Patents

Literature

729results about How to "Improve dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

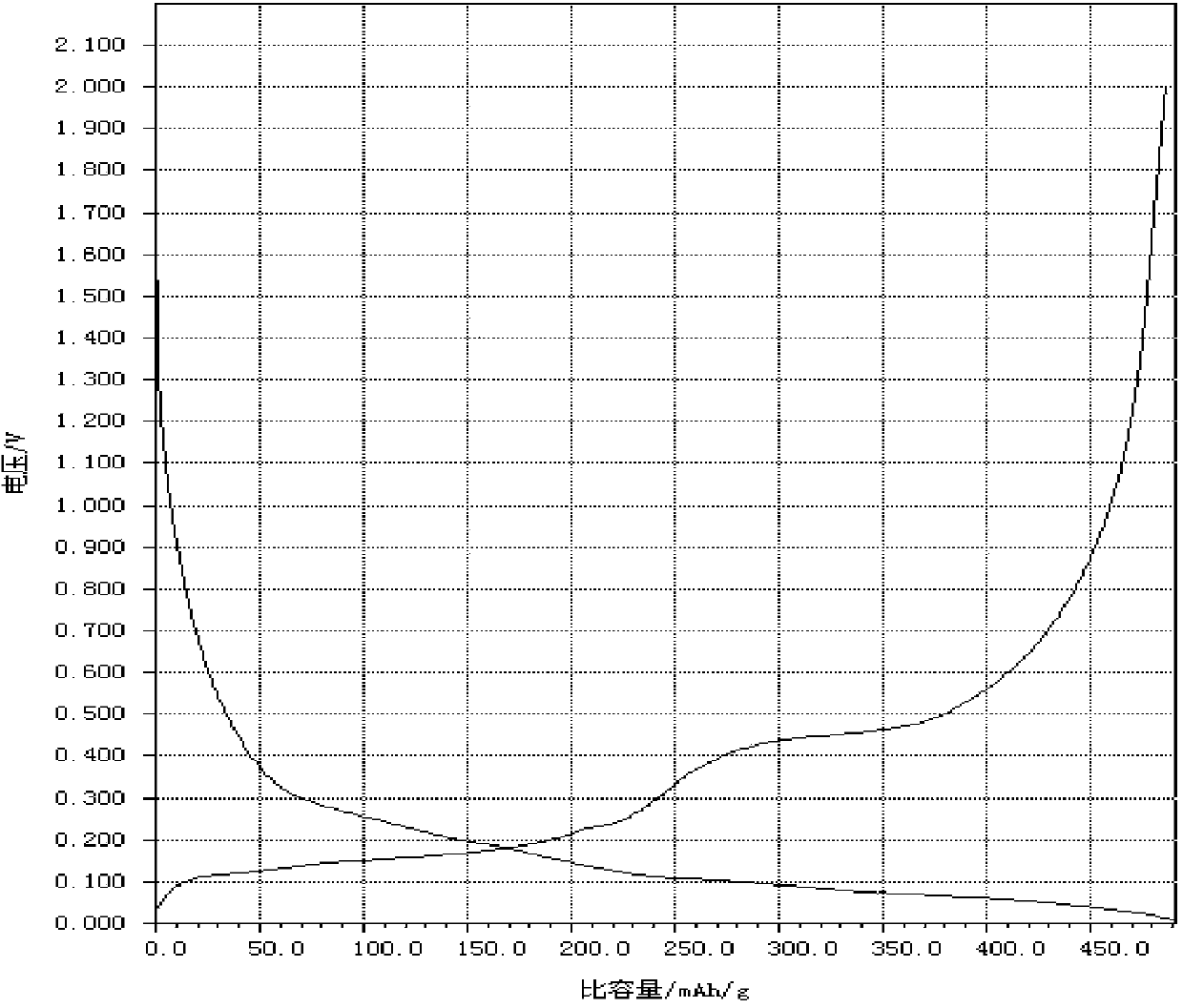

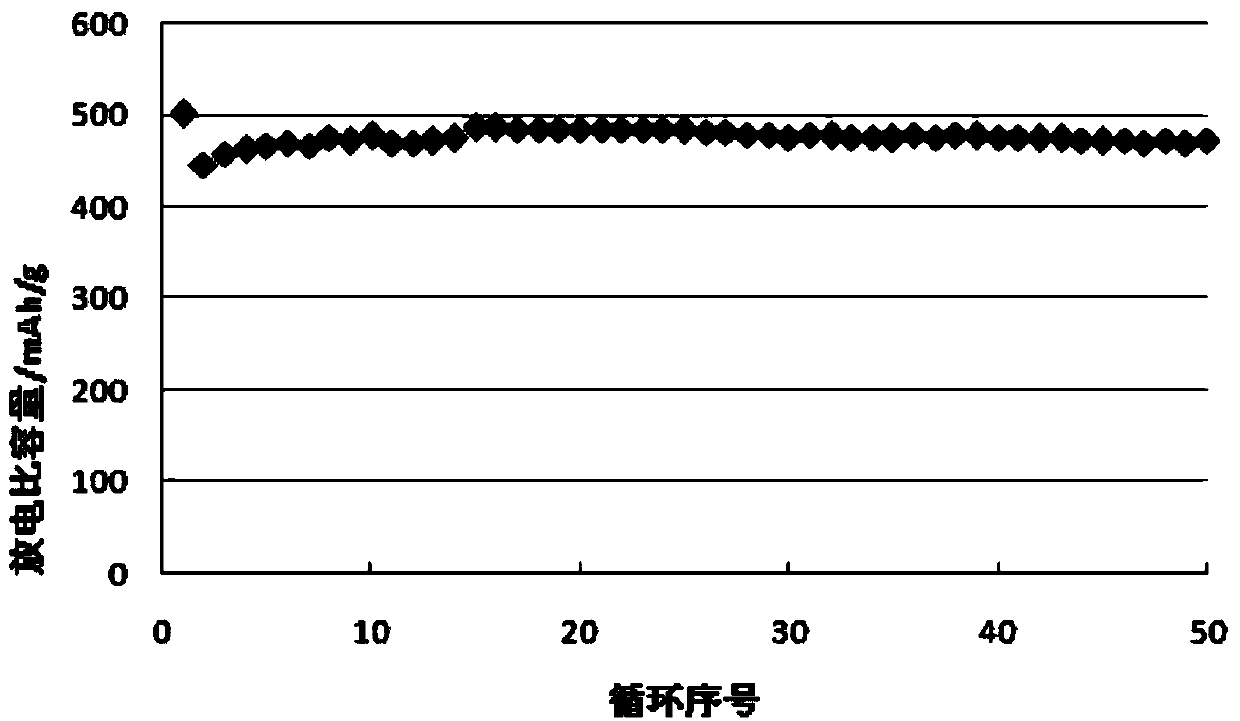

Method for preparing silicon carbide alloy negative electrode material for lithium ion battery

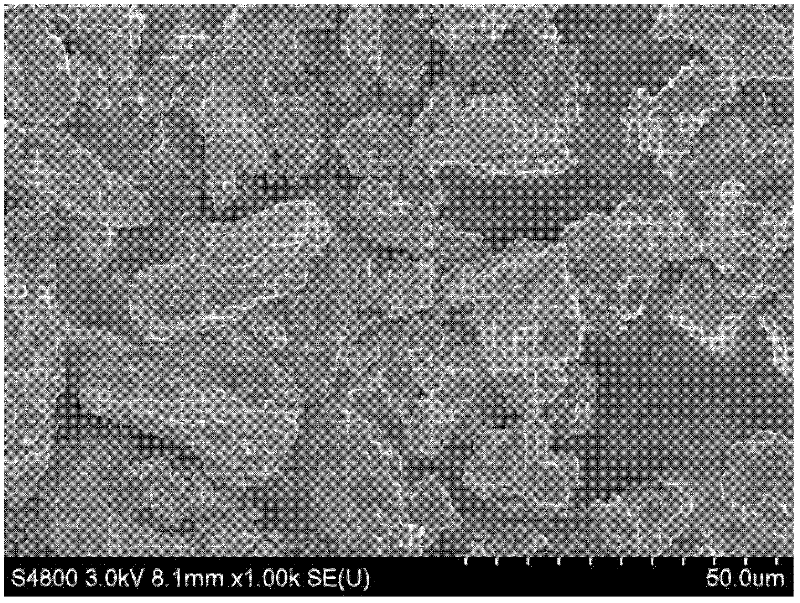

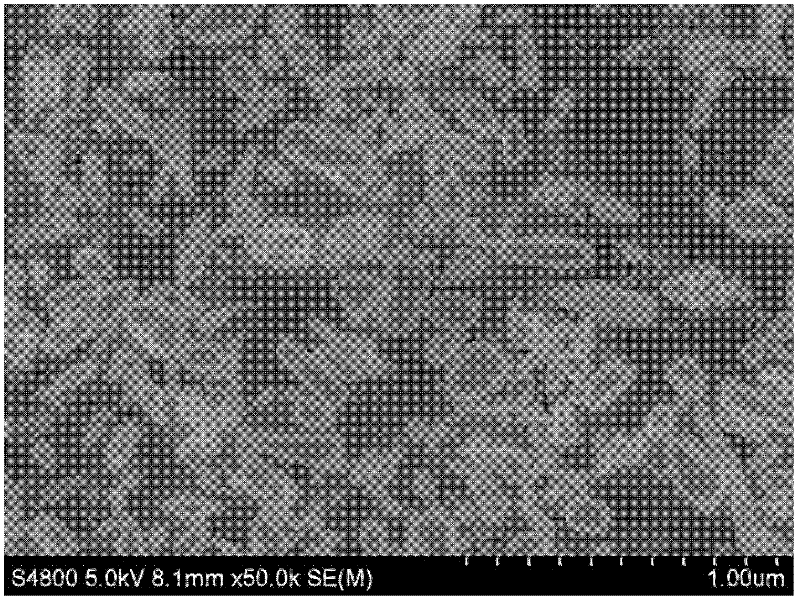

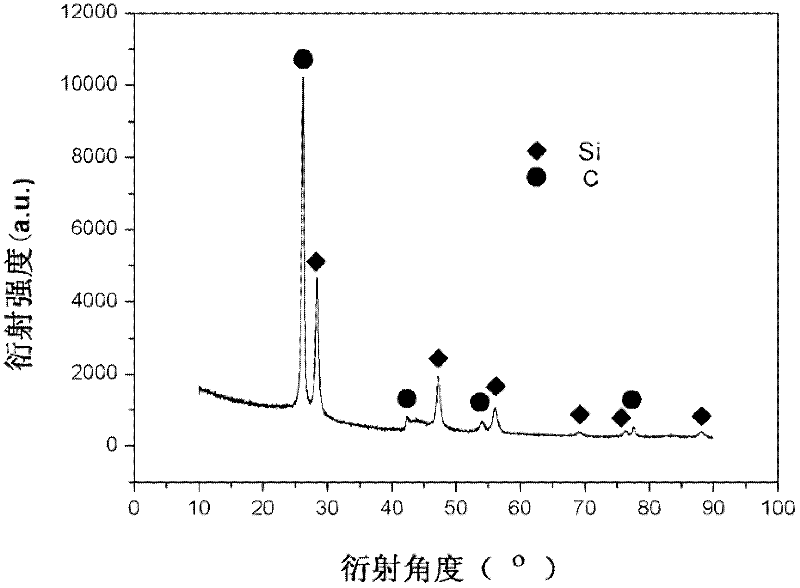

ActiveCN102376944AImprove dispersionInhibition of agglomerationCell electrodesSilica fumeCarbon coating

The invention discloses a method for preparing a silicon carbide alloy negative electrode material for a lithium ion battery; and a technical problem to be solved is to increase the circulation performance and the specific capacity of a silicon carbide composite negative electrode material. The method comprises the following steps of: dispersing nanometer silica powder in an organic solution to form a uniform nanometer silicon suspending liquid, then adding a silane coupling agent to the nanometer silicon suspending liquid, and finally carrying out carbon coating and thermal treatment. Compared with the prior art, the method has the advantages of increasing the dispersiveness of nanometer silicon particles in a silicon carbide composite material and inhibiting the volume effect caused by the conglobation of silicon in a lithium intercalation and deintercalation process by adding the silane coupling agent, thereby increasing the circulation performance and the specific capacity of the silicon carbide composite negative electrode material, wherein the capacity of the silicon carbide composite negative electrode material is larger than 500mAh / g, and the capacity retention rate is above 97% when the silicon carbide composite negative electrode material is circulated for 50 times; and according to the preparing method, the preparation cost is low, the technology is simple and controllable, and the silicon carbide alloy negative electrode materials with different capacities can be easily prepared by adjusting a weight proportion of Si powder, graphite and an organic matter.

Owner:BTR NEW MATERIAL GRP CO LTD

Fine metal particles and fine metal oxide particles in dry powder form, and use thereof

ActiveUS20070051927A1Simple preparation processImprove dispersionPigmenting treatmentMaterial nanotechnologyStable stateOrganic solvent

The present invention provides a process for simply and easily producing fine metal particles or fine metal oxide particles in the form of a dry powder which can be used as extremely fine particles in a good dispersion state without causing coagulation for a long time even if not stored in a dispersion solvent. Fine metal particles or fine metal oxide particles in the form of a dry powder are prepared using a dispersion in which fine metal particles or fine oxide metal particles having a surface oxidation film are dispersed in an organic solvent in a stable state, while once covering the particle surface with covering agent molecules containing, at a terminal, a functional group having an oxygen atom, a nitrogen atom, or a sulfur atom as a group capable of forming a coordinative bond with metal, and by removing the dispersion solvent, washing and removing excess covering agent molecules with a polar solvent without damaging the covering agent molecule layer covering the fine particle surface, finally evaporating the polar solvent used for washing and drying.

Owner:HARIMA CHEM INC

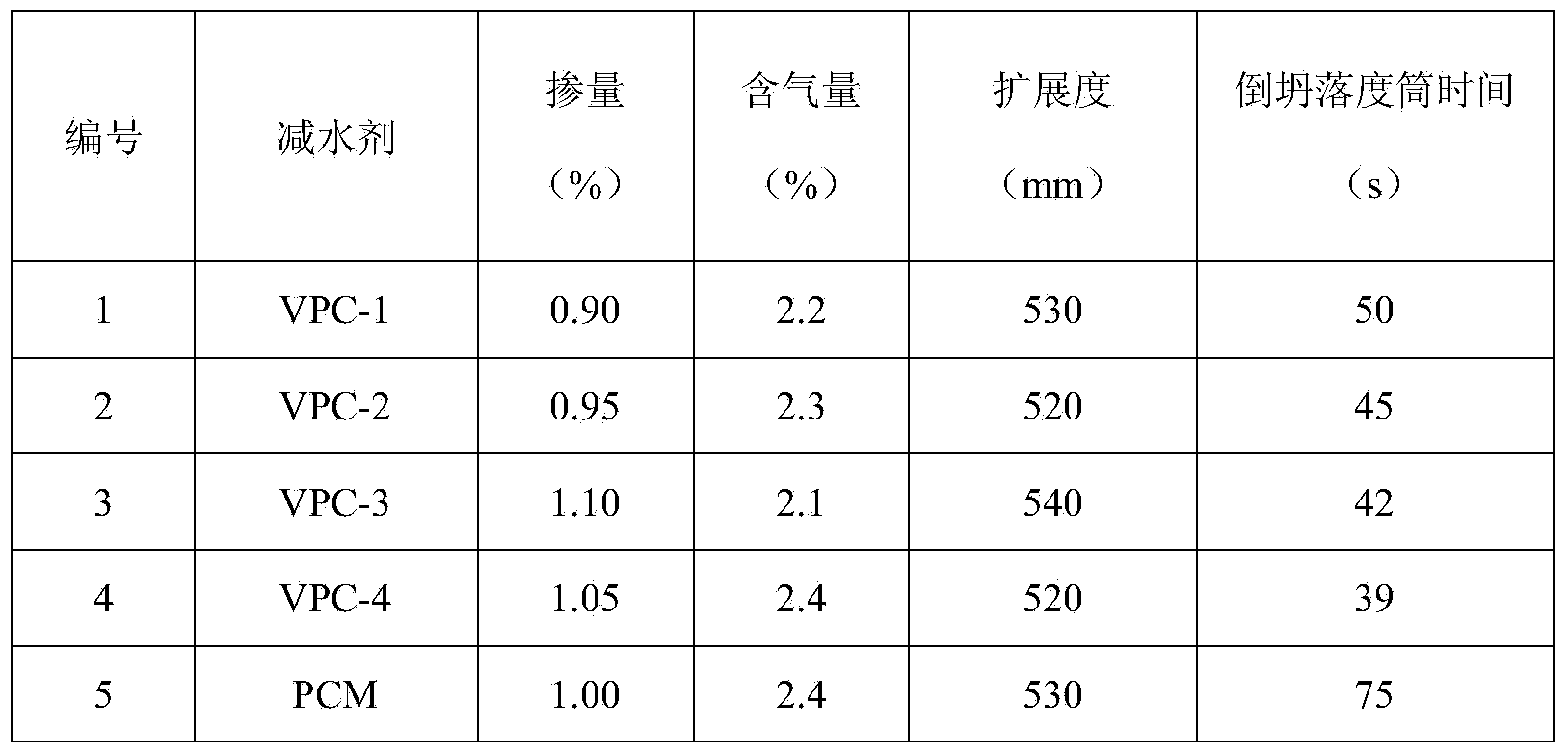

Preparation method of viscosity-reduction type polycarboxylate water reducer

InactiveCN103865007AGood viscosity reduction effectImprove dispersionChemistryHigh strength concrete

The invention discloses a preparation method of a viscosity-reduction type polycarboxylate water reducer, which belongs to the field of concrete admixtures. The water reducer is prepared from random polyoxyalkyl ether unsaturated acid ester, unsaturated modified polyoxyethylene ether, unsaturated acid alkyl ester, and (methyl) acrylic acid, by means of copolymerization with an aqueous solution and then adding alkali for neutralization, under the presence of an initiator and a molecular weight regulator. By a certain quantity of hydrophobic units and hydrophobic groups which are introduced into and controlled in carboxylic acid copolymer molecule structures, the viscosity of a cement-based material is reduced under the presence of the water reducer. The water reducer prepared by the method has the advantages of high viscosity reducing effect, high dispersibility, good adaptability to cement, and the like; the water reducer is especially applicable to preparation of high-strength concrete, self-compacting concrete, low-water-binder-ratio high-dosage mineral admixture concrete, and the like.

Owner:NANJING RUIDI HIGH TECH

Preparation method of nanometer modified corona-tolerant enamel of enameled wire

ActiveCN1546586AImprove dispersionImprove stabilityPolyurea/polyurethane coatingsPolyester coatingsOrganic solventRoom temperature

The invention discloses a preparation method of nanometer modified corona-tolerant enamel of enameled wire which comprises the steps of, taking 1-20 parts of inorganic oxide nano particles, charging 3-100 organic solvent, dispersing the inorganic oxide into uniform nano dispersed state at room temperature, charging 0.1-1.0 part of modifier for reacting 1-3 hours at 50-140 deg. C, obtaining modified nano material slurry, charging 60-100 parts of insulating resin into modified nano material slurry for reacting 3-6 hours at 70-120 deg. C.

