Patents

Literature

78results about How to "Unique process method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

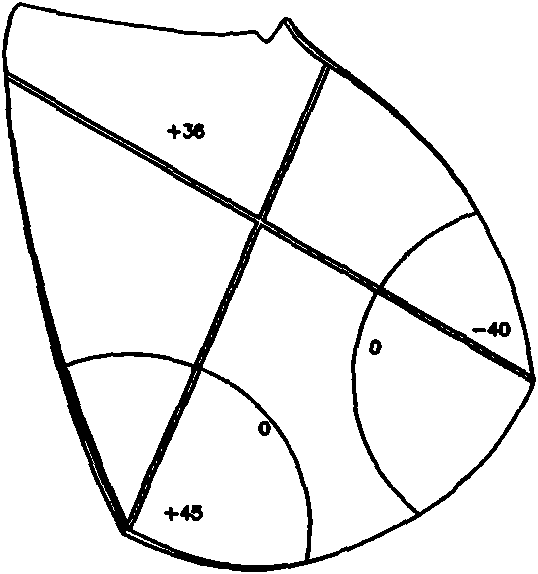

Casting method of large water turbine blade

ActiveCN101716655AUnique process methodRigid enoughFoundry mouldsFoundry coresWater turbineMaterials science

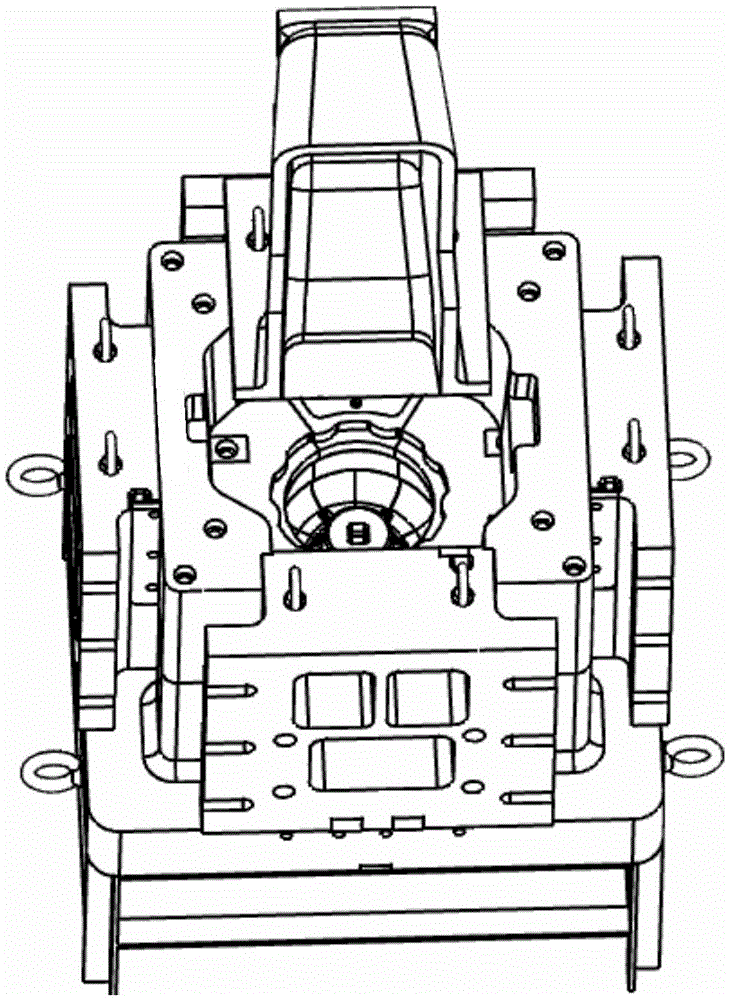

The invention relates to a stereoscopic core assembly casting method of a water turbine blade, in particular to a casting method of a large water turbine blade. The casting method is characterized in that the casting method comprises the steps of designing process, making a core box, making a core bar, making a core, patching a sand core, assembling the cores, putting the cores into a sand box, paving a spure, sounding the sand core with silica sand, assembling the box, pressing the box, pouring, cutting a dead head, tempering, detecting a mold line, grinding and shotblasting. The casting method obviously shortens production cycle, reduces equipment capacity requirements for blade production, is simple in operation and easy to control and achieves blade mass production.

