Patents

Literature

124results about How to "Knock suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

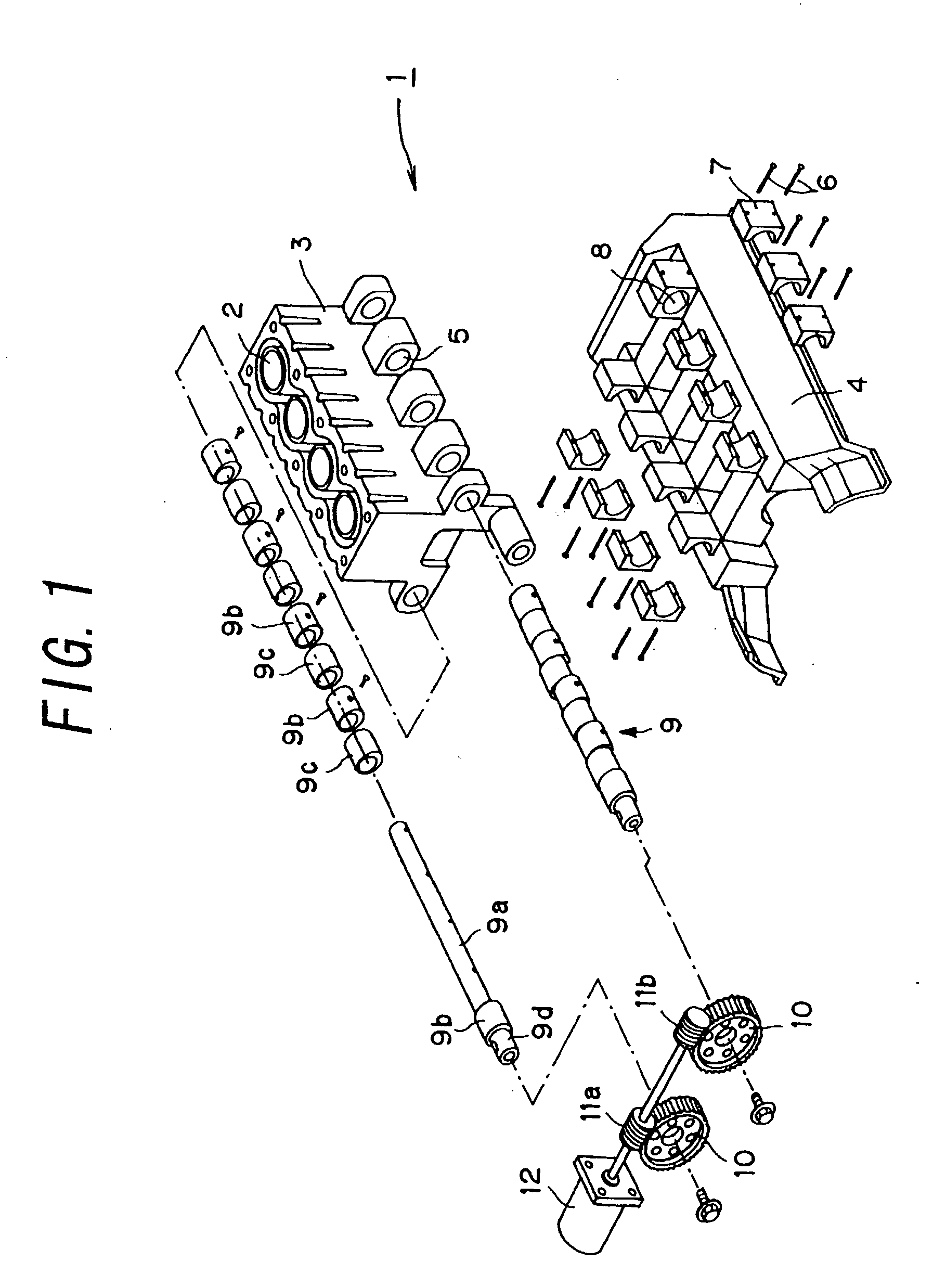

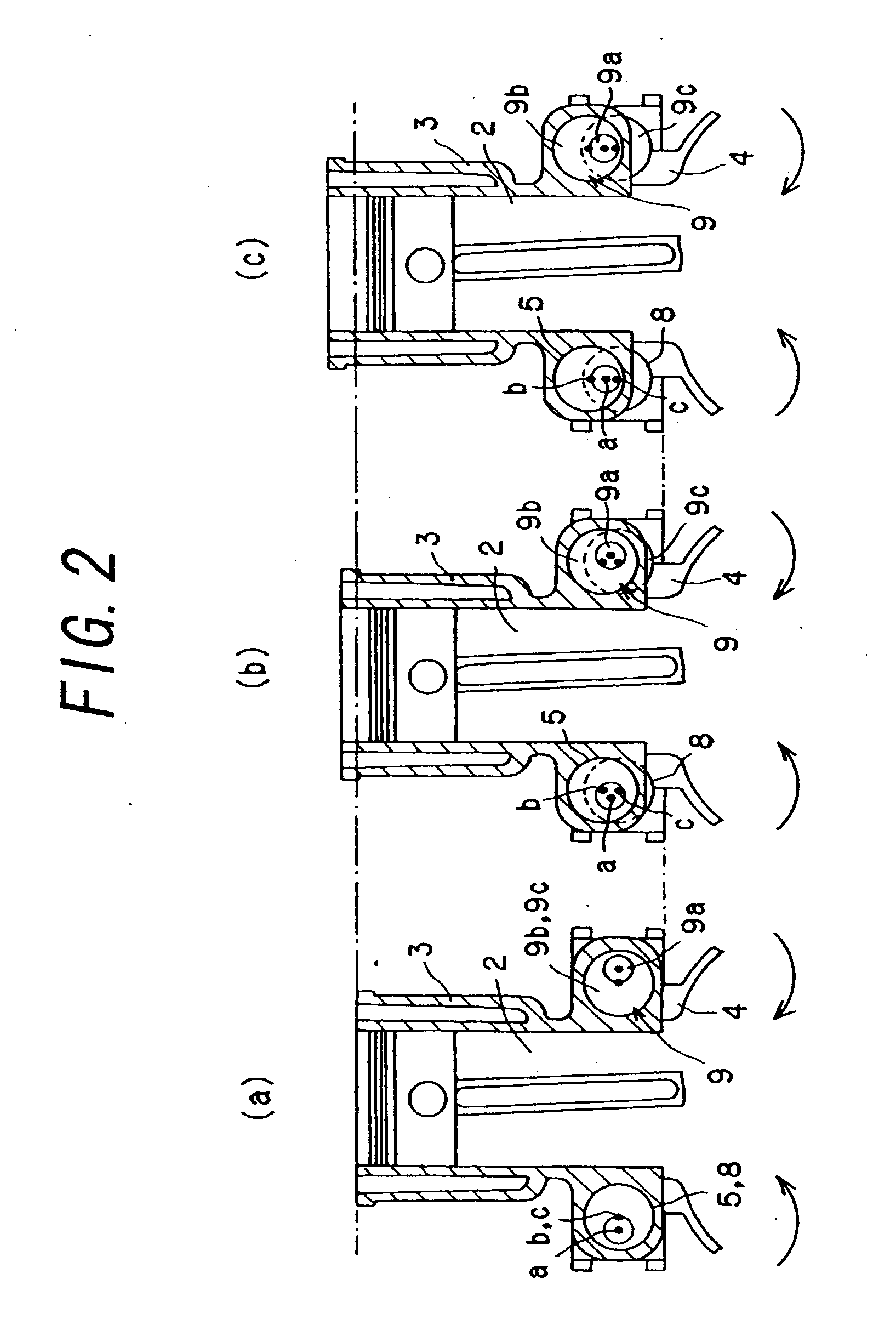

Variable Compression Ratio Internal Combustion Engine

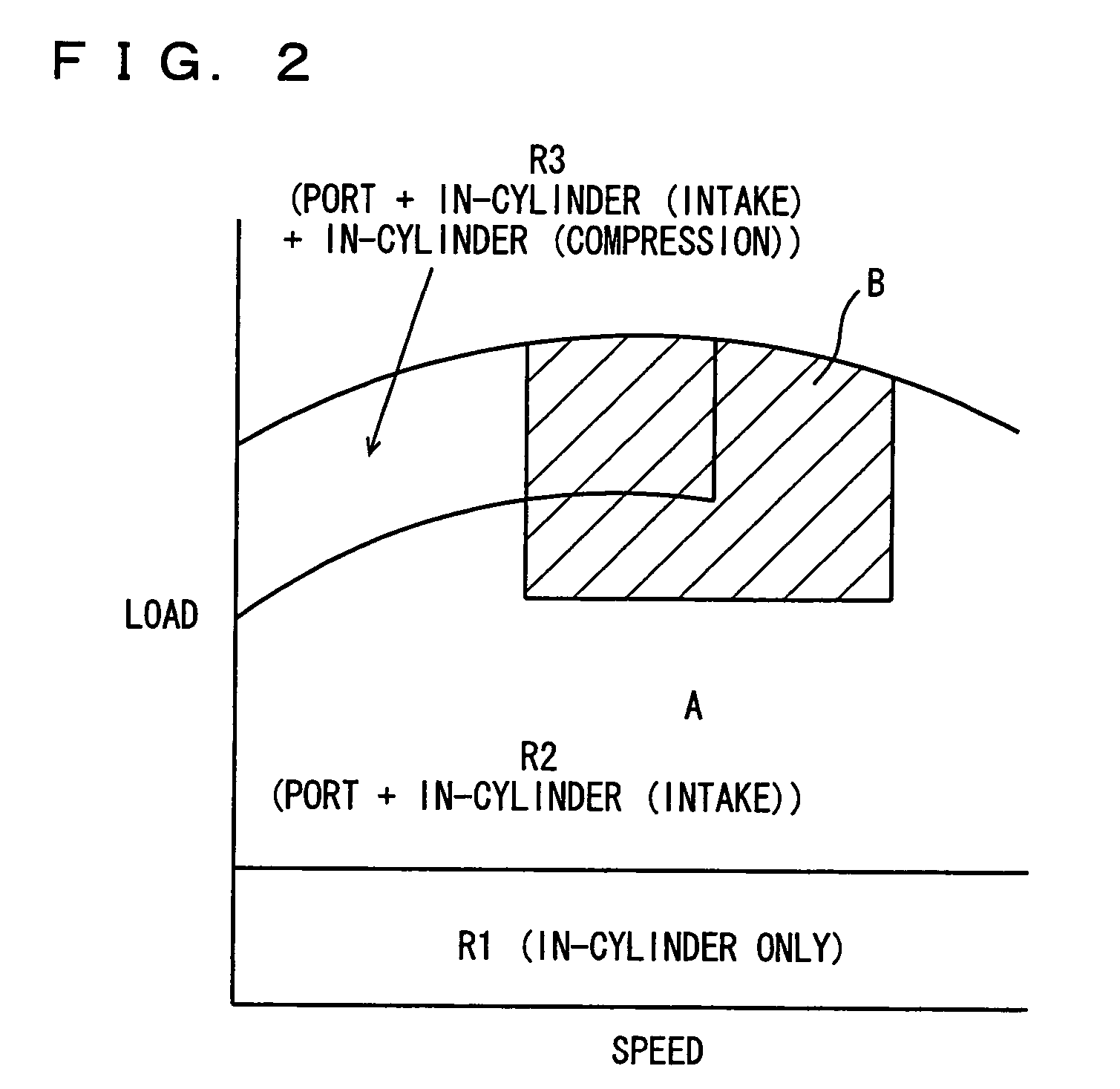

InactiveUS20080022982A1Improve engine performanceImprove combustion efficiencyElectrical controlInternal combustion piston enginesCombustionFuel injection

The invention is directed to a variable compression ratio internal combustion engine in which the compression ratio of the engine can be varied and multiple types of fuels having different combustion velocities are used. The invention provides a technology for achieving excellent engine performance for respective types of fuels. In the variable compression ratio internal combustion engine in which the compression ratio can be varied and multiple types of fuels having different combustion velocities are injected through multiple fuel injection valves, maps from which a target compression ratio of the internal combustion engine is read out are switched in accordance with the fuel used, thereby suppressing knocking or other disadvantages.

