Patents

Literature

70results about How to "High energy recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing beta-glucosidase fixed with magnetic nano-particle

InactiveCN101270352AEasy to operateLow costOn/in organic carrierBeta-glucosidaseMagnetite Nanoparticles

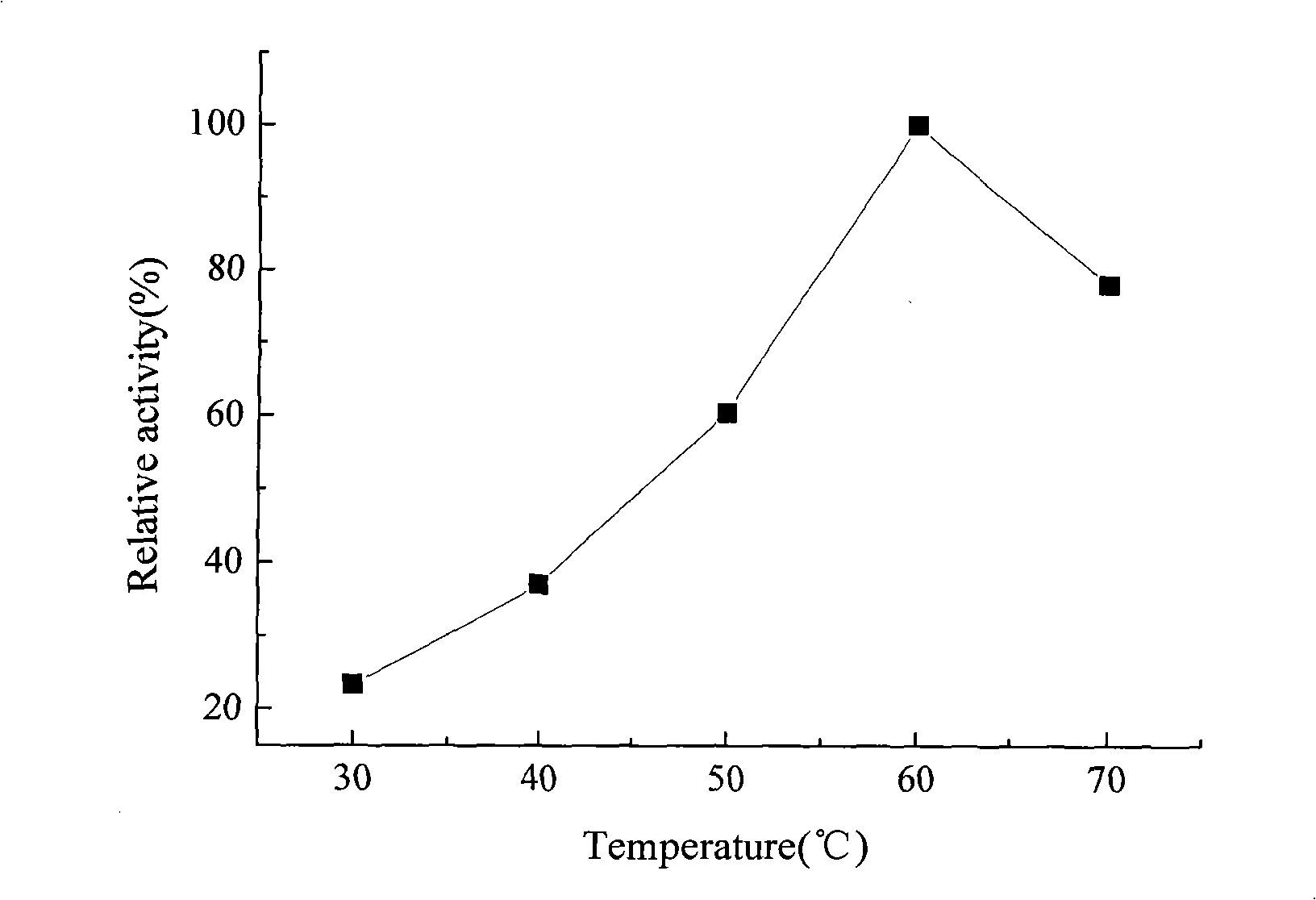

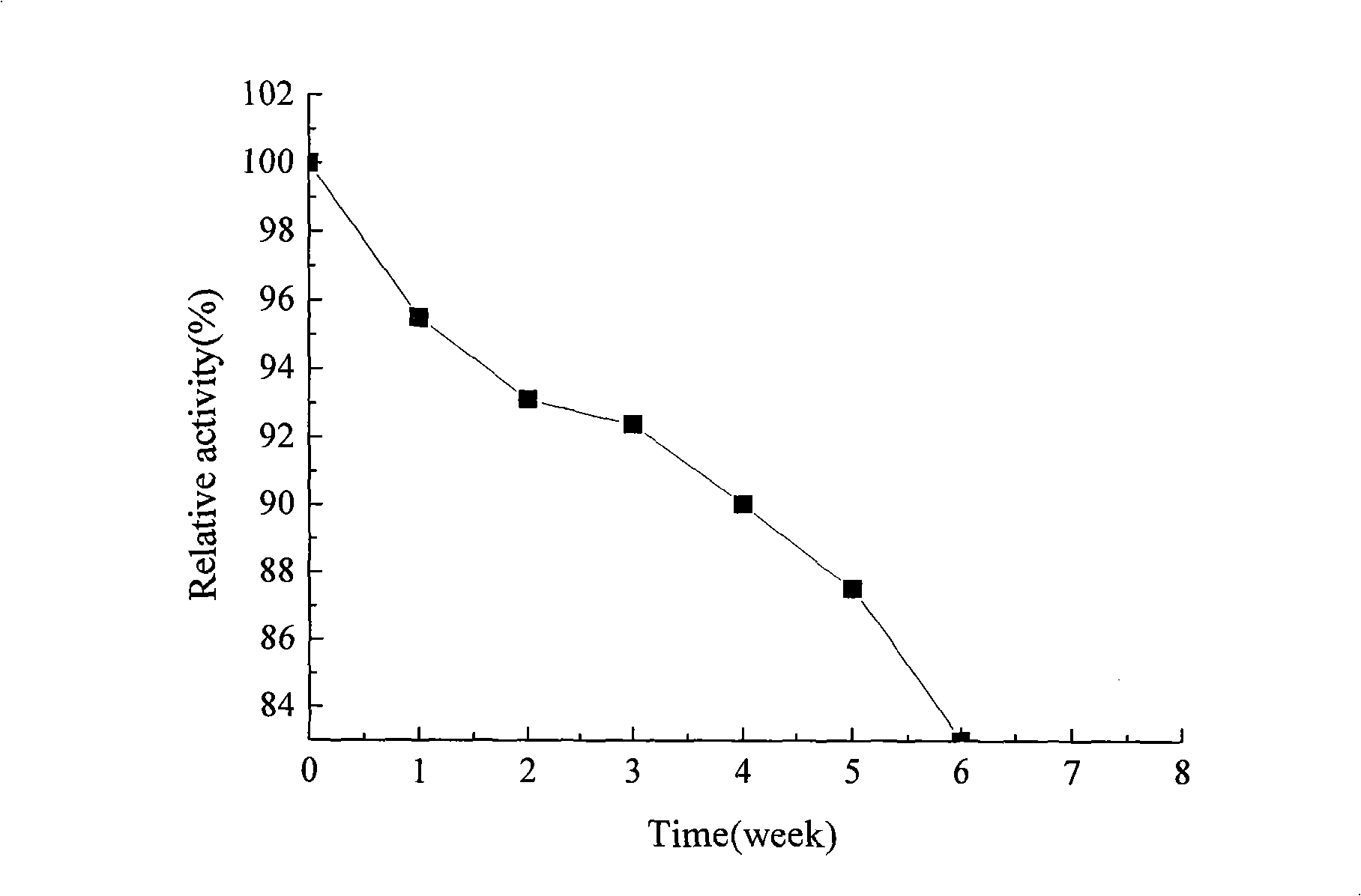

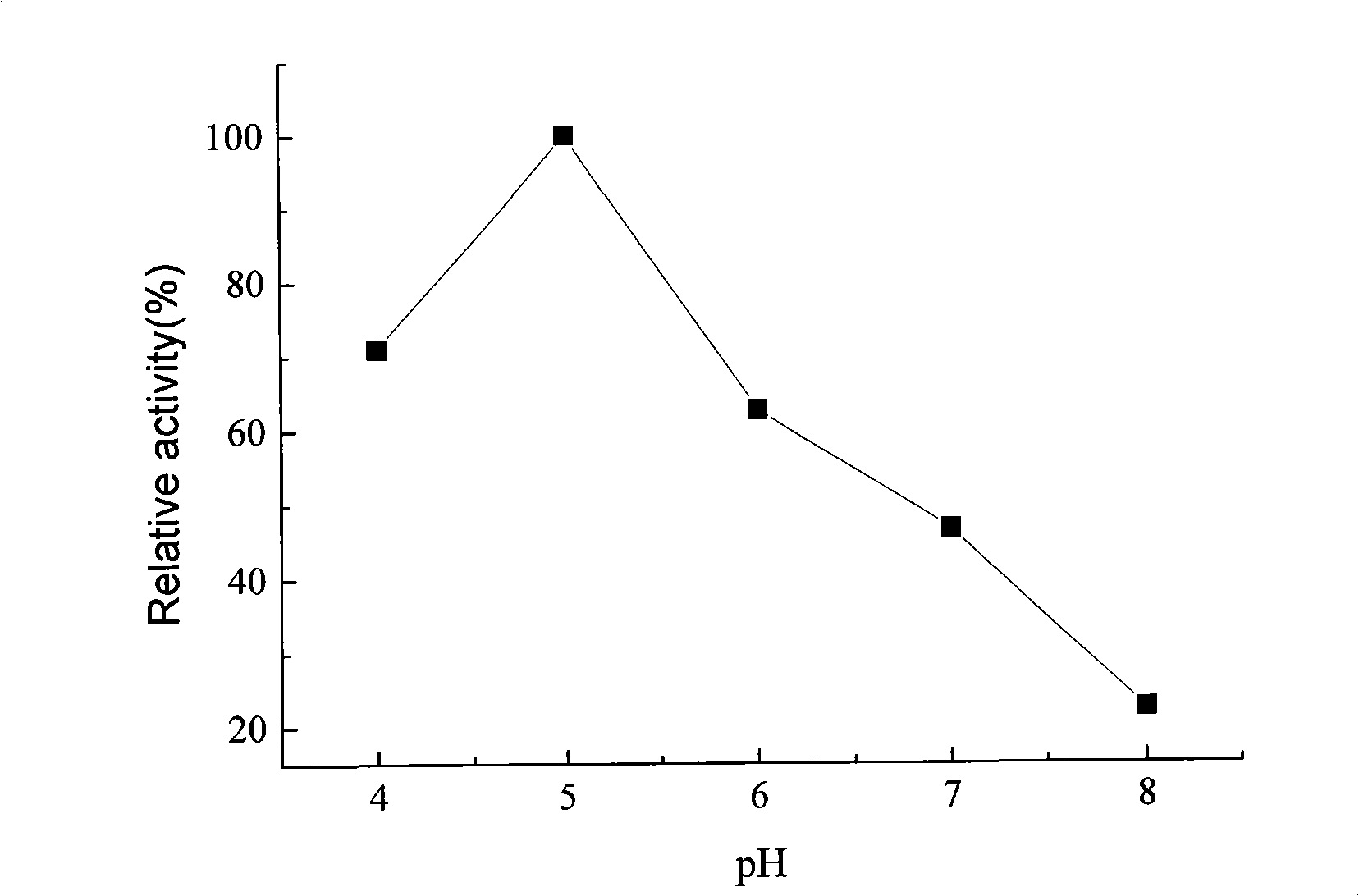

The invention relates to a preparation method for magnetic nanoparticle fixed Beta-glucosaccharase, which comprises the steps that (1) precipitation reaction occurs between chloride solution of Fe<2+> and Fe<3+> and NaOH solution to prepare Fe3O4 particles; (2) chitosan is dissolved in acetum to form homogeneous transparent colloidal solution, and Fe3O4 particles are mixed with the homogeneous transparent colloidal solution, and the mixture is beaten, thus getting magnetic nanoparticles; (3) the magnetic nanoparticles are added to Beta-glucosaccharase solution, thus getting chitosan magnetic nanoparticle immobilized enzyme through absorption and cross linkage of glutaric dialdehyde solution; (4) citric acid buffer solution is added to immobilized Beta-glucosaccharase and free Beta-glucosaccharase solution, respectively, and reaction occurs after the temperature is adjusted; and the enzyme activity is examined. The method is quick, simple, convenient and is low in cost. The product got has the characteristics of uniform shape, large specific area, high coefficient of recovery of enzyme activity and so on.

