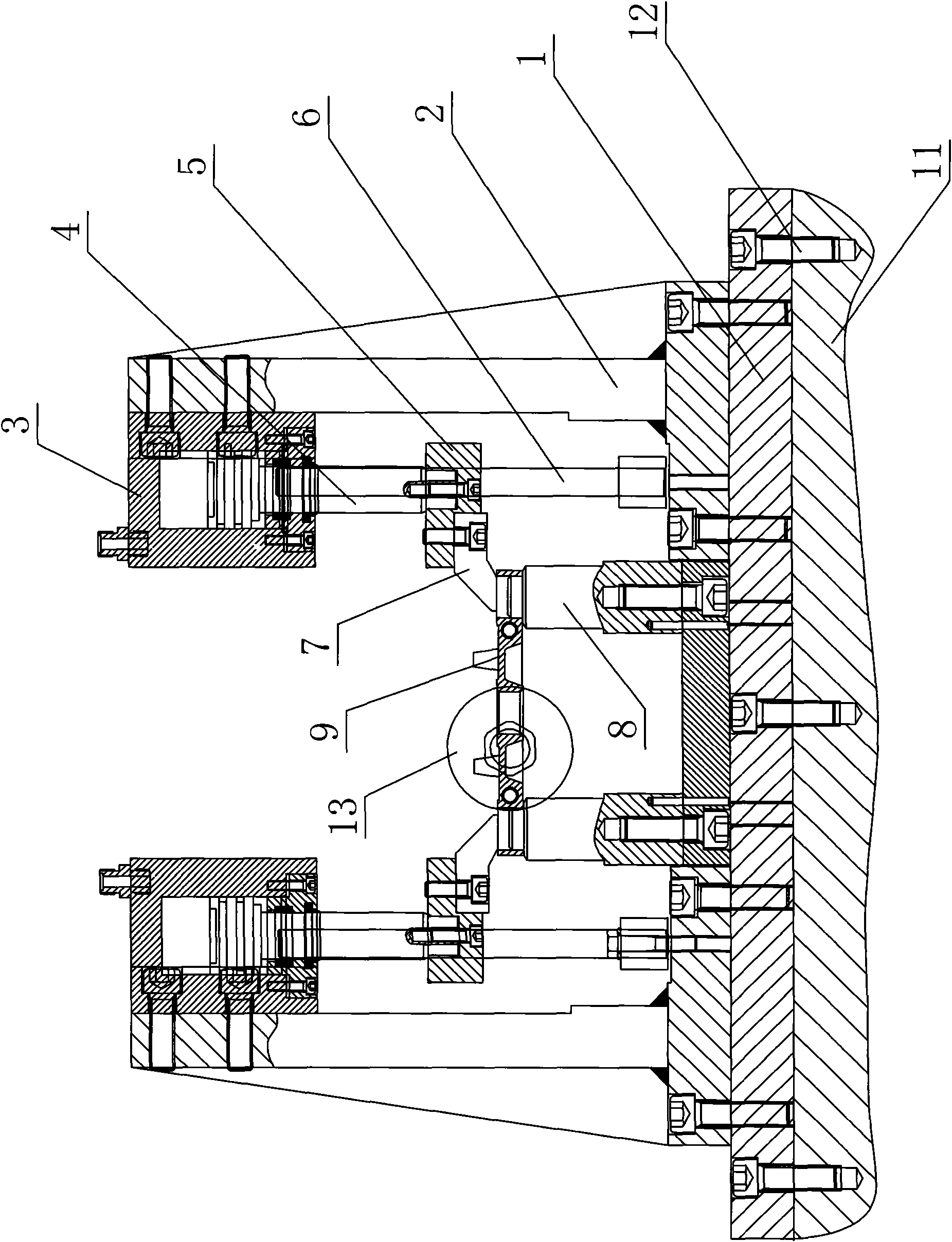

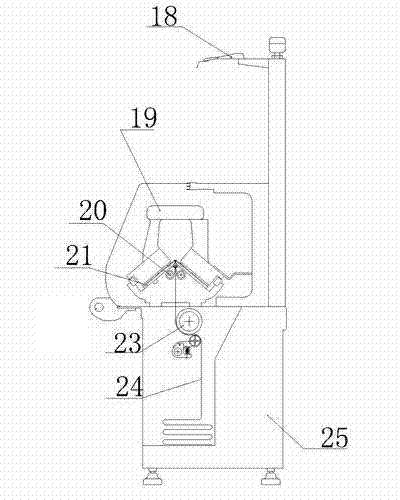

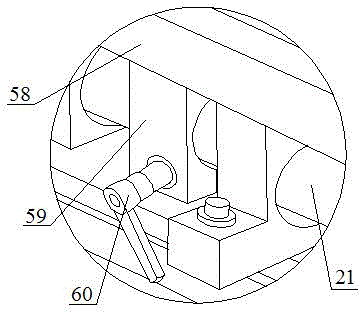

Pistol-drill clamping mechanism suitable for milling of circular groove

InactiveCN104028803AImprove machining accuracyImprove processing efficiencyPortable power-driven toolsWork benchesDrillHinge angle

The invention discloses a pistol-drill clamping mechanism suitable for milling of circular grooves. The pistol-drill clamping mechanism comprises at least two hoop-shaped hoop portions, a first sliding base, a second sliding base, a sliding block and a pedestal. The pedestal is further provided with a hinge rod, the hoop portions are parallel and are respectively fixed to one end of the second sliding base, the first sliding base and the second sliding base are respectively provided with a sliding rail, the sliding block is provided with a first sliding groove and a second sliding groove which are matched with the sliding rails respectively, and the first sliding groove is perpendicular to the second sliding groove. The hinge rod or the first sliding base is further provided with a hinge nail, the hinge rod is connected with the first sliding base in a hinged mode through the hinge nail, and the first sliding base can rotate around the axis of the hinge nail. The pistol-drill clamping mechanism is simple in structure, and hole milling is conveniently carried out through a pistol drill; compared with the situation that the pistol drill is held by an operator with hand in the prior art, arcs with the same diameter or arcs with different diameters are milled conveniently, and improvement on machining precision and machining efficiency of the pistol drill is facilitated.

Owner:API ZC PRECISION INSTUMENT CO LTD

Precise composite reamer

InactiveCN102672277AEffective protectionImprove roundnessReaming toolsPolycrystalline diamondEngineering

The invention discloses a precise composite reamer. The precise composite reamer comprises a reamer handle, a reamer head and two blades, wherein the reamer handle is welded with the tail part of the reamer head; the reamer head comprises a cylindrical section and a working section; the working section of the reamer head is provided with two diagonal V-shaped chip discharging grooves; the two blades are respectively arranged at the front ends of the two V-shaped chip discharging grooves and are composite blades made of polycrystalline diamond (PCD); the reamer head is made of YG8; the reamer handle is made of GCr15; the reamer handle and the tail part of the reamer head are in V-shaped welding, and the direction of V-shaped welding and the diagonal direction of the two V-shaped chip discharging grooves are vertical. The part of the reamer head participating in cutting is made of YG8, so that (1) the rigidity of the reamer is increased; and (2) the part of the reamer participates in machining of chamfering and arc transition and also participates in cutting similarly to the PCD blades, so that the process requirements are met, and the cost is saved. The handle part is made of GCr15, so that the production cost of the reamer is reduced, simultaneously the machining difficulty of a thread hole in the tail part of the reamer handle is reduced, the production efficiency is increased and the production cost of the reamer is reduced.

