Patents

Literature

2548results about "Props/chocks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

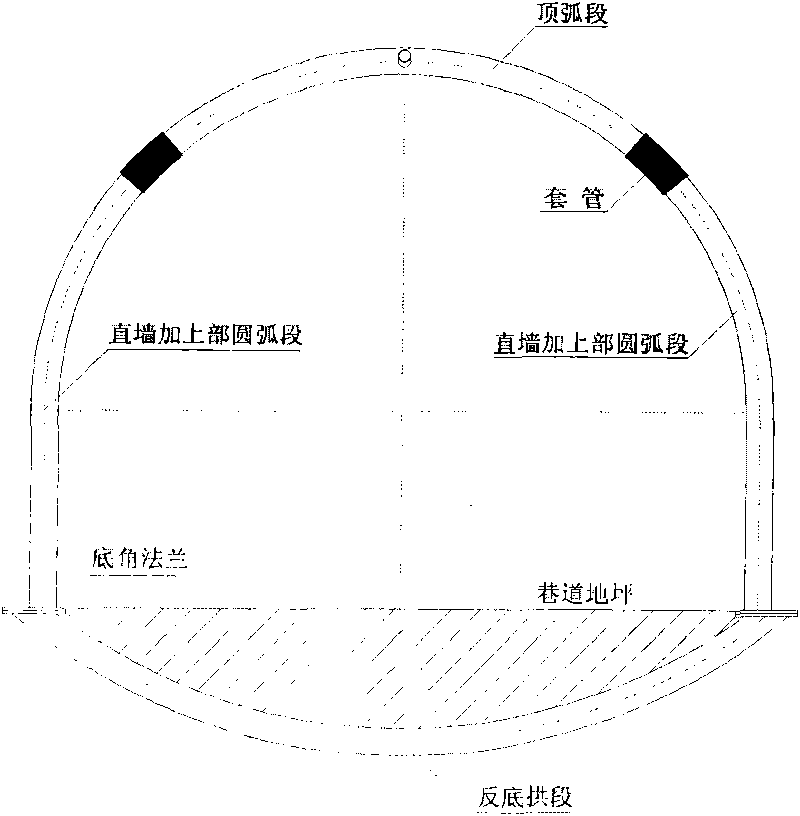

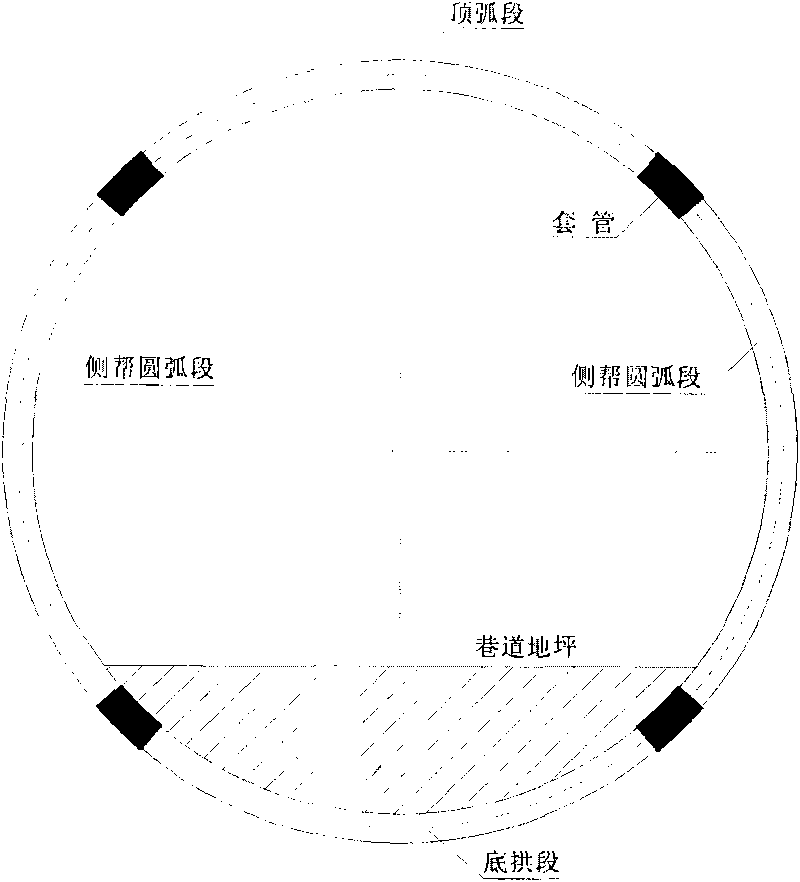

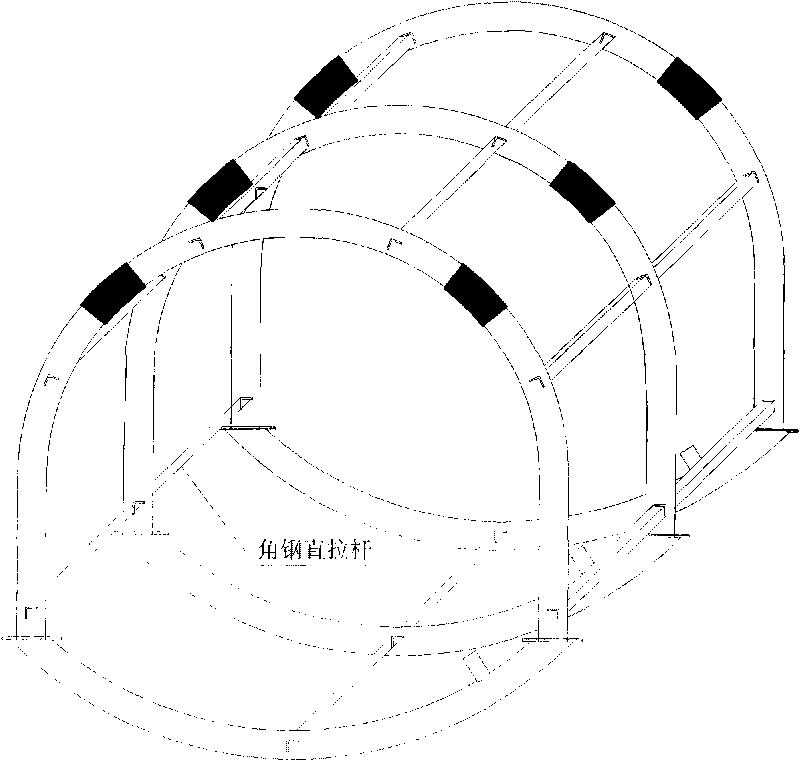

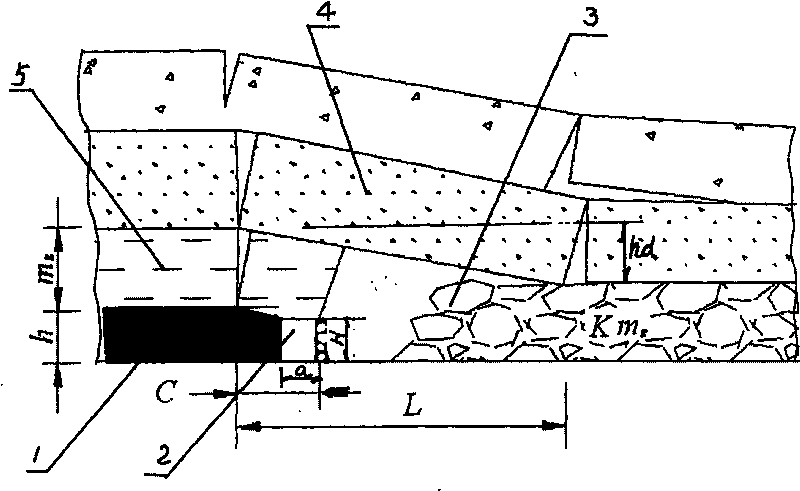

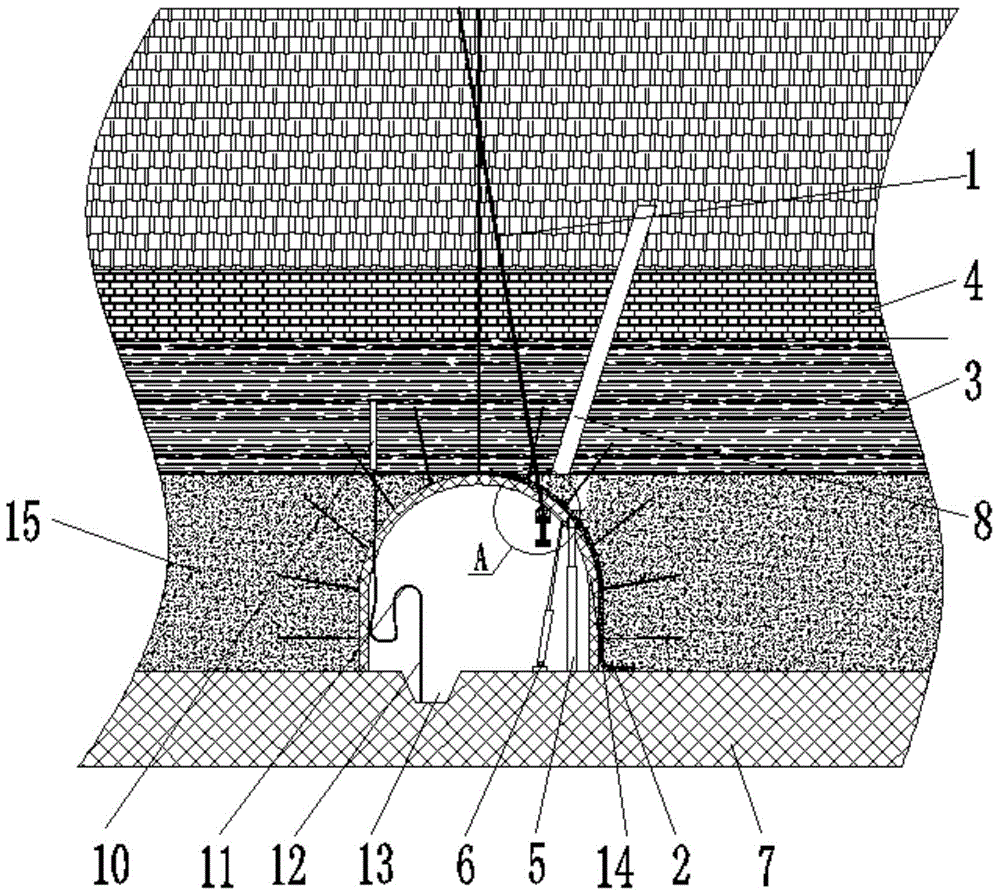

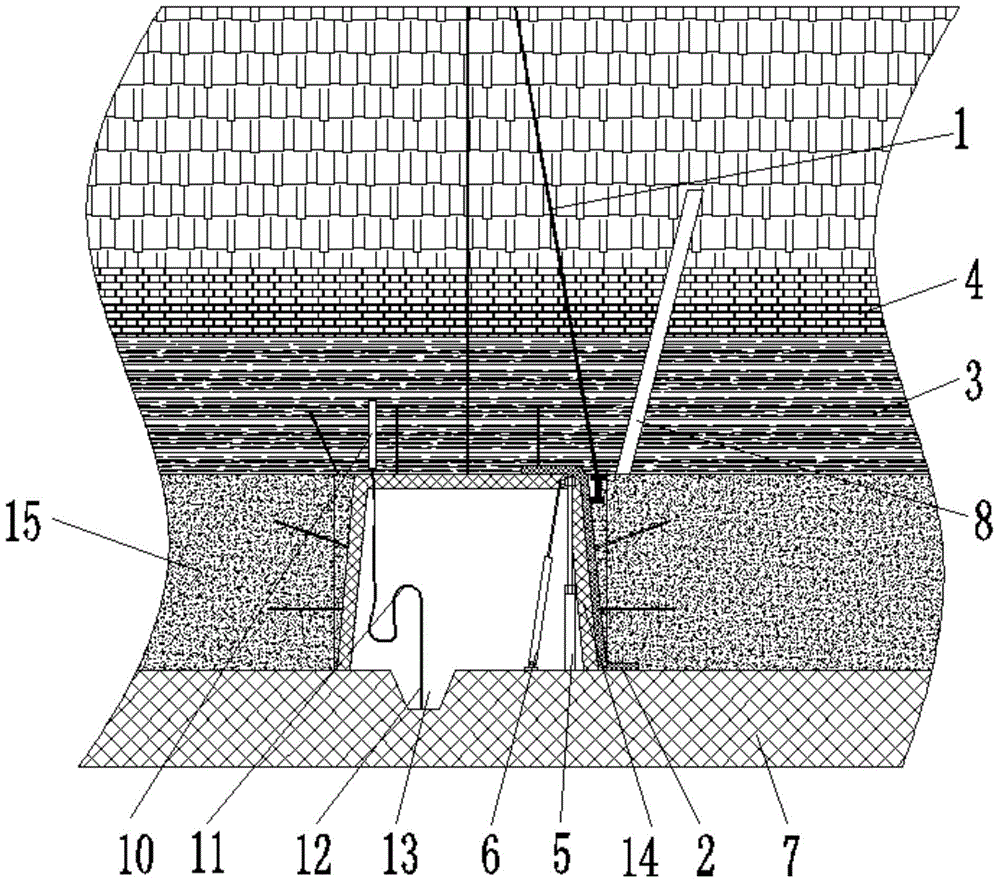

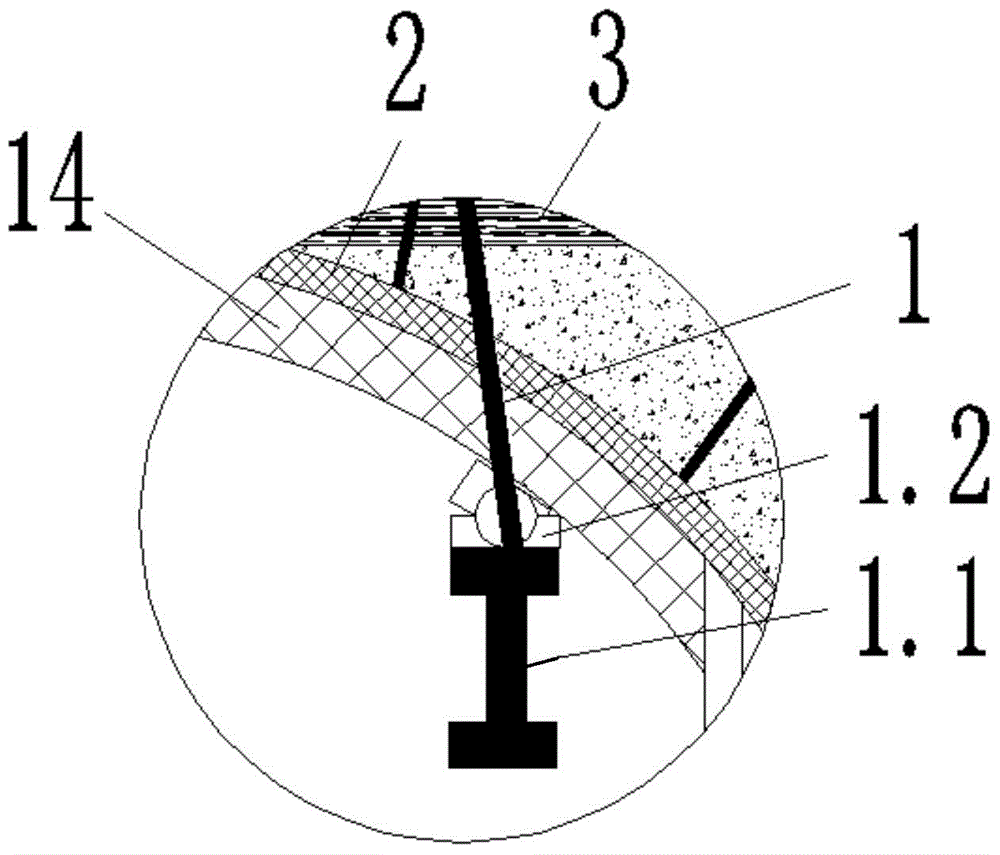

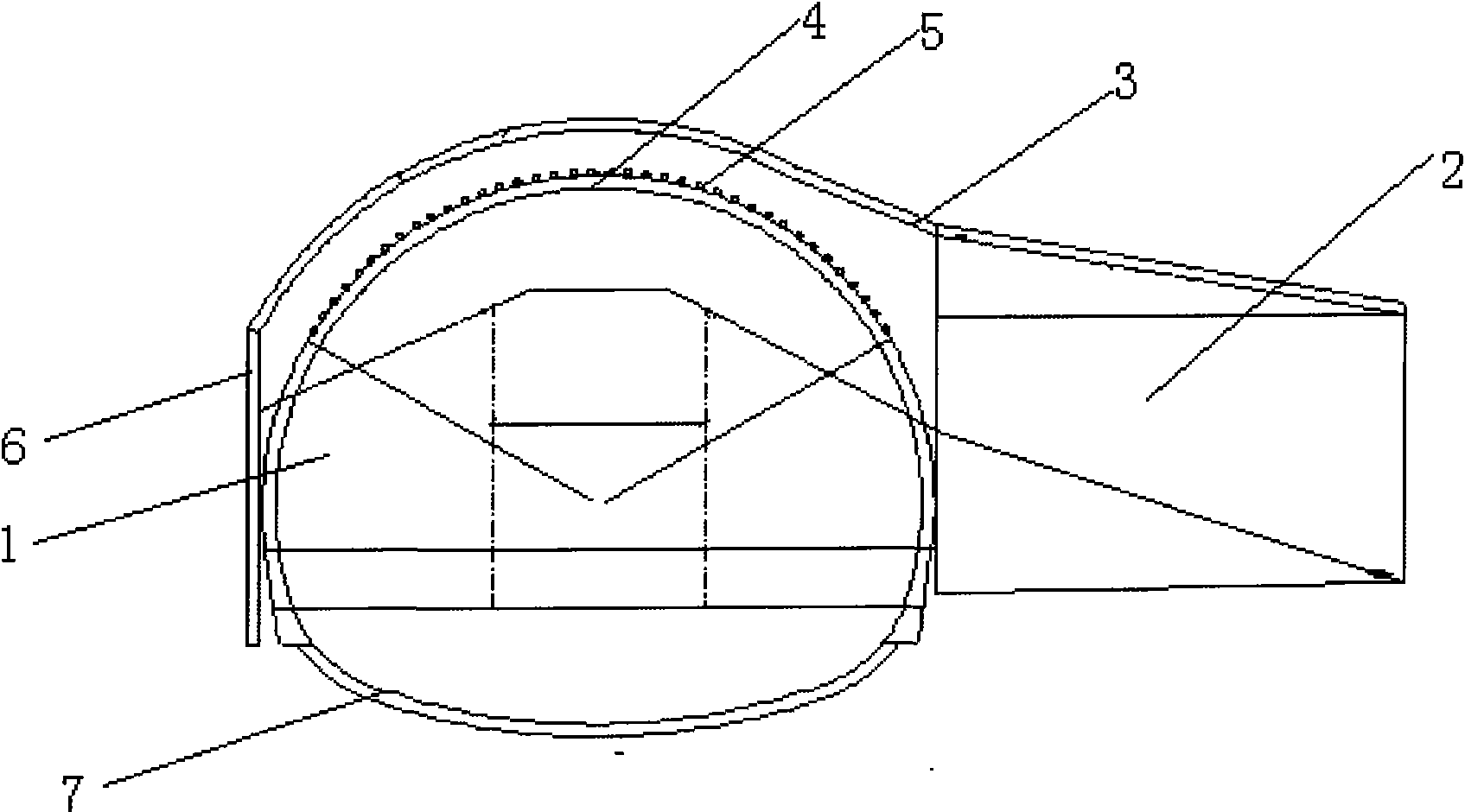

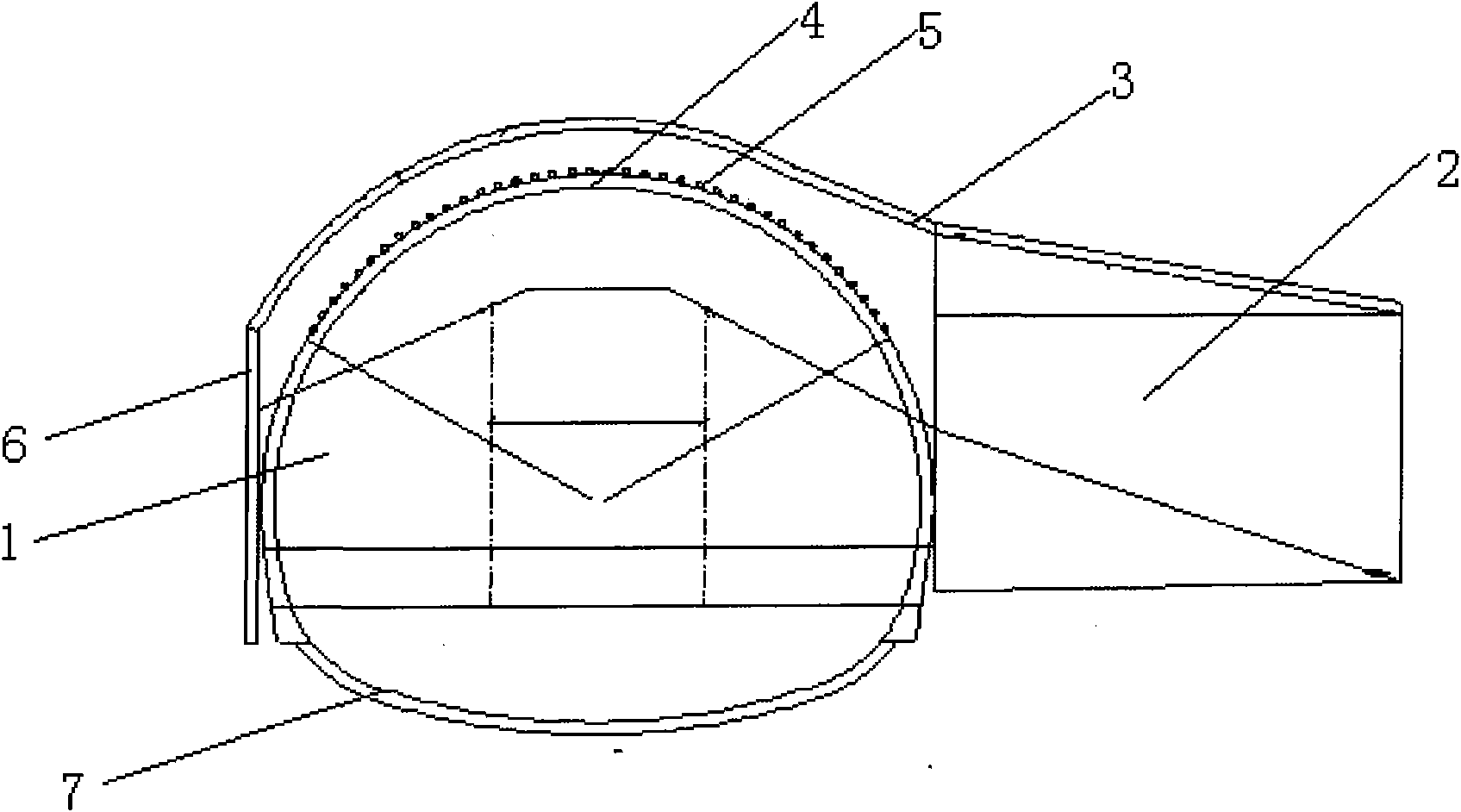

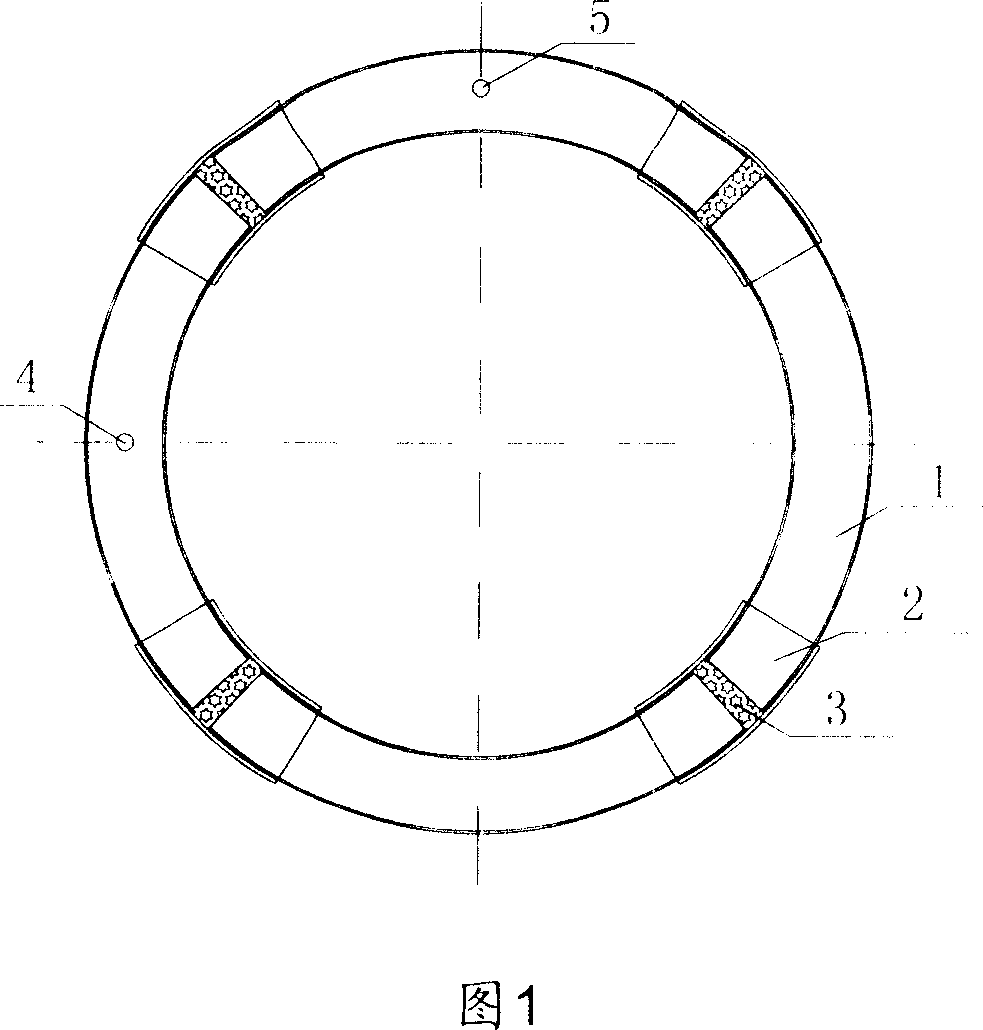

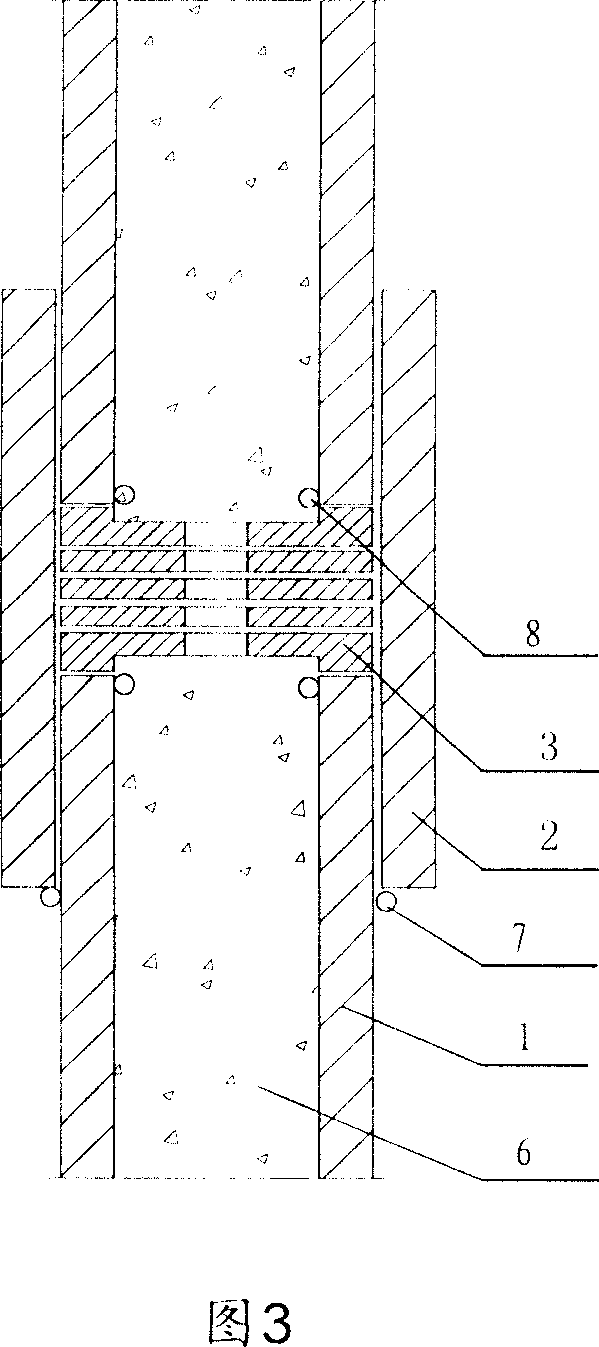

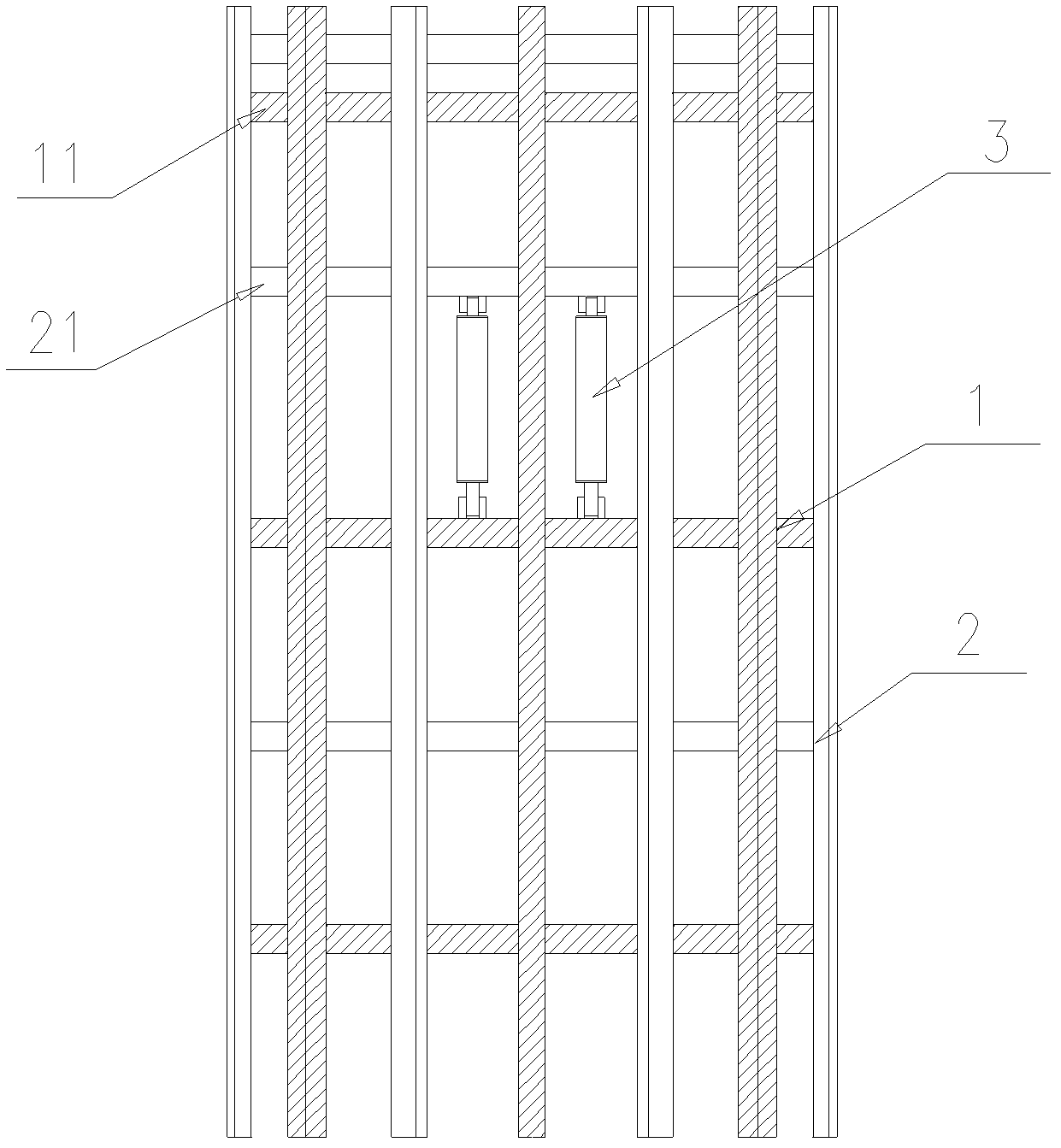

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

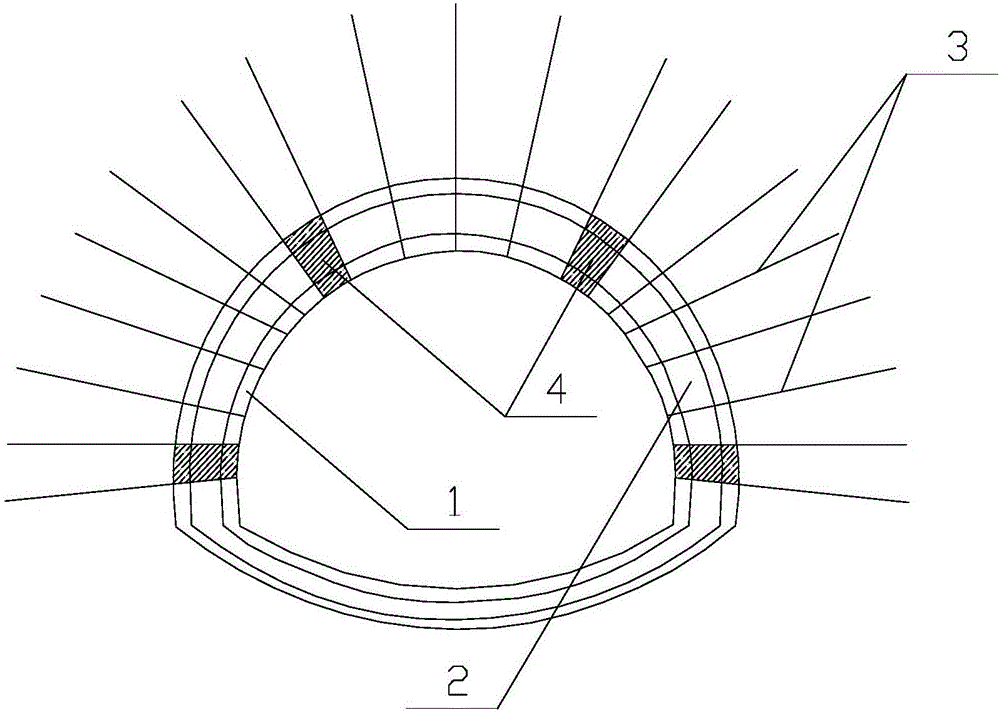

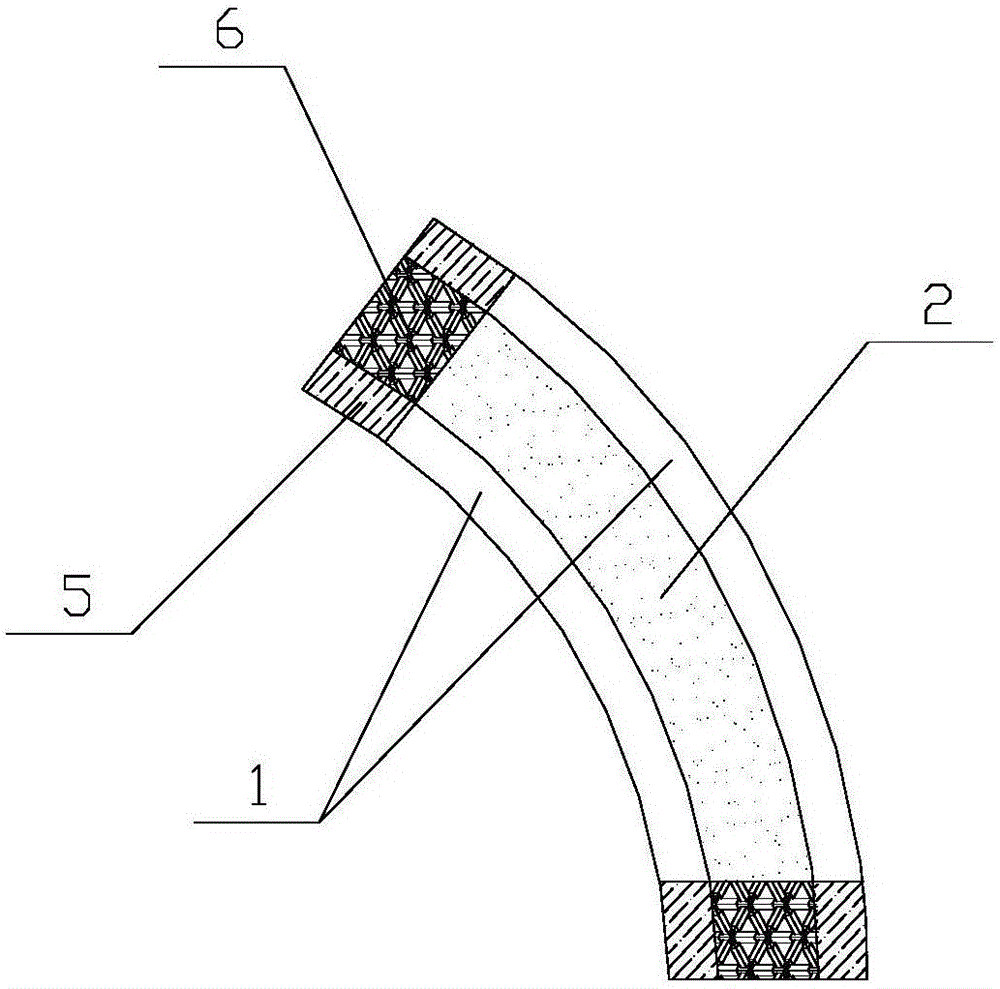

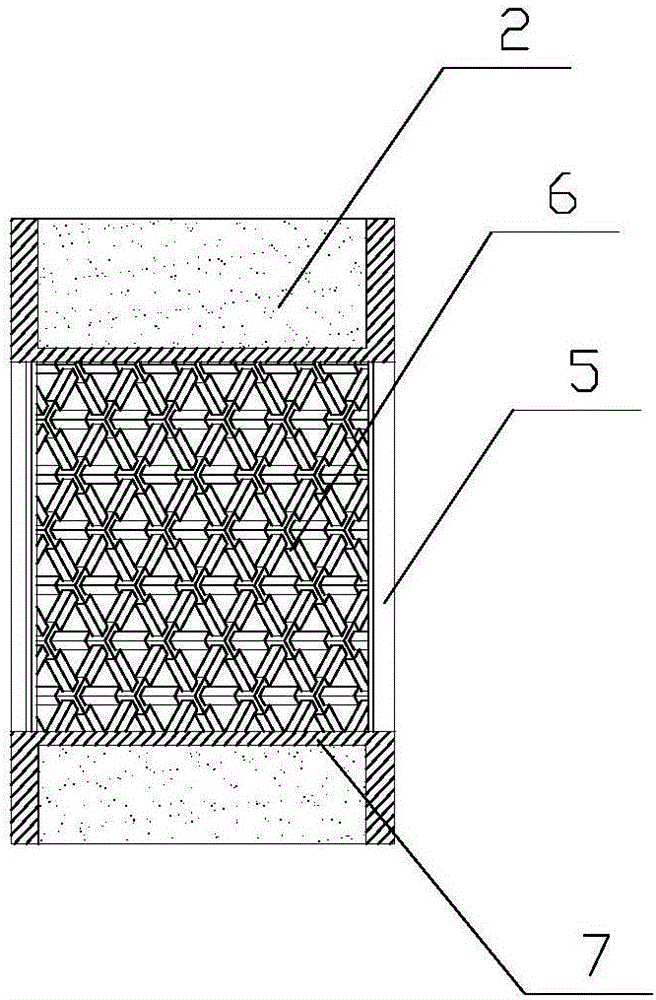

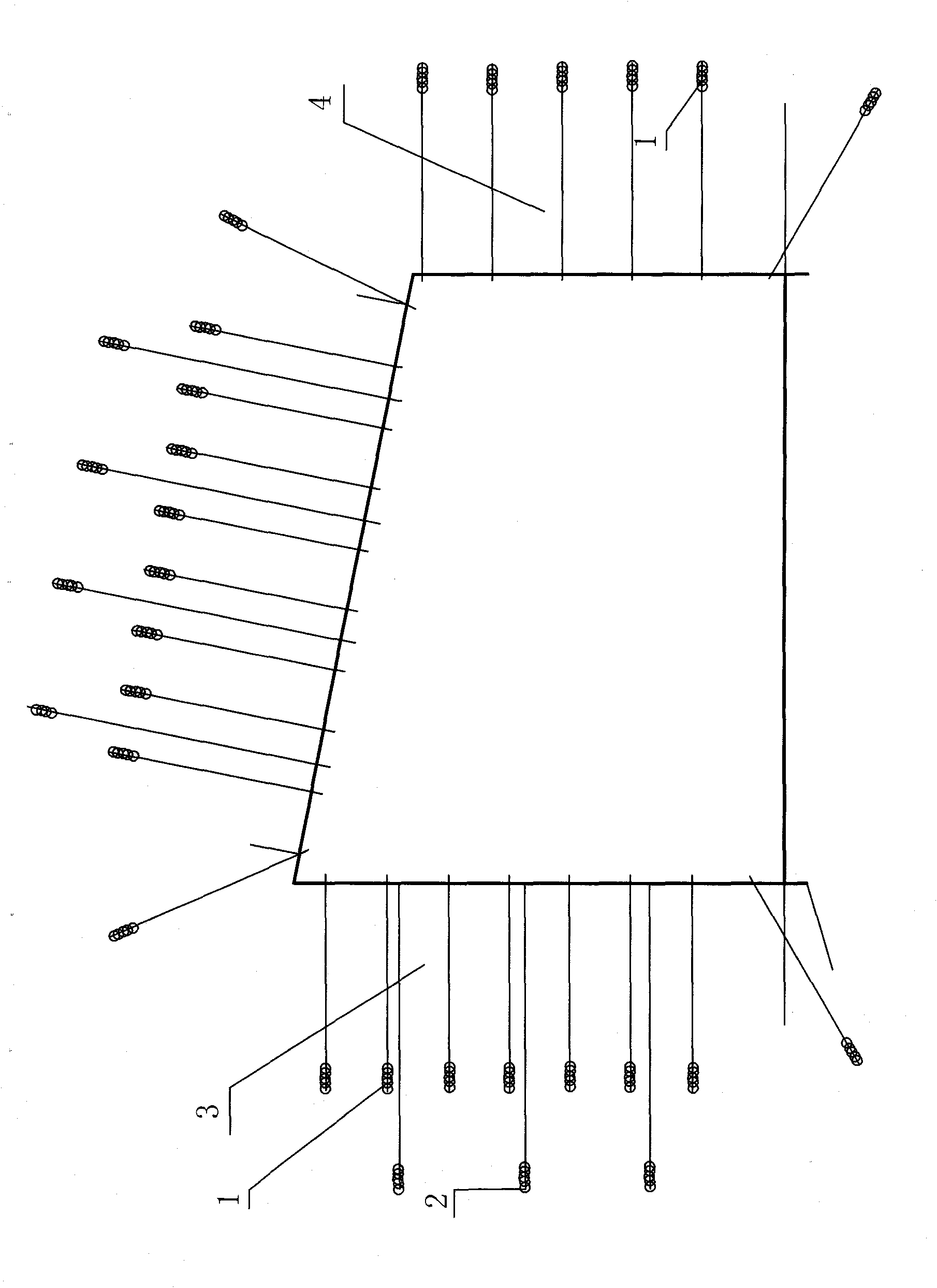

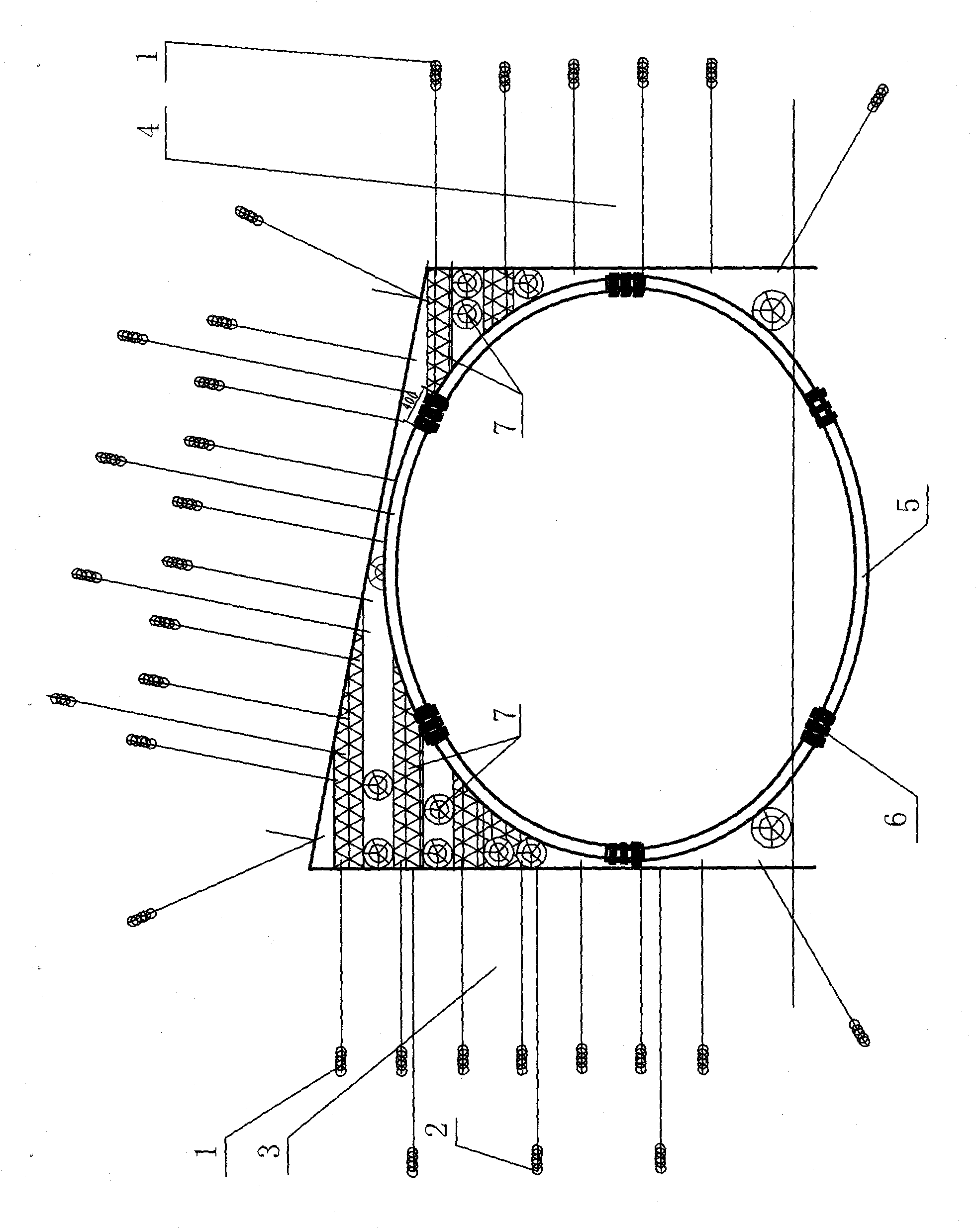

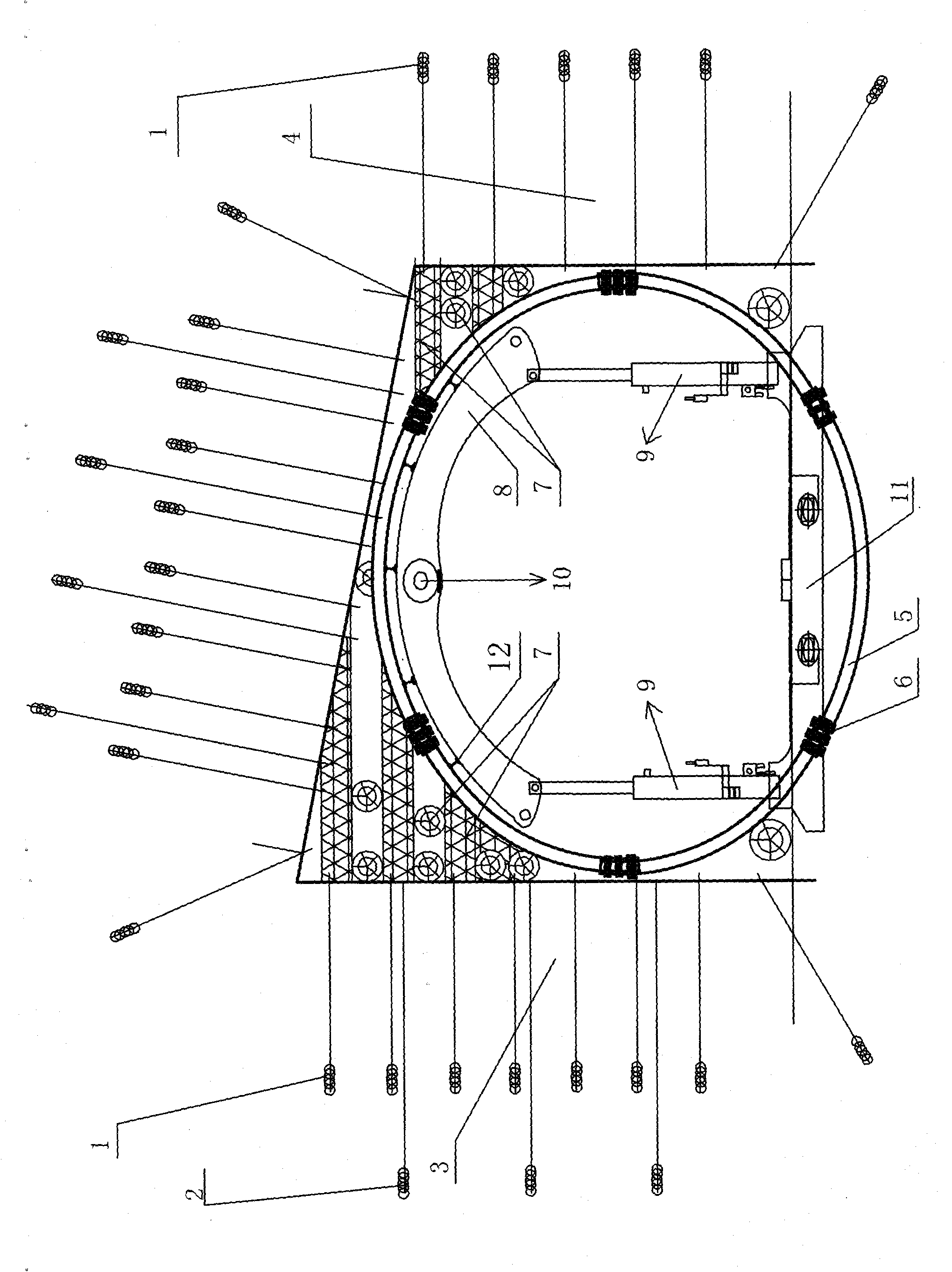

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

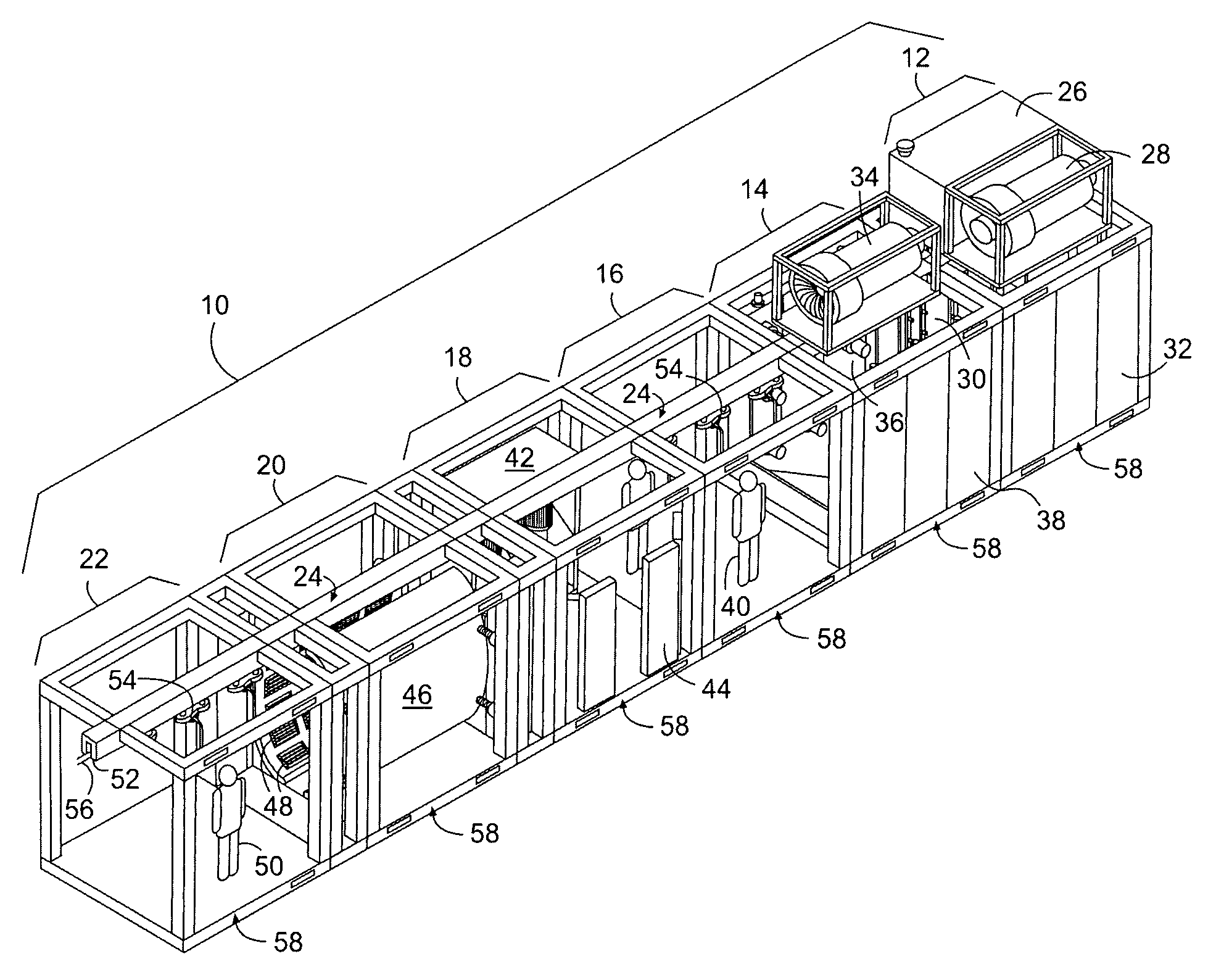

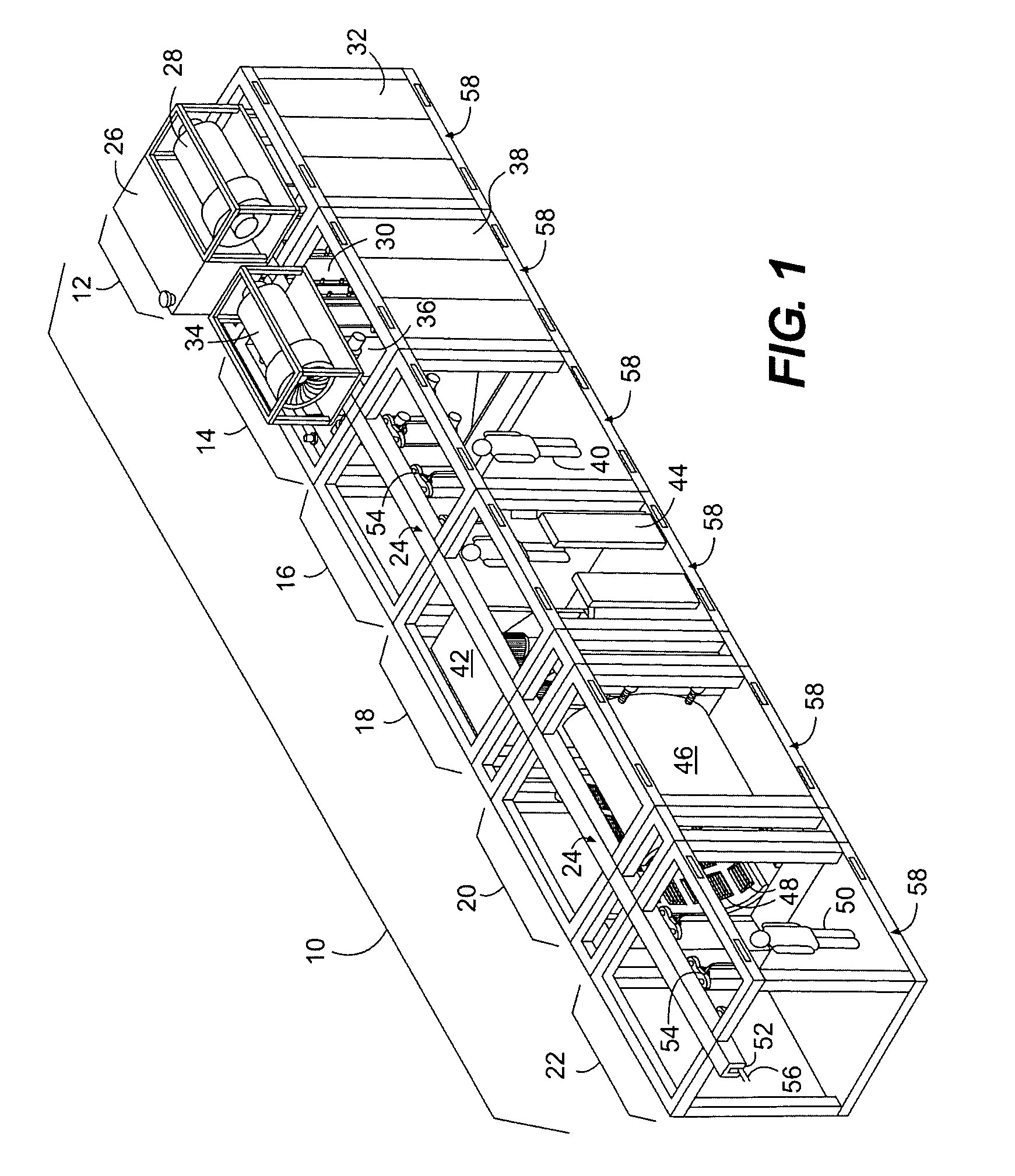

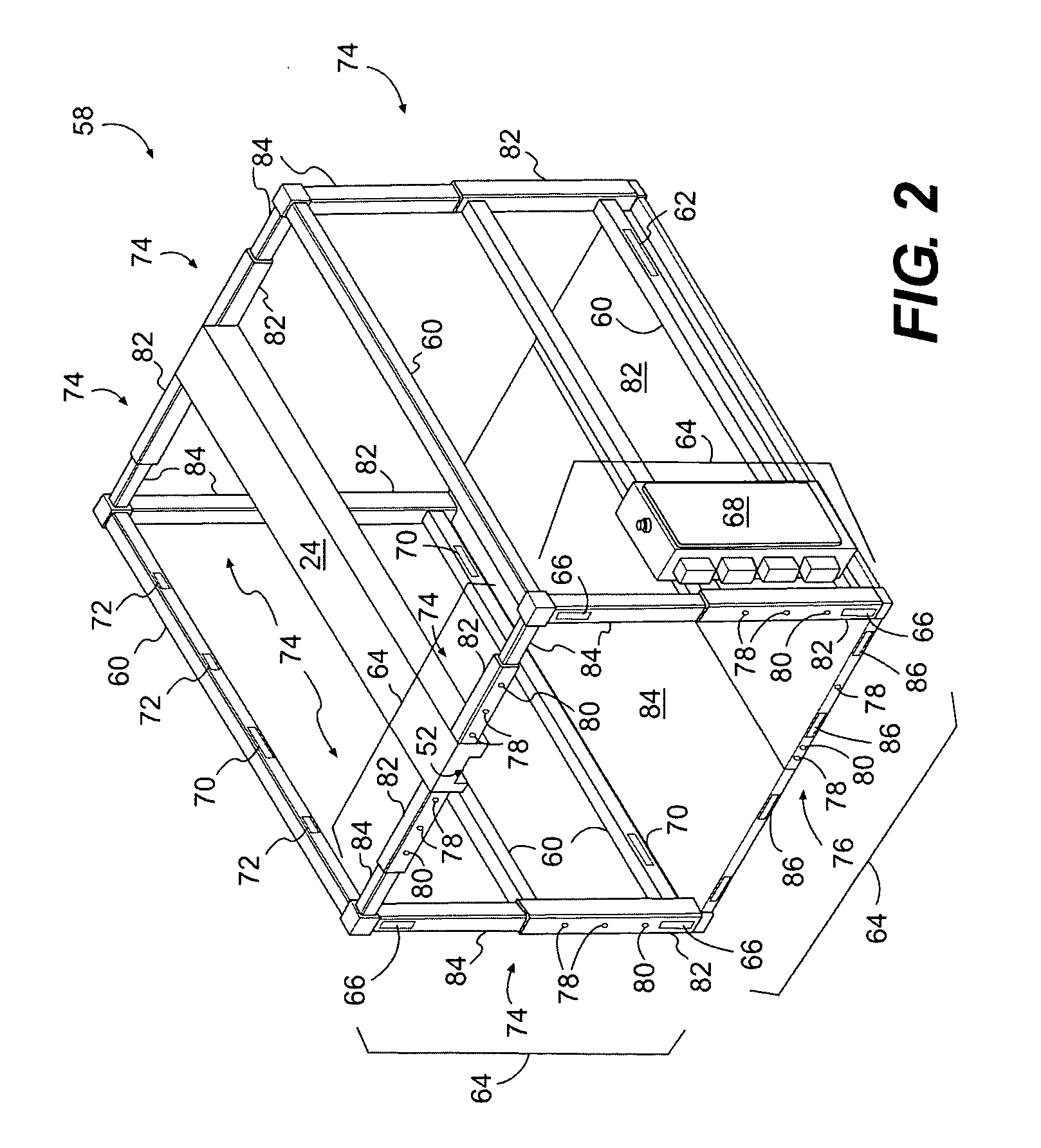

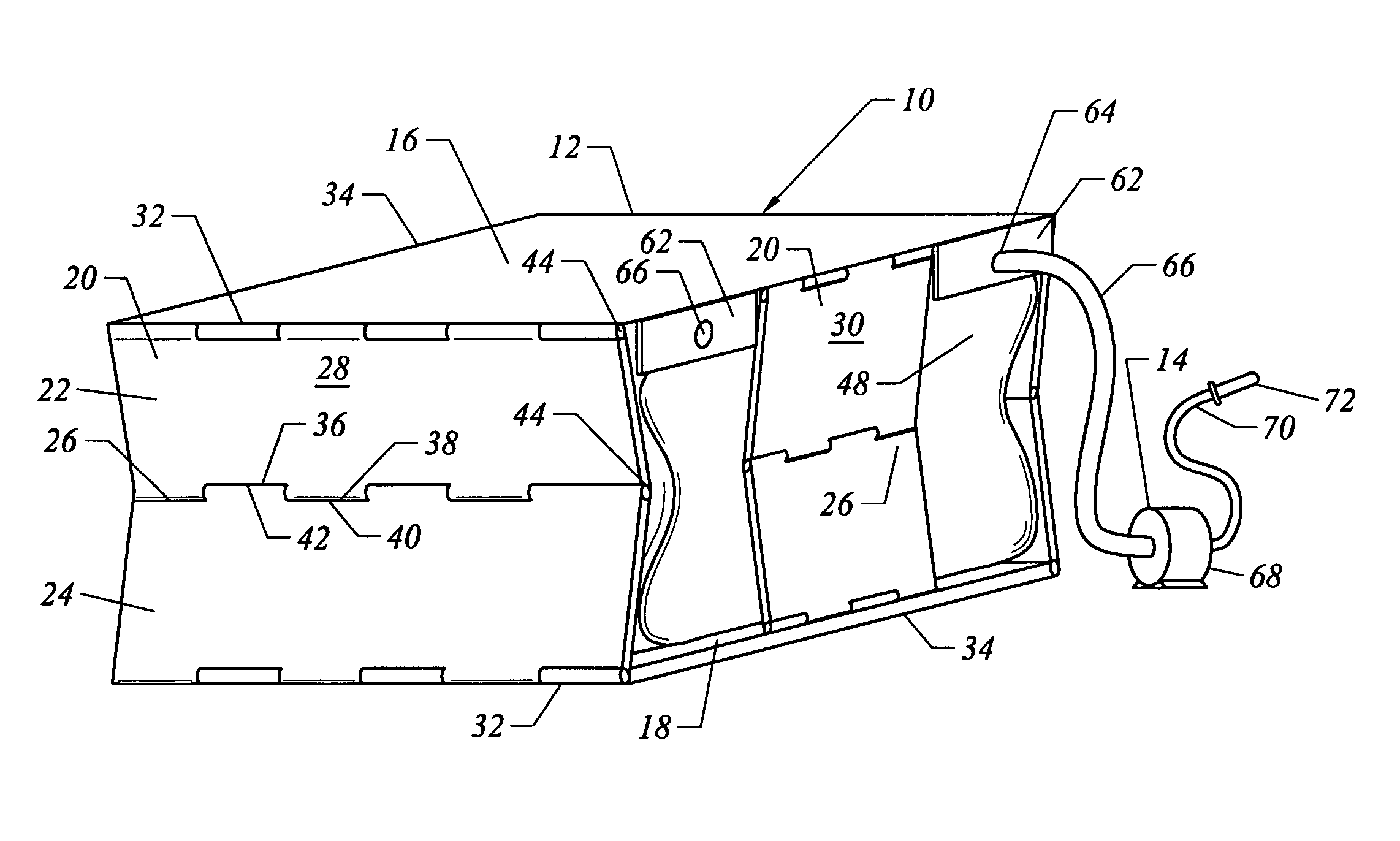

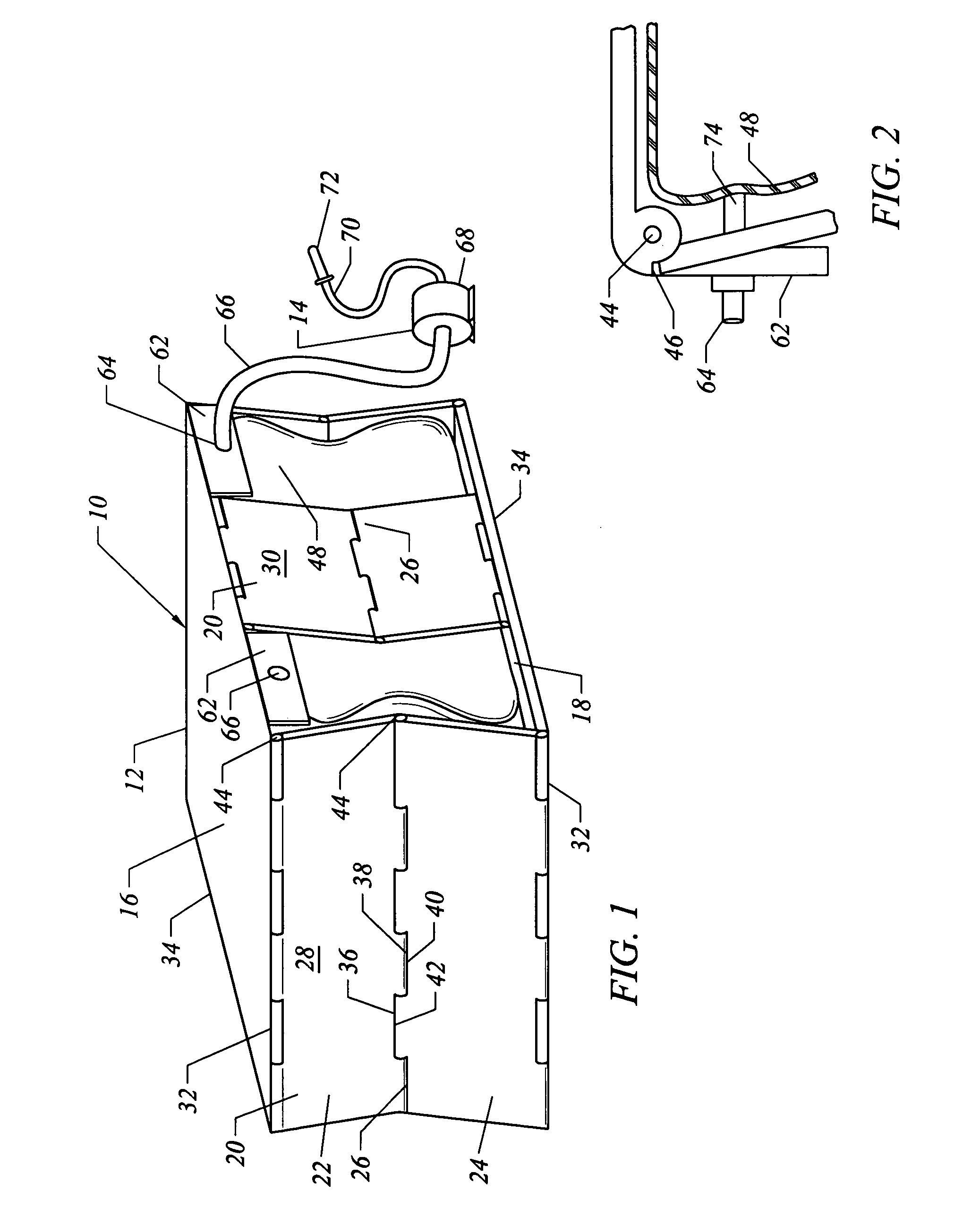

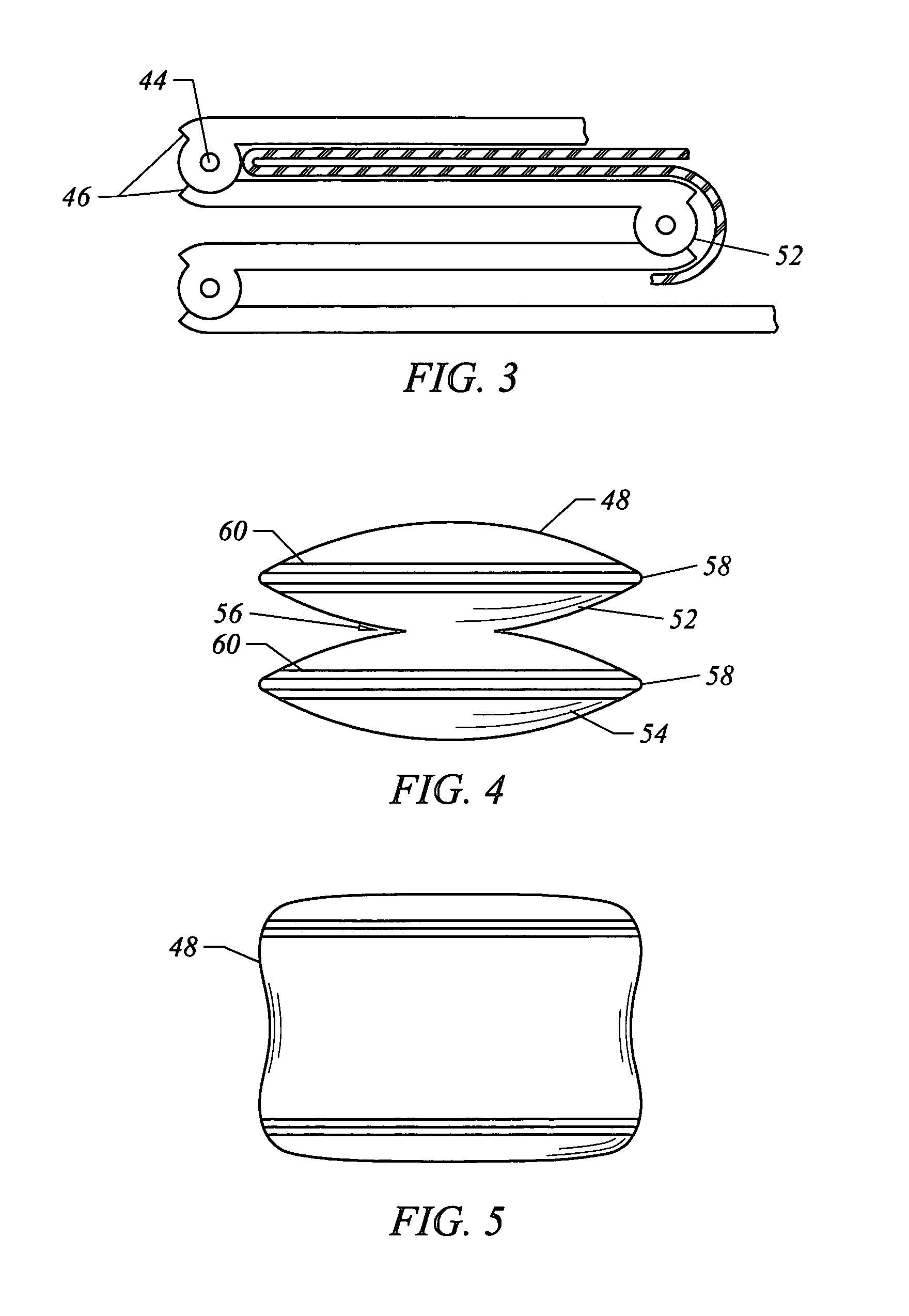

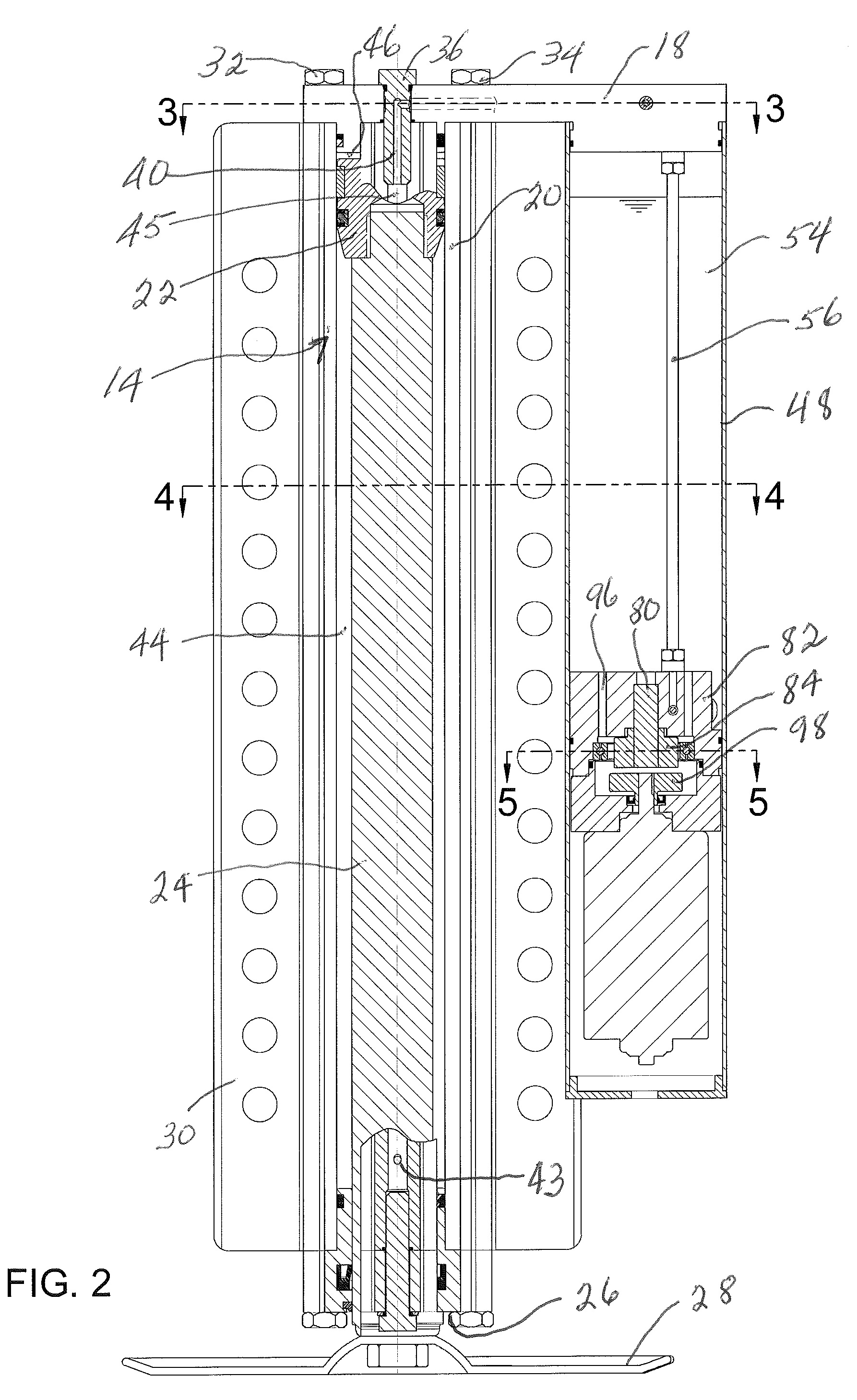

Portable modular manufacturing system

