Detachable solid fuel suspension combustion experiment testing device and detachable solid fuel suspension combustion experiment testing method

A solid fuel, suspension combustion technology, applied in the direction of chemical analysis using combustion, can solve the problems of unobservable combustion state, easy ignition of large particle samples, poor combustion effect of samples, etc., to improve combustion effect, improve combustion state, optimize effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

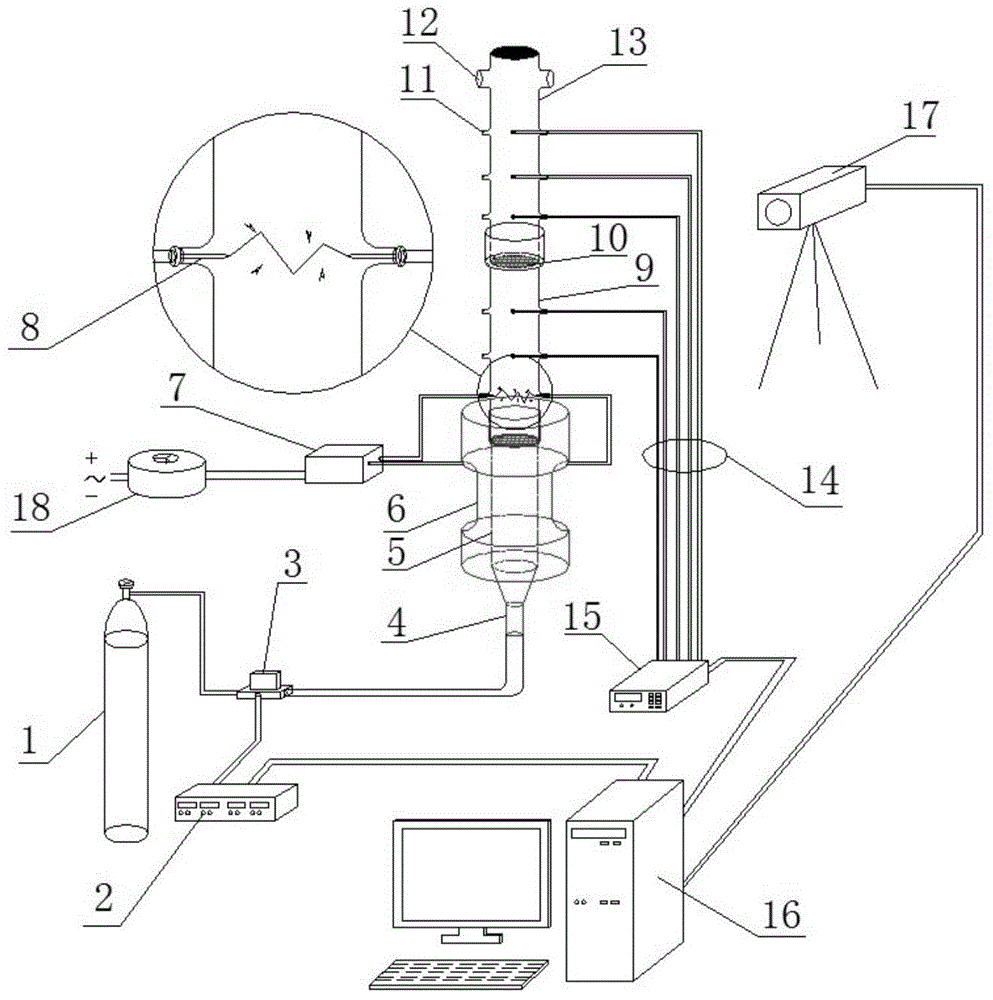

[0049] Such as figure 1 , figure 2 with image 3 As shown, a detachable solid fuel suspension combustion experimental testing device in this embodiment includes a suspension combustion mechanism, a combustion data collection mechanism, a gas supply mechanism and an ignition mechanism.