Owner:ZHENGZHOU DIAMOND PRECISION MFG

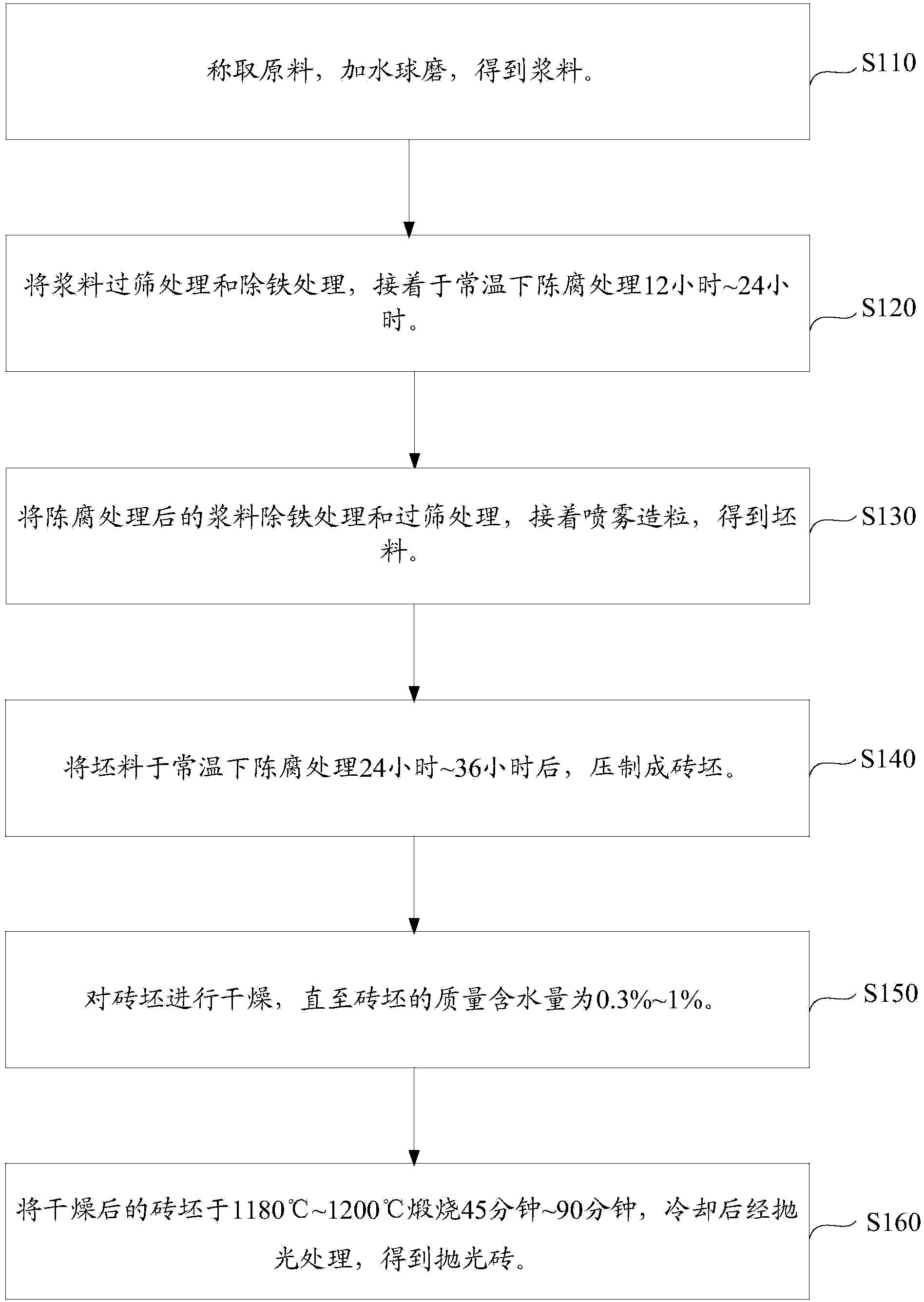

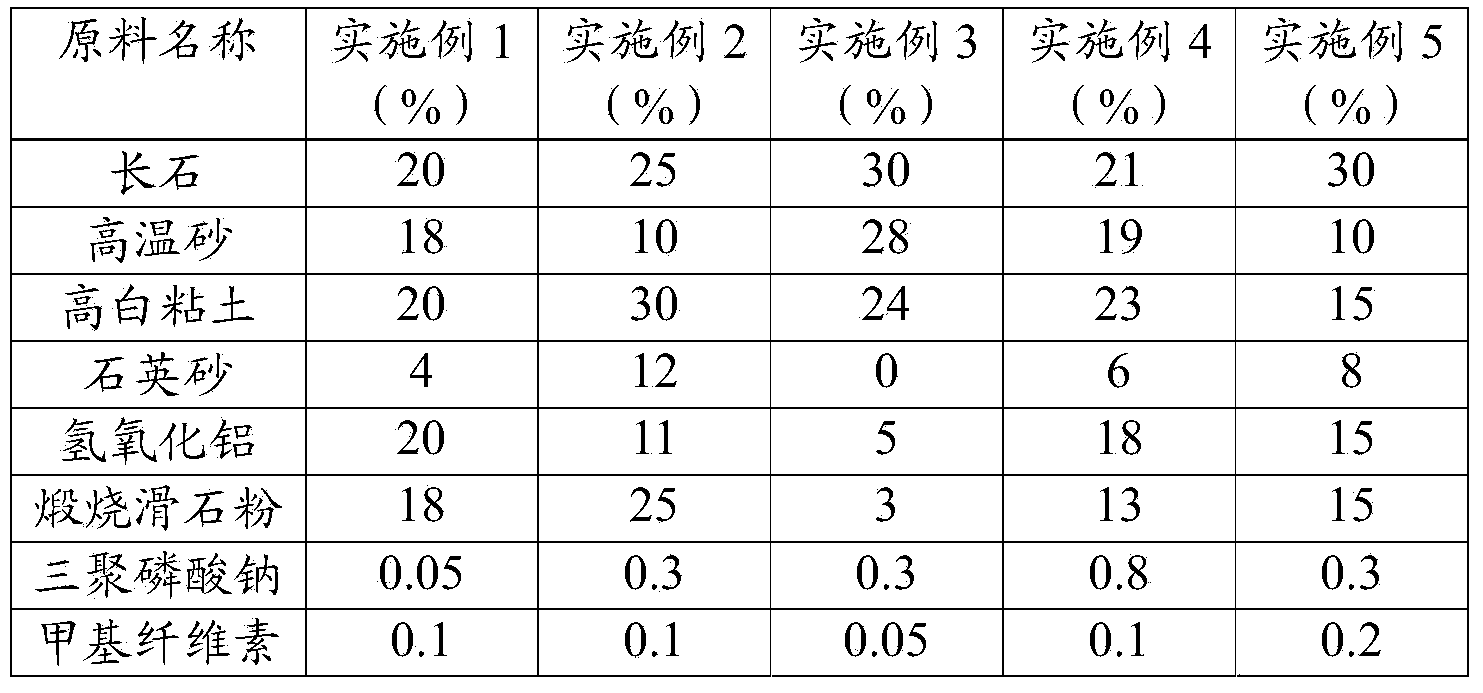

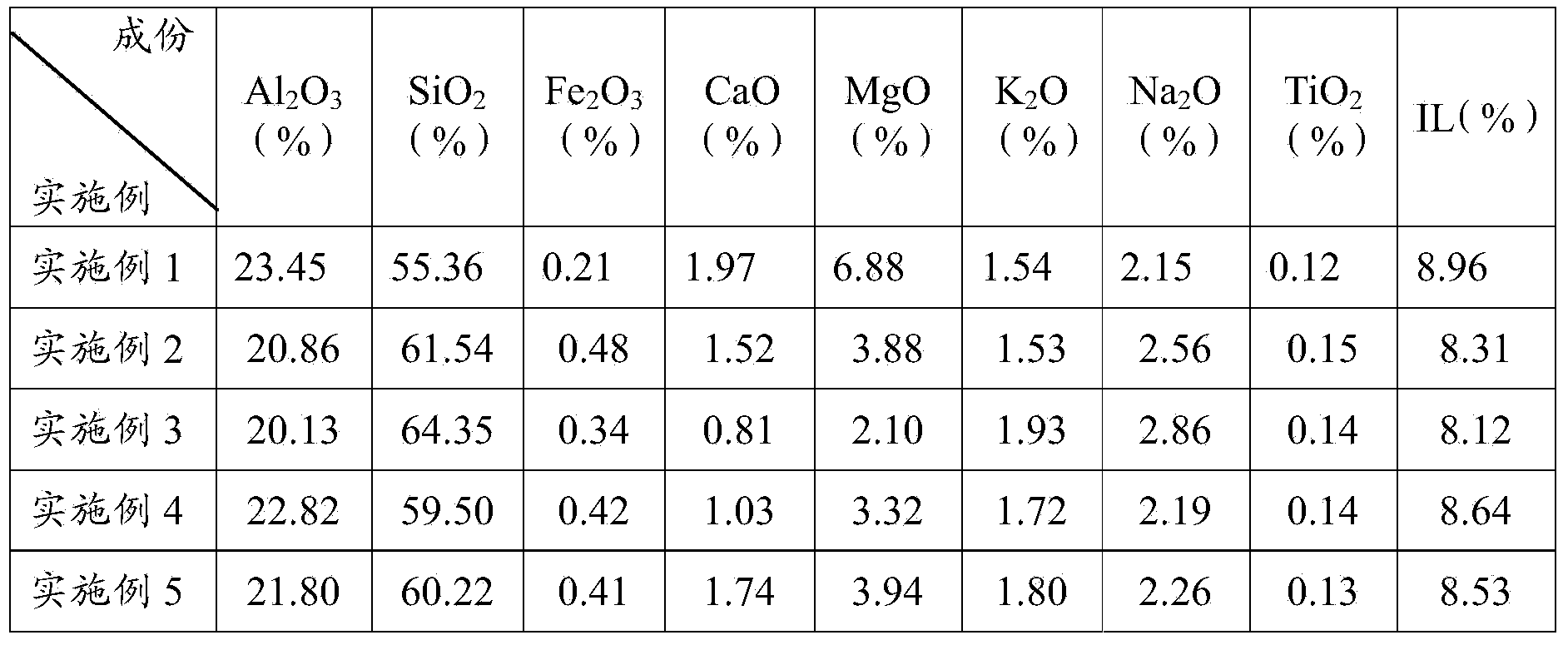

Polished tile, and preparation method and application thereof

InactiveCN103708811AHigh whitenessImprove the problem of poor luminosityClaywaresFeldsparSodium triphosphate

The invention discloses a polished tile. The polished tile is obtained by firing a blank prepared from the following raw materials in percentage by mass: 20-30 percent of feldspar, 10-28 percent of high-temperature sand, 15-30 percent of high white clay, 0-12 percent of quartz sand, 5-20 percent of aluminum hydroxide, 3-25 percent of calcined talcum powder, 0.5-0.8 percent of sodium tripolyphosphate and 0.05-0.2 percent of methylcellulose. The polished tile is environment-friendly, high in whiteness and good in performance. Furthermore, the invention also provides a preparation method and the application of the polished tile.