A modular manufacturing station is provided. The modular manufacturing station has a plurality of beams forming a skeleton and being capable of extension and retraction. The modular manufacturing station also has at least one utility connection for receiving external utilities. Additionally, the modular manufacturing station has at least one piece of manufacturing equipment. Furthermore, the modular frame has a control system configured to regulate operation of the manufacturing equipment.

Owner:CATERPILLAR INC

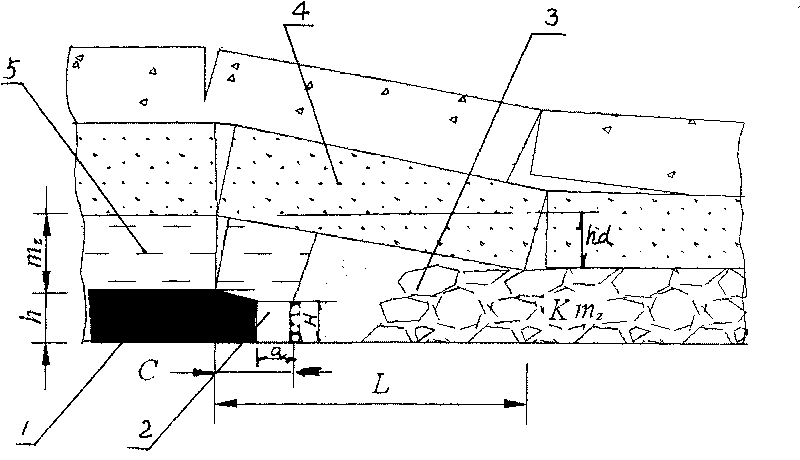

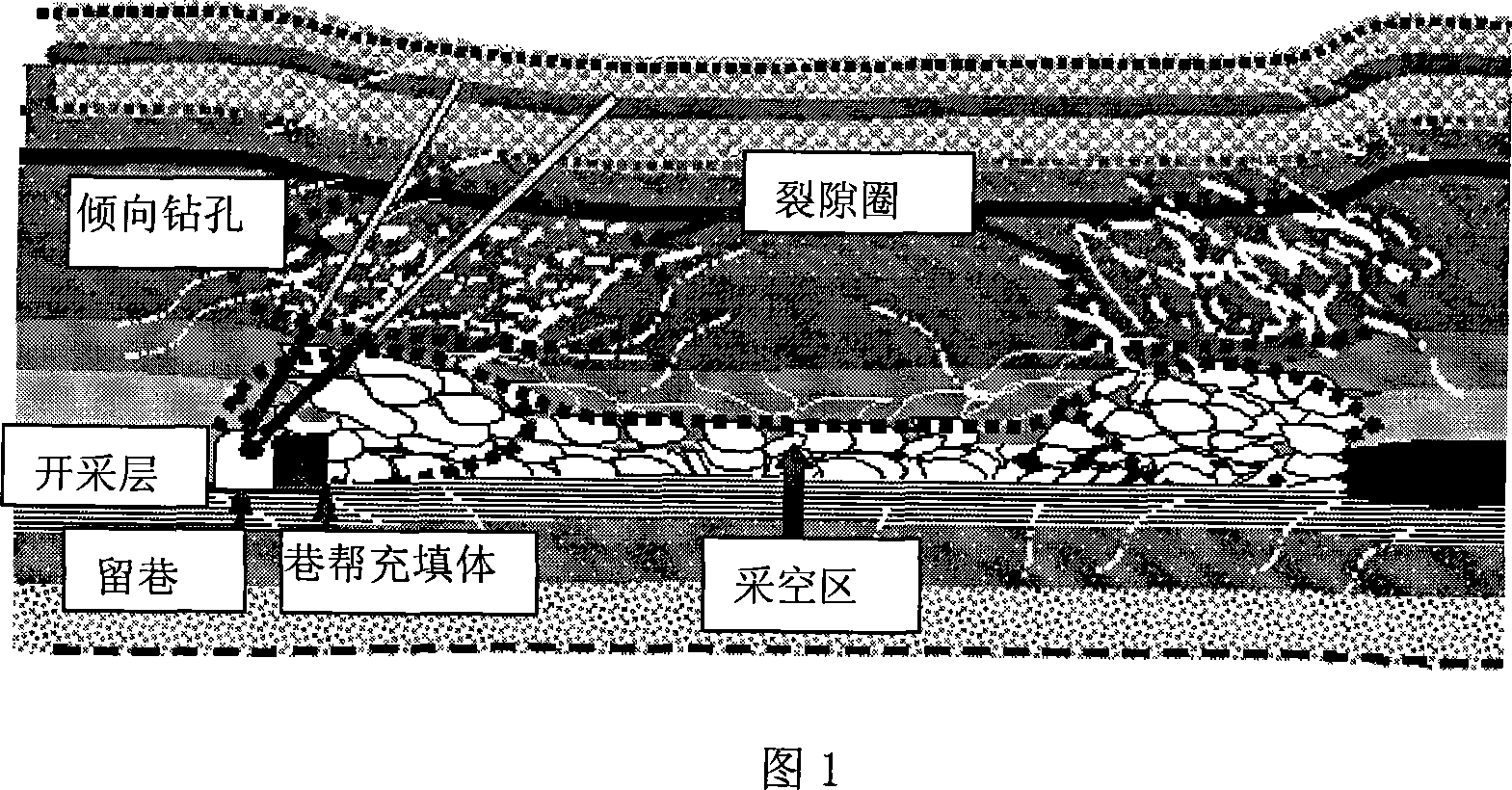

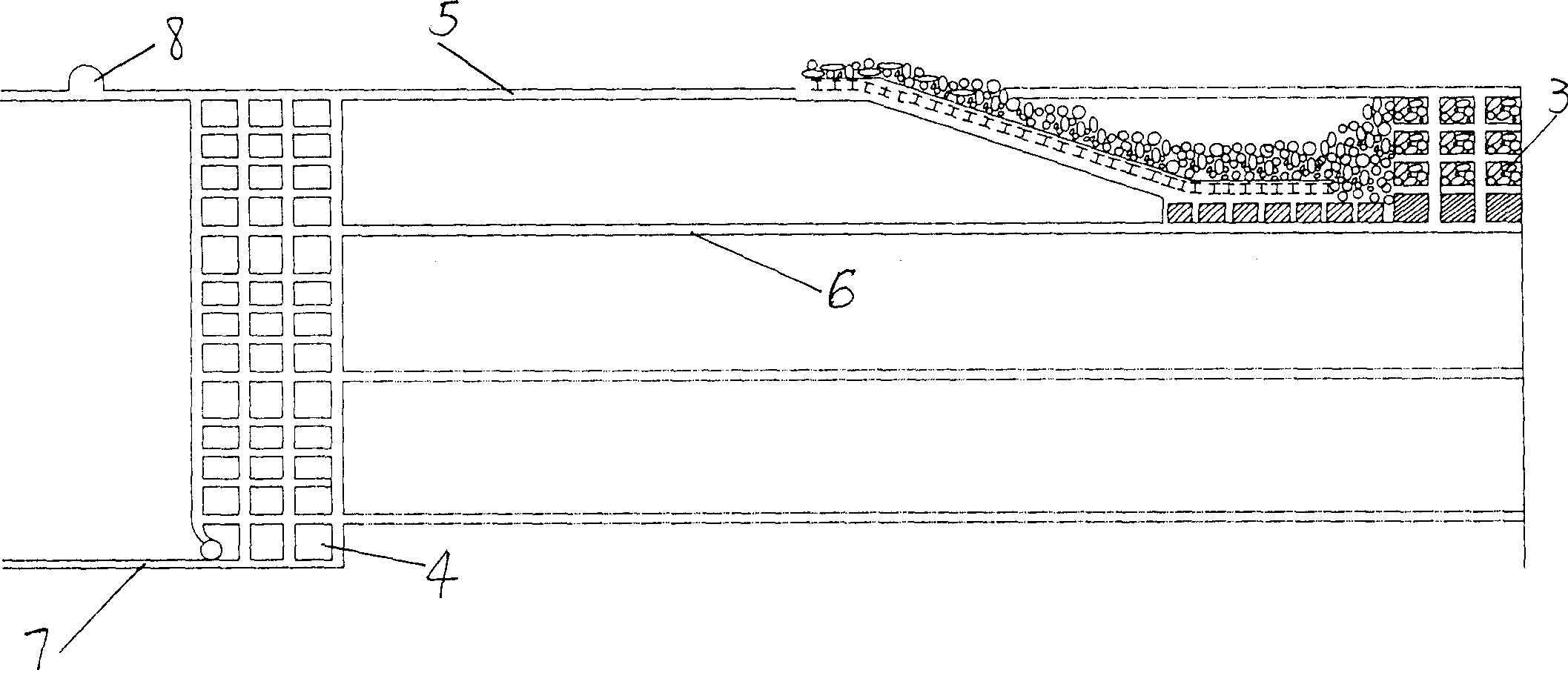

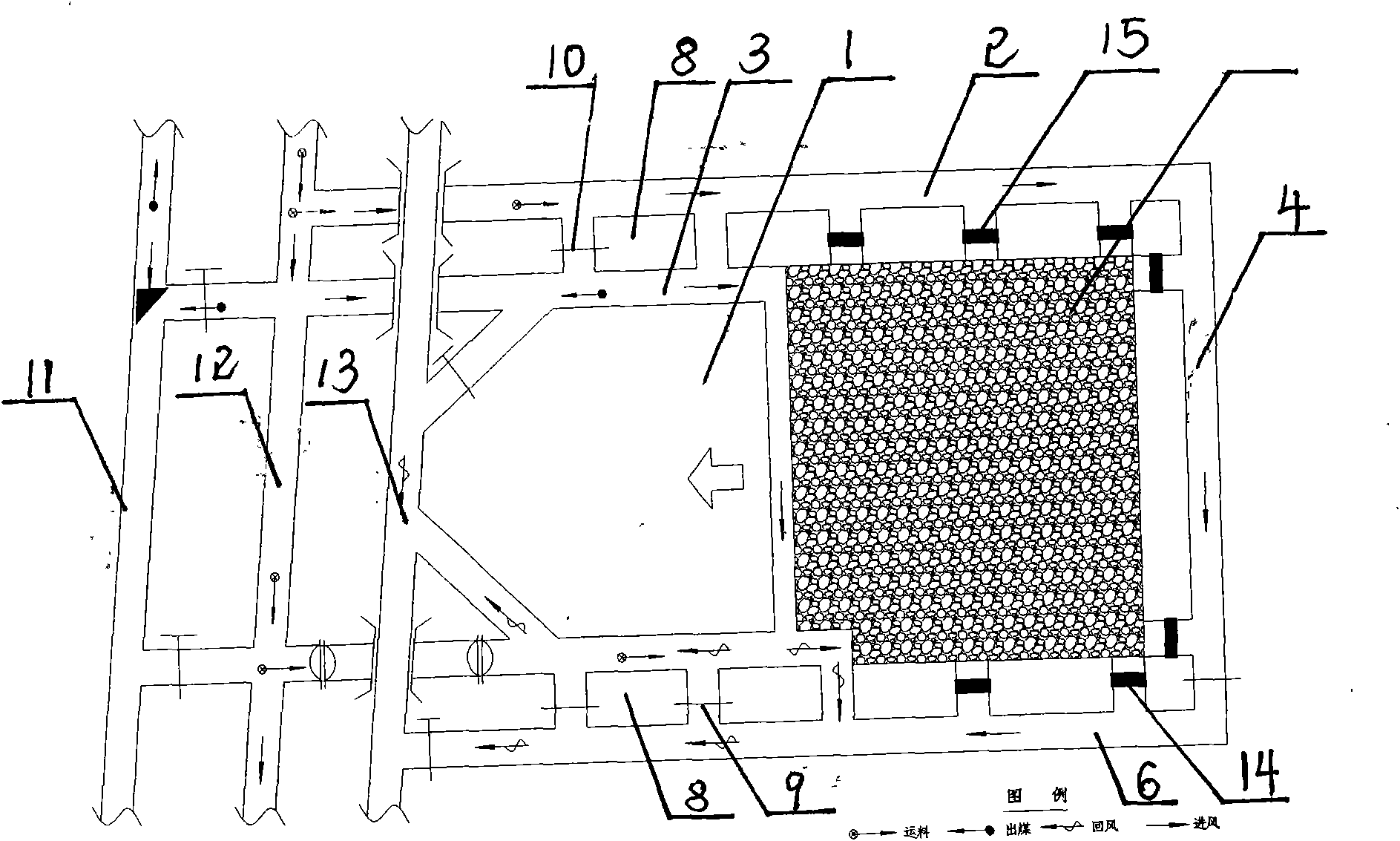

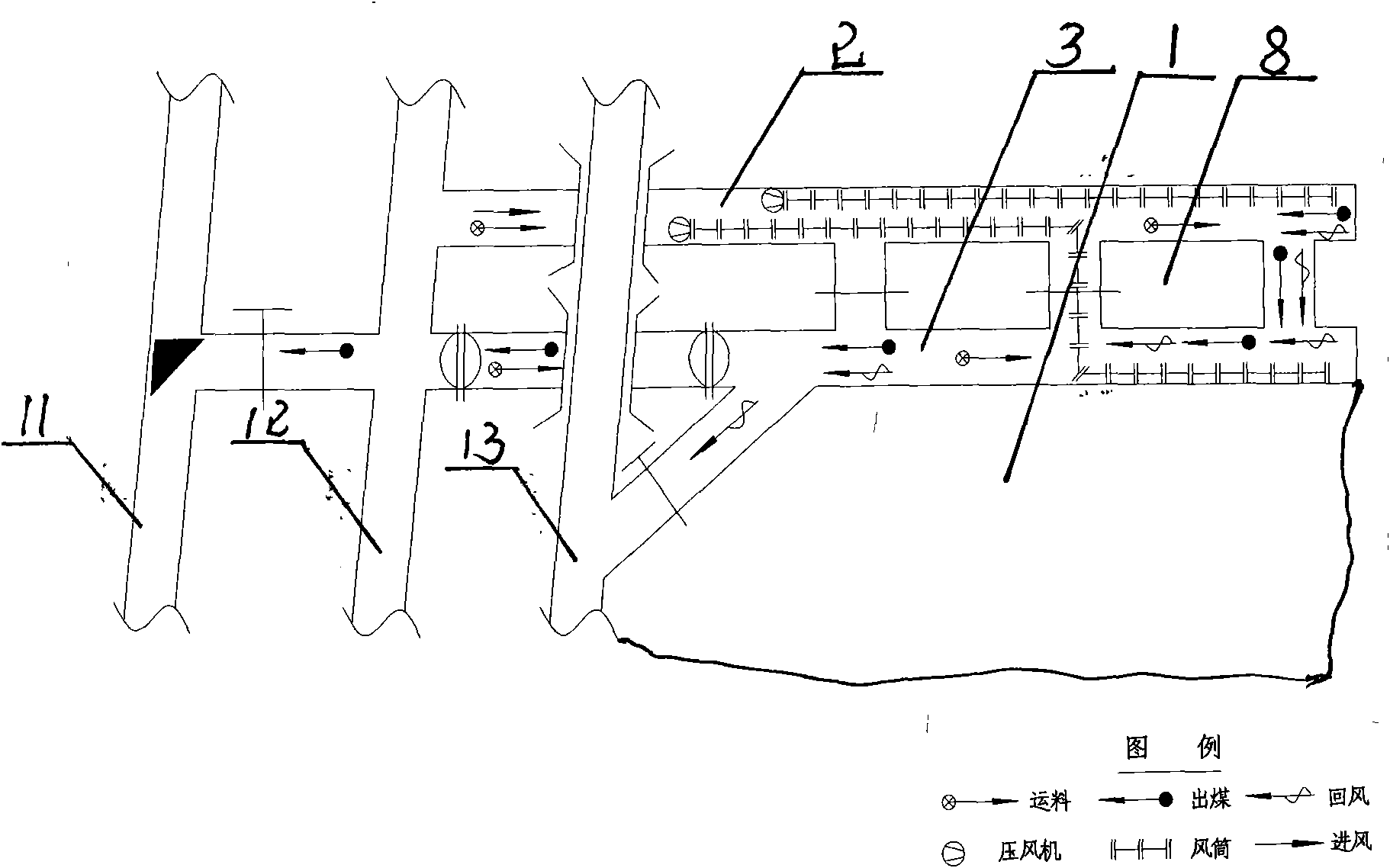

Thick seam large mining height working face gob-side entry retaining method

InactiveCN101725368APrevent overflowAvoid enteringMaterial fill-upMine roof capsSpontaneous combustionEngineering

The invention discloses a thick seam large mining height working face gob-side entry retaining method, wherein a flexible yield airbag is installed on the deformed space retained on the top part of the filling body besides the lane; the height of the filled airbag is equal to the prediction value of the sinking quantity of the top plate; the airbag is filled with air, the inflation pressure is 3MPa; a one-way decompression valve is installed on the bag body and the decompression