Patents

Literature

35results about How to "Reduced deformation tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel welding technique for hammering and forging high-temperature welding line

InactiveCN103506776AIncreased tissue densityGrain refinementWelding/cutting auxillary devicesFurnace typesWeld microstructureCushion

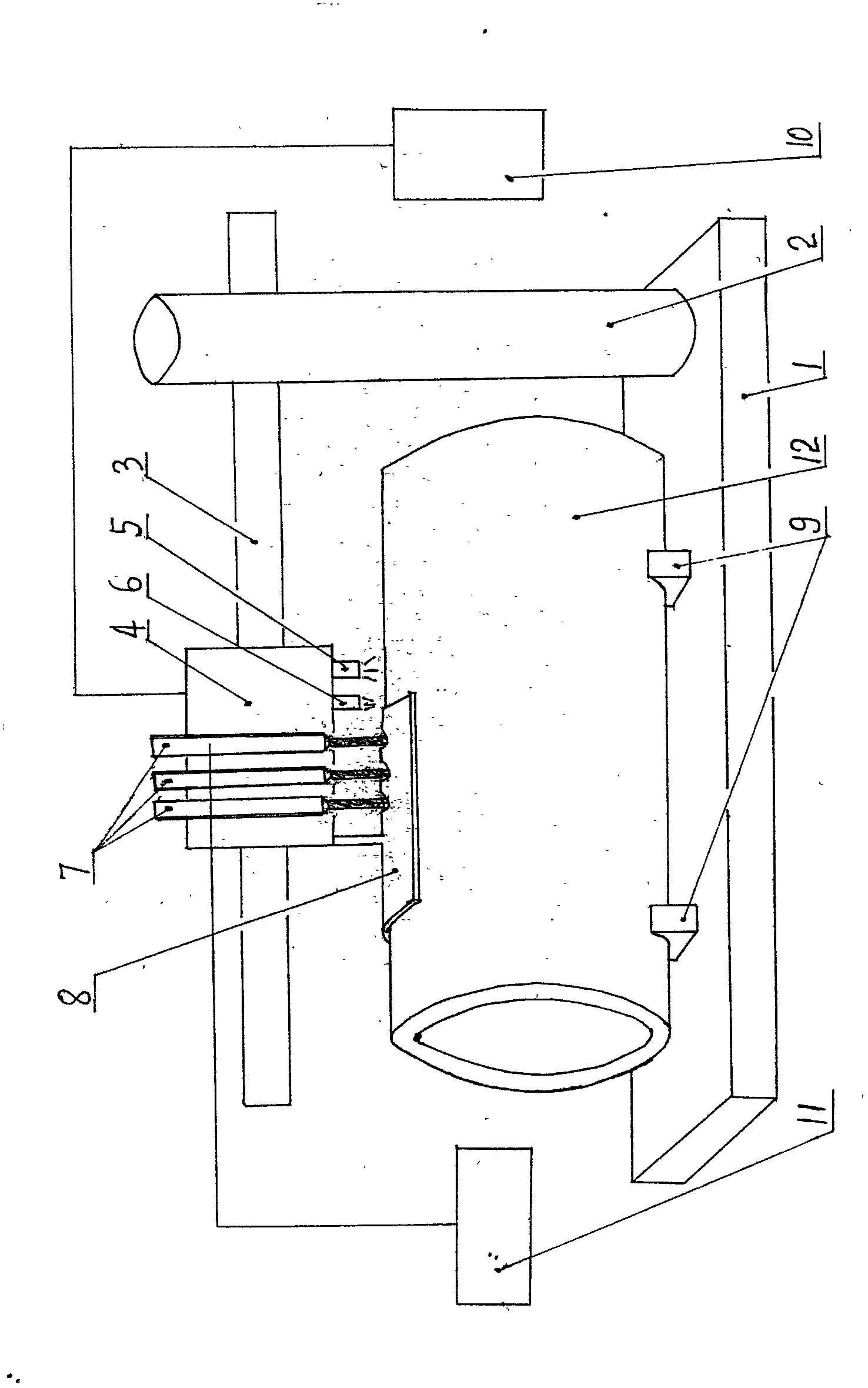

The invention discloses a novel welding technique for hammering and forging a high-temperature welding line. The novel welding technique for hammering and forging the high-temperature welding line relates to a working table, a stand column, a track cross beam, a servo trolley, elastic cushion blocks, a control cabinet and a pneumatic source. The novel welding technique for hammering and forging the high-temperature welding line is characterized in that an electric welding gun, a gas gun, an heat insulation cover plate and at least one pneumatic impact hammer are installed on the servo trolley and can move in a servo mode on the track cross beam under the control of the control cabinet, and a welding part is fixed on the working table through the elastic cushion blocks. According to the novel welding technique for hammering and forging the high-temperature welding line, the surface of the welding line which is just welded is heated through the gas gun during welding, a weld microstructure in the high-temperature state is hammered and forged contentiously through the at least one pneumatic impact hammer, and finally normalizing treatment is automatically carried out on the hammered and forged weld microstructure after heat insulation is carried out on the hammered and forged weld microstructure in the servo moving process of the heat insulation cover plate. The novel welding technique for hammering and forging the high-temperature welding line has the advantages that the structural compactness of the welding area of a component can be improved, welding stress deformation is reduced, residual stress is relieved, and high-carbon steel and alloy steel can be widely applied to the welding field.

Owner:崔景超

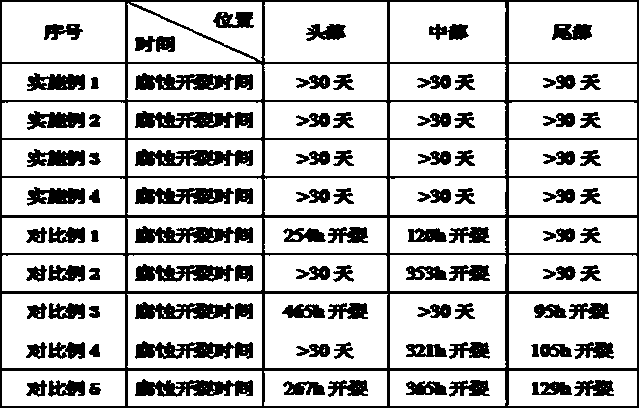

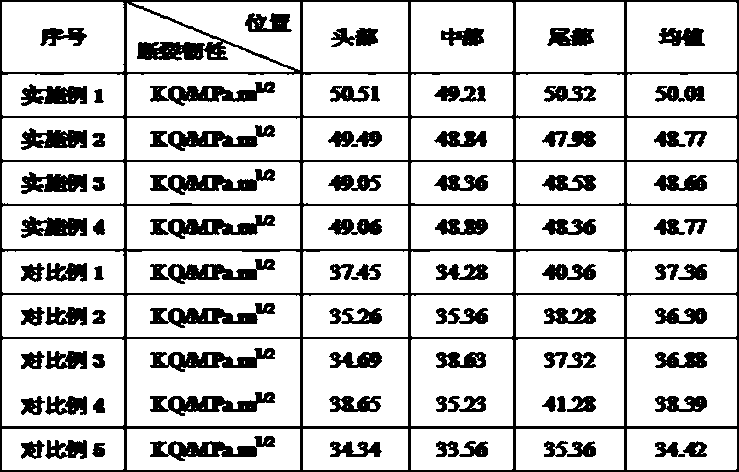

7xxx series aluminum alloy sheet and preparation process thereof

The invention discloses a 7xxx series aluminum alloy sheet and a preparation process thereof. The 7xxx series aluminum alloy sheet comprises the compositions of 1.7-1.9% of Mg, 5.0-6.5% of Zn, 0.25-0.40% of Cu, lass than or equal to 0.10% of Fe, less than or equal to 0.06% of Si, lass than or equal to 0.01% of Mn, less than or equal to 0.01% of Zr, less than or equal to 0.01% of Cr, 0.01-0.03% ofTi, and the balance Al and inevitable elements. The preparation process comprises the following steps that (1), smelting is performed; (2) degassing and filtration are performed; (3) casting is performed; (4) soaking is performed; (5) saw cutting and milling surface are performed; (6) preheating and hot rolling are performed; (7) edge trimming and transverse knife uncoiling are performed; (8) solid solution quenching is performed; (9) stretching is performed; (10) aging is performed; and (11) saw cutting is performed, and aluminum alloy sheet finished products are obtained. The surface hardness of the aluminum alloy sheet prepared by the preparation process is no less than 150HV, no bank mark on the surface after anodizing is achieved, the color is close to that of aluminum metal, and the7xxx series aluminum alloy sheet can be widely used in IT appearance structural parts.

Owner:广西南南铝加工有限公司

Grease protecting apparatus for heat sink

InactiveUS20070012421A1Increase flexibilityReduce internal stressCapsDigital data processing detailsThermal greaseEngineering

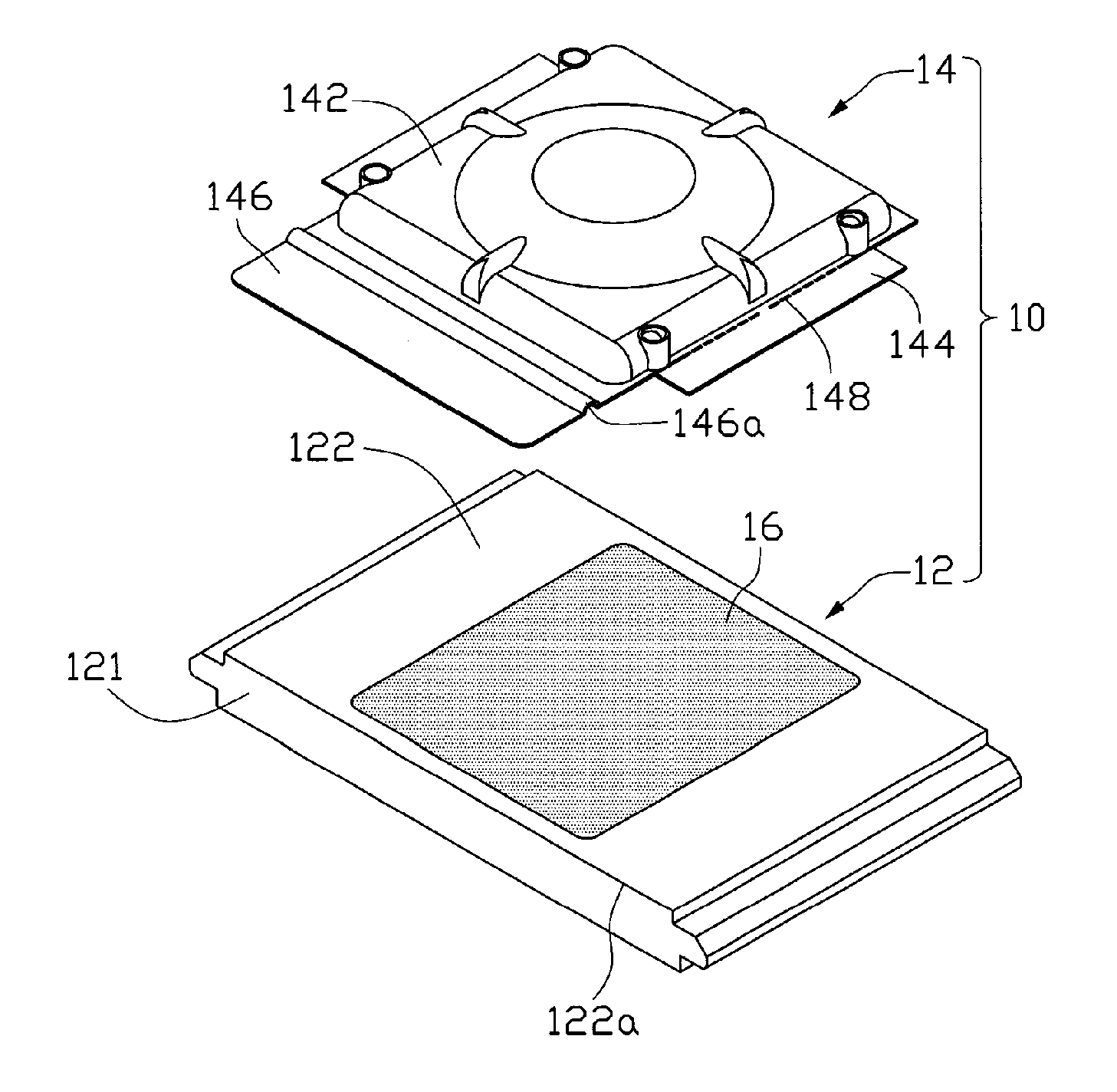

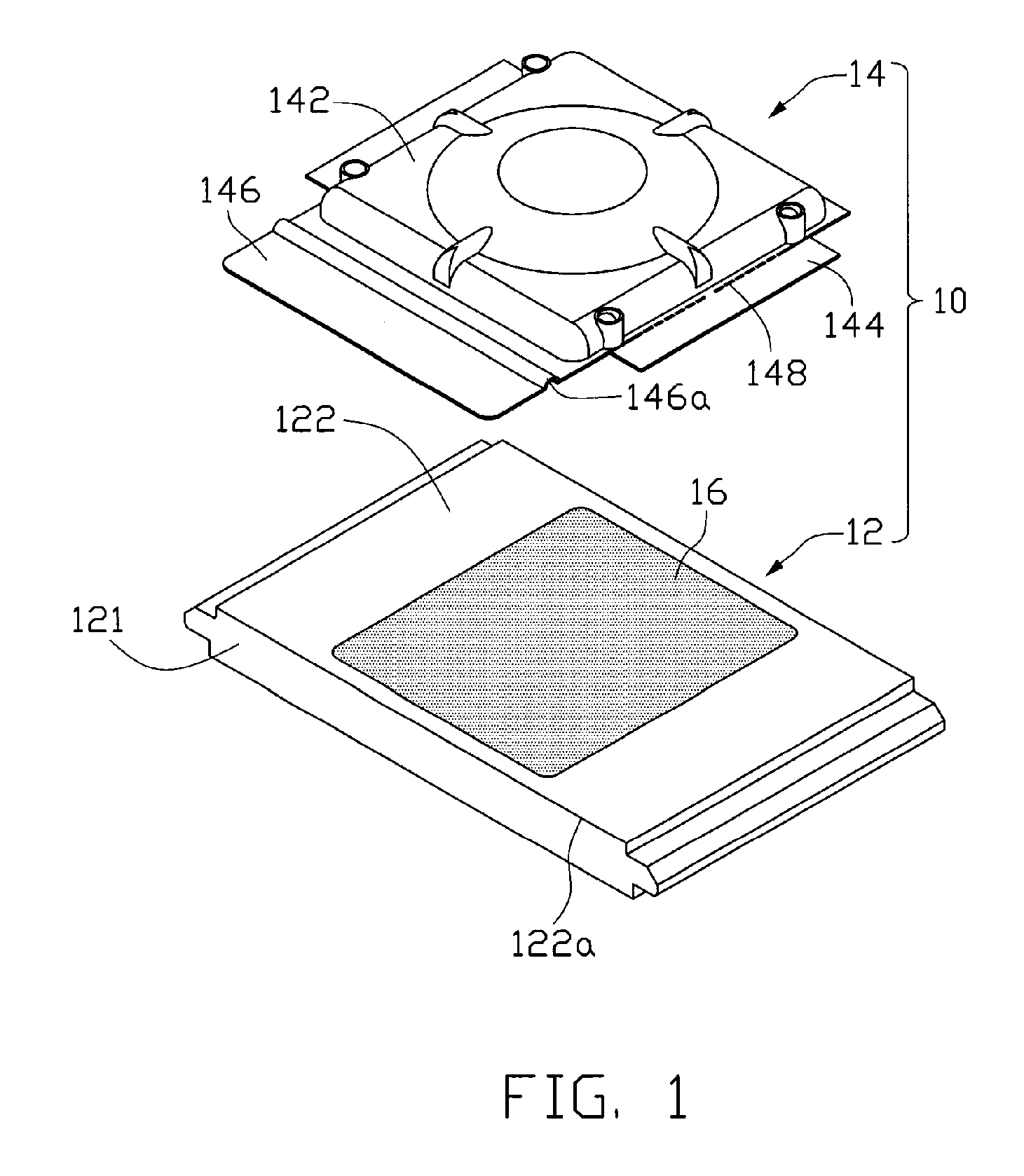

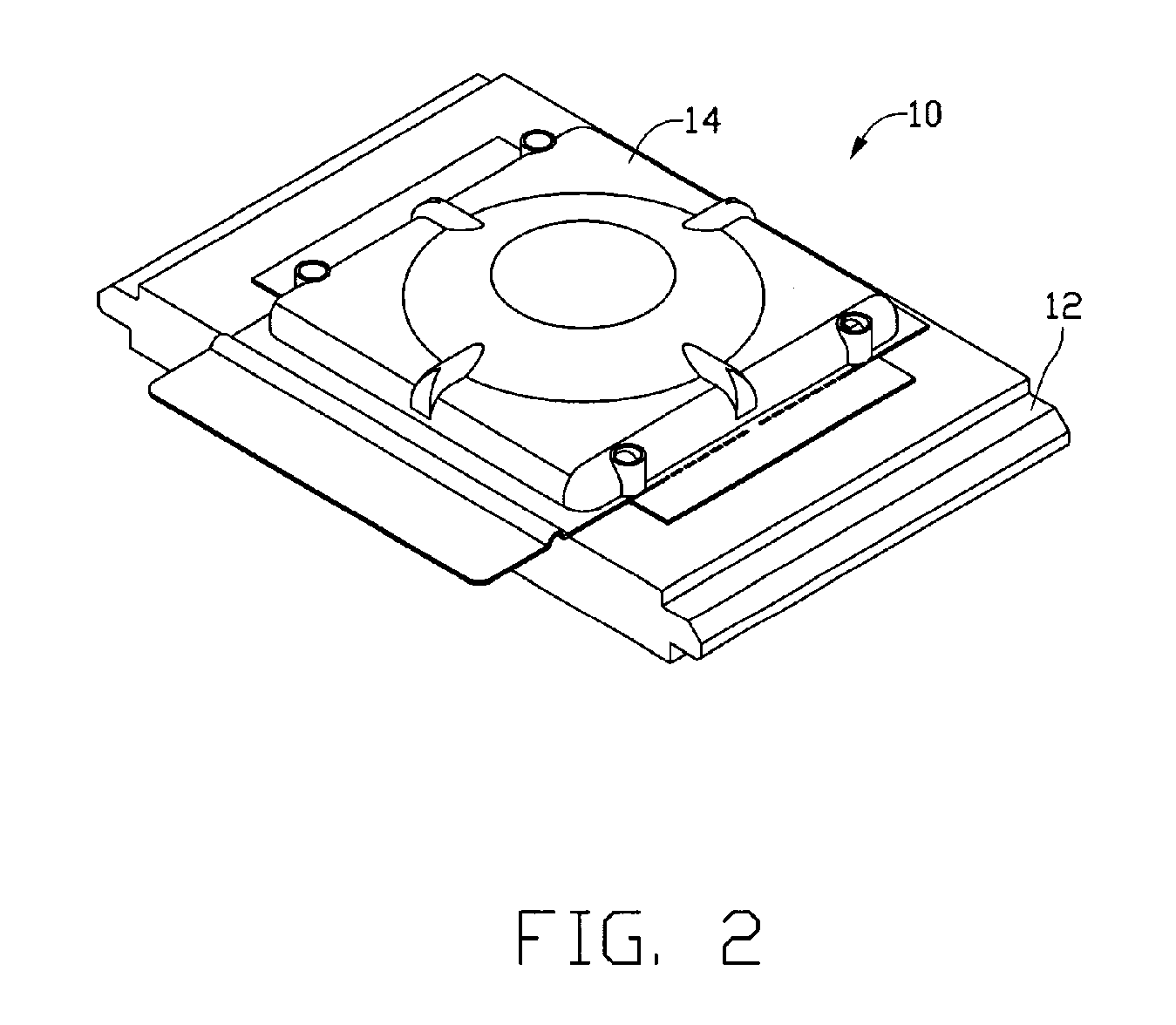

A grease protecting apparatus (10) includes a heat sink (12), and a grease cover (14). The heat sink includes a bottom surface (122) for contacting with a heat-generating component. A layer of thermal grease (16) is spread on the bottom surface of the heat sink. The grease cover is attached to the bottom surface of the heat sink and covers the grease to protect the grease from contamination. The cover includes a main body (142) defining a protecting space (143) therein for covering the grease, and two wings (144) extending from two opposite sides of the main body for attaching the grease cover to the bottom surface of the heat sink. The wings defines a plurality of perforations (148) therein to make the wings be capable of tilted upwardly and downwardly.