Owner:广州锦盈新型材料有限公司

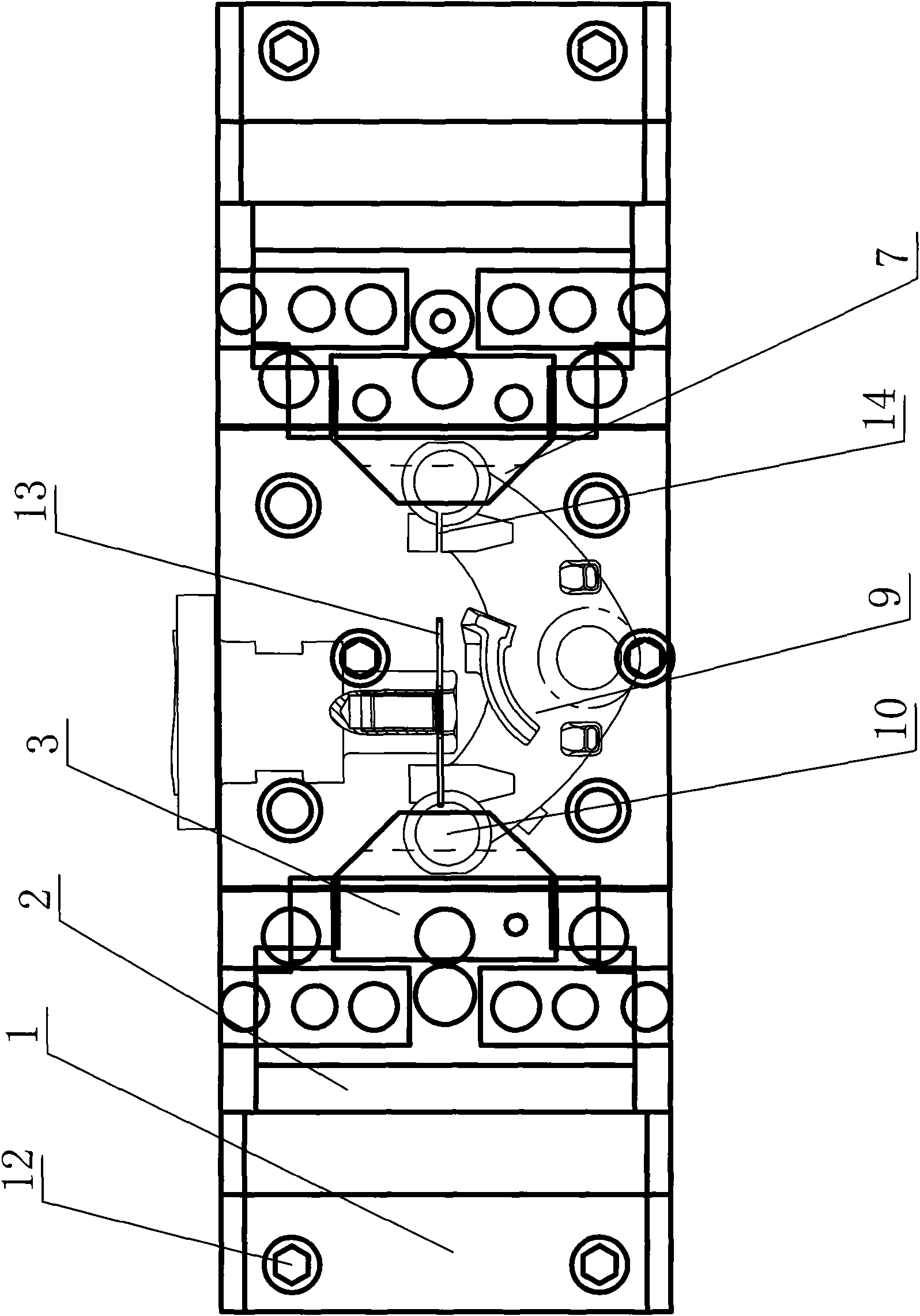

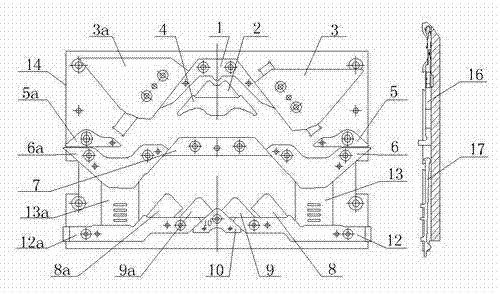

Special clamp for zero-angle opening of lower connecting plate of horizontal milling miller

InactiveCN101890644AEasy clampingEasy to fixMilling equipment detailsPositioning apparatusEngineeringMechanical engineering

The invention discloses a special clamp for a zero-angle opening of a lower connecting plate of a horizontal milling miller. The special clamp comprises a bottom plate fixedly arranged on a work table; the left end and the right end of the bottom plate are fixedly provided with an oil cylinder seat respectively; the upper ends of the oil cylinder seats are fixedly provided with a hydraulic oil cylinder respectively; the piston rods of the hydraulic oil cylinders are respectively provided with an active block; the active blocks are respectively arranged on a guide pillar matching therewith in a sliding manner; a pressure plate is arranged on each active block; the bottom plates below the pressure plates are respectively provided with a location pillar matching therewith; and the upper ends of the location pillars are mutually matched with two installation holes arranged on the lower connecting plate of the horizontal miller. The special clamp has the advantages of convenient clamping, high work efficiency and simple operation, can well fix the lower connection plate of the horizontal miller and facilitate milling of the zero-angle opening of the lower connecting plate of the horizontal miller; and the positions for clamping workpieces are the same every time, without the need of frequent tool setting.

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

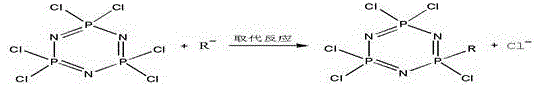

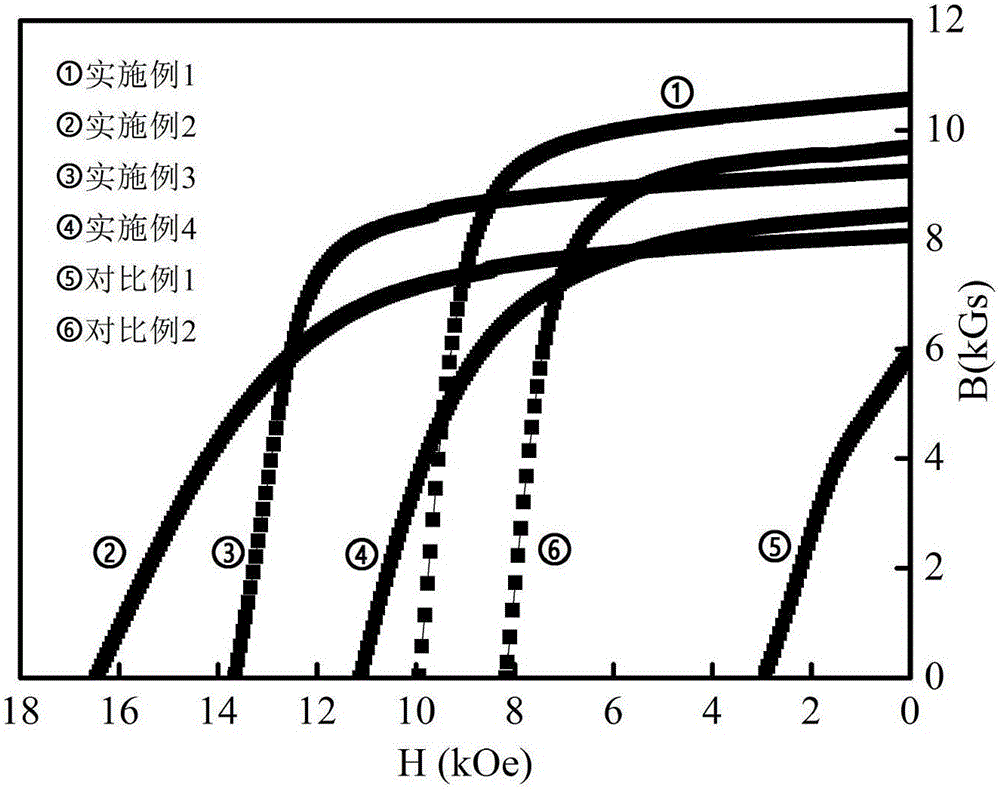

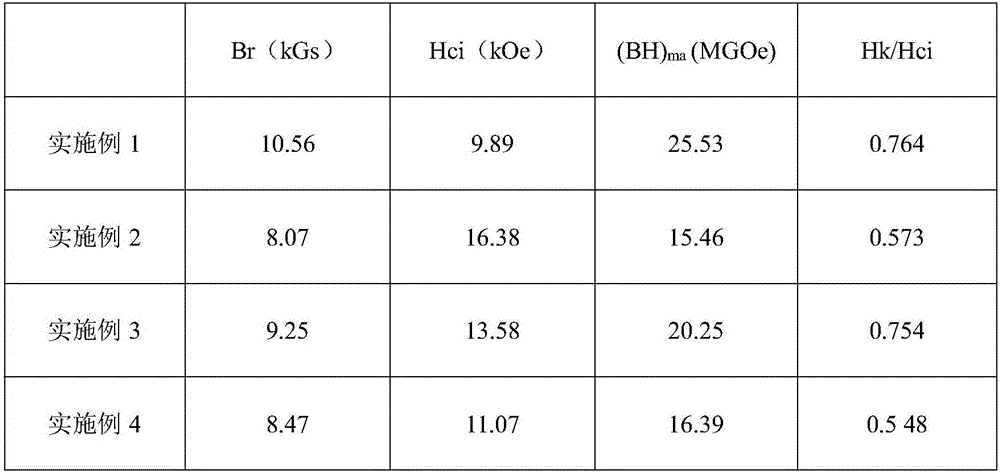

Method for preparing high-performance permanent magnet via diffusion permeation treatment of sintered neodymium iron boron recycled waste materials

ActiveCN106158339AImprove antioxidant capacityEasy MillingInductances/transformers/magnets manufactureMagnetic materialsRare earthAlloy

The invention relates to a recycling method of sintered neodymium iron boron recycled waste materials, belonging to the technical field of a rare earth permanent magnet material. The method comprises the steps of carrying out mechanical crushing on cleaned NdFeB recycled waste materials such as machining cutting leftover materials, electroplating non-qualified products and the like, and sieving to obtain large-particle magnetic powder (the size of a screen stencil is 60-300 meshes); after uniformly mixing with a dispersing agent, orienting and molding under an atmospheric environment to prepare into a workblank, wherein the density of the workblank can be up to 6.0g / cm<3>; and then, carrying out vacuum heat treatment on the workblank to obtain a high-coercivity high-performance NdFeB permanent magnet. According to the method disclosed by the invention, as raw material magnetic powder is the approximately hundred-micron magnetic powder obtained by crushing the NdFeB recycled waste materials, and the magnetic powder storage, the magnet orienting-molding process and the molded workblank storage can be carried out in the atmospheric environment, the production process is simplified; and in addition, by adding the dispersing agent to repair a Nd2Fe14B grain boundary, the coercivity of the magnet is further improved.