Owner:TOYOTA JIDOSHA KK

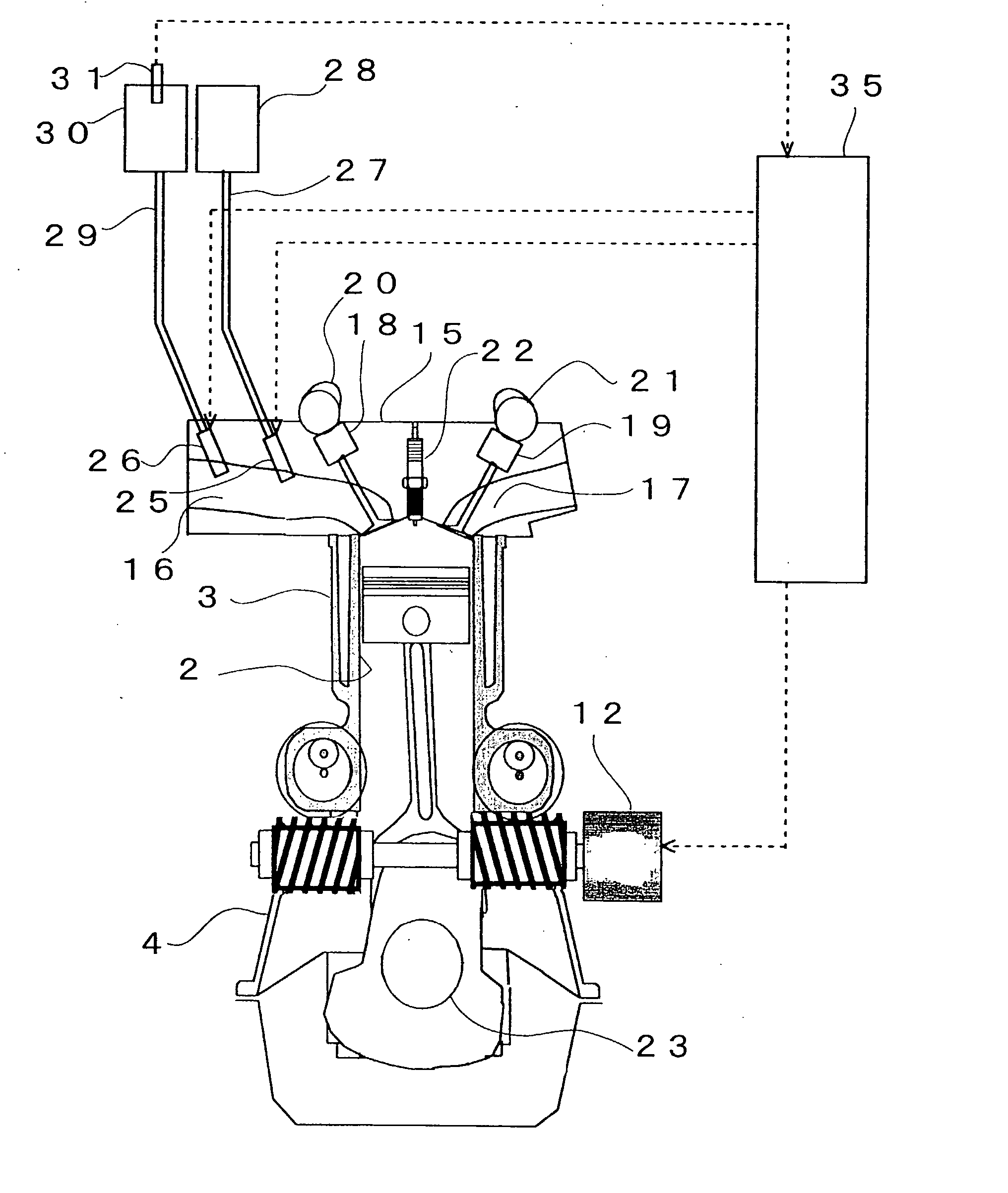

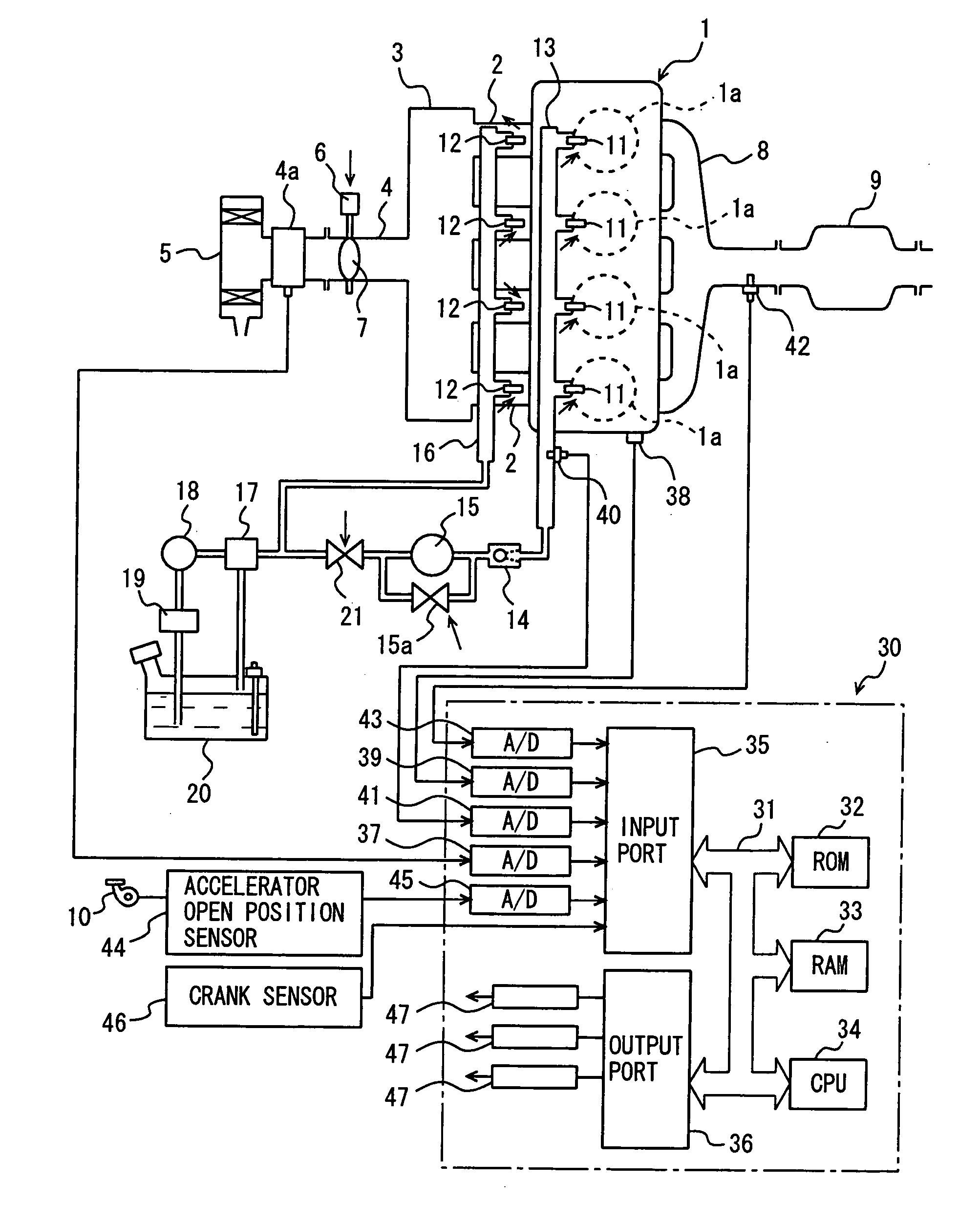

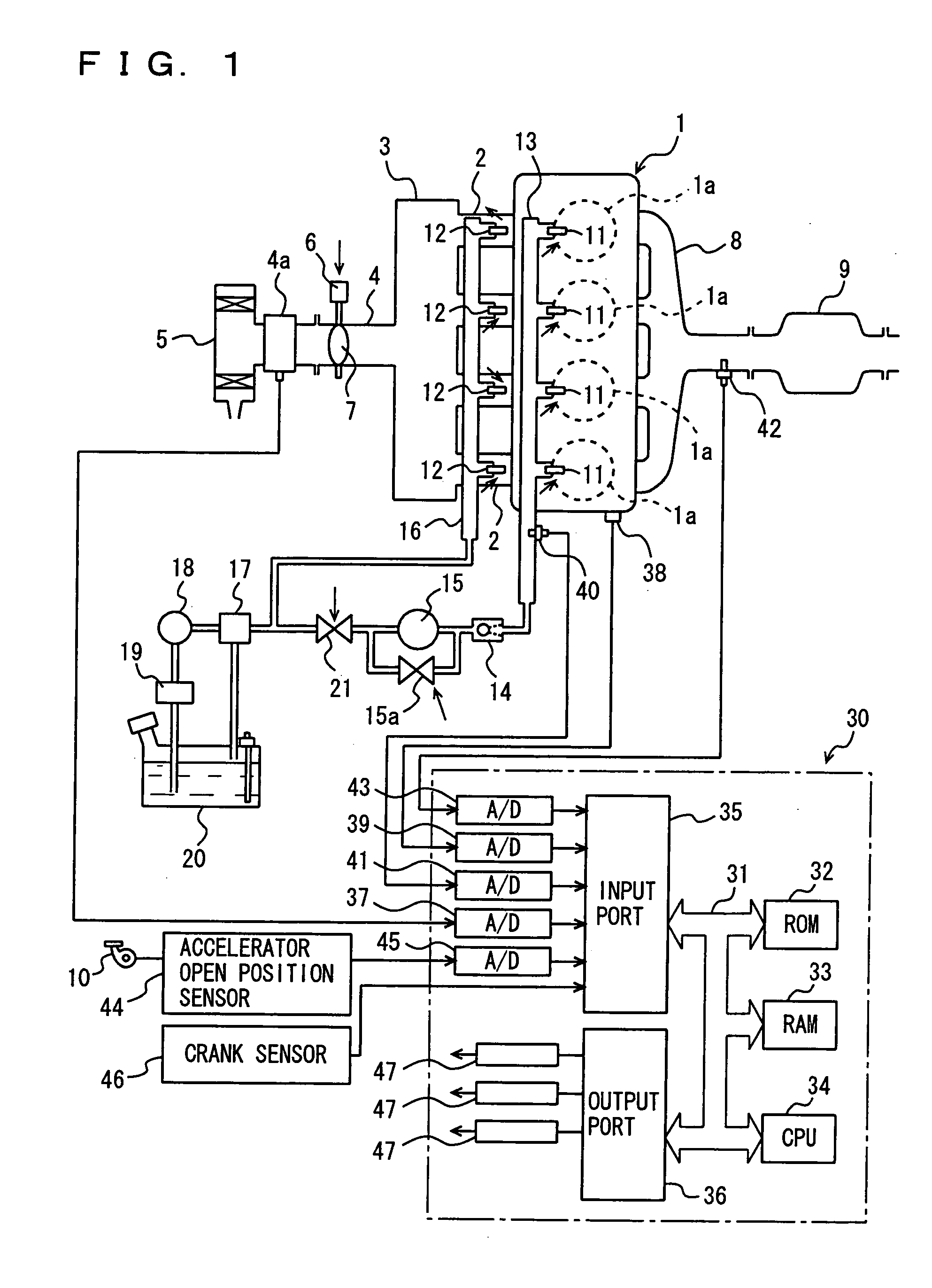

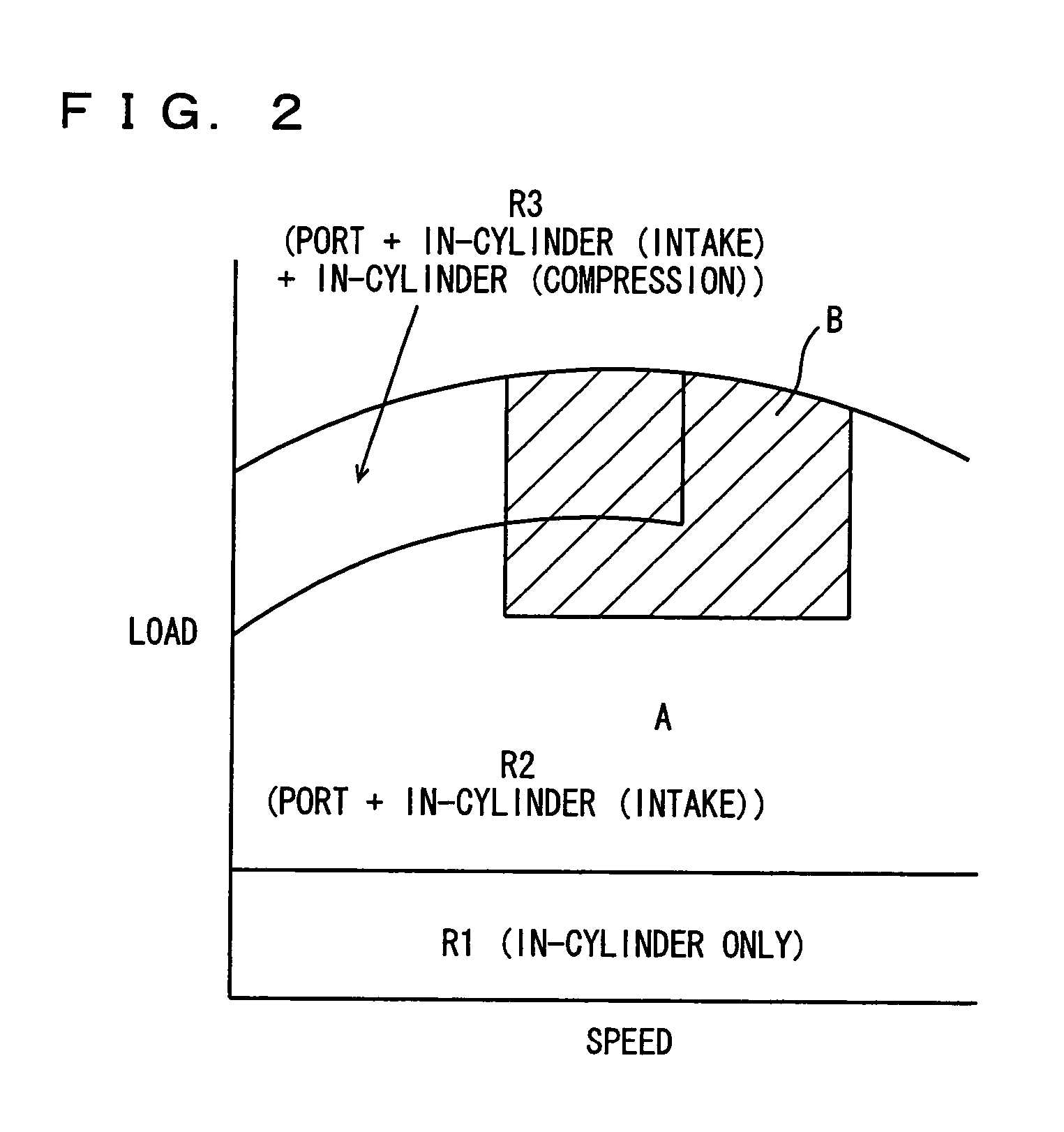

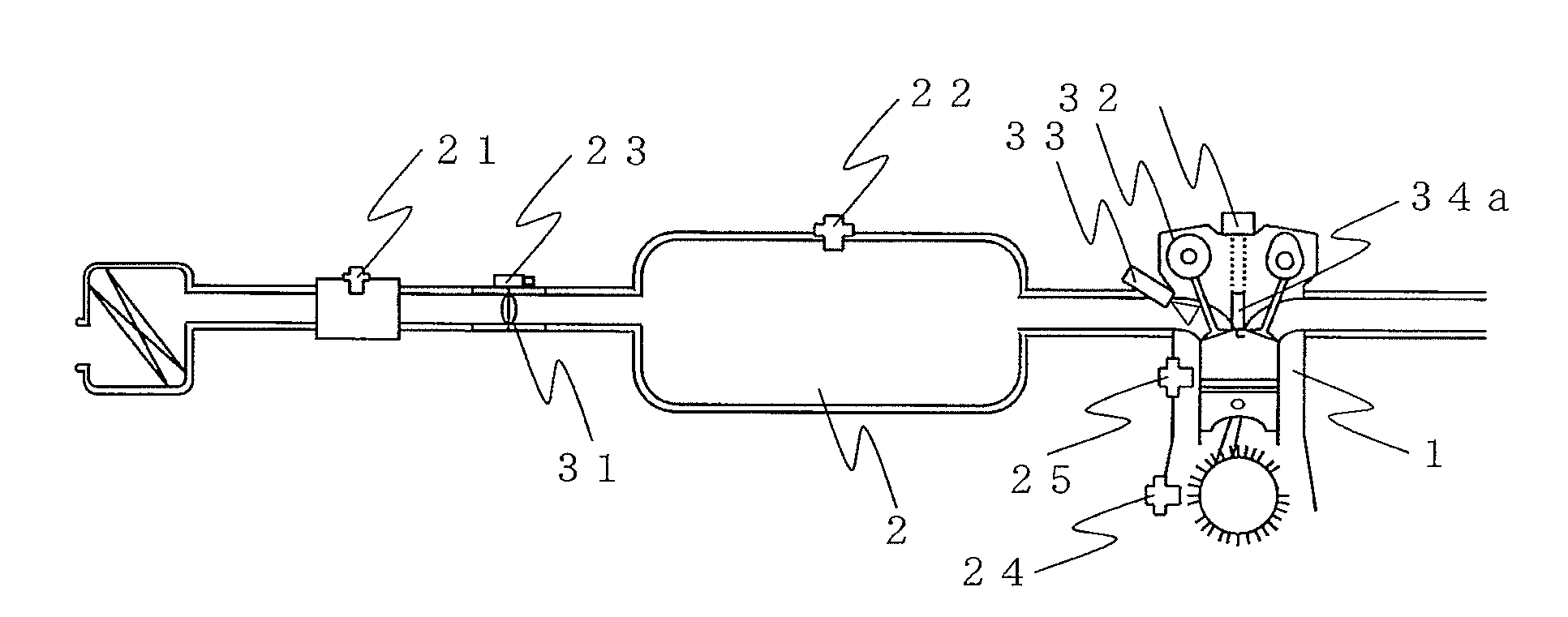

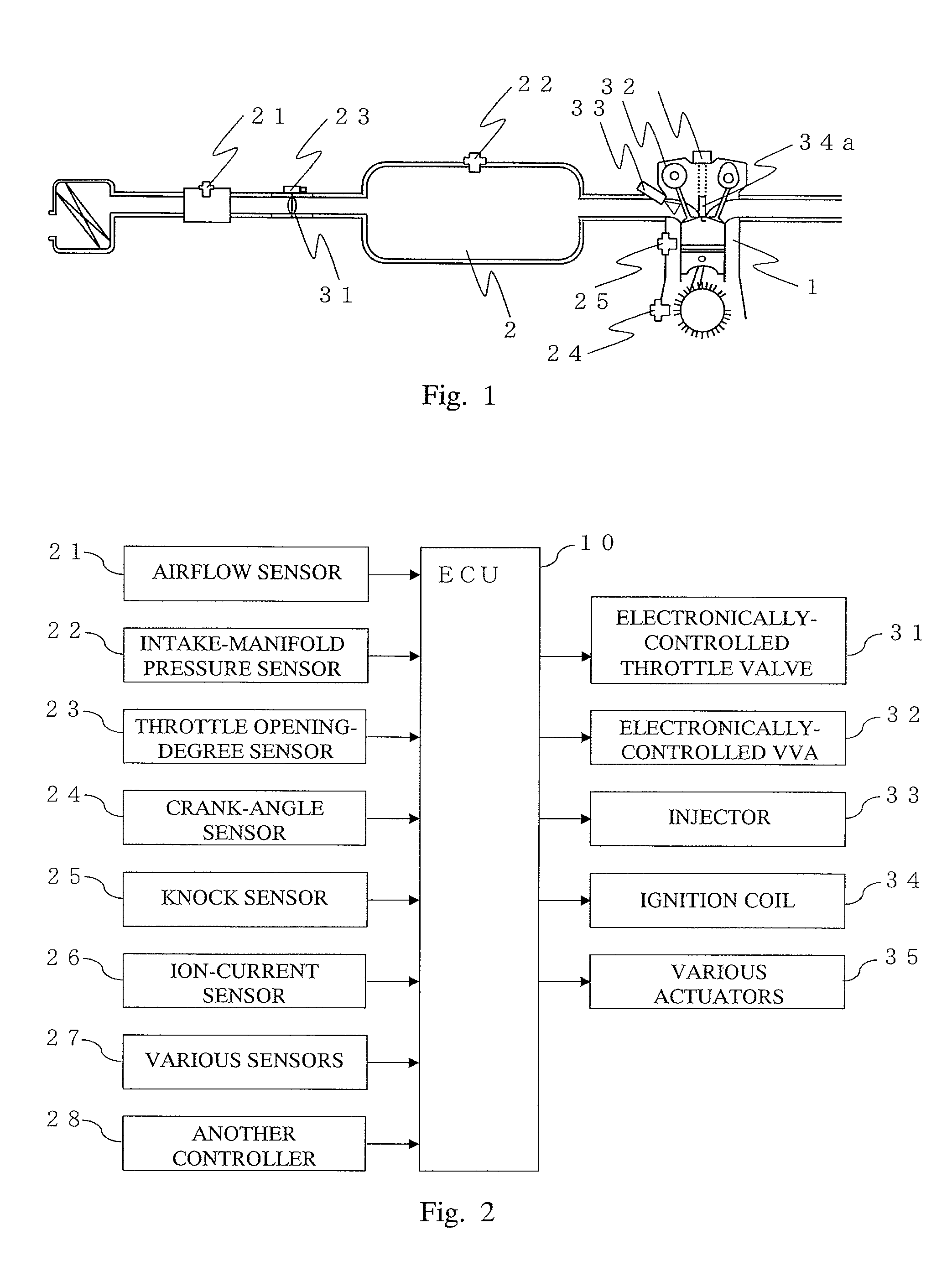

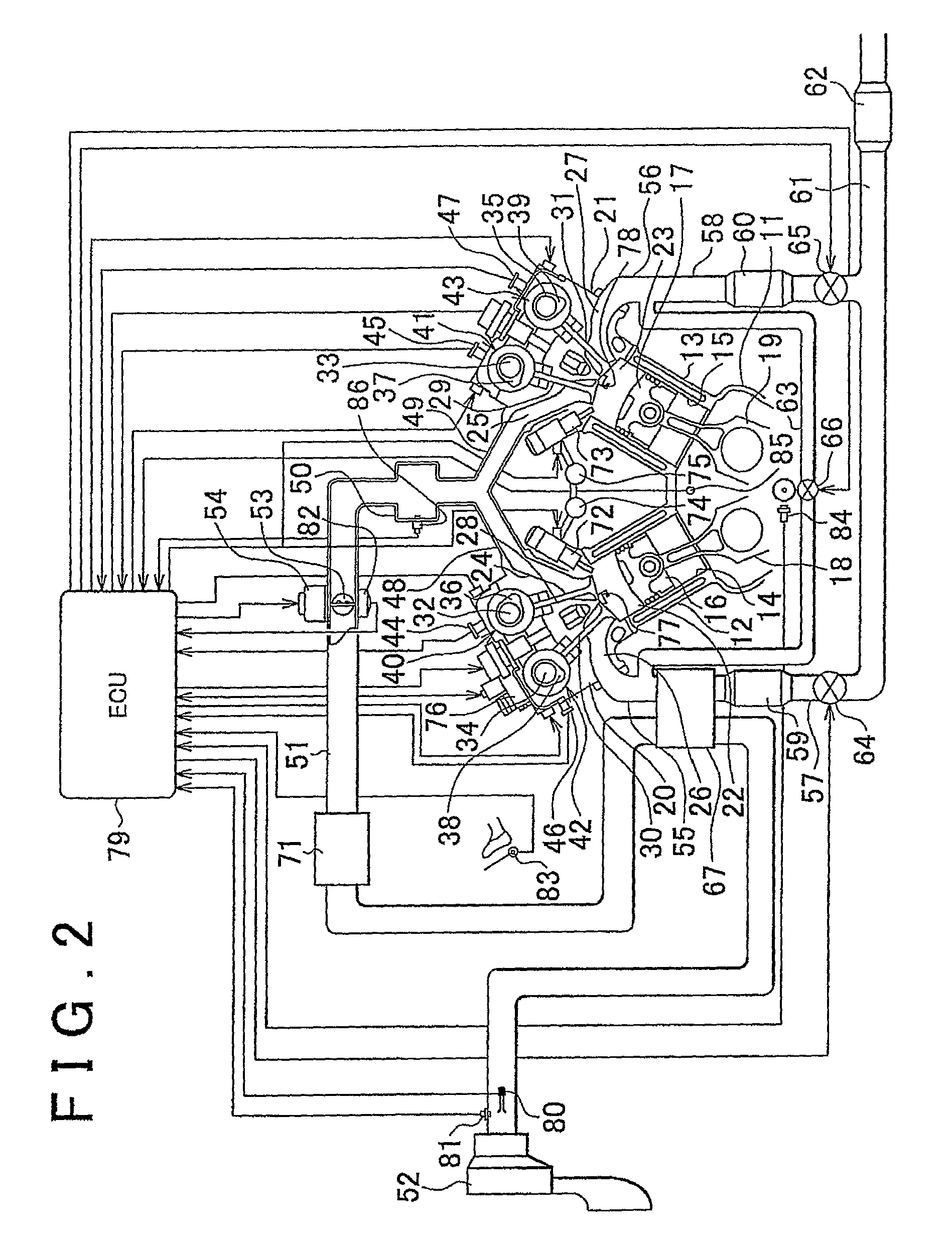

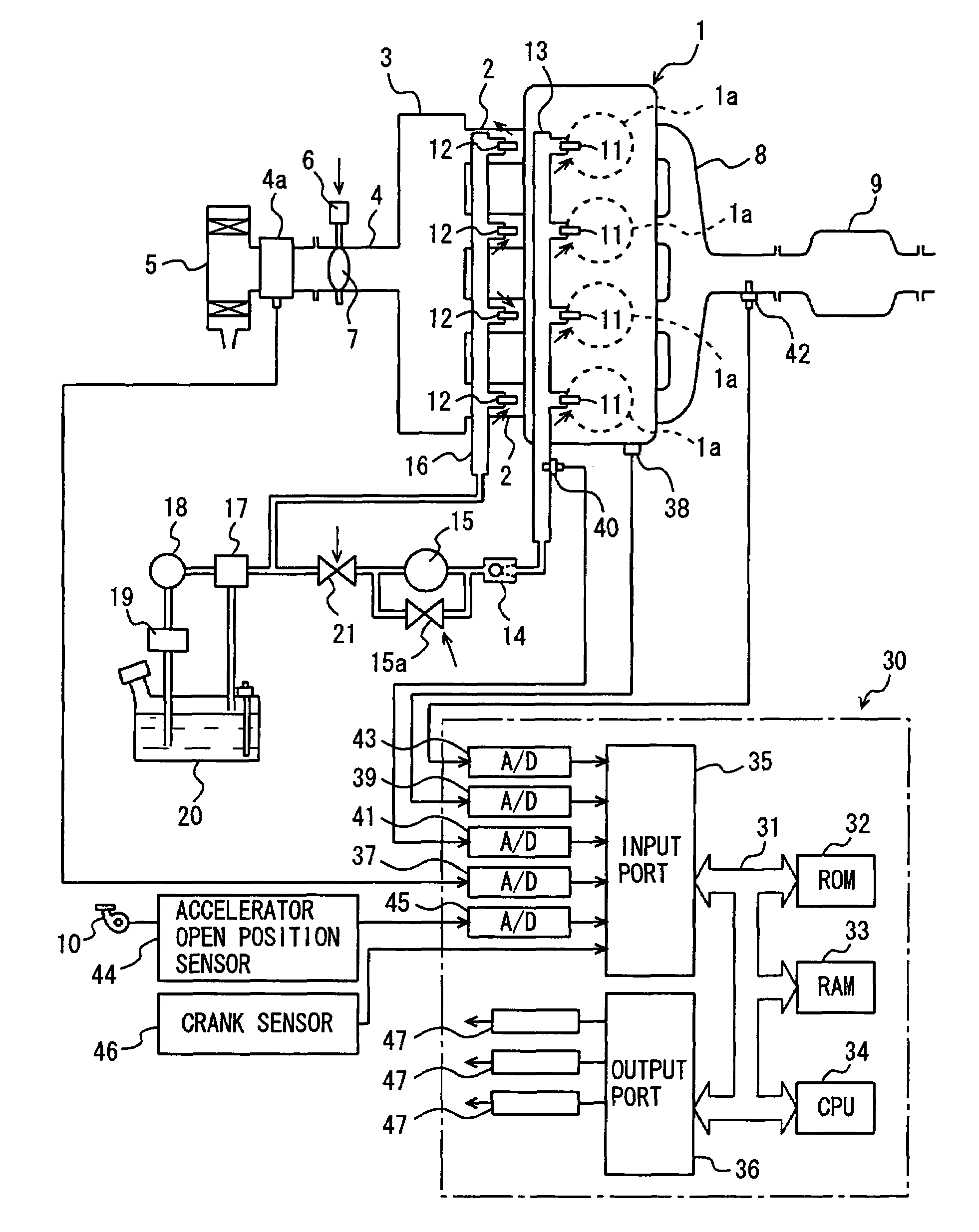

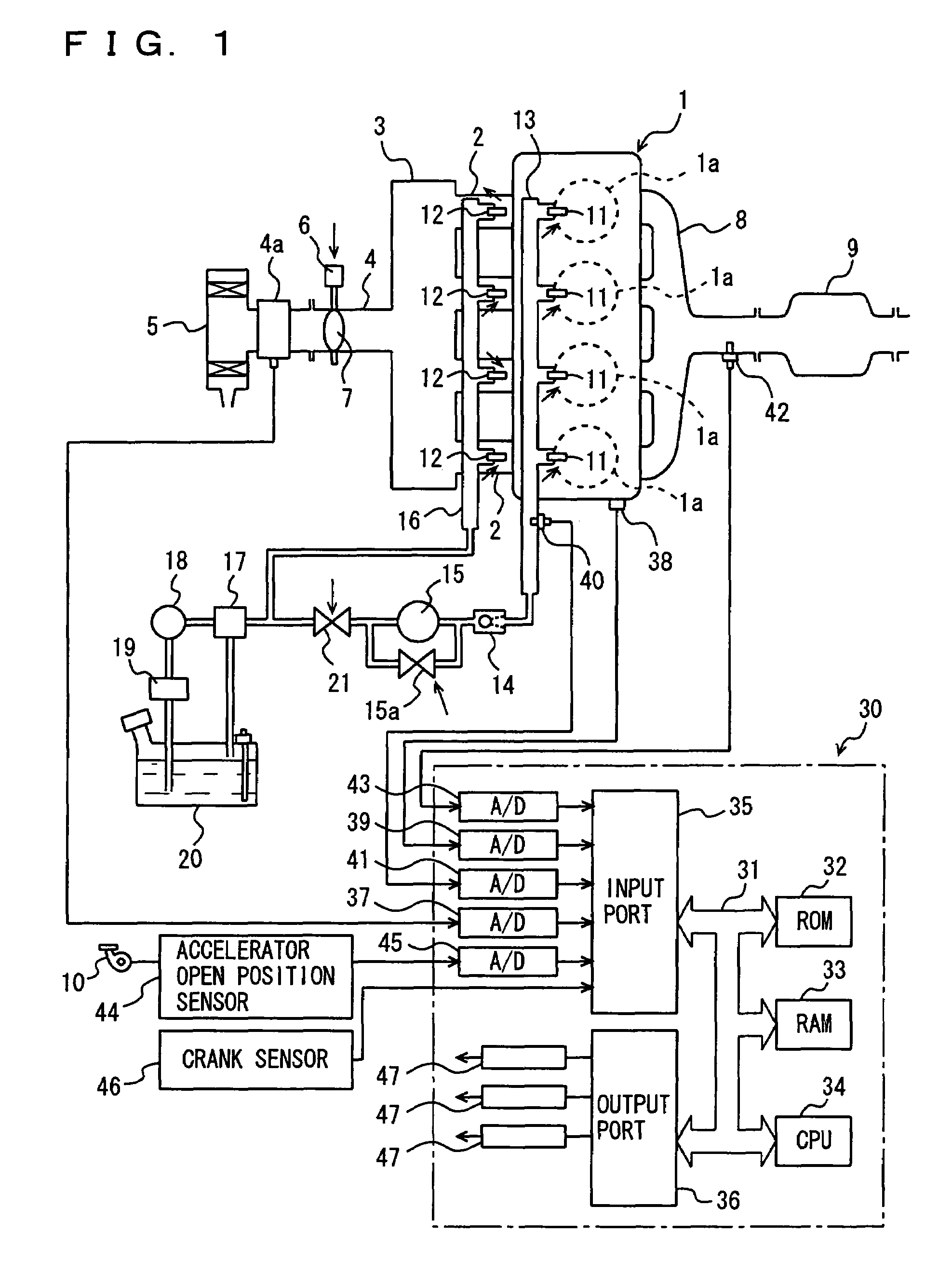

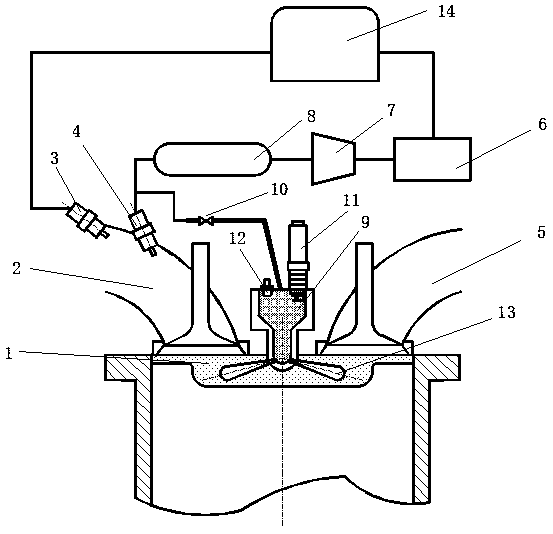

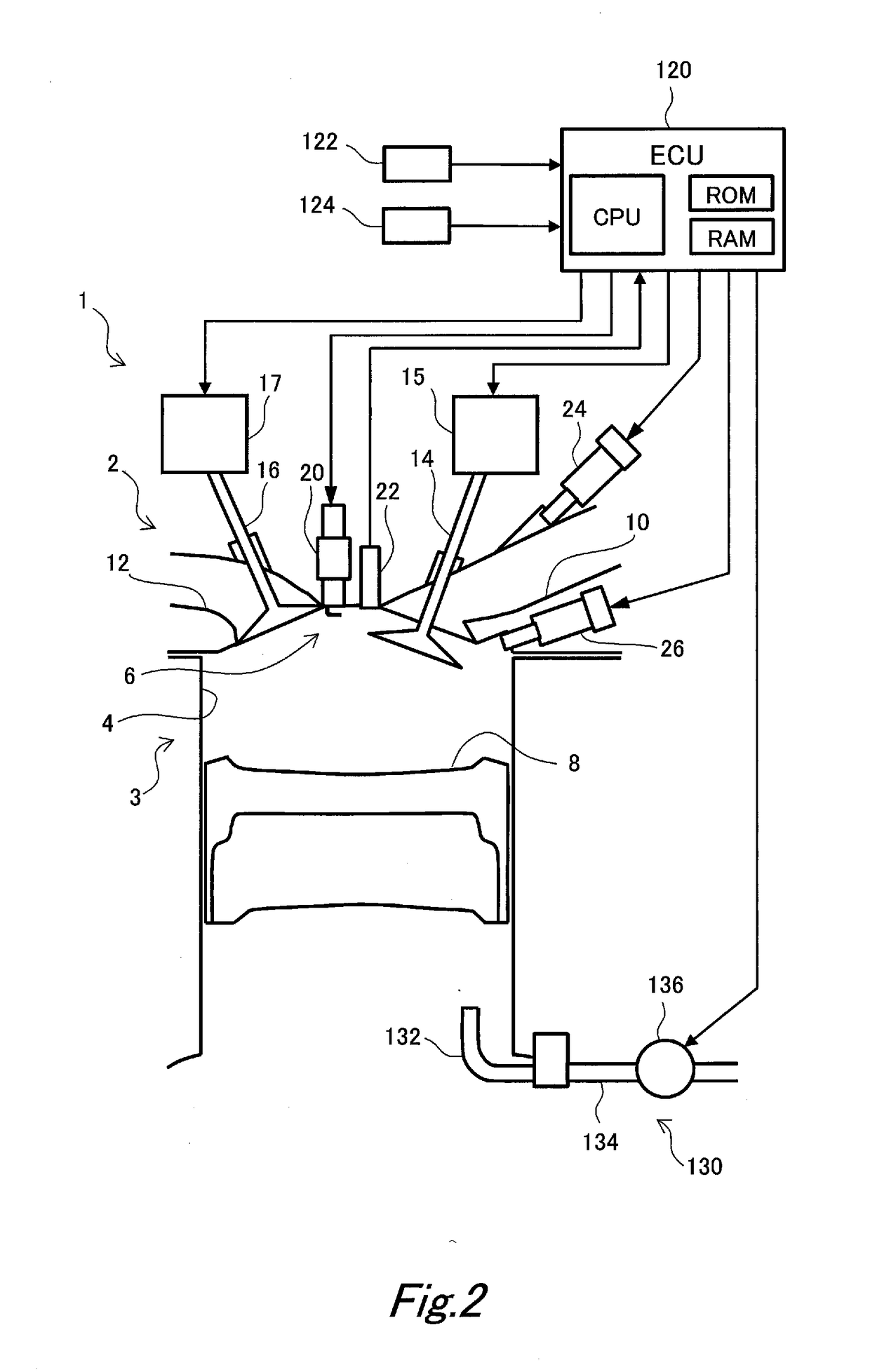

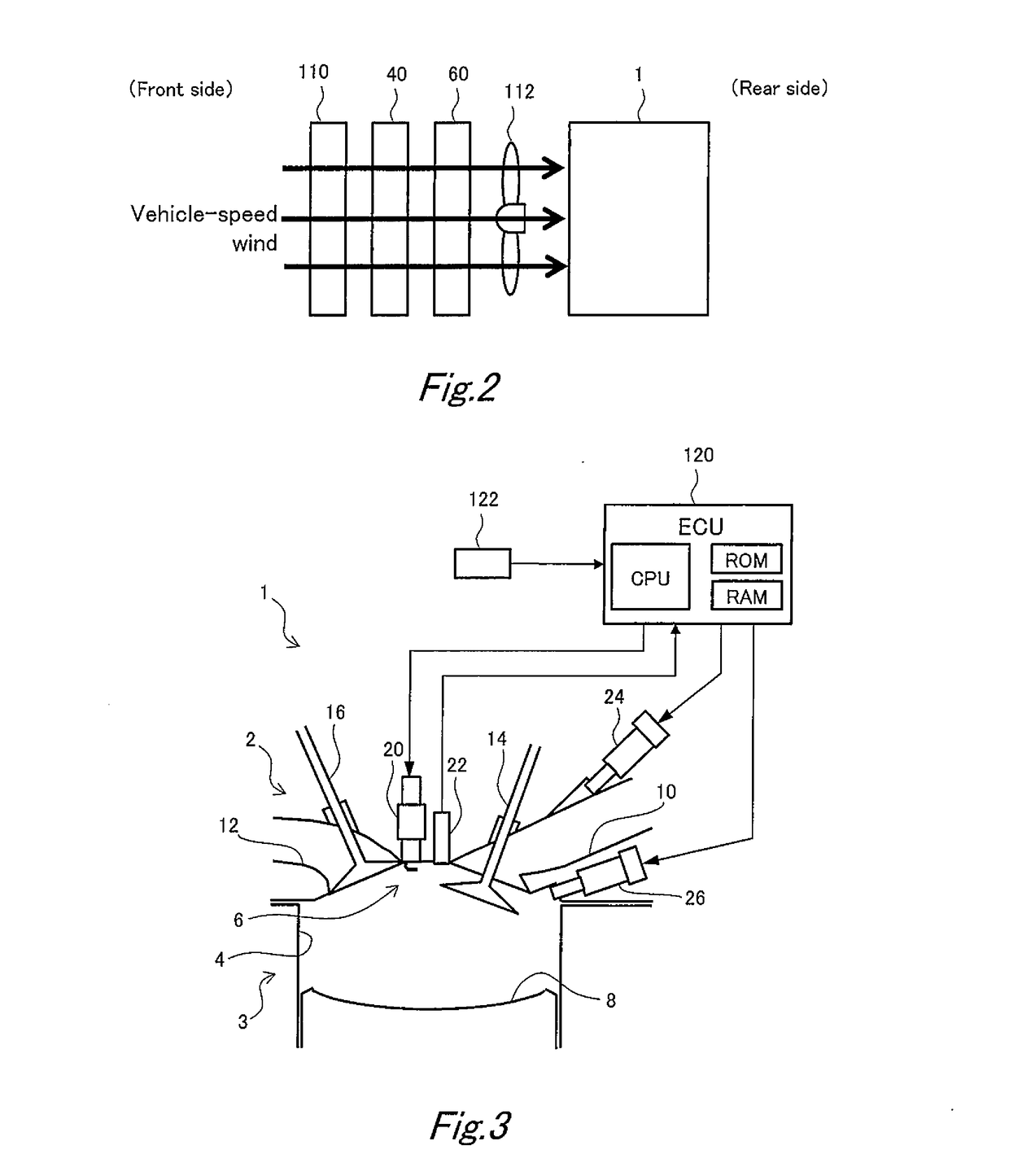

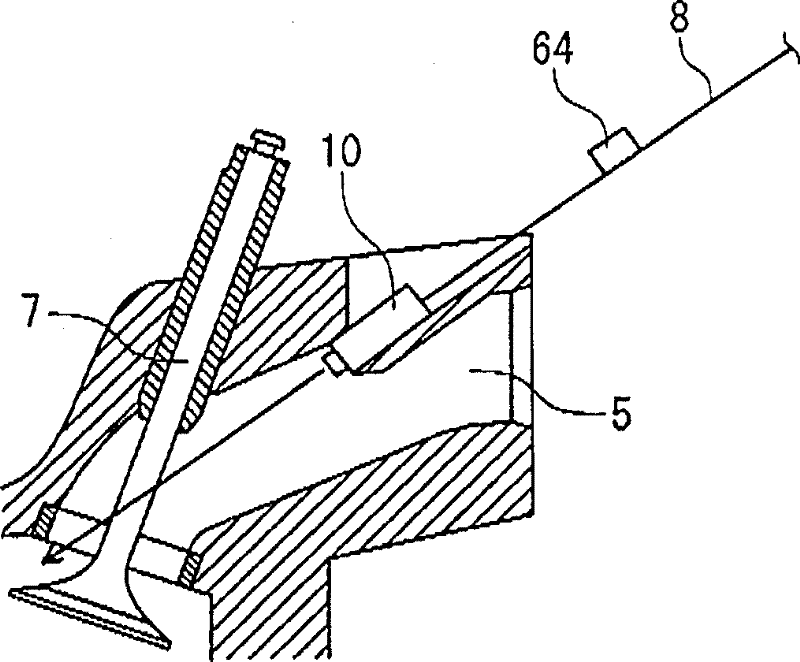

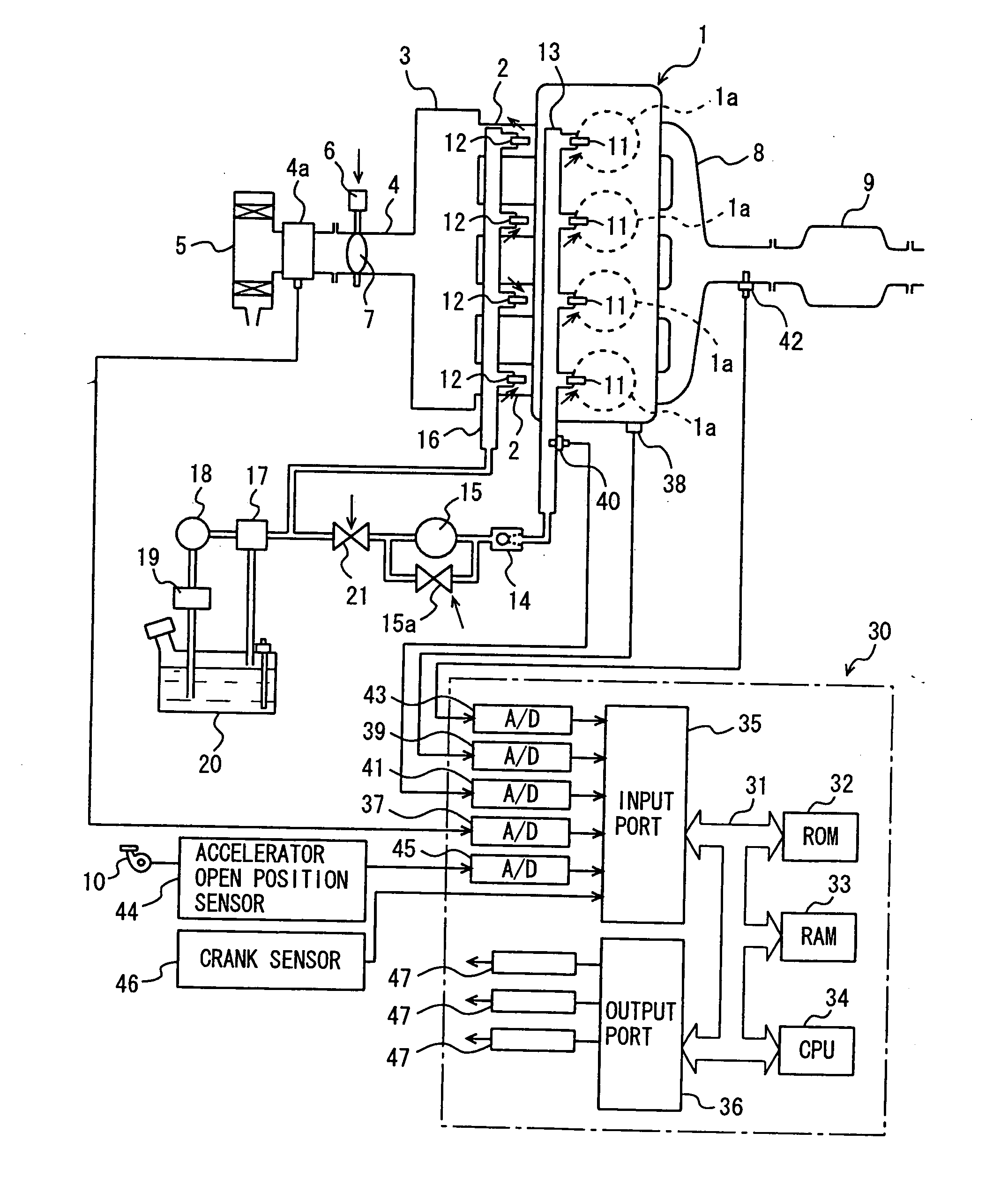

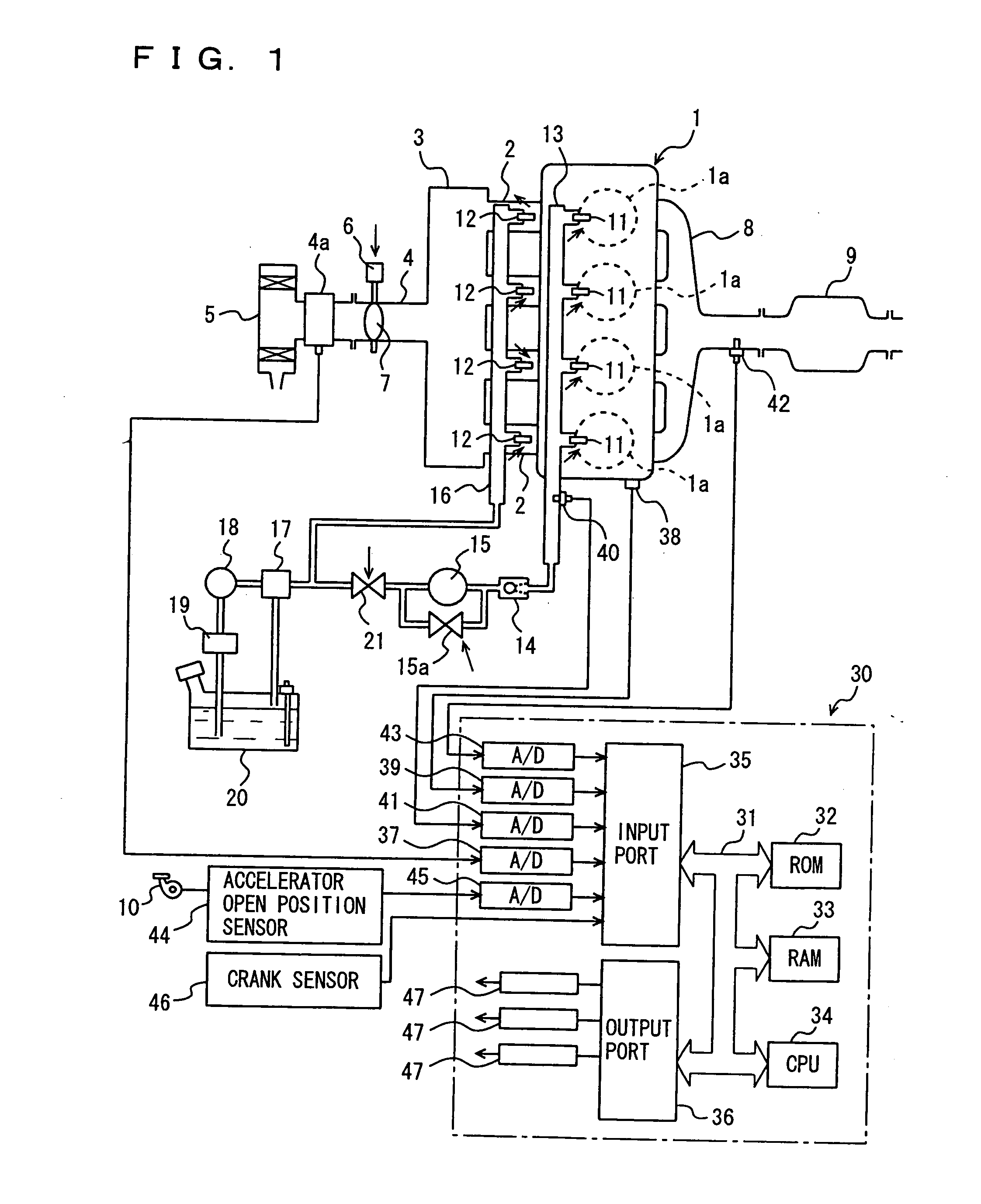

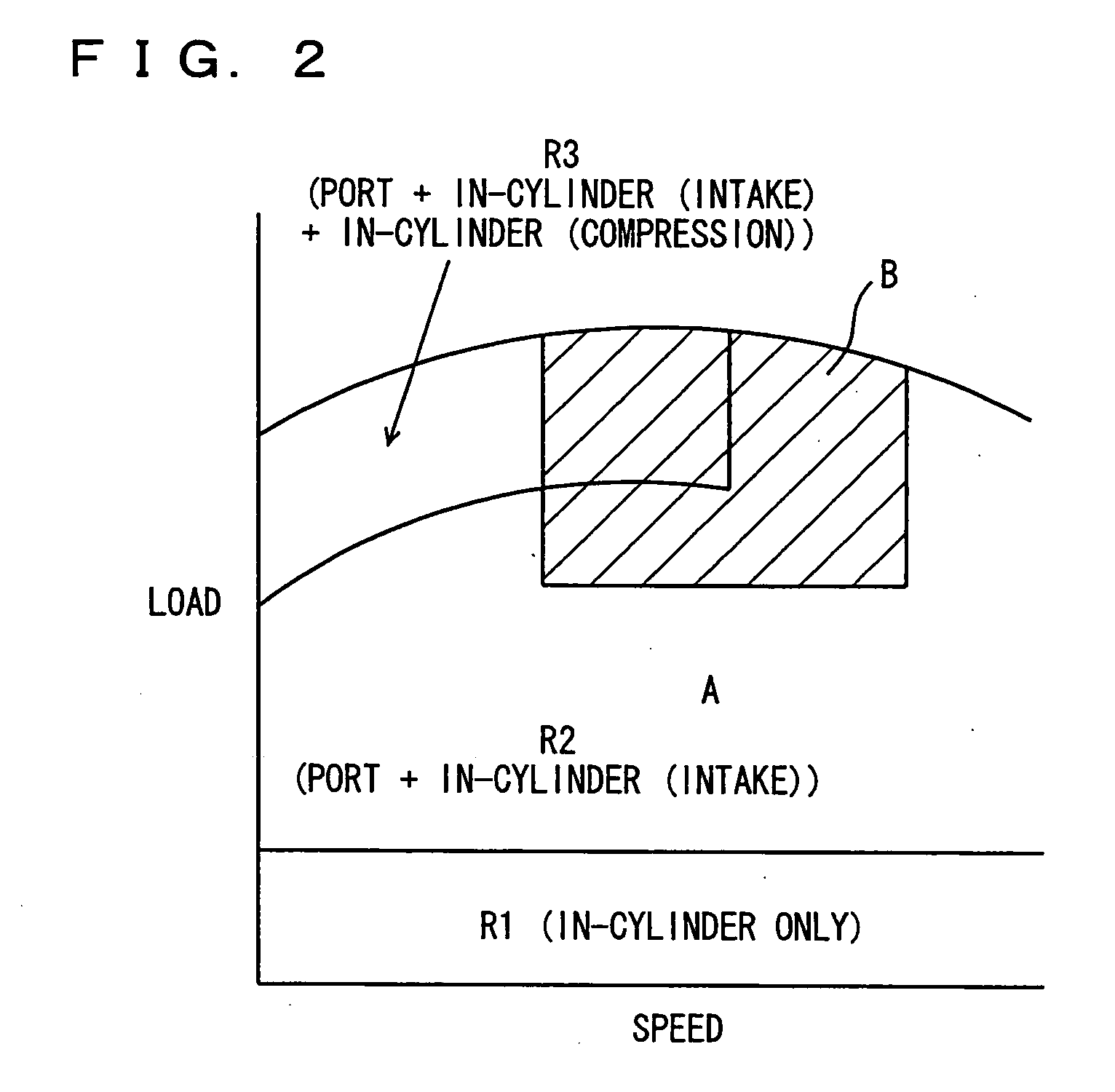

Dual injection type internal combustion engine

InactiveUS20060144365A1Accurate background learningKnock suppressionElectrical controlInternal combustion piston enginesDual injectionInjector

A dual injection type internal combustion engine including an injector for in-cylinder injection and an injector for intake manifold injection includes learning means for learning a background noise level based on an output signal of a knock sensor, and knocking suppression control means for performing, while learning the background noise level, knocking suppression control by controlling fuel injection of the injector for in-cylinder injection or the injector for intake manifold injection. Alternatively, the engine includes fixing means for fixing, while learning the background noise level, a start timing or end timing of fuel injection by the injector for in-cylinder injection at a basic timing determined by an operating state of the engine.