Owner:DONGHUA UNIV

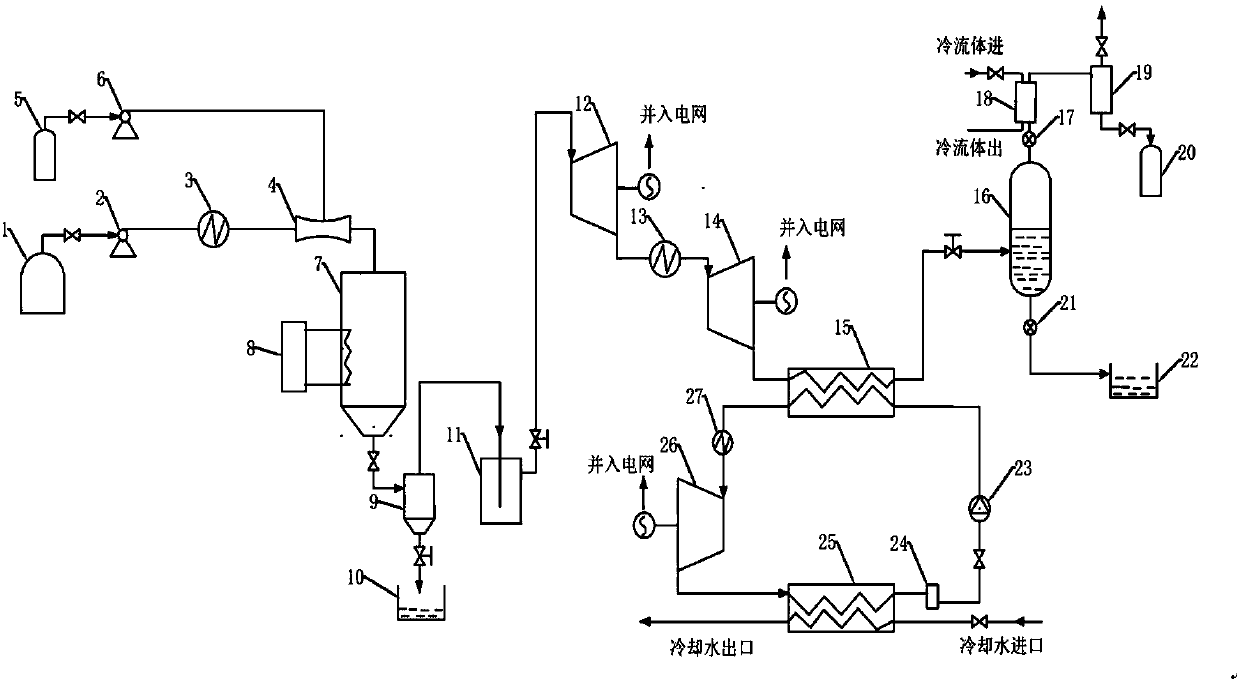

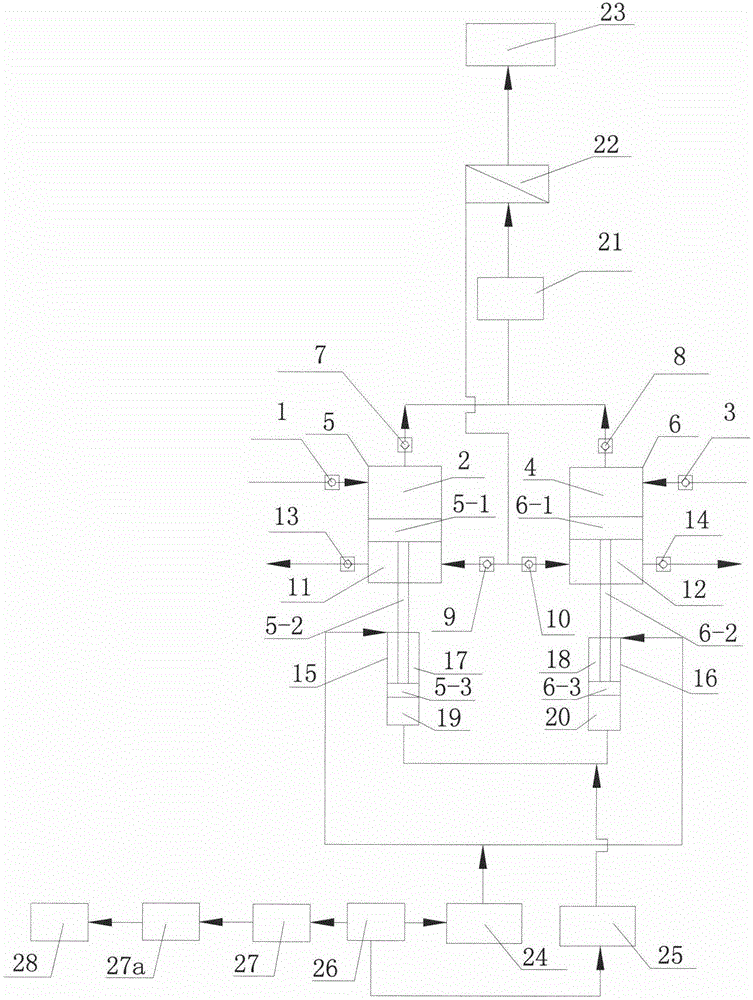

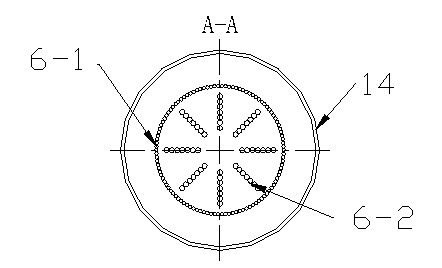

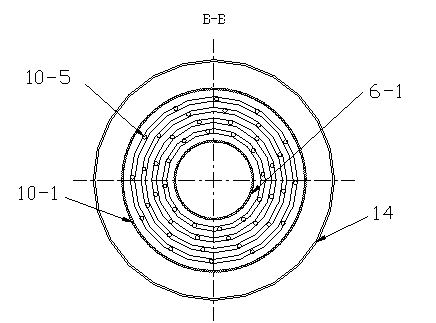

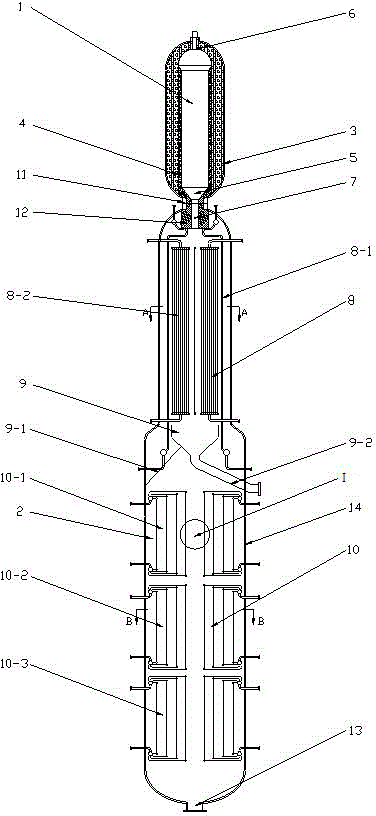

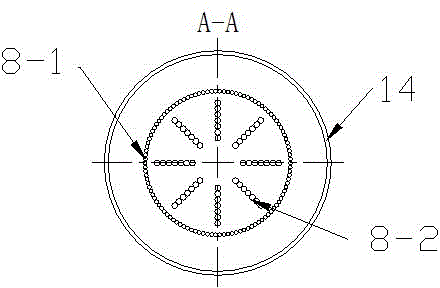

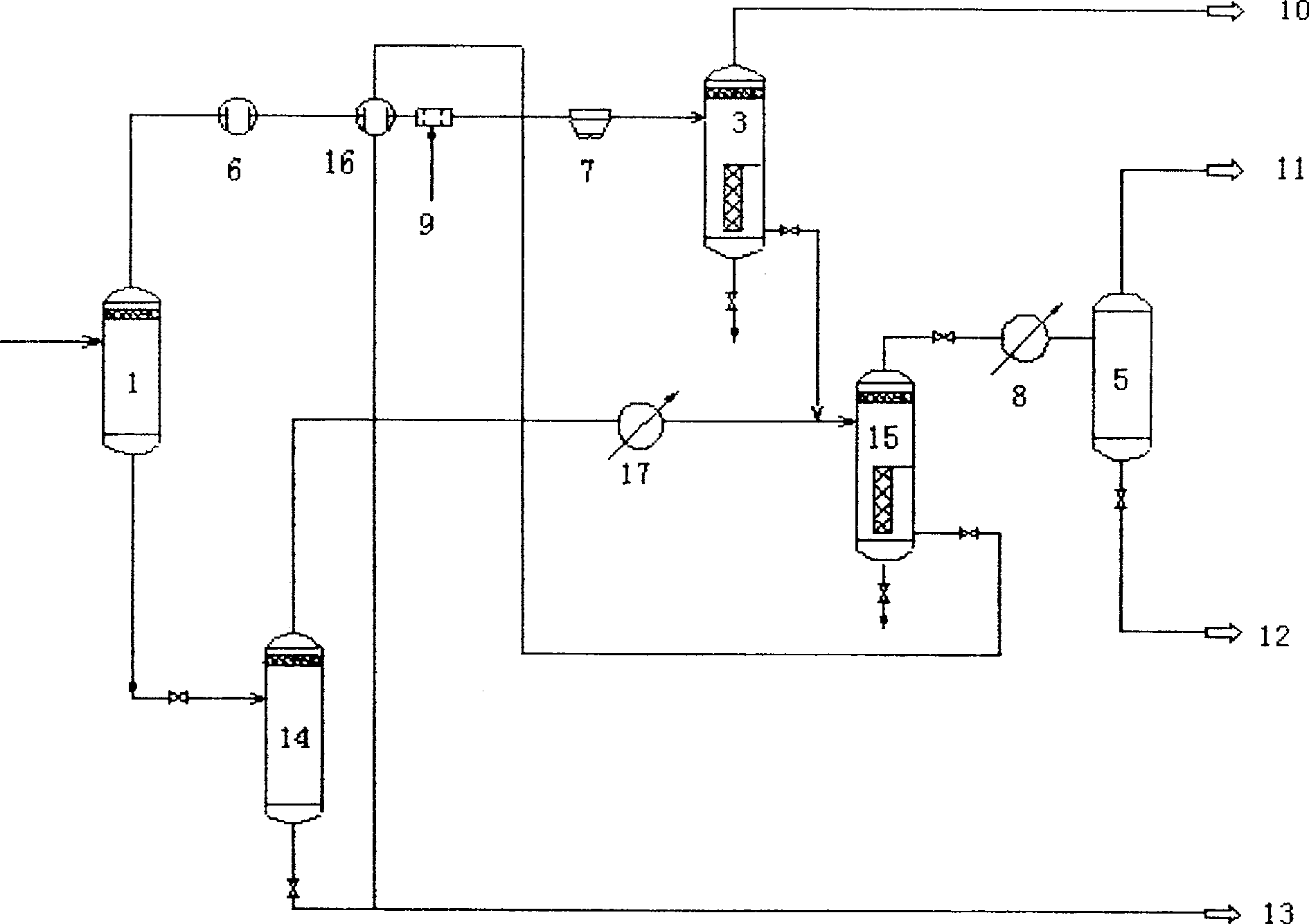

Supercritical-water-oxidation energy recovery system

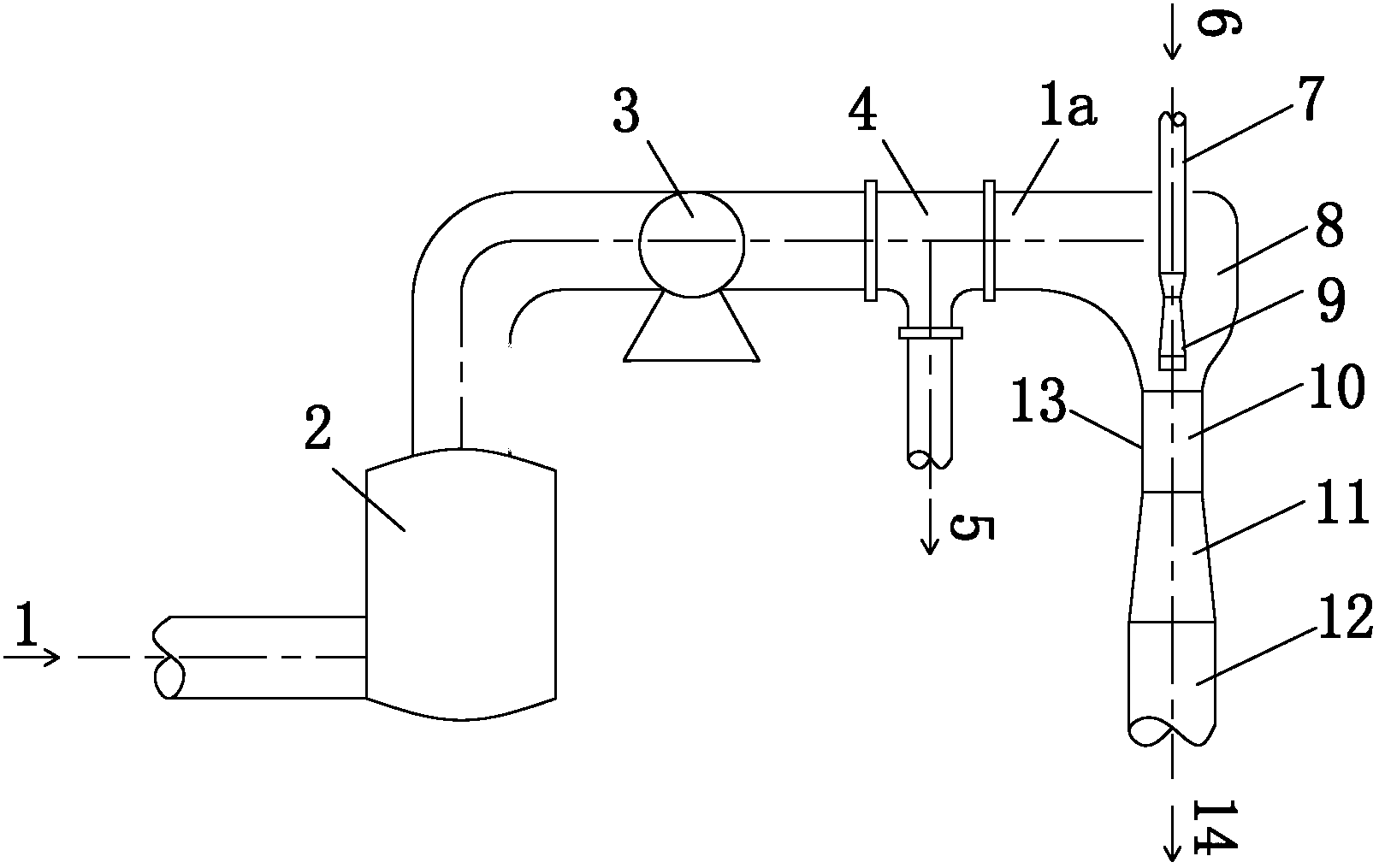

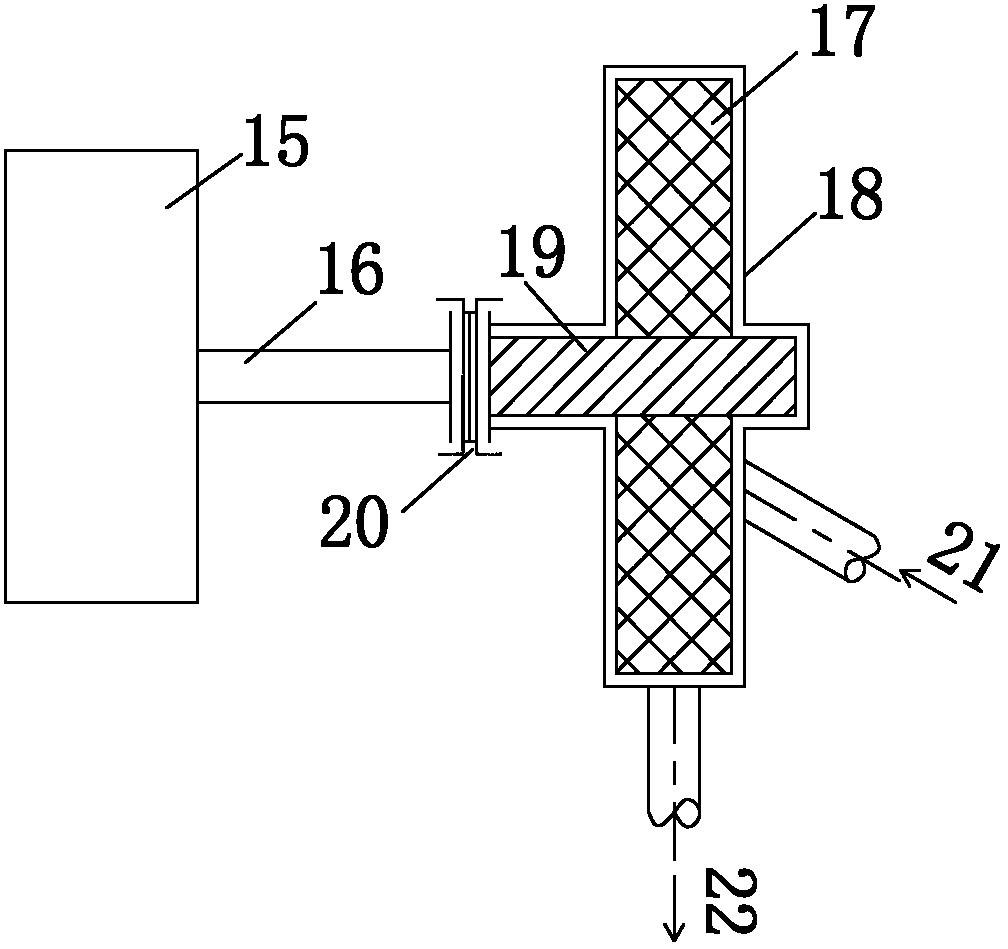

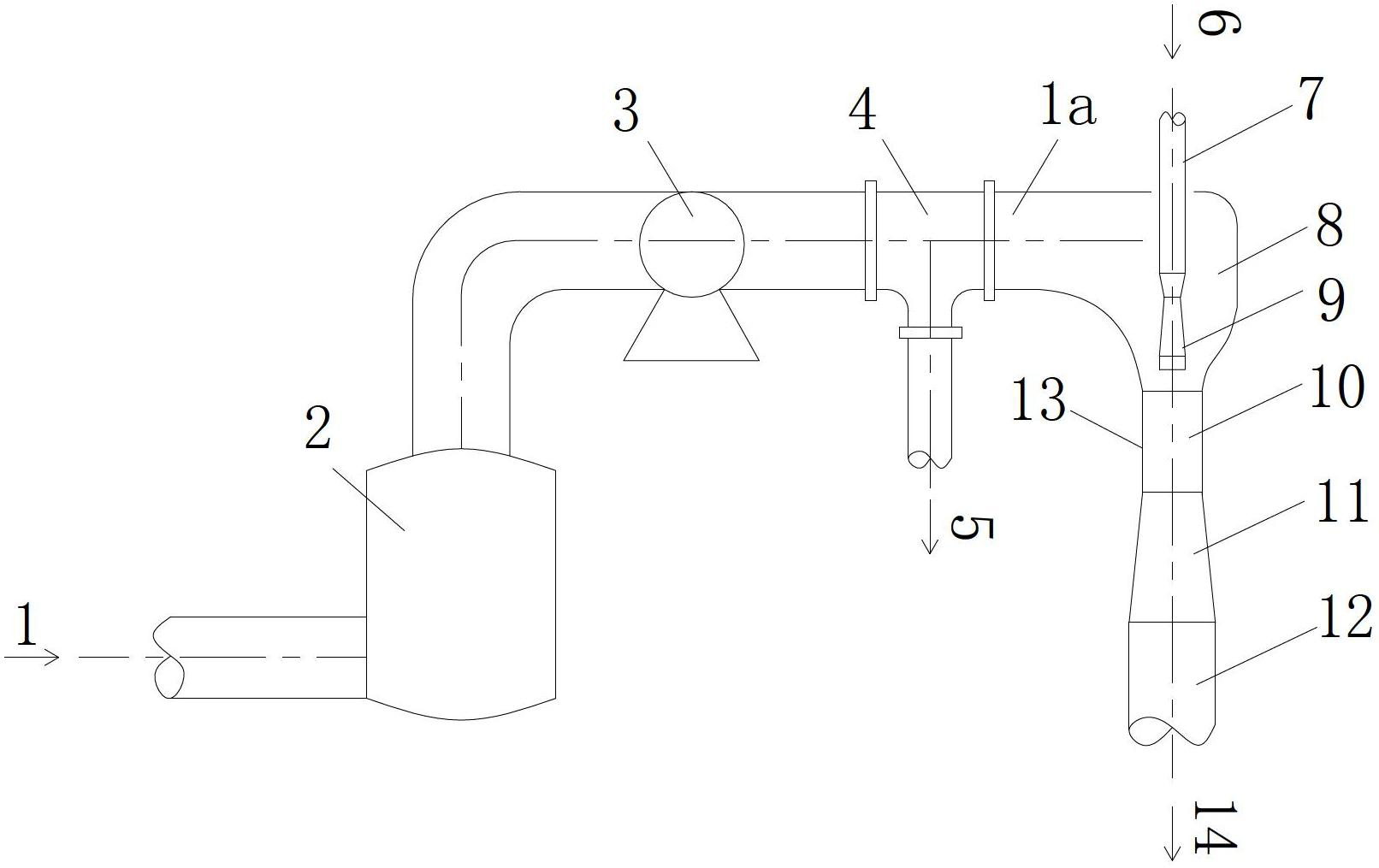

PendingCN107935287AEmission reductionReduce energy inputWater/sewage treatment by centrifugal separationWater treatment parameter controlInorganic saltsSewage outfall

The invention discloses a supercritical-water-oxidation energy recovery system. The supercritical-water-oxidation energy recovery system disclosed by the invention has the beneficial effects that theoutlet end of a supercritical water oxidation reactor is connected with a high-pressure hydrocyclone, inorganic salts in reaction products in the supercritical water oxidation reactor are discharged from a sewage discharging port, high-pressure and high-pressure gas generated is exhausted into a buffering tank to carry out flat-pressing treatment, then the flatly-pressed gas passes through a high-pressure turboexpander and a low-pressure turboexpander in sequence to carry out residual-heat utilization for generating power, an outlet of the low-pressure turboexpander is connected with an evaporator, a Rankine circulation system is connected on the evaporator and is utilized for further utilizing residual heat of fluid passing through the evaporator, so that the energy input of the Rankine circulation system is reduced; the supercritical water oxidation system and a residual-heat and residual-pressure recovery system are fully combined, and heat energy and pressure energy of supercritical water oxidation products are fully utilized, so that the energy recovery and utilization rate of the supercritical water oxidation system is increased; carbon dioxide in the products is separated and recovered by utilizing a gas-liquid separator and a rectifying tower, so that the emission of greenhouse gas is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

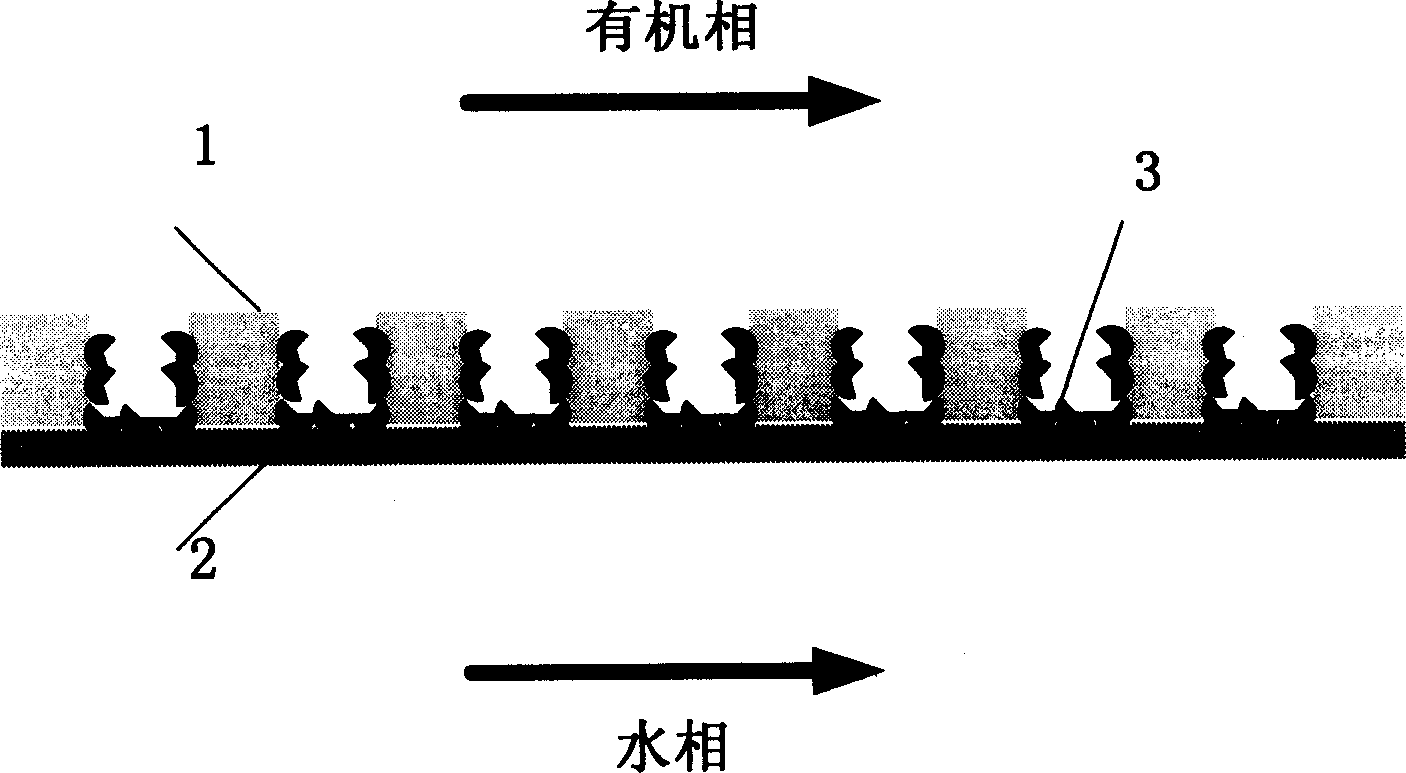

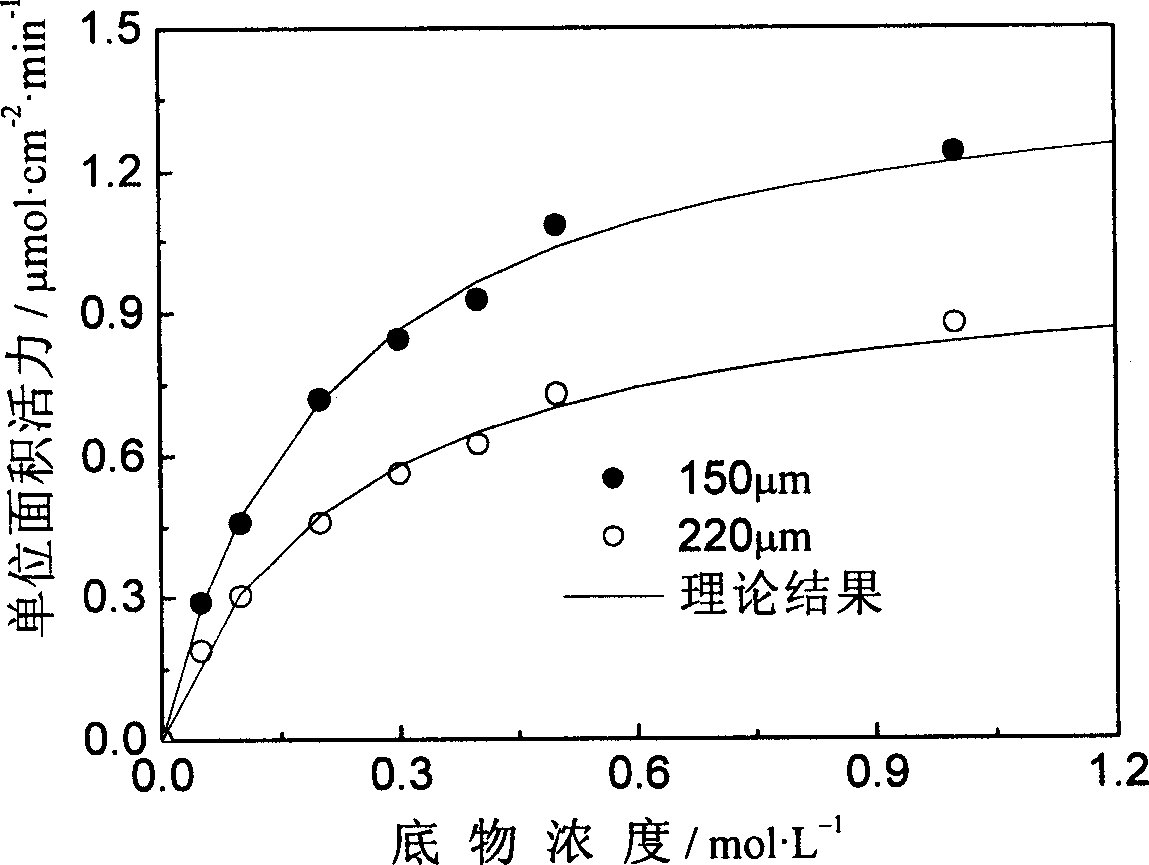

Method for immobilizing lipase using microstructure in hydrophilic/ hydrophobic composite membrane

The invention relates to a method of microstructure fixation lipase in the filed of enzyme fixation of biology projection. It dissolves hydrophilic film material acetate fiber into dimethyl form amide to prepare for hydrophilic film solution, it lays water repellency politef film on the glass plate, it spread coats hydrophilic film solution on its surface and uses dry-wet changing method to obtain the compensate film which is formed by fine and close hydrophilic layer and porous bleed layer, it uses filtering method and microstructure to achieve enzyme fixation.