Owner:UNIV OF SCI & TECH BEIJING

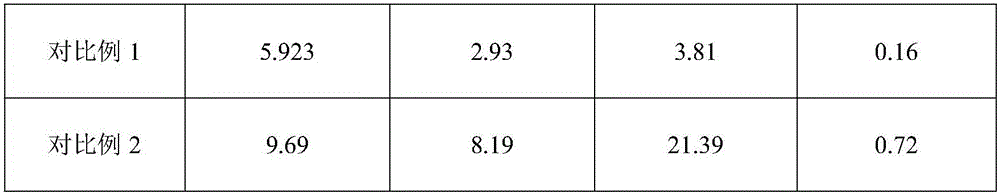

Emulsion

ActiveCN102493197AEasy to washEasy to wash off to facilitate subsequent stainingFibre treatmentYarnEngineering

The invention discloses emulsion, which comprises, by mass percentage, non-ionic surface active agent 62-66%, anionic surface active agent 1-3%, aqueous phase 23-27% and oil phase 6-10%. The emulsion can reduce electrostatic influence between yarns and a rotary drum in the spinning process, enable yarn levelness to be even, enable hairiness to be submissive and enable spinning to be performed smoothly. The emulsion is easily cleaned at a follow-up workshop section, thereby facilitating smooth performing of follow-up dyeing, rinsing, fulling and other workshop sections.

Owner:WUJIANG WANSHENG GREASE

Silicon-containing products

ActiveUS7588745B2Low levelEasy millingNitrogen compoundsOther chemical processesPorositySilicon dioxide

A method for producing carbon-silica products from silica-containing plant matter such as rice hulls or straw by leaching with sulfuric acid to remove non-silica minerals and metal while adjusting the mole ratio of fixed carbon to silica in the resultant product. The carbon and silica are intimately mixed on a micron or submicron scale and are characterized by high purity and reactivity, small particle size, high porosity, and contain volatile carbon that can be used as a source of energy for the production of silicon-containing products from the carbon-silica products. High purity silicon-containing products made from the carbon-silica products of the invention are also disclosed.

Owner:SI OPTIONS LLC

Residual tea processing device and method

InactiveCN109396164AEasy to millIncrease contact areaRotary stirring mixersSolid waste disposalResidual BlocksMillstone

The invention relates to the field of residual tea processing, in particular to a residual tea processing device and method. The device comprises a shell which is internally provided with a powderingdevice, a mixing device and a forming device; when residual tea is processed, most water in the residual tea is squeezed out through pressing, then the residual tea is dried, and thus millstone powdering is facilitated. The residual tea obtained after powdering is mixed with adhesive liquid, the mixture is sent into a forming box, the residual tea is made into residual blocks with multiple holes,and the good odor removing effect is achieved; by forming the holes in the residual tea blocks, the contact area of the residual tea and air can be increased, and the odor removing effect is improved.

Owner:白云松

Direct-selected coarse-gauge automatic flat knitting machine

InactiveCN102242456ACapable of knitting with coarse gaugeSmall form factorFlat-bed knitting machinesYarnLiquid-crystal display

The invention provides a direct-selected coarse-gauge automatic flat knitting machine, and belongs to the technical field of flat knitting equipment in textile machinery. The machine comprises a frame as well as a knitting system, a transmission system, a coiling system, a liquid crystal display (LCD) screen, a moving bed system, an electronic control system and a yarn conveying system which are arranged on the frame in a fit manner, wherein, the knitting system comprises a stitching track control mechanism, a needle bed connected with the stitching orbit control mechanism in a fit manner, and a knitting needle and a jacquard needle which are arranged on the needle bed. The direct-selected coarse-gauge automatic flat knitting machine has the beneficial effects that by means of innovation and improvement on a cam plate, the needle bed and the knitting needle in the knitting system, range of the knitting specification of the machine is broadened; a cast-off cam on the cam plate in the knitting system is placed at a knitting segment, which reduces size of the cam plate, lowers manufacturing difficulty and cost of the cam plate, and ensures stable and reliable operation of the cam and the knitting needle; overall dimensions of a left raising cam, a right raising cam, a left receiving cam and a right receiving cam are reduced so as to facilitate control; and accuracy of the moving bed is improved, and screw loss is lowered.