Owner:TOYOTA JIDOSHA KK

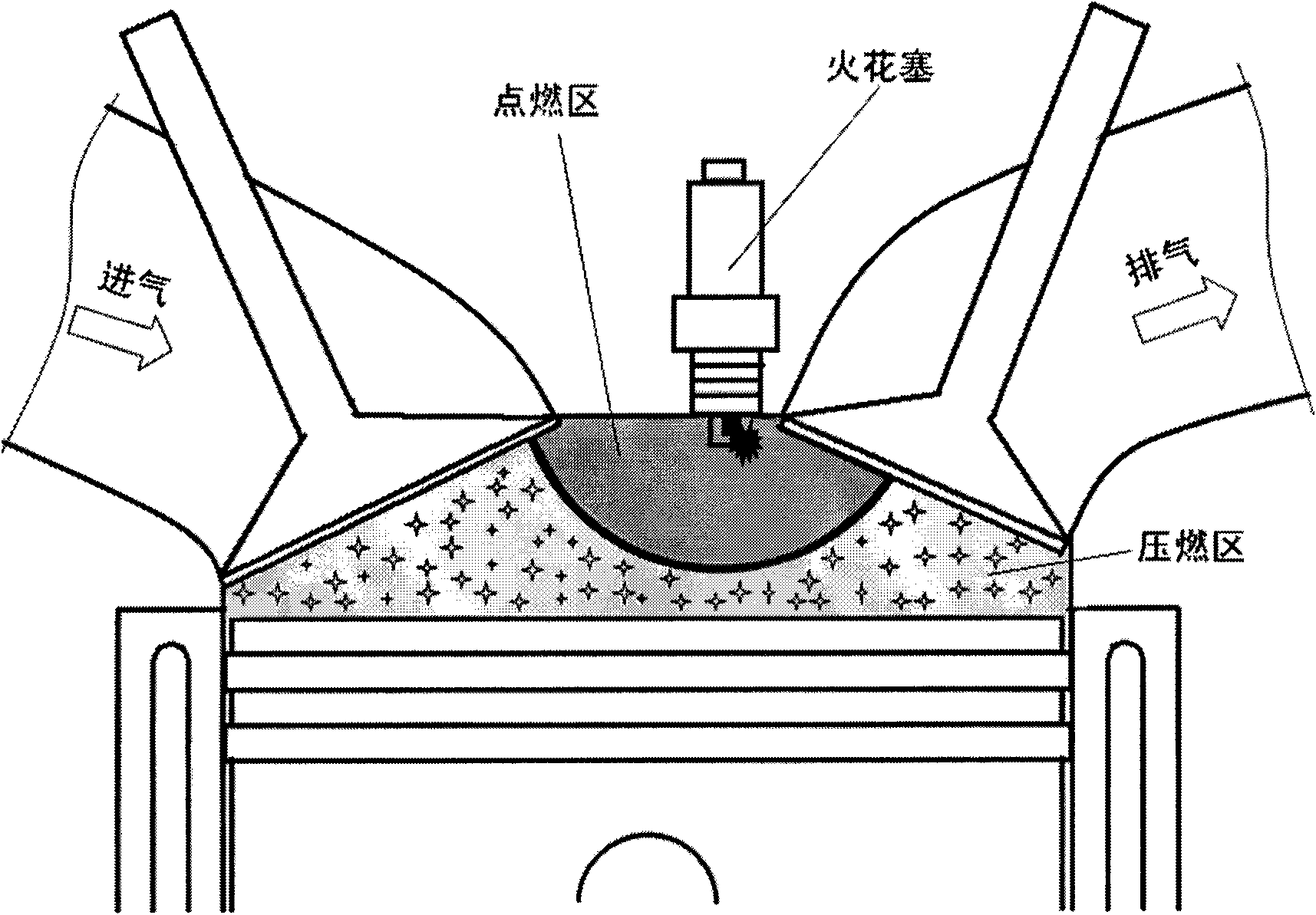

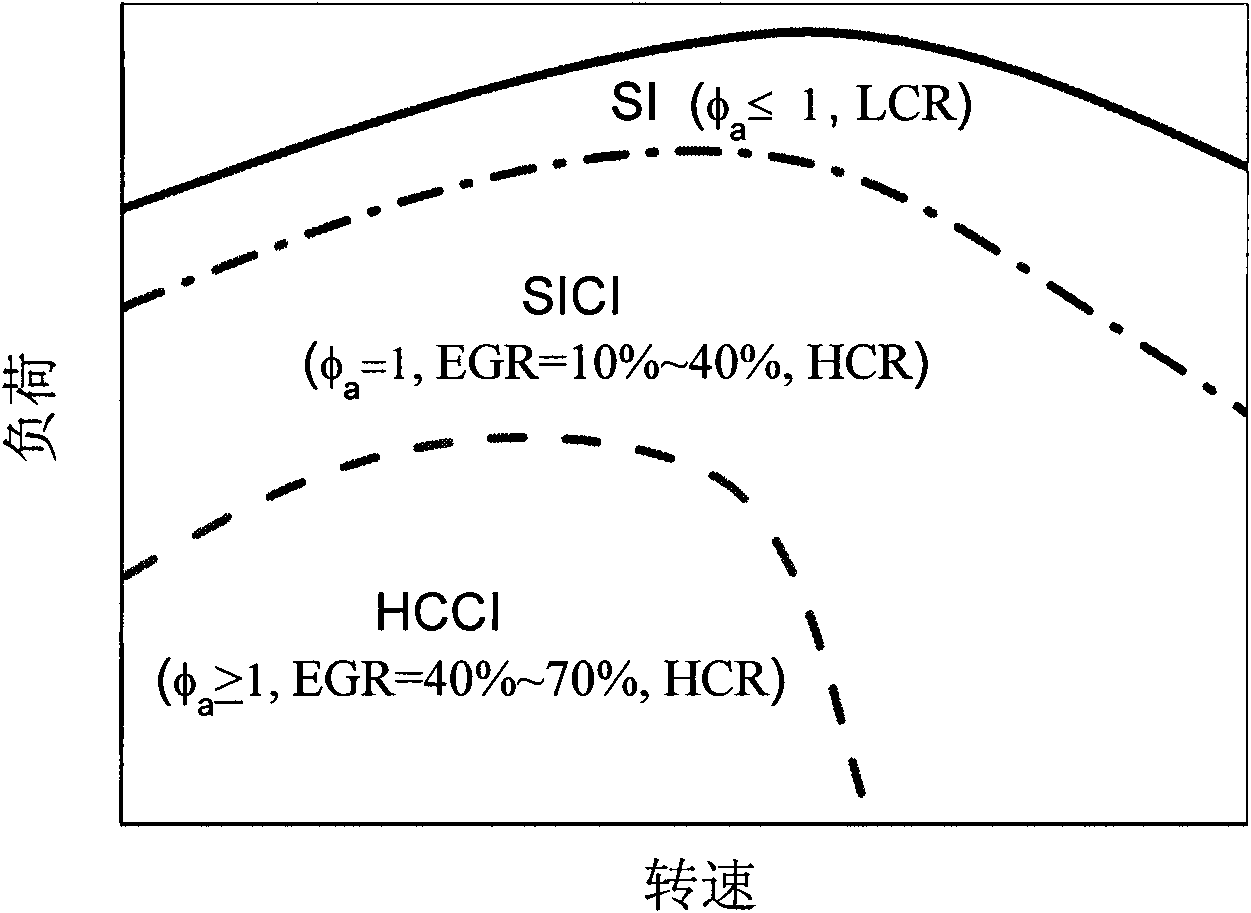

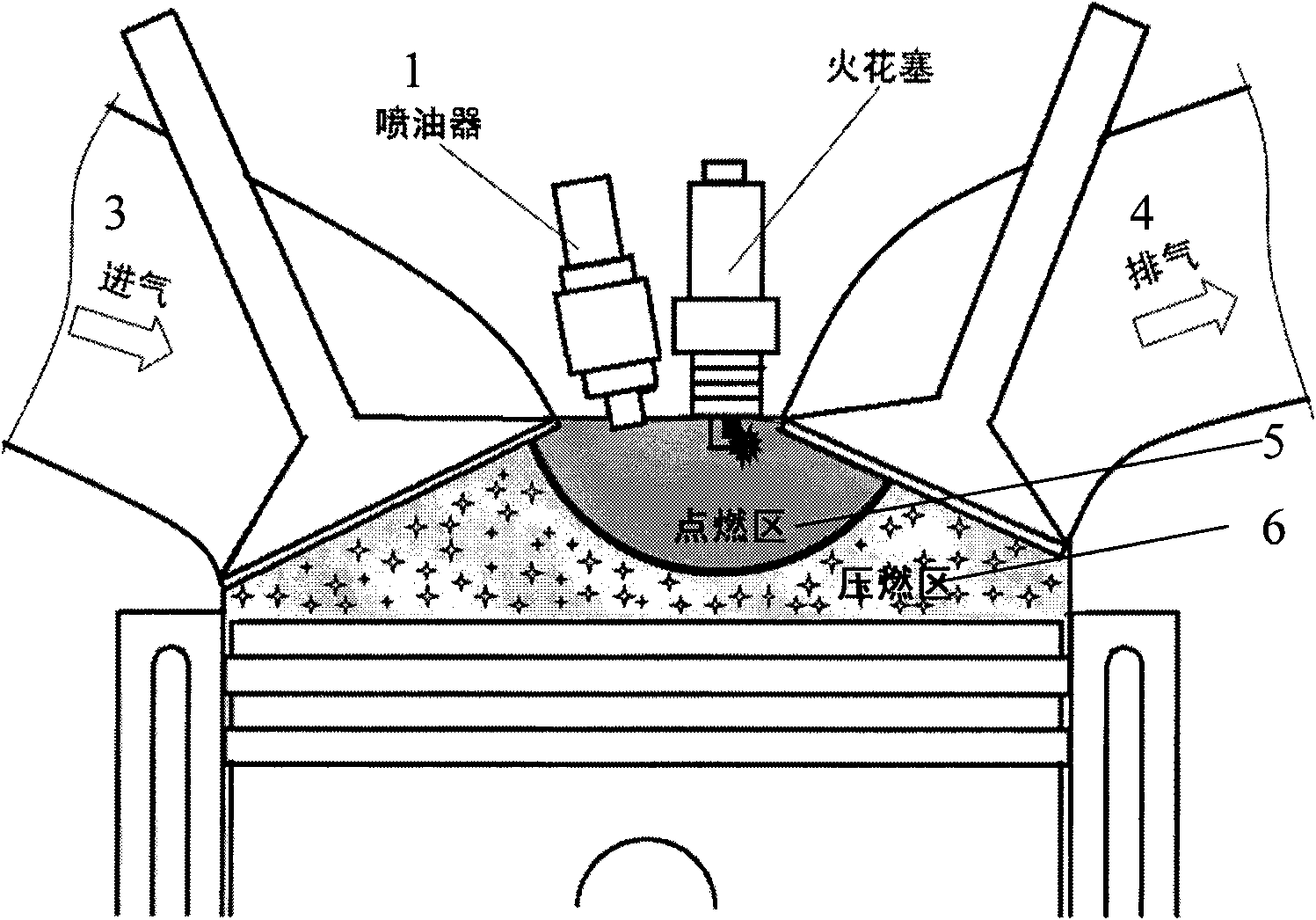

Petrol engine spark ignition excite homogeneous compression ignition combustion control method

ActiveCN101619670AReduced pressure rise rateControl the moment of fireElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionFlame propagation

The invention discloses a petrol engine spark ignition excite homogeneous compression ignition combustion control method which belongs to the technical field of internal combustion engines. In the control method, an ignition advance angle is used for controlling ignition moments, and a combustion rate is controlled by an EGR rate. The petrol engine spark ignition excite homogeneous compression ignition combustion control method comprises the following steps: spraying fuel firstly in an air inlet process to form homogeneous rarefied mixed gas when an upper dead center is compressed; spraying fuel secondly in a compression stroke to form local thicker mixed gas around a spark plug; igniting the local thicker mixed gas to produce flame propagation by the spark plug; releasing heat by the combustion of the local flame propagation; compressing the around large-area rarefied mixed gas to rise temperature and pressure to a self-ignite flammation state, thereby exciting the mixed gas in a whole cylinder to self-ignite in a large area in a multipoint mode, and quickly and completely burning the whole mixed gas; and otherwise, harmful emissions generated by burning the equivalent proportion mixed gas are effectively controlled by using a three-way catalyst of the traditional petrol engine.

Owner:TSINGHUA UNIV

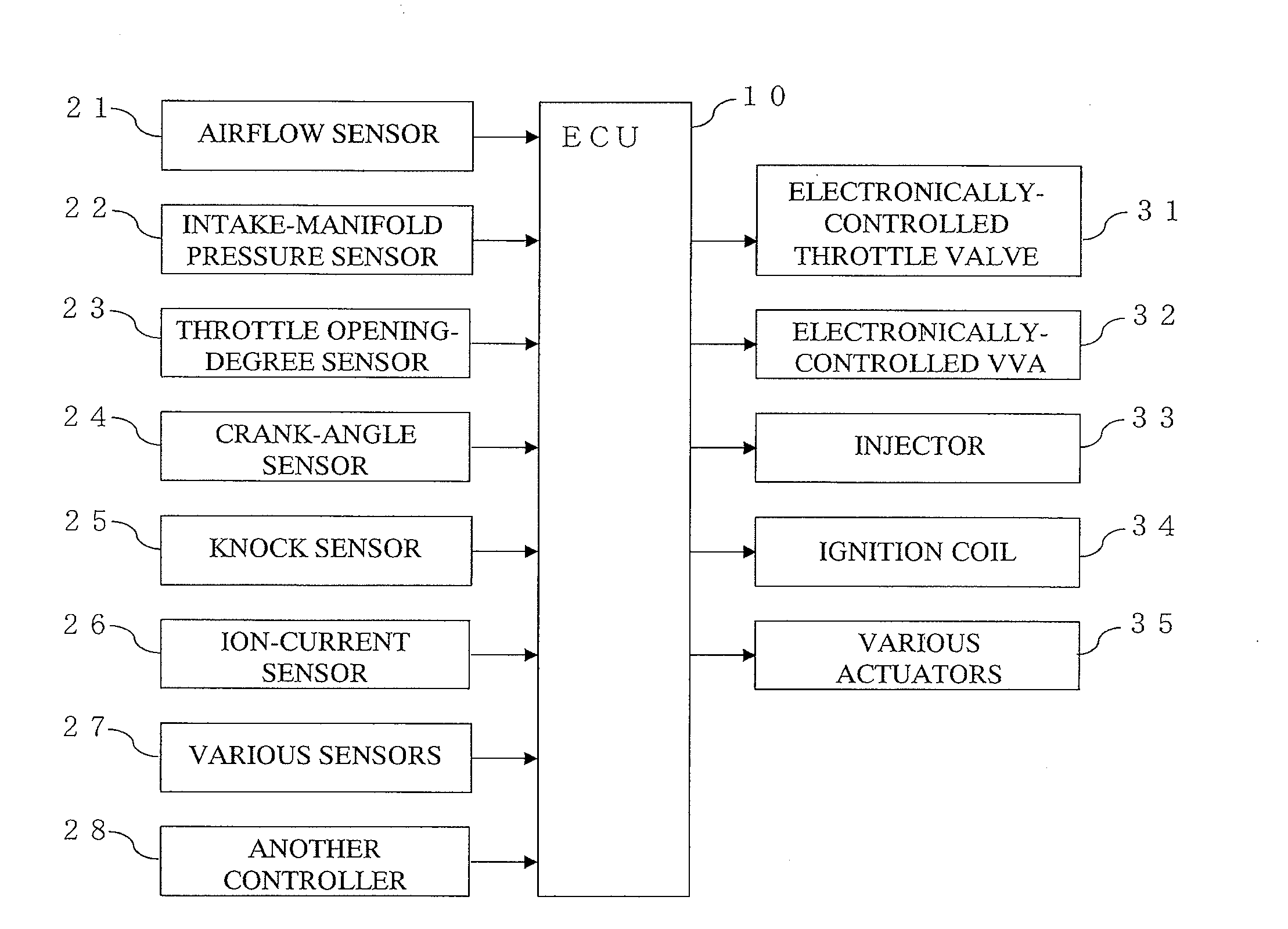

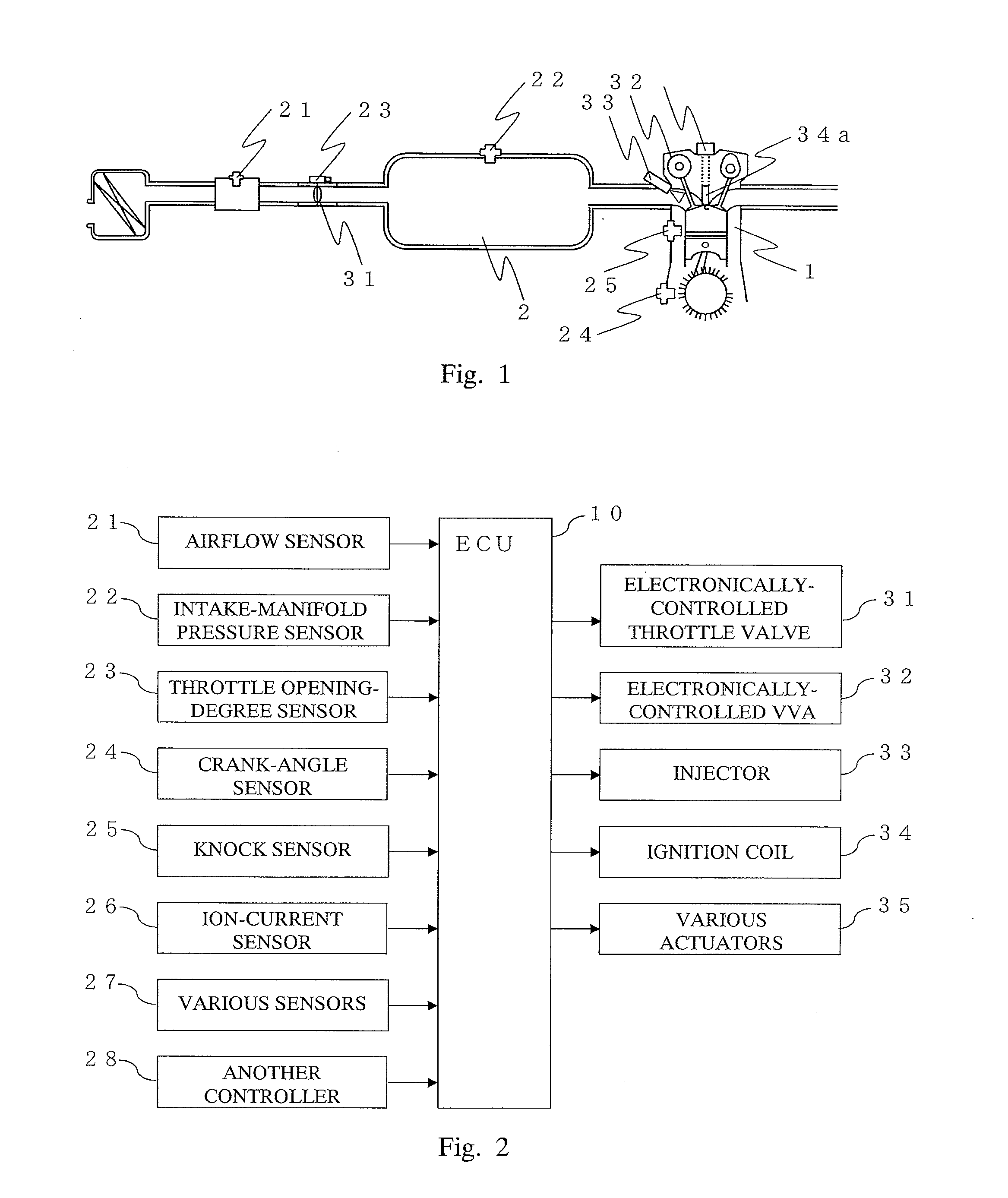

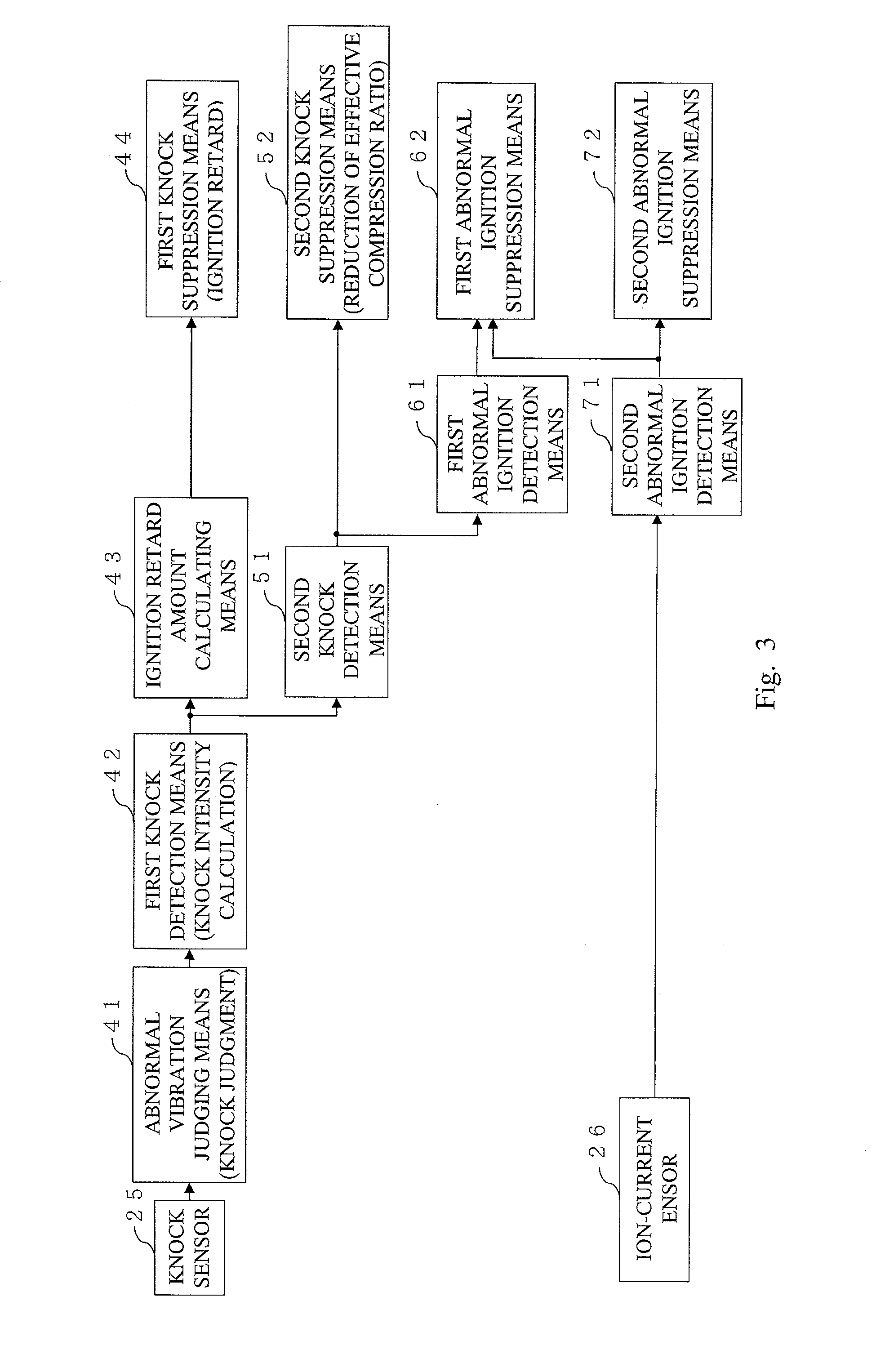

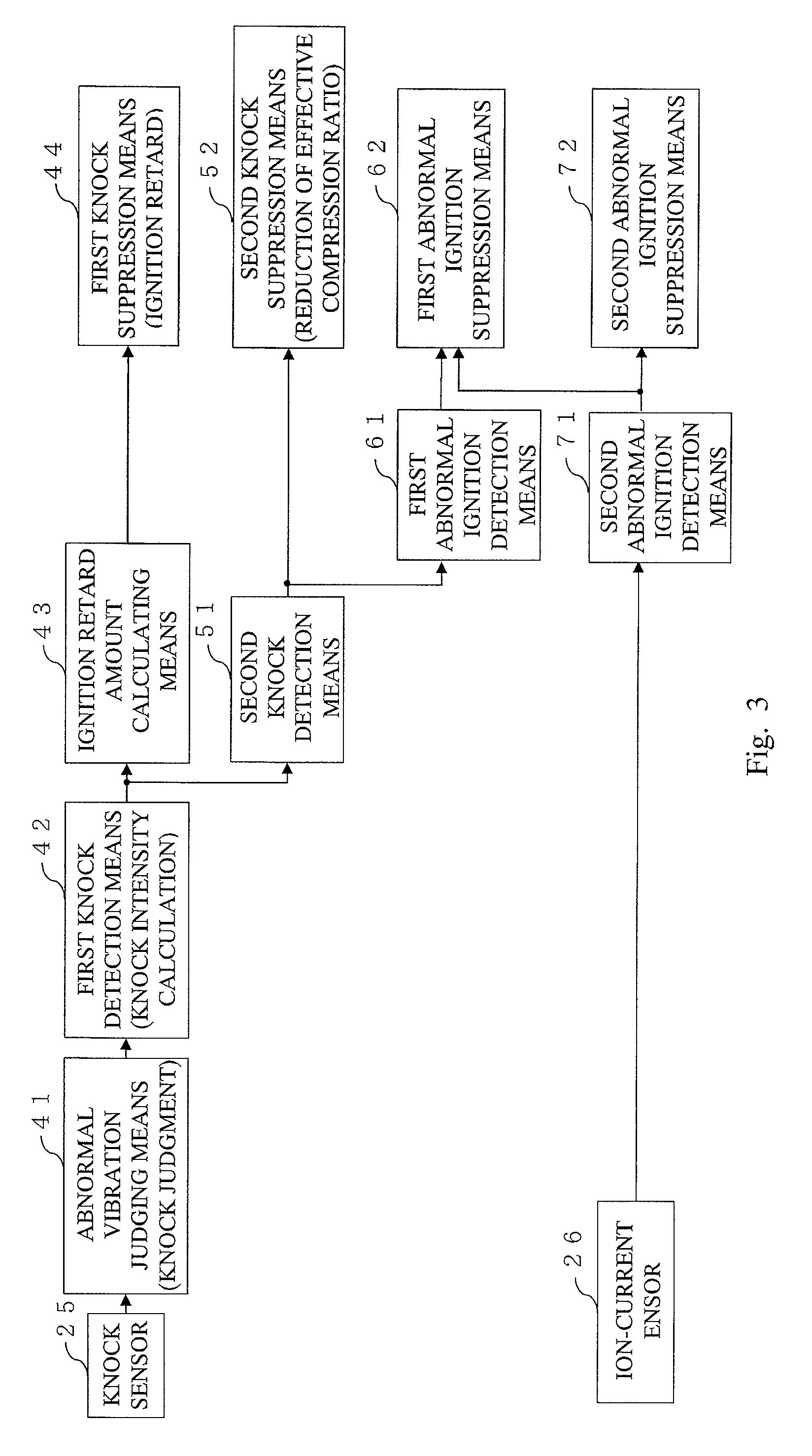

Control apparatus for internal combustion engine

ActiveUS20110093186A1Shorten the durationReduce fluctuationAnalogue computers for vehiclesElectrical controlIgnition timingCompression ratio

Control apparatus for an internal combustion engine including: a second knock detection unit for detecting occurrence of a second knock due to an effective compression ratio when ignition timing is on a retard side of a predetermined value in the case where a first knock is detected; a second knock suppression unit for suppressing the second knock when the second knock is detected; a first abnormal ignition detection means for detecting occurrence of first abnormal ignition due to the pre-ignition or the post-ignition when a knock intensity of the second knock is equal to or larger than a predetermined value; and a first abnormal ignition suppression unit for suppressing the first abnormal ignition by performing fuel control for the internal combustion engine when the first abnormal ignition is detected.

Owner:MITSUBISHI ELECTRIC CORP +1

Control apparatus for internal combustion engine

ActiveUS8316824B2Shorten the durationReduce fluctuationAnalogue computers for vehiclesElectrical controlIgnition timingUltimate tensile strength

Control apparatus for an internal combustion engine including: a second knock detection unit for detecting occurrence of a second knock due to an effective compression ratio when ignition timing is on a retard side of a predetermined value in the case where a first knock is detected; a second knock suppression unit for suppressing the second knock when the second knock is detected; a first abnormal ignition detection means for detecting occurrence of first abnormal ignition due to the pre-ignition or the post-ignition when a knock intensity of the second knock is equal to or larger than a predetermined value; and a first abnormal ignition suppression unit for suppressing the first abnormal ignition by performing fuel control for the internal combustion engine when the first abnormal ignition is detected.

Owner:MITSUBISHI ELECTRIC CORP +1

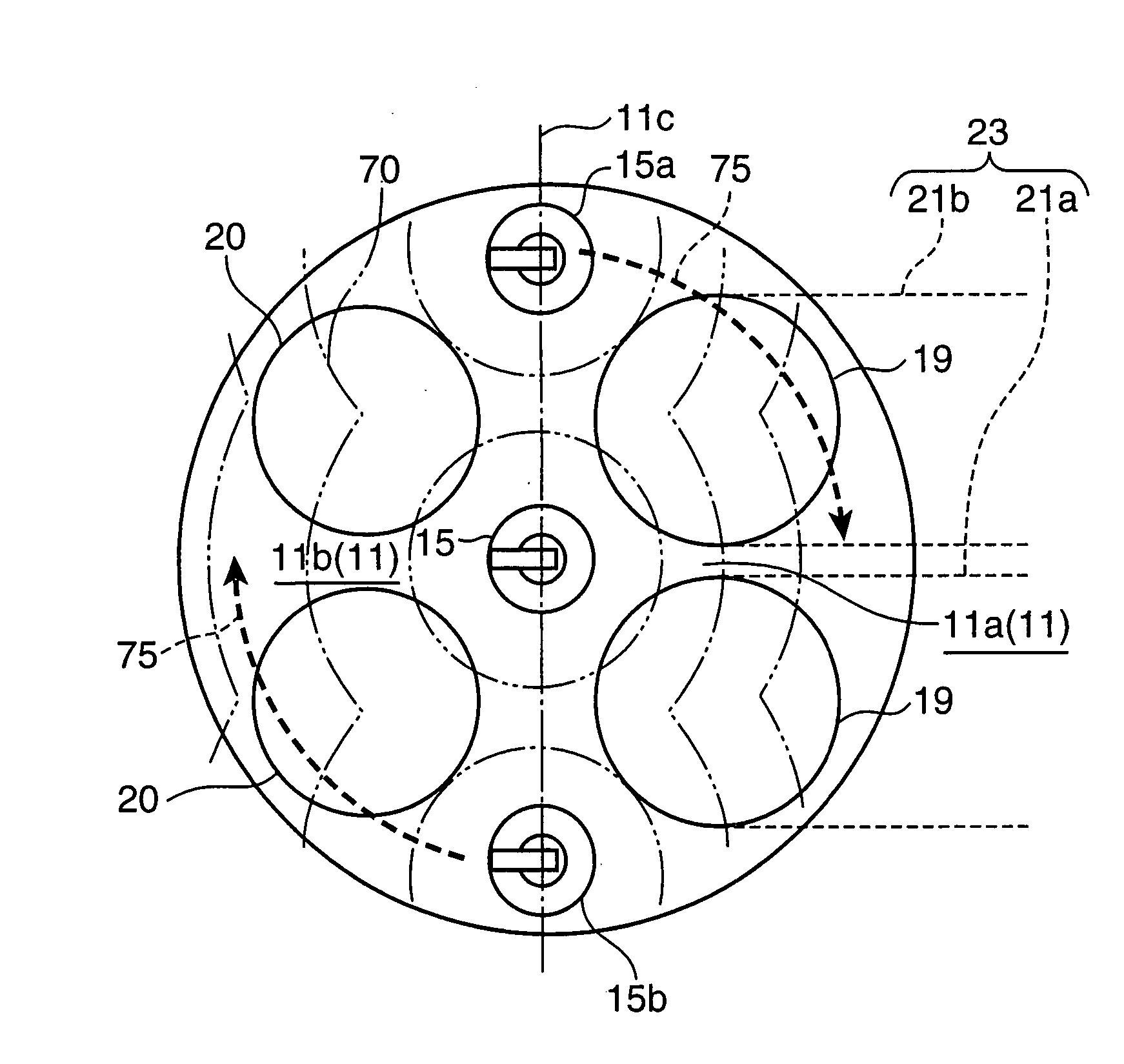

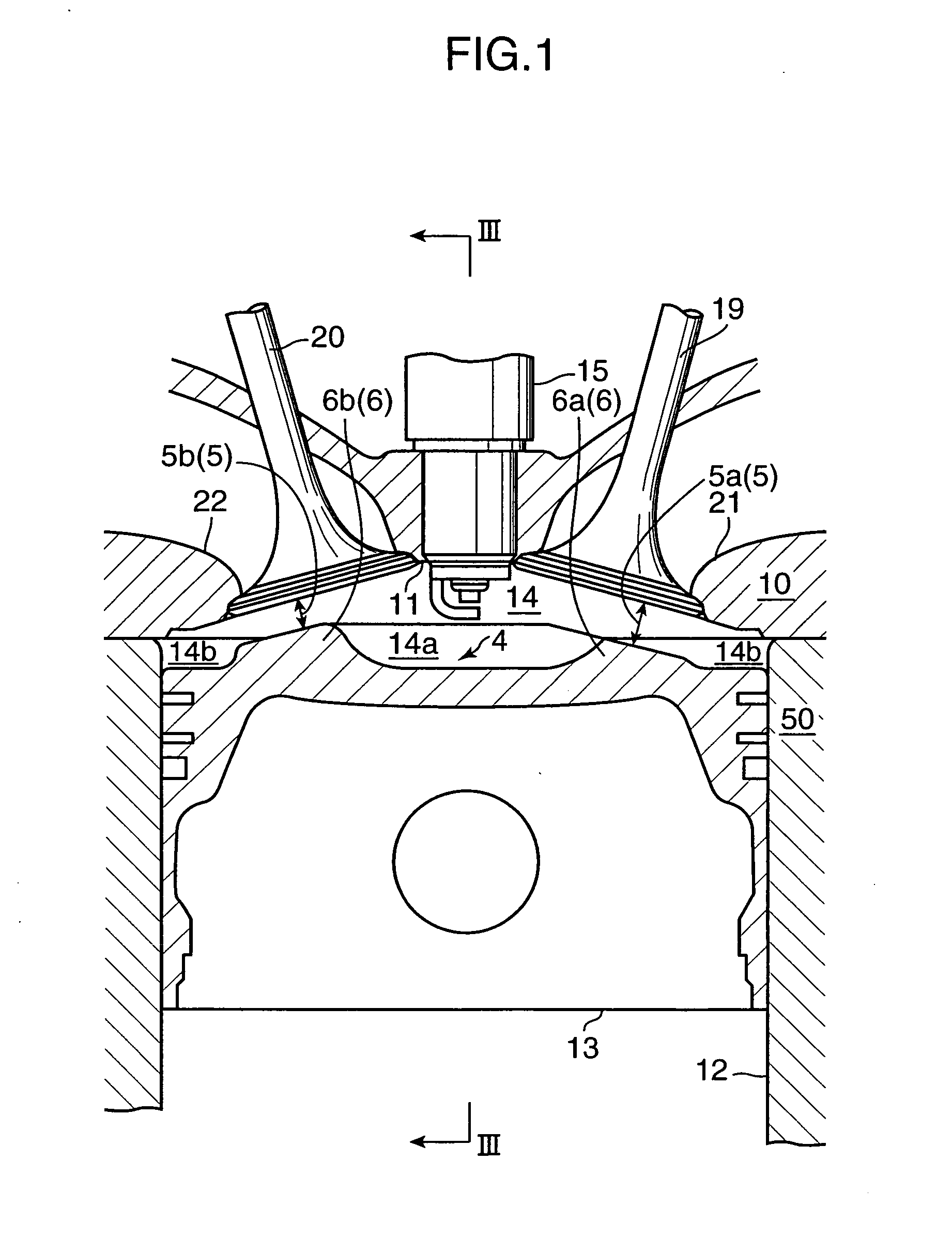

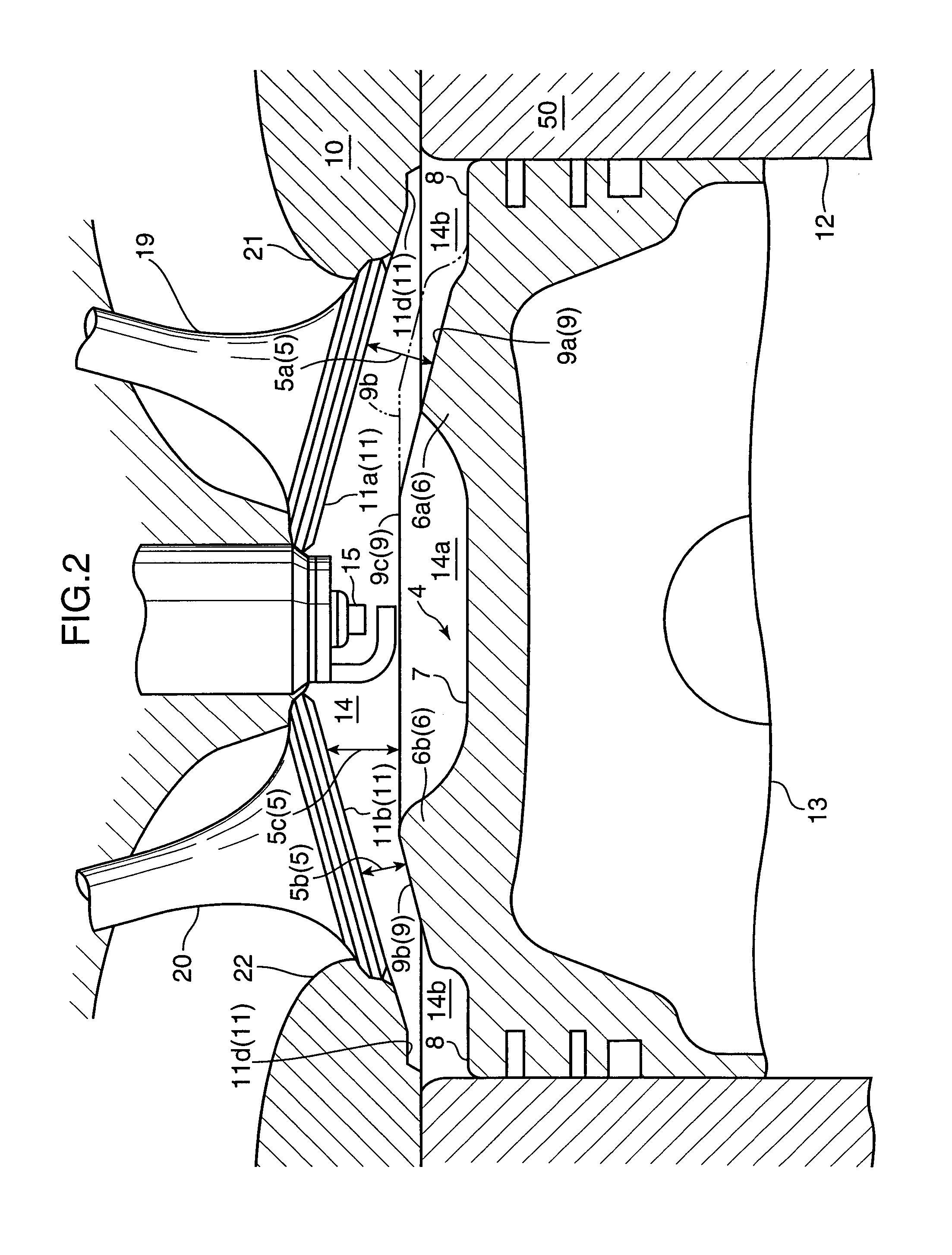

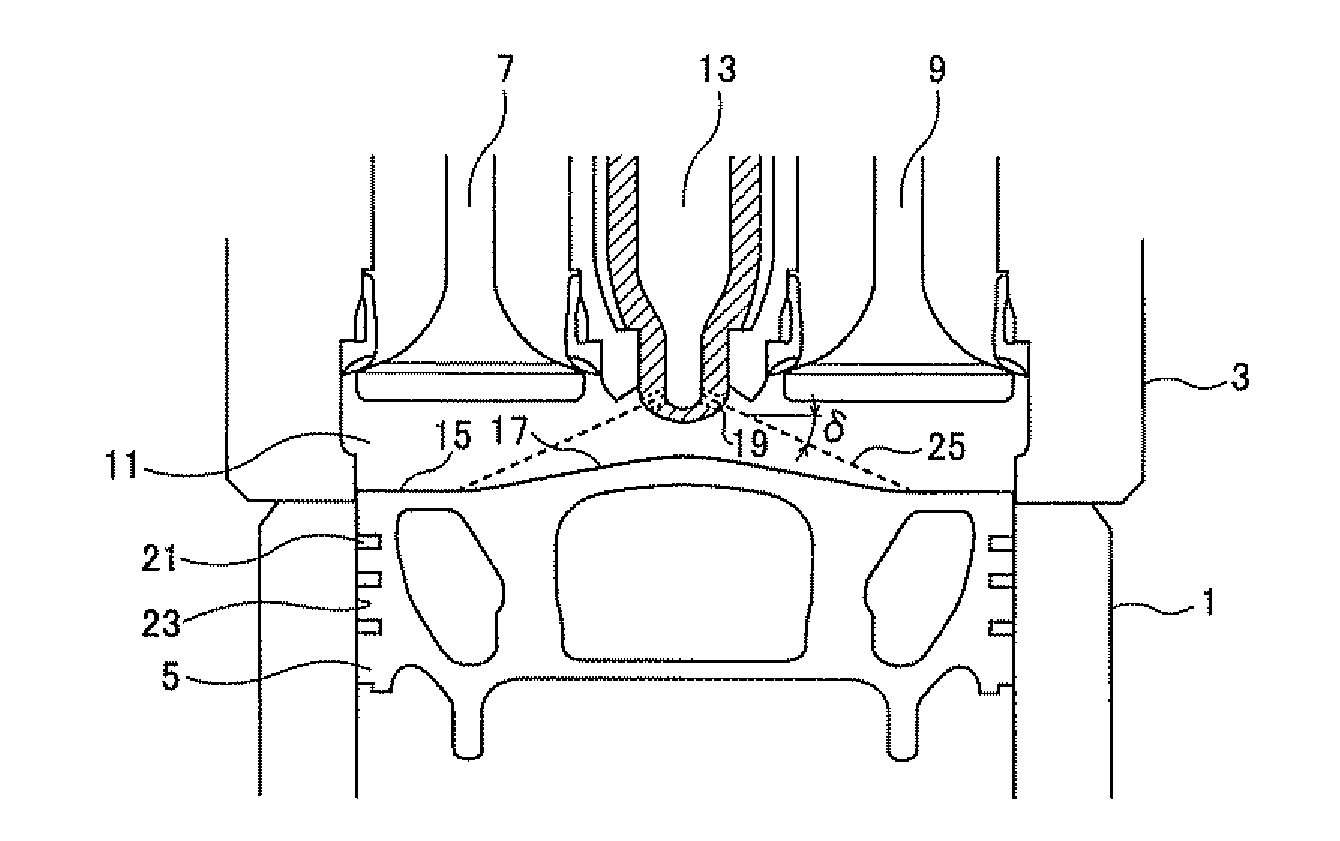

Combustion chamber structure for sparkignition engine

ActiveUS20070056556A1Suppress increase in in-cylinder pressureSuppression temperatureInternal combustion piston enginesElectric ignition installationCombustion chamberTop dead center

This invention relates to a combustion chamber structure for a spark-ignition engine, which comprises a combustion chamber defined between a bottom surface of a cylinder head and a top surface of a piston in such a manner that the bottom surface of the cylinder head serves as a ceiling wall thereof, and a spark plug having a sparking end protruding from the ceiling wall into the combustion chamber. In this combustion chamber structure, when the piston is at a top dead center, a principal space of the combustion chamber is comprised of a first combustion space around the sparking end of the spark plug and a second combustion space around a circumference of a cylinder bore. Further, the first combustion space and the second combustion space are communicated with each other through a small interspace zone where an interspace between the ceiling wall and the top surface of the piston is narrowed. The combustion chamber structure makes it possible to increase compression ratio in a practically effective manner.