pressure is 4MPa. The flexible yield airbag is arranged, thus on the one hand, effectively protecting the filling body besides the lane and achieving the purpose of gob-side entry retaining, and on the other hand, preventing the coal in the gob from spontaneous combustion, ensuring safe production and simultaneously improving the mining coefficient of the coal.

Owner:SHANDONG UNIV OF SCI & TECH

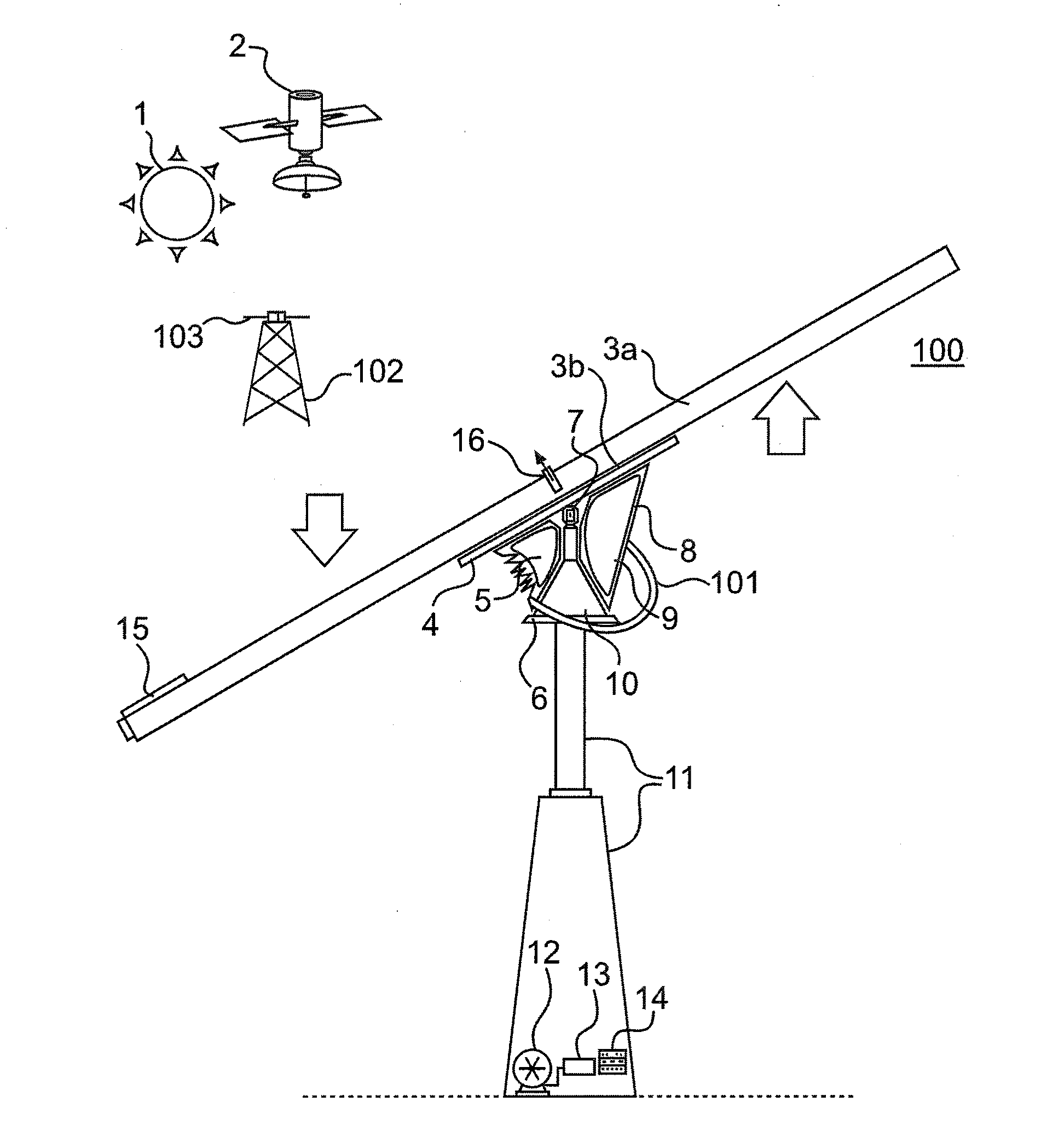

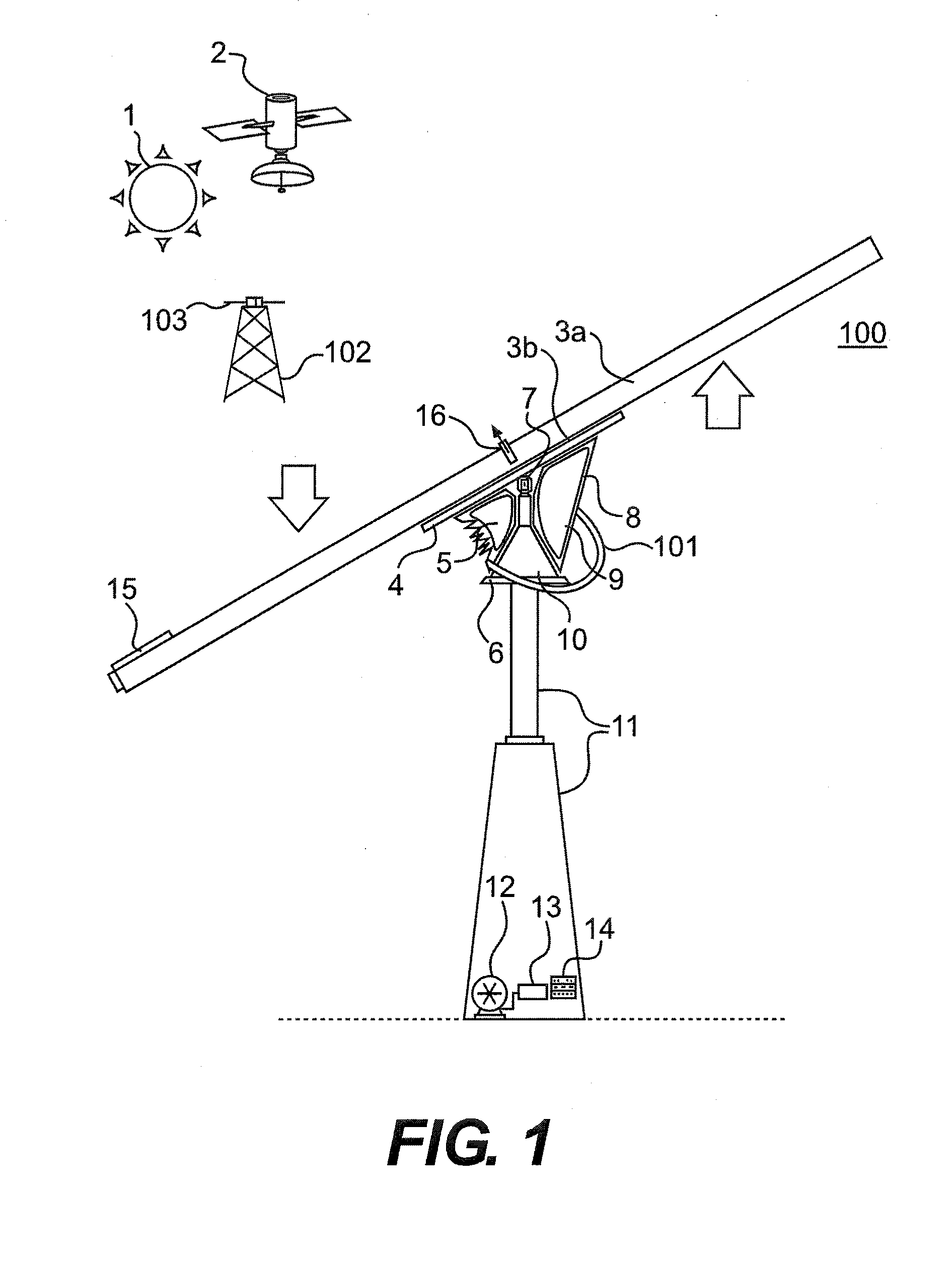

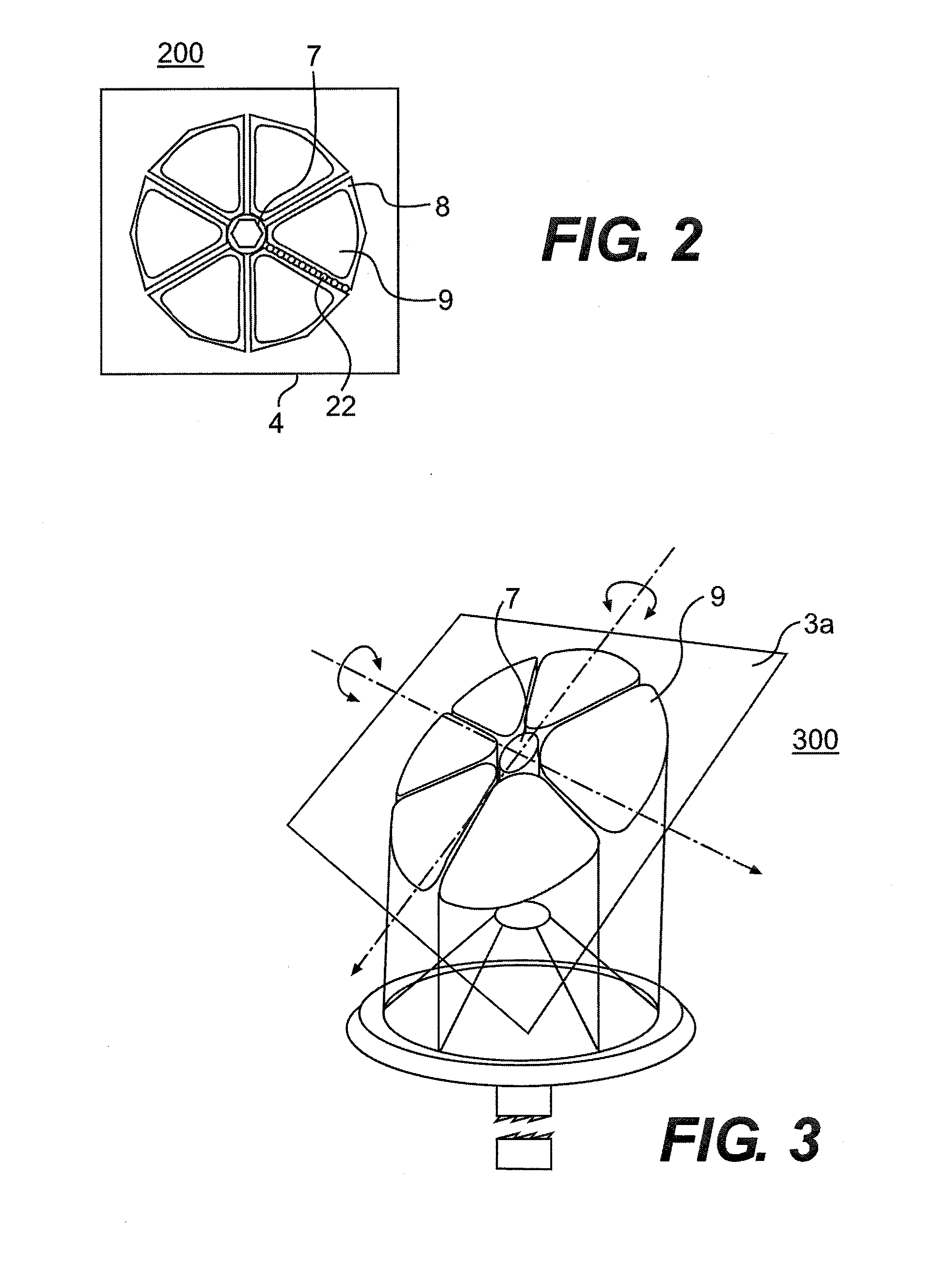

Multi-Axis Metamorphic Actuator and Drive System and Method

An embodiment of a system and method for moving an object in two or more axes includes one or more fluid containers, each of which is directly or indirectly in physical contact with the object. A volume of a fluid is placed in the one or more fluid containers. The system further includes a fluid mover operably connected to the one or more fluid containers for moving the fluid into the one or more containers, and a fluid volume control for controlling the volume of fluid in the one or more containers. By changing the volume of fluid in the one or more containers, the containers are variably pressurized, thereby moving the object in one or more axis. The object may be supported at one or more pivot points that allow the object to be moved in multiple axes.