Owner:江苏东材新材料有限责任公司

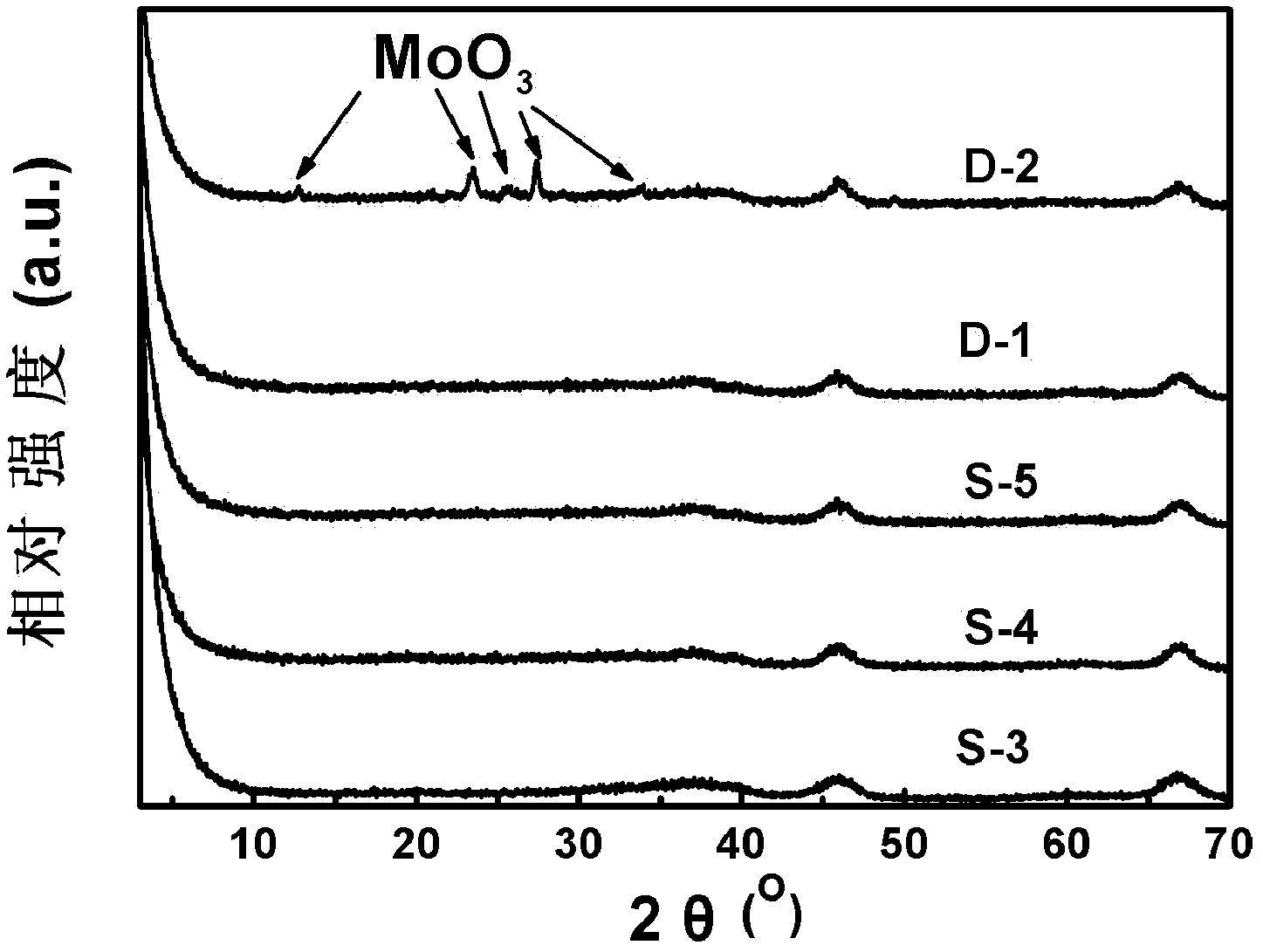

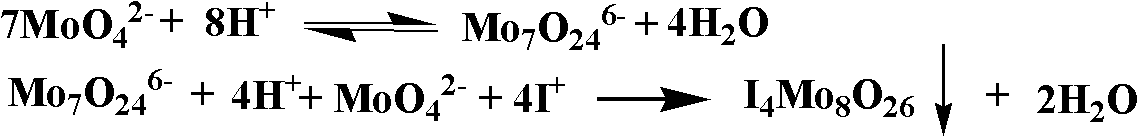

Hydrogenation catalyst and preparation method thereof

ActiveCN103143365AImprove dispersionIncrease loading capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsQuaternary ammonium surfactantOrganic inorganic

The invention provides a hydrogenation catalyst and a preparation method thereof. The preparation method uses metal active components of group VIB and VIII for step load, wherein metal of group VIB is molybdenum, metal of group VIII is cobalt or nickel, and a carrier is porous oxide. Load of group VIB metal uses a corresponding soluble salt as a raw material, inorganic acid is used as an acidifying agent, and a long-chain alkyl quaternary ammonium cation is used as a precipitating agent; and Mo-based single-component loaded catalyst is prepared by firstly synthesizing an organic-inorganic hybrid material suspension, performing aqueous phase diffusion and tunnel deposition, filtering, washing, drying, and roasting. Load of group VIII metal uses a corresponding soluble salt as a raw material, and the metal is loaded onto the carried through a normal-temperature isopyknic dipping technology. The method can effectively improve load capacity of the active components and dispersiveness of the active components in the tunnels; and the prepared hydrotreating catalysts is excellent in hydrodesulfurization activity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

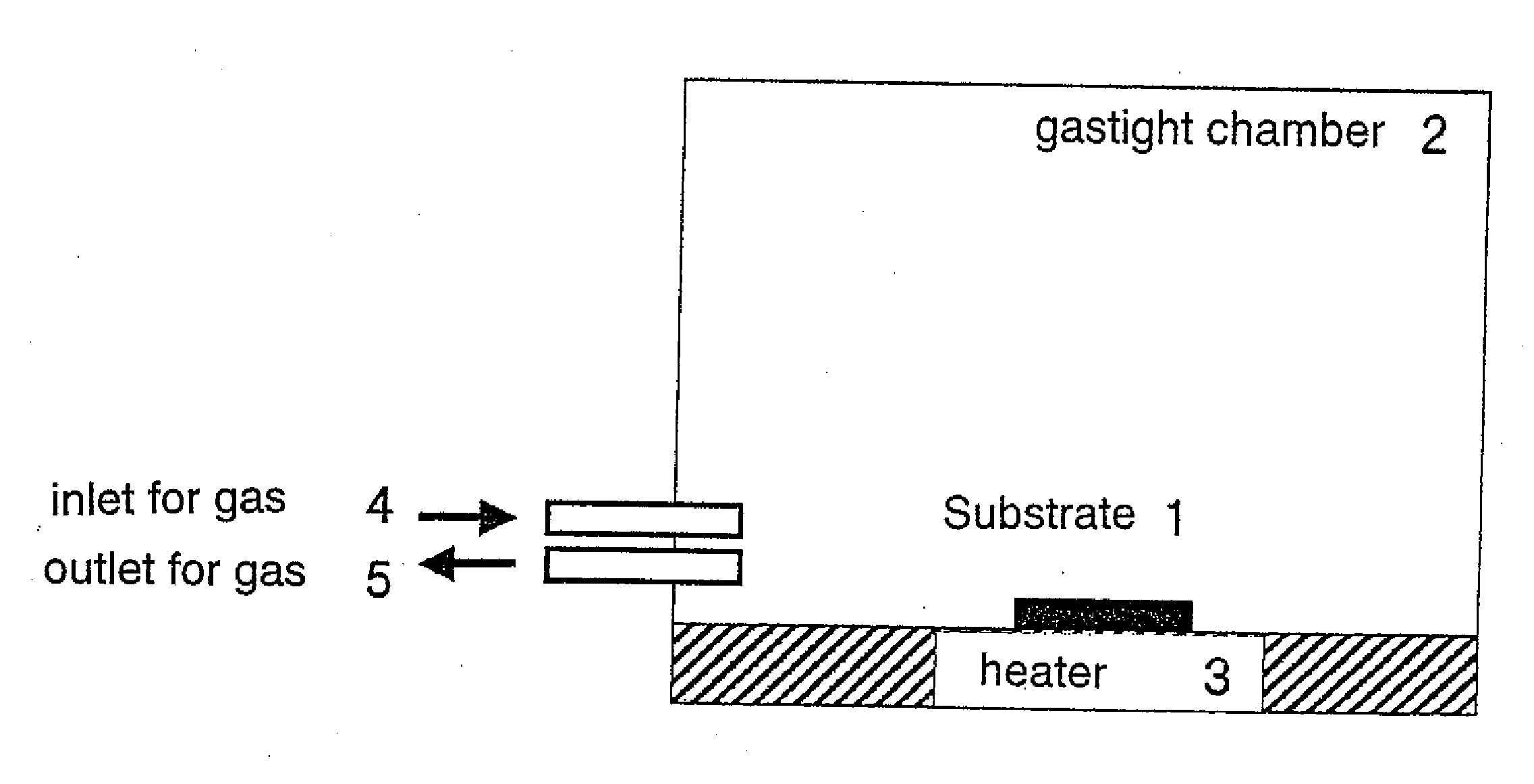

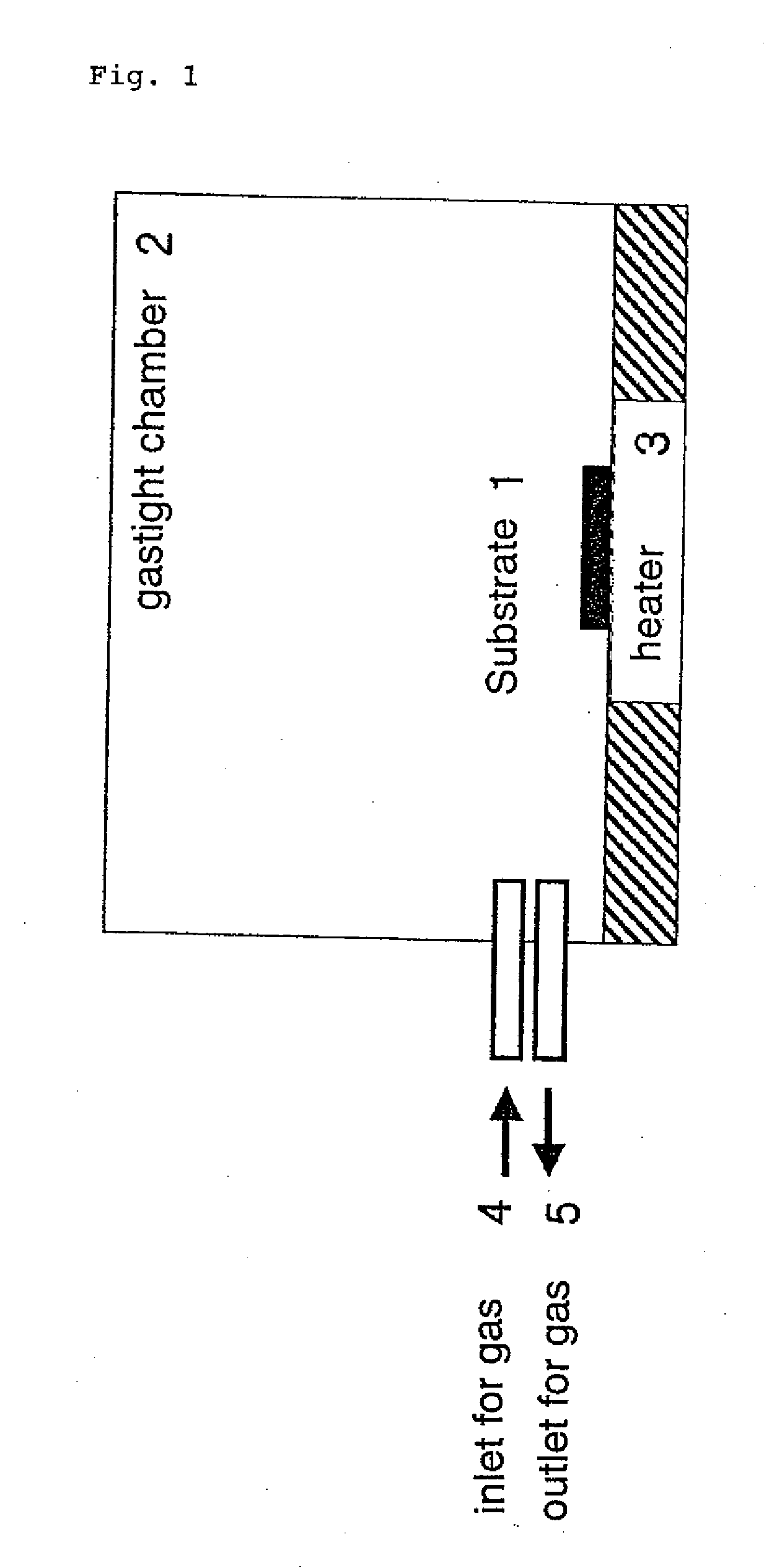

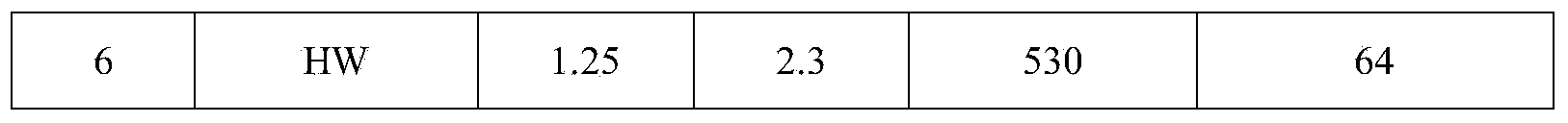

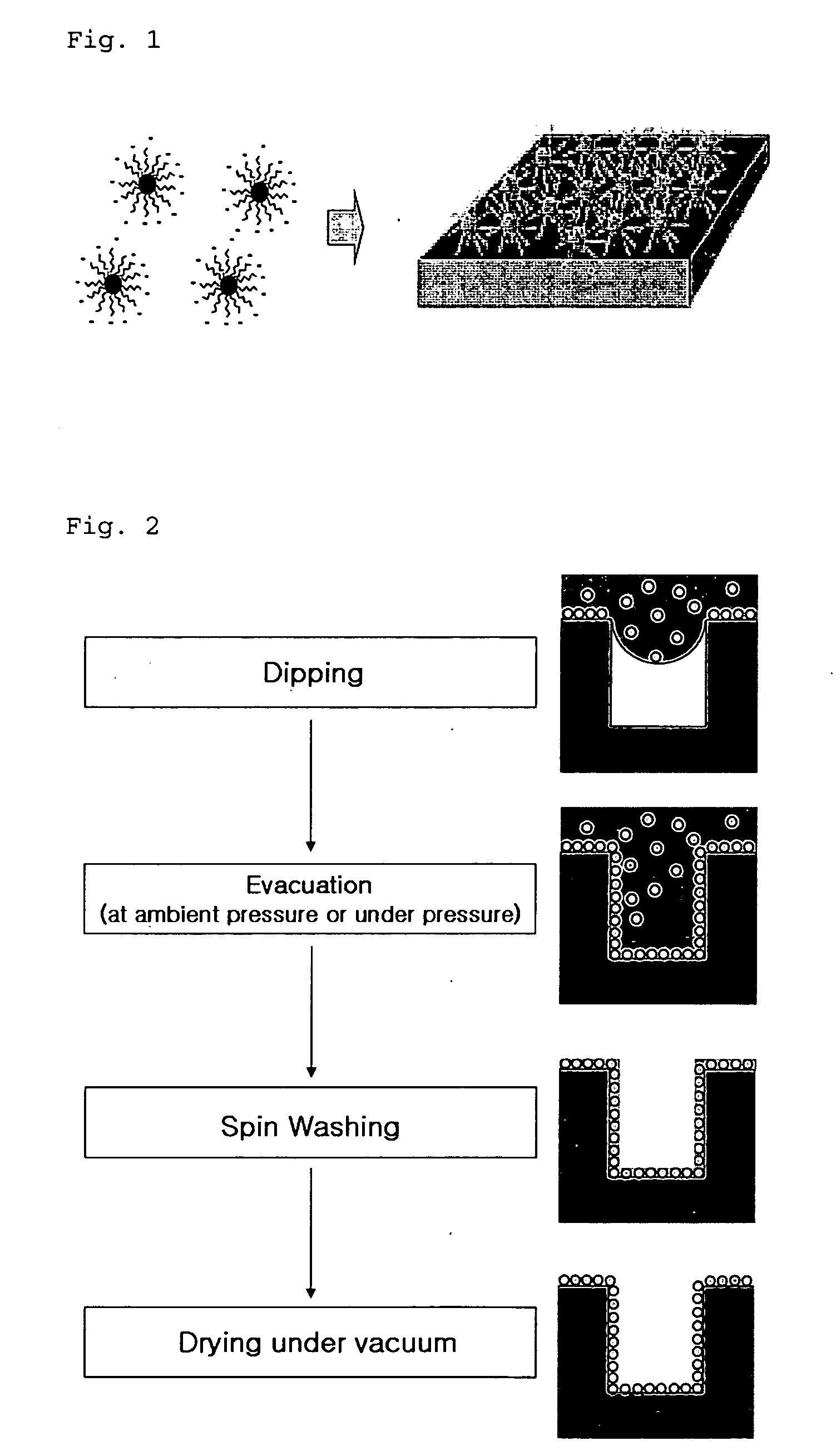

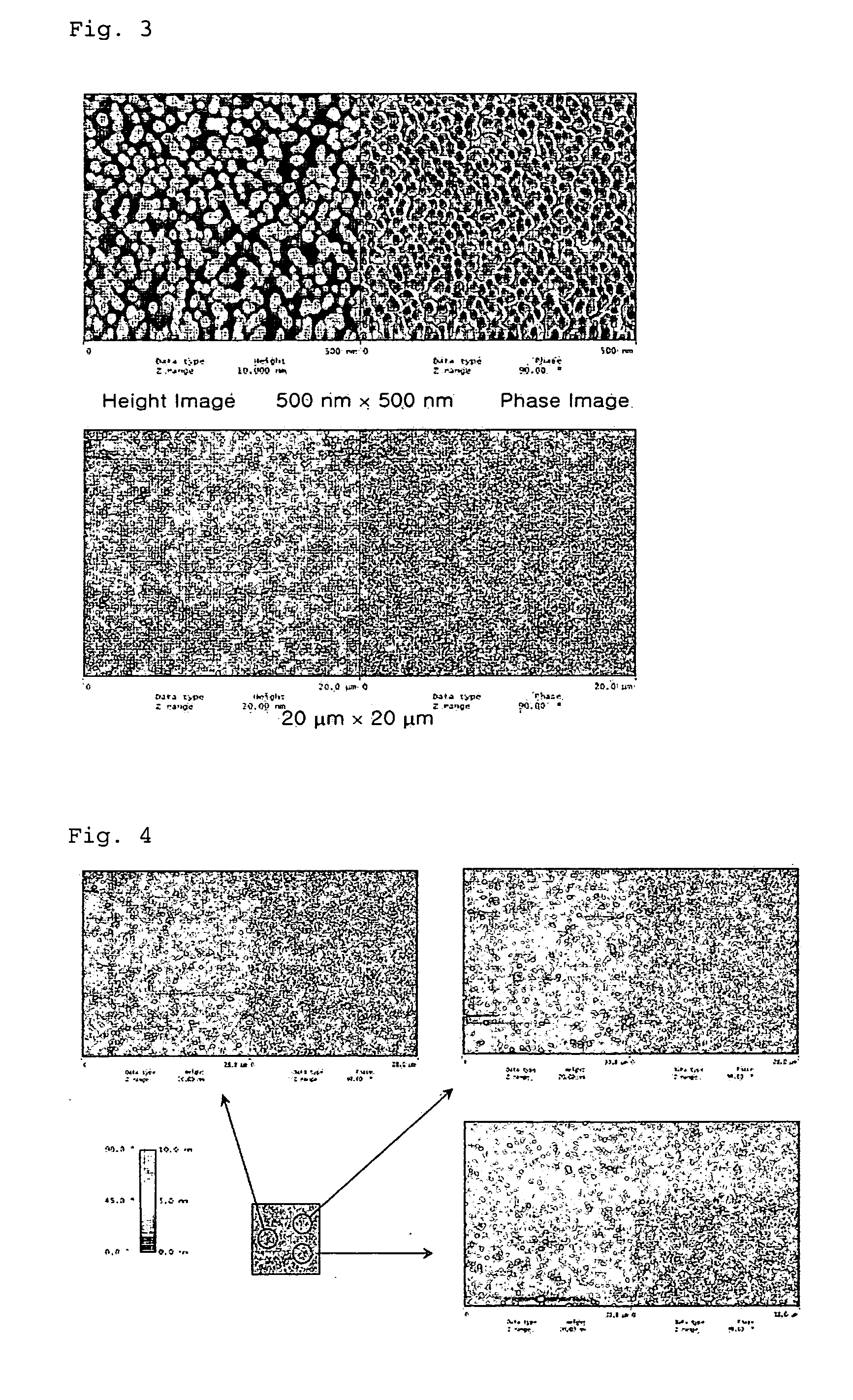

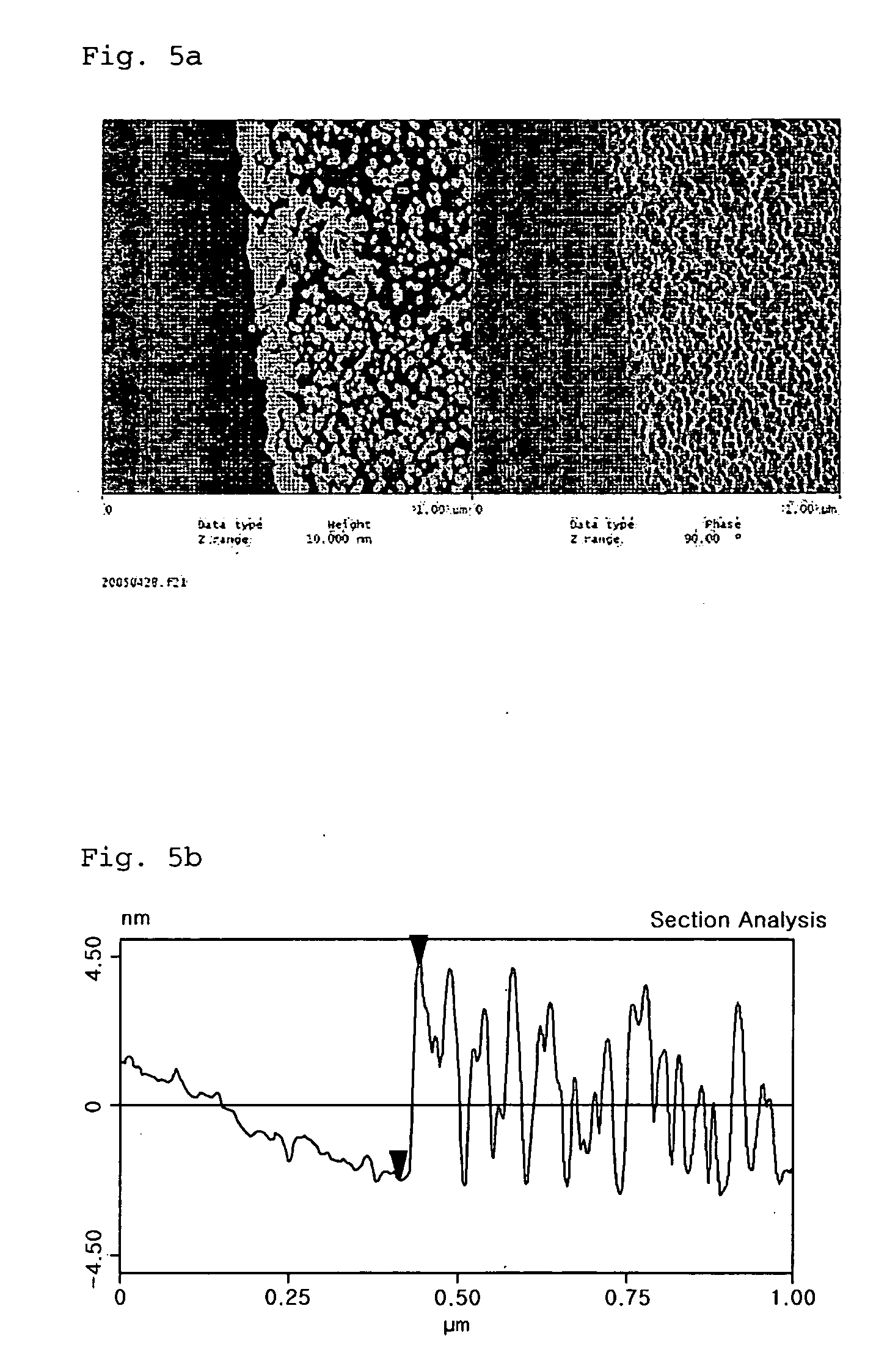

Nanoparticle thin film, method for dispersing nanoparticles and method for producing nanoparticle thin film using the same