Owner:唐永生

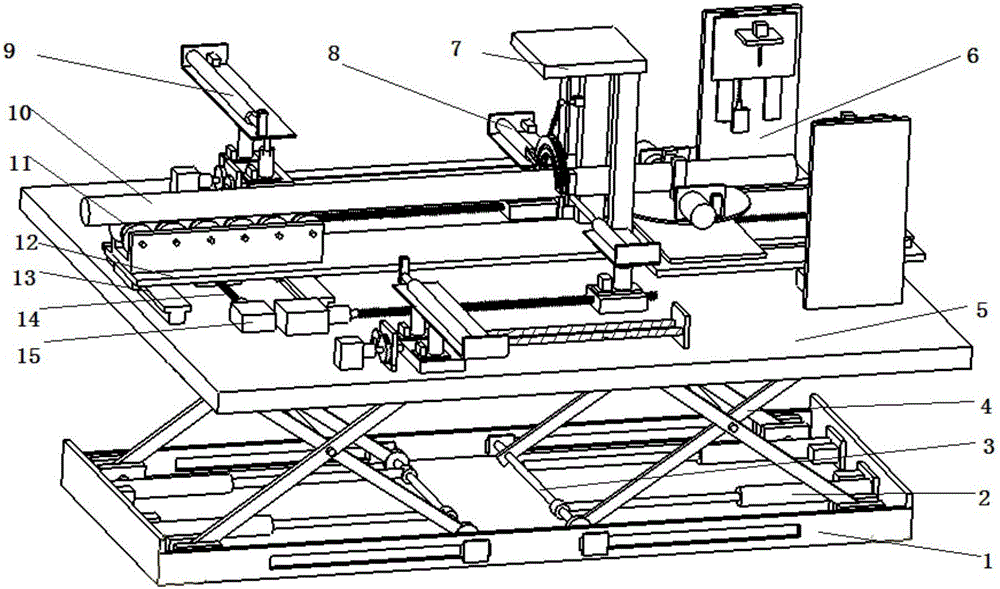

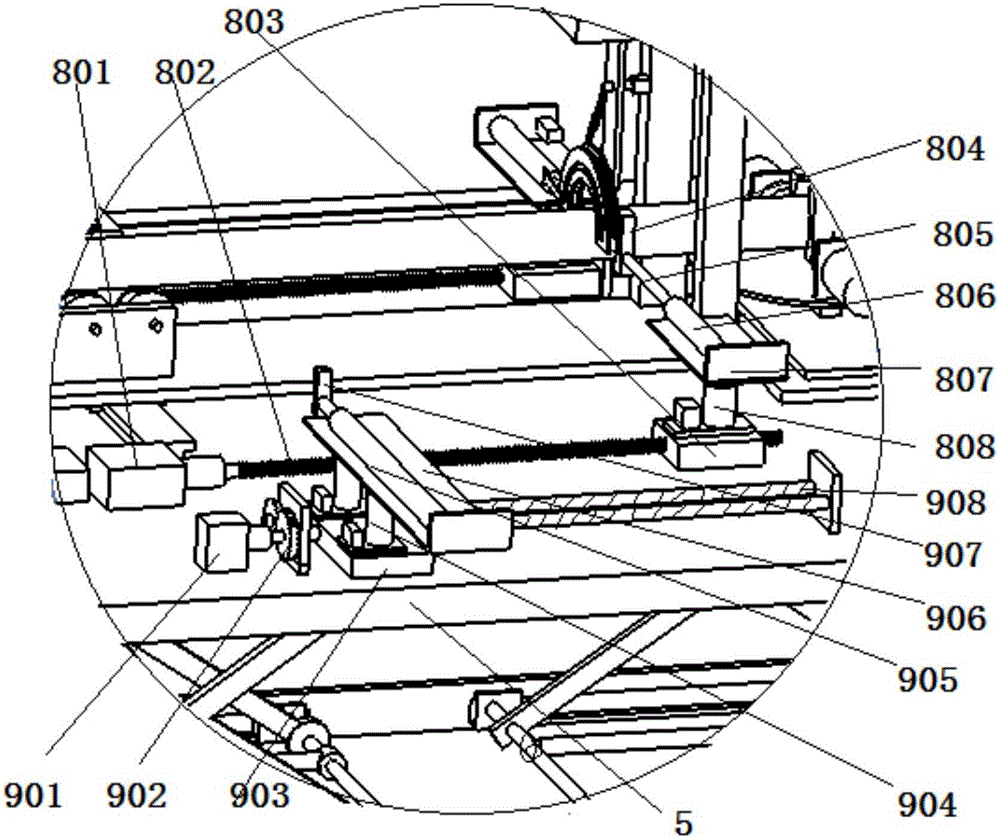

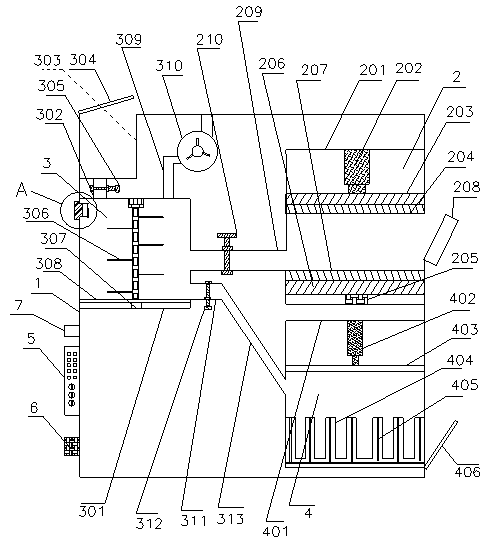

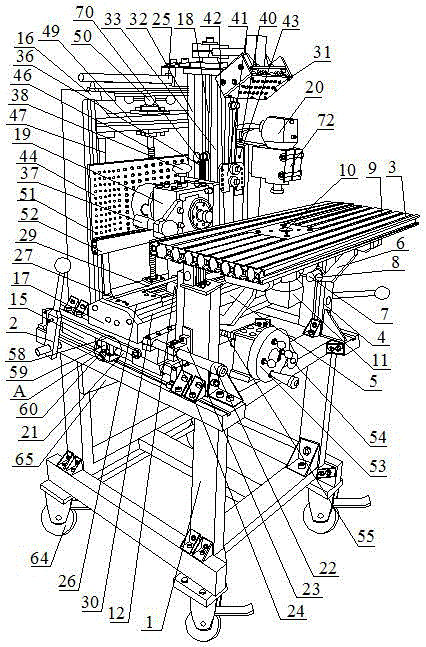

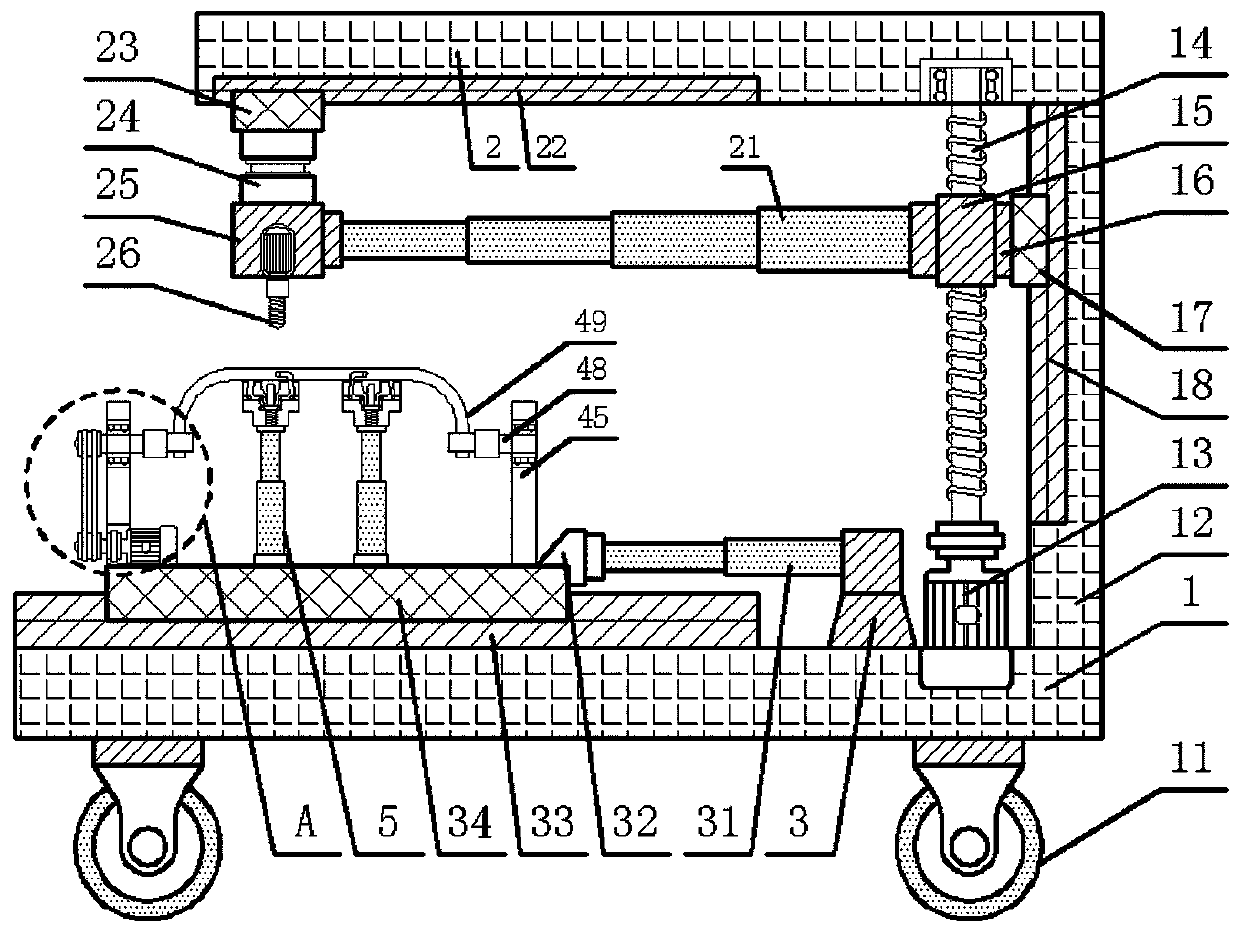

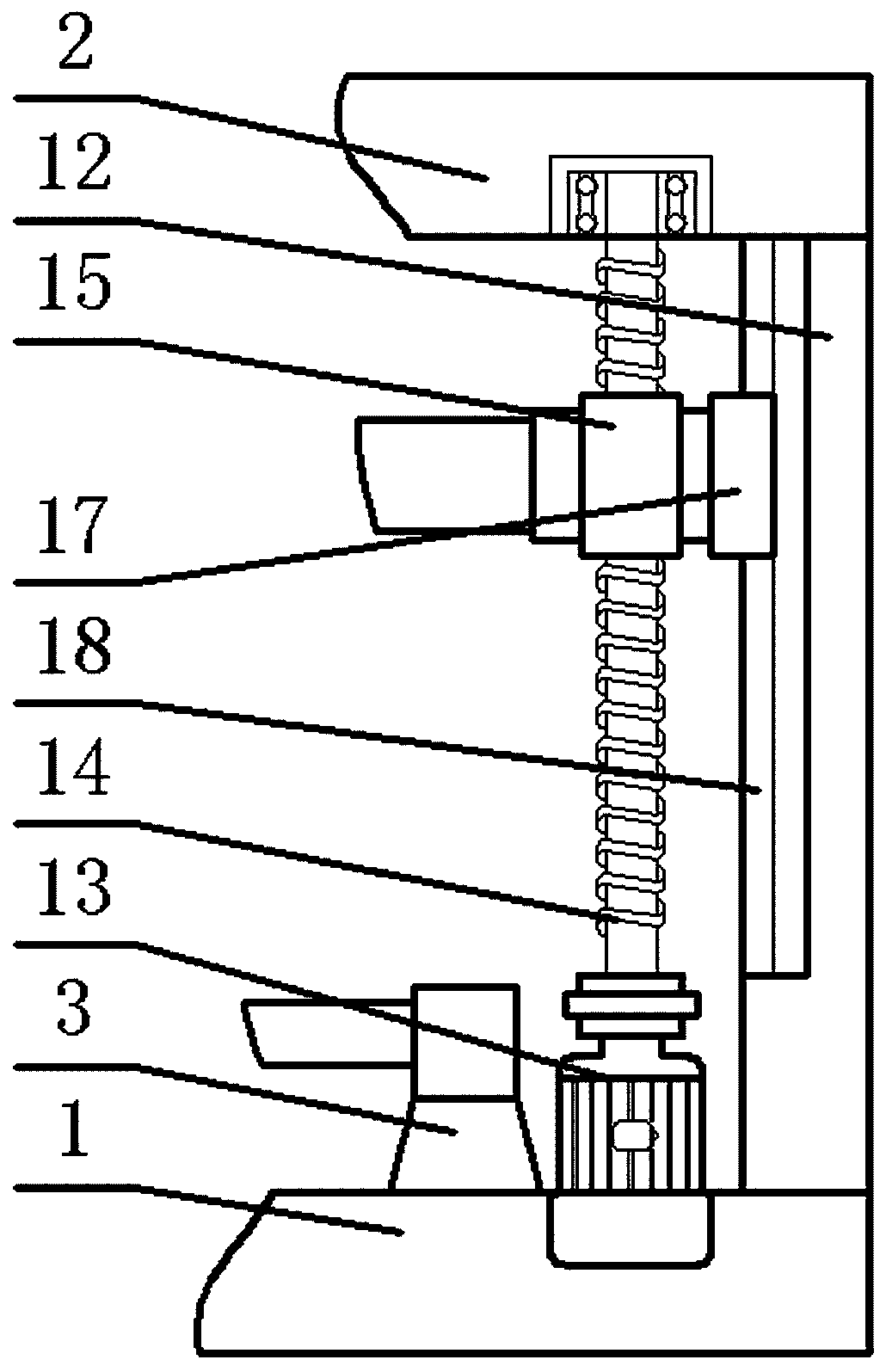

Special type woodworking compound milling machine

ActiveCN106738095AImprove use comfort performanceErgonomicLighting applicationsMechanical apparatusPunchingEngineering

The invention belongs to the technical field of machining equipment, in particular to a special type woodworking compound milling machine. The special type woodworking compound milling machine comprises a base frame, a main workbench mechanism, a feed mechanism, a power devive and a vice workbench mechanism. The main workbench mechanism comprises a main workbench and two fixed supports. The feed mechanism comprises a base, a gantry frame, a sliding table and the power device. The vice workbench mechanism comprises a vice workbench, a lead screw nut and a lead screw and is arranged in front of the gantry frame, a plurality of installing holes are formed in the vice workbench, the lead screw nut is fixed to the rear side of the vice workbench, and the lead screw penetrates through the lead screw nut and is connected with the lead screw nut in a threaded mode. The special type woodworking compound milling machine is reasonable in structure, capable of achieving multi-function and multi-angle milling, punching and copying machining of complicated surface woods, simple in operation, flexible in using, small in energy consumption and occupied area and has great application and promotion value.