Owner:MAZDA MOTOR CORP

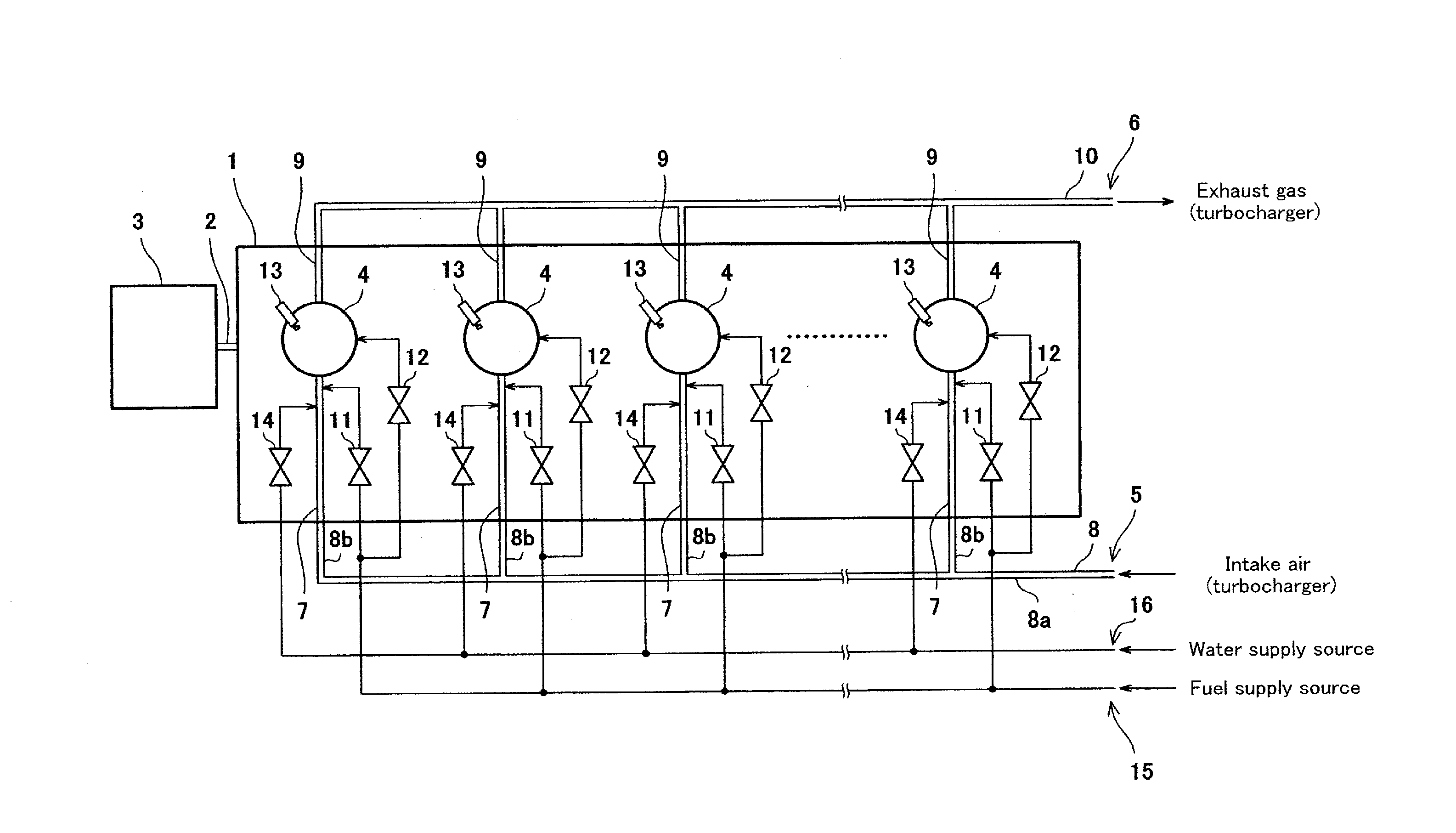

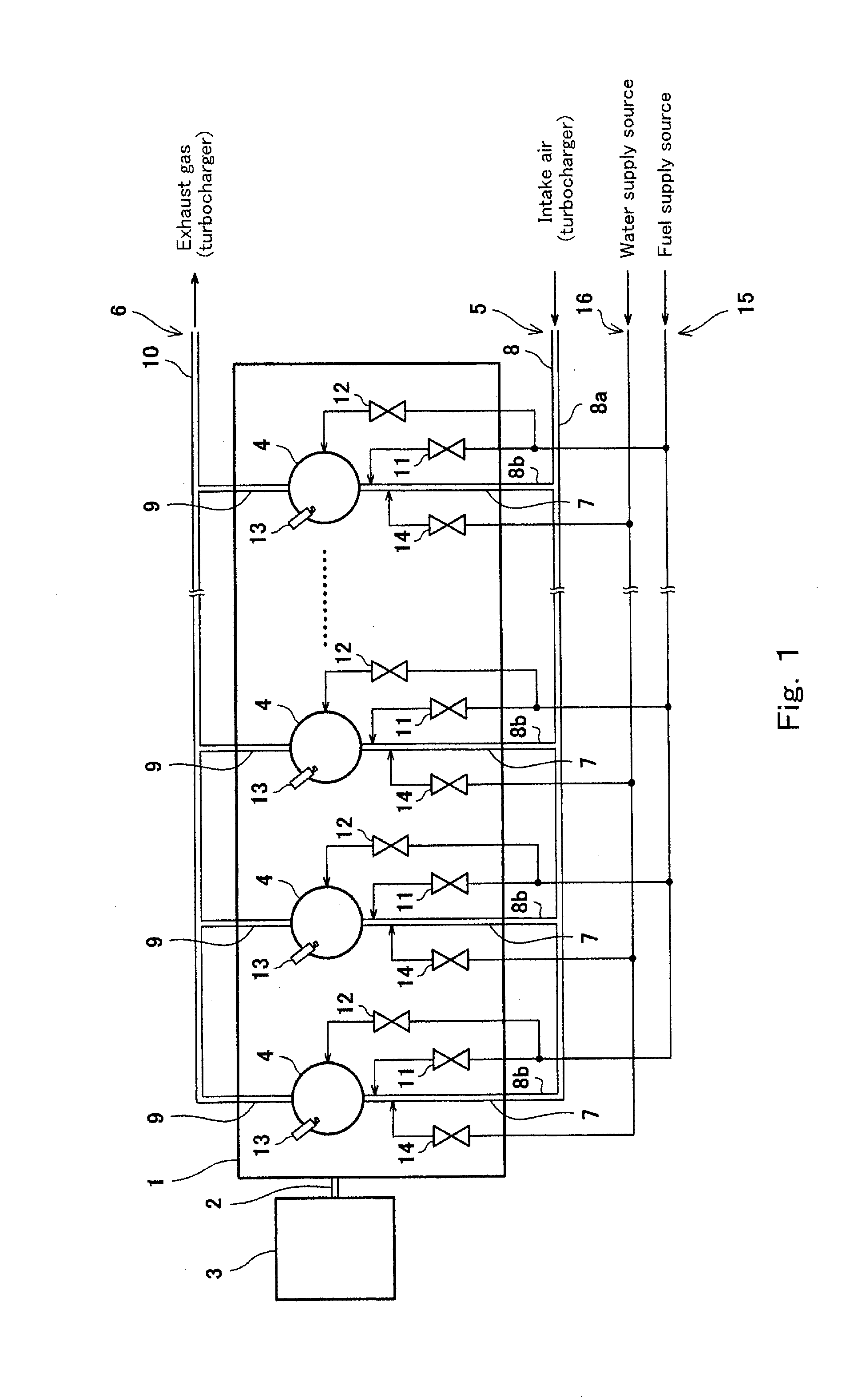

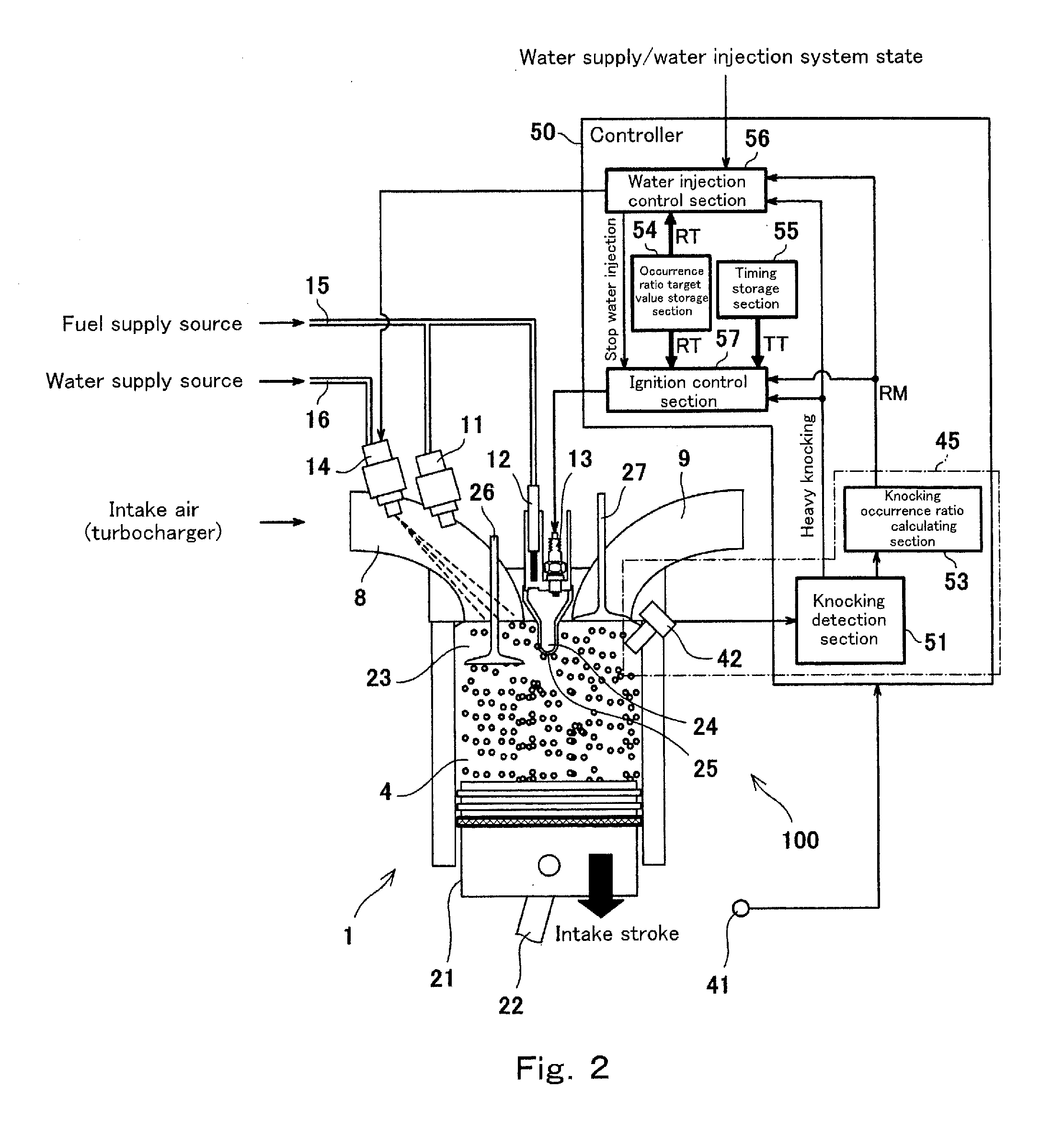

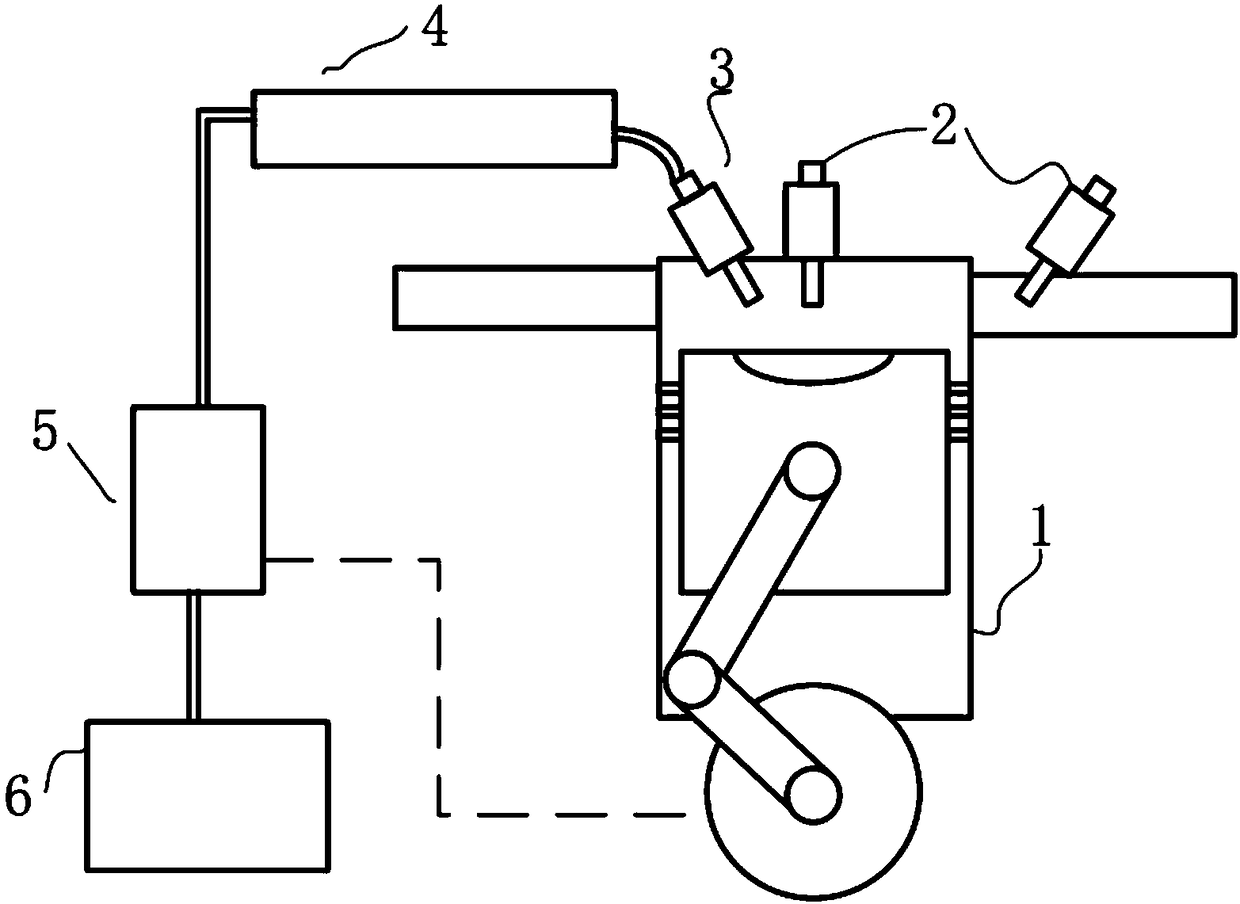

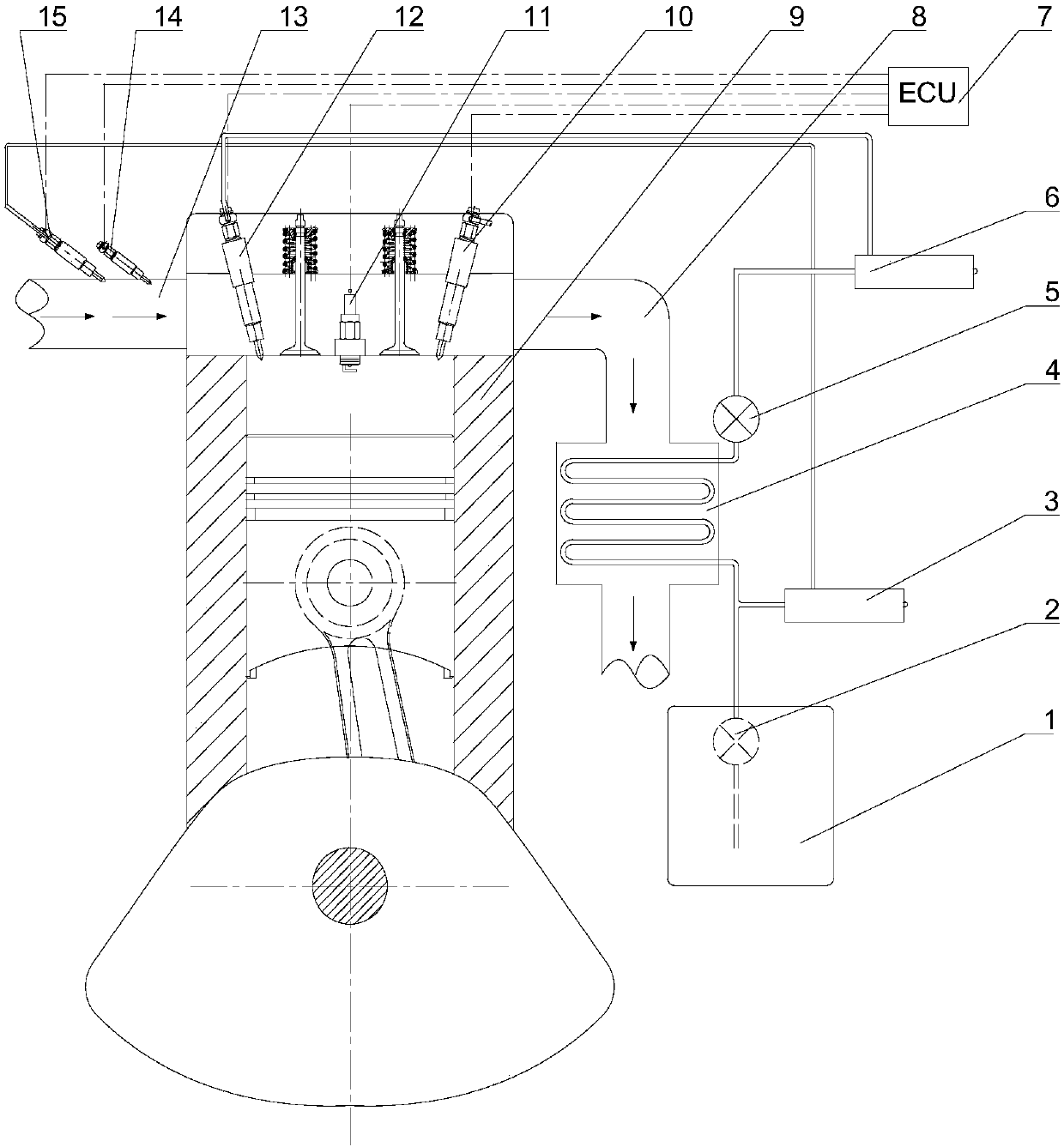

Gas engine, control system and control method for gas engine

ActiveUS20140102403A1Improve gas efficiencyKnock suppressionElectrical controlNon-fuel substance addition to fuelFuel gasControl system

A control system in a gas engine includes a water injection means which injects water toward an interior of a cylinder in the gas engine; a water injection control means which controls the water injection section; and a knocking occurrence ratio measuring means which measures a measurement value of a knocking occurrence ratio in the cylinder. The water injection control means controls the water injection means to set the amount of the water injected toward the interior of the cylinder, based on a deviation between the measurement value and a target value.