InactiveUS20070007511A1Reduce aggregationImprove dispersionMaterial nanotechnologySolid-state devicesSolventNanometre

A nanoparticle thin film, a method for dispersing nanoparticles and a method for producing nanoparticle thin film using the same. The method for dispersing nanoparticles may include modifying the surface of nanoparticles with a charged material, drying the surface-modified nanoparticles under vacuum and / or dispersing the dried nanoparticles in a solvent. According to the methods provided, the nanoparticle thin film may exhibit more stability, lesser defects and / or lesser aggregation of nanoparticles. In addition, 2-dimensional and / or 3-dimensional nanoparticle thin films may be produced in which nanoparticles may be more uniformly applied over larger areas. The nanoparticle thin films produced by the methods may be more effectively used for a variety of applications (e.g., flash memory devices, DRAMs, hard disks, luminescent devices, organic light-emitting diodes (OLEDs) or the like).

Owner:SAMSUNG ELECTRONICS CO LTD

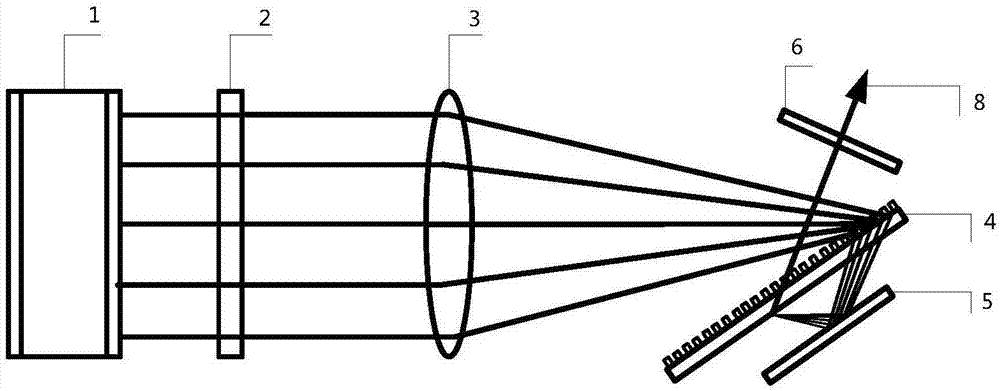

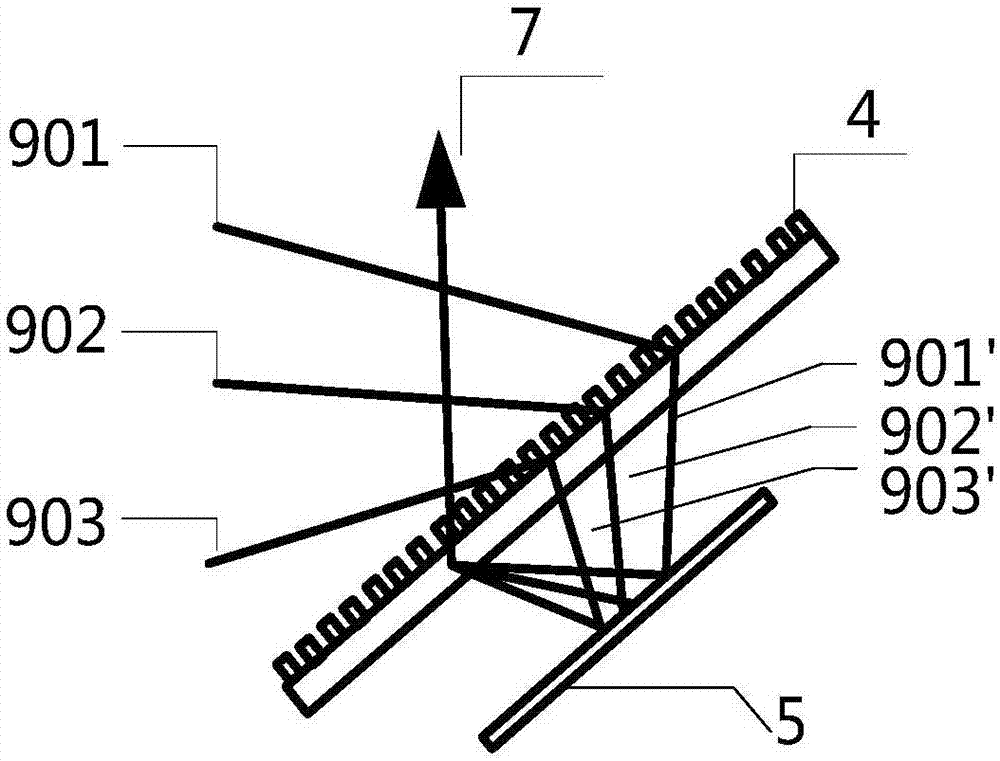

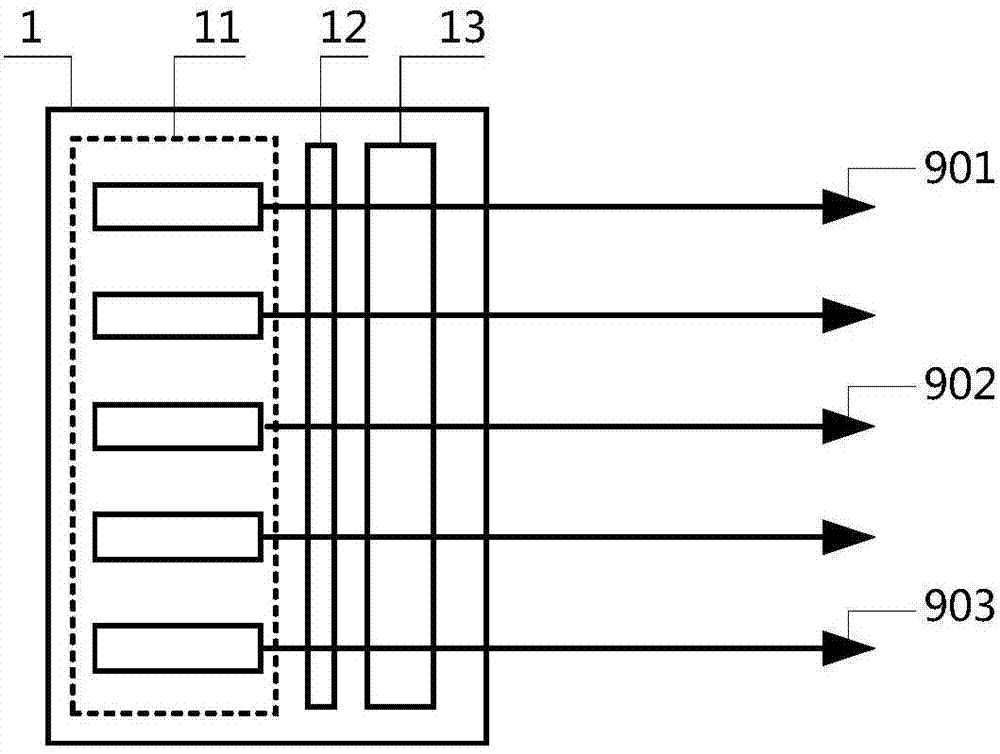

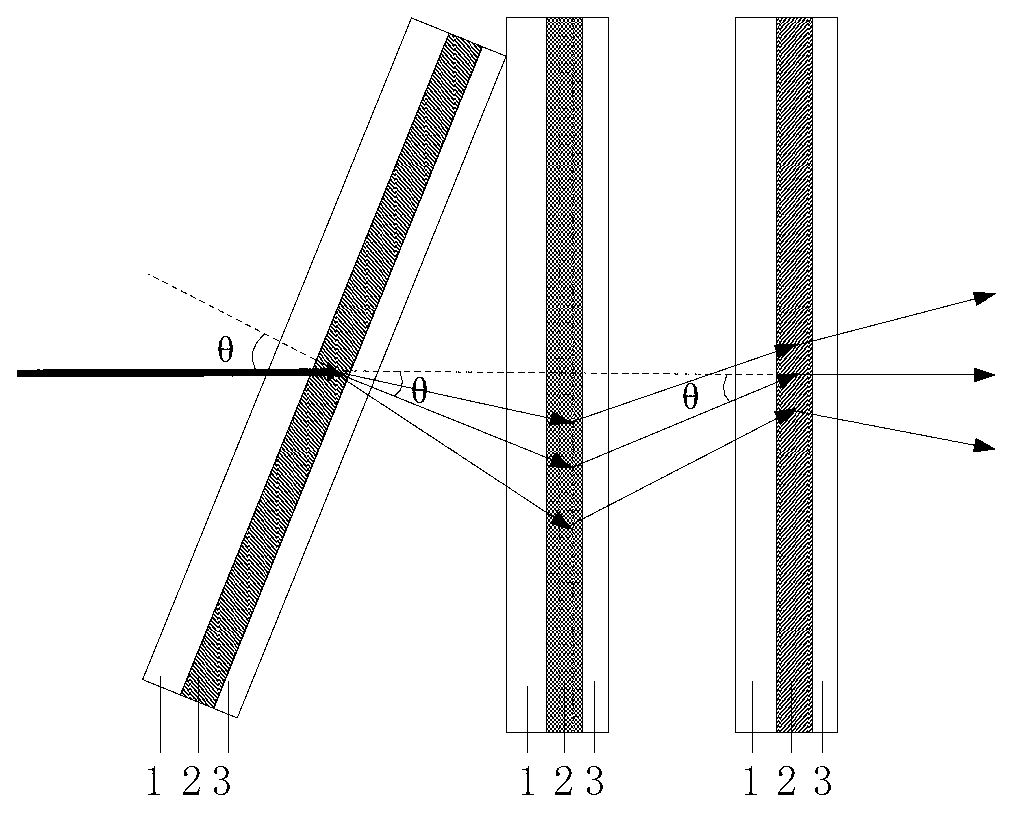

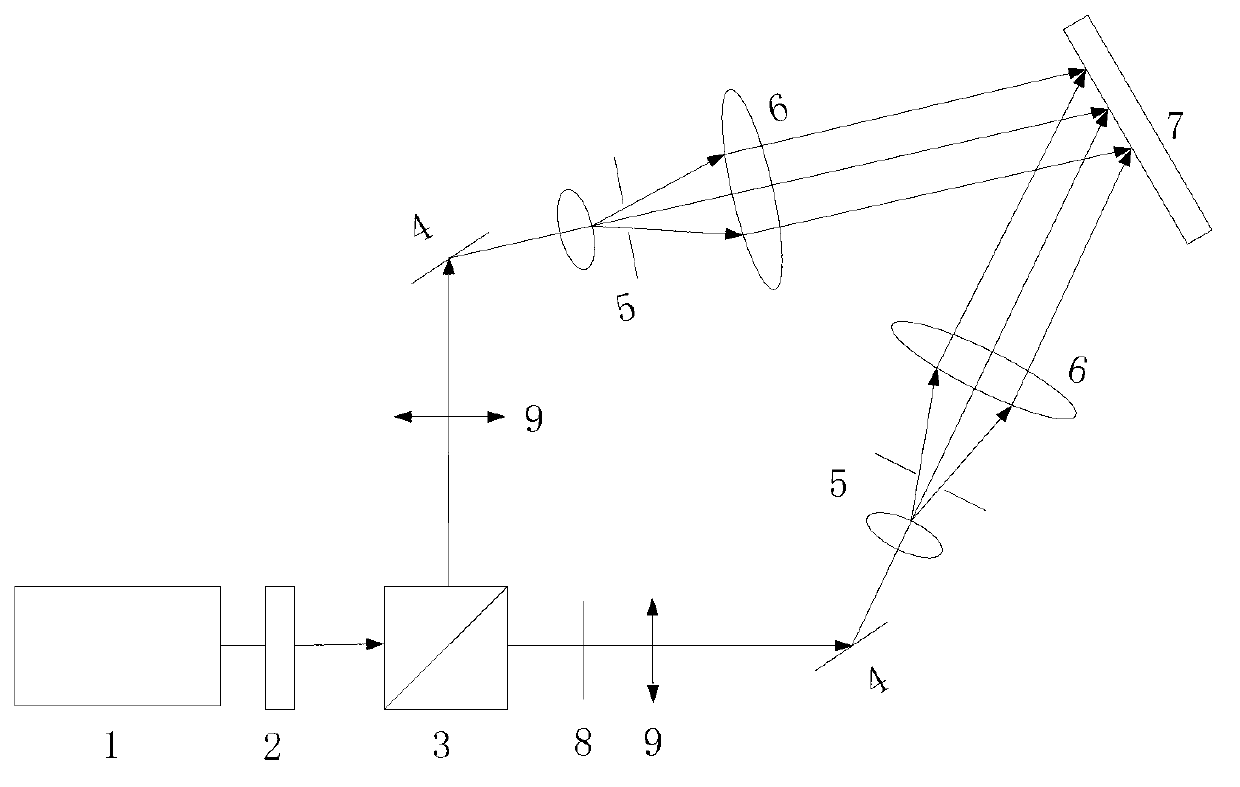

Spectral beam combining device for realizing spectral width compression through two-time diffraction by using grating and reflecting element

ActiveCN107272214AImprove dispersionAchieving secondary dispersionOptical elementsGratingLaser array

Disclosed is a semiconductor laser spectral beam combining device for for realizing spectral width compression through two-time diffraction by using a grating and a reflecting element. The device comprises a semiconductor laser light source, a slow axis collimating cylindrical lens, a transforming lens, a grating, a reflecting element and an output coupling mirror. In the invention, the single grating is used as a diffraction element, the reflecting element reflects the beam which is diffracted by the grating for the first time, the beam is secondarily dispersed when passing through the grating again, and the dispersive power is doubled. Through the feedback of the output coupling mirror, the laser of each unit of a semiconductor laser array is locked at a different wavelength to obtain a laser output of high power and high brightness. The device of the invention overcomes the limitation of the gain line width of a gain material in the traditional spectral beam combination to the number of beam combining units, can increase the number of beam combining units within the gain line width and the high-efficiency diffraction wavelength range of the grating, increases the output power significantly, reduces the resonant cavity length with a certain spectral width, makes the laser structure compact and improves laser mode stability.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

EPDM (ethylene propylene diene monomer) rubber insulated/jacketed cable with high strength, oil resistance and aging resistance

InactiveCN105255019AImprove heat resistanceGood weather resistanceRubber insulatorsInsulated cablesCarbon nanotubeEPDM rubber

The invention discloses an EPDM (ethylene propylene diene monomer) rubber insulated / jacketed cable with high strength, oil resistance and aging resistance. The EPDM rubber insulated / jacketed cable comprises following raw materials: EPDM rubber, nitrile butadiene rubber, maleic anhydride grafted polypropylene, an ethylene-vinyl acetate copolymer, diphenyl hexadiphthalein diamine, stearic acid, zinc oxide, superfine fully vulcanized powder nitrile butadiene rubber, tin(II) chloride dehydrate, bromo-octyl-phenolic curing resin, calcined kaolin, zinc methacrylate, carbon nano tubes, superfine silica, calcium sulfate whiskers, polyacrylonitrile fibers, a silane coupling agent, lanthanum glutamic dithiocarbamate, petroleum wax, naphthenic oil, an anti-aging agent and an accelerator. The EPDM rubber insulated / jacketed cable material with high strength, oil resistance and aging resistance serves as insulation and / or a jacket in a cable and has high strength, good oil resistance, aging resistance and combination properties and long service life.

Owner:ANHUI LAND GRP

Colorant concentrates for thermoplastic biofiber composites

InactiveUS20080119589A1Concentrated deliveryExcellent and substantially uniform dispersion of colorOrganic chemistryPaper coatingGramAdditive ingredient

Color concentrates for thermoplastic biofiber composites are disclosed. The concentrates employ three factors to achieve concentrated delivery of color to the processing machine and excellent and substantially uniform dispersion of color in the processing machine: melt flow of the concentrate exceeding at least 4 g / 10 min. using ASTM D-1238; pellet size of the concentrate such that at least 50 pellets weigh less than one gram; and weight percent of the colorant ingredients in the concentrate exceeding at least 30 weight percent.