Owner:HON HAI PRECISION IND CO LTD

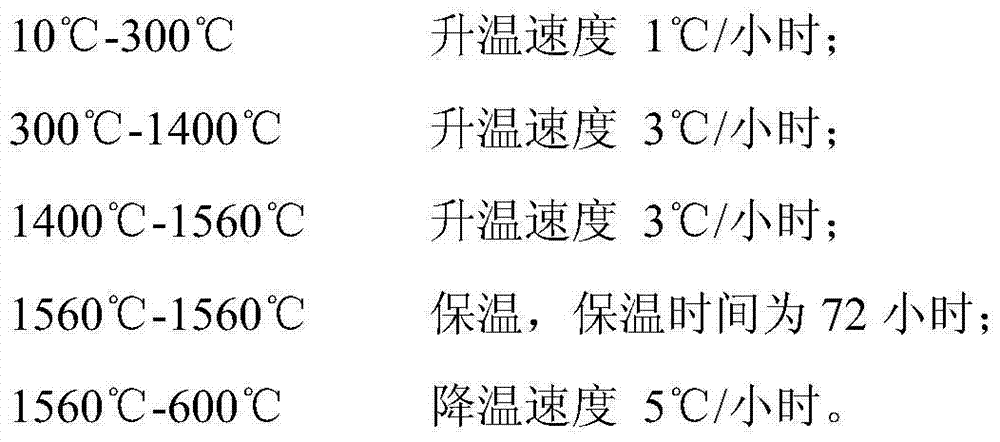

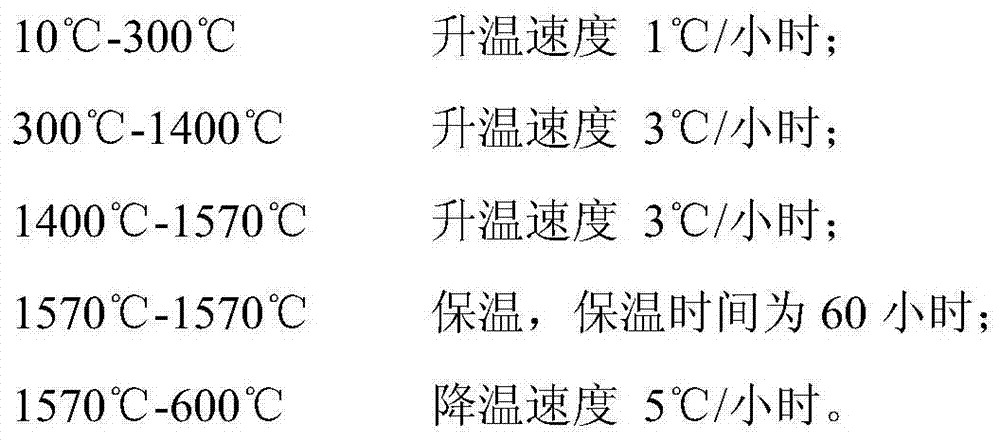

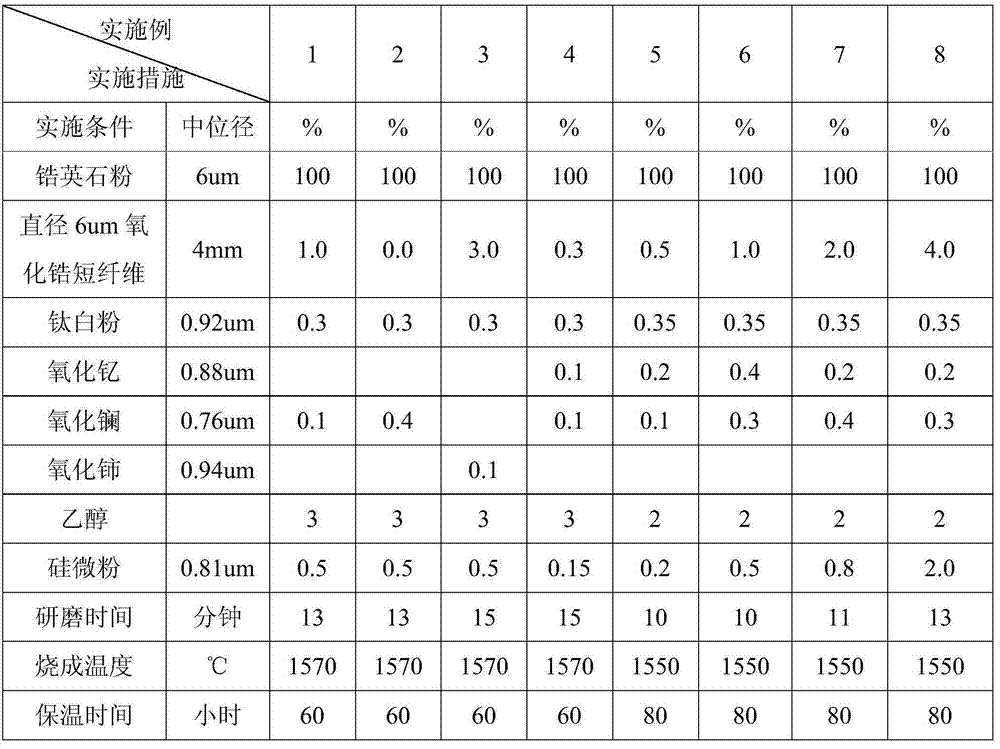

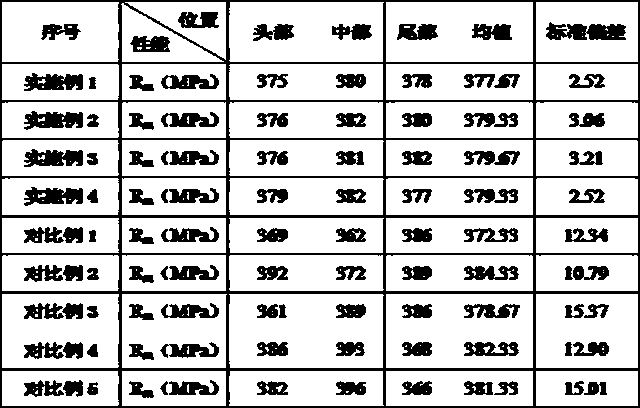

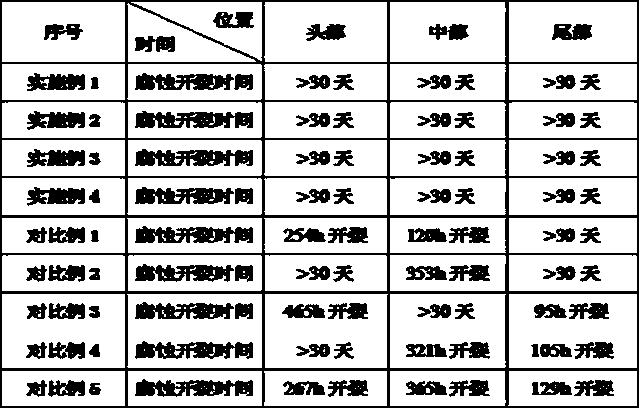

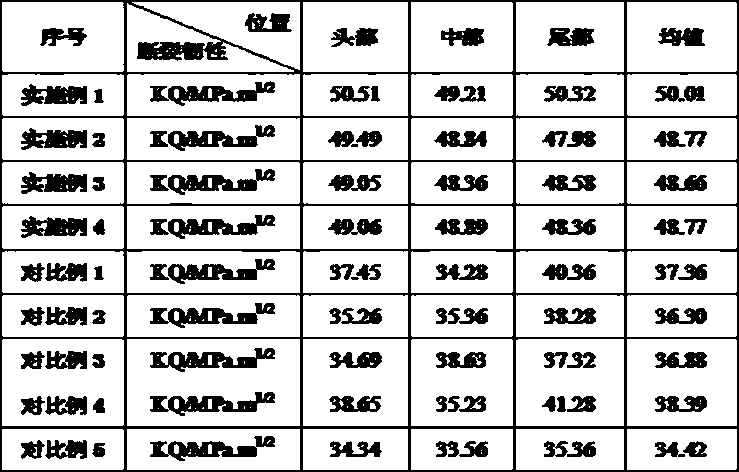

Low-creep zircon overflowing brick and preparation method thereof

ActiveCN103524139AHigh temperature low flexural strengthImproved high temperature flexural strengthFiberPolymer science

The invention relates to a low-creep zircon overflowing brick and a preparation method thereof. The low-creep zircon overflowing brick comprises, by mass, 100% of zircon powder, wherein zircon oxide short fibers account for, by mass, 0.0-4.0% of the zircon powder, silicon oxide powder accounts for, by mass, 0.1-2.0% of the zircon powder, and composite additives account for, by mass, 0.1-0.8% of the zircon powder. The composite additives can be La2O3, or CeO2, or combination of La2O3 and Y2O3, or combination of CeO2 and Y2O3, or combination of La2O3, CeO2 and Y2O3. According to the low-creep zircon overflowing brick and the preparation method thereof, strength of green bodies is improved, firing shrinkage of the green bodies is reduced, manufacturing yield of products is improved, bonding strength of crystal boundaries of zircon is enhanced, the high-temperature bend-creep rate of products is effectively lowered, and the service life of super-large-size overflowing bricks is prolonged.

Owner:ZIBO GT INDAL CERAMICS

Al-Zn-Mn alloy profile for rail transit vehicle body and preparation method thereof

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

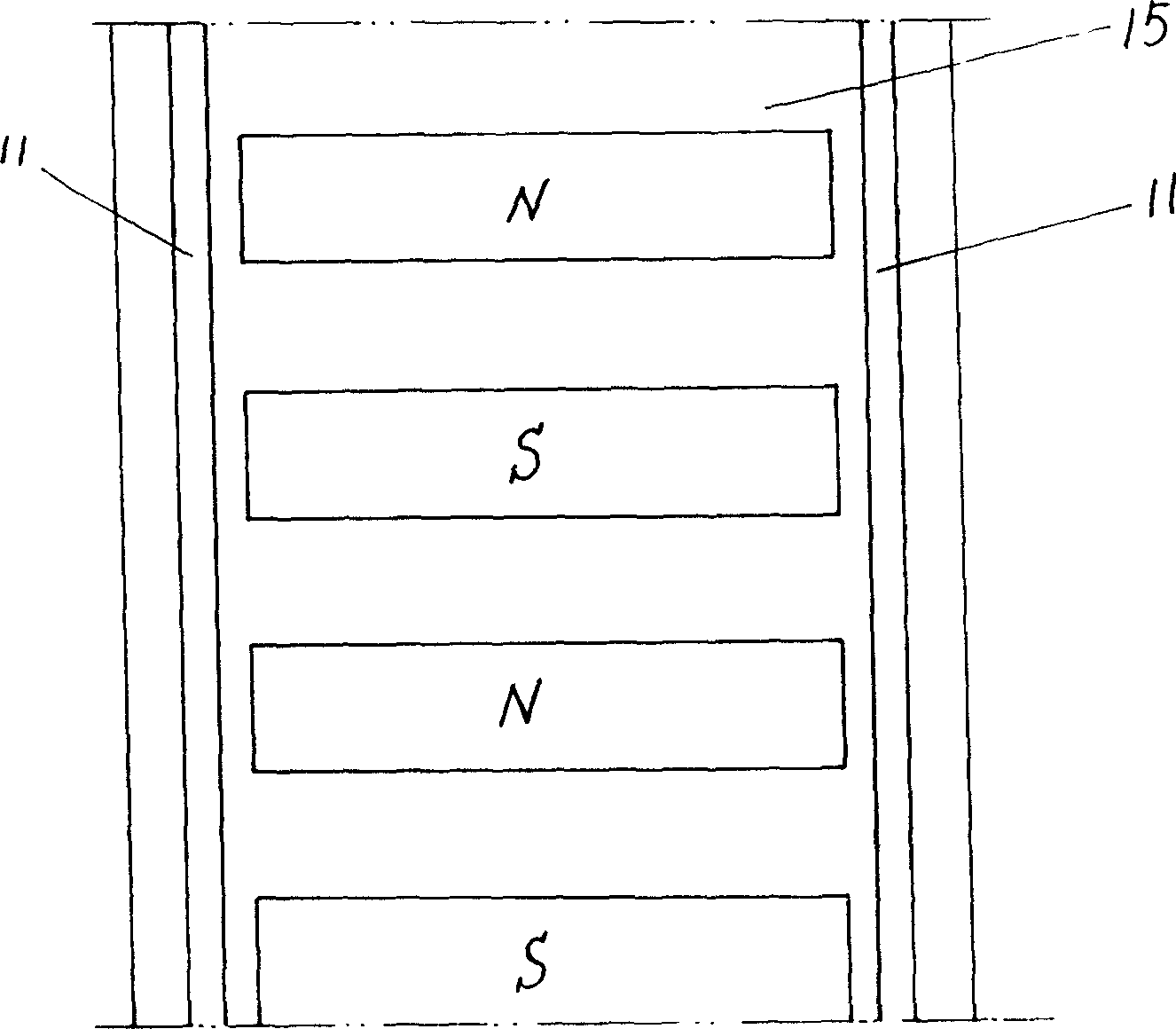

Anisotropic rare-earth magnet light wave microwave sintering method

ActiveCN101882504AFast heatingSpeed up the sintering processInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementLight wave

The invention relates to an anisotropic rare-earth magnet light wave microwave sintering method. Pressed and formed R-Fe-B (R is at least one of rare earth elements) series anisotropic rare-earth magnet green bodies after the completion of magnetic field orientation are placed in a light wave microwave oven, and the combination energy of light waves and microwaves are used for sintering. The frequency of microwaves is 500 MHz to 250 GHz, the atmosphere is vacuum or inert gas, the power of the light waves and the microwaves is proportionally controlled as required, and the sintering temperature is 980 DEG C to 1200 DEG C. The respective heating characteristics of the light waves and the microwaves are used, the heating speed is high, and the temperature gradient in the magnet green bodies is further reduced in sintering; the zero gradient even heating in a larger area in a sintered material can be realized, the grain growth inside the material is even and fine, and the magnetic performance of the finished product can be increased; meanwhile, the invention has the characteristics of low thermal stress, less cracking and deformation, energy saving, environment protection and the like.

Owner:上海京藤建设工程(集团)有限公司

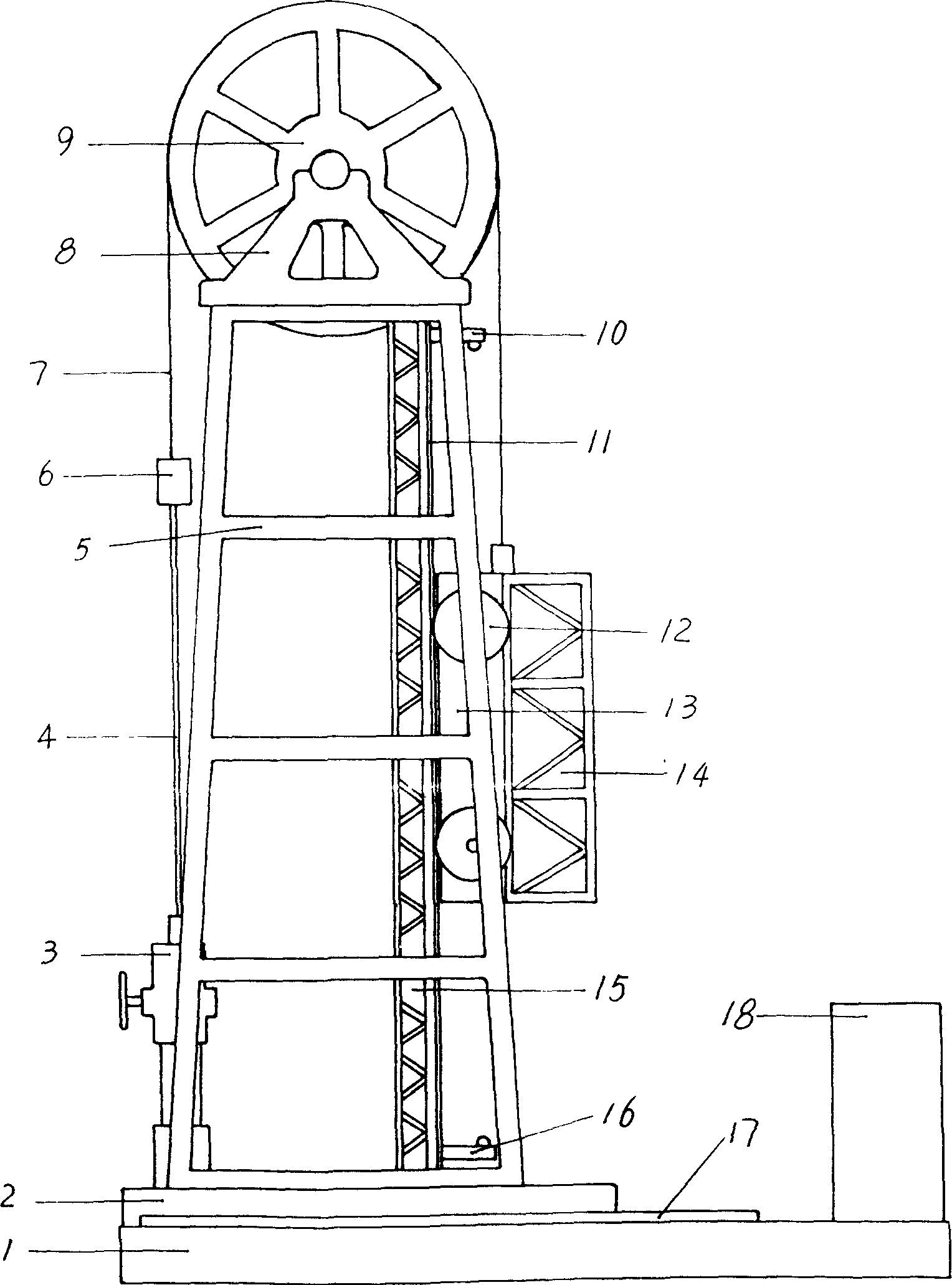

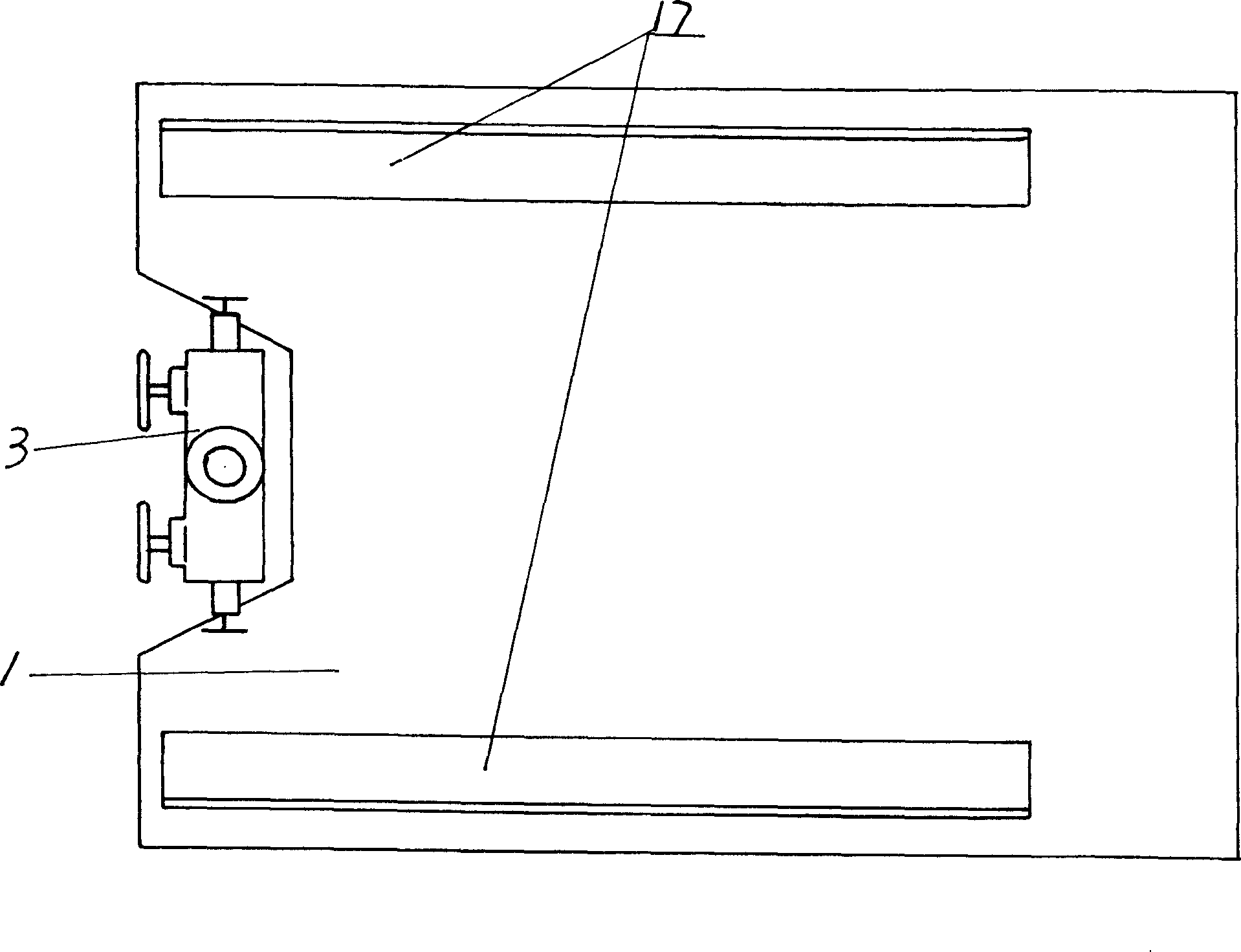

Non walking beam linear motor pumping unit

InactiveCN1525039AEasy to installStable structureFluid removalPropulsion systemsElectric machineLinear motor

The invention provides a beam-free linear electric-machine oil pump, having characters of stable structure, smooth working, high-efficiency energy saving and convenient use and maintenance, applied to oil pumping work in oil field and oil well. Its technical project: it includes main frame, stator fixed on the main frame, rope and rotor linked with the rope, as well as rotor guide rail, rotor guide wheel and spacing commutator, and its character: the stator is a unilateral structure and the rotor adapts to the stator. The rotor is fixed with balance weight box, there is a wind circulating cooling device in the cavity of the rotor, the spacing commutator can movably position, the top end of the main frame is set with head sheave and the main frame can move with the moving base.