Owner:KAWASAKI HEAVY IND LTD

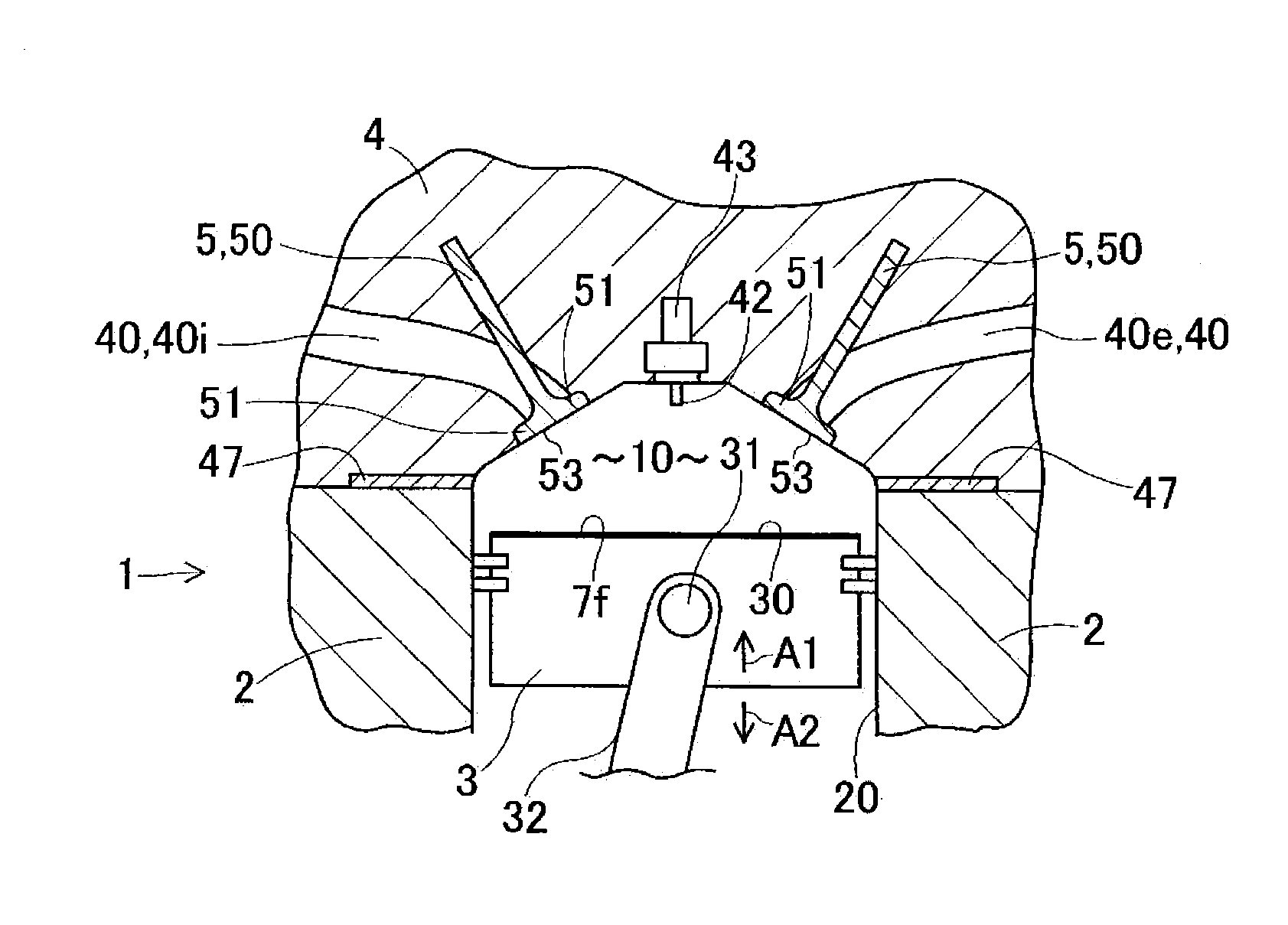

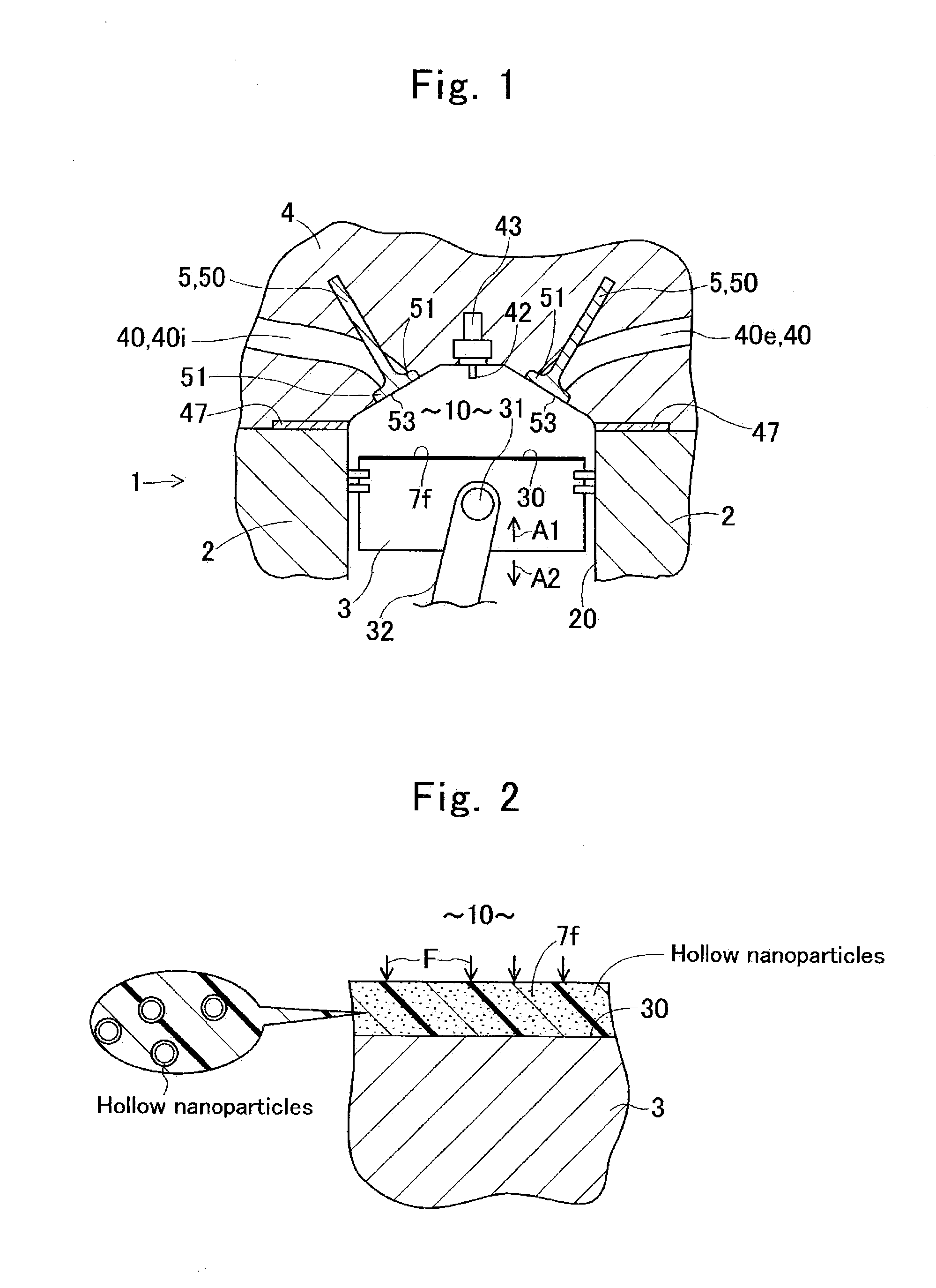

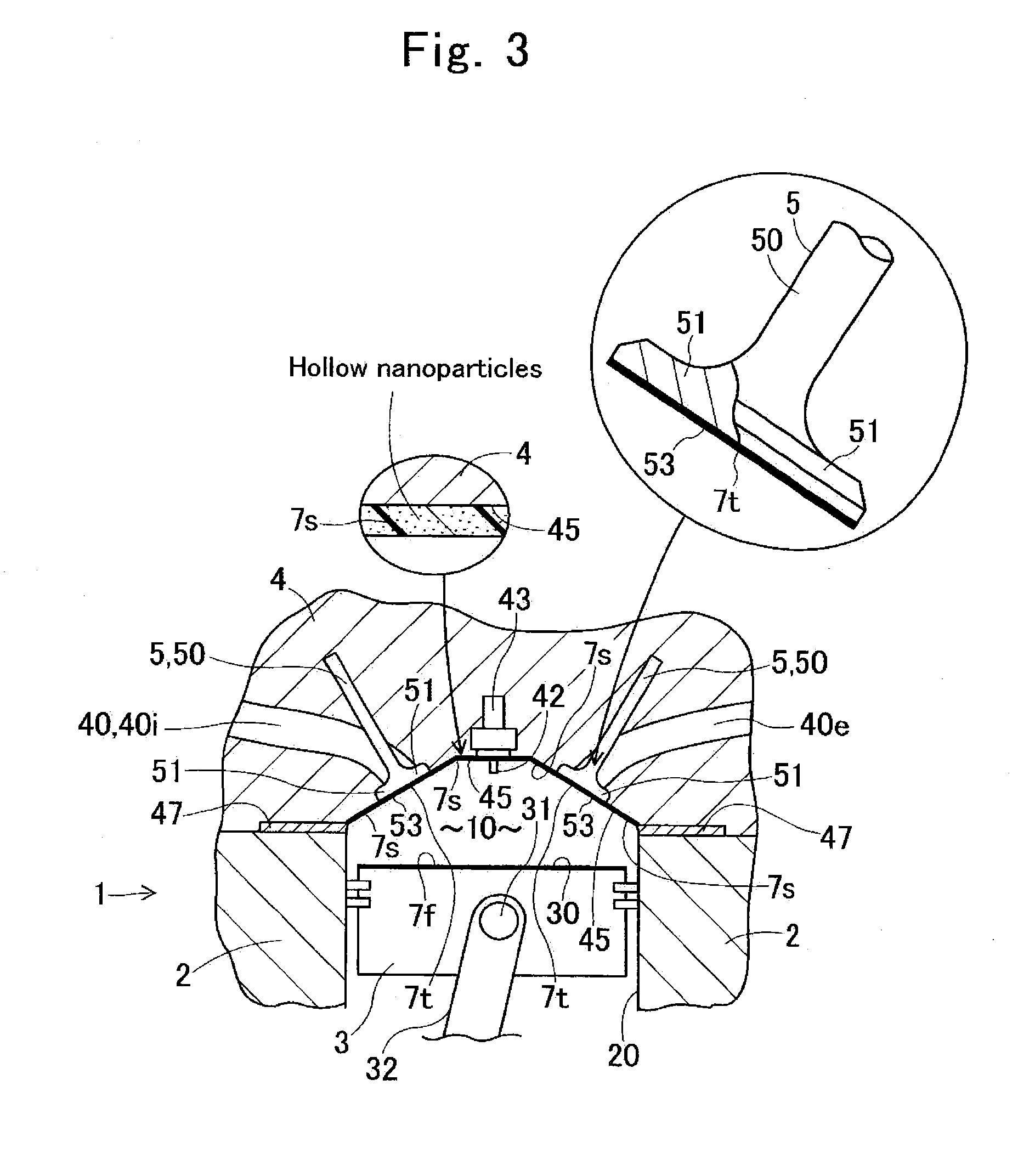

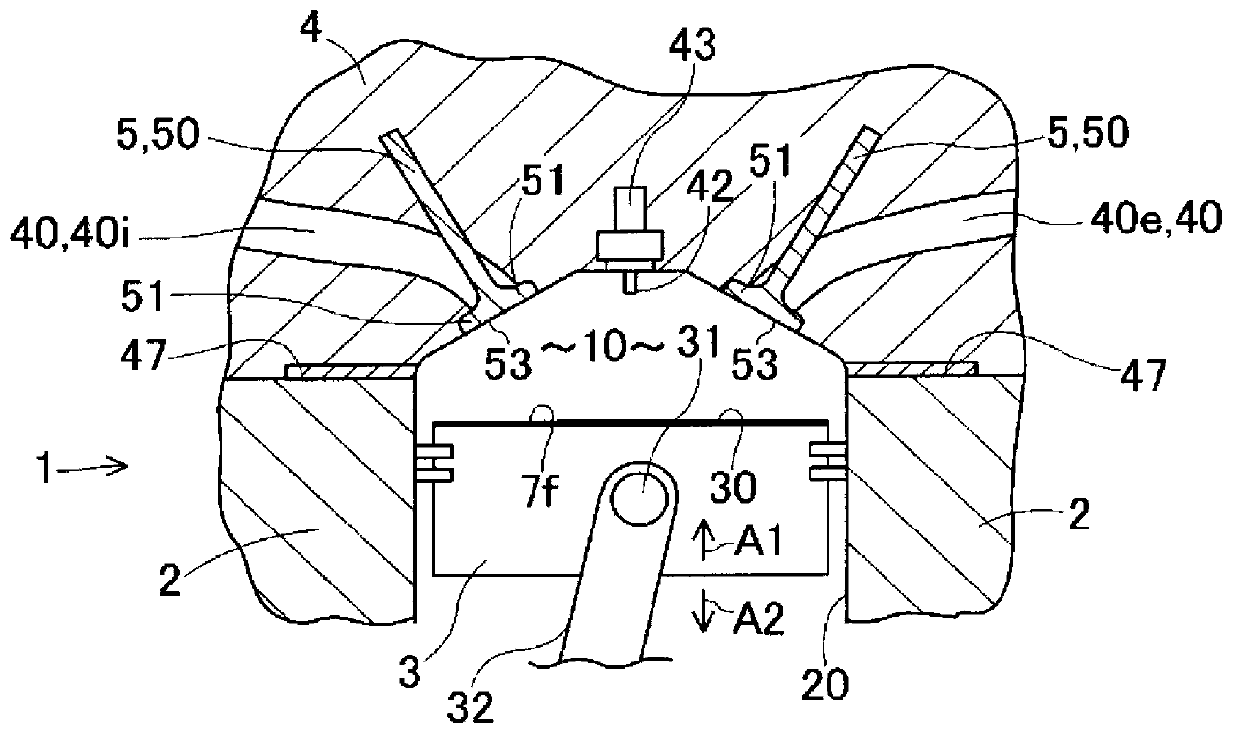

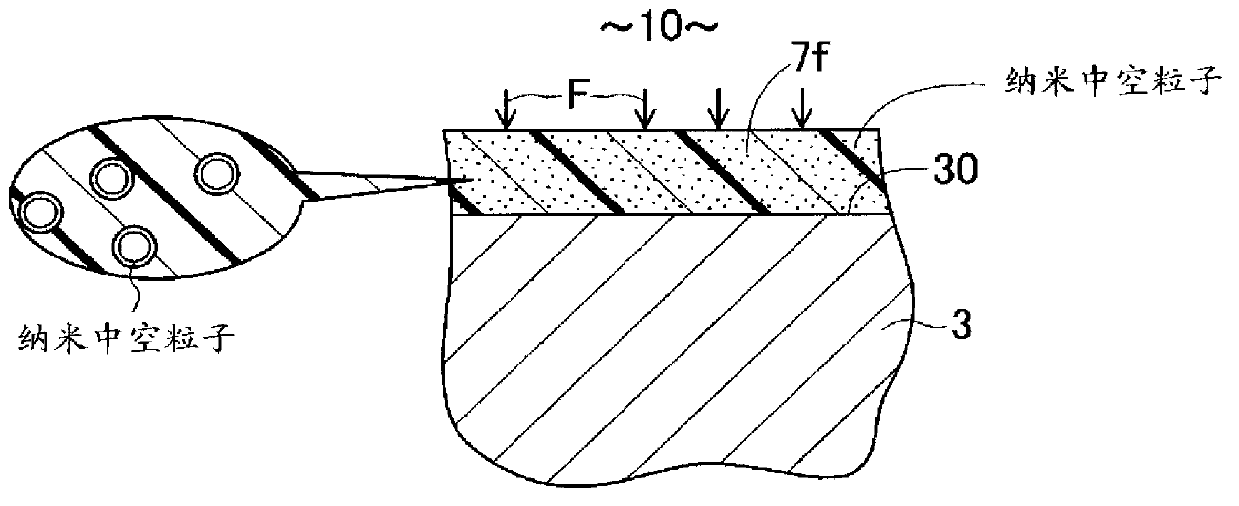

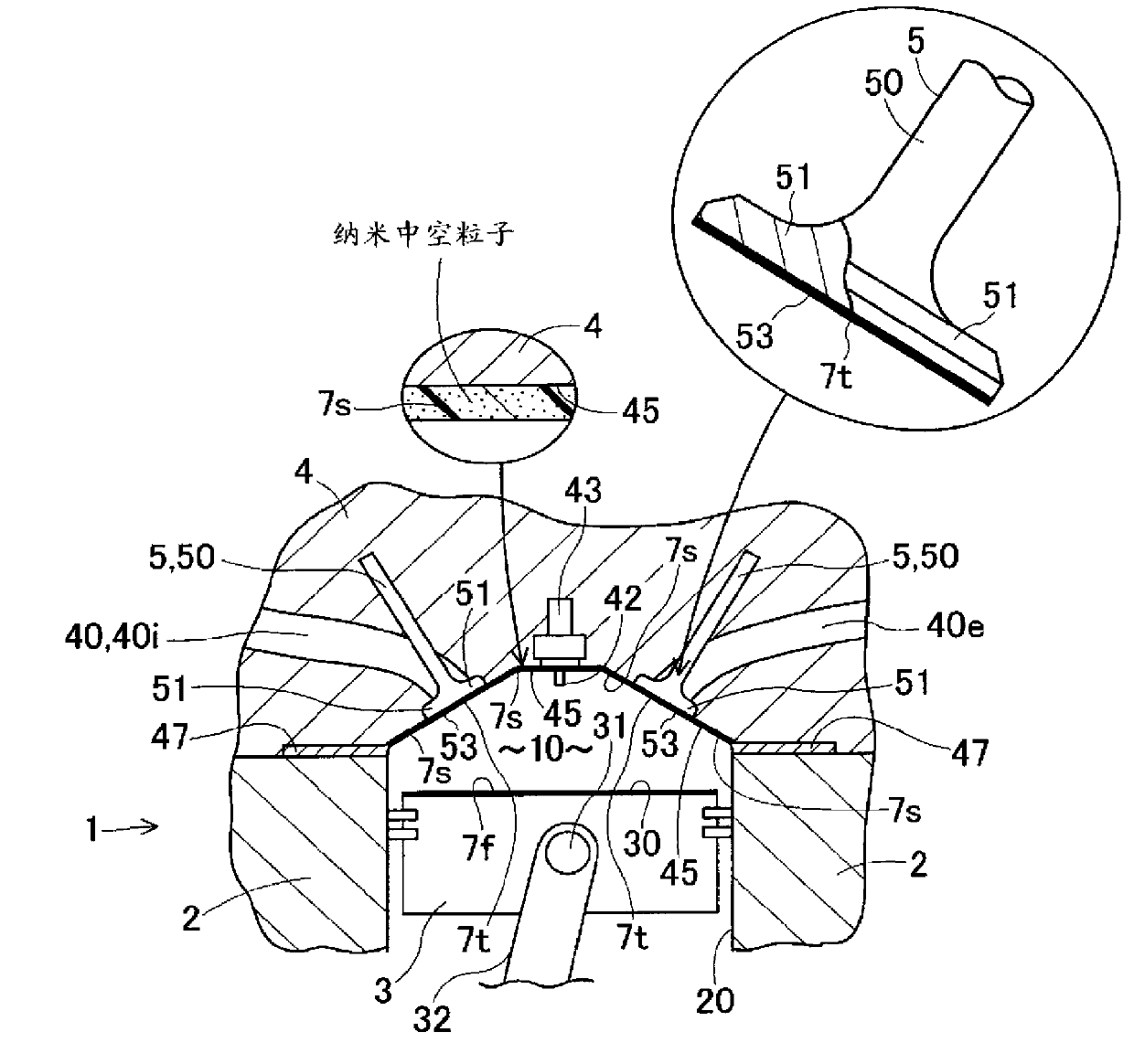

Engine and piston

InactiveUS20130327289A1Improve heat insulationImprove fuel efficiencyPlungersCylinder headsCombustion chamberCylinder head

An engine includes a cylinder block having a bore, a piston fitted into the bore so as to form a combustion chamber and to be able to reciprocate, a cylinder head for closing the combustion chamber and having valve bores communicating with the combustion chamber, and valves for opening and closing the valve bores. A heat insulating coating is applied on a wall face of at least one of the piston, the cylinder head, and the valves and facing the combustion chamber. The heat insulating coating includes resin and a plurality of hollow nanoparticles embedded in the resin, smaller in diameter than a thickness of the heat insulating coating, and smaller than or equal to 500 nanometers in size.

Owner:AISIN SEIKI KK +1

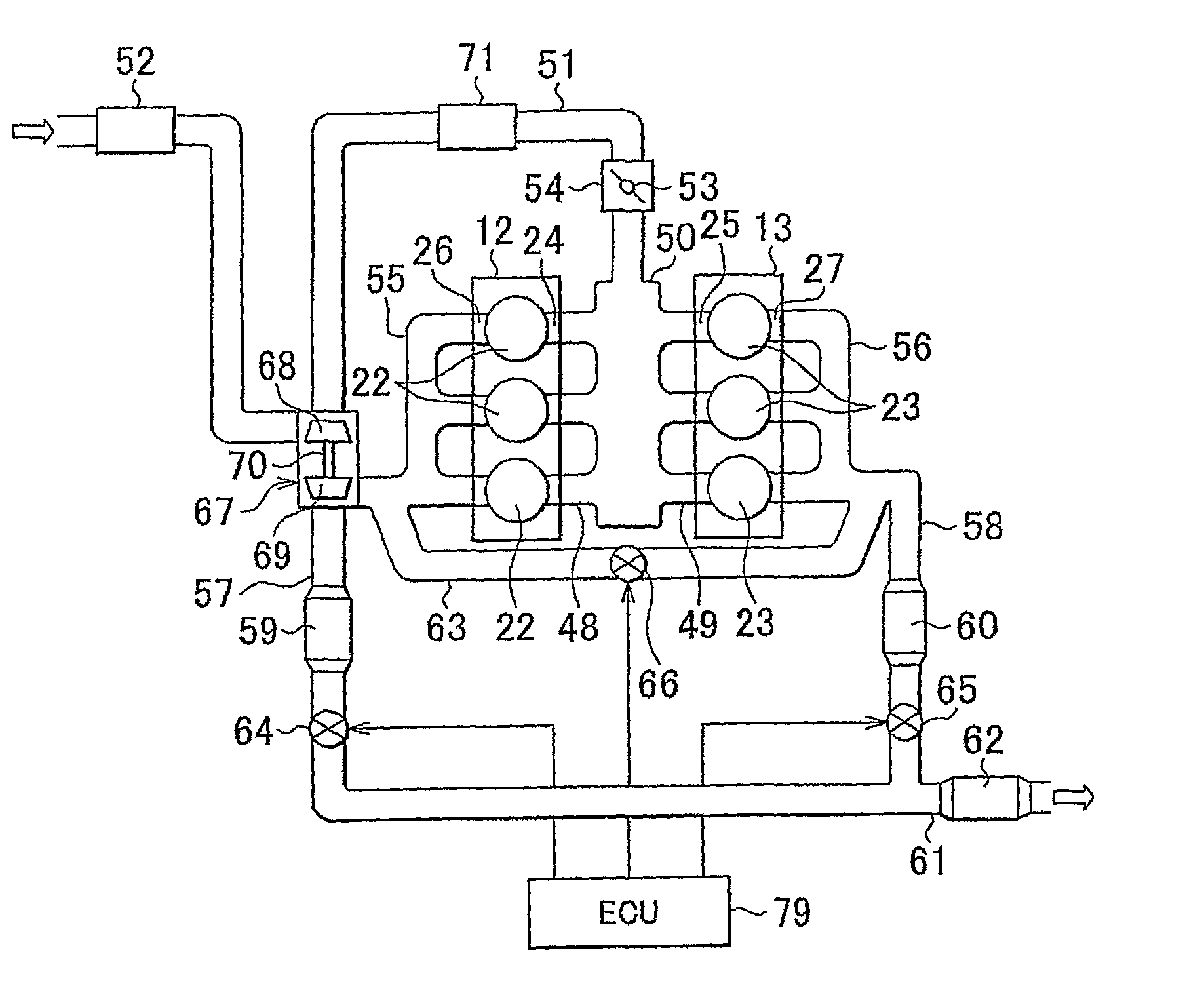

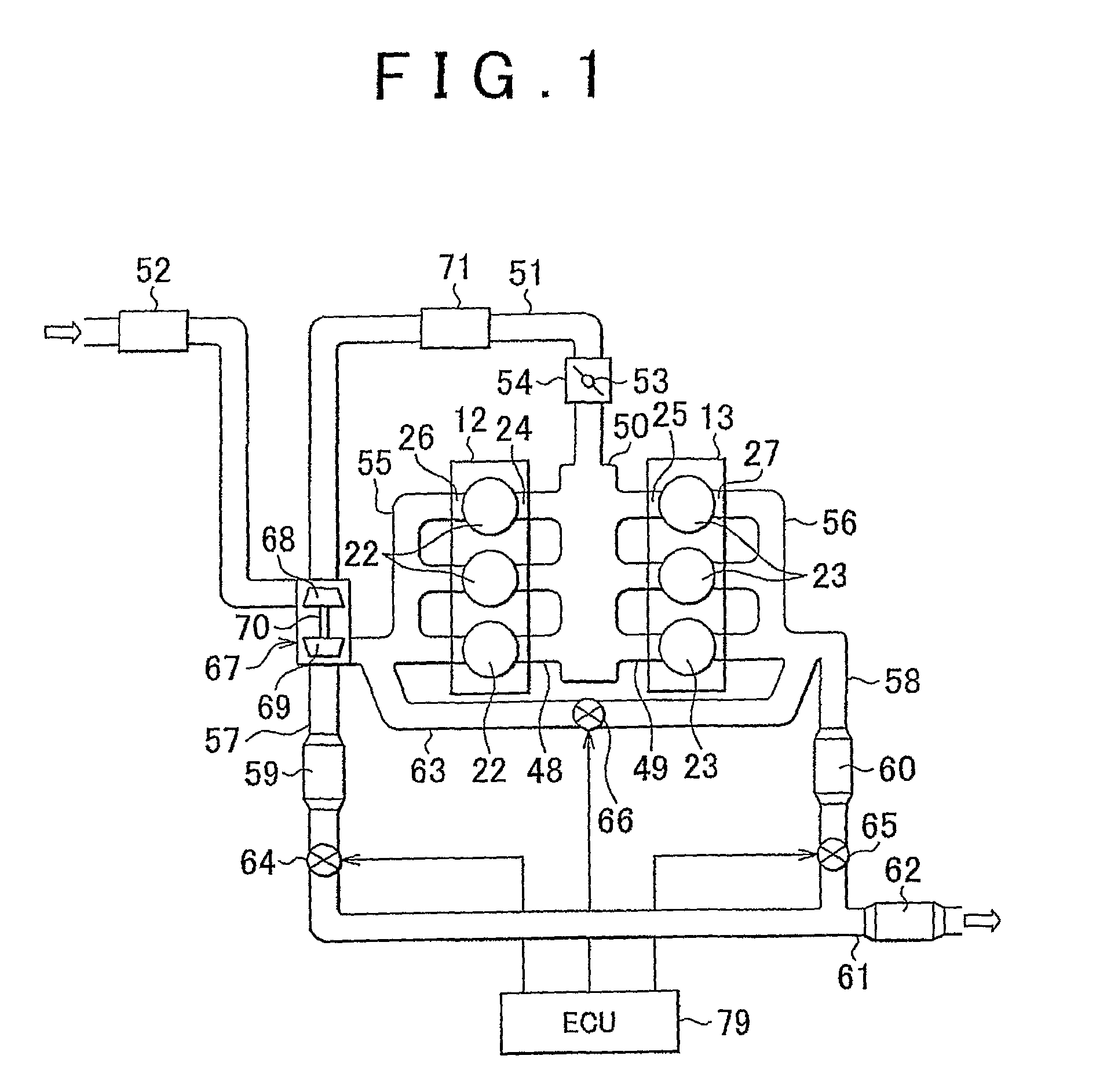

Internal combustion engine and control method thereof

InactiveUS8056337B2Easy to controlSuppresses deterioration of combustionInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

In a V-type six cylinder engine, cylinder groups are provided in which a plurality of cylinders are arranged divided into left and right first and second banks. An intake pipe, a first exhaust pipe, and a second exhaust pipe are connected to the cylinder groups of the banks. A first upstream three-way catalyst and a first control valve are provided in one exhaust pipe while a second upstream three-way catalyst and a second control valve are provided in the other exhaust pipe. The exhaust pipes are communicated together upstream of the upstream three-way catalysts and the control valves by a communicating pipe. A third control valve that adjusts the flowrate of exhaust gas is provided in the communicating pipe.

Owner:TOYOTA JIDOSHA KK

Engine and piston

InactiveCN103328797AAvoid crackingNot prone to crackingPlungersCylinder headsCombustion chamberCylinder head

Owner:AISIN SEIKI KK +1

Dual injection type internal combustion engine

InactiveUS7377255B2Knock suppressionAccurate background learningElectrical controlInternal combustion piston enginesDual injectionEngineering

A dual injection type internal combustion engine including an injector for in-cylinder injection and an injector for intake manifold injection includes a learning device for learning a background noise level based on an output signal of a knock sensor, and a knocking suppression control device for performing, while learning the background noise level, knocking suppression control by controlling fuel injection of the injector for in-cylinder injection or the injector for intake manifold injection. Alternatively, the engine includes a fixing device for fixing, while learning the background noise level, a start timing or end timing of fuel injection by the injector for in-cylinder injection at a basic timing determined by an operating state of the engine.

Owner:TOYOTA JIDOSHA KK

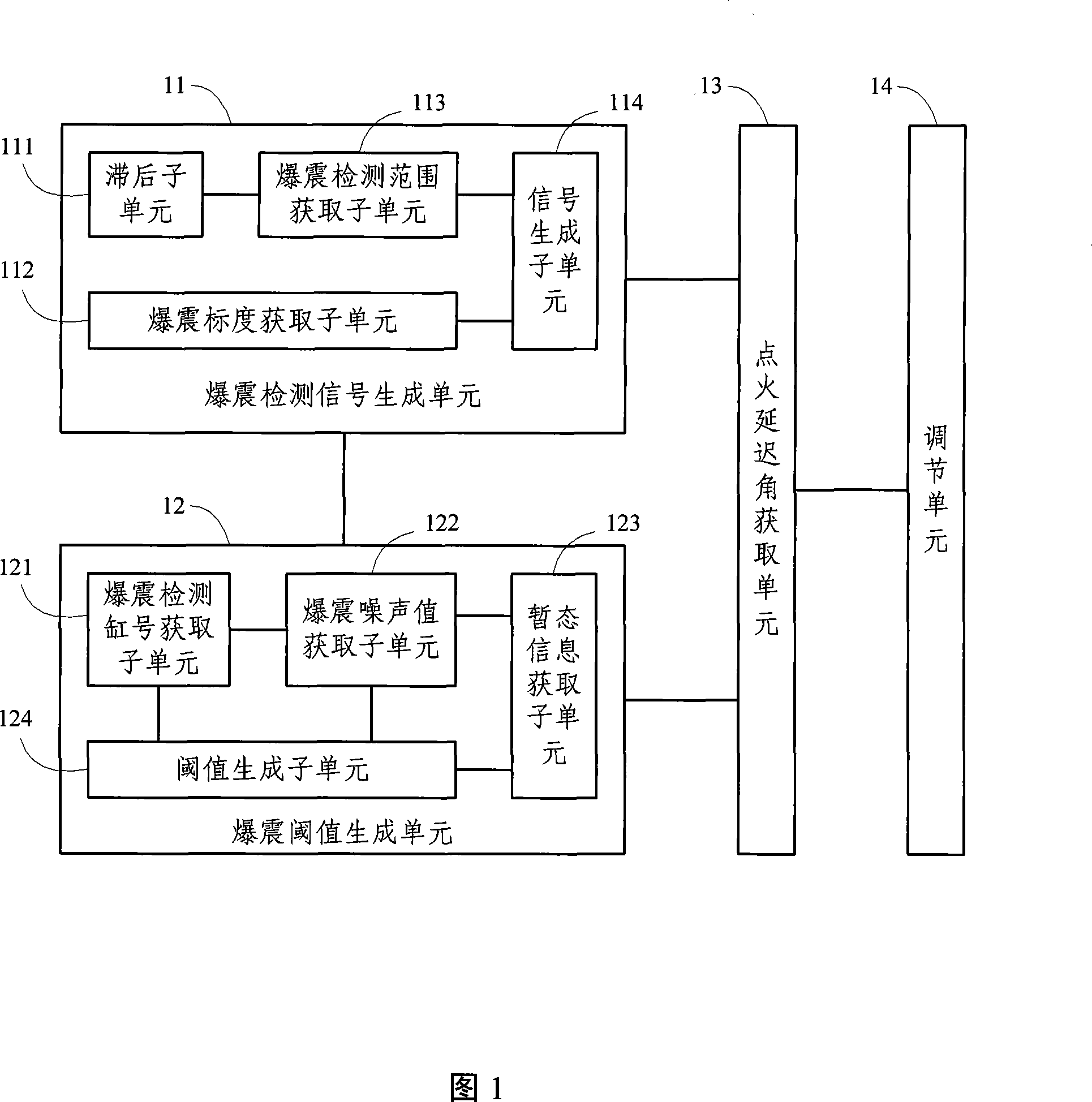

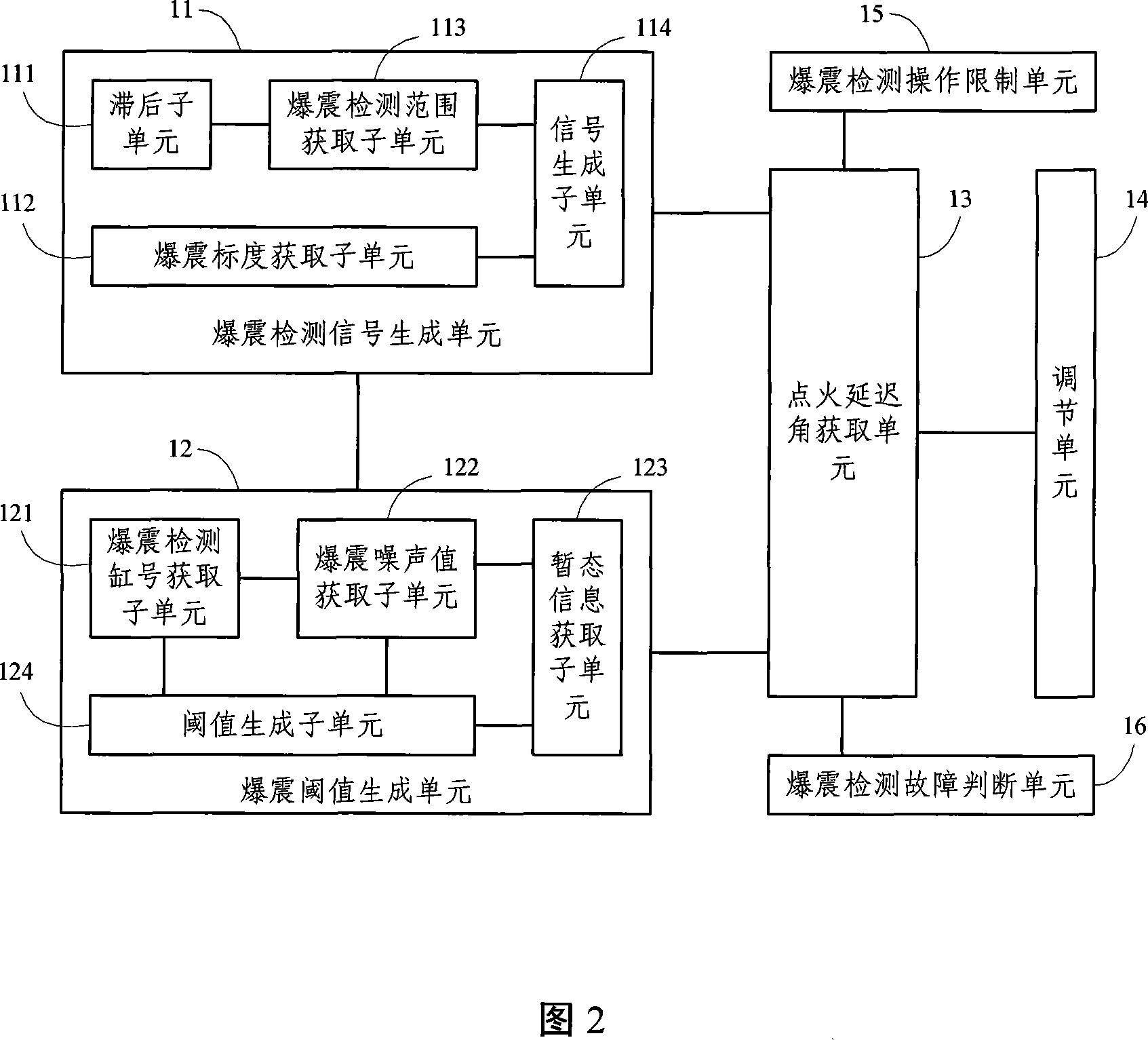

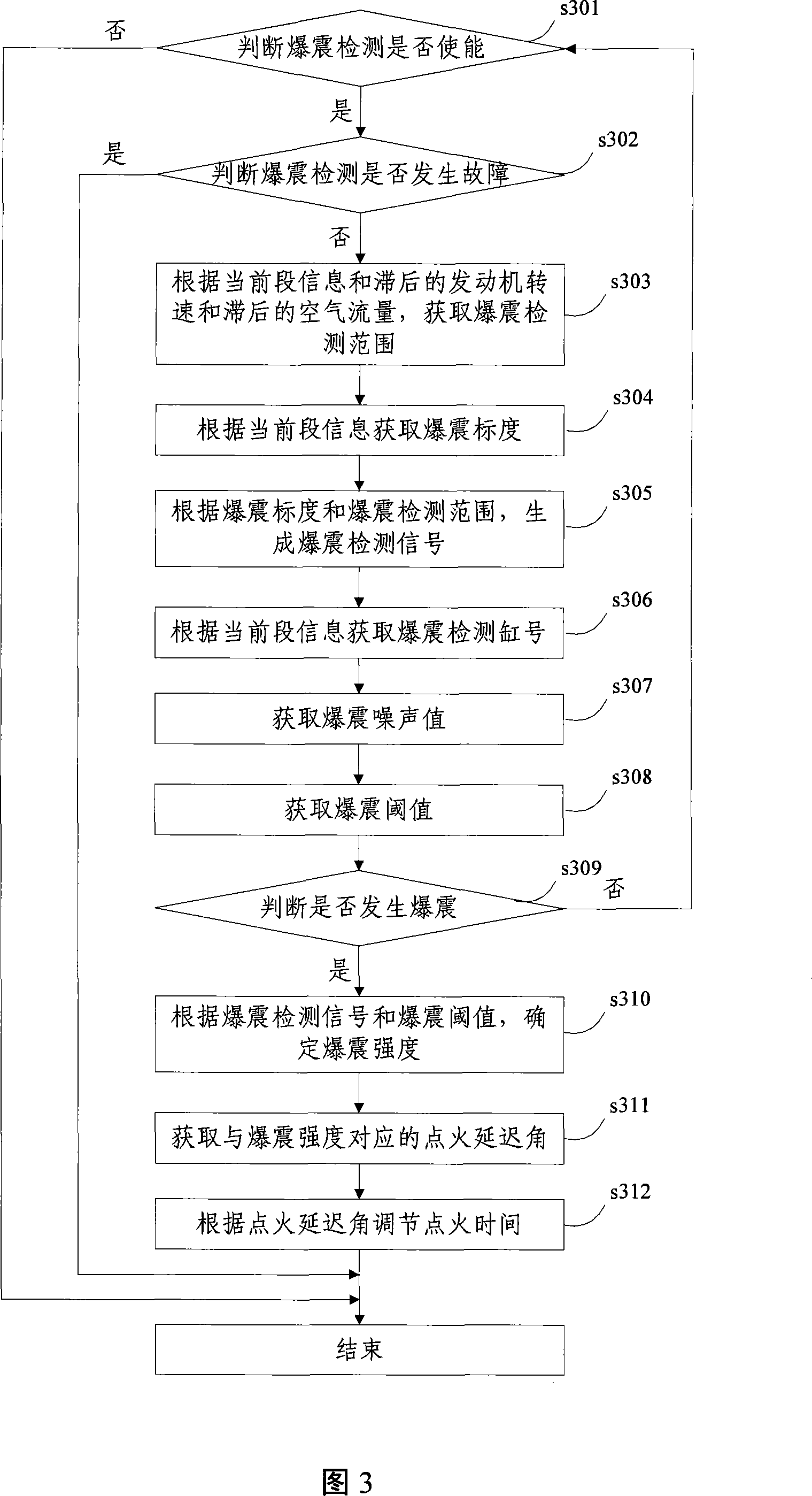

Knock controlling device and method

InactiveCN101235783ANo loss of performance efficiencyDoes not reduce engine efficiencyMachines/enginesAdvancing/retarding ignitionDetonationIgnition delay

The invention discloses a method for adjusting detonation, which comprises the following steps: first, obtaining detonation test signal and detonation threshold value, then, affirming detonation strength according to the detonation test signal and the detonation threshold value, last, obtaining the ignition delay angle corresponding to the detonation strength, adjusting ignition time according to the ignition delay angle. The invention also discloses an adjusting device of the detonation, which comprises a detonation test signal generation unit, a detonation threshold value generation unit, an ignition delay angle acquisition unit and an adjusting unit. The invention affirms the detonation strength according to the detonation test signal and the detonation threshold value and adjusts the ignition time according to the detonation strength corresponding to the ignition delay angle, which makes the detonation of different strengths do fitful ignition time adjusting, further, the detonation occurrence can be inhibited effectively and the engine capability and the motor efficiency can't be reduced.

Owner:CHINA VAGON AUTOMOTIVES HLDG CO LTD

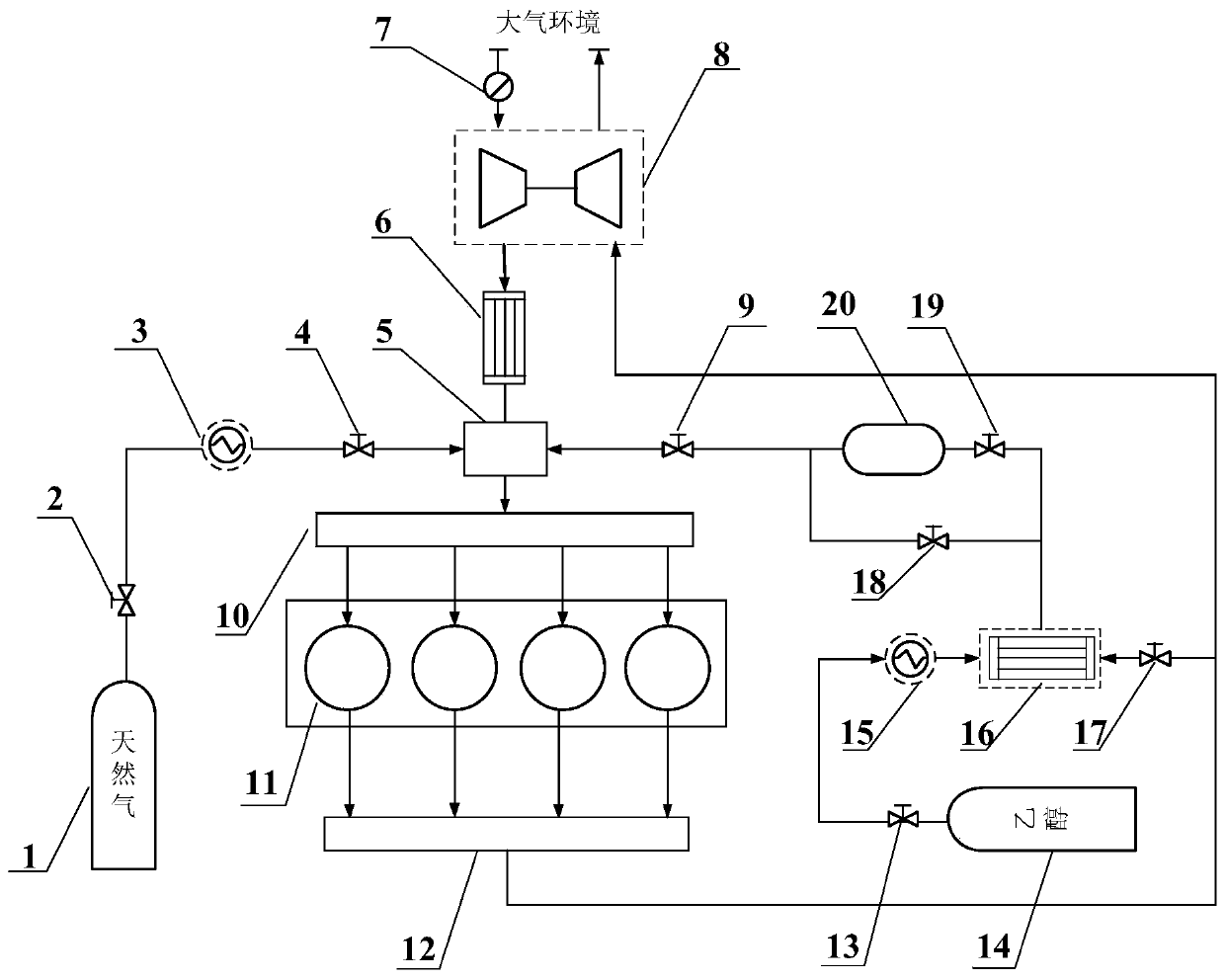

Natural gas engine, and combustion system and combustion method for natural gas engine

InactiveCN103758630ARaise the flammability limitBurn fasterInternal combustion piston enginesExhaust apparatusCombustion systemFlammability limit

The invention relates to the technical field of internal combustion engines, and discloses a natural gas engine, and a combustion system and a combustion method for the natural gas engine. The natural gas engine, the combustion system and the combustion method have the advantages that gas inlets of a part of cylinders of the natural gas engine are connected with natural gas supply equipment on the basis that a cooling EGR (exhaust gas recirculation) technology is applied to the natural gas engine, and excessive natural gas flows into the part of cylinders and is combusted to generate modified mixed gas containing H<2> and CO; exhaust ports of the part of cylinders are connected with a gas collecting cavity, the modified mixed gas is totally led into the gas collecting cavity, and the modified mixed gas and gas in the gas collecting cavity are mixed with each other and then flow into various cylinders to participate in combustion; a large quantity of hydrogen is contained in the gas which is modified by the part of cylinders, and can accelerate combustion of the mixed gas, so that the flammability limit of gas in the cylinders can be upgraded under the condition of a high EGR rate, NO<x> is reduced, the combustion temperature is lowered, knocking can be suppressed, the dynamic property and the economical efficiency of the engine can be improved, and the difficult problem of high heat load of an existing natural gas engine can be solved.