Owner:POLYONE CORPORATION

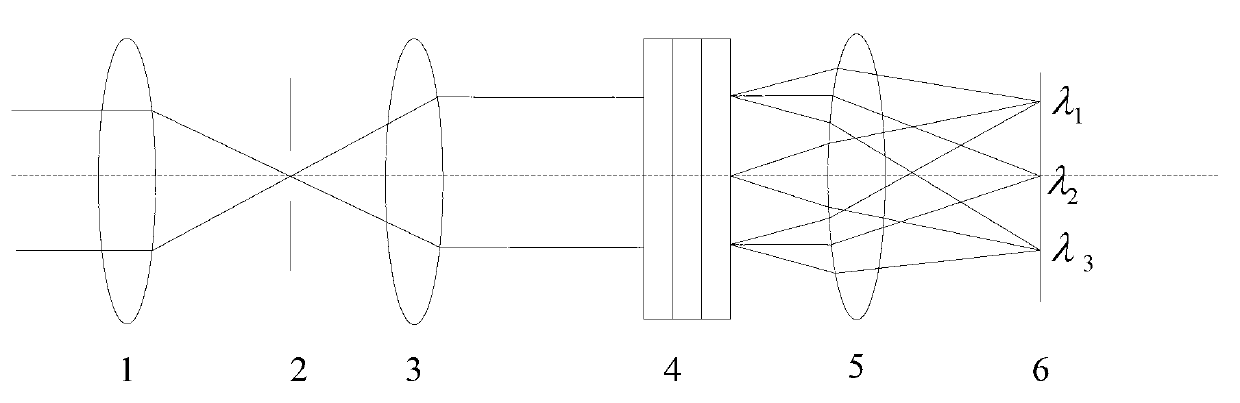

Spectrum light splitting imaging system light path based on volume hologram grating component light splitting

InactiveCN103134587AImprove light energy utilizationHigh dispersion rate of the systemRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsOptical pathVolume hologram

The invention relates to a spectrum light splitting imaging system light path based on volume hologram grating component light splitting. Volume hologram grating is adopted as a light splitting component by the spectrum light splitting imaging system light path. Parallel lights which pass through a front imaging lens, a slit and a collimating lens are conducted with diffraction light splitting, after the being split, the lights coalescent, form an image on an image plane through the imaging lens and received by a charge coupled device (CCD) detector. The whole system is small in size and compact in structure, the lights can pass in and out straightly, the utilization rate of light energy is high, and the light splitting performance is good.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

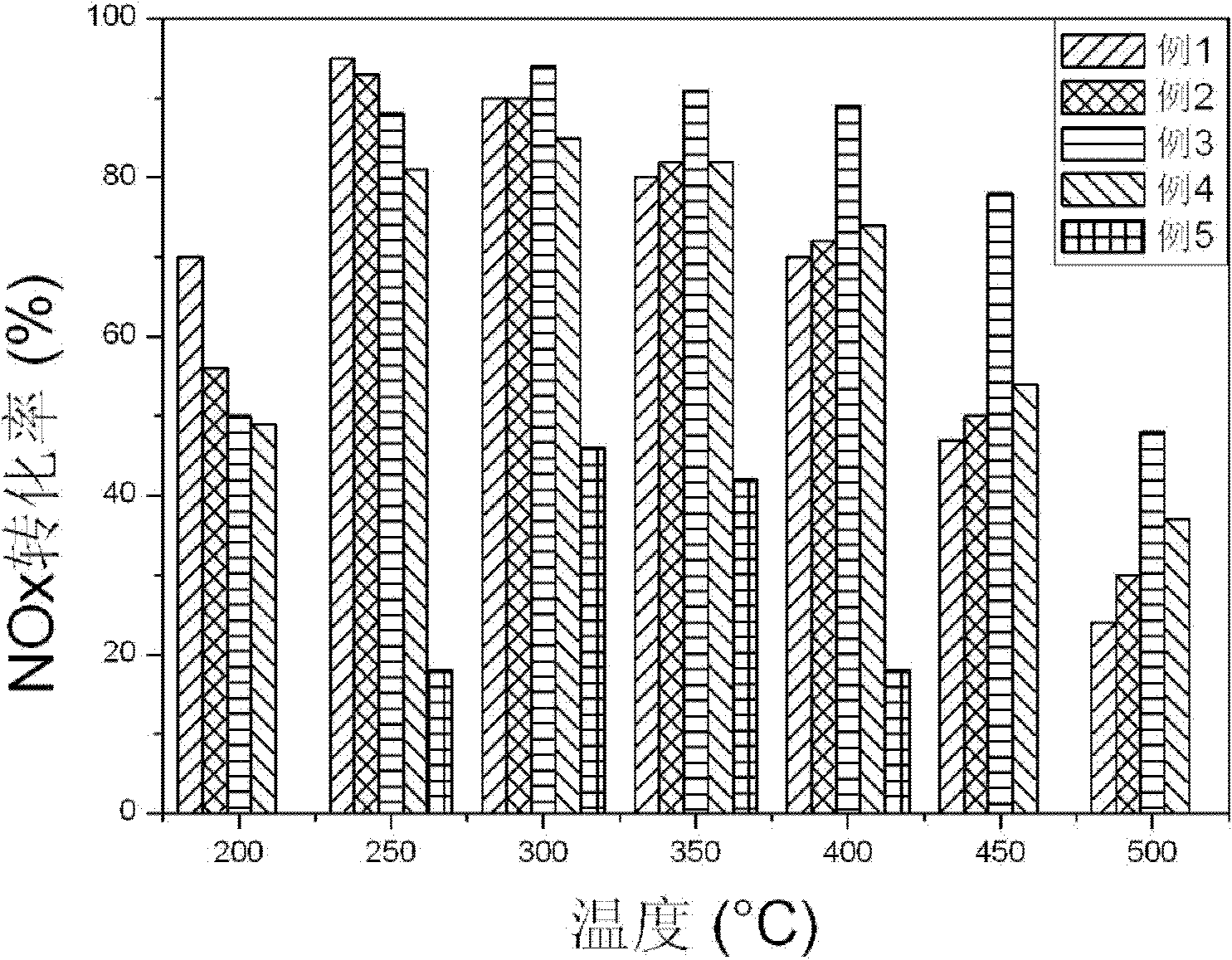

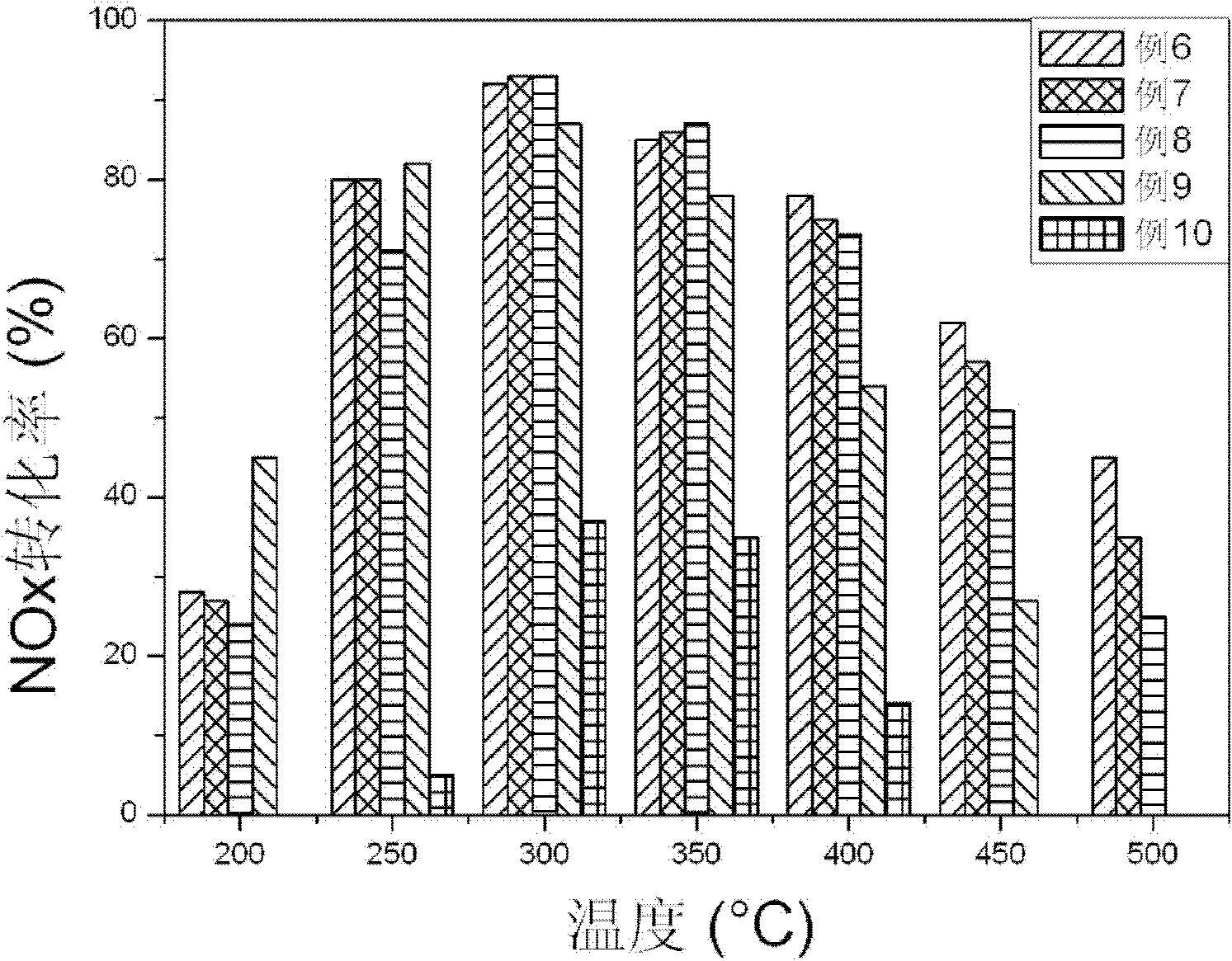

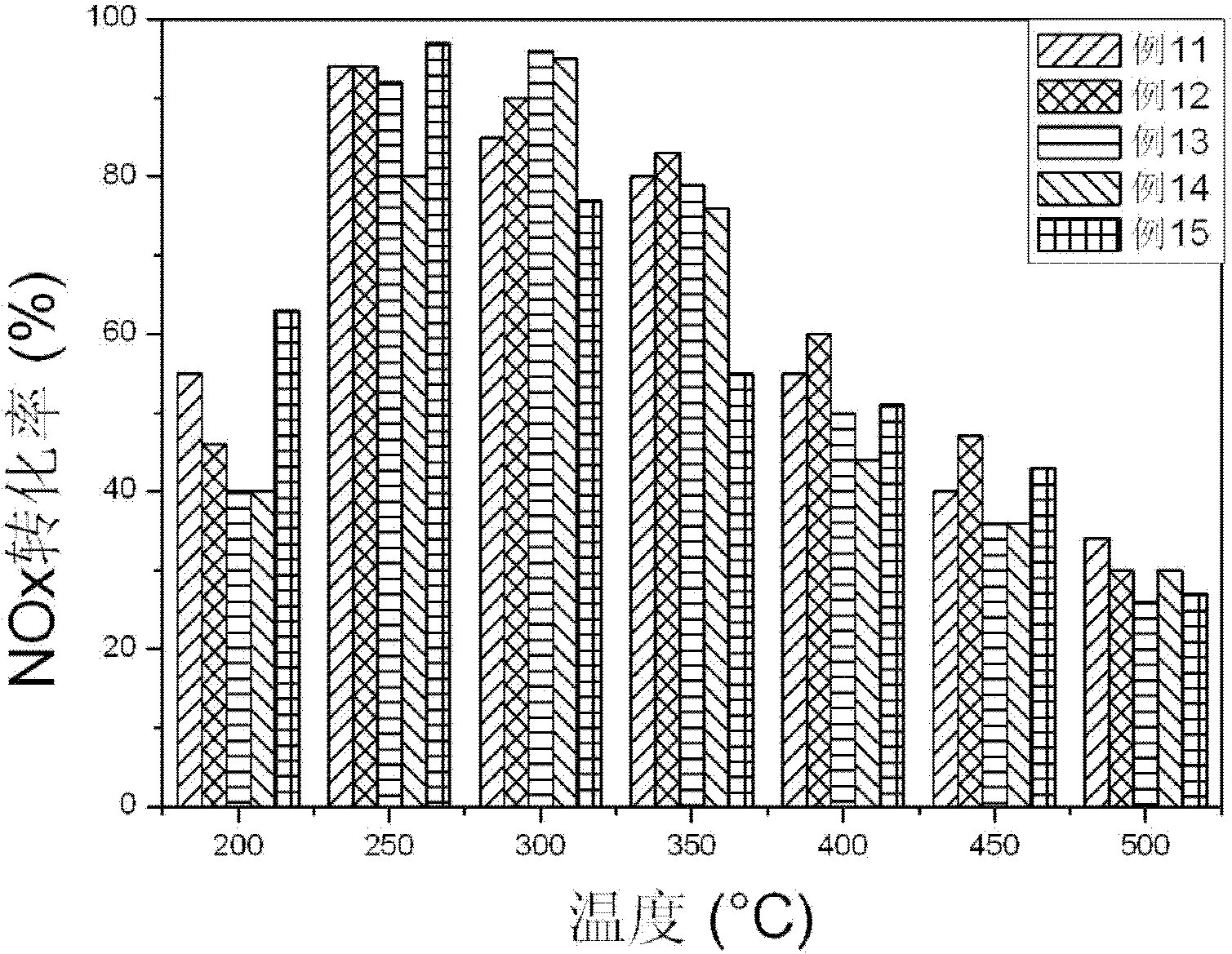

CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

ActiveCN102240543AImprove anti-sulfur poisoning performanceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurWorking temperature

The invention discloses a CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and a preparation thereof and belongs to the field of nitric oxide post-processing purification. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier; an active coating is loaded on the carrier; a modifying coating is loaded on the active coating; the cordierite carrier has a skeleton carrying function; the active coating of the catalyst mainly has a function of activating NOx and NH3; and the modifying coating mainly has functions of storing NH3, avoiding deep oxidation of NH3 on the surface of the catalyst when the catalyst is used at a high temperature and increasing the sulfur poisoning resistance of the catalyst. The preparation process of the catalyst is simple and can be easily industrialized. A working temperature window of the optimized catalyst can reach 250-450 DEG C, and denitration efficiency is above 80%. The catalyst has the significant advantage of being nontoxic and has excellent heat stability and excellent SO2 poisoning resisting property.

Owner:TSINGHUA UNIV +1

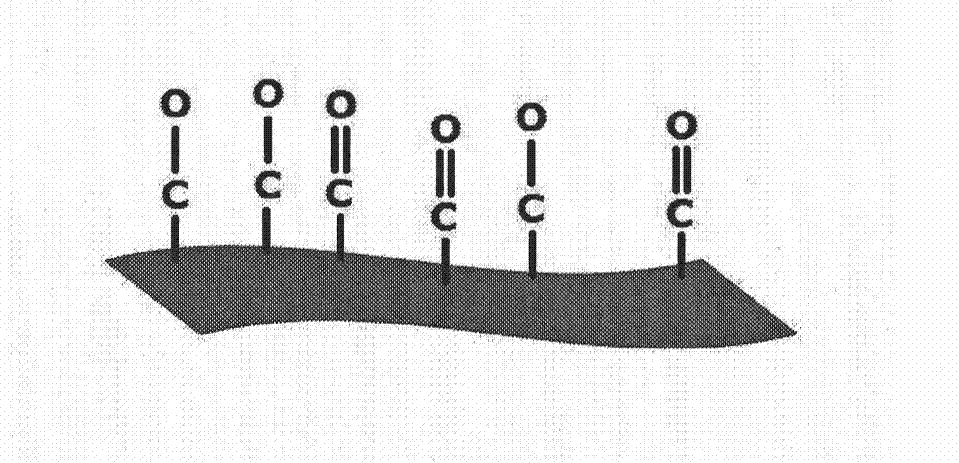

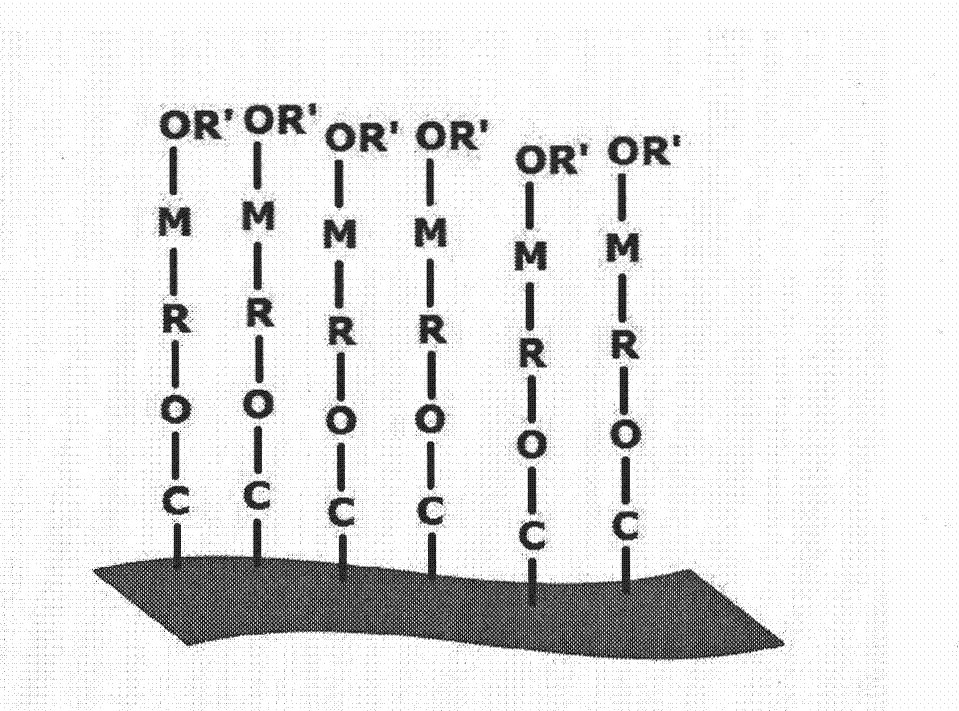

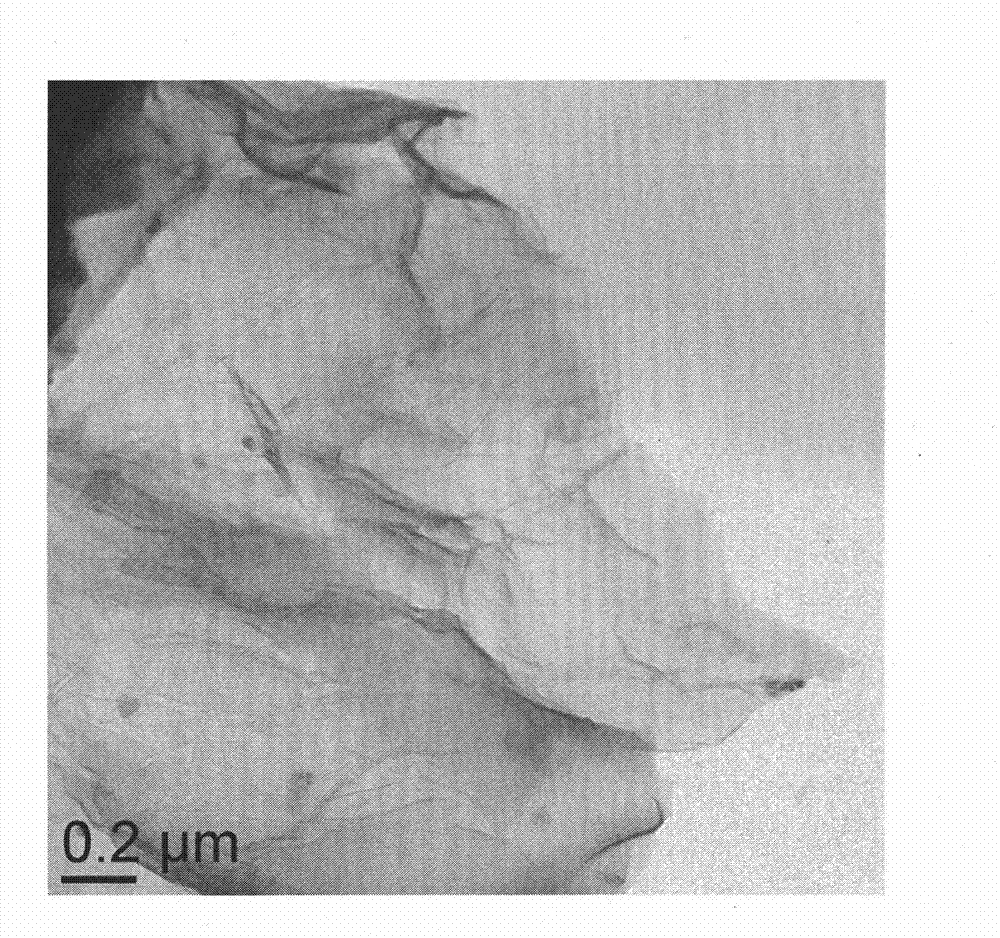

Surface-modified graphene

ActiveCN102898680AImprove dispersionImprove affinityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSolventSurface modification

The invention provides a surface-modified graphene, comprising a graphene powder and at least one surface-modified layer, wherein the least one surface-modified layer comprises a surface modification agent and at least two functional groups disposed at two ends of the surface modification agent respectively; one functional group of the at least two functional groups can generate a chemical bond with an organic functional group on the surface of the surface-modified graphene powder; and the other functional group of the at least two functional groups forms a surface characteristic of the surface-modified graphene, wherein the surface modification agent comprises at least one of a coupling agent, aliphatic acid and a resin. Therefore, the surface-modified graphene powder can increase the dispersibility of the graphene powder in a solvent, enhance the endophilicity between the graphene powder and an organic polymer, and make the composite material to be more durable and to have wider applications.

