Novel upright assembling and disassembling device for upright columns of hydraulic support

A hydraulic support column and vertical technology, used in mining equipment, support/support, earthwork drilling and other directions, can solve the problems of difficult to install the sleeve, scratches and damage to the sealing ring, etc., and achieves low output torque and extended service life. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

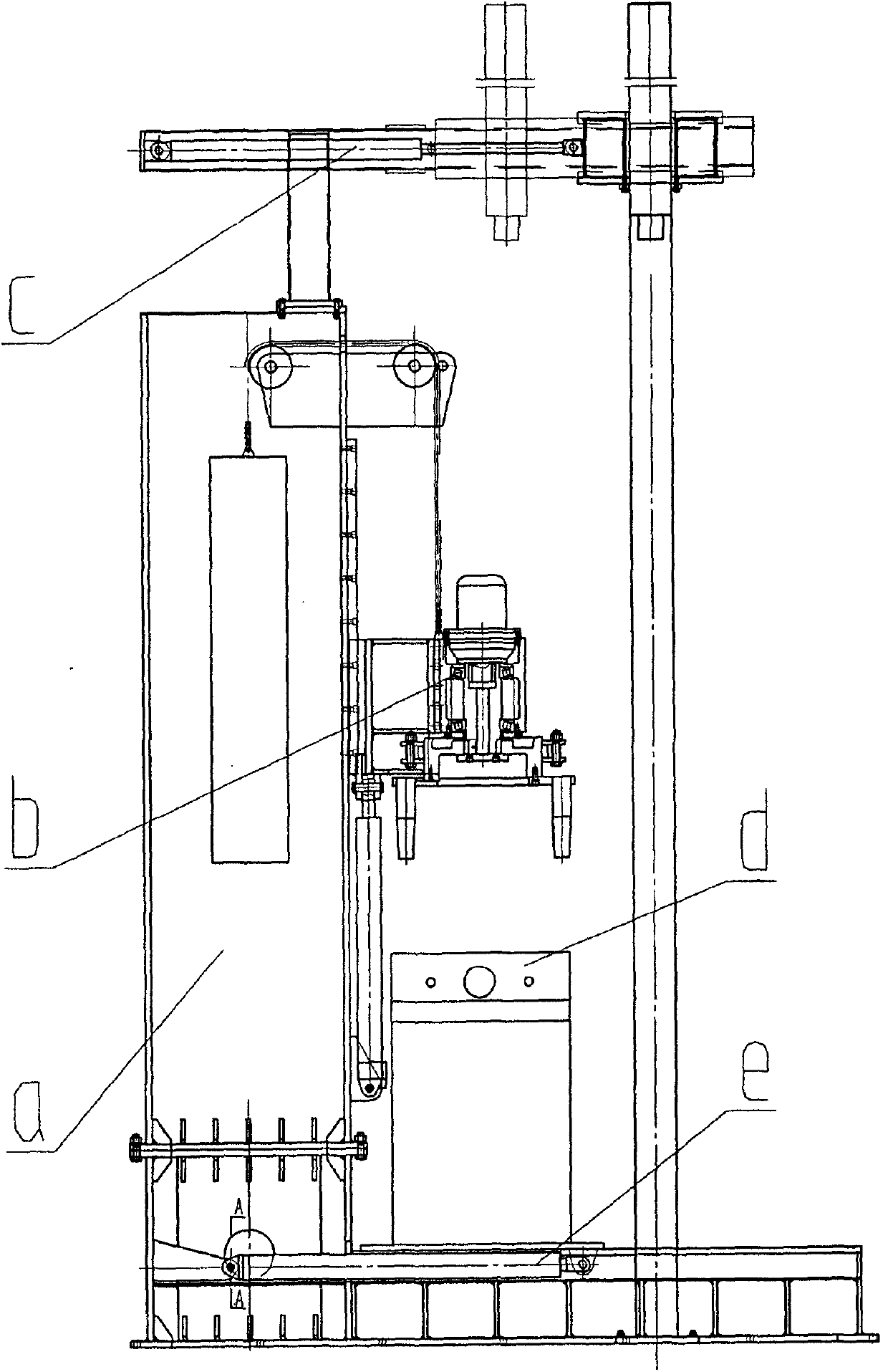

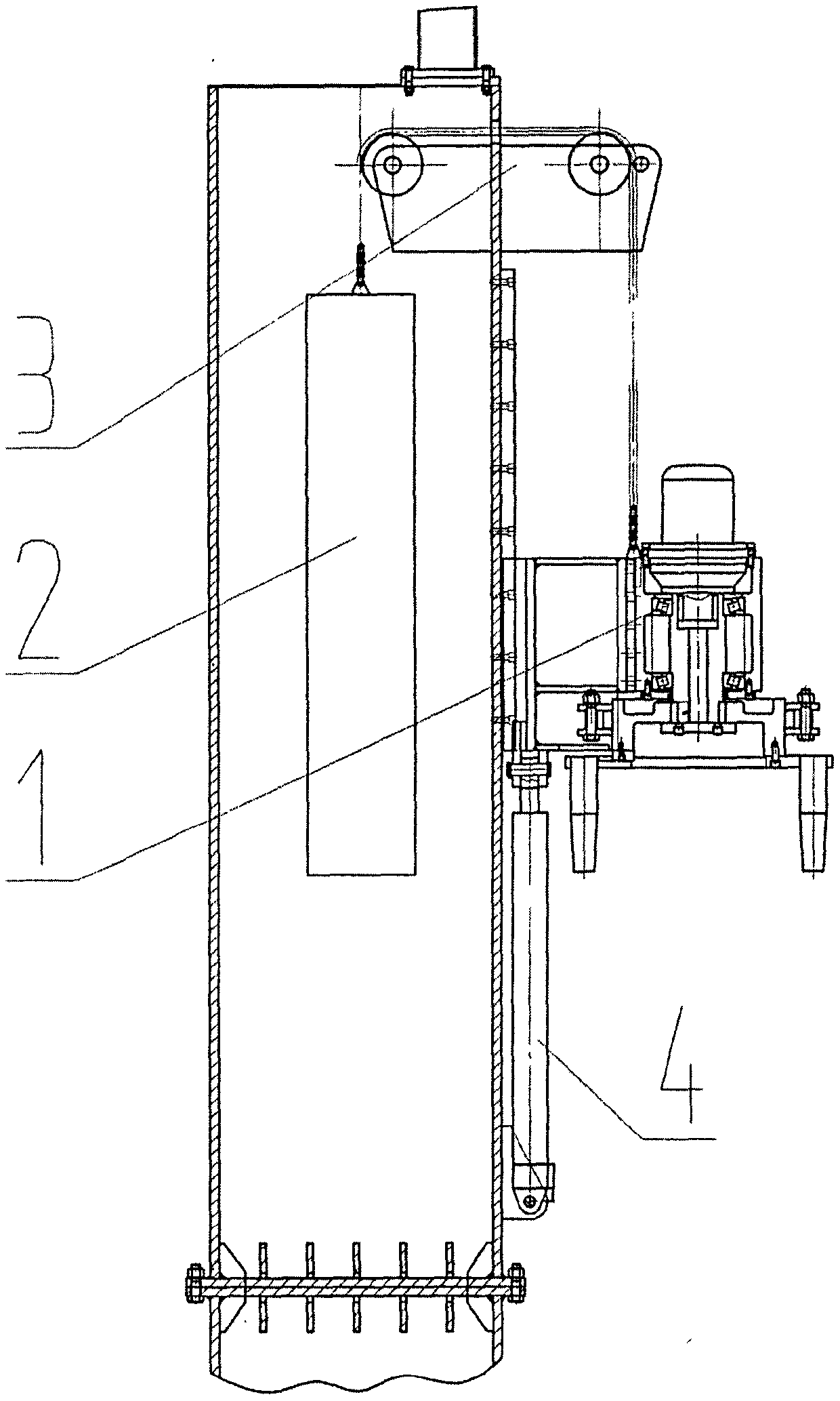