Owner:KOCEL EQUIP

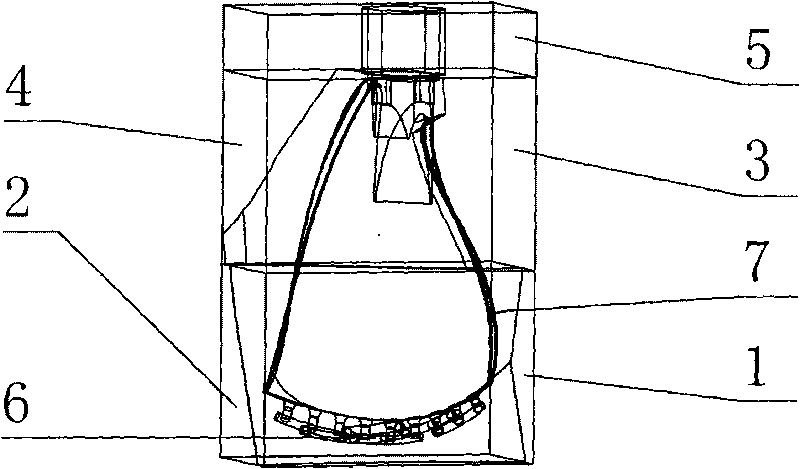

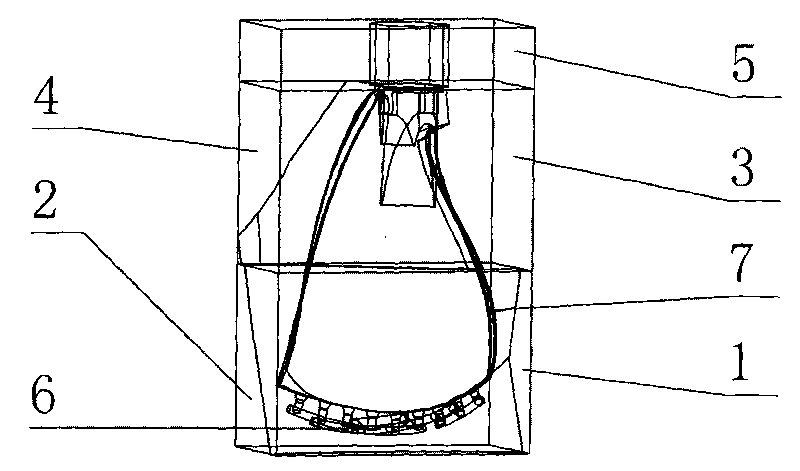

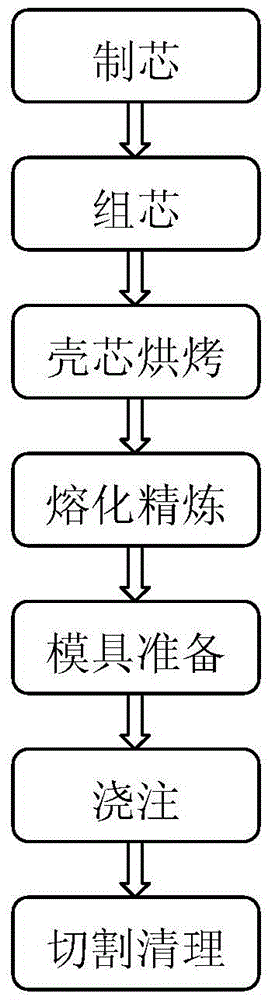

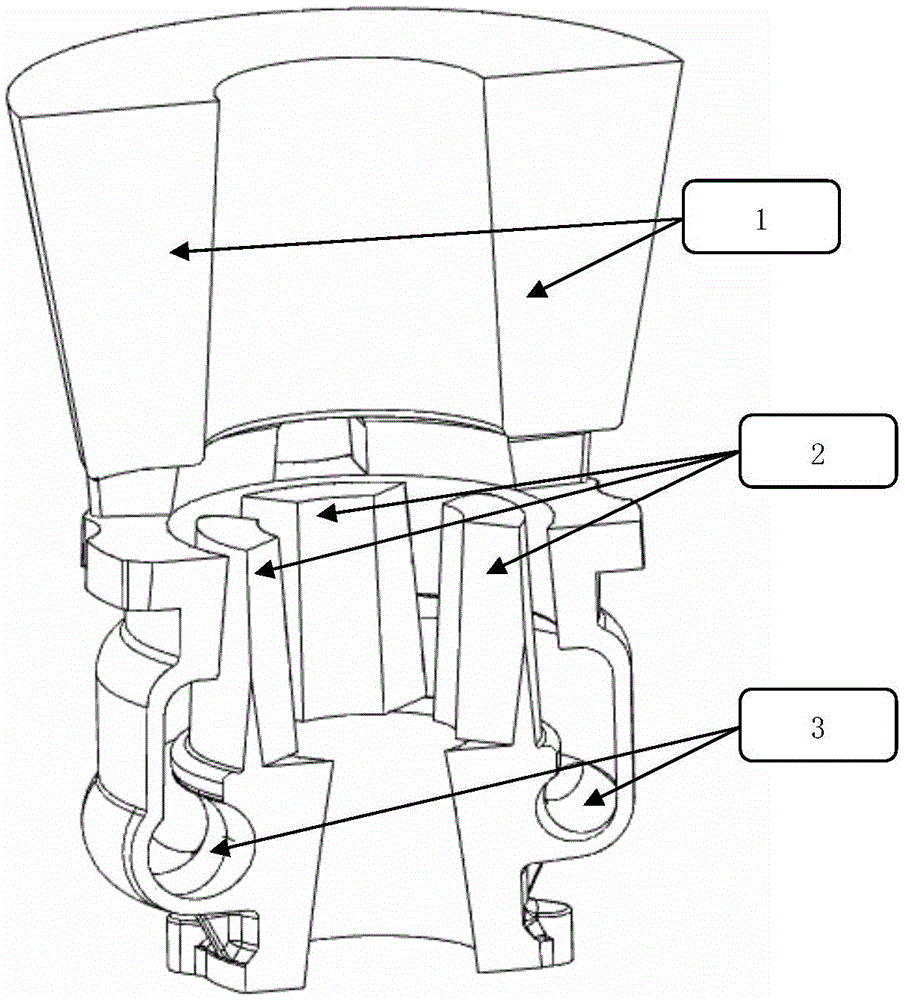

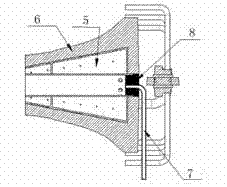

Casting method of turbine housing

ActiveCN105458182AIncrease productivityEffective control of solidification sequenceFoundry mouldsFoundry coresSlagTurbine

The invention provides a casting method of a turbine housing. The casting method includes the following steps of firstly, core manufacturing, secondly, core assembly, thirdly, shell core baking, fourthly, smelting and refining, fifthly, mold preparation, sixthly, casting and seventhly cutting and cleaning. In the core manufacturing process, a riser sand core mold is arranged on a core shooting machine, the core shooting machine is powered on to heat the mold, a layer of precoated sand is cured on a cavity of the riser sand core mold, and a riser sand core is obtained after mold opening. In the core assembly process, the riser sand core and a turbine housing core are assembled and bonded. In the shell core baking process, shell cores painted with coatings are put into a baking kiln. In the smelting and refining process, raw materials are added to a melting and heat preservation furnace, and the melting and heat preservation furnace is powered on for melting. In the casting process, the shell cores are put in a mold, and tilt casting is conducted after mold combination. In the cutting and cleaning process, a casting is cut, the riser is cast, and burrs and fins of the casting are ground and cleaned. The metal tilt casting method of an aluminum alloy turbine housing body can solves the problems of shrinkage porosities and cavities and slag holes in a big flange face of the aluminum alloy turbine housing; open risers and blind risers are arranged, in combination with the riser sand core, an ideal temperature field is formed after the casting is cast, and solidification can be conducted from the casting to the risers in sequence.

Owner:XIAN AERO ENGINE CONTROLS

Casting method for thin-wall annular cast

The invention relates to a casting method, in particular relates to a casting method for a thin-wall annular cast. The casting method is characterized by comprising the following steps: simulating by a computer; determining a cast scheme; manufacturing a die; manufacturing a core box and a core skeleton; manufacturing a core; putting the core; modeling; opening the box; closing the box; pressing the box; pouring; cutting a dead head; carrying out thermal treatment; detecting a molded line; and carrying out relief grinding and shot blasting. The technical method disclosed by the invention is peculiar, the problem of the casting crack and deformation of the thin-wall annular cast can be solved, the sand metal ratio is lowered, the cost is saved, and the production period is shortened.