Owner:杭州烯创科技有限公司

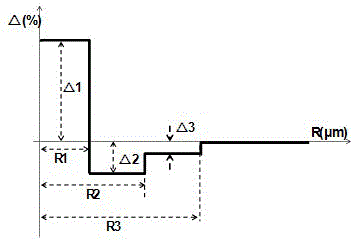

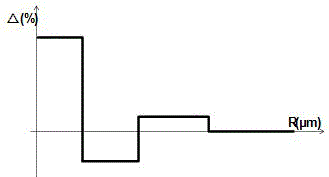

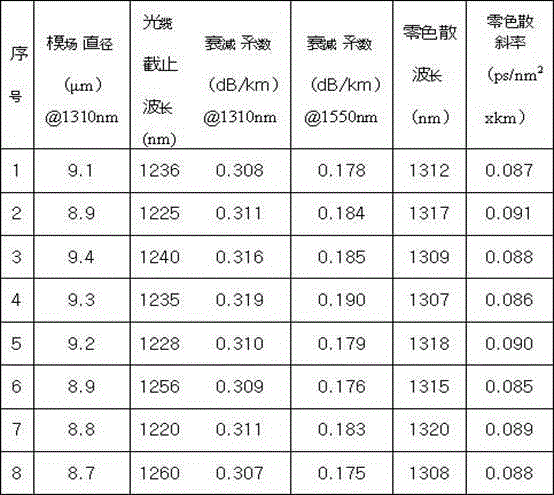

Low-attenuation single-mode optical fiber

ActiveCN103149630APrecise control of section structureReasonable design of refractive index profileOptical fibre with multilayer core/claddingOptical waveguide light guideStress concentrationUltrasound attenuation

The invention relates to a low-attenuation single-mode optical fiber. The low-attenuation single-mode optical fiber comprises a fiber core layer and cladding layers. The low-attenuation single-mode optical fiber is characterized in that a first inner cladding layer and a second inner cladding layer sequentially coat the fiber core layer; the radius R1 of the fiber core layer is 3.5 to 5 mu m, and the relative refractive index difference is 0.2 percent to 0.4 percent; the radius R2 of the first inner cladding layer is 6.5 to 11 mu m, and the relative refractive index difference is -0.06 percent to 0 percent; the radius R3 of the second inner cladding layer is 15 to 30 mu m, and the relative refractive index difference is -0.02 percent to 0.05 percent; the outermost layer is an outer cladding layer; and the outer cladding layer is a pure silica quartz glass layer. By the adoption of a double-inner-cladding-layer structure, the refractive index section of the optical fiber is designed more reasonably. By optimizing doping agents of the fiber core layer and the cladding layers, the material viscosity of the fiber core layer is reduced, the viscosities of the fiber core layer and the cladding layers can be matched, and the increase of optical fiber attenuation caused by stress concentration in a fiber corer part due to drawing tension is effectively avoided. On the basis of comprehensive compatibility with a G.652 standard, the attenuation performance of the optical fiber is much higher than that of a conventional G.652 optical fiber.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

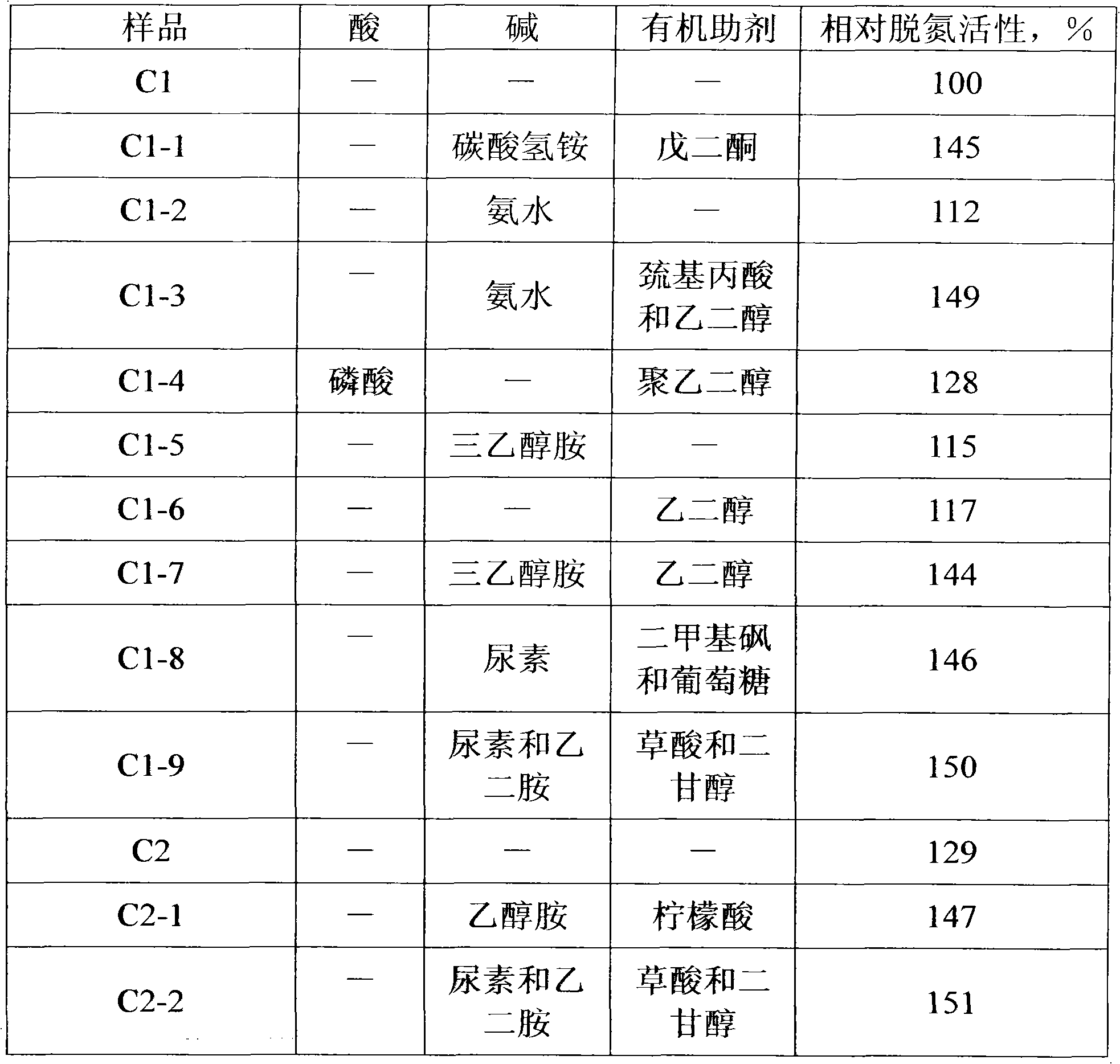

Activation method of catalyst

InactiveCN102463123AHigh activityImprove dispersionCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsThermal treatmentActivation method

The invention discloses an activation method of a catalyst which includes VIB group metal component and VIII group metal component. The metal components exist as the form of oxidation state. The catalyst contacts with alkaline matter containing solution and organic additive solution. At last, activated catalysts is obtained by thermal treatment. Compared with the existing technologies, the method provided by the invention can effectively enhance activity of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of nano-grade calcium carbonate

InactiveCN102491395AImprove dispersionHigh reinforcementCalcium/strontium/barium carbonatesNanotechnologyNanometreCalcium carbonate

The invention discloses a preparation method of nano-grade calcium carbonate. The invention belongs to the technical field of compound preparation. The method comprises steps that: S1, lime is digested; S2, a slurry obtained through digestion is sieved, and is then aged; S3, the aged slurry is carbonized; S4, the carbonized slurry is processed through primary cladding; S5, the slurry processed through primary cladding is subject to press-filtrating, drying, crushing, grading, and packaging, such that an intermediate product is obtained; S6, the intermediate product is subject to secondary cladding, such that a nano-grade calcium carbonate finished product is obtained. When the nano-grade calcium carbonate prepared with the method is used in RTV silicon rubber, the nano-grade calcium carbonate has both high dispersity and high reinforcing property.

Owner:曾庆铭

Plant composite engine oil containing graphene and preparation method thereof

The invention discloses plant composite engine oil containing graphene, which includes the following raw materials: castor oil, liquid graphene, modified castor oil, an antioxidant, an anti-corrosion agent, an anti-foam agent, an extreme pressure anti-wear agent, a pour point depressant, an anti-rust agent, a viscosity index improver, a dispersing agent, a cleaning agent, a lubrication modifier, an organic anti-aging agent, and modified nano cerium vanadate. By adding the liquid graphene to the plant composite engine oil, lubricating property of the engine oil is improved, wherein the mechanism of lubrication of the graphene is not same as that of an additive in the prior art. Because the molecular particle size of the graphene is very small, the graphene can generate a roll-ball effect during friction between a cylinder wall and a piston, thereby turning sliding friction into rolling friction, and also can flattening the uneven parts on the cylinder wall just like putty. The graphene, as an anti-wear agent, can promote low-viscosity engine oil better, and enables automobiles to be more energy-saving and environment-friendly.

Owner:梁海东

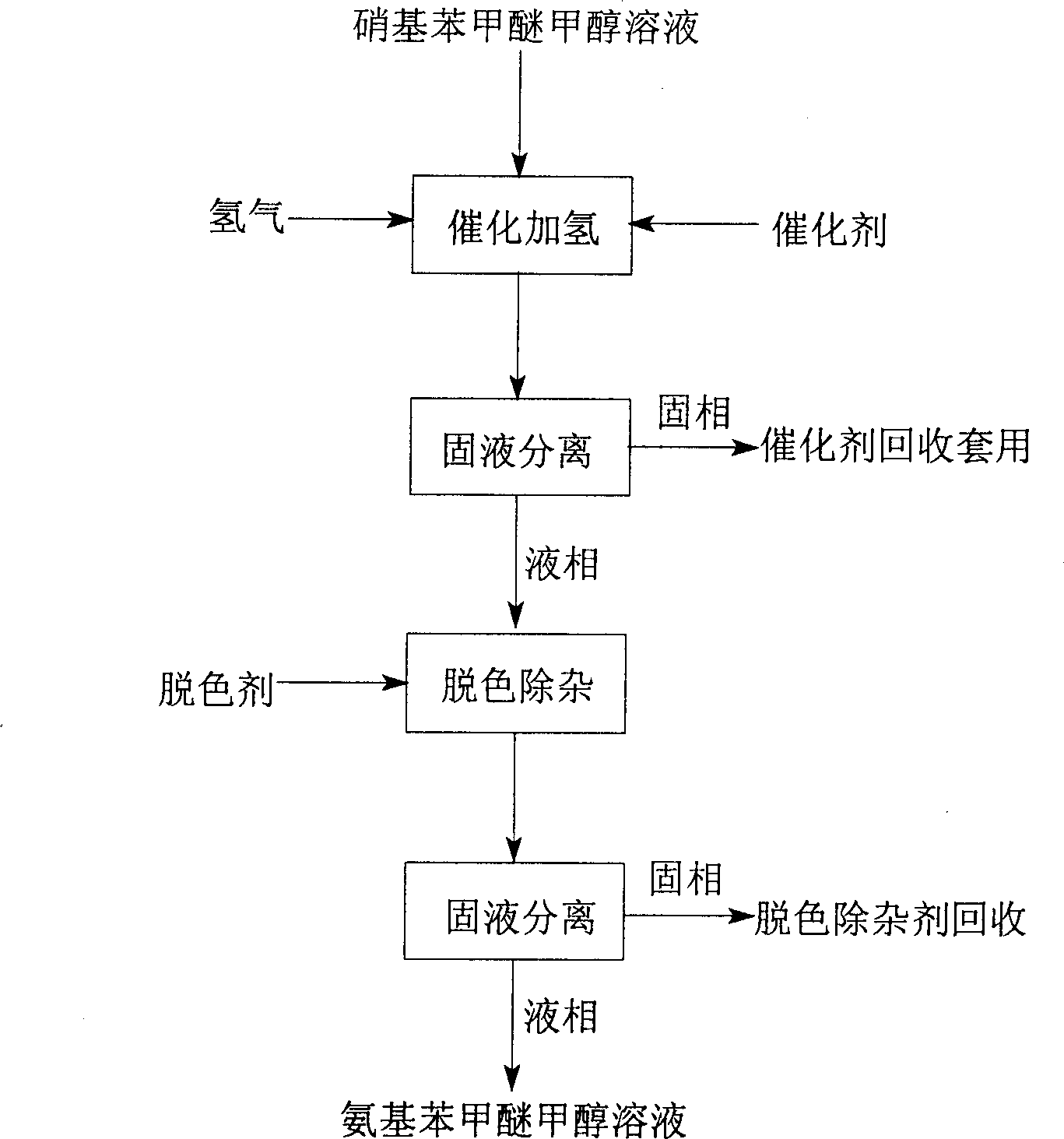

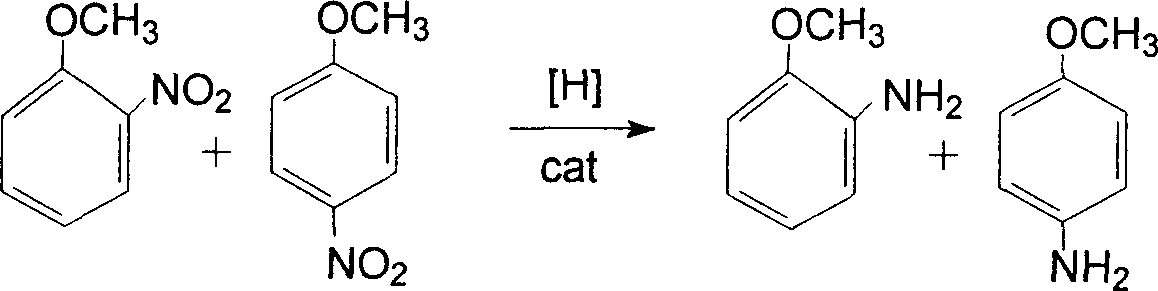

Tech. of preparing amino benz methyl-phenoxide by nitro methyl-phenoxide mixture catalyzing hydrogenation

InactiveCN1861570AImprove dispersionImprove recycling efficiencyOrganic compound preparationAmino-hyroxy compound preparationSolventImpurity

A process for preparing amino phenylmether from nitro phenylmether mixture by catalytic hydrogenating includes such steps as catalytic hydroreducing reaction between methanol, nitro phenylmether mixture and catalyst, recovering catalyst, decoloring, removing impurities, filtering to obtain liquid phase (the solution of amino phenylmether, methanol and water), separation and refining.

Owner:CHANGZHOU JIASEN CHEM +1

Modified attapulgite heavy metal ion adsorbing agent and preparation method thereof

ActiveCN104190381AImprove dispersionIncrease anti-acid and anti-salt propertiesOther chemical processesWater/sewage treatment by flocculation/precipitationIonAmmonium sulfate

The invention relates to a modified attapulgite heavy metal ion adsorbing agent. The modified attapulgite heavy metal ion adsorbing agent is prepared from the following raw materials in parts by weight: 1 to 2 parts of ammonium sulfate, 2 to 3 parts of water glass, 2 to 3 parts of malonic acid, 6 to 9 parts of layering expanded vermiculite, 0.2 to 0.4 part of citronellol, 1 to 2 parts of a silane coupling agent with amino group, 1 to 2 parts of sodium carboxymethylcellulose, 100 to 120 parts of attapulgite, an appropriate amount of water, 5 to 10 parts of assistants and 20 to 30 parts of a 2% to 3% sodium hydroxide solution. The dispersibility, suspension property, adsorption property and thickening performance of the attapulgite are improved, and the attapulgite is endowed with acid resistance and salt resistance as well as a toxic-free property; the attapulgite modification agent is uniform in modification and unlikely to drop, can be used as an adsorbing agent or a flocculating agent and can remove heavy metal ions, such as copper, in water.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

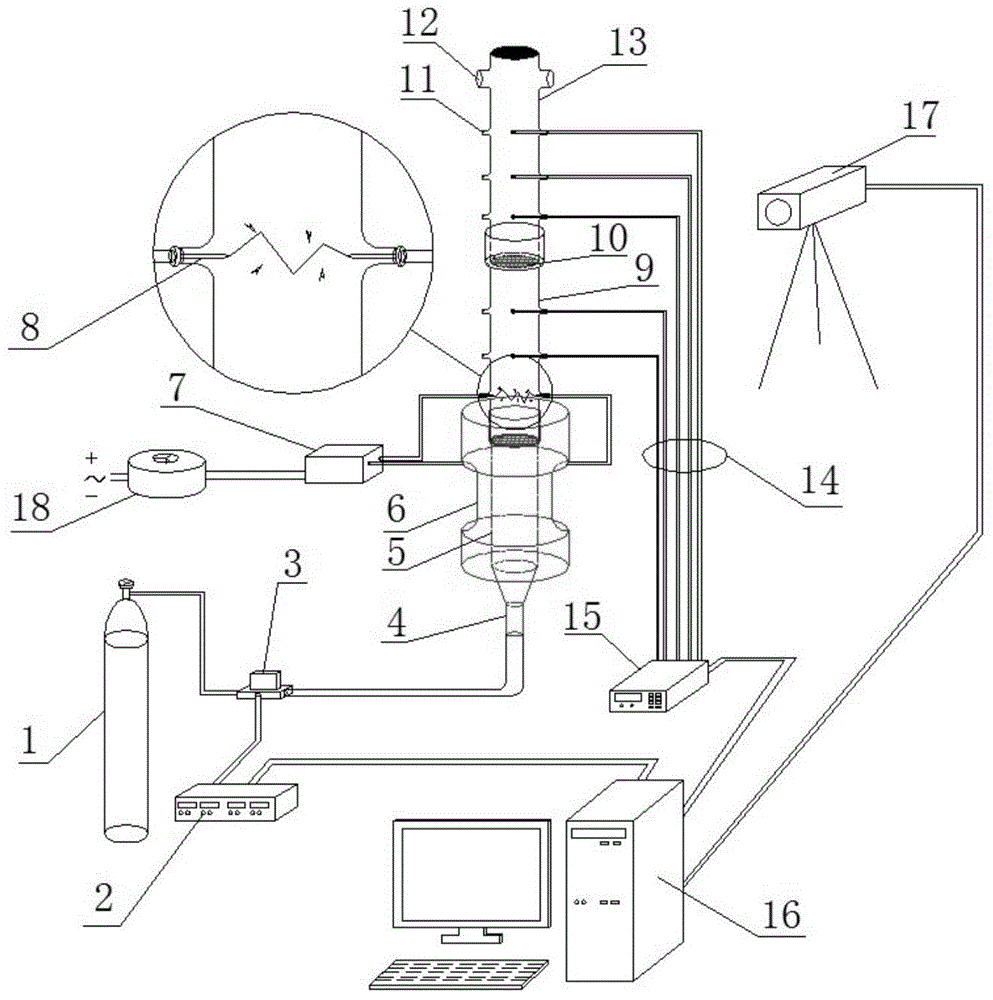

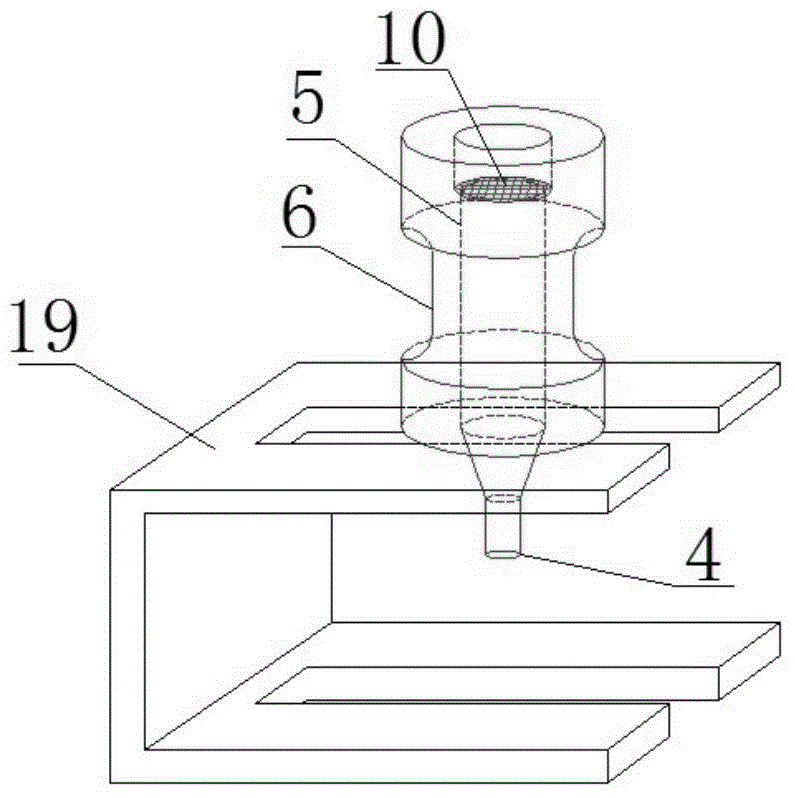

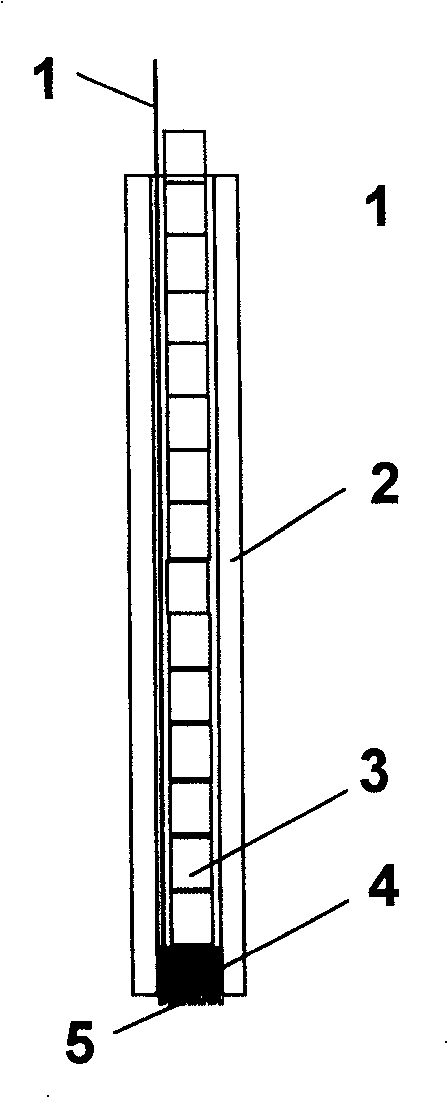

Detachable solid fuel suspension combustion experiment testing device and detachable solid fuel suspension combustion experiment testing method