Owner:TSINGHUA UNIV

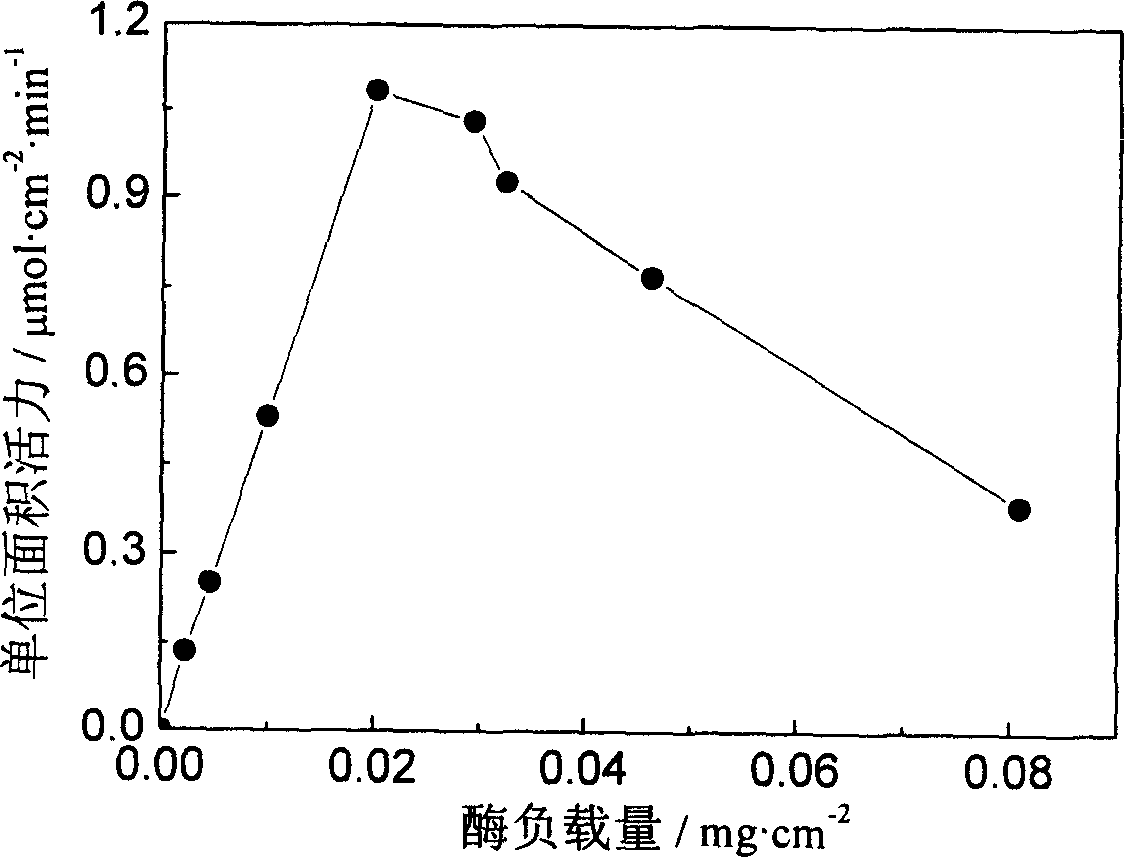

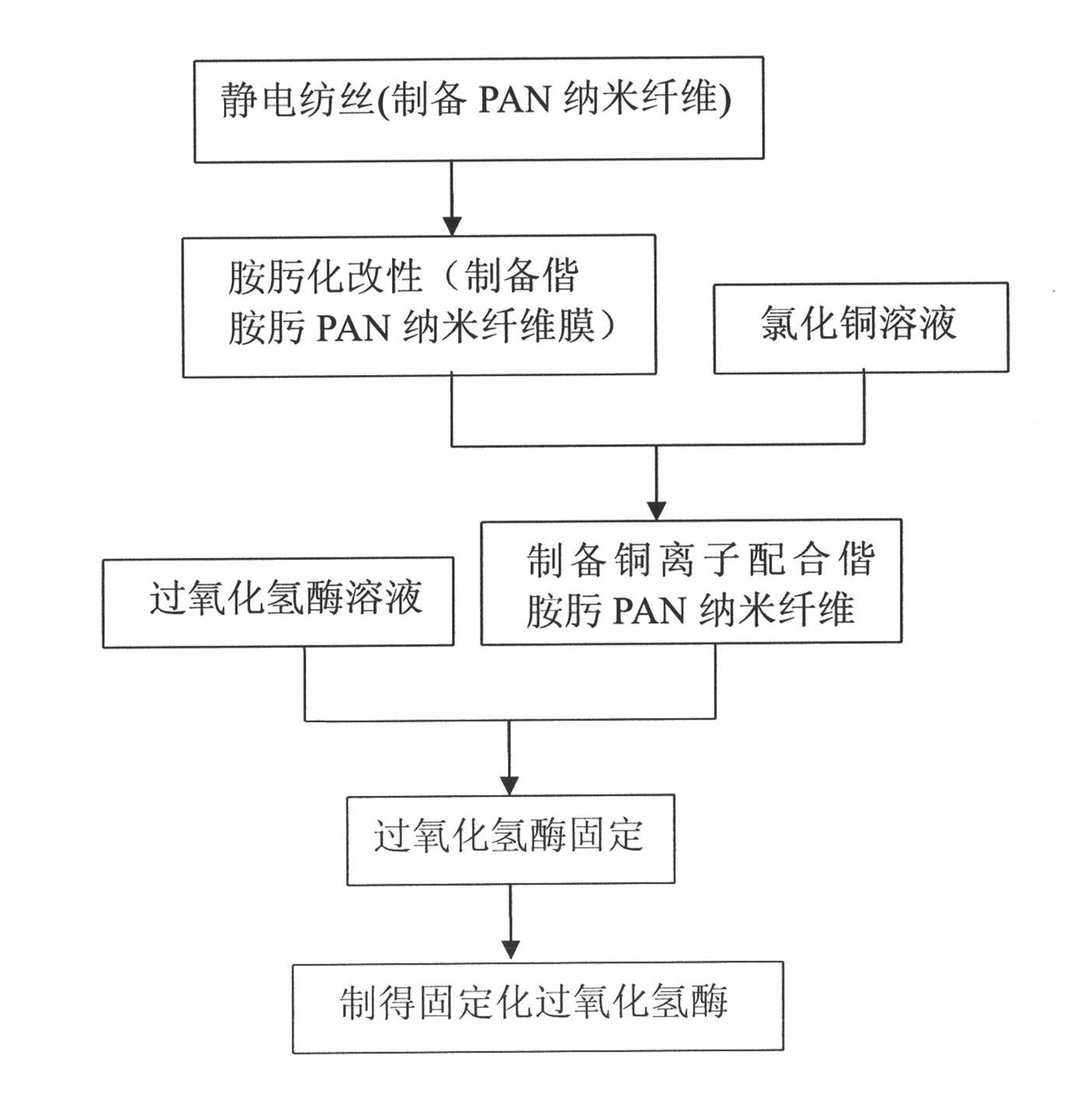

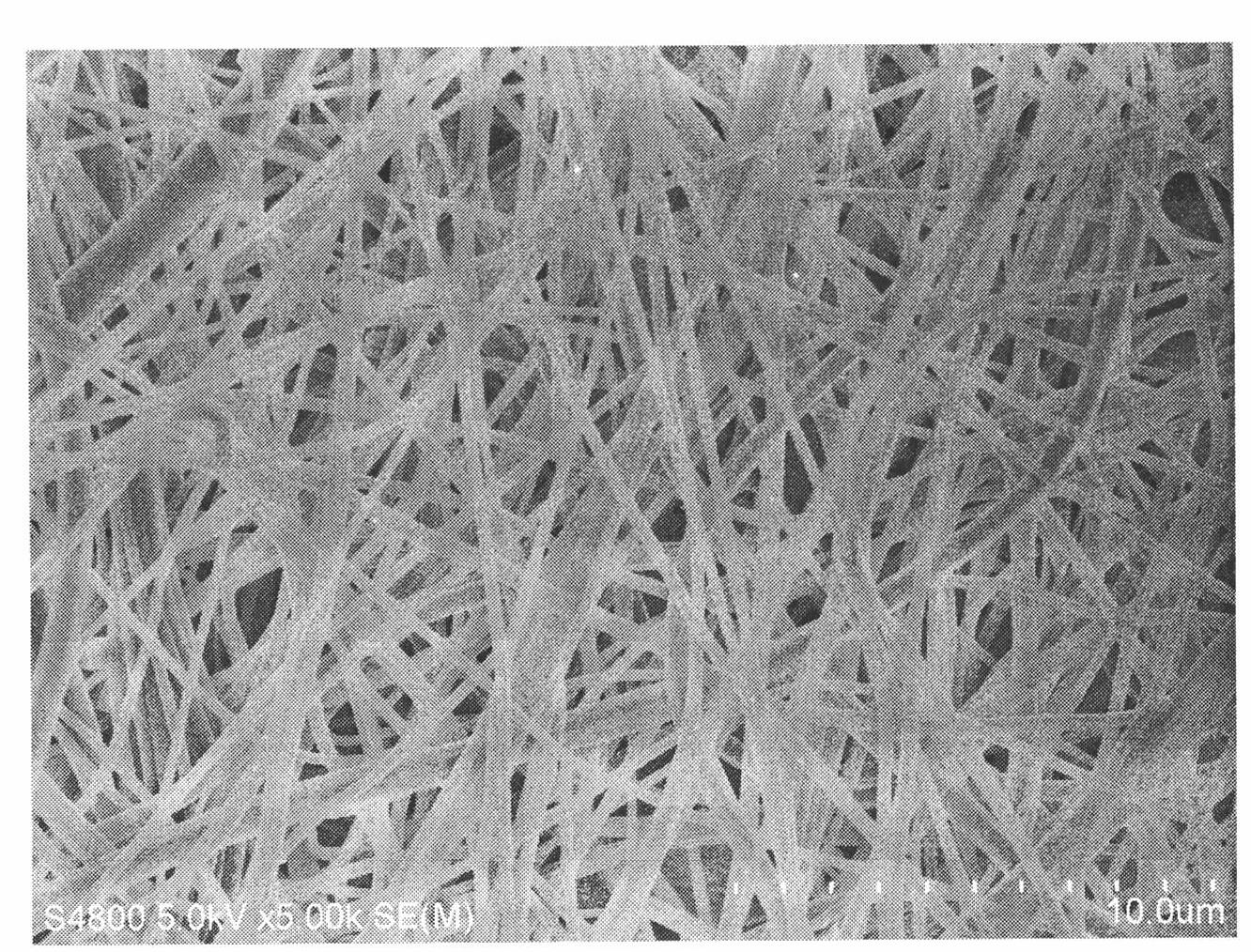

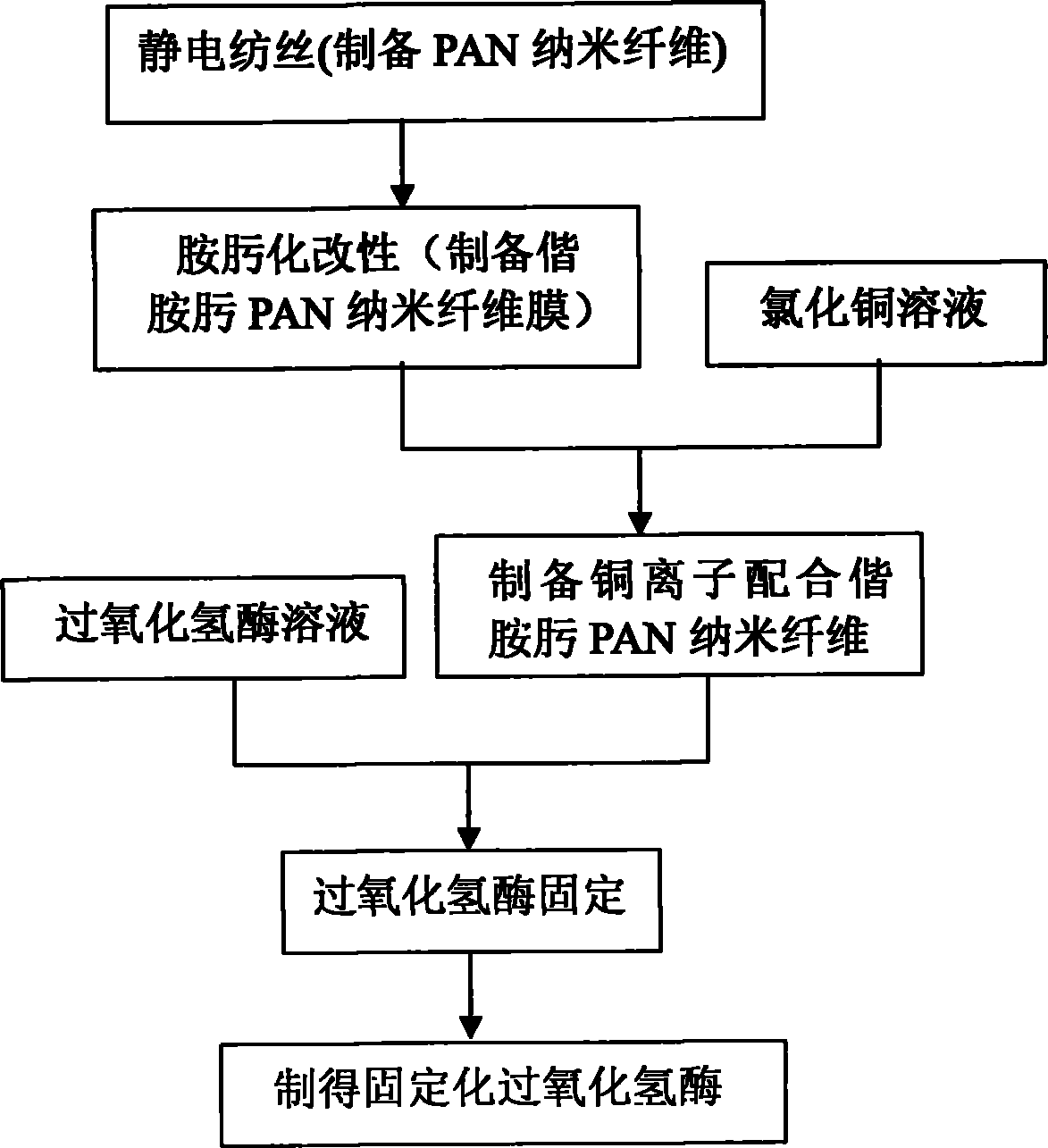

Catalase immobilization method on basis of using amidoxime PAN nanofibrous membrane as carrier

A catalase immobilization method on the basis of using an amidoxime PAN nanofibrous membrane as carrier relates to the technical fields of nanofibrous membrane preparation utilizing electrostatic spinning technology, PAN functional modification and enzyme immobilization. The method comprises the following steps: the electrostatic spinning technology is utilized to obtain a PAN nanofibrous membrane, amidoximation modification is performed to the nanofibrous membrane to obtain the amidoxime PAN nanofibrous membrane with stable morphology, high porosity and strong load capacity and biocompatibility, then Cu<2+> is used as centre body, and catalase is immobilized on the amidoxime PAN nanofibrous membrane through coordinate bond. Compared with the conventional catalase immobilization method, the method of the invention solves the defects of catalase immobilization that the recovery rate of enzyme activity is low, the storage instability is low and the reusability is unstable. The immobilized catalase on the basis of using the amidoxime PAN nanofibrous membrane as carrier can be used in various fields such as biosensor preparation, membrane bioreactor and environmentally friendly material.

Owner:JIANGNAN UNIV

Method for refining raw oil by using magnetic immobilized phospholipase A1

InactiveCN102559378AResponsiveness to strong magnetic fieldsQuick and Easy EnrichmentFatty-oils/fats refiningPhospholipase ACitric acid

The invention provides a method for refining raw oil by using magnetic immobilized phospholipase A1, which relates to a method for refining raw oil by using immobilized phospholipase A1. The invention aims to solve the problems that the separation and the recovery of an immobilized enzyme are complicated, the activity recovering rate is low and a magnetic immobilized enzyme is not used for refining raw oil at present, which exist in a traditional method for preparing immobilized phospholipase A1. The method for preparing and refining the raw oil comprises the following steps of: (1) preparingthe magnetic immobilized phospholipase A1; (2) heating the raw oil and adding a citric acid solution; and (3) cooling, regulating the pH value, then adding the magnetic immobilized phospholipase A1, stirring and separating the magnetic immobilized phospholipase A1 so as to finish the preparation method of the magnetic immobilized phospholipase A1 and the method for refining the raw oil. The recovering rate of the magnetic immobilized phospholipase A1 prepared by the method for refining the raw oil by using the magnetic immobilized phospholipase A1 reaches more than 85 percent, so that the phosphorus content of the raw oil is lowered to 7-10mg / kg. The method for refining the raw oil by using the magnetic immobilized phospholipase A1 is applied to the field of degumming of grease.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