Owner:TSINGHUA UNIV

Method and system for in-cylinder direct-injection gasoline engine stratified equivalent proportion combustion

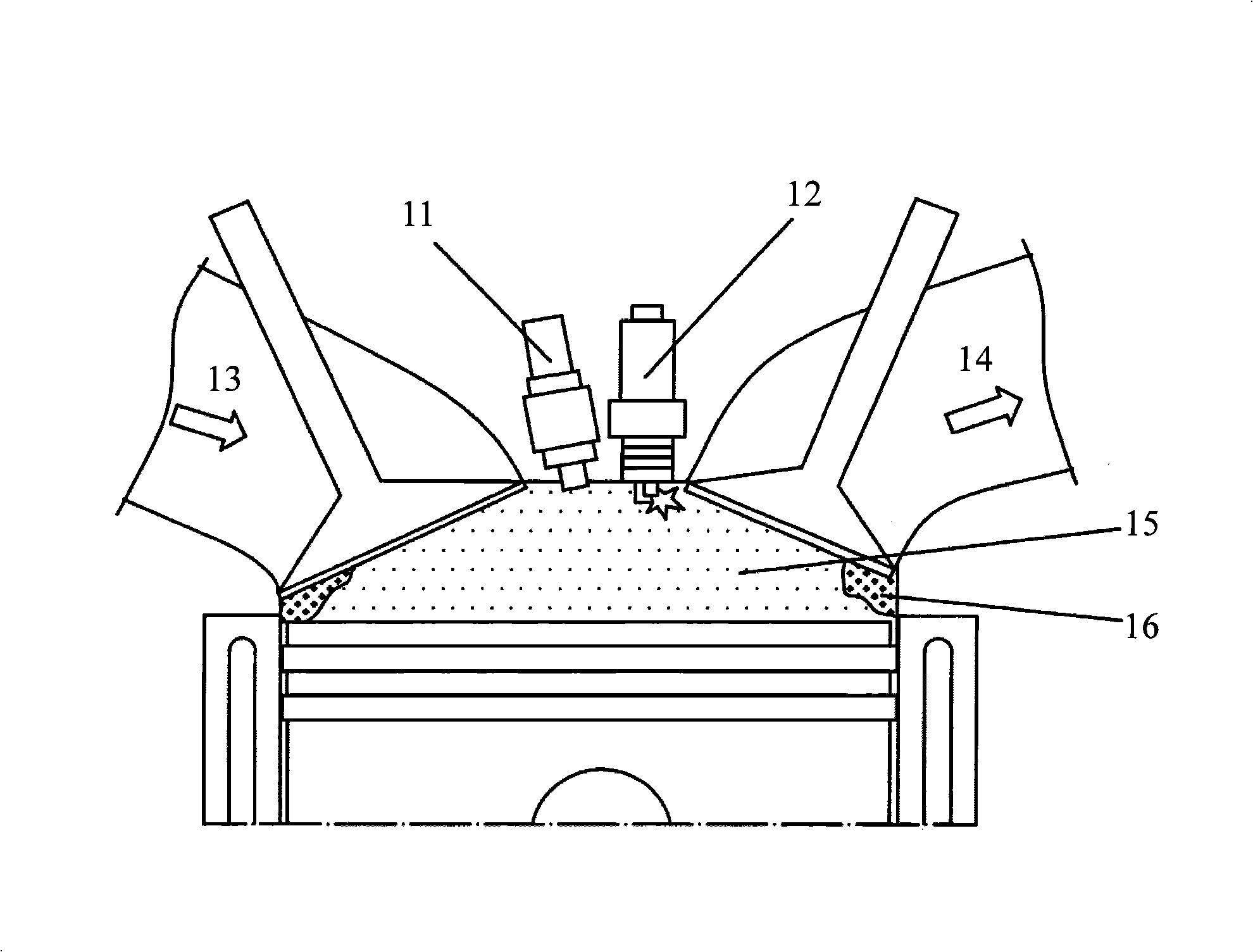

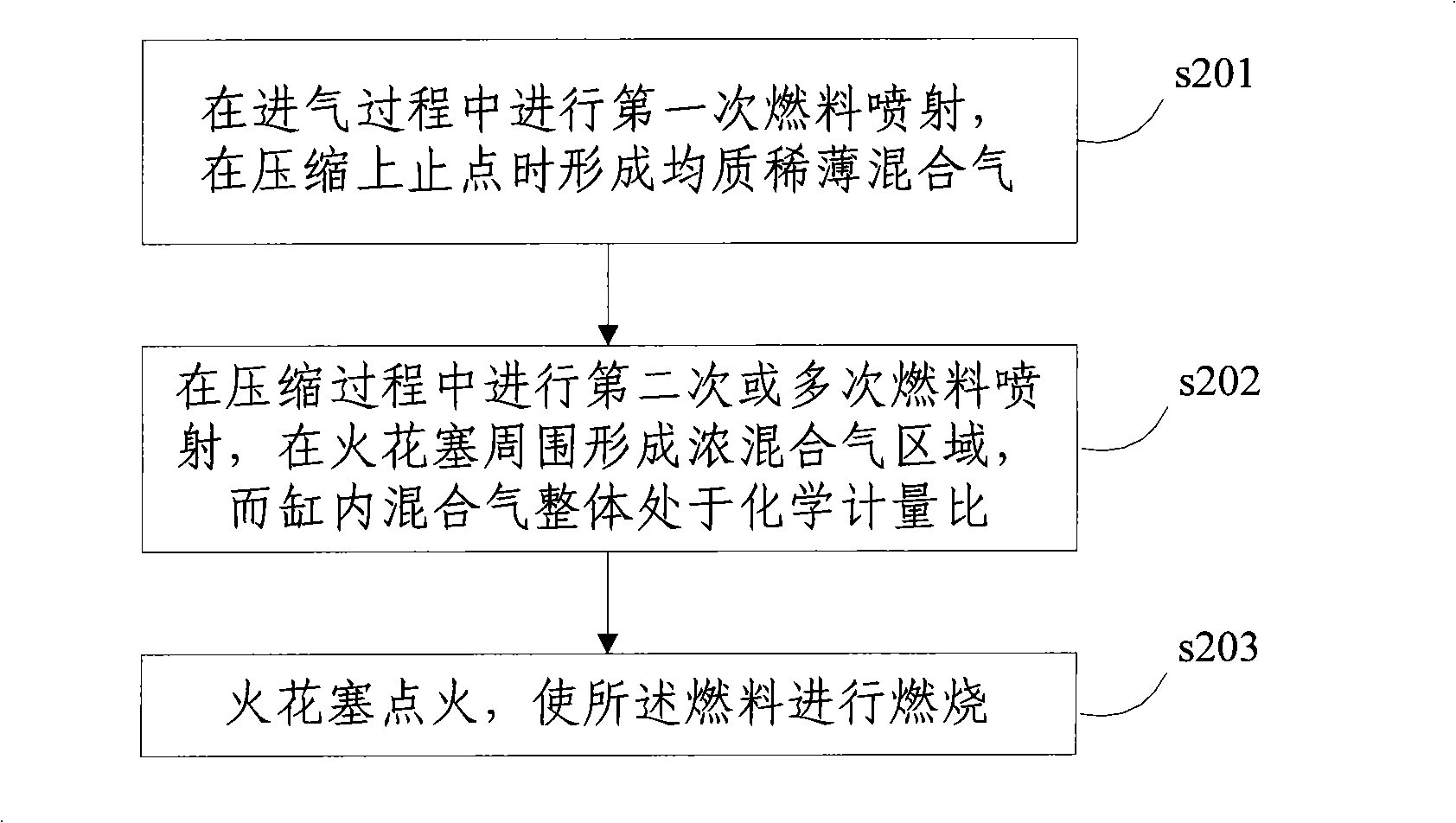

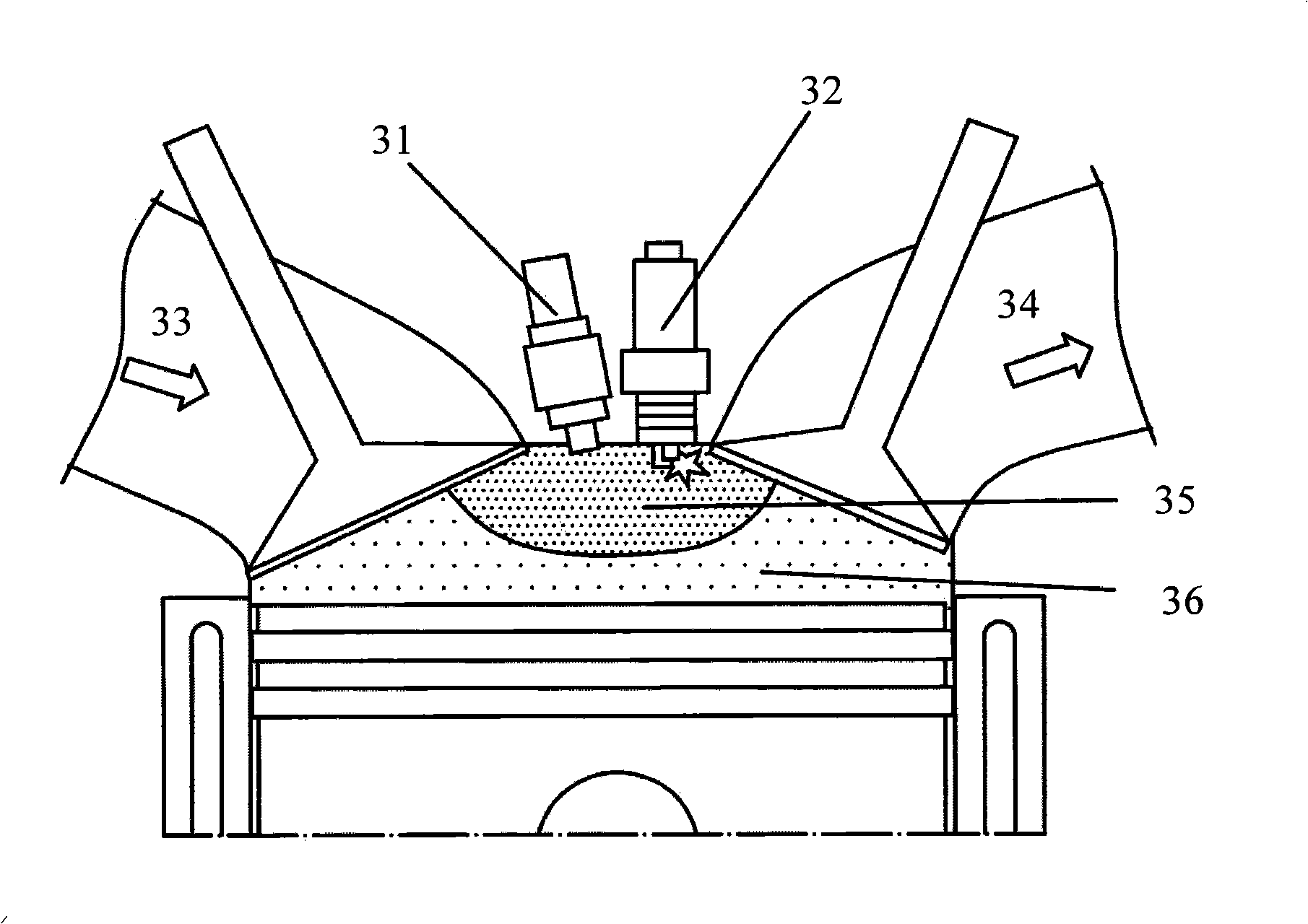

ActiveCN101338694ASolve difficultySolve the costElectrical controlInternal combustion piston enginesCombustion systemDetonation

The present invention discloses a direct injection gasoline engine stratified equivalent proportion combustion method which comprises the steps as follows: first fuel injection is processed during charging process, and homogeneous thin mixed gas is formed when an upper stop point is compressed; second or multiple fuel injections are processed during compressing process, and a dense mixed gas area is formed around a spark plug; the spark plug ignites to burn the fuel. The present invention also discloses a direct injection gasoline engine stratified equivalent proportion combustion system which comprises an oil atomizer, an electric control unit and the spark plug. When the method and the system of the present invention are used, harmful emission produced by gasoline delaminated equivalent proportion mixed gas combustion can be effectively controlled by the traditional gasoline engine three-way catalyst, thereby solving the problem that a first generation GDI stratified thin burning method has large difficulty for developing lean-burn catalyst and high cost and is not easy for controlling the discharge. At the same time, the stratified equivalent proportion combustion method can bring higher fuel economical efficiency than a second generation GDI homogeneous equivalent proportion combustion method and can inhibit detonation.

Owner:TSINGHUA UNIV

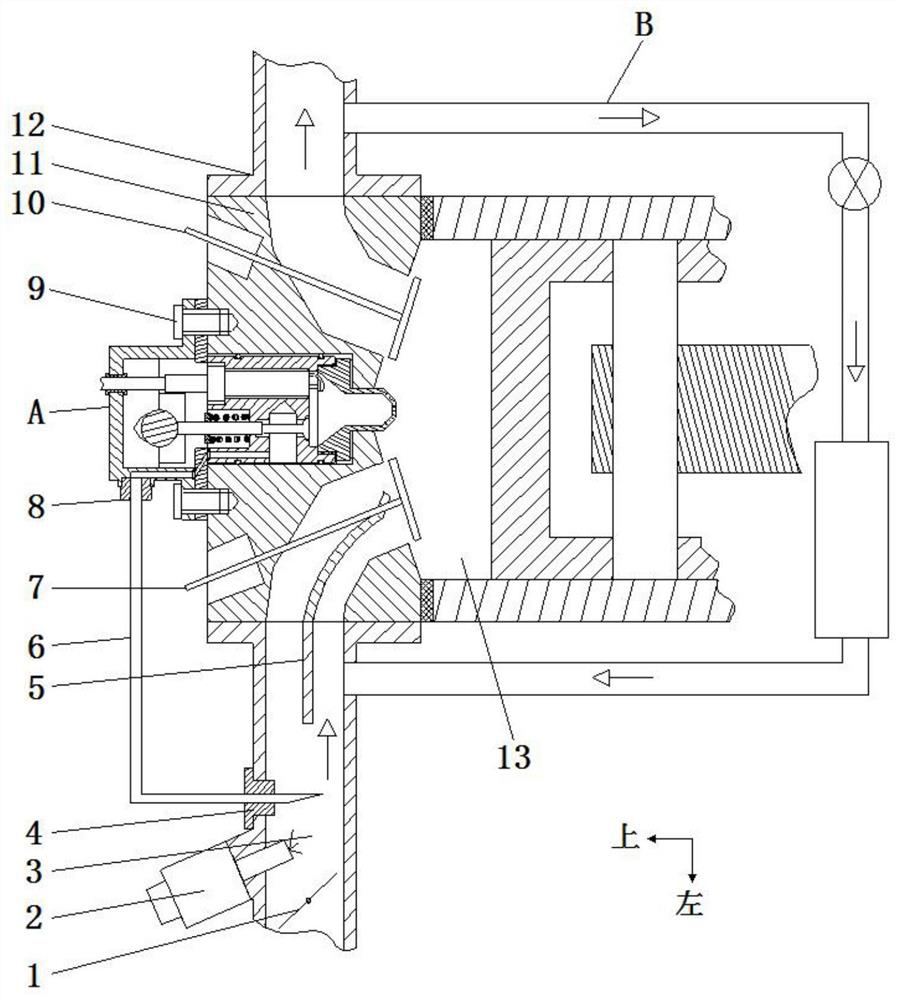

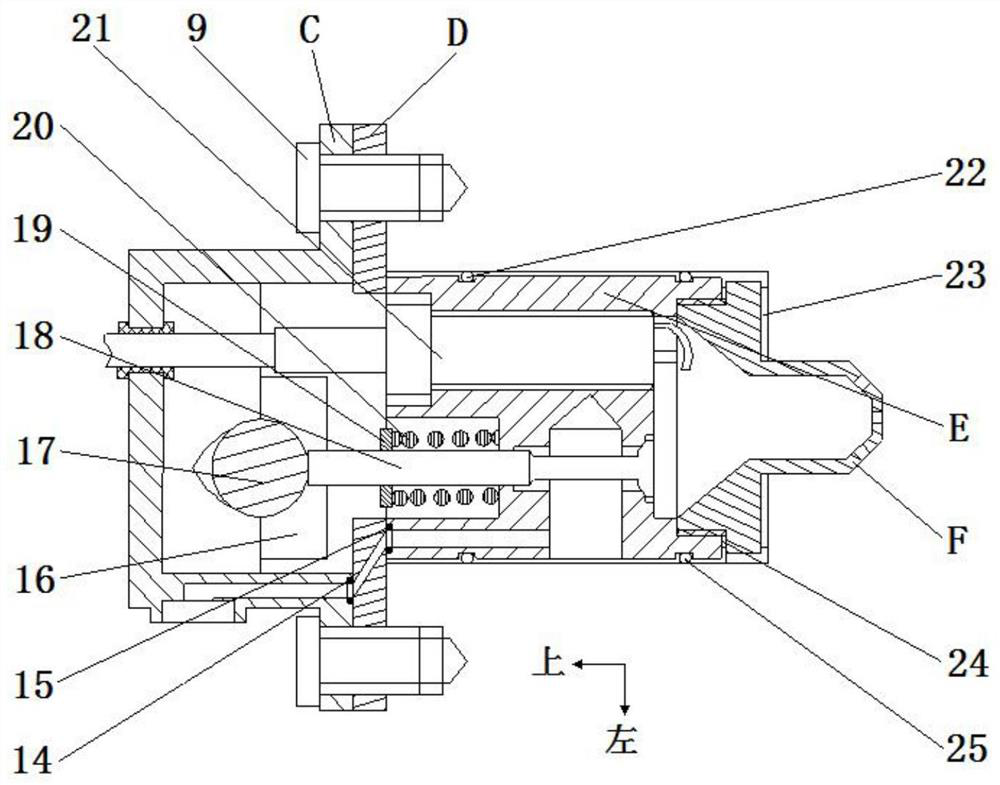

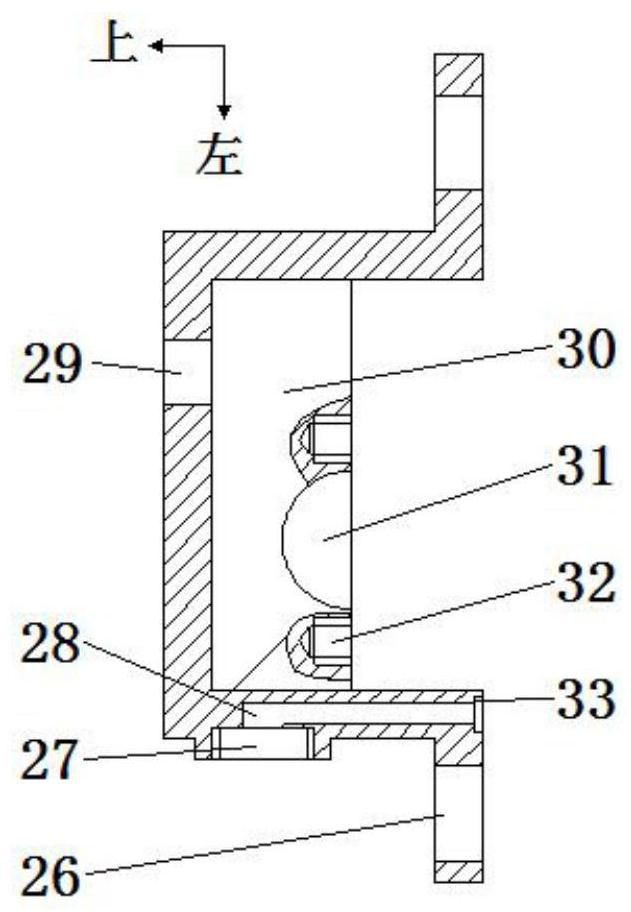

Heat jet mechanism of lean-burn engine and combustion system of heat jet mechanism

ActiveCN113006927AImprove combustion stabilityEasy to manufactureInternal combustion piston enginesExhaust gas recirculationCombustion systemCombustion chamber

The invention discloses a heat jet mechanism of a lean-burn engine and a combustion system of the heat jet mechanism, and belongs to the technical field of engines. A gas fuel thermal jet engine mechanism is improved, and high-concentration mixed gas at the outlet end of a fuel injector in a gas inlet channel is independently extracted and supplied to a pre-combustion chamber through a cam shaft and a valve mechanism. When the engine needs to be ignited, a sparking plug in the pre-combustion chamber ignites the rich mixed gas in the pre-combustion chamber in advance, and the high-temperature combusted compound in the pre-combustion chamber is jetted into a combustion chamber through the pressure difference between the pre-combustion chamber and the combustion chamber, so that the lean mixed gas in the combustion chamber is ignited, and the preparation process of the mixed gas in the pre-combustion chamber of the thermal jet engine is effectively simplified. Through the exhaust gas recirculation and air inlet layering technology, the combustion stability of the thermal jet engine is further improved, and meanwhile knocking and harmful pollutant emission are effectively restrained.

Owner:JILIN UNIV

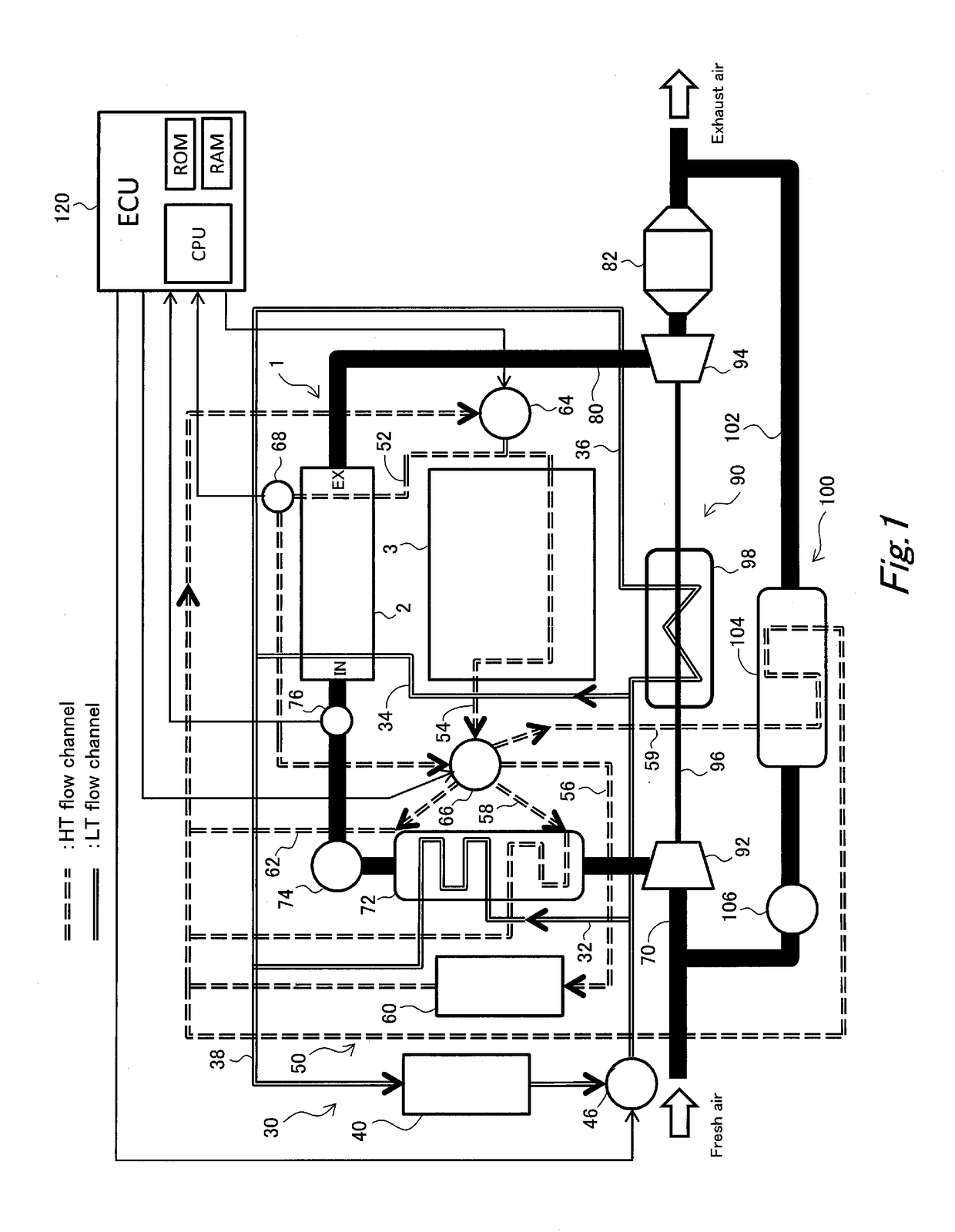

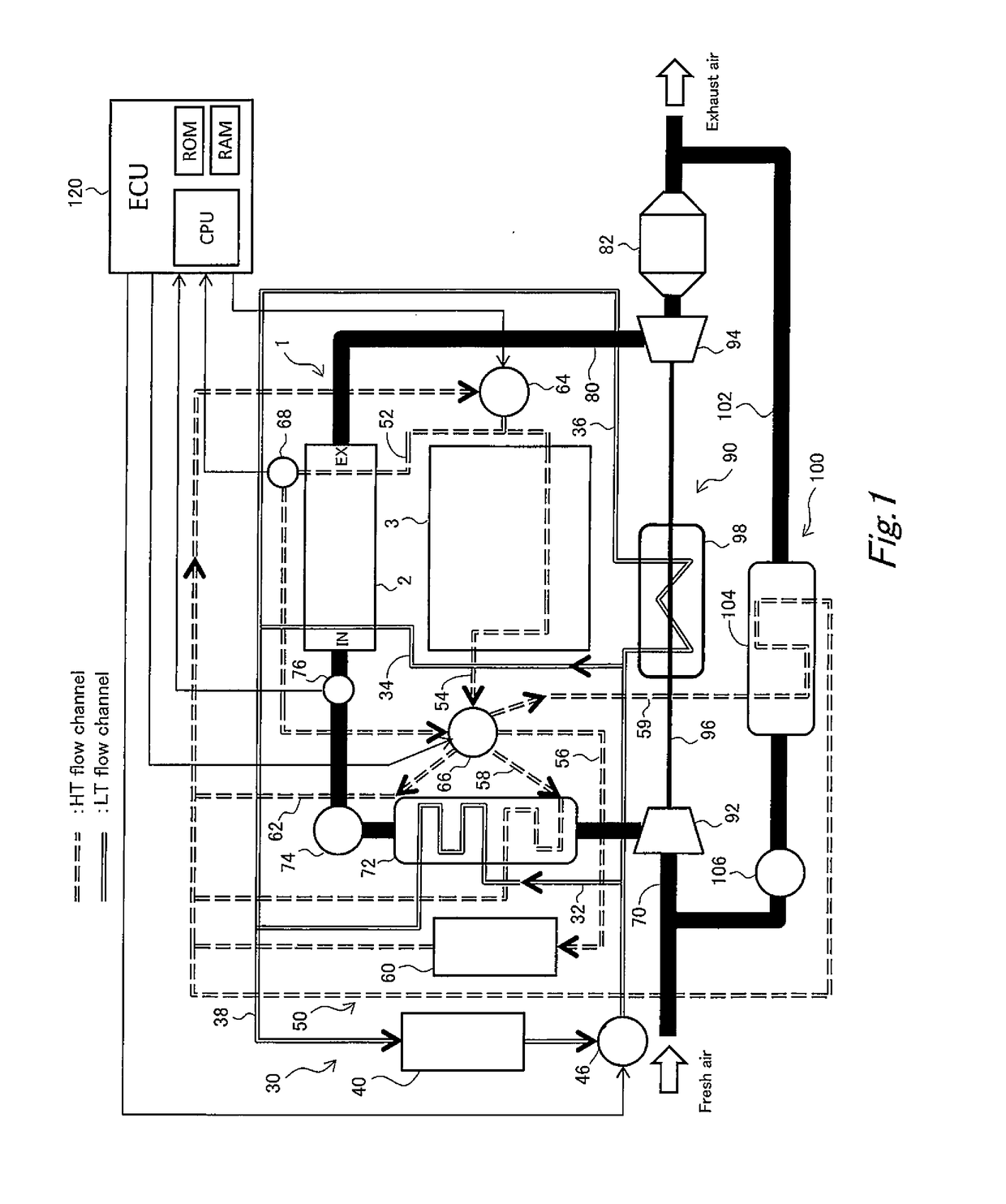

Waste gas recirculation system for spark ignition type supercharged engine and use method of waste gas recirculation system

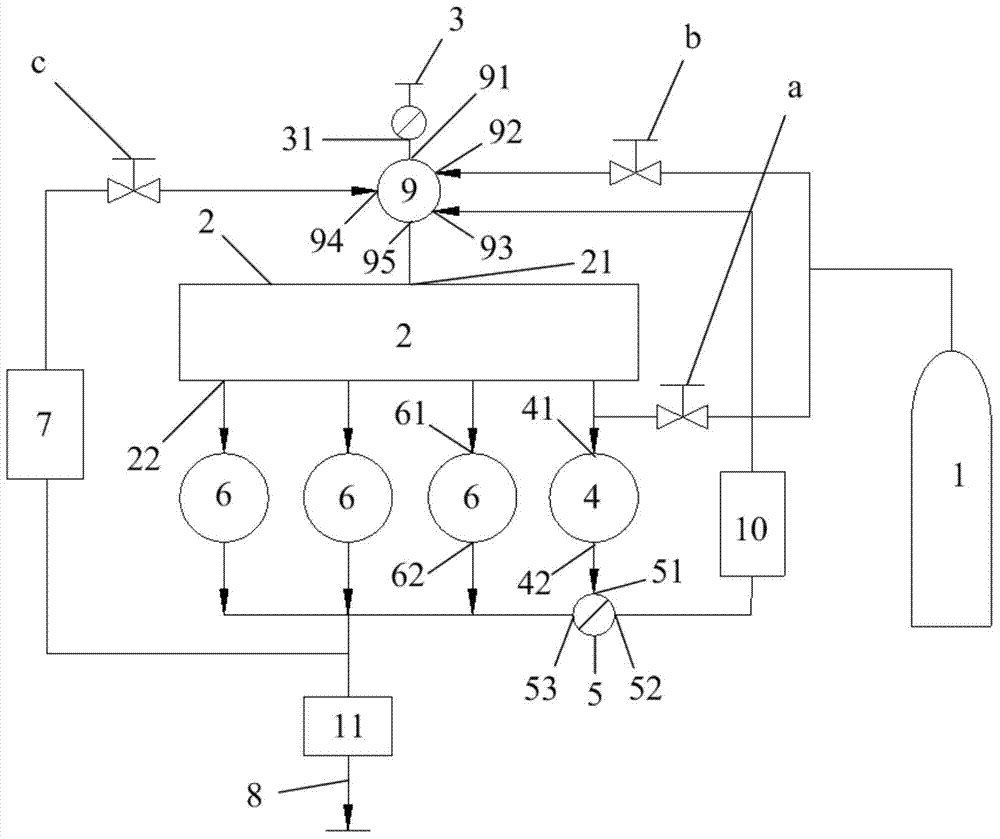

ActiveCN105508088AReduce fuel consumptionIncrease fuel consumptionElectrical controlExhaust gas recirculationIntercoolerProcess engineering

The invention provides a waste gas recirculation system for a spark ignition type supercharged engine. The waste gas recirculation system comprises a gas inlet pipeline, a throttle valve, a gas inlet manifold, a supercharger, an exhaust pipeline, an exhaust manifold, a waste gas posttreatment device, a first intercooler, a bypass valve, a first EGR valve, a first pipeline with a first port and a second port, a second intercooler connected with the bypass valve in parallel, a second EGR valve, a second pipeline with a fourth port and a third port communicated with the first pipeline, and a multiport valve communicated with the first pipeline and the second pipeline; the first port is communicated with the exhaust pipeline between the exhaust manifold and the waste gas posttreatment device; the second port is communicated with the gas inlet pipeline between the throttle valve and the gas inlet manifold; the fourth port is communicated with the gas inlet pipe at the upstream of the supercharger, the multiport valve is controlled to enable the first pipeline to convey waste gas, the bypass valve is controlled to enable the multiport valve to be communicated with the second port, or the waste gas is conveyed to the gas inlet manifold by the first port and the fourth port. The waste gas recirculation system improves EGR rate and improves oil consumption.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Combustion organization method of methanol/alcohol hydrogen fuel internal combustion engine and application thereof

ActiveCN109113880ABroaden the lean-burn boundaryPromote combustionElectrical controlInternal combustion piston enginesBurning tissueParticulates

The invention discloses a combustion organization method of a methanol / alcohol hydrogen fuel internal combustion engine and application thereof. The combustion organization method comprises the stepsthat part methanol fuel of methanol fuel of tail gas waste heat is catalytically reformed or pyrolyzed on line is used for preparing alcohol hydrogen, and the main component of the alcohol hydrogen ishydrogen; part of the prepared alcohol hydrogen is supplied to an ignition chamber, and hydrogen-enriched mixed gas is formed; and ignition is achieved through a spark plug, a high-energy turbulent flame jet ignition source is formed, and a homogeneous thin mixed gas, formed through methanol and alcohol hydrogen jetted from interior of a gas inlet channel or a cylinder, in the cylinder is ignited. According to the invention, part of methanol fuel is converted into the alcohol hydrogen, the combustion organization method is adopted and is applied to the internal combustion engine, ignition reliability can be improved, the in-cylinder combustion process is accelerated, the antiknock property is improved, and the internal combustion engine adapts to higher compression ratios, so that thermalefficiency of the engine is improved, and hazard emission of nitrogen oxides, particles and the like is reduced. A modification experiment on a diesel engine of which the cylinder diameter is 210 mmshows that thermal efficiency is improved by 4%, emission of nitrogen oxides is reduced by 85%, and emission of particles is reduced by 95%.