Owner:高旺

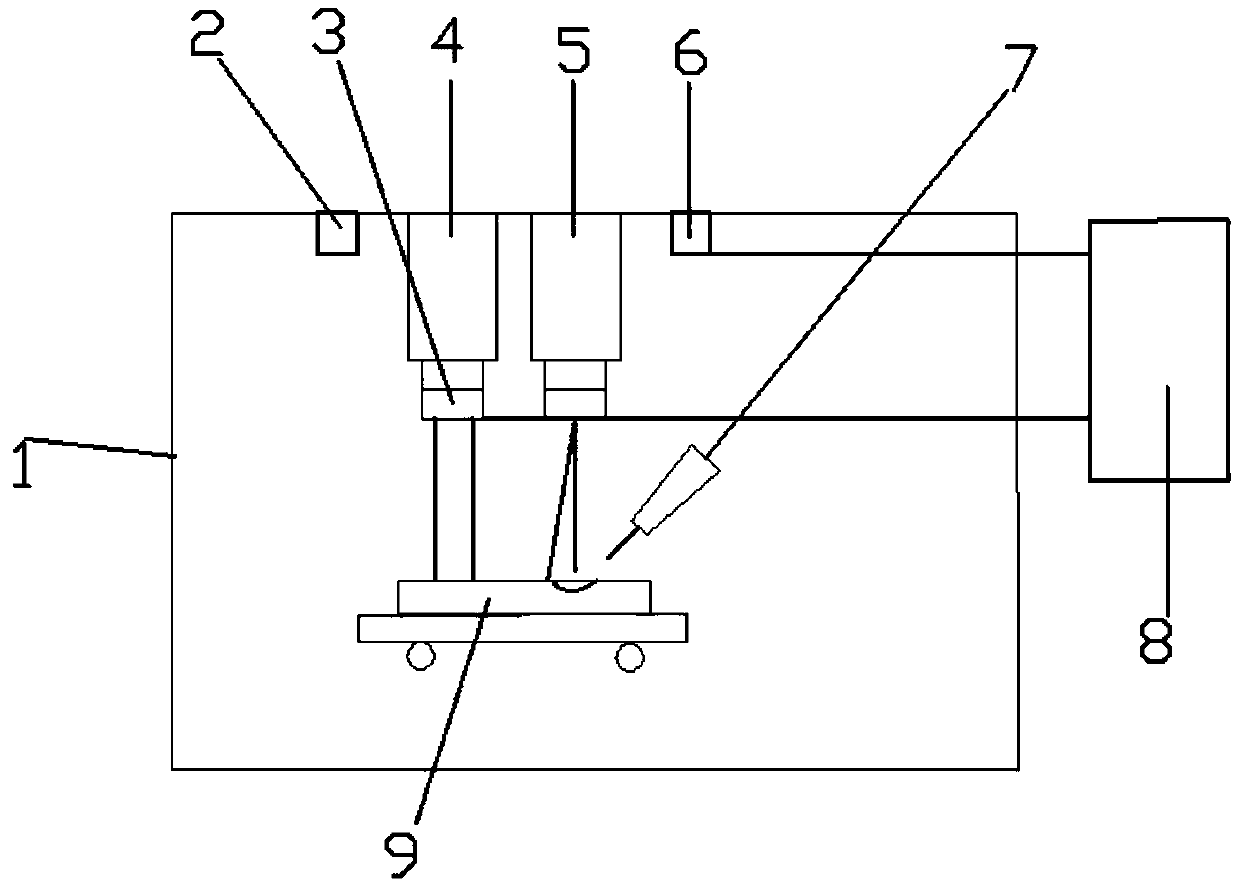

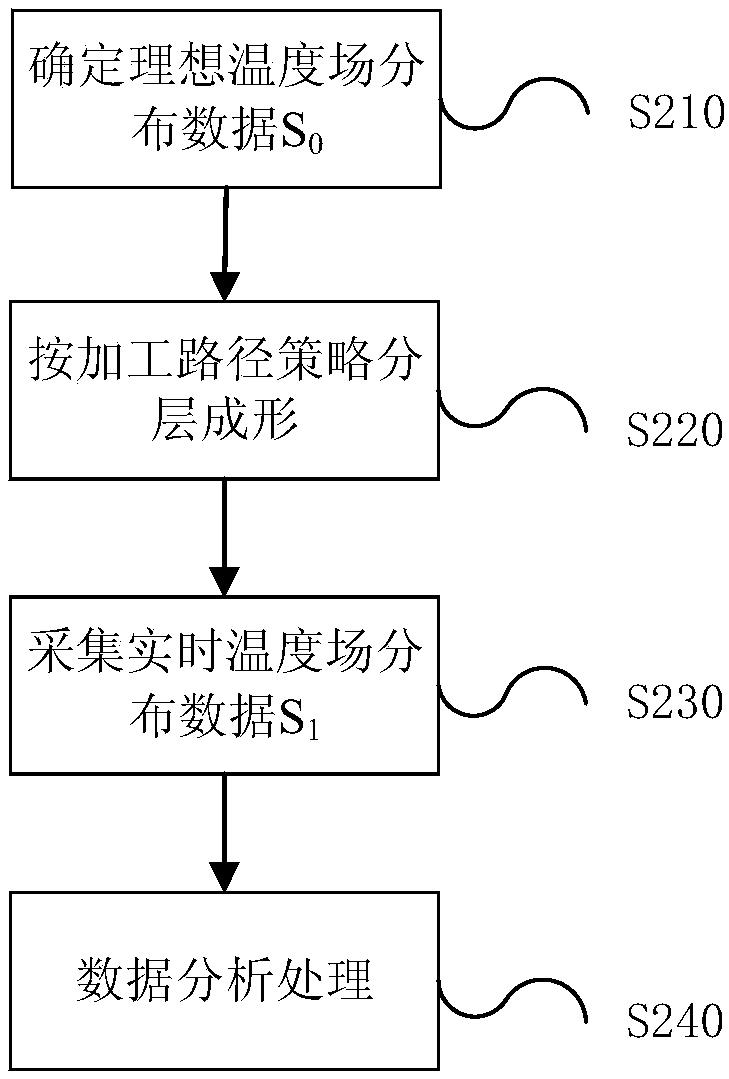

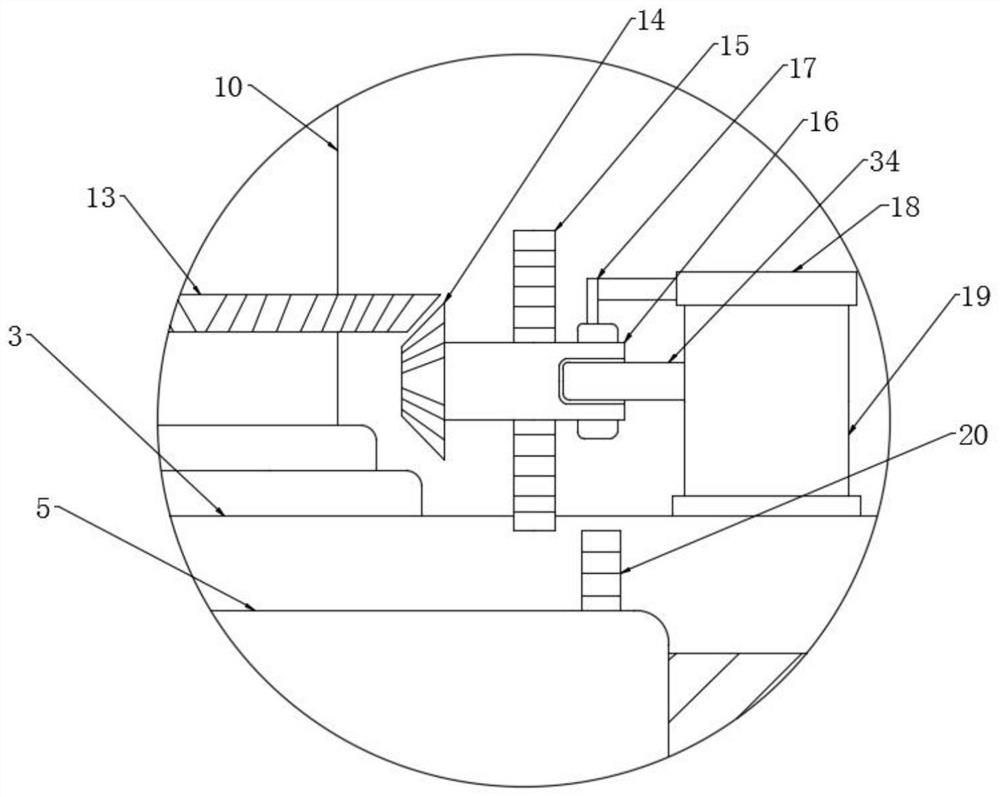

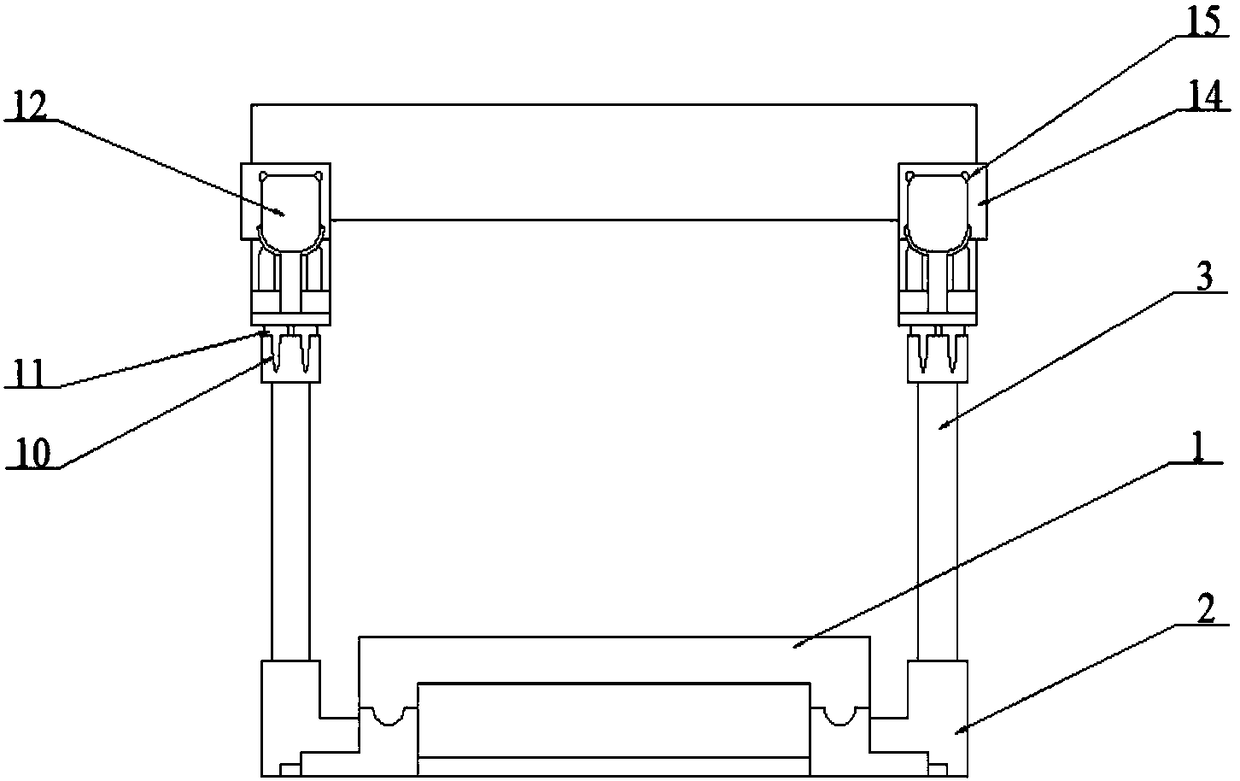

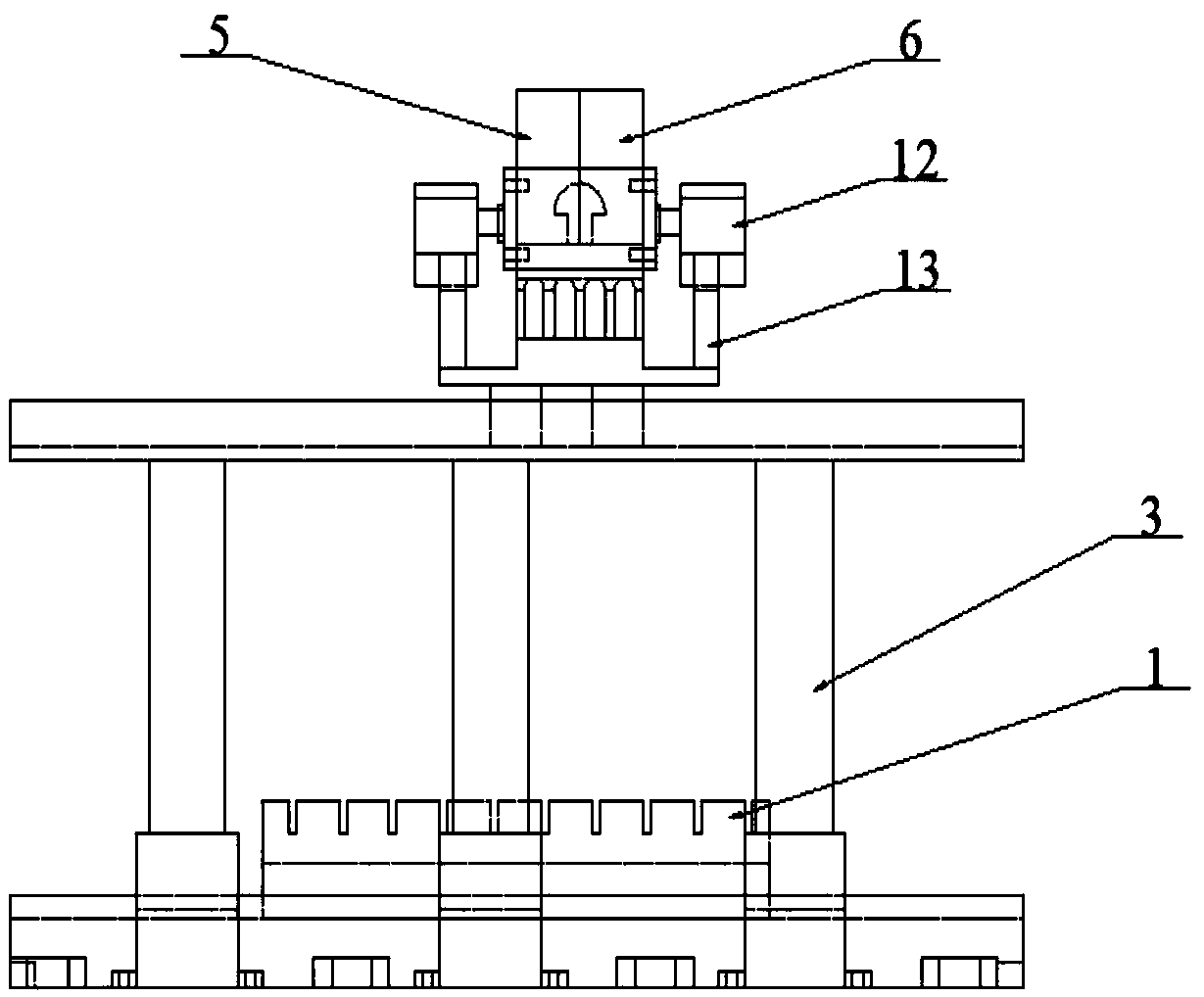

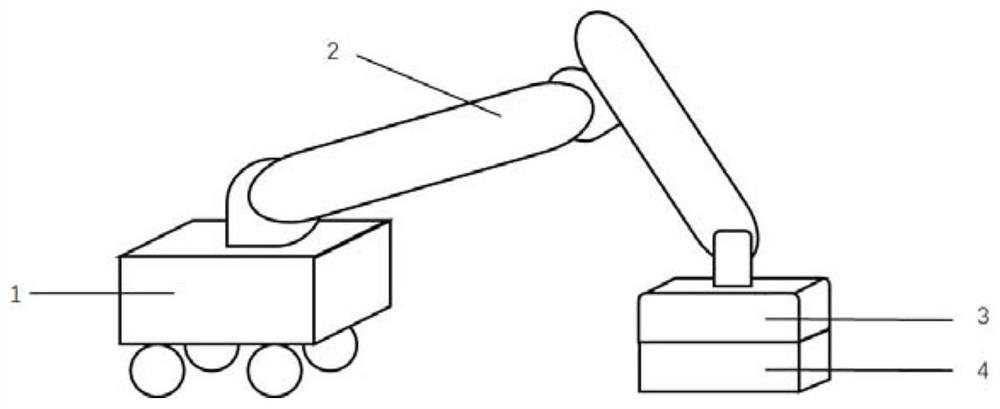

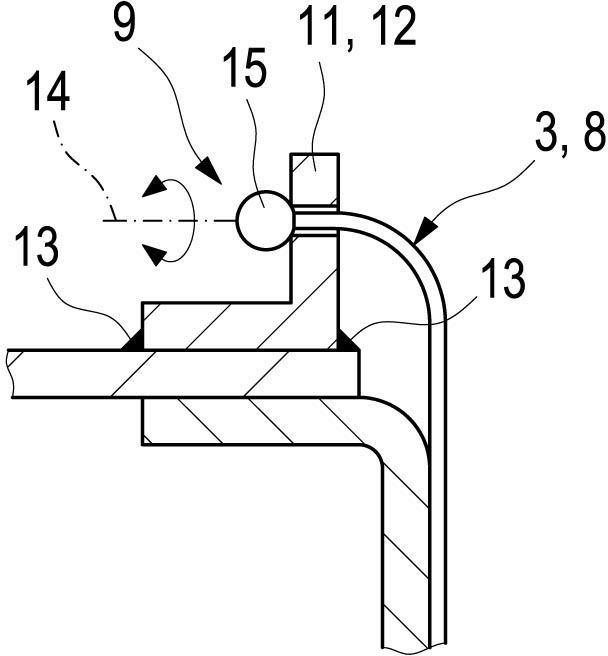

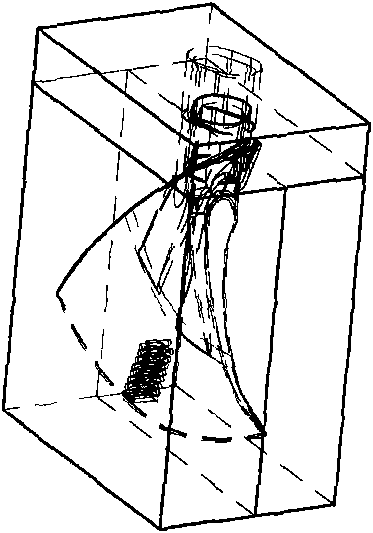

Stress deformation control method and device for electron beam fuse additive manufacturing process

ActiveCN109514069AReduce thermal stressReduced tendency to deformElectron beam welding apparatusMetalMaterials science

The invention relates to a stress deformation control method and device for an electron beam fuse additive manufacturing process. The method comprises the steps that ideal temperature field distribution data S0 for generating minimum thermal stress during additive manufacturing is determined based on material properties and thermal stress generation conditions of additive manufacturing; a metal wire is melted with a first electron gun, and layered forming is performed according to a machining path strategy of a part; a temperature monitoring probe is used for collecting real-time temperature field distribution data S1 of a forming layer; the real-time temperature field distribution data S1 is compared with the ideal temperature field distribution data S0, and when it is judged that S1 deviates from S0, an electron beam is emitted by a second electron gun, after the electron beam is controlled by a scanning coil, the electron beam is irradiated in a spot mode at a position at which thepart to be heated is formed, and when the real-time temperature field distribution data S1 in the forming process is equivalent to the ideal temperature field distribution data S0, the second electrongun and the scanning coil stop working, the first electron gun continues to work until all the layers of the part are formed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

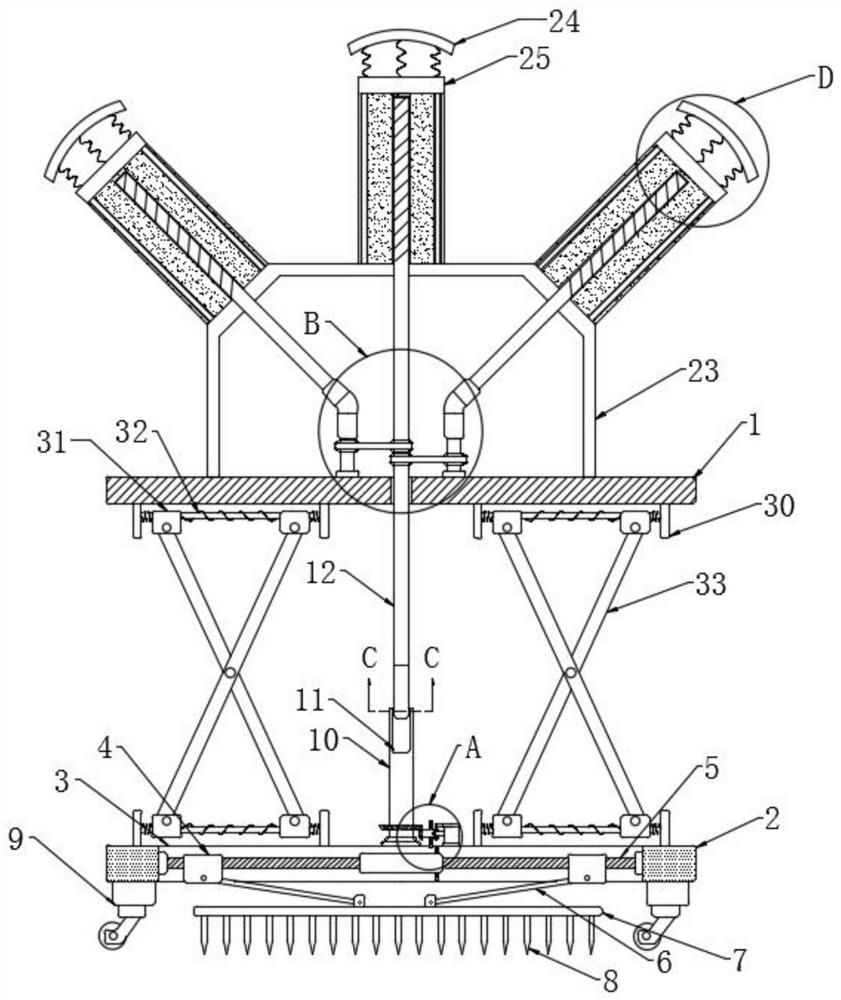

Contractible force transmission connecting device suitable for large-deformation tunnel primary support

The invention discloses a contractible force transmission connecting device suitable for a large-deformation tunnel primary support, and relates to the technical field of tunnel primary support devices. The device comprises a transverse plate and a bottom plate, a rotating rod is arranged on the transverse plate in a penetrating mode, and a fixing mechanism used for enhancing the connection firmness between the device and the ground is arranged on the bottom plate. According to the device, the trend of continuous deformation of a tunnel can be weakened, top plates are tightly attached to the top of the tunnel, and positioning cones are inserted into the deep position of the ground, so that the connection firmness between the device and the ground is enhanced, and shaking is not prone to happen; the three top plates make contact with the arc-shaped surface of the top of the tunnel, and multiple first springs are compressed, so that the effect of tight attachment to the surface of the top is achieved, and the supporting effect of the device is improved; and in addition, excessive deformation stress of the tunnel can be properly removed through compression deformation of the device, so that the trend of continuous deformation of the tunnel is weakened, the primary support cannot be damaged due to the fact that the primary support bears large deformation stress, and the primary support of the tunnel is effectively protected.

