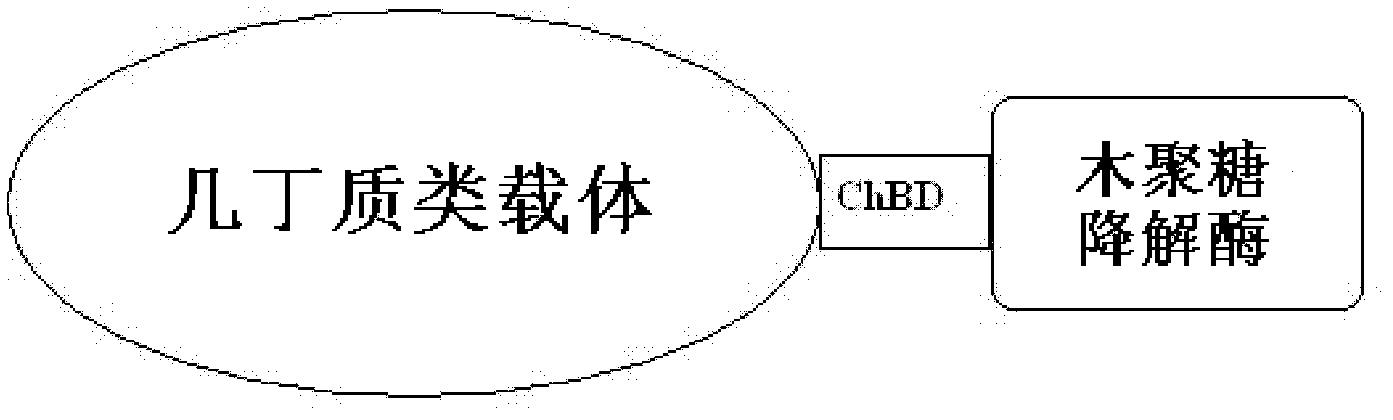

Method for preparing xylo-oligosaccharide and xylose with genetic engineering co-immobilized xylan degradation enzyme

A xylan degrading enzyme and genetic engineering technology, applied in the field of preparation of xylooligosaccharides and xylose, can solve the problems of limited application, weak binding force, etc., achieve good results, simplify the production process, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

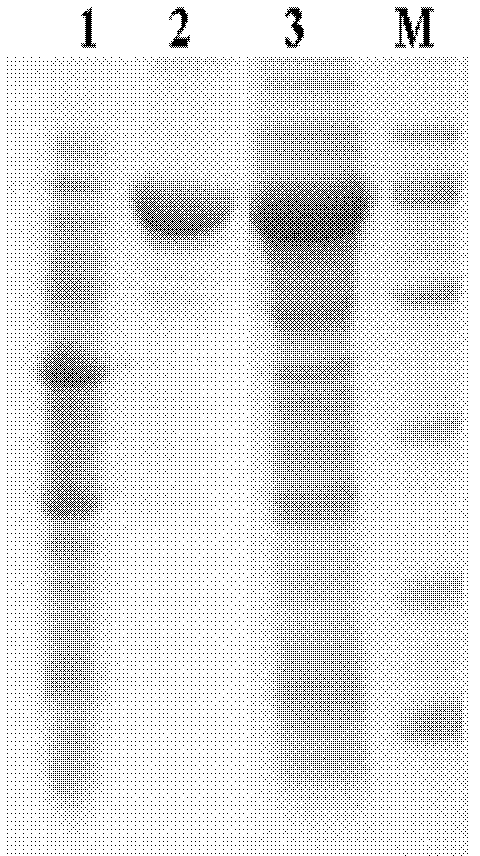

[0036] (1) Construction of recombinant expression vector pET-20b-ChBD: Primer 1:

[0037] 5'-GCATCCAGGCACATACCAGCCTGGTGGGTTGGGAACCGCCGAACGTG

[0038] CCG GCACTGTGGCAGCTGCAGTGAGATCCGGCTGCTAAC-3' (SEQ ID NO. 1);

[0039] Primer 2:

[0040] 5'-ATTTGTAGGTGATACCGTTGTAGGTCACCAGATCACCGATTTTGTAGT

[0041] AG GTGTTGCTTGCCCATTCTCGAGTGCGGCCGCAA 3' (SEQ ID NO. 2);

[0042] Using the plasmid pET-20b (Novagen) as a template, use the above primers 1 and 2 (Shanghai Sangong) as primers for reverse PCR amplification, and introduce the coding when designing the primers

[0043] Whole gene of EWASNTYYKIGDLVTYNGITYKCIQAHTSLVGWEPPNVPALWQLQ fragment. Amplification conditions:

[0044]

[0045] Amplification conditions: 95°C for 5min, 30 cycles (94°C for 40s, 55°C for 40s, 72°C for 3min and 40s), 72°C for 10min. The PCR product was recovered and purified using QIAquick Gel Extraction kit (QIAGEN Company), treated with phosphorylase, and ligated overnight at 16°C with T4 DNA ligase (TAKARA C...