Owner:曲艺

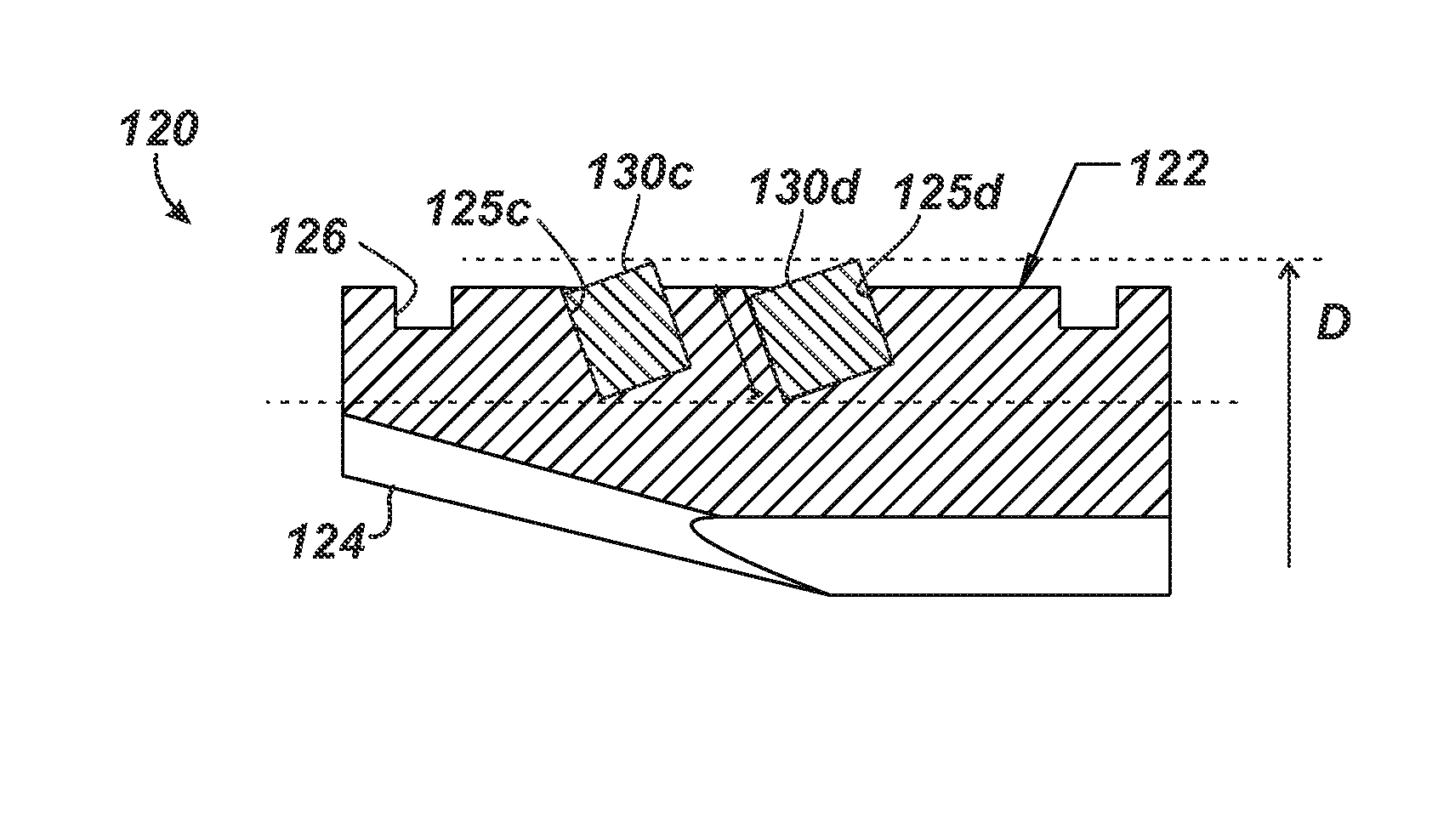

Slip Assembly for Anchoring Downhole Plugs and Retainers

A downhole plug assembly can be installed at a desired location within a subterranean wellbore that is capable of isolating one portion of the wellbore from another, while sealing fluid pressure within the wellbore from at least one direction. The plug assembly can include certain components constructed of non-metallic material that can be drilled, milled or mechanically broken up more quickly and efficiently than conventional wellbore plugs, thereby facilitating removal of said plug assembly when desired.

Owner:BLACKHAWK SPECIALTY TOOLS

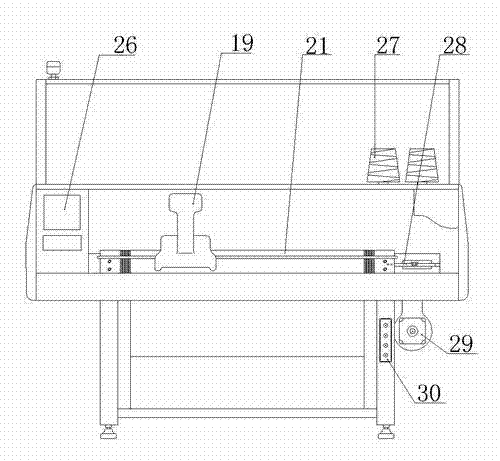

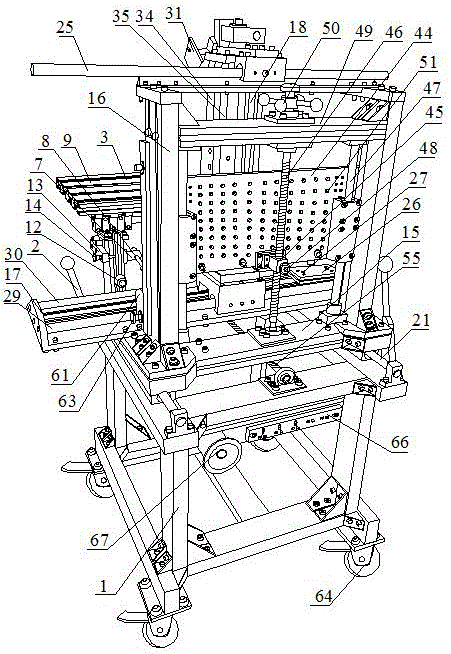

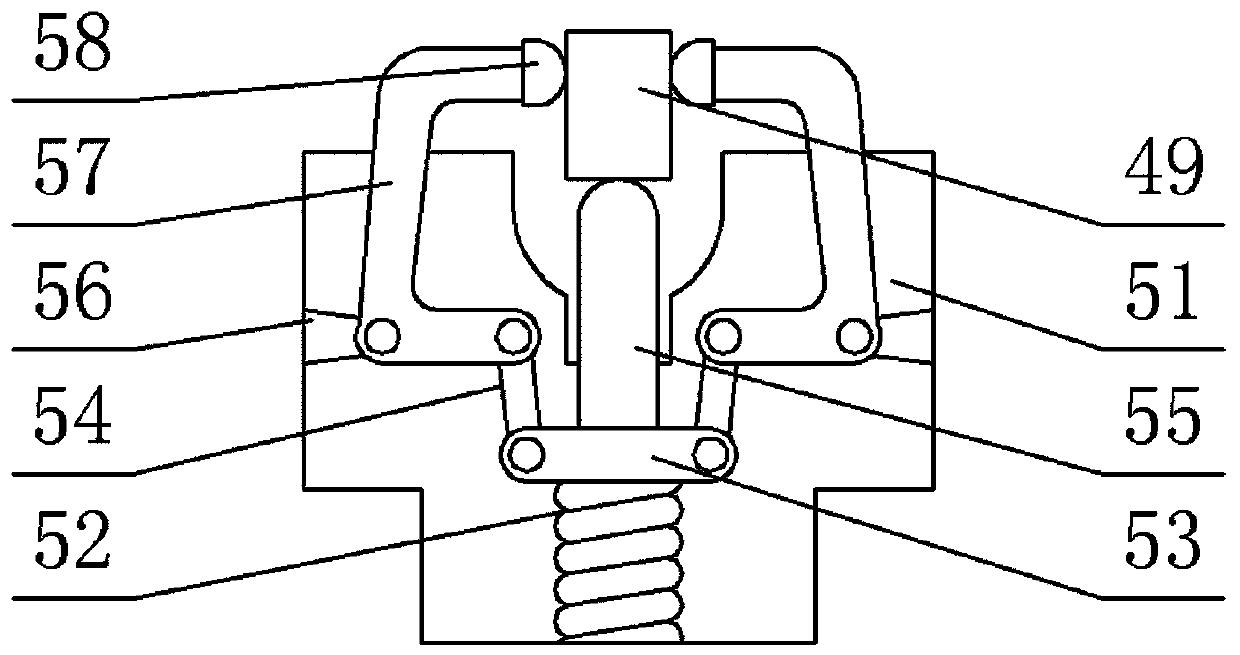

Milling machine fixing tool for intelligent carbon contact strip milling and using method of tool

ActiveCN111054957AConvenient for milling workReduce labor burdenWork clamping meansFeeding apparatusStrip millSlide plate