Owner:CBE GLOBAL HLDG

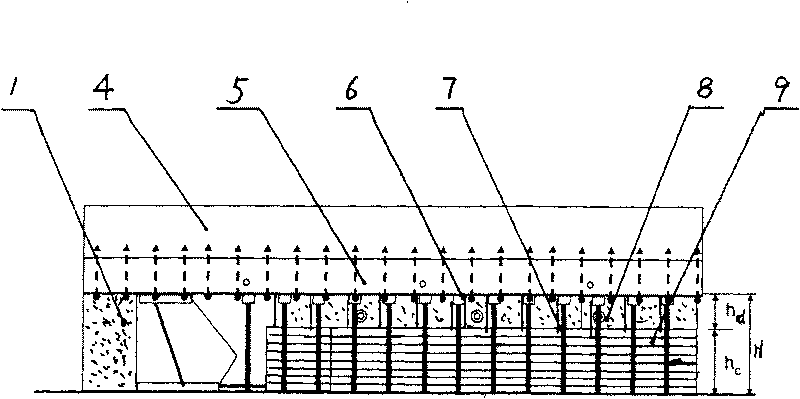

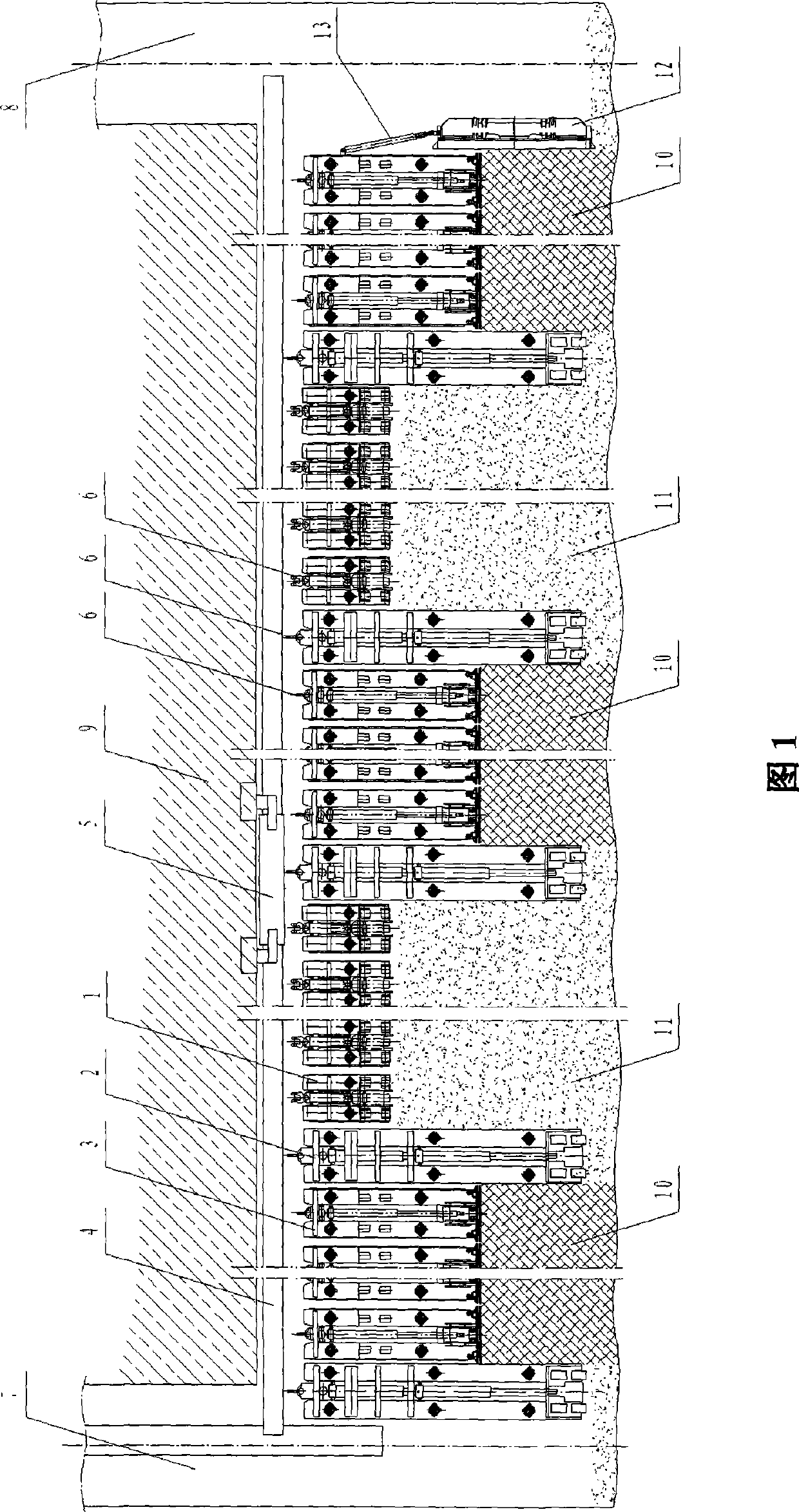

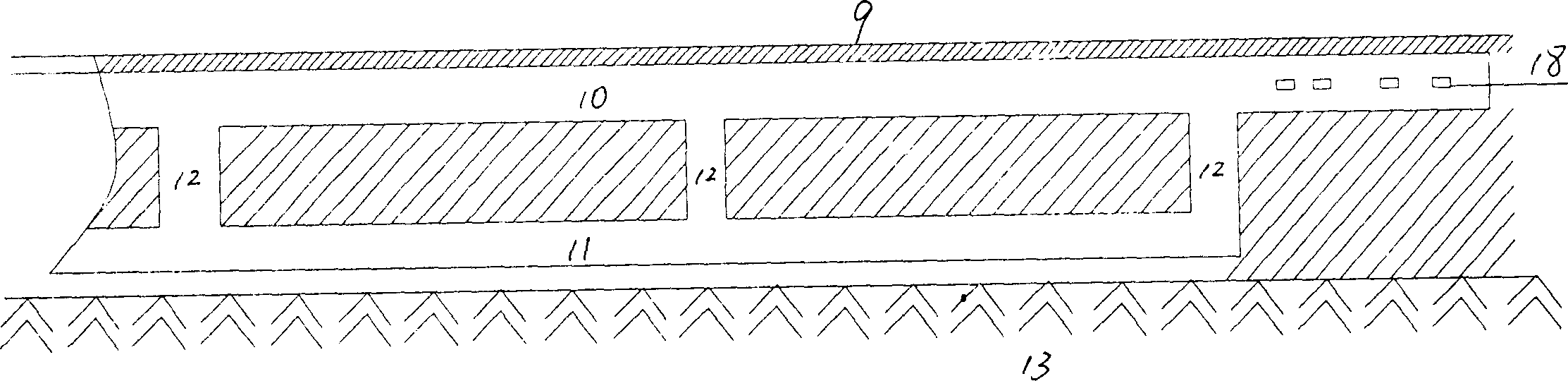

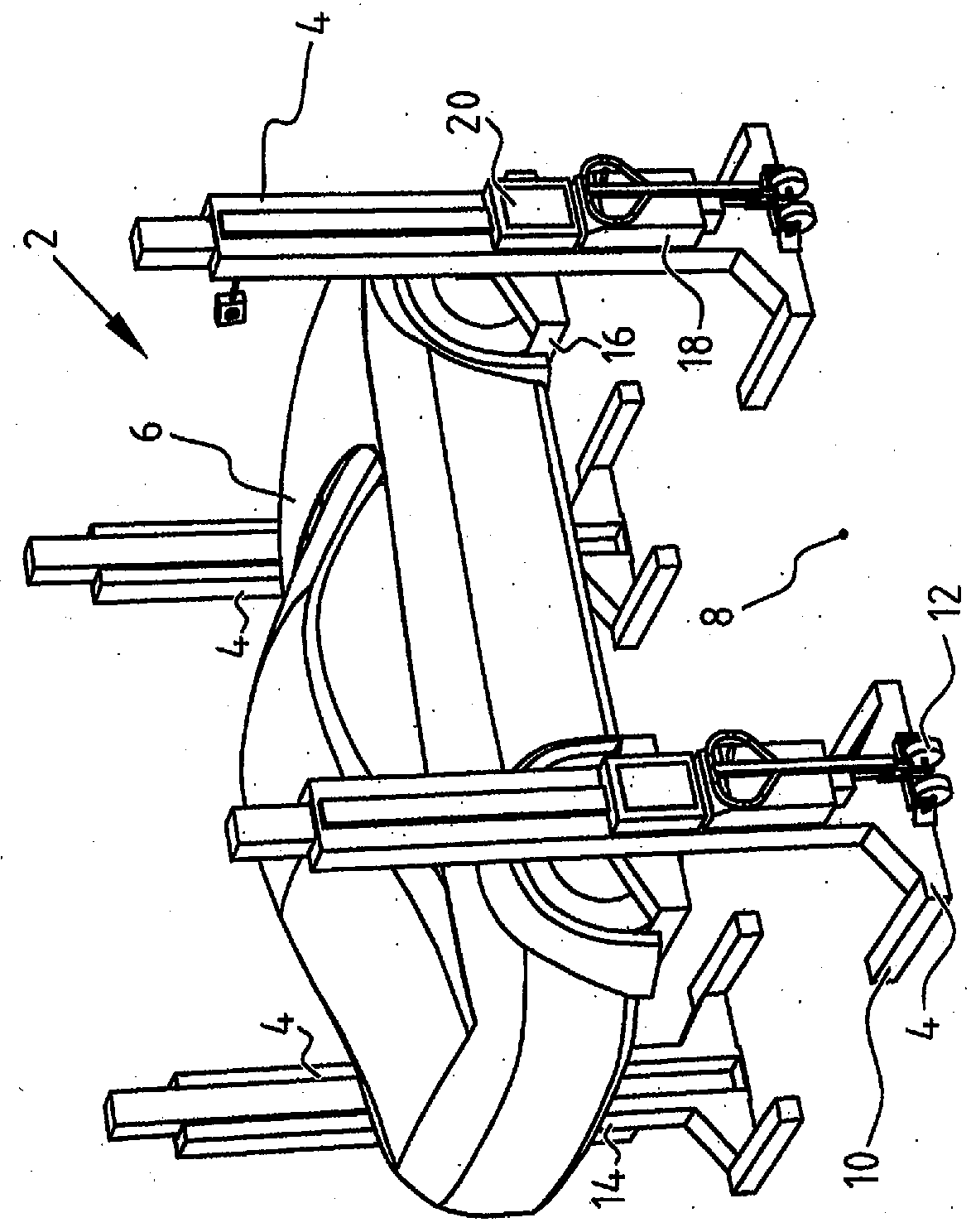

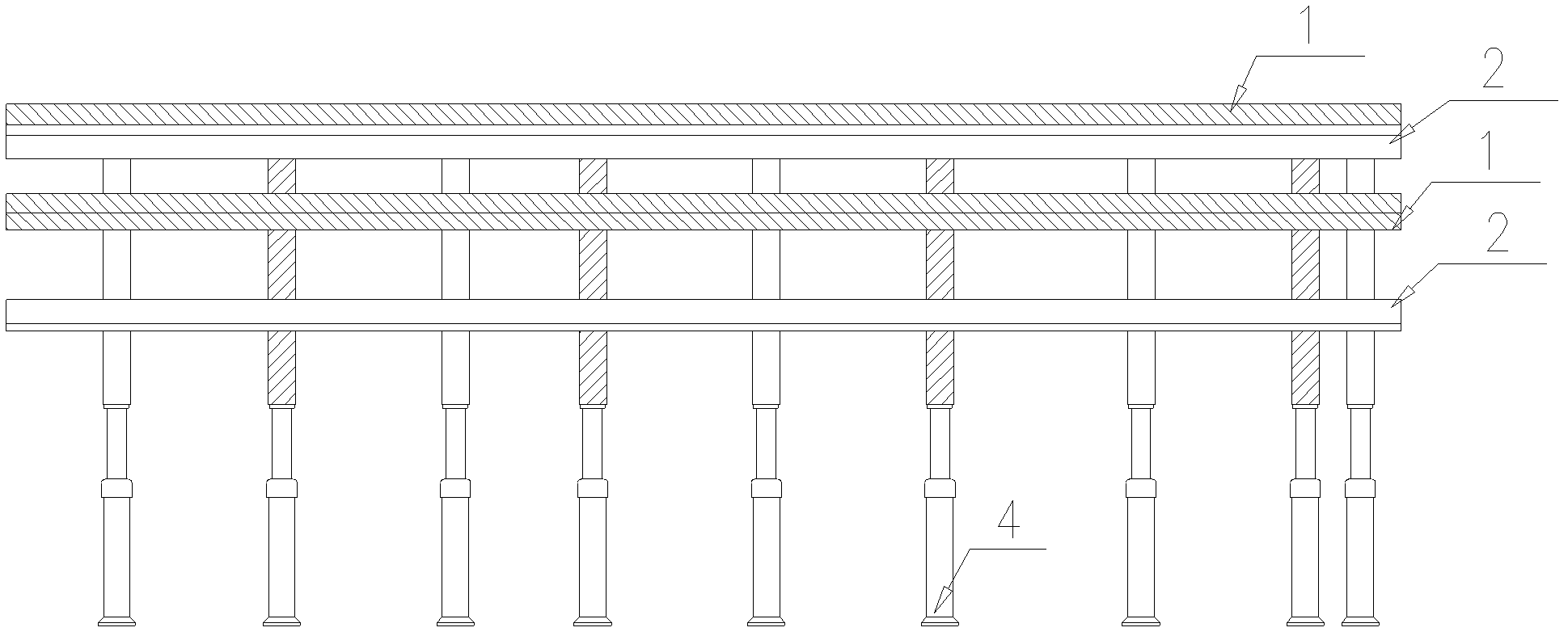

Strip filling integral backstopping coal mining method

ActiveCN101372891AHigh recovery rateMining operation safetyUnderground miningSurface miningResource recoveryBand shape

A band filling stoping mining method effectively solves the problems in the prior stoping mining of a 'three-low' coal bed, such as the sedimentation and distortion of the earth surface, the low recycling rate of coal and charcoal resources, the existence of safety hazards, etc. The method comprises the following steps: a transporter and a coal mining machine are laid on the working face of the mining area; in the direction perpendicular to the direction of the transporter movement, a timbering device which is composed of a hydraulic bracket of the working face, a side molding board bracket for filling beside the lane and a back molding board bracket for filling beside the lane, and connected with the connecting head of the transporter is arranged; after the brackets are pushed along the working face, paste concrete is injected through a pipeline into a filling mold cavity enclosed by the brackets, so as to form a band-shaped filling wall which is supported between the top plate above the goaf and the bottom plate of the coal bed. By the method, safe and convenient mining operation is ensured; the recycling rate for coal and charcoal is increased; meanwhile, the sedimentation and distortion of the overlying strata of the coal bed and the earth surface can be controlled in a very small range of deformation permitted by a building, thereby minimizing the amount of gentle sedimentation of the earth surface, and protecting buildings and attachments on the earth surface.

Owner:沈阳天安特种机器人有限公司

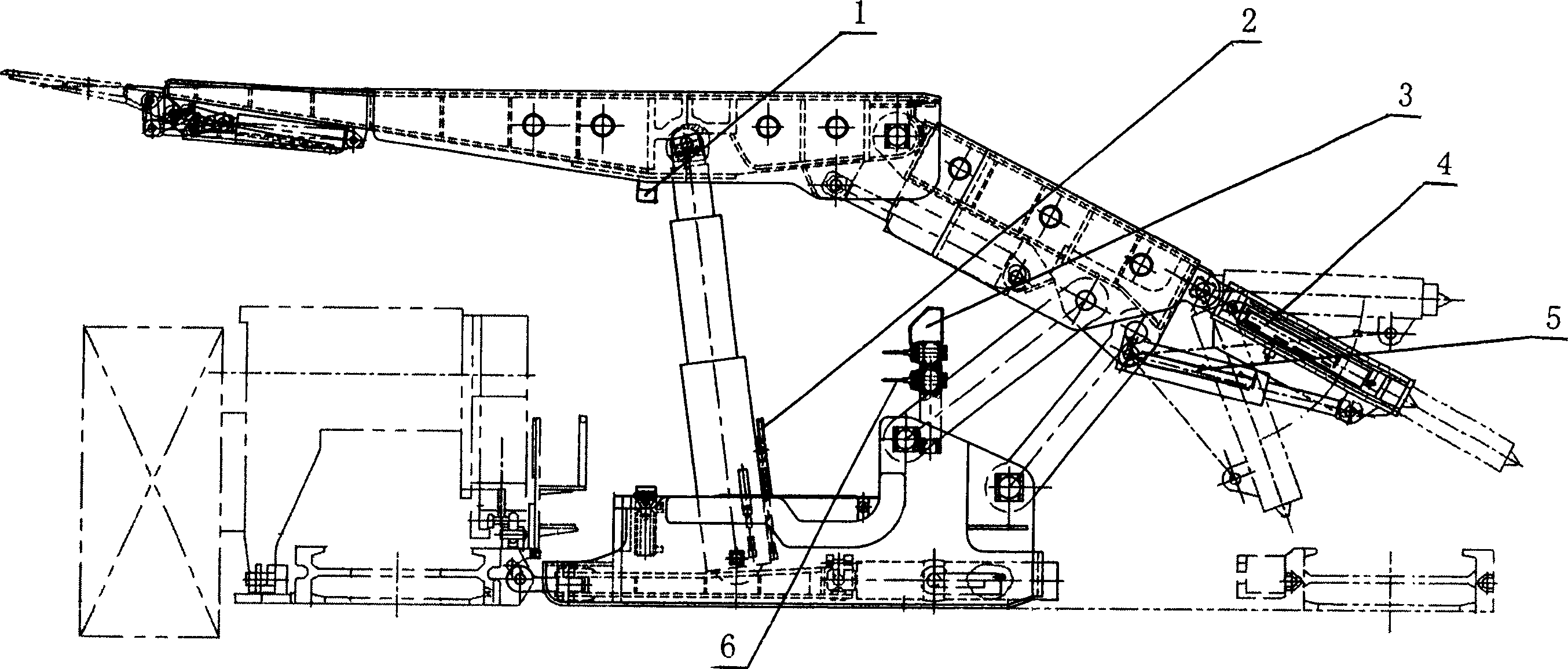

Electric hydraulic controlled caving coal method and it hydraulic supporter

ActiveCN1786420AAdd controlAdapt to process requirementsMine roof supportsProps/chocksControl systemElectro hydraulic

The invention relates to coal mine synthesizing exploiting caving top coal technique. Electro-hydraulic control caving top coal method is adopted hydraulic support to finish support caving top coal each procedure. The hydraulic support is made up of low order caving top coal hydraulic support and electro-hydraulic control system. In the electro-hydraulic control system, top beam incline sensor is added. The flash board jack is adopted travel sensor. The length of the flash board is increased, and the size of the coal discharging is adjusted in order to keep top beam horizontal and increase supporting stability. The coal discharging method includes the following steps: top coal sufficient crashing: adopting single sequence sublevel discharging; top coal middling crashing: adopting the same; top coal difficult crashing: adopting double sequence sublevel discharging. The invention can increase coal discharging control type, improve caving top coal technique adaptability, and realize high yield and high efficiency.

Owner:兖矿能源集团股份有限公司

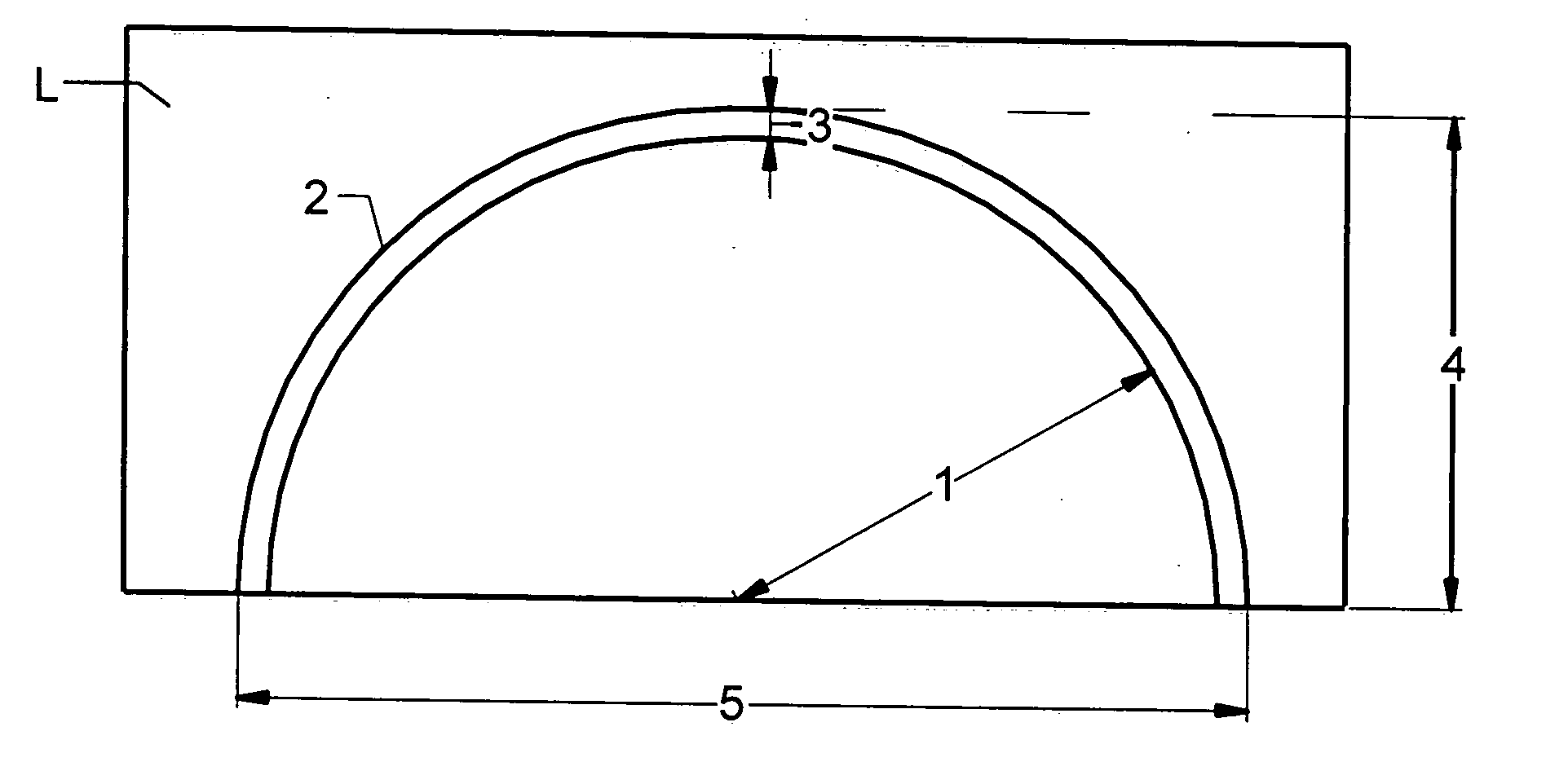

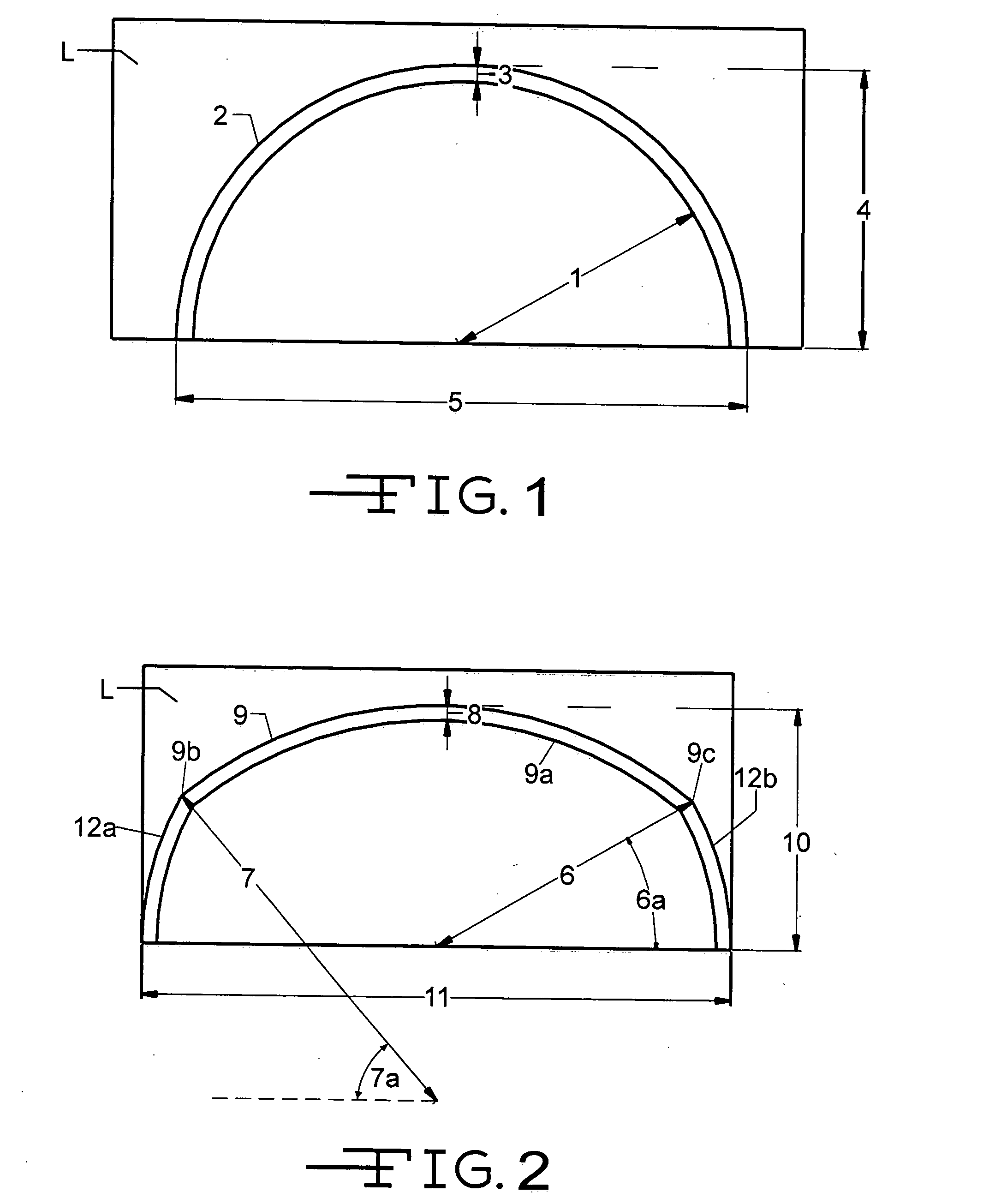

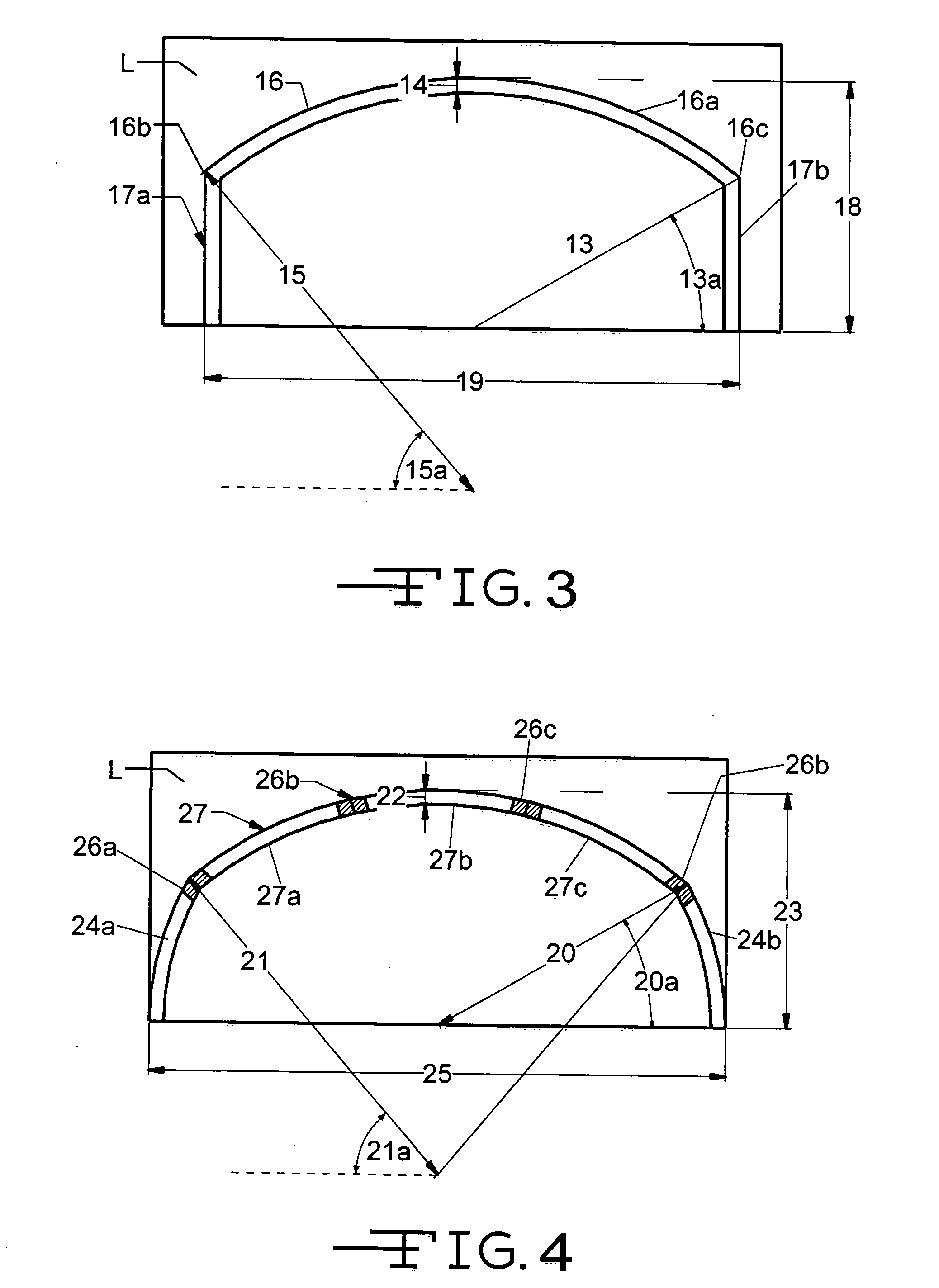

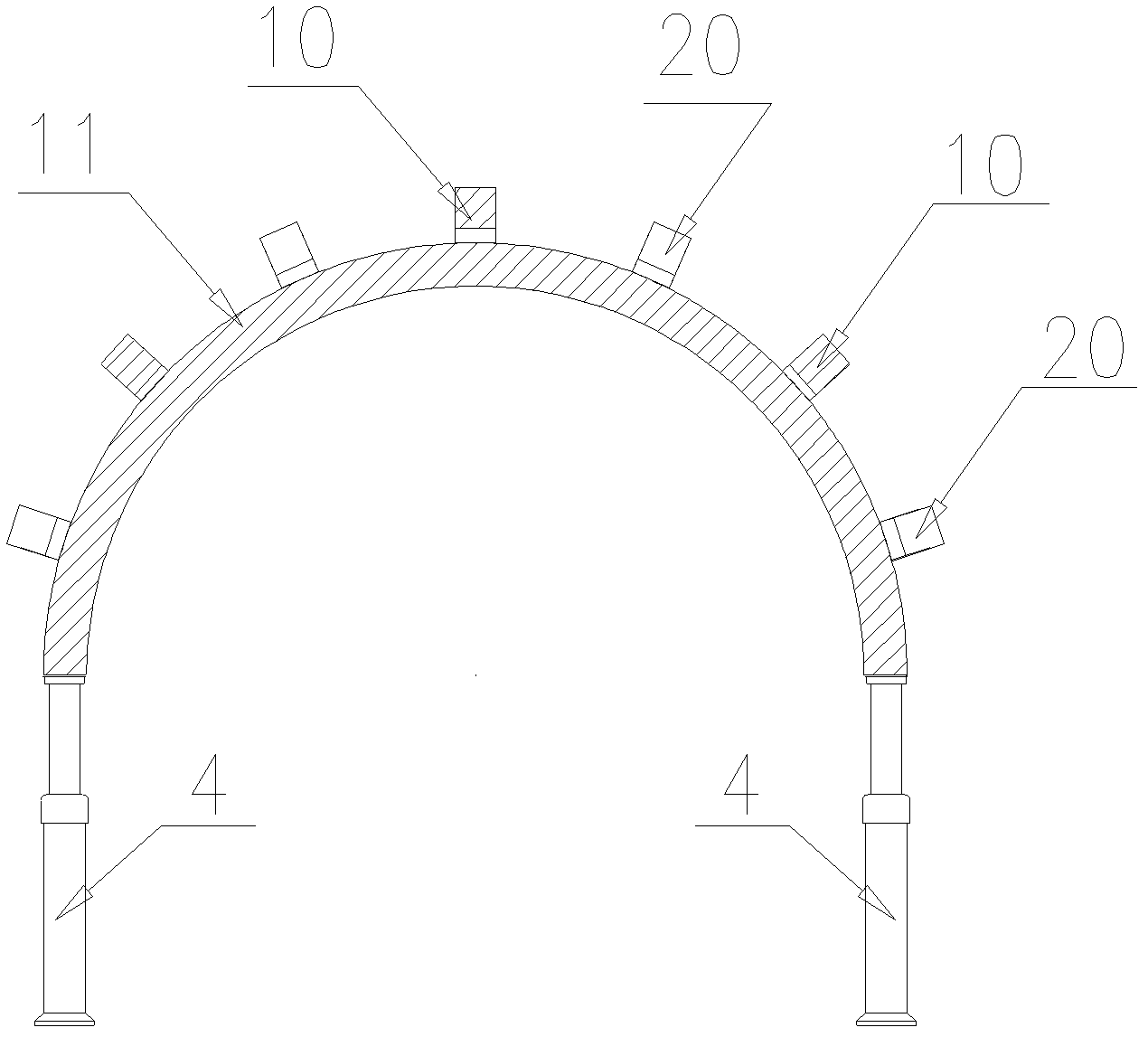

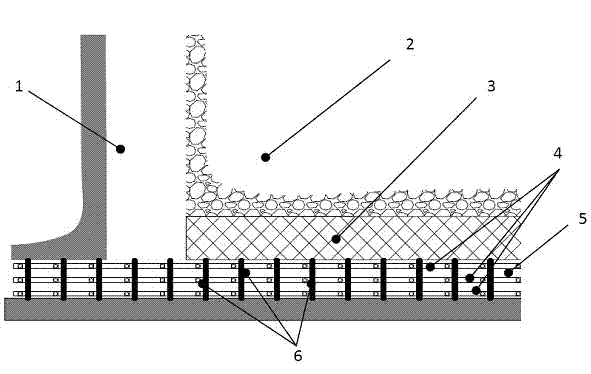

Rapidly-deployable lightweight load resisting arch system

ActiveUS20060174549A1Requires minimizationAdditional strength and stiffnessArched structuresVaulted structuresFiberVertical plane

A rapidly-erectable lightweight load resisting system for the construction of buried arched bridges, tunnels or underground bunkers, has a plurality of lightweight arched tubular support members which are formed of a fiber reinforced polymer material and are substantially oriented in a vertical plane. The lightweight tubular support members are connected by at least one or more lateral force resisting members which are positioned in a direction perpendicular to the vertical plane of the tubular support members, and which are capable of transferring vertical loads to the tubular support members and of providing lateral-load capacity to the load resisting system. The tubular support members are fitted with one or more holes near the top which allows them to be filled with a suitable material to provide additional strength or stiffness.