Owner:KUNMING UNIV OF SCI & TECH

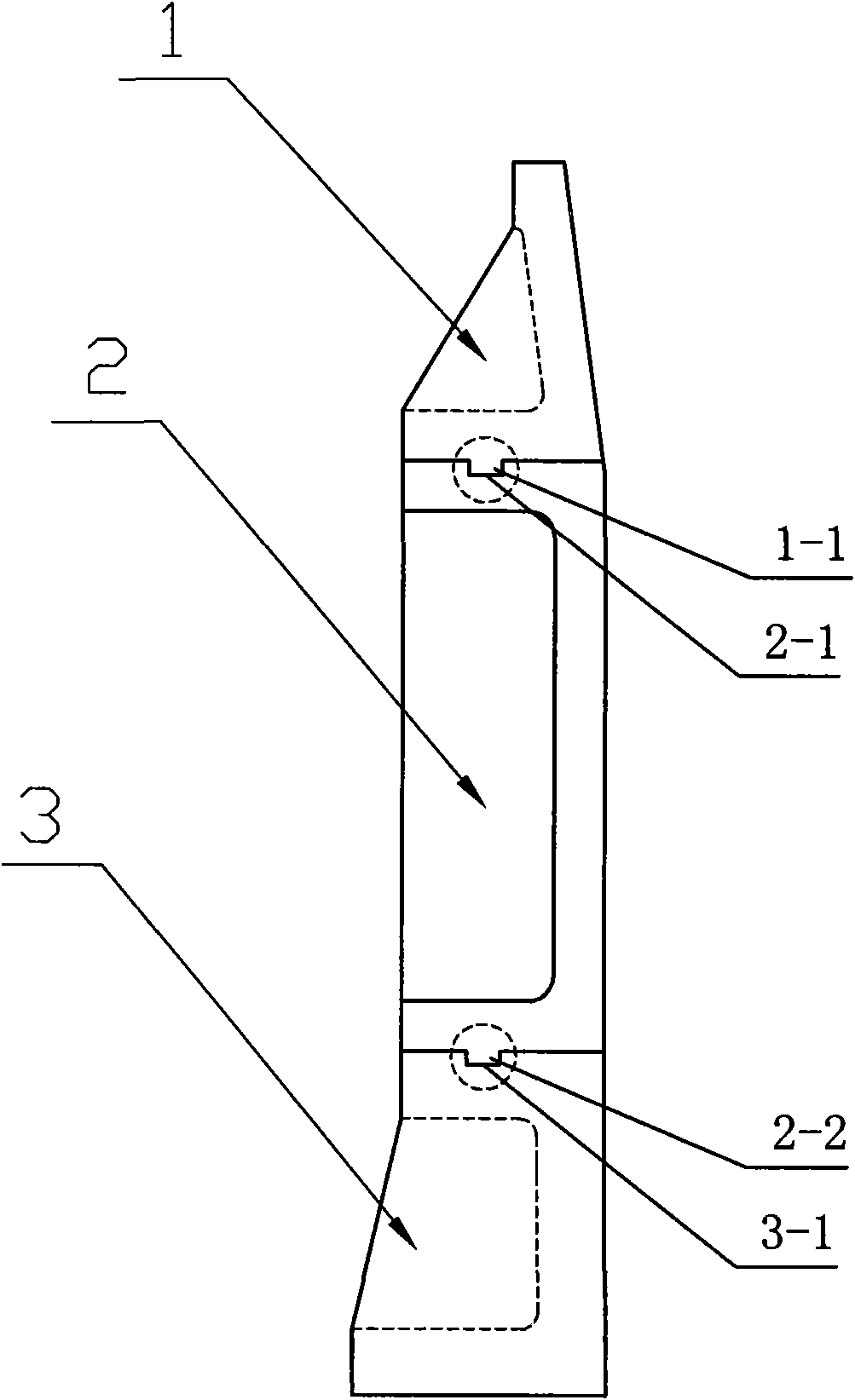

Nickel-based coating on surface of sucker rod and preparation method of nickel-based coating

InactiveCN108505036AShallow heating depthReduced deformation tendencyMetallic material coating processesWear coefficientHardness

The invention discloses a nickel-based coating on the surface of a sucker rod and a preparation method of the nickel-based coating. The nickel-based coating is mainly prepared from raw materials in aproper ratio, and one coating with high performance, wear resistance and corrosion resistance is obtained on the surface of the sucker rod with an induction cladding technology. The specific implementation method comprises following steps: (1), surface pretreatment of a base material; (2), preforming of the nickel-based coating; (3), drying treatment; (4), preparation of an induction cladding coating. The nickel-based coating forms good metallurgical bonding at a coating interface, and the coating structure is refined and overcomes defects of obvious cracks, gaps and the like. Microhardness from the base material to the coating is obviously improved, coating hardness value is about 5 times higher than that of the base material, wear extent and wear coefficient of the coating are far lowerthan those of the base material under the same condition, so that the service life of the sucker rod is substantially prolonged. Not only can high-performance coating be obtained, but also the methodhas the advantages of low production cost, high efficiency and environment-friendly production process and facilitates realization of industrialization.

Owner:SOUTHWEST PETROLEUM UNIV

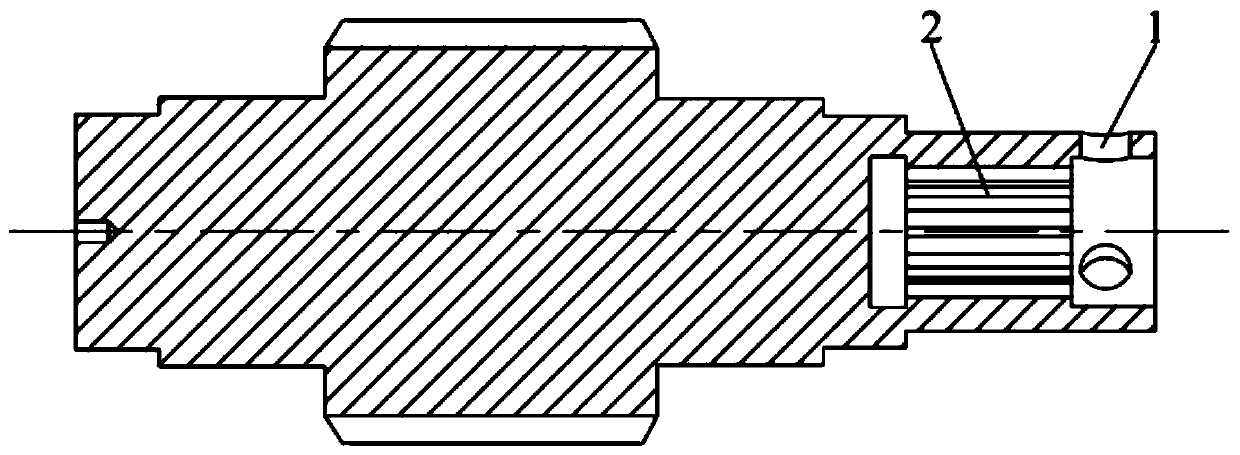

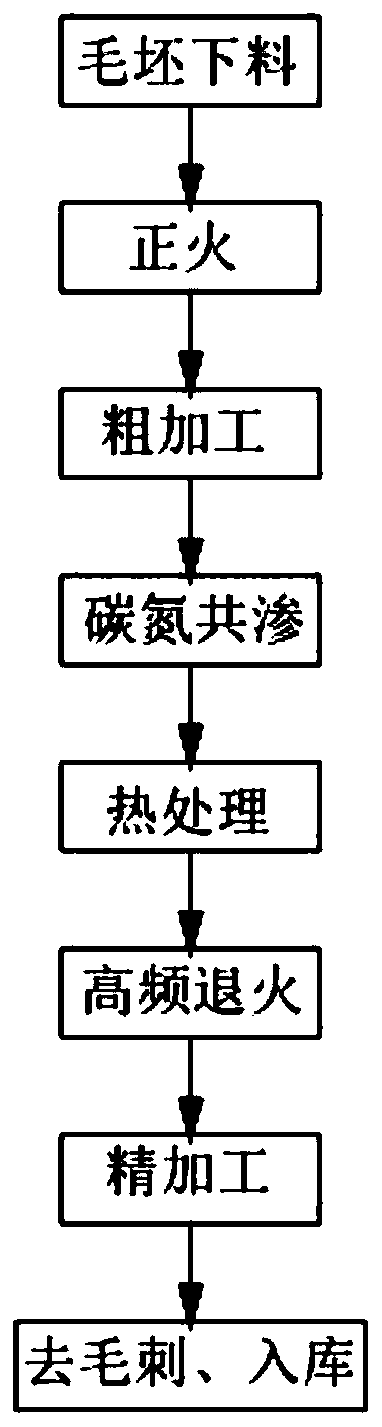

Speed reducer input shaft machining process

The invention discloses a speed reducer input shaft machining process, and belongs to the technical field of shaft machining. The speed reducer input shaft machining process comprises the steps of unloading, normalization, roughing, carbonitriding of the surfaces of blanks, heat treatment, high-frequency annealing of pin hole areas by using high-frequency equipment, finishing and warehousing; theroughing procedure is reasonably arranged; in carbonitriding, the blanks are strongly permeated by 4.5-5.5 h at 864-876 DEG C, and the dispersion time is 0.8-1.2 h. In the heat treatment, the quenching temperature is 846-857 DEG C, and the time is 0.45-0.53 h; the tempering temperature is 180-210 DEG C, and the time is 1.8-2.2 h; and the finishing comprises grinding of outer circles and grinding teeth of all shaft sections. Through reasonable arrangement of the machining process, the deformation of inner splines is reduced, and the hardness and the strength of the inner splines are improved.

Owner:昆山赫斯顿精密五金机械有限公司

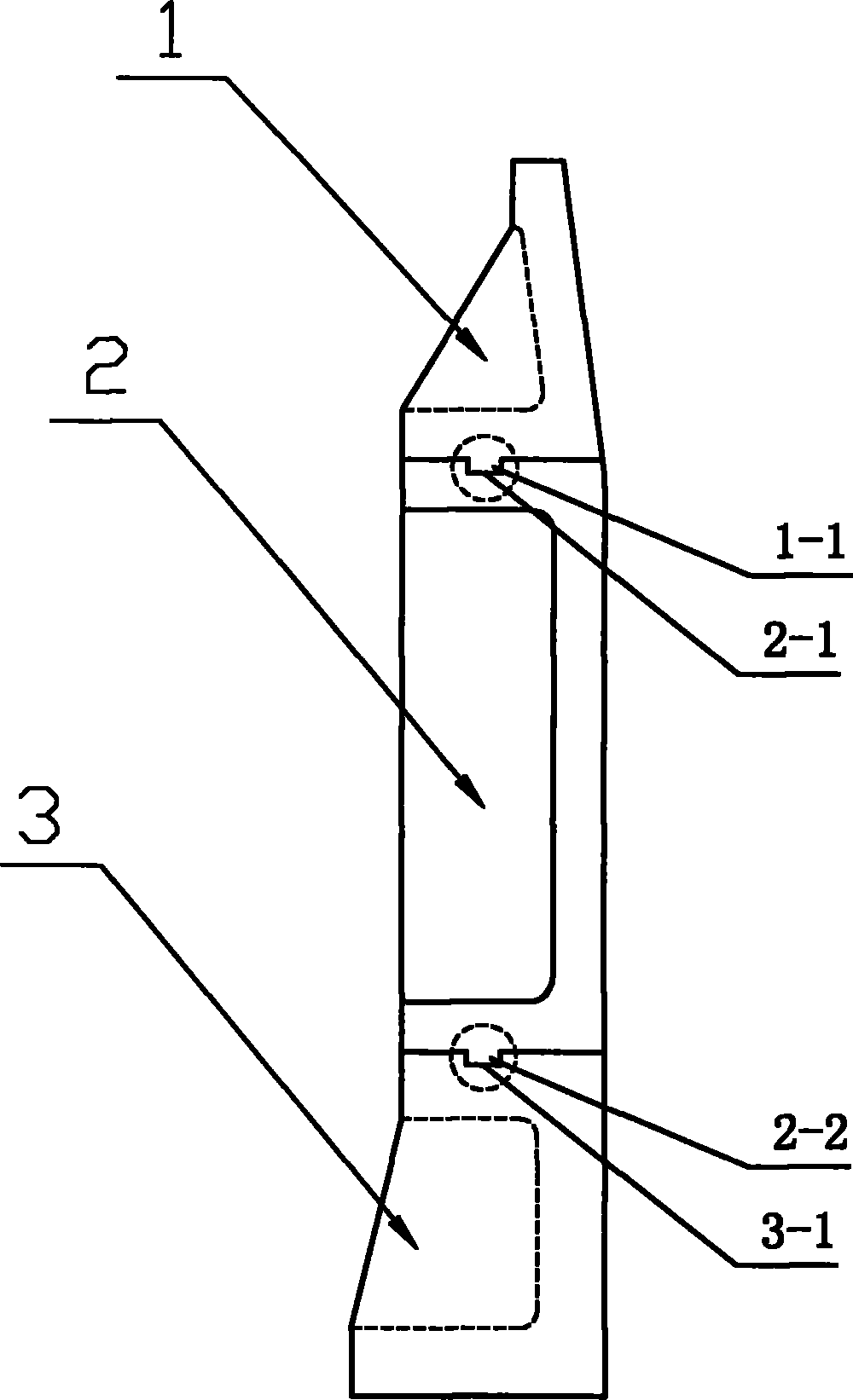

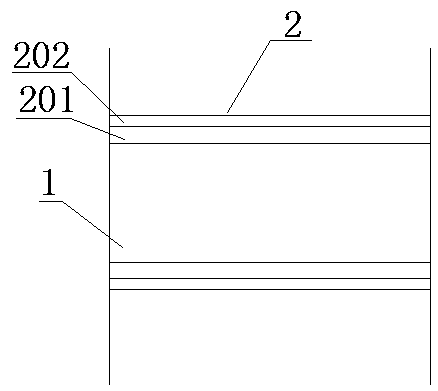

Sintering pallet side plate

The invention discloses a sintering pallet side plate, and relates to the technical field of sintering pallets in the metallurgy industry. The sintering pallet side plate comprises at least two side plates; and a lug boss and a groove mutually matched are arranged between two adjacent side plates. A pair of rabbets formed by the lug boss and the groove is arranged at opposite positions of the two connected side plates. Therefore, when the side plates are assembled, the rabbets have the positioning assistance function, and the assembly efficiency of workers is improved. In the using process, the rabbets limit the deformation direction of the side plates and reduce the deformation trend. Meanwhile, a planar joint face is changed into a curve joint face, so the air leak resistance is increased and the air leak quantity is reduced. Even if the side plates are slightly deformed, the material leak condition can be avoided due to the rabbets. Due to the novel side plate, the service life of the side plate is greatly prolonged, and the production efficiency is improved.