The invention discloses a milling machine fixing tool for intelligent carbon contact strip milling. The tool comprises a bottom plate and a carbon contact strip, and two ends of the carbon contact strip are respectively inserted into corresponding limit cylinders; a pair of rectangular block-shaped third bases are arranged at the center of the top surface of a first slide plate, a third telescopiccylinder with output facing upward is installed at the top surface of each third base, and the telescopic cylinder end part of each third telescopic cylinder is clamped with two sides of the middle of the carbon contact strip through a clamping mechanism; the other side of the top surface of the bottom plate is vertically provided with a rectangular long plate-shaped vertical plate, and a liftingmechanism is arranged at the inner end surface of the vertical plate; and a rectangular long plate-shaped horizontal plate is horizontally arranged directly above the bottom plate, a driving mechanism is arranged on one side of the bottom surface of the horizontal plate, and the other end of the bottom surface of the horizontal plate is fixedly connected with the top surface of the vertical plate. The invention also discloses a using method of the milling machine fixing tool for the intelligent carbon contact strip milling. By designing a complete set of tool structure, the tool can meet theprocessing requirements of a carbon contact strip airway, is convenient for disassembly and assembly, and can adapt to different heights of structures.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Method for producing dissymmetrical die forging

InactiveCN1827255AAvoid uneven forceExtended service lifeMetal-working apparatusMetallurgyMaterials science

The invention discloses a method for producing asymmetry dies forging, which according to the structure of single asymmetry dies forging product to produce one symmetry die forging formed by two symmetry connected asymmetry die forging elements, then along the symmetry axle of said symmetry die forging to be divided into two needed asymmetry die forging elements. The inventive method can simplify the process and improve the producing efficiency.

Owner:SOUTHWEST ALUMINUM GRP

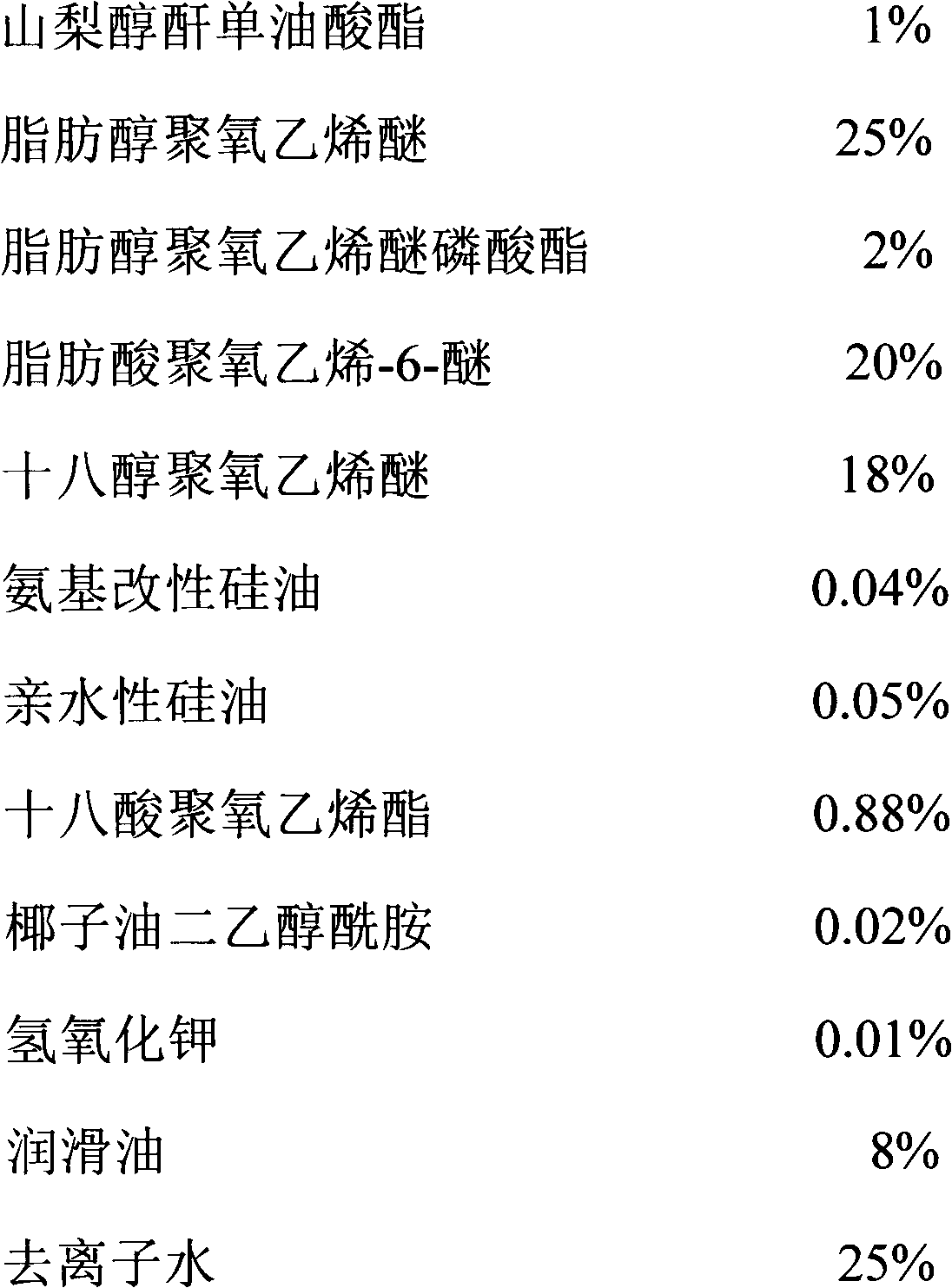

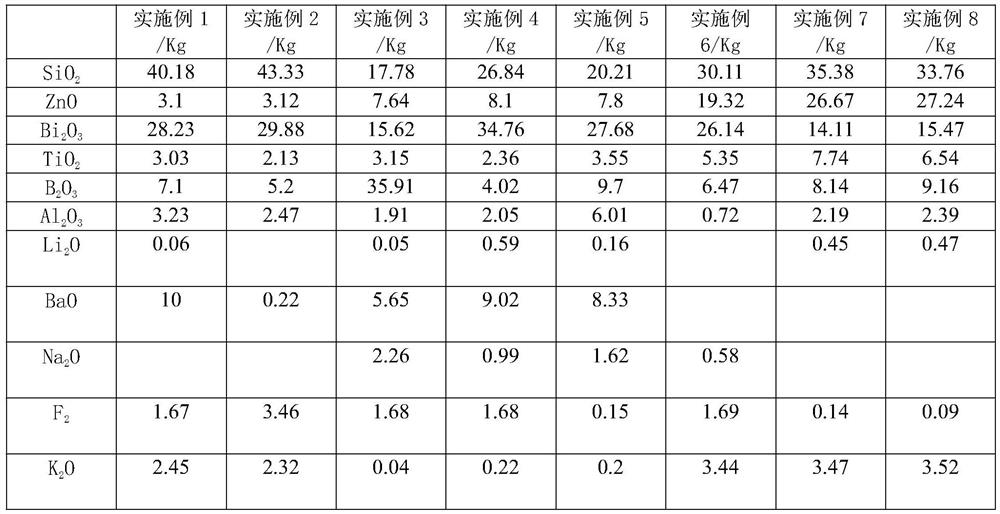

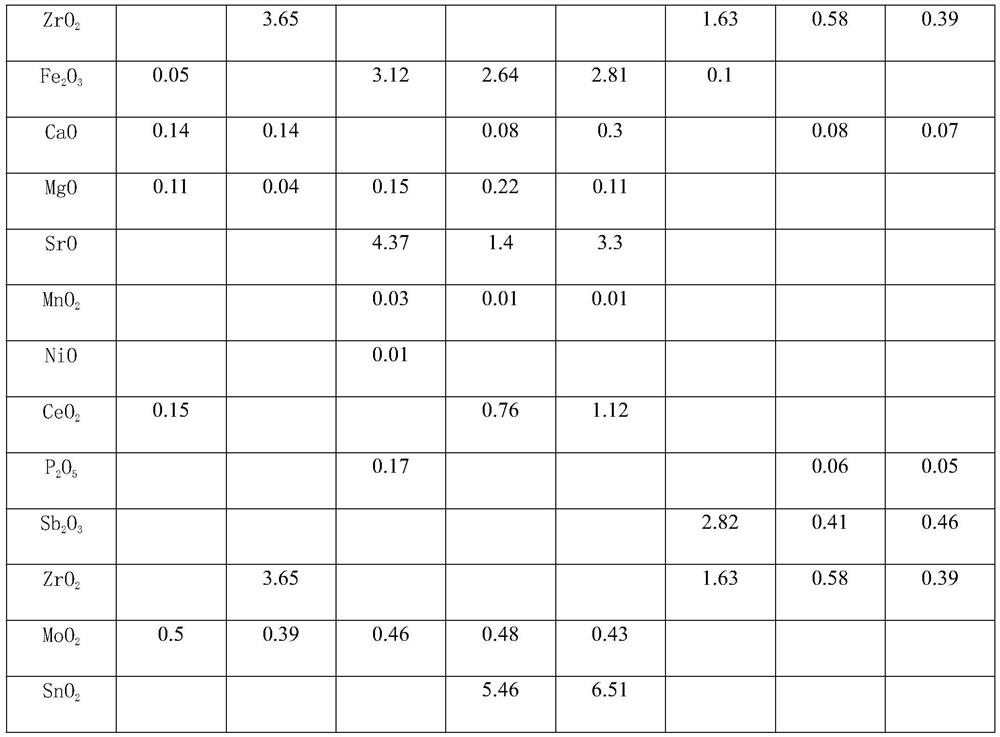

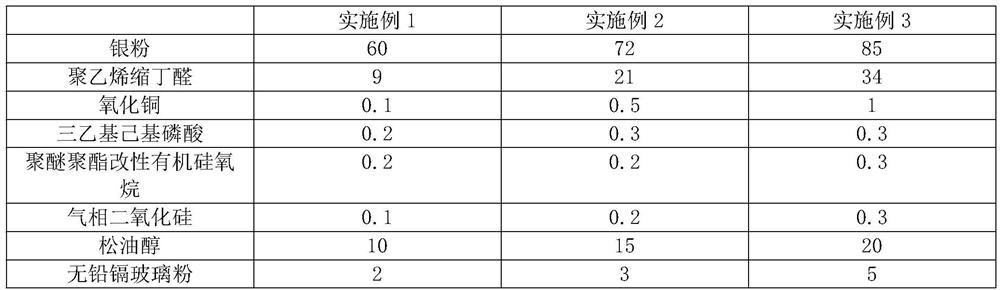

Lead-cadmium-free glass powder and preparation method thereof, and conductive aluminum paste and preparation method thereof