Owner:UNIVERSITY OF MAINE

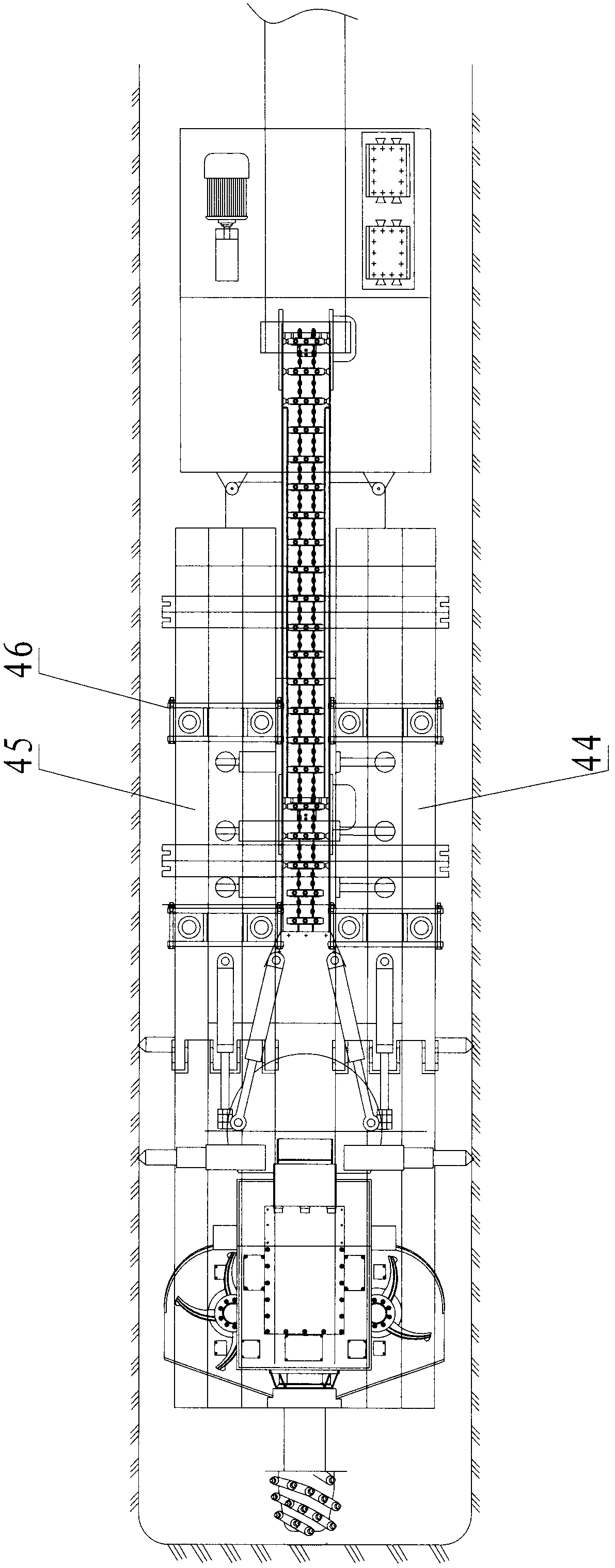

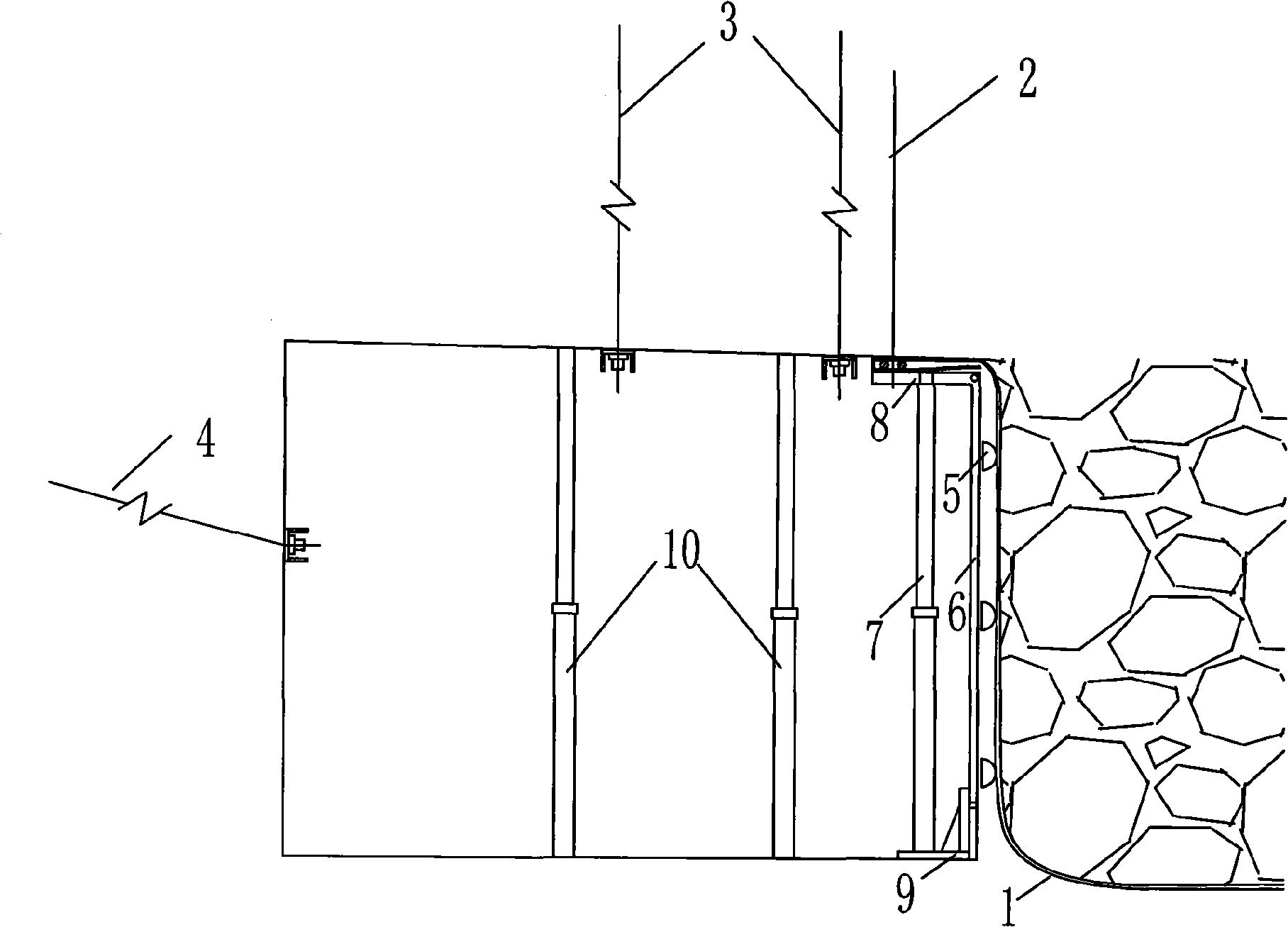

Integrated suspension device for retaining a lane for next sublevel

ActiveCN101289939AMining operation safetyEasy to operateMaterial fill-upMine roof supportsCoal pillarMechanical engineering

The invention relates to a gob-site entry retaining comprehensive support device, which effectively solves the problems not solved in the prior art that how mechanized formwork erection and whole support are carried out, and realizes difficult problem that filling and coal-mining production are carried out at the same time. The technical key points of the device are as follows: a roadway advancing and retaining support is arranged in a transportation roadway or a return airway; a roadway filling back formwork support, a roadway side filling formwork support and a set of working face hydraulic supports are arranged parallelly in sequence along a roadway; and all supports are vertically connected along the running direction of a transporter; the roadway side filling back formwork support, the roadway side filling formwork support which is arranged on the left of the roadway side filling back formwork support, and an adjustable hydraulic formwork which is arranged on the right of the roadway side filling back formwork support to surround a filling mould cavity which forms a gob-site entry retaining and filling wall. The device has the advantage that the device is favorable for mining a no-coal pillar, is safe and convenient to operate, and is strong in adaptability, can form an insulating gob area in the roadway side and a shield concrete filling wall which is solidified and hardened into a regular wall body, and can shield and match a working face transporter, a coal mining machine and a formwork support to perform normal coal-mining production.

Owner:SHENYANG TIAN AN TECH CO LTD +1

Method of support along spatially keeping lane

ActiveCN101117890ARelieve pressureMake sure not to breakMaterial fill-upProps/chocksSpontaneous combustionEngineering

A method for supporting and protecting gob roadway walls built along the gob road-way is characterized in that the filling bodies of gob roadway walls are built along the working surface at the side of the goaf to establish a supporting and protecting belt for gob roadway walls. The method can effectively control the roof delamination of a direct roof and can timely cut off the roof and the lower basic roof and also can fill out goaf with the falling recrement, thereby reducing the bending of the basic roof, and the loading of the inner supporting and protecting structure and the deformation of the wall rock of the gob roadway, as well as keeping the stability of the gob roadway, meanwhile, the method also can seal the goaf, prevent air leaking and spontaneous combustion of coal, and avoid harmful air coming into the working area.

Owner:HUAINAN MINING IND GRP +2

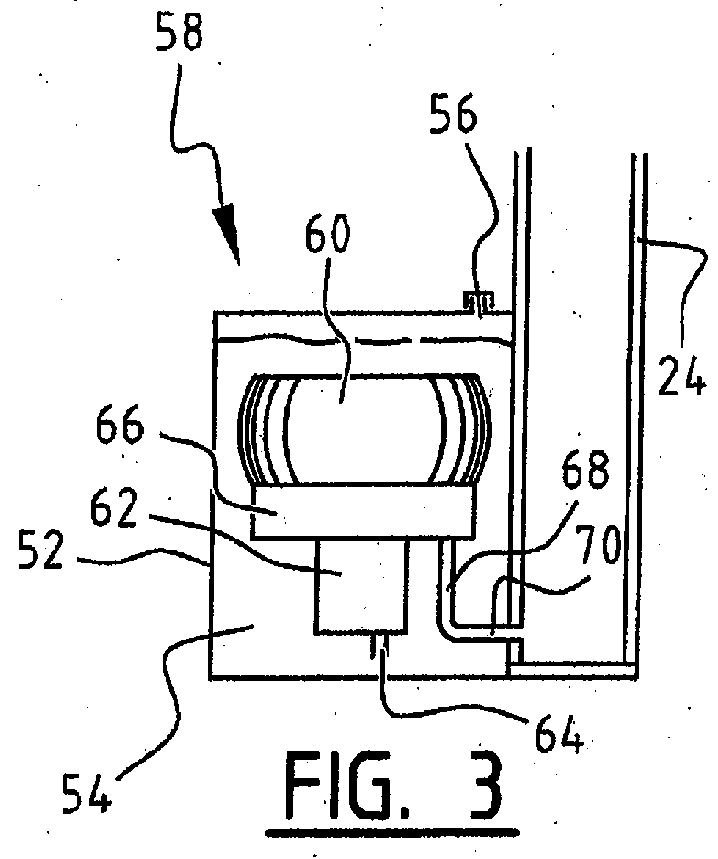

Pneumatic lift device

InactiveUS6929249B1Light weightLow costVehicle with pivoted armsBuilding rescueEngineeringMechanical engineering

Owner:KIM SUN Y

Top breaking gob-side entry retaining method for tender roofs

InactiveCN104929666ACollapse accident preventionAvoid damageUnderground chambersMine roof capsShotcreteStone wall

The invention discloses a top breaking gob-side entry retaining method for tender roofs. The top breaking gob-side entry retaining method includes steps of firstly, reinforcing and supporting the tender roofs of roadways jointly supported by original anchor meshes and cables or supported by sheds; secondly, laying wire meshes on gob sides; thirdly, preliminarily breaking the roofs of the roadways on the gob sides; fourthly, piling up preliminarily broken caved gangue until the caved gangue reaches rock of upper-end hard roofs to form gangue piled walls; fifthly, burying perforated grouting pipes in the formed gangue walls, spraying concrete on the surfaces of the wire meshes and the surfaces of the gangue walls to form concrete sprayed supporting layers; sixthly, injecting concrete grout in each preliminarily buried grouting steel pipe by the aid of a grouting pump after the concrete sprayed supporting layers are solidified; seventhly, sequentially detaching falling preventing devices and dense reinforcing columns along with advancing of working faces; eighthly, reinforcing and supporting the roofs under special conditions. The top breaking gob-side entry retaining method has the advantages that active bearing supporting effects can be realized for inherent characteristics of the tender roofs, supporting forms are simple, the cost is low, and entry retaining effects can be efficiently realized.

Owner:CHINA UNIV OF MINING & TECH

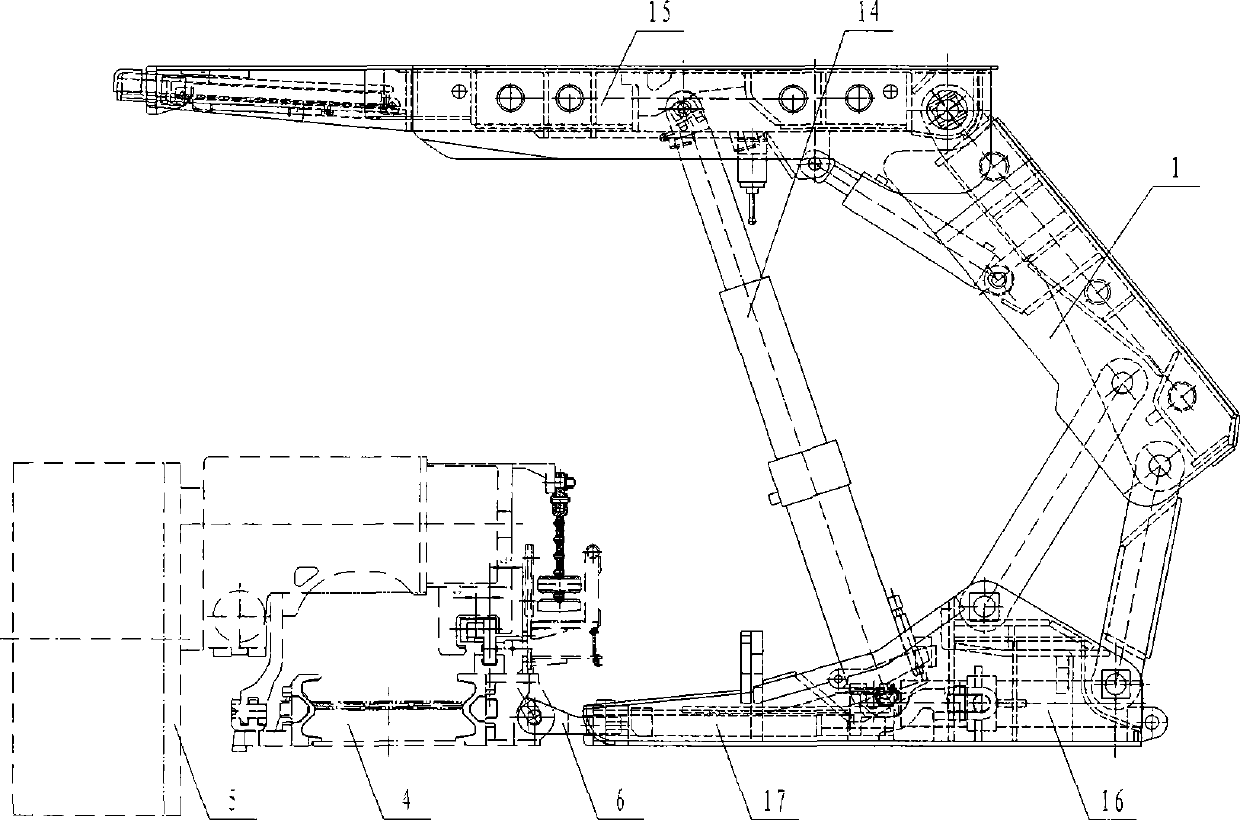

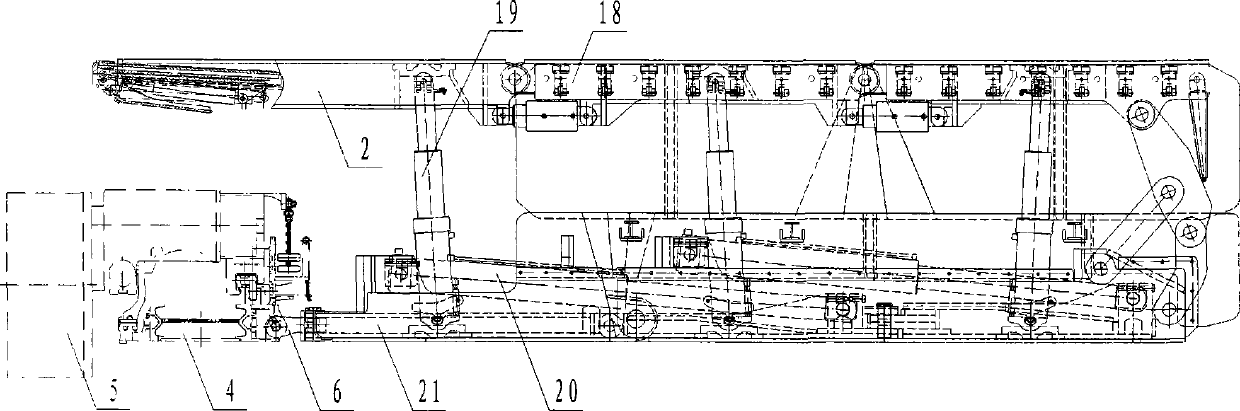

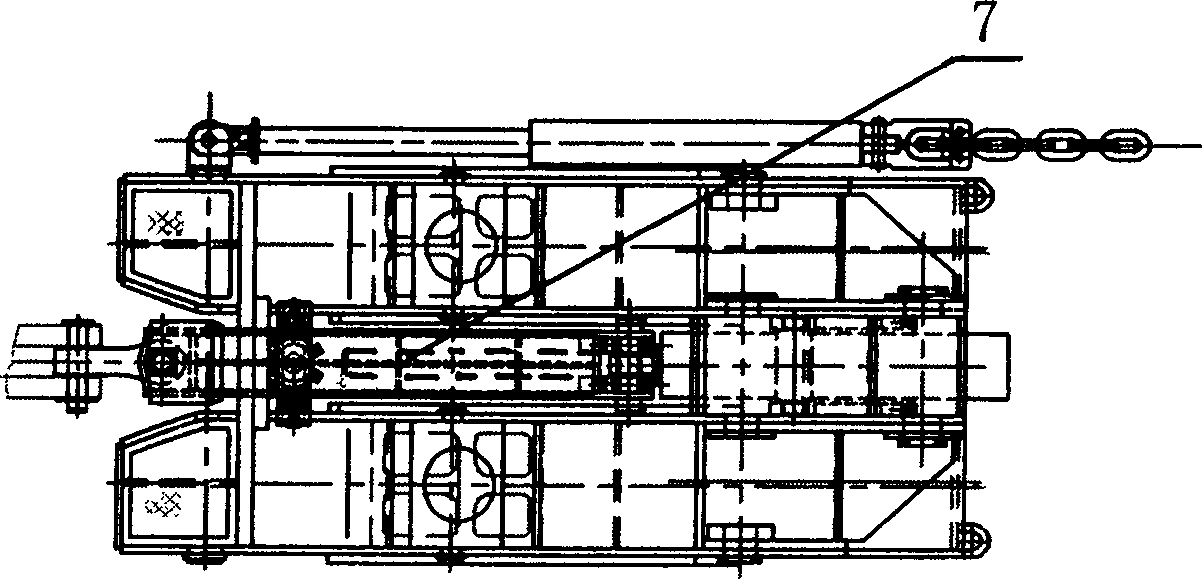

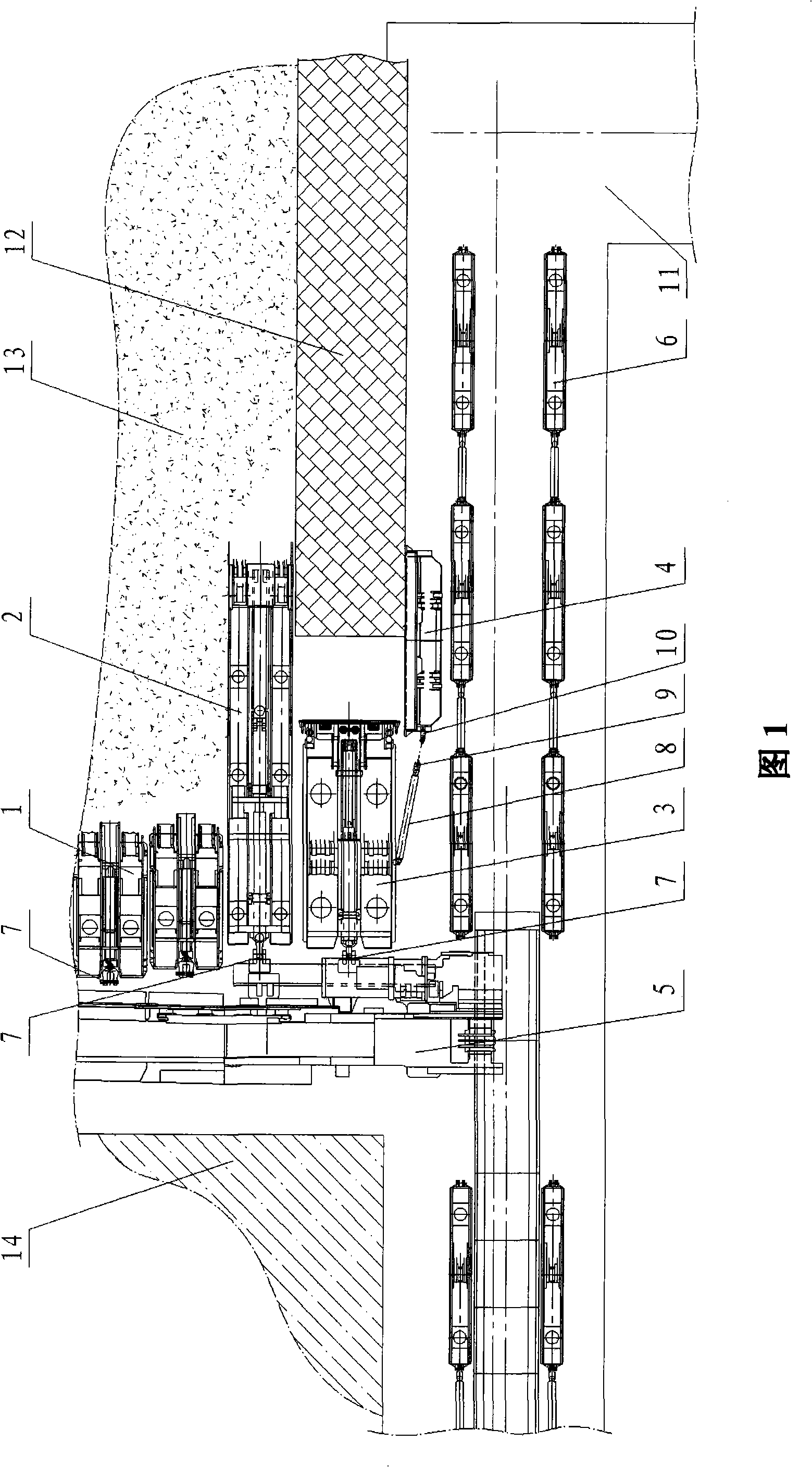

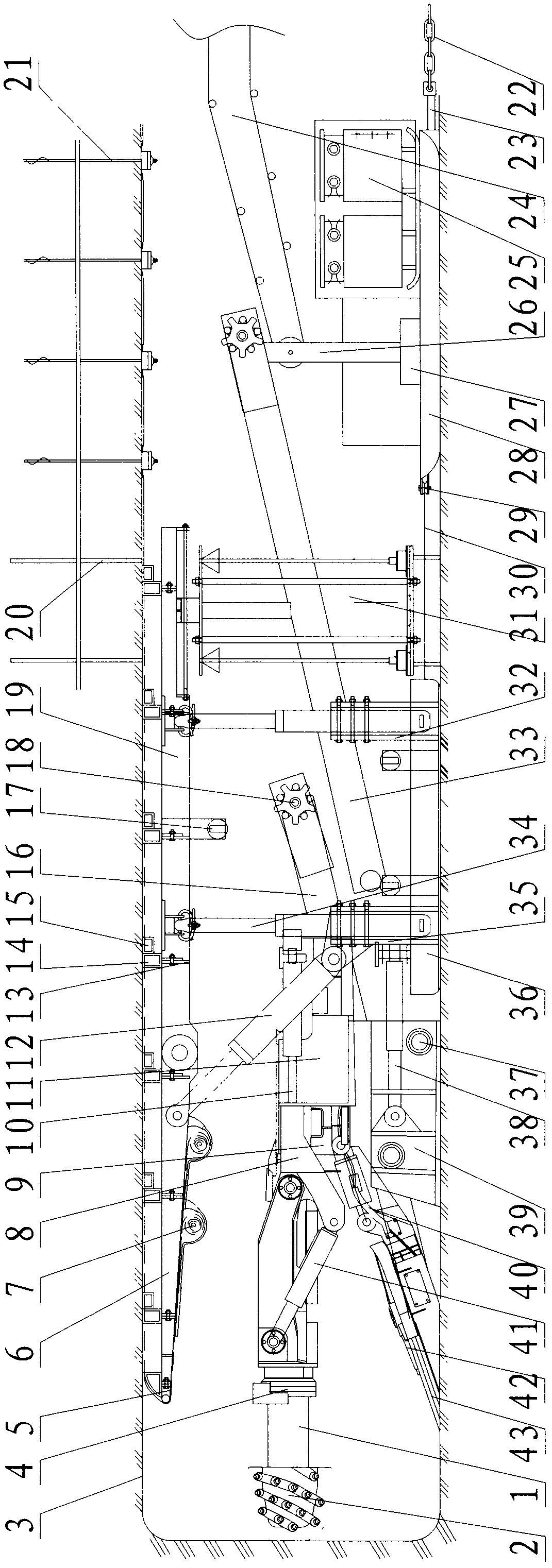

Support-type comprehensive tunneler

ActiveCN102022122AOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsEngineeringMetal mesh

The invention relates to a support-type comprehensive tunneler which comprises a non-tracked tunneler, a tunneler chassis, a left hydraulic support, a right hydraulic support, a drilling rig and scraper conveyors, wherein the tunneler is arranged on the tunneler chassis, and two advancing jacks are arranged on the tunneler chassis; the other ends of the two advancing jacks are respectively connected with the left hydraulic support and the right hydraulic support, and the two sides of the tunneler chassis are respectively provided with a lateral pushing oil cylinder; forestopes of the left andright hydraulic supports are respectively provided with a group of metal mesh storages, and the tail of a main top beam of the support is hung with the drilling rig; the tail of a first scraper conveyor is arranged on a spade plate of the tunneler, and the head of the first scraper conveyor and the tail of a second scraper conveyor are overlapped; and the head of the second scraper conveyor and the tail of a belt loader are overlapped, and sleds are arranged at the back of the two hydraulic supports. The tunneler has the advantage that the drilling support and the coal cutting of the tunnelerare simultaneously carried out, and also has the automatic lapping function, thus reducing labor intensity and increasing the coal mining efficiency by over 4 times.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

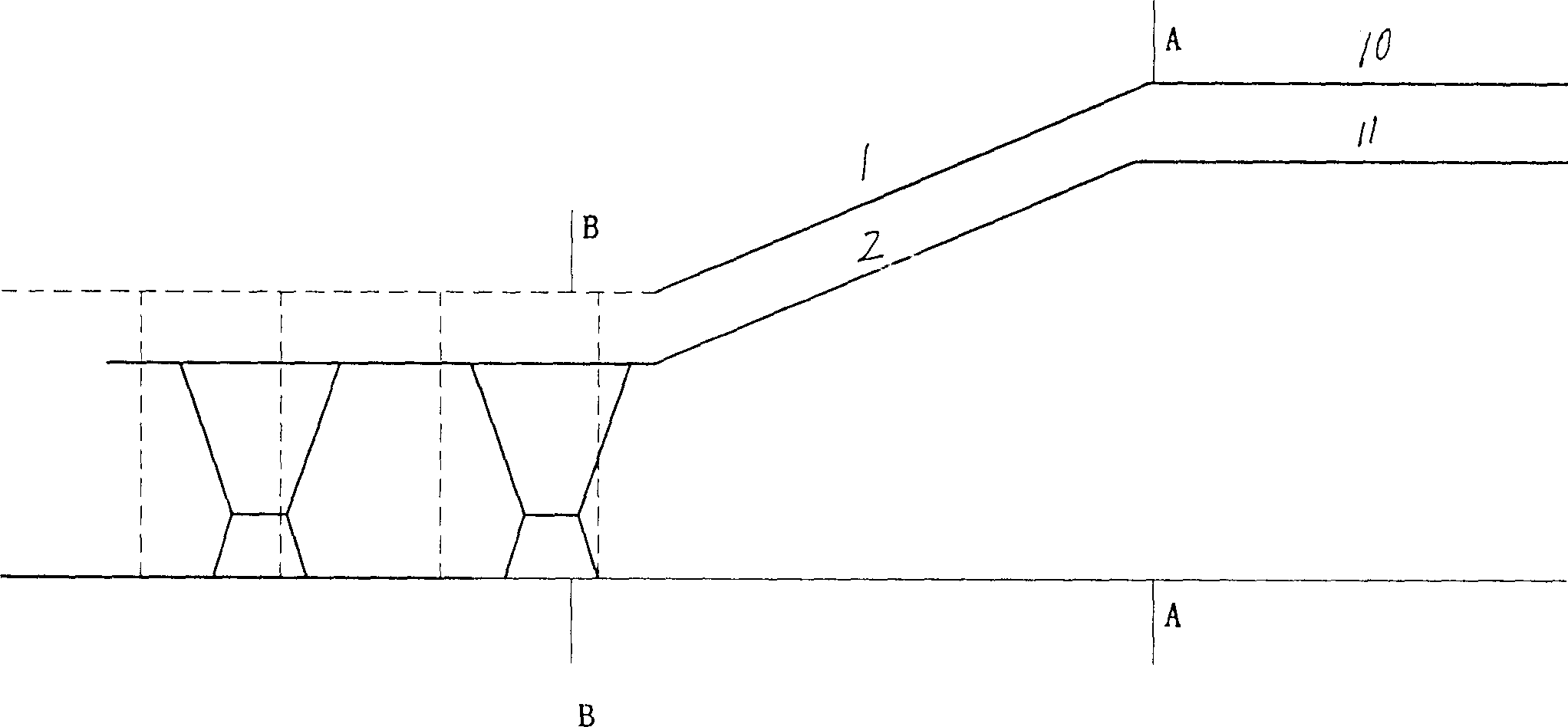

Method for constructing from inclined shaft to main tunnel in weak surrounding rock

ActiveCN101775988ASolve construction problemsThe schedule is smoothUnderground chambersTunnel liningContour lineSafety risk

The invention discloses a method for constructing from an inclined shaft to a main tunnel in weak surrounding rock, which is performed according to the following construction steps: 1) climbing at a gradient of 20 to 25 percent and expanding and excavating the inclined shaft at a position 8 to 12 meters away from a construction edge of the main tunnel, and expanding and excavating a curved roadway at a position 1 to 3m higher than a contour line of a main tunnel cross section wherein the climbing height from a starting point to an ending point is 1 to 3m; 2) installing a large arch supporting frame on the main tunnel cross section, cutting off side wall supporting legs of a small arch supporting frame, and overlapping the two supporting legs of the small arch supporting frame on the large arch supporting frame; 3) inserting a plurality of advanced small pipes into a rock strata transversely along the top of the large arch supporting frame and vertically excavating to three steps of preserved core soil of the main tunnel; and 4) excavating an upward arch at the bottom of the main tunnel because the other side of an intersection of the inclined shaft and the main tunnel is an end wall. The method solves the problem of difficult construction from the inclined shaft to the main tunnel in the weak surrounding rock or sites with complex geological condition changes, greatly reduces safety risks, and has obvious effects.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