Owner:JIANGSU UNIV +1

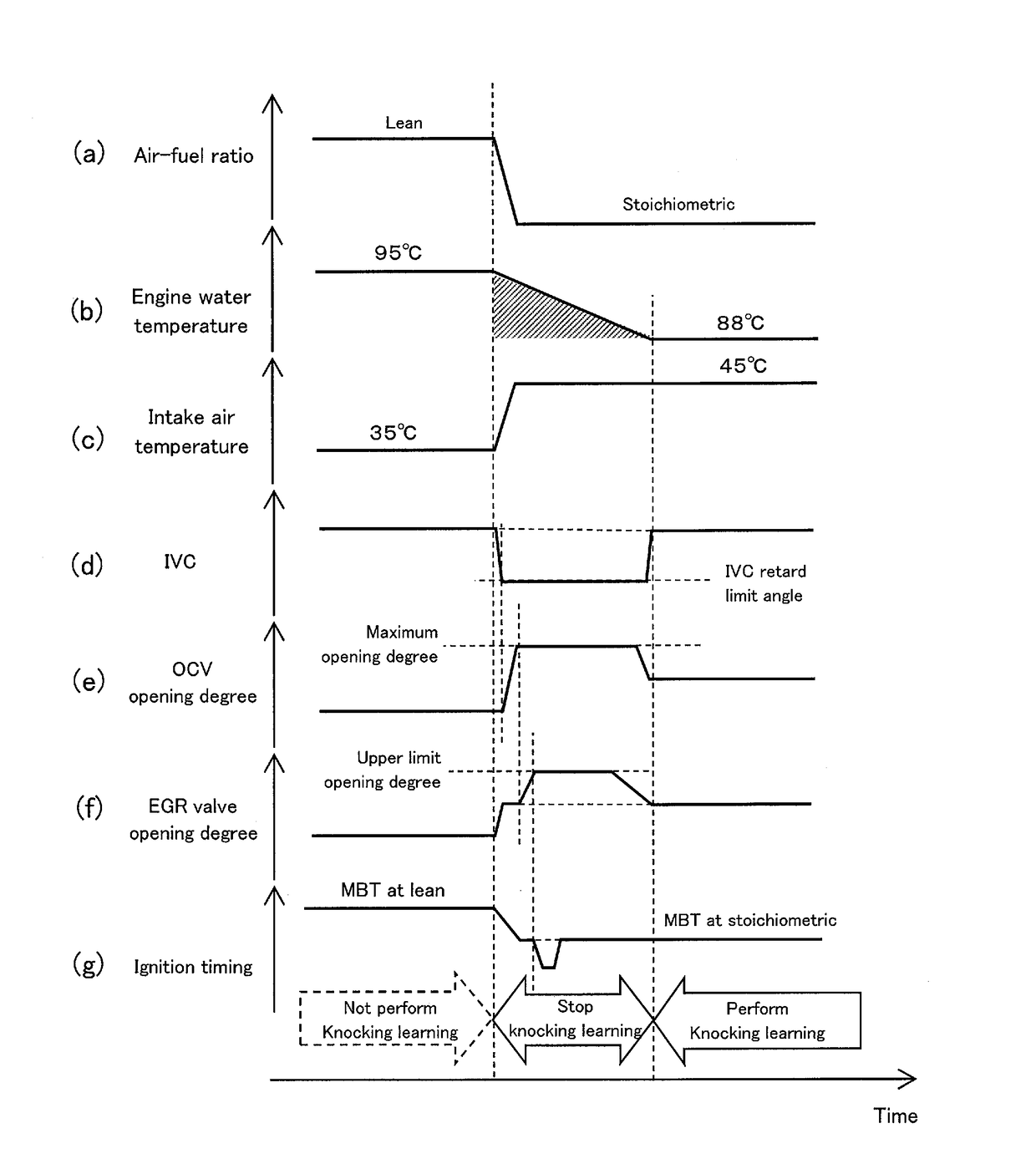

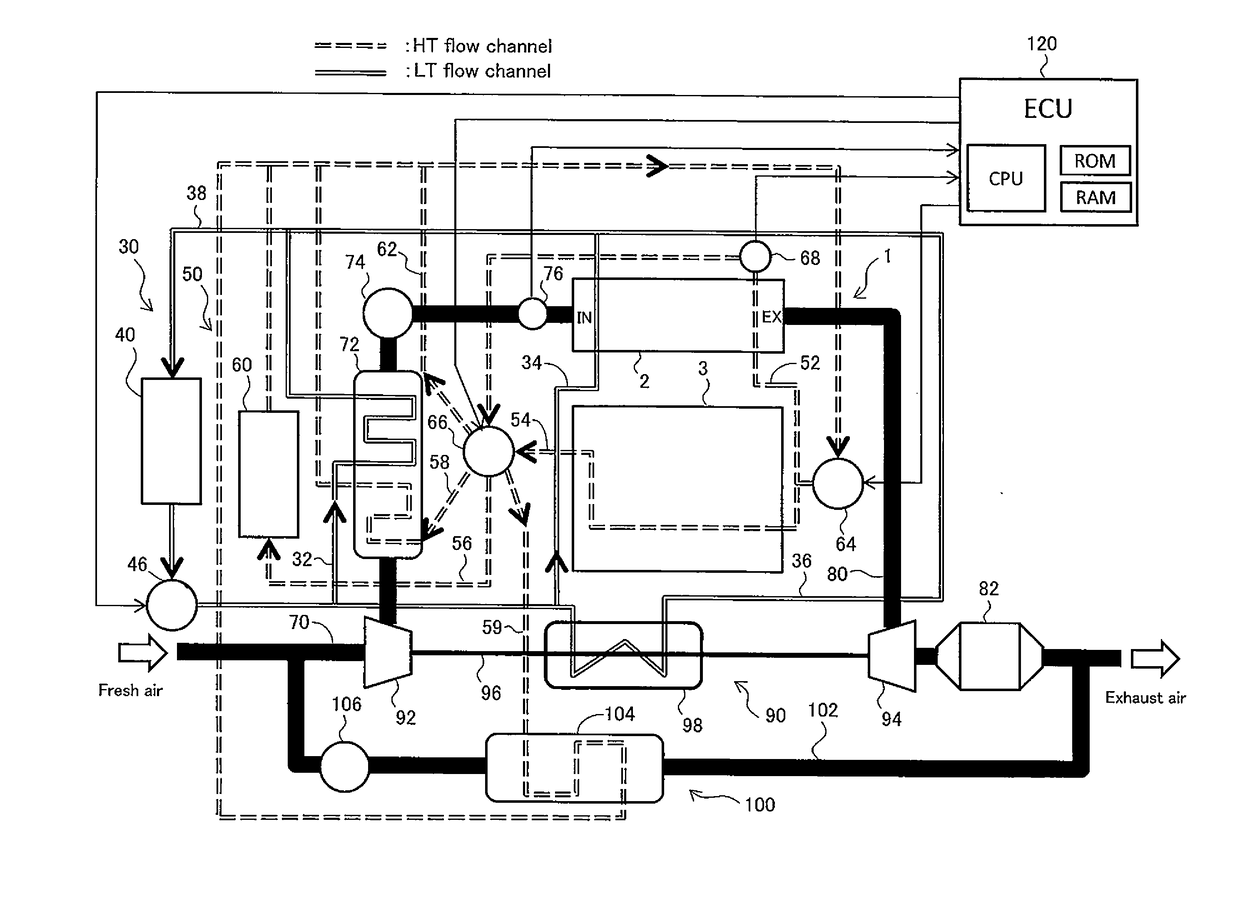

Internal combustion engine

ActiveUS20170276082A1Knock suppressionEasy to riseLiquid coolingValve arrangementsExternal combustion engineInlet valve

The control apparatus operates an engine water temperature adjustment apparatus so that the temperature of cooling water that passes through an engine head enters a first temperature region in a lean mode, and operates the engine water temperature adjustment apparatus so that the temperature of the cooling water enters a second temperature region that is lower than the first temperature region in a stoichiometric mode. When knocking is detected after switching is started from the stoichiometric mode to the lean mode, the control apparatus performs any one of a first operation to operate a variable valve apparatus so as to retard the closing timing of an intake valve, a second operation to operate an oil jet apparatus so as to increase an oil jet amount, and a third operation to operate an EGR apparatus so as to increase an EGR amount.

Owner:TOYOTA JIDOSHA KK

Internal combustion engine

ActiveUS20170276059A1Increase in wall surfaceOccurrence can be suppressedLiquid coolingElectrical controlExternal combustion engineEngineering

An internal combustion engine includes an intake air temperature adjustment apparatus that adjusts the temperature of intake air, and a control apparatus that operates at least the intake air temperature adjustment apparatus. When the internal combustion engine operates in a stoichiometric EGR mode, the control apparatus operates the intake air temperature adjustment apparatus so that the temperature of intake air entering a combustion chamber enters a first temperature region. When the internal combustion engine operates in a lean mode, the control apparatus operates the intake air temperature adjustment apparatus so that the temperature of intake air entering a combustion chamber enters a second temperature region that is a lower temperature region than the first temperature region.

Owner:TOYOTA JIDOSHA KK

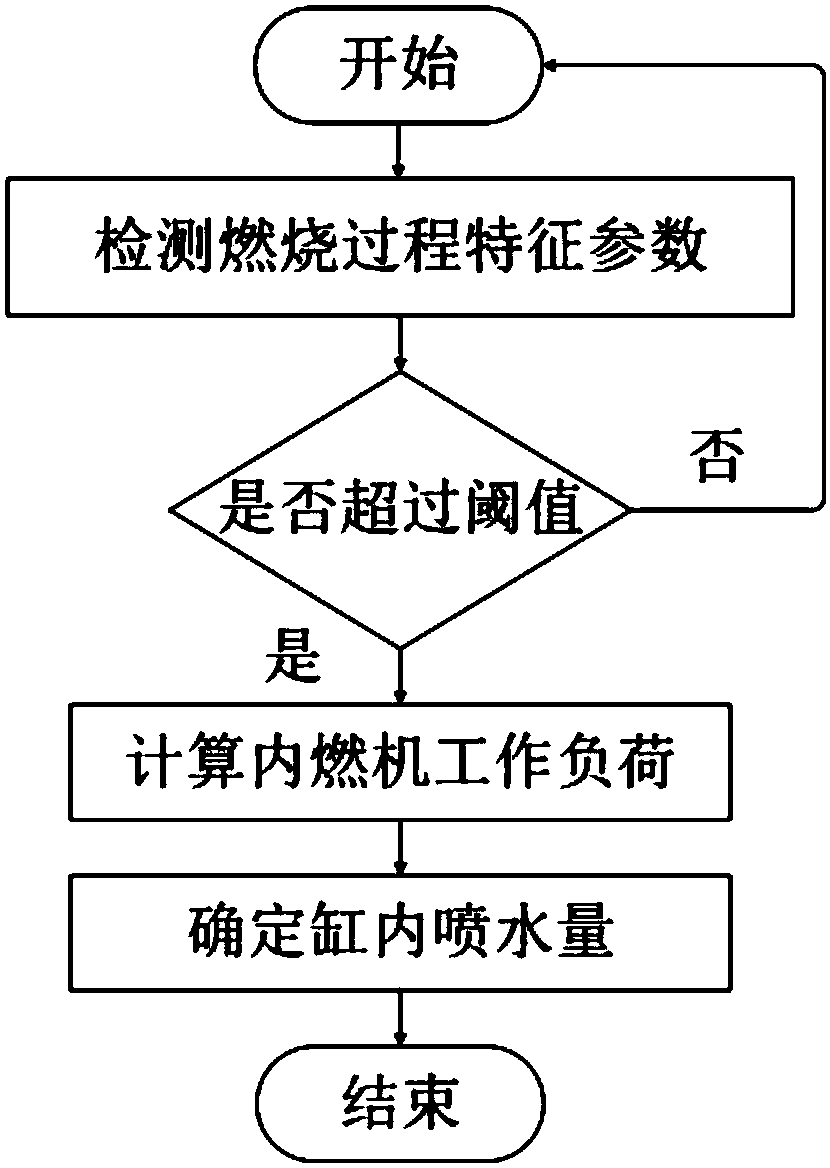

System and method for controlling homogeneous charge compression ignition of internal combustion engine through water spray in cylinder

ActiveCN108060992AAccurate determination of injection volumeGood control effectInternal combustion piston enginesNon-fuel substance addition to fuelHomogeneous charge compression ignitionExternal combustion engine

The invention relates to a system and method for controlling homogeneous charge compression ignition of an internal combustion engine through water spray in a cylinder. The system for controlling homogeneous charge compression ignition of the internal combustion engine through water spray in the cylinder comprises an internal combustion engine body, oil sprayers, a direct-spray water sprayer, a water spray common rail, a high-pressure water pump and a water tank. The direct-spray water sprayer is connected to the water spray common rail. The water spray pressure in the water spray common railis established by the high-pressure water pump. The high-pressure water pump is driven by an internal communication engine crankshaft or cam shaft. The water adopted in the homogeneous charge compression ignition process of the internal combustion engine is stored in the water tank. The system for controlling homogeneous charge compression ignition of the internal combustion engine through water spray in the cylinder effectively solves the problem that when the homogeneous charge compression ignition technology is adopted under a large-load working condition, knockings exist, so that the homogeneous charge compression ignition can be utilized in the full load work range of the internal combustion engine, and the full load fuel economical efficiency and emission feature of the internal combustion engine are improved; and besides, after absorbing heat emitted in the ignition process, the water sprayed into the cylinder is gasified, expands and does work, the system thermal efficiency ofthe homogeneous charge compression ignition internal combustion engine is further improved, and control and optimization of the homogeneous charge compression ignition process of the internal combustion engine are achieved.

Owner:TONGJI UNIV

Gasoline engine combustion control method and gasoline engine suitable for medium and heavy vehicle

PendingCN108843446AExpand the scope ofReduce dependenceInternal combustion piston enginesExhaust gas recirculationThermal efficiencySpark plug

The invention discloses a gasoline engine combustion control method and a gasoline engine suitable for a medium and heavy vehicle. On a traditional diesel engine platform, a gas inlet sprinkler systemand a spark plug are reconstructed and additionally mounted on the basis of a gas inlet channel and a cylinder cover, meanwhile, a set of EGR system is arranged in a matched mode, so that the modified gasoline engine adopts EGR strategy in the small and medium load working conditions and adopts EGR and gas inlet channel and sprinkler coupling strategies in the heavy load condition. The problem oflow displacement and low thermal efficiency of a traditional gasoline engine can be overcome, the detonation can be suppressed through EGR coupling gas inlet channel and sprinkler in the heavy load condition, the range of efficient clean combustion can be effectively widened, so that the application need in the medium and heavy vehicle can be met, and meanwhile, the strict emission regulations can be met by using a ternary catalytic converter.

Owner:TIANJIN UNIV

Device for internal combustion engine

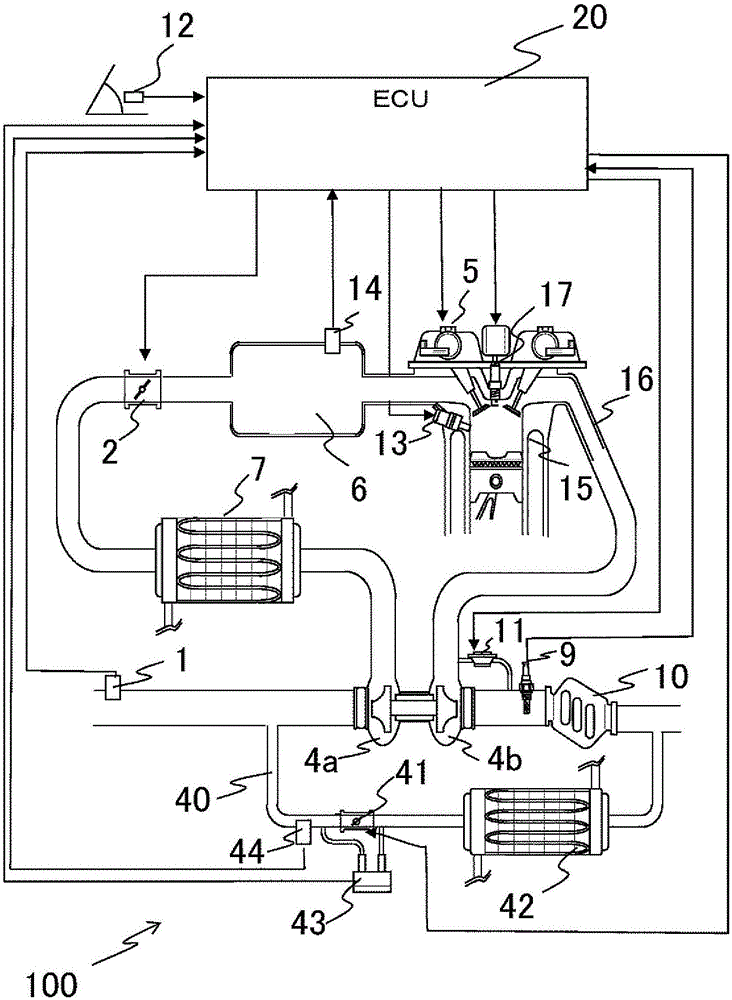

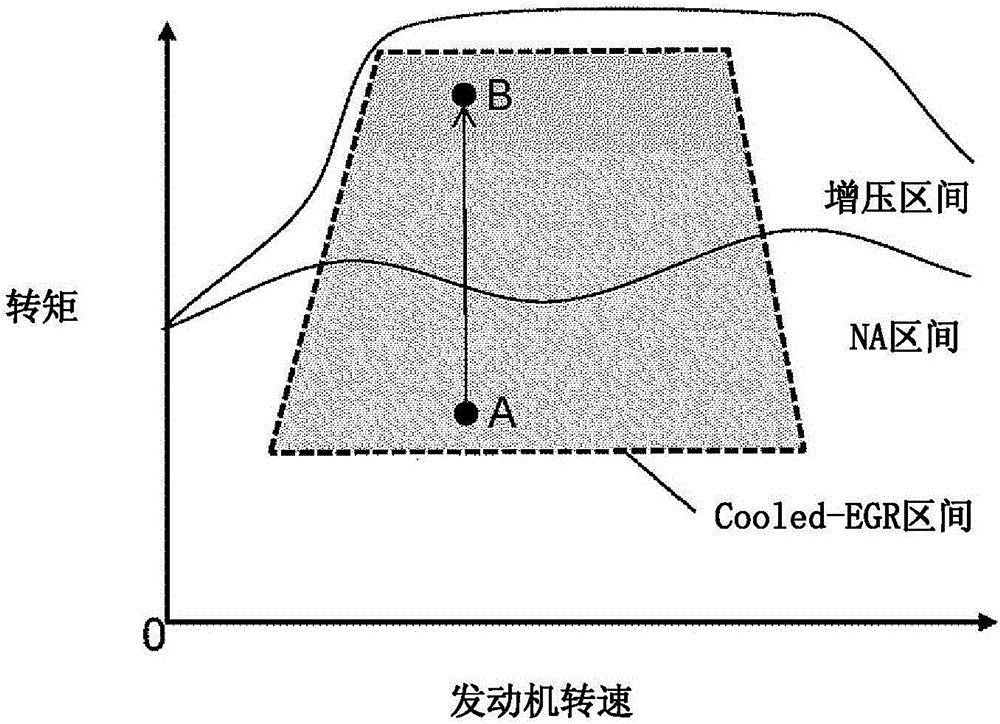

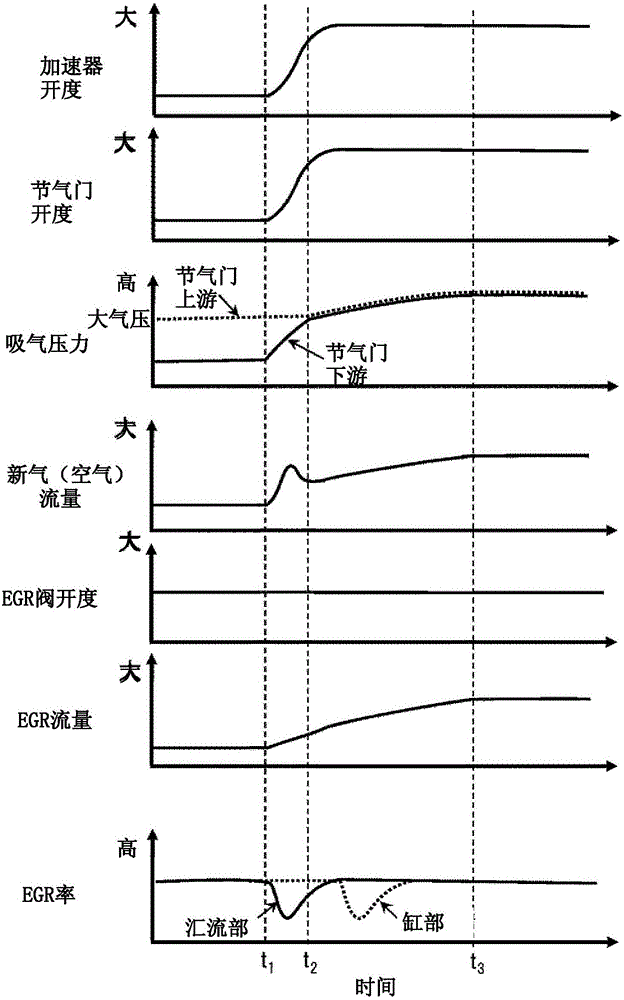

ActiveCN106662029ASuppress exhaust deteriorationKnock suppressionElectrical controlInternal combustion piston enginesCombustion chamberTurbocharger

In the case of an internal combustion engine equipped with a turbocharger having a low-pressure EGR flow passage, an EGR rate inside a combustion chamber temporarily drops when accelerating from a high-EGR operation, resulting in the occurrence of knocking and poor emission due to a deviation in air-fuel ratio. A control device for an internal combustion engine according to the present invention is provided with: a turbocharger; a low-pressure EGR flow passage which connects an exhaust pipe disposed on the downstream side of a turbine of the turbocharger with an intake pipe disposed on the upstream side of a compressor of the turbocharger; a throttle valve for controlling the amount of gas flowing into cylinders; and an EGR valve which is disposed in the EGR flow passage in order to control an EGR flow rate. When acceleration is requested while operating at an EGR rate equal to or higher than a predetermined value, a control amount of the opening degree of the throttle valve with respect to the opening degree of an accelerator is set smaller than when acceleration is requested while operating at an EGR rate equal to or lower than the predetermined value.

Owner:HITACHI ASTEMO LTD

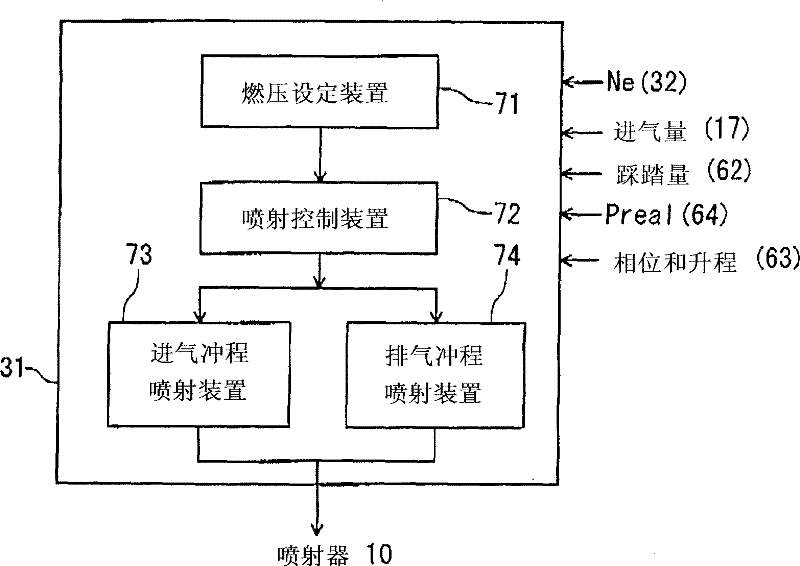

internal combustion engine

ActiveCN102287282AThe injection rate is largeKnock suppressionElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

In an internal combustion engine, an injector injects fuel into an intake passage, an intake stroke injection means causes the injector to inject fuel in an intake stroke, an exhaust stroke injection means causes the injector to inject fuel in an exhaust stroke, a fuel pressure setting means sets fuel pressure according to a rotation speed and a load of the internal combustion engine, and an injection control means controls an operation ratio of the intake stroke injection means and the exhaust stroke injection means according to the rotation speed and the load of the internal combustion engine and the fuel pressure which is set by the fuel pressure setting means. The injection control means sets fuel injection timing of the injector.

Owner:MITSUBISHI MOTORS CORP

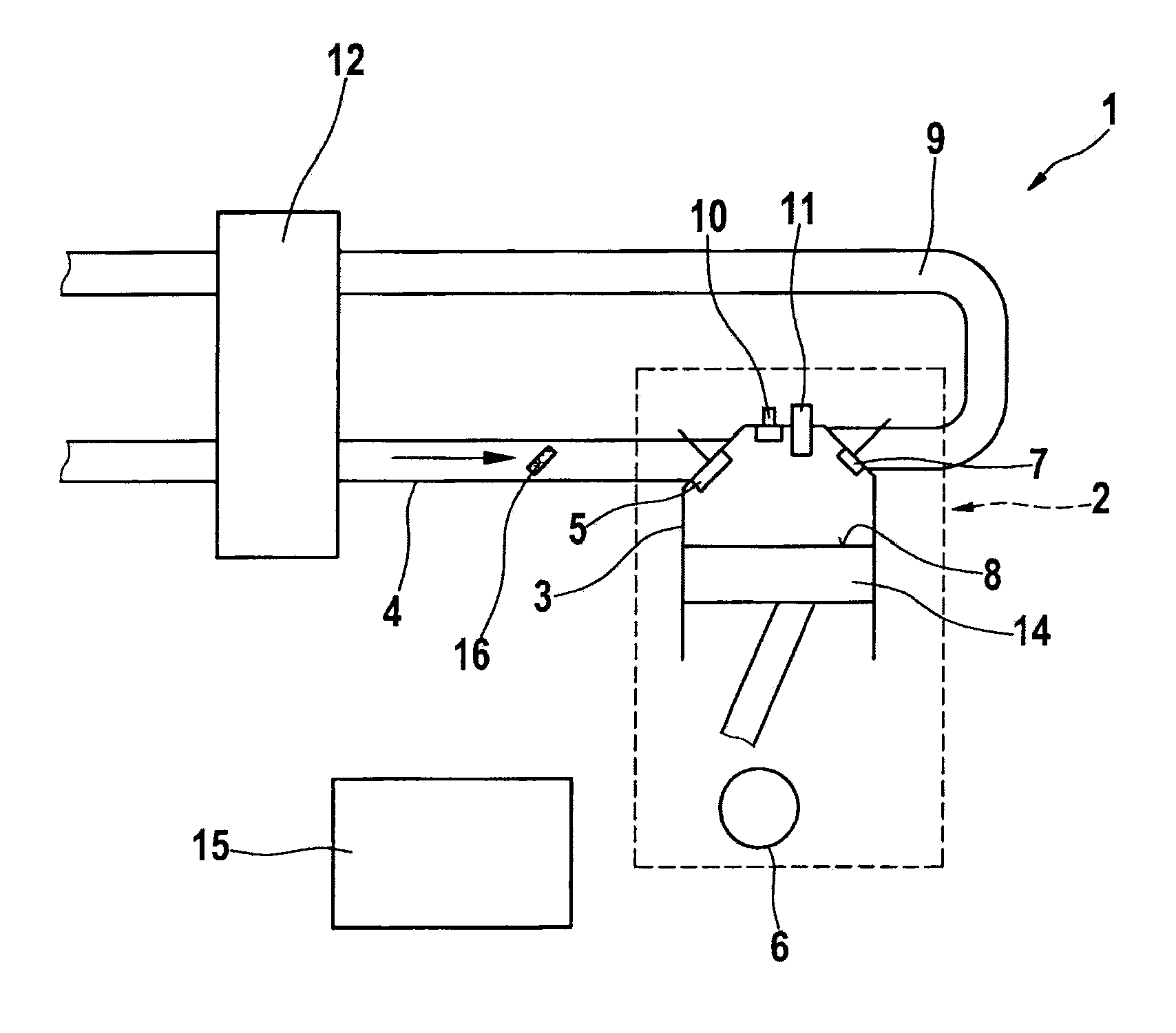

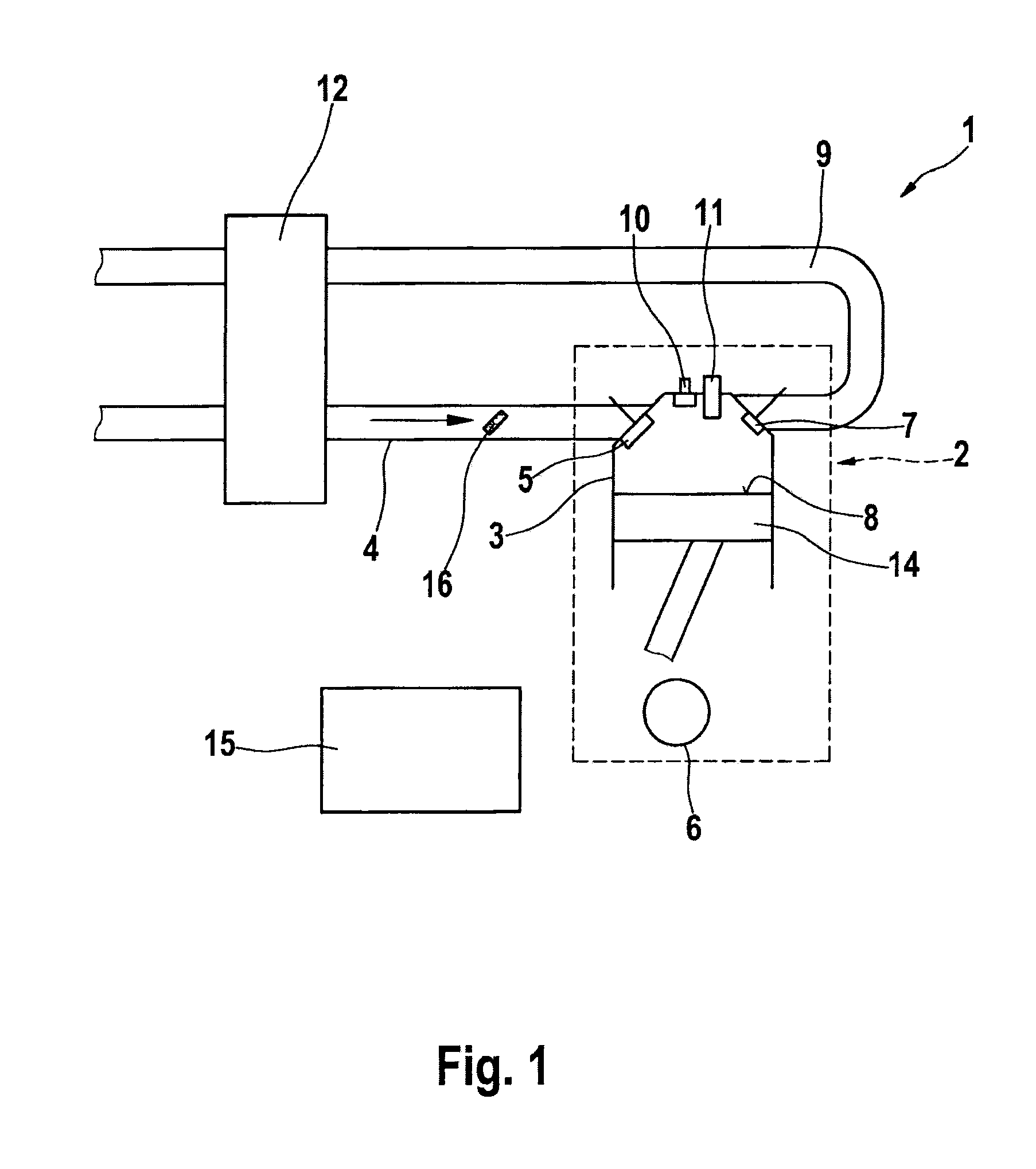

Injection method and device for controlling an injection process in an internal combustion engine

InactiveUS20110079198A1Reduced static flowReduce trafficElectrical controlInternal combustion piston enginesCombustionExternal combustion engine

A method for controlling an injection of fuel in an internal combustion engine, in particular in a gasoline engine having direct injection, a drive fuel quantity, which indicates the fuel quantity required by the internal combustion engine to provide a torque, being injected in a working cycle before a combustion stroke of the working cycle into a cylinder of the internal combustion engine, a cooling fuel quantity, which indicates the fuel quantity which is used to cool the combustion exhaust gases, being injected in the working cycle in addition to the drive fuel quantity, at least part of the cooling fuel quantity being injected after completion of the combustion in the combustion stroke and / or the immediately following exhaust stroke of the working cycle.

Owner:ROBERT BOSCH GMBH

Ethyl alcohol reforming system and control method for improving dynamic performance of natural gas engine

ActiveCN110360026AKnock suppressionEfficient and clean combustionInternal combustion piston enginesFuel supply apparatusAlcoholCombustion

The invention aims at providing an ethyl alcohol reforming system and an ethyl alcohol reforming control method for improving dynamic performance of a natural gas engine. The ethyl alcohol reforming system for improving the dynamic performance of the natural gas engine comprises an LNG (liquefied natural gas) storage tank, an LNG vaporizer, a mixer, a turbine supercharger, an ethyl alcohol storagetank, an ethyl alcohol vaporizer and an ethyl alcohol reformer, wherein a gas compressor in the turbine supercharger is connected with the mixer through an intercooler, the LNG storage tank is connected with the LNG vaporizer through a liquified natural gas flow valve, the LNG vaporizer is connected with the mixer through a gaseous natural gas flow valve, the mixer is connected with a gas inlet pipe, the gas inlet pipe is connected with a turbine of the turbine supercharger, a gas discharge pipe is connected with the ethyl alcohol reformer through a waste gas bypass pipe, a waste gas bypass valve is connected onto the waste gas bypass pipe, the ethyl alcohol storage tank is connected with the ethyl alcohol vaporizer through a liquified ethyl alcohol flow valve, the ethyl alcohol vaporizeris connected with the ethyl alcohol reformer, the ethyl alcohol reformer is connected with the mixer through a reforming pipeline, and a reformed gas flow valve is installed on the reforming pipeline. The ethyl alcohol reforming system and the ethyl alcohol reforming control method for improving the dynamic performance of the natural gas engine can effectively inhibit engine knocking and accidentfire phenomena of the natural gas engine, and also can achieve efficient combustion under cold start and low load work conditions and loading work conditions.

