Special type woodworking compound milling machine

A technology of woodworking and milling machines, applied in the field of woodworking compound milling machines, to achieve the effects of improving work efficiency, improving user comfort, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

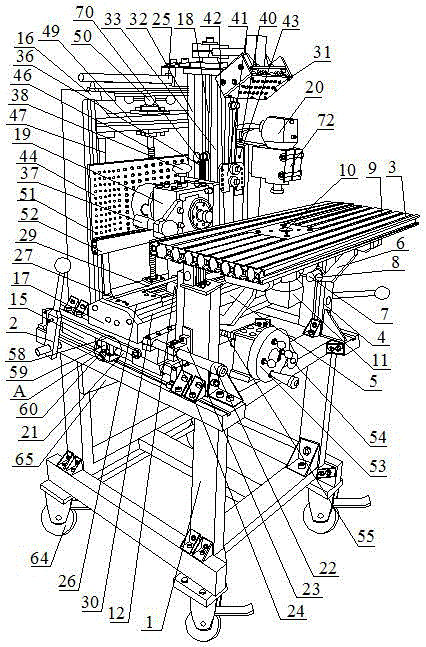

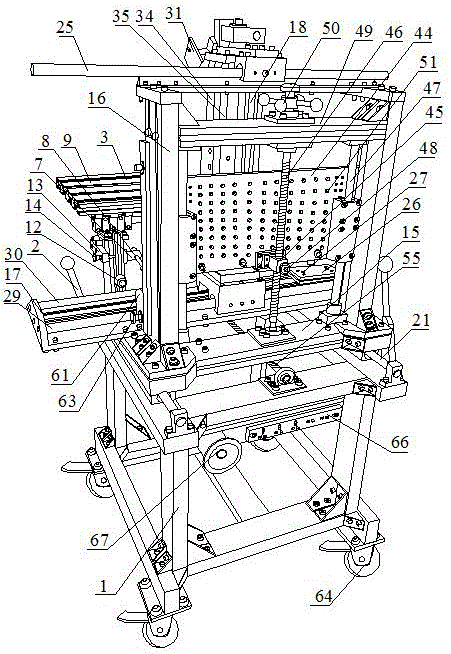

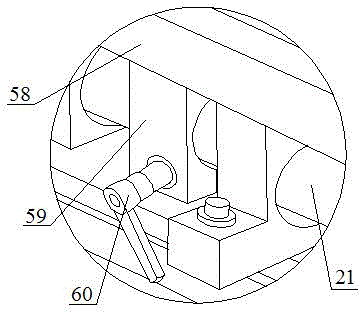

[0067] like figure 1 and figure 2 As shown, the composite woodworking milling machine of the present invention mainly includes an underframe 1 , a main table mechanism, an auxiliary table mechanism, a feed mechanism, a power unit, a handwheel mechanism and two handles 2 .

[0068] The underframe 1 is a square frame structure, and the four corners of the lower end of the underframe 1 are respectively equipped with universal wheels 64 . A fixed plate 65 is fixed on the top of the bottom frame 1, and a plug-in row 66 and a reel 67 are fixed on the fixed plate 65. Plug-in row 66 is externally connected power cord, is connected with power supply, and power cord is wound on the reel 67 when not needing work, keeps power cord clean and tidy. The main table mechanism includes a main table 3 , two fixed brackets 4 , a rotating shaft 5 and two rotating parts 6 . Two fixed brackets 4 are respectively vertically fixed on both sides of the front part of the underframe 1 , and the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com