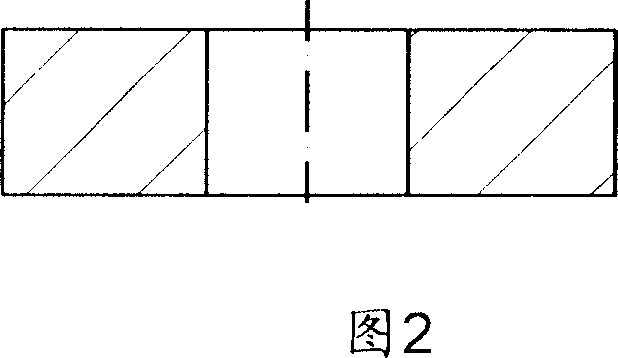

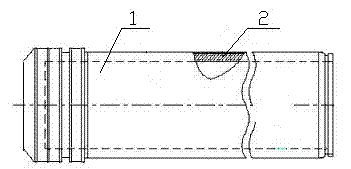

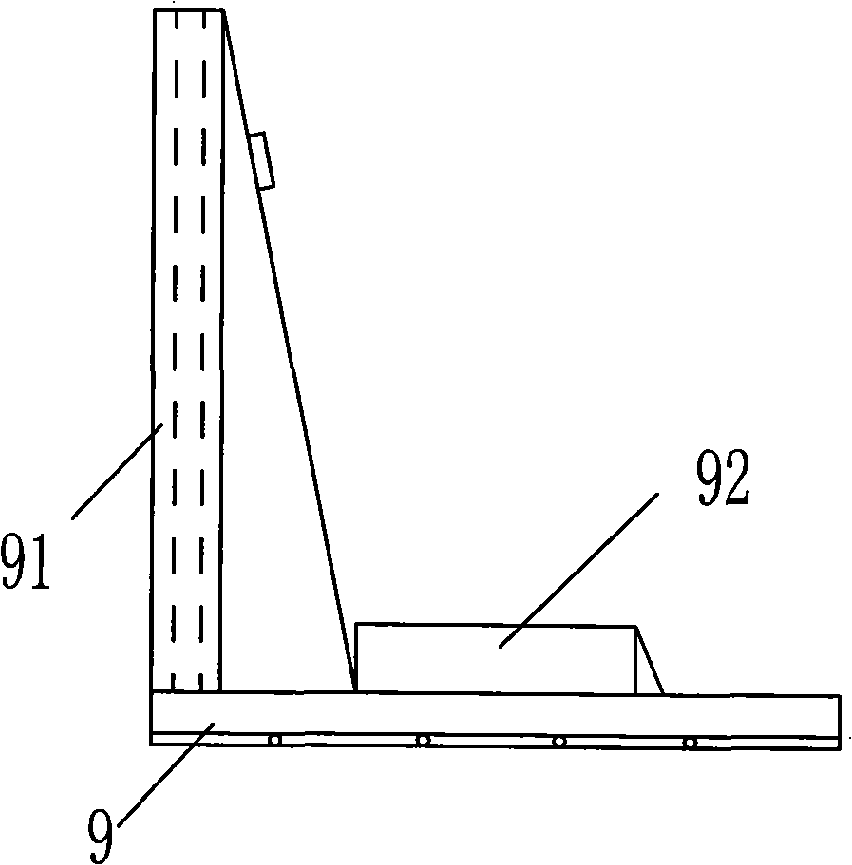

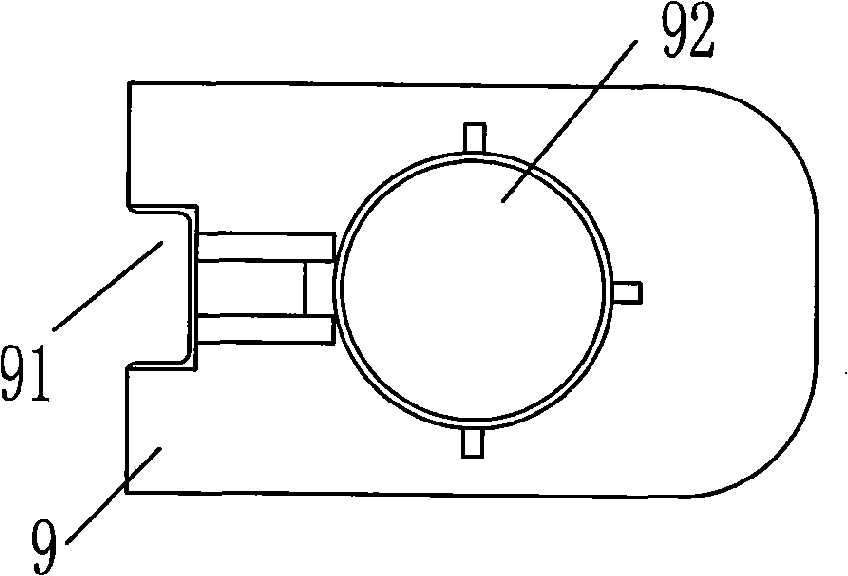

Supporting device

The present invention discloses a kind of supporting equipment. It includes several steel pipes, the adjacent two steel pipes are mutually connected by means of connecting pipe, the interior of every steel pipe is filled up with concrete, and the butt-jointed position of two adjacent steel pipes is equipped with wood pad or other flexible pad, in the centre of said flexible pad is cut a through hole through which the concrete can be flowed on the side portion pipe wall of said supporting equipment a grouting hole is cut, and on the upper portion pipe wall of said supporting equipment an air exhaust hole is cut. Said supporting equipment can be used for roadway support.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Coal-minin method of high-dipping thick seam

InactiveCN1657745AImprove ventilationReduce air volumeUnderground miningTunnel/mines ventillationEconomic benefitsEngineering

The invention discloses a method for coal mining to the greatly oblique coal layer, comprising two steps: designing the method and back producing technique, placing slit flexible shielding support in the coal layer of 8-10m and deciding return airway and cutting point; the back producing technique includes enlarging airway, installing support, put down support and desinence of working face, etc. The method has simple operational steps as well as remarkable economic benefit.

Owner:KAILUAN GRP

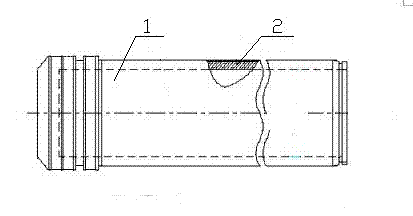

Laser cladding method for mining hydraulic support column and mining stainless steel hydraulic column

InactiveCN102242361AMetallic material coating processesLaser beam welding apparatusEngineeringErbium lasers

The invention relates to a laser cladding method for a mining hydraulic column and a mining hydraulic column. The laser cladding method for a mining hydraulic column comprises the steps as follows: a laser beam and a nickel-based alloy powder stream output by a powder feeder are utilized to form helical scanning along the surface of a movable column of a column body 1; the section of the laser beam output by a laser head is set into a (15-20mm)*(1.5-2.5mm) rectangular spot, the scanning linear velocity of the laser beam is set at 480-720 mm / min, and the output power of the laser for outputting the laser beam is set at 7200-7400 W, wherein the nickel-based alloy powder output by the powder feeder contains the following components in percentage by weight: not more than 0.15% of C, 0.5-1.0% of Si, 0.4-0.8% of Mn, 17.5-19.5% of Cr, 21-25% of Ni and the balance of Fe; and a mining hydraulic column with a laser cladding layer (2) which has a thickness of 0.4-0.7 mm and is formed by laser cladding of the nickel-based alloy powder is arranged on the movable column of the column body (1). Thus, the service life of the column is prolonged.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD +1

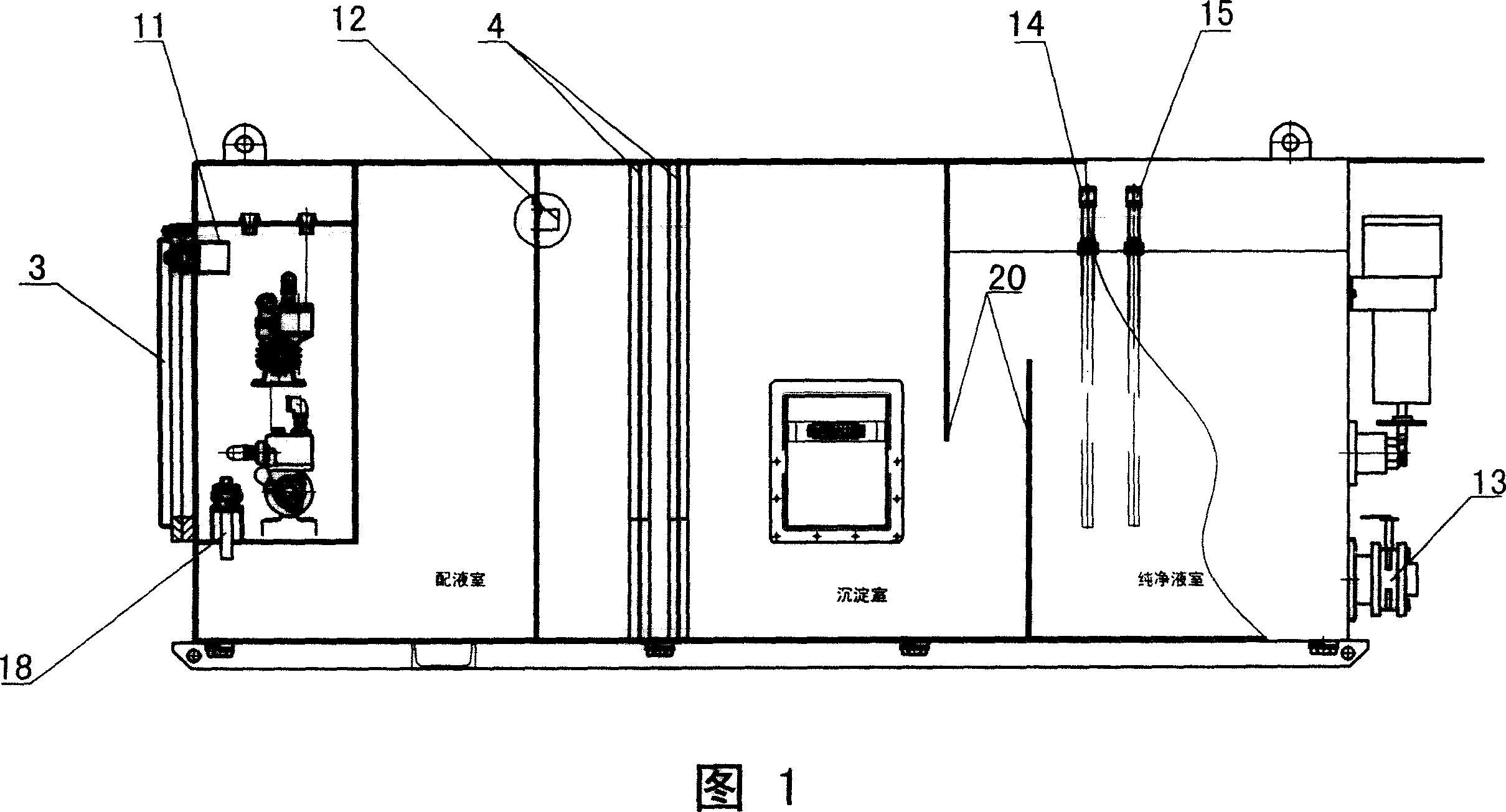

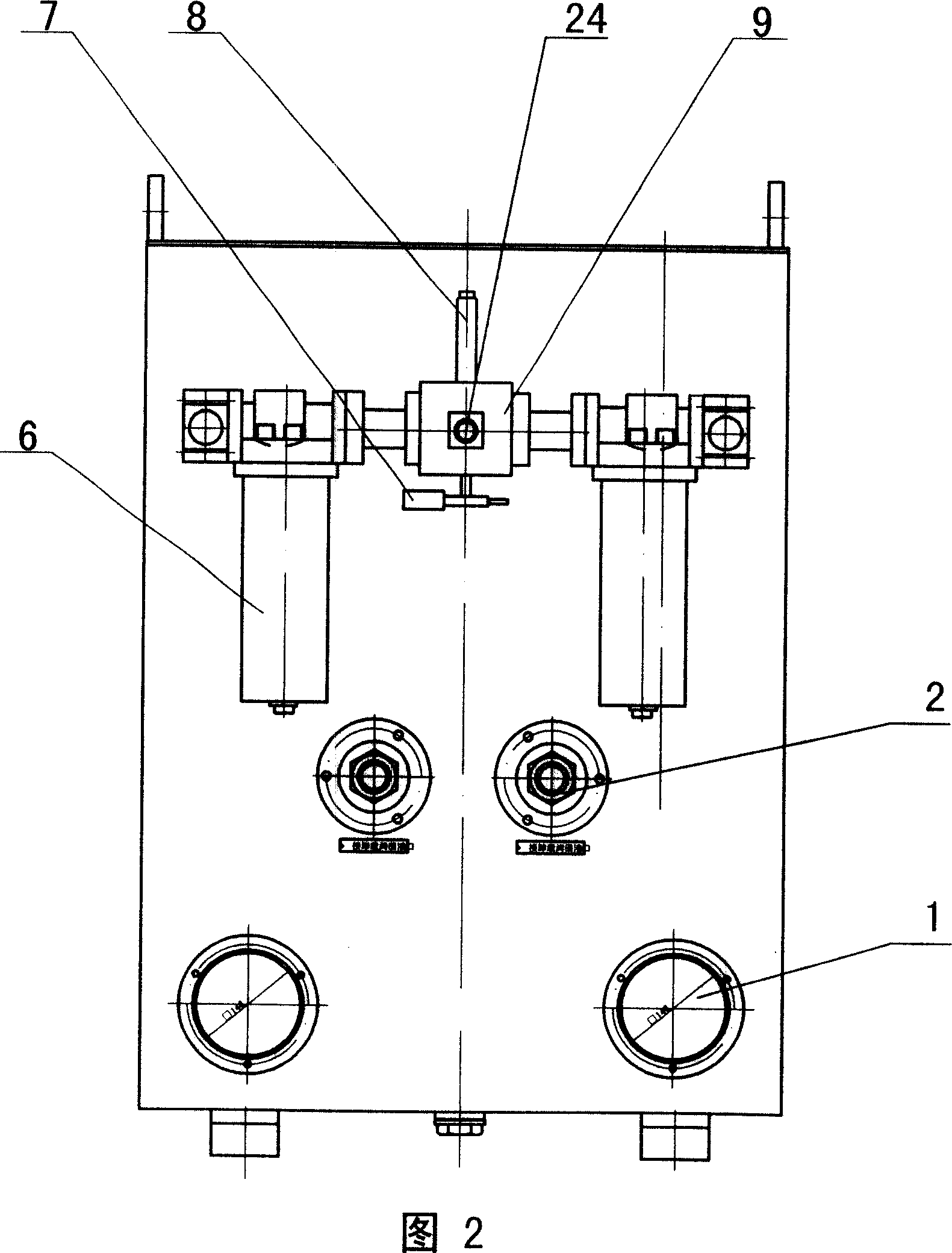

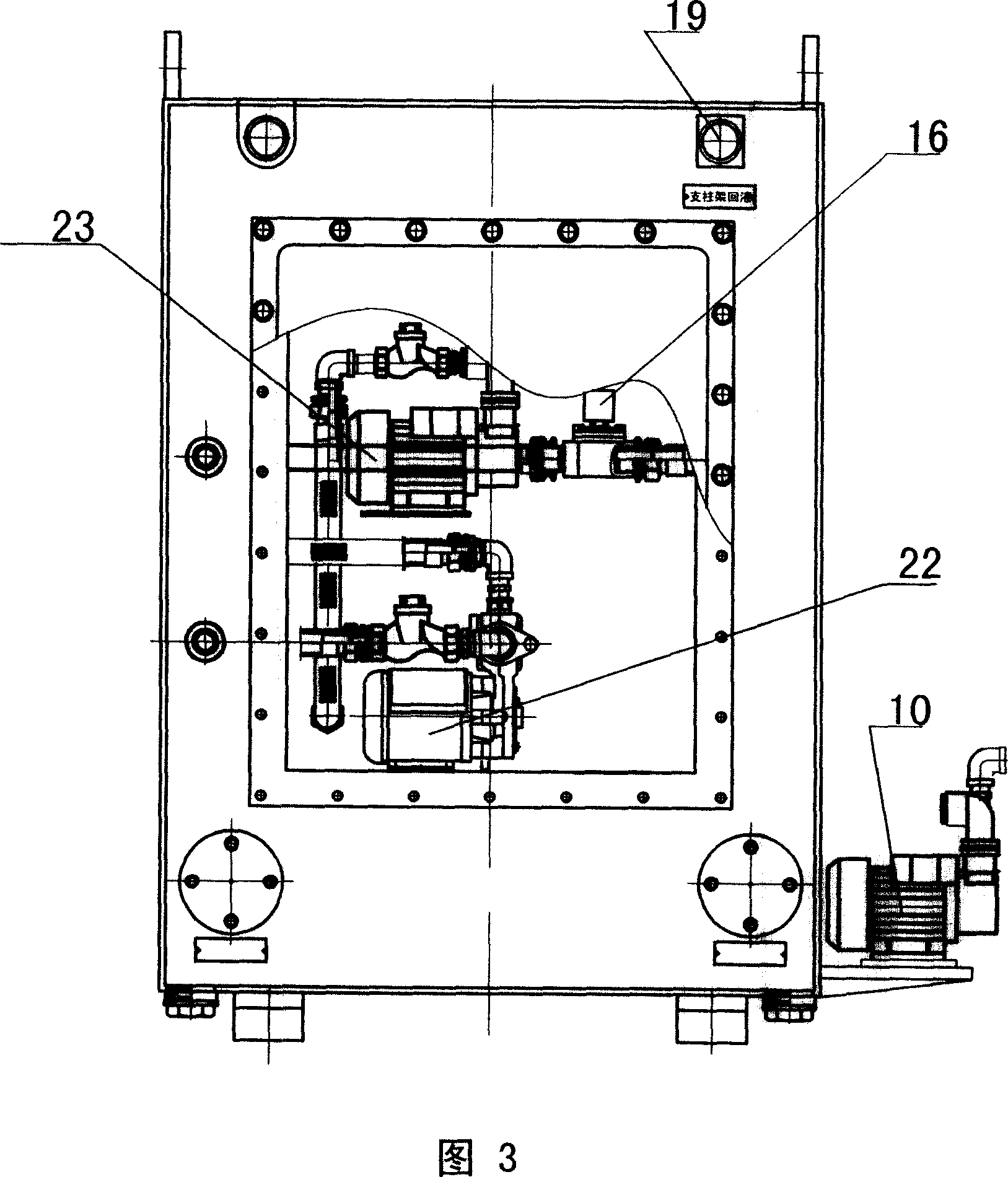

Intelligent emulsion pump station for mining

ActiveCN101126402AEconomical and energy efficient operationExtended service lifeAccumulator installationsFluid-pressure actuatorsAutomatic controlEmulsion

The invention relates to an intelligent emulsion pump station used in the mine, which belongs to a safe production equipment of coal excavation and comprises an emulsion tank, an emulsion pump, an emulsion pipeline, an emulsion pump station controller. The invention is characterized in that: the emulsion pump station controller comprises a primary control circuit, a secondary control circuit and a PLC programmable controller system control circuit; a pressure sensor (8), a liquid level sensor (14),a concentration sensor (15) and an oil level sensor (18) are arranged in the emulsion tank; a temperature sensor (5) is arranged on an emulsion pump (25); the pressure sensor (8), the liquid level sensor (14),the concentration sensor (15) and the oil level sensor (18) and the temperature sensor (5) are connected with the emulsion pump station controller through a cable. The pumping station adopts constant pressure variable feed liquid, speed control by frequency variation and intelligent control, the two pumps can mutually switch over automatically; the liquid level and the oil level are controlled automatically, the temperature of the emulsion pump is supervised automatically, the safe pressure relief protection and the automatic liquid blending improves the service life of the hydraulic support, highlights the explosion proof security in the coal mine; the working performance is reliable and the operation of the pumping station is economical and energy-saving.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

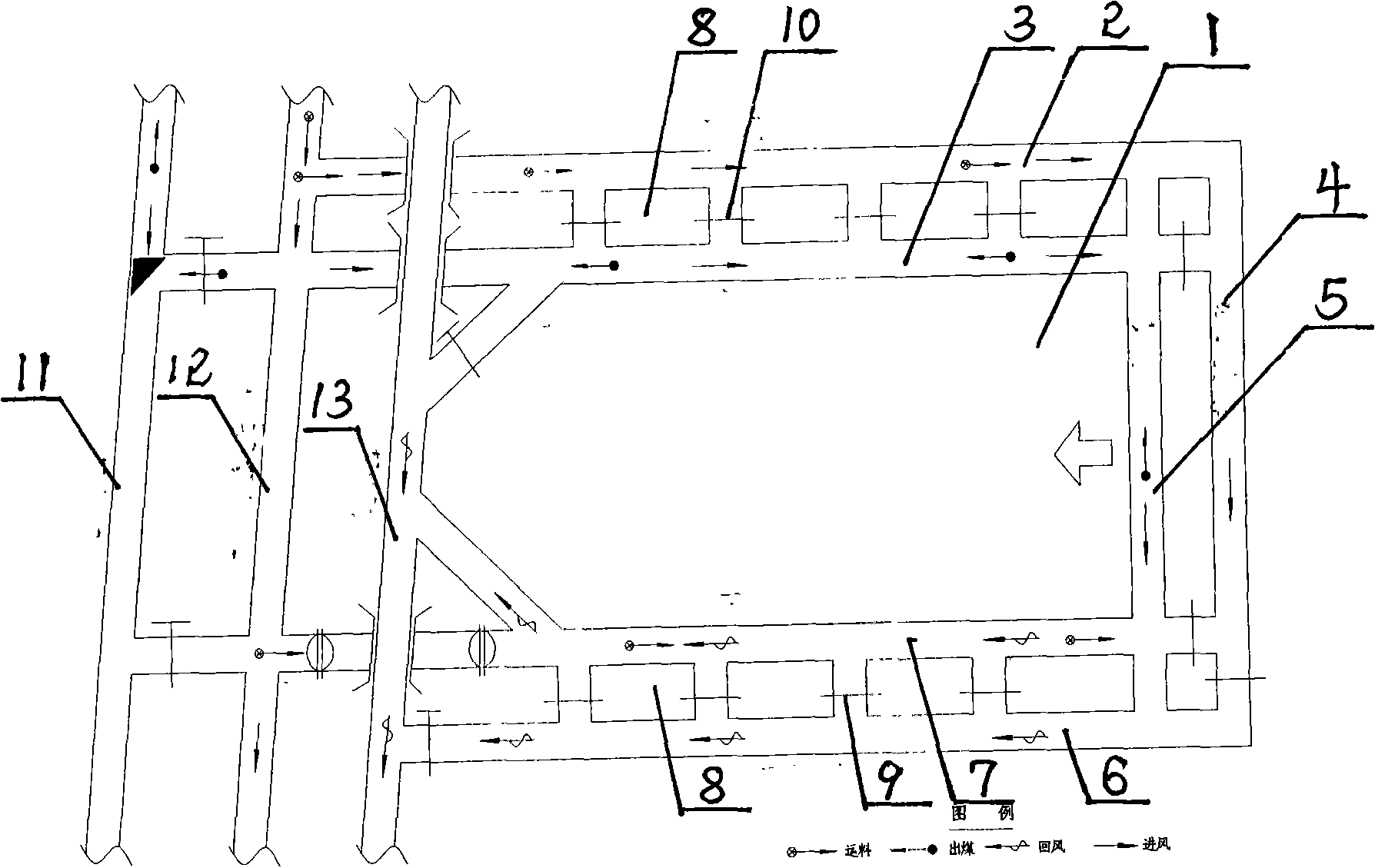

Laneway disposed by using large U to sleeve small u

InactiveCN101649741ARealize continuous excavationImprove governance effectUnderground miningTunnel/mines ventillationEngineeringCoal pillar

The invention relates to a laneway disposing shape of a coal mine, in particular to a laneway disposed by using large U to sleeve small u, which solves the problems of driving along a groove and gas control of a stope in the prior laneway disposing mode. The laneway comprises a stope, a small u-shaped laneway is arranged at the periphery of the stope, the small u-shaped laneway comprises a belt laneway and a return airway which are arranged on both sides of the stope, the front side of the stope is provided with a cutting hole, a large U-shaped laneway is arranged outside the small u-shaped laneway and comprises a head-to-tail connection device, a ventilation laneway, a ventilation connection laneway and a gas tail laneway, wherein the head-to-tail connection device and the ventilation laneway are positioned outside the belt laneway, the ventilation connection laneway is arranged outside the cutting hole, the gas tail laneway is positioned outside the return airway, and a plurality ofentity supporting coal pillars are arranged between the large U-shaped laneway and the small u-shaped laneway. The laneway disposing shape solves the problem of gas control of the stope and increaseswork efficiency.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

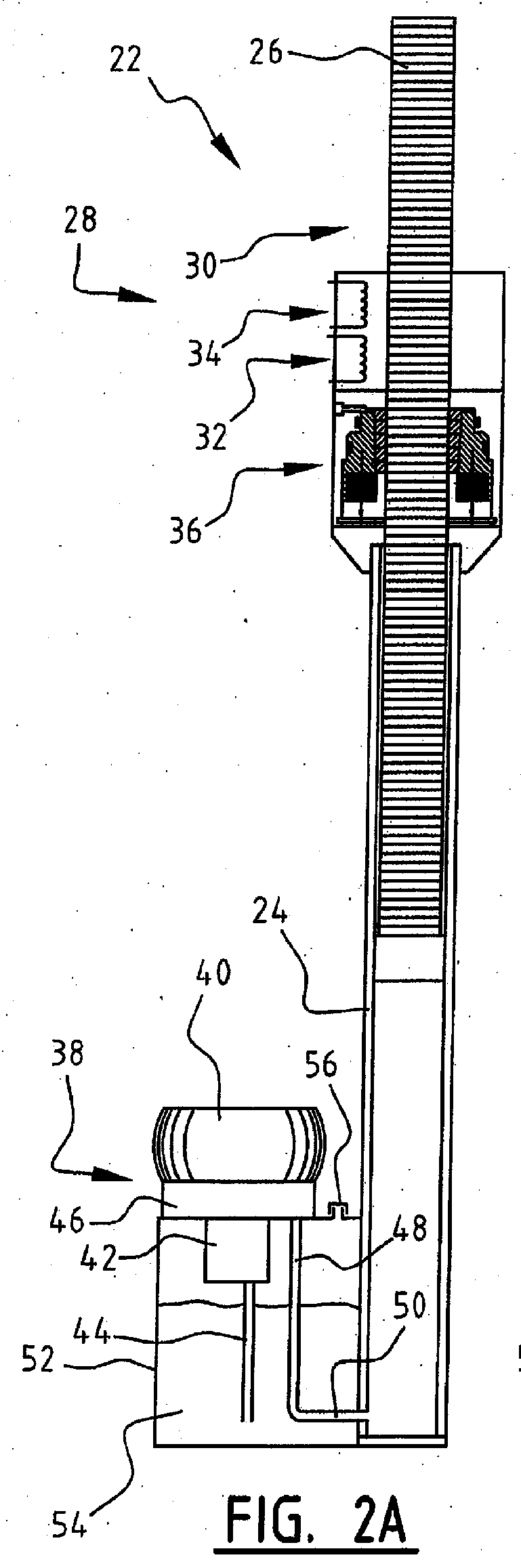

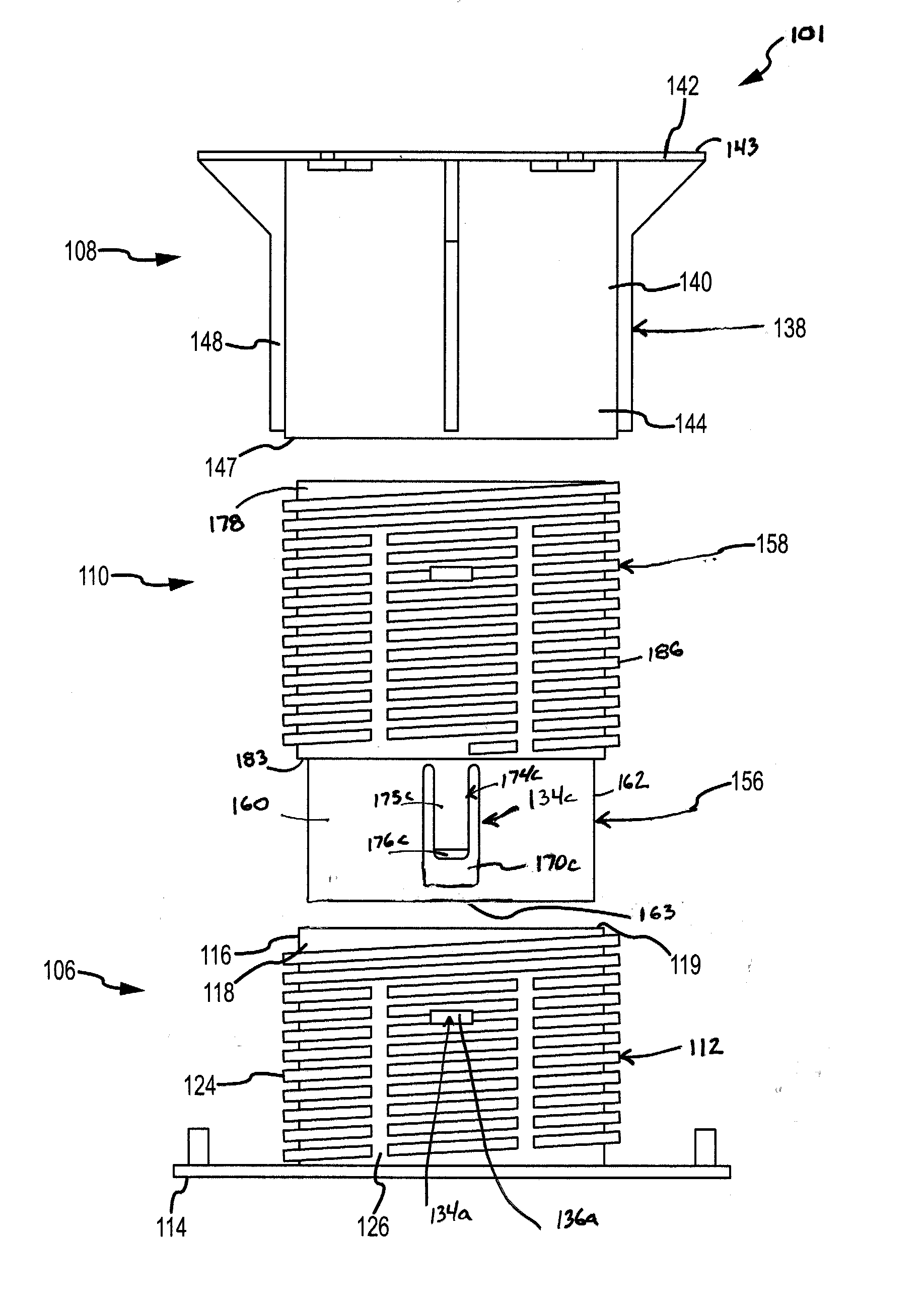

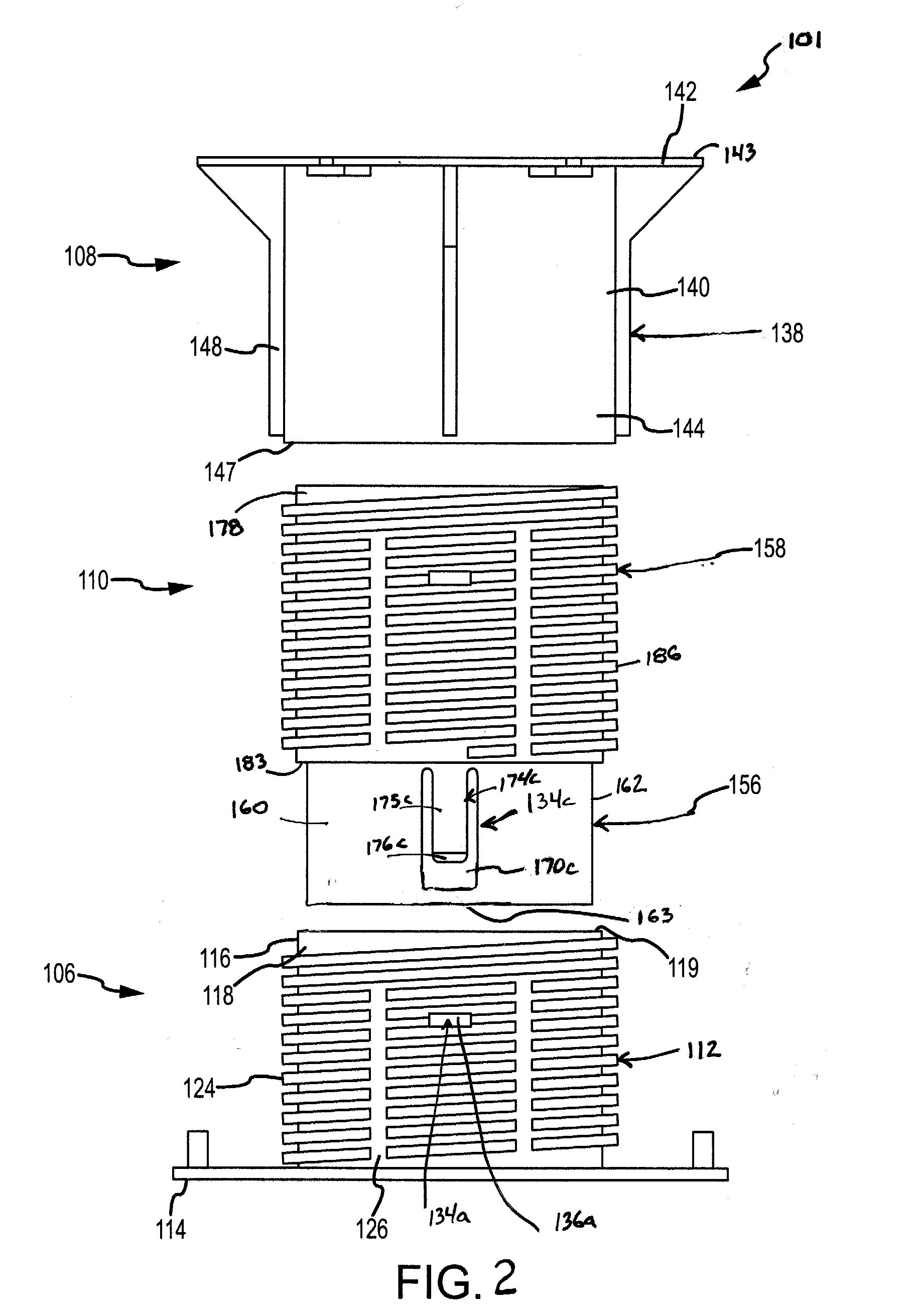

Lifting Device and System with Integrated Drive Unit for Lifting a Vehicle, and Method There For

ActiveUS20160052757A1Compact and effective hydraulic fluid circuitReduce in quantitySafety devices for lifting equipmentsLifting framesHydraulic cylinderFuel tank

Provided is a lifting device, lifting system and method for lifting a vehicle. The lifting device according to the invention includes a frame with a carrier configured for carrying the vehicle; a drive which acts on the carrier, wherein the drive includes an integrated hydraulic cylinder drive unit configured for raising the carrier with the integrated hydraulic cylinder drive unit including: a housing of a cylinder; a piston rod movable in the housing; a height measuring system configured for measuring the displacement of the piston rod; and an integrated hydraulic fluid tank and motor unit that is configured for driving the piston rod.