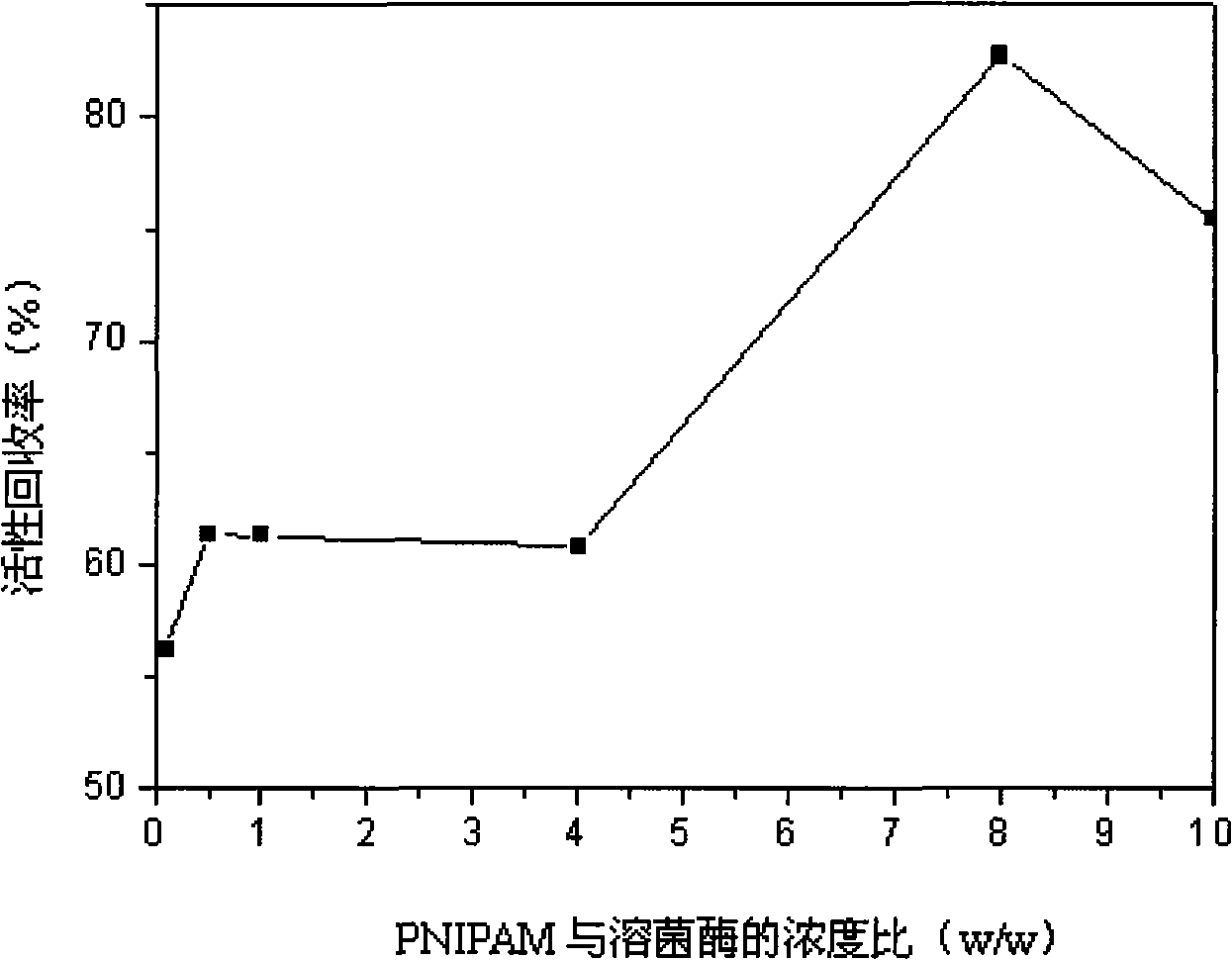

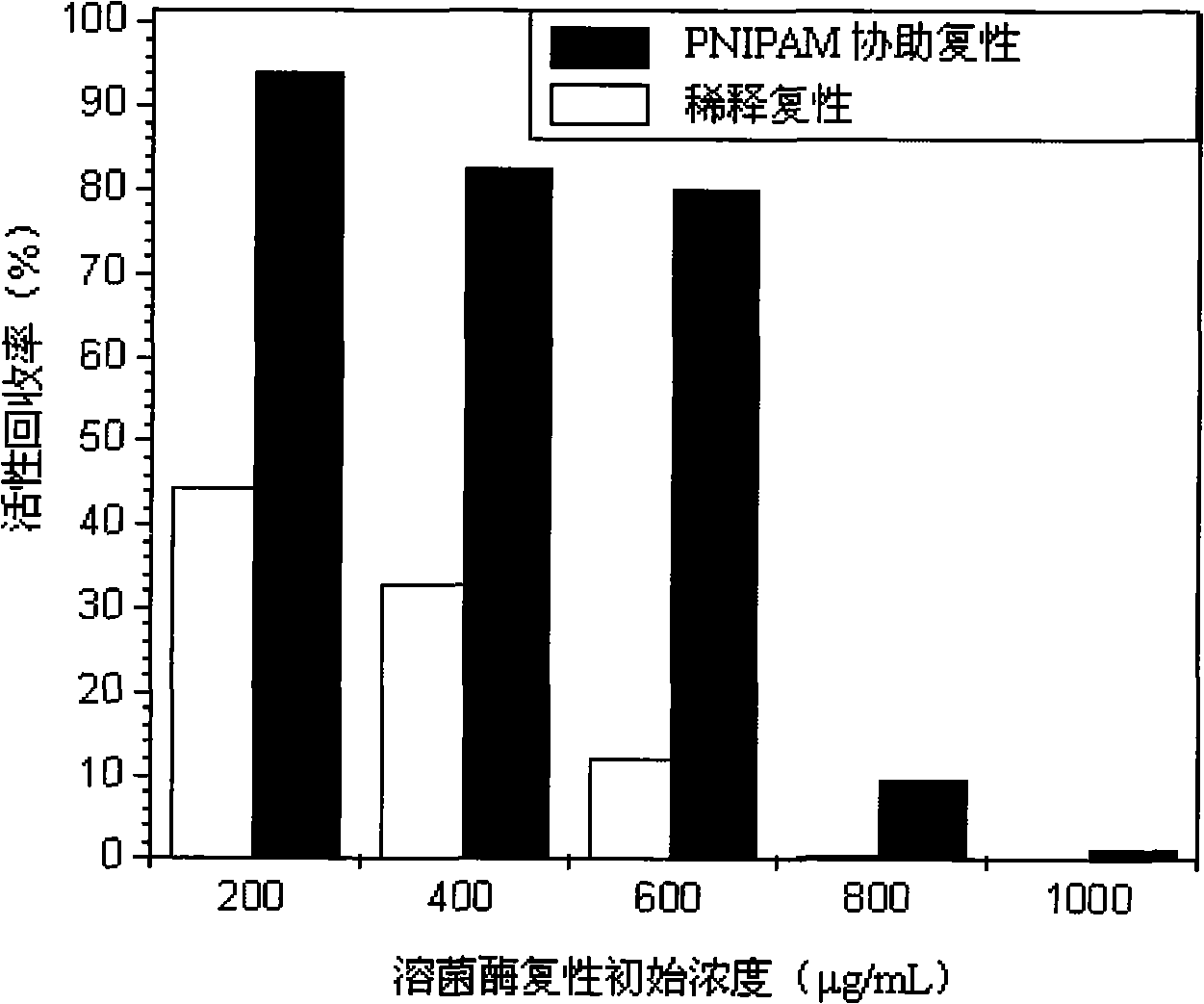

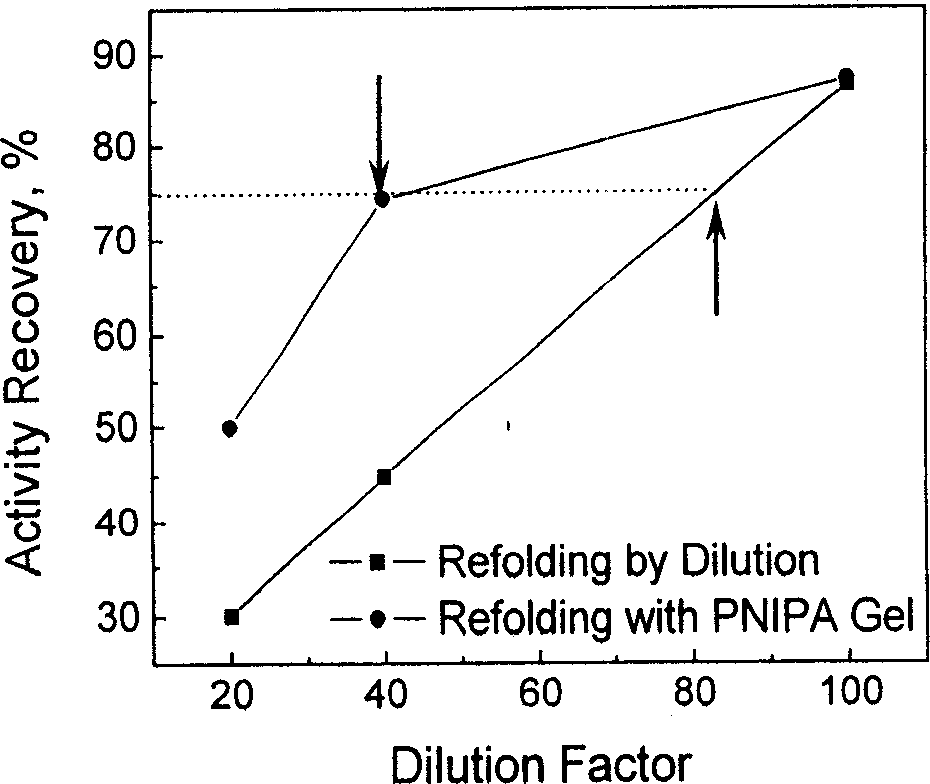

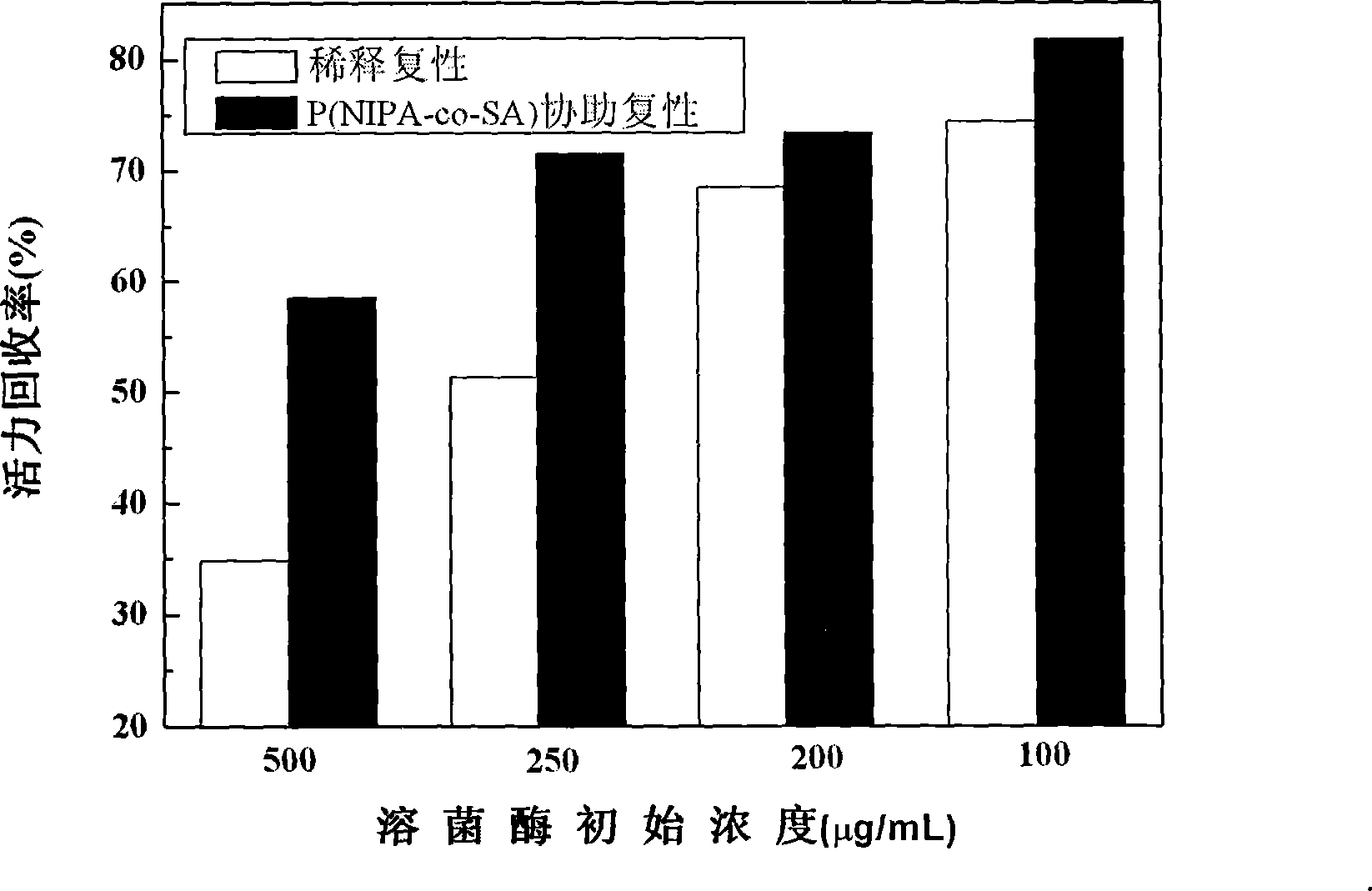

Method for assisting lysozyme in vitro refolding by means of linear poly N-isopropyl acrylamide

The invention discloses a method adopting linear poly N-isopropyl acrylamide adhesive to assist the renaturation of muramidase in vitro, comprising the following steps that: 1) the linear N-isopropyl acrylamide is prepared by a free radical polymerization method; 2) the linear poly N-isopropyl acrylamide is used to assist the renaturation of muramidase in vitro. The linear poly N-isopropyl acrylamide is taken as a novel protein in vitro additive which can increase the processing concentration of the renaturation muramidase, lower the production cost, and improve the activity recovery rate of the muramidase up to about 80 percent when the processing concentration is 600 Mug / mL; while the activity recovery rate of the dilution renaturation on the same condition is only 10 percent. The gel has the advantages of high efficiency, convenient operation and simple technique, etc., thereby having good potential application in the protein in vitro renaturation field.

Owner:ZHEJIANG UNIV

Method for preparing immobilized adenosylmethionine synthetase and adenosylmethionine

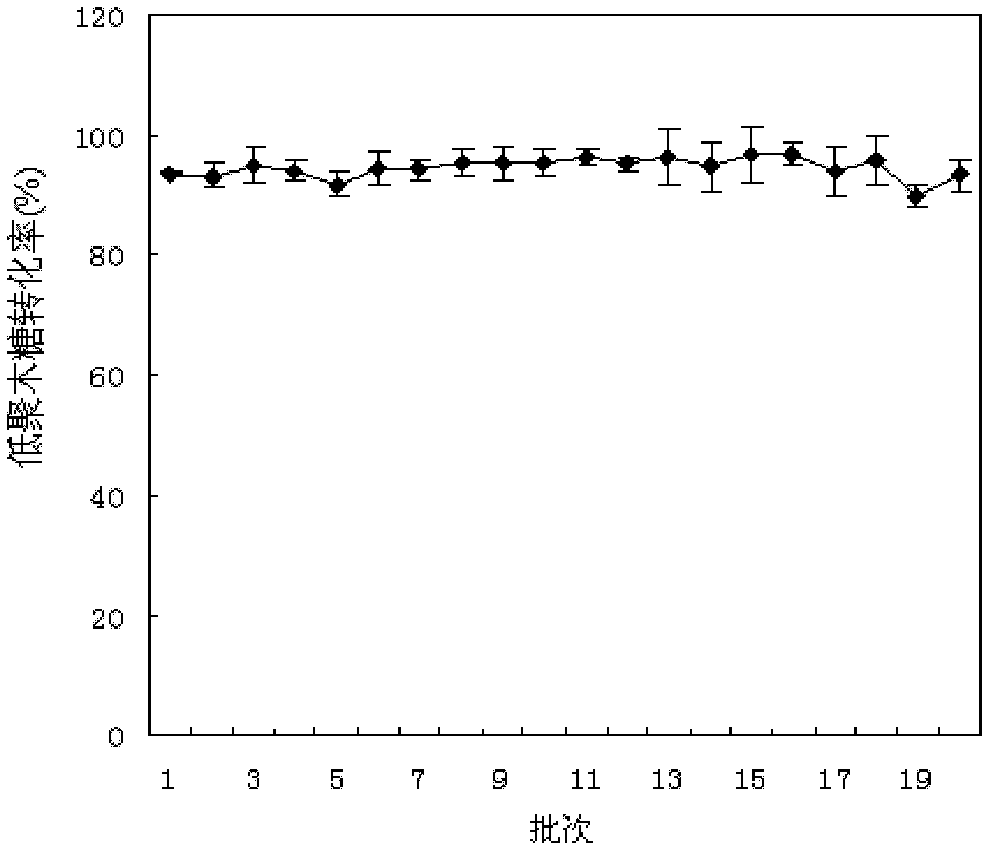

InactiveCN101985616AHigh recovery rate of enzyme activityExcellent continuous operation performanceChemical industryOn/in organic carrierS-Adenosyl-l-methionineImmobilized enzyme

The invention relates to a method for preparing immobilized adenosylmethionine synthetase and adenosylmethionine. The method has the following technical characteristics of: crosslinking amino resin carrier Seplite LX-1000HA and glutaraldehyde solution; and reacting the amino resin carrier crosslinked with glutaraldehyde with solution of recombinant adenosylmethionine synthetase to obtain the immobilized adenosylmethionine synthetase. The amino resin carrier has high protein fixation rate, the recovery rate of the enzyme activity of the immobilized adenosylmethionine synthetase is high, and the stability and continuous operation performance are good. When the immobilized adenosylmethionine synthetase is used for producing the adenosylmethionine, the reaction operation is simple, the production cycle is short, and products are easy to purify; the immobilized enzyme can be recycled, the production cost is greatly reduced, the production efficiency is improved, and a new way is provided for industrialized production of the adenosylmethionine.

Owner:江苏中丽新材料有限公司 +1

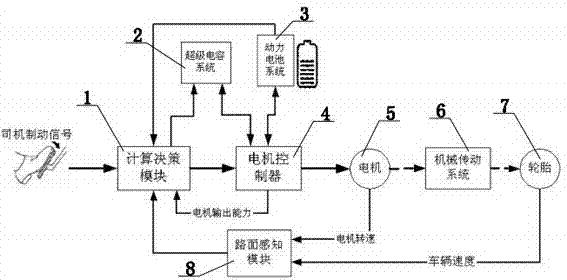

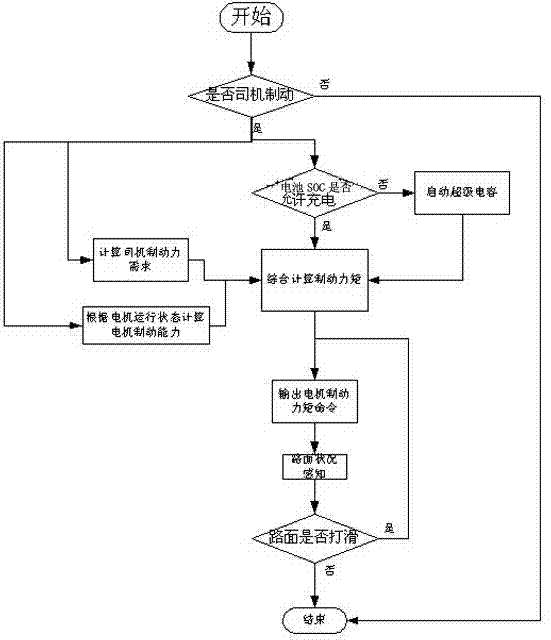

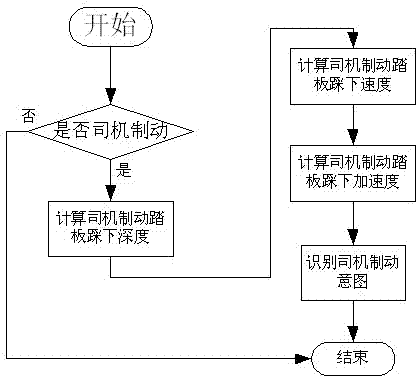

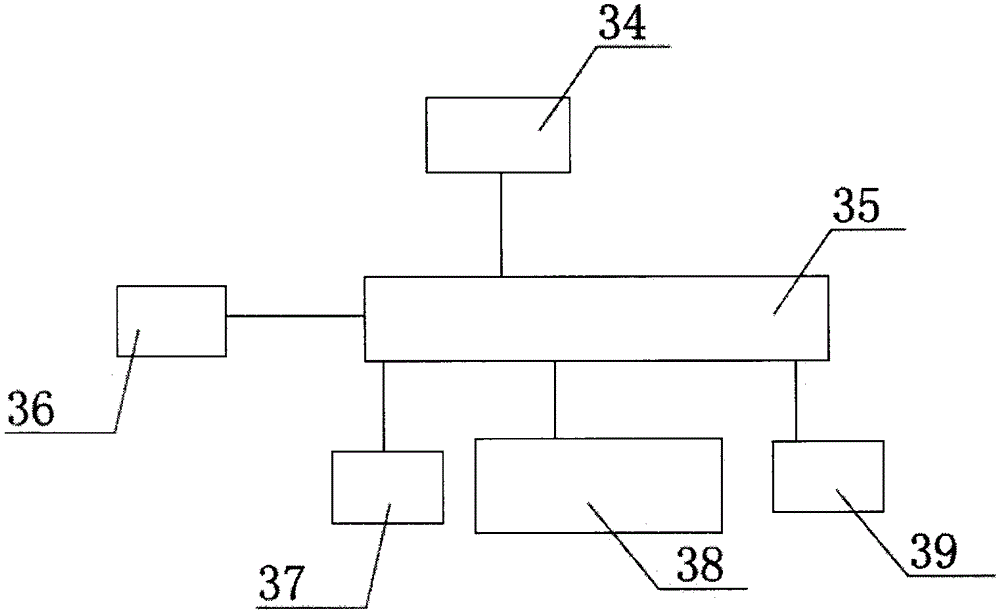

Control method of maximum energy recovery when electric vehicle brakes

ActiveCN103935251AHigh energy recovery rateEnsure safetyElectrodynamic brake systemsBrake torqueComputer module

The invention discloses a control method of the maximum energy recovery when an electric vehicle brakes and belongs to the technical field of electric vehicles. The control method is characterized by comprising the following steps that (1), a calculation decision module of a vehicle control unit calculates needed brake torque according to the current state of the vehicle and the current road state, and the obtained brake torque is analyzed and processed according to the following situations; (2), according to the analysis result, through the coordinated logic control over the brake torque according to the brake process, the control over the maximum energy recovery when the electric vehicle brakes is finished finally. According to the control method of the maximum energy recovery when the electric vehicle brakes, the utilization rate of recovered energy of the electric vehicle is improved to be 50% from 20%, the driving range is increased by 75%, and the safety performance is ensured when the electric vehicle brakes; the road state can be sensed dynamically, the brake requirement by a driver is met in real time, the brake torque is adjusted, the brake requirement of the vehicle is met, and safety is ensured.