PendingCN111675490ALow softening pointImprove corrosion resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureLithium oxideBoron trioxide

The invention relates to lead-cadmium-free glass powder, a preparation method of the lead-cadmium-free glass powder, conductive aluminum paste and a preparation method of the conductive aluminum paste, and belongs to the technical field of conductive paste. The lead-cadmium-free glass powder comprises, by weight, 15 to 45 parts of silicon dioxide, 5 to 30 parts of zinc oxide, 10 to 35 parts of bismuth oxide, 2 to 15 parts of titanium dioxide, 3 to 20 parts of diboron trioxide, 0.1 to 5 parts of aluminum oxide, 0.1 to 5 parts of lithium oxide, 0.015 to 5 parts of fluorine gas, 0.1 to 40 parts of a softening agent, 0 to 20 parts of a nucleating agent, 0 to 7 parts of a corrosion resistance enhancer, 0 to 10 parts of a glass clarifying agent and 0 to 15 parts of a filler. The corrosion-resistant coating has the advantage of being good in corrosion resistance.

Owner:厦门翰森达电子科技有限公司

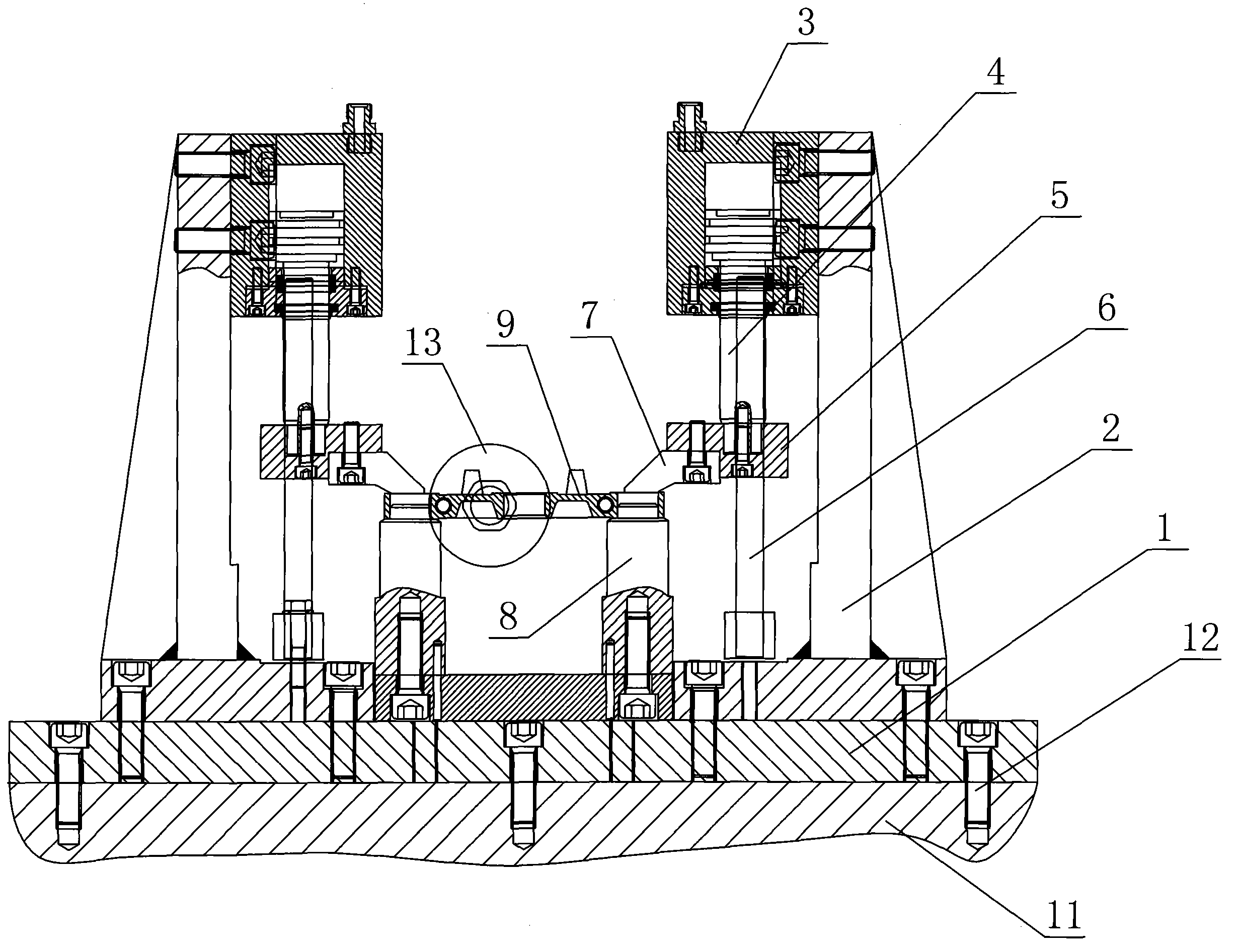

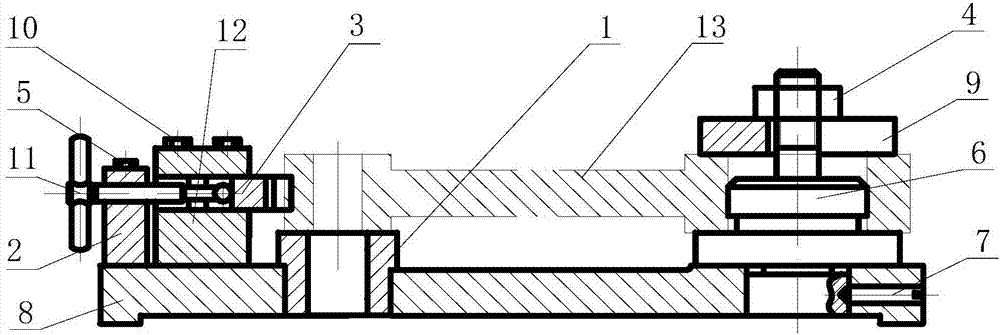

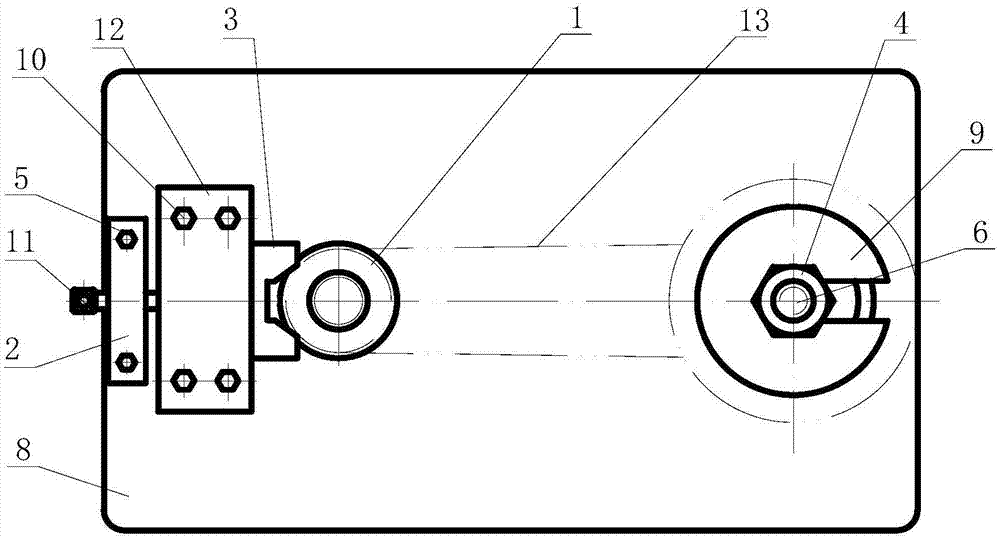

End face milling clamping device of automobile engine connecting rod small end

InactiveCN107443120AEasy millingImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringLarge head

The invention discloses an end face milling clamping device of an automobile engine connecting rod small end. The end face milling clamping device comprises a bottom plate (8), a locating assembly, a clamping assembly and a supporting block (1). The locating assembly and the clamping assembly are arranged at the two ends of the bottom plate (8) correspondingly. A large end round hole of a connecting rod (13) is formed in the locating assembly in a sleeving manner, and the clamping assembly clamps the small end of the connecting rod (13). The supporting block (1) is arranged between the connecting rod (13), and the supporting block (1) and the bottom plate (8) are mounted through interference or transition fit, so that the top end of the supporting block (1) abuts against the bottom end of the small end of the connecting rod (13). The end face milling clamping device of the automobile engine connecting rod small end is simple in structure, convenient to use, high in machining efficiency and good in machining effect.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com