Owner:徐宏亮

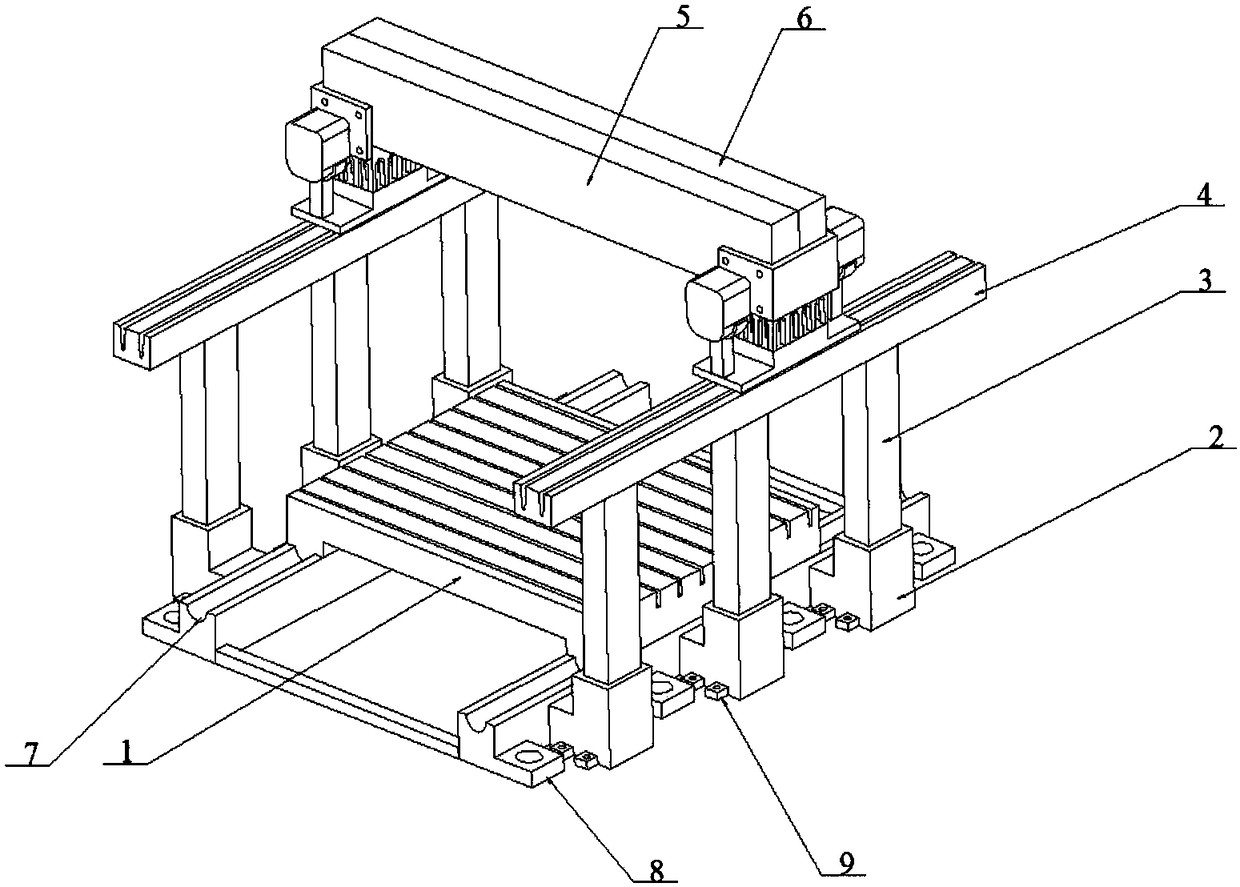

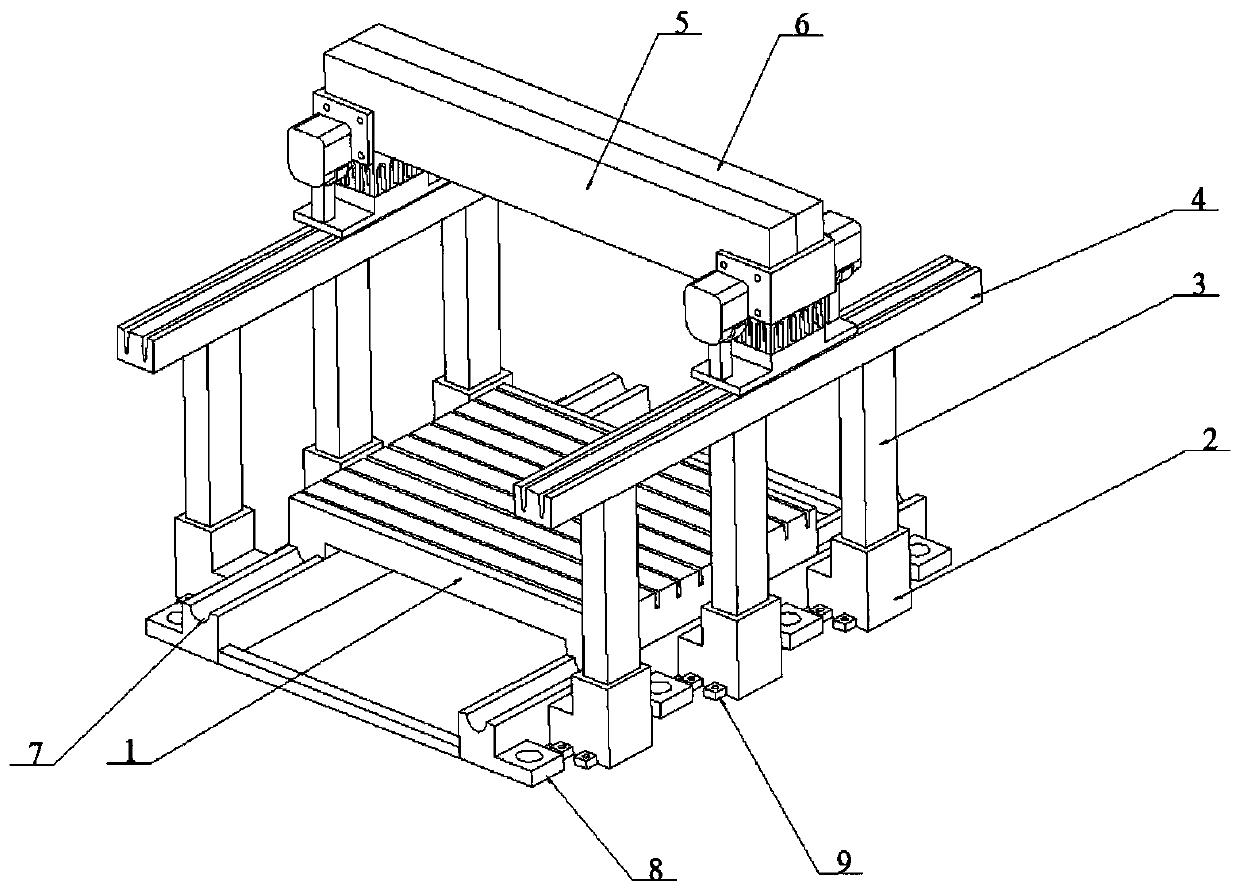

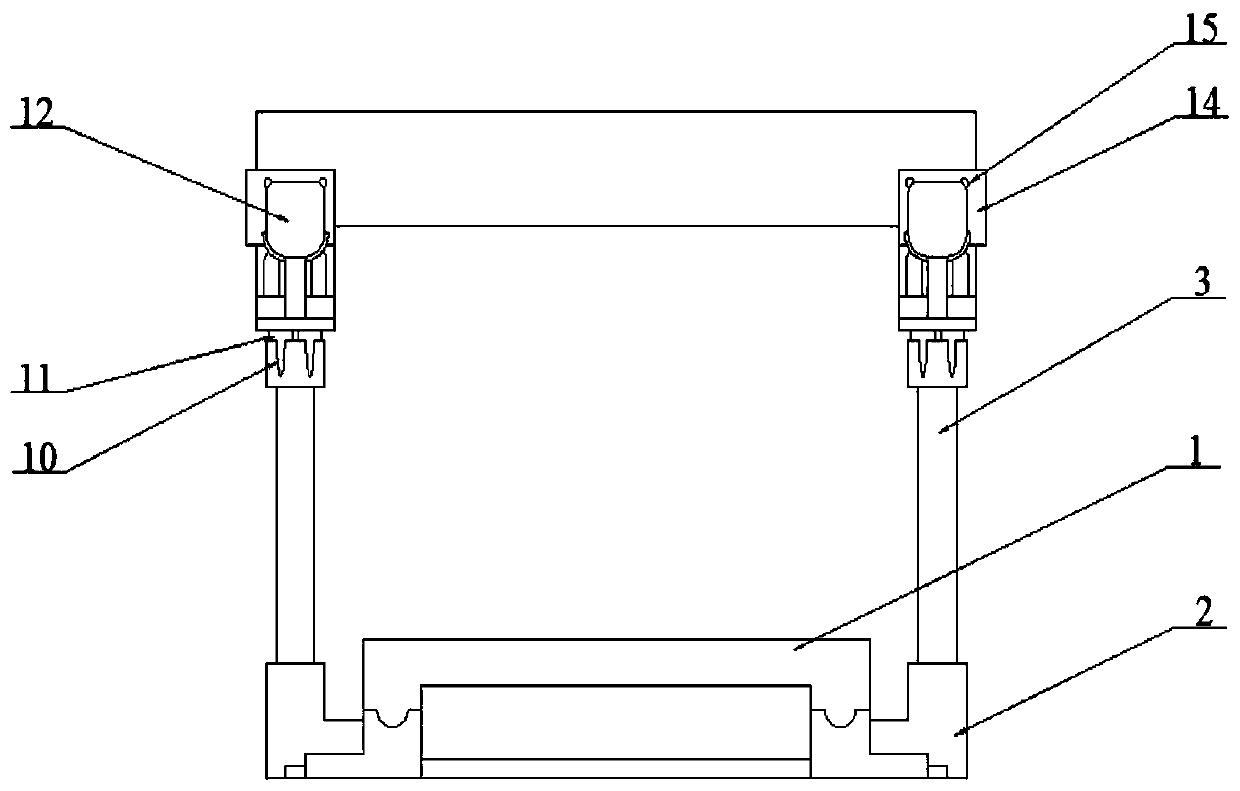

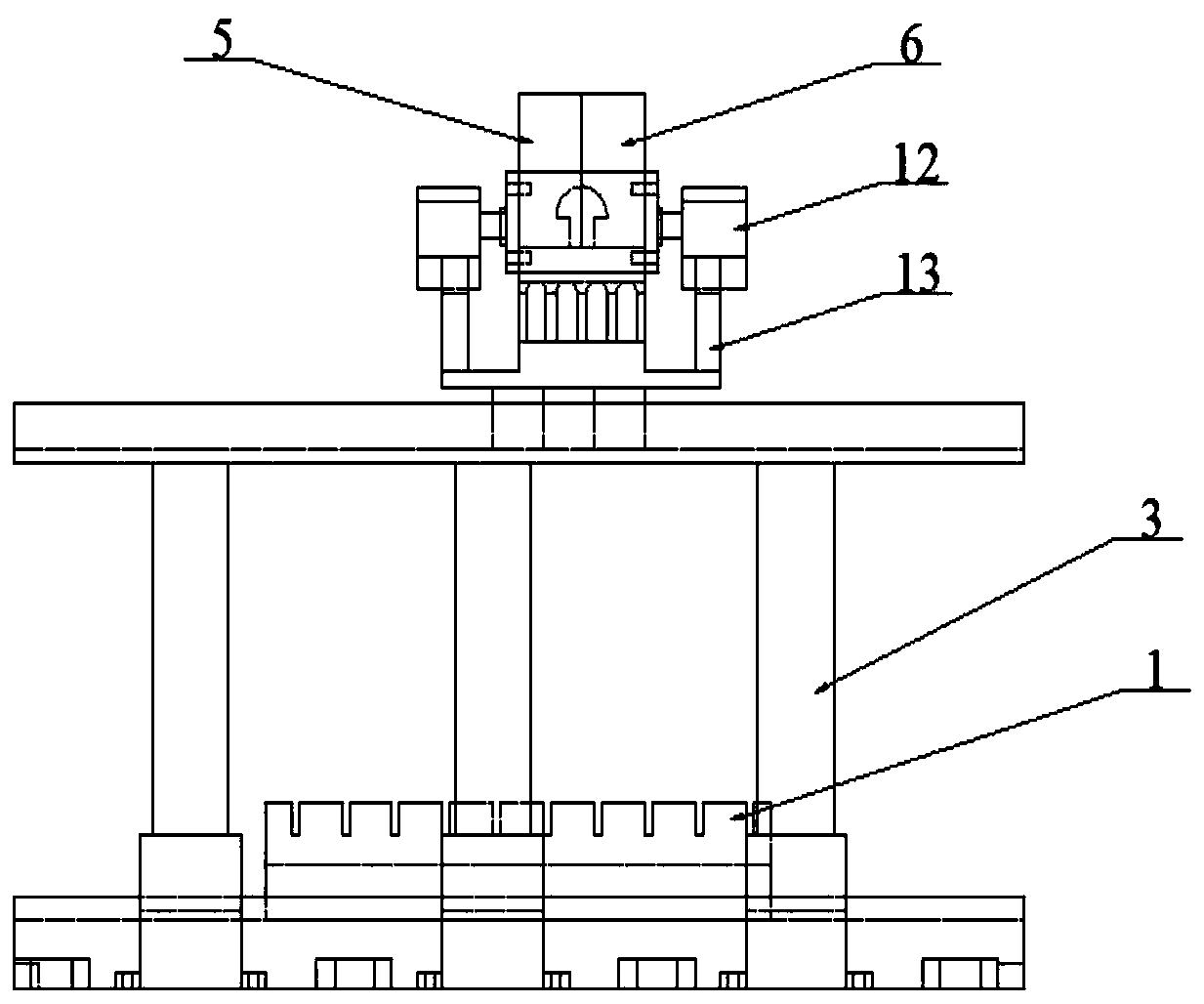

Movable cross beam locking device of gantry five-axis machine

The invention discloses a movable cross beam locking device of a gantry five-axis machine, which comprises a workbench, bases, uprights, second guide rails, a cross beam I, a cross beam II, first guide rails, slide grooves, slide blocks, hydraulic cylinders, brackets, locking platens, bolt holes I, support seats, connecting blocks, arched door posts, bolt holes II, anchor connecting structures, piston rods, inner grooves and bolt holes III. The device adopts the two independent cross beams; the inner grooves of the cross beams are matched with the anchor structures on the connecting blocks; the locking platens wrap the two ends of the cross beams; the hydraulic cylinders allows the piston rods to be propped against the side faces of the locking platen; the bolts are matched with the bolt holes, so that the movable cross beams and the connecting blocks form a whole; a machining precision error due to vibration in a moving process of the cross beams is avoided; at the same time, the arched door posts in the connecting blocks can bear and disperse more stress; and a deformation trend of the cross beams is reduced.