Owner:KOCEL EQUIP

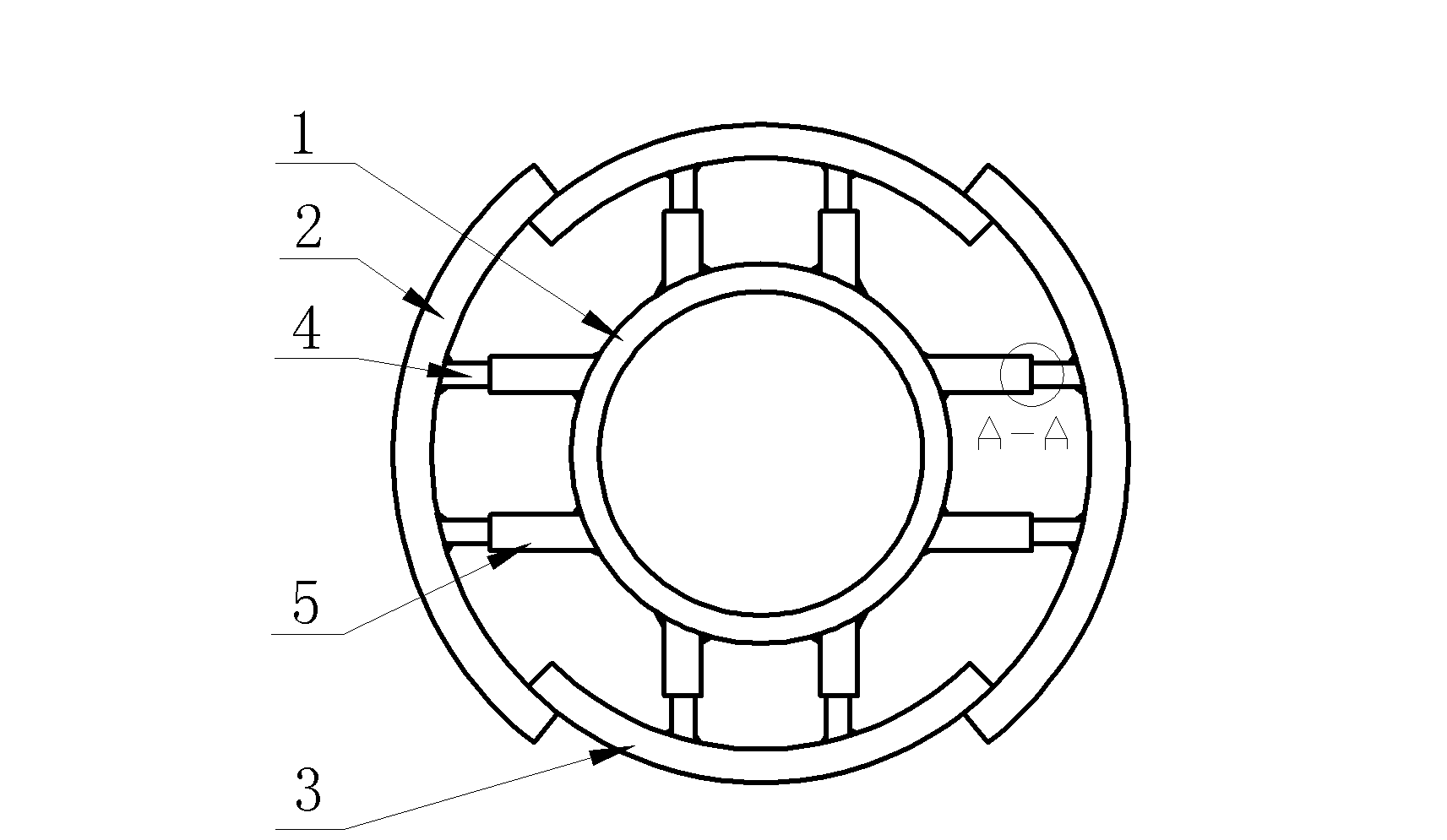

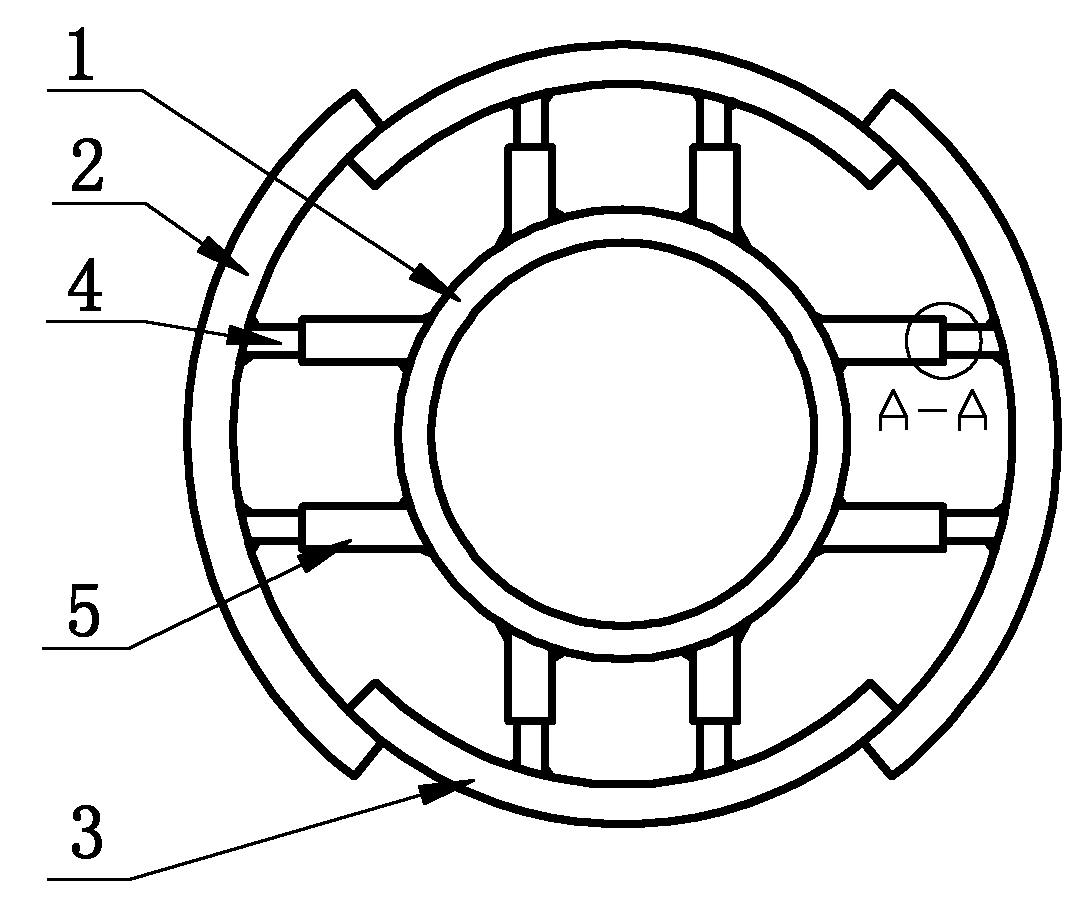

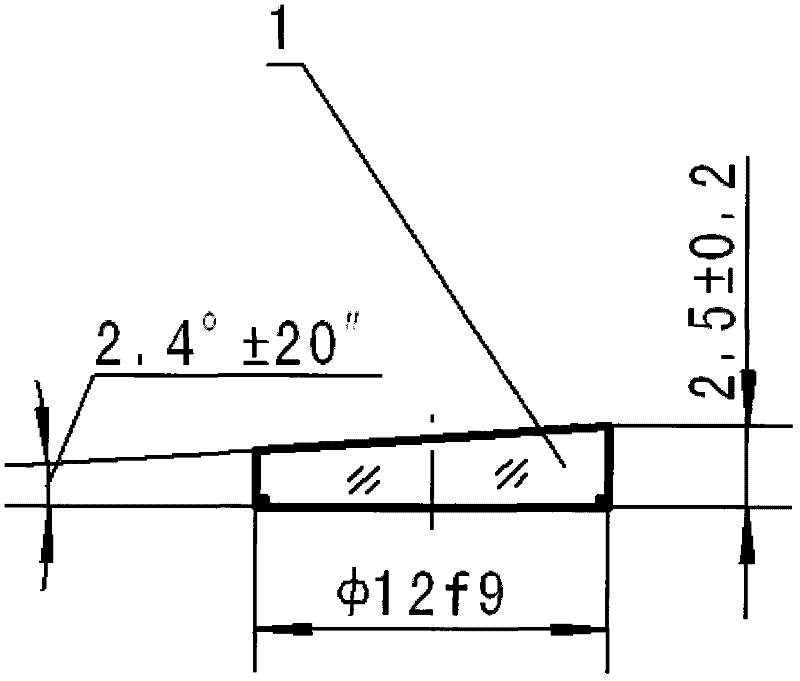

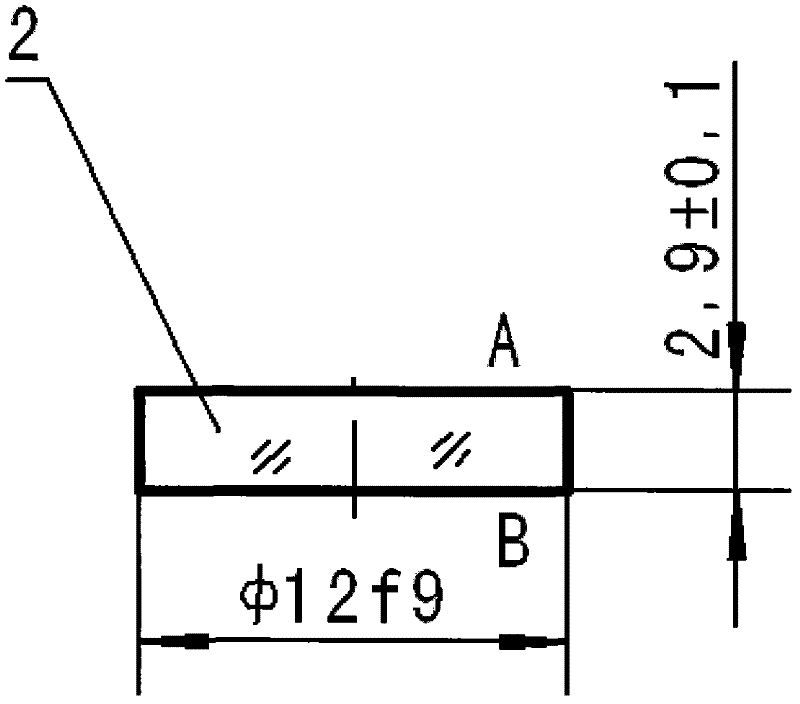

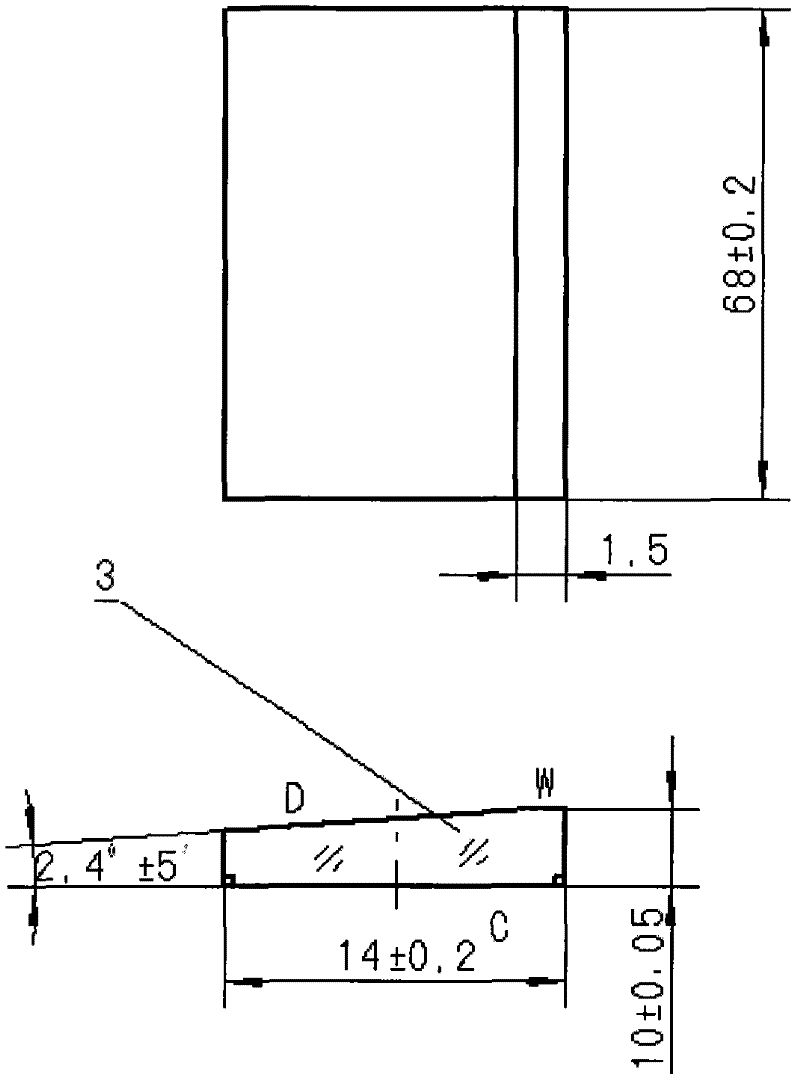

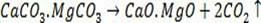

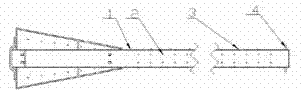

Manufacturing method of wedge-shaped lens

ActiveCN102229082ANovel technologyUnique process methodOptical surface grinding machinesOptical processingEngineering

The invention discloses a manufacturing method of a wedge-shaped lens, belonging to the technical field of optical cold processing. The manufacturing method comprises the specific steps of: manufacturing a wedge-shaped lens blank and a high-precision glass clamp by adopting a conventional optical processing technology so as to ensure that a first guide through face of the wedge-shaped lens as well as the surface shape and the surface defects of the wedge-shaped glass clamp meet formulated requirements; optically cementing the first light through face of the wedge-shaped lens onto the inclined surface of the wedge-shaped glass clamp which is already optically cemented onto a parallel planer optical cementing base plate, carrying out fine grinding and polishing on a second light through face of the wedge-shaped lens, and obtaining the wedge-shaped lens with second-level precision by controlling the thickness, the parallel difference and the surface shape precision of the second light through face and the parallel planer optical cementing base plate. The manufacturing method for machining the wedge-shaped lens, disclosed by the invention, not only has a simple process, strong operability and a greatly-prolonged manufacturing period, but also is easy to ensure the single-batch finished product ratio of wedge-shaped lens parts with small sizes, large angles and second-level precision and overcomes the difficulties of unstable quality, low efficiency and low finished product ratio in the conventional processing method.

Owner:CHINA NORTH IND NO 205 RES INST

Production technology of furan resin used for casting steel

ActiveCN102775572ASave resourcesUnique process methodFoundry mouldsFoundry coresFurfuryl alcoholProduction cycle

The invention relates to a production technology of furan resin, in particular to a production technology of furan resin used for casting steel. The technology comprises the following steps of: closing an outlet valve at the bottom of the reactor, opening a feed valve, starting a mixer, adding certain content of paraformaldehyde, urea and furfuryl alcohol, adding certain content of basic catalyst to adjust the PH value of the seasoning liquid; heating up to 80-100 DEG C, insulating for 60-80 minutes; stopping the insulation, opening cooling water and cooling down to 60-90 DEG C, adding 50% of the total amount of furfuryl alcohol; adding certain amount of acid catalyst to adjust the PH value of the seasoning liquid to 3-5 when the temperature drops to 60 DEG C; heating up to 85-100 DEG C, insulating for 50-70 minutes; adding the 