Owner:华晨新日新能源汽车有限公司

Method for preparing magnetic immobilized phospholipase A1 and method for refining crude oil by using magnetic immobilized phospholipase A1

InactiveCN102061293AResponsiveness to strong magnetic fieldsQuick and Easy EnrichmentFermentationOn/in inorganic carrierLow activityPhospholipase A

The invention relates to a method for preparing magnetic immobilized phospholipase A1 and a method for refining crude oil by using the magnetic immobilized phospholipase A1. The invention aims to solve the problems of complicated separation and recycling of immobilized enzyme and low activity recovery of the conventional method for preparing the immobilized phospholipase A1, and the problem that the magnetic immobilized enzyme is not used for refining the crude oil at present. The method for preparing and refining the crude oil comprises the following steps of: 1, preparing the magnetic immobilized phospholipase A1; 2, heating the crude oil, and adding citric acid solution; and 3, cooling, regulating the pH value, adding the magnetic immobilized phospholipase A1, stirring, and separating the magnetic immobilized phospholipase A1. The recovery rate of the prepared magnetic immobilized phospholipase A1 is over 85 percent, and the phosphorus content of the crude oil is reduced to 7-10mg / kg. The invention is applied to the field of oil degumming.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

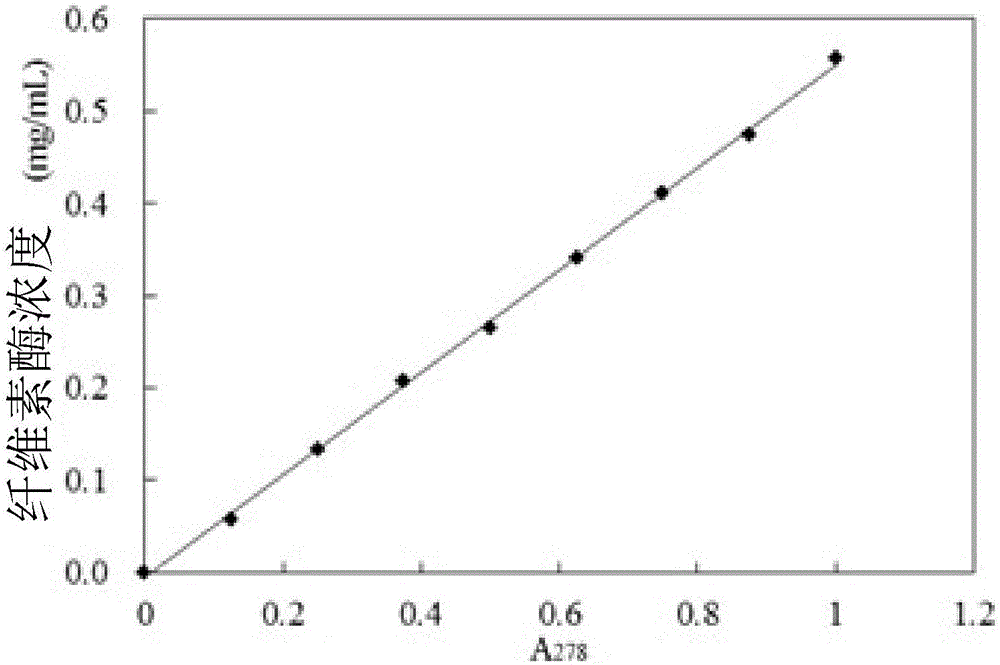

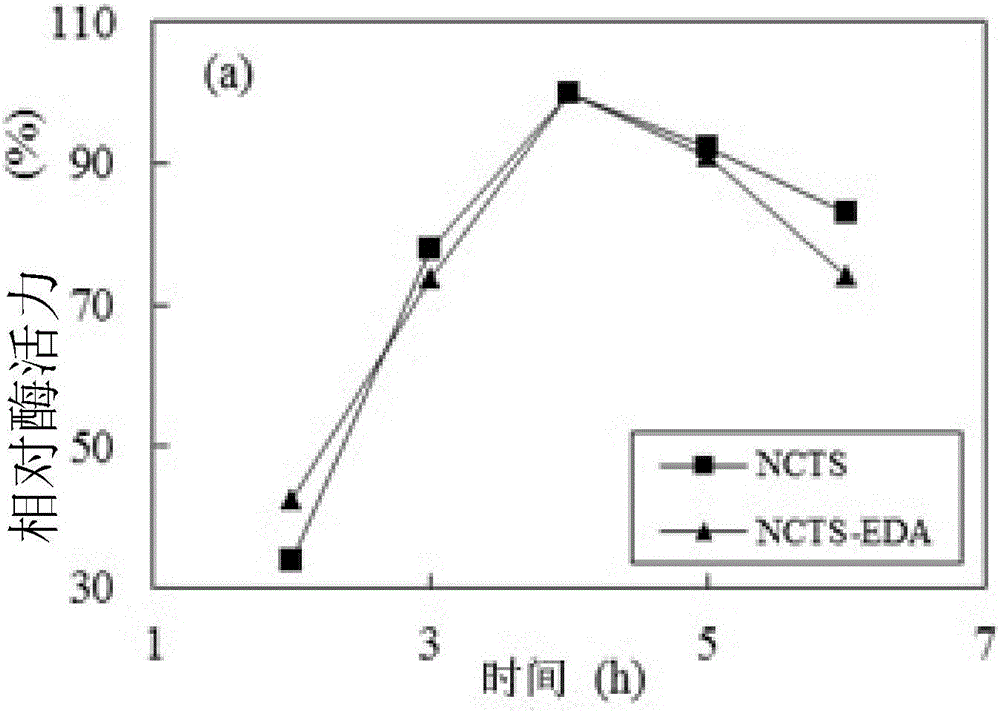

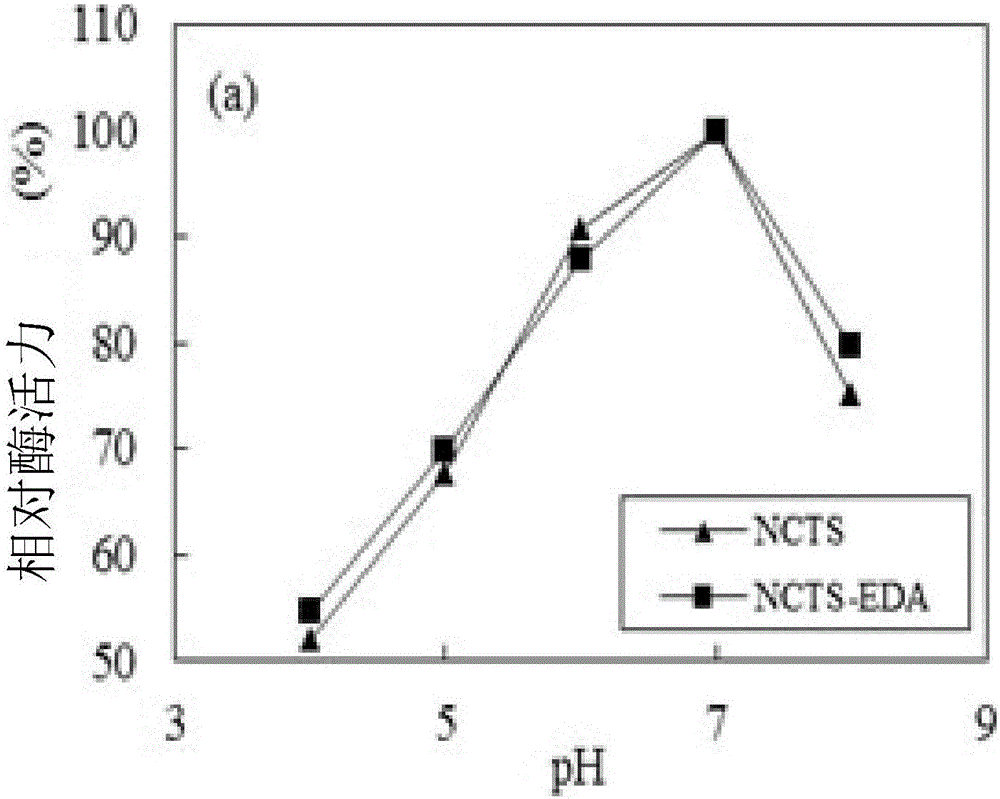

Chitosan microspheres for enzyme immobilization and preparation method and application thereof

InactiveCN105693883AGood mechanical propertiesGood heat resistanceOn/in organic carrierMicroballoon preparationImmobilized enzymePetroleum ether

The invention discloses chitosan microspheres for enzyme immobilization and a preparation method and application thereof.The preparation method comprises the steps that an acetic acid solution with the mass fraction of 5% is added to 0.5 g of chitosan powder, liquid paraffin is added after the chitosan powder is sufficiently dissolved, and stirring is conducted for 10 min; the temperature is increased to 50 DEG C, an emulsifier Span80 is dropwise added, and emulsification is conducted for 10 min; 0.5-2.0 mL of formaldehyde solution is added, and a stirring reaction is conducted for 1.5 h; the temperature is increased to 70 DEG C, a NaOH solution with the mass fraction of 10% is dropwise added, 1.0-2.5 mL of epoxy chloropropane is slowly and dropwise added on the condition that the pH value of the solution is kept alkaline, and filtering is conducted after a reaction is conducted for 5 h; an obtained product is washed with distilled water and then sequentially washed with petroleum ether, absolute ethyl alcohol and water, the product is subjected to heating treatment with hydrochloric acid of l mol / L for 9 h and then sequentially subjected to alkali washing, acid washing and water washing till the pH value of washing liquid is neutral, the product is dried to a constant weight, and the chitosan microspheres (NCTS) for enzyme immobilization are obtained.The chitosan microspheres are good carriers for immobilizing enzymes.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

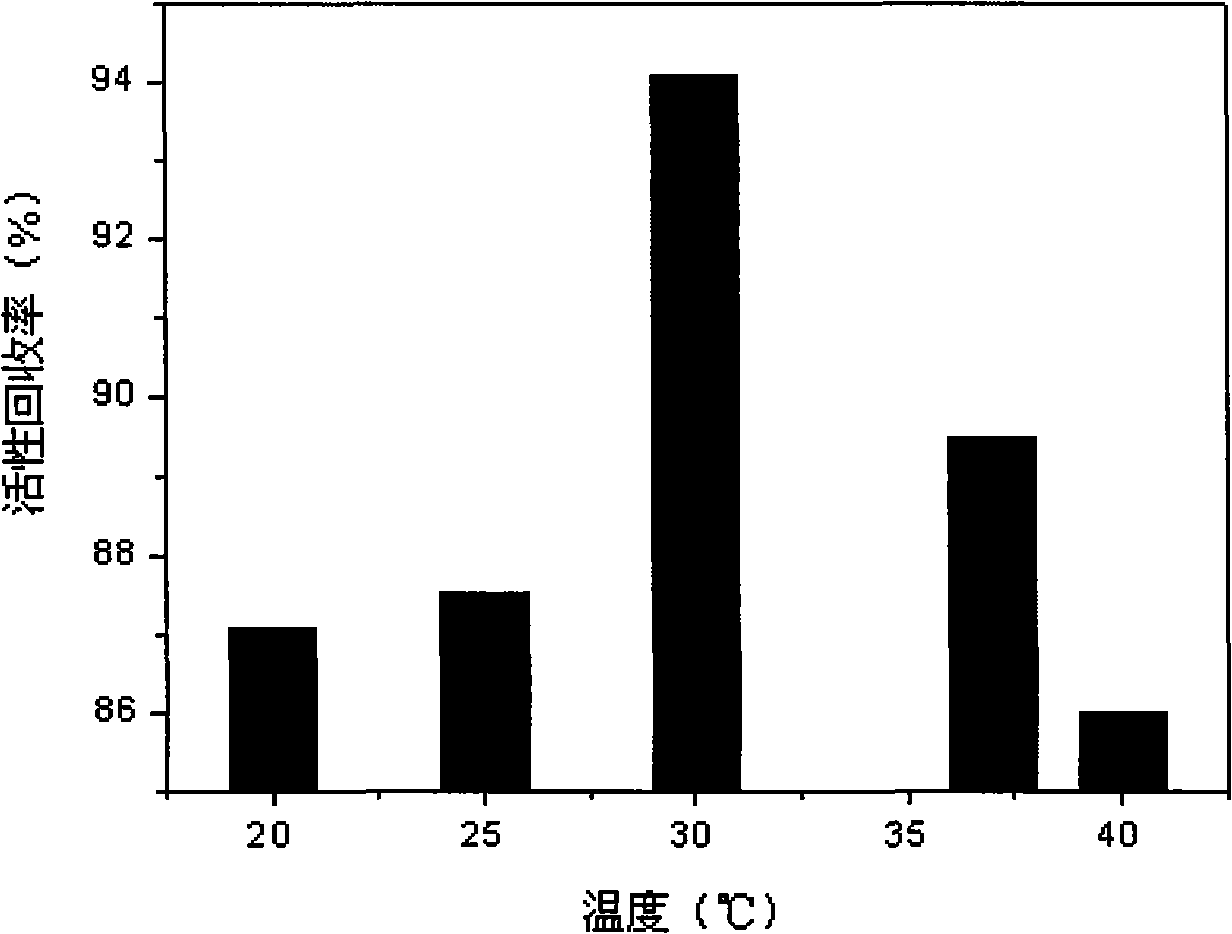

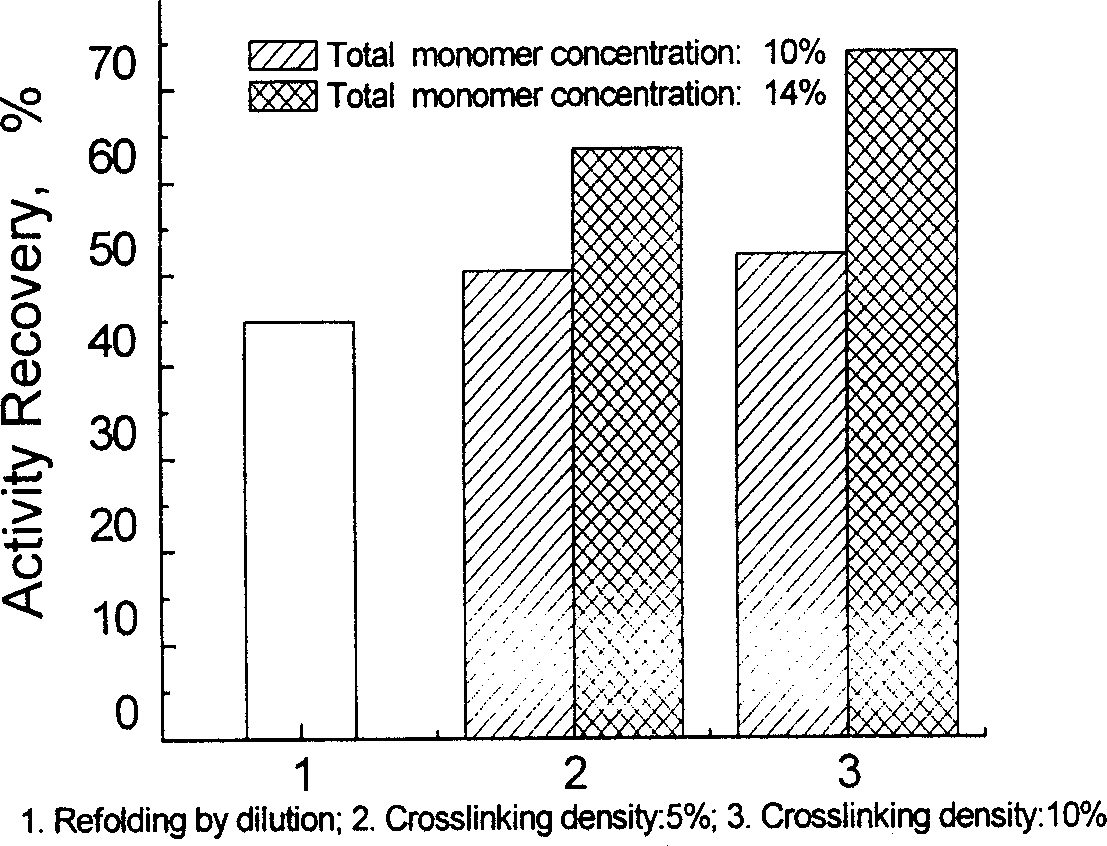

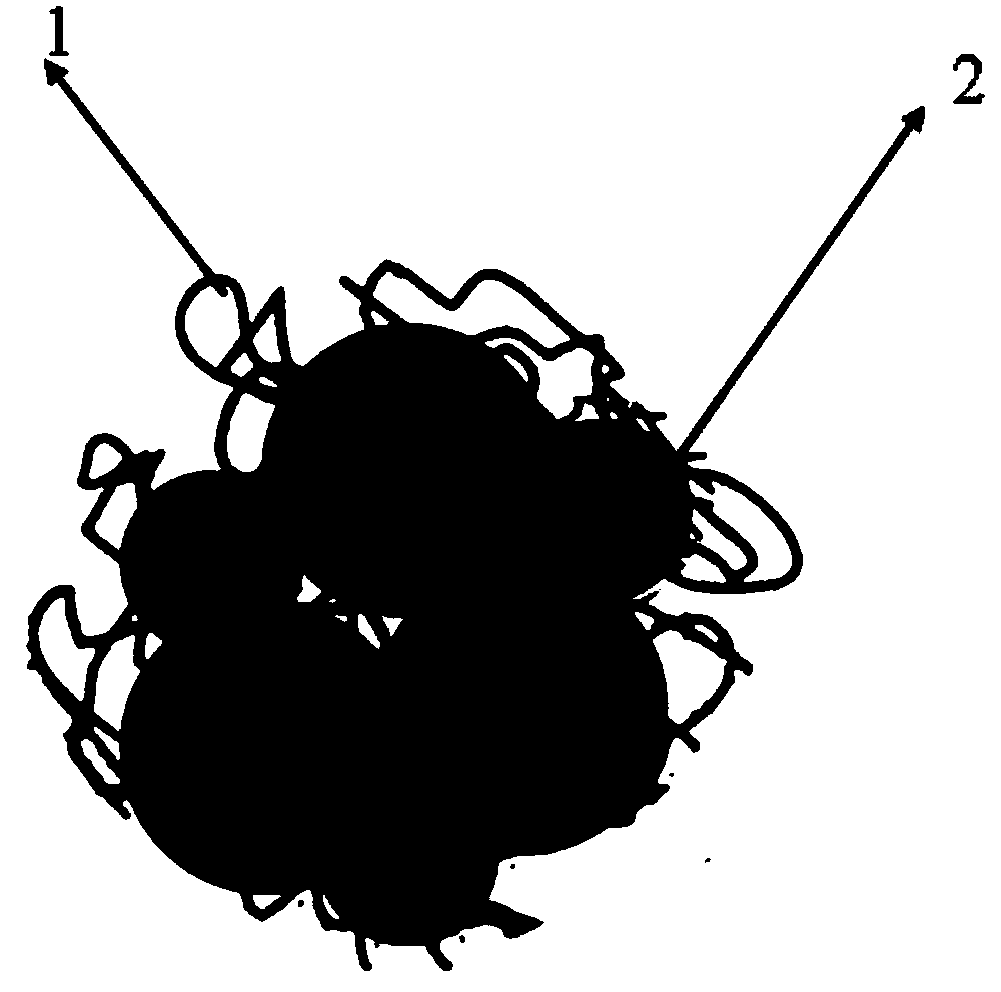

Method for assisting lysozyme renaturation by temperature sensitive type poly N-isopropyl acrylamide gel

The method for assisting lysozyme renaturation with temperature-sensitive poly N-isopropyl acrylamide gel includes the following steps: 1) compounding poly N-isopropyl acrylamide gel aqua; 2) preparing poly N-isopropyl acrylamide gel in reverse suspension process; and 3) assisting lysozyme renaturation with temperature-sensitive poly N-isopropyl acrylamide gel. The temperature-sensitive poly N-isopropyl acrylamide gel the present invention develops as one novel additive for extracorporeal renaturation of protein can raise the lysozyme activity recovering rate. The gel has high efficiency, less renaturation affecting parameters, convenient operation, relax requirement in instrument and apparatus, easy separation and recovery and other advantages. The present invention has excellent application foreground in extracorporeal renaturation of protein.

Owner:ZHEJIANG UNIV

Immobilization lipase using loofah sponge as carrier and preparation method thereof

InactiveCN101260396AGood biocompatibilityIncrease surface areaOn/in organic carrierBiodieselHigh activity

The invention relates to an immobilized lipase which takes fasciculus vascularis luffae as a carrier and preparation of the immobilized lipase. In the immobilized lipase, the mass ratio of the carrier lipase and the fasciculus vascularis luffae is between1:4 and 1:8. The concrete preparation method comprises deoiling treatment of the fasciculus vascularis luffae, refinement of the lipase and immobilization of the lipase. The invention takes the fasciculus vascularis luffae as the carrier for immobilizing the lipase, thereby the immobilized lipase obtained has high activity recovery rate and high repeated utilization ratio and can be used for a plurality of times without deactivation. Moreover, the technological method is simple in operation and has a chance of promoting the industrial progress for enzymatical production of biological diesel fuels.

