Ethyl alcohol reforming system and control method for improving dynamic performance of natural gas engine

A dynamic performance, natural gas technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of hydrogen storage, transportation difficulties, increase the overall cost, complex device system structure and control process, etc., to achieve the suppression of knocking and Misfire phenomenon, increase in air supply, and effects of reducing the possibility of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

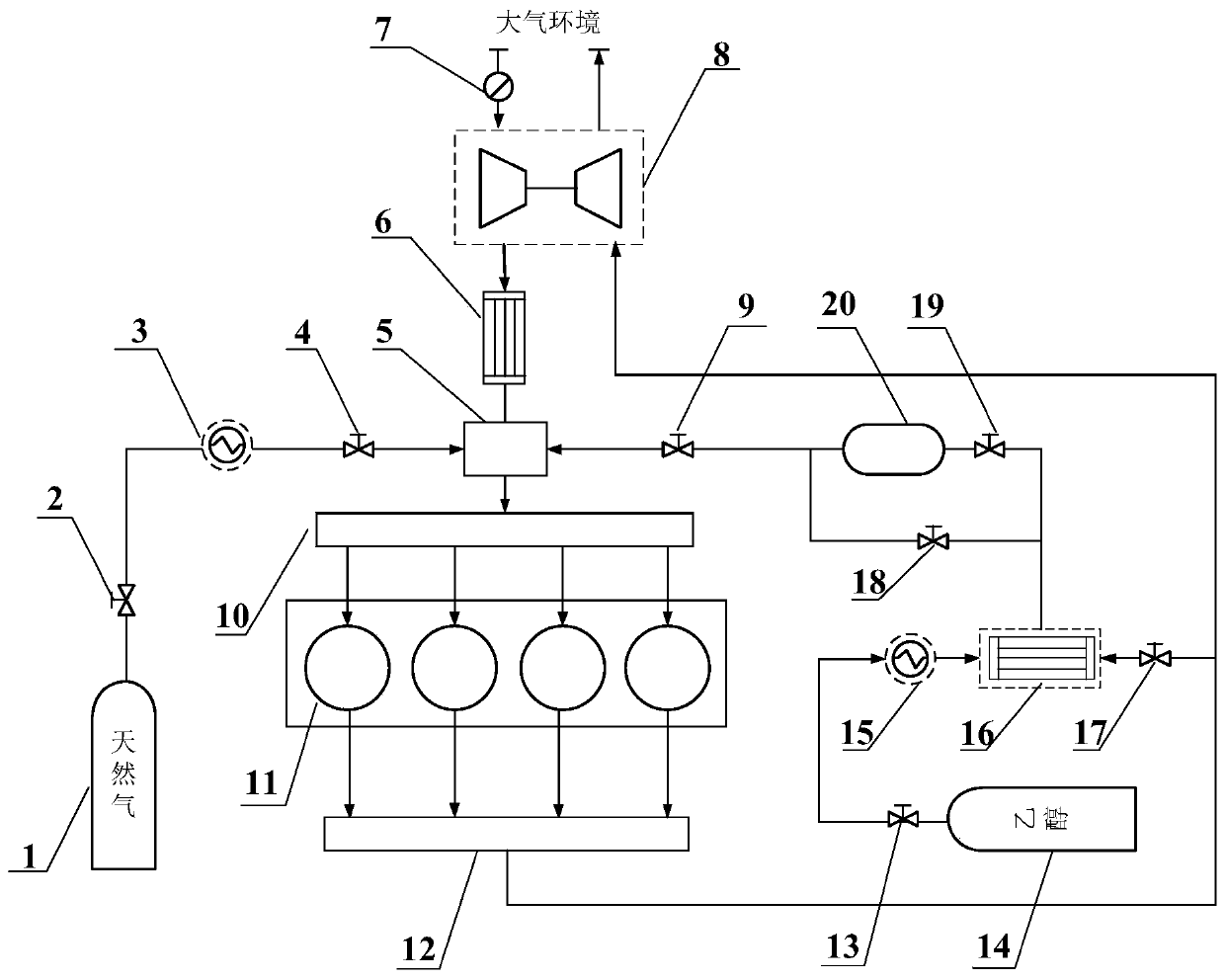

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] combine figure 1 , the present invention improves the dynamic performance of natural gas engine ethanol reforming system and control method, comprising: LNG storage tank 1, liquefied natural gas flow valve 2, LNG vaporizer 3, gaseous natural gas flow valve 4, mixer 5, intercooler 6, throttle Valve 7, turbocharger 8, gas flow valve 9, intake pipe 10, cylinder 11, exhaust pipe 12, ethanol storage tank 14, liquid ethanol flow valve 13, ethanol vaporizer 15, ethanol reformer 16, waste gas bypass Valve 17, buffer gas tank 20, etc.

[0021] A liquid flow valve 13 is arranged between the ethanol storage tank 14 and the ethanol vaporizer 15 to control the flow of liquid ethanol entering the ethanol reformer 16 .

[0022] The heat source for the ethanol reformer 16 is provided by the combustion exhaust gas discharged from the cylinder 11 . When the natural gas en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com