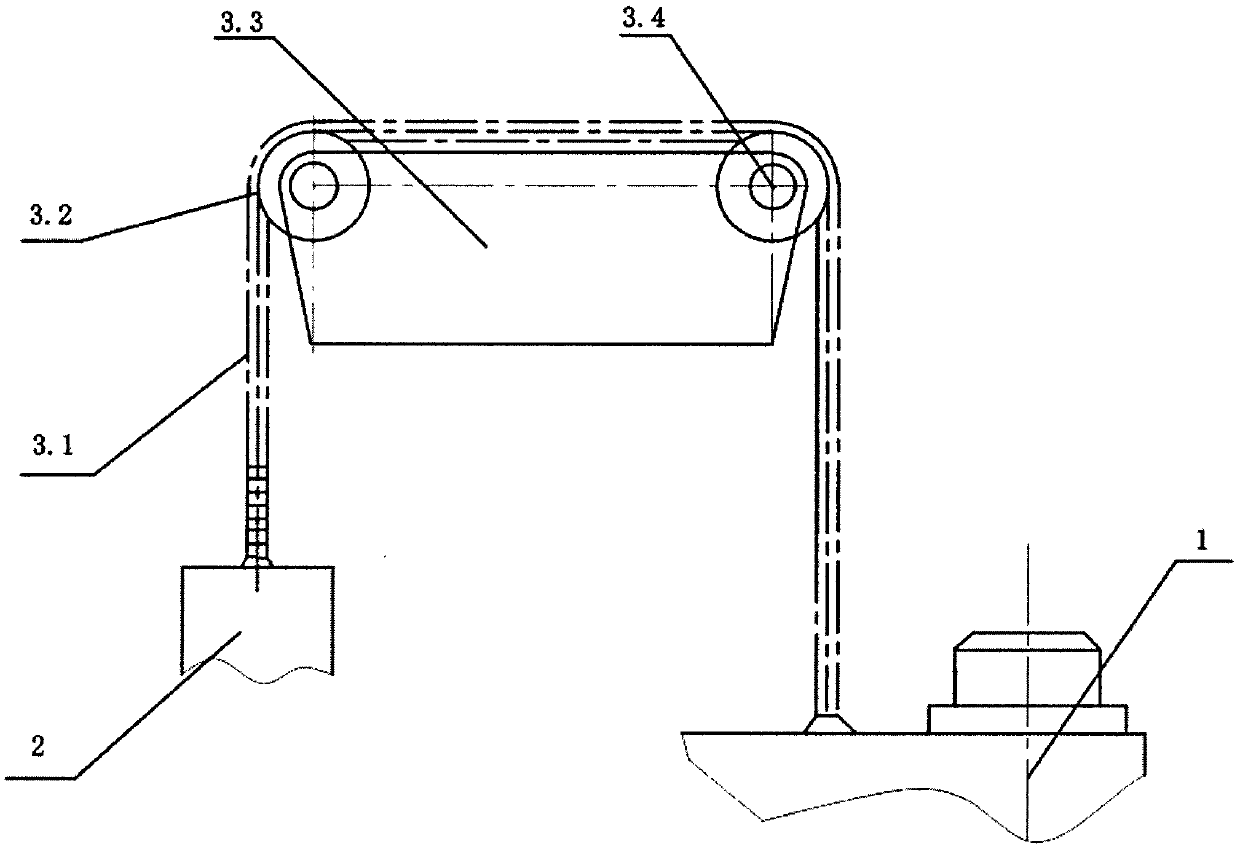

[0027] The dismantling equipment is composed of fuselage frame part a, machine head and lifting device b, press-pull cylinder mechanism c, workpiece feeding device d, workpiece feeding oil cylinder e, hydraulic pump station and electrical control system. See figure 1 shown. (not shown in the hydraulic pump station and electrical control system figure). image 3 , Figure 4 Among them, the upright beam and the base of the fuselage frame a are welded with steel plates to form a frame structure, the upright beam is placed vertically on the ground, the base is horizontally lying, and the upright beam and the base are fixed with screws to form an L-shaped frame layout; the inner cavity of the upright beam Used to place the counterweight 2, the dolly 28 of the workpiece feeding device d can move on the base guide rail. The upper end of the counterweight 2 is hung on the chain 3.1 in the slide rail guide device 3, the other end of the chain bypasses the pulley 3.2, and is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com