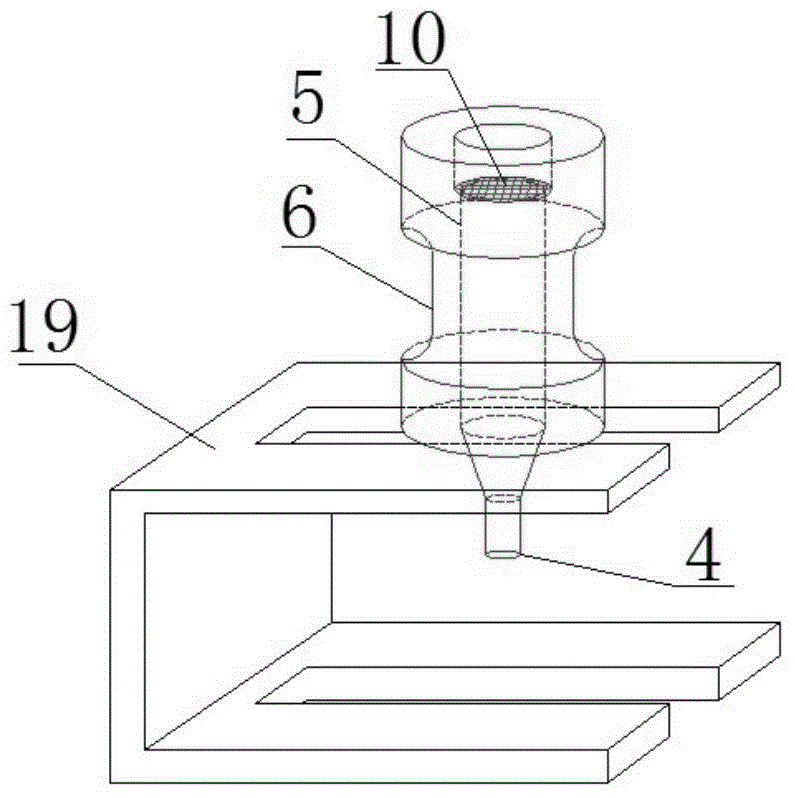

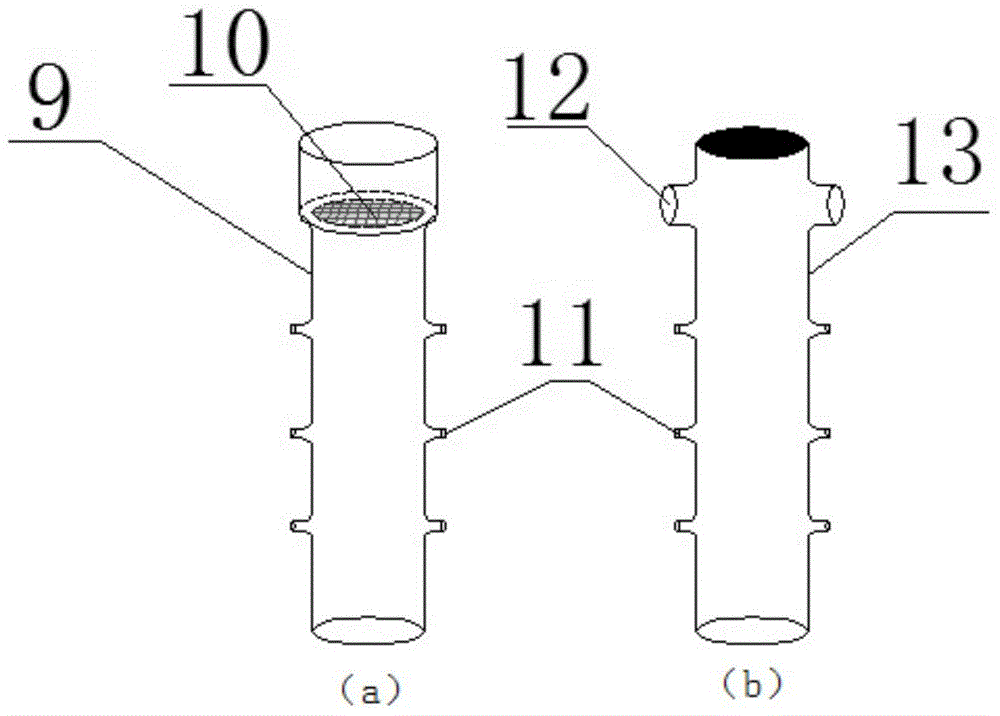

[0050] The suspended combustion mechanism includes a gas inlet 4 , a base 6 , a primary combustion tube 9 , a porous metal plate 10 , a gas outlet 12 , a secondary combustion tube 13 and a base bracket 19 . The base 6 is a stainless steel round steel with an outer diameter of 40mm and a height of 60mm. In order to facilitate the clamping of the base 6 by both hands, an inwardly curved annular groove is provided in the middle of the base 6 . The base support 19 is a channel steel, and the middle part of the upper and lower legs of this channel steel is provided with a rectangular groove respectively. The base support 19 is highly 100mm, wide and 80mm, and the width of the rectangular groove ...

Embodiment 2

[0069] A kind of detachable solid fuel suspension combustion experimental testing device of the present embodiment, its basic structure is identical with embodiment 1, and its difference is that, the outer diameter of base 6 is 50mm, and height is 100mm; Base support 19 height is 150mm , the width is 120mm, the width of the rectangular groove on the base support 19 is 40mm; the aperture of the gas outlet 12 is 10mm; the aperture of the temperature measuring hole 11 is 3mm.

Embodiment 3

[0071] A kind of detachable solid fuel suspension combustion experimental testing device of the present embodiment, its basic structure is identical with embodiment 1, and its difference is that, the outer diameter of base 6 is 45mm, and height is 80mm; Base support 19 height is 125mm , the width is 100mm, the width of the rectangular groove on the base bracket 19 is 25mm; the aperture of the gas outlet 12 is 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com