25% of the total amount of furfuryl alcohol, adding certain amount of silane coupling agent ammonia and methanol; and continuing to stir for 30 minutes after discharging and submitting for censorship. The invention provides a method of using imported paraformaldehyde and urea to produce urea-formaldehyde glue on the basis of traditional resin technology instead of using aqueous solution of formaldehyde. The production technology provided by the invention has the advantages of needlessness of dehydration in the post-synthetic phase, production cycle reducing, cost saving and environmental protection.

Owner:GANSU KOCEL CHEM

A thermal magnesium smelting process

The present invention relates to a magnesium smelting process, in particular to a thermal magnesium smelting process. The smelting process comprises the following steps: first, the ore raw material containing magnesium carbonate, the reducing agent, and the fluorite catalyst are crushed, and a reasonable Proportionally mixed and ground into powder, then the mixed powder is extruded into agglomerates with a press, and the pressed pellets are placed in a closed reactor, and finally the balls are heated, exhausted, and heated , vacuuming to produce metal magnesium; the invention has unique process method, good environmental protection effect and high utilization rate of raw materials.

Owner:开泰镁业有限公司

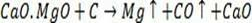

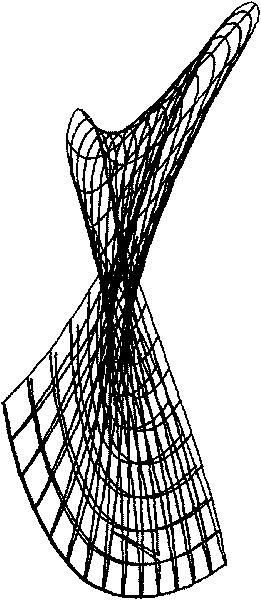

Anti-deformation method for casting vane of ultra-large mixed flow type water turbine

ActiveCN101716653AReduced deformation tendencyEliminate deformationFoundry mouldsFoundry coresWater turbineRebar

The invention relates to an anti-deformation casting method, in particular to an anti-deformation method for casting a vane of an ultra-large mixed flow type water turbine, which comprises the steps of mould manufacturing, molding, mould assembling, pouring, sand falling, cleaning and heat treatment. The method is characterized in that: the manufactured mould adopts a steel-wood mesh-shaped frame as aggregate which is filled with resin; a support is manufactured according to a molded line; a three-box T-type assembling, real pattern molding, flat building and vertical casting, combined sand boxes and resin self-hardening sand are adopted; facing sand adopts chromite sand; the inside of the molding sand is provided with a framework of steel reinforcement; the heat treatment adopts a vertical type charging method and uses a U-shaped supporting frock; and a dead head is cut and provided with a leveled dead head neck; the direction of the dead head neck is downward for supporting the vane; and two sides of the dead head neck are provided with a clamp for ensuring the vertical direction of the vane. The process method is unique, reduces the machining amount, reduces the ratio of gross and weight, shortens production period, reduces the cost, and solves the problems of deformation in vane production and manufacturing, and fat head and big ears caused by overlarge vane machining amount.