Owner:NOBOT INTELLIGENT EQUIP (SHANDONG) CO LTD

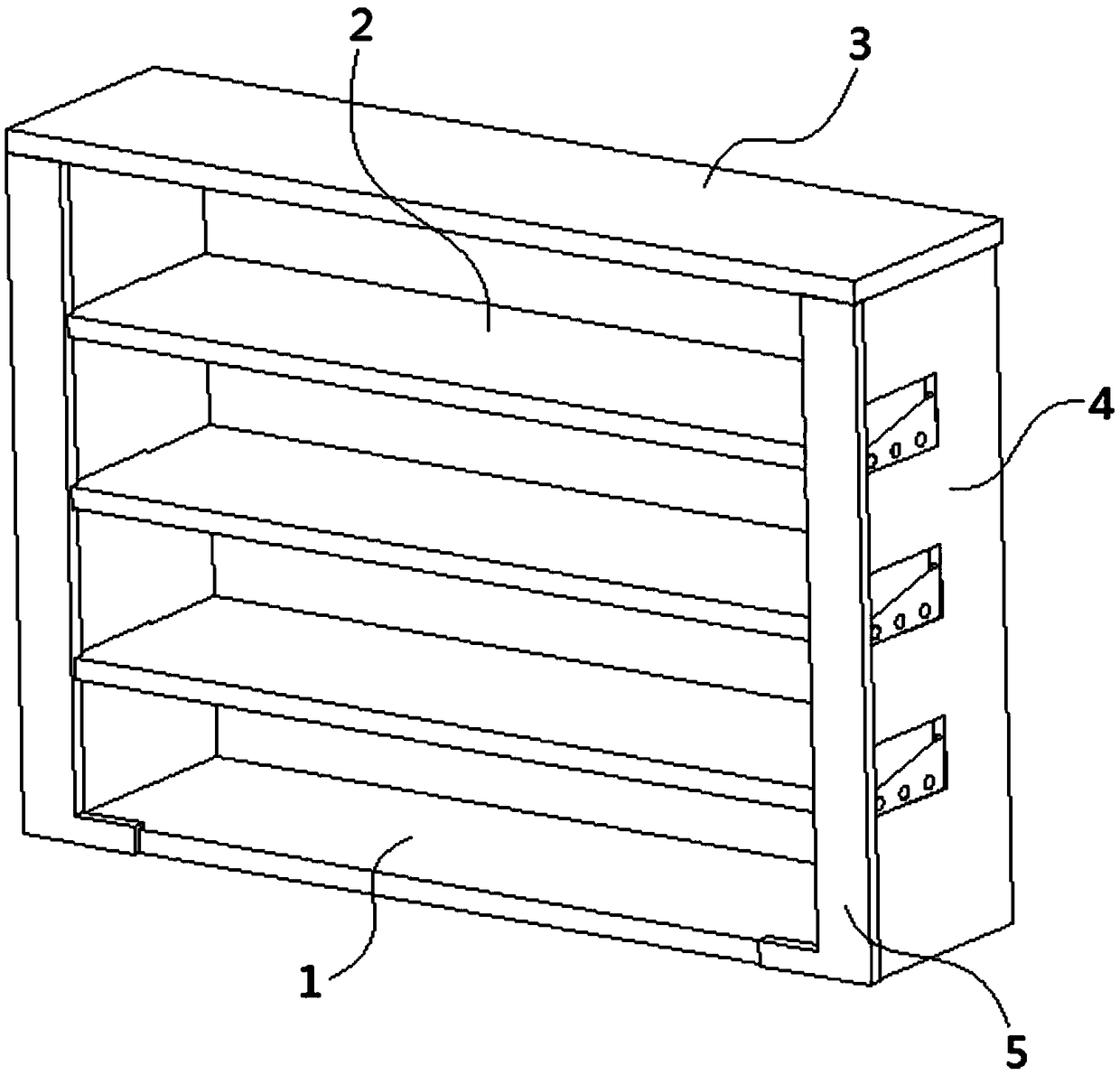

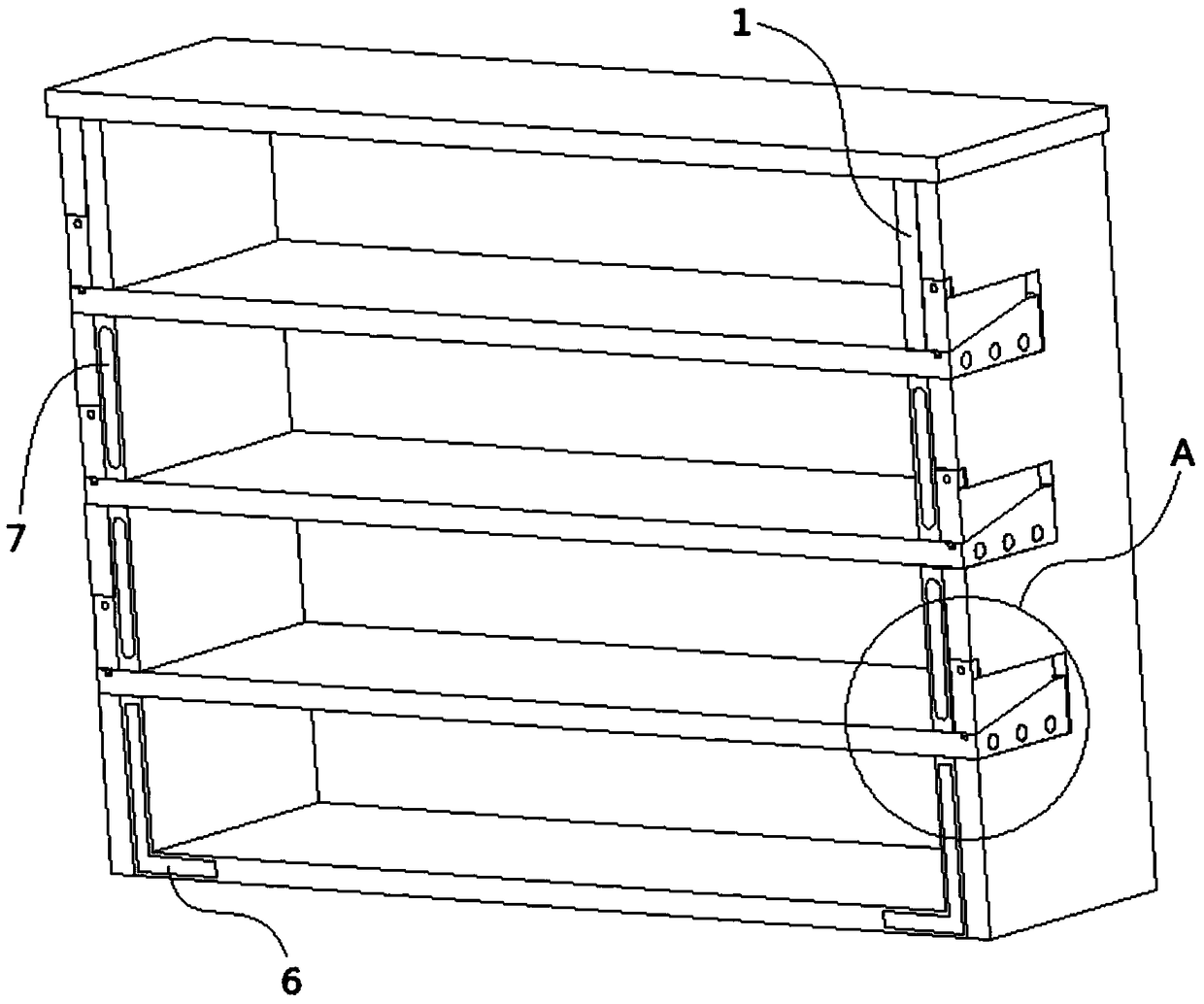

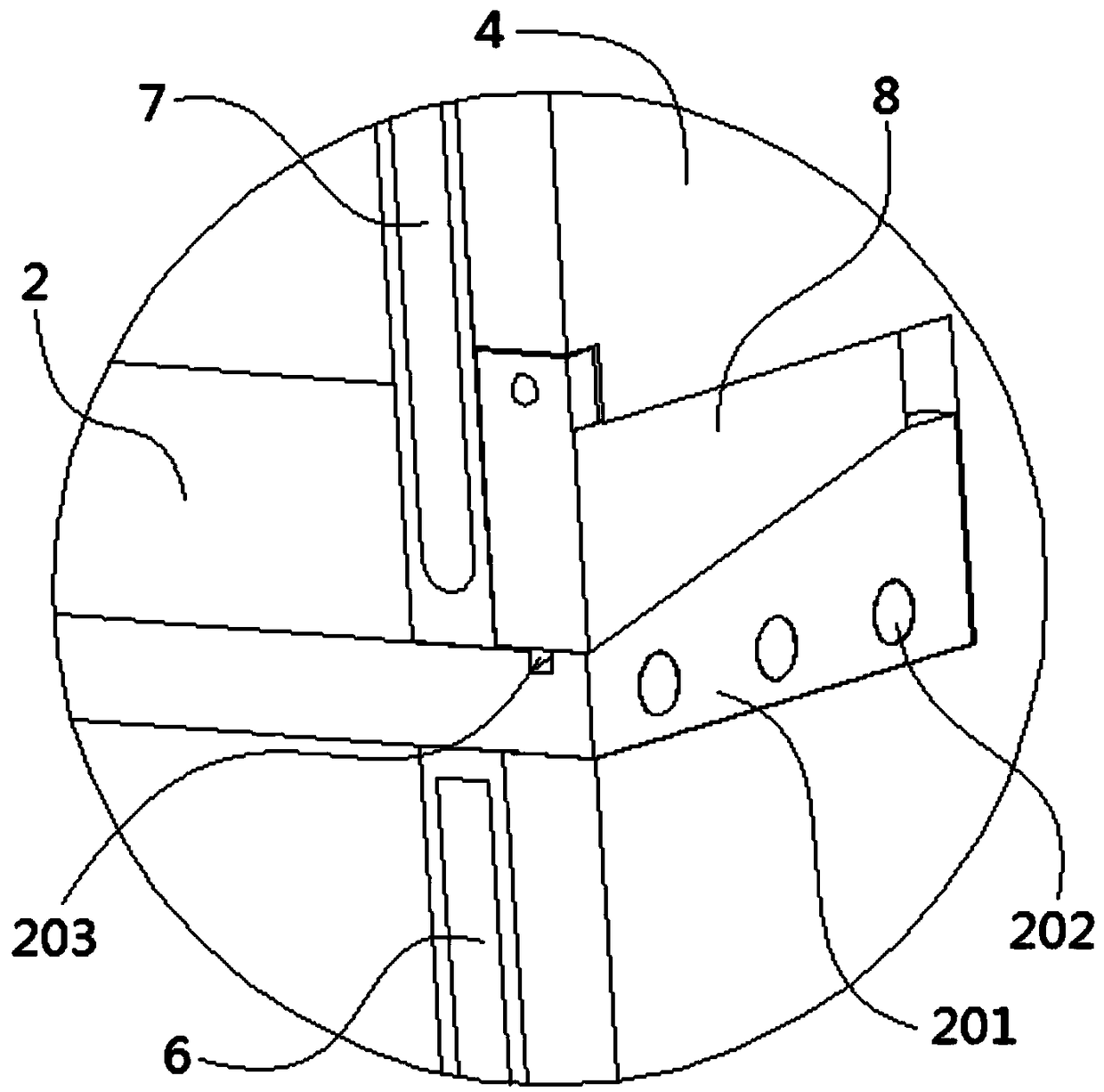

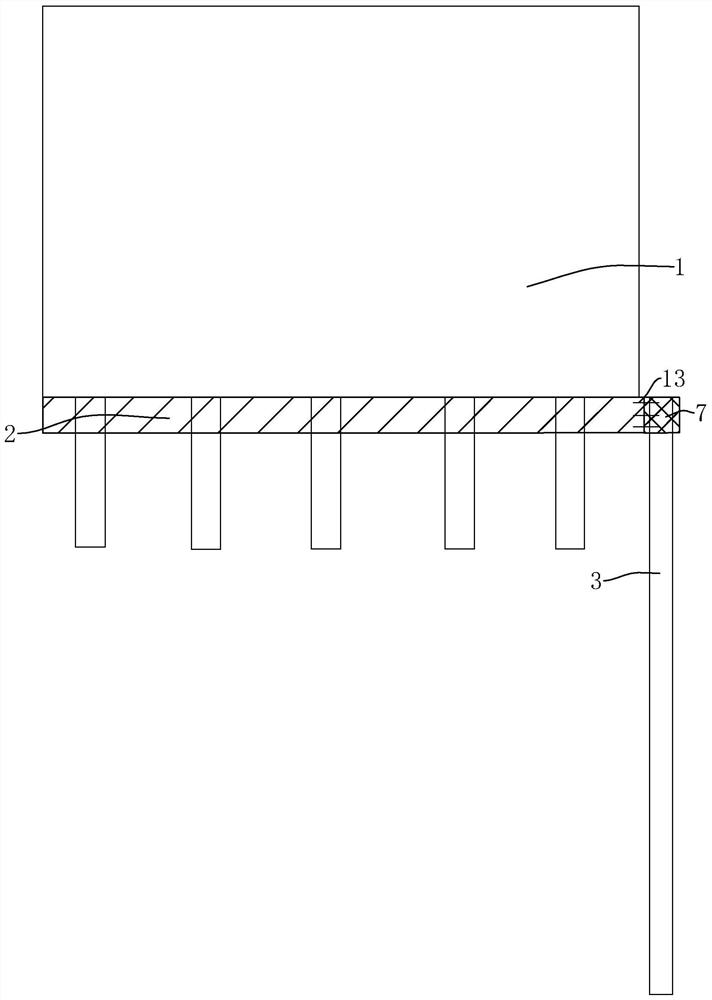

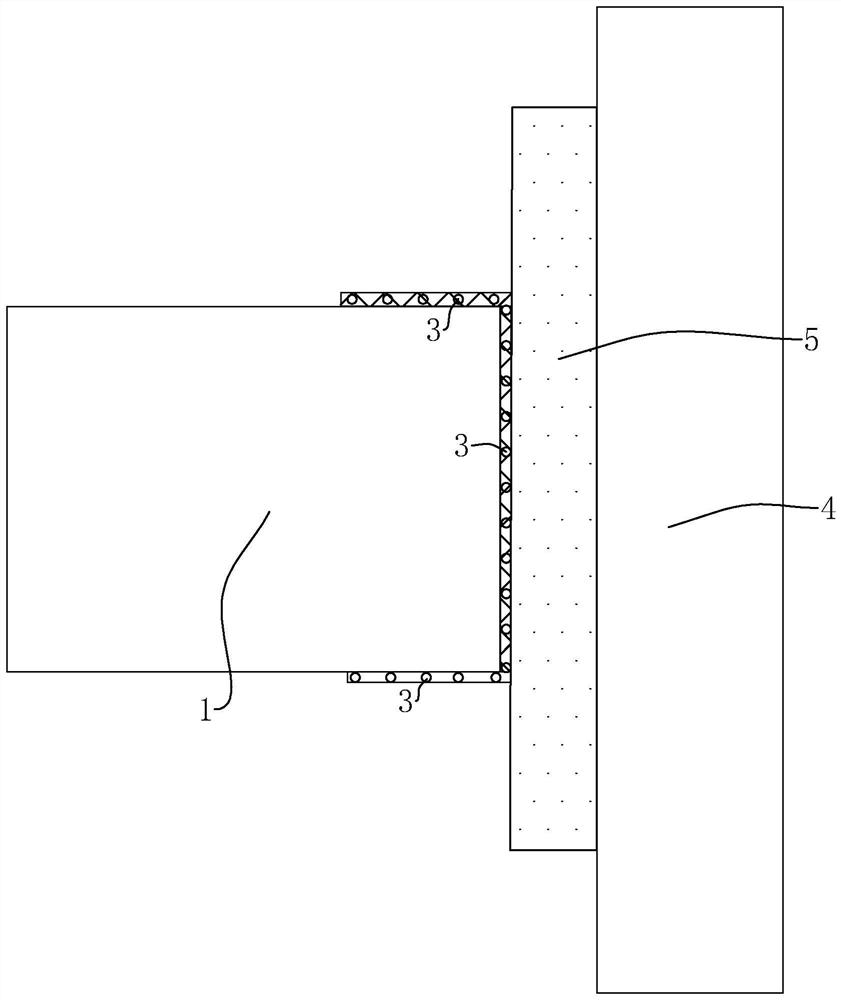

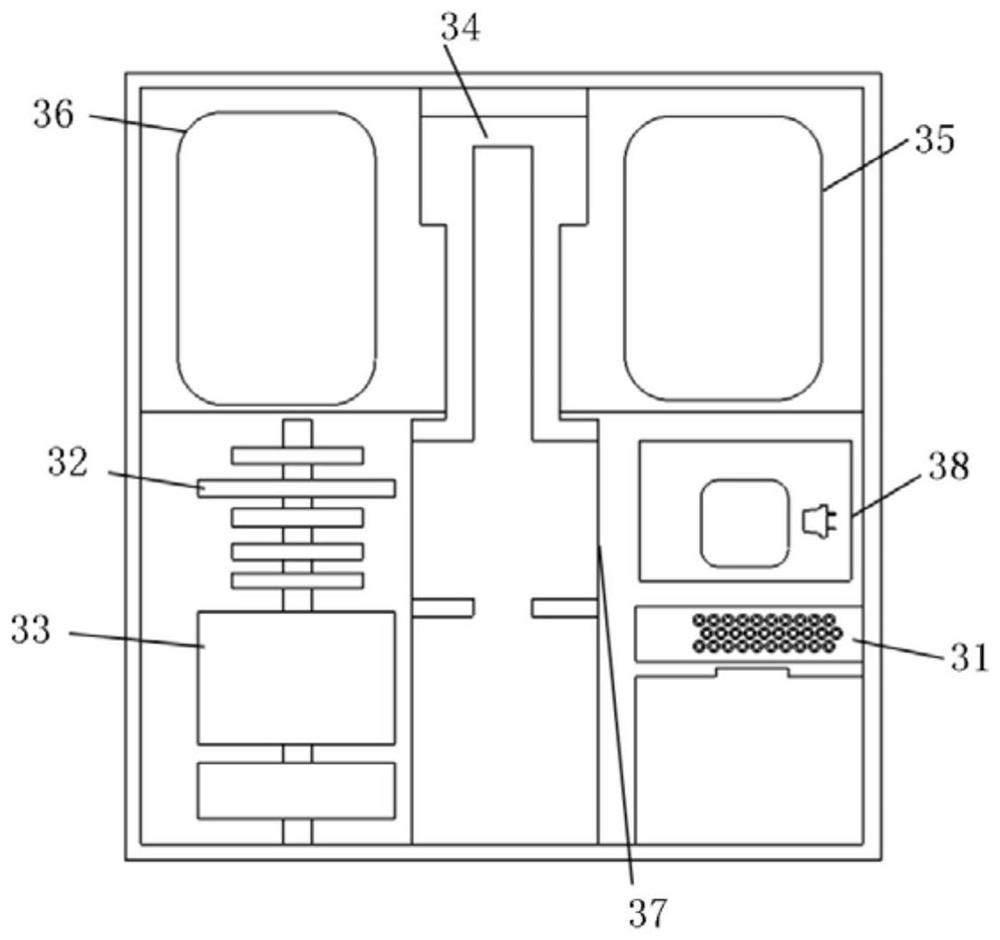

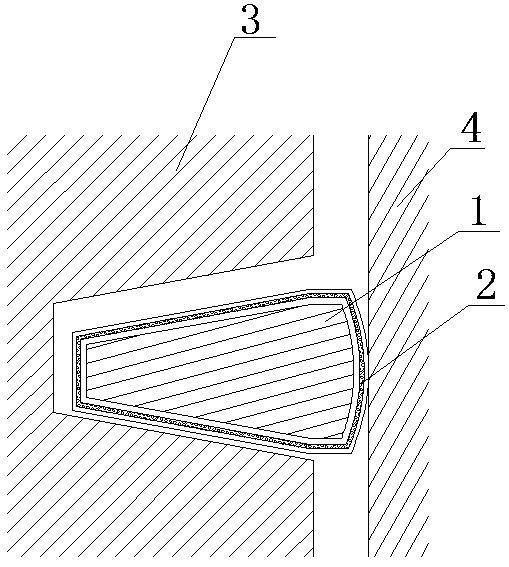

Building assembly embedded wall cabinet and assembly method thereof

InactiveCN108618423AReduced deformation tendencyIncreased durabilityCabinetsArchitectural engineering

The invention discloses a building assembly embedded wall cabinet and an assembly method thereof, and relates to the technical field of building assembly. The building assembly embedded wall cabinet comprises an inner frame and a detection device, a plurality of bearing plates are clamped on one surface of the inner frame, one surface of the inner frame is movably connected with a top plate, two sides of the inner frame are movably connected with side guard plates, a plurality of fastening edges are clamped on one side face of the inner frame and on one side face of each side guard plate, onesurface of the inner frame is connected with two angle blocks in a matched manner, two sides of the inner frame are connected with a plurality of supporting cores in a matched manner, one surface of each bearing plate is slidably connected with a squeezing block, one surface of each squeezing block is clamped with the corresponding side guard plate, a plurality of ribs penetrate the bearing plates, and anti-bending cores penetrate the two sides of the inner frame. Downward prestress is applied to two sides of each bearing plate by squeezing of the squeezing blocks and a supporting plate, so that the centers of the bearing plates have the trend of bending towards the top plate, part of the gravity of a placed article is offset, and the building assembly embedded wall cabinet has the advantage that durability of the wall cabinet is improved.

Owner:WENZHOU POLYTECHNIC

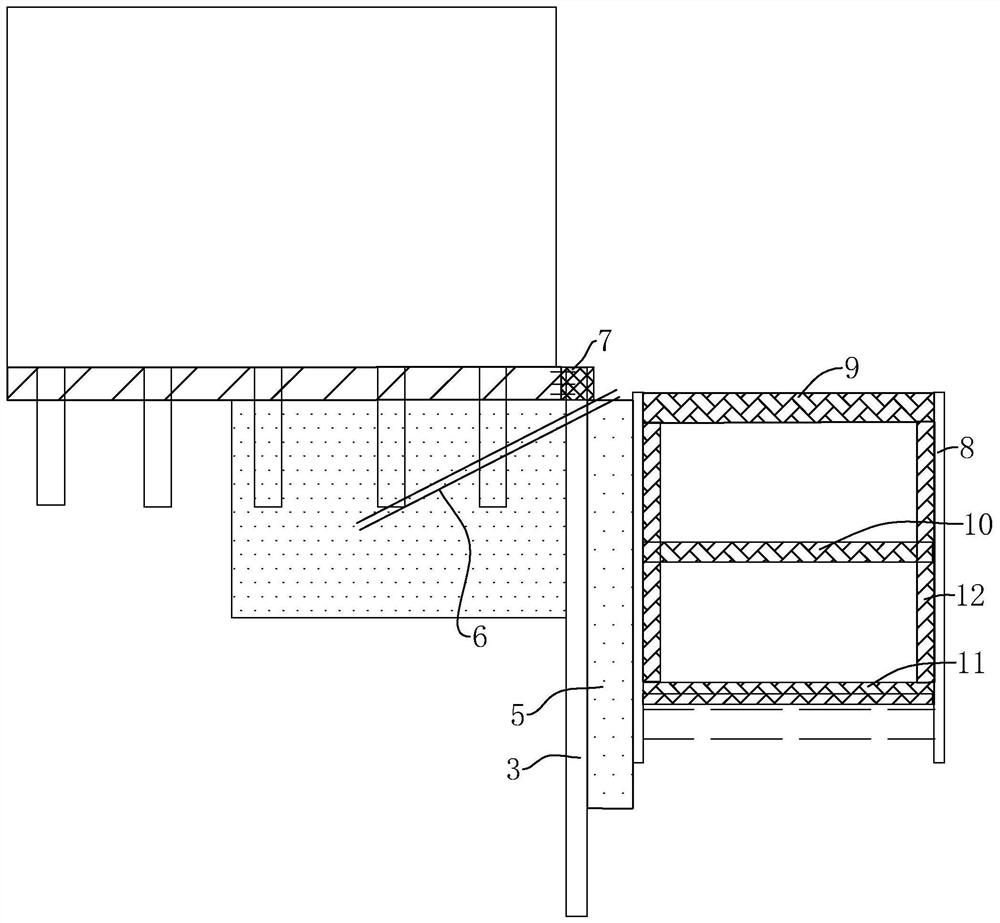

Shallow foundation building protection structure close to deep foundation pit engineering and construction method

PendingCN113431097AImprove stabilityGuaranteed stabilityProtective foundationSoil preservationArchitectural engineeringStructure support

The invention relates to a shallow foundation building protection structure close to deep foundation pit engineering and a construction method. The shallow foundation building protection structure close to the deep foundation pit engineering comprises deep pile foundations close to an original shallow foundation building, the upper ends of the multiple deep pile foundations are connected with a connecting beam, and the connecting beam is connected with a ring beam of the original shallow foundation building; and a soil body between the deep pile foundations and a newly-built deep foundation pit support structure is subjected to grouting reinforcement to form a grouting reinforcement layer, sleeve valve pipes are pre-buried at the bottom of the original shallow foundation building, and meanwhile the working procedure of backward mode first and forward mode second is adopted for deep foundation pit engineering construction. According to the shallow foundation building protection structure close to deep foundation pit engineering and the construction method, disturbance of deep foundation pit engineering to the adjacent original shallow foundation building is greatly reduced through an active and passive protection thought, and the effect of improving the stability of the original shallow foundation building is achieved.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

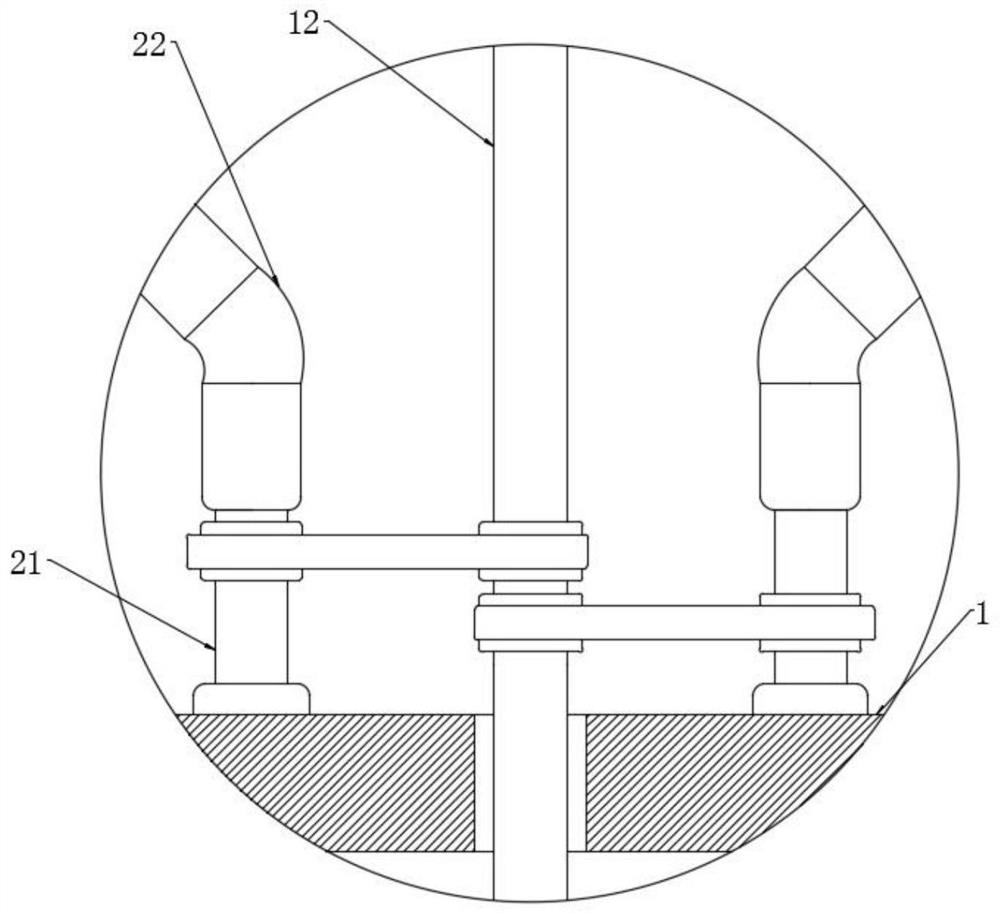

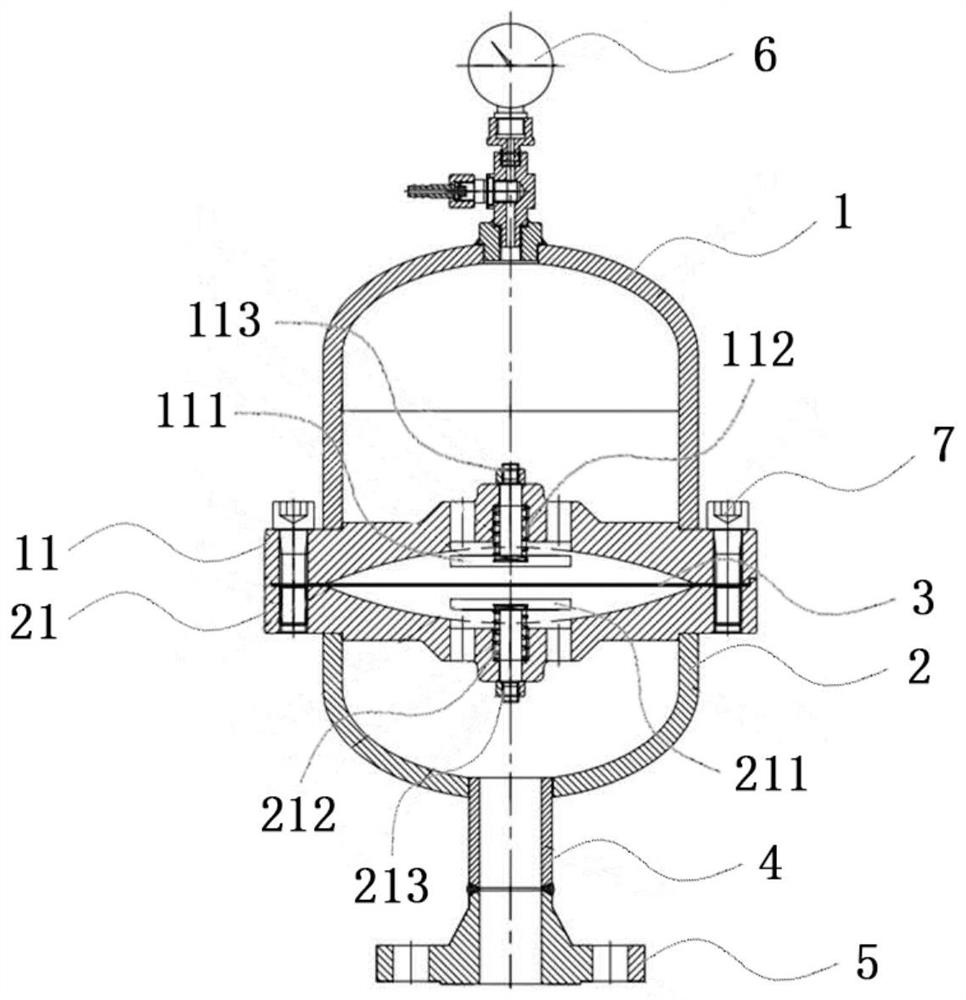

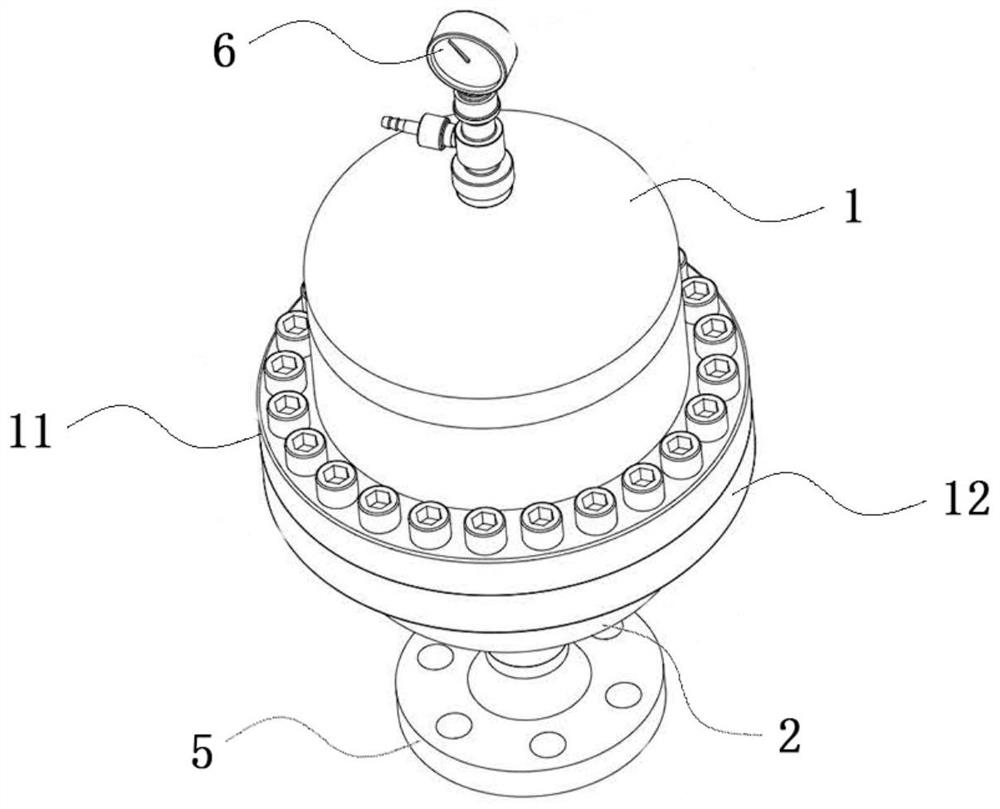

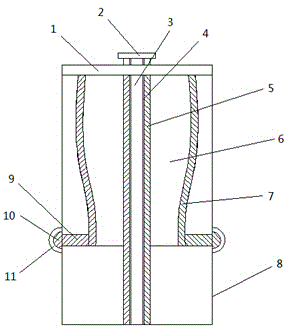

Diaphragm type pulsation damper with high pressure resistance

PendingCN114673857AReduced deformation tendencyReduce the chance of breakagePipe elementsEngineeringShock absorber

The invention relates to a diaphragm type pulsation damper with high pressure resistance, which comprises a first shell and a second shell, a first cavity is arranged in the first shell, a second cavity is arranged in the second shell, a diaphragm piece for isolating the first cavity from the second cavity is arranged between the first shell and the second shell, and the diaphragm piece is arranged in the first cavity and the second cavity. A first limiting block is arranged in the first shell and provided with a first through hole used for being communicated with the first cavity, the first limiting block is provided with a first film protection device, a first reset spring is arranged between the first limiting block and the first film protection device, and a second limiting block is arranged in the second shell and provided with a second reset spring. The second limiting block is provided with a second through hole used for being communicated with the second cavity, the second limiting block is provided with a second film protecting device, a second reset spring is arranged between the second limiting block and the second film protecting device, and the pulsation damper has the good high-pressure-resistant capacity.