Owner:STERTIL

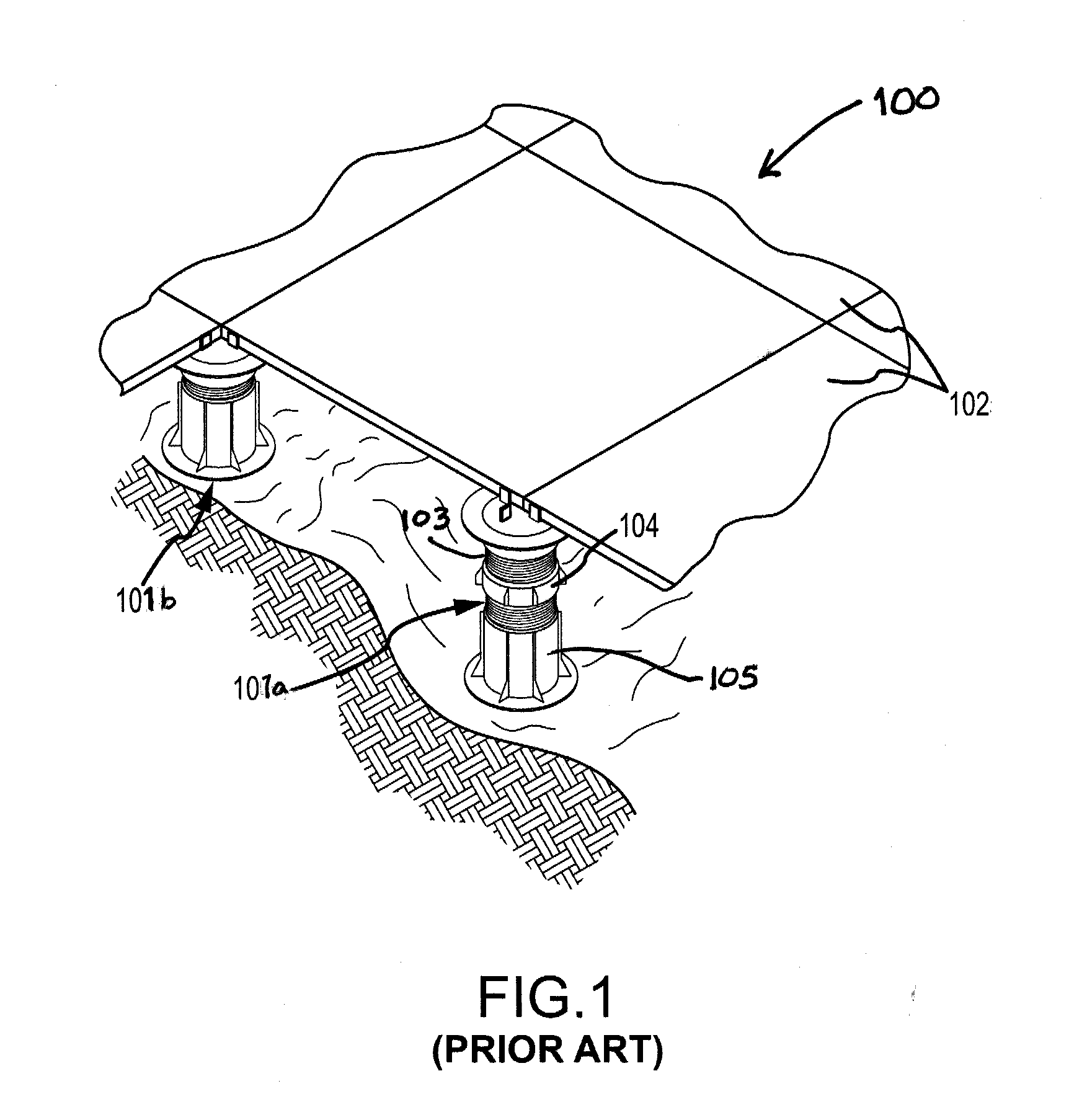

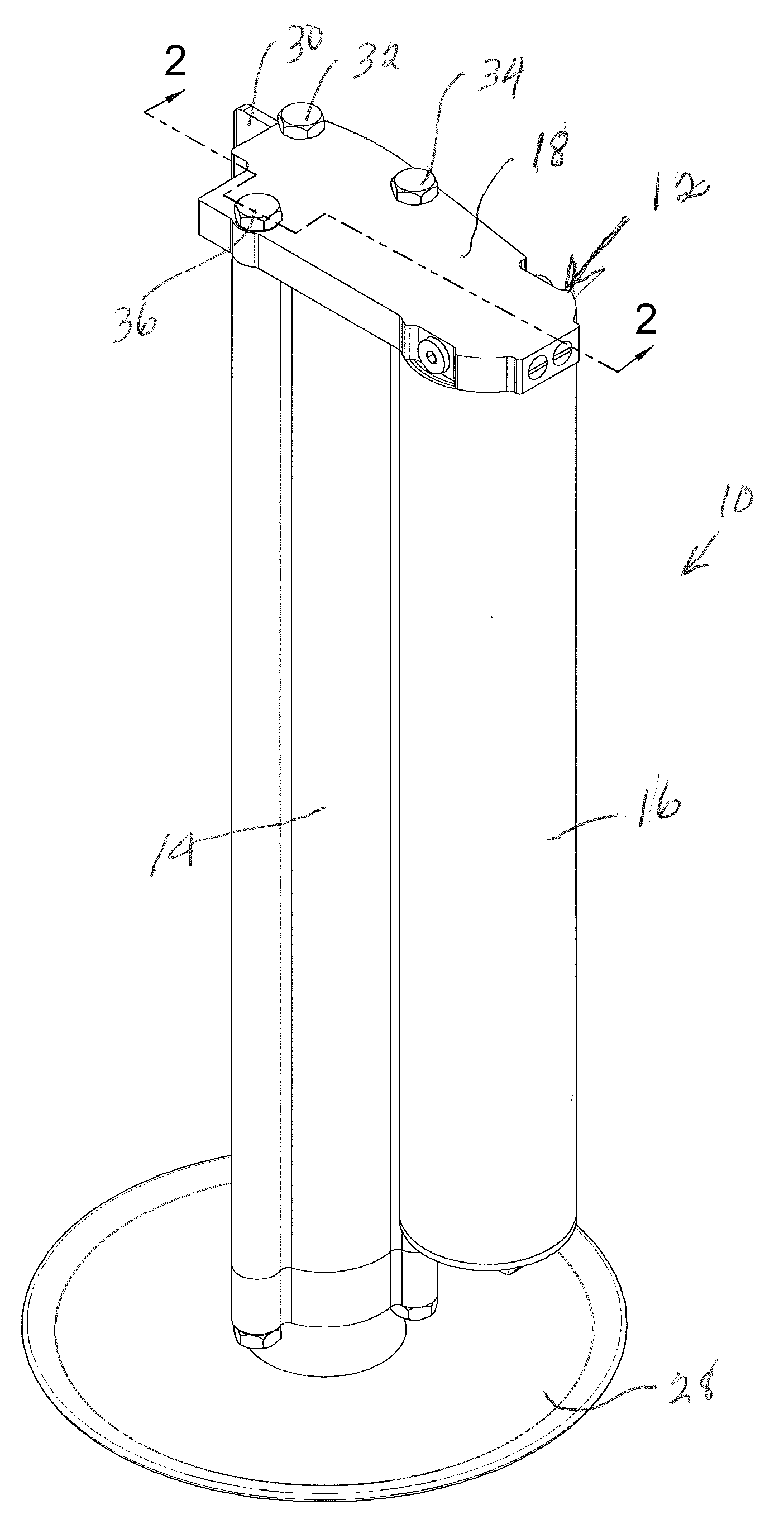

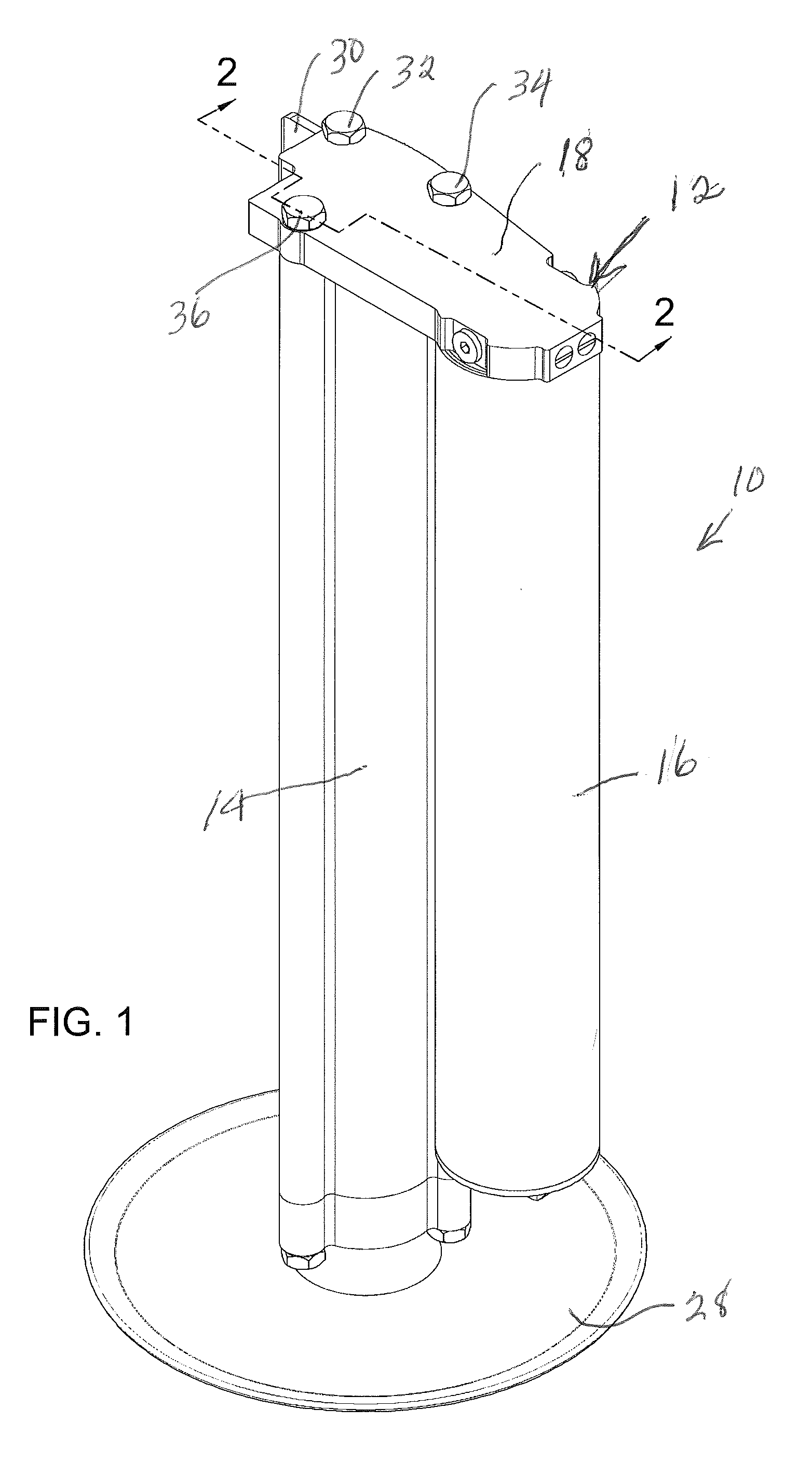

Support pedestal for supporting an elevated building surface

ActiveUS20110023385A1Prevent rotationImprove stabilityBuilding roofsCeilingsEngineeringMechanical engineering

A method and device for supporting a structure above a fixed surface. The device can include a support pedestal whose height is adjustable through a range of heights without a substantial gap in the obtainable heights. In one embodiment, the support pedestal can include a base member, a support member and a coupling member operatively connecting the base member and the support member. The coupling member can include first and second cylindrical walls, whereby an outer wall of the coupling member bears directly on an outer wall of the base member. Locking members can be utilized to operatively attach the coupling member to at least one of the base member or the support member. The locking members can function to increase the structural stability of support pedestal.

Owner:UNITED CONSTR PROD LLC

Tunnel self-advancing support shed

ActiveCN102628368ATo achieve the effect of safety supportTimely supportMine roof supportsTunnel liningStructural engineering

Owner:李信斌

Non-roadside supporting gob-side entry retaining process

InactiveCN101514633AEasy to operateImprove construction efficiencyMaterial fill-upMine roof supportsEngineeringCantilever

The invention discloses a non-roadside supporting gob-side entry retaining process comprising the following processing steps: 1) additionally constructing anchor rods, anchor craning beams and side anchor craning beams and mounting metal mesh in an entry to be retained in front of the stope face, wherein, one end of the metal mesh is fixed on the entry top which is 0.4m from the stope face side through the anchor rods, and the anchor cable of each anchor cable beam is anchored on the stable layer of a coal seam roof; 2) laying the metal mesh on a head beam of a support on a fully-mechanized face, mounting Pi-shaped steel legs and roof-cutting mono-blocks on the edge of a gob area at the back of the support, and mounting mono-blocks in the entry at the same time; 3) carrying out the roof-cutting with the roof-cutting mono-blocks, then, the immediate roof of the gob area is fully broken down, and the metal mesh is compacted on the floor by the broken gangue, so as to form a 'mesh-gangue' wall; and 4) withdrawing mono-blocks of roof-cutting mono-blocks in the retained entry and part in the later period of stoping, so as to form a stable cantilever beam structure. The invention is characterized in that the roof of the entry is supported mainly by an anchor cable, an anchor net and the 'mesh-gangue' wall to form and retain the stable cantilever beam structure. The process has the advantages of simple operation, high construction efficiency and speed, low impact on the working surfaces, low cost, safety and reliability, therefore, the process has wide practicability.

Owner:冀中能源股份有限公司葛泉矿

Leveling jack for vehicle

A leveling jack for a vehicle, such as a recreational vehicle, includes a leveling piston and cylinder, a bi-directional, reversible pump, and a reservoir within a common sealed housing that does not require exterior fluid connections. The piston is extended from the housing to contact the ground and effect leveling by operating the pump in one direction, and is retracted into the cylinder by operating the pump in the other direction. Accordingly, the leveling jack is a self-contained unit, and does not require a central hydraulic unit and the necessary hoses between the jack and the central hydraulic unit as needed in the prior art.

Owner:LIPPERT COMPONENTS MFG INC

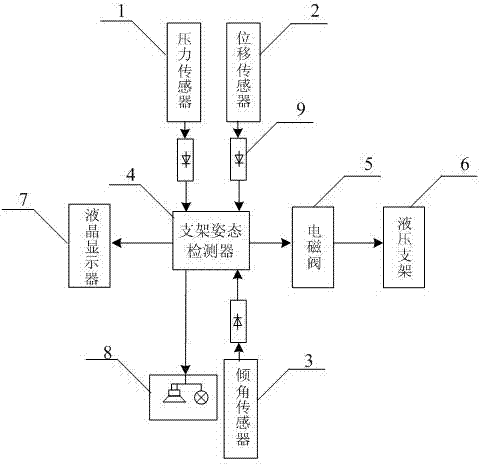

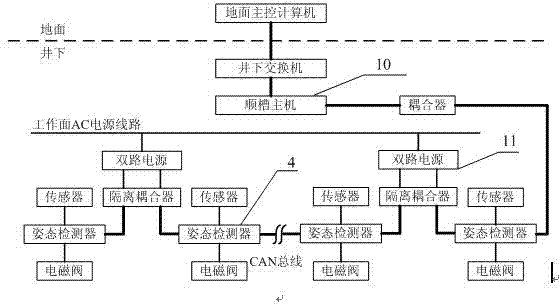

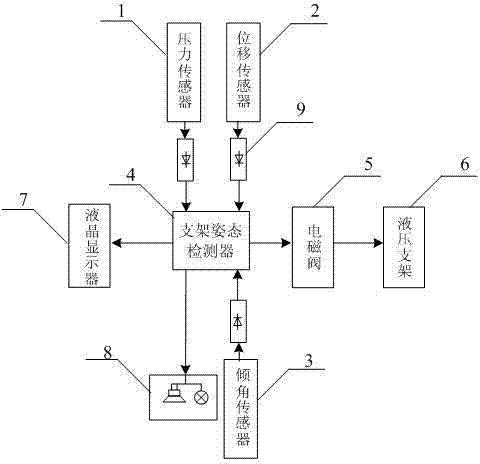

Hydraulic bracket posture detecting method and device based on multi-sensor data fusion

InactiveCN102337908ARealize fault diagnosis functionGet accurate attitude informationMeasurement devicesProps/chocksEngineeringSystem structure

Owner:CHINA UNIV OF MINING & TECH +1

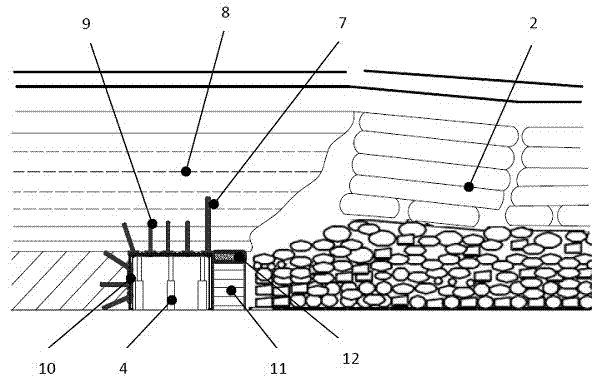

Tunnel yielding type shoring system

ActiveCN106285724AReach pressureReach uninstallUnderground chambersTunnel liningShotcreteLarge deformation

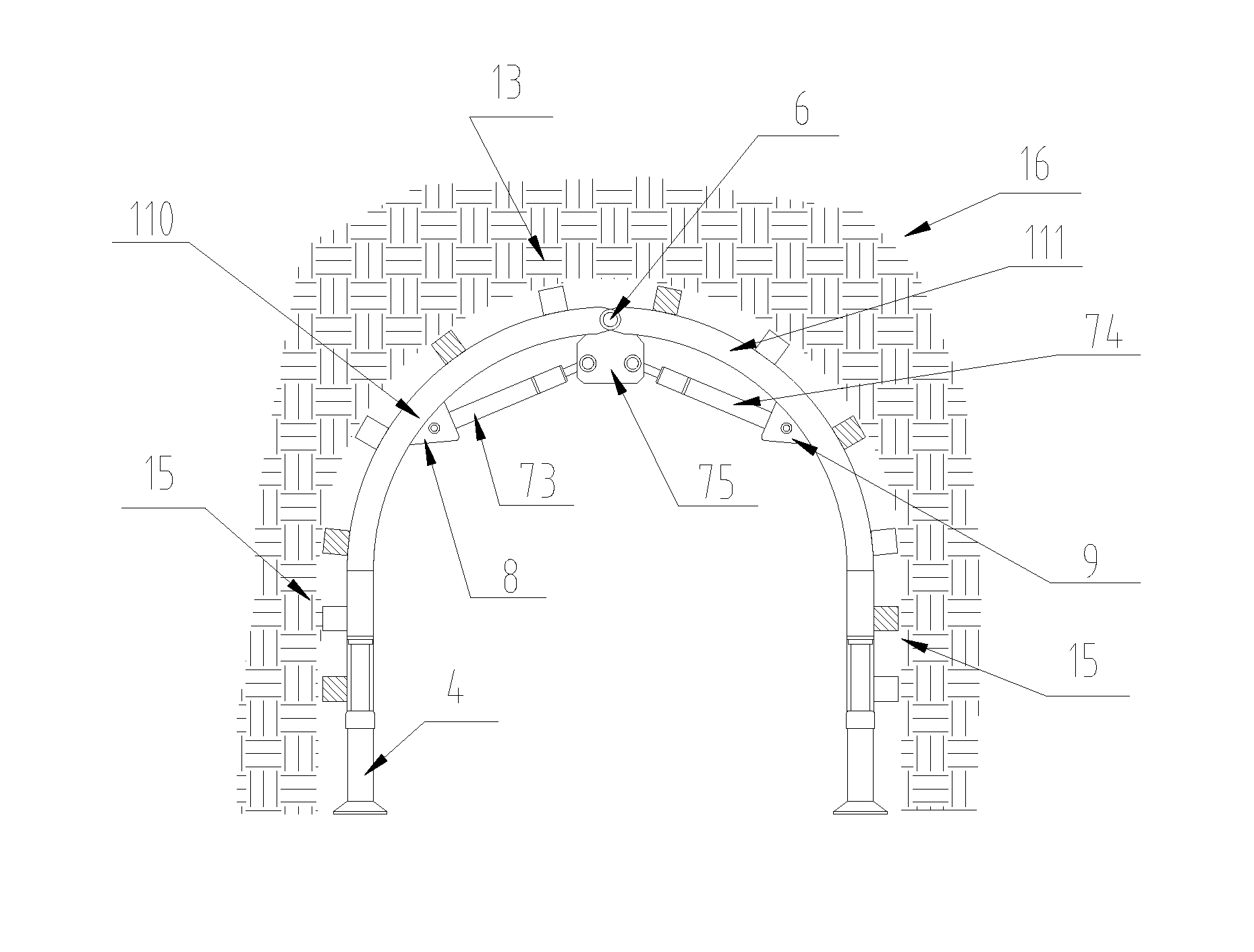

The invention discloses a tunnel yielding type shoring system and relates to the field of traffic and mining soft rock large-deformation tunnels. Stretchable units are arranged on a shoulder part and a waist part of each steel arch frame; the stretchable units are connected with the steel arch frame through flanges; each stretchable unit is composed of a stretchable component and a rectangular rubber damper; stretchable components are arranged at the two ends of each steel arch frame; a deforming slot is reserved between the stretchable components; the rectangular rubber damper is arranged in the deforming slot; a separating plate is arranged between the rectangular rubber damper and a sprayed concrete layer; a plurality of yielding anchor rods are arranged on the sprayed concrete layer at intervals. According to the invention, a combined body composed of the yielding anchor rods, the stretchable components, the steel arch frame, the rectangular rubber damper and the sprayed concrete generates uniformly harmonious deformation with the surrounding rock, so that the surrounding rock stability can be effectively maintained by a certain supporting resistance, and meanwhile, the shoring system is allowed to generate a certain displacement, and the functions of shoring, yielding and unloading can be achieved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

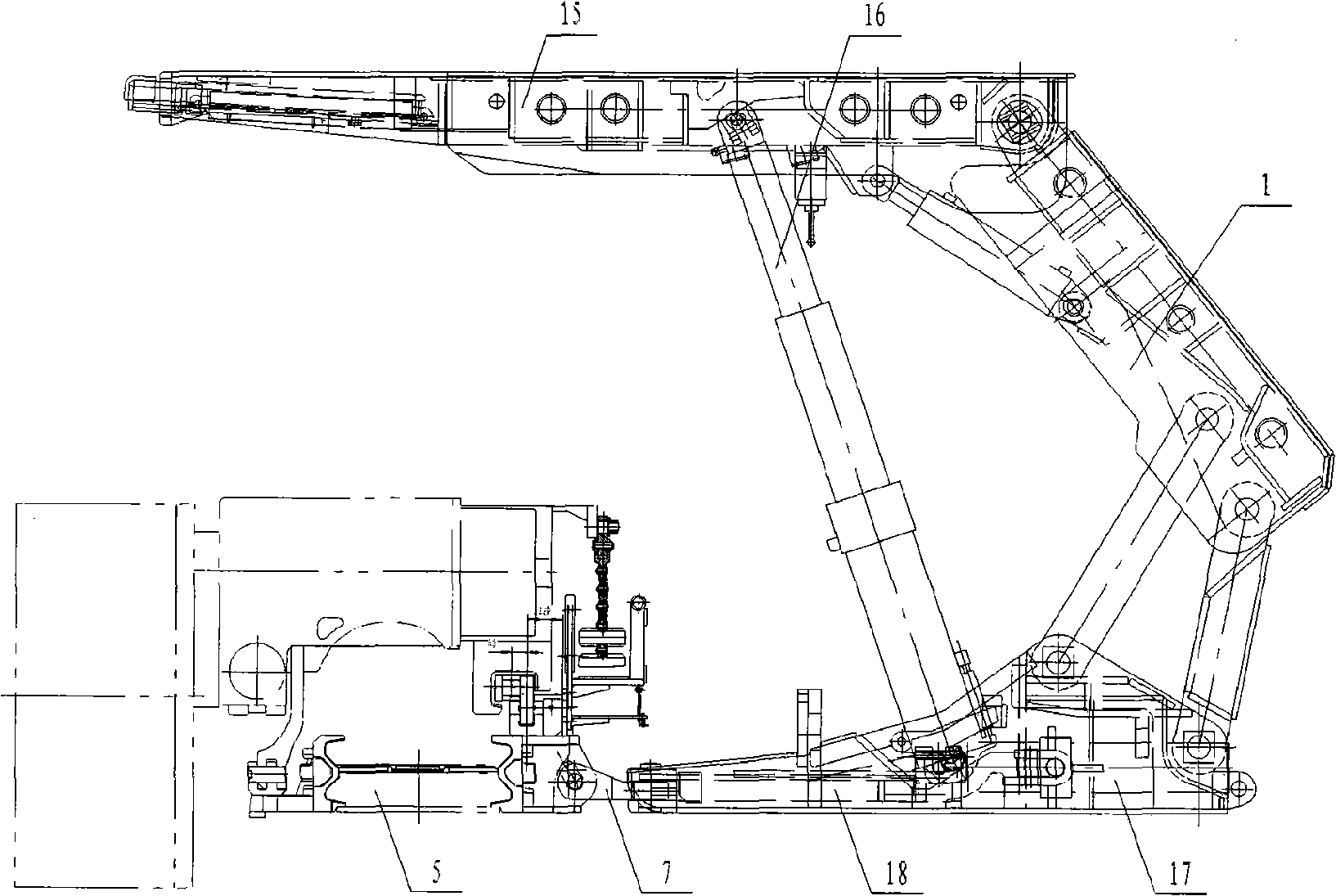

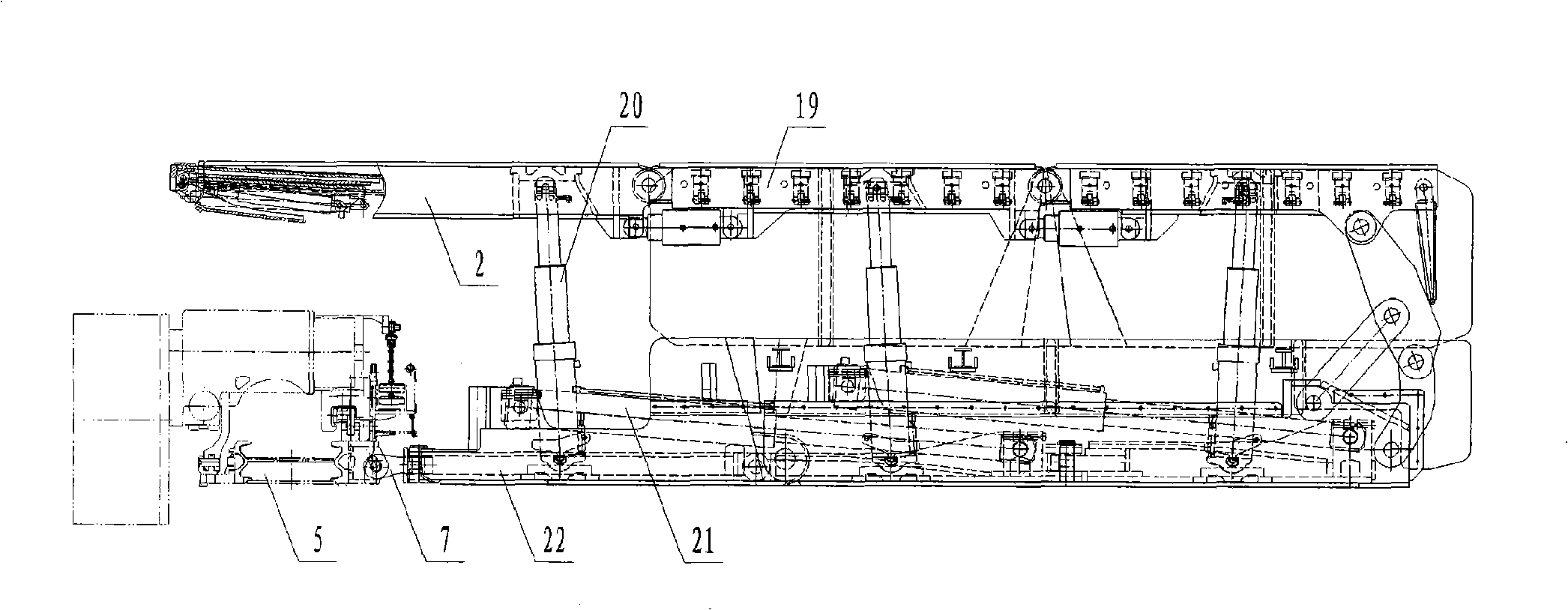

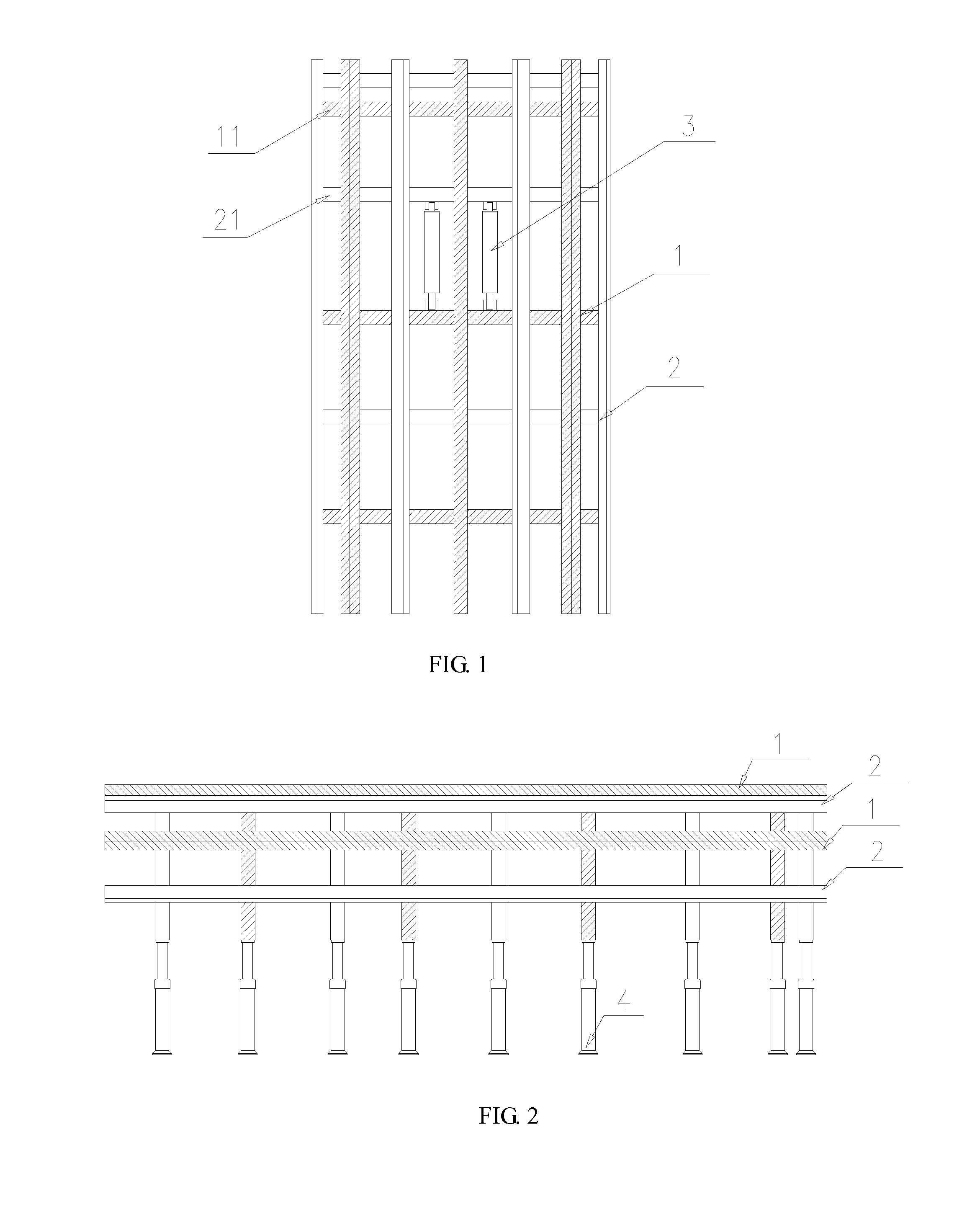

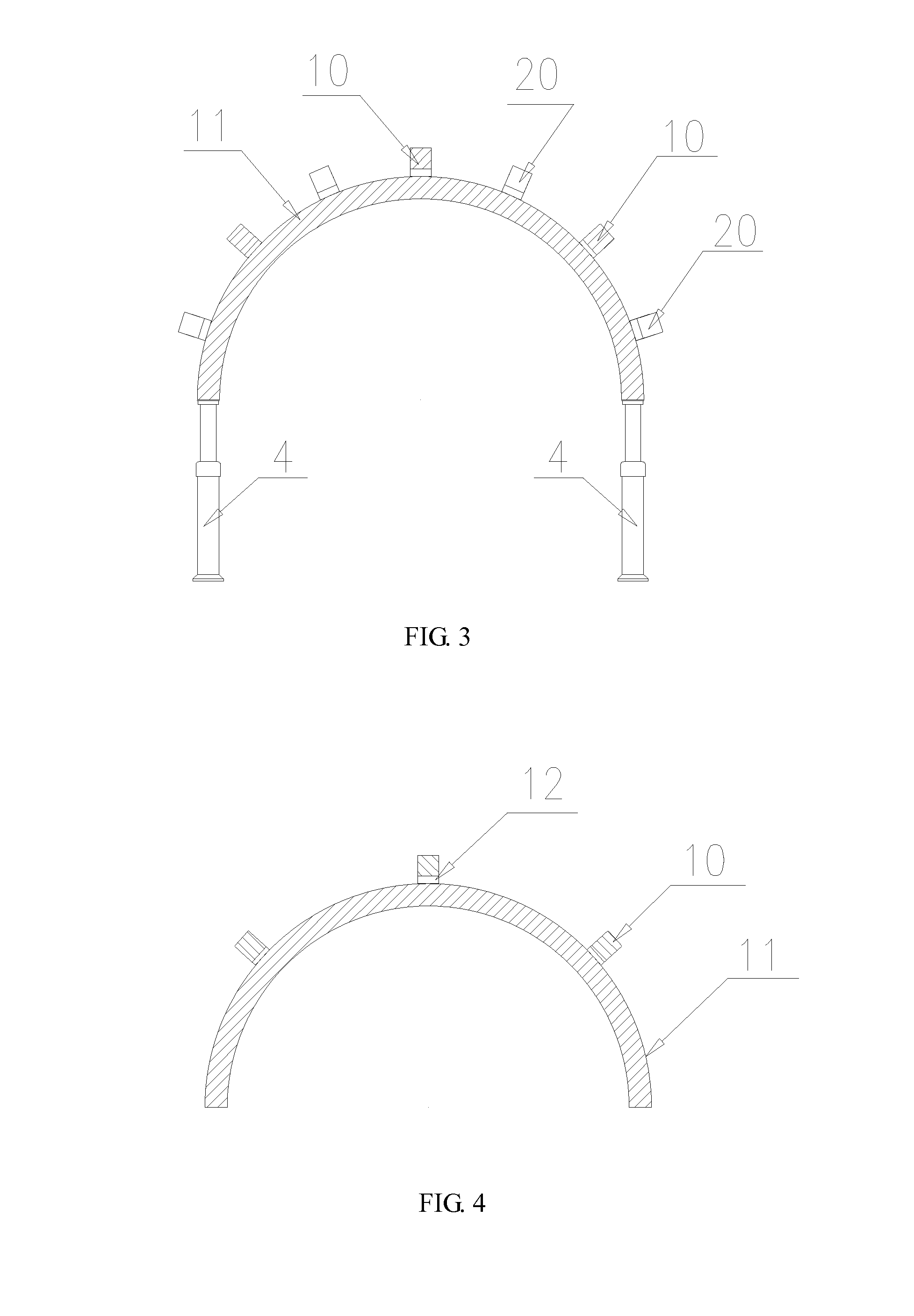

Self-moving tunnel support canopy

ActiveUS20150086272A1Safe and reliableSecure supportUnderground chambersMine roof supportsShaped beamStructural engineering

A self-moving tunnel support canopy includes front arch frame, rear arch frame, forward jack, and support jack disposed under the front arch frame. The front arch frame has front arch beams and front longitudinal beams longitudinally disposed along arch upper surfaces of front arch beams and coupled to all the front arch beams. The rear arch frame has rear arch beams and rear longitudinal beams longitudinally disposed along arch upper surfaces of the rear arch beams and coupled to all the rear arch beams. The front longitudinal beams and the rear arch beams are spacedly disposed, and a spacing is configured between the front arch beam and a front-adjacent rear arch beam. One end is coupled to the front arch frame, and the other end of the forward jack is coupled to the rear arch frame. The front arch beam and the rear arch beam are both arch-shaped beams.