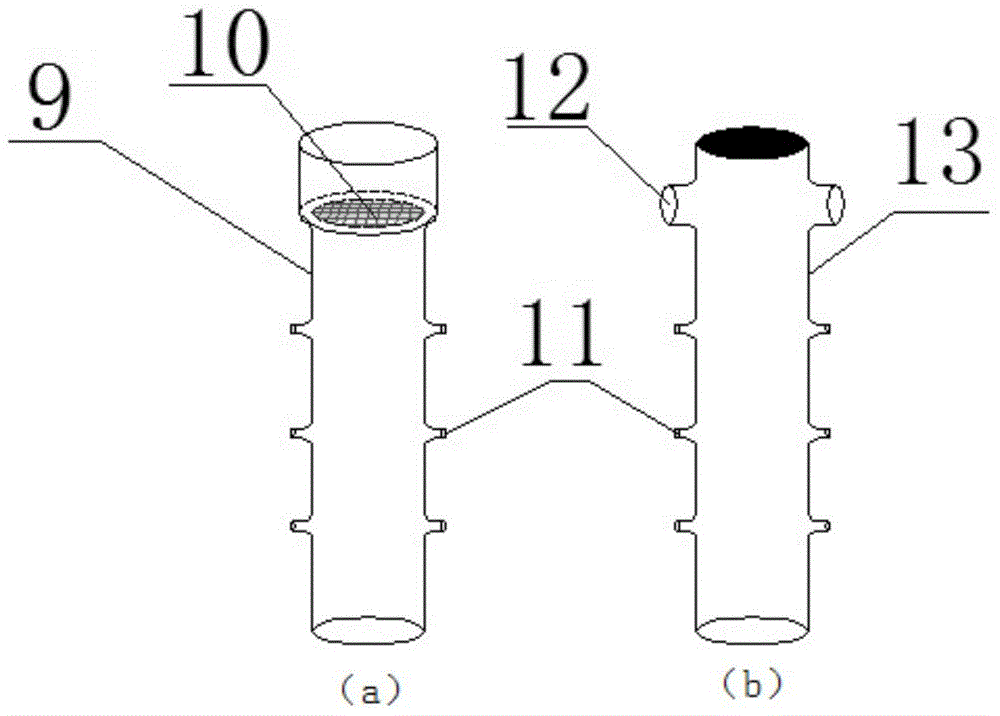

ActiveCN104634922ASolve the problem of not easy to igniteEasy to igniteChemical analysis using combustionData acquisitionSolid fuel

The invention discloses a detachable solid fuel suspension combustion experiment testing device and a detachable solid fuel suspension combustion experiment testing method, belonging to the technical field of a solid fuel combustion experiment. The testing device comprises a suspension combustion mechanism, a combustion data acquisition mechanism, a gas supply mechanism and an ignition mechanism; a base is arranged on a base bracket; the lower end hole of a primary combustion pipe is communicated and in detachable connection with the upper end hole of an inner pipe of the base; the lower end hole of a secondary combustion pipe is communicated and in detachable connection with the upper end hole of the primary combustion pipe; two porous metal plates are respectively arranged at the upper end hole of the inner pipe of the base and the upper end hole of the primary combustion pipe. The testing method comprises the steps of placing fuel; enabling the fuel to suspend; burning; acquiring combustion data; finishing the experiment. The device and the method mainly have the functions of realizing visualization of a combustion state, realizing uniform combustion at a suspended state, carrying out a combustion test on multiple samples for once and enabling the large-particle samples to be easily ignited.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

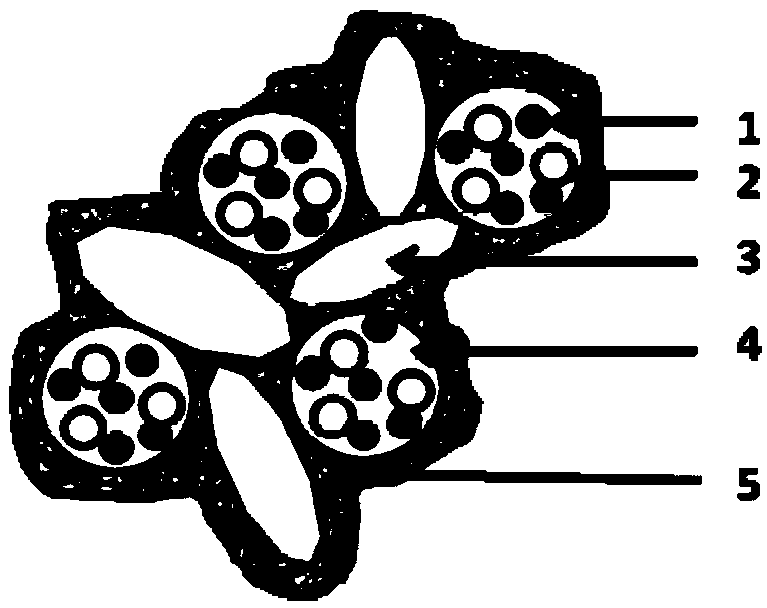

Lithium ion battery silicon carbon composite negative electrode material and preparation method thereof

InactiveCN103618074AImprove dispersionEfficient coatingCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention relates to a lithium ion battery silicon carbon composite negative electrode material and a preparation method thereof. The method comprises the following steps: fixing nanometer silicon in a macromolecule microsphere by preparing a micromolecule / silicon / (carbon black) composite microsphere emulsion, then compounding the microsphere emulsion and graphite, asphalt and the like, and carrying out thermal treatment, thereby obtaining the lithium ion battery silicon carbon composite negative electrode material. The macromolecule microsphere in the material has the effects that the macromolecule microsphere not only is a fixer for stabilizing and inlaying the nanometer silicon, but also is a bonding agent between the nanometer silicon and the graphite after being subjected to high-temperature sintering treatment. The method solves the problems that the nanometer silicon is high in specific surface energy and easy to agglomerate because of small granularity. The lithium ion battery silicon carbon composite negative electrode material prepared by the preparation method disclosed by the invention achieves the synergistic effect of graphite, high-dispersion silicon and carbon, and presents an excellent battery performance.

Owner:南京毕汉特威高分子材料有限公司

Preparation method of conductive macromolecule non-covalent functionalized graphene modified electrokinetic energy conversion polymer material

The invention discloses a preparation method of a conductive macromolecule non-covalent functionalized graphene modified electrokinetic energy conversion polymer material. according to the method, conductive macromolecules are non-covalent functionalized onto the surface of nano-graphene; and then, the conductive macromolecule non-covalent functionalized graphene nano-material undergoes ultrasonic-assisted dispersion into an electrokinetic energy conversion polymer solution so as to finally obtain a conductive macromolecule non-covalent functionalized graphene / electrokinetic energy conversion polymer composite material. The electro-stimulate response intelligent polymer composite material obtained by the method has high dielectric constant and high electrodeformation value. When content of poly(3,4-ethylenedioxythiophene): polystyrolsulfon acid non-covalent functionalized graphene nanofiller is 3%, dielectric constant of the modified polyurethane dielectric elastomer intelligent material reaches up to 350 at room temperature and at the frequency of 1000 Hz, dielectric loss is 0.20, and loss modulus is 200 MPa. Under the action of a 32.2 MV / m electric field, electrodeformation value in the thickness direction reaches 162%. Performance of the material provided by the invention is far more excellent than performance of a regular nano-ceramic or nano-conductive filler modified intelligent polymer composite material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

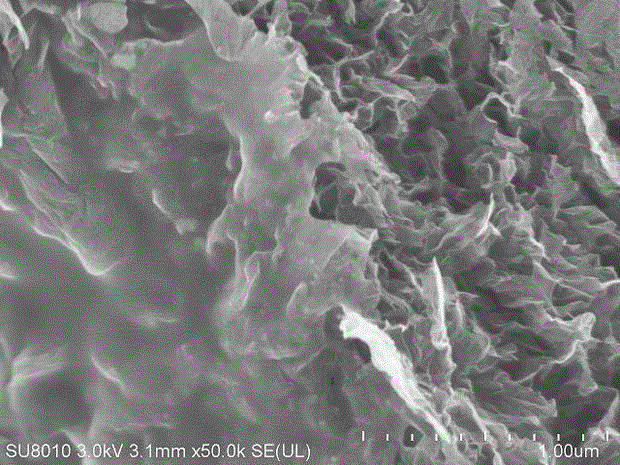

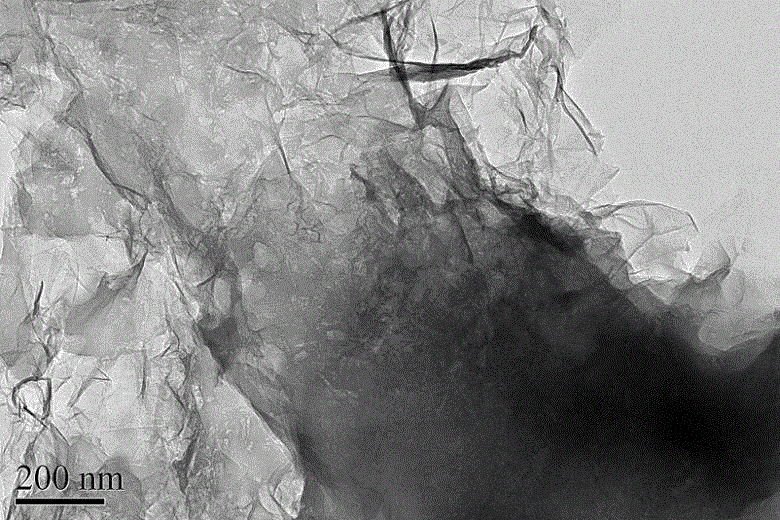

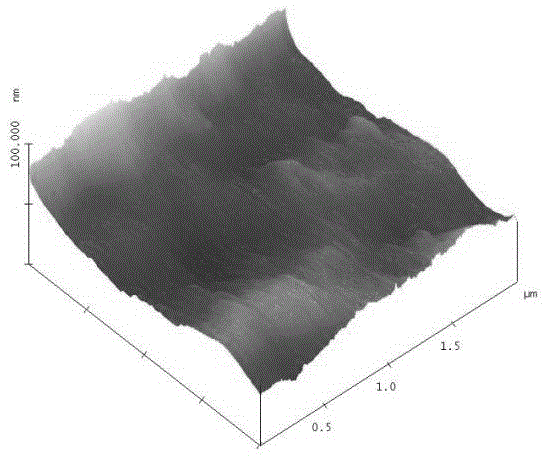

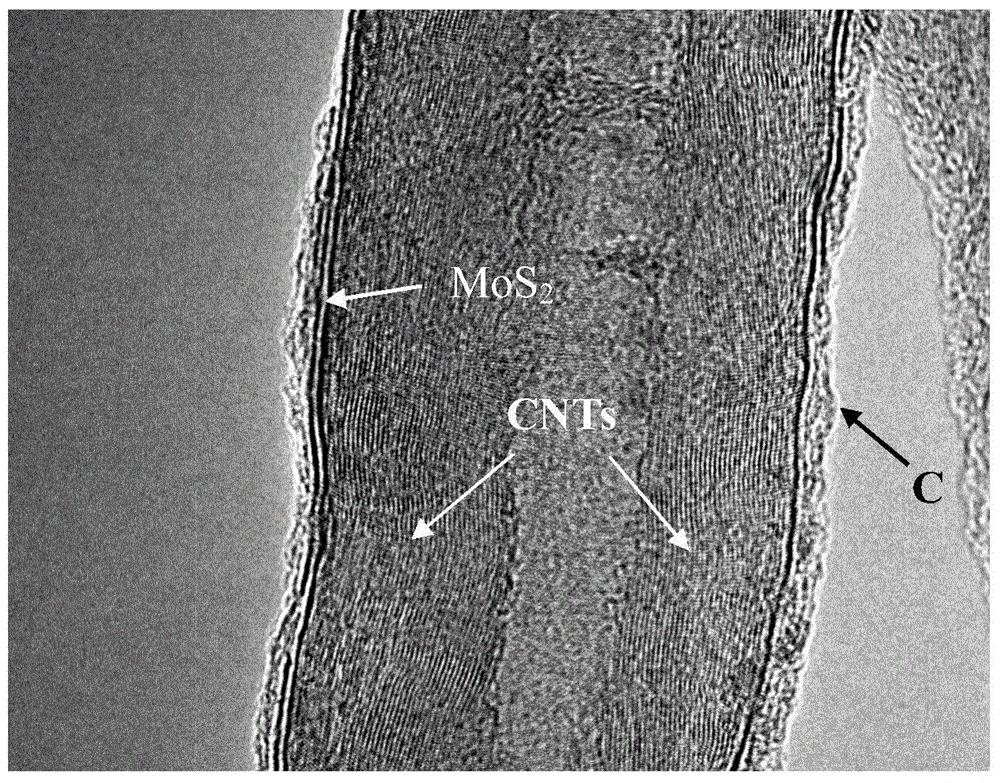

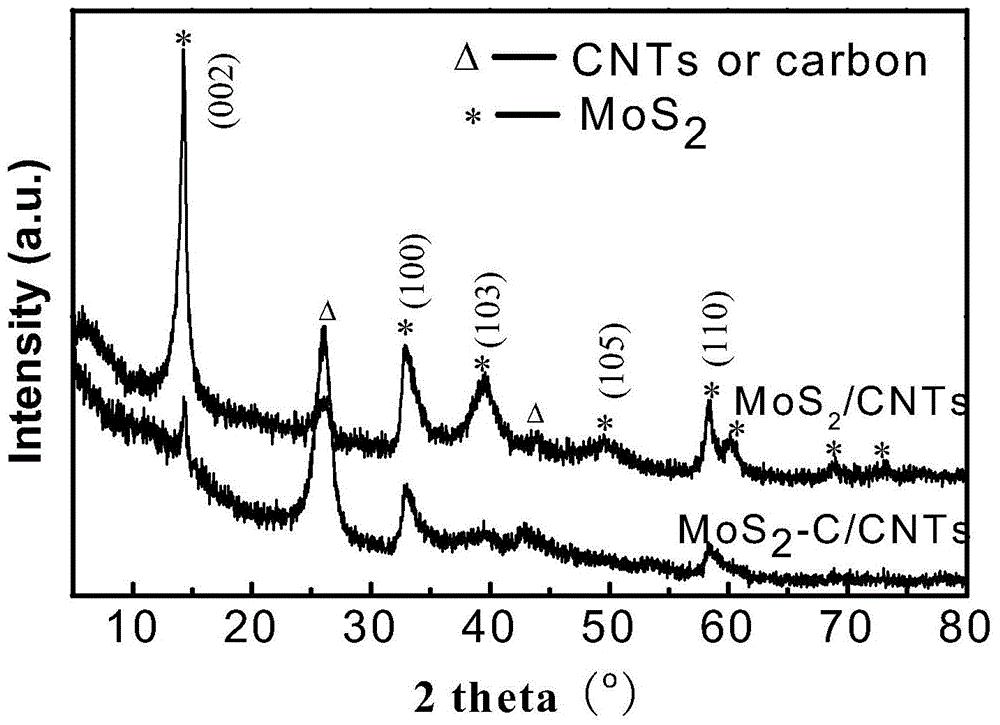

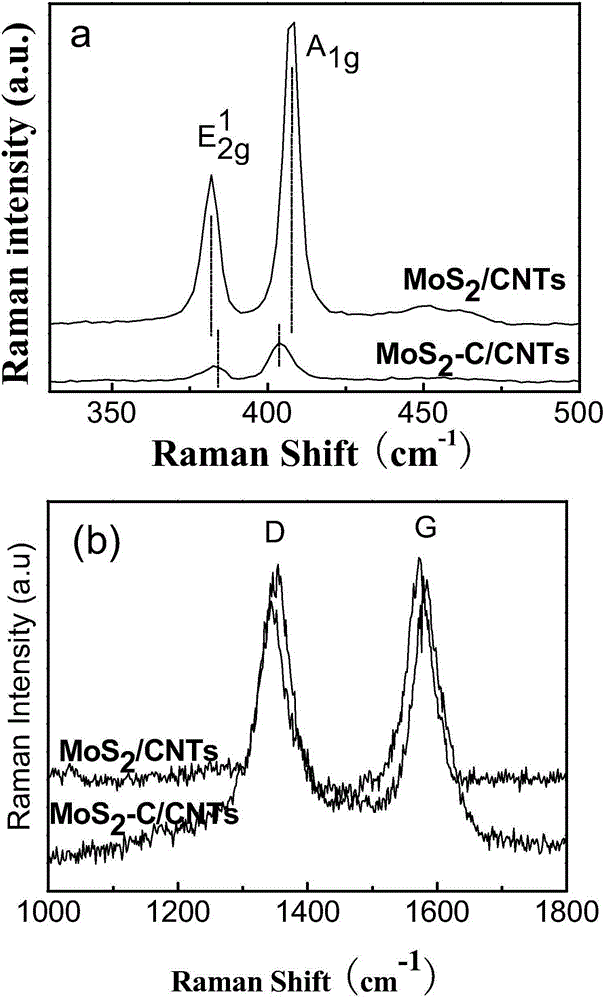

Composite nanotube composed of molybdenum disulfide-carbon-carbon nanotube and preparation method thereof

ActiveCN103553134AImprove dispersionImprove electrical conductivityMaterial nanotechnologyCarbon compoundsAmorphous carbonMolybdenum disulfide

The invention discloses a composite nanotube composed of a molybdenum disulfide-carbon-carbon nanotube and a preparation method thereof. The method comprises the following steps: firstly, orderly dissolving ammonium tetrathiomolybdate and a carbon high-molecular polymer with surface activity into water; then adding a multiwalled carbon nanotube; centrifuging, drying and burning after carrying out ultrasonic dispersing, so as to prepare MoS2-C / CNTs. By using the surface activity of a carbon high-molecular polymer, the molybdenum disulfide is more evenly dispersed on the surface of the carbon nanotube; on the other hand, the conductivity of a compound is improved through the compound of amorphous carbon and molybdenum disulfide left on the surface of the carbon nanotube when a mixture is burnt at high temperature.