Owner:DEPAMU HANGZHOU PUMP TECH

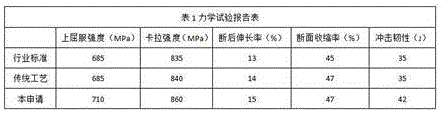

High-strength ZG40Mn2 material heat treatment method

The invention discloses a high-strength ZG40Mn2 material heat treatment method, and relates to the field of heat treatment. The high-strength ZG40Mn2 material heat treatment method comprises the following steps: 1, putting a ZG40Mn2 material in a vertical pit furnace for preheating to 670-710 DEG C, and carrying out heat preservation for 50-70 min; 2, reheating the material to 800-840 DEG C based on the step 1, and carrying out heat preservation for 70-90 min to obtain a primary ZG40Mn2 material; 3, putting the primary ZG40Mn2 material in a quenching liquid of which the oil temperature is 30-70 DEG C for quenching so as to obtain an intermediate ZG40Mn2 material; and 4, taking the intermediate ZG40Mn2 material out of the quenching liquid, putting the intermediate ZG40Mn2 material in the air for cooling, putting the intermediate ZG40Mn2 material which is cooled to room temperature in a bogie-hearth resistance furnace for heating to 530-590 DEG C, air-cooling to room temperature after carrying out heat preservation for 110-130 min, and carrying out high-temperature tempering to obtain the high-strength ZG40Mn2 material.

Owner:遵义金业机械铸造有限公司

Moon-based landing platform and construction method thereof

The invention relates to a moon-based landing platform and a construction method thereof, in particular to a platform used when a spacecraft lands on the moon and a construction method of the platform, and belongs to the technical field of deep space exploration of the moon. According to the invention, the microwave sintering molding of the multi-component simulated lunar soil material with small particles, light weight and large specific surface area in the aerospace field is realized, the molding precision and density requirements of a spacecraft landing platform are met, a technical basis is provided for subsequent lunar base construction and lasting operation, and good economic benefits and social benefits are achieved.

Owner:BEIJING SATELLITE MFG FACTORY

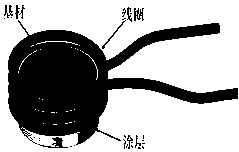

Electrophoretic deposition-microwave sintering combined processing method for nickel-chromium baked porcelain denture

ActiveCN106283156AUniform coatingImprove bindingElectrophoretic coatingsMetallic material coating processesNichromeMicrowave sintering

The invention discloses an electrophoretic deposition-microwave sintering combined processing method for a nickel-chromium baked porcelain denture. The method includes depositing a porcelain layer with a specific thickness on the surface of a nickel-chromium alloy by an electrophoretic deposition method and cladding the porcelain layer on the nickel-chromium alloy by means of microwave heating so as to obtain the nickel-chromium baked porcelain denture. The nickel-chromium baked porcelain denture prepared by the method is uniform in coating and good in bonding force, and accordingly the method can be widely applied to a nickel-chromium baked porcelain denture processing process.

Owner:CHINA UNIV OF MINING & TECH

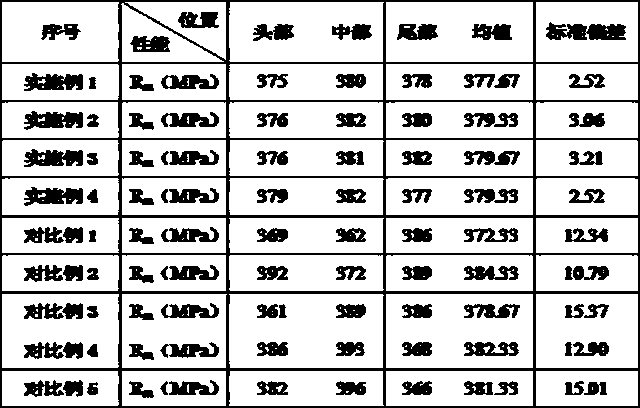

A kind of al-zn-mg alloy profile for rail transit car body and preparation method thereof

ActiveCN108251723BHigh tensile strengthImprove stress corrosion resistanceMetallic materialsToughness

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

Anisotropic rare-earth magnet light wave microwave sintering method

ActiveCN101882504BPlay a complementary roleFast heatingInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementProportional control

The invention relates to an anisotropic rare-earth magnet light wave microwave sintering method. Pressed and formed R-Fe-B (R is at least one of rare earth elements) series anisotropic rare-earth magnet green bodies after the completion of magnetic field orientation are placed in a light wave microwave oven, and the combination energy of light waves and microwaves are used for sintering. The frequency of microwaves is 500 MHz to 250 GHz, the atmosphere is vacuum or inert gas, the power of the light waves and the microwaves is proportionally controlled as required, and the sintering temperature is 980 DEG C to 1200 DEG C. The respective heating characteristics of the light waves and the microwaves are used, the heating speed is high, and the temperature gradient in the magnet green bodies is further reduced in sintering; the zero gradient even heating in a larger area in a sintered material can be realized, the grain growth inside the material is even and fine, and the magnetic performance of the finished product can be increased; meanwhile, the invention has the characteristics of low thermal stress, less cracking and deformation, energy saving, environment protection and the like.

Owner:上海京藤建设工程(集团)有限公司

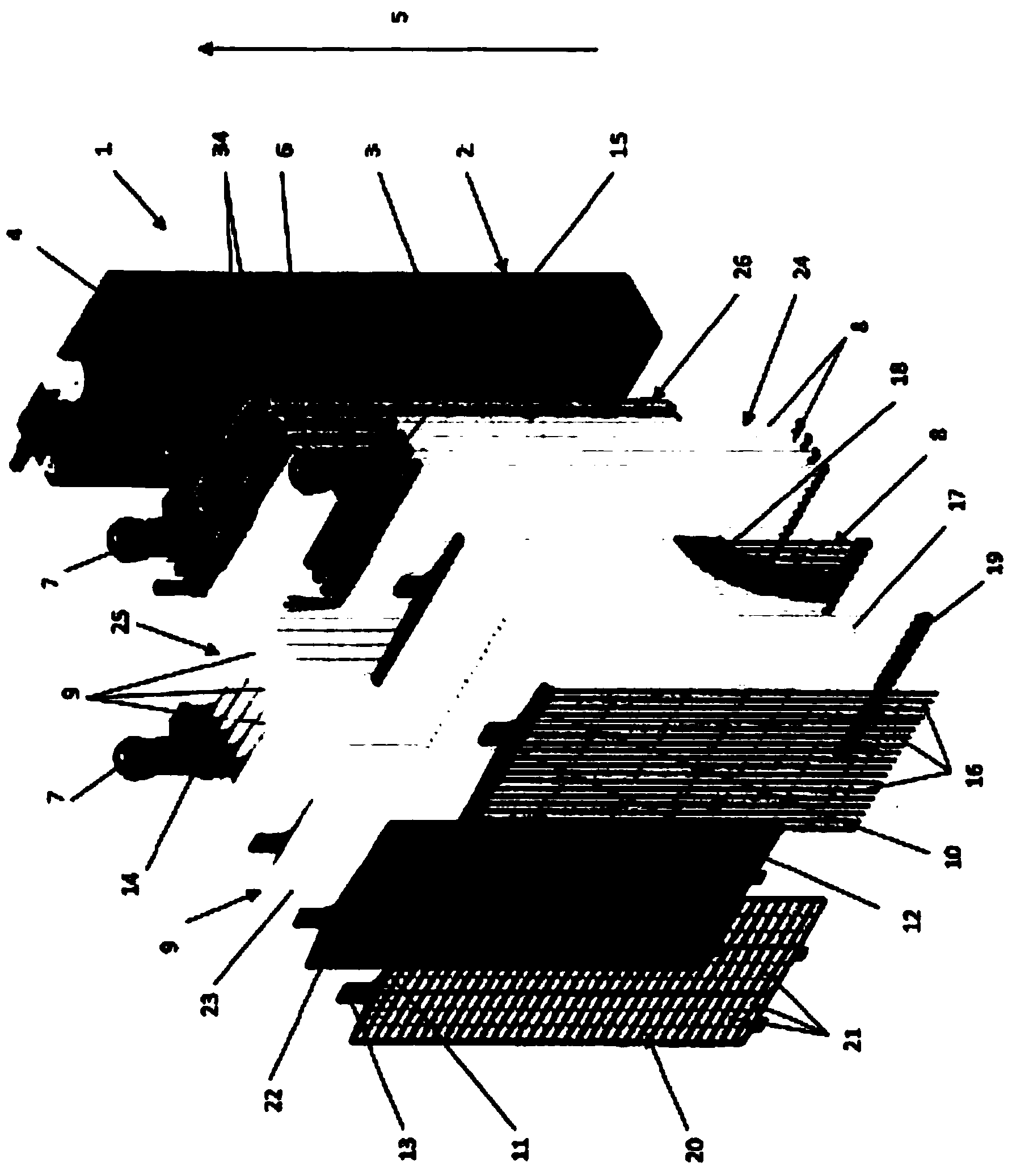

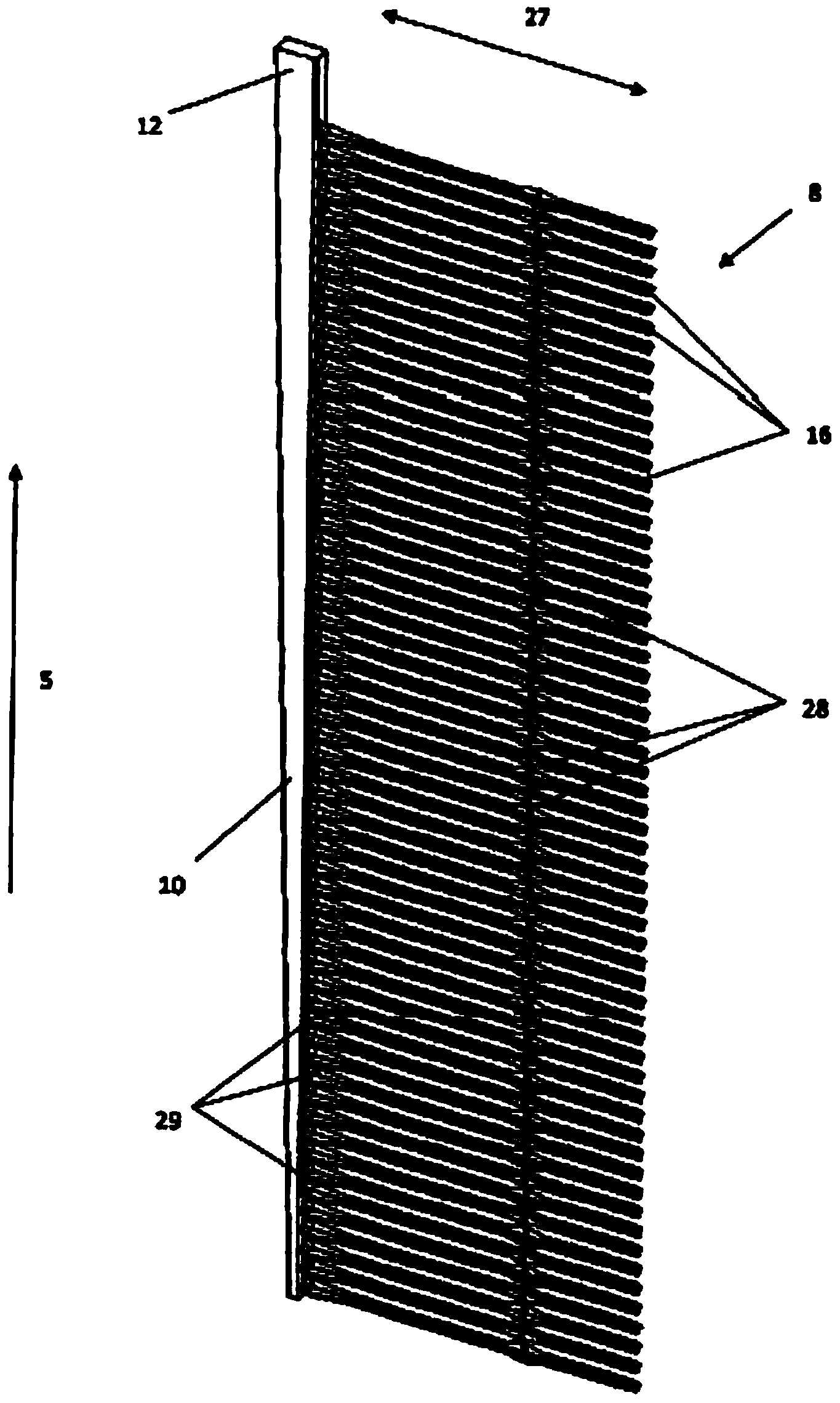

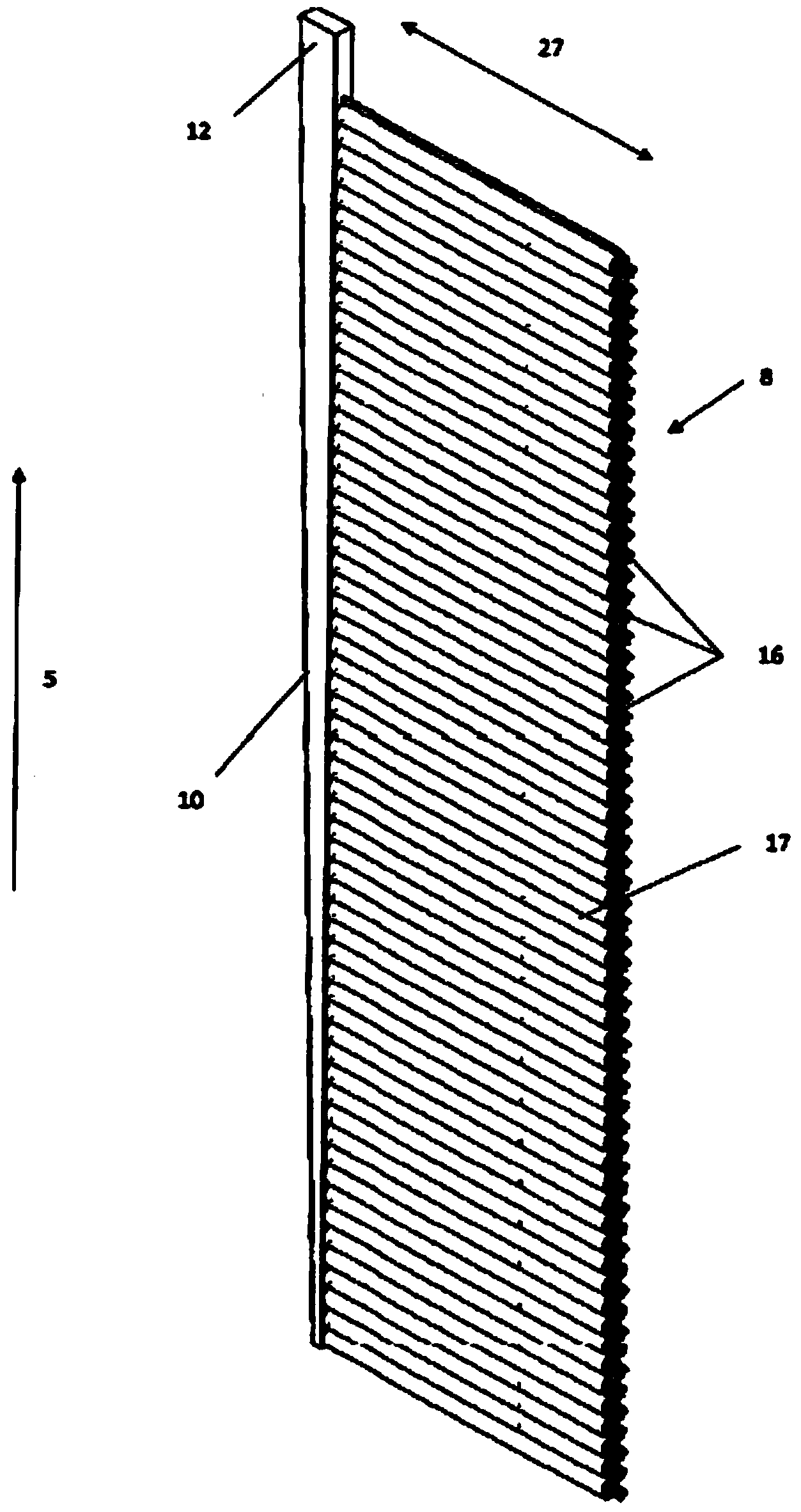

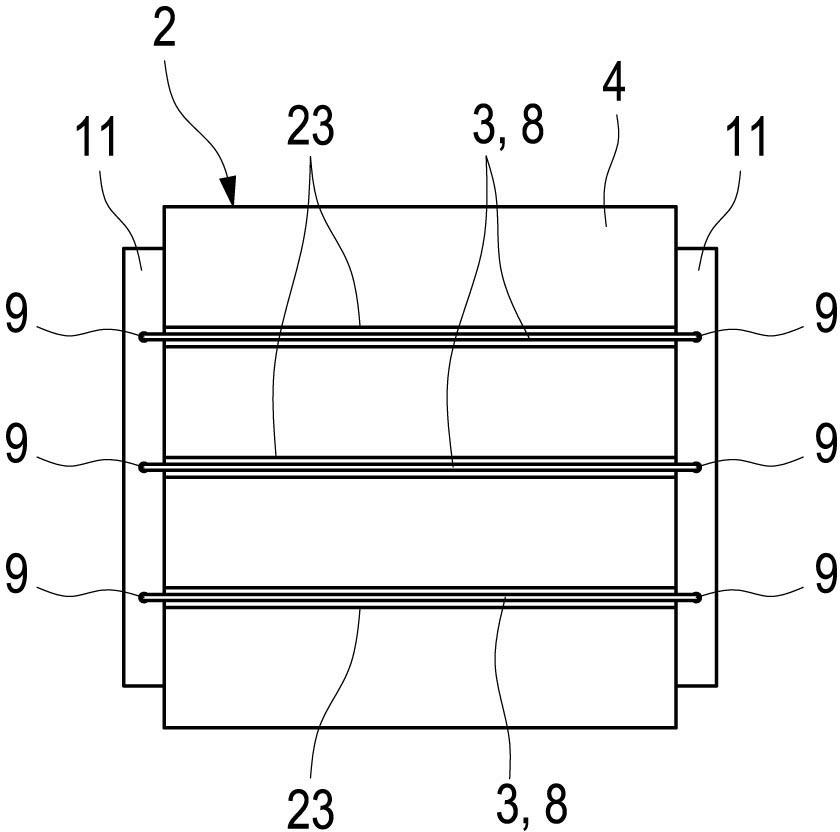

Storage battery, especially storage battery for traction

InactiveCN104409666ANovel structureReduce complexityFinal product manufactureElectrode carriers/collectorsEngineeringElectrical and Electronics engineering

The invention relates to a storage battery, especially a storage battery for traction. The battery comprises a storage battery housing. The upper side of the housing is provided with connection electrodes (6, 7) and provided with alternate negative and positive electrodes (8, 9) in connection with the connection electrodes (6, 7). Each positive electrode (8) is a tubular plate. Each tubular plate comprises an afflux strip (10) and a plurality of inner cores (16) parallelly extending from the afflux strip (10). The inner cores (16) are designed to transversely pass by, preferably vertical to, the height direction (5) of the storage battery housing (2).

Owner:霍普派克百特瑞恩有限公司

A moving beam locking device for a gantry five-axis machine

ActiveCN108526914BNo machining accuracy errorReduced deformation tendencyLarge fixed membersHydraulic cylinderMachine

The invention discloses a moving beam locking device for a gantry five-axis machine, which includes a workbench, a base, a column, a second guide rail, a beam I, a beam II, a first guide rail, a chute, a slider, a hydraulic cylinder, a bracket, Locking platen, bolt hole I, support seat, connecting block, arched door post, bolt hole II, anchor connection structure, piston rod, inner groove, bolt hole III; the present invention adopts two separate beams, through which The combination of the inner groove of the inner groove and the anchor structure on the connecting block, the locking pressure plate wraps the two ends of the beam together, the hydraulic cylinder presses the piston rod on the side of the locking pressure plate, and the cooperation between the bolt and the bolt hole makes the beam and the connection The blocks constitute a whole, which avoids machining accuracy errors due to vibration during the movement of the beam. At the same time, the arched pillars inside the connection block can withstand and disperse more stress, reducing the tendency of the beam to deform.