Owner:LI XINBIN

Method for actively supporting lane side filling gob-side entry retaining

InactiveCN103161480AEnhanced CapabilityReduce initial sinkageMaterial fill-upMine roof capsEngineeringActive support

The invention discloses a method for actively supporting a lane side filling gob-side entry retraining. Firstly, a lane interior support and an enforcing support are built on a reserved lane according to a sounding rock condition and a working face. On the back of the working face, nogs, gangues or blockworks and the like are adopted to build a lane side filling wall along the edge of a gob. High-strength and sealed filling bags are paved on the filling wall, and high-expanding materials or cement coagulation serous fluid added with a rapid hardening early strength agent is filled into the filling bags through a grouting pump. The enforcing support is dismounted after a top plate behind the working face is movably stabilized, the high-strength and sealed filling bags are enabled to be contacted tightly with the top plate, and active support force is formed to be exerted on the top plate. By means of the active support force provided for the lane side filing wall, the top cutting capacity of a lane side filling body is enhanced, initial deflection of the entry retaining top plate is reduced, the stability of the top plate is improved, the quality of the gob-side entry retaining is improved, and repair rate of the gob-side entry retaining is reduced. The method is simple, convenient to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Hydraulic support for filling waste rock

A hydraulic frame for filling waste rock is composed of top beam, vertical column, base, tail beam, jack of tail beam and scraper conveyor chute suspended under tail beam. It is featured as opening waste rock leaking hole on frid of suspension chute, connecting suspension chutes to each other in sequence then connecting them with chute head and chute end at working face to form a complete set of scraper conveyor.

Owner:佟强

Impact-resistant combined anti-pressure supporting system

InactiveCN102182482AImprove efficiencyReduce maintenanceProps/chocksAnchoring boltsSupporting systemSocial benefits

The invention discloses an impact-resistant combined anti-pressure supporting system which is characterized by comprises a three-grade supporting system; and the impact-resistant combined anti-pressure supporting system has the advantages that: (1) by an optimized three-grade supporting manner, the maintenance amount of engineering roadways is reduced, the coal mining rate and the recovery ratio of a working face are increased, the safety coefficient is enlarged, and the comprehensive benefits of a mine are increased; (2) by applying a combined supporting system technology, the deformation of the roadway is effectively controlled when the working face is influenced by the ground pressure; and when the rock burst generates during production, the system plays a role of impact-resisting, realizes shrinkage and buffering changes and protects the safety of equipments and operators; and (3) according to the supporting system during recovery, dynamic alternatively circulative operation is realized, thus the purposes of resisting impaction, removing pressure and solving danger are realized, the construction process is simplified, various costs are saved, the quality is easy to control, the economic benefit is remarkable, the social benefit is also gained at the same time, and the competition among enterprises is improved.

Owner:义马煤业集团股份有限公司跃进煤矿

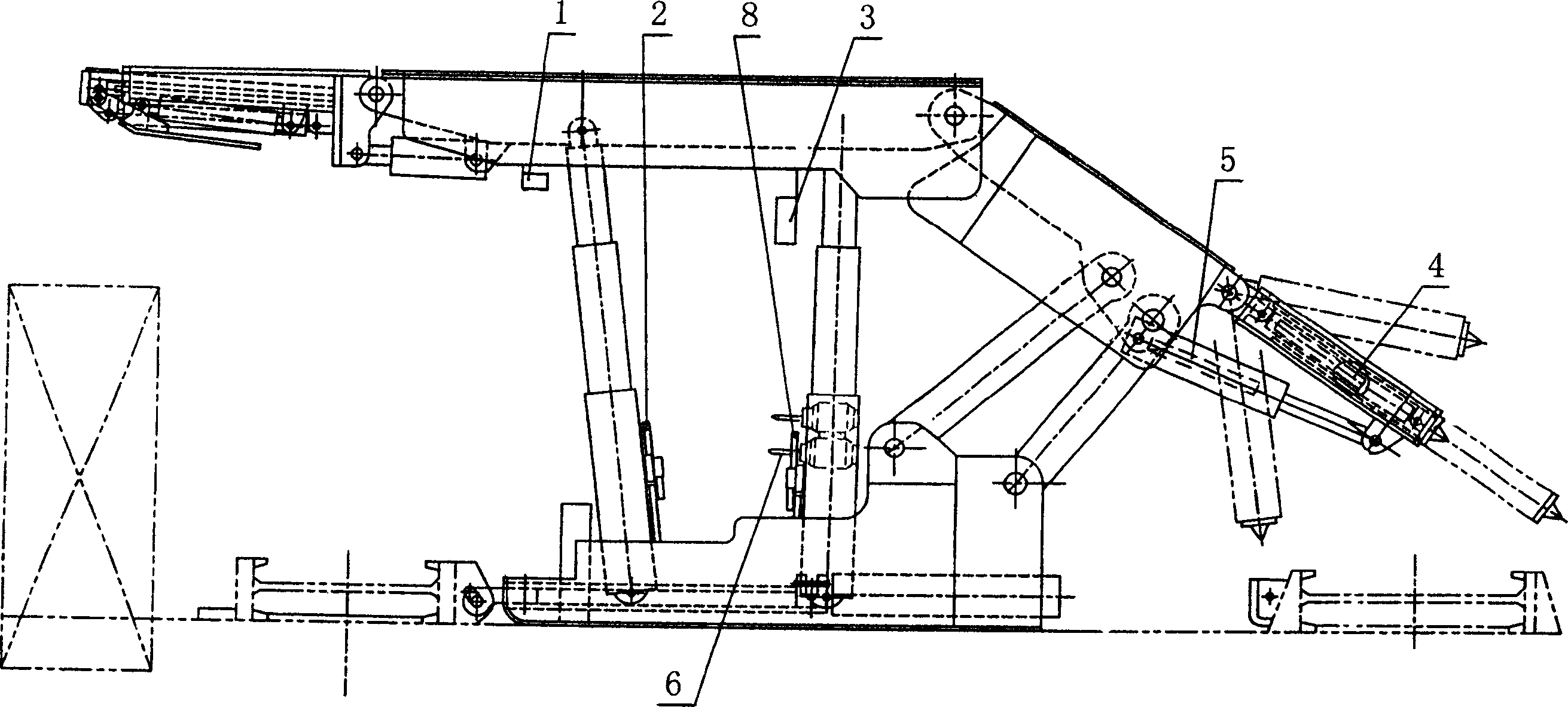

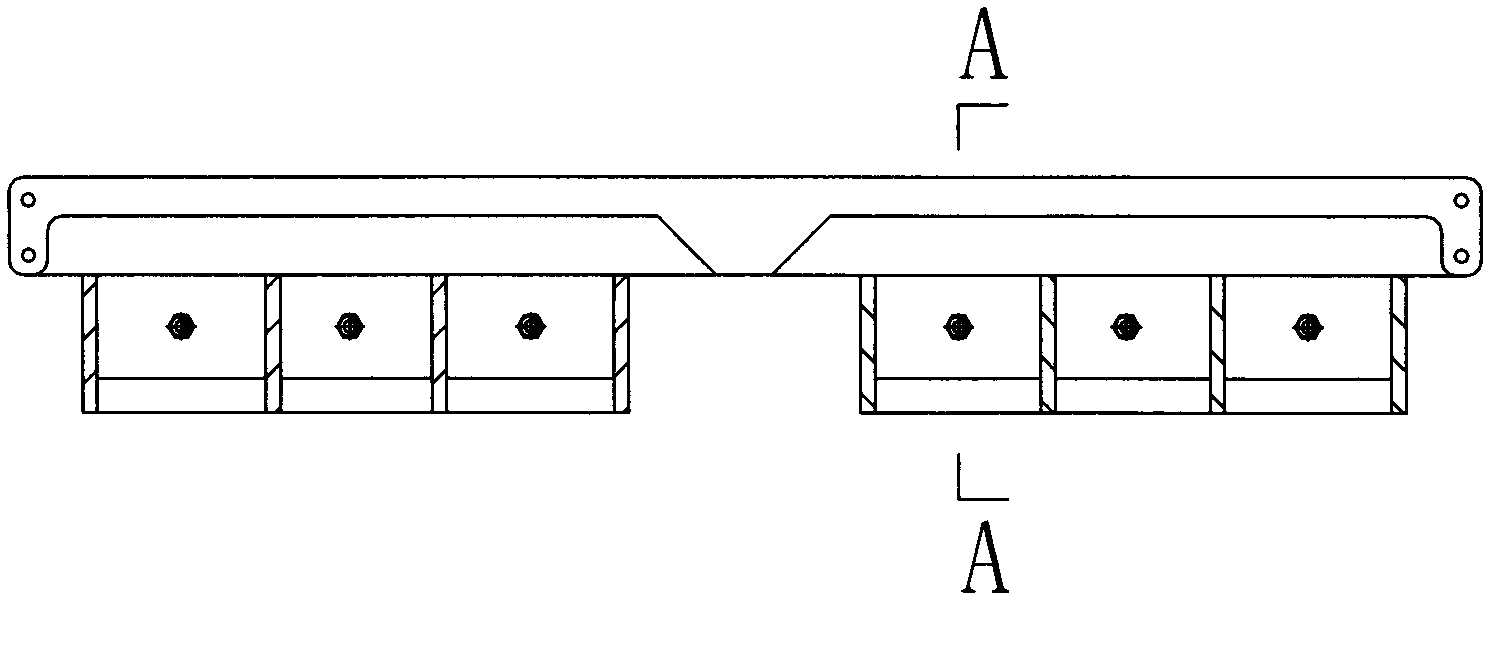

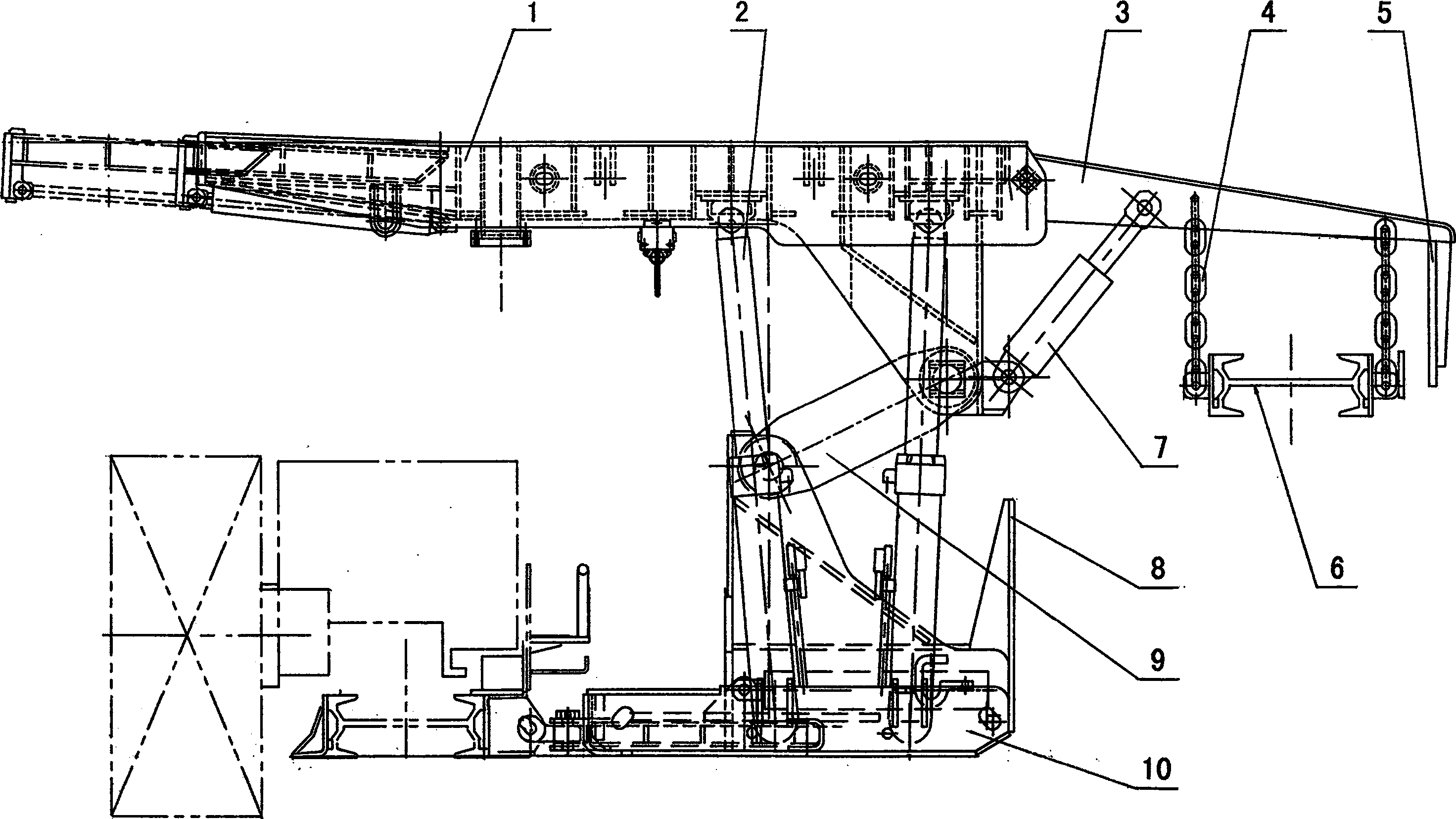

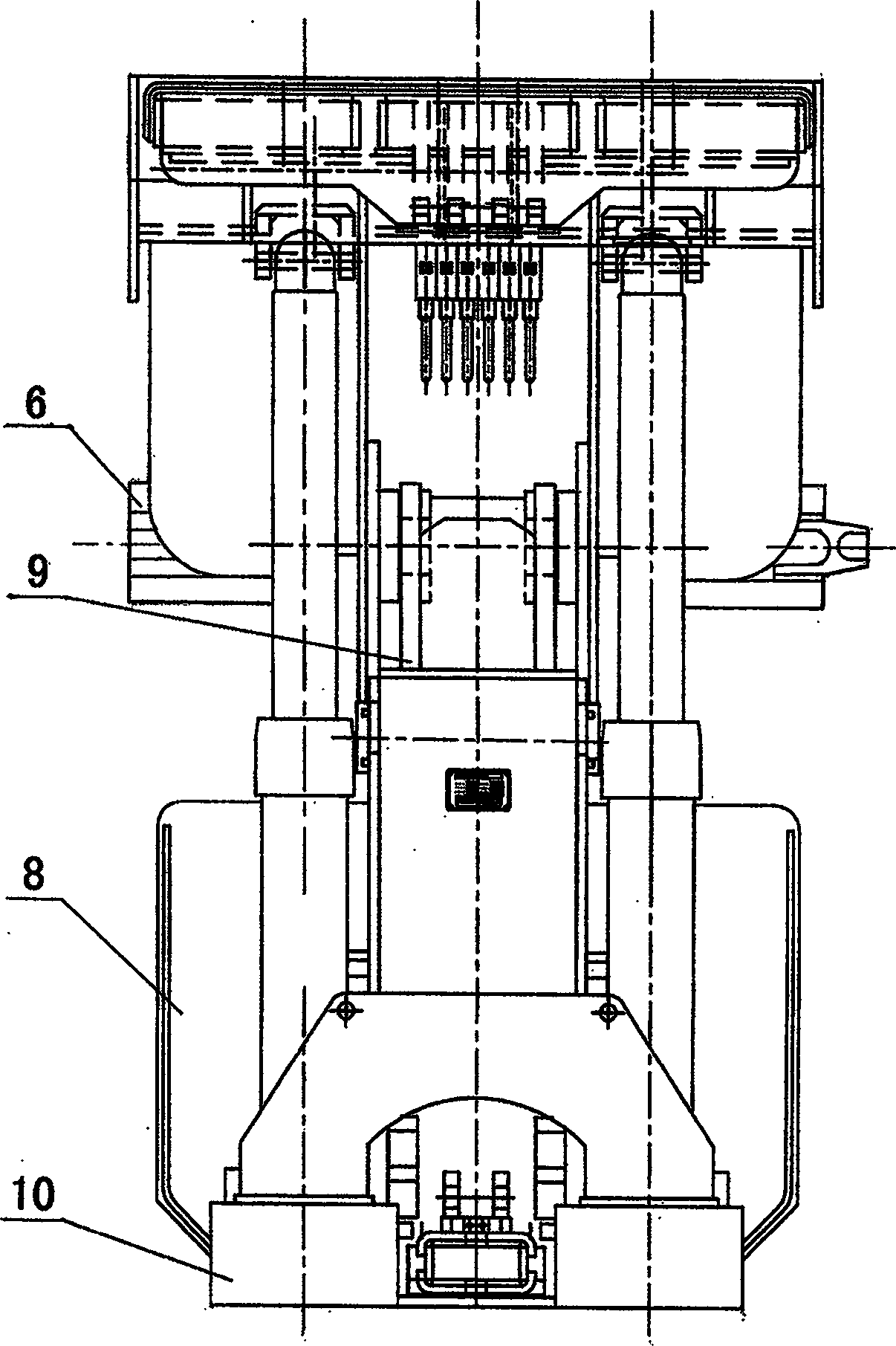

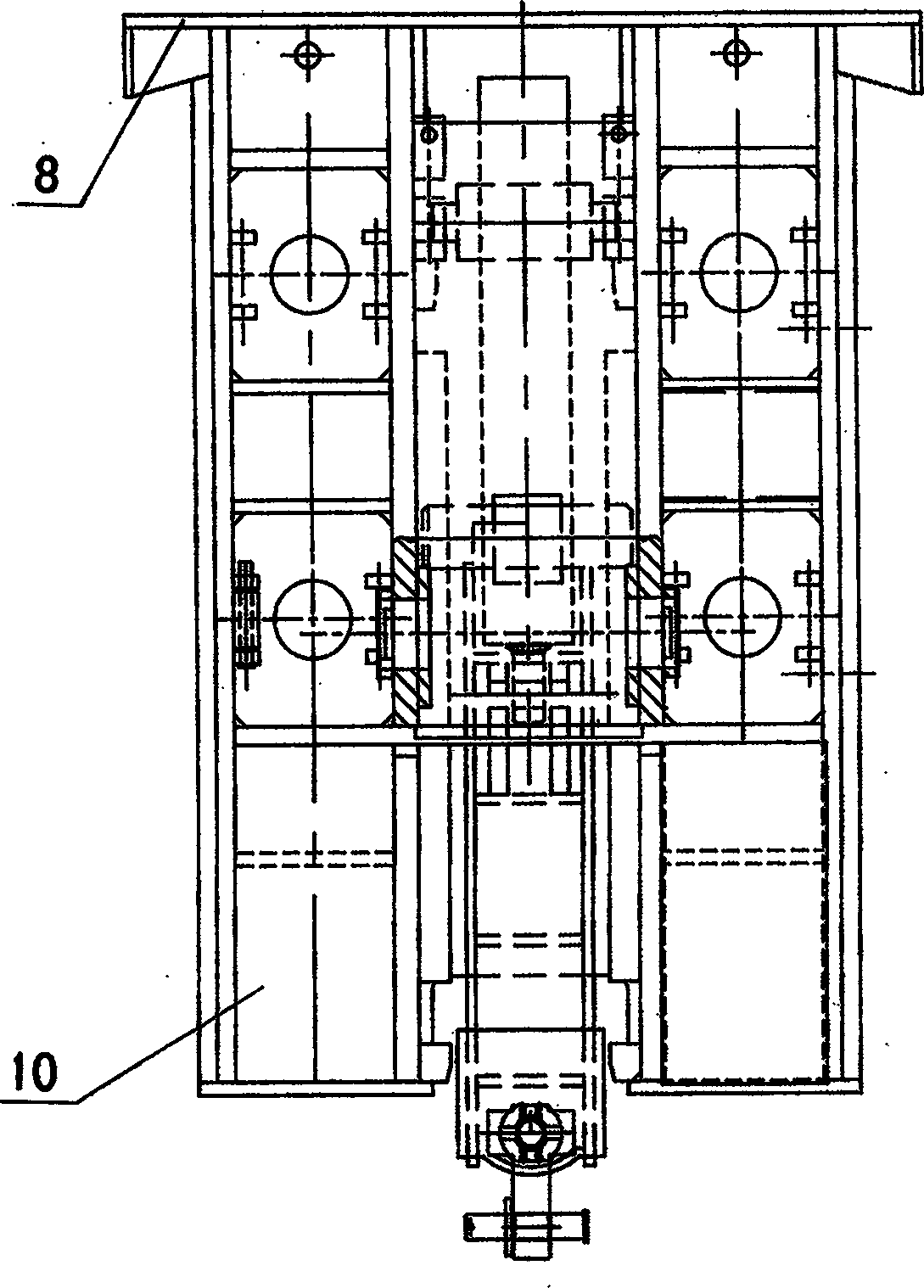

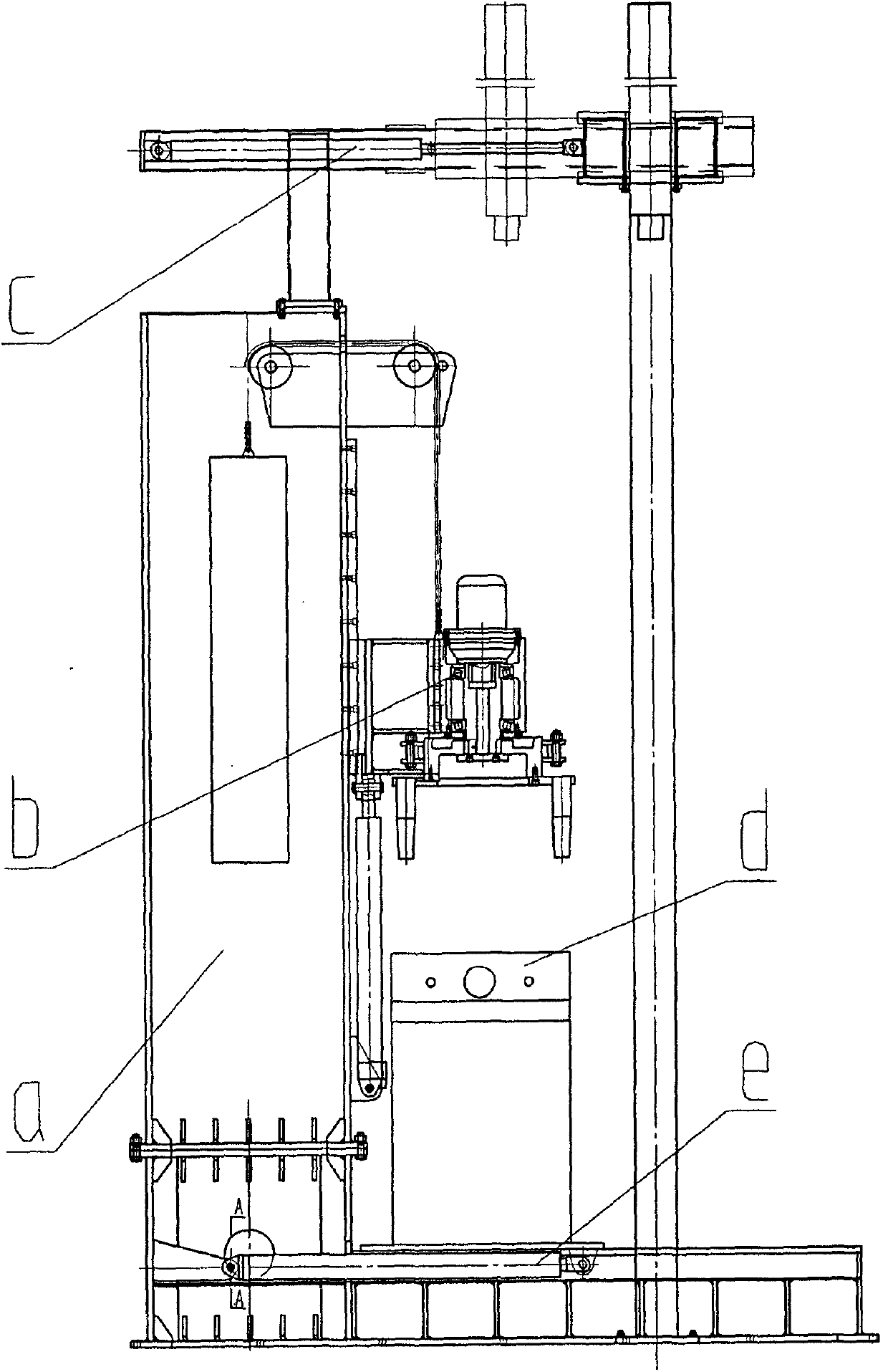

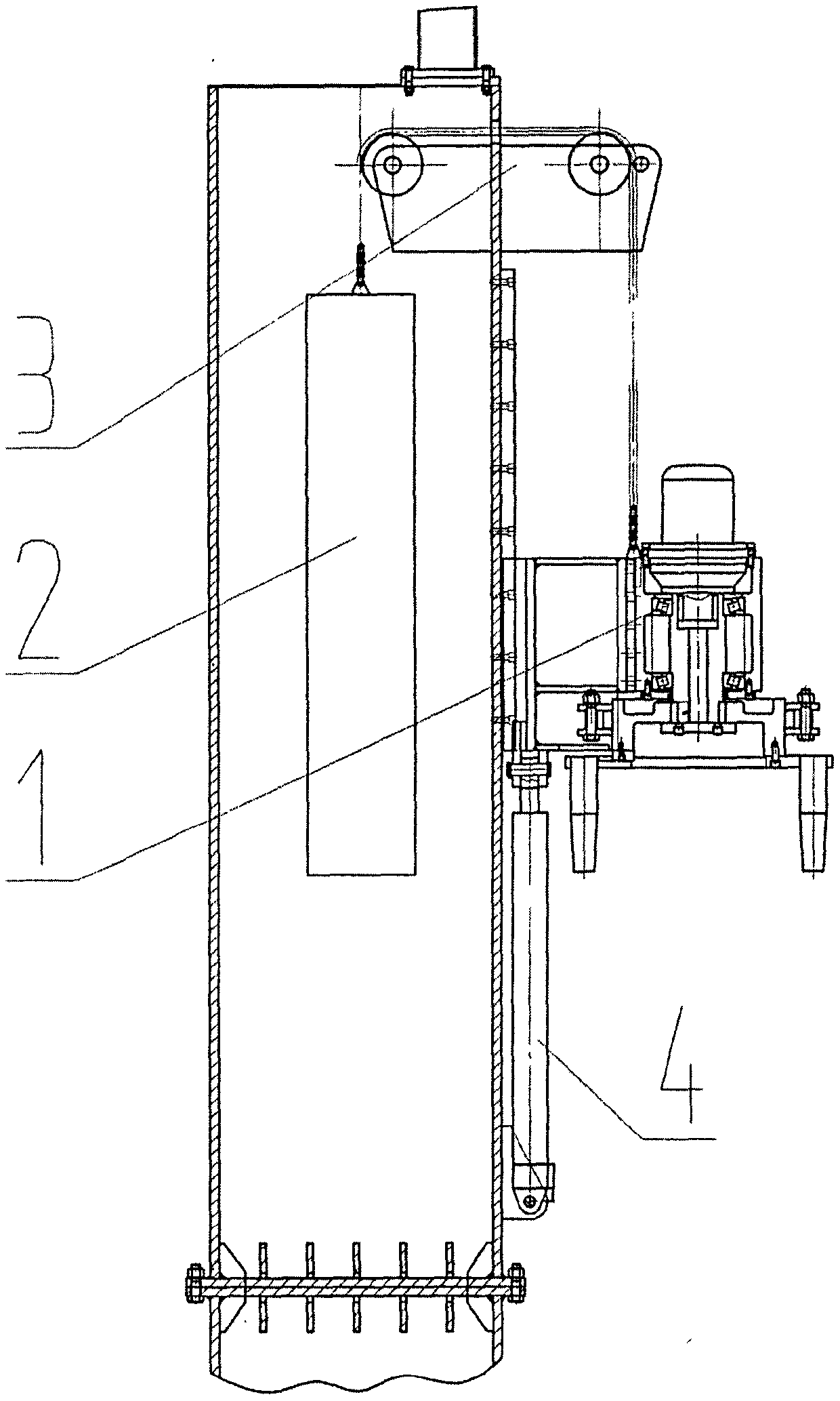

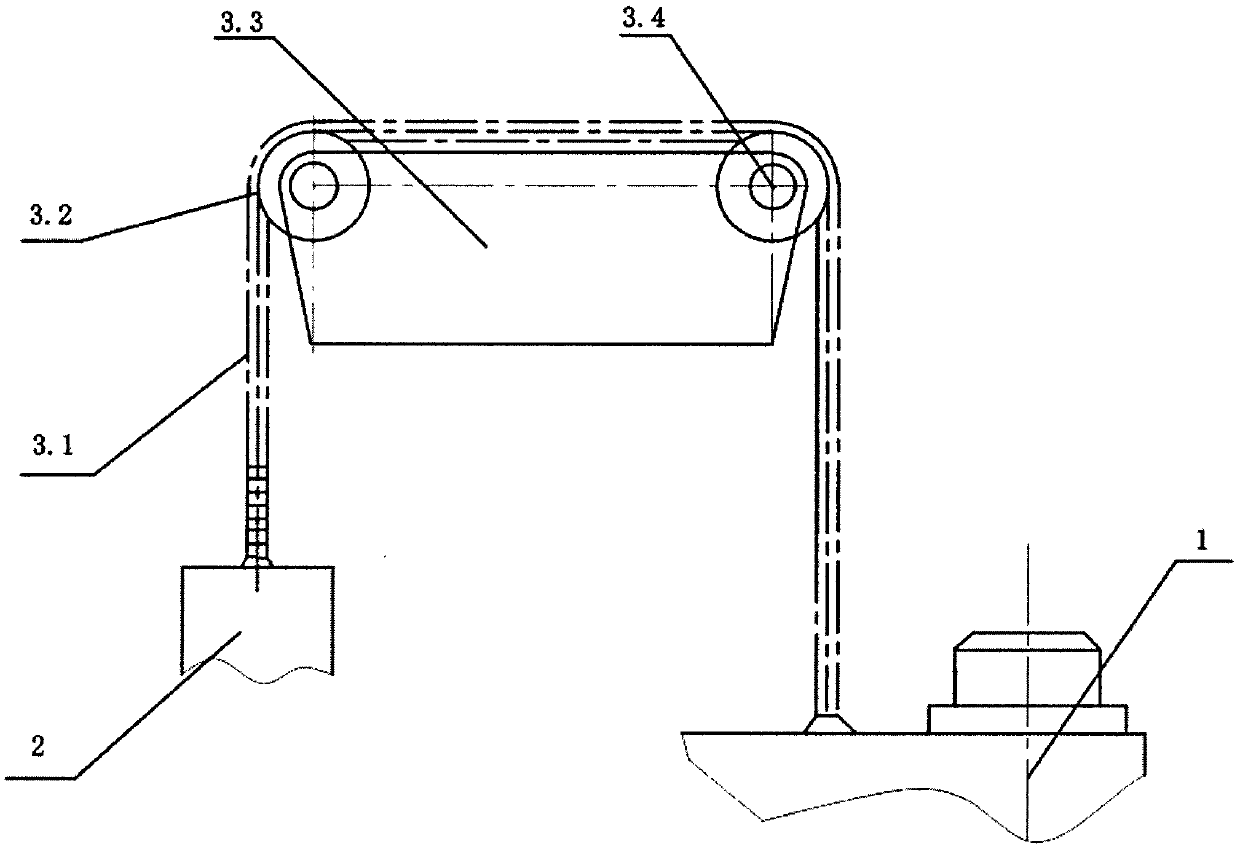

Novel upright assembling and disassembling device for upright columns of hydraulic support

A novel upright assembling and disassembling device for upright columns of a hydraulic support consists of a body rack portion (a), a head and lifting device (b), a cylinder pressing and pushing mechanism (c), a workpiece feeding device (d), a workpiece feeding cylinder (e), a hydraulic pump station and an electrical control system. By an integrated design scheme, assembling and disassembling operations of the upright columns are finished on the device, various problems in the existing horizontal assembling and disassembling device are effectively solved, the work efficiency is improved, the labor intensity is reduced, the energy consumption is decreased, and the assembling and disassembling quality of the upright column is improved. In addition, the novel upright assembling and disassembling device has high economic benefit and high social benefit; and the popularization and application prospects of the device is wide.

Owner:焦作欣扬程煤矿设备有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com