Owner:KOCEL EQUIP

Lycium ruthenicum murr. vinegar preparation method

InactiveCN102943025APrevent agingRegulate acid-base balanceVinegar preparationLycium barbarum fruitBULK ACTIVE INGREDIENT

The present invention provides a lycium ruthenicum murr. vinegar fermentation method, and two lycium ruthenicum murr. vinegar drink preparation methods. The lycium ruthenicum murr. vinegar takes fresh lycium ruthenicum murr. as the raw material, and is obtained by the selection of raw materials, juicing, low-temperature alcoholic fermentation, acetic acid fermentation, ageing, filtration, sterilization and other process procedures. The resulting lycium ruthenicum murr. vinegar is blended to obtain a lycium ruthenicum murr. vinegar drink. Anthocyanin, organic acids, vitamins, VC and other active ingredients, especially anthocyanin contained in the lycium ruthenicum murr. are maximally preserved by the high acid environment of the lycium ruthenicum murr. vinegar and the vinegar drinks. Therefore, the lycium ruthenicum murr. vinegar is superior to table vinegar taking grain as raw materials, has a sweet and sour taste and pure flavor, is sour, cool and soft, nutrient-rich and high-quality, and has the efficiency of invigorating stomach, promoting digestion, tonifying, protecting health and the like.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

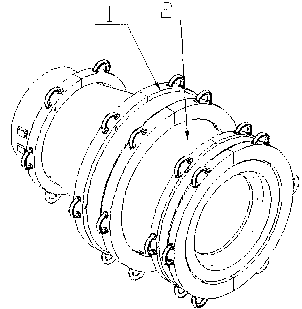

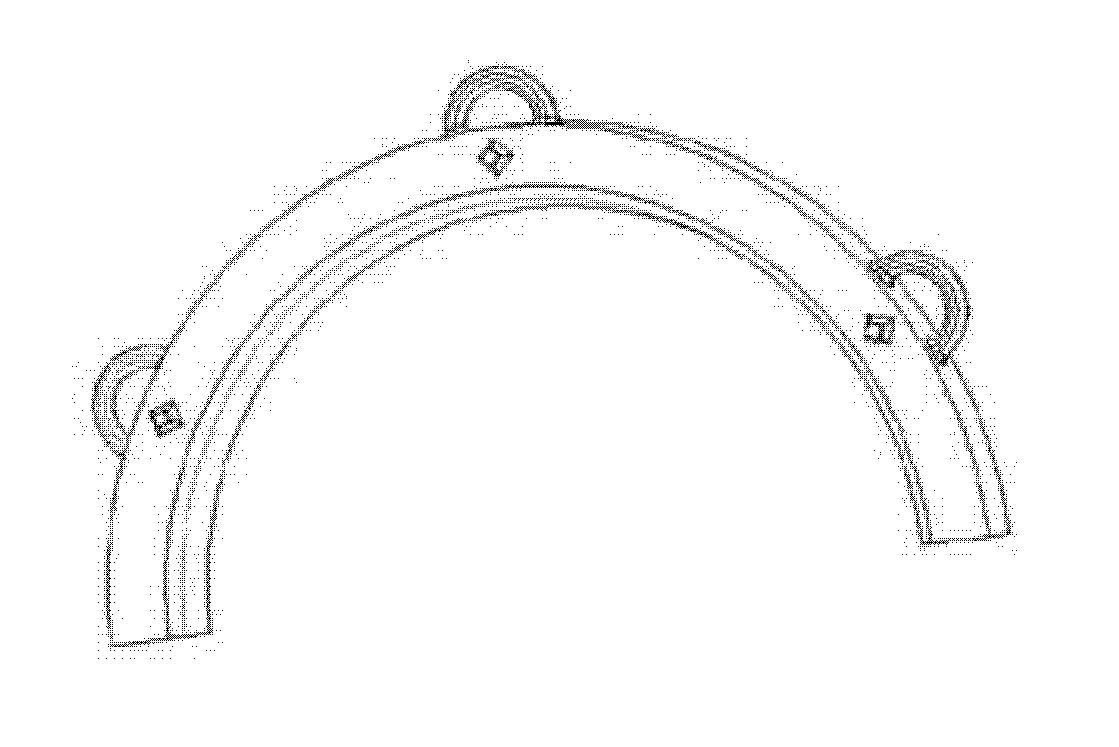

Modeling method of large-size ring-structure casting

ActiveCN102069152AAvoid deformationAvoid sinking deformationFoundry mouldsFoundry coresModel methodLarge size

The invention relates to a modeling method, in particular to a modeling method of a large-size ring-structure casting, which is characterized in that the method comprises the following steps: mould manufacturing, modeling, unpacking and packing. The method improves the prior independent modeling scheme of rings, greatly improves the production efficiency, and enhances the strength of a mould, and the cost for manufacturing, modeling and smelting the mould is greatly reduced.

Owner:KOCEL EQUIP

Machining method of coarse pitch threads

InactiveCN102778861AUnique process methodGuaranteed shape and position accuracyProgramme controlThread cutting machinesSurface smoothnessMathematical model

The invention relates to a machining method of threads, in particular to the machining method of coarse pitch threads. The machining method comprises the following steps of building a right-angle trapezoidal thread finish machining outline and rough machining outline mathematical models; designing cutter paths according to the physical dimension of a designed non-standard cutter; building a numerical control macroprogram by applying the rough machining outline and cutter path mathematical models, selecting appropriate cutting parameters according to tool nose fillet radius R0.8 and combining with actual machining equipment and building a numerical control macroprogram by applying thread right-angle side finish machining outline and cutter path mathematical models, mathematical models right-angle sides by repeatedly feeding, and adopting sample plate and feeler gauge detection until required accuracy is achieved; and adjusting numerical control macroprogram contents, using the sample plate and feeler gauge to detect in a matched mode and completing machining of right-angle trapezoidal thread slope side according to machining results. The machining method is unique in process method, capable of effectively guaranteeing thread accuracy of forms and positions and surface smoothness, improving processing efficiency and shortening machining period.

Owner:KOCEL GROUP +1

Smelting for ultra-large thick-wall spheroidal cast iron element and on site metamorphism treatment method thereof

The invention relates to a process of melting and field modification treatment of melting ductile iron castings, in particular to a process of melting and field modification treatment of super large ductile iron castings with thick walls, which is characterized in that the invention includes the steps of selecting melting devices, feeding to melt, heat preservation, spheroidization, inoculation and pouring. The processing method of the invention is unique and simple, thereby successfully and effectively resolving the melting of a small-tonnage electric induction furnace on large-tonnage molten iron and the modification treatment of large-tonnage spheroidal graphite cast-iron, which also solves the problems of inner decline of casings with inner walls, graphite segregation of the thick walls and the like.

Owner:KOCEL EQUIP

Method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red

InactiveCN102674480AReduce consumptionNo emissionsFerric oxidesIron sulfatesSludgeAmmonium Hydrogen Carbonate

The invention discloses a method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red and relates to a technological method for chemical extraction and separation. The method is an organic solvent effect crystallization process for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red, consists of four technical processes and realizes the chemical goal of extracting and separating iron and preparing ferrous sulfate and iron oxide red. The four technical processes are respectively as follows: 1) a diluted sulfuric acid leaching process of industrial waste iron sludge; 2) an iron crystallization and separation process under the effect of monobasic alcohol serving as organic solvent; 3) an iron oxide red preparation process through reaction between ferrous sulfate solution and ammonium hydrogen carbonate and oxidizing roasting of sediment; and 4) an ammonium sulfate preparation process through evaporative crystallization of sedimentation solution. The method is suitable for extracting and separating iron element from all kinds of iron-containing minerals and industrial waste residues, valuable components are comprehensively utilized and the environmental pollution and the resource wastage are reduced.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

In-situ spraying reparation method of horizontal aluminum busbar in electrolytic plant

InactiveCN102676970ASimple processing methodUnique process methodMolten spray coatingCoated surfaceElectrolysis

The invention relates to a reparation method of an aluminum busbar, in particular to an in-situ spraying reparation method of a horizontal aluminum busbar in an electrolytic plant. The method comprises firstly checking conditions of the busbar, performing leveling processing on the surface of the busbar, then performing preprocessing on the surface of the busbar to enable the preprocessed matrix surface to reach Sa 2.5-3.0 grade and to expose uniform metal natural color, performing rough processing on the surface of the busbar to enable roughness or riveting line depth of the surface to reach 40-80mu m, utilizing the electric arc spraying technology to spray a base layer and a working layer on the surface of the damaged busbar, finally utilizing a movable suspension milling cutter to mill the coating surface, and performing clean and smooth processing to complete the reparation of the horizontal aluminum busbar. The method can be achieved in the electrolytic plant, can effectively avoid interference of a strong magnetic field, reduces labor strength, has less consumption of labor and materials and simple and fast operation, can repair surface defects of the horizontal busbar serving as the upper structure of an aluminum cell, and can reproduce a repairing layer with excellent abrasion performance.