Owner:SHANGHAI UNIV +1

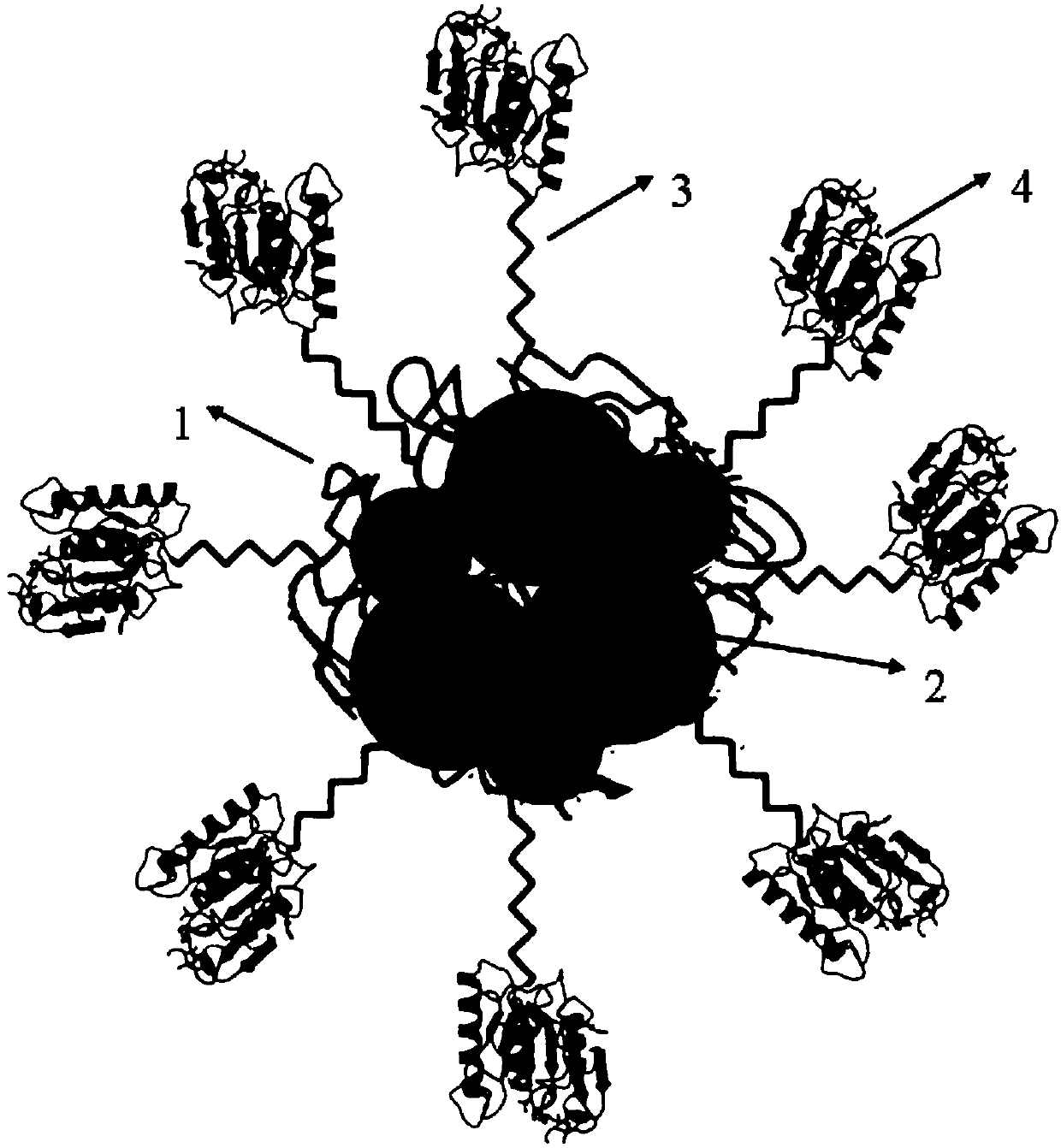

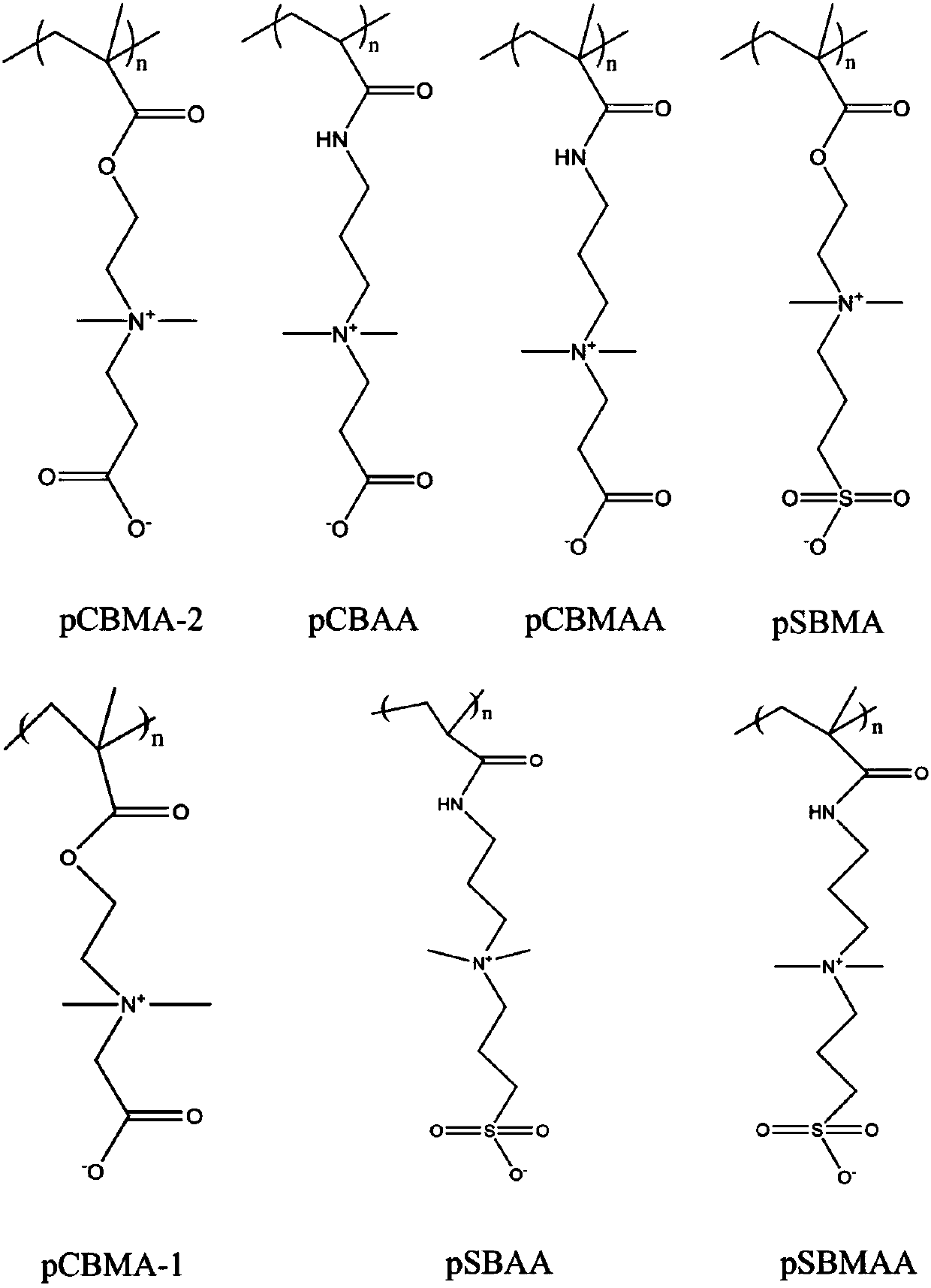

Zwitter-ion magnetic composite hydrogel immobilized enzyme supporter and preparation method

ActiveCN107746841AImprove mechanical propertiesImprove heat resistanceHydrolasesOxidoreductasesSolventMonomer

The invention relates to a zwitter-ion magnetic composite hydrogel immobilized enzyme supporter and a preparation method. The immobilized enzyme supporter is zwitter-ion hydrogel in which Fe3O4 nanoparticles are embedded; one end of glutaraldehyde, which has a bifunctional group, is connected to the zwitter-ion hydrogel, while the other end forms Schiff base with amino groups on the surface of theenzyme, so that the enzyme is covalently connected to the surface of the hydrogel supporter. The preparation method includes the steps of: mixing a zwitter-ion monomer, a crosslinking agent, an initiator and a solvent to obtain a liquid mixture, and mixing the liquid mixture with a Fe3O4 solution according to volume ratio of 3:5-3:10; and performing ultraviolet radiation, or heating or normal temperature treatment to the mixture solution containing Fe3O4 so that the Fe3O4 is embedded in the monomer via crosslinking polymerization, thereby forming the zwitter-ion magnetic composite hydrogel immobilized enzyme supporter in which the Fe3O4 is embedded. The enzyme immobilization method inherits the advantages in conventional covalent combination enzyme immobilization methods. The method is high in recovery rate of enzyme activity and has high application value.

Owner:TIANJIN UNIV

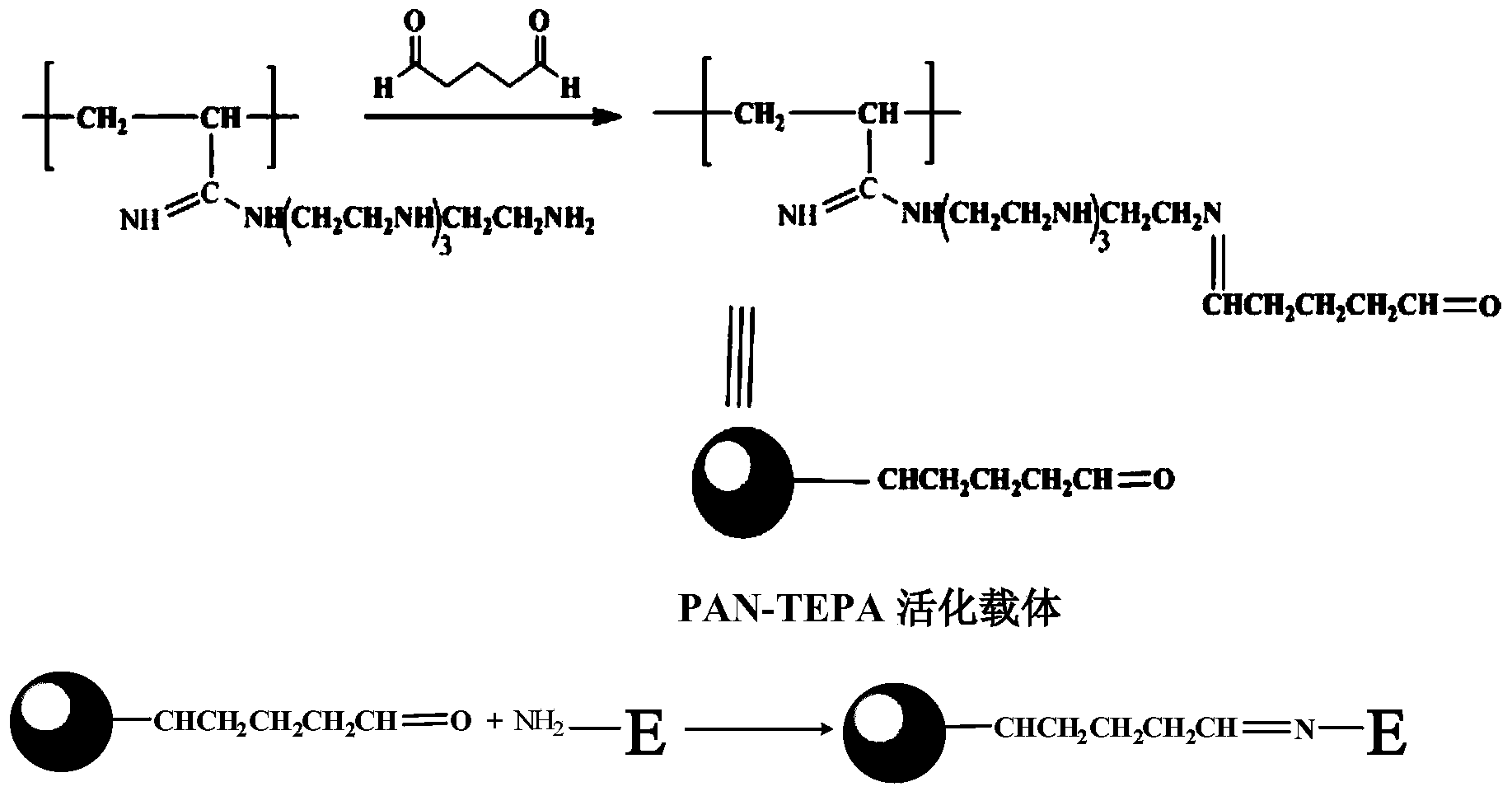

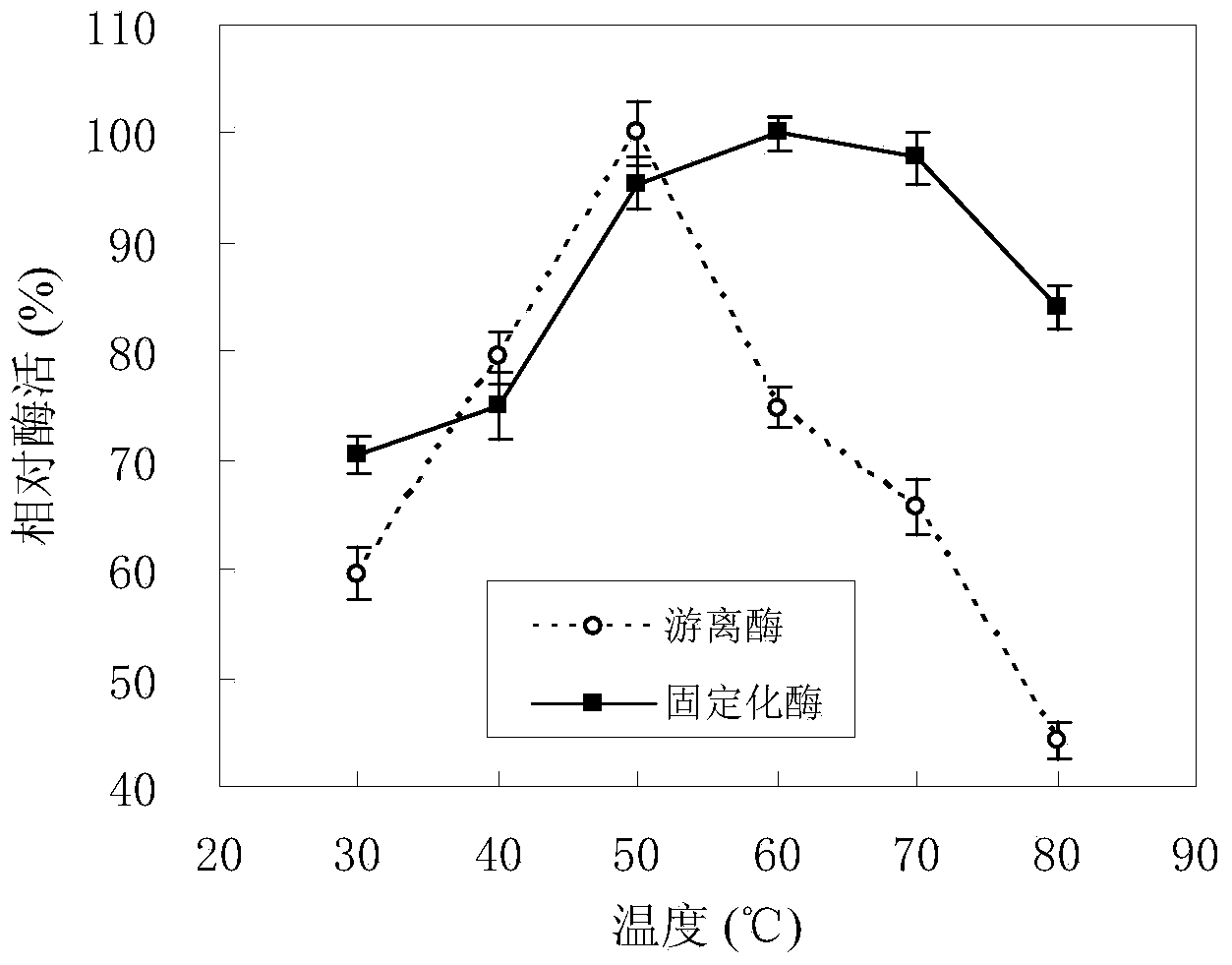

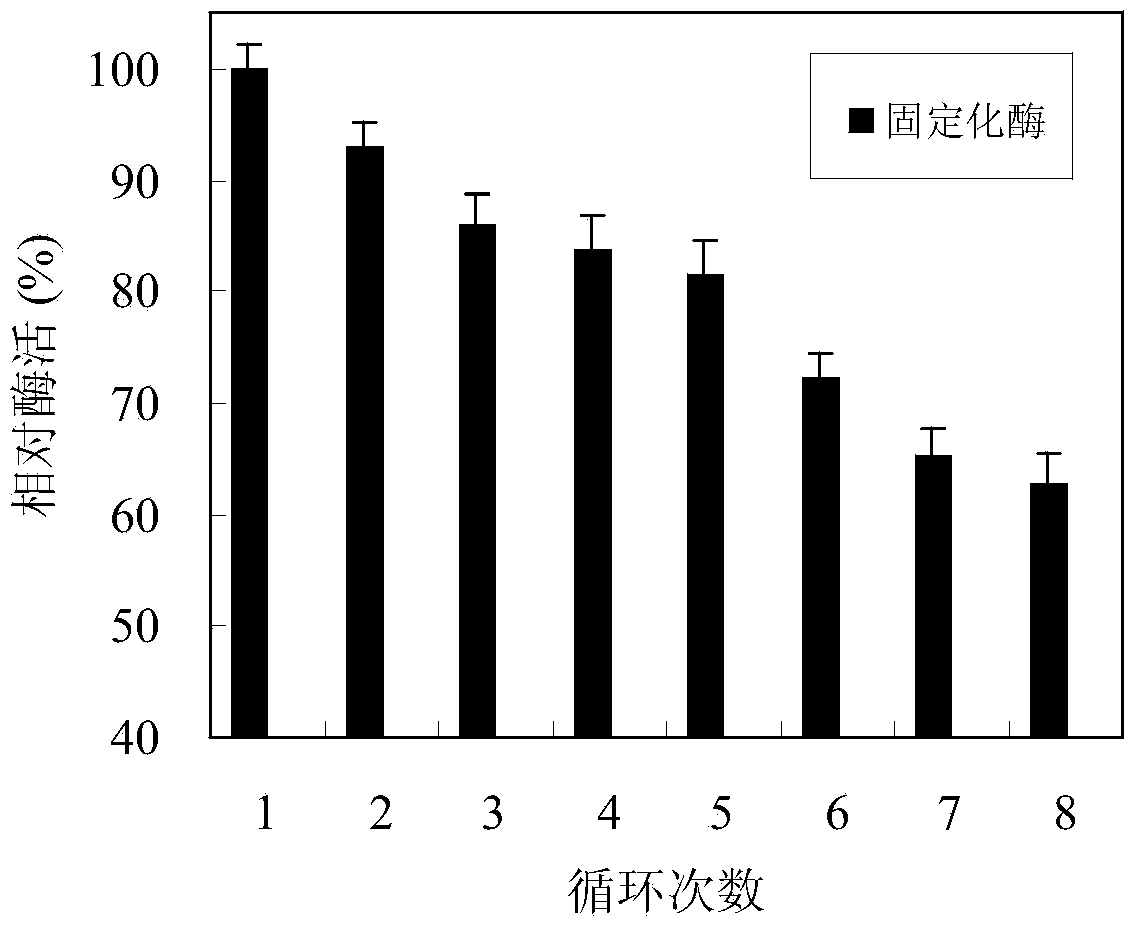

Method for flexibly immobilizing papain by using modified polyacrylonitrile resin

InactiveCN104031903AReduced loss of enzyme activityLarge specific surface areaOn/in organic carrierCovalent bindingHomogeneous catalysis

The invention discloses a method for flexibly immobilizing papain by using modified polyacrylonitrile resin, which comprises the following steps: 1) preparation of a flexible carrier: modifying polyacrylonitrile resin microspheres by use of tetraethylenepentamine to obtain a modified polyacrylonitrile flexible carrier; 2) activation of the carrier: soaking the modified polyacrylonitrile flexible carrier in a phosphate buffer solution, and performing crosslinking reaction by using glutaraldehyde to obtain a glutaraldehyde modified polyacrylonitrile flexible carrier; 3) preparation of immobilized papain: performing immobilization reaction between the glutaraldehyde modified polyacrylonitrile flexible carrier and papain to obtain immobilized papain. The method disclosed by the invention overcomes the enzyme activity loss caused by rigid collision in the enzyme immobilization process of the carrier synthesized by the prior art, and can maintain the homogeneous catalysis activity of free enzymes to the greatest degree so as to solve the problem of low recovery rate of the immobilized enzyme activity of a covalent binding method.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