Owner:HARBIN ENG UNIV

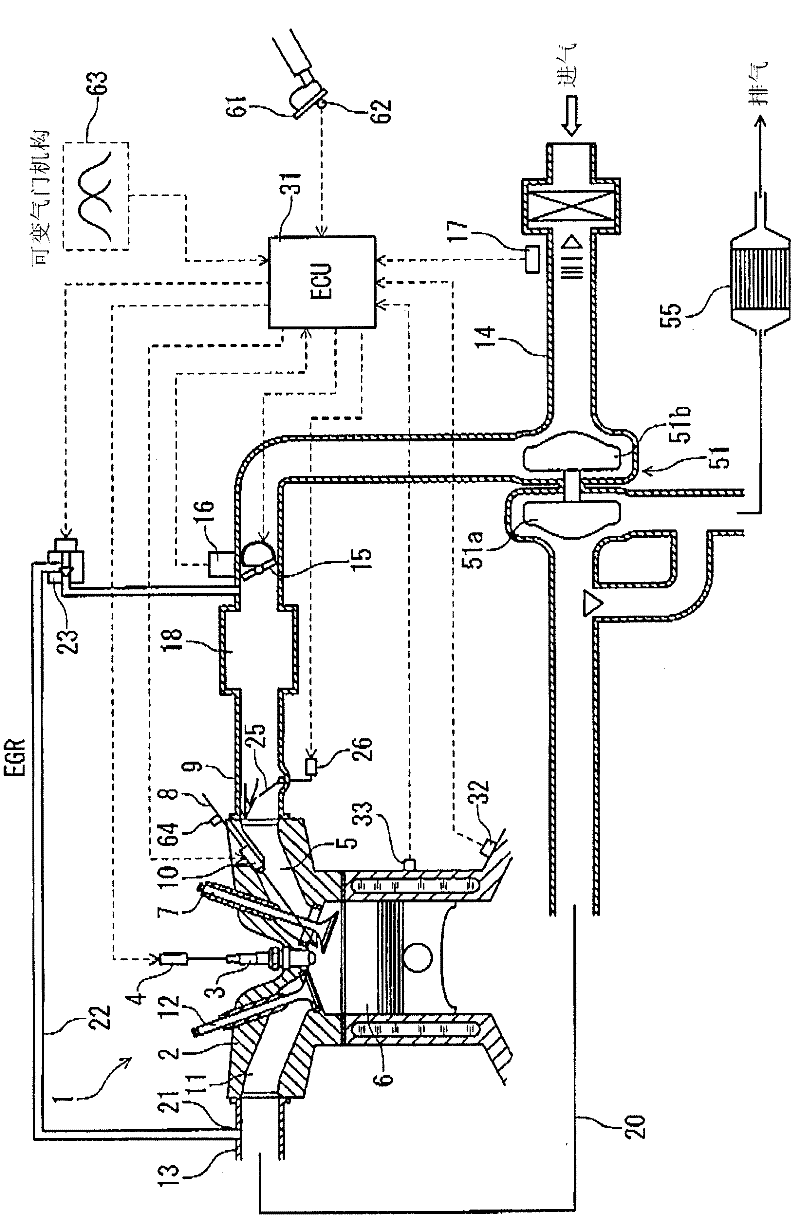

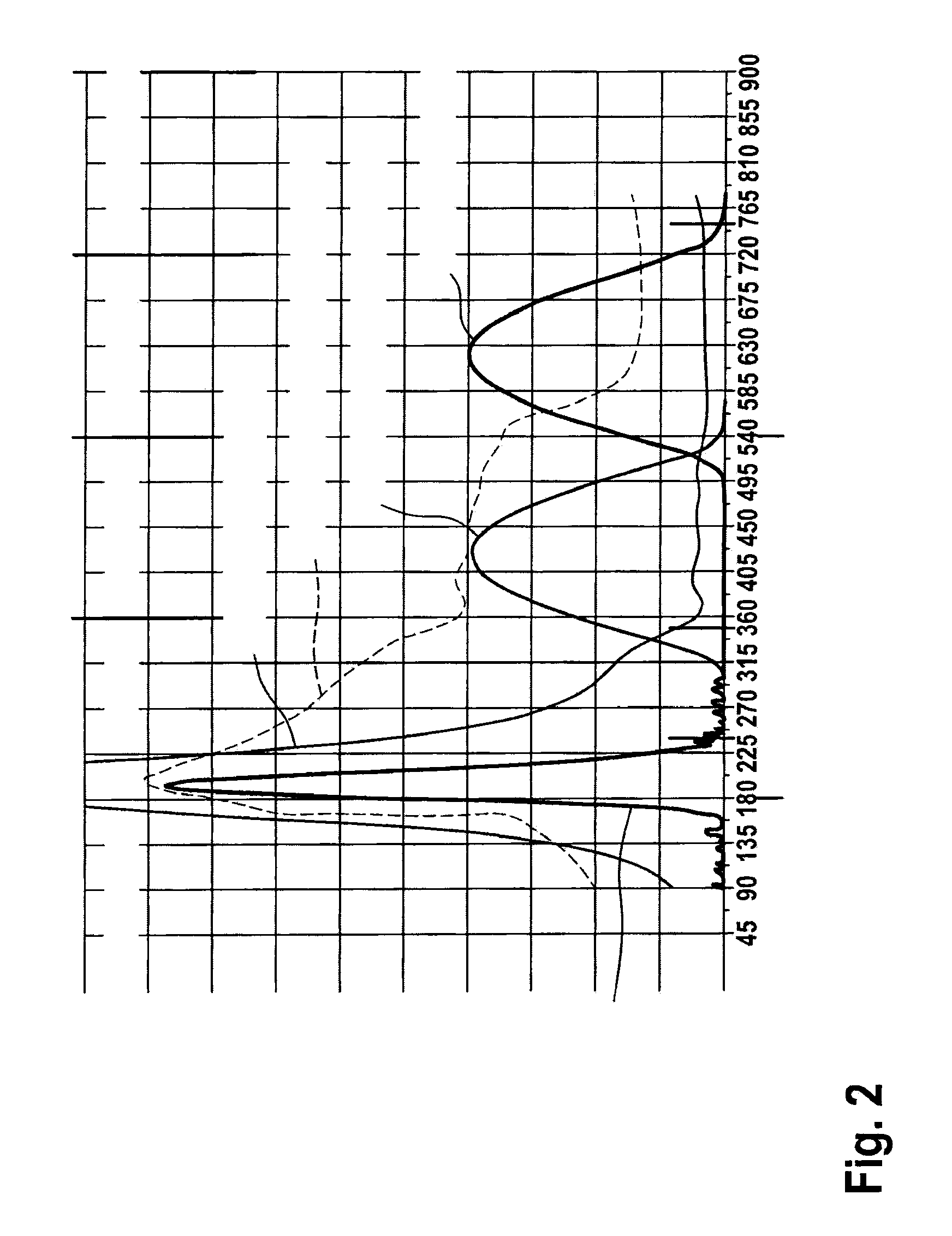

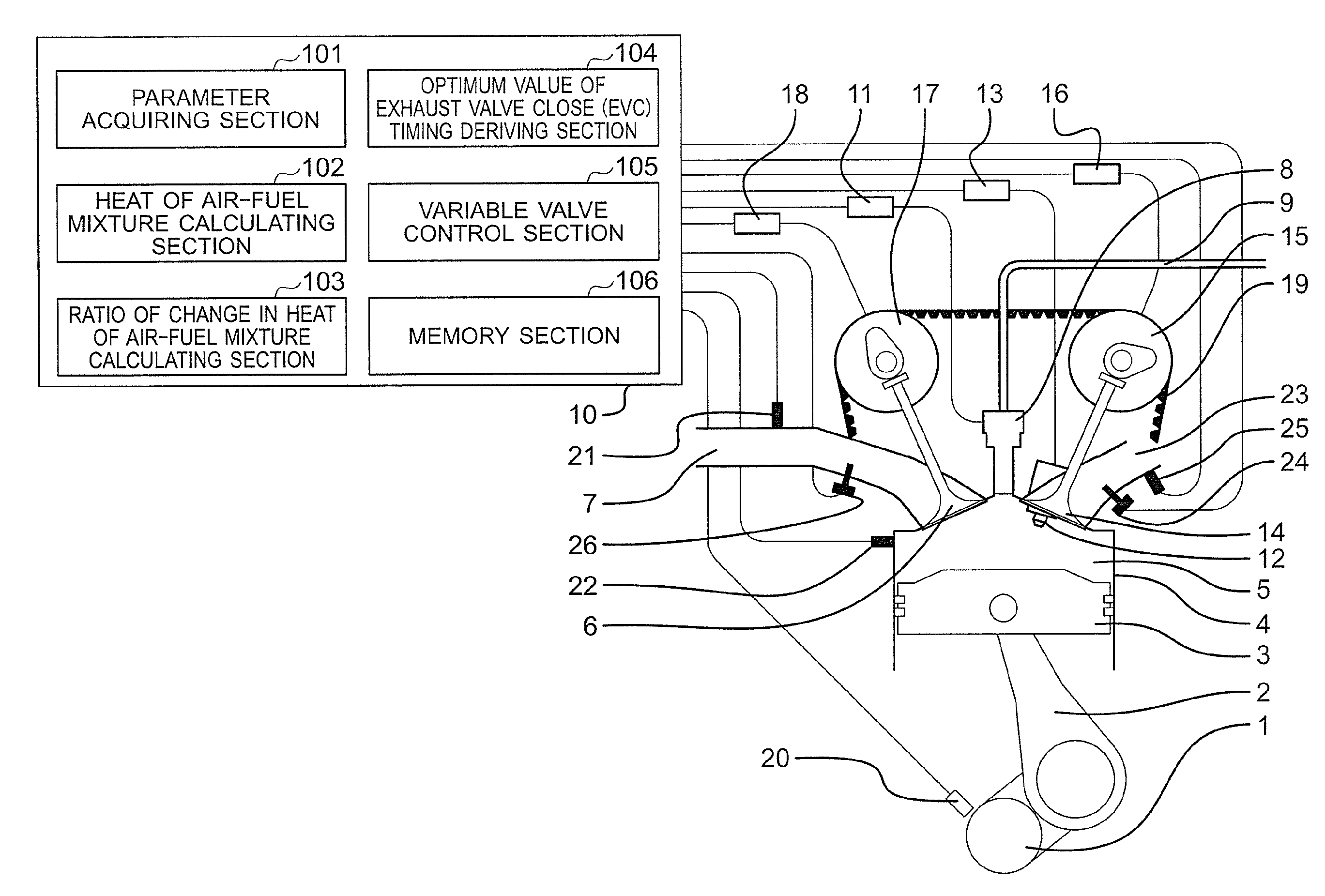

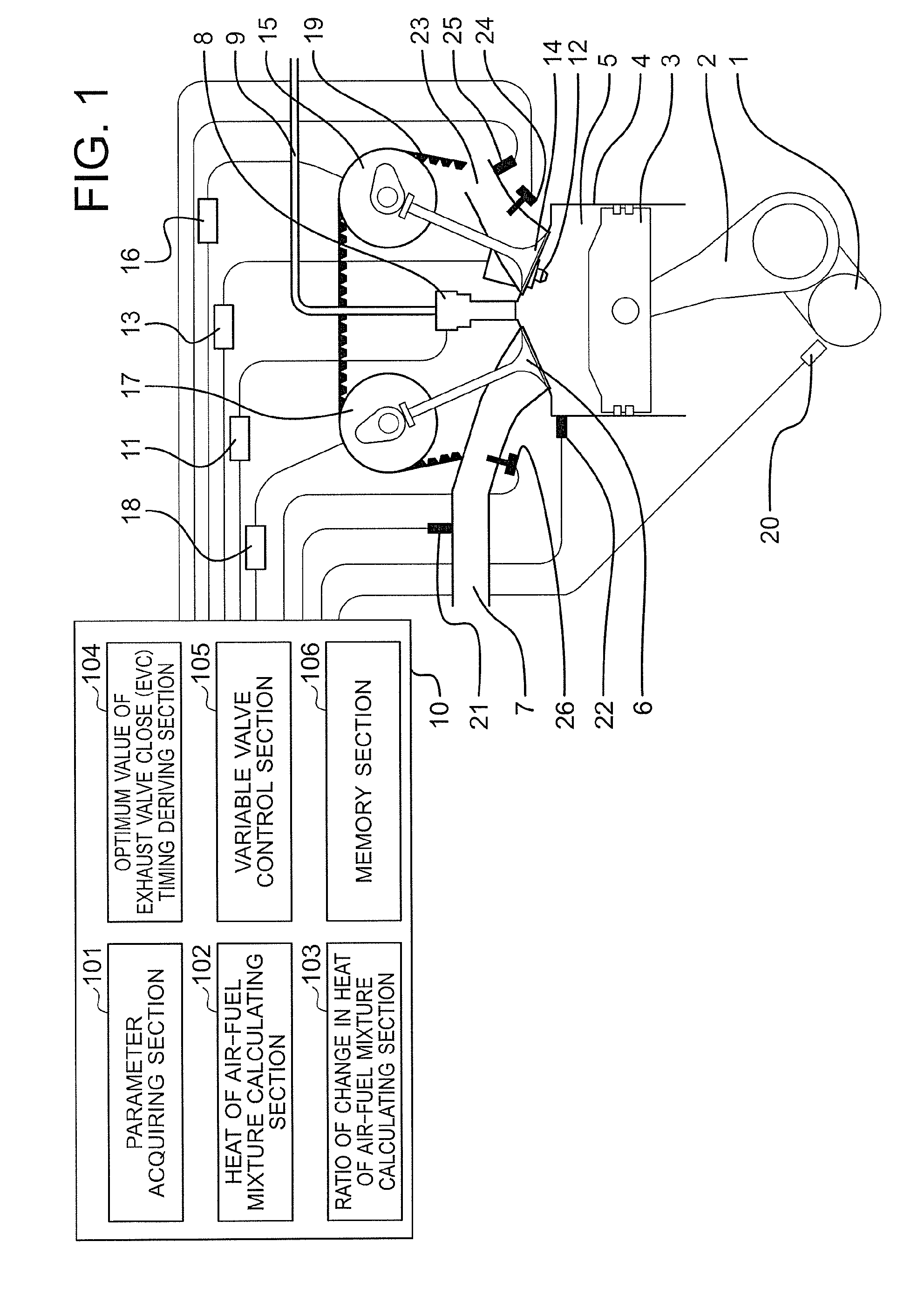

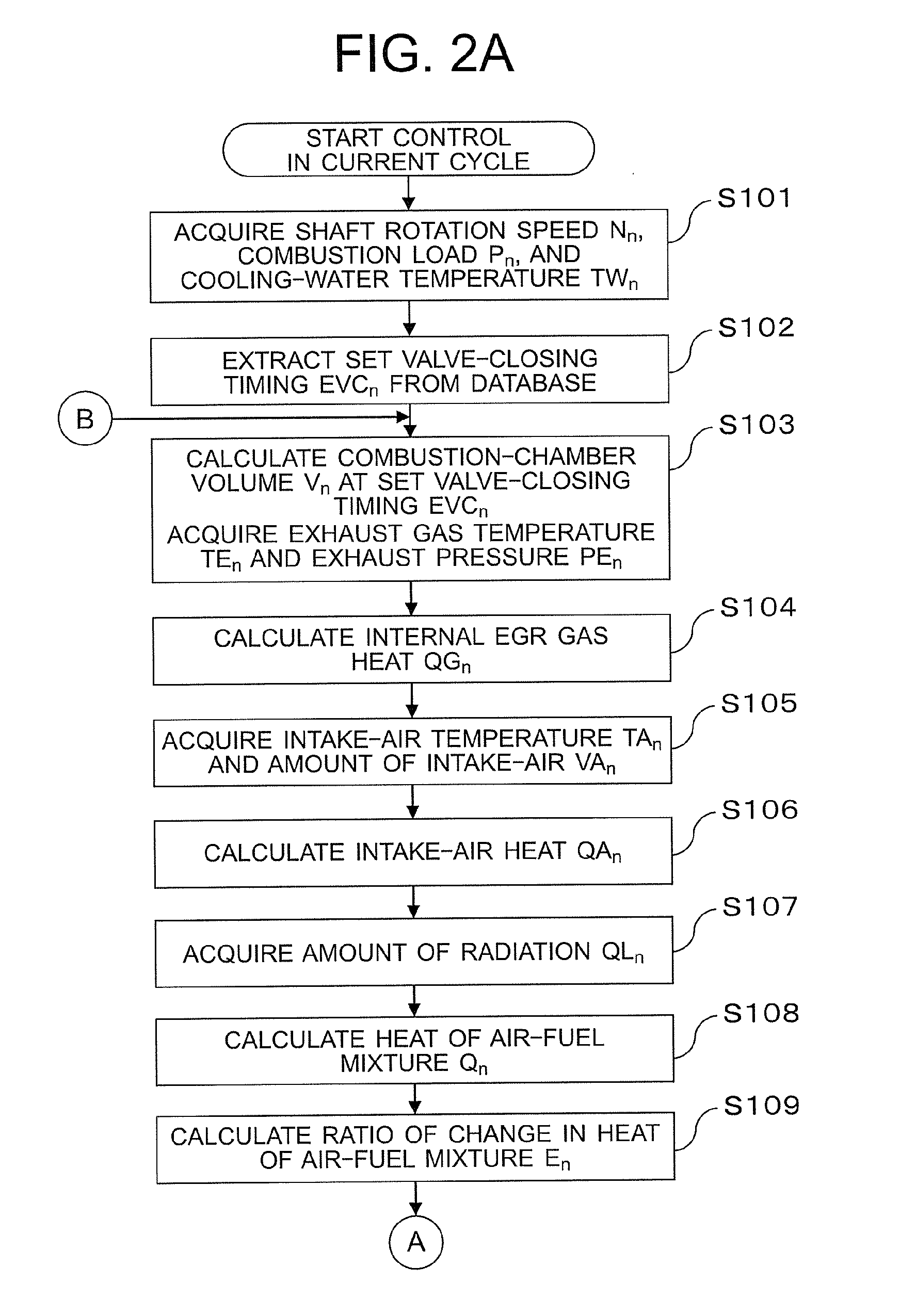

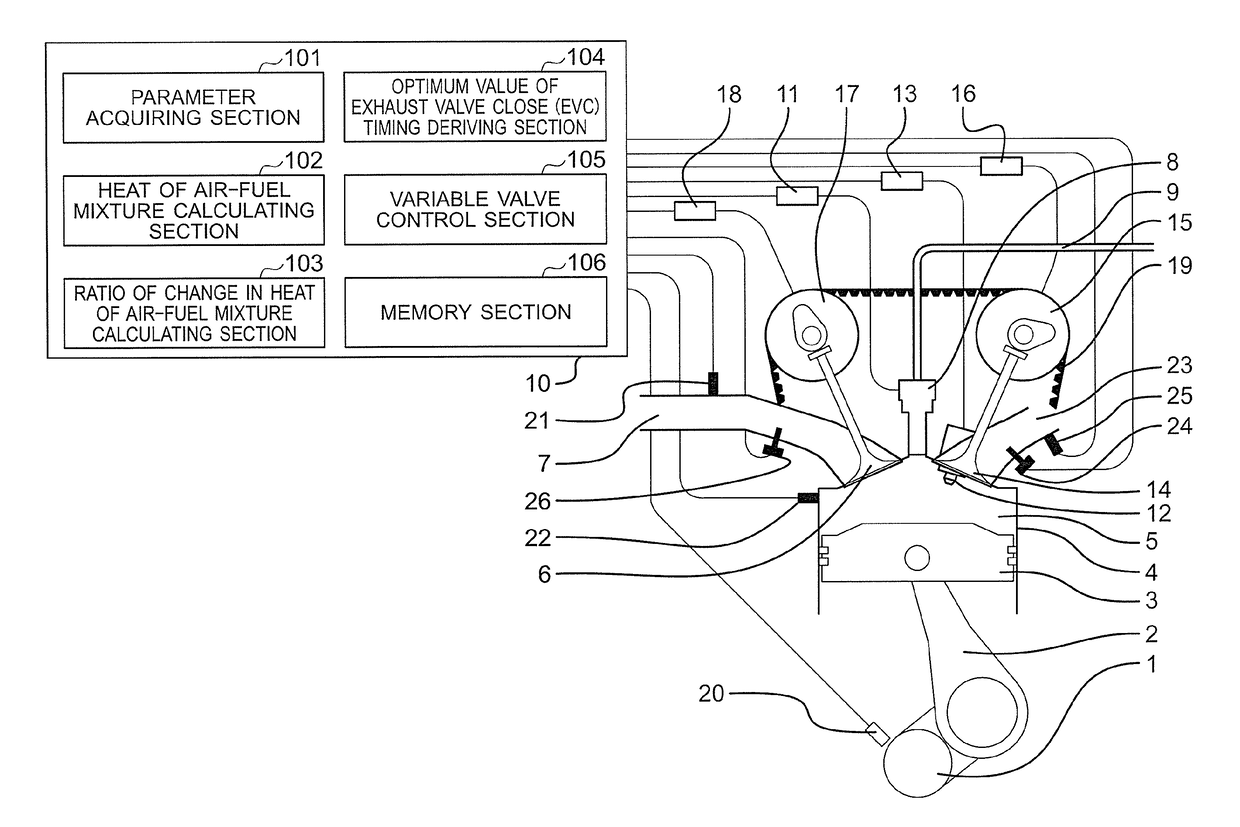

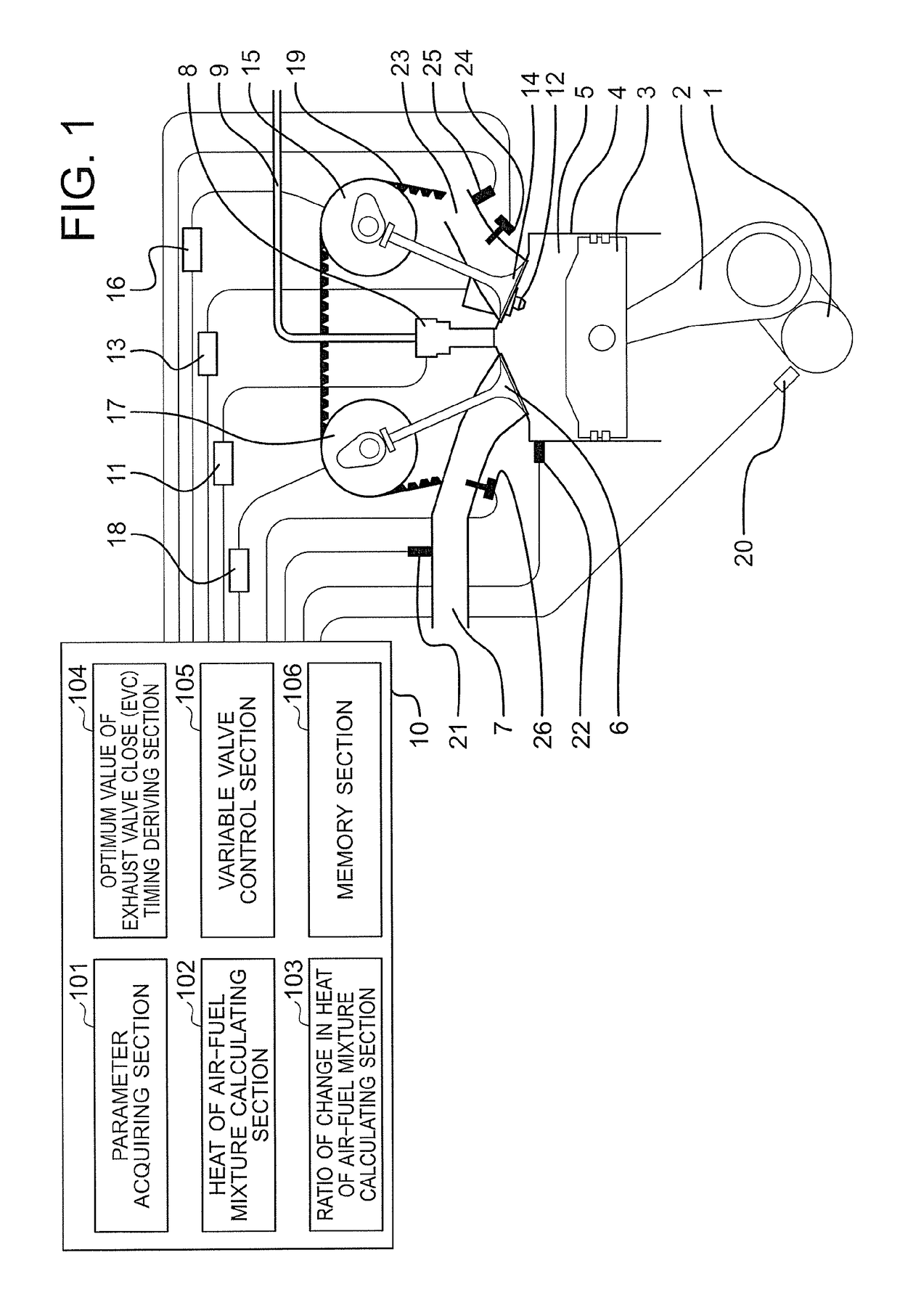

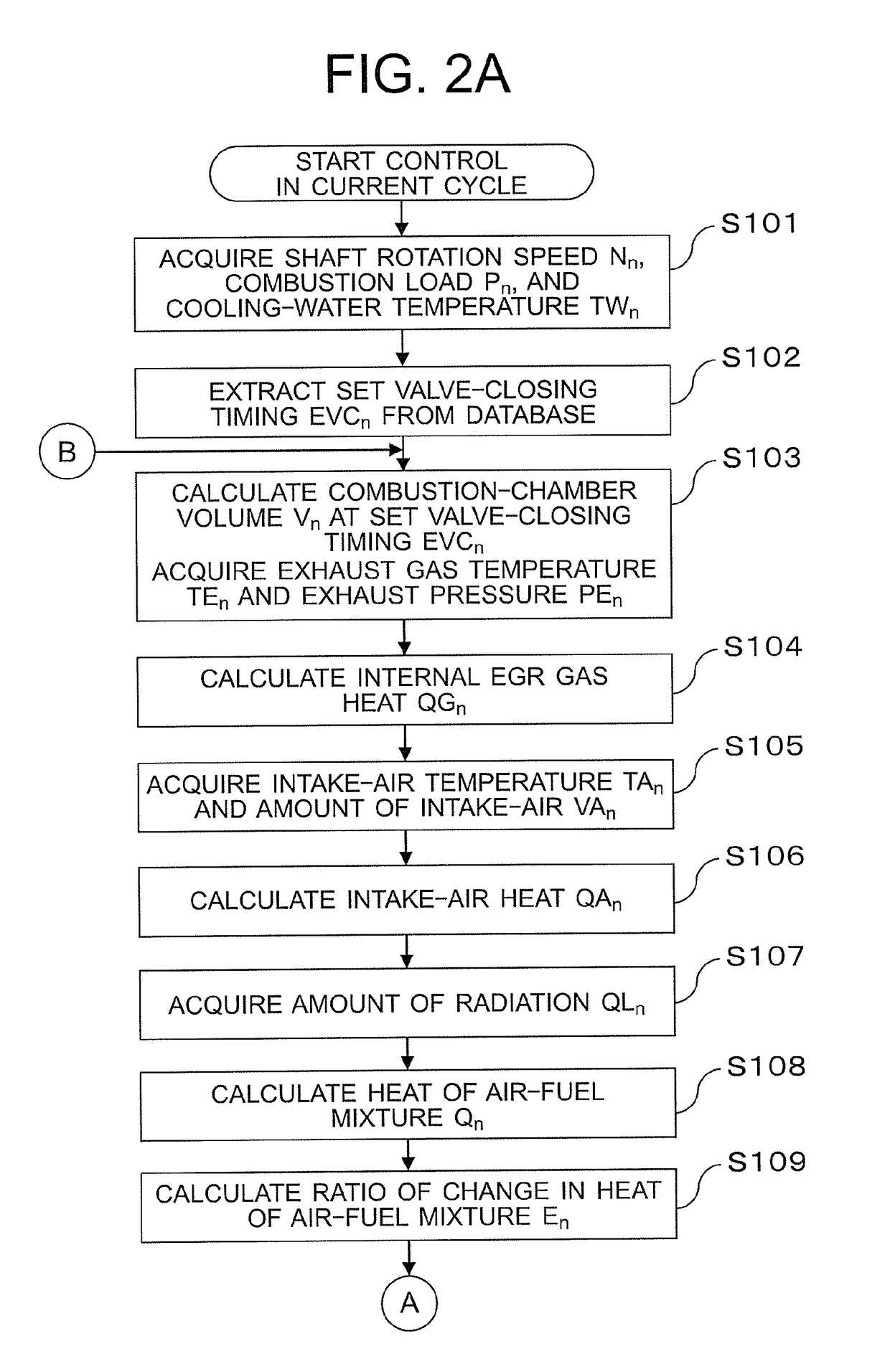

Control device for an internal combustion engine

InactiveUS20160061123A1Suppress occurrenceInhibitionValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

Provided is a control device for an internal combustion engine, which is capable of suppressing occurrence of knocking due to pre-ignition and occurrence of misfire even when an operating state in a previous cycle changes in a subsequent cycle. When a ratio of change in heat of air-fuel mixture, which is an index indicating how a heat of air-fuel mixture in the previous cycle changes in the subsequent cycle, does not fall within an allowable range, a variable valve control mechanism capable of changing a valve-closing timing of an exhaust valve for adjusting an internal EGR gas amount is controlled by using an optimum value of exhaust valve close (EVC) timing derived by correcting a set valve-closing timing of the exhaust valve so that the ratio of change in heat of air-fuel mixture falls within the allowable range.

Owner:MITSUBISHI ELECTRIC CORP

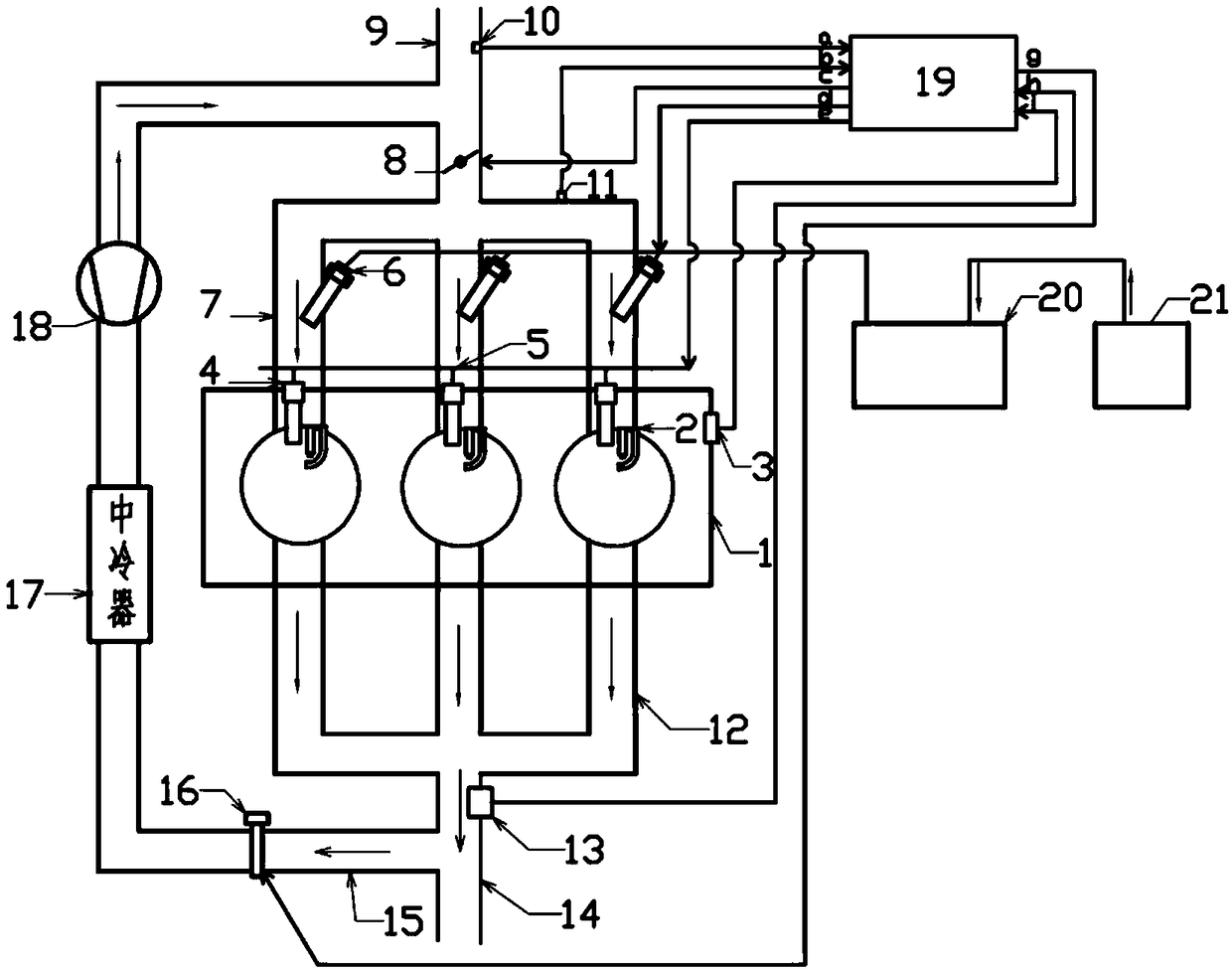

Natural gas engine structure for mixed double-injection of cylinder outer cold water and in-cylinder hot water

InactiveCN108049987AImprove powerImprove economyInternal combustion piston enginesNon-fuel substance addition to fuelElectronic controllerHigh pressure water

The invention relates to a natural gas engine structure for mixed double-injection of cylinder outer cold water and in-cylinder hot water. The natural gas engine structure comprises a natural gas engine body, an air inlet manifold, an exhaust manifold, a natural gas injector, a spark plug, an in-cylinder water sprayer, a high-pressure water pump unit, a cylinder outer water sprayer, a low-pressurewater pump unit, a heat exchanger and a electronic controller; and the in-cylinder water sprayer is arranged in the natural gas engine body, the high-pressure water pump unit communicates with the in-cylinder water sprayer, the cylinder outer water sprayer is arranged in the air inlet manifold, the low-pressure water pump unit communicates with the cylinder outer water sprayer and the electroniccontroller is electrically connected with the natural gas injector, the spark plug, the in-cylinder water sprayer, the high-pressure water pump unit, the cylinder outer water sprayer and the low-pressure water pump unit. Compared with the prior art, the natural gas engine structure has the advantages that hot water sprayed in a cylinder is used for rapidly vaporizing to absorb heat, so that the temperature in the part, close to a combustion top dead center, of the cylinder is reduced, and the generation of knocking is inhibited; meanwhile, the heat for heating the water comes from recovering tail gas energy by a exchanger, so that the working medium in the combustion process is increased, the heat loss is reduced, and the heat efficiency of the natural gas engine is improved.

Owner:TONGJI UNIV

Control device for an internal combustion engine

InactiveUS9650972B2InhibitionKnock suppressionValve arrangementsElectrical controlExhaust valveExternal combustion engine

Provided is a control device for an internal combustion engine, which is capable of suppressing occurrence of knocking due to pre-ignition and occurrence of misfire even when an operating state in a previous cycle changes in a subsequent cycle. When a ratio of change in heat of air-fuel mixture, which is an index indicating how a heat of air-fuel mixture in the previous cycle changes in the subsequent cycle, does not fall within an allowable range, a variable valve control mechanism capable of changing a valve-closing timing of an exhaust valve for adjusting an internal EGR gas amount is controlled by using an optimum value of exhaust valve close (EVC) timing derived by correcting a set valve-closing timing of the exhaust valve so that the ratio of change in heat of air-fuel mixture falls within the allowable range.

Owner:MITSUBISHI ELECTRIC CORP

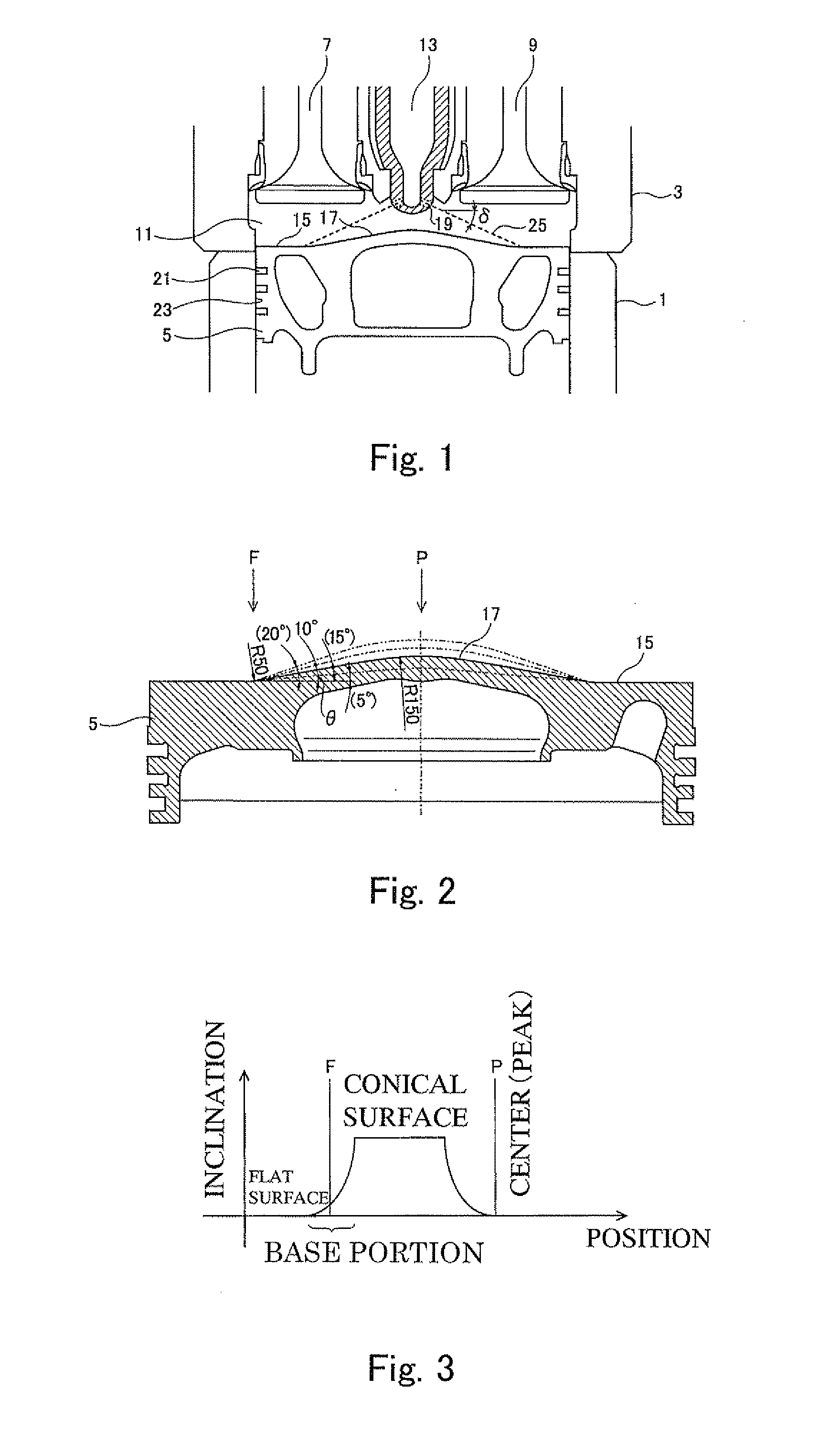

Combustion chamber for large gas engine

ActiveUS20130019837A1Reduce the amount requiredKnock suppressionInternal combustion piston enginesPlungersTop dead centerCombustion chamber

Provided is a combustion chamber applied in a gas engine including: a main combustion chamber including, at a central portion of its ceiling, an auxiliary combustion chamber; and a piston. A peripheral portion of a top surface of the piston is a flat surface. A raised portion, which has a curved surface and which is a solid of revolution, is formed at a central portion of the top surface, the raised portion being joined to the flat surface of the peripheral portion via a curved surface. When the piston is positioned at a top dead center, nozzle holes of the auxiliary combustion chamber jet out flame jets to a portion at which the raised portion of the top surface of the piston and the flat surface of the peripheral portion of the top surface of the piston are joined together.

Owner:KAWASAKI HEAVY IND LTD

Dual injection type internal combustion engine

InactiveUS20080208439A1Knock suppressionAccurate background learningAnalogue computers for vehiclesElectrical controlDual injectionEngineering

A dual injection type internal combustion engine including an injector for in-cylinder injection and an injector for intake manifold injection includes a learning device for learning a background noise level based on an output signal of a knock sensor, and a knocking suppression control device for performing, while learning the background noise level, knocking suppression control by controlling fuel injection of the injector for in-cylinder injection or the injector for intake manifold injection. Alternatively, the engine includes a fixing device for fixing, while learning the background noise level, a start timing or end timing of fuel injection by the injector for in-cylinder injection at a basic timing determined by an operating state of the engine.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com