Owner:QINGTONGXIA ALUMINUM GRP +1

Method for preparing activated carbon used for flue gas demercuration

InactiveCN101844074AImprove removal effectUnique process methodOther chemical processesDispersed particle separationActivated carbonFlue gas

The invention relates to a method for preparing activated carbon, in particular to the method for preparing the activated carbon used for flue gas demercuration. The method is characterized by comprising the following steps of: preparing feed coal, and performing anoxybiotic dry distillation, milling, stirring while adding coal tar, extrusion molding, carbonization, activation, milling and dipping on the feed coal to obtain finished products. The method for preparing the activated carbon used for the flue gas demercuration has the advantages of unique process, high technical indexes of produced products and wide application range.

Owner:NINGXIA HUAHUI ACTIVATED CARBON

Method for cooling pipe cast-in of machine tool guide

The invention relates to a cooling water pipe processing method on a machine-tool guide rail, in particular to a method for imbedding and casting a cooling water pipe on the machine-tool guide rail. The invention is characterized by including steps of preparation of imbedding pipes and clippers, modeling, core producing, assemble molding, casting, cleaning up and packaging; the invention provides an unique and simple technical method that realizes to process and fabricate the cooling water pipes in the machine-tool guide rail by the imbedding and casting method.

Owner:KOCEL GROUP

Method for solving problem of burnt-on sand of thick-wall steel casting

InactiveCN102794426ASmall modulusUnique process methodFoundry mouldsFoundry coresWater basedIsolation layer

The invention relates to a method for solving the problem of burnt-on sand of a casting, in particular to a method for solving the problem of burnt-on sand of a thick-wall steel casting. The method comprises the following steps of: preparing the materials Q235 steel and Phi 80 sand-isolation chiller; uniformly distributing and welding the sand-isolation chiller on an arbor, and placing the arbor in a core box, wherein the thickness of the sand-isolation layer of the sand-isolation chiller is controlled at 30-50mm; enabling a layer of 50mm-thick chrome ore to flow on the inner surface in the core box; reinforcing and compacting the key corner parts; enabling silica sand to flow; and opening the box and coating the whole box with water-based paint for three times. The method provided by the invention is unique and can solve the problem of burnt-on sand of the thick-wall casting.

Owner:NINGXIA KOCEL GRP CO LTD +1

Casting method of complex-structure ductile iron thin-wall casting of ship turbocharger

ActiveCN102784889ABottom shrinkage improvementImprove pass rateFoundry mouldsFoundry coresTurbochargerDuctile iron

The invention relates to the casting technology of complex-structure ductile iron thin-wall castings, such as a fuel feed case, which are important parts of a ship turbocharger, and in particular relates to a casting method of a complex-structure ductile iron thin-wall casting of the ship turbocharger. The casting method includes the steps of, in sequence, fabricating moulds, modeling, making a core, assembling the moulds, pouring and clearing the sand shakeout. The method is characterized in that a pouring system used in the pouring process consists of a riser runner, a chilling block, a live riser arranged on a bottom flange of the fuel feed case and a feeding head arranged at the lateral side of the bottom flange. A filter screen is arranged on the pouring system. With the casting method disclosed by the invention, the defect of shrinkage porosity of the bottom flange of the fuel feed case is solved, the conventional idea of changing the entire cast solidification sequence by increasing the number the chilling blocks is thoroughly changed, the problem of shrinkage porosity at the bottoms of the castings is completely improved by adopting the new feeding scheme, the percent of pass of the castings is improved, and regular batch production of the castings is ensured.

Owner:KOCEL EQUIP

Method for processing Chinese wolfberry health-care beverage

InactiveCN101940346APerfect comprehensivenessImprove immunityFood preparationFiltrationPasteurization

The invention relates to a health-care beverage, in particular to a method for processing a Chinese wolfberry health-care beverage. The method is characterized by comprising the following steps of: 1) performing raw material screening, cleaning, draining, crushing, juicing, coarse filtration, micro filtration, ultra-filtration concentration and pasteurization on Chinese wolfberry to obtain Chinese wolfberry concentrated juice; 2) performing picking, cleaning, draining, crushing, juicing, coarse filtration, micro filtration, ultra-filtration concentration and pasteurization on mulberry to obtain mulberry concentrated juice; and 3) performing proportioning, homogenization, nano refining, pasteurization, sterile filling, inspection, packing, labeling, coding and warehouse-in on the Chinese wolfberry concentrated juice and the mulberry concentrated juice. The unique method produces the Chinese wolfberry health-care beverage with effects of improving the immunity of the human body, enhancing bones, tonifying kidney, strengthening spirit, relieving fatigue, promoting longevity and the like, good mouthfeel, long quality guarantee period and no any additive.

Owner:黄博

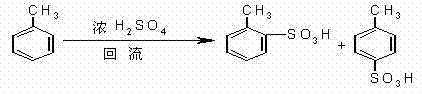

Production method for sulfonic acid curing agent used for casting

InactiveCN102516132AUnique process methodRealize environmentally friendly productionFoundry mouldsFoundry coresAlcoholSteam pressure

The invention relates to a production method for sulfonic acid curing agent and especially to a production method for sulfonic acid curing agent used for casting without generation of three wastes (waste gas, waste water and industrial residue). The method is characterized by comprising the following steps: a, closing a kettle bottom valve, opening a vacuum pump and taking in toluene with a desired weight; b, closing a vacuum valve, opening an air release valve and a sulfuric acid feeding valve, starting a mixer and adding concentrated sulfuric acid with a desired weight; c, opening a steam valve, maintaining steam pressure to be 0.2 to 0.3 MPa, allowing temperature to rise to 100 to 118 DEG C within 40 to 50 min and carrying out insulation for 90 min; d, opening a cooling water valve, allowing temperature to drop to 60 DEG C and slowly adding organic alcohol with a desired weight through an elevated tank; e, slowly adding water with a desired weight through the elevated tank after addition of organic alcohol is finished; and f, after addition of water is finished, allowing temperature to drop to 45 DEG C, adding an aqueous hydrogen peroxide solution with a desired weight, carrying out stirring for 20 min and carrying out inspection by sampling. According to the invention, control of total acidity of the curing agent and free acid is realized, production efficiency is effectively improved, and no discharge of industrial three wastes is realized.