Embodiment 2

[0058] It is basically the same as Example 1, except that the α-glucuronidase is Bacillus stearothermophilus α-glucuronidase, and the hydrolysis temperature is 65°C.

Embodiment 3

[0060] It is basically the same as Example 1, except that the raw material pretreatment method and the usage amount of enzymes, the specific operations are as follows:

[0061](1) Weigh 10 kg of sawdust, soak in water, squeeze dry and discard the water, control the water content to 30%, then cook at a high temperature of 1.5Mpa for 10 minutes, then suddenly reduce the pressure, cool, and centrifuge to obtain the steam explosion liquid.

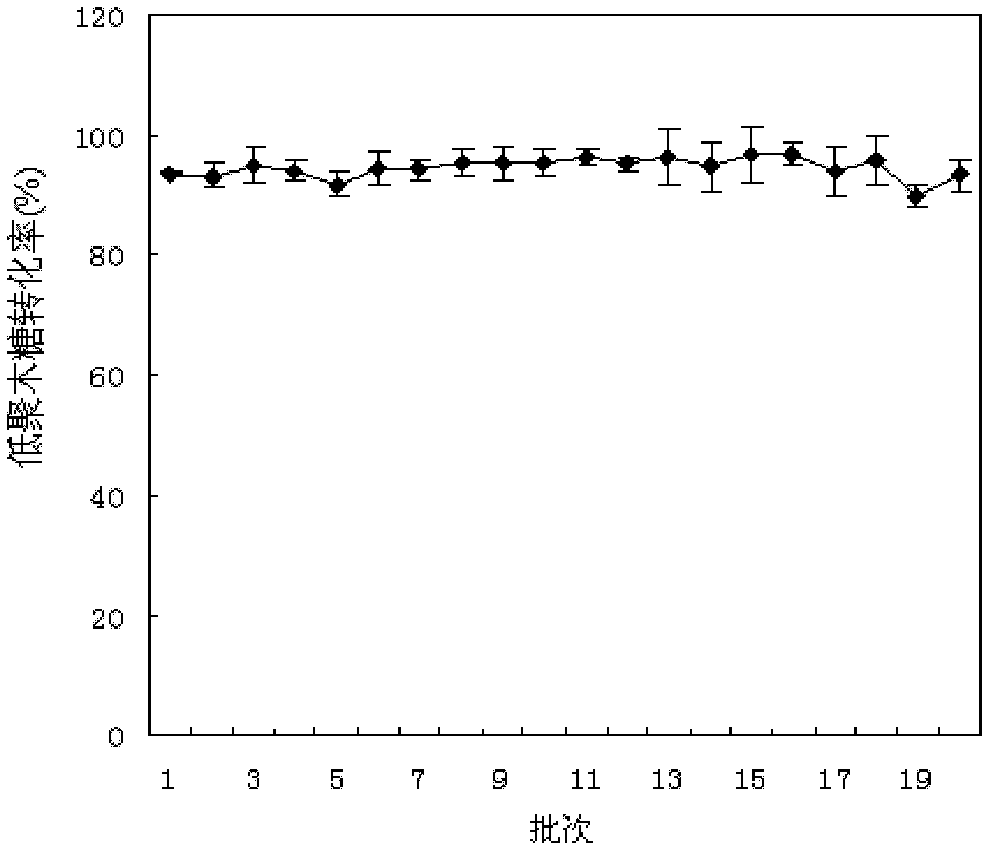

[0062] (2) While stirring, add the co-immobilized xylanase and α-glucuronidase solution into the steam explosion solution, the enzyme dosage is 15U / g, keep it warm at 80°C for 2 hours, and recover and immobilize by filtration after hydrolysis The enzyme is used for the preparation of xylose in the next batch. Add 4 times the volume of ethanol to the obtained filtrate and stir evenly, then centrifuge to take the supernatant, keep it at 75-80°C for evaporation and concentration, then cool to 60°C, and spray dry to obtain low Xylan products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com