Owner:HEFEI UNIV OF TECH

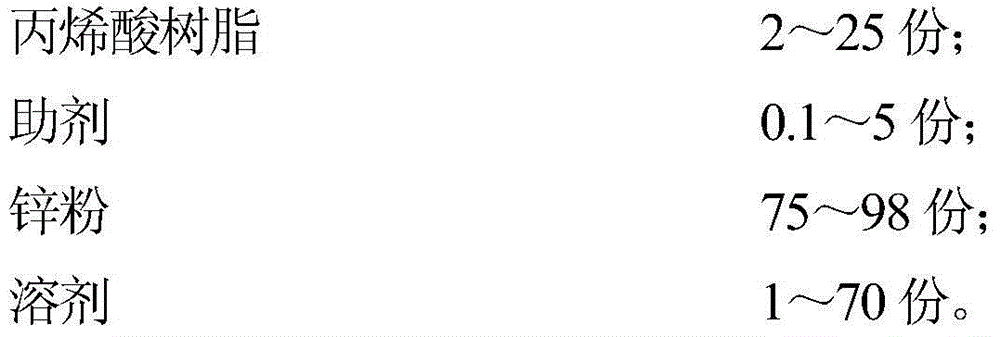

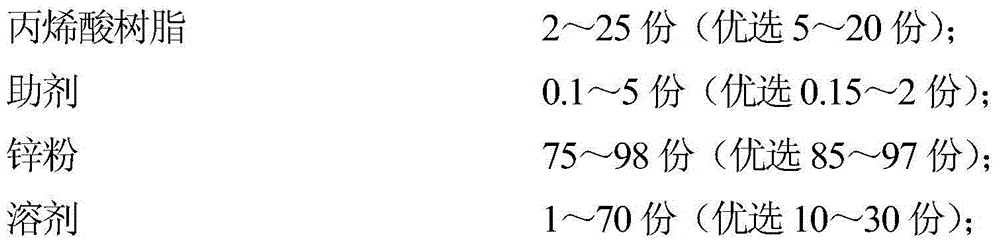

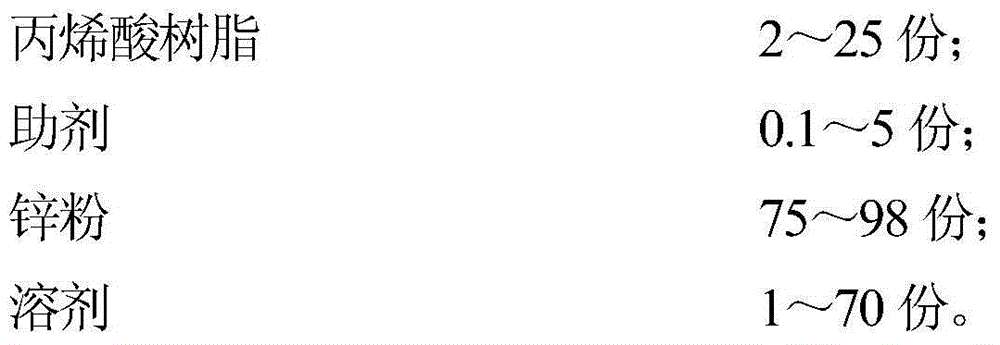

Nano composite cold galvanized coating and preparation method thereof

ActiveCN104449141AImprove dispersionImprove compatibilityAnti-corrosive paintsSolventHot-dip galvanization

The invention relates to a nano composite cold galvanized coating and a preparation method thereof and belongs to the field of nano coatings. The nano composite cold galvanized coating is prepared from the following raw materials in parts by weight: 2-25 parts of acrylic resin, 0.1-5 parts of an assistant, 75-98 parts of zinc powder and 1-70 parts of a solvent, wherein the zinc powder is a mixture of micro-scale zinc powder and nano-scale zinc powder modified by a fluorosilane coupling agent, so that the dispersity of the zinc powder is increased; the compatibility with resin is improved; the coat made of the nano composite cold galvanized coating has high hydrophobic property; the water contact angle is greater than or equal to 135 degrees; the porosity of the cold galvanized coating is significantly reduced; the corrosion resistance of the coating is improved; the nano composite cold galvanized coating disclosed by the invention can be widely applied to anti-corrosion engineering with a novel steel structure, old and new hot-dip galvanizing structures and an electric galvanized steel structure; and the difficulty in corrosion maintenance of transmission and substation facilities and substation equipments can be conveniently and rapidly solved.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST +1

Glucolase electrode based on magnetic carbon nano-tube and preparation method thereof

InactiveCN101329296AImprove dispersionHigh specific surface areaMaterial analysis by electric/magnetic meansNanometreCarbon nanotube

The invention belongs to the field of biological sensor technique, in particular to a glucolase electrode and a preparation method thereof on the basis of a magnetic carbon nano-tube. The preparation method of the invention disperses the carbon nano-tube ultrasonic into a chitosan acid aqueous solution containing ferric ions and ferrous ions so as to prepare the three-composition nanometer magnetic composite material which consists of the carbon nano-tube, ferroferric oxide and chitosan; the three-composition nanometer magnetic composite material is dispersed into glucose oxidase aqueous solution, adsorbs the glucolase and is dispersed into glutaraldehyde aqueous solution; by primary amino-group reaction crosslinking, the glucose oxidase is fixed on the surface of the magnetic composite material, thus obtaining the updatable glucolase electrode based on the magnetic carbon nano-tube; the glucolase electrode provided by the invention has high response speed, wide detection consistency range, simple and convenient electrode processing and simple and convenient preparation of the immobilized enzyme magnetic material; when the enzyme is deactivated, the electrode is regenerated by updating the enzyme material of the electrode surface based on the magnetic carbon nano-tube, therefore, the consumption of the electrode material is greatly reduced, the resource is saved and the cost of enzymatic determination is reduced.

Owner:FUDAN UNIV

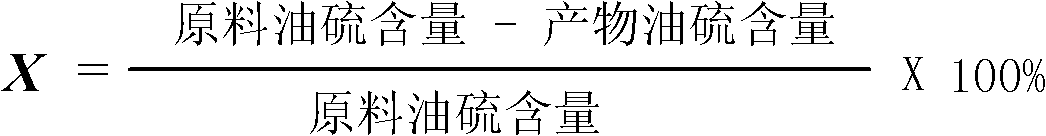

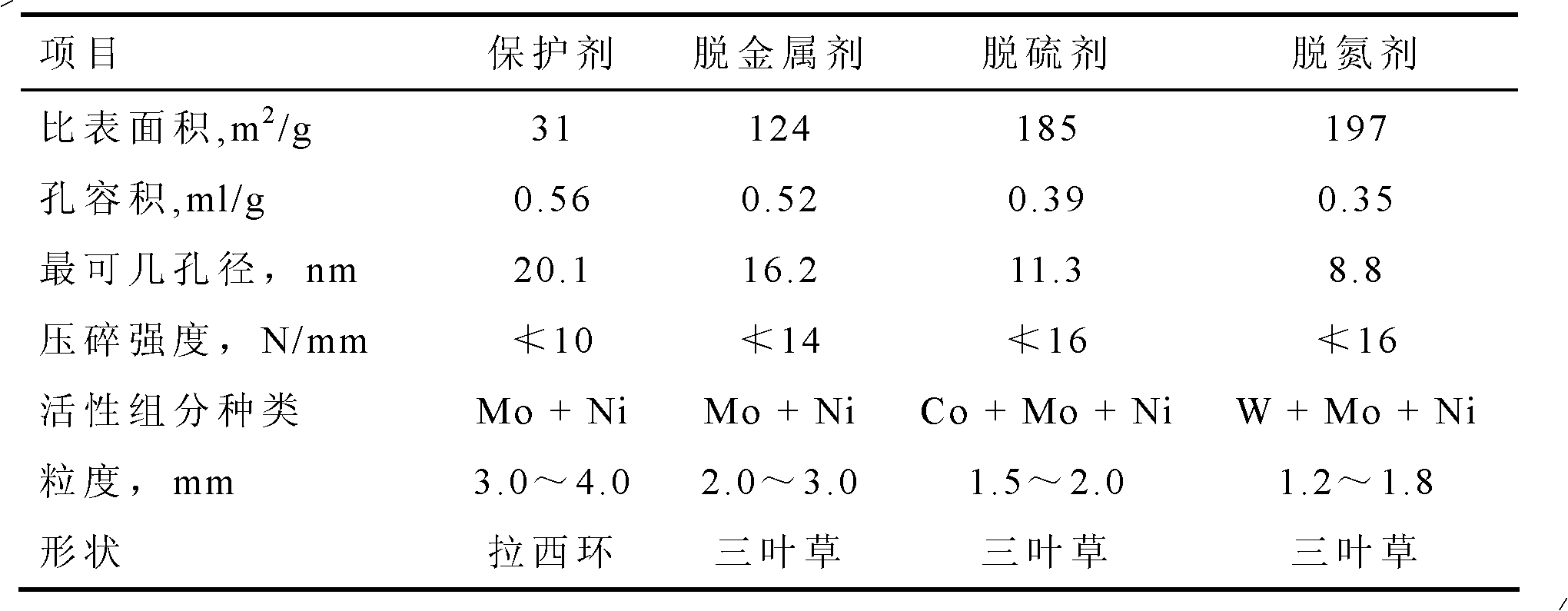

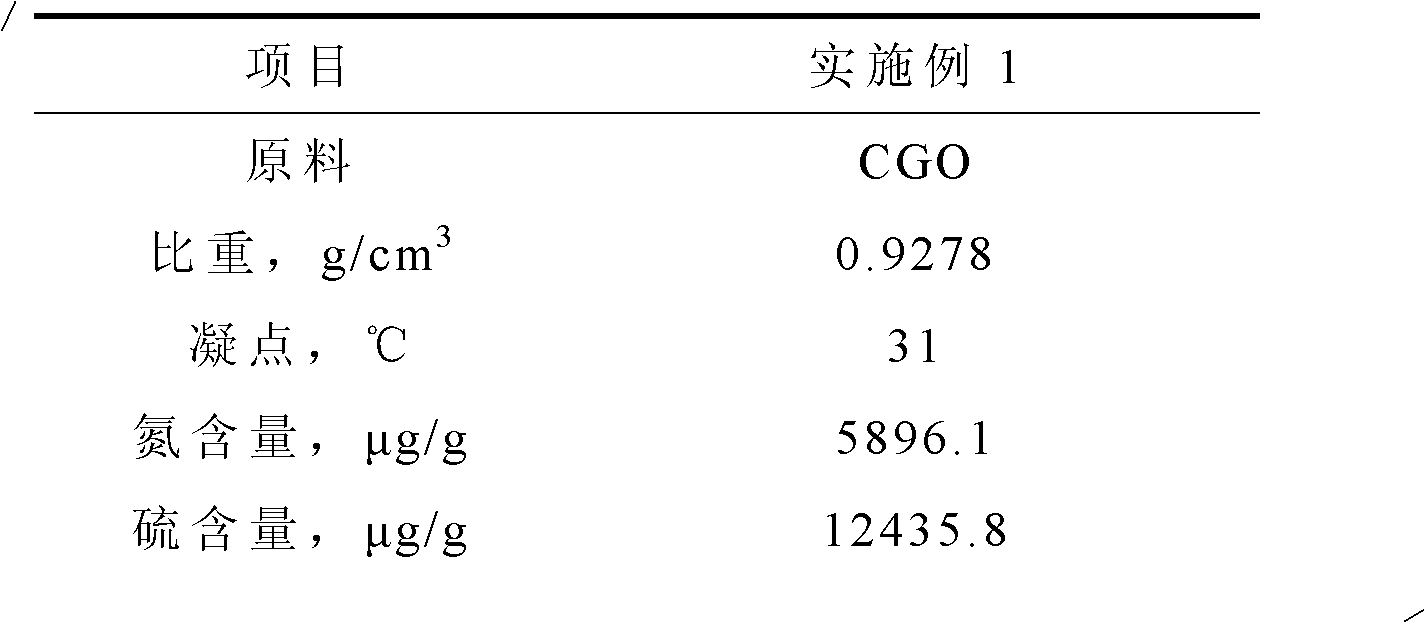

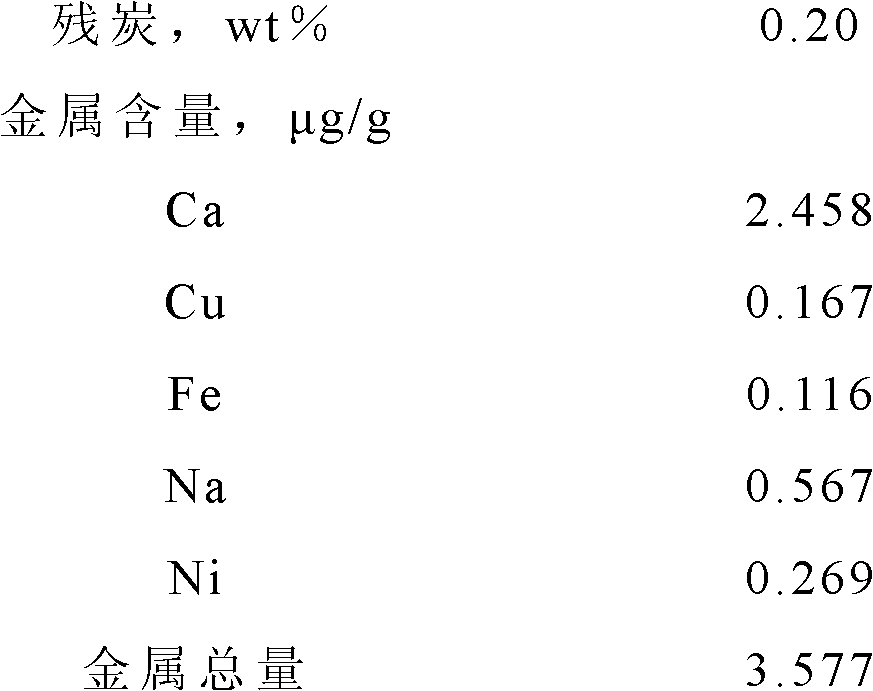

Inferior coker gas oil hydrotreatment method

ActiveCN103184069AIncrease the distributionImprove dispersionMolecular sieve catalystsTreatment with hydrotreatment processesEthanolChemistry

The present invention relates to an inferior coker gas oil hydrotreatment method. The catalyst is prepared by successively loaded a protection agent, a demetallization agent, a desulfurization agent and a denitrification agent from top to bottom with a volume ratio of 0.1-10:0.5-20:0.5-20:5-60. The catalyst is in accordance with grain size distribution and activity distribution. A magnesium aluminate spinel-macropore alumina carrier is modified by organosilicone in surface, and loaded with Mo and Ni to obtain the protection agent. The alumina-macropore alumina-zeolite carrier is pretreated by organosilicone and at least one selected from the group consisting of ethanol, propanol, and butanol, loaded with Mo and Ni to obtain the demetallization agent, loaded with W-Mo-Ni to obtain the denitrification agent, and loaded with Co-Mo -Ni to obtain the desulfurization agent. The method helps to improve the dispersion state of active metal components and the interaction thereof with the carrier, and improve the utilization efficiency of the active components thereby enhancing the activity of the catalyst. The raw material after hydrotreatment can be directly used as FCC or hydrocracking raw materials.

Owner:PETROCHINA CO LTD

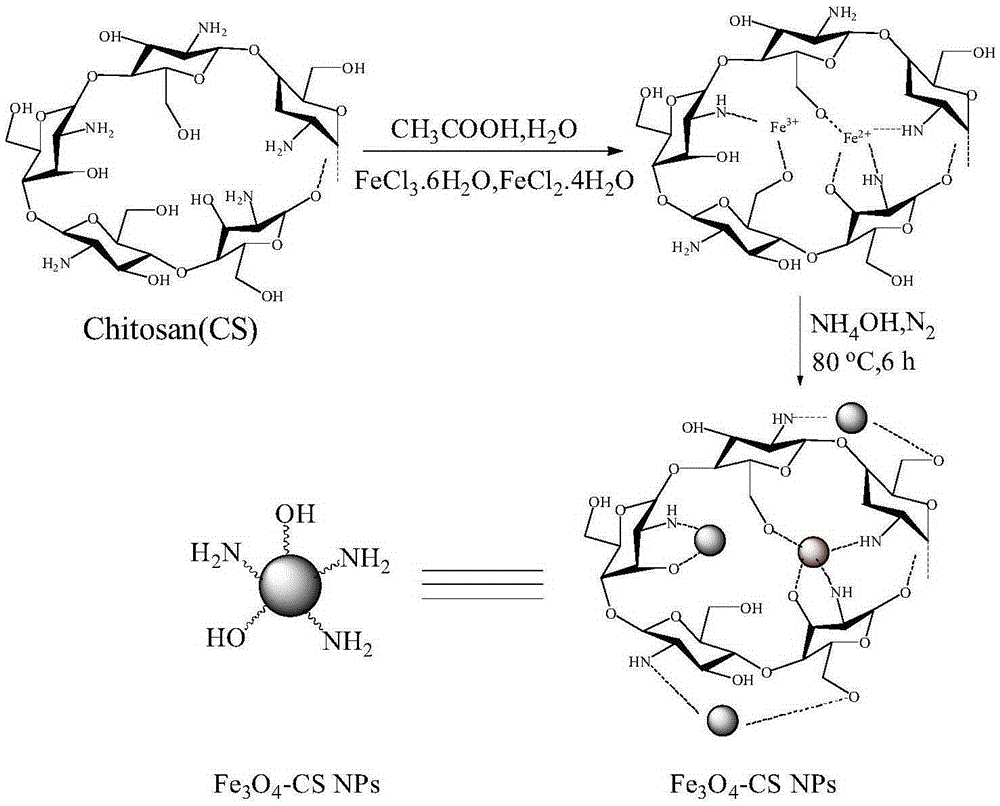

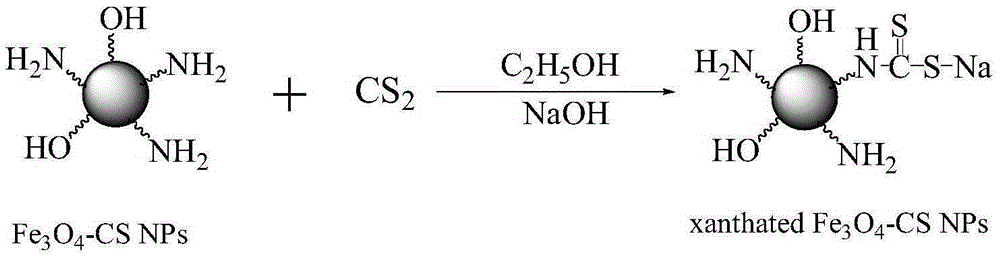

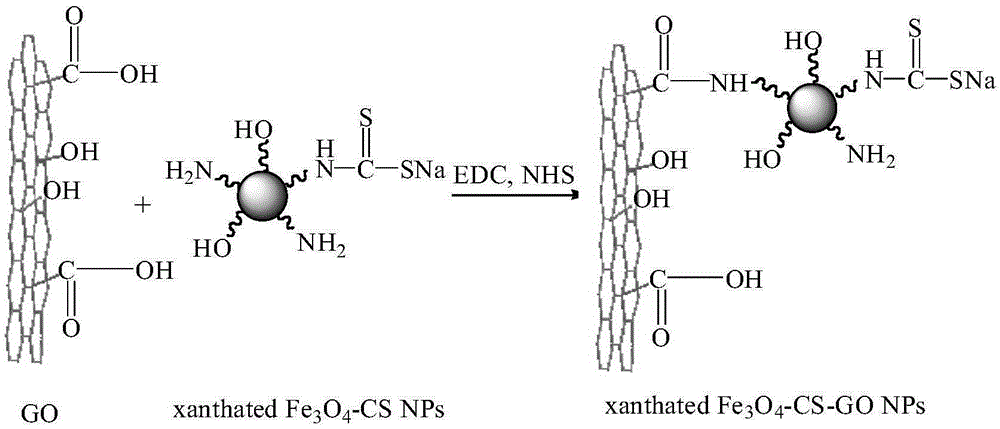

Preparation method and application of magnetic graphene oxide adsorbent material

ActiveCN105289515AImprove dispersionEasy to separateOther chemical processesAlkali metal oxides/hydroxidesCvd grapheneCarbon disulfide

The invention discloses a preparation method and application of a magnetic graphene oxide adsorbent material. The preparation method comprises the steps that chitosan reacts with ferrous ions and ferric ions to synthesize magnetic chitosan nanoparticles; the magnetic chitosan nanoparticles are subjected to reduction and acidification by carbon disulfide, then connect onto the surface of graphene oxide by an amidation reaction, thus a new magnetic graphene oxide adsorbent material capable of adsorbing metal ions, especially copper ions is obtained. The graphene oxide has unique two-dimension monoatomic layer structures, so that the surface area of the graphene oxide is large, then a large number of oxygen-containing groups distributed on the surface of the graphene oxide are capable of well adsorbing the metal ions in wastewater, and the magnetic chitosan modified by CS2 is added, not only are the adsorbability and the dispersibility in water improved, but also the separation is easier under the action of an applied magnetic field. The defects of low adsorbing capacity, difficult recovery and reuse, long separating time, low adsorption efficiency and the like in a process that a traditional adsorption material adsorbs the copper ions are overcome.