Owner:NINGXIA KOCEL GRP CO LTD +1

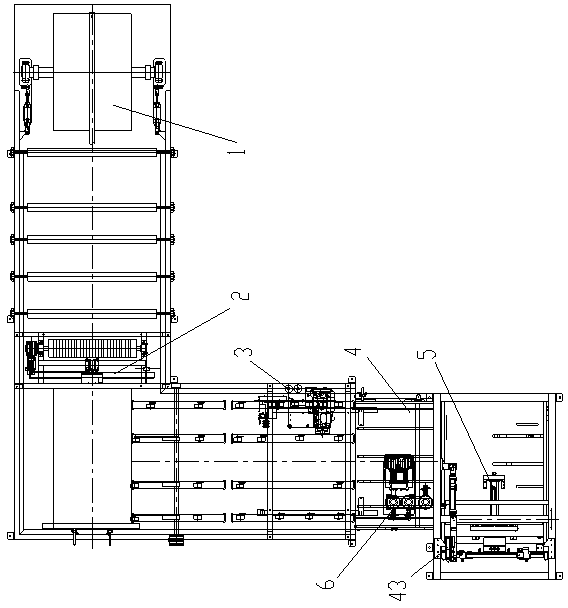

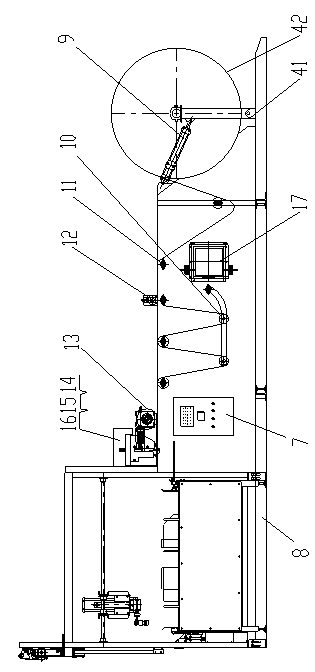

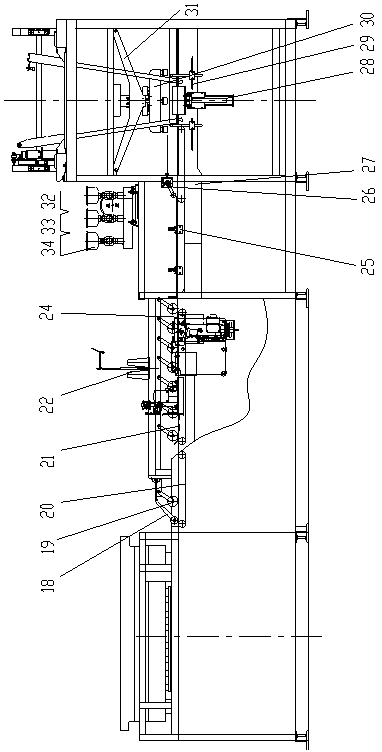

Automatic bag feeding device of bag hanging manipulator as well as production method

InactiveCN103770972AExtended duty cycleSolve the problem of the number of storage bagsWrapper twisting/gatheringAutomatic controlControl system

An automatic bag feeding device of a bag hanging manipulator comprises a rack and an automatic control system, wherein a rolling mechanism, a bag cutting mechanism, a bottom stitching mechanism or heat sealing mechanism, a transferring mechanism, a vacuum absorbing system and a bag opening manipulator are sequentially arranged on the rack, and the rolling mechanism, the bag cutting mechanism, the bottom stitching mechanism, the transferring mechanism, the vacuum absorbing system and the bag opening manipulator are controlled by and connected with the automatic control system; and the bag opening manipulator is located on a lateral side of the vacuum absorbing system side by side. The automatic bag feeding device is novel in structure and unique in technique, solves various problems of the bag hanging manipulator for bag feeding and achieves continuous and fast bag feeding, furthermore, the number of workers is reduced greatly, full-automatic operation is achieved, the labor cost is reduced, the bag feeding speed is increased, and the bag feeding precision is improved.

Owner:HENAN JINGU IND DEV

Medlar bee pollen tablet

InactiveCN102697038ARaw materials are uniqueUnique process methodFood preparationAdditive ingredientFreeze-drying

The invention relates to a medlar bee pollen product, in particular to a medlar bee pollen tablet, which is characterized in that medlar bee pollen freeze dry powder, starch and microcrystalline cellulose are mixed according to the weight part ratio being 1:(0.5-5):(0.5-5) and are sequentially subjected to granulation, drying and tabletting. The invention provides the medlar bee pollen tablet with the advantages that the raw material manufacture method is unique, the effects of resisting the fatigue, lowering the blood pressure, relieving and preventing prostatitis, maintaining beauty and nourishing the skin are realized, the taking is convenient, the activity of functional ingredients is maintained, the oxidative deterioration of products cannot easily occur, the reconstitution property is good, and the medlar bee pollen tablet is applicable to people with kidney deficiency and weakness, people with aching and limp waist and feet, hyperlipidemia patients, women with abdominal pain caused by blood stasis, gaunt people and dystrophia people.

Owner:NINGXIA DINGLI AGRI DEV

Sand-core molding method of ultra-large sand core structural casting

InactiveCN102019359AUnique process methodAvoid damageFoundry mouldsFoundry coresMaterials scienceCasting

The invention relates to a molding method of a large casting, in particular to a sand-core molding method of an ultra-large sand core structural casting. The method comprises the following steps of: coding a sand core; manufacturing the sand core; manufacturing a core box; coremaking; and setting the core. The process method provided by the invention is unique, can avoid partial or large-area size inconsistence of the casting, partial poor shape and hole shrinkage caused by the damaged sand core in the traditional process of making, conveying and setting an ultra-large sand core in a complicated structure and can ensure the product quality and shorten the production period.

Owner:KOCEL GROUP +1

Production technique of sand-type water based paint for casting

ActiveCN102773405ARaw materials are uniqueUnique process methodFoundry mouldsFoundry coresWater basedSuspending Agents

The invention relates to a manufacturing method in a production technique of paint for casting, in particular to a production technique of sand-type water based paint for casting, wherein the sand-type water based paint belongs to a casting accessory. The production technique comprises the following steps of: adding water, tributyl phosphate and CMC (carboxy methylated cellulose) in a dissolving pot firstly, stirring uniformly, dissolving the materials completely; filtering insoluble materials by a filter screen; adding water, sodium benzoate, a sodium base bentonite suspending agent, acetic acid and reducing glue in a stirring kettle, starting up electric stirring; slowly adding white corundum, sodium lignin sulfonate and water in the stirring kettle, stirring for 15-20min; adding water on the basis of the dilution situation, wherein the baum degree of the paint is higher than 95 after being stirred uniformly; transferring the paint prepared by the steps in a colloid mill, continuously milling for 2h, discharging and packaging into barrels to obtain the paint. The invention provides the novel production technique of the sand-type water based paint for casting, which has the following characteristics of environment friendliness, high coating strength and excellent painting property.

Owner:共享新材料(山东)有限公司

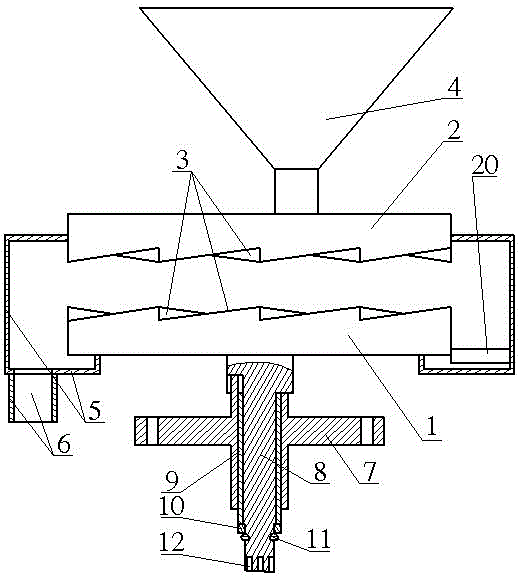

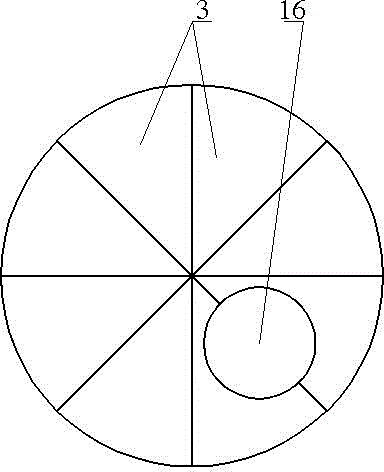

Forced cooling method for wind power cast

The invention relates to a forced cooling method for a wind power cast, in particular to a forced cooling method for a wind power cast. The method comprises the following steps of manufacturing a heat exchanger, when producing a sand core, embedding core iron into casting san, and placing the heat exchanger into an inner cavity of the sand core; embedding a ceramic pipe communicated with the heat exchanger into the central position of the end face of a core head of the sand core during modeling, and enabling the ceramic pipe to be connected with the outside of a sand box; when the box is closed, after placing the sand core into a cavity, connecting the core iron of the sand core and the ceramic pipe embedded in the cavity through the ceramic pipe, and filling the core sand into the rear portion of the heat exchanger; after the box is closed, communicating the ceramic pipe and a compressed air port through a flexible hose; and during pouring, when iron liquid of the cavity is full, feeding gas into the heat exchanger. The forced cooling method for the wind power cast is unique in process, the cast is cooled through air blowing by utilizing the heat exchanger, heat dissipation of the sand core of the inner cavity is accelerated, iron liquid crusting is accelerated while vibration ramming is utilized to enable the inside of the cast to be compact, and the requirements for flaw detection can be met.