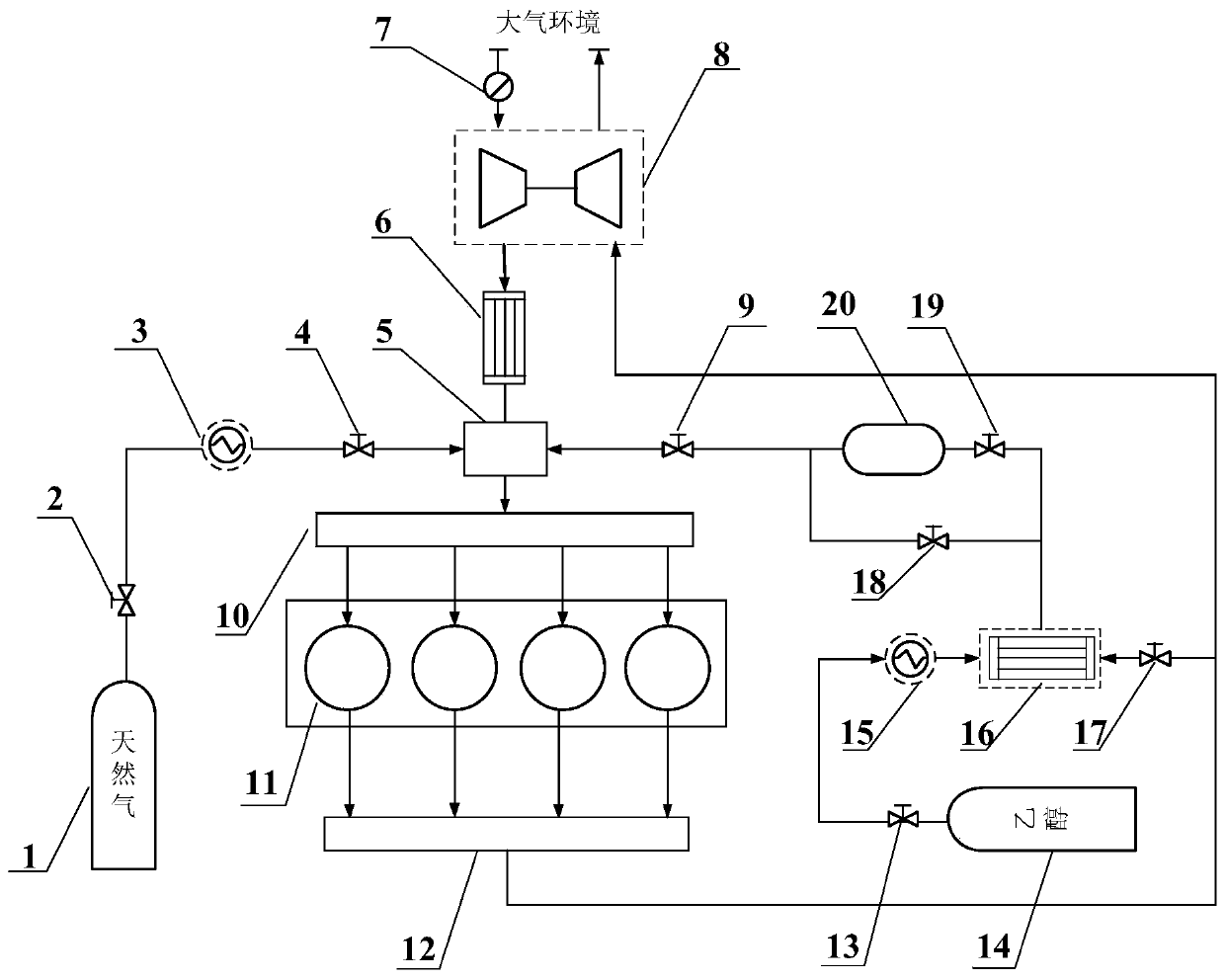

Ethyl alcohol reforming system and control method for improving dynamic performance of natural gas engine

ActiveCN110360026AKnock suppressionEfficient and clean combustionInternal combustion piston enginesFuel supply apparatusAlcoholCombustion

The invention aims at providing an ethyl alcohol reforming system and an ethyl alcohol reforming control method for improving dynamic performance of a natural gas engine. The ethyl alcohol reforming system for improving the dynamic performance of the natural gas engine comprises an LNG (liquefied natural gas) storage tank, an LNG vaporizer, a mixer, a turbine supercharger, an ethyl alcohol storagetank, an ethyl alcohol vaporizer and an ethyl alcohol reformer, wherein a gas compressor in the turbine supercharger is connected with the mixer through an intercooler, the LNG storage tank is connected with the LNG vaporizer through a liquified natural gas flow valve, the LNG vaporizer is connected with the mixer through a gaseous natural gas flow valve, the mixer is connected with a gas inlet pipe, the gas inlet pipe is connected with a turbine of the turbine supercharger, a gas discharge pipe is connected with the ethyl alcohol reformer through a waste gas bypass pipe, a waste gas bypass valve is connected onto the waste gas bypass pipe, the ethyl alcohol storage tank is connected with the ethyl alcohol vaporizer through a liquified ethyl alcohol flow valve, the ethyl alcohol vaporizeris connected with the ethyl alcohol reformer, the ethyl alcohol reformer is connected with the mixer through a reforming pipeline, and a reformed gas flow valve is installed on the reforming pipeline. The ethyl alcohol reforming system and the ethyl alcohol reforming control method for improving the dynamic performance of the natural gas engine can effectively inhibit engine knocking and accidentfire phenomena of the natural gas engine, and also can achieve efficient combustion under cold start and low load work conditions and loading work conditions.

Owner:HARBIN ENG UNIV

Method for preparing liquid-state chymosin preparation

The invention discloses a method for preparing a liquid-state chymosin preparation. The method comprises the following steps: (1) preparing fermentation liquor by taking bacillus amyloliquefaciens CCTCC NO:M2011045 or bacillus subtilis CCTCC NO:M2010259 as a fermentation strain; (2) performing plate-frame pressure filtration, and performing solid-liquid separation; (3) performing montmorillonite adsorption; (4) performing microfiltration; (5) performing ultrafiltration and concentration; and (6) adding cane sugar or trehalose with the final concentration of 20-40 weight percent, glycerol or sorbitol with the final concentration of 0-30 weight percent and calcium chloride with the final concentration of 0.01-0.05 weight percent into a concentrated enzyme solution, uniformly mixing, and preparing the finished product. According to the method, the chymosin is high in activity and recovery rate, protease, other impurities and residual bacteria in the enzyme solution can be effectively removed, and the prepared enzyme preparation has high quality and stability and is high in enzyme specifity, long in retention period, safe and non-toxic.

Owner:四川生力源生物工程有限公司

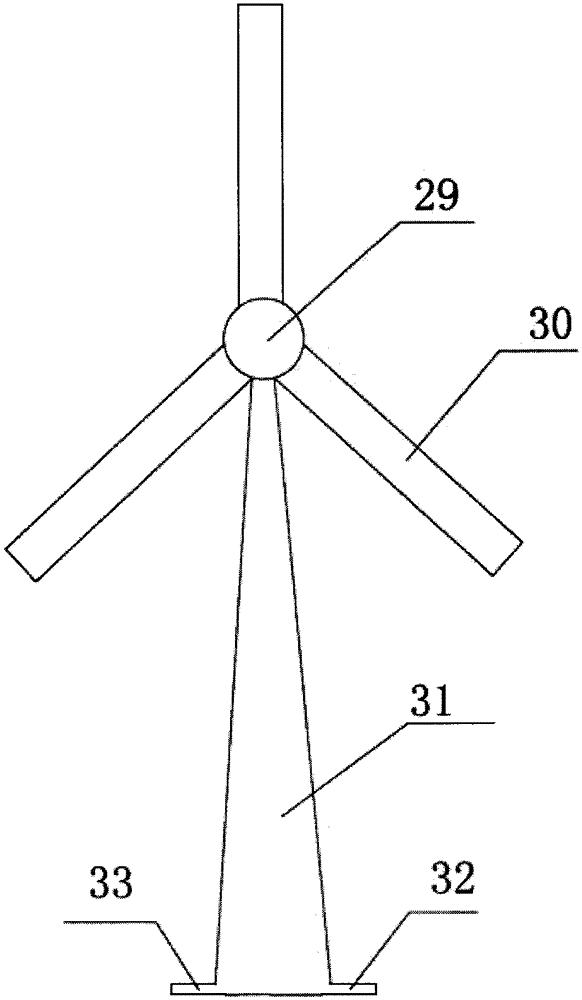

New energy efficient plunger pump seawater desalination plant system

ActiveCN105800734AImprove recycling ratesReduce energy lossGeneral water supply conservationSeawater treatmentNew energyPower grid

The invention relates to a new energy efficient plunger pump desalination plant system, and belongs to the technical field of seawater desalination. The new energy efficient plunger pump seawater desalination plant system includes a fan, a liquid plunger supercharging device and a seawater desalination processing apparatus. The fan is used to provide energy for the liquid plunger supercharging device; the liquid plunger supercharging device is used for pressurizing low-pressure fresh seawater in the seawater desalination unit. The seawater desalination plant and energy recovery device are integrated and installed in the fan tower, thereby greatly reducing the land occupation, improving energy recovery efficiency of the high-pressure concentrated seawater, optimizing the mechanism, and reducing the cost and failure rate. Due to the fan and the standby off-grid multi-energy cooperative power device, 100% wind energy is used for desalination, and the wind, light and grid cooperative power supply can be realized. The system comprehensively utilizes clean energy, reduces dependence on the power grid, saves energy and protects the environment.

Owner:南通通州湾风生海水淡化科技有限公司

Method for preparing glutamate decarboxylase (GAD)

InactiveCN103305495AAchieve serializationAchieve scaleMicroorganism based processesLyasesIonic strengthGlutamate decarboxylase

The invention relates to a method for preparing glutamate decarboxylase (GAD). The method comprises the following steps: (1) culturing a microbial cell containing GAD, centrifugally collecting the cell, disrupting the cell, and regulating the pH value and ionic strength of cell disruption solution; (2) preparing a reverse micelle extraction system solution and a reverse extraction aqueous phase solution; (3) utilizing reverse micelle for extraction; (4) carrying out reverse extraction to obtain an aqueous solution containing GAD; and (5) carrying out filtration and concentration with an ultrafiltration membrane, and freeze-drying trapped fluid, thus preparing the GAD product. The method has the beneficial effects that continuous and large-scale preparation of GAD can be achieved; the preparation process of GAD is simple and convenient, and the production cycle is short; the activity and recovery rate of GAD are high; the extraction agent can be recycled; and the production cost of GAD is lower.

Owner:QILU UNIV OF TECH

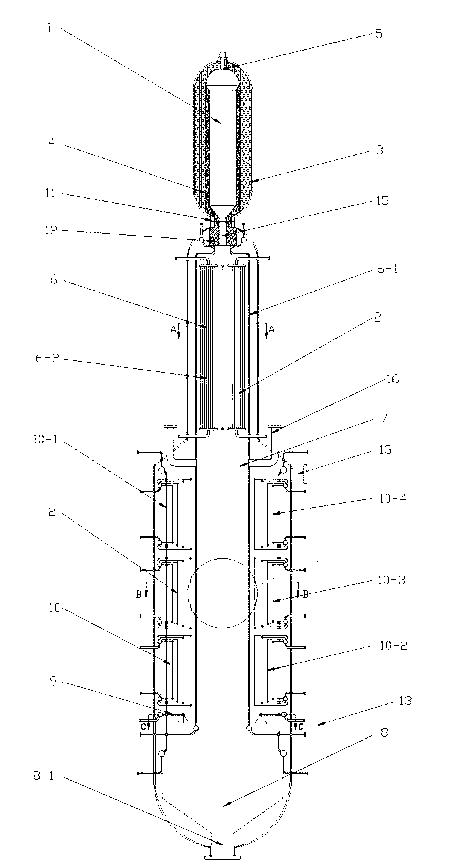

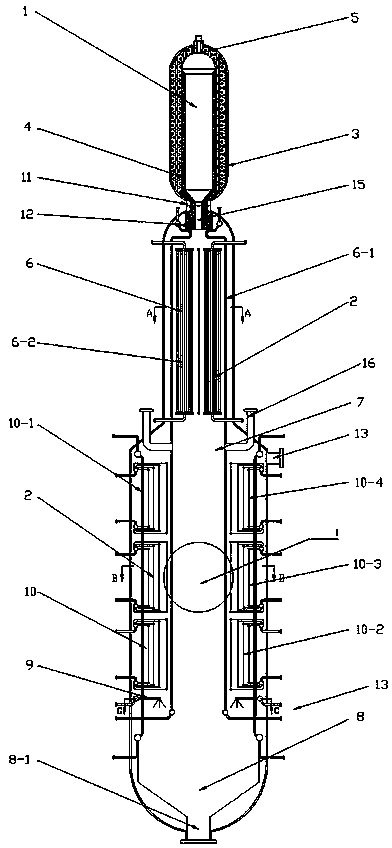

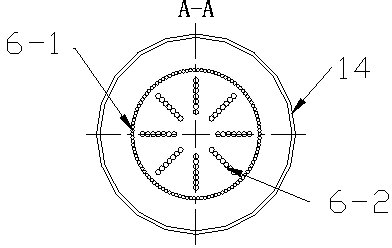

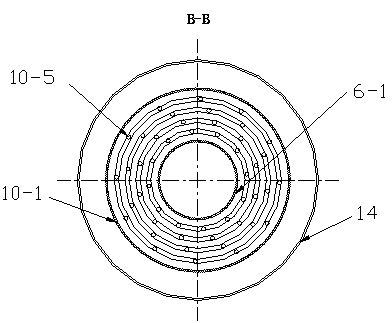

Integral rotational radiation preheating mixing energy utilization device with flue gas chilling

ActiveCN103013577AReduce slaggingGuaranteed safe operationEnergy inputCombined combustion mitigationSlagEnergy recovery

The invention relates to an integral rotational radiation preheating mixing energy utilization device with flue gas chilling. The device comprises a gasification furnace body and a heat recovery unit, which are connected with each other through a flange; the heat recovery unit comprises a pressurized shell, a syngas inlet, a radiation heat exchange component, a flue gas chilling component, a convection heat transfer component, an attemperator component, a slag tank and a syngas outlet; the gasification furnace body is communicated with the heat recovery unit through the syngas inlet; syngas is subjected to radiation heat exchange and then chilling for temperature reduction, and then liquid slag falls into the slag tank for discharge; and the syngas reversely flows up, and is subjected to convection heat transfer for temperature reduction. The device integrates radiation heat exchange, flue gas chilling and convection heat transfer effectively, and can be used for an IGCC (Integrated Gasification Combined Cycle) power generation system, the sensible heat of crude syngas is absorbed to produce high-pressure steam or medium-pressure steam to generate power, the entire energy utilization rate is increased greatly, the energy recycling rate is high, the overall dimension of a waste-heat recovery boiler is reduced effectively, the manufacturing, transporting and installing are more convenient, and the problem of dust stratification on convection heat transfer surface can be eliminated.

Owner:DONGFANG ELECTRIC CORP LTD

Immobilized lysine decarboxylase, preparation thereof, 1, 5-pentane diamine preparation method and product

The invention relates to immobilized lysine decarboxylase, a preparation thereof, a 1, 5-pentane diamine preparation method and the prepared 1, 5-pentane diamine. The invention specifically relates toimmobilized lysine decarboxylase comprising an aldehyde group-modified polymer carrier and lysine decarboxylase, and a method for preparing immobilized lysine decarboxylase by the aldehyde group-modified polymer carrier; a method for preparing 1, 5-pentane diamine by the immobilized lysine decarboxylase, and the prepared 1, 5-pentane diamine thereof. The immobilization method has high enzyme immobilization efficiency and good stability in use, improves the use efficiency of enzyme, solves the problem of poor use stability of free lysine decarboxylase (cells) in traditional processes, greatlyreduces the use cost of the carrier and the biological production cost of 1, 5-pentanediamine, simplifies the separation step of 1, 5-pentane diamine solution and enzyme, increases the degree of automation of the production of 1, 5-pentane diamine, and promotes the process of industrialization of biological production of 1, 5-pentanediamine.

Owner:CATHAY R&D CENT CO LTD +2

Mixed energy utilization device for integrated rotary radiant boiler preheating boiler

ActiveCN102977925AImprove energy efficiencyHigh energy recovery rateEnergy inputGranular/pulverulent flues gasificationSlagProcess engineering

The invention relates to a mixed energy utilization device for an integrated rotary radiant boiler preheating boiler. The device comprises a gasification furnace body and a heat recovery device, wherein the gasification furnace body is arranged above the heat recovery device; the heat recovery device comprises a synthetic gas inlet, a radiation heat exchange component, a slag bath, a convection heat exchange component and a pressure shell; the synthetic gas inlet is positioned on a seal head on the top of the pressure shell; the radiation heat exchange component is positioned on the upper part of the slag bath; the slag bath is positioned on the upper part of convection heat exchange component; the radiation heat exchange component, the slag bath and the convection heat exchange component are positioned in the pressure shell into a whole; a lower slag port of the gasification furnace body is connected with the top of the heat recovery device through a flange; and the lower slag port is communicated with the synthetic gas inlet. The sensible heat of the gasified coarse synthetic gas can be effectively absorbed, and the generated high-pressure steam or medium-pressure steam is used for power generation or preheating other working media, so that the energy utilization rate is greatly improved, and the energy recycling efficiency is high; and moreover, the overall size of a waste heat boiler is effectively reduced, the device is convenient to manufacture, transport and mount, and the dust accumulation problem in the convection heat exchange area can be eliminated.

Owner:DONGFANG ELECTRIC CORP LTD

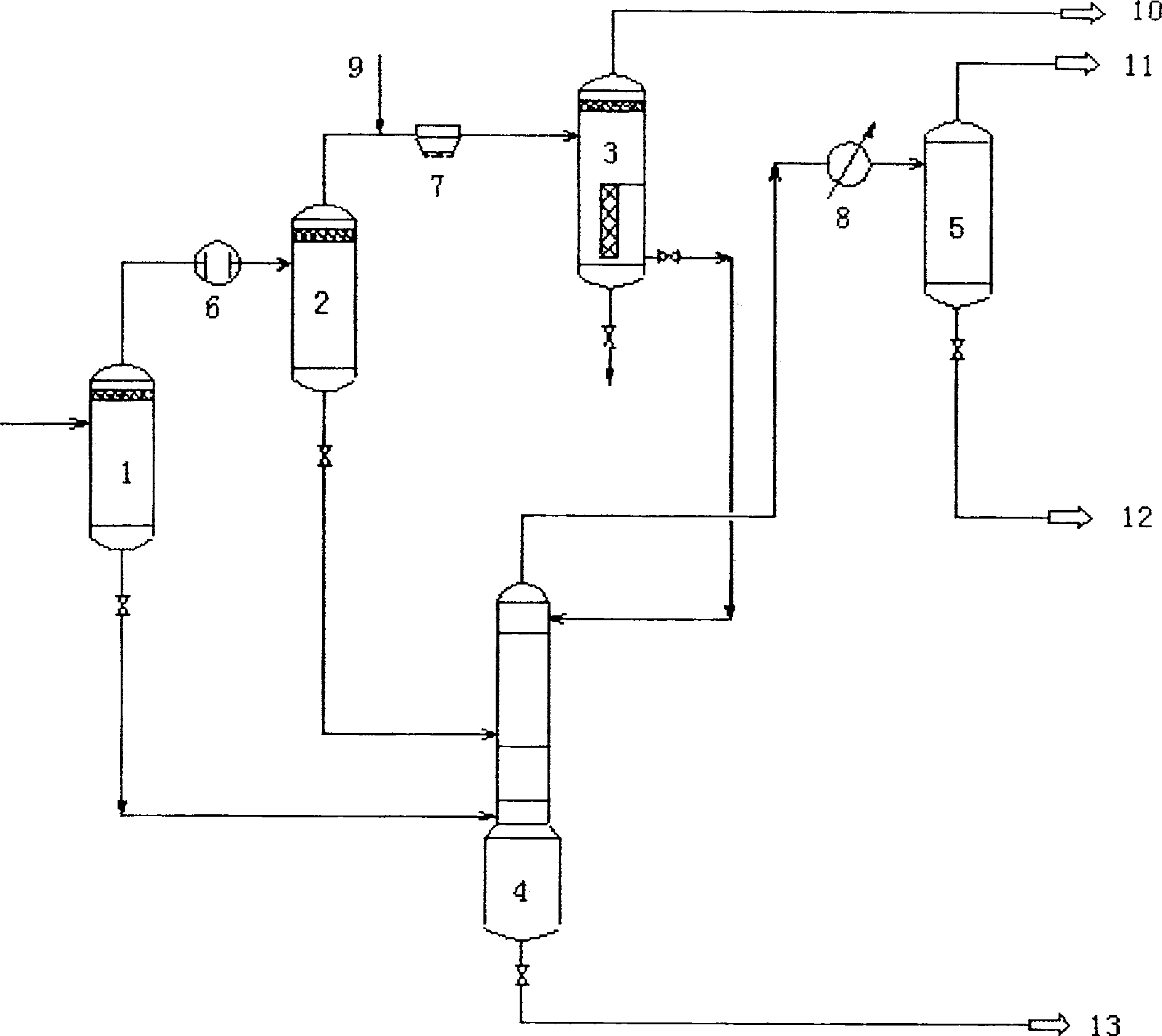

Flow for separating outflow from hydrogenation reaction

The invention relates to a hydrogenation reaction effluent separation process, comprising (1) the hydrogenation reaction effluent enters a hot high-pressure separator, (2) the gas phase separated from the hot high-pressure separator enters a medium-temperature high-pressure separator after cooling down, (3) The gas phase separated by the medium-temperature high-pressure separator cools down and enters the cold high-pressure separator, and the gas phase separated by the cold high-pressure separator is used as circulating hydrogen. (4) A heat exchange tower is installed, and the liquid phase of the hot high-pressure separator enters the heat exchange tower from the lower part. The liquid phase of the high-pressure separator enters the heat exchange tower from the middle, the liquid phase of the cold high-pressure separator enters the heat exchange tower from the top, the liquid phase is drawn out from the bottom of the heat exchange tower for stripping treatment, and the gas phase discharged from the top of the heat exchange tower enters the gas phase after being cooled. Liquid separator for separation. Compared with the prior art, the method of the invention has simple process flow, fewer high-pressure equipment stations, significantly reduced heat exchange area of heat exchange equipment, reduced cooling load and high energy recovery and utilization rate. The method of the invention is applicable to various hydrogenation reaction processes utilizing heat separation.