Owner:ANHUI NORMAL UNIV

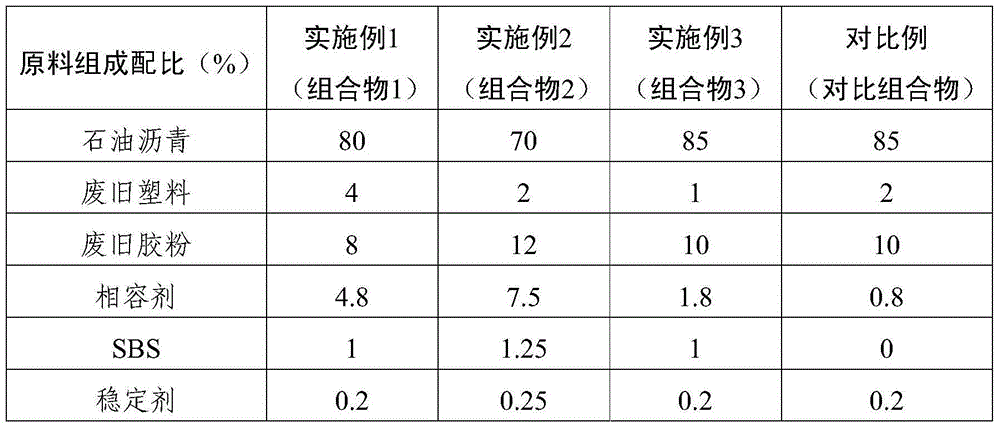

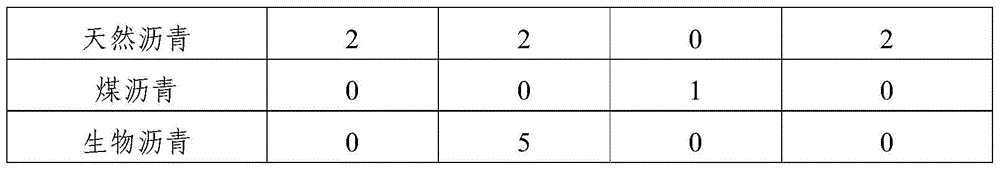

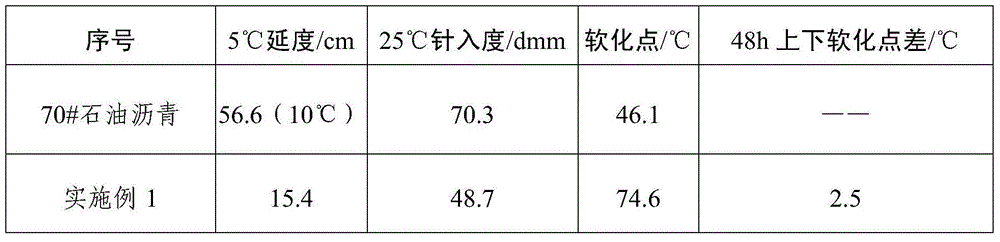

Waste polymer modified asphalt composition and preparation method thereof

The invention relates to a waste polymer modified asphalt composition. The waste polymer modified asphalt composition comprises following components in parts by weight; 60-85 parts of petroleum asphalt, 6-20 parts of a waste polymer material, 1-8 parts of a compatilizer, 1-1.5 parts of SBS, 0.01-0.5 parts of a stabilizing agent, and 1-10 parts of one or more of native asphalt, coal pitch or biological asphalt. The waste polymer modified asphalt composition can well increase high-temperature storage stability of waste polymer material modified asphalt; pre-swelling performance of the polymer material and similar compatibility with asphalt are improved as the compatilizer is added; storage stability of the waste polymer material in asphalt can be improved extremely as a small quantity of SBS and a small quantity of the stabilizing agent are added; producing cost of the composition can be decreased as the native asphalt, coal pitch or biological asphalt replaces a portion of the petroleum asphalt; the prepared modified asphalt is excellent in high-temperature performance and low-temperature ductility; and the preparation method is simple, safe, and convenient for industrial application.

Owner:河北省高速公路邢汾管理处 +1

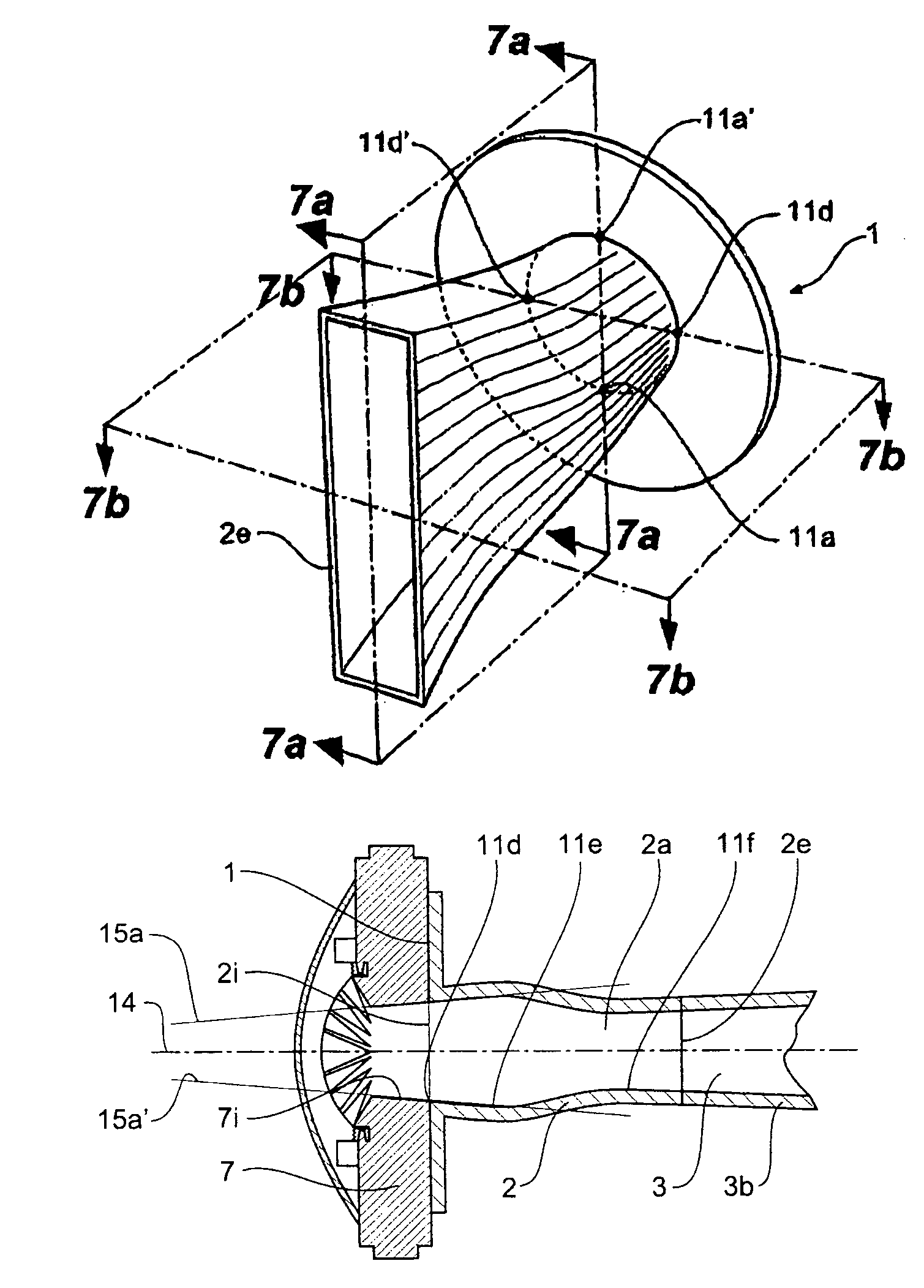

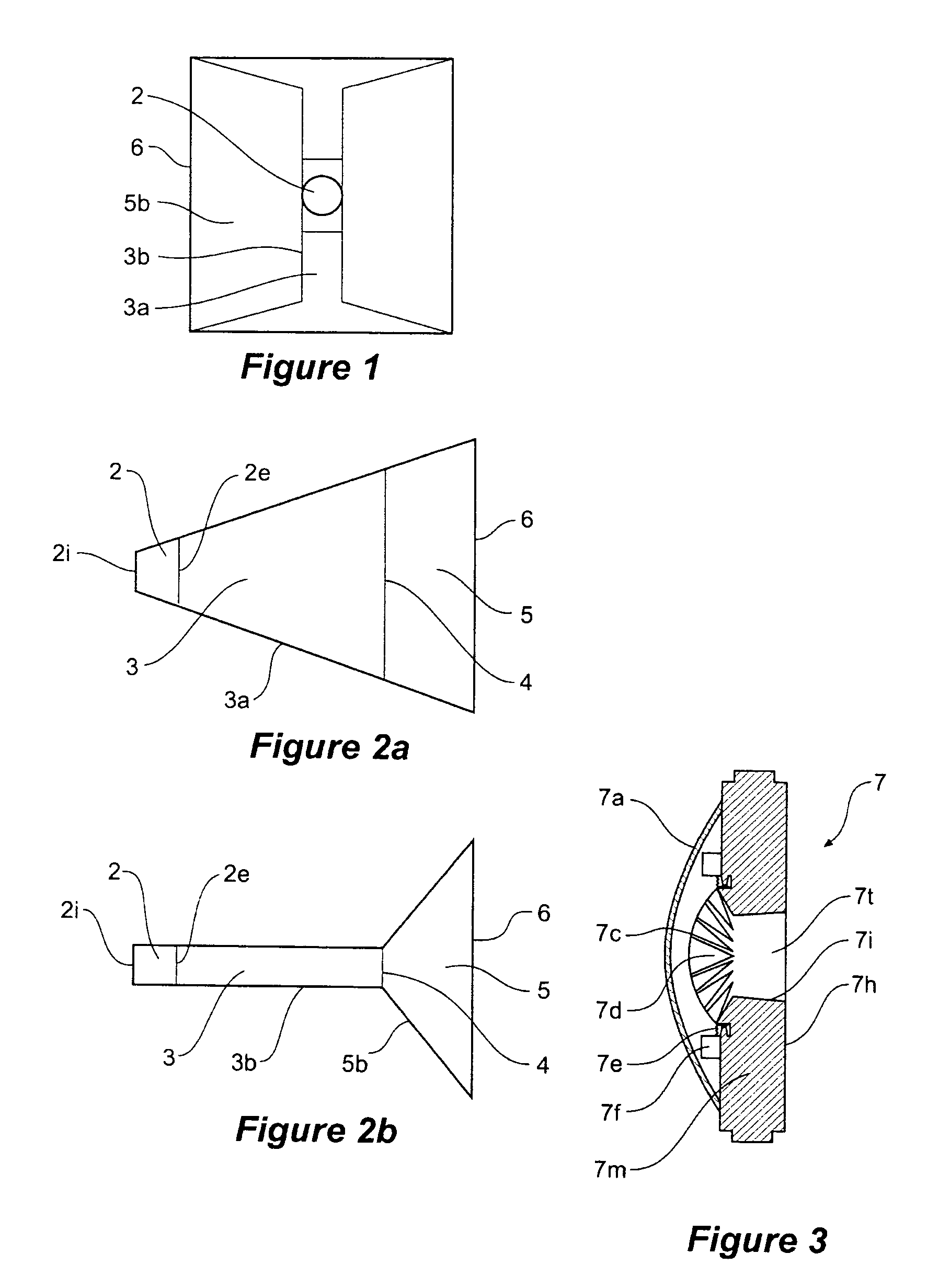

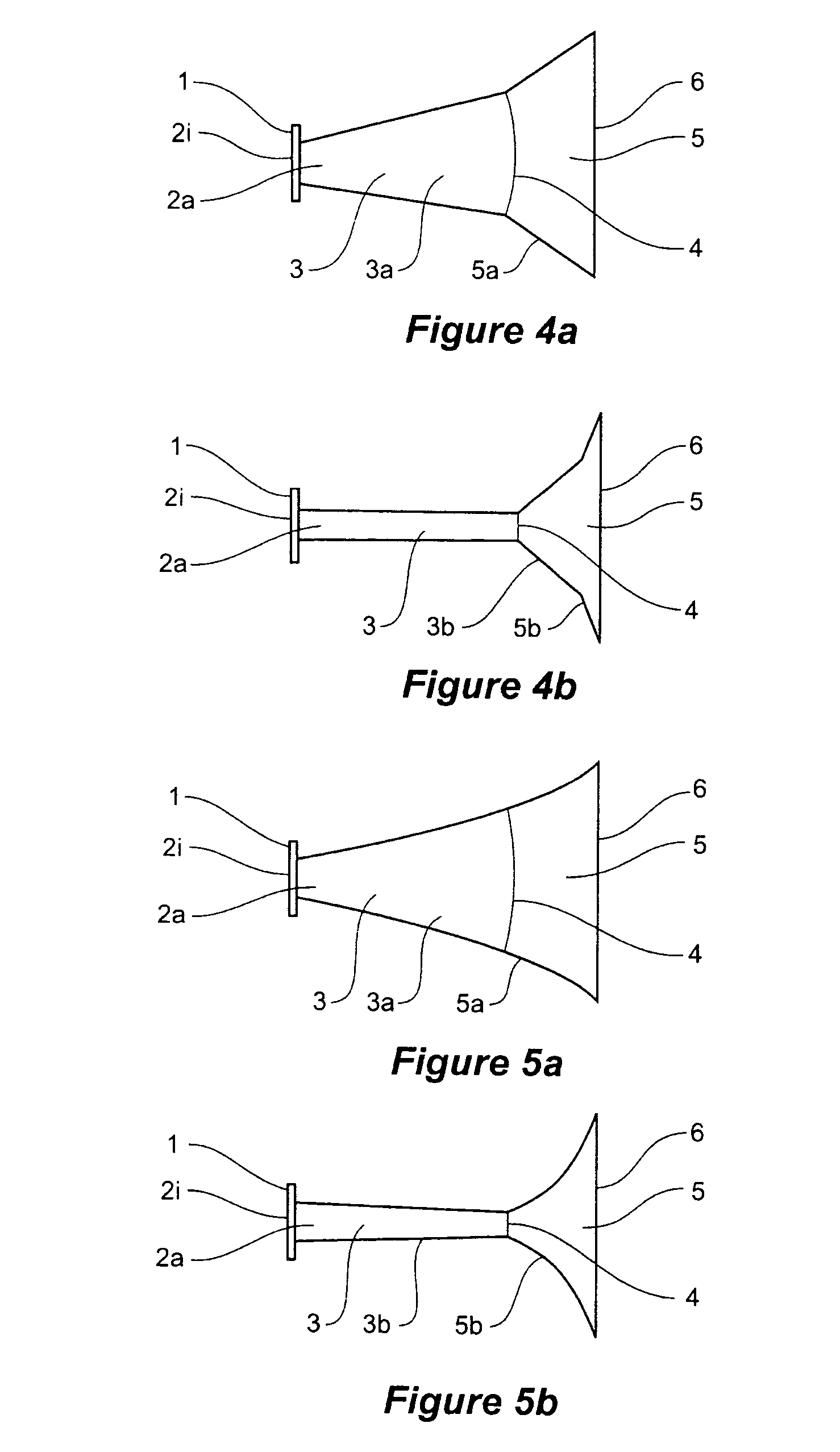

Constant directivity acoustic horn

ActiveUS7044265B2Improve dispersionSmoother transitionSound producing devicesFrequency/directions obtaining arrangementsThroatDirectivity

An improved throat (2) for transmitting acoustic energy from a source driver unit (7) to a feeder section (3) of a directivity controlling acoustic horn is disclosed. The throat (2) comprises: a circular throat entrance (2i) connectable to the source driver unit (7); a rectangular throat exit (2e) connectable to or integral with the feeder section (3); and a circular cross-section to rectangular cross-section transition portion (2a) extending between the throat entrance (2i) and the throat exit (2e). The throat (2) is shaped such that its profiles initially diverge from an axis longitudinal to the throat (14) at the same angle in a direction from the throat entrance (2i) towards the throat exit (2e). Such a throat, when fitted in an appropriate acoustic horn with a source driver unit having a taper matching the aforesaid profile angles, provides a smooth transition for sound waves propagating out from the source driver unit into the horn.

Owner:KRIX LOUDSPEAKERS

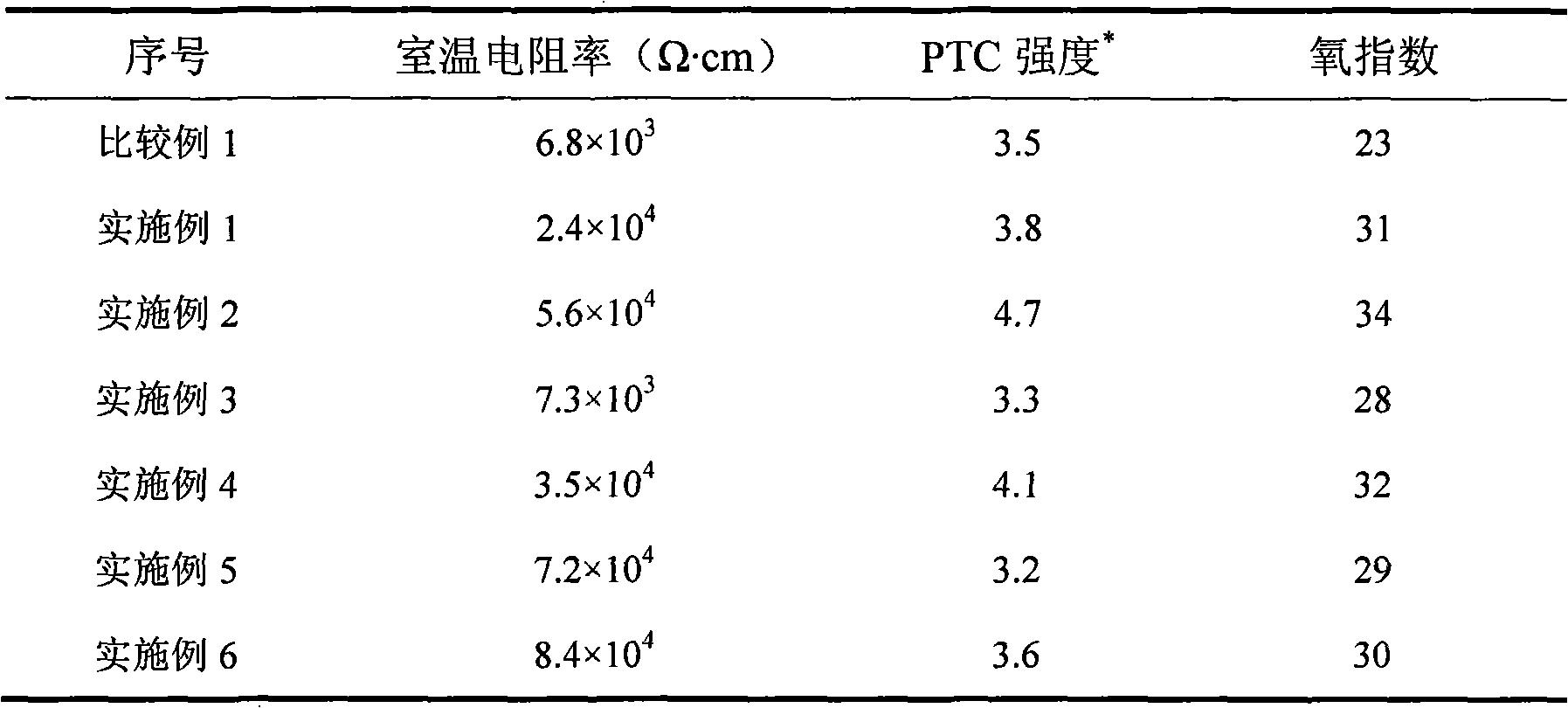

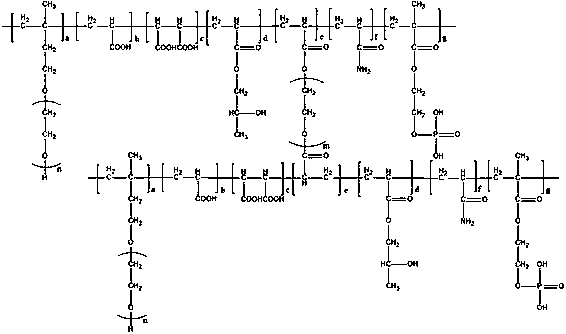

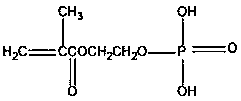

Flame retardant conducting polymer composition

InactiveCN101525495AImprove dispersionGood mechanical propertiesNon-conductive material with dispersed conductive materialTemperature coefficientElectric heating

The invention relates to a flame retardant conducting polymer composition with positive temperature coefficient (PTC) effect or characteristic. The composition is prepared by the following steps: placing a raw material mixture consisting of a crystalline thermoplastic polymer, a conductive filler, an adjuvant, a phosphorus flame retardant, a nitrogen flame retardant, a metal hydroxide and a polar polyolefin copolymer into a mixing device for mixing at the mixing temperature which is at least 20 DEG C higher than melting point of the crystalline thermoplastic polymer for 10-30 minutes; irradiating and crosslinking the mixed mixture with electron beams or gamma rays to obtain the composition. The PTC strength of the prepared target composition is more than 10<3>, resistivity is 10<3>omega.cm-10<5>omega.cm at the room temperature (25 DEG C), and oxygen index is larger than 27. The prepared composition also has the advantages of even joule heat distribution, excellent self-temperature conditioning property, low smoke and non-toxicity, and can be used for preparing environment-friendly self-temperature control electric heating devices with higher safety and reliability.

Owner:EAST CHINA UNIV OF SCI & TECH

Clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and preparation method thereof

InactiveCN109626859AStrong adsorption capacity and dispersion performanceImprove dispersionCarboxylic esterDibasic acid

The invention relates to the technical field of concrete admixtures, in particular to a clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and a preparation method thereof. With polyether macromonomers, unsaturated carboxylic acid, unsaturated carboxylic ester, dibasic acid anhydride, a crosslinking agent, amide monomers, unsaturated phosphate ester, phosphate, an oxidizing agent , a reducing agent, a chain transfer agent, a neutralizing agent and water as raw materials, the clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer is synthesized at normal temperature. Ester groups, amide groups and phosphate ester are introduced into the molecular structure of the polycarboxylate superplasticizer, and light crosslinking of the polycarboxylate superplasticizer is realized through the long-chain ester crosslinking agent, so that the superplasticizer has a good clay-resisting and slump-retaining effect and has the advantages of low mixing amount, high water reducing rate, high adaptability to clay-containing sand, good slump retaining performance and the like; besides, only normal-temperature polymerization is needed, the processis simple, the production cost is low, and the superplasticizer is suitable for industrial production.

Owner:山西黄河新型化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com