Owner:NOBOT INTELLIGENT EQUIP (SHANDONG) CO LTD

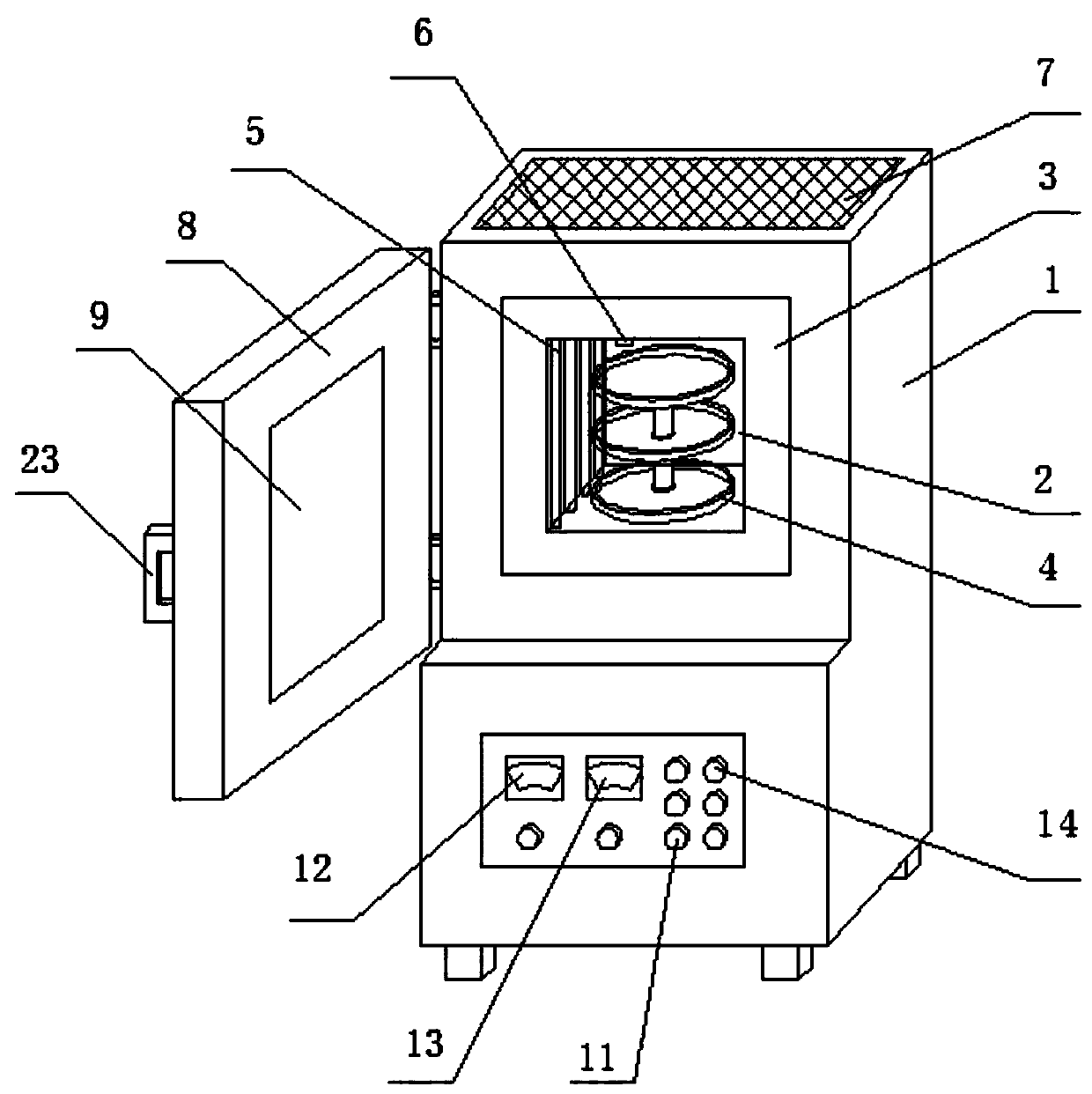

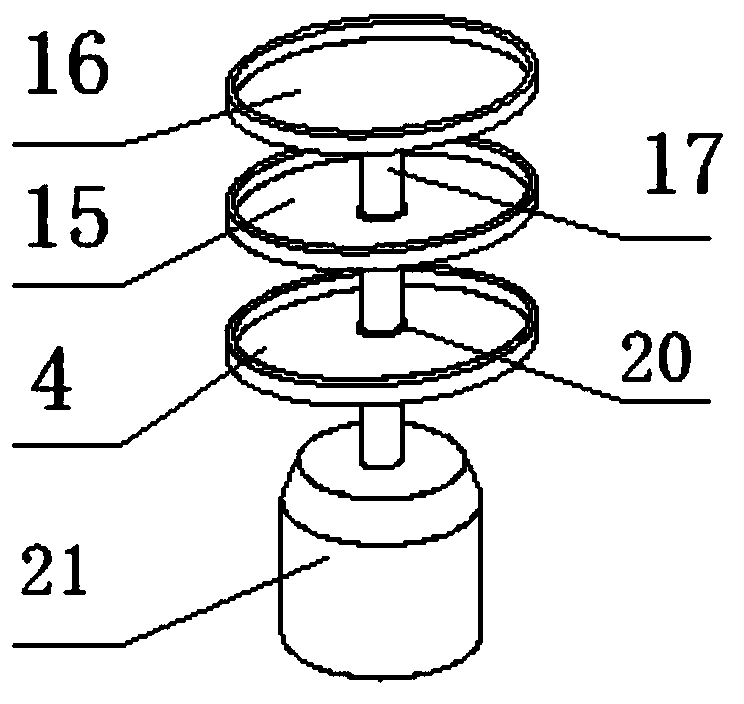

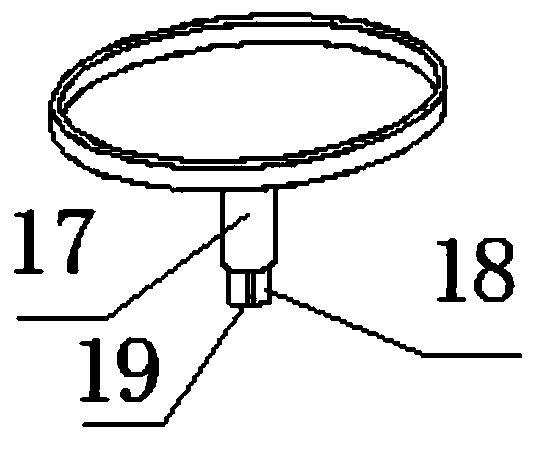

High-end material high-temperature sintering furnace

InactiveCN110375550AEasy to carryAvoid crackingCharge manipulationCharge treatment typeHot TemperatureSintering

The invention discloses a high-end material high-temperature sintering furnace. The high-end material high-temperature sintering furnace comprises a furnace body, wherein a high-temperature sinteringcabin is arranged inside the upper end of the furnace body; a gear motor is arranged inside the furnace body; the upper side of the gear motor is rotatably connected to a first placement tray througha rotating shaft; a second placement tray is inserted at the upper side of the first placement tray; a third placement tray is inserted at the upper side of the second placement tray; multiple magnetrons are arranged on the two side walls of the high-temperature sintering cabin; a cabin door is arranged at one side of the high-temperature sintering cabin through a hinge; and a control panel is arranged at one side of the lower part of the furnace body. The high-end material high-temperature sintering furnace can calcine lots of materials at a time at a high temperature through the arranged multiple placement trays and the up and down piling of the multiple placement trays; and the placement trays are driven to slowly rotate through the gear motor, so that the uniform sintering treatment isfacilitated, the material cracking caused by local high temperature is avoided, and the rate of finished products of the material high temperature sintering is increased.

Owner:TC KILNS

Electrophoretic deposition-microwave sintering combined machining method of titanium bonded porcelain layer

ActiveCN106835244AImprove the problem of decreased bonding strengthImprove uniformityElectrophoretic coatingsMetallic material coating processesElectrophoresisPollutant emissions

Disclosed is an electrophoretic deposition-microwave sintering combined machining method of a titanium bonded porcelain layer. The method comprises the steps that titanium powder and titanium bonded porcelain powder are mixed and ground to form composite titanium bonded porcelain powder, wherein the weight percentage of the titanium powder ranges from 2% to 20%, and the weight percentage of the titanium bonded porcelain powder ranges from 80% to 98%; a composite bonded porcelain layer with a certain thickness is formed on the surface of a dental pure titanium and titanium alloy substrate in a deposition mode through an electrophoretic deposition method; and then the porcelain layer is formed on the material surface of the dental pure titanium and titanium alloy substrate through fusion covering in a microwave heating mode, and therefore a dental titanium baked porcelain artificial tooth is formed. According to the electrophoretic deposition-microwave sintering combined machining method of the titanium bonded porcelain layer, operation is convenient, the technological process is easy to control, material liquid can be recycled, pollutant emission is avoided, the needed facilities are simple, the technological cost is low, and continuous production can be achieved.

Owner:CHINA UNIV OF MINING & TECH

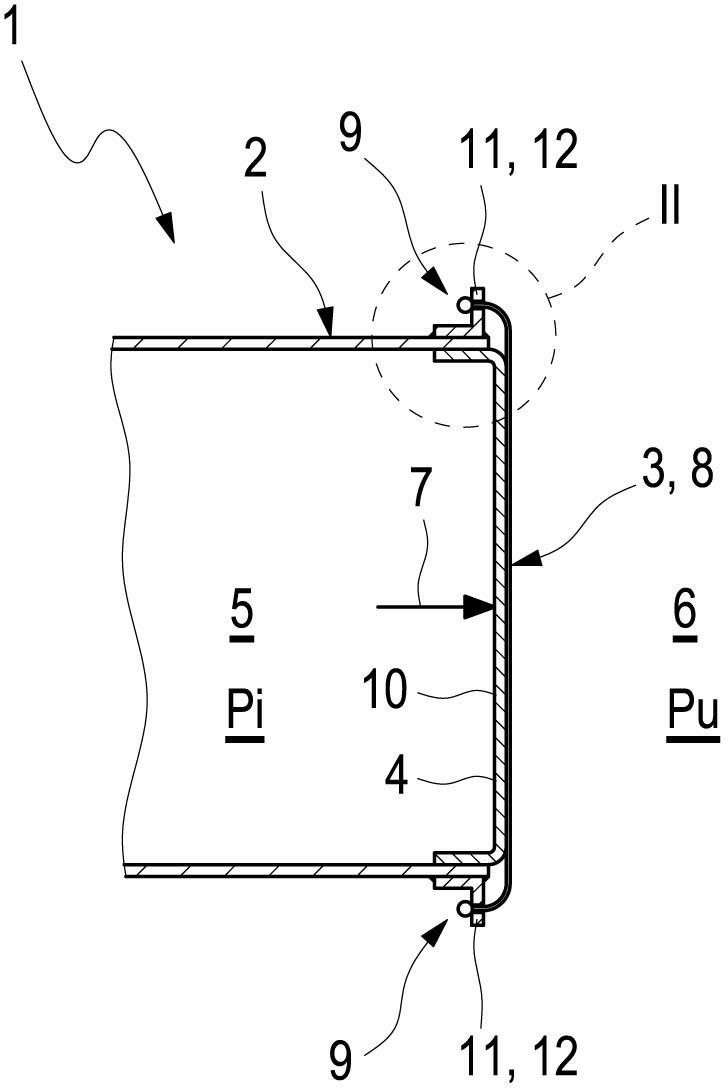

Exhaust system component

ActiveCN102678243AReduced deformation tendencyExhaust apparatusSilencing apparatusInternal pressureInterior space

The present invention relates to an exhaust system component (1) for an exhaust system of a combustion engine, in particular of a motor vehicle, with a housing (2) having at least one housing wall (4), which separates an interior space (5) of the housing (2) exposed to an internal pressure (Pi) during the operation of the exhaust system from a surroundings (6) surrounding the housing (2) and having an ambient pressure (Pu). In order to improve the durability of the component (1) even with small wall thicknesses, at least one stiffening element (3) can be provided, which is fastened to and arranged on the housing (2) such that it counteracts an internal pressure (Pi) that is above the ambient pressure (Pu) induced by the deformation of the housing wall (4).

Owner:EBERSPACHER EXHAUST TECH GMBH & CO

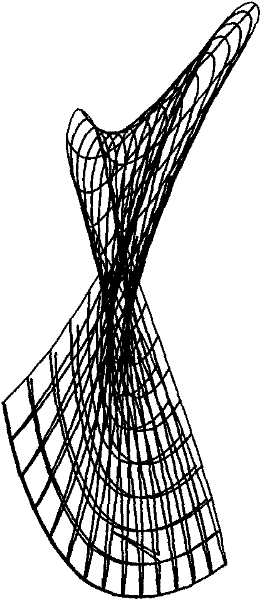

Anti-deformation method for casting vane of ultra-large mixed flow type water turbine

ActiveCN101716653BUnique process methodReduced deformation tendencyFoundry mouldsFoundry coresMixed flowWater turbine

The invention relates to an anti-deformation casting method, in particular to an anti-deformation method for casting a vane of an ultra-large mixed flow type water turbine, which comprises the steps of mould manufacturing, molding, mould assembling, pouring, sand falling, cleaning and heat treatment. The method is characterized in that: the manufactured mould adopts a steel-wood mesh-shaped frameas aggregate which is filled with resin; a support is manufactured according to a molded line; a three-box T-type assembling, real pattern molding, flat building and vertical casting, combined sand boxes and resin self-hardening sand are adopted; facing sand adopts chromite sand; the inside of the molding sand is provided with a framework of steel reinforcement; the heat treatment adopts a vertical type charging method and uses a U-shaped supporting frock; and a dead head is cut and provided with a leveled dead head neck; the direction of the dead head neck is downward for supporting the vane; and two sides of the dead head neck are provided with a clamp for ensuring the vertical direction of the vane. The process method is unique, reduces the machining amount, reduces the ratio of gross and weight, shortens production period, reduces the cost, and solves the problems of deformation in vane production and manufacturing, and fat head and big ears caused by overlarge vane machining amount.

Owner:KOCEL EQUIP

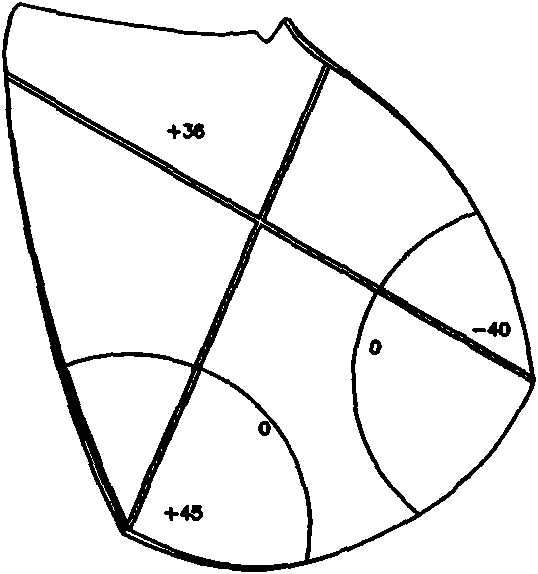

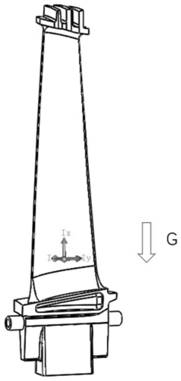

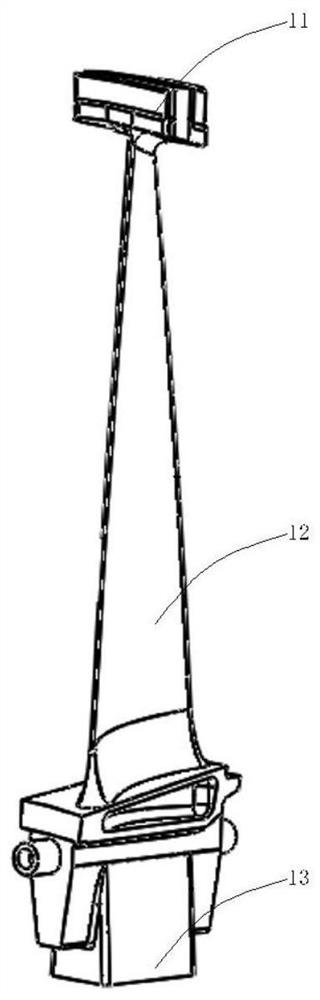

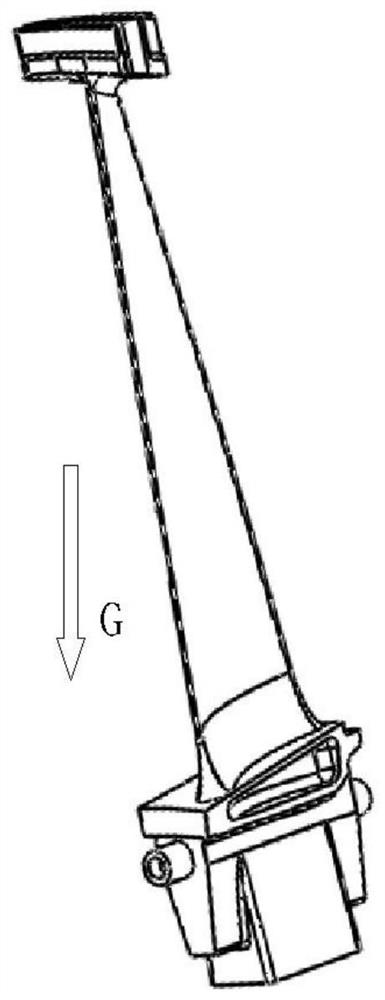

Tool and method for reducing hot isostatic pressing deformation of investment casting turbine blade

ActiveCN113798478ASimple structureEasy to useHydro energy generationPressesInvestment castingTurbine blade

The invention discloses a method for reducing hot isostatic pressing deformation of an investment casting turbine blade. The method comprises the following step a of finding the gravity center of the turbine blade by utilizing three-dimensional cartographic software, and adjusting the posture so that the inertia principal axis direction of the turbine blade is parallel with the gravity direction; the step b of designing a tool, so that the shape of a blade root containing cavity is matched with the blade root of the turbine blade adjusted in the step a; and the step c of putting the turbine blade into the tool for hot isostatic pressing, so that the inertia principal axis direction of the turbine blade is always kept parallel with the gravity direction in the hot isostatic pressing process. The invention further provides a tool for reducing the hot isostatic pressing deformation of the investment casting turbine blade, and the tool comprises a tool base which is horizontally arranged, and the tool base is provided with the blade root containing cavity. The shape of the blade root containing cavity is matched with the shape of the blade root when the inertia principal axis direction is parallel with the gravity direction of the turbine blade. By adopting the tool and method for reducing the hot isostatic pressing deformation of the investment casting turbine blade, the deformation risk of the turbine blade is reduced, and the consistency of casting dimensions is improved.

Owner:DONGFANG TURBINE CO LTD

Engine piston ring containing carbon fiber composite layer

ActiveCN106246400BExtended duty cycleExtended reaction timePiston ringsMachines/enginesWork periodShape change

The invention discloses an engine piston ring containing a carbon fiber composite layer. The engine piston ring comprises a piston ring body, the piston ring body is wrapped with the carbon fiber composite layer, the carbon fiber composite layer comprises a porous metal layer and a carbon fiber layer, the carbon fiber composite layer is in seamless connection with the piston ring in an extrusion manner, and the surface of the porous metal layer does not make contact with an air cylinder; the carbon fiber composite layer is tightly combined with the piston ring body, the serial problems of uneven loads and uneven heat generated by abnormal work of an engine can be solved, the reaction time of the piston ring for heat and load different motion changes is prolonged, heat stress and shape change tendency is reduced, pressure stabilizing and heat stabilizing effects re achieved, and the work period of the piston ring is finally prolonged; the carbon fiber layer has the beneficial effects of being high in strength, high in modulus and the like, the carbon fiber layer can be coordinated with the porous metal layer, the carbon fiber composite layer can better achieve the pressure stabilizing and heat stabilizing effects, and structural stability and safety of the piston ring are effectively improved.

Owner:浙江桓宇汽配股份有限公司

Cylinder body

InactiveCN104612847AImprove wear resistanceAccelerated corrosionCylinder headsCylindersEngineeringCylinder block

The invention relates to a cylinder body which comprises a cylinder cover, an end cap shaft sleeve, a cylinder hole, an anti-oxidation layer, an inner cylinder main body, a water sleeve, an outer cylinder main body, guide rods, a horizontal roller, a connecting piece and perpendicular rollers. The cylinder hole is formed in the inner cylinder main body. The anti-oxidation layer is sprayed on the inner surface of the cylinder hole and can improve the wear resistance and corrosion resistance of the cylinder body. The outer cylinder main body is arranged outside the inner cylinder main body and wraps the inner cylinder main body. The water sleeve is arranged between the inner cylinder main body and the outer cylinder main body. The cylinder cover is located at the upper end of the inner cylinder main body and the upper end of the outer cylinder main body. The end cap shaft sleeve is located above the cylinder cover. The two guide rods are parallel to the outer cylinder main body in the horizontal plane in the mode that the two guide rods surround the outer cylinder main body. The horizontal roller is arranged outside the outer cylinder main body. The perpendicular rollers are arranged at the two ends of the horizontal roller. The cylinder body can be prevented from shaking leftwards and rightwards. Thus, the problems that a cylinder sleeve is prone to deformation and a cylinder hole is prone to abrasion are solved.

Owner:CHANGSHU CITY DONGBANG COUNTY XUSHI JIAFENG MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com