Owner:KOCEL GROUP +1

Method of casting thick-wall casting through sand insulation cold iron

ActiveCN103128252AReduce manufacturing costReduce labor intensityManufacturing engineeringMolding sand

The invention relates to a casting method of a thick-wall casting, in particular to a method of casting the thick-wall casting through sand insulation cold iron. The method sequentially comprises mould manufacturing, modeling, core manufacturing, mould assembling, pouring and falling sand cleaning. The method is characterized in that the sand insulation cold iron is placed on a thermal center portion, namely the thick portion of the casting before modeling, a boss of the sand insulation cold iron is used for fixation, and the boss of the sand insulation cold iron is placed close to a casting format of the casting. After the sand insulation cold iron is placed, quicksand is conducted, comprehensive tiny compaction of moulding sand is conducted through a vibration ramming platform, the mould is opened after being placed for two hours, and after mould assembling, iron liquid after nodulizing inoculation is poured into the mould. The method is unique in technique, can guarantee quality of the casting, shortens the production period, improves production efficiency, and saves production cost. The method not only saves the production cost, but also reduces casting surface cleaning work and work intensity.

Owner:KOCEL EQUIP

Preparation method of wolfberry flower and wolfberry leaf health-care beverage

InactiveCN104188020APrevent oxidative browningSolve precipitationNatural extract food ingredientsFood ingredient functionsAdditive ingredientAntioxidant

The invention relates to a health-care beverage and a preparation method thereof, and particularly relates to a wolfberry flower and wolfberry leaf health-care beverage, and a preparation method thereof. The method comprises the steps of collecting raw materials; washing; extracting; protecting color; enzymolyzing; blending; homogenizing; degassing and sterilizing. By adding an antioxidant and a biological enzyme, the preparation method successfully overcomes the problems of easily oxidative browning and precipitation of the wolfberry flowers and wolfberry leaves during a storage period; and by adopting scientific proportions and preparation steps, nutritional ingredients are extracted sufficiently while retaining color and fragrance of fresh flowers and tender leaves. The wolfberry flower and wolfberry leaf health-care beverage has the effects of prolonging ageing, improving eyesight and clearing liver.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Regional blind-hole material taking method for solid

InactiveCN102788713AUnique process methodTo achieve the purpose of taking materialsWithdrawing sample devicesEngineeringCast iron

The invention relates to a regional blind-hole material taking method, in particular to a regional blind-hole material taking method for a solid. The method comprises the following steps: firstly, annularly drilling a test rod within a stated region by using a core taking drill bit, wherein the drilling depth is equal to the depth of the test rod to be taken out; secondly, drilling blind holes on the two sides of the justly annularly drilled test rod respectively, wherein the drilling depth is equal to the depth of the test rod to be taken out; and finally, knocking above the blind holes back and forth, and taking out the test rod. The regional blind-hole material taking method for the solid is unique; the blind-hole material taking problem of a cast iron component is solved; in the material taking process, the safety coefficient is high and the material taking efficiency is high; and the test rod can be taken out under the condition that the solid within the stated region is not destroyed.

Owner:KOCEL GROUP +1

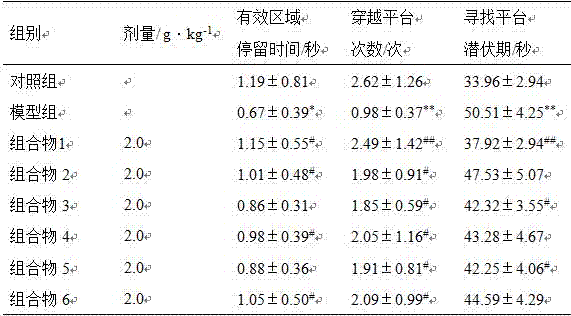

Composition having function of enhancing learning and memory abilities and preparation method of same

InactiveCN107158299AEnhance learning and memoryGood effect of enhancing learning and memoryNervous disorderAnthropod material medical ingredientsMedicineSemen

The invention discloses a composition having function of enhancing learning and memory abilities and a preparation method of same. The composition is prepared from, by weight, 10-30 parts of silkworm chrysalis, 2-10 parts of acorus gramineus, 2-10 parts of polygala tenuifolia, 1-5 parts of ginseng, 1-5 parts of schisandra chinensis, 1-5 parts of fructus alpiniae oxyphyllae, 1-5 parts of herba cistanche and 1-5 parts of semen cuscutae. The composition can effectively enhance learning and memory abilities, is a representative health care product of resisting senility and oxidization and enhancing immunity, and is especially suitable for elder learning and memory ability deterioration patients.

Owner:BEIHUA UNIV

Production device and production process for preserved and spicy mustard

InactiveCN104305075AEasy to industrializeThe production process is simple and applicableFood preparationEngineeringKnife blades

The invention discloses a production device and a production process for preserved and spicy mustard, comprising a preserved and spicy mustard kneading machine and a machine for squeezing crude mustard juice. The preserved and spicy mustard kneading machine mainly comprises a fixed tray, a kneading tray, a hopper, a storage shell, a discharge opening, a kneading support, a sliding bush, a separation blade, a snap spring, a rotating shaft, a spline sleeve, a variator and an electromotor. The machine for squeezing crude mustard juice mainly comprises a screw squeezing rod, a squeezing shell, an end cover, a storage hopper, a cutter shaft, a rotary blade, a liquid receiving tray and a funnel. With the adoption of the production device for the preserved and spicy mustard, which has a compact and reasonable structure and is convenient to manufacture, the preserved and spicy mustard is rapid, convenient and labor-saving to produce, and the industrialization is facilitated. The process for producing the preserved and spicy mustard by adopting the production device for the preserved and spicy mustard is simple, applicable and unique, and the produced preserved and spicy mustard is tender, delicious and crisp, and has a good taste, and industrial production of the preserved and spicy mustard is facilitated.

Owner:CHONGQING BEIJING TECH RES & DEV

Medicine mud mask and manufacturing technology thereof

ActiveCN103908142ADoes not rotNo pollutionGaseous substancesReligious equipmentManufacturing technologyRespiratory disease

The invention provides a medicine mud mask. Raw materials of the medicine mud comprise the flowing components, by mass ratio, the ratio of mud, medicine and water is 2 to a range from 0.8 to 1.5 to a range from 0.2 to 0.8; the mud is from mountains with the altitude more than 4600 m; the water is from mountains with the altitude more than 4600 m; the gross weight of the medicine which comprises 10 g of religious holy articles, 240 g of Tibetan medicine, 133 g of Chinese herbal medicine, 255 g of gem and 150 g of aromatic drugs is 788 g. The medicine mud mask has functions in sterilizing, cleaning air, resisting viruses in the air, resisting various respiratory diseases, increasing intelligence and maintaining health, relieving fatigue and the like, has high collection values and can be served as precious gifts to be given to others. The invention also discloses a manufacturing technology thereof. The manufacturing technology of the medicine mud mask comprises steps of preparing the medicine mud, manufacturing a medicine mud mask body, manufacturing a medicine mud mask product and the like. The manufacturing technology of the medicine mud mask is unique in method and the medicine mud mask product cannot be decayed, does not pollute and fade and is convenient to carry along.

Owner:四龙降泽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com