Owner:CNPC EASTCHINA DESIGN INST

SiO2 based macroporous material immobilized laccase and preparation method thereof

The invention relates to a SiO2 based macroporous material immobilized laccase and a preparation method thereof, and belongs to the technical field of immobilized laccase preparation. The immobilized laccase is prepared by fixing laccase on a carrier through a static and coordination effect, wherein the carrier is a SiO2 macroporous block material whose surface is modified. The preparation method comprises two steps namely carrier preparation and laccase immobilization, wherein the carrier preparation comprises the following steps: modifying a SiO2 macroporous block material by sodium aluminate under a hydrothermal condition, and then carrying out ion exchange to obtain a finished carrier product containing multivalent metal ions on the surface; and the laccase immobilization comprises the following steps: soaking the prepared carrier in a laccase solution, carrying vibration absorption at a room temperature, washing, and drying so as to obtain the finished immobilized laccase product. The provided immobilized laccase has the characteristics of simple preparation technology, low cost, high activity recycling rate, and stable property.

Owner:NINGBO UNIV

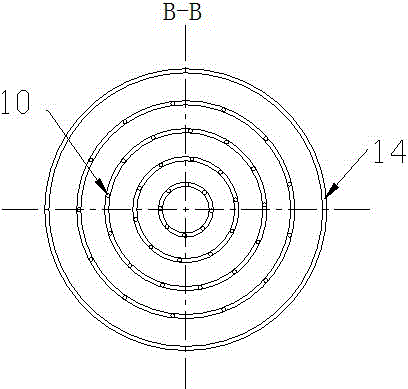

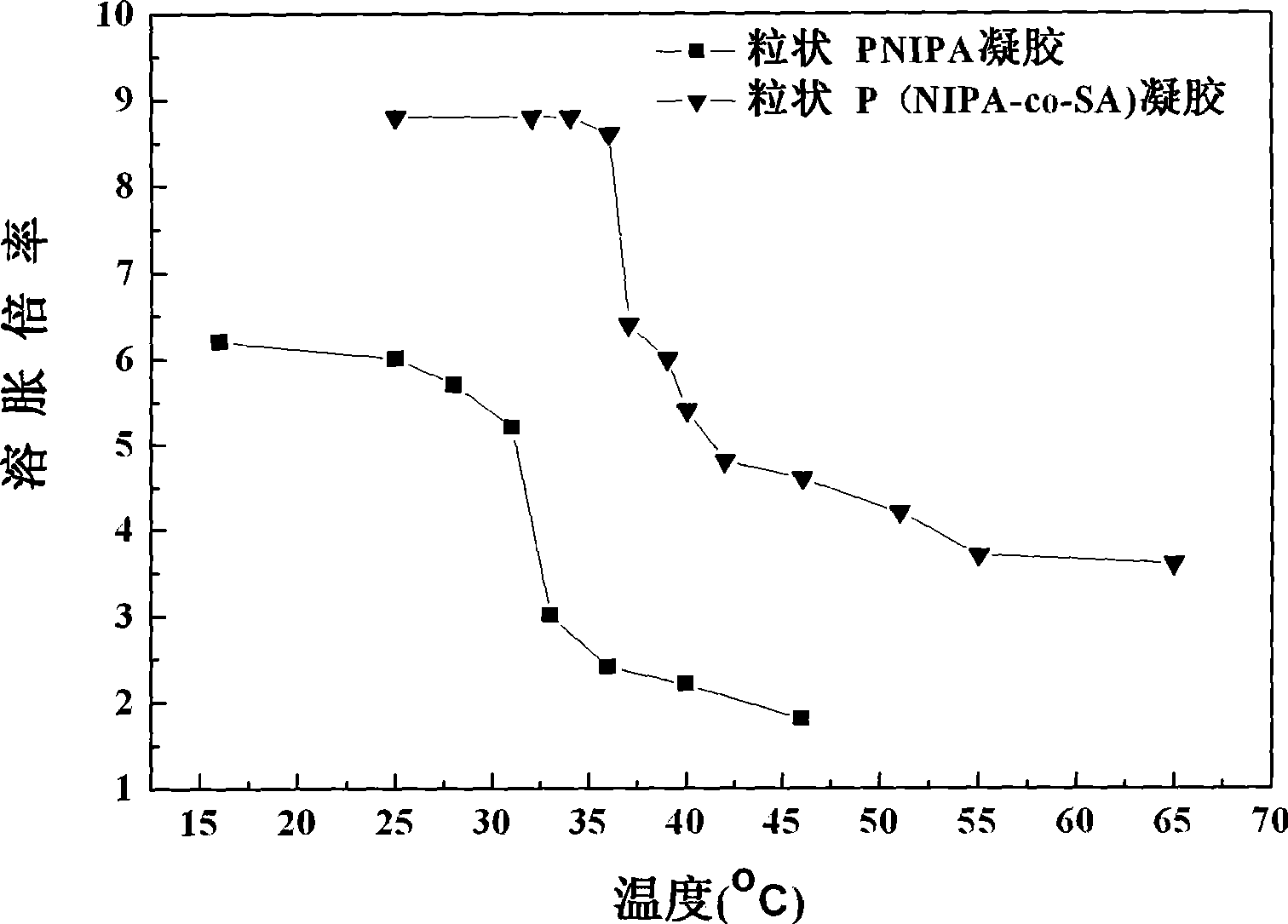

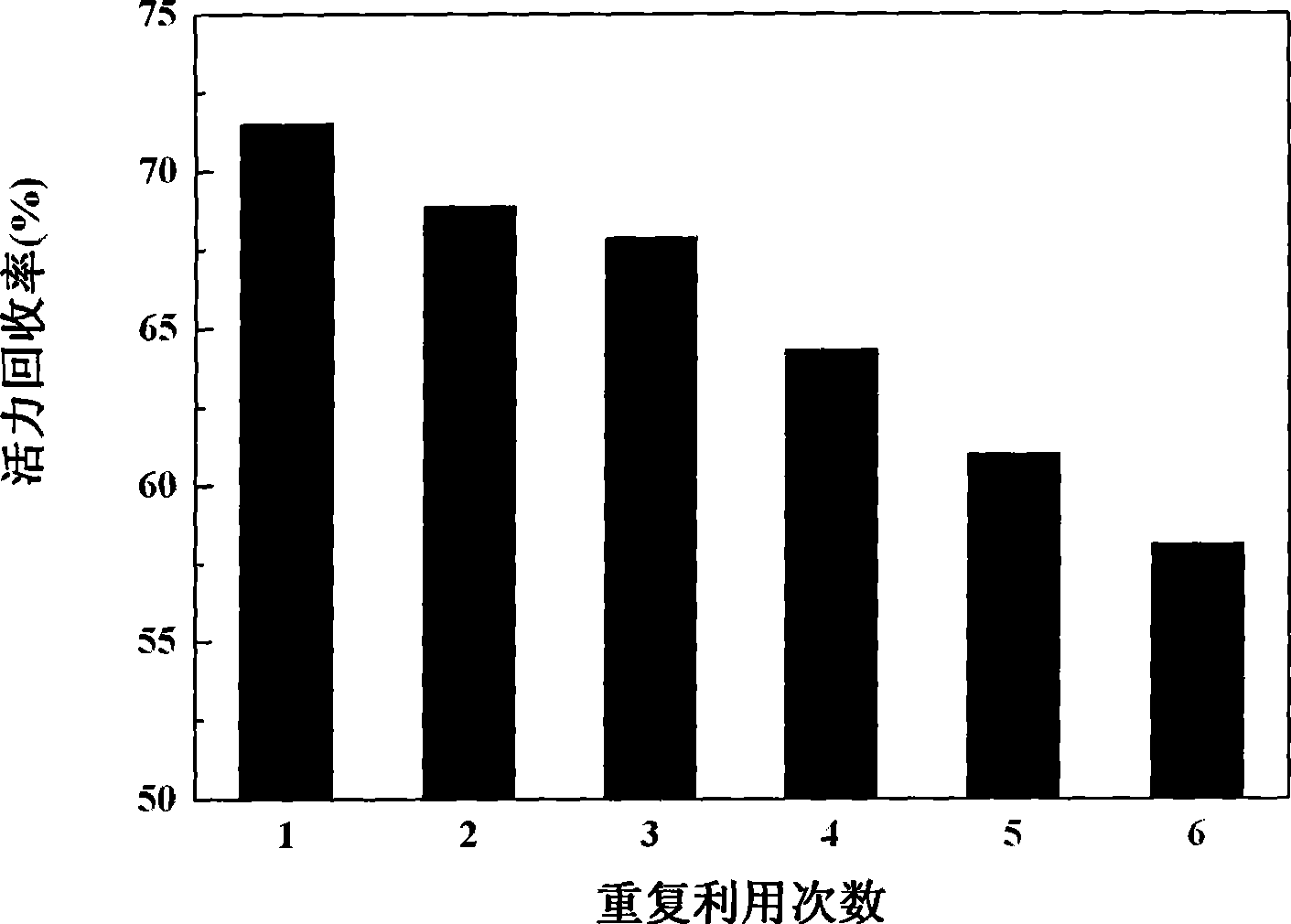

Method for assisting lysozyme renaturation in vitro by granular poly(N-isopropylacrylicamide-sodium acrylate) copolymer hydrogel

The invention discloses a method for assisting the in vitro renaturation of lysozyme by using granular poly (N-isopropylacrylamide-sodium acrylate) copolymer gel, the specific steps are as follows: 1) the granular poly (N-isopropylacrylamide-sodium acrylate) copolymer gel is prepared by using the inverse suspension copolymerization; 2) the granular poly (N-isopropylacrylamide-sodium acrylate) copolymer gel is used for assisting the in vitro renaturation of the lysozyme. The granular poly (N-isopropylacrylamide-sodium acrylate) copolymer gel which is developed by the method is taken as a novel protein in vitro renaturation additive, thereby having the following advantages: (1) the activity recovery rate of a target protein can be significantly improved under the condition of high denatured protein concentration; (2) the separation and the recovery are convenient by utilizing the thermosensitive characteristic of the gel after the completion of the renaturation, and the gel can be repeatedly utilized; (3) the hydrophobic performance of the gel can be regulated by controlling the content of the co-monomer sodium acrylate, thereby changing the low critical dissolution temperature and the largest swelling ratio and being applicable to the different target proteins. Therefore, the gel has better application prospect in the field of the protein renaturation.

Owner:ZHEJIANG UNIV

Method for preparing block macroporous composite immobilized laccase constructed by CS/SiO2 ultrathin membrane

InactiveCN105274085AHigh energy recovery rateEasy to separateOn/in organic carrierOn/in inorganic carrierLaccase activityImmobilized enzyme

The present invention relates to a method for preparing a block macroporous composite immobilized laccase, belonging to the technical field of preparing of an immobilized enzyme. The immobilized laccase is prepared by fixing laccase onto a carrier by physical adsorption method, wherein the block macroporous composite constructed by a silica / chitosan ultrathin membrane is used as the carrier. The preparation method comprises the steps preparation of the carrier and fixing of the laccase. The preparation of the carrier is as follows: chitosan is adsorbed on SiO2 macroporous material pore wall surface, and then the finished carrier, constructed by the silica / chitosan ultrathin membrane, is prepared by crosslinking of chitosan macromolecules by use of a bifunctional crosslinking agent; the fixing of the laccase is as follows: the carrier is immersed in a laccase solution and shaken for reaction at room temperature, and finished immobilized laccase can be obtained by washing and drying. The present invention provides a novel immobilized laccase and a preparation method thereof, and the novel immobilized laccase has the characteristics of simple preparation process, low cost, high immobilized laccase activity, and stable property and the like.

Owner:NINGBO UNIV

Immobilized lysine decarboxylase, preparation thereof, 1, 5-pentane diamine preparation method and product

The invention relates to immobilized lysine decarboxylase, a preparation thereof, a 1, 5-pentane diamine preparation method and a product. The invention specifically relates to immobilized lysine decarboxylase comprising a diazo group-modified polymer carrier and lysine decarboxylase, and a method for preparing immobilized lysine decarboxylase by the diazo group-modified polymer carrier; a methodfor preparing 1, 5-pentane diamine by the immobilized lysine decarboxylase, and the prepared 1, 5-pentane diamine thereof. The immobilization method has high enzyme immobilization efficiency and goodstability in use, improves the use efficiency of enzyme, solves the problem of poor use stability of free lysine decarboxylase (cells) in traditional processes, greatly reduces the use cost of the carrier and the biological production cost of 1, 5-pentanediamine, simplifies the separation step of 1, 5-pentane diamine solution and enzyme, increases the degree of automation of the production of 1, 5-pentane diamine, and promotes the process of industrialization of biological production of 1, 5-pentanediamine.

Owner:CATHAY R&D CENT CO LTD +2

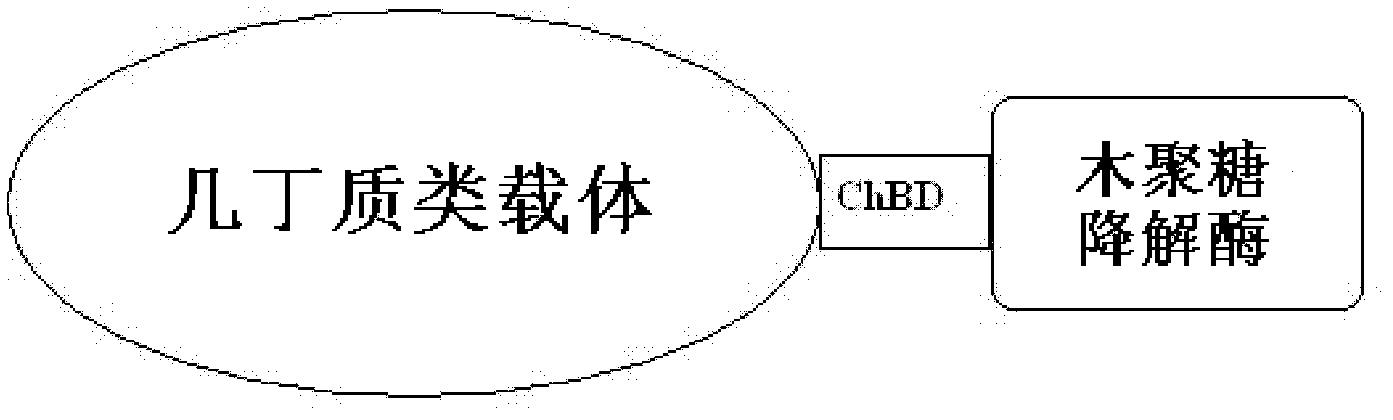

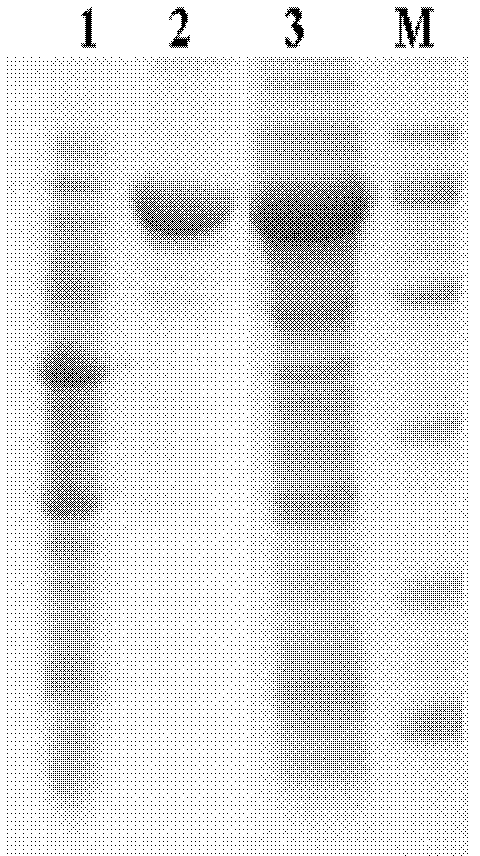

Method for preparing xylo-oligosaccharide and xylose with genetic engineering co-immobilized xylan degradation enzyme

InactiveCN102634558ASimultaneous fixation and purificationSimple production processOn/in organic carrierFermentationGenetic engineeringBiocompatibility Testing

The invention discloses a method for preparing xylo-oligosaccharide and xylose with genetic engineering co-immobilized xylan degradation enzyme. The method comprises the following steps of: firstly, applying an affinity label which has high bonding strength at high temperature and is efficient and stable to the xylan degradation enzyme by a gene recombination technology and then co-expressing, and preparing the genetic engineering co-immobilized xylan degradation enzyme by specifically combining with an immobilized carrier material; and then hydrolyzing a xylan solution or a steam explosion liquid of agricultural and forestry waste by utilizing the co-immobilized xylan degradation enzyme, thereby obtaining xylo-oligosaccharide and xylose. Through the method, one-step method production of multi-enzyme preparation is realized, multi-enzyme purification and immobilization are synchronous, the separation and recycling of products and repeated using of enzyme are coupled, and the stability of enzyme to temperature and pH is improved; and the synergistic effect of the series of xylan degradation enzymes is achieved, the catalytic efficiency is high, the reaction by-products are less, the yield and the purity are high, an the used carrier is polysaccharide which is inert, cheap and easy to obtain, has good biocompatibility, and is especially suitable for the fields of food, medicine and the like.

Owner:NANJING NORMAL UNIVERSITY

Method and device for mechanically pressurizing, injecting and recovering waste steam for suction section

InactiveCN102705273AImprove qualityIncrease pressureJet pumpsMachines/enginesSteam pressureWorking fluid

The invention relates to a method and a device for mechanically pressurizing, injecting and recovering waste steam for a suction section. The waste steam is injected and aspirated by utilizing working steam; a pressurizing machine is arranged on a waste steam pipeline; and the waste steam is sent into an injector after being pressurized. Water is utilized as a working fluid; after being pressurized by using a water pump, the water is sent into the injector and is used for aspirating the waste steam; the pressurizing machine is arranged on the waste steam pipeline; and the waste steam is sent into the injector after being pressurized by the pressuring machine. By using the method and the device, the pressure of the waste steam is improved by utilizing mechanical pressurization; the injection propelling force is increased; the injection effect is obviously improved; and the recovery and utilization rate of the energy of the waste steam is improved drastically. By using the method and the device, not only are the problems of the energy loss and the atmospheric environmental pollution caused by the waste of the waste steam of an ordinary evaporation operation unit solved, but also the method and the device, compared with a conventional steam saving technique, have the characteristics that equipment is simple, the recovery rate of the energy is high, and the economical efficiency is good.

Owner:TIANJIN UNIV

Preparation method of blocked macroporous material immobilized laccase

InactiveCN104694528ASimple preparation processLow costOn/in inorganic carrierGraft reactionOscillatory reaction

The invention relates to a preparation method of blocked macroporous material immobilized laccase, and belongs to the technical field of the preparation of immobilized enzyme. The immobilized laccase adopts a blocked SiO2 macroporous material with surface functionalized by virtue of an epoxy group as a carrier, and the laccase is immobilized on the carrier by virtue of a covalent binding method. The preparation method comprises the following two steps: preparation of the carrier and immobilization of the laccase. During the preparation of the carrier, gamma-(2,3-epoxy propoxy)propyl-trimethoxysilane (GPTMS) is adopted as a silane coupling agent, and the GPTMS has grafting reaction on the inner surface of a pore of the SiO2 macroporous material under the solvent thermal reaction condition to prepare the epoxy-group functionalized carrier which can be covalently bound with the laccase. During the immobilization of the laccase, the carrier is immersed in a laccase solution, the solution is vibrated at a room temperature to have the reaction, and a reaction product is washed and dried to obtain the immobilized laccase finished product. The novel immobilized laccase has the characteristics that the preparation process is simple, the cost is low, the activity of the immobilized laccase is high, and the like.

Owner:NINGBO UNIV

Integral rotational radiation preheating mixing energy utilization device with flue gas chilling

ActiveCN103013577BIncrease profitEffective sensible heatEnergy inputCombined combustion mitigationHigh pressureConvection heat

The invention relates to an integral rotational radiation preheating mixing energy utilization device with flue gas chilling. The device comprises a gasification furnace body and a heat recovery unit, which are connected with each other through a flange; the heat recovery unit comprises a pressurized shell, a syngas inlet, a radiation heat exchange component, a flue gas chilling component, a convection heat transfer component, an attemperator component, a slag tank and a syngas outlet; the gasification furnace body is communicated with the heat recovery unit through the syngas inlet; syngas is subjected to radiation heat exchange and then chilling for temperature reduction, and then liquid slag falls into the slag tank for discharge; and the syngas reversely flows up, and is subjected to convection heat transfer for temperature reduction. The device integrates radiation heat exchange, flue gas chilling and convection heat transfer effectively, and can be used for an IGCC (Integrated Gasification Combined Cycle) power generation system, the sensible heat of crude syngas is absorbed to produce high-pressure steam or medium-pressure steam to generate power, the entire energy utilization rate is increased greatly, the energy recycling rate is high, the overall dimension of a waste-heat recovery boiler is reduced effectively, the manufacturing, transporting and installing are more convenient, and the problem of dust stratification on convection heat transfer surface can be eliminated.

Owner:DONGFANG ELECTRIC CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com